Danfoss VLT FCD 303, VLT FCD 322, VLT FCD 305, VLT FCD 330, VLT FCD 335 Operating Instructions Manual

...Page 1

■ Contents

VLT®FCD Series

Introduction to FCD 300

Software version ...................................................................................................... 3

High voltage warning ............................................................................................... 4

These rules concern your safety ............................................................................... 4

Warning against unintended start ............................................................................. 4

................................................................................ 3

Installation ........................................................................................................... 7

Mechanical measurements ..................................................................................... 7

Mechanical dimensions, FCD, motor mounting ........................................................ 7

Mechanical dimensions, stand alone mounting ........................................................ 7

Mechanical installation ............................................................................................. 8

General information about electrical installation ...................................................... 10

Electronics purchased without installation box ....................................................... 10

EMC-correct electrical installation .......................................................................... 11

Diagram ................................................................................................................. 13

RFI switches J1, J2 ................................................................................................ 13

Location of terminals .............................................................................................. 14

Mains connection ................................................................................................... 16

Pre-fuses ................................................................................................................ 16

Motor connection ................................................................................................... 16

Direction of motor rotation ..................................................................................... 16

Mains and motor connection with service switch ................................................... 16

Connection of HAN 10E motor plug for T73 .......................................................... 16

Parallel connection of motors ................................................................................. 17

Motor cables .......................................................................................................... 17

Motor thermal protection ....................................................................................... 17

Brake resistor ......................................................................................................... 17

Control of mechanical brake .................................................................................. 18

Electrical installation, control cables ....................................................................... 19

Connection of sensors to M12 plugs for T53, T63, T73 ........................................ 20

Electrical installation, control terminals ................................................................... 21

PC communication ................................................................................................ 21

Relay connection ................................................................................................... 21

Connection examples ............................................................................................ 22

Programming, FCD 300 ............................................................................... 26

The LCP 2 control unit, option ............................................................................... 26

Parameter selection ............................................................................................... 29

Operation & Display ............................................................................................... 31

Setup configuration ................................................................................................ 31

Load and Motor ..................................................................................................... 39

DC Braking ............................................................................................................ 43

Motortype, par, 147 - FCD 300 ............................................................................. 48

References & Limits ............................................................................................... 49

Handling of references ........................................................................................... 49

Reference function ................................................................................................. 53

Inputs and outputs ................................................................................................. 57

Special functions .................................................................................................... 66

PID functions ......................................................................................................... 68

Handling of feedback ............................................................................................. 70

Serial communication for FCD 300 ........................................................................ 77

MG.04.B7.02 - VLT is a registered Danfoss trademark

1

Page 2

VLT®FCD Series

Control Word according to FC protocol ................................................................. 81

Status Word according to FC Profile ...................................................................... 83

Fast I/O FC-profile ................................................................................................. 84

Control word according to Fieldbus Profile ............................................................ 84

Status word according to Profidrive protocol ......................................................... 85

Serial communication ............................................................................................. 88

Technical functions ................................................................................................ 96

All about FCD 300 ......................................................................................... 101

Service ................................................................................................................. 101

Warnings/alarm messages ................................................................................... 102

Warning words, extended status words and alarm words ................................... 105

Aggressive environments ...................................................................................... 106

Cleaning ............................................................................................................... 106

Derating for running at low speed ........................................................................ 107

Galvanic isolation (PELV) ...................................................................................... 107

Derating for air pressure ...................................................................................... 108

Emission test results according to generic standards and PDS product standard 108

General technical data ......................................................................................... 109

Ordering form - FCD 300 ..................................................................................... 115

Technical data, mains supply 3 x 380 - 480 V ..................................................... 116

Available literature ............................................................................................... 117

Supplied with the unit ........................................................................................... 117

Factory Settings ................................................................................................... 118

Index .................................................................................................................... 125

2

MG.04.B7.02 - VLT is a registered Danfoss trademark

Page 3

VLT®FCD Series

FCD 300 Series

Operating instructions

Software version: 1.5x

These operating instructions can be used for all FCD 300

Series frequency converters with software version 1.5x.

The software version number can be seen from parameter

640 Software version no.

195NA195.12

300

Introduction to FCD

NB!:

Indicates something to be noted by the reader.

tes a general warning.

Indica

Indicates a high-voltage warning.

MG.04.B7.02 - VLT is a registered Danfoss trademark

3

Page 4

VLT®FCD Series

■High voltage warning

The voltage of the frequency converter

is dangerous whenever the converter

is connected to mains. Incorrect fitting

of the motor or frequency converter may cause

damage to the equipment, serious injury or death.

Consequently, it is essential to comply with the

instructions in this manual as well as local and

national rules and safety regulations.

■These rules concern your safety

1. The frequency converter must be disconnected from

the mains if repair work is to be carried out. Check

that the mains supply has been disconnected

and that the prescribed time has passed before

removing the inverter part from the installation.

2. The [STOP/RESET] key on the optional control

panel does not disconnect the equipment from

mains and is thus not to be used as a safety switch.

3. The unit must be properly connected to the

earth, the user must be protected against the

supply voltage and the motor must be protected

against overloading pursuant to prevailing

national and local regulations.

4. The earth leakage currents are higher than 3.5 mA.

5. Protection against motor overload is not included

in the factory setting. If this function is required,

set parameter 128 Motor thermal protection to

data value ETR trip or data value ETR warning.For

the North American market: The ETR functions

provide overload protection of the motor, class

20, in accordance with NEC.

■Warning against unintended start

1. The motor can be brought to a stop by

means of digital commands, bus commands,

references or a local stop, while the frequency

converter is connected to mains. If personal

safety considerations make it necessary to

ensure that no unintended start occurs, these

stop functions are not sufficient.

2. While parameters are being changed, the

motor may start. Consequently, the stop

key [STOP/RESET] on the optional control

panel must always be activated, following

which data can be modified.

3. A motor that has been stopped may start if faults

occur in the electronics of the frequency converter,

or if a temporary overload or a fault in the supply

mains or the motor connection ceases.

Warning:

It can be extremely dangerous to touch the electrical parts

even when the AC line supply has been disconnected.

For FCD 300: wait at least 4 minutes.

195NA194.10

4

MG.04.B7.02 - VLT is a registered Danfoss trademark

Page 5

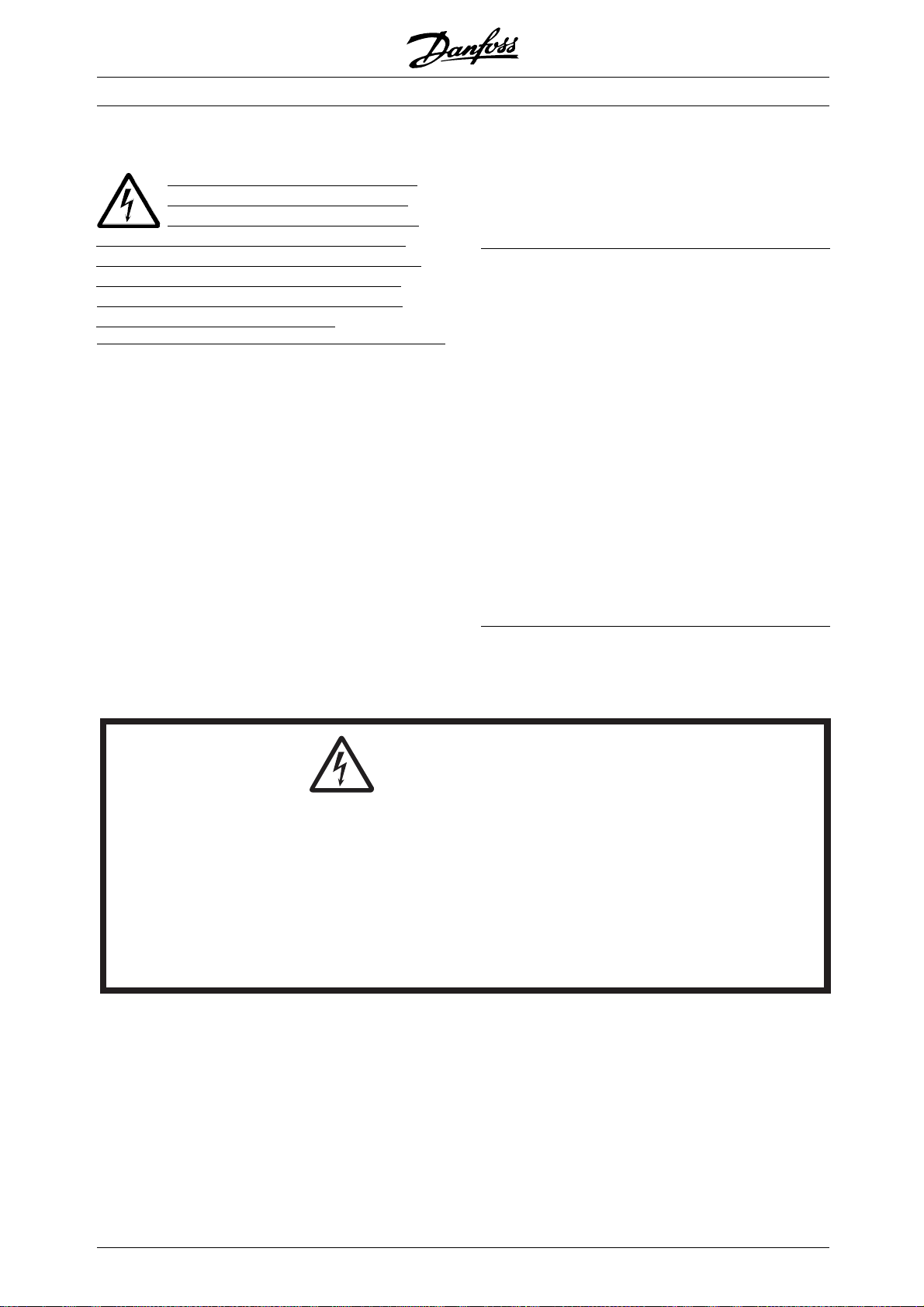

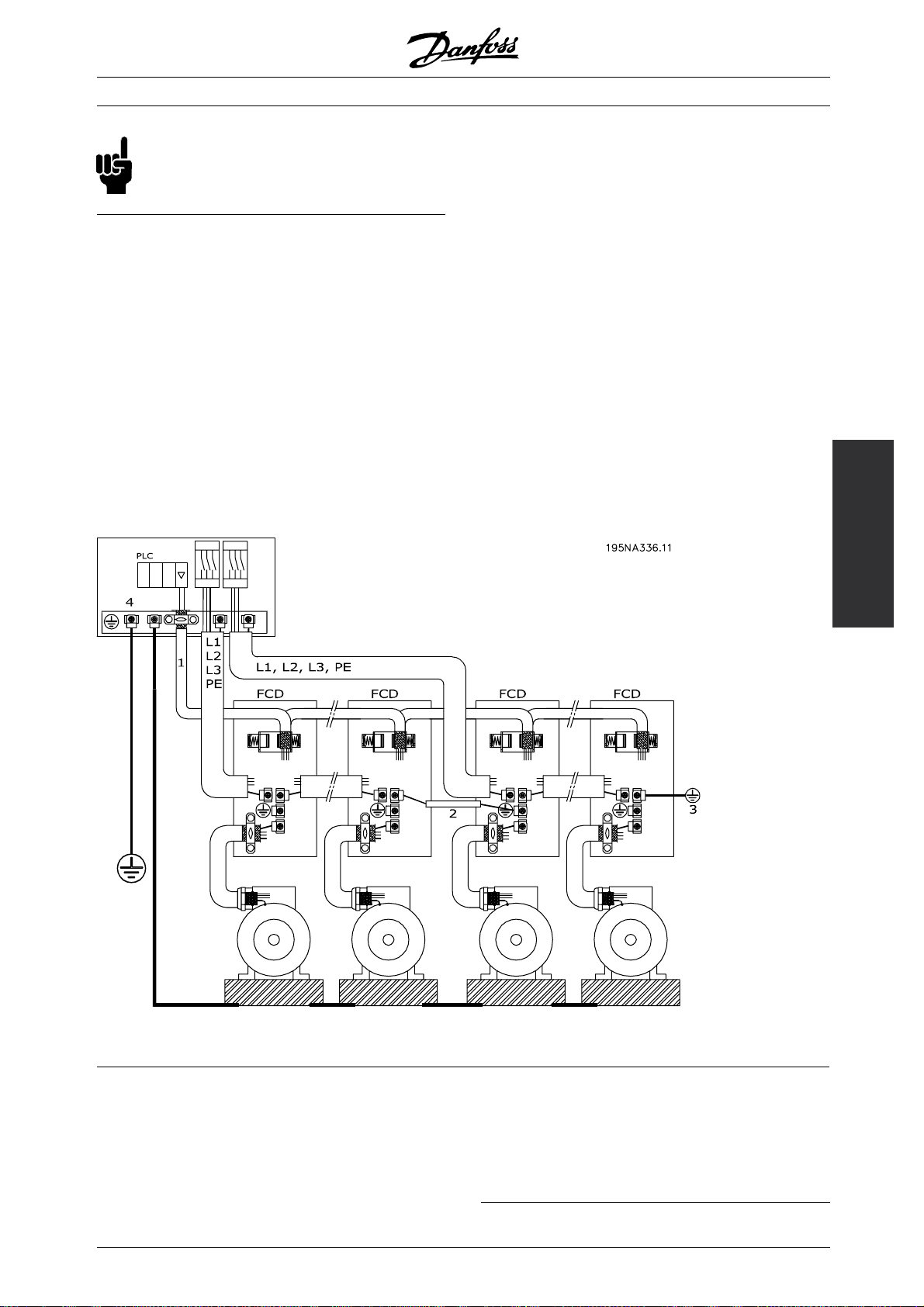

■The decentral concept

The FCD 300 Adjustable speed drive is designed

for decentral mounting, e.g. in the food and

beverage industry, in the automotive industry, or

for other material handling applications.

With the FCD 300 it is possible to utilize the cost saving

potential by placing the power electronics decentrally,

and thus make the central panels obsolete saving

cost, space and effort for installation and wiring.

VLT®FCD Series

2. Mounted directly onthe motor ("motor-mounted")

The unit is flexible in its mounting options for as

well stand alone mounting and motor mounting. It

is also possible to have the unit pre-mounted on

a Danfoss Bauer geared motor (3 in one solution).

Thebasicdesignwithaplugableelectronicpartand

a flexible and "spacious" wiring box is extremely

servicefriendly and easy to change electronics

without the need for unwiring.

The FCD 300 is a part of the VLT frequency converter

family, which means similar funcionality, programming,

and operating as the other family members.

■Flexible installation options

1. Stand alone close to the motor ("wall-mounted")

300

• Fair choice of motor brands

• No need for screened motor cable

Introduction to FCD

3. "Pre-mounted" on Danfoss Bauer

geared motors

• A fixed combination of motor and electronics

supplied by one supplier

• Easy mounting, only one unit

• No need for screened motor cable

• Clear responsibility regarding the complete solution

Astheelectronicpartsarecommon-samefunction

of terminals, similar operation and similar parts

and spare parts for all drives - you are free to

mix the three mounting concepts.

• Free choice of motor brand

• Easy retrofitting to existing motor

• Easy interfacing to motor (short cable)

• Easy access for diagnosis and optimal serviceability

MG.04.B7.02 - VLT is a registered Danfoss trademark

5

Page 6

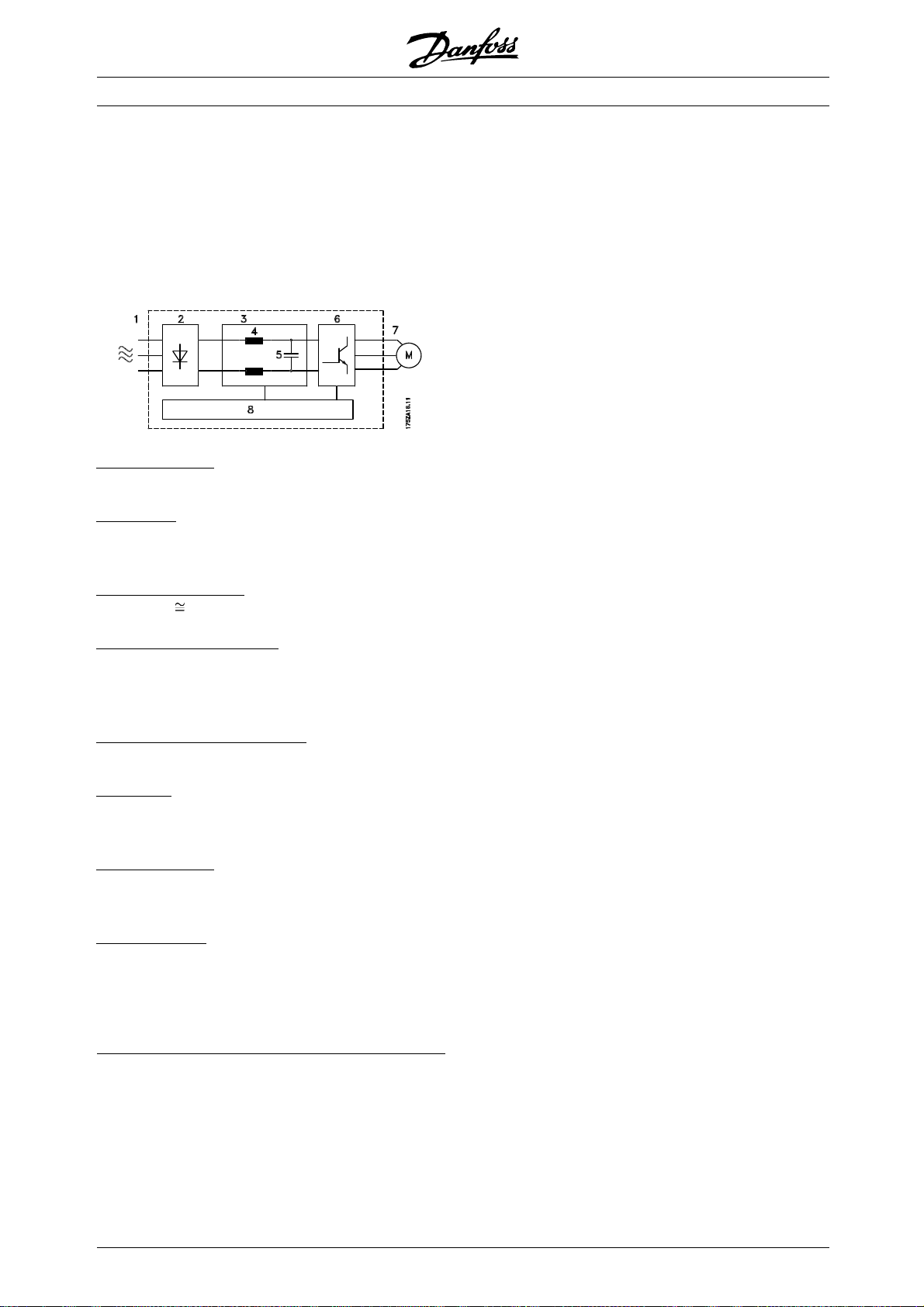

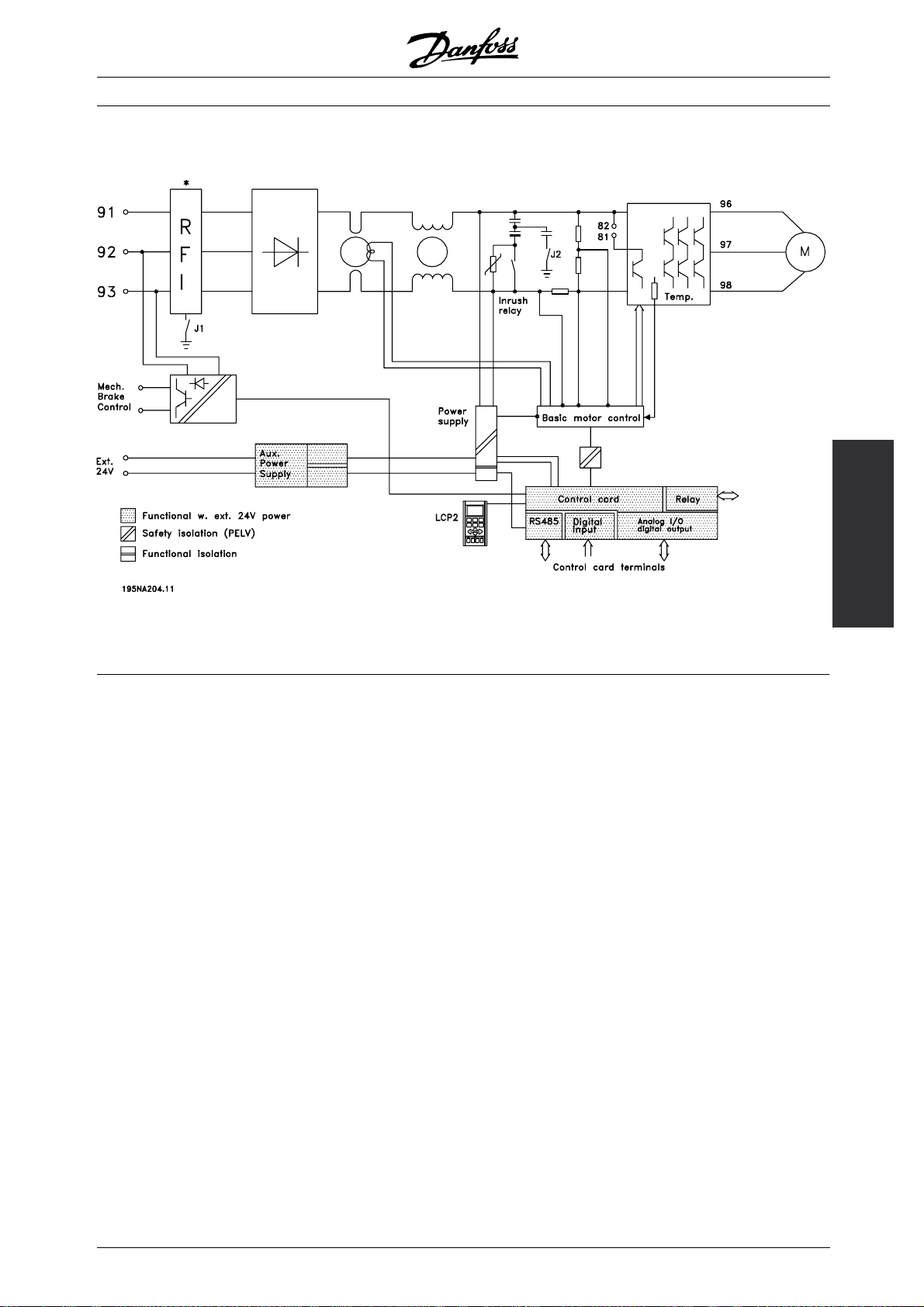

■Control principle

A frequency converter rectifies AC voltage from

the mains supply into DC voltage, following which

it changes this voltage to an AC voltage with

variable amplitude and frequency.

The motor thus receives a variable voltage and

frequency, which enables infinitely variable speed

control of three-phase, standard AC motors.

1. Mains voltage

3 x 380 - 480 V AC, 50 / 60 Hz.

2

. Rectifier

Three-phase rectifier bridge which rectifies AC

voltage into DC voltage.

VLT®FCD Series

3

. Intermediate circuit

DC voltage √2 x mains voltage [V].

4

. Intermediate circuit coils

Evens out the intermediate circuit current and

limits the load on mains and components (mains

transformer, cables, fuses and contactors).

. Intermediate circuit capacitor

5

Evens out the intermediate circuit voltage.

6

. Inverter

Converts DC voltage into a variable AC voltage

withavariablefrequency.

. Motor voltage

7

Variable AC voltage depending on supply voltage.

Variable frequency: 0.2 - 132 / 1 - 1000 Hz.

8

. Control card

Here is the computer that controls the inverter

which generates the pulse pattern by which

the DC voltage is converted into variable AC

voltage with a variable frequency.

6

MG.04.B7.02 - VLT is a registered Danfoss trademark

Page 7

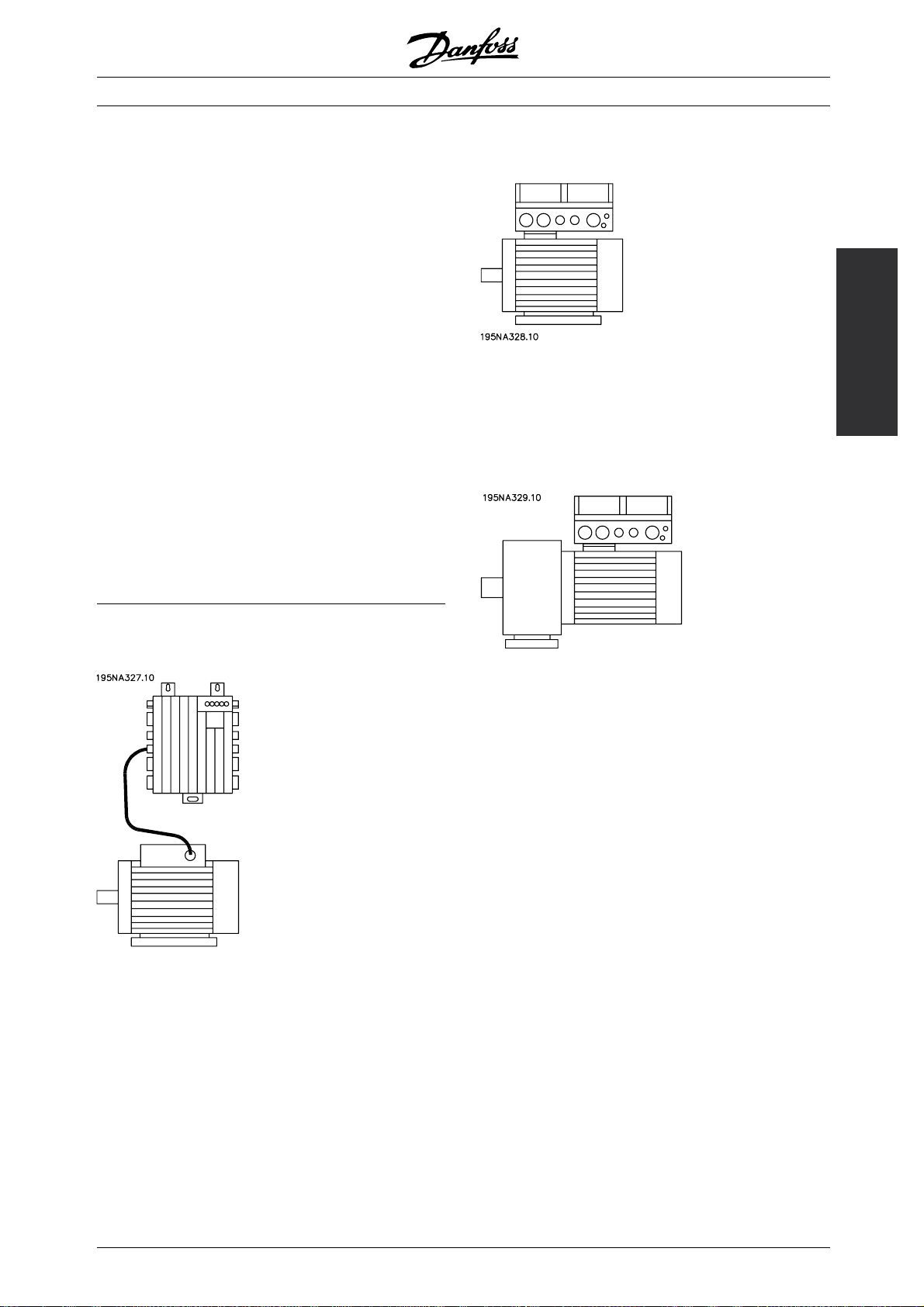

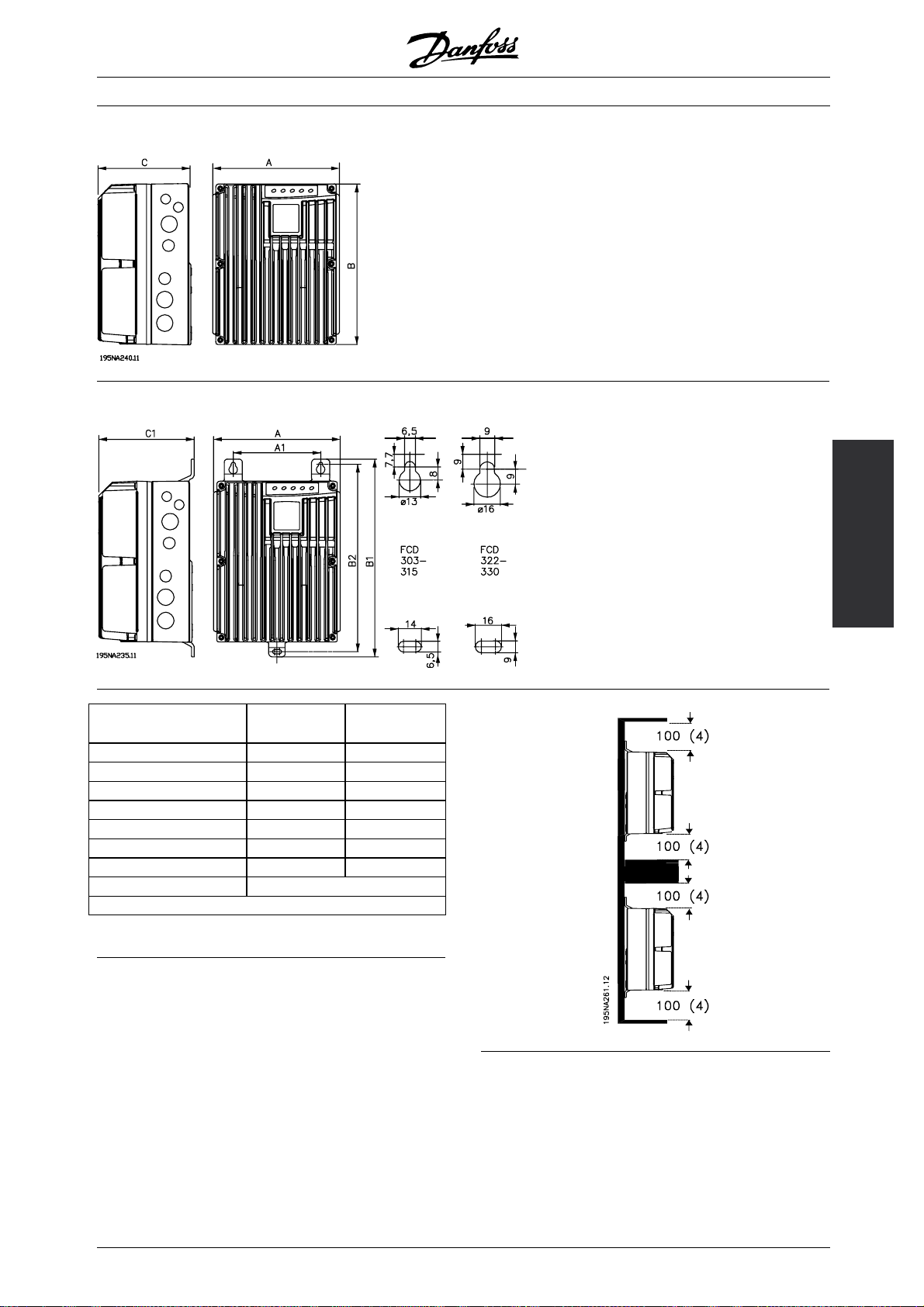

■Mechanical dimensions, FCD, motor mounting

■Mechanical dimensions, stand alone mounting

VLT®FCD Series

Mechanical dimensions inmmFCD 303-315 FCD 322-335

A 192 258

A1 133 170

B 244 300

B1 300 367

B2 284 346

C 142 151

C1 145 154

Cable Gland sizes M16, M20, M25 x 1.5 mm

Space for cable inlets and service switch handle 100-150 mm

■Spacing for mechanical installation

All units require a minimum of 100 mm air from other

components above and below the enclosure.

Installation

MG.04.B7.02 - VLT is a registered Danfoss trademark

7

Page 8

VLT®FCD Series

■Mechanical installation

Please pay attention to the requirements

that apply to integration and remote

mounting. These must be complied

with to avoid serious injury or damage, especially

when installing large units.

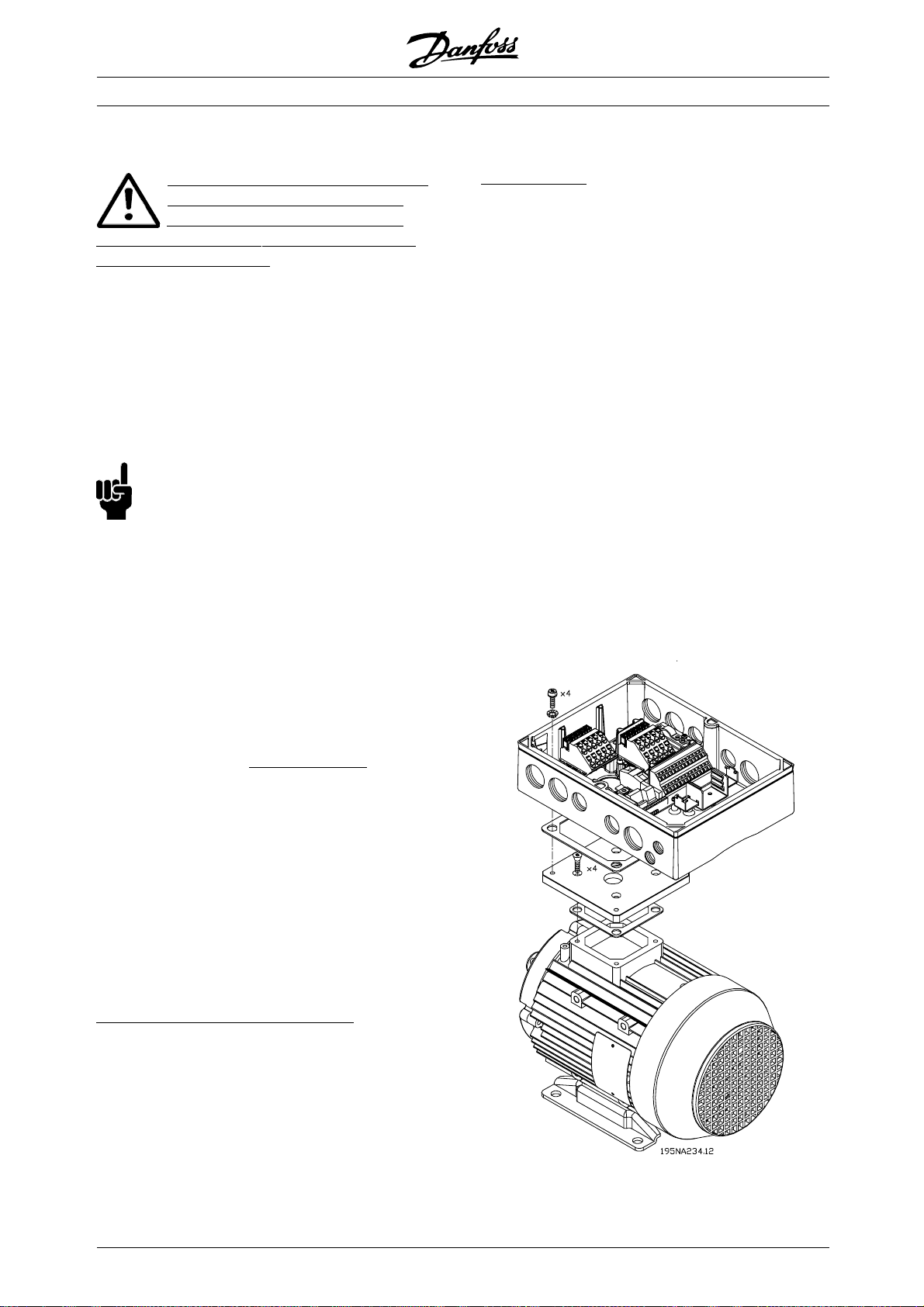

The FCD 300 consists of two parts: The installation

part and the electronics part.

The two parts must be separated, and the installation

part is to be mounted first. After wiring, the electronics

is to be fixed to the installation part by the attached

6 screws. For compressing the gasket the screws

must be tightened with 2-2.4 Nm, tighten both centre

screws first, thereafter the 4 corner srews "cross over".

NB!:

Do not switch on the mains before the

6 screws are tightened.

The FCD 300 can be applied as following:

- Stand alone mounted close to the motor

- Motor mounted

or might be delivered pre mounted on a Danfoss

Bauer (geared) motor. Please contact the Danfoss

Bauer sales organisation for further information.

See Dimensional Drawings.

otor mounting

M

The installation box should be mounted on the

surface of the motor frame, typically instead of the

motor terminal box. The motor/geared motor may

be mounted with the shaft vertically or horizontally.

The unit mustnot be mounted upside down (the heat

sink pointing down). The cooling of the electronics is

independent on the motor cooling fan. For mounting

directly on Danfoss Bauer geared motors no adaption

plate is necessary. For motor mounting (non Danfoss

Bauer motors), an adaptor plate should usually be

applied. For that purpose a neutral plate incl gasket

and screws for attaching to the installation box is

available. The appropriate drillings and gasket for the

motor housing are applied locally. Please make sure,

that the mechanical strength of the mounting screws

and the threads are sufficient for the application. The

specified resistance against mechanical vibrations

does not cover the mounting onto a non Danfoss

Bauer motor, as the stability of the motor frame

and threads are outside Danfoss Drive’s control and

responsibility and the same applies to the enclosure

class. Please be aware, that the frequency converter

may not be used to lift the motor/geared motor.

The frequency converter is cooled by means of air

circulation. For the unit to be able to release its

cooling air, the minimum free distance above and

below the unit must be m

the unit from overheating, it must be ensured that the

ambient temperature does not rise above the max.

temperature stated for the frequency converter and

that the 24-hour average temperature is not exceeded.

The max. temperature and 24-hour average can

be seen in Ge neral technical data. If the ambient

temperature is higher, derating of the frequency

converter is to be carried out. See Derating for

ambient temperature. Pleasenotethattheservicelife

of the frequency converter will be reduced if derating

for ambient temperature is not considered.

tand alone mounting ("wall mounting")

S

For best cooling the unit should be mounted vertically,

however where space limitations require it, horizontal

mounting is allowable. The integrated 3 wall mounting

brackets in the wall mounting version can be used

for fixing the installation box to the mounting surface,

keeping a distance for possible cleaning between

the box and the mounting surface. Use the three

supplied washers to protect the paint.

inimum 100 mm.Toprotect

Bolts must be M6 for the FCD 303 - 315

and M8 for FCD 322 - 335.

8

MG.04.B7.02 - VLT is a registered Danfoss trademark

Page 9

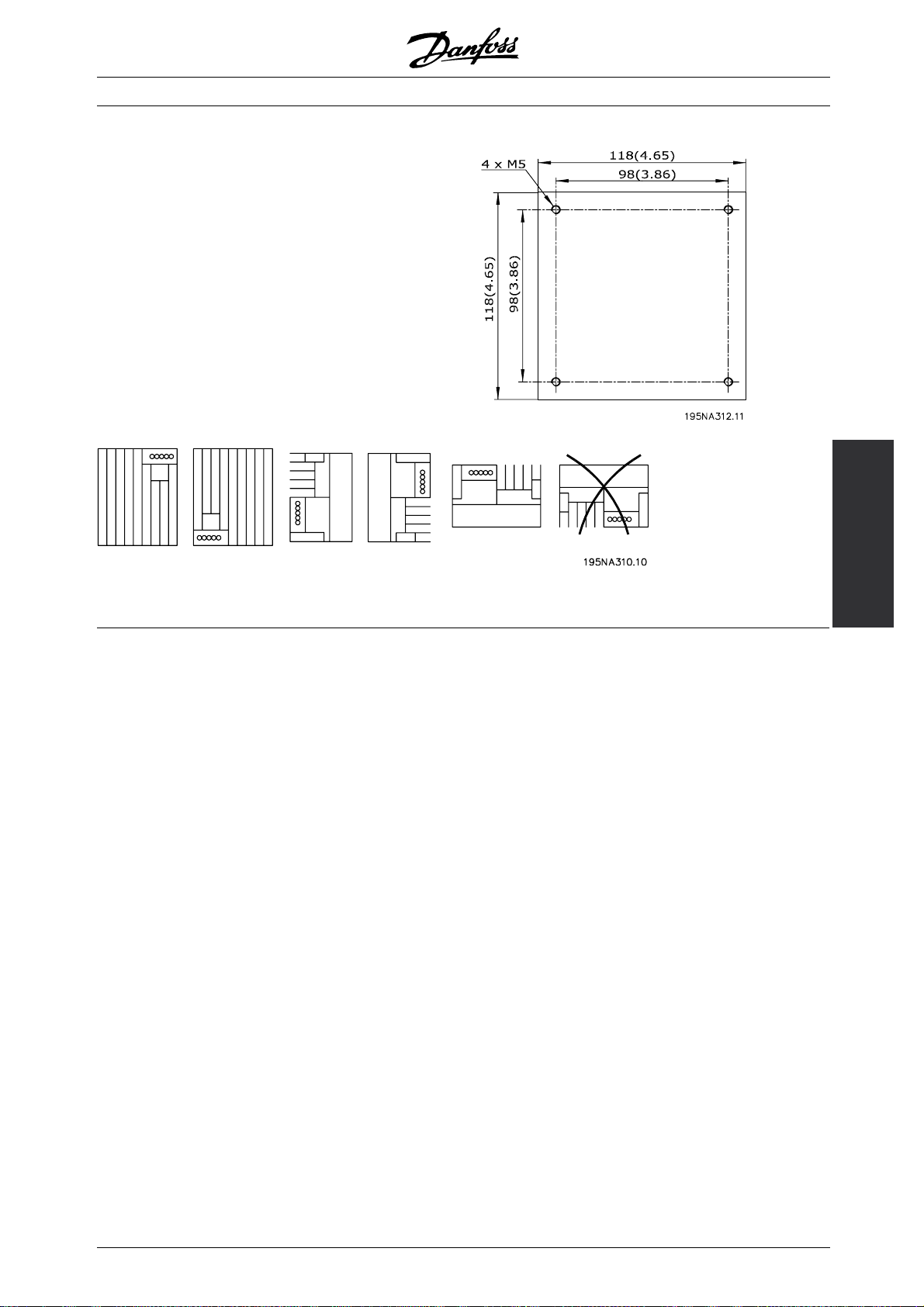

1. Prepare the adaptor plate for mounting on the motor by

drilling the fixing holes and the hole for the cables.

2. Mount the plate on the motor with the normal terminal

box gasket.

3. Knock out the 4 screw holes for mounting the adaptor

plate (outer holes).

4. Mount the terminal box onto the motor by the 4 sealing

screws and the gasket supplied.

Use the supplied star washers for securing PE

connection according to EN 60204. The screws must

be tightened with 5 Nm.

VLT®FCD Series

Universal adaptorplate

Allowed mounting positions

Installation

MG.04.B7.02 - VLT is a registered Danfoss trademark

9

Page 10

VLT®FCD Series

■General information about electrical installation

■High voltage warning

The voltage of the frequency converter

is dangerous whenever the equipment is

connected to mains. Incorrect installation

of the motor or frequency converter may cause

damage to the equipment, serious injury or death.

Comply with the instructions in this manual, as well as

national and local rules and safety regulations.

Touching the electrical parts may be fatal - even after

the equipment has been disconnected from mains:

Wait at least 4 minutes for current dissipate.

NB!:

It is the responsibility of the user or installer

to ensure correct earthing and protection in

accordance with national and local standards.

■Cables

The control cable and the mains cable should be

installed separately from motor cables to prevent

noisetransfer. Asaruleadistanceof20cmis

sufficient, but it is recommended that the distance

is as great as possible, particularly when cables are

installed in parallel over large distances.

For sensitive signal cables such as telephone or data

cables the greatest possible distance is recommended.

Please note that the required distance depends on

installation and the sensitivity of the signal cables, and

that for this reason exact values cannot be given.

■Extra protection

ELCB relays, multiple protective earthing or earthing

can be used as extra protection, provided that local

safety regulations are complied with. In the case of an

earth fault, a DC content may develop in the faulty

current. Never use an RCD (ELCB relay), type A, as

it is not suitable for DC faulty currents. If ELCB relays

are used, local regulations must be complied with.

If ELCB relays are used, they must be:

- Suitable for protecting equipment with a DC content

in the faulty current (3-phase bridge rectifier)

- Suitable for a pulse-shaped, brief discharge

on power-up

- Suitable for a high leakage current.

See also RCD Application Note MN.90.GX.02.

■High voltage test

A high voltage test can be performed by

short-circuitingterminalsU,V,W,L1,L2andL3,

and applying max. 2160 V DC in 1 sec. between

this short-circuit and PE-terminal.

■Electronics purchased without installation box

If the electronic part is purchased without the

Danfoss installation part, the earth connection

the

must be suitable for high leakage current. Use

of original Danfoss installation box or installation

kit 175N2207 is recommended.

When being placed in cable trays, sensitive cables

may not be placed in the same cable tray as t

motor cable. If signal cables run across power

cables, this is done at an angle of 90 degrees.

Remember that all noise-filled inlet

to a cabinet must be screened/armoured.

See also EMC-compliant electrical installation.

Cable glands

It must be assured that appropriat

glands needed for the environment are chosen

and carefully mounted.

■Screened/armoured cables

The screen must have low HF impe

achieved by a braided screen of copper, aluminium or

iron. Screen reinforcement intended for mechanical

protection, for example, is

installation. See also Use of EMC-correct cables.

10

not suitable for EMC-correct

and outlet cables

e cable

dance, which is

he

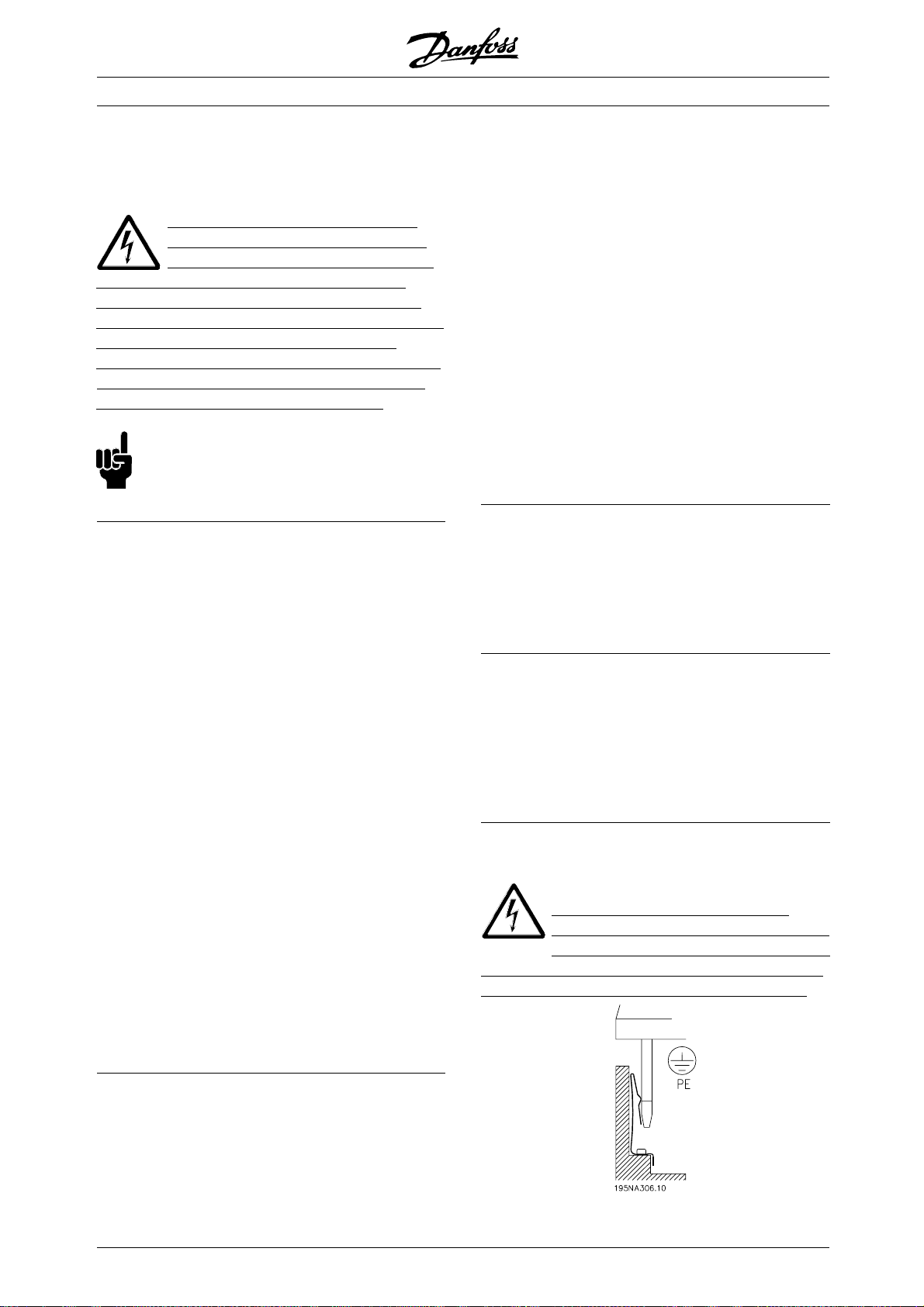

■Caution

PE connection

he metal pin in the corner(s) of the

T

electronic part and the bronze spring in the

corner(s) of the installation box are essential

for the protective earth connection. Mak

are not loosened, removed, or violated in any way.

MG.04.B7.02 - VLT is a registered Danfoss trademark

e sure they

Page 11

VLT®FCD Series

NB!:

Do not plug/unplug the electronic part with

mains voltage switched on.

■Protective earth

The earth connection serves several purposes.

• Safety earth (Protective earth, PE)

The equipment must be properly earthed according

to local regulation. This equipment has a leakage

current > 3.5 mA AC. It must be connected to

an earth connection complying with the local

rules for high leakage current equipment.

Typically, this implies that the PE conductors

must be mechanically enhanced (minimum cross

2

section 10 mm

) or duplicated

• Noise "clamping" (high frequencies)

Stable communication between units call for

screening of the communication cables (1).

Cables must be properly attached to screen

clamps provided for that purpose.

• Equalisation of voltage potential (low frequencies)

To reduce alignment currents in the screen

of the communication cable, always apply a

short earthing cable between units that are

connected to the same communication cable (2)

or connect to an earthed frame (3).

• Potential equalization: All metal parts, where the

motors are fastened, must be potential equalized

PE connections, voltage equalising cables and the

screen of the communication cable should be

connected to the same potential (4).

Keep the conductor as short as possible and use

the greatest possible surface area.

The numbering refers to the figure.

Installation

Proper installation earthing

■EMC-correct electrical installation

General points to be observed to ensure

EMC-correct electrical installation.

- Use only screened/armoured motor cables and

screened/armoured control cables.

- Connect the screen to earth at both ends.

MG.04.B7.02 - VLT is a registered Danfoss trademark

- Avoid installation with twisted screen ends (pigtails),

since this ruins the screening effect at high

frequencies. Use cable clamps instead.

-Don’t remove the cable screen between the

cable clamp and the terminal.

11

Page 12

■ATEX correct installation

The following issues must be taken into account when

installing the FCD 300 in ATEX zone 22 environments:

• Motor must be designed, tested and certified by the

motor manufacturer for variable speed application

• Motor must be designed for Zone 22 operation.

I.e. with type of protection "tD" acc. to

EN61241-0 and -1 or EN50281-1-1.

• Motor must be provided with thermistor protection.

The thermistor protection must either be connected

to an external thermistor relay, with EC Type

Examination Certificate or compatible with

the FCD 300 thermistor input.

If the FCD 300 thermistor protection is used,

the thermistor must be wired to terminals

31a and 31b, and thermistor trip activated by

programming parameter 128 to thermistor trip

[2]. See parameter 128 for further details.

• Cable entries must be chosen for the enclosure

protection to be maintained. It must also be

ensured that the cable entries comply with the

requirements for clamping force and mechanical

strengths as described in EN 50014:2000.

• The FCD must be installed with appropriate earth

connecting according to local/national regulations.

• The installation, inspection and maintenance of

electrical apparatus for use in combustible dusts,

must only be carried out by personnel that is

trained and familiar with the concept of protection.

VLT®FCD Series

For a declaration of conformity, please consult

your local Danfoss representative.

12

MG.04.B7.02 - VLT is a registered Danfoss trademark

Page 13

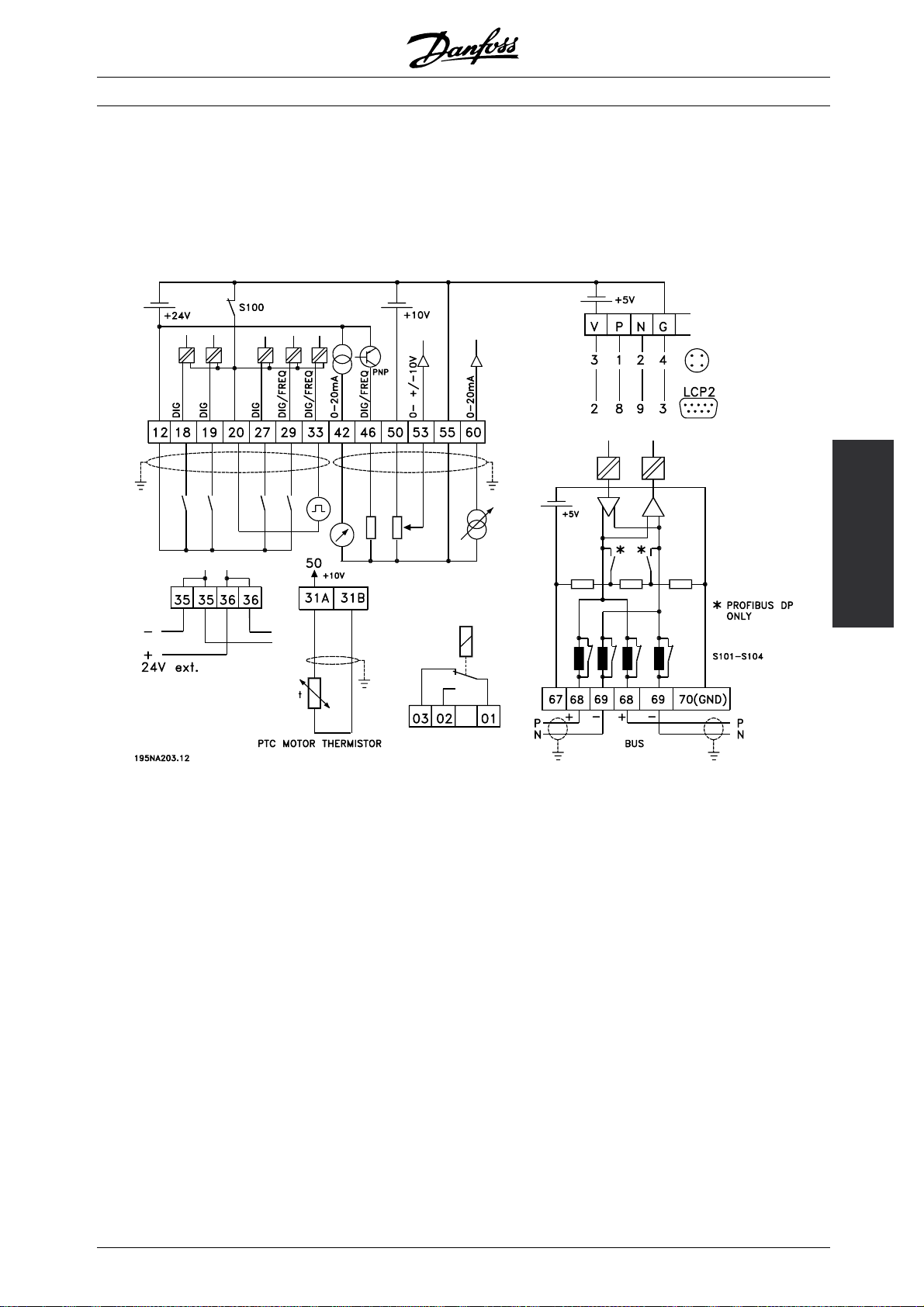

■Diagram

VLT®FCD Series

* Integrated brake and mechanical brake control

and external 24 V are options.

■RFI switches J1, J2

J1 and J2 must be removed at IT mains and

delta grounded mains with phase to earth voltage

> 300 V also during earth failure.

J1 and J2 can be removed to reduce leakage current.

Caution: No correct RFI filtering.

Installation

MG.04.B7.02 - VLT is a registered Danfoss trademark

13

Page 14

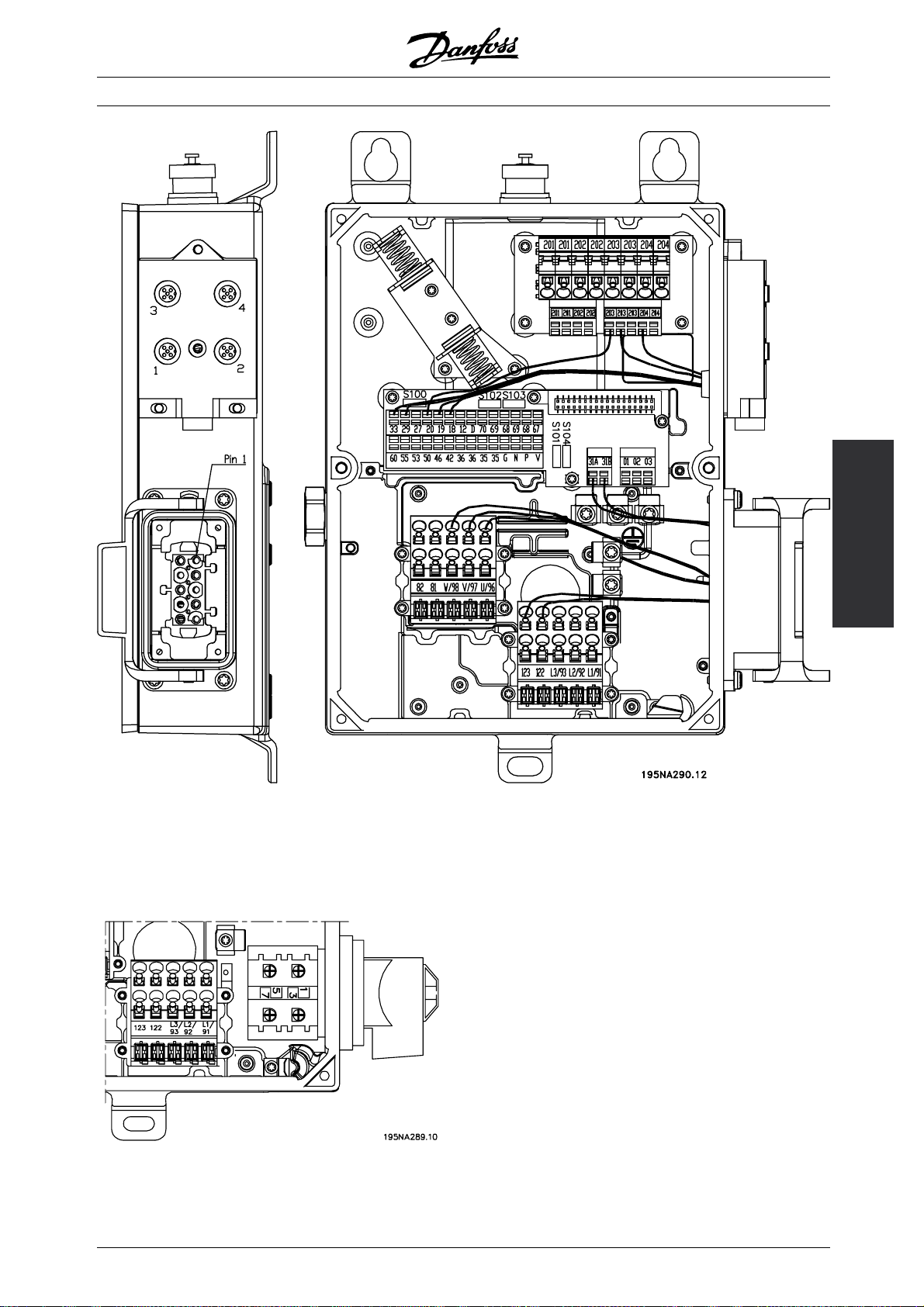

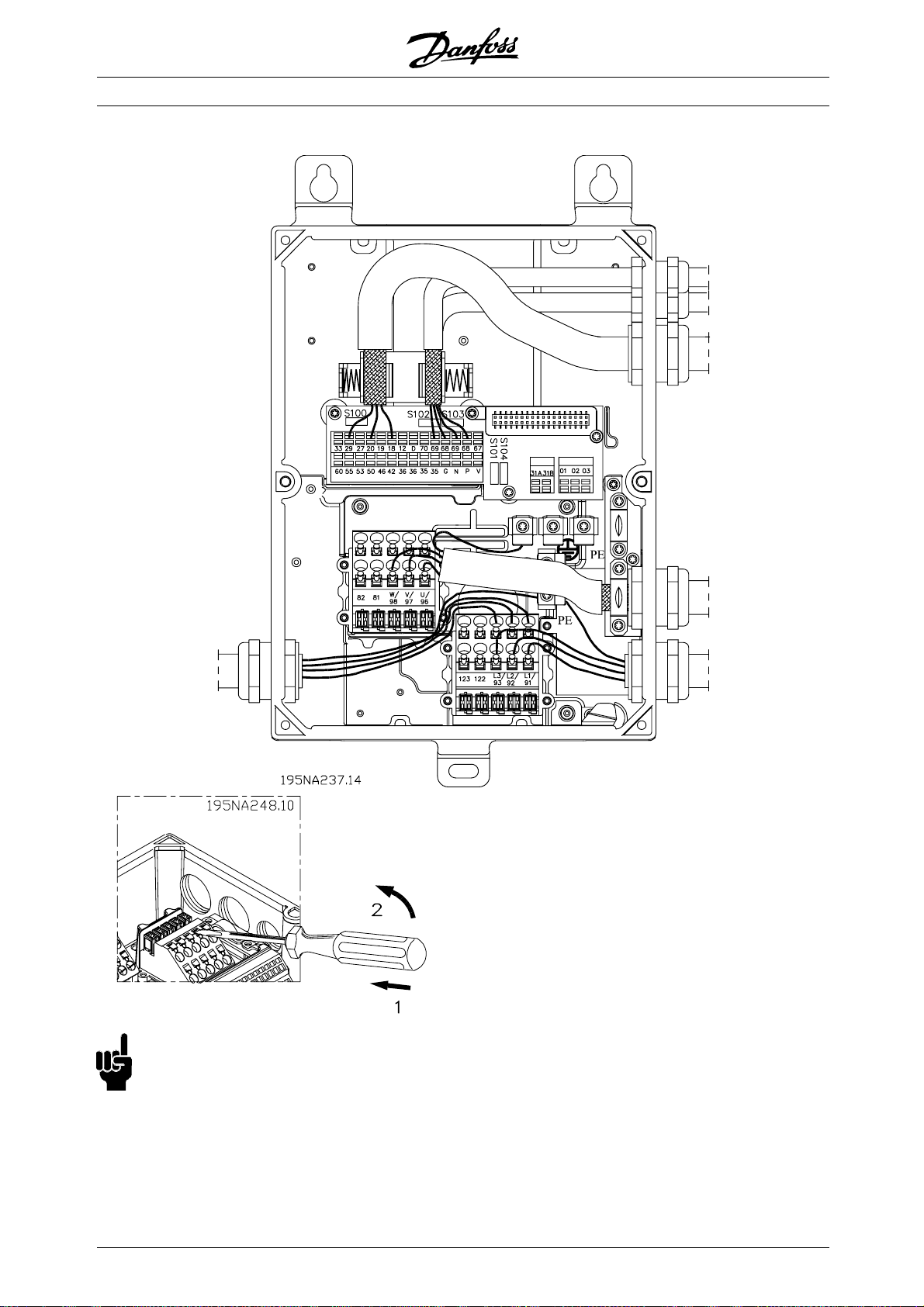

■Location of terminals

VLT®FCD Series

T11, T12, T16, T52, T56

T22, T26, T62, T66versions with service switch

14

MG.04.B7.02 - VLT is a registered Danfoss trademark

Page 15

VLT®FCD Series

T73 version with motor plug and sensor plugs

Version is supplied from Danfoss with wiring as shown

Installation

versionwithserviceswitch(nomotorplug)

T63

MG.04.B7.02 - VLT is a registered Danfoss trademark

15

Page 16

VLT®FCD Series

■Mains connection

No. 91 92 93 Mains voltage 3 x 380-480 V

L1 L2 L3

PE Earth connection

NB!:

Please check that the mains voltage fits the

mains voltage of the frequency converter, which

can be seen from the nameplate.

See Technical data for correct dimensioning

of cable cross-section.

■Pre-fuses

See Technical data for correct dimensioning

of pre-fuses.

■Motor connection

Connect the motor to terminal

s 96, 97, 98.

Connect earth to PE-terminal.

No. 96 97 98 Motor voltage 0-100% of mains voltage

UVW3 wires out of motor

U1W2V1U2W1V26 wires out of motor, Delta connected

■Direction of motor rotation

The factory setting is for clockwise rotation

with the frequency converter transformer output

connected as follows:

Terminal 96 connected to U-phase.

Terminal 97 connected to V-phase.

Terminal 98 connected to W-phase.

The direction of rotation can be changed by switching

two phases on the motor terminals.

U1 V1 W1 6 wires out of motor, Star connected

U2, V2, W2 to be interconnected

separately (optional terminal block)

PE Earth connection

See Technical data for correct dimensioning

of cable cross-section.

All types of three-phase asynchronous standard

motors can be connected to a frequency converter.

Normally, small motors are star-connected (230/400

/ Y). Large motors are delta-connected (400/690

V,

/ Y). The correct connection mode and voltage

V,

can be read from the motor nameplate.

NB!:

In motors without phase insulation paper,

an LC filter should be fitted on the output

of the frequency converter.

■Mains and motor connection with service switch

16

MG.04.B7.02 - VLT is a registered Danfoss trademark

Page 17

VLT®FCD Series

■Connection of HAN 10E motor plug for T73

HAN 10E pin no 1 - Motor phase U

HAN 10E pin no 2 - Motor phase V

HAN 10E pin no 3 - Motor phase W

HAN 10E pin no 4 - Motor brake, see Operating

Instructions MG.04.BX.YY, terminal 122

HAN 10E pin no 5 - Motor brake, see Operating

Instructions MG.04.BX.YY, terminal 123

HAN 10E pin no 9 - Motor thermistor, see Operating

Instructions MG .04.BX.YY, terminal 31A

HAN 10E pin no 10 - Motor thermistor, see

Operating Instructions MG.04.BX.YY, terminal 31B

PE = protective earth

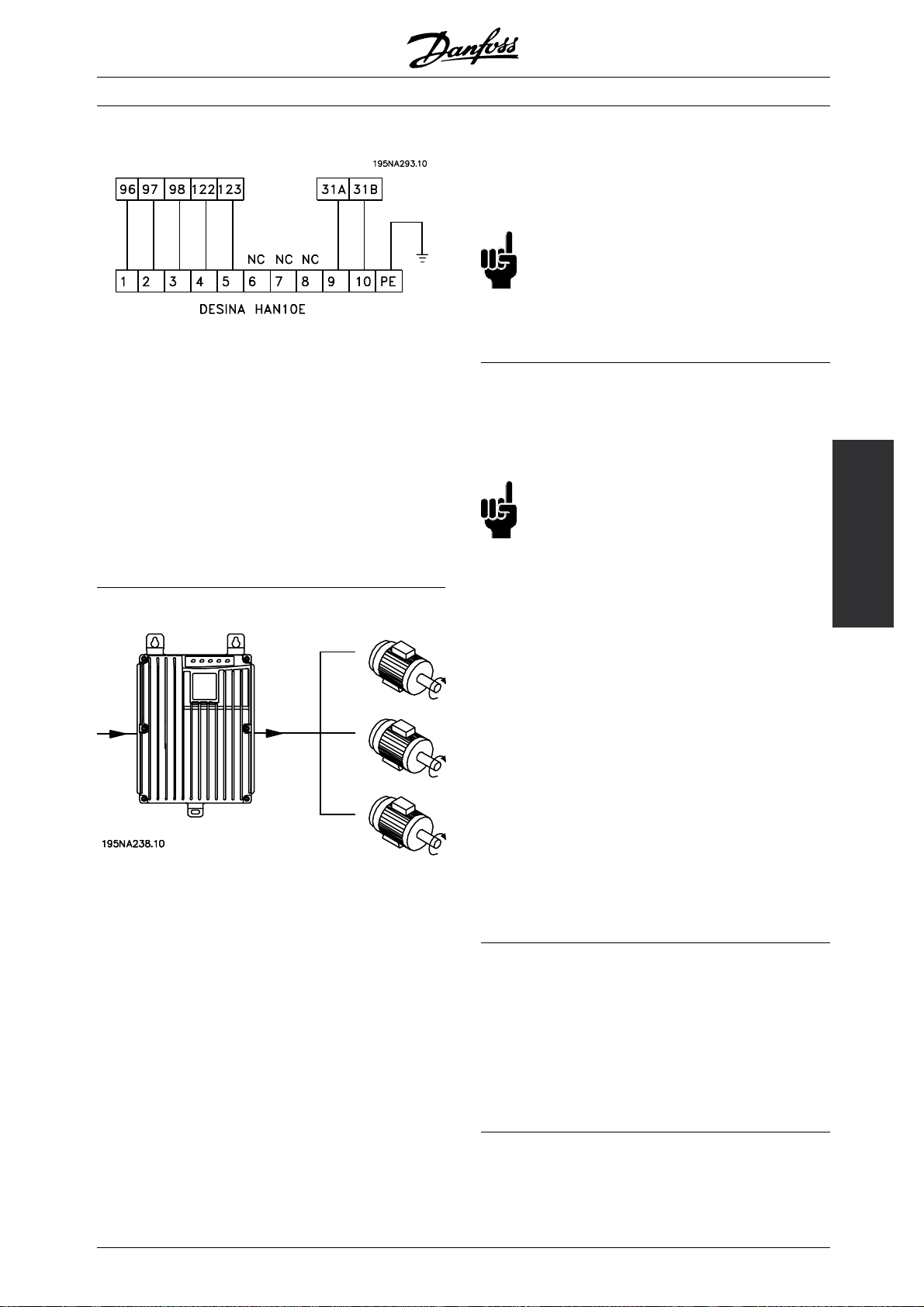

■Parallel connection of motors

The frequency converter is able to control several

motors connected in parallel. If the motors are

to have different rpm values, use motors with

different rated rpm values. Motor rpm is changed

simultaneously, which means that the ratio between

the rated rpm values is maintained across the range.

The total current consumption of the motors is

not to exceed the maximum rated output current

for the frequency converter.

I

INV

Problems may arise at the start and at low rpm

values if the motor sizes are widely different. This

is because the small motors’ relatively high ohmic

resistance in the stator calls for a higher voltage

at the start and at low rpm values.

converter cannot be used as motor protection for

the individual motor. For this reason further motor

protection must be used, e.g. thermistors in each

motor (or an individual thermal relay).

NB!:

Parameter 107 Automatic motor tuning, AMT

cannot be used when motors are connected

in parallel. Parameter 101 Torque characteristic

must be set to Special motor characteristics [8]

when motors are connected in parallel.

■Motor cables

See Technical data for correct dimensioning of motor

cable cross-section and length. Always comply with

national and local regulations on cable cross-section.

NB!:

If an unscreened/unarmoured cable is used,

some EMC requirements are not complied with,

see EMC test results in the Design Guide.

If the EMC specifications regarding emission are

to be complied with, the motor cable must be

screened/armoured, unless otherwise stated for the

RFI filter in question. It is important to keep the motor

cable as short as possible so as to reduce the noise

level and leakage currents to a minimum. The motor

cable screen must be connected to the metal cabinet

of the frequency converter and to the metal cabinet of

the motor. The screen connections are to be made

with the biggest possible surface area (cable clamp).

This is enabled by different installation devices in

different frequency converters. Mounting with twisted

screen ends (pigtails) is to be avoided, since these

spoil the screening effect at high frequencies. If it

is necessary to break the screen to install a motor

isolator or motor relay, the screen must be continued

at the lowest possible HF impedance.

■Motor thermal protection

The electronic thermal relay in UL-approved frequency

converters has received the UL-approval for single

motor protection, when parameter 128 Motor thermal

protection has been set for ETR Trip and parameter

105 Motor current, I

has been programmed to

M, N

the rated motor current (see motor nameplate).

Installation

In systems with motors connected in parallel, the

electronic thermal relay (ETR) of the frequency

MG.04.B7.02 - VLT is a registered Danfoss trademark

17

Page 18

■Brake resistor

VLT®FCD Series

No. 81 (optional

function)

R- R+

82 (optional

function)

Brake resistor

terminals

The connection cable to the brake resistor must

be screened/armoured. Connect the screen to the

metal cabinet of the frequency conver

ter and to the

metal cabinet of the brake resistor by means of

cable clamps. Dimension the cross-section of the

brake cable to match the brake to

See chapter Dynamic Brak

ing in the Design Guide

rque.

MG.90.FX.YY for dimensionering of brake resistors.

NB!:

Please note that voltages up to 850 V

DC occur on the te

rminals.

■Control of mechanical brake

No. 122 (optional

function)

MBR+ MBR- Mechanical brake

123

(optional

function)

(UDC=0.45 X Mains

Voltage) Max 0.8 A

In lifting/lowering applications you need to be able

to control an electromagnetic brake. The brake

is controlled using the special mechanical brake

control/supply terminals 122/123.

When the output frequency exceeds the brake cut

out value set in par. 138, the brake is released if the

motor current exceeds the preset value in parameter

140. When stopping the brake is engaged when

the output frequency is less than the brake engaging

frequency, which is set in par. 139.

If the frequency converter is at alarm status

or in an overvoltage situation the mechanical

brake is cut in immediately.

If not using the special mechanical brake control/supply

terminals (122-123), select Mechanical brake control

in parameter 323 or 341 for applications with

an electromagnetic brake.

A relay output or digital output (terminal 46)

can be used. See Connection of mechanical

brake for further details.

18

MG.04.B7.02 - VLT is a registered Danfoss trademark

Page 19

VLT®FCD Series

■Electrical installation, control cables

Control cables must be screened/armoured. The

screen must be connected to the frequency converter

chassis by means of a clamp. Normally, the screen

must also be connected to the chassis of the

controlling unit (use the instructions for the unit in

question). In connection with very long control cables

and analogue signals, in rare cases depending on

the installation, 50/60 Hz earth loops may occur

because of noise transmitted from mains supply

cables. In this connection, it may be necessary

to break the screen and possibly insert a 100 nF

capacitor between the screen and the chassis.

Installation

Switches S101-104

Bus line coils, leave switches ON

MG.04.B7.02 - VLT is a registered Danfoss trademark

19

Page 20

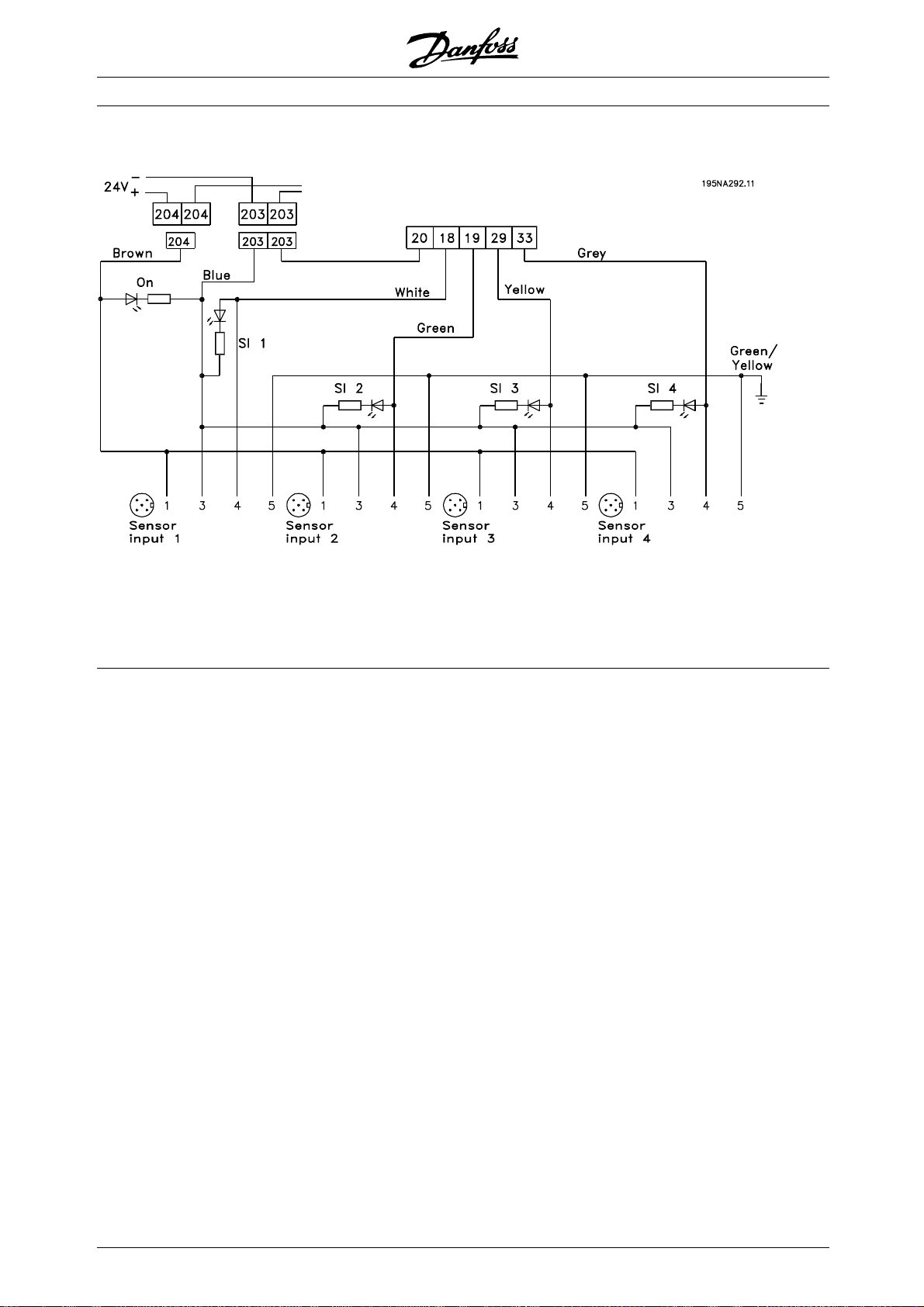

■Connection of sensors to M12 plugs for

T53, T63, T73

VLT®FCD Series

For rating specifications see the Operating Instructions

MG.04.BX.YY, digital inputs terminals 18, 19, 29, 33.

Terminals 203/204 are used for sensor supply.

Terminal 203 = common

Terminal 204 = +24 V

Terminals 201/202 can be used for a

separate 24 V supply.

20

MG.04.B7.02 - VLT is a registered Danfoss trademark

Page 21

VLT®FCD Series

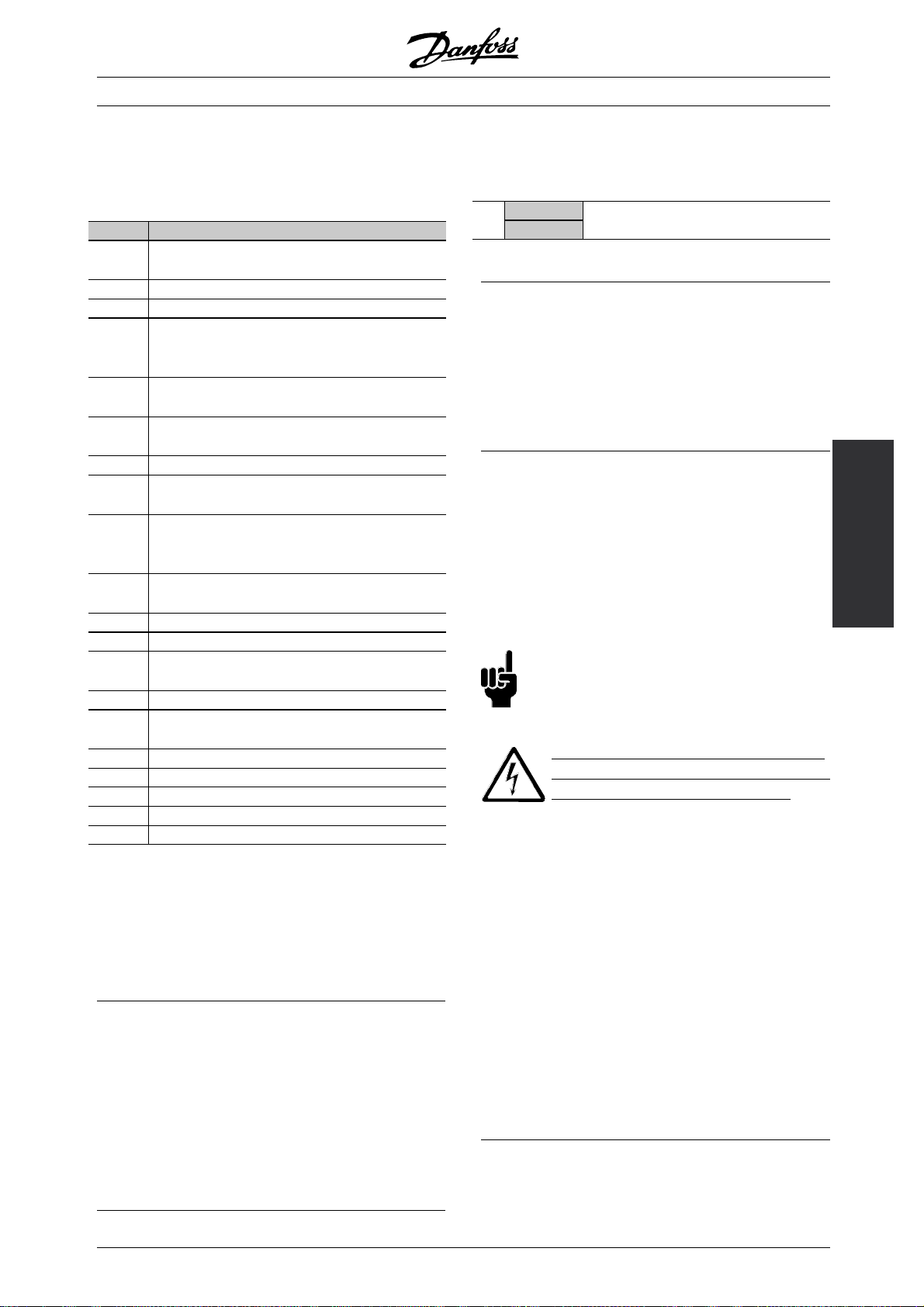

■Electrical installation, control terminals

See section entitled Earthing of screened/armoured

control cables in the Design Guide for the correct

termination of control cables.

No. Function

01-03 Relay outputs 01-03 can be used for

indicating status and alarms/warnings.

12 24 V DC voltage supply.

18-33 Digital inputs.

20, 55 Common frame for input

and output terminals. Can be separated with switch

S100

31a,

31b

35 Common (-) for external 24 V control back up

36 External + 24 V control back up supply. Optional.

42 Analog output for displaying frequency,

46 Digital output for displaying status,

50 +10 V DC supply

53 Analogue voltage input 0 - +/- 10 V DC.

60 Analogue current input 0/4 - 20 mA.

67 + 5 V DC supply voltage

68, 69 Fieldbus serial communication*

70 Ground for terminals 67, 68 and 69.

D For future use

V +5V, red

P RS485(+), LCP2/PC, yellow

N RS485(-), LCP2/PC, green

G OV, blue

*SeeVLT 2800/FCM 300/

Motor thermistor

supply. Optional.

reference, current or torque.

warnings or alarms, as well as

frequency output.

voltage for potentiometer

to Profibus.

Normally this terminal is not to be used.

FCD 300 Profibus DP

V1 Operating Instructions (MG.90.AX.YY), VLT

2800/FCD 300 DeviceNet Operating Instructions

(MG.90.BX.YY) or FC

D 300 AS-interface Operating

Instructions (MG.04.EX.YY).

■Relay connection

See parameter 323 Relay output for programming

of relay output.

No. 01 - 02 1 - 2 make (normally open)

01 - 03 1-3break(normallyclosed)

■LCP 2 plug, optional

An LCP 2 control unit can be connected to a

plug which is optionally mounted in the housing.

Ordering number: 175N0131.

LCP control units with ordering number 175Z0401

are not to be connected.

■Installation of 24 Volt external supply (optional)

24 V external DC supply can be use

d as low-voltage

supply to the control card. This enables full

operation of the LCP2 and serial bus (incl. parameter

setting) without connecti

on to mains.

Please note that a warning of low voltage will

be given when 24 V DC has been connected;

however there will be n

o tripping.

NB!:

Use24VDCsupplyoftypePELVtoensure

correct galvanic isolation (type PELV) on the

control terminal

Beware of unin

s of the VLT frequency converter.

tended start of the motor, if

the mains power is applied during operation

on the external 24 V back up supply.

■Software version 1.5x

A Field bus equipped FCD shows the status Unit

ready even with bridged terminals 12-27 and cannot

be set into RUNNING mode by digital inputs alone

until one of the following parameters is set:

- Par. 502 is set to Digital input or Logic and or

- Par. 833 or 928 is set to Disable or

- Par. 678 is set to Standard version

Installation

■PC communication

Connect to terminals P and N for PC-access to single

parameters. Mot

or and field bus communication

should be stopped before performing automatic

transfer of multiple parameters.

On non-fieldb

us and Profibus variants, terminals

68 and 69 can be used provided Profibus

communication is stopped.

MG.04.B7.02 - VLT is a registered Danfoss trademark

The field bus status word at power up might be

different (typically 0603h instead of 0607h) until the

first valid control word is sent. After sending the first

valid control word (bit 10 = Data valid) the status

is exactly as in earlier software versions.

21

Page 22

■Connection examples

VLT®FCD Series

NB!:

Avoid leading the cables over the plugs

to the electronics.

Dont loosen screw fixing the spring

for the PE connection.

22

MG.04.B7.02 - VLT is a registered Danfoss trademark

Page 23

NB!:

In the connection examples below, it should

be noted, that the Switch S100 must not be

changed from factory settings (on).

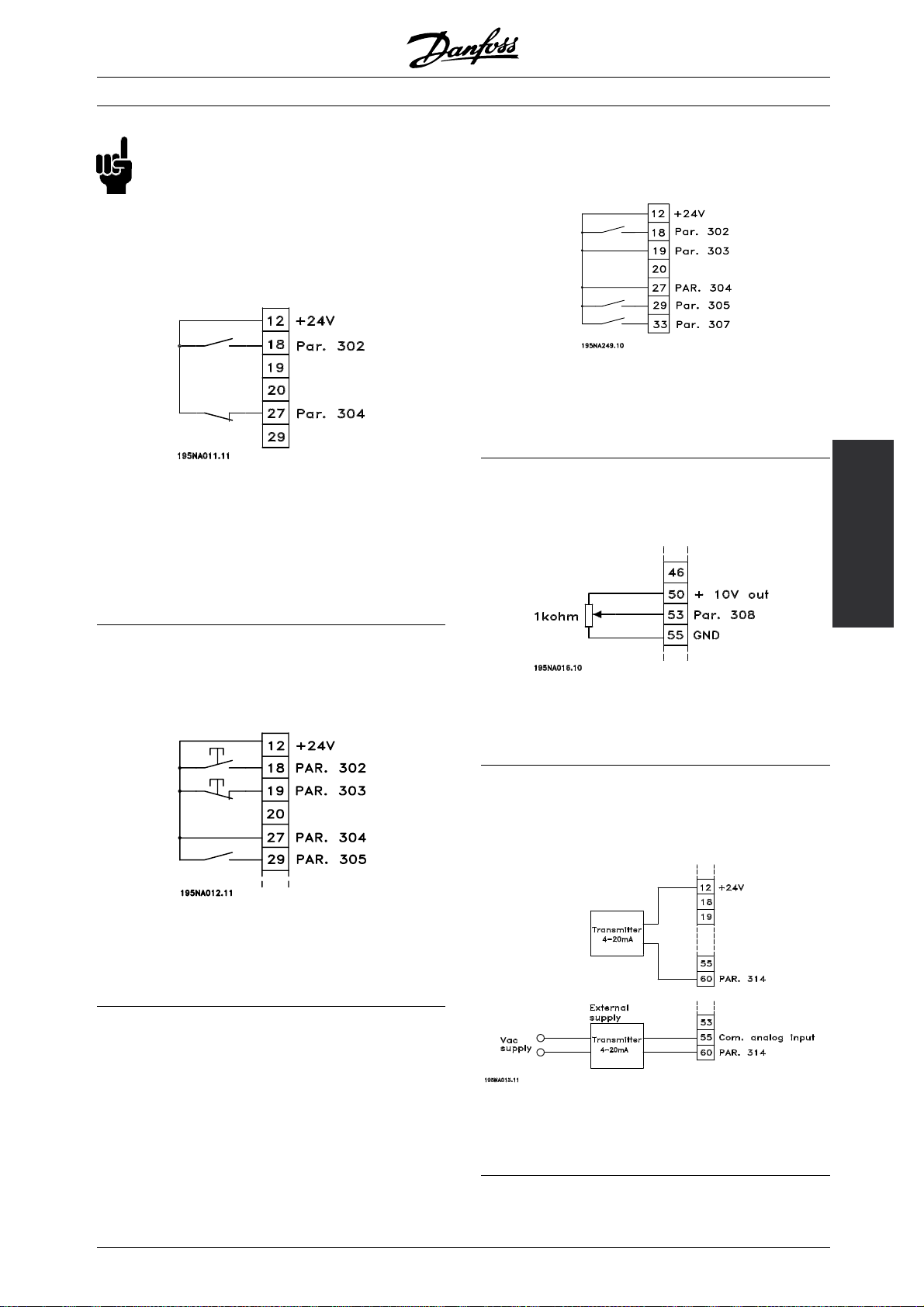

■Start/stop

Start/stop using terminal 18 and coasting

stop using terminal 27.

VLT®FCD Series

■Speed up/down

Speed up/down using terminals 29/33.

Par. 302 Digital input = Start [7]

Par. 303 Digital input = Freeze reference [14]

Par. 305 Digital input = Speed up [16]

Par. 307 Digital input = Speed down [17]

Par. 302 Digital input = Start [7]

Par. 304 Digital input = Coasting stop inverted [2]

For Precise start/stop the following settings are made:

Par. 302 Digital input = Precise start/stop [27]

Par. 304 Digital input = Coasting stop inverted [2]

■Pulse start/stop

Pulse start using terminal 18 and pulse stop

using terminal 19. In addition, the jog frequency

is activated via terminal 29.

Par. 302 Digital input = Pulse start [8]

Par. 303 Digital input = Stop inverted [6]

Par. 304 Digital input = Coasting stop inverted [2]

Par. 305 Digital input = Jog [13]

■Potentiometer reference

Voltage reference via a potentiometer.

Installation

Par. 308 Analog input = Reference [1]

Par. 309 Terminal 53, min. scaling =0Volt

Par. 310 Terminal 53, max. scaling =10Volt

■Connection of a 2-wire transmitter

Connection of a 2-wire transmitter as feedback

to terminal 60.

MG.04.B7.02 - VLT is a registered Danfoss trademark

Par. 314 Analog input = Feedback [2]

Par. 315 Terminal 60, min. scaling =4mA

Par. 316 Terminal 60, max. scaling =20mA

23

Page 24

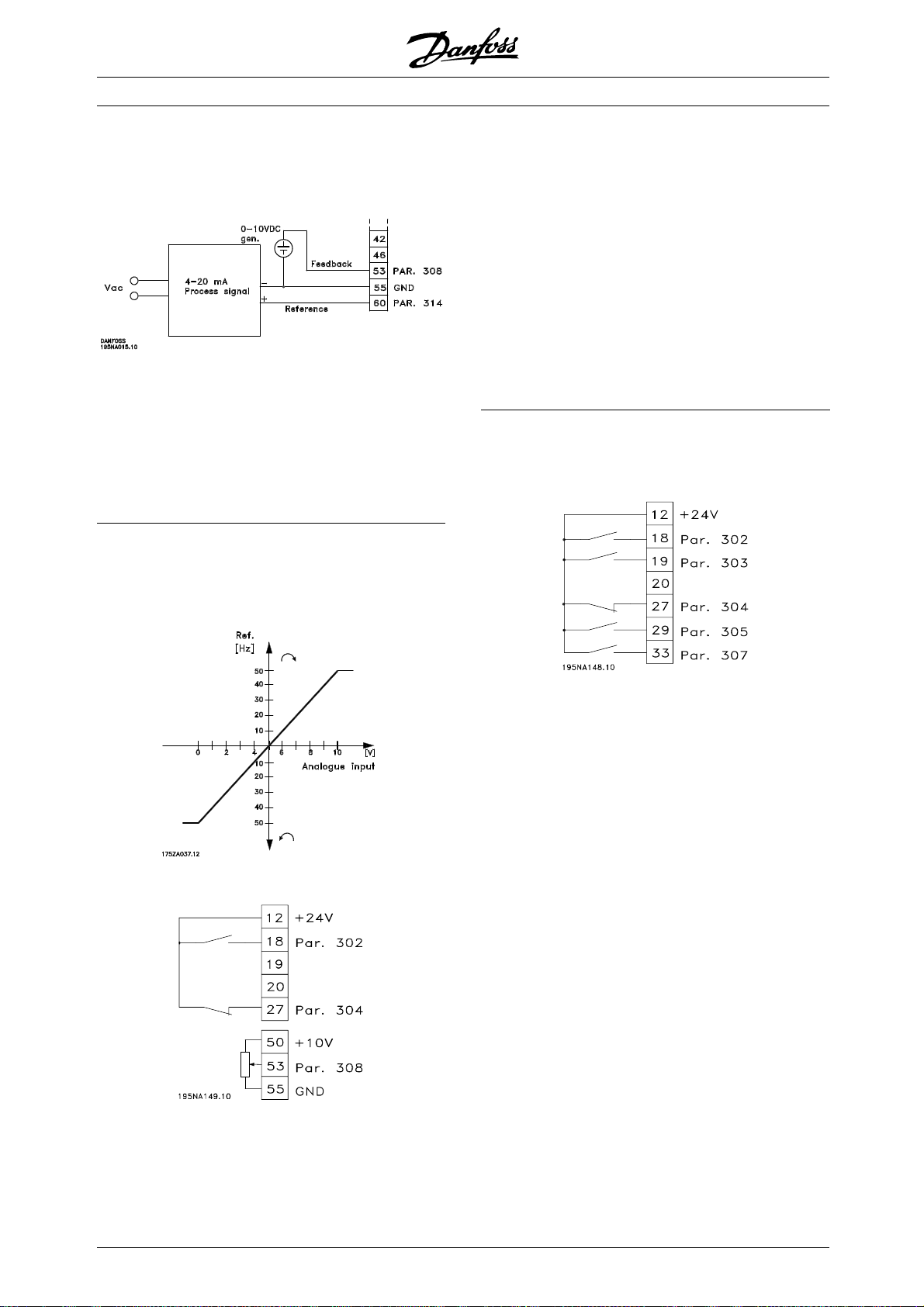

■4-20 mA reference

4-20 mA reference on terminal 60 and speed

feedback signal on terminal 53.

Par. 100 Configuration = Speedclosedloop[1]

Par. 308 Analog input = Feedback [2]

Par. 309 Terminal 53, min. scaling =0Volt

Par. 310 Terminal 53, max. scaling =10Volt

Par. 314 Analog input = Reference [1]

Par. 309 Terminal 60, min. scaling =4mA

Par. 310 Teminal 60, max. scaling =20mA

VLT®FCD Series

Par. 100 Configuration = Speed regulation

open loop [0]

Par. 200 Output frequency range = Both

directions, 0-132 Hz [1]

Par. 203 Reference range = Min. ref. - Max. ref. [0]

Par. 204 Min. reference =-50Hz

Par. 205 Max. reference =50Hz

Par. 302 Digital input = Start [7]

Par. 304 Digital input = Coasting stop inverted [2]

Par. 308 Analogue input = Reference [1]

Par. 309 Terminal 53, min. scaling =0Volt.

Par. 310 Terminal 53, max. scaling =10Volt.

■Preset references

Switch between 8 preset references via two digital

inputs and Setup 1 and Setup 2.

■ 50 Hz anti-clockwise to 50 Hz clockwise.

With internally supplied potentiometer.

Par. 004 Active Setup = Multisetup 1 [5]

Par. 204 Min. reference =0Hz

Par. 205 Max. reference =50Hz

Par. 302 Digital input = Start [7]

Par. 303 Digital input = Choice of Setup, lsb [31]

Par. 304 Digital input = Coasting stop inverted [2]

Par. 305 Digital input = Preset ref., lsb [22]

Par. 307 Digital input = Preset ref., msb [23]

Setup 1 contains the following preset references:

Par. 215 Preset reference 1 = 5.00%

Par. 216 Preset reference 2 = 10.00%

Par. 217 Preset reference 3 = 25.00%

Par. 218 Preset reference 4 = 35.00%

24

Setup 2 contains the following preset references:

Par. 215 Preset reference 1 = 40.00%

Par. 216 Preset reference 2 = 50.00%

Par. 217 Preset reference 3 = 70.00%

Par. 218 Preset reference 4 = 100.00%

MG.04.B7.02 - VLT is a registered Danfoss trademark

Page 25

VLT®FCD Series

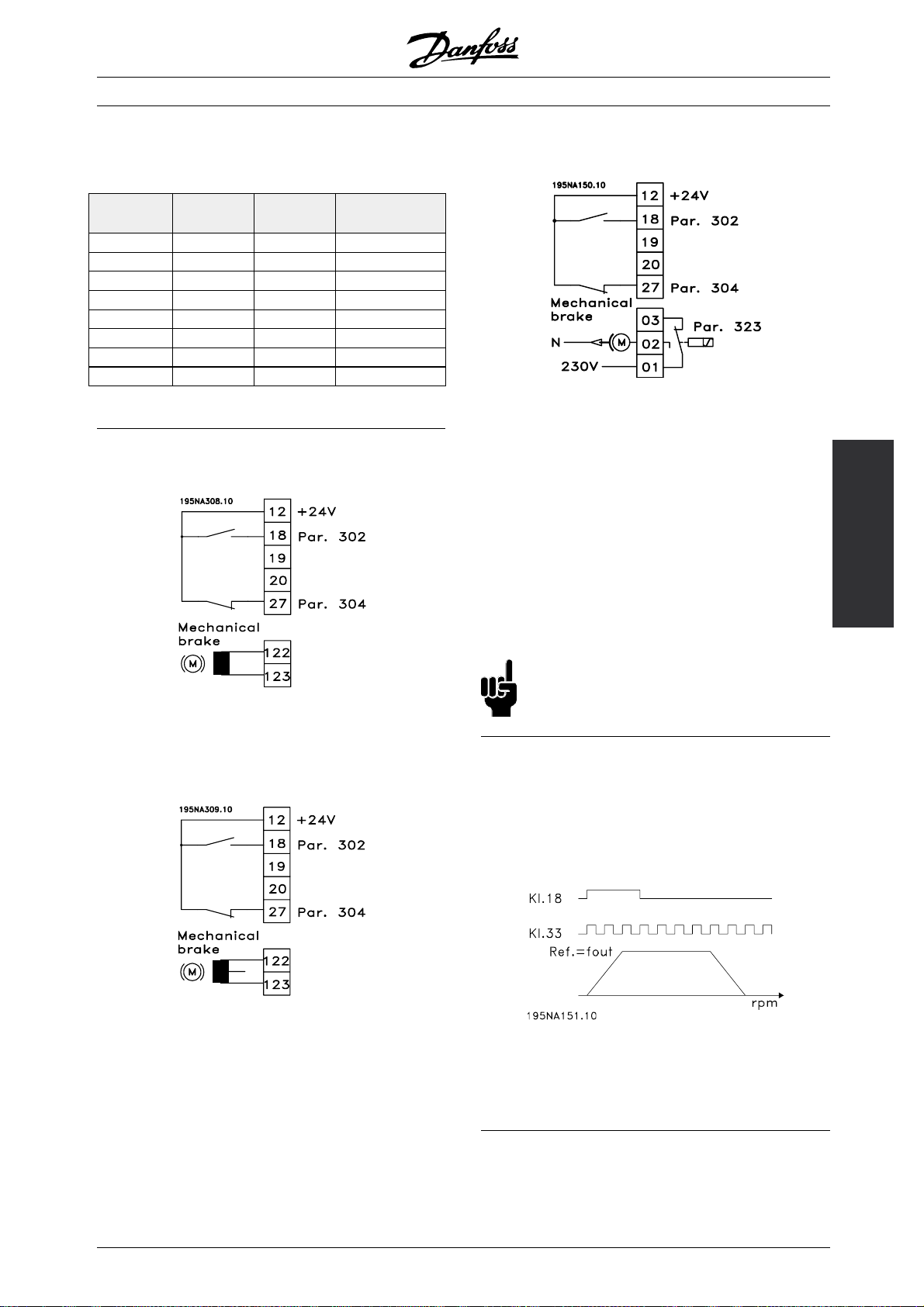

This table shows what the output frequency is:

Preset ref.,

msb

0 0 0 2.5

0 1 0 5

1 0 0 10

1 1 0 17.5

0 0 1 20

0 1 1 25

1 0 1 35

1 1 1 50

Preset ref.,

lsb

Selection of

Setup

■Connection of mechanical brake

Using terminal 122/123

Output

frequency[Hz]

Use of the relay for 230 V AC brake

Par. 302 Digital input = Start [7]

Par. 304 Digital input = Coasting stop inverted [2]

Par. 323 Relay output = Mechanical

brake control [25]

See also par. 138, 139, 140

Mechanical brake control [25] = ’0’ => Brake is closed.

Mechanical brake control [25] = ’1’ => The

brake is open.

See more detailed parameter settings under

Control of mechanical brake.

Installation

Par. 302 Digital

input = Start [7]

Par. 304 Digital input = Coasting stop inverted [2]

See also par. 138, 139, 140

Mechanical brake with accelerator winding

Par. 302 Digital input = Start [7]

Par. 304 Digital input = Coasting stop inverted [2]

See also par. 138, 139, 140

NB!:

Do not use the internal relay for DC brakes

or brake voltages > 250 V.

■Counter stop via terminal 33

The start signal (terminal 18) must be active, i.e. logical

’1’, until the output frequency is equal to the reference.

The start signal (terminal 18 = logical ’0’) must then be

removed before the counter value in parameter 344

has managed to stop the VLT frequency converter.

Par. 307 Digital input = Pulse input [30]

Par. 343 Precise stop function = Counter

stop with reset [1]

Par. 344 Counter value = 100000

MG.04.B7.02 - VLT is a registered Danfoss trademark

25

Page 26

VLT®FCD Series

■The LCP 2 control unit, option

■Control keys for parameter Setup

The control keys are divided into functions, in

such a way that the keys between the display

and the indicator lamps are used for parameter

Setup, including selection of the display’sview

mode during normal operation.

[DISPLAY/STATUS] is used to select the display’s

view mode or to change back to Display mode

from either Quick Menu or Menu mode.

[QUICK MENU] provides access to the parameters

used in the Quick Menu. It is possible to switch

between Quick Menu and Menu mode.

The FCD 300 can be combined with an LCP control

unit (Local Control Panel - LCP 2) which makes up a

complete interface for operation and pro

the frequency converter. The LCP 2 control unit can

be attached up to three metres from the frequency

converter, e.g. on a front panel, usin

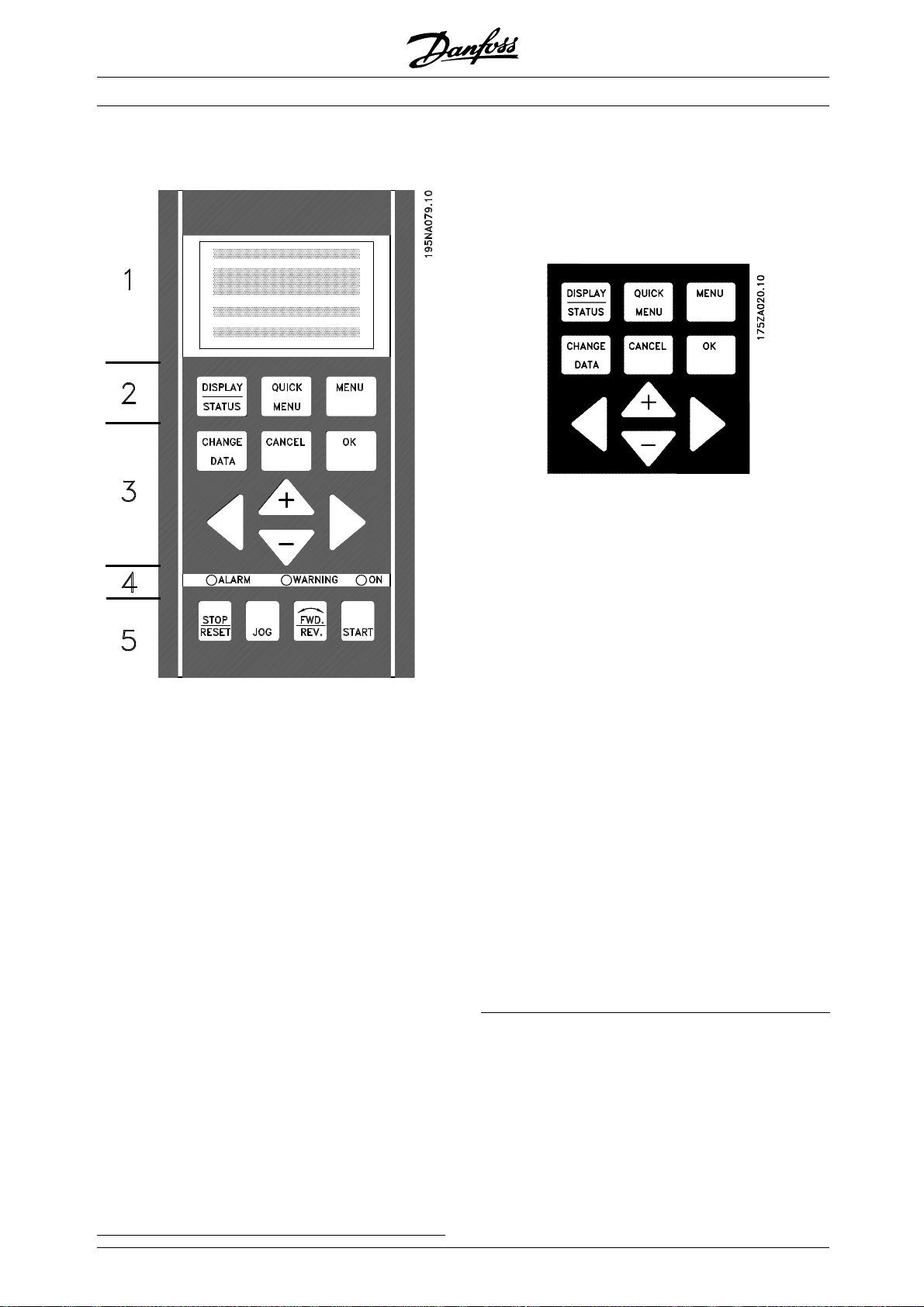

The control panel is divided into f

1. Display.

2. Keys used to change the display function.

3. Keys used to change the programme par

4. Indicator lamps.

5. Local control keys.

Alldataisdisplayedviaa4-linealphanumeric

display, which during normal ope

to continuously display 4 items of operating data

and 3 operating modes. During programming all

information needed for quick,

setup of the frequency converter will be displayed. As

asupplementtothedisplay,therearethreeindicator

lamps for voltage (ON), w

(ALARM). All frequency converter parameter Setups

can be changed immediately from the control panel,

unless this function h

[1] via parameter 018 Lock for data c hanges.

arning (WARNING) and alarm

as been programmed as Locked

ive functional groups:

ration will be able

effective parameter

gramming of

g an accessory kit.

ameters.

[MENU] givesaccesstoallparameters. Itispossible

to switch between Menu mode and Quick Menu.

[CHANGE DATA] is used to change a parameter that

has been selected either in Menu mode or Quick Menu.

[CANCEL] is used if a change to the selected

parameter is not to be implemented.

[OK] is used to confirm a change to a

selected parameter.

[+ / -] are used for selecting parameters and

for changing parameter values.

These keys are also used in Display mode to switch

between the readouts of operating variables.

[< >] are used for selecting parameter group and to

move the cursor when changing a numerical value.

26

MG.04.B7.02 - VLT is a registered Danfoss trademark

Page 27

VLT®FCD Series

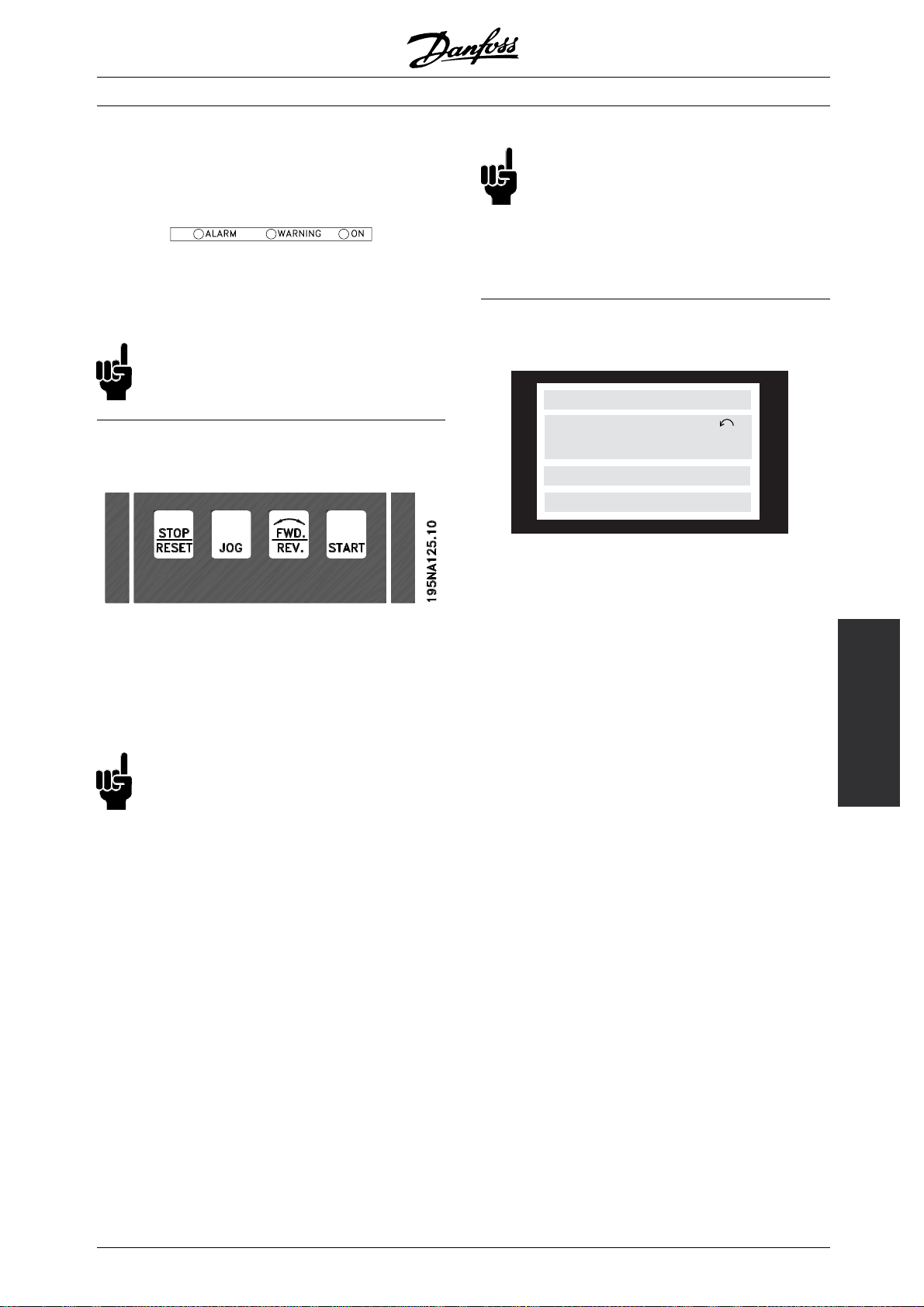

■Indicator lamps

At the bottom of the control panel are a red

alarm lamp, a yellow warning lamp and a

green voltage indicator lamp.

If certain threshold values are exceeded, the alarm

and/or warning lamp are activated, while a status

or alarm text is shown on the display.

NB!:

The voltage indicator lamp is activated when

voltage is connected to the frequency converter.

■Local control

[STOP/RESET] is used for stopping the motor

connected or for resetting the frequency converter

after a drop-out (trip). Can be set to active or

inactive via parameter 014 Local stop.

If stop is activated Display line 2 will flash.

NB!:

If an external stop function is not selected and

the [STOP/RESET] key is set to inactive, the

motor can only be stopped by disconnecting

the voltage to the motor or the frequency converter.

[JOG] changes the output frequency to a preset

frequency while the key is held down. Can be set to

active or inactive via parameter 015 Local jog.

NB!:

If the local control keys are set to inactive,

these will both become active when the

frequency converter is set to Loc al control

and Remote control via parameter 002 Local/remote

operation, with the exception of [FWD/REV], which

is only active in Local control.

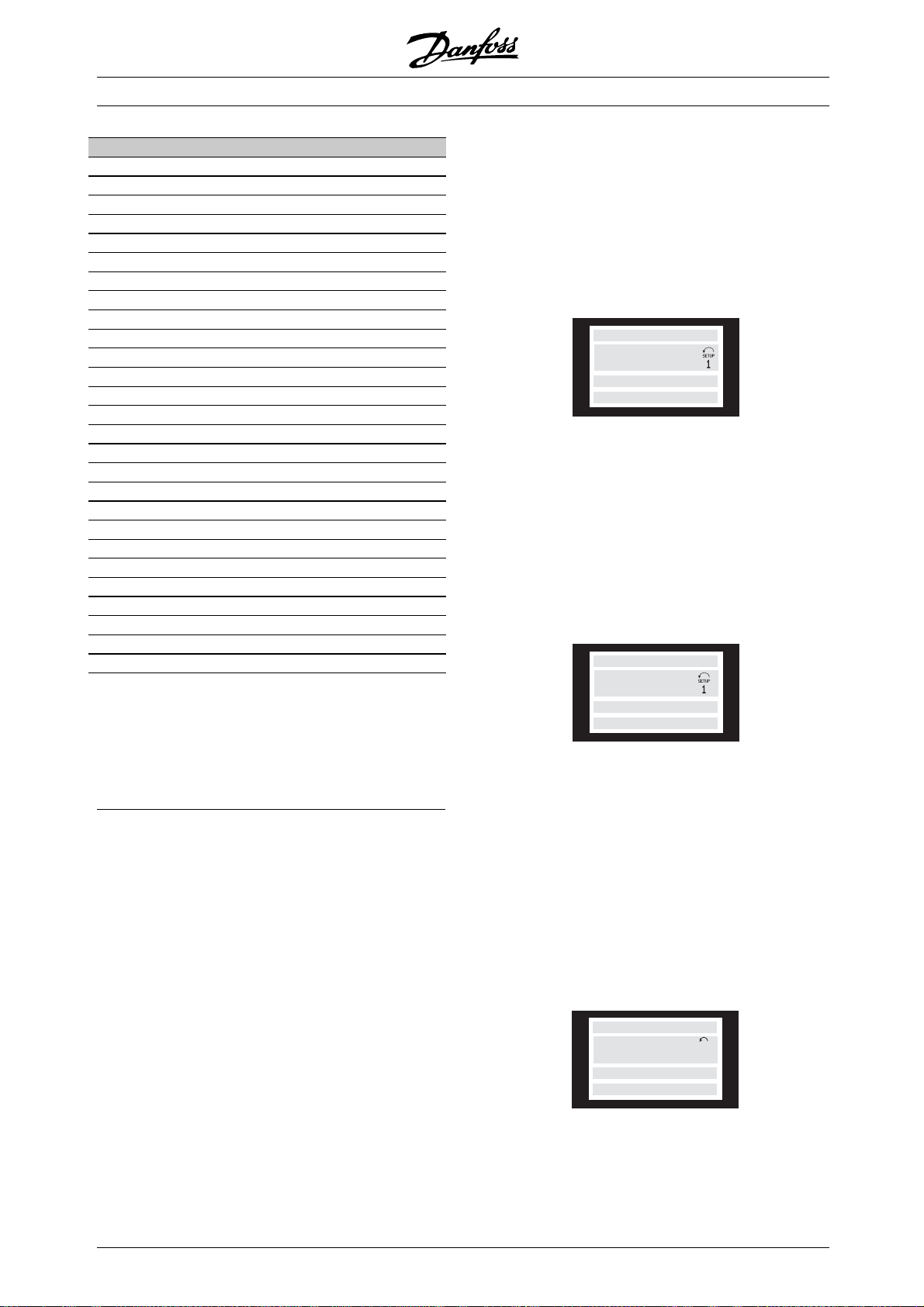

■Display mode

VAR 1.1 VAR 1.2 VAR 1.3

SETUP

VAR 2

1

STATUS

In normal operation, up to 4 different display data

items can optionally be shown continuously: 1,1,

1,2, 1,3 and 2. The present operation status or

alarms and warnings that have been generated are

displayed in line 2 in the form of a number.

In the event of alarms this is displayed in lines

3and4withexplanatorytext.

A warning will appear flashing in line 2 with

explanatory text in line 1. The active Setup

will also appear on the display.

The arrow indicates the selected direction of rotation.

Here the frequency converter shows that it has

an active reversing signal. The body of the arrow

will disappear if a stop command is given, or if the

output frequency drops below 0.1 Hz.

The bottom line displays the frequency transformer’s

status. The scrollbar shows which operating values

can be displayed in lines 1 and 2 in Display mode.

Changes are made using the [+ / -] keys.

195NA113.10

300

Programming, FCD

[FWD / REV] changes the direction of rotation of

the motor, which is indicated by means of the arrow

on the display. Can be set to active or inactive via

parameter 016 Local reversing.The[FWD/REV]key

is only active when parameter 002 Local/remote

operation is set to Local control.

[START] is used to start the frequency converter. Is

always active, but cannot override a stop command.

MG.04.B7.02 - VLT is a registered Danfoss trademark

Switching between AUTO and HAND modes

By activating the [CHANGE DATA] key in [DISPLAY

MODE] the display will indicate the mode of

the frequency converter.

Switch mode by using [+/-] key [HAND...AUTO]

In [HAND] mode the reference can be changed

by [+] or [-] keys.

27

Page 28

VLT®FCD Series

Operating data Unit

Resulting reference [%]

Resulting reference [unit]

Feedback [unit]

Output frequency [Hz]

Output frequency x scaling [-]

Motor current [A]

Torque [%]

Power [kW]

Power [HP]

Motor voltage [V]

DC link voltage [V]

Thermal load motor [%]

Thermal load [%]

Hours run [hours]

Digital input [binary]

Pulse input 29 [Hz]

Pulse input 29 [Hz]

Pulse input 33 [Hz]

External reference [%]

Status word [hex]

Heatsink temperature [°C]

Alarm word [hex]

Control word [hex]

Warning word [hex]

Extended status word [hex]

Analogue input 53 [V]

Analogue input 60 [mA]

Three operating data items can be shown in the

first display line, and one operating variable can be

shown in the second display line. Is programmed via

parameters 009, 010, 011 and 012 Display readout .

■Display modes

The LCP control unit has different display

modes, which depend on the mode selected

for the frequency converter.

Display mode I:

This display mode is standard after startup

or initialisation.

FREQUENCY

50.0 Hz

MOTOR IS RUNNING

Line 2 shows the data value of an operating data item

with unit, and line 1 contains a text that explains line

2. In the example, Frequency has been selected as

readout via parameter 009 Large display readout.In

normal operation, another variable can be entered

immediately using the [+ / -] keys.

Display mode II:

Switch between Display modes I and II is performed

by briefly pressing the [DISPLAY / STATUS] key.

24.3% 30.2% 13.8A

50.0 Hz

MOTOR IS RUNNING

In this mode, all data values for four operating

data items with any pertaining units are shown,

see table. In the example, the following have been

selected: Frequency, Reference, Torque and Current

as readout in the first and second line.

28

Display mode III:

This display mode is called up as long as the [DISPLAY

/ STATUS] key is held down. When the key is released

it switches back to Display mode II, unless

the key is

held down for less than approx. 1 sec., in which case

the system always reverts to Display mode I.

REF% TORQUE CURR A

50.0 Hz

MOTOR IS RUNNING

SETUP

1

Here you can read out the parameter names and

units for operating data in the first and second lines.

Line 2 in the display remains unchanged.

MG.04.B7.02 - VLT is a registered Danfoss trademark

Page 29

DisplaymodeIV:

This display mode can be called up during operation

if a change has to be made in another Setup without

stopping the frequency converter. This function is

activated in parameter 005 Programming Setup.

24.3% 30.2% 13.8A

SETUP

50.0 Hz

MOTOR IS RUNNING

12

Here the programming Setup number 2 will flash

to the right of the active Setup.

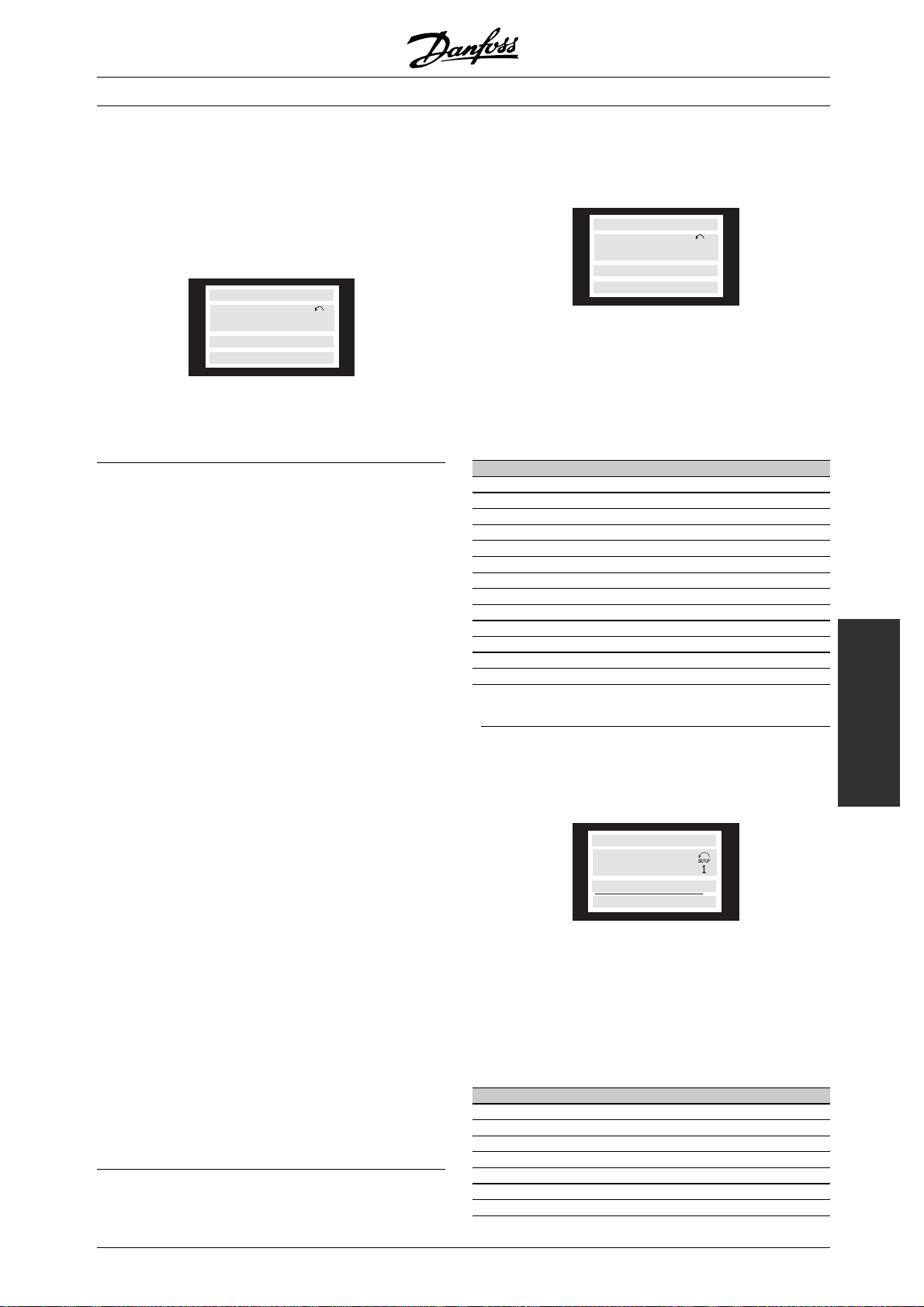

■Parameter Setup

A frequency converter’s comprehensive work area can

be accessed via a large number of parameters, making

it possible to adapt its functionality for a specific

application. To provide a better overview of the many

parameters, there is a choice of two programming

modes - Menu mode and Quick Menu mode. The

former provides access to all parameters. The latter

takes the user through the parameters, which make

it possible to start operating the frequency converter

in most cases, in accordance with the Setup made.

Regardless of the mode of programming, a change

of a parameter will take effect and be visible both in

the Menu mode and in the Quick menu mode.

Structure for Quick menu m ode v Menu mode

In addition to having a name, each parameter is linked

up with a number which is the same regardless of

the programming mode. In Menu mode, paramet

will be split into groups, with the first digit (left)

of the parameter number indicating the group

number of the parameter in question.

VLT®FCD Series

■Quick m enu with LCP 2 control unit

Start Quick Setup by pressing the [QUICK MENU] key,

which will bring out the following display values:

QUICK MENU X OF Y

50.0 Hz

001 LANGUAGE

ENGLISH

At the bottom of the display, the parameter number

and name are given together with the status/value

of the first parameter under the Quick menu. The

first time the [QUICK MENU] key is pressed after

the unit has been switched on, the readouts always

start in pos. 1 - see table below.

Pos. Parameter no. Unit

1 001 Language

2 102 Motor power [kW]

3 103 Motor voltage [V]

4 104 Motor frequency [Hz]

5 105 Motor current [A]

6 106 Rated motor speed [rpm]

7 107 AMT

8 204 Minimum reference [Hz]

9 205 Maximum reference [Hz]

10 207 Ramp-up time [sec]

11 208 Ramp-down time [sec]

12 002 Local/remote operation

13 003 Local reference [Hz]

■Parameter selection

Menu mode is started by pressing the [MENU] key,

which produces the following readout on the display:

ers

FREQUENCY

50.0 Hz

0 KEYB.&DISPLAY

SETUP

1

300

Programming, FCD

• Using the [QUICK MENU] key, it is possibl

eto

get access to the most important parameters

of the frequency converter. After programming,

the frequency converter is in most

cases ready

for operation. Scroll through the Quick menu

using the [+ / -] keys and change the data values

by pressing [CHANGE DATA] + [OK

].

• The Menu mode allows choosing and changing

all parameters as required. However, some

parameters will be "shaded

off", depending on the

choice in parameter 100 Configuration .

MG.04.B7.02 - VLT is a registered Danfoss trademark

Line 3 on the display shows the parameter

group number and name.

In Menu mode, the parameters are divided

into groups. Selection of parameter group is

effected using the [< >] keys.

The following parameter groups will be accessible:

Group no. Parameter group

0 Operation & Display

1Load&Motor

2 References & Limits

3 Inputs & Outputs

4 Special functions

5 Serial communication

6 Technical functions

29

Page 30

VLT®FCD Series

When the required parameter group has been

selected, each parameter can be chosen by

means of the [+ / -] keys:

FREQUENCY

50.0 Hz

001 LANGUAGE

ENGLISH

The 3rd line of the display shows the parameter

number and name, while the status/value of the

selected parameter is shown in line 4.

Changing data

Regardless of whether a parameter has been

selected under the Quick menu or the Menu mode,

theprocedureforchangingdatawillbethesame.

Pressing the [CHANGE DATA] key gives access

to changing the selected parameter, following

which the underlining in line 4 will flash on the

display. The procedure for changing data depends

on whether the selected parameter represents a

numerical data value or a text value.

Changing a data value

If the selected parameter is a text value, the text

value is changed by means of the [+ / -] keys.

The chosen digit is indicated by the digit flashing. The

bottom display line shows the data value that will be

entered (saved) when signing off with [OK].

■ Manual initialisation

NB!:

Manual initialisation is n

the LCP 2 175N0131 control unit. It is,

however, possible to perform an initialisation

via par. 620 Operation mode:

The following parameters are not changed when

initialising via par. 620 Operation mode.

- par. 500 Address

- par. 501 Baud rate

- par. 600 Operat ing hours

- par. 601 Hours run

- par. 602 kWh counter

- par. 603 Number of power-ups

- par. 604 Number of overtemperatures

- par. 605 Number of overvoltages

- par. 615-617 Fault log

- par. 678 Configure Control Card

ot possible on

FREQUENCY

50.0 Hz

001 LANGUAGE

ENGLISH

The bottom display line will show the value that will be

entered (saved) when acknowledgment is given [OK].

Changeofnumericdatavalue

If the selected parameter is represented by a numerical

data value, a digit is first chosen using the [< >] keys.

FREQUENCY

50.0 Hz

130 START FREQUENCY

09.0 HZ

The selected digit can then be changed infinitely

variably using the [+ / -] keys:

FREQUENCY

50.0 Hz

130 START FREQUENCY

10.0 HZ

SETUP

1

SETUP

1

30

MG.04.B7.02 - VLT is a registered Danfoss trademark

Page 31

VLT®FCD Series

■Operation & Display

001 Language

(LANGUAGE)

Value:

✭English (ENGLISH)

German (DEUTSCH)

French (FRANCAIS)

Danish (DANSK)

Spanish (ESPANOL)

Italian (ITALIANO)

Function:

This parameter is used to choose the language

to be shown in the display whenever the LCP

control unit is connected.

Description of choice:

There is a choice of the languages shown.

The factory setting may vary.

002 Local/remote operation

(OPERATION SITE)

Value:

✭Remote operation (REMOTE)

Local operation (LOCAL)

Function:

There is a choice of two different modes of operation

of the frequency converter; Remote operation [0] or

Local operation [1]. See also parameter 013 Local

control if Local operation [1] is selected.

Description of choice:

If Remote operation [0] is selected, the frequency

converter is controlled via:

1. the control terminals or via serial communication.

2. the [START] key. This cannot, however, override

stop commands transmitted via the digital

inputs or via serial communication.

3. the [STOP/RESET] and [JOG] keys, on the

condition that these are active.

If Local operation [1], is selected, the frequency

converter is controlled via:

1. the [START] key. This cannot, however, override

stop commands via the digital inputs (see

parameter 013 Local control).

2. the [STOP/RESET] and [JOG] keys, on the

condition that these are active.

3. the [FWD/REV] key, on the condition that is has

been selected as active in parameter 016 Local

reversing, and that parameter 013 Local control

is set at Local control and open loop [1] or Local

control as parameter 100 [3]. Parameter 200

Output frequency range is set at Both directions.

4. parameter 003 Local reference where the reference

can be set using the [+] and [-] keys.

[0]

[1]

[2]

[3]

[4]

[5]

5. an external control command that can be

connected to the digital inputs (see parameter

013 Local control).

NB!:

The [JOG] and [FWD/REV] keys are located

on the LCP control unit.

003 Local reference

(LOCAL REFERENCE)

Value:

Par. 013 Local control must be set to [1] or [2]:

0-f

MAX

Par. 013 Local control must be set to [3] or [4].

Ref

MIN

[0]

[1]

Function:

In this parameter, the local reference can be set

manually. The unit of the local reference depends on the

configuration selected in parameter 100 Configuration.

Description of choice:

In order to protect the local reference, parameter

002 Local/remote operation must be set to

Local operation [1]. Local reference cannot be

set via serial communication.

■Setup configuration

There is a choice of four Setups (parameter Setups),

which can be programmed independently of one

another. The active Setup can be selected in

parameter 004 Act ive Setup. WhenanLCPcontrol

unit is connected, the active Setup number will be

appear in the display under "Setup". It is also possible

to preset the frequency converter to Multisetup,sothat

it is possible to shift Setups using the digital inputs

or serial communication. Setup shift can be used in

a plant in which, for example, one Setup is used for

daytime operation and another one at night time.

In parameter 006 Se tup copying it is possible to copy

from one Setup to another. Using parameter 007 LCP

copy all Setups can be transferred from one frequency

converter to another by moving the LCP control panel.

(par. 202)

-Ref

MAX

(par. 204-205)

✭ 50 Hz

✭ 0,0

300

Programming, FCD

= factory setting. () = display text [] = value for use in communication via serial communication port

✭

MG.04.B7.02 - VLT is a registered Danfoss trademark

31

Page 32

VLT®FCD Series

First all parameter values are copied to the LCP control

panel, which can then be moved to another frequency

converter. Here all parameter values can be copied

from the LCP control unit to the frequency converter.

■Setup shift

- Selection of Setup via terminals 29 and 33.

Par. 305 Digital input = Selection of Setup, lsb [31]

Par. 307 Digital input = Selection of Setup, msb [32]

Par. 004 Active setup = Multi Setup [5]

004 Active Setup

(ACTIVE SETUP)

Value:

Factory Setup (FACTORY SETUP)

✭Setup 1 (SETUP 1)

Setup 2 (SETUP 2)

Setup 3 (SETUP 3)

Setup 4 (SETUP 4)

Multi Setup (MULTI SETUP)

Function:

The active parameter Setup is selected here. All

parameters can be programmed in four individual

parameter Setups. Shifts between Setups can

be made in this parameter via a digital input

or via serial communication.

Description of choice:

Factory Setup [0] contains the factory-set parameter

values. Setup 1-4 [1]-[4] are four individual

Setups which can be selected as required. Multi

Setup [5] is used where remote-controlled shifts

between the four Setups via a digital input or via

serial communication is required.

005 Programming S etup

(EDIT SETUP)

Value:

Factory Setup (FACTORY SETUP)

Setup 1 (SETUP 1)

Setup 2 (SETUP 2)

= factory setting. () = display text [] = value for use in communication via serial communication port

✭

[0]

[1]

[2]

[3]

[4]

[5]

[0]

[1]

Setup 3 (SETUP 3)

Setup 4 (SETUP 4)

✭Active Setup (ACTIVE SETUP)

Function:

You can select which Setup you want to programme

during operation (applies both via the control

panel and the serial communication port). It is,

for example, possible to programme Setup 2

[2], while the active Setup is set to Setup 1 [1]

in parameter 004 Active Setup .

Description of choice:

Factory Setup [0] contains the factory-set data

and can be used as a source of data if the

other Setups are to be reset to a known status.

Setup 1-4 [1]-[4] are individual Setups that can

be programmed freely during operation. If Active

Setup [5] is selected, the programming Setup will

be equal to parameter 004 Active Setup.

NB!:

If data is modified or copied to the active

Setup, the modifications have an immediate

effect on the unit’soperation.

006 Setup copying

(SETUP COPY)

Value:

✭No copying (NO COPY)

Copy to Setup 1 from #

(COPY TO SETUP 1)

Copy to Setup 2 from #

(COPY TO SETUP 2)

Copy to Setup 3 from #

(COPY TO SETUP 3)

Copy to Setup 4 from #

(COPY TO SETUP 4)

Copy to all Setups from # (COPY TO ALL)

Function:

You can copy from the selected active Setup in

parameter 005 Programming setup to the selected

Setup or Setups in this parameter.

NB!:

Copying is only possible in Stop (motor stopped

in connection with a stop command).

Description of choice:

Copying begins when the required copying function

has been selected and the [OK]/[CHANGE DATA]

[2]

[3]

[4]

[5]

[0]

[1]

[2]

[3]

[4]

[5]

32

MG.04.B7.02 - VLT is a registered Danfoss trademark

Page 33

VLT®FCD Series

key has been pushed. The display indicates

when copying is in progress.

007 LCP copy

(LCP COPY)

Value:

✭No copying (NO COPY)

Upload all parameters (UPL. ALL PAR.)

Download all parameters (DWNL. ALL PAR.)

Download size-independent parameters

(DWNL.OUTPIND.PAR.)

Function:

Parameter 007 LCP copy is used if you want to use

the LCP 2 control panel’s integral copy function. The

function is used if you want to copy all parameter

setups from one frequency converter to another

by moving the LCP 2 control panel.

Description of choice:

Select Upload all parameters [1] if you want all

parameter values to be transferred to the control

panel. Select Download all parameters [2] if all

parameter values transferred are to be copied to the

frequency converter to which the control panel is

attached. Select Download size-independent par. [3]

if you only want to downloade the size-independent

parameters. This is used when downloading to a

frequency converter with a different rated power size

than that from which the parameter setup originates.

NB!:

Upload/download can only be performed

in stop mode. Download can o

performed to a frequency converter with

the same software version number, see parameter

626 Database identification no.

008 Display scaling of output frequency

(FREQUENCY SCALE)

Value:

0.01 - 100.00

Function:

In this parameter, the factor is selected by which the

output frequency is to be multiplied. The value is shown

in the display, provided parameters 009-012 Disp

readout have been set to Output frequency x scaling [5].

Description of choice:

Set the required scaling factor.

nly be

✭ 1.00

lay

[0]

[1]

[2]

[3]

009 Large d isplay readout

(DISPLAY LINE 2)

Value:

No readout (NONE)

Resulting reference [%]

(REFERENCE [%])

Resulting reference [unit]

(REFERENCE [UNIT])

Feedback [unit] (FEEDBACK [UNIT])

✭Frequency [Hz] (FREQUENCY [HZ])

Output frequency x scaling

(FREQUENCY X SCALE)

Motor current [A] (MOTOR CURRENT [A])

Torque [ %] ( TORQUE [%])

Power [kW] (POWER [KW])

Power [HP] (POWER [HP][US])

Motor voltage [V]

(MOTOR VOLTAGE [V])

DC link voltage [V]

(DC LINK VOLTAGE [V])

Thermal load motor [%]

(MOTOR THERMAL [%])

Thermal load [%]

(FC. THERMAL[%])

Running hours [Hours]

(RUNNING HOURS])

Digital input [Bin]

(DIGITAL INPUT[BIN])

Analog input 53 [V]

(ANALOG INPUT 53 [V])

Analog input 60 [mA]

(ANALOG INPUT 60 [MA])

Pulse reference [Hz]

(PULSE INPUT 33. [HZ])

External reference [%]

(EXTERNAL REF. [%])

Status word [Hex] (STATUS WORD [HEX])

Heatsink temperature [°C]

(HEATSINK TEMP [°C])

Alarm word [Hex] (ALARM WORD [HEX])

Control word [Hex] (CONTROL WORD [HEX])

Warning word [Hex]

(WARNING WORD [HEX])

Extended status word [Hex]

(EXT. STATUS [HEX])

Communication option card warning

(COMM OPT WARN [HEX])

Pulse count

(PULSE COUNTER)

Pulse input 29

(PULSE INPUT 29)

[0]

[1]

[2]

[3]

[4]

[5]

[6]

[7]

[8]

[9]

[11]

[12]

[13]

[14]

[15]

[16]

300

[17]

Programming, FCD

[19]

[20]

[21]

[22]

[25]

[26]

[27]

[28]

[29]

[30]

[31]

[32]

= factory setting. () = display text [] = value for use in communication via serial communication port

✭

MG.04.B7.02 - VLT is a registered Danfoss trademark

33

Page 34

VLT®FCD Series

Function:

In this parameter you can select the data value that

you wish to display in the L C P c o n t r o l u nit display

line 2 when the frequency converter is switched on.

The display will also be included in the scrollbar

in display mode. In parameters 010-012 Display

readout you can select a further three data values,

whicharedisplayedindisplayline1.

Description of choice:

No readout can only be selected in parameters

010-012 Small display readout.

Resulting reference [%] gives, as a percentage,

the resulting reference in the range from Minimum

reference, Ref

to Maximum reference, Ref

MIN

MAX

.

Reference [unit] gives the resulting reference with unit

Hz in Open loop.InClosed loop the reference unit

is selected in parameter 416 Process units.

Feedback [unit] gives the resulting signal value

using the unit/scaling selected in parameter 414

Minimum feedback, FB

FB

and 416 Process units.

HIGH

, 415 Maximum feedback,

LOW

Frequency [Hz] gives the output frequency of

the frequency converter.

Output frequency x scaling [-] equals the present

output frequency f

multiplied by the factor set in

M

parameter 008 Display scaling of output frequency .

Running hours [Hours] gives the number of hours that

the motor has tun since the last reset in parameter

619 Reset of running hours counter.

Digital input [Binar y code] gives the signal status

from the 5 digital inputs (18, 19, 27, 29 and 33).

Terminal 18 corresponds to the bit on the extreme

left. ‘0’ = no signal, ‘1’ = signal connected.

Analog input 53 [V] gives the voltage value

of terminal 53.

Analog input 60 [mA] gives the present

value of terminal 60.

Pulse input 33[Hz] gives the frequency in Hz

connected to terminal 33.

External reference [%] gives the sum of

external references as a percentage (sum of

analogue/pulse/serial communication) in the

range from Minimum reference, Ref

Maximum reference, Ref

MAX

.

MIN

to

Status word [Hex] gives one or several status

conditions in a Hex code. See Serial communic ation

in the Design Guide for further information.

Heatsink temp.[°C] gives the present heatsink

temperature of the frequency converter. The

cut-out limit is 90-100 °C, while cutting back

in occurs at 70 ± 5 °C.

Motor current [A] gives the phase current of the

motor measured as an effective value.

Torque [%] denotes the motor’s present load in