Page 1

Data Sheet

Pressure operated water valve

Type WVFX and WVS

Opens on rising condensing pressure

Pressure operated water valves types WVFX

and WVS are used for regulating the ow of

water in refrigeration plants with water-cooled

condensers.

The pressure operated water valves give

modulating regulation of the condensing

pressure within dened limits during operation.

When the refrigeration plant is stopped, the

cooling water ow is shut o automatically.

Pressure operated water valves can be used

with ammable refrigerants. Double sealing

between the refrigerant and the water line

ensures that in case the bellows damage and

the refrigerant leak, it cannot enter into the

water. This severely limits the safety

implications. It means that the valve can be

used together with a double walled heat

exchanger and water circuit in such a system

does not need to be considered as a part of the

installation for ammable refrigerants

(EN378-1:2008, clause 4.4.2.2).

Features

• Media: Fresh water and Neutral brine

• Needs no power supply – self acting

• Opens on rising condensing pressure

• Complete ow range from 1.4 – 300 m3/h

• Low ow version of WVFX – 0,63 m3/h,

(available on request)

• Insensitive to dirt

• WVFX 10 – 25 are available in stainless steel

housing

• Suitable for ammable refrigerants

• May be used in the following EX range:

Category 3 (Zone 2)

AI250886497511en-001401

Page 2

Danfoss

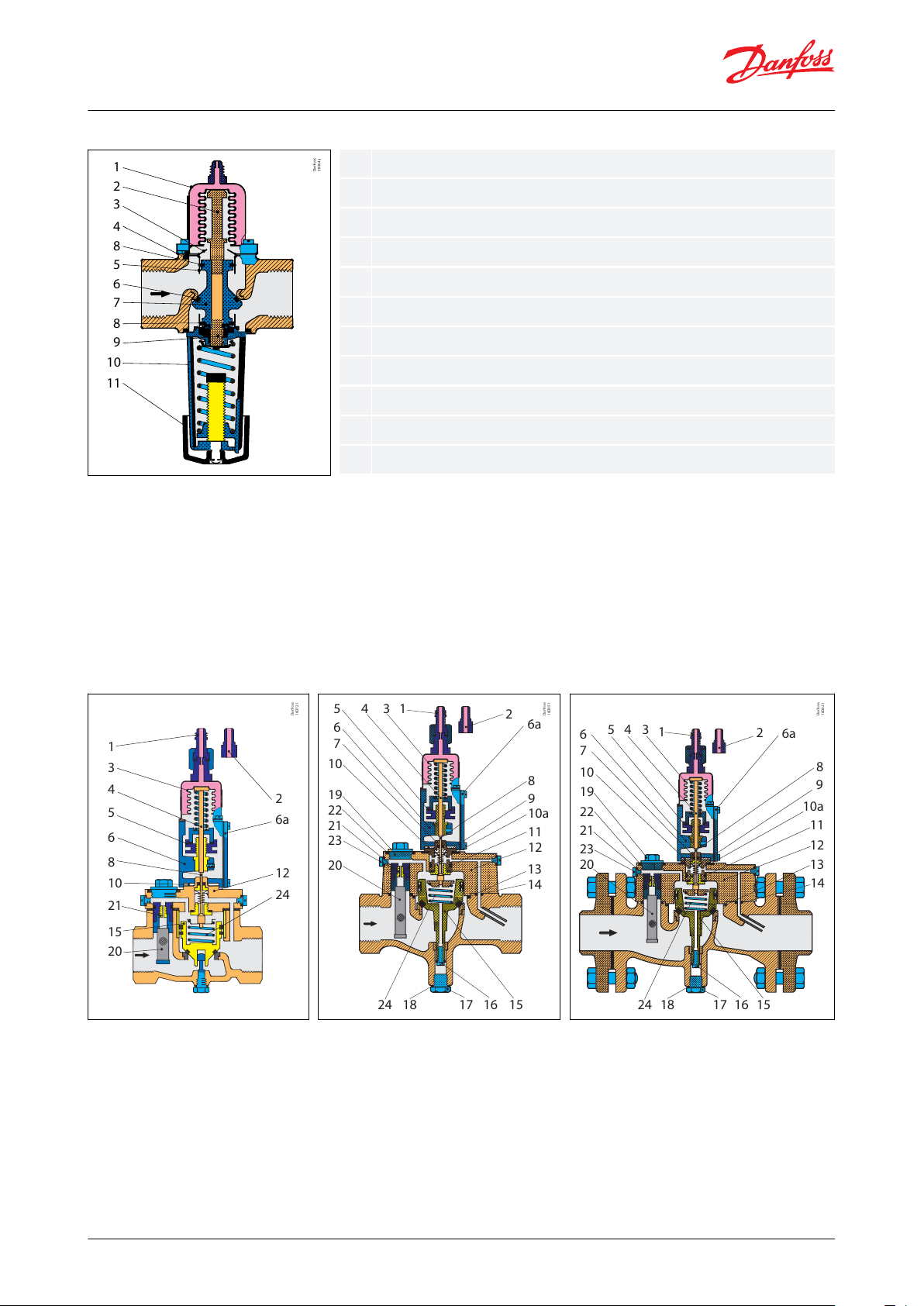

3N162

5

7

5

9

6

4

3

2

1

8

6

3

10

12345678910Handwheel

Spring housing

Spindle guide

Spring retainer

O-ring

Guide bush

Diaphragm

Valve cone

Thrust pad

Bellows element

Pressure operated water valve, Type WVFX and WVS

Functions

Condensing pressure impulses are transmitted via the bellows element to the valve cone so that the valve – even at

very small pressure variations – is able to adapt the quantity of water required by the condenser.

The valves are pressure-relieved in such a way that a variation in the water pressure will not aect their setting.

To protect the refrigeration plant against high head pressures in the event that the water supply to the condenser

fails, a safety switch type KP or RT should be tted on the high pressure side.

Water side connections are internal BSP and the compressor discharge side connection is

1

⁄4 in. / 6 mm are.

The valve body WVFX 10 – 25 is made of hot-stamped brass and for WVFX 32 – 40 of cast iron. WVFX 15, WVFX 20

and WVFX 25 can also be supplied in stainless steel housing.

All metal external valve parts are surface-treated to resist corrosion from condensate, etc.

It is possible to order reverse acting WVFX valve, which opens on refrigerant pressure decrease.

Reverse acting valve are mostly used in bypass lines and heat pump applications.

Figure 1: Design / Function for WVFX 10 – 25

The valve cone (8) is a brass plate with a vulcanized layer of articial rubber to form an elastic seal against the valve

seat. The valve is externally sealed by the diaphragms (7).

The top and bottom of the valve plate holder are extended by a guide that is tted with O-rings (5) to ensure the

internal operating parts move correctly. These O-rings, tted in conjunction with the diaphragms, also provide extra

protection against external leakage.

The valve seat is made of stainless steel and is pressed to the valve body.

The spring housing (2) is of aluminium and has a guide slot for the spring holder that is extended in the form of an

indicating pointer. An associated indicator label is riveted to the housing and is graduated from 1 – 5.

© Danfoss | Climate Solutions | 2021.02 AI250886497511en-001401 | 2

Page 3

Danfoss

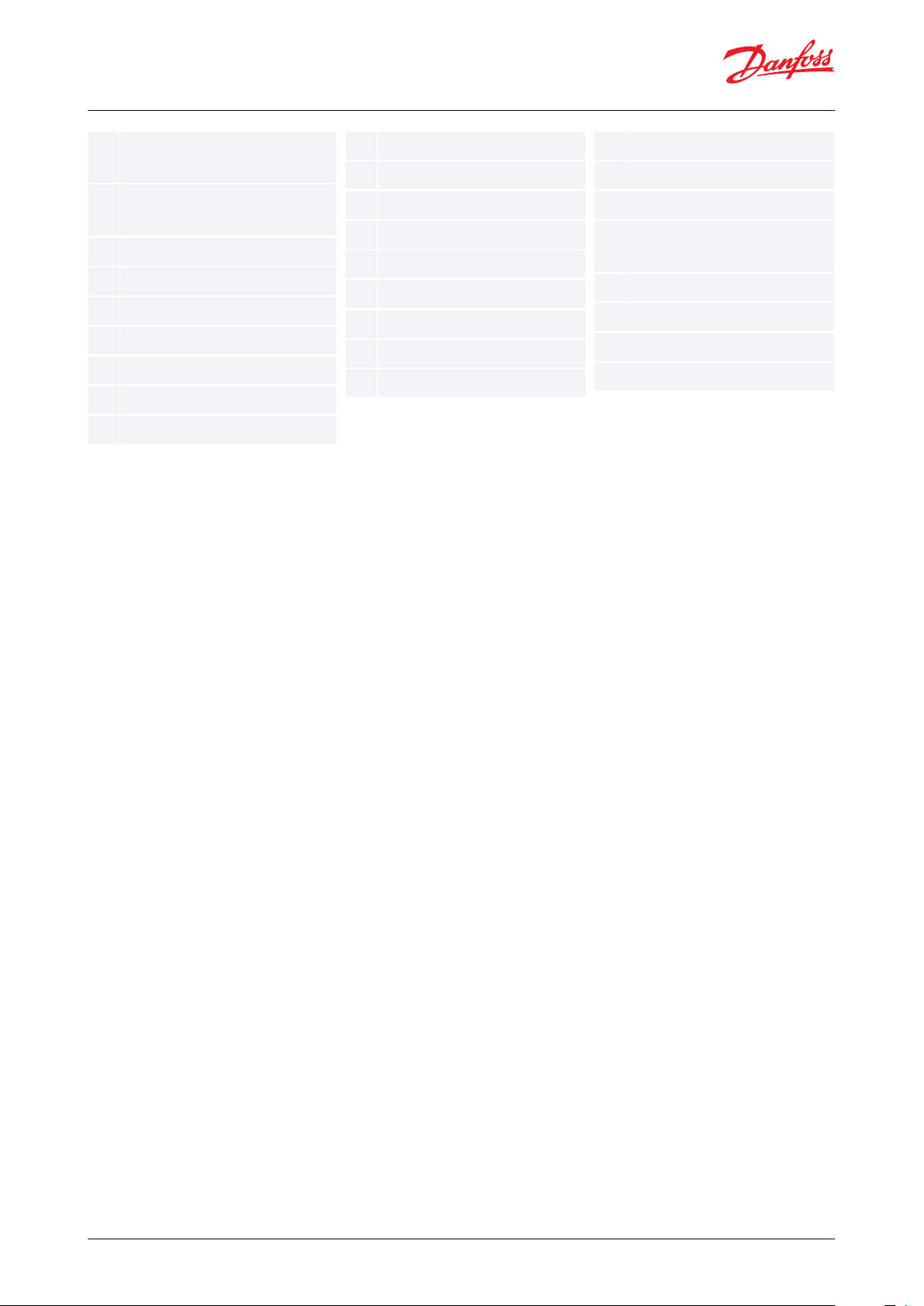

3N164-j

1

2

3

4

8

5

7

8

9

10

11

6

1234567891011

Bellows element

Upper pressure spindle

Top plate

Guide bush gland

Guide bush

T-ring

Valve cone

O-ring

Lower pressure spindle

Spring housing

Handwheel

Danfoss

16D721

2

6a

12

24

20

15

21

10

8

6

5

4

3

1

Danfoss

16D051

2

6a

8

9

10a

11

12

13

14

20

23

21

22

19

10

7

6

5

4 3 1

24 18 17 16 15

Danfoss

16D021

1

345

6

7

10

19

22

21

23

20

24 18 17 16 15

14

13

12

11

10a

9

8

6a

2

Pressure operated water valve, Type WVFX and WVS

Figure 2: Design / Function for WVFX 32 – 40

The valve cone (7) is made of brass with a T-ring (6) of articial rubber forming a exible seal against the valve seat.

The O-rings (8) are external seals for the cooling water.

The valve cone guide bushes (5) are specially treated to counteract lime deposits from the cooling water inside the

cylinder, and also to reduce friction in the valve to a minimum.

The valve seat is made of stainless steel and is pressed to the valve body.

The spring housing (2) is of aluminium and has a guide slot for the spring holder that is extended in the form of an

indicating pointer.

Figure 3: WVS 32

Figure 4: WVS 40

Figure 5: WVS 50 – 100

© Danfoss | Climate Solutions | 2021.02 AI250886497511en-001401 | 3

Page 4

1

2

34566a78910

10a1112131415161718

1920212223

24

Pressure connection (are

nipple)

Pressure connection (weld

nipple)

Bellows element

Push rod

Regulating nut

Spring housing

Cover

Pilot assembly

Spindle for pilot cone

Teon sleeves

Insulating gasket

Gasket

O-ring

Valve cover

O-ring

O-ring

Servo piston

Bottom screw

Drain plug

Gasket

Strainer assembly, complete

Self-cleaning strainer

assembly

Pilot orice

Gasket

O-ring

Servo spring

Pressure operated water valve, Type WVFX and WVS

WVS 32 – 40 valves have internal BSP connections, while WVS 50 – 100 can be supplied with either BSP connections

or weld anges.

Connection to the plant condenser can be made by copper tube or steel tube, the valves being supplied with both a

are nipple for

1

⁄4 in. (6 mm) copper tube and a weld nipple for ø6 mm / ø10 mm steel tube.

1. Main valve with servo piston

The main valve body is made of cast iron with a pressed-in bronze seat. The servo piston is of gun metal and has a

sleeve and a proled rubber seal ring.

2. Pilot valve

The pilot valve is made of gun metal, the pilot cone and seat of stainless steel and the pilot orice of brass. These

materials are particularly resistant to water corrosion. However, the valve is not resistant to sea water.

The strainer ahead of the pilot orice is made of nickel gauze.

The degree of opening of the pilot valve (which corresponds to the increase in condensing pressure above the set

opening pressure) determines the degree of opening of the main valve and thereby amount of the water ow.

3. Bellows unit with connection to condenser

The bellows unit is made of aluminium and corrosion-proofed steel.

© Danfoss | Climate Solutions | 2021.02 AI250886497511en-001401 | 4

Page 5

Type

Condenser side

Liquid side

Kv value

(1)

Refrigerant

Control press.

adjustable

opening press.

Max. working

pressure

PS/MWP

Max. test pres‐

sure Pe

Media

Max. working

pressure

PS/MWP

Max. test pres‐

sure Pe

[bar]

[bar]

[bar]

[bar]

[bar]

[m3/h]

WVFX 10

R22, R134a,

R290, R404A,

R407A, R407C,

R407F, R407H,

R410A

(4)

, R422B,

R422D, R448A,

R449A, R449B,

R450A, R452A,

R454A, R454C,

R455A, R507A,

R513A, R515B,

R516A, R600,

R600a, R1234yf,

R1270

3.5 – 16.0

26.4

29.0

Fresh water,

neutral brine,

sea water

(3)

16241.4

WVFX 10

(2)

4.0 – 23.0

26.4

29.01624

1.4

WVFX 10

15.0 – 29.0

45.2

60.01624

1.4

WVFX 15

3.5 – 16.0

26.4

29.01624

1.9

WVFX 15

(2)

4.0 – 23.0

26.4

29.01624

1.9

WVFX 15

15.0 – 29.0

45.2

60.01624

1.9

WVFX 20

3.5 – 16.0

26.4

29.01624

3.4

WVFX 20

(2)

4.0 – 23.0

26.4

29.01624

3.4

WVFX 20

15.0 – 29.0

45.2

60.01624

3.4

WVFX 25

3.5 – 16.0

26.4

29.01624

5.5

WVFX 25

(2)

4.0 – 23.0

26.4

29.01624

5.5

WVFX 25

15.0 – 29.0

45.2

60.01624

5.5

WVFX 32

4.0 – 17.0

24.1

26.51010

11.0

WVFX 40

4.0 – 17.0

24.1

26.51010

11.0

WVS 32

R22, R134a,

R290, R404A,

R407A, R407C,

R407F, R407H,

R410A

(4)

, R422B,

R422D, R448A,

R449A, R449B,

R450A, R452A,

R507A, R513A,

R600, R600a,

R717

(5)

, R1270

2.2 – 19.0

26.4

29.0

Fresh water,

neutral brine

101612.5

WVS 32

15.0 – 29.0

45.2

60.01016

12.5

WVS 40

2.2 – 19.0

26.4

29.01016

21.0

WVS 40

15.0 – 29.0

45.2

60.01016

21.0

WVS 50

2.2 – 19.0

26.4

29.01016

32.0

WVS 50

15.0 – 29.0

45.2

60.01016

32.0

WVS 65

2.2 – 19.0

26.4

29.01016

45.0

WVS 65

15.0 – 29.0

45.2

60.01016

45.0

WVS 80

2.2 – 19.0

26.4

29.01016

80.0

WVS 80

15.0 – 29.0

45.2

60.01016

80.0

WVS 100

2.2 – 19.0

26.4

29.01016

125.0

WVS 100

15.0 – 29.0

45.2

60.01016

125.0

Pressure operated water valve, Type WVFX and WVS

Product specication

Technical data

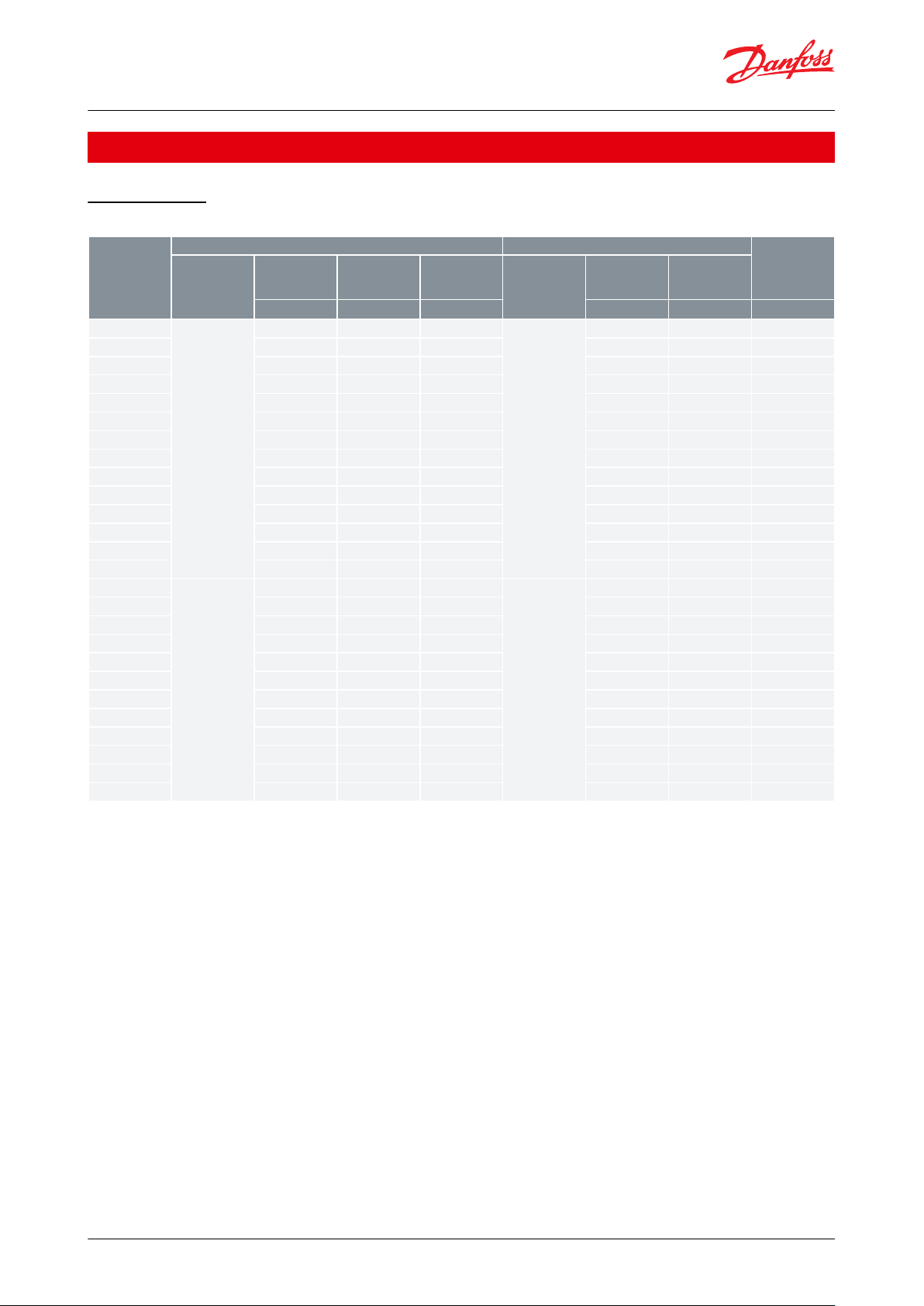

Table 1: Technical data

(1)

(1)

The Kv value is the ow of water in [m3/h] at a pressure drop across valve of 1 bar, ρ = 1000 kg/m3.

The Kv value is the ow of water in [m3/h] at a pressure drop across valve of 1 bar, ρ = 1000 kg/m3.

(2)

(2)

Fully open valve requires 33% higher pressure than a WVFX, range 3.5 – 16 bar.

Fully open valve requires 33% higher pressure than a WVFX, range 3.5 – 16 bar.

(3)

(3)

WVFX 15, WVFX 20 and WVFX 25 with stainless steel housing only.

WVFX 15, WVFX 20 and WVFX 25 with stainless steel housing only.

(4)

(4)

High pressure refrigerants version (45,2 MWP) only

High pressure refrigerants version (45,2 MWP) only

(5)

(5)

WVS, WVFX 10 – 25 and WVO with are connection only; versions with capillary tube or with solder connections are not compatible with R717.

WVS, WVFX 10 – 25 and WVO with are connection only; versions with capillary tube or with solder connections are not compatible with R717.

WVFX 32 and WVFX 40 are not compatible with R717

WVFX 32 and WVFX 40 are not compatible with R717

WVFX is evaluated for R290, R454A, R454C, R455A, R600, R600a, R1234yf, R1270 by ignition source assessment in

accordance with standard EN ISO80079-36. Flare connections are only approved for A1 and A2L refrigerants.

WVS is evaluated for R290, R600, R600a, R1270 by ignition source assessment in accordance with standard EN

ISO80079-36. Flare connections are only approved for A1 and A2L refrigerants.

For complete list of approved refrigerants, visit store.danfoss.com and search for individual code numbers, where

refrigerants are listed as part of technical data

WVFX 10 – 40 are direct actuated valves. WVS 32 – 100 are servo-operated valves.

Media temperature range

• WVFX 10 – 25: -25 – 130 °C

• WVFX 32 – 40: -25 – 90 °C

• WVS: -25 – 90 °C

© Danfoss | Climate Solutions | 2021.02 AI250886497511en-001401 | 5

Page 6

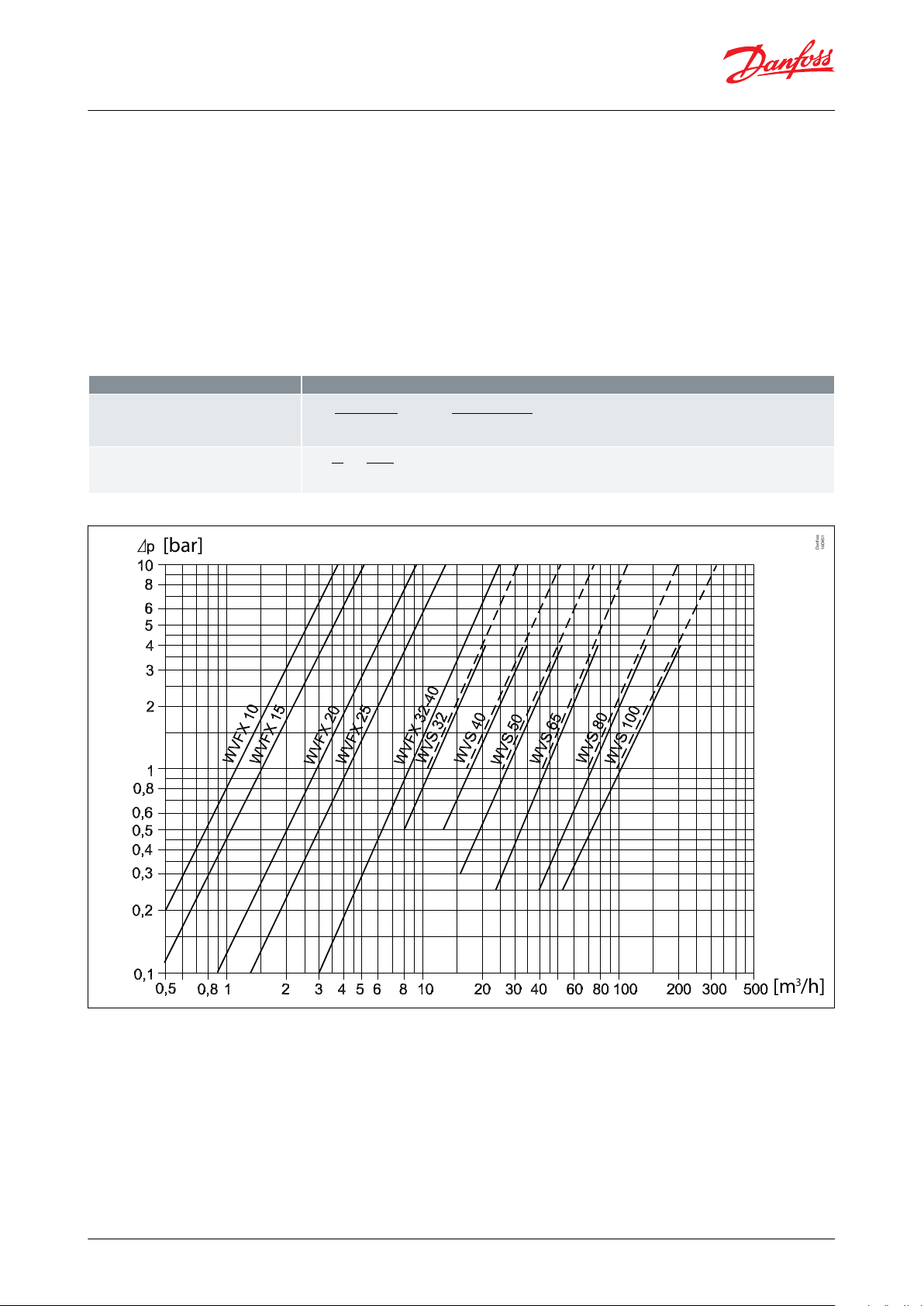

[bar]

Danfoss

16D851

[m /h]

3

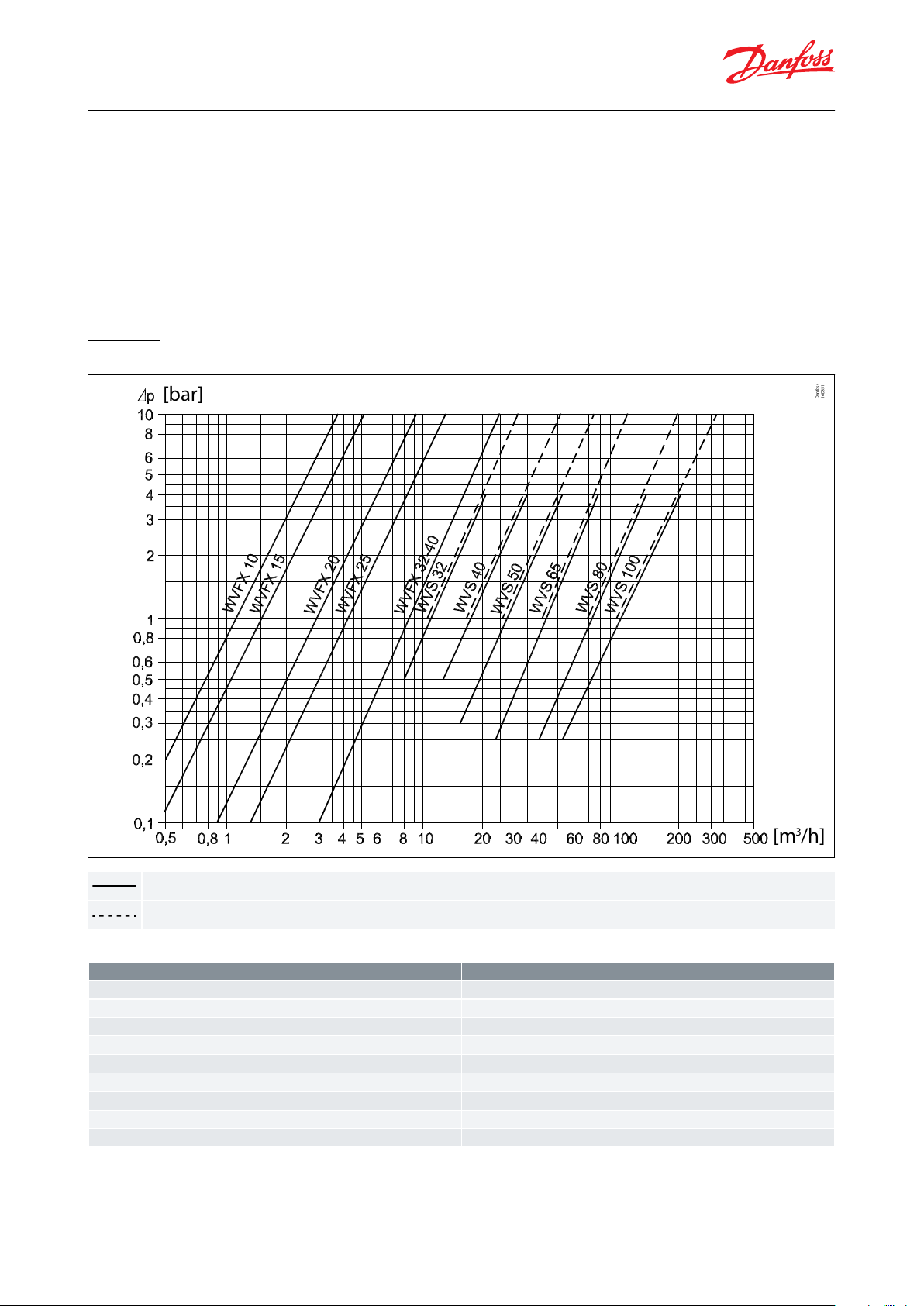

Standard servo spring type WVS

Special servo spring type WVS

Type

∆p oset [bar]

WVFX 10

2.0

WVFX 15

2.5

WVFX 20

3.0

WVFX 25

3.5

WVFX 32 – 40

3.0

WVS 32

0.6

WVS 40

0.7

WVS 50 – 80

0.8

WVS 100

0.9

Pressure operated water valve, Type WVFX and WVS

If a WVS is required with an opening dierential pressure of 1 – 10 bar, the valve servo spring must be replaced. See

Ordering.

Opening dierential pressure

• WVFX 10 – 25: max. 10 bar

• WVFX 32 – 40: max. 10 bar

• WVS 32 – 40: min. 0.5 bar; max. 4 bar

• WVS 50 – 100: min. 0.3 bar; max. 4 bar

Below 20% of max. capacity the WVS will act as an on-o regulator.

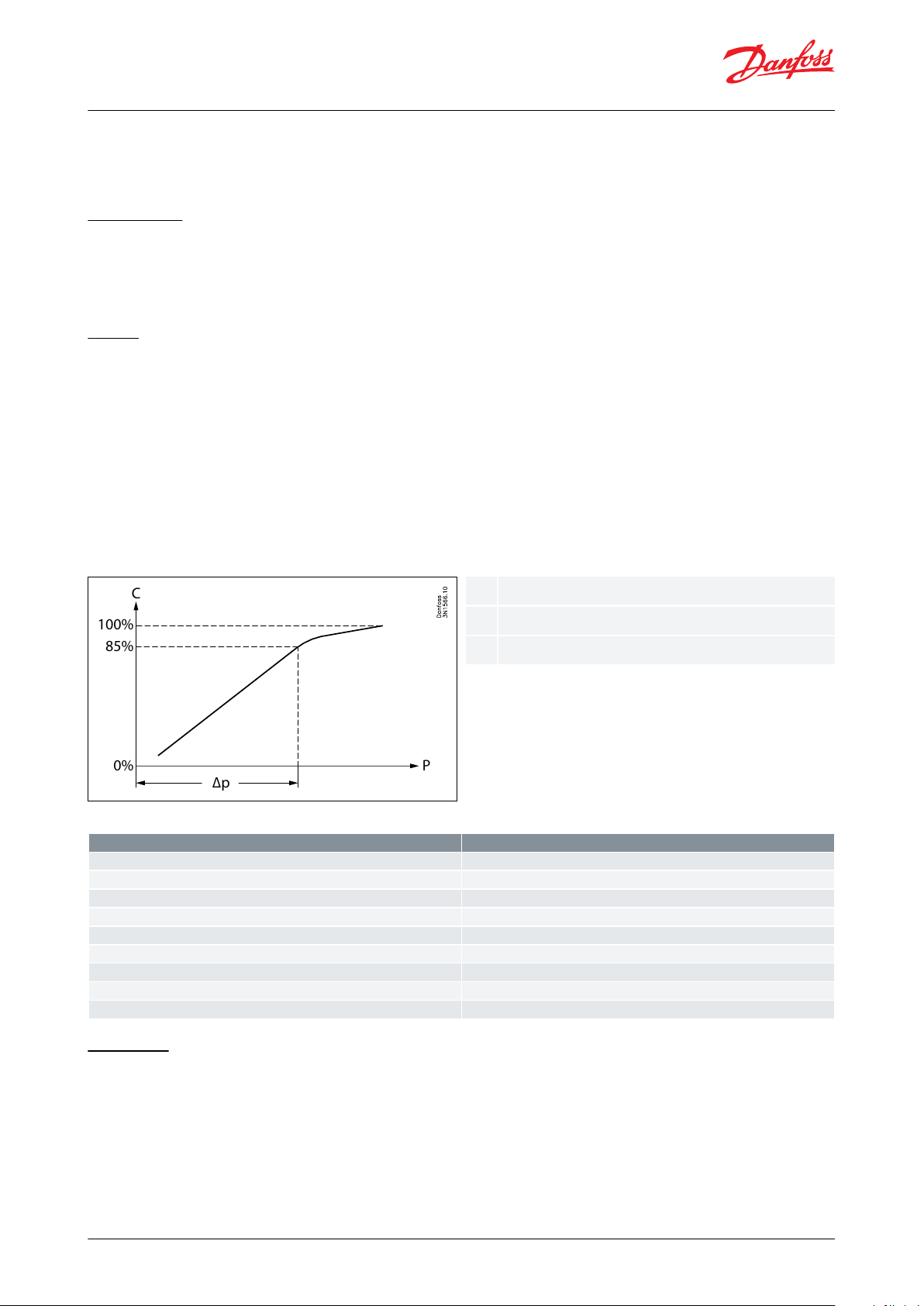

Capacity

Figure 6: Capacity

Table 2: Water Valves Oset – rise in condensing pressure

© Danfoss | Climate Solutions | 2021.02 AI250886497511en-001401 | 6

Page 7

C

P

100%

85%

0%

∆p

CPΔp

Water capacity

Condensing pressure

Δp oset

Type

∆p

oset [bar]

WVFX 10

2.0

WVFX 15

2.5

WVFX 20

3.0

WVFX 25

3.5

WVFX 32 – 40

3.0

WVS 32

0.6

WVS 40

0.7

WVS 50 – 80

0.8

WVS 100

0.9

Pressure operated water valve, Type WVFX and WVS

The capacity curves show the capacities of individual valves (water quantity in [m3/h]) depending on the pressure

drop across valves. The capacities given apply at 85% valve opening and are obtained with the following oset (rise

in condensing pressure).

Installation

WVS and WVFX 32, WVFX 40 is to be tted in the cooling water inlet with ow in the direction of the arrow and with

the bellows element facing upwards. Horizontal mounting is a must.

WVFX 10, WVFX 15 and WVFX 25 can be mounted in any position. Horizontal mounting is not required.

Sizing

When sizing and selecting water regulating valves it is most important to ensure that the valve at any time is able to

give the necessary quantity of cooling water.

To select a suitable size of valve it is necessary to know the precise amount of cooling required.

On the other hand, to avoid the risk of unstable regulation (hunting) the valve should not be oversized. In general,

the aim should be to select the smallest valve capable of giving the required ow.

To obtain a precise control it can be recommended to only use 85% of the capacity. Below 85% the ratio between

ow and condensing dierence pressure is linear. Above 85% the ratio is no longer linear. To reach a 100% capacity

the water valve needs signicant increase of condensing pressure. See g. below.

Figure 7: Oset

Table 3: Oset

Valve size

The following data is used when selecting the size of the water valve

• Cooling capacity of condenser

• Temperature rise in cooling media

• Dierential pressure across valve

• Condensing temperature

• Specic heat capacity of cooling media

• Refrigerant

© Danfoss | Climate Solutions | 2021.02 AI250886497511en-001401 | 7

Page 8

Features

Calculation

Necessary mass ow

m. =

Q

c

Cp.(t2 − t1)

.3600 =

30

4.19 . (25 − 15)

. 3600 = 2577kg/h

Volume ow

V. =

m

.

ρ

=

2577

1000

= 2 . 6m3/h

[bar]

Danfoss

16D851

[m /h]

3

Pressure operated water valve, Type WVFX and WVS

Sizing Examples

Example 1:

• Condenser capacity Q0: 30 kW

• Condensing temperature tc: 35 °C

• Refrigerant: R404A

• Cooling media: water

• Specic heat capacity of water Cp: 4.19 kj / (kg*K)

• Water inlet temperature t1: 15 °C

• Water outlet temperature t2: 25 °C

• Pressure drop across valve ∆p: max. 1.0 bar

Table 4: Calculation for size

Figure 8: Selecting size

Selecting WVFX 20 code number

The saturated pressure for R404A: Tc = 35 °C → Pc = 15.5 barg

Choose a WVFX 20 with 4 – 23 barg range

Example 2:

• Condenser capacity Q0: 20 kW

• Condensing temperature tc: 35 °C

• Refrigerant: R134a

• Cooling media: Brine

• Density of brine ρ: 1015 kg / m

3

© Danfoss | Climate Solutions | 2021.02 AI250886497511en-001401 | 8

Page 9

Danfoss

3N15731

D

H2

H1

L1

L

L1

15

22

25

62

40

50

56

9

Ø4

Ø7.15

Danfoss

3N200.11

Danfoss

3-193.15

18 18

117148

71

128

Features

Calculation

Necessary mass ow

m. =

Q

c

Cp.(t2 − t1)

.3600 =

20

4.35 . (25 − 20)

. 3600 = 3310kg/h

Volume ow

V. =

m

.

ρ

=

3310

1015

= 3 . 26m3/h

kv value

Kv≥

V

.

1000 . Δp

ρ

=

V

.

1000 . 2.0

1015

= 2.32m3/h

Pressure operated water valve, Type WVFX and WVS

• Specic heat capacity of brine Cp : 4.35 kj (kg*K)

• Brine inlet temperature t1: 20 °C

• Brine outlet temperature t2: 25 °C

• Pressure drop across valve ∆p: max. 2.0 bar

Table 5: Calculation for size - SI units

Selecting size of WVFX 20

kv ≥ 2.32 m3 / h → WVFX 20

WVFX 20 has kv = 3.4 m3 / h and the necessary

capacity is below 85% of full capacity.

Code number

The saturated pressure for 134a: Tc = 35 °C Pc = 7.9 barg

Choose a WVFX 20 with 3.5 – 16 barg range

Dimensions [mm] and weights [kg]

Figure 9: WVFX 10 – 25

Figure 10: Bracket for WVFX 10 – 25

Figure 11: WVFX 32 – 40

© Danfoss | Climate Solutions | 2021.02 AI250886497511en-001401 | 9

Page 10

Danfoss

16D691

H3

H2

H1

L1 L1

B

L

Danfoss

16D031

L1

H1

H2

H3

D

L

TypeH1H2H3LL1B

ø

Net weight

WVFX 1091133–7211–551

WVFX 1591133–7214–551

WVFX 2091133–9016–552

WVFX 2596138–9519–552

WVS 3242243

234

1382085–4

WVS 4072271

262

19830100–7

WVS 5078277

268

315

218–16519WVS 6582293

284

320

224–18524WVS 8090325

316

370

265–20034WVS 100

100

345

336

430

315–220

44

TypeH1H2H3LL1B

ø

Net weight

WVS 3242259

250

1382085–4

WVS 4072287

278

19830100–7

WVS 5078293

2684

315

218–16519WVS 6582309

300

320

224–18524WVS 8090341

332

370

265–20034WVS 100

100

361

352

430

315–220

44

Pressure operated water valve, Type WVFX and WVS

Figure 12: WVS 32 – 40

Table 6: Pressure operated water valve

Figure 13: WVS 50 – 100

Table 7: Pressure operated water valve, type WVS - high pressure refrigerants

NOTE:

The diamentions for WVFX 32 - 40 is mentioned in Figure 11: WVFX 32 – 40. The net weight for WVFX 32 is 3.2 kg and

for WVFX 40 is 3.3 kg

© Danfoss | Climate Solutions | 2021.02 AI250886497511en-001401 | 10

Page 11

Type

Connection

(1)

Range

Code no.

Water side

Condenser side

[bar]

WVFX 10

G

3

⁄8

1

⁄4 in. / 6 mm are

3.5 – 16

003N1100

WVFX 10

G

3

⁄8

1

⁄4 in. / 6 mm are

4.0 – 23

003N1105

WVFX 15

G

1

⁄2

1

⁄4 in. / 6 mm are

3.5 – 16

003N2100

WVFX 15

G

1

⁄2

1

⁄4 in. / 6 mm are

4.0 – 23

003N2105

WVFX 15

G

1

⁄2

1

⁄4 in. / 6 mm are nut

4.0 – 23

003N2205

(2)

WVFX 20

G

3

⁄4

1

⁄4 in. / 6 mm are

3.5 – 16

003N3100

WVFX 20

G

3

⁄4

1

⁄4 in. / 6 mm are

4.0 – 23

003N3105

WVFX 20

G

3

⁄4

1

⁄4 in. / 6 mm are nut

4.0 – 23

003N3205

(2)

WVFX 25

G 1

1

⁄4 in. / 6 mm are

3.5 – 16

003N4100

WVFX 25

G 1

1

⁄4 in. / 6 mm are

4.0 – 23

003N4105

WVFX 32

G 1

1

⁄4

1

⁄4 in. / 6 mm are

4.0 – 17

003F1232

WVFX 40

G 1

1

⁄2

1

⁄4 in. / 6 mm are

4.0 – 17

003F1240

Type

Connection

(1)

Range

Code no.

Water side

Condenser side

[bar]

WVFX 15

G

1

⁄2

1

⁄4

in. / 6 mm

are

3.5 – 16

003N2101

WVFX 15

G

1

⁄2

1

⁄4

in. / 6 mm

are

4.0 – 23

003N2104

WVFX 20

G

3

⁄4

1

⁄4

in. / 6 mm

are

4.0 – 23

003N3104

WVFX 25

G 1

1

⁄4

in. / 6 mm

are

3.5 – 16

003N4101

WVFX 25

G 1

1

⁄4

in. / 6 mm

are

4.0 – 23

003N4104

Type

Connection

(1)

Range

Code no.

Water side

Condenser side

[bar]

WVFX 10

G

3

⁄8

1

⁄4

in. / 6 mm

are

15.0 – 29.0

003N1410

WVFX 15

G

1

⁄2

1

⁄4

in. / 6 mm

are

15.0 – 29.0

003N2410

WVFX 20

G

3

⁄4

1

⁄4

in. / 6 mm

are

15.0 – 29.0

003N3410

WVFX 25

G 1

1

⁄4

in. / 6 mm

are

15.0 – 29.0

003N4410

Type

Connection

(1)

Code no.

Valve body

Pilot unit

(3)

Pilot unit for R410A

and R744

(3)

Flange set

(4)

Servo spring for dif‐

ferential pressure

range of 1 – 10 bar

WVS 32

G 1 1⁄2

(1)

016D5032

016D1017

016D1018

–

016D1327

WVS 40

G 1 1⁄2

(1)

016D5040

016D1017

016D1018

–

016D0575

WVS 50

2 in. weld

ange

016D5050

(2)

016D1017

016D1018

027N3050

016D0576

Pressure operated water valve, Type WVFX and WVS

Ordering

Ordering WVFX, commercial type

Table 8: Ordering WVFX, commercial type

(1)

(1)

ISO 228-1

ISO 228-1

(2)

(2)

WVFX 15 with 1 m capillary tube and are nut with valve depressor

WVFX 15 with 1 m capillary tube and are nut with valve depressor

Ordering WVFX, maritime type (stainless steel version)

Table 9: Ordering WVFX, maritime type (stainless steel version)

(1)

(1)

ISO 228-1

ISO 228-1

Ordering WVFX, commercial type (high pressure refrigerants, MWP 45.2 bar)

Table 10: Ordering WVFX, commercial type (high pressure refrigerants, MWP 45.2 bar)

(1)

(1)

ISO 228-1

ISO 228-1

Ordering WVS, commercial type

Table 11: Ordering WVS, commercial type

© Danfoss | Climate Solutions | 2021.02 AI250886497511en-001401 | 11

Page 12

Type

Connection

(1)

Code no.

Valve body

Pilot unit

(3)

Pilot unit for R410A

and R744

(3)

Flange set

(4)

Servo spring for dif‐

ferential pressure

range of 1 – 10 bar

WVS 65

2 1⁄2 in. weld ange

016D5065

(2)

016D1017

016D1018

027N3065

016D0577

WVS 80

3 in. weld ange

016D5080

(2)

016D1017

016D1018

027N3080

016D0578

WVS 100

4 in. weld ange

016D5100

(2)

016D1017

016D1018

027N3100

016D0579

Description

Code no.

1 m capillary tube

1

⁄4 in. (6 mm) are coupling nuts at each end

060-017166

Bracket for WVFX 10 – 25

003N0388

Pressure operated water valve, Type WVFX and WVS

(1)

(1)

ISO 228-1

ISO 228-1

(2)

(2)

Parts included: valve body, ange gaskets, ange bolts and screws for pilot valve.

Parts included: valve body, ange gaskets, ange bolts and screws for pilot valve.

(3)

(3)

Parts included: control element and spring housing.

Parts included: control element and spring housing.

(4)

(4)

Parts included: 2 anges

Parts included: 2 anges

Accessories

Table 12: Accessories

© Danfoss | Climate Solutions | 2021.02 AI250886497511en-001401 | 12

Page 13

Document name

Document type

Document topic

Approval authority

003N9613.AB

Manufacturers Declaration

PED

Danfoss

003N9614.AA

Manufacturers Declaration

China RoHS

Danfoss

003N9616.AA

Manufacturers Declaration

ATEX

Danfoss

003N9617.AB

Manufacturers Declaration

PED/RoHS

Danfoss

UL SA7200

Mechanical - Safety Certicate

UL

Pressure operated water valve, Type WVFX and WVS

Certicates, declarations, and approvals

The list contains all certicates, declarations, and approvals for this product type. Individual code number may have

some or all of these approvals, and certain local approvals may not appear on the list.

Some approvals may change over time. You can check the most current status at danfoss.com or contact your local

Danfoss representative if you have any questions.

Table 13: Valid Certicates, declarations, and approvals

© Danfoss | Climate Solutions | 2021.02 AI250886497511en-001401 | 13

Page 14

Online support

Danfoss oers a wide range of support along with our products, including digital product information, software,

mobile apps, and expert guidance. See the possibilities below.

The Danfoss Product Store

The Danfoss Product Store is your one-stop shop for everything product related—no matter where

you are in the world or what area of the cooling industry you work in. Get quick access to essential

information like product specs, code numbers, technical documentation, certications, accessories,

and more.

Start browsing at store.danfoss.com.

Find technical documentation

Find the technical documentation you need to get your project up and running. Get direct access to

our ocial collection of data sheets, certicates and declarations, manuals and guides, 3D models

and drawings, case stories, brochures, and much more.

Start searching now at www.danfoss.com/en/service-and-support/documentation.

Danfoss Learning

Danfoss Learning is a free online learning platform. It features courses and materials specically

designed to help engineers, installers, service technicians, and wholesalers better understand the

products, applications, industry topics, and trends that will help you do your job better.

Create your Danfoss Learning account for free at www.danfoss.com/en/service-and-support/learning.

Get local information and support

Local Danfoss websites are the main sources for help and information about our company and

products. Find product availability, get the latest regional news, or connect with a nearby expert—all

in your own language.

Find your local Danfoss website here: www.danfoss.com/en/choose-region.

Coolselector®2 - nd the best components for you HVAC/R system

Coolselector®2 makes it easy for engineers, consultants, and designers to nd and order the best

components for refrigeration and air conditioning systems. Run calculations based on your operating

conditions and then choose the best setup for your system design.

Download Coolselector®2 for free at coolselector.danfoss.com.

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its

products without notice. This also applies to products already on order provided that such alterations can be made without subsequential

changes being necessary in specications already agreed. All trademarks in this material are property of the respective companies. Danfoss and

the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | Climate Solutions | 2021.02 AI250886497511en-001401 | 14

Loading...

Loading...