Installation Guide

Pumping Smart Card

VLT® Soft Starter MCD 600

Installation Guide | Pumping Smart Card

Contents

Contents

1 Safety 5

1.1 Disclaimer 5

1.2 Warnings 5

2 Overview 6

2.1 Features of the Pumping Smart Card 6

2.1.1 Monitoring 6

2.1.2 Protection 6

2.1.3 Control 6

3 Setting up the Smart Card 7

3.1 Set-up Procedure 7

4 Installation 8

4.1 Installing the Expansion Card 8

4.2 Compatible Input Devices 8

4.3 Active and Passive 4–20 mA Input Devices 8

4.4 Minimizing Noise 9

4.5 Inputs 9

5 Operation 11

5.1 Monitoring 11

5.2 Protection and Monitoring 11

5.3 Protecting, Monitoring, and Controlling the Soft Starter 11

6 Configuration 12

6.1 Parameter Configuration 12

6.2 Off-line Configuration 12

6.3 Flow Protection 12

6.3.1 Operation 12

6.3.1.1 Using an Analog 4–20 mA Sensor 13

6.3.1.2 Using a Switch Sensor 13

6.3.1.3 Using a Pulse Sensor 13

6.3.2 Parameter Group 30-** Pump Input Configuration 14

6.3.3 Parameter Group 31-** Flow Protection 15

6.3.4 Parameter Group 36-** Pump Trip Action 15

6.4 Pressure Protection 16

6.4.1 Operation 17

6.4.1.1 Using an Analog 4–20 mA Sensor 17

6.4.1.2 Using a Switch Sensor 17

AN279052730268en-000102 / 175R1183 | 3Danfoss A/S © 2018.10

Installation Guide | Pumping Smart Card

6.4.1.3 Parameter Group 30-** Pump Input Configuration 18

6.4.1.4 Parameter Group 32-** Pressure Protection 18

6.4.1.5 Parameter Group 36-** Pump Trip Action 19

6.5 Pressure Control 20

6.5.1 Configuring Pressure Control 20

6.5.2 Operation 20

6.5.2.1 Level Control Operation 21

6.5.2.2 Pressure-based Operation 22

6.5.2.3 Parameter Group 30-** Pump Input Configuration 23

6.5.2.4 Parameter Group 33-** Pressure Control 23

6.5.2.5 Parameter Group 36-** Pump Trip Action 24

6.6 Depth Protection 24

6.6.1 Operation 25

6.6.1.1 Using an Analog 4–20 mA Sensor 25

6.6.1.2 Using a Switch Sensor 25

6.6.1.3 Parameter Group 30-** Pump Input Configuration 26

6.6.1.4 Parameter Group 34-** Depth Protection 26

6.6.1.5 Parameter Group 36-** Pump Trip Action 27

6.7 Thermal Protection 27

6.7.1 Parameter Group 35-** Thermal Protection 28

6.7.2 Parameter Group 36-** Pump Trip Action 28

Contents

7 Trip Messages 29

7.9 Pressure Sensor 31

8 Specifications 33

8.1 Connections 33

8.2 Certification 33

AN279052730268en-000102 / 175R11834 | Danfoss A/S © 2018.10

Installation Guide | Pumping Smart Card

Safety

1 Safety

1.1 Disclaimer

The examples and diagrams in this manual are included solely for illustrative purposes. The information contained in this manual is

subject to change at any time and without prior notice. Responsibility or liability is never accepted for direct, indirect, or consequential

damage resulting from the use or application of this equipment.

1.2 Warnings

WARN IN G

UNEXPECTED BEHAVIOR

When the soft starter is connected to mains voltage, the Pumping Smart Card can start or stop the motor without warning.

Unexpected behavior can lead to personal injury.

To ensure personnel safety, isolate the soft starter from mains voltage before installing the smart card.

-

WA RN IN G

RISK OF PERSONAL INJURY AND EQUIPMENT DAMAGE

Inserting foreign objects or touching the inside of the soft starter while the expansion port cover is open may endanger

personnel and can damage the soft starter.

Do not insert foreign objects in the soft starter with the port cover open.

-

Do not touch the inside of the soft starter with the port cover open.

-

NO TI CE

The hydraulic characteristics of pump systems vary considerably. The default parameter settings may not be suitable for every

application and care should be taken to configure the soft starter appropriately.

Danfoss A/S © 2018.10

AN279052730268en-000102 / 175R1183 | 5

Installation Guide | Pumping Smart Card

Overview

2 Overview

2.1 Features of the Pumping Smart Card

The Pumping Smart Card provides dedicated inputs for pressure, depth, temperature, and flow sensors to allow protection, control,

and monitoring integration in a range of pumping applications.

2.1.1 Monitoring

Data from analog or pulse sensors can be shown directly on the display of the soft starter.

A real-time graph is also available if the optional remote LCP is installed.

2.1.2 Protection

The smart card can trip the soft starter based on user-selected levels for high or low pressure, depth, temperature, or flow.

2.1.3 Control

The smart card can automatically start and stop the soft starter in response to rising or falling pressure, or rising or falling depth.

Smart card control can be used with the VLT® Soft Starter MCD 600 scheduling function to restrict starting or stopping to specified days

and times.

6 | Danfoss A/S © 2018.10

AN279052730268en-000102 / 175R1183

Installation Guide | Pumping Smart Card

Setting up the Smart Card

3 Setting up the Smart Card

3.1 Set-up Procedure

Context:

WA RN IN G

SHOCK HAZARD

Attaching or removing accessories while the soft starter is connected to mains voltage may cause personal injury.

Before attaching or removing accessories, isolate the soft starter from mains voltage.

-

Procedure

1. Insert the smart card into the soft starter.

2. Connect sensors to the inputs:

A Depth protection: B13, B14 or C13, C14

B Pressure protection: B23, B24 or C33, C34, C43, C44.

C Flow protection: B33, B34 or C23, C24.

D Motor temperature protection: R1, R2, R3.

E Pressure or depth-based control: B23, B24.

3. Configure the soft starter's auto-reset as required (parameter 6-1 Auto-Reset Count and parameter 6-2 Auto-Reset Delay).

4. Configure flow protection operation if required.

5. Configure pressure protection operation if required.

6. Configure pressure or depth-based control if required.

NO TI CE

Protection features still operate even if control is set to Off.

7. Configure depth protection if required.

8. Configure temperature protection if required.

9. Select the command source (parameter 1-1 Command Source).

• For protection and monitoring, use Digital input, Remote LCP, or Clock.

• For control, use Smart card or Smart card+Clock.

Danfoss A/S © 2018.10

AN279052730268en-000102 / 175R1183 | 7

1 2

e77ha739.10

Installation Guide | Pumping Smart Card

Installation

4 Installation

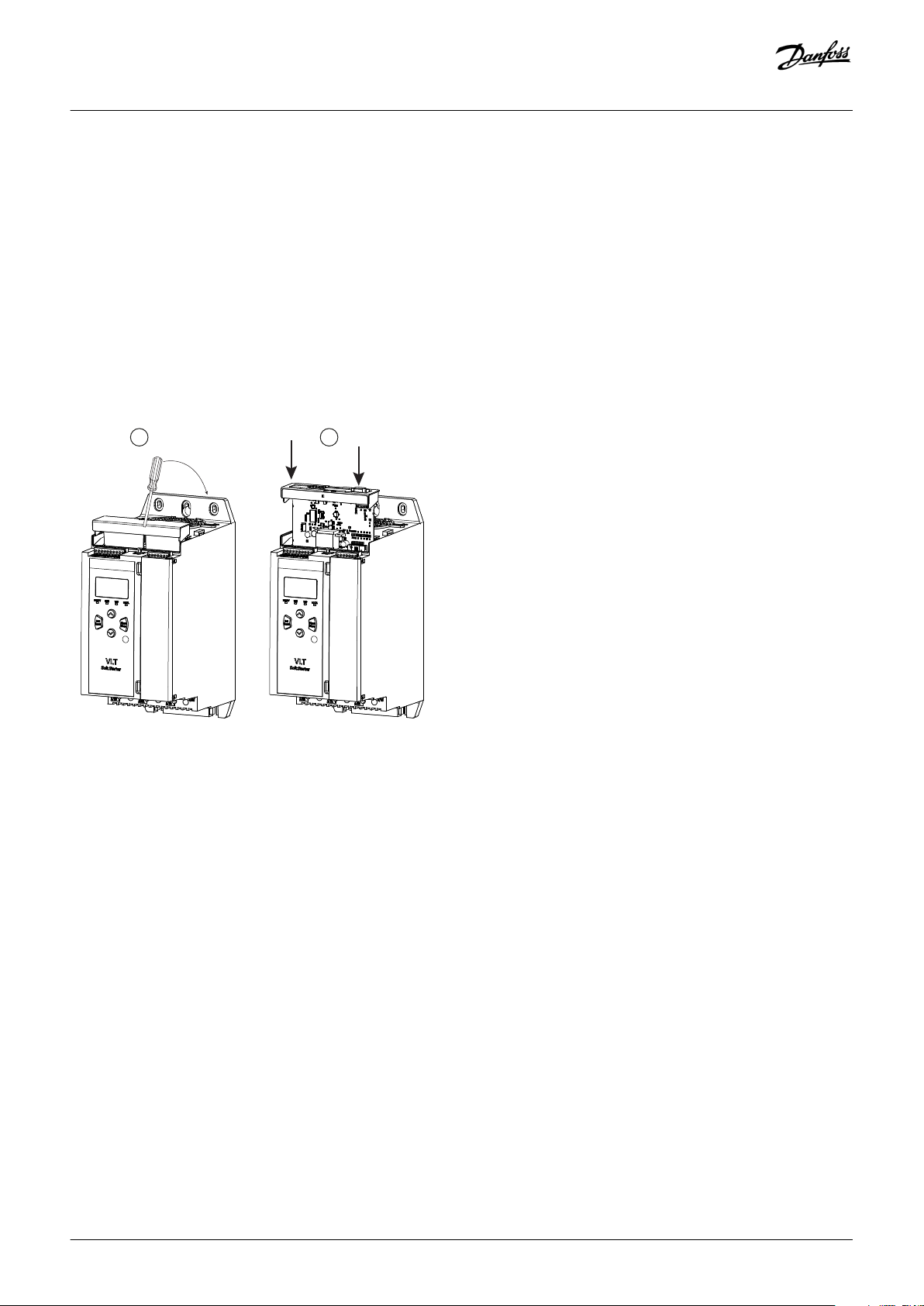

4.1 Installing the Expansion Card

Procedure

1. Push a small flat-bladed screwdriver into the slot in the center of the expansion port cover and ease the cover away from the soft

starter.

2. Line up the card with the expansion port.

3. Gently push the card along the guide rails until it clicks into the soft starter.

Example:

Illustration 1: Installation of the Expansion Cards

4.2 Compatible Input Devices

The smart card supports the following types of input devices:

• Analog 4–20 mA active (self-powered) and passive (loop-powered)

• Pulse

• Digital switch

4.3 Active and Passive 4–20 mA Input Devices

The wiring connections for 4–20 mA sensors vary depending on how the sensor is powered. This manual describes the wiring

connections for passive (loop-powered) sensors, but active (self-powered) sensors can also be used by changing the wiring

connections.

• Passive (loop-powered) sensors are powered from the 4–20 mA terminals of the smart card. For these sensors, use B13-B14, B23B24, B33-B34.

• Active (self-powered) sensors have either an internal or external power supply. The sensor is not powered from the smart card

terminals. For these sensors, connect the 0 V to terminal R1 and connect the active input to B13, B23, or B33 as required.

8 | Danfoss A/S © 2018.10

AN279052730268en-000102 / 175R1183

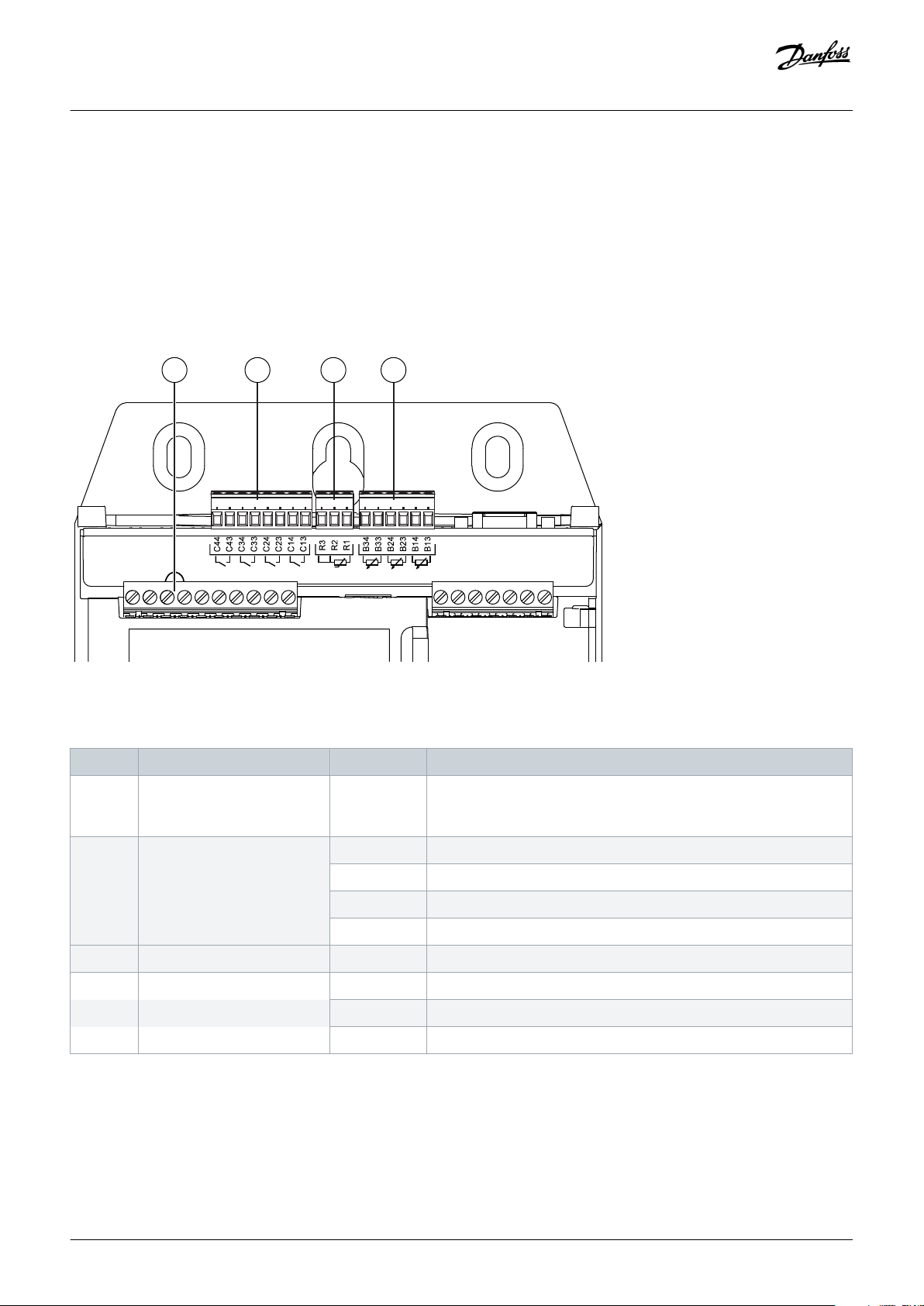

USB

DIGITAL INPUTS 4/20mA INPUTSRTD

Keypad

C24

C33

C34

C43

C13

C14

C23

C44

B14

B13B23

B24

B33

B34R2R1

R3

e77ha745.10

2

1

3

4

Installation Guide | Pumping Smart Card

Active and passive sensors can be used in the same installation.

4.4 Minimizing Noise

To minimize noise when using the analog 4–20 mA inputs, use twisted pair wiring.

4.5 Inputs

Installation

Illustration 2: Location of Inputs

Table 1: Legend to Location of Inputs

Number Function Terminals Description

1 Reset input RESET, COM+ If the reset input is active, the soft starter does not operate. If a reset

switch is not required, fit a link across terminals RESET, COM+ on the

soft starter. The reset input is normally closed by default.

2 Digital inputs (normally open) C13, C14 Depth protection

C23, C24 Flow protection and monitoring

C33, C34 Low-pressure protection

C43, C44 High-pressure protection

3 RTD/PT100 input R1, R2, R3 Motor temperature protection

4 4–20 mA inputs B13, B14 [+] Depth protection and monitoring

B23, B24 [+] Pressure protection and monitoring/pressure or depth-based control

B33, B34 [+] Flow protection and monitoring

Danfoss A/S © 2018.10

AN279052730268en-000102 / 175R1183 | 9

Installation Guide | Pumping Smart Card

NO TI CE

The reset input can be configured for normally open or normally closed operation. Use parameter 7-9 Reset/ Enable Logic to

select the configuration.

NO TI CE

FLOW PROTECTION AND MONITORING

When used with a switch sensor, C23, C24 provide flow protection only. When used with a pulse sensor, C23, C24 provide flow

protection and monitoring.

Installation

10 | Danfoss A/S © 2018.10

AN279052730268en-000102 / 175R1183

Installation Guide | Pumping Smart Card

Operation

5 Operation

5.1 Monitoring

Data from analog or pulse sensors can be shown directly on the soft starter display.

A real-time graph is also available if the optional remote LCP is installed.

• To scroll to the graph screen, press [▵] and [▿].

• To change which data is shown on the graph, press [GRAPH] on the remote LCP.

5.2 Protection and Monitoring

The smart card can stop or trip the soft starter based on user-selected levels for high or low pressure, depth, temperature, or flow.

Smart card protection features are always active while the soft starter is operating. Protection levels are set via parameter groups 31 to

35.

5.3 Protecting, Monitoring, and Controlling the Soft Starter

Context:

The smart card can automatically start and stop the soft starter in response to rising or falling pressure, or rising and falling depth.

NO TI CE

Smart card protection features are always active while the soft starter is operating. Smart card protection is not affected by the

command source.

NO TI CE

To use the smart card to control the soft starter, use sensors connected to B23, B24.

NO TI CE

If the reset input is active, the soft starter does not operate. If a reset switch is not required, fit a link across terminals RESET,

COM+ on the soft starter.

Procedure

1. Set parameter 1-1 Command Source to Smart Card or Smart Card+Clock.

2. Set parameter 33-1 Pressure Control Mode as required.

3. Set parameter 4-1 Auto-Start/Stop Mode to Enable to use clock-based scheduling.

Danfoss A/S © 2018.10

AN279052730268en-000102 / 175R1183 | 11

C

B

A

2

1

D

E

e77ha746.10

Run

Ready

Time

Installation Guide | Pumping Smart Card

Configuration

6 Configuration

6.1 Parameter Configuration

Operating parameters for the Pumping Smart Card are set and stored in the soft starter. Parameters can be configured via the main

menu or uploaded using the USB Save & Load function.

For details on how to configure the soft starter, see the VLT® Soft Starter MCD 600 Operating Guide.

In the parameter descriptions, an asterisk (*) indicates the default setting.

6.2 Off-line Configuration

NO TI CE

Parameters for smart card functions are only visible in the parameter list if the smart card is installed.

To configure smart card settings in the soft starter before the card is installed, generate a parameter file in the MCD PC Software and

load it into the soft starter using USB Save & Load.

6.3 Flow Protection

Flow protection uses terminals B33, B34 or C23, C24 on the smart card.

• B33, B34: Use an analog 4–20 mA sensor.

• C23, C24: Use a normally open digital switch sensor for protection only, or use a pulse sensor for protection and monitoring.

Flow protection is active when the soft starter is in start, stop, or run mode.

The smart card trips the soft starter when the flow rate passes through the programmed trip level. If the flow rate is still outside the

expected operating range when the trip is reset (including auto-reset), the soft starter does not trip again.

6.3.1 Operation

A Off (Ready

C Flow protection active

12 | Danfoss A/S © 2018.10

B Start signal

D Protection event (parameter 31-1 High Flow Trip Level and

parameter 31-2 Low Flow Trip Level)

1 Flow protection start delay (parameter 31-3 Flow Start Delay)

AN279052730268en-000102 / 175R1183

Installation Guide | Pumping Smart Card

E Protection response (parameter 36-2 Flow Sensor, parameter

36-6 High Flow, parameter 36-7 Low Flow, parameter 36-8 Flow

Switch)

2 Flow protection response delay (parameter 31-4 Flow

Response Delay)

Illustration 3: Operation - Flow Protection

6.3.1.1 Using an Analog 4–20 mA Sensor

Context:

An analog 4–20 mA sensor provides protection and monitoring.

Procedure

1. Connect the sensor to B33, B34.

2. Set parameter 30-5 Flow Sensor Type to Analog.

3. Set parameters 30-6 to 30-8 according to the sensor specifications.

4. Set parameters 31-1 to 31-4, parameter 36-2 Flow Sensor, and parameter 36-7 Low Flow as required.

Configuration

6.3.1.2 Using a Switch Sensor

Context:

A switch sensor provides protection only.

Procedure

1. Connect the sensor to C23, C24.

2. Set parameter 30-5 Flow Sensor Type to Switch.

3. Set parameters 31-3 to 31-4, parameter 36-2 Flow Sensor, and parameter 36-8 Flow Switch as required.

Parameters 31-1 to 31-2 are not used with a switch sensor.

6.3.1.3 Using a Pulse Sensor

Context:

A pulse sensor provides protection and monitoring.

Procedure

1. Connect the sensor to C23, C24.

2. Set parameter 30-5 Flow Sensor Type to Pulses per Minute or Pulses per Unit.

3. Set parameter 30-6 Flow Units, 30-11 Units per Pulse, and either parameter 30-9 Units per Minute at Max Flow or parameter 30-10 Pulses

per Minute at Max Flow according to the sensor specifications.

4. Set parameters 31-1 to 31-4, and parameter 36-2 Flow Sensor, parameter 36-6 High Flow, and parameter 36-7 Low Flow as required.

Danfoss A/S © 2018.10

AN279052730268en-000102 / 175R1183 | 13

Installation Guide | Pumping Smart Card

6.3.2 Parameter Group 30-** Pump Input Configuration

Table 2: 30-5 - Flow Sensor Type

Option Function

Selects which type of sensor is associated with the flow sensor input on the smart card.

* None

Switch

Analog

Pulses per minute

Pulses per unit

Table 3: 30-6 - Flow Units

Option Function

Selects which units the sensor uses to report the measured flow.

* liters/second

Configuration

liters/minute

gallons/second

gallons/minute

Table 4: 30-7 - Flow at 4 mA

Range Function

*0 0–5000 Calibrates the soft starter to the 4 mA (0%) level of the flow sensor input.

Table 5: 30-8 - Flow at 20 mA

Range Function

*0 0–5000 Calibrates the soft starter to the 20 mA (100%) level of the flow sensor input.

Table 6: 30-9 - Units per Minute at Max Flow

Range Function

*0 0–5000 Calibrates the soft starter to the maximum flow volume of the flow sensor.

Table 7: 30-10 - Pulses per Minute at Max Flow

Range Function

*0 0–20000 Calibrates the soft starter to the maximum flow volume of the flow sensor.

Table 8: 30-11 - Units per Pulse

Range Function

*0 0–1000 Set to match how many units the flow sensor measures for each pulse.

14 | Danfoss A/S © 2018.10

AN279052730268en-000102 / 175R1183

Installation Guide | Pumping Smart Card

6.3.3 Parameter Group 31-** Flow Protection

Flow protection uses terminals B33, B34 or C23, C24 on the smart card.

Table 9: 31-1 - High Flow Trip Level

Range Function

*10 0–5000 Sets the trip point for high flow protection.

Table 10: 31-2 - Low Flow Trip Level

Range Function

* 5 1–5000 Sets the trip point for low flow protection.

Table 11: 31-3 - Flow Start Delay

Range Function

Configuration

*00:00:500 ms 00:00:100–

30:00:000

mm:ss:ms

Table 12: 31-4 - Flow Response Delay

Range Function

* 00:00:500 ms 00:00:100–30:00:000

mm:ss:ms

Sets a delay before a flow protection trip can occur. The delay is counted from the time a start

signal is received. The flow level is ignored until the start delay has elapsed.

Sets a delay between the flow passing the high or low flow trip levels, and the soft starter tripping.

6.3.4 Parameter Group 36-** Pump Trip Action

Table 13: 36-2 - Flow Sensor

Option Function

Selects the soft starter's response if it detects a fault with the flow sensor.

* Soft Trip and Log

Soft Trip and Reset

Trip Starter

Trip and Reset

Warn and Log

Log Only

Table 14: 36-6 - High Flow

Option Function

* Soft Trip and Log

Danfoss A/S © 2018.10

Selects the soft starter's response if the flow exceeds the high flow trip level (parameter 31-1 High Flow

Trip Level).

AN279052730268en-000102 / 175R1183 | 15

Installation Guide | Pumping Smart Card

Option Function

Soft Trip and Reset

Trip Starter

Trip and Reset

Warn and Log

Log Only

Table 15: 36-7 - Low Flow

Option Function

Selects the soft starter's response if the flow drops below the low flow trip level (set in parameter 31-2 Low

Flow Trip Level).

* Soft Trip and Log

Soft Trip and Reset

Trip Starter

Trip and Reset

Configuration

Warn and Log

Log Only

Table 16: 36-8 - Flow Switch

Option Function

Selects the soft starter's response if the flow sensor closes (switch type sensors only).

* Soft Trip and Log

Soft Trip and Reset

Trip Starter

Trip and Reset

Warn and Log

Log Only

6.4 Pressure Protection

Pressure protection uses terminals B23, B24 or C33, C34, C43, C44 on the smart card.

• B23, B24: Use an analog 4–20 mA sensor.

• C33, C34 (low-pressure protection): Use a normally open digital switch sensor.

• C43, C44 (high-pressure protection): Use a normally open digital switch sensor.

Pressure protection is active when the soft starter is in the start, run, or stop mode.

The smart card trips the soft starter when the pressure level passes through the programmed trip level. If the pressure is still outside

the expected operating range when the trip is reset (including auto-reset), the soft starter does not trip again.

16 | Danfoss A/S © 2018.10

AN279052730268en-000102 / 175R1183

C

B

A

2

1

D

E

e77ha746.10

Run

Ready

Time

Installation Guide | Pumping Smart Card

6.4.1 Operation

Configuration

A Off (Ready)

C Pressure protection active

E Protection response (parameter 36-1 Pressure Sensor,

parameter 36-4 High Pressure, parameter 36-5 Low Pressure)

2 Pressure protection response delay (parameter 32-3 High

Pressure Response Delay and parameter 32-6 Low Pressure

Response Delay)

Illustration 4: Operation - Pressure Protection

B Start signal

D Protection event (parameter 32-1 High Pressure Trip Level and

parameter 32-4 Low Pressure Trip Level)

1 Pressure protection start delay (parameter 32-2 High Pressure

Start Delay and parameter 32-5 Low Pressure Start Delay)

6.4.1.1 Using an Analog 4–20 mA Sensor

Context:

An analog 4–20 mA sensor provides protection and monitoring.

Procedure

1. Connect the sensor to B23, B24.

2. Set parameter 30-1 Pressure Sensor Type to Analog.

3. Set parameters 30-2 to 30-4 according to the sensor specifications.

4. Set parameters 32-1 to 32-6, parameter 36-1 Pressure Sensor, and parameters 36-4 to 36-5 as required.

6.4.1.2 Using a Switch Sensor

Context:

A switch sensor provides protection only.

Procedure

1. Connect the low-pressure sensor to C33, C34 and the high-pressure sensor to C43, C44.

2. Set parameter 30-1 Pressure Sensor Type to Switch.

3. High-pressure protection: Set parameters 32-2 to 32-3, parameter 36-1 Pressure Sensor, and parameter 36-4 High Pressure as required.

4. Low-pressure protection: Set parameters 32-5 to 32-6, parameter 36-1 Pressure Sensor, and parameter 36-5 Low Pressure as required.

Parameter 32-1 High Pressure Trip Level and parameter 32-4 Low Pressure Trip Level are not used with a switch sensor.

Danfoss A/S © 2018.10

AN279052730268en-000102 / 175R1183 | 17

Installation Guide | Pumping Smart Card

6.4.1.3 Parameter Group 30-** Pump Input Configuration

Table 17: 30-1 - Pressure Sensor Type

Option Function

Selects which type of sensor is associated with the pressure sensor input on the smart card.

* None

Switch

Analog

Table 18: 30-2 - Pressure Units

Option Function

Selects which units the sensor uses to report the measured pressure.

Bar

* kPa

Psi

Configuration

Table 19: 30-3 - Pressure at 4 mA

Range Function

*0 0–5000 Calibrates the soft starter to the 4 mA (0%) level of the pressure sensor input.

Table 20: 30-4 - Pressure at 20 mA

Range Function

*0 0–5000 Calibrates the soft starter to the 20 mA (100%) level of the pressure sensor input.

6.4.1.4 Parameter Group 32-** Pressure Protection

Pressure protection uses terminals B23, B24 or C33, C34, C44 on the smart card.

Table 21: 32-1 - High Pressure Trip Level

Range Function

*10 0–5000 Sets the trip point for high-pressure protection.

Table 22: 32-2 - High Pressure Start Delay

Range Function

* 0.5 s 00:00:100–

30:00:000

mm:ss:ms

18 | Danfoss A/S © 2018.10

Sets a delay before a high-pressure protection trip can occur. The delay is counted from the time a

start signal is received. The pressure is ignored until the start delay has elapsed.

AN279052730268en-000102 / 175R1183

Installation Guide | Pumping Smart Card

Table 23: 32-3 - High Pressure Response Delay

Range Function

Configuration

* 0.5 s 00:00:100–30:00:000

mm:ss:ms

Table 24: 32-4 - Low Pressure Trip Level

Sets a delay between the pressure passing the high-pressure trip level and the soft starter tripping.

Range Function

* 5 0–5000 Sets the trip point for low-pressure protection.

Table 25: 32-5 - Low Pressure Start Delay

Range Function

* 0.5 s 00:00:100–

30:00:000

Sets a delay before a low-pressure protection trip can occur. The delay is counted from the time a

start signal is received. The pressure is ignored until the start delay has elapsed.

mm:ss:ms

Table 26: 32-6 - Low Pressure Response Delay

Range Function

* 0.5 s 00:00:100–30:00:000

mm:ss:ms

Sets a delay between the pressure passing the low-pressure trip level and the soft starter tripping.

6.4.1.5 Parameter Group 36-** Pump Trip Action

Table 27: 36-1 - Pressure Sensor

Option Function

* Soft and Trip Log

Soft Trip and Reset

Trip Starter

Trip and Reset

Warn and Log

Log Only

Table 28: 36-4 - High Pressure

Option Function

Selects the soft starter's response if the pressure exceeds the high-pressure trip level (parameter 32-1 High

Pressure Trip Level) or the high-pressure switch sensor closes.

* Soft Trip and Log

Soft Trip and Reset

Trip Starter

Selects the soft starter's response if it detects a fault with the pressure sensor.

Danfoss A/S © 2018.10

AN279052730268en-000102 / 175R1183 | 19

Installation Guide | Pumping Smart Card

Option Function

Trip and Reset

Warn and Log

Log Only

Table 29: 36-5 - Low Pressure

Option Function

Selects the soft starter's response if the pressure drops below the low-pressure trip level (parameter 32-4

Low Pressure Trip Level) or the low-pressure sensor switch closes.

* Soft Trip and Log

Soft Trip and Reset

Trip Starter

Trip and Reset

Warn and Log

Log Only

Configuration

6.5 Pressure Control

The smart card can start or stop the soft starter (wake or sleep the pump) according to the measured pressure. This can be used for

direct pressure-based control, or the pressure measurement can be used to indicate water depth.

Other sensors can also be used to provide protection and monitoring.

Pressure control uses terminals B23, B24 on the smart card. Use an analog 4–20 mA sensor.

6.5.1 Configuring Pressure Control

Procedure

1. Connect the sensor to B23, B24.

2. Set parameter 30-1 Pressure Sensor Type to Analog.

3. Set parameters 30-2 to 30-4 according to the sensor specifications.

4. Set parameters 33-1 to 33-5 as required.

5. Set parameter 1-1 Command Source to Smart Card or Smart Card+Clock.

6.5.2 Operation

There are 2 different operating modes when using pressure control:

• Level control operation.

• Pressure-based operation.

20 | Danfoss A/S © 2018.10

AN279052730268en-000102 / 175R1183

2

1

4

3

A

D

B

C

e77ha748.10

20 mA

4 mA

A

Time

1

2

A

A

D

D

B

C

e77ha749.10

20 mA

4 mA

Time

Installation Guide | Pumping Smart Card

Configuration

6.5.2.1 Level Control Operation

A pressure sensor can be used to control the pump based on fluid level in a storage tank on the principle that deeper water exerts

higher pressure on the sensor.

Set parameter 33-1 Pressure Control Mode to Falling Pressure Start to fill the tank or Rising Pressure Start to empty the tank.

1 Parameter 32-1 High Pressure Trip Level

3 Pump wake (parameter 33-2 Start Pressure Level)

A Pump on (wake)

C Falling fluid level

Illustration 5: Falling Pressure (Fill Tank)

2 Pump sleep (parameter 33-4 Stop Pressure Level)

4 Parameter 32-4 Low Pressure Trip Level

B Pump off (sleep)

D Rising fluid level

1 Pump wake (parameter 33-2 Start Pressure Level) 2 Pump sleep (parameter 33-4 Stop Pressure Level)

Danfoss A/S © 2018.10

AN279052730268en-000102 / 175R1183 | 21

2

1

4

6 6

3

A

D

B

C

E

F

K

G

L

H

I

J

M

N

O

e77ha750.10

20 mA

4 mA

5 7

Analog output

Time

Installation Guide | Pumping Smart Card

Configuration

A Pump on (wake)

C Falling fluid level

Illustration 6: Rising Pressure (Tank Empty)

6.5.2.2 Pressure-based Operation

B Pump off (sleep)

D Rising fluid level

1 Parameter 32-1 High Pressure Trip Level

3 Pump wake (parameter 33-2 Start Pressure Level)

5 Parameter 33-5 Stop Response Delay

7 Parameter 6-2 Aute-Reset Delay

B Pipe filling

D Pressure at stop threshold, pump stops (sleep)

F Pressure below start threshold, start response delay

H Pump running

J Falling system pressure

L Low-pressure trip level

N Pump wakes

Illustration 7: Example of Pressure-based Operation

22 | Danfoss A/S © 2018.10

2 Pump sleep (parameter 33-4 Stop Pressure Level)

4 Parameter 32-4 Low Pressure Trip Level

6 Parameter 33-3 Start Response Delay

A Smart card control enabled, pump starts

C Normal pressure variation

E Falling system pressure

G Pump wakes

I Normal pressure variation

K Pressure below start threshold, start response delay

M Soft starter auto-reset

O Normal operation

AN279052730268en-000102 / 175R1183

Installation Guide | Pumping Smart Card

6.5.2.3 Parameter Group 30-** Pump Input Configuration

Table 30: 30-1 - Pressure Sensor Type

Option Function

Selects which type of sensor is associated with the pressure sensor input on the smart card.

* None

Switch

Analog

Table 31: 30-2 - Pressure Units

Option Function

Selects which units the sensor uses to report the measured pressure.

Bar

* kPa

Psi

Configuration

Table 32: 30-3 - Pressure at 4 mA

Range Function

*0 0–5000 Calibrates the soft starter to the 4 mA (0%) level of the pressure sensor input.

Table 33: 30-4 - Pressure at 20 mA

Range Function

*0 0–5000 Calibrates the soft starter to the 20 mA (100%) level of the pressure sensor input.

6.5.2.4 Parameter Group 33-** Pressure Control

Pressure control uses terminals B23, B24 on the smart card. Use an anlog 4–20 mA sensor.

Table 34: 33-1 - Pressure Control Mode

Option Function

Selects how the soft starter uses data from the pressure sensor to control the motor.

* Off The soft starter does not use the pressure sensor to control soft starting.

Falling Pressure

Start

The soft starter starts when the pressure drops below the level selected in parameter 33-2 Start Pressure

Level.

Rising Pressure

Start

Danfoss A/S © 2018.10

The soft starter starts when the pressure rises above the level selected in parameter 33-2 Start Pressure Lev-

el.

AN279052730268en-000102 / 175R1183 | 23

Installation Guide | Pumping Smart Card

Table 35: 33-2 - Start Pressure Level

Range Function

* 5 1–5000 Sets the pressure level to trigger the soft starter to perform a soft start.

Table 36: 33-3 - Start Response Delay

Range Function

Configuration

* 0.5 s 00:00:100–30:00:000

mm:ss:ms

Table 37: 33-4 - Stop Pressure Level

Range Function

* 10 0–5000 Sets the pressure level to trigger the soft starter to stop the motor.

Table 38: 33-5 - Stop Response Delay

Range Function

* 0.5 s 00:00:100–30:00:000

mm:ss:ms

Sets a delay between the pressure passing the pressure control start level and the soft starter performing a soft start.

Sets a delay between the pressure passing the pressure control stop level and the soft starter

stopping the motor.

6.5.2.5 Parameter Group 36-** Pump Trip Action

Table 39: 36-1 - Pressure Sensor

Option Function

Selects the soft starter's response if it detects a fault with the pressure sensor.

* Soft and Trip Log

Soft Trip and Reset

Trip Starter

Trip and Reset

Warn and Log

Log Only

6.6 Depth Protection

Depth protection uses terminals B13, B14 or C13, C14 on the smart card.

• B13, B14: Use an analog 4–20 mA sensor.

• C13, C14: Use a normally open digital switch sensor.

Depth protection is always active (ready, start, run, and stop modes).

The smart card trips the soft starter when the depth level passes through the programmed trip level. The trip cannot be reset until the

depth has returned above the reset level (parameter 34-2 Depth Reset Level).

24 | Danfoss A/S © 2018.10

AN279052730268en-000102 / 175R1183

C

B

A

1

D

E

e77ha747.10

Run

Ready

Time

Installation Guide | Pumping Smart Card

Configuration

NO TI CE

If the depth has not returned above the reset level when the soft starter auto-resets, the smart card trips the soft starter again.

6.6.1 Operation

A Off (ready)

C Start signal

E Protection response (parameter 36-3 Depth Sensor and

parameter 36-9 Well Depth)

Illustration 8: Operation - Depth Protection

B Depth protection active

D Protection event (parameter 34-1 Depth Trip Level)

1 Depth protection response delay (parameter 34-4 Depth

Response Delay)

6.6.1.1 Using an Analog 4–20 mA Sensor

Context:

An analog 4–20 mA sensor provides protection and monitoring.

Procedure

1. Connect the sensor to B13, B14.

2. Set parameter 30-12 Depth Sensor Type to Analog.

3. Set parameters 30-13 to 30-15 according to the sensor specifications.

4. Set parameters 34-1 to 34-4, parameter 36-3 Depth Sensor, and parameter 36-9 Well Depth as required.

6.6.1.2 Using a Switch Sensor

Context:

A switch sensor provides protection only.

Procedure

1. Connect the sensor to C13, C14.

2. Set parameter 30-12 Depth Sensor Type to Switch.

3. Set parameters 34-3 to 34-4, parameter 36-3 Depth Sensor, and parameter 36-9 Well Depth as required.

Parameters 34-1 to 34-2 are not used with a switch sensor.

Danfoss A/S © 2018.10

AN279052730268en-000102 / 175R1183 | 25

Installation Guide | Pumping Smart Card

6.6.1.3 Parameter Group 30-** Pump Input Configuration

Table 40: 30-12 - Depth Sensor Type

Option Function

Selects which type of sensor is associated with the depth sensor input on the smart card.

* None

Switch

Analog

Table 41: 30-13 - Depth Units

Option Function

Selects which units the sensor uses to report the measured depth.

* meters

feet

Table 42: 30-14 - Depth at 4 mA

Configuration

Range Function

*0 0–1000 Calibrates the soft starter to the 4 mA (0%) level of the depth sensor input.

Table 43: 30-15 - Depth at 20 mA

Range Function

*0 0–1000 Calibrates the soft starter to the 20 mA (100%) level of the depth sensor input.

6.6.1.4 Parameter Group 34-** Depth Protection

Depth protection uses terminals B13, B14 or C13, C14 on the smart card.

Table 44: 34-1 - Depth Trip Level

Range Function

* 5 0–1000 Sets the trip point for depth protection.

Table 45: 34-2 - Depth Reset Level

Range Function

* 10 0–1000 Sets the level for the soft starter to allow a depth trip to be reset.

Table 46: 34-3 - Depth Start Delay

Range Function

* 0.5 s 00:00:100–

30:00:000

Sets a delay before a depth protection trip can occur. The delay is counted from the time a start signal is received. The depth input is ignored until the start delay has elapsed.

mm:ss:ms

26 | Danfoss A/S © 2018.10

AN279052730268en-000102 / 175R1183

Installation Guide | Pumping Smart Card

Table 47: 34-4 - Depth Response Delay

Range Function

Configuration

* 0.5 s 00:00:100–30:00:000

mm:ss:ms

Sets a delay between the depth passing the depth protection trip level and the soft starter tripping.

6.6.1.5 Parameter Group 36-** Pump Trip Action

Table 48: 36-3 - Depth Sensor

Option Function

Selects the soft starter's response if it detects a fault with the depth sensor.

* Soft Trip and Log

Soft Trip and Reset

Trip Starter

Trip and Reset

Warn and Log

Log Only

Table 49: 36-9 - Well Depth

Option Function

Selects the soft starter's response if the depth drops below the depth trip level (parameter 34-1 Depth Trip

Level) or the depth switch sensor closes.

* Soft Trip and Log

Soft Trip and Reset

Trip Starter

Trip and Reset

Warn and Log

Log Only

6.7 Thermal Protection

Thermal protection uses terminals R1, R2, R3 on the smart card.

Thermal protection is active only when the soft starter is in run mode.

Danfoss A/S © 2018.10

AN279052730268en-000102 / 175R1183 | 27

Installation Guide | Pumping Smart Card

Configuration

6.7.1 Parameter Group 35-** Thermal Protection

Table 50: 35-1 - Temperature Sensor Type

Option Function

Selects which type of sensor is associated with the temperature sensor input on the smart card.

* None

PT100

Table 51: 35-2 - Temperature Trip Level

Range Function

* 40 ° 0–240 ° Sets the trip point for temperature protection. Use parameter 10-2 Temperature Scale to configure the tempera-

ture scale.

6.7.2 Parameter Group 36-** Pump Trip Action

Table 52: 36-10 - RTD/PT100 B

Option Function

* Soft Trip and Log

Soft Trip and Reset

Trip Starter

Trip and Reset

Warn and Log

Log Only

Selects the soft starter's response to the protection event.

28 | Danfoss A/S © 2018.10

AN279052730268en-000102 / 175R1183

Installation Guide | Pumping Smart Card

7 Trip Messages

7.1 Depth Sensor

Cause

The smart card has detected a fault with the depth sensor.

Troubleshooting

• Check the following parameters:

- Parameter 30-12 Depth Sensor Type.

- Parameter 36-3 Depth Sensor.

7.2 Flow Sensor

Cause

The smart card has detected a fault with the flow sensor.

Trip Messages

Troubleshooting

• Check the following parameters:

- Parameter 30-5 Flow Sensor Type.

- Parameter 36-2 Flow Sensor.

7.3 Flow Switch

Cause

The flow switch sensor (smart card terminals C23, C24) has closed.

Troubleshooting

• Check the following parameters:

- Parameter 30-5 Flow Sensor Type.

- Parameter 36-8 Flow Switch.

7.4 High Flow

Cause

The flow sensor connected to the smart card has activated high-flow protection.

Danfoss A/S © 2018.10

AN279052730268en-000102 / 175R1183 | 29

Installation Guide | Pumping Smart Card

Troubleshooting

• Check the following parameters:

- Parameter 30-5 Flow Sensor Type.

- Parameter 30-7 Flow at 4 mA.

- Parameter 30-8 Flow at 20 mA.

- Parameter 31-1 High Flow Trip Level.

- Parameter 31-3 Flow Start Delay.

- Parameter 31-4 Flow Response Delay.

- Parameter 36-6 High Flow.

7.5 High Pressure

Cause

The pressure sensor connected to the smart card has activated high-pressure protection.

Troubleshooting

• Check the following parameters:

- Parameter 30-1 Pressure Sensor Type.

- Parameter 30-3 Pressure at 4 mA.

- Parameter 30-4 Pressure at 20 mA.

- Parameter 32-1 High Pressure Trip Level.

- Parameter 32-2 High Pressure Start Delay.

- Parameter 32-3 High Pressure Response Delay.

- Parameter 36-4 High Pressure.

Trip Messages

7.6 Low Flow

Cause

The flow sensor connected to the smart card has activated low-flow protection. Related parameters:

Troubleshooting

• Check the following parameters:

- Parameter 30-5 Flow Sensor Type.

- Parameter 30-7 Flow at 4 mA.

- Parameter 30-8 Flow at 20 mA.

- Parameter 31-2 Low Flow Trip Level.

- Parameter 31-3 Flow Start Delay.

- Parameter 31-4 Flow Response Delay.

- Parameter 36-7 Low Flow.

30 | Danfoss A/S © 2018.10

AN279052730268en-000102 / 175R1183

Installation Guide | Pumping Smart Card

7.7 Low Pressure

Cause

The pressure sensor connected to the smart card has activated low-pressure protection.

Troubleshooting

• Check the following parameters:

- Parameter 30-1 Pressure Sensor Type.

- Parameter 30-3 Pressure at 4 mA.

- Parameter 30-4 Pressure at 20 mA.

- Parameter 32-4 Low Pressure Trip Level.

- Parameter 32-5 Low Pressure Start Delay.

- Parameter 32-6 Low Pressure Response Delay.

- Parameter 36-5 Low Pressure.

7.8 Low Water

Cause

Trip Messages

The depth sensor connected to the smart card has activated depth protection.

Troubleshooting

• Check the following parameters:

- Parameter 30-12 Depth Sensor Type.

- Parameter 30-14 Depth at 4 mA.

- Parameter 30-15 Depth at 20 mA.

- Parameter 34-1 Depth Trip Level.

- Parameter 34-2 Depth Reset Level.

- Parameter 34-3 Depth Start Relay.

- Parameter 36-9 Well Depth.

7.9 Pressure Sensor

Cause

The smart card has detected a fault with the pressure sensor.

Troubleshooting

• Check the following parameters:

- Parameter 30-1 Pressure Sensor Type.

- Parameter 36-1 Pressure Sensor.

Danfoss A/S © 2018.10

AN279052730268en-000102 / 175R1183 | 31

Installation Guide | Pumping Smart Card

7.10 RTD Circuit

Cause

The smart card has detected a fault with the RTD sensor, or the RTD has activated temperature protection.

Troubleshooting

• Check the following parameters:

- Parameter 35-2 Temperature Trip Level.

- Parameter 36-10 RTD/PT100 B.

Trip Messages

32 | Danfoss A/S © 2018.10

AN279052730268en-000102 / 175R1183

Installation Guide | Pumping Smart Card

Specifications

8 Specifications

8.1 Connections

External equipment Unpluggable connectors (supplied)

Maximum cable size

8.2 Certification

RCM IEC 60947-4-2

CE EN 60947-4-2

RoHS Compliant with EU Directive 2011/65/EU

2.5 mm2 (14 AWG)

Danfoss A/S © 2018.10

AN279052730268en-000102 / 175R1183 | 33

Installation Guide | Pumping Smart Card

Index

C

Cable size 33

Certification

CE

RCM 33

RoHS

Compatibility 8

E

Expansion port cover 8

F

Features

I

Inputs, location of 9

33

33

Index

6

L

Low flow 30

Low pressure

31

P

Programmable input

29

R

Real-time graph 6, 11

S

Sensors

Active

Analog 4–20 mA

Passive 8

Pulse sensor

Switch sensor 13, 17, 25

8, 13, 17, 25

13

T

Thermal protection

Tools

Flat-bladed screwdriver

27

8

8

W

Wiring

34 | Danfoss A/S © 2018.10

8

AN279052730268en-000102 / 175R1183

Installation Guide | Pumping Smart Card

Danfoss A/S © 2018.10

AN279052730268en-000102 / 175R1183 | 35

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alterations can be made without subsequential changes being necessary in specifications already agreed. All trademarks in this material are property of the respective

companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

Danfoss A/S

Ulsnaes 1

DK-6300 Graasten

vlt-drives.danfoss.com

Danfoss A/S © 2018.10 MG15U102

*MG15U102

AN279052730268en-000102/ 175R1183

*

Loading...

Loading...