Page 1

Data sheet

VDHT Solenoid valves

Standard NPT (National Pipe Thread)

hpp.danfoss.com

Page 2

Data sheet | Solenoid valve VDHT - NPT Thread

Table of Contents 1. Picture overview.........................................................................3

2. Introduction.............................................................................4

3. VDHT valve .............................................................................4

4. Overview single valves...................................................................5

5. Overview block valves ...................................................................6

6. Overview coils and accessories...........................................................7

7. VDHT drawing spare part ................................................................8

8. Overview spare parts .................................................................. 18

9. Pressure losses p INLET to OUTLET ..................................................... 19

2

AI263125695737us-US0701 | 521B1224| 05.2021

Page 3

Data sheet | Solenoid valve VDHT - NPT Thread

1. Picture overview

VDHT for small ows

VDHT for small and medium ows

VDHT for big ows

VDHT 1/4 E

VDHT 3/8 E

VDHT 1/2 E

VDHT block valve

VDHT B 2-5 stations

Input G 1/2 / G 3/4

Output G 1/2

VDHT Cetop 3 manifold

VDHT 1 ED VDHT 1 EA

VDHT BL 2-4 stations

Input G 3/4 / G 1

Output G 3/4 / G 1

VDHT 30 EC 3

G 3/8 / Cetop 3 manifold

AI263125695737us-US0701 | 521B1224| 05.2021

3

Page 4

Data sheet | Solenoid valve VDHT - NPT Thread

2. Introduction

The VDHT valve series are designed for several

applications in neutral media compatible with

the sealing and O-ring materials used. Typical

media are water, cleaning uids and light

heating oil.

The valves are used in several applications: car

wash systems, stationary high pressure cleaning, mobile cleaning vehicles and dust bindings

systems, ect.

Function

The directional valves are pilot operated ON/OFF

– seat valves electrically activated by a coil.

Features

• Corrosion resistant

• Easy-to-clean

• Reliability

• Dirt tolerant, max. sieve (strainer) width 200

μm or better

• High temperature-resistant

• Robust design prevents leakage

• High coil density IP67 (NEMA 4X)

• Compact design

Versions

The valve housing, blocks and manifolds are

made of stainless steel AISI 304 (W.No. 1.4301),

and the piston of stainless steel AISI 316 (W.No.

1.4401). Standard valves are delivered with PTFE

piston and FPM sealings.

VDHT inline valves are available with a number

of mounting possibilities, ow direction, port

3

size: ¼,

the following designation. The VDHT valves are

also available in BSP.

VDHT integrated valve blocks provide a space

and cost-saving solution in applications where

valves are placed next to each other. Furthermore, integrated valves blocks provide a pressure loss reduction.

/8, ½, ¾ and 1” NPT and more - dening

3. VDHT valve

selection overview

E Straight ow direction N New version slimline

EA Angular ow direction BL N Block version large / New version stroke

EC 3 Cetop 3 manifold F Flange port input

ED Displaced ow diretion NC Normally closed

HP High pressure variant NO Normally opened

B Block version small BSP British Standard Pipe

BL Block version large NPT National Pipe Thread

BLM Block version manual bypass SAE Unied national ne thread

Temperature

• Medium temperature: 2–90 °C

(35 –194 ° F)

• Ambient temperature: 2–80 °C

• Storage temperature: -40–80 °C

(-40–176 °F) Provided that the valve is

drained from uid and stored “plugged”.

(35–176 °F) depending on the coil

specication

General

Pin > P

out

Pilot ow

Viscosity

For correct functioning of the VDHT valves, always ensure the inlet pressure to be higher than the outlet

pressure

The VDHT pilot oprated poppet type (armature + poppet) always needs min. 1 l/min. (0.26 gpm) ow to

ensure correct functioning

Max viscosity of uid: 45mm

time of the VDHT valves.

2

/s. Remark uid viscosity has inuence on pressure drop and opening/closing

4

AI263125695737us-US0701 | 521B1224| 05.2021

Page 5

Data sheet | Solenoid valve VDHT - NPT Thread

4. Overview single valves

2/2-way solenoid valve, type VDHT 1/4" NPT

Opening / Closing time NC (at Qnom) 100–200 ms / 100–200 ms

Description Code no.

VDHT 1/4 E NC NPT 180 L0243 15 (4. 0)

VDHT 1/4 E NO NPT 180L024 4 15 (4. 0)

Q nom

l/min.

(gpm)

p max

barg

(psig)

100

(1450 )

100

(1450 )

T max

°C (°F)

90

(194)

90

(194)

Connec-

NP T 1/4 0.3 (4.0) 0.6 (1.7) Ø11.9 -

NP T 1/4 0.3 (4.0) 0.6 (1.7) Ø11.9 -

2/2 - way solenoid valve, type VDHT 3/8" and 1/2" NPT

Opening / Closing time NC (at Qnom) 100–125 ms / 200–300 ms

Description Code no.

Q nom

VDHT 3/8 E HP NC NPT 180L 0127 30 (8)

VDHT 3/8 E NO NPT 180L0205 30 (8)

VDHT 1/2 E HP NC NPT 180L0128 60 (16)

VDHT 1/2 E NO NPT 180L0209 60 (16)

l/min.

(gpm)

p max

barg

(psig)

210

(3000)

160

(2400)

210

(3000)

160

(2400)

T max

°C (°F)

90

(194)

90

(194)

90

(194)

90

(194)

Connec-

NPT 3/8 3.5 (51) 1.2 (2.6) Ø18.1 1

NPT 3/8 3.5 (51) 1.2 (2.6) Ø18.1 1

NP T 1/2 3 .5 (51) 1.2 (2.6) Ø18.1 1

NP T 1/2 3 .5 (51) 1.2 (2.6) Ø18.1 1

2/2 - way solenoid valve, type VDHT 1" ED and EA NPT

Opening / Closing time NC (at Qnom) 500–900 ms / 1200–2000 ms

Description Code no.

Q nom

VDHT 1 ED NC NPT N 180L1013 150 (40)

VDHT 1 ED NO NP T N 18 0L10 35 150 (40)

VDHT 1 EA NC NPT N 180L10 04 150 ( 40)

l/min.

(gpm)

p max

barg

(psig)

140

(2000)

140

(2000)

140

(2000)

T max

°C (°F)

90

(194)

90

(194)

90

(194)

Connec-

Weight

excl. coil

kg (lbs)

Weight

excl. coil

kg (lbs)

Piston

Ø

mm

Piston

mm

Piston

mm

Orice

kit

Orice

Ø

Orice

Ø

Operating

tion

tion

tion

NPT 1 3 .5 ( 51) 2.6 (5.0) Ø35.1 1

NPT 1 3. 5 (51) 2.6 (5.0) Ø35.1 1

NPT 1 3. 5 (51) 2.6 (5.0) Ø35.1 1

pressure/

barg (psig)

Operating

pressure/

barg (psig)

Operating

pressure/

barg (psig)

Weight

excl. coil

kg (lbs)

kit

kit

AI263125695737us-US0701 | 521B1224| 05.2021

5

Page 6

Data sheet | Solenoid valve VDHT - NPT Thread

5. Overview block valves

2/2 - way solenoid block valve, type VDHT B2, B3, B4 NPT

Opening / Closing time NC (at Qnom) 500–900 ms / 1200–2000 ms

Q nom

p max

Description Code no.

VDHT B2 1/2 NC NPT 180L0269 60 (16)

VDHT B2 1/2 NC-NO NPT 18 0L0177 60 (16)

VDHT B3 3/4-1/2 NC NPT 180 L0255 60 (16)

VDHT B4 3/4-1/2 NC NPT 180 L0207 60 (16)

l/m

(gpm)

barg

(psig)

160

(2400)

160

(2400)

160

(2400)

160

(2400)

T max

°C (°F)

Connection

90

NP T 1/2-NP T 1/2 3. 5 (51) 3.7 (8. 2) Ø18.1 1

(194)

90

NP T 1/2-NP T 1/2 3. 5 (51) 3.7 (8. 2) Ø18.1 1

(194)

90

NPT 3/4-NPT 1/2 3 .5 (51)

(194)

90

NPT 3/4-NPT 1/2 3 .5 (51)

(194)

2/2 - way solenoid block valve, type VDHT BL2, BL2S, BL3 NPT

Opening / Closing time NC (at Qnom) 500–900 ms / 1200–2000 ms

Q nom

p max

Description Code no.

VDHT BL2S 1 NC NO NPT N 180L1006

VDHT BL2S 1 NC NPT N 18 0L10 01

VDHT BL2S 1 NC-NO NPT N 180L0296

VDHT BL3 3/4 NC NPT N 180L1010

l/m

(gpm)

150

(40)

150

(40)

150

(40)

120

(32)

barg

(psig)

140

(2000)

140

(2000)

140

(2000)

140

(2000)

T max

°C (°F)

Connection

90

NPT 1 - NPT 1 3.5 (51) 7 (15.5 )

(194)

90

NPT 1 - NPT 1 3.5 (51) 7 (15.5 )

(194)

90

NPT 1 - NPT 1 3.5 (51) 7 (15.5 )

(194)

90

NPT 3/4 - NPT

(194)

3/4

Operating

pressure/

barg (psig)

Operating

pressure/

barg (psig)

3. 5 (51)

Weight

excl. coil

kg (lbs)

5.5

(12.2 )

7.4

(16. 3)

Weight

excl. coil

kg (lbs)

10.5

(23.2)

Piston

Ø

mm

Ø18.1 1

Ø18.1 1

Piston

Ø

mm

Ø35 .1

N

Ø35 .1

N

Ø35 .1

N

Ø35 .1

N

Orice

kit

Orice

kit

1

1

1

1

2/2 way cetop 3 valves , BSP

Opening / Closing time NC (at Qnom) 100–125 ms / 200–300 ms

Q nom

p max

Description Code no.

VDHT 30 EC NC 180L0096 30 (8)

VDHT 30 EC NO 180L0097 30 (8)

l/m

(gpm)

barg

(psig)

160

(2400)

160

(2400)

T max

°C (°F)

Cetop 3 block for 2/2 way valves

Q nom

p max

Description Code no.

Cetop 3 block f. 2 VDH or

VDHT 30 EC3

Cetop 3 block f. 3 VDH or

VDHT 30 EC3

Cetop 3 block f. 4 VDH or

VDHT 30 EC3

l/m

(gpm)

180L0062 30 (8)

180L0063 30 (8)

180L0064 30 (8)

barg

(psig)

160

(2400)

160

(2400)

160

(2400)

T max

°C (°F)

Connection

90

(194)

90

(194)

N/A BSP 3/8" – 1.8 (4.0) – –

N/A BSP 3/8" – 2.6 (5.7) – –

N/A BSP 3/8" – 3.4 (7. 5) – –

Cetop 3 3.5 (51) 1 (2.2) Ø18.1 1

Cetop 3 3.5 (51) 1 (2.2) Ø18.1 1

Connection

Operating

pressure/

barg (psig)

Operating

pressure/

barg (psig)

Weight

excl. coil

kg (lbs)

Weight

kg (lbs)

Piston

Piston

Ø

mm

Ø

mm

Orice

Orice

kit

kit

6

AI263125695737us-US0701 | 521B1224| 05.2021

Page 7

Data sheet | Solenoid valve VDHT - NPT Thread

6. Overview coils and

accessories

Description

Code no.

HPP

Voltage Power

Voltage

tolerance

T max

Ambiente

°C (°F)

Connection

Enclosure

Weight

kg (lbs)

Type BB / Without LED / for Hirschmann plug / excl. plug

Coil 240V-50Hz-10W-IP65 018F7906 240V 50 Hz 11W

Coil 24V-50H z-10W- IP65 018F790 5 24V 50Hz 11W 80 (176) DIN 43650-A IP65 0.2 (0.5)

+/- 10-15%

80 (176) DIN 43650-A IP65 0.2 (0.5)

Coil 240V-50Hz-10W-IP65 018F7 928 24V DC 16W +/- 10% 50 (122) DIN 43650-A IP65 0.2 (0.5)

Type BE / Without LED / incl. Terminal box

Coil 240V- 60Hz-10W -IP67 018F7926 240V 60Hz 15W

80 (176) Terminal box IP67 0.3 (0.7)

Coil 240V-50Hz-10W-IP67 018F7924 240V 50Hz 11W 8 0 (176 ) Terminal box IP67 0.3 (0.7)

Coil 220-230V-50Hz-10WIP67

Coil 220-230V-50- 60Hz10W- IP67

018F7921

018F 7919

Coil 220V-60Hz-10W-IP67 018F7925 220V 60Hz 13 W 80 (176) Terminal box IP67 0.3 (0.7)

Coil 200V-50- 60Hz-10WIP67

Coil 110V-5 0-6 0Hz-10WIP67

018F7929 200V 50/60Hz 10 W 80 (176) Terminal box IP67 0.3 (0.7)

018F7923 110V 50 -6 0H z

220-230 V

50 Hz

220-230 V

50-60Hz

12W 80 (176) Terminal box IP67 0. 3 (0.7)

17W

14W

50 (122) Terminal box IP67 0. 3 (0.7)

+/- 10-15%

15W

13W

50 (122) Terminal box IP67 0. 3 (0.7)

Coil 24V-60 Hz-10W- IP67 018F7922 24V 60Hz 14W 80 ( 176) Terminal box I P67 0.3 (0.7)

Coil 24V-50H z-10W- IP67 018F7920 24V 50Hz 12 W 80 (176) Terminal box IP 67 0.3 (0.7)

Coil 42V-50H z-10W- IP67 018F 7927 42V 50Hz 10W 8 0 (176 ) Terminal box IP67 0. 3 (0.7)

Coil 24V-DC-18W-IP67 018F7914 24V DC 16 W +/- 10% 50 (12 2) Terminal box IP 67 0.3 (0.7)

Coil 12V-DC-18W-IP67 018 F7913 12 V DC 15W +/- 10 % 5 0 (122 ) Terminal box IP67 0. 3 (0.7)

Type BE / Without LED / for Hirschmann plug / prepa re for terminal box

Coil 200V-50- 60Hz-10WIP67

018F7918

200V

50/60 Hz

10W

+/- 10-15%

50 (122) Terminal box IP67 0.2 (0.5)

Coil 240V-50Hz-10W-IP67 018 F7917 240V 50 Hz 11W 80 (176) Terminal box IP67 0.2 (0.5)

Coil 24V-DC-18W-IP67 018F 7912 24V DC 16 W +/- 10% 50 (12 2) Terminal box IP67 0.3 (0.7)

Type BY / Withou t LED / for Hirschm ann plug / excl. plug / UL Reco gnised

Coil 208-240V-50- 60Hz14W-IP65-UL

Coil 110V-50-60Hz-14WIP65-UL

Coil 24V-50-6 0Hz -14WIP65-UL

018F790 8

018F790 9

018F7907

208 -240V

50/60 Hz

110 V

50-60 Hz

24V

50-60 Hz

16W

14W

+/- 10-15%

14W 50 (12 2) DIN43650-A IP65 0.2 (0.5)

14W

12W

50 (122) DIN43650-A IP65 0.2 (0.5)

50 (122) DIN43650-A IP65 0.2 (0.5)

Type BE / excl. LED / Incl. cable

Coil 48V-50-60Hz-10WIP67-4m cable

Type BO / Eex mb II Ta Gb -2014/34/EU (ATEX) E60 079-D-20112+A11:2013, EN 60079 -D<.2018, EN60 079-18:2015 +

Coil Eex mb IIC TA 24V50/60 Hz 10W-IP67

Coil Eex mb IIC TA 110V50/60 Hz 10W-IP67

Coil Eex mb IIC TA 230V50/60 Hz 10W-IP67

Coil Eex mb IIC TA 240V50/60 Hz 10W-IP67

Coil Eex mb IIC TA

24V DC -10W-IP67

1)

Due to physical dimensions of the ATEX coil, it is not possible to use these in combination with the

HPP block valves (BL 2-5)

2)

Code nos. to be ordered in Danfoss Sensing Solutions (PL04)

018F7915 48V 50Hz 10W +/- 10 -15% 8 0 (176) 4 m. cable IP67 0.3 (0.7)

1)

018Z6 595

018Z6 593

018Z6 592

018Z6 591

018Z6 596

A1:2017, EN 50730 -1:2011

24V

2)

50/60 Hz

110 V

2)

50/60 Hz

230V

2)

50/60 Hz

240V

2)

50/60 Hz

2)

24V DC 10W +/- 10% 6 0 (140) 5 m. cable IP67 0.6 (1.4)

10W +/- 10% 60 (140) 5 m. cable IP67 0.6 (1.4)

10W +/- 10% 60 (140) 5 m. cable IP67 0.6 (1.4)

10W +/- 10% 60 (140) 5 m. cable IP67 0.6 (1.4)

10W +/- 10% 60 (140) 5 m. cable IP67 0.6 (1.4)

AI263125695737us-US0701 | 521B1224| 05.2021

7

Page 8

Data sheet | Solenoid valve VDHT - NPT Thread

Connec ting plug / Typ BY / excl. LED / for Hirschmann connec tion (DIN 43650- A) UL Recognised

Plug EN175301-803 A PG9 0 42N12 56

Plug EN175301-803 A PG8 0 42N1278

042N1256

042N1278

Connec ting plug / Typ BY / incl. LED / for Hirschmann connec tion (DIN 43650-A) UL Reco gnised

Plug EN175301-803 A

230V AC/DC LED

Plug EN175301-803 A

24V AC/DC LED + PACK

Terminal box excl. LED

pack unit 100 Pe

Terminal box incl. LED 48220V DC 24-250V-50Hz /

only BE

Permanent magnet 18 0Z0212 for testing – – – – – 0.3 (0.7)

1)

Code nos. to be ordered in Danfoss Sensing Solutions (PL04)

1)

1)

1)

1)

230V AC

24V AC/DC

042N0265

042N0263

Connection terminal box / Permanent magnet

018Z0279 –

48 -220V DC24

1)

018Z0 089

-250V 50/60

–

–

Excl

LED

Excl

LED

Incl

LED

Incl

LED

– 125 (257) BE-BB-BY IP67 0.1 (0.3)

– 9 0 (194) BE-BB-BY IP65 0.1 (0.3

– 6 0 (140) BE-BB-BY IP65 0.1 (0.3)

– 6 0 (140) BE-BB-BY IP65 0.1 (0.3)

Excl

LED

– 80 (17 6) BE IP67 0.1 (0.3)

100 PE

Incl.

Hz

LED

– 80 (17 6) BE IP67 0.1 (0.3)

8

AI263125695737us-US0701 | 521B1224| 05.2021

Page 9

Data sheet | Solenoid valve VDHT - NPT Thread

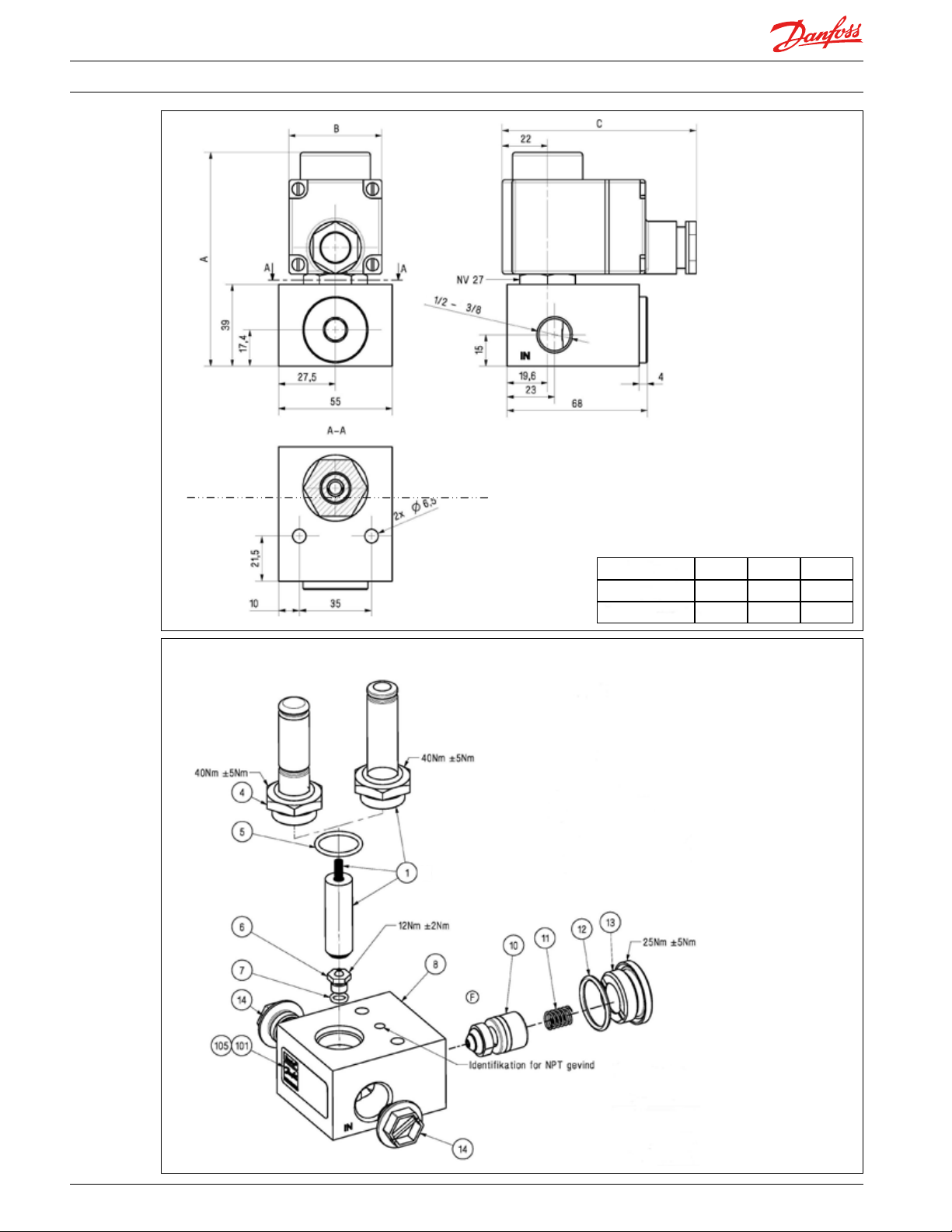

7. VDHT drawing spare part

VDHT 1/4 E

Drawings

Spare parts

Spare parts

Armature kit NC 180L5002 / Pos.: 1, 5

Armature kit NO VDHT 1/4 180L5013 / Pos.: 4,5

Piston kit Ø11.9 180Z0251 / Pos.: 3

AI263125695737us-US0701 | 521B1224| 05.2021

9

Page 10

OUT

IN

Data sheet | Solenoid valve VDHT - NPT Thread

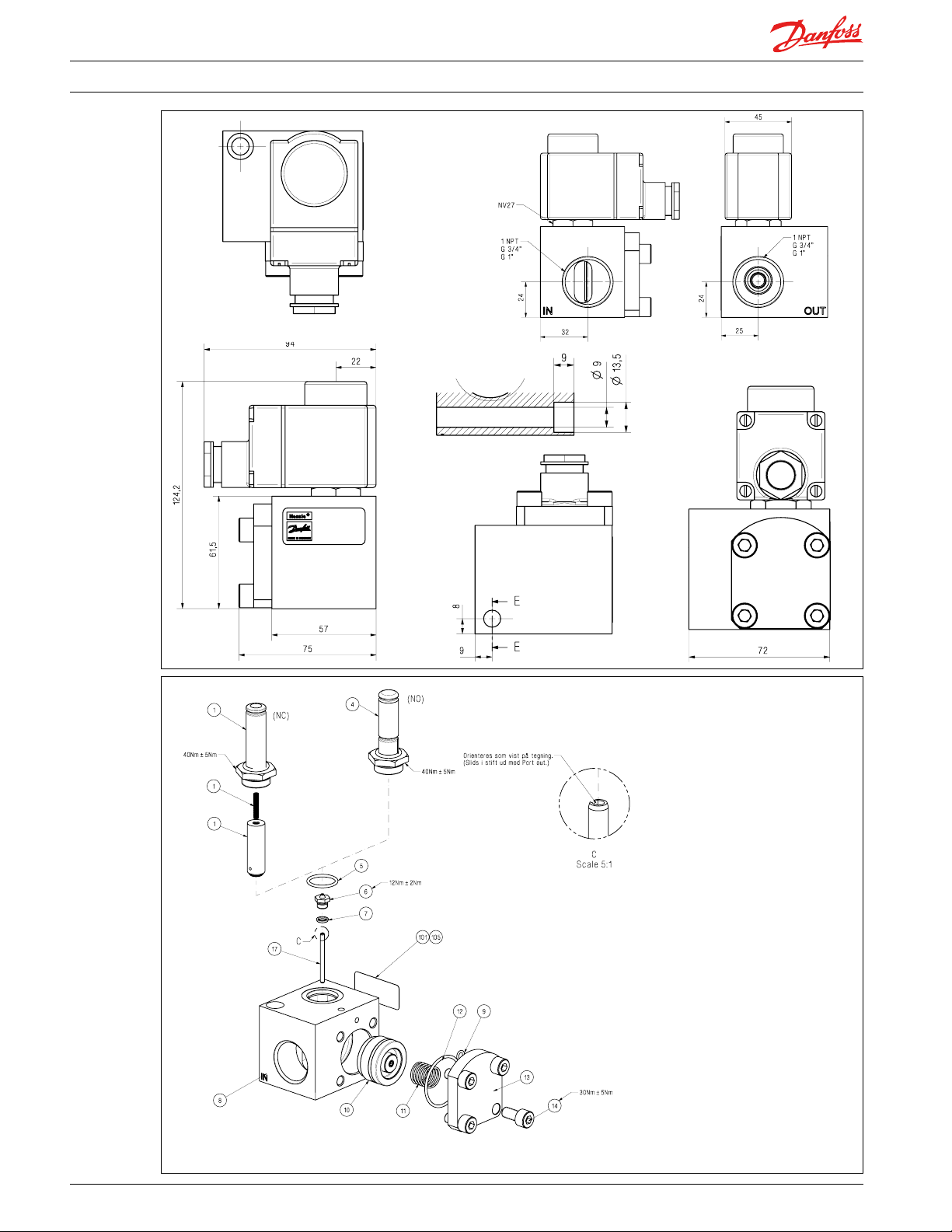

VDHT 3/8 E

VDHT 1/2 E

Drawings

Spare parts

Valve t ype A B C

NO / NC 102 45 94

EEX 112 68 12 5

Spare parts

Armature kit NC 180L5002 / Pos.: 1, 5

Armature kit NC HP 180L5011 / Pos.: 1, 5

Armature kit NO 180L5010 / Pos.: 4, 5

Orice kit 1 180Z0098 / Pos.: 6, 7

Piston kit Ø18.1 180Z0024 / Pos.: 10, 11

10

AI263125695737us-US0701 | 521B1224| 05.2021

Page 11

Data sheet | Solenoid valve VDHT - NPT Thread

VDHT 1 ED N

Drawings

Spare parts

Spare parts

Armature kit NC 180L5002 / Pos.: 1, 5

Armature kit NC HP 180L5011 / Pos.: 1, 5

Armature kit NO 180L5010 / Pos.: 4, 5

Orice kit 1 180Z0098 / Pos.: 6, 7

Piston kit Ø35.1 N 180Z0138 / Pos.: 10, 11

AI263125695737us-US0701 | 521B1224| 05.2021

11

Page 12

Data sheet | Solenoid valve VDHT - NPT Thread

VDHT 1 EA

Drawings

Spare parts

Spare parts

Armature kit NC 180L5002 / Pos.: 1, 5

Armature kit NC HP 180L5011 / Pos.: 1, 5

Armature kit NO 180L5010 / Pos.: 4, 5

Orice kit 1 180Z0098 / Pos.: 6, 7

Piston kit Ø35.1 N 180Z0138 / Pos.: 10, 11

12

AI263125695737us-US0701 | 521B1224| 05.2021

Page 13

Data sheet | Solenoid valve VDHT - NPT Thread

VDHT B

Drawings

Extension module:

180L0090 VDHT 3/4 - 1/2 EA NC BSP

AI263125695737us-US0701 | 521B1224| 05.2021

13

Page 14

Data sheet | Solenoid valve VDHT - NPT Thread

VDHT B

Spare parts

Spare parts

Armature kit NC 180L5002 / Pos.: 1, 5

Armature kit NC HP 180L5011 / Pos.: 1, 5

Armature kit NO 180L5010 / Pos.: 4, 5

Orice kit 1 180Z0098 / Pos.: 6, 7

Piston kit Ø18.1 180Z0024 / Pos.: 10, 11

14

AI263125695737us-US0701 | 521B1224| 05.2021

Page 15

Data sheet | Solenoid valve VDHT - NPT Thread

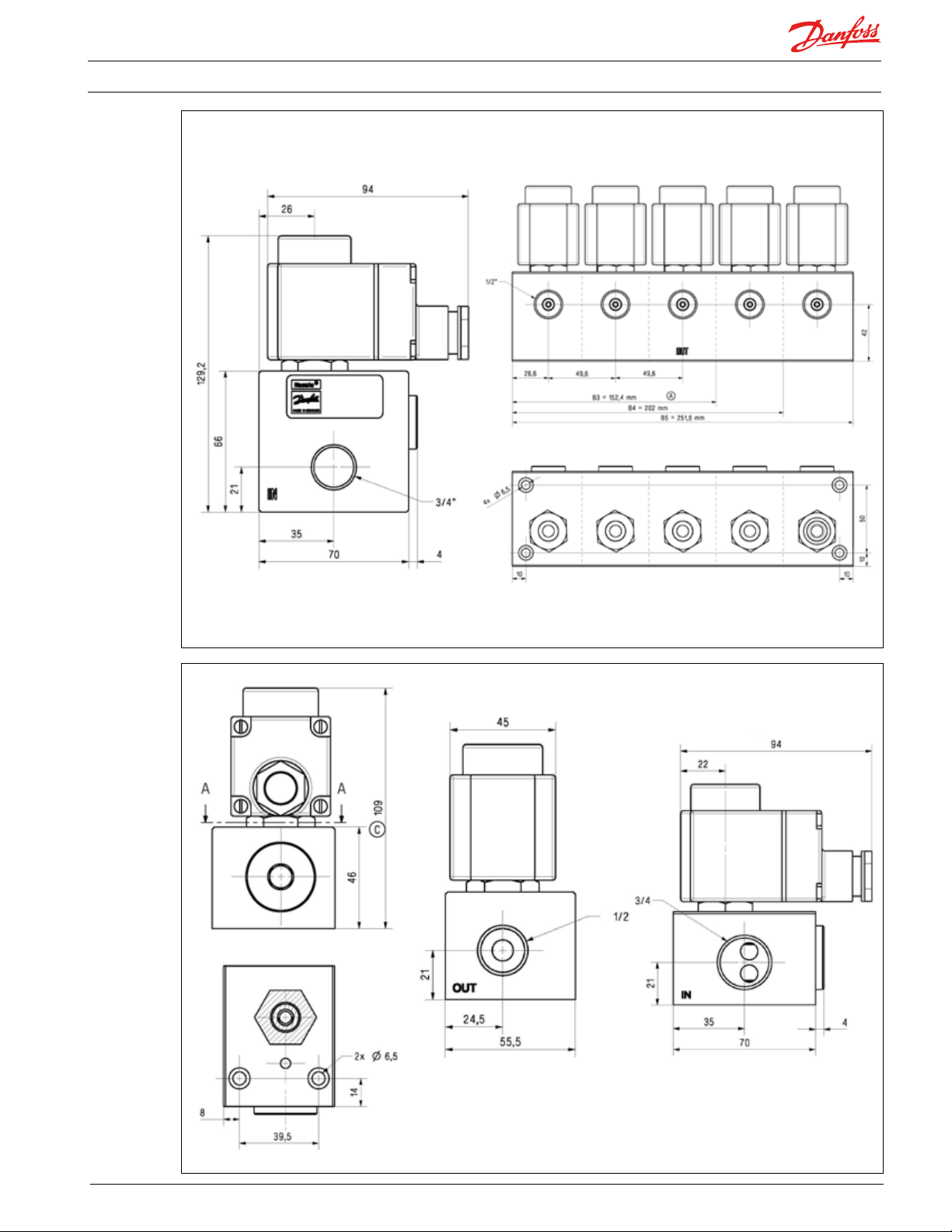

VDHT BL N

Drawings

AI263125695737us-US0701 | 521B1224| 05.2021

15

Page 16

Data sheet | Solenoid valve VDHT - NPT Thread

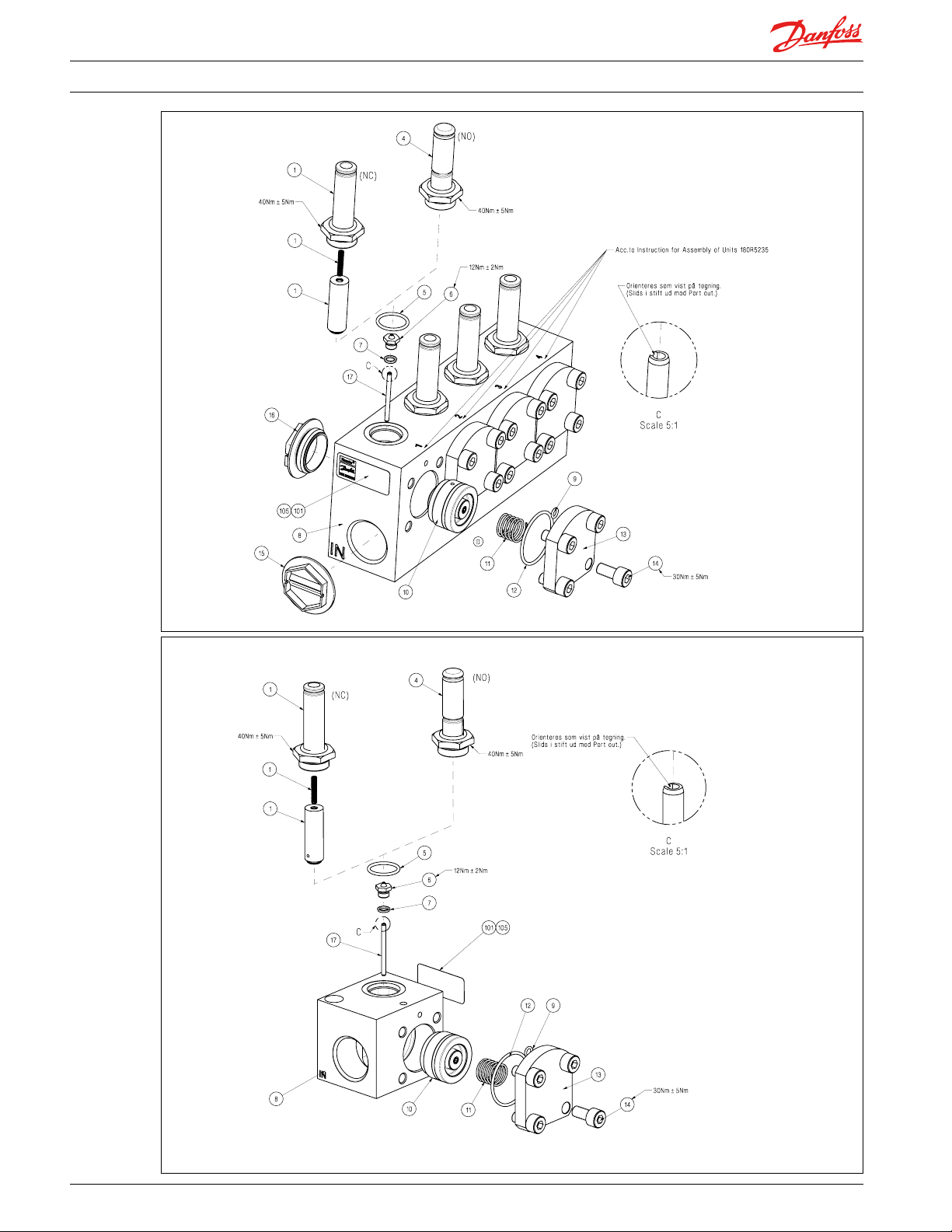

VDHT BL N

Spare parts

Spare parts

Armature kit NC 180L5002 / Pos.: 1, 5

Armature kit NC HP 180L5011 / Pos.: 1, 5

Armature kit NO 180L5010 / Pos.: 4, 5

Orice kit 1 180Z0098 / Pos.: 6, 7

Piston kit Ø35.1 N 180Z0138 / Pos.: 10, 11

16

AI263125695737us-US0701 | 521B1224| 05.2021

Page 17

Data sheet | Solenoid valve VDHT - NPT Thread

VDHT 30 EC3

Drawings

AI263125695737us-US0701 | 521B1224| 05.2021

Cetop 3 block for VDHT 30 EC

2 Manifold 180L0062

3 Manifold 180L0063

4 Manifold 180L0064

17

Page 18

Data sheet | Solenoid valve VDHT - NPT Thread

VDHT 30 EC3

Spare parts

Spare parts

Armature kit NC 180L5002 / Pos.: 1, 5

Armature kit NC HP 180L5011 / Pos.: 1, 5

Armature kit NO 180L5010 / Pos.: 4, 5

Orice kit 1 180Z0098 / Pos.: 6, 7

Piston kit Ø18.1 N 180Z0024 / Pos.: 10, 11

18

AI263125695737us-US0701 | 521B1224| 05.2021

Page 19

Data sheet | Solenoid valve VDHT - NPT Thread

8. Overview spare parts

Valve t ype Code no Other

Piston kit Ø11.9

VDHT 1/4 E

Piston kit Ø18.1

VDHT 3/8

VDHT B

Piston kit Ø35.1

VDHT 1

VDHT BL

Piston kit Ø35.1 N

VDHT 3/4 to 1 N

VDHT BL N

Piston kit Ø35.1 HP N

VDHT 3/4 to 1 N

VDHT BL HP N

Pos. no.

explosion

drawing

180Z 0251 3 90 (194) 0.09 (0.2) Ø11. 9 -

180Z 0024 10 , 11 90 (194 ) 0.09 (0.2) Ø18 .1 -

180Z 0026 10 , 11 90 (194) 0.1 (0.4) Ø35.1 -

180 Z0138 Slimline 1 0, 11 90 (194 ) 0.1 (0.4) Ø35.1 N -

180Z0468 Slimline 10, 11 9 0 (194) 0.1 (0.4) Ø35.1 N -

T max

°C (°F)

Weight

kg (lbs)

Piston

Ø

mm

Orice kit

Orice kit 1 VDHT 18 0Z0098 standard 6, 7 9 0 (194) 0.09 (0.2) - 1

Armature kit NC

VDHT 1/4 to 1

VDHT B / BL / BL N

Armature kit NC HP

VDHT 3/8 to 1

VDHT B / BL / BL N

Armature kit NO

VDHT 3/8 to 1

VDHT B / BL / BL N

Armature kit NO HP

VDHT 1/4

VDHT B / BL / BL N

180L5002 1, 5 90 (194 ) 0.1 (0.4) - -

18 0L 5011 1, 5 90 (194 ) 0.1 (0.4) - -

180L5010 4, 5 9 0 (194) 0.1 (0.4) - -

180 L5013 4, 5 9 0 (194) 0.1 (0.4) - -

AI263125695737us-US0701 | 521B1224| 05.2021

19

Page 20

0.5

1.5

2.5

3.5

024681012141600.511.52 2.53 3.54

∆P [barg]

0

10

20

30

40

50

60

0

∆P [psig]

Q [gpm]

10

20

30

40

50

60

0

∆P [psig]

100

120

∆P [psig]

Q [gpm]

0

1

2

3

4

5

6

7

8

01020304050600246810 12 14 16

∆P [barg]

0

20

40

60

80

100

120

0

∆P [psig]

Q [gpm]

0

1

2

3

4

5

6

7

024681012

∆P [barg]

0

10

40

20

30

70

80

90

100

50

60

0

∆P [psig]

Q [gpm]

100

∆P [psig]

Q [gpm]

Data sheet | Solenoid valve VDHT - NPT Thread

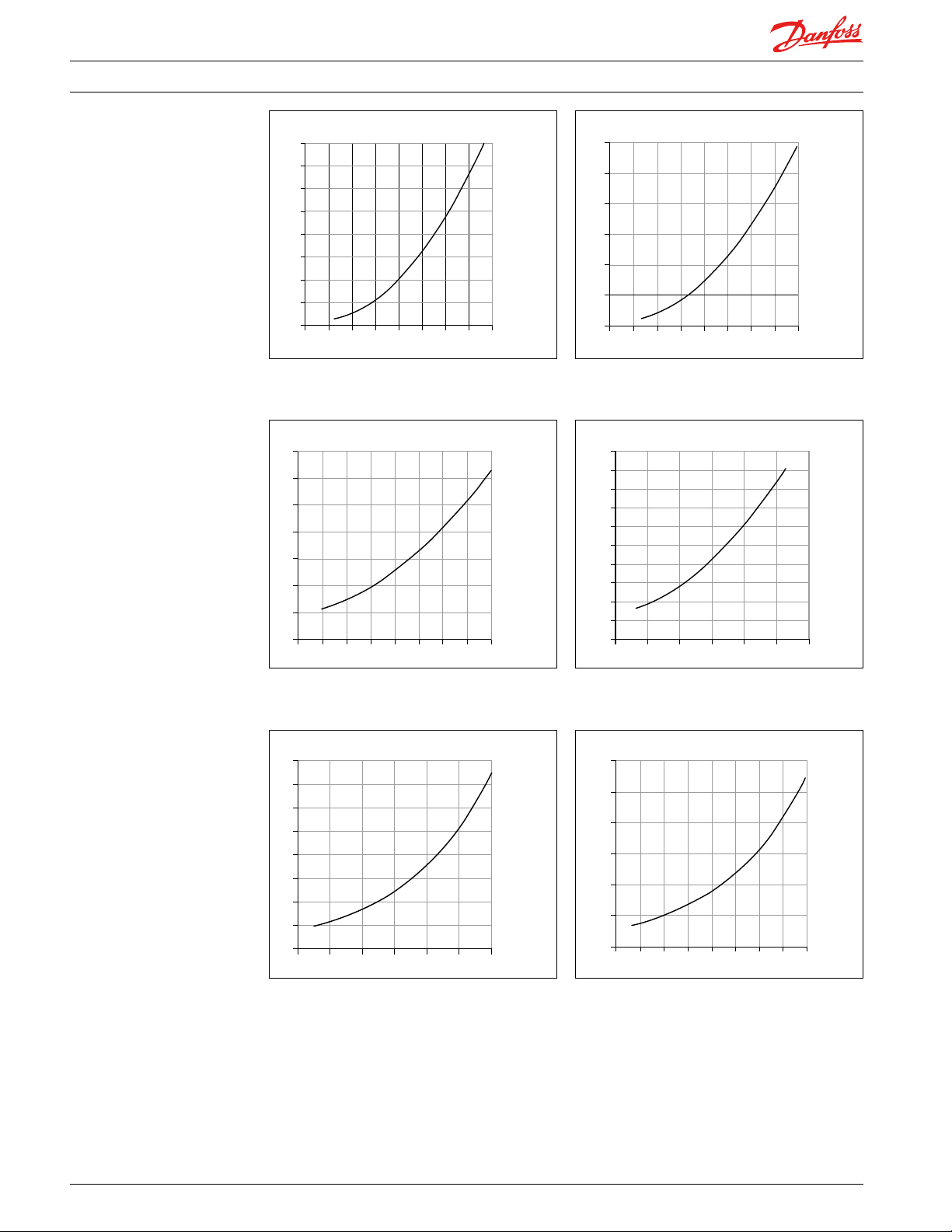

9. Pressure losses p

INLET to OUTLET

Pressure losses p

INLET to OUTLET

4

3

VDHT 1/4 E

Pressure losses p

INLET to OUTLET

VDHT 3/8 E

2

1

0

0510 15 20 25 30 35 40

Q [l/min]

Q [l/min]

0

90

80

70

60

50

40

30

20

10

0

0

024681012

Q [gpm]

Pressure losses p

INLET to OUTLET

VDHT 1/2 E

Q [l/min]

20

AI263125695737us-US0701 | 521B1224| 05.2021

80

60

40

20

0

246810 12 14 16

0

Page 21

02 684

∆P [psig]

0

20

40

60

80

100

120

02 684

Q

[gpm]

∆P [psig]

∆P [psig]

Data sheet | Solenoid valve VDHT - NPT Thread

Pressure losses p

INLET to OUTLET

VDHT EA 3/4

VDHT EA 1

5

4

3

2

1

0

0

20 40 60 80 100120 140160

80

70

60

VDHT EA 1

VDHT EA 3/4

Q [l/min

50

40

30

20

10

0

5101520 25 30 35 40

0

VDHT EA 1

VDHT EA 3/4

Q [gpm]

Pressure losses p

INLET to OUTLET

VDHT 30 EC3

∆P [barg]

8

7

6

5

4

3

2

1

0

0102030

Q [l/min]

120

100

80

60

40

20

Q

0

[gpm]

AI263125695737us-US0701 | 521B1224| 05.2021

21

Page 22

Danfoss A/S

High Pressure Pump

Nordborgvej 81

DK-6430 Nordborg

Denmark

© Danfoss | DCS (im) | 2021.05

AI263125695737us-US0701 | 521B1224 | 22

Loading...

Loading...