Page 1

VLT® Micro Drive

The VLT® Micro Drive is a general purpose drive that can control AC motors up to 22 kW.

It’s a small drive with maximum strength and reliability.

Perfect

match for:

– Industrial appliances

– HVAC applications

– OEM

VLT® Micro Drive is a full member of

the VLT® family sharing the overall

quality of design, reliability and userfriendliness.

Due to high quality components and

genuine VLT® solutions, VLT® Micro

Drive is extremely reliable.

RoHS compliant

The VLT® Micro Drive is manufactured

with respect for the environment, and

it complies with the RoHS Directive.

Power range:

1 phase 200–240 V AC: 0.18–2.2 kW

3 phase 200–240 V AC: 0.25–3.7 kW

3 phase 380–480 V AC: 0.37–22 kW

Feature Benet

User-friendly

Minimum commissioning Saves time

Mount – connect – go! Minimum eort – minimum time

Copy settings via local control panel Easy programming of multiple drives

Intuitive parameter structure Minimal manual reading

Complies with VLT® software Saves commissioning time

Self-protecting features Lean operation

Process PI-controller No need for external controller

Automatic Motor Tuning

150% motor torque up to 1 minute

Flying start (catch a spinning motor)

Electronic Thermal Relay (ETR) Replaces external motor protection

Smart Logic Controller Often makes PLC unnecessary

Built-in RFI lter Saves cost and space

Energy saving Less operation cost

Energy eciency 98 %

Automatic Energy Optimisation (AEO) Saves 5–15% energy in HVAC applications

Reliable Maximum uptime

Earth fault protection Protects the drive

Over temperature protection

Short circuit protection Protects the drive

Optimum heat dissipation Longer lifetime

Unique cooling concept with no

forced air ow over electronics

High quality electronics Low lifetime cost

High quality capacitors Tolerates uneven mains supply

All drives full load tested from factory High reliability

Dust resistant Increased lifetime

RoHS compliant Protects the environment

Designed for WEEE Protects the environment

Ensures optimal match between

drive and motor

Plenty of brake-away and

acceleration torque

Doesn’t trip when started on a spinning

(freewheeling) motor

Minimises heat loss

Protects the motor and drive

Problem-free operation in

harsh environments

Page 2

Coated PCB standard

For harsh environments.

Power options

Danfoss VLT Drives oers a range

of external power options for use

together with our drives in critical

networks or applications:

n VLT® Advanced Harmonic Filter:

For applications where reducing

harmonic distortion is critical.

PC software tools

n MCT 10

Ideal for commissioning and

servicing the drive including

guided programming of cascade

controller, real-time clock, smart

logic controller and preventive

maintenance.

n VLT® Energy Box

Comprehensive energy analysis

tool, shows the drive payback

time.

n MCT 31

Harmonics calculations tool.

Specications

Mains supply (L1, L2, L3)

Supply voltage

Supply frequency 50/60 Hz

Displacement Power Factor (cos φ) near unity (> 0.98)

Switching on input supply L1, L2, L3 1–2 times/min.

Output data (U, V, W)

Output voltage 0–100% of supply voltage

Output frequency 0–200 Hz (VVC+ mode), 0–400 Hz (U/f mode)

Switching on output Unlimited

Ramp times 0.05–3600 sec

Digital inputs

Programmable digital inputs 5

Logic PNP or NPN

Voltage level 0–24 VDC

Pulse inputs

Programmable pulse inputs 1*

Voltage level 0–24 V DC (PNP positive logic)

Pulse input frequency 20–5000 Hz

* One of the digital inputs can be used for pulse inputs.

Analogue input

Analogue inputs 2

Modes 1 current/1 voltage or current

Voltage level 0 – 10 V (scaleable)

Current level

Analogue output

Programmable analogue outputs 1

Current range at analogue output 0/4–20 mA

Relay outputs

Programmable relay outputs 1 (240 VAC, 2 A)

Approvals

CE, C-tick, UL

Fieldbus communication

FC Protocol, Modbus RTU

1 x 200–240 V ± 10%, 3 x 200–240 V ±10 %

3 x 380–480 V ± 10%

0/4 to 20 mA (scaleable)

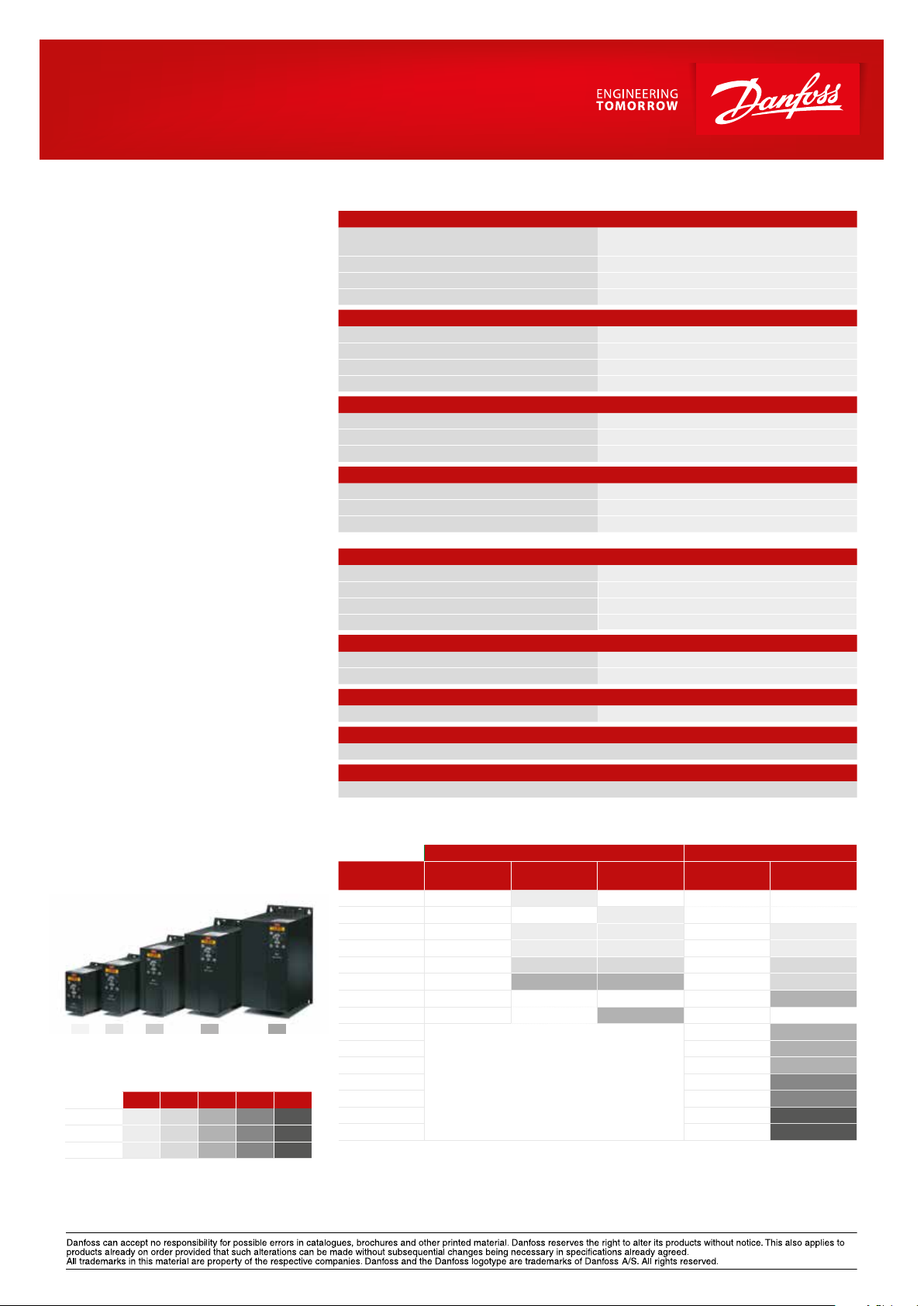

Ordering numbers

200 V 400 V

Power

[kW]

0.18 1.2 132F 0001

0.25 1.5 132F 0008

0.37 2.2 132F 0002 132F 0009 1.2 132 F 0 017

0.75 4.2 132F 0003 132F 0010 2.2 132F 0018

1.5 6.8 132F 0005 13 2F 0012 3.7 132F 0020

2.2 9.6 132F 0007 132F 0014 5.3 132F 0022

3.0 7.2 132F 0024

M3 M4 M5M2M1

Cabinet sizes

(mounting ange incl.)

[mm]

Height

Width 70 75 90 125 165

Depth 148 168 194 241 248

+ 6 mm with potentiometer

Danfoss VLT Drives, Ulsnaes 1, DK-6300 Graasten, Denmark, Tel. +45 74 88 22 22, Fax +45 74 65 25 80

www.danfoss.com/drives • E-mail: info@danfoss.com

DKDD.PFP.500.A2.02 VLT® is a trademark of Danfoss A/S Produced by PE-MMSC 2014.09

M1 M2 M3 M4 M5

150 176 239 292 335

3.7 15. 2 132F 0016

4.0

5.5 12. 0 132F 0028

7.5 15.5 132F 0030

11. 0 23.0 132F 0058

15. 0 31.0 132F 0059

18. 5 37.0 132 F 0060

22.0 43.0 132F 00 61

VLT® Control panel LCP 11 ............................................................................ Without potentiometer: 132B 0100

VLT® Control panel LCP 12 ....................................................................................With potentiometer: 132B0101

Current

[I-nom.]

Micro Drives from 1.5 kW and up

have built-in brake chopper

1 ph. 3 ph.

Current

[I-nom.]

9.0 132 F 0026

3 ph.

Loading...

Loading...