Page 1

VLT® HVAC Drive FC 102 Application Note 1 Temperature Derating Guide

1 Temperature Derating Guide

1.1.1 Abstract

This paper provides detailed data regarding the operation of the VLT HVAC Drive FC102 at varying

ambient temperature and load. There is given application specific guidelines, and the influence

on the switching frequency is documented.

1.1.2 Introduction

This paper provides detailed information regarding the operation of the VLT HVAC Drive FC102 at

different ambient temperature and load conditions. Application specific guidelines are given and

the influence of the switching frequency is detailed.

VLT HVAC Drive FC102 General Specifications

The VLT HVAC Drive FC102 has a specified continuous output current to be able to supply a wide

range of motors with different efficiencies. Full continuous rated output current can be supplied

in ambient temperatures up to 45°C. With a typical full load current of EFF2 motors (see

Efficiency

in ambient temperatures up to 50°C.

Frequency Converter Selection and Derating

The sizing of the frequency converter is generally dependant on a number of factors including:

), full output shaft power can be maintained with the VLT HVAC Drive FC102 operating

• Motor efficiency and full load current

• Ambient temperature

• Mains supply voltage

• Motor cable length and type (e.g. screened or unscreened)

• Number of options installed (impacts the internal temperature within the frequency converter)

• Switching frequency and/or switching pattern (impacts the heat generation within the

frequency converter)

1

Motor

Motor Efficiency

EFF classification of motors is predominantly relevant in European Union countries although it is

also adopted or being considered to be adopted in other countries. It is applicable to specific motor

types (e.g. totally enclosed fan ventilated, three phase AC squirrel cage induction motors in the

range 1.1 to 90kW, having 2 or 4 poles, rated for 400V, 50Hz, S1 duty class).

Other motor efficiency classifications or Minimum Efficiency Performance Standards (MEPS) exist

elsewhere in the world. For example in North America NEMA MG1 defines motor efficiency levels

for “energy efficient” and “premium efficiency” motors for a wider range of motors than those

under the EFF classification (e.g. 1 to 500HP, 2, 4 and 6 pole) and in Australia and New Zealand

AS/NZS 1359.5-2004, applicable to three phase, 2, 4, 6 and 8 pole motors from 0.73kW to

<185kW, defines minimum efficiency levels approximately equivalent to those of the European

EFF1 level and high efficiency motors as having an even higher efficiency. Some of these efficiency

requirements are voluntary and others are legally enforceable.

The efficiency of a motor is one factor that affects the full load current rating of a motor and

therefore has an impact on the ambient temperature rating of the frequency converter for use

with that motor when operating at full load. For example the frequency converter may be rated

MN.11.A1.02 - VLT® is a registered Danfoss trademark

1

Page 2

1

1 Temperature Derating Guide VLT® HVAC Drive FC 102 Application Note

for operation in an ambient temperature of say 50 °C when operating at full load current of a

15kW EFF2 motor but it may be rated for operation in say 54 °C when operating at full load current

of a 15kW high efficient motor according to AS/NZS 1359.5-2004 or rated for operation in say 52

°C when operating at full load current of a 20HP premium efficiency motor according to NEMA

MG1.

Ambient Temperature

If the maximum ambient temperature in which the frequency converter will be installed is equal

to or below the limit defined for full continuous FC output current in the

the

Operating Instructions

Guide

and if the factory default switching frequency will be used, there is no need to consider

derating of the output current.

However if the maximum ambient temperature is higher than that defined, this guide should be

used to ensure the derated continuous output current of the frequency converter at this higher

maximum ambient temperature is higher than the full load current of the motor or at least higher

than the maximum running current of the motor for the application.

Mains supply voltage

The mains supply voltage has a minimal affect for low powers and therefore the ambient temperature rating, current rating and derating curves are shown for the worst case situation (i.e.

highest mains voltage). For higher powers (enclosure size D and above), different derating curves

dependant on the mains supply voltage are shown.

or the

General Specifications and Troubleshooting section

Specifications section

of the

Design

of

Motor cable length and type

The motor cable length and type has an affect because due to the high switching frequency of

the frequency converter it not only has to supply the full load current of the motor but also

“charging” currents in the motor cable. The longer the motor cable or if the cable is screened

instead of unscreened, the higher these charging currents. The motor cable length and type has

more affect at low powers and much less at higher powers. For all powers the ambient temperature, current rating and derating curves are given for the worst case situation (150m screened/

300m unscreened motor cable).

Number of options installed

The frequency converter can have up to three options installed (Option A (BMS high level interface

communication options), Option B (I/O extension options) and Option C (application options) ).

The number of options installed can affect the internal temperature of the frequency converter

(depending on enclosure size). Therefore for some enclosure sizes different derating curves are

shown depending on the number of options installed.

Switching frequency, switching pattern and automatic adaptation

The frequency converter can be programmed to use a different switching pattern (60 AVM or

SFAVM (parameter 14-00)) or switching frequency (1kHz to 16kHz (depending on size) (parameter

14-01)).

For most applications the default settings (60 AVM and 4kHz (depending on size)) will be adequate

because the frequency converter automatically adapts these to ensure performance if necessary.

The frequency converter constantly checks for critical levels of internal temperature, load current,

high voltage on the intermediate circuit and low motor speeds. As a response to a critical level,

the frequency converter can adjust the switching frequency and/or change the switching pattern

in order to ensure the performance of the frequency converter. The capability to automatically

reduce the output current (i.e. automatically derate the output current) extends the acceptable

operating conditions even further. This automatic ad aptation function ensures continued operation

of the fan, pump or compressor even in extreme operating conditions. It also helps to minimize

2

MN.11.A1.02 - VLT® is a registered Danfoss trademark

Page 3

VLT® HVAC Drive FC 102 Application Note 1 Temperature Derating Guide

the acoustic noise from the motor resulting from the frequency converter when operating at low

speeds, which is the most critical area of operation for acoustic noise because at low speeds the

acoustic noise from the motor and fan themselves is low.

The graphs that follow provide information about the mutual influence on load, ambient temperature, switching frequency, and switching pattern.

1

1.1.3 Motor Acoustic Noise Optimization

Additional acoustic noise from a motor when using a frequency converter can be a concern on

some applications. On pump or compressor applications it is typically not a concern but on fan

applications it may be. Typically it is a concern when the fan is operating at mid to low speeds.

At high speeds any additional noise as a result of the frequency converter, is drowned out by the

noise from the motor and fan themselves but at mid to low speeds it may be noticeable.

Changing the switching frequency to a higher value can help to reduce acoustic noise from the

motor and is the most common solution to this.

Changing the switching pattern from the default setting is not often done. However, the acoustic

noise from a motor will typically be less when using SFAVM than 60 AVM for the same switching

frequency, although the internal frequency converter losses will be higher. The automatic adaptation function described above sets the switching pattern to SFAVM when operating at low output

frequencies (approximately <30% nominal motor frequency) to help minimize acoustic motor

noise. It also sets the switching pattern to 60 AVM when operating at high output frequencies

(approximately >80% of nominal motor frequency) to help minimize internal losses when the

frequency converter load is at its highest (particularly applicable to fans, centrifugal pumps and

centrifugal chiller compressors.) To minimize acoustic motor noise in the operating range between

approximately 30% and 80% motor nominal frequency a combination of changing the switching

pattern and/or switching frequency can give the best results.

However, if the switching frequency is increased and depending on the application, if t he switching

pattern is changed from default, this can result in increased full load losses in the frequency converter and therefore the continuous current rating of the frequency converter should be derated

in accordance with the graphs that follow.

MN.11.A1.02 - VLT® is a registered Danfoss trademark

3

Page 4

1

1 Temperature Derating Guide VLT® HVAC Drive FC 102 Application Note

1.1.4 Application Dependant Derating

Fans, centrifugal pumps and centrifugal chiller compressors

Due to the nature of these loads the maximum load (i.e. output current) occurs at nominal/maximum output frequency. The automatic adaptation function described above, ensures that when

the frequency converter is operating at its highest load and therefore when its internal losses are

greatest, it is operating with 60 AVM switching pattern irrespective of what the switching pattern

(parameter 14-00) is programmed to. Therefore for these applications it is only necessary to refer

to the graphs that follow in illustration 1.1 - 1.9 even if the switching pattern parameter is changed

from default to minimize motor audible noise at mid to low output frequencies.

Screw, scroll and reciprocating compressors

Due to the nature of these loads the maximum load (i.e. output current) could occur at all output

frequencies (e.g. the torque and current required to operate a screw compressor at 60% speed

will typically be similar to that at 100% speed.) Therefore for these applications it is necessary to

refer to either the graphs in illustration 1.1 - 1.9 (60 AVM) OR the graphs in illustration 1.10 - 1-18

(SFAVM), depending on the switching pattern programmed (parameter 14-00.) Typically this parameter will not be changed from default, so only the graphs in illustration 1.1 - 1.9 need be used,

but additional graphs are shown in illustration 1.10 - 1-18 for SFAVM switching pattern for completeness. (SFAVM results in higher internal losses than 60 AVM and therefore the derating factors

are different.)

1.1.5 How to Find the Derating Factor

1. Determine the application.

1a If it is a fan, centrifugal pump or centrifugal compressor use steps 2 to 4 to

determine which graph applies from illustration 1.1 - 1.9.

1b If it is a screw, scroll or reciprocating compressor and the switching pattern

(parameter 14-00) is not changed from default (60 AVM), use steps 2 to 4 to

determine which graph applies from illustration 1.1 - 1.9.

1c If it is a screw, scroll or reciprocating compressor and the switching pattern

(parameter 14-00) has been changed from default to SFAVM, use steps 2 to 4

to determine which graph applies from illustration 1.10 - 1-18.

2. Find the enclosure type from the tables below, e.g. a 7.5 kW with mains supply 3 x 380

– 480 V and IP 55 rating is enclosure type A5.

3. If the drive is enclosure type D or E then take note of the supply voltage for the drive.

4. Find the relevant derating curve based on the information found above: a pplicat ion and

switching pattern, enclosure type and supply voltage (if relevant).

4

MN.11.A1.02 - VLT® is a registered Danfoss trademark

Page 5

VLT® HVAC Drive FC 102 Application Note 1 Temperature Derating Guide

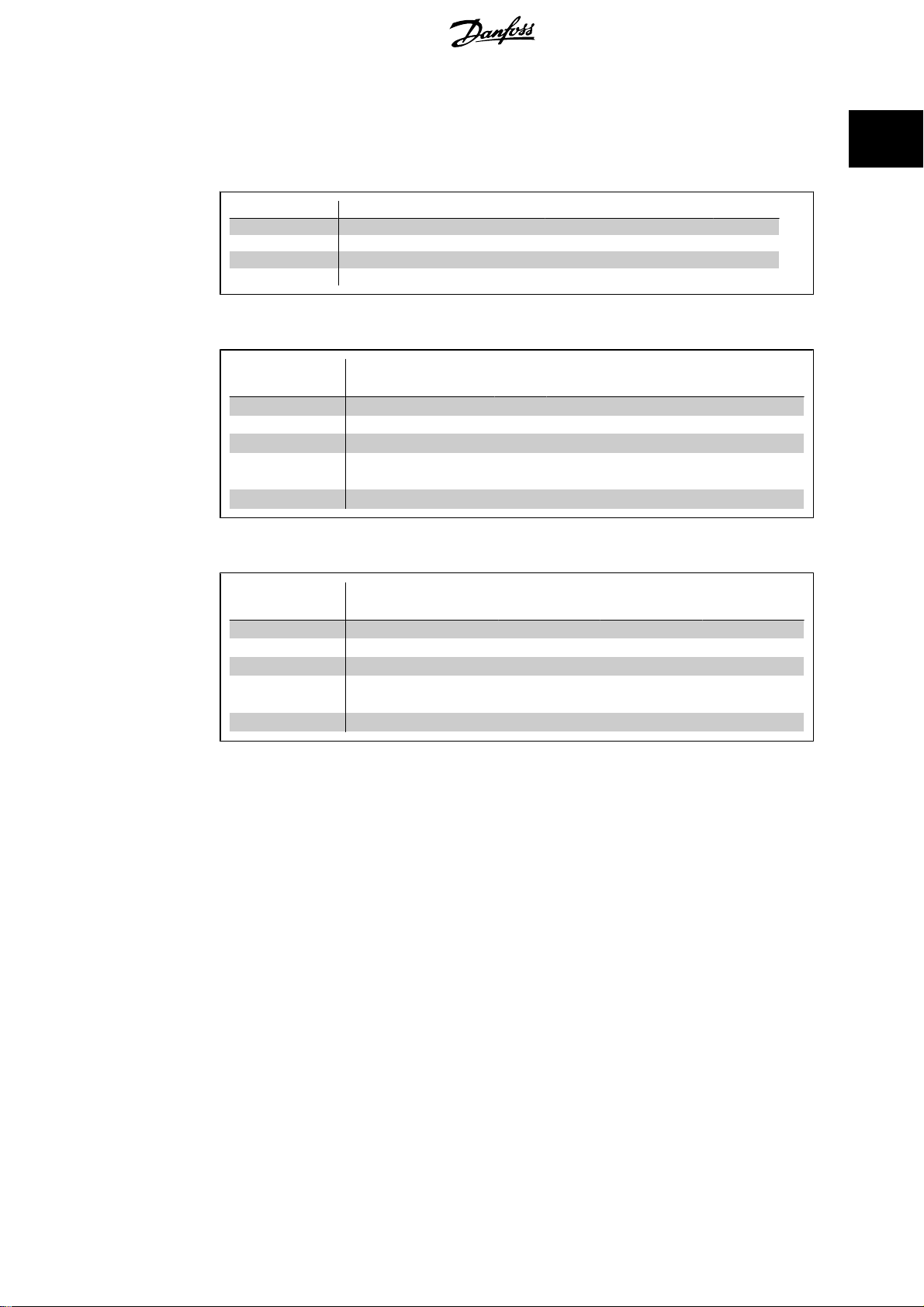

1.1.6 Enclosure Types

1

3 x 200 – 240 Volt

IP 20 / chassis A2 A3 B3 B4 B4 C3 C4

IP 21 / NEMA 1 A2 A3 B1 B2 C1 C1 C2

IP 55 / NEMA 12 A5 A5 B1 B2 C1 C1 C2

IP 66 / NEMA 12

3 x 380 - 480 Volt

IP 00 - - - - - - D3 D4 E2

IP 20 / chassis A2 A3 B3 B4 C3 C4 - - IP 21 / NEMA - - B1 B2 C1 C2 D1 D2 E1

IP 54-55 / NEMA

12

IP 66 / NEMA 12 A5 A5 B1 B2 C1 C2 - - -

3 x 525 - 600 Volt

IP 00 - - - - - - D3 D4 E2

IP 20 / chassis A2 A3 B3 B4 C3 C4 - - IP 21 / NEMA 1 A2 A3 B1 B2 C1 C2 D1 D2 E1

IP 54-55 / NEMA

12

IP 66 / NEMA 12 A5 A5 B1 B2 C1 C2 - - -

1,1-2,2 kW 3-3,7 kW 5 5-11 kW 15 kW 18,5 kW 22-30 kW 37-45 kW

A5 A5 B1 B2 C1 C1 C2

1,1-4kW5,5-7,5kW11-18,

5 kW

A5 A5 B1 B2 C1 C2 D1 D2 E1

1,1-4kW5,5-7,5kW11-18,

A5 A5 B1 B2 C1 C2 D1 D2 E1

22-37kW45-55kW75-90kW110-13

22-37kW45-55kW75-90kW110-13

5 kW

2 kW

2 kW

160-25

0 kW

160-31

5 kW

315-45

0 kW

355-56

0 kW

MN.11.A1.02 - VLT® is a registered Danfoss trademark

5

Page 6

1 Temperature Derating Guide VLT® HVAC Drive FC 102 Application Note

1

1.2 Application Dependant Derating Curves

1.2.1 Typical HVAC Applications

The curves that follow in this section are applicable for the following applications:

• Fans, Centrifugal Pumps and Centrifugal Compressors

• Screw, Scroll and Reciprocating Compressors where the switching pattern is not changed

from default (i.e. parameter 14-00 remains at 60 AVM).

A Enclosures

Illustration 1.1: A Enclosure Derating Curves. Derating of full continuous FC output current for different

T

MAX and Switching Frequency

AMB

6

MN.11.A1.02 - VLT® is a registered Danfoss trademark

Page 7

VLT® HVAC Drive FC 102 Application Note 1 Temperature Derating Guide

B1 Enclosures

1

Illustration 1.2: B1 Enclosure Derating Cu rves. Derating of full continuous FC output current for dif ferent

MAX and Switching Frequency

T

AMB

B2 Enclosures

Illustration 1.3: B2 Enclosure Derating Cu rves. Derating of full continuous FC output current for dif ferent

T

MAX and Switching Frequency

AMB

MN.11.A1.02 - VLT® is a registered Danfoss trademark

7

Page 8

1

1 Temperature Derating Guide VLT® HVAC Drive FC 102 Application Note

C Enclosures

Illustration 1.4: C Enclosure Derating Curves. Derating of full continuous FC output cur rent for different

MAX and Switching Frequency

T

AMB

D Enclosures 380-480V

Illustration 1.5: D Enclosures 380-480V Derating Curves. Derating of full continuous FC output current for

different T

MAX and Switching Frequency

AMB

8

MN.11.A1.02 - VLT® is a registered Danfoss trademark

Page 9

VLT® HVAC Drive FC 102 Application Note 1 Temperature Derating Guide

D Enclosures 525-600V excluding 315kW

1

Illustration 1.6: D Enclosures 525-600V excluding 315kW Derating Curves. Derating of full continuous FC

output current for different T

MAX and Switching Frequency

AMB

D Enclosure 525-600V 315kW

Illustration 1.7: D Enclosure 525-600V 315kW Derating Curves. Derating of full continuous FC output current

for different T

MAX and Switching Frequency

AMB

MN.11.A1.02 - VLT® is a registered Danfoss trademark

9

Page 10

1

1 Temperature Derating Guide VLT® HVAC Drive FC 102 Application Note

E Enclosures 380-480V

Illustration 1.8: E Enclosures 380-480V Derating Curves. Derating of full continuous FC output current for

different T

MAX and Switching Frequency

AMB

E Enclosures 525-600V

Illustration 1.9: E Enclosures 525-600V Derating Curves. Derating of full continuous FC output current for

different T

MAX and Switching Frequency

AMB

10

MN.11.A1.02 - VLT® is a registered Danfoss trademark

Page 11

VLT® HVAC Drive FC 102 Application Note 1 Temperature Derating Guide

1.2.2 Applications with Specific Demands

1

The curves that follow in this section are applicable for the following applications:

• Screw, Scroll and Reciprocating Compressors where the switching pattern is changed

from default (i.e. parameter 14-00 is changed to SFAVM).

A Enclosures

Illustration 1.10: A Enclosure Derating Curves. Derating of full continuous FC output current for dif ferent

T

MAX and Switching Frequency

AMB

MN.11.A1.02 - VLT® is a registered Danfoss trademark

11

Page 12

1

1 Temperature Derating Guide VLT® HVAC Drive FC 102 Application Note

B1 Enclosures

Illustration 1.11: B1 Enclosure Derating Curves. Derating of full conti nuous FC output current for different

MAX and Switching Frequency

T

AMB

B2 Enclosures

Illustration 1.12: B2 Enclosure Derating Curves. Derating of full conti nuous FC output current for different

T

MAX and Switching Frequency

AMB

12

MN.11.A1.02 - VLT® is a registered Danfoss trademark

Page 13

VLT® HVAC Drive FC 102 Application Note 1 Temperature Derating Guide

C Enclosures

1

Illustration 1.13: C Enclosure Derating Curves. Derating of full continuous FC output current for dif ferent

T

MAX and Switching Frequency

AMB

D Enclosures 380-480V

Illustration 1.14: D Enclosures 380-480V Derating Curves. Derating of full continuous FC output current for

different T

MAX and Switching Frequency

AMB

MN.11.A1.02 - VLT® is a registered Danfoss trademark

13

Page 14

1

1 Temperature Derating Guide VLT® HVAC Drive FC 102 Application Note

D Enclosures 525-600V excluding 315kW

Illustration 1.15: D Enclosures 525-600V excluding 315kW Derating Curves. Derating of full continuous FC

output current for different T

MAX and Switching Frequency

AMB

D Enclosure 525-600V 315kW

Illustration 1.16: D Enclosure 525-600V 315kW Derating Curves. Derating of full continuous FC output current for different T

MAX and Switching Frequency

AMB

14

MN.11.A1.02 - VLT® is a registered Danfoss trademark

Page 15

VLT® HVAC Drive FC 102 Application Note 1 Temperature Derating Guide

E Enclosures 380-480V

1

Illustration 1.17: E Enclosures 380-480V Derating Curves. Derating of full continuous FC output current for

different T

MAX and Switching Frequency

AMB

E Enclosures 525-600V

Illustration 1.18: E Enclosures 525-600V Derating Curves. Derating of full continuous FC output current for

different T

MAX and Switching Frequency

AMB

MN.11.A1.02 - VLT® is a registered Danfoss trademark

15

Loading...

Loading...