Page 1

MAKING MODERN LIVING POSSIBLE

Operating Instructions

VLT® Integrated Servo Drive ISD® 510 System

vlt-drives.danfoss.com

Page 2

Page 3

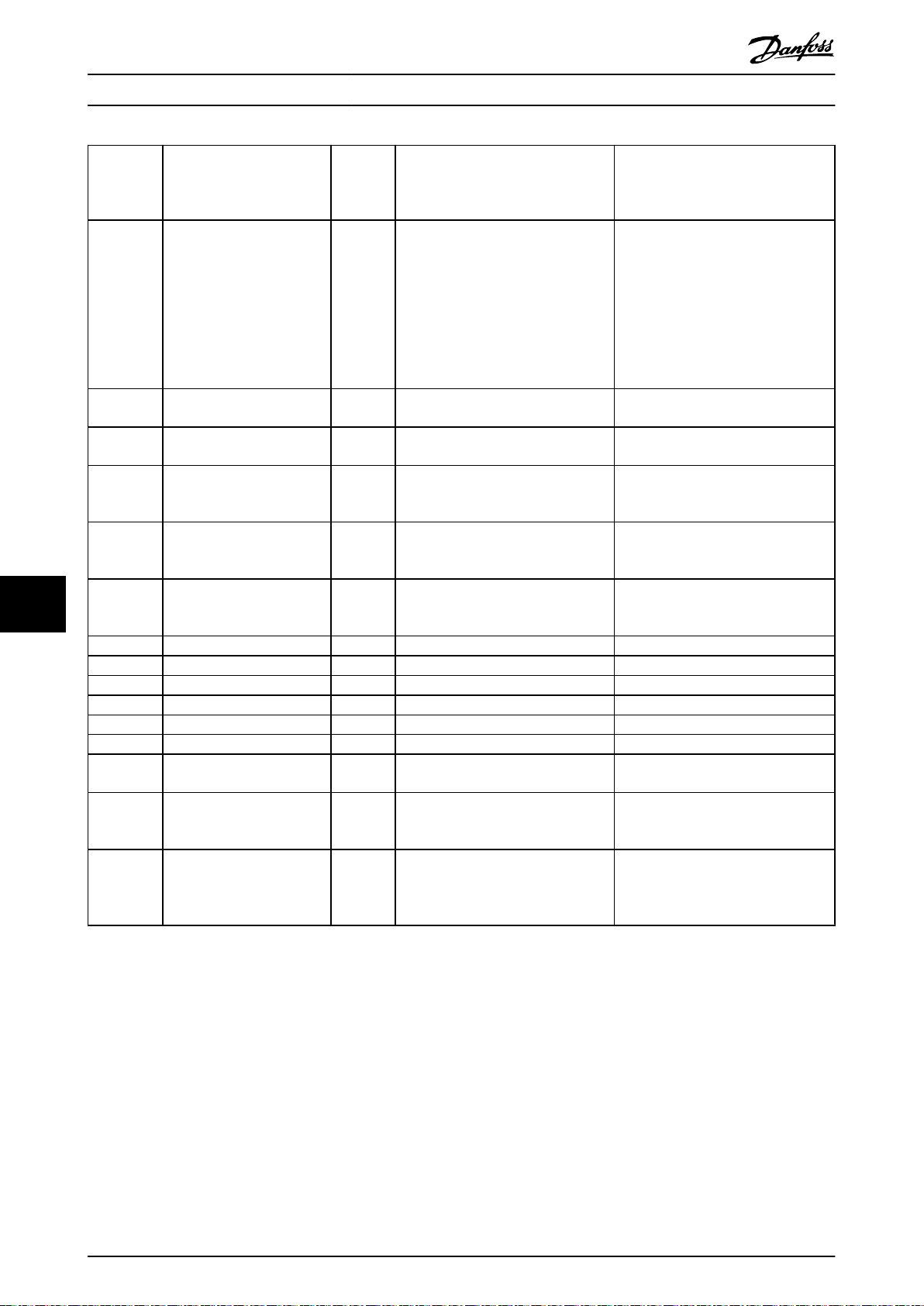

Contents Operating Instructions

Contents

1 Introduction

1.1 Purpose of the Operating Instructions

1.2 Additional Resources

1.3 Copyright

1.4 Approvals and Certications

1.5 System Overview

1.5.1 Areas of Application 8

1.6 Software

1.7 Terminology

2 Safety

2.1 Symbols Used in this Manual

2.2 General

2.3 Safety Instructions and Precautions

2.4 Important Safety Warnings

2.5 Qualied Personnel

2.6 Due Diligence

2.7 Intended Use

6

6

6

6

6

7

8

8

9

9

9

9

10

11

11

11

2.8 Foreseeable Misuse

2.9 Service and Support

3 System Description

3.1 Overview

3.2 Servo Drive

3.2.1 Servo Drive Types 14

3.2.2 Motor Components 14

3.2.2.1 Shaft 14

3.2.2.2 Brake (Optional) 14

3.2.2.3 Cooling 15

3.2.2.4 Thermal Protection 15

3.2.2.5 Built-In Feedback Devices 15

3.2.3 Drive Components 15

3.2.3.1 Connectors on the Servo Drives 15

3.3 Servo Access Box (SAB)

3.3.1 Connections on the SAB 19

3.3.1.1 STO Connectors 20

12

12

13

13

13

18

3.3.1.2 Mains Connectors 20

3.3.1.3 Brake Connectors 21

3.3.1.4 Relay Connectors 21

3.3.1.5 Encoder Connectors 21

MG75K102 Danfoss A/S © 12/2015 All rights reserved. 1

Page 4

Contents

VLT® Integrated Servo Drive ISD® 510 System

3.3.1.6 Ethernet Connectors (not included) 22

3.3.1.7 AUX Connectors 22

3.3.1.8 24/48 V IN Connector 22

3.3.1.9 UDC Connectors 22

3.3.1.10 Hybrid Cable PE 22

3.4 Local Control Panel (LCP)

3.4.1 Overview 23

3.4.2 Local Control Panel (LCP) Layout 23

3.5 Cables

3.5.1 Hybrid Cable 25

3.5.2 I/O and/or Encoder Cable 25

3.5.3 Additional Cables 25

3.6 Connection Cables/Cabling

3.6.1 Layout and Routing 26

3.6.1.1 Standard Cabling Concept for 2 Lines 26

3.6.1.2 Standard Cabling Concept for 1 Line 26

3.7 Software

3.8 Fieldbus

3.8.1 EtherCAT

3.8.2 Ethernet POWERLINK

®

4 Mechanical Installation

4.1 Transport and Delivery

23

25

26

27

27

27

®

28

29

29

4.1.1 Items Supplied 29

4.1.2 Transport 29

4.1.3 Inspection on Receipt 29

4.2 Safety Measures during Installation

4.3 Installation Environment

4.4 Preparation for Installation

4.4.1 Servo Drive 30

4.4.2 Servo Access Box (SAB) 31

4.5 Installation Procedure

4.5.1 Installation and Space Requirements 32

4.5.2 Installation Aids and Tools Required 32

4.5.3 Fitting Instructions Servo Drive 32

4.5.4 Tightening Torques 33

4.5.5 Fitting Instructions Servo Access Box (SAB) 33

5 Electrical Installation

5.1 Warnings

5.2 Electrical Environmental Conditions

29

29

30

32

35

35

35

2 Danfoss A/S © 12/2015 All rights reserved. MG75K102

Page 5

Contents Operating Instructions

5.3 EMC-Compliant Installation

5.4 Grounding

5.5 Mains Supply Requirements

5.6 Auxiliary Supply Requirements

5.7 Safety Supply Requirements

5.8 Connecting the Components

5.8.1 Servo Access Box 37

5.8.2 Servo Drive 39

5.8.2.1 Connecting/Disconnecting Hybrid Cables 39

5.8.2.2 Connecting/Disconnecting Cables from Ports X3, X4, and X5 41

6 Commissioning

6.1 Pre-Commissioning Checklist

6.2 ID Assignment

6.2.1 EtherCAT

6.2.2 Ethernet POWERLINK

6.2.2.1 Single Device ID Assignment 43

6.2.2.2 Multiple Device ID Assignment 43

®

35

35

36

36

36

37

43

43

43

43

®

43

6.3 Switching on the ISD 510 Servo System

6.4 Basic Programming

6.4.1 Programming with Automation Studio™

6.4.1.1 Requirements 44

6.4.1.2 Creating an Automation Studio™ Project

6.4.1.3 Connecting to the PLC 48

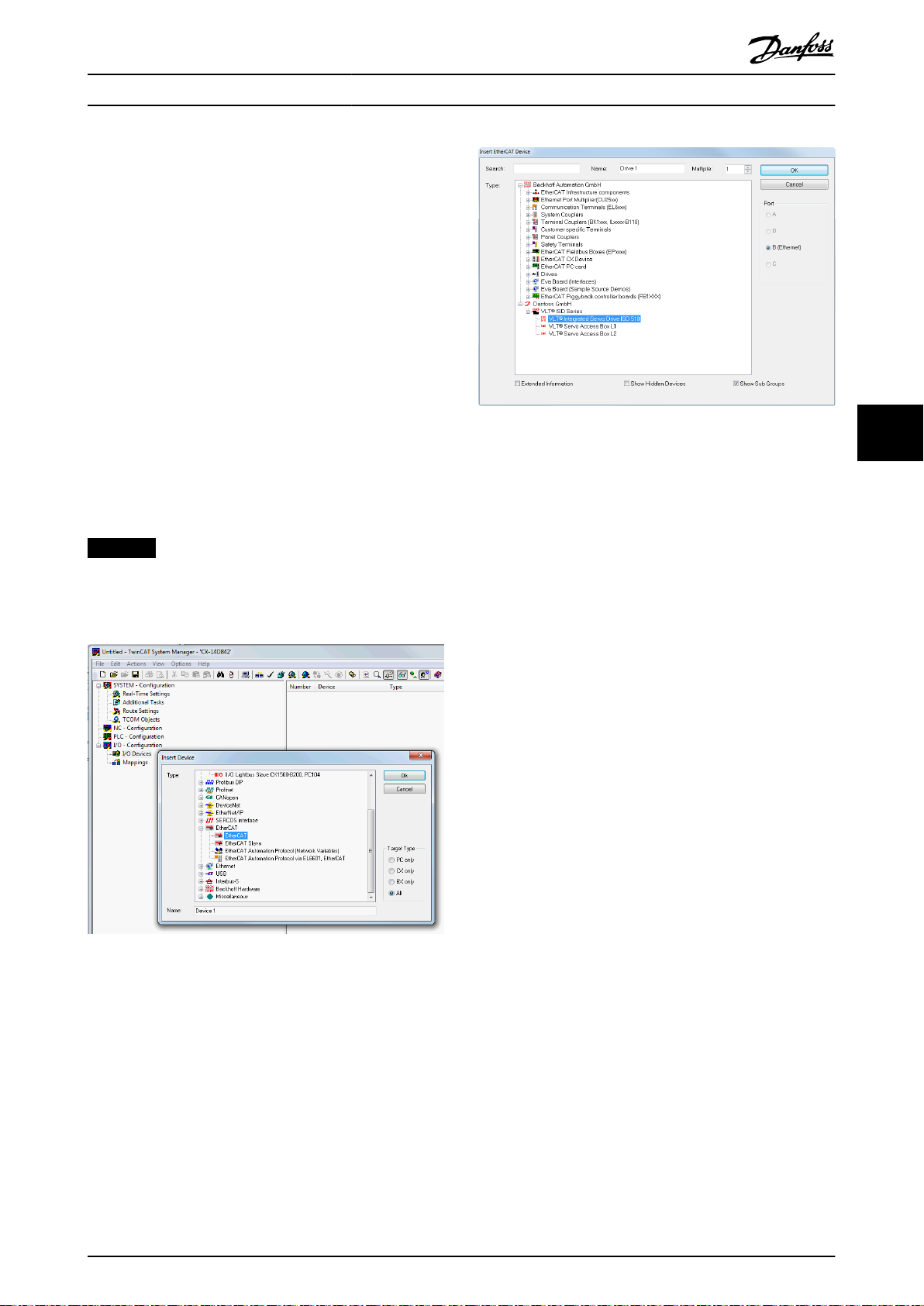

6.4.2 Programming with TwinCAT

®

6.4.2.1 ISD Deliverables 48

6.4.2.2 Creating a TwinCAT® Project 48

6.4.2.3 Conguration as a TwinCAT® NC Axis 54

6.4.2.4 Connecting to the PLC 55

6.4.3 Programming Guidelines 55

6.5 ISD Toolbox

6.5.1 Overview 56

6.5.2 System Requirements 56

6.5.3 Installation 56

6.5.4 ISD Toolbox Communication 56

44

44

44

44

48

56

6.5.4.1 Network Settings for Indirect Communication 57

6.5.4.2 Network Settings for Direct Communication with Ethernet POWERLINK

6.5.4.3 Network Settings for Direct Communication with EtherCAT

®

®

58

59

6.5.5 ISD Toolbox Commissioning 60

6.6 Motion Library

MG75K102 Danfoss A/S © 12/2015 All rights reserved. 3

62

Page 6

Contents

VLT® Integrated Servo Drive ISD® 510 System

6.6.1 Function Blocks 62

6.6.2 Simple Programming Template 62

7 Operation

7.1 Operating Modes

7.1.1 Motion Functions 63

7.2 Operating Status Indicators

7.2.1 Operating LEDs on the Servo Drive 64

7.2.2 Operating LEDs on the Servo Access Box 64

8 ISD Safety Concept

8.1 Applied Standards and Compliance

8.2 Abbreviations and Conventions

8.3 Qualied Personnel for Working with the STO Function

8.4 Safety Precautions

8.5 Functional Description

8.6 Installation

8.7 Operation of the ISD Safety Concept

8.7.1 Statusword 68

8.7.2 Error Codes 69

8.8 Fault Reset

63

63

63

66

66

66

66

67

68

68

68

69

8.9 Commissioning Test

8.10 Application Example

8.11 Safety Function Characteristic Data

8.12 Maintenance, Security, and User Accessibility

9 Diagnostics

9.1 Faults

9.2 Servo Drive

9.2.1 Troubleshooting 74

9.2.2 Error Codes 75

9.3 Servo Access Box (SAB)

9.3.1 Troubleshooting 77

9.3.2 Error Codes 78

10 Maintenance, Decommissioning, and Disposal

10.1 Maintenance Tasks

10.2 Inspection during Operation

10.3 Repair

69

72

73

73

74

74

74

77

81

81

82

82

10.3.1 Cable Replacement 82

10.3.1.1 Feed-In Cable Replacement 82

10.3.1.2 Loop Cable Replacement 83

4 Danfoss A/S © 12/2015 All rights reserved. MG75K102

Page 7

Contents Operating Instructions

10.4 Servo Drive Replacement

10.4.1 Dismounting 83

10.4.2 Fitting and Commissioning 83

10.5 SAB Replacement

10.5.1 Dismounting 83

10.5.2 Fitting and Commissioning 83

10.6 Decommissioning of the ISD 510 Servo System

10.7 Product Returns

10.8 Recycling and Disposal

10.8.1 Recycling 84

10.8.2 Disposal 84

11 Specications

11.1 Servo Drive

11.1.1 Nameplate 85

11.1.2 Characteristic Data 85

11.1.3 Dimensions 86

11.1.4 Permitted Forces 88

83

83

84

84

84

85

85

11.1.5 General Specications and Environmental Conditions 88

11.2 Servo Access Box

11.2.1 Nameplate 89

11.2.2 Characteristic Data 89

11.2.3 Dimensions 90

11.2.4 General Specications and Environmental Conditions 92

11.3 Cables

11.4 Storage

11.4.1 Long-Term Storage 92

12 Appendix

12.1 Glossary

Index

89

92

92

93

93

95

MG75K102 Danfoss A/S © 12/2015 All rights reserved. 5

Page 8

Introduction

VLT® Integrated Servo Drive ISD® 510 System

11

1 Introduction

1.1 Purpose of the Operating Instructions

The purpose of these operating instructions is to describe

the VLT® Integrated Servo Drive ISD® 510 System.

These operating instructions contain information about:

Installation

•

Commissioning

•

Programming

•

Operation

•

Troubleshooting

•

Service and maintenance

•

These operating instructions are intended for use by

qualied personnel. Read it in full to use the ISD 510 servo

system safely and professionally, and pay particular

attention to the safety instructions and general warnings.

These operating instructions are an integral part of the ISD

510 servo system and also contains important service

information. Therefore, keep it available with the ISD 510

servo system at all times.

Compliance with the information in these operating

instructions is a prerequisite for:

Trouble-free operation.

•

Recognition of product liability claims.

•

Therefore, read these operating instructions before working

with the ISD 510 servo system.

Additional Resources

1.2

Available manuals for the ISD 510 servo system:

Document Contents

VLT® Integrated Servo Drive

ISD® 510 System Operating

Instructions

VLT® Integrated Servo Drive

ISD® 510 System Design

Guide

VLT® Integrated Servo Drive

ISD® 510 System

Programming Guide

Table 1.1 Available Documents for the ISD 510 Servo System

Technical literature for Danfoss drives is also available

online at vlt-drives.danfoss.com/Support/Technical-Documen-

tation/.

Information about the installation,

commissioning, and operation of

the ISD 510 servo system.

Information about the set-up of

the ISD 510 servo system and

detailed technical data.

Information about the

programming of the ISD 510 servo

system.

Copyright

1.3

VLT®, ISD®, and SAB® are Danfoss registered trademarks.

1.4 Approvals and Certications

The ISD 510 servo system fullls the standards listed in

Table 1.2.

IEC/EN 61800-3 Adjustable speed electrical power drive

systems.

Part 3: EMC requirements and specic test

methods.

IEC/EN

61800-5-1

IEC/EN

61800-5-2

IEC/EN 61508 Functional safety of electrical/electronical/

EN ISO 13849-1 Safety of machinery - Safety-related parts of

EN ISO 13849-2 Safety of machinery - Safety-related parts of

IEC/EN 60204-1 Safety of machinery - Electrical equipment of

IEC/EN 62061 Safety of machinery - Functional safety of

IEC/EN

61326-3-1

UL508C UL Standard for Safety for Power Conversion

2006/42/EC Machinery Directive

CE

2014/30/EU EMC Directive

2014/35/EU Low Voltage Directive

RoHS

(2002/95/EC)

Adjustable speed electrical power drive

systems.

Part 5-1: Safety requirements - Electrical,

thermal and energy.

Adjustable speed electrical power drive

systems.

Part 5-2: Safety requirements - Functional.

programmable electronic safety-related

systems.

control systems.

Part 1: General principles for design.

control systems.

Part 2: Validation.

machines.

Part 1: General requirements.

safety-related electrical, electronic, and

programmable electronic control systems.

Electrical equipment for measurement, control,

and laboratory use – EMC requirements.

Part 3-1: Immunity requirements for safety-

related systems and for equipment intended

to perform safety-related functions (functional

safety) – General industrial applications.

Equipment.

Restriction of hazardous substances.

6 Danfoss A/S © 12/2015 All rights reserved. MG75K102

Page 9

AUX 1

Status

Hand

On

O

Reset

Auto

On

OK

Back

Cancel

Info

Quick

Menu

Main

Menu

Alarm

Log

AUX 2

SAFE 1

SAFE 2

Status

Hand

On

O Reset

Auto

On

OK

Back

Cancel

Info

Quick

Menu

Main

Menu

Alarm

Log

LCP

SAB

400-480 V AC

1

ISD 510

2 3 n

UDC + Real-Time Ethernet Bus + STO + U

AUX

. . .

. . .

130BE384.10

Real-Time Ethernet

Introduction Operating Instructions

EtherCAT

®

Ethernet for Control Automation Technology.

Ethernet-based eldbus system (see

chapter 12.1 Glossary for further information).

Ethernet

POWERLINK

®

PLCopen

Ethernet-based eldbus system:

®

Technical specication.

Function blocks for motion control (formerly

Part 1 and Part 2) Version 2.0 March 17, 2011.

Table 1.2 Approvals and Certications

1.5 System Overview

Illustration 1.1 Overview of the ISD 510 Servo System

The servo drives are self-contained distributed drives,

whereby the drive electronics is housed together with the

motor in the same casing. There are 2 versions of the

ISD 510 servo drive:

1 1

Standard With 2 hybrid connectors (M23) that connect power

and communication signals from a hybrid cable.

Advanced As standard plus 3 additional interfaces for external

encoder or I/Os, eldbus devices, and for the local

control panel (LCP) to be connected directly.

Table 1.3 ISD 510 Servo Drive Versions

In this decentral system, the servo drives are operated in a

DC group and controlled by a PLC. The motion control

software runs independently in the servo drive, reducing

the load on the PLC.

The ISD 510 servo system requires hybrid cables that

contain the DC supply voltage, the Real-Time Ethernet,

U

, and STO signals.

AUX

The Servo Access Box (SAB®) is the central power supply

for the ISD 510 servo system.

The ISD 510 servo system is designed to accommodate up

to 64 ISD 510 servo drives and consists of:

ISD 510 servo drives

•

Servo Access Box (SAB)

•

1 PLC (not included)

•

Cabling

•

Blind caps

•

Software:

•

MG75K102 Danfoss A/S © 12/2015 All rights reserved. 7

Page 10

Introduction

VLT® Integrated Servo Drive ISD® 510 System

11

- Firmware for the servo drive

- Firmware for the SAB

- PC software tool: ISD Toolbox

- PLC libraries

Danfoss Motion library for VLT

•

Integrated Servo Drive ISD 510

system for AutomationStudio™

Danfoss Motion library for VLT

•

Integrated Servo Drive ISD 510

system for TwinCAT® 2

®

®

NOTICE

The ISD 510 servo drives cannot be used in servo

systems from other manufacturers without changing the

cabling infrastructure. Contact Danfoss for further

information.

Drives from other manufacturers cannot be used in the

ISD 510 servo system when using Danfoss hybrid cables.

1.5.1 Areas of Application

Potential areas of application are:

Food and beverage machines

•

Packaging machines

•

Pharmaceutical machines

•

Applications running with a group of decentral

•

servo drives.

Software

1.6

Updates to the rmware, ISD Toolbox software, and PLC

libraries may be available. When updates are available,

they can be downloaded from the danfoss.com website.

The ISD Toolbox software or the PLC libraries can be used

to install the rmware on the servo drives or on the SAB.

Terminology

1.7

ISD Integrated servo drive

ISD 510 Servo

Drive

VLT® Servo Access

Box (SAB)

PLC External device for controlling the ISD 510

Loop cable Hybrid cable for connecting drives in daisy-

Feed-in cable Hybrid cable for connection from the SAB to

Table 1.4 Terminology

Decentral servo drive

Unit that generates the DC-link voltage and

passes the U

signals to the ISD 510 servo drives via a

hybrid cable.

servo system.

chain format.

the 1st servo drive.

, Real-Time Ethernet, and STO

AUX

An explanation of all terminology and abbreviations can be

found in chapter 12.1 Glossary.

8 Danfoss A/S © 12/2015 All rights reserved. MG75K102

Page 11

Safety Operating Instructions

2 Safety

2.1 Symbols Used in this Manual

The following symbols are used in this manual:

WARNING

Indicates a potentially hazardous situation that could

result in death or serious injury.

CAUTION

Indicates a potentially hazardous situation that could

result in minor or moderate injury. It can also be used to

alert against unsafe practices.

NOTICE

Indicates important information, including situations that

can result in damage to equipment or property.

2.2 General

The following safety instructions and precautions relate to

the ISD 510 servo system.

Read the safety instructions carefully before starting to

work in any way with the ISD 510 servo system or its

components.

Pay particular attention to the safety instructions in the

relevant sections of this manual.

WARNING

HAZARDOUS SITUATION

If the servo drive, SAB, or the bus lines are incorrectly

connected, there is a risk of death, serious injury, or

damage to the unit.

Always comply with the instructions in this manual and

national and local safety regulations.

2.3 Safety Instructions and Precautions

Compliance with the safety instructions and precautions is

necessary at all times.

Orderly and proper transport, storage,

•

installation, as well as careful operation and

maintenance, are essential for the trouble-free

and safe operation of the ISD 510 servo system

and its components.

Only suitably trained and qualied personnel may

•

work on the ISD 510 servo system and its

components or in its vicinity. See

chapter 2.5 Qualied Personnel.

tting, and

Only use accessories and spare parts approved by

•

Danfoss.

Comply with the specied ambient conditions.

•

For further information, see chapter 11.1.5 General

Specications and Environmental Conditions and

chapter 11.2.4 General Specications and Environmental Conditions.

The information in this manual about the use of

•

available components is provided solely by way

of examples of applications and suggestions.

The plant engineer or system engineer is

•

personally responsible for checking the suitability

of the supplied components and the information

provided in this manual for the specic

application concerned:

- For compliance with the safety

regulations and standards relevant to

the specic application.

- For implementing the necessary

measures, changes, and extensions.

Commissioning the ISD 510 servo system or its

•

components is not allowed until it has been

ascertained that the machine, system, or plant in

which they are installed conforms to the statutory

provisions, safety regulations, and standards that

apply to the application in the country of use.

Operation is only allowed in compliance with the

•

national EMC regulations for the application

concerned.

Compliance with the limit values specied by

•

national regulations is the responsibility of the

producer of the plant, system, or machine.

Compliance with the specications, connection

•

conditions, and installation conditions in this

manual is mandatory.

The safety regulations and safety provisions of

•

the country in which the equipment is used must

be observed.

To protect the user against electrical shock and to

•

protect the servo drive and the SAB against

overload, protective grounding is obligatory and

must be performed in accordance with local and

national regulations.

2 2

MG75K102 Danfoss A/S © 12/2015 All rights reserved. 9

Page 12

Safety

VLT® Integrated Servo Drive ISD® 510 System

WARNING

the discharge safety warning in

chapter 2.4 Important Safety Warnings).

GROUNDING HAZARD

22

The ground leakage current is >3.5 mA. Improper

grounding of the ISD 510 servo system components may

result in death or serious injury.

For reasons of operator safety, ground the

•

components of the ISD 510 servo system

correctly in accordance with national or local

electrical regulations and the information in this

manual.

Operational safety

Safety-related applications are only allowed if

•

they are explicitly and unambiguously mentioned

in this manual.

All applications that can cause hazards to people

•

or damage to property are safety-related

applications.

The stop functions implemented in the software

•

of the PLC do not interrupt the mains supply to

the SAB. Therefore, they must not be used as

safety switches for the ISD 510 servo system.

The servo drive can be brought to a stop by a

•

software command or a zero speed setpoint,

however DC voltage remains present on the servo

drive and/or mains voltage in the SAB. Also when

the servo drive is stopped, it may start up again

on its own if the circuitry of the servo drive is

defective or after the elimination of a temporary

overload, a problem with the supply voltage, or a

problem with the servo drive. If personal safety

considerations (for example, risk of personal

injury caused by contact with moving machine

parts after an unintended start) make it necessary

to ensure that an unintended start cannot occur,

these stop functions are not

case, ensure that the ISD 510 servo system is

detached from the mains network, or that a

suitable stop function is implemented.

The servo drive may start running unintentionally

•

during parameter conguration or programming.

If this poses a risk to personal safety (for example,

risk of personal injury due to contact with

moving machine parts), prevent unintended

motor starting, for example by using the Safe

Torque O function, or by safe disconnection of

the servo drives.

In addition to the L1, L2, and L3 supply voltage

•

inputs on the SAB, the ISD 510 servo system has

other supply voltage inputs, including external

auxiliary voltage. Before commencing repair work,

check that all supply voltage inputs have been

switched o and that the necessary discharge

time for the DC-link capacitors has elapsed (see

sucient. In this

2.4 Important Safety Warnings

WARNING

HIGH VOLTAGE

The ISD 510 servo system contains components that

operate at high voltage when connected to the electrical

supply network.

A hazardous voltage is present on the servo drives and

the SAB whenever they are connected to the mains

network.

There are no indicators on the servo drive or SAB that

indicate the presence of mains supply.

Incorrect installation, commissioning, or maintenance can

lead to death or serious injury.

Installation, commissioning, and maintenance

•

may only be performed by qualied personnel

(see chapter 2.5 Qualied Personnel).

WARNING

UNINTENDED START

The ISD 510 servo system contains servo drives and the

SAB that are connected to the electrical supply network

and can start running at any time. This may be caused

by a eldbus command, a reference signal, or clearing a

fault condition. Servo drives and all connected devices

must be in good operating condition. A decient

operating condition may lead to death, serious injury,

damage to equipment, or other material damage when

the unit is connected to the electrical supply network.

Take suitable measures to prevent unintended

•

starts.

WARNING

DISCHARGE TIME

The servo drives and the SAB contain DC-link capacitors

that remain charged for some time after the mains

supply is switched o at the SAB. Failure to wait the

specied time after power has been removed before

performing service or repair work could result in death

or serious injury.

To avoid electrical shock, fully disconnect the

•

SAB from the mains and wait for at least the

time listed in Table 2.1 for the capacitors to fully

discharge before carrying out any maintenance

or repair work on the ISD 510 servo system or

its components.

10 Danfoss A/S © 12/2015 All rights reserved. MG75K102

Page 13

Safety Operating Instructions

Number Minimum waiting time (minutes)

0–64 servo drives 10

Table 2.1 Discharge Time

NOTICE

Never connect or disconnect the hybrid cable to or from

the servo drive when the ISD 510 servo system is

connected to mains or auxiliary supply, or when voltage

is still present. Doing so damages the electronic circuitry.

Ensure that the mains supply is disconnected and the

required discharge time for the DC-link capacitors has

elapsed before disconnecting or connecting the hybrid

cables or disconnecting cables from the SAB.

2.5 Qualied Personnel

Installation, commissioning, and maintenance of the

ISD 510 servo system may only be carried out by qualied

personnel.

For the purposes of this manual and the safety instructions

in this manual, qualied personnel are trained personnel

who are authorized to t, install, commission, ground, and

label equipment, systems, and circuits in accordance with

the standards for safety technology and who are familiar

with the safety concepts of automation engineering.

Additionally, the personnel must be familiar with all the

instructions and safety measures described in this manual.

They must have suitable safety equipment and be trained

in rst aid.

Due Diligence

2.6

The operator and/or fabricator must ensure that:

The ISD 510 servo system and its components are

•

used only as intended.

The components are operated only in a perfect

•

operational condition.

The operating instructions are always available

•

near the ISD 510 servo system in complete and

readable form.

The ISD 510 servo system and its components are

•

tted, installed, commissioned, and maintained

only by adequately qualied and authorized

personnel.

These personnel are regularly instructed on all

•

relevant matters of occupational safety and

environmental protection, as well as the contents

of the operating instructions and the instructions

it contains.

The product markings and identication markings

•

applied to the components, as well as safety and

warning instructions, are not removed and are

always kept in a legible condition.

The national and international regulations

•

regarding the control of machinery and

equipment, that are applicable at the place of use

of the ISD 510 servo system, are complied with.

The users always have all current information

•

relevant to their interests about the ISD 510 servo

system and its use and operation.

2.7 Intended Use

The components of the ISD 510 servo system are intended

to be installed in machines used in industrial environments

in accordance with local laws and standards.

NOTICE

In a domestic environment, this product may cause radio

interferences, in which case supplementary mitigation

measures may be required.

To ensure that the product is used as intended, the

following conditions must be fullled before use:

Everyone who uses Danfoss products in any

•

manner must read and understand the

corresponding safety regulations and the

description of the intended use.

Hardware must be left in its original state.

•

Software products must not be reverse-

•

engineered and their source code must not be

altered.

Damaged or faulty products must not be installed

•

or put into operation.

It must be ensured that the products are installed

•

in conformance with the regulations mentioned

in the documentation.

Any specied maintenance and service intervals

•

must be observed.

All protective measures must be complied with.

•

Only the components described in these

•

operating instructions may be tted or installed.

Third-party devices and equipment may be used

only in consultation with Danfoss.

The ISD 510 servo system may not be used in the

following application areas:

Areas with potentially explosive atmospheres.

•

Mobile or portable systems.

•

Floating or airborne systems.

•

Inhabited facilities.

•

Sites where radioactive materials are present.

•

2 2

MG75K102 Danfoss A/S © 12/2015 All rights reserved. 11

Page 14

Safety

Areas with extreme temperature variations or in

•

which the maximum rated temperatures may be

exceeded.

22

•

Under water.

VLT® Integrated Servo Drive ISD® 510 System

2.8 Foreseeable Misuse

Any use not expressly approved by Danfoss constitutes

misuse. This also applies to failure to comply with the

specied operating conditions and applications.

Danfoss assumes no liability of any sort for damage attributable to improper use.

2.9 Service and Support

Contact the local service representative for service and

support:

vlt-drives.danfoss.com/Support/Service/

12 Danfoss A/S © 12/2015 All rights reserved. MG75K102

Page 15

1

2

130BE385.10

System Description Operating Instructions

3 System Description

3.1 Overview

The VLT® Integrated Servo Drive ISD® 510 system is a highperformance decentral servo motion solution.

It comprises:

A central power supply VLT® Servo Access Box

•

(SAB®).

VLT® Integrated Servo Drives ISD® 510.

•

Cabling infrastructure.

•

The decentralization of the drive unit

mounting, installation, and operation. Depending on the

application, the SAB can power up to 64 drives in a servo

drive system when using 2 hybrid lines. It generates a DClink voltage of 565–680 V DC ±10% and guarantees high

power density. It has a removable local control panel (LCP),

and is based on the proven quality of a Danfoss frequency

converter.

The motion control is integrated into the servo drive so

that the motion sequences can take place independently.

This reduces the required computing power of the central

PLC and oers a highly exible drive concept. Danfoss

oers libraries for various IEC 61131-3 programmable PLCs.

Due to the standardized and certied eldbus interfaces of

the ISD devices, any PLC with an EtherCAT® master

functionality or Ethernet POWERLINK® managing node

functionality according to the standards can be used.

Hybrid cables are used to connect the drives, making

installation fast and simple. These hybrid cables contain

the DC-link supply, the Real-Time Ethernet, U

signals.

Servo Drive

3.2

oers benets in

and STO

AUX

encoder or I/Os, eldbus devices, and for the local control

panel (LCP) to be connected directly.

3 3

LEDs on the top of the servo drive show the current status

(see chapter 7.2 Operating Status Indicators for further

information). Data transfer takes place via Real-Time

Ethernet.

1 Operating LEDs (see chapter 7.2.1 Operating LEDs on the Servo

Drive for further information).

2 Connectors

Illustration 3.1 ISD 510 Servo Drive

The ISD 510 servo drive has the following ange sizes:

76 mm, 84 mm.

ISD is the abbreviation of integrated servo drive, which is a

compact drive with an integrated permanent magnet

synchronous motor (PMSM). This means the entire power

drive system consisting of motor, position sensor,

mechanical brake, and also power and control electronics

is integrated into 1 housing. Additional circuits, such as

main low voltage supply, bus drivers, and functional safety

are implemented within the servo drive electronics. All

servo drives have 2 hybrid connectors (M23) that connect

power and communication signals from a hybrid cable. The

advanced version has 3 additional interfaces for external

MG75K102 Danfoss A/S © 12/2015 All rights reserved. 13

Further ange sizes of 108 mm and 138 mm are in

planning.

Size 1,

1.5 Nm

Flange size 76 mm 84 mm

Table 3.1 Motor and Flange Sizes

All dimensions of the servo drive are listed in

chapter 11.1.3 Dimensions.

Size 2,

2.1 Nm

Size 2,

2.9 Nm

Size 2,

3.8 Nm

Page 16

System Description

VLT® Integrated Servo Drive ISD® 510 System

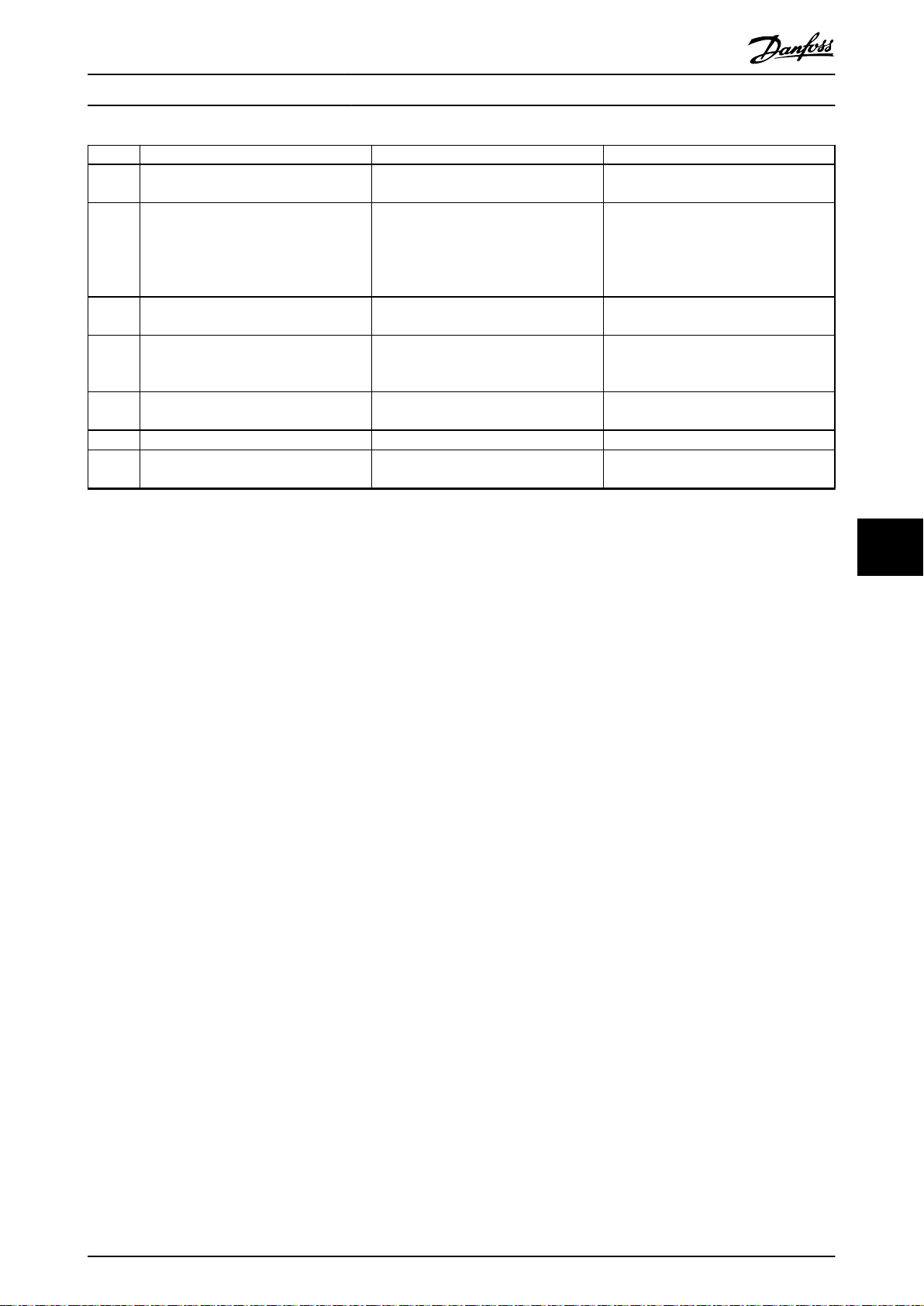

3.2.1 Servo Drive Types

Pos. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40

Fixed I S D 5 1 0 T D 6

Variant A 0 1 C 5 E 5 4 F R X P L S X X T F 0 7 6 S X N 4 6 X S X S X

33

S 0 2 C 1 E 6 7 F S 1 E C S C O F F 0 8 4 C 0 N 4 0 B K S C X

0 2 C 9 F M 1 P N F 1 0 8 N 2 9 C

0 3 C 8 E N F 1 3 8 N 2 4

Table 3.2 Type Code

[01–03] Product group [21–22] Bus system [33–35] Motor speed

ISD

[04–06] Product variant EC

510

[07] Hardware conguration EN

A Advanced [23–25] Firmware [36] Mechanical brake

S Standard SXX Standard X Without brake

[08] Drive torque SC0 Customized version B With brake

T Torque [26] Safety [37] Motor shaft

[09–12] Torque T Safe Torque O (STO) S Standard smooth shaft

01C5 1.5 Nm F

02C1 2.1 Nm [27–30] Flange size C Customized

02C9 2.9 Nm F076 76 mm [38] Motor sealing

03C8 3.8 Nm F084 84 mm X Without sealing

[13–14] DC voltage F108

D6 600 V DC-link voltage F138

[15–17] Drive enclosure [31–32] Flange type SX Standard

E54 IP54 SX Standard CX Customized

E67 IP67 (shaft IP65) C0 Customized version

[18–20] Drive feedback

FRX Resolver

FS1 Single-turn feedback

FM1 Multi-turn feedback

VLT® Integrated Servo Drive

ISD® 510

PL

PN

Ethernet POWERLINK

EtherCAT

PROFINET

Ethernet/IP

Functional safety

108 mm

138 mm

®

®1)

™1)

1)

1)

®

N46 Rated speed 4600 RPM

N40 Rated speed 4000 RPM

N29 Rated speed 2900 RPM

N24 Rated speed 2400 RPM

1)

K

S With sealing

[39–40] Surface coating

Standard tted key

1)

Table 3.3 Legend to Type code

1) In preparation

3.2.2 Motor Components

3.2.2.1 Shaft

3.2.2.2 Brake (Optional)

The optional mechanical holding brake is designed as a

single-disc brake. The emergency stop function can be

The shaft transfers the motor force (torque) to the machine

coupled to the shaft.

The shaft material is C45+C or equivalent according to

EN 10277-2.

The ISD 510 servo drives can be sealed by a shaft seal

(optional) to achieve IP65 on the A-side of the motor (see

chapter 11.1.5 General Specications and Environmental

Conditions for further information).

initiated at most once every 3 minutes and up to 2000

times in total, depending on the load.

The eective holding torque is:

Size 1: 2.5 Nm

•

Size 2: 5.3 Nm

•

The brake operates as a holding brake according to the

fail-safe principle closed when no current. It is powered

from the 24–48 V DC auxiliary supply. This enables lowbacklash load holding when no current is present.

Electrical data: Power consumption:

Size 1: 1.5 W

•

Size 2: 1.8 W

•

14 Danfoss A/S © 12/2015 All rights reserved. MG75K102

Page 17

1

2

3

8

4

5

6

7

130BE386.10

System Description Operating Instructions

NOTICE

Do not misuse the holding brake as a working brake

because this causes increased wear, resulting in

premature failure.

NOTICE

Using servo drives with brakes can reduce the number of

drives allowed, depending on the total length of each

hybrid line. See the shell diagram in the VLT® Integrated

Servo Drive ISD® 510 System Design Guide for further

information.

3.2.2.3 Cooling

The servo drives are self-cooling.

Cooling (heat dispersal) is primarily via the ange, with a

small amount dispersed by the housing.

3.2.2.4 Thermal Protection

Thermal sensors monitor the maximum allowable

temperature of the motor winding and switch the motor

o if the limit of 140 °C is exceeded. Thermal sensors are

also present in the drive to protect the electronics against

overtemperature. An error message is sent via Real-Time

Ethernet to the higher-level PLC and is also shown on the

LCP.

3.2.2.5 Built-In Feedback Devices

The built-in feedback device measures the rotor position.

There are 3 feedback variants available:

Resolver

•

17-Bit single-turn encoder

•

17-Bit multi-turn encoder

•

Table 3.4 summarizes the characteristic data of each

variant.

3.2.3 Drive Components

3.2.3.1 Connectors on the Servo Drives

This chapter details all possible connections for the

standard and advanced servo drive. Refer to the tables in

this chapter for maximum cable lengths, ratings, and other

limits.

There are 5 connectors on the servo drives.

Connector Description

X1 M23 Feed-in or loop hybrid cable input

X2 M23 Loop hybrid cable output or eldbus

extension cable

X3 (advanced version

only)

X4 (advanced version

only)

X5 (advanced version

only)

Illustration 3.2 Connectors on the ISD 510 Servo Drive

M8 Ethernet cable (minimum CAT5,

shielded)

M12 I/O and/or encoder cable (shielded)

M8 LCP cable (shielded)

3 3

Data/type Resolver Single-turn

encoder

Signal Sin/cos BiSS-B BiSS-B

Accuracy

Resolution 14 bit 17 bit 17 bit

Maximum

number of

turns

Table 3.4 Characteristic Data of Available Feedback Devices

MG75K102 Danfoss A/S © 12/2015 All rights reserved. 15

±10 arc min ±1.6 arc min ±1.6 arc min

– – 4096 (12 bit)

Multi-turn

encoder

Page 18

130BE381.10

CB

A

3

7

6

D

PE

2

8

5

BC

AD

PE

2

8

5

3

7

6

130BE382.10

130BE435.10

1

23

4

System Description

VLT® Integrated Servo Drive ISD® 510 System

X1 and X2: Hybrid connector (M23)

The hybrid cable provides the supply (mains and auxiliary),

the communication lines, and the safety supply for each

line of servo drives. Input and output connectors are

connected inside the servo drive.

33

Illustration 3.3 X1: Male Hybrid Connector (M23)

Pin Description Notes Rating/parameter

A UDC– Negative DC mains

supply

B UDC+ Positive DC mains

supply

C AUX+ Auxiliary supply 24–48 V DC, 15 A

D AUX– Auxiliary supply

ground

PE PE PE connector 15 A

2 STO+ Safety supply 24 V DC ±10%, 1 A

3 STO– Safety supply

ground

5 TD+ Positive Ethernet

transmit

6 RD+ Positive Ethernet

receive

7 TD– Negative Ethernet

transmit

8 RD– Negative Ethernet

receive

Operating voltage:

Negative DC supply

(maximum –15 A)

Operating voltage:

Positive DC supply

(maximum 15 A)

Absolute maximum

55 V DC

15 A

1 A

According to standard

100BASE-T

Table 3.5 Pin Assignment of X1 and X2 Hybrid Connectors (M23)

X3: 3rd Ethernet connector (M8, 4 pole)

The ISD 510 advanced servo drive has an additional

eldbus port (M8) for connecting a device that

communicates via the selected eldbus.

Illustration 3.4 X2: Female Connector (M23)

Pin Description Notes Rating/parameter

1 TD+ Positive Ethernet

transmit

2 RD+ Positive Ethernet

receive

3 TD– Negative Ethernet

transmit

4 RD– Negative Ethernet

receive

Illustration 3.5 Pin Assignment of X3 3rd Ethernet Connector

(M8, 4 pole)

According to standard

100BASE-T

16 Danfoss A/S © 12/2015 All rights reserved. MG75K102

Page 19

130BE433.10

1

8

2

3

4

56

7

130BE434.10

1

2

3

4

5

6

System Description Operating Instructions

X4: M12 I/O and/or encoder connector (M12, 8-pole)

The M12 I/O and/or encoder connector is available on the

advanced servo drive and can be used or congured as:

Digital output

•

Digital input

•

Analog input

•

24 V supply

•

External encoder interface (SSI or BiSS).

•

Pin Description Notes Rating/parameter

1 Digital

output

2 Ground Ground isolated –

3 Input 1 Analog/Digital input Digital input:

4 /SSI CLK Negative SSI/BiSS

5 SSI DAT Positive SSI/BiSS data

6 SSI CLK Positive SSI/BiSS clock

7 Input 2 Analog/Digital input Digital input:

Switched 24 V as

digital output or

supply (24 V/150 mA)

clock out

in

out

Nominal voltage

24 V ±15%

Maximum current

150 mA

Maximum switching

frequency 100 Hz

Nominal voltage 0–

24 V

Bandwidth: ≤ 100 kHz

Analog input:

Nominal voltage 0–

10 V

Input impedance

5.46 kΩ

Bandwidth: ≤ 25 kHz

SSI:

Bus Speed: 0.5 Mbit

with 25 m cable

BiSS:

Fullls the RS485

specication.

Maximum cable length

(SSI & BiSS): 25 m

Nominal voltage 0–

24 V

Bandwidth: ≤ 100 kHz

Analog input:

Nominal voltage 0–

10 V

Input impedance

5.46 kΩ

Bandwidth: ≤ 25 kHz

Pin Description Notes Rating/parameter

8 /SSI DAT Negative SSI/BiSS datainSSI:

Bus Speed: 0.5 Mbit

with 25 m cable

BiSS:

Fullls the RS485

specication.

Maximum cable length

(SSI & BiSS): 25 m

Illustration 3.6 Pin Assignment of X4 M12 I/O and/or Encoder

Connector (M12)

X5: LCP connector (M8, 6 pole)

The X5 connector is used to connect the LCP directly to

the advanced servo drive via a cable.

Pin Description Notes Rating/

parameter

1 Not connected – –

2 /LCP RST Reset Active at

<0.5 V

3 LCP RS485 Positive RS485

signal

4 /LCP RS485 Negative RS485

signal

5 GND GND –

6 VCC 5 V Supply for

LCP

Illustration 3.7 Pin Assignment of X5 LCP Connector

(M8, 6-pole)

Speed:

38.4 kBd

The levels

fulll the

RS485 speci-

cation.

5 V ±10% at

120 mA

maximum load

3 3

MG75K102 Danfoss A/S © 12/2015 All rights reserved. 17

Page 20

1

3 4

2

5

6

7

8

9

10

11

12

13

14

17

16

15

18

192021

2224 2325

26

27

28

29

30

33

31

32

130BE387.10

System Description

VLT® Integrated Servo Drive ISD® 510 System

3.3 Servo Access Box (SAB)

The SAB is the power supply and central interface/gateway to the ISD 510 servo system. It guarantees the connection of the

servo drives to the eldbus, generates the DC-link voltage for the ISD 510 servo system, and delivers a high-density output.

It can be controlled using the local control panel (LCP) or via Ethernet-based eldbus.

The LEDs on the front of the unit show the operating status and warnings (see chapter 7.2.2 Operating LEDs on the Servo

33

Access Box for further information).

NOTICE

The SAB has an IP-rating of IP20. It is only designed for use within a control cabinet. The SAB may be damaged if

exposed to uids.

All power and signal cables are wired into the SAB and 2 independent lines of servo drives can be connected.

Service functions, such as voltage measuring, are performed by the SAB.

Illustration 3.8 Explosion Drawing of the Servo Access Box

18 Danfoss A/S © 12/2015 All rights reserved. MG75K102

Page 21

System Description Operating Instructions

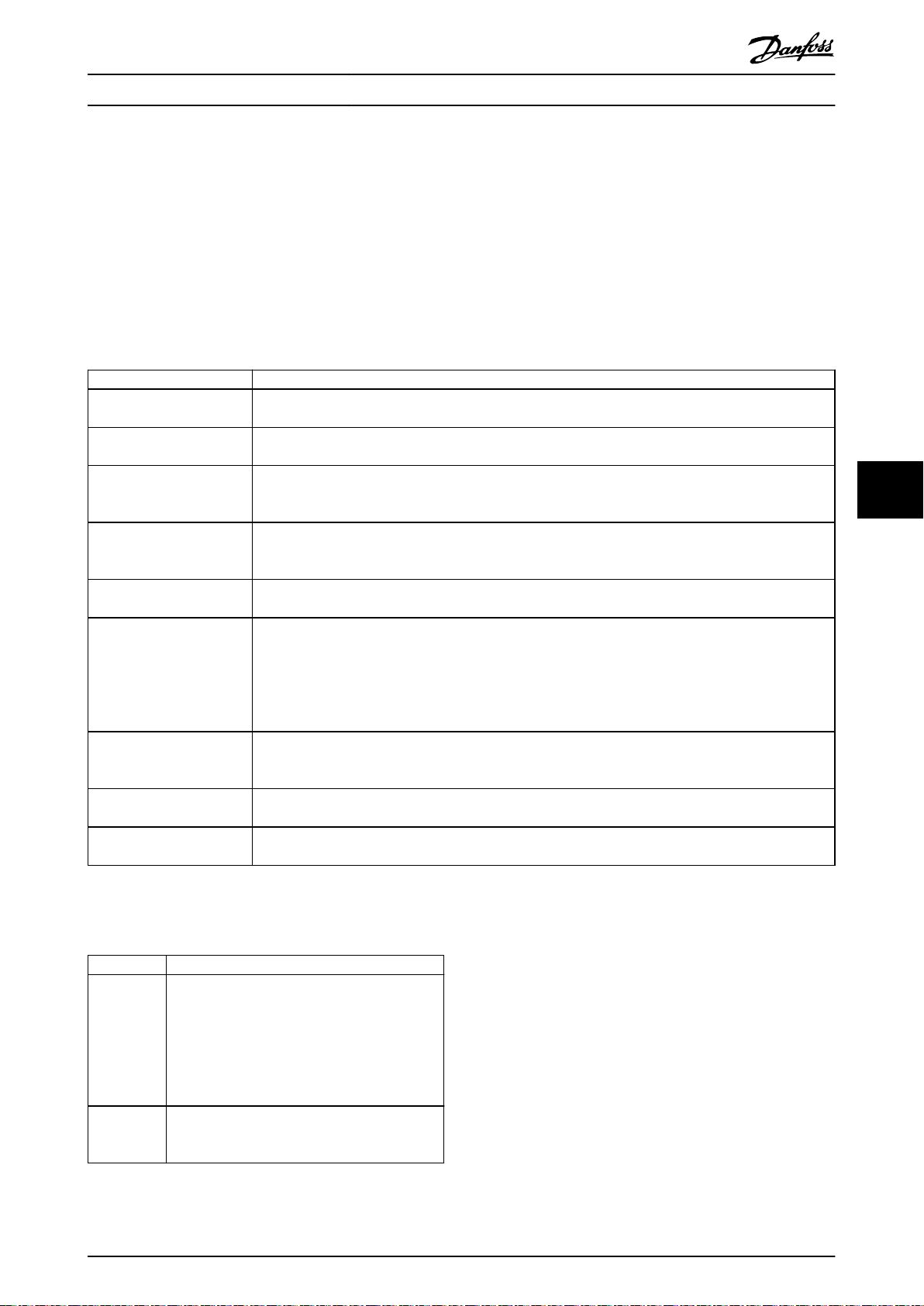

Number Description/connector name Name on

corresponding

connector

1 Local control panel (LCP) – 18 Hybrid cable line 2 –

2 Front cover – 19 Decoupling plate –

3 STO 1 IN: STO

(Used for STO input voltage 1)

4 STO 1 IN: 24 V

(Used for bridging when the STO function

is not required, see chapter 3.3.1.1 STO

Connectors)

5 LEDs for status of auxiliary output and

STO

6 Decoupling clamp for STO cable – 23 Relay 2 Relay 2

7 ISD Line 2: STO 2

(STO output to hybrid cable line 2)

8 ISD Line 2: NET 2 X4

(Ethernet output to hybrid cable line 2)

9 ISD Line 2: AUX 2

(Auxiliary output to hybrid cable line 2)

10 ISD Line 2: UDC 2

(UDC output to hybrid cable line 2)

11 ISD Line 1: STO 1

(STO output to hybrid cable line 1)

12 ISD Line 1: NET 1 X3

(Ethernet output to hybrid cable line 1)

13 ISD Line 1: AUX 1

(Auxiliary output to hybrid cable line 1)

14 ISD Line 1: UDC 1

(UDC output to hybrid cable line 1)

15 Grounding PE clamp for hybrid cable line2– 32 STO 2 IN: 24 V

16 Grounding PE clamp for hybrid cable line1– 33 Cover –

+STO– 20 Shielded cable grounding

+24V– 21 24/48 V IN

– 22 Relay 1 Relay 1

+STO– 24 Brake R– (81), R+ (82)

RJ45 connector

(without label)

+AUX– 26 Decoupling xture for Ethernet

+UDC– 27 Decoupling clamp for encoder

+STO– 28 X1

RJ45 connector

(without label)

+AUX– 30 GND, 24 V, GX, /RS422 TXD,

+UDC– 31 STO 2 IN: STO

Number Description/connector name Name on

corresponding

connector

–

clamp and strain relief

+AUX–

(Auxiliary input terminal)

25 Mains

(Input terminal)

inputs

cable

(Ethernet input line 1)

29 X2

(Ethernet input line 2)

RS422 TXD, /RS422 RXD, RS422

RXD

(Encoder terminal)

(Used for STO input voltage 2)

(Used for bridging when the

STO function is not required,

see chapter 3.3.1.1 STO

Connectors)

L1 (91), L2 (92), L3

(93)

–

–

RJ45 connector

(not included)

RJ45 connector

(not included)

Not labeled

+STO–

+24V–

3 3

17 Hybrid cable line 1 – – – –

Table 3.6 Legend to Illustration 3.8

3.3.1 Connections on the SAB

All required connectors are included with the SAB.

All cabling must comply with national and local regulations

on cable cross-sections and ambient temperature. Use

shielded/armored cables to comply with EMC emission

specications.

MG75K102 Danfoss A/S © 12/2015 All rights reserved. 19

Page 22

130BE393.10

+ STO –

130BE396.10

+ 24V –

130BE394.10

+ STO –

130BE388.10

L1 L2 L3

130BE706.10

1

System Description

VLT® Integrated Servo Drive ISD® 510 System

3.3.1.1 STO Connectors

Item Position

on SAB

STO

Front Used for STO

33

1 IN:

STO

STO

Front Used for STO

2 IN:

STO

STO

Front These

1 IN:

24 V

STO

Front

2 IN:

24 V

Description Drawing/

pins

input voltage

1.

input voltage

2.

Pins (left

to right):

STO+

STO-

connectors can

only be used

to make a

bridge to STO

1 IN: STO and

STO 2 IN: STO

if the STO

Pins (left

to right):

24+

24-

Ratings

Nominal voltage:

24 V DC ±10%

Nominal current:

Depends on the

number of servo

drives in the

application.

Maximum current:

1 A

Maximum cross-

section:

2

1.5 mm

Nominal voltage:

24 V DC ±10%

Nominal current:

1 A

Maximum cross-

section:

2

1.5 mm

3.3.1.2 Mains Connectors

Item Description Drawing/

pins

AC

mains

supply

MainsPEThe PE screw is

Used to connect

L1/L2/L3

Pins (left

to right):

L1

L2

L3

– Cross-section:

used to connect

the protective

earth, see

Illustration 3.9.

Table 3.8 Mains Connectors

Ratings

Nominal voltage:

400–480 V AC

Nominal current:

12.5 A

Maximum cross-section:

2

4 mm

2

10 mm

See

chapter 5.4 Grounding for

further information.

function is not

required in the

application.

This connector

cannot be

used for any

other function.

ISD

Underside Used for STO

Line

1:

STO

1

ISD

Underside Used for STO

Line

2:

STO

2

output voltage

1.

output voltage

2.

Pins (left

to right):

STO+

STO-

Nominal voltage:

24 V DC ±10%

Nominal current:

Depends on the

number of servo

drives in the

application.

Maximum current:

1 A

Maximum cross-

1 PE screw

section:

2

0.5 mm

Illustration 3.9 PE Screw

Table 3.7 STO Connectors

20 Danfoss A/S © 12/2015 All rights reserved. MG75K102

Page 23

88 89 81 82

-DC +DC R- R+

130BE389.10

130BE390.10

RELAY 1

RELAY 2

130BE391.10

130BE392.10

GND

24 V

GX

RS422 TXD

RS422 TXD

RS422 RXD

RS422 RXD

System Description Operating Instructions

3.3.1.3 Brake Connectors

Item Description Drawing/pins Ratings

Brake Used for

connecting a

brake resistor

Nominal

voltage:

565–778 V DC

Maximum brake

current:

–DC (88) = Do not use

+DC (89) = Do not use

R– (81) = Brake –

R+ (82)= Brake +

14.25 A

Maximum cross-

section:

4 mm

Table 3.9 Brake Connectors

NOTICE

The maximum length of the brake cable is 20 m

(shielded).

3.3.1.4 Relay Connectors

Item Description Drawing/pins Ratings

3.3.1.5 Encoder Connectors

Item Description Drawing/pins Ratings

Encoder

connector

Used to

connect SSI or

BiSS encoders.

Maximum

cross-

section:

3 3

0.5 mm2.

Pins (left to right

on SAB label):

See

Table 3.12.

RS422 RXD

/RS422 RXD

2

RS422 TXD

/RS422 TXD

GX

24 V

GND

Table 3.11 Encoder Connectors

NOTICE

The maximum length of the encoder cable is 25 m

(shielded).

Relay1Used for a customer-

dened reaction. For

example, the relay

can be triggered if

the SAB issues a

warning.

Relay

2

Pins (left to

right):

1: Common

2: Normally

open

3: Normally

closed

Pins (left to

right):

4: Common

5: Normally

open

6: Normally

closed

Pin 1: Common

Pin 2: 240 V AC

Pin 3: 240 V AC

Nominal current:

2 A

Maximum cross-

section: 2.5 mm

Pin 4: Common

Pin 5: 400 V AC

Pin 6: 240 V AC

Nominal current:

2 A

Maximum cross-

section: 2.5 mm

Number Description Notes Rating/

parameter

SSI BiSS

1 RS422 RXD Positive data Bus speed:

2 /RS422 RXD Negative data

3 RS422 TXD Positive clock

2

4 /RS422 TXD Negative clock

SSI: 0.5 Mbit

with 25 m cable

BiSS: Fullls the

RS485 speci-

cation

5 GX Isolated ground

–

If encoders are

powered externally, the

ground of the external

supply must be

connected to GX.

6 24 V

24 V DC ±10%

(used for powering the

encoder)

2

7 GND Ground for pin 6 –

Maximum

current:

250 mA

Table 3.12 Pin Assignment for SSI and BiSS Encoders

Table 3.10 Relay Connectors

MG75K102 Danfoss A/S © 12/2015 All rights reserved. 21

Page 24

130BE395.10

8

1

130BE398.10

+ AUX –

130BE397.10

+ AUX –

130BE399.10

+ UDC –

System Description

VLT® Integrated Servo Drive ISD® 510 System

3.3.1.6 Ethernet Connectors (not included)

Connector

name

Ethernet X1 Connection to

33

Ethernet X2 Connection to

Ethernet X3 Connection to

Ethernet X4 Connection to

Description Drawing/pins Ratings

Fulll the

eldbus

100BASE-T

specication

eldbus

Pins:

servo line 1

1: TD+

2: TD–

servo line 2

3: RD+

6: RD–

3.3.1.8 24/48 V IN Connector

Connector

name

24/48 V IN

Connector

Description Drawing/

pins

Used for 24–

48 V DC input

to the SAB.

Pins (left to

right):

AUX+

AUX–

Ratings

Nominal voltage: 24–

48 V DC ±10%

Nominal current:

Depends on the

number of servo

drives in the

application

Maximum current:

34 A

Maximum cross-

Table 3.13 Ethernet Connectors

NOTICE

The maximum length of the X1 and X2 shielded Ethernet

cables is 30 m.

3.3.1.7 AUX Connectors

Connector

name

ISD Line 1:

AUX 1

ISD Line 2:

AUX 2

Description Drawing/

pins

Used to connect

the AUX output

from the SAB to

the hybrid cable.

Pins (left to

right):

AUX+

AUX–

Ratings

Nominal voltage:

24–48 V DC±10%

Nominal current:

Depends on the

number of servo

drives in the

application

Maximum current:

15 A

Maximum cross-

section: 2.5 mm

2

Table 3.15 24/48 V IN Connector

3.3.1.9 UDC Connectors

Connector

name

ISD Line 1:

UDC 1

ISD Line 2:

UDC 2

Description Drawing/

Used to connect

the DC-link

voltage from the

SAB to the

hybrid cable.

pins

Pins (left to

right):

UDC+

UDC–

section:

2

4 mm

Maximum cable

length: 3 m

Ratings

Nominal voltage:

565–778 V DC

Nominal current:

Depends on the

number of servo

drives in the

application

Maximum current:

15 A

Maximum cross-

section:

Table 3.14 AUX Connectors

2.5 mm

2

Table 3.16 UDC Connectors

3.3.1.10 Hybrid Cable PE

Item Description Drawing/pins Ratings

Hybrid

cable PE

Table 3.17 Hybrid Cable PE

22 Danfoss A/S © 12/2015 All rights reserved. MG75K102

Used to connect the

PE wire from the

hybrid cable to the

decoupling plate.

See callout 15 in

Illustration 3.8.

Maximum

cross-

section:

2.5 mm

2

Page 25

130BE692.11

Auto

on

Reset

Hand

on

O

Status

Quick

Menu

Main

Menu

Alarm

Log

Back

Cancel

Info

OK

Status

271°

2850 RPM

On

Alarm

Warn.

A

38 °C

3.1 Nm

B

C

D

1.8 A

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18 19 20 21

System Description Operating Instructions

3.4 Local Control Panel (LCP)

3.4.1 Overview

The LCP is the graphical user interface on the SAB for

diagnostic and operating purposes. It is included as

standard with the SAB but can also be connected to the

advanced version servo drives using an optional cable

(M8 to LCP D-SUB extension cable).

The LCP display provides the operator with a quick view of

the state of the servo drive or SAB, depending on which

device it is connected to. The display shows parameters

and alarms/errors and can be used for commissioning and

troubleshooting. It can also be used to perform simple

functions, for example activating and deactivating the

output lines on the SAB. The LCP can be mounted on the

front of the control cabinet and then connected to the SAB

via SUB-D cables (available as an accessory).

3.4.2 Local Control Panel (LCP) Layout

The local control panel is divided into 4 functional groups

(see Illustration 3.10).

A. Display area.

B. Display menu keys.

C. Navigation keys and indicator lights (LEDs).

D. Operation keys and reset.

A. Display area

The values in the display area dier depending on whether

the LCP is connected to an ISD 510 servo drive or the SAB

as shown in Illustration 3.10 and Illustration 3.11.

The display area is activated when the ISD 510 servo drive

or SAB it is connected to receives power from the mains

supply, a DC bus terminal, or U

AUX

.

3 3

1 Actual torque

2 Temperature drive module

3 Position

MG75K102 Danfoss A/S © 12/2015 All rights reserved. 23

4 Speed

5 Current

Display Description

Illustration 3.10 Display Area when Connected to an ISD 510

Servo Drive

Page 26

130BE693.11

Auto

on

Reset

Hand

on

O

Status

Quick

Menu

Main

Menu

Alarm

Log

Back

Cancel

Info

OK

Status

11.5 A

2.1 kW

On

Alarm

Warn.

A

38 °C

24 V

B

C

D

565 V

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18 19 20 21

System Description

VLT® Integrated Servo Drive ISD® 510 System

C. Navigation keys and indicator lights (LEDs)

Navigation keys are used for moving the display cursor

and provide operation control in local operation. There are

also 3 status LEDs in this area.

Key Function

33

Display Description

1 U

2 Temperature

3 Actual UDC (current)

4 ISD power consumption

5 Actual UDC (voltage)

Illustration 3.11 Display Area when Connected to the SAB

line voltage

AUX

10 Back Reverts to the previous step or list in the

menu structure.

11 Cancel Cancels the last change or command as long

as the display mode is not changed.

12 Info Press for a denition of the function being

shown.

13 Navigation

keys

Use the 4 navigation keys to move between

items in the menu.

14 OK Use to access parameter groups or to enable

a selection.

Table 3.19 Navigation Keys

LED Color Function

15 On Green The On LED activates when the

ISD 510 servo drive or SAB it is

connected to receives power from

the mains or auxiliary supply, or a

DC bus terminal.

16 Warn Yellow When warning conditions are met,

the yellow Warn LED activates and

text appears in the display area

identifying the problem.

17 Alarm Red A fault condition causes the red

Alarm LED to ash and an alarm

text is shown.

Table 3.20 Indicator Lights (LEDs)

B. Display menu keys

Menu keys are used for menu access for parameter set-up,

toggling through status display modes during normal

operation, and viewing fault log data.

Key Function

6 Status Shows operational information.

7 Quick Menu Allows access to parameters.

8 Main Menu Allows access to parameters.

9 Alarm Log Shows the last 10 alarms.

Table 3.18 Display Menu Keys

24 Danfoss A/S © 12/2015 All rights reserved. MG75K102

Page 27

130BE383.10

System Description Operating Instructions

D. Operation keys and reset

Operation keys are located at the bottom of the LCP.

Key Function

18 Hand On Enables the connected ISD 510 servo drive

or SAB to be controlled via the LCP.

Switching between Hand On and Auto On

modes is only possible in certain states (see

the VLT® Integrated Servo Drive ISD® 510

System Programming Guide for further

information).

19 O Puts the SAB into state Standby and the

drive to state Switch on Disabled.

This only works in Hand On mode.

O mode enables transition from Hand On

mode to Auto On mode.

20 Auto On Puts the system in remote operational mode.

In Auto On mode, the device is controlled

•

by eldbus (PLC).

Note that switching between Auto On

and Hand On modes is only possible

when the drive is in state Switch on

disabled and/or the SAB is in state

Standby.

21 Reset Resets the ISD 510 servo drive or SAB after a

fault has been cleared.

The reset is only possible when in Hand On

mode

Table 3.21 Operation Keys and Reset

Both ends of the loop cable are tted with M23

connectors.

The feed-in cable is tted with an M23 connector at the

output end for connection to the 1st servo drive. At the

input end it is pigtailed with individual connectors for

connection to the corresponding terminals on the SAB.

Minimum bending radius

The maximum number of bending cycles is 5 million at

7.5 x cable diameter (15.6 mm).

Permanently exible: 12 x cable diameter

•

Permanently installed: 5 x cable diameter

•

Description Shielded/

unshielded

Feed-in

cable

Loop cable Shielded

Shielded

Maximum

cable

length

1)

40 m

1)

25 m

Port Notes

Signal/

control

Signal/

control

Hybrid cable

(overall shield

with additional

eldbus and

safety section

shield).

Hybrid cable

(overall shield

with additional

eldbus and

safety section

shield).

3 3

NOTICE

To adjust the display contrast, press [Status] and the

[▲]/[▼] keys.

3.5 Cables

3.5.1 Hybrid Cable

Illustration 3.12 Hybrid Loop Cable

There are 2 types of hybrid cables that are available with

both angled and straight M23 connectors:

Feed-in cable for connecting the 1st servo drive of

•

a group to the connection point on the SAB.

Loop cable for connecting the ISD 510 servo

•

drives in daisy-chain format in an application.

Both these cables are provided by Danfoss and are

available in various lengths. See the VLT® Integrated Servo

Drive ISD® 510 System Design Guide for further information.

Table 3.22 Hybrid Cables

1) Maximum 100 m total length for each line.

3.5.2 I/O and/or Encoder Cable

This cable connects the I/O and/or encoder to the servo

drive (see X4 in chapter 3.2.3.1 Connectors on the Servo

Drives). The cable is not included with the servo drives.

I/O and/or encoder cables with M12 connectors can be

used for the ISD 510 servo system if they comply with the

form factor dened in IEC 61076-2-101.

3.5.3 Additional Cables

Fieldbus extension cable

If this cable is not used, t the M23 blind cap to the X2

female connector on the last servo drive in the application.

LCP cables

There are 2 kinds of cable for the LCP module that can be

purchased from Danfoss (see the VLT® Integrated Servo

Drive ISD® 510 System Design Guide):

To connect the LCP to the servo drive.

•

To connect the LCP to the SAB.

•

MG75K102 Danfoss A/S © 12/2015 All rights reserved. 25

Page 28

130BE437.10

AUX 1

Status

Hand

On

Reset

Auto

On

OK

Back

Cancel

Info

Quick

Menu

Main

Menu

Alarm

Log

AUX 2

SAFE 1

SAFE 2

Status

Hand

On

Reset

Auto

On

OK

Back

Cancel

Info

Quick

Menu

Main

Menu

Alarm

Log

LCP

SAB

400-480 V AC

Real-Time Ethernet

1

ISD 510

2

. . .

. . .

130BE436.10

AUX 1

Status

Hand

On

Reset

Auto

On

OK

Back

Cancel

Info

Quick

Menu

Main

Menu

Alarm

Log

AUX 2

SAFE 1

SAFE 2

Status

Hand

On

Reset

Auto

On

OK

Back

Cancel

Info

Quick

Menu

Main

Menu

Alarm

Log

LCP

SAB

400-480 V AC

Real-Time Ethernet

1

ISD 510

2

. . .

System Description

VLT® Integrated Servo Drive ISD® 510 System

3.6 Connection Cables/Cabling

3.6.1.1 Standard Cabling Concept for 2

Lines

3.6.1 Layout and Routing

The servo drives are interconnected by hybrid loop cables.

A hybrid feed-in cable with quick-release connectors

33

provides the supply voltage from the SAB to the 1st servo

drive.

Routing in drag chains

The hybrid cable is compatible with drag chains and

therefore suitable for use in moving systems. The number

of bending cycles is dependent on individual conditions

and must therefore be determined in advance for each

application, see chapter 3.5.1 Hybrid Cable for further

information.

Maximum cable lengths

M23 Feed-in cable 40 m

M23 Loop cable 25 m

Fieldbus extension cable Length: 2 m

Maximum length to next port:

100 m

Maximum cable length per line 100 m

Table 3.23 Maximum Cable Lengths

1 M23 Feed-in cable

2 M23 Loop cable

Chapter 3.6.1.1 Standard Cabling Concept for 2 Lines and

chapter 3.6.1.2 Standard Cabling Concept for 1 Line show the

standard cabling concept without redundancy that can be

used to connect 1 or 2 lines, each with up to 32 servo

drives in an application.

NOTICE

For cabling with redundancy, see the VLT® Integrated

Servo Drive ISD® 510 System Design Guide.

Illustration 3.13 Standard Cabling Concept for 2 Lines

3.6.1.2 Standard Cabling Concept for 1 Line

1 M23 Feed-in cable

2 M23 Loop cable

Illustration 3.14 Standard Cabling Concept for 1 Line

26 Danfoss A/S © 12/2015 All rights reserved. MG75K102

Page 29

EtherCAT

Slave Controller

(ESC)

OUT

Port 1 (B)

OUT

Port 2 (C)

IN

Port 0 (A)

X2X1

X3

130BE695.10

System Description Operating Instructions

3.7 Software

The software for the ISD 510 servo system comprises:

The rmware of the VLT® Integrated Servo Drive

•

ISD® 510 that is already installed on the device

and provides the functionality described in

chapter 7 Operation.

rmware of the VLT® Servo Access Box that is

The

•

already installed on the device.

A package of PLC libraries for Automation

•

Studio™ for operating the ISD 510 devices (see

chapter 6.4.1 Programming with Automation

Studio™ for further information).

A PLC library for TwinCAT® 2 for operating the

•

ISD 510 devices (see chapter 6.4.2 Programming

®

with TwinCAT

ISD Toolbox: A Danfoss PC-based software tool for

•

commissioning and debugging the devices (see

chapter 6.5 ISD Toolbox for further information).

for further information).

3.8 Fieldbus

The ISD 510 servo system has an open system architecture

realized by fast Ethernet (100BASE-T) based communi-

cation. The system supports both EtherCAT® and Ethernet

POWERLINK®

ISD® 510 System Programming Guide for further information.

eldbuses. See the VLT® Integrated Servo Drive

3.8.1

EtherCAT

The servo drive and the SAB support the following

EtherCAT® protocols:

CANopen over EtherCAT® (CoE)

•

File Access over EtherCAT® (FoE)

•

Ethernet over EtherCAT® (EoE)

•

The servo drive and the SAB support distributed clocks. To

compensate for the failure of a communication cable

section in the system, cable redundancy is available for

eldbuses. See the VLT® Integrated Servo Drive

both

ISD® 510 System Design Guide for further information.

The EtherCAT® port assignment for the servo drive and

SAB are shown in Illustration 3.15 and Illustration 3.16.

®

3 3

In productive environments, communication to the devices

always takes place via a PLC that acts as a master. The

servo drives and the SABs can be controlled by these

communication methods:

Using the ISD library (available for TwinCAT® and

•

Automation Studio™).

Using the NC axis functionality of TwinCAT®.

•

Using the CANopen® CiA DS 402 standard by

•

reading and writing to objects.

The servo drives and the SABs can be operated with the

following cycle times (for both eldbuses):

400 µs and multiples of it (for example, 800 µs,

•

1200 µs, and so on).

500 µs and multiples of it (for example, 500 µs,

•

1 ms, and so on).

When the cycle time is a multiple of 400 µs and 500 µs,

the time base of 500 µs is used.

certied for both

®

The servo drive and the SAB are

eldbuses according to the corresponding rules and

regulations. The servo drive conforms to the CANopen

CiA DS 402 Drive Prole.

X1 M23 hybrid cable connector to SAB or previous servo drive.

X2 M23 hybrid cable connector to the next servo drive.

X3

M8 Ethernet cable connector to other EtherCAT® slaves, for

example EtherCAT® encoder.

The connector is only available on the advanced servo drive.

Illustration 3.15 EtherCAT® Port Assignment for the Servo

Drive

MG75K102 Danfoss A/S © 12/2015 All rights reserved. 27

Page 30

ESC SAB L1

Main EtherCAT

slave

OUT

Port 2 (C)

OUT

Port 1 (B)

IN

Port 0 (A)

X1

ESC SAB L2

AL emulated

junction slave

IN

Port 0 (A)

OUT

Port 1 (B)

OUT

Port 2 (C)

X2

X3

X4

1

R

130BE696.10

System Description

VLT® Integrated Servo Drive ISD® 510 System

33

X1 RJ45 cable connector to the PLC or previous slave.

X2 RJ45 cable connector to the PLC or next slave.

X3

RJ45 to M23 hybrid adapter cable to the 1st servo drive on

line 1.

X4

RJ45 to M23 hybrid adapter cable to the 1st servo drive on

line 2.

1 Ports always connected internally in the SAB.

Illustration 3.16 EtherCAT® Port Assignment for the SAB in

Line Topology Mode (default)

3.8.2

Ethernet POWERLINK

®

The ISD drive and the SAB are certied according to

DS301 V1.1.0. The following features are supported for the

ISD servo drive and the SAB:

Work as controlled node.

•

Can be operated as multiplexed stations.

•

Support of cross-communication.

•

Ring redundancy is supported for media

•

redundancy.

Specic ports are not assigned for Ethernet POWERLINK®.

28 Danfoss A/S © 12/2015 All rights reserved. MG75K102

Page 31

Mechanical Installation Operating Instructions

4 Mechanical Installation

4.1 Transport and Delivery

4.1.1 Items Supplied

The items supplied for the ISD 510 servo system are:

ISD 510 servo drives

•

Servo Access Box (SAB) including connectors

•

This manual

•

Feed-in (hybrid) cable

•

Loop (hybrid) cable

•

Blind caps for connectors M8, M12, and M23

•

The packaging unit depends on the number of servo

drives delivered. Save the packaging for use in the event of

product return.

4.1.2 Transport

Always use means of transport and lifting gear

•

with sucient load capacity to transport the

servo drives and the SAB.

Avoid vibration during transport.

•

Avoid heavy impacts and blows.

•

4.1.3 Inspection on Receipt

1. After receiving the delivery, immediately check

whether the items supplied match the shipping

documents. Danfoss does not honor claims for

faults registered later.

2. Register a complaint immediately:

With the carrier if there is visible

•

transport damage.

With the responsible Danfoss represen-

•

tative if there are visible defects or the

delivery is incomplete.

Safety Measures during Installation

4.2

Always observe the safety instructions in chapter 2 Safety

during installation.

Pay particular attention to ensuring that the following

points are always observed:

Installation may only be performed by

•

personnel - see chapter 2.5 Qualied Personnel.

Installation must be performed with due care and

•

attention.

All safety regulations and protective measures

•

must be complied with, and the environmental

conditions must be observed.

The manual is read and understood.

•

qualied

4.3 Installation Environment

The installation must provide the following environmental

conditions to allow the ISD 510 servo system to be

operated safely and eciently.

Servo Drive

The allowable operating ambient temperature

•

range and vibration levels must not be exceeded

(see chapter 11.1.5 General Specications and

Environmental Conditions for further information).

The allowable relative humidity range is 3–93%,

•

non-condensing.

Unrestricted ventilation must be available.

•

The mounting structure must be suitable for the

•

application, adequately rigid, and so on.

SAB

The allowable operating ambient temperature

•

range and vibration levels must not be exceeded

(see chapter 11.2.4 General Specications and

Environmental Conditions for further information).

The allowable relative humidity range is 5–93%,

•

non-condensing.

Minimum 100 mm space is required above and

•

below the SAB (see chapter 4.5.1 Installation and

Space Requirements for further information).

Contact Danfoss if it is not possible to comply with these

environmental conditions.

4 4

MG75K102 Danfoss A/S © 12/2015 All rights reserved. 29

Page 32

Mechanical Installation

VLT® Integrated Servo Drive ISD® 510 System

4.4 Preparation for Installation

4.4.1 Servo Drive

Make the following preparations to ensure that the

ISD 510 servo system can be installed reliably and

eectively.

44

1. Provide a suitable mounting arrangement for the

application. This depends on the type, weight,

and torque of the servo drives.

2. Seat the motor ange ush against the mounting