Page 1

MAKING MODERN LIVING POSSIBLE

Quick Guide

VLT® HVAC Basic Drive FC 101

Page 2

Contents

1 Quick Guide

1-1

1.1 Safety

1-1

1.1.1 Warnings 1-1

1.1.2 Safety Instructions 1-1

1.2 Introduction

1-2

1.2.1 Available Literature 1-2

1.2.2 Approvals 1-2

1.2.3 IT Line Power 1-2

1.2.4 Avoid Unintended Start 1-3

1.2.5 Disposal Instruction 1-3

1.3 Installation

1-3

1.3.1 Before Starting Repair Work 1-3

1.3.2 Side-by-Side Installation 1-3

1.3.3 Dimensions 1-4

1.3.4 Electrical Installation in General 1-6

1.3.5 Connecting to Line Power and Motor 1-7

1.3.6 Fuses 1-14

1.3.7 EMC-compatible Electrical Installation 1-16

1.3.8 Control Terminals 1-18

1.3.9 Electrical Overview 1-19

1.4 Programming

1-20

1.4.1 Programming with the Local Control Panel (LCP) 1-20

1.4.3 The Start-up Wizard for Open-loop Applications 1-21

1.5.1 Main menu structure 1-32

1.6 Warnings and Alarms

1-34

1.7 General Specifications

1-36

1.7.1 Line Power Supply 3x200–240 V AC 1-37

1.7.2 Line Power Supply 3x380–480 V AC 1-38

1.7.3 Line Power Supply 3x380–480 V AC 1-40

1.7.4 Line Power Supply 3x525–600 V AC 1-42

1.8 Special Conditions

1-47

1.8.1 Derating for Ambient Temperature and Switching Frequency 1-47

1.8.2 Derating for Low Air Pressure 1-47

1.9 Options for VLT® HVAC Basic Drive FC 101

1-47

1.10 MCT 10 Support

1-47

Contents

VLT® HVAC Basic Drive Quick Guide

MG18A422 - VLT® is a registered Danfoss trademark

Page 3

Contents

VLT® HVAC Basic Drive Quick Guide

MG18A422 - VLT® is a registered Danfoss trademark

Page 4

1 Quick Guide

1.1 Safety

1.1.1 Warnings

WARNING

High Voltage Warning

The voltage of the adjustable frequency drive is dangerous

whenever it is connected to line power. Incorrect installation of the motor or adjustable frequency drive may

cause damage to the equipment, serious injury or death.

Consequently, it is essential to comply with the

instructions in this manual as well as local and national

rules and safety regulations.

WARNING

DISCHARGE TIME!

Adjustable frequency drives contain DC link capacitors that

can remain charged even when the adjustable frequency

drive is not powered. To avoid electrical hazards,

disconnect AC line power, any permanent magnet type

motors, and any remote DC link power supplies, including

battery backups, UPS and DC link connections to other

adjustable frequency drives. Wait for the capacitors to fully

discharge before performing any service or repair work.

The wait time required is listed in the Discharge Time table.

Failure to wait for the specified period of time after power

has been removed to do service or repair could result in

death or serious injury.

Voltage [V] Power range hp/[kW] Minimum waiting time

[min]

3x200 0.34–5 [0.25–3.7] 4

3x200 7.5–15 [5.5–11] 15

3x400 0.5–10 [0.37–7.5] 4

3x400 15–125 [11–90] 15

3x600 3–10 [2.2–7.5] 4

3x600 15–125 [11–90] 15

Table 1.1 Discharge Time

CAUTION

Leakage Current:

The ground leakage current from the adjustable frequency

drive exceeds 3.5 mA. According to IEC 61800-5-1 a

reinforced Protective Ground connection must be ensured

with a min. 10 mm² Cu or an additional PG wire - with the

same cable cross-section as the line power wiring - must

be terminated separately.

Residual Current Device:

This product can cause a DC current in the protective

conductor. Where a residual current device (RCD) is used

for extra protection, only an RCD of Type B (time delayed)

shall be used on the supply side of this product. See also

Danfoss Application Note on RCD, MN90G.

Protective grounding of the adjustable frequency drive and

the use of RCDs must always follow national and local

regulations.

Motor thermal protection:

Motor overload protection is possible by setting Parameter

1-90 Motor thermal protection to the value Electronic

Thermal Relay (ETR) trip.

WARNING

Installation at high altitudes

For altitudes above 6,600 feet [2 km], contact Danfoss

regarding PELV.

1.1.2 Safety Instructions

•

Make sure the adjustable frequency drive is

properly grounded.

•

Do not remove AC line input connections, motor

connections or other power connections while

the adjustable frequency drive is connected to

line power.

•

Protect users against supply voltage.

•

Protect the motor against overloading according

to national and local regulations.

•

The ground leakage current exceeds 3.5 mA.

•

The [Off/Reset] key is not a safety switch. It does

not disconnect the adjustable frequency drive

from line power.

Quick Guide

VLT® HVAC Basic Drive Quick Guide

MG18A422 - VLT® is a registered Danfoss trademark 1-1

1 1

Page 5

1.2 Introduction

1.2.1 Available Literature

This Quick Guide contains the basic information necessary

for installing and running the adjustable frequency drive. If

more information is needed, literature can be found on the

enclosed CD or downloaded from:

www.danfoss.com/BusinessAreas/DrivesSolutions/Documentations/Technical+Documentation.htm

1.2.2 Approvals

Table 1.2

IP54 enclosure adjustable

frequency drive do not have UL

approvals.

Table 1.3

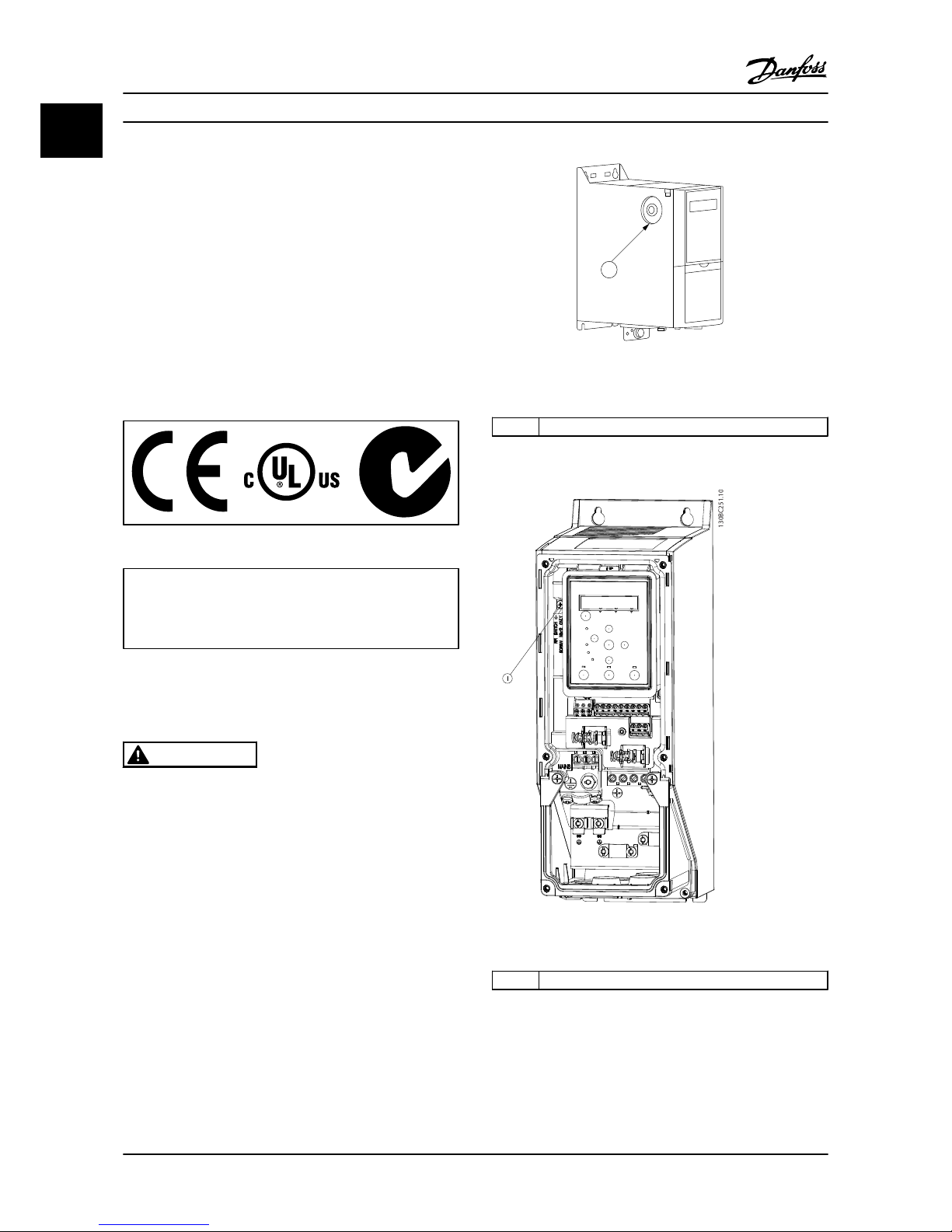

1.2.3

IT Line Power

CAUTION

IT Line Power

Installation on isolated line power source, that is, IT line

power.

Max. supply voltage allowed when connected to line

power: 440 V (3x380–480 V units).

On IP20 200–240 V 0.34–15 hp [0.25–11 kW] and 380–480

V IP20 0.5–30 hp [0.37–22 kW], open the RFI switch by

removing the screw on the side of the adjustable

frequency drive when at IT grid.

130BB612.10

1

Figure 1.1 IP20 200–240 V 0.34–15 hp [0.25–11 kW], IP20 0.5–30

hp [0.37–22 kW] 380–480 V.

1 EMC screw

Table 1.4

130BC251.10

Figure 1.2 IP54 400 V 1–25 hp [0.75–18.5 kW]

1

EMC screw

Table 1.5

On all units, set to [Off] when operating in IT line power.

Quick Guide

VLT® HVAC Basic Drive Quick Guide

1-2 MG18A422 - VLT® is a registered Danfoss trademark

11

Page 6

CAUTION

If reinserted, only use M3x12 screws.

1.2.4 Avoid Unintended Start

While the adjustable frequency drive is connected to line

power, the motor can be started/stopped using digital

commands, bus commands, references or via the LCP.

•

Disconnect the adjustable frequency drive from

line power whenever personal safety considerations make it necessary to avoid unintended

start of any motors.

•

To avoid unintended start, always press [Off/

Reset] before changing parameters.

1.2.5

Disposal Instruction

Equipment containing electrical components

may not be disposed of together with domestic

waste.

It must be separately collected with electrical

and electronic waste according to local and

currently valid legislation.

Table 1.6

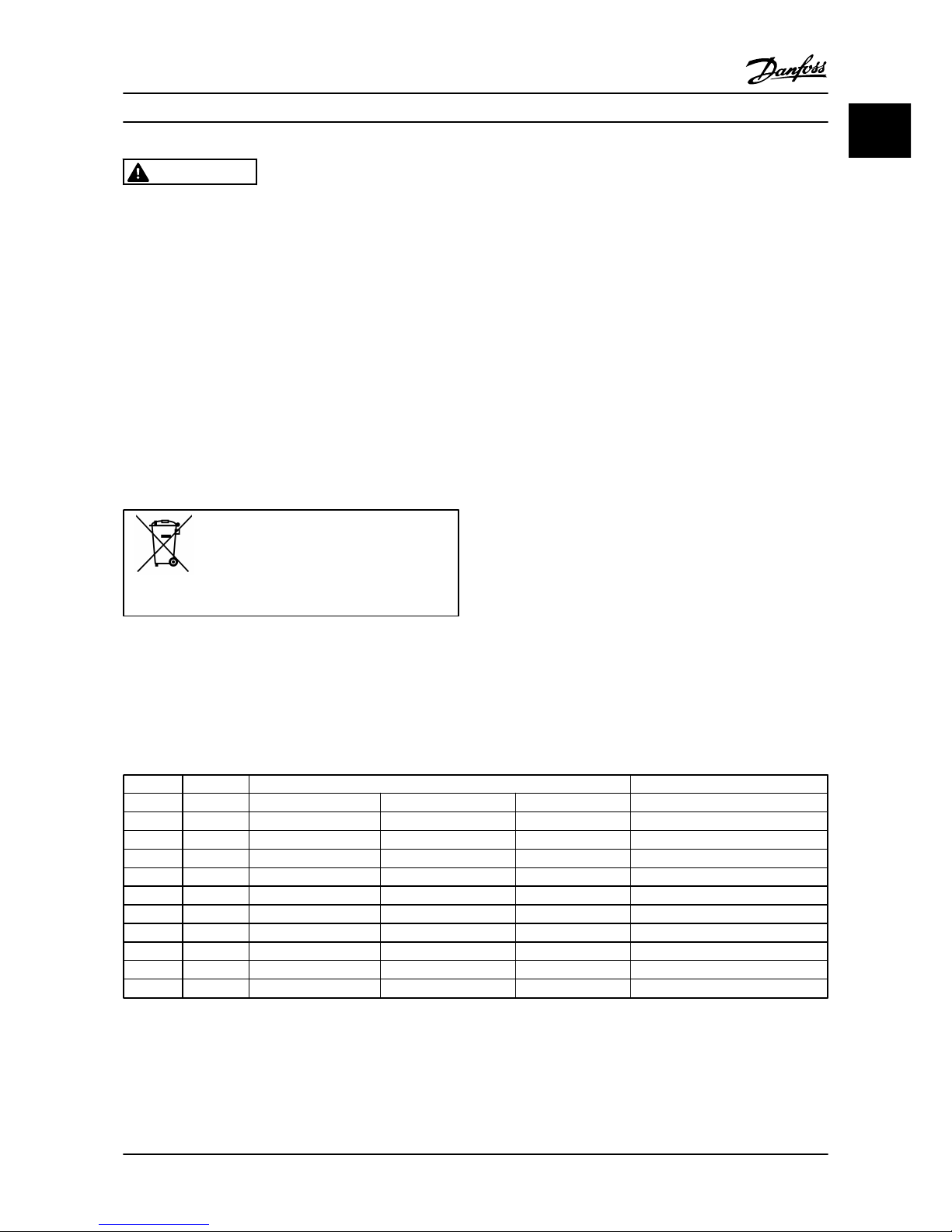

1.3

Installation

1.3.1 Before Starting Repair Work

1. Disconnect FC 101 from line power (and external

DC supply, if present).

2.

Wait as stated in Table 1.1 for discharge of the DC

link.

3. Remove motor cable.

1.3.2 Side-by-Side Installation

The adjustable frequency drive can be mounted side-byside and requires the clearance above and below for

cooling.

Power (hp [kW]) Clearance above/below mm/[inch]

Frame IP class 3x200–240 V 3x380–480 V 3x525–600 V

H1 IP20 0.34–2 [0.25–1.5] 0.5–2 [0.37–1.5] 100 [4]

H2 IP20 3 [2.2] 3–5 [2.2–4] 100 [4]

H3 IP20 5 [3.7] 7.5–10 [5.5–7.5] 100 [4]

H4 IP20 7.5–10 [5.5–7.5] 15–20 [11–15] 100 [4]

H5 IP20 15 [11] 25–30 [18.5–22] 100 [4]

H6 IP20 20–25 [15–18.5] 45–60 [30–45] 25–45 [18.5–30] 200/[8]

H7 IP20 30–45 [22–30] 75–100 [55–75] 50–75 [37–55] 200/[8]

H8 IP20 50–60 [37–45] 125 [90] 100–125 [75–90] 225/[8.9]

H9 IP20 3–10 [2.2–7.5] 100 [4]

H10 IP20 15–20 [11–15] 200/[8]

Table 1.7

NOTE!

With IP21/Nema Type1 option kit mounted, a distance of 2

in [50 mm] between the units is required.

Quick Guide

VLT® HVAC Basic Drive Quick Guide

MG18A422 - VLT® is a registered Danfoss trademark 1-3

1 1

Page 7

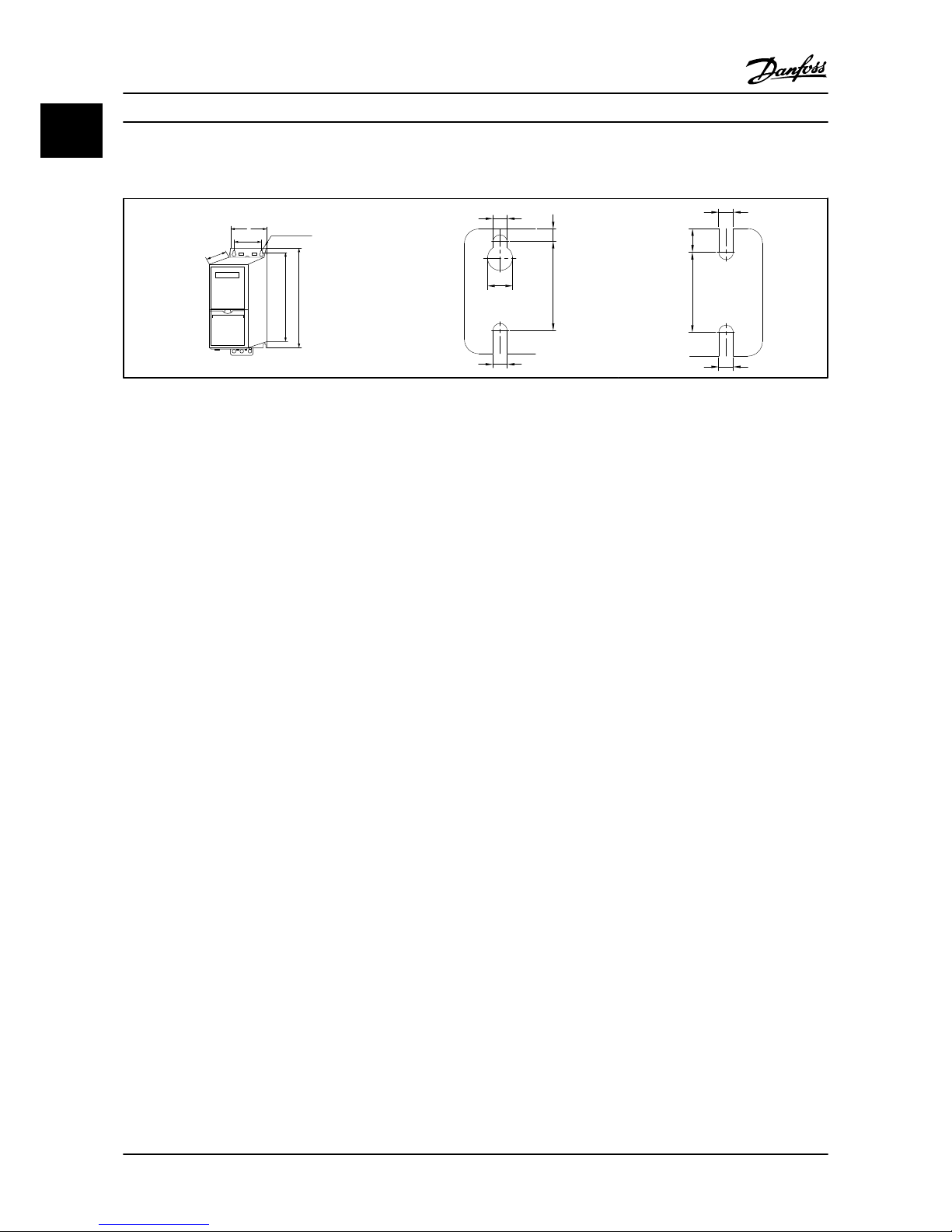

1.3.3 Dimensions

A

a

b

B

C

D

130BB614.10

e

f

a

d

e

130BC205.10

e

f

a

e

130BC246.10

Table 1.8

Quick Guide

VLT® HVAC Basic Drive Quick Guide

1-4 MG18A422 - VLT® is a registered Danfoss trademark

11

Page 8

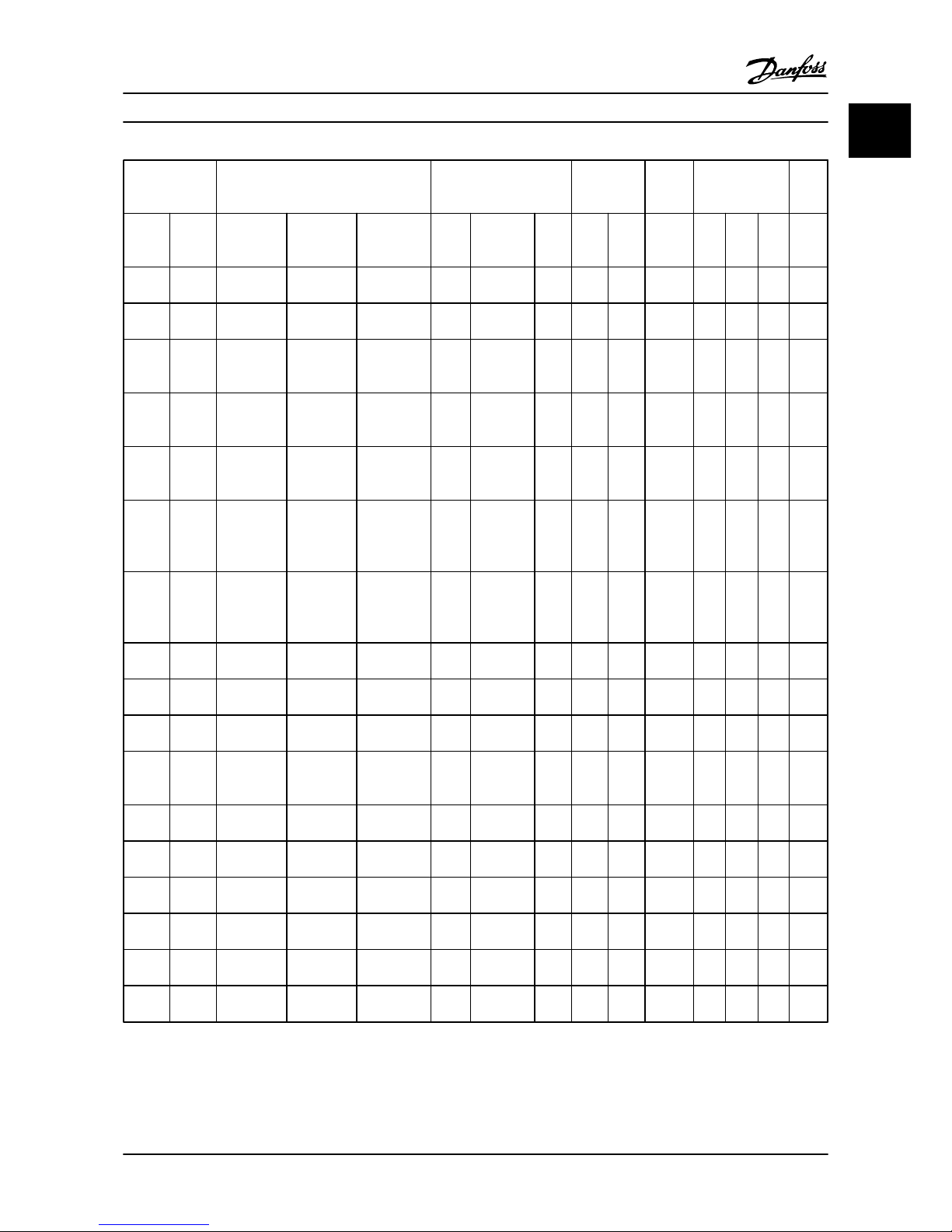

Enclosure Power (hp [kW]) Height (in [mm]) Width (in

[mm])

Depth

(in

[mm])

Mounting hole

(in [mm])

Max.

Weig

ht

Frame IP Class 3x200–240V3x380–480V3x525–600 V A "A incl De-

coupling

Plate"

a B b C d e f lb

[kg]

H1 IP20 0.34–2

[0.25–1.5]

0.5–2 [0.37–

1.5]

7.68

[195]

10.79 [273] 7.21

[183]

2.95

[75]

2.21

[56]

6.61

[168]

0.35

[9]

0.18

[4.5]

0.21

[5.3]

4.63

[2.1]

H2 IP20 3 [2.2] 3–5 [2.2–

4.0]

8.94

[227]

11.93 [303] 8.35

[212]

3.54

[90]

2.56

[65]

7.48

[190]

0.43

[11]

0.22

[5.5]

0.29

[7.4]

7.5

[3.4]

H3 IP20 5 [3.7] 7.5–10 [5.5–

7.5]

10.04

[255]

12.95 [329] 9.45

[240]

3.94

[100]

2.91

[74]

8.11

[206]

0.43

[11]

0.22

[5.5]

17.8

6

[8.1]

9.9

[4.5]

H4 IP20 7.5–10 [5.5–

7.5]

15–20 [11–

15]

11.65

[296]

14.13 [359] 10.83

[275]

5.32

[135]

4.13

[105]

9.5

[241]

0.5

[12.6

]

0.28

[7]

0.33

[8.4]

17.42

[7.9]

H5 IP20 15 [11] 25–30

[18.5–22]

13.2

[334]

15.83 [402] 12.36

[314]

5.91

[150]

[97/1

20]

10.04

[255]

0.5

[12.6

]

0.28

[7]

0.33

[8.5]

20.94

[9.5]

H6 IP20 20–25 [15–

18.5]

45–60 [30–

45]

25–45 [18.5–

30]

20.39

[518]

23.43/25

[595/635]

(60 hp [45

kW])

19.5

[495]

9.41

[239]

7.87

[200]

9.53

[242]

- 0.33

[8.5]

0.6

[15]54[24.5]

H7 IP20 30–45 [22–

30]

75–100 [55–

75]

50–75 [37–

55]

21.7

[550]

24.8/27.17

[630/690]

(100 hp

[75 kW])

20.51

[521]

12.32

[313]

10.63

[270]

13.2

[335]

- 0.33

[8.5]

0.67

[17]

79.4

[36]

H8 IP20 50–60 [37–

45]

125 [90] 100–125 [75–

90]

25.98

[660]

31.5 [800] 28.84

[631]

14.76

[375]

12.99

[330]

13.2

[335]

- 0.33

[8.5]

0.67

[17]

112.4

4 [51]

H9 IP20 3–10 [2.2–

7.5]

10.6

[269]

14.72 [374] 10.12

[257]

5.12

[130]

0.148

[110]

8.1

[205]

0.43

[11]

0.22

[5.5]

0.35

[9]

14.6

[6.6]

H10 IP20 15–20 [11–

15]

15.71

[399]

16.5 [419] 14.96

[380]

6.5

[165]

5.51

[140]

9.76

[248]

0.47

[12]

0.27

[6.8]

0.3

[7.5]

26.46

[12]

I2 IP54 1–5 [0.75–

4.0]

13.1

[332]

- 12.54

[318.5

]

4.53

[115]

2.91

[74]

88.58

[225]

0.43

[11]

0.22

[5.5]

0.35

[9]

11.69

[5.3]

I3 IP54 7.5–10 [5.5–

7.5]

14.5

[368]

- 11.94

[354]

5.32

[135]

3.5

[89]

9.33

[237]

0.47

[12]

0.26

[6.5]

0.37

[9.5]

15.87

[7.2]

I4 IP54 15–25 [11–

18.5]

18.74

[476]

- 18.11

[460]

7.1

[180]

5.24

[133]

11.42

[290]

0.47

[12]

0.26

[6.5]

0.37

[9.5]

30.42

[13.8]

I5 IP54 15–25 [11–

18.5]

18.9

[480]

- 17.9

[454]

9.53

[242]

8.27

[210]

10.24

[260]

0.75

[19]

0.35

[9]

0.35

[9]

50.71

[23]

I6 IP54 30–50 [22–

37]

25.6

[650]

- 2.6

[624]

9.53

[242]

8.27

[210]

10.24

[260]

0.75

[19]

0.35

[9]

0.35

[9]

59.52

[27]

I7 IP54 60–75 [45–

55]

26.8

[680]

- 25.51

[648]

12.13

[308]

10.71

[272]

12.21

[310]

0.75

[19]

0.35

[9]

0.39

[9.8]

99.21

[45]

I8 IP54 100–125

[75–90]

30.32

[770]

- 29.1

[739]

14.57

[370]

13.2

[334]

13.2

[335]

0.75

[19]

0.35

[9]

0.39

[9.8]

143.3

[65]

Table 1.9

Quick Guide

VLT® HVAC Basic Drive Quick Guide

MG18A422 - VLT® is a registered Danfoss trademark 1-5

1 1

Page 9

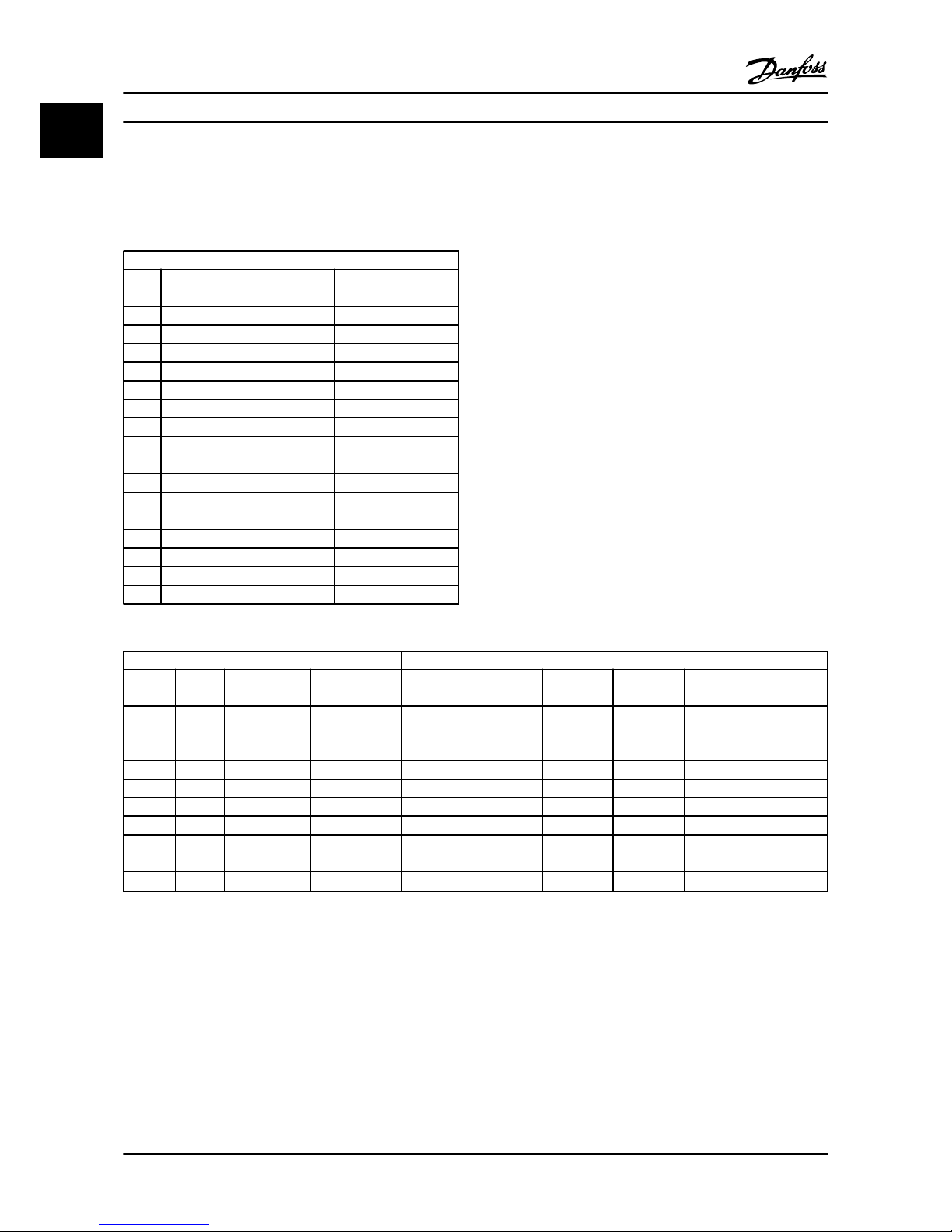

The dimensions are only for the physical units, but when

installing in an application it is necessary to add space for

free air passage both above and below the units. The

amount of space for free air passage is listed in Table 1.10:

Enclosure Clearance needed for free air passage (in [mm])

Frame IP class Above unit Below unit

H1 0.79 [20] 3.94 [100] 3.94 [100]

H2 0.79 [20] 3.94 [100] 3.94 [100]

H3 0.79 [20] 3.94 [100] 3.94 [100]

H4 0.79 [20] 3.94 [100] 3.94 [100]

H5 0.79 [20] 3.94 [100] 3.94 [100]

H6 0.79 [20] 7.87 [200] 7.87 [200]

H7 0.79 [20] 7.87 [200] 7.87 [200]

H8 0.79 [20] 88.58 [225] 88.58 [225]

H9 0.79 [20] 3.94 [100] 3.94 [100]

H10 0.79 [20] 7.87 [200] 7.87 [200]

I2 2.13 [54] 3.94 [100] 3.94 [100]

I3 2.13 [54] 3.94 [100] 3.94 [100]

I4 2.13 [54] 3.94 [100] 3.94 [100]

I5 2.13 [54] 7.87 [200] 7.87 [200]

I6 2.13 [54] 7.87 [200] 7.87 [200]

I7 2.13 [54] 7.87 [200] 7.87 [200]

I8 2.13 [54] 88.58 [225] 88.58 [225]

Table 1.10 Clearance Needed for Free Air Passage (in [mm])

1.3.4

Electrical Installation in General

All cabling must comply with national and local

regulations on cable cross-sections and ambient

temperature. Copper conductors required, (167° F [75°C])

recommended.

Power (hp [kW]) Torque [Nm]

Frame IP class 3x200–240 V 3x380–480 V Line Motor DC

connection

Control

terminals

Ground Relay

H1 IP20 0.34–2 [0.25–

1.5]

0.5–2 [0.37–1.5] 1.4 0.8 0.8 0.5 0.8 0.5

H2 IP20 3 [2.2] 3–5 [2.2–4] 1.4 0.8 0.8 0.5 0.8 0.5

H3 IP20 5 [3.7] 7.5–10 [5.5–7.5] 1.4 0.8 0.8 0.5 0.8 0.5

H4 IP20 7.5–10 [5.5–7.5] 15–20 [11–15] 1.2 1.2 1.2 0.5 0.8 0.5

H5 IP20 15 [11] 25–30 [18.5–22] 1.2 1.2 1.2 0.5 0.8 0.5

H6 IP20 20–25 [15–18] 45–60 [30–45] 4.5 4.5 - 0.5 3 0.5

H7 IP20 30–45 [22–30] 75 [55] 10 10 - 0.5 3 0.5

H7 IP20 - 100 [75] 14 14 - 0.5 3 0.5

H8 IP20 50–60 [37–45] 125 [90]

24

2

24

2

- 0.5 3 0.5

Table 1.11

Quick Guide

VLT® HVAC Basic Drive Quick Guide

1-6 MG18A422 - VLT® is a registered Danfoss trademark

11

Page 10

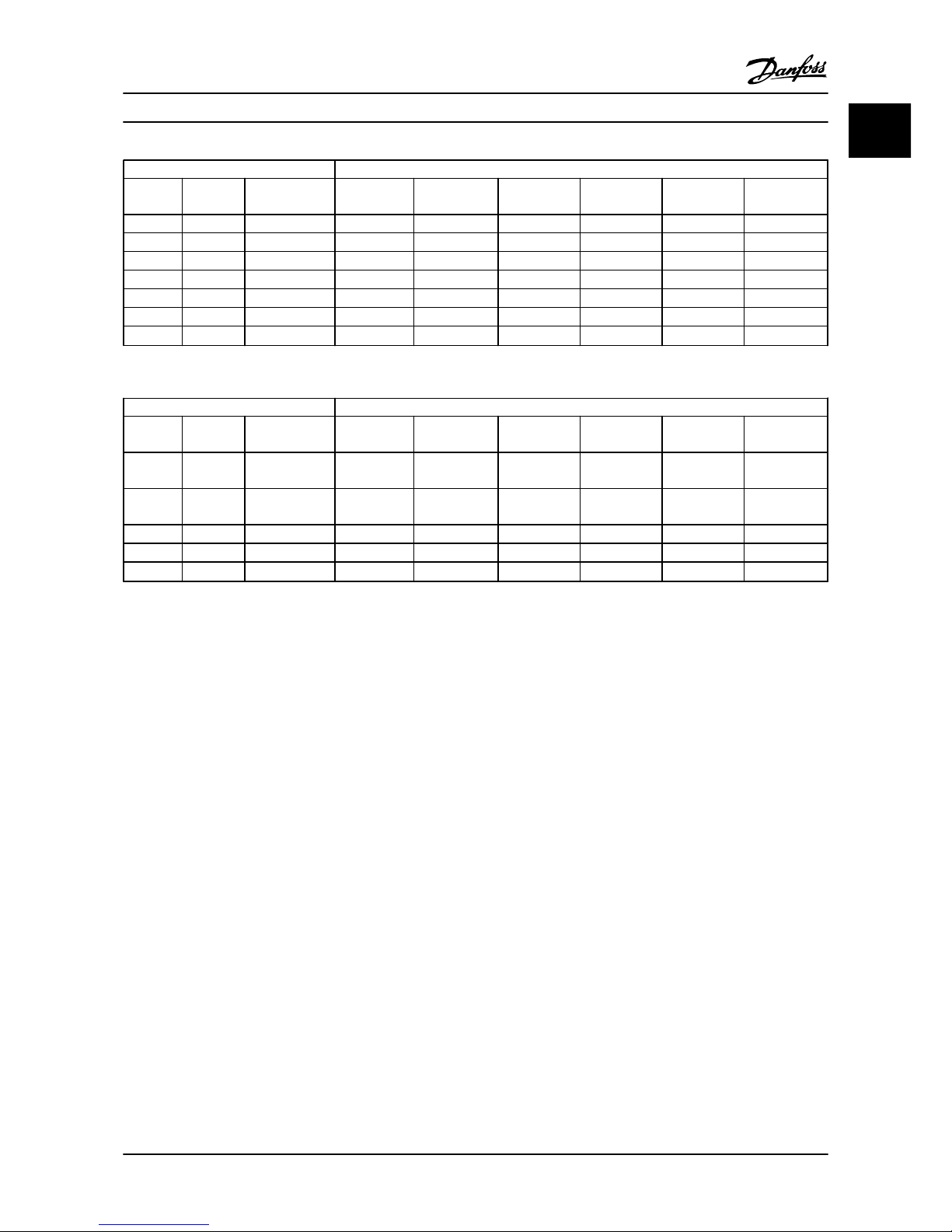

Power (hp [kW]) Torque [Nm]

Frame IP class 3x380–480 V Line Motor DC connection Control

terminals

Ground Relay

I2 IP54 1–5 [0.75–4.0] 1.4 0.8 0.8 0.5 0.8 0.5

I3 IP54 7.5–10 [5.5–7.5] 1.4 0.8 0.8 0.5 0.8 0.5

I4 IP54 15–25 [11–18.5] 1.4 0.8 0.8 0.5 0.8 0.5

I5 IP54 15–25 [11–18.5] 1.8 1.8 - 0.5 3 0.6

I6 IP54 30–50 [22–37] 4.5 4.5 - 0.5 3 0.6

I7 IP54 60–75 [45–55] 10 10 - 0.5 3 0.6

I8 IP54 100–125 [75–90]

14/24

1

14/24

1

- 0.5 3 0.6

Table 1.12

Power (hp [kW]) Torque [Nm]

Frame IP class 3x525–600 V Line Motor DC connection Control

terminals

Ground Relay

H9 IP20 3–10 [2.2–7.5] 1.8 1.8 not

recommended

0.5 3 0.6

H10 IP20 15–20 [11–15] 1.8 1.8 not

recommended

0.5 3 0.6

H6 IP20 25–45 [18.5–30] 4.5 4.5 - 0.5 3 0.5

H7 IP20 50–75 [37–55] 10 10 - 0.5 3 0.5

H8 IP20 100–125 [75–90]

14/24

1

14/24

1

- 0.5 3 0.5

Table 1.13 Details of Tightening Torques

1

Cable dimensions ≤0.1472 [95 mm2]

2

Cable dimensions >0.1472 [95 mm2]

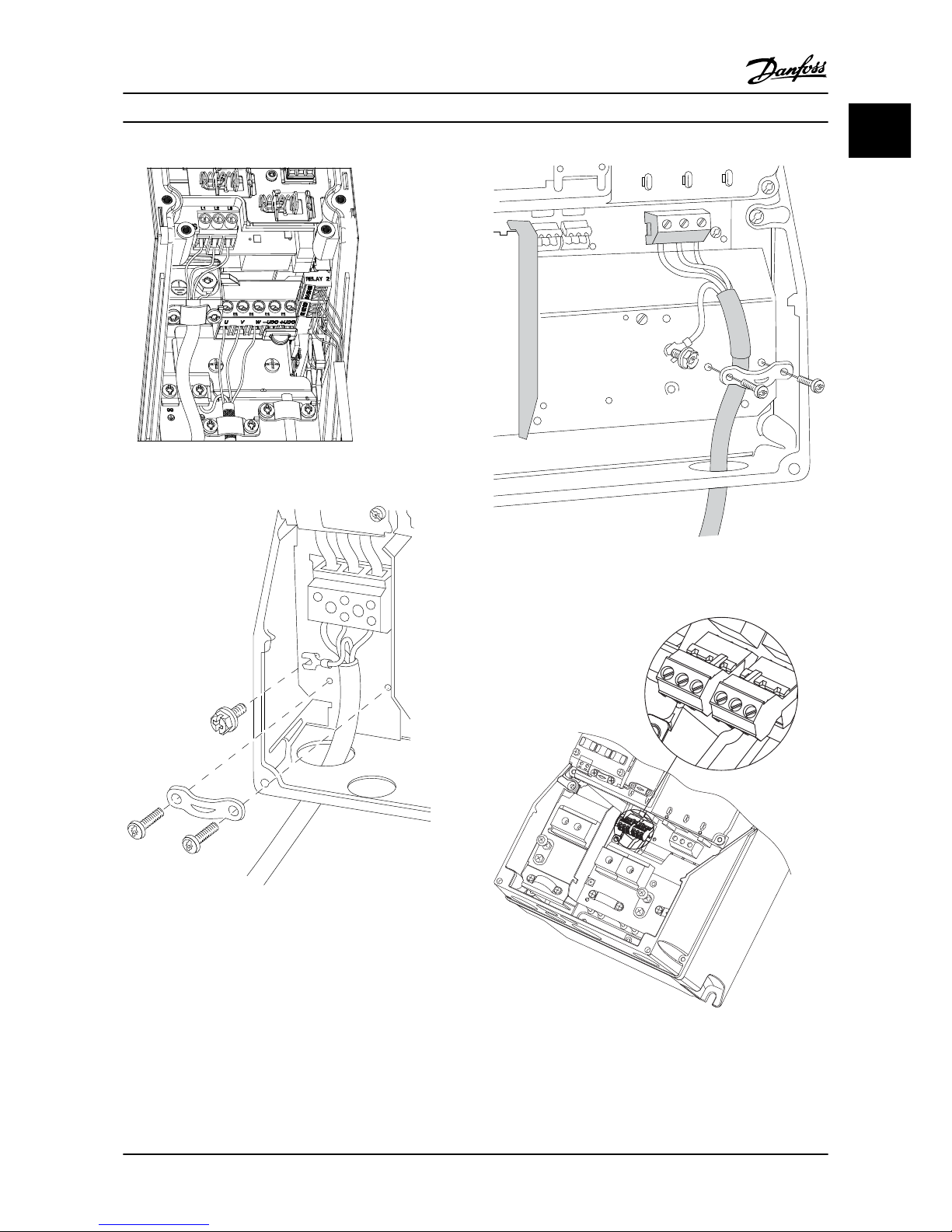

1.3.5 Connecting to Line Power and Motor

The adjustable frequency drive is designed to operate all

standard three-phased asynchronous motors. For

maximum cross-section on wires, see 1.6 General Specifi-

cations.

•

Use a shielded/armored motor cable to comply

with EMC emission specifications, and connect

this cable to both the decoupling plate and the

motor metal.

•

Keep motor cable as short as possible to reduce

the noise level and leakage currents.

•

For further details on mounting of the

decoupling plate, see FC 101 De-coupling Plate

Mounting Instruction MI02Q.

•

Also see EMC-compatible Installation in the VLT

®

HVAC Basic Design Guide, MG18C.

1. Mount the ground wires to the ground terminal.

2. Connect the motor to terminals U, V and W.

3. Mount line power supply to terminals L1, L2 and

L3 and tighten.

Quick Guide

VLT® HVAC Basic Drive Quick Guide

MG18A422 - VLT® is a registered Danfoss trademark 1-7

1 1

Page 11

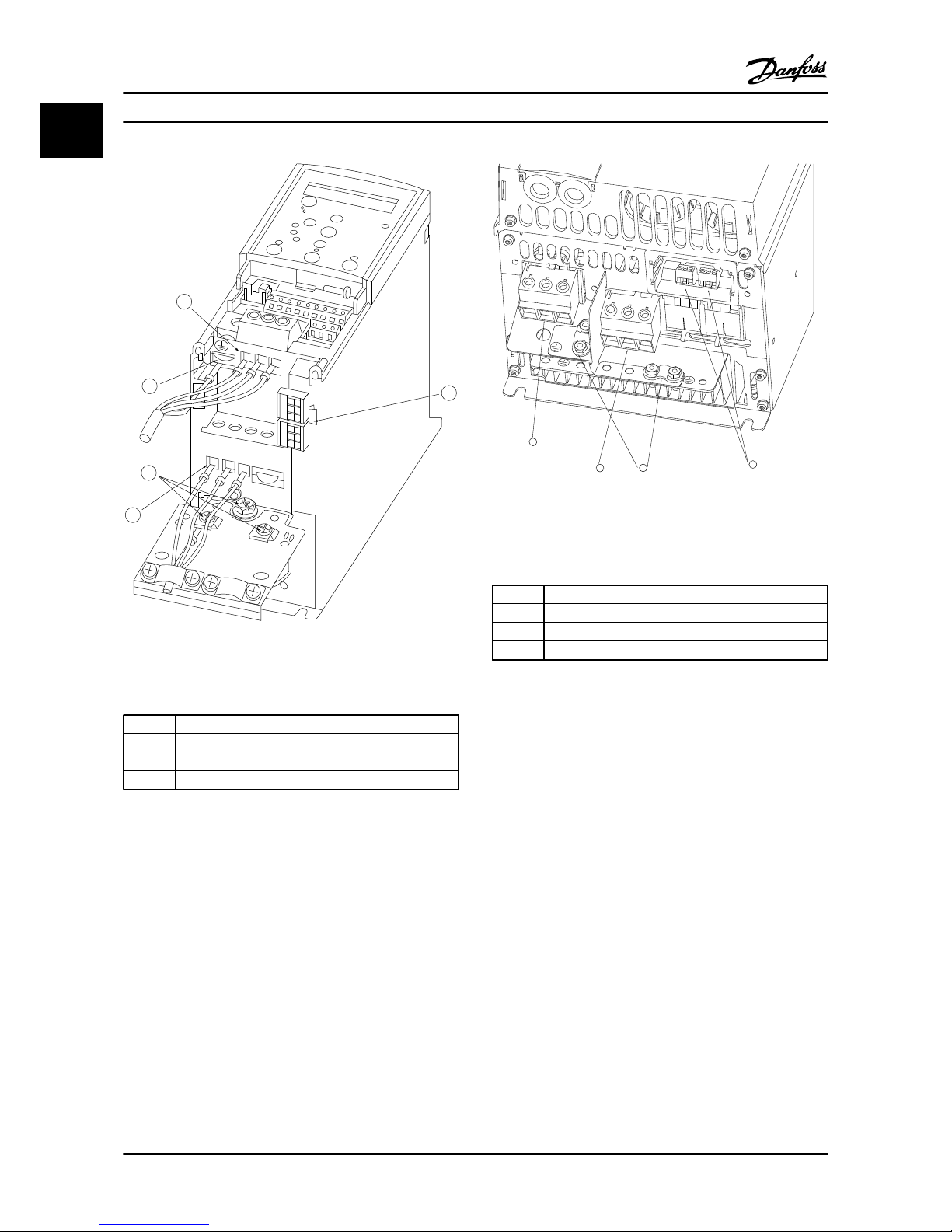

130BB634.10

1

2

2

3

4

Motor

U

V

W

-DC

+DC

MAINS

Figure 1.3 H1-H5 Frame

IP20 200–240 V 0.34–15 hp [0.25–11 kW] and IP20 380–480 V

0.5–30 hp [0.37–22 kW].

1

Line

2 Ground

3 Motor

4 Relays

Table 1.14

1

95

99

L1 91 / L2 92 / L3 93

U 96 / V 97 / W 98

03 02 01

06 05 04

2

3

4

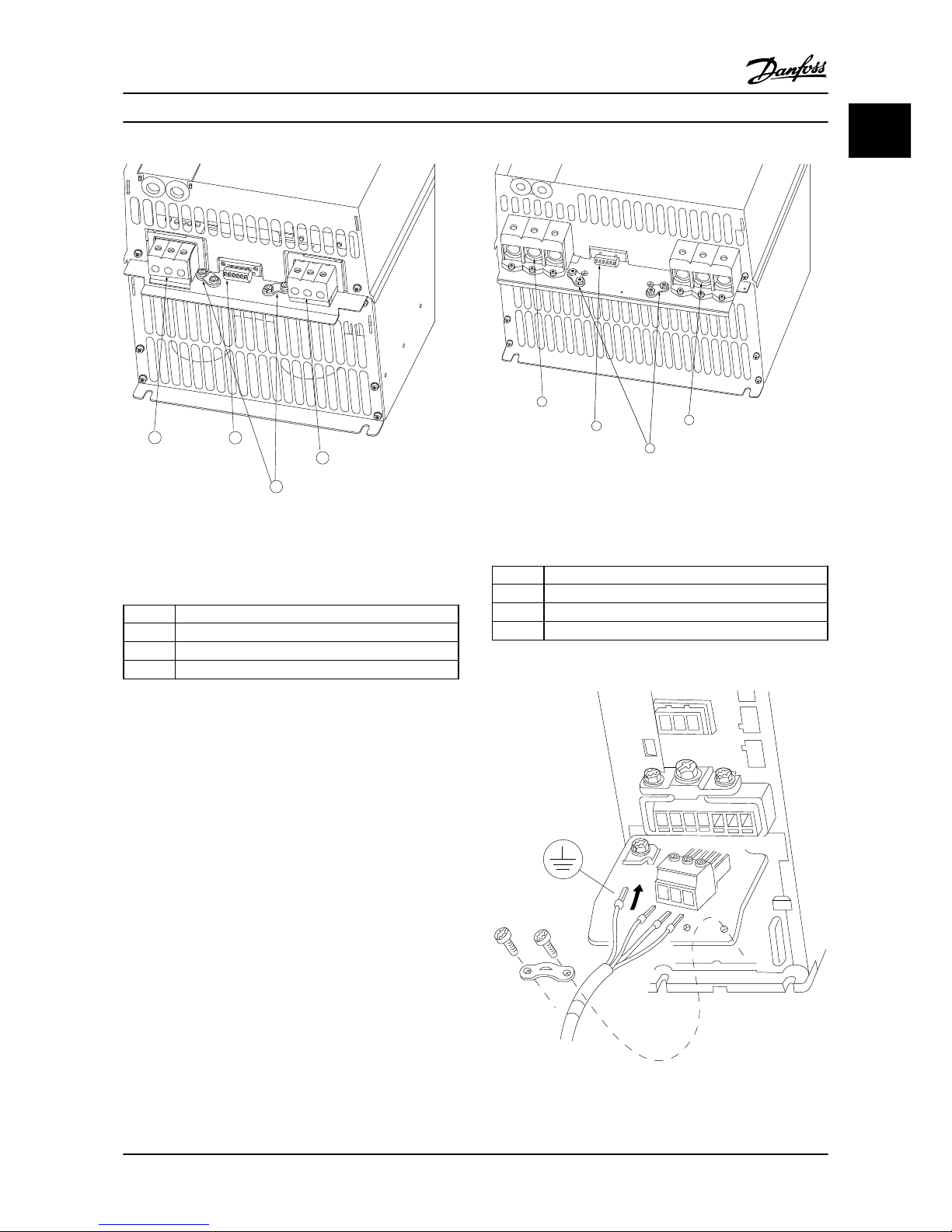

130BB762.10

Figure 1.4 H6 Frame

IP20 380–480 V 40–60 hp [30–45 kW]

IP20 200–240 V 20–25 hp [15–18.5 kW]

IP20 525–600 V 30–40 hp [22–30 kW|

1 Line

2 Motor

3 Ground

4 Relays

Table 1.15

Quick Guide

VLT® HVAC Basic Drive Quick Guide

1-8 MG18A422 - VLT® is a registered Danfoss trademark

11

Page 12

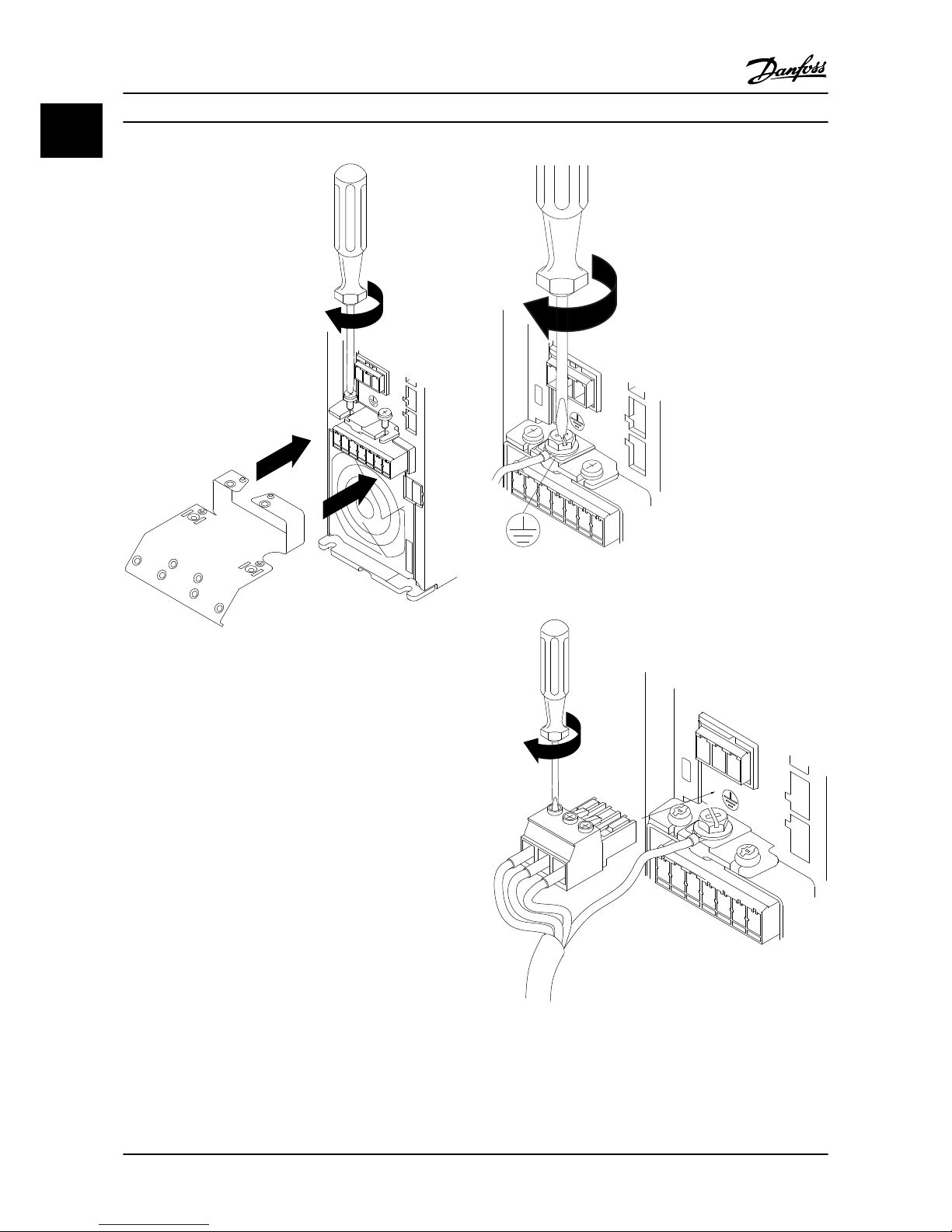

1

2

3

4

130BB763.10

Figure 1.5 H7 Frame

IP20 380–480 V 75–100 hp [55–75 kW]

IP20 200–240 V 30–40 hp [22–30 kW]

IP20 525–600 V 60–75 hp [45–55 kW]

1

Line

2 Relays

3 Ground

4 Motor

Table 1.16

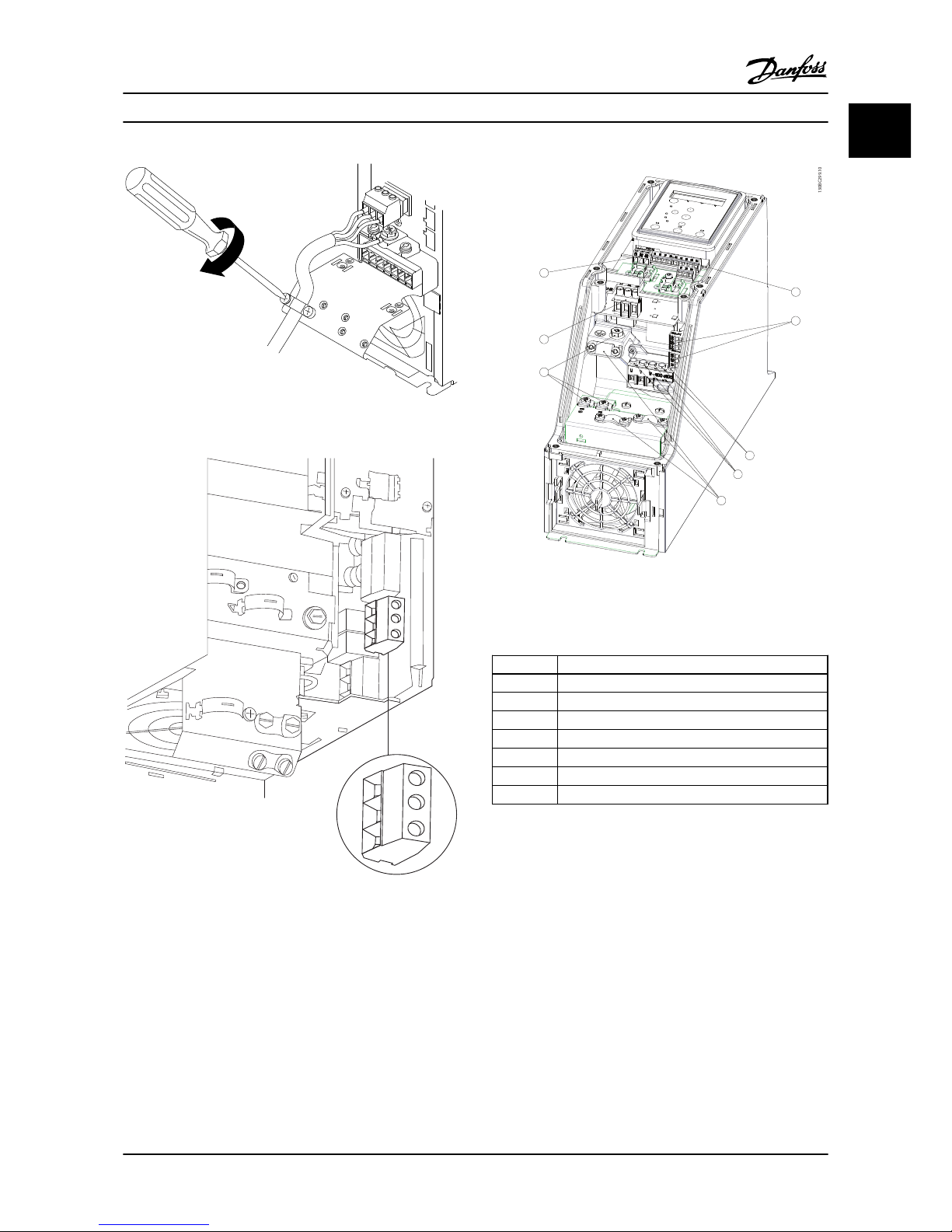

130BB764.10

1

2

3

4

98

97

96

99

95

93

92

91

L1

L1

L1

U

V

w

Figure 1.6 H8 Frame

IP20 380-480 V 125 hp [90 kW]

IP20 200–240 V 50–60 hp [37–45 kW]

IP20 525–600 V 100–125 hp [75–90 kW]

1 Line

2 Relays

3 Ground

4 Motor

Table 1.17

MOTOR

MOTOR

U V W

99

130BT302.12

Figure 1.7 H9 Frame

IP20 600 V 3–10 hp [2.2–7.5 kW]

Quick Guide

VLT® HVAC Basic Drive Quick Guide

MG18A422 - VLT® is a registered Danfoss trademark 1-9

1 1

Page 13

-DC+DC

BR- BR+ U V W

99

M A I N S

95

RELAY 1 RELAY 2

- LC +

130BA261.10

Figure 1.8

130BA262.10

M

I N S

+DC

BR-

BR+

U

V

W

RELAY 1 RELAY 2

95

Figure 1.9

130BA263.10

95

M

A

INS

+DC

BR-

BR+

U

V

W

91

92

93

L1

L2

L3

RELAY 1 RELAY 2

Figure 1.10

Quick Guide

VLT® HVAC Basic Drive Quick Guide

1-10 MG18A422 - VLT® is a registered Danfoss trademark

11

Page 14

+DC

BR-

BR+

U

V

W

MAINS

L1 L2 L3

91 92 93

RELAY 1 RELAY 2

99

- LC -

130BA264.10

Figure 1.11

130BA725.10

Figure 1.12 H10 Frame

IP20 600 V 15–20 hp [11–15 kW]

130BC299.10

7

3

2

5

1

8

4

6

Figure 1.13 I2 Frame

IP54 380–480 V 1–5 hp [0.75–4.0 kW]

1

RS-485

2 Line in

3 Ground

4 Wire clamps

5 Motor

6 UDC

7 Relays

8 I/O

Table 1.18

Quick Guide

VLT® HVAC Basic Drive Quick Guide

MG18A422 - VLT® is a registered Danfoss trademark 1-11

1 1

Page 15

130BC201.10

Figure 1.14 I3 Frame

IP54 380–480 V 75–100 hp [5.5–7.5 kW]

1

RS-485

2 Line in

3 Ground

4 Wire clamps

5 Motor

6 UDC

7 Relays

8 I/O

Table 1.19

130BD011.10

Figure 1.15 I4 Frame

IP54 380–480 V 1–5 hp [0.75–4.0 kW]

1

RS-485

2 Line in

3 Ground

4 Wire clamps

5 Motor

6 UDC

7 Relays

8 I/O

Table 1.20

Quick Guide

VLT® HVAC Basic Drive Quick Guide

1-12 MG18A422 - VLT® is a registered Danfoss trademark

11

Page 16

130BC203.10

Figure 1.16 IP54 I2-I3-I4 frame

130BT326.10

Figure 1.17 I6 Frame

IP54 380-480 V 30–50 hp [22–37 kW]

130BT325.10

Figure 1.18 I6 Frame

IP54 380-480 V 30–50 hp [22–37 kW]

311

130BA215.10

RELAY 1

RELAY 2

9

9

6

03 02 01

90 05 04

Figure 1.19 I6 Frame

IP54 380-480 V 30–50 hp [22–37 kW]

Quick Guide

VLT® HVAC Basic Drive Quick Guide

MG18A422 - VLT® is a registered Danfoss trademark 1-13

1 1

Page 17

91

L1

92

L2

93

L3

96

U

97

V

98

W

88

DC-

89

DC+

81

R-

8

R+

99

95

130BA248.10

Figure 1.20 I7, I8 Frame

IP54 380–480 V 60–75 hp [45–55 kW]

IP54 380–480 V 100–125 hp [75–90 kW]

1.3.6

Fuses

Branch circuit protection

In order to protect the installation from electrical and fire

hazards, all branch circuits in an installation, switch gears,

machines etc., must be protected from short-circuits and

overcurrents according to national/international

regulations.

Short circuit protection

Danfoss recommends using the fuses mentioned in the

following tables to protect service personnel or other

equipment in case of an internal failure in the unit or

short-circuit on DC link. The adjustable frequency drive

provides full short-circuit protection in case of a shortcircuit on the motor.

Overcurrent protection

Provide overload protection to avoid overheating of the

cables in the installation. Overcurrent protection must

always be carried out according to national regulations.

Fuses must be designed for protection in a circuit capable

of supplying a maximum of 100,000 A

rms

(symmetrical),

480 V maximum.

Non-UL compliance

If UL/cUL is not to be complied with, Danfoss recommends

using the fuses mentioned in Table 1.21, which ensures

compliance with IEC 61800-5-1.

In case of malfunction, not following the fuse recommendation may result in damage to the adjustable frequency

drive.

Circuit Breaker Fuse

UL Non-UL UL Non-UL

Bussmann Bussmann Bussmann Bussmann Max fuse

Power (hp [kW]) Type RK5 Type RK1 Type J Type T Type G

3x200–240 V IP20

0.34 [0.25]

FRS-R-10 KTN-R10 JKS-10 JIN-10 10

0.5 [0.37] FRS-R-10 KTN-R10 JKS-10 JIN-10 10

1 [0.75] FRS-R-10 KTN-R10 JKS-10 JIN-10 10

2 [1.5] FRS-R-10 KTN-R10 JKS-10 JIN-10 10

3 [2.2] FRS-R-15 KTN-R15 JKS-15 JIN-15 16

5 [3.7] FRS-R-25 KTN-R25 JKS-25 JIN-25 25

7.5 [5.5] FRS-R-50 KTN-R50 JKS-50 JIN-50 50

10 [7.5] FRS-R-50 KTN-R50 JKS-50 JIN-50 50

15 [11] FRS-R-80 KTN-R80 JKS-80 JIN-80 65

Quick Guide

VLT® HVAC Basic Drive Quick Guide

1-14 MG18A422 - VLT® is a registered Danfoss trademark

11

Page 18

Circuit Breaker Fuse

UL Non-UL UL Non-UL

Bussmann Bussmann Bussmann Bussmann Max fuse

Power (hp [kW]) Type RK5 Type RK1 Type J Type T Type G

20 [15]

Cutler-Hammer

EGE3100FFG

Moeller NZMB1-

A125

FRS-R-100 KTN-R100

125

25 [18.5] FRS-R-100 KTN-R100 125

30 [22]

Cutler-Hammer

JGE3150FFG

Moeller NZMB1-

A160

FRS-R-150 KTN-R150 160

40 [30] FRS-R-150 KTN-R150 160

50 [37]

Cutler-Hammer

JGE3200FFG

Moeller NZMB1-

A200

FRS-R-200 KTN-R200 200

60 [45] FRS-R-200 KTN-R200 200

3x380–480 V IP20

0.5 [0.37]

FRS-R-10 KTS-R10 JKS-10 JJS-10 10

1 [0.75] FRS-R-10 KTS-R10 JKS-10 JJS-10 10

2 [1.5] FRS-R-10 KTS-R10 JKS-10 JJS-10 10

3 [2.2] FRS-R-15 KTS-R15 JKS-15 JJS-15 16

4 [3] FRS-R-15 KTS-R15 JKS-15 JJS-15 16

5 [4] FRS-R-15 KTS-R15 JKS-15 JJS-15 16

7.5 [5.5] FRS-R-25 KTS-R25 JKS-25 JJS-25 25

10 [7.5] FRS-R-25 KTS-R25 JKS-25 JJS-25 25

15 [11] FRS-R-50 KTS-R50 JKS-50 JJS-50 50

20 [15] FRS-R-50 KTS-R50 JKS-50 JJS-50 50

25 [18.5] FRS-R-80 KTS-R80 JKS-80 JJS-80 65

30 [22] FRS-R-80 KTS-R80 JKS-80 JJS-80 65

40 [30]

Cutler-Hammer

EGE3125FFG

Moeller NZMB1-

A125

FRS-R-80 KTS-R80 JKS-R80 JJS-R80 80

50 [37] FRS-R-100 KTS-R100 JKS-R100 JJS-R100 100

60 [45] FRS-R-125 KTS-R125 JKS-R125 JJS-R125 125

75 [55]

Cutler-Hammer

JGE3200FFG

Moeller NZMB1-

A200

FRS-R-150 KTS-R150 JKS-R150 JJS-R150 150

100 [75] FRS-R-200 KTS-R200 JKS-R200 JJS-R200 200

125 [90]

Cutler-Hammer

JGE3250FFG

Moeller NZMB2-

A250

FRS-R-250 KTS-R250 JKS-R250 JJS-R250 250

Table 1.21

Quick Guide

VLT® HVAC Basic Drive Quick Guide

MG18A422 - VLT® is a registered Danfoss trademark 1-15

1 1

Page 19

Circuit Breaker Fuse

UL Non-UL UL Non-UL

Bussmann Bussmann Bussmann Bussmann Max fuse

Power (hp [kW]) Type RK5 Type RK1 Type J Type T Type G

3x525–600 V IP20

3 [2.2]

KTS-R20

20

3 KTS-R20 20

5 [3.7] KTS-R20 20

5.5 KTS-R20 20

10 [7.5] KTS-R20 30

11

KTS-R30 35

20 [15] KTS-R30 35

18.5

Cutler-Hammer

EGE3080FFG

Cutler-Hammer

EGE3080FFG

FRS-R-80 KTN-R80 80

30 [22] FRS-R-80 KTN-R80 80

40 [30] FRS-R-80 KTN-R80 80

50 [37]

Cutler-Hammer

JGE3125FFG

Cutler-Hammer

JGE3125FFG

FRS-R-125 KTN-R125 125

60 [45] FRS-R-125 KTN-R125 125

75 [55] FRS-R-125 KTN-R125 125

100 [75]

Cutler-Hammer

JGE3200FAG

Cutler-Hammer

JGE3200FAG

FRS-R-200 KTN-R200 200

125 [90] FRS-R-200 KTN-R200 200

3x380–480 V IP54

1 [0.75]

2 [1.5]

3 [2.2]

4 [3]

5 [4]

7.5 [5.5]

10 [7.5]

15 [11]

20 [15]

25 [18.5]

30 [22]

Moeller NZMB1-A125

125

40 [30] 125

50 [37] 125

60 [45]

Moeller NZMB2-A160

160

75 [55] 160

100 [75]

Moeller NZMB2-A250

200

125 [90] 200

Table 1.22 Fuses

1.3.7

EMC-compatible Electrical Installation

General points to be observed to ensure EMC-compatible

electrical installation.

•

Use only shielded/armored motor cables and

shielded/armored control cables.

•

Connect the shield to ground at both ends.

•

Avoid installation with twisted shield ends

(pigtails), since this ruins the shielding effect at

high frequencies. Use the cable clamps provided

instead.

•

It is important to ensure good electrical contact

from the installation plate through the installation

screws to the metal cabinet of the adjustable

frequency drive.

•

Use star-washers and galvanically grounding

plates.

•

Do not use shielded/armored motor cables in the

installation cabinets.

Quick Guide

VLT® HVAC Basic Drive Quick Guide

1-16 MG18A422 - VLT® is a registered Danfoss trademark

11

Page 20

L1

L2

L3

PE

Min. 0.0248 in

2

[16 mm2]

Equalizing cable

Control cables

All cable entries in

one side of panel

Grounding rail

Cable insulation stripped

Output contactor, etc.

Motor cable

Motor, 3 phases and

PLC etc.

Panel

Line power supply

Min. 7.9 in [200 mm]

between control

cable, line cable

and between line power

motor cable

PLC

Protective ground

Reinforced protective ground

130BB761.10

Figure 1.21 EMC-compatible Electrical Installation

NOTE!

For North America, use metal conduits instead of shielded

cables.

Quick Guide

VLT® HVAC Basic Drive Quick Guide

MG18A422 - VLT® is a registered Danfoss trademark 1-17

1 1

Page 21

1.3.8 Control Terminals

IP20 200–240 V 0.34–15 hp [0.25–11 kW] and IP20 380–480

V 0.5–30 hp [0.37–22 kW]:

130BB622.10

Figure 1.22 Location of Control Terminals

1. Place a screwdriver behind the terminal cover to

activate snap.

2. Tilt the screwdriver outwards to open the cover.

130BB624.10

Figure 1.23 IP20 380–480 V 40–125 hp [30–90 kW]

1. Place a screwdriver behind the terminal cover to

activate snap.

2. Tilt the screwdriver outwards to open the cover.

Digital input 18, 19 and 27 mode is set in 5-00 Digital Input

Mode (PNP is default value) and digital input 29 mode is

set in 5-03 Digital Input 29 Mode (PNP is default value).

130BC249.10

Figure 1.24 IP54 400 V 1–10 hp [0.75–7.5 kW]

1. Remove the front cover.

Control terminals

Figure 1.25 shows all control terminals of the adjustable

frequency drive. Applying Start (term. 18), connection

between terminal 12-27 and an analog reference (term. 53

or 54 and 55) make the adjustable frequency drive run.

18

19

12 20 55

27 29 42 45 50 53 54

DIGI IN

DIGI IN

DIGI IN

DIGI IN

61 68 69

N

P

COMM. GND

+24V

0/4-20mA A OUT / DIG OUT 0/4-20mA A OUT / DIG OUT

GND

GND

10V/20mA IN

10V/20mA IN

10V OUT

130BB625.10

BUS TER.

OFF ON

Figure 1.25 Control Terminals

Quick Guide

VLT® HVAC Basic Drive Quick Guide

1-18 MG18A422 - VLT® is a registered Danfoss trademark

11

Page 22

1.3.9 Electrical Overview

L1

L2

L3

3 Phase

power

input

PE

PE

+10Vdc

0-10Vdc-

0-10Vdc-

50 (+10V OUT)

54 (A IN)

53 (A IN)

55 (COM A IN/OUT)

0/4-20 mA

0/4-20 mA

42 0/4-20mA A OUT / DIG OUT

45 0/4-20mA A OUT / DIG OUT

18 (DIGI IN)

19 (DIGI IN)

27 (DIGI IN)

29 (DIGI IN)

12 (+24V OUT)

24V (NPN)

20 (COM D IN)

OV (PNP)

24V (NPN)

OV (PNP)

24V (NPN)

OV (PNP)

24V (NPN)

OV (PNP)

Bus ter.

Bus ter.

RS-485

Interface

RS-485

(N PS-485) 69

(P RS-485) 68

(Com RS-485) 61

(PNP) Source

(NPN) Sink

ON=Terminated

OFF=Unterminated

ON

1 2

240Vac 2A

Not present on all power sizes

Do not connect shield to

61 on 116, 117 and 118 units

01

02

03

relay1

relay2

UDC+

UDC-

Motor

U

V

W

130BB626.10

06

05

04

240Vac 2A

Figure 1.26

NOTE!

There is no access to UDC- and UDC+ on the following units:

IP20 380–480 V 40–125 hp [30–90 kW]

IP20 200–240 V 20–60 hp [15–45 kW]

IP20 525–600 V 3–125 hp [2.2–90 kW]

IP54 380–480 V 30–125 hp [22–90 kW]

Quick Guide

VLT® HVAC Basic Drive Quick Guide

MG18A422 - VLT® is a registered Danfoss trademark 1-19

1 1

Page 23

1.4 Programming

1.4.1 Programming with the Local Control

Panel (LCP)

NOTE!

The adjustable frequency drive can also be programmed

from a PC via RS-485 COM port by installing the MCT 10

Set-up Software. This software can either be ordered using

code number 130B1000 or downloaded from the Danfoss

website: www.danfoss.com/BusinessAreas/DrivesSolutions/

softwaredownload

1.4.2 Local Control Panel (LCP)

The following instructions are valid for the FC 101 LCP. The

LCP is divided into four functional sections.

A. Alphanumeric display

B. Menu key

C. Navigation keys and LEDs

D. Operation keys and LEDs

130BB765.11

B

a

c

k

Com.

1-20 Motor Power

[5] 0.37kW - 0.5HP

Setup 1

A

B

1

12

13 14 15

11

11

10

9

8

7

6

5

4

3

2

C

D

Status

Main

Menu

Quick

Menu

Hand

On

OK

Menu

O

Reset

Auto

On

Alarm

Warn.

On

11

Figure 1.27

A. Alpha Numeric Display

The LCD display is backlit with two alpha-numeric lines. All

data is displayed on the LCP.

Information can be read from the display.

1 Parameter number and name.

2 Parameter value.

3 Set-up number shows the active set-up and the edit set-

up. If the same set-up acts as both the active and edit setup, only that set-up number is shown (factory setting).

When the active and edit set-up differ, both numbers are

shown in the display (Set-up 12). The flashing number

indicates the edit set-up.

4 Motor direction is shown to the bottom left of the display

– indicated by a small arrow pointing either clockwise or

counter-clockwise.

5 The triangle indicates if the LCP is in status, quick menu or

main menu.

Table 1.23

B. Menu key

Use the menu key to select between status, quick menu or

main menu.

C. Navigation keys and LEDs

6 COM LED: Flashes when bus communication is communi-

cating.

7 Green LED/On: Control section is working.

8 Yellow LED/Warn.: Indicates a warning.

9 Flashing Red LED/Alarm: Indicates an alarm.

10 [Back]: For moving to the previous step or layer in the

navigation structure

11

[▲] [▼] [►]: For navigating between parameter groups,

parameters and within parameters. Can also be used for

setting local reference.

12 [OK]: For selecting a parameter and for accepting changes to

parameter settings

Table 1.24

D. Operation keys and LEDs

13

[Hand On]: Starts the motor and enables control of the

adjustable frequency drive via the LCP.

NOTE!

Terminal 27 Digital Input (5-12 Terminal 27 Digital

Input) has coast inverse as default setting. This means

that [Hand On] not starts the motor if there is no 24

V to terminal 27. Connect terminal 12 to terminal 27.

14 [Off/Reset]: Stops the motor (Off). If in alarm mode the

alarm will be reset.

15 [Auto On]: The adjustable frequency drive is controlled

either via control terminals or serial communication.

Table 1.25

Quick Guide

VLT® HVAC Basic Drive Quick Guide

1-20 MG18A422 - VLT® is a registered Danfoss trademark

11

Page 24

At power-up

At the first power-up, select the preferred language. Once

selected, this screen never shows again in the following

power-ups, but language can still be changed in

0-01 Language.

130BB628.10

Select Language

[ 0 ] English

Set-up 1

Figure 1.28

1.4.3 The Start-up Wizard for Open-loop

Applications

The built-in “wizard” menu guides the installer through the

set-up of the adjustable frequency drive in a clear and

structured manner to set up an open-loop application. An

open-loop application is here an application with a start

signal, analog reference (voltage or current) and optionally

also relay signals (but no feedback signal from the process

applied).

FC

+24V

DIG IN

DIG IN

DIG IN

DIG IN

COM DIG IN

A OUT / D OUT

A OUT / D OUT

18

19

27

29

42

55

50

53

54

20

12

01

02

03

04

05

06

R2

R1

0-10 V

Reference

Start

+10V

A IN

A IN

COM

130BB674.10

45

+

-

Figure 1.29

The wizard will initially be shown after power-up until any

parameter has been changed. The wizard can always be

accessed again through the Quick Menu. Press [OK] to start

the wizard. If [Back] is pressed, the FC 101 returns to the

status screen.

130BB629.10

Press OK to start Wizard

Push Back to skip it

Set-up 1

Figure 1.30

Quick Guide

VLT® HVAC Basic Drive Quick Guide

MG18A422 - VLT® is a registered Danfoss trademark 1-21

1 1

Page 25

Setup 1

Power kW/50 Hz

Setup 1

Set Motor Speed low Limit

Hz

Setup 1

Set Motor Speed high Limit

Hz

Setup 1

Set Ramp 1 ramp-up time

s

Setup 1

Set Ramp 1 ramp-down Time

s

Setup 1

Active Flying start?

Disable

OK

5

Setup 1

Set Motor Power

7

Setup 1

Set Motor Voltage

8

Setup 1

Set Motor frequency

9

Setup 1

Set Motor current

10

Setup 1

Set Motor nominal speed

11

if

17

20

21

22

Select Regional Settings

... the HVAC FC 101 Wizard starts

Setup 1

200-240V/50Hz/Delta

Grid Type

4

Asynchronous Motor

Setup 1

Asynchronous

Select Motor Type

6

Setup 1

Set Motor current

12

Setup 1

Select Motor nominal speed

13

Setup 1

Set Motor Cont. Rated Torque

14

Setup 1

Stator resistance

15

Setup 1

Motor poles

16

Setup 1

Back EMF at 1000 rpm

18

Setup 1

d-axis inductance

19

Setup 1

Set Max Output Frequency

23

24

Setup 1

Setup 1Setup 1

Setup 1

Set T53 low Voltage

V

Set T53 high Voltage

V

Set T53 Low Current

A

Set T53 High Current

A

Current

Voltage

28

29

26

27

Setup 1

Setup 1

Setup 1

Setup 1

Setup 1

Setup 1

Setup 1

Setup 1

Setup 1

AMA Failed

0.0 Hz

0.0 kW

Wizard completed

Press OK to accept

Automatic Motor Adaption

O

Auto Motor Adapt OK

Press OK

Select Function of Relay 2

No function

Select Function of Relay 1

[0] No function

Set Max Reference

Hz

Set Min Reference

Hz

AMA running

-----

AMA failed

Do AMA

(Do not AMA)

AMA OK

30

31

32

33

34

37

38

39

35 36

[0]

[0]

[0]

Setup 1

Select T53 Mode

Current

25

[0]

[0]

3.8

A

3000

RPM

5.4

Nm

0.65

Ohms

8

57

V

5

mH

0065

Hz

1.50

kW

0050

V

0050

Hz

04.66

A

1420

RPM

[0]

PM motor

Motor Type = Asynchronous

Motor Type = PM Motor

0000

0050

0003

0003

[0]

[0]

04.66

13.30

0050

0220

0000

0050

OK

B

a

c

k

Status

Main

Menu

Quick

Menu

Hand

On

OK

Menu

O

Reset

Auto

On

Alarm

Warn.

On

Status Screen

The Wizard can always be

reentered via the Quick Menu!

Power Up Screen

At power up the user is

asked to choose the

prefered laguage.

Select language

[1] English

0.0 Hz

0.0 kW

Setup 1

Setup 1

Status

Main

Menu

Quick

Menu

Hand

On

OK

Menu

O

Reset

Auto

On

Alarm

Warn.

On

Press OK to start Wizard

Press Back to skip it

Setup 1

Status

Main

Menu

Quick

Menu

Hand

On

OK

Menu

O

Reset

Auto

On

Alarm

Warn.

On

The next screen will be

the Wizard screen.

Wizard Screen

1

2

if

3

B

a

c

k

B

a

c

k

B

a

c

k

Com.

Com.

Com.

130BC244.11

Figure 1.31

Quick Guide

VLT® HVAC Basic Drive Quick Guide

1-22 MG18A422 - VLT® is a registered Danfoss trademark

11

Page 26

The FC 101 Start-up Wizard for Open-loop Applications

No & Name Range Default Function

0-03 Regional Settings [0] International

[1] US

0

0-06 GridType [0] 200–240 V/50 Hz/IT grid

[1] 200–240 V/50 Hz/Delta

[2] 200–240 V/50 Hz

[10] 380–440 V/50 Hz/IT grid

[11] 380–440 V/50 Hz/Delta

[12] 380–440 V/50 Hz

[20] 440–480 V/50 Hz/IT grid

[21] 440–480 V/50 Hz/Delta

[22] 440–480 V/50 Hz

[30] 525–600 V/50 Hz/IT grid

[31] 525–600 V/50 Hz/Delta

[32] 525–600 V/50 Hz

[100] 200–240 V/60 Hz/IT grid

[101] 200–240 V/60 Hz/Delta

[102] 200–240 V/60 Hz

[110] 380–440 V/60 Hz/IT grid

[111] 380–440 V/60 Hz/Delta

[112] 380–440 V/60 Hz

[120] 440–480 V/60 Hz/IT grid

[121] 440–480 V/60 Hz/Delta

[122] 440–480 V/60 Hz

[130] 525–600 V/60 Hz/IT grid

[131] 525–600 V/60 Hz/Delta

[132] 525–600 V/60 Hz

Size related

Select operating mode for restart upon

reconnection of the drive to AC line voltage after

power-down

1-10 Motor Construction *[0] Asynchron

[1] PM, non-salient SPM

[0] Asynchron Setting the parameter value might change these

parameters:

1-01 Motor Control Principle

1-03 Torque Characteristics

1-14 Damping Gain

1-15 Low Speed Filter Time Const.

1-16 High Speed Filter Time Const.

1-17 Voltage filter time const.

1-20 Motor Power [kW]

1-22 Motor Voltage

1-23 Motor Frequency

1-24 Motor Current

1-25 Motor Nominal Speed

1-26 Motor Cont. Rated Torque

1-30 Stator Resistance (Rs)

1-33 Stator Leakage Reactance (X1)

1-35 Main Reactance (Xh)

1-37 d-axis Inductance (Ld)

1-39 Motor Poles

1-40 Back EMF at 1000 RPM

1-66 Min. Current at Low Speed

1-72 Start Function

1-73 Flying Start

4-19 Max Output Frequency

4-58 Missing Motor Phase Function

1-20 Motor Power

0.12–110 kW/0.16–150 hp Size related Enter motor power from nameplate data

Quick Guide

VLT® HVAC Basic Drive Quick Guide

MG18A422 - VLT® is a registered Danfoss trademark 1-23

1 1

Page 27

No & Name Range Default Function

1-22 Motor Voltage 50.0–1,000.0 V Size related Enter motor voltage from nameplate data

1-23 Motor Frequency 20.0–400.0 Hz Size related Enter motor frequency from nameplate data

1-24 Motor Current 0.01–10,000.00 A Size related Enter motor current from nameplate data

1-25 Motor Nominal

Speed

100.0–9,999.0 RPM Size related Enter motor nominal speed from nameplate data

1-26 Motor Cont. Rated

Torque

0.1–1,000.0 Size related This parameter is available only when 1-10 Motor

Construction Design is set to [1] PM, non-salient

SPM.

NOTE!

Changing this parameter will affect settings

of other parameters

1-29 Automatic Motor

Adaption (AMA)

See 1-29 Automatic Motor Adaption

(AMA)

Off Performing an AMA optimizes motor performance.

1-30 Stator Resistance

(Rs)

0.000–99.990 Size related Set the stator resistance value

1-37 d-axis Inductance

(Ld)

0–1,000 Size related Enter the value of the d-axis inductance.

Obtain the value from the permanent magnet

motor data sheet. The de-axis inductance cannot

be found by performing an AMA.

1-39 Motor Poles 2–100 4 Enter the number of motor poles

1-40 Back EMF at 1000

RPM

10–9,000 Size related Line-Line RMS back EMF voltage at 1000 RPM

1-73 Flying Start When PM is selected, Flying Start is enabled and

cannot disable

1-73 Flying Start [0] Disabled

[1] Enabled

0

Select [1] Enable to enable the drive to catch a

motor spinning due to line drop-out. Select [0]

Disable if this function is not required. When is

enabled 1-71 Start Delay and 1-72 Start Function

have no function. is active in VVC+ mode only.

3-02 Minimum Reference -4,999–4,999 0 The minimum reference is the lowest value

obtainable by summing all references.

3-03 Maximum Reference -4,999–4,999 50 The maximum reference is the lowest obtainable

by summing all references.

3-41 Ramp 1 Ramp Up

Time

0.05–3,600.0 s Size related Ramp-up time from 0 to rated 1-23 Motor

Frequency if Asynchron motor is selected; ramp-up

time from 0 to 1-25 Motor Nominal Speed if PM

motor is selected

3-42 Ramp 1 Ramp

Down Time

0.05–3,600.0 s Size related Ramp-down time from rated 1-23 Motor Frequency

to 0 if Asynchron motor is selected; ramp-down

time from 1-25 Motor Nominal Speed to 0 if PM

motor is selected.

4-12 Motor Speed Low

Limit [Hz]

0.0–400 Hz 0 Hz Enter the minimum limit for low speed

4-14 Motor Speed High

Limit [Hz]

0.0–400 Hz 65 Hz Enter the maximum limit for high speed

4-19 Max Output

Frequency

0–400 Size related Enter the maximum output frequency value

5-40 Function Relay [0]

Function relay

See 5-40 Function Relay Alarm Select the function to control output relay 1.

Quick Guide

VLT® HVAC Basic Drive Quick Guide

1-24 MG18A422 - VLT® is a registered Danfoss trademark

11

Page 28

No & Name Range Default Function

5-40 Function Relay [1]

Function relay

See 5-40 Function Relay Drive running Select the function to control output relay 2.

6-10 Terminal 53 Low

Voltage

0–10 V 0.07 V Enter the voltage that corresponds to the low

reference value.

6-11 Terminal 53 High

Voltage

0–10 V 10 V Enter the voltage that corresponds to the high

reference value.

6-12 Terminal 53 Low

Current

0–20 mA 4 Enter the current that corresponds to the low

reference value.

6-13 Terminal 53 High

Current

0–20 mA 20 Enter the current that corresponds to the high

reference value.

6-19 Terminal 53 mode [0] Current

[1] Voltage

1 Select if terminal 53 is used for current or voltage

input.

Table 1.26

Quick Guide

VLT® HVAC Basic Drive Quick Guide

MG18A422 - VLT® is a registered Danfoss trademark 1-25

1 1

Page 29

Closed-loop Set-up Wizard

Quick Guide

VLT® HVAC Basic Drive Quick Guide

1-26 MG18A422 - VLT® is a registered Danfoss trademark

11

Page 30

6-29 Terminal 54 Mode

[1]

Voltage

6-25 T54 high Feedback

0050

Hz

20-94 PI integral time

0020.00

s

Current

Voltage

This dialog is forced to be set to

[1] Analog input 54

27

28

29

30

31

32

33

34

20-00 Feedback 1 source

[1]

Analog input 54

3-10 Preset reference [0]

0.00

3-03 Max Reference

50.00

3-02 Min Reference

0.00

Asynchronous Motor

1-73 Flying Start

[0]

No

1-22 Motor Voltage

0050

V

1-24 Motor current

04.66

A

1-25 Motor nominal speed

1420

RPM

3-41 Ramp 1 ramp-up time

0003

s

3-42 Ramp1 ramp-down time

0003

s

5

6

7

8

9

18

19

20

21

22

22a

23

24

25

26

35

36

37

38

39

40

0-06 Grid Type

4-12 Motor speed low limit

0016

Hz

4-13 Motor speed high limit

0050

Hz

130BC402.10

1-20 Motor Power

1.10

kW

1-23 Motor frequency

0050

Hz

6-22 T54 Low Current

A

6-24 T54 low Feedback

0016

Hz

6-23 T54 high Current

13.30

A

6-25 T54 high Feedback

0050

0.01

s

20-81 PI Normal/Inverse Control

[0]

Normal

20-83 PI Normal/Inverse Control

0050

Hz

20-93 PI Proportional Gain

00.50

1-29 Automatic Motor Adaption

[0]

O

6-20 T54 low Voltage

0050

V

6-24 T54 low Feedback

0016

Hz

6-21 T54 high Voltage

0220

V

6-26

T54 Filter time const.

1-00 Conguration Mode

[3]

Closed Loop

3

0-03 Regional Settings

[0]

Power kW/50 Hz

1

3-16 Reference Source 2

[0]

No Operation

22b

1-10 Motor Type

[0]

Asynchronous

4

2

[0]

200-240V/50Hz/Delta

1-30 Stator resistance

0.65

Ohms

1-25 Motor nominal speed

3000

RPM

1-24 Motor Current

3.8

A

1-26 Motor Cont. Rated Torque

5.4

Nm

1-37 d-axis inductance(Ld)

5

mH

4-19 Max Ouput Frequency

0065

Hz

1-40 Back EMF at 1000 rpm

57

V

10

11

12

13

14

15

16

17

PM motor

1-39 Motor poles

8

%

04.66

Hz

MotorType = Asynchronous

MotorType = PM Motor

Figure 1.32

Quick Guide

VLT® HVAC Basic Drive Quick Guide

MG18A422 - VLT® is a registered Danfoss trademark 1-27

1 1

Page 31

Closed-loop Set-up Wizard

No & Name Range Default Function

0-03 Regional Settings [0] International

[1] US

0

0-06 GridType [0] -[[132] see start-up wizard

for open-loop application

Size selected Select operating mode for restart upon

reconnection of the adjustable frequency

drive to AC line voltage after power-down.

1-00 Configuration Mode [0] Open-loop

[3] Closed-loop

0 Change this parameter to Closed-loop

1-10 Motor Construction *[0] Motor construction

[1] PM, non-salient SPM

[0] Asynchron Setting the parameter value might change

these parameters:

1-01 Motor Control Principle

1-03 Torque Characteristics

1-14 Damping Gain

1-15 Low Speed Filter Time Const.

1-16 High Speed Filter Time Const.

1-17 Voltage filter time const.

1-20 Motor Power [kW]

1-22 Motor Voltage

1-23 Motor Frequency

1-25 Motor Nominal Speed

1-26 Motor Cont. Rated Torque

1-30 Stator Resistance (Rs)

1-33 Stator Leakage Reactance (X1)

1-35 Main Reactance (Xh)

1-37 d-axis Inductance (Ld)

1-39 Motor Poles

1-40 Back EMF at 1000 RPM

1-66 Min. Current at Low Speed

1-72 Start Function

1-73 Flying Start

4-19 Max Output Frequency

4-58 Missing Motor Phase Function

1-20 Motor Power

0.125–150 hp [0.09–110 kW] Size related Enter motor power from nameplate data

1-22 Motor Voltage 50.0–1,000.0 V Size related Enter motor voltage from nameplate data

1-23 Motor Frequency 20.0–400.0 Hz Size related Enter motor frequency from nameplate data

1-24 Motor Current 0.0–10,000.00 A Size related Enter motor current from nameplate data

1-25 Motor Nominal Speed 100.0–9,999.0 RPM Size related Enter motor nominal speed from nameplate

data

1-26 Motor Cont. Rated Torque 0.1–1,000.0 Size related This parameter is available only when

1-10 Motor Construction Design is set to [1]

PM, non-salient SPM.

NOTE!

Changing this parameter affects the

settings of other parameters

1-29 Automatic Motor Adaption

(AMA)

Off Performing an AMA optimizes motor

performance.

1-30 Stator Resistance (Rs) 0.000–99.990 Size related Set the stator resistance value

1-37 d-axis Inductance (Ld) 0–1,000 Size related Enter the value of the d-axis inductance.

Obtain the value from the permanent magnet

motor data sheet. The de-axis inductance

cannot be found by performing an AMA.

Quick Guide

VLT® HVAC Basic Drive Quick Guide

1-28 MG18A422 - VLT® is a registered Danfoss trademark

11

Page 32

No & Name Range Default Function

1-39 Motor Poles 2–100 4 Enter the number of motor poles

1-40 Back EMF at 1000 RPM 10–9,000 Size related Line-Line RMS back EMF voltage at 1000 RPM

1-73 Flying Start [0] Disabled

[1] Enabled

0

Select [1] Enable to enable the adjustable

frequency drive to catch a spinning motor,

e.g., in fan applications. When PM is selected,

Flying Start is enabled.

3-02 Minimum Reference -4,999–4,999 0 The minimum reference is the lowest value

obtainable by summing all references.

3-03 Maximum Reference -4,999–4,999 50 The maximum reference is the highest value

obtainable by summing all references.

3-10 Preset Reference -100–100% 0 Enter the setpoint.

3-41 Ramp 1 Ramp Up Time 0.05–3,600.0 s Size related Ramp-up time from 0 to rated 1-23 Motor

Frequency if Asynchron motor is selected;

ramp-up time from 0 to 1-25 Motor Nominal

Speed if PM motor is selected.

3-42 Ramp 1 Ramp Down Time 0.05–3,600.0 s Size related Ramp-down time from rated 1-23 Motor

Frequency to 0 if Asynchron motor is selected;

ramp-down time from 1-25 Motor Nominal

Speed to 0 if PM motor is selected.

4-12 Motor Speed Low Limit [Hz] 0.0–400 Hz 0.0 Hz Enter the minimum limit for low speed

4-14 Motor Speed High Limit [Hz] 0–400 Hz 65 Hz Enter the minimum limit for high speed

4-19 Max Output Frequency 0–400 Size related Enter the maximum output frequency value

6-29 Terminal 54 mode [0] Current

[1] Voltage

1 Select if terminal 54 is used for current or

voltage input

6-20 Terminal 54 Low Voltage 0–10 V 0.07 V Enter the voltage that corresponds to the low

reference value.

6-21 Terminal 54 High Voltage 0–10 V 10 V Enter the voltage that corresponds to the low

high reference value.

6-22 Terminal 54 Low Current 0–20 mA 4 Enter the current that corresponds to the high

reference value.

6-23 Terminal 54 High Current 0–20 mA 20 Enter the current that corresponds to the high

reference value.

6-24 Terminal 54 Low Ref./Feedb.

Value

-4,999–4,999 0 Enter the feedback value that corresponds to

the voltage or current set in 6-20 Terminal 54

Low Voltage/6-22 Terminal 54 Low Current

6-25 Terminal 54 High Ref./Feedb.

Value

-4,999–4,999 50 Enter the feedback value that corresponds to

the voltage or current set in 6-21 Terminal 54

High Voltage/6-23 Terminal 54 High Current

6-26 Terminal 54 Filter Time

Constant

0–10 s 0.01 Enter the filter time constant.

20-81 PI Normal/ Inverse Control [0] Normal

[1] Inverse

0

Select [0] Normal to set the process control to

increase the output speed when the process

error is positive. Select [1] Inverse to reduce

the output speed.

20-83 PI Start Speed [Hz] 0–200 Hz 0 Enter the motor speed to be attained as a

start signal for commencement of PI control.

20-93 PI Proportional Gain 0–10 0.01 Enter the process controller proportional gain.

Quick control is obtained at high amplifi-

cation. However, if amplification is too great,

the process may become unstable

Quick Guide

VLT® HVAC Basic Drive Quick Guide

MG18A422 - VLT® is a registered Danfoss trademark 1-29

1 1

Page 33

No & Name Range Default Function

20-94 PI Integral Time 0.1–999.0 s 999.0 s Enter the process controller integral time.

Obtain quick control through a short integral

time, though if the integral time is too short,

the process becomes unstable. An excessively

long integral time disables the integral action.

Table 1.27

Motor Set-up

The Quick Menu Motor Set-up guides you through the

needed motor parameters.

No & Name Range Default Function

0-03 Regional

Settings

[0] International

[1] US

0

0-06 GridType [0] -[132] see

start-up wizard

for open-loop

application

Size selected Select operating

mode for restart

upon

reconnection of

the drive to AC

line voltage after

power-down

1-10 Motor

Construction

*[0] Motor

construction

[1] PM, nonsalient SPM

[0]

Asynchron

1-20 Motor

Power

0.12–110 kW/

0.16–150 hp

Size related Enter motor

power from

nameplate data

1-22 Motor

Voltage

50.0–1,000.0 V Size related Enter motor

voltage from

nameplate data

1-23 Motor

Frequency

20.0–400.0 Hz Size related Enter motor

frequency from

nameplate data

1-24 Motor

Current

0.01–10,000.00ASize related Enter motor

current from

nameplate data

1-25 Motor

Nominal

Speed

100.0–9,999.0

RPM

Size related Enter motor

nominal speed

from nameplate

data

No & Name Range Default Function

1-26 Motor

Cont. Rated

Torque

0.1–1,000.0 Size related This parameter is

available only

when 1-10 Motor

Construction

Design is set to

[1] PM, nonsalient SPM.

NOTE!

Changing this

parameter

affects the

settings of

other

parameters

1-30 Stator

Resistance (Rs)

0.000–99.990 Size related Set the stator

resistance value

1-37 d-axis

Inductance

(Ld)

0–1,000 Size related Enter the value

of the d-axis

inductance.

Obtain the value

from the

permanent

magnet motor

data sheet. The

de-axis

inductance

cannot be found

by performing an

AMA.

1-39 Motor

Poles

2–100 4 Enter the number

of motor poles

1-40 Back EMF

at 1000 RPM

10–9,000 Size related Line-Line RMS

back EMF voltage

at 1000 RPM

1-73 Flying

Start

[0] Disabled

[1] Enabled

0 Select Enable to

enable the

adjustable

frequency drive

to catch a

spinning motor.

Quick Guide

VLT® HVAC Basic Drive Quick Guide

1-30 MG18A422 - VLT® is a registered Danfoss trademark

11

Page 34

No & Name Range Default Function

3-41 Ramp 1

Ramp Up

Time

0.05–3,600.0 s Size related Ramp-up time

from 0 to rated

1-23 Motor

Frequency

3-42 Ramp 1

Ramp Down

Time

0.05–3,600.0 s Size related Ramp-down time

from rated

1-23 Motor

Frequency to 0

4-12 Motor

Speed Low

Limit [Hz]

0.0–400 Hz 0.0 Hz Enter the

minimum limit

for low speed

4-14 Motor

Speed High

Limit [Hz]

0.0–400 Hz 65 Enter the

maximum limit

for high speed

4-19 Max

Output

Frequency

0–400 Size related Enter the

maximum output

frequency value

Table 1.28

Changes Made

Changes Made lists all parameters changed since factory

setting. Only the changed parameters in current edit-setup

are listed in changes made.

If the parameter's value is changed back to the factory

setting value from another different value, the parameter

will NOT be listed in Changes Made.

1. Press [Menu] key to enter the Quick Menu until

indicator in display is placed above Quick Menu.

2.

Press [▲] [▼] to select either FC 101 wizard,

closed-loop set-up, motor set-up or changes

made, then press [OK].

3.

Press [▲] [▼] to browse through the parameters

in the Quick Menu.

4. Press [OK] to select a parameter.

5.

Press [▲] [▼] to change the value of a parameter

setting.

6. Press [OK] to accept the change.

7. Press either [Back] twice to enter “Status”, or

press [Menu] once to enter “Main Menu”.

The Main Menu accesses all parameters.

1. Press [Menu] key until indicator in display is

placed above “Main Menu”.

2.

Press [▲] [▼] to browse through the parameter

groups.

3. Press [Ok] to select a parameter group.

4.

Press [▲] [▼] to browse through the parameters

in the specific group.

5. Press [Ok] to select the parameter.

6.

Press [▲] [▼] to set/change the parameter value.

Quick Guide

VLT® HVAC Basic Drive Quick Guide

MG18A422 - VLT® is a registered Danfoss trademark 1-31

1 1

Page 35

1.5.1 Main menu

structure

0-** Operation/Display

0-0* Basic Settings

0-01 Language

0-03 Regional Settings

0-04 Operating State at Power-up

0-06 GridType

0-07 Auto DC Braking

0-1* Set-up Operations

0-10 Active Set-up

0-11 Programming Set-up

0-12 Link Set-ups

0-3* LCP Custom Readout

0-30 Custom Readout Unit

0-31 Custom Readout Min Value

0-32 Custom Readout Max Value

0-37 Display Text 1

0-38 Display Text 2

0-39 Display Text 3

0-4* LCP Keypad

0-40 [Hand on] Key on LCP

0-42 [Auto on] Key on LCP

0-44 [Off/Reset] Key on LCP

0-5* Copy/Save

0-50 LCP Copy

0-51 Set-up Copy

0-6* Password

0-60 Main Menu Password

1-** Load and Motor

1-0* General Settings

1-00 Configuration Mode

1-01 Motor Control Principle

1-03 Torque Characteristics

1-06 Clockwise Direction

1-1* Motor Selection

1-10 Motor Construction

1-14 Damping Gain

1-15 Low Speed Filter Time Const

1-16 High Speed Filter Time Const

1-17 Voltage filter time const

1-2* Motor Data

1-20 Motor Power

1-22 Motor Voltage

1-23 Motor Frequency

1-24 Motor Current

1-25 Motor Nominal Speed

1-26 Motor Cont. Rated Torque

1-29 Automatic Motor Adaption (AMA)

1-3* Adv. Motor Data

1-30 Stator Resistance (Rs)

1-33 Stator Leakage Reactance (X1)

1-35 Main Reactance (Xh)

1-37 d-axis Inductance (Ld)

1-39 Motor Poles

1-4* Adv. Motor Data II

1-40 Back EMF at 1000 RPM

1-42 Motor Cable Length

1-43 Motor Cable Length Feet

1-5* Load Indep. Setting

1-50 Motor Magnetization at Zero Speed

1-52 Min Speed Normal Magnetizing [Hz]

1-55 U/f Characteristic - U

1-56 U/f Characteristic - F

1-6* Load Depen. Setting

1-60 Low Speed Load Compensation

1-61 High Speed Load Compensation

1-62 Slip Compensation

1-63 Slip Compensation Time Constant

1-64 Resonance Dampening

1-65 Resonance Dampening Time

Constant

1-66 Min. Current at Low Speed

1-7* Start Adjustments

1-71 Start Delay

1-72 Start Function

1-73 Flying Start

1-8* Stop Adjustments

1-80 Function at Stop

1-82 Min Speed for Function at Stop [Hz]

1-9* Motor Temperature

1-90 Motor Thermal Protection

1-93 Thermistor Source

2-** Brakes

2-0* DC Brake

2-00 DC Hold/Motor Preheat Current

2-01 DC Brake Current

2-02 DC Braking Time

2-04 DC Brake Cut-in Speed

2-06 Parking Current

2-07 Parking Time

2-1* Brake Energy Funct.

2-10 Brake Function

2-16 AC Brake, Max current

2-17 Over-voltage Control

3-** Reference / Ramps

3-0* Reference Limits

3-02 Minimum Reference

3-03 Maximum Reference

3-1* References

3-10 Preset Reference

3-11 Jog Speed [Hz]

3-14 Preset Relative Reference

3-15 Reference 1 Source

3-16 Reference 2 Source

3-17 Reference 3 Source

3-4* Ramp 1

3-41 Ramp 1 Ramp-up Time

3-42 Ramp 1 Ramp-down Time

3-5* Ramp 2

3-51 Ramp 2 Ramp-up Time

3-52 Ramp 2 Ramp-down Time

3-8* Other Ramps

3-80 Jog Ramp Time

3-81 Quick Stop Ramp Time

4-** Limits / Warnings

4-1* Motor Limits

4-10 Motor Speed Direction

4-12 Motor Speed Low Limit [Hz]

4-14 Motor Speed High Limit [Hz]

4-18 Current Limit

4-19 Max Output Frequency

4-4* Adj. Warnings 2

4-40 Warning Freq. Low

4-41 Warning Freq. High

4-5* Adj. Warnings

4-50 Warning Current Low

4-51 Warning Current High

4-54 Warning Reference Low

4-55 Warning Reference High

4-56 Warning Feedback Low

4-57 Warning Feedback High

4-58 Missing Motor Phase Function

4-6* Speed Bypass

4-61 Bypass Speed From [Hz]

4-63 Bypass Speed To [Hz]

4-64 Semi-Auto Bypass Set-up

5-** Digital In/Out

5-0* Digital I/O mode

5-00 Digital Input Mode

5-03 Digital Input 29 Mode

5-1* Digital Inputs

5-10 Terminal 18 Digital Input

5-11 Terminal 19 Digital Input

5-12 Terminal 27 Digital Input

5-13 Terminal 29 Digital Input

5-3* Digital Outputs

5-34 On Delay, Digital Output

5-35 Off Delay, Digital Output

5-4* Relays

5-40 Function Relay

5-41 On Delay, Relay

5-42 Off Delay, Relay

5-5* Pulse Input

5-50 Term. 29 Low Frequency

5-51 Term. 29 High Frequency

5-52 Term. 29 Low Ref./Feedb. Value

5-53 Term. 29 High Ref./Feedb. Value

5-9* Bus Controlled

5-90 Digital & Relay Bus Control

6-** Analog In/Out

6-0* Analog I/O Mode

6-00 Live Zero Timeout Time

6-01 Live Zero Timeout Function

6-1* Analog Input 53

6-10 Terminal 53 Low Voltage

6-11 Terminal 53 High Voltage

6-12 Terminal 53 Low Current

6-13 Terminal 53 High Current

6-14 Terminal 53 Low Ref./Feedb. Value

6-15 Terminal 53 High Ref./Feedb. Value

6-16 Terminal 53 Filter Time Constant

6-19 Terminal 53 mode

6-2* Analog Input 54

6-20 Terminal 54 Low Voltage

6-21 Terminal 54 High Voltage

6-22 Terminal 54 Low Current

6-23 Terminal 54 High Current

6-24 Terminal 54 Low Ref./Feedb. Value

6-25 Terminal 54 High Ref./Feedb. Value

6-26 Terminal 54 Filter Time Constant

6-29 Terminal 54 mode

6-7* Analog/Digital Output 45

6-70 Terminal 45 Mode

6-71 Terminal 45 Analog Output

6-72 Terminal 45 Digital Output

6-73 Terminal 45 Output Min Scale

6-74 Terminal 45 Output Max Scale

6-76 Terminal 45 Output Bus Control

6-9* Analog/Digital Output 42

6-90 Terminal 42 Mode

6-91 Terminal 42 Analog Output

6-92 Terminal 42 Digital Output

6-93 Terminal 42 Output Min Scale

6-94 Terminal 42 Output Max Scale

6-96 Terminal 42 Output Bus Control

6-98 Drive Type

8-** Comm. and Options

8-0* General Settings

8-01 Control Site

8-02 Control Source

8-03 Control Timeout Time

8-04 Control Timeout Function

8-3* FC Port Settings

8-30 Protocol

8-31 Address

8-32 Baud Rate

8-33 Parity / Stop Bits

8-35 Minimum Response Delay

8-36 Maximum Response Delay

8-37 Maximum Inter-char delay

8-4* FC MC protocol set

8-43 PCD Read Configuration

8-5* Digital/Bus

8-50 Coasting Select

8-51 Quick Stop Select

8-52 DC Brake Select

8-53 Start Select

8-54 Reversing Select

8-55 Set-up Select

8-56 Preset Reference Select

8-7* BACnet

8-70 BACnet Device Instance

8-72 MS/TP Max Masters

8-73 MS/TP Max Info Frames

8-74 "I am" Service

8-75 Intialisation Password

8-8* FC Port Diagnostics

8-80 Bus Message Count

8-81 Bus Error Count

8-82 Slave Messages Rcvd

8-83 Slave Error Count

8-84 Slave Messages Sent

8-85 Slave Timeout Errors

8-88 Reset FC Port Diagnostics

8-9* Bus Feedback

8-94 Bus Feedback 1

13-** Smart Logic

13-0* SLC Settings

13-00 SL Controller Mode

13-01 Start Event

13-02 Stop Event

13-03 Reset SLC

13-1* Comparators

13-10 Comparator Operand

13-11 Comparator Operator

13-12 Comparator Value

13-2* Timers

13-20 SL Controller Timer

13-4* Logic Rules

13-40 Logic Rule Boolean 1

13-41 Logic Rule Operator 1

13-42 Logic Rule Boolean 2

13-43 Logic Rule Operator 2

13-44 Logic Rule Boolean 3

13-5* States

13-51 SL Controller Event

13-52 SL Controller Action

14-** Special Functions

14-0* Inverter Switching

14-01 Switching Frequency

14-03 Overmodulation

14-08 Damping Gain Factor

14-1* Mains On/Off

14-10 Mains Failure

14-12 Function at Mains Imbalance

14-2* Reset Functions

14-20 Reset Mode

14-21 Automatic Restart Time

14-22 Operation Mode

14-23 Typecode Setting

14-27 Action At Inverter Fault

14-28 Production Settings

14-29 Service Code

14-4* Energy Optimizing

14-40 VT Level

14-41 AEO Minimum Magnetization

14-5* Environment

14-50 RFI Filter

14-51 DC Link Voltage Compensation

14-52 Fan Control

14-53 Fan Monitor

14-55 Output Filter

14-6* Auto Derate

14-63 Min Switch Frequency

15-** Drive Information

15-0* Operating Data

15-00 Operating hours

15-01 Running Hours

15-02 kWh Counter

15-03 Power-ups

15-04 Over Temps

15-05 Over Volts

Quick Guide

VLT® HVAC Basic Drive Quick Guide

1-32 MG18A422 - VLT® is a registered Danfoss trademark

11

Page 36

15-06 Reset kWh Counter

15-07 Reset Running Hours Counter

15-3* Alarm Log

15-30 Alarm Log: Error Code

15-31 InternalFaultReason

15-4* Drive Identification

15-40 FC Type

15-41 Power Section

15-42 Voltage

15-43 Software Version

15-44 Ordered TypeCode

15-46 Drive Ordering No

15-47 Power Card Ordering No.

15-48 LCP ID Num.

15-49 SW ID Control Card

15-50 SW ID Power Card

15-51 Drive Serial Number

15-53 Power Card Serial Number

15-9* Parameter Info

15-92 Defined Parameters

15-97 Application Type

15-98 Drive Identification

16-** Data Readouts

16-0* General Status

16-00 Control Word

16-01 Reference [Unit]

16-02 Reference [%]

16-03 Status Word

16-05 Main Actual Value [%]

16-09 Custom Readout

16-1* Motor Status

16-10 Power [kW]

16-11 Power [hp]

16-12 Motor Voltage

16-13 Frequency

16-14 Motor current

16-15 Frequency [%]

16-18 Motor Thermal

16-3* Drive Status

16-30 DC Link Voltage

16-34 Heatsink Temp.

16-35 Inverter Thermal

16-36 Inv. Nom. Current

16-37 Inv. Max. Current

16-38 SL Controller State

16-5* Ref. & Feedb.

16-50 External Reference

16-52 Feedback[Unit]

16-6* Inputs & Outputs

16-60 Digital Input

16-61 Terminal 53 Setting

16-62 Analog Input AI53

16-63 Terminal 54 Setting

16-64 Analog Input AI54

16-65 Analog Output AO42 [mA]

16-66 Digital Output

16-67 Pulse Input #29 [Hz]

16-71 Relay Output [bin]

16-72 Counter A

16-73 Counter B

16-79 Analog Output AO45

16-8* Fieldbus & FC Port

16-86 FC Port REF 1

16-9* Diagnosis Readouts

16-90 Alarm Word

16-91 Alarm Word 2

16-92 Warning Word

16-93 Warning Word 2

16-94 Ext. Status Word

16-95 Ext. Status Word 2

18-** Info & Readouts

18-1* Fire Mode Log

18-10 FireMode Log:Event

20-** Drive Closed-loop

20-0* Feedback

20-00 Feedback 1 Source

20-01 Feedback 1 Conversion

20-8* PI Basic Settings

20-81 PI Normal/ Inverse Control

20-83 PI Start Speed [Hz]

20-84 On Reference Bandwidth

20-9* PI Controller

20-91 PI Anti Windup

20-93 PI Proportional Gain

20-94 PI Integral Time

20-97 PI Feed Forward Factor

22-** Appl. Functions

22-4* Sleep Mode

22-40 Minimum Run Time

22-41 Minimum Sleep Time

22-43 Wake-up Speed [Hz]

22-44 Wake-up Ref./FB Diff

22-45 Setpoint Boost

22-46 Maximum Boost Time

22-47 Sleep Speed [Hz]

22-6* Broken Belt Detection

22-60 Broken Belt Function

22-61 Broken Belt Torque

22-62 Broken Belt Delay

24-** Appl. Functions 2

24-0* Fire Mode

24-00 FM Function

24-05 FM Preset Reference

24-09 FM Alarm Handling

24-1* Drive Bypass

24-10 Drive Bypass Function

24-11 Drive Bypass Delay Time

38-** Debug only - see PNU 1429 (service

code) also

38-0* All debug parameters

38-00 TestMonitorMode

38-01 Version And Stack

38-02 Protocol SW version

38-06 LCPEdit Set-up

38-07 EEPROMDdataVers

38-08 PowerDataVariantID

38-09 AMA Retry

38-10 DAC selection

38-12 DAC scale

38-20 MOC_TestUS16

38-21 MOC_TestS16

38-23 TestMocFunctions

38-24 DC Link Power Measurement

38-25 CheckSum

38-30 Analog Input 53 (%)

38-31 Analog Input 54 (%)

38-32 Input Reference 1

38-33 Input Reference 2

38-34 Input Reference Setting

38-35 Feedback (%)

38-36 Fault Code

38-37 Control Word

38-38 ResetCountersControl

38-39 Active Set-up For BACnet

38-40 Name Of Analog Value 1 For BACnet

38-41 Name Of Analog Value 3 For BACnet

38-42 Name Of Analog Value 5 For BACnet

38-43 Name Of Analog Value 6 For BACnet

38-44 Name Of Binary Value 1 For BACnet

38-45 Name Of Binary Value 2 For BACnet

38-46 Name Of Binary Value 3 For BACnet

38-47 Name Of Binary Value 4 For BACnet

38-48 Name Of Binary Value 5 For BACnet

38-49 Name Of Binary Value 6 For BACnet

38-50 Name Of Binary Value 21 For BACnet

38-51 Name Of Binary Value 22 For BACnet

38-52 Name Of Binary Value 33 For BACnet

38-53 Bus Feedback 1 Conversion

38-54 Run Stop Bus Control

38-58 Inverter ETR counter

38-59 Rectifier ETR counter

38-60 DB_ErrorWarnings

38-61 Extended Alarm Word

38-69 AMA_DebugS32

38-74 AOCDebug0

38-75 AOCDebug1

38-76 AO42_FixedMode

38-77 AO42_FixedValue

38-78 DI_TestCounters

38-79 Protect Func. Counter

38-80 Highest Lowest Couple

38-81 DB_SendDebugCmd

38-82 MaxTaskRunningTime

38-83 DebugInformation

38-85 DB_OptionSelector

38-86 EEPROM_Address

38-87 EEPROM_Value

38-88 Logger Time Remain