Data sheet

Directional control valve

VDH 30EC 4/3

For Cetop 3 flange mounting (ISO 4401)

and inline mounting

hpp.danfoss.com

Data Sheet | Directional Control Valve VDH 30EC 4/3

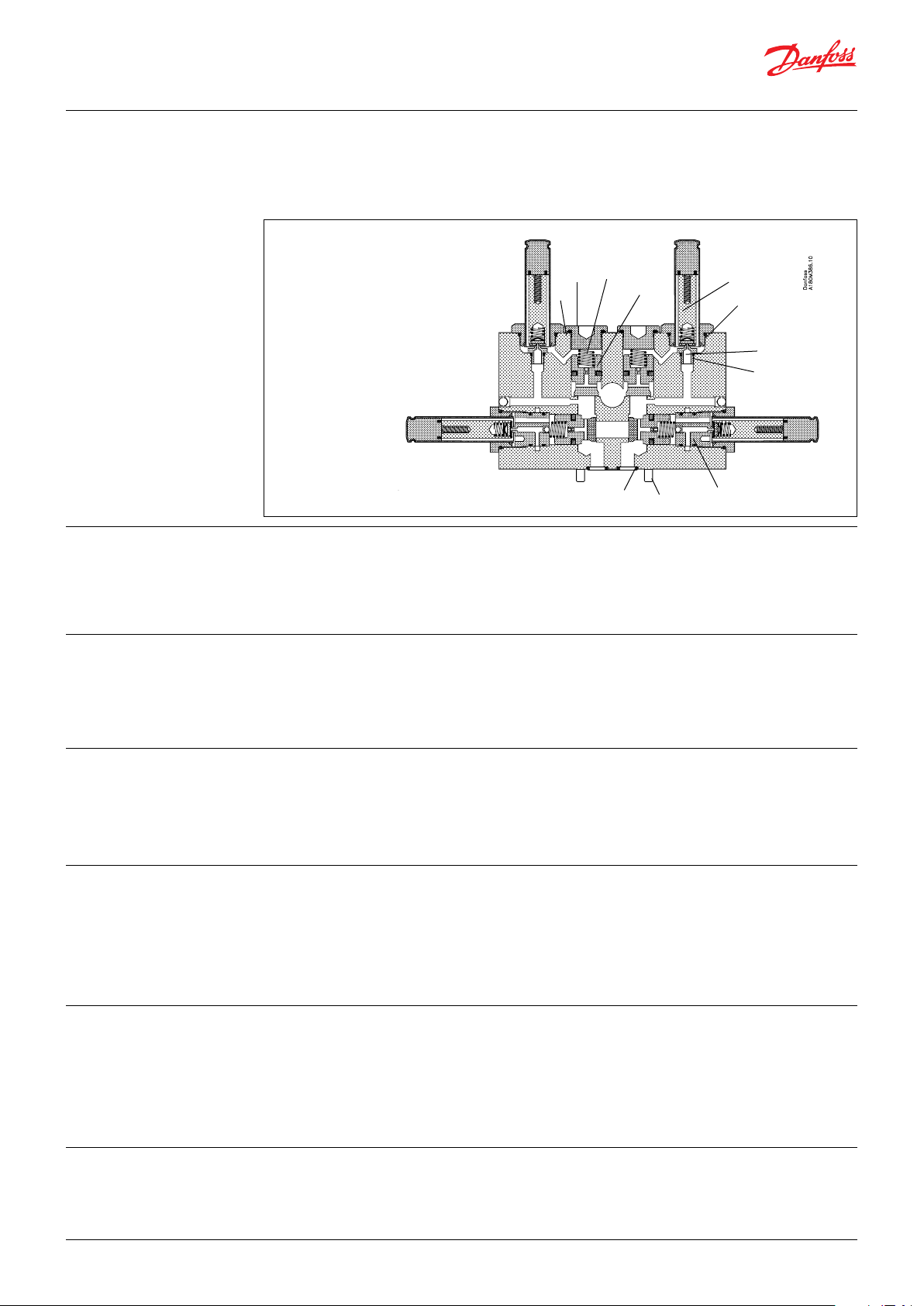

Introduction The VDH 30 EC is designed for controlling the

direction of water ow.

The valves are designed for tap water, i.e. without

additives (EU-Directive 98/83/EC).

1. Armature

2. O-ring

3. Orice

4. O-ring

5. O-ring

6. Plug

7. Spring

8. Poppet

9. Orice insert

10. Screw

11. O-ring

Function

The directional valves are pilot operated On/O

seat valves electrically activated by 4 coils.

The valves are designed according to the seat

valve principle where each individual seat valve is

controlled by its own pilot stage.

7

6

5

8

1

2

3

4

11

10

9

This valve type contains 4 seat valves altogether:

two inlet valves and two outlet valves. As each

seat valve is individually controlled by its own

pilot, this design oers many

dierent valve congurations to the end user.

Features

• Installable on all Cetop 3 blocks and inline

blocks

• Corrosion resistant surfaces

• Easy-to-clean surfaces

Versions The valve housing comes in standard version

in stainless steel AISI 304 (W. No. 1.4301) or

ISI 316 (W. No. 1.4401)

Temperature

Storage temperature:

• -40°C to +70°C [ -40 to 158 °F] – provided

that the valve is drained of uid and stored

”plugged”

Operation on (clean) water:

• Fluid temperature and ambient temperature:

+3°C to +50°C [37 to 122 °F]

Antifreeze Protection

If a system requires antifreeze protection, Danfoss

recommends Dowcall N or Chillsafe mono propylene glycol from the Dow Chemical Company

and Arco Chemical Company, respectively. Both

antifreezes are biologically degradable and must

be used together with demineralized water.

• The seat valve design ensures minimum

leakage

• High degree of enclosure, IP67

• Many valve congurations available

The valve is available as a Normally Close

valve (NC) or in a combination of Normally

Open (NO) and Normally Closed (NC

Operation on water containing antifreeze:

• Fluid temperature and ambient temperature:

-30°C 1) to +50°C [-22 to 122 °F]

1)

please see paragraph on antifreeze protection

Mixing ratio must be:

• min. 30% antifreeze and 70% demine ralized water providing frost protection to

–13°C [9 °F] and preventing biolm in the

system.

• max. 50% antifreeze and 50% demine ralized water due to increased viscosity,

providing frost protection to –30°C [-22 °].

Filtration

2 | © Danfoss | DCS (im) | 2019.10

The water supply must be ltered through a

10 µm abs., β

-value > 5000 lter.

10

For further lter details, please contact the

Danfoss Sales Organization.

AI319740679646en-000801| 521B0605 |

Data Sheet | Directional Control Valve VDH 30EC 4/3

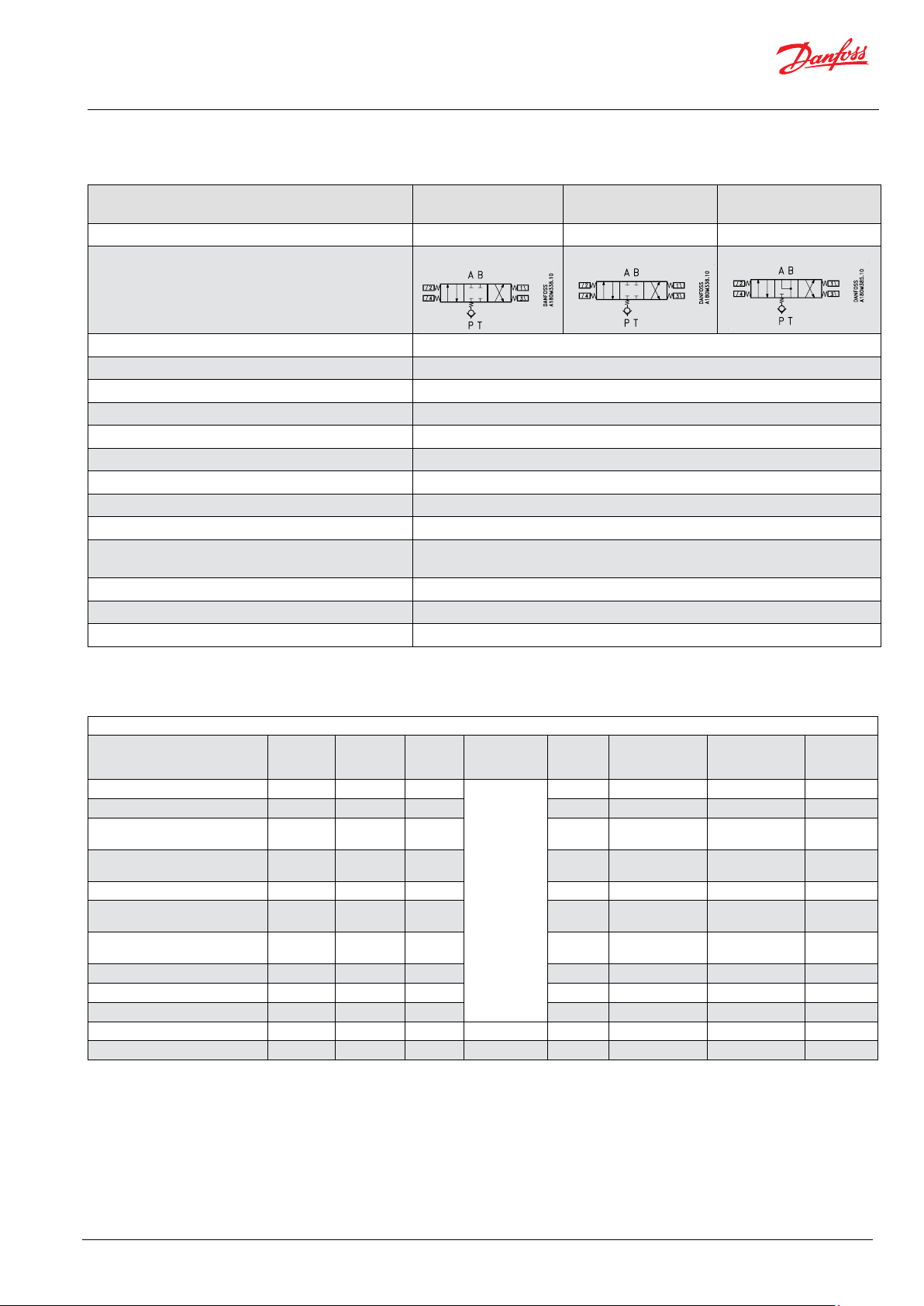

Technical data and

Code numbers

Valve body

VDH 30EC - NC

Stainless steel, AISI 304

VDH 30EC - NC

Stainless steel, AISI 316

VDH 30 EC 2xNC + 2x NO

Stainless steel, AISI 3040

Code number 180L0046 180L0047 180L0050

Function symbol

Max. pressure port P, A and B

Return pressure, port T (T ≤ A, B pressure

1)

1)

140 barg [2030 psig]

140 barg [2030 psig]

Min. inlet pressure 5 barg [72.5 psig]

Max. ow 30 l/min [8 gpm]

Min. ow 1 l/min [0.2 gpm]

Pressure loss See curve page 4

Leakage, port P → A, B, T 0 ml/min [ 0 gpm]

Leakage, port A, B → T 0 ml/min [ 0 gpm]

Leakage, port A, B → P (inlet pressure port P = 0 barg) max. 5 ml/min [ max. 0.0013 gpm]

Leakage, port A, B → P

(inlet pressure port P = pressure port A,B)

Opening time when changing direction

Closing time when changing direction

2)

2)

0 ml/min [0 gpm]

110 ms

130 ms

Weight 3.8 kg [ 8 lbs]

The valves are supplied with screw and O-rings,

but without coils.

Coils type BE / Without LED / incl. Terminal box

Description Code no. Voltage Power

Coil 240V-60Hz-IP67 018F7926 240V 60Hz 15W

Voltage

tolerance

T max

Ambient

°C [°F]

Connection Enclosure

Weight

kg [lbs]

80 [176] Terminal box IP67 0.3 [0.7]

Coil 240V-50Hz-IP67 018F7924 240V 50Hz 11W 80 [176] Terminal box IP67 0.3 [0.7]

Coil 220-230V-50Hz-IP67 018F7921

Coil 220-230V-50-60Hz-IP67 018F7919

Coil 220V-60Hz-IP67 018F7925 220V 60Hz 13W 80 [176] Terminal box IP67 0.3 [0.7]

Coil 200V-50-60Hz-IP67 018F7929

Coil 110V-50-60Hz-IP67 018F7923

220-230 V

50 Hz

220-230 V

50-60Hz

200V

50/60Hz

110V 50-

60Hz

12W 80 [176] Terminal box IP67 0.3 (0.7)

17W

14W

50 [122] Terminal box IP67 0.3 [0.7]

± 10-15%

10W 80 [176] Terminal box IP67 0.3 [0.7]

15W

13W

50 [122] Terminal box IP67 0.3 [0.7]

Coil 24V-60Hz-IP67 018F7922 24V 60Hz 14W 80 [176] Terminal box IP67 0.3 [0.7]

Coil 24V-50Hz-IP67 018F7920 24V 50Hz 12W 80 [176] Terminal box IP67 0.3 [0.7]

Coil 42V-50Hz-IP67 018F7927 42V 50Hz 10W 80 [176] Terminal box IP67 0.3 [0.7]

Coil 24V-DC- IP67 018F7914 24V DC 16W ± 10% 50 [122] Terminal box IP67 0.3 [0.7]

Coil 12V-DC- IP67 018F7913 12V DC 15W ± 10% 50 [122] Terminal box IP67 0.3 [0.7]

© Danfoss | DCS (im) | 2019.10 AI319740679646en-000801| 521B0605| 3

Data Sheet | Directional Control Valve VDH 30EC 4/3

Code numbers

(continued)

Pressure losses at

dierent ows

Cetop 3 blocks

Description

Inline block for 1 valve (P&T direct for VPH 15E) 0.8 [1.7] 180L0060

Block for 1 valve 2.4 [5.3] 180L0081

Block for 2 valves 4.4 [9.7] 180L0082

Block for 3 valves 7.3 [16.1] 180L0083

Block for 4 valves 9.6 [21.2] 180L0084

Cover plate incl. screws and O-ring

(for covering-up non-used valve outlets on block)

Weight

kg [lbs]

0.1 [0.2] 180L0079

Code number

4 | © Danfoss | DCS (im) | 2019.10

AI319740679646en-000801| 521B0605 |

Data Sheet | Directional Control Valve VDH 30EC 4/3

Available valve

congurations

The table below shows the possible valve

congurations, depending on which coils are

activated.

For VDH 30EC 4/3 NC

Diagram showing ow routes through the valve,

port lettering and coil numbers.

For VDH 30EC 4/3 NC + NO

For VDH 30EC 4/3 NC

© Danfoss | DCS (im) | 2019.10 AI319740679646en-000801| 521B0605| 5

For VDH 30EC 4/3 NC + NO

Data Sheet | Directional Control Valve VDH 30EC 4/3

Dimensions (mm)

VDH 30EC 4/3

6 | © Danfoss | DCS (im) | 2019.10

AI319740679646en-000801| 521B0605 |

Data Sheet | Directional Control Valve VDH 30EC 4/3

Dimensions (mm)

Inline block for 1 valve

180L0060

Dimensions (mm)

Cetop blocks

P and T ports:

G ½, 15,5 mm deep

A and B ports:

G 3/8, 13 mm deep

© Danfoss | DCS (im) | 2019.10 AI319740679646en-000801| 521B0605| 7

Data Sheet | Directional Control Valve VDH 30EC 4/3

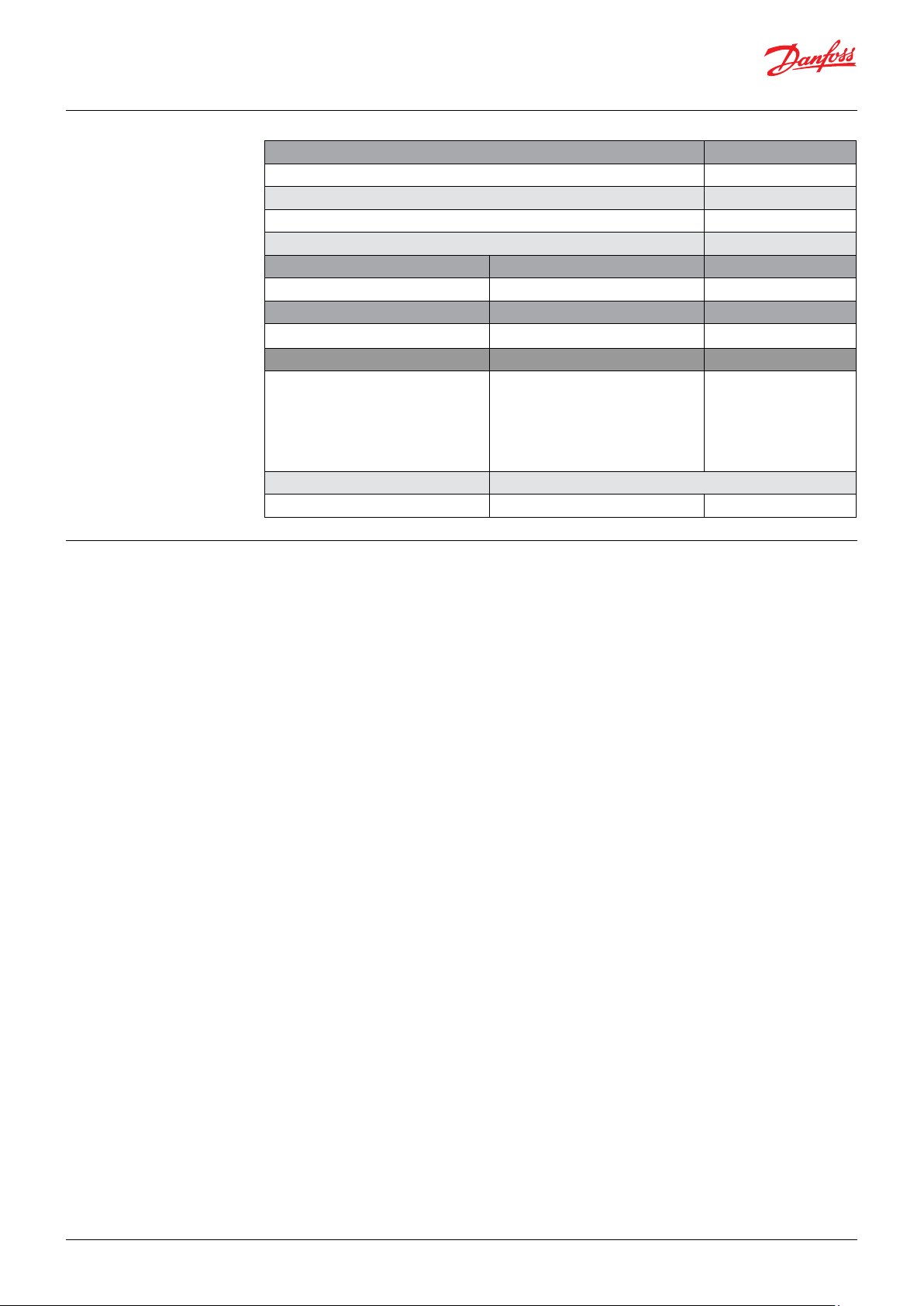

Spare parts

Code numbers

Mounting of v alve on Cetop

block

Spare parts Code number

Poppet kit (pos. 8) 180L5005

Armature kit, NC (pos. 1) 180L5002

Armature kit, NO (pos. 1) 180L5010

Orice kit 180Z0099 + 180Z0098

O-ring for mounting on block Dimensions Code number

NBR, 1 pc (pos. 11) 9.25 x 1.78 633B1243

Assembly screw Tightening torque Code number

M5 x 40 ISO 4762 A4, 1 pc (pos. 10) 7 Nm 681X0162

Tools Application Code number

Mounting/dismounting of orice

Orice inser in valve housing:

Special tool for orice insert

Spool tool incl. in 180L5005 Mounting of spool

Permanent magnent For mounting activation of valve 180Z0212

The valve is designed to be mounted on a block

with CETOP 3-port connection. Four stainless

steel screws and four O-rings are supplied with

the valve for mounting. Remember to smear/

12 Nm ± 2 NM

Armature to be screwed into the

valve housing:

60 Nm ± 2 Nm

spray the threads on the screws with Molykote®

D pasta from Dow Corning, or Klüber UH1 84-201

from Klüber lubrication, before mounting the

valve.

180Z0034

8 | © Danfoss | DCS (im) | 2019.10

AI319740679646en-000801| 521B0605 |

Data Sheet | Directional Control Valve VDH 30EC 4/3

Mounting of coil

Coil on valves with short armature tubes (NC and

NO valves)

1. Place the o-ring on the armature tube.

2. The coil is clicked on by means of a light pressure by hand – without using tools.

Dismounting of coil

© Danfoss | DCS (im) | 2019.10 AI319740679646en-000801| 521B0605| 9

Danfoss A/S

High Pressure Pumps

Nordborgvej 81

DK-6430 Nordborg

Denmark

© Danfoss | DCS (im) | 2019.10

AI319740679646en-000801| 521B0605 | 10

Loading...

Loading...