Page 1

■ Contents

VLT®8000 AQUA

Introduction

Software version ....................................................................................................... 4

Definitions ................................................................................................................ 5

Safety regulations ..................................................................................................... 7

Warning against unintended start ............................................................................. 7

Introduction to Operating Instructions ....................................................................... 9

Control principle ..................................................................................................... 10

AEO - Automatic Energy Optimization .................................................................... 10

Example of application - Constant pressure regulation in water supply system ....... 12

PC software and serial communication ................................................................... 13

PC Software tools .................................................................................................. 13

Fieldbus options ..................................................................................................... 13

Profibus .................................................................................................................. 13

LON - Local Operating Network ............................................................................. 14

DeviceNet .............................................................................................................. 14

Modbus RTU .......................................................................................................... 14

Cascade Controller Option ..................................................................................... 17

Unpacking and ordering a VLT frequency converter ................................................ 25

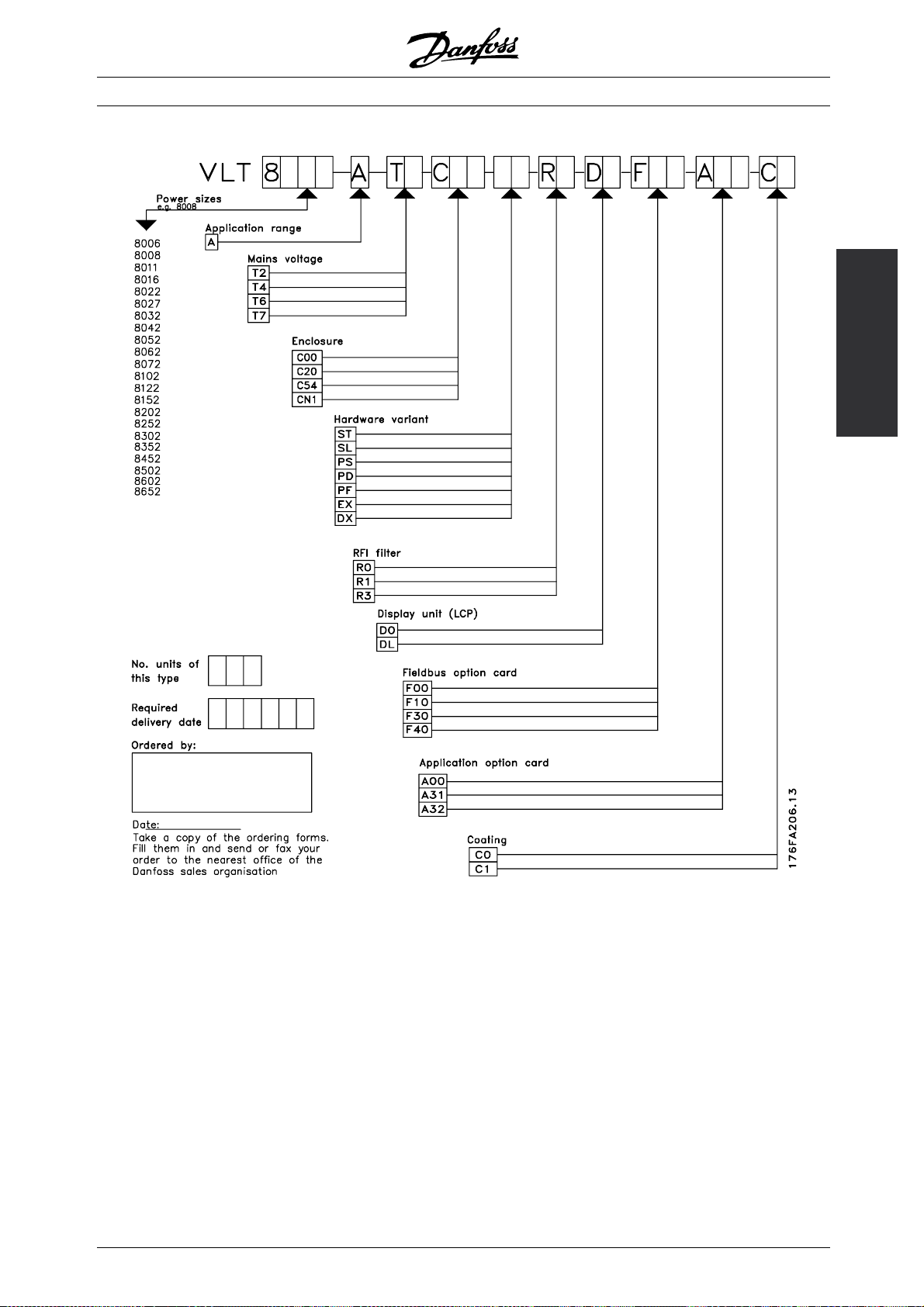

Type code ordering number string ......................................................................... 25

TYPE CODE Table/Ordering form ........................................................................... 29

......................................................................................................... 4

Installation ......................................................................................................... 30

General technical data ............................................................................................ 30

Technical data, mains supply 3 x 200 - 240 V ......................................................... 36

Technical data, mains supply 3 x 380 - 480 V ........................................................ 38

Technical data, mains supply 3 x 525 - 600 V ......................................................... 43

Fuses ..................................................................................................................... 48

Mechanical dimensions .......................................................................................... 51

Mechanical installation ............................................................................................ 54

General information about electrical installation ...................................................... 56

High voltage warning .............................................................................................. 56

Earthing .................................................................................................................. 56

Cables .................................................................................................................... 56

Screened/armoured cables .................................................................................... 56

Extra protection with regard to indirect contact ....................................................... 57

RFI switch .............................................................................................................. 58

High voltage test .................................................................................................... 61

Heat emission from VLT 8000 AQUA ...................................................................... 61

EMC-correct electrical installation ........................................................................... 62

Earthing/Grounding of screened/armoured control cables ...................................... 64

Electrical installation, enclosures ............................................................................. 65

Use of emc-correct cables ..................................................................................... 73

Tightening torque and screw sizes ......................................................................... 74

Mains connection ................................................................................................... 75

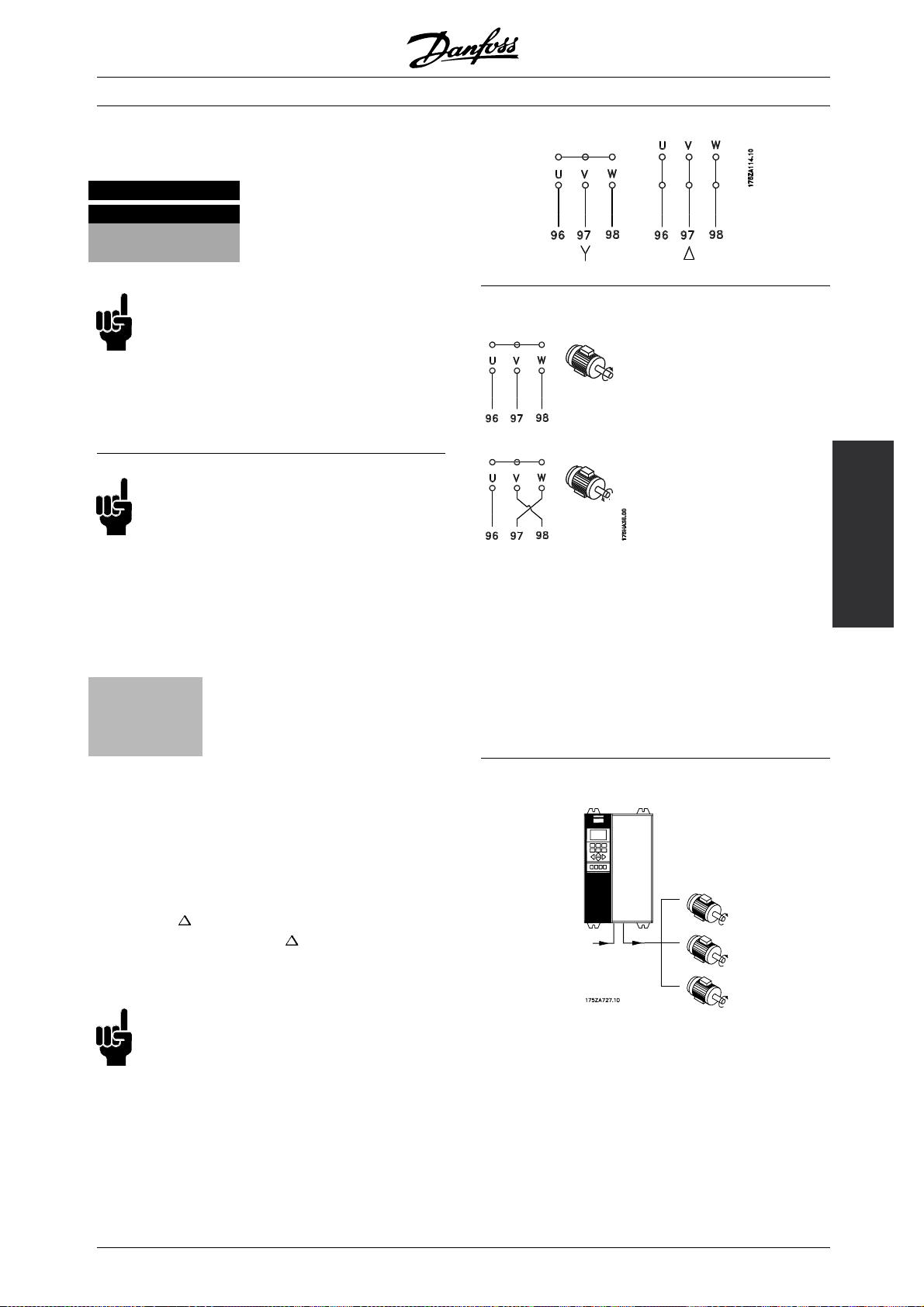

Motor connection ................................................................................................... 75

DC bus connection ................................................................................................ 77

High-voltage relay ................................................................................................... 77

Electrical installation, control cables ........................................................................ 78

Switches 1-4 .......................................................................................................... 79

Connection example VLT 8000 AQUA .................................................................... 81

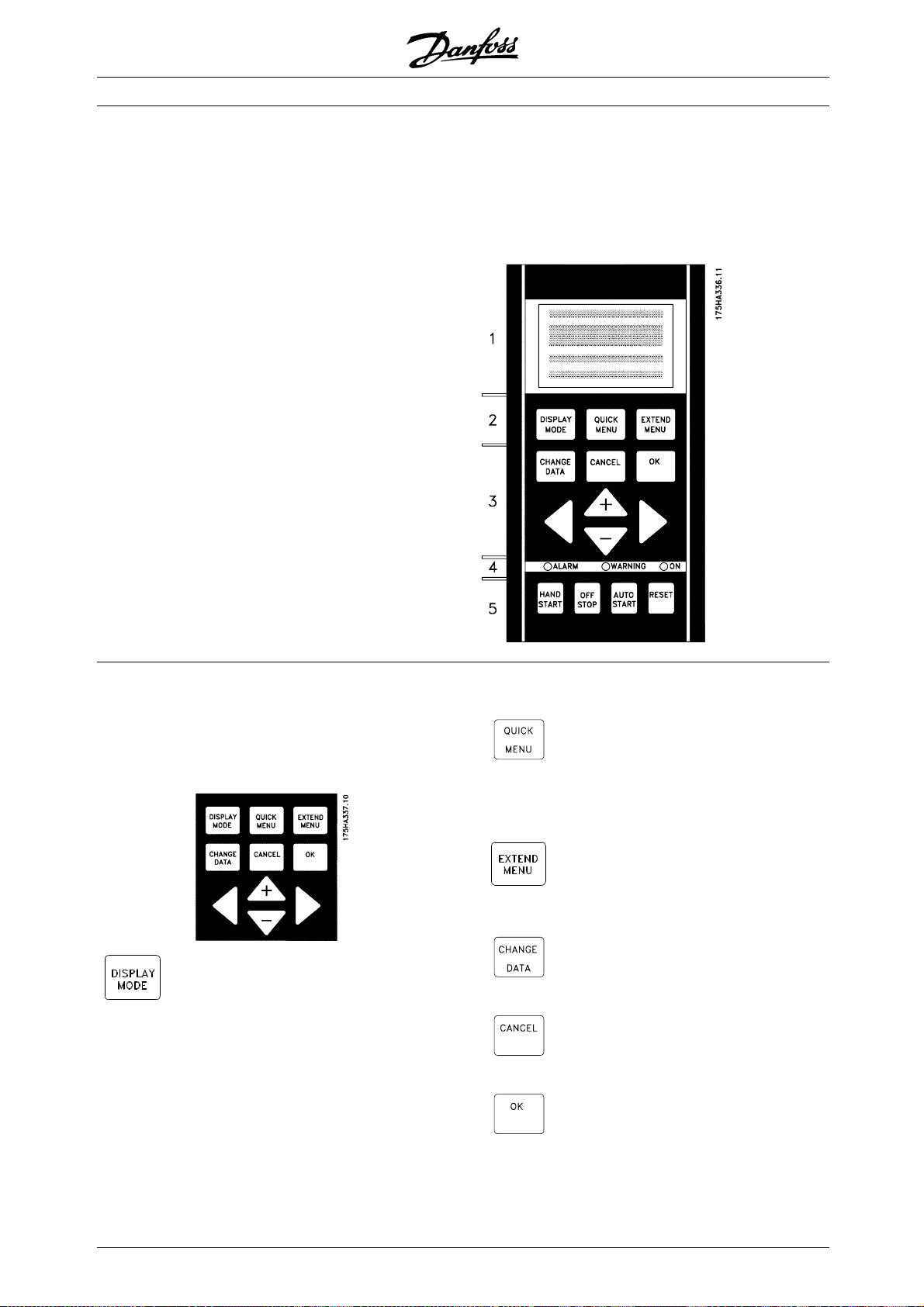

Control unit LCP ..................................................................................................... 84

MG.83.A2.02 - VLT is a registered Danfoss trademark

1

Page 2

VLT®8000 AQUA

Control keys for parameter setup ........................................................................... 84

Indicator lamps ....................................................................................................... 85

Local control .......................................................................................................... 85

Display mode ......................................................................................................... 85

Navigation between display modes ........................................................................ 88

Changing data ........................................................................................................ 89

Manual initialisation ................................................................................................. 89

Quick Menu ............................................................................................................ 90

Programming .................................................................................................... 92

Operation and Display 001-017 .............................................................................. 92

The Setup configuration ......................................................................................... 92

Setup of user-defined readout ................................................................................ 93

Load and motor 100-124 ....................................................................................... 99

Configuration .......................................................................................................... 99

Motor power factor (Cos ø) .................................................................................. 105

References and limits 200-228 ............................................................................. 108

Reference handling ............................................................................................... 109

Reference type ..................................................................................................... 112

Initial ramp parameter 229 .................................................................................... 116

Fill Mode .............................................................................................................. 116

Fill Rate parameter 230 ........................................................................................ 117

Filled Setpoint parameter 231 ............................................................................... 117

Inputs and outputs 300-328 ................................................................................. 118

Analog inputs ....................................................................................................... 122

Analog/digital outputs ........................................................................................... 125

Relay outputs ....................................................................................................... 128

Application functions 400-434 .............................................................................. 131

Sleep mode .......................................................................................................... 132

PID for process control ......................................................................................... 137

PID overview ........................................................................................................ 139

Feedback handling ............................................................................................... 139

Enhanced Sleep Mode ......................................................................................... 145

Serial communication for FC protocol ................................................................... 149

Protocols .............................................................................................................. 149

Telegram communication ..................................................................................... 149

Telegram build-up under FC protocol ................................................................... 149

Data character (byte) ............................................................................................ 151

Process word ....................................................................................................... 154

Control word according to FC protocol ................................................................. 155

Status word according to FC protocol .................................................................. 156

Serial communication 500-556 ............................................................................. 159

Warning words 1+2 and Alarm word .................................................................... 167

Service functions 600-631 .................................................................................... 168

Electrical installation of the relay card .................................................................... 173

All about VLT 8000 AQUA ......................................................................... 174

Status messages .................................................................................................. 174

List of warnings and alarms .................................................................................. 176

Special conditions ................................................................................................ 181

Aggressive environments ...................................................................................... 181

Calculation of resulting reference .......................................................................... 182

Extreme running conditions .................................................................................. 184

Peak voltage on motor ......................................................................................... 185

2

MG.83.A2.02 - VLT is a registered Danfoss trademark

Page 3

VLT®8000 AQUA

Derating for ambient temperature ......................................................................... 187

Switching on the input .......................................................................................... 187

Efficiency .............................................................................................................. 189

Mains supply interference/harmonics .................................................................... 190

CE labelling .......................................................................................................... 191

EMC test results (Emission, Immunity) .................................................................. 192

EMC Immunity ..................................................................................................... 194

Factory settings .................................................................................................... 196

Index .................................................................................................................... 204

MG.83.A2.02 - VLT is a registered Danfoss trademark

3

Page 4

VLT®8000 AQUA

VLT 8000 AQUA

Operating Instructions

Software version: 1.7x

These Operating Instructions can be used for all VLT 8000 AQUA

frequency converters with software version 1.7x.

The software version number can be seen from parameter 624

Software version no.

176FA145.16

4

MG.83.A2.02 - VLT is a registered Danfoss trademark

Page 5

■Definitions

Definitions are given in alphabetical order.

A

EO:

Automatic Energy Optimization - function that

dynamically adjusts the current supplied to a

variable torque load to optimize motor power

factor and motor efficiency.

nalog inputs:

a

The analog inputs can be used for controlling various

functions of the frequency converter.

There are two types of analog inputs:

Current input, 0-20 mA

Voltage input, 0-10 V DC.

nalog ref.

a

A signal transmitted to input 53, 54 or 60.

Can be voltage or current.

analog outputs:

There are two analog outputs, which are able to supply

a signal of 0-20 mA, 4-20 mA or a digital signal.

utomatic motor adjustment, AMA:

A

Automatic motor adjustment algorithm, which

determines the electrical parameters for the

connected motor, at standstill.

VLT®8000 AQUA

T:

C

Constant torque: used for e.g. heavy, solid

sludge pumps and centrifuges.

igital inputs:

D

The digital inputs can be used for controlling various

functions of the frequency converter.

D

igital outputs:

There are four digital outputs, two of which activate

a relay switch. The outputs are able to supply

a24VDC(max. 40mA)signal.

f

JOG

Theoutputfrequencyfromthefrequencyconverter

transmitted to the motor when the jog function is

activated (via digital terminals or serial communication).

f

M

Theoutputfrequencyfromthefrequencyconverter

transmitted to the motor.

f

M,N

The rated motor frequency (nameplate data).

f

MAX

Maximum output frequency transmitted to the motor.

Introduction

WG:

A

AWG means American Wire Gauge, i.e. the American

measuring unit for cable cross-section.

C

ontrol command:

By means of the control unit and the digital inputs, it is

possible to start and stop the connected motor.

Functions are divided into two groups, with

the following priorities:

Group 1 Reset, Coasting stop, Reset and

Coasting stop, DC braking, Stop and the

[OFF/ STOP] key.

Group 2 Start, Pulse start, Reversing, Start

reversing, Jog and Freeze output

Group 1 funct

ions are called Start-disable commands.

The difference between group 1 and group 2 is that

in group 1 all stop signals must be cancelled for the

motor to st

art. The motor can then be started by

means of a single start signal in group 2.

A stop command given as a group 1 command

in the display indication STOP.

results

A missing stop command given as a group 2 command

results in the display indication STAND BY.

f

MIN

Minimum output frequency transmitted to the motor.

I

M

The current transmitted to the motor.

I

M,N

The rated motor current (nameplate data).

I

nitializing:

If initializing is carried out (see parameter 620

Operating mode), the frequency converter

returns to the factory setting.

I

VLT,MAX

The maximum output current.

I

VLT,N

The rated output current supplied by the

frequency converter.

CP:

L

The control panel, which makes up a complete

interface for control and programming of VLT 8000

AQUA. The control panel is detachable and may,

as an alternative, be installed up to 3 metres away

MG.83.A2.02 - VLT is a registered Danfoss trademark

5

Page 6

from the frequency converter, i.e. in a front panel,

by means of the installation kit option.

L

SB:

Least significant bit.

Used in serial communication.

CM:

M

Stands for Mille Circular Mil, an American measuring

unit for cable cross-section.

SB:

M

Most significant bit.

Used in serial communication.

n

M,N

The rated motor speed (nameplate data).

η

VLT

The efficiency of the frequency converter is defined as

the ratio between thepower output andthe power input.

O

n-line/off-line parameters:

On-line parameters are activated immediately after the

data value is changed. Off-line parameters are not

activated until OK has been entered on the control unit.

ID:

P

The PID regulator maintains the desired speed

(pressure, temperature, etc.) by adjusting the output

frequency to match the varying load.

P

M,N

The rated power delivered by the motor

(nameplate data).

reset ref.

P

A permanently defined reference, which can be

set from -100% to +100% of the reference range.

There are four preset references, which can be

selected via the digital terminals.

ef

R

MAX

The maximum value which the reference signal

may have. Set in parameter 205 Maximum

reference, Ref

MAX

.

VLT®8000 AQUA

S

etup:

There are four Setups, in which it is possible to

save parameter settings. It is possible to change

between the four parameter Setups and to edit one

Setup, while another Setup is active.

tart-disable command:

S

A stop command that belongs to group 1 of the

control commands - see this group.

top command:

S

See Control commands.

T

hermistor:

A temperature-dependent resistor placed where the

temperature is to be monitored (VLT or motor).

rip:

T

A state which occurs in different situations, e.g.

if the frequency converter is subjected to an

over-temperature. A trip can be cancelled by pressing

reset or, in some cases, automatically.

rip locked:

T

Trip locked is a state which occurs in different

situations, e.g. if the frequency converter is subject to

an over-temperature. A locked trip can be cancelled by

cutting off mains and restarting the frequency converter.

U

M

The voltage transmitted to the motor.

U

M,N

The rated motor voltage (nameplate data).

U

VLT, MAX

The maximum output voltage.

V

T characteristics:

Variable torque characteristics, used for

pumps and fans.

R

ef

MIN

The smallest value which the reference signal may

have. Set in parameter 204 Minimum reference, Ref

6

MIN

.

MG.83.A2.02 - VLT is a registered Danfoss trademark

Page 7

VLT®8000 AQUA

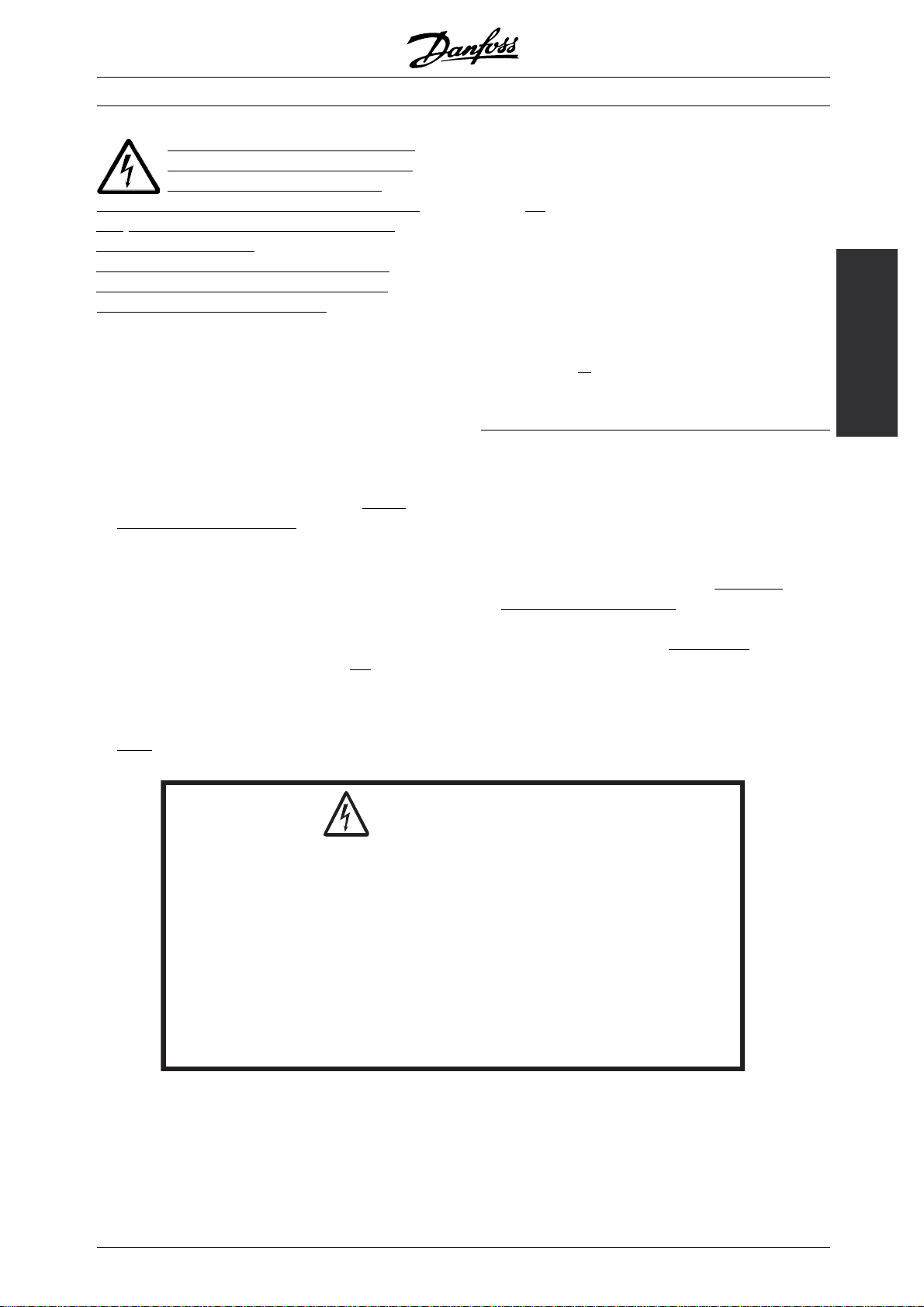

The voltage of the frequency converter

is dangerous whenever the equipment

is connected to mains. Incorrect

installation of the motor or the frequency converter

may cause damage to the equipment, serious

personal injury or death.

Consequently, the instructions in this manual,

as well as national and local rules and safety

regulations, must be complied with.

■Safety regulations

1. The frequency converter must be disconnected

from the mains if repair work is to be carried out.

Check that the mains supply has been disconnected

and that the necessary time has passed before

removing motor and mains plugs.

2. The [OFF/STOP] key on the control panel of

the frequency converter does not disconnect

the equipment from mains and is thus

be used as a safety switch.

3. Correct protective earthing/grounding of the

equipment must be established, the user must be

protected against supply voltage, and the motor

must be protected against overload in accordance

with the National Electrical Code and local codes.

4. The earth leakage currents are higher than 3.5mA.

5. Protection against motor overload is n

the factory setting. If this function is required, set

parameter 117, Motor thermal protection,todata

value ETR trip or data value ETR warning.

ote: The function is initialised at 1.0 x rated motor

N

current and rated motor frequency (see parameter

not to

ot included in

117, Motor thermal protection).InUL/cUL

applications ETR provides Class 20, over-load

®

protection in accordance with the NEC

6. Do n

7. Please note that the frequency converter has more

■Warning against unintended start

1. The motor can be brought to a stop by means

2. While parameters are being changed, the motor

3. A stopped motor may start if a fault occurs in

ot remove the plugs for the motor and

mains supply while the frequency converter is

connected to mains. Check that the mains supply

has been disconnected and that the necessary time

has passed before removing motor and mains plugs.

voltage inputs than L1, L2, L3 when the DC-bus

terminals or AUX 24 V option are used.

Check that a

disconnected and that the necessary time has

passed before repair work is commenced.

of digital commands, bus commands, references

or a local stop, while the frequency converter

is connected to mains. If personal safety

considerations make it necessary to ensure

that no unintended start occurs, t

functions are not sufficient.

may start. Consequently, t

STOP] must always be activated, following

which data can be modified.

the electronics of the frequency converter, or

if a temporary overload or a fault in the supply

mains or the motor connection ceases.

ll voltage inputs have been

he stop key [OFF/

.

hese stop

Introduction

Warning:

Touching the electrical parts may be fatal - even after the equipment has

been disconnected from line.

VLT 8006-8062, 200-240 V: wait at least 15 minutes

VLT 8006-8072, 380-480 V: wait at least 15 minutes

VLT 8102-8352, 380-480 V: wait at least 20 minutes

VLT 8452-8652, 380-480 V: wait at least 40 minutes

VLT 8002-8006, 525-600 V: wait at least 4 minutes

VLT 8008-8027, 525-600 V: wait at least 15 minutes

VLT 8032-8072, 525-600 V: wait at least 30 minutes

VLT 8052-8402, 525-690 V: wait at least 20 minutes

VLT 8502-8652, 525-690 V: wait at least 30 minutes

MG.83.A2.02 - VLT is a registered Danfoss trademark

176FA159.15

7

Page 8

■Use on isolated mains

See section RFI Switch regarding use on isolated mains.

It is important to follow the recommendations regarding

installation on IT-mains, since sufficient protection

of the complete installation must be observed.

Not taking care using relevant monitoring devices

for IT-mains may result in damage.

It is the responsibility of the user or the

person installing the VLT to provide proper

earthing/grounding, as well as motor

overload and branch circuit protection according to

local codes such as the Nation Electrical Code (NEC).

NB!:

Electrostatic Precaution; Electrostatic discharge

(ESD). Many electronic components are

sensitive to static electricity. Voltages so low

that they cannot be felt, seen or heard, can reduce

the life, affect performance, or completely destroy

sensitive electronic components. When performing

service, proper ESD equipment should be used to

prevent possible damage from occurring.

VLT®8000 AQUA

The frequency converter contains dangerous

voltages when connected to mains voltage.

After disconnecting from mains wait at least

15 minutes for VLT 8006-8062, 200-240 V

15 minutes for VLT 8006-8072, 380-480 V

20 minutes for VLT 8102-8352, 380-480 V

40 minutes for VLT 8452-8652, 380-480 V

4 minutes for VLT 8002-8006, 525-600 V

15 minutes for VLT 8008-8027, 525-600 V

30 minutes for VLT 8032-8072, 525-600 V

20 minutes for VLT 8052-8402, 525-690 V

30 minutes for VLT 8502-8652, 525-690 V

before touching any electrical components. Also

make sure that other voltage inputs have been

disconnected, such as external 24 VDC and

load-sharing (linkage of DC intermediate circuit). Only

a competent electrician should carry out the electrical

installation. Improper installation of the motor or the

VLT may cause equipment failure, serious injury or

death. Follow this manual and National Electrical

Codes (NEC) and local safety codes.

8

MG.83.A2.02 - VLT is a registered Danfoss trademark

Page 9

VLT®8000 AQUA

■Introduction to Operating Instructions

These Operating Instructions are divided into four

sections with information about VLT 8000 AQUA.

Introduction to AQUA: This section tells you the advantages you can obtain by using a VLT

8000 AQUA - such as Automatic Energy Optimization, Constant Torque

or Variable Torque and other AQUA relevant functions.

This section also contains examples of applications as well as

information about Danfoss.

Installation: This section tells you how to carry out a mechanically correct installation

of the VLT 8000 AQUA.

Furthermore, a list is given of mains and motor connections, together

with a description of the control card terminals.

Programming: This section describes the control unit and the software parameters for

the VLT 8000 AQUA. Also included is a guide to the Quick Setup menu,

which allows you to get started on your application very quickly.

All about VLT 8000 AQUA: This section gives information about status, warning and error messages

from the VLT 8000 AQUA. Additionally, information is given on technical

data, ser-vice, factory settings and special conditions.

Introduction

NB!:

Indicate

s something to be noted by the reader.

Indicates a general warning

Indicates a high-voltage warning

MG.83.A2.02 - VLT is a registered Danfoss trademark

9

Page 10

■Control principle

A frequency converter rectifies AC voltage from

mains into DC voltage, after which this DC

voltage is converted into a AC current with a

variable amplitude and frequency.

VLT®8000 AQUA

The motor is thus supplied with variable voltage and

frequency, which enables infinitely variable speed

control of three-phased, standard AC motors.

1. Mains voltage

3 x 200 - 240 V AC, 50 / 60 Hz.

3 x 380 - 480 V AC, 50 / 60 Hz.

3 x 525 - 600 V AC, 50 / 60 Hz.

3 x 525 - 690 V AC, 50 / 60 Hz.

. Rectifier

2

A three-phase rectifier bridge that rectifies AC

current into DC current.

3

. Intermediate circuit

DC voltage = 1.35 x mains voltage [V].

4

. Intermediate circuit coils

Even out the intermediate circuit voltage

the harmonic current feedback to the mains supply.

■AEO - Automatic Energy Optimization

Normally, the U/f characteristics have to be set on the

basis of the expec

However, knowing the load at a given frequency in an

installation is often a problem. This problem can be

solved by usin

Automatic Energy Optimization (AEO), which ensures

optimum energy utilization. All VLT 8000 AQUA units

feature thi

not necessary to adjust the frequency converter U/f

ratio in order to obtain maximum energy savings.

In other

voltage/frequency ratio (U/f) must be assessed to carry

out correct setting of the frequency converter.

Using A

no longer need to calculate or assess the system

characteristics of the installation, since Danfoss VLT

800

energy consumption by the motor at all times.

The figure on the right illustrates the working

range of the AEO function, within which energy

optimization is enabled.

s function as a factory setting, i.e. it is

frequency converters, the given load and

utomatic Energy Optimization (AEO), you

0 AQUA units guarantee optimum, load-dependent

ted load at different frequencies.

g a VLT 8000 AQUA with its integral

and reduce

5

. Intermediate circuit capacitors

Even out the intermediate circuit voltage.

6

. Inverter

Converts DC voltage into variable AC voltage

withavariablefrequency.

7

. Motor voltage

Variable AC voltage, 0-100% of mains supply voltage.

8

. Control card

This is where to find the computer that controls

the inverter which generates the pulse pattern by

which the DC voltage is converted into variable

AC voltage with a variable frequency.

he AEO function has been selected in parameter 101,

If t

Torque characteristics, this function will be constantly

active. If there is a major deviation from the optimum U/f

atio, the frequency converter will quickly adjust itself.

r

Advantages of the AEO function

• Automatic energy optimization

• Compensation if an oversize motor is used

• AEO matches operations to daily or

seasonal fluctuations

10

MG.83.A2.02 - VLT is a registered Danfoss trademark

Page 11

• Energy savings in a constant air volume system

• Compensation in the oversynchronous

working range

• Reduces acoustic motor noise

VLT®8000 AQUA

Introduction

MG.83.A2.02 - VLT is a registered Danfoss trademark

11

Page 12

VLT®8000 AQUA

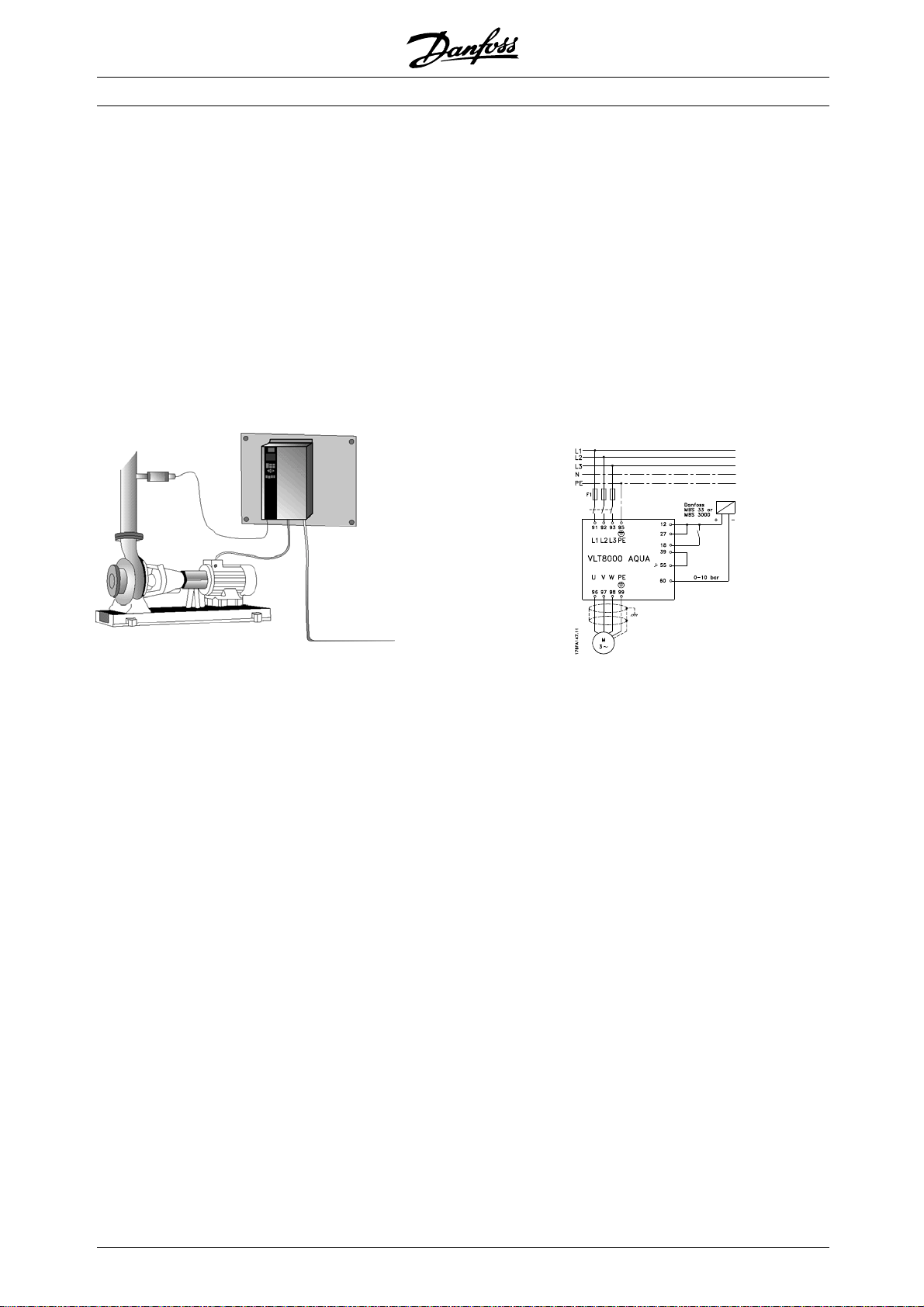

■Example of application - Constant pressure

regulation in water supply system

The demand for water from waterworks varies considerably during the course of a day. In the night,

practically no water is used, while in the morning and in the evening the consumption is high. In order to

maintain a suitable pressure in the water supply lines in relation to the current demand, the water supply

pumps are equipped with speed control. The use of a frequency converter enables the energy consumed by

the pumps to be kept at a minimum, while optimizing the water supply to consumers.

A VLT 8000 AQUA with its integral PID controller ensures simple and quick installation. For example, an

IP54/NEMA 12 unit can be mounted close to the pump on the wall and the existing mains cables can be

used as mains supply to the frequency converter. A Pressure transmitter (e.g. Danfoss MBS 33 or MBS

3000) can be fitted a few meters (feet) from the joint outlet point from the waterworks to obtain closed loop

regulation. Danfoss MBS 33 and MBS 3000 is a two-wire transmitter (4-20 mA) that can be powered directly

from a VLT 8000 AQUA. The required setpoint (e.g. 5 bar) can be set locally in parameter 418 Setpoint 1.

Assume:

Transmitter is scaled 0-10 Bar, minimum flow

is achieved at 30 Hz. An increase in motor

speed increases the pressure.

Set the following parameters:

Par. 100 Configuration Closed loop [1]

Par. 201 Minimum Output Frequency 30 Hz

Par. 202 Maximum Output Frequency 50 Hz (or 60 Hz)

Par. 204 Minimum Reference 0 Bar

Par. 205 Maximum Reference 10 Bar

Par. 302 Terminal 18 Digital inputs Start [1]

Par. 314 Terminal 60, analog input current Feedback signal [2]

Par. 315 Terminal 60, min. scaling 4 mA

Par. 316 Terminal 60, max. scaling 20 mA

Par. 403 Sleep mode timer 10 sec.

Par. 404 Sleep frequency 35 Hz

Par. 405 Wake-up frequency 45 Hz

Par. 406 Boost setpoint 125%

Par. 413 Minimum Feedback 0 Bar

Par. 414 Maximum Feedback 10 Bar

Par. 415 Process units Bar [16]

Par. 418 Setpoint 1 5 bar

Par. 420 PID control action Normal

Par. 423 PID Proportional gain 0.3*

Par. 424 PID Integral time 30 sec.*

* The PID tuning parameters depend on the actual system dynamics.

12

MG.83.A2.02 - VLT is a registered Danfoss trademark

Page 13

VLT®8000 AQUA

■PC software and serial communication

Danfoss offers various options for serial communication.

Using serial communication, it is possible to monitor,

program and control one or several frequency

converters from a centrally located computer.

All VLT 8000 AQUA units have an RS 485 port as

standard with a choice of two protocols. The protocols

selectable in parameter 500 protocols are:

• FC Protocol

• Modbus RTU

A bus option card allows higher transmission speed

than RS 485. In addition, a higher number of units

can be linked to the bus and alternative transmission

media can be used. Danfoss offers the following

option cards for communication:

• Profibus

• LonWorks

• DeviceNet

Information on the installation of various options is

not included in these operating instructions.

Using the RS 485 port enables communication,

TM

e.g. with a PC. A Windows

program, called

MCT 10, is available for this purpose. It can be

used to monitor, program and control one or

several VLT 8000 AQUA units.

■PC Software tools

PC Software - MCT 10

All drives are equipped with a serial communication

port. We provide a PC tool for communication

between PC and frequency converter, VLT Motion

Control Tool MCT 10 Set-up Software.

MCT 10 Set-up Software

MCT 10 has been designed as an easy to use interactive

tool for setting parameters in our frequency converters.

The MCT 10 Set-up Software will be useful for:

• Planning a communication network off-line. MCT 10

contains a complete frequency converter database

• Commissioning frequency converters on line

• Saving settings for all frequency converters

• Replacing a drive in a network

• Expanding an existing network

• Future developed drives will be supported

MCT10Set-upSoftwaresupportProfibusDP-V1via

a Master class 2 connection. It makes it possible to

on line read/write parameters in a frequency converter

via the Profibus network. This will eliminate the need

for an extra communication network.

The MCT 10 Set-up Software Modules

The following modules are included in the

software package:

MCT10Set-upSoftware

Setting parameters

Copy to and from frequency converters

Documentation and print out of parameter

settings incl. diagrams

SyncPos

Creating SyncPos programme

Ordering number:

Please order your CD containing MCT 10 Set-up

Software using code number 130B1000.

Introduction

■Fieldbus options

The increasing need for information in building

management systems makes it necessary to collect

or visualise many different types of process data.

Important process data can help the system technician

in the day to day monitoring of the system, which

means that a negative development, e. g. an increase

in energy consumption, can be rectified in time.

The substantial amount of data in large buildings

may generate a need for a higher transmission

speed than 9600 baud.

MG.83.A2.02 - VLT is a registered Danfoss trademark

■Profibus

Profibus is a fieldbus system with FMS and DP,

which can be used for linking automation units,

such as sensors and actuators, to the controls

by means of a two-conductor cable.

Profibus FMS is used if major communication

tasks are to be solved at cell and system level by

means of large volumes of data.

Profibus DP is an extremely fast communication

protocol, made specially for communication between

the automation system and various units.

VLT 8000 AQUA only supports DP.

13

Page 14

■LON - Local Operating Network

LonWorks is an intelligent fieldbus system which

improves the possibility of decentralising control,

as communication is enabled between individual

units in the same system (Peer-to-Peer).

This means that there is no need for a big main station

for handling all the signals of the system (Master-Slave).

Signals are sent direct to the unit that needs them

via a common network medium. This makes

communication much more flexible and the central

building state control and monitoring system can be

changed into a dedicated building state monitoring

system whose task is to ensure that everything is

running as planned. If the potential of LonWorks is

fully utilised, sensors will also be connected to the

bus, which means that a sensor signal can quickly

be moved to another controller. If room dividers are

mobile, this is a particularly useful feature.

■DeviceNet

DeviceNet is a digital, multi-drop network, based

on the CAN protocol, that connects and serves

as a communication network between industrial

controllers and I/O devices.

Each device and/or controller is a node on the

network. DeviceNet is a producer-consumer

network that supports multiple communication

hierarchies and message prioritization.

DeviceNet systems can be configured to operate in a

master-slave or a distributed control architecture using

peer-to-peer communication. This system offers a

single point of connection for configuration and control

by supporting both I/O and explicit messaging.

DeviceNet also has the feature of having power

on the network. This allows devices with limited

power requirements to be powered directly from

the network via the 5-conductor cable.

VLT®8000 AQUA

■Modbus RTU

MODBUS RTU (Remote Terminal Unit) Protocol is

a messaging structure developed by Modicon in

1979, used to establish master-slave/client-server

communication between intelligent devices.

MODBUS is used to monitor and program

devices; to communicate intelligent devices

with sensors and instruments; to monitor field

devicesusingPCsandHMIs.

MODBUS is often applied in Gas and Oil applications,

but also in building, infrastructure, transportation and

energy, applications are making use of its benefits.

14

MG.83.A2.02 - VLT is a registered Danfoss trademark

Page 15

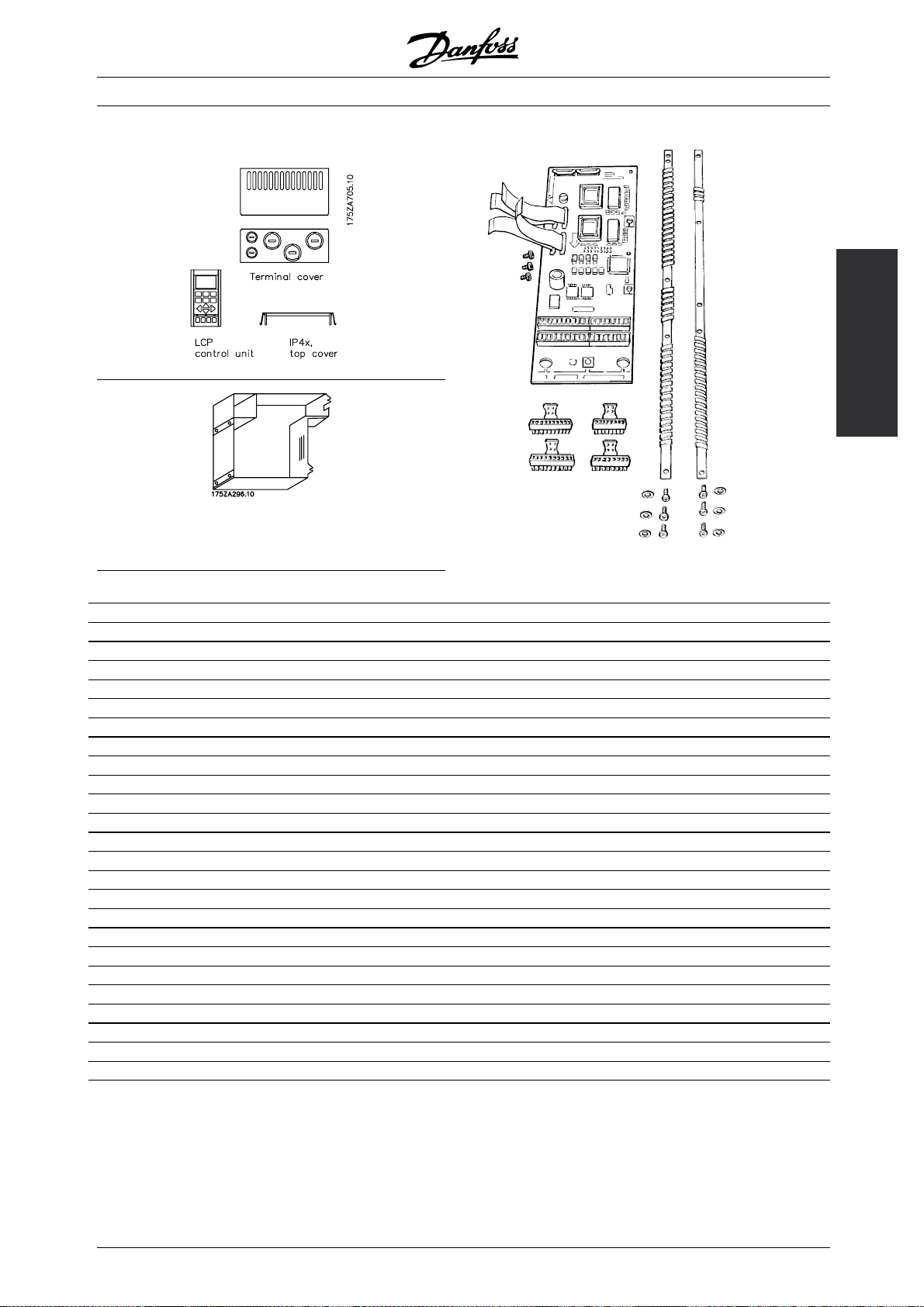

■Accessories

IP 20 bottom cover

VLT®8000 AQUA

Introduction

Application option

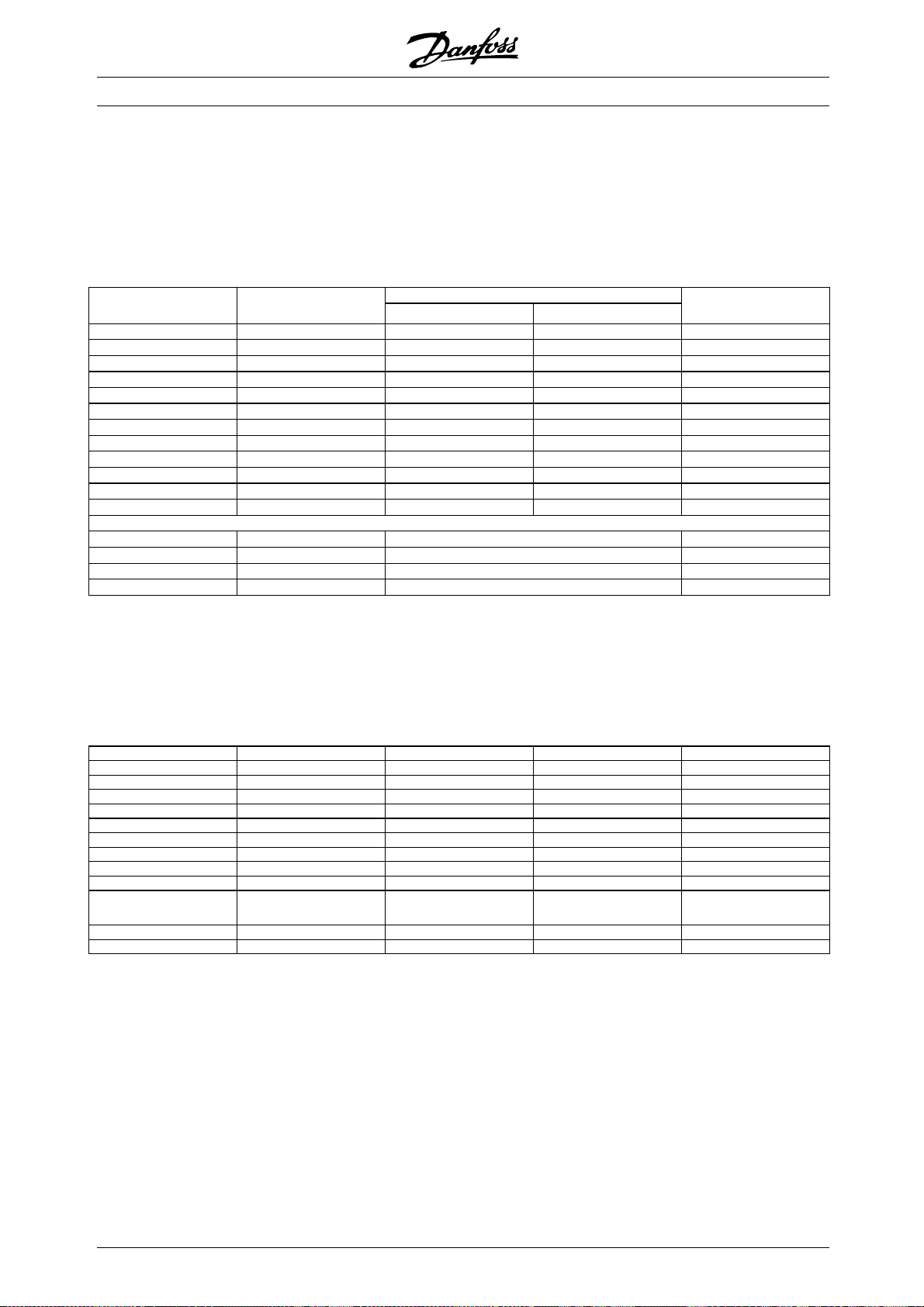

Type Description Order no.

IP 4x top cover IP

IP 4 x top cover

NEMA 12 bonding plate

IP 20 terminal cover Option, VLT type 8006-8022 200-240 V 175Z4622

IP 20 terminal cover Option, VLT type 8027-8032 200-240 V 175Z4623

IP 20 terminal cover Option, VLT type 8016-8042 380-480 V 175Z4622

IP 20 terminal cover Option, VLT type 8016-8042 525-600 V 175Z4622

IP 20 terminal cover Option, VLT type 8052-8072 380-480 V 175Z4623

IP 20 terminal cover Option, VLT type 8102-8122 380-480 V 175Z4280

IP 20 terminal cover Option, VLT type 8052-8072 525-600 V 175Z4623

IP 20 bottom cover Option, VLT type 8042-8062 200-240 V 176F1800

Terminal adaptor kit VLT type 8042-8062 200-240 V, IP 54 176F1808

Terminal adaptor kit VLT type 8042-8062 200-240 V, IP 00/NEMA 1 176F1805

Control panel LCP Separate LCP 175Z7804

LCP remote-mounting kit IP 00 & 20

LCP remote-mounting kit IP 54

LCP blind cover for all IP00/IP20 drives 175Z7806

Cable for LCP Separate cable (3 m) 175Z0929

Relay card Application card with four relay outputs 175Z3691

Cascade controller card With conformal coating 175Z3692

Profibus option Without/with conformal coating 175Z3685/175Z3686

LonWorks option, Free topology Without conformal coating 176F0225

Modbus RTU option Without conformal coating 175Z3362

DeviceNet option Without conformal coating 176F0224

MCT 10 Set-up software CD-Rom 130B1000

MCT 31 Harmonic calculation CD-Rom 130B1031

1)

1)

2)

3)

4)

Option, VLT type 8006-8011 380-480 V compact 175Z0928

Option, VLT type 8002-8011 525-600 V compact 175Z0928

Option, VLT type 8006-8011 380-480 V 175H4195

Remote-mounting kit, incl. 3 m cable 175Z0850

Remote-mounting kit, incl. 3 m cable 175Z7802

MG.83.A2.02 - VLT is a registered Danfoss trademark

15

Page 16

VLT®8000 AQUA

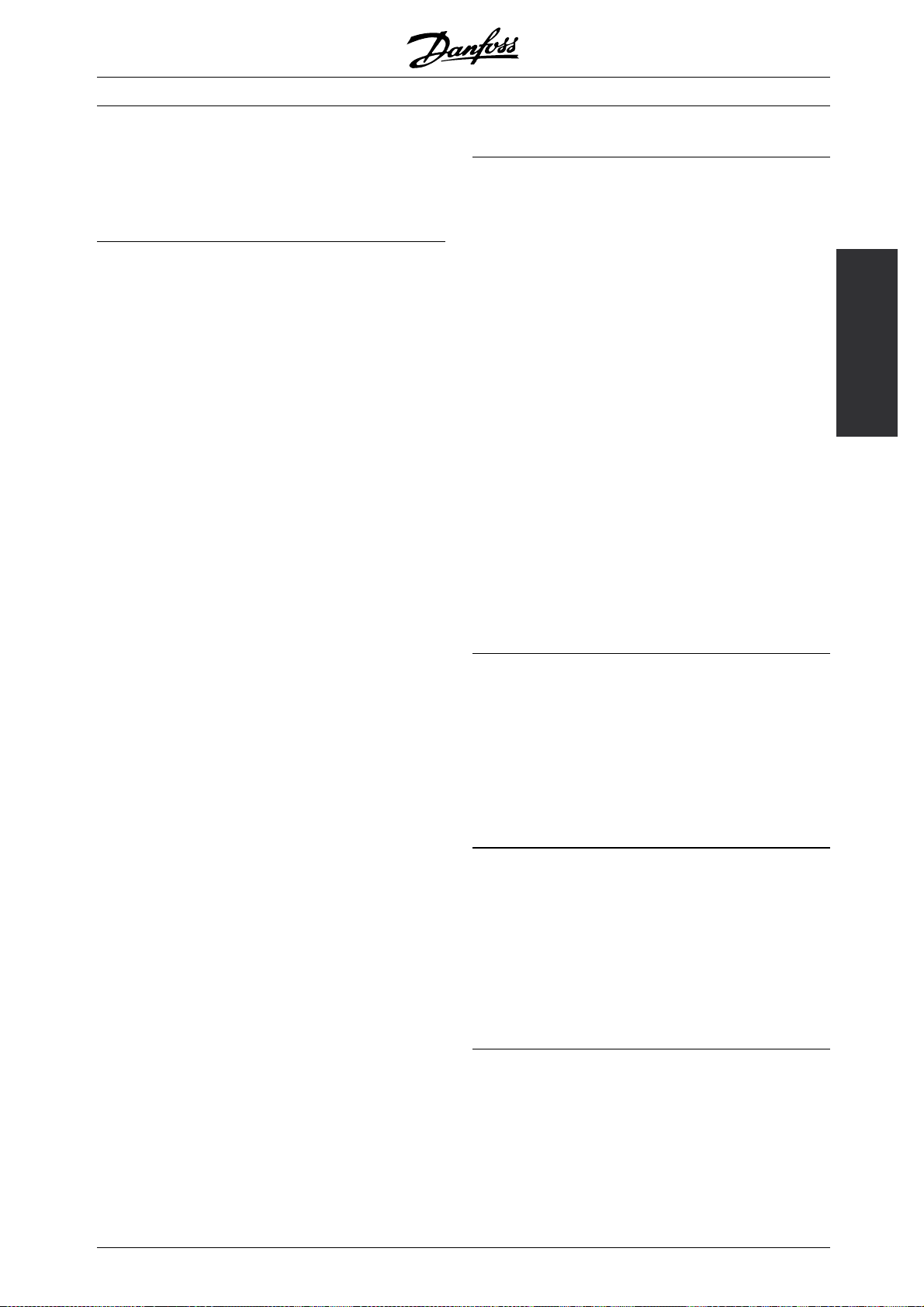

Rittal Installation Kit

Type Description Order No.

Rittal TS8 enclosure for IP00

Rittal TS8 enclosure for IP00

Rittal TS8 enclosure for IP00

Rittal TS8 enclosure for IP00

Rittal TS8 enclosure for IP00

Floor stand for IP21 and IP54

5)

enclosure

Mains shield kit Protection kit, VLT 8152-8352, 380-480 V; VLT 8052-8402, 525-690 V 176F0799

Mains shield kit Protection kit, VLT 8452-8652, 380-480 V; VLT 8502-8652, 525-690V 176F1851

1) IP 4x/NEMA 1 top cover is for IP 20 units only and only horizontal surfaces comply with IP 4x. The kit also

contains a bonding plate (UL).

2) NEMA 12 bonding plate (UL) is only for IP 54 units.

3) The remote-mounting kit is only for IP 00 and IP 20 units. Enclosure of the remote-mounting kit is IP 65.

4) The remote-mounting kit is only for IP 54 units. Enclosure of the remote-mounting kit is IP 65.

5) For details: See High Power Installation Guide, MI.90.JX.YY.

VLT 8000 AQUA is available with an integral fieldbus option or application option. Ordering numbers for the

individual VLT types with integrated options can be seen from the relevant manuals or instructions. In addition,

the ordering number system can be used for ordering a frequency converter with an option.

5)

Installation kit for 1800mm high enclosure, VLT8152-8202, 380-480V; VLT8052-8202, 525-690V 176F1824

5)

Installation kit for 2000mm high enclosure, VLT8152-8202, 380-480V; VLT8052-8202, 525-690V 176F1826

5)

Installation kit for 1800mm high enclosure, VLT8252-8352, 380-480V; VLT8252-8402, 525-690V 176F1823

5)

Installation kit for 2000mm high enclosure, VLT8252-8352, 380-480V; VLT8252-8402, 525-690V 176F1825

5)

Installation kit for 2000mm high enclosure, VLT8452-8652, 380-480V/VLT 8502-8652, 525-690V 176F1850

Option, VLT8152-8352, 380-480V; VLT 8052-8402, 525-690V 176F1827

16

MG.83.A2.02 - VLT is a registered Danfoss trademark

Page 17

■Cascade Controller Option

In "Standard Mode", one motor is controlled by

the drive that has the Cascade Controller Option

card installed in it. Up to four additional fixed speed

motors can be sequenced on & off, as required

by the process, in lead-lag mode.

In "Master/Slave Mode", the drive that has the

Cascade Controller option card installed in it, along

with its associated motor, is designated as the

master. Up to four additional motors, each with

its own drive, can be operated in slave mode. The

Cascade Controller functions to stage the slave

drives/motors - on & off (as required), as a function

of "best system operating efficiency".

In "Lead Pump Alternation Mode", it is possible to

averageouttheusageofthepumps.Thisisdoneby

making the frequency converter switch between the

pumps (max. 4) by means of a timer. Please note

that this mode requires an external relay setup.

VLT®8000 AQUA

This filter reduces the voltage rise time, the peak voltage

and the ripple current I to the motor, thereby

U

PEAK

making current and voltage almost sinusoidal. The

acoustic motor noiseis thereforereducedto a minimum.

Because of the ripple current in the coils, there will be

some noise from the coils. This problem can be solved

entirely by integrating the filter in a cabinet or similar.

Introduction

Consult your Danfoss Sales Office for

additional information.

■LC filters for VLT 8000 AQUA

When a motor is controlled by a frequency converter,

resonance noise will be heard from the motor. This

noise, which is caused by the design of the motor,

occurs each time one of the inverter switches in

the frequency converter is activated. Consequently,

the resonance noise frequency corresponds to the

switching frequency of the frequency converter.

For the VLT 8000 AQUA, Danfoss offers a LC filter

to dampen the acoustic motor noise.

■Examples of the use of LC filters

ubmersible pumps

S

For small motors with up to and including 5.5 kW

rated motor power, use an LC filter, unless the motor

is equipped with phase separation paper. This applies

e.g. to all wet running motors. If these motors are

used without LC filter in connection with a frequency

converter, the motor windings will short-circuit. If in

doubt, ask the motor manufacturer whether the motor

in question is equipped with phase separation paper.

ell pumps

W

If immersion pumps are used, e.g. submerged

pumps or well pumps, the supplier should be

contacted for clarification of requirements. It is

recommended to use a LC filter if a frequency converter

is used for well pump applications.

MG.83.A2.02 - VLT is a registered Danfoss trademark

17

Page 18

VLT®8000 AQUA

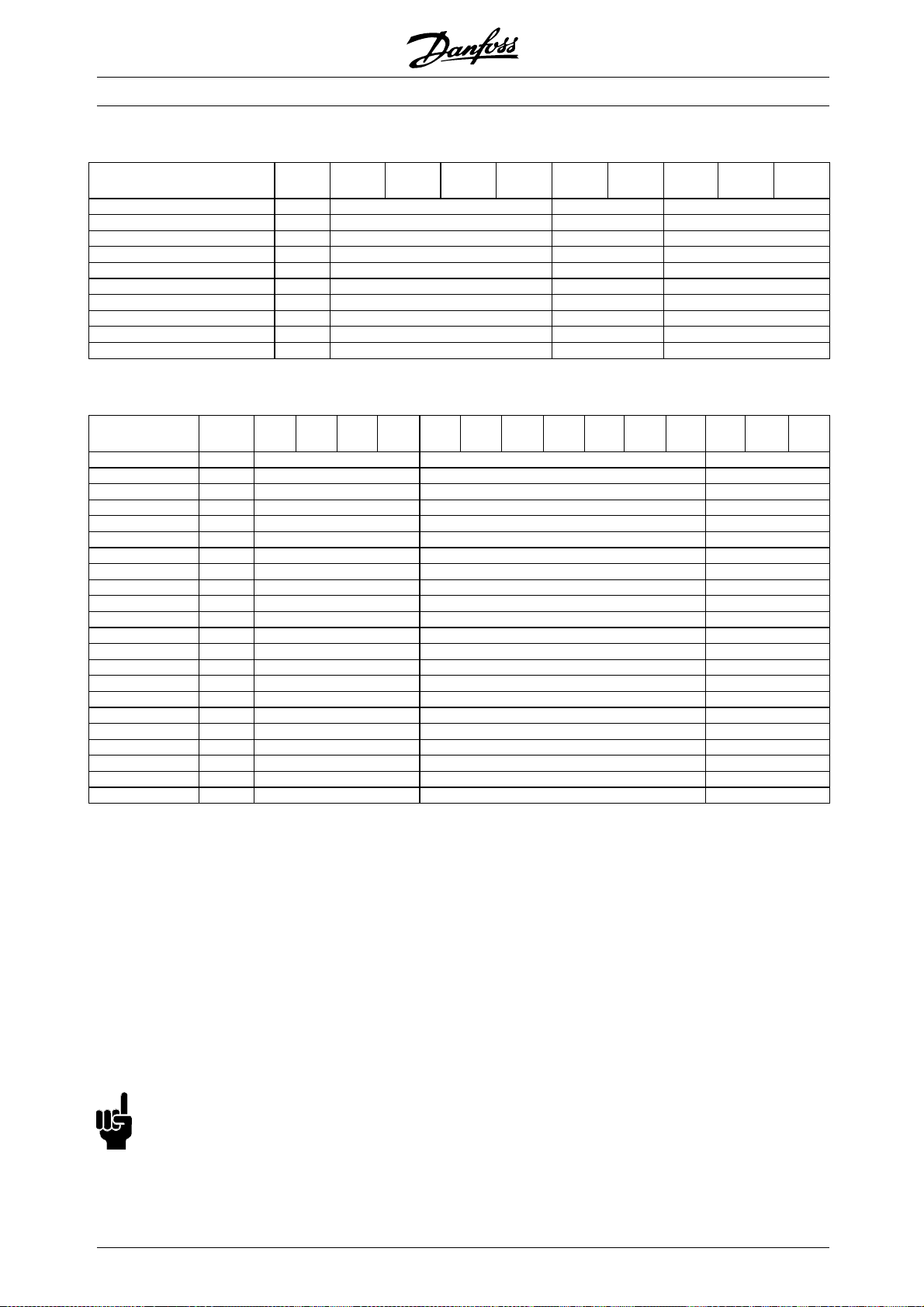

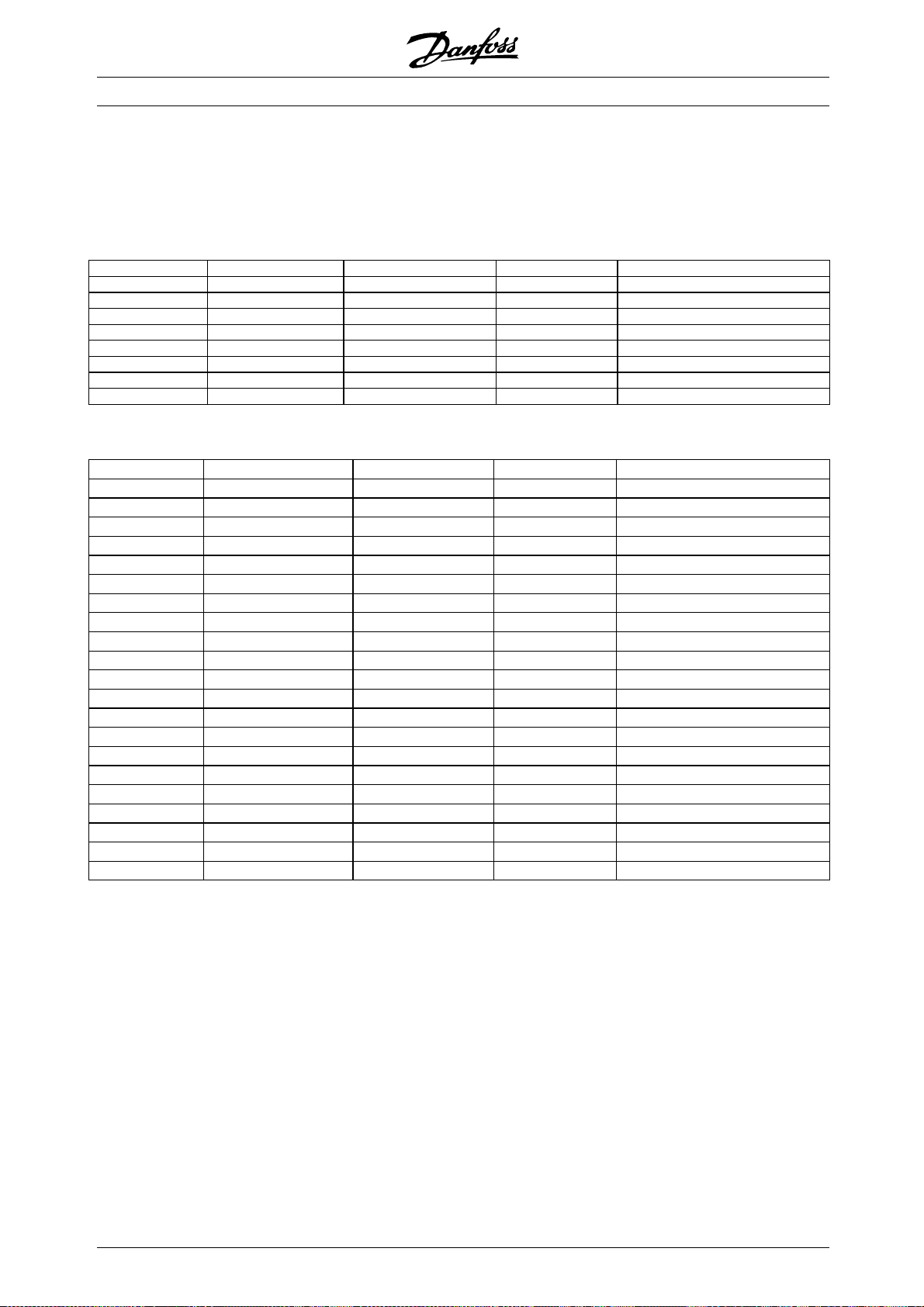

■Ordering numbers, LC filter modules

Mains supply 3 x 200 - 240 V

LC filter LC filter Rated current Max. output Power

for VLT type enclosure at 200 V frequency loss Order no.

8006-8008 IP 00 25.0 A 60 Hz 110 W 175Z4600

8011 IP 00 32 A 60 Hz 120 W 175Z4601

8016 IP 00 46 A 60 Hz 150 W 175Z4602

8022 IP 00 61 A 60 Hz 210 W 175Z4603

8027 IP 00 73 A 60 Hz 290 W 175Z4604

8032 IP 00 88 A 60 Hz 320 W 175Z4605

8042 IP 00 115 A 60 Hz 600 W 175Z4702

8052 IP 00 143 A 60 Hz 600 W 175Z4702

8062 IP 00 170 A 60 Hz 700 W 175Z4703

Mainssupply3x380-480

LC filter LC filter Rated current Max. output Power

for VLT type enclosure at 400/480 V frequency loss Order no.

8006-8011 IP 20 16 A / 16 A 120 Hz 175Z0832

8016 IP 00 24 A/ 21.7 A 60 Hz 170 W 175Z4606

8022 IP 00 32 A / 27.9 A 60 Hz 180 W 175Z4607

8027 IP 00 37.5 A / 32 A 60 Hz 190 W 175Z4608

8032 IP 00 44 A / 41.4 A 60 Hz 210 W 175Z4609

8042 IP 00 61 A / 54 A 60 Hz 290 W 175Z4610

8052 IP 00 73 A / 65 A 60 Hz 410 W 175Z4611

8062 IP 00 90 A / 78 A 60 Hz 480 W 175Z4612

8072 IP 20 106 A / 106 A 60 Hz 500 W 175Z4701

8102 IP 20 147 A / 130 A 60 Hz 600 W 175Z4702

8122 IP 20 177 A / 160 A 60 Hz 750 W 175Z4703

8152 IP 20 212 A / 190 A 60 Hz 750 W 175Z4704

8202 IP 20 260 A / 240 A 60 Hz 900 W 175Z4705

8252 IP 20 315 A / 302 A 60 Hz 1000 W 175Z4706

8302 IP 20 395 A / 361 A 60 Hz 1100 W 175Z4707

8352 IP 20 480 A / 443 A 60 Hz 1700 W 175Z3139

8452 IP 20 600 A / 540 A 60 Hz 2100 W 175Z3140

8502 IP 20 658 A / 590 A 60 Hz 2100 W 175Z3141

8602 IP 20 745 A / 678 A 60 Hz 2500 W 175Z3142

Regarding LC filters for 525 - 600 V and VLT 8652,

380-480 V, please contact Danfoss.

NB!:

When using LC filters, the switching frequency

must be 4.5 kHz (see parameter 407).

For VLT 8452-8602 parameter 408 must be set to

LC filter fitted to obtain proper operation.

18

MG.83.A2.02 - VLT is a registered Danfoss trademark

Page 19

Mainssupply3x690V

VLT®8000 AQUA

VLT

8052 54 60 290 130B2223 130B2258

8062 73 60 390 130B2225 130B2260

8072 86 60 480 130B2225 130B2260

8102 108 60 600 130B2226 130B2261

8122 131 60 550 130B2228 130B2263

8152 155 60 680 130B2228 130B2263

8202 192 60 920 130B2229 130B2264

8252 242 60 750 130B2231 130B2266

8302 290 60 1000 130B2231 130B2266

8352 344 60 1050 130B2232 130B2267

8402 400 60 1150 130B2234 130B2269

8502 530 60 500 130B2241 130B2270

8602 600 60 570 130B2242 130B2271

8652 630 60 600 - -

Rated Current at 690VMax. output

frequency (Hz)

Power

dissipation (W)

Ordering no. IP00

Ordering no.

IP20

dU/dt filters

The dU/dt filters reduce dU/dt to approx. 500 V / µsec. These filters do not red

uce noise or Upeak.

NB!:

When using dU/dt filters, the switching

frequency must be 1.5 kHz (see parameter 411)

Introduction

Mains supply3x690V

VLT

8052 54 60 90 130B2154 130B2188

8062 73 60 100 130B2155 130B2189

8072 86 60 110 130B2156 130B2190

8102 108 60 120 130B2157 130B2191

8122 131 60 150 130B2158 130B2192

8152 155 60 180 130B2159 130B2193

8202 192 60 190 130B2160 130B2194

8252 242 60 210 130B2161 130B2195

8302 290 60 350 130B2162 130B2196

8352 344 60 480 130B2163 130B2197

8402 400 60 540 130B2165 130B2199

8502 530 60 500 130B2236 130B2239

8602 600 60 570 130B2237 130B2240

8652 630 60 600 - -

Rated Current at 690VMax. output

frequency (Hz)

Power

dissipation (W)

Ordering no. IP 00

Ordering no.

IP20

MG.83.A2.02 - VLT is a registered Danfoss trademark

19

Page 20

VLT®8000 AQUA

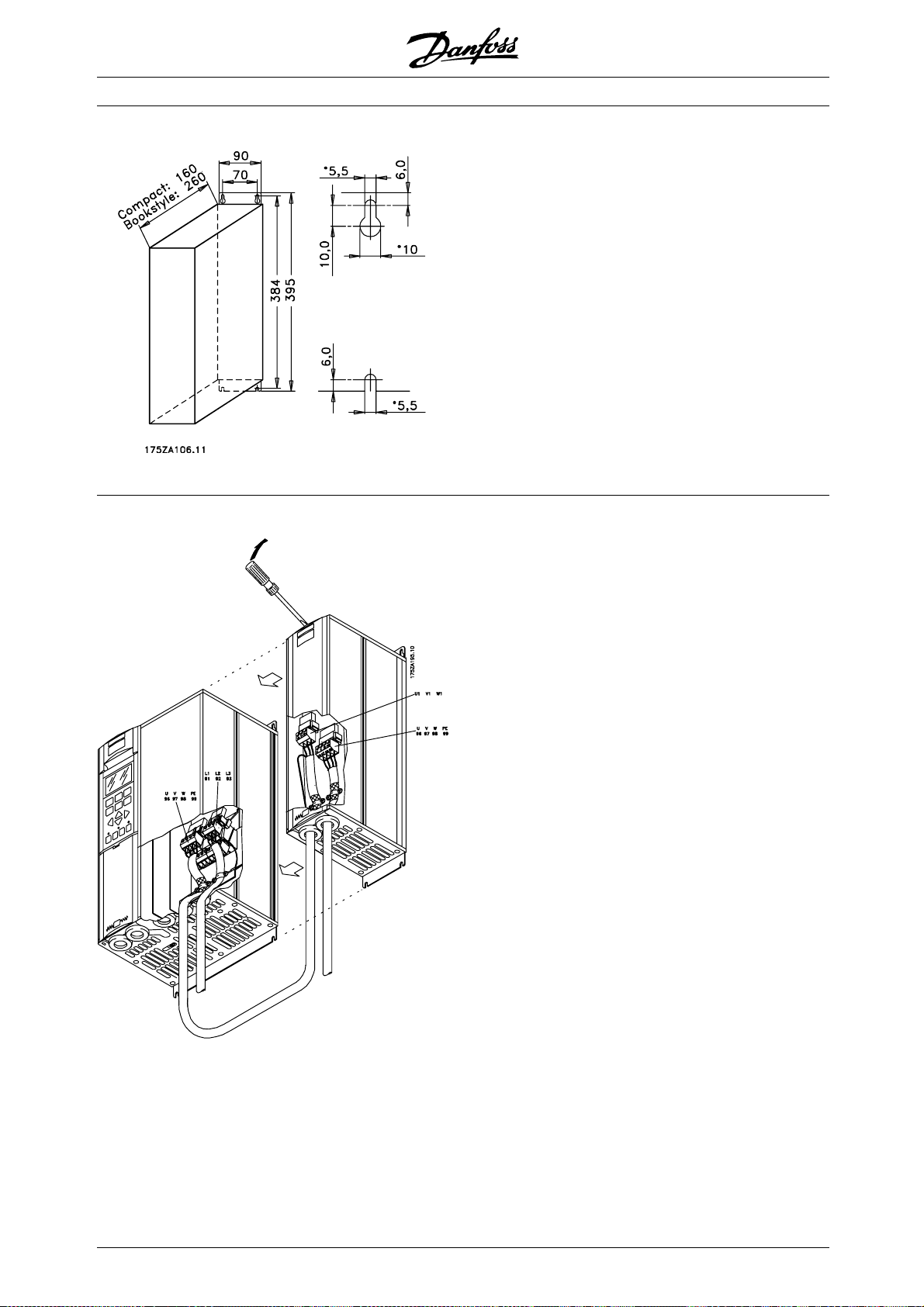

■LC filters VLT 8006-8011 380 - 480 V The drawing on the left gives the measurements of IP

20 LC filters for the above-mentioned power range.

Min. space above and under enclosure: 100 mm.

IP 20 LC filters have been designed for side-by-side

installation without any space between enclosures.

Max. motor cable length:

- 150 m screened/armoured cable

- 300 m unscreened/unarmoured cable

If EMC standards are to be complied with:

EN 55011-1B: Max. 50 screened/armoured

cable

EN 55011-1A: Max. 150 m screened/armoured

cable

Weight: 175Z0832 9.5 kg

■Installation of LC filter IP 20

20

MG.83.A2.02 - VLT is a registered Danfoss trademark

Page 21

VLT®8000 AQUA

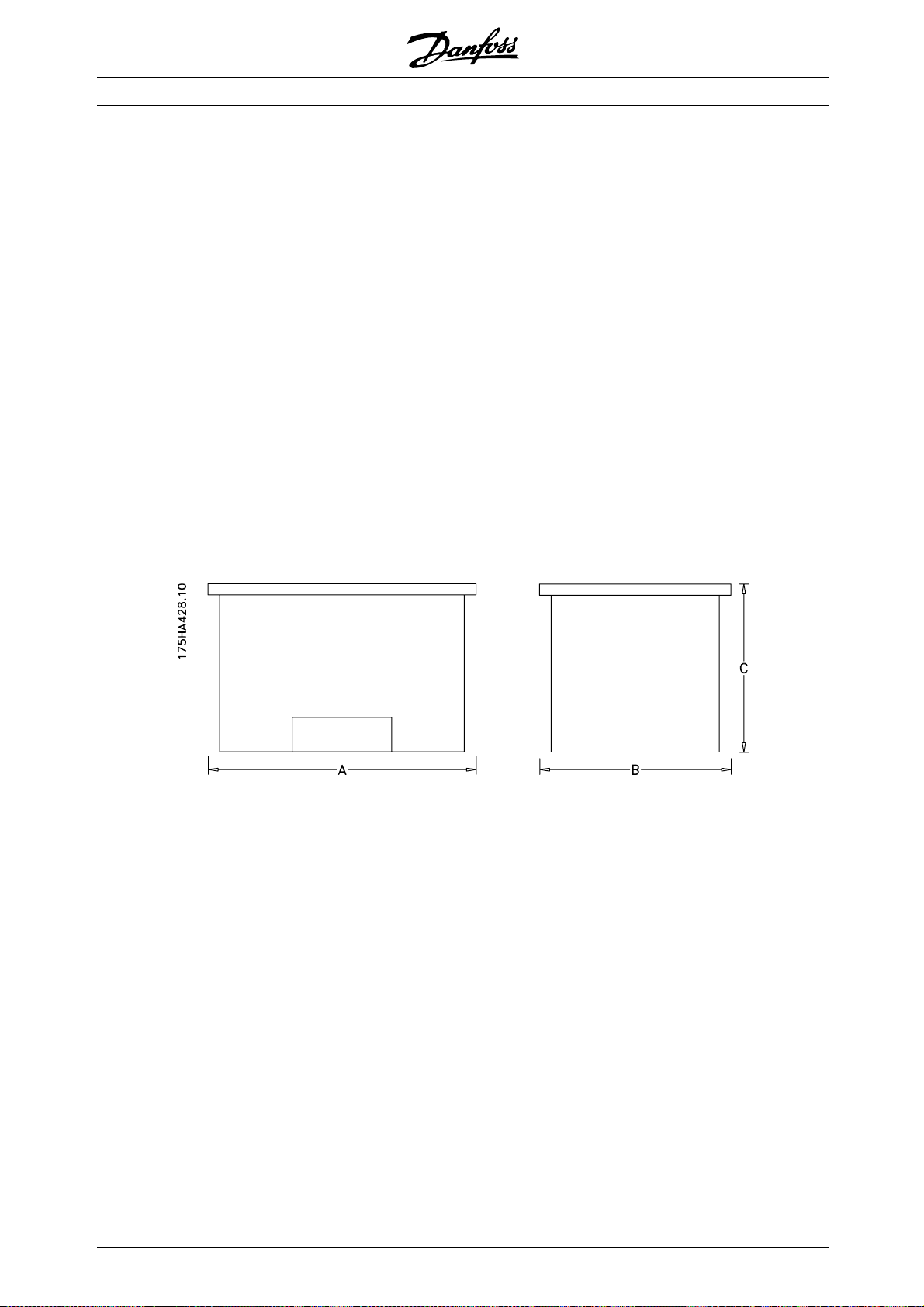

■LC filters VLT 8006-8032, 200 - 240 V /

8016-8062 380 - 480 V

The table and the drawing give the measurements

of IP 00 LC filters for Compact units.

IP 00 LC filters must be integrated and protected

against dust, water and corrosive gases.

Max. motor cable length:

- 150 m screened/armoured cable

- 300 m unscreened/unarmoured cable

If EMC standards are to be complied with:

- EN 55011-1B: Max. 50 screened/armoured

cable

- EN 55011-1A: Max. 150 m screened/armoured

cable

LC filter IP 00

LC type A [mm] B [mm] C [mm] D [mm] E [mm] F [mm] G [mm] Weight [kg]

175Z4600 220 135 92 190 68 170 8 10

175Z4601 220 145 102 190 78 170 8 13

175Z4602 250 165 117 210 92 180 8 17

175Z4603 295 200 151 240 126 190 11 29

175Z4604 355 205 152 300 121 240 11 38

175Z4605 360 215 165 300 134 240 11 49

175Z4606 280 170 121 240 96 190 11 18

175Z4607 280 175 125 240 100 190 11 20

175Z4608 280 180 131 240 106 190 11 23

175Z4609 295 200 151 240 126 190 11 29

175Z4610 355 205 152 300 121 240 11 38

175Z4611 355 235 177 300 146 240 11 50

175Z4612 405 230 163 360 126 310 11 65

Introduction

MG.83.A2.02 - VLT is a registered Danfoss trademark

21

Page 22

VLT®8000 AQUA

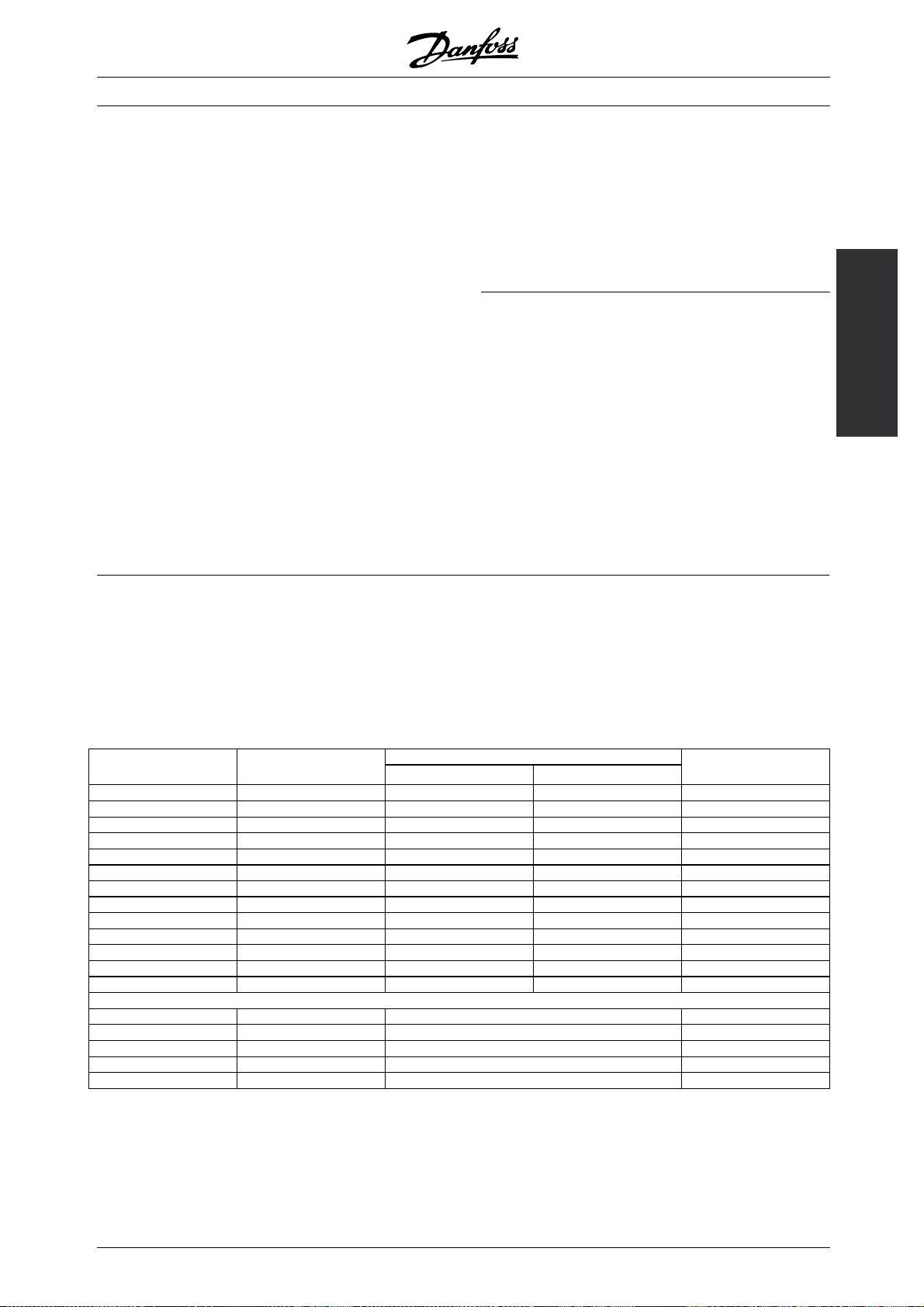

■LC filter VLT 8042-8062 200-240 V /

8072-8602 380 - 480 V

The table and the drawing give the measurements of IP

20 LC filters. IP 20 LC filters must be integrated and

protected against dust, water and aggressive gases.

Max. motor cable length:

- 150 m screened/armoured cable

- 300 m unscreened/unarmoured cable

If EMC standards are to be complied with:

- EN 55011-1B: Max. 50 m screened/armoured

cable

- EN 55011-1A: Max. 150 m screened/armoured

cable

LC-filter IP 20

LC type A [mm] B [mm] C [mm] D [mm] E [mm] F [mm] G [mm] Weight [kg]

175Z4701 740 550 600 70

175Z4702 740 550 600 70

175Z4703 740 550 600 110

175Z4704 740 550 600 120

175Z4705 830 630 650 220

175Z4706 830 630 650 250

175Z4707 830 630 650 250

175Z3139 1350 800 1000 350

175Z3140 1350 800 1000 400

175Z3141 1350 800 1000 400

175Z3142 1350 800 1000 470

22

MG.83.A2.02 - VLT is a registered Danfoss trademark

Page 23

VLT®8000 AQUA

■Harmonic filter

Harmonic currents do not directly affect the electricity

consumption but has an impact on following conditions:

Higher total current to be handled by the installations

- Increases load on transformer (sometimes it will

require a larger transformer, particular at retrofit)

- Increases heat losses in transformer and installation

- In some cases demands larger cables,

switches and fuses

Higher voltage distortion due to higher current

- Increase risk for disturbing electronic equipment

connected to same grid

A high percentage of rectifier load from eg frequency

converters, will increase the harmonic current, which

must be reduced to avoid the above consequences.

Therefore the frequency converter has as standard,

built in DC coils reducing the total current with about

40% (compared to devices without any arrangement

for harmonic suppression), down to 40-45% ThiD.

In some cases there is a need for further suppression

(eg retrofit with frequency converters). For this purpose

Danfoss can offer two advanced harmonic filters

AHF05 and AHF10, bringing the harmonic current

down to around 5% and 10% respectively. For further

details see instruction MG.80.BX.YY.

MCT 31

The MCT 31 harmonic calculation PC tool enables

easy estimation of the harmonic distortion in a given

application. Both the harmonic distortion of Danfoss

frequency converters as well as non-Danfoss frequency

converters with different additional harmonic reduction

measurements, such as Danfoss AHF filters and

12-18-pulse rectifiers, can be calculated.

Ordering number:

Please order your CD containing the MCT 31 PC

tool using code number 130B1031.

Introduction

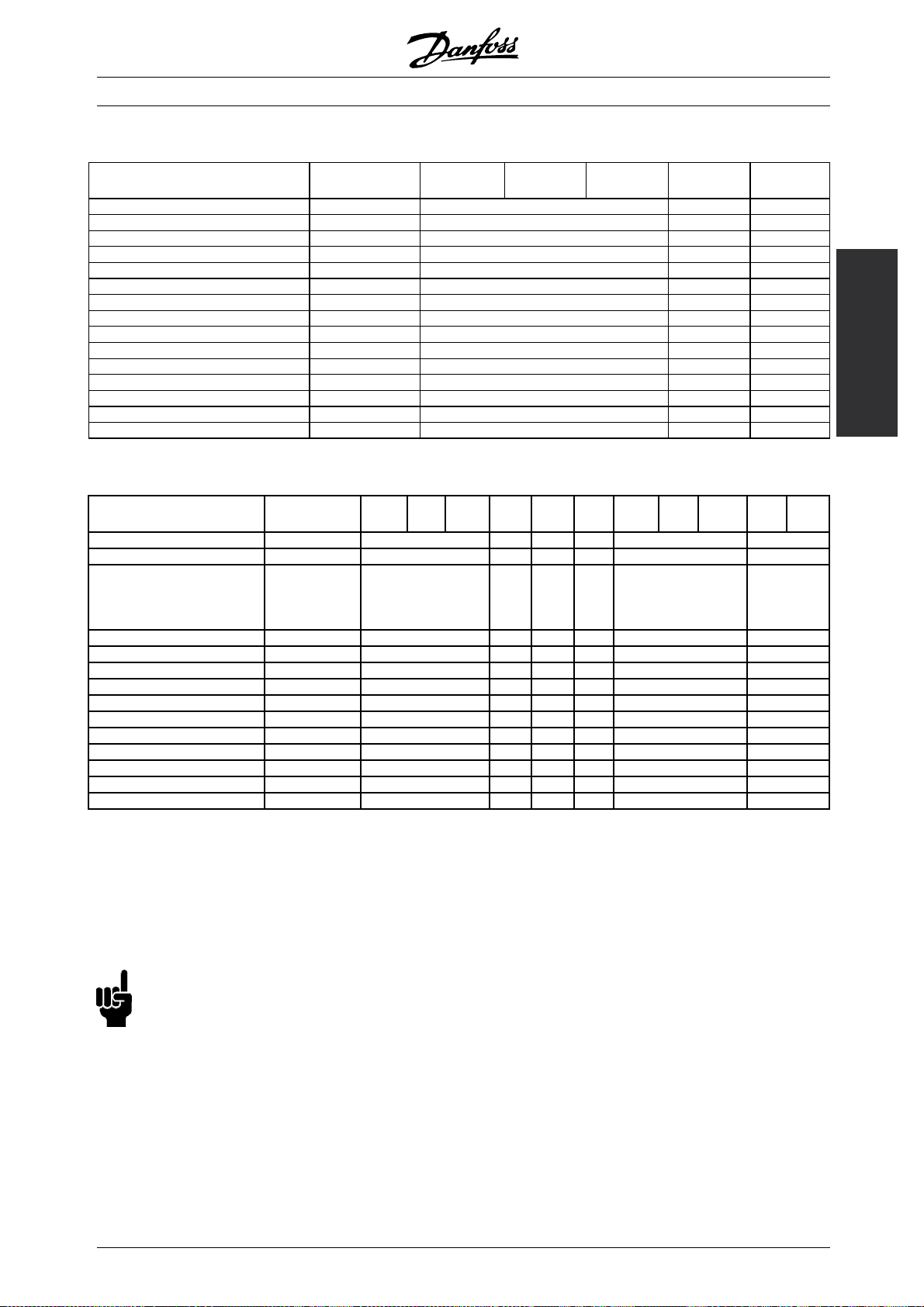

■Ordering numbers, Harmonic filters

Harmonic filters are used to reduce mains harmonics

• AHF 010: 10% current distortion

• AHF 005: 5% current distortion

380-415 V, 50 Hz

AHF,N

10 A 4, 5.5 175G6600 175G6622 8006, 8008

19 A 7.5 175G6601 175G6623 8011, 8016

26 A 11 175G6602 175G6624 8022

35 A 15, 18.5 175G6603 175G6625 8027

43 A 22 175G6604 175G6626 8032

72 A 30, 37 175G6605 175G6627 8042, 8052

101 A 45. 55 175G6606 175G6628 8062, 8072

144 A 75 175G6607 175G6629 8102

180 A 90 175G6608 175G6630 8122

217 A 110 175G6609 175G6631 8152

289 A 132, 160 175G6610 175G6632 8202, 8252

324 A 175G6611 175G6633

370 A 200 175G6688 175G6691 8302

Higher ratings can be achieved by paralleling the filter units

434 A 250 Two 217 A units 8352

578 A 315 Two 289 A units 8452

613 A 355 289 A and 324 A units 8502

648 A 400 Two 324 A units 8602

740 A 450 Two 370 A units 8652

Typical Motor Used

[kW]

Danfoss ordering numberI

AHF 005 A HF 010

VLT 8000

MG.83.A2.02 - VLT is a registered Danfoss trademark

23

Page 24

VLT®8000 AQUA

Please note that the matching of the typical Danfoss frequency converter and filter is pre-calculated based on

400 V and assuming typical motor load (4 or 2 pole motor). VLT 8000 is based on a max. 110% torque

application.

The pre-calculated filter current may be different than the input current ratings of VLT 8000 as stated in the

respective operating instructions, as these numbers are based on different operating conditions.

440-480 V, 60 Hz

AHF,N

19 A 10, 15 175G6612 175G6634 8011, 8016

26 A 20 175G6613 175G6635 8022

35 A 25, 30 175G6614 175G6636 8027, 8032

43 A 40 175G6615 175G6637 8042

72 A 50, 60 175G6616 175G6638 8052, 8062

101 A 75 175G6617 175G6639 8072

144 A 100, 125 175G6618 175G6640 8102, 8122

180 A 150 175G6619 175G6641 8152

217 A 200 175G6620 175G6642 8202

289 A 250 175G6621 175G6643 8252

324 A 300 175G6689 175G6692 8302

370 A 350 175G6690 175G6693 8352

Higher ratings can be achieved by p

506 A 450 217 A and 289 A units 8452

578 A 500 Two 289 A units 8502

578 A 550 Two 289 A units 8602

648 A 600 Two 324 A units 8652

Typical Motor Used

[HP]

aralleling the filter units

Danfoss ordering numberI

AHF 005 A HF 010

VLT 8000

Please note that the matching of the Danfoss frequency converter and filter is pre-calculated based on 480 V

and assuming typical motor load. VLT 8000 is based on 110 % torque application.

The pre-calculated filter current may be varying from the input current ratings of VLT 8000 as stated in the

respective operating instructions, as these numbers are based on different operating conditions.

690 V, 50 Hz

IAHF,N Ty p ic a l m o to r u s ed Ordering no. AHF 005 Ordering no. AHF 010 VLT 8000 110%

43 37, 45 130B2328 130B2293 8052

72 55, 75 130B2330 130B2295 8062, 8072

101 90 130B2331 130B2296 8102

144 110, 132 130B2333 130B2298 8122, 8152

180 160 130B2334 130B2299 8202

217 200 130B2335 130B2300 8252

289 250 130B2331 & 130B2333 130B2301 8302

324 315 130B2333 & 130B2334 130B2302 8352

370 400 130B2334 & 130B2335 130B2304 8402

469 500 130B2333 & 2 x

130B2334

578 560 3 x 130B2334 2 x 130B2301 8602

613 630 3 x 130B2335 130B2301 & 130B2302 8652

130B2299 & 130B2301 8502

24

MG.83.A2.02 - VLT is a registered Danfoss trademark

Page 25

VLT®8000 AQUA

■Unpacking and ordering a VLT frequency converter

If you are in doubt as to which frequency converter

you have received and which options it contains,

use the following to find out.

■Type code ordering number string

On the basis of your order, the frequency converter is

given an ordering number that can be seen from the

nameplate on the unit. The number may look as follows:

VLT-8008-A-T4-C20-R3-DL-F10-A00-C0

This means that the frequency converter ordered is a

VLT 8008 for three-phase mains voltage of 380-480 V

(T4) in Compact enclosure IP 20 (C20). The hardware

variant is with integral RFI filter, classes A & B (R3). The

frequency converter features a control unit (DL)witha

PROFIBUS option card (F10). No option card (A00)

and no conformal coating (C0) Character no. 8 (A)

indicates the application range of the unit: A =AQUA.

IP 00: This enclosure is only available for the larger

power sizes of the VLT 8000 AQUA series. It is

recommended for installation in standard cabinets.

IP 20/NEMA 1: This enclosure is used as standard

enclosure for VLT 8000 AQUA. It is ideal for

cabinet installation in areas where a high degree

of protection is required. This enclose also

permits side-by-side installation.

IP 54: This enclosure can be fitted direct to the

wall. Cabinets are not required. IP 54 units can

also be installed side-by-side.

Hardware variant

Theunitsintheprogrammeareavailableinthe

following hardware variants:

ST: Standard unit with or without control

unit. Without DC terminals, except for

VLT 8042-8062, 200-240 V

VLT 8016-8300, 525-600 V

SL: Standard unit with DC terminals.

EX: Extended unit with control unit, DC

terminals, connection of external 24 V

DC supply for back-up of control PCB.

DX: Extended unit with control unit, DC

terminals, built-in mains fuses and

disconnector, connection of external 24

V DC supply for back-up of control PCB.

PF: Standard unit with 24 V DC supply for

back-up of control PCB and built-in

main fuses. No DC terminals.

PS: Standard unit with 24 V DC supply

for back-up of control PCB. No DC

terminals.

PD: Standard unit with 24 V DC supply for

back-up of control PCB, built-in main

fuses and disconnect. No DC terminals.

RFI filter

Units for a mains voltage of 380-480 V and a motor

power of up to 7.5 kW (VLT 8011) are always

supplied with an integral class A1 & B filter. Units

for higher motor power than these can be ordered

either with or without an RFI filter. RFI filters are not

available for 525-600 V units.

Introduction

A1 RFI is not offered on the VLT 8502 -8652 525-690V

Control unit (keypad and display)

All types of units in the programme, except for IP

54 units (and IP 21 VLT 8452-8652, 380-480 V and

VLT 8502-8652, 525-690 V), can be ordered either

with or without the control unit. IP 54 units always

come with acontrolunit.

All types of units in the programme are available

with built-in application options including a relay

card with four relays or a cascade controller card.

Conformal Coating

All types of units in the programme are available

with or without conformal coating of the PCB.

Please note VLT 8452-8652, 380-480 V and

VLT 8052-8652, 525-690 V are only available as

conformal coated.

MG.83.A2.02 - VLT is a registered Danfoss trademark

25

Page 26

200-240 V

VLT®8000 AQUA

Typecode

Position in string

T2

9-10

C00

11-13

C20

11-13

CN1

11-13

C54

11-13ST14-15SL14-15R016-17R116-17R316-17

4.0 kW/5.0 HP 8006 XXXXXX

5.5 kW/7.5 HP 8008 XXXXXX

7.5 kW/10 HP 8011 XXXXXX

11 kW/15 HP 8016 XXXXXX

15 kW/20 HP 8022 XXXXXX

18.5 kW/25 HP 8027 XXXXXX

22 kW/30 HP 8032 XXXXXX

30 kW/40 HP 8042 XXXX XX

37 kW/50 HP 8052 XXXX XX

45 kW/60 HP 8062 XXXX XX

380-480 V

Typecode

Position in stringT49-10

4.0 kW/5.0 HP 8006 XXXX X

5.5 kW/7.5 HP 8008 XXXX X

7.5 kW/10 HP 8011 XXXXX

11 kW/15 HP 8016 XXXX X XX

15 kW/20 HP 8022 XXXX X XX

18.5 kW/25 HP 8027 XXXX X XX

22 kW/30 HP 8032 XXXX X XX

30 kW/40 HP 8042 XXXX X XX

37 kW/50 HP 8052 XXXX X XX

45 kW/60 HP 8062 XXXX X XX

55 kW/75 HP 8072 XXXX X XX

75 kW/100 HP 8102 XXXX X XX

90 kW/125 HP 8122 XXXX X XX

110 kW/150 HP 8152 XXXXXXXXXXX

132 kW/200 HP 8202 XXXXXXXXXXX

160 kW/250 HP 8252 XXXXXXXXXXX

200 kW/300 HP 8302 XXXXXXXXXXX

250 kW/350 HP 8352 XXXXXXXXXXX

315 kW/450 HP 8452 XXXXXXXXXXX

355 kW/500 HP 8502 XXXXXXXXXXX

400 kW/550 HP 8602 XXXXXXXXXXX

450 kW/600 HP 8652 XXXXXXXXXXX

C00

11-13

C20

11-13

CN1

C54

11-13

11-13ST14-15SL14-15EX14-15DX14-15PS14-15PD14-15PF14-15R016-17R116-17R316-17

Voltage

T2: 200-240 VAC

T4: 380-480 VAC

Enclosure

C00: Compact IP 00

C20: Compact IP 20

CN1: Compact NEMA 1

C54: Compact IP 54

NB!:

NEMA 1 exceeds IP 20

26

Hardware variant

ST: Standard

SL: Standard with DC terminals

EX: Extended with 24 V supply and DC terminals

DX: Extended with 24 V supply, DC terminals, disconnect and fuse

PS: Standard with 24 V supply

PD: Standard with 24 V supply, fuse and disconnect

PF: Standard with 24 V supply and fuse

RFI filter

R0: Without filter

R1: Class A1 filter

R3: Class A1 and B filter

MG.83.A2.02 - VLT is a registered Danfoss trademark

Page 27

525-600 V

VLT®8000 AQUA

Typecode

Position in string

1.1 kW/1.5 HP 8002 XXX X

1.5 kW/2.0 HP 8003 XXX X

2.2 kW/3.0 HP 8004 XXX X

3.0 kW/4.0 HP 8005 XXX X

4.0 kW/5.0 HP 8006 XXX X

5.5 kW/7.5 HP 8008 XXX X

7.5 kW/10 HP 8011 XXX X

11 kW/15 HP 8016 X X X

15 kW/20 HP 8022 X X X

18.5 kW/25 HP 8027 X X X

22 kW/30 HP 8032 X X X

30 kW/40 HP 8042 X X X

37 kW/50 HP 8052 X X X

45 kW/60 HP 8062 X X X

55 kW/75 HP 8072 X X X

T6

9-10

C00

11-13

C20

11-13

CN1

11-13

ST

14-15

R0

16-17

525-690 V

Typecode

Position in string

45 kW/50 HP 8052 XXXX X X XX X XX

55 kW/60 HP 8062 XXXX X X XX X XX

75 kW/75 HP 8072 XXXX X X XX X XX

T7

9-10

C00

11-13

CN1

C54

11-13

11-13ST11-13EX11-13DX14-15PS14-15PD14-15PF14-15R016-17R116-17

Introduction

1)

90 kW/100 HP 8102 XXXX X X XX XXX

110 kW/125 HP 8122 XXXX X X XX XXX

132 kW/150 HP 8152 XXXX X X XX XXX

160 kW/200 HP 8202 XXXX X X XX XXX

200 kW/250 HP 8252 XXXX X X XX XXX

250 kW/300 HP 8302 XXXX X X XX XXX

315 kW/350 HP 8352 XXXX X X XX XXX

400 kW/400 HP 8402 XXXX X X XX XXX

500 kW/400 HP 8502 XXXX X X XX XX

560 kW/500 HP 8602 XXXX X X XX XX

630 kW/600 HP 8652 XXXX X X XX XX

1) R1 is not available with DX, PF and PD variants.

T7: 525-690 VAC

C00: Compact IP 00

C20: Compact IP 20

CN1: Compact NEMA 1

ST: Standard

R0: Without filter

R1: Class A1 filter

NB!:

NEMA 1 exceeds IP 20

MG.83.A2.02 - VLT is a registered Danfoss trademark

27

Page 28

Optional selections, 200-600 V

Display Position: 18-19

D01)Without LCP

DL With LCP

Fieldbus option Position: 20-22

F00 No options

F10 Profibus DP V1

F30 DeviceNet

F40 LonWorks free topology

Application option Position: 23-25

A00 No options

A312)Relay card 4 relays

A32 Cascade Controller

Coating Position: 26-27

C03)No coating

C1 With coating

1) Not available with enclosure compact IP 54

2) Not available with fieldbus options (Fxx)

3) Not available for power sizes from 8452 to 8652, 380-480 V and VLT

8052-8652, 525-690 V

VLT®8000 AQUA

28

MG.83.A2.02 - VLT is a registered Danfoss trademark

Page 29

■TYPE CODE Table/Ordering form

VLT®8000 AQUA

Introduction

MG.83.A2.02 - VLT is a registered Danfoss trademark

29

Page 30

VLT®8000 AQUA

■General technical data

Mains supply (L1, L2, L3):

Supply voltage 200-240 V units ........................................................................ 3 x 200/208/220/230/240 V ±10%

Supply voltage 380-480 V units ................................................................ 3 x 380/400/415/440/460/480 V ±10%

Supply voltage 525-600 V units ............................................................................... 3 x 525/550/575/600 V ±10%

Supply voltage 525-690 V units ........................................................................ 3 x 525/550/575/600/690 V ±10%

Supply frequency ......................................................................................................................... 48-62 Hz +/- 1%

Max imbalance of supply voltage:

VLT 8006-8011/380-480 V and VLT 8002-8011/525-600 V .................................... ±2.0% of rated supply voltage

VLT 8016-8072/525-600 V, 380-480 V and VLT 8006-8032/200-240 V ................. ±1.5% of rated supply voltage

VLT 8102-8652/380-480 V and VLT 8042-8062/200-240 V ................................... ±3.0% of rated supply voltage

VLT 8052-8652/525-690 V ..................................................................................... ±3.0% of rated supply voltage

Displacement factor / cos. ϕ ...................................................................................................... near unity (> 0.98)

True Power Factor (λ) ..................................................................................................... nominal 0.90 at rated load

Input Mains (L1, L2, L3) Allowable On-OFF Switching Sequences ......................................... approx. 1 time/2 min.

Max. short-circuit current ............................................................................................................................ 100 kA

VLT output data (U, V, W):

Output voltage ................................................................................................................ 0-100% of supply voltage

Output frequency 8006-8032, 200-240V ............................................................................ 0 - 120 Hz, 0-1000 Hz

Output frequency 8042-8062, 200-240V .............................................................................. 0 - 120 Hz, 0-450 Hz

Output frequency 8072-8652, 380-460V .............................................................................. 0 - 120 Hz, 0-450 Hz

Output frequency 8002-8016, 525-600V ............................................................................ 0 - 120 Hz, 0-1000 Hz

Output frequency 8022-8062, 525-600V .............................................................................. 0 - 120 Hz, 0-450 Hz

Output frequency 8072, 525-600V ....................................................................................... 0 - 120 Hz, 0-450Hz

Output frequency 8052-8352, 525-690V .............................................................................. 0 - 132 Hz, 0-200 Hz

Output frequency 8402-8652, 525-690V .............................................................................. 0 - 132 Hz, 0-150 Hz

Rated motor voltage, 200-240 V units .............................................................................. 200/208/220/230/240V

Rated motor voltage, 380-480 V units ...................................................................... 380/400/415/440/460/480 V

Rated motor voltage, 525-600 V units ............................................................................................ 525/550/575 V

Rated motor voltage, 525-690 V units ..................................................................................... 525/550/575/690 V

Rated motor frequency ............................................................................................................................ 50/60 Hz

Switching on output ................................................................................................................................. Unlimited

Ramp times ........................................................................................................................................ 1- 3600 sec.

Torque characteristics:

Starting torque ............................................................................................................................... 110% for 1 min.

Starting torque (parameter 110 High break-away torque) ....................................... Max. torque: 130% for 0.5 sec.

Acceleration torque ....................................................................................................................................... 100%

Overload torque ............................................................................................................................................ 110%

30

MG.83.A2.02 - VLT is a registered Danfoss trademark

Page 31

VLT®8000 AQUA

Control card, digital inputs:

Number of programmable digital inputs ................................................................................................................ 8

Terminal nos. ............................................................................................................ 16, 17, 18, 19, 27, 29, 32, 33

Voltage level ........................................................................................................... 0-24 V DC (PNP positive logics)

Voltage level, logical "0" ........................................................................................................................... < 5 V DC

Voltage level, logical "1" ......................................................................................................................... > 10 V DC

Maximum voltage on input ........................................................................................................................ 28 V DC

Input resistance, R

Scanning time per input ............................................................................................................................. 3 msec.

Reliable galvanic isolation: All digital inputs are galvanically isolated from the supply voltage (PELV). In

addition, the digital inputs can be isolated from the other terminals on the control card by connecting

an external 24 V DC supply and opening switch 4. See switches 1-4.

Control card, analog inputs:

No. of programmable analog voltage inputs/thermistor inputs .............................................................................. 2

Terminal nos. ................................................................................................................................................ 53, 54

Voltage level .......................................................................................................................... 0 - 10 V DC (scalable)

Input resistance, R

No. of programmable analog current inputs .......................................................................................................... 1

Terminal no. earth ............................................................................................................................................... 55

Current range ...................................................................................................................... 0/4 - 20 mA (scalable)

Input resistance, R

Resolution .......................................................................................................................................... 10 bit + sign

Accuracy on input .......................................................................................................... Max. error 1% of full scale

Scanning time per input ............................................................................................................................. 3 msec.

Reliable galvanic isolation: All analog inputs are galvanically isolated from the supply voltage

(PELV) and other high-voltage terminals.

........................................................................................................................... approx. 2 k

i

......................................................................................................................... approx.10k

i

......................................................................................................................... approx. 200

i

Installation

Control card, pulse input:

No. of programmable pulse inputs ........................................................................................................................ 3

Terminal nos. .......................................................................................................................................... 17, 29, 33

Max. frequency on terminal 17 ...................................................................................................................... 5 kHz

Max. frequency on terminals 29, 33 ............................................................................ 20 kHz (PNP open collector)

Max. frequency on terminals 29, 33 ........................................................................................... 65 kHz (Push-pull)