Page 1

At the end of this document you will find links to products related to this catalog. You can go directly to our shop by

clicking HERE. HERE

Page 2

MAKING MODERN LIVING POSSIBLE

Operating Instructions

VLT® Active Filter AAF006

www.danfoss.com/drives

Page 3

Page 4

Contents

1 Introduction

4

1.1 Purpose of the Manual

4

1.2 Additional Resources

4

1.3 Product Overview

4

1.3.1 Working Principle 4

1.3.2 IEEE519 Compliance 5

1.4 Ordering Information

6

1.4.1 Filter Configurator 6

1.4.2 Ordering Form Type Code 6

2 Safety

7

2.1 Safety Symbols

7

2.2 Qualified Personnel

7

2.3 Safety Precautions

7

3 Mechanical Installation

8

3.1 Pre-installation

8

3.1.1 Planning the Installation Site 8

3.1.2 Receiving the Active Filter 8

3.1.3 Transportation and Unpacking 8

3.1.4 Lifting 8

3.1.5 Mechanical Dimensions 9

3.2 Mechanical Installation

11

3.2.1 Tools Needed 11

3.2.2 Clearance Requirements 11

3.2.3 Power Terminal Locations 12

3.2.4 Cooling and Airflow 13

3.2.5 Gland/Conduit Entry - IP21 (NEMA 1) and IP54 (NEMA12) 14

4 Electrical Installation

15

4.1 Safety Instructions

15

4.2 Electrical Installation

15

4.2.1 Power Connections 15

4.2.2 Grounding 16

4.2.3 EMC Interference 17

4.2.4 Extra Protection (RCD) 18

4.2.5 RFI Switch 18

4.2.6 Torque 18

4.2.7 Current Transformer (CT) 18

4.2.8 Auto CT Detection 22

Contents Operating Instructions

MG90V302 Danfoss A/S © 09/2014 All rights reserved. 1

Page 5

4.2.9 Summation Transformers 23

4.2.10 Operating with Capacitor Banks 24

4.2.11 Fuses 26

4.2.12 Mains Disconnectors 26

4.2.13 Control and CT Cable Routing 26

4.2.14 Control Wire Installation 26

4.2.15 Unscreened Control Wires 27

4.2.16 Electrical Installation, Control Cables 28

4.3 Installation Checklist

29

5 User Interface

30

5.1 Local Control Panel Operation

30

5.1.1 Modes of Operation 30

5.1.2 How to Operate Graphical LCP (GLCP) 30

5.1.3 Changing Data 33

5.1.4 Changing a Text Value 33

5.1.5 Changing a Group of Numeric Data Values 33

5.1.6 Changing of Data Value, Step-by-Step 33

5.1.7 Readout and Programming of Indexed Parameters 33

5.1.8 Quick Transfer of Parameter Settings with the LCP 34

5.1.9 Initialisation to Default Settings 34

5.1.10 RS485 Bus Connection 35

5.1.11 Connection to a PC 35

6 Applications and Basic Programming

36

6.1 Paralleling of Active Filters

36

6.2 Programming

38

6.3 Description of Parameters

41

6.4 0-** Operation/Display

41

6.5 5-** Digital I/O Mode

46

6.6 8-** General Settings

48

6.7 14-2* Trip Reset

50

6.8 15-** Drive Information

52

6.9 16-** Data Readouts

56

6.10 300-** AF Settings

58

6.11 301-** AF Readouts

61

6.12 Parameter Lists

62

6.12.1 Default Settings 62

6.12.2 0-** Operation/Display 63

6.12.3 5-** Digital In/Out 64

6.12.4 8-** Comm. and Options 64

Contents Operating Instructions

2 Danfoss A/S © 09/2014 All rights reserved. MG90V302

Page 6

6.12.5 14-** Special Functions 65

6.12.6 15-** FC Information 65

6.12.7 16-** Data Readouts 67

6.12.8 300-** AF Settings 68

6.12.9 301-** AF Readouts 68

7 RS485 Installation and Set-up

69

7.1 Installation and Set-up

69

7.2 Network Configuration

70

7.3 FC Protocol Message Framing Structure

70

7.3.12 Conversion 73

7.4 How to Access Parameters in Modbus RTU

74

8 Maintenance, Diagnostics and Troubleshooting

75

8.1 Maintenance and Service

75

8.2 Warning and Alarm Types

75

8.3 Active Filter Warning and Alarm Definitions

76

9 Specifications

81

9.1 Power Rating

81

9.2 Derating for Altitude and Ambient Temperature

84

9.3 Acoustic Noise

84

10 Appendix

85

10.1 Abbreviations and Conventions

85

Index

86

Contents Operating Instructions

MG90V302 Danfoss A/S © 09/2014 All rights reserved. 3

Page 7

1 Introduction

1.1 Purpose of the Manual

These operating instructions provide information for safe

installation and commissioning of the filter.

The operating instructions are intended for use by

qualified personnel.

Read and follow the operating instructions to use the filter

properly, and pay particular attention to the safety

instructions and general warnings. Keep these operating

instructions available with the filter at all times.

VLT® is a registered trademark.

1.2 Additional Resources

Resources available to understand advanced active filter

functions and programming:

•

The VLT® Advanced Active Filter Service Manual

provides information on troubleshooting and

testing for field service technicians, as well as

disassembly and assembly instructions.

1.3

Product Overview

1.3.1 Working Principle

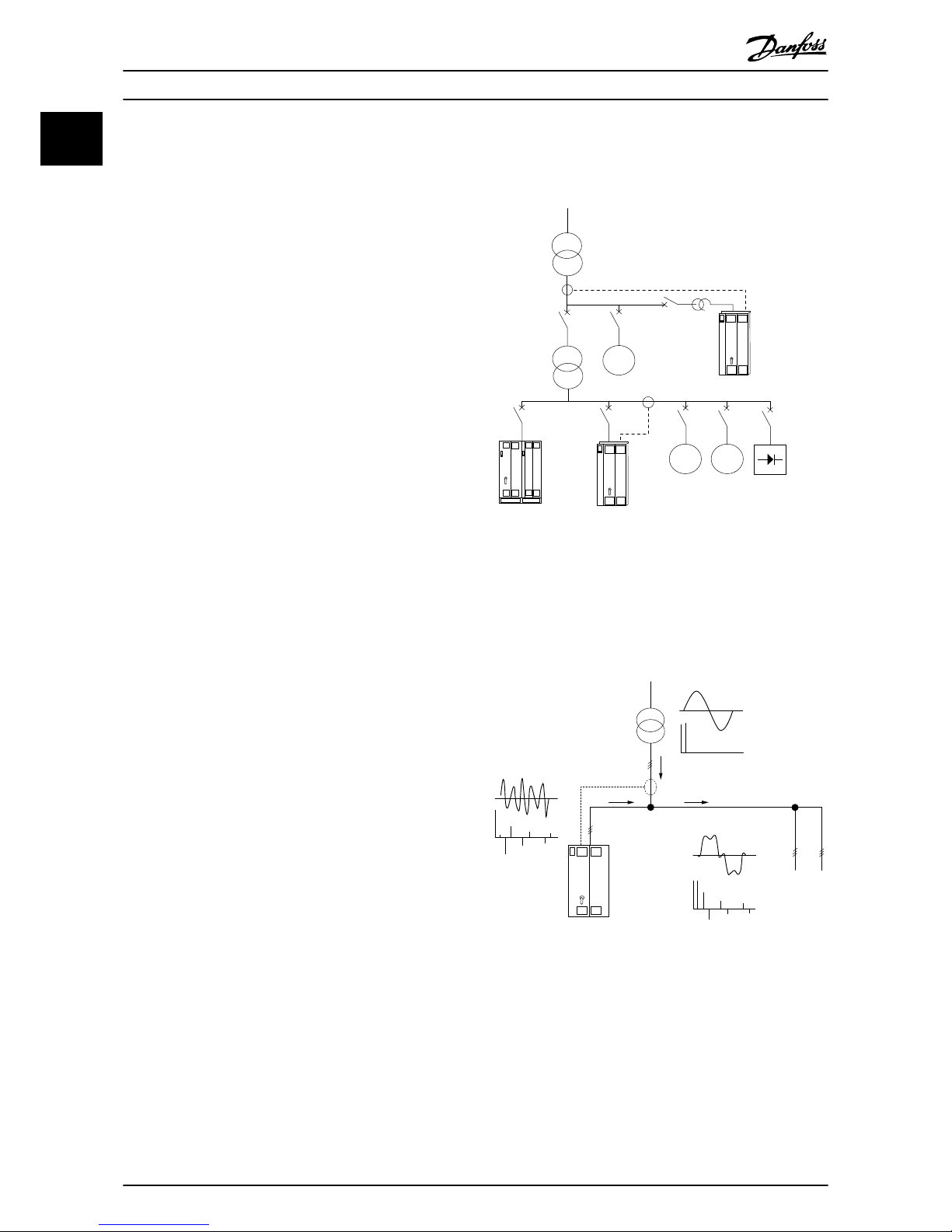

The VLT® Advanced Active Filter is used for harmonic

current mitigation and reactive current compensation. The

unit can integrate with various systems and applications as

a centrally installed filter or be combined with a VLT

®

frequency converter as a packaged low harmonic drive

solution.

M

M M

130BB717.10

Illustration 1.1 Multiple Working Environments

The active shunt filter monitors all 3-phase line currents

and processes the measured current signal via a digital

signal processor system. The filter then compensates by

actively imposing signals in counter phase to the

unwanted elements of the current (harmonic distortion).

130BB718.10

Illustration 1.2 Active Filter Principles

The filter sets different IGBT switches in real time feeding a

DC voltage into the grid, which creates counter phase

signals. A built-in LCL filter smooths the compensated

current waveform, ensuring that the IGBT switching

frequency and DC component is not imposed to the grid.

The filter operates on generator or transformer supply and

can reduce individual motor loads, non-linear loads, or

Introduction

Operating Instructions

4 Danfoss A/S © 09/2014 All rights reserved. MG90V302

1

Page 8

mixed loads. Non-linear loads (diode feed loads) must hold

AC coils to protect against overcurrent of the input diodes.

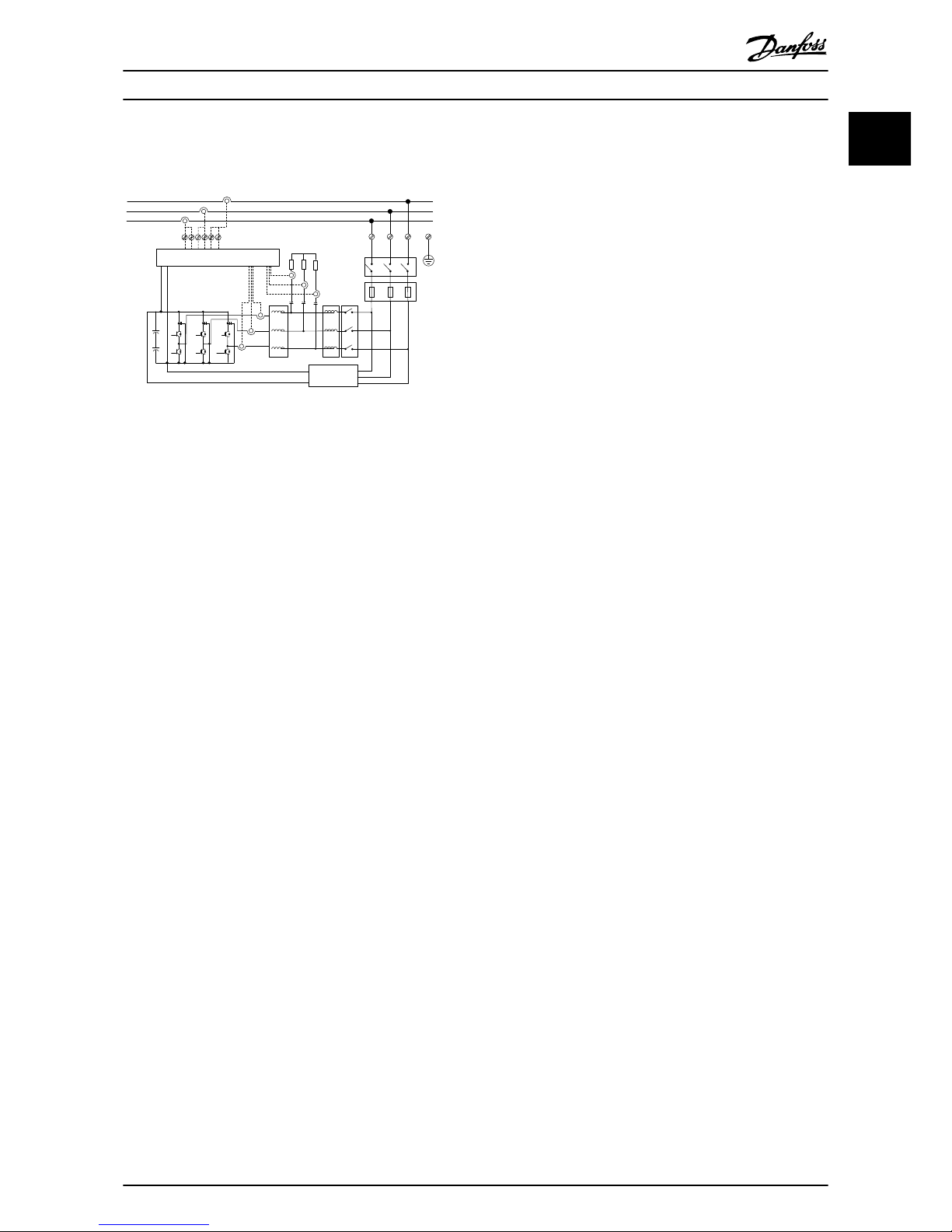

Control

Manual

Disconnect

Fuse

Option

Soft charge

circuit

130BB719.10

Illustration 1.3 Block Diagram

The filter allows either overall or selective harmonic

compensation modes. In overall compensation mode, all

harmonics are reduced. In this mode, the filter balances

the load to reduce uneven load distribution among the 3

phases. The steady state performance allows compensation

of harmonics to the 40th order, but the ultra-quick current

injection allows the filter to compensate flicker and other

quick and short-term phenomena. In selective mode, the

user can program acceptable individual harmonic levels

between 5th and 25th order. In selective mode, the filter

does not reduce harmonics in twos and threes, and does

not support phase load balancing and flicker reduction.

See parameter 300-00 Harmonic Cancellation Mode.

Program the filter priority as either reactive current or

harmonic compensation. If harmonic compensation is first

priority, the filter uses the current needed for harmonic

reduction and uses energy for reactive current correction

only if there is excess. The filter automatically and continuously assigns energy between first and second priority to

provide the highest possible mitigation of both reactive

and harmonic compensation. The power factor is

optimised continuously and the supply transformer is used

to its maximum capacity. See parameter 300-01 Compen-

sation Priority.

The active filter has an optional RFI filter for Class A1 equal

to category C2.

1.3.2

IEEE519 Compliance

The active filter is designed to meet IEEE519 recommendation for Isc/Il >20 for even individual harmonic levels.

The filter has a progressive switching frequency that

creates a wide frequency spread, giving lower individual

harmonic levels above the 50th harmonic level.

Introduction

Operating Instructions

MG90V302 Danfoss A/S © 09/2014 All rights reserved. 5

1

1

Page 9

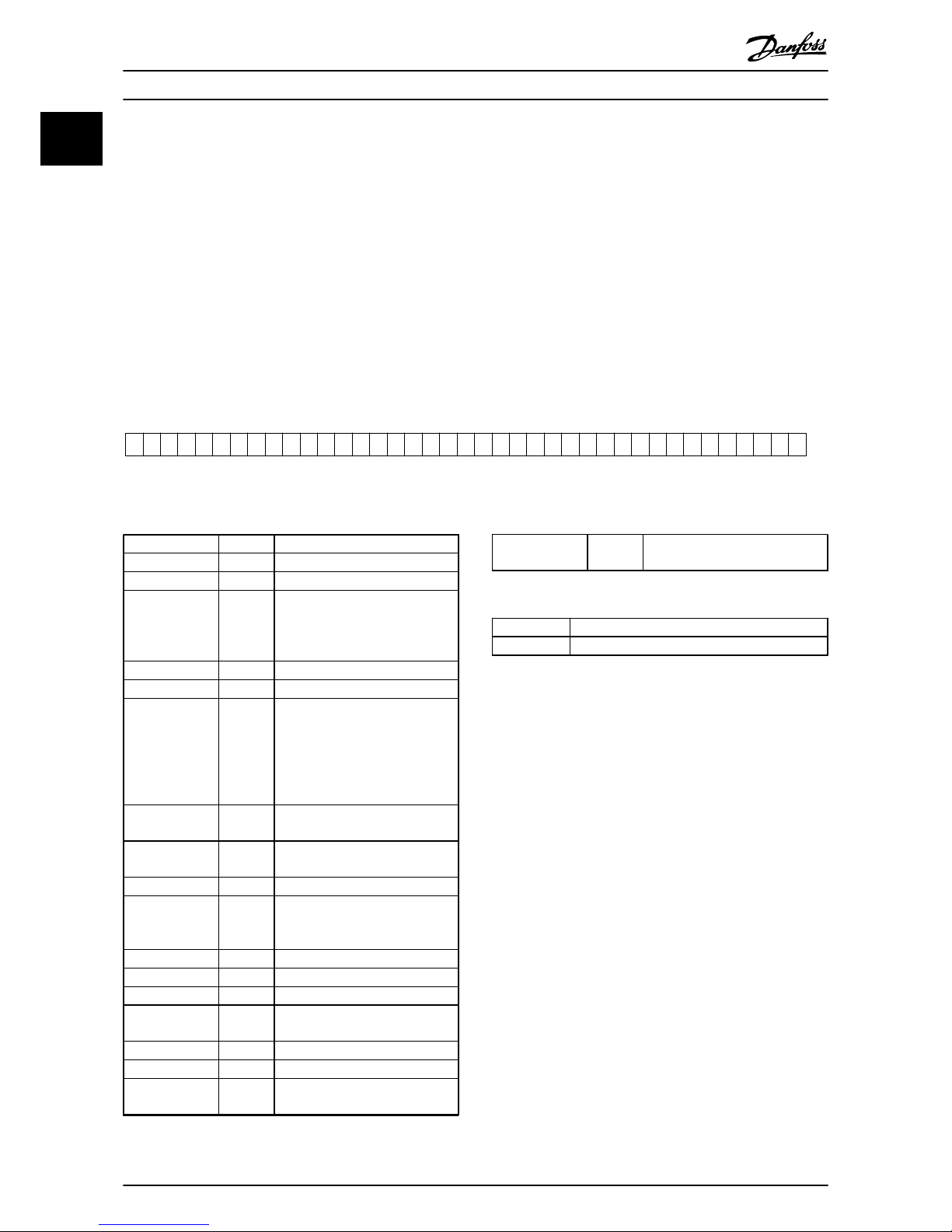

1.4 Ordering Information

1.4.1 Filter Configurator

Use the ordering number system to design an active filter according to the application requirements. For the VLT® Active

Filter AAF 006 Series, it is possible to order standard filters and filters with integral options by sending a type code string

describing the product to the local Danfoss sales office. For example: AAF006A190T4E21HXXGCXXXSXXXXAXBXCFXXXDX

This section describes each character in the type code. In the example, a standard 190 A active filter in an enclosure with

IP21 protection rating is selected for a 380–480 V net. The internet-based configurator configures the right filter for the right

application and generates a type code string. The configurator automatically generates an 8-digit sales number to be

delivered to the local sales office. It is also possible to establish a project list with several products and send it to a Danfoss

sales representative. The configurator can be found at www.danfoss.com/BusinessAreas/DrivesSolutions/.

1.4.2 Ordering Form Type Code

130BB504.10

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39

A FA x0 0 A T 4 E H x G C x x x x x x x B x C x x x x xDAS

Illustration 1.4 Type Code Example

Possible choice

Product groups 1-3 AAF

Series 4-6 006

Current rating 7-10 A190: 190 A

A250: 250 A

A310: 310 A

A400: 400 A

Phases 11 T: 3 Phases

Mains Voltage 12 4: 380–480 V AC

Enclosure 13-15 E21: IP21/Nema Type1

E54: IP54/Nema Type 12

E2M: IP21/Nema Type 1 with

mains shield

E5M: IP54/Nema Type 12 with

mains shield

RFI filter 16-17 HX: No RFI filter

H4: RFI filter, Class A1 (optional)

Display (LCP) 19 G: Graphical Local Control Panel

(LCP)

Coating PCB 20 C: Coated PCB

Mains option 21 X: No mains option

3: Mains disconnect and fuse

7: Fuse

Adaptation A 22 Reserved

Adaptation B 23 Reserved

Software release 24-27 Reserved

Software

language

28 Reserved

A options 29-30 AX: No A option

B options 31-32 BX: No B option

C-option configuration

33-37 CFxxx: CO-option occupied with

active filter control card

D options 38-39 DO: 24 V back-up

DX: No options

Table 1.1 Type Code Definitions

176F3535 Backwall cooling kit for D14 (IP54)

176F3537 Backwall cooling kit for E1 (IP54)

Table 1.2 Optional Kits

Introduction

Operating Instructions

6 Danfoss A/S © 09/2014 All rights reserved. MG90V302

1

Page 10

2 Safety

2.1 Safety Symbols

The following symbols are used in this document:

WARNING

Indicates a potentially hazardous situation that could

result in death or serious injury.

CAUTION

Indicates a potentially hazardous situation that could

result in minor or moderate injury. It can also be used to

alert against unsafe practices.

NOTICE

Indicates important information, including situations that

can result in damage to equipment or property.

2.2 Qualified Personnel

Correct and reliable transport, storage, installation,

operation and maintenance are required for the troublefree and safe operation of the active filter. Only qualified

personnel are allowed to install or operate this equipment.

Qualified personnel is defined as trained staff, who are

authorised to install, commission, and maintain equipment,

systems and circuits in accordance with pertinent laws and

regulations. Additionally, the personnel must be familiar

with the instructions and safety measures described in this

document.

2.3

Safety Precautions

WARNING

HIGH VOLTAGE

Active filters contain high voltage when connected to AC

mains input. Failure to perform installation, start-up, and

maintenance by qualified personnel can result in death

or serious injury.

WARNING

DISCHARGE TIME

The active filter contains DC-link capacitors, which can

remain charged even when the filter is not powered.

Failure to wait the specified time after power has been

removed before performing service or repair work can

result in death or serious injury.

Voltage

[V]

Output Current

[A]

Minimum waiting

time

(minutes)

380–480 190–400 20

High voltage can be present even when the warning indicator

lights are off.

Table 2.1 Discharge Time

WARNING

LEAKAGE CURRENT HAZARD

Leakage currents exceed 3.5 mA. Failure to ground the

filter properly can result in death or serious injury.

•

Ensure correct grounding of the equipment by

a certified electrical installer.

WARNING

EQUIPMENT HAZARD

Contact with rotating shafts and electrical equipment

can result in death or serious injury.

•

Ensure that only trained and qualified

personnel perform installation, start up, and

maintenance.

•

Ensure that electrical work conforms to national

and local electrical codes.

•

Follow the procedures in this document.

CAUTION

INTERNAL FAILURE HAZARD

An internal failure in the filter can result in serious injury

when the filter is not properly closed.

•

Before applying power, ensure all safety covers

are in place and securely fastened.

Safety Operating Instructions

MG90V302 Danfoss A/S © 09/2014 All rights reserved. 7

2 2

Page 11

3 Mechanical Installation

3.1 Pre-installation

3.1.1 Planning the Installation Site

NOTICE

Due to the size and clearance requirements of the active

filter, it is important to pre-plan installation. Failure to

do so may result in additional work during and after

installation.

Select the best possible operation site by considering

the following:

•

Ambient temperature conditions.

•

Altitude at installation point.

•

Installation and compensation method.

•

Cooling.

•

Position of the active filter.

•

CT installation point and possibility to reuse

existing CTs.

•

Cable routing and EMI conditions.

•

Ensure the power source supplies the correct

voltage and frequency.

•

If the unit is without built-in fuses, ensure that

the external fuses are rated correctly.

3.1.2

Receiving the Active Filter

When receiving the unit, ensure that the packaging is

intact, and note any damage that may have occurred

during transport. In case of damage, immediately contact

the shipping company to claim the damage.

NOTICE

Damaged packaging can indicate rough transportation

which may have caused interior failures in the unit.

Claim damages even if the exterior of the unit seems

intact.

3.1.3 Transportation and Unpacking

Place the active filter as close as possible to its final installation site before unpacking it. Keep the filter on the pallet

and boxed as long as possible to avoid damage.

3.1.4

Lifting

Always lift the unit in the dedicated lifting eyes. Use a bar

to avoid bending the lifting holes.

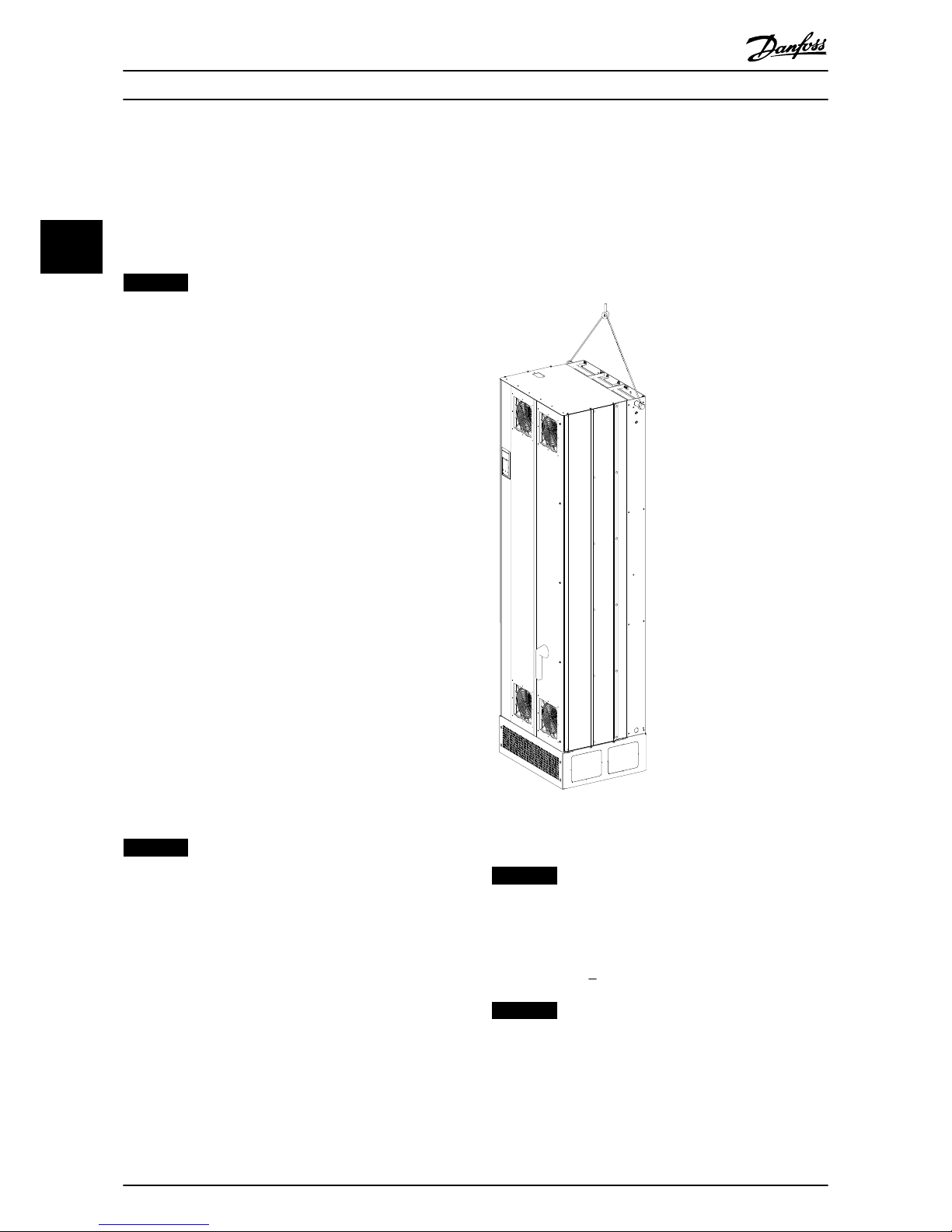

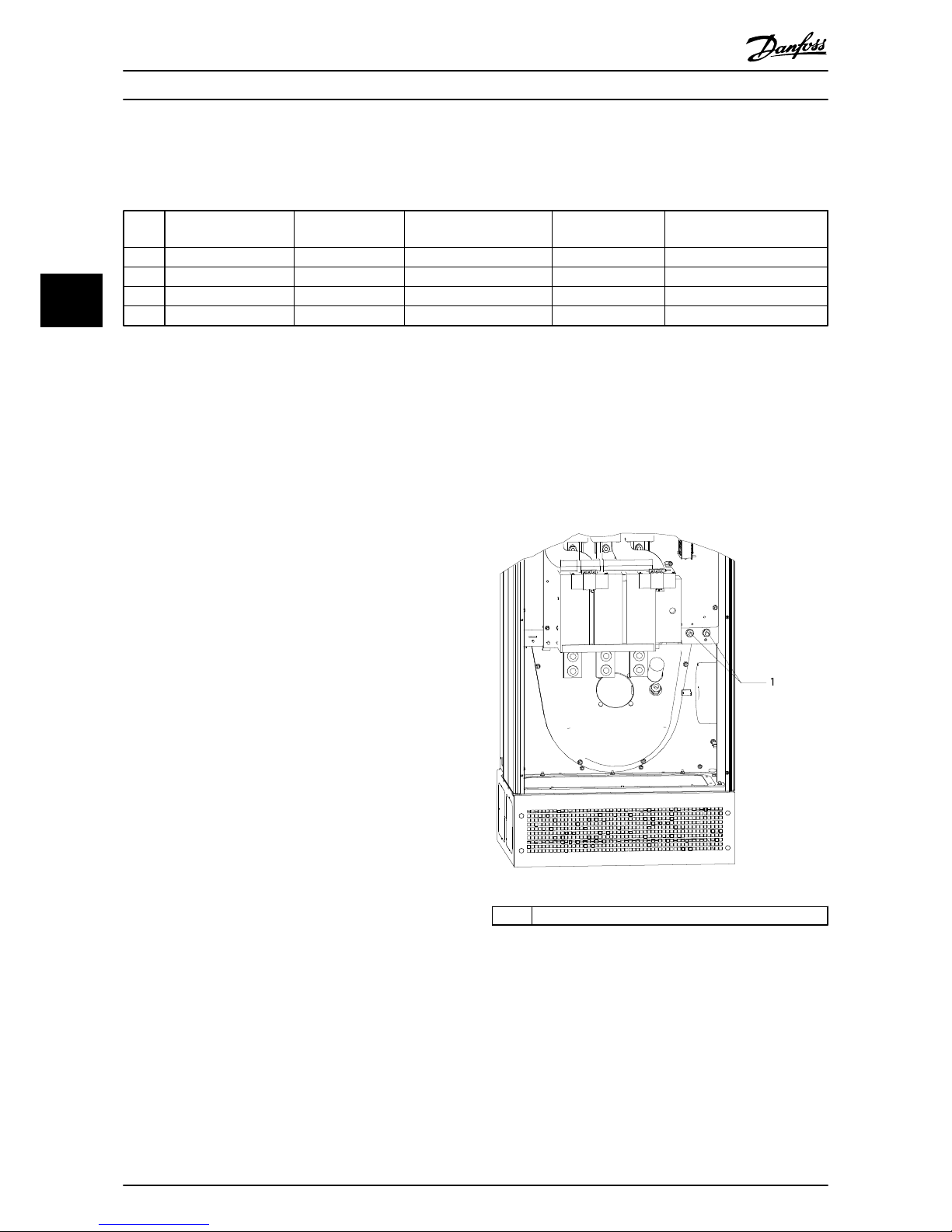

130BB642.10

Illustration 3.1 Recommended Lifting Method for AAF 006,

Enclosure Sizes D14 and E1

NOTICE

The lifting bar must be able to handle the weight of the

unit. See chapter 3.1.5 Mechanical Dimensions for

weights. Maximum diameter for the bar is 25 mm (1

inch). The angle from the top of the unit to the lifting

cable should be > 60°.

NOTICE

The plinth is required to allow airflow to the unit to

provide proper cooling.

Mechanical Installation Operating Instructions

8 Danfoss A/S © 09/2014 All rights reserved. MG90V302

33

Page 12

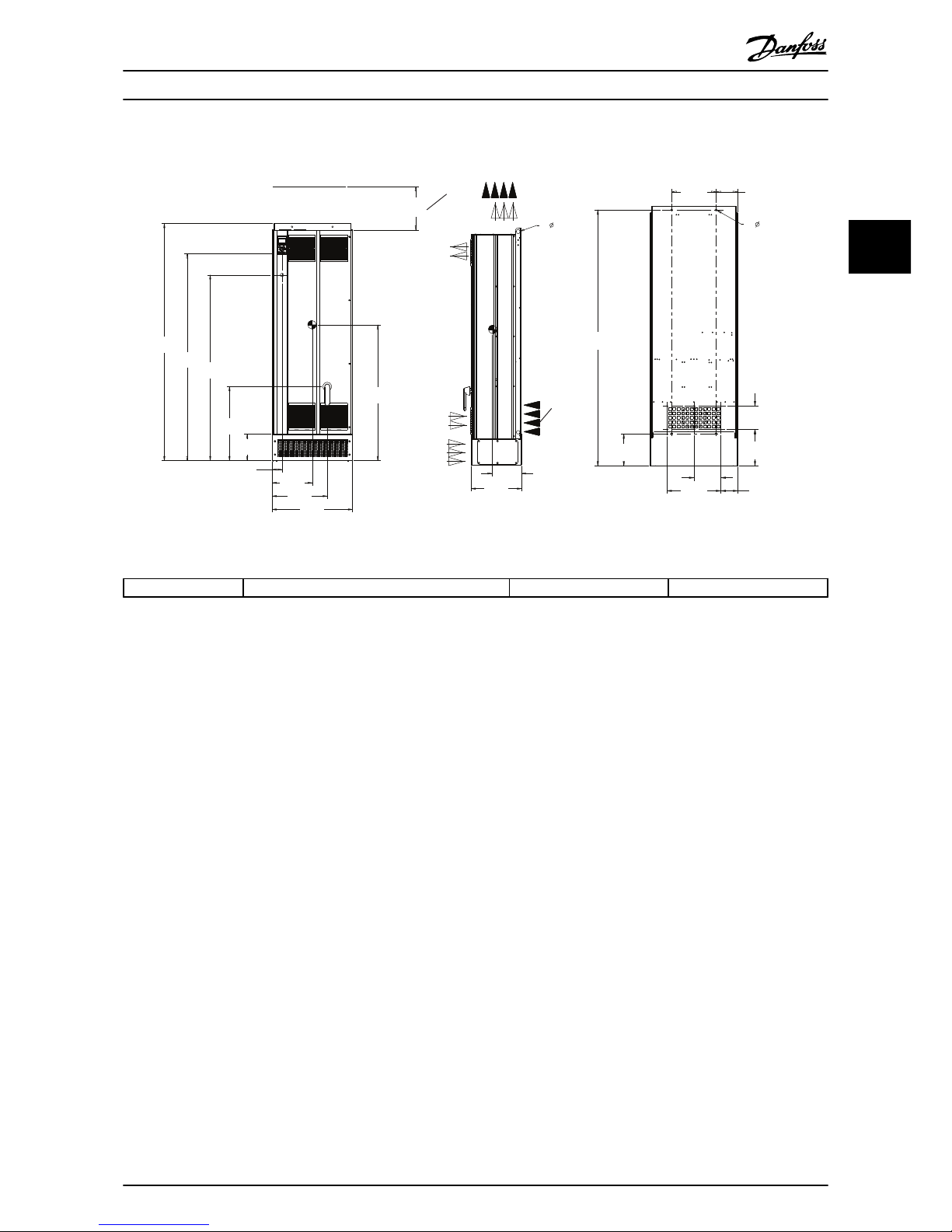

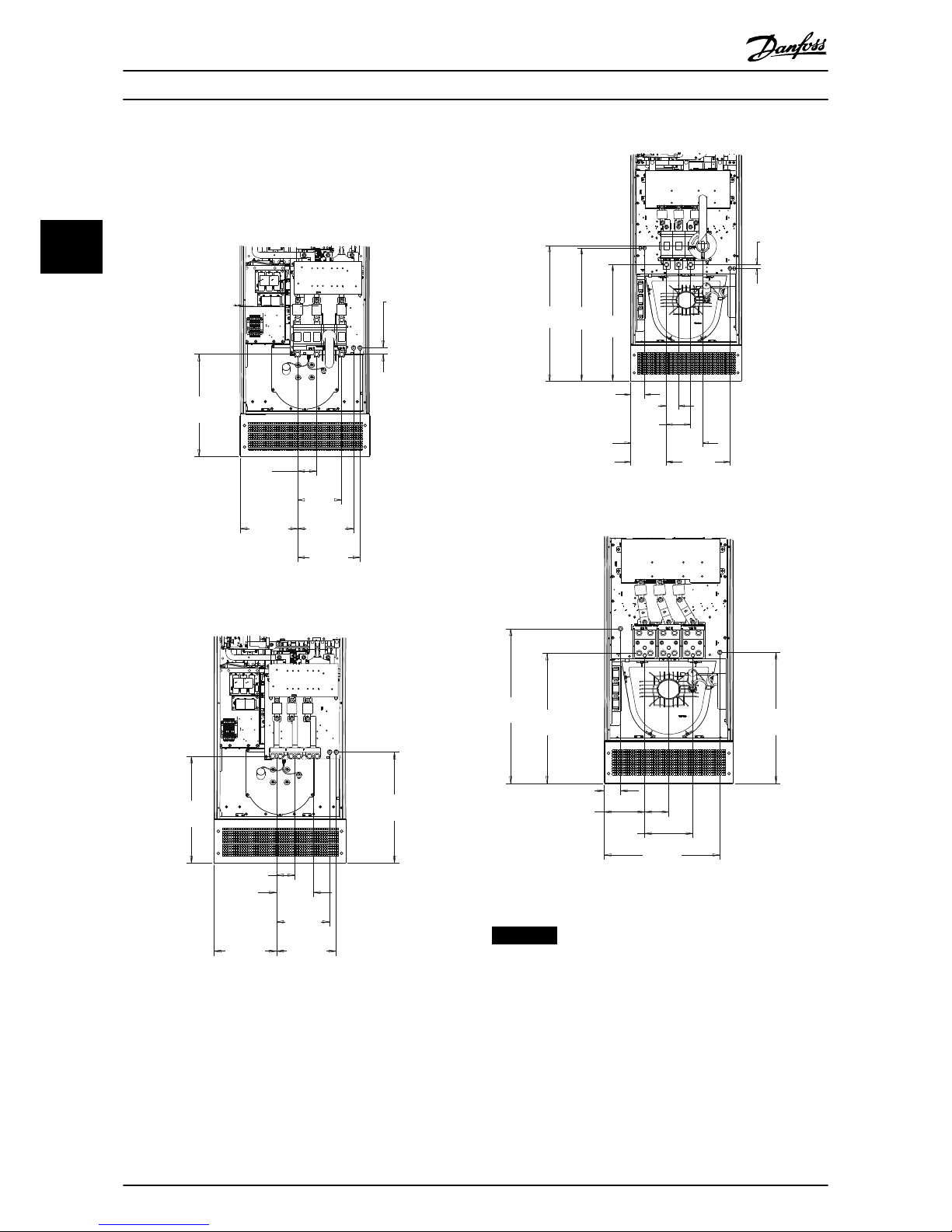

3.1.5 Mechanical Dimensions

1020.1

[40.2]

199.5

[7.9]

1394.0

[54.9]

1552.8

[61.1]

603.8

[23.8]

555.9

[21.9]

377.8

[14.9]

2X

27.0

[1.1]

414.1

[16.3]

74.1

[2.9]

[8.9]

1780.5

[70.1]

221.6

[8.7]

273.2

[10.8]

130BC632.10

117.4

[4.6]

184.5

[7.3]

369.0

[14.5]

148.0

[5.8]

304.0

[12.0]

1755.5

[69.1]

251.0

[9.9]

160.0

[6.3]

2X

13.0

[.5]

221.0

[8.7]

[225.0]

1

2

Illustration 3.2 AAF006 190 A, Enclosure Size D13

1 Minimum clearance from the ceiling 2 Backwall cooling option

Table 3.1 Legend to Illustration 3.2 and Illustration 3.3

Mechanical Installation Operating Instructions

MG90V302 Danfoss A/S © 09/2014 All rights reserved. 9

3 3

Page 13

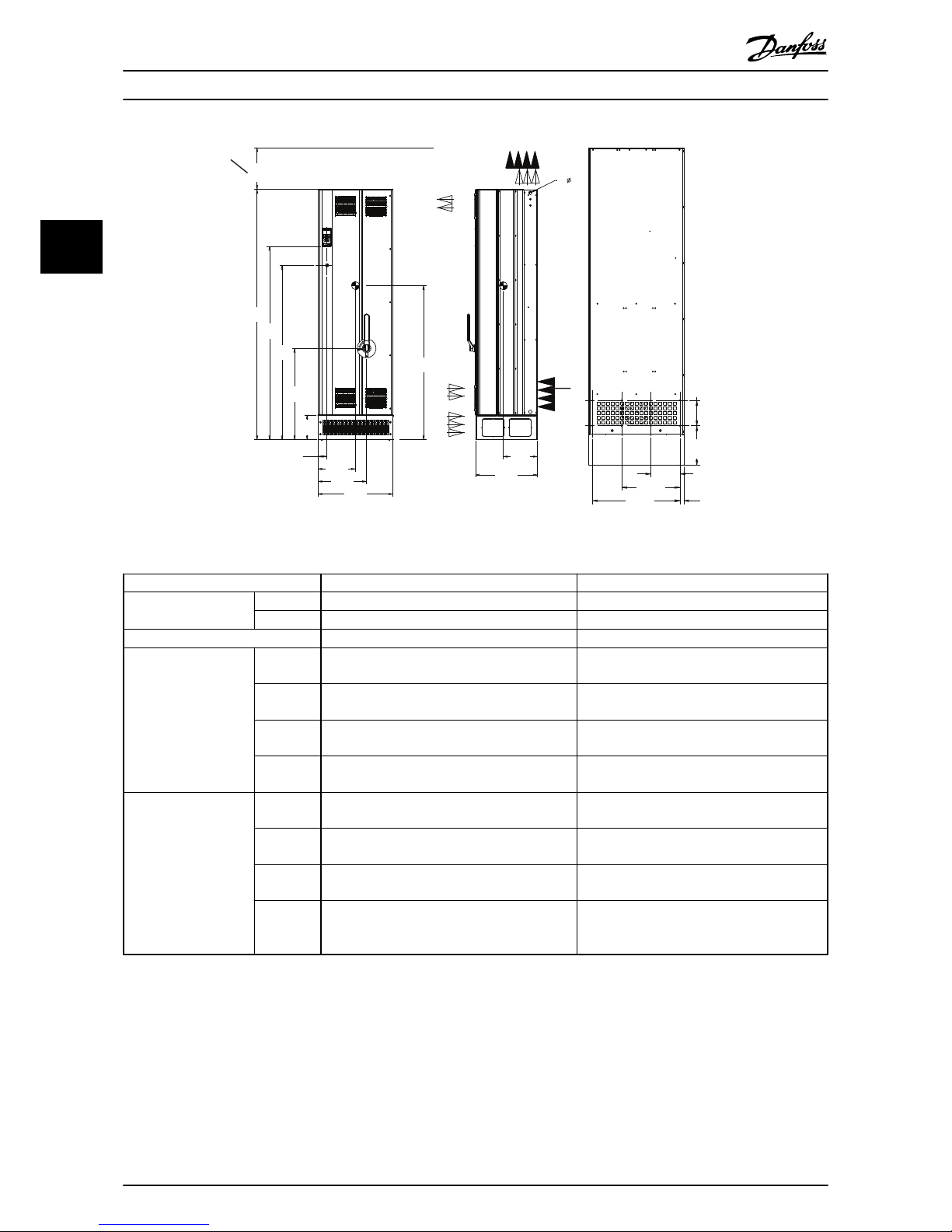

600.0

[23.6]

493.5

[19.4]

1230.0

[48.4]

2X

27.0

[1.1]

72.2

[2.8]

389.0

[15.3]

[8.9]

283.3

[11.2]

270.9

[11]

198.2

[7.8]

730.7

[28.8]

1394.1

[54.9]

1544.5

[60.8]

2001.0

[78.8]

184.5

[7.3]

369.0

[14.5]

553.5

[21.8]

23.3

[.9]

249.1

[9.8]

160.0

[6.3]

130BC633.10

225.0

1

2

Illustration 3.3 AAF006 250-400 A, Enclosure Size E1

Enclosure D14 E1

Enclosure protection

IP 21/54 21/54

NEMA Type 1/12 Type 1/12

Nominal current rate

190 A 250 A, 310 A, 400 A

Shipping dimensions Height

(mm/in.)

750/29.5 864/34

Width

(mm/in.)

737/29 737/29

Depth

(mm/in.)

1943/76.5 2203/86.7

Weight (kg/

lbs.)

283/623.9 500/1102.3

Unit dimensions Height

(mm/in.)

1780/70 2000/78.7

Width

(mm/in.)

600/23.6 600/23.6

Depth

(mm/in.)

380/14.9 494/19.4

MaximumWeight (kg/

lbs.)

238/524.7 453/998.7

Table 3.2 Mechanical Dimensions

Mechanical Installation

Operating Instructions

10 Danfoss A/S © 09/2014 All rights reserved. MG90V302

33

Page 14

3.2 Mechanical Installation

Before installing the active filter, examine the mechanical

drawings in chapter 3.1.5 Mechanical Dimensions to become

familiar with the space demands.

3.2.1 Tools Needed

To perform the mechanical installation, the following

tools are needed:

•

Drill with a 10 or 12 mm drill bit.

•

Tape measure.

•

Screw driver.

•

Wrench with 7–17 mm metric sockets.

•

Wrench extensions.

•

Sheet metal punch for conduits or cable glands.

•

Lifting bar to lift the unit (rod or tube maximum

Ø 25 mm/0.9 in., able to lift minimum 1000 kg/

2205 lbs.).

•

Crane or other lifting aid to place the unit in

position.

•

Torx T50 tool.

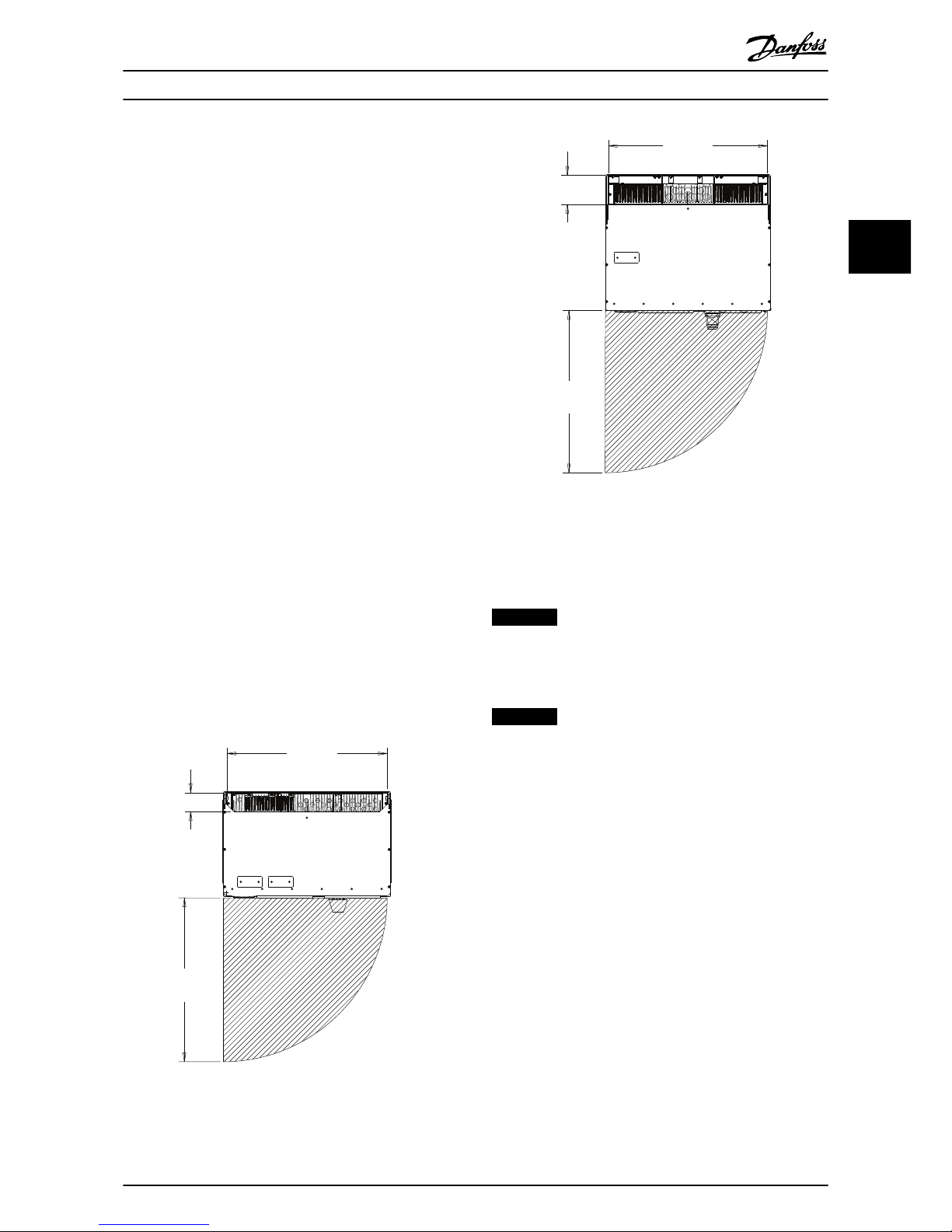

3.2.2

Clearance Requirements

Space

Ensure proper space above and below the unit to allow

airflow and cable access. In addition, ensure adequate

space in front of the unit for the door to open

(Illustration 3.4, Illustration 3.5).

67.3

[2.7]

575.9

[22.7]

574.2

[22.6]

130BC634.10

Illustration 3.4 Door Clearance IP21/IP54 Enclosure Type, Size

D14

105.7

[4.2]

577.4

[22.7]

576.7

[22.7]

130BC635.10

Illustration 3.5 Door Clearance, IP21/IP54 Enclosure Type, Size

E1

Wire access

Ensure that proper cable access including the necessary

bending allowance.

NOTICE

Power cables are heavy and difficult to bend. To make

installation easier, consider the optimum position of the

unit before delivery.

NOTICE

All cable lugs/shoes must mount within the width of the

terminal bus bar.

Mechanical Installation Operating Instructions

MG90V302 Danfoss A/S © 09/2014 All rights reserved. 11

3 3

Page 15

3.2.3 Power Terminal Locations

Consider the position of the terminals when designing for

cable access. See Illustration 3.6, Illustration 3.7,

Illustration 3.8, and Illustration 3.9

88.0

[3.5]

204.0

[8.0]

289.7

[11.4]

29.0

[1.1]

266.2

[10.5]

476.0

[18.7]

259.7

[10.2]

130BC636.10

Illustration 3.6 Terminal Location of D14 with Disconnect

284.1

[11.2]

83.7

[3.3]

167.2

[6.6]

241.9

[9.5]

271.9

[10.7]

505.0

[19.9]

486.0

[19.1]

130BC637.10

Illustration 3.7 Terminal Location of D14 without Disconnect

65.0

[2.6]

130.0

[5.1]

343.0

[13.5]

19.6

[.8]

628.7

[24.8]

194.0

[7.6]

75.0

[3.0]

719.1

[28.3]

389.0

[15.3]

730.7

[28.8]

130BC638.10

Illustration 3.8 Terminal Location of E1 with Disconnect

719.1

[28.3]

609.1

[24.0]

75.0

[3.0]

188.0

[7.4]

112.0

[4.4]

224.0

[8.8]

537.0

[21.1]

605.6

[23.8]

130BC639.10

Illustration 3.9 Terminal Location of E1 without Disconnect

NOTICE

Each terminal allows up to 4 cables with cable lugs or

use of a standard box lug. Ground is connected to the

relevant termination point in the unit.

Mechanical Installation Operating Instructions

12 Danfoss A/S © 09/2014 All rights reserved. MG90V302

33

Page 16

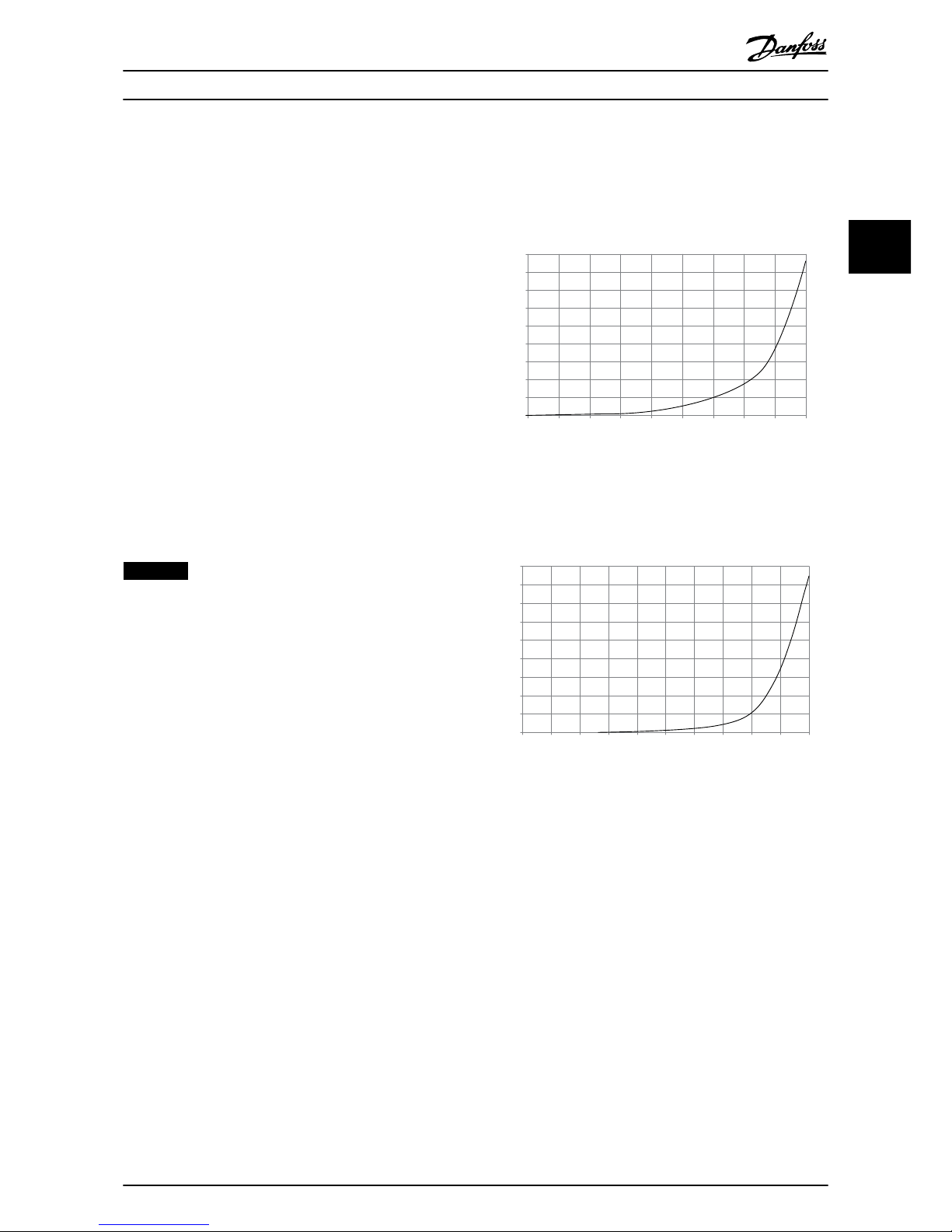

3.2.4 Cooling and Airflow

There are different ways to cool the active filter:

•

Use the cooling ducts in the top and bottom of

the unit

•

Take air into the back of the unit

•

Combine top, bottom, and back airflow

Back cooling

The active filter has a back channel cooling system where

85% of all heat is ducted via an IP54 segregated back

channel. This reduces the needed airflow inside the

enclosure and ensures less moisture and dust across vital

components.

The back channel air is normally ventilated via the plinth

inlet and ducted out the top of the enclosure. The design

of the back channel can also take air from the control

room and duct it back out again. This is supported to ease

stress on the control room air conditioner and conserve

energy. To support a backwall inlet, the unit air inlet has to

be blocked via an optional cover and the air outlet ducted

via an optional top duct.

NOTICE

The active filter fan runs for the following reasons:

•

Active filter running.

•

Specific heat sink temperature exceeded (power

size dependent).

•

Specific power card ambient temperature

exceeded (power size dependent).

•

Specific control card ambient temperature

exceeded.

Once the fan is started, it runs for a minimum of 10

minutes.

External ducts

If additional duct work is added externally to the

enclosure, the pressure drop in the ducting must be

calculated. Use Illustration 3.10 and Illustration 3.11 to

derate the unit according to the pressure drop.

90

80

70

60

50

40

30

20

10

0

0 0.5 4.9 13 27.3 45.9 66 89.3 115.7 147

(%)

(Pa)

Pressure Increase

Filter Derating

130BB932.10

Illustration 3.10 Enclosure Size D, Derating vs. Pressure

Change

Air Flow: 450 cfm (765 m3/h)

90

80

70

60

50

40

30

20

10

0

(%)

Filter Derating

0 0 0.1 3.6 9.8 21.5 43.4 76 237.5 278.9

(Pa)

Pressure Change

130BB933.10

147.1

Illustration 3.11 Enclosure Size E, Derating vs. Pressure Change

Air Flow: 725 cfm (1230 m3/h)

Mechanical Installation Operating Instructions

MG90V302 Danfoss A/S © 09/2014 All rights reserved. 13

3 3

Page 17

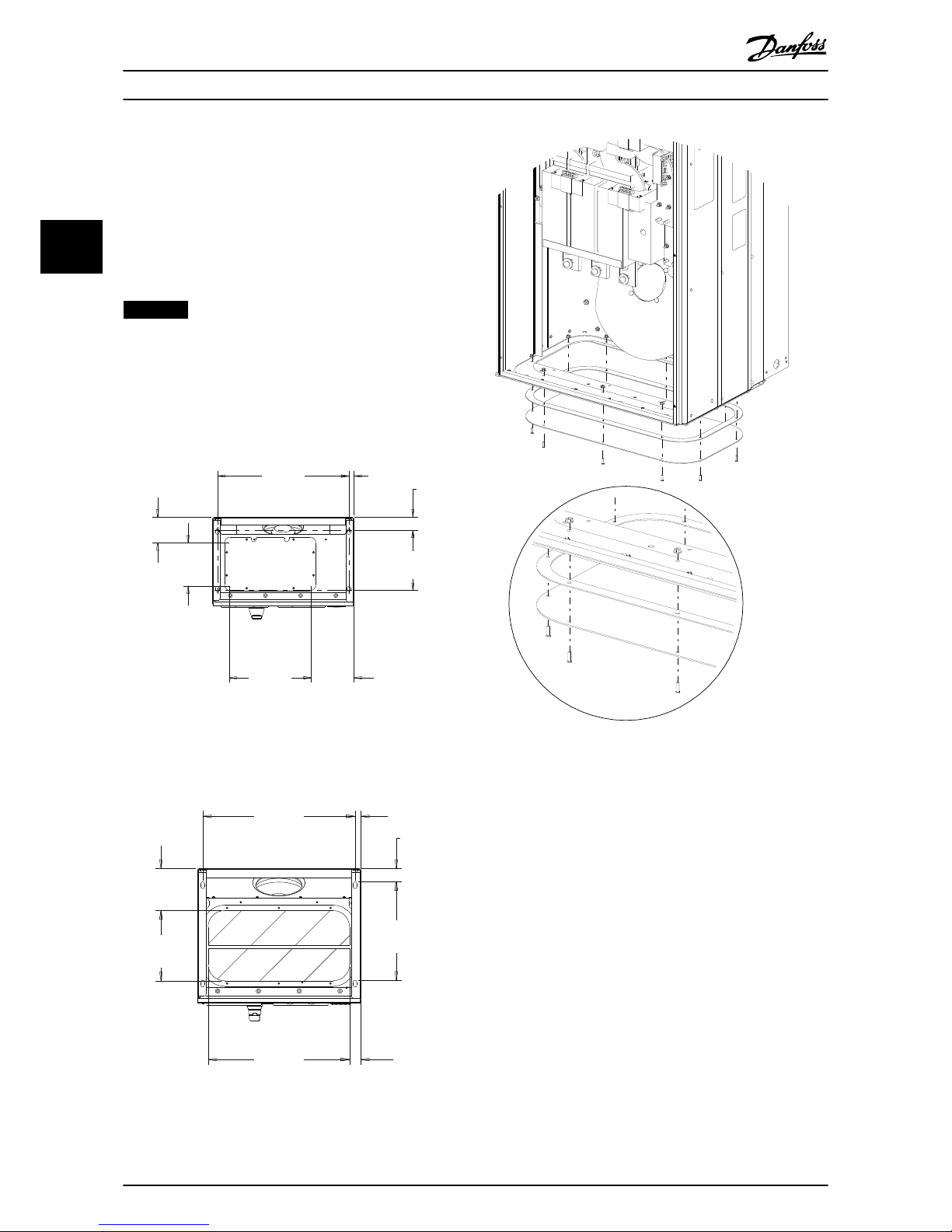

3.2.5 Gland/Conduit Entry - IP21 (NEMA 1)

and IP54 (NEMA12)

Cables are connected through the gland plate from the

bottom. Remove the plate and plan where to place the

entry for the glands or conduits. Illustration 3.12 and

Illustration 3.13 show the gland plate openings in bottom

views.

NOTICE

The gland plate ensures the specified protection degree,

and enables proper cooling of the unit. If the gland plate

is not mounted, the unit may trip on Alarm 69, Pwr. Card

Temp.

55.9

[2.2]

257.0

[10.1]

21.9

[.9]

560.0

[22.0]

110.6

[4.4]

182.8

[7.2]

181.9

[7.2]

350.0

[13.8]

130BC640.10

Illustration 3.12 Enclosure Size D14, Bottom View

361.7

[14.2]

20.0

[.8]

560.0

[22.0]

154.8

[6.1]

257.6

[10.1]

40.0

[1.6]

520.0

[20.5]

48.9

[2]

Illustration 3.13 Enclosure Size E1, Bottom View

130BB736.11

Illustration 3.14 Mounting of Base Plate, E1

The base plate of the enclosure size E can be mounted

from either inside or outside of the enclosure, allowing

flexibility in the installation process. If mounted from the

bottom, the glands and cables can be mounted before the

unit is placed on the pedestal.

Mechanical Installation Operating Instructions

14 Danfoss A/S © 09/2014 All rights reserved. MG90V302

33

Page 18

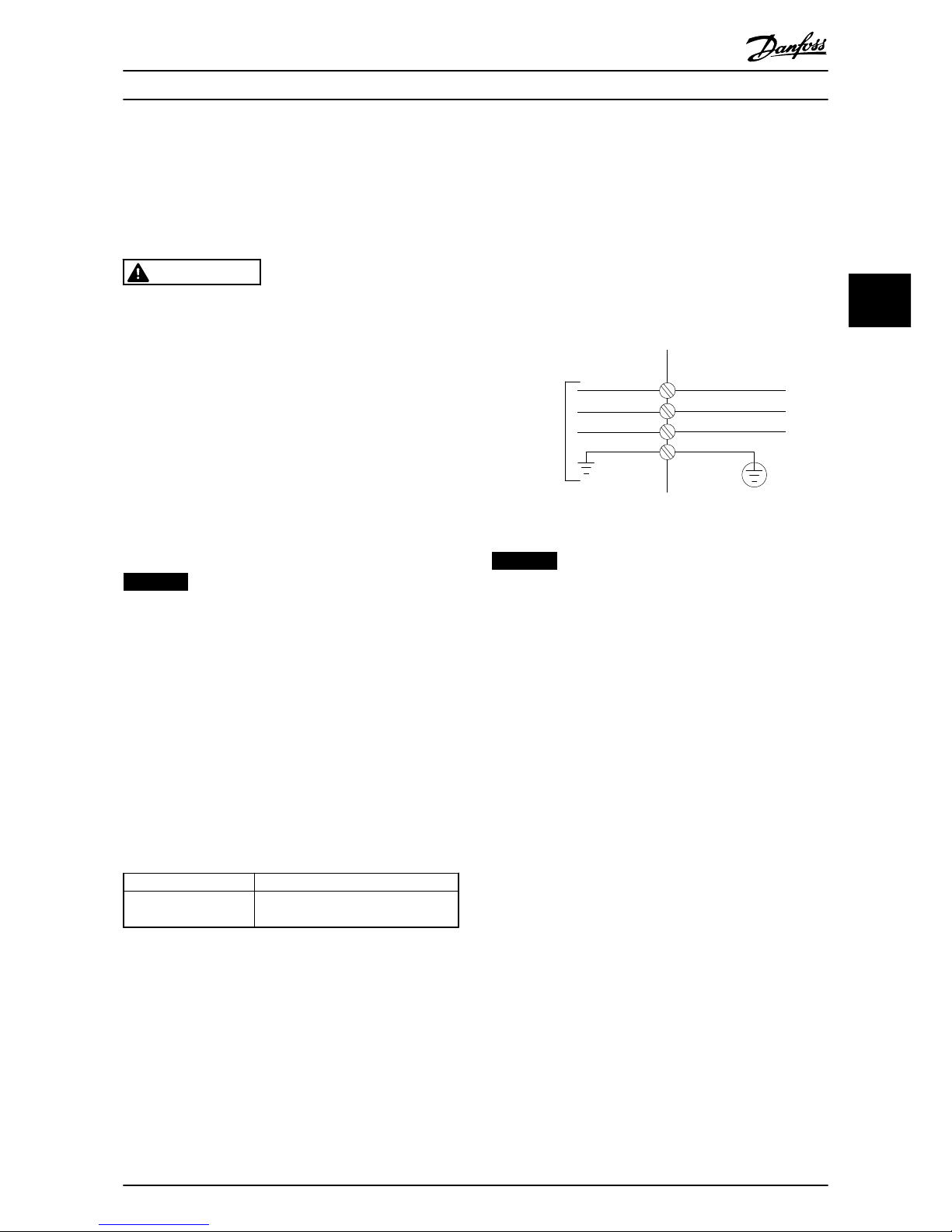

4 Electrical Installation

4.1 Safety Instructions

See chapter 2 Safety for general safety instructions.

CAUTION

SHOCK HAZARD

The active filter can cause a DC current in the PE

conductor.

•

When a residual current-operated protective

device (RCD) is used for protection against

electrical shock, only an RCD of Type B is

permitted on the supply side.

Failure to follow the recommendation means the RCD

may not provide the intended protection.

4.2 Electrical Installation

4.2.1 Power Connections

Cabling and fusing

NOTICE

All cabling must comply with national and local

regulations on cable cross-sections and ambient

temperature. UL applications require 75 °C copper

conductors. 75° and 90 °C copper conductors are

thermally acceptable for use in non-UL applications.

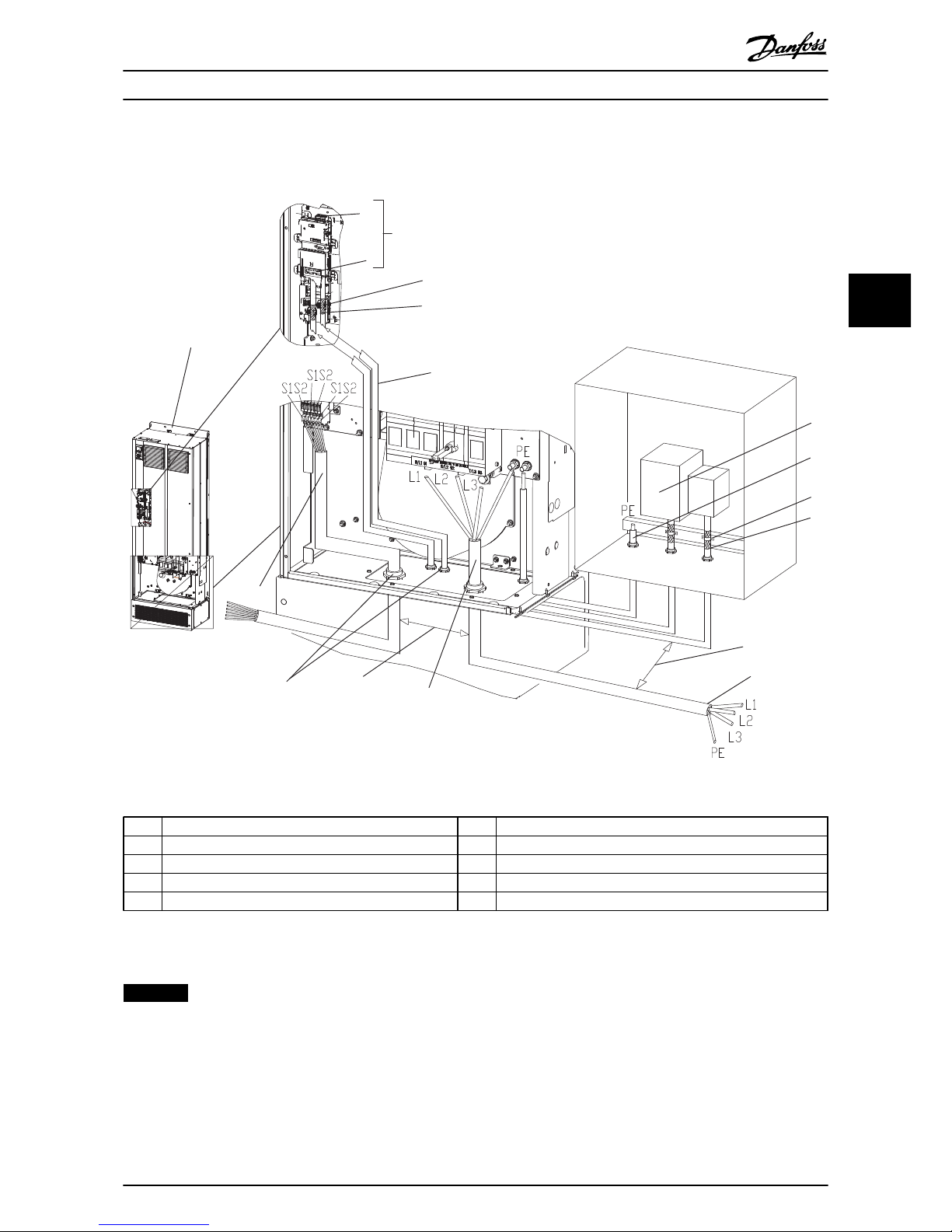

The power cable connections are situated as shown in

Illustration 4.1. The mains connection is fitted to the mains

switch if this is included. Dimension the cable cross-section

in accordance with the filter current rating, including skin

and proximity effects, derating, and local legislation.

Connect mains to terminals 91, 92 and 93. Connect ground

to the terminal on the immediate right of terminal 93.

Terminal number Function

91, 92, 93

94

Mains R/L1, S/L2, T/L3

Ground

Table 4.1 Mains and Ground Connections

The conductor predominantly carries currents of high

frequencies so the distribution of current is not evenly

dispersed throughout the cross-section of the conductor.

This is due to 2 independent effects known as skin effect

and proximity effect. Both require derating and,

consequently, the mains cable of the active filter is rated at

a higher current than the filter rating itself.

3 Phase

power

input

130BA026.10

91 (L1)

92 (L2)

93 (L3)

95 PE

Illustration 4.1 Mains Connection Diagram

NOTICE

It is insufficient to rate the power cable for the filter

current rating alone due to skin and proximity effects.

The required derating is calculated as 2 separate factors:

•

The skin factor depends on frequency of current,

cable material, and cable dimensions.

•

The proximity factor depends on the number of

conductors, diameters and distance between the

individual cables.

The proximity effect is depending on the number of

conductors, diameters and distance between the individual

cables.

The optimised mains cable is:

•

Copper wires.

•

Single conductors.

•

Bus bars.

Electrical Installation Operating Instructions

MG90V302 Danfoss A/S © 09/2014 All rights reserved. 15

4 4

Page 19

Copper affects skin less than aluminum, and bus bars have a larger surface area than cables, reducing the skin effect factor.

Proximity effects of single conductors are negligible.

The cable specifications in Table 4.2 take both skin and proximity effects into account:

Filter Minimum CU wire

mm2 (AWG)

Equivalent RMS

cable for CU

Minimum ALU wire

mm2 (AWG)

Equivalent RMS

current for ALU

Maximum wire

mm2 (AWG)

190 A

70 mm2 (2/0)

225 A

95 mm2 (3/0)

240 A

2*150 mm2 (2*300 MCM)

250 A

120 mm2 (4/0)

295 A

150 mm2 (300 MCM)

315 A

4x240 mm2 (4x500 MCM)

310 A

240 mm2 (500 MCM)

365 A

2*95 mm2 (2*3/0)

390 A

4x240 mm2 (4x500 MCM)

400 A

2*95 mm2 (2*3/0)

470 A

2*150 mm2 (2*300 MCM)

500 A

4x240 mm2 (8x900 MCM)

Table 4.2 Allowed Active Filter Mains Cable with Typical Cable Manufacturer Data

Due to the built-in LCL filter, the unit does not feed the main wire with high dU/dt signals. Doing so reduces the radiated

emission through the mains cable. Cable screen/shielding can thus be omitted allowing the mains cables to be connected

without considering EMC requirements.

The active filter can run at long cable runs. Cable length is limited by the voltage drop. It is advised to keep the cable

lengths to less then 200 m.

Active filters have either built-in or customer-supplied fuses. See chapter 4.2.11 Fuses for fuse recommendations. Always

ensure proper fusing according to local regulation.

4.2.2

Grounding

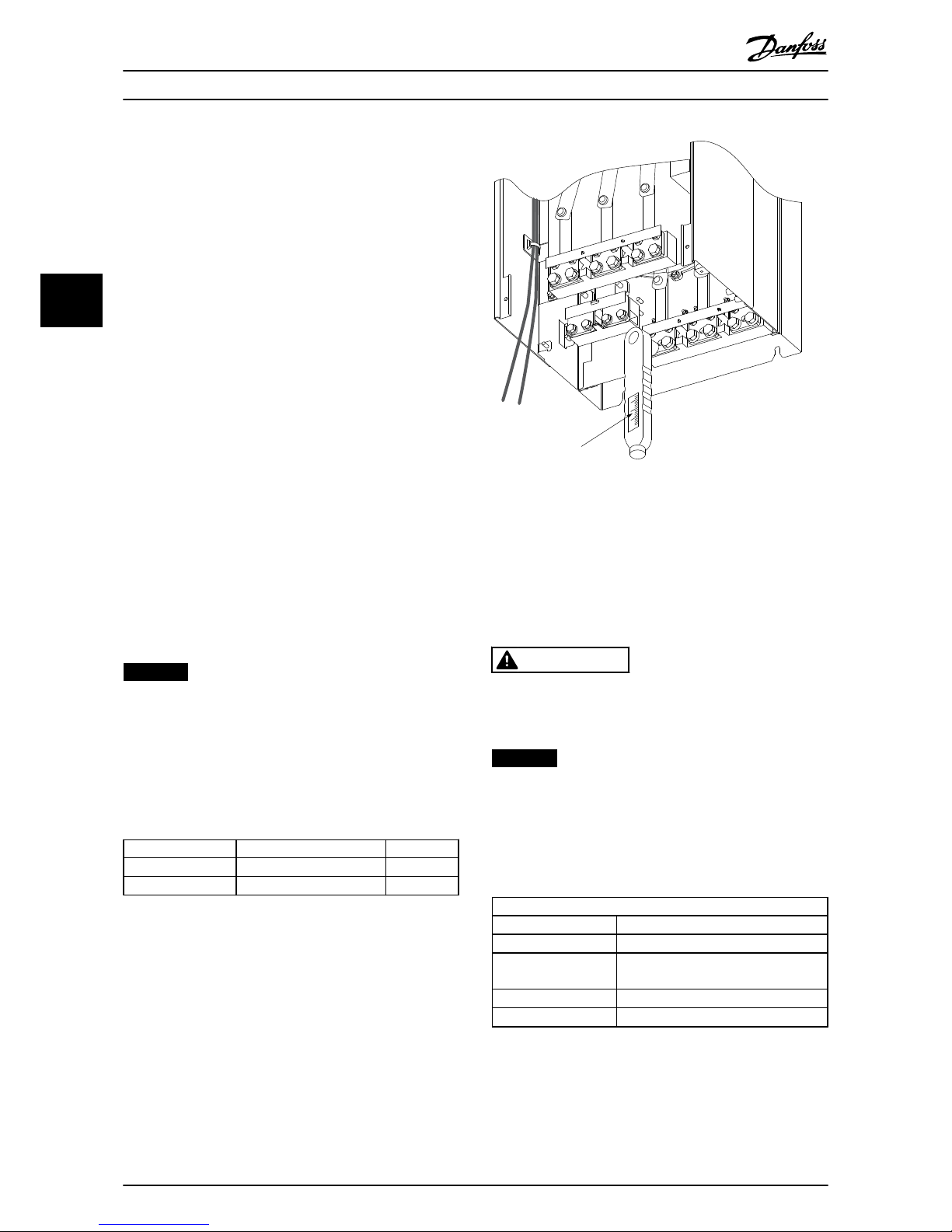

Consider the following basic issues when installing an

active filter, to obtain electromagnetic compatibility (EMC):

•

Safety grounding: The active filter has leakage

current and must be grounded appropriately for

safety reasons. Apply local safety regulations.

•

High-frequency grounding: Keep the ground wire

connections as short as possible.

•

Use high-strand wire to reduce electrical

interference.

•

Do not use pigtails.

Connect the different ground systems at the lowest

possible conductor impedance. Obtain the lowest possible

conductor impedance by keeping the conductor as short

as possible and using the greatest possible surface area.

The metal cabinets of the different devices are mounted

on the enclosure back plate using the lowest possible high

frequency impedance. This avoids having different high

frequency voltages for the individual devices and avoids

the risk of radio interference currents running in

connection cables that may be used between the devices.

The radio interference is reduced. To obtain a low HF

impedance, use the fastening bolts of the devices as a

high-frequency connection to the back plate. Remove any

insulating paint or similar substances from the fastening

points.

1

130BB739.11

1

Ground terminals

Illustration 4.2

Electrical Installation Operating Instructions

16 Danfoss A/S © 09/2014 All rights reserved. MG90V302

44

Page 20

4.2.3 EMC Interference

1

2

A

B

3

4

4

5

6

3

4

7

8

8

7

9

10

130BC643.10

1 Advanced active filter (AAF) 6

Potential equalisation wire [minimum 16 mm2/AWG 6]

2 Customer control termination points for options A and B 7 Clearance, minimum 200 mm (7.9 in)

3 Cable clamp 8 Mains, 3-phase and reinforced PE

4 Screened control wiring 9 Cable gland

5 Customer control input 10 External current transformer connections

Illustration 4.3 EMC-correct Installation

NOTICE

EMC INTERFERENCE

Use screened cables for control wiring. Separate AAF mains input cable from other cables and control wiring. Minimum

200 mm (7.9 in) clearance between mains and control cables is required. Maximise this clearance to minimise EMC

emissions. Doing so reduces the risk of interference between the AAF and other electronic devices.

Electrical Installation Operating Instructions

MG90V302 Danfoss A/S © 09/2014 All rights reserved. 17

4 4

Page 21

4.2.4 Extra Protection (RCD)

ELCB, RCD, GFCI relays or multiple protective groundings

are often used as extra protection, or needed to provide

compliance with local safety regulations. In case of a

ground fault, a DC component may develop in the fault

current. Observe local regulations when using ELCB relays.

To reassure effective protection and unintended tripping of

protective relays, all relays must be suitable for protection

of 3-phase equipment with active current infeed and for a

brief discharge during power-up. Use a relay type with

adjustable trip amplitude and time characteristics. Select a

current sensor with sensitivity of more then 200 mA and

not less than 0.1 s operation time.

4.2.5

RFI Switch

Mains supply isolated from ground (IT mains)

If the active filter is supplied from an isolated mains source

(IT mains, floating delta and grounded delta) or TT/TN-S

mains with grounded leg, the RFI switch is recommended

to be turned off (OFF) 1) via 14-50 RFI Filter on the unit.

For further reference, see IEC 364-3. In OFF mode, the

internal RFI capacities between the chassis and the

intermediate circuit are cut off to avoid damage to the

intermediate circuit. Refer to the application note VLT® on

IT mains. It is important to use isolation monitors that are

capable for use together with power electronics (IEC

61557-8).

NOTICE

Marine grids are typically IT type grids.

4.2.6 Torque

Correct torque is imperative for all electrical connections.

Incorrect torque results in a bad electrical connection.

Torque values are provided in Table 4.3.

Enclosure size Torque Bolt size

D 19 Nm (168 in.-lbs.) M10

E 19 Nm (168 in.-lbs.) M10

Table 4.3 Correct Torque Values

Use a torque wrench to ensure correct torque.

176FA247.12

Nm/in-lbs

-DC 88

+DC 89

R/L1 91

S/L2 92

T/L3 93

U/T1 96

V/T2 97

W/T3

Illustration 4.4 Use a Torque Wrench to Tighten the Bolts

4.2.7

Current Transformer (CT)

The filter operates in close loop operation by receiving

current signals for external current transformers. The

received signal is processed and the filter reacts according

to programmed actions.

CAUTION

Incorrect current transformer connection, installation or

configuration leads to unintended and uncontrollable

behaviour of the filter.

NOTICE

The current transformers are not part of the filter

package and must be purchased separately.

CT specification

The active filter supports most CTs. The CTs must have the

following specifications:

Technical specification of active filter, passive CT

RMS Maximum measured RMS current

Accuracy 0.5% or better (Class 0.5)

Secondary rated

current

1A or 5A (5A is recommended)

Set-up via hardware

Rated frequency 50/60 Hz

Rated power/burden

See Table 4.5 (AAF burden equals 2 mΩ)

Table 4.4 CT Specifications

Electrical Installation

Operating Instructions

18 Danfoss A/S © 09/2014 All rights reserved. MG90V302

44

Page 22

Rated power/

burden [VA]

5 7.5 10 15 30

Impedance of

current CT [Ω]

≤ 0.15 ≤ 0.25 ≤ 0.35 ≤ 0.55 ≤ 1.15

Table 4.5 Rated Power/Burden

NOTICE

All other technical data such as dynamic rated current,

maximal permitted operating voltage, thermal

dimensioning of continuous current, thermal

dimensioning of short-time current, overcurrent limit,

isolation class, working temperature range etc. are

specific values of the system and have to be defined

during the project planning phase of the equipment.

RMS specification

The minimum RMS is determined by the total current that

passes through the current transformer. It is important that

the current sensor is not too small, leading to saturation of

the sensor. Add 10% margin and pick the next following

bigger standard RMS rate. Use current transformers that

have an RMS rating close to the maximum current flowing

through it to allow the highest possible accuracy of the

measurement and so an ideal compensation.

CT burden

To ensure that the current transformer performs according

to specifications, the rated burden should not be above

the true current requirement of the active filter. The

burden of the CT depends on the wire type and the cable

length between the CT and the filter CT connection

terminal. The filter itself contributes with 2 mΩ.

NOTICE

The accuracy of the CT is depending on wire type and

length of the cable between filter and current

transformer.

Calculate the required (minimum) CT burden as:

[VA]=25*[Ω/M] *[M]+1.25

[Ω/M] being the cable resistance in Ω/meter, [M] being the

cable length in meters.

Table 4.6 shows the minimum CT burden for different wire

gauge at wire length of 50 m and standard wire resistance

value:

Wire Gauge

[mm2/AWG]

Resistance

[Ω/km]

Wire length

[meters/feet]

Minimum CT

burden [VA]

1.5/#16 13.3 50/164 >16.6

2.5/#14 8.2 50/164 >10.2

4/#12 5.1 50/164 > 6.3

6/#10 3.4 50/164 > 4.2

10/#8 2 50/164 > 2.5

Table 4.6 Minimum CT Burden

For a fixed CT burden, calculate the maximum allowed

wire length as:

[M]=([VA]-1.25)/(25*[Ω/M])

Below the maximum wire length of CT with 2.5 mm2 wires

and resistor value equal 8.2 Ω/km:

Wire Gauge

[mm2/ AWG]

Resistance

[Ω/km]

Minimum CT

burden [VA]

Wire length

[meter/feet]

2.5/#14 8.2 5 <18/60

2.5/#14 8.2 7.5 <30/100

2.5/#14 8.2 10 <42/140

2.5/#14 8.2 15 <67/220

2.5/#14 8.2 30 <140/460

Table 4.7 Maximum CT Wire Length

Example

Calculation example for correct current transformer for an

application with:

RMS=653 A, Distance between filter and CTs of 30 m.

RMS=653*1.1=719 A, CT RMS=750 A. Burden: 30 m@2.5

mm2 wire =>25*0.0082*30+1.25=7.4=>7.5 [VA].

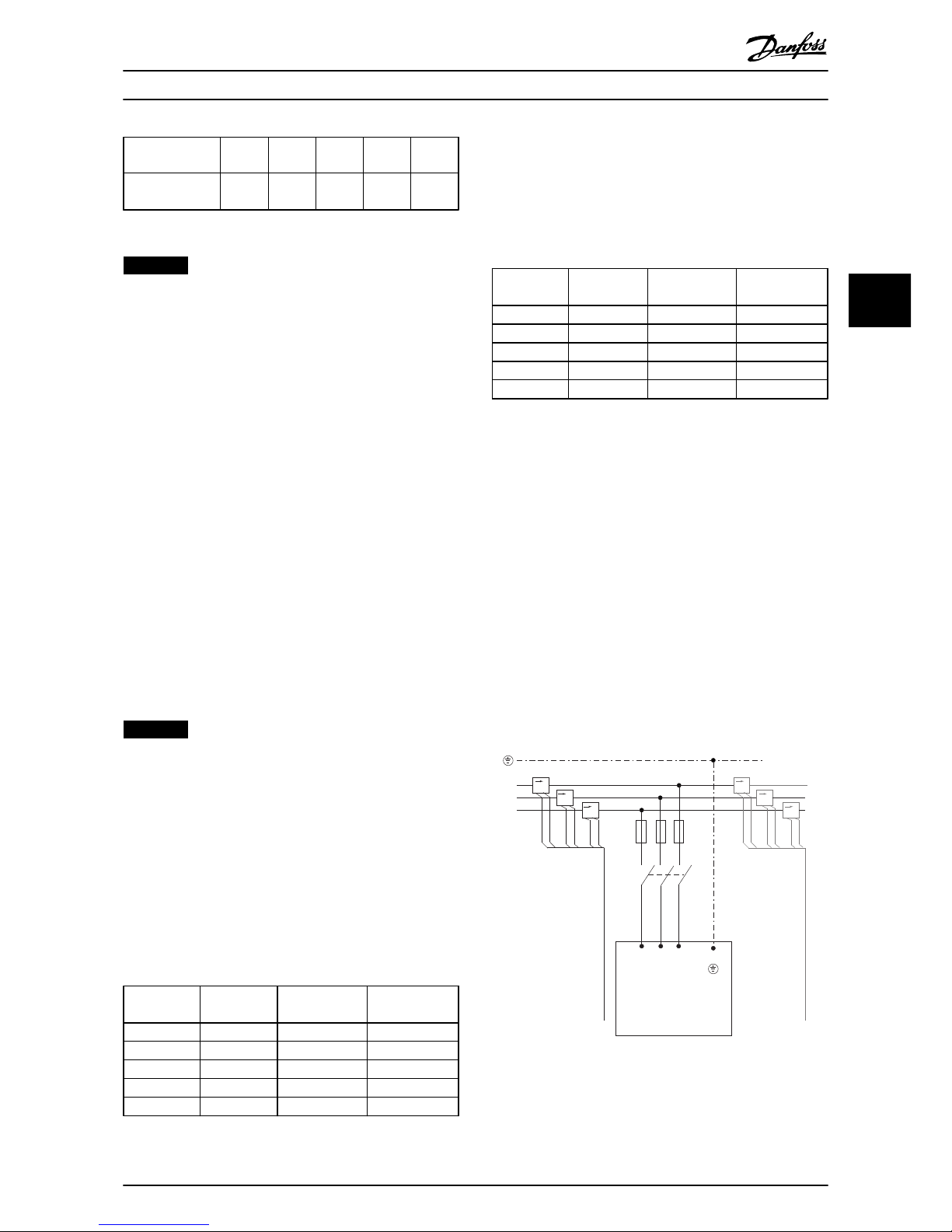

Current transformer installation

The unit only supports 3 CT installations. Install external

CTs on all 3 phases to detect the harmonic content of the

grid. The flow direction of the sensor is indicated by an

arrow in most cases. The arrow points in the direction of

the current flow and so towards the load. If the flow

direction is programmed incorrectly, the polarity can be

changed via active filter parameter 300-25 CT Polarity,

which can program the polarity of the CTs in each of the 3

phases individually.

L1

L2

L3

K L

K L

K L

K L

K L

K L

1

2

91 92 93

L1 L2 L3

95

130BB510.12

Illustration 4.5 CT Connections

Electrical Installation Operating Instructions

MG90V302 Danfoss A/S © 09/2014 All rights reserved. 19

4 4

Page 23

1 or 5 A CT set-up

To allow for possible reuse of already present CT

transformers, the active filter allows use of either 1 A or 5

A CTs. The filter is as standard set-up for 5 A CT feedback.

If the CTs are 1 A, redirect the CT terminal plug from slot

MK101, position 1, to MK108, position 2, on the AFC card.

See Illustration 4.6.

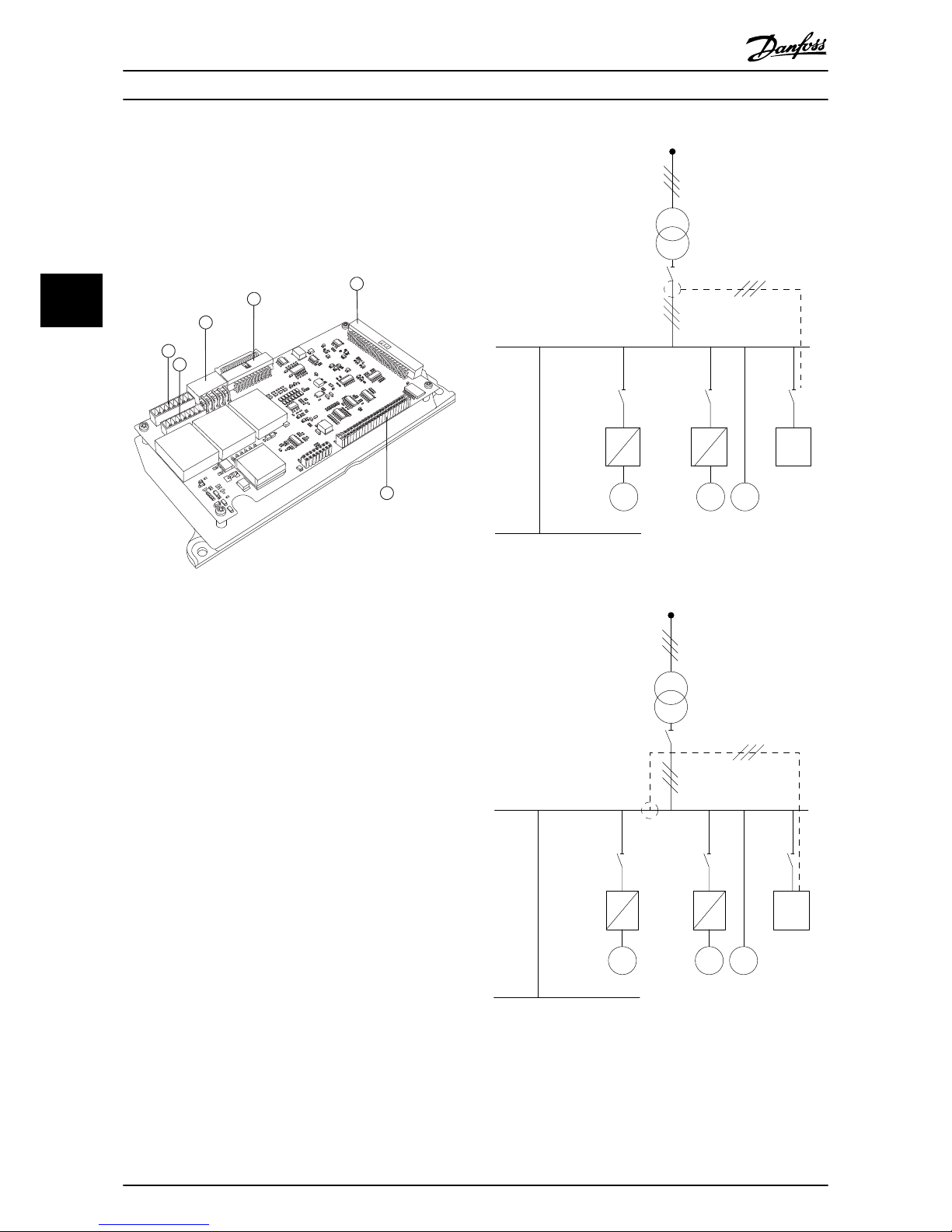

130BB950.10

1

3

4

5

6

2

Illustration 4.6 AFC Card

Individual or group compensation

The compensation of the filter depends on the signal that

is returned from the current transformers. The point of

installation for these sensors is to determine the loads that

are corrected.

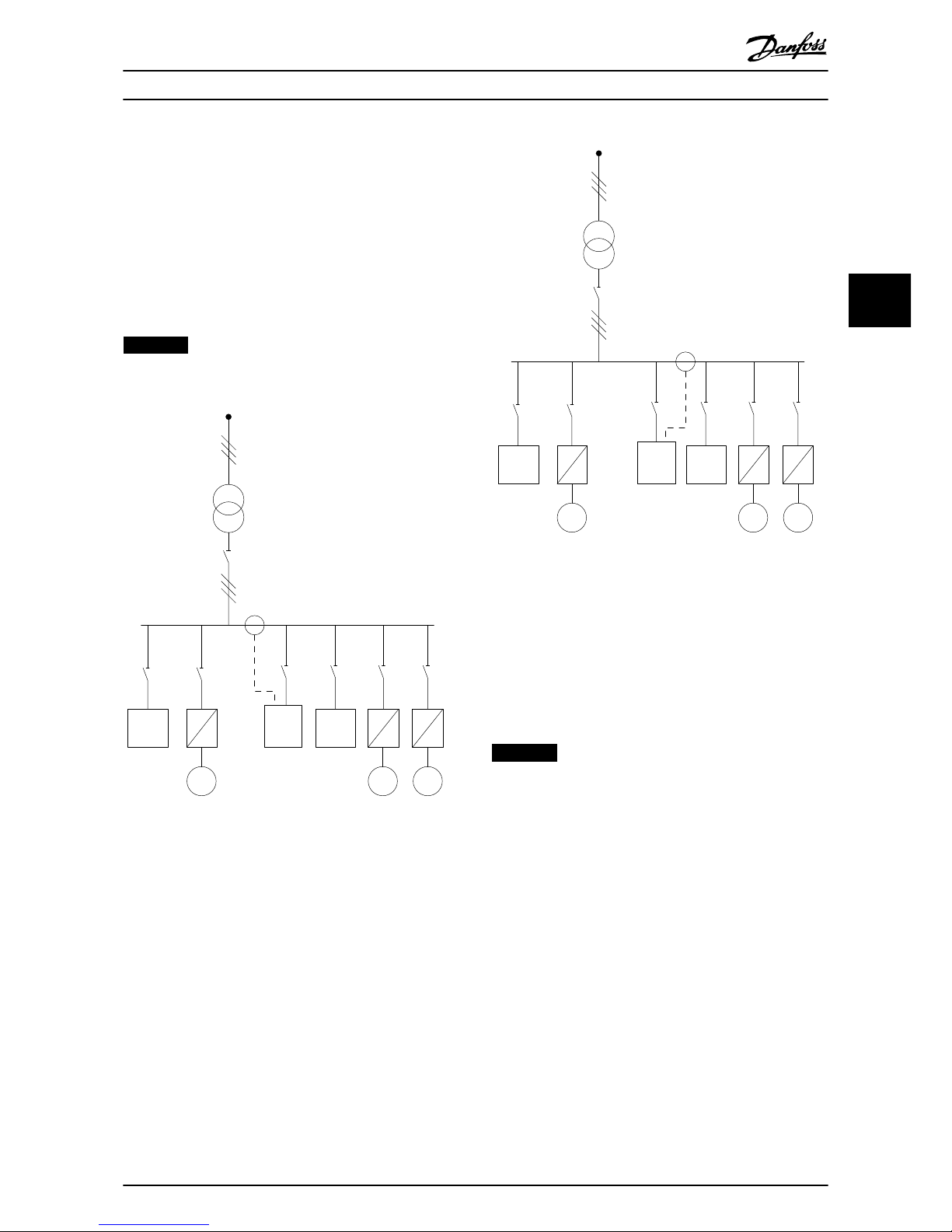

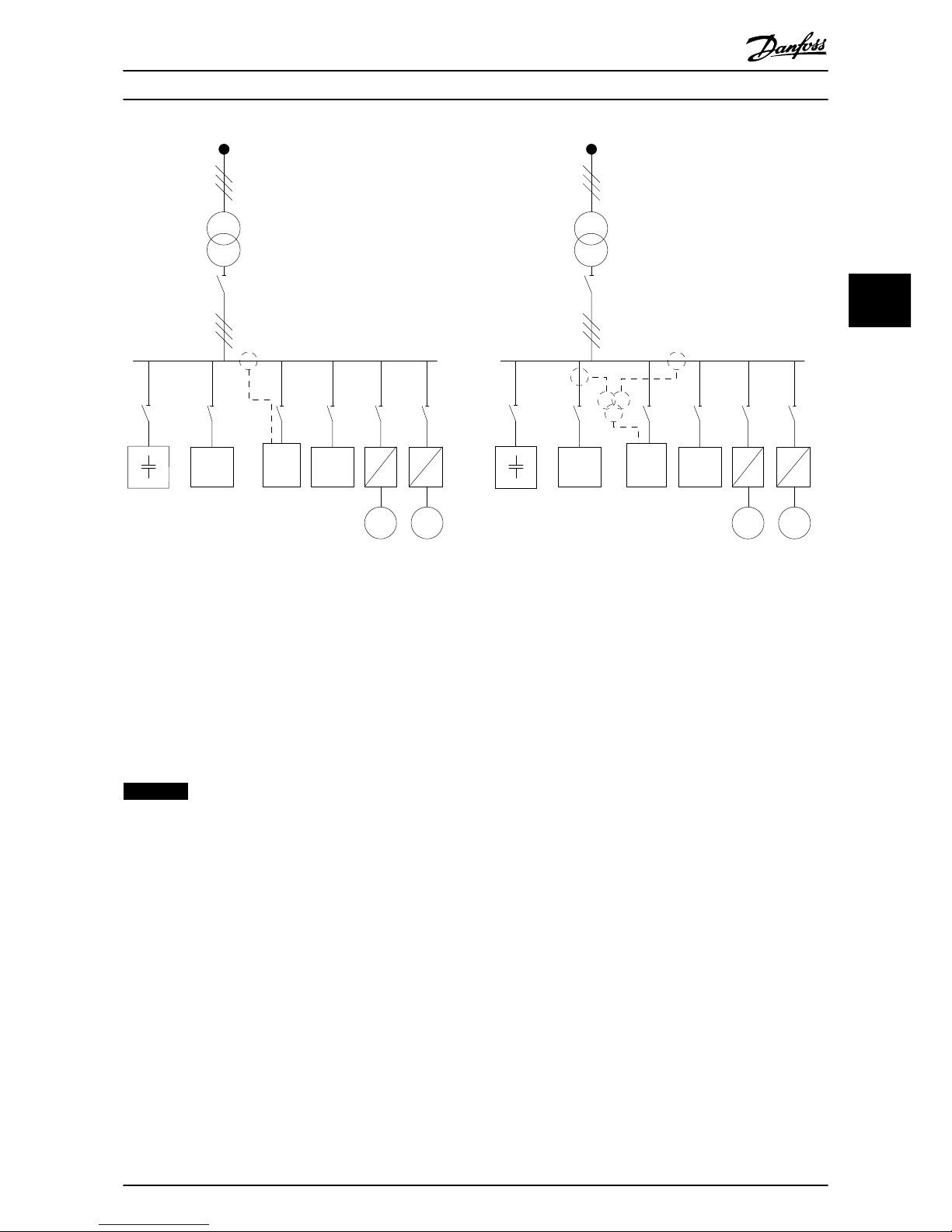

Illustration 4.7 shows current transformers installed in front

of the entire installation with the filter compensating all

loads on the transformer. Illustration 4.8 shows current

transformers installed in front of distribution bus 2 and 1

frequency converter, so the filter only compensates for

those.

M M

M

PCC1

PCC2

130BB511.11

AAF

Illustration 4.7 CT on PCC Side

M

M

M

PCC1

PCC2

130BB512.10

AAF

Illustration 4.8 CT on Load Side

If the CTs are installed on the secondary side of the

transformer and so in front of the entire load, the filter

compensates all loads simultaneously. See Illustration 4.7.

Electrical Installation

Operating Instructions

20 Danfoss A/S © 09/2014 All rights reserved. MG90V302

44

Page 24

If, as in Illustration 4.8, the CTs are installed in front of only

some of the loads, the filter does not compensate

unwanted current deformation of the frequency converter

and motor on the right hand side. If CTs are installed in

front of a single load, the filter only compensates the 1

load and so form individual load compensation.

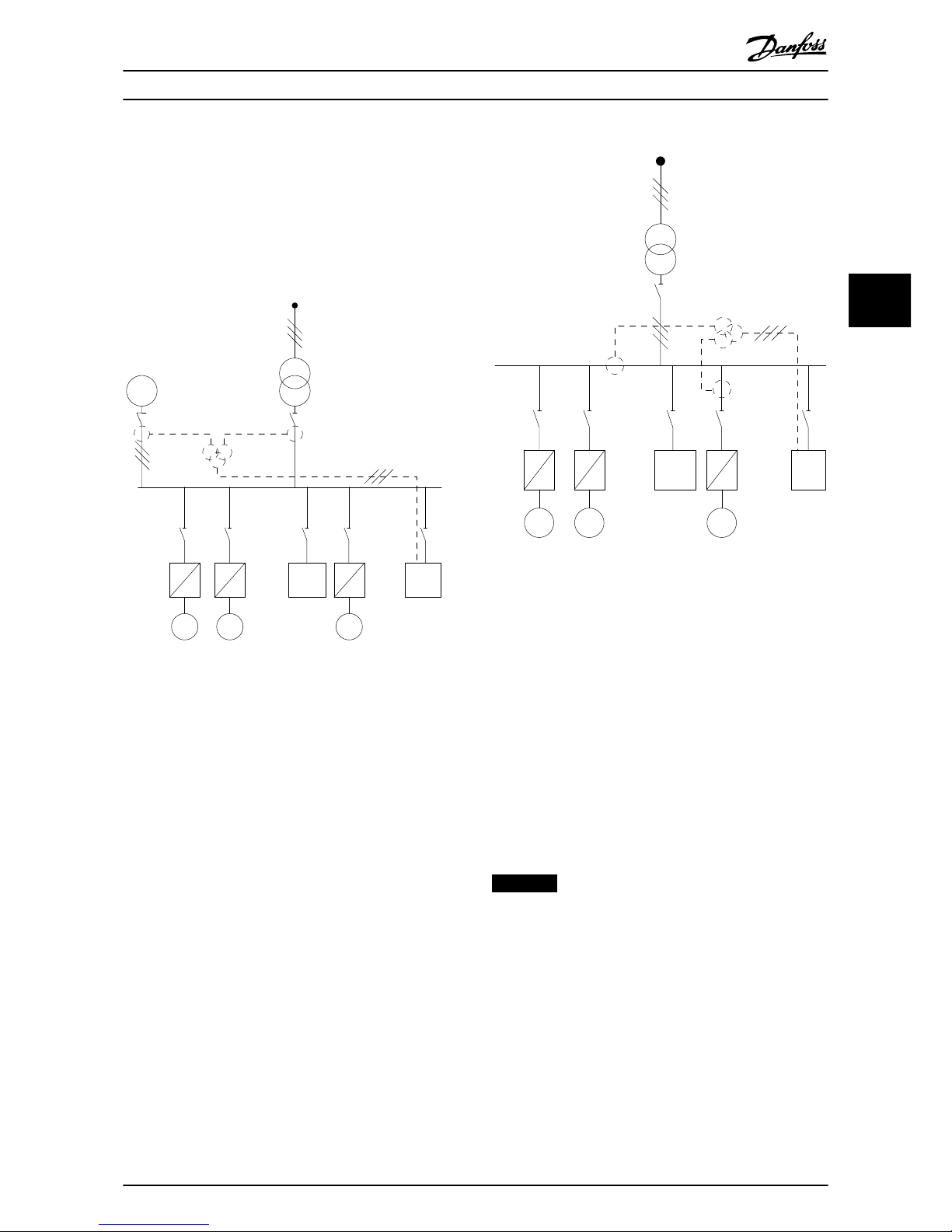

CTs can be installed on the source side (PCC–point of

common coupling), or on the load side via

parameter 300-26 CT Placement

NOTICE

The default setting is PCC side installation

PCC1

AAF

M

M

M

130BB513.11

Illustration 4.9 Current Transformers Installed on Source (PCC)

Side for Group Compensation

PCC1

AAF

M

M M

130BB514.11

Illustration 4.10 Current Transformers Installed on Load Side

for Group Compensation

If the current transformers are installed on the source

(PCC) side, the filter expects a sinusoidal (corrected) signal

feedback from the 3 sensors. If the sensors are installed on

the load side, the received signal is subtracted from the

ideal sine wave to calculate the necessary corrected

current.

NOTICE

Erratic filter operation can be a result of incorrect current

transformers connection point programming

parameter 300-26 CT Placement.

Electrical Installation Operating Instructions

MG90V302 Danfoss A/S © 09/2014 All rights reserved. 21

4 4

Page 25

4.2.8 Auto CT Detection

The active filter performs an auto detection of the installed CT. The CT auto detection can be conducted both while the

system is running and when there is no load. The filter injects a prefixed current of known amplitude and phase angle and

measures the returned CT input. The performance is conducted on each phase individually for several frequencies to check

that phase sequence and RMS are set correctly.

The Auto CT detection is pending on the following conditions:

•

Active filter bigger than 10% of CT RMS rate.

•

CTs installed on source (PCC) side (auto CT not possible for load side CT installation).

•

Only one CT per phase (not possible for summation CTs).

•

CTs are part of below standard range:

600 750

1000 1250 1500 2000 2500 3000 3500 4000

Table 4.8 Primary Rating [A]

Most restrictions on the CTs come from the installation, such as required cable length, temperature conditions, square

section of conductors, standard or split core layout, etc. A broad range of different current transformers can be used

independently of brand and type.

For specific CT requirements contact the local supplier or go to www.deif.com/

Secondary Primary Accuracy Burden Type Description

5 or 1A 30–7500A 0.2–0.5-1 1.0–45 V A ASR

ASK

EASR

EASK

Measuring current transformer for cables and bus bars

5 or 1A 100–5000A 0.5–1 1.25–30 V A KBU Split core current transformer

5 or 1A 5 or 1A 0.5–1 15–30 V A KSU/SUSK Summation current transformer

Table 4.9 Standard CT Range from Deif: Fits Most Applications

Electrical Installation Operating Instructions

22 Danfoss A/S © 09/2014 All rights reserved. MG90V302

44

Page 26

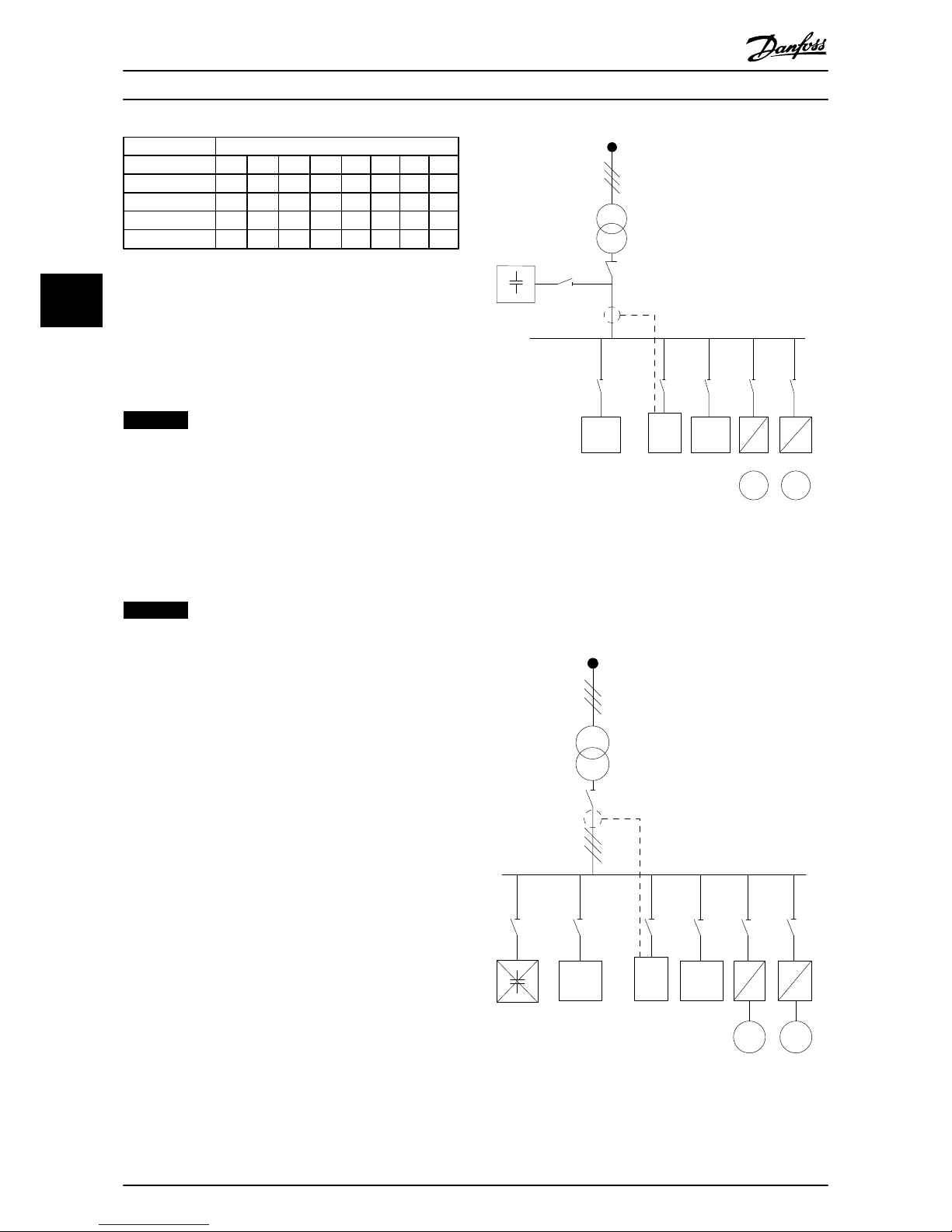

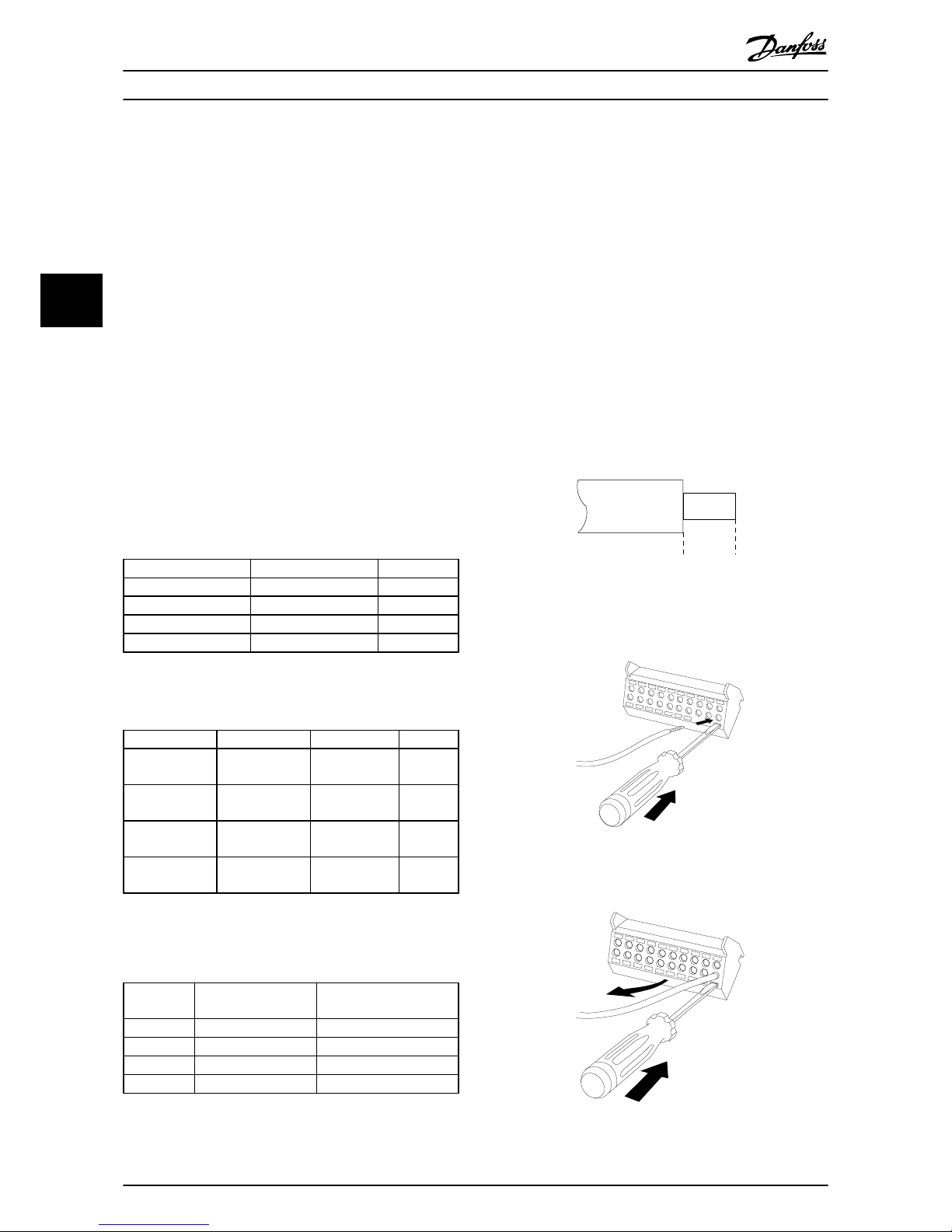

4.2.9 Summation Transformers

Multiple current sources

Summation CTs are needed when the filter is to

compensate current from several sources. This is often the

case if a filter is installed in systems with generator backup or where the filter is only to compensate a limited

number of loads, for example, marine installations.

M M

M

PCC1

130BB515.11

AAF

G

Illustration 4.11 Summation CTs on Generator Back-up

Applications (PCC-side)

M

M

M

AAF

PCC1

130BB516.11

Illustration 4.12 Summation CTs Example for Individual

Harmonic Compensation (Load Side)

Summation current transformers are available with

multiple (2–5) inputs and a common output. For

applications where summations CTs are used to add

current from several sources, make sure that all CTs

connected to the summation are from the same

manufacturer and that the following aspects are the same:

•

Polarity.

•

Primary rating.

•

RMS value.

•

Accuracy (class 0.5).

•

Location (PCC or load-side).

•

Phase sequence.

NOTICE

Use summation CTs with great caution and always

ensure correct phase sequence, current direction,

primary and secondary rating. Incorrect installation

causes problems with filter operation.

The current transformers burden calculation includes all

wires in the installation and must be conducted for the

longest total wire string when using summation CTs.

Electrical Installation

Operating Instructions

MG90V302 Danfoss A/S © 09/2014 All rights reserved. 23

4 4

Page 27

Total current [A] Maximum individual harmonic compensation

I5 I7 I11 I13 I17 I19 I23 I25

190 133 95 61 53 38 34 30 27

250 175 125 80 70 50 45 40 35

310 217 155 99 87 62 56 50 43

400 280 200 128 112 80 72 64 56

Table 4.10 Maximum Individual Harmonic Compensation

4.2.10 Operating with Capacitor Banks

The active filter is able to run with capacitor banks as long

as the resonance frequency of the capacitor bank is not in

the operation range of the active filter.

NOTICE

Always use de-tuned capacitor banks in installations with

frequency converters and active filters to avoid

resonance phenomena, unintended tripping or

component breakdown.

For de-tuned capacitors, the resonance frequency

capacitors should be tuned for an inter-harmonic number

lower than the 3rd harmonic.

NOTICE

If installed with capacitor banks of any kind, the active

filter must operate in selective compensation mode.

The capacitor bank should be installed upstream of the

filter toward the transformer. If this is not possible, install

the current transformers such that they do not measure

both needed current compensation and the capacitor

corrected current.

PCC1

M

M

AAF

130BB517.11

Illustration 4.13 Capacitor bank mounted upstream. CTs do

not measure capacitor current.

Illustration 4.13 shows recommended installation of the

active filter and CT placement in installations containing

capacitor banks.

PCC1

130BB518.11

M

M

AAF

Illustration 4.14 Incorrect Installation

Electrical Installation Operating Instructions

24 Danfoss A/S © 09/2014 All rights reserved. MG90V302

44

Page 28

PCC1

130BB519.11

M

M

AAF

Illustration 4.15 CTs Do Not Measure Capacitor Current

For installations where the CT connection point can be

moved, the configuration shown in Illustration 4.15 is also

possible. In some retrofit applications, summation CTs are

needed to ensure that the capacitor current is not

measured.

Summation CTs can also be used to subtract 2 signals from

each other and so subtract the capacitor bank corrected

current from the total current.

NOTICE

Use summation CTs with an accuracy of 0.5% of better.

PCC1

130BB520.11

M

M

AAF

Illustration 4.16 Capacitor Bank Mounted on PCC with CTs

Ensuring that Capacitor Corrected Current is not Measured.

Electrical Installation Operating Instructions

MG90V302 Danfoss A/S © 09/2014 All rights reserved. 25

4 4

Page 29

4.2.11 Fuses

Branch circuit protection

To protect the installation against electrical and fire hazard,

all branch circuits in an installation, switch gear, machines

etc., must be short-circuited and overcurrent protected

according to national/international regulations.

Short circuit protection

Protect the active filter against short circuit to avoid

electrical or fire hazard. Danfoss recommends using the

fuses in Table 4.11 and Table 4.12 to protect service

personnel and equipment in case of an internal failure in

the device.

Overcurrent protection

The active filter is equipped with an internal overcurrent

protection that avoids overload in normal running

conditions. Overload protection is needed in case of

internal failures to avoid fire hazard due to overheating of

the cables in the installation. Use fuses or circuit breakers

for overcurrent protection and comply with local and

national regulations.

Mains fuses

Active Filter Bussmann Rating

AAF006, 190 A 170M3018 350 A, 700 V

AAF006, 250 A 170M4017 700 A, 700 V

AAF006, 310 A 170M4017 700 A, 700 V

AAF006, 400 A 170M6013 900 A, 700 V

Table 4.11 Recommended Mains Fuses

Supplemental fuses

Active Filter Protection Fuse Rating

AAF006, 190–

400A SMPS

Bussmann

KTK-4 4 A, 600 V

AAF006, 190–

400A Fan

Littelfuse

KTK-15

15 A, 600

V

AAF006, 190–

400A

Soft-charge

resistor

Bussmann FNQ-

R 1 A, 600 V

AAF006, 190–

400A CT

Bussmann FNQ-

R 3 A, 600 V

Table 4.12 Recommended Supplemental Fuses

4.2.12

Mains Disconnectors

Enclosure

size Power & voltage Type

D A190 380–480 V ABB OETL-NF200A

E A250 380–480 V ABB OETL-NF400A

E A310 380–480 V ABB OETL-NF400A

E A400 380–480 V ABB OETL-NF800A

Table 4.13 Mains Disconnect Part Numbers

4.2.13

Control and CT Cable Routing

Tie down all control wires to the designated control cable

routing. Connect the shields properly to ensure optimum

electrical immunity.

CT connection

Make connections on the terminal block below the active

filter card. Place the cable in the path inside the filter and

secure it with other control wires.

4.2.14 Control Wire Installation

All terminals to the control cables are located on the

control or AFC board.

To connect the cable to the terminal:

1. Strip insulation 9–10 mm (0.4 in.)

130BA150.10

9 - 10 mm

(0.37 in)

Illustration 4.17 Stripped Insulation

2. Insert a screwdriver (maximum 0.4x2.5 mm) in the

square hole.

130BT312.10

Illustration 4.18 Inserting the Cable

3. Insert the cable in the adjacent circular hole.

130BT311.10

Illustration 4.19 Removing the Screwdriver

Electrical Installation Operating Instructions

26 Danfoss A/S © 09/2014 All rights reserved. MG90V302

44

Page 30

4. Remove the screwdriver. The cable is now

mounted in the terminal.

To remove the cable from the terminal:

1. Insert a screwdriver (maximum 0.4x2.5 mm) in the

square hole.

2. Pull out the cable.

4.2.15 Unscreened Control Wires

CAUTION

INDUCED VOLTAGE

Run input power and control wiring in separate metallic

conduits or raceways for high-frequency noise isolation.

Failure to isolate power and control wiring could result

in less than optimum controls and associated equipment

performance.

Isolate control wiring, including CT wires, from the highvoltage power wiring. When screened/armoured cable is

not used, ensure that control wires are twisted pairs and

keep the maximum possible distance between mains wire

and control cables.

Long control cables and analog signals may result in 50/60

Hz ground loops due to noise from mains supply cables.

If ground loops occur, break the screen or insert a 100 nF

capacitor between screen and chassis, if needed.

12 13 18 19 27 29 32 33 20 37

+24 VDC

0 VDC

130BT106.10

PNP (Source)

Digital input wiring

Illustration 4.20 Input Polarity of Control Terminals, PNP

NPN (Sink)

Digital input wiring

12 13 18 19 27 29 32 33 20 37

+24 VDC

0 VDC

130BT107.11

Illustration 4.21 Input Polarity of Control Terminals, NPN

NOTICE

To comply with EMC emission specifications, use

screened/armoured cables. If using unscreened control

cables, use ferrite cores to improve EMC performance.

Connect the shields in a proper way to ensure optimum

electrical immunity.

130BT340.10

Illustration 4.22 Connecting Shielded Control Cables

Electrical Installation Operating Instructions

MG90V302 Danfoss A/S © 09/2014 All rights reserved. 27

4 4

Page 31

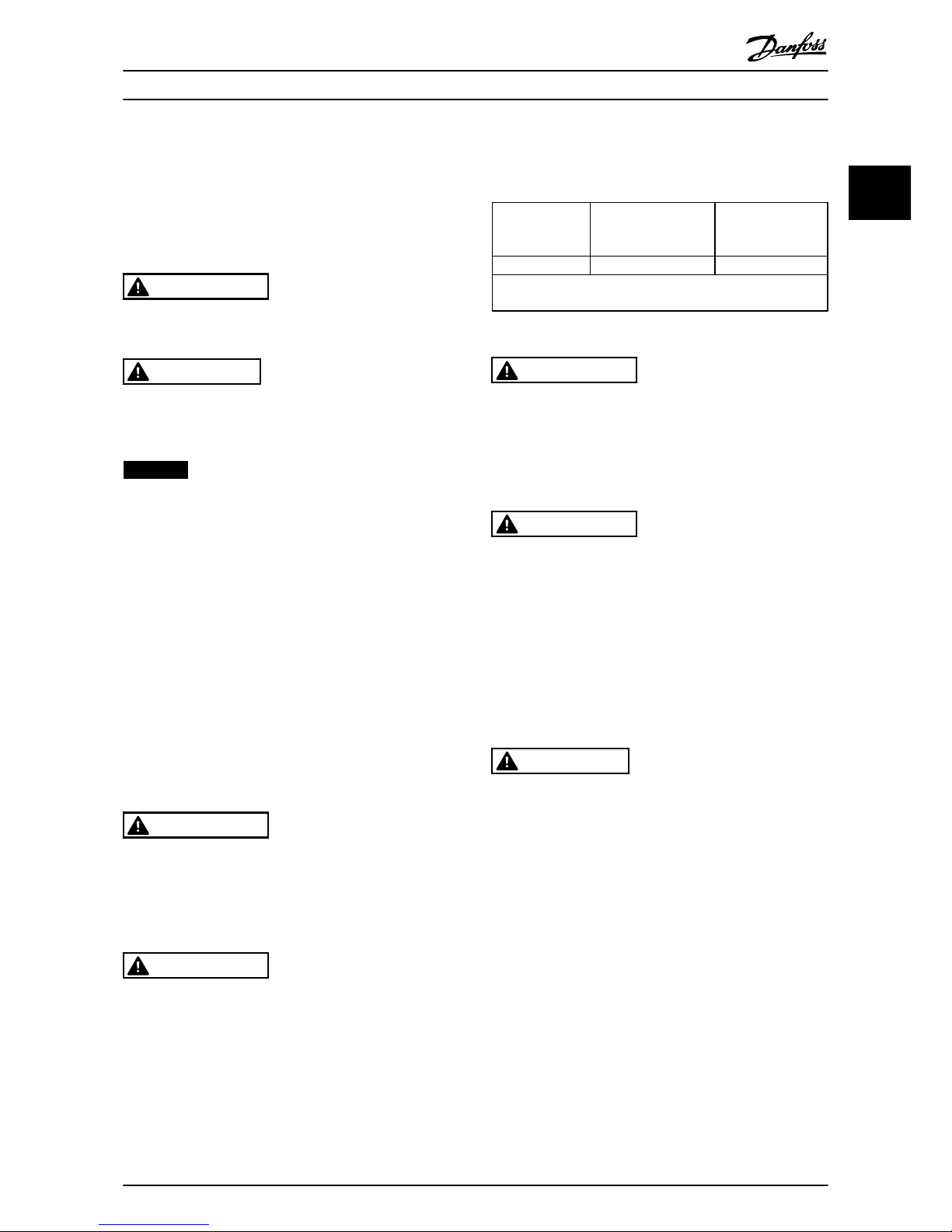

4.2.16 Electrical Installation, Control Cables

Switch Mode

Power Supply

Analog Output

Interface

relay1

relay2

(PNP) = Source

(NPN) = Sink

ON=Terminated

OFF=Open

50 (+10 V OUT)

53 (A IN)

54 (A IN)

55 (COM A IN)

0/4-20 mA

12 (+24V OUT)

13 (+24V OUT)

18 (D IN)

20 (COM D IN)

10Vdc

15mA 130/200mA

+ - + -

(COM A OUT) 39

(A OUT) 42

(P RS-485) 68

(N RS-485) 69

(COM RS-485) 61

0V

5V

S801

0/4-20 mA

RS-485

RS-485

03

+10Vdc

-10Vdc -

+10Vdc

+10Vdc

0/4-20 mA

-10Vdc -

240Vac, 2A

24Vdc

02

01

05

04

06

240Vac, 2A

24V (NPN)

0V (PNP)

0V (PNP)

24V (NPN)

19 (D IN)

24V (NPN)

0V (PNP)

27

24V

0V

(D IN/OUT)

0V (PNP)

24V (NPN)

(D IN/OUT)

0V

24V

29

24V (NPN)

0V (PNP)

0V (PNP)

24V (NPN)

33 (D IN)

32 (D IN)

1 2

ON

S201

ON

21

S202

ON/I=0-20mA

OFF/U=0-10V

400Vac, 2A

P 5-00

21

ON

S801

*

Optional

RFI

Optional

Fuses

Optional

Manual

Disconnect

HI Reactor

L

m

L

m

L

m

L

ac

L

ac

L

ac

AC

Contactor

Relay 12

Control & AUX

Feedback

Relay 12

Control & AUX

Feedback

Soft-Charge

Converter

Side Filter

Power Stage

AF Current

Sensors

Capacitor

Current Sensors

3

3

NC

Relay

L

c

L

c

L

c

CefCefC

ef

RefRefR

ef

I

r

I

s

I

t

91 (L1)

92 (L2)

93 (L3)

130BC642.10

Illustration 4.23 Terminal Diagram

Electrical Installation

Operating Instructions

28 Danfoss A/S © 09/2014 All rights reserved. MG90V302

44

Page 32

4.3 Installation Checklist

Before completing installation of the unit, inspect the entire installation as detailed in Table 4.14. Check and mark the items

when completed.

Inspect for Description

☑

Auxiliary equipment•Ensure that all auxiliary equipment, such as switches, disconnects, or input fuses/circuit breakers are ready

for operation.

•

Check function and installation of any sensors used for feedback to the active filter.

Cable routing

•

Ensure that power wiring and control wiring are separated, screened, or in 3 separate metallic conduits for

high-frequency interference isolation.

Control wiring

•

Check for broken or damaged wires and loose connections.

•

Check that control wiring is isolated from power wiring for noise immunity.

•

Check the voltage source of the signals, if necessary.

•

The use of shielded cable or twisted pair is recommended. Ensure that the shield is terminated correctly.

Cooling clearance

•

Measure that top and bottom clearance is adequate to ensure proper air flow for cooling, see

chapter 3.2.4 Cooling and Airflow .

Ambient conditions•Check that requirements for ambient conditions are met.

Fusing and circuit

breakers

•

Check for proper fusing or circuit breakers.

•

Check that all fuses are inserted firmly and are in operational condition and that all circuit breakers are in

the open position.

Grounding

•

Check for good ground connections that are tight and free of oxidation.

•

Grounding to conduit, or mounting the back panel to a metal surface, is not a suitable grounding.

Input and output

power wiring

•

Check for loose connections.

•

Check that motor and mains are in separate conduit or separated screened cables.

Panel interior

•

Inspect that the unit interior is free of dirt, metal chips, moisture, and corrosion.

•

Check that the unit is mounted on an unpainted, metal surface.

Switches

•

Ensure that all switch and disconnect settings are in the proper positions.

Vibration

•

Check that the unit is mounted solidly, or that shock mounts are used, as necessary.

•

Check for an unusual amount of vibration.

Table 4.14 Installation Check List

CAUTION

POTENTIAL HAZARD IN THE EVENT OF INTERNAL FAILURE

Risk of personal injury when the active filter is not properly closed.

•

Before applying power, ensure all safety covers are in place and securely fastened.

Electrical Installation Operating Instructions

MG90V302 Danfoss A/S © 09/2014 All rights reserved. 29

4 4

Page 33

5 User Interface

5.1 Local Control Panel Operation

5.1.1 Modes of Operation

There are 2 ways to operate the unit:

•

Graphical Local Control Panel (GLCP)

•

RS485 serial communication or USB, both for PC

connection

5.1.2 How to Operate Graphical LCP (GLCP)

NOTICE

The active filter should be in Auto mode. Press [Auto On]

on the filter LCP.

Graphical display:

The LCD display is backlit with a total of 6 alpha-numeric

lines. All data is displayed on the LCP, which can show up

to 5 operating variables while in Status mode.

Illustration 5.1 shows an example of the frequency

converter LCP. The filter LCP looks identical but displays

information related to the filter operation.

1. Display:

1a

Status line: Status messages displaying

icons and graphics.

1b

Line 1–2: Operator data lines displaying

data and variables the user defines. Add

an extra line by pressing the [Status]

key.

1c

Status line: Status messages displaying

text.

2. Menu soft keys.

3. Indicator lights/navigation panel.

4. Operational keys.

Auto

on

Reset

Hand

on

O

Status

Quick

Menu

Main

Menu

Alarm

Log

Back

Cancel

Info

OK

Status

1(0)

1234rpm 10,4A 43,5Hz

Run OK

43,5Hz

On

Alarm

Warn.

130BA018.13

1

2

3

4

b

a

c

Illustration 5.1 Example LCP

The display is divided into 3 sections:

Top section (a)

Shows the status when in status mode or up to 2 variables

when not in status mode and in the case of alarm/

warning.

The number of the active set-up (selected as the active

set-up in parameter 0-10 Active Set-up) is shown. When

programming in another set-up than the active set-up, the

number of the set-up being programmed appears to the

right in brackets.

Middle section (b)

Shows up to 5 variables with related unit, regardless of

status. In case of alarm/warning, the warning is shown

instead of the variables.

It is possible to toggle among 3 status readout displays by

pressing [Status].

User Interface

Operating Instructions

30 Danfoss A/S © 09/2014 All rights reserved. MG90V302

55

Page 34

Operating variables with different formatting are shown on

each status screen.

Several values or measurements can be linked to each of

the displayed operating variables. Define the values/

measurements to be displayed via parameters 0-20, 0-21,

0-22, 0-23, and 0-24.

Each value/measurement readout parameter selected in

parameters 0-20 to 0-24 has its own scale and number of

digits after a possible decimal point. Larger numeric values

are displayed with few digits after the decimal point.

Example: Current readout

5.25 A; 15.2 A 105 A.

Status display I

This readout state is standard after start-up or initialisation.

Press [Info] to obtain information about the

value/ measurement linked to the displayed operating

variables (1.1, 1.2, 1.3, 2, and 3).

See the operating variables shown in the display in

Illustration 5.2. 1.1, 1.2 and 1.3 are shown in small size. 2

and 3 are shown in medium size.

1.1

2

3

1.3

1.2

130BP041.10

799 RPM

Auto Remote Ramping

1 (1)

36.4 kw7.83 A

0.000

53.2 %

Status

Illustration 5.2 Status Display I - Operating Variables

Status display II

See the operating variables (1.1, 1.2, 1.3, and 2) shown in

the display in Illustration 5.3.

In the example, speed, motor current, motor power, and

frequency are selected as variables in the first and second

lines.

1.1, 1.2 and 1.3 are shown in small size. 2 is shown in large

size.

1.1

1.2

2

1.3

130BP062.10

207RPM

Auto Remote Running

1 (1)

24.4 kW5.25A

6.9

Hz

Status

Illustration 5.3 Status Display II - Operating Variables

Bottom section

The bottom section always shows the state of the

frequency converter in Status mode.

Top section

Middle section

Bottom section

Status

43 RPM

1.4 Hz

Auto Remote Running

! Pwr.card temp (W29)

2.9%

5.44 A 25.3kW

1(1)

130BP074.10

!

Illustration 5.4 Bottom Section Status Mode

Display contrast adjustment

Press [status] and [▲] for darker display

Press [Status] and [▼] for brighter display

Indicator lights (LEDs):

If certain threshold values are exceeded, the alarm and/or

warning indicator lights are illuminated. A status and alarm

text appear on the control panel.

The On indicator light is activated when the active filter

receives power from:

•

Mains voltage.

•

A 24 V external supply.

Indicator lights (LEDs)

•

Green LED/On: Control section is working.

•

Yellow LED/Warn: Indicates a warning.

•

Flashing Red LED/Alarm: Indicates an alarm.

On

Warn.

Alarm

130BP044.10

Illustration 5.5 LED Status Indicator Lights

LCP keys

Menu keys

The menu keys are divided into functions. The keys below

the display and indicator lights are used for parameter setup, including option of display indication during normal

operation.

130BP045.10

Status

Quick

Menu

Main

Menu

Alarm

Log

Illustration 5.6 Menu Keys

User Interface Operating Instructions

MG90V302 Danfoss A/S © 09/2014 All rights reserved. 31

5 5

Page 35

[Status]

Indicates the status of the active filter. Use [Status] for

selecting display mode or reverting to display mode from:

•

Quick menu.

•

Main menu.

•

Alarm mode.

Press the [Status] key to toggle single or double readout

mode.

[Quick Menu]

The quick menu allows quick set-up of the frequency

converter or the filter and programming of the most

common functions.

The [Quick Menu] consists of:

•

Q1: My personal menu.

•

Q2: Quick set-up.

•

Q5: Changes made.

•

Q6: Loggings.

The active filter LCP displays information about operation

such as THD of current, corrected current, injected current

or Cos ϕ, and true power factor.

The Quick Menu parameters can be accessed immediately

unless a password has been created via parameters 0-60,

0-61, 0-65 or 0-66.

It is possible to switch directly between Quick Menu mode

and Main Menu mode.

[Main Menu]

The main menu is used for programming all parameters.

The Main Menu parameters can be accessed immediately

unless a password has been created via parameters 0-60,

0-61, 0-65 or 0-66.

It is possible to switch directly between Main Menu mode

and Quick Menu mode.

A parameter shortcut can be carried out by pressing down

[Main Menu] for 3 s. The parameter shortcut allows direct

access to any parameter.

[Alarm Log]

The alarm log displays an alarm list of the 5 latest alarms

(numbered A1-A5). To obtain more details about an alarm,

press the navigation keys to navigate to the alarm number

and press [OK]. Information is displayed about the

condition of the frequency converter or filter before it

enters the alarm mode.

[Back]

The back key reverts to the previous step or layer in the

navigation structure.

B

a

c

k

Illustration 5.7 Back Key

[Cancel]

The last change or command is cancelled as long as the

display has not been changed.

C

a

n

c

e

l

Illustration 5.8 Cancel Key

[Info]

The info key displays information about a command,

parameter, or function in any display window. [Info]

provides detailed information when needed.

Exit Info mode by pressing either [Info], [Back], or [Cancel].

I

n

f

o

Illustration 5.9 Info Key

Navigation keys

The 4 navigation keys are used to navigate between the

options available in [Quick Menu], [Main Menu], and [Alarm

Log]. Move the cursor with the navigation keys.

[OK]

The OK key is used for selecting a parameter marked by

the cursor and for enabling the change of a parameter.

130BT117.10

OK

Back

Info

Warn

Alarm

On

Cancel

Illustration 5.10 Navigation Keys

Operation keys

For local control. Found at the bottom of the control

panel.

130BP046.10

Hand

on

O

Auto

on

Reset

Illustration 5.11 Operation Keys

User Interface Operating Instructions

32 Danfoss A/S © 09/2014 All rights reserved. MG90V302

55

Page 36

[Hand On]

Press [Hand On] to begin operation of the active filter via

the LCP. The key can be [1] Enabled or [0] Disabled via

0-40 [Hand on] Key on LCP.

The following control signals are active when [Hand On]

is pressed:

•

[Hand On] - [Off] - [Auto On].

•

Reset.

•

Stop inverse.

•

Set-up select bit 0; Set-up select bit 1.

NOTICE

External stop signals activated with control signals or a

serial bus overrides a Start command via the LCP.

[Off]

The OFF key stops the active filter (when pressed on the

filter LCP). The key can be [1] Enabled or [0] Disabled via

parameter 0-41 [Off] Key on LCP. If no external stop function

is selected, and the [Off] key is inactive, the active filter

can only be stopped by disconnecting the mains supply.

[Auto On]

The Auto On key enables the active filter to be controlled

via the control terminals and/or serial communication.

When a start signal is applied on the control terminals

and/or the bus, the active filter starts. The key can be [1]

Enabled or [0] Disabled via parameter 0-42 [Auto on] Key on

LCP.

NOTICE

An active HAND-OFF-AUTO signal via the digital inputs

has higher priority than the control keys [Hand On] –

[Auto On].

[Reset]

The Reset key is used for resetting the filter after an alarm

(trip). The key can be [1] Enabled or [0] Disabled via

parameter 0-43 [Reset] Key on LCP on the LCP.

Parameter shortcut

A parameter shortcut can be carried out by holding down

[Main Menu] for 3 s. The parameter shortcut allows direct

access to any parameter.

5.1.3

Changing Data

1. Press [Quick Menu] or [Main Menu].

2.

Press [▲] and [▼] to find the parameter group to

edit.

3. Press [OK].

4.

Press [▲] and [▼] to find the parameter to edit.

5. Press [OK].

6.

Press [▲] and [▼] to select the correct parameter

setting. Or, to move to digits within a number,

use [◄] and [►]. The cursor indicates the digit

selected to change. [▲] increases the value, [▼]

decreases the value.

7. Press [Cancel] to ignore the change, or press [OK]

to accept the change and enter a new setting.

5.1.4 Changing a Text Value

If the selected parameter is a text value, change the text

value by pressing the [▲]/[▼] keys.

[▲] increases the value, and [▼] decreases the value. Place

the cursor on the value to be saved and press [OK].

5.1.5

Changing a Group of Numeric Data

Values

If the selected parameter represents a numeric data value,

change the selected data value by pressing the [◄] and [►]

navigation keys as well as [▲] and [▼] keys. Press [◄] and

[►] to move the cursor horizontally.

Press [▲]/[▼] to change the data value. [▲] increases the

data value, and [▼] decreases the data value. Place the

cursor on the value to be saved and press [OK].

5.1.6

Changing of Data Value, Step-by-Step

Certain parameters can be changed step-by-step or

infinitely variably. This method applies to

parameter 300-10 Active Filter Nominal Voltage.

The parameters are changed both as a group of numeric

data values and as numeric data values infinitely variably.

5.1.7

Readout and Programming of

Indexed Parameters

Parameters are indexed when placed in a rolling stack.

15-30 Alarm Log: Error Code to parameter 15-32 Alarm Log:

Time contain a fault log that can be read out. Select a

parameter, press [OK], and use [▲]/[▼] to scroll through the

value log.

Use 3-10 Preset Reference as another example:

Select the parameter, press [OK], and press [▲]/[▼] to scroll

through the indexed values. To change the parameter

value, select the indexed value and press [OK]. Change the

value by using [▲]/[▼]. Press [OK] to accept the new

setting. Press [Cancel] to abort. Press [Back] to leave the

parameter.

User Interface

Operating Instructions

MG90V302 Danfoss A/S © 09/2014 All rights reserved. 33

5 5

Page 37

5.1.8 Quick Transfer of Parameter Settings

with the LCP

Once the set-up is complete, store (back up) the parameter

settings in the LCP or on a PC via MCT 10 set-up software

tool.

WARNING

Running the unit during these operations can cause

unexpected operation. Stop the unit before performing

any of these operations. Failure to do so can cause

damage or injury..

Data storage in LCP

1.

Go to 0-50 LCP Copy.

2. Press [OK].

3.

Select [1] All to LCP.

4. Press [OK].

All parameter settings are now stored in the LCP indicated

by the progress bar. When 100% is reached, press [OK].

The LCP can now be connected to another active filter and

the parameter settings copied to this active filter.

Data transfer from LCP to the unit

1.

Go to 0-50 LCP Copy.

2. Press [OK].

3.

Select [2] All from LCP.

4. Press [OK].

The parameter settings stored in the LCP are now

transferred to the active filter indicated by the progress

bar. When 100% is reached, press [OK].

5.1.9

Initialisation to Default Settings

There are 2 ways to initialise the unit to default:

Recommended initialisation and manual initialisation.

Each method has a different impact.

5.1.9.1

Recommended Initialisation Method

Initialisation via 14-22 Operation Mode

1.

Select 14-22 Operation Mode.

2. Press [OK].

3.

Select Initialisation.

4. Press [OK].

5. Remove power to the unit and wait for the

display to turn off.

6. Reconnect power to reset the unit.

7. Press [Reset].

14-22 Operation Mode

initialises all except:

•

Parameter 14-50 RFI Filter.

•

8-31 Address.

•

8-32 Baud Rate

•

8-35 Minimum Response Delay

•

Parameter 8-36 Max Response Delay

•

8-37 Maximum Inter-Char Delay

•

Parameter 15-00 Operating hours to

parameter 15-05 Over Volt's

•

Parameter 15-20 Historic Log: Event to

parameter 15-22 Historic Log: Time

•

15-30 Alarm Log: Error Code to

parameter 15-32 Alarm Log: Time

NOTICE

Parameters selected in 0-25 My Personal Menu, stay

present with default factory setting.

5.1.9.2 Manual Initialisation Method

NOTICE

When carrying out manual initialisation, serial communication, RFI filter settings, and fault log settings are reset.

Manual initialisation removes parameters selected in

0-25 My Personal Menu.

1. Disconnect from mains and wait until the display

turns off.

2. Press [Status] - [Main Menu] - [OK] at the same

time during power-up for graphical LCP .

3. Release the keys after 5 s.

4. The unit is now programmed according to default

settings.

This parameter initialises all except:

•

Parameter 15-00 Operating hours

•

Parameter 15-03 Power Up's

•

Parameter 15-04 Over Temp's

•

Parameter 15-05 Over Volt's

User Interface

Operating Instructions

34 Danfoss A/S © 09/2014 All rights reserved. MG90V302

55