Danfoss VLT PROFIBUS DP MCA 101, VLT FC 102 Series, VLT FC 103 Series, VLT FC 301, VLT FC 202 Programming Manual

...Page 1

MAKING MODERN LIVING POSSIBLE

Programming Guide

VLT® PROFIBUS DP MCA 101

VLT® Frequency Converter Series FC 102 • FC 103 • FC 202 • FC

301/302 • FCD 302

www.danfoss.com/drives

Page 2

Page 3

Contents Programming Guide

Contents

1 Introduction

1.1 Purpose of the Manual

1.2 Additional Resources

1.3 Document and Software Version

1.4 Product Overview

1.5 Approvals and Certifications

1.6 Symbols, Abbreviations and Conventions

2 Safety

2.1 Safety Symbols

2.2 Qualified Personnel

2.3 Safety Precautions

3 Configuration

3.1 Configure the PROFIBUS Network

3.2 Configure the Master

3.2.1 GSD File 9

3.3 Configure the Frequency Converter

3

3

3

3

3

4

5

6

6

6

6

8

8

9

11

3.3.1 Frequency Converter Parameters 11

3.3.2 LEDs 11

4 Control

4.1 PPO Types

4.2 Process Data

4.2.1 Process Control Data 14

4.2.2 Process Status Data 14

4.2.3 Reference Handling 15

4.2.4 Process Control Operation 15

4.2.5 Influence of the Digital Input Terminals upon FC Control Mode 16

4.3 Control Profile

4.4 PROFIdrive Control Profile

4.4.1 Control Word according to PROFIdrive Profile (CTW) 16

4.4.2 Status Word according to PROFIdrive Profile (STW) 18

4.4.3 PROFIdrive State Transition Diagram 19

4.5 Danfoss FC Control Profile

4.5.1 Control Word according to FC Profile (CTW) 20

13

13

14

16

16

20

4.5.2 Status Word according to FC Profile (STW) 21

4.6 Synchronise and Freeze

4.6.1 SYNC/UNSYNC 22

4.6.2 FREEZE/UNFREEZE 22

MG37G102 Danfoss A/S © Rev. 05/2014 All rights reserved. 1

22

Page 4

Contents Programming Guide

5 Parameter Access

5.1 Parameter Access in General

5.2 DP-V1 Parameter Access

5.3 PCV Parameter Access

5.4 PROFIBUS DP Parameter and Data Type

6 Parameters

6.1 8-** PROFIBUS Parameters

6.2 9-** and 16-** PROFIBUS Parameters

6.3 PROFIBUS-specific Parameter List

7 Application Examples

7.1 Example 1: Process Data with PPO Type 6

7.2 Example 2: Control Word Telegram using PPO Type

7.3 Example 3: Status Word Telegram using PPO Type

7.4 Example 4: PLC Programming

8 Troubleshooting

23

23

23

28

31

33

33

35

42

43

43

44

45

46

48

8.1 Diagnosis

8.2 No Response to Control Signals

8.3 Warnings and Alarms

8.4 Fault Messages via DP Diagnosis

8.5 Extended Diagnosis

Index

48

48

50

53

54

55

2 Danfoss A/S © Rev. 05/2014 All rights reserved. MG37G102

Page 5

Introduction

1 Introduction

Programming Guide

1

1

1.1 Purpose of the Manual

The VLT® PROFIBUS DP MCA 101 Programming Guide

provides information about configuring the system,

controlling the frequency converter, parameter access,

programming, troubleshooting, as well as some typical

application examples.

The programming guide is intended for use by qualified

personnel who are familiar with the VLT® frequency

converter, with PROFIBUS technology, and with the PC or

PLC that is used as a master in the system.

Read the instructions before programming and follow the

procedures in this manual.

VLT® is a registered trademark.

1.2 Additional Resources

Resources available for the frequency converters and

optional equipment:

The VLT® Operating Instructions provide the

•

necessary information for getting the frequency

converter up and running.

The VLT

•

information about capabilities and functionality to

design motor control systems.

The VLT® Programming Guide provides greater

•

detail on working with parameters and many

application examples.

The VLT® PROFIBUS DP MCA 101 Installation Guide

•

provides information about installing the

PROFIBUS and troubleshooting.

The VLT® PROFIBUS DP MCA 101 Programming

•

Guide provides information about configuring the

system, controlling the frequency converter,

parameter access, programming, troubleshooting,

as well as some typical application examples.

Supplementary publications and manuals are available

from Danfoss. See www.danfoss.com/BusinessAreas/DrivesSo-

lutions/Documentations/VLT+Technical+Documentation.htm

for listings.

®

Design Guide provides detailed

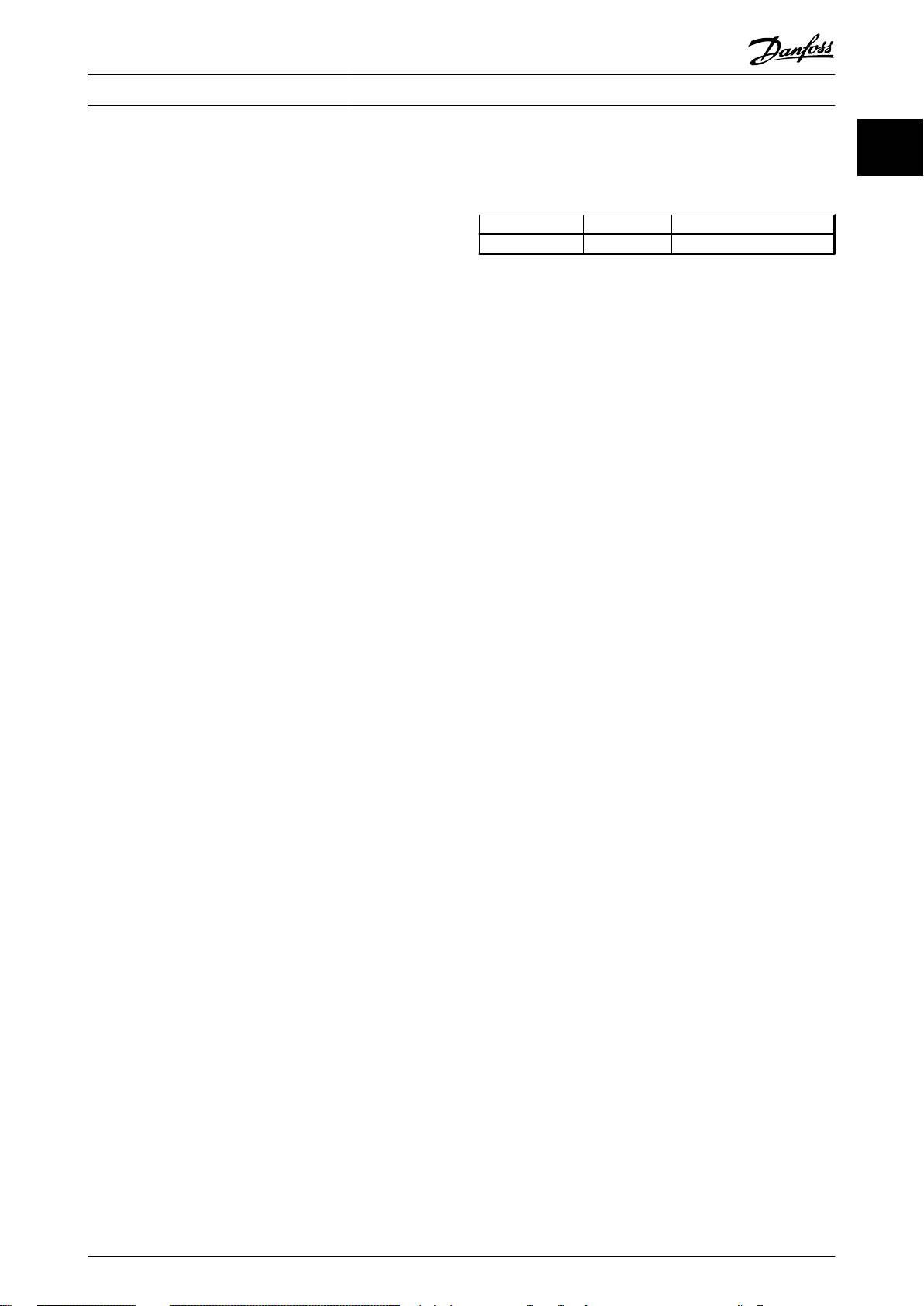

Edition Remarks Software version

MG37G1xx - -

Table 1.1 Document and Software Version

1.4 Product Overview

1.4.1 Features of PROFIBUS DP-V1

2 different state machines can be selected:

•

PROFIdrive profile or Danfoss FC profile

Communication using PROFIBUS DP-V1, Master

•

Class 1 and Master Class 2.

Downward compatibility: New protocol

•

extensions retain all the functions of the previous

versions.

Intelligent base for future technologies such as

•

OPC, FDT/DTM, PROFINET.

Bus time-out reaction.

•

PLC/CPU stop reaction.

•

8 PPO types available.

•

Numerous relevant process data (PCD) types

•

available.

Automatic detection of baud rate and PPO type.

•

Extended diagnosis available.

•

Alarms and warnings available as text messages

•

within the PLC.

Configuration via MCT 10 Set-up Software.

•

Equidistant bus cycle time configurable in PLC

•

system.

Improved network efficiency, since the cyclic

•

parameter channel is no longer required.

Very short bus cycle times compared to industrial

•

ethernet .

Backwards compatibility with DP.

•

Technical Overview

1.4.2

1.3

Document and Software Version

This manual is regularly reviewed and updated. All

suggestions for improvement are welcome. Table 1.1 shows

the document version and the corresponding software

version.

MG37G102 Danfoss A/S © Rev. 05/2014 All rights reserved. 3

PROFIBUS

PROFIBUS is an international standard for fieldbus

communication in automation technology (IEC 61158 and

IEC 61784). The standard is supported by the member

companies of the PROFIBUS International User Community.

For information about PROFIBUS and downloads for

PROFIBUS DP and the PROFIdrive profile, refer to

www.Profibus.com.

Page 6

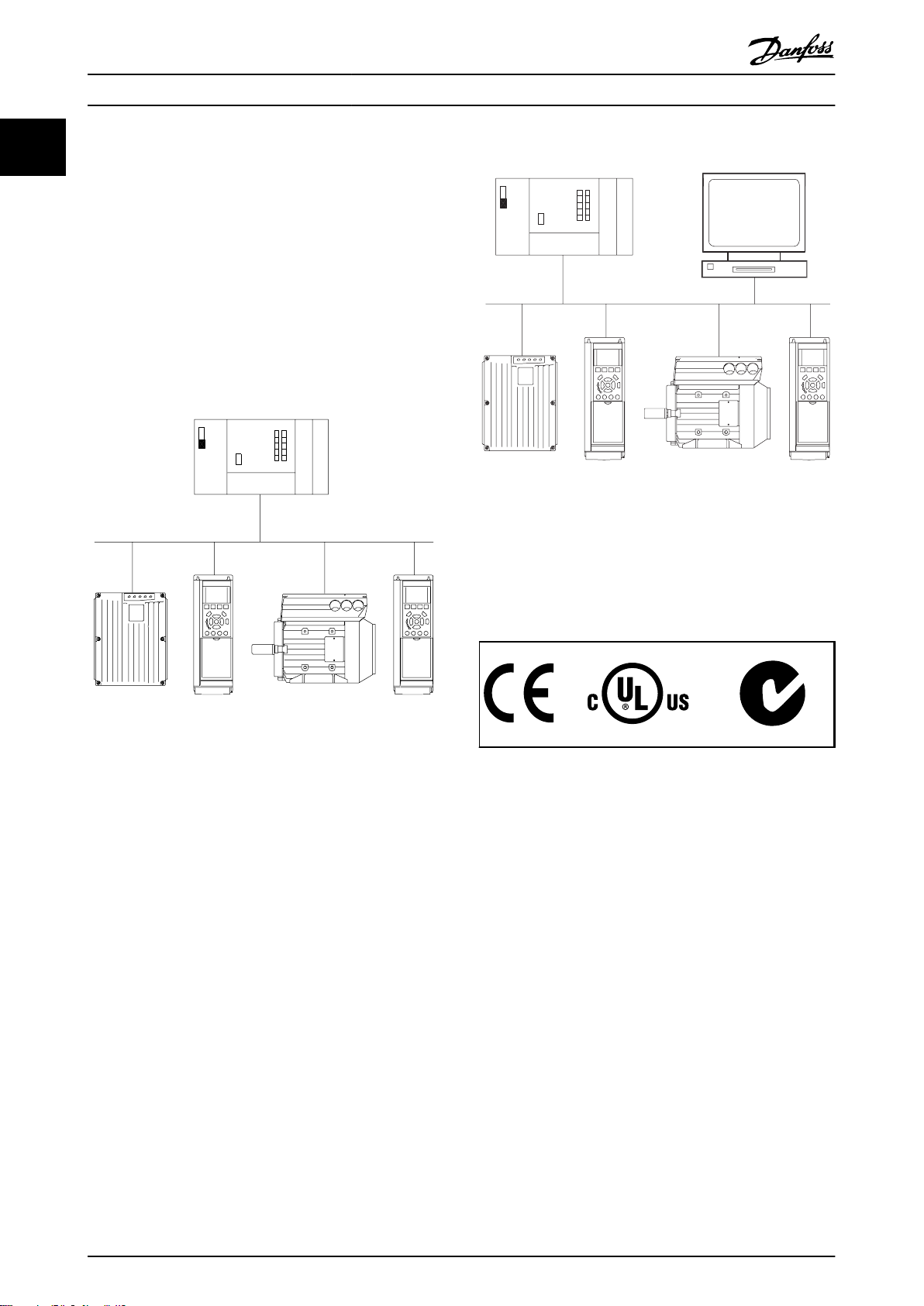

PLC

130BA078.10

PLC

Master class 1

PC tool

Master class 2

130BA079.10

Introduction Programming Guide

1

PROFIBUS DP-V1

The PROFIBUS DP protocol enables communication

between PROFIBUS masters and followers.

Communication can be configured via MCT 10 Set-up

Software.

Cyclical/Acyclical Communication

PLC communicates with telegrams of constant

•

length.

Fits time-critical requirements.

•

Cyclical transmission via PPO types.

•

Extended diagnosis.

•

Illustration 1.2 PROFIBUS DP-V1

The PROFIBUS DP extension DP-V1 permits acyclical as well

as cyclical data communication. This feature can be used

by a DP master class 1 (for example, PLC), as well as a DP

master class 2 (for example, PC tool).

Illustration 1.1 PROFIBUS DP-V0

Features of a Master class 1 connection:

Cyclical data exchange (DP-V0).

•

Acyclical read/write on parameters.

•

Extended diagnosis.

•

The acyclical connection is fixed, and cannot be changed

during operation.

Features of a Master class 2 connection:

Initiate/Abort acyclical connection.

•

Acyclical read/write on parameters.

•

The acyclical connection can be established (Initiate) or

removed (Abort) dynamically even when a master class 1 is

active on the network. The DP-V1 acyclical connection can

be used for general parameter access as an alternative to

the PCV parameter channel.

1.5

Approvals and Certifications

More approvals and certifications are available. For more

information, contact a local Danfoss partner.

4 Danfoss A/S © Rev. 05/2014 All rights reserved. MG37G102

Page 7

Introduction Programming Guide

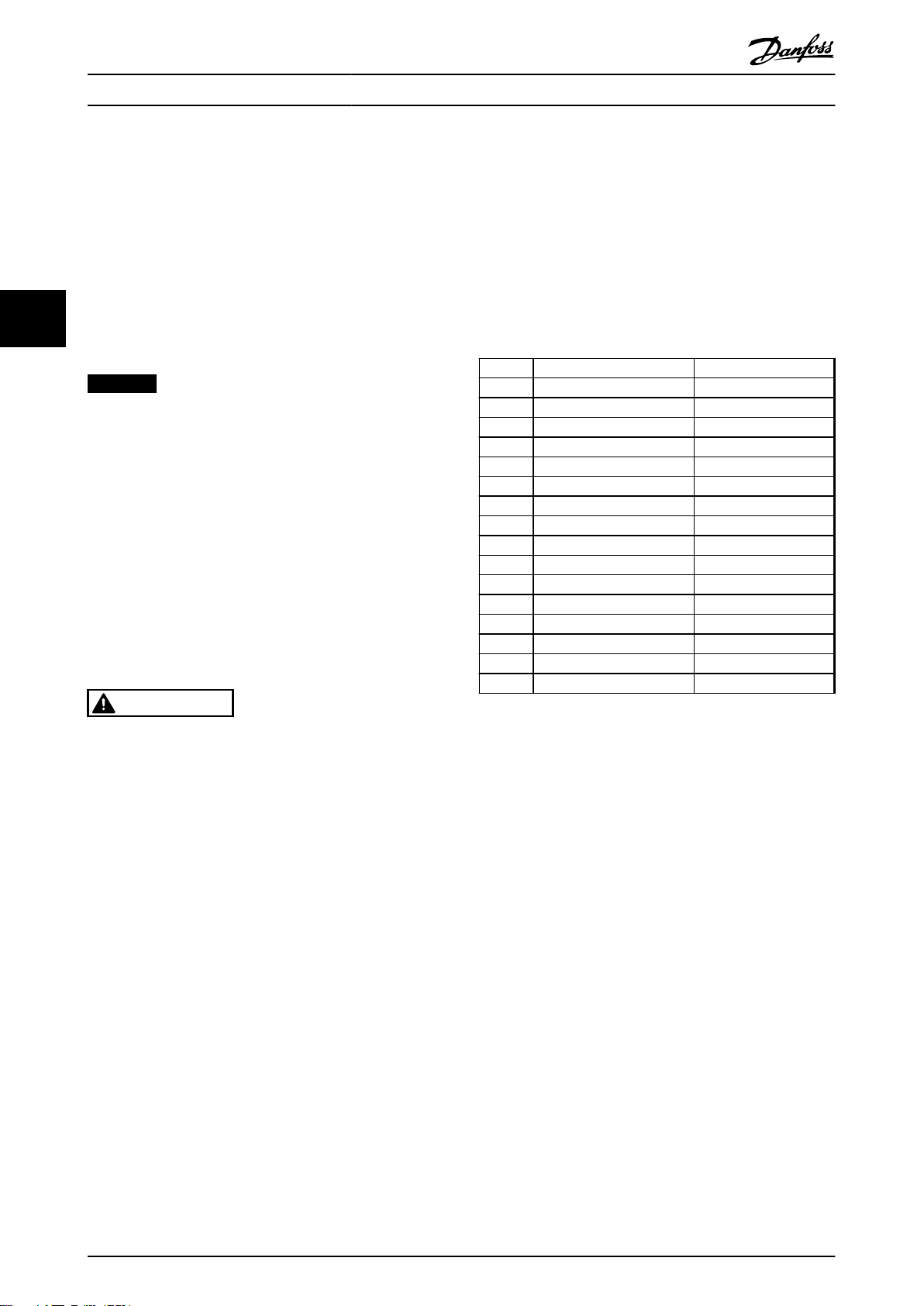

1.6 Symbols, Abbreviations and

Conventions

CAN Controller area network

CTW Control word

DP Distributed periphery

DU Data unit

EEPROM Electrical erasable programmable read only memory

EMC Electromagnetic compatibility

FDT Field device tool

IND Sub index

LCD Liquid crystal display

LCP Local control panel

LED Light emitting diode

MAV Main actual value

MC1 Master class 1

MC2 Master class 2

MRV Main reference value

PC Personal computer

PCD Process data

PCA Parameter characteristics

PCV Parameter characteristics value

PDU Protocol data unit

PLC Programmable logic control

PNU Parameter number

PPO Parameter-process data

PVA Parameter value

RC Request/Response characteristics

SAP Service access point

SMP Spontaneous message

STW Status word

1

1

Table 1.2 Symbols and Abbreviations

Conventions

Numbered lists indicate procedures.

Bullet lists indicate other information and description of illustrations.

* indicates a default setting in a parameter.

Italicised text indicates

cross reference

•

link

•

parameter name

•

MG37G102 Danfoss A/S © Rev. 05/2014 All rights reserved. 5

Page 8

Safety Programming Guide

2 Safety

22

2.1 Safety Symbols

The following symbols are used in this document:

WARNING

Indicates a potentially hazardous situation which could

result in death or serious injury.

CAUTION

Indicates a potentially hazardous situation which could

result in minor or moderate injury. It can also be used to

alert against unsafe practices.

NOTICE

Indicates important information, including situations that

can result in damage to equipment or property.

2.2 Qualified Personnel

Correct and reliable transport, storage, installation,

operation, and maintenance are required for the troublefree and safe operation of the frequency converter. Only

qualified personnel are allowed to install or operate this

equipment.

Qualified personnel are defined as trained staff, who are

authorised to install, commission, and maintain equipment,

systems, and circuits in accordance with pertinent laws and

regulations. Additionally, the personnel must be familiar

with the instructions and safety measures described in

these operating instructions.

2.3

Safety Precautions

WARNING

HIGH VOLTAGE

Frequency converters contain high voltage when

connected to AC mains input, DC power supply, or load

sharing. Failure to perform installation, start-up, and

maintenance by qualified personnel can result in death

or serious injury.

Installation, start-up, and maintenance must be

•

performed by qualified personnel only.

WARNING

UNINTENDED START

When the frequency converter is connected to AC mains,

DC power supply, or load sharing, the motor may start at

any time. Unintended start during programming, service

or repair work can result in death, serious injury, or

property damage. The motor can start by means of an

external switch, a serial bus command, an input

reference signal from the LCP or LOP, via remote

operation using MCT 10 software, or after a cleared fault

condition.

To prevent unintended motor start:

Disconnect the frequency converter from mains.

•

Press [Off/Reset] on the LCP, before

•

programming parameters.

The frequency converter, motor, and any driven

•

equipment must be fully wired and assembled

when the frequency converter is connected to

AC mains, DC power supply, or load sharing.

WARNING

DISCHARGE TIME

The frequency converter contains DC-link capacitors,

which can remain charged even when the frequency

converter is not powered. Failure to wait the specified

time after power has been removed before performing

service or repair work, can result in death or serious

injury.

Stop motor.

•

Disconnect AC mains and remote DC-link power

•

supplies, including battery back-ups, UPS, and

DC-link connections to other frequency

converters.

Disconnect or lock PM motor.

•

Wait for the capacitors to discharge fully, before

•

performing any service or repair work. The

duration of waiting time is specified in the

relevant frequency converter Operating

Instructions, Chapter 2 Safety.

6 Danfoss A/S © Rev. 05/2014 All rights reserved. MG37G102

Page 9

Safety Programming Guide

WARNING

LEAKAGE CURRENT HAZARD

Leakage currents exceed 3.5 mA. Failure to ground the

frequency converter properly can result in death or

serious injury.

Ensure the correct grounding of the equipment

•

by a certified electrical installer.

WARNING

EQUIPMENT HAZARD

Contact with rotating shafts and electrical equipment

can result in death or serious injury.

Ensure that only trained and qualified

•

personnel perform installation, start up, and

maintenance.

Ensure that electrical work conforms to national

•

and local electrical codes.

Follow the procedures in these operating

•

instructions.

2 2

CAUTION

INTERNAL FAILURE HAZARD

An internal failure in the frequency converter can result

in serious injury, when the frequency converter is not

properly closed.

Ensure that all safety covers are in place and

•

securely fastened before applying power.

MG37G102 Danfoss A/S © Rev. 05/2014 All rights reserved. 7

Page 10

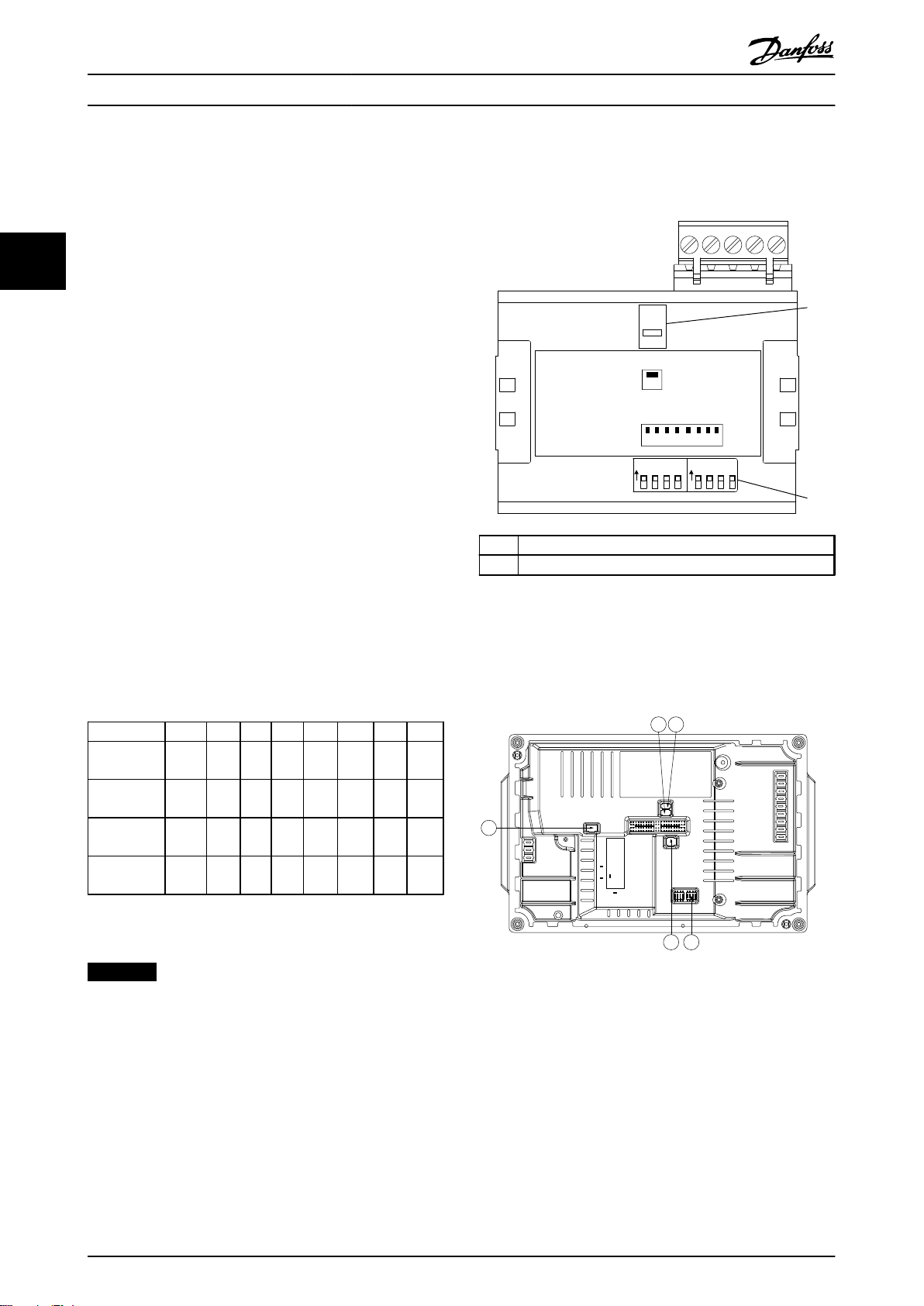

130BD878.10

ON

1 2

SW. ver. XX.XX

MS

NS

ON

OFF

Code No. 130B1100

Termination

SN

SW

Address

ON

OFF

S600

S300

LD202 LD200

LD201 LD203

ON ON

8 7 6 5 4 3 2 1

PROFIBUS Option A

1

2

130BB708.10

1

2

4

3

5

Configuration

Programming Guide

3 Configuration

3.1 Configure the PROFIBUS Network

33

Ensure that all PROFIBUS stations connected to the same

bus network have a unique station address.

Select the PROFIBUS address of the frequency converter

via:

Hardware switches

•

9-18 Node Address

•

The PROFIBUS command SSA (Set Station

•

Address)

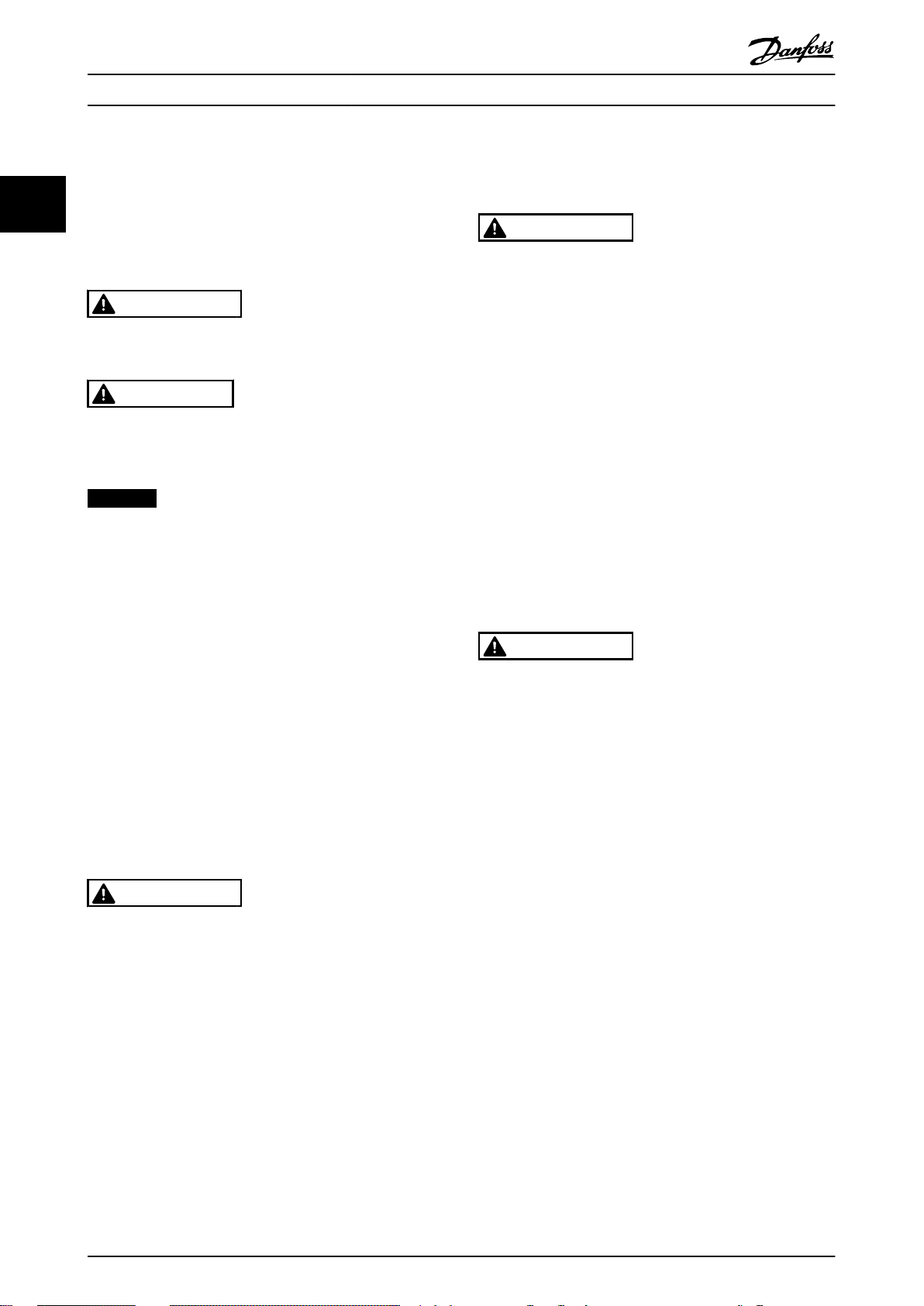

Setting the PROFIBUS Address using

3.1.1

the DIP Switches

To set the PROFIBUS address using the DIP switches:

1. Switch off the power supply.

2. Select an address in the range 0 to 125. Factory

setting is 127.

3. For location of the DIP switches, refer to

Illustration 3.1 and Illustration 3.2.

4. Set the switches according to the address, see

Table 3.1.

1 Termination switch

2 DIP switches

Illustration 3.1 Location and Sequence of the DIP Switches

The DIP switch in the FCD 302 are placed below the

inverter part, see Illustration 3.2.

Switch 8 7 6 5 4 3 2 1

Address

value

5 Not

35 Not

82 Not

Table 3.1 Examples: Setting the PROFIBUS Address using the

DIP Switches

NOTICE

Not

+64 +32 +16 +8 +4 +2 +1

used

OFF OFF OFF OFF ON OFF ON

used

OFF ON OFF OFF OFF ON ON

used

ON OFF ON OFF OFF ON OFF

used

Illustration 3.2 FCD 302 Dip Switches

Switch off the power supply before changing the DIP

switches.

Setting the PROFIBUS Address via 9-18 Node Address

1. Switch off the power supply.

8 Danfoss A/S © Rev. 05/2014 All rights reserved. MG37G102

2. Set the DIP switch to 126 or 127 (factory switch

setting).

3.

Set the address via 9-18 Node Address or the

PROFIBUS SSA-command.

4. The address change comes into effect at the next

power-up.

Page 11

130BC915.10

130BC913.11

Configuration

Setting the PROFIBUS Address with Set Station Address

Command

1. Switch off the power supply.

2. Set the DIP switch to 126 or 127 (factory switch

setting).

3. Set the address via the "Set Station Address"

command. Use the "Set Station Address"

command to lock the programmed address and

to change the address. Unlock the address setting

by changing the 9-18 Node Address or the address

switch, followed by a power cycle. A new address

is effective immediately after the "Set Station

Address" command.

Programming Guide

3.2 Configure the Master

3.2.1 GSD File

To configure a PROFIBUS Master, the configuration tool

needs a GSD file for each type of follower on the network.

The GSD file is a PROFIBUS DP standard text file containing

the necessary communications set-up data for a follower.

Download the GSD file for the FC 102, FC 202 and FC

301/302 frequency converters at www.danfoss.com/Busines-

sAreas/DrivesSolutions/.

3 3

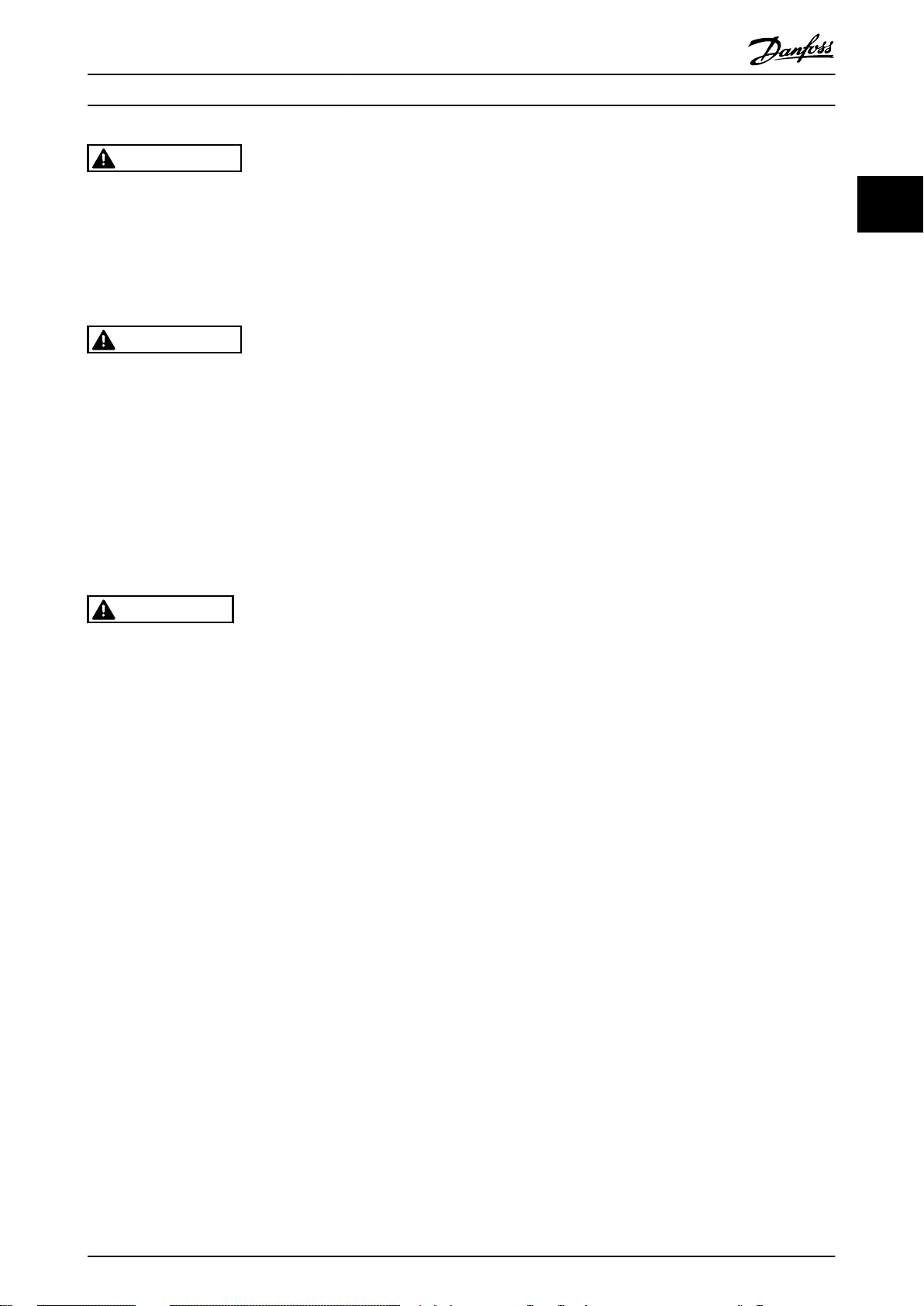

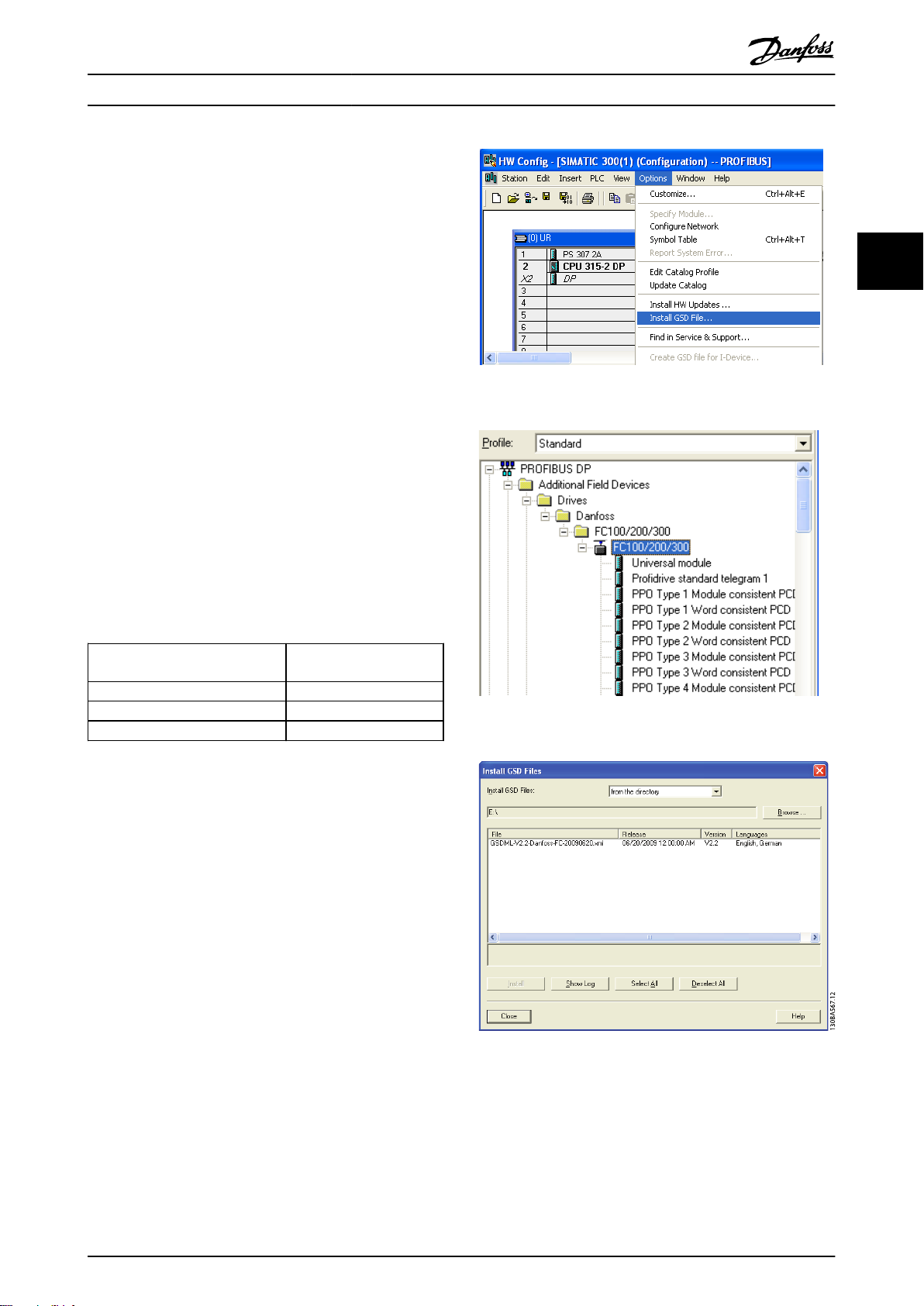

Illustration 3.3 Install GSD File

PROFIBUS SW version

(15-61 Option SW Version)

1.x da01040A.GSD

2.x da02040A.GSD

FCD 302 da01040B.GSD

Table 3.2 GSD File

The example below show the procedure of configuring a

PROFIBUS Master for FC 301/302, but the procedure is also

valid for the FCD 302.

1. Import the GSD file in the configuration tool.

2. Import the GSD file to the Simatic Manager

software tool. Import a GSD file once only for

each frequency converter series, following the

initial installation of the software tool. See

Illustration 3.3.

3. Use the browser for the GSD file, install all files,

and import both a GSD file and a bitmap for the

device into the hardware catalogue. See

Illustration 3.4 and Illustration 3.5.

GSD file

Illustration 3.4 Import a GSD File and a Bitmap

Illustration 3.5 Add a new GSD File

4. Import and access the FC 301/302 GSD file via

the path in the hardware catalogue, see

Illustration 3.6.

MG37G102 Danfoss A/S © Rev. 05/2014 All rights reserved. 9

Page 12

130BA564.11

130BC912.11

130BC911.11

Configuration

Programming Guide

33

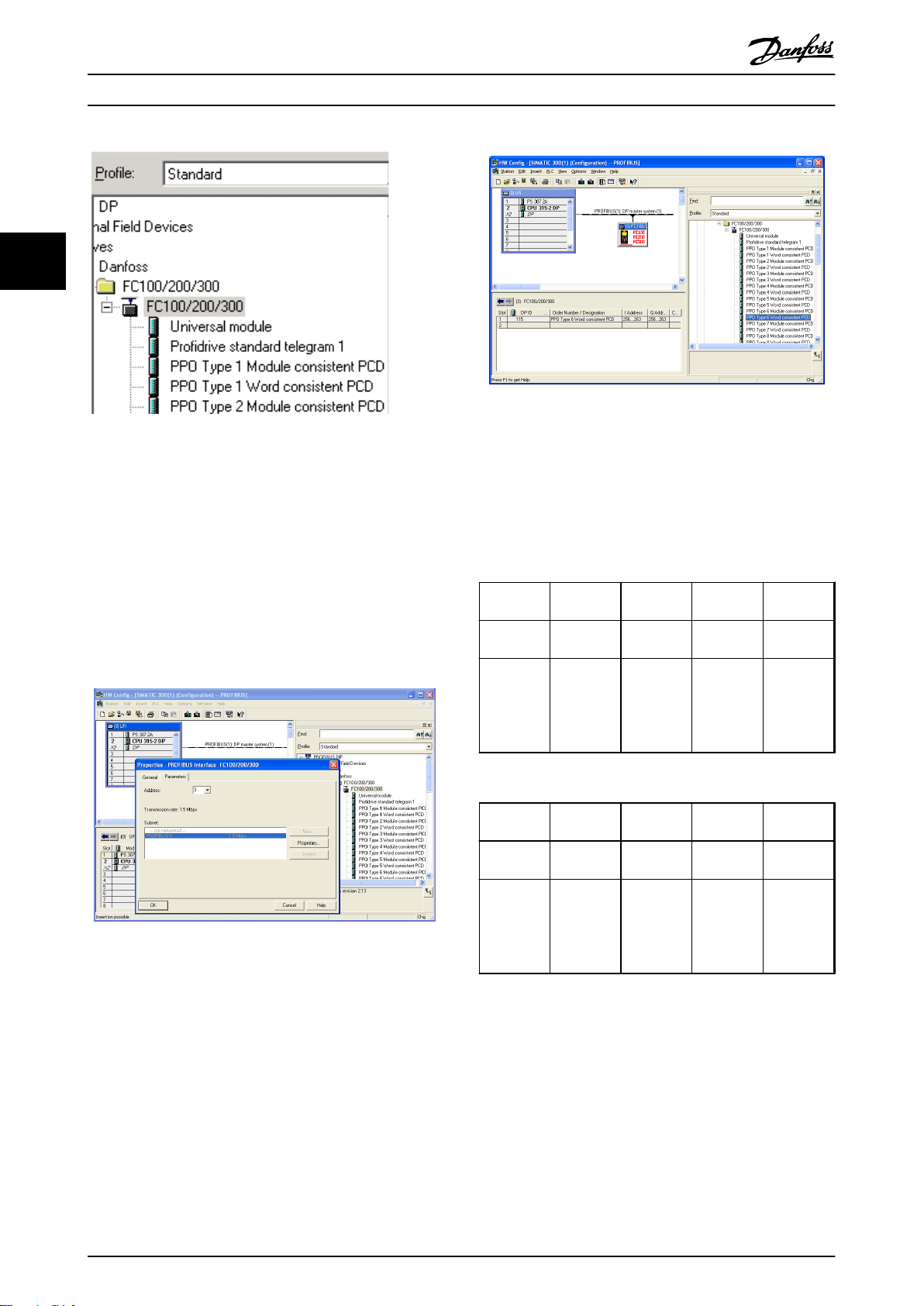

Illustration 3.8 Drag and Drop PPO Type 6 Word Consistent to

Illustration 3.6 Import and Access the GSD file via the Path in

the Hardware Catalogue

5. Open a project, set up the hardware and add a

PROFIBUS master system.

6. Select FC 300, then drag and drop it onto the

PROFIBUS in the hardware diagram.

7. A window for the address of the FC 300 appears.

Select the address from the scroll-down list.

Ensure that the address setting matches the

previous address setting in 9-18 Node Address. See

Illustration 3.7.

the first slot

The configuration tool automatically assigns addresses in

the peripheral address area. In this example, the input and

output area have the following configurations:

PPO type 6

PCD word

number

Input

address

Set-up STW MAV

1 2 3 4

256-257 258-259 260-261 262-263

parameter 9

-16 PCD

Read

Configu-

ration.2

parameter 9

-16 PCD

Read

Configu-

ration.3

Illustration 3.7 Select the Address

8. Set up the peripheral input and output data. Data

set up in the peripheral area is transmitted

cyclically via PPO types. Drag and drop a PPO

type 6 word consistent to the first slot, see

Illustration 3.8. See the PPO types in

chapter 4 Control for more information.

Table 3.3 PCD read (VLT to PLC)

PCD word

number

Output

address

Set-up CTW MRV

Table 3.4 PCD write (PLC to VLT)

1 2 3 4

256-257 258-259 260-261 262-263

parameter 9

-15 PCD

Write

Configu-

ration.2

parameter 9

-15 PCD

Write

Configu-

ration.3

Alternative: For PROFIBUS SW version 2.x and higher, Autoconfiguration of process data is supported. This feature

makes it possible to configure the process data

(parameter 9-15 PCD Write Configuration and

parameter 9-16 PCD Read Configuration) from the PLC/

Master. To use Auto-configuration, make sure to enable the

feature under DP follower Properties. See Illustration 3.9.

10 Danfoss A/S © Rev. 05/2014 All rights reserved. MG37G102

Page 13

130BT322.11

Configuration

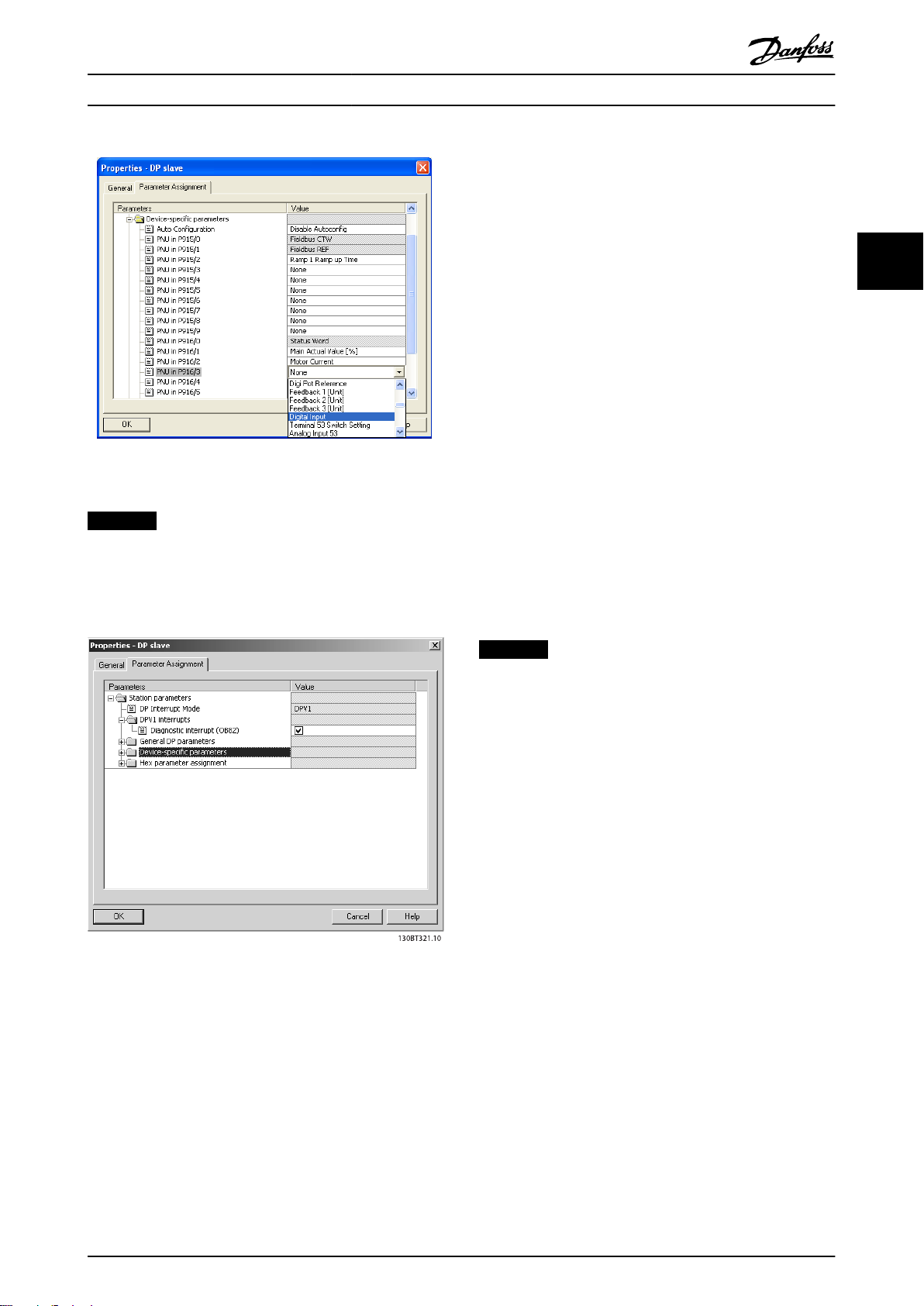

Illustration 3.9 Enable Feature under DP Follower Properties

Programming Guide

NOTICE

DP V1 diagnosis is supported for PROFIBUS SW version

2.x and higher. The default setting of the PROFIBUS

option is DP V1 diagnosis. If DP V0 diagnosis is required,

change the setting under DP follower Properties.

0-40 [Hand on] Key on LCP. Pressing [Hand on]

•

disables control of the frequency converter via

PROFIBUS.

Parameter 8-02 Control Word Source. After an

•

initial power-up, the frequency converter

automatically detects whether a fieldbus option is

installed in slot A, and sets parameter 8-02 Control

Word Source to [Option A]. If an option is added

or changed in or removed from an already

commissioned frequency converter, it does not

change parameter 8-02 Control Word Source, but

enters Trip mode, and the frequency converter

displays an error.

Parameter 8-10 Control Word Profile. Select

•

between the Danfoss FC Profile and the

PROFIdrive profile.

8-50 Coasting Select to 8-56 Preset Reference Select.

•

Select how to gate PROFIBUS control commands

with digital input command of the control card.

Parameter 8-03 Control Word Timeout Time to

•

8-05 End-of-Timeout Function. Set the reaction in

the event of a bus time-out via these parameters.

9-18 Node Address.

•

Parameter 8-07 Diagnosis Trigger.

•

NOTICE

When 8-01 Control Site is set to , the settings in

8-50 Coasting Select to 8-56 Preset Reference Select are

overruled, and all act on Bus-control.

3 3

Illustration 3.10 DP V1 Diagnosis

Download the configuration file to the PLC. The PROFIBUS

system is able to go online, and it starts to exchange data

when the PLC is set to Run mode.

3.3

Configure the Frequency Converter

3.3.1 Frequency Converter Parameters

The following parameters are important when configuring

the frequency converter with a PROFIBUS interface:

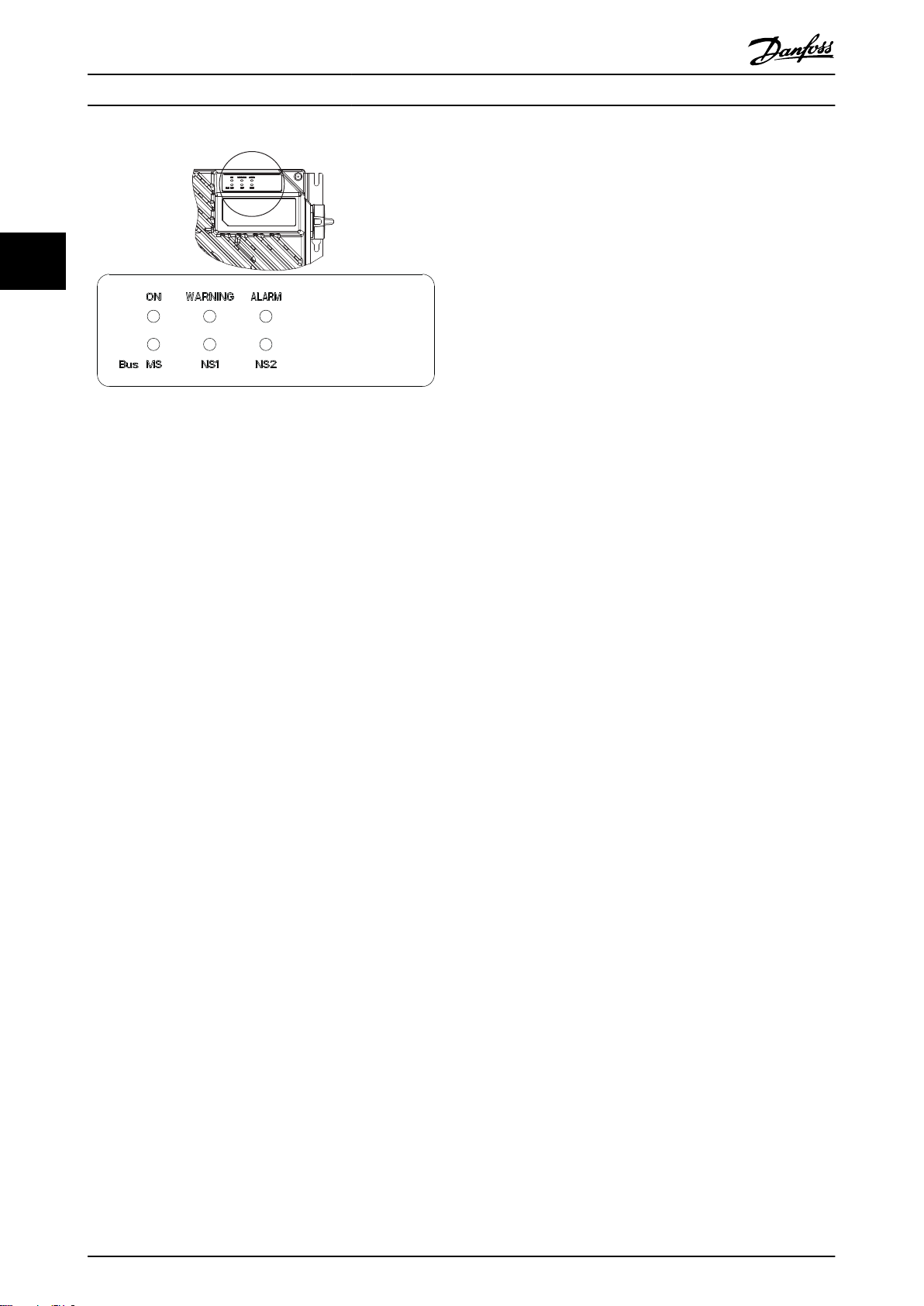

3.3.2 LEDs

The 2 bi-colour LEDs in the PROFIBUS card indicate the

status of PROFIBUS communication.

The LED marked NS (FCD 302: NS2) indicates the network

status, that is, the cyclical communication to the PROFIBUS

master. When this light is constant green, data exchange

between the master and the frequency converter is active.

The LED marked MS (FCD 302: BUS MS) indicates the

module status, that is, acyclical DP V1 communication from

either a PROFIBUS master class 1 (PLC) or a master class 2

(MCT 10, FDT tool). When this light is constant green, DP

V1 communication from master classes 1 and 2 is active.

For details of the full range of communications status

indicated by the LEDs, refer to chapter 8 Troubleshooting.

MG37G102 Danfoss A/S © Rev. 05/2014 All rights reserved. 11

Page 14

A

130BC259.10

Configuration Programming Guide

33

Illustration 3.11 FCD 302 LED Panel

12 Danfoss A/S © Rev. 05/2014 All rights reserved. MG37G102

Page 15

Control Programming Guide

4 Control

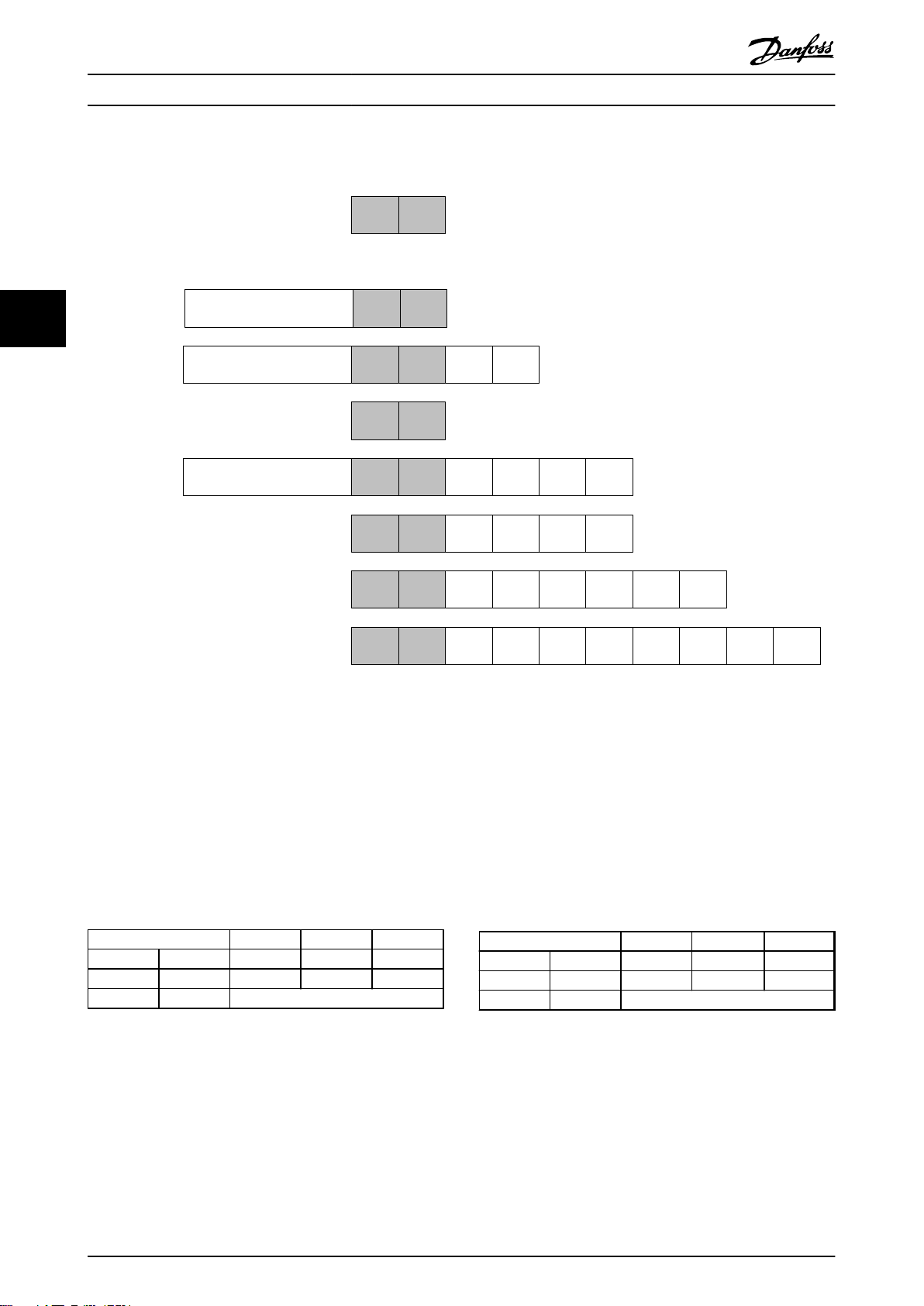

4.1 PPO Types

The PROFIBUS profile for frequency converters specifies a

number of communication objects (Parameter process data

objects, PPO). The PROFIBUS profile for frequency

converters is suitable for data exchange between a process

controller (for example PLC) and a frequency converter. All

PPOs are defined for cyclic data transfer (that is, DP V0), so

that process data (PCD) and parameters (PCA) can be

transferred from the master to the follower and vice versa.

Pure process data objects

PPO types 3, 4, 6, 7 and 8 are pure process data objects

for applications requiring no cyclic parameter access. The

PLC sends out process control data, and the frequency

converter then responds with a PPO of the same length,

containing process status data.

Illustration 4.1 shows the available PPO types:

PCD 1: The first 2 bytes of the process data area

•

(PCD 1) comprise a fixed part present in all PPO

types.

PCD 2: The next 2 bytes (PCD 2) are fixed for PCD

•

write entries (see parameter 9-15 PCD Write

Configuration [1]), but configurable for PCD read

entries (see parameter 9-16 PCD Read Configuration [1]).

PCD 3-10: In the remaining bytes, from PCD 3

•

and on, the process data can be parameterised

with process signals, see

parameter 9-23 Parameters for Signals.

The signals for transmission from the master to the

frequency converter are determined by the setting in

parameter 9-15 PCD Write Configuration (request from

master to the frequency converter).

The signals for transmission from the frequency converter

to the master (response from the frequency converter to

master) are determined by the setting in

parameter 9-16 PCD Read Configuration .

Parameter channel and process data

PPO types 1, 2 and 5 consist of a parameter channel and

process data. Use the parameter channel for reading

and/or updating of parameters (successively). Alternatively,

for better utilisation of I/O and thus PLC capacity, access

parameters via DP V1, by selecting a pure process data

object (PPO type 3, 4, 6, 7 or 8).

Select the PPO type in the master configuration. The

selection is automatically recorded in the frequency

converter. No manual setting of PPO types in the

frequency converter is required. Read the current PPO type

in 9-22 Telegram Selection. The setting [1] Standard telegram

1 is equivalent to PPO type 3.

In addition, all PPO types can be set up as word-consistent

or module-consistent. The process data area can be word

or module consistent, whereas the parameter channel

must always be module consistent.

Word-consistent data is transmitted as individual

•

independent words between the PLC and the

frequency converter.

Module-consistent data is transmitted as sets of

•

interrelated words transferred simultaneously

between the PLC and the frequency converter.

4 4

MG37G102 Danfoss A/S © Rev. 05/2014 All rights reserved. 13

Page 16

CTW/STW

REF/MAV

PCD 2

Read/

Write

PCD 3

Read/

Write

Standard telegram

1

PCD 4

Read/

Write

PCD 5

Read/

Write

PPO 4

PPO 6

PPO 7

PPO 8

Danfoss telegram

(The old PPO type 3)

PCV

CTW/STW REF/MAV

PCD 2

Read/

Write

PCD 3

Read/

Write

PCD 4

Read/

Write

PCD 5

Read/

Write

CTW/STW

REF/MAV

PCD 2

Read/

Write

PCD 3

Read/

Write

PCD 4

Read/

Write

PCD 5

Read/

Write

PCD 6

Read/

Write

PCD 7

Read/

Write

PCD 8

Read/

Write

PCD 9

Read/

Write

CTW/STW REF/MAV

PCD 2

Read/

Write

PCD 3

Read/

Write

PCD 4

Read/

Write

PCD 5

Read/

Write

PCD 6

Read/

Write

PCD 7

Read/

Write

CTW/STW REF/MAV

CTW/STW REF/MAV

PPO 3

CTW/STW REF/MAV

PCD 2

Read/

Write

PCD 3

Read/

Write

PPO 2

PCV

CTW/STW

REF/MAV

PPO 1

PCV

130BD911.10

Control Programming Guide

44

Illustration 4.1 Available PPO Types

4.2

Process Data

Use the process data part of the PPO to control and

monitor the frequency converter via the PROFIBUS.

4.2.1 Process Control Data

Process control data (PCD) is the process data sent from

the PLC to the frequency converter.

Master/follower

1 2 3 ....... 10

CTW MRV PCD ....... PCD

PCD write

Table 4.1 Process Control Data

PCD 1 contains a 16-bit control word, and each bit controls

a specific function of the frequency converter, see

chapter 4.3 Control Profile.

PCD 2 contains a 16-bit speed setpoint in percentage

format. See chapter 4.2.3 Reference Handling.

The content of PCD 3 to PCD 10 is determined by the

settings in parameter 9-15 PCD Write Configuration and

parameter 9-16 PCD Read Configuration.

4.2.2 Process Status Data

Process status data is the process data sent from the

frequency converter, and contains information about the

current state.

Follower master

1 2 3 ...... 10

STW MAV PCD ...... PCD

PCD read

Table 4.2 Process Status Data

PCD 1 contains a 16-bit status word, and each bit contains

information regarding a possible state of the frequency

converter.

PCD 2 contains per default the value of the current speed

of the frequency converter in percentage format (see

chapter 4.2.3 Reference Handling). PCD 2 can be configured

to contain other process signals.

14 Danfoss A/S © Rev. 05/2014 All rights reserved. MG37G102

Page 17

Control

Programming Guide

The content of PCD 3 to PCD 10 is determined by the

settings in parameter 9-16 PCD Read Configuration.

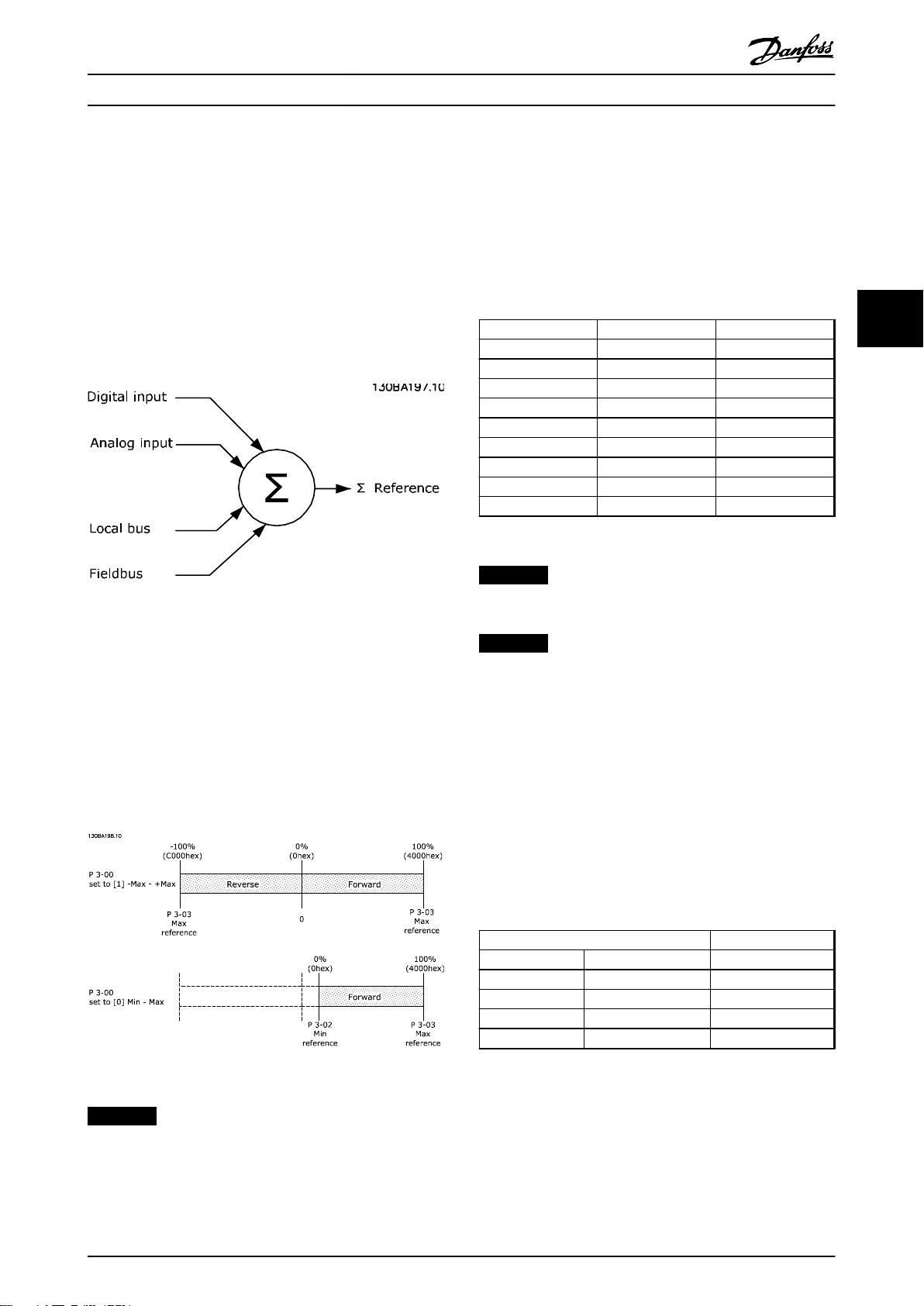

4.2.3 Reference Handling

The reference handling is an advanced mechanism that

sums up references from different sources, as shown in

Illustration 4.2.

For more information on reference handling, refer to the

Design Guide of the relevant frequency converter.

Illustration 4.2 Reference

The actual output of the frequency converter is limited by

the speed limit parameters Motor Low/High Speed Limit

[RPM/Hz] in 4-11 Motor Speed Low Limit [RPM] to 4-14 Motor

Speed High Limit [Hz].

The final speed limit is set in 4-19 Max Output Frequency.

Table 4.3 lists the reference (MRV) and the feedback (MAV)

formats.

MRV/MAV Integer in hex Integer in decimal

100% 4000 16,384

75% 3000 12,288

50% 2000 8,192

25% 1000 4,096

0% 0 0

-25% F000 -4,096

-50% E000 -8,192

-75% D000 -12,288

-100% C000 -16,384

Table 4.3 Reference/Feedback (MRV/MAV) Format

NOTICE

Negative numbers are formed as complement of 2.

4 4

The reference, or speed setpoint, is sent via PROFIBUS and

is always transmitted to the frequency converter in

percentage format as integers represented in hexadecimal

(0-4000 hex).

The reference (MRV) and feedback (MAV) are always scaled

equally. The setting of 3-00 Reference Range determines the

scaling of the reference and feedback (MAV), see

Illustration 4.3.

Illustration 4.3 Reference (MRV) and Feedback (MAV), Scaled

NOTICE

The data type for MRV and MAV is a N2 16-bit

standardised value, expressing a range from -200% to

+200% (8001 to 7FFF).

Example

The following settings determine the speed, as shown in

Table 4.4:

1-00 Configuration Mode set to [0] Speed open

•

loop.

3-00 Reference Range set to [0] Min-Max.

•

3-02 Minimum Reference set to 100 RPM.

•

3-03 Maximum Reference set to 3000 RPM.

•

MRV/MAV Actual speed [RPM]

0% 0 hex 100

25% 1000 hex 825

50% 2000 hex 1550

75% 3000 hex 2275

100% 4000 hex 3000

Table 4.4 Actual Speed for MRV/MAV

4.2.4

NOTICE

When 3-00 Reference Range is set to [0] Min - Max, a

negative reference is handled as 0%.

MG37G102 Danfoss A/S © Rev. 05/2014 All rights reserved. 15

Process Control Operation

In process control operation, 1-00 Configuration Mode is set

to [3] Process.

The reference range in 3-00 Reference Range is always [0]

Min - Max.

Page 18

Control

•

•

Programming Guide

MRV represents the process setpoint.

MAV expresses the actual process feedback

(range ±200%).

4.4

PROFIdrive Control Profile

This section describes the functionality of the control word

and status word in the PROFIdrive profile.

4.2.5 Influence of the Digital Input

Terminals upon FC Control Mode

Set the influence of the digital input terminals upon

44

control of the frequency converter in 8-50 Coasting Select

to 8-56 Preset Reference Select.

NOTICE

The setting of 8-01 Control Site overrules the settings in

8-50 Coasting Select to 8-56 Preset Reference Select. The

setting of terminal 37 Coast stop (safe) overrules any

other parameter.

Each of the digital input signals can be programmed to

logic AND, logic OR, or to have no relation to the

corresponding bit in the control word. In this way the

following signal sources initiate a specific control

command, for example stop/coast:

fieldbus only,

•

fieldbus AND digital input, or

•

either fieldbus OR digital input terminal.

•

CAUTION

To control the frequency converter via PROFIBUS, set

8-50 Coasting Select to either [1] Bus , or to [2] Logic AND,

and set 8-01 Control Site to [0] or [2].

For more detailed information and examples of logical

relationship options, see chapter 8 Troubleshooting.

4.3

Control Profile

Control the frequency converter according to

the PROFIdrive profile, see chapter 4.4 PROFIdrive

•

Control Profile, or

the Danfoss FC control profile, see

•

chapter 4.5 Danfoss FC Control Profile.

Select the desired control profile in parameter 8-10 Control

Word Profile. The choice of profile affects the control and

status word only.

Chapter 4.4 PROFIdrive Control Profile and

chapter 4.5 Danfoss FC Control Profile provide a detailed

description of control and status data.

4.4.1 Control Word according to PROFIdrive

Profile (CTW)

The control word is used to send commands from a master

(e.g. a PC) to a follower.

Bit Bit=0 Bit=1

00 OFF 1 ON 1

01 OFF 2 ON 2

02 OFF 3 ON 3

03 Coasting No coasting

04 Quick stop Ramp

05 Hold frequency output Use ramp

06 Ramp stop Start

07 No function Reset

08 Jog 1 OFF Jog 1 ON

09 Jog 2 OFF Jog 2 ON

10 Data invalid Data valid

11 No function Slow down

12 No function Catch up

13 Parameter set-up Selection lsb

14 Parameter set-up Selection msb

15 No function Reverse

Table 4.5 Control Word Bits

Explanation of the control bits

Bit 00, OFF 1/ON 1

Normal ramp stops using the ramp times of the actual

selected ramp.

Bit 00="0" leads to the stop and activation of the output

relay 1 or 2 if the output frequency is 0 Hz and if [Relay

123] has been selected in 5-40 Function Relay.

When bit 0="1", the frequency converter is in State 1:

“Switching on inhibited”.

Refer to Illustration 4.4.

Bit 01, OFF 2/ON 2

Coasting stop.

When bit 01="0", a coasting stop and activation of the

output relay 1 or 2 occurs if the output frequency is 0 Hz

and if [Relay 123] has been selected in 5-40 Function Relay.

When bit 01="1", the frequency converter is in State 1:

“Switching on inhibited”. Refer to Illustration 4.4.

Bit 02, OFF 3/ON 3

Quick stop using the ramp time of 3-81 Quick Stop Ramp

Time.

When bit 02="0", a quick stop and activation of the output

relay 1 or 2 occurs if the output frequency is 0 Hz and if

[Relay 123] has been selected in 5-40 Function Relay.

When bit 02="1", the frequency converter is in State 1:

“Switching on inhibited”.

16 Danfoss A/S © Rev. 05/2014 All rights reserved. MG37G102

Page 19

Control Programming Guide

Refer to Illustration 4.4.

Bit 03, Coasting/No coasting

Coasting stop Bit 03="0" leads to a stop.

When bit 03="1", the frequency converter can start if the

other start conditions are fulfilled.

NOTICE

The selection in 8-50 Coasting Select determines how bit

03 is linked with the corresponding function of the

digital inputs.

Bit 04, Quick stop/Ramp

Quick stop using the ramp time of 3-81 Quick Stop Ramp

Time.

When bit 04="0", a quick stop occurs.

When bit 04="1", the frequency converter can start if the

other start conditions are fulfilled.

NOTICE

The selection in parameter 8-51 Quick Stop Select

determines how bit 04 is linked with the corresponding

function of the digital inputs.

Bit 05, Hold frequency output/Use ramp

When bit 05="0", the current output frequency is being

maintained even if the reference value is modified.

When bit 05="1", the frequency converter can perform its

regulating function again; operation occurs according to

the respective reference value.

Bit 06, Ramp stop/Start

Normal ramp stop using the ramp times of the actual

ramp as selected. In addition, activation of the output relay

01 or 04 if the output frequency is 0 Hz if Relay 123 has

been selected in 5-40 Function Relay. Bit 06="0" leads to a

stop. When bit 06="1", the frequency converter can start if

the other start conditions are fulfilled.

NOTICE

The selection in 8-53 Start Select determines how bit 06

is linked with the corresponding function of the digital

inputs.

Bit 07, No function/Reset

Reset after switching off. Acknowledges event in fault

buffer.

When bit 07="0", no reset occurs.

When there is a slope change of bit 07 to "1", a reset

occurs after switching off.

Bit 08, Jog 1 OFF/ON

Activation of the pre-programmed speed in 8-90 Bus Jog 1

Speed. JOG 1 is only possible if bit 04="0" and bit

00-03="1".

Bit 09, Jog 2 OFF/ON

Activation of the pre-programmed speed in 8-91 Bus Jog 2

Speed. JOG 2 is only possible if bit 04="0" and bit

00-03="1".

Bit 10, Data invalid/valid

Used to tell the frequency converter whether the control

word is to be used or ignored. Bit 10=“0” causes the

control word to be ignored, giving the opportunity to turn

off the control word when updating/reading parameters.

Bit 10=“1” causes the control word to be used. This

function is relevant, because the control word is always

contained in the telegram, regardless of which type of

telegram is used.

Bit 11, No function/Slow down

Used to reduce the speed reference value by the amount

given in 3-12 Catch up/slow Down Value value.

When bit 11="0", no modification of the reference value

occurs.

When bit 11="1", the reference value is reduced.

Bit 12, No function/Catch up

Used to increase the speed reference value by the amount

given in 3-12 Catch up/slow Down Value.

When bit 12="0", no modification of the reference value

occurs.

When bit 12="1", the reference value is increased.

If both slowing down and accelerating are activated (bit 11

and 12="1"), slowing down has priority, and the speed

reference value is reduced.

Bits 13/14, Set-up selection

Bits 13 and 14 are used to select between the 4 parameter

set-ups according to Table 4.6.

The function is only possible if Multi Set-up has been

selected in 0-10 Active Set-up. The selection in 8-55 Set-up

Select determines how bits 13 and 14 are linked with the

corresponding function of the digital inputs. Changing setup while running is only possible if the set-ups have been

linked in 0-12 This Set-up Linked to.

Set-up Bit 13 Bit 14

1 0 0

2 1 0

3 0 1

4 1 1

Table 4.6 Parameter Set-ups

Bit 15, No function/Reverse

Bit 15=“0” causes no reversing.

Bit 15=“1” causes reversing.

NOTICE

In the factory setting, reversing is set to digital in

parameter 8-54 Reversing Select.

NOTICE

Bit 15 causes reversing only when Ser. communication,

Logic or or Logic and is selected.

4 4

MG37G102 Danfoss A/S © Rev. 05/2014 All rights reserved. 17

Page 20

Control

Programming Guide

4.4.2 Status Word according to PROFIdrive

Profile (STW)

When bit 02 of the control word is "1", bit 05="1".

Bit 06, Start possible/Start not possible

If PROFIdrive has been selected in parameter 8-10 Control

The status word is used to notify a master (e.g. a PC)

about the status of a follower.

Word Profile, bit 06 is "1" after a switch-off acknowledgment, after activation of OFF2 or OFF3, and after

switching on the mains voltage. Start not possible is reset,

Bit Bit=0 Bit=1

00 Control not ready Control ready

44

01 Drive not ready Drive ready

02 Coasting Enable

03 No error Trip

04 OFF 2 ON 2

05 OFF 3 ON 3

06 Start possible Start not possible

07 No warning Warning

08

09 Local operation Bus control

10 Out of frequency limit Frequency limit ok

11 No operation In operation

12 Drive OK Stopped, autostart

13 Voltage OK Voltage exceeded

14 Torque OK Torque exceeded

15 Timer OK Timer exceeded

Table 4.7 Status Word Bits

Speed ≠ reference

Speed = reference

with bit 00 of the control word being set to "0" and bit 01,

02 and 10 being set to "1".

Bit 07, No warning/Warning

Bit 07=“0” means that there are no warnings.

Bit 07=“1” means that a warning has occurred.

Bit 08, Speed≠reference/Speed=reference

When bit 08="0", the current speed of the motor deviates

from the set speed reference value. This may occur, for

example, when the speed is being changed during start/

stop through ramp up/down.

When bit 08="1", the current speed of the motor

corresponds to the set speed reference value.

Bit 09, Local operation/Bus control

Bit 09="0" indicates that the frequency converter has been

stopped with [Stop] on the LCP, or that [Linked to hand]

or [Local] has been selected in 3-13 Reference Site.

When bit 09="1", the frequency converter can be

controlled through the serial interface.

Bit 10, Out of frequency limit/Frequency limit OK

Explanation of the status bits

Bit 00, Control not ready/Ready

When bit 00="0", bit 00, 01 or 02 of the control word is "0"

(OFF 1, OFF 2 or OFF 3) - or the frequency converter is

switched off (trip).

When bit 00="1", the frequency converter control is ready,

but there is not necessarily power supply to the unit

present (in the event of external 24 V supply of the control

system).

Bit 01, VLT not ready/Ready

Same significance as bit 00, however, there is a supply of

the power unit. The frequency converter is ready when it

receives the necessary start signals.

Bit 02, Coasting/Enable

When bit 02="0", bit 00, 01 or 02 of the control word is "0"

(OFF 1, OFF 2 or OFF 3 or coasting) - or the frequency

converter is switched off (trip).

When bit 02="1", bit 00, 01 or 02 of the control word is

"1"; the frequency converter has not tripped.

Bit 03, No error/Trip

When bit 03="0", no error condition of the frequency

converter exists.

When bit 03="1", the frequency converter has tripped and

requires a reset signal before it can start.

Bit 04, ON 2/OFF 2

When bit 01 of the control word is "0", bit 04="0".

When bit 01 of the control word is "1", bit 04="1".

Bit 05, ON 3/OFF 3

When bit 10="0", the output frequency is outside the limits

set in 4-52 Warning Speed Low and 4-53 Warning Speed

High.

When bit 10="1", the output frequency is within the

indicated limits.

Bit 11, No operation/Operation

When bit 11="0", the motor does not turn.

When bit 11="1", the frequency converter has a start

signal, or the output frequency is higher than 0 Hz.

Bit 12, Drive OK/Stopped, autostart

When bit 12="0", there is no temporary overloading of the

inverter.

When bit 12="1", the frequency converter has stopped due

to overloading. However, the frequency converter has not

switched off (trip) and starts again after the overloading

has ended.

Bit 13, Voltage OK/Voltage exceeded

When bit 13="0", the voltage limits of the frequency

converter are not exceeded.

When bit 13="1", the direct voltage in the intermediate

circuit of the frequency converter is too low or too high.

Bit 14, Torque OK/Torque exceeded

When bit 14="0", the motor torque is below the limit

selected in 4-16 Torque Limit Motor Mode and 4-17 Torque

Limit Generator Mode.

When bit 14="1", the limit selected in 4-16 Torque Limit

Motor Mode or 4-17 Torque Limit Generator Mode is

exceeded.

When bit 02 of the control word is "0", bit 05="0".

18 Danfoss A/S © Rev. 05/2014 All rights reserved. MG37G102

Page 21

130BD806.10

Control Programming Guide

Bit 15, Timer OK/Timer exceeded

When bit 15="0", the timers for the thermal motor

protection and thermal frequency converter protection

have not exceeded 100%.

When bit 15="1", one of the timers has exceeded 100%.

4.4.3 PROFIdrive State Transition Diagram

In the PROFIdrive control profile, the control bits:

0 to 3 perform the basic start-up/power down functions.

•

4-15 perform application-oriented control.

•

Illustration 4.4 shows the basic state transition diagram, where control bits 0 to 3 control the transitions, and the

corresponding status bit indicates the actual state. The black bullets indicate the priority of the control signals, where fewer

bullets indicate lower priority, and more bullets indicate higher priority.

4 4

Illustration 4.4 PROFIdrive State Transition Diagram

MG37G102 Danfoss A/S © Rev. 05/2014 All rights reserved. 19

Page 22

Control

Programming Guide

4.5 Danfoss FC Control Profile

4.5.1 Control Word according to FC Profile

(CTW)

To select Danfoss FC protocol in the control word, set

parameter 8-10 Control Word Profile to [0] frequency

converter profile. Use the control word to send commands

from a master (PLC or PC) to a follower (frequency

44

converter).

Bit Bit value=0 Bit value=1

00 Reference value External selection lsb

01 Reference value External selection msb

02 DC brake Ramp

03 Coasting No coasting

04 Quick stop Ramp

05 Hold output frequency Use ramp

06 Ramp stop Start

07 No function Reset

08 No function Jog

09 Ramp 1 Ramp 2

10 Data invalid Data valid

11 No function Relay 01 active

12 No function Relay 04 active

13 Parameter set-up selection lsb

14 Parameter set-up selection msb

15 No function Reverse

Table 4.8 Bit Values for FC Control Word

Explanation of the control bits

Bits 00/01 Reference value

Bits 00 and 01 are used to select between the 4 reference

values, which are pre-programmed in 3-10 Preset Reference

according to Table 4.9.

NOTICE

In 8-56 Preset Reference Select a selection is made to

define how bit 00/01 gates with the corresponding

function on the digital inputs.

Bit 01 Bit 00 Programmed

ref. value

0 0 1

0 1 2

1 0 3

1 1 4

Table 4.9 Programmed Reference Values for Bits

Bit 02, DC brake

Bit 02=“0” - leads to DC braking and stop. Braking current

and duration are set in 2-01 DC Brake Current and 2-02 DC

Braking Time.

Bit 02=“1” - leads to ramping.

Parameter

[0] 3-10 Preset Reference

[1] 3-10 Preset Reference

[2] 3-10 Preset Reference

[3] 3-10 Preset Reference

Bit 03, Coasting

Bit 03=“0” - causes the frequency converter immediately to

coast the motor to a standstill.

Bit 03=“1” - enables the frequency converter to start the

motor if the other starting conditions have been fulfilled.

NOTICE

In 8-50 Coasting Select a selection is made to define how

bit 03 gates with the corresponding function on a digital

input.

Bit 04, Quick stop

Bit 04=“0” - causes a quick stop, ramping the motor speed

down to stop via 3-81 Quick Stop Ramp Time.

Bit 04=“1” - the frequency converter ramps the motor

speed down to stop via 3-42 Ramp 1 Ramp Down Time or

3-52 Ramp 2 Ramp Down Time.

Bit 05, Hold output frequency

Bit 05=“0” - causes the present output frequency (in Hz) to

freeze. The frozen output frequency can only be changed

with the digital inputs (5-10 Terminal 18 Digital Input to

5-15 Terminal 33 Digital Input) programmed to Speed up

and Speed down.

Bit 05=“1” - use ramp.

NOTICE

If Freeze output is active, stop the frequency converter

with

Bit 03 Coasting stop.

•

Bit 02 DC braking.

•

Digital input (5-10 Terminal 18 Digital Input to

•

5-15 Terminal 33 Digital Input) programmed to

DC braking, Coasting stop, or Reset and coasting

stop.

Bit 06, Ramp stop/start

Bit 06=“0” - causes a stop in which the motor speed is

ramped down to stop via the selected ramp down

parameter.

Bit 06=“1" - permits the frequency converter to start the

motor, if the other starting conditions have been fulfilled.

NOTICE

In 8-53 Start Select a selection is made to define how bit

06 Ramp stop/start gates with the corresponding

function on a digital input.

Bit 07, Reset

Bit 07="0" - does not cause a reset.

Bit 07="1" - causes the reset of a trip. Reset is activated on

the signal’s leading edge, that is, when changing from

logic "0" to logic "1".

Bit 08, Jog

Bit 08="0" - no function.

20 Danfoss A/S © Rev. 05/2014 All rights reserved. MG37G102

Page 23

Control

Programming Guide

Bit 08="1" - 3-19 Jog Speed [RPM] determines the output

frequency.

Bit 09, Selection of ramp 1/2

Bit 09="0" - ramp 1 is active (3-40 Ramp 1 Type to

3-47 Ramp 1 S-ramp Ratio at Decel. Start).

Bit 09="1" - ramp 2 (3-50 Ramp 2 Type to 3-57 Ramp 2 Sramp Ratio at Decel. Start) is active.

Bit 10, Data not valid/Data valid

Tells the frequency converter whether it should use or

ignore the control word.

Bit 10="0" - the control word is ignored.

Bit 10="1" - the control word is used. This function is

relevant, because the control word is always contained in

the telegram, regardless of which type of telegram is used.

Thus, it is possible to turn off the control word, if it is not

wished to use it when updating or reading parameters.

Bit 11, Relay 01

Bit 11="0" - relay 01 not activated.

Bit 11="1" - relay 01 activated, provided control word bit

11 has been selected in 5-40 Function Relay.

Bit 12, Relay 04

Bit 12="0" - relay 04 has not been activated.

Bit 12="1" - relay 04 has been activated, provided Control

word bit 12 has been selected in 5-40 Function Relay.

Bit 13/14, Selection of set-up

Bits 13 and 14 are used to select from the 4 menu set-ups

according to Table 4.10:

The function is only possible when Multi-Set-ups is selected

in 0-10 Active Set-up.

Set-up Bit 14 Bit 13

1 0 0

2 0 1

3 1 0

4 1 1

Table 4.10 Selection of Set-up

NOTICE

In 8-55 Set-up Select a selection is made to define how

bit 13/14 gates with the corresponding function on the

digital inputs.

Bit 15 Reverse

Bit 15="0" - no reversing.

Bit 15="1" - reversing.

4.5.2

Status Word according to FC Profile

(STW)

The status word is used to inform the master (e.g. a PC) of

the operation mode of the slave (frequency converter).

Refer to

chapter 7 Application Examples for an example of a

status word telegram using PPO type 3.

Bit Bit=0 Bit=1

00 Control not ready Control ready

01 Frequency converter

not ready

02 Coasting Enable

03 No error Trip

04 No error Error (no trip)

05 Reserved 06 No error Triplock

07 No warning Warning

08 Speed reference Speed=reference

09 Local operation Bus control

10 Out of frequency limit Frequency limit ok

11 No operation In operation

12 Frequency converter OK Stopped, autostart

13 Voltage OK Voltage exceeded

14 Torque OK Torque exceeded

15 Timer OK Timer exceeded

Table 4.11 Definition of Status Bits

Frequency converter ready

Explanation of the status bits

Bit 00, Control not ready/ready

Bit 00="0" - the frequency converter has tripped.

Bit 00="1" - the frequency converter controls are ready, but

the power component is not necessarily receiving any

power supply (in case of 24 V external supply to controls).

Bit 01, frequency converter ready

Bit 01="0" - the frequency converter is not ready for

operation.

Bit 01="1" - the frequency converter is ready for operation,

but there is an active coasting command via the digital

inputs or via serial communication.

Bit 02, Coasting stop

Bit 02="0" - the frequency converter has released the

motor.

Bit 02="1" - the frequency converter can start the motor

when a start command is given.

Bit 03, No error/Trip

Bit 03="0" - the frequency converter is not in fault mode.

Bit 03="1" - the frequency converter is tripped, and that a

reset signal is required to re-establish operation.

Bit 04, No error/Error (no trip)

Bit 04="0" - the frequency converter is not in fault mode.

Bit 04=“1” - there is a frequency converter error but no

trip.

Bit 05, Not used

Bit 05 is not used in the status word.

Bit 06, No error/triplock

Bit 06="0" - the frequency converter is not in fault mode.

Bit 06=“1” - the frequency converter is tripped, and locked.

4 4

MG37G102 Danfoss A/S © Rev. 05/2014 All rights reserved. 21

Page 24

Control Programming Guide

Bit 07, No warning/Warning

Bit 07="0" - there are no warnings.

Bit 07="1" - a warning has occurred.

Bit 08, Speed reference/Speed = reference

Bit 08="0" - the motor is running, but the present speed is

different from the preset speed reference. It could, for

example, be the case while the speed is being ramped up/

down during start/stop.

44

Bit 08="1" - the present motor present speed matches the

preset speed reference.

Bit 09, Local operation/bus control

Bit 09="0" - [Stop/Reset] is pressed on the LCP, or that

Local control in 3-13 Reference Site is selected. It is not

possible to control the frequency converter via serial

communication.

Bit 09="1" - it is possible to control the frequency

converter via the fieldbus/serial communication.

Bit 10, Out of frequency limit

Bit 10="0" - the output frequency has reached the value in

4-11 Motor Speed Low Limit [RPM] or 4-13 Motor Speed High

Limit [RPM].

Bit 10="1" - the output frequency is within the defined

limits.

Bit 11, No operation/In operation

Bit 11="0" - the motor is not running.

Bit 11="1" - the frequency converter has a start signal or

the output frequency is higher than 0 Hz.

Bit 12, frequency converter OK/Stopped, auto start

Bit 12="0" - there is no temporary over-temperature on the

frequency converter.

Bit 12="1" - the frequency converter has stopped because

of over-temperature, but the frequency converter has not

tripped and resumes operation once the over-temperature

stops.

Bit 13, Voltage OK/Limit exceeded

Bit 13="0" - there are no voltage warnings.

Bit 13="1" - the DC voltage in the frequency converters

intermediate circuit is too low or too high.

Bit 14, Torque OK/Limit exceeded

Bit 14="0" - the motor current is lower than the torque

limit selected in 4-16 Torque Limit Motor Mode or

4-17 Torque Limit Generator Mode.

Bit 14="1" - the torque limits in 4-16 Torque Limit Motor

Mode and 4-17 Torque Limit Generator Mode have been

exceeded.

Bit 15, Timer OK/Limit exceeded

Bit 15="0" - the timers for motor thermal protection and

frequency converter thermal protection, have not

exceeded 100%.

Bit 15="1" - one of the timers has exceeded 100%.

SYNC/UNSYNC is used to synchronise control commands

and/or speed reference to all the connected frequency

converters.

FREEZE/UNFREEZE is used to freeze the status feedback in

the slaves to get synchronized feedback from all

connected slaves.

The synchronise and freeze commands affect only process

data (the PCD part of the PPO).

4.6.1 SYNC/UNSYNC

SYNC/UNSYNC can be used to obtain simultaneous

reactions in several slaves, for example synchronised start,

stop or speed change.

A SYNC command freezes the relevant control word and

speed reference. Incoming process data are stored but not

used until a new SYNC command or a UNSYNC command

is received.

An UNSYNC command stops the synchronisation

mechanism and enables normal DP data exchange.

FREEZE/UNFREEZE

4.6.2

FREEZE/UNFREEZE can be used for simultaneous reading of

process data, for example, output current, from several

slaves.

A FREEZE command freezes the actual values and upon

request the slave sends back the value that was present

when the FREEZE command was received.

Upon receipt of an UNFREEZE command the values once

again is continuously updated and the slave returns a

present value, for example, a value generated by

conditions at present time.

The values is updated when a new FREEZE or UNFREEZE

command is received.

4.6

Synchronise and Freeze

The control commands SYNC/UNSYNC and FREEZE/

UNFREEZE are broadcast functions.

22 Danfoss A/S © Rev. 05/2014 All rights reserved. MG37G102

Page 25

Parameter Access

5 Parameter Access

5.1 Parameter Access in General

Programming Guide

5.1.2

Read/Write in Double Word Format

In an automated system, frequency converter parameters

can be accessed either from the process controller (that is,

PLC), or from various kinds of HMI equipment. For

parameter access from controllers and HMI, observe the

following:

Parameters are located in 4 separate set-ups. Parameter

access in the frequency converter is performed via several

separated parameter channels. Use the separated channels

individually to access a certain parameter set-up. Select the

desired set-up in 0-11 Edit Set-up or 9-70 Edit Set-up.

Using the above mechanism it is possible to read or write

to and from parameters in a certain set-up from a master

class 1, for example a PLC. And it is also possible to

simultaneously access parameters in a different set-up

from a master class 2, for example a PC tool, without

interfering with the set-up selection for the programming

sources.

Parameters can be accessed via the following sites:

LCP

•

FC Protocol on RS485 or USB

•

Cyclical data access on DP-V0 (PCV Channel)

•

PROFIBUS Master Class 1

•

PROFIBUS Master Class 2 (3 connections possible)

•

Using the special request IDs 0X51 (read) and 0X52 (write),

it is possible to read and write to all parameters containing

numeric values in a general format of double word. The

value element must be right aligned and unused MSBs

filled with zeros.

Example: Read of a parameter of type U8 is transmitted as

00 00 00 xx, where xx is the value to be transmitted. The

data type signalled by the telegram is 43h (dword).

5.1.3 PROFIBUS DP-V1

Using the acyclic DP-V1 transmission, it is possible to read

and write parameter values, as well as to read a number of

descriptive attributes for each parameter. Access to

parameters via DP-V1 is described in chapter 5.2 DP-V1

Parameter Access.

PROFIBUS DP-V0/PCV Channel

5.1.4

Parameter access via the PCV channel is performed using

PROFIBUS DP-V0 cyclic data exchange, where the PCV

channel is part of the PPOs described in chapter 4.1 PPO

Types. Using the PCV channel, it is possible to read and

write parameter values, as well as read a number of

descriptive attributes for each parameter. The functionality

of the PCV channel is described in chapter 5.3 PCV

Parameter Access.

5 5

NOTICE

Although the parameter channels are separated, data

conflict can occur if write to parameters is made from an

HMI unit into a set-up which is actively in use by the

frequency converter or the process controller (e.g. a

PLC).

5.1.1 Data Store

Parameters write via the PCV channel (DP-V0) is stored in

RAM only. If data has to be stored in non-volatile memory,

the 9-71 Profibus Save Data Values can be used for storing

one or more set-ups.

Using DP-V1 access, store parameters either in RAM or

non-volatile memory by choice of a specific write-request

command. At any time, store non-stored data in nonvolatile memory by activating 9-71 Profibus Save Data

Values.

NOTICE

Object and data types common to both DP-V1 and PCV

parameter access are listed in chapter 5 Parameter Access.

5.2 DP-V1 Parameter Access

This section is useful for the developer with some

experience in:

PLC programs with PROFIBUS master class 1

•

functionality.

PC applications with PROFIBUS master class 2

•

functionality.

For more detailed instructions in use of the DP-V1

function, refer to the PROFIBUS master manual from the

PLC supplier.

MG37G102 Danfoss A/S © Rev. 05/2014 All rights reserved. 23

Page 26

Parameter Access

Programming Guide

5.2.1 PROFIBUS DP-V1 Introduction

5.2.5

Principle of Data Exchange by

PROFIBUS DP-V1

The PROFIBUS DP extension DP-V1 offers acyclical

communication in addition to the cyclical data communication of DP-V0. This feature is possible using a DP master

class 1 (for example, PLC), as well as a DP master class 2

(for example, PC Tool).

Cyclical communication means that data transfer takes

place continuously with a certain refresh rate. This is the

known DP-V0 function normally used for quick update of

I/O process data.

In a DP cycle, the master class 1 (MC1) first updates the

cyclical process data for all slaves in the system. The MC1

then sends one acyclical message to one slave. If a master

class 2 (MC2) is connected, the MC1 hands over the bus

rights to MC2, which is then permitted to send one

acyclical message to one slave. The token is then handed

back to the MC1, and a new DP cycle begins.

55

Acyclical communication takes the form of a once-off data

transfer event, mainly used for read/write from and to

parameters from process controllers, PC-based tools or

monitoring systems.

Features of a Master Class 1

5.2.2

Connection

Cyclical data exchange (DP-V0)

•

Acyclical read/write from and to parameters

•

A master class 1 is used as the process controller (either

PLC or PC-based), responsible for commands, speed

reference, status of the application, etc. The master class 1

acyclical connection can be used for general parameter

access in the slaves. However, the acyclical connection is

fixed, and cannot be changed during operation.

Features of a Master Class 2

5.2.3

Connection

Initiate/abort acyclical connection

•

Acyclical read/write from and to parameters

•

The master class 2 acyclical connection is typically used for

configuration or commissioning tools for easy access to

each parameter in any slave in the system. The acyclical

connection can be dynamically established (initiate) or

removed (abort) even when a master class 1 is active on

the network.

Illustration 5.1 DP Cycle

MC: Master class

•

C1...Cn: Cyclical data

•

AC1: Acyclical data master class 1

•

AC2: Acyclical data master class 2

•

PROFIBUS DP services are activated via specific service

access points (SAP). Table 5.2 shows the SAP specified for

acyclical communication.

Master

SAP

50 (32H) 49 (31H) Master Class 2: Initiate request

50 (32H) 0..48 (0..30H) Master Class 2: Abort, read, write, data

51 (33H) 50, 51 (32H,

51 (33H) 51 (33H) Master Class 2: Read, write

Table 5.2 Service Access Points (SAP)

5.2.6

Follower SAP Meaning

transfer

Master Class 2: Alarm

33H)

DP-V1 Features for Parameter Access

5.2.4

Services Overview

Master

Service

type

Master

Class 1

Master

Class 2

Table 5.1 Services Overview

24 Danfoss A/S © Rev. 05/2014 All rights reserved. MG37G102

Read Write Data

read

data

from

follower

write

data to

follower

yes yes yes - - -

yes yes yes yes yes -

transport

read and

write data

Initiate Abort Alarm

open a

connection

close a

connection

This section describes how to use DP-V1 for accessing VLT

parameters.

The standard PROFIBUS DP-V1 read and write services are

not sufficient for accessing the many parameters and

attributes in the frequency converter. For this reason, the

PROFIdrive parameter channel is defined. Using this

parameter read/write is performed by addressing a single

DP-V1 object in the frequency converter as shown in the

example, Table 5.3.

Page 27

Parameter Access

Programming Guide

For a detailed description of the DP-V1 command

handling, refer to the PROFIBUS DP-V1 Design Guide.

Example

Slot=0

Index=47

PROFIBUS

telegram

header

DU0DU1D

Table 5.3 General Structure for Telegram

Data unit PROFIBUSDP-V1

Command/

response

PROFIdrive V3.0 parameter

channel

D

Req./Res.

U

U

Header

2

3

Data

telegram

trailer

Use the DP-V1 command/response part for the standard

DP-V1 read/write on slot 0, index 47 data block.

Use the PROFIdrive V3 parameter channel to access

specific parameter data in the frequency converter.

DP-V1 Read/Write Services

5.2.7

Table 5.4 shows the content of the DP-V1 command/

Response headers and their possible attributes.

DU byte

0 Function

1 Always zero Slot number DPV1

2 47 Index DPV1

3 xx Data length DPV1

4..n User data PNO drive profile V3.0

Table 5.4 DP-V1 Command/Response Headers

Value Meaning Specified

number

0x48

0x51 Data transport REQ,

0x56 Resource manager

0x57 Initiate REQ, RES

0x58 Abort REQ

0x5C Alarm REQ, RES

0x5E Read REQ, RES

0x5F Write REQ, RES

0xD1 Data transport

0xD7 Initiate negative

0xDC Alarm negative

0xDE Read negative

0xDF Write negative

Idle REQ, RES

RES

REQ

negative response

response

response

response

response

Descriptive text for parameter values.

•

Access to multiple parameters in one telegram is

•

also possible.

Table 5.5 shows the structure of the PROFIdrive parameter

channel.

PROFIBUS DP-V1 telegram for read/write from or to a

frequency converter parameter:

PROFIBUS

telegram

header

DU0DU1DU2DU3Req./

Table 5.5 Structure of the PROFIdrive Parameter Channel

Data unit PROFIBUS

DP-V1

command/response

PROFIdrive V3.0

parameter channel

Data

Res.

Header

telegram

trailer

Table 5.6 shows the principle structure of the PROFIdrive

parameter channel.

The DP-V1 parameter request telegram consists of 3 data

blocks:

A request header, which defines the request (read

•

or write), and the number of parameters to

access. The master sets the request reference, and

uses this information to evaluate the response.

An address field, where all addressing attributes

•

of the desired parameters are defined.

A data field, where all parameter data values are

•

placed.

DP-V1

Request

header

Address field No. of parameters 3

Data field Data format 4+6*n

Table 5.6 Principle Structure of the PROFIdrive Parameter Channel

Parameter request Byte no.

Request reference 0

Request ID 1

Axis 2

Attribute 4

No. of elements 5

Parameter no. 6

7

Sub index 8

9

n'th parameter no. 4+6*(n-1)

...

No. of values (4+6*n)+1

Values (4+6*n)+2

n'th data value ...

5 5

5.2.8

DP-V1 Acyclical Parameter Channel

The DP-V1 parameter response telegram consists of 2 data

blocks:

Use the PROFIdrive parameter channel for read and write

access to parameter values and attributes.

Parameter values of simple variable, array and

•

A response header, which indicates if the request

•

is performed without errors (response ID), the

number of parameters, and the request reference

visible string.

Parameter description elements such as type,

•

minimum/maximum value, and so on.

MG37G102 Danfoss A/S © Rev. 05/2014 All rights reserved. 25

Page 28

Parameter Access

Programming Guide

set by the master within the corresponding

request telegram

A data field, where the requested data are placed.

•

If one or more internal requests have failed, an

PROFIdrive Parameter Channel

1) U8 - Unsigned8, U16 - Unsigned16

5.2.10 Request Reference

error code is placed instead of the data values

Unique identification of request/response pair for the

DP-V1 Parameter response Byte no.

Response header Request ref. mirrored 0

Parameter values No. of parameters 3

55

Table 5.7 DP-V1 Parameter Response Telegram

Response ID 1

Axis mirrored 2

Format 4

No. of values 5

Values of error values 6

n'th parameter value ...

As the response telegram does not include parameter

addressing information, the master must identify the

structure of the response data from the request telegram.

Request/Response Attributes

5.2.9

Table 5.8 contains an overview of the possible attributes of

the PROFIdrive parameter channel.

master. The master changes the request reference with

each new request. The slave mirrors the request reference

in the response.

5.2.11 Request ID

0x01 Request parameter.

0x02 Change parameter (data is NOT stored in non-volatile memory,

lost at power cycle).

0x42 Change parameter non-volatile (data is stored in non-volatile

memory).

0x51 Request parameter value double word. All parameters are

formatted and transferred as double word size, regardless of the

actual data type.

0x52 Change parameter value double word. All parameters must be

formatted and sent as double word size, regardless of data type.

Table 5.9 Defined Request Identification

5.2.12

Response ID

Data

Field

Request

reference

Request ID U8 0x01 Request parameter

ResponseIDU8 0x01 Request parameter

Axis U8 0x00..0xFFNumber (always 0)

No. of

parameter

s

Attribute U8 0x10 Value

No. of

elements

Values Remark

1)

type

U8 0x01..0xFF

0x02 Change parameter

0x42 Change parameter

0x51 Request par. value

0x52 Change par. value

0x02 Change parameter

0x81 Request parameter

0x82 Change parameter (-)

U8 0x01..0x25 Limitation: DP-V1

0x20 Description Data description

0x30 Text

U8 Limitation: DP-V1

0x01-0xFAQuantity 1-234

value

value

non-volatile

double word

double word

(+) Positive

(+) Positive

(-) Negative

Negative

Identification for

read or write

request

Identification for

the response

telegram length

telegram length

The response ID indicates if the read or write request was

successfully performed in the frequency converter. If the

response is negative, the request is answered negative

(first bit=1) and an error code is entered per partial

response, instead of the value.

5.2.13

Axis

The axis attribute should be set to 0.

5.2.14

Number of Parameters

For multi-parameter requests specifying the number of the

parameter address and/or parameter value areas. For a

single request, the number is 1.

5.2.15

Attribute

The attribute determines which data to access. The

frequency converter responds to the attributes value (10

H), description (20 H) and text (30 H).

5.2.16

Attribute Value (10H)

Parameter

no.

Subindex U16 0x0000 Number 0-65535 Array pointer

Format U8 See table

No. of

values

Error no. U16 0x0000... Error number

Table 5.8 Overview: Possible Attributes of the

26 Danfoss A/S © Rev. 05/2014 All rights reserved. MG37G102

U16 0x0001... Number 1-65535 Parameter

number

0xFFFF

0xFFFF

U8 0x01..0xEAQuantity 0-234 Limitation: DP-V1

telegram length

The attribute value permits reading or writing of parameter

values.

Page 29

Parameter Access

Programming Guide

5.2.17 Attribute Description (20H)

The attribute description permits access to the parameter

description. It is possible to read out one single description

element, or all elements for one parameter in one

telegram. Table 5.10 provides an overview of the existing

parameter description, which exists for each parameter in

the frequency converter.

Sub-index Meaning Data type

1 Identifier ID V2

2 Number of array elements or

3 Standardisation factor float

4 Variable attribute Octet string 2

5 Reserved Octet string 4

6 Name Visible string 16

7 Lower limit Octet string 4

8 Upper limit Octet string 4

9 Reserved Octet string 2

10 ID extension V2

11 PCD reference parameter U16

12 PCD normalisation V2

0 Complete description Octet string 46

Table 5.10 Parameter Description Elements (all Elements are

Read-only)

length or string

Table 5.11 explains each description element.

Identifier ID

Bit

15 Reserved

14 Array

13 Parameter value can be reset only.