Data sheet

Pressure balanced valves (PN 25)

VM 2 – 2-way valve, external thread

VB 2 – 2-way valve, ange

Description

VM 2 VB 2

Ordering

Example:

2-way valve VM 2; DN 15; kVS 1,6;

PN 25; t

- 1× VM 2 DN 15 valve

Option:

- 1× Tailpieces

Code No.: 003H6908

150 °C; ext. thread

max

Code No.: 06 5B2014

VM 2 and VB 2 are two-way valves designed to

work with Danfoss electric actuators AMV(E)10,

AMV(E) 20, AMV(E) 30 or Danfoss electric

actuators with spring return function AMV(E) 13,

AMV(E) 23 and AMV(E) 33.

These VM 2 and VB 2 valves are generally

recommended for use in most demanding

conditions in systems such as:

- district heating,

- heating

- hot water service with heat exchanger or

storage tank where they ensure long and

unproblematic performance.

Features:

• SPLIT characteristic developed for most

demanding applications

• High closing p with small sized actuators

• Several kVS values

VM 2 (ext. thread)

Ext. thread k

DN

ISO 228/1 (m3/h) (mm)

15 G ¾ A

20 G 1 A

25 G 1¼ A

G 1½ A 10 7 065 B2018

32

G 1⁄ A 10 7 065B2029

40 G 2 A 16 10 065 B2019

50 G 2½ A 25 10 065B2020

Stroke

VS

0,25 5 065 B2010

0,4 5 0 65B 2011

0,63 5 06 5B2012

1,0 5 06 5B2013

1,6 5 06 5B2014

2,5 5 06 5B2015

4,0 5 065B2026

4,0 5 065 B2016

6,3 7 065B2027

6,3 5 06 5B20 17

8,0 5 065B2028

Code No.

• Push connection for easy mechanical

connection with actuator

• Control range min. 50:1

Benefits:

• Fast and stable regulation

• More comfort due to stable DHW temp.

• Energy saving due to stable control

• Longer lifetime of components due to less

temperature oscillation

Main data:

• DN 15-50

• kVS 0,25-40 m3/h

• PN 25

• Temperature:

- Circulation water/glycolic water up to 30 %:

2 … 150 °C

• Connections:

- External thread

- Flange

VB 2 (flange)

1)

k

DN

15

20 6,3 5 065B2057

25 10 7 065B2058

32 16 10 065B2059

40 25 10 065B2060

50 40 10 065B2061

1)

kVS according to VDI/ VDE 2173

VS

(m3/h) (mm)

0,25 5 065B2050

0,4 5 065B2051

0,63 5 065B2052

1,0 5 065B2053

1,6 5 065B2054

2,5 5 065B2055

4,0 5 065B2056

Stroke

Code No.

© Danfoss | 2017.03

ED.LH.M4.02 | 1

Data sheet VM 2, VB 2

Ordering (continuous)

Technical data

Spare parts VM 2

Valve insert

Valve s ize Code No.

DN 15/1,0 065B2033

DN 15/1,6 065B2034

DN 15/ 2,5 065B2035

DN 15/4,0 065B2036

DN 20/4,0 065B2036

DN 20/6, 3 065B2037

DN 25/6, 3 065B2037

DN 25/8,0 065B2041

DN 32 /10 065B2038

DN 4 0/16 065B2039

DN 50/25 065B2040

Accessories for VM 2 (set of 2 tailpieces)

Ext. thread

DN

ISO 228/1

15 G ¾ A 003H6908 003H6902

20 G 1 A 003H6909 0 03H6903

25 G 1¼ A 0 03H6910 003H690 4

32 G 1⁄ A 0 03 H69 11

32 G 1½ A 003 H6914

40 G 2 A 065B2006 065B2004

50 G 2½ A 065B2007 065B2005

1)

weld-o n tailpieces (steel), ext thre ad (brass)

2)

for valve code No. 0 65B2029 (G 1⁄ A)

3)

for valve code No. 0 65B2018 (G 1½ A)

Weld-on tailpieces

Code No. Cod e No.

2)

3)

Spare parts VB 2

Stuffing box

Nominal diameter

kVS value

Stroke

Control range > 50:1

Control characteristic split characteristic

Cavitation factor z ≥ 0,5

Leakage acc. to standard IEC 534 max. 0,05% of k

Nominal pressure

Medium Circulation water / Glycolic water up to 30 %

Medium pH Min. 7, Max. 10

Medium temperature

Connections

Materials VM2 VB2

Valve body Red bronze (Rg 5) Ductile iron

Valve cover -

Valve cone, seat and stem Stainless steel

Stuffing box sealing EPDM O-rings

Valve s ize Code No.

DN 15- 50 065B2070

DN

VM 2

m3/h 0,25 0,40 0,63 1,0 1,6 2,5 4,0

VB 2 6,3 10 16 25 40

VM 2

mm 5

VB 2 5 7 10

PN

°C

VM 2

VB 2

15 20 25 32 40 50

4,0 6,3 6,3 8,0 10 16 25

5 7 5 5 7 10

VS

25

2 … 150

External thread acc. to ISO 228-1

Flange PN 25 ass. to EN 1092-2

EN-GJS-400-18-LT (GGG 40.3)

Tailpieces with

1)

ext. thread

003H6905

003H6906

1)

2)

3)

2 | © Danfoss | 2017.03

Δp closing pressure VM 2

Typ e

VM 2

DN k

(mm) (m3/h) (bar) (bar)

VS

15 0,25-4,0 16 16

20 4,0 25 25

20 6,3 16 25

25 6,3 16 25

25 8,0 16 25

32 10 16 25

40 16 - 16

50 25 - 16

AMV(E) 10/13 AMV(E) 20/ 23, 30/33

Δp closing pressure VB 2

Typ e

VB 2

DN k

(mm) (m3/h) (bar) (bar)

15-25 0, 25-10 16 16

32-50 16-40 - 16

VS

Max. closing pressure: 16bar or 25 bar (see table above) depends on valve and actuator combination.

Max. closing pressure means that the valve can close against this pressure if the pressure is applied after closing of the valve.

Max. operating pressure: 12bar (recommended 4bar to avoid high noise level and cavitation).

Max. operating pressure means no sucking will occur in entire valve stroke and valve can close against this pressure

from open position.

AMV(E) 10/13 AMV(E) 20/ 23, 30/33

ED.LH.M4.02

Data sheet VM 2, VB 2

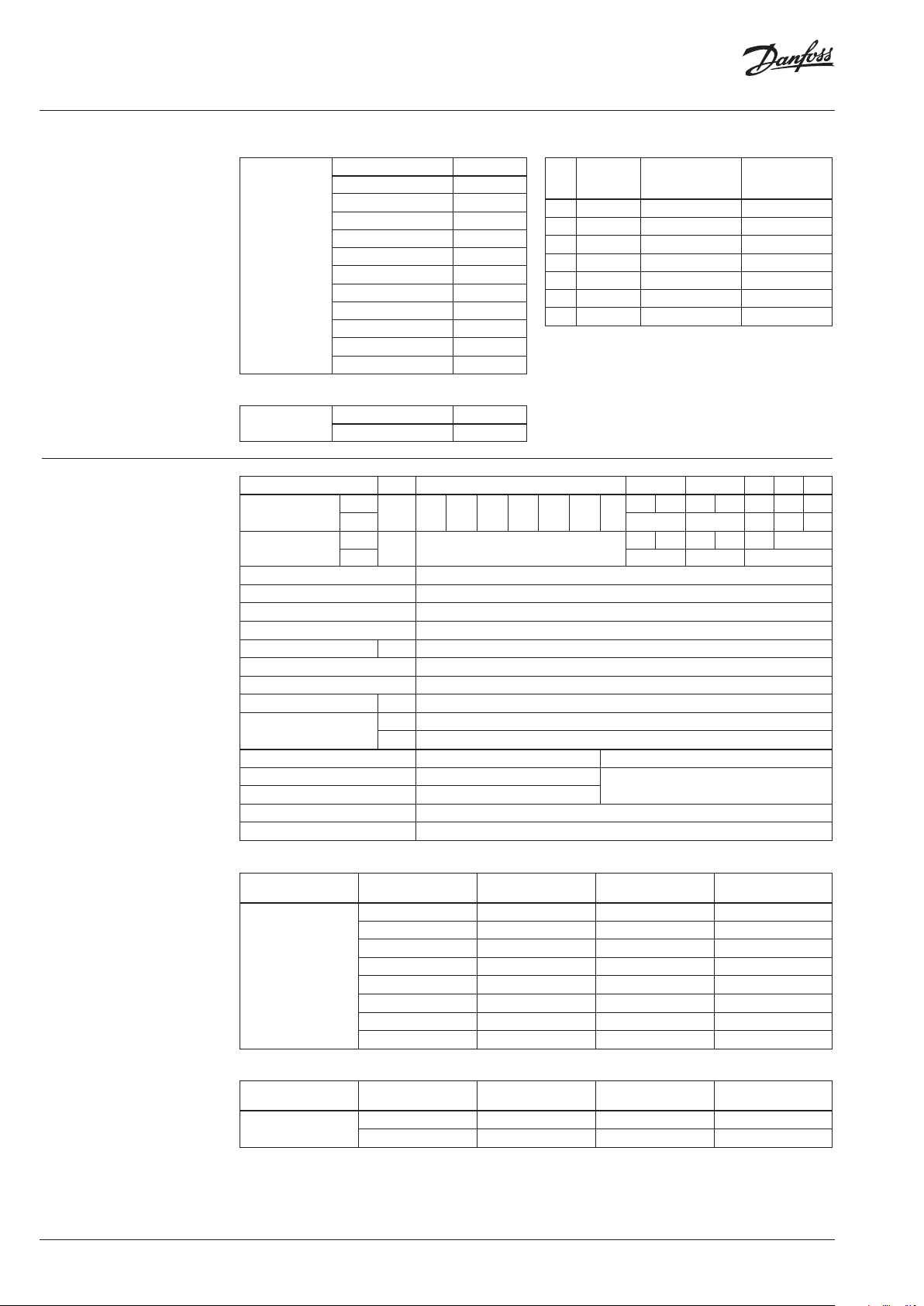

Application principles

Pressure temperature

diagram

Split characteristic

Hot water service application with heat e xchanger

Maximum allowed operating pressure as a function of medium temperature (according to EN 1092-2 and EN 1092-3).

Heating application, indirect district heating substation

EN-GJS-400 -18-LT (GGG 40.3) PN 25

CuSn5ZnPb (Rg5) PN 25

Fast and stable regulation also at small flow rates. Less temperature oscillation.

Disposal The valve must be dismantled and the elements

sorted into various material groups before

disposal.

ED.LH.M4.02

© Danfoss | 2017.03 | 3

Data sheet VM 2, VB 2

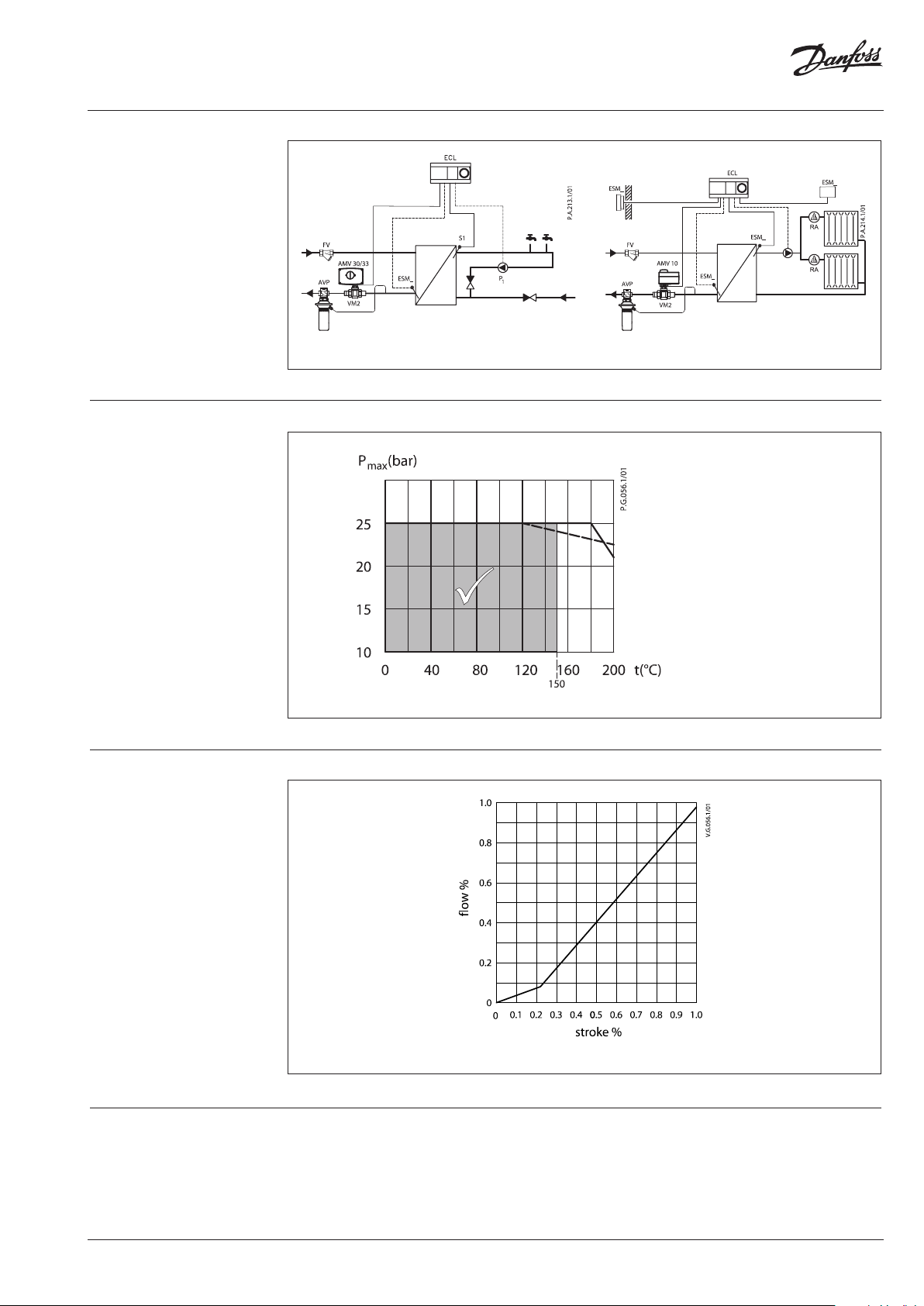

Sizing

max

p

VM 2

max

p

4 | © Danfoss | 2017.03

VB 2

ED.LH.M4.02

Data sheet VM 2, VB 2

21

1

pp

p

a authority, Valve

5,0

p2

p

a

1

1

64,0

2036

36

authorityhencevalve

41,0

2014

14

authorityhencevalve

Sizing (continuous)

Example

Design data:

Flow rate: 0,6 m3/h

System pressure drop: 20 kPa

Locate the horizontal line representing a flow

rate of 0,6 m3/h (line A-A). The valve authority is

given by the equation:

Where:

p1 = pressure drop across the fully open

valve

p2 = pressure drop across the rest of the

circuit with a full open valve

The ideal valve would give a pressure drop equal

to the system pressure drop (i.e. an authority of

0,5):

if: p1 = p

2

In this example an authority of 0,5 would be

given by a valve having a pressure drop of

20 kPa at that flow rate (point B). The intersection

of line A–A with a vertical line drawn from B lies

between two diagonal lines; this means that no

ideally-sized valve is available.

The intersection of line A–A with the diagonal

lines gives the pressure drops stated by real,

rather than ideal, valves. In this case, a valve with

kVS 1,0 would give a pressure drop of 36,0 kPa

(point C):

The second largest valve, with kVS 1,6, would give

a pressure drop of 14 kPa (point D):

Generally, the smaller valve would be selected

(resulting in a valve authority higher than 0,5

and therefore improved control). However, this

will increase the total pressure and should be

checked by the system designer for compatibility

with available pump heads, etc. The ideal

authority is 0,5 with a preferred range of

between 0,4 and 0,7.

ED.LH.M4.02

© Danfoss | 2017.03 | 5

Data sheet VM 2, VB 2

Dimensions

3

H

4

H

VM 2 + AMV(E) 10 VM 2 + AMV(E) 13 VM 2 + AMV(E) 20/30, 23/33

Typ e

H1H

VM 2 15 33 70 163 166 17 6 65 139 120 30 G ¾A 0,80

VM 2 20/4,0 33 70 163 166 176 70 15 4 131 37 G 1A 0,83

VM 2 20/6,3 33 70 163 166 176 70 15 4 131 37 G 1A 0,83

VM 2 25 38 70 163 16 6 176 75 159 14 5 46 G 1¼A 0,98

VM 2 32 38 70 163 16 6 176 100 18 4

VM 2 40 38 88 - - 194 11 0 244 200 64 G 2A 2,34

VM 2 50 44 88 - - 194 13 0 298 244 81 G 2½A 3,25

M30 ×1,5

SW

L

1

L

2

L

3

H

H

H

L

L

2

3

4

5

mm

1

Typ e DN

L3SW

2

177

63

182 G 1¾A 1, 22

kVS

(m3/h)

AMV(E) 10/13

15 0,25-4,0

2

H

20 4,0

20 6,3

1

H

VM 2

25 6,3-8,0

32 10

a

40 16

50 25

a

ISO 228/1

G 1½ A 1,18

AMV(E) 20/23;

AMV(E) 30/33

Weight

(kg)

5

H

6 | © Danfoss | 2017.03

Weld-on tailpieces

G

Ød

L

Weld on

Ød L

DN

G

(“)

mm

15 ¾ 15 35 0,18

20 1 20 40 0,26

25 1 ¼ 27 40 0,38

1 ½ 35 40 0,48

32

1 ¾ 37 40 0,48

40 2 40 65 0,90

50 2 ½ 50 82 1,70

Weight

(kg)

Tailpieces with external threads

G

L

Ext. thread

DN

G R

“

15 ¾ ½ 25,5 0,18

20 1 ¾ 28,5 0,26

25 1 ¼ 1 33 0,38

1 ½ 1 ¼ 36,5 0,62

32

1 ¾ 1 ¼ 36,5 0,62

40 2 1 ½ 43 0,9 0

50 2 ½ 2 55 1,70

L

(mm)

R

Weight

(kg)

ED.LH.M4.02

Data sheet VM 2, VB 2

Dimensions (continuo us)

M30 ×1,5

45°

1

H

DC

L

2

H

d

3

H

n

VB 2 + AMV(E) 10 VB 2 + AMV(E) 13 VB 2 + AMV(E) 20/30, 23/33

H

H

H

H

Typ e

VB 2 15

VB 2 20

VB 2 25

VB 2 32

VB 2 40

VB 2 50

1

2

3

L DC d n

4

mm

99 192 195 205 130 65 14 4 3,40

99 192 195 205 150 75 14 4 4,23

99 192 195 205 160 85 14 4 4,65

123 - - 229 180 10 0 18 4 8,40

123 - - 229 200 110 18 4 9,24

123 - - 229 230 12 5 18 4 10,91

Weight

(kg)

4

H

ED.LH.M4.02

Typ e DN

VB 2

15-2 5 0, 25-10

32-50 16-40

k

VS

(m3/h)

AMV(E) 10/13

AMV(E) 20/23;

AMV(E) 30/33

© Danfoss | 2017.03 | 7

Danf

already on order pro

All trademarks in this material are property of the respec

Data sheet VM 2, VB 2

oss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

vided that such alterations can be made without subsequential changes being necessary eady agreed.

8 | © Danfoss | DHS-SRMT/SI | 2017.03

tive companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

ED.LH.M4.02

Loading...

Loading...