Page 1

MAKING MODERN LIVING POSSIBLE

Operating Instructions

VLT® AQUA Drive FC 202

110–1400 kW

www.danfoss.com/drives

Page 2

Page 3

Contents VLT AQUA Drive FC 202 Operation Instructions

Contents

1 How to Read these Operating Instructions

2 Safety

2.1 Safety Note

2.1.1 General Warning 6

2.1.2 Before Commencing Repair Work 7

2.1.3 Special Conditions 7

2.1.4 Avoid Unintended Start 7

2.1.5 Safe Torque Off (STO) 7

2.1.6 IT Mains 8

3 How to Install

3.1 How to Get Started

3.2 Pre-installation

3.2.1 Planning the Installation Site 9

3.2.2 Receiving the Frequency Converter 10

3.2.3 Transportation and Unpacking 10

3.2.4 Lifting 10

4

6

6

9

9

9

3.2.5 Mechanical Dimensions 12

3.2.6 Rated Power 18

3.3 Mechanical Installation

3.3.1 Tools Needed 20

3.3.2 General Considerations 20

3.3.3 Terminal Locations - Enclosure Type D 21

3.3.4 Terminal Locations - E Enclosures 24

3.3.5 Terminal Locations - Enclosure type F 29

3.3.6 Cooling and Airflow 33

3.3.7 Installation on the Wall - IP21 (NEMA 1) and IP54 (NEMA 12) Units 35

3.3.8 Gland/Conduit Entry - IP21 (NEMA 1) and IP54 (NEMA12) 35

3.3.9 IP21 Drip Shield Installation (Enclosure Types D1 and D2) 37

3.4 Field Installation of Options

3.4.1 Installation of Duct Cooling Kit in Rittal Enclosures 37

3.4.2 Outside Installation/NEMA 3R Kit for Rittal Enclosures 38

3.4.3 Installation on Pedestal 39

3.4.4 Installation of Input Plate Options 40

20

37

3.4.5 Installation of Mains Shield for Frequency Converters 41

3.5 Enclsoure Type F Panel Options

3.5.1 Enclsoure Type F Options 41

3.6 Electrical Installation

3.6.1 Power Connections 42

MG20P402 - Rev. 2013-12-16 1

41

42

Page 4

Contents VLT AQUA Drive FC 202 Operation Instructions

3.6.2 Grounding 53

3.6.3 Extra Protection (RCD) 53

3.6.4 RFI Switch 53

3.6.5 Torque 53

3.6.6 Shielded Cables 54

3.6.7 Motor Cable 54

3.6.8 Brake Cable for Frequency Converters with Factory Installed Brake Chopper Option 55

3.6.9 Brake Resistor Temperature Switch 55

3.6.10 Load Sharing 55

3.6.11 Shielding against Electrical Noise 55

3.6.12 Mains Connection 56

3.6.13 External Fan Supply 56

3.6.14 Fuses 56

3.6.15 Mains Disconnectors 59

3.6.16 F Enclosure Circuit Breakers 59

3.6.17 F Enclosure Mains Contactors 60

3.6.18 Motor Insulation 60

3.6.19 Motor Bearing Currents 60

3.6.20 Control Cable Routing 60

3.6.21 Access to Control Terminals 62

3.6.22 Electrical Installation, Control Terminals 62

3.6.23 Electrical Installation, Control Cables 63

3.6.24 Switches S201, S202, and S801 65

3.7 Connection Examples

3.7.1 Start/Stop 66

3.7.2 Pulse Start/Stop 66

3.8 Final Set-up and Test

3.9 Additional Connections

3.9.1 Mechanical Brake Control 68

3.9.2 Parallel Connection of Motors 68

3.9.3 Motor Thermal Protection 69

66

67

68

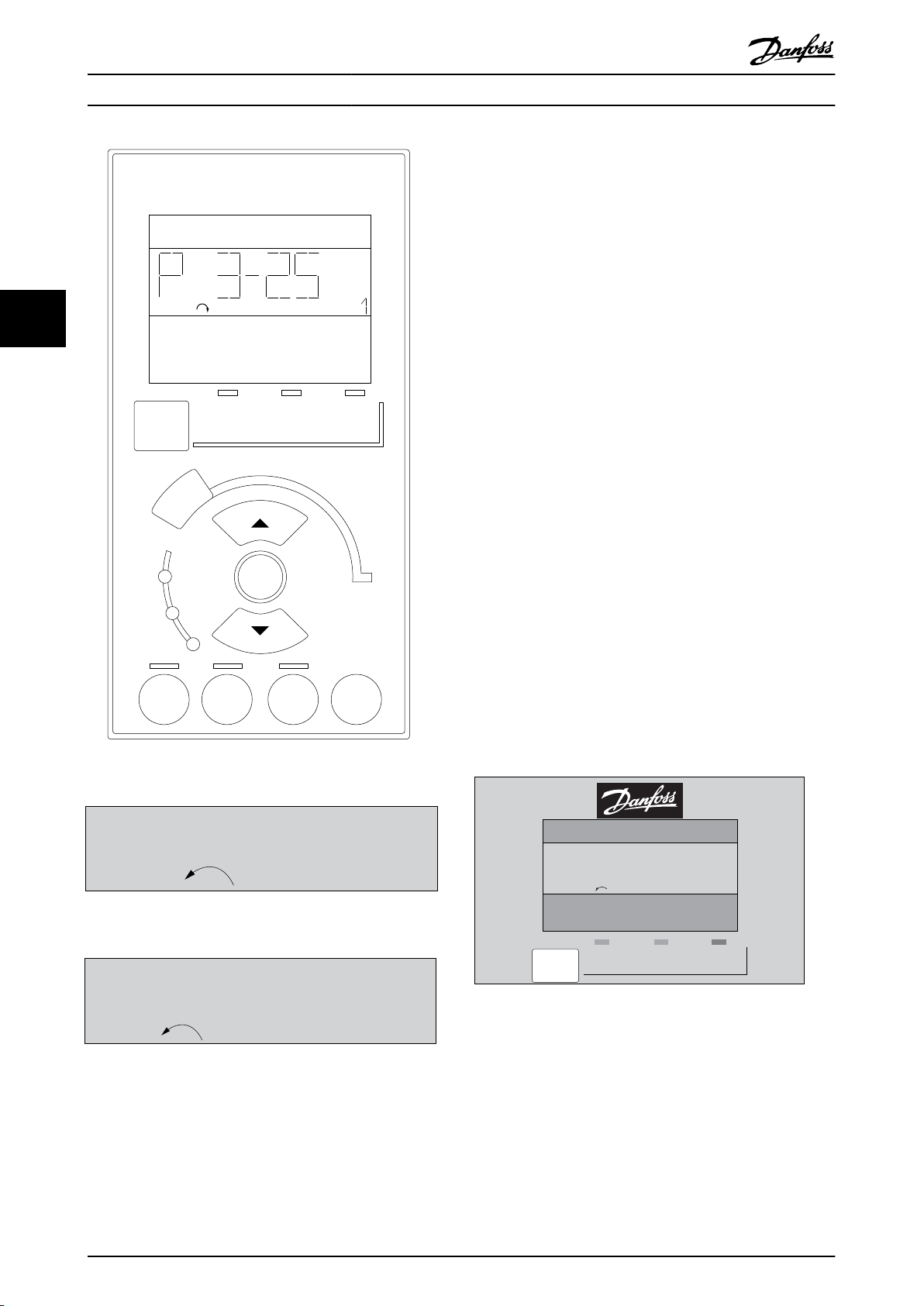

4 How to operate the frequency converter

4.1 Ways of Operation

4.1.1 How to operate graphical LCP (GLCP) 70

4.1.2 How to Operate Numeric LCP (NLCP) 73

4.1.3 Changing Data 75

4.1.4 Changing a Text Value 75

4.1.5 Changing a Group of Numeric Data Values 75

4.1.6 Changing of Data Value, Step-by-Step 76

2 MG20P402 - Rev. 2013-12-16

70

70

Page 5

Contents VLT AQUA Drive FC 202 Operation Instructions

4.1.7 Read-out and Programming of Indexed Parameters 76

4.1.8 Tips and Tricks 76

5 How to programme the frequency converter

5.1 How to programme

5.2 Commonly Used Parameters - Explanations

5.3 Parameter Menu Structure

6 General Specifications

7 Troubleshooting

Index

79

79

84

112

117

130

142

MG20P402 - Rev. 2013-12-16 3

Page 6

How to Read these Operating... VLT AQUA Drive FC 202 Operation Instructions

1

1 How to Read these Operating Instructions

notice or any obligation to notify former or present users

VLT AQUA Drive

FC 200 Series

Software version: 2.1x

This guide can be used with all FC

202 frequency converters with

software

version 2.1x or later.

The actual software version

number can be read from

15-43 Software Version.

This publication contains information proprietary to

Danfoss. By accepting and using this manual the user

agrees that the information contained herein is used solely

for operating equipment from Danfoss or equipment from

other vendors if such equipment is intended for communication with Danfoss equipment over a serial

communication link. This publication is protected under

the Copyright laws of Denmark and most other countries.

Danfoss does not warrant that a software program

produced according to the guidelines provided in this

manual functions properly in every physical, hardware or

software environment.

Although Danfoss has tested and reviewed the documentation within this manual, Danfoss makes no warranty or

representation, neither expressed nor implied, with respect

to this documentation, including its quality, performance,

or fitness for a particular purpose.

In no event shall Danfoss be liable for direct, indirect,

special, incidental, or consequential damages arising out of

the use, or the inability to use information contained in

this manual, even if advised of the possibility of such

damages. In particular, Danfoss is not responsible for any

costs, including but not limited to those incurred as a

result of lost profits or revenue, loss or damage of

equipment, loss of computer programs, loss of data, the

costs to substitute these, or any claims by third parties.

of such revisions or changes.

1.1.1 Available Literature

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Danfoss technical literature is also available online at

www.danfoss.com/BusinessAreas/DrivesSolutions/

Documentations/Technical+Documentation.htm.

VLT® AQUA Drive FC 202 Operating Instructions

provide the neccessary information for getting

the frequency converter up and running.

VLT® AQUA Drive FC 202, 110-1400 kW Operating

Instructions provide the neccessary information

for getting the high power frequency converter

up and running.

®

VLT

AQUA Drive FC 202 Design Guide entails all

technical information about the frequency

converter and customer design and applications.

®

VLT

AQUA Drive FC 202 Programming Guide

provides information on how to programme and

includes complete parameter descriptions.

VLT® AQUA Drive FC 202 Profibus

®

VLT

AQUA Drive FC 202 DeviceNet

Output Filters Design Guide

VLT® AQUA Drive FC 202 Cascade Controller

Application Note MN20A: Submersible Pump

Application

Application Note MN20: Master/Follower Operation

Application

Application Note MN20F: Drive Closed Loop and

Sleep Mode

Installation Instruction for Mounting Brackets

Enclosure type A5, B1, B2, C1 and C2 IP21, IP55 or

IP66

Instruction for Analog I/O Option MCB109

Instruction for Panel through mount kit

®

Active Filter Operating Instruction

VLT

Danfoss reserves the right to revise this publication at any

time and to make changes to its contents without prior

4 MG20P402 - Rev. 2013-12-16

Page 7

How to Read these Operating... VLT AQUA Drive FC 202 Operation Instructions

The frequency converter complies with UL508C thermal

memory retention requirements. For more information,

refer to the section Motor Thermal Protection in the Design

Guide.

NOTICE

Imposed limitations on the output frequency

(due to export control regulations):

From software version 6.72 the output frequency of the

frequency converter is limited to 590 Hz. Software

versions 6x.xx also limit the maximum output frequency

to 590 Hz, but these versions cannot be flashed, i.e.

neither downgraded nor upgraded.

The following symbols are used in this document:

WARNING

Indicates a potentially hazardous situation which could

result in death or serious injury.

1

1

CAUTION

Indicates a potentially hazardous situation which could

result in minor or moderate injury. It may also be used

to alert against unsafe practices.

NOTICE

Indicates important information, including situations that

may result in damage to equipment or property.

MG20P402 - Rev. 2013-12-16 5

Page 8

Safety VLT AQUA Drive FC 202 Operation Instructions

2 Safety

22

2.1 Safety Note

WARNING

The voltage of the frequency converter is dangerous

whenever connected to mains. Incorrect installation of

the motor, frequency converter or fieldbus may cause

damage to the equipment, serious personal injury or

death. Consequently, the instructions in this manual, as

well as national and local rules and safety regulations,

must be complied with.

Safety Regulations

1. The frequency converter must be disconnected

from mains if repair work is to be carried out.

Check that the mains supply has been disconnected and that the necessary time has passed

before removing motor and mains plugs.

2. The [STOP/RESET] key on the control panel of the

frequency converter does not disconnect the

equipment from mains and is thus not to be used

as a safety switch.

3. Correct protective earthing of the equipment

must be established, the user must be protected

against supply voltage, and the motor must be

protected against overload in accordance with

applicable national and local regulations.

4. The earth leakage currents are higher than 3.5

mA.

5. Protection against motor overload is set by par.

1-90 Motor Thermal Protection. If this function is

desired, set par. 1-90 to data value [ETR trip]

(default value) or data value [ETR warning]. Note:

The function is initialised at 1.16 x rated motor

current and rated motor frequency. For the North

American market: The ETR functions provide class

20 motor overload protection in accordance with

NEC.

6. Do not remove the plugs for the motor and

mains supply while the frequency converter is

connected to mains. Check that the mains supply

has been disconnected and that the necessary

time has passed before removing motor and

mains plugs.

7. Note that the frequency converter has voltage

inputs other than L1, L2 and L3, when load

sharing (linking of DC intermediate circuit) and

external 24 V DC have been installed. Check that

all voltage inputs have been disconnected and

that the necessary time has passed before

commencing repair work.

NOTICE

Installation at high altitude:

380 - 480 V: At altitudes above 3,000 m, contact Danfoss

regarding PELV.

525 - 690 V: At altitudes above 2,000 m, contact Danfoss

regarding PELV.

Warning against Unintended Start

1. The motor can be stopped with digital

commands, bus commands, references or a local

stop, while the frequency converter is connected

to mains. To avoid personal injury, these stop

functions are not sufficient to ensure that no

unintended start occurs.

2. While parameters are being changed, the motor

may start. Consequently, always press [RESET];

following which data can be modified.

3. A motor that has been stopped may start if faults

occur in the electronics of the frequency

converter, or if a temporary overload or a fault in

the supply mains or the motor connection ceases.

WARNING

Warning:

Touching the electrical parts may be fatal - even after

the equipment has been disconnected from mains.

Also make sure that other voltage inputs have been

disconnected, such as external 24 V DC, load sharing

(linkage of DC intermediate circuit), as well as the motor

connection for kinetic back-up.

General Warning

2.1.1

WARNING

Warning:

Touching the electrical parts may be fatal - even after

the equipment has been disconnected from mains.

Also make sure that other voltage inputs have been

disconnected, (linkage of DC intermediate circuit), as well

as the motor connection for kinetic back-up.

Before touching any potentially live parts of the

frequency converter, wait at least as follows: Be aware

that there may be high voltage on the DC link even

when the Control Card LEDs are turned off. A red LED is

mounted on a circuit board inside the frequency

converter to indicate the DC bus voltage. The red LED

stays lit until the DC link is 50 V DC or lower.

6 MG20P402 - Rev. 2013-12-16

Page 9

Safety

VLT AQUA Drive FC 202 Operation Instructions

WARNING

Leakage Current

The earth leakage current from the frequency converter

exceeds 3.5 mA. According to IEC 61800-5-1 a reinforced

Protective Earth connection must be ensured by means

of: a min. 10mm² Cu or 16mm² Al PE-wire or an

addtional PE wire - with the same cable cross section as

the Mains wiring - must be terminated separately.

Residual Current Device

This product can cause a D.C. current in the protective

conductor. Where a residual current device (RCD) is used

for extra protection, only an RCD of Type B (time

delayed) shall be used on the supply side of this

product. See also RCD Application Note MN.90.GX.02.

Protective earthing of the frequency converter and the

use of RCD's must always follow national and local

regulations.

Grid configuration (IT,TN, grounded leg, etc.)

•

Safety of low-voltage ports (PELV conditions)

•

Consult the relevant clauses in these instructions and in

the Design Guide for information about the installation

requirements.

WARNING

The frequency converter's DC link capacitors remain

charged after power has been disconnected. To avoid an

electrical shock hazard, disconnect the frequency

converter from the mains before carrying out

maintenance. Before doing service on the frequency

converter, wait at least the amount of time indicated

below:

Voltage Power size

Min. Waiting Time

2 2

Before Commencing Repair Work

2.1.2

1. Disconnect the frequency converter from mains.

2. Disconnect DC bus terminals 88 and 89.

3.

Wait at least the time mentioned in

chapter 2.1.1 General Warning.

Special Conditions

2.1.3

Electrical ratings

The rating indicated on the nameplate of the frequency

converter is based on a typical 3-phase mains power

supply, within the specified voltage, current and

temperature range, which is expected to be used in most

applications.

The frequency converters also support other special

applications, which affect the electrical ratings of the

frequency converter. Special conditions which affect the

electrical ratings might be:

Single phase applications

•

High temperature applications which require

•

derating of the electrical ratings

Marine applications with more severe environ-

•

mental conditions.

Consult the relevant clauses in these instructions and in

the Design Guide for information about the electrical

ratings.

Installation requirements

The overall electrical safety of the frequency converter

requires special installation considerations regarding:

Fuses and circuit breakers for over-current and

•

short-circuit protection

Selection of power cables (mains, motor, brake,

•

loadsharing and relay)

380 - 480 V 110 - 250 kW 20 minutes

315 - 1000 kW 40 minutes

525 - 690 V 45 - 400 kW 20 minutes

450- 1400 kW 30 minutes

Be aware that there may be high voltage on the DC link even

when the LEDs are turned off.

Table 2.1 Discharge Time

Avoid Unintended Start

2.1.4

WARNING

While the frequency converter is connected to mains, the

motor can be started/stopped using digital commands,

bus commands, references or via the Local Control Panel.

Disconnect the frequency converter from mains

•

whenever personal safety considerations make

it necessary to avoid unintended start.

To avoid unintended start, always activate the

•

[Off] key before changing parameters.

Unless terminal 37 is turned off, an electronic

•

fault, temporary overload, a fault in the mains

supply, or lost motor connection may cause a

stopped motor to start.

Safe Torque Off (STO)

2.1.5

To run Safe Torque Off, additional wiring for the frequency

converter is required, refer to Safe Torque Off Operating

Instructions for Danfoss VLT® Frequency Converters for

further information.

MG20P402 - Rev. 2013-12-16 7

Page 10

Safety VLT AQUA Drive FC 202 Operation Instructions

2.1.6 IT Mains

22

WARNING

IT mains

Do not connect frequency converters with RFI-filters to

mains supplies with a voltage between phase and earth

of more than 440 V for 400 V converters and 760 V for

690 V converters.

For 400 V IT mains and delta earth (grounded leg), mains

voltage may exceed 440 V between phase and earth.

For 690 V IT mains and delta earth (grounded leg), mains

voltage may exceed 760 V between phase and earth.

Failure to follow recommendations could result in death

or serious injury.

14-50 RFI Filter can be used to disconnect the internal RFI

capacitors from the RFI filter to ground.

Disposal Instruction

2.1.7

Equipment containing electrical components

must not be disposed of together with

domestic waste.

It must be separately collected with electrical

and electronic waste according to local and

currently valid legislation.

8 MG20P402 - Rev. 2013-12-16

Page 11

M

3

96 97 9998

37

91 92 93

12

L1

W PEVU

F1

L2

L3

PE

130BA015.13

1

18

81 82

R+R-

95

55

50

53

27

88

89

DC- DC+

L1 L2 PEL3

How to Install

3 How to Install

3.1 How to Get Started

VLT AQUA Drive FC 202 Operation Instructions

This chapter covers mechanical and electrical installations

to and from power terminals and control card terminals.

Electrical installation of options is described in the relevant

Operating Instructions and Design Guide.

The frequency converter is designed to achieve a quick

and EMC-correct installation by following the steps

described below.

WARNING

Read the safety instructions before installing the unit.

Failure to follow recommendations could result in death

or serious injury.

Mechanical Installation

Mechanical mounting

•

Electrical Installation

Connection to Mains and Protecting Earth

•

Motor connection and cables

•

Fuses and circuit breakers

•

Control terminals - cables

•

Quick Setup

Local Control Panel, LCP

•

Automatic Motor Adaptation, AMA

•

Programming

•

Frame size is depending on enclosure type, power range

and mains voltage

3 3

Illustration 3.1 Diagram showing basic installation including

mains, motor, start/stop key, and potentiometer for speed

adjustment.

3.2 Pre-installation

3.2.1 Planning the Installation Site

CAUTION

Before performing the installation it is important to plan

the installation of the frequency converter. Neglecting

this may result in extra work during and after installation.

Select the best possible operation site by considering

the following (see details on the following pages, and

the respective Design Guides)

Ambient operating temperature

MG20P402 - Rev. 2013-12-16 9

•

Installation method

•

How to cool the unit

•

Position of the frequency converter

•

Cable routing

•

Ensure the power source supplies the correct

•

voltage and necessary current

Ensure that the motor current rating is within the

•

maximum current from the frequency converter

If the frequency converter is without built-in

•

fuses, ensure that the external fuses are rated

correctly.

Page 12

176FA245.10

130BA832.11

130BA834.11

How to Install VLT AQUA Drive FC 202 Operation Instructions

3.2.2 Receiving the Frequency Converter

When receiving the frequency converter, make sure that

the packaging is intact, and be aware of any damage that

might have occurred to the unit during transport. In case

damage has occurred, contact immediately the shipping

33

company to claim the damage.

3.2.3 Transportation and Unpacking

Before unpacking the frequency converter it is

recommended that it is located as close as possible to the

final installation site.

Remove the box and handle the frequency converter on

the pallet, as long as possible.

Lifting

3.2.4

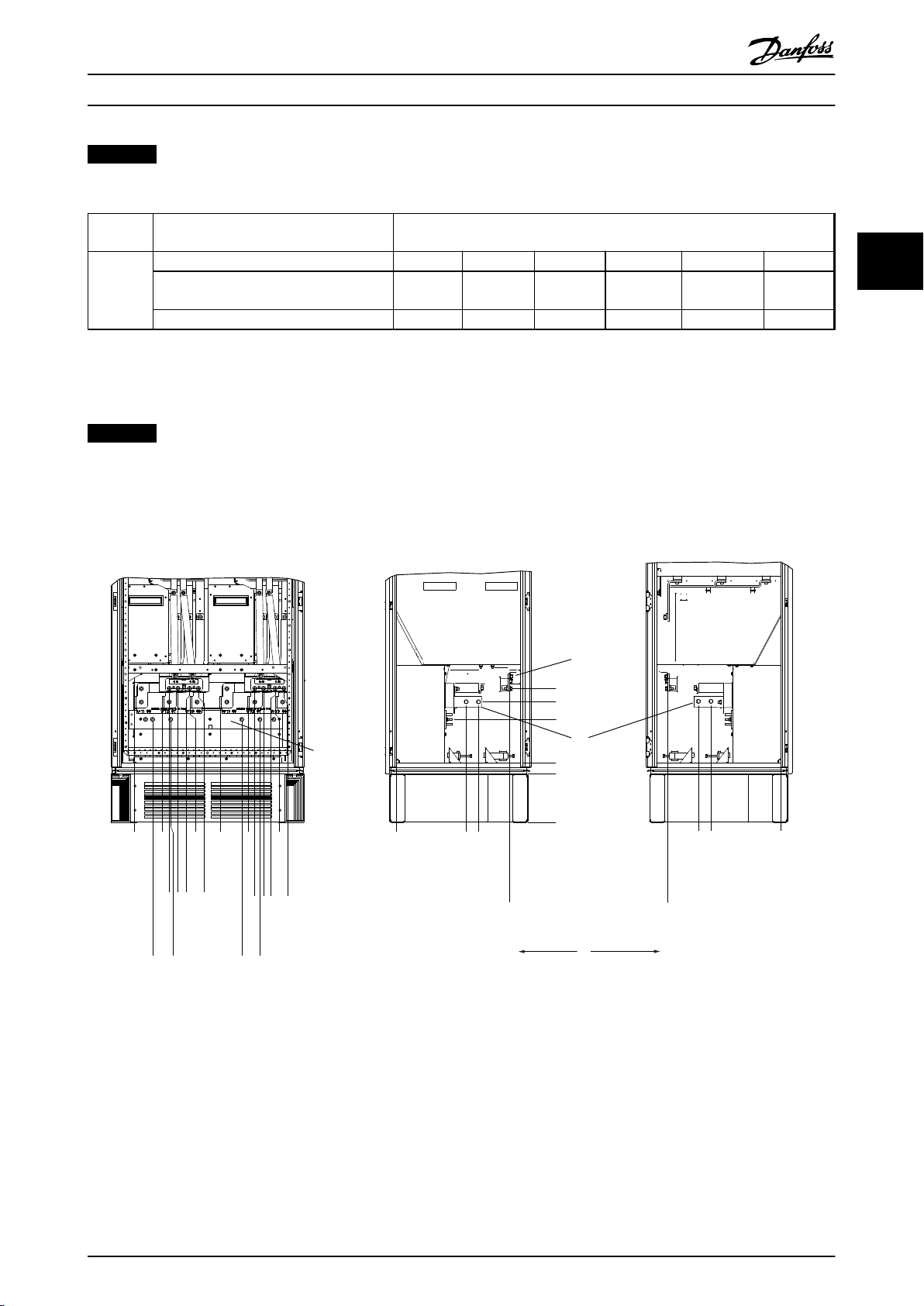

Illustration 3.3 Recommended Lifting Method, Enclsoure Type

Always lift the frequency converter in the dedicated lifting

eyes. For all D and E2 (IP00) enclosures, use a bar to avoid

bending the lifting holes of the frequency converter.

F1 (460 V, 600 to 900 HP, 575/690 V, 900 to 1150 HP)

Illustration 3.2 Recommended Lifting Method, Enclosure Types

D and E

WARNING

The lifting bar must be able to handle the weight of the

frequency converter. See Mechanical Dimensions for the

weight of the different enclosure type. Maximum

diameter for bar is 2.5 cm (1 inch). The angle from the

top of the frequency converter to the lifting cable should

be 60° or greater.

Illustration 3.4 Recommended Lifting Method, Enclosure Type

F2 (460 V, 1000 to 1200 HP, 575/690 V, 1250 to 1350 HP)

10 MG20P402 - Rev. 2013-12-16

Page 13

130BA833.11

130BA835.11

130BB753.10

130BB688.10

130BB689.10

How to Install VLT AQUA Drive FC 202 Operation Instructions

Illustration 3.5 Recommended Lifting Method, Enclosure Type

F3 (460 V, 600 to 900 HP, 575/690 V, 900 to 1150 HP)

3 3

Illustration 3.6 Recommended Lifting Method, Enclosure Type

F4 (460 V, 1000 to 1200 HP, 575/690 V, 1250 to 1350 HP)

Illustration 3.7 Recommended lifting method, Enclosure Type

F8

Illustration 3.8 Recommended lifting method, Enclosure Type

F9/F10

Illustration 3.9 Recommended lifting method, Enclosure Type

F11/F12/F13/F14

MG20P402 - Rev. 2013-12-16 11

Page 14

IP21 AND IP54 / UL AND NEMA TYPE 1 AND 12

A

B

C

120

(4.7)

177.0

(7.0)

354.0

(13.9)

1166

(45.9)

310

(12.2)

163

(6.4)

420

(16.5)

981

(38.6)

74

(2.9)

417

(16.4)

380

(15.0)

D1

D2

130BA443.11

417

(16.4)

380

(15.0)

225

(8.9)

225

(8.9)

225.0

(8.9)

225.0

(8.9)

369.0

(14.5)

849

(33.4)

1209

(47.6)

160.0

(6.3)

160.0

(6.3)

160.0

(6.3)

160.0

(6.3)

304

(12.0)

304

(12.0)

25

(1.0)

25

(1.0)

1154

(45.4)

1362

(53.6)

420

(16.5)

157

(6.2)

72

(2.8)

1547

(60.9)

1589

(62.6)

423

(16.6)

120

(4.7)

1535

(60.4)

184.5

(7.3)

977

(38.5)

A

B

C

IP00 / CHASSIS

IP00/IP21/IP54 - ALL SIZES

1099

43.3( )

1280

50.4( )

1327

52.2()

375

14.8( )

417

16.4( )

298

11.7(

)

304

12.0(

)

120

4.7(

)

977

38.5( )

160

6.3( )

185

7.3( )

369

14.5( )

1282

50.5( )

25

1.0( )

161

6.3( )

225

(8.9)

225

(8.9)

997

39.3( )

818

32.2( )

408

16.1( )

66

2.6( )

408

16.1(

)

66

2.6( )

298

11.7

( )

375

14.8( )

1046

41.2( )

120

4.7( )

696

27.4( )

160

6.3( )

1001

25

1.0( )

39.4(

)

304

12.0( )

151

5.9( )

157

6.2( )

147

5.8( )

417

16.4( )

177

7.0( )

354

13.9( )

25

1.0( )

22

0.9

( )

49

1.9( )

25

1.0( )

Ø 11

.4( )

20.0

0.8

( )

10

0.4

( )

51

2.0( )

11

0.4( )

160.0

6.30(

)

160.0

6.30( )

225.0

8.9( )

225.0

8.9( )

D3 D4

BA

C

22

0.9

( )

138BA442.10

How to Install VLT AQUA Drive FC 202 Operation Instructions

NOTICE

The plinth is provided in the same packaging as the frequency converter but is not attached to enclosure types F1-F4

during shipment. The plinth is required to allow airflow to the frequency converter to provide proper cooling. The F

enclosures should be positioned on top of the plinth in the final installation location. The angle from the top of the

frequency converter to the lifting cable should be 60° or greater.

33

In addition to the drawings above a spreader bar is an acceptable way to lift the F enclosures.

3.2.5 Mechanical Dimensions

Illustration 3.10

*

Note airflow directions

Illustration 3.11

12 MG20P402 - Rev. 2013-12-16

Page 15

E1

225

8.86( )

1551

61.1( )

2000

(78.74)

727

28.6( )

72

2.8( )

164

600

(23.62)

198

7.8( )

145

5.7( )

494

19.4( )

392

15.4( )

538

21.2( )

160

6.3( )

1043

41.1( )

160

6.3( )

72

2.8( )

27

1.1( )

23

0.9( )

185

7.3( )

185

7.3( )

58

2.3( )

484

19.1()

2X13

0.5

( )

25

1.0

(

)

56

2.2( )

6.5( )

185

7.3( )

1.0( )

F

F

130BA444.10

SIDE CABLE ENTRY

KNOCK-OFF PLATE

CABLE BASE

BOTTOM CABLE ENTRY

IP21 AND IP54 / UL AND NEMA TYPE 1 AND 12

Ø 25

How to Install VLT AQUA Drive FC 202 Operation Instructions

*

Note airflow directions

3 3

Illustration 3.12

*

Note airflow directions

MG20P402 - Rev. 2013-12-16 13

Page 16

130BA445.10

225

64

1320

585

269

156

23

25

498

539

1547

1502

160

1043

14

184

184

184

139

304

2X13

(2.5)

(23.0)

(52.0)

(6.2)

(19.5)

(10.6)

(21.2)

(60.9)

(5.5)

(12.0)

(7.3) (7.3)

(0.5)

(1.5)

120

(4.7)

25

(1.0)

(59.1)

(41.1)

(6.3)

(8.9)

225

(8.9)

(1.0)

25

(1.0)

(0.9)

27

(1.0)

13

(0.5)

E2

D

E

D

E

IP00 / CHASSIS

How to Install VLT AQUA Drive FC 202 Operation Instructions

33

Illustration 3.13

*

Note airflow directions

14 MG20P402 - Rev. 2013-12-16

Page 17

1

130BB027.10

2281.4

(89.82)

2206.4

(86.87)

1499.2

(59.02)

1400.0

(55.12)

ø29.0

(1.14)

225.0

(8.85)

607.0

(23.9)

225.0

(8.85)

1

130BB029.10

2280

(89.7)

2205

(86.8)

1497

(58.9)

1997

(78.6)

ø29

( 1.1)

607

(23.9)

How to Install VLT AQUA Drive FC 202 Operation Instructions

3 3

F1 IP 21/54 - NEMA 1/12 F3 IP 21/54 - NEMA 1/12

Table 3.1

MG20P402 - Rev. 2013-12-16 15

1) Minimum clearance from ceiling

Page 18

225.0

(8.85)

2281

(89.8)

1499

(59.0)

Ø29

(1.1)

1804

(71.0)

2206

(86.9)

606

(23.8)

130BB028.10

1

1

130BB030.10

2280

(89.7)

2205

(86.8)

1497

(58.9)

2401

(94.5)

Ø29

(1.1)

225.0

(8.85)

604

(23.8)

How to Install VLT AQUA Drive FC 202 Operation Instructions

33

1) Minimum clearance from ceiling

F2 IP 21/54 - NEMA 1/12 F4 IP 21/54 - NEMA 1/12

Table 3.2

16 MG20P402 - Rev. 2013-12-16

Page 19

How to Install VLT AQUA Drive FC 202 Operation Instructions

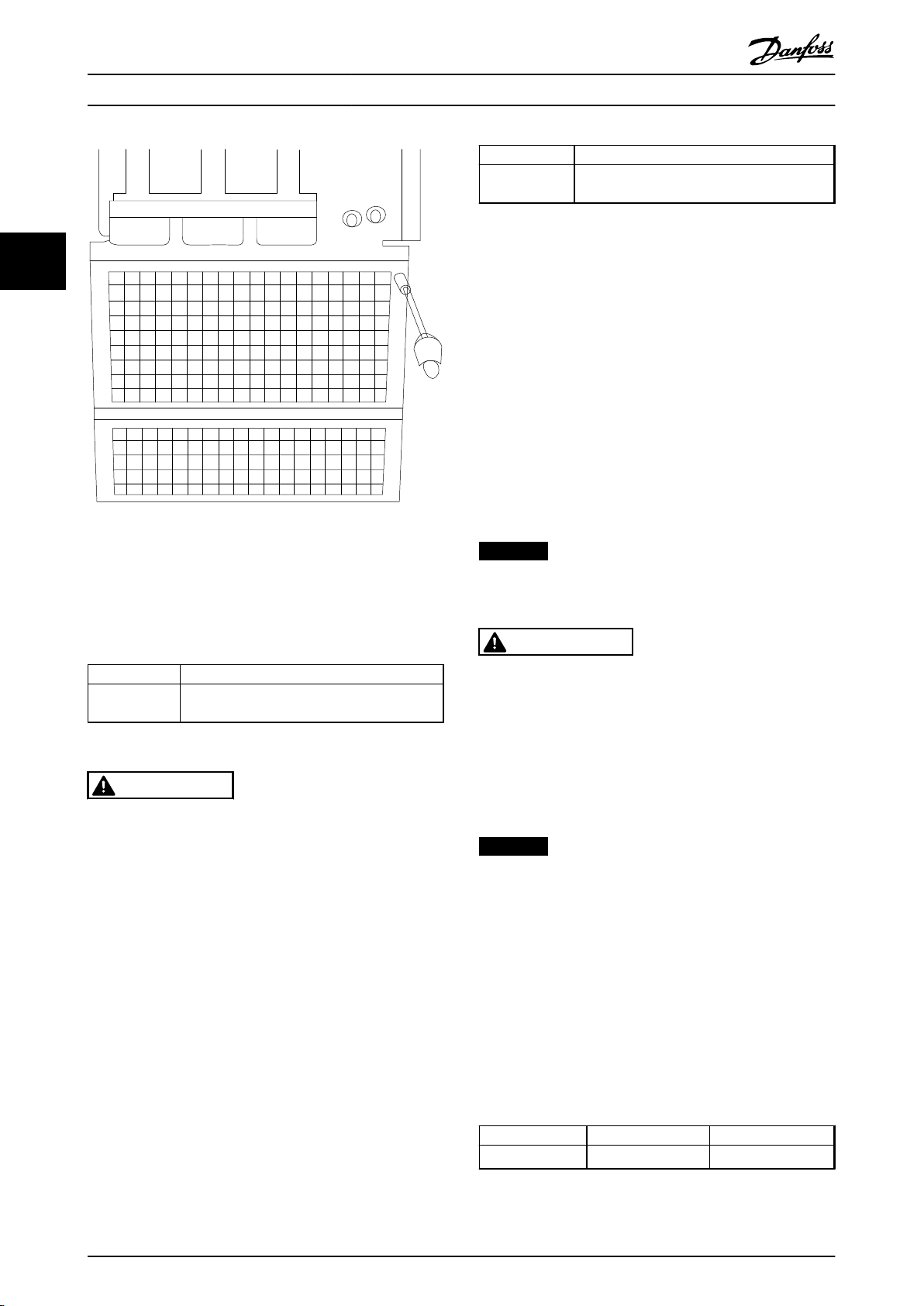

Enclosure type Size D1 D2 D3 D4

160 - 250 kW

IP

NEMA

Shipping

dimensions

[mm]

Frequency

converter

dimensions

[mm]

110-132 kW at 400 V

(380-480 V)

45-160 kW at 690 V

(525-690 V)

21

Type 1

Height

650 650 650 650 650 650

Width 1730 1730 1730 1730 1220 1490

Depth 570 570 570 570 570 570

Height 1209 1209 1589 1589 104 1327

Width 420 420 420 420 408 408

Depth 380 380 380 380 375 375

Max

weight

[kg]

104 104 151 151 91 138

54

Type 12

160-250 kW at 400 V

(380-480 V)

200-400 kW at 690 V

(525-690 V)

21

Type 1

54

Type 12

110-132 kW at 400 V

(380-480 V)

45-160 kW at 690 V

(525-690 V)

00

Chassis

at 400 V

(380-480 V)

200-400 kW

at 690 V

(525-690 V)

Chassis

3 3

00

Table 3.3 Mechanical dimensions, Enclosure type D

MG20P402 - Rev. 2013-12-16 17

Page 20

130BA816.10

130BA817.10

130BA819.10

130BA820.10

How to Install VLT AQUA Drive FC 202 Operation Instructions

Enclosure Type Size E1 E2 F1 F2 F3 F4

315-450 kW at

400 V

(380-480 V)

450-630 kW at

690 V

33

IP

NEMA

Shipping

dimensions

[mm]

Frequency

converter

dimensions

[mm]

Height

Width 2197 1705 1569 1962 2159 2559

Depth 736 736 1130 1130 1130 1130

Height 2000 1547 2204 2204 2204 2204

Width 600 585 1400 1800 2000 2400

Depth 494 498 606 606 606 606

Max

weight

[kg]

(525-690 V)

21, 54

Type 1/ Type 12

840 831 2324 2324 2324 2324

313 277 1004 1246 1299 1541

315-450 kW at

400 V

(380-480 V)

450-630 kW at

690 V

(525-690 V)

00

Chassis

500-710 kW at

400 V

(380-480 V)

710-900 kW at

690 V

(525-690 V)

21, 54

Type 1/Type 12

800-1000 kW at

400 V

(380-480 V)

1000-1200 kW at

690 V

(525-690 V)

21, 54

Type 1/Type 12

500-710 kW at

400 V

(380-480 V)

710-900 kW at

690 V

(525-690 V)

21, 54

Type 1/Type 12

800-1000 kW at

400 V

(380-480 V)

1000-1400 kW at

690 V

(525-690 V)

21, 54

Type 1/Type 12

Table 3.4 Mechanical dimensions, Enclosure Types E and F

Rated Power

3.2.6

Enclosure type D1 D2 D3 D4

Enclosure

protection

Normal overload

rated power - 110%

overload torque

IP 21/54 21/54 00 00

NEMA Type 1/Type 12 Type 1/Type 12 Chassis Chassis

110 - 132 kW at 400 V

(380 - 480 V)

45 - 160 kW at 690 V

(525-690 V)

150 - 250 kW at 400 V

(380 - 480 V)

200 - 400 kW at 690 V

(525-690 V)

110 - 132 kW at 400 V

(380 - 480 V)

45 - 160 kW at 690 V

(525-690 V)

150 - 250 kW at 400 V

200 - 400 kW at 690 V

(380 - 480 V)

(525-690 V)

Table 3.5

18 MG20P402 - Rev. 2013-12-16

Page 21

130BA818.10

130BA821.10

F3

F1

130BA959.10

F4

F2

130BB092.11

How to Install VLT AQUA Drive FC 202 Operation Instructions

Enclosure type E1 E2 F1/F3 F2/F4

Enclosure

protection

Normal overload

rated power -

110% overload

torque

Table 3.6

IP 21/54 00 21/54 21/54

NEMA Type 1/Type 12 Chassis Type 1/Type 12 Type 1/Type 12

315 - 450 kW at 400 V

(380 - 480 V)

450 - 630 kW at 690 V

(525-690 V)

315 - 450 kW at 400 V

(380 - 480 V)

450 - 630 kW at 690 V

(525-690 V)

500 - 710 kW at 400 V

(380 - 480 V)

710 - 900 kW at 690 V

(525-690 V)

800 - 1000 kW at 400 V

(380 - 480 V)

1000 - 1400 kW at 690 V

(525-690 V)

NOTICE

The F enclosures are available in 4 different sizes, F1, F2, F3 and F4 The F1 and F2 consist of an inverter cabinet on the

right and rectifier cabinet on the left. The F3 and F4 have an additional options cabinet left of the rectifier cabinet. The

F3 is an F1 with an additional options cabinet. The F4 is an F2 with an additional options cabinet.

3 3

MG20P402 - Rev. 2013-12-16 19

Page 22

176FA235.11

<105,0°

526

(20.7)

399

(15.7)

748

(29.5)

579

(22.8)

176FA276.12

≤105,0°

130BB003.13

578

(22.8)

776

(30.6)

2X578

[22.8]

776

[30.6]

130BB004.13

130BB005.13

624

[24.6]

579

[22.8]

578

[22.8]

How to Install VLT AQUA Drive FC 202 Operation Instructions

3.3 Mechanical Installation

Preparation of the mechanical installation of the frequency

converter must be done carefully to ensure a proper result

and to avoid additional work during installation. Start

taking a close look at the mechanical drawings at the end

33

of this instruction to become familiar with the space

demands.

3.3.1 Tools Needed

To perform the mechanical installation the following

tools are needed:

Drill with 10 or 12 mm drill

•

Tape measure

•

Wrench with relevant metric sockets (7-17mm)

•

Extensions to wrench

•

Sheet metal punch for conduits or cable glands

•

in IP21/Nema 1 and IP54 units

Lifting bar to lift the unit (rod or tube max. Ø 5

•

mm (1 inch), able to lift minimum 400 kg (880

lbs).

Crane or other lifting aid to place the frequency

•

converter in position

A Torx T50 tool is needed to install the E1 in IP21

•

and IP54 enclosure types.

General Considerations

3.3.2

Wire access

Ensure that proper cable access is present including

necessary bending allowance. As the IP00 enclosure is

open to the bottom cables must be fixed to the back

panel of the enclosure where the frequency converter is

mounted, i.e. by using cable clamps.

Illustration 3.14 Space in Front of IP21/IP54 Rated Enclosure

Types D1 and D2

Illustration 3.15 Space in Front of IP21/IP54 Rated Enclosure

Type E1

Illustration 3.16 Space in Front of IP21/IP54 Rated Enclosure

Type F1

CAUTION

All cable lugs/shoes must mount within the width of the

terminal bus bar.

Space

Ensure proper space above and below the frequency

converter to allow airflow and cable access. In addition

space in front of the unit must be considered to enable

opening of the door of the panel.

20 MG20P402 - Rev. 2013-12-16

Illustration 3.17 Space in Front of IP21/IP54 Rated Enclosure

Type F3

Illustration 3.18 Space in Front of IP21/IP54 Rated Enclosure

Type F2

Page 23

624

(24.6)

2x579

578

(22.8)

130BB006.10

0,

(0,)

0,

(0,)

O

P

Q0,

(0,)

NMLJ KE F G H I

A

B

C

D

176FA238.10

R/12 91

W/T3 98V/T2 97U/T1 96

+R 82-R 81

+DC 89-DC 88

T/L3 93S/L2 92

How to Install VLT AQUA Drive FC 202 Operation Instructions

Illustration 3.19 Space in Front of IP21/IP54 Rated Enclosure

Type F4

3.3.3 Terminal Locations - Enclosure Type D

Consider the following terminal positions when designing for cables access.

3 3

Illustration 3.20 Position of Power Connections, Enclosure Types D3 and D4

MG20P402 - Rev. 2013-12-16 21

Page 24

R/L1 S/L2

U/T1 96 V/T2 97 W/T398

T/L391

81 82

9392

-DC +DC

-R +R

0,

(0,)

UTS

R

0,

(0,)

176FA239.10

0,

(0,)

V

How to Install VLT AQUA Drive FC 202 Operation Instructions

33

Illustration 3.21 Position of Power Connections with Disconnect Switch, Enclosure Types D1 and D2

Be aware that the power cables are heavy and hard to bend. Consider the optimum position of the frequency converter for

ensuring easy installation of the cables.

22 MG20P402 - Rev. 2013-12-16

Page 25

How to Install VLT AQUA Drive FC 202 Operation Instructions

NOTICE

All D enclosures are available with standard input terminals or disconnect switch. All terminal dimensions can be found

in Table 3.7.

IP21 (NEMA 1)/IP54 (NEMA 12) IP00/Chassis

D1 D2 D3 D4

A 277 (10.9) 379 (14.9) 119 (4.7) 122 (4.8)

B 227 (8.9) 326 (12.8) 68 (2.7) 68 (2.7)

C 173 (6.8) 273 (10.8) 15 (0.6) 16 (0.6)

D 179 (7.0) 279 (11.0) 20.7 (0.8) 22 (0.8)

E 370 (14.6) 370 (14.6) 363 (14.3) 363 (14.3)

F 300 (11.8) 300 (11.8) 293 (11.5) 293 (11.5)

G 222 (8.7) 226 (8.9) 215 (8.4) 218 (8.6)

H 139 (5.4) 142 (5.6) 131 (5.2) 135 (5.3)

I 55 (2.2) 59 (2.3) 48 (1.9) 51 (2.0)

J 354 (13.9) 361 (14.2) 347 (13.6) 354 (13.9)

K 284 (11.2) 277 (10.9) 277 (10.9) 270 (10.6)

L 334 (13.1) 334 (13.1) 326 (12.8) 326 (12.8)

M 250 (9.8) 250 (9.8) 243 (9.6) 243 (9.6)

N 167 (6.6) 167 (6.6) 159 (6.3) 159 (6.3)

O 261 (10.3) 260 (10.3) 261 (10.3) 261 (10.3)

P 170 (6.7) 169 (6.7) 170 (6.7) 170 (6.7)

Q 120 (4.7) 120 (4.7) 120 (4.7) 120 (4.7)

R 256 (10.1) 350 (13.8) 98 (3.8) 93 (3.7)

S 308 (12.1) 332 (13.0) 301 (11.8) 324 (12.8)

T 252 (9.9) 262 (10.3) 245 (9.6) 255 (10.0)

U 196 (7.7) 192 (7.6) 189 (7.4) 185 (7.3)

V 260 (10.2) 273 (10.7) 260 (10.2) 273 (10.7)

3 3

Table 3.7 Cable Positions Dimensions in mm (inch)

MG20P402 - Rev. 2013-12-16 23

Page 26

176FA278.10

0[0.0]

0[0.0]

600[23.6]

525[20.7]

412[16.2]

300[11.8]

188[7.4]

75[3.0]

B

492[19.4]

323[12.7]

195[7.7]

0[0.0]

155[6.1]

193[7.6]

280[11.0]

371[14.6]

409[16.1]

How to Install VLT AQUA Drive FC 202 Operation Instructions

3.3.4 Terminal Locations - E Enclosures

Terminal Locations - E1

Take the following position of the terminals into consideration when designing the cable access.

33

Illustration 3.22 IP21 (NEMA Type 1) and IP54 (NEMA Type 12) Enclosure Power Connection Positions

24 MG20P402 - Rev. 2013-12-16

Page 27

176FA272.10

0[0.0]

55[2.2]

91[3.6]

139[5.5]

175[6.9]

0[0.0]

453[17.8]

B

A A A A

-R 81

9

19 Nm [14 FTa

How to Install VLT AQUA Drive FC 202 Operation Instructions

3 3

Illustration 3.23 IP21 (NEMA type 1) and IP54 (NEMA type 12)

Enclosure Power Connection Positions (Detail B)

MG20P402 - Rev. 2013-12-16 25

Page 28

E

F

B

C

D

0 0.0[ ]

51 2.0[ ]

226 8.9[ ]

266 10.5[ ]

441 17.4[ ]

0 0.0[ ]

28 1.1[ ]

167 6.6[ ]

195 7.7[ ]

A

0 0.0[ ]

176FA279.11

How to Install

VLT AQUA Drive FC 202 Operation Instructions

33

Illustration 3.24 IP21 (NEMA type 1) and IP54 (NEMA type 12) Enclosure Power Connection Position of Disconnect Switch

Enclosure

types

E1

IP54/IP21 UL AND NEMA1/NEMA12

250/315 kW (400 V) AND 355/450-500/630

Unit type Dimensions [mm]/(inch)

KW (690 V)

396 (15.6) 267 (10.5) 332 (13.1) 397 (15.6) 528 (20.8) N/A

315/355-400/450 kW (400 V) 408 (16.1) 246 (9.7) 326 (12.8) 406 (16.0) 419 (16.5) 459 (18.1)

Table 3.8 Dimensions for Disconnect Terminal

26 MG20P402 - Rev. 2013-12-16

Page 29

176FA280.10

585[23.0]

518[20.4]

405[15.9]

68[2.7]

0[0.0]

186[7.3]

0[0.0]

0[0.0]

181[7.1]

293[11.5]

409[16.1]

371[14.6]

280[11.0]

192[7.6]

154[6.1]

17[0.7]

A

R/L1 91

9

S/L2 92

U/T1 96 V/T2 97

T/L3 93

W/T3 98

FASTENER TORQUE M8 9.6 Nm (7 FT-LB) FASTENER TORQUE M8 9.6 Nm (7 FT-LB)

176FA282.10

0(0.0)

47(1.9)

83(3.3)

131(5.2)

167(6.6)

0(0.0)

147(5.8)

A A A A

019Nm (14 F)

9

A

R 81

How to Install VLT AQUA Drive FC 202 Operation Instructions

Terminal locations - enclosure type E2

Take the following position of the terminals into consideration when designing the cable access.

3 3

Illustration 3.25 IP00 Enclosure Power Connection Positions

Illustration 3.26 IP00 Enclosure Power Connection Positions

MG20P402 - Rev. 2013-12-16 27

Page 30

E

0

0.0[ ]

F

B

0 0.0[ ]

C

D

A

0 0.0[ ]

176FA281.11

104[4.1]

35[1.4]

10[0.4]

0[0.0]

0[0.0]

40[1.6]

78[3.1]

0[0.0]

26[1.0]

26[1.0]

176FA271.10

How to Install VLT AQUA Drive FC 202 Operation Instructions

33

Illustration 3.27 IP00 Enclosure Power Connections Positions of Disconnect Switch

NOTICE

The power cables are heavy and difficult to bend. Consider the optimum position of the frequency converter for

ensuring easy installation of the cables.

Each terminal allows use of up to 4 cables with cable lugs or use of standard box lug. Earth is connected to relevant

termination point in the frequency converter.

If lugs are wider than 39 mm, install supplied barriers on the mains input side of the disconnect.

Illustration 3.28 Terminal in Details

28 MG20P402 - Rev. 2013-12-16

Page 31

130BA849.13

.0 [.0]

54.4[2.1]

169.4 [6.7]

284.4 [11.2]

407.3 [16.0]

522.3 [20.6]

637.3 [25.1]

287.4 [11.3]

253.1 [10.0]

.0 [.0]

.0 [.0]

339.4 [13.4]

287.4 [11.3]

.0 [.0]

339.4 [13.4]

308.3 [12.1]

465.6 [18.3]

465.6 [18.3]

198.1[7.8]

234.1 [9.2]

282.1 [11.1]

318.1 [12.5]

551.0 [21.7]

587.0 [23.1]

635.0 [25.0]

671.0 [26.4]

44.40 [1.75]

244.40 [9.62]

204.1 [8.0]

497.1 [19.6]

572.1 [22.5]

180.3 [7.1]

129.1 [5.1]

4

6

4

1

2

3

5

How to Install VLT AQUA Drive FC 202 Operation Instructions

NOTICE

Power connections can be made to positions A or B

Enclosure

type

Unit type Dimensions [mm]/(inch)

IPOO/CHASSIS A B C D E F

250/315 kW (400 V) AND 355/450-500/630

E2

KW (690 V)

396 (15.6) 268 (10.6) 333 (13.1) 398 (15.7) 221 (8.7) N/A

315/355-400/450 kW (400 V) 408 (16.1) 239 (9.4) 319 (12.5) 399 (15.7) 113 (4.4) 153 (6.0)

Table 3.9 Dimensions for Disconnect Terminal

3.3.5 Terminal Locations - Enclosure type F

NOTICE

The F enclosures have 4 different sizes, F1, F2, F3 and F4. The F1 and F2 consist of an inverter cabinet on the right and

rectifier cabinet on the left. The F3 and F4 have an additional options cabinet left of the rectifier cabinet. The F3 is an

F1 with an additional options cabinet. The F4 is an F2 with an additional options cabinet.

Terminal locations - enclosure types F1 and F3

3 3

Illustration 3.29 Terminal Locations - Inverter Cabinet - F1 and F3 (Front, Left and Right Side View). The Gland Plate is 42 mm

below .0 Level.

1) Earth ground bar

2) Motor terminals

3) Brake terminals

MG20P402 - Rev. 2013-12-16 29

Page 32

S1 F1

F1

DC ‘-’

DC ‘+’

1739.1

805.0

765.0

1694.1

1654.1

710.0

130BB377.10

287.4 [11.32]

0.0 [0.00]

339.4 [13.36]

253.1 [9.96]

0.0 [0.00]

287.4 [11.32]

0.0 [0.00]

339.4 [13.36]

465.6 [18.33]

465.6 [18.33]

308.3 [12.14]

180.3 [7.10]

210.1 [8.27]

0.0 [0.00]

66.4 [2.61]

181.4 [7.14]

296.4 [11.67]

431.0 [16.97]

546.0 [21.50]

661.0 [26.03]

795.7 [31.33]

910.7 [35.85]

1025.7 [40.38]

246.1 [9.69]

294.1 [11.58]

330.1 [13.00]

574.7 [22.63]

610.7 [24.04]

658.7 [25.93]

694.7 [27.35]

939.4 [36.98]

975.4 [38.40]

1023.4 [40.29]

1059.4 [41.71]

144.3 [5.68]

219.3 [8.63]

512.3 [20.17]

587.3 [23.12]

880.3 [34.66]

955.3 [37.61]

6

4

130BA850.12

FASTENER TORQUE: MIO 19 Nm (14 FT -LB)

U/T1 96 V/T2 97 W/T3 98

FASTENER TORQUE: MIO 19 Nm (14 FT -LB)

U/T1 96 V/T2 97 W/T3 98

FASTENER TORQUE: MIO 19 Nm (14 FT -LB)

U/T1 96 V/T2 97 W/T3 98

1

2

3

4

5

How to Install VLT AQUA Drive FC 202 Operation Instructions

33

Illustration 3.30 Terminal Locations - Regen Terminals - F1 and

F3

Terminal locations - enclosure types F2 and F4

Illustration 3.31 Terminal Locations - Inverter Cabinet - F2 and F4 (Front, Left and Right Side View). The Gland Plate is 42 mm

below .0 Level.

1) Earth Ground Bar

30 MG20P402 - Rev. 2013-12-16

Page 33

S1 S2

S2

F1

F1

S2F1

DC ‘-’

DC ‘+’

1739.1

1203.2

1163.2

1694.1

1654.1

1098.1

130BB378.10

74.6 [2.9]

0.0 [0.0]

125.8 [4.95]

218.6 [8.61]

293.6 [11.56]

362.6 [14.28]

437.6 [17.23]

149.6 [5.89]

486.6 [19.16]

183.4 [7.22]

373.4 [14.70]

0.0 [0.00]

70.4 [2.77]

193.9 [7.64]

343.1 [13.51]

38.1 [1.50]

0.0 [0.00]

90.1 [3.55]

136.6 [5.38]

188.6 [7.42]

B

A

435.5 [17.15]

LOAD SHARE LOCATION

DIM F1/F2 F3/F4

A 380.5 [14.98] 29.4 [1.16]

B 432.5 [17.03] 81.4 [3.20]

6

5

4

130BA848.12

CH22 CH22

R/L1 91 S/L2 92

FASTENER TORQUE: M8 9.6 Nm (7 FT-LB)

T/L3 93

FASTENER TORQUE: M10 19 Nm (14 FT-LB)

FASTENER TORQUE: M10 19 Nm (14 FT-LB)

DC 89

FASTENER TORQUE: M10 19 Nm (14 FT-LB)

DC 89

CH22 CH22 CH22 CH22

CTI25MB CTI25MB

AUXAUXAUXAUXAUX

3

2

1

How to Install VLT AQUA Drive FC 202 Operation Instructions

Illustration 3.32 Terminal Locations - Regen Terminals - F2 and

F4

Terminal locations - Rectifier (F1, F2, F3 and F4)

3 3

Illustration 3.33 Terminal Locations - Rectifier (Left Side, Front and Right Side View). The Gland Plate is 42 mm below .0 Level.

1) Loadshare Terminal (-)

2) Earth Ground Bar

3) Loadshare Terminal (+)

MG20P402 - Rev. 2013-12-16 31

Page 34

1 2 3

4

0.0[0.00]

76.4[3.01]

128.4[5.05]

119.0[4.69]

171.0[6.73]

294.6[11.60]

344.0[13.54]

3639[14.33]

438.9[17.28]

75.3[2.96]

150.3[5.92]

154.0[6.06]

219.6[18.65]

0.0[0.00]

244.4[9.62]

244.4[1.75]

939.0[36.97]

1031.4[40.61]

0.0[0.00]

134.6[5.30]

130BA851.12

0.0[1.75]

How to Install VLT AQUA Drive FC 202 Operation Instructions

Terminal locations - Options Cabinet (F3 and F4)

33

Illustration 3.34 Terminal Locations - Options Cabinet (Left Side, Front and Right Side View). The Gland Plate is 42 mm below .0

Level.

1) Earth Ground Bar

32 MG20P402 - Rev. 2013-12-16

Page 35

0.0 [0.00]

134.6 [5.30]

104.3 [4.11]

0.0 [0.00]

179.3 [7.06]

219.6 [8.65]

294.6 [11.60]

334.8 [13.18]

409.8 [16.14]

436.9 [17.20]

0.0 [0.00]

532.9 [20.98]

0.0 [0.00]

44.4 [1.75]

244.4 [9.62]

154.0 [6.06]

344.0 [13.54]

1

234

5

130BA852.11

How to Install VLT AQUA Drive FC 202 Operation Instructions

Terminal locations - Options Cabinet with circuit breaker/ molded case switch (F3 and F4)

3 3

Illustration 3.35 Terminal Locations - Options Cabinet with Circuit Breaker/Molded Case Switch (Left Side, Front and Right Side View).

The Gland Plate is 42 mm below .0 Level.

1) Earth Ground Bar

Power size 2 3 4 5

500 kW (480

34.9 86.9 122.2 174.2

V), 710-800

kW (690 V)

560-1000 kW

46.3 98.3 119.0 171.0

(480 V),

900-1400 kW

(690 V)

Table 3.10 Dimensions for Terminal

3.3.6 Cooling and Airflow

Cooling

Cooling can be obtained in different ways, by using the

cooling ducts in the bottom and the top of the unit, by

taking air in and out the back of the unit or by combining

the cooling possibilities.

Duct cooling

A dedicated option has been developed to optimize installation of IP00/chassis frequency converters in Rittal TS8

enclosures utilizing the fan of the frequency converter for

forced air cooling of the backchannel. The air out of the

top of the enclosure could but ducted outside a facility so

the heat loses from the backchannel are not dissipated

within the control room reducing air-conditioning

requirements of the facility.

See chapter 3.4.1 Installation of Duct Cooling Kit in Rittal

Enclosures, for further information.

Back cooling

The backchannel air can also be ventilated in and out the

back of a Rittal TS8 enclosure. This offers a solution where

the backchannel could take air from outside the facility

and return the heat loses outside the facility thus reducing

air-conditioning requirements.

MG20P402 - Rev. 2013-12-16 33

Page 36

90

80

70

60

50

40

30

20

10

0

0 0.5 4.9 13 27.3 45.9 66 89.3 115.7 147

(%)

(Pa)

Pressure Increase

Drive Derating

130BB007.10

90

80

70

60

50

40

30

20

10

0

(%)

Drive Derating

0 0 0.1 3.6 9.8 21.5 43.4 76 237.5 278.9

(Pa)

Pressure Change

130BB010.10

147.1

How to Install VLT AQUA Drive FC 202 Operation Instructions

CAUTION

A door fan(s) is required on the enclosure to remove the

heat losses not contained in the backchannel of the

frequency converter and any additional losses generated

from other components installed inside the enclosure.

33

The total required air flow must be calculated so that the

appropriate fans can be selected. Some enclosure

NOTICE

The fan runs for the following reasons:

1. AMA

2. DC Hold

3. Pre-Mag

4. DC Brake

manufacturers offer software for performing the

calculations (i.e. Rittal Therm software). If the frequency

converter is the only heat generating component in the

enclosure, the minimum airflow required at an ambient

temperature of 45 oC for the D3 and D4 frequency

converters is 391 m3/h (230 cfm). The minimum airflow

required at an ambient temperature of 45oC for the E2

frequency converter is 782 m3/h (460 cfm).

Airflow

The necessary airflow over the heat sink must be secured.

The flow rate is in Table 3.11.

Enclosure

protection Enclosure type

IP21/NEMA 1

D1 and D2

IP54/NEMA 12

E1 P315T5,

P450T7,

P500T7

E1 P355P450T5, P560P630T7

IP21/NEMA 1 F1, F2, F3 and

F4

IP54/NEMA 12 F1, F2, F3 and

F4

IP00/Chassis D3 and D4

E2 P315T5,

P450T7,

P500T7

E2 P355P450T5, P560P630T7

* Airflow per fan. enclosure type F contain multiple fans.

Door fan(s)/

Top fan

airflow

170 m3/h

(100 cfm)

340 m3/h

(200 cfm)

340 m3/h

(200 cfm)

700 m3/h

(412 cfm)*

525 m3/h

(309 cfm)*

255 m3/h

(150 cfm)

255 m3/h

(150 cfm)

255 m3/h

(150 cfm)

Heat sink

fan(s)

765 m3/h

(450 cfm)

1105 m3/h

(650 cfm)

1445 m3/h

(850 cfm)

985 m3/h

(580 cfm)*

985 m3/h

(580 cfm)*

765 m3/h

(450 cfm)

1105 m3/h

(650 cfm)

1445 m3/h

(850 cfm)

5. 60% of nominal current is exceeded

6. Specific heat sink temperature exceeded (power

size dependent)

7. Specific Power Card ambient temperature

exceeded (power size dependent)

8. Specific Control Card ambient temperature

exceeded

Once the fan is started it will run for minimum 10

minutes.

External ducts

If additional duct work is added externally to the Rittal

cabinet the pressure drop in the ducting must be

calculated. Use the charts below to derate the frequency

converter according to the pressure drop.

Illustration 3.36 D Enclosure Derating vs. Pressure Change

Frequency converter air flow: 450 cfm (765 m3/h)

Table 3.11 Heat Sink Air Flow

34 MG20P402 - Rev. 2013-12-16

Illustration 3.37 E Enclosure Derating vs. Pressure Change

(Small Fan), P315T5 and P450T7-P500T7

Frequency converter air flow: 650 cfm (1105 m3/h)

Page 37

90

80

70

60

50

40

30

20

10

0

(%)

Drive Derating

0 0.2 0.6 2.2 5.8 11.4 18.1 30.8 152.8 210.8

(Pa)

Pressure Change

130BB011.10

69.5

90

80

70

60

50

40

30

20

10

0

(%)

Drive Derating

0 25 50 75 100 125 150 175 225

130BB190.10

200

Pressure Change

176FA245.10

130BB073.10

How to Install

VLT AQUA Drive FC 202 Operation Instructions

Illustration 3.38 E Enclosure Derating vs. Pressure Change

(Large Fan), P355T5-P450T5 and P560T7-P630T7

Frequency converter air flow: 850 cfm (1445 m3/h)

Illustration 3.40 Lifting Method for Mounting Frequency

Converter on Wall

Gland/Conduit Entry - IP21 (NEMA 1)

3.3.8

and IP54 (NEMA12)

Cables are connected through the gland plate from the

bottom. Remove the plate and plan where to place the

entry for the glands or conduits. Prepare holes in the

marked area on the drawing.

3 3

Illustration 3.39 F1, F2, F3, F4 Enclosures Derating vs. Pressure

Change

Frequency converter air flow: 580 cfm (985 m3/h)

Installation on the Wall - IP21 (NEMA

3.3.7

1) and IP54 (NEMA 12) Units

This only applies to enclosure types D1 and D2. It must be

considered where to install the unit.

Take the relevant points into consideration before

selecting the final installation site:

Free space for cooling

•

Access to open the door

•

Cable entry from the bottom

•

Mark the mounting holes carefully using the mounting

template on the wall and drill the holes as indicated.

Ensure proper distance to the floor and the ceiling for

cooling. A minimum of 225 mm (8.9 inch) below the

frequency converter is needed. Mount the bolts at the

bottom and lift the frequency converter up on the bolts.

Tilt the frequency converter against the wall and mount

the upper bolts. Tighten all 4 bolts to secure the frequency

converter against the wall.

NOTICE

The gland plate must be fitted to the frequency

converter to ensure the specified protection degree, as

well as ensuring proper cooling of the unit. If the gland

plate is not mounted, the frequency converter may trip

on Alarm 69, Pwr. Card Temp

Illustration 3.41 Example of Proper Installation of Gland Plate.

MG20P402 - Rev. 2013-12-16 35

Page 38

2

1

176FA289.12

35

350

202.8

98.6

130.0

62.5

2

1

176FA289.12

35

350

202.8

98.6

130.0

62.5

1

130BA837.12

1328.8

(52.315)

595.8

(23.457)

533.0

(20.984)

36.2

(1.425)

281.8

(11.096)

535.0

(21.063)

216.5

(8.524)

37.7

(1.485)

460.0

(18.110)

668.3

(26.311)

593.0

(23.346)

199.5

(7.854)

258.5

(10.177)

35.5

(1.398)

533.0

[20.984]

594.8

[23.417] 1727.8

[68.024]

35.5

[1.398]

[21.063]

258.2

[10.167]

199.5

[7.854]

37.7

[1.485]

460.0

[18.110]

994.3

[39.146]

216.5

[8.524]

36.2

[1.425]

281.8

[11.096]

1

130BA841.12

535.0

655.9

25.825

1

130BA843.12

37.7

(1.485)

535.0

(21.063)

35.5

(1.398)

36.2

(1.425)

533.0

(20.984)

597.0

(23.504)

1130.0

(44.488)

1192.8

(46.961)

1925.8

(75.819)

258.5

(10.177)

199.5

(7.854)

2X 460.0

(18.110)

634.7

(24.989)

1265.3

(49.815)

593.0

(23.346)

2X 281.3

(11.075)

2X 216.5

(8.524)

How to Install VLT AQUA Drive FC 202 Operation Instructions

Cable entries viewed from the bottom of the frequency

converter - 1) Mains side 2) Motor side

Enclosure types F1-F4: Cable entries viewed from the

bottom of the frequency converter - 1) Place conduits in

marked areas

33

Illustration 3.44 Enclosure Type F1

Illustration 3.42 Enclosure Types D1 + D2

Illustration 3.43 Enclosure Type E1

36 MG20P402 - Rev. 2013-12-16

Illustration 3.45 Enclosure Type F2

Illustration 3.46 Enclosure Type F3

Page 39

130BA839.10

1

37.7

(1.485)

533 (20.984)

597.0 (23.504)

1130.0 (44.488)

2324.8 (91.528)

535.0

(21.063)

2X 216.5

(8.524)

2X 460.0

(18.110)

634.7 (24.989)

35.5

(1.398)

258.2

(10.167)

199.5

(7.854)

1252.8

(49.321)

994.3

(39.146)

2X 281.8

(11.096)

36.2

(1.425)

1191.8 (46.921)

176FA285.10

176FA252.10

How to Install

Illustration 3.47 Enclosure Type F4

VLT AQUA Drive FC 202 Operation Instructions

3.3.9 IP21 Drip Shield Installation

(Enclosure Types D1 and D2)

To comply with the IP21 rating, a separate drip shield is

to be installed as explained below:

Remove the 2 front screws

•

Insert the drip shield and replace screws

•

Tighten the screws to 5.6 Nm (50 in-lbs)

•

3 3

Illustration 3.48 Drip Shield Installation.

3.4 Field Installation of Options

3.4.1 Installation of Duct Cooling Kit in

Rittal Enclosures

This section deals with the installation of IP00/chassis

enclosed frequency converters with duct work cooling kits

in Rittal enclosures. In addition to the enclosure a 200 mm

base/plinth is required.

Illustration 3.49 Installation of IP00 in Rittal TS8 Enclosure.

The minimum enclosure dimension is:

D3 and D4 enclosures: Depth 500 mm and width

•

600 mm.

E2 enclosure: Depth 600 mm and width 800 mm.

•

The maximum depth and width are as required by the

installation. When using multiple frequency converters in

one enclosure, it is recommended that each frequency

converter is mounted on its own back panel and

MG20P402 - Rev. 2013-12-16 37

Page 40

176FT261.10

How to Install

VLT AQUA Drive FC 202 Operation Instructions

supported along the mid-section of the panel. These duct

work kits do not support the “in frame” mounting of the

panel (see Rittal TS8 catalogue for details). The duct work

cooling kits listed in Table 3.12 are suitable for use only

with IP00/Chassis frequency converters in Rittal TS8 IP 20

and UL and NEMA 1 and IP 54 and UL and NEMA 12

33

enclosures.

3.4.2

Outside Installation/NEMA 3R Kit for

Rittal Enclosures

CAUTION

For the E2 enclosures it is important to mount the plate

at the absolute rear of the Rittal enclosure due to the

weight of the frequency converter.

CAUTION

A doorfan(s) is required on the enclosure to remove the

heat losses not contained in the backchannel of the

frequency converter and any additional losses generated

from other components installed inside the enclosure.

The total required airflow must be calculated so that the

appropriate fans can be selected. Some enclosure

manufacturers offer software for performing the

calculations (i.e. Rittal Therm software). If the frequency

converter is the only heat generating component in the

enclosure, the minimum airflow required at an ambient

temperature of 45 °C for the D3 and D4 frequency

converters is 391 m3/h (230 cfm). The minimum airflow

required at an ambient temperature of 45 °C for the E2

frequency converter is 782 m3/h (460 cfm).

Illustration 3.50

Rittal TS-8

Enclosure

1800 mm 176F1824 176F1823 Not possible

2000 mm 176F1826 176F1825 176F1850

2200 mm 176F0299

Table 3.12 Ordering Information

Enclosure type

D3 Kit Part

No.

Enclosure type

D4 Kit Part No.

Enclosure

type E2 Part

No.

NOTICE

See the instruction Duct Work Cooling Kit Instruction for

Frames D3, D4 and E2 for further information.

External ducts

If additional duct work is added externally to the Rittal

cabinet the pressure drop in the ducting must be

calculated. See chapter 3.3.6 Cooling and Airflow for further

information.

This section is for the installation of NEMA 3R kits available

for the frequency converter enclosure types D3, D4 and E2.

These kits are designed and tested to be used with IP00/

Chassis versions of these enclosure types in Rittal TS8

NEMA 3R or NEMA 4 enclosures. The NEMA-3R enclosure is

an outdoor enclosure that provides a degree of protection

against rain and ice. The NEMA-4 enclosure is an outdoor

enclosure that provides a greater degree of protection

against weather and hosed water.

The minimum enclosure depth is 500 mm (600 mm for

enclosure type E2) and the kit is designed for a 600 mm

(800 mm for enclosure type E2) wide enclosure. Other

enclosure widths are possible, however additional Rittal

hardware is required. The maximum depth and width are

as required by the installation.

38 MG20P402 - Rev. 2013-12-16

Page 41

175ZT976.10

How to Install VLT AQUA Drive FC 202 Operation Instructions

NOTICE

The current rating of frequency converters in enclosure

types D3 and D4 are de-rated by 3%, when adding the

NEMA 3R kit. Frequency converters in enclosure type E2

require no derating.

NOTICE

A doorfan(s) is required on the enclosure to remove the

heat losses not contained in the backchannel of the

frequency converter and any additional losses generated

from other components installed inside the enclosure.

The total required airflow must be calculated so that the

appropriate fans can be selected. Some enclosure

manufacturers offer software for performing the

calculations (i.e. Rittal Therm software). If the frequency

converter is the only heat generating component in the

enclosure, the minimum airflow required at an ambient

temperature of 45 °C for the D3 and D4 frequency

converters is 391 m3/h (230 cfm). The minimum airflow

required at an ambient temperature of 45 °C for the E2

frequency converter is 782 m3/h (460 cfm).

Ordering information

Enclosure type D3: 176F4600

Enclosure type D4: 176F4601

Enclosure type E2: 176F1852

NOTICE

See the instructions Installation of NEMA 3R Kit for IP00

Frames D3, D4 & E2 for further information.

3 3

3.4.3 Installation on Pedestal

This section describes the installation of a pedestal unit

available for the frequency converters enclosure types D1

and D2. This is a 200 mm high pedestal that allows these

enclosure types to be floor mounted. The front of the

pedestal has openings for input air to the power

components.

The frequency converter gland plate must be installed to

provide adequate cooling air to the control components of

the frequency converter via the door fan and to maintain

the IP21/NEMA 1 or IP54/NEMA 12 degrees of enclosure

protections.

Illustration 3.51 Frequency Converter on Pedestal

There is one pedestal that fits both enclosure types D1 and

D2. Its ordering number is 176F1827. The pedestal is

standard for enclosure type E1.

MG20P402 - Rev. 2013-12-16 39

Page 42

176FA242.10

How to Install VLT AQUA Drive FC 202 Operation Instructions

NOTICE

See the Pedestal Kit Instruction Manual, for further

information.

3.4.4 Installation of Input Plate Options

33

This section is for the field installation of input option kits

available for frequency converters in all enclosure types D

and E.

Do not attempt to remove RFI filters from input plates.

Damage may occur to RFI filters if they are removed from

the input plate.

Illustration 3.52 Mounting of Frequency Converter to Pedestal

NOTICE

Where RFI filters are available, there are 2 different type of RFI filters depending on the input plate combination and

the RFI filters interchangeable. Field installable kits in certain cases are the same for all voltages.

D1 All D1 power sizes 176F8442 176F8450 176F8444 176F8448 176F8446

D2 All D2 power sizes 176F8443 176F8441 176F8445 176F8449 176F8447

E1 FC 102/ FC 202: 315 kW

Table 3.13 Fuses

D1 FC 102/ FC 202: 45-90

D2 All D2power sizes 175L8827 175L8826 175L8825 NA NA

E1 FC 102/ FC 202:

380-480 V

380-500 V

FC 302: 250 kW

FC 102/ FC 202: 355 450 kW

FC 302: 315 - 400 kW

525 - 690 V Fuses Disconnect Fuses RFI RFI Fuses RFI Disconnect

kW

FC 302: 37-75 kW

FC 102/ FC 202:

110-160 kW

FC 302: 90-132 kW

450-500 kW

FC 302: 355-400 kW

FC 102/ FC 202:

560-630 kW

FC 302: 500-560 kW

Fuses Disconnect Fuses RFI RFI Fuses RFI Disconnect

Fuses

176F0253 176F0255 176F0257 176F0258 176F0260

176F0254 176F0256 176F0257 176F0259 176F0262

Fuses

175L8829 175L8828 175L8777 NA NA

175L8442 175L8445 175L8777 NA NA

176F0253 176F0255 NA NA NA

176F0254 176F0258 NA NA NA

Table 3.14

40 MG20P402 - Rev. 2013-12-16

Page 43

How to Install

VLT AQUA Drive FC 202 Operation Instructions

NOTICE

For further information, see the Instruction Installation of

Field Installable Kits for VLT Drives

3.4.5 Installation of Mains Shield for

Frequency Converters

This section is for the installation of a mains shield for the

frequency converter series with enclosure types D1, D2

and E1. It is not possible to install in the IP00/Chassis

versions as these have included as standard a metal cover.

These shields satisfy VBG-4 requirements.

Ordering numbers:

Enclosure types D1 and D2: 176F0799

Enclosure type E1: 176F1851

NOTICE

For further information, see the Instruction Sheet,

175R5923

3.5 Enclsoure Type F Panel Options

3.5.1 Enclsoure Type F Options

Space Heaters and Thermostat

Mounted on the cabinet interior of enclosure type F

frequency converters, space heaters controlled via

automatic thermostat help control humidity inside the

enclosure, extending the lifetime of frequency converter

components in damp environments. The thermostat

default settings turn on the heaters at 10 °C (50 °F) and

turn them off at 15.6 °C (60 °F).

Cabinet Light with Power Outlet

A light mounted on the cabinet interior of enclosure type

F frequency converters increase visibility during servicing

and maintenance. The housing the light includes a power

outlet for temporarily powering tools or other devices,

available in two voltages:

230 V, 50 Hz, 2.5 A, CE/ENEC

•

120 V, 60 Hz, 5 A, UL/cUL

•

Transformer Tap Setup

If the cabinet light & outlet and/or the space heaters &

thermostat are installed Transformer T1 requires it taps to

be set to the proper input voltage. A 380-480/500 V

frequency converter is set initially to the 525 V tap and a

525-690 V frequency converter is set to the 690 V tap to

insure no overvoltage of secondary equipment occurs if

the tap is not changed before power is applied. See

Table 3.15 to set the proper tap at terminal T1 located in

the rectifier cabinet. For location in the frequency

converter, see Illustration 3.53.

Input Voltage Range [V] Tap to Select

380-440 400 V

441-490 460 V

491-550 525 V

551-625 575 V

626-660 660 V

661-690 690 V

Table 3.15

NAMUR Terminals

NAMUR is an international association of automation

technology users in the process industries, primarily

chemical and pharmaceutical industries in Germany.

Selection of this option provides terminals organized and

labeled to the specifications of the NAMUR standard for

frequency converter input and output terminals. This

requires MCB 112 PTC Thermistor Card and MCB 113

Extended Relay Card.

RCD (Residual Current Device)

Uses the core balance method to monitor ground fault

currents in grounded and high-resistance grounded

systems (TN and TT systems in IEC terminology). There is a

pre-warning (50% of main alarm set-point) and a main

alarm set-point. Associated with each set-point is an SPDT

alarm relay for external use. Requires an external “windowtype” current transformer (supplied and installed by

customer).

Integrated into the frequency converter’s safe-

•

stop circuit

IEC 60755 Type B device monitors AC, pulsed DC,

•

and pure DC ground fault currents

LED bar graph indicator of the ground fault

•

current level from 10–100% of the set-point

Fault memory

•

[TEST/RESET]

•

Insulation Resistance Monitor (IRM)

Monitors the insulation resistance in ungrounded systems

(IT systems in IEC terminology) between the system phase

conductors and ground. There is an ohmic pre-warning

and a main alarm set-point for the insulation level.

Associated with each set-point is an SPDT alarm relay for

external use. Note: only one insulation resistance monitor

can be connected to each ungrounded (IT) system.

Integrated into the frequency converter’s safe-

•

stop circuit

LCD display of the ohmic value of the insulation

•

resistance

Fault Memory

•

[INFO], [TEST], and [RESET]

•

3 3

MG20P402 - Rev. 2013-12-16 41

Page 44

3 Phase

power

input

130BA026.10

91 (L1)

92 (L2)

93 (L3)

95 PE

How to Install VLT AQUA Drive FC 202 Operation Instructions

33

IEC Emergency Stop with Pilz Safety Relay

Includes a redundant 4-wire emergency-stop push-button

mounted on the front of the enclosure and a Pilz relay that

monitors it in conjunction with the frequency converter’s

safe-stop circuit and the mains contactor located in the

options cabinet.

Safe Stop + Pilz Relay

Provides a solution for the "Emergency Stop" option

without the contactor in F-Enclosure frequency converters.

Manual Motor Starters

Provides 3-phase power for electric blowers often required

for larger motors. Power for the starters is provided from

the load side of any supplied contactor, circuit breaker, or

disconnect switch. Power is fused before each motor

starter, and is off when the incoming power to the

frequency converter is off. Up to 2 starters are allowed

(one if a 30 A, fuse-protected circuit is ordered). Integrated

into the frequency converter’s safe-stop circuit.

Unit features include:

Operation switch (on/off)

•

Short-circuit and overload protection with test

•

function

Manual reset function

•

30 A, Fuse-Protected Terminals

3-phase power matching incoming mains voltage

•

for powering auxiliary customer equipment

Not available if 2 manual motor starters are

•

selected

Terminals are off when the incoming power to

•

the frequency converter is off

Power for the fused protected terminals will be

•

provided from the load side of any supplied

contactor, circuit breaker, or disconnect switch.

24 V DC Power Supply

5 A, 120 W, 24 V DC

•

Protected against output over-current, overload,

•

short circuits, and over-temperature

For powering customer-supplied accessory

•

devices such as sensors, PLC I/O, contactors,

temperature probes, indicator lights, and/or other

electronic hardware

Diagnostics include a dry DC-ok contact, a green

•

DC-ok LED, and a red overload LED

External Temperature Monitoring

Designed for monitoring temperatures of external system

components, such as the motor windings and/or bearings.

Includes five universal input modules. The modules are

integrated into the frequency converter’s safe-stop circuit

and can be monitored via a fieldbus network (requires the

purchase of a separate module/bus coupler).

42 MG20P402 - Rev. 2013-12-16

Universal inputs (5)

Signal types:

•

•

•

Additional features:

•

•

•

•

•

3.6 Electrical Installation

3.6.1 Power Connections

Cabling and Fusing

NOTICE

Cables General

All cabling must comply with national and local

regulations on cable cross-sections and ambient

temperature. UL applications require 75 °C copper

conductors. 75 and 90 °C copper conductors are

thermally acceptable for the frequency converter to use

in non UL applications.

The power cable connections are situated as shown below.