Fact sheet

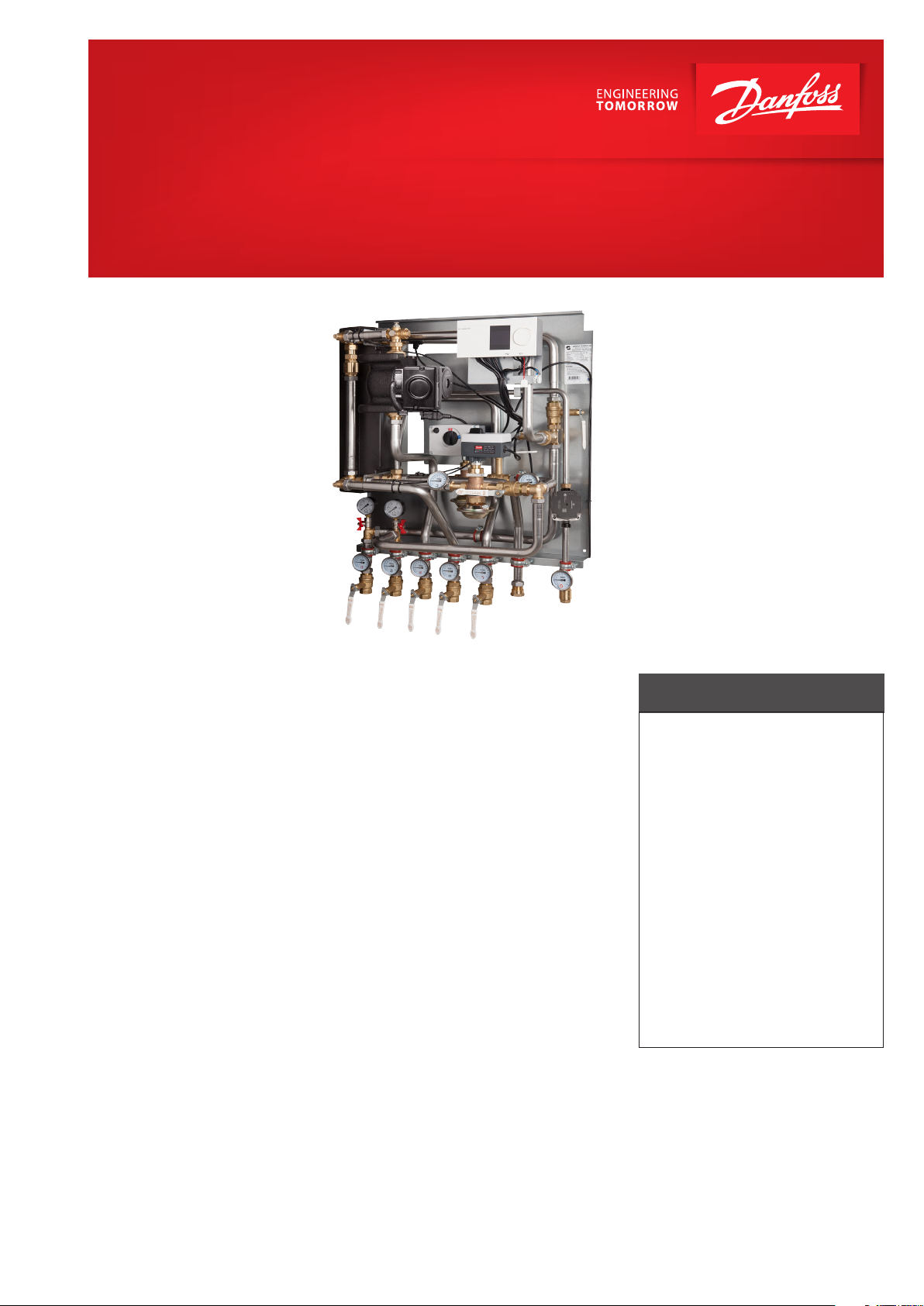

Termix VMTD MIX Compact 28

Direct substation for apartment buildings with up to 25 apartments

Application

The Termix VMTD MIX Compact

28 is a complete solution with a

built-in water heater and a heating circuit with mixing loop.

The substation is the perfect solution

for apartment buildings with up to 25

apartments.

District heating (DH)

The district heating circuit is

prefabricated with a flow controller with integrated control

valve and primary ball valves.

Furthermore the substation is delivered with a mixing loop, which includes pump and non-return valve.

Heating (HE)

The heating circuit is designed for

direct connection. The flow controller with integrated control valve

sets the optimum operation conditions for radiator thermostats

in order to enable individual temperature control in each room.

The mixing loop creates a suitable

temperature level for the heating system.

Domestic hot water (DHW)

The domestic hot water is prepared

in the plate heat exchanger and the

temperature is regulated with an

electronic controller. The efficient

heat exchanger offers exceptionally

good heat extraction with high output. No readjustment of the DHW

temperature is required after installation and initial setting of the controls.

The electronic control automatically

retains the comfort tempe rature of

the hot water, even when the heating system is in reduced operation

during summer or if the district heating plant changes operat ing parameters between summer and winter. An

integrated circulation pump for DHW

is installed.

Options

Termix VMTD MIX Compact 28 can be

delivered with white-lacquered steel

cover.

Construction

All pipes are made of stainless steel.

The connections are made by nuts

and gaskets.

FEATURES AND BENEFITS

• Substation for apartment buildings

• Direct heating with mixing loop

• Thermostatic or electronic controls

• Capacity: 100-150 kW DHW, 100 kW HE

• DHW in sufficient quantity

• Operates independently

of differential pressure

and flow temperature

• Minimum space required

for installation

• Pipes and plate heat exchanger

made of stainless steel

• Minimized risk of lime scale

and bacteria formation

www.danfoss.com

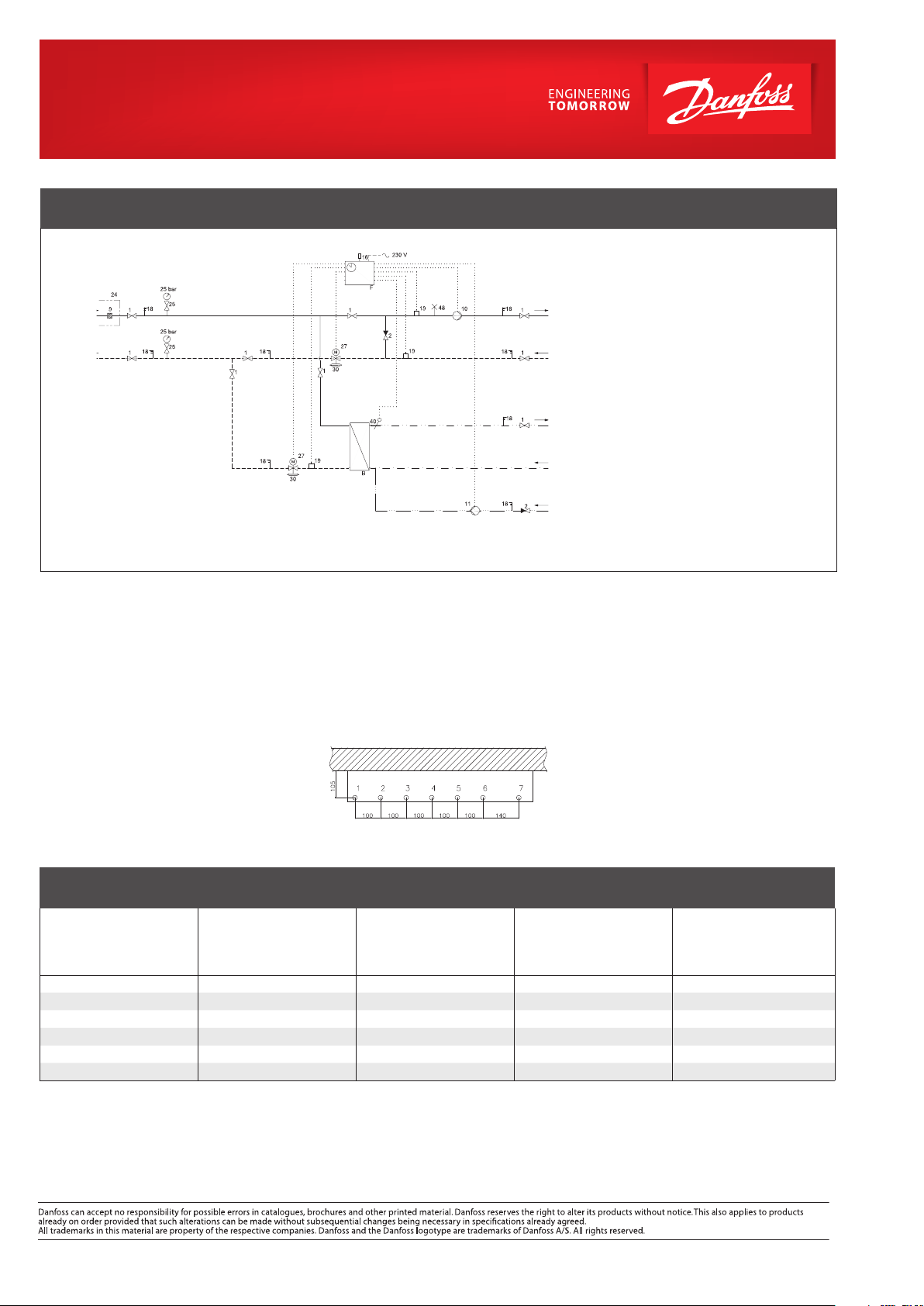

CIRCUIT DIAGRAM EXAMPLE

DH

supply

DH

return

HE

Supply

HE

Return

DHW

DCW

Circ.

B Heat exchanger DHW

F Electronic controller

1 Ball valve

2 Non-return valve

10 Circulation pump HE

11 Circulation pump DHW

16 Outdoor sensor

18 Thermometer

19 Surface sensor

25 Manometer with ball valve

27 Actuator

30 Flow control w. control

valve

40 Immersion sensor

48 Air vent, manual

Technical parameters:

Nominal pressure: PN 10/16

DH supply temperature: T

DCW static pressure: p

Brazing material (HEX): Copper

Weight: 40-50 kg

Dimensions (mm):

without cover: H 940 x W 750 x D 440

With cover: H 940 x W 800 x D 522

Electrical supply: 230 V AC

= 120 °C

max

= 0,5 bar

min

DHW: CAPACITY EXAMPLES

DHW

capacity

[kW]

100 70 22 50 2150

110 70 22 50 2365

120 70 22 50 2580

130 70 22 50 2795

140 70 22 50 3010

150 70 22 50 3225

Supply

flow

primary

[°C]

Connections:

1. District heating (DH) supply

2. District heating (DH) return

3. Heating (HE) Supply

4. Heating (HE) return

5. Domestic hot water (DHW)

6. Domestic cold water (DCW)

7. DHW circulation (Cirk.)

Seen from above

Return

flow

primary

[°C]

Wall

Connections sizes:

DH + HE + DCW + DHW: G 1” (int. thread)

Circulation: G 3/4” (int. thread)

Options:

• Cover

Temperature

secondary

[°C]

secondary

Flow rate

[l/h]

Gemina Termix A/S · Member of the Danfoss Group · Navervej 15-17 · DK-7451 Sunds · Denmark

Tel.: +45 9714 1444 · Fax: +45 9714 1159 · mail@termix.dk · www.heating.danfoss.com

© Danfoss | DHS-SRMT/ PL | 2016 . 05

VC.LB.T4.02

Loading...

Loading...