Page 1

FCM 300 PROFIBUS / VLT 2800 PROFIBUS

■ Introduction ..............................................................3

■ Quick Setup..............................................................4

■ The PROFIBUS interface .......................................... 5

FCM 300FCM 300

■

FCM 300 - Physical connection ...............................7

FCM 300FCM 300

VLVL

T 2800T 2800

■

VL

T 2800 - Physical connection ............................. 10

VLVL

T 2800T 2800

■ System layout......................................................... 13

■ Timing ....................................................................15

■ DP (Distributed Periphery)....................................... 16

■ Parameters............................................................. 30

■ Warning and alarm messages ................................ 35

■ Glossary and parameter list.................................... 36

Contents

■ Index ...................................................................... 39

Copyrights, Limitation of Liability and Revision Rights.

This publication contains information proprietary to Danfoss A/S. By accepting and using this manual the user

agrees that the information contained herein will be used solely for operating equipment of Danfoss A/S or

equipment from other vendors provided that such equipment is intended for communication with Danfoss

equipment over a PROFIBUS serial communication link. This publication is protected under the Copyright laws of

Denmark and most other countries.

Danfoss A/S does not warrant that a software program produced according to the guidelines provided in this

manual will function properly in every physical, hardware or software environment.

Although Danfoss A/S has tested and reviewed the documentation within this manual, Danfoss A/S makes no

warranty or representation, either express or implied, with respect to this documentation, including its quality,

performance, or fitness for a particular purpose.

In no event shall Danfoss A/S be liable for direct, indirect, special, incidental, or consequential damages arising

out of the use, or the inability to use information contained in this manual, even if advised of the possibility of such

damages. In particular, Danfoss A/S is not responsible for any costs including but not limited to those incurred as

a result of lost profits or revenue, loss or damage of equipment, loss of computer programs, loss of data, the

costs to substitute these, or any claims by third parties.

Danfoss A/S reserves the right to revise this publication at any time and to make changes in its contents without

prior notice or any obligation to notify previous users of such revisions or changes.

MG.90.A2.02 – VL T is a registered Danfoss trademark

1

Page 2

FCM 300 PROFIBUS / VLT 2800 PROFIBUS

When reading through this manual, you will come

across various symbols that require special attention.

The symbols used are the following:

Indicates a general warning.

Indicates something to be noted by

the reader.

Indicates a high-voltage warning.

PROFIBUS is a registered trademark.

2

MG.90.A2.02 – VL T is a registered Danfoss trademark

Page 3

FCM 300 PROFIBUS / VLT 2800 PROFIBUS

■ About this manual

This manual is intended to be used both as an

instructional and as a reference manual. It only briefly

touches on the basics of the PROFIBUS protocol

whenever it is necessary for gaining an understanding

of the PROFIDRIVE implementation of the PROFIBUS

Profile for Variable Speed Drives (VDI/VDE 3689) and

the DANFOSS PROFIBUS for the FC motor and the

VLT 2800.

The manual is also intended to serve as a guideline

when you specify and optimize your communication

system.

If you are not completely familiar with PROFIBUS or

the Profile for Variable Speed Drives, it may be

advisable to read some of the material provided on

these subjects, eg DIN 19245 parts 1 and 3 and VDI/

VDE 3689.

Even if you are an experienced PROFIBUS

programmer, we suggest that you read this manual in

its entirety before you start programming, since

important information can be found in all chapters.

Introduction

■ Assumptions

This manual assumes that you are using a DANFOSS

FCM 300 and VLT 2800 with PROFIBUS. It is also

assumed that you, as a master, are using a PLC or

PC that is equipped with a serial communication card

supporting all the PROFIBUS communication services

required by your application, and that all

requirements stipulated in the PROFIBUS standard as

well as those set up in the PROFIBUS Variable Speed

Drives Profile and its company-specific

implementation PROFIDRIVE, as well as those

pertaining to the VLT Variable Speed Drive are strictly

observed as well as all limitations therein fully

respected.

■ What you should already know

The DANFOSS PROFIBUS is designed to

communicate with any master abiding by the

PROFIBUS DP standard. It is therefore assumed that

you have full knowledge of the PC or PLC you intend

to use as a master in your system. Any questions

pertaining to hardware or software produced by any

other manufacturer is beyond the scope of this

manual and is of no concern to DANFOSS.

If you have questions about how to set up master master communication or communication to a nonDanfoss slave, the appropriate manuals should be

consulted.

MG.90.A2.02 – VL T is a registered Danfoss trademark

3

Page 4

FCM 300 PROFIBUS / VLT 2800 PROFIBUS

Programming: See the design guide:

FC motor (MG.03.Bx.02)

VLT 2800 (MG.28.Ex.02)

for descriptions on how to programme the ordinary

FC motor and VLT 2800.

Quick Setup

■ General information

Parameter 918:

Set the station address, - one unique address per

unit.

In parameters 502-508 it is possible to define how to

gate the control commands from the PROFIBUS with

the equivalent control commands of the digital inputs.

The FC motor/VLT 2800 adjusts to the baudrate and

the configuration from the master.

Communication is established by setting the

parameters stated below.

Setting up the master: See the manual on the master

as well as the chapters of this manual giving details

on the PROFIBUS interface for information on how to

set up the master.

4

MG.90.A2.02 – VL T is a registered Danfoss trademark

Page 5

FCM 300 PROFIBUS / VLT 2800 PROFIBUS

■ Master controlled Variable Speed Drives (VSD)

The PROFIBUS Field-bus was designed to give you

unprecedented flexibility and command over your

VSD controlled system. The PROFIBUS will perform

as an integrated part of your VLT VSD, giving you

access to all parameters relevant to your application.

The VSD will always act as a slave, and together with

a master it can exchange a multitude of information

and commands. Control signals such as speed

reference, start / stop of motor, reverse operation,

etc. are transmitted from the master in the form of a

telegramme. The VSD acknowledges receipt by

transmitting status signals, such as running, on

reference, motor stopped and so on to the master.

The VSD may also transmit fault indications, alarms

and warnings to the master, such as Overcurrent or

Phaseloss.

The PROFIBUS communicates according to the

PROFIBUS Protocol Standard DIN 19245 parts 1 and

3. This means that it can communicate with all

masters that comply with this standard, but it does

not necessarily mean that all services available in the

PROFIBUS standard are supported. The VDI / VDE

3689 PROFIBUS Profile for Variable Speed Drives is a

subset of PROFIBUS which only supports the

services relevant to speed control applications.

PROFIDRIVE is an implementation of VDI / VDE 3689

profile created by DANFOSS and a number of other

companies.

Communication partners

In a control system the VSD will always act as a slave,

and as such it may communicate with a single master

or multiple masters depending on the nature of the

application. A master may be a PLC or a PC that is

equipped with a PROFIBUS communication card.

■ Physical layer

The field of application of a field-bus system is

primarily determined by the transmission media and

the physical bus interface selected. The type of bus

cable required for the application and its installation

(physical layer) are particularly important factors, in

addition to the required transmission reliability of the

physical level.

Though a fundamental feature of the PROFIBUS standard is the possibility of specifying several different

physical interfaces, the standard, at the time of

printing, has allowed for one universal specification

only, namely the EIA Standard RS 485-A, which has

found acceptance both in the field of factory automation and in several areas of the processing industry.

The PROFIBUS Interface

■ Cable lengths/number of nodes

The maximum cable length in one segment is

depending on the transmission speed. The total cable

length includes drop cables if any. A drop cable is the

connection from the main bus cable to each node if a

T-connection is used instead of connecting the main

bus cable directly to the nodes, see drop cable

length. The table below shows the maximum allowed

cable length and maximum number of nodes/VLT’s

with 1, 2, 3 and 4 bus segments.

Max. total bus cable lenght

1 segment: 2 segments: 3 segments: 4 segments:

32 nodes 64 nodes 96 nodes 128 nodes

Transmission (31 VLT) (1 repeater, 61 VLT) (2 repeaters, 91 VLT) (3 repeaters, 121 VLT)

speed [m] [m] [m] [m]

9.6-187.5 kBaud 1000 2000 3000 4000

500 kBaud 400 800 1200 1600

1.5 MBaud 200 400 600 800

3 MBaud 100 200 300 400

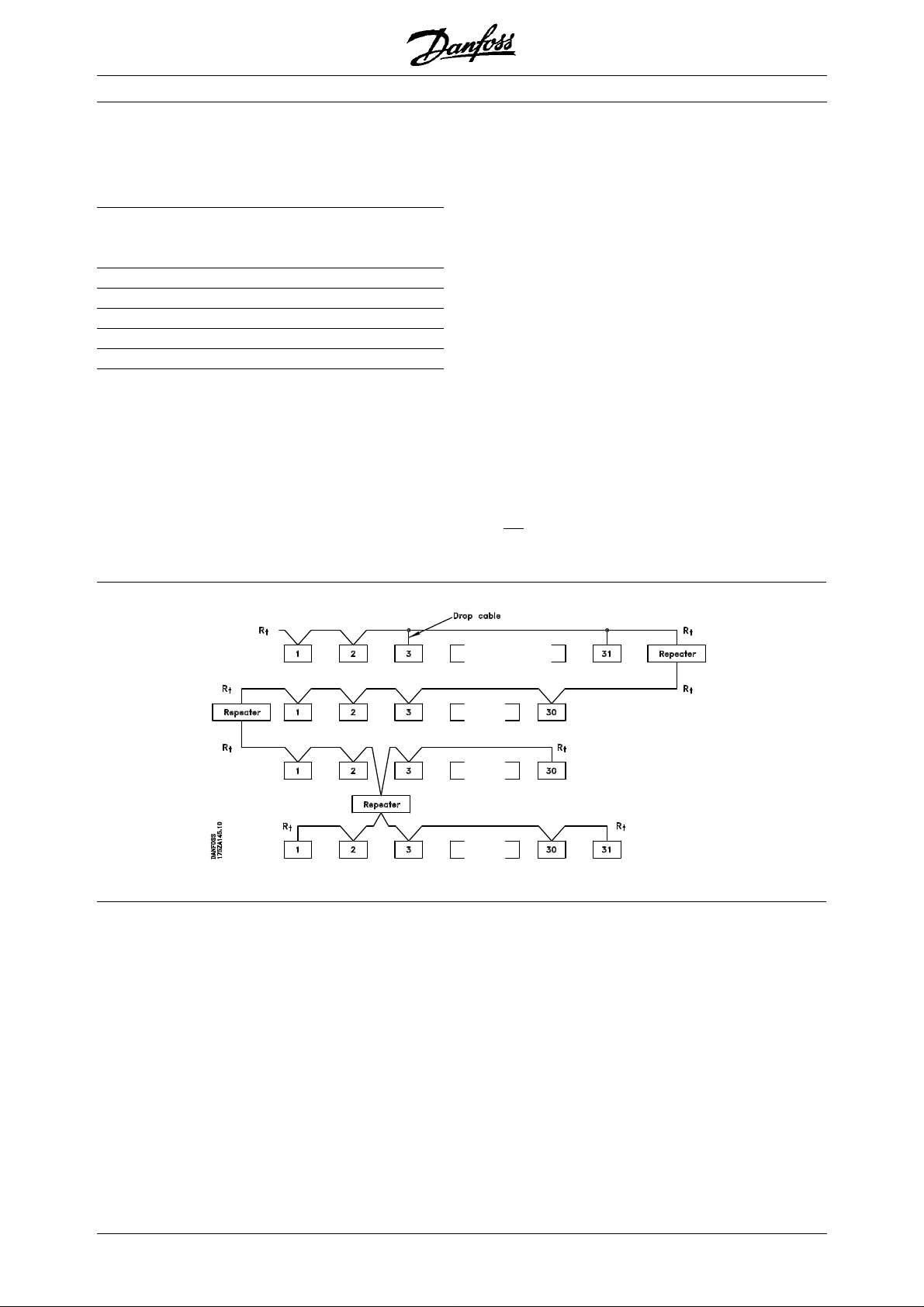

Note that a repeater is a node in both of the two

segments it connects. The number of VLT is based on

a single master system. If there are more masters the

number of VLT must be reduced correspondingly.

MG.90.A2.02 – VL T is a registered Danfoss trademark

5

Page 6

FCM 300 PROFIBUS / VLT 2800 PROFIBUS

The total drop cable length for one segment is limited

as stated in the table below.

Drop cable length

Max. drop cable

length per segment

Transmission speed [m]

9.6-93.75 kBaud 96

187.5 kBaud 75

500 kBaud 30

The PROFIBUS Interface

1.5 MBaud 10

3 MBaud none

The length statements in the tables above are valid

provided that bus cable with the following properties

is used:

- Impedance: 135 to 165 ohm

at a measuring frequency from 3 to

20 MHz

- Resistance: <110 ohm/km

- Capacity: < 30pF/m

- Damping: max. 9 dB over the whole wire

length

- Cross section: max. 0.34 mm

2

,

corresponding to AWG 22

- Cable type: twisted in pairs,

1 x 2, or 2 x 2, or 1 x 4 wires

- Screening: Copper-braided screen

or braided screen and foil screen

It is recommended to use the same cable type in the

entire network to avoid impedance mismatch.

The numbers on the following drawing indicate the

maximum number of stations in each segment. They

are

not the station addresses as each station in the

network must have a unique address.

Segment 1

Segment 2

Segment 3

Segment 4

Rt = termination

resistors

6

MG.90.A2.02 – VL T is a registered Danfoss trademark

Page 7

FCM 300:FCM 300:

FCM 300:

FCM 300:FCM 300:

FCM 300 PROFIBUS / VLT 2800 PROFIBUS

The PROFIBUS Interface

■ Physical connection

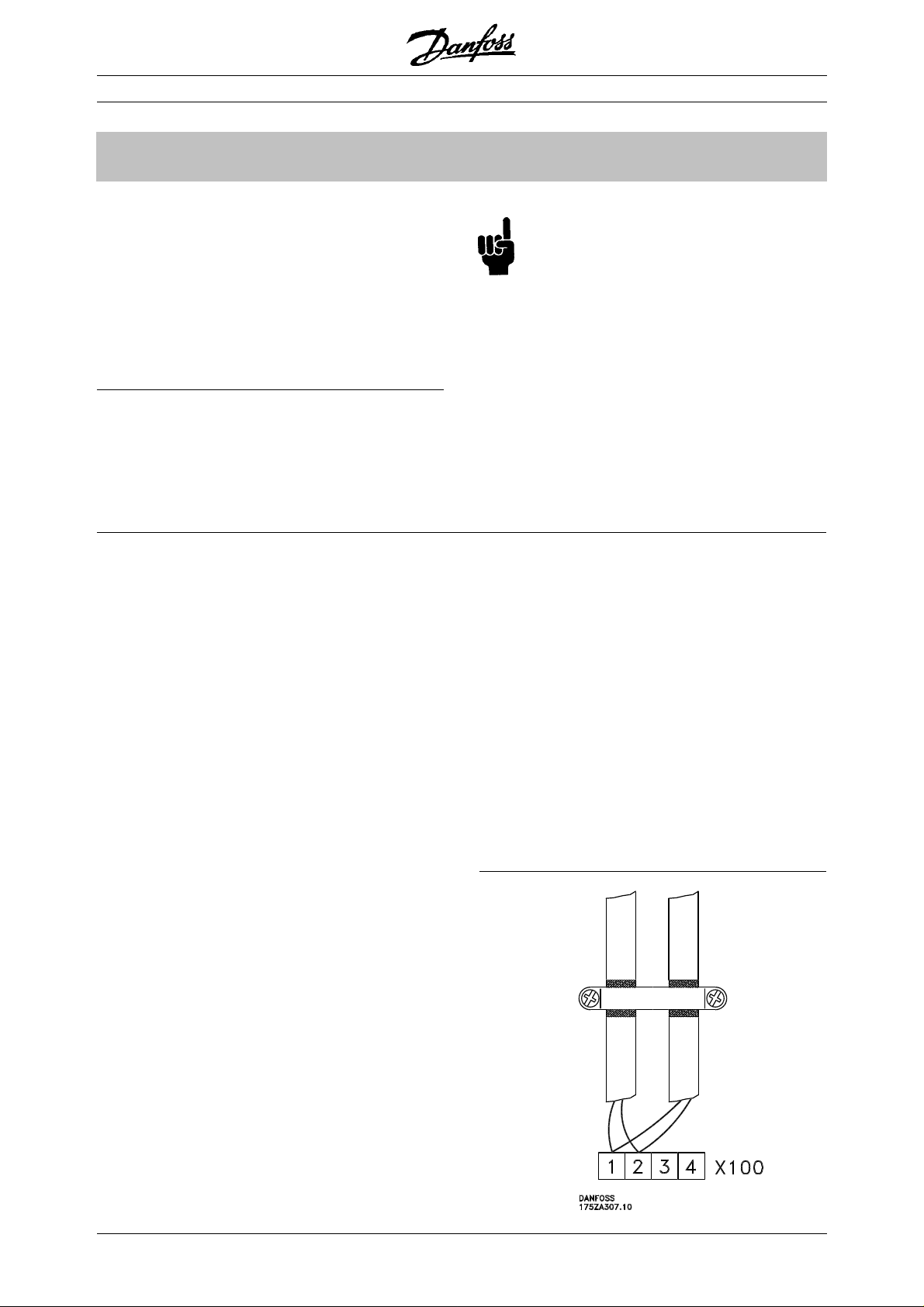

The PROFIBUS is connected to the bus line via X100,

terminals 1 and 2.

It is recommended to use a master with a galvanic

isolated bus driver and with over voltage protection

(e.g. zenerdiode).

EMC precautions

The following EMC precautions are recommended to

obtain interference free operation of the PROFIBUS

network. Additional information on EMC can be found

in the design guide on the FC motor (MG.03.Bx.02).

Please also consult the manual of the PROFIBUS

master for further installation guidelines.

If the PROFIBUS cable has to cross a motor and

brake resistor cable they must cross each other at

an angle of 90°.

- Connection of the cable screen

The screen of the PROFIBUS cable must always

be connected to ground at both ends, that means

the screen must be connected to ground in all

stations connected to the PROFIBUS network. It

is very important to have a low impedance

ground connection of the screen, also at high

frequencies.This can be obtained by connecting

the surface of the screen to ground, for example

by means of a cable clamp or a conductive cable

gland.

The FC motor Series is provided with different

clamps and brackets to enable a proper ground

connection of the PROFIBUS cable screen. The

screen connection is shown in the following

drawing.

Relevant national and local regulations, for

example regarding protective earth

connection, must be observed.

- Cable routing

The PROFIBUS communication cable must be

kept away from motor and brake resistor cables to

avoid coupling of high frequency noise from one

cable to the other. Normally a distance of 200 mm

is sufficient, but it is generally recommended to

keep the greatest possible distance between the

cables, especially where cables are running in

parallel over long distances.

- Earth connection

It is important that all stations connected to the

PROFIBUS network are connected to the same

earth potential. The earth connection must have a

low HF (high frequency) impedance. This can be

achieved by connecting a large surface area of the

cabinet to earth, for example by mounting the FC

motor on a conductive rear plate.

Especially when having long distances between

the stations in a PROFIBUS network it can be

necessary to use additional potential equalizing

cables, connecting the individual stations to the

same earth potential.

Connecting the bus line

MG.90.A2.02 – VL T is a registered Danfoss trademark

7

Page 8

FCM 300:FCM 300:

FCM 300:

FCM 300:FCM 300:

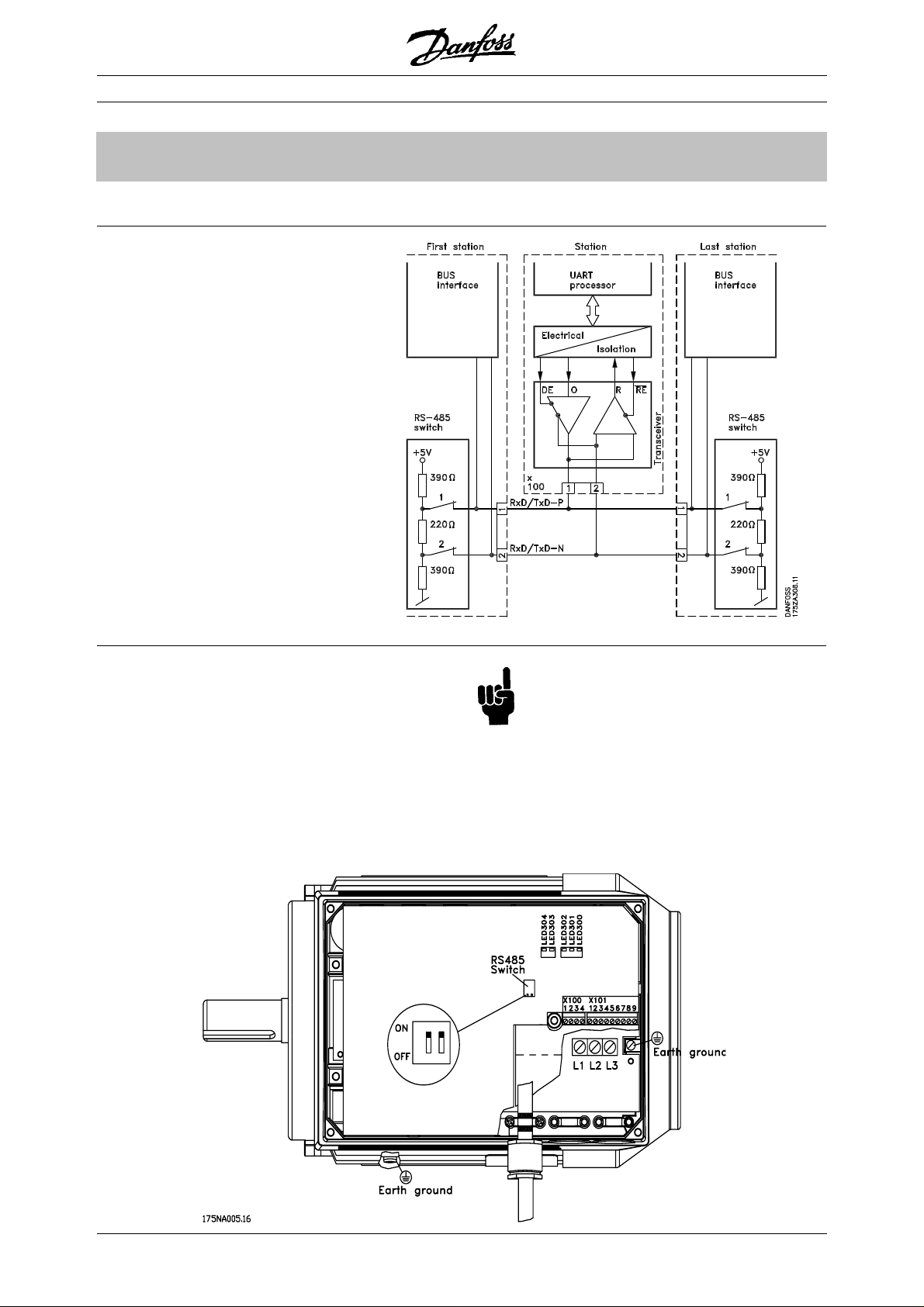

The bus termination

See drawing on page 6

The PROFIBUS Interface

FCM 300 PROFIBUS / VLT 2800 PROFIBUS

It is essential that the bus line be terminated properly.

A mismatch of impedance may result in reflections

on the line that will corrupt data transmission.

- The PROFIBUS is provided with a suitable

termination which may be activated by the

switches of the RS485 switch block located

just to the left of the terminal block X100 (see

drawing below). The switches should be on to

terminate the bus.

The switches should never be left in opposite

positions. They should either both be ON or

both be OFF!

- Most masters and repeaters are equipped with

their own termination.

- If an external termination circuit consisting of three

resistors is connected to the bus line a 5 V d.c.

power supply must be used, please note that this

must be galvanically isolated from the a.c. line.

8

MG.90.A2.02 – VL T is a registered Danfoss trademark

Page 9

FCM 300:FCM 300:

FCM 300:

FCM 300:FCM 300:

■ LEDs

There are 2 LEDs on the PROFIBUS:

LED303: Lights up when the card is initialized

and ready to communicate. It will

flash while auto baudrate detection is

attempting to detect the actual

baudrate.

LED304: Lights up when the card is

communicating, depending on

baudrate.

A high baudrate results in dim light in LED304.

FCM 300 PROFIBUS / VLT 2800 PROFIBUS

The PROFIBUS Interface

MG.90.A2.02 – VL T is a registered Danfoss trademark

9

Page 10

VLVL

T 2800T 2800

VL

T 2800

VLVL

T 2800T 2800

FCM 300 PROFIBUS / VLT 2800 PROFIBUS

::

:

::

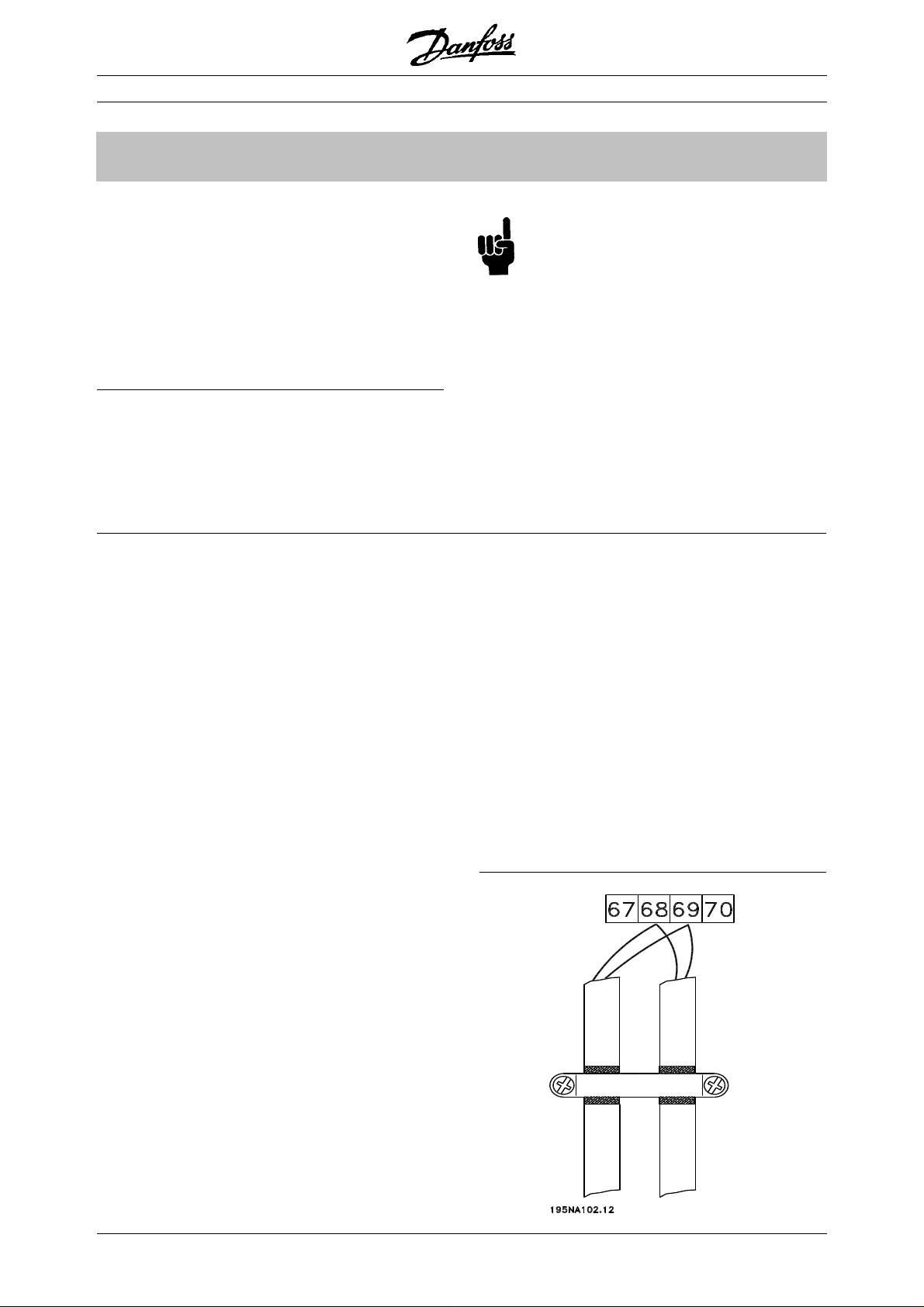

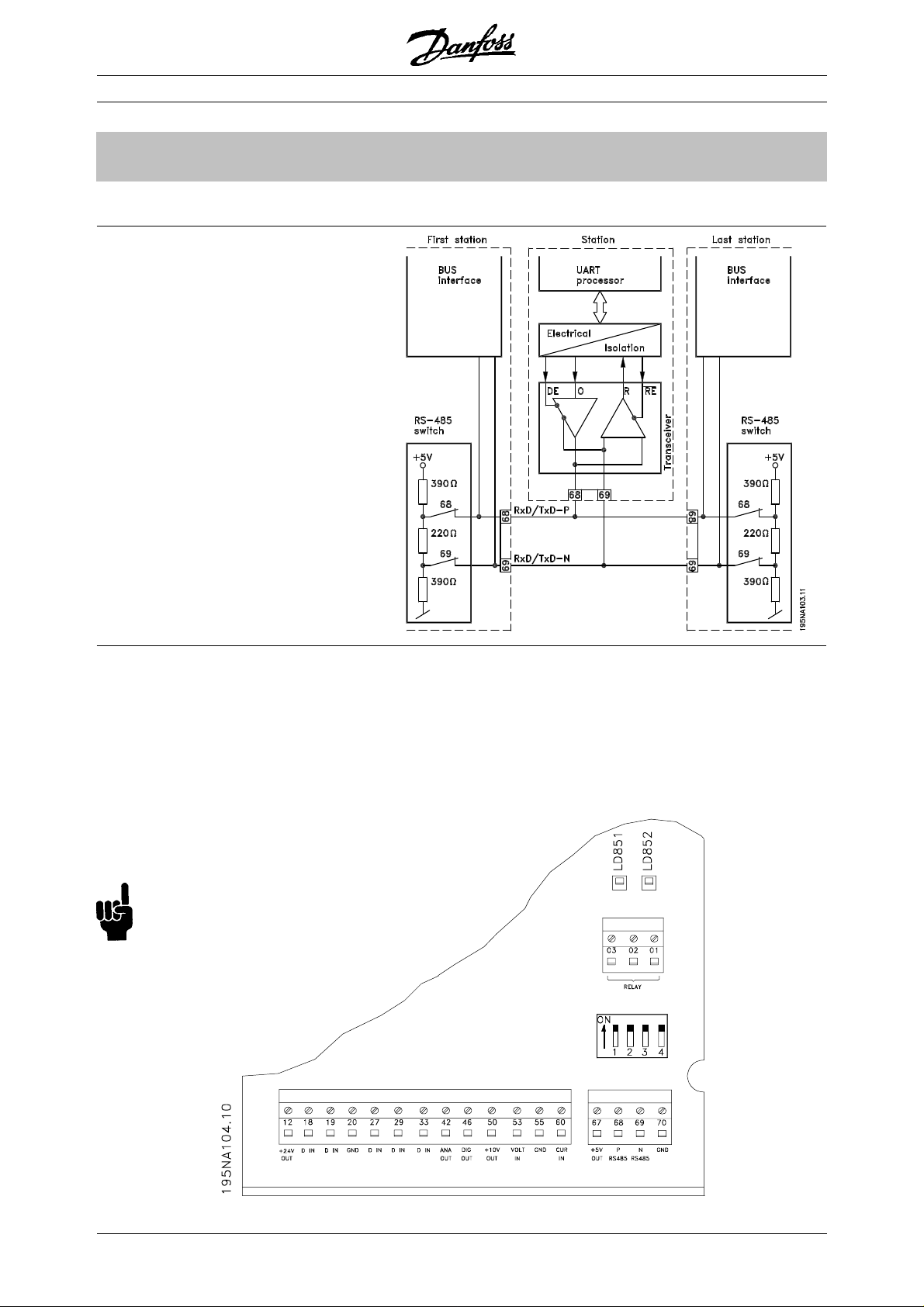

■ Physical connection

The PROFIBUS is connected to the bus line via,

terminals 68 and 69.

It is recommended to use a master with a galvanic

isolated bus driver and with over voltage protection

(e.g. zenerdiode).

The PROFIBUS Interface

EMC precautions

The following EMC precautions are recommended to

obtain interference free operation of the PROFIBUS

network. Additional information on EMC can be found

in the design guide on the VLT 2800 (MG.28.Ex.02).

Please also consult the manual of the PROFIBUS

master for further installation guidelines.

If the PROFIBUS cable has to cross a motor and

brake resistor cable they must cross each other at

an angle of 90°.

- Connection of the cable screen

The screen of the PROFIBUS cable must always

be connected to ground at both ends, that means

the screen must be connected to ground in all

stations connected to the PROFIBUS network. It

is very important to have a low impedance

ground connection of the screen, also at high

frequencies.This can be obtained by connecting

the surface of the screen to ground, for example

by means of a cable clamp or a conductive cable

gland.

The VLT 2800 Series is provided with different

clamps and brackets to enable a proper ground

connection of the PROFIBUS cable screen. The

screen connection is shown in the following

drawing.

Relevant national and local regulations, for

example regarding protective earth

connection, must be observed.

- Cable routing

The PROFIBUS communication cable must be

kept away from motor and brake resistor cables to

avoid coupling of high frequency noise from one

cable to the other. Normally a distance of 200 mm

is sufficient, but it is generally recommended to

keep the greatest possible distance between the

cables, especially where cables are running in

parallel over long distances.

- Earth connection

It is important that all stations connected to the

PROFIBUS network are connected to the same

earth potential. The earth connection must have a

low HF (high frequency) impedance. This can be

achieved by connecting a large surface area of the

cabinet to earth, for example by mounting the VLT

2800 on a conductive rear plate.

Especially when having long distances between

the stations in a PROFIBUS network it can be

necessary to use additional potential equalizing

cables, connecting the individual stations to the

same earth potential.

Connecting the bus line

10

MG.90.A2.02 – VL T is a registered Danfoss trademark

Page 11

VLVL

T 2800T 2800

VL

T 2800

VLVL

T 2800T 2800

The bus termination

See drawing on page 6

FCM 300 PROFIBUS / VLT 2800 PROFIBUS

The PROFIBUS Interface

::

:

::

It is essential that the bus line be terminated properly.

A mismatch of impedance may result in reflections on

the line that will corrupt data transmission.

- The PROFIBUS is provided with a suitable

termination which may be activated by the

switches of the RS485 switch block located

just to the left of the terminal block X100 (see

drawing below). The switches should be on to

terminate the bus.

The switches should never be left in opposite

positions. They should either both be ON or

both be OFF!

- Most masters and repeaters are equipped with

their own termination.

- If an external termination circuit consisting of three

resistors is connected to the bus line a 5 V d.c.

power supply must be used, please note that this

must be galvanically isolated from the a.c. line.

MG.90.A2.02 – VL T is a registered Danfoss trademark

11

Page 12

VLVL

T 2800T 2800

VL

T 2800

VLVL

T 2800T 2800

■ LEDs

There are 2 LEDs on the PROFIBUS:

LD851: Lights up when the card is initialized

and ready to communicate. It will

flash while auto baudrate detection is

attempting to detect the actual

The PROFIBUS Interface

LD852: Lights up when the card is

A high baudrate results in dim light in LD852.

baudrate.

communicating, depending on

baudrate.

::

:

::

FCM 300 PROFIBUS / VLT 2800 PROFIBUS

12

MG.90.A2.02 – VL T is a registered Danfoss trademark

Page 13

FCM 300 PROFIBUS / VLT 2800 PROFIBUS

■ Bus topology

Single master operation with DP

FeaturFeatur

es of DPes of DP

Featur

es of DP (Distributed Periphery)

FeaturFeatur

es of DPes of DP

- Is used by several PLC manufacturers for remote

peripheral I/O communication.

- Supports cyclical communication.

- SRD service gives fast cyclical exchange of

process data between master and slaves.

- Freeze and synchronize function is supported

- Fixed data structure.

- Fixed telegramme size.

- Occupies I/O memory space in PLC proportional

to the number of slaves employed, which may limit

the number of participants. Additional data

require additional I/O memory space.

- Single master

- PLC communicates with telegrams of constant

length

- Fits to time critical requirements

- No need for equidistant transmissions of

set points

Cyclical transmission

1. Set point transmission

2. Actual value feed back

3. New setpoints computed

4. New setpoint transfer

DP should be used when fast cyclical process control

is needed. Such a concept would typically call for

single master operation with a limited number of slave

stations. (A high number of slaves will reduce the

system response).

This could also be the case where control loops are

closed over the bus.

As a very fast alternative it is of course possible to

close the control loop outside the bus.

System layout

Transferring large amount of data where rapid transfer

of process data does not have highest priority

MG.90.A2.02 – VL T is a registered Danfoss trademark

13

Page 14

FCM 300 PROFIBUS / VLT 2800 PROFIBUS

Closing the control loop over the bus

System layout

Closing the control loop outside the fieldbus

for extremely fast feed-back

Rapid Cyclical transmission with PPO using DP

Parameter up-/downloads can be achieved by using

the so-called Parameter / Process Objects - PPOs of 12, 20 or 28 bytes length as specified in the VDI/

VDE 3689 profile, see drawing page 16.

This procedure, however, occupies 8 bytes additional

I/O memory space in the PLC bytes per slave, and

slows down the system (see also “Timing” page 15).

Control of the drives during normal operation is often

very time critical, but it involves very few data, such

as control commands and speed reference. DP is

optimized for fast cyclical communication.

■ Features and services supported by FC motor

and the VLT 2800

Features available as described by the unit

classification

The unit classification as layed out in the PROFIBUS

Profile for VSDs describes the functionality of the unit.

There are 4 classes where class 1 signifies the lowest

performance class, and class 4 the highest.

The FC motor / VLT 2800 is a class 3 unit except for

the following features:

- Fault buffer

- Change access rights for parameter write

- Change access rights for process control

- Time difference

- Hardware configuration ident.

The FC motor / VLT 2800 complies with the following

class 4 features:

- Baudrate > 500 kBaud

- Programmable content of PCD 3 through 6 (10) of

the PPO’s

- PPO type 5

14

MG.90.A2.02 – VL T is a registered Danfoss trademark

Page 15

FCM 300 PROFIBUS / VLT 2800 PROFIBUS

■■

■ FC motor / VLT 2800 response time

■■

The update time via the PROFIBUS connection can

be divided in two parts:

1) The communication time, which is the time it takes

to transmit data from the master to the slave (FC

motor / VLT 2800 with PROFIBUS), and 2) the

internal update time, which is the time it takes to

transmit data between the FC motor / VLT 2800

control card and the PROFIBUS.

Communication time (t

) depends on the actual

com

transmission speed (baudrate) and the type of master

in use. The minimum obtainable communication time

with the FC motor / VLT 2800 with PROFIBUS is

approx. 100 µsec per slave, when using DP

communication with 4 bytes of data (PPO type 3) at 3

Mbaud. More data or lower transmission speed will

increase the communication time.

The internal update time (t

) depends on the type of

int

data in question as there are different channels for the

data transfer where time critical data e.g. control

word has highest priority. The internal update time for

the different types of data are stated below.

Update

Data time, t

Control word/Main reference

(part of PPO) 42 msec

Status word/Actual output frequency

(part of PPO) 40 msec

Parameter read (PCD 1-8) 40 msec

Parameter write (PCD 1-2) 160 msec

Parameter write (PCD 3-4) 320 msec

Parameter write (PCD 5-8) 640 msec

Parameter read (PCV) 41 msec

Parameter write (PCV) 40 msec

Timing

int

■■

■ System update time

■■

The system update time is the time it takes to

update all the slaves in the network when using

cyclical communication. The drawing below shows

the value which is obtainable in theory at 2 input

and 2 output bytes.

MG.90.A2.02 – VL T is a registered Danfoss trademark

15

Page 16

FCM 300 PROFIBUS / VLT 2800 PROFIBUS

■ DP communication relations

DP

Communication according to PROFIBUS DP, i.e. DIN

19245 part 1 & 3, is supported. Consequently a

master that supports PROFIBUS DP must be used.

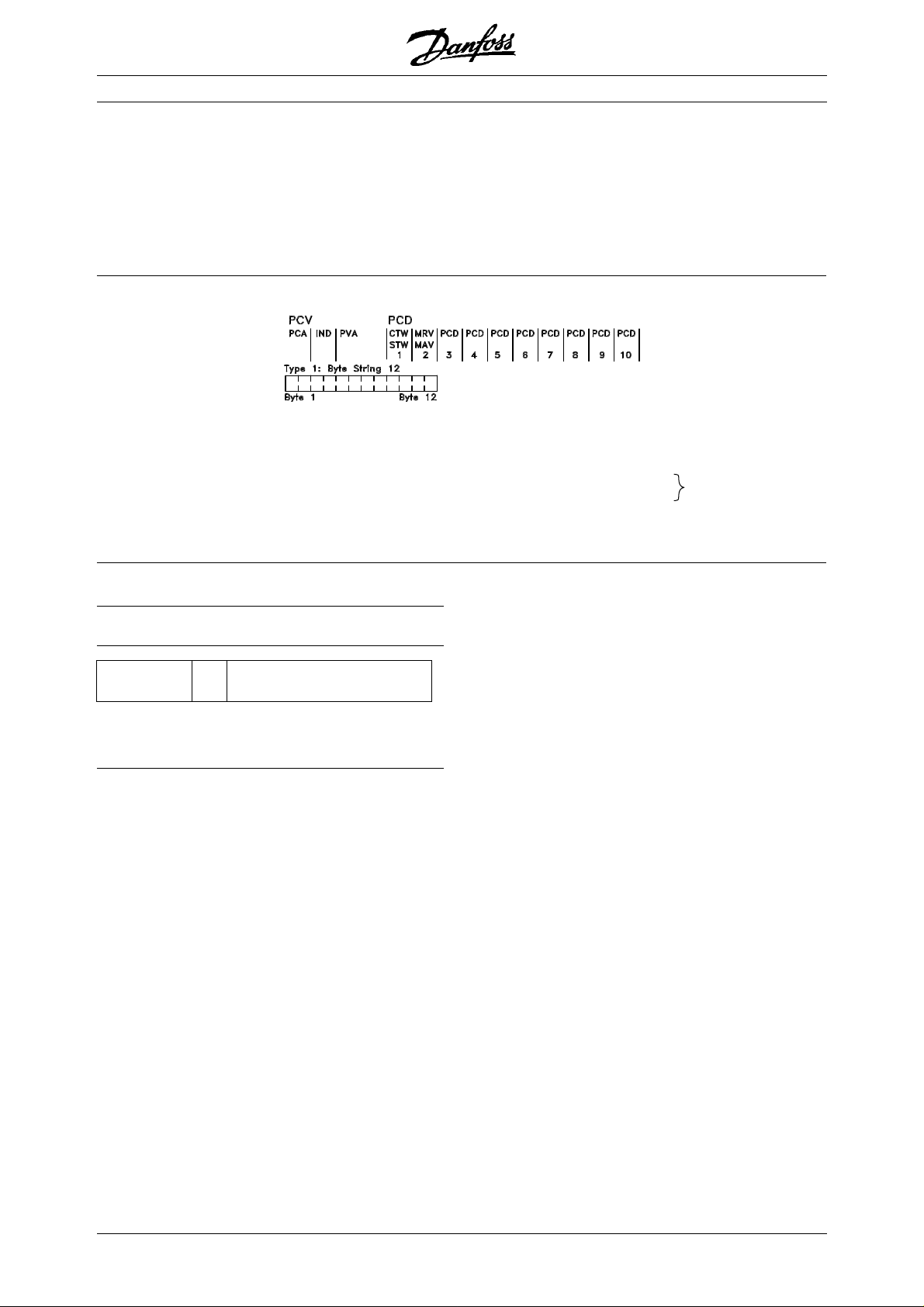

■ PPO description

A special feature of the PROFIBUS Profile for VSD’s is

the communication object called a PPO, meaning

Parameter-Process Data Object.

The PPO is well suited for fast cyclical data transfer,

and may, as the name implies, carry both process

data and parameters.

The selection of PPO type is made according to the

master request.

A PPO may consist of a parameter part and process

data part. The parameter part can be used for

reading and/or updating the parameters one by one.

PPO. Parameter-Process Data Object

By DP one of the following shown PPO’s must be used:

By DP communication one of the parameter-process

data objects (PPO’s) described below must be used.

The process data part consists of a fixed part (4

bytes) and a parametrable part (8 or 16 bytes). In the

fixed part control word and speed reference are

transfered to the VLT while status word and actual

output frequency feedback are transfered from the

VLT. In the parametrable part the user chooses which

parameters have to be transfered to (parameter 915)

and which from (parameter 916) the VLT.

Type 1, 2 and 5 consist of the parameter part and 4,

12 and 20 byte process data, respectively.

Type 3 and 4 consist of 4 and 12 byte process data,

respectively.

PCD: Process Data

PCV: Parameter-Characteristics-Value

PCA: Parameter-Characteristics (Bytes 1, 2)

PCA handling below

IND: Subindex (Byte 3), (Byte 4 is not used)

PVA: Parameter value (Bytes 5 to 8)

CTW: Control word

STW: Status word

MRV: Main reference value

MAV: Main actual value (Actual output frequency)

see page 22

16

MG.90.A2.02 – VL T is a registered Danfoss trademark

Page 17

FCM 300 PROFIBUS / VLT 2800 PROFIBUS

■ PCA handling

The PCA portion of the PPO types 1, 2 and 5 will

handle a number of tasks. The master may control

and supervise parameters and request a response

from the slave, while the slave, apart from responding

to a request from the master may transmit a

spontaneous message.

Requests and responses is a handshake procedure

and cannot be batched, meaning that if the master

sends out a Read/write request, it has to wait for the

response, before it sends a new request. The request

or response data value will be limited to max. 4 bytes,

which implies that text strings are not transferable.

PCA - Parameter Characteristics

15141312 11 109876543210

RC SMP PNU

RC: Request/respons Characteristics (Range: 0..15)

SPM: Toggle-Bit for Spontaneous Messages

PNU: Parameter # (Range: 1..1999)

Response Function

0 No response

1 Transfer parameter value (word)

2 Transfer parameter value (long word)

3 Transfer description element

4 Transfer parameter value (array word)

5

Transfer parameter value (array long word)

6 Transfer number of array elements

7 Request rejected (incl. fault #, see below)

8 Not seviceable by PCV interface

9 Spontaneous message (word)

10 Spontaneous message (long word)

11 Spontaneous message (array word)

12 Spontaneous message (array long word)

13-15 Not used

If the slave rejects a request from the master, the RC word in

the PPO-read will indicate this by assuming the value 7.

The fault # will be carried by bytes 7 and 8 in the PVA element.

DP

Request/response handling

The RC portion of the PCA word defines the requests

that may be issued from the master to the slave as

well as what other portions of the PCV (IND and PVA)

are involved.

The PVA portion will transmit word-size parameter

values in bytes 7 and 8, while long word size values

require bytes 5 to 8 (32 bits).

If the Response / Request contains array elements,

the IND will carry the Array Subindex. If parameter

descriptions are involved, the IND will hold the Record

Subindex of the Parameter description.

RC content

Request Function

0 No request

1 Request parameter value

2 Change parameter value (word)

3 Change parameter value (long word)

4 Request description element

5 Change description element

6 Request parameter value (array)

7 Change parameter value (array word)

8

Change parameter value (array long word)

9 Request number of array elements

10-15 Not used

Fault # Interpretation

0 Illegal PNU

1 Parameter value cannot be changed

2 Upper or lower limit exceeded

3 Subindex corrupted

4 No array

5 Data type false

6 Cannot be set by user (reset only)

7 Description element cannot be changed

8 IR required PPO-write not available

9 Description data not available

10 Access group

11 No parameter write access

12 Key word missing

13

14

Text in cyclical transmission not readable

Name in cyclical transmission not readable

15 Text array not available

16 PPO-write missing

17 Request temporarily rejected

18 Other fault

19

Date in cyclical transmission not readable

130 There is no bus access to the parameter

called

131 Data change is not possible because

factory Setup has been selected

MG.90.A2.02 – VL T is a registered Danfoss trademark

17

Page 18

FCM 300 PROFIBUS / VLT 2800 PROFIBUS

■ Parameter and data type structure description

DP

Parameter description:

PNU

Characteristics

Subindex 1

DP has a number of describing attributes (see rigth).

Size of elements

Read/write on parameter description is made by the

PCV part using the RC commands 4/5 and subindex

of the desired description element.

Size attribute

The size index and the conversion index for each

parameter can be taken from the parameter list on

page 36.

Subindex 2

Size attributes

Subindex 4

Lower limit

Subindex 7

Upper limit

Subindex 8

Extended characteristics

Subindex 10

Physical unit Size index Measuring unit Designation Conversion index Conversion factor

0 No dimension 0 1

second s 0 1

-1 0.1

-2 0.01

Time 4 millisecond ms -3 0.001

minute min 70 60

hour h 74 3600

day d 77 86400

watthour Wh 0 1

Energy 8 kilowatthour kWh 3 1000

megawatthour MWh 6 10

milliwatt mW -3 0.001

Power 9

watt W 0 1

kilowatt kW 3 1000

megawatt MW 6 10

Rotation 11 rotation per minute RPM 0 1

Torque 16

newtonmeter Nm 0 1

kilonewtonmeter kNm 3 1000

Temperature 17 degree Celsius °C 0 1

millivolt mV -3 0.001

Voltage 21 volt V 0 1

kilovolt kV 3 1000

milliampere mA -3 0.001

Current 22 ampere A 0 1

kiloampere kA 3 1000

milliohm mOhm -3 0.001

Resistance 23 ohm Ohm 0 1

kiloohm kOhm 3 1000

Ratio 24 per cent % 0 1

Relative change 27 per cent % 0 1

hertz Hz 0 1

Frequency 28

kilohertz kHz 3 1000

megahertz MHz 6 10

gigahertz GHz 9 10

6

6

6

9

18

MG.90.A2.02 – VL T is a registered Danfoss trademark

Page 19

FCM 300 PROFIBUS / VLT 2800 PROFIBUS

■ Object and data types supported by FC motor

and VLT 2800

Data types supported by FC motor and VLT 2800

Data Object Short Description

type Code name

3 5 12 Integer 16

5 5 Unsigned 8

6 5 O2 Unsigned 16

7 5 O4 Unsigned 32

10 5 Byte string

13 5 Time difference

1)

33 5 N2 Standardized value (16 bit)

35 5 V2 Bit sequence

1)

See elaboration below

1)

Time difference

The data type time difference is a time indication in

milliseconds.

Notation: Time difference

Value range: 0 ≤ i ≤ (2

32

-1) milliseconds

Coding: The time is presented as a binary

value of 32 bits (4 bytes). The first

four (MSB) bits are always zero.

Time difference is thus a byte string

of 4 bytes.

Data coding of the data type time difference

Bit Byte 1 Byte 2 Byte 3 Byte 4

80ms223ms 215ms 27ms MSB

70ms222ms 214ms 26ms MSB

60ms221ms 213ms 25ms MSB

50ms220ms 212ms 24ms MSB

4227ms 219ms 211ms 23ms

3226ms 218ms 210ms 22ms

2225ms 217ms 29ms 21ms

1224ms 216ms 28ms 20ms

Standardized value

1)

A liniary value.

14

0% = 0 (0h), 100% is 2

(4000h)

Data type N 2

Range -200% ... 200% – 2

Resolution 2

–14

= 0.0061%

Length 2 bytes

Notation: 2’s complement notation.

MSB is 1st bit after sign bit in 1st byte.

Sign bit = 0 = positive number

Sign bit = 1 = negative number

Bit 8 7 6 5 4 3 2 1

0

Byte 1 SIGN 2

Byte 2 2–72

–12–22–32–42–52–6

2

–82–92–102–112–122–132–14

DP

–14

■ Spontaneous messages

The Spontaneous message is activated by the active

parameters i.e. 538, 540, or 953 and will be carried

with the PCV response, stating PNU and PVA of the

changed active parameter that triggered the

message.

Spontaneous messages are generated when the

value is changed in one of the abovementioned

parameters. It means that a message will be sent

when a warning comes, and when a warning

disappears.

Simultaneously the VLT will toggle the SPM bit (11) of

PCA word (see “PCA handling” page 17).

Bit sequence

16 boolean values for control and presentation of user

functions. Notation is binary.

Bit 87654321

Byte 1 15 14 13 12 11 10 9 8

Byte 2 7 6 5 4 3 2 1 0

The Spontaneous messages will be transmitted until

the master has acknowledged reception of the

message by changing the SPM bit.

Spontaneous messages are only active when

parameter 917 is “ON”!

MG.90.A2.02 – VL T is a registered Danfoss trademark

19

Page 20

Example of SPM execution

DP

In the VLT the SPMs are temporarily stored in a FIFO

buffer. This means that up to 16 consecutive SPMs

can be retained. If only one SPM has entered the

FIFO, the VLT will resume normal communication as

soon as the SPM has been acknowledged by the

master (and the condition causing the SPM been

rectified). If more SPMs are in the FIFO, these will be

transmitted consecutively upon acknowledgement. If

more SPMs are triggered when the FIFO is full, these

will be ignored.

FCM 300 PROFIBUS / VLT 2800 PROFIBUS

PCA

MASTER

REQ 1

REQ 2

SPM 1 ACK.

SPM 2 NOT ACK.

REQ 2

SPM 2 ACK.

SPM BIT

0

0

0

1

1

0

1

0

0

0

SLAVE

RES. 1

SPM 1

SPM 2

SPM 2

RES. 2

■ Synchronize and freeze

The control commands SYNC/UNSYNC and

FREEZE/UNFREEZE are broadcast functions. SYNC/

UNSYNC is used to send syncronized control

commands and/or speed reference to all the

connected slaves (FC motor Series/VLT 2800 Series).

FREEZE/UNFREEZE is used to freeze the status

feedback in the slaves to get syncronized feedback

SYNC/UNSYNC

SYNC/UNSYNC can be used to obtain simultaneous

reactions in several slaves, for example synchronised

start, stop or speed change. A SYNC command will

freeze the actual control word and speed reference,

incoming Process Data will be stored but not used

until a new SYNC command or a UNSYNC command

is received.

from all connected slaves.

See the example below where the left column holds

The synchronize and freeze commands only affect

Process Data (the PCD part of the PPO).

the speed reference send out by the master and the

three right columns hold the actual speed reference

used in each of the three slaves.

Actual slave speed reference

VLT VLT VLT

From DP master to address: Address 3 Address 4 Address 5

1. Speed reference = 50% to address 3 ⇒ 50 % 0 % 0 %

2. Speed reference = 50% to address 4 50% ⇒ 50 % 0 %

3. Speed reference = 50% to address 5 50% 50 % ⇒ 50 %

4. SYNC command to all addresses ⇒ 50 % ⇒ 50 % ⇒ 50 %

5. Speed reference = 75% to address 3 ⇒ 50 % 50 % 50 %

6. Speed reference = 75% to address 4 50% ⇒ 50 % 50 %

7. Speed reference = 75% to address 5 50% 50 % ⇒ 50 %

8. SYNC command to all addresses ⇒ 75 % ⇒ 75 % ⇒ 75 %

9. Speed reference = 100% to address 3 ⇒ 75 % 75 % 75 %

10. Speed reference = 50% to address 4 75 % ⇒ 75 % 75 %

11. Speed reference = 25% to address 5 75 % 75 % ⇒ 75 %

12. UNSYNC command to all addresses ⇒ 100 % ⇒ 50 % ⇒ 25 %

13. Speed reference = 0% to address 3 ⇒ 0% 50% 25%

14. Speed reference = 0% to address 4 0 % ⇒ 0% 25%

15. Speed reference = 0 % to address 5 0 % 0 % ⇒ 0%

20

MG.90.A2.02 – VL T is a registered Danfoss trademark

Page 21

FCM 300 PROFIBUS / VLT 2800 PROFIBUS

FREEZE/UNFREEZE

FREEZE/UNFREEZE can be used to get simultaneous

reading of Process Data for example output current

from several slaves. A FREEZE command will freeze

the current actual values and on request the slave will

send back the value that was present when the

FREEZE command was received. The actual values

will be updated when a new FREEZE or UNFREEZE

command is received.

DP master reads address: Address 3 Address 4 Address 5

1. Address 3 output current = 2A ⇐ 2A 3A 4A

2. Address 4 output current = 5A 2 A ⇐ 5A 2A

3. Address 5 output current = 3A 3 A 2 A ⇐ 3A

4. FREEZE command to all addresses ⇒ 1A ⇒ 3A ⇒ 3A

5. Address 3 output current = 1A ⇐ 4A 2A 5A

6. Address 4 output current = 3A 2 A ⇐ 2A 2A

7. Address 5 output current = 3A 3 A 1 A ⇐ 2A

8. UNFREEZE command to all adresses ⇒ 2A ⇒ 3A ⇒ 4A

Reading as by 1, 2 and 3

See the example below where the left column holds

the current values read by the master and the three

right columns hold the actual output current of the

three slaves.

Actual slave output current

VLT VLT VLT

DP

MG.90.A2.02 – VL T is a registered Danfoss trademark

21

Page 22

FCM 300 PROFIBUS / VLT 2800 PROFIBUS

■ Control word / status word

DP

The bits of the “Control word” tell the VLT how to

react, while the “Status word” bit status will tell the

master the condition of the VLT.

Control word

According to PROFIDRIVE control word (para. 512=0) According to VLT standard (para. 512=1)

Bit Bit = 0 Bit = 1 Bit = 0 Bit = 1

00 (LSB) OFF 1 ON 1 Preset reference

01 OFF 2 ON 2

02 OFF 3 ON 3 DC brake Ramp

03 Motor coasting Enable Coasting Enable

04 Quick-stop Ramp Quick-stop Ramp

05 Freeze output frequency Ramp enable Freeze output Ramp enable

06 Ramp stop Start Ramp stop Start

07 No function Reset No function Reset

08 Jog 1 OFF ON No function Jog

09 Jog 2 OFF ON

10 Data not valid Valid Data not valid Valid

11 No function Slow down No function

12 No function Catch-up No function

13 Setup select Setup select

14

15 (MSB) No function Reversing No function Reversing

Control word

The control words are used to send control

commands to the frequency converter when the

telegram is sent from the master.

The FC motor Series Design Guide (MG.03.BX.02) and the VLT 2800 Series Design Guide (MG.28.EX.02) holds a

detailed description of the control word.

Status word

When the frequency converter returns the frame to

the master, the same two bytes operate as status

from the frequency converter with the following

functions:

Status word

According to PROFIDRIVE control word (para. 512=0) According to VLT standard (para. 512=1)

Bit Bit = 0 Bit = 1 Bit = 0 Bit = 1

00 (LSB) Control not ready Ready

01 VLT not ready Ready VLT not ready Ready

02 Motor coasting Enable Coasting Enable

03 No fault Trip No fault Tri p

04 ON 2 OFF 2 R e s e r v e d

05 ON 3 OFF 3 R e s e r v e d

06 Start enable Start disable R e s e r v e d

07 No warning Warning No warning Warning

08 Speed ≠ ref. Speed = ref. Speed ≠ ref. Speed = ref.

09

10 Out of range Frequency OK Out of range Frequency OK

11 Not running Running Not running Running

12

13 Voltage OK Limit Voltage OK Above limit

14 Torque OK Limit Current OK Above limit

15 (MSB) No thermal warning Thermal warning No thermal warning Thermal warning

The FC motor Series Design Guide (MG.03.BX.02) and the VLT 2800 Series Design Guide (MG.28.EX.02 ) holds a

detailed description of the status word.

22

MG.90.A2.02 – VL T is a registered Danfoss trademark

Page 23

FCM 300 PROFIBUS / VLT 2800 PROFIBUS

■ Example

This example shows how PPO type 1 is used for

changing the ramp-up time (parameter 207) to

10 seconds and for commanding a start and speed

reference of 50%.

PPO. Parameter-Process Data Object

PCD: Process Data

PCV: Parameter-Characteristics-Value

PCA: Parameter-Characteristics (Bytes 1, 2)

PCA handling below

IND: Subindex (Byte 3), (Byte 4 is not used)

PVA: Parameter value (Bytes 5 to 8)

CTW: Control word

STW: Status word

see page 22

MRV: Main reference value

MAV: Main actual value

DP

PCVPCV

PCV

PCVPCV

PCA - Parameter Characteristics

15141312 11 109876543210

RC SMP PNU

RC: Request/respons Characteristics (Range: 0..15)

SPM: Toggle-Bit for Spontaneous Messages

PNU: Parameter # (Range: 1..1999)

PCA part (byte 1-2)

The R

C part tells what the PCV part must be used for.

The functions available appear from the table, page

17.

When a parameter is to be changed, choose value 2

or 3, in this example 3 is chosen, because parameter

207 covers a long word (32 bits).

SPM bit:

The function is explained on page 19, in the example

the function Spontaneous Messages is not applied

(parameter 917 = OFF), therefore SPM is set for 0.

PNU = Parameter number:

Parameter number is set for: 207 = CF Hex.

This means that the value of the PCA part is 30CF

Hex.

IND (bytes 3-4):

Used when reading/changing parameters with

subindex, for example parameter 915. In the example

bytes 3 and 4 are set for 00 Hex.

PVA (bytes 5-8):

The data value of parameter 207 must be changed to

10.00 seconds. The value transmitted must be 1000,

because the conversion index for parameter 207 is

-2, this means that the value received by VLT is

divided by 100, making VLT perceive 1000 as 10.00.

Bytes 5-8 = 1000 = 03E8 Hex.

MG.90.A2.02 – VL T is a registered Danfoss trademark

23

Page 24

PCDPCD

PCD

PCDPCD

DP

CTW according to Profidrive profile:

Control words consisting of 16 bits, the meaning of

the various bits appears from the table, page 22.

The following bit pattern sets all necessary start

commands: 0000 0100 0111 1111 = 047F Hex.*

0000 0100 0111 1110 = 047E Hex.*

0000 0100 0111 1111 = 047F Hex.

Quickstop: 0000 0100 0110 1111 = 046F Hex.

Stop: 0000 0100 0011 1111 = 043F Hex.

* Only necessary at power up.

MRV:

Speed reference, the data format is "Standardized

value", see page 19. 0 Hex = 0% and 4000 Hex =

100%.

FCM 300 PROFIBUS / VLT 2800 PROFIBUS

- A positive response of the above example may

look like this:

Byte Value

PCA 1 20

PCA 2 CF

IND 3 00

PCV

PCD

IND 4 00

PVA 5 00

PVA 6 00

PVA 7 03

PVA 8 E8

STW 9 0F

STW 10 07

MAV 11 20

MAV 12 00

In the example 2000 Hex is used corresponding to

50% of maximum frequency (parameter 202).

The whole PPO therefore gets the following value in

Hex:

Byte Value

PCA 1 30

PCA 2 CF

IND 3 00

PCV

PCD

The Process data within the PCD part is acting on the

VLT immediately, and can be updated from the

master as quickly as possible.

IND 4 00

PVA 5 00

PVA 6 00

PVA 7 03

PVA 8 E8

CTW 9 04

CTW 10 7F

MRV 11 20

MRV 12 00

The PCD part responds according to the state and

parametration of the VLT.

The PCV part responds as:

PCA: As the request telegram, but here the RC part is

taken from the response table on page 16. In this

example RC is 2Hex, which is a confirmation that a

parameter value of the type long word (32 bit) has

been transferred.

IND is not used in this example.

PVA: 03E8Hex in the PVA part tells that the value of

the parameter in question (207) is 1000 which

corresponds to 10.00.

STW: 0F07 Hex means that the motor is running and

there are no warnings or faults (for details see Status

word table on page 22).

MAV: 2000 Hex tells that the output frequency is 50%

of max. frequency.

The PCV part is a “hand shake” procedure which

means that the VLT has to acknowledge the

command, before a new one can be written.

24

MG.90.A2.02 – VL T is a registered Danfoss trademark

Page 25

FCM 300 PROFIBUS / VLT 2800 PROFIBUS

- A negative response may look like this:

Byte Value

PCA 1 70

PCA 2 00

IND 3 00

PCV

PCD

RC is 7 Hex which means that the request has been

rejected, and the fault number can be found in the

PVA part. In this case the fault number is 2 which

means that the upper or lower limit of the parameter

is exceeded. See fault number table on page 17.

IND 4 00

PVA 5 00

PVA 6 00

PVA 7 00

PVA 8 02

STW 9 0F

STW 10 07

MAV 11 20

MAV 12 00

DP

MG.90.A2.02 – VL T is a registered Danfoss trademark

25

Page 26

DP

FCM 300:FCM 300:

FCM 300:

FCM 300:FCM 300:

■■

■ GSD-file

■■

The GSD-file is a DP “standard” text file containing

the necessary data for configuring DP slaves within a

standard DP master.

FCM 300 PROFIBUS / VLT 2800 PROFIBUS

GSD-file: DA010403.GSD

GSD-file for Danfoss FCM 300 Series with

PROFIBUS

#Profibus_DP

Vendor_Name = "DANFOSS DRIVES A/S";

Model_name = "VLT SERIES FCM 300 PROFIBUS“;

Revision = "00";

Ident_Number = 0x0403;

Protocol_Ident = 0;

Station_type = 0;

FMS_supp = 0;

Hardware_Release = "2.0";

Software_Release = "1.10";

9.6_supp = 1;

19.2_supp = 1;

93.75_supp = 1;

187.5_supp = 1;

500_supp = 1;

1.5M_supp = 1;

3M_supp = 1;

6M_supp = 0;

12M_supp = 0;

MaxTsdr_9.6 = 60;

MaxTsdr_19.2 = 60;

MaxTsdr_93.75 = 60;

MaxTsdr_187.5 = 60;

MaxTsdr_500 = 100;

MaxTsdr_1.5M = 150;

MaxTsdr_3M = 250;

Redundancy = 0;

Repeater_Ctr_Sig = 0;

24V_Pins = 0;

Freeze_Mode_supp = 1;

Sync_Mode_supp = 1;

Auto_Baud_supp = 1;

Set_Slave_add_supp = 1;

Usr_Prm_Data_Len = 0;

Min_Slave_intervall = 40;

Modular_Station = 1;

Max_Module = 2;

Max_Input_Len = 28;

Max_Output_Len = 28;

Max_Data_Len = 56;

Module = "PPO Typ 1 Module consistent PCD" 0xF3,

0xF1; EndModule;

Module = "PPO Typ 1 Word consistent PCD" 0xF3,

0x71; EndModule;

Module = "PPO Typ 2 Module consistent PCD" 0xF3,

0xF5; EndModule;

Module = "PPO Typ 2 Word consistent PCD" 0xF3,

0x75; EndModule;

Module = "PPO Typ 3 Module consistent PCD" 0xF1;

EndModule;

Module = "PPO Typ 3 Word consistent PCD" 0x71;

EndModule;

Module = "PPO Typ 4 Module consistent PCD" 0xF5;

EndModule;

Module = "PPO Typ 4 Word consistent PCD" 0x75;

EndModule;

Module = "PPO Typ 5 Module consistent PCD" 0xF3,

0xF9; EndModule;

Module = "PPO Typ 5 Word consistent PCD" 0xF3,

0x79; EndModule;

The VLT can also accept word concistency in

the PCD modules, whereas the PCV portion

must be module consistent.

26

MG.90.A2.02 – VL T is a registered Danfoss trademark

Page 27

VLVL

T 2800T 2800

VL

T 2800

VLVL

T 2800T 2800

■■

■ GSD-file

■■

The GSD-file is a DP “standard” text file containing

the necessary data for configuring DP slaves within a

standard DP master.

::

3 MBaud 3 MBaud

:

3 MBaud

::

3 MBaud 3 MBaud

FCM 300 PROFIBUS / VLT 2800 PROFIBUS

DP

GSD-file: DA010404.GSD

GSD-file for Danfoss VLT® 2800 Series

with PROFIBUS

#Profibus_DP

Vendor_Name = „DANFOSS DRIVES A/S“;

Model_name = „VLT® SERIES 2800“;

Revision = „00“;

Ident_Number = 0x0404;

Protocol_Ident = 0;

Station_type = 0;

FMS_supp = 0;

Hardware_Release = „2.0“;

Software_Release = „1.00“;

9.6_supp = 1;

19.2_supp = 1;

93.75_supp = 1;

187.5_supp = 1;

500_supp = 1;

1.5M_supp = 1;

3M_supp = 1;

6M_supp = 0;

12M_supp = 0;

MaxTsdr_9.6 = 60;

MaxTsdr_19.2 = 60;

MaxTsdr_93.75 = 60;

MaxTsdr_187.5 = 60;

MaxTsdr_500 = 100;

MaxTsdr_1.5M = 150;

MaxTsdr_3M = 250;

Redundancy = 0;

Repeater_Ctr_Sig =0;

24V_Pins = 0;

Freeze_Mode_supp = 1;

Sync_Mode_supp = 1;

Auto_Baud_supp = 1;

Set_Slave_add_supp = 1;

Usr_Prm_Data_Len = 0;

Min_Slave_Intervall = 10;

Modular_Station = 1;

Max_Module = 2;

Max_Input_Len = 28;

Max_Output_Len = 28;

Max_Data_Len = 56;

Max_Diag_Data_Len = 6;

Module = „PPO Typ 1 Module consistent PCD“ 0xF3,

0xF1;

EndModule;

Module = „PPO Typ 1 Word consistent PCD „ 0xF3,

0x71;

EndModule;

Module = „PPO Typ 2 Module consistent PCD“ 0xF3,

0xF5;

EndModule;

Module = „PPO Typ 2 Word consistent PCD „ 0xF3,

0x75;

EndModule;

Module = „PPO Typ 3 Module consistent PCD“ 0xF1;

EndModule;

Module = „PPO Typ 3 Word consistent PCD „ 0x71;

EndModule;

Module = „PPO Typ 4 Module consistent PCD“ 0xF5;

EndModule;

Module = „PPO Typ 4 Word consistent PCD „ 0x75;

EndModule;

Module = „PPO Typ 5 Module consistent PCD“ 0xF3,

0xF9;

EndModule;

Module = „PPO Typ 5 Word consistent PCD „ 0xF3,

0x79;

EndModule;

The VLT can also accept word concistency in

the PCD modules, whereas the PCV portion

must be module consistent.

MG.90.A2.02 – VL T is a registered Danfoss trademark

27

Page 28

VLVL

T 2800: 12 MBaudT 2800: 12 MBaud

VL

T 2800: 12 MBaud

VLVL

DP

■■

■ GSD-file

■■

T 2800: 12 MBaudT 2800: 12 MBaud

The GSD-file is a DP “standard” text file containing

the necessary data for configuring DP slaves within a

standard DP master.

FCM 300 PROFIBUS / VLT 2800 PROFIBUS

GSD-file: DA010405.GSD

GSD-file for Danfoss VLT® 2800 Series

with PROFIBUS

#Profibus_DP

Vendor_Name = "DANFOSS DRIVES A/S";

Model_name = "VLT® 2800 12MB";

Revision = "00";

Ident_Number = 0x0405;

Protocol_Ident = 0;

Station_type = 0;

FMS_supp = 0;

Hardware_Release = "5.0";

Software_Release = "2.20";

9.6_supp = 1;

19.2_supp = 1;

93.75_supp = 1;

187.5_supp = 1;

500_supp = 1;

1.5M_supp = 1;

3M_supp = 1;

6M_supp = 1;

12M_supp = 1;

MaxTsdr_9.6 = 60;

MaxTsdr_19.2 = 60;

MaxTsdr_93.75 = 60;

MaxTsdr_187.5 = 60;

MaxTsdr_500 = 100;

MaxTsdr_1.5M = 150;

MaxTsdr_3M = 250;

MaxTsdr_6M = 450;

MaxTsdr_12M = 800;

Redundancy = 0;

Repeater_Ctr_Sig =0;

24V_Pins = 0;

Freeze_Mode_supp = 1;

Sync_Mode_supp = 1;

Auto_Baud_supp = 1;

Set_Slave_add_supp = 1;

Usr_Prm_Data_Len = 0;

Min_Slave_Intervall = 06;

Modular_Station = 1;

Max_Module = 2;

Max_Input_Len = 28;

Max_Output_Len = 28;

Max_Data_Len = 56;

Max_Diag_Data_Len = 6;

Module = "PPO Typ 1 Module consistent PCD" 0xF3,

0xF1;

EndModule;

Module = "PPO Typ 1 Word consistent PCD " 0xF3,

0x71;

EndModule;

Module = "PPO Typ 2 Module consistent PCD" 0xF3,

0xF5;

EndModule;

Module = "PPO Typ 2 Word consistent PCD " 0xF3,

0x75;

EndModule;

Module = "PPO Typ 3 Module consistent PCD" 0xF1;

EndModule;

Module = "PPO Typ 3 Word consistent PCD " 0x71;

EndModule;

Module = "PPO Typ 4 Module consistent PCD" 0xF5;

EndModule;

Module = "PPO Typ 4 Word consistent PCD " 0x75;

EndModule;

Module = "PPO Typ 5 Module consistent PCD" 0xF3,

0xF9;

EndModule;

Module = "PPO Typ 5 Word consistent PCD " 0xF3,

0x79;

EndModule;

The VLT can also accept word concistency in

the PCD modules, whereas the PCV portion

must be module consistent.

28

MG.90.A2.02 – VL T is a registered Danfoss trademark

Page 29

FCM 300 PROFIBUS / VLT 2800 PROFIBUS

MG.90.A2.02 – VL T is a registered Danfoss trademark

29

Page 30

FCM 300 PROFIBUS / VLT 2800 PROFIBUS

■ FC motor and VLT 2800 parameters

Only the PROFIBUS specific parameters (800 - 805

and 904 . . ) are described in this manual. All other

parameters and their functions are unaffected by the

PROFIBUS option. We refer to the parameter

Parameters

description in the design guide on the FC motor

Series (MG.03.Bx.02) and the design guide on the

VLT 2800 Series (MG.28.Ex.02).

Special attention must be given to the following

parameters that are not described in this manual:

- 502 - 508: Selection of how to gate PROFIBUS

control commands with control

commands on the digital inputs of the

FC motor / VLT2800.

- 512: Control word profile, selects a control

word according to PROFIDRIVE or a

Danfoss specified control word.

- 515 - 543:Data readout parameters that can be

used to read various actual data from

the VLT, as for example actual status

on the analog and digital inputs of the

FC motor / VLT 2800 thus using these

as inputs to the master.

■ PROFIBUS specific parameters

800 Protocol select (PROTOCOL SELECT)

✭ DP [1]

804 Bus time out function (TIME OUT FUNCT.)

Selection:

✭ Off (OFF) [0]

Freeze output frequency (FREEZE OUTPUT) [1]

Stop with auto restart (STOP) [2]

Output frequency = JOG freq. (JOGGING) [3]

Output freq. = Max. freq. (MAX SPEED) [4]

Stop with trip (STOP AND TRIP) [5]

Select Setup 2 [8]

Function:

The time out counter is triggered at the first reception

of a valid control word i.e. bit 10 = ok, when DP is

used.

The time out function can be activated in two different

ways:

1. CTW is not updated within the time specified in

parameter 803.

2. Time out is triggered if the CTW is not valid, see

parameter 805.

The FC motor / VLT 2800 remains in time out state

until one of the following conditions is true:

1. Valid control word (Bit 10 = ok) is received. If Stop

with trip is selected, reset must also be activated.

If Select setup 2 is selected, the FC motor / VLT

2800 will remain in Setup 2 until parameter 4 is

changed.

2. Parameter 804 = Off ⇒ control via PROFIBUS is

resumed and the most recent control word is

used.

Function:

Selection of the PROFIBUS protocol supported by the

master.

Description of selections:

-DP: Communication according to DIN 19245 part

3.

Updating parameter 800, even with an

unchanged data value, will initialise the

PROFIBUS option, meaning that all

communication parameters such as slave addresses,

PPO type etc. will be updated.

803 Bus time out (BUS TIME OUT)

Selection:

✭ 1 - 99sec 1 sec

✭ Factory setting

Description of selections:

- Freeze output frequency: Freeze output frequency

until communication is resumed.

- Stop with auto restart: Stop with auto restart

when communication is resumed.

- Output frequency = JOG freq.: Motor will run at

JOG frequency until communication is

resumed.

- Output frequency = Max. freq.: Motor will run at

max. frequency until communication is resumed.

- Stop with trip: Motor is stopped, reset needed for

restart, see explanation above.

- Select setup 2.

30

MG.90.A2.02 – VL T is a registered Danfoss trademark

Page 31

FCM 300 PROFIBUS / VLT 2800 PROFIBUS

805 Function of control word bit 10

(Bit 10 function)

Selection:

No function (NO FUNCTION) [0]

✭ Bit 10 = 1 ⇒ CTW active

(BIT 10 = 1 ⇒ CTW ACTIVE) [1]

Bit 10 = 0 ⇒ CTW active

(BIT 10 = 0 ⇒ CTW ACTIVE) [2]

Bit 10 = 0 ⇒ time out

(BIT 10 = 0 ⇒ TIME OUT) [3]

Function:

According to the PROFIDRIVE profile, control word

and speed reference will be ignored if bit 10 of the

control word is 0, but parameter 805 lets the user

change the function of bit 10. This is some times

necessary as some masters are setting all bits to 0 in

various fault situations. In these cases it makes sense

to change the function of bit 10 so that the FC motor/

VLT 2800 is commanded to stop (coast) when all bits

are 0.

Description of selections:

- Bit 10 = 1 ⇒ CTW active: Control word and speed

reference is ignored if bit 10 = 0.

- Bit 10 = 0

reference is ignored if bit 10 = 1. If all bits of the

control word are 0 the FC motor / VLT 2800

reaction will be coasting.

- Bit 10 = 0

selected in parameter 804 is activated when bit 10

is 0.

- No function: Bit 10 is ignored, i.e. control word

and speed reference is always valid.

⇒

CTW active: Control word and speed

⇒

time out: The time out function

904 PPO type select for DP (PPO TYPE SELECT)

Parameters

Selections:

✭ PPO type 1 (PPO TYPE 1) [900]

PPO type 2 (PPO TYPE 2) [901]

PPO type 3 (PPO TYPE 3) [902]

PPO type 4 (PPO TYPE 4) [903]

PPO type 5 (PPO TYPE 5) [905]

Function:

The selection is valid for read and write, i.e. the same

PPO type must be used for read and write.

Description of selections:

- PPO type 1: 12 byte PPO with parameter channel

for read and write of parameters and 4 bytes of

process data (control/status word and reference/

actual output frequency).

- PPO type 2: 20 byte PPO as PPO type 1 with 8

additional bytes of selectable process data.

- PPO type 3: 4 byte process data (control/status

word and reference/actual output frequency).

- PPO type 4: 12 byte process data, as process

data part of PPO type 2.

- PPO type 5: 28 byte as PPO type 2 with 8

additional bytes of selectable process data.

A detailed description of the PPO types can be found

on page 23.

Change of parameter 904 is executed when

parameter 800 is updated or at next power up.

✭ Factory setting

MG.90.A2.02 – VL T is a registered Danfoss trademark

31

Page 32

FCM 300 PROFIBUS / VLT 2800 PROFIBUS

915 PCD config. write (PCD IN WR-)

Selections:

Sub index 1 (PCD1) Parameter #

Sub index 2 Parameter #

Parameters

Sub index 3 Parameter #

Sub index 4 Parameter #

Sub index 5 Parameter #

Sub index 6 Parameter #

Sub index 7 Parameter #

Sub index 8 Parameter #

Function:

Different parameters can be assigned to PCD 1-8 of

the PPO’s (the number of PCD’s depends on the PPO

type). The values in PCD 1-8 will be written to the

selected parameters as data values.

Write access via PROFIBUS or standard RS 485.

Description of selections:

The order of the subindexes corresponds to the order

of the PCD’s in the PPO, i.e. subindex 1 ≈ PCD 1,

subindex 2 ≈ PCD 2 and so on. Each subindex can

hold the number of the FC motor / VLT 2800

parameters with write access, but it is only possible

to write 2 byte values (least significant bytes) to

parameters with 4 byte data values because 1 PCD

consists of only 2 bytes.

916 PCD config. read (PCD IN RD-)

Selections:

Sub index 1 (PCD 1) Parameter #

Sub index 2 Parameter #

Sub index 3 Parameter #

Sub index 4 Parameter #

Sub index 5 Parameter #

Sub index 6 Parameter #

Sub index 7 Parameter #

Sub index 8 Parameter #

Function:

Different parameters can be assigned to PCD 1-8 of

the PPO’s (the number of PCD’s depends on the PPO

type). PCD 1-8 will hold the actual data value of the

selected parameters.

Description of selections:

The order of the subindexes corresponds to the order

of the PCD’s in the PPO, i.e. subindex 1 ≈ PCD 1,

subindex 2 ≈ PCD 2 and so on. Each subindex can

hold the number of any of the FC motor / VLT 2800

parameters, but it is only possible to read 2 byte

values (least significant bytes) from parameters with 4

byte data values as 1 PCD consists of only 2 bytes.

917 Activate spontaneous messages

(SPONT. MES)

Selections:

✭ Off (OFF) [0]

On (ON) [1]

Function:

The spontaneous messages function can be switched

on if it is desired to make the FC motor / VLT 2800 issue

a message when a warning or an alarm comes up.

Unread spontaneous messages will be stored

in a 16 elements FIFO buffer.

Description of selections:

- OFF: The FC motor / VLT 2800 will not issue

spontaneous messages or event notification in

case of a warning or an alarm.

- ON: The FC motor / VLT 2800 will issue a

spontaneous message when warnings or alarms

are coming up.

918 Station address (STATION ADDR)

Selections:

1-126

✭ 0

Function:

All stations connected to the same bus must have a

unique address. The station address can be set in

parameter 918.

Change parameter 918 is executed at next

power up and if parameter 800 is updated.

Write access via Profibus or standard RS 485.

✭ Factory setting

32

MG.90.A2.02 – VL T is a registered Danfoss trademark

Page 33

FCM 300 PROFIBUS / VLT 2800 PROFIBUS

953 Warning parameter 1 (WARN. PARA)

Selections:

Read only

Function:

A 16 bit bitstring where each bit is associated with a

specific warning according to the list below.

Bit Bit = “1” when:

0 LSB Connection with DP-master is not ok

1 Not used

2 FDL (Field-bus Data link Layer) is not ok

3 Clear data command received

4 Actual value is not updated

5 Spontaneous message FIFO overflow

6 PROFIBUS ASIC is not transmitting

7 Initialising of PROFIBUS option is not ok

8 Not used

9 Not used

10 Not used

11 Not used

12 Fatal DPR-handling error/Error code

during init.: Bit 0

13 Fatal DPR-handling error/Error code

during init.: Bit 1

14 Fatal DPR-handling error/Error code

during init.: Bit 2

15 MSB Fatal DPR-handling error/Error code

during init.: Bit 3

If errors occur during DPR-handling (bit 7 not

asserted)

Code

0OK

1 Fatal error in warning channel

2 Fatal error in spontaneous channel

3 Fatal error in channel for input of process data

4 Fatal error in channel for output of process data

5 Fatal error in parameter channel 1

6 Fatal error in parameter channel 2

7 Fatal error in parameter channel 3

15 Fatal error in DPR form SPC3

967 Control word

Selections:

16 bits binary code

See page 22.

968 Status word

Selections:

Read only

See page 22.

Parameters

Explanation of errExplanation of err

Explanation of err

Explanation of errExplanation of err

If init. went wrong (bit 7 asserted) following codes are

defined:

Code

0OK

1 Init. channel not empty

2 No resp. on command „Init SPC3 controller“

3 No resp. on command „No action“

4 No resp. on writing init.-data

5 No valid resp. on writing init.-data

6 No positive resp. on writing init.-data

MG.90.A2.02 – VL T is a registered Danfoss trademark

or codes:or codes:

or codes:

or codes:or codes:

33

Page 34

FCM 300 PROFIBUS / VLT 2800 PROFIBUS

970 Edit set up selection (EDIT SETUP SELECT)

Selections:

Factory setup (FACTORY SETUP) [0]

Setup 1 (SETUP 1) [1]

Parameters

Setup 2 (SETUP 2) [2]

✭ Active setup (ACTIVE SETUP) [5]

Function:

As parameter 005, described in the FCM 300 design

guide (MG.03.Bx.02) and the VLT 2800 design guide

(MG.28.Ex.02).

971 Store data values (STORE DATA VALUE)

Selections:

✭ No action (NO ACTION) [0]

Store active setup (STORE ACTIVE SETUP) [1]

Store edit setup (STORE EDIT SETUP) [2]

Store all setups (STORE ALL SETUPS) [3]

Function:

Parameter values changed via PROFIBUS is only

stored in RAM meaning that the changes are lost at

power down. This parameter is used to activate a

function that stores all parameter values in the

EEPROM thus retaining changed parameter values at

power down.

Description of selections:

No action: The store function is inactive.

Store active setup: All parameter values in the active

setup will be stored in the EEPROM. The value

returns to No action when all parameter values have

been stored.

Store edit setup: All parameter values in the setup

you are editing will be stored in the EEPROM. The

value returns to No action when all parameter values

have been stored.

Store all setups: All parameter values in both setups

will be stored in the EEPROM. The value returns to

No action when all parameter values have been

stored.

980-982 Defined parameters (DEFINED PNU'S)

Selections:

Read only

Function:

The three parameters hold a list of all the parameters

that are defined in the FC motor / VLT 2800. It is

possible to read single elements of the list by DP by

using the corresponding subindex. The subindexes

start at 1 and follow the order of the parameter

numbers.

Each parameter holds up to 116 elements (parameter

numbers).

When a 0 is returned as parameter number the list

ends.

990-992 Modified parameters

(MODIFIED PNU'S)

Selections:

Read only

Function:

The three parameters hold a list of all the FC motor /

VLT 2800 parameters that have been changed from

factory setting. It is possible to read single elements

of the list by DP by using the corresponding subindex.

The subindexes start at 1 and follow the order of the

parameter numbers. Each parameter holds up to 116

elements (parameter numbers). The number of

parameters (990, 991 and 992) in use depends on

how many parameters have been changed from

factory setting.

Read only parameters, as for example data read out

parameters, will not be registered as modified

eventhough they are changing.

When a 0 is returned as parameter number the list

ends.

✭ Factory setting

34

MG.90.A2.02 – VL T is a registered Danfoss trademark

Page 35

FCM 300 PROFIBUS / VLT 2800 PROFIBUS

■ Warning and alarm messages

There is a clear distinction between alarms and

warnings. In the case of an alarm, the FC motor / VLT

2800 will enter a fault condition. After the cause for

the alarm has been cleared, the master will have to

acknowledge the alarm message for the FC motor /

VLT 2800 to start operating again. A warning, on the

other hand may come when a warning condition

appears, and disappear when conditions return to

normal without interfering with the process.

Warnings

Any warning within the FC motor / VLT 2800 is

represented by a single bit within a warning word. A

warning word is always an active parameter. Bit

status FALSE [0] means no warning, while bit status

TRUE [1] means warning.

Any bit change in the warning word will result in a

Spontaneous message being issued.

In addition to the warning word message the master

will also be notified through a change of bit 7 in the

Status Word.

■ Spontaneous messages

If a fault or warning condition should occur, the FC

motor / VLT 2800 will, if the proper communicative

relationship has been established, issue a

Spontaneous message to communication partners.

Instead of responding to the master’s request, the FC

motor / VLT 2800 will exchange the requested

response with the alarm or the warning message.

Warnings and alarms will trigger a Spontaneous

message. The same is true with any change to an

active parameter.

Warning and alarm messages

Alarms

Following an Alarm message the FC motor / VLT

2800 will enter Fault condition. Only after the fault has

been alleviated and the master has acknowledged the

alarm message by setting bit 7 in the Control word,

can the FC motor /VLT 2800 resume operation.

Any alarm within the FC motor / VLT 2800 is

represented by a single bit within an alarm word. An

alarm word is always an action parameter. Bit status

FALSE [0] means no fault, while bit status TRUE [1]

means fault.

Any bit change in the alarm word will result in a

Spontaneous message being issued.

MG.90.A2.02 – VL T is a registered Danfoss trademark

35

Page 36

■ Abbreviations

English German Elaboration

Glossary

ACI - Acyclical Control Interval

ALI - Aplication Layer Interface

ATTR - Attribute

BRCT - Broadcast

CCI - Cyclical Control Interval

CR KR Communication Reference

CRL KBL Communication Reference List

CSRD - Cyclical Send and Request Data

CT Typ Connection Type

CTW STW Control Word

DA - Destination Address

DP - Distributed Periphery

EIA - Electronic Industries Association: Specifiers of the EIA Standard RS 485-A

EMC EMV Electromagnetic Compatibility

EN - Event Notification

FIFO - First In First Out

HSA - Highest Station Address

Hd - Hamming distance

HPFB - High Performance Field Bus

IND - Subindex

I/O E/A Input/Output

ISO - International Standards Organization

IR - Information Report

LSAP - Local Service Access Point

LSB - Least Significant Bit

MSB - Most Significant Bit

MAP - Manufacturing Automation Protocol

MAV HIW Main Actual Value

MMS - Manufacturing Message Specification

MRV HSW Main Reference Value

MSAC MZAC Master-Slave connection for acyclical transmission

MSAC_SI MZAC_SI Master-Slave connection for acyclical transmission with slave initiative

MSCY MSZY Master-Slave connection for cyclical transmission

MSCY_SI MSZY_SI Master-Slave connection for cyclical transmission with slave initiative

MULT - Multicast

OD OV Object Directory

PC - Personal Computer

PCA PKE Parameter Characteristics

PCD PZD Process Data

PCV PKW Parameter-Characteristics-Value

PDU - Protocol Data Unit

PLC SPS Programmable Logic Control

PNU - Parameter Number

PPO - Parameter-Process Data Object

PVA PWE Parameter Value

RAC - Receive Acknowledged request Counter

RADR - Remote Address

RC AK Request/Response Characteristics

RCC - Receive Confirmed request Counter

RSAP - Remote Service Access Point

FCM 300 PROFIBUS / VLT 2800 PROFIBUS

36

MG.90.A2.02 – VL T is a registered Danfoss trademark

Page 37

FCM 300 PROFIBUS / VLT 2800 PROFIBUS

English German Elaboration

SAC - Send Acknowledged request Counter

SAP - Service Access Point

SCC - Send Confirmed request Counter

SPM - Spontaneous Notification

STW ZSW Status Word

TRT - Target Rotation Time

VDE - Association of German Electrical Technicians

VDI - Association of German Electrical Engineers

VSD FU Variable Speed Drive

Glossary

MG.90.A2.02 – VL T is a registered Danfoss trademark

37

Page 38

FCM 300 PROFIBUS / VLT 2800 PROFIBUS

PNU

#

800

803

804

Parameter list

805

904

915

916

4

917

918

967

968

970

S

971

980

981

982

990

991

992

* Automatic reset to (0).

4

) Available in all 4 setups.

S

) Only in stop mode

ParameterParameter

Parameter Default value Range

ParameterParameter

DesignationDesignation

Designation

DesignationDesignation

PrPr

otocol selectotocol select

Pr

otocol select 1 0 0 5

PrPr

otocol selectotocol select

Bus time outBus time out

Bus time out 1 4 0 5

Bus time outBus time out