Danfoss VLT AQUA Drive FC 202, VLT Refrigeration Drive FC 103, FC 102, VLT FC 103 Operating Manual

Page 1

ENGINEERING TOMORROW

Operating Guide

VLT® AQUA Drive FC 202

355–800 kW, Enclosure Size E

vlt-drives.danfoss.com

Page 2

Page 3

Contents Operating Guide

Contents

1 Introduction

1.1 Purpose of the Manual

1.2 Additional Resources

1.3 Manual and Software Version

1.4 Approvals and Certications

1.5 Disposal

2 Safety

2.1 Safety Symbols

2.2 Qualied Personnel

2.3 Safety Precautions

3 Product Overview

3.1 Intended Use

3.2 Power Ratings, Weights, and Dimensions

3.3 Interior View of Enclosures E1h and E2h

3.4 Interior View of Enclosures E3h and E4h

3.5 Control Shelf

3

3

3

3

3

3

4

4

4

4

6

6

6

7

8

9

3.6 Local Control Panel (LCP)

4 Mechanical Installation

4.1 Items Supplied

4.2 Tools Needed

4.3 Storage

4.4 Operating Environment

4.5 Installation and Cooling Requirements

4.6 Lifting the Unit

4.7 E1h/E2h Mechanical Installation

4.8 E3h/E4h Mechanical Installation

5 Electrical Installation

5.1 Safety Instructions

5.2 EMC-compliant Installation

5.3 Wiring Schematic

5.4 Connecting the Motor

5.5 Connecting the AC Mains

10

12

12

12

12

13

14

14

15

17

20

20

20

23

24

26

5.6 Connecting to Ground

5.7 Terminal Dimensions

5.8 Control Wiring

5.9 Pre-start Check List

MG22A102 Danfoss A/S © 01/2017 All rights reserved. 1

28

30

40

45

Page 4

Contents VLT® AQUA Drive FC 202

6 Commissioning

6.1 Safety Instructions

6.2 Applying Power

6.3 LCP Menu

6.4 Programming the Drive

6.5 Testing Before System Start-up

6.6 System Start-up

6.7 Parameter Settings

7 Wiring Conguration Examples

7.1 Wiring for Open-loop Speed Control

7.2 Wiring for Start/Stop

7.3 Wiring for External Alarm Reset

7.4 Wiring for a Motor Thermistor

7.5 Wiring for Regeneration

8 Maintenance, Diagnostics, and Troubleshooting

8.1 Maintenance and Service

46

46

46

47

48

51

52

52

54

54

55

56

57

57

58

58

8.2 Heat Sink Access Panel

8.3 Status Messages

8.4 Warning and Alarm Types

8.5 List of Warnings and Alarms

8.6 Troubleshooting

9 Specications

9.1 Electrical Data

9.2 Mains Supply

9.3 Motor Output and Motor Data

9.4 Ambient Conditions

9.5 Cable Specications

9.6 Control Input/Output and Control Data

9.7 Fuses

9.8 Enclosure Dimensions

9.9 Enclosure Airow

9.10 Fastener Torque Ratings

58

59

61

62

71

73

73

78

78

78

79

79

82

83

99

100

10 Appendix

10.1 Abbreviations and Conventions

10.2 International/North American Default Parameter Settings

10.3 Parameter Menu Structure

Index

2 Danfoss A/S © 01/2017 All rights reserved. MG22A102

101

101

102

102

108

Page 5

Introduction Operating Guide

1 Introduction

1.1 Purpose of the Manual

This operating guide provides information for safe instal-

lation and commissioning of the VLT® drives in an

enclosure size E (E1h, E2h, E3h, and E4h).

The operating guide is intended for use by qualied

personnel. To use the unit safely and professionally, read

and follow this operating guide. Pay particular attention to

the safety instructions and general warnings. Always keep

the operating guide with the drive.

VLT® is a registered trademark.

1.2 Additional Resources

Other resources are available to understand advanced E1h–

E4h drive functions and programming.

The VLT® AQUA Drive FC 202 Programming Guide

•

provides greater detail on working with

parameters and aqua application examples.

The VLT® AQUA Drive FC 202, 110–1400 kW Design

•

Guide provides detailed capabilities and

functionality to design motor control systems for

aqua applications.

The Safe Torque O Operating Guide.

•

Supplementary publications and manuals are available

from Danfoss. See drives.danfoss.com/knowledge-center/

technical-documentation/ for listings.

Manual and Software Version

1.3

This manual is regularly reviewed and updated. All

suggestions for improvement are welcome. Table 1.1 shows

the version of the manual and the corresponding software

version.

Manual version Remarks Software version

MG22A1xx Initial release 2.70

Approvals and Certications

1.4

Table 1.2 Approvals and

More approvals and certications are available. Contact the

local Danfoss oce or partner. Drives of voltage T7 (525–

690 V) are UL certied for only 525–600 V.

The drive complies with UL 61800-5-1 thermal memory

retention requirements. For more information, refer to the

section Motor Thermal Protection in the product-specic

design guide.

Certications

NOTICE

IMPOSED LIMITATIONS ON THE OUTPUT

FREQUENCY

From software version 1.99, the output frequency of the

drive is limited to 590 Hz due to export control

regulations.

1.4.1 Compliance with ADN

For compliance with the European Agreement concerning

International Carriage of Dangerous Goods by Inland

Waterways (ADN), refer to ADN-compliant Installation in the

design guide.

Disposal

1.5

Do not dispose of equipment containing

electrical components together with

domestic waste.

Collect it separately in accordance with

local and currently valid legislation.

1 1

Table 1.1 Manual and Software Version

MG22A102 Danfoss A/S © 01/2017 All rights reserved. 3

Page 6

Safety VLT® AQUA Drive FC 202

2 Safety

22

2.1 Safety Symbols

The following symbols are used in this guide:

WARNING

Indicates a potentially hazardous situation that could

result in death or serious injury.

CAUTION

Indicates a potentially hazardous situation that could

result in minor or moderate injury. It can also be used to

alert against unsafe practices.

NOTICE

Indicates important information, including situations that

can result in damage to equipment or property.

2.2 Qualied Personnel

WARNING

UNINTENDED START

When the drive is connected to AC mains, DC supply, or

load sharing, the motor can start at any time.

Unintended start during programming, service, or repair

work can result in death, serious injury, or property

damage. The motor can start with an external switch, a

eldbus command, an input reference signal from the

LCP or LOP, via remote operation using MCT 10 Set-up

Software, or after a cleared fault condition.

To prevent unintended motor start:

Press [O/Reset] on the LCP before

•

programming parameters.

Disconnect the drive from the mains.

•

Completely wire and assemble the drive, motor,

•

and any driven equipment before connecting

the drive to the AC mains, DC supply, or load

sharing.

Correct and reliable transport, storage, installation,

operation, and maintenance are required for the troublefree and safe operation of the drive. Only qualied

personnel are allowed to install or operate this equipment.

Qualied personnel are dened as trained sta, who are

authorized to install, commission, and maintain equipment,

systems, and circuits in accordance with pertinent laws and

regulations. Also, the personnel must be familiar with the

instructions and safety measures described in this manual.

Safety Precautions

2.3

WARNING

HIGH VOLTAGE

Drives contain high voltage when connected to AC mains

input, DC supply, load sharing, or permanent motors.

Failure to use qualied personnel to install, start up, and

maintain the drive can result in death or serious injury.

Only qualied personnel must install, start up,

•

and maintain the drive.

WARNING

DISCHARGE TIME

The drive contains DC-link capacitors, which can remain

charged even when the drive is not powered. High

voltage can be present even when the warning LED

indicator lights are o. Failure to wait 40 minutes after

power has been removed before performing service or

repair work can result in death or serious injury.

Stop the motor.

•

Disconnect AC mains and remote DC-link

•

supplies, including battery back-ups, UPS, and

DC-link connections to other drives.

Disconnect or lock motor.

•

Wait 40 minutes for the capacitors to discharge

•

fully.

Before performing any service or repair work,

•

use an appropriate voltage measuring device to

make sure that the capacitors are fully

discharged.

WARNING

LEAKAGE CURRENT HAZARD

Leakage currents exceed 3.5 mA. Failure to ground the

drive properly can result in death or serious injury.

Ensure the correct grounding of the equipment

•

by a certied electrical installer.

4 Danfoss A/S © 01/2017 All rights reserved. MG22A102

Page 7

Safety Operating Guide

WARNING

EQUIPMENT HAZARD

Contact with rotating shafts and electrical equipment

can result in death or serious injury.

Ensure that only trained and qualied personnel

•

install, start up, and maintain the drive.

Ensure that electrical work conforms to national

•

and local electrical codes.

Follow the procedures in this guide.

•

CAUTION

HOT SURFACES

The drive contains metal components that are still hot

even after the drive has been powered o. Failure to

observe the high temperature symbol (yellow triangle)

on the drive can result in serious burns.

Be aware that internal components, such as

•

busbars, may be extremely hot even after the

drive has been powered o.

Exterior areas marked by the high temperature

•

symbol (yellow triangle) are hot while the drive

is in use and immediately after being powered

o.

2 2

WARNING

INTERNAL FAILURE HAZARD

Under certain circumstances, an internal failure can

cause a component to explode. Failure to keep the

enclosure closed and properly secured can cause death

or serious injury.

Do not operate the drive with the door open or

•

panels o.

Ensure that the enclosure is properly closed and

•

secured during operation.

NOTICE

MAINS SHIELD SAFETY OPTION

A mains shield option is available for enclosures with a

protection rating of IP21/IP 54 (Type 1/Type 12). The

mains shield is a Lexan cover installed inside the

enclosure to protect against the accidental touch of the

power terminals, according to BGV A2, VBG 4.

MG22A102 Danfoss A/S © 01/2017 All rights reserved. 5

Page 8

Product Overview VLT® AQUA Drive FC 202

3 Product Overview

3.1 Intended Use

33

The drive is an electronic motor controller that converts AC mains input into a variable AC waveform output. The frequency

and voltage of the output are regulated to control the motor speed or torque. The drive is designed to:

Regulate motor speed in response to system feedback or to remote commands from external controllers.

•

Monitor system and motor status.

•

Provide motor overload protection.

•

The drive is allowed for use in industrial and commercial environments in accordance with local laws and standards.

Depending on conguration, the drive can be used in standalone applications or form part of a larger system or installation.

NOTICE

In a residential environment, this product can cause radio interference, in which case supplementary mitigation

measures can be required.

Foreseeable misuse

Do not use the drive in applications which are non-compliant with specied operating conditions and environments. Ensure

compliance with the conditions specied in chapter 9 Specications.

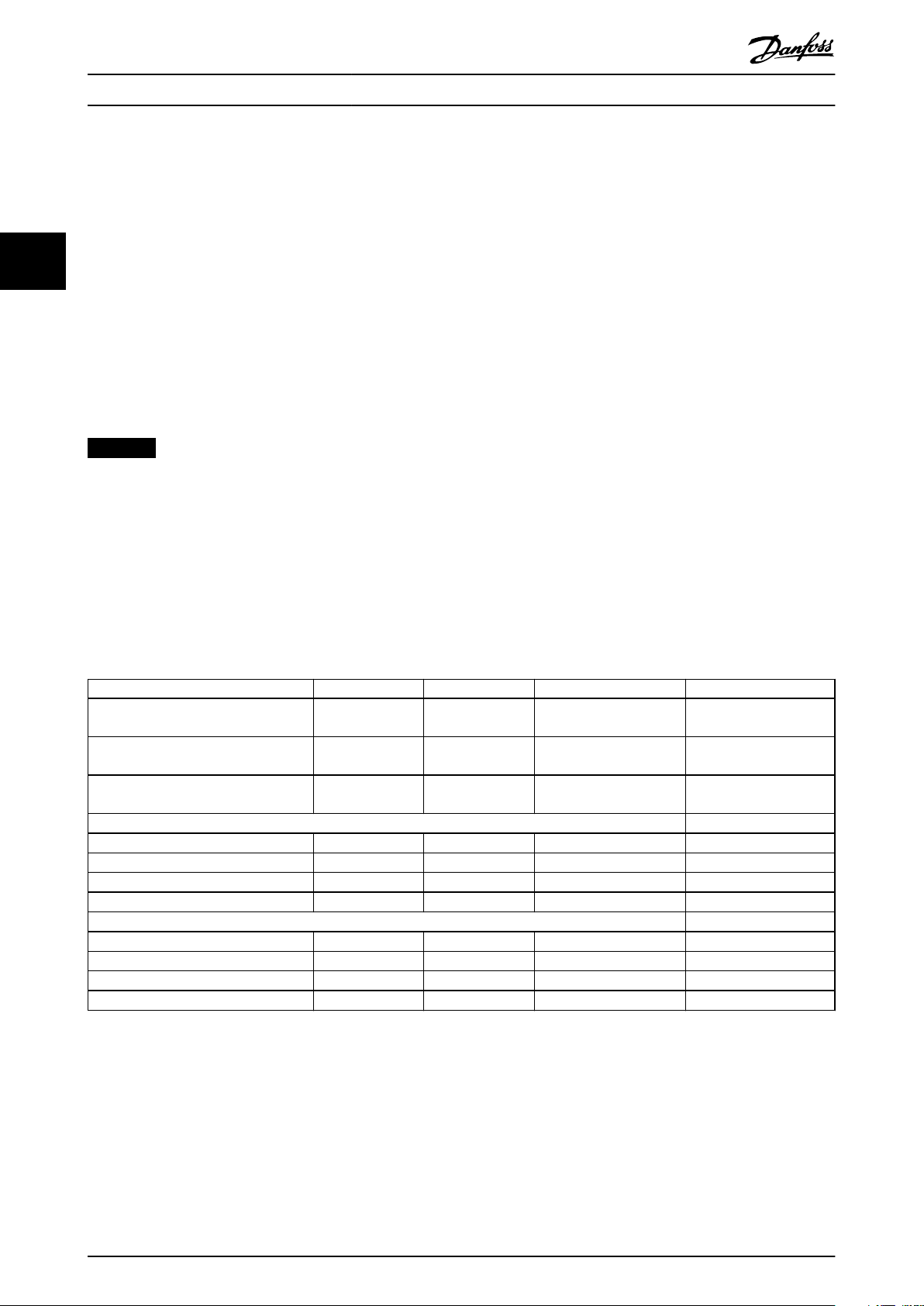

3.2 Power Ratings, Weights, and Dimensions

Table 3.1 provides dimensions for standard congurations. For dimensions on optional congurations, see

chapter 9.8 Enclosure Dimensions.

Enclosure size E1h E2h E3h E4h

Rated power at 380–480 V [kW (hp)] 355–450

(500–600)

Rated power at 525–690 V [kW (hp)] 450–630

(450–650)

Enclosure protection rating IP21/Type 1

IP54/Type 12

Unit dimensions

Height [mm (in)] 2043 (80.4) 2043 (80.4) 1578 (62.1) 1578 (62.1)

Width [mm (in)] 602 (23.7) 698 (27.5) 506 (19.9) 604 (23.89)

Depth [mm (in)] 513 (20.2) 513 (20.2) 482 (19.0) 482 (19.0)

Weight [kg (lb)] 295 (650) 318 (700) 272 (600) 295 (650)

Shipping dimensions

Height [mm (in)] 768 (30.2) 768 (30.2) 746 (29.4) 746 (29.4)

Width [mm (in)] 2191 (86.3) 2191 (86.3) 1759 (69.3) 1759 (69.3)

Depth [mm (in)] 870 (34.3) 870 (34.3) 794 (31.3) 794 (31.3)

Weight [kg (lb)] – – – –

500–560

(650–750)

710–800

(750–950)

IP21/Type 1

IP54/Type 12

355–450

(500–600)

450–630

(450–650)

IP20/

Chassis

500–560

(650–750)

710–800

(750–950)

IP 20/

Chassis

Table 3.1 Enclosure Power Ratings and Dimensions

6 Danfoss A/S © 01/2017 All rights reserved. MG22A102

Page 9

130BF206.11

FASTENER TORQUE:

M10 19Nm (14FT-LB)

M12 35Nm (26FT-LB)

- REGEN 83

FASTENER TORQUE:

M10 19Nm (14FT-LB)

M12 35Nm (26FT-LB)

+ REGEN 82

2

6

4

5

11

12

9

1

7

10

8

3

Product Overview Operating Guide

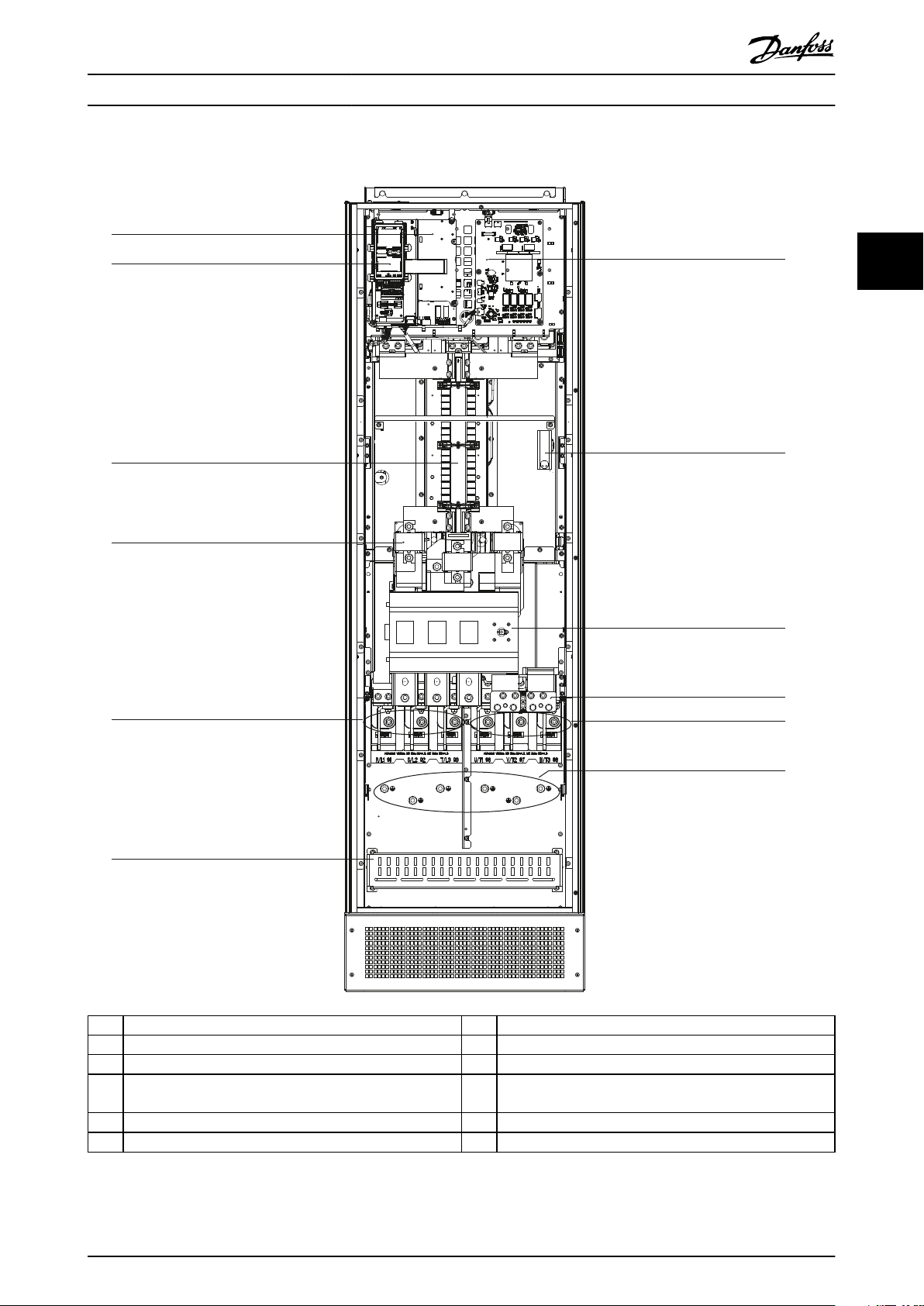

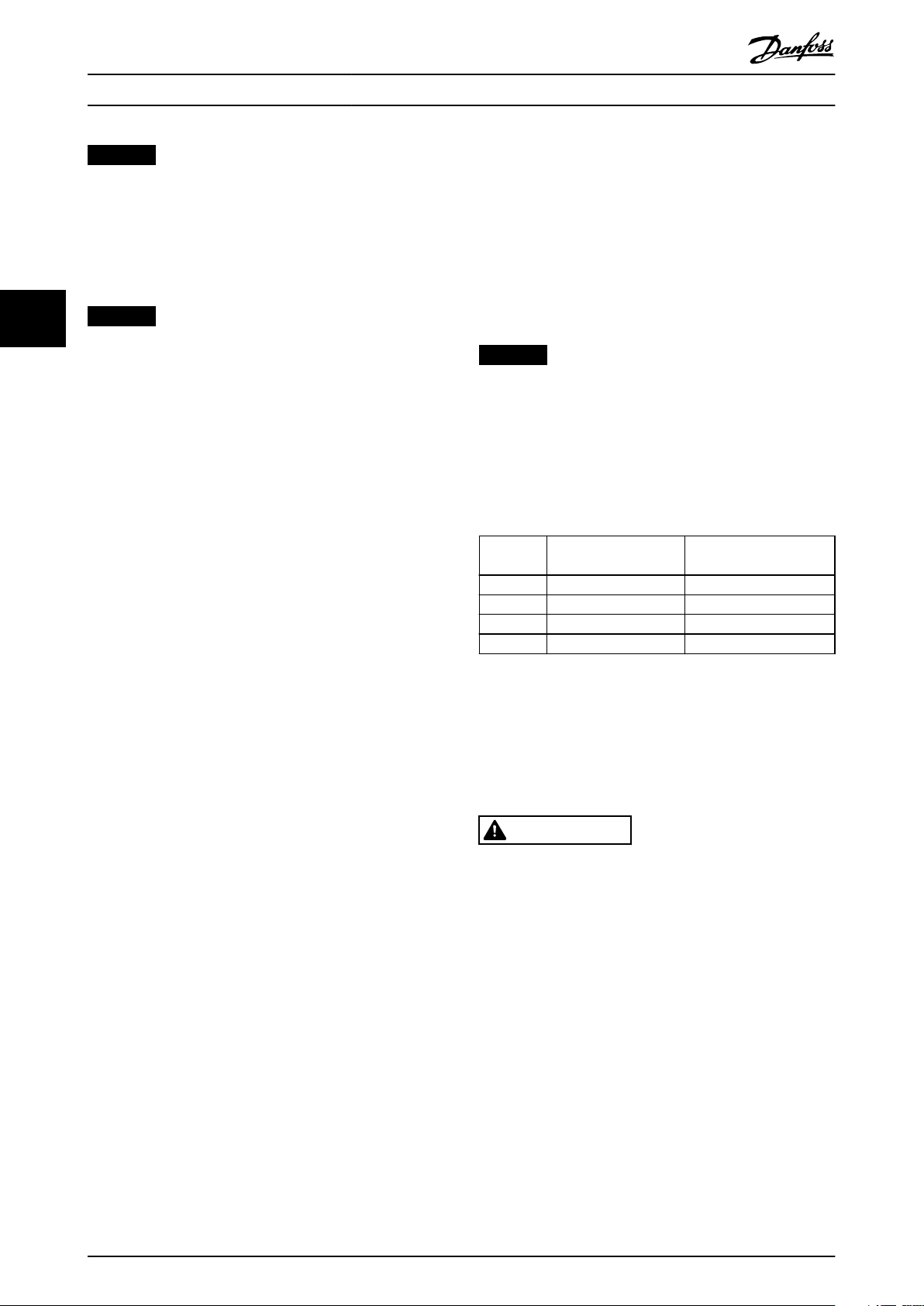

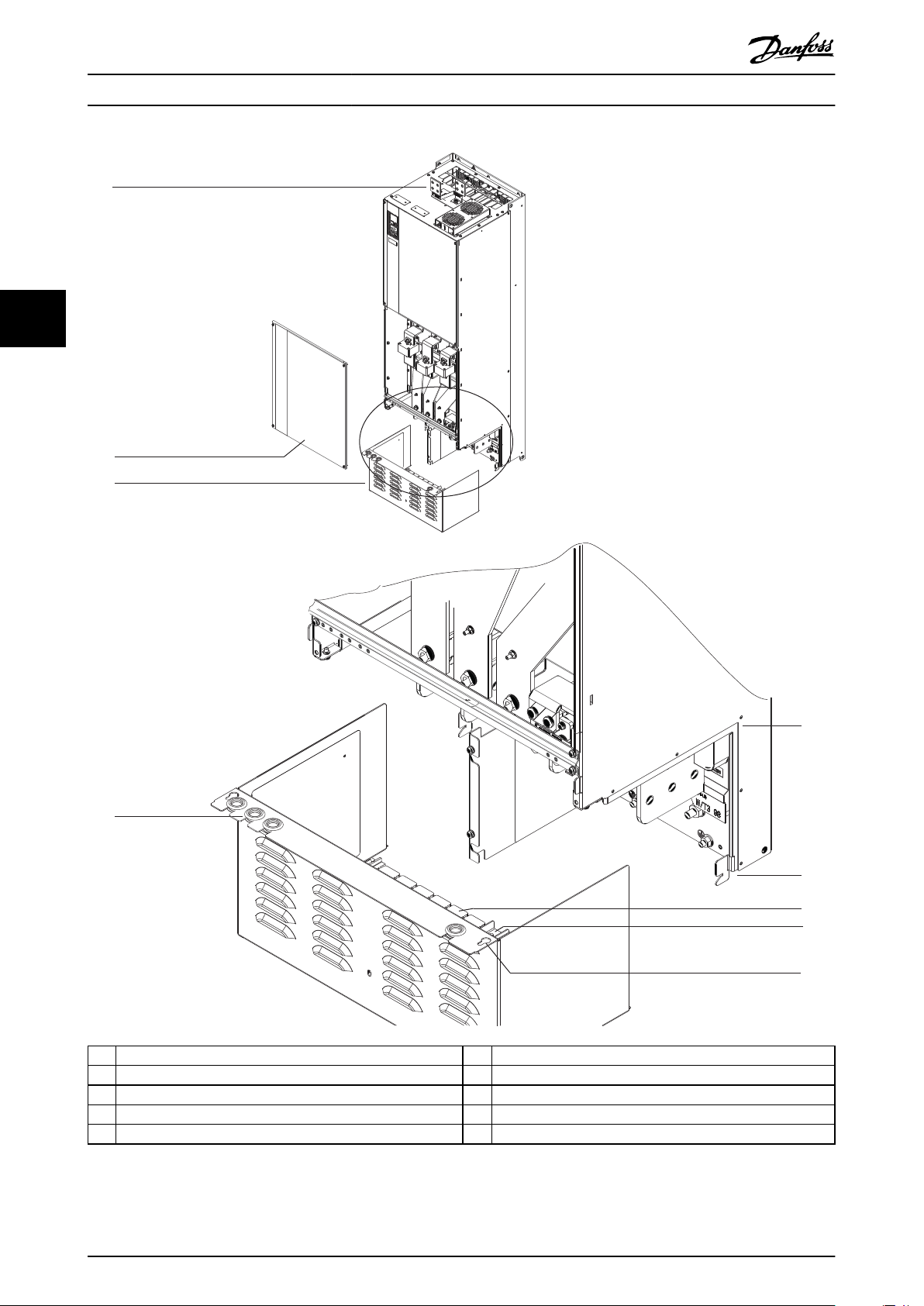

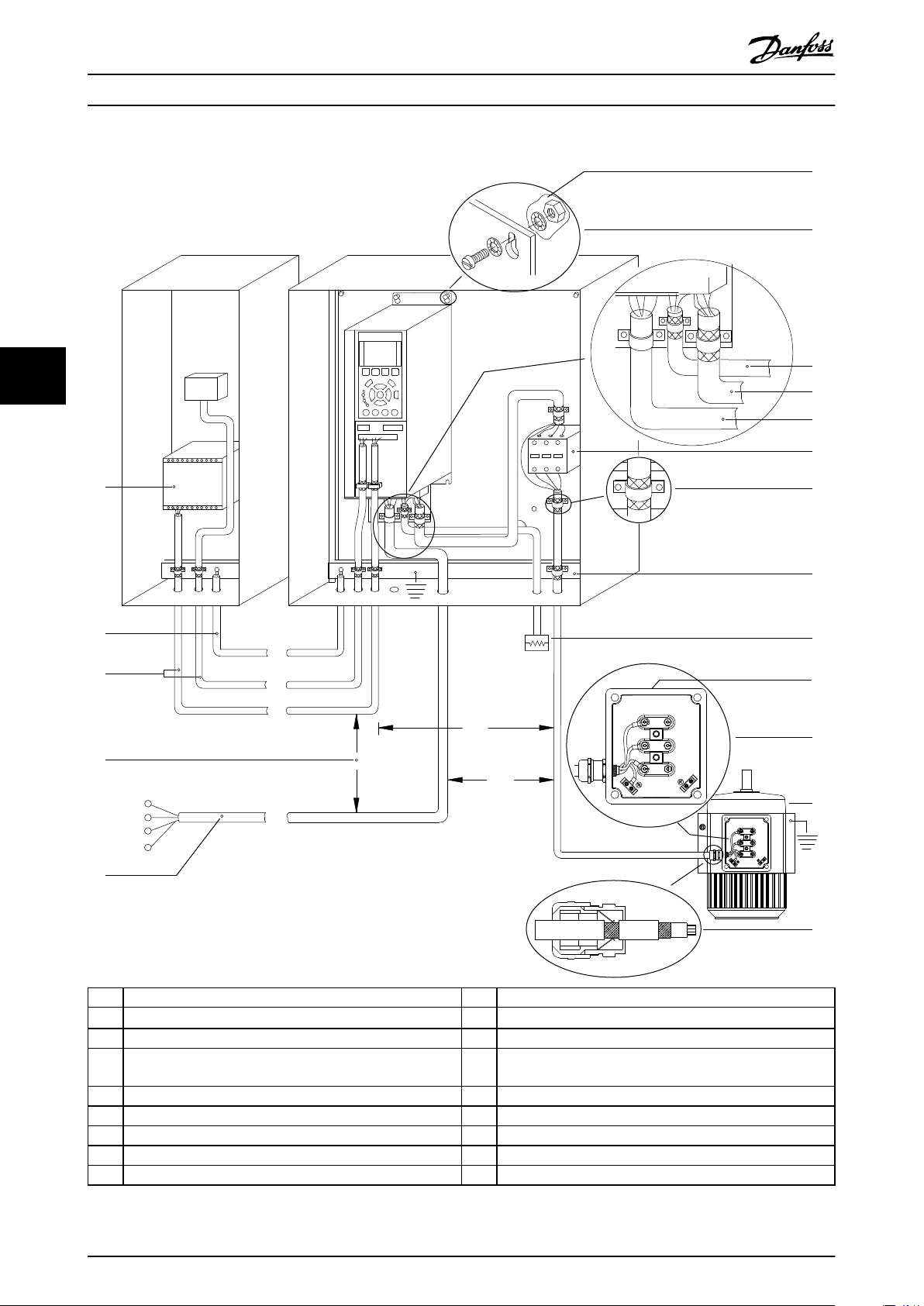

3.3 Interior View of Enclosures E1h and E2h

3 3

1 Control shelf (see Illustration 3.3) 7 Fan power card

2 Local control panel (LCP) cradle 8 Space heater (optional)

3 RFI lter (optional) 9 Mains disconnect (optional)

4 Mains fuses (required for UL compliance, but otherwise

10 Brake/regeneration terminals (optional)

optional)

5 Mains terminals 11 Motor terminals

6 RFI shield termination 12 Ground terminals

Illustration 3.1 Interior View of Enclosure E1h (Enclosure E2h is Similar)

MG22A102 Danfoss A/S © 01/2017 All rights reserved. 7

Page 10

FASTENER TORQUE:

M10 19Nm (14FT-LB)

M12 35Nm (26FT-LB)

+ DC 89

FASTENER TORQUE:

M10 19Nm (14FT-LB)

M12 35Nm (26FT-LB)

- BRAKE 83

FASTENER TORQUE:

M10 19Nm (14FT-LB)

M12 35Nm (26FT-LB)

+ BRAKE 82

FASTENER TORQUE:

M10 19Nm (14FT-LB)

M12 35Nm (26FT-LB)

- DC 88

130BF211.11

1

6

2

5

9

12

13

11

7

8

3

10

4

Product Overview VLT® AQUA Drive FC 202

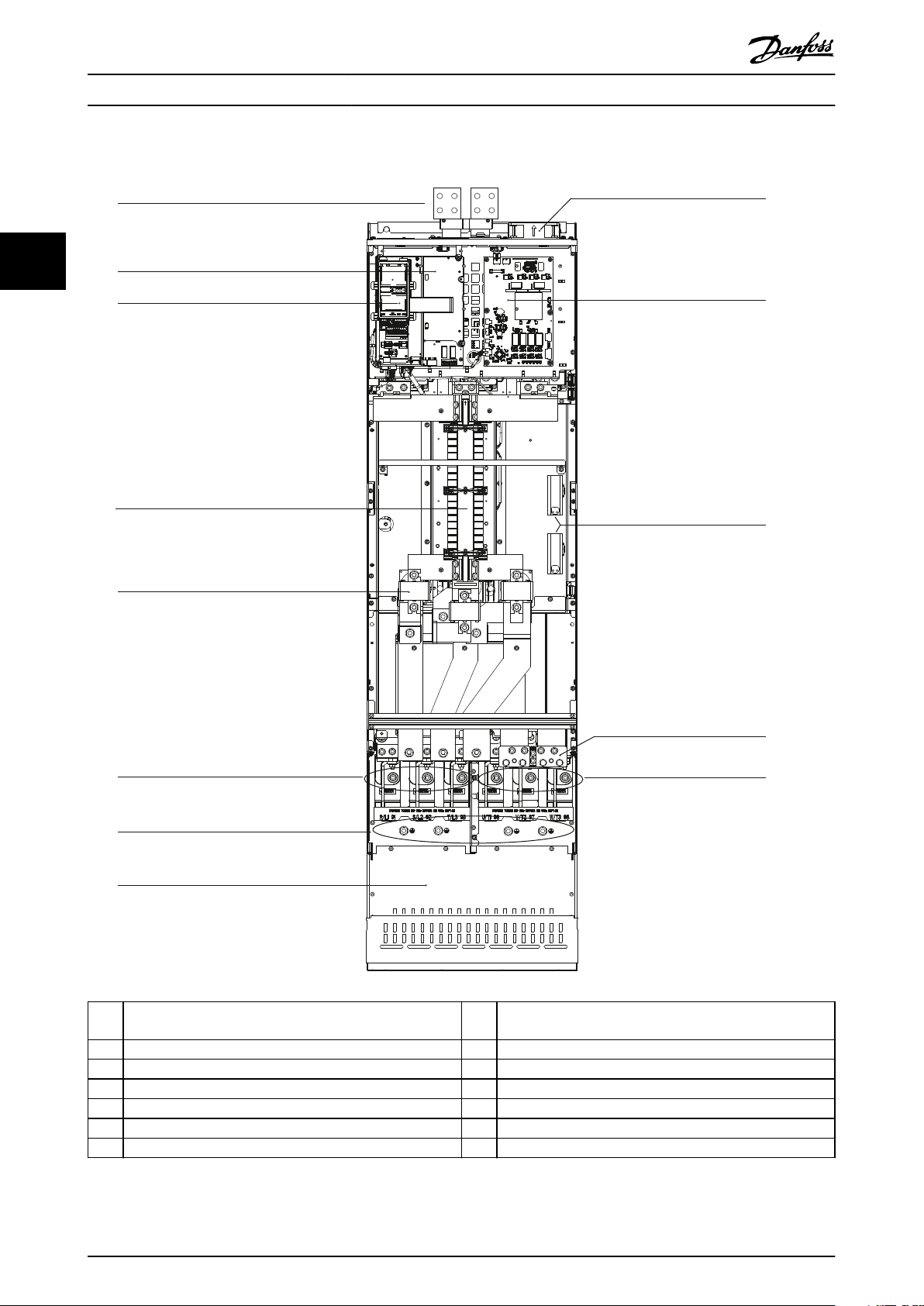

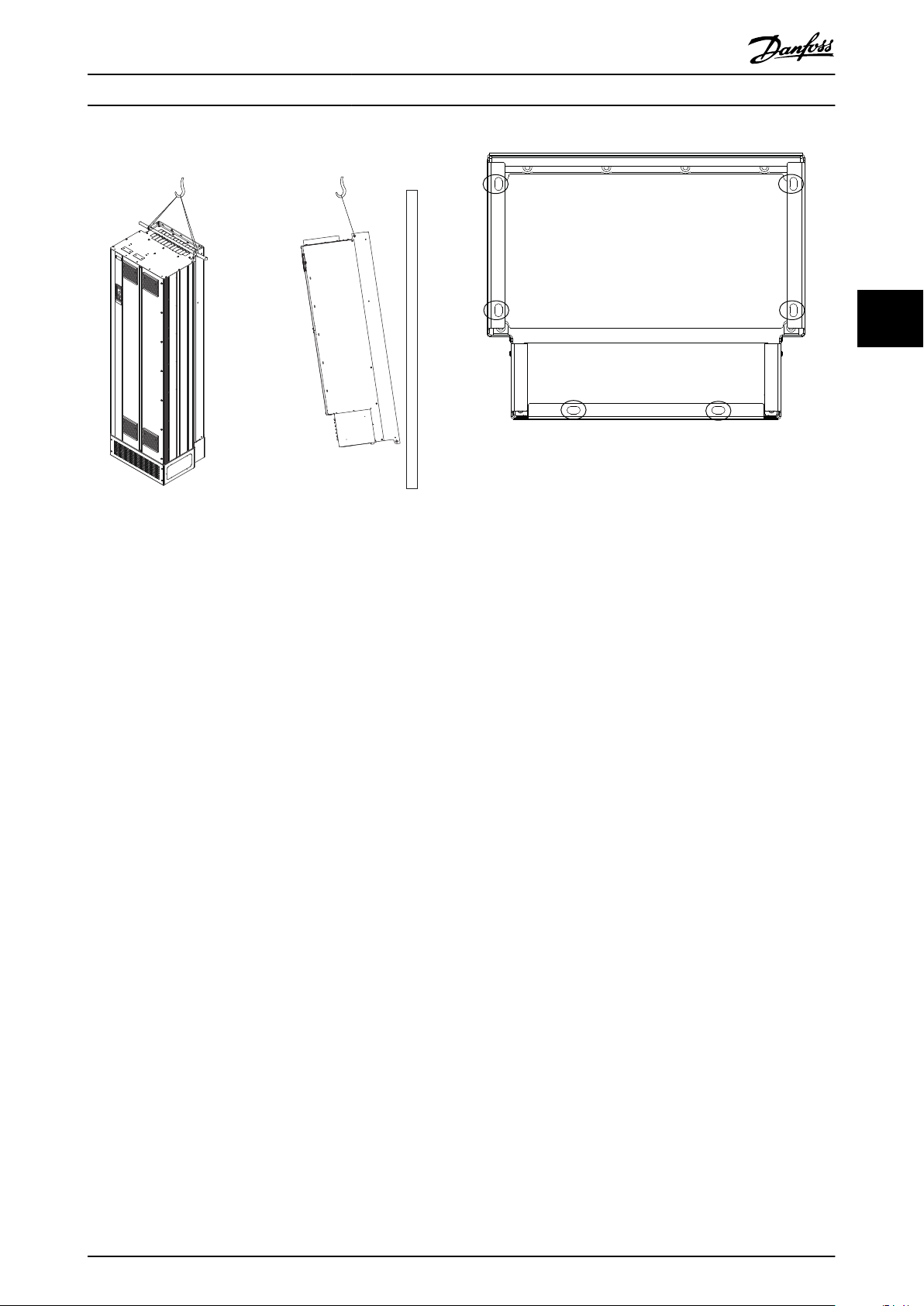

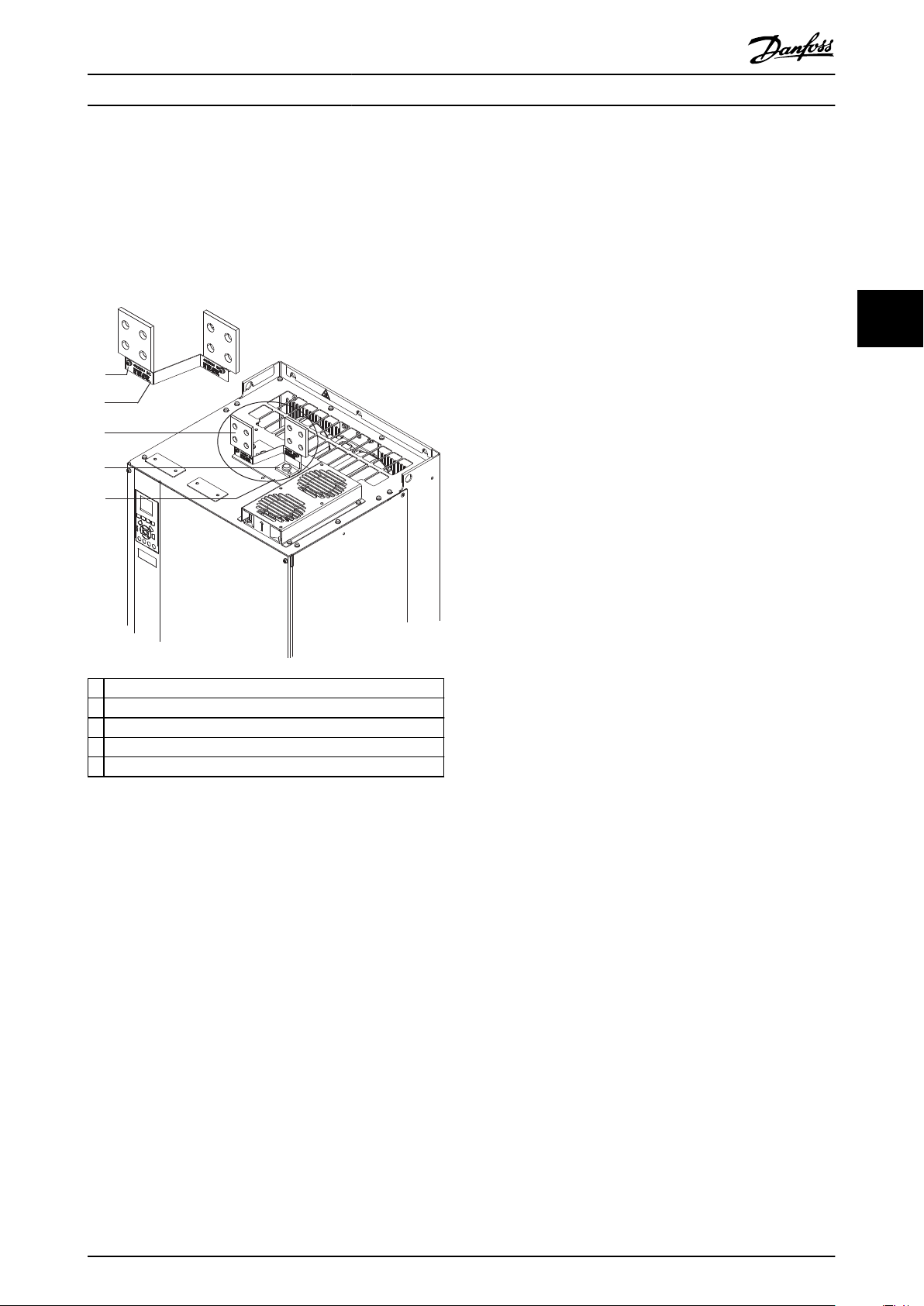

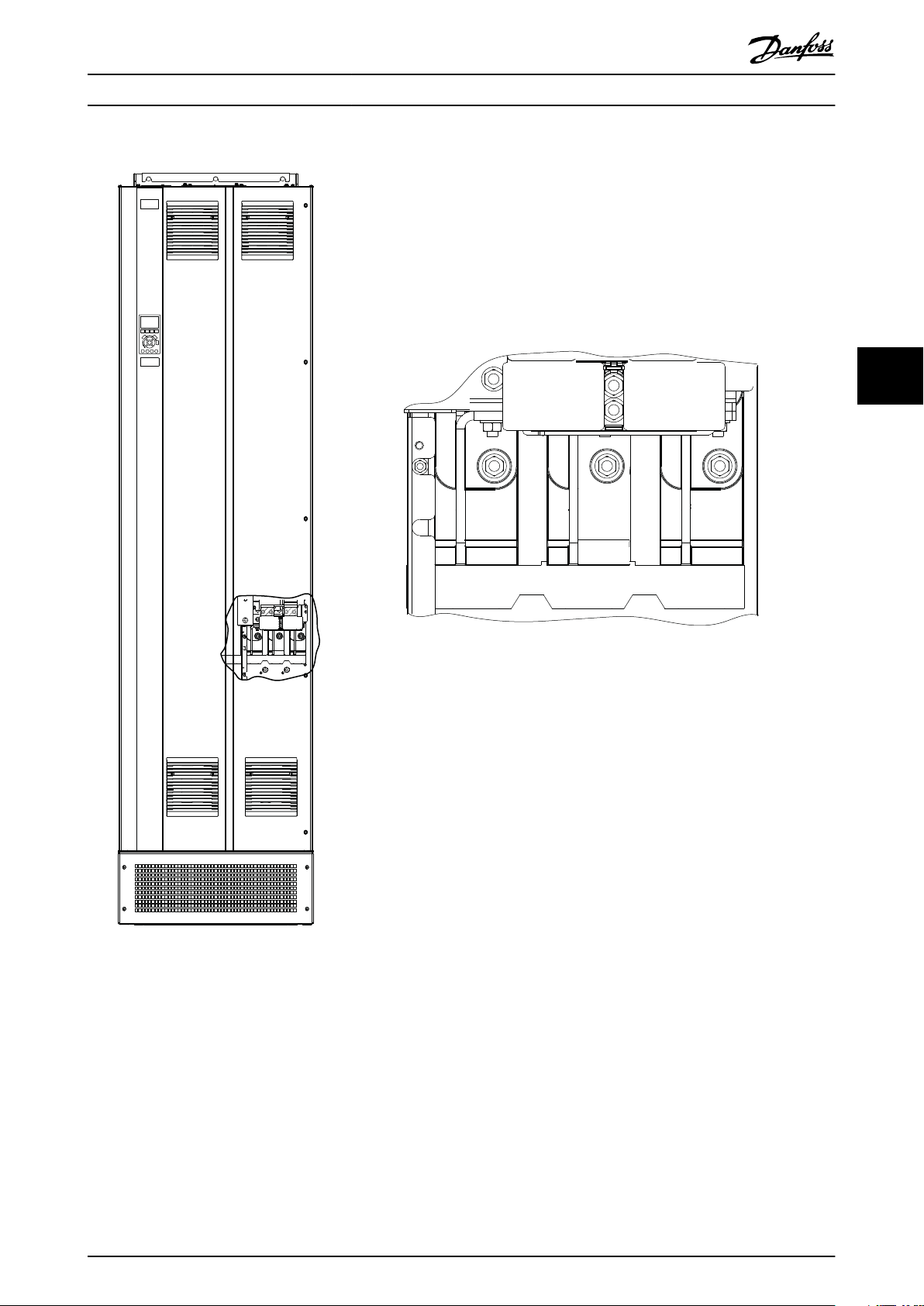

3.4 Interior View of Enclosures E3h and E4h

33

1 Load share/regeneration terminals (optional) 8 RFI shield termination (optional, but is standard when RFI

2 Control shelf (see Illustration 3.3) 9 Fans (used to cool the front section of enclosure)

lter is ordered)

3 Local control panel (LCP) cradle 10 Fan power card

4 RFI lter (optional) 11 Space heater (optional)

5 Mains fuses (optional) 12 Brake terminals (optional)

6 Mains terminals 13 Motor terminals

7 Ground terminals – –

Illustration 3.2 Interior View of Enclosure E3h (Enclosure E4h is Similar)

8 Danfoss A/S © 01/2017 All rights reserved. MG22A102

Page 11

130BF148.11

Remove Jumper to activate Safe Stop

12 13 18 19 27 29 32 33 20 37

39 42 50 53 54 55

61 68 69

1

3

4

12

9

8

RELAY 1 RELAY 2

01 02 0304 05 06

2

6

10

7

5

11

13

Product Overview Operating Guide

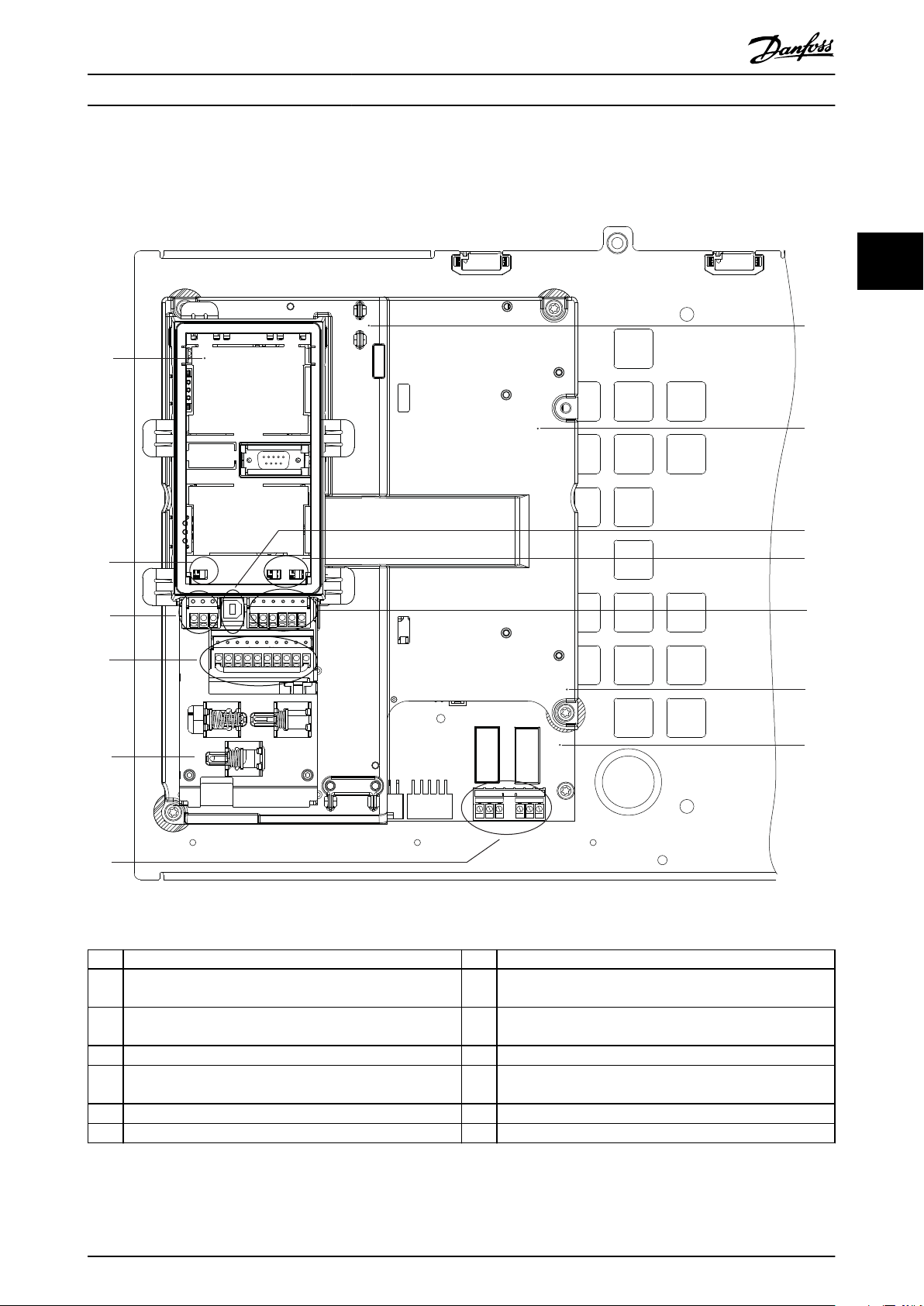

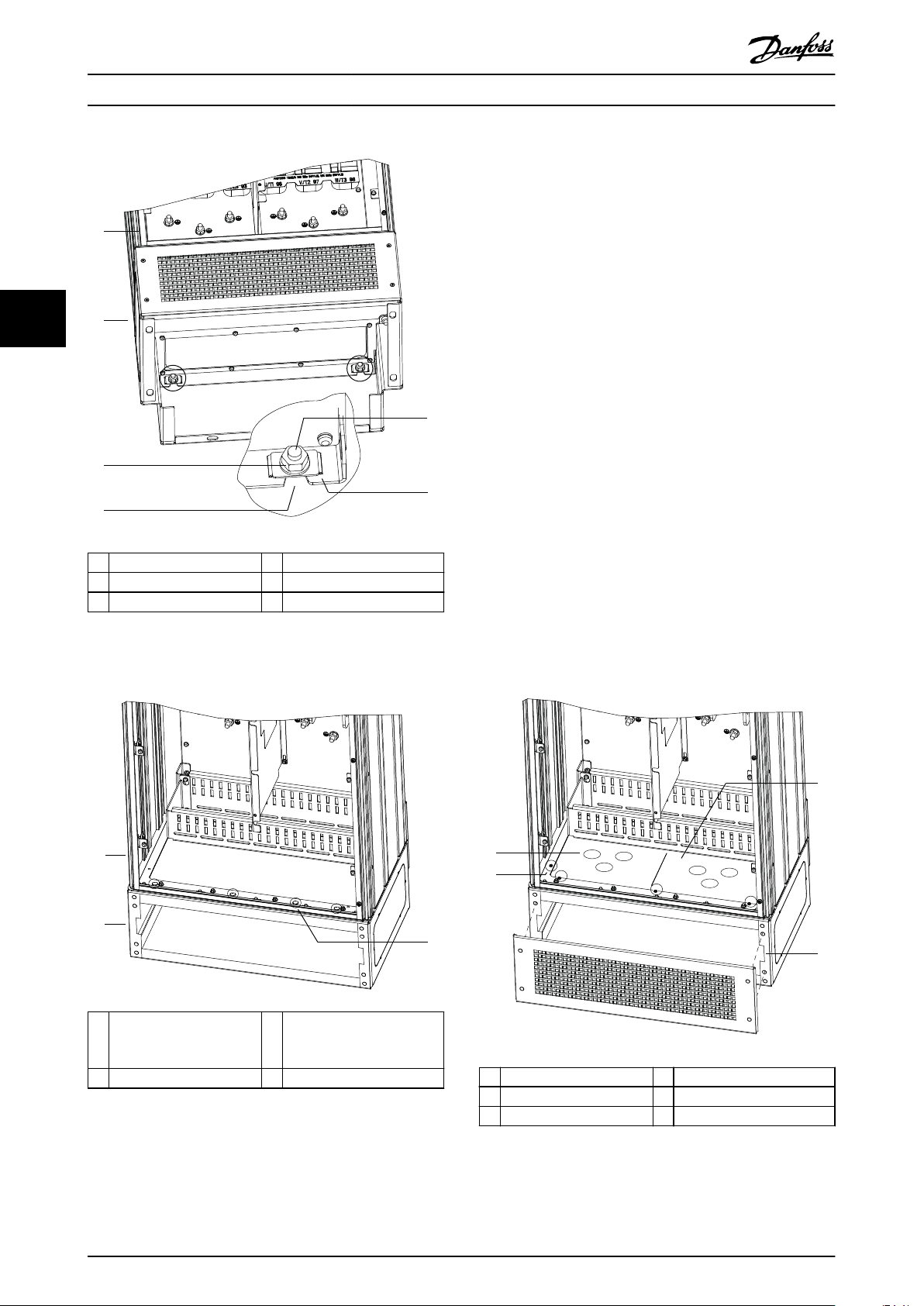

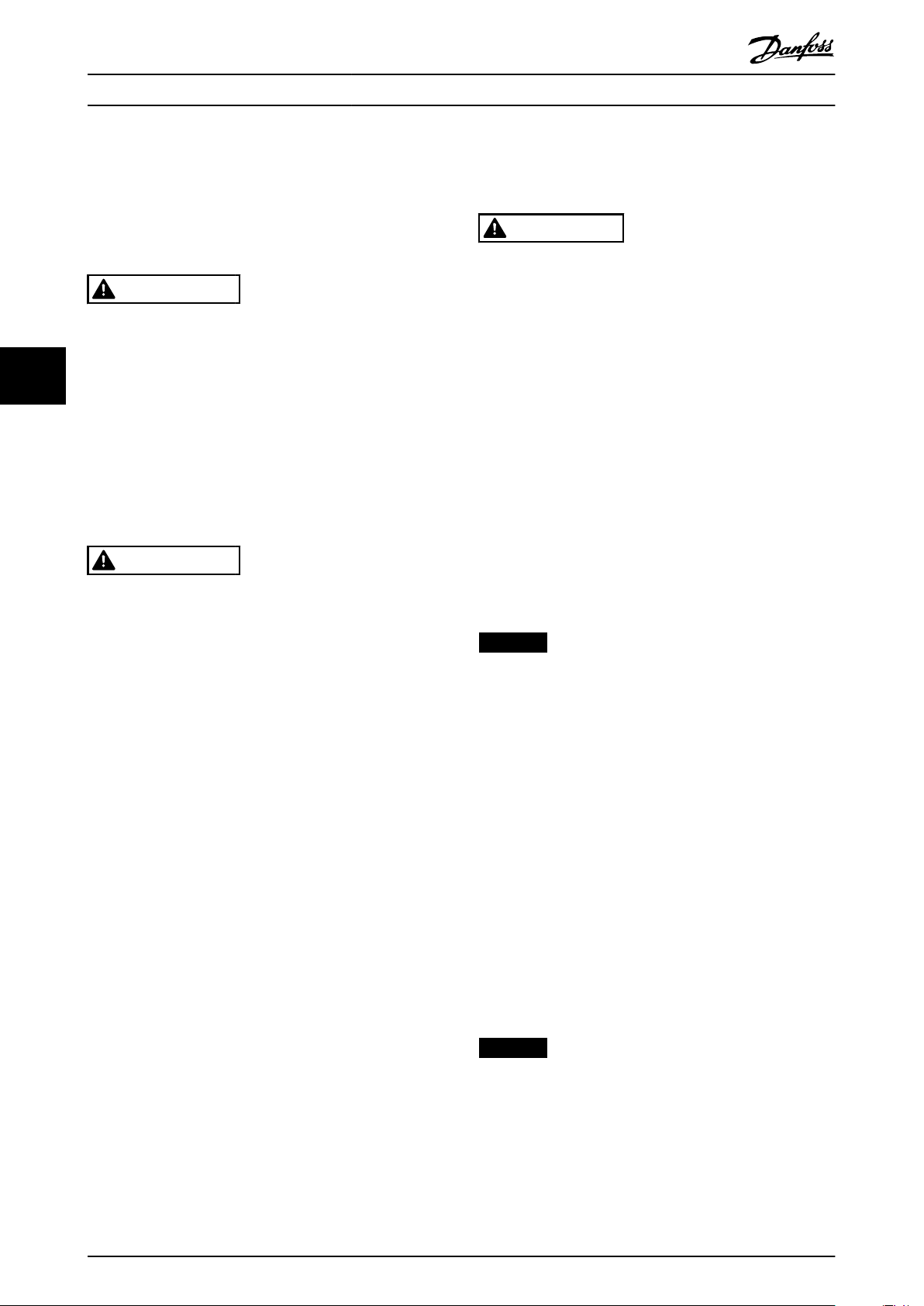

3.5 Control Shelf

3 3

1 LCP cradle (LCP not shown) 8 Control shelf

2 Bus terminal switch

3 Serial communication terminals (see Table 5.1) 10 Analog input switches A53/A54

(see chapter 5.8.5 Conguring RS485 Serial Communication)

4 Digital input/output terminals (see Table 5.2) 11 Analog input/output terminals (see Table 5.3)

5 Cable/EMC clamps 12 Brake resistor terminals, 104–106

6 Relay 1 and relay 2 (see Illustration 5.19) 13 Power card (underneath the control shelf)

7 Control card (underneath LCP and control terminals) – –

9 USB port

(see chapter 5.8.10 Selecting Voltage/Current Input Signal)

(on power card underneath control shelf)

Illustration 3.3 View of Control Shelf

MG22A102 Danfoss A/S © 01/2017 All rights reserved. 9

Page 12

130BF154.10

Auto

on

Reset

Hand

on

O

Status

Quick

Menu

Main

Menu

Alarm

Log

Back

Cancel

Info

OK

Status

1(1)

0.00 A

O Remote Stop

0.0 Hz

On

Alarm

Warn.

0.000

0.000 RPM

0.0000

A1.1

A1.2

A1.3

A2

A3

B1

B2

B4

B3

C1

C2

C3

C4

C5

D1

D2

D3

E1

E2

E3

E4

Product Overview VLT® AQUA Drive FC 202

3.6 Local Control Panel (LCP)

33

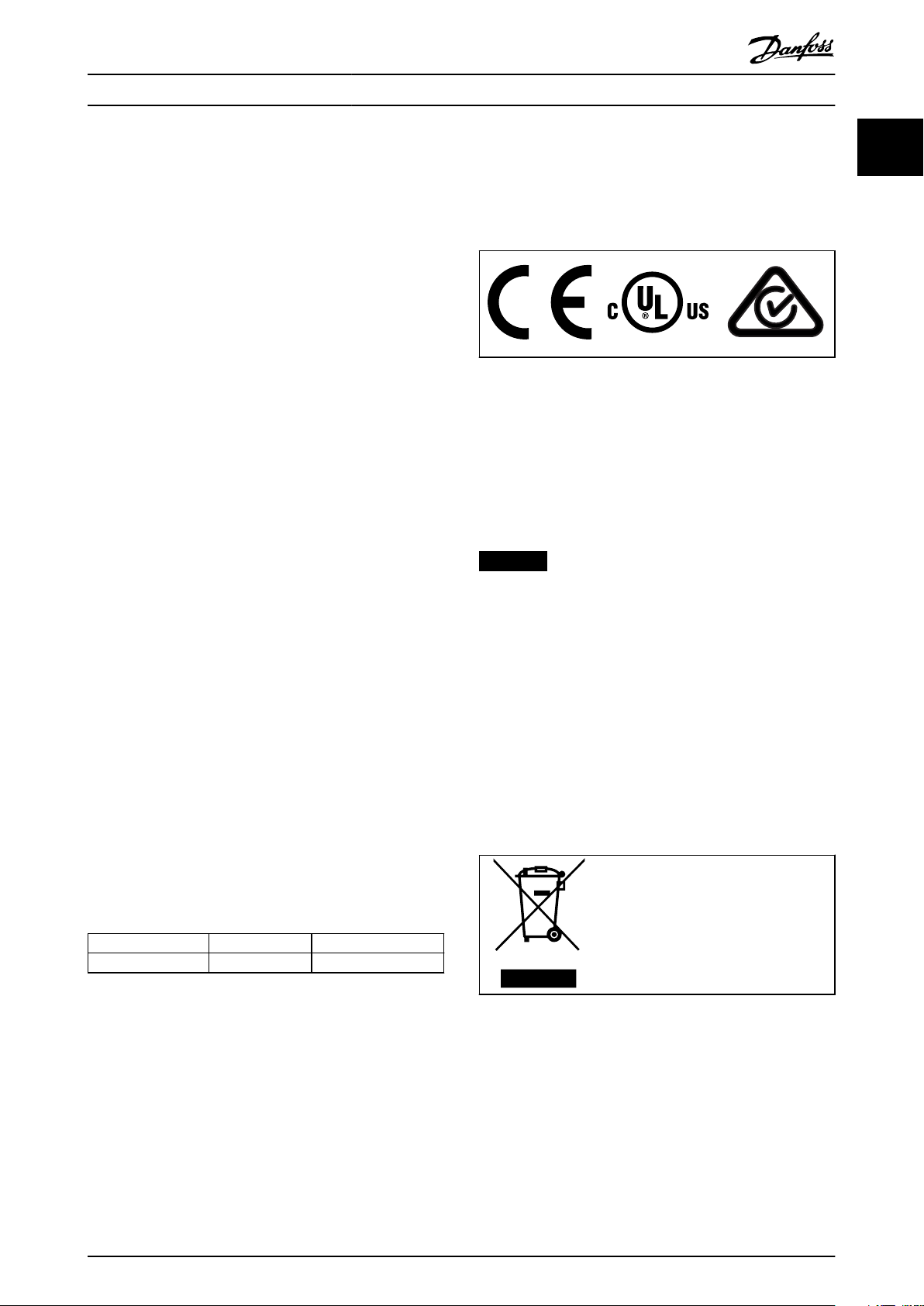

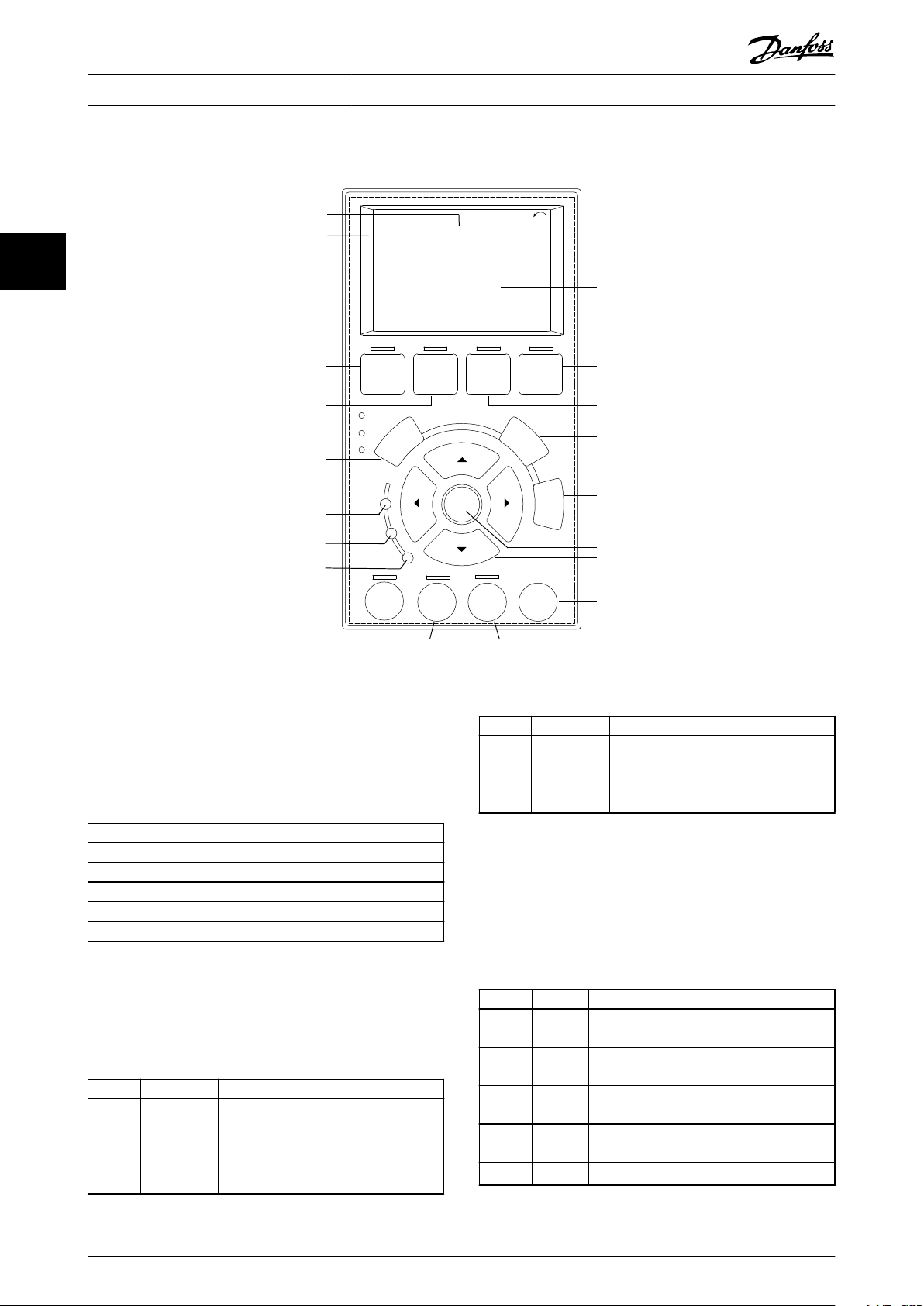

Illustration 3.4 Graphical Local Control Panel (LCP)

A. Display area

Each display readout has a parameter associated with it.

See Table 3.2. The information shown on the LCP can be

customized for specic applications. Refer to

chapter 6.3.1.2 Q1 My Personal Menu.

Callout Parameter number Default setting

A1.1 0-20 Reference [Unit]

A1.2 0-21 Analog input 53 [V]

A1.3 0-22 Motor current [A]

A2 0-23 Frequency [Hz]

A3 0-24 Feedback [Unit]

Table 3.2 LCP Display Area

B. Menu keys

Menu keys are used to access the menu for setting up

parameters, toggling through status display modes during

normal operation, and viewing fault log data.

Callout Key Function

B1 Status Shows operational information.

B2 Quick Menu Allows access to parameters for initial

set-up instructions. Also provides

detailed application steps. Refer

to chapter 6.3.1.1 Quick Menu Mode.

Callout Key Function

B3 Main Menu Allows access to all parameters. Refer to

chapter 6.3.1.9 Main Menu Mode.

B4 Alarm Log Shows a list of current warnings and the

last 10 alarms.

Table 3.3 LCP Menu Keys

C. Navigation keys

Navigation keys are used for programming functions and

moving the display cursor. The navigation keys also

provide speed control in local (hand) operation. The

display brightness can be adjusted by pressing [Status] and

[▲]/[▼] keys.

Callout Key Function

C1 Back Reverts to the previous step or list in the

menu structure.

C2 Cancel Cancels the last change or command as

long as the display mode has not changed.

C3 Info Shows a denition of the function being

shown.

C4 OK Accesses parameter groups or enables an

option.

C5

▲ ▼

Table 3.4 LCP Navigation Keys

Moves between items in the menu.

◄ ►

10 Danfoss A/S © 01/2017 All rights reserved. MG22A102

Page 13

Product Overview Operating Guide

D. Indicator lights

Indicator lights are used to identify the drive status and to

provide a visual notication of warning or fault conditions.

Callout Indicator Indicator

D1 On Green Activates when the drive receives

D2 Warn. Yellow Activates when warning

D3 Alarm Red Activates during a fault

Table 3.5 LCP Indicator Lights

Function

light

power from the mains voltage or

a 24 V external supply.

conditions are active. Text

appears in the display area

identifying the problem.

condition. Text appears in the

display area identifying the

problem.

E. Operation keys and reset

The operation keys are found toward the bottom of the

local control panel.

Callout Key Function

E1 [Hand on] Starts the drive in local control. An

external stop signal by control input or

serial communication overrides the local

[Hand On].

E2 O Stops the motor but does not remove

power to the drive.

E3 Auto on Puts the system in remote operational

mode so it can respond to an external

start command by control terminals or

serial communication.

E4 Reset Resets the drive manually after a fault has

been cleared.

Table 3.6 LCP Operation Keys and Reset

3 3

MG22A102 Danfoss A/S © 01/2017 All rights reserved. 11

Page 14

Tamb. 55

C/131

F at Full Output Current Derating

IN: 3x525-600V 50/60Hz 743/711 A (UL)

OUT: MOTOR 3x0-Vin 0-500Hz 763/730 A

IN: 3x525-690V 50/60Hz 743/711 A (CE)

710 kW / 750 HP, High Overload

OUT: MOTOR 3x0-Vin 0-500Hz 889/850 A

IN: 3x525-690V 50/60Hz 866/828 A (CE)

800 kW / 950 HP, Normal Overload

VLT

T/C: FC-202N710T7E21H2XGC7XKSXXXXA0BXCXXXXD0

P/N: 131N2885 S/N:

R

AQUA Drive

www.danfoss.com

130BF712.10

IN: 3x525-690V 50/60Hz 866/828 A (UL)

ASSEMBLED IN USA

Tamb. 45

C/113

F at Full Output Current

IP21 / TYPE 1

SCCR 100 kA at UL Voltage range 525-600 V

Listed 36U0 E70524 IND. CONT. EQ.

UL Voltage range 525-600 V

CAUTION - ATTENTION:

Stored charge, wait 40 min.

Charge residuelle, attendez 40

See manual for special condition / prefuses

Voir manuel de conditions speciales / fusibles

WARNING - AVERTISSEMENT:

`

`

123456H123

1

2

3

4

5

6

Danfoss A/S

6340 Nordborg

Denmark

Mechanical Installation VLT® AQUA Drive FC 202

4 Mechanical Installation

4.1 Items Supplied

Items supplied can vary according to product congu-

ration.

4.2 Tools Needed

Receiving/unloading

I-beam and hooks rated to lift the weight of the

•

drive. Refer to chapter 3.2 Power Ratings, Weights,

Make sure that the items supplied and the

44

•

information on the nameplate correspond to the

order conrmation.

Visually check the packaging and the drive for

•

damage caused by inappropriate handling during

Installation

shipment. File any claim for damage with the

carrier. Retain damaged parts for clarication.

and Dimensions.

Crane or other lifting aid to place the unit into

•

position.

Drill with 10 mm or 12 mm drill bits.

•

Tape measurer.

•

Various sizes of Phillips and at bladed

•

screwdrivers.

Wrench with relevant metric sockets (7–17 mm).

•

Wrench extensions.

•

Torx drives (T25 and T50).

•

Sheet metal punch for conduits or cable glands.

•

I-beam and hooks to lift the weight of the drive.

•

Refer to chapter 3.2 Power Ratings, Weights, and

Dimensions.

Crane or other lifting aid to place the drive onto

•

pedestal and into position.

Storage

4.3

Store the drive in a dry location. Keep the equipment

sealed in its packaging until installation. Refer to

chapter 9.4 Ambient Conditions for recommended ambient

temperature.

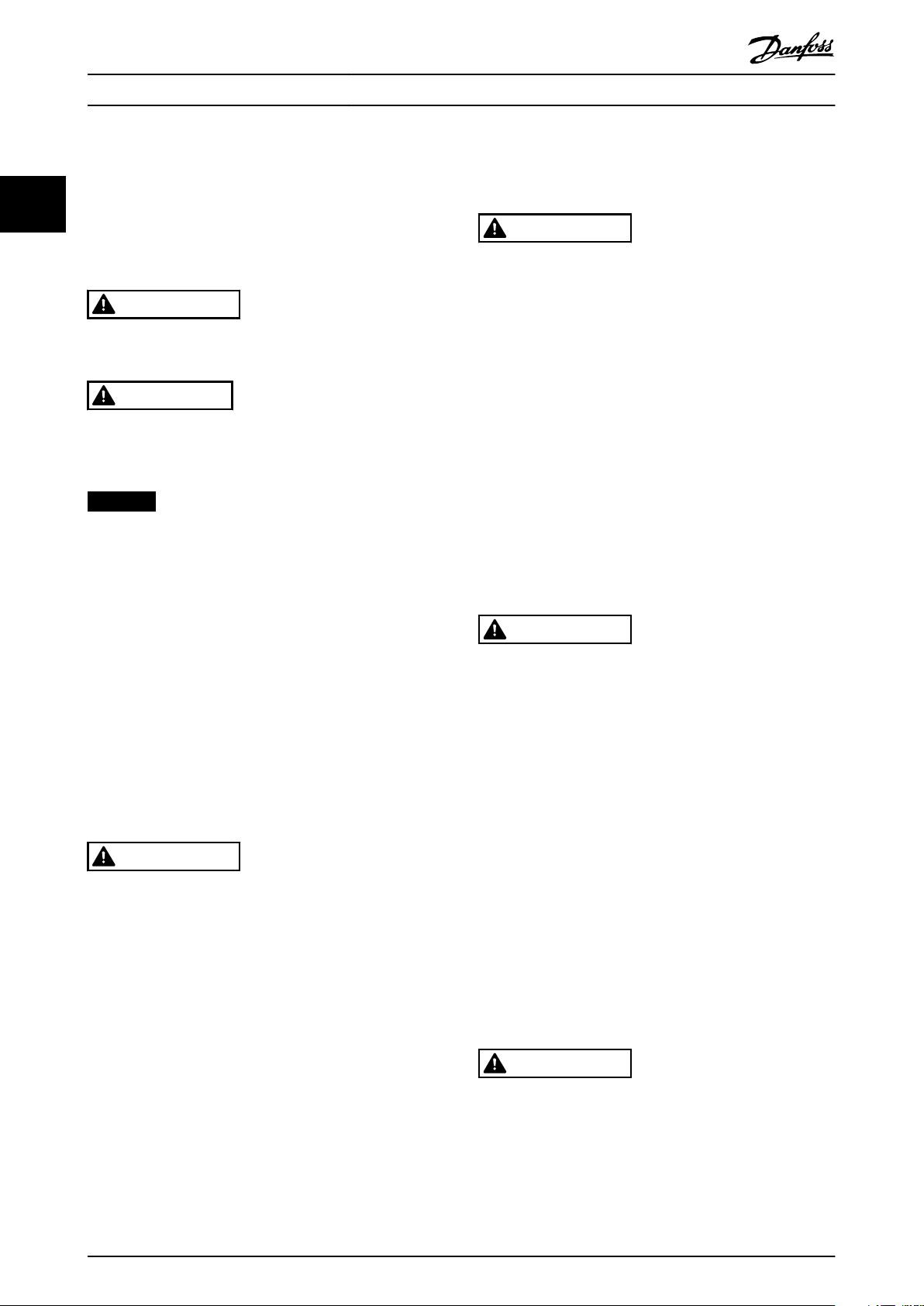

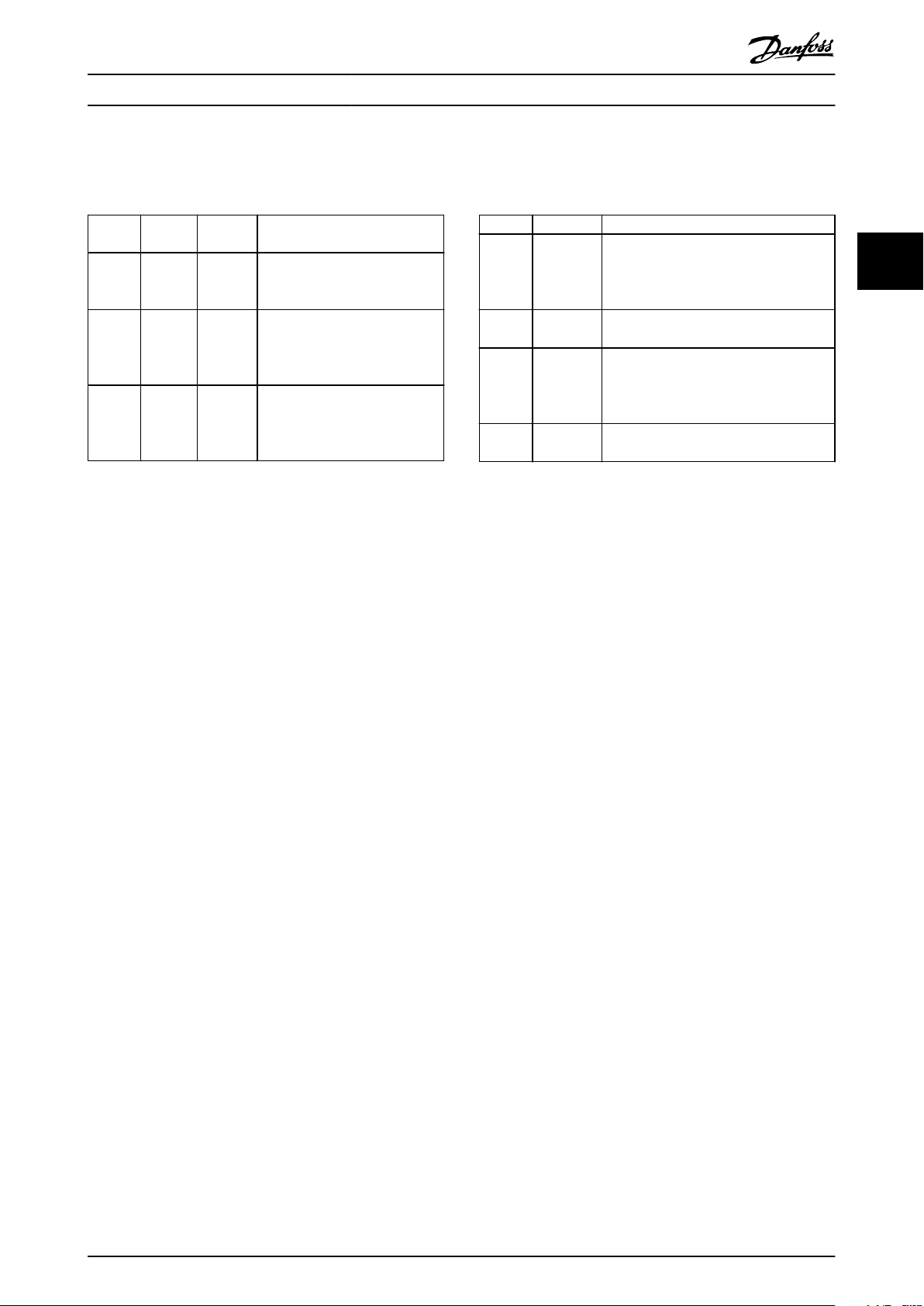

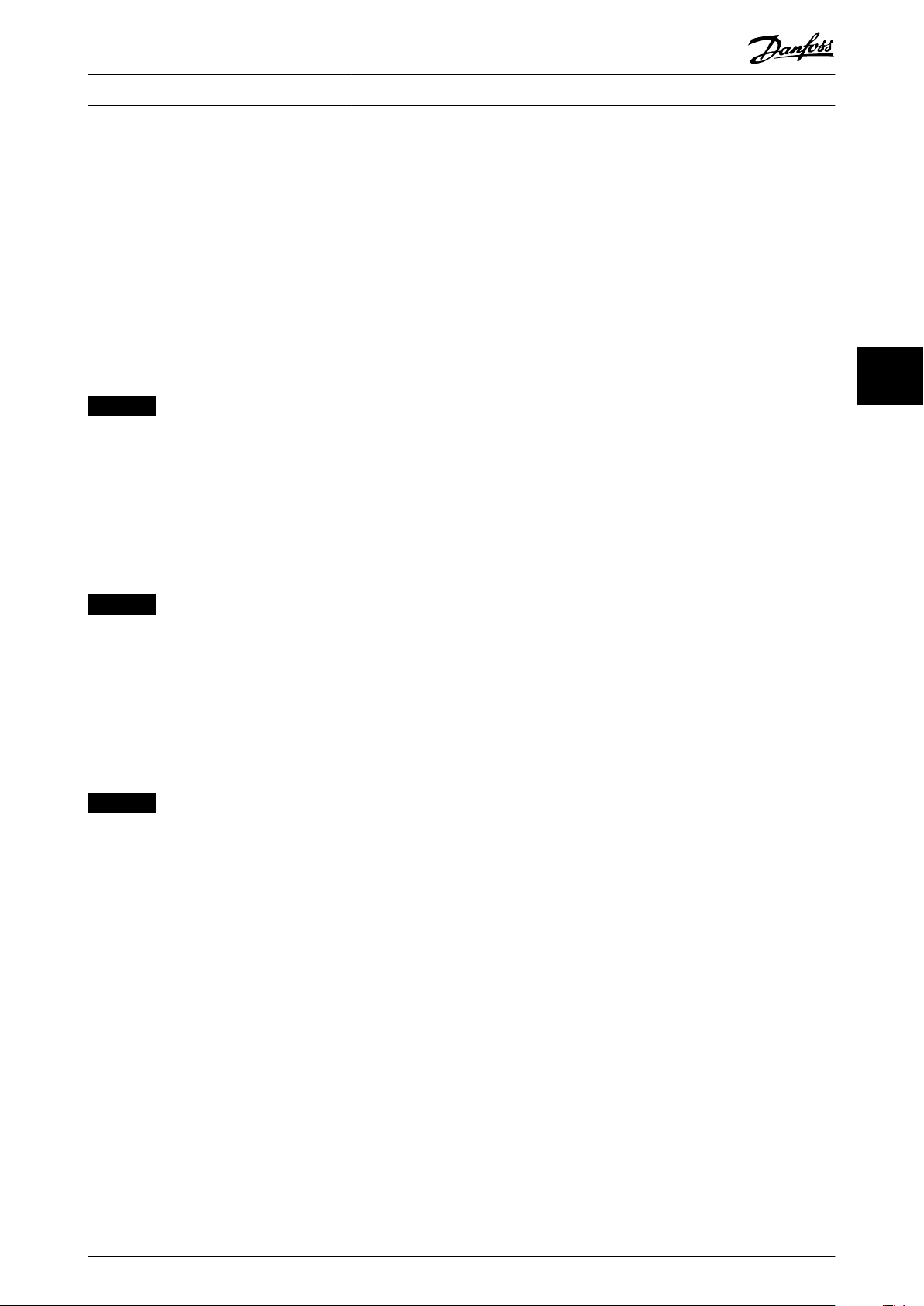

1 Type code

2 Code number

3 Power rating

Input voltage, frequency, and current (at low/high

4

voltages)

Output voltage, frequency, and current (at low/high

5

voltages)

6 Discharge time

Illustration 4.1 Product Nameplate for E2h Enclosure (Example)

NOTICE

Removing the nameplate from the drive can result in the

loss or warranty.

Periodic forming (capacitor charging) is not necessary

during storage unless storage exceeds 12 months.

12 Danfoss A/S © 01/2017 All rights reserved. MG22A102

Page 15

Mechanical Installation Operating Guide

4.4 Operating Environment

In environments with airborne liquids, particles, or

corrosive gases, ensure that the IP/Type rating of the

equipment matches the installation environment. For

specications regarding ambient conditions, see

chapter 9.4 Ambient Conditions.

NOTICE

CONDENSATION

Moisture can condense on the electronic components

and cause short circuits. Avoid installation in areas

subject to frost. Install an optional space heater when

the drive is colder than the ambient air. Operating in

standby mode reduces the risk of condensation as long

as the power dissipation keeps the circuitry free of

moisture.

NOTICE

EXTREME AMBIENT CONDITIONS

Hot or cold temperatures compromise unit performance

and longevity.

Do not operate in environments where the

•

ambient temperature exceeds 55 °C (131 °F).

The drive can operate at temperatures down to

•

-10 °C (14 °F). However, proper operation at

rated load is only guaranteed at 0 °C (32 °F) or

higher.

Extra air conditioning of the cabinet or instal-

•

lation site is required if temperature exceeds

ambient temperature limits.

4.4.1 Gases

Aggressive gases, such as hydrogen sulphide, chlorine, or

ammonia can damage the electrical and mechanical

components. The unit uses conformal-coated circuit boards

to reduce the eects of aggressive gases. For conformalcoating class specications and ratings, see

chapter 9.4 Ambient Conditions.

4.4.2 Dust

When installing the drive in dusty environments, pay

attention to the following:

Periodic maintenance

When dust accumulates on electronic components, it acts

as a layer of insulation. This layer reduces the cooling

capacity of the components, and the components become

warmer. The hotter environment decreases the life of the

electronic components.

Keep the heat sink and fans free from dust buildup. For

more service and maintenance information, refer to

chapter 8 Maintenance, Diagnostics, and Troubleshooting.

Cooling fans

Fans provide airow to cool the drive. When fans are

exposed to dusty environments, the dust can damage the

fan bearings and cause premature fan failure. Dust also can

accumulate on fan blades causing an imbalance which

prevents the fans from properly cooling the unit.

4.4.3 Potentially Explosive Atmospheres

WARNING

EXPLOSIVE ATMOSPHERE

Do not install the drive in a potentially explosive

atmosphere. Install the unit in a cabinet outside of this

area. Failure to follow this guideline increases risk of

death or serious injury.

Systems operated in potentially explosive atmospheres

must fulll special conditions. EU Directive 94/9/EC (ATEX

95) classies the operation of electronic devices in

potentially explosive atmospheres.

species that if a spark occurs, it is

Class d

•

contained in a protected area.

Class e prohibits any occurrence of a spark.

•

Motors with class d protection

Does not require approval. Special wiring and containment

are required.

Motors with class e protection

When combined with an ATEX approved PTC monitoring

device like the VLT® PTC Thermistor Card MCB 112, installation does not need an individual approval from an

approbated organization.

Motors with class d/e protection

The motor itself has an e ignition protection class, while

the motor cabling and connection environment is in

compliance with the d

peak voltage, use a sine-wave lter at the drive output.

When using a drive in a potentially explosive

atmosphere, use the following:

Motors with ignition protection class d or e.

•

PTC temperature sensor to monitor the motor

•

temperature.

Short motor cables.

•

Sine-wave output lters when shielded motor

•

cables are not used.

classication. To attenuate the high

4 4

MG22A102 Danfoss A/S © 01/2017 All rights reserved. 13

Page 16

Mechanical Installation VLT® AQUA Drive FC 202

Duct cooling

NOTICE

MOTOR THERMISTOR SENSOR MONITORING

VLT® AutomationDrive units with the VLT® PTC

Thermistor Card MCB 112 option are PTB-certied for

potentially explosive atmospheres.

4.5 Installation and Cooling Requirements

44

NOTICE

Improper mounting can result in overheating and

reduced performance.

Installation requirements

Locate the unit as near to the motor as possible.

•

See chapter 9.5 Cable Specications for the

maximum motor cable length.

Ensure unit stability by mounting the unit to a

•

solid surface.

Enclosures E3h and E4h can be mounted:

•

- Vertically on the back plate of the panel

(typical installation).

- Vertically upside down on the back

plate of the panel.

- Horizontally on its back, mounted on

the back plate of the panel.

- Horizontally on its side, mounted on

oor of the panel.

Ensure that the strength of the mounting location

•

supports the unit weight.

Ensure that there is enough space around the

•

unit for proper cooling. Refer to

chapter 9.9 Enclosure Airow.

Ensure enough access to open the door.

•

Ensure cable entry from the bottom.

•

1) For non-typical installation, contact the factory.

Cooling requirements

Ensure that top and bottom clearance for air

•

cooling is provided. Clearance requirement:

225 mm (9 in).

Provide

•

Consider derating for temperatures starting

•

between 45 °C (113 °F) and 50 °C (122 °F) and

elevation 1000 m (3300 ft) above sea level. See

the design guide for detailed information.

The drive utilizes a back-channel cooling concept that

removes heat sink cooling air. The heat sink cooling air

carries approximately 90% of the heat out of the back

channel of the drive. Redirect the back-channel air from

the panel or room by using:

sucient airow ow rate. See Table 4.1.

1)

1)

1)

•

Back-channel cooling kits are available to direct

the heat sink cooling air out of the panel when

IP20/Chassis drives are installed in Rittal

enclosures. Use of these kits reduce the heat in

the panel and smaller door fans can be specied.

Back-wall cooling

•

Installing top and base covers to the unit allows

the back-channel cooling air to be ventilated out

of the room.

NOTICE

For E3h and E4h enclosures (IP20/Chassis), at least 1

door fan is required on the enclosure to remove the heat

not contained in the back-channel of the drive. It also

removes any additional losses generated by other

components inside the drive. To select the appropriate

fan size, calculate the total required airow.

Secure the necessary airow over the heat sink.

Frame Door fan/top fan

[m3/hr (cfm)]

E1h 510 (300) 994 (585)

E2h 552 (325) 1053–1206 (620–710)

E3h 595 (350) 994 (585)

E4h 629 (370) 1053–1206 (620–710)

Table 4.1 Airow Rate

Lifting the Unit

4.6

Lifting

Always lift the drive using the dedicated lifting eyes. To

avoid bending the lifting holes, use a bar.

Heat sink fan

[m3/hr (cfm)]

WARNING

RISK OF INJURY OR DEATH

Follow local safety regulations for lifting heavy weights.

Failure to follow recommendations and local safety

regulations can result in death or serious injury.

Ensure that the lifting equipment is in proper

•

working condition.

See chapter 3.2 Power Ratings, Weights, and

•

Dimensions for the weight of the dierent

enclosure types.

Maximum diameter for bar: 20 mm (0.8 in).

•

The angle from the top of the drive to the

•

lifting cable: 60° or greater.

14 Danfoss A/S © 01/2017 All rights reserved. MG22A102

Page 17

130BF685.10

130BF208.10

Mechanical Installation Operating Guide

4 4

Illustration 4.3 Pedestal to Floor Mounting Points

4.7.2 Attaching the E1h/E2h to the Pedestal

Illustration 4.2 Recommended Lifting Method

4.7 E1h/E2h Mechanical Installation

The E1h and E2h enclosure size is intended only for oor

installation, and is shipped with a pedestal and a gland

plate. The pedestal and gland plate must be installed for

proper installation.

The pedestal is 200 mm (7.9 in) and has an opening in the

front to allow airow necessary to cool the power

components of the drive.

The gland plate is necessary to provide cooling air to the

control components of the drive via the door fan, and to

maintain the IP21/Type 1 or IP54/Type 12 protection rating.

4.7.1 Securing the Pedestal to the Floor

The pedestal must be secured to the oor using 6 bolts

before installing the enclosure.

1. Determine proper placement of the unit,

concerning operating conditions and cable

access.

2. Access the mounting holes by removing the front

panel of the pedestal.

3. Set the pedestal on the oor and secure using 6

bolts through the mounting holes. Refer to the

circled areas in Illustration 4.3.

1. Lift the drive and position it on the pedestal.

There are 2 bolts in the rear of the pedestal that

slide into the 2 slotted holes in the rear of the

enclosure. Position the drive by adjusting the

bolts up or down. Loosely secure with 2 M10 nuts

and locking brackets. See Illustration 4.4.

2. Verify that there is 225 mm (9 in) top clearance

for air exhaust.

3. Verify that the air intake at the bottom front of

the unit is not obstructed.

4. Around the top of the pedestal, secure the

enclosure using 6 M10x30 fasteners. Refer to

Illustration 4.5. Loosely tighten each bolt until all

bolts are installed.

5. Fasten each bolt securely and torque to 19 Nm

(169 in-lb).

6. Torque the 2 M10 nuts at the rear of the

enclosure to 19 Nm (169 in-lb).

MG22A102 Danfoss A/S © 01/2017 All rights reserved. 15

Page 18

130BF225.10

1

2

5

4

6

3

130BF207.10

1

2

3

130BF209.10

1

3

4

2

Mechanical Installation VLT® AQUA Drive FC 202

4.7.3 Creating Cable Openings

The gland plate is a sheet of metal with studs along the

outer edge. The gland plate provides cable entry and cable

termination points, and must be installed to maintain the

IP21/IP54 (Type 1/Type 12) protection rating. The plate is

placed between the drive enclosure and the pedestal.

Depending on stud orientation, the plate can be installed

from inside the enclosure or the pedestal. For gland plate

44

1 Enclosure 4 Slotted hole in enclosure

2 Pedestal 5 Bolt at rear of pedestal

3 M10 nut 6 Locking bracket

Illustration 4.4 Pedestal to Enclosure Back Mounting Points

dimensions, see chapter 9.8.1 E1h Exterior Dimensions.

Refer to Illustration 4.6 for the following steps.

1. Create cable entry holes in the gland plate using

a sheet metal punch.

2. Insert the gland plate using 1 of the following

methods:

2a To insert the gland plate through the

pedestal, slide the gland plate through

the slot (4) in the front of the pedestal.

2b To insert the gland plate through the

enclosure, angle the gland plate until it

can be slid under the slotted brackets.

3. Align the studs on the gland plate to the holes in

the pedestal and secure with 10 M5 nuts (2).

4. Torque each nut to 2.3 Nm (20 in-lb).

1 Enclosure 3 M10x30 fasteners

(rear corner bolts not

shown)

2 Pedestal – –

Illustration 4.5 Pedestal to Enclosure Mounting Points

16 Danfoss A/S © 01/2017 All rights reserved. MG22A102

1 Cable entry hole 4 Slot in pedestal base

2 M5 nut 5 Front cover/grill

3 Gland plate – –

Illustration 4.6 Installing the Gland Plate

Page 19

1

130BF662.10

2

Mechanical Installation Operating Guide

4.8 E3h/E4h Mechanical Installation

The E3h and E4h enclosure sizes are intended to be

mounted on a wall or on a mounting panel within an

enclosure. A plastic gland plate is installed on the

enclosure. It is designed to prevent unintentional access to

the terminals in an IP20/protected chasis unit.

NOTICE

Regeneration/Load share Option

Due to the exposed terminals at the top of the

enclosure, units with the regeneration/load share option

have an IP00 protection rating.

4.8.1 Attaching the E3h/E4h to a Mounting

Plate or Wall

1. Drill the mounting holes according to the

enclosure size. Refer to chapter 9.8 Enclosure

Dimensions.

2. Secure the top of the drive enclosure to the

mounting plate or wall.

3. Secure the base of the drive enclosure to the

mounting plate or wall.

3. Based on the measurement and positions of the

cables, create openings in the plastic gland plate

by cutting out the necessary squares.

4. Slide the plastic gland plate (7) onto the bottom

rails of the terminal cover.

5. Tilt the front of the terminal cover downward

until the fastener points (8) rest on the slotted

drive brackets (6).

6. Make sure the side panels of the terminal cover

are on the outside track guide (5).

7. Push the terminal cover until it is up against the

slotted drive bracket.

8. Tilt the front of the terminal cover upward until

the fastener hole in the bottom of the drive

aligns with the keyhole opening (9) in the

terminal. Secure with 2 T25 screws and torque to

2.3 Nm (20 in-lb).

9. Secure the bottom panel with 3 T25 screws and

torque to 2.3 Nm (20 in-lb).

4 4

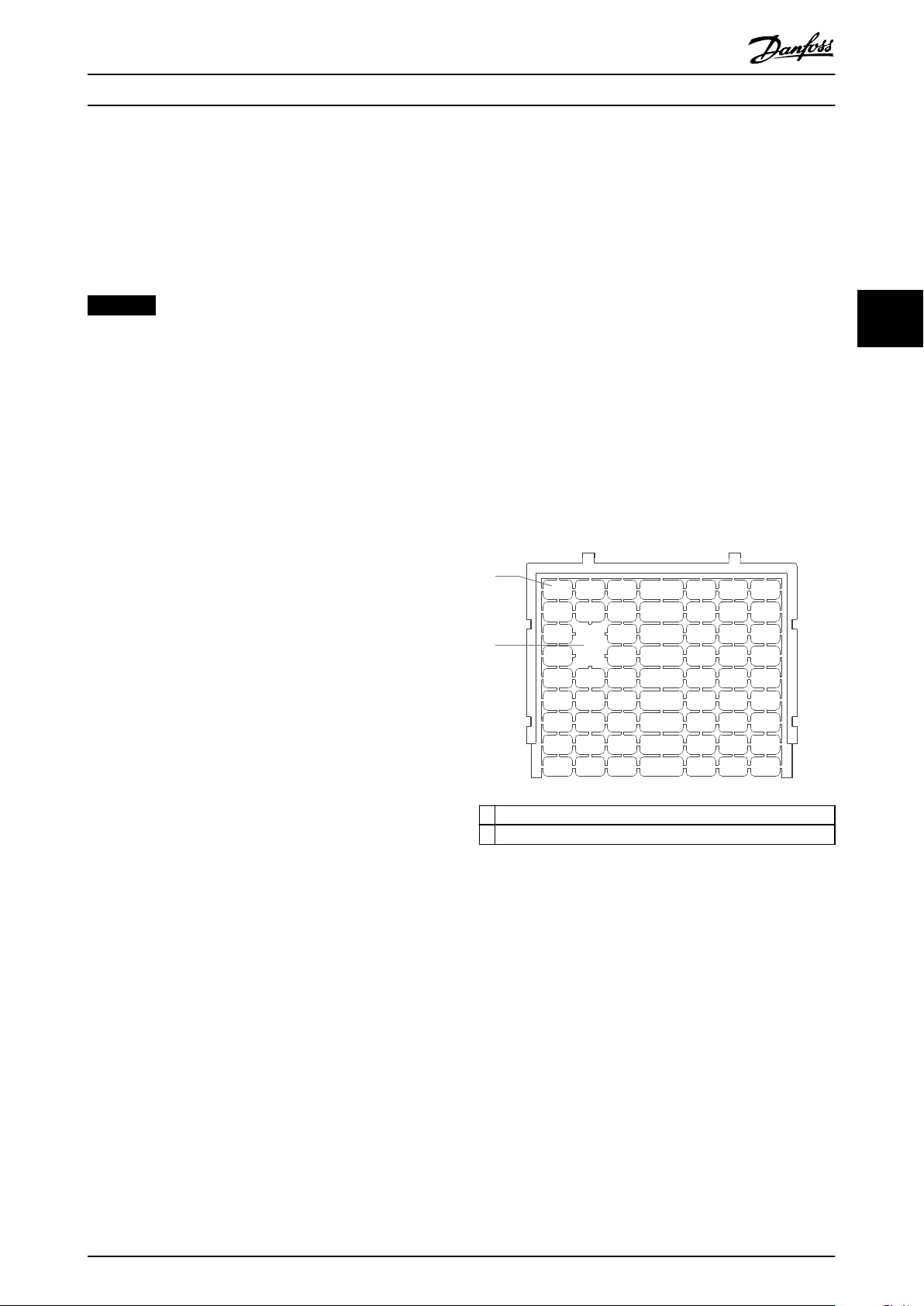

4.8.2 Creating Cable Openings

The gland plate covers the bottom part of the drive

enclosure and must be installed to maintain the IP20/

Chassis protection rating. The gland plate consists of

plastic squares that can be cut out to provide cable access

to the terminals. See Illustration 4.7.

1. Remove the bottom panel and terminal cover.

See Illustration 4.8.

1a Detach the bottom panel by removing 4

T25 screws.

1b Remove 5 T20 screws that secure the

bottom of the drive to the top of the

terminal cover, and then pull the

terminal cover straight out.

2. Determine the size and position of the motor,

mains, and ground cables. Note their position and

measurements.

1 Plastic square

2 Squares removed for cable access

Illustration 4.7 Plastic Gland Plate

MG22A102 Danfoss A/S © 01/2017 All rights reserved. 17

Page 20

6

7

9

5

8

4

130BF688.10

2

3

1

Mechanical Installation VLT® AQUA Drive FC 202

44

1 Load share/regeneration terminals (optional) 6 Slotted drive bracket

2 Bottom panel 7 Plastic gland plate (installed)

3 Terminal cover 8 Fastener point

4 Grommet access hole for control wiring 9 Keyhole opening

5 Track guide – –

Illustration 4.8 Assembling the Gland Plate and Terminal Cover

18 Danfoss A/S © 01/2017 All rights reserved. MG22A102

Page 21

130BF697.10

3

5

4

1

2

Mechanical Installation Operating Guide

4.8.3 Installing Load share/Regeneration

Terminals

The load share/regeneration terminals, located on the top

of the drive, are not installed from the factory to prevent

damage during shipping. Refer to Illustration 4.9 for the

following steps.

4 4

1 Label fastener, M4

2 Label

3 Load share/regeneration terminal

4 Terminal fastener, M10

5 Terminal plate with 2 openings

Illustration 4.9 Load share/Regeneration Terminals

1. Remove the terminal plate, 2 terminals, label, and

fasteners from the accessory bag included with

the drive.

2. Remove the cover from the load share/

regeneration opening on the top of the drive. Put

aside the 2 M5 fasteners for reuse later.

3. Remove the plastic backing and install the

terminal plate over the load share/regeneration

opening. Secure with the 2 M5 fasteners and

torque to 2.3 Nm (20 in-lb).

4. Install the both terminals to the terminal plate

using 1 M10 fastener per terminal. Torque to 19

Nm (169 in-lb).

5. Install the label on the front of the terminals as

shown in Illustration 4.9. Secure with 2 M4 screws

and torque to 1.2 Nm (10 in-lb).

MG22A102 Danfoss A/S © 01/2017 All rights reserved. 19

Page 22

Electrical Installation VLT® AQUA Drive FC 202

5 Electrical Installation

5.1 Safety Instructions

See chapter 2 Safety for general safety instructions.

WARNING

INDUCED VOLTAGE

Induced voltage from output motor cables from dierent

drives that are run together can charge equipment

55

capacitors even with the equipment turned o and

locked out. Failure to run output motor cables separately

or use shielded cables could result in death or serious

injury.

Run output motor cables separately, or

•

Use shielded cables.

•

Simultaneously lock out all the drives.

•

WARNING

SHOCK HAZARD

The drive can cause a DC current in the ground

conductor and thus result in death or serious injury.

When a residual current-operated protective

•

device (RCD) is used for protection against

electrical shock, only an RCD of Type B is

allowed on the supply side.

Failure to follow the recommendation means that the

RCD cannot provide the intended protection.

CAUTION

PROPERTY DAMAGE!

Protection against motor overload is not included in the

default setting. To add this function, set

parameter 1-90 Motor Thermal Protection to [ETR trip] or

[ETR warning]. For the North American market, the ETR

function provides class 20 motor overload protection in

accordance with NEC. Failure to set parameter 1-90 Motor

Thermal Protection to [ETR trip] or [ETR warning] means

that motor overload protection is not provided and

property damage can occur if the motor overheats.

5.2 EMC-compliant Installation

To obtain an EMC-compliant installation, follow the

instructions provided in:

chapter 5.3 Wiring Schematic.

•

chapter 5.4 Connecting the Motor.

•

chapter 5.6 Connecting to Ground.

•

chapter 5.8 Control Wiring.

•

NOTICE

TWISTED SHIELD ENDS (PIGTAILS)

Twisted shield ends increase the shield impedance at

higher frequencies, which reduces the shield eect and

increases the leakage current. Avoid twisted shield ends

by using integrated shield clamps.

Overcurrent protection

Extra protective equipment such as short-circuit

•

protection or motor thermal protection between

drive and motor is required for applications with

multiple motors.

Input fusing is required to provide short circuit

•

and overcurrent protection. If fuses are not

factory-supplied, the installer must provide them.

See maximum fuse ratings in chapter 9.7 Fuses.

Wire type and ratings

All wiring must comply with local and national

•

regulations regarding cross-section and ambient

temperature requirements.

Power connection wire recommendation:

•

Minimum 75 °C (167 °F) rated copper wire.

See chapter 9.5.1 Cable Specications for recommended

wire sizes and types.

For use with relays, control cables, a signal

•

interface, eldbus, or brake, connect the shield to

the enclosure at both ends. If the ground path

has high impedance, is noisy, or is carrying

current, break the shield connection on 1 end to

avoid ground current loops.

Convey the currents back to the unit using a

•

metal mounting plate. Ensure good electrical

contact from the mounting plate through the

mounting screws to the drive chassis.

Use shielded cables for motor output cables. An

•

alternative is unshielded motor cables within

metal conduit.

NOTICE

SHIELDED CABLES

If shielded cables or metal conduits are not used, the

unit and the installation does not meet regulatory limits

on radio frequency (RF) emission levels.

20 Danfoss A/S © 01/2017 All rights reserved. MG22A102

Page 23

Electrical Installation Operating Guide

Ensure that motor and brake cables are as short

•

as possible to reduce the interference level from

the entire system.

Avoid placing cables with a sensitive signal level

•

alongside motor and brake cables.

For communication and command/control lines,

•

follow the particular communication protocol

standards. For example, USB must use shielded

cables, but RS-485/ethernet can use shielded UTP

or unshielded UTP cables.

Ensure that all control terminal connections are

•

PELV.

NOTICE

EMC INTERFERENCE

Use shielded cables for motor and control wiring, and

separate cables for mains input, motor wiring, and

control wiring. Failure to isolate power, motor, and

control cables can result in unintended behavior or

reduced performance. Minimum 200 mm (7.9 in)

clearance between mains input, motor, and control

cables is required.

5 5

NOTICE

INSTALLATION AT HIGH ALTITUDE

There is a risk for overvoltage. Isolation between

components and critical parts could be insucient, and

may not comply with PELV requirements. Reduce the risk

for overvoltage by using external protective devices or

galvanic isolation.

For installations above 2000 m (6500 ft) altitude, contact

Danfoss regarding PELV compliance.

NOTICE

PELV COMPLIANCE

Prevent electric shock by using protective extra low

voltage (PELV) electrical supply and complying with local

and national PELV regulations.

MG22A102 Danfoss A/S © 01/2017 All rights reserved. 21

Page 24

130BF228.10

L1

L2

L3

PE

PE

u

v

w

2

1

3

5

16

17

18

14

12

8

7

10

9

4

11

13

4

4

6

15

90

55

Electrical Installation VLT® AQUA Drive FC 202

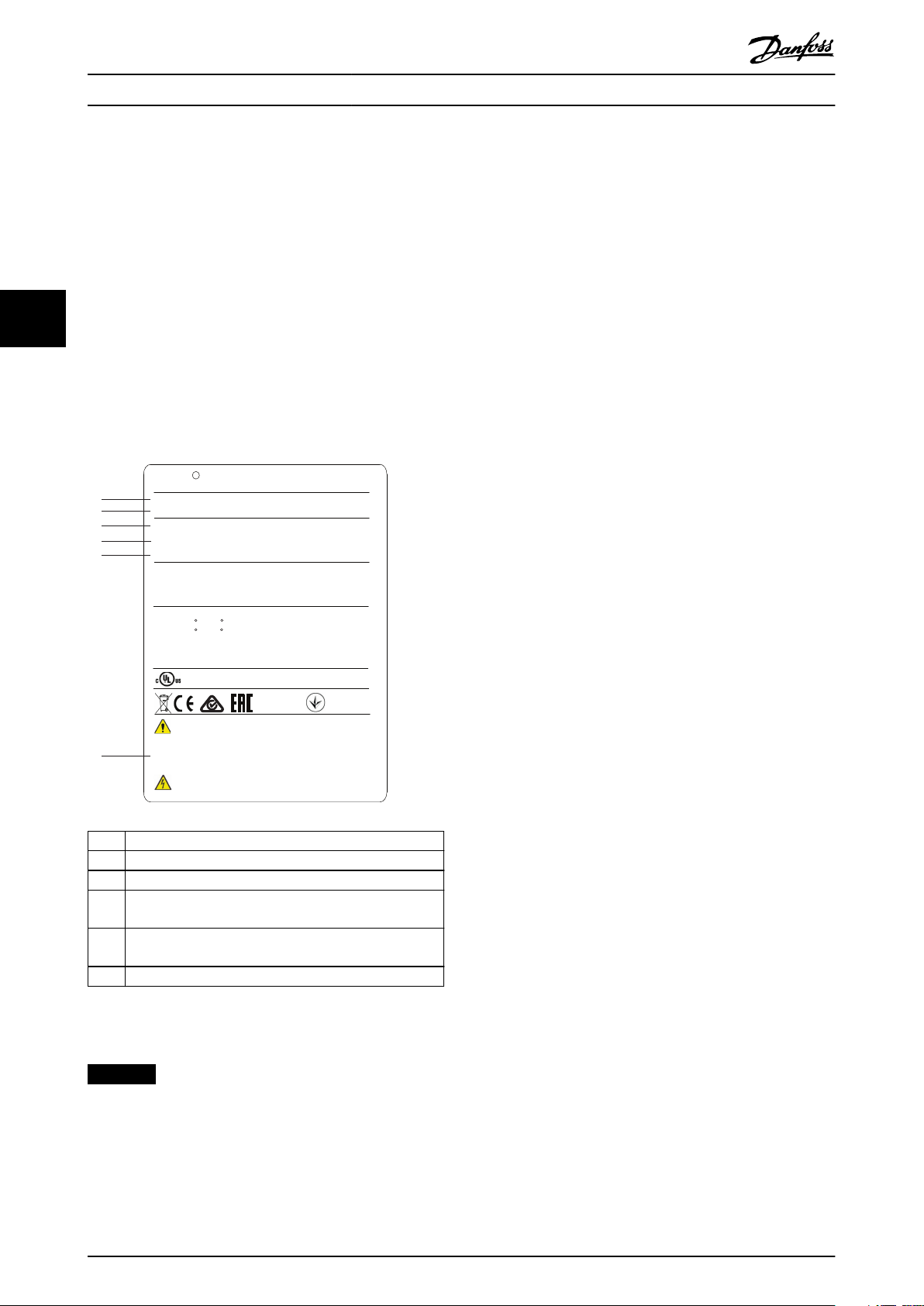

1 PLC 10 Mains cable (unshielded)

2

Minimum 16 mm2 equalizing cable

3 Control cables 12 Cable insulation stripped

4 Minimum 200 mm between control cables, motor cables, and

mains cables.

5 Mains supply 14 Brake resistor

6 Bare (unpainted) surface 15 Metal box

7 Star washers 16 Connection to motor

8 Brake cable (shielded) 17 Motor

9 Motor cable (shielded) 18 EMC cable gland

11 Output contactor, and so on

13 Common ground busbar. Follow local and national

requirements for cabinet grounding.

Illustration 5.1 Example of Proper EMC Installation

22 Danfoss A/S © 01/2017 All rights reserved. MG22A102

Page 25

130BF111.11

230 V AC

50/60 Hz

TB5

R1

Regen +

Regen -

83

Regen (optional)

1

2

Brake temperature

(NC)

Space heater (optional)

91 (L1)

92 (L2)

93 (L3)

PE

88 (-)

89 (+)

50 (+10 V OUT)

53 (A IN)

54 (A IN)

55 (COM A IN)

0/4-20 mA

12 (+24 V OUT)

13 (+24 V OUT)

18 (D IN)

20 (COM D IN)

15 mA

200 mA

(U) 96

(V) 97

(W) 98

(PE) 99

(COM A OUT) 39

(A OUT) 42

0/4-20 mA

03

+10 V DC

-10 V DC - +10 V DC

0/4-20 mA

24 V DC

02

01

05

04

06

240 V AC, 2A

24 V (NPN)

0 V (PNP)

0 V (PNP)

24 V (NPN)

19 (D IN)

24 V (NPN)

0 V (PNP)

27

24V

0V

(D IN/OUT)

0 V (PNP)

24 V (NPN)

(D IN/OUT)

0V

24V

29

24 V (NPN)

0 V (PNP)

0 V (PNP)

24 V (NPN)

33 (D IN)

32 (D IN)

1 2

ON

A53 U-I (S201)

ON

21

A54 U-I (S202)

ON=0-20 mA

OFF=0-10 V

95

400 V AC, 2A

P 5-00

(R+) 82

(R-) 81

37 (D IN)

1)

+ - + -

(P RS485) 68

(N RS485) 69

(COM RS485) 61

0V

5V

S801

RS485

RS485

21

ON

S801/Bus Term.

OFF-ON

3-phase

power

input

Load share

Switch mode

power supply

Motor

Analog output

interface

Relay1

Relay2

ON=Terminated

OFF=Open

Brake

resistor

(NPN) = Sink

(PNP) = Source

= ==

240 V AC, 2A

400 V AC, 2A

-10 V DC - +10 V DC

10 V DC

(optional)

(optional)

Electrical Installation Operating Guide

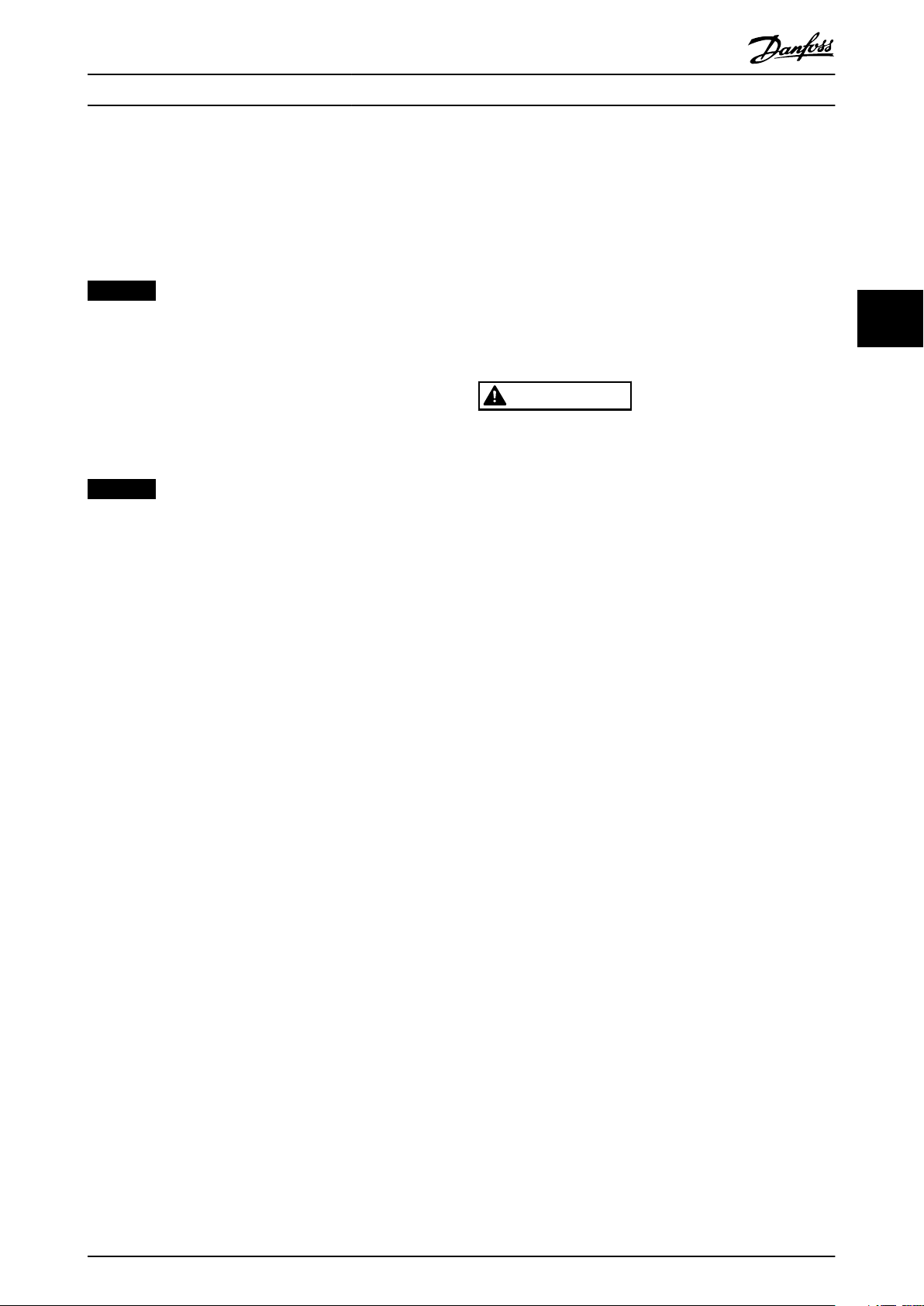

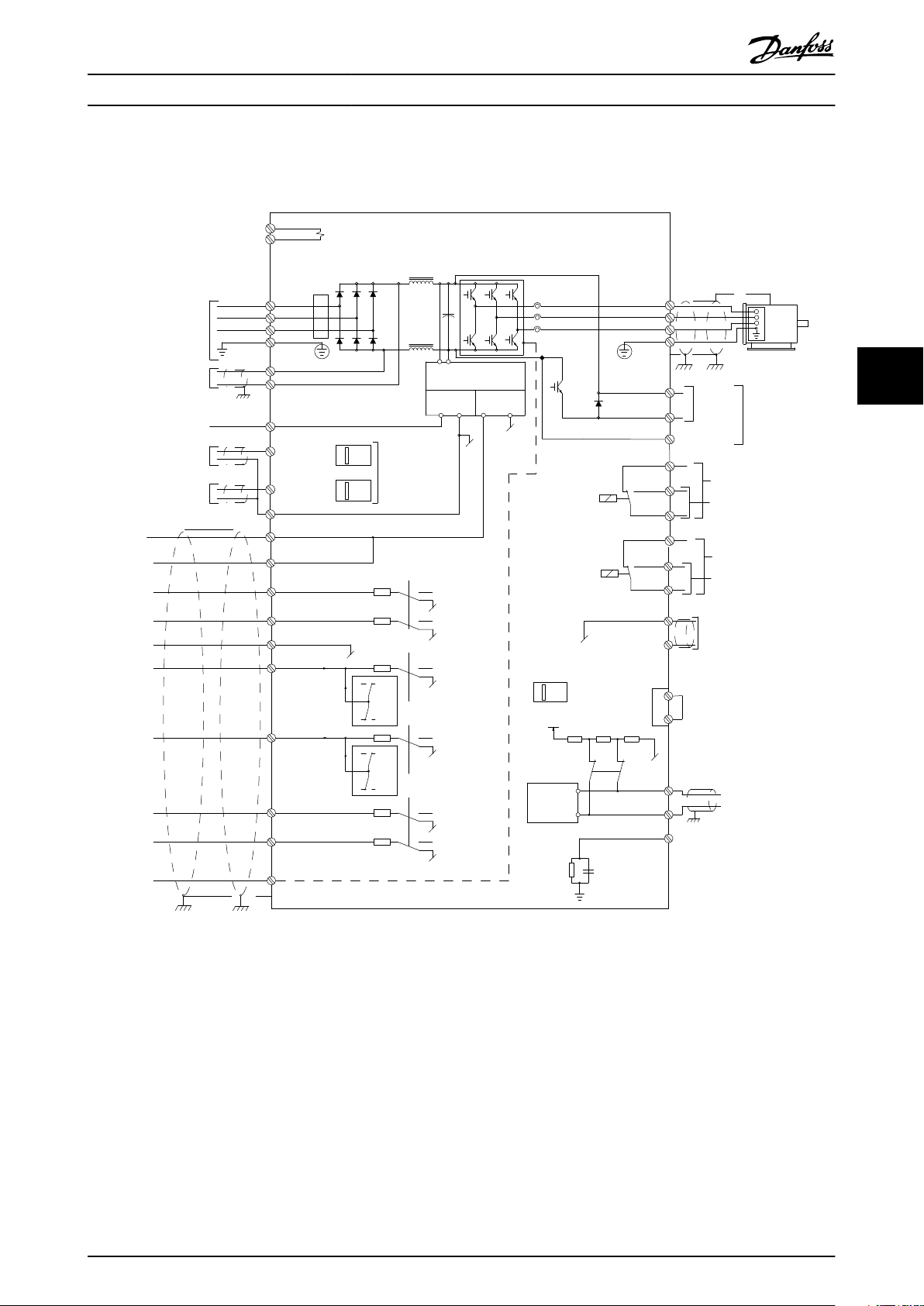

5.3 Wiring Schematic

5 5

Illustration 5.2 Basic Wiring Schematic

A=Analog, D=Digital

1) Terminal 37 (optional) is used for Safe Torque O. For Safe Torque O installation instructions, refer to the Safe Torque O

Operating Guide.

MG22A102 Danfoss A/S © 01/2017 All rights reserved. 23

Page 26

Electrical Installation VLT® AQUA Drive FC 202

5.4 Connecting the Motor

WARNING

INDUCED VOLTAGE

Induced voltage from output motor cables that run together can charge equipment capacitors, even with the

equipment turned o and locked out. Failure to run output motor cables separately or use shielded cables could result

in death or serious injury.

Comply with local and national electrical codes for cable sizes. For maximum wire sizes, see chapter 9.1 Electrical

•

Data.

Follow motor manufacturer wiring requirements.

55

•

Motor wiring knockouts or access panels are provided on the pedestal of IP21/IP54 (Type 1/Type 12) units.

•

Do not wire a starting or pole-changing device (for example Dahlander motor or slip ring asynchronous motor)

•

between the drive and the motor.

Procedure

1. Strip a section of the outer cable insulation.

2. Establish mechanical xation and electrical contact between the cable shield and ground by positioning the

stripped wire under the cable clamp.

3. Connect the ground wire to the nearest grounding terminal in accordance with the grounding instructions

provided in chapter 5.6 Connecting to Ground.

4. Connect the 3-phase motor wiring to terminals 96 (U), 97 (V), and 98 (W), see Illustration 5.3.

5. Tighten the terminals in accordance with the information provided in chapter 9.10.1 Fastener Torque Ratings.

24 Danfoss A/S © 01/2017 All rights reserved. MG22A102

Page 27

130BF150.10

U/T1 96 V/T2 97

W/T3 98

FASTENER TORQUE M10 19Nm (14FT-LB), M12 35Nm (26FT-LB)

U/T1 96 V/T2 97

W/T3 98

FASTENER TORQUE M10 19Nm (14FT-LB), M12 35Nm (14FT-LB)

+ REGEN 82

FASTENER TORQUE:

M10 19Nm (14FT-LB)

M12 35Nm (26FT-LB)

- REGEN 83

FASTENER TORQUE:

M10 19Nm (14FT-LB)

M12 35Nm (26FT-LB)

Electrical Installation Operating Guide

5 5

Illustration 5.3 AC motor terminals (E1h shown). For a detailed view of terminals, refer to chapter 5.7 Terminal Dimensions.

MG22A102 Danfoss A/S © 01/2017 All rights reserved. 25

Page 28

Electrical Installation VLT® AQUA Drive FC 202

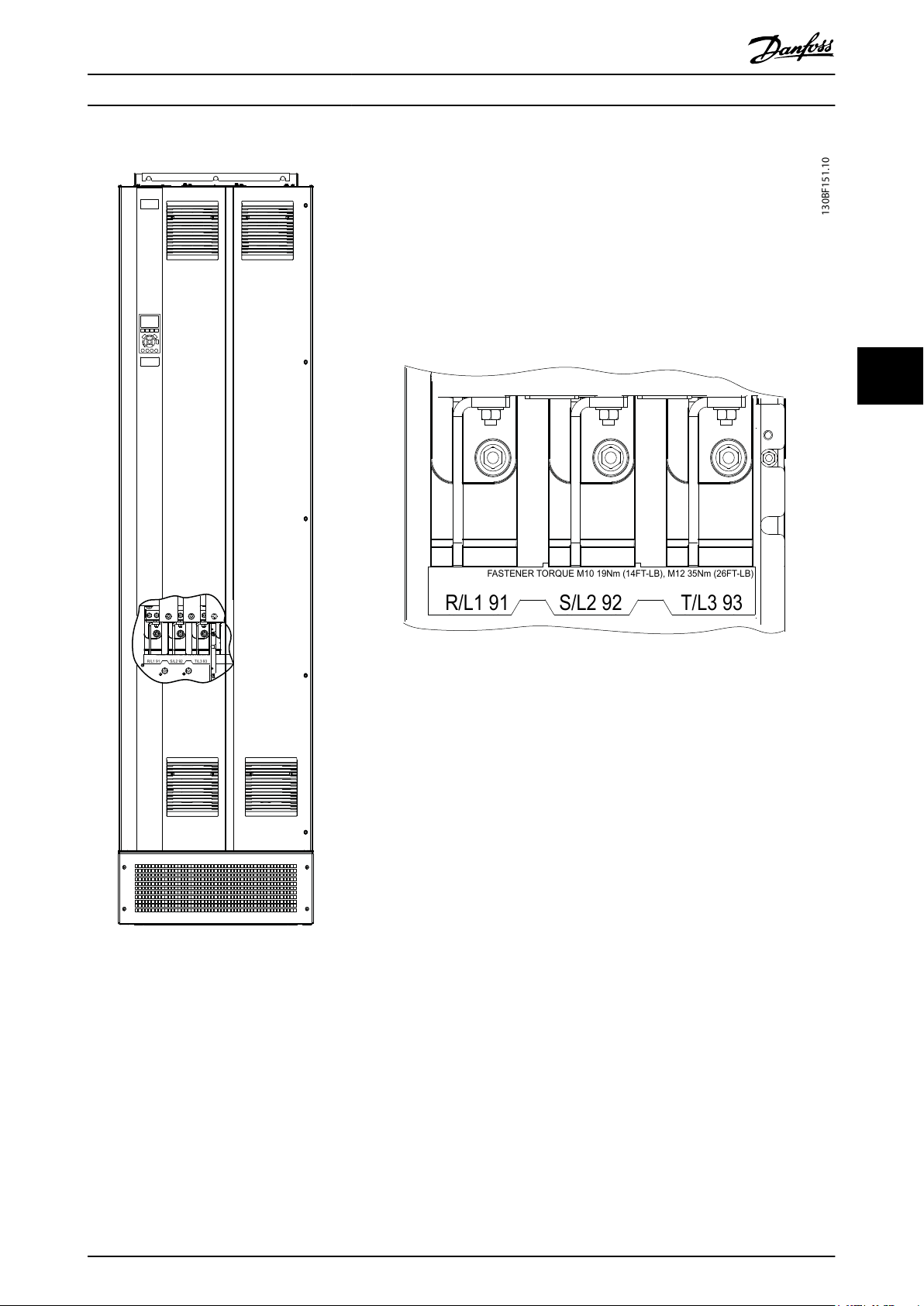

5.5 Connecting the AC Mains

Size the wiring according to the input current of the drive. For maximum wire sizes, see chapter 9.1 Electrical Data.

•

Comply with local and national electrical codes for cable sizes.

•

Procedure

1. Strip a section of the outer cable insulation.

2. Establish mechanical xation and electrical contact between the cable shield and ground by positioning the

stripped wire under the cable clamp.

3. Connect the ground wire to the nearest grounding terminal in accordance with the grounding instructions

provided in chapter 5.6 Connecting to Ground.

55

4. Connect the 3-phase AC input power wiring to terminals R, S, and T (see Illustration 5.4).

5. When supplied from an isolated mains source (IT mains or oating delta) or TT/TN-S mains with a grounded leg

(grounded delta), ensure that parameter 14-50 RFI Filter is set to [0] O to avoid damage to the DC link and to

reduce ground capacity currents.

6. Tighten the terminals in accordance with the information provided in chapter 9.10.1 Fastener Torque Ratings.

26 Danfoss A/S © 01/2017 All rights reserved. MG22A102

Page 29

130BF151.10

T/L3 93

S/L2 92

R/L1 91

FASTENER TORQUE M10 19Nm (14FT-LB), M12 35Nm (26FT-LB)

T/L3 93

S/L2 92

R/L1 91

FASTENER TORQUE M10 19Nm (14FT-LB), M12 35Nm (26FT-LB)

Electrical Installation Operating Guide

5 5

Illustration 5.4 AC mains terminals (E1h shown). For a detailed view of terminals, refer to chapter 5.7 Terminal Dimensions.

MG22A102 Danfoss A/S © 01/2017 All rights reserved. 27

Page 30

Electrical Installation VLT® AQUA Drive FC 202

5.6 Connecting to Ground

WARNING

LEAKAGE CURRENT HAZARD

Leakage currents exceed 3.5 mA. Failure to ground the drive properly can result in death or serious injury.

Ensure the correct grounding of the equipment by a certied electrical installer.

•

For electrical safety

Ground the drive in accordance with applicable standards and directives.

•

Use a dedicated ground wire for input power, motor power, and control wiring.

55

•

Do not ground 1 drive to another in a daisy chain fashion.

•

Keep the ground wire connections as short as possible.

•

Follow motor manufacturer wiring requirements.

•

Minimum cable cross-section: 10 mm2 (6 AWG) (or 2 rated ground wires terminated separately).

•

Tighten the terminals in accordance with the information provided in chapter 9.10.1 Fastener Torque Ratings.

•

For EMC-compliant installation

Establish electrical contact between the cable shield and the drive enclosure by using metal cable glands or by

•

using the clamps provided on the equipment.

Reduce burst transient by using high-strand wire.

•

Do not use pigtails.

•

NOTICE

POTENTIAL EQUALIZATION

There is a risk of burst transient when the ground potential between the drive and the control system is dierent.

Install equalizing cables between the system components. Recommended cable cross-section: 16 mm2 (5 AWG).

28 Danfoss A/S © 01/2017 All rights reserved. MG22A102

Page 31

130BF152.10

U/T1 96 V/T2 97

W/T3 98

T/L3 93S/L2 92R/L1 91

FASTENER TORQUE M10 19Nm (14FT-LB), M12 35Nm (26FT-LB)

FASTENER TORQUE M10 19Nm (14FT-LB), M12 35Nm (26FT-LB)

U/T1 96 V/T2 97

W/T3 98

T/L3 93S/L2 92R/L1 91

FASTENER TORQUE M10 19Nm (14FT-LB), M12 35Nm (26FT-LB)

FASTENER TORQUE M10 19Nm (14FT-LB), M12 35Nm (26FT-LB)

Electrical Installation Operating Guide

5 5

Illustration 5.5 Ground terminals (E1h shown). For a detailed view of terminals, refer to chapter 5.7 Terminal Dimensions.

MG22A102 Danfoss A/S © 01/2017 All rights reserved. 29

Page 32

130BF683.10

6X 613 (24.1)

383 (15.1)

472 (18.6)

423 (16.7)

165 (6.5)

0 (0.0)

101 (4.0)

82 (3.2)

721 (28.4)

0 (0.0)

1

2

3

4

200 (7.9)

515 (20.3)

485 (19.1)

248 (9.8)

241 (9.5)

171 (6.7)

414 (16.3)

361 (14.2)

331 (13.0)

501 (19.7)

497 (19.6)

431 (17.0)

512 (20.2)

5

Electrical Installation VLT® AQUA Drive FC 202

5.7 Terminal Dimensions

5.7.1 E1h Terminal Dimensions

55

1 Mains terminals 3 Motor terminals

2 Brake or regeneration terminals 4 Ground terminals, M10 nut

Illustration 5.6 E1h Terminal Dimensions (Front View)

30 Danfoss A/S © 01/2017 All rights reserved. MG22A102

Page 33

130BF650.10

A

A

649 (25.5)649 (25.5)

0 (0.0)

0 (0.0)

0 (0.0)

164 (6.4)

290 (11.4)

377 (14.8)

0 (0.0)

164 (6.4)

290 (11.4)

18 (0.7)

0 (0.0)

84 (3.3)

42 (1.7)

5X

0 (0.0)

36 (1.4)

44 (1.8)

14 (0.5)

Electrical Installation Operating Guide

5 5

Illustration 5.7 E1h Terminal Dimensions (Side Views)

MG22A102 Danfoss A/S © 01/2017 All rights reserved. 31

Page 34

130BF689.10

721 (28.4)

6X 613 (24.1)

1

515 (20.3)

485 (19.1)

0 (0.0)

200 (7.9)

185 (7.3)

0 (0.0)

101 (4.0)

89 (3.5)

289 (11.4)

281 (11.1)

195 (7.7)

483 (19.0)

409 (16.1)

387 (15.2)

597 (23.5)

579 (22.8)

503 (19.8)

479 (18.9)

568 (22.4)

519 (20.4)

608 (23.9)

2

3

4

Electrical Installation VLT® AQUA Drive FC 202

5.7.2 Mains, Motor, and Ground for E2h

55

1 Mains terminals 3 Motor terminals

2 Brake or regeneration terminals 4 Ground terminals, M10 nut

Illustration 5.8 E2h Terminal Dimensions (Front View)

32 Danfoss A/S © 01/2017 All rights reserved. MG22A102

Page 35

649 (25.5)649 (25.5)

0 (0.0)

0 (0.0)

0 (0.0)

164 (6.4)

290 (11.4)

377 (14.8)

0 (0.0)

164 (6.4)

290 (11.4)

130BF690.10

A

18 (0.7)

0 (0.0)

84 (3.3)

42 (1.7)

5X

0 (0.0)

36 (1.4)

44 (1.8)

14 (0.5)

A

Electrical Installation Operating Guide

5 5

Illustration 5.9 E2h Terminal Dimensions (Side Views)

MG22A102 Danfoss A/S © 01/2017 All rights reserved. 33

Page 36

130BF660.10

336 (13.2)

425 (16.7)

376 (14.8)

465 (18.3)

256 (10.1)

33 (1.3)

6X 148 (5.8)

90 (3.5)

50 (2.0)

0 (0.0)

0 (0.0)

64 (2.5)

35 (1.4)

91 (3.6)

118 (4.6)

194 (7.6)

174 (6.9)

201 (7.9)

284 (11.2)

340 (13.4)

314 (12.3)

367 (14.4)

444 (17.5)

423 (16.7)

450 (17.7)

2

3

4

1

Electrical Installation VLT® AQUA Drive FC 202

5.7.3 Mains, Motor, and Ground for E3h

55

1 Mains terminals 3 Motor terminals

2 Brake or regeneration terminals 4 Ground terminals, M8 and M10 nuts

Illustration 5.10 E3h Terminal Dimensions (Front View)

34 Danfoss A/S © 01/2017 All rights reserved. MG22A102

Page 37

130BF661.10

0 (0.0)

0 (0.0)

160 (6.3)

0 (0.0)

373 (14.7)

287 (11.3)

287 (11.3)

160 (6.3)

0 (0.0)

184

(7.2)

184

(7.2)

A

5X 14 (0.5)

44 (1.8)

0 (0.0)

36 (1.4)

18 (0.7)

0 (0.0)

84 (3.3)

42 (1.7)

A

Electrical Installation Operating Guide

5 5

Illustration 5.11 E3h Mains, Motor, and Ground Terminal Dimensions (Side Views)

MG22A102 Danfoss A/S © 01/2017 All rights reserved. 35

Page 38

130BF663.10

0 (0.0)

234 (9.2)

314 (12.4)

0 (0.0)

176 (6.9)

A

A

8X 14 (0.5)

20 (0.8)

0 (0.0)

35(1.4)

0 (0.0)

15 (0.6)

35 (1.4)

50 (2.0)

75 (3.0)

90 (3.5)

125 (4.9)

140 (5.5)

2X 125 (4.9)

0 (0.0)

Electrical Installation VLT® AQUA Drive FC 202

55

Illustration 5.12 E3h Load Share/Regeneration Terminal Dimensions

36 Danfoss A/S © 01/2017 All rights reserved. MG22A102

Page 39

130BF668.10

6X 148 (5.8)

90 (3.5)

50 (2.0)

0 (0.0)

1

0 (0.0)

64 (2.5)

41 (1.6)

105 (4.1)

137 (5.4)

194 (7.6)

200 (7.9)

233 (9.2)

402 (15.8)

339 (13.4)

410 (16.1)

499 (19.6)

435 (17.1)

531 (20.9)

256 (10.1)

33 (1.3)

2

3

4

540 (21.2)

432 (17.0)

521 (20.5)

472 (18.6)

561 (22.1)

Electrical Installation Operating Guide

5.7.4 Mains, Motor, and Ground for E4h

5 5

1 Mains terminals 3 Motor terminals

2 Brake or regeneration terminals 4 Ground terminals, M8 and M10 nuts

Illustration 5.13 E4h Terminal Dimensions (Front View)

MG22A102 Danfoss A/S © 01/2017 All rights reserved. 37

Page 40

130BF681.10

5X 14 (0.5)

44 (1.8)

0 (0.0)

36 (1.4)

0 (0.0)

373 (14.7)

287 (11.3)

160 (6.3)

0 (0.0)

0 (0.0)

160 (6.3)

0 (0.0)

287 (11.3)

184

(7.2)

184

(7.2)

A

18 (0.7)

0 (0.0)

84 (3.3)

42 (1.7)

Electrical Installation VLT® AQUA Drive FC 202

55

Illustration 5.14 E4h Mains, Motor, and Ground Terminal Dimensions (Side Views)

38 Danfoss A/S © 01/2017 All rights reserved. MG22A102

Page 41

130BF682.10

A

20 (0.8)

0 (0.0)

35(1.4)

0 (0.0)

15 (0.6)

35 (1.4)

50 (2.0)

75 (3.0)

90 (3.5)

125 (4.9)

140 (5.5)

8X 14 (0.5)

2X 125 (4.9)

0 (0.0)

0 (0.0)

234 (9.2)

314 (12.4)

0 (0.0)

219 (8.6)

A

Electrical Installation Operating Guide

5 5

Illustration 5.15 E4h Load Share/Regeneration Terminal Dimensions

MG22A102 Danfoss A/S © 01/2017 All rights reserved. 39

Page 42

130BF715.10

130BF144.10

12 13 18 19 27 29 32 33 20 37

39696861 42 50 53 54 55

130BF145.10

1

2

3

Electrical Installation VLT® AQUA Drive FC 202

5.8 Control Wiring

All terminals to the control cables are inside the drive

below the LCP. To access, either open the door (E1h and

E2h) or remove the front panel (E3h and E4h).

5.8.2 Control Terminal Types

Illustration 5.17 shows the removable drive connectors.

Terminal functions and default settings are summarized in

Table 5.1 – Table 5.3.

5.8.1 Control Cable Routing

Tie down and route all control wires as shown in

Illustration 5.16. Remember to connect the shields in a

proper way to ensure optimum electrical immunity.

55

Fieldbus connection

Connections are made to the relevant options on the

control card. For more detail, see the relevant eldbus

instruction. The cable must be tied down and routed along

with other control wires inside the unit. See

Illustration 5.16.

Isolate control wiring from high-power cables in

•

the drive.

When the drive is connected to a thermistor,

•

ensure that the thermistor control wiring is

shielded and reinforced/double insulated. A 24 V

DC supply voltage is recommended.

Illustration 5.17 Control Terminal Locations

1 Serial communication terminals

Illustration 5.16 Control Card Wiring Path

40 Danfoss A/S © 01/2017 All rights reserved. MG22A102

2 Digital input/output terminals

3 Analog input/output terminals

Illustration 5.18 Terminal Numbers Located on the Connectors

Serial communication terminals

Terminal Parameter Default

setting

61 – – Integrated RC-lter for

Description

cable shield. ONLY for

connecting the shield

in the event of EMC

problems.

Page 43

RELAY 1 RELAY 2

01 02 03 04 05 06

130BF156.10

Electrical Installation Operating Guide

Serial communication terminals

Terminal Parameter Default

setting

68 (+) Parameter

group 8-3* FC

Port Settings

69 (-) Parameter

group 8-3* FC

Port Settings

01, 02, 03 Parameter 5-40

Function Relay

[0]

04, 05, 06 Parameter 5-40

Function Relay

[1]

Table 5.1 Serial Communication Terminal Descriptions

Digital input/output terminals

Terminal Parameter Default

12, 13 – +24 V DC 24 V DC supply

18 Parameter 5-10

Terminal 18

Digital Input

19 Parameter 5-11

Terminal 19

Digital Input

32 Parameter 5-14

Terminal 32

Digital Input

33 Parameter 5-15

Terminal 33

Digital Input

27 Parameter 5-12

Terminal 27

Digital Input

29 Parameter 5-13

Terminal 29

Digital Input

20 – – Common for digital

– RS485 interface. A

–

Relays

[0] No

operation

[0] No

operation

setting

[8] Start Digital inputs.

[10]

Reversing

[0] No

operation

[0] No

operation

[2] Coast

inverse

[14] JOG

Description

switch (BUS TER.) is

provided on the

control card for bus

termination

resistance. See

Illustration 5.22.

Form C relay output.

For AC or DC voltage

and resistive or

inductive loads.

Description

voltage for digital

inputs and external

transducers.

Maximum output

current 200 mA for all

24 V loads.

For digital input or

output. Default

setting is input.

inputs and 0 V

potential for 24 V

supply.

Digital input/output terminals

Terminal Parameter Default

setting

37 – STO When not using the

Table 5.2 Digital Input/Output Terminal Descriptions

Analog input/output terminals

Terminal Parameter Default

setting

39 – – Common for analog

42 Parameter 6-50

Terminal 42

Output

50 – +10 V DC 10 V DC analog

53 Parameter

group 6-1*

Analog Input 1

54 Parameter

group 6-2*

Analog Input 2

55 – – Common for analog

Table 5.3 Analog Input/Output Terminal Descriptions

[0] No

operation

Reference Analog input. For

Feedback

Description

optional STO feature,

a jumper wire is

required between

terminal 12 (or 13)

and terminal 37. This

set-up allows the

drive to operate with

factory default

programming values.

Description

output.

Programmable analog

output. 0–20 mA or

4–20 mA at a

maximum of 500 Ω.

supply voltage for

potentiometer or

thermistor. 15 mA

maximum.

voltage or current.

Switches A53 and

A54 select mA or V.

input.

Relay terminals:

Illustration 5.19 Relay 1 and Relay 2 Terminals

Relay 1 and relay 2. The location of the outputs

•

depends on the drive conguration. See

chapter 3.5 Control Shelf.

Terminals on built-in optional equipment. See the

•

manual provided with the equipment option.

5 5

MG22A102 Danfoss A/S © 01/2017 All rights reserved. 41

Page 44

130BD546.11

2

1

10 mm

[0.4 inches]

12 13 18 19 27 29 32 33

Electrical Installation VLT® AQUA Drive FC 202

5.8.3 Wiring to Control Terminals

Control terminal connectors can be unplugged from the

drive for ease of installation, as shown in Illustration 5.20.

55

Illustration 5.20 Connecting Control Wires

NOTICE

Minimize interference by keeping control wires as short

as possible and separate from high-power cables.

1. Open the contact by inserting a small screwdriver

2. Insert the bare control wire into the contact.

3. Remove the screwdriver to fasten the control wire

4. Ensure that the contact is rmly established and

See chapter 9.1 Electrical Data for control terminal wiring

sizes and chapter 7 Wiring Conguration Examples for

typical control wiring connections.

5.8.4 Enabling Motor Operation

(Terminal 27)

A jumper wire is required between terminal 12 (or 13) and

terminal 27 for the drive to operate when using factory

default programming values.

•

•

•

into the slot above the contact and push the

screwdriver slightly upwards.

into the contact.

not loose. Loose control wiring can be the source

of equipment faults or reduced performance.

Digital input terminal 27 is designed to receive

24 V DC external interlock command.

When no interlock device is used, wire a jumper

between control terminal 12 (recommended) or

13 to terminal 27. This wire provides an internal

24 V signal on terminal 27.

When the status line at the bottom of the LCP

reads AUTO REMOTE COAST, the unit is ready to

operate, but is missing an input signal on

terminal 27.

When factory-installed optional equipment is

•

wired to terminal 27, do not remove that wiring.

NOTICE

The drive cannot operate without a signal on terminal

27, unless terminal 27 is reprogrammed using

parameter 5-12 Terminal 27 Digital Input.

5.8.5 Conguring RS485 Serial

Communication

RS485 is a 2-wire bus interface compatible with multi-drop

network topology, and it contains the following features:

Either Danfoss FC or Modbus RTU communication

•

protocol, which are internal to the drive, can be

used.

Functions can be programmed remotely using

•

the protocol software and RS485 connection or in

parameter group 8-** Communications and

Options.

Selecting a

•

changes various default parameter settings to

match the specications of the protocol, making

more protocol-specic parameters available.

Option cards for the drive are available to provide

•

more communication protocols. See the option

card documentation for installation and operation

instructions.

A switch (BUS TER) is provided on the control

•

card for bus termination resistance. See

Illustration 5.22.

For basic serial communication set-up, perform the

following steps:

1. Connect RS485 serial communication wiring to

terminals (+)68 and (-)69.

1a Use shielded serial communication cable

1b See chapter 5.6 Connecting to Ground for

2. Select the following parameter settings:

2a Protocol type in parameter 8-30 Protocol.

2b Drive address in parameter 8-31 Address.

2c Baud rate in parameter 8-32 Baud Rate.

specic communication protocol

(recommended).

proper grounding.

42 Danfoss A/S © 01/2017 All rights reserved. MG22A102

Page 45

61

68

69

+

130BB489.10

RS485

Electrical Installation Operating Guide

5.8.8 Wiring the Auxiliary Contacts to the

Disconnect

The disconnect is an option that is installed at the factory.

The auxiliary contacts, which are signal accessories used

with the disconnect, are not installed at the factory to

allow more exibility during installation. The contacts snap

into place without the need for tools.

Illustration 5.21 Serial Communication Wiring Diagram

5.8.6 Wiring Safe Torque O (STO)

The Safe Torque O (STO) function is a component in a

safety control system. STO prevents the unit from

generating the voltage required to rotate the motor.

To run STO, more wiring for the drive is required. Refer to

Safe Torque

O Operating Guide for further information.

5.8.7 Wiring the Space Heater

The space heater is an option used to prevent condensation from forming inside the enclosure when the unit is

turned o. It is designed to be eld wired and controlled

by an HVAC management system.

Specications

Nominal voltage: 100–240

•

Wire size: 12–24 AWG

•

Contacts must be installed in

disconnect depending upon their functions. Refer to the

datasheet included in the accessory bag that comes with

the drive.

Specications

Ui/[V]: 690

•

U

/[kV]: 4

imp

•

Pollution degree: 3

•

Ith/[A]: 16

•

Cable size: 1...2x0.75...2.5 mm

•

Maximum fuse: 16 A/gG

•

NEMA: A600, R300, wire size: 18–14 AWG, 1(2)

•

specic locations on the

2

5.8.9 Wiring the Brake Resistor Temperature

Switch

The brake resistor terminal block is located on the power

card and allows for the connection of an external brake

resistor temperature switch. The switch can be congured

as normally closed or normally open. If the input changes,

a signal trips the drive and shows alarm 27, Brake chopper

fault on the LCP display. At the same time, the drive stops

braking and the motor coasts.

1. Locate the brake resistor terminal block (terminals

104–106) on the power card. See Illustration 3.3.

2. Remove the M3 screws that hold the jumper to

the power card.

3. Remove the jumper and wire the brake resistor

temperature switch in 1 of the following congu-

rations:

3a Normally closed. Connect to terminals

104 and 106.

3b Normally open. Connect to terminals

104 and 105.

4. Secure the switch wires with the M3 screws.

Torque to 0.5-0.6 Nm (5 in lb).

5 5

MG22A102 Danfoss A/S © 01/2017 All rights reserved. 43

Page 46

130BF146.10

BUS TER.

OFF-ON

A53 A54

U- I U- I

1

2

N O

1

2

N O

1

2

N O

1

2

N O

Electrical Installation VLT® AQUA Drive FC 202

5.8.10 Selecting Voltage/Current Input

Signal

The analog input terminals 53 and 54 allow setting of

input signal to voltage (0–10 V) or current (0/4–20 mA).

Default parameter setting:

Terminal 53: Speed reference signal in open loop

•

(see parameter 16-61 Terminal 53 Switch Setting).

Terminal 54: Feedback signal in closed loop (see

•

parameter 16-63 Terminal 54 Switch Setting).

55

NOTICE

Disconnect power to the drive before changing switch

positions.

1. Remove the LCP (local control panel).

See chapter 6.3 LCP Menu.

2. Remove any optional equipment covering the

switches.

3. Set switches A53 and A54 to select the signal

type (U = voltage, I = current).

Illustration 5.22 Location of Terminal 53 and 54 Switches

44 Danfoss A/S © 01/2017 All rights reserved. MG22A102

Page 47

Electrical Installation Operating Guide

5.9 Pre-start Check List

Before completing installation of the unit, inspect the entire installation as detailed in Table 5.4. Check and mark the items

when completed.

Inspect for Description

Auxiliary equipment•Look for auxiliary equipment, switches, disconnects, or input fuses/circuit breakers that reside on the input

power side of the drive or output side to the motor. Ensure that they are ready for full-speed operation.

Check function and installation of any sensors used for feedback to the drive.

•

Remove any power factor correction caps on motor.

•

Adjust any power factor correction caps on the mains side and ensure that they are dampened.

•

Cable routing

Control wiring

Cooling clearance

Ambient conditions

Fusing and circuit

breakers

Grounding

Input and output

power wiring