Page 1

Data sheet

3/2-Way Zone-Drain-Valves

VDHT 2E, VDHT 15E and

VDHT 15EC

hpp.danfoss.com

Page 2

Data sheet | 3/2-Way Zone-Drain-Valves

Table of Contents

Contents

1. Introduction ............................................................................2

2. Overview ...............................................................................3

3. Technical data...........................................................................4

3.1 3/2 way principle........................................................................5

4. Pressure losses at dierent ows.........................................................6

5. Overview coils and accessories ..........................................................7

6. Sub-base manifold ......................................................................8

7. VDHT drawings and spare parts .........................................................9

1. Introduction

The 3/2-way valves are designed for applications

in high-pressure humidication and adiabatic

cooling systems.

Each valve has an IN, OUT and DRAIN port.

When the valve is not in operation the connection between IN and OUT is closed while the

connection between OUT and DRAIN stays

open. This allows to instantanously relief the

pressure at shut down from the application,

typically a nozzle branch, to prevent the nozzle

from dripping. If desired, the nozzle branch can

be entirely drained after shut down to avoid

bacterial growth. Furthermore, each valve has its

individual properties to match exactly the

specic needs in size and functionality.

All of our valves are made of stainless steel (AISI

304) and are suitable for potable and technical

water. They have an extremely long service life for

at least one million operations and are even then

very easy to service.

Inline valves are available with European BSP

thread (G-thread) and American National Pipe

Thread (NPT). For the VDHT 15EC Danfoss oers a

wide range of single and multiple manifolds.

The enclosure rating is IP67, including any

standard coil. A large variety of coils for various

supply voltages is available for all our valves.

AI268451941578en-001101

Page 3

Data Sheet | 3/2-Way Zone-Drain-Valves

2. Overview

VDHT 2E for small ows

VDHT 15E for medium ows

VDHT 15EC Cetop 3

The VDHT 2E is a small valve for minor ow rates

up to 2 litres per minute (0.52 gpm).

It is a direct operated valve with one NO and NC

armature.

The VDHT 2E requires 2 coils activated by a

common signal (ie. 24V a.c.).

It is suitable for systems with many zones with

few nozzles and is a very cost eective solution.

The VDHT 15E is a medium size single inline valve

for ow rates up to 15 litres per minute (4 gpm).

It is comprising a piston type NC valve and a NO

pilot stage in one housing. The NO part has a

relative small orice, so it cannot drain a big

volume very fast.

It covers a very wide ow range already starting

from 1 litre per minute (0.26 gpm).

The VDHT 15E requires 2 coils activated by

acommon signal (ie. 24 V a.c.)

The VDHT 15EC 3/2 is the Cetop 3 variant of the

VDHT 15E, by means that connections are made

through a valve block or multiple vave manifolds.

In multiple valve applicatons up to 5 valves can

be installed on a common manifold side by side,

saving time, space and plumbing eort.

Sub-base valve manifolds

Danfoss oers sub-base manifolds for installin 3,

4 or 5 VDHT 3/2 way valves side by side.

The sub-base manifolds represent a very

cost-eective solution, saving signicantly on

time, space and plumbing eorts, as the number

of connections is minimized.

© Danfoss | DCS (im) | 2021.05 | 3AI268451941578en-001101

Page 4

Data sheet | 3/2-Way Zone-Drain-Valves

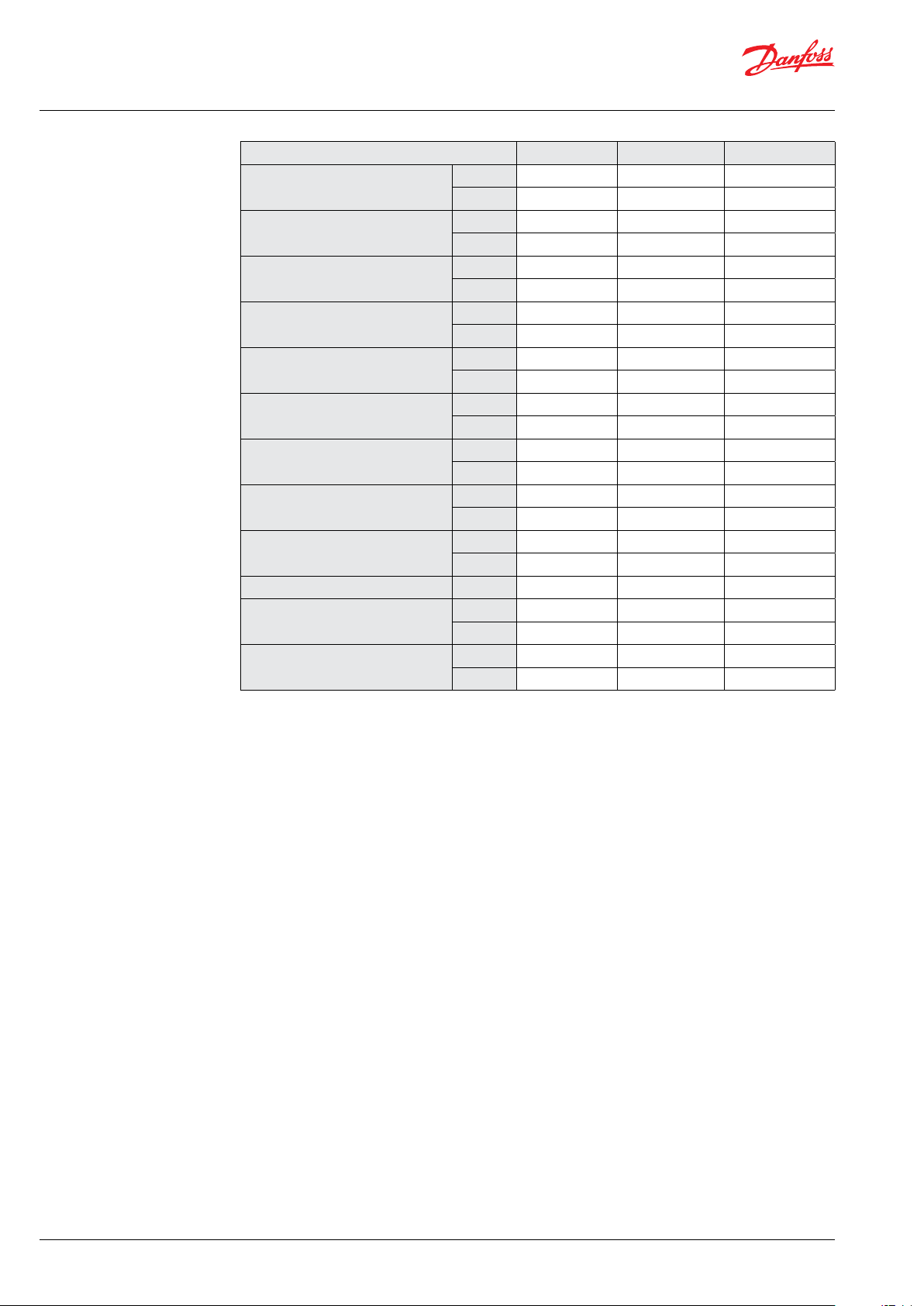

3. Technical data

Description VDHT 2E VD HT 15E VD HT 15EC

Code number

Connection

Max. continuous inlet pressure

Max. peak inlet pressure

Min. operation pressure at inlet

port

Drain opening pressure

Max. ow

Min. ow

Max. drain ow

Opening/closing time ms 250 250 250

Water temperature

Weight without coils

BSP 180L0298 180L0173 180L0240

NPT 180L1017 180L0174

BSP 3 x ¼ ³⁄₈, ³⁄₈, ¼ CETOP 3

NPT 3 x ¼ 3 x ³⁄₈

barg 80 140 140

psig 1150 2000 2000

barg 100 160 160

psig 1450 2300 2300

barg 1 2 2

psig 14.5 29 29

barg 80 80 80

psig 1150 1150 115 0

l/min 2 15 15

gpm 0.52 4 4

l/min 0 1 1

gpm 0 0.26 0.26

l/min 2 5 5

gpm 0.52 1.3 1.3

°C 2-50 2-50 2-50

°F 37-122 37-122 37-122

kg 1.4 1.6 1.7

lbs 3.1 3.5 3.7

AI268451941578en-001101

Page 5

Data Sheet | 3/2-Way Zone-Drain-Valves

3.1 3/2-way principle

Coil de-energized Coil energized

2.3 Soft-Charge principle

Both coils de-energized NC coil energized only

P-port (IN) closed,

B- and t_port conneted

(OUT and DRAIN), application drained

Both coils energized

P-and B-port (IN and OUT) connected,

T-port (DRAIN) closed, full ow to application

P-, T- and B-port

(IN, OUT and DRAIN) connected;

ow partially to application and drain

© Danfoss | DCS (im) | 2021.05 | 5AI268451941578en-001101

Page 6

Data sheet | 3/2-Way Zone-Drain-Valves

4. Pressure losses at

dierent ows

VDHT 2E

psig barg

VDHT 15E and VDHT 15EC

psig

barg

AI268451941578en-001101

Page 7

Data Sheet | 3/2-Way Zone-Drain-Valves

5. Overview coils and

accessories

Description

Code no.

HPP

Voltage Power

Voltage

tolerance

T max

Ambiente

°C (°F)

Connection

Enclosure

Weight

kg (lbs)

Type BB / Without LED / for Hirsch mann plug / excl. plug

Coil 240V-50Hz-10W-IP65 018F7906 240V 50 Hz 11W

Coil 24V-50H z-10W- IP65 018F790 5 24V 50Hz 11W 8 0 (176) DIN 43650-A IP65 0. 2 (0.5)

+/- 10-15%

80 (176) DIN 43650-A IP65 0.2 (0.5)

Coil 24V-DC-18W-IP65 018 F7928 24V DC 16W +/- 10% 50 (122) DIN 43650-A IP65 0.2 (0.5)

Type BE / Without LED / incl. Terminal box

Coil 240 V-6 0Hz-10W -IP67 018F7926 24 0V 60Hz 15W

80 (176) Terminal box IP67 0. 3 (0.7)

Coil 240V-50Hz-10W-IP67 018F7924 240V 50 Hz 11W 8 0 (176) Terminal box IP67 0.3 (0.7)

Coil 220-230V-50Hz-10W-

IP67

Coil 220-230V-50- 60Hz-

10W- IP67

018F7921

018F 7919

Coil 220V-60Hz-10W-IP67 018F7925 220V 60Hz 13 W 80 (17 6) Terminal box IP67 0.3 (0.7)

Coil 200V-50- 60Hz-10W-

IP67

Coil 110V-5 0-6 0Hz-10W-

IP67

018F7929 200V 50/60Hz 10W 8 0 (176 ) Terminal box I P67 0.3 (0.7)

018F7923 110V 50 -6 0H z

220-230 V

50 Hz

220-230 V

50-60Hz

12W 80 (17 6) Terminal box IP67 0.3 (0.7)

17W

14W

50 (122) Terminal box IP67 0.3 (0.7)

+/- 10-15%

15W

13W

50 (122) Terminal box IP67 0.3 (0.7)

Coil 24V-60 Hz-10W- IP67 018F 7922 24V 60Hz 14 W 80 (176) Terminal box IP67 0.3 (0.7)

Coil 24V-50H z-10W- IP67 018F7920 24V 50Hz 12W 80 (176) Terminal box IP67 0.3 (0.7)

Coil 42V-50H z-10W- IP67 018F7927 42V 50Hz 10 W 80 (176) Terminal box IP67 0.3 (0.7)

Coil 24V-DC-18W-IP67 018F7914 24V DC 16W +/- 10% 50 (122) Terminal box IP67 0.3 (0.7)

Coil 12V-DC-18W-IP67 018F7913 12V DC 15 W +/- 10% 50 (122) Terminal box IP67 0.3 (0.7)

Type BE / Without LED / for Hirsch mann plug / prepare for terminal box

Coil 200V-50- 60Hz-10WIP67

018F7918

200V

50/60 Hz

10W

+/- 10-15%

50 (122) Terminal box IP67 0.2 (0.5)

Coil 240V-50Hz-10W-IP67 018F7917 240V 50 Hz 11W 8 0 (176) Terminal box IP67 0.2 (0.5)

Coil 24V-DC-18W-IP67 018F7 912 24V DC 16W +/- 10% 5 0 (122 ) Terminal box IP67 0.3 (0.7)

Type BY / Withou t LED / for Hirschm ann plug / excl. plug / UL Reco gnised

Coil 208-240V-50- 60Hz14W-IP65-UL

Coil 110V-50-60Hz-14WIP65-UL

Coil 24V-50- 60Hz-14WIP65-UL

018F790 8

018F790 9

018F7907

208 -240V

50/60 Hz

110 V

50-60 Hz

24V

50-60 Hz

16W

14W

+/- 10-15%

14W 50 (122 ) DIN43650-A IP65 0.2 (0.5)

14W

12W

50 (122) DIN43650-A IP65 0.2 (0.5)

50 (122) DIN43650-A IP65 0.2 (0.5)

Type BE / excl. LED / Incl. c able

Coil 48V-50-60Hz-10WIP67-4m cable

Type BO / Ex mb II T4 Gb - 2014/34/EU (ATEX) EN60 079-D-2012+A11:2013, EN6 0079-D:2018, EN60079-18:2015 + A1:2017,

Coil Ex mb IIC T4 24V50/60 Hz 10W-IP67

Coil Ex mb IIC T4 110V50/60 Hz 10W-IP67

Coil Ex mb IIC T4 230V50/60 Hz 10W-IP67

Coil Ex mb IIC T4 240V50/60 Hz 10W-IP67

Coil Ex mb IIC T4 Gb

24V DC - IP67-10W-IP67

1)

Due to physical dimensions of the ATEX coil, it is not possible to use these in combination with the

018F7915 48V 50Hz 10W +/- 10 -15% 8 0 (176) 4 mtr. cable IP67 0.3 (0.7)

1)

018Z6 595

018Z6 593

018Z6 592

018Z6 591

018Z6 596

EN60730 -1:2011

24V

2)

50/60 Hz

110 V

2)

50/60 Hz

230V

2)

50/60 Hz

240V

2)

50/60 Hz

2)

24V DC 10W ± 10% 60 (140) 5 m. cable IP67 0 .6 (1.4)

10W ±1 0% 60 (140 ) 5 m. cable IP67 0.6 (1.4))

10W ±1 0% 60 (140 ) 5 m. cable IP67 0.6 (1.4))

10W ±1 0% 60 (140 ) 5 m. cable IP67 0.6 (1.4))

10W ±1 0% 60 (140 ) 5 m. cable IP67 0.6 (1.4))

HPP block valves (BL2 - 5)

2)

Code nos. to be ordered in Danfoss Sensing Solutions (PL04)

© Danfoss | DCS (im) | 2021.05 | 7AI268451941578en-001101

Page 8

Data sheet | 3/2-Way Zone-Drain-Valves

Plug EN175301-803 A

PG9

Plug EN175301-803 A

PG9

Connec ting plug / Typ BY / excl. LED / for Hirschmann connection (DIN 43650-A) UL Recog nised

04 2N125 6

04 2N1278

1)

–

1)

–

Excl

LED

Excl

LED

– 125 (257) BE-BB-BY IP67 0.1 (0.3)

– 90 (194 ) BE-BB-BY IP65 0.1 (0.3)

04 2N125 6

04 2N1278

Connec ting plug / Typ BY / incl. LED / for Hirschmann connec tion (DIN 43650-A) UL Recognised

Plug EN175301-803 A

230V AC/DC LED

Plug EN175301-803 A

24V AC/DC LED + PACK

Terminal box excl. LED

pack unit 100 Pe

Terminal box incl. LED 48220V DC 24-250V-50Hz /

only BE

Permanent magnet 180Z0212 for testing – – – – – 0.3 (0.7)

1)

Code nos. to be ordered in Danfoss Sensing Solutions (PL04)

6. Sub-base manifold 6.1 Manifolds

Typ e Description Code No.

Sub-base manifold for 3 VDHT 15EC 180L0261

Sub-base manifold for 4 VDHT 15EC 180L0262

Sub-base manifold for 5 VDHT 15EC 180L0263

Blind plate to cover spare position 180L0079

1)

042N0265

042N0263

018Z0279 –

018Z0 089

230V AC

1)

24V AC/DC

Connection terminal box / Permanent magnet

48 -220V DC24

1)

-250V 50/60

Incl

LED

Incl

LED

Excl

LED

100 PE

Incl.

Hz

LED

– 60 (140) BE-BB-BY IP65 0.1 (0.3)

– 60 (140) BE-BB-BY IP65 0.1 (0.3)

– 80 (176) BE IP67 0.1 (0.3)

– 80 (176) BE IP67 0.1 (0.3)

AI268451941578en-001101

Page 9

Data Sheet | 3/2-Way Zone-Drain-Valves

7. VDHT drawing spare part

VDHT 2E

Drawings

Spare parts

Spare parts

Armature kit NC 180L5002 / Pos.: 1, 5

Armature kit NO 180L5010 / Pos.: 4, 5

Orice kit NO & NC (1.4 mm) 180Z0097 / Pos.: 6, 7

© Danfoss | DCS (im) | 2021.05 | 9AI268451941578en-001101

Page 10

Data sheet | 3/2-Way Zone-Drain-Valves

VDHT 15 E

Drawings

Spare parts

Spare parts

Armature kit NC 180L5002 / Pos.:1, 5

Armature kit NO 180L5010 / Pos.: 4, 5

Orice kit NC 180Z0098 / Pos.: 6, 7

Orice kit NO 180Z0097 / Pos.: 6, 7

Piston kit Ø18.1 180Z0024 / Pos.: 9, 10, 11

AI268451941578en-001101

Page 11

Data Sheet | 3/2-Way Zone-Drain-Valves

VDHT 15 EC

Drawings

Spare parts

Spare parts

Armature kit NC 180L5002 / Pos.: 1, 5

Armature kit NO 180L5010 / Pos.: 4, 5

Orice kit NC 180Z0098 / Pos.: 6, 7

Orice kit NO 180Z0097 / Pos.: 6, 7

Piston kit 180Z0024 / Pos.: 9, 10

© Danfoss | DCS (im) | 2021.05 | 11AI268451941578en-001101

Page 12

Danfoss A/S

High Pressure Pumps

DK-6430 Nordborg

Denmark

Danfoss ca n accept no respons ibility for pos sible errors in ca talogues, bro chures and other pr inted material. Da nfoss reserves t he right to alter its p roducts with out notice.

This also a pplies to produc ts already on ord er provided that su ch alterations ca n be made without su bsequential cha nges being nece ssary in speci cations alread y agreed.

All trade marks in this mate rial are proper ty of the respec tive companies . Danfoss and the Dan foss logotyp e are trademark s of Danfoss A/S. Al l rights reserv ed.

12 | © Danfoss | DCS (im) | 2021.05

AI268451941578en-001101

Loading...

Loading...