Page 1

Installation guide

16

17

18

19

19

9

Pressure operated water valve

WVS 32 – WVS 100

WVS 32 WVS 40 WVS 50 - WVS 100

016R9556

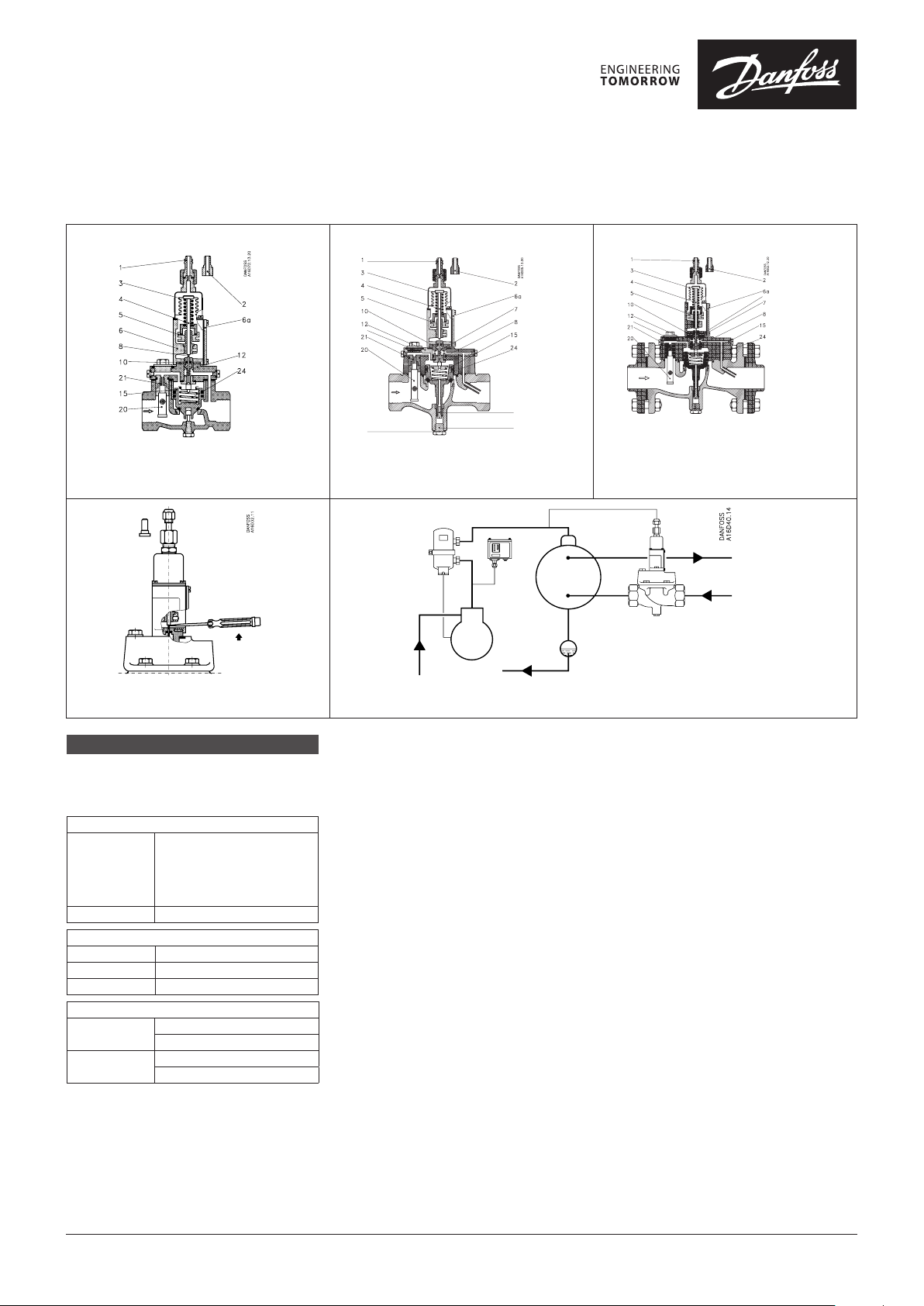

Fig. 1 Fig. 2 Fig. 3

Fig. 4 Fig. 5

016R9556

ENGLISH

Pressure operated water valve,

types WVS 32 – WVS 100

Technical data

Media

R22, R1270, R134a, R290, R404A,

R407A, R407C, R4 07F, R410A*,

Refrigerant side

Water side Fresh water and brine

Max. test pressure

Refrigerant side Pe= 29 bar = 2900 k Pa

R410a/R744 (CO2) Pe= 60 bar = 6000 kPa

Water side Pe= 16 bar = 1600 kPa

Opening differential pressure

WVS 32 – WV S 40

WVS 50 – W VS 100

For complete list of approved refrigerants,

visit www.products.danfoss.com and search

for individual code numbers, where

refrigerants are listed as part of technical

data.

R448A , R449A, R450A, R452A,

R507A, R513A, R600, R60 0a, R717

* High pressure refrigerants version

(45, 2 MWP) only

Min. 0.5 b ar = 50 kPa

Max. 4 bar = 400 kPa

Min. 0.3 b ar = 30 kPa

Max. 4 bar = 400 kPa

Fig. 1–3

1. Flare connection

2. Weld nipple

3. Bellows element

4. Push rod

5. Regulating nut

6. Top part

6a. Cover

7. Pilot insert

8. Spindle

9. Teflon sleeves

10. Insulating disc

10a. Gasket

12. Valve cover

15. Servo piston *)

16. Bottom screw

17. Drain plug

18. Gasket

19. Strainer assembly, complete *)

20. Self-cleaning strainer

21. Pilot nozzle

24. Servo spring **)

*) Please state valve size

**) See table Fig. 6

Assembly

Screws connecting pilot unit with

valve body to be tighten with 8.5 Nm.

Fitting

WVS is to be fitted in the cooling water

inlet with flow in the direction of the

arrow and with the bellows element

facing upwards. It is recommended

that a strainer should be inserted

before the valve.

The bellows element is to be

connected to the pressure side of

the refrigeration system at a point

where pressure pulsations from the

compressor do not affect the valve,

e.g. on the top of the condenser or

after the oil separator. The pressure

line must be connected so that

impurities cannot enter it. See Fig. 5.

Do not remove white insluting disk

(10). It needs to be always fitted

between pilot element and valve

housing.

Setting

Remove the cover (6a).

WVS can be set to begin opening

at a condensing pressure of

min. 2.2 bar = 220 kPa and

max. 19 bar = 1900 kPa.

© Danfoss | DCS (az) | 2018.02 DKRCC.PI.DA0.A8.52 | 1

Page 2

The valve is completely open when

the condensing pressure has increased

by 1 bar = 100 kPa above the preset

opening pressure. A lower condensing

pressure is obtained by turning the

regulating nut (5) anticlockwise (to

slacken the regulating spring) – and

vice versa. When the refrigerating

system stops, the condensing pressure

falls, and so the WVS closes.

Service

The pressure operated water valve

must shut off the cooling water when

the refrigeration system is stopped. If

not, it may be due to the fact that large

impurities have settled on the valve

seat of the servo piston or pilot cone.

The strainer (20) or the pilot nozzle (21)

may be clogged up.

Impurities can be removed as shown

in Fig. 4. Insert a screwdriver between

the pilot cone spindle (8) and the push

rod (4). Tilting the screwdriver forces

the pilot cone down, and the valve

opens to full cooling water flow.

If still the valve does not close tightly,

shut off the cooling water supply to

the water valve. Unscrew the strainer

assembly (19) and clean both the

strainer and the pilot nozzle.

If the strainer or pilot nozzle is not

clogged up, dismount the top part

(6) and the valve cover (12), which can

be done without relieving the system

of its pressure. Remove the strainer

assembly from the valve cover, clean

it, and apply a coat of water-resistant,

acid-free grease to it. Fill the same

kind of grease into the space over the

Teflon sleeves (9). It may be necessary

to grind the pilot cone in its seat. Clean

the servo piston and valve seat and

apply a coat of water- resistant, acidfree grease to the servo cylinder and

the servo piston guide.

The pilot channels in the valve cover

can be cleaned after the screws have

been unscrewed from the sides of the

valve cover.

Check whether the O-rings need

replacement.

After fitting or overhaul the water

valve must be flushed vigorously for

some minutes in order to remove any

impurities from pipelines, etc. See Fig. 4.

If there is any risk of the valve bursting

due to frost during standstill periods,

it should be drained of water. It can be

done unscrewing the drain plug (17)

and the bottom screw (16).

DANSK

Trykstyret vandventil,

types WVS 32 – WVS 100

Tekniske dat a

Medier

R22, R1270, R134a, R290, R404A,

R407A, R407C, R4 07F, R410A*, R448A,

Kølemiddelside

Vandside Ferskvand og brine

Maks. prøvetryk

Kølemiddelside Pe= 29 bar = 2900 k Pa

R410 a/R 744 (CO2) Pe= 60 bar = 6000 kPa

Vandside Pe= 16 bar = 1600 kPa

Åbningsdifferenstryk

WVS 32 – WV S 40

WVS 50 – W VS 100

For komplet liste over godkendte

kølemidler, besøge

www.products.danfoss.com og søg

efter individuelle bestillingsnumre, hvor

kølemidler er opført som en del af tekniske

data.

R449A, R450A , R452A, R507A, R513A,

R600, R600a, R717

* Højtryksversio n (45,2 MWP)

min. 0.5 b ar = 50 kPa

maks. 4 b ar = 400 kPa

min. 0.3 b ar = 30 kPa

maks. 4 b ar = 400 kPa

Fig. 1–3

1. Flaretilslutning

2. Svejsenippel

3. Bælgelement

4. Trykstang

5. Reguleringsmøtrik

6. Topstykke

6a. Dæksel

7. Pilotindsats

8. Spindel

9. Teflonmanchetter

10. Isolationsskive

10a. Pakning

12. Ventildæksel

15. Servostempel *)

16. Bundskrue

17. Bundprop

18. Pakning

19. Komplet filterindsats *)

20. Selvrensende filter

21. Pilotdyse

24. Servoeder **)

*) Angiv ventilstørrelsen

**) Se tabellen fig. 6

Samling

Skruer, der forbinder pilotenhed med

Ventilhus der skal spændes med 8,5

Nm.

Montering

WVS monteres i kølevandstilgangen

med gennemstrømning i pilens

retning og med bælg-elementet

opad. Det anbefales at montere et

smudsfilter foran ventilen.

Bælgelementet tilsluttes

køleanlæggets

trykside et sted, hvor trykpulsationer

fra kompressoren ikke vil få nogen

indvirkning på ventilen, f. eks. på

toppen af kondensatoren eller efter

olieudskilleren. Trykrøret skal tilsluttes

sådan, at eventuelle urenheder ikke

kan løbe ind i røret. Se fig. 5.

Fjern ikke den hvide isolationsskive

(10). Isolationsskiven skal altid være

monteret mellem pilotelement og

ventilhus.

Indstilling

Fjern dækslet (6a).

WVS kan indstilles til at begynde

at åbne ved et kondenseringstryk

på min. 2.2 bar = 220 kPa og maks.

19 bar = 1900 kPa.

Ventilen er helt åben, når

kondenseringstrykket er steget

1 bar = 100 kPa over det indstillede

åbningstryk.

Lavere kondenseringstryk opnås ved

at dreje reguleringsmøtrikken (5) mod

venstre (reguleringsederen slækkes)

– og omvendt. Når køleanlægget

stopper, falder kondenseringstrykket,

og WVS vil derfor lukke.

Service

Trykstyret vandventil skal lukke tæt

for kølevandet når køleanlægget

er stoppet. Hvis den ikke gør det,

kan årsagen muligvis være, at større

snavs-partikler har sat sig fast på

servostemplets eller pilotkeglens

ventilsæde. Måske er filteret (20) eller

pilotdysen (21) tilstoppet.

Snavspartikler kan man forsøge

at erne som vist på fig. 4. Stik en

skruetrækker ind mellem pilotkeglens

spindel (8) og trykstangen (4). Når

skruetrækkeren vippes, presses

pilotkeglen nedad, og ventilen åbner

for fuld kølevands-gennemstrømning

gennem ventilen.

Hvis vandventilen stadig ikke

lukker tæt luk da for kølevandet til

vandventilen. Skru filter-indsatsen (19)

af og rens både filteret og pilotdysen.

Er filteret eller pilotdysen ikke

tilstoppet, afmontér så topstykket (6)

© Danfoss | DCS (az) | 2018.02 DKRCC.PI.DA0.A8.52 | 2

Page 3

og ventildækslet (12). Topstykket og

ventildækslet kan afmonteres, uden

at det er nødvendigt at tage trykket

af anlægget. Tag pilotindsatsen ud af

ventildækslet, rens den og smør den

ind i vandfast, syrefrit fedtstof. Fyld

rummet over teflonmanchetterne (9)

med samme fedtstof. Måske er det

nødvendigt at indslibe pilotkeglen i

pilotsædet.

Rens servostemplet og ventilsædet

og smør servocylinderen og

servostemplets styr med vandfast,

syrefrit fedtstof.

Pilotkanalerne i ventildækslet

kan renses, efter at skruerne i

ventildækslets sider er ernet.

Undersøg om O-ringene trænger til at

skiftes ud.

Efter monteringen eller efter et

eftersyn skal vandventilen skylles

kraftigt igennem i nogle minutter for

at erne evt. snavs fra rørledninger

m.v. Se fig. 4.

Er der fare for frostsprængning af

ventilen i stilstandsperioder, bør den

tømmes for vand. Det gøres ved at

erne bundproppen (17) og skruen

(16).

DEUTSCH

Druckgesteuerter Kühlwasserregler

Types WVS 32 – WVS 100

Technische Daten

Medien

R22, R1270, R134a, R290, R404A,

R407A, R407C, R4 07F, R410A*,

Kältemittels eite

Wasserseite Frischwasser und Sole

Max. Prüfdruck

Kältemittels eite Pe= 29 bar

R410a/R744 (CO2) Pe= 60 bar

Wasserseite Pe= 16 bar

Öffnungsdifferenzdruck

WVS 32 – WV S 40

WVS 50 – W VS 100

Eine vollständige Liste der zugelassenen

Kältemitteln finden Sie auf:

www.products.danfoss.com Suchen Sie

hier nach den verfügbaren

Das Kältemittel ist ein Bestandteil der

jeweiligen Technischen Daten.

R448A , R449A, R450A, R452A,

R507A, R513A, R600, R60 0a, R717

* Nur Hochdruckversion (45,2 bar

zulässiger Betriebsüberdruck)

min. 0.5 b ar

max. 4 bar

min. 0.3 b ar

max. 4 bar

Artikelnummern.

Abb. 1–3

1. Bördelanschluß

2. Schweissnippel

3. Wellrohrelement

4. Druckbolzen

5. Regelmutter

6. Einstellgehäuse

6a. Deckel

7. Piloteinsatz

8. Spindel

9. Teflonmanschetten

10. Isolierscheibe

10a. Dichtung

12. Ventildeckel

15. Servokolben *)

16. Bodenschraube

17. Bodenstopfen

18. Dichtung

19. Filtereinsatz, komplett *)

20. Selbstreinigendes Filter

21. Pilotdüse

24. Servofeder **)

*) Ventilgröße angeben

**) Siehe Tabelle, Abb. 6

Montage

Die Schrauben zur Befestigung der

Piloteinheit auf dem Ventilkörper sind

mit 8,5 Nm anzuziehen.

Montage

WVS wird mit nach oben gerichtetem

Wellrohrelement und mit Durchfluß in

Pfeilrichtung in den Kühlwassereintritt

eingebaut. Es empfiehlt sich, vor dem

Ventil ein Schmutzfilter einzubauen.

Das Wellrohrelement wird an

der Druckseite der Kälteanlage

angeschlossen, wo vom Kompressor

herrührende Druckpulsationen das

Ventil nicht beeinflussen können, z.B.

zuoberst am Verflüssiger oder hinter

dem Ölabscheider. Das Druckrohr

ist so anzuschliessen, daß etwaige

Schmutzteilchen nicht in das Rohr

gelangen können. Siehe Abb. 5.

Isolierscheibe (10) nicht entfernen.

Diese muss immer zwischen

dem Einstellelement und dem

Ventilgehäuse montiert sein.

Einstellung

Deckel (6a) entfernen.

WVS kann so eingestellt werden, daß

es bei einem Verflüssigungsdruck von

min. 2,2 bar und max. 19 bar zu öffnen

beginnt.

Das Ventil ist völlig geöffnet, wenn der

Verflüssigungsdruck um 1 bar über

den eingestellten Öffnungsdruck

gestiegen ist.

Durch Linksdrehen der Regelmutter

(5) (Lockern der Regelfeder) ergibt sich

ein niedrigerer Verflüssigungsdruckund umgekehrt. Sobald die

Kälteanlage ausgeschaltet wird, geht

der Verflüssigungsdruck zurück und

das Ventil WVS wird daher schließen.

Wartung

Bei stillgesetzter Kälteanlage muß das

druckgesteuerter Kühlwasserregler

die Kühlwasserzufuhr völlig absperren.

Ist dies nicht der Fall, können sich

möglicherweise an den Ventilsitzen

des Servokolbens oder des Pilotkegels

grössere Schmutzteilchen festgesetzt

ha ben. Vielleicht sind auch das Filter

(20) oder die Pilotdüse (21) verstopft.

Abb. 4 zeigt, wie man möglicherweise

Schmutzteilchen entfernen kann.

Zwischen der Spindel des Pilotkegels

(8) und dem Druckbolzen (4) steckt

man einen Schrau benzieher und

drückt damit den Pilotkegel nach

unten, so daß dabei das Ventil den

vollen Kühlwasserdurchfluß freigibt.

Wenn danach das Ventil immer noch

nicht völlig dicht absperrt, so muß die

Kühl wasserzufuhr unterbrochen

werden. Darauf sind der Filtereinsatz

(19) auszuschrauben und Filter und

Pilotdüse zu reinigen.

Wenn keine Verstopfung des Filters

oder der Pilotdüse festgestellt werden

konnte, müssen das Einstellgehäuse

(6) und der Ventildeckel (12) ausgebaut

werden. Dieser Ausbau kann bei unter

Druck stehender Kälteanlage erfolgen.

Piloteinsatz aus dem Ventildeckel

herausnehmen, reinigen und mit

einem wasserbeständigen säurefreien

Fett schmieren. Der Raum über den

Teflonmanschetten (9) ist mit dem

gleichen Schmierfett zu füllen. Unter

Umständen muß der Pilotkegel neu in

den Pilotsitz eingeschliffen werden.

Servokolben und Ventilsitz reinigen.

Servo-zylinder und Führung des

Servokolbens mit wasserfestem

säurefreiem Fett schmieren.

Die Pilotkanäle im Ventildeckel lassen

sich nach Entfernung der Schrauben

aus den Deckelseiten reinigen.

Prüfen Sie, ob eine Auswechslung der

O-Ringe erforderlich ist.

Nach dem erneuten Zusammenbau –

und überhaupt nach jeder Inspektion

– muß das Ventil einige Minuten lang

© Danfoss | DCS (az) | 2018.02 DKRCC.PI.DA0.A8.52 | 3

Page 4

gründlich durchgespült werden,

um etwaige Schmutzteilchen aus

Rohrleitungen u.s.w. zu entfernen.

Siehe Abb. 4.

Wenn in Standzeiten die Gefahr einer

Frostsprengung des Ventils besteht,

so sollte man das Wasser daraus

ablassen. Zu diesem Zweck sind der

Bodenstopfen (17) und die Schraube

(16) zu entfernen.

FRANÇAIS

Vanne à eau pressostatique,

types WVS 32 – WVS 100

Caractéristiques techniques

Médiums

R22, R1270, R134a, R290, R404A,

R407A, R407C, R4 07F, R410A*,

Côté fluide

frigorigène

Côté eau Eau douce et saumure

Pression d’essai max.

Côté fluide frigorigène

R410a/R744 (CO2) Pe= 60 bar = 6000 kPa

Côté eau Pe= 16 bar = 1600 kPa

Pression différentielle d’ouverture

WVS 32 – WV S 40

WVS 50 – W VS 100

Pour consulter la liste complète liste de

fluides frigorigènes, rendez-vous sur

www.products.danfoss.com et

recherchez les numéros de code

individuel, où les fluides sont répertoriés

dans le cadre de données techniques.

R422B, R422D, R44 8A, R449A,

R450A, R452A , R507A, R513A,

R600, R600a, R717

* Version réf rigérants haute

pression uniquement (45,2MWP)

Pe= 29 bar = 2900 k Pa

min. 0.5 b ar = 50 kPa

max. 4 bar = 4 00 kPa

min. 0.3 b ar = 30 kPa

max. 4 bar = 4 00 kPa

Fig. 1–3

1. Raccord flare

2. Tubulure à souder

3. Soufflet

4. Tige de pression

5. Ecrou de réglage

6. Partie supérieure

6a. Couvercle

7. Cartouche pilote

8. Tige

9. Manchons en téflon

10. Disque isolant

10a. Joint

12. Couvercle de vanne

15. Servo-piston *)

16. Vis de fond

17. Bouchon de fond

18. Joint

19.

Cartouche de filtre, complète

*)

20. Filtre auto-nettoyant

21. Orifice pilote

24. Servo-ressort **)

*) Indiquer la dimension de la vanne

**) Voir le tableau, fig. 6

Assemblage

Les vis, liant le pilot au corps de vanne,

doivent être serrées avec un couple de

8.5Nm.

Montage

Monter la WVS sur l’entrée d’eau froide

avec une circulaltion d’eau dans le sens

de la flèche et le soufflet orienté vers

le haut. Il est recomandé de monter un

filtre à eau en amont de la vanne.

Raccorder le raccord flare du soufflet

au refoulement de installation à un

endroit où les pulsations compresseur

n’influent pas sur la vanne, p.ex., au

sommet du condenseur ou en aval

du séparateur d’huile. La conduite de

refoulement doit être reliée de façon

que d’éventuelles saletés ne puissent y

pénétrer. Voir fig 5.

Ne pas enlever le disque isolant blanc

(10). Il doit toujours être placé entre le

pilote et le corps de vanne.

Réglage

Enlever le couvercle (6a).

La WVS peut être réglée pour

commencer à s’ouvrir à une pression

de condensation de min. 2,2 bar =

220 kPa et au maxi 19 bar = 1900 kPa.

La vanne est complètement ouverte

quand la pression de condensation

s’est élevée de 1 bar = 100 kPa audessus de la pression d’ouverture de

réglage.

Une pression de condensation plus

basse est obtenue en tournant l’écrou

de réglage (5) vers la gauche (le

ressort de réglage est déchargé) – et

inversement.

A l’arrêt de l’installation frigorifique, la

pression de condensation tombe et,

par conséquent, la WVS se ferme.

Entretien

A l’arrêt de l’installation frigorifique,

la vanne doit couper totalement le

passage de l’eau de refroidissement.

Si ce n’est pas le cas, celà peut être dû

à des saletés assez grosses fixées sur

le siège du servo- piston ou du cône

pilote. Le filtre (20) ou l’orifice pilote

(21) sont peut-être bouchés.

On peut essayer d’enlever les saletés

comme montré sur la fig. 4. Introduire

un tournevis entre la tige (8) du cône

pilote et la tige de pression (4). En

basculant le tournevis, le cône pilote

est pressé vers le bas et la vanne

s’ouvre en plein passage de l’eau de

refroidissement.

Dans le cas où la vanne à eau ne ferme

toujours pas hermétiquement, couper

l’accès d’eau de refroidissement à la

vanne. Dévisser la cartouche de filtre

(19) et nettoyer le filtre et l’orifice

pilote.

Si ni le filtre ni l’orifice pilote ne

sont bouchés, démonter la partie

supérieure (6) et le couvercle (12) de

la vanne. La partie supérieure et le

couvercle de la vanne peuvent être

démontés sans décharger l’installation.

Sortir la cartouche pilote du couvercle

de la vanne, la nettoyer et la graisser

avec une graisse non acide résistante

à l’eau. Remplir l’espace au-dessus des

manchons en téflon (9) de la même

graisse. Il peut être nécessaire d’ajuster

le cône pilote dans son siège.

Nettoyer le servo-piston et le siège de

la vanne et enduire le servo-cylindre et

le guide du servo-piston d’une graisse

non acide résistante à l’eau.

Les canaux pilotes du couvercle de la

vanne peuvent être nettoyés après

avoir dévissé les vis des côtés du

couvercle de la vanne.

Examiner si les joints toriques doivent

être remplacés.

Apres le montage ou après un entretien,

il est nécessaire, pendant quelques

minutes, de purger énergiquement la

vanne afin d’éliminer des conduites,

etc. d’éventuelles salétes. Voir fig. 4.

En cas de risque d’éclatement par le

gel de la vanne pendant les périodes

d’arrêt, celle-ci doit être vidée. Pour

celà, enlever le bouchon de fond (17)

et la vis (16).

© Danfoss | DCS (az) | 2018.02 DKRCC.PI.DA0.A8.52 | 4

Loading...

Loading...