Page 1

Fact Sheet

VLT® AQUA Drive deragging feature

keeps your wastewater pumps clean

The deragging feature has been developed

specifically for the VLT® AQUA Drive.

Wastewater from households and

industry contains particles and fibres

that are not removed by the screen

filters. The VLT® AQUA Drive deragging

feature removes clogs to protect the

pump and reduce maintenance.

Clogged impellers in wastewater

pumps can be a permanent and serious

problem. Over time, fibres and particles

will build up on the impeller vanes,

leading to poor efficiency and extensive wear of the pump. Clogging

reduces the capacity of the pump and

risks blocking the pump, resulting in

downtime for maintenance and ultimately a shorter lifetime expectency.

Avoid costly maintenance

Manually cleaning the pump is time

consuming, as maintenance staff must

travel to the site to lift, clean and

reinstall the pump; a process that often

needs special equipment.

With Deragging, Danfoss has added an

innovative pump cleaning and protection feature to the VLT® AQUA Drive,

which ensures the preservation of the

maximum pump capacity by minimizing deposits on the impeller. At the

same time the Deragging feature can

be optimized for the system by

configuring the delay times, the speed

and the energy monitoring system.

Proactive Deragging

With Deragging the pump cleaning can

be done proactively. During the

commissioning process, it can be

specified when the system is to

respond: At start and/or stop, at a

certain time, via digital input, via serial

communications or by using the Smart

Logic Controller.

For easy programming, all parameters

are arranged in one group.

The intelligent feature is flexible and

can be adapted to the individual

requirements of each application.

Reduce

maintenance costs

with regular deragging; a unique

feature that increases

pump lifetime and

eciency.

The deragging feature of the VLT® AQUA Drive provides effective protection and maximum uptime.

Clogging is a common problem, especially in wastewater pumps.

www.vlt-drives.danfoss.com

Page 2

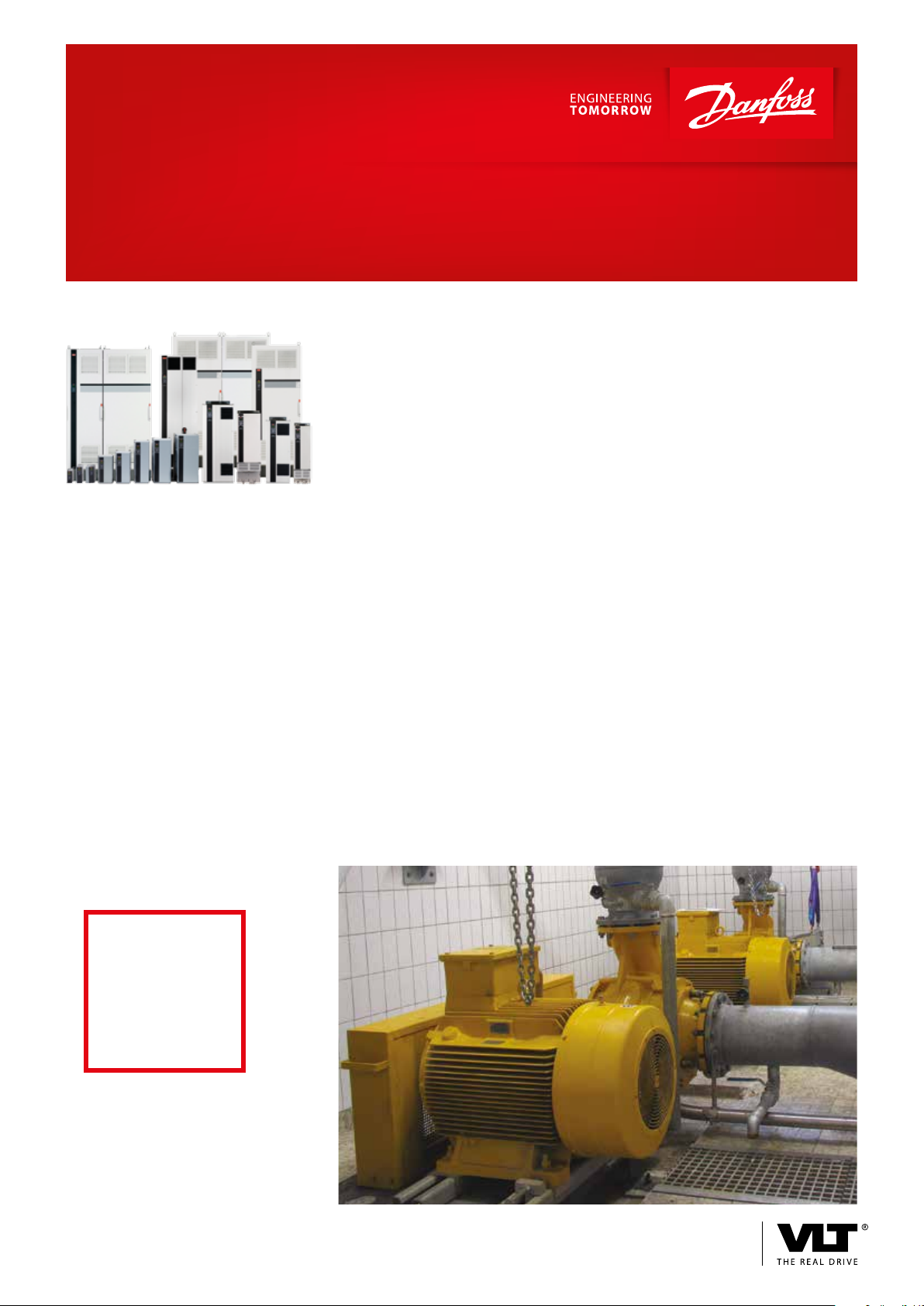

Intelligent Energy Monitoring

Power [kW/HP]

Power

high speed

Par. 29-30

Par. 29-31

Deragging activated

Power

low speed

Par. 29-26

Par. 29-27

Calculated power and

Power factor (read out)

Par. 29-20, Par. 29-21

Derag power factor

Par. 29-22

Reactive Deragging

During operation, an energy monitoring system initiates a cleaning cycle

when pumping consumes more

energy, as it normally should do. At

this stage, the pump already starts to

with getting clogged - what proactive

deragging can prevent.

With the Danfoss VLT® AQUA Drive,

proactive and reactive deragging can

be combined. Therefore, we recommend to program the proactive Deragging, and the reactive deragging to be

carried out automatically between the

proactive deragging as needed.

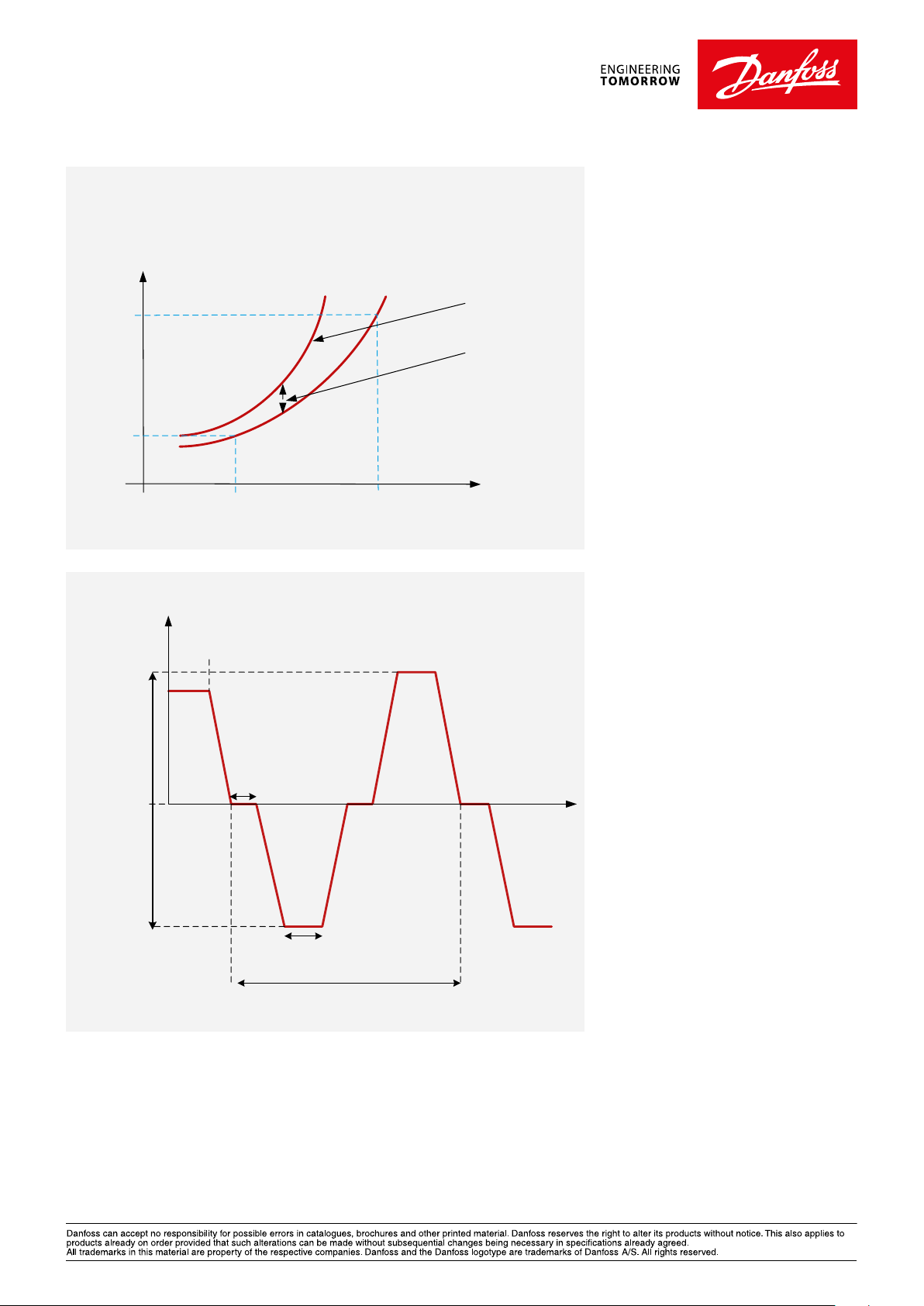

Deragging Cycle

Speed

+/- Deragspeed:

Par.: 29-13

Par.: 29-14

0 Hz/RPM

Low Speed

Par. 29-24, Par. 29-25

Derag

function

activated

Derag O Delay:

Par. 29-15

High Speed

Par. 29-28, Par. 29-29

Speed [Hz/RPM]

The Cleaning Pattern

The new deragging feature of the

VLT® AQUA Drive cleans the impeller

by cyclic operation of the pump in

both directions. The user can specify

how often, how fast and how long the

impeller rotates. The graphical display

of the frequency indicates the status of

the deragging mode.

Please note that not every type of

pump can operate in the opposite

direction. Operators should always

consult the pump manufacturer before

using this function.

Time

Deragging Run Time: Par. 29-12

Number of cycles: Par. 29-10

Danfoss Drives, Ulsnaes 1, DK-6300 Graasten, Denmark, Tel. +45 74 88 22 22, Fax +45 74 65 25 80, www.vlt-drives.danfoss.com, E-mail: info@danfoss.com

DKDD.PFF.200.A2.02 © Copyright Danfoss Drives | 2015.10

1 Cycle

Loading...

Loading...