Page 1

■ Contents

VLT®2800/5000/5000 FLUX/FCD 300

Introduction

Description of the brake system ............................................................................. 2

....................................................................................................... 2

Examples ............................................................................................................ 3

Example 1 - Conveyor belt ..................................................................................... 3

Example 2 - Centrifuge ........................................................................................... 5

Calculation of the brake resistor ............................................................ 6

Brake setup ........................................................................................................... 6

Calculation of brake resistor values ......................................................................... 6

Calculation of braking power .................................................................................. 7

Calculation of the brake resistor peak power .......................................................... 7

Calculation of the brake resistor average power ..................................................... 8

Braking ................................................................................................................. 9

Braking of inertia .................................................................................................... 9

Continuous braking ................................................................................................ 9

D.C. injection braking ............................................................................................. 9

AC-braking VLT 2800 and FCD 300 ....................................................................... 9

Optimum braking ................................................................................................... 9

Brake cable ............................................................................................................ 10

Protective functions during installation .................................................................... 10

Description of VLT 5000 brake ............................................................................... 11

Programming .................................................................................................... 12

VLT 5000 Process parameters ............................................................................... 12

VLT 5000 FLUX parameters .................................................................................... 12

VLT 2800 parameters ............................................................................................. 13

FCD 300 parameters .............................................................................................. 13

Brake resistor overview .............................................................................. 14

Brake resistor for VLT 5001-5500 10% duty-cycle data and codenumber .............. 14

Brake resistor for VLT 5001-5102 40% duty-cycle data and codenumber .............. 16

Brake resistor for VLT 2803-2882 duty-cycle 40% data and codenumber .............. 17

Brake resistor for VLT FCD 303-335 duty-cycle 40% data and codenumber .......... 17

Brake resistor for VLT 5001-5500 10% duty-cycle cablegland, weight and drawing

no. ......................................................................................................................... 19

Brake resistor for VLT 5001-5102 40% duty-cycle cablegland, weight and drawing

no. ......................................................................................................................... 20

Brake resistor for VLT 2803-2882 40% duty-cycle cablegland, weig

no. ......................................................................................................................... 21

Brake resistor for VLT FCD 303-335 40% duty-cycle cablegland, weight and drawing

no. ......................................................................................................................... 21

ht and drawing

Drawings 1 - 19 ................................................................................................ 22

MI.90.F1.02 - VLT is a registered Danfoss trademark

1

Page 2

Danfoss offers a range of brake resistors for

frequency converters, types 2800, 5000, 5000

FLUX and FCD 300.

■Description of the brake system

When the speed reference of a frequency converter is

reduced, the motor acts as a generator and brakes.

When a motor acts as a generator, it supplies energy

to the frequency converter which is collected in

the intermediate circuit. The function of the brake

resistor is to provide a load on the intermediate circuit

during braking, thereby ensuring that the braking

power is absorbed by the brake resistor.

If a brake resistor was not used, the intermediate circuit

voltage of the frequency converter would continue to

increase, until it cuts out for protection. The advantage

of using a brake resistor is it enables braking of a

heavy load quickly, e.g. on a conveyor belt.

Danfoss has chosen a solution in which the

brake resistor does not form an integral part

of the frequency converter.

This offers the user the following advantages:

- The resistor time cycle can be selected as required

- The heat developed during braking can be

conveyed beyond the panel cabinet to allow

theenergytobeused

- There is no overheating of the electronic

components, even if the brake resistor is overloaded

VLT®2800/5000/5000 FLUX/FCD 300

■Knowledge of the system

If the right brake resistor is to be selected, it

is necessary to know how often and by how

much the motors are to brake.

In the following, some examples are given of

calculations of the required braking for a conveyor

belt and a centrifuge, respectively.

2

MI.90.F1.02 - VLT is a registered Danfoss trademark

Page 3

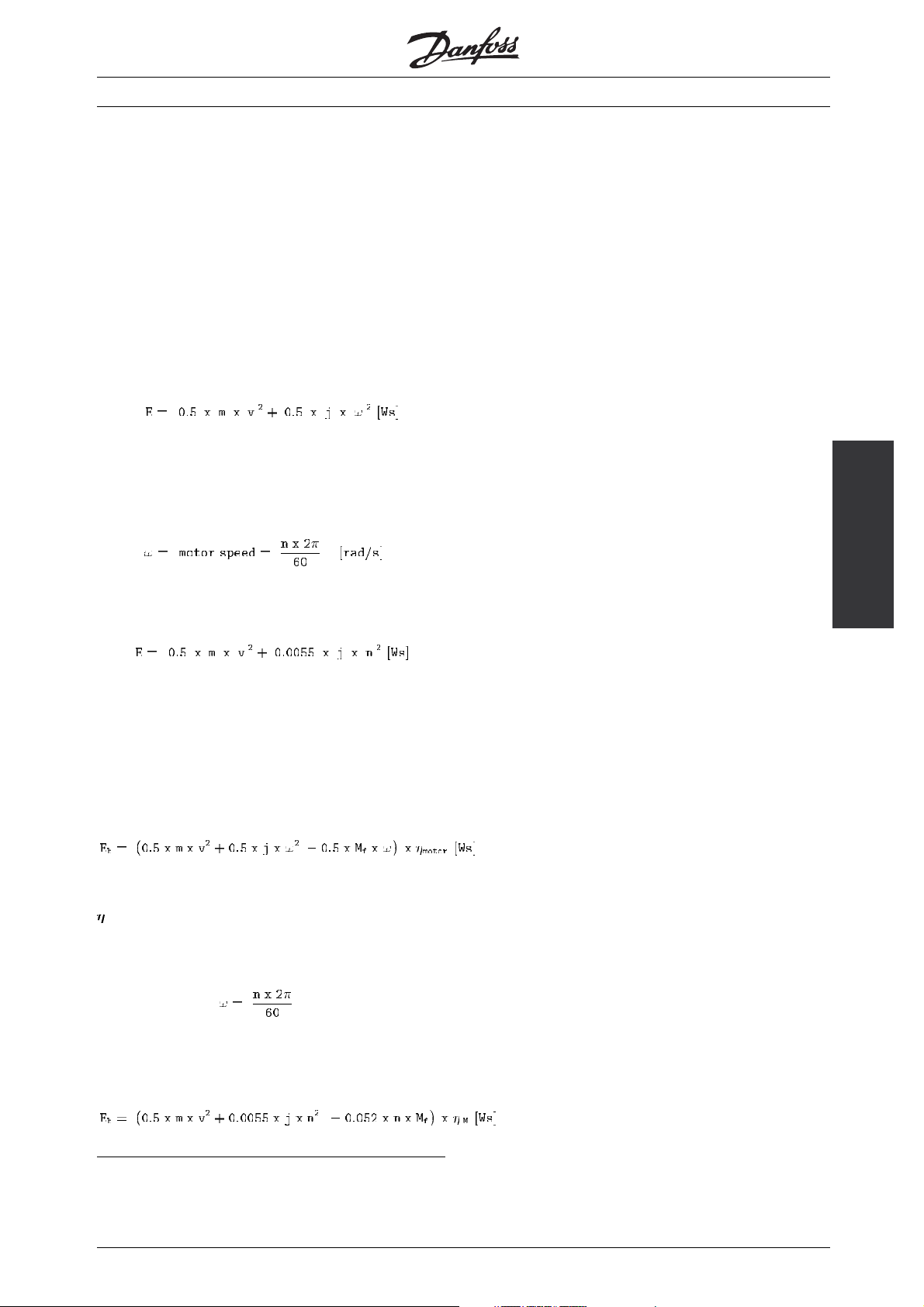

■Example 1 - Conveyor belt

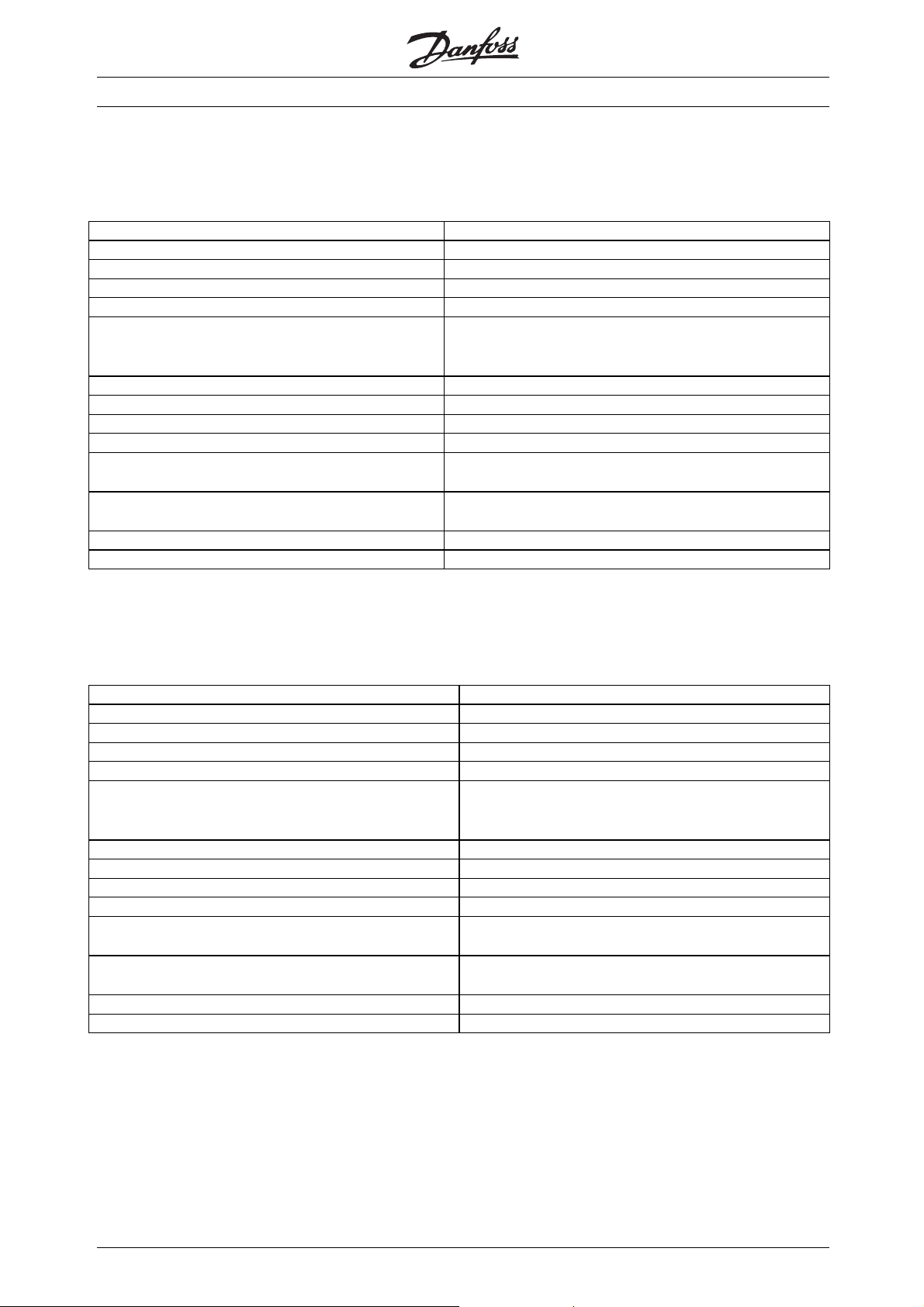

Fig. 1 shows the relation between the braking power

and the acceleration/braking of a conveyor belt. As can

be seen, the motor power during braking is negative,

since the torque on the motor shaft is negative. The

braking power, i.e. the power to be dissipated to the

brake resistor, corresponds almost to the negative

motor power, taking the losses in the motor and the

frequency converter into account. The example also

shows that the motor power is time-dependent.

Kinetic energy (E) in conveyor belt + motor:

m = mass with linear movement [kg]

v = speed of mass with linear movement [m/s]

2

j = inertia of motor and gear box (kgm

]

VLT®2800/5000/5000 FLUX/FCD 300

This formula may also be expressed as follows:

However, not all of the energy is to be dissipated to

the brake resistor. The friction of the conveyor belt

andthepowerlossofthemotoralsocontributetothe

braking function. Consequently, the formula for energy

dissipation (E

) to the brake resistor is as follows:

b

Mf= Friction torque [Nm]

= Motor efficiency

M

When:

Examples

is inserted, the result is as follows:

MI.90.F1.02 - VLT is a registered Danfoss trademark

3

Page 4

■Fig. 1

The relation between braking power and

acceleration/braking of a conveyor belt.

VLT®2800/5000/5000 FLUX/FCD 300

4

MI.90.F1.02 - VLT is a registered Danfoss trademark

Page 5

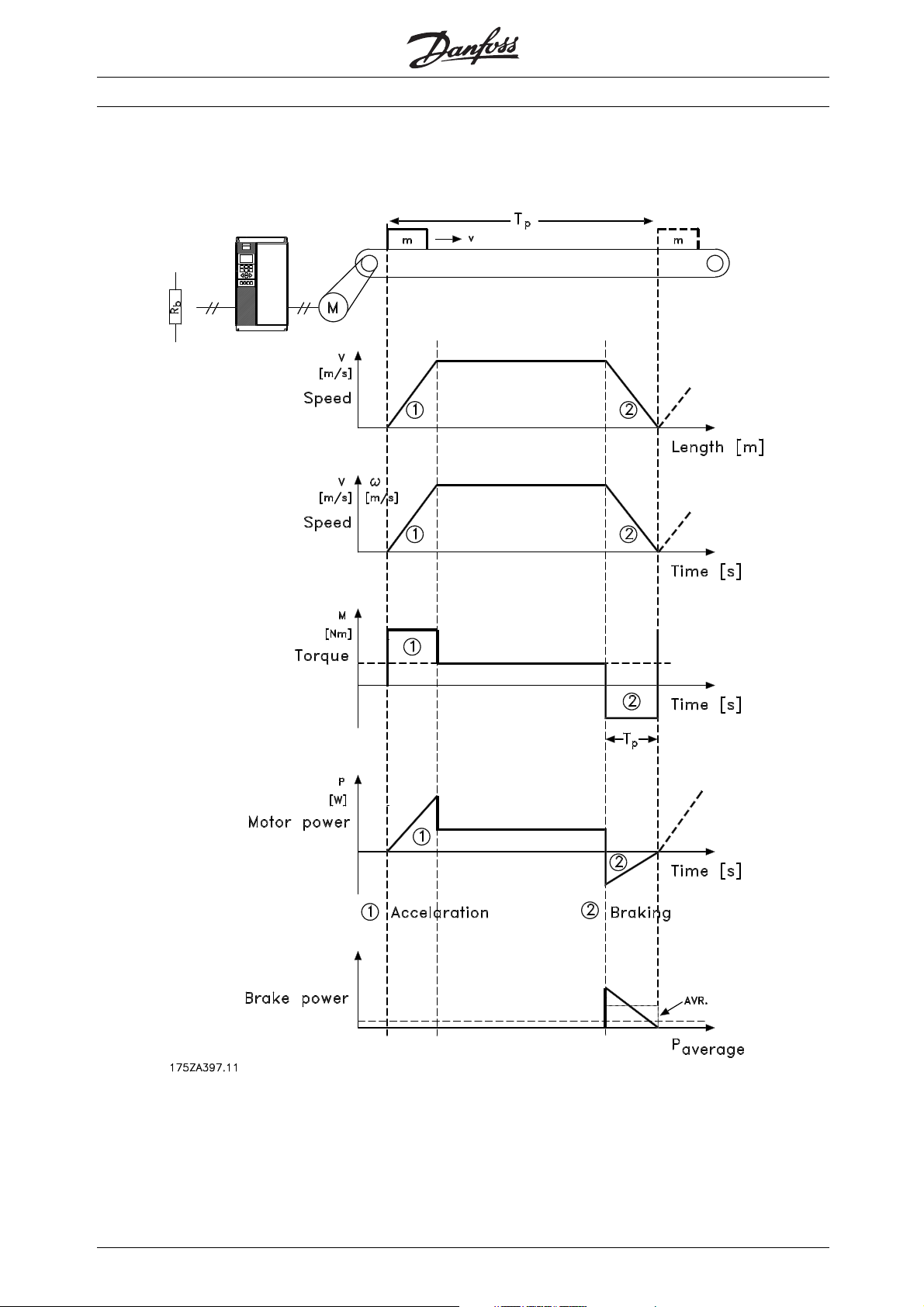

■Example 2 - Centrifuge

Another typical application in which braking

can be required on centrifuges. The weight of

the centrifuge content is m.

VLT®2800/5000/5000 FLUX/FCD 300

jC= centrifuge inertia =

2

2

+r

½xmx(r

j

= Gear motor inertia [kgm2]

M

= Gear motor efficiency

η

M

n

= max. motor speed [rpm]

1

= max. centrifuge speed [rpm]

n

2

1

)[kgm2]

2

Examples

MI.90.F1.02 - VLT is a registered Danfoss trademark

5

Page 6

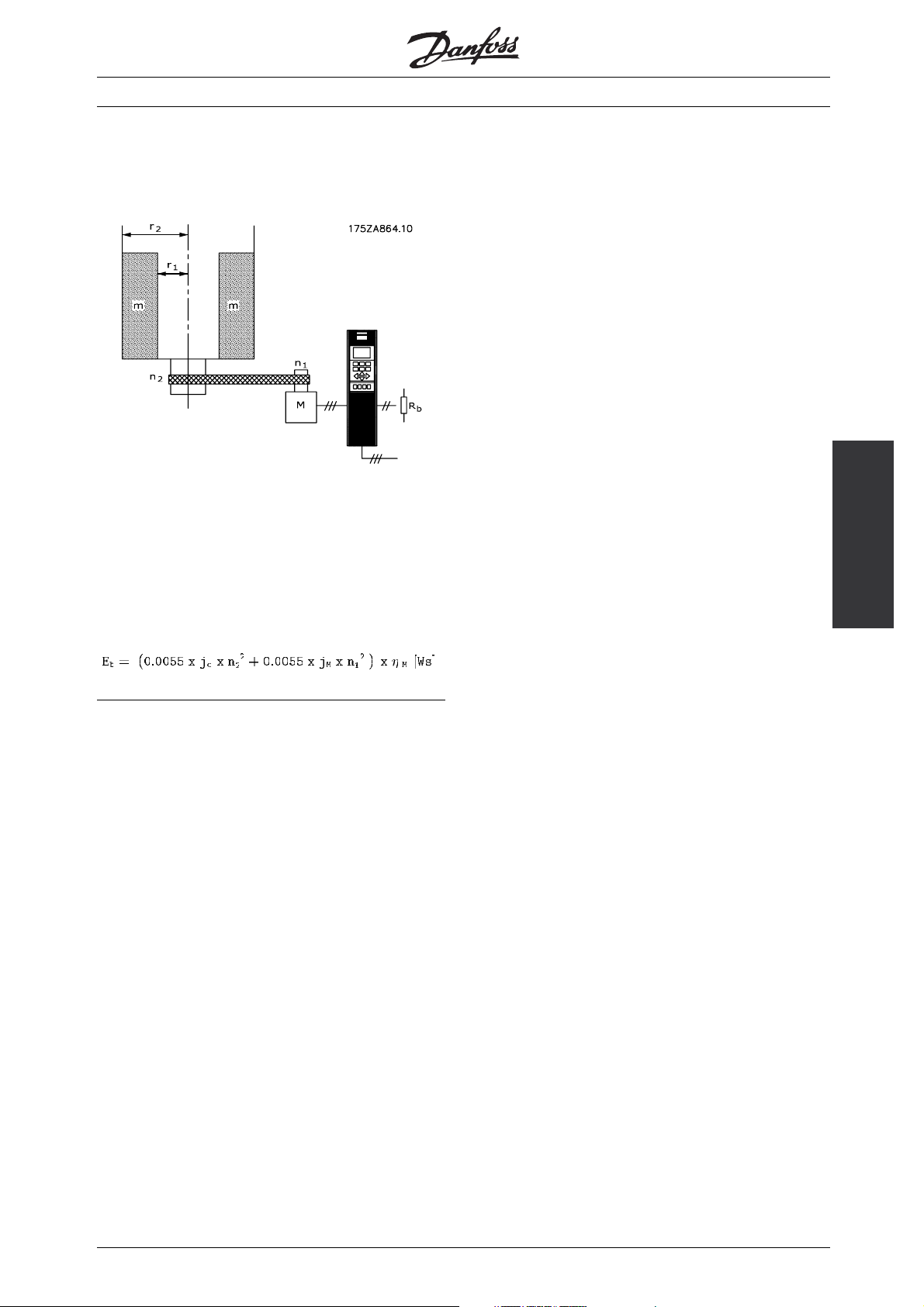

■Brake setup

Fig. 2 shows a brake set-up using a

frequency converter.

The following sections use expressions and

abbreviations with respect to a brake set-up

that can be seen from fig. 2.

Fig. 2

VLT®2800/5000/5000 FLUX/FCD 300

■Calculation of brake resistor values

To keep the VLT frequency converter from cutting out

for protection when the motor brakes, the resistor

values are to be selected on the basis of the peak

braking power and the intermediate circuit voltage:

As can be seen, the brake resistor depends on

the intermediate circuit voltage (Udc).

Udc is the voltage, where the brake is activated. For

values see further on in this instruction.

Another option is to use the brake resistor

recommended by Danfoss (Rrec). This guarantees

that the frequency converter is able to brake at the

highest braking torque (Mbr), i.e. 160% / 150% /

100%. See the tables further on in this instruction.

6

MI.90.F1.02 - VLT is a registered Danfoss trademark

Page 7

NB!:

Remember to check whether your brake resistor

is able to handle the intermediate voltage (Udc

for your specific drive can be found in the table

below) if you do not use Danfoss brake resistors.

VLT®2800/5000/5000 FLUX/FCD 300

ηηηη

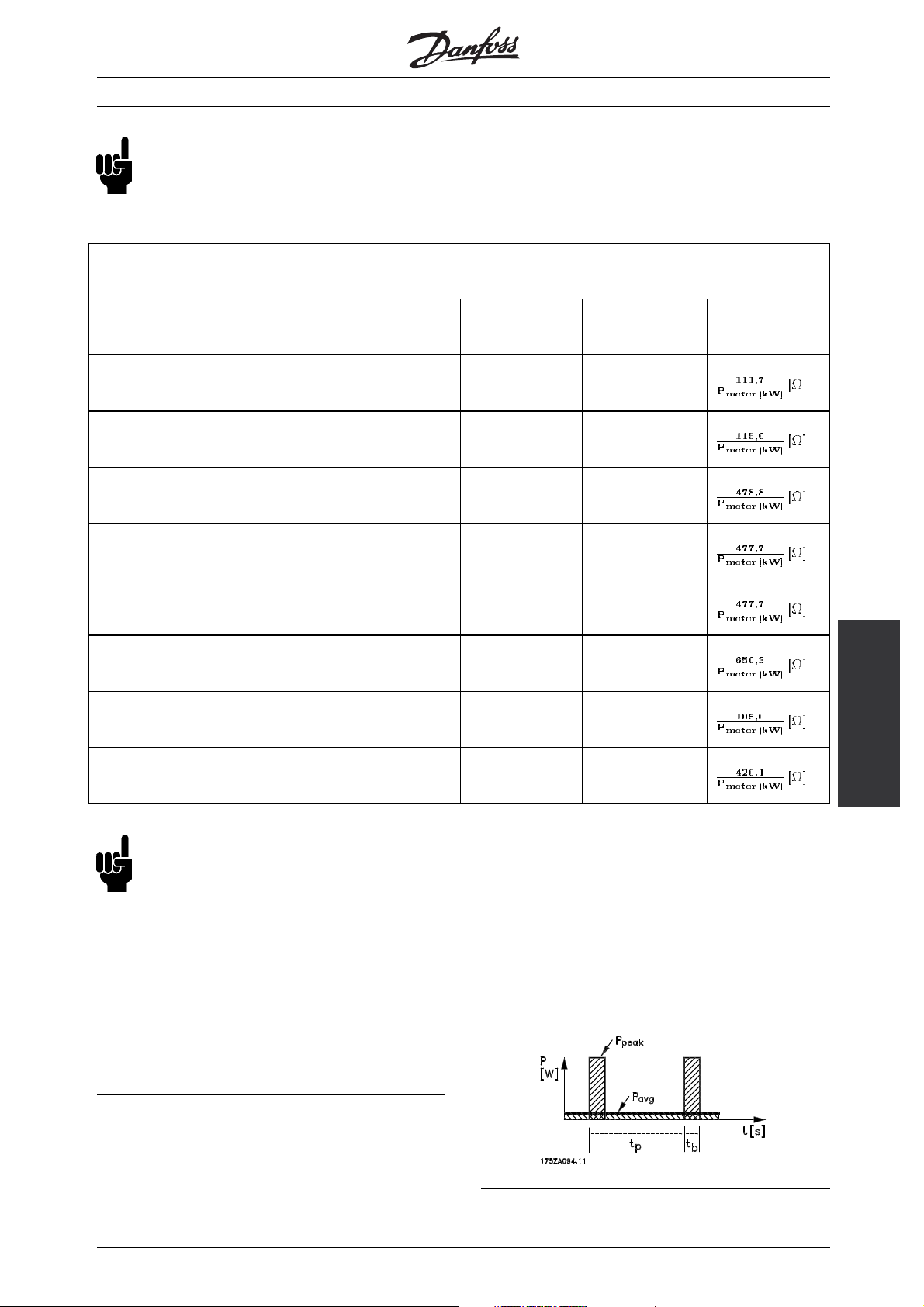

VLT type Udc

is typically 0,9, while ηηηη

motor

is typically 0,98. R

vlt

can be expressed as follows:

rec

Max. Braking

torque

5001-5027 Process and FLUX / 200-240 Volt 397 Volt 160 %

5032-5052 Process and FLUX / 200-240 Volt 390 Volt 150 %

5001-5062, 5072 and 5102 Process and FlLUX /

380-500 Volt

822 Volt 160 %

5075, 5100 and 5125-5500 Process / 380-500 Volt 795 Volt 150 %

5075, 5100 and 5125-5500 FLUX / 380-500 Volt 795 Volt 100 %

5001-5250 Process / 550-600 Volt 958 Volt 160 %

2803-2840 / 200-240 Volt 385 Volt 160 %

R

=

rec

2805-2882 and FCD 303-335 / 380-480 Volt 770 Volt 160%

NB!:

Choose a brake resistor which is max. 10%

below the value recommended by Danfoss.

If a bigger brake resistor is selected, 160% /

150% / 100% braking torque cannot be obtained,

and there is a risk that the frequency converter

will cut out for protection.

Ifbrakingisonlye.g. at80%torque,itispossibleto

install a bigger brake resistor, the size of which can

be calculated using the formula R

■Calculation of braking power

When calculating the braking power, it is to be ensured

that the brake resistor is able to handle the average

power as well as the peak power. The average power is

, no. 1.

rec

determined by the process period time, i.e. the length

of the braking time in relation to the process period time.

The peak power is determined by the braking torque,

which means that as braking progresses, the brake

resistor must be able to dissipate the energy input.

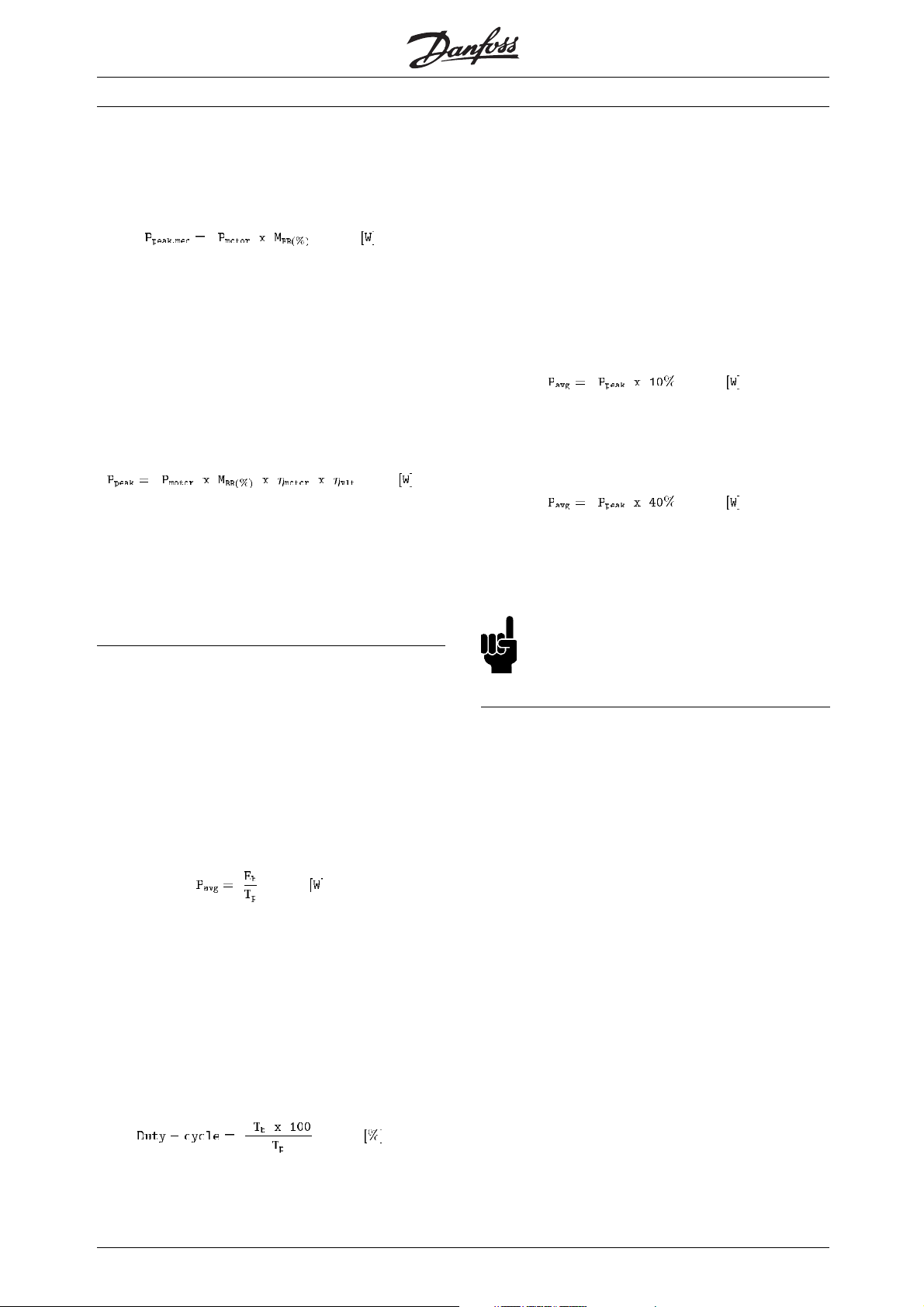

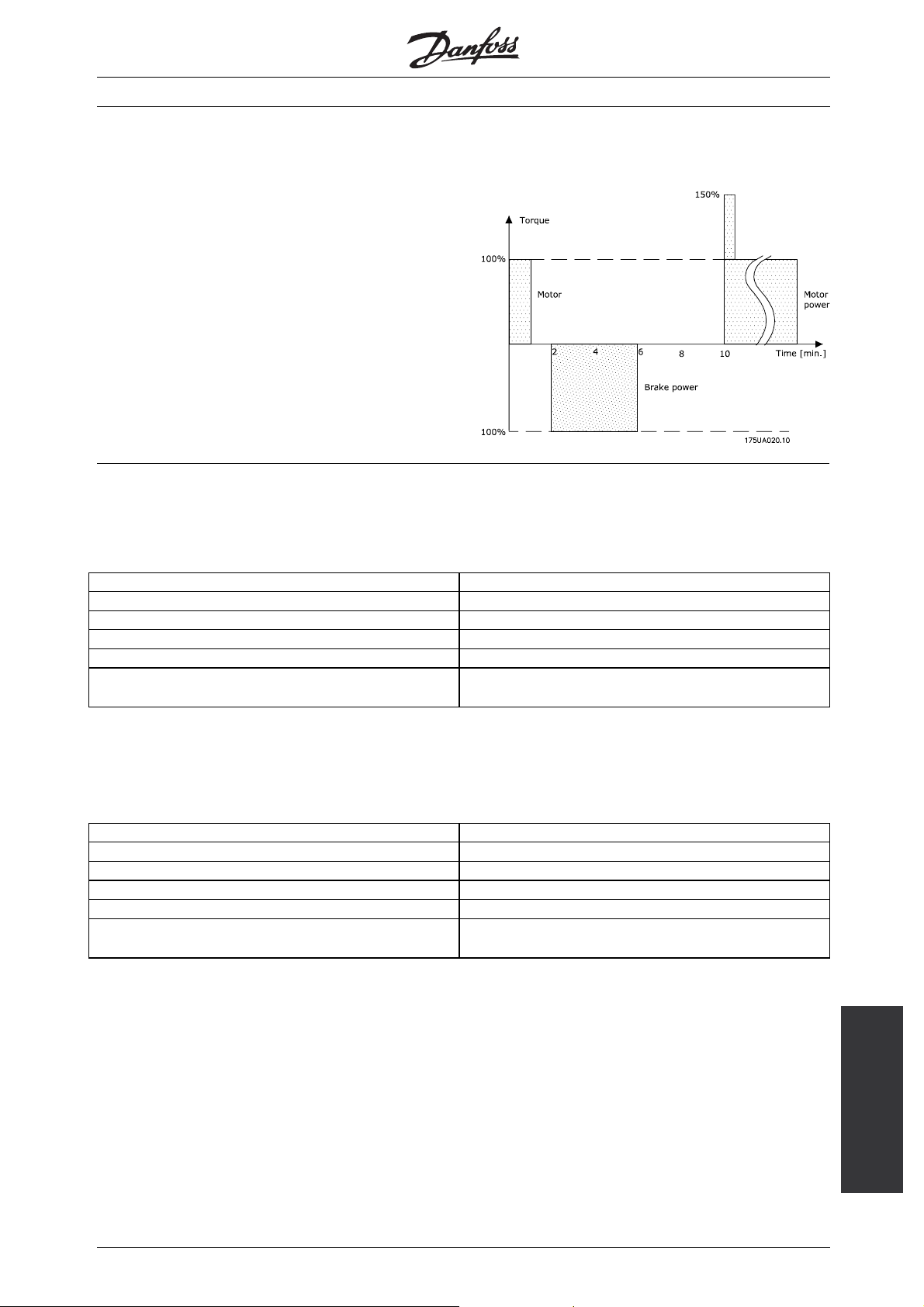

Fig. 3 shows the relation between the average

power and the peak power.

Fig. 3

brake resistor

Calculation of the

MI.90.F1.02 - VLT is a registered Danfoss trademark

7

Page 8

VLT®2800/5000/5000 FLUX/FCD 300

■Calculation of the brake resistor peak power

P

peak, mec

is the peak power by which the motor brakes

on the motor shaft. It is calculated as follows:

P

is the name used for the braking power dissipated

peak

to the brake resistor when the motor brakes.

is lower than P

P

peak

peak,mec

since the power

is reduced by the efficiencies of the motor and

the VLT frequency converter.

The peak power is calculated as follows:

If the brake resistor recommended by Danfoss is

selected (R

) on the basis of the tables further

rec

on in this instruction, the brake resistor will be

certain to provide a braking torque of 160% /

150% / 100% on the motor shaft.

■Calculation of the brake resistor average power

The average power is determined by the process

period time, i.e. the length of the braking time in

relation to the process period time.

Danfoss offers brake resistors with a duty-cycle of

max. 10% and 40%, respectively (some drives are

only available with a duty-cycle of max. 10%). If

a 10% duty-cycle is applied, the brake resistors

are able to absorb Ppeak for 10% of the period

time. The remaining 90% of the period time will

be used on deflecting excess heat.

The average power with 10% duty-cycle can

be calculated as follows:

The average power with 40% duty-cycle can

be calculated as follows:

The calculations apply to intermittent braking using a

period time of 120/300 seconds (to define whether it is

120 or 300 seconds. Please see the tables further on).

NB!:

Longer time than the specified intermittent

braking period time may result in overheating

of the resistor.

If the amount of kinetic energy (Eb) transferred to

the resistor in each braking sequence (see examples

1 and 2) is known, the average power of the

resistor can be calculated as follows:

Tp= period time in seconds (see drawing on page 3).

If the amount of kinetic energy transferred to the

resistor in each braking sequence is not known, the

average power can be calculated on the basis of the

process period time and the braking time.

The duty-cycle for the braking sequence is

calculated as follows:

Tp= process period time in seconds.

T

= braking time in seconds.

b

8

MI.90.F1.02 - VLT is a registered Danfoss trademark

Page 9

VLT®2800/5000/5000 FLUX/FCD 300

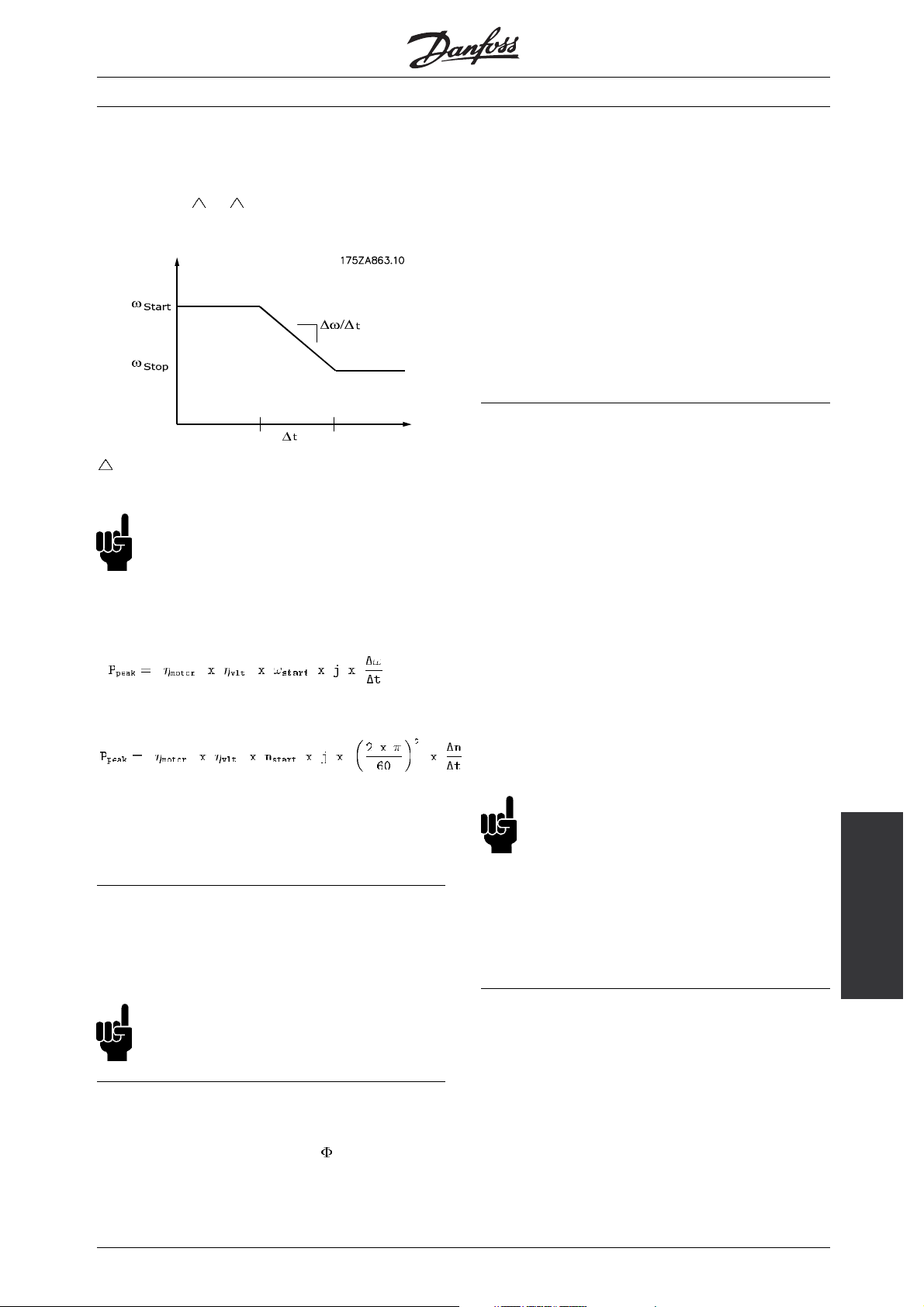

■Braking of inertia

In the case of braking of high inertia values on the

motor shaft, the brake resistor values can be based

on the inertia,

ω, t. See fig. 4.

Fig. 4

t is determined by the ramp-down time

in parameter 208.

NB!:

The ramp-down time goes from the rated motor

frequency in parameter 104 to 0 Hz.

P

can be calculated as:

peak

Since the electrical resistance of the rotor cage is very

low, even small induced voltages can create a high

rotor current. This current will produce a strong braking

effect on the bars and hence on the rotor. As the speed

falls, the frequency of the induced voltage falls and with

it the inductive impedance. The ohmic resistance of the

rotor gradually becomes dominant and so increases

the braking effect as the speed comes down. The

braking torque generated falls away steeply just before

standstill and finally ceases when there is no further

movement. Direct current injection braking is therefore

not suitable for actually holding a load at rest.

■AC-braking VLT 2800 and FCD 300

WhenthemotoractsasabraketheDC-linkvoltagewill

increase because energy is fed back to the DC-link. The

principle in AC-brake is to increase the magnetisation

during the braking and thereby increase the thermal

losses of the motor. Using par. 144 in VLT 2800 and

FCD 300 it is possible to adjust the size of the generator

torque that can be applied to the motor without the

intermediate circuit voltage exceeding the warning level.

The braking torque depends on the speed. With

the AC-brake function enabled and parameter 144

= 1,3 (factory setting) it is possible to brake with

about 50 % of rated torque below 2/3 of rated speed

and with about 25 % at rated speed. The function

is not working at low speed (below 1/3 of nominal

motor speed). It is only possible to run for about 30

seconds with parameter 144 greater than 1.2.

jistheinertiaofthemotorshaft.

Calculate the value on the brake resistor as described

under the preceding paragraphs.

■Continuous braking

For continuous braking, select a brake resistor in

which the constant braking power does not exceed

the average power P

of the brake resistor.

avg

NB!:

Please contact your Danfoss distributor

for further information.

■D.C. injection braking

If the three-phase winding of the stator is fed with direct

current, a stationary magnetic field

will be set up in

the stator bore causing a voltage to be induced in the

bars of the cage rotor as long as the rotor is in motion.

NB!:

If the value in parameter 144 is increased,

the motor current will simultaneously increase

significantly when generator loa

ds are applied.

The parameter should therefore only be changed if

it is guaranteed during measurement that the motor

current in all operating situa

tions will never exceed the

maximum permitted current in the motor. Please note:

The current can not be read out from the display.

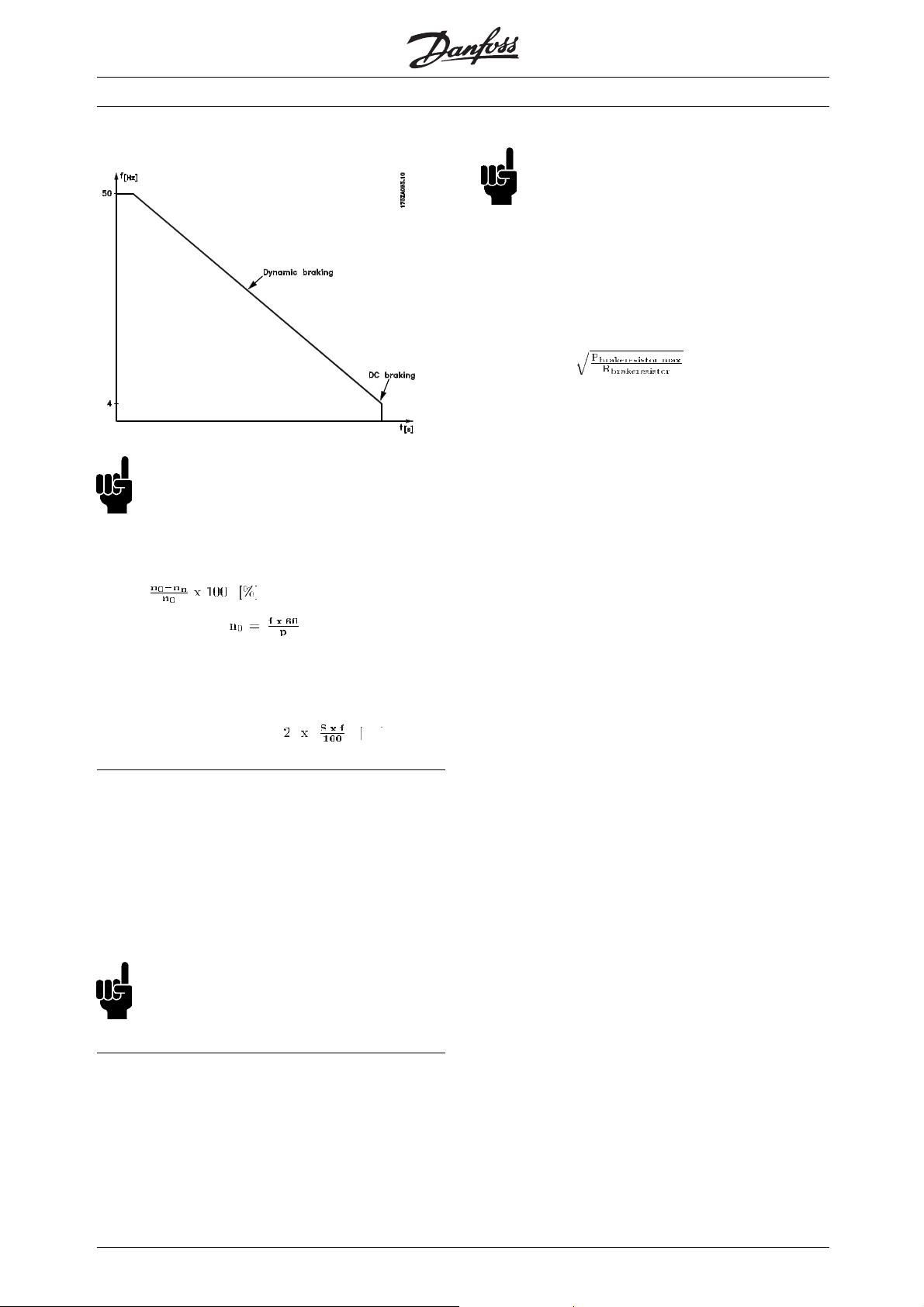

■Optimum braking

Dynamic braking is useful from max. speed down to a

certain frequency. Below this frequency DC braking

is to be applied as required. The most efficient way

of doing this is to use a combination of dynamic

and DC braking. See fig. 5. The parameters can

be found further on in this instruction.

Braking

MI.90.F1.02 - VLT is a registered Danfoss trademark

9

Page 10

VLT®2800/5000/5000 FLUX/FCD 300

Fig. 5

NB!:

When changing from dynamic to DC braking,

there will be a short period (2-6 milliseconds)

with very low braking torque.

How to calculate optimum DC-brake cut in frequency:

Slip S=

NB!:

The brake resistor is to be fitted on a

non-flammable material.

For protection of the installation, a thermal relay

should be fitted that cuts off the frequency converter

if the brake current becomes too high.

Calculate the brake current setting of the

thermal relay as follows:

Itherm relay =

Rbris the current brake resistor value calculated in the

section on "Calculation of brake resistor values". Fig.

6 shows an installation with a thermal relay.

The brake current setting of thermal relay for

Danfoss brake resistors can be found in tables

further on in this instruction.

Synchronous speed [1/min]

f = frequency

p=no. ofpolepairs

= speed of the rotor

n

n

DC-brake cut in frequency =

Hz

■Brake cable

Max. length [m]: 20 m

The connection cable to the brake resistor is t

screened/armoured. Connect the screen/armouring

to the conductive back plate at the VLT frequency

converter and to the brake resistor metal c

by means of cable clamps.

NB!:

If Danfoss brake resistors are not used,

make sure that the brake resistors used

are induction-free.

obe

abinet

■Protective functions during installation

When installing a brake resistor

, every measure

should be taken to avoid the risk of overloading,

since a fire hazard may arise owing to the heat

generated in the heat resistor

.

10

MI.90.F1.02 - VLT is a registered Danfoss trademark

Page 11

Fig. 6

VLT®2800/5000/5000 FLUX/FCD 300

Some of the Danfoss Brakeresistors contain a thermal

switch (see tables further on in this instruction). This

switch is NC (normally closed) and can be used e.g.

coasting stop reverse between terminal 12 and 27. The

drive will then coast, if the thermal switch is opened.

NB!:

The thermal switch is not a protective

device. For protection, use a thermal

switch as shown in fig. 6.

■Description of VLT 5000 brake

Danfoss VLT 5000 Series enables activation of an

integral brake monitor to guarantee that the braking

power does not exceed a given limit.

The power is calculated on the basis of the resistor

ohm value (parameter 401), the intermediate

circuit voltage and the resistor running time. For

further information, see page 10.

NB!:

The brake power monitoring system is not

a protective device. For protection, use a

thermal switch as shown in fig. 6.

Via the digital/relay outputs, it is possible to get a

status message concerning the brake, e.g. indicating

brake faults. Furthermore, VLT 5000 Series features an

integral function to check whether the brake resistor

has been connected/is intact at the time of power-up.

Additionally, the brake is protected against

short-circuiting by the brake resistor. The brake

circuit is not earthing proof.

Braking

MI.90.F1.02 - VLT is a registered Danfoss trademark

11

Page 12

VLT®2800/5000/5000 FLUX/FCD 300

■VLT 5000 Process parameters

The following is a list of parameters for the VLT 5000

Process Series which are important or relevant for

thedynamicbrakeandtheDCbrake.

Parameter Suggestion of settings

125 DC braking current Depends on the desired braking torque

126 DC braking time Set the desired DC braking time

127 DC brake cut-in frequency Set the desired DC brake cut-in frequency

222 Torque limit for generating operation 160 %

319 Output (terminal 42) Brake no warning,

Brake ready no fault or

Brake fault

321 Output (terminal 45) Same as 319

323 Output (relay 01) Same as 319

326 Output (relay 4) Same as 319

400 Brake function/overvoltage control Resistor brake

401 Brake resistor, ohm Depends on the unit, see the tables further on in this

instruction

402 Brake power limit, kW Depends on the unit, see the tables further on in this

instruction

403 Power monitoring Warning or trip

404 Brake check Warning or trip

■VLT 5000 FLUX parameters

The following is a list of parameters for the VLT

5000 FLUX Series which are important or relevant

for the dynamic brake and the DC brake.

Parameter Suggestion of settings

125 DC braking current Depends on the desired braking torque

126 DC braking time Set the desired DC braking time

127 DC brake cut-in frequency Set the desired DC brake cut-in frequency

222 Torque limit for generating operation 160 %

323 Output (relay 01) Brake no warning,

Brake ready no fault or

Brake fault

326 Output (relay 4) Same as 323

341 Output (terminal 46) Same as 323

355 Output (terminal 26) Same as 323

400 Brake function/overvoltage control Resistor brake

401 Brake resistor, ohm Depends on the unit, see the tables further on in this

instruction

402 Brake power limit, kW Depends on the unit, see the tables further on in this

instruction

403 Power monitoring Warning or trip

404 Brake check Warning or trip

12

MI.90.F1.02 - VLT is a registered Danfoss trademark

Page 13

The sizes VLT 5125 and 5150 are equipped with

a better dynamic brake performance compared to

the same sizes in VLT 5000 Process.

Itispossibletobrake4minout10mininatotal

cycle (Duty type S% 40% EN 60034-1)

■VLT 2800 parameters

The following is a list of parameters for the VLT

2800 Series which are important or relevant for the

dynamic brake and the DC brake.

VLT®2800/5000/5000 FLUX/FCD 300

VLT 5125 FLUX and VLT 5150 FLUX

Parameter Suggestion of settings

126 DC braking time Set the desired DC braking time

127 DC brake engaging frequency Set the desired DC brake engaging frequency

132 DC brake voltage Depends on the desired braking torque

400 Brake function Resistor or AC brake

456 Brake voltage reduce 0 should only be used if there are problems with

overvoltage in the intermediate circuit

■FCD 300 parameters

The following is a list of parameters for the VLT

FCD 300 Series which are important or relevant for

thedynamicbrakeandtheDCbrake.

Parameter Suggestion of settings

126 DC braking time Set the desired DC braking time

127 DC brake engaging frequency Set the desired DC brake engaging frequency

132 DC brake voltage Depends on the desired braking torque

400 Brake function Resistor or AC brake

456 Brake voltage reduce 0 should only be used if there are problems with

overvoltage in the intermediate circuit

MI.90.F1.02 - VLT is a registered Danfoss trademark

Programming

13

Page 14

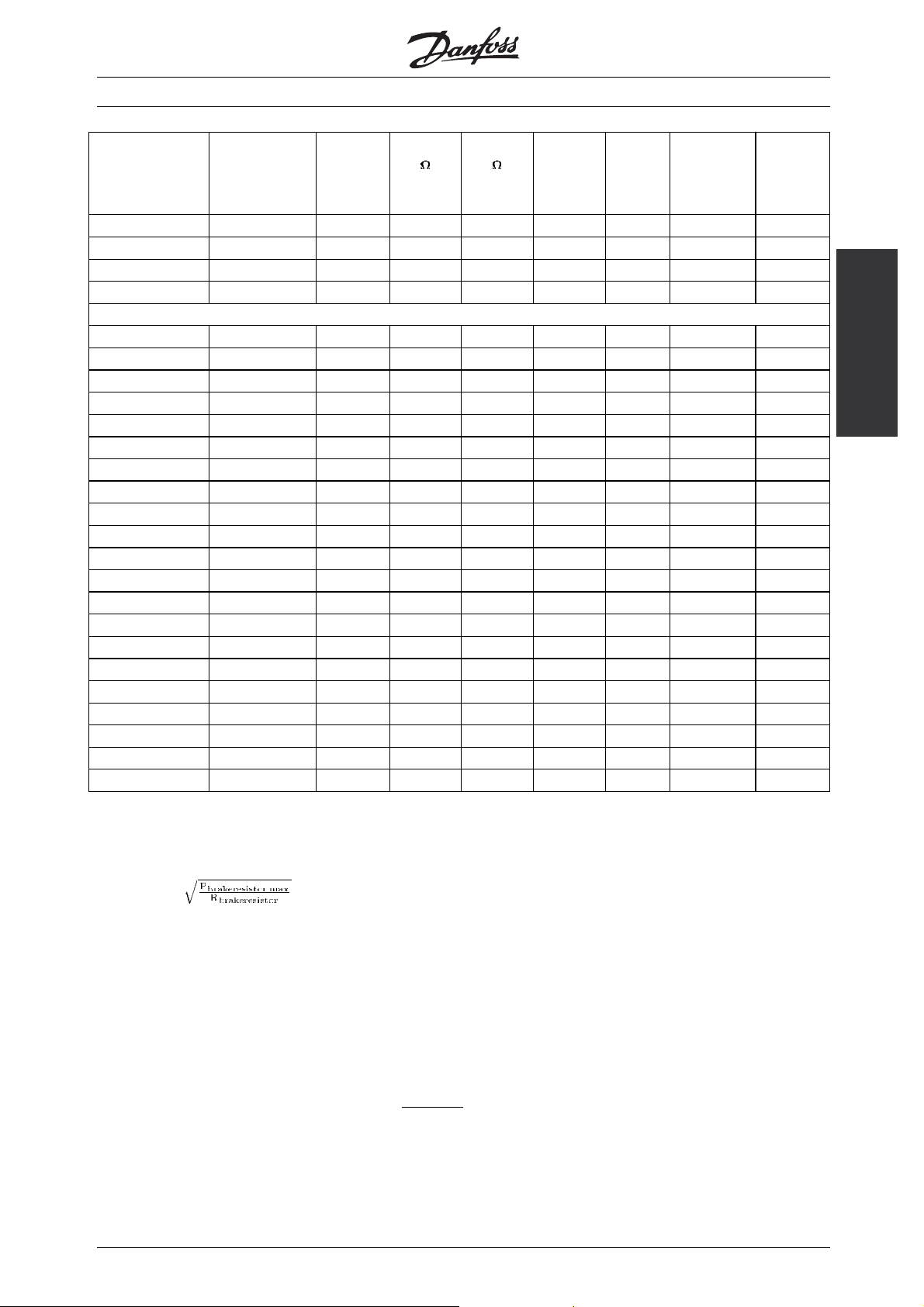

■Brake resistor for VLT 5001-5500 10% duty-cycle

data and codenumber

VLT®2800/5000/5000 FLUX/FCD 300

VLT type

P=Process

F=FLUX

5001 P, F (200V) 120 0,75 130 145 0,065 0,7 1820 1,5******

5002 P, F (200V) 120 1,1 81 90 0,095 1,0 1821 1,5******

5003 P, F (200V) 120 1,5 58 65 0,25 2,0 1822 1,5******

5004 P, F (200V) 120 2,2 45 50 0,285 2,4 1823 1,5******

5005 P, F (200V) 120 3,0 31 35 0,43 2,5 1824 1,5******

5006 P, F (200V) 120 4,0 22 25 0,8 5,7 1825 1,5******

5008 P, F (200V) 120 5,5 18 20 1,0 7,1 1826 1,5******

5011 P, F (200V) 120 7,5 13 15 2,0 11 1827 1,5******

5016 P, F (200V) 120 11,0 9,0 10 2,8 17 1828 2,5******

5022 P, F (200V) 120 15,0 6,3 7,0 4,0 24 1829 4******

5027 P, F (200V) 120 18,5 5,2 6,0 4,8 28 1830 4******

5032 P, F (200V) 300 22,0 4,2 4,7 6,0 36 1954 10******

5042 P, F (200V) 300 30,0 3,0 3,3 8,0 49 1955 10******

5052 P, F (200V) 300 37,0 2,4 2,7 10,0 61 1956 16******

5001 P, F (500V) 120 0,75 557 620 0,065 0,3 1840 1,5******

5002 P, F (500V) 120 1,1 382 425 0,095 0,5 1841 1,5******

5003 P, F (500V) 120 1,5 279 310 0,25 0,9 1842 1,5******

5004 P, F (500V) 120 2,2 189 210 0,285 1,2 1843 1,5******

5005 P, F (500V) 120 3,0 135 150 0,43 1,7 1844 1,5******

5006 P, F (500V) 120 4,0 99 110 0,6 2,3 1845 1,5******

5008 P, F (500V) 120 5,5 72 80 0,85 3,3 1846 1,5******

5011 P, F (500V) 120 7,5 58,5 65 1,0 3,9 1847 1,5******

5016 P, F (500V) 120 11,0 36 40 2,0 7,1 1848 1,5******

5022 P, F (500V) 120 15,0 27 30 2,8 9,7 1849 1,5******

5027 P, F (500V) 120 18,5 22 25 3,5 12 1850 1,5******

5032 P, F (500V) 120 22,0 18 20 4,0 14 1851 1,5******

5042 P, F (500V) 120 30,0 13 15 4,8 18 1852 2,5******

5052 P, F (500V) 120 37,0 10,8 12 5,5 21 1853 2,5******

5060 P, F (500V)**** 300 45,0 7,0 7,8 12 39 N.A. 10******

5062 P, F (500V) 120 45,0 9,8 9,8 15 39 2008 10******

5072 P, F (500V) 120 55,0 7,3 7,3 13 42 0069 10******

5075 P (500V)* 300 55,0 5,1 5,7 14 50 1958 10******

5075 F (500V) * 600******* 55,0 5,1 5,7 21 61 0076 16******

5100 P (500V)** 300 75,0 4,2 4,7 18 62 1959 16******

5100 F (500V)** 600******* 75,0 4,2 4,7 29 79 0077 25******

5102 P, F (500V) 120 75,0 5,7 6,33 15 49 0067 10******

5125 P (500V) 300 90,0 3,4 3,8 22 76 1960 25******

5125 F (500V) 600******* 90,0 3,4 3,8 36 97 0078 35******

5150 P (500V) 300 110 2,9 3,2 27 92 1961 35******

5150 F (500V) 600******* 110 2,9 3,2 42 115 0079 50******

5200 P, F (500V) 300 132 2,3 2,6 32 111 1962 50******

5250 P, F (500V) 300 160 1,9 2,1 39 136 1963 70******

Intermittent

braking period

time

[seconds]

P

motor

[kW]

R

[ ]

min

R

[ ]

rec

Pb,max

[kW]

Therm.

relay

[Amp]

Code

number

175Uxxxx

Cable

cross

section

[mm

2

]

14

MI.90.F1.02 - VLT is a registered Danfoss trademark

Page 15

VLT®2800/5000/5000 FLUX/FCD 300

VLT type

P=Process

F=FLUX

5300 P, F (500V) 300 200 3,14 3,3 56 130 2 x 1061*** 50******

5350 P, F (500V) 300 250 2,47 2,6 72 166 2 x 1062*** 70******

5450 P, F (500V) 300 315 2,19 2,3 90 198 2 x 1063*** 95******

5500 P, F (500V) 300 355 2,00 2,1 100 218 2 x 1064*** 120******

5001 P (600V) 120 0,75 797 797 R.d. ***** N.A.

5002 P (600V) 120 1,1 534 534 R.d. ***** N.A.

5003 P (600V) 120 1,5 398 398 R.d. ***** N.A.

5004 P (600V) 120 2,2 267 267 R.d. ***** N.A.

5005 P (600V) 120 3,0 199 199 R.d. ***** N.A.

5006 P (600V) 120 4,0 149 149 R.d. ***** N.A.

5008 P (600V) 120 5,5 107 107 R.d. ***** N.A.

5011 P (600V) 120 7,5 80 80 R.d. ***** N.A.

5016 P (600V) 120 11,0 53,4 53,4 R.d. ***** N.A.

5022 P (600V) 120 15,0 39,8 39,8 R.d. ***** N.A.

5027 P (600V) 120 18,5 32,0 32,0 R.d. ***** N.A.

5032 P (600V) 120 22,0 26,7 26,7 R.d. ***** N.A.

5042 P (600V) 120 30,0 19,9 19,9 R.d. ***** N.A.

5052 P (600V) 120 37,0 16,0 16,0 R.d. ***** N.A.

5062 P (600V) 120 45,0 13,3 13,3 R.d. ***** N.A.

5075 P (600V) 300 55,0 11,0 11,0 R.d. ***** N.A.

5100 P (600V) 300 75,0 8,2 8,2 R.d. ***** N.A.

5125 P (600V) 300 90,0 6,8 6,8 R.d. ***** N.A.

5150 P (600V) 300 110 5,6 5,6 R.d. ***** N.A.

5200 P (600V) 300 132 4,3 4,3 R.d. ***** N.A.

5250 P (600V) 300 160 3,3 3,3 R.d. ***** N.A.

Intermittent

braking period

time

[seconds]

P

motor

[kW]

R

[ ]

min

R

[ ]

rec

Pb,max

[kW]

Therm.

relay

[Amp]

Code

number

175Uxxxx

Cable

cross

section

[mm

2

]

overview

Brake resistor

*to be replaced by VLT 5072

**to be replaced by VLT 5102

***Order 2 pcs.

****Replaced by VLT 5062

*****Itherm relay =

******Always observe national and local regulations

******* Please observe drawing at VLT 5000 FLUX parameters

P

motor

R

min

R

rec

P

b, max

: Rated motor size for VLT type

: Minimum permissible brake resistor

: Recommended brake resistor (Danfoss)

: Brake resistor rated power as stated by supplier

Therm. relay : Brake current setting of thermal relay

Code number : Order numbers for Danfoss brake resistors

Cable cross section : Recommended m

inimum value based upon PVC insulated cober cable, 30

degree Celsius ambient temperature with normal heat dissipation

R.d. : Resistor dependent

MI.90.F1.02 - VLT is a registered Danfoss trademark

15

Page 16

■Brake resistor for VLT 5001-5102 40% duty-cycle

data and codenumber

VLT®2800/5000/5000 FLUX/FCD 300

VLT type

P=Process

F=FLUX

5001 P, F (200V) 120 0,75 130 145 0,26 1,3 1920 1,5**

5002 P, F (200V) 120 1,1 81 90 0,43 2,2 1921 1,5**

5003 P, F (200V) 120 1,5 58 65 0,8 3,5 1922 1,5**

5004 P, F (200V) 120 2,2 45 50 1,0 4,5 1923 1,5**

5005 P, F (200V) 120 3,0 31 35 1,35 6,2 1924 1,5**

5006 P, F (200V) 120 4,0 22 25 3,0 11,0 1925 1,5**

5008 P, F (200V) 120 5,5 18 20 3,5 13,0 1926 1,5**

5011 P, F (200V) 120 7,5 13 15 5,0 18,0 1927 2,5**

5016 P, F (200V) 120 11,0 9 10 9,0 30,0 1928 10**

5022 P, F (200V) 120 15,0 6,5 7 10,0 38,0 1929 16**

5027 P, F (200V) 120 18,5 5,2 6 12,7 46,0 1930 16**

5001 P, F (500V) 120 0,75 557 620 0,26 0,6 1940 1,5**

5002 P, F (500V) 120 1,1 382 425 0,43 1,0 1941 1,5**

5003 P, F (500V) 120 1,5 279 310 0,8 1,6 1942 1,5**

5004 P, F (500V) 120 2,2 189 210 1,35 2,5 1943 1,5**

5005 P, F (500V) 120 3,0 135 150 2,0 3,7 1944 1,5**

5006 P, F (500V) 120 4,0 99 110 2,4 4,7 1945 1,5**

5008 P, F (500V) 120 5,5 72 80 3,0 6,1 1946 1,5**

5011 P, F (500V) 120 7,5 59 65 4,5 8,3 1947 1,5**

5016 P, F (500V) 120 11,0 36 40 5,0 11 1948 1,5**

5022 P, F (500V) 120 15,0 27 30 9,3 18 1949 2,5**

5027 P, F (500V) 120 18,5 22 25 12,7 23 1950 4**

5032 P, F (500V) 120 22,0 18 20 13,0 25 1951 4**

5042 P, F (500V) 120 30,0 14 15 15,6 32 1952 10**

5052 P, F (500V) 120 37,0 10 12 19,0 40 1953 16**

5062 P, F (500V) 120 45,0 9,8 9,8 38,0 62 2007 16**

5072 P, F (500V) 120 55,0 7,3 7,3 38,0 72 0068 25**

5102 P, F (500V) 120 75,0 5,7 6,0 45,0 87 0066 25**

5125 F (500V) 600*** 90,0 3,4 3,8 75 140 2 x 0072 2x70**

5150 F (500V) 600*** 110 2,9 3,2 90 168 2 x 0073 2x70**

Intermittent

braking period

time [seconds]

P

motor

[kW]

R

[ ]

min

R

[ ]

rec

P

b, max

[kW]

Therm.re-

lay

[Amp]

Code

number

175Uxxxx

Cable

cross

section

2

[mm

]

5001 P (600V) 120 0,75 797 797 R.d. * N.A.

5002 P (600V) 120 1,1 534 534 R.d. * N.A.

5003 P (600V) 120 1,5 398 398 R.d. * N.A.

5004 P (600V) 120 2,2 267 267 R.d. * N.A.

5005 P (600V) 120 3,0 199 199 R.d. * N.A.

5006 P (600V) 120 4,0 149 149 R.d. * N.A.

5008 P (600V) 120 5,5 107 107 R.d. * N.A.

5011 P (600V) 120 7,5 80 80 R.d. * N.A.

5016 P (600V) 120 11,0 53,4 53,4 R.d. * N.A.

5022 P (600V) 120 15,0 39,8 39,8 R.d. * N.A.

5027 P (600V) 120 18,5 32,0 32,0 R.d. * N.A.

16

MI.90.F1.02 - VLT is a registered Danfoss trademark

Page 17

VLT®2800/5000/5000 FLUX/FCD 300

VLT type

P=Process

F=FLUX

5032 P (600V) 120 22,0 26,7 26,7 R.d. * N.A.

5042 P (600V) 120 30,0 19,9 19,9 R.d. * N.A.

5052 P (600V) 120 37,0 16,0 16,0 R.d. * N.A.

5062 P (600V) 120 45,0 13,3 13,3 R.d. * N.A.

*Itherm relay =

**Always observe national and local regulations

*** Please observe drawing at VLT 5000 Flux parameters

P

motor

R

min

R

rec

P

b, max

Intermittent

braking period

time [seconds]

: Rated motor size for VLT type

: Minimum permissible brake resistor

: Recommended brake resistor (Danfoss)

: Brake resistor rated power as stated by supplier

P

motor

[kW]

R

[ ]

min

R

[ ]

rec

P

b, max

[kW]

Therm.re-

lay

[Amp]

number

175Uxxxx

Therm. relay : Brake current setting of thermal relay

Code number : Order numbers for Danfoss brake resistors

Cable cross section : Recommended m

inimum value based upon PVC insulated cober cable, 30

degree Celsius ambient temperature with normal heat dissipation

R.d. : Resistor dependent

Code

Cable

cross

section

2

[mm

]

overview

Brake resistor

■Brake resistor for VLT 2803-2882 duty-cycle

40% data and codenumber

VLT type Intermit-

tent brak-

ing period

time

[seconds]

2803 (200V) 120 0,37 297 330 0,16 0,7 1900* 1,5**

2805 (200V) 120 0,55 198 220 0,25 1,1 1901* 1,5**

2807 (200V) 120 0,75 135 150 0,32 1,5 1902* 1,5**

2811 (200V) 120 1,1 99 110 0,45 2,0 1975* 1,5**

2815 (200V) 120 1,5 74 82 0,85 3,2 1903* 1,5**

2822 (200V) 120 2,2 50 56 1,00 4,2 1904* 1,5**

2840 (200V) 120 3,7 22 25 3,00 11,0 1925 1,5**

2805 (400V) 120 0,55 747 830 0,45 0,7 1976* 1,5**

2807 (400V) 120 0,75 558 620 0,32 0,7 1910* 1,5**

2811 (400V) 120 1,1 387 430 0,85 1,4 1911* 1,5**

2815 (400V) 120 1,5 297 330 0,85 1,6 1912* 1,5**

2822 (400V) 120 2,2 198 220 1,00 2,1 1913* 1,5**

2830 (400V) 120 3,0 135 150 1,35 3,0 1914* 1,5**

2840 (400V) 120 4,0 99 110 1,60 3,8 1979* 1,5**

2855 (400V) 120 5,5 80 80 2,00 5,0 1977* 1,5**

2875 (400V) 120 7,5 56 56 3,00 6,8 1978* 1,5**

2880 (400V) 120 11 40 40 5,00 11,2 1997* 1,5**

2881 (400V) 120 15 30 30 10,0 18,3 1998 2,5**

2882 (400V) 120 18,5 25 25 13,0 22,8 1999 4**

P

motor

[kW]

R

min

[ ]

R

[ ]

rec

P

b, max

[kW]

Therm.re-

lay

[Amp]

Code

number

175Uxxxx

Cable

cross

section

2

[mm

]

*With KLIXON switch

**Always observe national and local regulations

MI.90.F1.02 - VLT is a registered Danfoss trademark

17

Page 18

■Brake resistor for VLT FCD 303-335 duty-cycle

40% data and codenumber

VLT®2800/5000/5000 FLUX/FCD 300

VLT type Intermit-

tent brak-

ing period

time

[seconds]

303 (400 V) 120 0,37 520 830 0,45 0,7 1976 1,5*

305 (400 V) 120 0,55 405 830 0,45 0,7 1976 1,5*

307 (400 V) 120 0,75 331 620 0,32 0,7 1910 1,5*

311 (400 V) 120 1,1 243 430 0,85 1,4 1911 1,5*

315 (400 V) 120 1,5 197 330 0,85 1,6 1912 1,5*

322 (400 V) 120 2,2 140 220 1,00 2,1 1913 1,5*

330 (400 V) 120 3,0 104 150 1,35 3,0 1914 1,5*

335 (400 V) 120 3,3 104 150 1,35 3,0 1914 1,5*

*Always observe national and local regulations

P

motor

R

min

R

rec

P

b, max

P

motor

[kW]

R

min

[ ]

R

[ ]

rec

P

b, max

[kW]

: Rated motor size for VLT type

: Minimum permissible brake resistor

: Recommended brake resistor (Danfoss)

: Brake resistor rated power as stated by supplier

Therm.re-

lay

[Amp]

Code

number

175Uxxxx

Therm. relay : Brake current setting of thermal relay

Code number : Order numbers for Danfoss brake resistors

Cable cross section : Recommended m

inimum value based upon PVC insulated cober cable, 30

degree Celsius ambient temperature with normal heat dissipation

Cable

cross

section

2

[mm

]

18

MI.90.F1.02 - VLT is a registered Danfoss trademark

Page 19

■Brake resistor for VLT 5001-5500 10% duty-cycle

cablegland, weight and drawing no.

VLT®2800/5000/5000 FLUX/FCD 300

VLT type

P=Process

F=FLUX

5001 P, F (200V) PG 9 1,1 1820 1

5002 P, F (200V) PG 9 1,1 1821 1

5003 P, F (200V) PG 9 2,1 1822 3

5004 P, F (200V) PG 9 2,1 1823 3

5005 P, F (200V) PG 9 2,2 1824 4

5006 P, F (200V) PG 9 3,0 1825 6

5008 P, F (200V) PG 9 3,5 1826 7

5011 P, F (200V) PG 16 5,8 1827 9

5016 P, F (200V) PG 21 13,5 1828 12

5022 P, F (200V) PG 21 15,0 1829 12

5027 P, F (200V) PG 21 16,5 1830 12

5032 P, F (200V) PG 21 19,0 1954 12

5042 P, F (200V) PG 21 20,0 1955 13

5052 P, F (200V) PG 21 32,0 1956 14

5001 P, F (500V) PG 9 1,1 1840 1

5002 P, F (500V) PG 9 1,2 1841 2

5003 P, F (500V) PG 9 2,1 1842 3

5004 P, F (500V) PG 9 2,1 1843 3

5005 P, F (500V) PG 9 2,2 1844 4

5006 P, F (500V) PG 9 2,4 1845 5

5008 P, F (500V) PG 9 3,0 1846 6

5011 P, F (500V) PG 9 3,5 1847 7

5016 P, F (500V) PG 16 5,8 1848 9

5022 P, F (500V) PG 16 13,5 1849 12

5027 P, F (500V) PG 16 15,0 1850 12

5032 P, F (500V) PG 16 15,0 1851 12

5042 P, F (500V) PG 21 16,5 1852 12

5052 P, F (500V) PG 21 19,0 1853 12

5062 P, F (500V) PG 21 36,0 2008 15

5072 P, F (500V) PG 21 40,0 0069 15

5075 P (500V) PG 21 49,0 1958 15

5075 F (500V) PG 29 65,0 0076 17

5100 P (500V) PG 21 52,0 1959 15

5100 F (500V) PG 36 67,0 0077 17

5102 P, F (500V) PG 21 40,0 0067 15

5125 P (500V) PG 29 56,0 1960 16

5125 F (500V) PG 36 90,0 0078 18

5150 P (500V) PG 29 66,0 1961 17

5150 F (500V) PG 36 94,0 0079 18

5200 P, F (500V) PG 36 72,0 1962 17

5250 P, F (500V) PG 36 125,0 1963 18

5300 P, F (500V) PG 36 70/pcs 2 x 1061 2x17

5350 P, F (500V) PG 36 90/pcs 2 x 1062 2x18

5450 P, F (500V) PG 36 90/pcs 2 x 1063 2x18

5500 P, F (500V) PG 42 125/pcs 2 x 1064 2x19

Cablegland Weight

[kg]

Code

number

175Uxxxx

Drawing

No.

overview

Brake resistor

MI.90.F1.02 - VLT is a registered Danfoss trademark

19

Page 20

■Brake resistor for VLT 5001-5102 40% duty-cycle

cablegland, weight and drawing no.

VLT®2800/5000/5000 FLUX/FCD 300

VLT type

P=Process

F=FLUX

5001 P, F (200V) PG 9 2,1 1920 3

5002 P, F (200V) PG 9 2,2 1921 4

5003 P, F (200V) PG 9 3,0 1922 6

5004 P, F (200V) PG 9 3,5 1923 7

5005 P, F (200V) PG 16 4,6 1924 8

5006 P, F (200V) PG 16 13,5 1925 12

5008 P, F (200V) PG 16 15,0 1926 12

5011 P, F (200V) PG 21 16,5 1927 12

5016 P, F (200V) PG 21 25,0 1928 14

5022 P, F (200V) PG 21 25,0 1929 14

5027 P, F (200V) PG 21 32,0 1930 15

5001 P, F (500V) PG 9 2,1 1940 3

5002 P, F (500V) PG 9 2,2 1941 4

5003 P, F (500V) PG 9 3,0 1942 6

5004 P, F (500V) PG 16 4,6 1943 8

5005 P, F (500V) PG 16 5,8 1944 9

5006 P, F (500V) PG 16 7,2 1945 10

5008 P, F (500V) PG 16 7,6 1946 11

5011 P, F (500V) PG 16 16,5 1947 12

5016 P, F (500V) PG 16 17,0 1948 12

5022 P, F (500V) PG 21 25,0 1949 14

5027 P, F (500V) PG 21 32,0 1950 14

5032 P, F (500V) PG 21 34,0 1951 15

5042 P, F (500V) PG 21 35,0 1952 15

5052 P, F (500V) PG 29 47,0 1953 16

5062 P, F (500V) PG 36 95,0 2007 18

5072 P, F (500V) PG 36 125 0068 18

5102 P, F (500V) PG 36 150 0066 18

5125 F (500V) PG 36 90/pcs 2 x 0072 2x18

5150 F (500V) PG 36 95/pcs 2 x 0073 2x18

Cablegland Weight

[kg]

Code

number

175Uxxxx

Drawing

No.

20

MI.90.F1.02 - VLT is a registered Danfoss trademark

Page 21

■Brake resistor for VLT 2803-2882 40% duty-cycle

cablegland, weight and drawing no.

VLT®2800/5000/5000 FLUX/FCD 300

VLT type Cablegland Weight

[kg]

2803 (200 V) PG 7 (Thermo) / PG 9 (power) 1,2 1900 2

2805 (200 V) PG 7 (Thermo) / PG 9 (power) 2,1 1901 3

2807 (200 V) PG 7 (Thermo) / PG 9 (power) 2,1 1902 3

2811 (200 V) PG 7 (Thermo) / PG 9 (power) 2,2 1975 4

2815 (200 V) PG 7 (Thermo) / PG 9 (power) 2,4 1903 5

2822 (200 V) PG 7 (Thermo) / PG 9 (power) 3,5 1904 7

2840 (200 V) PG 16 13,5 1925 12

2805 (400 V) PG 7 (Thermo) / PG 9 (power) 2,2 1976 4

2807 (400 V) PG 7 (Thermo) / PG 9 (power) 2,2 1910 4

2811 (400 V) PG 7 (Thermo) / PG 9 (power) 2,4 1911 5

2815 (400 V) PG 7 (Thermo) / PG 9 (power) 3,0 1912 6

2822 (400 V) PG 7 (Thermo) / PG 9 (power) 3,5 1913 7

2830 (400 V) PG 7 (Thermo) / PG 16 (power) 4,6 1914 8

2840 (400 V) PG 7 (Thermo) / PG 16 (power) 4,6 1979 8

2855 (400 V) PG 7 (Thermo) / PG 16 (power) 5,8 1977 9

2875 (400 V) PG 7 (Thermo) / PG 16 (power) 7,6 1978 11

2880 (400 V) PG 21 17 1997 12

2881 (400 V) PG 21 25 1998 14

2882 (400 V) PG 21 34 1999 15

Code

number

175Uxxxx

Drawing

No.

overview

Brake resistor

■Brake resistor for VLT FCD 303-335 40% duty-cycle

cablegland, weight and drawing no.

VLT type Cablegland Weight

303 (400 V) PG 7 (Thermo) / PG 9 (power) 2,2 1976 4

305 (400 V) PG 7 (Thermo) / PG 9 (power) 2,2 1976 4

307 (400 V) PG 7 (Thermo) / PG 9 (power) 2,2 1910 4

311 (400 V) PG 7 (Thermo) / PG 9 (power) 2,4 1911 5

315 (400 V) PG 7 (Thermo) / PG 9 (power) 3,0 1912 6

322 (400 V) PG 7 (Thermo) / PG 9 (power) 3,5 1913 7

330 (400 V) PG 7 (Thermo) / PG 16 (power) 4,6 1914 8

335 (400 V) PG 7 (Thermo) / PG 16 (power) 4,6 1914 8

[kg]

Code

number

175Uxxxx

Drawing

No.

MI.90.F1.02 - VLT is a registered Danfoss trademark

21

Page 22

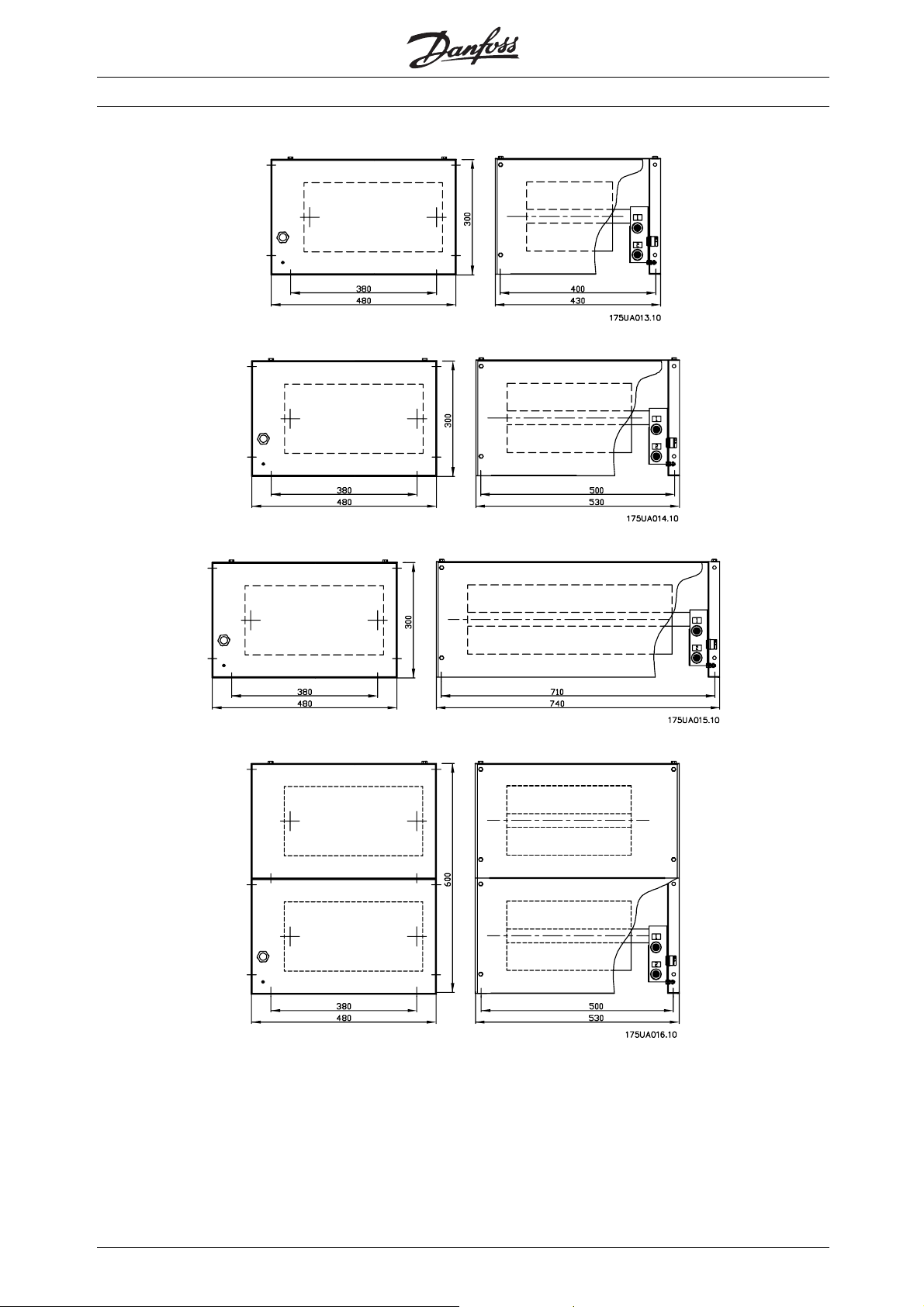

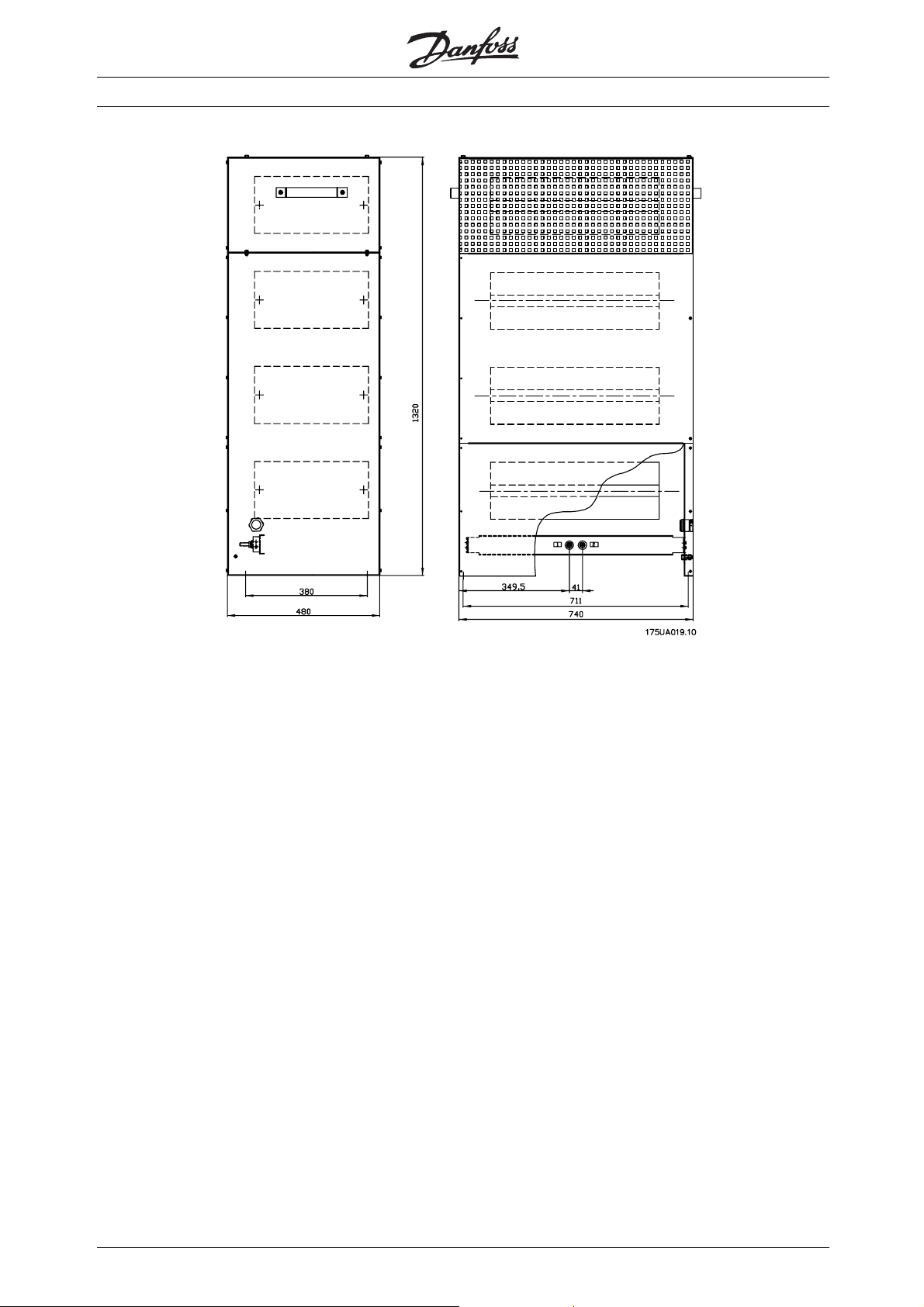

■Drawing no. 1

■Drawing no. 2

VLT®2800/5000/5000 FLUX/FCD 300

■Drawing no. 3

22

MI.90.F1.02 - VLT is a registered Danfoss trademark

Page 23

■Drawing no. 4

■Drawing no. 5

VLT®2800/5000/5000 FLUX/FCD 300

- 19

■Drawing no. 6

Drawings 1

MI.90.F1.02 - VLT is a registered Danfoss trademark

23

Page 24

■Drawing no. 7

■Drawing no. 8

VLT®2800/5000/5000 FLUX/FCD 300

■Drawing no. 9

24

MI.90.F1.02 - VLT is a registered Danfoss trademark

Page 25

■Drawing no. 10

VLT®2800/5000/5000 FLUX/FCD 300

■Drawing no. 11

■Drawing no. 12

- 19

Drawings 1

MI.90.F1.02 - VLT is a registered Danfoss trademark

25

Page 26

■Drawing no. 13

■Drawing no. 14

VLT®2800/5000/5000 FLUX/FCD 300

■Drawing no. 15

■Drawing no. 16

26

MI.90.F1.02 - VLT is a registered Danfoss trademark

Page 27

■Drawing no. 17

■Drawing no. 18

VLT®2800/5000/5000 FLUX/FCD 300

- 19

Drawings 1

MI.90.F1.02 - VLT is a registered Danfoss trademark

27

Page 28

■Drawing no. 19

VLT®2800/5000/5000 FLUX/FCD 300

28

MI.90.F1.02 - VLT is a registered Danfoss trademark

Loading...

Loading...