Page 1

MAKING MODERN LIVING POSSIBLE

Instruction Manual

Vertical Bypass/Non Bypass Panel

Page 2

Safety Vertical Bypass/Non Bypass Panel

Safety

WARNING

EQUIPMENT HAZARD!

The vertical bypass/non bypass panel contains dangerous

voltages when connected to mains voltage. It is strongly

recommended that all electrical work conform to the

National Electrical Code (NEC) and all national and local

regulations. Installation, start-up and maintenance should

be performed only by qualified personnel. Failure to follow

the NEC or local regulations could result in death or

serious injury.

Motor control equipment and electronic controls are

connected to hazardous mains voltages. Extreme care

should be taken to protect against shock. The user must

be protected against supply voltage and the motor must

be protected against overload in accordance with

applicable national and local regulations. Be sure

equipment is properly grounded. Wear safety glasses

whenever working on electric control or rotating

equipment.

WARNING

UNINTENDED START!

When the vertical bypass/non bypass panel is connected

to AC input power, the motor may start at any time. The

drive, panel, motor, and any driven equipment must be in

operational readiness. Failure to be in operational

readiness when panel and drive are connected to AC input

power could result in death, serious injury, or equipment

or property damage.

Grounding

Correct protective grounding of the equipment must be

established in accordance with national and local codes.

Ground currents are higher than 3mA.

Safety Guidelines

1. Disconnect the drive and vertical bypass/non

bypass panel from mains before commencing

service work

2. DO NOT touch electrical parts of the vertical

bypass/non bypass panel or drive when mains is

connected. After mains has been disconnected,

wait 15 minutes before touching any electrical

components or read the label on vertical

bypass/non bypass panel.

3. The user must be protected against supply

voltage and the motor must be protected against

overload in accordance with applicable national

and local regulations.

4. While programming parameters, the motor may

start without warning. Activate the [Off] key on

the LCP when changing parameters.

5. The [Off] key on the LCP does not isolate the

drive from mains voltage and is not to be used as

a safety switch.

Warning against unintended start

When the vertical bypass/non bypass panel is connected

to mains, the motor may be started by means of an

external switch, a serial bus command, an input reference

signal, or a cleared fault condition. Use appropriate

cautions to guard against an unintended start.

WARNING

GROUNDING HAZARD!

For operator safety, it is important to ground drive, vertical

bypass panel, and motor properly. Follow the grounding

guidelines of local and national codes. Failure to follow

grounding guidelines could result in death or serious

injury.

MG.13.A1.22 - VLT® is a registered Danfoss trademark

Page 3

Safety Vertical Bypass/Non Bypass Panel

MG.13.A1.22 - VLT® is a registered Danfoss trademark

Page 4

Contents Vertical Bypass/Non Bypass Panel

Contents

1 Introduction

1.1.1 Purpose of the Manual 2-1

1.1.2 Overview 2-1

1.1.3 Typical Bypass Operation 2-1

1.2 Bypass Circuits

1.2.1 Three-contactor Bypass 2-1

1.3 Bypass Options

1.3.1 Common Run/Stop with Bypass 2-2

1.3.2 Automatic Bypass 2-2

1.3.3 Run Permissive in Bypass 2-2

1.3.4 Basic Fire Mode in Bypass 2-2

1.3.5 Advanced Fire Mode in Bypass 2-2

1.3.6 Overload Protection 2-2

1.4 Bypass Platform Configurations

1.5 Switch Mode Power Supply

1.5.1 Control Transformer 2-3

1.6 Disconnects

2-1

2-1

2-2

2-3

2-3

2-3

1.6.1 Main Disconnect 2-3

1.6.2 Mode Selector Switch 2-4

1.6.3 Panel Configurations 2-5

1.6.4 Panel Voltage and Frame Ratings 2-6

1.7 Power Component Functions

1.7.1 Power Fusing 2-6

2 Pre-installation

2.1.1 Receiving Inspection 3-1

2.1.2 Pre-installation Check 3-1

2.1.3 Installation Site Check 3-1

2.2 Harsh Environments

2.2.1 Airborne Liquids 3-2

2.2.2 Airborne Solids 3-2

2.2.3 Corrosive Chemicals 3-2

3 Installation

3.1.1 Tools Required 4-1

2-6

3-1

3-2

4-1

3.1.2 Drive Fuses 4-1

3.1.3 Internal Main Panel Fuses 4-5

3.2 Mechanical Installation

MG.13.A1.22 - VLT® is a registered Danfoss trademark

4-5

Page 5

Contents Vertical Bypass/Non Bypass Panel

3.2.1 Lifting 4-5

3.2.2 Hoist or Overhead Lift 4-5

3.2.3 Forklift 4-5

3.2.4 Shipping Weights 4-5

3.3 Cooling

3.4 Electrical Installation

3.4.1 Component Identification & Customer Connection 4-8

3.4.2 Wire and Cable Access 4-16

3.4.3 Wire Size 4-19

3.4.4 Wire Type Rating 4-21

3.4.5 Terminal Tightening Torques 4-21

3.4.6 Input Line Connection 4-25

3.4.7 Motor Wiring 4-25

3.4.8 Grounding (Earthing) 4-26

3.4.9 Control Wiring 4-26

3.4.10 Serial Communication Bus Connection 4-26

3.4.11 Drive Control Terminals 4-27

4 Start Up

4.1.1 Inspection Prior to Start Up 5-2

4.1.2 Start Up Procedure 5-2

4-6

4-7

5-1

5 Electromechanical Bypass (EMB2) Operation

5.1.1 Typical Control Connections for Common HVAC Applications 6-1

5.1.2 EMB2 Auto Bypass 6-3

5.1.3 EMB2 Common Run/Stop 6-3

5.1.4 EMB2 Run Permissive 6-4

5.1.5 EMB2 Overload 6-4

5.1.6 EMB2 Safety Interlock 6-5

5.1.7 EMB2 Fire Mode 6-5

5.1.8 EMB2 Fault Reporting 6-5

5.1.9 EMB2 Switches 6-6

6 Electronically Controlled Bypass (ECB) Operation

6.1 Electronically Controlled Bypass (ECB) Operation

6.1.1 Overview 7-1

6.1.2 ECB Control Card 7-2

6.1.3 ECB Drive or Bypass Selection 7-5

6.1.4 ECB Programming 7-7

6-1

7-1

7-1

MG.13.A1.22 - VLT® is a registered Danfoss trademark

Page 6

Contents Vertical Bypass/Non Bypass Panel

6.1.5 ECB Hand/OFF/Auto 7-8

6.1.6 ECB Mode of Operation 7-8

6.1.7 Bypass Status Word Bit Examples 7-10

6.1.8 ECB Auto Bypass 7-10

6.1.9 ECB Run Permissive 7-11

6.1.10 ECB Overload 7-11

6.1.11 ECB Safety Interlock 7-12

6.1.12 ECB Common Run/Stop 7-12

6.1.13 ECB Advanced Fire Mode 7-13

6.1.14 ECB Fault Reporting 7-13

7 Start Up Troubleshooting

7.1.1 Option Panel Alarm and Warnings 8-1

8 Appendix

8.1.1 Dimensions 9-1

8.1.2 Mechanical Diagrams 9-2

8.1.3 Typical Wiring Diagrams 9-6

8-1

9-1

MG.13.A1.22 - VLT® is a registered Danfoss trademark

Page 7

Contents Vertical Bypass/Non Bypass Panel

Contents | Figure

Figure 1.1: Basic Non Bypass Circuit 1-2

Figure 1.2: Basic Bypass Circuit 1-3

Figure 2.1: Sample Panel Label 2-1

Figure 3.1: Proper Lifting Method 3-5

Figure 3.2: Side Cooling Clearance 3-6

Figure 3.3: Cooling Airflow 3-6

Figure 3.4: Power Connections 3-7

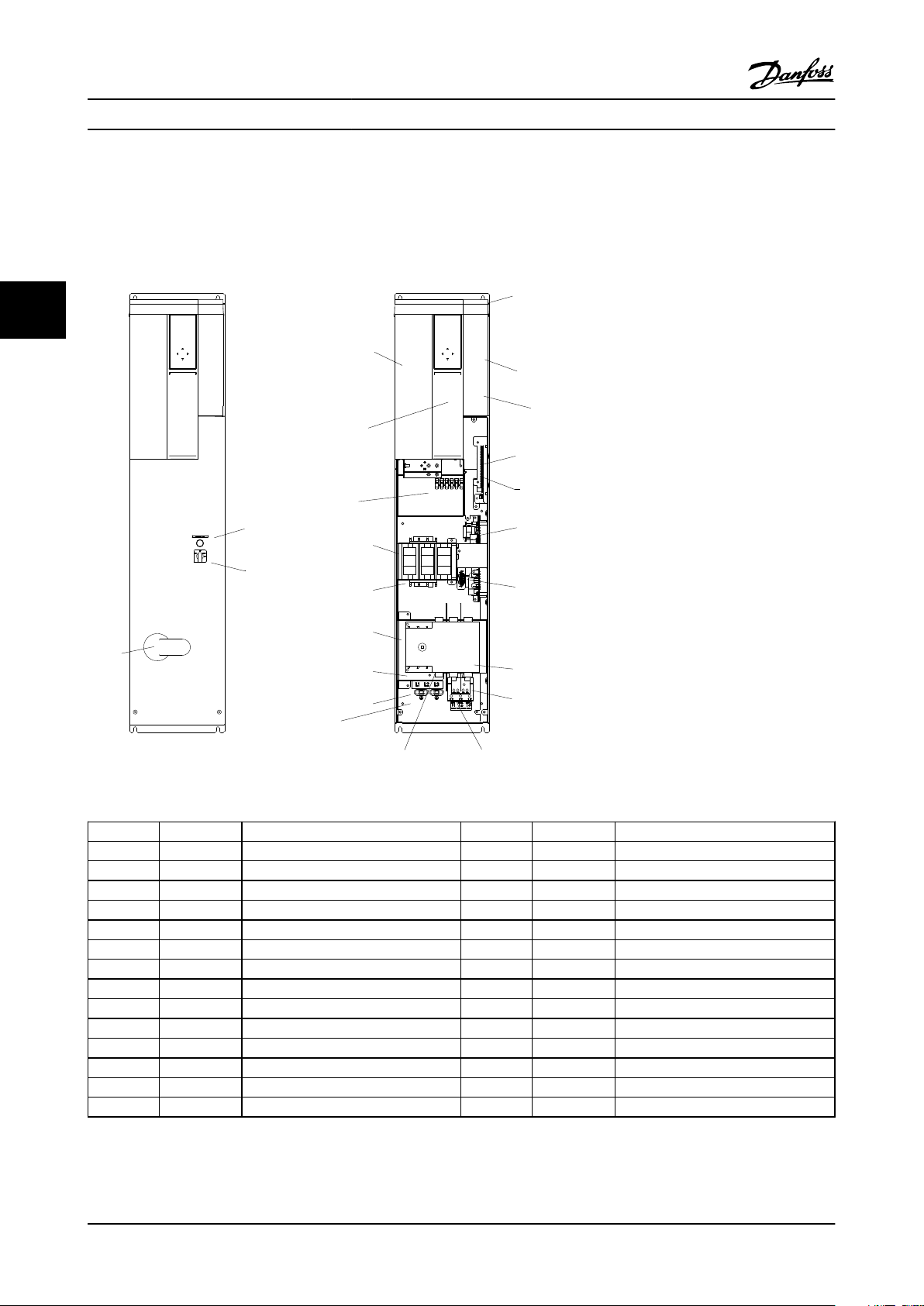

Figure 3.5: P2 Bypass Mechanical Layout Diagram 3-8

Figure 3.6: P2 Non Bypass Mechanical Layout Diagram. 3-9

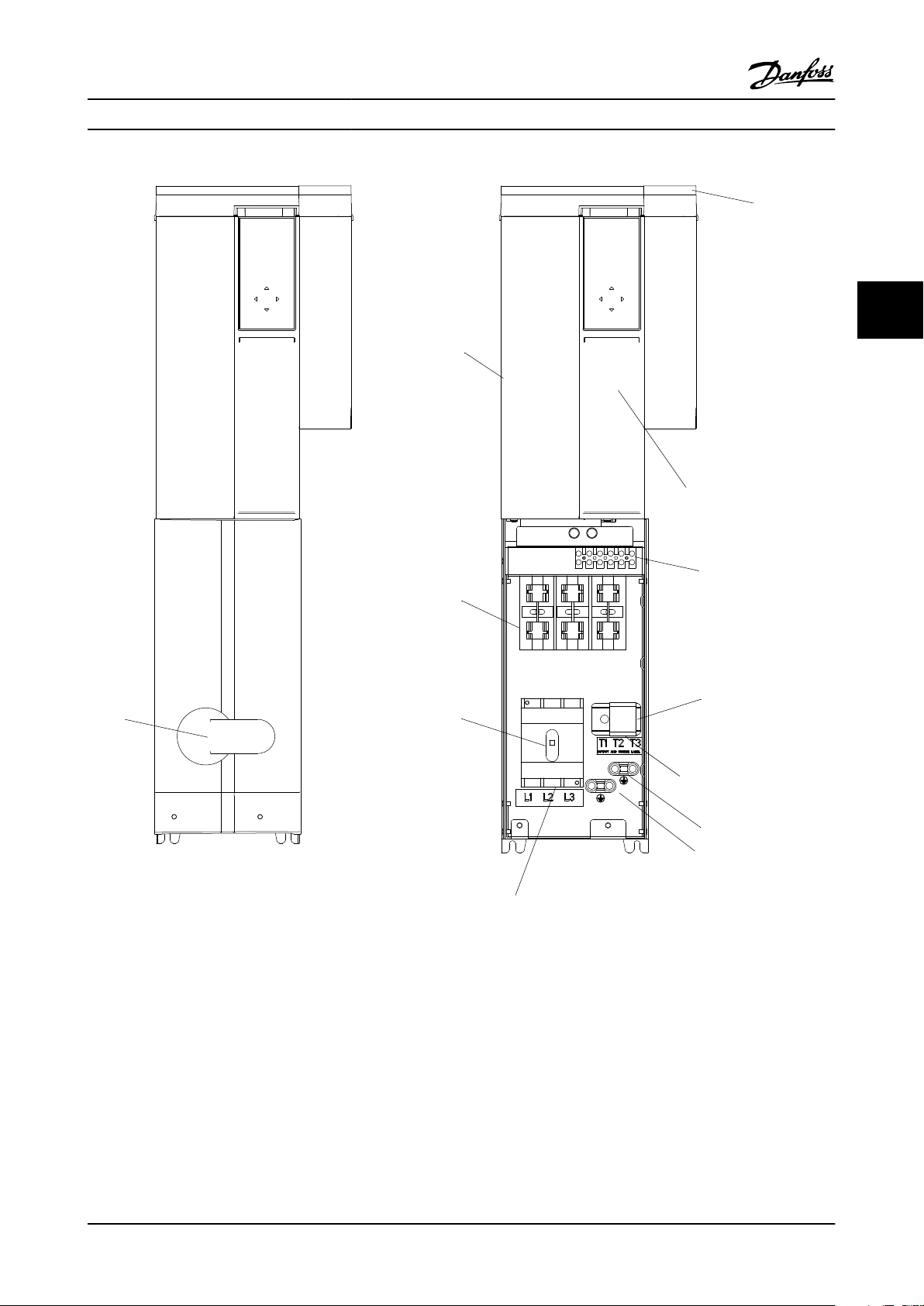

Figure 3.7: P3 Bypass Mechanical Layout Diagram. 3-10

Figure 3.8: P3 Non Bypass Mechanical Layout Diagram. 3-11

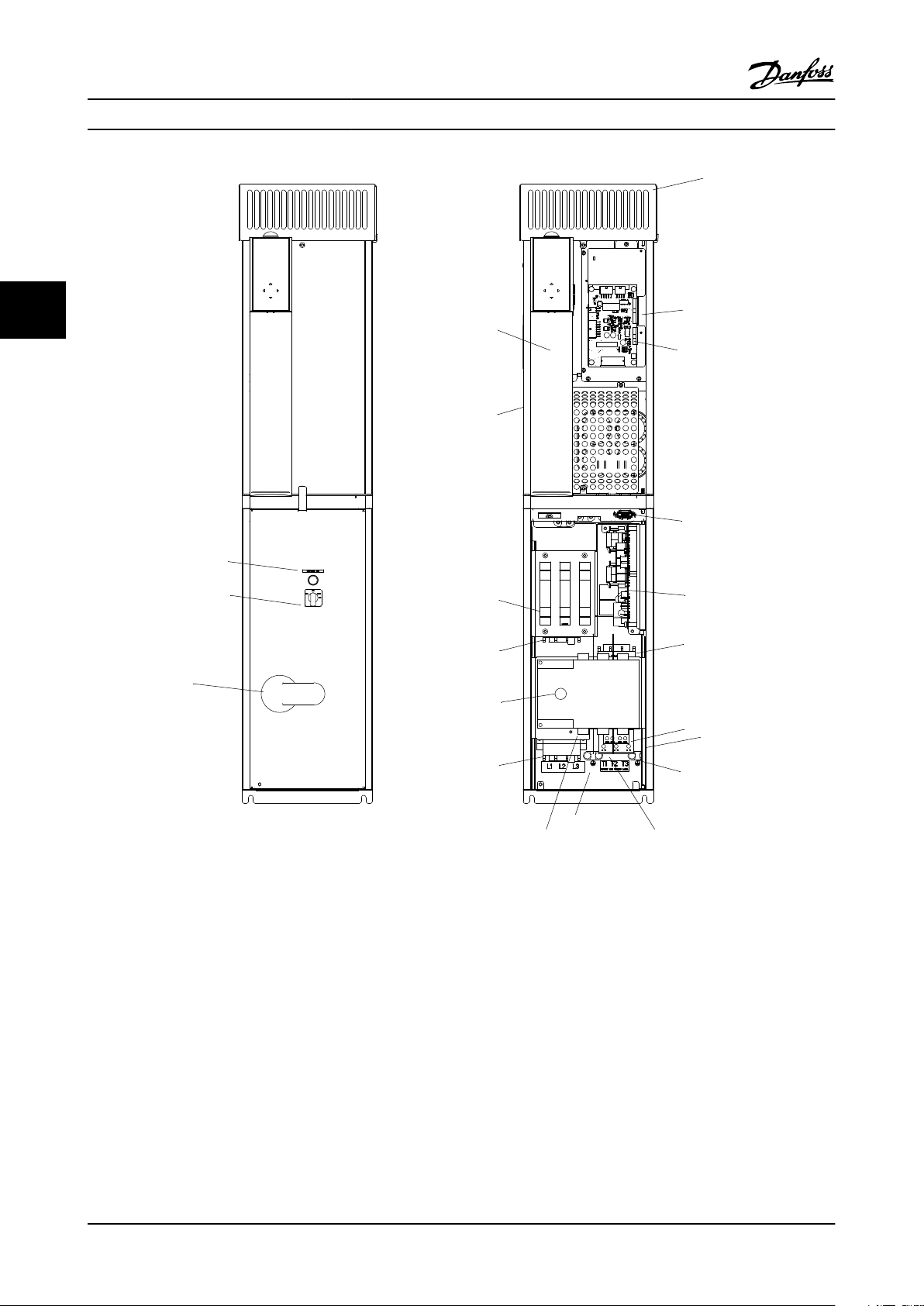

Figure 3.9: P4 Bypass Mechanical Layout Diagram. 3-12

Figure 3.10: P4 Non Bypass Mechanical Layout Diagram. 3-13

Figure 3.11: P5 Bypass Mechanical Layout Diagram. 3-14

Figure 3.12: P5 Non Bypass Mechanical Layout Diagram. 3-15

Figure 3.13: Bypass Panel Conduit Entry Diagram 3-16

Figure 3.14: Non Bypass Panel Conduit Entry Diagram 3-16

Figure 3.15: P2 Panel 3-17

Figure 3.16: P3 Panel 3-17

Figure 3.17: P4 Panel 3-18

Figure 3.18: P5 Panel 3-19

Figure 3.19: Control Terminals Location 3-26

Figure 3.20: Removable Drive Connectors and Terminals 3-27

Figure 5.1: Customer Side EMB2 Control Card Terminal Connections 5-2

Figure 5.2: Sample Overload Device 5-5

Figure 6.1: Local Control Panel (LCP) 6-1

Figure 6.2: ECB Control Card Terminal Connections 6-3

Figure 6.3: Bypass Trip Time Delay 6-10

Figure 6.4: Drive Display with Bypass Start Time Delay Active 6-11

Figure 6.5: Sample Overload Device 6-12

Figure 8.1: P2 Bypass 8-2

Figure 8.2: P2 Non-bypass 8-3

Figure 8.3: P3 P4 P5 Bypass 8-4

Figure 8.4: P3 P4 P5 Non-bypass 8-5

Figure 8.5: EMB2 with Control Relay, Part 1 8-6

Figure 8.6: EMB2 with Control Relay, Part 2 8-7

Figure 8.7: EMB2, Part 1 8-8

MG.13.A1.22 - VLT® is a registered Danfoss trademark

Page 8

Contents Vertical Bypass/Non Bypass Panel

Figure 8.8: EMB2, Part 2 8-9

Figure 8.9: ECB, Part 1 8-10

Figure 8.10: ECB, Part 2 8-11

Figure 8.11: ECB with Control Relays, Part 1 8-12

Figure 8.12: ECB with Control Relays, Part 2 8-13

Figure 8.13: Non-bypass 8-14

MG.13.A1.22 - VLT® is a registered Danfoss trademark

Page 9

Contents Vertical Bypass/Non Bypass Panel

Contents | Table

Table 1.1: Contactor Operation 1-2

Table 1.2: Bypass Configurations 1-3

Table 1.3: Tier Definitions and Features 1-5

Table 1.4: Panel Voltage and Frame Ratings 1-6

Table 3.1: Tools Required 3-1

Table 3.2: Drive Fuses 208 V 3-1

Table 3.3: Drive Fuses 230 V 3-2

Table 3.4: Drive Fuses 460 V 3-3

Table 3.5: Drive Fuses 600 V 3-4

Table 3.6: Sample Fuse Rating Label 3-5

Table 3.7: Approximate Shipping Weights 3-5

Table 3.8: Reference Designator Definitions 3-8

Table 3.9: Wire Size Chart, 208 and 230 V 3-20

Table 3.10: Wire Size Chart 460 and 600 V 3-21

Table 3.11: Tightening Torques, 208 and 230 V 3-22

Table 3.12: Tightening Torques, 460 V 3-23

Table 3.13: Tightening Torques, 600 V 3-24

Table 3.14: Sample Tightening Torque and Wire Rating Label 3-25

Table 3.15: Drive Control Terminals Functions 3-27

Table 4.1: Inspection prior to Startup 4-2

Table 5.1: EMB2 Default Parameter Settings for Common HVAC Applications 5-1

Table 5.2: Common Functions for Controlling Motor using Bypass and Typical Terminal Connections. 5-1

Table 6.1: Parameter Group 5-** Factory Default Settings 6-2

Table 6.2: ECB Card Terminals 6-4

Table 6.3: LCP Control Keys Programming 6-8

Table 6.4: Bypass Parameter Functions 6-9

Table 6.5: Parameter 31-10 Bypass Status Word Bit Definitions 6-9

Table 7.1: Panel Alarms and Warnings (ECB only) 7-1

Table 7.2: Panel Status Display (ECB only) 7-1

Table 7.3: Fault Table 7-2

MG.13.A1.22 - VLT® is a registered Danfoss trademark

Page 10

Introduction Vertical Bypass/Non Bypass Panel

1 Introduction

1.1.1 Purpose of the Manual

This manual is intended to provide detailed information for

the installation and operation of the vertical panel used in

conjunction with a Danfoss variable frequency drive (VFD).

To enable efficient handling of the equipment,

requirements are provided for installation of mechanical,

electrical, control wiring, proper grounding, and environmental considerations. Pre-start and start up procedures

are detailed. Also included is a detailed overview of the

panel bypass function. In addition, identification of other

optional components and their operation and start up

troubleshooting instructions are included. For the electronically controlled bypass, additional programming and

operation information is provided.

Overview

1.1.2

A variable frequency drive regulates the speed and

operation of an electric motor. The drive is programmable

and offers many features and savings compared to

operating a motor from unregulated line voltage. The

panel is a protective enclosure in which the drive and

various optional components are assembled and mounted.

The vertical non bypass panel is always configured with a

disconnect switch and fuses to protect the drive. The

vertical bypass panel allows switching between running

the motor from the drive (variable speed) or across the line

input power (constant speed).

The vertical bypass panel comes with one of two control

options:

The electromechanical bypass (EMB2)

•

Electronically controlled bypass (ECB)

•

The EMB2 is operated by a selector switch on the front of

the panel. The EMB2 controls a motor by switching

between drive control, operation in bypass, or off. In

addition, a test selection is available, which disengages the

motor from the drive but keeps the drive operational while

the motor runs in bypass. The switching function activates

contactors to provide power to the motor through the

drive or bypass circuitry, as required.

inputs, and status reporting. The VFD’s logic circuitry is

backed up by an independent panel-mounted power

supply so that, even if the drive loses power, control and

communication functions are maintained. Programming

and display are provided by the LCP. An important feature

of the ECB is the ability to accept commands from a

building automation system (BAS) and to report

operational status in return.

See more detailed descriptions of the EMB2 in 5 Electrome-

chanical Bypass (EMB2) Operation and ECB in 6 Electronically

Controlled Bypass (ECB) Operation of this manual.

Typical Bypass Operation

1.1.3

With contactors M1 and M2 closed and contactor M3

open, the motor is running in drive control. Opening

contactor M2 removes power to the motor but allows the

drive to remain under power. This is referred to as test

mode. With contactors M1 and M2 open and contactor M3

closed, the motor is running in bypass from the line input

power.

1.2

Bypass Circuits

1.2.1 Three-contactor Bypass

The bypass circuit consists of a bypass contactor (M3)

interlocked with a drive output contactor (M2), a drive

input contactor (M1), and an overload relay. For the EMB2,

a door mounted Drive/OFF/Bypass/Test Selector switch is

used to electrically select whether the motor is powered

by the drive, connected to the full speed bypass, or

disconnected from both. The test position applies power

to the motor through the bypass (M3 closed) contactor but

removes power from the drive (M2 open) while keeping

the drive powered (M1 closed). A Pilot light indicates when

in bypass. For the ECB, control selection is made through

the drive keypad by pressing the DRIVE BYPASS key and

selecting from the available options shown. Display data

indicates when in bypass. The circuitry may be supplied

with either an input disconnect switch or an input circuit

breaker.

1 1

The ECB also uses contactors to provide power to the

motor through the drive or bypass circuitry. However, the

ECB contains a local processor that interacts with the

drive’s control logic for programmable options, remote

MG.13.A1.22 - VLT® is a registered Danfoss trademark 1-1

Page 11

T3

T2

T1

CUSTOMER SUPPLIED

AC MOTOR.

INPUT

POWER

EARTH

GROUND

TYPE 1 ENCLOSURE

130BX360.11

W/98

U/96

V/97

VFD

L1

L2

L3

Fuse

Fuse

Fuse

DISCONNECT

DS1

DRIVE

1L1

1L2

1L3

2L1

2L2

2L3

L2/92

L1/91

L3/93

Introduction Vertical Bypass/Non Bypass Panel

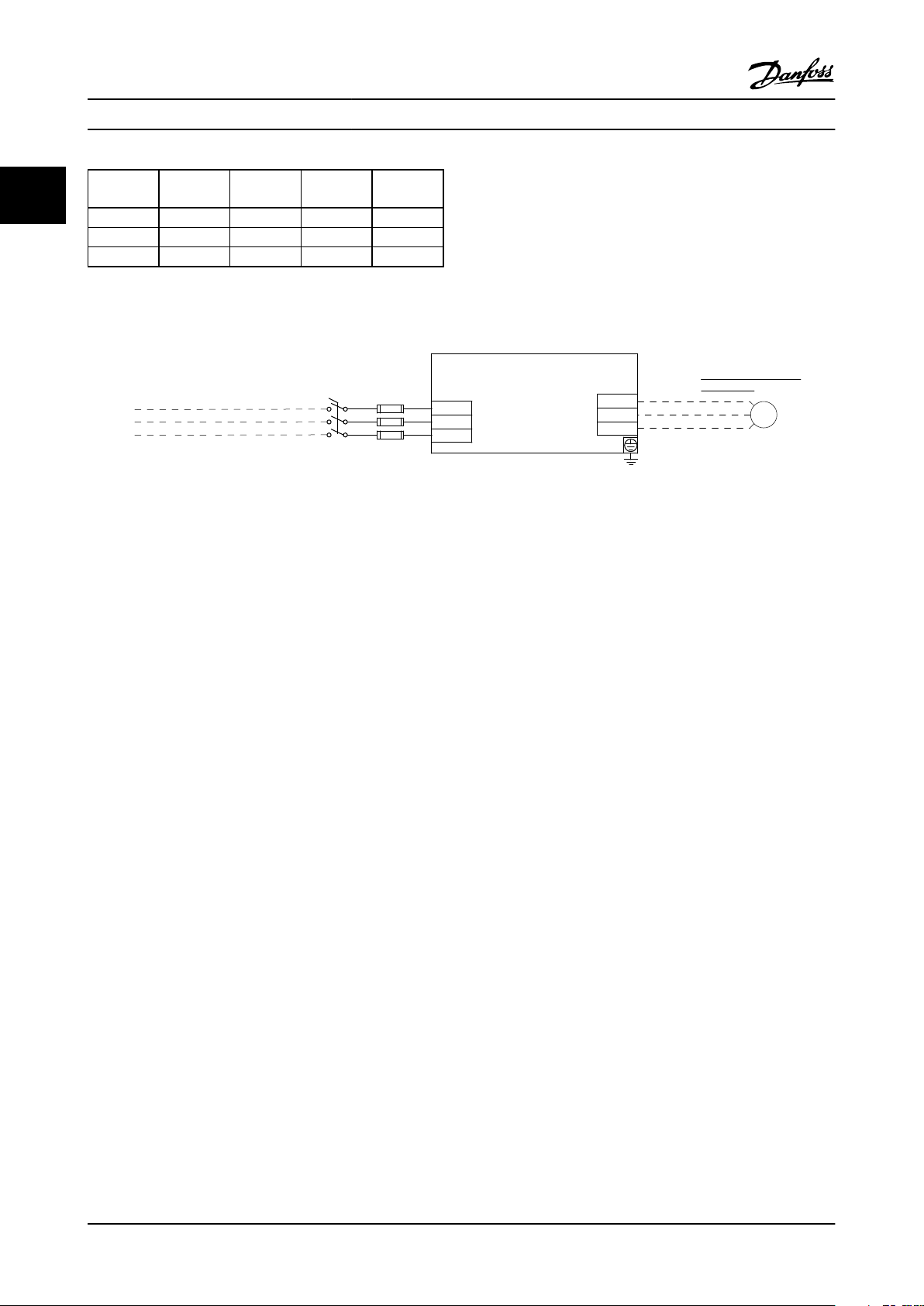

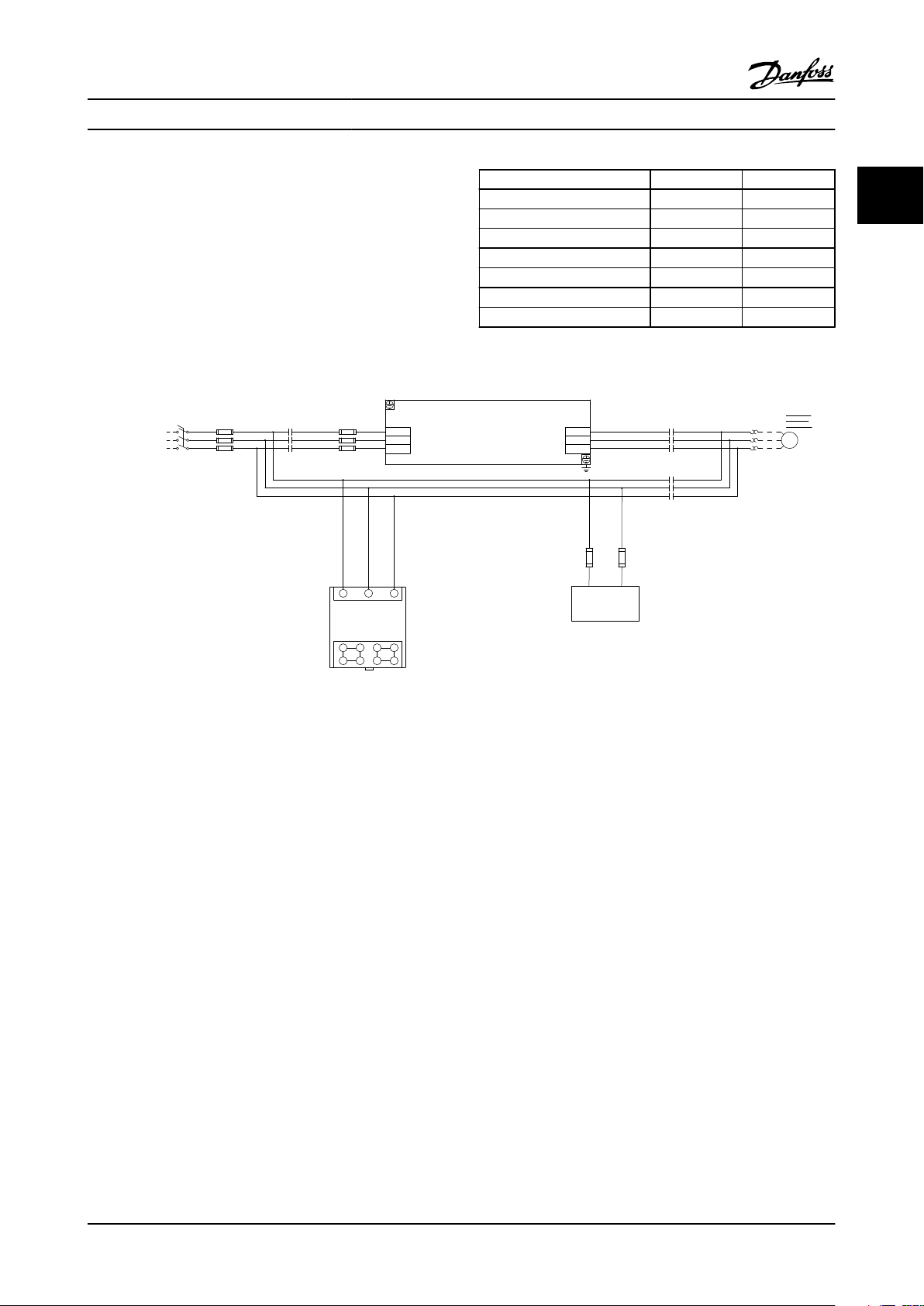

Contactor Drive Mode OFF Bypass

11

M1 Closed Open Open Closed

M2 Closed Open Open Open

M3 Open Open Closed Closed

Table 1.1 Contactor Operation

Figure 1.1 Basic Non Bypass Circuit

Mode

1.3 Bypass Options

1.3.1 Common Run/Stop with Bypass

Test Mode

Basic Fire Mode in Bypass

1.3.4

This option switches the panel to bypass whenever a

remote fire mode signal is given to the VFD through the

input terminals. In either drive or bypass, fire mode is

Allows a remote signal to initiate operation in either drive

control or bypass depending upon the position of the

bypass selector switch.

intended to ignore common safety and overload inputs for

emergency situations. The motor will continue to run in

bypass until fire mode is removed or the drive, panel, or

motor fails. External safety signals and motor overload are

1.3.2 Automatic Bypass

ignored when in fire mode.

This feature automatically transfers the motor from drive to

1.3.5 Advanced Fire Mode in Bypass

bypass without operator intervention when a fault

condition trips the drive, after a programmable time-out

period. The VFD’s internal fault circuitry controls this

action. The time delay permits all automatically resettable

faults to clear prior to transfer to bypass. Run permissive or

safety circuit signals override the auto bypass function and

The advanced fire mode allows for a variety of

programmable responses to an external fire mode

command signal. Bypass options are programmed through

the drive’s fire mode parameters. See 6.1.13 ECB Advanced

Fire Mode.

may prevent or delay bypass operation.

Overload Protection

1.3.6

Run Permissive in Bypass

1.3.3

This thermally activated device provides mechanical

With run permissive active, the drive sends a run request

and waits for a remote response before commanding the

motor to start. The response indicates the system is safe to

operate.

overload protection for the motor while in bypass

operation. It measures motor current and is set to the full

load amps (FLA) of the motor. A 1.2 x FLA service factor is

built-in and maintained, meaning that should the motor

current increase above that value, the overload will

calculate the level of increase to activate timing for the trip

function. The higher the current draw, the quicker the trip

response. The overload provides Class 20 motor protection.

1-2 MG.13.A1.22 - VLT® is a registered Danfoss trademark

Page 12

W/98

U/96

V/97

Fuse

Fuse

Fuse

Fuse

Fuse

INPUT

POWER

2T1

2T2

2T3

M2

M3

CUSTOMER

SUPPLIED

AC MOTOR

1T1

1T3

1T2

OL1

T1

T3

T2

MK902

2

6

24 V DC SMPS

MK901

1

5

MK903 MK904

374

8

- +

EARTH

GROUND

Type 1 Enclosure

VFD

EARTH

GROUND

2L3

M1

2L1

2L2

L2/92

L1/91

L3/93

TRANSFORMER

CONTROL

600V

600V

3L3

3L1

3L2

130BX361.11

MAIN DISCONNECT

DS1

Fuse

Fuse

Fuse

1L1

1L2

1L3

L2

L3

L1

Introduction Vertical Bypass/Non Bypass Panel

Control Features EMB2 ECB

1.4 Bypass Platform Configurations

The two bypass platform configurations are ECB and EMB2.

The features available as options with each platform are

listed in Table 1.2. The ECB, also listed below, has all option

features available. See 5 Electromechanical Bypass (EMB2)

Operation for additional details on the EMB2 and

Safety Interlock X X

Common Start / Stop X X

Automatic Bypass X X

Run Permissive X X

Basic Fire Mode X X

Advanced Fire Mode X

Serial Communication X

6 Electronically Controlled Bypass (ECB) Operation for the

ECB.

Table 1.2 Bypass Configurations

1 1

1.5 Switch Mode Power Supply

The VFD’s logic circuitry is backed up by an independent

panel-mounted switch mode power supply so if the drive

loses power, control and communication functions are

maintained. The SMPS converts three-phase AC input

power to 24 V DC control power. Since the SMPS draws

power from all three phases, it offers immunity protection

from most phase-loss and brown-out conditions. The SMPS

is internally protected from short circuit on its output and

three board-mounted fuses provide additional protection.

The SMPS is not designed for external use and may take

up to 5 sec. to initialize at power-up. The SMPS will

maintain a 24 V DC output with a low input line voltage.

The 200 Volt SMPS will maintain the 24 V DC output with

a line voltage as low as 150 V AC and the 600 V SMPS to

335 V AC. Refer to Figure 1.2.

Figure 1.2 Basic Bypass Circuit

Control Transformer

1.5.1

A control transformer is included on larger horsepower

units where the contactor coils are AC. The control

transformer steps down the line input voltage to 120V AC.

The coils of AC contactors are isolated from the Switch

Mode Power Supply via relays.

1.6 Disconnects

1.6.1 Main Disconnect

The main disconnect removes line input power to the

drive and bypass. A main disconnect is available in four

options.

Fused disconnect. Two-position (ON/OFF) rotary

•

switch, padlock compatible, with three fuses, one

on each phase, built into the switch. For safety,

the switch must be in the OFF position before

MG.13.A1.22 - VLT® is a registered Danfoss trademark 1-3

Page 13

Introduction Vertical Bypass/Non Bypass Panel

the option panel door can be opened. (Bypass

11

1.6.2

The mode selector switch is used for 3-contactor bypass

on EMB2 units. The selector switch allows the operator to

select from four modes of operation.

Drive mode: When drive mode is selected, the M1 and M2

contactors are closed allowing power to flow in and out of

the drive to the motor.

Off mode: This mode opens all contactors removing any

power to the motor.

Bypass mode:When bypass mode is selected, the M3

contactor closes and allows the motor to run directly from

the input line power.

Test mode:Test mode closes the M1 and M3 contactors

and allows the motor to be powered by the input line

power. This also allows the drive to power up without

being connected to the motor. Refer to Figure 1.2.

panel only.)

Disconnect without fuses. For user-supplied fuses

•

option. (Bypass panel only.)

Main circuit breaker. A thermal/ magnetic current

•

interrupt device using an ON/TRIP/OFF/RESET

switch. When in the ON position, a trip fault

removes power from the drive/bypass circuit and

the switch moves to the TRIP setting. The switch

must be moved to the RESET position

momentarily after the fault has been cleared to

reset the circuit breaker. (Bypass panel only.)

Main Disconnect with drive fuses. Non-bypass

•

panel two-position (ON/OFF) rotary switch that

disconnects the main AC line power to the drive

only.

Mode Selector Switch

1-4 MG.13.A1.22 - VLT® is a registered Danfoss trademark

Page 14

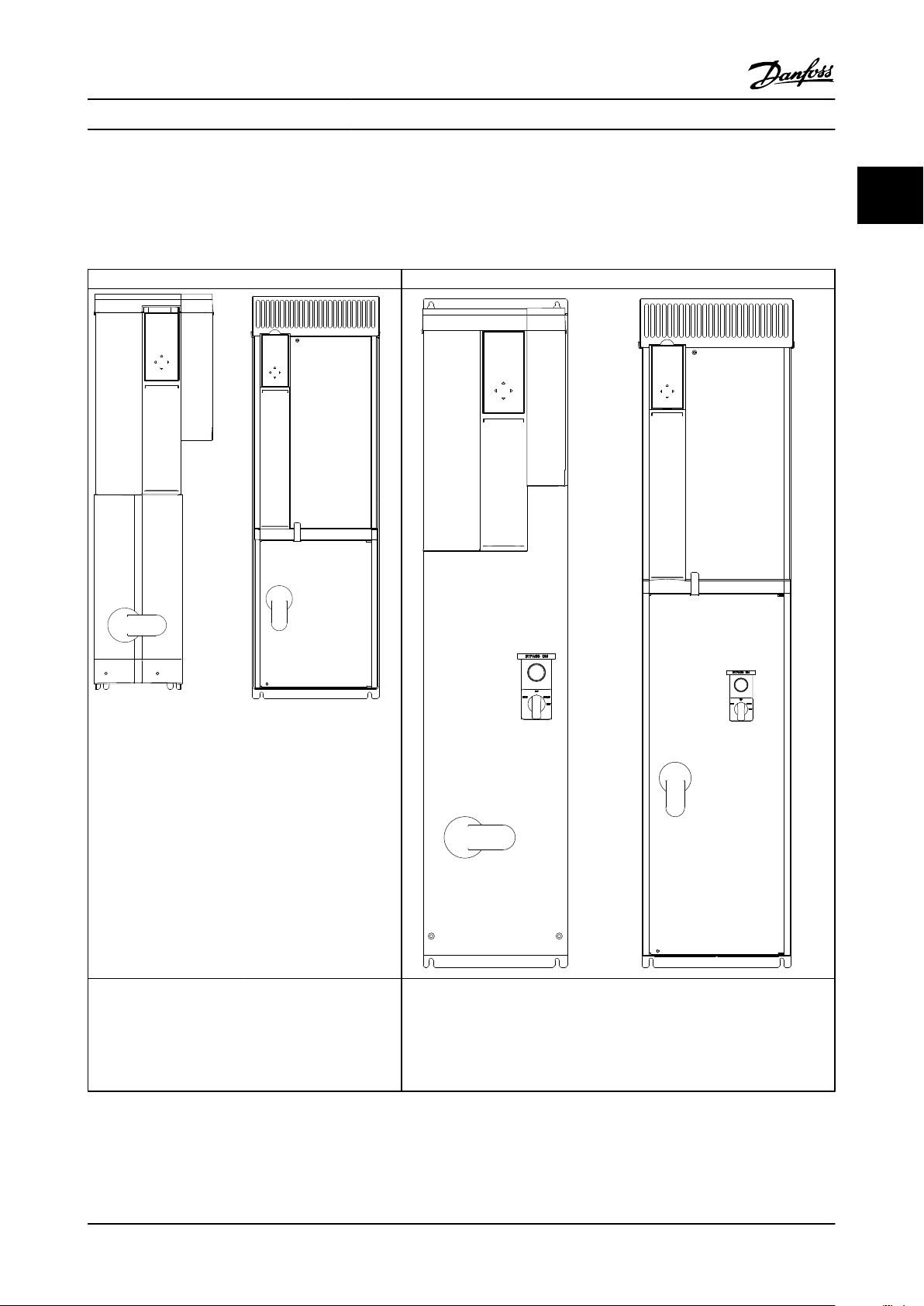

130BX363.10

130BX365.10

130BX362.10

130BX364.10

Introduction Vertical Bypass/Non Bypass Panel

1.6.3 Panel Configurations

The VLT FC Drive Series comes in two panel enclosure types. One is the non bypass and the other is the bypass. See

Table 1.3 for descriptions and available options.

Non bypass Bypass

1 1

Drive plus both of the following:

1. Fuses

2. Disconnect

Table 1.3 Tier Definitions and Features

Drive with bypass:

1. Fuses

2. Disconnect/Circuit Breaker

3. Contactors

4. Power Supply

5. Control Module

MG.13.A1.22 - VLT® is a registered Danfoss trademark 1-5

Page 15

Introduction Vertical Bypass/Non Bypass Panel

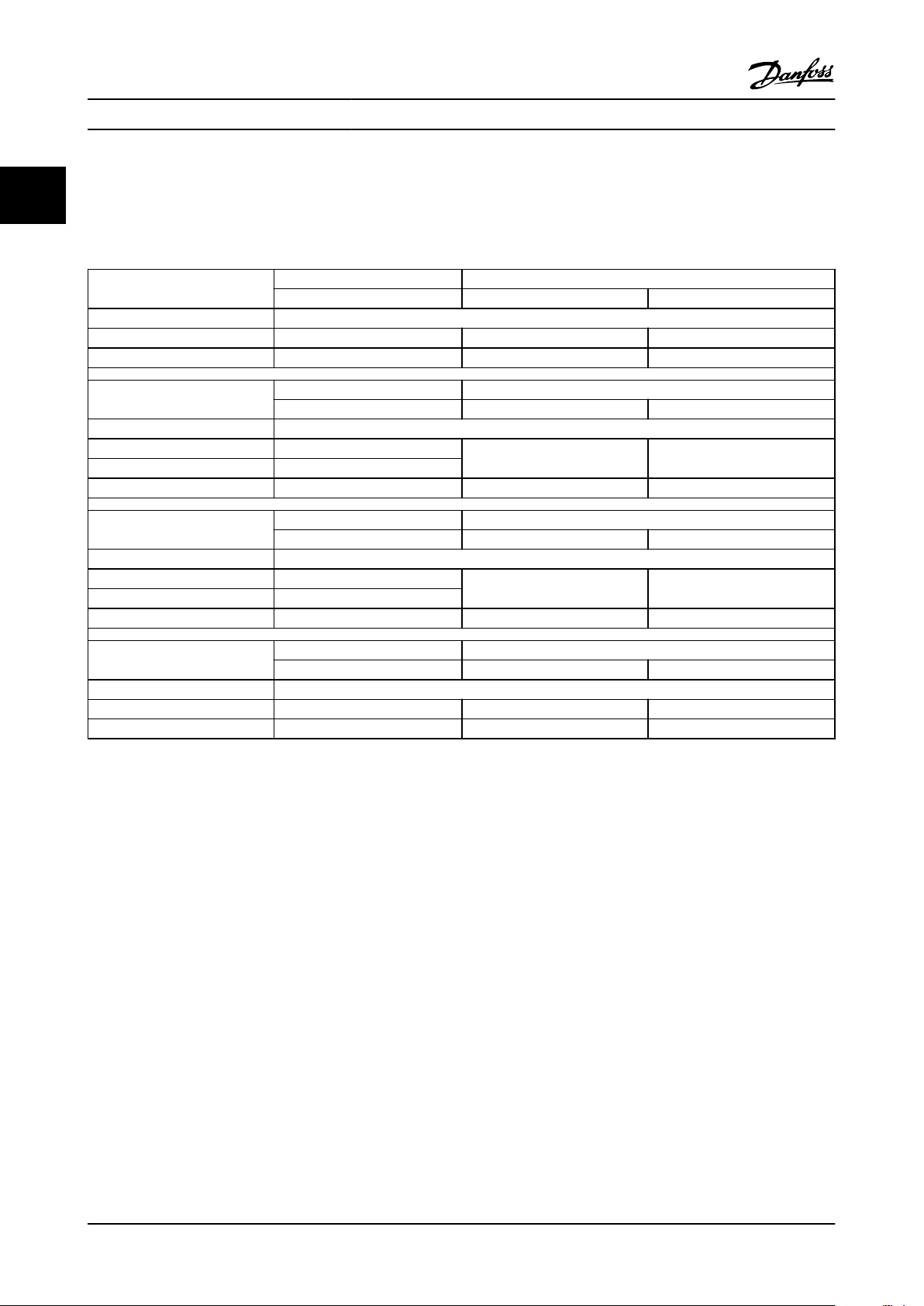

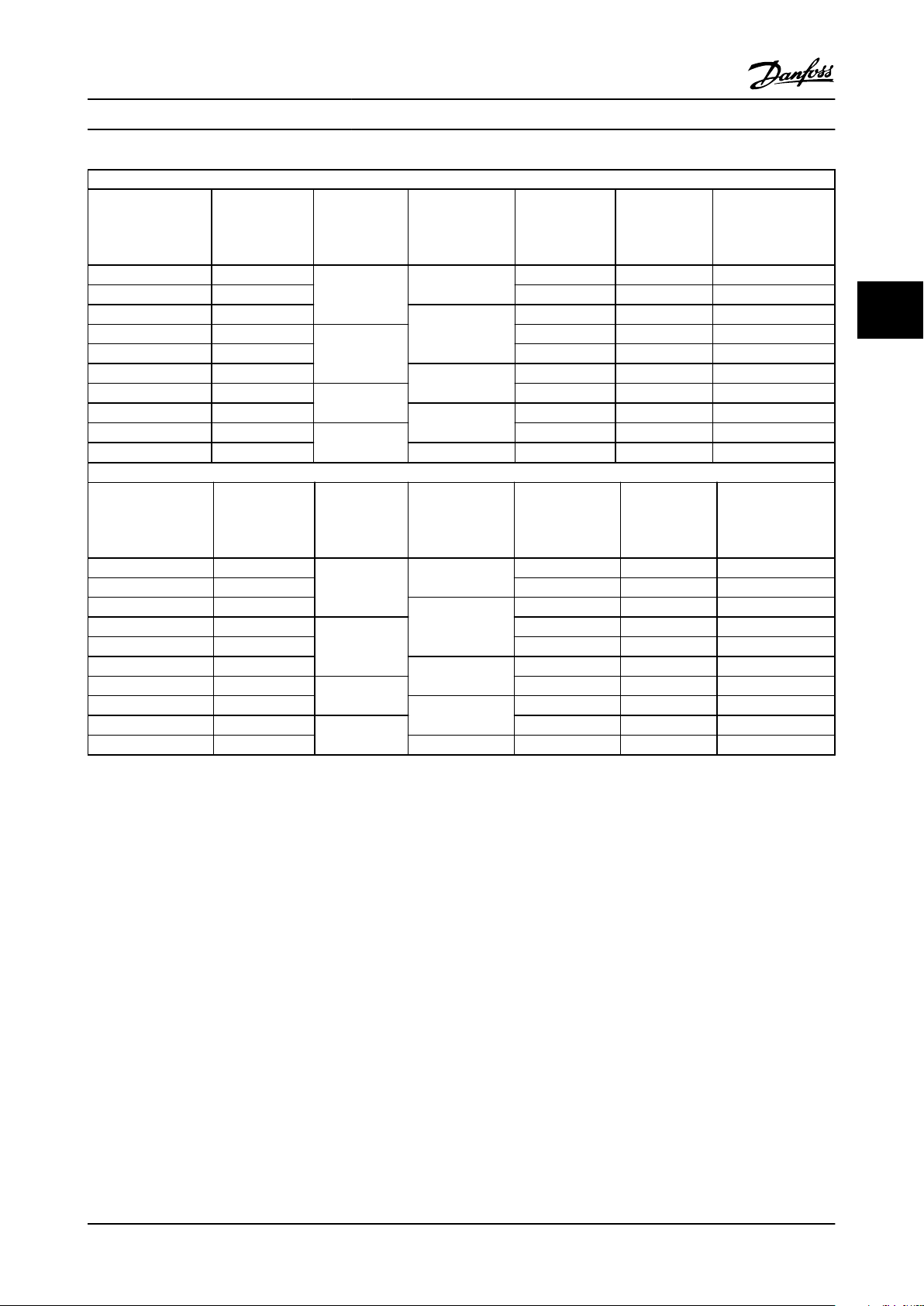

1.6.4 Panel Voltage and Frame Ratings

11

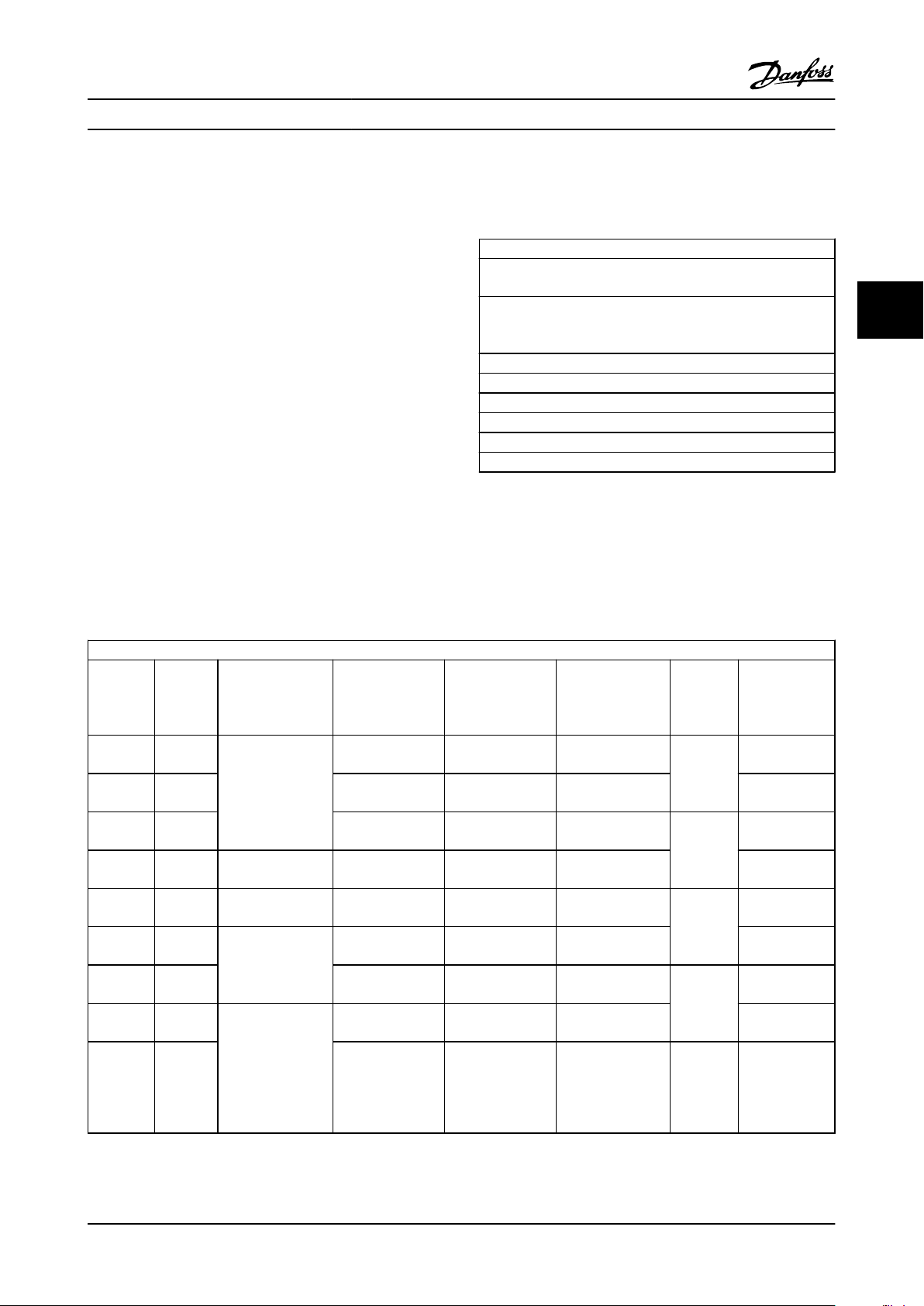

Table 1.4Table 1.5 defines the voltage and hp ratings of the frames sizes for the panel. See 8 Appendix for overall and

mounting dimensions.

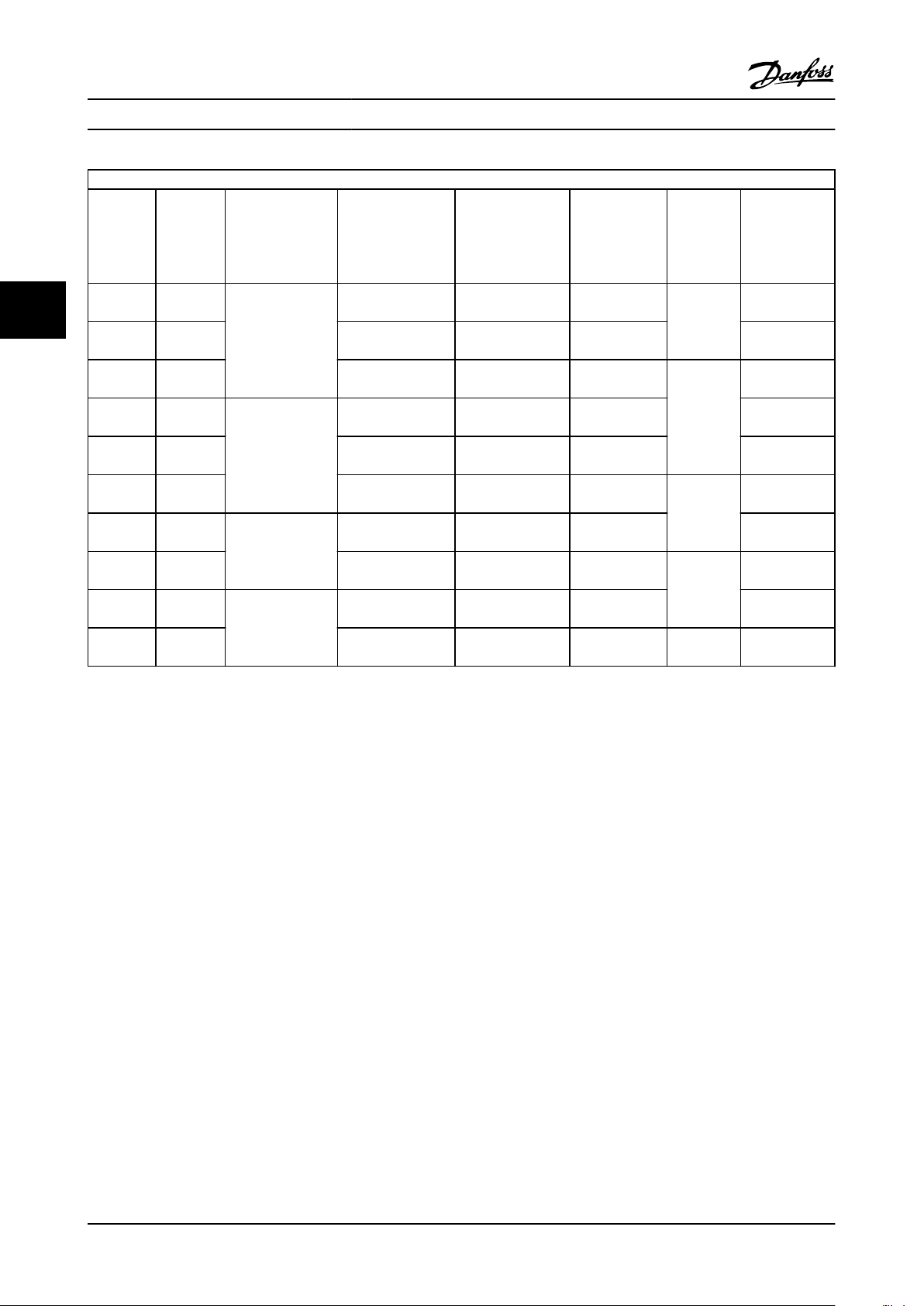

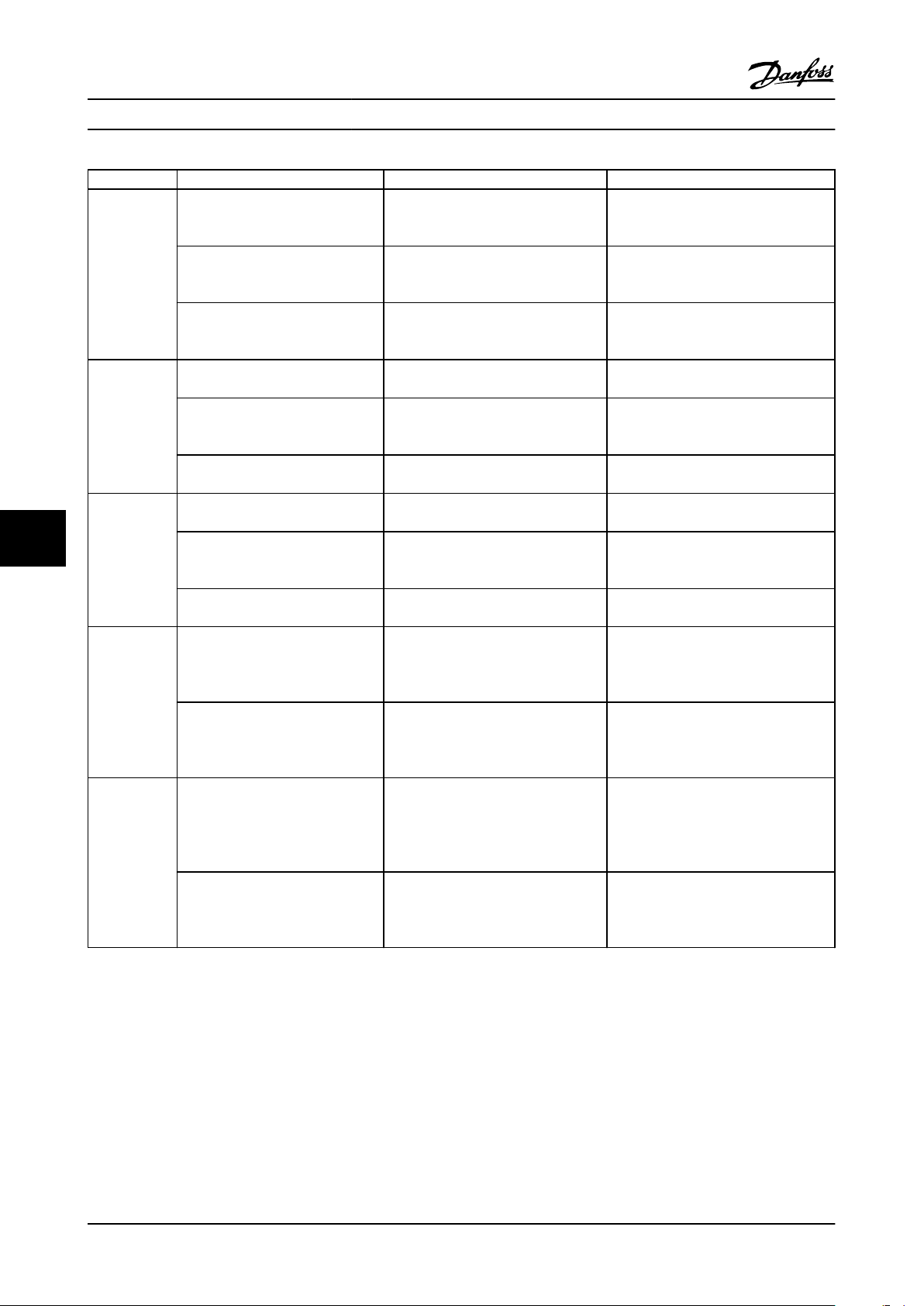

Panel P2

(B3 - Drive)

Volts VAC HP (KW)

208 & 230 7.5 (5.5) - 15 (11) 7.5 (5.5) - 15 (11) 7.5 (5.5) - 10 (7.5)

460 & 600 15 (11) - 25 (18.5) 15 (11) -25 (18.5) 15 (11) - 20 (15)

Panel P3

(B4 - Drive)

Volts VAC HP (KW)

208 20(15)

230 20 (15) - 25 (18.5)

460 & 600 30 (22) - 50 (37) 30 (22) - 50 (37) 25 (18.5) - 40 (30)

Panel P4

(C3 - Drive)

Volts VAC HP (KW)

208 25 (18.5) - 40 (30)

230 30 (22) - 40 (30)

460 & 600 60 (45) - 75 (55) 60 (45) - 75 (55) 50 (37) - 60 (45)

Panel P5)

(C4 - Drive)

Volts VAC HP (KW)

208 & 230 50 (37) - 60 (45) 50 (37) - 60 (45) 40 (30) - 50 (37)

460 & 600 100 (75) - 125 (90) 100 (75) - 125 (90) 75 (55) - 100 (75)

Bypass Non Bypass

FC102/202/322 FC102/202/322 FC302

Bypass Non Bypass

FC102/202/322 FC102/202/322 FC302

20 (15) - 25 (18.5) 15 (11) - 20 (15)

Bypass Non Bypass

FC102/202/322 FC102/202/322 FC302

30 (22) - 40 (30) 25 (18.5) - 30 (22)

Bypass Non Bypass

FC102/202/322 FC102/202/322 FC302

Table 1.4 Panel Voltage and Frame Ratings

1.7

Power Component Functions

1.7.1 Power Fusing

For main panel power fuses, only use the specified fuse or

an equivalent replacement. For drive fuses only use the

specified fuse. See the fuse ratings label on the inside

cover of the unit or Table 3.2Table 3.3, Table 3.3Table 3.4,

Table 3.4Table 3.5 and Table 3.5Table 3.6.

Main fusing

Main fuses are located ahead of the drive and bypass.

Main fuses are designed to protect the circuitry within the

bypass panel but is not adequate to protect the drive.

Main fuses are dual-element, time-delay types and mount

inside the bypass enclosure.

Drive fusing

Drive fuses are located ahead of the drive and are a fastacting type. Drive fuses are standard in all bypass and nonbypass panels.

5,000 or 100,000 amp SCCR

The bypass panel supplied with a non fusible Main

Disconnect Switch is 5,000 amps short-circuit current rating

(SCCR). The bypass panel supplied with a Fusible

disconnect or circuit breaker is 100,000 amp SCCR. The

non bypass panel supplied with a non-fusible Main

Disconnect is 100,000 amp SCCR. See the panel label for

SCCR rating.

NOTE!

The 600 V circuit breaker option is 5,000 amp (SCCR).

1-6 MG.13.A1.22 - VLT® is a registered Danfoss trademark

Page 16

130BX366.10

Pre-installation Vertical Bypass/Non Bypass Panel

2 Pre-installation

2.1.1 Receiving Inspection

Inspect the packaging and equipment closely when

received. Any indication of careless handling by the carrier

should be noted on the delivery receipt, especially if the

equipment will not be immediately uncrated. Obtain the

delivery person’s signed agreement to any noted damages

for any future insurance claims. Ensure that the model

number and power match the order and intended use for

the drive.

IMPORTANT!

LOST OR DAMAGED GOODS

INSPECT THIS SHIPMENT IMMEDIATELY UPON ARRIVAL

If goods are received short or in damaged condition, insist

on a notation of the loss or damage across the face of the

freight bill. Otherwise no claim can be enforced against

the transportation company. If concealed loss or damage is

discovered, notify your carrier at once and request an

inspection. This is absolutely necessary. Unless you do this

the carrier will not entertain any claim for loss or damage.

The agent will make an inspection and can grant a

concealed damage notation. If you give the transportation

company a clear receipt for equipment that has been

damaged or lost in transit, you do so at your own risk and

expense.

Danfoss is willing to assist you to collect claims for loss or

damage, but willingness on our part does not make us

responsible for collection of claims or replacement of

material. The actual filing and processing of the claim is

your responsibility.

2.1.2

Pre-installation Check

1. Compare panel model number to what was

ordered.

2. Ensure each of the following are rated for the

same voltage:

Drive

•

Panel

•

Power line

•

Motor

•

3. Ensure that the panel output rating is equal to or

greater than motor total full load current for full

motor performance.

Motor power size and panel must match

•

for proper overload protection.

If panel rating is less than motor; full

•

motor output cannot be achieved.

4. Check motor wiring:

Any disconnect between drive and

•

motor should be interlocked to drive

safety interlock circuit to avoid

unwanted drive trips.

Do not connect power factor correction

•

capacitors between the drive and motor.

Two speed motors must be wired

•

permanently for full speed.

Y-start, Δ-run motors must be wired

•

permanently for run.

2

2

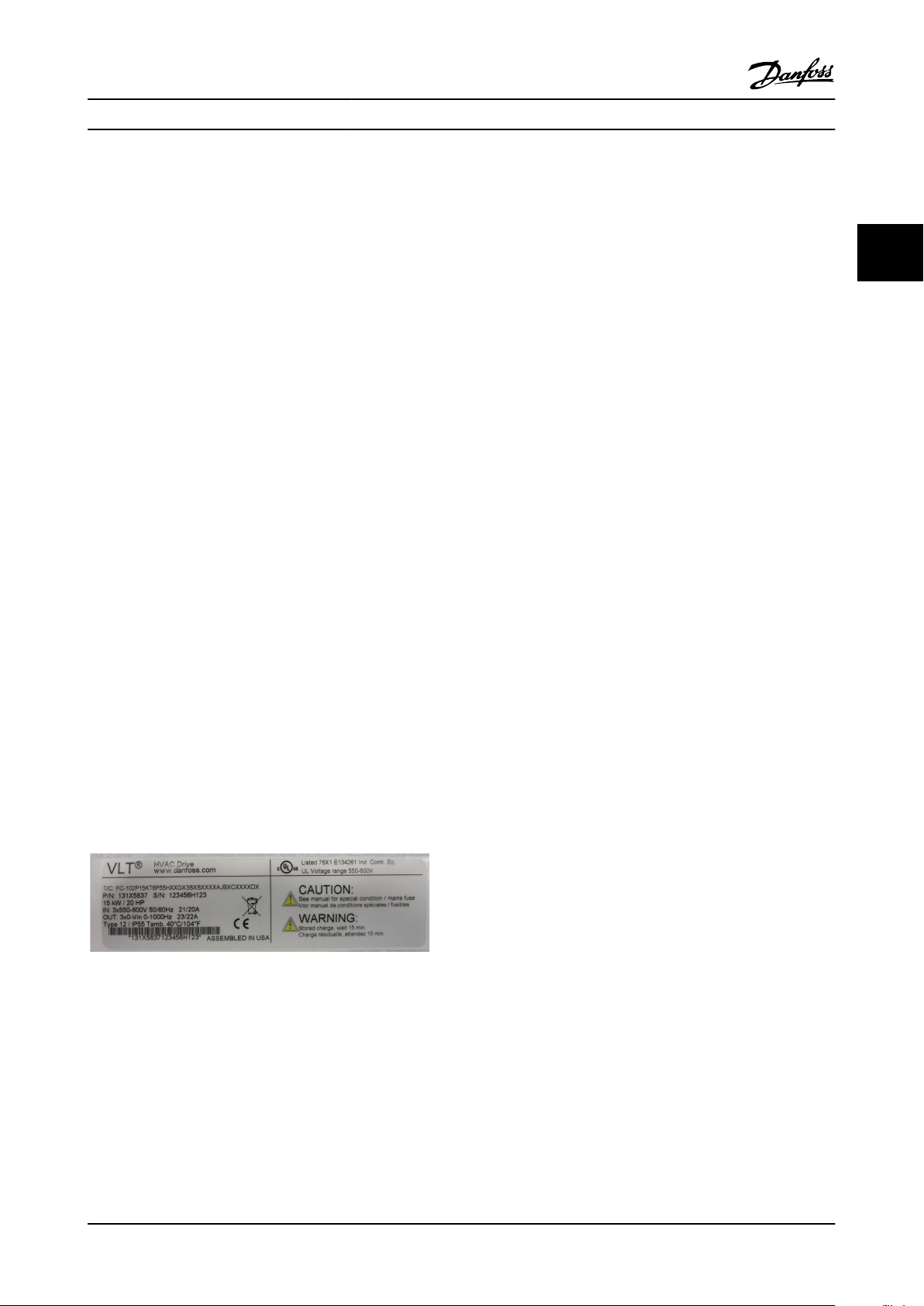

Figure 2.1 Sample Panel Label

Ensure that the model number and power match the order

and intended use for the drive.

MG.13.A1.22 - VLT® is a registered Danfoss trademark 2-1

Installation Site Check

2.1.3

Because the panel relies on the ambient air for

•

cooling, it is important to observe the limitations

on ambient air temperature. Derating concerns

start above 104°F (40°C) and 3300 feet (1000m)

elevation above sea level.

It is important with multiple panels to check wall

•

strength. Make sure that the proper mounting

screws or bolts are used.

Ensure that the wall or floor area for installation

•

will support the weight of the unit.

If construction work continues after the

•

equipment is mounted, it is important to keep

the interior free from concrete dust and similar

Page 17

2

Pre-installation Vertical Bypass/Non Bypass Panel

dirt. If the unit does not have power applied to it,

supply a protective covering. It is important to

ensure that the components stay as clean as

possible. It may be necessary to clean the interior

once construction is completed.

Keep drawings and manuals accessible for

•

detailed installation and operation instructions. It

is important that the manuals be available for

equipment operators.

2.2 Harsh Environments

The mechanical and electrical components within the

panel can be adversely affected by the environment. The

effects of contaminants in the air, either solid, liquid, or

gas, are difficult to quantify and control.

Airborne Liquids

2.2.1

Liquids in the air can condense in components. Water

carried in the air is easily measured as relative humidity,

but other vapors are often more difficult to measure or

control. Steam, oil and salt water vapor may cause

corrosion of components. In such environments, use TYPE

12 enclosures to limit the exchange of outside air into the

option enclosure. Extremely harsh environments may

require a higher level of protection.

Airborne Solids

2.2.2

Particles in the air may cause mechanical, electrical or

thermal failure in components. A TYPE 1 enclosure

provides a reasonable degree of protection against falling

particles, but it will not prevent the fan from pulling dirty

air into the enclosure.

Corrosive Chemicals

2.2.3

In environments with high temperatures and humidity,

corrosive gases such as sulfur, nitrogen and chlorine

compounds cause corrosion to occur in components.

Indications of corrosion are blackened copper or rust on

steel or oxidized aluminum. In such environments, it is

recommended that the equipment be mounted in a

cabinet with fresh air ventilation and that corrosive

compounds be kept away. A non-ventilated cabinet fitted

with an air conditioner as a heat exchanger may be used.

Conformal coated circuit boards may be specified to

reduce the corrosive effects of a harsh environment.

2-2 MG.13.A1.22 - VLT® is a registered Danfoss trademark

Page 18

Installation Vertical Bypass/Non Bypass Panel

3 Installation

3.1.1 Tools Required

In addition to the standard tool kit, the tools in Table 3.1

are recommended for installation of the panel.

Drive Fuses

3.1.2

Spreader bar capable of lifting up to 750 lbs.

Max diameter 0.5 in.

Forklift, crane, hoist or other lifting device capable of handling

up to 750 lbs. (Qualified device operator available for operating

the equipment.)

Metric Socket Set: 7 - 19mm

Socket Extensions: 4, 6, and 12 inch

Torx driver set: T10 - T40

Torque wrench: 6 - 375 lbs-in

Allen Wrenches:1/8, 3/16, 1/4, & 5/16 inches

Metric or English wrenches: 7 - 19mm

Table 3.1 Tools Required

TOOLS

To maintain UL, the drive fuses should be replaced only with the fuses specified in , , , and . If an alternate drive fuse is

desired please consult the factory. See the specifications label inside the cover of the unit for acceptable replacement drive

fuses. A sample of this data can be seen in Table 3.6

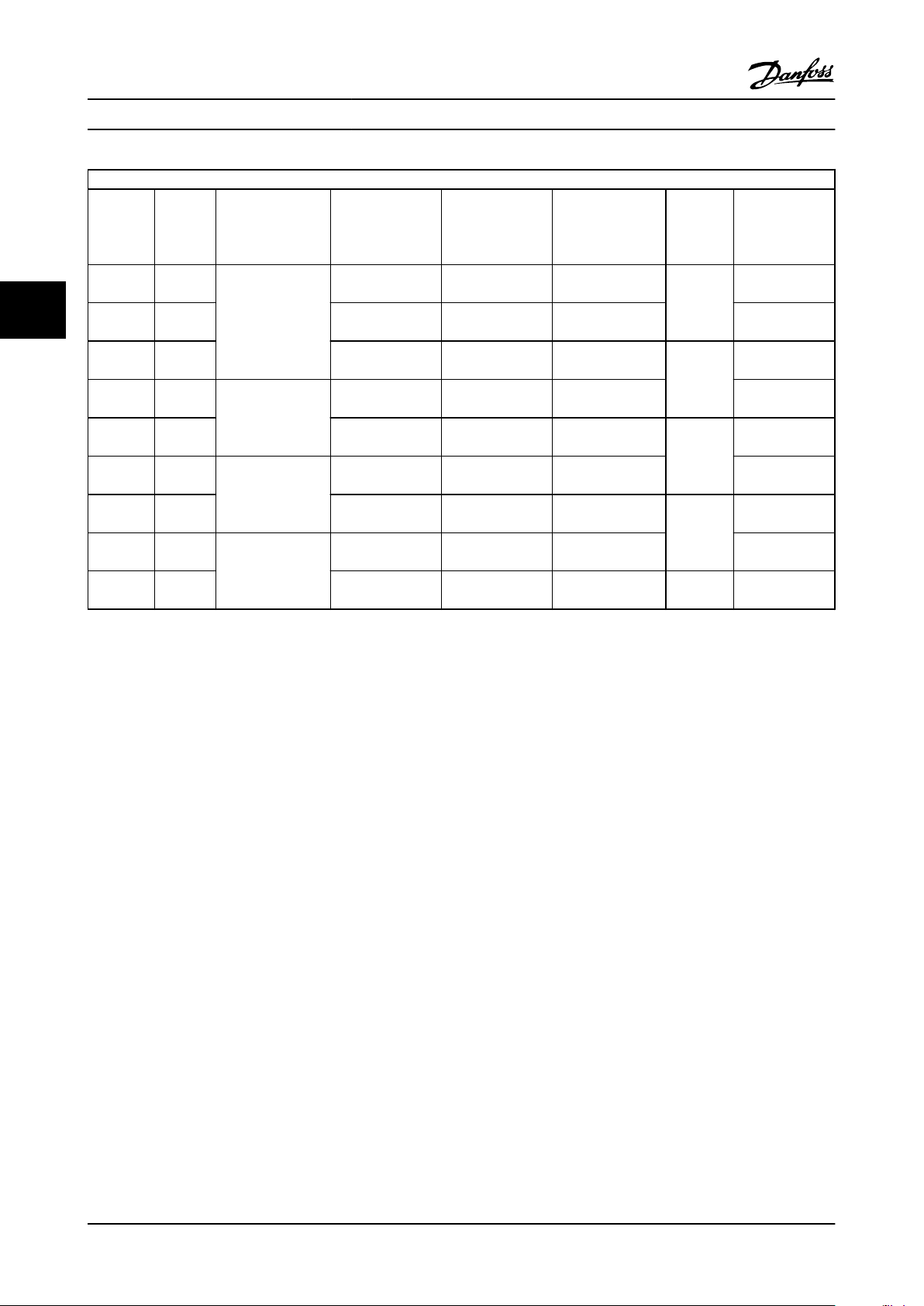

208 V AC

HP (KW)

7.5 (5.5) 24.2

10 (7.5) 30.8

15 (11) 46.2

20 (15) 59.4 P3

25 (18.5) 74.8

30 (22) 88

40 (30) 114

50 (37) 143

UL Motor

Current

(FC102/202/322)

Non Bypass &

Bypass

P3 - Non Bypass P4

- Bypass

Panel

P2

P4

Main Fuse

(FC102/202/322)

Danfoss (Bussman)

34035600 (LPJ-40-

SP)

34035700 (LPJ-50-

SP)

34042800 (LPJ-70-

SP)

34042900 (LPJ-90-

SP)

34043100 (LPJ-125-

SP)

34043200 (LPJ-150-

SP)

34043300 (LPJ-175-

SP)

34042300 (LPJ-250-

SP)

Drive Fuse

(FC102/202/322)

Danfoss (Bussman)

176F8953 (JJN-50)

176F8953 (JJN-50)

176F8955 (JJN-60)

176F8957 (JJN-80)

176F8960 (JJN-125)

176F8960 (JJN-125)

174N6538 (JJN-150)

174N6839 (JJN-200)

Transformer Fuse

(FC102/202/322)

Danfoss (Bussman)

34046200 (FNQ-

R-1.25)

Panel

(FC302)

Non

Bypass

P2

P3

P4

P5

Drive Fuse

(FC302) Danfoss

(Bussman)

176F8953

(JJN-50)

176F8955

(JJN-60)

176F8957

(JJN-80)

176F8960

(JJN-125)

176F8960

(JJN-125)

174N6538

(JJN-150)

174N6839

(JJN-200)

174N6840

(JJN-250)

3 3

60 (45) 169

Table 3.2 Drive Fuses 208 V

P5

34042300 (LPJ-250-

SP)

MG.13.A1.22 - VLT® is a registered Danfoss trademark 3-1

174N6840 (JJN-250)

34046200 (FNQ-

R-1.25)

Page 19

Installation Vertical Bypass/Non Bypass Panel

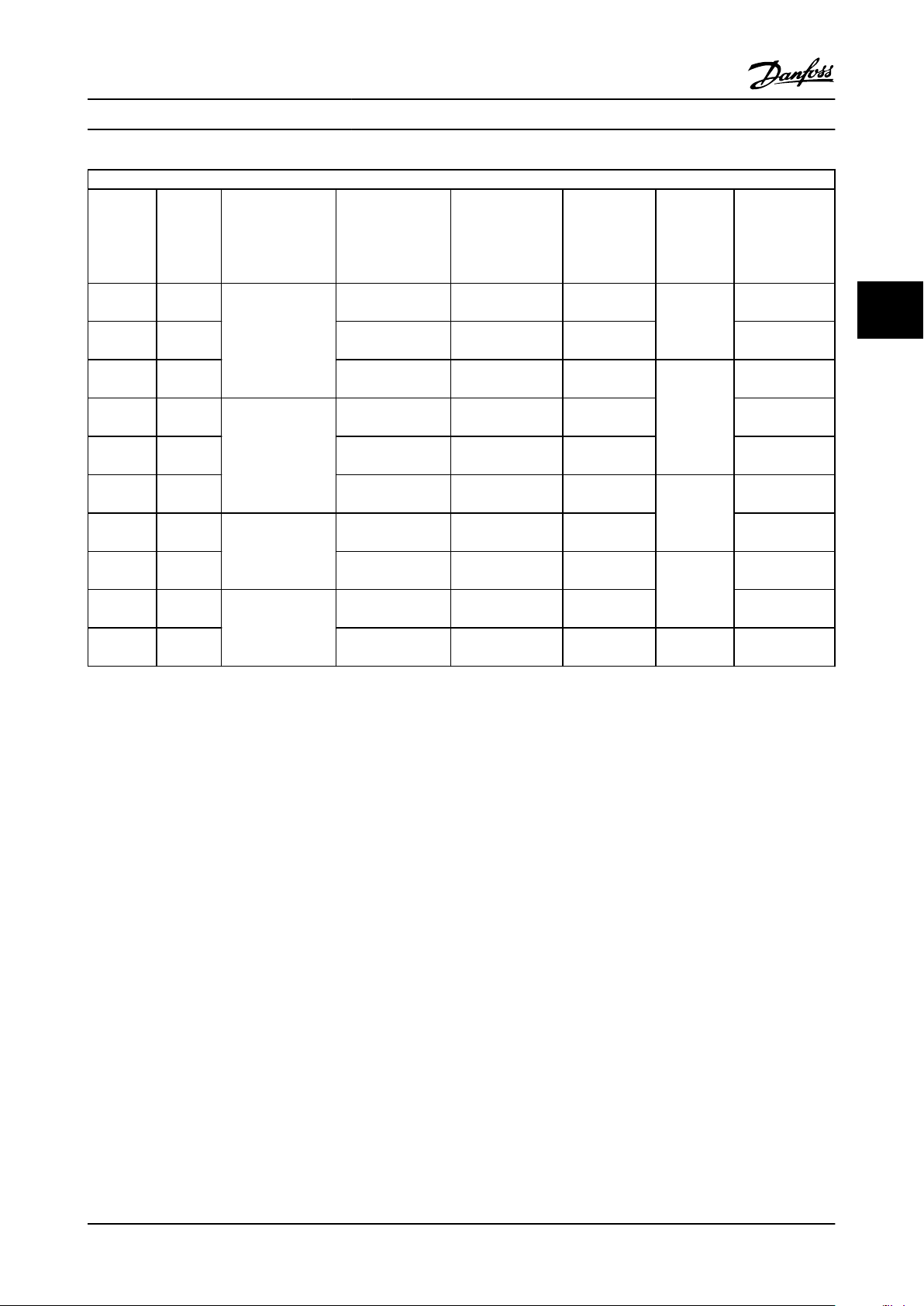

230 V AC

Panel

HP (KW)

7.5 (5.5) 22

33

10 (7.5) 28

15 (11) 42

20 (15) 54

25 (18.5) 68

30 (22) 80

40 (30) 104

50 (37) 130

60 (45) 154

UL Motor

Current

(FC102/202/322)

Non Bypass &

Bypass

P2

P3

P4

P5

Main Fuse

(FC102/202/322)

Danfoss (Bussman)

34042600 (LPJ-35-

SP)

34042700 LPJ-45-

SP

34042800 (LPJ-70-

SP)

34042900 (LPJ-90-

SP)

34043000 (LPJ-100-

SP)

34043100 (LPJ-125-

SP)

34043200 (LPJ-150-

SP)

34043400 (LPJ-200-

SP)

34042300 (LPJ-250-

SP)

Drive Fuse

(FC102/202/322)

Danfoss (Bussman)

176F8953 (JJN-50)

176F8953 (JJN-50)

176F8955 (JJN-60)

176F8957 (JJN-80)

176F8960 (JJN-125)

176F8960 (JJN-125)

174N6538

(JJN-150)

174N6839

(JJN-200)

174N6840

(JJN-250)

Transformer Fuse

(FC102/202/322)

Danfoss (Bussman)

34046200 (FNQ-

R-1.25)

34046200 (FNQ-

R-1.25)

Panel

(FC302)

Non

Bypass

P2

P3

P4

P5

Drive Fuse

(FC302) Danfoss

(Bussman)

176F8953

(JJN-50)

176F8955

(JJN-60)

176F8957 JJN-80

176F8960

(JJN-125)

176F8960

(JJN-125)

174N6538

(JJN-150)

174N6839

(JJN-200)

174N6840

(JJN-250)

Table 3.3 Drive Fuses 230 V

3-2 MG.13.A1.22 - VLT® is a registered Danfoss trademark

Page 20

Installation Vertical Bypass/Non Bypass Panel

460 V AC

HP (KW)

15 (11) 21

20 (15) 27

25 (18.5) 34

30 (22) 40

40 (30) 52

50 (37) 65

60 (45) 77

75 (55) 96

100 (75) 124

125 (90) 156

UL Motor

Current

Panel

(FC102/202/322)

Non Bypass &

Bypass

P2

P3

P4

P5

Main Fuse

(FC102/202/322)

Danfoss (Bussman)

34042600 (LPJ-35-

SP)

34035600 (LPJ-40-

SP)

34035700 (LPJ-50-

SP)

34035800 (LPJ-60-

SP)

176U5037 (LPJ-80-

SP)

34043000 (LPJ-100-

SP)

34043100 (LPJ-125-

SP)

34043200 (LPJ-150-

SP)

34043400 (LPJ-200-

SP)

34042300 (LPJ-250-

SP)

Drive Fuse

(FC102/202/322)

Danfoss (Bussman)

176F8952 (JJS-40)

176F8952 (JJS-40)

176F8954 (JJS-50)

176F8956 (JJS-60)

176F8958 (JJS-80)

176F8959 (JJS-100)

176F8961 (JJS-125)

176F9078 (JJS-150)

34051200 (JJS-200)

00002051 (JJS-250)

Transformer

Fuse

(FC102/202/322

) Danfoss

(Bussman)

34046000 (FNQ-

R-0.60)

34046000 (FNQ-

R-0.60)

Panel

(FC302) Non

Bypass

P2

P3

P4

P5

Drive Fuse

(FC302) Danfoss

(Bussman)

176F8952

(JJS-40)

176F8954

(JJS-50)

176F8956

(JJS-60)

176F8958

(JJS-80)

176F8959

(JJS-100)

176F8961

(JJS-125)

176F9078

(JJS-150)

34051200

(JJS-200)

00002051

(JJS-250)

3 3

Table 3.4 Drive Fuses 460 V

MG.13.A1.22 - VLT® is a registered Danfoss trademark 3-3

Page 21

Installation Vertical Bypass/Non Bypass Panel

600 V AC

Panel

HP (KW)

15 (11) 17

UL Motor

Current

(FC102/202/322)

Non Bypass &

Bypass

33

20 (15) 22

25 (18.5) 27

30 (22) 32

40 (30) 41

50 (37) 52

60 (45) 62

75 (55) 77

100 (75) 99

125 (90) 125

P2

P3

P4

P5

Main Fuse

(FC102/202/322)

Danfoss (Bussman)

34035500 (LPJ-30-

SP)

34042600 (LPJ-35-

SP)

34042700 (LPJ-45-

SP)

34035700 (LPJ-50-

SP)

34035800 (LPJ-60-

SP)

176U5037 (LPJ-80-

SP)

34043000 (LPJ-100-

SP)

34043100 (LPJ-125-

SP)

34043200 (LPJ-150-

SP)

34043400 (LPJ-200-

SP)

Drive Fuse

(FC102/202/322)

Danfoss (Bussman)

176F9076 (JJS-35)

176F9076 (JJS-35)

176F9077 (JJS-45)

176F8954 (JJS-50)

176F8956 (JJS-60)

176F8958 (JJS-80)

176F8959 (JJS-100)

176F8961 (JJS-125)

176F9078 (JJS-150)

130G0488 (JJS-175)

Transformer

Fuse

(FC102/202/322)

Danfoss

(Bussman)

34053600 (FNQ-

R-0.50)

34053600 (FNQ-

R-0.50)

Panel

(FC302) Non

Bypass

P2

P3

P4

P5

Drive Fuse

(FC302) Danfoss

(Bussman)

176F9076

(JJS-35)

176F9077

(JJS-45)

176F8954

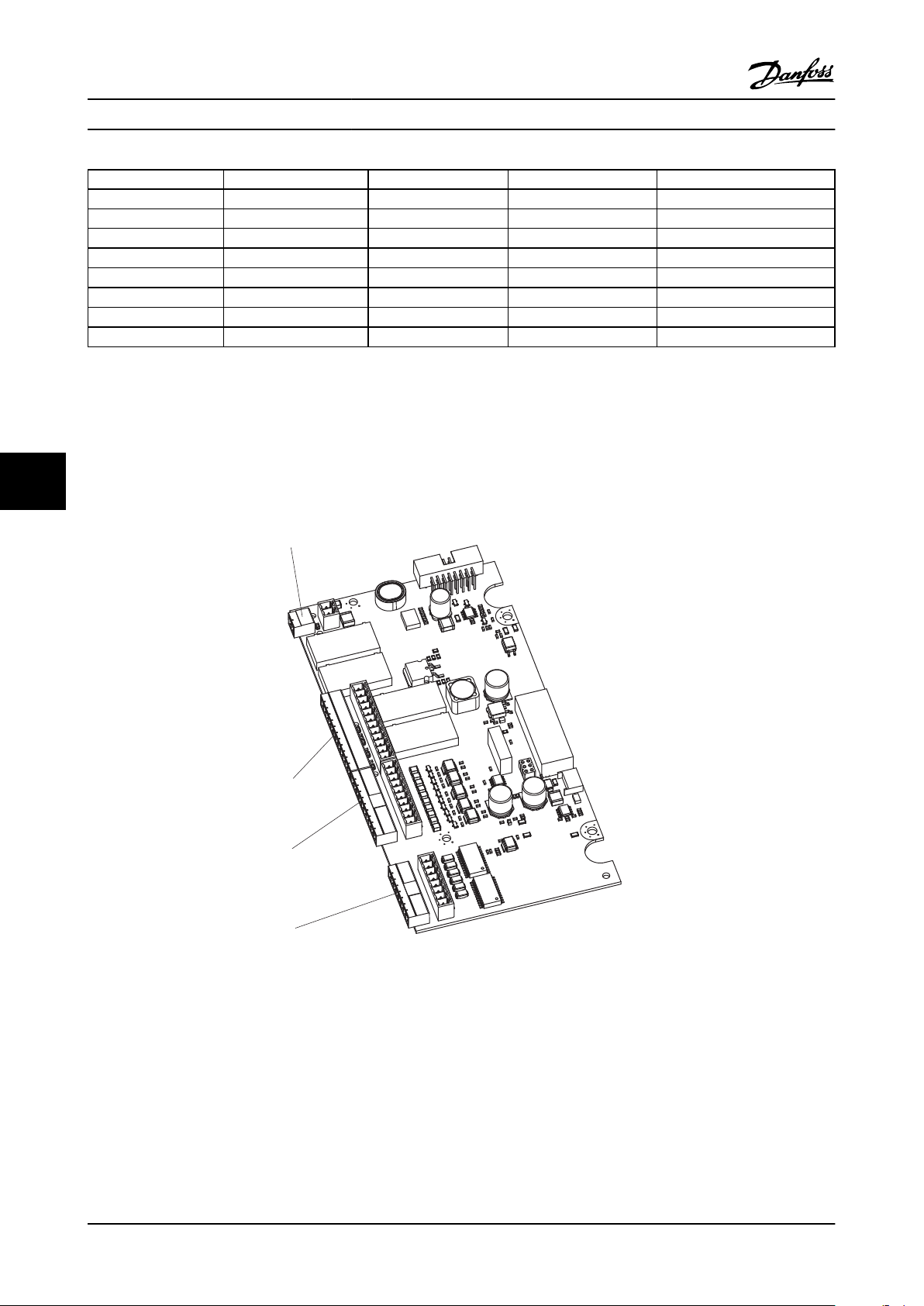

(JJS-50)

176F8956

(JJS-60)

176F8958

(JJS-80)

176F8959

(JJS-100)

176F8961

(JJS-125)

176F9078

(JJS-150)

130G0488

(JJS-175)

Table 3.5 Drive Fuses 600 V

3-4 MG.13.A1.22 - VLT® is a registered Danfoss trademark

Page 22

130BX367.10

Installation Vertical Bypass/Non Bypass Panel

3.1.3 Internal Main Panel Fuses

Use only the specified fuse or an equivalent replacement for the internal main fuses. See the specifications label inside the

cover of the unit for acceptable replacement main fuses. A sample of this can be seen in Table 3.6.

Fuse Description Manufacturer Part Number/Size

F13A & C Primary Transformer Bussmann FNQ-R-0.50

F15A, B, & C Main Fuses Bussmann LPJ-30-SP

F16A, B, & C Drive Fuses Bussmann JJS-35

F900, F901,F902 SMPS - Power Supply Bussmann FWH-020A6F, 500V

Table 3.6 Sample Fuse Rating Label

3.2 Mechanical Installation

3 3

3.2.1 Lifting

Check the weight of the unit before attempting to lift.

Ensure that the lifting device is suitable for safely lifting

the panel. If necessary, plan for a hoist, crane or forklift

with appropriate rating to move the units.

3.2.2 Hoist or Overhead Lift

Use a solid steel spreader bar for lifting. Slide the

•

spreader bar through the two (2) lifting holes on

the panel. Lifting rings are 0.59in (15mm) in

diameter (see Figure 3.1). If VFD mounting screws

interfere with the spreader bar, lifting hooks can

be used instead of the lifting bar.

Connect the spreader bar to a hoist or other

•

lifting device.

Carefully lift the unit and secure it to the wall.

•

Refer to 8 Appendix for dimensional drawings to

determine fasteners size and location.

Forklift

3.2.3

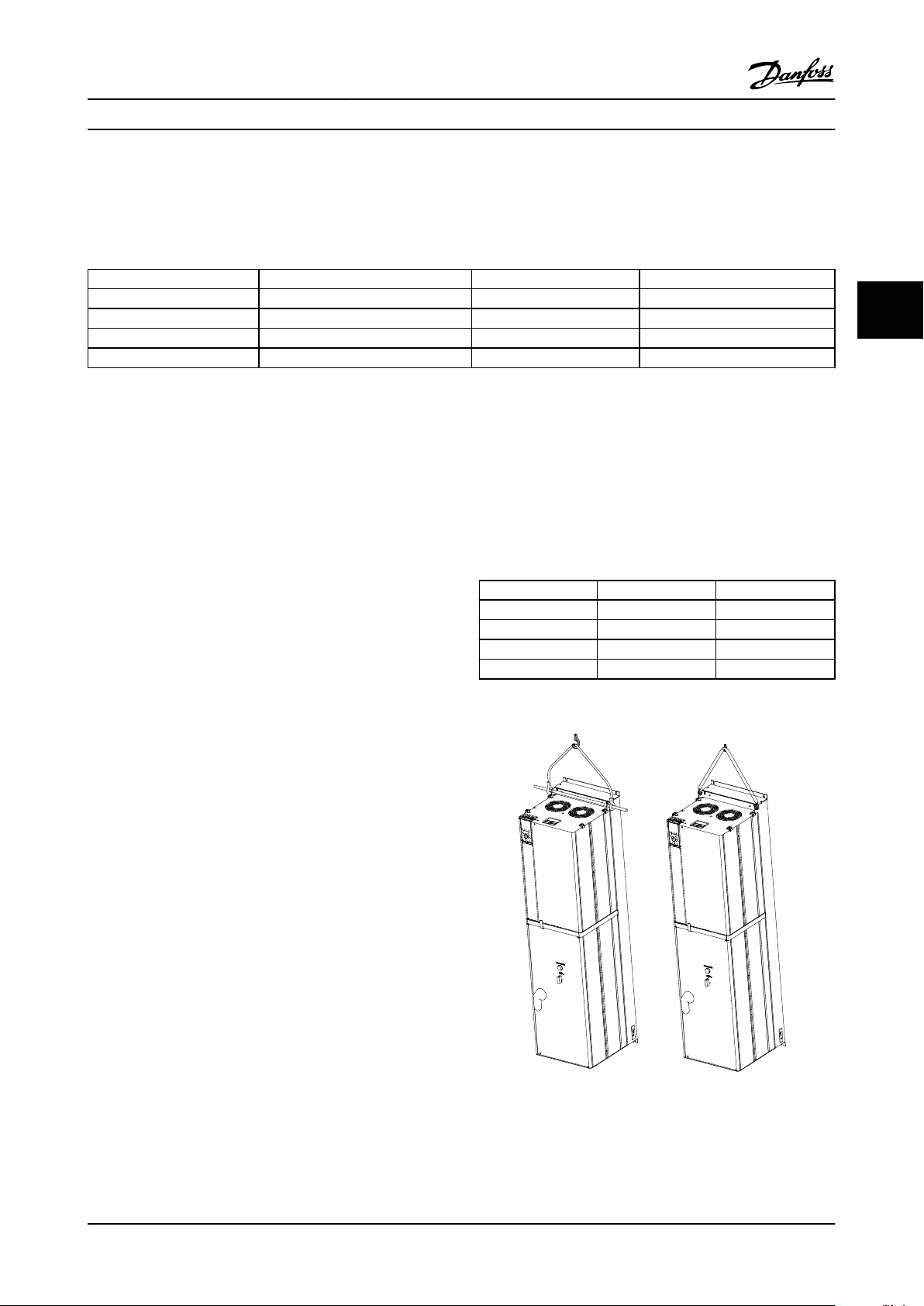

Shipping Weights

3.2.4

Weights listed in Table 3.7 are approximate for base units.

Options can add or reduce weight of unit. Weights listed

are in lbs.

Frame Non Bypass Panel Bypass Panel

P2 36 84

P3 66 106

P4 106 167

P5 155 248

Table 3.7 Approximate Shipping Weights

Only a competent lift operator with additional

•

support personnel should attempt moving the

unit.

Carefully position forklift and ensure stability prior

•

to lift.

MG.13.A1.22 - VLT® is a registered Danfoss trademark 3-5

Figure 3.1 Proper Lifting Method

Page 23

38.1 [1.5]

130BX368.10

50.8 [2.0] min

101.6 [4.0] min

FLOOR

CEILING

AIRFLOW

AIRFLOW

130BX369.12

Installation Vertical Bypass/Non Bypass Panel

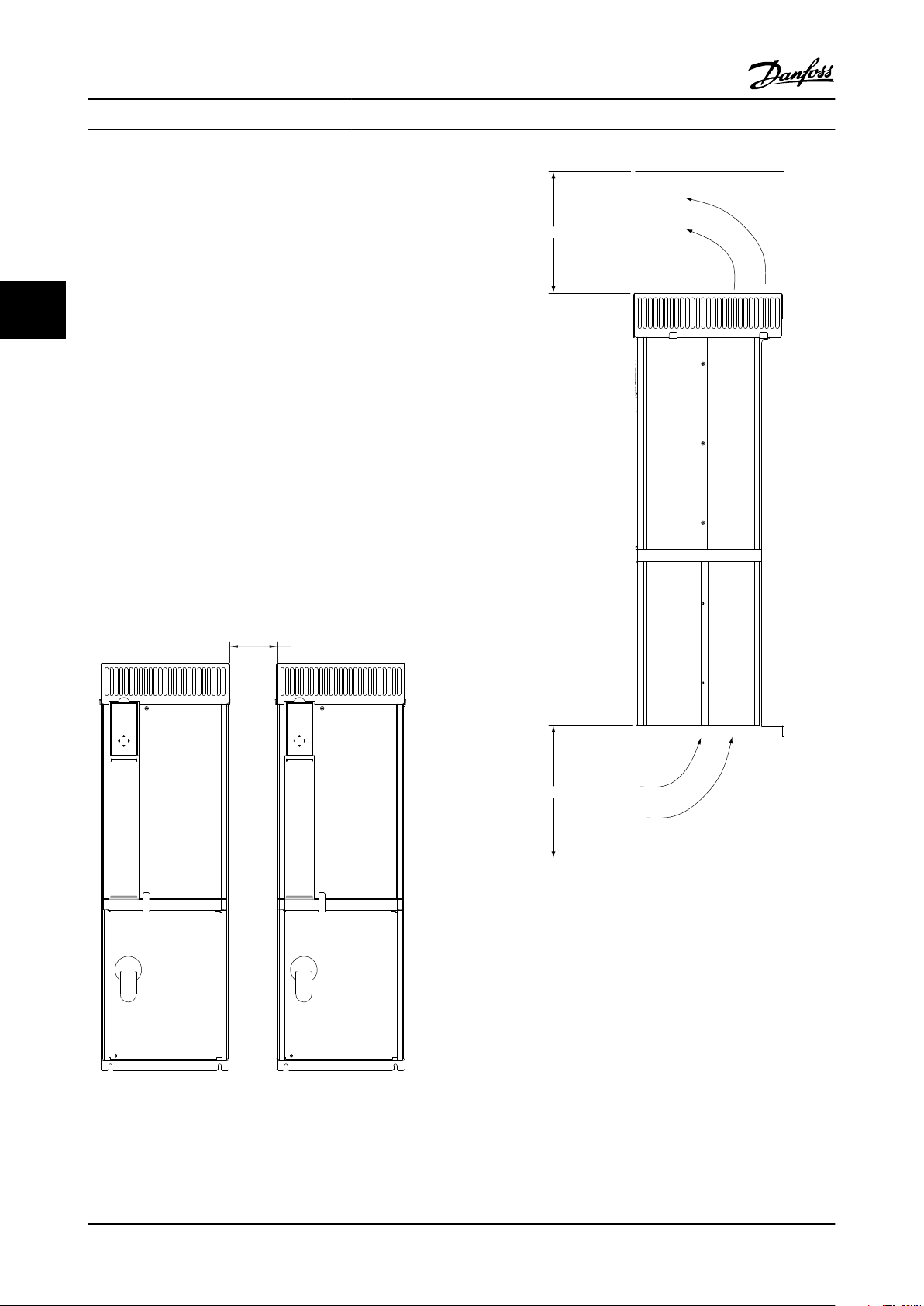

3.3 Cooling

Only mount the drive and panel vertically.

•

Panels rely on the ambient air for cooling. It is

•

important to observe the limitations on ambient

33

air temperature. The maximum ambient

temperature for all bypass panels is 40°C and

45°C for non bypass panels. Derating concerns

start above 3300 feet elevation above sea level.

Most panels may be mounted side-by-side

•

without additional side clearance. However, the

P2 (B3 frame size) units require 1.5 in. minimum

clearance between units (see Figure 3.2).

Top and bottom clearance is required for cooling

•

(see Figure 3.3). Generally, 2 to 10 inches (50 to

250mm) minimum clearance is required,

depending upon the hp (kW) of the unit. See the

dimensional drawings in 8 Appendix for specific

requirements.

No additional back plate is required for drives

•

with the bypass and non bypass panels.

Figure 3.2 Side Cooling Clearance

Figure 3.3 Cooling Airflow

3-6 MG.13.A1.22 - VLT® is a registered Danfoss trademark

Page 24

Motor

Line Power

Stop

Start

Speed

Control

130BX370.10

Installation Vertical Bypass/Non Bypass Panel

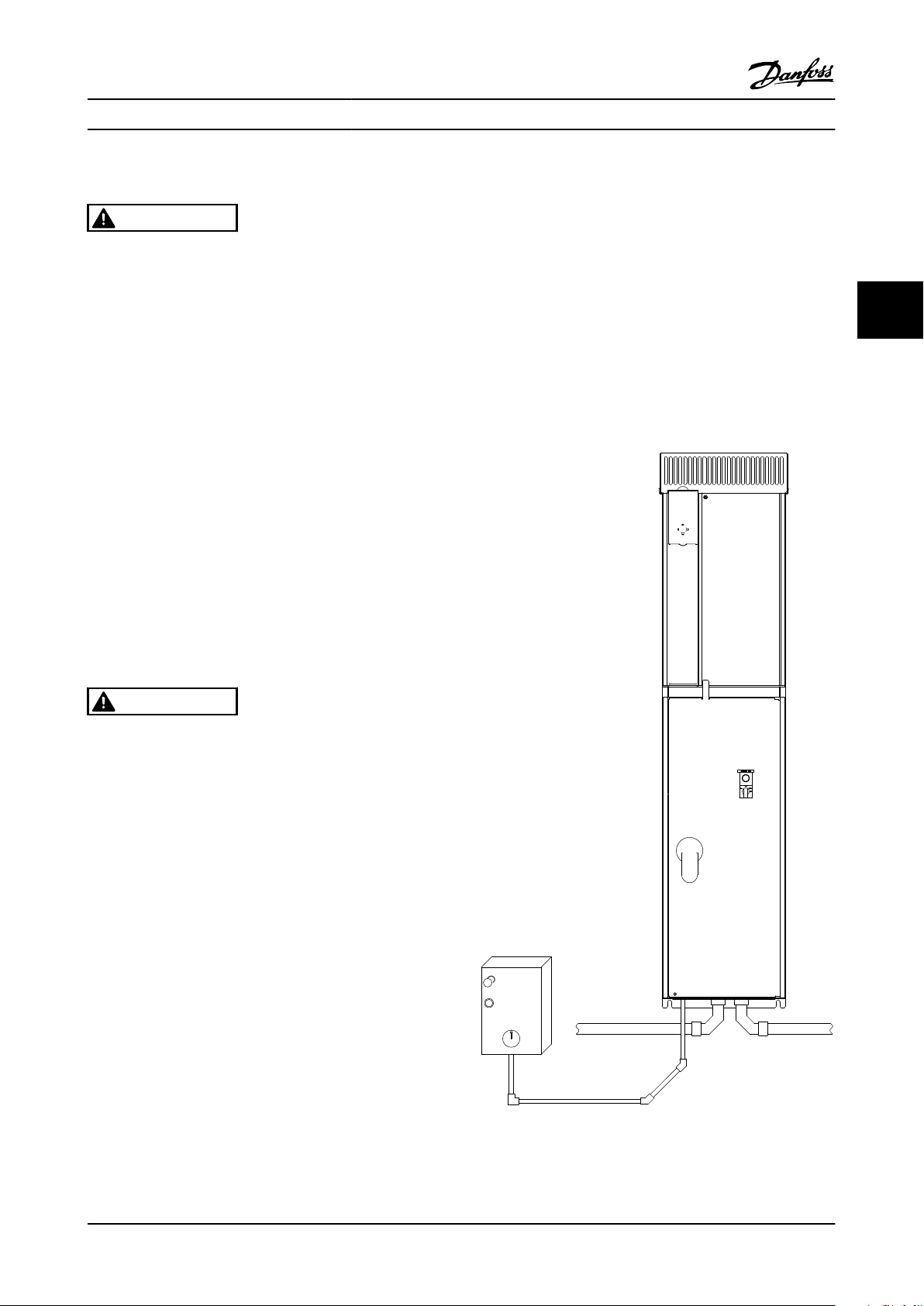

3.4 Electrical Installation

WARNING

•

•

EQUIPMENT HAZARD!

Rotating shafts and electrical equipment can be hazardous.

It is strongly recommended that all electrical work conform

to all national and local regulations. Installation, start-up

and maintenance should be performed only by qualified

personnel. Failure to follow local regulations could result in

death or serious injury.

•

Control wiring should always be isolated from the high

voltage power wiring.

Avoid getting metal chips into electronics.

Power into the panel (and ground back to the

distribution panel)

Power from the panel to the motor and earth

insulated motor ground

Control wiring

3 3

Motor control equipment and electronic controls

•

are connected to hazardous line voltages.

Extreme care should be taken to protect against

electrical hazard.

Correct protective grounding of the equipment

•

must be established. Ground currents are higher

than 3mA.

A dedicated ground wire is required.

•

Wear safety glasses whenever working on electric

•

control or rotating equipment.

NOTE!

Make all power connections with a minimum of 60°C/

140°F rated copper wire.

WARNING

INDUCED VOLTAGE!

Run output motor cables from multiple drives separately.

Induced voltage from output motor cables run together

can charge equipment capacitors even with the equipment

turned off and locked out. Failure to run output motor

cables separately could result in death or serious injury.

Follow the connection procedures as illustrated in the

drawing provided with the unit.

NOTE!

Run input power, motor wiring and control wiring in three

separate metallic conduits or raceways for high frequency

noise isolation. Failure to isolate power, motor and control

wiring could result in less than optimum drive and

associated equipment performance.

Because the motor wiring carries high frequency

•

electrical pulses, it is important that no other

wires are run together. If the incoming power

wiring is run in the same conduit as the motor

wiring, these pulses can couple electrical noise

back onto the building power grid.

At least three separate conduits must be connected to the

panel (Figure 3.4).

MG.13.A1.22 - VLT® is a registered Danfoss trademark 3-7

Figure 3.4 Power Connections

Page 25

(EMB2 OPTION ONLY)

(ECB OPTION ONLY)

(EMB2 OPTION ONLY)

(EMB2 OPTION ONLY)

CUST. CONNECTION

INPUT POWER

L1 L2 L3

CUST. CONNECTION

POWER TO MOTOR

T1 T2 T3

CUST. CONNECTION

EMB2 CONTROL WIRES

14

15

17

7

10

4,5,6

12

8

19

18

1

2

11

13

130BX372.12

27

26

CUST. CONNECTION

DRIVE CONTROL

TERMINALS

CUSTOMER CONNECTION

TERMINAL BLOCK 1

CUST. CONNECTION

INPUT & OUTPUT

GROUND

CUST. CONNECTION

ECB CONTROL WIRES

Installation Vertical Bypass/Non Bypass Panel

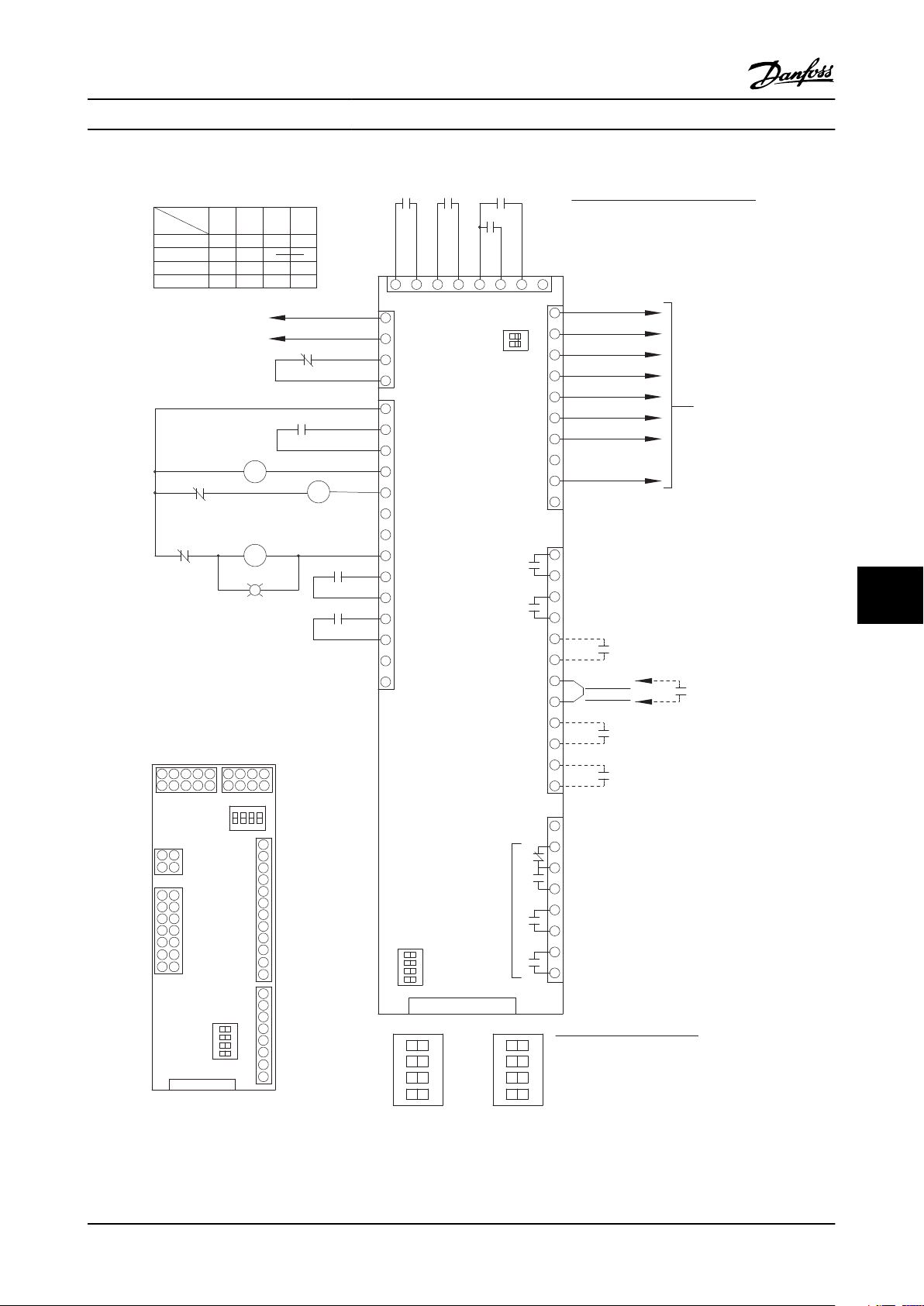

3.4.1 Component Identification & Customer Connection

Mechanical layout drawings are intended to provide the installer or equipment user with component identification and

location for that specific unit. Figure 3.5 represents a typical layout drawing. Table 3.8 provides definitions for drawing

reference designators. (Not all reference designators are shown.)

33

Figure 3.5 P2 Bypass Mechanical Layout Diagram

ID

1 24 V DC Panel 24 V DC SMPS 15 S1 Auto Bypass Selector Switch

2 HPC High Pot Connector 16 TF 120 V AC control transformer

3 F13 T1 primary fuse 17 VFD Variable frequency drive

4 CB1 Main Circuit Breaker 18 EMB2 Control Module

Device Definition ID Device Definition

5 DS1 Main or Drive Disconnect 19 ECB Control Module

6 F15 Main fuse 20 TB1-C Terminal block 1 - Control

7 F16 Drive fuse 21 TB1-P Terminal block 1 - Power

8 GND Ground terminal 22 PR1 Control Relay for M1 Contactor

9 LCP LCP 23 PR2 Control Relay for M2 Contactor

10 M1 Drive Input contactor 24 PR3 Control Relay for M3 Contactor

11 M2 Drive Output contactor 25 UVM Under voltage module

12 M3 Bypass contactor 26 TC Top Cover

13 OL1 Overload for Motor 27 DH Disconnect Handle

14 PL1 Bypass indicator light

Table 3.8 Reference Designator Definitions

3-8 MG.13.A1.22 - VLT® is a registered Danfoss trademark

Page 26

CUST. CONNECTION

INPUT POWER

L1 L2 L3

CUST. CONNECTION

POWER TO MOTOR

T1 T2 T3

5

7

17

CUSTOMER CONNECTION

TERMINAL BLOCK 1

21

8

130BX374.11

27

26

CUST. CONNECTION

DRIVE CONTROL

TERMINALS

CUST. CONNECTION

INPUT AND OUTPUT GROUND

Installation Vertical Bypass/Non Bypass Panel

3 3

Figure 3.6 P2 Non Bypass Mechanical Layout Diagram.

Table 3.8 for reference designator definitions.

See

MG.13.A1.22 - VLT® is a registered Danfoss trademark 3-9

Page 27

(EMB2 OPTION ONLY)

(EMB2 OPTION ONLY)

CUST. CONNECTION

EMB2 / ECB CONTROL WIRES

CUST. CONNECTION

INPUT POWER

L1 L2 L3

CUST. CONNECTION

POWER TO MOTOR

T1 T2 T3

14

15

18 OR 19

2

1

11

13

8

12

4,5,6

10

7

17

130BX375.12

27

26

CUST. CONNECTION

OUTPUT GROUND

CUST. CONNECTION

DRIVE CONTROL

TERMINALS

CUST. CONNECTION

INPUT GROUND

Installation Vertical Bypass/Non Bypass Panel

33

Figure 3.7 P3 Bypass Mechanical Layout Diagram.

See

Table 3.8 for reference designator definitions.

3-10 MG.13.A1.22 - VLT® is a registered Danfoss trademark

Page 28

CUST. CONNECTION

INPUT POWER

L1 L2 L3

CUST.CONNECTION

POWER TO MOTOR

T1 T2 T3

17

5

8

7

130BX376.12

CUST. CONNECTION

DRIVE CONTROL

TERMINALS

CUST. CONNECTION

OUTPUT GROUND

26

27

CUST. CONNECTION

INPUT GROUND

Installation Vertical Bypass/Non Bypass Panel

3 3

Figure 3.8 P3 Non Bypass Mechanical Layout Diagram.

Table 3.8 for reference designator definitions.

See

MG.13.A1.22 - VLT® is a registered Danfoss trademark 3-11

Page 29

(EMB2 OPTION ONLY)

CUSTOMER CONNECTION

INPUT POWER

L1 L2 L3

CUSTOMER CONNECTION

OUTPUT POWER

T1 T2 T3

CUSTOMER CONNECTION

EMB/ECB CONTROL WIRES

(EMB2 OPTION ONLY)

18 OR 19

10

11

13

1

8

12

4,5,6

7

17

14

15

CUSTOMER CONNECTION

DRIVE CONTROL

TERMINALS

CUSTOMER CONNECTION

INPUT AND OUTPUT GROUND

26

130BX378.12

27

Installation Vertical Bypass/Non Bypass Panel

33

Figure 3.9 P4 Bypass Mechanical Layout Diagram.

Table 3.8 for reference designator definitions.

See

3-12 MG.13.A1.22 - VLT® is a registered Danfoss trademark

Page 30

CUSTOMER CONNECTION

INPUT POWER

L1 L2 L3

CUSTOMER CONNECTION

OUTPUT POWER

T1 T2 T3

17

7

5

8

130BX380.12

CUSTOMER CONNECTION

OUTPUT GROUND

26

CUSTOMER CONNECTION

DRIVE CONTROL TERMINALS

27

CUSTOMER CONNECTION

INPUT GROUND

Installation Vertical Bypass/Non Bypass Panel

3 3

Figure 3.10 P4 Non Bypass Mechanical Layout Diagram.

Table 3.8 for reference designator definitions.

See

MG.13.A1.22 - VLT® is a registered Danfoss trademark 3-13

Page 31

CUSTOMER CONNECTION

INPUT POWER

L1 L2 L3

CUSTOMER CONNECTION

OUTPUT POWER

T1 T2 T3

CUSTOMER CONNECTION

EMB/ECB CONTROL WIRES

18 OR 19

10

11

2

25

13

1

8

22

23

24

3 & 16

4,5,6

12

7

17

14

15

(EMB2 OPTION ONLY)

(EMB2 OPTION ONLY)

130BX381.11

CUSTOMER CONNECTION

DRIVE CONTROL

TERMINALS

CUSTOMER CONNECTION

INPUT & OUTPUT GROUND

27

26

Installation Vertical Bypass/Non Bypass Panel

33

Figure 3.11 P5 Bypass Mechanical Layout Diagram.

See

Table 3.8 for reference designator definitions.

3-14 MG.13.A1.22 - VLT® is a registered Danfoss trademark

Page 32

CUSTOMER CONNECTION

INPUT POWER

L1 L2 L3

CUSTOMER CONNECTION

OUTPUT POWER

T1 T2 T3

17

7

5

8

26

CUSTOMER CONNECTION

DRIVE CONTROL

TERMINALS

CUSTOMER CONNECTION

INPUT GROUND

CUSTOMER CONNECTION

OUTPUT GROUND

130BX382.12

27

Installation Vertical Bypass/Non Bypass Panel

3 3

Figure 3.12 P5 Non Bypass Mechanical Layout Diagram.

Table 3.8 for reference designator definitions.

See

MG.13.A1.22 - VLT® is a registered Danfoss trademark 3-15

Page 33

POWER WIRES

CONTROL WIRES

130BX383.12

BYPASS PANEL CONDUIT ENTRY DIAGRAM

USE EITHER CONDUIT PLATE FOR CONVENIENCE

CONTROL WIRES

POWER WIRES

130BX384.12

NON BYPASS PANEL CONDUIT ENTRY DIAGRAM

USE EITHER CONDUIT PLATE FOR CONVENIENCE

Installation Vertical Bypass/Non Bypass Panel

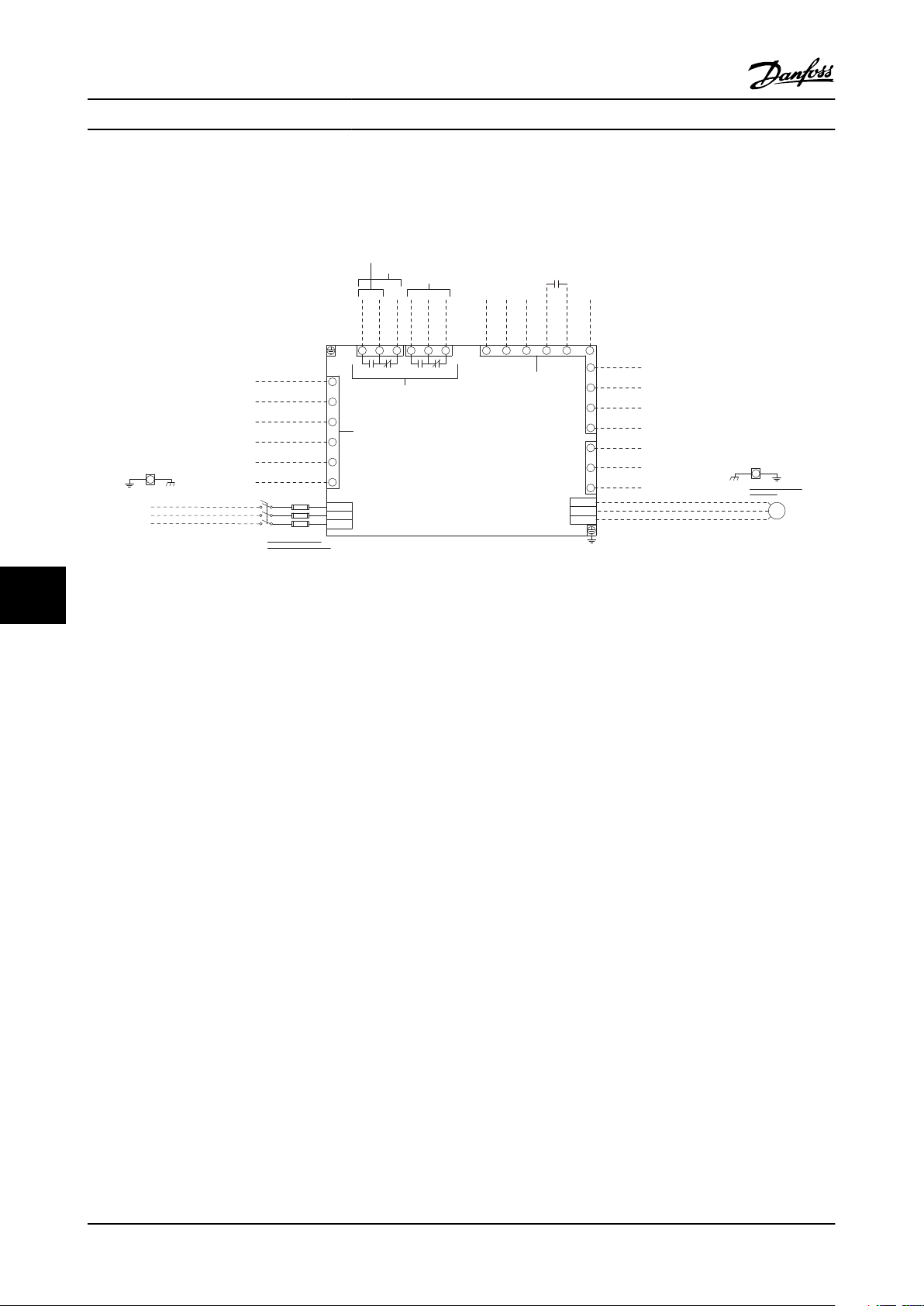

3.4.2 Wire and Cable Access

Refer to through for wire routing and termination

•

locations.

Removable access knockout covers are provided

•

for cable connections (see Figure 3.13 and

33

Figure 3.14).

Access holes are provided for input power, motor

•

leads, and control wiring.

Run input power, motor wiring, and control

•

wiring in three separate conduits for isolation.

NOTE!

RUN INPUT POWER, MOTOR WIRING AND CONTROL

WIRING IN THREE SEPARATE METALLIC CONDUITS OR

RACEWAYS FOR HIGH FREQUENCY NOISE ISOLATION.

FAILURE TO ISOLATE POWER, MOTOR AND CONTROL

WIRING COULD RESULT IN LESS THAN OPTIMUM DRIVE

AND ASSOCIATED EQUIPMENT PERFORMANCE.

Figure 3.13 Bypass Panel Conduit Entry Diagram

The drive always resides in the upper section of

•

the panel. Connections to the ECB and EMB2 are

in this area except on the P2 bypass panels.

Power connections are typically towards the

•

bottom side of the panel.

Control wiring should be isolated from power

•

components inside the unit as much as possible.

Danfoss has included hardware to allow for the

separation.

See the mechanical layout drawings in through

•

for connection details and recommended wire

routing.

Figure 3.14 Non Bypass Panel Conduit Entry Diagram

3-16 MG.13.A1.22 - VLT® is a registered Danfoss trademark

Page 34

INPUT POWER WIRES

OUTPUT POWER WIRES

CONTROL WIRES

INPUT POWER WIRES

OUTPUT POWER WIRES

CONTROL WIRES

Non Bypass

Bypass

130BX387.11

CONTROL WIRES

INPUT POWER WIRES

OUTPUT POWER WIRES

OUTPUT POWER WIRES

INPUT POWER WIRES

CONTROL WIRES

Bypass

Non Bypass

130BX388.11

Installation Vertical Bypass/Non Bypass Panel

3 3

Figure 3.15 P2 Panel

Figure 3.16 P3 Panel

MG.13.A1.22 - VLT® is a registered Danfoss trademark 3-17

Page 35

CONTROL WIRES

INPUT POWER WIRES

OUTPUT POWER WIRES

CONTROL WIRES

INPUT POWER WIRES

OUTPUT POWER WIRES

Bypass

Non Bypass

130BX389.12

Installation Vertical Bypass/Non Bypass Panel

33

Figure 3.17 P4 Panel

3-18 MG.13.A1.22 - VLT® is a registered Danfoss trademark

Page 36

CONTROL WIRES

OUTPUT POWER WIRES

INPUT POWER WIRES

CONTROL WIRES

INPUT POWER WIRES

OUTPUT POWER WIRES

Non Bypass

Bypass

130BX390.11

Installation Vertical Bypass/Non Bypass Panel

3 3

Figure 3.18 P5 Panel

Wire Size

3.4.3

WARNING

ELECTROCUTION AND FIRE HAZARDS WITH IMPROPERLY INSTALLED AND GROUNDED FIELD WIRING!

Improperly installed and grounded field wiring poses FIRE & ELECTROCUTION hazards. To avoid these hazards, you MUST

follow requirements for field wiring installation and grounding as described in the National Electrical Codes (NEC) and your

local/state electrical codes. All field wiring MUST be performed by qualified personnel.

Failure to follow these requirements could result in death or serious injury.

NOTE!

Make all power connections with minimum 60 or 75°C/140 or 155°F rated copper wiring for installations in North America.

MG.13.A1.22 - VLT® is a registered Danfoss trademark 3-19

Page 37

Installation Vertical Bypass/Non Bypass Panel

208 V AC

Panel

HP (KW)

7.5 (5.5) 24.2

10 (7.5) 30.8 8 AWG 10 AWG 60

33

15 (11) 46.2

20 (15) 59.4 P3 3 AWG 10 AWG 60

25 (18.5) 74.8

30 (22) 88

40 (30) 114

50 (37) 143

60 (45) 169 4/0 AWG 6 AWG 75

HP (KW)

7.5 (5.5) 22

10 (7.5) 28 8 AWG 10 AWG 60

15 (11) 42

20 (15) 54

25 (18.5) 68

30 (22) 80

40 (30) 104

50 (37) 130

60 (45) 154 3/0 AWG 6 AWG 75

UL Motor

Current

UL Motor

Current

(FC102/202/322)

Non Bypass &

Bypass

P2

P3 - Non Bypass

P4 -Bypass

P4

P5

Panel

(FC102/202/322)

Non Bypass &

Bypass

P2

P3

P4

P5

Panel (FC302)

Non Bypass

P2

P3

P4

P5

230 V AC

Panel (FC302) Non

Bypass

P2

P3

P4

P5

Maximum Field

Wiring Size Class

B or C

8 AWG 10 AWG 60

4 AWG 10 AWG 60

2 AWG 8 AWG 60

2 AWG 8 AWG 60

1/0 AWG 6 AWG 75

3/0 AWG 6 AWG 75

Maximum Field

Wiring Size

Class B or C

10 AWG 10 AWG 60

6 AWG 10 AWG 60

4 AWG 10 AWG 60

3 AWG 8 AWG 60

3 AWG 8 AWG 60

1 AWG 6 AWG 75

2/0 AWG 6 AWG 75

Field Ground

Wiring Size Class

B or C

Field Ground

Wiring Size

Class B or C

Minimum

Temperature Wire

Rating "°C" Copper

Conductor

Minimum

Temperature Wire

Rating "Degree C"

Copper Conductor

Table 3.9 Wire Size Chart, 208 and 230 V

3-20 MG.13.A1.22 - VLT® is a registered Danfoss trademark

Page 38

Installation Vertical Bypass/Non Bypass Panel

460 V AC

Panel

HP (KW) UL Motor Current

15 (11) 21

20 (15) 27 8 AWG 10 AWG 60

25 (18.5) 34

30 (22) 40

40 (30) 52 4 AWG 10 AWG 60

50 (37) 65

60 (45) 77

75 (55) 96

100 (75) 124

125 (90) 156 3/0 AWG 6 AWG 75

HP (KW) UL Motor Current

15 (11) 17

20 (15) 22 10 AWG 10 AWG 60

25 (18.5) 27

30 (22) 32

40 (30) 41 6 AWG 10 AWG 60

50 (37) 52

60 (45) 62

75 (55) 77

100 (75) 99

125 (90) 125 2/0 AWG 6 AWG 75

(FC102/202/322)

Non Bypass &

Bypass

P2

P3

P4

P5

Panel

(FC102/202/322)

Non Bypass &

Bypass

P2

P3

P4

P5

Panel (FC302) Non

Bypass

P2

P3

P4

P5

600 VAC

Panel (FC302) Non

Bypass

P2

P3

P4

P5

Maximum Field

Wiring Size Class

B or C

10 AWG 10 AWG 60

6 AWG 10 AWG 60

6 AWG 10 AWG 60

3 AWG 8 AWG 60

1 AWG 8 AWG 60

1 AWG 8 AWG 60

2/0 AWG 6 AWG 75

Maximum Field

Wiring Size Class

B or C

10 AWG 10 AWG 60

8 AWG 10 AWG 60

8 AWG 10 AWG 60

4 AWG 10 AWG 60

3 AWG 8 AWG 60

1 AWG 8 AWG 60

1 AWG 8 AWG 60

Field Ground

Wiring Size Class

B or C

Field Ground

Wiring Size Class

B or C

Minimum

Temperature Wire

Rating "°C" Copper

Conductor

3 3

Minimum

Temperature Wire

Rating "Degree C"

Copper Conductor

Table 3.10 Wire Size Chart 460 and 600 V

Wire Type Rating

3.4.4

The wire style rating specifications are provided inTable 3.9 and Table 3.10

•

Terminal Tightening Torques

3.4.5

Tighten all connections to the torque specifications provided in Table 3.11 and Table 3.12

•

The torque specifications are also located on the tightening torque and wire rating label inside the panel cover.

•

See Table 3.14 for a sample of the torque and wire rating data.

MG.13.A1.22 - VLT® is a registered Danfoss trademark 3-21

Page 39

Installation Vertical Bypass/Non Bypass Panel

Torque lb-in

Overload T1,

Single Motor

L1, L2, & L3

Circuit Breaker

Disconnect Switch

Disconnect Switch

(N-m)

T2, & T3

Torque lb-in

Torque lb-in

L2, & L3 Torque

Fusible UL98 L1,

L1, L2, & L3 Torque

(w/o Fuses) UL508A

(N-m)

(N-m)

lb-in (N-m)

lb-in (N-m)

(N-m)

Torque lb-in

Ground Wire

Fusible UL98 L1,

T2, & T3

Torque lb-in

L2, & L3 Torque

UL508A L1, L2, &

Torque lb-in

lb-in (N-m)

L3 Torque lb-in

(N-m)

(N-m)

(N-m)

200 (22.5) 500 (56.5) 274 (31) 275 (31) 40 (4.5)

33

Overload T1,

Single Motor

L1, L2, & L3

Circuit Breaker

Disconnect Switch

(w/o Fuses)

Disconnect Switch

Ground Wire

208 V

Non Bypass Bypass

Input Output Input Output

(N-m)

T3 Torque lb-in

Motor T1, T2, &

Drive

Disconnect

L3 Torque lb-in

Switch L1, L2, &

Non Bypass

Panel (FC302)

Non Bypass & Bypass

Panel (FC102/202/322)

(N-m)

55 (6.2) 16 (1.8) 7 (0.8) 30 (3.3) 40 (4.5) 24 (2.7) 40 (4.5)

P2

P2

55 (6.2) 16 (1.8) 18 (2) 120 (13.5) 45 (5) 50 (5.6) 40 (4.5)

P3

70 (7.9) 40 (4.5) 55 (6.2) 200 (22.5) 50 (5.6) 50 (5.6) 40 (4.5)

P4

200 (22.5) 40 (4.5) 200 (22.5) 200 (22.5) 50 (5.6) 50 (5.6) 40 (4.5)

P4

200 (22.5) 88.5 (10) 200 (22.5) 200 (22.5) 50 (5.6) 275 (31) 40 (4.5)

P5

200 (22.5) 88.5 (10) 200 (22.5) 500 (56.5) 274 (31) 275 (31) 40 (4.5)

230 V

124/212.4

(14/24) *Note 1

200 (22.5)

P5

Non Bypass Bypass

Input Output Input Output

(N-m)

T3 Torque lb-in

Motor T1, T2, &

Drive

Disconnect

& L3 Torque

Switch L1, L2,

Non Bypass

Panel (FC302)

Non Bypass & Bypass

Panel (FC102/202/322)

lb-in (N-m)

55 (6.2) 16 (1.8) 7 (0.8) 30 (3.3) 40 (4.5) 24 (2.7) 40 (4.5)

P2

P2

55 (6.2) 16 (1.8) 18 (2) 120 (13.5) 45 (5) 50 (5.6) 40 (4.5)

P3

55 (6.2) 40 (4.5) 18 (2) 120 (13.5) 50 (5.6) 50 (5.6) 40 (4.5)

P3

70 (7.9) 40 (4.5) 18 (2) 120 (13.5) 50 (5.6) 50 (5.6) 40 (4.5)

P4

70 (7.9) 40 (4.5) 55 (6.2) 200 (22.5) 50 (5.6) 50 (5.6) 40 (4.5)

P4

200 (22.5) 88.5 (10) 200 (22.5) 200 (22.5) 50 (5.6) 50 (5.6) 40 (4.5)

200 (22.5) 88.5 (10) 200 (22.5) 200 (22.5) 274 (31) 275 (31) 40 (4.5)

P5

P5

*Note 1 - Tightening of terminals for different cable dimensions x/y, where x <0.147in sq [95mm sq] and y>0.147 in sq [95mm sq]

15 (11)

20 (15) P3 - Non Bypass 55 (6.2) 40 (4.5) 18 (2) 120 (13.5) 50 (5.6) 50 (5.6) 40 (4.5)

30 (22)

40 (30)

50 (37)

10 (7.5) 55 (6.2) 16 (1.8) 7 (0.8) 30 (3.3) 40 (4.5) 24 (2.7) 40 (4.5)

HP (KW)

3-22 MG.13.A1.22 - VLT® is a registered Danfoss trademark

7.5 (5.5)

25 (18.5) P4 - Bypass

60 (45)

HP (KW)

7.5 (5.5)

10 (7.5) 55 (6.2) 16 (1.8) 7 (0.8) 30 (3.3) 40 (4.5) 24 (2.7) 40 (4.5)

15 (11)

20 (15)

25 (18.5)

30 (22)

40 (30)

50 (37)

60 (45) 200 (22.5) 124 (14) 200 (22.5) 500 (56.5) 274 (31) 275 (31) 40 (4.5)

Table 3.11 Tightening Torques, 208 and 230 V

Page 40

Installation Vertical Bypass/Non Bypass Panel

(N-m)

Torque lb-in

Ground Wire

Overload T1, T2,

L1, L2, & L3

L2, & L3 Torque

& T3 Torque lb-

Torque lb-in

lb-in

in (N-m)

(N-m)

(N-m)

Single Motor

Circuit Breaker

Fusible UL98 L1,

Disconnect Switch

3 3

460 V

Non Bypass Bypass

Input Output Input Output

Disconnect

Switch (w/o

Fuses) UL508A

Motor T1, T2, &

Drive

Disconnect

Non Bypass

Panel (FC302)

Non Bypass & Bypass

Panel (FC102/202/322)

L1, L2, & L3

T3 Torque lb-in

Switch L1, L2, &

Torque lb-in

(N-m)

L3 Torque lb-in

(N-m)

(N-m)

55 (6.2) 16 (1.8) 7 (0.8) 30 (3.3) 40 (4.5) 24 (2.7) 40 (4.5)

P2

P2

55 (6.2) 16 (1.8) 7 (0.8) 30 (3.3) 45 (5) 24 (2.7) 40 (4.5)

55 (6.2) 40 (4.5) 18 (2) 30 (3.3) 45 (5) 50 (5.6) 40 (4.5)

P3

P3

55 (6.2) 40 (4.5) 18 (2) 120 (13.5) 50 (5.6) 50 (5.6) 40 (4.5)

P4

70 (7.9) 88.5 (10) 55 (6.2) 200 (22.5) 50 (5.6) 50 (5.6) 40 (4.5)

P4

200 (22.5) 88.5 (10) 200 (22.5) 200 (22.5) 50 (5.6) 50 (5.6) 40 (4.5)

200 (22.5) 124 (14) 200 (22.5) 200 (22.5) 274 (31) 275 (31) 40 (4.5)

P5

P5

*Note 1 - Tightening of terminals for different cable dimensions x/y, where x <0.147in sq [95mm sq] and y>0.147 in sq [95mm sq]

HP (KW)

15 (11)

20 (15) 55 (6.2) 16 (1.8) 7 (0.8) 30 (3.3) 40 (4.5) 24 (2.7) 40 (4.5)

25 (18.5)

MG.13.A1.22 - VLT® is a registered Danfoss trademark 3-23

30 (22)

40 (30) 55 (6.2) 40 (4.5) 18 (2) 120 (13.5) 50 (5.6) 50 (5.6) 40 (4.5)

50 (37)

60 (45)

75 (55)

100 (75)

125 (90) 200 (22.5) 124 (14) 200 (22.5) 500 (56.5) 274 (31) 275 (31) 40 (4.5)

Table 3.12 Tightening Torques, 460 V

Page 41

Installation Vertical Bypass/Non Bypass Panel

(N-m)

Torque lb-in

Ground Wire

33

lb-in (N-m)

Overload T1,

Single Motor

T2, & T3 Torque

(N-m)

L1, L2, & L3

Torque lb-in

Circuit Breaker

Torque lb-in

L1, L2, & L3

T3 Torque lb-in

(N-m)

(N-m)

Torque lb-in

(N-m)

600 V

Non Bypass Bypass

Disconnect

Switch Fusible

Disconnect

Switch (w/o

Fuses) UL508A

Motor T1, T2, &

UL98 L1, L2, & L3

Drive

Input Output Input Output

3-24 MG.13.A1.22 - VLT® is a registered Danfoss trademark

Disconnect

Non Bypass

Panel (FC302)

Non Bypass & Bypass

Panel (FC102/202/322)

HP (KW)

(N-m)

55 (6.2) 16 (1.8) 7 (.79) 17 (1.92) 62 (7) 24 (2.7) 40 (4.5)

L3 Torque lb-in

Switch L1, L2, &

P2

15 (11)

P2

20 (15) 55 (6.2) 16 (1.8) 7 (.79) 30 (3.3) 62 (7) 24 (2.7) 40 (4.5)

55 (6.2) 16 (1.8) 7 (.79) 30 (3.3) 62 (7) 24 (2.7) 40 (4.5)

25 (18.5)

55 (6.2) 40 (4.5) 7 (.79) 30 (3.3) 62 (7) 50 (5.6) 40 (4.5)

P3

30 (22)

P3

40 (30) 55 (6.2) 40 (4.5) 18 (2) 30 (3.3) 62 (7) 50 (5.6) 40 (4.5)

55 (6.2) 40 (4.5) 18 (2) 120 (13.5) 62 (7) 50 (5.6) 40 (4.5)

P4

50 (37)

55 (6.2) 88.5 (10) 55 (6.2) 120 (13.5) 62 (7) 50 (5.6) 40 (4.5)

P4

60 (45)

70 (7.9) 88.5 (10) 55 (6.2) 200 (22.5) 62 (7) 50 (5.6) 40 (4.5)

P5

75 (55)

200 (22.5) 124 (14) 200 (22.5) 200 (22.5) 200 (22.5) 275 (31) 40 (4.5)

P5

100 (75)

*Note 1 - Tightening of terminals for different cable dimensions x/y, where x <0.147in sq [95mm sq] and y>0.147 in sq [95mm sq]

125 (90) 200 (22.5) 124 (14) 200 (22.5) 200 (22.5) 200 (22.5) 275 (31) 40 (4.5)

Table 3.13 Tightening Torques, 600 V

Page 42

Installation Vertical Bypass/Non Bypass Panel

Field Connection Tightening Torque lb-in (N-m) Temperature & Type Rating

L1, L2, L3/Ground 25 (2.8) 25 (2.8) Use 75°C Copper Conductor

2T1, 2T2, 2T3/Ground 25 (2.8) 25 (2.8) Use 75°C Copper Conductor

TB1 25 (2.8) 25 (2.8) Use 75°C Copper Conductor

Table 3.14 Sample Tightening Torque and Wire Rating Label

3.4.6 Input Line Connection

CAUTION

Run input power, motor wiring and control wiring in three

separate metallic conduits or raceways for high frequency

noise isolation. Failure to isolate power, motor and control

wiring could result in less than optimum drive and

associated equipment performance.

Connect 3-phase AC input power wire to

•

terminals L1, L2, and L3. See the connection

drawing inside the cover of the unit.

Depending on the configuration of the

•

equipment, input power may be connected to a

circuit breaker or disconnect switch.

Torque terminals in accordance with the

•

information provided inTable 3.11 and Table 3.12

on the label inside the panel cover.

Use with Isolated Input Source. Many utility

•

power systems are referenced to earth ground.

Although not as common, the input power may

be an isolated source. All drives may be used

with an isolated input source as well as with

ground reference power lines.

Motor Wiring

3.4.7

WARNING

ELECTROCUTION AND FIRE HAZARDS WITH

IMPROPERLY INSTALLED AND GROUNDED FIELD

WIRING!

Improperly installed and grounded field wiring poses FIRE

& ELECTROCUTION hazards. To avoid these hazards, you

MUST follow requirements for field wiring installation and

grounding as described in the National Electrical Codes

(NEC) and your local/state electrical codes. All field wiring

MUST be performed by qualified personnel. Failure to

follow these requirements could result in death or serious

injury.

WARNING

INDUCED VOLTAGE!

Run output motor cables from multiple drives separately.

Induced voltage from output motor cables run together

can charge equipment capacitors even with the equipment

turned off and locked out. Failure to run output motor

cables separately could result in death or serious injury.

NOTE!

Run input power, motor wiring and control wiring in three

separate metallic conduits or raceways for high frequency

noise isolation. Failure to isolate power, motor and control

wiring could result in less than optimum drive and

associated equipment performance.

Connect the 3-phase motor wiring to bypass

•

terminals T1 (U), T2 (V), and T3 (W). See the

connection drawing inside the cover of the unit.

Depending on the configuration of the

•

equipment, motor wiring may be connected to

overload or terminal block.

Torque terminals in accordance with the

•

information provided on the connection diagram

inside the cover of the unit.

Motor wiring should never exceed the following

•

maximum distances: 300m (1000 ft) for

unshielded, 150m (500 ft) for shielded.

Motor wiring should always be as short as

•

practical.

3 3

MG.13.A1.22 - VLT® is a registered Danfoss trademark 3-25

Page 43

130BX224.10

1

2

3

4

Installation Vertical Bypass/Non Bypass Panel

3.4.8 Grounding (Earthing)

WARNING

GROUNDING HAZARD!

for operator safety, it is important to ground the option

panel properly. Failure to do so could result in death or

33

serious injury.

NOTE!

It is the responsibility of the user or certified electrical

installer to ensure correct grounding (earthing) of the

equipment in accordance with national and local electrical

codes and standards.

Follow all local and national codes for proper

•

electrical equipment grounding (earthing).

Correct protective grounding of the equipment

•

must be established. Ground currents are higher

than 3 mA.

A dedicated ground wire is required for input

•

ground.

Connect the ground wire directly to a reliable

•

earth ground. Grounding studs are provided on

the back plate of the panel for grounding.

Do not use conduit connected to the panel as a

•

replacement for a ground wire.

A high strand count ground wire is preferred for

•

dissipating high frequency electrical noise.

Keep the ground wire connections as short as

•

possible.

Ground the motor to the panel with insulated

•

wire run inside metal conduit with motor leads.

Figure 3.19 Control Terminals Location

1. EIA-485 terminal

2. Jumper wire

3. Control terminals

4. Grounded restraining clips

3.4.10

Serial Communication Bus

Connection

The ECB reports serial communication data to host systems

through the drive. Connection to the serial communication

network is made either through the EIA-485 terminals on

the drive (see Figure 3.19) or, for other protocols, terminals

located on the communication option card. For option

card connection, see the option card instructions provided

with the unit.

For ECB serial communication protocols using the

Control Wiring

3.4.9

Detailed instructions for terminal connection, control

wiring installation, and operation are shown in Section 5

Electromechanical Bypass (EMB2) Operation and Section 6

Electronically Controlled Bypass (ECB) Operation.

It is recommended that control wiring is rated for

•

600 V for 480 V and 600 V drives and 300 V for

200-240 V drives.

Isolate control wiring from high power

•

components in the drive.

See 3.4.2 Wire and Cable Access for details.

•

3-26 MG.13.A1.22 - VLT® is a registered Danfoss trademark

•

EIA-485 terminals, make connections in the

following manner.

NOTE!

It is recommended to use braided-shielded, twisted-pair

cables to reduce noise between conductors.

1. Connect signal wires to terminal (+) 68 and

terminal (-) 69 on control terminals of drive. (See

the drive support materials for wire size and

tightening torque.)

2. Terminate shield to grounded restraining clip

provided by stripping wire insulation at point of

contact.

3. If shielded cabling is used, do not connect the

end of the shield to terminal 61.

Page 44

130BX231.10

Installation Vertical Bypass/Non Bypass Panel

Programming

Serial communication point maps, parameter settings, and

other details for bypass option functionality are included in

the serial communication materials supplied with the unit.

Also provided are two Form C relay outputs that

•

are in various locations depending upon the drive

configuration and size.

3.4.11 Drive Control Terminals

Definitions of the drive terminals are summarized in

Table 3.15.

Connector 1 provides four digital inputs; two

•

selectable digital inputs or outputs, 24 V DC

terminal supply voltage, and a common for

optional customer supplied 24 V DC voltage.

Serial communications use EIA-485 connector 2

•

with terminal 68 (+) and 69 (-).

Connector 3 provides two analog inputs, one

•

analog output, 10 V DC supply voltage, and

commons for the inputs and output.

A USB port, connector 4, is also available for use

•

with the MCT 10 Set-up Software available on the

Danfoss website.

Terminal No. Function

01, 02, 03, 04,

05, 06

12, 13 24 V DC digital supply voltage. Useable for digital inputs and external transducers. To use the 24 V DC for digital input

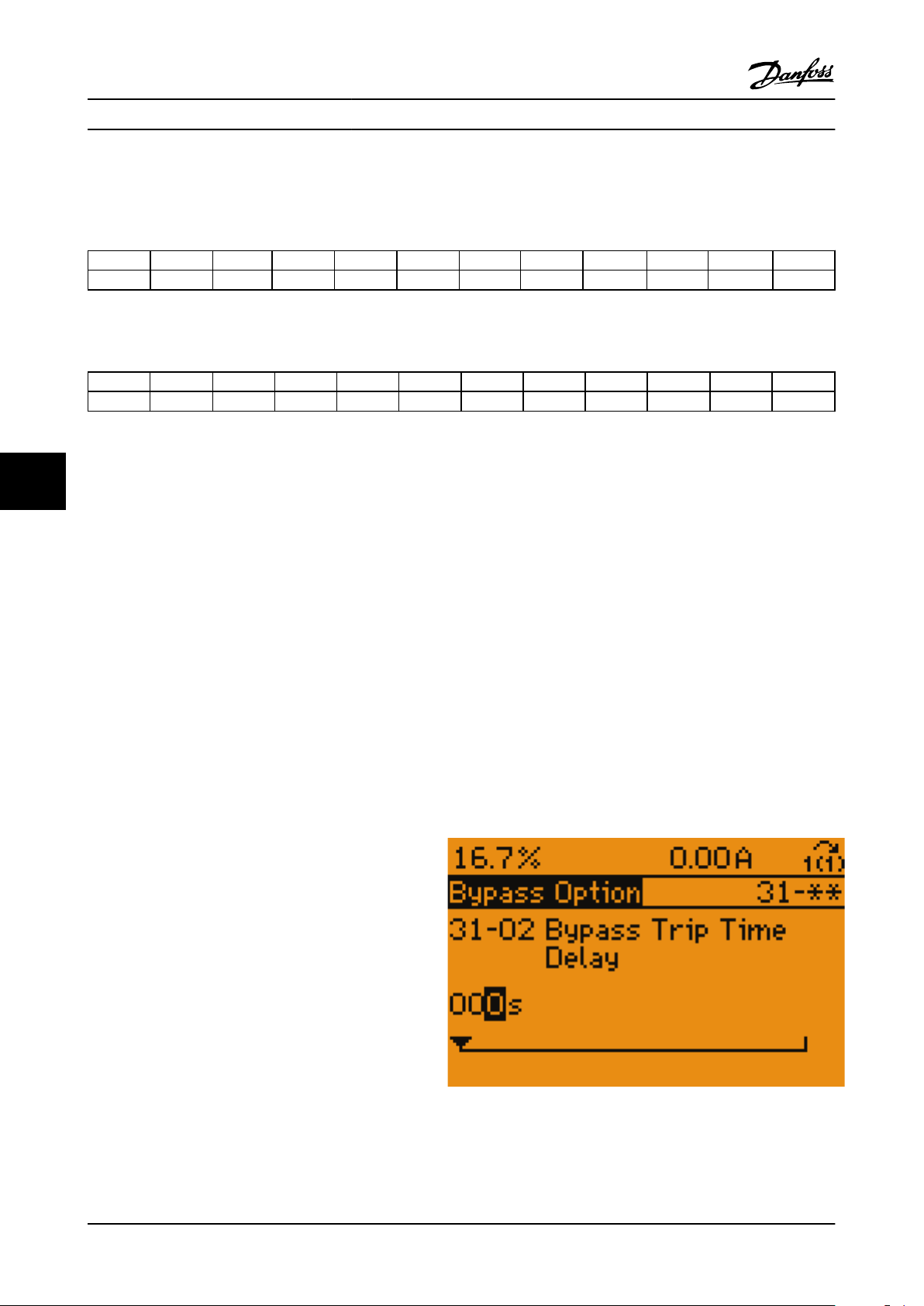

18, 19, 32, 33 Digital inputs. Selectable for NPN or PNP function in parameter 5-00. Default is PNP.