Page 1

MAKING MODERN LIVING POSSIBLE

Quick Setup

VLT® FCM 300 Series

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 2

MG.03.A3.62 – VLT is a registered Danfoss trademark6

VLT® DriveMotor FCM 300 Quick Setup

ENGLISH

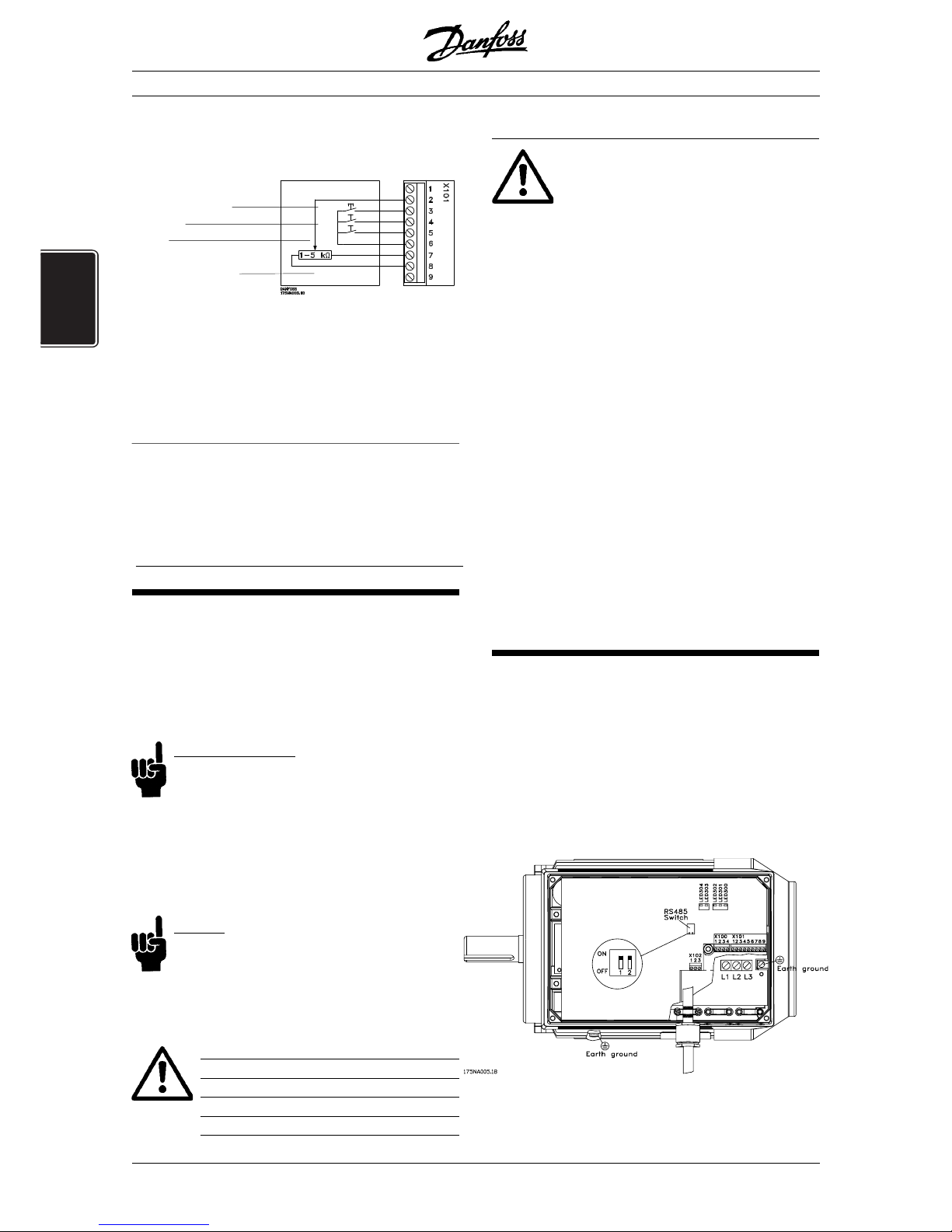

Reset

(pushbutton)

Start

Jog

Speed

reference

Terminals

1: Analogue input 6: 24 V DC supply

2: Analogue input 7: 10 V DC supply

3: Digital input 8: 0 V

4: Digital input 9: Output

5: Digital input

- Reset to be closed short time for resetting fault trips

- Start to be closed for changing to run mode

- Jog will run at fixed speed while closed (10 Hz)

- Speed reference (0-10 V) determines speed while in

run mode

Fig. 1

Factory setting

1 Mechanical installation

Install the FC motor with adequate access for routine

maintenance. Adequate space, particularly at the fan

inlet (50 mm), is necessary to facilitate airflow.

Where several FC motors are installed in close proximity,

care must be taken to ensure that there is no

recirculation of exhausted warm air.

NB!:

Ambient temperature

To avoid the FC part getting overheated, the

ambient temperature is not to exceed 40 °C and

the 24-hour average temperature is not to exceed 35

°C. If the ambient temperature is in the range of 40 °C 55 °C, a reduction of the service life of the FC part is to

be expected. For further information, please see the

section on derating in the Design Guide.

NB!:

Bearings

Ball and roller bearings are despatched from the

works fully charged with grease. Shielded

bearings have sufficient grease for an operating life of at

least two years in normal ambient temperatures,

providing there is little or no leakage.

Tapping of fitments onto the motor shaft,

with a hammer or mallet, causes bearing

damage. This results in increased bearing

noise and a significant reduction in bearing

life.

Motors type B14 & B34 mounting

1) Max length of the fixing bolts / screws

penetrating the B14 flange:

FCM 305-307 (frame 80) = 12.0mm

FCM 311-315 (frame 90) = 10.0mm

FCM 322-330 (frame 100) = 10.0mm

FCM 340 (frame 112) = 10,0mm

FCM 355-375 (frame 132) = 12.0mm

2) The following precautions must be taken:

a) A non-setting jointing and sealing compound must

be used to seal the bolt / screw threads in the motor

flange.

b) A soft copper washer must be inserted

underneath the bolt / screw head.

c) The joint face between the motor flange and the

mounting must be sealed using non-setting jointing

and sealing compound.

For B34 types where it is only foot mounted, the flange

is not used. Then the bolts should be fitted in

accordance with parts a) & b) of item 2 to maintain the

IP55.

2 Electrical connections

Remove the inverter box cover, which is held by four

screws, to obtain access to the terminals.

Remove the detachable terminal plugs from the terminal

blocks X100 and X101 to obtain access to the mains

terminals.

Lift only the corner of the black plastic cover by the

cable entries to expose the mains terminals L1, L2 and L

3

(see fig. 2).

The control cables must be screened cables.

Fig. 2

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 3

VLT® DriveMotor FCM 300 Quick Setup

ENGLISH

NB!:

Do not lift or remove the entire plastic cover.

The voltage on the FC motor is dangerous

and may lead to material damage, serious

injury or it may be fatal.

NB!:

Mains terminals L1, L2 and L3:

Make sure that your mains supply corresponds

to the voltage required by the FC motor (see

inverter label), TT and NT mains .

Connect the three mains phases to terminals L1, L2 and

L

3

and the earth to the separate terminal provided.

Tightening Torques

L1, L2, L

3

FCM 305-340 0,5-0,6 Nm

L1, L2, L

3

FCM 355-375 1,2-1,5 Nm

Earth ground FCM 305-375 3,4 Nm

Fixed wires:

Rated temperature for fixed wires min. 60° C or 140° F.

Use copper conduction only.

NB!:

You cannot change the rotation direction of the

motor by shifting around the phases. The direct-

ion of rotation is clockwise by default. Another

direction of rotation can be programmed, see the Design

Guide.

Prefuses Max.

UL

1)

FCM 305-322 10A

FCM 330-340 15A

FCM 355-375 25A

IEC

1)

FCM 305-375 25A

1)

Type gG prefuses must be used. If you want to maintain

UL/cUL you must use prefuses of the type Bussmann KTS-R

500 V or Ferraz Shawmut, type ATMR (max. 30A). The fuses

must be placed for protection in a circuit that is capable of

supplying a maximum of 100,000 amps RMS (symmetrical),

500 V maximum.

Control terminals

For information on terminal blocks X100, X101 and

X102, please see table A, B and C.

X100: Terminal block for data communication

Terminal Function

No.

1 P RS 485 for connection to

2 N RS 485 bus or PC

3 5 V DC

Supply for RS 485 bus

4 0 V DC

Table A

X101: Terminal block for analog/digital control signals

Terminal Function Example

No.

1 Analog input (0-20 mA) Feedbacksignal

2 Analog (0-10 V)/ Hastigheds-

digital input 2 reference

3 Digital input (or pulse) 3 Reset

4 Digital input

(or precise stop) 4

Start

5 Digital input (other) 5

Jog

(fixed speed)

6 24 V DC supply for digital

inputs (max 50 mA)

7 10 V DC supply

for potentiometer

(max. 15 mA)

8 0 V for terminals 1-7 and 9

9 Analog (0-20 mA)

digital output

Fault indication

Table B

X102: Terminal block for relay output

Terminal Function

No.

1-2 Make (normally open)

1-3 Brake (normally closed)

Table C

RS 485 switch

For terminating an RS 485 interface serial

communication, the bus must be terminated by a

resistor network at both ends. This is provided by setting

both switches to ON.

LEDs

The FC motor has five LEDs which indicate the status of

the FC motor:

LED 300 (red): Fault trip

LED 301 (yellow): Warning

LED 302 (green): Power on

LED 303-304 (green): Communication

EMC-correct installation

The control cables must be screened cables to ensure

EMC-correct electrical installation.

Connect the screen to earth at both ends.

Avoid installation with twisted screen ends (pigtails),

since this ruins the screening effect at high frequencies.

Use cable clamps instead.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 4

MG.03.A3.62 – VLT is a registered Danfoss trademark8

VLT® DriveMotor FCM 300 Quick Setup

ENGLISH

3 Start the FC motor

Connect mains. LED 302 (green) lights up to indicate

that the power is on. In Profibus versions, LED 303 will

flash. For further information on Profibus, please see the

Profibus manual.

Connect terminal 4 and 6 to the start button (see fig. 1).

Connect terminal 2, 7 and 8 to the potentiometer (see

fig. 1).

Use the start button to start the FC motor and adjust the

speed by means of the potentiometer.

Warning

The voltage on the FC motor is dangerous

when the motor is connected to mains.

Incorrect installation of the FC motor may

lead to material damage or serious injury

or it may be fatal.

4 Mount the inverter box cover.

Fastening torque: 2.2 - 2.4 Nm

SafetySafety

SafetySafety

Safety

All operations must be carried out by

appropriately trained personnel.

Use all lifting facilities provided e.g. both

lifting points, if fitted, or single lifting point, if

fitted*.

Vertical lifting - Prevent uncontrolled rotation.

Lift machine - Do not lift other equipment with motor

lifting points only.

Before installation check for fan cover damage, shaft

damage, foot/mounting damage, and loose

fasteners. Check nameplate details.

Ensure level mounting surface, balanced mounting,

not misaligned.

Gaskets, and/or sealants, and guards must be

correctly fitted.

Correct belt tension.

Please observe derating rules, see Design Guide

* Note: maximum hand lift is 20 kg below shoulder, but

above ground level.

Max. weights:

- Frame size 80: 15 kg

- Frame size 90 & 100: 30 kg

- Frame size 112: 65 kg

The voltage on the FC motor is dangerous

when the motor is connected to mains.

Incorrect installation of the FC motor may

lead to material damage or serious injury or

it may be fatal.

Consequently, the instructions in this Quick Setup as

well as national and local rules and safety regulations

must be complied with.

Touching the electrical parts may be fatal, even after the

mains supply has been disconnected.

Wait at least 4 minutes.

- Installation must be fused and isolated correctly.

- Covers and cable entries must be fitted

NB!:

It is the user's or certified electrician's

responsibility to ensure correct earthing and

protection in accordance with applicable national

and local requirements and standards.

Safety regulations

1. The FC motor must be disconnected from mains if

repair work is to be carried out. Check that the mains

supply has been disconnected and that the

necessary time has passed (4 minutes).

2. Correct protective earthing of the equipment must

be established, the user must be protected against

supply voltage, and the motor must be protected

against overload in accordance with applicable

national and local regulations.

In UL/cUL applications ETR provides class 20,

overload protection in accordance with the NEC

®

.

RCD's (ELCB relays), multiple protective earthing or

earthing can be used as extra protection, provided

that local safety regulations are complied with.

In case of an earth fault, a DC content may develop

in the fault current.

If RCD's are used, local regulations must be

observed. Relays must be suitable for protection of

3-phase equipment with a bridge rectifier and for a

brief discharge on power-up.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 5

VLT® DriveMotor FCM 300 Quick Setup

ENGLISH

■■

■■

■ What if the motor does not start?

- Make sure no parameters have been changed from

initial delivery status (factory setting). Use the Local

Control Panel or serial port to reset to factory setting.

- Make sure no STOP command have been issued by

the optional control panel keyboard (local stop)

Control Panel STOP can only be restarted by the

Control Panel START button.

- Remove lid to check the Light Emitting Diodes visible

through a hole in the inside isolation cover (See the

drawing), follow table below.

Warning:

Extreme care must be taken when

operating the unit with open lid.

Green Yellow Red Action

LED 302LED 302

LED 302LED 302

LED 302

LED 301LED 301

LED 301LED 301

LED 301

LED 300LED 300

LED 300LED 300

LED 300

OFF OFF OFF Apply power

(see point 2)(see point 2)

(see point 2)(see point 2)

(see point 2)

ON OFF OFF Apply start and

reference signals ,

(see figur(see figur

(see figur(see figur

(see figur

e 1 ande 1 and

e 1 ande 1 and

e 1 and

point 3)point 3)

point 3)point 3)

point 3)

ON OFF ON Apply reset signal

according to figure 1.

ON ON ON Switch off power until

all LED's have turned

off. After power on

reset signal is required.

This Quick Setup gives information on safety and helps

you to get your FCM 300 Series motors installed and

running in factory setting, see fig. 1.

For additional information, please see the Design

Guide.

Tools for installation

1 cross-point screwdriver

1 large screwdriver

1 small screwdriver

Min. 2 glands:

Gland sizes

FCM 305-330 3 x M20 x 1.5 mm

FCM 340-375 1 x M25 x 1.5 mm,

2 x M20 x 1.5 mm

1 mains cable

1 control cable

Max. cable cross section

Mains supply cable 4.0 mm2/10 AWG

Control cable 1.5 mm2/16 AWG

Serial communication cable 1.5 mm2/16 AWG

For further information see the design guide and/or

PROFIBUS manual.

3. The earth leakage currents are higher than 3.5

mA (approx. 7 mA). This means that the FC motor

requires a fixed, permanent installation as well as

reinforced protective earthing.

■ Warning against unintended start

1. The motor can be brought to a stop by means

of digital commands, bus commands, or

references, while the FC motor is connected to

mains. If personal safety considerations make it

necessary to ensure that no unintended start

occurs,

these stop functions are not sufficient.

2. While parameters are being changed, the motor

may start.

3. A motor that has been stopped may start if

faults occur in the electronics of the FC motor, or if

a temporary overload or a fault in the supply

mains or the motor connection ceases.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Loading...

Loading...