Contents

■

VLT®5000/6000/8000 Series

Introd

Mechanical installation

Electri

uction

General warning ..................................................................................................... 2

Introduction ........................................................................................................... 3

ortation and uncrating ................................................................................ 4

Transp

Key diagram for VLT 5300-5500 / VLT 6350-6550 / VLT 8350-8550 ................... 6

Technical data ........................................................................................................ 7

Mechanical dimensions ......................................................................................... 11

stallation ...................................................................................................... 12

Pre-in

Installation site ....................................................................................................... 12

Cable site .............................................................................................................. 13

g for high altitude ........................................................................................ 13

Deratin

Derating for ambient temperature .......................................................................... 13

cal installation

Electrical installation .............................................................................................. 14

Pre-fuses .............................................................................................................. 14

g ................................................................................................................ 14

Earthin

RFI switch ............................................................................................................. 15

Electrical installation, power cables ........................................................................ 15

cal installation, enclosure .............................................................................. 17

Electri

Terminal adapter kit .............................................................................................. 18

Tightening-up torques ........................................................................................... 18

tion of 24 Volt external DCsupply ............................................................... 18

Installa

Installation of brake resistor temperature switch ................................................... 18

Cable cross-section and length ............................................................................. 19

Mains con

Motor connection .................................................................................................. 21

Brake connection (VLT 5000 Series ONLY) .......................................................... 22

Load shar

Motor and DC coils connections on IP 00 ............................................................. 23

Control cable routing ............................................................................................ 24

Connectio

Electrical installation procedures ........................................................................... 27

Electrical installation, control leads ........................................................................ 28

Programmi

Programming the VLT 6000 and VLT 8000 AQUA ................................................ 28

Motor start ............................................................................................................ 28

....................................................................................................... 2

................................................................................ 11

.................................................................................... 14

nection .................................................................................................. 20

ing connection ...................................................................................... 22

n example ............................................................................................. 25

ng the VLT 5000 .................................................................................. 28

MG.56.A2.02 - VLT is a registered Danfoss trademark

1

VLT®5000/6000/8000 Series

General warning

■

The voltage of the frequency converter

is dangerous whenever the converter is

connected to mains. Incorrect fitting of the

motor or frequency converter may cause damage to the

equipment, serious injury or death. Consequently, it is

essential to comply with the instructions in this manual

as well as local and national rules and safety regulations.

1. The VLT frequency converter must be disconnected

mains if repair work is to be carried out. Check

from

that the mains supply has been disconnected

and that the necessary time has passed before

ving motor and mains plugs.

remo

2. The [STOP/RESET] or [OFF/STOP] key on the

control panel of the VLT frequency converter does

isconnect the equipment from mains and is

n

ot d

thus n

ot to be used as a safety switch.

3. Correct protective earthing of the equipment

t be established, the user must be protected

mus

against supply voltage, and the motor must be

protected against overload in accordance with

licable national and local regulations.

app

4. The earth leakage currents are higher than 3.5 mA.

5. Protection against motor overload is n

he factory setting. If this function is desired, set

in t

parameter 128 to data value ETR trip or data value

ETR warning. On VLT 6000, set parameter 117 to

ta value ETR trip or data value ETR warning.

da

N

ote: The function is initialised at 1.16 x

rated motor current and rated motor frequency

ee Operating manual).

(s

ot included

For the North American market: The ETR

functions provide class 20 motor overload

tion in accordance with NEC.

protec

6. Do n

7. Please note that the VLT frequency converter has

Warning against unintended start

■

1. The m

2. While parameters are being changed, the

3. A motor that has been stopped may start if faults

ot remove the plugs for the motor and

mains supply while the VLT frequency converter

nected to mains. Check that the mains

is con

supply has been disconnected and that the

necessary time has passed before removing

and mains plugs.

motor

more voltage inputs than L1, L2 and L3, when

haring (linking of DC intermediate circuit) and

loads

external 24 V DC have been installed. Check

that all voltage inputs have been disconnected

hat the necessary time has passed before

and t

repair work is commenced.

otor can be brought to a stop by

means of digital commands, bus commands,

references or a local stop, while the frequency

verter is connected to mains. If personal

con

safety considerations make it necessary to

ensure that no unintended start occurs, these

p functions are not sufficient.

sto

motor may start. Consequently, the stop key

OP/RESET] or [OFF/STOP] must always be

[ST

activated, following which data can be modified.

cur in the electronics of the frequency converter,

oc

or if a temporary overload or a fault in the supply

mains or the motor connection ceases.

176FA055.11

Warning:

Touching the electrical parts may be fatal - even after the

equipment has been disconnected from mains.

Also make sure that other voltage inputs have been disconnected,

such as external 24 V DC, load-sharing (linkage of DC intermediate

circuit), as well as the motor connection for kinetic back-up.

Using VLT 5300-5500 / 6350-6550 /8350-8550:

wait at least 15 minutes

2

MG.56.A2.02 - VLT is a registered Danfoss trademark

Introduction

■

Manual objectives

The pur

with the necessary information to install, program and

start up the Danfoss VLT 5300-5500, VLT 6350-6550

and VL

manual should be read thoroughly before operating,

servicing or initializing the drives. This manual is

inten

Instructions Manual for the VLT 5000/6000/8000

frequency converters for detailed information.

pose of this manual is to provide the user

T 8350-8550 frequency converters. This

ded for use along with the Danfoss Operating

VLT®5000/6000/8000 Series

Who should use this manual

This manual is intended for qualified service

personnel responsible for setting up and servicing

the Danfoss VLT 5300-5500, VLT 6350-6550 and

VLT 8350-8550 frequency converters. Qualified

personnel have previous experience with the

frequency converters and understand electrical

fundamentals, programming procedures, required

equipment and safety precautions.

Organization of the manual

This manual is arranged in equipment installation

connection sequence. The order of tasks

and

are arranged as follows:

•

Safety instructions

•

nsportation and unpacking

Tra

•

Technical data

•

Mechanical installation

•

-installation

Pre

•

Electrical installation guidelines

•

Control cable routing

•

•

•

ection examples

Conn

Electrical installation procedures

Motor start

Introduction

MG.56.A2.02 - VLT is a registered Danfoss trademark

3

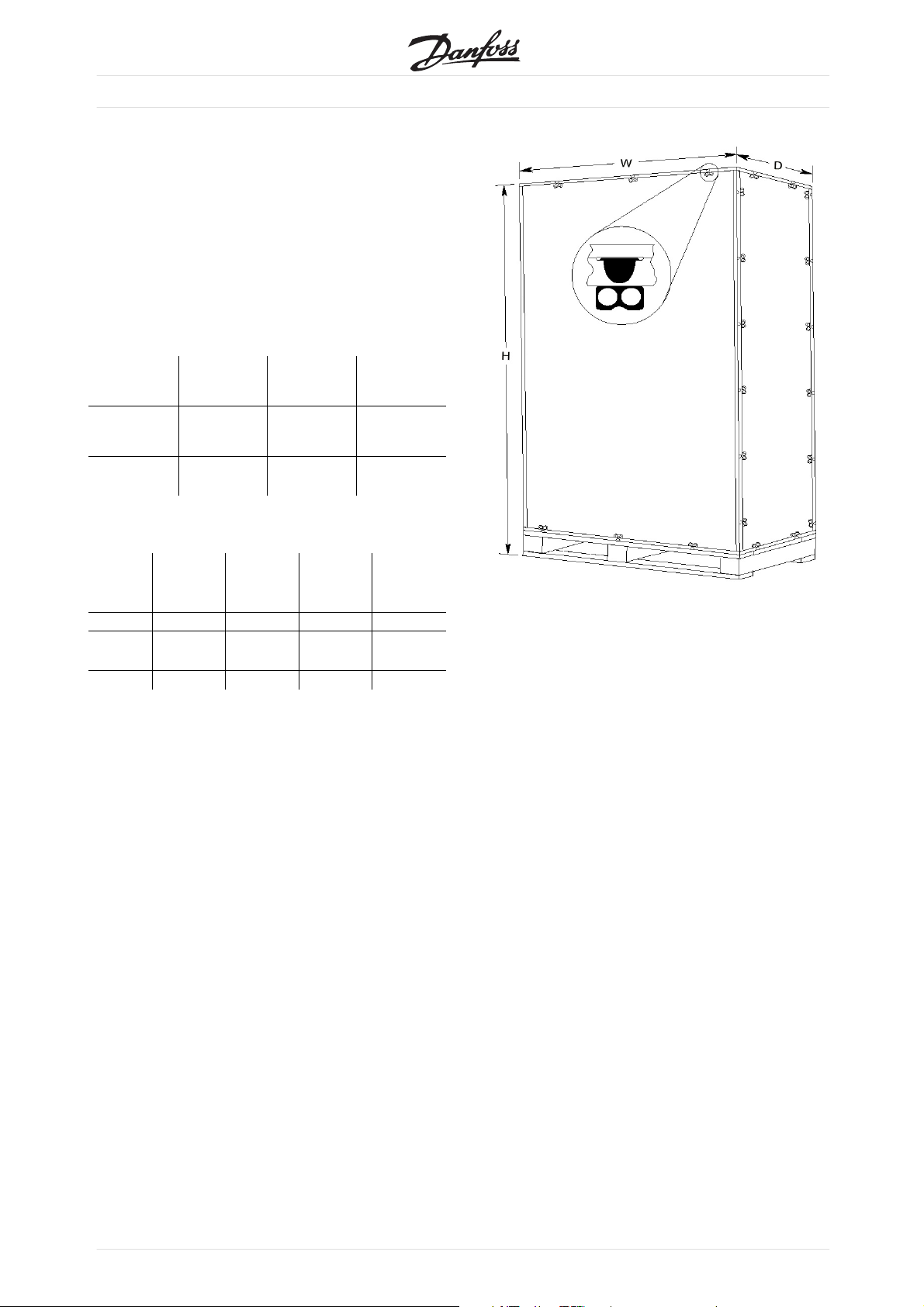

Transportation and uncrating

■

To lessen the possibility of damage it is recommended

e crated VLT frequency converter is

that th

located as close to the final installation site

as possible before uncrating.

Door and ceiling clearances must be considered when

moving and installing the VLT frequency converter.

Seebelowtableforthecratedimensions:

Dimensions mm (inches):

H W D

VLT®5000/6000/8000 Series

IP 00 2096

(82.52)

Nema 1 (IP

20) / 54

2324

(91.5)

1219

(48.0)

1321

(52.0)

699

(27.52)

724

(28.5)

Weight kg (lbs):

VLT

5300/6350/

8350/8550

IP 00 548 (1208) 583 (1385) 628 (1385) 653 (1440)

Nema 1

(IP 20)

IP 54 664 (1464) 699 (1541) 744 (1640) 769 (1695)

654 (1442) 689 (1519) 734 (1618) 759 (1673)

VLT

5350/6400/

8350/8550

VLT

5450/6500/

8350/8550

VLT

5500/6550/

8350/8550

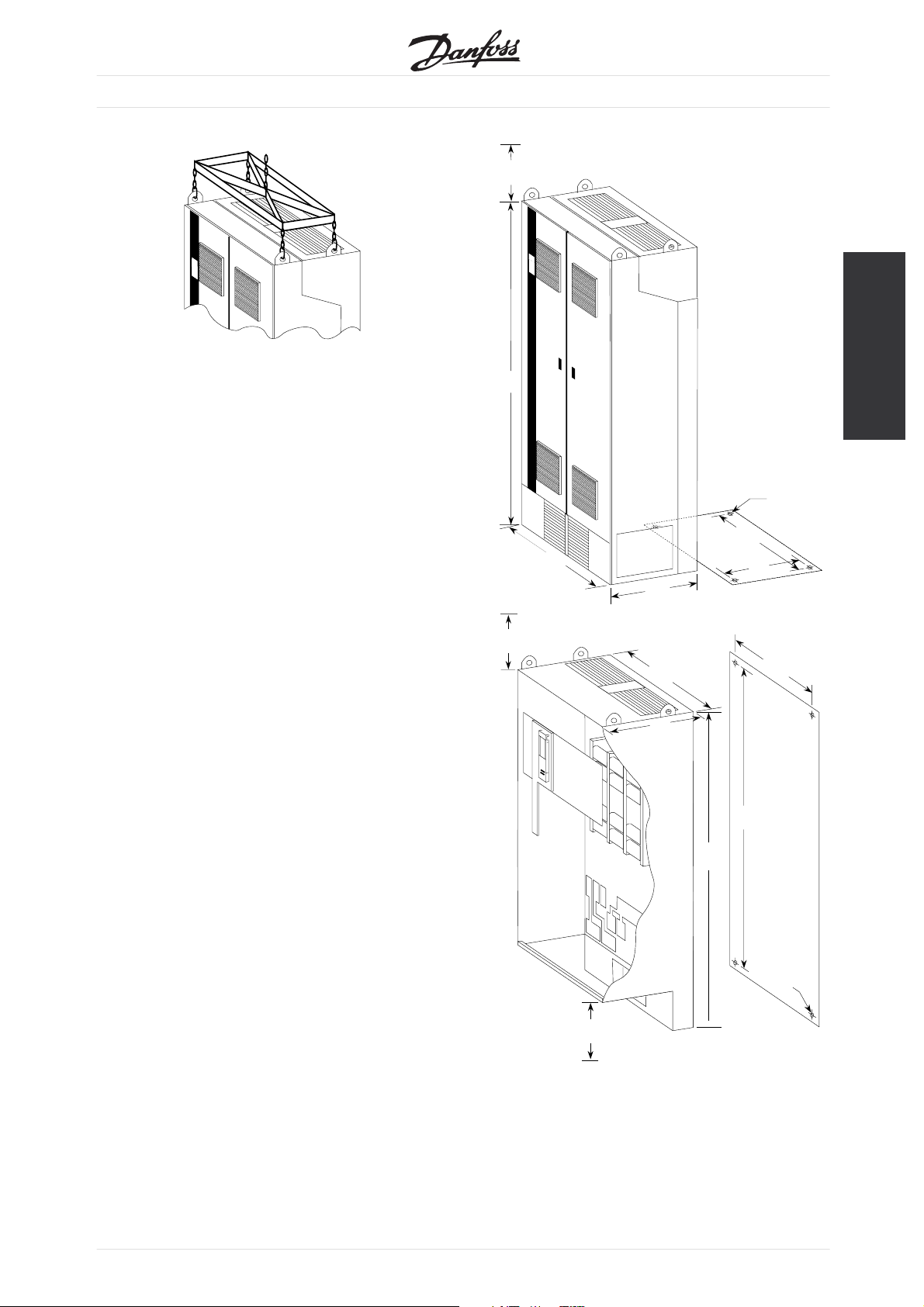

A qualified person with a forklift or other similar

lifting device will be needed to remove the VLT

frequency converter from the crate.

To open the crate:

•

Remove the metal locking tabs that secure the top

panel of the crate, this will give access to the lifting

rings on the top of the VLT frequency converter.

•

On IP 00 versions remove the supporting

brace bolted to the lifting rings.

•

A forklift or similar lifting device should be

used at this time to ensure the stability of the

VLT frequency converter while the rest of the

crate is removed. Position the lifting device

to the front side of the crate.

•

The VLT frequency converter should be lifted using

a spreader bar or other similar lifting device. Lift the

LT frequency converter slightly, using all four lifting

V

rings, distributing the weight as evenly as possible.

4

MG.56.A2.02 - VLT is a registered Danfoss trademark

•

Remove the metal locking tabs and the

remaining crate panels.

•

On IP 00 versions remove the clear plastic safety

ier from the front of the unit to prevent

barr

the possibility of breaking during positioning

of the VLT frequency converter.

•

The VLT frequency converter is now ready to

be lifted and positioned in the installation site.

NOTE: On IP 00 versions there are inductors

bolted to the bottom of the crate. Lift the

VLT frequency converter high enough to allow

clearance over these inductors.

VLT®5000/6000/8000 Series

Min. free air space

above the drive

15.7

(400)

79.1

(2010)

47.2

Min. free air space

15.7

above the drive

(400)

(1200)

23.6

(600)

43.3

(1099)

Mounting holes in

bottom panel

4 x ø0.63

(16)

42.3

(1075)

18.7

(475)

41.9

(1065)

Introduction

•

erve cooling and ventilation requirements given

Obs

in the "Installation Site" section of this manual.

•

Secure to the floor using the four holes provided

in the bottom of the unit. On IP 00 versions

secure to the panel using the four mounting holes

provided in the back. Refer to the dimensional

drawings in this instruction manual.

Min. free air space

below the drive

15.7

(400)

19.3

(490)

74.6

(1896)

Mounting holes

in back panel

72.7

(1847)

4 x ø0.63

(16)

MG.56.A2.02 - VLT is a registered Danfoss trademark

5

VLT®5000/6000/8000 Series

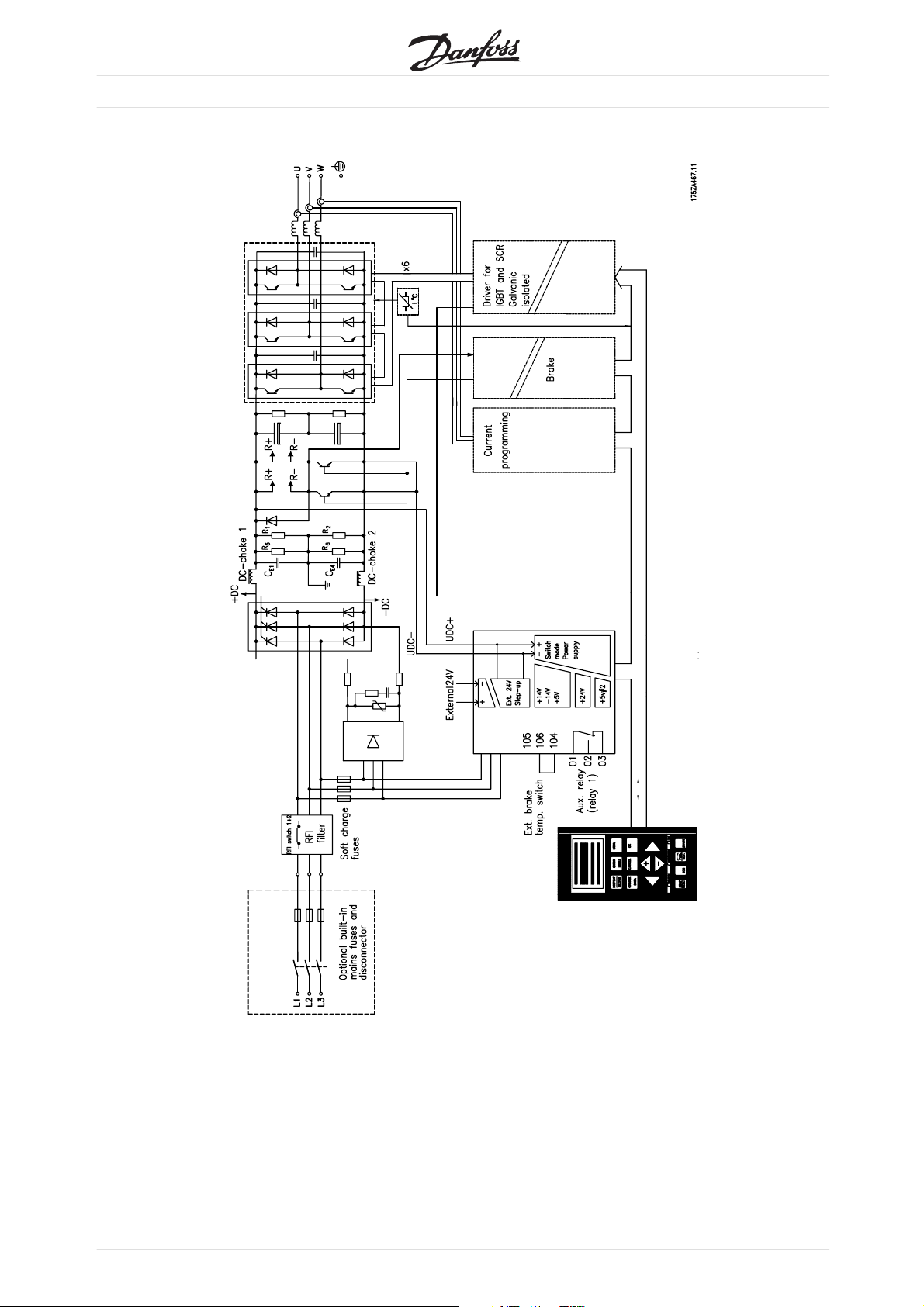

Key diagram for VLT 5300-5500 / VLT 6350-6550 / VLT 8350-8550

■

Brake terminals 81, 82 and 104-106 are not

available in VLT 6000 HVAC.

6

MG.56.A2.02 - VLT is a registered Danfoss trademark

VLT®5000/6000/8000 Series

Compact, Mains supply 3 x 380 - 500 V

■

According to international requirements VLT type 5300 5350 5450 5500

Normal overload torque (110 %):

Output current I

I

VLT, MAX

I

VLT, MAX

Output S

S

Typical shaft output (380-440 V) P

Typical shaft output (380-440 V) P

Typical shaft output (441-500 V) P

Typical shaft output (441-500 V) P

High overload torque (150 %):

Output current I

I

VLT, MAX

I

VLT, MAX

Output S

S

Typical shaft output (380-440 V) P

Typical shaft output (380-440 V) P

Typical shaft output (441-500 V) P

Typical shaft output (441-500 V) P

Max. cross-section of copper cable to motor, brake 2x150 2x185 2x240 2x300

and loadsharing (380-440 V) [mm

Max. cross-section of copper cable to motor, brake 2x120 2x150 2x185 2x300

and loadsharing (441-500 V) [mm

Max. cross-section of aluminium cable to motor, brake 2x185 2x240 2x300

and loadsharing (380-440 V) [mm

Max. cross-section of aluminium cable to motor, brake 2x150 2x185 2x240

and loadsharing (441-500) [mm

2]5)

Max. cross-section of copper cable to motor, brake 2x250mcm 2x350mcm 2x400mcm 2x500mcm

and loadsharing (380-440 V) AWG]

Max. cross-section of copper cable to motor, brake 2x4/0 2x300mcm 2x350mcm 2x500mxm

and loadsharing (441-500 V) AWG]

Max. cross-section of aluminium cable to motor, brake 2x350mcm 2x500mcm 2x600mcm 2x700mcm

and loadsharing (380-440 V) AWG]

Max. cross-section of aluminium cable to motor, brake 2x300mcm 2x400mcm 2x500mcm 2x600mcm

and loadsharing (441-500 V) AWG]

[A] (380-440 V) 480 600 658 745

VLT,N

(60 s) [A] (380-440 V) 528 660 724 820

I

[A] (441-500 V) 443 540 590 678

VLT,N

(60 s) [A] (441-500 V) 487 594 649 746

[kVA] (380-440 V) 333 416 456 516

VLT,N

[kVA] (441-500 V) 384 468 511 587

VLT,N

[kW] 250 315 355 400

VLT,N

[HP] 300 350 450 500

VLT,N

[kW] 315 355 400 500

VLT,N

[HP] 350 450 500 600

VLT,N

[A] (380-440 V) 395 480 600 658

VLT,N

(60 s) [A] (380-440 V) 593 720 900 987

I

[A] (441-500 V) 361 443 540 590

VLT,N

(60 s) [A] (441-500 V) 542 665 810 885

[kVA] (380-440 V) 274 333 416 456

VLT,N

[kVA] (441-500 V) 313 384 468 511

VLT,N

[kW] 200 250 315 355

VLT,N

[HP] 300 350 450 500

VLT,N

[kW] 250 315 355 400

VLT,N

[HP] 350 450 500 600

VLT,N

2]5)

2]5)

2]5)

3x70 3x95 3x120 3x150

3x70 3x95 3x95 3x120

3x120 3x150 3x185 3x185

3x95 3x120 3x150 3x185

2) 5)

2) 5)

2) 5)

2) 5)

3x2/0 3x3/0 3x4/0 3x250mcm

31/0 3x3/0 3x3/0 3x4/0

3x4/0 3x250mcm 3x300mcm 3x350mcm

3x3/0 3x4/0 3x250mcm 3x300mcm

Introduction

1. For type of

fuse see section Fuses.

2. American Wire Gauge.

3. Measured using 30 m screened motor cables at rated load and rated frequency.

4. Min. cable

cross-section is the smallest cable cross-section allowed to be fitted on the terminals. Always

comply with national and local regulations on min. cable cross-section.

5. Connection stud 2 x M12/3 x M12.

MG.56.A2.02 - VLT is a registered Danfoss trademark

7

VLT®5000/6000/8000 Series

Compact, Mains supply 3 x 380 - 500 V

■

According to international requirements VLT type 5300 5350 5450 5500

Rated input current

110%

Rated input current

150%

Max. cross-section of copper cable 2x150 2x185 2x240 2x300

to power (380-440 V) [mm

Max. cross-section of copper cable 2x120 2x150 2x185 2x300

to power (441-500 V) [mm

Max. cross-section of aluminium cable 2x185 2x240 2x300

to power (380-440 V) [mm

Max. cross-section of aluminium cable 2x150 2x185 2x240

to power (441-500 V) [mm

Max. cross-section of copper cable 2x250mcm 2x350mcm 2x400mcm 2x500mcm

to power (380-440 V) [AWG]

Max. cross-section of copper cable 2x4/0 2x300mcm 2x350mcm 2x500mcm

to power (441-500 V) [AWG]

Max. cross-section of aluminium cable 2x350mcm 2x500mcm 2x600mcm 2x700mcm

to power (380-440 V) [AWG]

Max. cross-section of aluminium cable 2x300mcm 2x400mcm 2x500mcm 2x600mcm

to power (441-500 V) [AWG]

Max. pre-fuses (mains) [-]/UL1)[A] 630/600 700/700 800/800 800/800

Integral pre-fuses (softcharge circuit)

6)

[-]/UL

[A]

Integral pre-fuses (snubber resistors)

7)

[-]/UL

Integral

[A]

pre-fuses (SMPS) [-]/UL

Efficiency 0.97 0.97 0.97 0.97

Weight IP

00

Weight Nema 1 kg (lb) 595 (1132) 630 (1389) 675 (1488) 700 (1543)

Weight IP 5

4

Power loss at max. load [W] 7500 9450 10650 12000

Enclosure IP 00 / Nema

I

[A] (400 V) 467 584 648 734

L,MAX

[A] (460 V)

I

L,MAX

I

[A] (400 V) 389 467 584 648

L,MAX

I

[A] (460 V) 356 431 526 581

L,MAX

2]5)

2]5)

2]5)

2]5)

2) 5)

2) 5)

2) 5)

2) 5)

431 526 581 668

3x70 3x95 3x120 3x150

3x70 3x95 3x95 3x120

3x120 3x150 3x185 3x185

3x95 3x120 3x150 3x185

3x2/0 3x3/0 3x4/0 3x250mcm

31/0 3x3/0 3x3/0 3x4/0

3x4/0 3x250mcm 3x300mcm 3x350mcm

3x3/0 3x4/0 3x250mcm 3x300mcm

9/9 9/9 9/9 9/9

15/15 15/15 15/15 15/15

8)

[A]

5.0/5.0 5.0/5.0 5.0/5.0 5.0/5.0

kg (lb) 480 (1058)515 (1135)560 (1235)585 (1290

kg (lb) 605 (1334) 640 (1411) 685 (1510) 710 (1565)

1 (IP 20) / IP 54

)

1. For type of fuse see section Fuses.

2. American Wire Gauge.

3. Measure

d using 30 m screened motor cables at rated load and rated frequency.

4. Min. cable cross-section is the smallest cable cross-section allowed to be fitted on the terminals. Always

comply with national and local regulations on min. cable cross-section.

5. Connect

ion stud 2 x M12/3 x M12.

6. If UL/cUL is to be complied with, AC Littelfuse type KLK, Danfoss ordering no. 175L3489 must be used.

7. If UL/cUL is to be complied with, DC Littelfuse type KLKD, Danfoss ordering no. 176F1147 must be

used.

8. If UL/cUL is to be complied with, Bussmann type KTK-5, Danfoss ordering no. 175L3437 must be used.

8

MG.56.A2.02 - VLT is a registered Danfoss trademark

VLT®5000/6000/8000 Series

Mains supply 3 x 380-500 V

■

ing to international

Accord

requirements VLT type 6350 6450 6500 6550

8350 8450 8500 8550

Output

current

I

VLT, MAX

I

VLT, MAX

Output S

S

VLT,N

VLT,N

Typical shaft output (380-415 V) P

Typical shaft output (380-415 V) P

Typical shaft output (440-460 V) P

Typical shaft output (440-460 V) P

[A] (380-415 V)

I

VLT,N

480 600 658 745

(60 s)[A](380-415 V) 528 660 724 820

I

[A] (440-460 V) 443 540 590 678

VLT,N

(60 s)[A](440-460 V) 487 594 649 746

[kVA] (380-415 V) 333 416 456 516

kVA] (440-460 V)

[

[kW] 250 315 355 400

VLT,N

[HP] 300 350 450 500

VLT,N

[kW] 315 355 400 500

VLT,N

[HP] 350 450 500 600

VLT,N

384 468 511 587

Max. cross-section of copper cable to motor, 2 x 150 2 x 185 2 x 240 2 x 300

brake and

loadsharing (380-415 V) [mm

2]5)

3x70 3x95 3x120 3x150

Max. cross-section of copper cable to motor 2 x 120 2 x 150 2 x 185 2 x 300

and loadsharing (440-460 V) [mm

2]5)

Max. cross-section of aluminium cable to

motor and loadsharing (380-415 V) [mm

2]5)

Max. cross-section of aluminium cable to

motor and loadsharing (440-460) [mm

2]5)

Max. cross-section of copper cable to motor

and loadsharing (380-415 V) AWG]

2) 5)

Max. cross-section of copper cable to motor

and loadsharing (440-460 V) AWG]

2) 5)

Max. cross-section of aluminium cable to

motor and loadsharing (380-415 V) AWG]

2) 5)

Max. cross-section of aluminium cable to

motor and loadsharing (440-460 V) AWG]

2) 5)

3 x 70 3 x 95 3 x 95 3 x 120

2 x 185 2 x 240 2 x 300

3 x 120 3 x 150 3 x 185 3 x 185

2 x 150 2 x 185 2 x 240

3 x 95 3 x 120 3 x 150 3 x 185

2x250mcm 2x350mcm 2x400mcm 2x500mcm

3 x 2/0 3 x3/0 3 x 4/0 3x250mcm

2 x 4/0 2x300mcm 2x350mcm 2x500mcm

3 x 1/0 3 x 3/0 3 x 3/0 3 x 4/0

2x350mcm 2x500mcm 2x600mcm 2x700mcm

3 x 4/0 3x250mcm 3x300mcm 3x350mcm

2x300mcm 2x400mcm 2x500mcm 2x600mcm

3 x 3/0 3 x 4/0 3x250mcm 3x300mcm

Introduction

1. For type of fuse see section Fuses.

2. American Wire Gauge.

3. Measured using 30 m screened motor cables

atratedloadandratedfrequency.

4. Min. cable cross-section is the smallest cable

cross-section allowed to be fitted on the terminals.

Always comply with national and local regulations

on min. cable cross-section.

5. Connection stud 2 x M12/3 x M12.

6. If UL/cUL is to be complied with, AC

Littelfuse type KLK, Danfoss ordering no.

175L3489 must be used.

7. If UL/cUL is to be complied with, DC

Littelfuse type KLKD, Danfoss ordering no.

176F1147 must be used.

MG.56.A2.02 - VLT is a registered Danfoss trademark

8. If UL/cUL is to be complied with, Bussmann type

KTK-5, Danfoss ordering no. 175L3437

must be used.

9

According to international

ements

requir

Rated input

current

Max. cross-section of copper cable to power

(380-415 V) [mm

2]5)

Max. cross-section of copper cable to power

(440-460 V) [mm2]

5)

Max. cross-section of aluminium cable to

power (380-415 V) [mm2]

5)

Max. cross-section of aluminium cable to

power (440-460 V) [mm

2]5)

Max. cross-section of copper cable to power

(380-415 V) AWG]

2) 5)

Max. cross-section of copper cable to power

(440-460 V) AWG]

2) 5)

Max. cross-section of aluminium cable to

power (380-415 V) AWG]

2) 5)

Max. cross-section of aluminium cable to

power (440-460 V) AWG]

2) 5)

Max. pre-fuses (mains)[-]/UL1)[A] 630/600 700/700 800/800 800/800

Integral pre-fuses (softcharge circuit)[-]/UL6)[A] 9/9 9/9 9/9 9/9

Integral p

re-fuses (snubber resistors)[-]/UL

Integral pre-fuses (SMPS) 5.0/5.0

Efficiency 0.97

Weight IP 00 kg (lb)

Weight Nema 1 (IP 20) kg (lb)

Weight IP 54 kg (lb)

Power loss a

tmax. load[W]

Enclosure IP 00 / Nema 1 (IP 20) / IP 54

1. For t

ype of fuse see section Fuses.

2. American Wire Gauge.

3. Measured using 30 m screened motor cables

tedloadandratedfrequency.

at ra

4. Min. cable cross-section is the smallest cable

cross-section allowed to be fitted on the terminals.

ys comply with national and local regulations

Alwa

on min. cable cross-section.

5. Connection stud 2 x M12/3 x M12.

6. If UL

/cUL is to be complied with, AC

Littelfuse type KLK, Danfoss ordering no.

175L3489 must be used.

7. If UL

/cUL is to be complied with, DC

Littelfuse type KLKD, Danfoss ordering no.

176F1147 must be used.

VLT®5000/6000/8000 Series

VLT type6350 6450 6500 6550

8350 8450 8500 8550

I

[A] (400 V) 467 584 648 734

L,N

I

(460 V) 431 526 581 668

L, N

2 x 150 2 x 185 2 x 240 2 x 300

3x70 3x95 3x120 3x150

2 x 120 2 x 150 2 x 185 2 x 300

3 x 70 3 x 95 3 x 95 3 x 120

2 x 185 2 x 240 2 x 300

3 x 120 3 x 150 3 x 185 3 x 185

2 x 150 2 x 185 2 x 240

3 x 95 3 x 120 3 x 150 3 x 185

2x250mcm 2x350mcm 2x400mcm 2x500mcm

3 x 2/0 3 x3/0 3 x 4/0 3x250mcm

2 x 4/0 2x300mcm 2x350mcm 2x500mcm

3 x 1/0 3 x 3/0 3 x 3/0 3 x 4/0

2x350mcm 2x500mcm 2x600mcm 2x700mcm

3 x 4/0 3x250mcm 3x300mcm 3x350mcm

2x300mcm 2x400mcm 2x500mcm 2x600mcm

3 x 3/0 3 x 4/0 3x250mcm 3x300mcm

7)

[A]

15/15 15/15 15/15 15/15

480

(1058)

595

(1132)

605

(1334)

7500 9450 10650 12000

8. If UL

/cUL is to be complied with, Bussmann type

KTK-5, Danfoss ordering no. 175L3437

must be used.

515

(1135)

630

(1389)

640

(1411)

560

(1235)

675

(1488)

685

(1510)

585

(1290)

700

(1543)

710

(1565)

10

MG.56.A2.02 - VLT is a registered Danfoss trademark

VLT®5000/6000/8000 Series

Mechanical installation

■

Mechanical dimensions

■

VLT 5300-5500 380-500 Volt, VLT 6350-6550 380-460 Volt and VLT 8350-8550 380-480 Volt

VLT type A mm (in) B mm (in) C mm (in) ab mm (in) l/r mm (in)

5300-5500/6350-6550/

8350-8550 IP 00

5300-5500/6350-6550/

8350-8550 Nema 1 (IP 20)

5300-5500/6350-6550/

8350-8550 IP 54

ab: Min. space above enclosure.

l/r: Min. distance between VLT frequency converter

and other plant components, left and right sides.

1896 (74.65) 1099 (43.27) 494 (19.45) 400 (15.75) 0

2010 (79.13) 1200 (47.24) 600 (23.62) 400 (15.75) 0

2010 (79.13) 1200 (47.24) 600 (23.62) 400 (15.75) 0

VLT 5300-5500, VLT 6350-6550 and VLT 8350-8550

must be fastened to the floor with bolts. The

drawing shows the dimensions.

Mechanical installation

MG.56.A2.02 - VLT is a registered Danfoss trademark

11

Pre-installation

■

The most important part of the mechanical

-lation is the pre-installation planning. Neglecting

instal

this planning may very well result in extra work

during and after the installation

Before you install your VLT frequency converter you

should select the best possible operational site.

Consider the following in the pre-installation plan:

•

Ambient operating temperature.

•

Installation method.

•

The position of the VLT frequency converter.

•

The cable routing.

•

Ensure that the power source supplies the

correct voltage and necessary current.

•

If the VLT frequency converter is without

built-in mains disconnector and fuses, ensure

that the external disconnector or fuses have

the correct current rating.

VLT®5000/6000/8000 Series

Installation site

■

The VLT

installed vertically.

The VLT frequency converter is cooled by means of

air circulation. For the unit to be able to release its

cooling air, the minimum distance over the unit must

be as shown in the table under Mechanical Dimension.

To protect the unit from overheating, it must be

ensured that the ambient temperature does not rise

above the max. temperature stated for the VLT

frequency converter and that the 24-hour average

temperature is not exceeded. The max. tempe-rature

and 24-hour average can be seen from the General

Technical Data in the Operating Instructions.

If the ambient temperature is in the range of

45

converter will become relevant, see Derating

for ambient temperature.

The service life of the VLT frequency converter will

be reduced if derating for ambient temperature

is not taken into account.

frequency converter must be

-55 C, derating of the VLT frequency

Installation of VLT 5300-5500 380-500 V, VLT 6350-6550 380-460 V and VLT 8350-8550

■

380-480 Volt Nema 1 (IP 20) and IP 54

Cooling

Side-by-side

All units in the above-mentioned series require a

minimum space of 400 mm (15.75 in) above the

enclosure and must be installed on a plane floor. This

applies to both Nema 1 (IP 20) and IP 54 units.

Nema 1 (IP 20) and IP 54

All Nema 1 (IP 20) and IP 54 units in the

above-mentioned series can be installed side by

side without any space between them, since these

units do not require cooling on the sides.

12

MG.56.A2.02 - VLT is a registered Danfoss trademark

VLT®5000/6000/8000 Series

Cable site

■

The drawing and table show the mechanical setup

of the cable which can be done before the VLT

frequency converter is installed.

VLT type Mains terminal

VLT 5300-5500/6350-6550/8350-8550 969 mm (38.15 in)

VLT 5300-5500/6350-6550/8350-8550 with RFI 516 mm (20.31 in)

VLT 5300/6350/8350 with RFI/Disconnector 626 mm (24.65 in)

VLT 5350-5500/6400-6550/8350-8550 with RFI/Disconnector 516 mm (20.31 in)

Derating for high altitude

■

Below 1000 m altitude no derating is necessary for

VLT 5300-5500, VLT 6350-6550 or VLT 8350-8550.

Derating for ambient temperature

■

The ambient temperature (T

AMB,MAX

temperature allowed. The average (T

) is the maximum

AMB,AVG

measured over 24 hours must be at least 5ºC lower.

Above 1000 m the ambient temperature (T

max. output current (I

) must be derated in

VLT,MAX

accordance with the diagram below:

AMB

)or

If VLT 5300-5500, VLT 6350-6550 or VLT 8350-8550

is operated at temperatures above 45 ºC, a derating

of the continuous output current is necessary.

1. Derating of output current versus altitude

at T

2. Derating of max. T

= max. 45 C

AMB

versus altitude at

AMB

100% output current.

Mechanical installation

)

MG.56.A2.02 - VLT is a registered Danfoss trademark

13

Electrical installation

■

The voltage on the frequency converter

is dangerous when the unit is

connected to mains.

Incorrect installation of the motor or VLT

frequency converter may lead to material damage

or serious injury or it may be fatal.

quently, the instructions in this manual

Conse

as well as national and local rules and safety

regulations must be complied with.

ing the electrical parts may be fatal, even

Touch

after the mains supply has been disconnected.

Pre-fuses

■

For VLT type 5300-5500, VLT type 6350-6550

and VLT 8350-8550, external pre-fuses must be

VLT®5000/6000/8000 Series

Wait at least 15 minutes if using VLT 5300-5500,

VLT 6350-6550 or VLT 8350-8550.

NB!:

It is the user’s or certified electrician’s

responsibility to ensure correct earthing and

protection in accordance with applicable

national and local norms and standards.

rminals for the control cables and power cables

All te

are located behind the protective cover of the VLT

frequency converter. The protective cover can be

ved by means of a screwdriver.

remo

Once the protective cover has been removed, the

actual EMC-correct installation can start.

installed in the mains supply to the VLT frequency

converter or ordered with built-in pre-fuses and

a mains disconnect switch.

UL compliance

To comply with UL/cUL approvals, pre-fuses according to the table below must be used.

Bussmann SIBA Littel fuse Ferraz-Shawmut

5300/6350/8350 FWH-600 206xx32-600 L50S-600 A50-P600

5350/6450/8450 FWH-700 206xx32-700 L50S-700 A50-P700

5450/6500/8500 FWH-800 206xx32-800 L50S-800 A50-P800

5500/6550/8550 FWH-800 206xx32-800 L50S-800 A50-P800

Non UL compliance

If UL/cUL is not to be complied with, we recommend

the above mentioned fuses or type gR.

Not following the recommendation may result

in unnecessary damage of the drive in case of

malfunction. Fuses must be designed for protection

in a circuit capable of supplying a maximum of

Earthing

■

The following basic issues need to be considered

when installing a frequency converter, so as to

obtain electromagnetic compatibility (EMC).

•

Safety earthing: Please note that the frequency

converter has a high leakage current and must

be earthed appropriately for safety reasons.

Apply local safety regulations.

•

High-frequency earthing: Keep the earth wire

connections as short as possible.

Connect the different earth systems at the lowest

100000 A

The metal cabinets of the different devices are

mounted on the cabinet rear plate using the lowest

possible HF impedance. This avoids having different

HF voltages for the individual devices and avoids the

risk of radio interference currents running in connection

cables that may be used between the devices. The

radio interference will have been reduced.

In order to obtain a low HF impedance, use the

fastening bolts of the devices as HF connection to

the rear plate. It is necessary to remove insulating

paint or similar from the fastening points.

(symmetrical), 500 V maximum.

rms

possible conductor impedance. The lowest possible

conductor impedance is obtained by keeping

the conductor as short as possible and by using

the greatest possible surface area.

14

MG.56.A2.02 - VLT is a registered Danfoss trademark

VLT®5000/6000/8000 Series

RFI switch

■

ains supply isolated from earth:

M

If the V

isolated mains source (IT mains), the RFI switch

can be turned off (OFF). In OFF position, the

intern

the chassis and the intermediate circuit are cut off

to avoid damage to the intermediate circuit and

to red

to IEC 1800-3). See position of RFI switch by

Electrical installation, enclosures.

before operating the RFI switch.

LT frequency converter is supplied from an

al RFI capacities (filter capacitors) between

uce the earth capacity currents (according

NB!:

The RFI switch is not to be operated with

mains connected to the unit. Check that

the mains supply has been disconnected

NB!:

Open RFI switch is only allowed at factory

set swi

NB!:

The RFI switch disconnects the capacitors

galvanically; however, transients higher

than a

by a spark gap.

M

ains supply connected to earth:

The RFI switch must be in ON position in order for the

frequency converter to comply with the EMC-standard.

Electrical installation, power cables

■

tching frequencies.

pprox. 1,000 V will be bypassed

Compact Nema 1 (IP 20)/IP 54

Without disconnector and mains fuses

Electrical installation

VLT 5300-5500

VLT 6350-6550

VLT 8350-8550

MG.56.A2.02 - VLT is a registered Danfoss trademark

15

VLT®5000/6000/8000 Series

Compact Nema 1 (IP 20)/IP 54

With disconnector and mains fuses

VLT 5300-5500

VLT 6350-6550

VLT 8350-8550

Brake terminals 81, 82 and 104-106 are not

available in VLT 6000 HVAC.

16

MG.56.A2.02 - VLT is a registered Danfoss trademark

Electrical installation, enclosure

■

VLT®5000/6000/8000 Series

Compact Nema 1 (IP 20) / IP 54

VLT 5300-5500

VLT 6350-6550

VLT 8350-8550

Brake terminals 81, 82 and 104-106 are not

available in VLT 6000 HVAC.

Electrical installation

MG.56.A2.02 - VLT is a registered Danfoss trademark

17

Terminal adapter kit

■

VLT®5000/6000/8000 Series

VLT type Tightening-up

torque

VLT 5300-5500

1)

42 Nm

(31 lb-ft)

VLT 6350-6550 42 Nm

(31 lb-f

t)

VLT 8350-8550 42 Nm

(31 lb-ft)

1)

For the brake terminals, the tightening-up torque

is 11.3 (8.33 lb-ft) Nm and the bolt size M8.

Bolt

size

M12

M12

M12

The terminal adapter kit is an optional kit for VLT

5300-5500, VLT 6350-6650 and VLT 8350-8550.

The terminal adapter kit makes it possible to connect

the power wires with the power terminals i.e. the

mains-, motor-, load sharing and brake terminals.

The ordering numbers of the terminal adapter kit are:

VLT 5300-5500/6350-6550 EX, DX 176F1815

VLT 5300-5500 EB, DE 176F1816

VLT 8350-8550 EX, DX 175F1815

Tightening-up torques

■

The table shows the torque required when fitting

terminals to the VLT frequency converter.

For VLT 5300-5500, VLT 6350-6550 and VLT

8350-8550 the cables must be fastened with

bolts or the terminal adapter kit. These figures

apply to the following terminals:

Mains terminals Nos R, L1, 91

S, L2, 92

T, L3, 93

Motor terminals Nos U, T1, 96

V, T2, 97

W, T3, 98

Earth terminal No 95

Brake resistor R- 81

terminals R+ 82

Loadsharing DC- 88

DC+ 89

Installation of 24 Volt external DCsupply

■

Torque: 0.5 - 0.6 Nm

Screw size: M3

No. Function

35, 36 24 V external DC supply

24 V external DC supply can be used as low-voltage

supply to the control card and any option cards

installed. This enables full operation of the LCP

(incl. parameter setting) without connection to mains.

Please note that a warning of low voltage will be

given when 24 V DC has been connected; however,

there will be no tripping. If 24 V external DC supply

is connected or switched on at the same time as

the mains supply, a time of min. 200 msec. must

be set in parameter 120 Start delay.

A pre-fuse of min. 6 Amp, slow-blow, can be

fitted to protect the external 24 V DC supply.

The power consumption is 15-50 W, depending

on the load on the control card.

NB!:

Use 24 V DC supply of type PELV to ensure

correct galvanic isolation (type PELV) on the

control terminals of the VLT frequency converter.

Installation of brake resistor temperature switch

■

Torque: 0.5-0.6 Nm

Screw size: M3

No. Function

106, 104,

Brake resistor temperature switch.

105

18

MG.56.A2.02 - VLT is a registered Danfoss trademark

NB!:

This function is only available on VLT

5300-5

If the temperature of the brake resistor

gets too high and the KLIXON switch drops out,

the VLT

The motor will start coasting.

A KLIXON switch must be installed that can either be

lly closed’or normally open’. Ifthisfunctionisnot

norma

used, 106 and 104 must be short-circuited together.

Cable cross-section and length

■

See Technical data for correct sizing of motor

cable and mains cable cross-section. Always

comply with national and local regulations on cable

cross-sections. It is important to keep the motor

cableasshortaspossiblesoastoreducethenoise

level and leakage currents to a minimum.

Max. motor cable length for screened cable

is 150 m (500 ft.).

Max. motor cable length for unscreened

cable is 300 m (1000 ft.).

500 units.

frequency converter will stop braking.

VLT®5000/6000/8000 Series

Electrical installation

MG.56.A2.02 - VLT is a registered Danfoss trademark

19

Mains connection

■

Mains must be connected to terminals R/L1/91,

2, T/L3/93.

S/L2/9

NB!:

Check the name plate to ensure that the

mains voltage of the VLT frequency converter

matches the power supply of your plant.

e that the power supply can supply

Ensur

the necessary current to the VLT frequency

converter, see Technical data.

unit is without built-in mains disconnector and

If the

fuses, ensure that the appropriate disconnector or

fuses have the correct current rating.

See Technical data for correct sizing of

cable cross-sections.

lectrical installation prodedures for how install

See E

the mains connections to the VLT frequency converter.

VLT®5000/6000/8000 Series

Mains connection from the side without

built-in disconnector and fuses

Mains connection from the bottom without

built-in disconnector and fuses

20

Mains connection from the side with built-in

disconnector and fuses

MG.56.A2.02 - VLT is a registered Danfoss trademark

VLT®5000/6000/8000 Series

Terminal W/T3/98 connected to W-phase

The direction of rotation can be changed by switching

two phases in the motor cable.

See Technical data for correct sizing of

cable cross-sections.

See Electrical installation prodedures for how install

the motor connections to the VLT frequency converter.

Mains connection from the bottom with

built-in disconnector and fuses

Motor connection

■

e motor must be connected to terminals U/T1/96,

Th

V/T2/97, W/T3/98. Earth to terminal 99.

All types of three-phase asynchronous standard motors

n be used with a VLT frequency converter unit.

ca

The factory setting is for clockwise rotation with the VLT

frequency transformer output connected as follows.

Motor connection from the side

Electrical installation

Motor connection from the bottom

Terminal U/T1/96 connected to U-phase

Terminal V/T2/97 connected to V-phase

MG.56.A2.02 - VLT is a registered Danfoss trademark

21

VLT®5000/6000/8000 Series

Brake connection (VLT 5000 Series ONLY)

■

The con

be screened. Connect the screen by means of

cable clamps to the conductive back plate at

the VLT

cabinet of the brake resistor. Size the brake cable

cross-section to match the brake torque.

See Electrical installation prodedures for how install

the brake connections to the VLT frequency converter.

nection cable to the brake resistor must

frequency converter and to the metal

NB!:

Please note that voltages up to 850 V DC

may occur on the terminals.

Load sharing connection

■

The con

max. length from the VLT frequency converter

to the DC bar is 25 metres. Load sharing

enable

several VLT frequency converters.

Load sharing calls for extra equipment. For

further information please consult Loadsharing

Instructions MI.50.NX.XX.

See Electrical installation prodedures for how

inst

VLT frequency converter.

nection cable must be screened and the

s linking of the DC intermediate circuits of

NB!:

Please note that voltages up to 850 V DC

will occur on the terminals.

all the load sharing connections to the

Brake connection from the side

Brake connection from the bottom

22

MG.56.A2.02 - VLT is a registered Danfoss trademark

Motor and DC coils connections on IP 00

■

IP 00 en

VLT 8350-8550 require installation of the motor and

DC coils by the customer. Minimum length of cables

are sup

closed VLTs 5300-5500, VLT 6350-6550 and

plied with the VLT frequency converter.

To DC bus line

+DC 118, - DC 117

To DC bus line

+DC 89, - DC 88

VLT®5000/6000/8000 Series

See below drawing for the connection between DC

coils and the VLT frequency converter and motor

nd the VLT frequency converter.

coils a

To motor

U/T1/96, V/T2/97, W/T3/98

DC bus coils

Motor coils

U2/T1/119, V2/T2/120, W2/T3/121

To motor terminals on VLT

Electrical installation

MG.56.A2.02 - VLT is a registered Danfoss trademark

23

Control cable routing

■

The drawing below shows how to route your control

n the VLT frequency converter.

cable i

VLT®5000/6000/8000 Series

Terminals 104-106 are not available in VLT 6000

and VLT 8000 AQUA series.

24

MG.56.A2.02 - VLT is a registered Danfoss trademark

VLT®5000/6000/8000 Series

Connection example

■

The diagram below gives an example of a typical

lation of a VLT frequency converter.

instal

The mains supply is connected to terminals

R/L1/91, S/L2/92 and T/L3/93, while the motor

is conn

ected to U/T1/96, V/T2/97 and W/T3/98.

These numbers can also be seen from the terminals

of the VLT frequency converter.

ernal DC supply (load sharing) can be

An ext

connected to terminals 88 and 89.

Analogue inputs can be connected to terminals 53 [V],

and 60 [mA]. These inputs can be programmed

54 [V]

for either reference, feedback or thermistor. See

Analogue inputs in parameter group 300.

There are 8 digital inputs, which can be connected

to terminals 16-19, 27, 29, 32, 33. These inputs

can be p

rogrammed in accordance with the

table in the Operating instruction. See Digital

inputs in parameter group 300.

are two analogue/digital outputs (terminals

There

42 and 45), which can be programmed to show

the present status or a process value, such as

. Relay outputs 1 and 2 can be used for

0-f

max

giving the present status or a warning.

On terminals 68 (P+) and 69 (N-) RS 485 interface,

T frequency converter can be controlled and

the VL

monitored via serial communication.

Brake terminals 81, 82 and 104-106 are not available

in VLT 6000 and VLT 8000 AQUA series.

Electrical installation

MG.56.A2.02 - VLT is a registered Danfoss trademark

25

* Depends on parameter settings.

VLT®5000/6000/8000 Series

26

MG.56.A2.02 - VLT is a registered Danfoss trademark

Electrical installation procedures

■

The following procedure will guide you through

a corre

frequency converter.

Before you start, please read the safety instructions

on the f

Note that the user is responsible, that the VLT

frequency converter, motor and other units are

insta

Pay special attention to cable dimensioning, pre-fuses,

earthing and over-current protection.

1. Mechanical installation check

Check the following before the electrical installation:

1. Check for proper ambient operating conditions.

2. Check for free flow of cooling air.

3. Check that no visible damage has occured to the

2. Bef

Remove the protective cover to get access to

terminals for control and power cables. The protective

cove

3. Load sharing connection

1. Tighten the load sharing terminals with

2. Install the wire for DC+ to terminal 89.

3. Install the wire for DC- to terminal 88.

4. Mains connection

1. Check that the mains voltage matches the VLT

2. Ensure that the power supply can supply

3. Tighten the mains and earth terminals with

4. Install earth from the power supply to

5. Install line 1 from the power supply to

6. Install line 2 from the power supply to

7. Install line 3 from the power supply to

ct electrical installation of your VLT

irst page of this instruction.

lled according to recognized local regulations.

See Derating for ambient temperature.

crate and drive during transport and that the tilt

indicator on the crate indicates a correct transport.

ore electrical installation

r can be removed by means of a screwdriver.

atorqueof42Nm.

Note that voltages up to 850 V DC will occur

on the terminals when power is connected.

frequency converter nominal input voltage.

the necessary current to the VLT frequency

converter, see Technical data.

atorqueof42Nm.

the earth bus bar.

terminal R/L1/91.

terminal S/L2/92.

terminal T/L3/93.

VLT®5000/6000/8000 Series

5. Brake resistor (only VLT 5000)

1. Tighten the brake resistor terminals with

a torque of 11.3 Nm.

2. Install the wire for R+ to terminal 81.

3. Install the wire for R- to terminal 82.

6. Motor connection

1. Tighten the motor and earth terminals with

atorqueof42Nm.

2. Install earth from the motor to the earth bus bar.

3. Install W from the motor to terminal W/T3/98.

4. Install V from the motor to terminal V/T2/97.

5. Install U from the motor to terminal U/T1/96.

7. Protective cover

Remount the protective cover.

8. Power up

Check the following before you power up the

VLT frequency converter:

1. Check for proper mains fuses. See Technical data.

2. Check for a proper earthing.

3. Check for proper mains, load sharing, brake

and motor connection.

4. Check that there are no tools in the enclosure.

Close the doors and connect the power to the VLT

frequency converter. The green voltage indicator

lamp (ON) on the control panel is activated when

the VLT frequency converter receives voltage.

The VLT frequency converter can now be

programmed via the control panel.

Note that in parameter 620 Operating mode you

can select Function with de-activated inverter

[1]. This means that without the motor shaft

running you can control the influence of the

control signal on the control card.

Wait at least 15 minutes before you open

the doors, after the VLT frequency converter

has been disconnected from mains

Electrical installation

MG.56.A2.02 - VLT is a registered Danfoss trademark

27

Electrical installation, control leads

■

Note: The terminals on the control card are detachable.

Connec

24 Volt and 27 Coast.

t a jumper between terminals 12 +

VLT®5000/6000/8000 Series

Min. reference Parameter 204

Max. reference Parameter 205

Ramp up time Parameter 207

Ramp down time Parameter 208

Mount screened cable to external start/stop of control

terminals 12 +24Voltand 18 Start.

Set Operation site, parameter 002 for Local.

Programming the VLT 6000 and VLT 8000 AQUA

■

The frequency converter is programmed

over the control panel.

Press QUICK MENU

The Quick Menu appears in the display. You choose

parameters by means of ↑ and ↓.

Press CHANGE DATA

Data values are changed using ↑ and ↓.

Press → or ← to move the cursor. Press OK

to save your parameter setting.

Set the desired language in parameter 001. You have

nine possibilities: English, German, French, Danish,

Spanish, Italian, Swedish, Dutch and Portuguese.

Set motor parameters according to the motor plate:

.

to change parameter value.

Motor power Parameter 102

Motor voltage Parameter 103

Motor frequency Parameter 104

Motor current Parameter 105

Rated motor speed Parameter 106

ogramming the VLT 5000

Pr

■

The frequency converter is programmed

over the control panel.

Press QUICK MENU

The Quick Menu appears in the display. You choose

parameters by means of ↑ and ↓.

Press CHANGE DATA

Data values are changed using ↑ and ↓.

Press → or ← to move the cursor. Press OK

to save your parameter setting.

Set the desired language in parameter 001.

ou have six possibilities: English, German,

Y

French, Danish, Spanish, Italian.

Set motor parameters according to the motor plate:

.

to change parameter value.

Motor power Parameter 102

Motor voltage Parameter 103

Motor frequency Parameter 104

Motor current Parameter 105

Rated motor speed Parameter 106

Set frequency interval and ramp times.

Min. reference Parameter 204

Max. reference Parameter 205

Ramp up time Parameter 207

Ramp down time Parameter 208

Relay 1 function Parameter 323

Relay 2 function Parameter 326

Motor start

■

Press START

HAND START on VLT 6000 HVAC to start the motor.

Set motor speed in parameter 003 by VLT 5000.

Set motor speed with the +/- keys on LCP

of VLT 6000 and VLT 8000.

Check if the direction of rotation is as shown

in the display. It can be changed by swapping

two phases of the motor cable.

on VLT 5000 to start the motor or

Set frequency interval and ramp times.

28

Press STOP

MG.56.A2.02 - VLT is a registered Danfoss trademark

or OFF/STOP to stop the motor.

Select total or reduced Automatic Motor Adaption

(AMA) in parameter 107. For further description

of AMA, please see the manual.

VLT®5000/6000/8000 Series

Press START

Motor Adaption (AMA).

Press DISPLAY/STATUS

to start the Automatic

to leave the Quick Menu.

Electrical installation

MG.56.A2.02 - VLT is a registered Danfoss trademark

29

VLT®5000/6000/8000 Series

B

Brake connection (VLT 5000 Series ONLY) ....................... 22

esistor temperature switch

Brake r

................................... 18

C

Cable cross-section ...................................................... 19

ite

Cable s

Connection example

Control cable routing

Control

................................................................... 13

...................................................... 25

..................................................... 24

leads

.............................................................. 28

D

Derating...................................................................... 13

E

Earthing...................................................................... 14

Electrical installation

cal installation procedures

Electri

External DCsupply

...................................................... 14

..................................... 27

........................................................ 18

Terminal adapter kit ...................................................... 18

Tightening-up torques

ortation

Transp

.................................................... 18

.............................................................. 4

U

Uncrating.................................................................... 4

I

ction

Introdu

................................................................. 3

K

Key diagram ................................................................ 6

L

Load sharing connection ............................................... 22

M

Mains co

Mains supply 3 x 380 - 500 V

Mains supply 3 x 380 - 500 V

Mechani

Motor connection

Motor start

nnection

cal dimensions

......................................................... 20

......................................... 7

........................................ 8

.................................................. 11

......................................................... 21

.................................................................. 28

P

Pre-fuses .................................................................... 14

Pre-installation

Program

............................................................. 12

ming the VLT 5000

............................................ 28

R

RFI switch................................................................... 15

T

30

MG.56.A2.02 - VLT is a registered Danfoss trademark

Loading...

Loading...