Page 1

Data sheet

2 - way seated valve (PN 16)

VMA - external thread

Description

Ordering

Example:

2-way seated valve, DN 15; kVS 1,6;

PN 16; t

- 1× VMA DN 15 valve

Option:

- 1× Weld-on tailpieces

130 °C; ext. thread

max

Code No: 065F2034

Code No: 003H6908

It can be combined with:

- ABV thermohydraulic actuators and

- VMA DN 15 can additionally be combined

with self-acting thermostatic actuators RAVI,

RAVK and RAVV

All sizes have external thread for flat packing

(DIN 7603).

Main data:

• DN15

• kVS 0,25 - 2,5 m3/h

• PN16

• Temperature:

- Circulation water / glycolic water up to 30 %:

2 … 130 °C

VMA is 2-way seated valve primarily for use in

district heating systems.

• Connections:

- Ext. thread (weld-on and thread tailpieces)

VMA valve

Picture

DN k

(mm) (m3/h)

15

VS

0,25

0,4 065F2031

0,63 065F2032

1,0 065F2033

1,6 065F2034

2,5 065F2035

Cylindrical external thread

acc. to ISO 228/1

Connec tion Code No.

G ¾ A

Accessories

Picture Type designations DN Connec tion Code No.

Weld-on tailpieces 15 - 003H6908

External thread tailpieces 15

Conical ex t. thread acc.

to EN 10226-1

R ½ 003H6902

065F2030

DEN-SMT/SI

Service kits

Picture Type designations Code No.

1)

The produc ts can only be ordered in mult iple packing containing 10 pieces ea ch

VD.52. J8.02 © Danfoss 12/2011

Valve stuffing box 065F0006

1)

1

Page 2

Data sheet 2 - way seated valve VMA (PN 16)

Technical data

Valve

Nomina l diameter DN 15

k

value m3/h 0,25 0,4 0,63 1,0 1,6 2,5

VS

Stroke mm 3

Control ratio 1:50

Control characteristic Approximately linear

Cavitation factor z ≥ 0.5

Leakage acc. to standard IEC 534 0,05 %

Nominal pressure PN 16

Medium Circulation water / glycolic water up to 30 %

Medium pH Min. 7, max. 10

Medium temperature

Connections

Materi als

Valve body Dezincing free brass

Valve seat Stainless steel 18/8, mat. No. 1.4305, DIN 17440, SS 14.23.46

Valve cone EPDM

Spindle Dezincing free brass

Valve insert Dezincing free brass

Valve stuffing box Dezincing free brass

o

C 2 … 130

valve Ext. thread

tailpieces Weld-on and external thread

Max. differential pressure

Nomina l diameter DN 15

k

value m3/h 0,25 0,4 0,63 1,0 1,6 2,5

VS

RAVI / RAVV

RAVK 3,0 3,0 1,5 1,5 1,5 0,5

ABV 7,0 7,0 7,0 7,0 7,0 4,0

bar

5,0 5,0 2,0 2,0 2,0 1,0

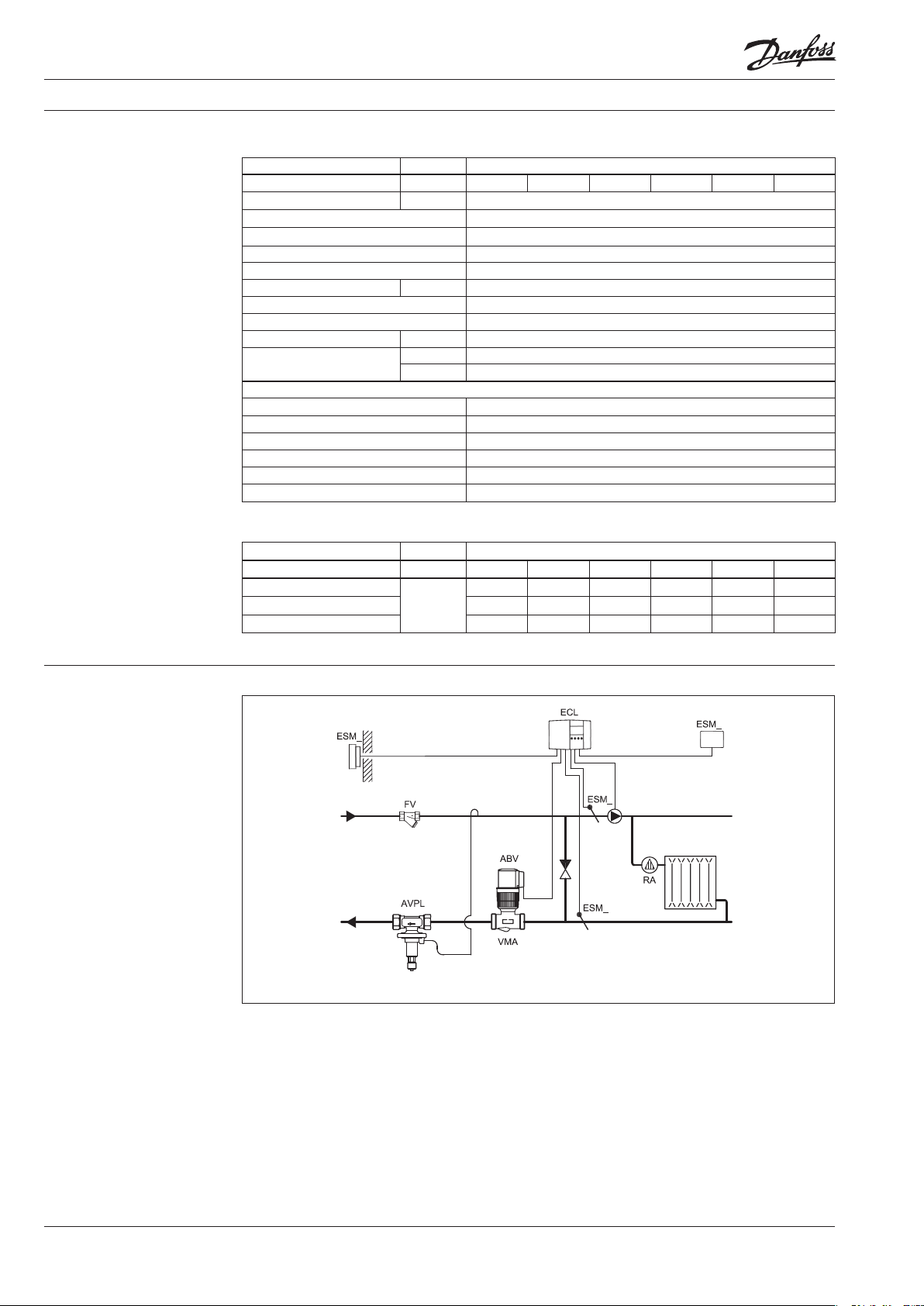

Application principle

Direct-connected heating system

2

VD.52. J8.02 © Danfoss 12/2011

DEN-SMT/SI

Page 3

Data sheet 2 - way seated valve VMA (PN 16)

Sizing

DEN-SMT/SI

Given data:

P

= 9,3 kW

max

∆t = 20 K

∆pv = 0,2 bar

P

- heating power (kW)

max

∆t -temperature difference (K)

∆pv - differential pressure across the valve

Maximum flow Q

calculated according to formula:

max

= 0,4 m3/h

max

max

Q

Q

VD.52. J8.02 © Danfoss 12/2011

(m3/h) through the valve is

max

86,0P

t

20

86,03,9

kv value is calculated according to formula:

Q

max

k

V

p

4,0

2,0

v

kV = 0,89 m3/h

Chosen kVS = 1,0 m3/h

or read from the sizing diagram by taking a line

through Q scale (0,4 m3/h) and ΔpV scale (0,2 bar)

to intersect kV-scale at 0,89 m3/h

Chosen kVS = 1,0 m3/h

Solution:

The example selects ext. thread seated valve

VMA DN 15, kVS value 1,0

3

Page 4

110

Data sheet 2 - way seated valve VMA (PN 16)

Dimensions

VMA DN 15 + RAVI-RAVK VMA DN 15 + RAVV

98

115

VMA DN 15 + ABV

Type

VMA 15 65 131 139 G ¾ A R ½ 0.26

L L1 L2 a b Weight

(mm) (mm) (mm) ISO 228/1 ISO 7/1 (kg)

Weld-on tailpieces External thread tailpieces

G Ød L Weight

(mm) (mm) (mm) (kg)

15 15 35 0.18

G R L Weight

(“) (“) (mm) (kg)

¾ ½ 25.5 0.17

4

VD.52. J8.02

ProducedbyDanfossA /S©12/2011

Loading...

Loading...