Syncronising Controller MCO 350 Operating

Instructions

Contents

Contents

1. Safety Regulation

Approvals 5

Symbols 5

Disposal Instruction 5

High Voltage 6

Safety Instructions 6

Avoid Unintended Start 7

Safe Stop of FC 300 7

Safe Stop Installation (FC 302 and FC 301 - A1 enclosure only) 9

IT Mains 9

2. Introduction

Function Description 11

Introduction 11

Speed Synchronisation 11

Position Synchronisation (angle synchronisation) 11

Marker Synchronisation

Mechanical Brake Control 12

5

11

11

Tips and Tricks for Synchronisation Tasks 12

Introduction 12

Example 12

Calculation with Insufficient Numerical Values 13

Example with Corrected Numerical Values 13

Hardware 14

VLT Control Card Terminals 14

Technical Data 14

Introduction 14

Option Card Terminals 14

Encoder Monitor 16

Option Card Layout 16

General Technical Data 17

Example of Encoder Interface connections 19

Description of Terminals 20

Standard RS 485-Interface 22

MCO 350 Terminal X57 22

MCO 350 Terminal X59 23

Description of Fieldbus Interface 23

Data Layout 23

MG.33.Q1.02 - VLT

®

is a registered Danfoss trademark

1

Contents

Syncronising Controller MCO 350 Operating

Instructions

3. Programming

Description of Parameters 27

4. Synchronisation

Speed Synchronisation 47

SyncStart 47

Function Diagrams for Speed Synchronisation 47

SyncStart 47

Up/Down Factor 48

Hold Function 49

Gear Changing 50

Changing the Gear Ratio with an Analogue Value 51

Application Examples - Admixture 51

Setting the Parameters 52

How to Check the Motor Connection 54

How to Test the Incremental Encoders 54

How to Optimise the Controller 55

How to Programme Synchronisation 56

27

47

Starting Synchronisation 58

Stopping Synchronisation 58

Fine Setting of the Gear Ratio 58

Switching to Another Gear Ratio 58

Error Procedure 58

Position Synchronisation 58

Position Synchronisation (angle synchronisation) 58

Function Diagrams for Position Synchronisation 60

SyncStart to a Stationary Master 60

SyncStart to a Running Master 60

Position Displacement with a Running Master 61

Application Example - Embossing Patterns on Mould 61

Description of Terminals and Terminal Configuration 62

Setting the Parameters 63

How to Check the Motor Connection 64

How to Test the Incremental Encoders

How to Optimise the Controller 65

64

How to Programme Synchronisation 66

Operation and Operating Functions 68

Marker Synchronisation - Function Diagrams for Marker Synchronisation 69

Marker Synchronising 69

SyncStart to a Running Master after Power ON 70

2

MG.33.Q1.02 - VLT

®

is a registered Danfoss trademark

Syncronising Controller MCO 350 Operating

Instructions

Marker Correction during Operation 71

Application Example - Packaging 71

Terminals and Terminal Configuration 72

Setting the Parameters 72

How to Check the Motor Connection 74

How to Test the Incremental Encoders 75

How to Optimise the Controller 75

How to Programme Synchronisation 77

Operation and Operating Functions 79

Contents

5. Appendix

Messages and Error Reference 81

Warnings and Error Messages 81

Errors 82

Parameter Overview 86

Glossary of Key Terms 96

Index

81

100

MG.33.Q1.02 - VLT

®

is a registered Danfoss trademark

3

1

1. Safety Regulation

Syncronising Controller MCO 350 Operating

Instructions

4

MG.33.Q1.02 - VLT

®

is a registered Danfoss trademark

Syncronising Controller MCO 350 Operating

Instructions

1. Safety Regulation

1. Safety Regulation

1.1.1. Approvals

1.1.2. Symbols

Symbols used in these Operating Instructions.

NB!

Indicates something to be noted by the reader.

1

Indicates a general warning.

Indicates a high-voltage warning.

∗ Indicates default setting

1.1.3. Disposal Instruction

Equipment containing electrical components may not be disposed of

together with domestic waste.

It must be separately collected with Electrical and Electronic waste

according to local and currently valid legislation.

The FC 300 AutomationDrive DC link capacitors remain charged after power has

been disconnected. To avoid electrical shock hazard, disconnect the FC 300 from

the mains before carrying out maintenance. When using a PM-motor, make sure it

is disconnected. Before doing service on the frequency converter wait at least the

amount of time indicated below:

MG.33.Q1.02 - VLT

®

is a registered Danfoss trademark

5

1

1. Safety Regulation

FC 300 380 - 500 V 0.25 - 7.5 kW 4 minutes

11 - 22 kW 15 minutes

30 - 75 kW 15 minutes

90 - 200 kW 20 minutes

250 - 400 kW 40 minutes

525 - 690 V 37 - 250 kW 20 minutes

315 - 560 kW 30 minutes

Syncronising Controller MCO 350 Operating

Instructions

MCO 350 Synchronising Controller for

VLT AutomationDrive FC 30x

Operating Instructions

Software version: 1.1x

These Operating Instructions can be used for all MCO 350 Synchronising Controller for VLT

AutomationDrive FC 30x frequency converters with software version 1.1x.

The software version number can be seen from parameter 19-92.

1.1.4. High Voltage

The voltage of the frequency converter is dangerous whenever the frequency converter is connected to mains. Incorrect installation or operation of the motor or

frequency converter may cause damage to the equipment, serious personal injury

or death. The instructions in this manual must consequently be observed, as well as

applicable local and national rules and safety regulations.

Installation in high altitudes

At altitudes above 2 km, please contact Danfoss Drives regarding PELV.

1.1.5. Safety Instructions

• Make sure the FC 300 is properly connected to earth.

• Do not remove mains plugs or motor plugs while the FC 300 is connected to mains.

• Protect users against supply voltage.

• Protect the motor against overloading according to national and local regulations.

• Motor overload protection is not included in the default settings. To add this function,

set parameter 1-90

North American market: ETR functions provide class 20 motor overload protection, in

accordance with NEC.

• The earth leakage current exceeds 3.5 mA.

• The [OFF] key is not a safety switch. It does not disconnect the FC 300 from mains.

Motor thermal protection

to value

ETR trip

or

ETR warning

. For the

6

MG.33.Q1.02 - VLT

®

is a registered Danfoss trademark

Syncronising Controller MCO 350 Operating

Instructions

1.1.6. General Warning

Warning:

Touching the electrical parts may be fatal - even after the equipment has been disconnected from mains.

Also make sure that other voltage inputs have been disconnected, such as loadsharing (linkage of DC intermediate circuit), as well as the motor connection for

kinetic back-up.

Using VLT

Shorter time is allowed only if indicated on the nameplate for the specific unit.

Leakage Current

The earth leakage current from the FC 300 exceeds 3.5 mA. To ensure that the earth

cable has a good mechanical connection to the earth connection (terminal 95), the

cable cross section must be at least 10 mm

separately.

Residual Current Device

This product can cause a D.C. current in the protective conductor. Where a residual

current device (RCD) is used for extra protection, only an RCD of Type B (time delayed) shall be used on the supply side of this product. See also RCD Application

Note MN.90.GX.02.

Protective earthing of the FC 300 and the use of RCD's must always follow national

and local regulations.

®

AutomationDrive FC 300: wait at least 15 minutes.

1. Safety Regulation

2

or 2 times rated earth wires terminated

1

1.1.7. Before Commencing Repair Work

1. Disconnect the frequency converter from mains

2. Wait for discharge of the DC-link. See period of time on the warning label.

3. Disconnect DC bus terminals 88 and 89

4. Remove motor cable

1.1.8. Avoid Unintended Start

While FC 300 is connected to mains, the motor can be started/stopped using digital commands,

bus commands, references or via the Local Control Panel (LCP).

• Disconnect the FC 300 from mains whenever personal safety considerations make it

necessary to avoid unintended start.

• To avoid unintended start, always activate the [OFF] key before changing parameters.

• An electronic fault, temporary overload, a fault in the mains supply, or lost motor connection may cause a stopped motor to start. FC 300 with Safe Stop (i.e. FC 301 in A1

enclosure and FC 302) provides protection against unintended start, if the Safe Stop

Terminal 37 is on low voltage level or disconnected.

1.1.9. Safe Stop of FC 300

The FC 302, and also the FC301 in A1 enclosure, can perform the safety function

(As defined by IEC 61800-5-2) or

Off

Stop Category 0

Safe Torque

(as defined in EN 60204-1).

FC 301 A1 enclosure: When Safe Stop is included in the drive, position 18 of Type Code must be

either T or U. If position 18 is B or X, Safe Stop Terminal 37 is not included!

Example:

Type Code for FC 301 A1 with Safe Stop: FC-301PK75T4Z20H4TGCXXXSXXXXA0BXCXXXXD0

MG.33.Q1.02 - VLT

®

is a registered Danfoss trademark

7

1

1. Safety Regulation

It is designed and approved suitable for the requirements of Safety Category 3 in EN 954-1. This

functionality is called Safe Stop. Prior to integration and use of Safe Stop in an installation, a

thorough risk analysis on the installation must be carried out in order to determine whether the

Safe Stop functionality and safety category are appropriate and sufficient. In order to install and

use the Safe Stop function in accordance with the requirements of Safety Category 3 in EN 954-1,

the related information and instructions of the FC 300 Design Guide MG.33.BX.YY must be followed! The information and instructions of the Operating Instructions are not sufficient for a

correct and safe use of the Safe Stop functionality!

Syncronising Controller MCO 350 Operating

Instructions

8

MG.33.Q1.02 - VLT

®

is a registered Danfoss trademark

Syncronising Controller MCO 350 Operating

Instructions

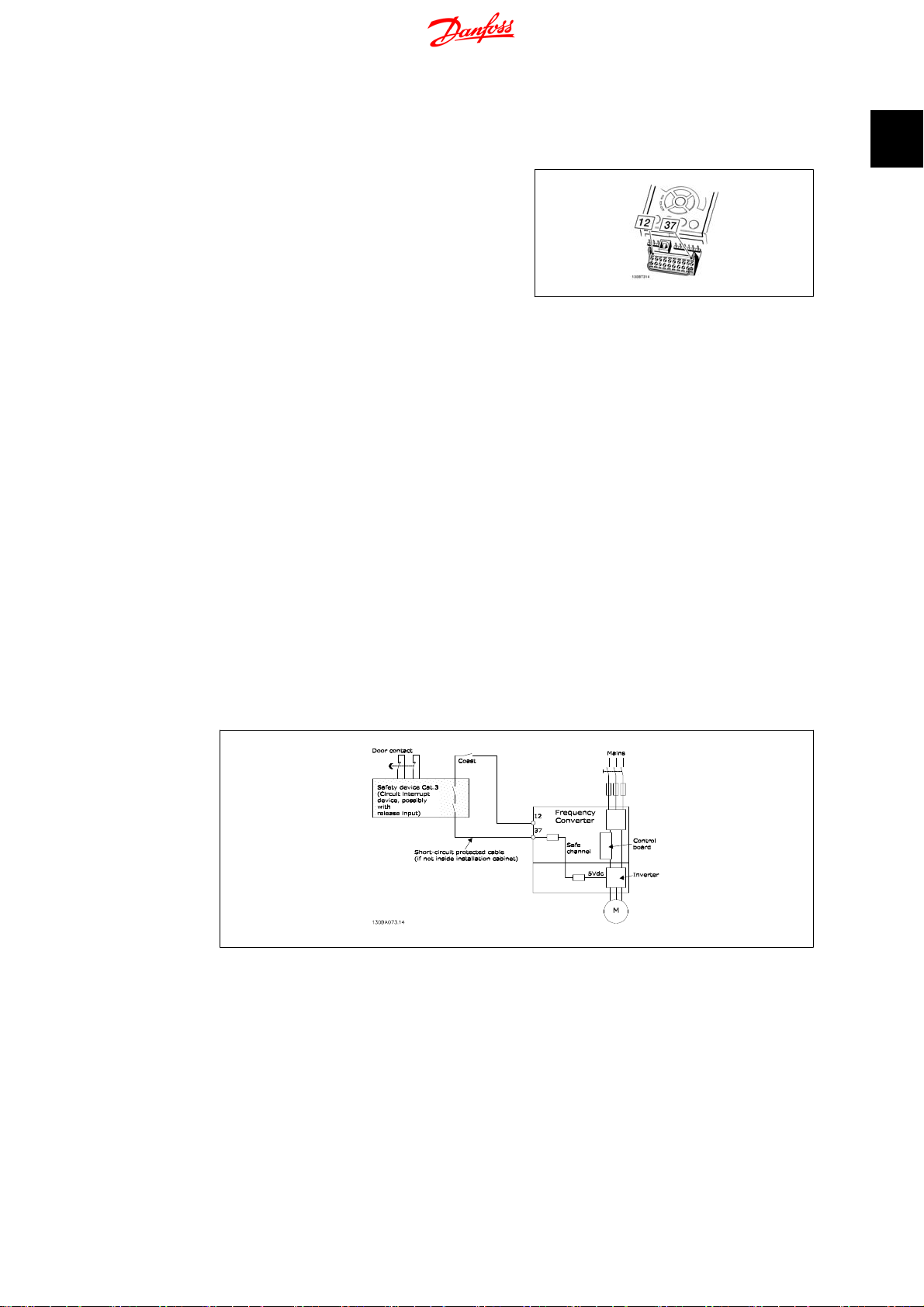

1.1.10. Safe Stop Installation (FC 302 and FC 301 - A1 enclosure only)

To carry out an installation of a Category 0 Stop (EN60204) in conformance

with Safety Category 3 (EN954-1), follow these instructions:

1. The bridge (jumper) between Terminal 37 and 24 V DC must be removed. Cutting or breaking the

jumper is not sufficient. Remove it

entirely to avoid short-circuiting. See

jumper on illustration.

2. Connect terminal 37 to 24 V DC by a

short-circuit protected cable. The 24

V DC voltage supply must be interruptible by an EN954-1 Category 3

circuit interrupt device. If the interrupt device and the frequency converter are placed in the same installation panel, you can use a regular

cable instead of a protected one.

3. Unless the FC302 itself has protection class IP54 and higher, it must be

placed in an IP 54 enclosure. Consequently, FC301 A1 must always be

placed in an IP 54 enclosure.

1. Safety Regulation

1

Illustration 1.1: Bridge jumper between terminal

37 and 24 VDC

The illustration below shows a Stopping Category 0 (EN 60204-1) with safety Category 3 (EN

954-1). The circuit interrupt is caused by an opening door contact. The illustration also shows how

to connect a non-safety related hardware coast.

Illustration 1.2: Illustration of the essential aspects of an installation to achieve a Stopping Category 0 (EN

60204-1) with safety Category 3 (EN 954-1).

1.1.11. IT Mains

Par. 14-50

the RFI filter to ground. If this is done it will reduce the RFI performance to A2 level.

RFI 1

can on FC 102/202/302 be used to disconnect the internal RFI capacitors from

MG.33.Q1.02 - VLT

®

is a registered Danfoss trademark

9

2

2. Introduction

Syncronising Controller MCO 350 Operating

Instructions

10

MG.33.Q1.02 - VLT

®

is a registered Danfoss trademark

Syncronising Controller MCO 350 Operating

Instructions

2. Introduction

2. Introduction

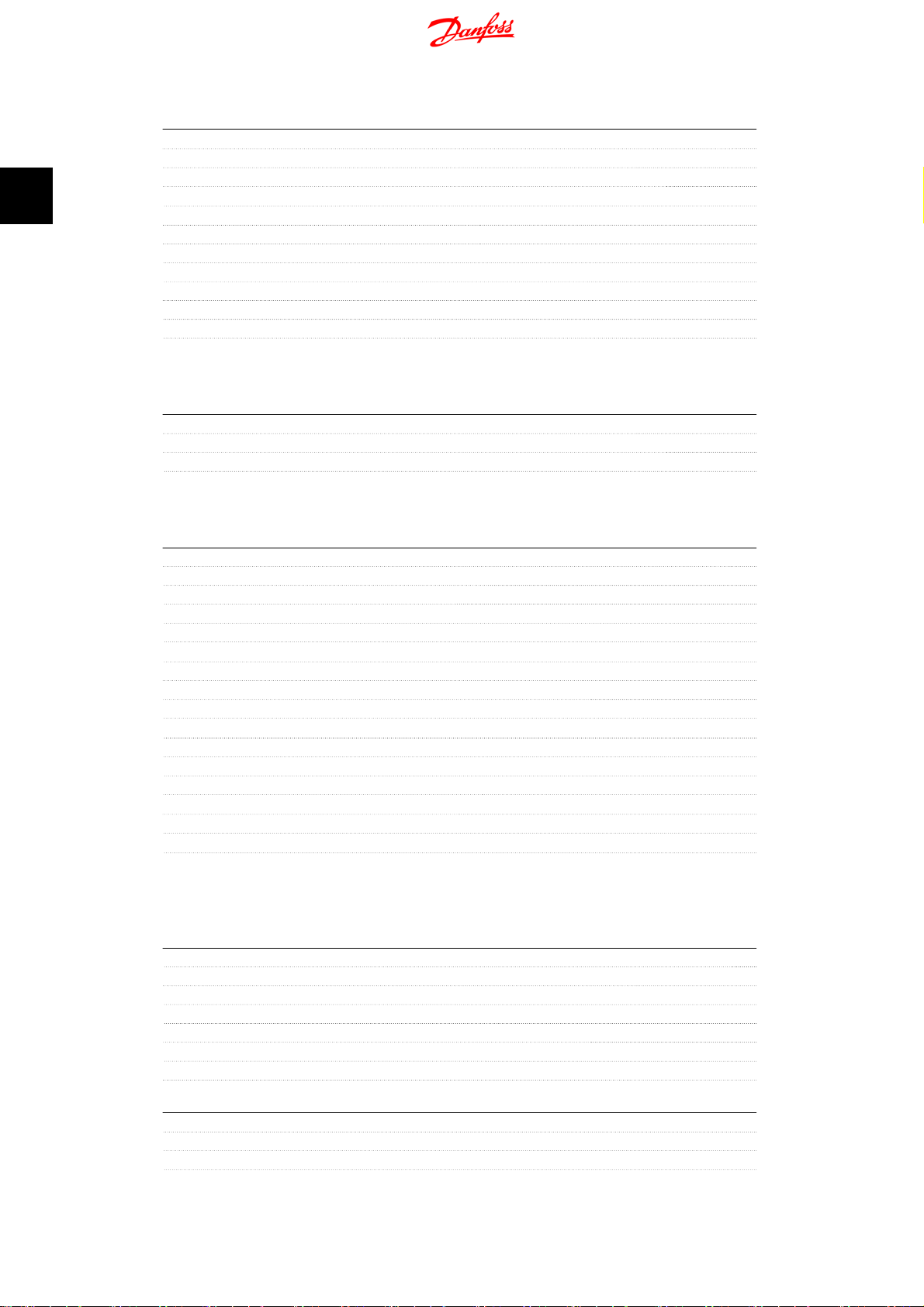

The synchronising Controller is an application option for VLT Automation Drive FC 301 and 302.

The application option consists of two parts:

• synchronising controller part

• Test Run part

2.2. Function Description

2.2.1. Introduction

The synchronising controller can be used in any application where a drive is to operate synchronously with a master drive. The synchronising controller acts as an electronic shaft. The gear ratio

is freely selectable and can also be changed during operation. The speed or the position is automatically and accurately controlled based on encoder feedback signals from both the master drive

and the slave drives.

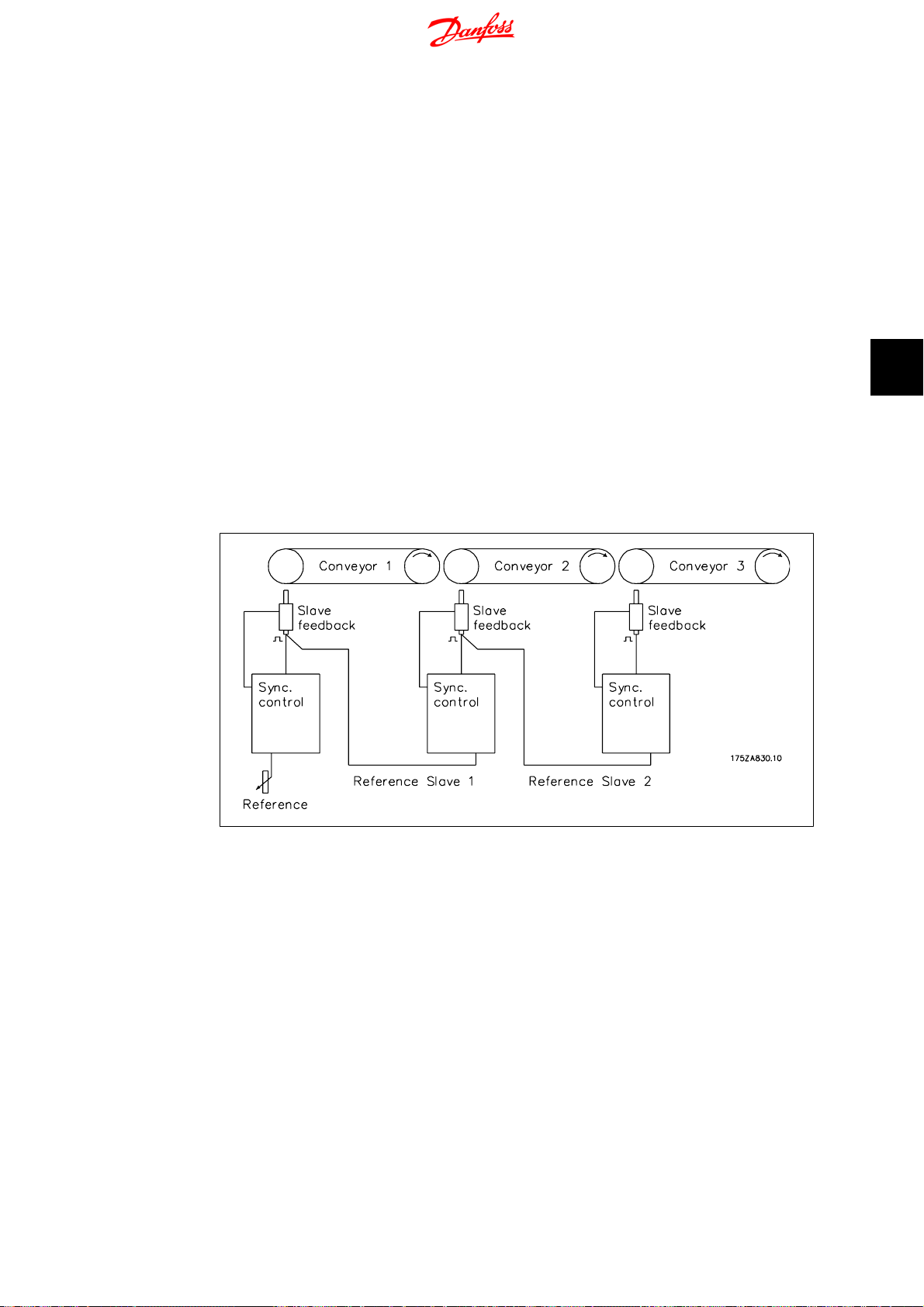

For synchronous operation of two or more drives you can use:

• Speed synchronisation

• Position synchronisation or

• Marker synchronisation

2.2.2. Speed Synchronisation

2

This is the simplest type of synchronisation. It can be used to compensate for speed differences,

where it is not necessary to compensate for position errors.

The speed synchronisation between master and slave is done at maximum acceleration. To obtain

optimum control the slave drive should therefore be set for a quicker acceleration speed than that

of the master drive.

2.2.3. Position Synchronisation (angle synchronisation)

This is the electronic shaft ensuring a constant angle position ratio between master and slave

drives. In case of a position deviation the slave drive is automatically accelerated to a speed level

that is sufficient for regaining its position to the master drive (I-control like).

2.2.4. Marker Synchronisation

Marker synchronisation is an extended position control. Apart from ensuring a constant angle

position between master and slave drives, marker synchronisation provides the option of using

either an additional sensor or the zero track of the incremental encoder to compensate for any

deviations between master and slave that may occur during operation. Using marker synchronisation the slave is position synchronised until the markers is reached and then the control

compensates for the position difference between master marker and slave marker. This type of

control is used where precision cannot be achieved by using a motor mounted encoder. That could

be because of gearbox slack or other disturbance like belt elongation etc. that are not directly

measurable. Similarly, with marker synchronisation, the slave drive does not need to be brought

into the start position of the master drive at initial start-up, as this is affected automatically by

marker correction.

MG.33.Q1.02 - VLT

®

is a registered Danfoss trademark

11

2

Syncronising Controller MCO 350 Operating

2. Introduction

2.2.5. Mechanical Brake Control

The synchronising controller has a 24 V DC digital output (Output 4) and a relay output (Relay 1)

to control an electromechanical brake; this is very useful in applications when a motor (shaft)

must be kept in the same position for a longer time. This is usually the case in hoisting applications.

The brake output will be active (low) in case of an error and when synchronisation is stopped,

that means whenever motor control is switched off. The brake signal can be delayed when switched on and off in two individual parameters (par. 19-21

). Please note that the brake output is kept low in VLT mode (when input 8 is high). That

Delay

means the brake must be opened for example by means of the VLT mechanical brake function in

set-up 2.

Brake on Delay

and par. 19-22

2.3. Tips and Tricks for Synchronisation Tasks

2.3.1. Introduction

When configuring the drives to be synchronised please keep in mind that the ratios should be of

integer size. When using gear it is also important to know the number of teeth of the various gear

stages (ask the gear manufacturer) as gears are normally set up with infinite gear ratios. When

calculating the ratios between master and slave you must either use the figure PI for both of them

or not use PI at all.

Instructions

Brake off

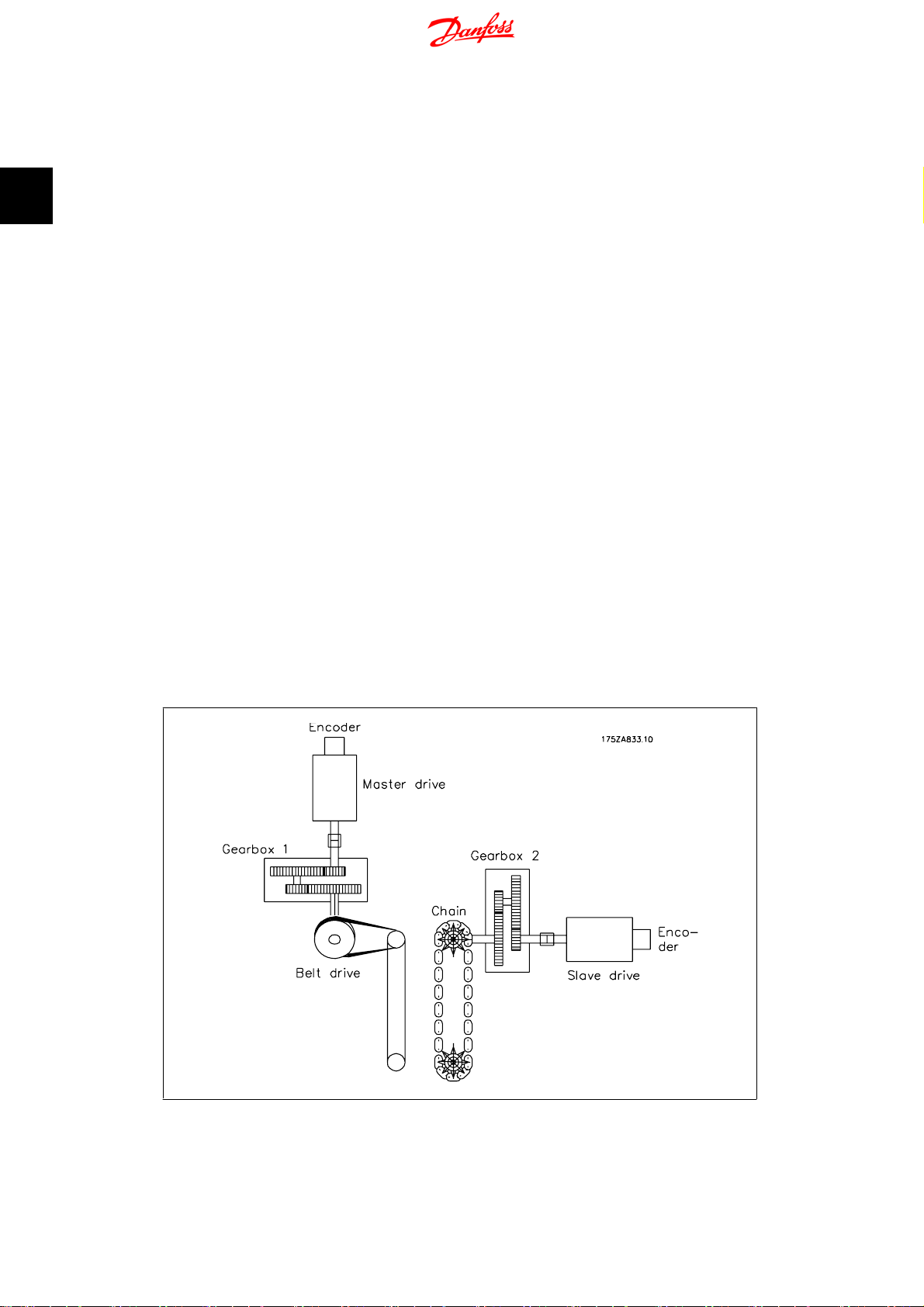

2.3.2. Example

A master drive with a 4-pole motor and an incremental encoder of 1024 increments/revolution

works on a 2-stage gear. i is specified to be 30.33. At the gear output, a belt ratio of 40:20 is

placed, driving a conveyor belt on the drive side with a diameter of 102mm. Via a 3-stage gear (i

is specified to be 46,54) the slave drive is connected to an 8-toothed chain conveyor with a tooth

pitch of 200mm.

Illustration 2.1: Calculation Example

12

MG.33.Q1.02 - VLT

®

is a registered Danfoss trademark

Syncronising Controller MCO 350 Operating

Instructions

2.3.3. Calculation with Insufficient Numerical Values

The master/slave gear ratio (numerator to denominator) is now calculated as follows:

2. Introduction

Master side = increments * i1 * i2 * power take off =

1024

incr x

Slave side = increments * i1 * power take off

=

This gives a ratio of:

That gives a numerical value of 48,460995 for the numerator and 29,7856 for the denominator.

Note: It is only possible to enter integer values. The most serious error: The master expression

contains the value Pi, an infinite number sequence. Even with small numerical values for master

and slave, the effect would always be that the drives drifted apart, as the Numerator: Denominator

expression can never be an integer.

Another error arises from the gear ratios given, as the master drive was specified with a value of

i = 30.33. The correct ratio is easily found by recalculating the individual numbers of teeth. The

gear is a 2-stage gear; the first stage is formed from two pinions, 126 to 27, and the second stage

from two pinions, 117 to 18.

The ratio is calculated as:

30.33

20

x

x

40

48, 460995

29, 7856

126x117

27

102

x

mm x

18

1

π

=30,33

= 48, 460995

1024

incr x

46.54

x

1

x

200

8

mm

2

= 29, 7856

The specified value of 30.33 thus deviates by 0.1 ‰.

This may appear small; if this error is related to the encoder resolution, however, it will be seen

that even this error is serious.

From the example it can be seen that it is important to maintain the exact values of the gear

stages and to ensure that the data include Pi either for both drives or for none of them.

2.3.4. Example with Corrected Numerical Values

Master side: Gear 1st stage 126/27 2nd stage 117/18; belt ratio 40/20; drive shaft 100 mm

Slave side: Gear 1st stage 97/10, 2nd stage 43/11, 3rd stage 27/22; effective diameter of the

sprocket wheel 510mm

1024

Master side:

Slave side:

To remove Pi from the equations, substitute both equations into the combined formula:

1024

10

Masterside

Slaveside

Incr x

x

27

Incr x97x

x

11x22x510xπ

1024

=

126x117x20

18x40x102xπ

43x27

27

Incr x

x

126x117x20

18x40x102xπ

1024

÷

10

x

Incr x

11x22x510xπ

97x43x27

MG.33.Q1.02 - VLT

®

is a registered Danfoss trademark

13

2. Introduction

1024

27

Incr x

x

18x40x1024

126x117x20x510xπx10x11x22

Incr x97x

43x27x102

Syncronising Controller MCO 350 Operating

Instructions

x

π

2

Reduce by Pi and 1024 incr.:

Reduce further:

7x5x54x11x22x117

x

97x43x27

27

This gives a ratio of

This is an absolute value, as it contains no infinite number sequences and no rounded values.

4954950

3040659

126x117x20x510x10x11x22

x

18x40x97x43x27x102

27

2.4. Hardware

2.4.1. VLT Control Card Terminals

The terminals on the control card are allocated for synchronising controller functions the following

parameter settings should therefore not be changed in synchronising mode (set-up 1):

Digital inputs 18, 19, 27, 32 and 33

Parameters 510–515 are set to

control card but they are used as inputs for the synchronising controller.

No operation

(default setting), then the inputs are ignored by the

Analogue inputs 53, 54

Parameters 315, 316 and 317 are set to

card but they are used as inputs to the synchronising controller.

Digital/analogue outputs 42

Parameters 650 are set to:

MCO 0 … 20 mA [52] analogue output

2.5. Technical Data

2.5.1. Introduction

Technical data on the control card terminals can be found in the VLT Automation Drive FC 300

Design Guide.

2.5.2. Option Card Terminals

There are two encoder interfaces, which coveers the following functions:

• Feedback encoder input

• Master encoder input / virtual master output

No function

, then the inputs are ignored by the control

14

MG.33.Q1.02 - VLT

®

is a registered Danfoss trademark

Syncronising Controller MCO 350 Operating

Instructions

2. Introduction

Terminal X55

Terminal Number Descriptive Name

Encoder 2 (Feedback)

1 + 24 V Supply

2 + 8 V Supply

3+ 5 V Supply

4 GND

5A

6 A not

7B

8 B not

9Z / Clock

10 Z / Clock not

11 Data

12 Data not

There are 2 digital input/output terminal blocks, 10 inputs and 8 outputs. (See figure below)

Terminal X57

Terminal Number Descriptive Name

Digital Inputs

1Digital Input

2 Digital Input

3Digital Input

4 Digital Input

5Digital Input

6 Digital Input

7Digital Input

8 Digital Input

9Digital Input

10 Digital Input

Terminal Number Descriptive Name

1 + 24 V Supply

2 NC

3+ 5 V Supply

4 GND

5A

6 A not

7B

8 B not

9Z / Clock

10 Z / Clock not

11 Data

12 Data not

Terminal Number Descriptive Name

1Digital Output

2 Digital Output

3Digital Output

4 Digital Output

5Digital Output

6 Digital Output

7Digital Output

8 Digital Output

Terminal X56

Encoder (Master)

Terminal X59

Digital Output

2

Terminal X58

Terminal Number Descriptive Name

24 V Supply

1 + 24 V Supply

2 GND

There are 2 digital input/output terminal blocks, 10 inputs and 8 outputs. (See figure below)

MG.33.Q1.02 - VLT

®

is a registered Danfoss trademark

15

2

2. Introduction

Syncronising Controller MCO 350 Operating

Instructions

2.5.3. Encoder Monitor

Both encoder interfaces are equipped with a monitoring circuit that can detect open circuit as well

as short circuit of each encoder channel. Each encoder channel has a LED showing the status:

Green light means OK, no light means fault. An encoder fault will result in an ”Option error” 192

if encoder monitoring is activated via parameter 3239 (master) and 3209 (slave).

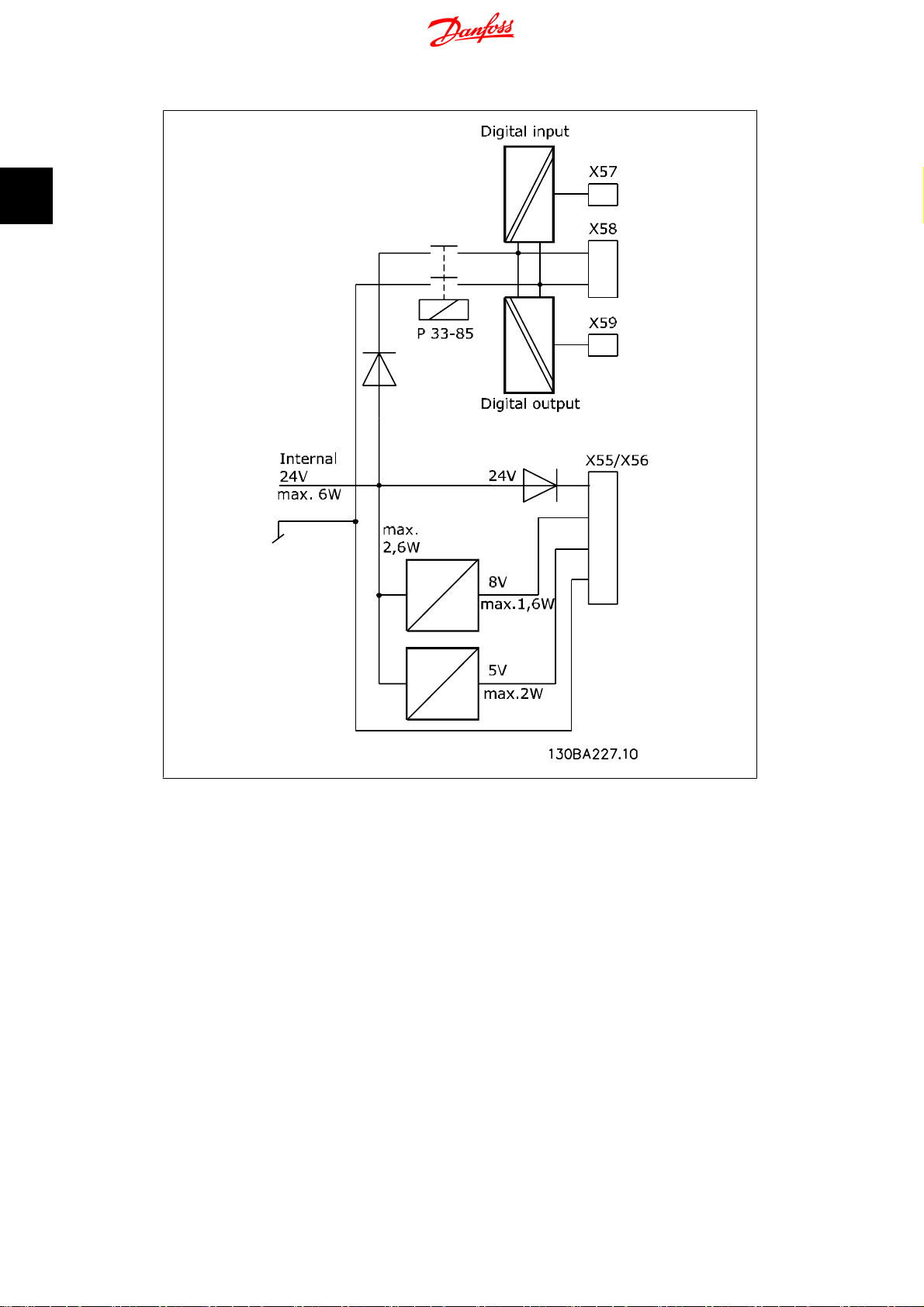

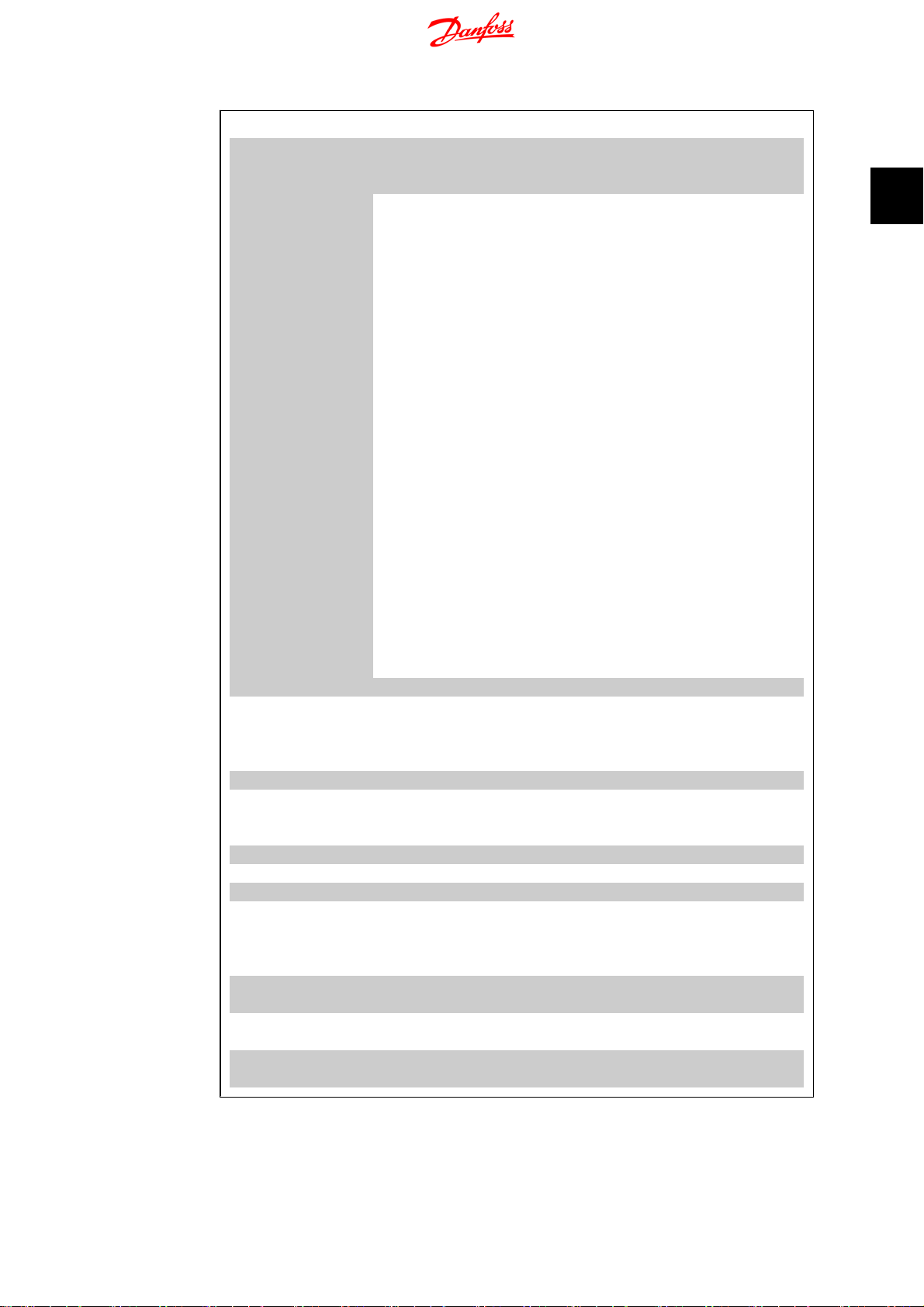

2.5.4. Option Card Layout

MCO 350 control terminals are plug connectors with screw terminals; the terminal blocks are

duplicated to enable use of the same MCO 350 in all frame sizes. See illustration to locate the

terminal blocks:

16

MG.33.Q1.02 - VLT

®

is a registered Danfoss trademark

Syncronising Controller MCO 350 Operating

Instructions

(1) is used with frame sizes A2 and A

(2) is used with frame sizes A5, B1 and B2

X55 = Encoder 2

X56 = Encoder 1

X57 = Digital inputs

X58 = 24VDC supply

X59 = Digital outputs

2.5.5. General Technical Data

− All inputs, outputs and supply voltages are protected against short circuit.

− All inputs, outputs and supply voltages are galvanic isolated from high voltages such as mains

supply and motor voltage (PELV).

− Encoder signals are monitored during operation and standstill.

− All MCO 350 parameters including user defined application parameters are accessible via the

FC 300 Local Control Panel.

− MCO 350 can be combined with other FC 300 options, namely PROFIBUS and DeviceNet interface.

− All digital inputs and outputs are galvanic isolated from the internal electronics and can be

sourced from an external 24V power supply.

2. Introduction

2

Connection Terminals:

Maximum cross section, rigid wire 1.5 mm2/AWG 16

Maximum cross section, flexible wire 1.5 mm2/AWG 16

Maximum cross section, wire with enclosed core 1.5 mm2/AWG 16

Minimum cross section 0.082/AWG 28

Digital inputs:

Number of programmable digital inputs 10

Terminal block X57

Terminal number 11),21),3,4,5,6,7,8,9,10

Logic PNP or NPN

Voltage level 0 - 24 V DC

Voltage level 0 - 24 V DC

Voltage level, logic '0' PNP < 5 DC

Voltage level, logic'1' PNP > 10 V DC

Voltage level, logic '0' NPN

Voltage level, logic '1' NPN

Maximum voltage on input 28 V DC

2)

2)

> 19 V DC

< 14 V DC

1) ) Selected in parameter 5-00 Digital I/O mode.

The digital inputs are galvanic isolated from the internal electronics and can be sourced by an

external 24V power supply.

Digital outputs:

Number of programmable digital outputs 8 (6)

Terminal block X59

Terminal number 11), 21),3,4,5,6,7,8

Driver type push/pull

Logic PNP or NPN

Voltage level 0 - 24 V DC

Max. output current (sink or source) with internal power supply (total Σ) 40 mA

Max. output current (sink or source) with external power supply (per output) 100 mA

Terminals X59-1 and X59-2 can be programmed as input, parameter 33-60.

1)

1

2)

MG.33.Q1.02 - VLT

®

is a registered Danfoss trademark

17

2. Introduction

Syncronising Controller MCO 350 Operating

Instructions

2

Combined Digital Inputs/Outputs:

Number of digital outputs which can be used as digital inputs 2

Terminal block X59

Terminal number 1,2

Logic PNP or NPN

Voltage level 0 - 24 V DC

Voltage level 0 - 24 V DC

Voltage level, logic '0' PNP < 10 V DC

Voltage level, logic'1' PNP > 17 V DC

Voltage level, logic '0' NPN > 13 V DC

Voltage level, logic '1' NPN < 6 V DC

Maximum voltage on input 28 V DC

1) Terminals X59-1 and X59-2 can be programmed as input, parameter 33-60.

2) Selected in parameter 5-00 Digital I/O mode.

24 V DC Supply Output

Terminal block X58

Terminal number 1,2

Maximum load 65 mA

The internal 24V power supply can be disconnected via parameter 33-85, an external 24V power

supply must then be connected to X58-1 and X58-2.

Encoder Inputs

Number of encoder inputs 2

Terminal block X55 and X56

Terminal number 5,6,7,8,9,10,11,12

Input impedance 120Ω

Maximum voltage on inputs 5 V DC

Cable type Screened cable with a twisted pair of wires for each encoder channel

Incremental encoder type RS422/TTL

Maximum frequency 410 kHz

Phase displacement between A and B 90°±30°

Maximum cable length 300 m

Absolute encoder type SSI

Data coding Gray

Data length 12 - 37 bit

Clock frequency 78 kHz - 2 MHz

Absolute encoder type SSI

Maximum cable length 150 m

1) Always observe specifications/limitations prescribed by the encoder supplier.

2) 150 m cable is possible up to 500 kHz clock frequency, above 500 kHz cable length must be

limited further.

1)

2)

1)

1)

1)

1)

Encoder Output

Number of encoder outputs 1

Terminal block X56

Terminal number 5,6,7,8,9,10,11,12

Signal type RS 422Ω

Maximum frequency 410 kHz

Maximum number of slaves 31 (more with repeater)

Maximum cable length 400 m

Encoder Output

Number of supply voltages 3

Terminal block X55 and X56

Terminal number 1,2,3,4

18

MG.33.Q1.02 - VLT

®

is a registered Danfoss trademark

Syncronising Controller MCO 350 Operating

Instructions

2. Introduction

24 V, max load 250 mA

8 V, max load 250 mA

5 V, max load 400 mA

Absolute encoder type SSI

Maximum cable length 150 m

1) This is maximum load when only one supply voltage is used; when 2 or 3 supply voltages are

used simultaneously the load must be reduced accordingly. The following must be observed:

load24V + load8V + load5V ≤ 6W and load8V + load5V ≤ 2W.

2) 8 V is only available at terminal block X55.

2.6. Example of Encoder Interface connections

1) 2)

1)

1)

1)

2

MG.33.Q1.02 - VLT

®

is a registered Danfoss trademark

19

2

2. Introduction

2.7. Description of Terminals

I/O Number Designation Description

12 24 V DC 24V power supply for switches etc.

13 24 V DC 24V power supply for switches etc.

18 Disable Resync The Resync function (to be enabled by param

19 Home run Starts the homing.

20 GND Ground for 24 V.

27 Reset/Enable Error reset on rising edge. To enable opera-

32 Test run reverse Test run; Program 1:

Speed/Pos - Synchronous operation; Program 2:

Syncronising Controller MCO 350 Operating

Instructions

1924) can be temporarily disabled by setting

this input to 1

tion, this input must be switched to “1”. “0” =

motor coast.

Test run reverse at the speed defined in Parameter 19-01

In velocity synchronous mode (P. 1901 = 0, 3,

6 or 7) the gear ratio and thus the velocity of

the slave can be changed by the value specified in parameter 1912.

In position synchronous and marker synchronous operation (P. 1901 = 1, 2, 4 or 5), the

position offset of the slave can be changed by

the value specified in Parameter 1912. The

sign of the value in parameter 1912 selects the

offset type to be absolute or relative.

Absolute offset means that the fixed offset of

parameter 1912 is changed and this offset is

executed when restarting synchronisation.

Relative offset means that the actual slave position is displaced but the fixed offset of parameter 1912 is unchanged. This again means

that the actual slave position is maintained

when restarting synchronisation. Relative offset is useful when always changing the offset

in the same direction as this would give a very

high fixed offset when using absolute offset.

This high fixed offset would then be executed

when restarting synchronisation and the min.

or max. limit of parameter 1912 would eventually be reached.

20

MG.33.Q1.02 - VLT

®

is a registered Danfoss trademark

Syncronising Controller MCO 350 Operating

Instructions

I/O Number Designation Description

33 Test run forward Test run; Program 1:

Speed/Pos + Synchronous operation; Program 2:

01 COM; 240V AC/2A Relay output 1:

02 Electromechanical

brake: NO

03 NC

04 COM; 50V AC/1A; 75V

DC/1A

05 NO

06 NC

39 GND Ground for analogue inputs/outputs.

42 Slave/Master velocity The output value is scaled to maximum slave

50 10V DC 15mA Power supply for reference value potentiome-

53 0 - 10V In Serves as reference input for the virtual mas-

54 0 - 10V In Serves as numerator for the gear ratio if “6” or

2. Introduction

Test run forward at the speed defined in Parameter 1901

2

In velocity synchronous mode (P. 1901 = 0, 3,

6 or 7) the gear ratio and thus the velocity of

the slave can be changed by the value specified in parameter 19-12.

In position synchronous and marker synchronous operation (par. 19-01 = 1, 2, 4 or 5), the

position offset of the slave can be changed by

the value specified in Parameter 1912. The

sign of the value in parameter 1912 selects the

offset type to be absolute or relative.

Absolute offset means that the fixed offset of

parameter 19-12 is changed and this offset is

executed when restarting synchronisation.

Relative offset means that the actual slave position is displaced but the fixed offset of parameter 19-12 is unchanged. This again

means that the actual slave position is maintained when restarting synchronisation. Relative offset is useful when always changing the

offset in the same direction as this would give

a very high fixed offset when using absolute

offset. This high fixed offset would then be

executed when restarting synchronisation and

the min. or max. limit of parameter 1912

would eventually be reached.

Relay 1 is open (brake activated) during power

off, and start-up of the frequency converter.

Afterwards the brake-control depends on the

selected Sync mode.

Relay output 2:

Function can be configured by means of Parameter 540.

velocity (parameter 32-80);

The output can be selected between slave or

master velocity by means of parameter 19-25

ter

ter if “0“ is selected in Parameter 19-16.

“7” is selected in parameter 19-01.

MG.33.Q1.02 - VLT

®

is a registered Danfoss trademark

21

2

2. Introduction

2.7.1. Standard RS 485-Interface

I/O Number Designation Description

61 Ground RS 485 Not used

68 RS 485-P Not used

69 RS 485-N Not used

2.7.2. MCO 350 Terminal X57

I/O Number Designation Description

1 I1 - Sync-Start Start and stop of synchronisation. Input

2 I2 - Take over gear ratio Activates the gear ratio selected at Ter-

3 I3 - Start/Stop virtual master Test run; Program 1: Start test run

4 I4 - Hold The drive is held at a programmable

5 I5 - Master marker input When using external marker signal for

6 I6 - Slave marker input When using external marker signal for

7 I7 - Measuring of the master marker

interval

Home switch Synchronous operation; Program

8 I8 - measuring of the slave marker

interval

I8 - VLT mode selection Synchronous operation; Program

9

10

Gear ratio 2

Gear ratio 2

0

1

Syncronising Controller MCO 350 Operating

Instructions

1 must be toggled if synchronisation

was interrupted by an error or by input

27 (motor coast). Behaviour at stop can

be selected via parameter 1901.

minals 9 and 10.

with virtual master. Synchronous op-

eration; Program 2: The virtual master is accelerated up to the set pulse

frequency, or stopped, with the set

ramp time.

(parameter 1903) speed, or the current

speed (parameter 1902 = 1). Synchronous control is not activated.

the master drive it must be connected

to this input.

the slave drive it must be connected to

this input.

Test run; Program 1:

Measuring of the master marker interval

is started.

2:

If a home position is to be attained, the

home switch must be connected here.

The signal must show a rising edge

Test run; Program 1:

Measurement of the slave marker interval is started.

2:

Switches the VLT to normal frequency

converter operation. The settings for

this operating mode are to be made in

Parameter set-up 2. Refer to the VLT

Automation Drive Product Manual.

Gear ratio least significant bit

Gear ratio most significant bit

22

MG.33.Q1.02 - VLT

®

is a registered Danfoss trademark

Syncronising Controller MCO 350 Operating

Instructions

2.7.3. MCO 350 Terminal X59

I/O Number Designation Description

1 O1 - READY Ready, i.e. for the number of marker signals that were

2 O2 - FAULT Fault, i.e. for the number of marker signals that were

3 O3 - ACCURACY The drive runs within the tolerance specified in Param-

4 O4 - Brake control This output can be used to control a mechanical brake.

5 O5 - Saving This output stays high while saving is in progress. The

6 O6 - Drive running Signal “1” when the drive is running.

7 O7 - Home reached If the data value “1” was chosen in Parameter 3300, this

8 O8 - Ready, no error The synchronising controller is ready for operation.

2. Introduction

specified in Parameter 3325, the slave drive has run

within the tolerance (Accuracy).

specified in Parameter 3324, the slave drive has run outside the tolerance (Accuracy). OR when the number of

marker signals have been missing when marker monitor

is activated in parameter 1923.

eter 3313.

“0” means that the brake must be closed (braking) “1”

means that the brake must be open (not braking)

saving is initiated by Parameter 1900, Input 4 or fieldbus

bit 4.

output shows “1” when homing is completed.

2

2.8. Description of Fieldbus Interface

NB!

This section is only relevant if the VLT is equipped with a Field bus interface (option)

as well as the synchronising controller.

The synchronising controller can be controlled via the digital/analogue inputs or via field bus. The

control source can be selected individually for test-run and synchronising in the parameters 1919

(test-run) and 1920 (synchronising). There can only be one control source at a time meaning that

the digital/analogue inputs are inactive when Field bus is selected as control source and visa versa.

The only exception is input 27, which is always stop/enable also when Field bus is selected as

control source. In synchronising mode three signals are only available as digital inputs even when

Field bus is selected as control source that is the marker signals for marker synchronisation and

the Home switch. This is because these signals are too time-critical for Field bus control. Status

signals are always available on the digital/analogue outputs but they are only available via Field

bus when Field bus is selected as control source.

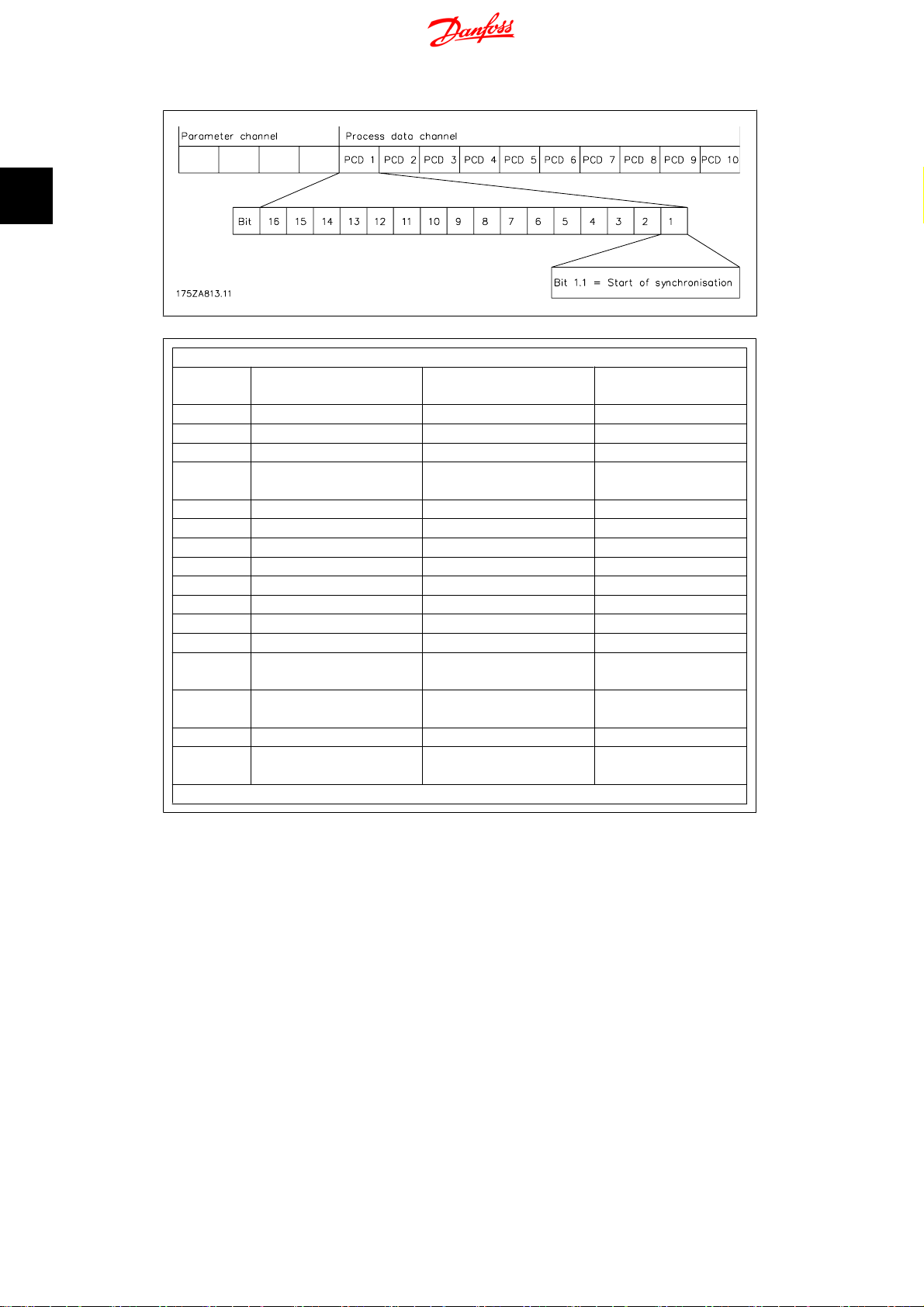

2.8.1. Data Layout

Control and status signals are transferred via the so-called process data channel (PCD) of the

various fieldbus interfaces. The telegram structure and the available number of data words depends on the Fieldbus used, please refer to the manual of the Fieldbus option in use for further

details. The below example is based on the layout of a PROFIBUS telegram, the so-called PPO:

Example using PROFIBUS PPO type 5:

MG.33.Q1.02 - VLT

®

is a registered Danfoss trademark

23

2

2. Introduction

Fieldbus Control Signals

Fieldbus

[word.bit]

1.1 Not used Start of synchronisation 1

1.2 Not used Take over gear ratio 2

1.3 Start/stop virtual master Start/stop virtual master 3

1.4 Not used Save gear-settings (only

1.5 Not used VLT-mode 8

1.6 Not used Gear-ratio select LSB 9

1.7 Not used Gear-ratio select MSB 10

1.8 Not used Start homing 19

1.9 Reset/enable Reset/enable 27

1.10 Not used Hold 29

1.11 Not used Speed/position - 32

1.12 Not used Speed/position + 33

1.13 Measuring master marker

1.14 Measuring slave marker

1.15 Test-run left Not used 32

1.16 Test-run right Virtual master negative di-

2 Virtual master reference* Virtual master reference* 53

Syncronising Controller MCO 350 Operating

Instructions

Test Run synchronising Corresponding Input

4

possible when stopped!)

Not used 7

distance

Not used 8

distance

33

rection

*) Only when par. 19-16 = 2.

24

MG.33.Q1.02 - VLT

®

is a registered Danfoss trademark

Syncronising Controller MCO 350 Operating

Instructions

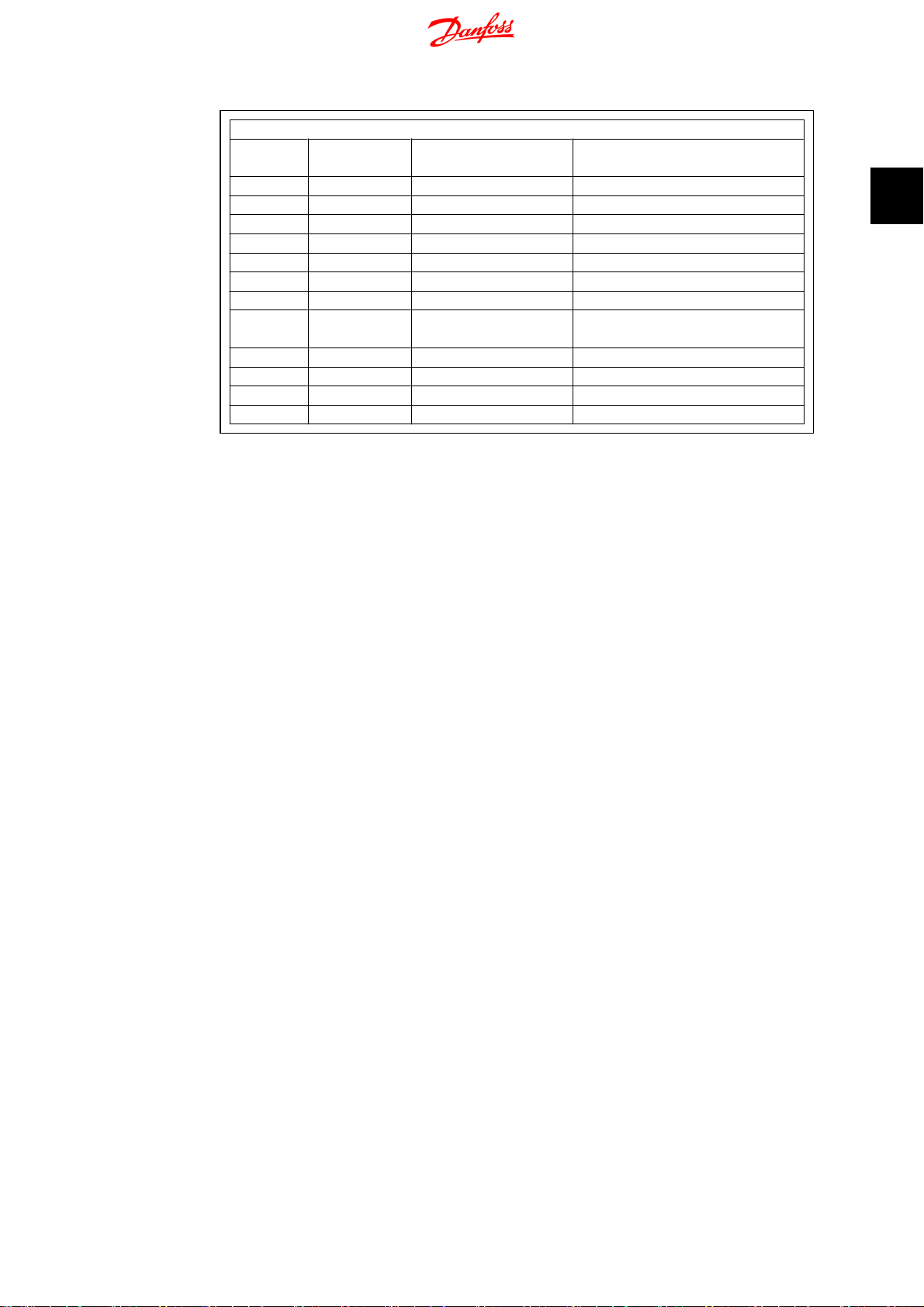

Fieldbus Status Signals

Fieldbus

[word.bit]

1.1 Not used Ready 1

1.2 Not used Fault 2

1.3 Not used Accuracy 3

1.5 Saving Saving 5

1.6 Running Running 6

1.7 Not used Home reached 7

1.8 Ready, no error Ready, no error 8

2 Track error Track error Par. 19-93 (testrun)/

3 Not used synchronising error Par. 19-93

4 Not used Status of synchronisation Par. 34-60

5 Slave speed Slave speed Par. 19-94

6 Master speed Master speed Par. 19-95

Test Run synchronising Corresponding Output/Parame-

2. Introduction

ter

2

Par. 19-96 (synchronising)

MG.33.Q1.02 - VLT

®

is a registered Danfoss trademark

25

3

3. Programming

Syncronising Controller MCO 350 Operating

Instructions

26

MG.33.Q1.02 - VLT

®

is a registered Danfoss trademark

Syncronising Controller MCO 350 Operating

Instructions

3. Programming

3.1. Description of Parameters

3. Programming

19-00 Store data

Option: Function:

Here you can save the gear-ratio data permanently in the EEPROM

[0] no function

[1] Gear data is being

saved

19-01 Test run; Program 1

Option: Function:

19-01 Synchronous operation; Program 2

Option: Function:

While saving, the value remains “1“; when saving is finished,

the value automatically reverts to “0“. At the same time, during

saving, Output O5 “Saving“ is set to “1“. Saving is not possible

during operation, but only in the stopped state.

Test run speed: Specify here the speed at which the test runs

are to be carried out. The speed is specified as a percentage of

the maximum speed defined in par. 32-80.

Type of operation: Select here the type of operation of the synchronising Controller

3

[0] Speed synchronising

[1] Position synchronising

[2] Marker synchronising

[3] Speed synchronising with motor coast after stop

[4] Position synchronising with motor coast after stop

[5] Marker synchronising with motor coast after stop

[6] . Speed synchronising with motor coast after stop and setting of

gear ratio via analogue input 54

[7] Speed synchronising with setting of gear ratio via analogue in-

put 54.

With the selections “0” - “2” and “7” the motor is always controlled keeping the actual position

when stopping synchronisation (input 1 = “0”).

MG.33.Q1.02 - VLT

®

is a registered Danfoss trademark

27

3

3. Programming

19-02 Test run; Program 1

Option: Function:

[0] If “0“ is set, the slave drive is brought to the speed set in par.

[1] If “1“ is set, the actual speed is maintained. While these signals

Syncronising Controller MCO 350 Operating

Instructions

Test run acceleration: Specify here the acceleration for the

test run as a percentage of the maximum acceleration. 100 %

means that the drive accelerates with the minimum ramp specified in par. 32- 8 1 . 5 0 % m e a ns that the drive only proceeds with

half the acceleration, i.e. the acceleration takes twice as long as

with the minimum ramp specified in par. 32-81.

Synchronous operation; Program 2: Hold function:

If the contact at Terminal 29 is closed, the slave drive is disengaged, i.e. it no longer runs in synchrony with the master.

19-03.

are present, the current Hold speed can be changed by means

of Inputs 32 and 33.

19-03 Test run; Program 1

Option: Function:

Test run distance: Specify the distance for the test run in quad

counts.

Synchronous operation; Program 2:

Hold speed: If Hold function “0“ was selected, enter here the

speed as a percentage of the maximum speed (par. 32-80).

19-04 Test run, program 1: synchronising type (Sync type)

Option: Function:

This parameter is used to specify the type of synchronisation

used when optimising the PID controller for synchronisation by

means of the virtual master.

[0] Speed synchronising Select “0” if speed synchronising should be used in synchronous

mode

[1] Position synchronis-

ing

Select “1” if position or marker synchronising should be used in

synchronous mode.

Synchronous operation; Program 2:

Delta hold speed: Specify the percentage by which the hold

speed is to change when Input 32 or 33 is activated during Hold

mode.

19-05 Test run, program 1: Activate feed forward and PID calculation (FFVEL calc.)

Option: Function:

This parameter is used to trigger automatic calculation of the

optimal value for velocity feed forward (par. 32-65) as well as

PID sample time (par. 32-69), proportional factor (par. 32-60)

and derivative factor (par. 32-61).

[0] No action

28

MG.33.Q1.02 - VLT

®

is a registered Danfoss trademark

Syncronising Controller MCO 350 Operating

Instructions

3. Programming

[1] Activate calculation of

velocity feed forward

(par. 3265)

[2] Activate calculation of velocity feed forward (par. 32-65), PID

The parameter value is automatically reset to

“0” when the calculation is done.

NB!

If any of the above mentioned parameters are changed the calculation must be

repeated.

The calculation is based on the following parameters that must

be set before the calculation is started:

Par. 32-00/32-02 “Slave encoder type”,

Par. 3201/3203 “Slave encoder resolution”,

Par. 32-80 “encoder velocity”

Par. 32-69 “PID sample time”.

sample time (par. 32-69), Proportional factor (par. 32-60) and

derivative factor (par. 32-61). The calculations are based on the

following parameters that must be set before the calculation is

started:

Par. 32-00/32-02 “Slave encoder type”,

Par. 32-01/32-03 “Slave encoder resolution”,

Par. 32-80 “Maximum velocity”,

3

Synchronous operation; Program 2:

Gear ratio no.: Select the number of the gear ratio that you want to edit in parameters 19-06

to 19-10.

19-06 Gear ratio numerator

Option: Function:

Enter the numerator for the gear ratio selected in par. 19-05.

Ensure that the gear ratio matches the marker ratio.

19-07 Gear ratio denominator

Option: Function:

Enter the denominator for the gear ratio selected in par. 19-05.

Ensure that the gear ratio matches the marker ratio.

19-08 Slave marker quantity

Option: Function:

Enter the number of slave markers for the marker ratio. Ensure

that the gear ratio matches the marker ratio.

MG.33.Q1.02 - VLT

NB!

This parameter is only used in marker synchronising mode (par. 19-01 = 2 or 5).

®

is a registered Danfoss trademark

29

3

3. Programming

19-09 Master marker quantity

Option: Function:

19-10 Fixed offset

Option: Function:

Syncronising Controller MCO 350 Operating

Instructions

Enter the number of master markers for the marker ratio. Ensure that the marker ratio matches the gear ratio.

NB!

This parameter is only used in marker synchronising mode (par. 1901 = 2 or 5).

Enter the position offset. This makes it possible to compensate

for differences in the placing of the encoder or markers. Input

is in quad counts.

Offset_slave

19-11 Step time

Option: Function:

Enter the time after which

• with the Hold function activated and the presence of

• in the engaged state, without Hold, the next change of

Input is in milliseconds.

19-12 Step Length

Option: Function:

Enter the step value for changing the position offset in quad

counts. Par. 19-10 is changed accordingly. The sign of this parameter selects the offset type when changing the offset via the

position + and - inputs:

A positive value selects absolute offset (see Input 32/33).

A negative value selects relative offset (see Input 32/33).

NB!

Offset is related to the master position. Offset related to the slave position can be calculated as

follows:

O ffest x Parameter

:

one of the signals at Terminal 32 or 33, a change in

speed takes place;

the slave position takes place.

Parameter

19 − 06

19 − 07

30

MG.33.Q1.02 - VLT

®

is a registered Danfoss trademark

Syncronising Controller MCO 350 Operating

Instructions

19-13 Slave speed factor

Option: Function:

19-14 Master speed factor

Option: Function:

3. Programming

Enter here the factor by which the slave speed must be scaled,

so that the desired value is displayed. The following formula

applies for calculation of the factor:

N

x

400

Factor

Example: Resolution 1024 PPR, desired display 100 at 15001/

min

Factor

Enter here the factor by which the master speed must be scaled,

so that desired value is displayed. The formula for calculation of

the factor is:

Factor

Set

=

1

1500

=

=

min

N

x

Set

x Slaveencoder_resolution

60

xDisplay_value

x

400x1024

60x100

400

x Slaveencoder_resolution

60

xDisplay_value

Incr

Rev

.

.

= 102400

3

19-15 synchronising error display factor

Option: Function:

Enter the factor by which the error must be scaled, so that the

desired value is displayed. The formula for calculation of the

factor is:

Speed synchronisation: The factor should be 100, the synchronising error is then displayed in RPM related to the slave.

Position synchronisation:

N

x

400

Factor

Example: Resolution 1024 PPR, user unit is 100 mm/revolution

Factor

19-16 Virtual master reference value

Option: Function:

Select the type of reference value for the virtual master.

[0] reference value signal 0.. *10V via Terminal 53,

Set

=

N

x

Set

=

xSlaveencoder_resolution

U ser unit

400x1024

100

= 4096

[1] reference value can be set via par. 310 subindex 1.

[2] reference value is set via Field bus (PCD 2). +/- 1000 corre-

sponds to maximum virtual master velocity (par. 1918).

MG.33.Q1.02 - VLT

®

is a registered Danfoss trademark

31

3. Programming

19-17 Virtual master acceleration

Option: Function:

Syncronising Controller MCO 350 Operating

Instructions

Enter here the acceleration for the virtual master in Hz/s.

Virtual master acceleration =

Pulsfrequenz Hz

t s

3

Example: The virtual master must correspond to an encoder

with 1024 inc/rotation. The maximum speed of 25 encoder rotations per second must be attained in 1 second.

Virtual master acceleration =

1

25

x

1024

s

19-18 Virtual master maximum speed

Option: Function:

Enter here the maximum speed of the virtual master in Hz.

Virtual master maximum speed =

Increments

.

Rev

Example: The maximum virtual master signal must correspond

to an incremental encoder with 1024 inc/rotation at a rotational

speed of 50 rotations/s.

Virtual master maximum speed =

1024

x

1

1

s

x

50

s

Incr

.

Rev

.

= 25600

Rev

.

s

= 51200 1

/

Hz

s

/

s

19-19 Control source test run (Contr. testrun)

Option: Function:

This parameter is used to select the control source in test run

mode (par. 33-80 = “1”). There can only be one control source

at a time: Digital inputs or field bus control word. Only exception

is input 27 which is always stop also with field-bus control.

When digital control is selected status signals are updated on

the digital outputs, when field bus control is selected status signals are updated on digital outputs as well as field bus.

[0] Digital Inputs “0” means that all control commands are activated via the digital

inputs according to the description of the terminals.

[1] Fieldbus “1” means that all control commands are activated via the field

bus control word according to the description of field bus control.

NB!

The new control source selected in this parameter

is not active before next power up (power cycle).

32

MG.33.Q1.02 - VLT

®

is a registered Danfoss trademark

Syncronising Controller MCO 350 Operating

Instructions

19-20 Control source synchronising (Contr. synchron)

Option: Function:

[0] Digital Inputs means that all control commands are activated via the digital

[1] Fieldbus means that all control commands are activated via the field bus

3. Programming

This parameter is used to select the control source in synchronising mode (par. 33-80 = “2”). There can only be one control

source at a time: Digital inputs or field bus control word. Only

exception is input 27 which is always stop also with field-bus

control.

When digital control is selected status signals are updated on

the digital outputs, when field bus control is selected status signals are updated on digital outputs as well as field bus.

inputs according to the description of the terminals.

control word according to the description of field bus control.

NB!

The new control source selected in this parameter

is not active before next power up (power cycle).

3

19-21 Brake on delay (Brake on delay)

Range: Function:

This parameter is used to specify the delay time between closing

the mechanical brake (output 4) and disabling motor control

(motor coast). This is necessary to avoid loosing the load because of the reaction time of the mechanical brake.

[0...5000 msec.] The value must be set according to the reaction time of the me-

chanical brake.

19-22 Brake off delay (Brake off delay)

Range: Function:

This parameter is used to specify the delay time between activating motor control and opening the mechanical brake (output

4). This is necessary to avoid loosing the load because of the

reaction time of the mechanical brake.

[0...5000 msec.] The value must be set according to the reaction time of the me-

chanical brake.

19-23 Marker monitor

Option: Function:

This parameter specifies the behaviour when markers are missing in Marker synchronising mode (par. 1901 = 2 or 5)

[0] Output 2 Fault is set when “not accuracy” for x number of markers (x =

par. 33-24).

[1] Output 2 Fault is set when “not accuracy” for x number of markers (x =

par. 33-24) OR when x number of markers are missing.

MG.33.Q1.02 - VLT

®

is a registered Danfoss trademark

33

3

3. Programming

[2] Output 2 Fault is set when “not accuracy” for x number of markers (x =

19-24 Resync.

Option: Function:

[0] Inactive

[1] Active

Syncronising Controller MCO 350 Operating

Instructions

par. 33-24) and Output 2, fault is set and the error handler is

called when x number of markers are missing.

NB!

This function can only be used if marker windows

are used (par. 33-22 and 33-21).

With resync active synchronisation will remain active while the

slave is stopped (Input 1 and/or Input 27 = 0). The actual synchronising error will be corrected with the set velocity and

acceleration when restarting synchronisation.

19-25 Select Analogue output 42

Option: Function:

[0] Slave speed

[1] Master speed

19-92 Software version number

Option: Function:

The software version of the synchronising controller is displayed

here.

19-93 Test run; Program 1

Option: Function:

Track error“: The track error is displayed in quad counts.

Synchronous operation; Program 2: “Sync-error”: The syn-

chronisation error is displayed with the value calculated in par.

19-15.

19-94 Slave speed (read only)

Option: Function:

The slave speed is displayed with the value calculated in par.

19-13.

19-95 Master speed (read only)

Option: Function:

The master speed is displayed with the value calculated in par.

19-14.

34

MG.33.Q1.02 - VLT

®

is a registered Danfoss trademark

Syncronising Controller MCO 350 Operating

Instructions

19-96 Track error (read only)

Option: Function:

32-00 Incremental Signal Type (Slave)

Option: Function:

[0] None Choose if an absolute encoder is used

[1] RS422 (TTL/Line driv-

er)

[2] Sinusoidal 1 Vpp Choose if 1 V peak to peak analog incremental encoder is used.

32-01 Incremental Resolution (Slave)

Option: Function:

3. Programming

“Track-error”: The synchronisation error is displayed with the

value calculated in par. 19-15.

3

Enter the pulses per revolution

32-02 Absolute Protocol (Slave)

Option: Function:

[0] None choose if an incremental encoder is used.

[1] SSI.

[2] SSI with filter choose if the encoder signal is unstable.

32-03 Absolute Resolution (Slave)

Option: Function:

Enter the positions per revolution.

32-05 Absolute Encoder Data Length (Slave)

Option: Function:

Enter the number of data bits of the connected absolute encoder.

32-06 Absolute Encoder Clock Frequency (Slave)

Option: Function:

Enter the clock frequency according to the encoder manufacturer specifications.

32-07 Absolute Encoder Clock Generation (Slave)

Option: Function:

Off Clock signal is not generated.

On Clock signal is generated, this is most commonly used.

MG.33.Q1.02 - VLT

®

is a registered Danfoss trademark

35

3

3. Programming

32-08 Absolute Encoder Cable Length (Slave)

Option: Function:

32-09 Encoder Monitoring (Slave)

Option: Function:

32-10 Direction of rotation

Option: Function:

[1] standard, position is counting positive when the drive is running

Syncronising Controller MCO 350 Operating

Instructions

Enter the cable length of the encoder, please note that 300 meters is the maximum.

Off No monitoring of encoder hardware.

On Monitoring of encoder hardware, open- or short-curcuit will

generate error 192.

forward.

[3] position is counting negative when the drive is running forward.

[2] as “1”, but with opposite sign of the reference to the drive. This

can be used as alternative to swapping two motor phases if direction of motor rotation is wrong.

[4] as “3”, but with opposite sign of the reference to the drive. This

can be used as alternative to swapping two motor phases if direction of motor rotation is wrong.

32-30 Incremental Signal Type (Master)

Option: Function:

[0] None choose if an absolute encoder is used

[1] RS422 (TTL/Line driv-

er).

[2] Sinusoidal 1 Vpp choose if 1 V peak to peak analog incremental encoder is used.

32-31 Incremental Resolution (Master)

Option: Function:

Enter the pulses per revolution.

32-32 Absolute Protocol (Master)

Option: Function:

[0] None choose if an incremental encoder is used.

[1] SSI.

[2] SSI with filter choose if the encoder signal is unstable.

36

MG.33.Q1.02 - VLT

®

is a registered Danfoss trademark

Syncronising Controller MCO 350 Operating

Instructions

32-33 Absolute Resolution (Master)

Option: Function:

32-35 Absolute Encoder Data Length (Master)

Option: Function:

32-36 Absolute Encoder Clock Frequency (Master)

Option: Function:

32-37 Absolute Encoder Clock Generation (Master)

Option: Function:

Off Clock signal is not generated.

3. Programming

Enter the positions per revolution.

Enter the number of data bits of the connected absolute encoder.

Enter the clock frequency according to the encoder manufacturer specifications.

3

On Clock signal is generated, this is most commonly used.

32-38 Absolute Encoder Cable Length (Master)

Option: Function:

Enter the cable length of the encoder, please note that 300 meters is the maximum.

32-39 Encoder Monitoring (Master)

Option: Function:

Off No monitoring of encoder hardware.

On Monitoring of encoder harware, open- or short-curcuit will gen-

erate O.ERR_192.

32-40 Encoder Termination (Master)

Option: Function:

If only one encoder is connected then select “ON”, for all other

configurations select “OFF”

32-60 P-portion of the synchronising controller

Option: Function:

Setting: see Examples.

32-61 D-portion of the synchronising controller

Option: Function:

Setting: see Examples.

MG.33.Q1.02 - VLT

®

is a registered Danfoss trademark

37

3

3. Programming

32-62 I-portion of the synchronising controller

Option: Function:

32-63 Limitation for I-portion

Option: Function:

32-64 Band width for PID controller

Option: Function:

32-65 Velocity feed forward

Option: Function:

Syncronising Controller MCO 350 Operating

Instructions

Setting: see Examples.

Setting: see Examples.

Setting: see Examples.

32-66 Acceleration feed forward

Option: Function:

Setting: see Examples.

32-67 Maximum track error

Option: Function:

Enter here the maximum track error. This is the permitted error

between the calculated position and the feedback position. If

the value is exceeded, the drive stops and displays the error

message: O.ERR_108 “Position error“. The value should be set

higher than the permitted tolerance range ACCURACY in par.

33-13. Input in quad counts.

32-68 Reversing behaviour

Option: Function:

[0] means that the slave drive may always reverse, e.g. after over-

shooting the target position.

[1] the slave drive may only reverse when the master is reversing.

[2] the slave drive may never reverse.

32-69 PID-sample time

Option: Function:

The parameter is setting the sample time of the control algorithm. The value should be increased if:

• The pulse frequency is very low, e.g. 1 to 2 quad

38

MG.33.Q1.02 - VLT

counts per sample time (you need at least 10 to 20

quad counts per sample time).

®

is a registered Danfoss trademark

Syncronising Controller MCO 350 Operating

Instructions

32-80 Maximum speed

Option: Function:

3. Programming

• The system is very slow and heavy (high inertia). Controlling systems with 1 ms can make big motors vibrate.

The correct value can be calculated automatically, see test run

par. 19-05.

NB!

The parameter setting has direct influence on the

PID loop; if for example the Sample time is doubled, the P-portion (par. 32-60) also has the double effect.

Enter here the maximum speed of the slave drive, measured at

the slave encoder in revolutions per minute.

3

32-81 Minimum ramp

Option: Function:

Enter here the minimum possible ramp in which the slave drive

can accelerate from 0 to the speed specified in par. 3280. This

is input in milliseconds.

33-00 Home_Force

Option: Function:

If this param is set to 1, a home has to be carried out before

sync can start

33-02 Home acceleration

Option: Function:

Specify here the acceleration for the homing as a percentage of

the maximum acceleration. 100% means that the drive accelerates with the minimum ramp specified in par. 32-81. 50%

means that the drive only proceeds with half the acceleration,

i.e. the acceleration takes twice as long as the minimum ramp

specified in par. 32-81.

33-03 Velocity of Home Motion

Option: Function:

In % of the Maximum Velocity 3280

33-04 Synchronous operation; Program 2

Option: Function:

[0] The homing only has to be carried out after power up

MG.33.Q1.02 - VLT

®

is a registered Danfoss trademark

39

3

3. Programming

[1-3] The homing has to be carried out before every sync start.

33-13 Synchronous operation; Program 2

Option: Function:

33-14 Synchronous operation; Program 2

Option: Function:

Syncronising Controller MCO 350 Operating

Accuracy: This parameter specifies that maximum master –

slave position deviance, this is used to control the accuracy output (O 3). The accuracy output will only be “1” if the actual

master – slave position deviance is within this value. In velocity

synchronisation (par. 19-01 = 0, 3, 6 or 7) the value must be

set in RPM (Rounds Per Minute) in all other modes it must be

set in quad counts. With a negative value in this parameter the

synchronising error (par. 19-93) is shown with a sign otherwise

the synchronising error is unsigned.

M-S tolerance speed: Specify here the tolerated speed deviation

between master and slave while synchronising. The following

apply here:

Slave must catch up:

mitted speed or at the speed: master speed + master speed *

M-S tolerance speed / 100, whichever of the two is lowest.

Slave must slow down:

master speed - master speed * M-S tolerance speed / 100. If

the M-S tolerance speed value is set to 50, the slave will not

travel more slowly than half the master speed.

The slave can travel at the maximum per-

The slave travels at the minimum speed:

Instructions

33-17 Marker interval at the master

Option: Function:

Enter here the interval between two markers at the master drive

in quad counts. If this value is not known, it can be determined

during the test run. For procedure, see as described in the section “Testing the incremental encoders“ in the Loading belt,

Marker synchronisation, application example.

33-18 Marker interval at the slave

Option: Function:

Enter here the interval between two markers at the slave drive

in quad counts. If this value is not known, it can be determined

during the test run. For procedure, see description in the section

“Testing the incremental encoders“ in the packaging application

example.

NB!

This parameter is only used in marker synchronising mode (par. 19-01 = 2 or 5).

40

MG.33.Q1.02 - VLT

®

is a registered Danfoss trademark

Syncronising Controller MCO 350 Operating

Instructions

3. Programming

NB!

This parameter is only used in marker synchronising mode (par. 19-01 = 2 or 5).

33-19 Master marker type

Option: Function:

[0] rising edge of the zero

track

[1] falling edge of the

zero track

[2] rising edge at I5

[1] falling edge of the

zero track

[3] falling edge at I5

33-20 Slave marker type

Option: Function:

[0] rising edge of the zero

track

[1] falling edge of the

zero track

[2] rising edge at I6

[1] falling edge of the

zero track

[3] falling edge at I6

Select here the type of marker signal for the master drive

Select here the type of marker signal for the slave drive

3

NB!

This parameter is only used in marker synchronising mode (par. 19-01 = 2 or 5).

NB!

This parameter is only used in marker synchronising mode (par. 19-01 = 2 or 5).

33-21 Marker window master

Option: Function:

Enter how large the permitted tolerance for the occurrence of

the marker is. The factory setting “0” means all markers are

used. At every other setting only those markers are accepted

which are within the window. Example: Marker interval = 30000

and marker window = 1000. Only markers with an interval of

29000 to 31000 is accepted.

MG.33.Q1.02 - VLT

®

is a registered Danfoss trademark

41

3. Programming

Syncronising Controller MCO 350 Operating

Instructions

NB!

This parameter is only used in marker synchronising mode (par. 19-01 = 2 or 5).

3

33-22 Marker window slave

Option: Function:

Enter how large the permitted tolerance for the occurrence of

the marker is. The factory setting “0” means all markers are

used. At every other setting only those markers are accepted

which are within the window. Example: Marker interval = 30000

and marker window = 1000. Only markers with an interval of

29000 to 31000 is accepted.

NB!

This parameter is only used in marker synchronising mode (par. 1901 = 2 or 5).

33-23 Marker synchronous operation

Option: Function:

[0] last marker pulse, i.e. the slave synchronises to the last detected

marker pulse. This is achieved by accelerating to this position.

[1] next marker pulse: The slave waits for the next marker pulse

and synchronises to it.

[2] once the master speed is reached marker correction to next fol-

lowing markers take place(may catch up slow down).

[3] same as “0” but after master speed is reached.

[4] same as “1” but after master speed is reached.

[5] once the master speed is reached marker correction to closest

marker take place.

If 1000 is added to the previous choices the fixed offset is not executed before the marker correction has taken place.

NB!

This parameter is only used in marker synchronising mode (par. 19-01 = 2 or 5).

33-24 Marker quantity FAULT

Option: Function:

Enter when a FAULT signal (O2) must be set. Input the number

of marker pulses, i.e. a setting of 10 means that ACCURACY

must be low for 10 marker pulses before the FAULT signal is set.

42

MG.33.Q1.02 - VLT

®

is a registered Danfoss trademark

Syncronising Controller MCO 350 Operating

Instructions

3. Programming

In position synchronisation (par. 19-01 = 1 or 4) only the slave

marker is used; in marker synchronisation (par. 19-01 = 2 or 5)

both slave and master marker must be detected before counting.

33-25 Marker quantity READY

Option: Function:

Enter when a READY signal (O1) must be set. Enter the number

of marker pulses, i.e. a setting of 10 means that ACCURACY

must be present for 10 marker pulses before the READY signal

is set.

In position synchronisation (par. 19-01 = 1 or 4) only the slave

marker is used; in marker synchronisation (par. 19-01 = 2 or 5)

both slave and master marker must be detected before counting.

33-26 Velocity filter

Option: Function:

In speed synchronisation it is recommended to set a filter time

based on resolution. This is to avoid speed fluctuation at low

speed or when using low resolution of encoders. Please see following table:

Encoder Resolution

250 39500

500 19500

1000 9500

2000 4500

2500 3500

4096 1900

5000 1400

3

Filter Time Value

For all other types of synchronisation: Changing the sign of the

filter value enables the use of filtering the other types of synchronisation. This means that unstable position or marker synchronisation can be smoothened.

33-80 Selection of the Operation Mode

Option: Function:

[1]

[2]

34-40 Input status (read only)

Option: Function:

Test run

synchronisation

MG.33.Q1.02 - VLT

This parameter is showing the actual status of the 10 digital

inputs (I1 - I10) on X 57 as a binary code.

®

is a registered Danfoss trademark

43

3

3. Programming

34-50 Slave position (read only)

Option: Function:

34-52 Master position (read only)

Option: Function:

Syncronising Controller MCO 350 Operating

Instructions

Input 3, 7 and 8 high

Par 3440 = 11000100

Input 1 and 3 high

Par 3440 = 101

Table 3.1: Example:

The slave position is displayed in quad counts.

The master position is displayed in quad counts.

34-56 Track error (read only)

Option: Function:

This parameter indicates the actual PID error during synchronisation

34-60 Status of synchronisation

Option: Function:

The following status flags are defined for position and marker

synchronisation. The flags are not updated when using speed

synchronisation:

Flag: Decimal value Bit

SYNCREADY 1 0

SYNCFAULT 2 1

SYNCACCURACY 4 2

Only marker synchronisation:

Master marker HIT 8 3

Slave marker HIT 16 4

Master marker Error 32 5

Slave marker Error 64 6

The flags are reset when restarting synchronisation (SyncStart).

SYNCACCURACY

Each millisecond it is checked if the actual position deviance between master and slave is smaller than par. 33-13(accuracy), if

this is true the SYNCACCURACY flag is set (1), otherwise the flag

is reset. (0).

SYNCFAULT / SYNCREADY

For every marker pulse it is checked whether the SYNCACCURACY flag is present or not. If it is not present the fault counter

44

MG.33.Q1.02 - VLT

®

is a registered Danfoss trademark

Syncronising Controller MCO 350 Operating

Instructions

3. Programming

is increased and the ready counter set to 0, if it is present the

ready counter is increased and the fault counter set to 0.

If the ready counter is higher than the value set in par. 33-25

(marker quantity ready) then the flag SYNCREADY is set, if not

the flag is reset.

If the fault counter is higher than the value in par. 33-24 (marker quantity fault) the flag SYNCFAULT is set (1), if not the flag

is reset (0).

Marker HIT flags:

The marker HIT flags are set (1) after detecting n marker pulses

(n = par. 19-08 and 19-09).

Marker error flags:

It is checked at each n marker pulse (n = par. 19-08 or 19-09)

whether the distance between the actual marker position and

the last registered marker position is lower than 1.8 times the

value of par. 33-18 or 33-17. If this is not true, then the associated flag is set. (1). When using marker windows (par. 33-22

and 33-21) it is checked whether a marker is detected within

the window. If no marker is detected the error flag is set (1).

3

MG.33.Q1.02 - VLT

®

is a registered Danfoss trademark

45

4

4. Synchronisation

Syncronising Controller MCO 350 Operating

Instructions

46

MG.33.Q1.02 - VLT

®

is a registered Danfoss trademark

Syncronising Controller MCO 350 Operating

Instructions

4. Synchronisation

4.1. Speed Synchronisation

4.1.1. SyncStart

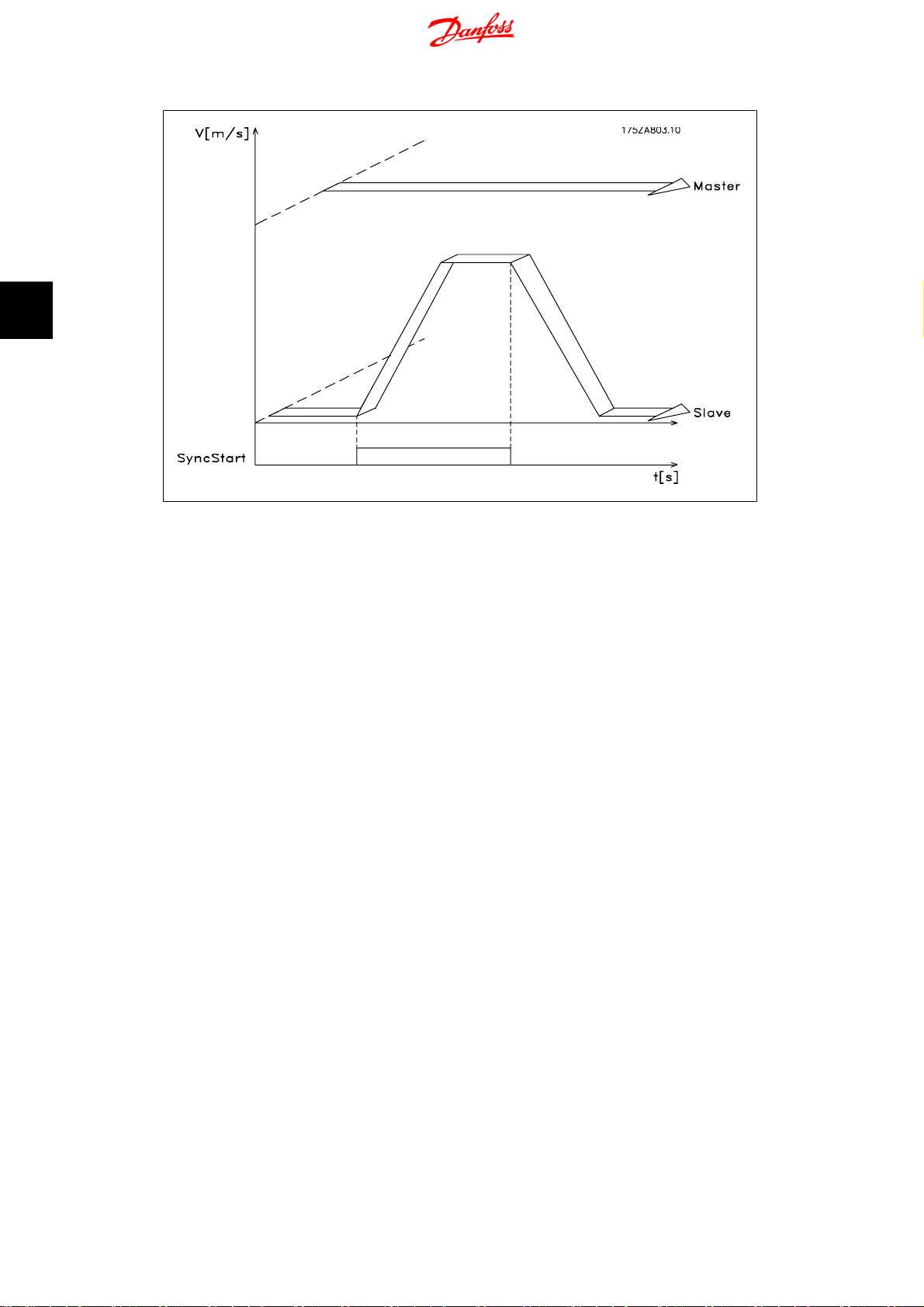

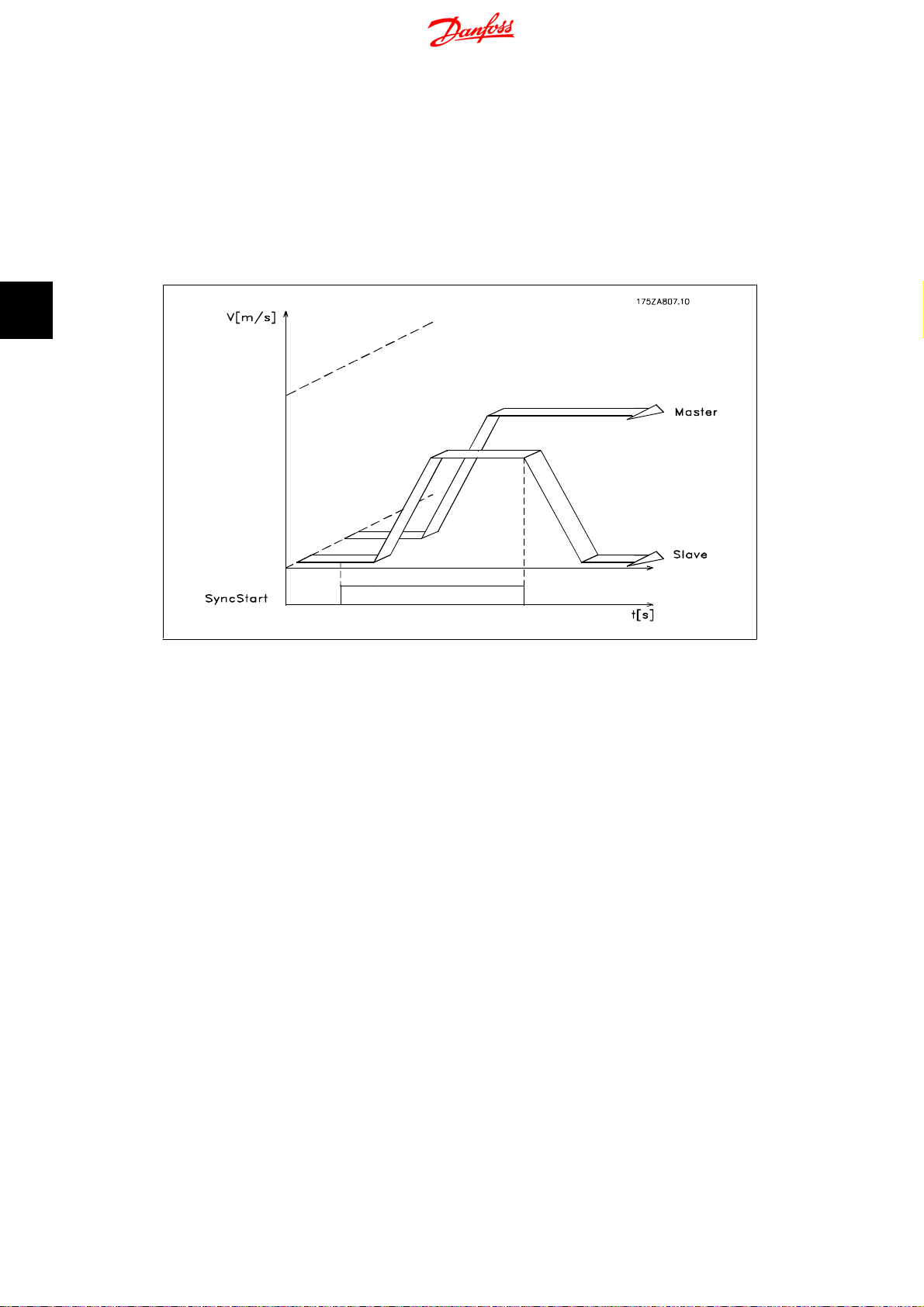

When closing the SyncStart contact (Terminal I1), the slave drive accelerates with minimum ramp

time to the speed of the master drive, taking the gear ratio into account. When I1 is opened, the

slave drive ramp or coast to stop. Stop behaviour is selected in par. 19-01.

4. Synchronisation

4

Illustration 4.1: Figure 10: SyncStart with speed synchronisation

4.2. Function Diagrams for Speed Synchronisation

4.2.1. SyncStart

When closing the SyncStart contact (Terminal I1), the slave drive accelerates with minimum ramp

time to the speed of the master drive, taking the gear ratio into account. When I1 is opened, the