Danfoss VLT 6102 HVAC, VLT 6002 HVAC, VLT 6006 HVAC, VLT 6062 HVAC, VLT 6072 HVAC Quick Setup Manual

...Page 1

■ Contents

VLT®6000 HVAC

Introduction to HVAC

Safety regulations .................................................................................................. 2

Warning against unintended start ........................................................................... 2

.................................................................................... 2

Installation ......................................................................................................... 4

Mechanical installation ........................................................................................... 4

IP 00 VLT 6400-6550 380-460 V .......................................................................... 5

High voltage warning ............................................................................................. 6

Earthing .................................................................................................................. 6

Cables .................................................................................................................... 6

Screened/armoured cables .................................................................................... 6

Extra protection with regard to indirect contact ...................................................... 6

RFI switch .............................................................................................................. 7

High voltage test .................................................................................................... 10

Heat emission from VLT 6000 HVAC ..................................................................... 10

Ventilation of integrated VLT 6000 HVAC .............................................................. 10

Electrical installation - earthing of control cables .................................................... 11

Tightening-up torque and screw sizes .................................................................... 11

Mains connection ................................................................................................... 12

Pre-fuses ................................................................................................................ 12

Motor connection ................................................................................................... 12

Direction of motor rotation ..................................................................................... 13

Motor cables .......................................................................................................... 13

Motor thermal protection ....................................................................................... 14

Earth connection .................................................................................................... 14

DC bus connection ................................................................................................ 14

High-voltage relay .................................................................................................. 14

Control card ........................................................................................................... 14

Connection examples, VLT 6000 HVAC ................................................................ 15

Programming .................................................................................................... 17

Control unit LCP .................................................................................................... 17

Control keys for parameter setup ........................................................................... 17

Indicator lamps ...................................................................................................... 18

Local control .......................................................................................................... 18

Display mode ......................................................................................................... 19

Navigation between display modes ........................................................................ 21

Changing data ....................................................................................................... 22

Manual initialisation ................................................................................................. 22

Quick Menu ........................................................................................................... 23

All about VLT 6000 HVAC ............................................................................ 24

Status messages .................................................................................................... 24

List of warnings and alarms ................................................................................... 26

Index ...................................................................................................................... 27

MG.60.C7.02 - VLT is a registered Danfoss trademark

1

Page 2

VLT®6000 HVAC

The voltage of the frequency converter

is dangerous whenever the equipment

is connected to mains. Incorrect

installation of the motor or the frequency converter

may cause damage to the equipment, serious

personal injury or death.

Consequently, the instructions in this manual,

as well as national and local rules and safety

regulations, must be complied with.

■Safety regulations

1. The frequency converter must be disconnected

from mains if repair work is to be carried out. Check

that the mains supply has been disconnected

and that the necessary time has passed before

removing motor and mains plugs.

2. The [OFF/STOP] key on the control panel of

the frequency converter does n

the equipment from mains and is thus n

to be used as a safety switch.

3. Correct protective earthing of the equipment

must be established, the user must be protected

against supply voltage, and the motor must be

protected against overload in accordance with

applicable national and local regulations.

4. The earth leakage currents are higher than 3.5 mA.

5. Protection against motor overload is included in

the factory setting. Parameter 117, Motor thermal

protection default value is ETR trip 1.

ote: The function is initialised at 1.0 x rated

N

motor current and rated motor frequency (see

parameter 117, Motor thermal protection).

6. Do n

7. Reliable galvanic isolation (PELV) is not complied

8. Please note that the frequency converter has

ot remove the plugs for the motor and mains

supply while the frequency converter is connected

to mains. Check that the mains supply has been

disconnected and that the necessary time has

passed before removing motor and mains plugs.

with if the RFI switch is placed in OFF position.

This means that all control in - and outputs

can only be considered low-voltage terminals

with basic galvanic isolation.

more voltage inputs than L1, L2 and L3, when

theDC-busterminalsareused.

Check that a

disconnected and that the necessary time has

passed before repair work is commenced.

ll voltage inputs have been

ot disconnect

ot

If personal safety considerations make it necessary

to ensure that no unintended start occurs, t

stop functions are not sufficient.

2. While parameters are being changed, the

motor may start. Consequently, t

[OFF/STOP] must always be activated, following

which data can be modified.

3. A motor that has been stopped may start if faults

occur in the electronics of the frequency converter,

or if a temporary overload or a fault in the supply

mains or the motor connection ceases.

■Use on isolated mains

See section RFI S witch regarding use on isolated mains.

It is important to follow the recommendations

regarding installation on IT-mains, since sufficient

protection of the complete installation must be

observed. Not taking care using relevant monitoring

devices for IT-mains may result in damage.

he stop key

hese

■Warning against unintended start

1. The motor can be brought to a stop by

means of digital commands, bus commands,

references or a local stop, while the frequency

converter is connected to mains.

2

MG.60.C7.02 - VLT is a registered Danfoss trademark

Page 3

VLT®6000 HVAC

Warning:

Touching the electrical parts may be fatal - even after the equipment has been

disconnected from mains.

175HA490.11

Using VLT 6002 - 6005, 200-240 V: Wait at least 4 minutes

Using VLT

Using VLT

Using VLT

6006 - 6062, 200-240 V: Wait at least 15 minutes

6002 - 6005, 380-460 V: Wait at least 4 minutes

6006 - 6072, 380-460 V: Wait at least 15 minutes

Using VLT 6102 - 6352, 380-460 V: Wait at least 20 minutes

Using VLT 6400 - 6550, 380-460 V: Wait at least 15 minutes

Using VLT

Using VLT

Using VLT

6002 - 6006, 525-600 V: Wait at least 4 minutes

6008 - 6027, 525-600 V: Wait at least 15 minutes

6032 - 6275, 525-600 V: Wait at least 30 minutes

HVAC

Introduction to

MG.60.C7.02 - VLT is a registered Danfoss trademark

3

Page 4

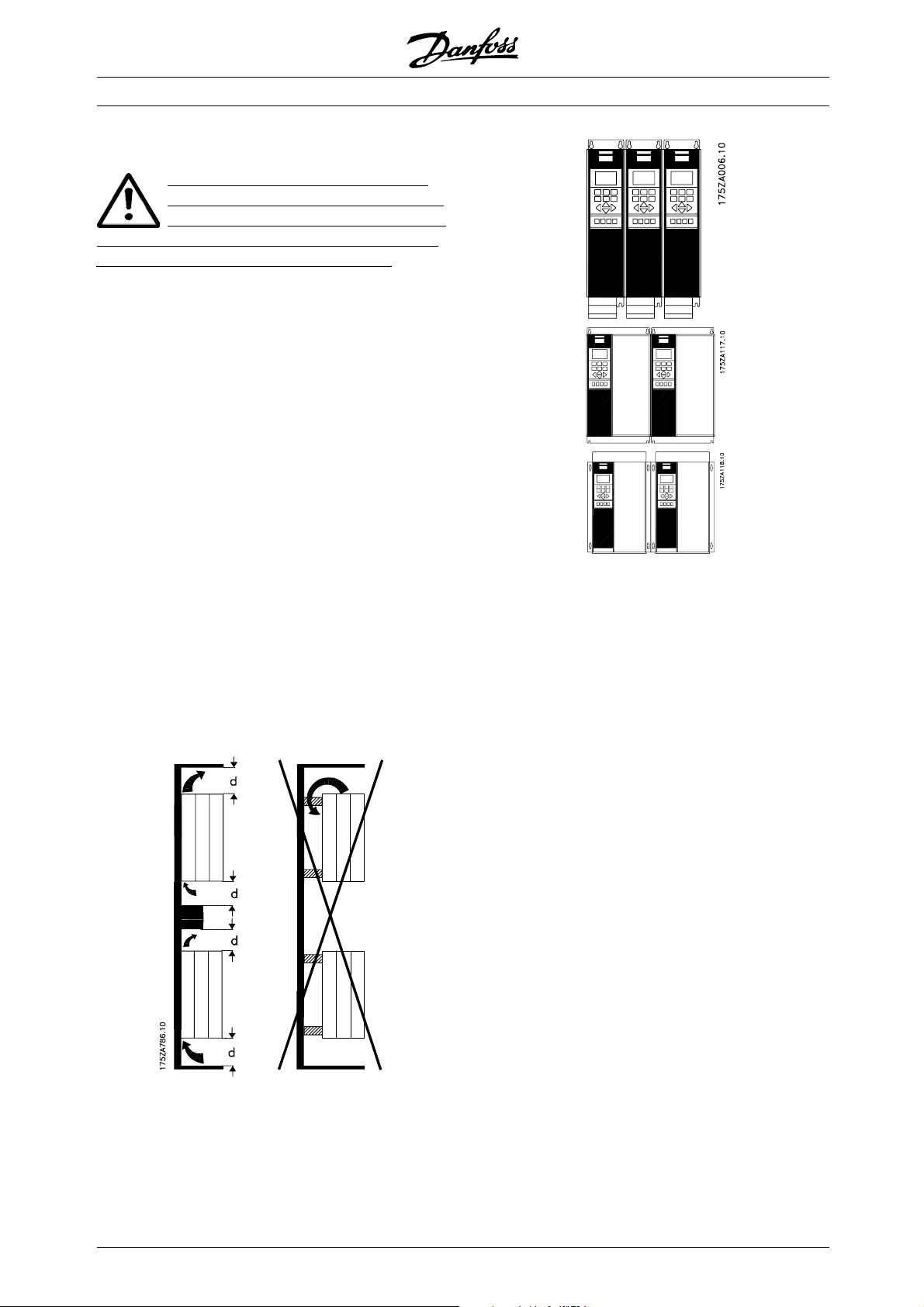

■Mechanical installation

Please pay attention to the requirements

that apply to integration and field mounting

kit, see the below list. The information given

in the list must be observed to avoid serious damage

or injury, especially when installing large units.

The frequency converter must be installed vertically.

The frequency converter is cooled by means of air

circulation. For the unit to be able to release its cooling

air, the minimum distance over and below the unit

must be as shown in the illustration below.

To protect the unit from overheating, it must be

ensured that the ambient temperature does not rise

above the max. temperature stated for the frequency

converter and that the 24-hour average temperature is

not exceeded . The max. temperature and 24-hour

average can be seen from the General Technical Data.

If the ambient temperature is in the range of 45°C -55°

C, derating of the frequency converter will become

relevant, see Derating for ambient temperature.

The service life of the frequency converter will

be reduced if derating for ambient temperature

is not taken into account.

VLT®6000 HVAC

■Installation of VLT 6002-6352

All frequency converters must be installed in a

way that ensures proper cooling.

Cooling

All Bookstyle and Compact units require a minimum

space above and below the enclosure.

Side by side/flange by flange

All frequency converters can be mounted side

by side/flange by flange.

4

MG.60.C7.02 - VLT is a registered Danfoss trademark

Page 5

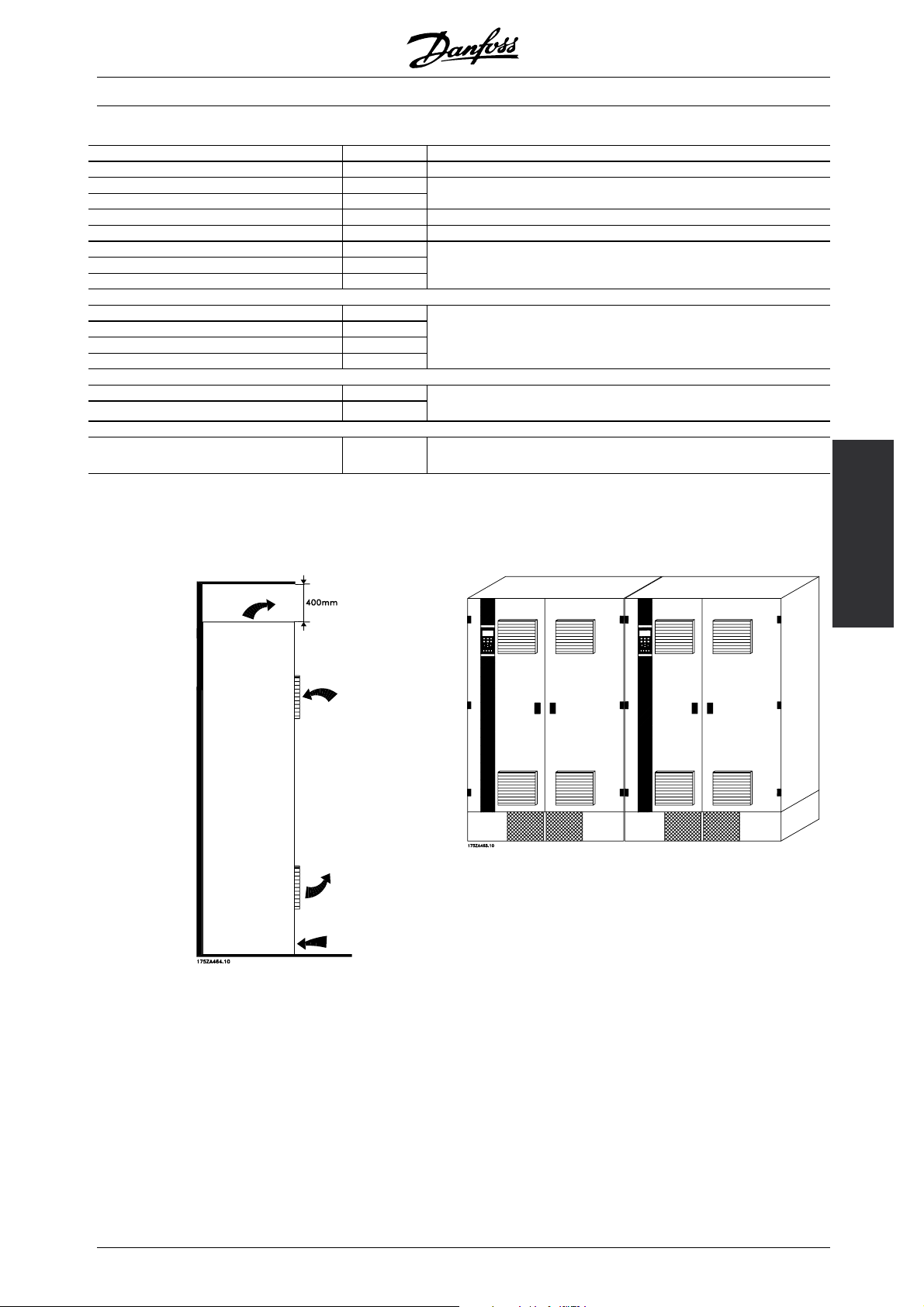

d[mm] Comments

Bookstyle

VLT 6002-6005, 200-240 V 100

VLT 6002-6011, 380-460 V 100

Compact (all enclosure types)

VLT 6002-6005, 200-240 V 100

VLT 6002-6011, 380-460 V 100

VLT 6002-6011, 525-600 V 100

VLT 6006-6032, 200-240 V 200

VLT 6016-6072, 380-460 V 200

VLT 6102-6122, 380-460 V 225

VLT 6016-6072, 525-600 V 200

VLT®6000 HVAC

Installation on a plane, vertical surface (no spacers)

Installation on a plane, vertical surface (no spacers)

Installation on a plane, vertical surface (no spacers)

VLT 6042-6062, 200-240 V 225

VLT 6100-6275, 525-600 V 225

VLT 6152-6352, 380-460 V 225 Installation on a plane, vertical surface (spacers can be used). IP 54 filter

Installation on a plane, vertical surface (no spacers)

IP 54 filter mats must be changed when they are dirty.

mats must be changed when they are dirty.

■Installation of VLT 6400-6550 380-460 V Compact

IP 00, IP 20 and IP 54

Cooling Side-by-side

Installation

All units in the above-mentioned series require a

minimum spac

e of 400 mm above the enclosure

and must be installed on a plane floor. This applies

to both IP 00, IP 20 and IP 54 units.

Gaining acce

ss to VLT 6400-6550 requires a

minimum space of 605 mm in front of the frequency

converter.

■IP 00 VLT 6400-6550 380-460 V

The IP 00 unit is designed for installation in a cabinet

when installed according to the instructions in the

MG.60.C7.02 - VLT is a registered Danfoss trademark

All IP 00, IP 20 and IP 54 units in the

above-menti

oned series can be installed side by side

without any space between them, since these units

do not require cooling on the sides.

VLT 6400-6550 Installation Guide MG.56.AX.YY.

Please note, that the same conditions as for NEMA

1/ IP20 and IP54 must be fulfilled.

5

Page 6

VLT®6000 HVAC

■High voltage warning

The voltage of the frequency converter

is dangerous whenever the equipment is

connected to mains. Incorrect installation

of the motor or the frequency converter may cause

damage to the equipment, serious personal injury

or death. Consequently, the instructions in this

Design Guide, as well as national and local safety

regulations, must be complied with. Touching

the electrical parts may be fatal - even after

disconnection from mains: Using VLT 6002-6005,

200-240 V wait at least 4 minutes

Using VLT 6006-6062, 200-240 V wait at

least 15 minutes

Using VLT 6002-6005, 380-460 V wait at

least 4 minutes

Using VLT 6006-6072, 380-460 V wait at

least 15 minutes

Using VLT 6102-6352, 380-460 V wait at

least 20 minutes

Using VLT 6400-6550, 380-460 V wait at

least 15 minutes

Using VLT 6002-6006, 525-600 V wait at

least 4 minutes

Using VLT 6008-6027, 525-600 V wait at

least 15 minutes

Using VLT 6032-6275, 525-600 V wait at

least 30 minutes

NB!:

It is the user’s or certified electrician’s

responsibility to ensure correct earthing and

protection in accordance with applicable

national and local norms and standards.

■Earthing

The following basic issues need to be considered

when installing a frequency converter, so as to obtain

electromagnetic compatibility (EMC).

the cabinet rear plate, which must be made of

metal, should be used as a common earth reference

plate. The metal cabinets of the different devices

are mounted on the cabinet rear plate using the

lowest possible HF impedance. This avoids having

different HF voltages for the individual devices and

avoids the risk of radio interference currents running

in connection cables that may be used between

the devices. The radio interference will have been

reduced. In order to obtain a low HF impedance, use

the fastening bolts of the devices as HF connection

to the rear plate. It is necessary to remove insulating

paint or similar from the fastening points.

■Cables

Control cables and the filtered mains cable should

be installed separate from the motor cables so as to

avoid interference overcoupling. Normally, a distance

of 20 cm will be sufficient, but it is recommended

to keep the greatest possible distance wherever

possible, especially where cables are installed in

parallel over a substantial distance.

With respect to sensitive signal cables, such as

telephone cables and data cables, the greatest

possible distance is recommended with a minimum

of 1 m per 5 m of power cable (mains and

motor cable). It must be pointed out that the

necessary distance depends on the sensitivity of

the installation and the signal cables, and that

therefore no precise values can be stated.

If cable jaws are used, sensitive signal cables are not

to be placed in the same cable jaws as the motor

cable or brake cable. If signal cables are to cross

power cables, this should be done at an angle of

90 degrees. Remember that all interference-filled

in- or outgoing cables to/from a cabinet should

be screened/armoured or filtered.

See also EMC-correct electrical installation.

• Safety earthing: Please note that the frequency

converter has a high leakage current and must

be earthed appropriately for safety reasons.

Apply local safety regulations.

• High-frequency earthing: Keep the earth wire

connections as short as possible.

Connect the different earth systems at the lowest

possible conductor impedance. The lowest possible

conductor impedance is obtained by keeping the

conductor as short as possible and by using the

greatest possible surface area. A flat conductor, for

example, has a lower HF impedance than a round

conductor for the same conductor cross-section

. If more than one device is installed in cabinets,

C

VESS

6

■Screened/armoured cables

The screen must be a low HF impedance screen.

This is ensured by using a braided screen of

copper, aluminium or iron. Screen armour intended

for mechanical protection, for example, is not

suitable for an EMC-correct installation. See

also Use of EMC-correct cables.

■Extra protection with regard to indirect contact

ELCB relays, multiple protective earthing or earthing

can be used as extra protection, provided that

MG.60.C7.02 - VLT is a registered Danfoss trademark

Page 7

local safety regulations are complied with. In

the case of an earth fault, a DC content may

develop in the faulty current.

Never use ELCB relays, type A, since such relays

are not suitable for DC fault currents.

If ELCB relays are used, this must be:

• Suitable for protecting equipment with a direct

current content (DC) in the faulty current

(3-phase bridge rectifier)

• Suitable for power-up with short charging

current to earth

• Suitable for a high leakage current

■RFI switch

ains supply isolated from earth:

M

If the frequency converter is supplied from an isolated

mains source ( IT mains) or TT/TN-S mains with

grounded leg, the RFI switch is recommended

to be turned off (OFF). For further reference, see

IEC 364-3. In case optimum EMC performance is

needed, parallel motors are connected or the motor

cable length is above 25 m, it is recommended

to set the switch in ON position.

In OFF position, the internal RFI capacities (filter

capacitors) between the chassis and the intermediate

circuit are cut off to avoid damage to the intermediate

circuit and to reduce the earth capacity currents

(according to IEC 61800-3).

Please also refer to the application note VLT on

IT mains, MN.90.CX.02. It is important to use

isolation monitors that are capable for use together

with power electronics (IEC 61557-8).

VLT®6000 HVAC

Mains supply connected to earth:

The RFI switch must be in ON position in order for the

frequency converter to comply with the EMC standard.

Bookstyle IP 20

VLT 6002 - 6011 380 - 460 V

VLT 6002 - 6005 200 - 240 V

Installation

NB!:

The RFI switch is not to be operated with

mains connected to the unit. Check that

the mains supply has been disconnected

before operating the RFI switch.

NB!:

Open RFI switch is only allowed at factory

set switching frequencies.

NB!:

The RFI switch connects the capacitors

galvanically to earth.

The red switches are operated by means of e.g. a

screwdriver. They are set in the OFF position when

they are pulled out and in ON position when they

are pushed in. Factory setting is ON.

Compact IP 20 and NEMA 1

VLT 6002 - 6011 380 - 460 V

VLT 6002 - 6005 200 - 240 V

VLT 6002 - 6011 525 - 600 V

MG.60.C7.02 - VLT is a registered Danfoss trademark

7

Page 8

VLT®6000 HVAC

Compact IP 20 and NEMA 1

VLT 6016 - 6027 380 - 460 V

VLT 6006 - 6011 200 - 240 V

VLT 6016 - 6027 525 - 600 V

Compact IP 20 and NEMA 1

VLT 6032 - 6042 380 - 460 V

VLT 6016 - 6022 200 - 240 V

VLT 6032 - 6042 525 - 600 V

Compact IP 54

VLT 6102 - 6122 380 - 460 V

Compact IP 54

VLT 6002 - 6011 380 - 460 V

VLT 6002 - 6005 200 - 240 V

Compact IP 20 and NEMA 1

VLT 6052 - 6122 380 - 460 V

VLT 6027 - 6032 200 - 240 V

VLT 6052 - 6072 525 - 600 V

8

Compact IP 54

VLT 6016 - 6032 380 - 460 V

VLT 6006 - 6011 200 - 240 V

MG.60.C7.02 - VLT is a registered Danfoss trademark

Page 9

Compact IP 54

VLT 6042 - 6072 380 - 460 V

VLT 6016 - 6032 200 - 240 V

VLT®6000 HVAC

Installation

MG.60.C7.02 - VLT is a registered Danfoss trademark

9

Page 10

■High voltage test

A high voltage test can be carried out by

short-circuiting terminals U, V, W, L1, L2 and L3

and energizing by max. 2.5 kV DC for one second

between this short-circuit and the chassis.

NB!:

The RFI switch must be closed (position

ON) when high voltage tests are carried out.

The mains and motor connection must be

interrupted in the case of high voltage tests of the total

installation if the leakage currents are too high.

■Heat emission from VLT 6000 HVAC

The tables in General technical data show the

power loss P

maximum cooling air temperature t

(W) from VLT 6000 HVAC. The

, is 40°

IN MAX

at 100% load (of rated value).

VLT®6000 HVAC

■Ventilation of integrated VLT 6000 HVAC

The quantity of air required for cooling frequency

converters can be calculated as follows:

1. AddupthevaluesofP

for all the frequency

converters to be integrated in the same panel.

The highest cooling air temperature (t

must be lower than t

(40°C). The day/night

IN, MAX

IN

average must be 5°C lower (VDE 160). The

outlet temperature of the cooling air must

not exceed: t

OUT, MAX

(45° C).

2. Calculate the permissible difference between

the temperature of the cooling air (t

its outlet temperature (t

OUT

):

)and

IN

t = 45° C-tIN.

3. Calculate the required

quantity of air =

insert

tinKelvin

m3/h

The outlet from the ventilation must be placed

above the highest-mounted frequency converter.

Allowancemustbemadeforthepressureloss

across the filters and for the fact that the pressure

is going to drop as the filters are choked.

)present

10

MG.60.C7.02 - VLT is a registered Danfoss trademark

Page 11

■Electrical installation - earthing of control cables

Generally speaking, control cables must be braided

screened/armoured and the screen must be

connected by means of a cable clamp at both

ends to the metal cabinet of the unit.

VLT®6000 HVAC

Correct earthing

Control cables and cables for serial communication

must be fitted with cable clamps at both ends to

ensure the best possible electrical contact

The drawing below indicates how correct earthing is

carried out and what to be done if in doubt.

Wrong earthing

Do not use twisted cable ends (pigtails), since these

increase the screen impedance at high frequencies.

Protection with respect to earth potential

between PLC and VLT

If the earth potential between the frequency converter

and the PLC (etc.) is different, electric noise may

occur that will disturb the whole system. This

problem can be solved by fitting an equalising

cable, to be placed next to the control cable.

2

Minimum cable cross-section: 16 mm

.

For 50/60 Hz earth loops

If very long control cables are used, 50/60 Hz earth

loops may occur. This problem can be solved by

connecting one end of the screen to earth via a

100nF capacitor (keeping leads short).

Cables for serial communication

Low-frequency noise currents between two frequency

converters can be eliminated by connecting one end

of the screen to terminal 61. This terminal is connected

to earth via an internal RC link. It is recommended

to use twisted-pair cables to reduce the differential

mode interference between the conductors.

Installation

■Tightening-up torque and screw sizes

The table shows the torque required when fitting

terminals to the frequency converter. For VLT

6002-6032, 200-240 V, VLT 6002-6122, 380-460

and 525-600 V the cables must be fastened

with screws. For VLT 6042-6062, 200-240 V

and for VLT 6152-6550, 380-460 V, the cables

must be fastened with bolts.

These figures apply to the following terminals:

Mains terminals (Nos.) L1, L2, L3

Motor terminals (Nos.) U, V, W

Earth terminal (Nos.) 94, 95, 99

91, 92, 93

96, 97, 98

MG.60.C7.02 - VLT is a registered Danfoss trademark

11

Page 12

VLT®6000 HVAC

VLT type

3 x 200 - 240 V

VLT 6002-6005 0.5-0.6 Nm M3

VLT 6006-6011 1.8 Nm (IP 20) M4

VLT 6006-6016 1.8 Nm (IP 54) M4

VLT 6016-6027 3.0 Nm (IP 20) M5

VLT 6022-6027 3.0 Nm (IP 54)

VLT 6032 6.0 Nm M6

VLT 6042-6062 11.3 Nm M8 (bolt)

VLT type

3 x 380-460 V

VLT 6002-6011 0.5-0.6 Nm M3

VLT 6016-6027 1.8 Nm (IP 20) M4

VLT 6016-6032 1.8 Nm (IP 54) M4

VLT 6032-6052 3.0 Nm (IP 20) M5

VLT 6042-6052 3.0 Nm (IP 54)

VLT 6062-6072 6.0 Nm M6

VLT 6102-6122 15 Nm (IP 20) M8

VLT 6152-6352 19 Nm

VLT 6400-6550 42 Nm M12 (bolt)

Tightening-up

torque

Tightening-up

torque

24 Nm (IP 54)

4)

Screw/bolt

size

2)

M5

Screw/bolt

size

2)

M5

1) 3)

M10 (bolt)

3)

3)

3)

3)

3)

3)

3)

Allen

key

size

4mm

4mm

5mm

Allen

key

size

4mm

4mm

5mm

6mm

8mm

■Pre-fuses

See Technical data for correct sizing of pre-fuses.

■Motor connection

The motor must be connected to terminals 96,

97, 98. Earth to terminal 94/95/99.

Nos.

96. 97. 98

U, V, W

No. 94/95/99 Earth connection

Motor voltage 0-100 % of mains voltage

See Technical data for correct sizing of

cable cross-sections.

All types of three-phase asynchronous standard

motors can be used with a VLT 6000 HVAC unit.

Small-size motors are normally star-connected.

(220/380 V,

/Y). Large-size

delta-connected (380/660 V,

motors are

/Y). The correct

connection and voltage can be read from

the motor nameplate.

VLT type

3 x 525-600 V

VLT 6002-6011 0.5-0.6 Nm M3

VLT 6016-6027 1.8 Nm M4

VLT 6032-6042 3.0 Nm

VLT 6052-6072 6.0 Nm M6

VLT 6100-6150 11.3 Nm M8

VLT 6175-6275 11.3 Nm M8

1. Loadsharing terminals 14 Nm/M6, 5 mm Allen key

2. IP 54 units with RFI filter line terminals 6 Nm

3. Allen screws (hexagon)

4. Loadsharing terminals 9.5 Nm/M8 (bolt)

Tightening-up

torque

2)

Screw/bolt

size

3)

M5

3)

■Mains connection

Mains must be connected to terminals 91, 92, 93.

Mains voltage 3 x 200-240 V

91, 92, 93 Mains voltage 3 x 380-460 V

L1, L2, L3 Mains voltage 3 x 525-600 V

NB!:

Check that the mains voltage fits the mains

voltage of the frequency converter, which

can be seen from the nameplate.

Allen

key

size

4mm

5mm

NB!:

In older motors without phase coil

insulation, a LC filter should be fitted to

the frequency con

verter output. See the

Design Guide or contact Danfoss.

See Technical data for correct sizing of

cable cross-sections.

12

MG.60.C7.02 - VLT is a registered Danfoss trademark

Page 13

■Direction of motor rotation

The factory setting is for clockwise rotation with the

frequency transformer output connected as follows.

Terminal 96 connected to U-phase

Terminal 97 connected to V-phase

Terminal 98 connected to W-phase

VLT®6000 HVAC

Problemsmayariseatthestartandatlowrpmvalues

if the motor sizes are widely different. This is because

the relatively high ohmic resistance in small motors

calls for a higher voltage at the start and at low rpm

values. In systems with motors connected in parallel,

the electronic thermal relay (ETR) of the frequency

converter cannot be used as motor protection for

the individual motor. Consequently, additional motor

protection is required, such as thermistors in each

motor (or individual thermal relays).

NB!:

Parameter 107 Automatic Motor Adaptation,

AMA and Automatic Energy Optimization,AEO

in parameter 101 Torque characteristics cannot

be used if motors are connected in parallel.

■Motor cables

See Technical data for correct sizing of motor

cable cross-section and length.

Always comply with national and local regulations

on cable cross-sections.

Installation

The direction of motor rotation can be changed by

switching two phases in the motor cable.

■Parallel coupling of motors

VLT 6000 HVAC is able to control several motors

connected in parallel. If the motors are to have

different rpm values, the motors must have

different rated rpm values. Motor rpm is changed

simultaneously, which means that the ratio between

the rated rpm values is maintained across the range.

The total current consumption of the motors is

not to exceed the maximum rated output current

for the frequency converter.

I

VLT,N

NB!:

If an unscreened cable is used, some

EMC requirements are not complied with,

see EMC test results.

If the EMC specifications regarding emission are

to be complied with, the motor cable must be

screened, unless otherwise stated for the RFI filter

in question. It is important to keep the motor cable

as short as possible so as to reduce the noise level

and leakage currents to a minimum.

The motor cable screen must be connected to the

metal cabinet of the frequency converter and to the

metal cabinet of the motor. The screen connections

are to be made with the biggest possible surface (cable

clamp). This is enabled by different installation devices

in the different frequency converters. Mounting with

twisted screen ends (pigtails) is to be avoided, since

these spoil the screening effect at higher frequencies.

If it is necessary to break the screen to install a

motor isolator or motor contactor, the screen must be

continued at the lowest possible HF impedance.

MG.60.C7.02 - VLT is a registered Danfoss trademark

13

Page 14

■Motor thermal protection

The electronic thermal relay in UL-approved frequency

converters has received UL approval for single

motor protection, as long as parameter 117 Motor

thermal protection has been set to ETR Trip and

parameter 105 Motor current I

VLT,N

, has been

programmed for the rated motor current (can be

read from the motor nameplate).

■Earth connection

Since the leakage currents to earth may be higher

than 3.5 mA, the frequency converter must always

be earthed in accordance with applicable na-tional

and local regulations. In order to ensure good

mechanical connection of the earth cable, its cable

2

cross-section must be at least 10 mm

. For added

security, an RCD (Residual Current Device) may be

installed. This ensures that the frequency converter

will cut out if the leakage currents get too high.

See RCD instructions MI.66.AX.02.

VLT®6000 HVAC

■DC bus connection

The DC bus terminal is used for DC back-up,

with the intermediate circuit being supplied

from an external DC source.

Terminal nos. 88, 89

t Danfoss if you require further information.

Contac

■High-

voltage relay

The cable for the high-voltage relay must be connected

to terminals 01, 02, 03. The high-voltage relay is

rammed in parameter 323, Relay 1, output.

prog

1

No.

Max Cross-

Torque: 0.5-0.6 Nm

Screw size: M3

section:

ay ouput 1

Rel

reak, 1+2 make

1+3 b

0 V AC, 2 Amp

Max 24

VDC10mAor

Min. 24

24 V AC, 1

2

4mm

/10 AW

00 mA

G

■Control card

All terminals for the control cables are located under

the protective cover of the frequency converter. The

protective cover (see drawing below) can be removed

by means of a pointed object - a screwdriver or similar.

14

MG.60.C7.02 - VLT is a registered Danfoss trademark

Page 15

■Connection examples, VLT 6000 HVAC

The diagram below gives an example of a typical

VLT 6000 HVAC installation.

The mains supply is connected to terminals 91 (L1),

92 (L2) and 93 (L3), while the motor is connected to

96 (U), 97 (V) and 98 (W). These numbers can also be

seen from the terminals of the frequency converter.

An external DC supply or a 12-pulse option can

be connected to terminals 88 and 89. Please ask

Danfoss for a Design Guide to learn more.

Analogue inputs can be connected to terminals 53 [V],

54 [V] and 60 [mA]. These inputs can be programmed

for either reference, feedback or thermistor. See

Analogue inputs in parameter group 300.

VLT®6000 HVAC

There are 8 digital inputs, which can be connected

to terminals 16-19, 27, 29, 32, 33. These inputs

can be programmed in accordance with the table

in Inputs and outputs 300-328.

There are two analogue/digital outputs (terminals

42 and 45), which can be programmed to show

the present status or a process value, such as

. Relay outputs 1 and 2 can be used for

0-f

MAX

giving the present status or a warning.

On terminals 68 (P+) and 69 (N-) RS 485 interface,

the frequency converter can be controlled and

monitored via serial communication.

Installation

MG.60.C7.02 - VLT is a registered Danfoss trademark

15

Page 16

■Electrical installation, control cables

Max. control cable cross section: 1.5 mm

Torque: 0.5-0.6 Nm

Screw size: M3

See Earthing of screened/armoured control cables

for correct termination of control cables.

2

/16 AWG

VLT®6000 HVAC

No. Function

04, 05 Relay output 2 can be used for indicating

status and warnings.

12, 13 Voltage supply to digital inputs. For the 24 V

DC to be used for digital inputs, switch 4 on

the control card must be closed, position "on".

16-33 Digital inputs. See parameters 300-307 Digital

inputs.

20 Ground for digital inputs.

39 Ground for analogue/digital outputs. Must

be connected to terminal 55 by means of

a three-wire transmitter. See Examples of

connection.

42, 45 Analogue/digital outputs for indicating

frequency, reference, current and torque. See

parameters 319-322 Analogue/digital outputs.

50 Supply voltage to potentiometer and thermistor

10 V DC.

53, 54 Analogue voltage input, 0 - 10 V DC.

55 Ground for analogue voltage inputs.

60 Analogue current input 0/4-20 mA. See

parameters 314-316 Terminal 60.

61 Termination of serial communication. See

Earthing of screened/armoured con trol cables.

Th is termin al is n ot n orma lly to be u sed .

68, 69 RS 485 interface, serial communication.

Where the frequency converter is connected

to a bus, switches 2 and 3 (switches 1- 4 -

see next page) must be closed on the first

and the last frequency converter. On the

remaining frequency converters, switches 2

and 3 must be open. The factory setting is

closed (position on).

16

MG.60.C7.02 - VLT is a registered Danfoss trademark

Page 17

■Control unit LCP

The front of the frequency converter features a

control panel - LCP(Local Control Panel). This is a

complete interface for operation and programming

of the frequency converter.

The control panel is detachable and can - as an

alternative - be installed up to 3 metres away from

the frequency converter, e.g. on the front panel,

by means of a mounting kit option.

The functions of the control panel can be

divided into five groups:

1. Display

2. Keys for changing display mode

3. Keys for changing program parameters

4. Indicator lamps

5. Keys for local operation

All data are indicated by means of a 4-line

alphanumeric display, which, in normal operation,

is able to show 4 operating data values and 3

operating condition values continuously. During

programming, all the information required for quick,

effective parameter Setup of the frequency converter

will be displayed. As a supplement to the display, there

are three indicator lamps for voltage (ON), warning

(WARNING) and alarm (ALARM), respectively.

All frequency converter parameter Setups can be

changed immediately via the control panel, unless this

function has been programmed to be Locked [1] via

parameter 016 Lock for data change orviaadigital

input, parameters 300-307 Data change lock.

VLT®6000 HVAC

Programming

■Control keys for parameter setup

The control keys are divided into functions. This means

that the keys between display and indicator lamps

are used for parameter Setup, including selecting the

display indication during normal operation.

[DISPLAY MODE] is used for selecting

the indication mode of the display or

whenreturningtotheDisplaymode

from either the Quick menu or the

Extend menu mode.

MG.60.C7.02 - VLT is a registered Danfoss trademark

17

Page 18

[QUICK MENU] gives access to the

parameters used for the Quick menu.

It is possible to switch between the

Quick menu and the Extend menu

modes.

[EXTEND MENU] gives access to all

parameters. It is possible to switch

between the Extend menu and the

Quick menu modes.

[CHANGE DATA] is used for changing

a setting selected either in the Extend

menu or the Quick menu mode.

[CANCEL] is used if a change of

the selected parameter is not to be

carried out.

[OK] is used for confirming a change

of the parameter selected.

[+/-] is used for selecting parameters

and for changing a chosen

parameter. These keys are also used

to change the local reference.

In addition, the keys are used in

Display mode to switch between

operation variable readouts.

VLT®6000 HVAC

[HAND START] is used if the frequency

converter is to be controlled via the

control unit. The frequency converter

will start the motor, since a start

command is given by means of [HAND

START].

On the control terminals, the following

control signals will still be active when

[HAND START] is activated:

• Hand start - Off stop - Auto start

• Safety Interlock

• Reset

• Coasting stop inverse

• Reversing

• Setup select lsb - Setup select msb

• Jog

• Run permissive

• Lock for data change

• Stop command from serial

communication

NB!:

If parameter 201 Output frequency low limit

is set to an output frequency greater than

f

MIN

0 Hz, the motor will start and ramp up to this

frequency when [HAND START] is activated.

[<>] is used when selecting a

parameter group and for moving

the cursor when changing numerical

values.

■Indicator lamps

At the bottom of the control panel is a red

alarm lamp and a yellow warning lamp, as

well as a green voltage LED.

If certain threshold values are exceeded, the

alarm and/or warning lamp is activated, and a

status or alarm text is displayed.

NB!:

The voltage indicator lamp is activated when

the frequency converter receives voltage.

■Local control

Underneath the indicator lamps are keys

for local control.

[OFF/STOP] is used for stopping the

connected motor. Can be selected as

Enable [1] or Disable [0] via parameter

013. If the stop function is activated,

line 2 will flash.

[AUTO START] is used if the frequency

converter is to be controlled via

the control terminals and/or serial

communication. When a start signal is

active on the control terminals and/or

the bus, the frequency converter will

start.

NB!:

An active HAND-OFF-AUTO signal via the digital

inputs will have higher priority than the control

keys [HAND START]-[AUTO START].

18

MG.60.C7.02 - VLT is a registered Danfoss trademark

Page 19

VLT®6000 HVAC

[RESET] is used for resetting the

frequency converter after an alarm

(trip). Can be selected as Enable [1]

or Disable [0] via parameter 015 Reset

on LCP.

See also List of warnings and alarms.

■Display mode

In normal operation, any 4 different operating variables

can be indicated continuously: 1.1 and 1.2 and

1.3 and 2. The present operating s

and warnings that have arisen are shown in line 2

in the form of a number. In the case of alarms, the

alarm in question will be sho

accompanied by an explanatory note. Warnings will

flash in line 2, with an explanatory note in line 1. In

addition, the displ

The arrow indicates the direction of rotation; here the

frequency converter has an active reversing signal. The

arrow body disapp

the output frequency falls below 0.01 Hz. The bottom

line gives the status of the frequency converter.

The scroll lis

data that can be shown for variable 2 in display

mode. Changes are made via the [+/-] keys.

ay shows the active Setup.

ears if a stop command is given or if

t on the next page gives the operating

tatus or alarms

wn in lines 3 and 4,

The left part of the status line indicates the

control element of the frequency converter that is

active. AUTO means that control is via the control

terminals, while HAND indicates that control is

via the local keys on the control unit.

OFF means that the frequency converter ignores all

control commands and stops the motor.

The centre part of the status line indicates the

reference element that is active. REMOTE means that

the reference from the control terminals is active, while

LOCAL indicates that the reference is determined

via the [+/-] keys on the control panel.

The last part of the status line indicates the current

195NA113.10

status, for example "Running", "Stop" or "Alarm".

80.0% 5.08A 2.15kW

40.0Hz

AUTO REMOTE RUNNING

HAND LOCAL STOP

OFF

LOCAL STOPRAMPING

HAND JOGGING

.

.

.

.

STAND BY

SETUP

1

175ZA701.10

1st line

2nd line

VAR 1.1 VAR 1.2 VAR 1.3

SETUP

VAR 2

1

3rd line

STATUS

4th line

■Display mode , cont.

Three operating data values can be shown in the first

display line, while one operating variable can be shown

in the second display line. To be programmed via

parameters 007, 008, 009 and 010 Display read-out.

• Status line (4th line):

■DisplaymodeI:

VLT 6000 HVAC offers different display modes depending on the mode selected for the frequency

converter. The figure on the next page shows t

to navigate between different display modes.

Below is a display mode, in which the frequency

converter is in Auto mode with remote ref

at an output frequency of 40 Hz.

In this display mode, reference and control are

determined via the control terminals.

The text in line 1 gives the operating variable

showninline2.

FREQUENCY

40.0Hz

AUTO REMOTE RUNNING

Line 2 gives the current output frequency

and the active Setup.

SETUP

1

erence

Programming

he way

175ZA683.10

MG.60.C7.02 - VLT is a registered Danfoss trademark

19

Page 20

Line 4 says that the frequency converter is in Auto mode

with remote reference, and that the motor is running.

■Display mode II:

This display mode makes it possible to have three

operating data values displayed at the same time in

line 1. The operating data values are determined

in parameters 007-010 Display readout.

100% 7.8A 5.9kW

SETUP

50.0Hz

AUTO REMOTE RUNNING

■Display mode III:

This display mode is active as long as the [DISPLAY

MODE] key is kept depressed. In the first line,

operating data names and units of operating data

are displayed. In the second line, operating data 2

remains unchanged. When the key is released, the

different operating data values are shown.

1

175ZA685.10

VLT®6000 HVAC

REF% CURR.A.POW.,KW

SETUP

50.0Hz

AUTO REMOTE RUNNING

■Display mode IV:

This display mode is only active in connection with

local reference, see also Reference handling.Inthis

display mode, the reference is determined via the

[+/-] keys and control is carried out by means of the

keys underneath the indicator lamps. The first line

indicates the required reference. The third line gives

the relative value of the present output frequency at

any given time in relation to the maximum frequency.

The display is in the form of a bar graph.

USE +/- 40Hz

40.0Hz

----60

0

HAND LOCAL RUNNING

1

SETUP

1

176FA156.10

175ZA695.10

20

MG.60.C7.02 - VLT is a registered Danfoss trademark

Page 21

■Navigation between display modes

Press briefly

HAND LOCAL RUNNING

USE +/- 40Hz

40.0Hz

FREQUENCY

40.0Hz

AUTO REMOTE RUNNING

▲▲

▲

▲▲

SETUP

1

Display mode I

With remote

reference

VLT®6000 HVAC

▲▲

▲

▲▲

▲▲

▲

▲▲

80% 7,8A 5,9 KW

40.0 Hz

0 ---- 60

HAND LOCAL RUNNING

Display mode IV

175ZA697.10

▲▲

▲▲

▲

With local reference

Keep the [DISPLAY

MODE] key down

AUTO REMOTE RUNNING

Display mode II

▲▲

▲

▲▲

REF% CURR.A POW.,KW

40.0 Hz

AUTO REMOTE RUNNING

Display mode III

Programming

MG.60.C7.02 - VLT is a registered Danfoss trademark

21

Page 22

■Changing data

Regardless of whether a parameter has been

selected under the Quick menu or the Extended

menu, the procedure for changing data is the same.

Pressing the [CHANGE DATA] key allows change

of the selected parameter, and the underlining

in line 4 will flash on the display.

The procedure for changing data depends on whether

the selected parameter represents a numerical

data value or a functional value.

If the chosen parameter represents a numeric data

value, the first digit can be changed by means of

the [+/-] keys. If the second digit is to be changed,

first move the cursor by using the [<>] keys, then

change the data value using the [+/-] keys.

FREQUENCY

24.2 Hz

205 MAX. REFERENCE

000060,000 Hz

5

SETUP

1

175ZA698.10

VLT®6000 HVAC

FREQUENCY

SETUP

50.0

209 JOG FREQUENCY

1

0.0 Hz

The chosen digit flashes. The bottom display

line shows the data value that will be entered

(saved) when signing off with [OK].

■Changing of data value, step-by-step

Certain parameters can be changed both step by

step and infinitely variably. This applies to Motor

power (parameter 102), Motor voltage (parameter

103) and Motor frequency (parameter 104).

This means that the parameters are changed

both as a group of numeric data values and as

numeric data values infinitely variably.

SETUP

1

1

175ZA700.10

The selected digit is indicated by a flashing cursor.

The bottom display line gives the data value that will

be entered (saved) when signing off by pressing the

[OK] button. Use [CANCEL] to cancel the change.

If the selected parameter is a functional value,

the selected text value can be changed by

means of the [+/-] keys.

MOTOR CURRENT

3.90 A

210 REFERENCE TYPE

SUM

SETUP

1

175ZA689.10

The functional value flashes until signing off by pressing

the [OK] button. The functional value has now been

selected. Use [CANCEL] to cancel the change.

■Infinitely variable change of numeric data value

If the chosen parameter represents a numeric data

value, a digit is first selected by means of the [<>] keys.

■Manual initialisation

Disconnect from mains and hold the [DISPLAY

MODE] + [CHANGE DATA] + [OK] keys down while

at the same time reconnecting the mains supply.

Release the keys; the frequency converter has now

been programmed for the factory setting.

The following parameters are not zeroed by means of man

initialisation:

Parameter 500, Protocol

600, Operating hours

601, hours run

602, kWh counter

603, Number of power-ups

604, Number of overtemperatures

605, Number of overvoltages

It is also possible to carry out initialisation via

parameter 620 Operating mode.

ual

FREQUENCY

SETUP

50.0 Hz

209 JOG FREQUENCY

0

9 .0 Hz

SETUP

1

1

175ZA699.10

Then the chosen digit is changed infinitely by

means of the [+/-] keys:

22

MG.60.C7.02 - VLT is a registered Danfoss trademark

Page 23

VLT®6000 HVAC

■Quick Menu

The QUICK MENU key gives access to 12 of the

most important setup parameters of the drive. After

programming, the drive will, in many cases, be ready

for operation. The 12 Quick Menu parameters are

Quick Menu Parameter Description

Item Number Name

1 001 Language Selects language used for all displays.

2 102 Motor Power Sets output characteristics of drive based on kW size

3 103 Motor Voltage Sets output characteristics of drive based on voltage

4 104 Motor Frequency Sets output characteristics of drive based on nominal

5 105 Motor Current Sets output characteristics of drive based on nominal

6 106 Motor Nominal Speed Sets output characteristics of drive based on nominal

7 201 Minimum Frequency Sets minimum controlled frequency at which motor

8 202 Maximum Frequency Sets maximum controlled frequency at which motor

9 206 Ramp Up Time Sets time to accelerate motor from 0 Hz to nominal

10 207 Ramp Down Time Sets time to decelerate motor from nominal motor

11 323 Relay 1 Function Sets function of high voltage Form C relay.

12 326 Relay 2 Function Sets function of low voltage Form A relay.

shown in the table below. A complete description

of the function is given in the parameter

sections of this manual.

of motor.

of motor.

frequency of motor. This is typically equal to line

frequency.

current in amps of motor.

full load speed of motor.

will run.

will run.

motor frequency set in Quick Menu Item 4.

frequency set in Quick Menu Item 4 to 0 Hz.

Programming

MG.60.C7.02 - VLT is a registered Danfoss trademark

23

Page 24

■Status messages

Status messages appear in the 4th line of the

display - see example below.

The left part of the status line indicates the active

type of control of the frequency converter.

The centre part of the status line indicates

the active reference.

The last part of the status line gives the present

status, e.g. "Running", "Stop" or "Stand by".

80.0% 5.08A 2.15kW

SETUP

40.0Hz

1

AUTO REMOTE RUNNING

HAND LOCAL STOP

OFF

LOCAL STOPRAMPING

HAND JOGGING

.

.

.

.

STAND BY

Ramp operation (RAMPING)

The output frequency is now changed in accordance

with the preset ramps.

Auto-ramp (AUTO RAMP)

Parameter 208 Automatic ramp-up/down is enabled,

i.e. the frequency converter is trying to avoid a trip

from overvoltage by increasing its output frequency.

Sleep Boost (SLEEP .BST)

The boost function in parameter 406 Boost

setpoint is enabled. This function is only possible

in Closed loop operation.

175ZA701.10

Sleep mode (SLEEP)

The energy saving function in parameter 403

Sleep mode timer is enabled. This means that

atpresentthemotorhasstopped,butthatitwill

restart automatically when required.

Start delay (START DEL)

A start delay time has been programmed i

parameter 111 Start delay. When the delay

has passed, the output frequency will start by

rampinguptothereference.

VLT®6000 HVAC

Auto mode (AUTO)

The frequency converter is in Auto mode, i.e. control

is carried out via the control terminals and/or serial

communication. See also Auto start.

Hand mode (HAND)

The frequency converter is in Hand mode, i.e. control

is carried out via the control keys. See Hand start.

OFF (OFF)

OFF/STOP is activated either by means of the control

key, or by the digital inputs Hand start and Auto start

both being a logic "0". See also OFF/STOP

Local reference (LOCAL)

If LOCAL has been selected, the reference is set via the

[+/-] keys on the control panel. See also Display modes.

Remote reference (REM.)

If REMOTE has been selected, the reference is set

via the control terminals or via serial communication.

See also Display modes .

Running (RUNNING)

The motor speed now corresponds to the

resulting reference.

Run request (RUN REQ.)

A start command has been given, but the motor

will be stopped until a Run permissive signal

is received via a digital input.

Jogging (JOG)

Jog has been enabled via a digital input or

via serial communication.

Jog request (JOG REQ.)

A JOG command has been given, but the motor

will remain stopped until a Run permissive signal

is received via a digital input.

Freeze output (FRZ.OUT.)

Freeze output has been enabled via a digital input.

Freeze output request (FRZ.REQ.)

A freeze output command has been given, but the

motor will remain stopped until a Run permissive

signal is received via a digital input.

Reversing and start (START F/R)

Reversing and start [2] on terminal 19 (parameter

303 Digital inputs)andStart [1] on terminal 18

(parameter 302 Digital inputs) are enabled at the

same time. The motor will remain stopped until

one of the signals becomes a logic ‘0’.

24

MG.60.C7.02 - VLT is a registered Danfoss trademark

Page 25

Automatic Motor Adaptation running (AMA RUN)

Automatic motor adaptation has been enabled in

parameter 107 Automatic Motor Adaptation, AMA.

Automatic Motor Adaptation completed

(AMA STOP)

Automatic motor adaptation has been completed.

The frequency converter is now ready for operation

after the Reset signal has been enabled. Please

note that the motor will start after the frequency

converter has received the Reset signal.

Stand by (STANDBY)

The frequency converter is able to start the motor

when a start command is received.

Stop (STOP)

The motor has been stopped via a stop

signal from a digital input, [OFF/STOP] button

or serial communication.

VLT®6000 HVAC

DC stop (DC STOP)

The DC brake in parameter 114-116 has been enabled.

DRIVE ready (UN. READY)

The frequency converter is ready for operation, but

terminal 27 is a logic "0" and/or a Coasting command

has been received via the serial communication.

Not ready (NOT READY)

The frequency converter is not ready for operation,

because of a trip or because OFF1, OFF2

or OFF3 is a logic ‘0’.

Start disabled (START IN.)

This status will only be displayed if, in parameter

599 Statemachine, Profidrive [1] has been selected

and OFF2 or OFF3 is a logic ‘0’.

Exceptions XXXX (EXCEPTIONS XXXX)

The microprocessor of the control card has stopped

and the frequency converter is out of operation.

The cause may be noise on the mains, motor

or control cables, leading to a stop of the

control card microprocessor.

Check for EMC-correct connection of these cables.

HVAC

All about VLT 6000

MG.60.C7.02 - VLT is a registered Danfoss trademark

25

Page 26

VLT®6000 HVAC

■List of warnings and alarms

The table gives the different warnings and alarms

and indicates whether the fault locks the frequency

converter. After Trip locked, the mains supply must be

cut and the fault must be corrected. Reconnect the

mains supply and reset the frequency converter before

being ready. A Trip can be reset manually in three ways

1. Via the control key [RESET]

2. Via a digital input

3. Via serial communication In addition, an

automatic reset may be selected in parameter

400 Reset function.

Wherever a cross is placed under both Warning and

Alarm, this can mean that a warning precedes the

alarm. It can also mean that it is possible to program

whether a given fault is to result in a warning or an

alarm. This is possible, e.g. in parameter 117 Motor

thermal protection. Afteratrip,themotorwillbe

coasting and on the frequency converter alarm and

warning will flash. If the fault is removed, only the

alarm will flash. After a reset, the frequency converter

will be ready to start operation again.

No. Description Warning Alarm Trip locked

1 10 Volts low (10 VOLT LOW) x

2 Live zero fault (LIVE ZERO ERROR) x x

4 Mains imbalance (MAINS IMBALANCE) x x x

5 Voltage warning high (DC LINK VOLTAGE HIGH) x

6 Voltage warning low (DC LINK VOLTAGE LOW) x

7 Overvoltage (DC LINK OVERVOLT) x x

8 Undervoltage (DC LINK UNDERVOLT) x x

9 Inverter overloaded (INVERTER TIME) x x

10 Motor overloaded (MOTOR TIME) x x

11 Motor thermistor (MOTOR THERMISTOR) x x

12 Current limit (CURRENT LIMIT) x x

13 Overcurrent (OVERCURRENT) x x x

14 Earth fault (EARTH FAULT) x x

15 Switch mode fault (SWITCH MODE FAULT) x x

16 Short-circuit (CURR.SHORT CIRCUIT) x x

17 Serial communication timeout (STD BUSTIMEOUT) x x

18 HPFB bus timeout (HPFB TIMEOUT) x x

19 Fault in EEprom on power card (EE ERROR POWER) x

20 Fault in EEprom on control card (EE ERROR CONTROL) x

22 Auto-optimisation not OK (AMA FAULT) x

29 Heat-sink temperature too high (HEAT SINK OVERTEMP.) x

30 Motor phase U missing (MISSING MOT.PHASE U) x

31 Motor phase V missing (MISSING MOT.PHASE V) x

32 Motor phase W missing (MISSING MOT.PHASE W) x

34 HPFB communication fault (HPFB COMM. FAULT) x x

37 Inverter fault (GATE DRIVE FAULT) x x

39 Check parameters 104 and 106 (CHECK P.104 & P.106) x

40 Check parameters 103 and 105 (CHECK P.103 & P.106) x

41 Motor too big (MOTOR TOO BIG) x

42 Motor too small (MOTOR TOO SMALL) x

60 Safety stop (EXTERNAL FAULT) x

61 Output frequency low (FOUT < FLOW) x

62 Output frequency high (FOUT > FHIGH) x

63 Output current low (I MOTOR < I LOW) x x

64 Output current high (I MOTOR > I HIGH) x

65 Feedback low (FEEDBACK < FDB LOW) x

66 Feedback high (FEEDBACK > FDB HIGH) x

67 Reference low (REF. < REF. LOW) x

68 Reference high (REF. > REF. HIGH) x

69 Temperature auto derate (TEMP.AUTO DERATE) x

80 Fire mode was active (FIRE MODE WAS ACTIVE) x x

81 RTC not ready (RTC NOT READY) x

99 Unknown fault (UNKNOWN ALARM) x x

26

MG.60.C7.02 - VLT is a registered Danfoss trademark

Page 27

VLT®6000 HVAC

■Index

C

control panel - LCP....................................................... 17

Cable clamp

Cables

Changing data

Connection examples

Control card

Control keys

Control unit LCP

Cooling

............................................................... 11

....................................................................... 6

............................................................. 22

.................................................... 15

................................................................ 14

............................................................... 17

........................................................... 17

....................................................................... 4

D

direction of motor rotation .............................................. 13

DC bus connection

Direction of motor rotation

Display

....................................................................... 17

Display mode

....................................................... 14

.............................................. 13

............................................................... 19

E

earthing ...................................................................... 11

Earth connection

Earthing

...................................................................... 6

Electrical installation - earthing of control cables

Equalising cable,

Extra protection

.......................................................... 14

.................. 11

........................................................... 11

............................................................ 6

G

General warning ........................................................... 2

H

Heat emission from VLT 6000 HVAC ................................ 10

High voltage test

High voltage warning

High-voltage relay

.......................................................... 10

..................................................... 6

......................................................... 14

Mains connection ......................................................... 12

Mechanical installation

Motor cables

Motor connection

Motor thermal protection

............................................................... 13

................................................... 4

......................................................... 12

................................................ 14

P

Parallel coupling ........................................................... 13

........................................................................... 11

PLC

Pre-fuses

.................................................................... 12

Q

Quick Menu................................................................. 23

R

RFI switch ................................................................... 7

S

screw sizes ................................................................. 11

Safety regulations

Screened/armoured cables

serial communication

Status messages

......................................................... 2

............................................. 6

..................................................... 11

.......................................................... 24

T

Tightening-up torque ..................................................... 11

Trip locked

.................................................................. 26

U

Unintended start........................................................... 2

V

Ventilation of integrated VLT 6000 HVAC ........................... 10

I

IT mains ..................................................................... 7

Indicator lamps

Initialisation

....................................................... 17, 18

.................................................................. 22

L

Local control ............................................................... 18

Local Control Panel

....................................................... 17

M

MG.60.C7.02 - VLT is a registered Danfoss trademark

W

Warning ..................................................................... 3

Warning against unintended start

Warnings and alarms

..................................................... 26

..................................... 2

27

Index

Loading...

Loading...