Page 1

VLT HVAC Drive in Fan Appli... Application note

1 VLT HVAC Drive in Fan Application with Resonance vibrations in the

Fan

1.1 Application

In applications where Motor with fan mounted directly on

the drive end shaft and where the running point is in field

weakening area, a small number of customers have

experienced vibrations when applying FC102 drives in the

power range (7,5 [kW]-18 [kW]). This Application note

answers the question of the causes for these Vibrations

and give solutions to solve it

1.2 Definitions

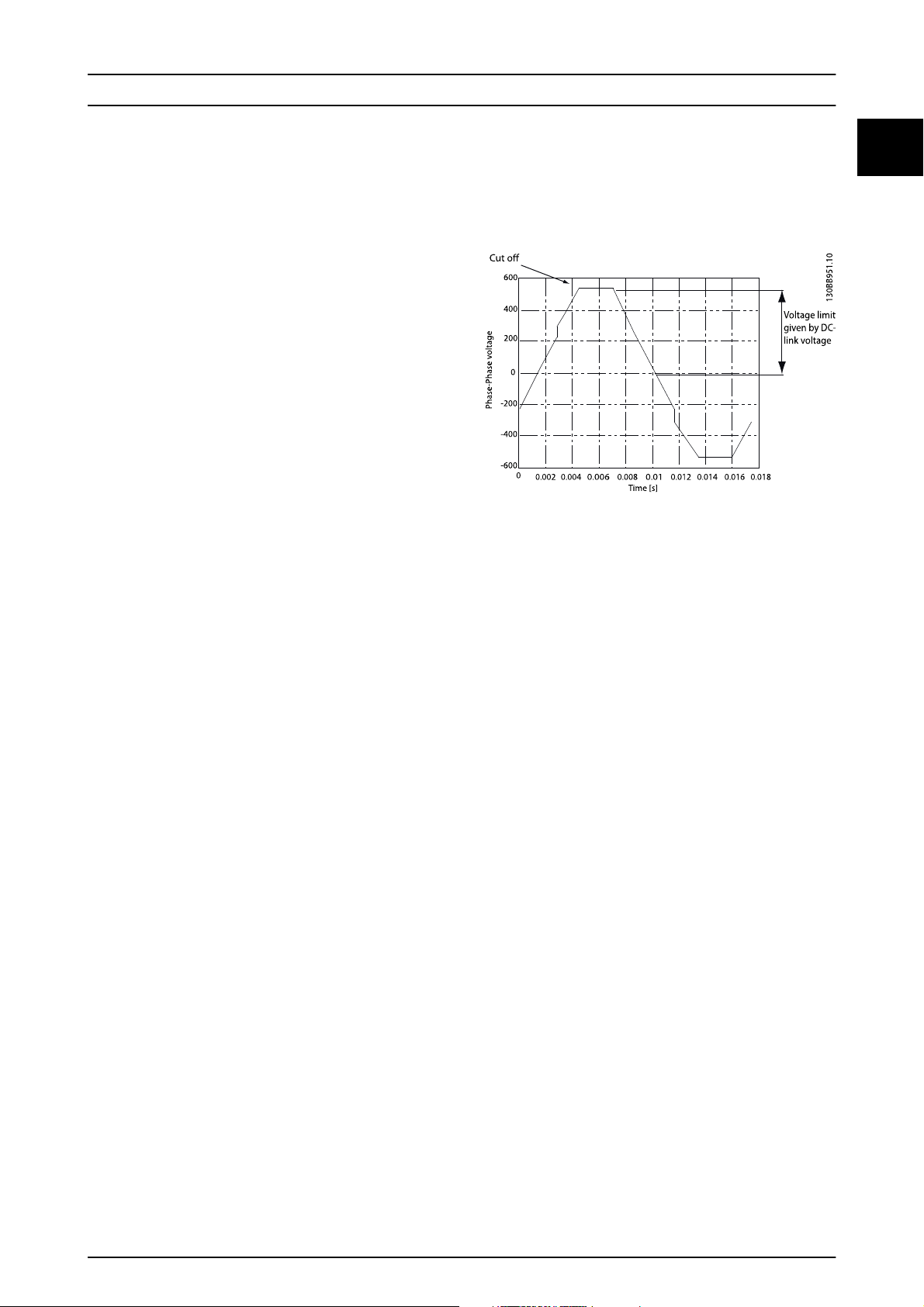

Over modulation: Over modulation is a way to

•

increase the motor voltage delivered by the drive

between f

Hz and < 65Hz

The advantage of over modulation is:

•

- Lower currents and higher efficiency at

- That the drive can give nominal Grid

- If the mains voltage sometimes goes

Over modulation means that a voltage is

•

modulated above the possible level given by the

DC-link voltage.

- The result is non-sinusoidal output

The non-sinusoidal voltages increases the

•

harmonics of the voltages, thereby generating

harmonic currents which again generates noise

and torque ripple

The degree of over modulation is depending on

•

the voltage reference from the VVC+ control,

which depends on the motor frequency, torque

characteristic, load compensation, mains-voltage,

etc.

depends on the motor frequency, torque characteristic,

load compensation, mains-voltage, etc. Over modulation

begins when the required output voltage is higher than 95

% of the input voltage, in VT mode this means from

approx. 47 Hz and up.

> 45Hz and f

mot

over field weakening area. Speed wise?

voltage at nominal at nominal grid

frequency

below the correct motor voltage at e.g.

43 Hz over-modulation can again add

the needed motor voltage.

voltages, because of the shape of the

sinus wave

< 55Hz or f

mot

mot

< 55

1.3 Cause to the vibrations

I expect that this is just an example with one motor

frequency.

The vibrations occur at frequencies corresponding to the

6th harmonic of the drive output frequency, fout.

The system vibrates when the motor is supplied by a

output frequency of approximately 55 Hz (6 multiplied fout

= 6*55=330 Hz) (Depends of the resonance frequency of

the fan) which is approximately 330 [Hz] on the fan wheel .

This 6th harmonics is generated only by the over

modulation. If the resonance frequency of the fan is close

to this 330Hz, The resonance will cause vibrations. Those

vibrations can in the end cause cracks in the Fan and in

worst cases a broken fan or /and broken Bearings

1.4 Solutions

1. The best solution is disabling the overmodulation

By disabling over-modulation, vibrations will be

reduced to a minimum but this solution might

also cause a derating of the applied motor in the

range of 5-10% because of the missing voltage

applied by the over modulation.

2. Skipping a small frequency band of the output

frequencies may also be a solution

In some applications it is not possible to disable

the over modulation If the motor is designed to

the limit of the fan application the voltage losses

in the FC will cause missing torque. In these

situations the problem of vibration might be

reduced significantly by skipping a small

frequency band around the mechanical resonance

1

1

MN.11.B1.02 - VLT® is a registered Danfoss trademark 1

Page 2

VLT HVAC Drive in Fan Appli... Application note

1

frequency approximately 330Hz. This can be done

by setting parameters (p4-6*) or by using the

Semi auto bypass setup p4-46. However, there is

no general design rule for making an optimal

skip of frequency bands as this is highly

dependent on the width of the resonance peak.

In most situations it is possible to hear the

resonance

2 MN.11.B1.02 - VLT® is a registered Danfoss trademark

Loading...

Loading...