Page 1

Data sheet.

2/2 way Directional Control Valves, type VDH

2/2-way Directional Control Valves

For inline mounting and Cetop 3 ange mounting (ISO 4401)

VDH

For inline mounting and Cetop 3 ange

mounting (ISO 4401)

Inline versions:

Cetop 3 block version:

Application

Function

Advantages

Variants

Filtration

• VDH 30 E 2/2,

• VDH 60 E 2/2,

• VDH 120 E 2/2

Directional valves are used to control water ow

direction.

The directional valves are pilot operated On/O

2/2-way seat valves electrically activated by 1

coil.

• Corrosion resistant surfaces

• Easy to clean surfaces

• The seat valve design ensures zero leakage

The valve housing comes in standard version in

stainless steel AISI 304 (W. nr. 1.4301).

The valve is available as a normally closed valve

(NC) or as a normally open valve (NO).

The water supplied to the valve must be ltered:

10 µm absolute, β

recommended.

-value > 5000 lter is

10

• VDH 30 EC 2/2

The valves are designed for tap water, i.e. without

additives (EU-Directive 98/83/EC).

• High degree of protection, IP 67

• Cetop valve installable on all cetop 3 blocks

On request the valve housing is obtainable in

stainless steel AISI 316 L (W. nr. 1.4401), please

contact the Danfoss Sales Organization for Water

Hydraulics.

For further information on lters, please contact

the Danfoss sales department for water hydraulics.

hpp.danfoss.com.

Page 2

Data sheet | Directional Control valves VDH

1. Introduction

2. VDH valve

selection overview

The VDH directional control valves are designed

for applications with tap water, i.e. without

additives (EU-Directive 98/83/EC).

The directional valves are used to control water

ow direction.

Function

The directional valves are pilot operated On/O

2/2-way seat valves electrically activated by 1 coil.

Features

• Corrosion resistant surfaces

• Easy to clean surfaces

• The seat valve design ensures zero leakage

• High degree of protection, IP 67

• Cetop valve installable on all cetop 3 blocks

•

Filtration

The water supplied to the valve must be ltered:

10 µm absolute, ß

-value > 5000 lter is

10

recommended.

For further information on lters, please contact

the Danfoss sales department for High Pressure

Pumps.

E Straight ow direction

EC Cetop 3 manifolde

Versions

Inline versions:

• VDH 30 E 2/2

• VDH 60E 2/2

• VDH 120 E 2/2

Cetop 3 block version:

• VDH 30 EC 2/2

The valve housing comes in standard version in

stainless steel AISI 304 (W.no. 1.4301).

The valve is available as a normally closed valve

(NC) or as a normally open valve (NO).

On request the valve housing is obtainable in

stainless stel AISI 316L (W.no. 1.4401), please

contact the Danfoss Sales Organization for High

Pressure Pumps.

Temperature

Operation on (clean) water:

Fluid temperature and ambient temperature:

3 °C – 50 °C.

Operation on water containing antifreexe:

Fluid temperature and ambient temperature:

-30 °C – 50 °C

1).

Storage temperature:

-40 °C – 70 °C

provided that the valve is drained of uid and

stored "plugged".

Antifreeze protection

1)

If a system requires antifreeze protection, Danfoss

recommends Dowcall N or Chillsafe mono propylene glycol from the Dow Chemical Company and

Arco Chemical Company, respectively.

Both antifreezes are biologically degradable and

must be used together with demineralized water.

Mixing ratio must be:

• Min. 30% antifreeze and 70% demineralize

water providing frost protection to -13 °C

and preventing biolm in the system.

• Max. 50% antifreeze and 50% demineralize

water due to increased viscosity, providin

frost protection to -30 °C.

2

521B0613 | DKCFN.PD.042.G4.02 | 02.2020

Page 3

Data sheet | Directional Control valves VDH

3. Code numbers and

technical data

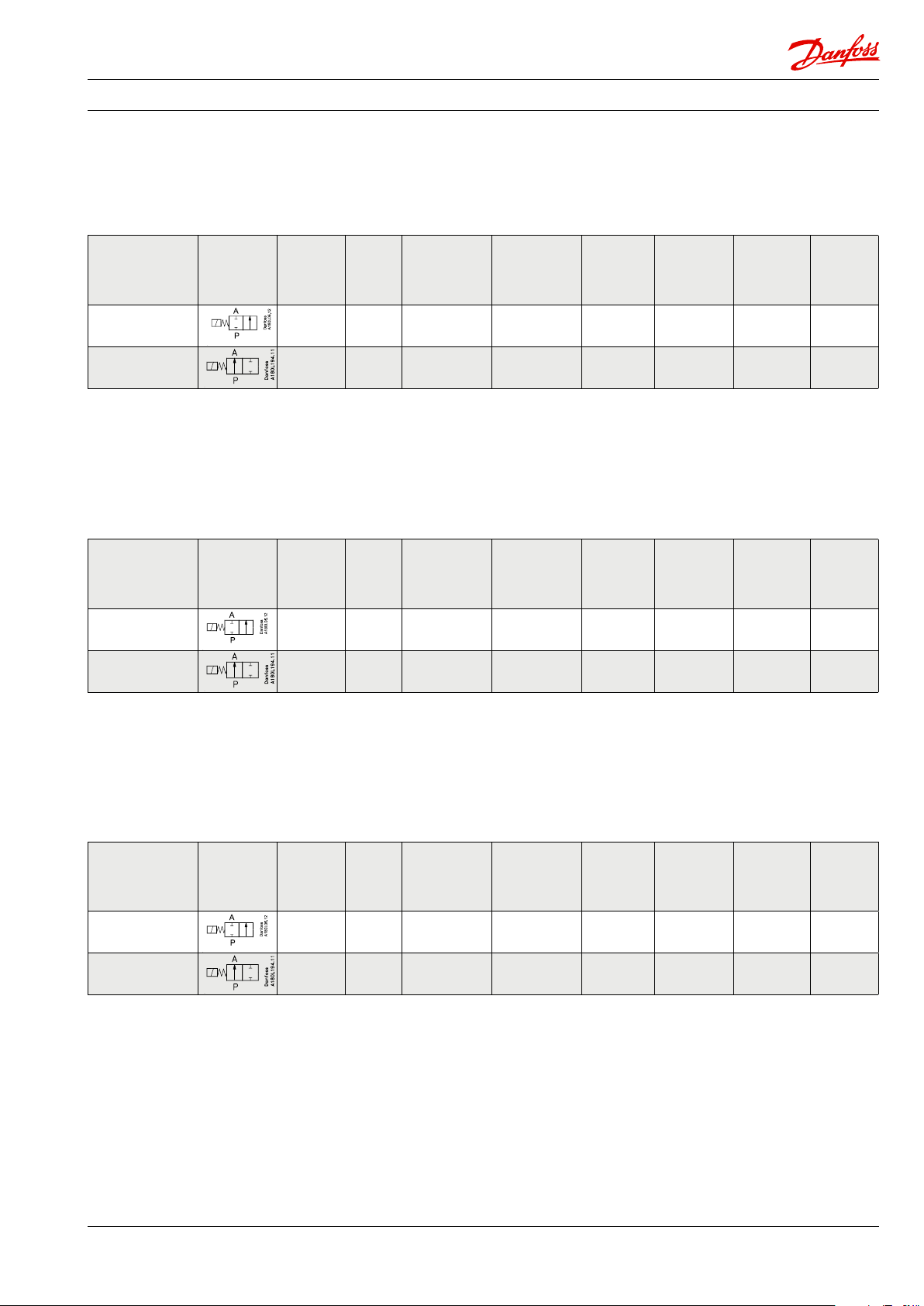

2/2-way directional control valves, type VDH 30 E

Pressure loss at max. ow: 6 barg (87 psig)

Max. opening/closing time: 150 ms/350 ms

Leakage at pressure higher tha 10 barg (145 psig): 0 ml/min (0 GPM) drip proof

Degree of protection: IP 67

Type

Function

symbol

VDH 30 E 2/2 NC

VDH 30 E 2/2 NO

1)

The pressure in port P must always be higher than the pressur in port A (Pp>Pa)

Code

number

Connection

180L0002 G 3/8 " 140 (2.030) 200 (2,900) 3.5 (50.7) 30 (7.9) 1 (0.3) 1.6 (3.8)

180L0003 G 3/8 " 140 (2.030) 170 (2,465) 3.5 (50.7) 30 (7.9) 1 (0.3) 1.6 (3.8)

Max. inlet

pressure cont.

barg (psig)

Max inlet

pressure peak

barg (psig)

2/2-way directional control valves, type VDH 30 EC

Pressure loss at max. ow: 7 barg (101.5 psig)

Max. opening/closing time: 150 ms/350 ms

Leakage at pressure higher tha 10 barg (145 psig): 0 ml/min (0 GPM) drip proof

Degree of protection: IP 67

Type

Function

symbol

Code

number

Connection

Max. inlet

pressure cont.

barg (psig)

Max inlet

pressure peak

barg (psig)

Operation

pressure

barg (psig)

Operation

pressure

barg (psig)

1)

Max. ow

l/min (GPM)

1)

Max. ow

l/min (GPM)

Min. ow

l/min

(GPM)

Min. ow

l/min

(GPM)

Weight

incl. coil

kg (lb)

Weight

incl. coil

kg (lb)

VDH 30 EC2/2

NC

VDH 30 EC 2/2

NO

1)

The pressure in port P must always be higher than the pressur in port A (Pp>Pa)

180L0048 Cetop 3 140 (2.030) 200 (2,900) 3.5 (50.7) 30 (7.9) 1 (0.3) 1.2 (2.1)

180L0049 Cetop 3 140 (2.030) 170 (2,465) 3.5 (50.7) 30 (7.9) 1 (0.3) 1.2 (2.1)

VDH 30EC 2/2-way valves are supplied with screws and O-rings.

2/2-way directional control valves, type VDH 60 E

Pressure loss at max. ow: 8 barg (116 psig)

Max. opening/closing time: 150 ms/350 ms

Leakage at pressure higher tha 10 barg (145 psig): 0 ml/min (0 GPM) drip proof

Degree of protection: IP 67

Type

Function

symbol

VDH 60 E 2/2 NC

VDH 60 E 2/2 NO

1)

The pressure in port P must always be higher than the pressur in port A (Pp>Pa)

Code

number

Connection

180L0011 G ½" 140 (2.030) 200 (2,900) 3.5 (50.7) 60 (15.8) 1 (0.3) 1.6 (3.8)

180L0015 G ½" 140 (2.030) 170 (2,465) 3.5 (50.7) 60 (15.8) 1 (0.3) 1.6 (3.8)

Max. inlet

pressure cont.

barg (psig)

Max inlet

pressure peak

barg (psig)

Operation

pressure

barg (psig)

1)

Max. ow

l/min (GPM)

Min. ow

l/min

(GPM)

Weight

incl. coil

kg (lb)

521B0613 | DKCFN.PD.042.G4.02 | 02.2020

3

Page 4

Data sheet | Directional Control valves VDH

2/2-way directional control valves, type VDH 120 E

Pressure loss at max. ow: 6 barg (87 psig)

Max. opening/closing time: 150 ms/400 ms

Leakage at pressure higher tha 10 barg (145 psig): 0 ml/min (0 GPM) drip proof

Degree of protection: IP 67

Type

Function

symbol

VDH 120 E 2/2 NC

VDH 120 E 2/2 NO

1)

The pressure in port P must always be higher than the pressur in port A (Pp>Pa)

Code

number

Connection

180L0001 G ½" 140 (2.030) 200 (2,900) 1 (14.5) 120 (31.6) 5 (1.5) 1.8 (3.9)

180L0005 G ½" 140 (2.030) 170 (2,465) 1 (14.5) 120 (31.6) 5 (1.5) 1.8 (3.9)

Max. inlet

pressure cont.

barg (psig)

Max inlet

pressure peak

barg (psig)

All valves are supplied without coils which must be

ordered separately.

3. Code numbers for

CETOP block

Cetop 3 block Steel type Weight kg (lb) Code number

Block for Cetop 2 valves AISI 304 1.8 (3.9) 180L0062

Block for Cetop 3 valves AISI 304 2.6 (5.7) 180L0063

Block for Cetop 4 valves AISI 304 3.4 (7.5) 180L0064

4. Code numbers for

Coils

Coil voltage Code number

Coil 24V-50Hz-12W-IP 67 018F7920

Coil 220-230V-50Hz-12W-IP 67 018F7921

Coil 240V-50Hz-11W-IP 67 018F7924

Coil 24V-60Hz-14W-IP 67 018F7922

Coil 220V-60Hz-13W-IP 67 018F7925

Coil 240V-60Hz-15W-IP 67 018F7926

Coil 110V-50-60 Hz-15/13W-IP 67 018F7923

Coil 12V -DC-16W-IP 67 018F7913

Coil 24V-DC-16W-IP67 018F7914

Operation

pressure

barg (psig)

1)

Max. ow

l/min (GPM)

Min. ow

l/min

(GPM)

Weight

incl. coil

kg (lb)

ATEX - please consult the Danfoss salesorganization for High Pressure Pumps.

4

521B0613 | DKCFN.PD.042.G4.02 | 02.2020

Page 5

Data sheet | Directional Control valves VDH

5. Pressure losses at

dierent ows

VDH 30 E 2/2 and VDH 30 EC 2/2

VDH 60 E 2/2 and VDH 120 E 2/2

521B0613 | DKCFN.PD.042.G4.02 | 02.2020

5

Page 6

Data sheet | Directional Control valves VDH

6. Cross-section of

valves

VDH 30 E 2/2 and VDH 60 E 2/2

1. Armature

2. O-ring

3. Orice

4. Spring

5. Poppet

VDH 120 E 2/2

1. Armature

2. O-ring

3. O-ring

4. Orice

5. Spring

6. Poppet

6

521B0613 | DKCFN.PD.042.G4.02 | 02.2020

Page 7

Data sheet | Directional Control valves VDH

VDH 30 E C 2/2 (Cetop)

1. Armature

2. O-ring

3. O-ring

4. Orice

5. O-ring

6. Plug

7. Spring

8. Poppet

9. O-ring

10. Screw

7. Dimensions

VDH 30 E 2/2 and VDH 60 E 2/2

All dimensions in mm

521B0613 | DKCFN.PD.042.G4.02 | 02.2020

7

Page 8

Data sheet | Directional Control valves VDH

VDH 120 E 2/2

All dimensions in mm

VDH 30 EC 2/2 (Cetop)

All dimensions in mm

8

521B0613 | DKCFN.PD.042.G4.02 | 02.2020

Page 9

Data sheet | Directional Control valves VDH

Cetop blocks

All dimensions in mm

A B C D E F

Block for 2 valves 30 80 - - 110 86

Block for 3 valves 30 80 130 - 160 136

Block for 4 valves 30 80 130 180 210 186

8. Mounting of in-line

valves

9. Mounting of valve on

Cetop block

10. Mounting of coil on

valve

Inline valves are mounted in line in ow direction

(follow the arrow on the valve) and xed either

The valve is designed to be mounted on a block

with CETOP 3-port connection. Four stainless

steel screws and four O-rings are supplied with

the valve for mounting. Remember to smear/

directly in the pipe connections or with bolts in

the xation holes on the valve.

spray the threads on the screws with Molykote® D

pasta from Dow Corning, or Klüber UH1 84-201

from Klüber lubrication, before mounting the

valve.

Coil on valves with short armature tubes (NC and

NO valves)

1. Place the o-ring on the armature tube.

2. The coil is clicked on by means of a light

pressure by hand – without using tools.

521B0613 | DKCFN.PD.042.G4.02 | 02.2020

9

Page 10

11. Dismounting of coil

12. Accessories

Code numbers

Spare parts Code mumber

Poppet kit for VDH 30E 2/2, VDH 30 EC2/2 and 2/2 VDH 60E 2/2 180L5005

Poppet kit for VDH120E 2/2 (pos. 6) 180L5001

Armature kit, NC (pos. 1) 180L5002

Armature kit, NO (pos. 1) 180L5010

Orice kit VDH 30 E 2/2 180Z0099

Orice kit VDH 60 E 2/2 180Z0099

Orice kit VDH 120 E 2/2 180Z0098

Tools Application Code number

Mounting/dismounting of orice

Special tool for orice insert

Spool tool included in 180L5005 Mounting of spool

Permanent magnet For manual activation of valve 180Z0212

Orice insert in valve housing:

12 Nm ± 2 Nm

Armature to be screwed into the valve

housing: 60 Nm ± 2 Nm

180Z0034

Danfoss A/S

High Pressure Pumps

Nordborgvej 81

DK-6430 Nordborg

Denmark

© Danfoss | DCS (im) | 2020.02

521B0613 | DKCFN.PD.042.G4.02 | 10

Loading...

Loading...