Page 1

OperatingGuide

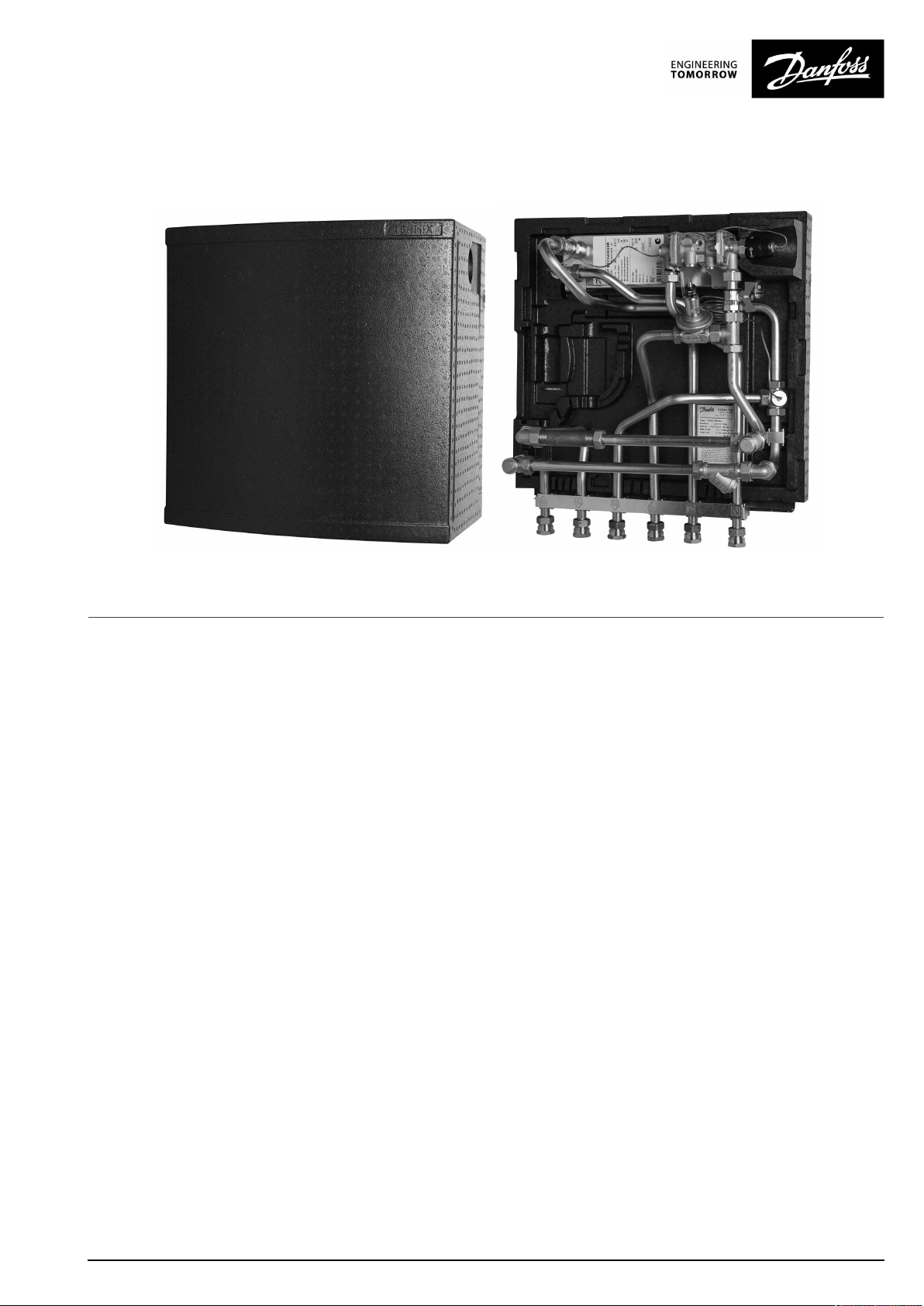

TermixVMTD-Iwithcompleteinsulation

1.0TableofContents

1.0TableofContents.............................................1

........................................................................2

2.0VMTD-IinsuIHPTFunctionaldescription...........3

3.0Safetynotes.....................................................4

3.1SafetyNotes–general............................................4

4.0Mounting........................................................5

4.1Mounting...........................................................5

4.2Start-up..............................................................7

5.0Design.............................................................8

5.1Design...............................................................8

5.2Schematicdiagram................................................9

6.0Controls..........................................................10

6.1Heatingcircuit......................................................10

6.2DHWtemperaturecontrol........................................11

6.3Other.................................................................12

6.4Extras................................................................14

6.5Mountingplateforenergymeterdisplay.....................15

6.6Maintenance........................................................16

7.0Troubleshooting..............................................17

7.1Troubleshootingingeneral......................................17

7.2TroubleshootingDHW............................................18

7.3TroubleshootingHE...............................................19

7.4Disposal.............................................................21

8.0Declaration......................................................22

8.1Declarationofconformity........................................22

©Danfoss|2019.05VM.IE.C3.02/LUK40143|1

Page 2

OperatingGuideT ermixVMTD-Iwithcompleteinsulation

2|©Danfoss|2019.05

VM.IE.C3.02/LUK40143

Page 3

OperatingGuideT ermixVMTD-Iwithcompleteinsulation

2.0VMTD-IinsuIHPTFunctionaldescription

Districtheatingsubstationfordirectheatingand

instantaneousdomestichotwaterwithflow-compensated

temperaturecontroller .Designedforwall-mounting.

Application

TheTermixVMTD-Iisacompletesolutionwithbuilt-inwaterheater

andadifferentialpressurecontrolledheatingsystem.Termix

VMTD-Iisapplicableforsinglefamilyhousesandfordecentralized

systems.

Districtheating(DH)

Thesubstationisprefabricatedwithadifferentialpressure

controller,afittingpieceandsensorpocketsforinsertionofan

energymeteraswellasstrainer.Thedisplayoftheenergymeteris

tobemountedonabracketunderneaththesubstation.

Heating(HE)

Theheatingcircuitisdesignedfordirectgenerationofheat.

Thedifferentialpressurecontrolsetstheoptimumoperation

conditionsforradiatorthermostaticvalvesinordertoenable

individualtemperaturecontrolineachroom.Inordertoenablea

time-dependingtemperaturecontrolprogram,azonevalvewith

actuatorisincluded,andaroomthermostatcanbeincludedas

anoption.

Domestichotwater(DHW)

Thedomestichotwaterispreparedintheheatexchangerandthe

temperatureisregulatedwithaflowcompensatedtemperature

controllerwithintegrateddifferentialpressurecontroller.Theheat

exchanger-whichisinsulated-coolstheDHwaterveryefficiently,

therebycreatinganexcellentoperatingeconomy.TheIHPTvalve

ensuresastablehotwatertemperaturebyvaryingloads,supply

temperaturesandbyhighandvaryingdifferentialpressurewithout

theneedforreadjustingthevalve.Thisprotectstheheatexchanger

againstoverheatingandlimescaleformation.Furthermorethe

IHPTvalvehasanintegratedidletemperaturecontroller,which

keepsthehousesupplylinewarm.Thisshortensthewaiting

periodsduringsummerwhentheheatingsystemisinreduced

operation,whichisidealwherehighcomfortisrequested.AWRAS

approvednon-returnvalveisfittedinthecoldwatersupply.

VM.IE.C3.02/LUK40143

©Danfoss|2019.05|3

Page 4

OperatingGuideT ermixVMTD-Iwithcompleteinsulation

3.0Safetynotes

3.1SafetyNotes–general

Thefollowinginstructionsrefertothestandarddesignof

substation.Specialversionsofsubstationsareavailableon

request.

Thisoperatingmanualshouldbereadcarefullybeforeinstallation

andstart-upofthesubstation.Themanufactureracceptsno

liabilityfordamageorfaultsthatresultfromnon-compliancewith

theoperatingmanual.Pleasereadandfollowalltheinstructions

carefullytopreventaccidents,injuryanddamagetoproperty.

Assembly,start-upandmaintenanceworkmustbeperformedby

qualifiedandauthorizedpersonnelonly.

Pleasecomplywiththeinstructionsissuedbythesystem

manufacturerorsystemoperator.

Corrosionprotection

Allpipesandcomponentsaremadeofstainlesssteelandbrass.

Themaximumchloridecompoundsoftheflowmediumshouldnot

behigherthan150mg/l.

Theriskofequipmentcorrosionincreasesconsiderablyifthe

recommendedlevelofpermissiblechloridecompoundsis

exceeded.

Energysource

Thesubstationisdesignedfordistrictheatingastheprimary

sourceofenergy.However,alsootherenergysourcescanbeused

wheretheoperatingconditionsallowitandalwaysarecomparable

todistrictheating.

Application

Thesubstationisdesignedtobeconnectedtothehouse

installationinafrost-freeroom,wherethetemperaturedoesnot

exceed50°Candthehumiditydoesnotexceed60%.Donotcover

orwallupthesubstationorinanyotherwayblocktheentrance

tothestation.

Authorizedpersonnelonly

Assembly,start-upandmaintenanceworkmustbeperformedby

qualifiedandauthorizedpersonnelonly.

Pleaseobserveinstructionscarefully

Toavoidinjurytopersonsanddamagetothedevice,itisabsolutely

necessarytoreadandobservetheseinstructionscarefully.

Warningofhighpressureandtemperature

Beawareoftheinstallation’spermissiblesystempressureand

temperature.

Themaximumtemperatureoftheflowmediuminthesubstationis

120°C.

Themaximumoperatingpressureofthesubstationis10bar.PN16

versionsareavailableonenquiry.

Theriskofpersonsbeinginjuredandequipmentdamagedincreases

considerablyiftherecommendedpermissibleoperatingparameters

areexceeded.

Thesubstationinstallationmustbeequippedwithsafetyvalves,

however,alwaysinaccordancewithlocalregulations.

Choiceofmaterial

Choiceofmaterialsalwaysincompliancewithlocallegislation.

Safetyvalve(s)

Werecommendmountingofsafetyvalve(s),however,alwaysin

compliancewithlocalregulations.

Connection

Thesubstationmustbeequippedwithfeaturesthatensurethat

thesubstationcanbeseparatedfromallenergysources(also

powersupply).

Emergency

Incaseofdangeroraccidents-fire,leaksorotherdangerous

circumstances-interruptallenergysourcestothestationif

possible,andseekexperthelp.

Incaseofdiscolouredorbad-smellingdomestichotwater,closeall

shut-offvalvesonthesubstation,informtheoperatingpersonnel

andcallforexperthelpimmediately.

REACH

AllDanfossA/SproductsfulfilltherequirementsinREACH.

OneoftheobligationsinREACHistoinformcustomersabout

presenceofCandidatelistsubstancesifany,weherebyinform

youaboutonesubstanceonthecandidatelist:Theproduct

containsbrasspartswhichcontainslead(CASno:7439-92-1)ina

concentrationabove0.1%w/w.

Storage

Anystorageofthesubstationwhichmaybenecessarypriorto

installationshouldbeinconditionswhicharedryandheated.

Warningofhotsurface

Thesubstationhasgothotsurfaces,whichcancauseskinburns.

Pleasebeextremelycautiousincloseproximitytothesubstation.

Powerfailurecanresultinthemotorvalvesbeingstuckinopen

position.Thesurfacesofthesubstationcangethot,whichcancause

skinburns.Theballvalvesondistrictheatingsupplyandreturnshould

beclosed.

Warningoftransportdamage

Beforesubstationinstallation,pleasemakesurethatthesubstation

hasnotbeendamagedduringtransport.

IMPORTANT-Tighteningofconnections

Duetovibrationsduringtransportallflangeconnections,screwjoints

andelectricalclampandscrewconnectionsmustbecheckedand

tightenedbeforewaterisaddedtothesystem.Afterwaterhasbeen

addedtothesystemandthesystemhasbeenputintooperation,

re-tightenALLconnections.

4|©Danfoss|2019.05

VM.IE.C3.02/LUK40143

Page 5

OperatingGuideT ermixVMTD-Iwithcompleteinsulation

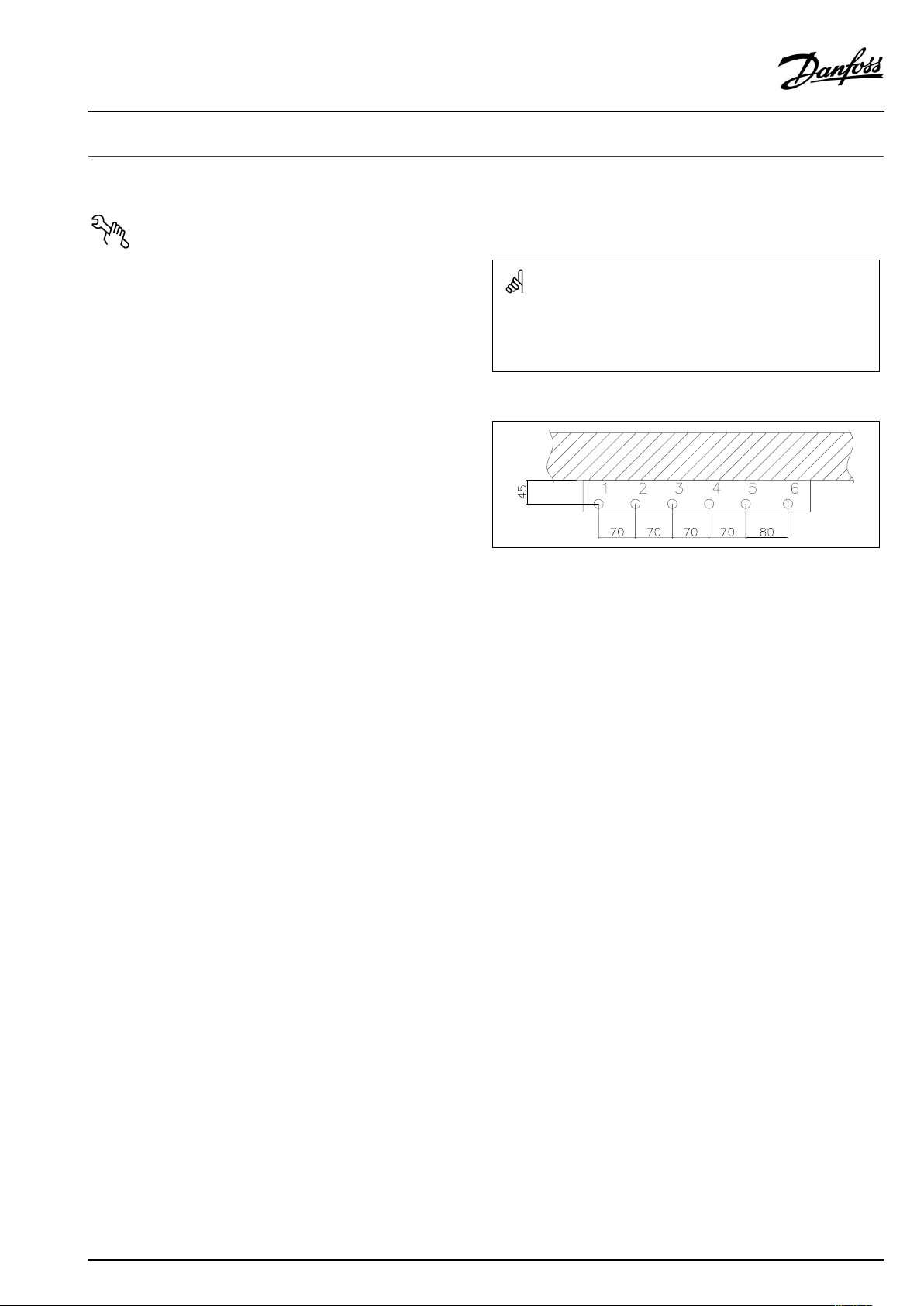

4.0Mounting

4.1Mounting

Installationmustbeincompliancewithlocalstandardsand

regulations.

Districtheating(DH)-Inthefollowingsections,DHreferstothe

heatsourcewhichsuppliesthesubstations.Avarietyofenergy

sources,suchasoil,gasorsolarpower,couldbeusedasthe

primarysupplytoDanfosssubstations.Forthesakeofsimplicity,

DHcanbetakentomeantheprimarysupply.

Connections:

1.Districtheating(DH)supply

2.Districtheating(DH)return

3.Heating(HE)supply

4.Heating(HE)return

5.Domestichotwater(DHW)

6.Domesticcoldwater(DCW)

Authorizedpersonnelonly

Assembly,start-upandmaintenanceworkmustbeperformedby

qualifiedandauthorizedpersonnelonly.

Connectionsizes:

DH+HE:

DCW+DHW:

Dimensions(mm):

Withinsulation:

H610xW540xD345

Weight(approx.):15kg

Thepipeplacementcandeviatefromtheshowndrawing.Pleasenote

themarkingsonthestation.

G¾”(int.thread)

G¾”(int.thread)

VM.IE.C3.02/LUK40143

©Danfoss|2019.05|5

Page 6

OperatingGuideT ermixVMTD-Iwithcompleteinsulation

4.1.1Installation

Mounting:

Adequatespace

Pleaseallowadequatespacearoundthesubstationformounting

andmaintenancepurposes.

Orientation

Thestationmustbemountedsothatcomponents,keyholes

andlabelsareplacedcorrectly.Ifyouwishtomountthestation

differentlypleasecontactyoursupplier.

Drillings

Wheresubstationsaretobewall-mounted,drillingsareprovided

inthebackmountingplate.Floormountedunitshavesupport.

Labelling

Eachconnectiononthesubstationislabelled.

Beforeinstallation:

Cleanandrinse

Priortoinstallation,allsubstationpipesandconnectionsshouldbe

cleanedandrinsed.

Keyholeformounting.

Tightening

Duetovibrationduringtransport,allsubstationconnectionsmust

becheckedandtightenedbeforeinstallation.

Unusedconnections

Unusedconnectionsandshut-offvalvesmustbesealedwitha

plug.Shouldtheplugsrequireremoval,thismustonlybedoneby

anauthorizedservicetechnician.

Installation:

Strainer

Ifastrainerissuppliedwiththestationitmustbefittedaccording

toschematicdiagram.Pleasenotethatthestrainermaybe

suppliedloose.

Connections

Internalinstallationanddistrictheatingpipesconnectionsmustbe

madeusingthreaded,flangedorweldedconnections.

6|©Danfoss|2019.05

VM.IE.C3.02/LUK40143

Page 7

OperatingGuideT ermixVMTD-Iwithcompleteinsulation

4.2Start-up

Start-up,Directheating

Theshut-offvalvesshouldbeopenedandtheunitobservedas

itentersservice.Visualcheckingshouldconfirmtemperatures,

pressures,acceptablethermalexpansionandabsenceofleakage.

Iftheheatexchangeroperatesinaccordancewithdesign,itcanbe

puttoregularuse.

Afterwaterhasbeenaddedtothesystemandthesystemhasbeen

putintooperation,re-tightenALLconnections.

Re-thightenconnections

Afterwaterhasbeenaddedtothesystemandthesystemhasbeen

putintooperation,re-tightenALLconnections.

VM.IE.C3.02/LUK40143

©Danfoss|2019.05|7

Page 8

OperatingGuideT ermixVMTD-Iwithcompleteinsulation

5.0Design

5.1Design

Yoursubstationmightlookdifferentthanthesubstationshown.

Designdescription

B

Heatexchanger,DHW

N

Circulationconnection

9

Strainer

14

Sensorpocket,energymeter

8|©Danfoss|2019.05

31

Differentialpressurecontroller

41

Fittingpiece,energymeter

63

Sieve

74

IHPTcontroller,DHW

VM.IE.C3.02/LUK40143

Page 9

OperatingGuideT ermixVMTD-Iwithcompleteinsulation

5.2Schematicdiagram

DHW

DCW

DH

Supply

DH

Return

Yoursubstationmightlookdifferentthantheschematicdiagramshown.

Schematicdescription

B

Heatexchanger,DHW

1

Ballvalve

9

Strainer

DHW:DomesticHotWater

DCW:

DHSupply:DistrictHeatingSupply

DHReturn:DistrictHeatingReturn

HESupply:HeatingSupply

HEReturn:HeatingReturn

DomesticColdWater

14

Sensorpocket,heatmeter

31

Differentialpressurecontroller

39

Connectionclosed

41

Fittingpiece,energymeter

63

Sieve

74

IHPTcontroller

HE

Supply

HE

Return

5.2.1Technicalparameters

Technicalparameters

Nominalpressure:PN10(PN16versionsareavailableonenquiry)

Max.DHsupplytemperature:

Min.DCWstaticpressure:

Brazingmaterial(HEX):

Heatexchangerstestpressure:30bar

Soundlevel:≤55dB

VM.IE.C3.02/LUK40143

120°C

1.0bar

Copper

©Danfoss|2019.05|9

Page 10

OperatingGuideT ermixVMTD-Iwithcompleteinsulation

6.0Controls

6.1Heatingcircuit

6.1.1Differentialpressurecontroller

Thedifferentialpressurecontrollersmoothsoutthefluctuationsin

pressurearrivingfromthedistrictheatingnetwork.Theoperating

pressureinthesubstationisthusheldsteady.

10|©Danfoss|2019.05

VM.IE.C3.02/LUK40143

Page 11

OperatingGuideT ermixVMTD-Iwithcompleteinsulation

6.2DHWtemperaturecontrol

DHWtemperaturecontrol

TherearevarioustypesofDHWtemperaturecontrolusedin

Danfosssubstations.

DHWtemperatureshouldbeadjustedto45-50°C,asthisprovides

optimalutilisationofDHwater.AtDHWtemperaturesabove55°C,

thepossibilityoflimescaledepositsincreasessignificantly.

6.2.1IHPT90controller(45–65°)

IHPTisaself-actingflow-compensatedtemperaturecontrollerwith

integrateddifferentialpressurecontroller.

TheIHPToperatesatitsbestatDHsupplytemperaturesofupto

100°C.

Byturningthehandlefortemperaturesettingin(+)direction

thesettingisincreased,byturningitin(-)directionthesettingis

decreased.

Turns*

0

1

2

3

4

5

6

7

*Startposition:Handleturnedfullyin(+)direction.

Thevaluesareintendedasaguide.

Scale

7

661

5

455

352

248

144

043

DHWT emperatureSetting[°C]

64

58

VM.IE.C3.02/LUK40143

©Danfoss|2019.05|11

Page 12

OperatingGuideT ermixVMTD-Iwithcompleteinsulation

6.3Other

6.3.1Safetyvalve

Thepurposeofthesafetyvalveistoprotectthesubstationfrom

excessivepressure.

Theblow-offpipefromthesafetyvalvemustnotbeclosed.The

blow-offpipeoutletshouldbeplacedsothatitdischargesfreely

anditispossibletoobserveanydrippingfromthesafetyvalve.

Itisrecommendedtochecktheoperationofsafetyvalvesat

intervalsof6months.Thisisdonebyturningthevalveheadin

directionindicated.

6.3.2Strainer

Strainersshouldbecleanedregularlybyauthorizedpersonnel.The

frequencyofcleaningwoulddependonoperatingconditionsand

themanufacturer’sinstructions.

6.3.3GTUPressureEqualizer

TheGTUPressureEqualizerabsorbstheexpansiononthe

secondarysideoftheTermixwaterheatersandcanbeusedasa

substitutetothesafetyvalve.

Furthermorethepressureequalizerabsorbsapossibleincreasein

pressure,soadischargeoutletisomitted.

TheGTUPressureEqualizermaynotbeappliedinsystemswithhot

watercirculation.

12|©Danfoss|2019.05

VM.IE.C3.02/LUK40143

Page 13

OperatingGuideT ermixVMTD-Iwithcompleteinsulation

6.3.4Fittingpiece

Thesubstationisequippedwithafittingpieceforenergymeter.

Assemblyofenergymeters:

1:Closeballvalves

ClosetheballvalvesonDHSupplyandDHReturn,ifthereiswater

onthesystem.

2:Loosennuts

Loosenthenutsonthefittingpiece.

3:Removefittingpiece

Removethefittingpieceandreplaceitwiththeenergymeter.Do

notforgetthegaskets.

4:Tightenconnections

Aftermountingoftheenergymeterremembertocheckand

tightenallthreadedconnections.

Sensorpocket,energymeter

Thesensorsoftheenergymeterismountedinthesensorpockets.

VM.IE.C3.02/LUK40143

©Danfoss|2019.05|13

Page 14

OperatingGuideT ermixVMTD-Iwithcompleteinsulation

6.4Extras

6.4.1Circulationpipe

Thecirculationpipesetismounteddirectlyonthecontroller.

Thesetincludescirculationpipe,singlecheckvalveandfitting.

Whenmountingthehotwatercirculationdirectlyonthecontroller

thehotwatercirculationtemperaturewillbeequaltotheidle

temperature.Theidletemperatureisafewdegreeslowerthanthe

setdomestichotwatertemperature.

14|©Danfoss|2019.05

VM.IE.C3.02/LUK40143

Page 15

OperatingGuideT ermixVMTD-Iwithcompleteinsulation

6.5Mountingplateforenergymeterdisplay

Bracketforthedisplayoftheenergymeterdeliveredloosewith

theDistrictHeatingsubstation.

Mountthewallclipforthedisplayontothebracket.

Fixthebracketontothepipeclipsusingapairofpliers.

Slidethedisplayoftheenergymeterontheclip.

ThedisplayisnowneatlypositionedbelowtheDistrictHeating

substation.

VM.IE.C3.02/LUK40143

©Danfoss|2019.05|15

Page 16

OperatingGuideT ermixVMTD-Iwithcompleteinsulation

6.6Maintenance

Thesubstationrequireslittlemonitoring,apartfromroutine

checks.Itisrecommendedtoreadtheenergymeteratregular

intervals,andtowritedownthemeterreadings.

RegularinspectionsofthesubstationaccordingtothisInstruction

arerecommended,whichshouldinclude:

Strainers

Cleaningofstrainers.

Meters

Checkingofalloperatingparameterssuchasmeterreadings.

Temperatures

Checkingofalltemperatures,suchasDHsupplytemperatureand

DHWtemperature.

Connections

Checkingallconnectionsforleakages.

Safetyvalves

Theoperationofthesafetyvalvesshouldbecheckedbyturning

thevalveheadintheindicateddirection.

Venting

Checkingthatthesystemisthoroughlyvented.

Authorizedpersonnelonly

Assembly,start-upandmaintenanceworkmustbeperformedby

qualifiedandauthorizedpersonnelonly.

Inspectionsshouldbecarriedoutminimumeverytwoyears.

SparepartscanbeorderedfromDanfoss.Pleaseensurethatany

enquiryincludesthesubstationserialnumber.

16|©Danfoss|2019.05

VM.IE.C3.02/LUK40143

Page 17

OperatingGuideT ermixVMTD-Iwithcompleteinsulation

7.0Troubleshooting

7.1Troubleshootingingeneral

Intheeventofoperatingdisturbances,thefollowingbasicfeatures

shouldbecheckedbeforecarryingoutactualtroubleshooting:

•thesubstationisconnectedtoelectricity,

•thestrainerontheDHsupplypipeisclean,

•thesupplytemperatureoftheDHisatthenormallevel

(summer,atleast60°C-winter,atleast70°C),

•thedifferentialpressureisequaltoorhigherthanthenormal

(local)differentialpressureintheDHnetwork–ifindoubt,ask

theDHplantsupervisor,

•pressureonthesystem-checktheHEpressuregauge.

Authorizedpersonnelonly

Assembly,start-upandmaintenanceworkmustbeperformedby

qualifiedandauthorizedpersonnelonly.

VM.IE.C3.02/LUK40143

©Danfoss|2019.05|17

Page 18

OperatingGuideT ermixVMTD-Iwithcompleteinsulation

7.2TroubleshootingDHW

ProblemPossiblecauseSolution

ToolittleornoDHW.

Taptemperaturetoohigh;DHWtapload

toohigh.

Temperaturedropduringtapping.

Thermostaticcontrolvalvedoesnotclose

Idletemperaturetoolow(forstations

equippedwithIHPT).

Strainerinsupplyorreturnlineclogged.Cleanstrainer(s).

DHWcirculationpumpoutoforderorwith

toolowsetting.

Defectiveorcloggednon-returnvalve.

Noelectricity.Check.

Wrongsettingofautomaticcontrols,ifany.Toadjustanelectroniccontrollerfor

Scalingoftheplateheatexchanger.

Defectivemotorizedvalve.Check(usemanualfunction)–replace.

Defectivetemperaturesensors.

Defectivecontroller.

DCWisbeingmixedwiththeDHW,e.g.ina

defectivethermostaticmixingvalve.

Defectiveorcloggednon-returnvalveon

circulationvalve.

Thermostaticvalveadjustedtoatoohigh

level.

Scalingoftheplateheatexchanger.

LargerDHWflowthanthesubstationhas

beendesignedfor.

TemperaturedifferencebetweenDH

supplyandDHWsetpointtoolow.

Setpointtoolow.Turnthermostatin(+)direction.

Checkcirculationpump.

Replace–clean.

DHW,pls.noteenclosedinstructionsfor

electroniccontroller.

Replace–rinseout.

Check–replace.

Check–replace.

Check–replace. Hotwaterinsometapsbutnotinall.

Replace–clean.

Check–set.

Replace–rinseout.

ReduceDHWflow.

Lowerthesetpointtemperatureorincrease

theDHsupplytemperature.

18|©Danfoss|2019.05

VM.IE.C3.02/LUK40143

Page 19

OperatingGuideT ermixVMTD-Iwithcompleteinsulation

7.3TroubleshootingHE

ProblemPossiblecauseSolution

Toolittleornoheat.StrainercloggedinDHorHEcircuit

Unevenheatdistribution.Airpocketsinthesystem.Venttheinstallationthoroughly.

DHsupplytemperaturetoohigh.

DHsupplytemperaturetoolow.

(radiatorcircuit).

ThefilterintheenergymeteronDHcircuit

clogged.

Defectiveorwronglyadjusteddifferential

pressurecontroller.

Sensordefective–orpossiblydirtinthe

valvehousing.

Automaticcontrols,ifany,wronglysetor

defective-possiblypowerfailure.

Pumpoutofoperation.Checkifthepumpisreceivingpowerand

Thepumpissetattoolowspeedof

rotation.

Pressuredrop–thepressuredropon

theradiatorcircuitshowslowerthan

recommendedoperatingpressure.

Airpocketsinthesystem.Venttheinstallationthoroughly.

Limitingofthereturntemperatureadjusted

toolow.

Defectiveradiatorvalves.

Unevenheatdistributioninbuilding

becauseofincorrectlysetbalancingvalves,

orbecausetherearenobalancingvalves.

Diameterofpipetosubstationtoosmallor

branchpipetoolong.

Wrongsettingofthermostatorof

automaticcontrols,ifany.

Defectivecontroller.Thecontrollerdoes

notreactasitshouldaccordingtothe

instructions.

Defectivesensoronself-actingthermostat.

Wrongsettingofautomaticcontrols,ifany.

Defectivecontroller.Thecontrollerdoes

notreactasitshouldaccordingtothe

instructions.

Defectivesensoronself-actingthermostat.

Wrongplacement/fittingofoutdoor

temperaturesensor.

Strainerclogged.Cleangate/strainer.

Cleangate/strainer(s).

Cleanthefilter(afterconsultingtheDH

plantoperator).

Checktheoperationofthedifferential

pressurecontroller–cleanthevalveseatif

required.

Checktheoperationofthethermostat–

cleanthevalveseatifrequired.

Checkifthesettingofthecontroller

iscorrect–seeseparateinstructions.

Checkthepowersupply.Temporary

settingofmotorto“manual”control–see

instructionsonautomaticcontrols.

thatitturns.Checkifthereisairtrappedin

thepumphousing–seepumpmanual.

Setthepumpathigherspeedofrotation.

Fillwateronthesystemandcheckthe

functioningofthepressureexpansion

vesselifrequired.

Adjustaccordingtoinstructions.

Check–replace.

Adjust/installbalancingvalves.

Checkpipedimensions.

Adjustautomaticcontrols,–see

instructionsforautomaticcontrols.

Callautomaticcontrolsmanufactureror

replacetheregulator.

Replacethermostat–orsensoronly.

Adjustautomaticcontrols–seeinstructions

forautomaticcontrols.

Callinautomaticcontrolsmanufactureror

replacecontroller.

Replacethermostat–orsensoronly.

Adjustlocationofoutdoortemperature

sensor.

VM.IE.C3.02/LUK40143

©Danfoss|2019.05|19

Page 20

OperatingGuideT ermixVMTD-Iwithcompleteinsulation

ToohighDHreturntemperature.

Noiseinsystem.

Heatloadtoohigh.

Toosmallheatingsurface/toosmall

radiatorscomparedtothetotalheating

requirementofthebuilding.

Poorutilizationofexistingheatingsurface.

Defectivesensoronself-actingthermostat.

Thesystemissinglepipeloop.

Pumppressuretoohigh.Adjustpumptoalowerlevel.

Airinsystem.

Defectiveorincorrectlysetradiatorvalve(s).

Singlepipeloopsystemsrequirespecial

one-piperadiatorvalves.

Dirtinthemotorizedvalveorinthe

differentialpressurecontroller.

Defectivemotorizedvalve,sensoror

automaticcontroller.

Electroniccontrollernotadjustedcorrectly.Adjustaccordingtoinstructions.

Pumppressuretoohigh.Adjustpumptoalowerlevel.

Defectivemotorizedvalve,sensoror

electroniccontroller.

Increasetotalheatingsurface.

Makesuretheheatisdistributedevenly

acrossthefullheatingsurface–openall

radiatorsandkeeptheradiatorsinthe

systemfromheatingupatthebottom.It

isextremelyimportanttokeepthesupply

temperaturetotheradiatorsaslowas

possible,whilemaintainingareasonable

levelofcomfort.

Thesystemshouldfeatureelectronic

controlsaswellasreturnsensors.

Ventthesystem.

Check–set/replace.

Check–cleanout.

Check–replace.

Check–replace.

20|©Danfoss|2019.05

VM.IE.C3.02/LUK40143

Page 21

OperatingGuideT ermixVMTD-Iwithcompleteinsulation

7.4Disposal

Disposal

Thisproductshouldbedismantledanditscomponents

sorted,ifpossible,invariousgroupsbeforerecycling

ordisposal.

Alwaysfollowthelocaldisposalregulations.

VM.IE.C3.02/LUK40143

©Danfoss|2019.05|21

Page 22

OperatingGuideT ermixVMTD-Iwithcompleteinsulation

8.0Declaration

8.1Declarationofconformity

Category0withoutelectricalequipment

22|©Danfoss|2019.05

VM.IE.C3.02/LUK40143

Page 23

OperatingGuideT ermixVMTD-Iwithcompleteinsulation

Category0withelectricalequipment

VM.IE.C3.02/LUK40143

©Danfoss|2019.05|23

Page 24

OperatingGuideT ermixVMTD-Iwithcompleteinsulation

24|©Danfoss|2019.05

VM.IE.C3.02/LUK40143

Loading...

Loading...