Page 1

VLT® FC 100, FC 200 & FC 300 Drives

Application Note

1 Motor Protection

1 Motor Protection

1.1.1 Abstract

This Application Note describes how the VLT® FC 100, FC 200 and FC 300 Drives protects the

motor from being overloaded.

1.1.2

How Danfoss VLT

When using a Danfoss VLT® the application is protected in the following way.

First of all the drive contains several measurements and features to protect it self for overload,

over voltage and over temperature. The protecting features can keep the application running by

controlling the reason for the over load etc.

When for instance a pump is overloaded the drive will default give a warning in the display and

derate the speed of the pump in order to reduce the current and in that way keep the pump in

operation. If it is preferred to make the drive give a trip alarm and stop the application is configurable by parameter settings.

When the drive temperature is too high it will automatically reduce the switching frequency in

order to lower the heat dissipation.

®

AQUA protects the application

1

The motor is protected by a current or torque limit feature, which again can derate the speed,

give a warning or trip the drive if chosen.

Further more the drive contains an ETR timer which is estimating the motor temperature based

on motor current and speed. This is exactly the same way of protecting the motor as using a TI16

contactor with a motor protective switch attached. (Bimetal)

The torque limit feature is protecting the system for being overloaded no matter the speed. When

the drive is operating in VT mode the torque limit is reached at a lower level than if the system is

operating at nominal speed.

The following test results show that the torque limit is different at different speed. The curve

marked (a) shows the torque where the warning is triggered.

MN.90.01.02 - VLT® is a registered Danfoss trademark

1

Page 2

1

1 Motor Protection

When the speed is decreased the current is increased due to lower motor impedance at reduced

frequency.

Zm = 2*pi*f*L

Tm = C*Flux*I (Tm is torque, C is a constant, I is current)

At lower speed the flux is reduced (lower voltage), hence the current I is increased at the same

torque.

1.1.3 ETR (Electronic Thermal relay)

This is the way Danfoss protect the motor from being overheated. It is an electr onic f eature that

simulates a bimetal relay based on internal measurements.

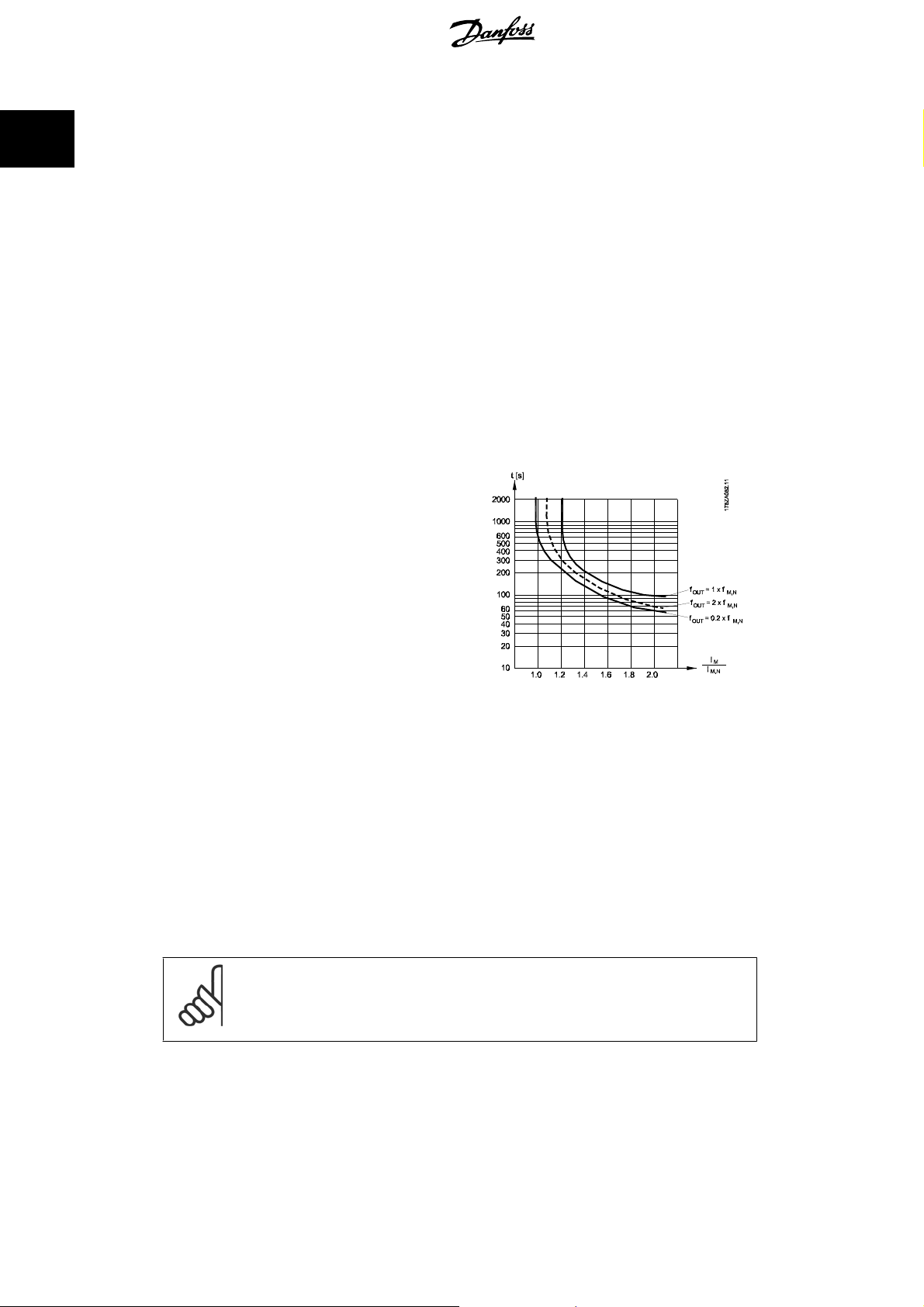

The characteristic is shown in the following figure.

VLT® FC 100, FC 200 & FC 300 Drives

Application Note

Figure ETR: The X-axis is showing the ratio

between Imotor and Imotor nominal. The Yaxis is showing the time in seconds before the

ETR cut of and trip the drive. The curves are

showing the characteristic nominal speed, at

twice the nominal speed and at 0,2*the nominal speed.

It is clear that at lower speed the ETR cuts of

at lower heat due to less cooling of the motor.

In that way the motor are protected from being over heated even at low speed.

The ETR feature is calculating the motor temperature based on actual current and speed. The

calculated temperature is visible as a read out parameter in P16-18 in the FC202.

1.1.4 Summary

With the Torque limit feature the motor is protected for being overloaded independent of the

speed. With the ETR the motor is protected for being over heated and there is no need for any

further motor protection. That means when the motor is heated up the ETR timer controls for how

long time the motor can be running at the high temperature before it is stopped in order to prevent

over heating. If the motor is overloaded without reaching the temperature where the ETR shuts

of the motor, the torque limit is protecting the motor and application for being overloaded.

NB!

ETR is activated in P1-90

Torque limit is controlled in P4-16 and the timer before the torque limit warning shall

trip is controlled in P14-25.

2

MN.90.01.02 - VLT® is a registered Danfoss trademark

Loading...

Loading...