Page 1

vacon

ac drives

devicenet option board opte7

user manual

®

Page 2

Page 3

vacon • 0

TABLE OF CONTENTS

Document: DPD01171B

Release date : 30.01.2015

1. Safety...............................................................................................................2

1.1 Danger................................................................................................................................2

1.2 Warnings ............................................................................................................................3

1.3 Earthing and earth fault protection ...................................................................................4

2. DeviceNet option board OPTE7 - General.........................................................5

2.1 Overview .............................................................................................................................5

2.1.1 DeviceNet physical layer and media..................................................................................5

2.2 DeviceNet protocol description .........................................................................................7

2.2.1 EDS (Electronic Data Sheet) file ........................................................................................8

3. DeviceNet option board OPTE7 - technical data ...............................................9

3.1 General...............................................................................................................................9

3.2 CAN cable...........................................................................................................................9

3.2.1 Recommended cable .......................................................................................................10

4. OPTE7 layout and connections .......................................................................11

4.1 Layout and connections ...................................................................................................11

4.2 LED Indications ................................................................................................................12

4.3 Jumpers ...........................................................................................................................14

5. Installation.....................................................................................................16

5.1 Installation in Vacon® 100...............................................................................................16

5.2 Prepare for use through fieldbus ....................................................................................18

5.3 Installation in Vacon® 20.................................................................................................21

5.3.1 Frames MI1, MI2, MI3 ......................................................................................................21

5.3.2 Frames MI4, MI5 ..............................................................................................................24

5.4 Installation in Vacon® 20 X and 20 CP ............................................................................28

5.5 Installation in Vacon® 100 X (Frames MM4-MM6) .........................................................31

6. Commissioning ..............................................................................................35

6.1 Parameter view ................................................................................................................35

6.2 Monitor view .....................................................................................................................35

6.3 Software info view ............................................................................................................36

6.4 Fieldbus parametrisation ................................................................................................36

6.4.1 Fieldbus control and basic reference selection ..............................................................36

6.4.2 Torque control parametrisation ......................................................................................37

6.4.3 Process data mapping and default settings....................................................................37

7. DeciveNet interface........................................................................................39

7.1 I/O messaging ..................................................................................................................39

7.1.1 Connection behaviour ......................................................................................................39

7.1.2 Input and Output Assemblies...........................................................................................40

7.1.3 Control Supervisor Behaviour .........................................................................................49

7.2 Explicit messaging ...........................................................................................................51

7.2.1 Connection behaviour ......................................................................................................51

8. Fault handling................................................................................................52

8.1 General and additional error codes.................................................................................53

9. Appendix A: Object dictionary ........................................................................54

9.1 Implemented CIP objects.................................................................................................54

9.1.1 List of Object Classes.......................................................................................................54

9.1.2 List of Services.................................................................................................................55

9.1.3 Class Code 0x01 - Identity Object ....................................................................................56

9.1.4 Class Code 0x02 - Message Router Object......................................................................58

9.1.5 Class Code 0x03 - DeviceNet Object................................................................................58

24-hour support +358 (0)201 212 575 • Email: vacon@vacon.com

Page 4

vacon • 1

9.1.6 Class Code 0x04 - Assembly Object ................................................................................61

9.1.7 Class Code 0x05 - DeviceNet Connection Object ............................................................62

9.1.8 Class Code 0x28 - Motor Data Object ..............................................................................65

9.1.9 Class Code 0x29 - Control Supervisor Object .................................................................67

9.1.10 Class Code 0x2A - AC/DC Drive Object............................................................................70

9.1.11 Class Code 0xA0 - Vendor Parameter Object..................................................................72

10. Appendix B: Communication attribute details................................................74

10.1 DeviceNet’s use of the CAN Identifier Field ....................................................................74

10.2 Connection object paths...................................................................................................74

11. Appendix C: Fault and warning codes ............................................................76

Tel. +358 (0) 201 2121 • Fax +358 (0)201 212 205

Page 5

Safety vacon • 2

9000.emf

13006.emf

9001.emf

9000.emf

9000.emf

9000.emf

9000.emf

9000.emf

9000.emf

1. SAFETY

This manual contains clearly marked cautions and warnings that are intended for your personal

safety and to avoid any unintentional damage to the product or connected appliances.

Please read the information included in cautions and warnings carefully.

The cautions and warnings are marked as follows:

Table 1. Warning signs

= DANGER! Dangerous voltage

= WARNING or CAUTION

= Caution! Hot surface

1.1 Danger

The components of the power unit are live when the drive is connected to mains

potential. Coming into contact with this voltage is extremely dangerous and may

cause death or severe injury.

The motor terminals U, V, W and the brake resistor terminals are live when the

AC drive is connected to mains, even if the motor is not running.

After disconnecting the AC drive from the mains, wait until the indicators on the

keypad go out (if no keypad is attached, see the indicators on the cover). Wait 5

more minutes before doing any work on the connections of the drive. Do not open

the cover before this time has expired. After expiration of this time, use a

measuring equipment to absolutely ensure that no

ensure absence of voltage before starting any electrical work!

The control I/O-terminals are isolated from the mains potential. However, the

relay outputs and other I/O-terminals may have a dangerous control voltage

present even when the AC drive is disconnected from mains.

voltage is present.

Always

Before connecting the AC drive to mains make sure that the front and cable

covers of the drive are closed.

During a ramp stop (see the Application Manual), the motor is still generating

voltage to the drive. Therefore, do not touch the components of the AC drive

before the motor has completely stopped. Wait until the indicators on the keypad

go out (if no keypad is attached, see the indicators on the cover). Wait additional 5

minutes before starting any work on the drive.

24-hour support +358 (0)201 212 575 • Email: vacon@vacon.com

1

Page 6

vacon • 3 Safety

13006.emf

13006.emf

13006.emf

13006.emf

13006.emf

13006.emf

13006.emf

13006.emf

13006.emf

13006.emf

1.2 Warnings

The AC drive is meant for fixed installations only.

Do not perform any measurements when the AC drive is connected to the mains.

The earth leakage current of the AC drives exceeds 3.5mA AC. According to

standard EN61800-5-1, a reinforced protective ground connection must be

ensured. See Chapter 1.3.

If the AC drive is used as a part of a machine, the machine manufacturer is

responsible for providing the machine with a supply disconnecting device (EN

60204-1).

Only spare parts delivered by Vacon can be used.

At power-up, power brake or fault reset the motor will start immediately if the

start signal is active, unless the pulse control for

Furthermore, the I/O functionalities (including start inputs) may change if

parameters, applications or software are changed. Disconnect, therefore, the

motor if an unexpected start can cause danger.

Start/Stop logic has been selected

.

The motor starts automatically after automatic fault reset if the auto restart

function is activated. See the Application Manual for more detailed information.

Prior to measurements on the motor or the motor cable, disconnect the motor

cable from the AC drive.

Do not touch the components on the circuit boards. Static voltage discharge may

damage the components.

Check that the EMC level of the AC drive corresponds to the requirements of your

supply network.

Tel. +358 (0) 201 2121 • Fax +358 (0)201 212 205

1

Page 7

Safety vacon • 4

13006.emf 13006.emf

1.3 Earthing and earth fault protection

CAUTION!

The AC drive must always be earthed with an earthing conductor connected to the earthing terminal

marked with .

The earth leakage current of the drive exceeds 3.5mA AC. According to EN61800-5-1, one or more

of the following conditions for the associated protective circuit must be satisfied:

a) The protective conductor must have a cross-sectional area of at least 10 mm

Al, through its total run.

b) Where the protective conductor has a cross-sectional area of less than 10 mm

2

Al, a second protective conductor of at least the same cross-sectional area must be

mm

provided up to a point where the protective conductor has a cross-sectional area not less

than 10 mm

2

Cu or 16 mm2 Al.

c) Automatic disconnection of the supply in case of loss of continuity of the protective

conductor.

2

Cu or 1 6 mm2

2

Cu or 16

The cross-sectional area of every protective earthing conductor which does not form part of the

supply cable or cable enclosure must, in any case, be not less than:

-2.5mm

-4mm

2

if mechanical protection is provided or

2

if mechanical protection is not provided.

The earth fault protection inside the AC drive protects only the drive itself against earth faults in the

motor or the motor cable. It is not intended for personal safety.

Due to the high capacitive currents present in the AC drive, fault current protective switches may

not function properly.

Do not perform any voltage withstand tests on any part of the AC drive. There is

a certain procedure according to which the tests must be performed. Ignoring

this procedure can cause damage to the product.

NOTE! You can download the English and French product manuals with applicable safety,

warning and caution information from www.vacon.com/downloads

.

REMARQUE Vous pouvez télécharger les versions anglaise et française des manuels produit

contenant l’ensemble des informations de sécurité, avertissements et mises en garde

applicables sur le site www.vacon.com/downloads

.

24-hour support +358 (0)201 212 575 • Email: vacon@vacon.com

1

Page 8

vacon • 5 DeviceNet option board OPTE7 - General

DeviceNet

master

9391.emf

Slave Slave Slave Slave Slave

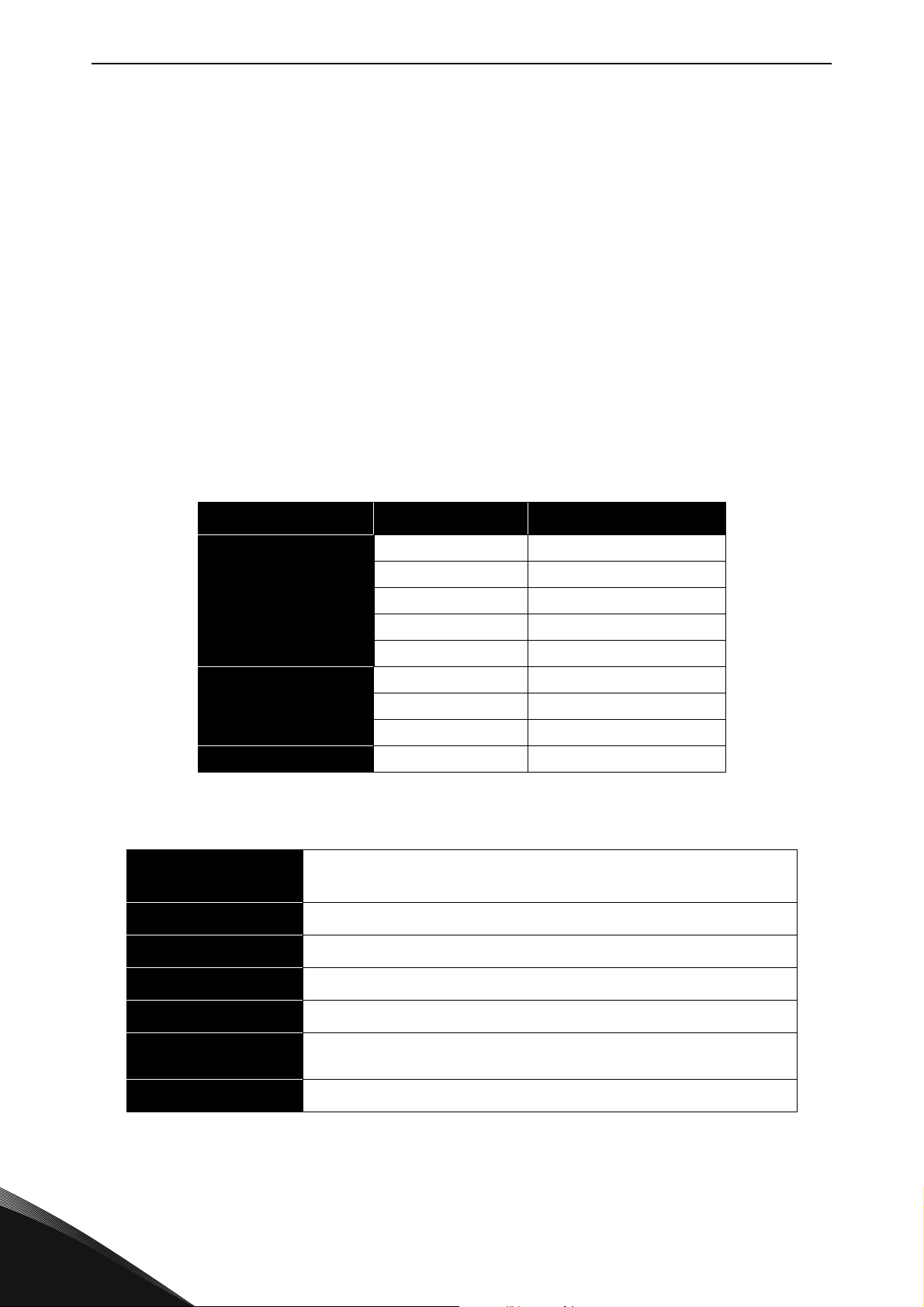

2. DEVICENET OPTION BOARD OPTE7 - GENERAL

2.1 Overview

OPTE7 is a DeviceNet option board for Vacon AC drives. It allows the AC drive to be controlled using

the DeviceNet protocol. The option board implements the AC Drive device profile as defined by CIP.

The OPTE7 option board connects a drive into the DeviceNet network. There can be 64 nodes in one

network. The baud rate is up to 500 kbit/s. The DeviceNet master can control and monitor the drives.

Figure 1. Typical DeviceNet network structure

2.1.1 DeviceNet physical layer and media

The basic trunkline-dropline topology provides separate twisted pair busses for both signal and

power distribution. Thick or thin cable can be used for either trunklines or droplines. End-to-end

network distance varies with data rate and cable size.

Devices can be powered directly from the bus and communicate with each other using the same

cable. Nodes can be removed from or inserted to the network without powering down the network.

Power taps can be added at any point in the network which makes redundant power supplies

possible. The trunkline current rating is 8 amperes. An opto-isolated design option allows externally

powered devices (e.g. AC drive’s starters and solenoid valves) to share the same bus cable. Other

CAN-based networks allow only a single power supply (if at all) for the entire network.

2

Tel. +358 (0) 201 2121 • Fax +358 (0)201 212 205

Page 9

DeviceNet option board OPTE7 - General vacon • 6

9392.emf

Terminator

Trunk Line

Zero drop Short drops

Node Node

Node

Node

Node

Node

Node

Node

Node

Node

Node

Node

Node

Drop•

line

TerminatorTap

Figure 2. Thick or thin cable for either trunklines or droplines

24-hour support +358 (0)201 212 575 • Email: vacon@vacon.com

2

Page 10

vacon • 7 DeviceNet option board OPTE7 - General

2.2 DeviceNet protocol description

DeviceNet is a communication protocol that is managed by the ODVA (Open DeviceNet Vendors

Association). It uses CAN (Controller Area Network) as the backbone technology and at the higher

level it implements CIP (Common Industrial Protocol). CIP is used by the following protocols:

• DeviceNet

• EtherNet/IP

• ControlNet

•CompoNet

CIP ensures high integrity/interoperability between all of these, especially from the end user

perspective. CIP is object-oriented. It defines objects with its attributes and supported services. The

objects can have multiple instances. Instance zero indicates object’s class itself. Depending on the

implemented profile, some objects are mandatory and have to be implemented. Additionally, each

vendor can implement vendor-specific objects.

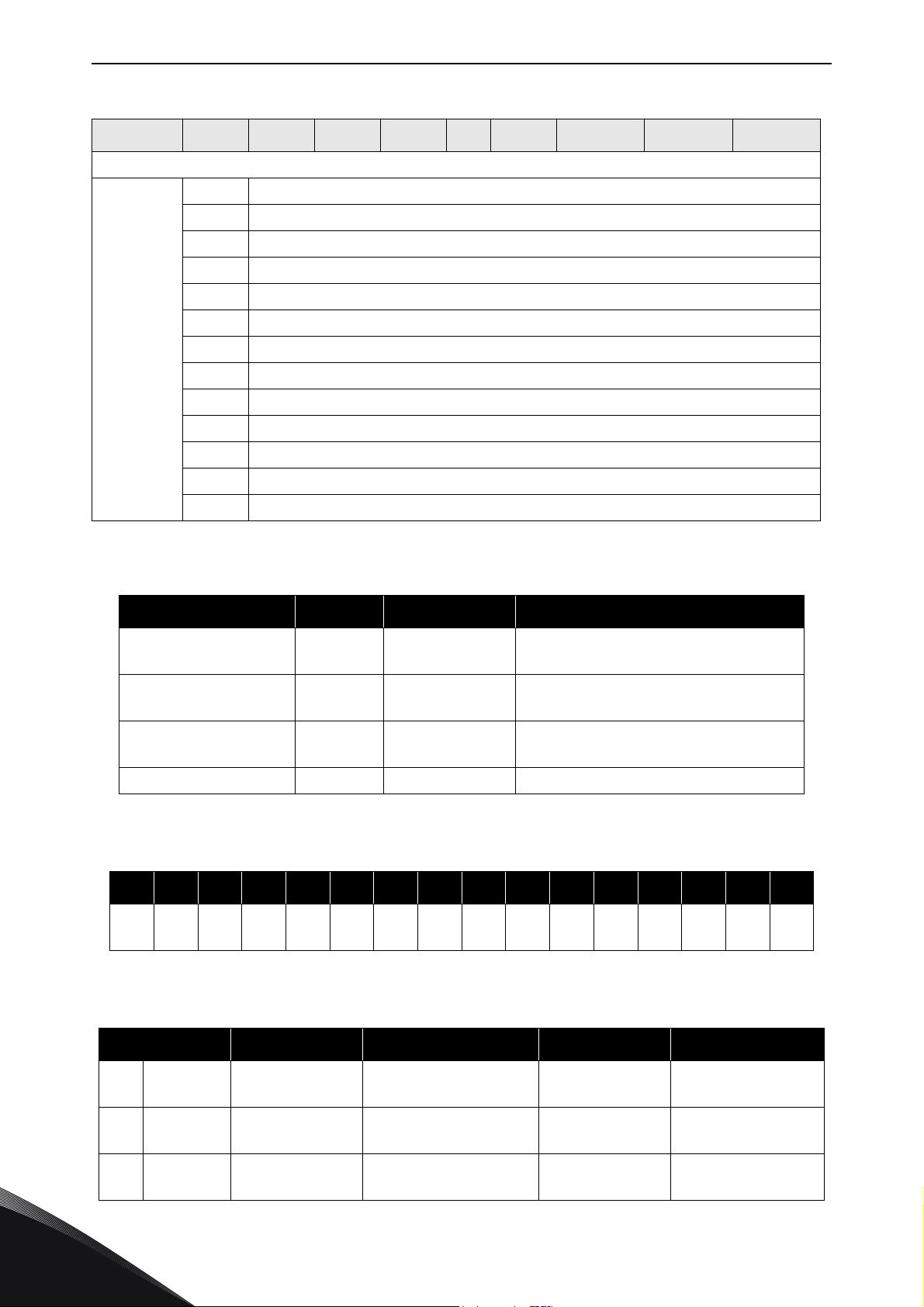

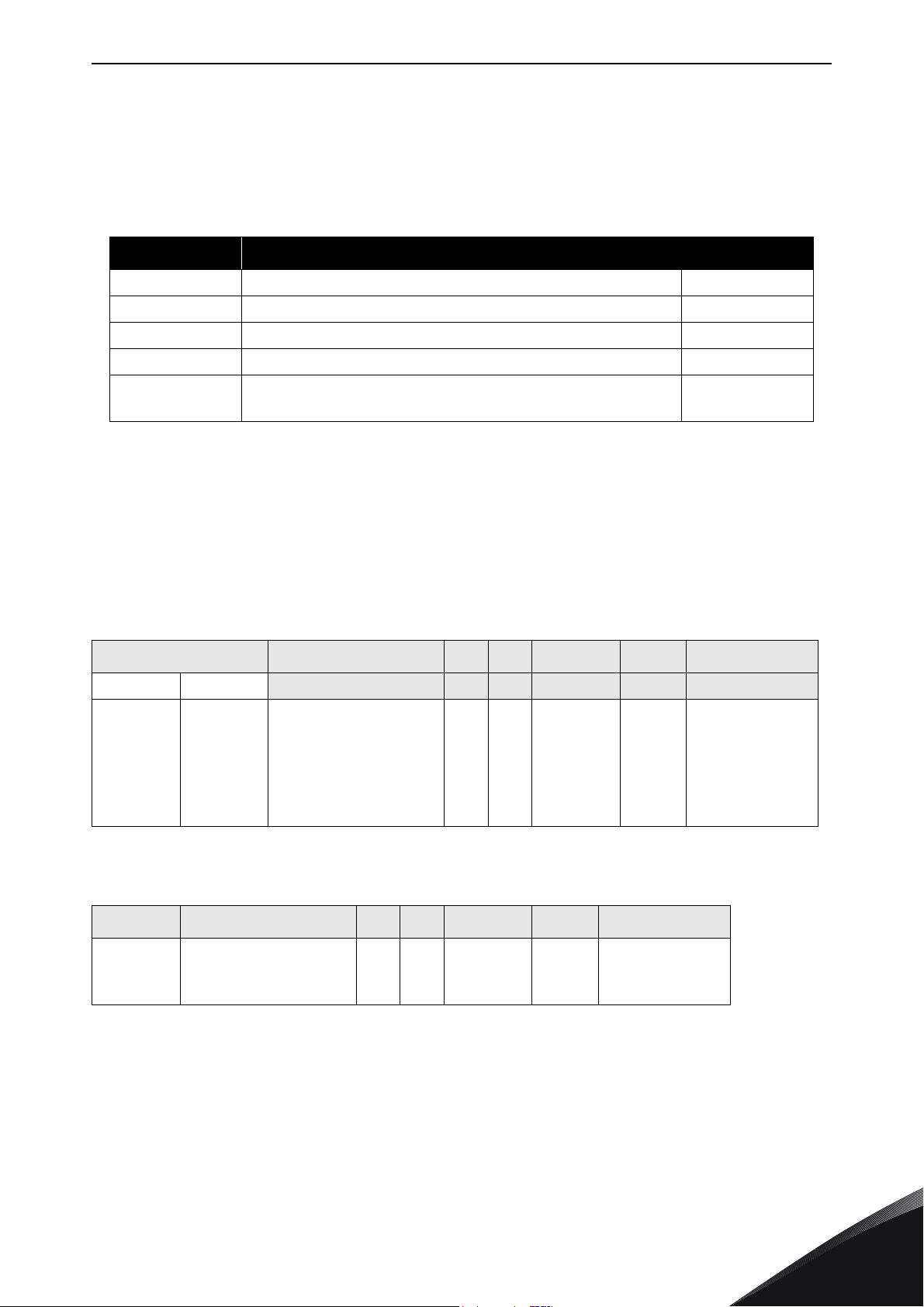

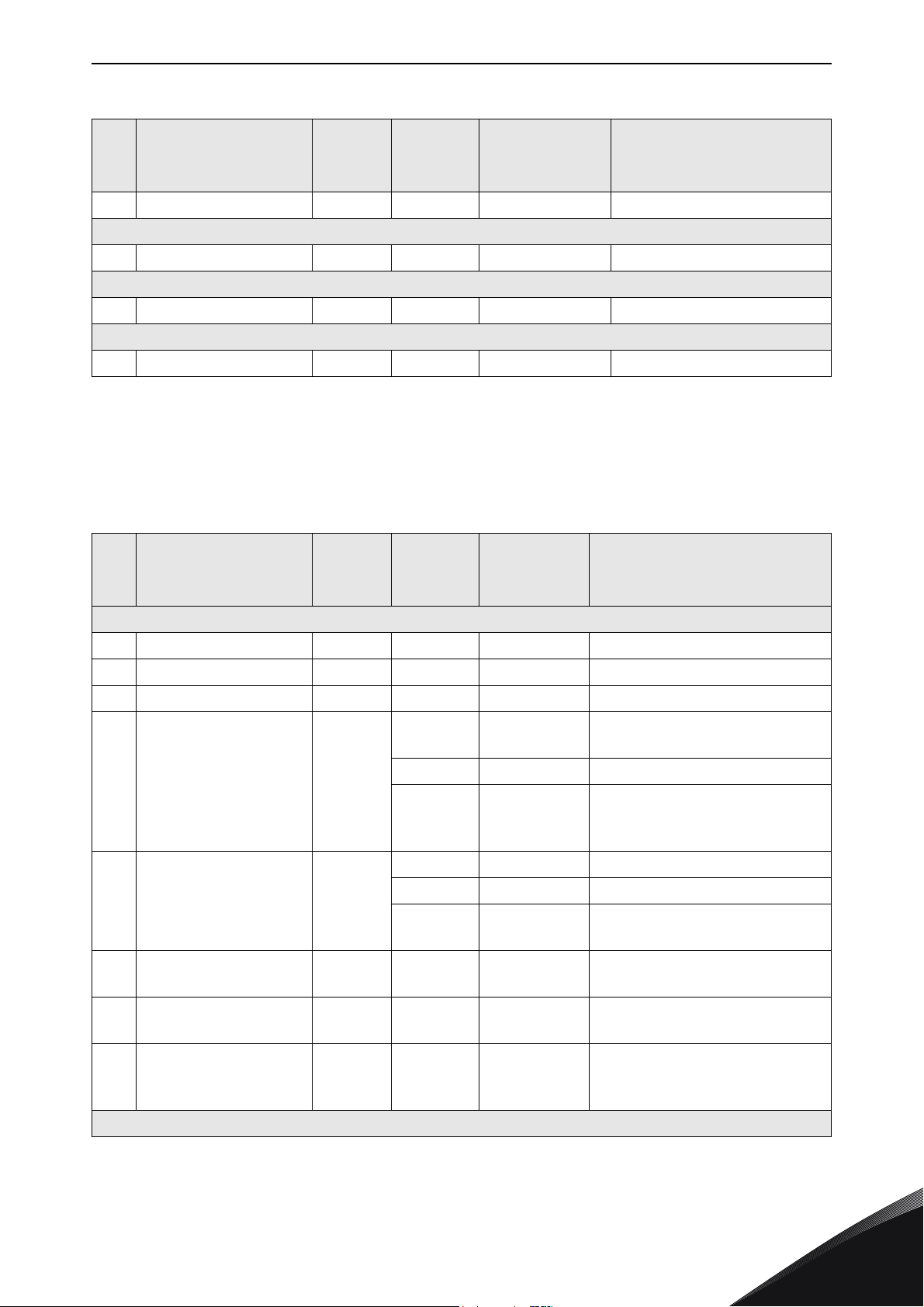

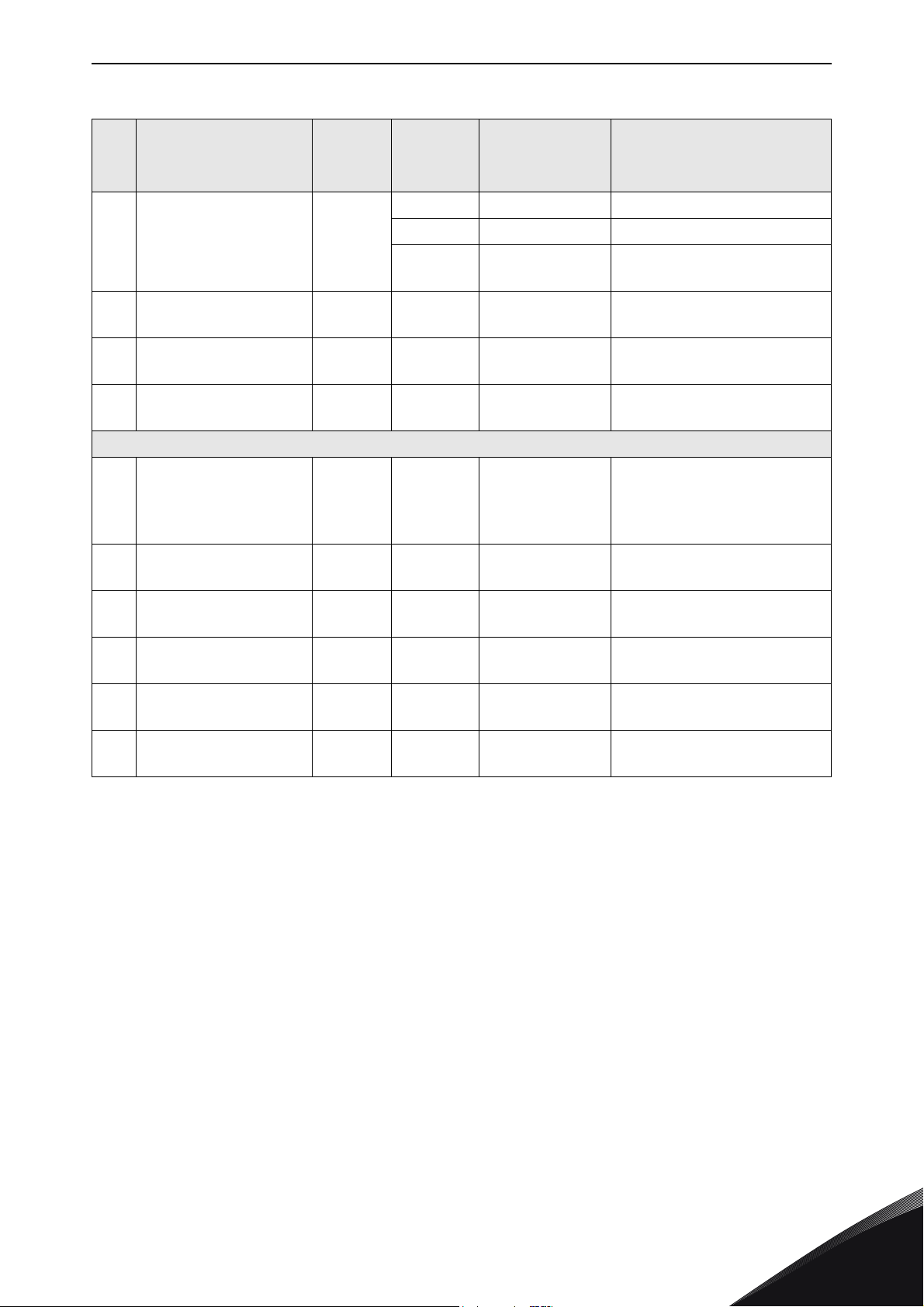

The following objects are implemented by the OPTE7 option board:

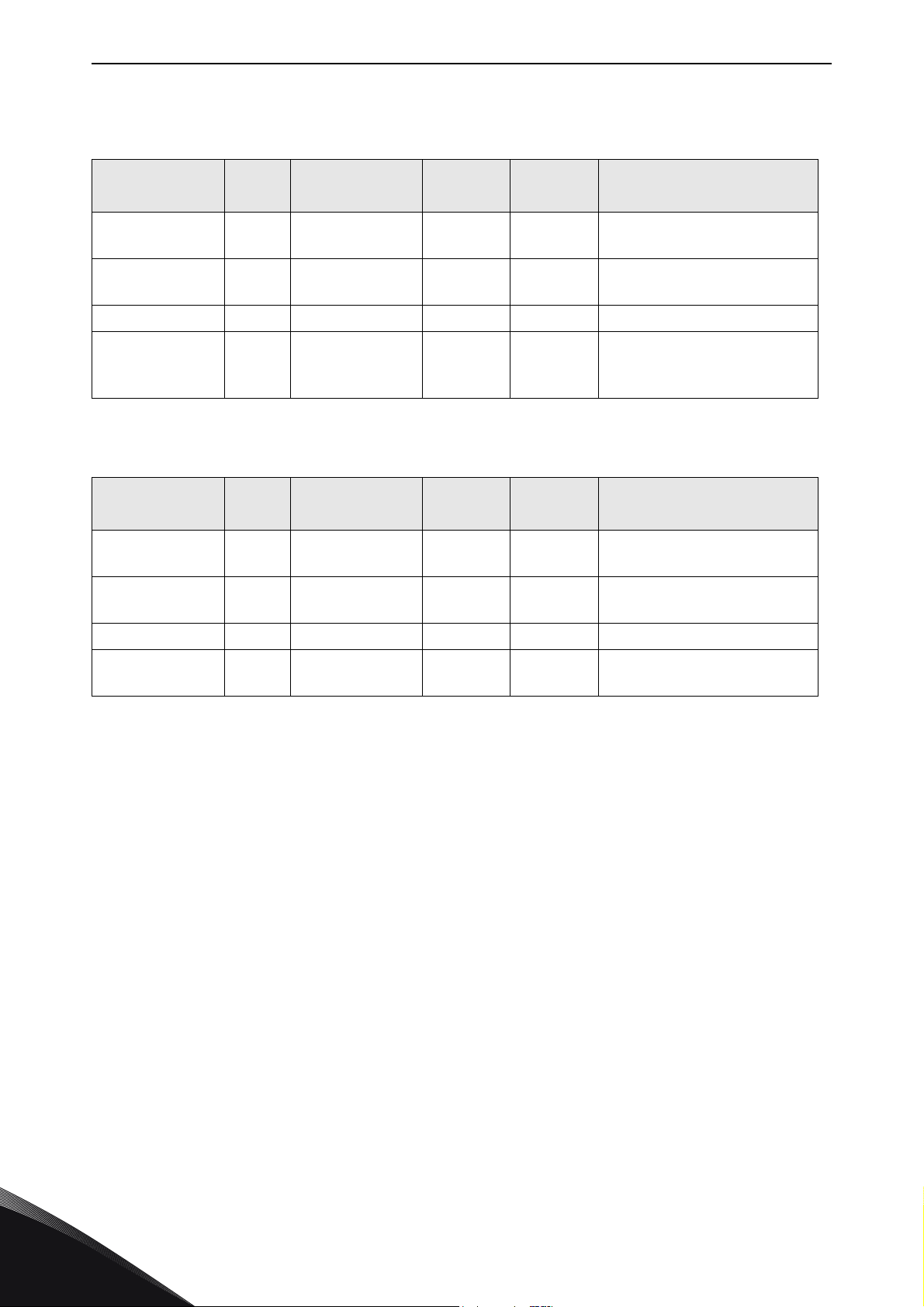

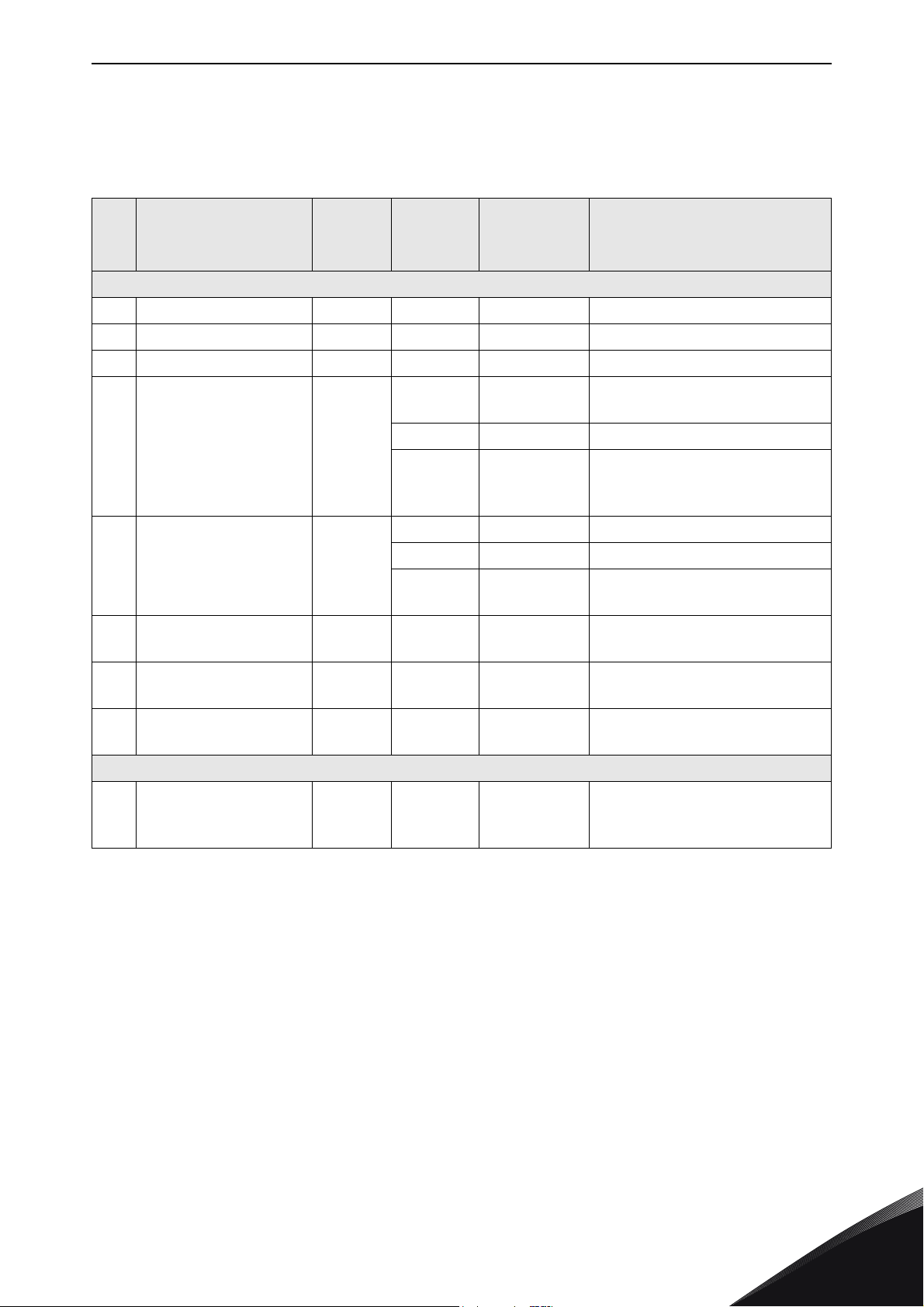

Table 2.

Class Object

0x01 Identity

0x02 Message Router

Required by

DeviceNet

Required by Drive

Profile

Vendor-Specific 0xA0 Vendor Parameter

Physical / Data link

layer

Application layer CIP - Common Industrial Protocol

Profiles AC/DC Drives

CAN - Controller Area Network

0x03 DeviceNet

0x04 Assembly

0x05 DeviceNet Connection

0x28 Motor Data

0x29 Control Supervisor

0x2A AC/DC Drive

Table 3.

2

Configuration file EDS - Electronic Data Sheet

Baud rates 125 kbit/s, 250 kbit/s, and 500 kbit/s

Bus length

Max nodes 64

Trunk length is inversely proportional to the speed, i.e. 500, 250

and 100 meters respectively

Tel. +358 (0) 201 2121 • Fax +358 (0)201 212 205

Page 11

DeviceNet option board OPTE7 - General vacon • 8

2.2.1 EDS (Electronic Data Sheet) file

EDS is a configuration file that describes the capabilities of the DeviceNet node. It can be used by

the configuration tool to simplify the process of commissioning. EDS is actually a simple text file that

follows the rules specified by the ODVA in the DeviceNet specification. Therefore, it could be opened

and viewed with a simple text editor e.g. Notepad.

The EDS file for the OPTE7 option board can be downloaded from www.vacon.com

.

24-hour support +358 (0)201 212 575 • Email: vacon@vacon.com

2

Page 12

vacon • 9 DeviceNet option board OPTE7 - technical

3. DEVICENET OPTION BOARD OPTE7 - TECHNICAL DATA

3.1 General

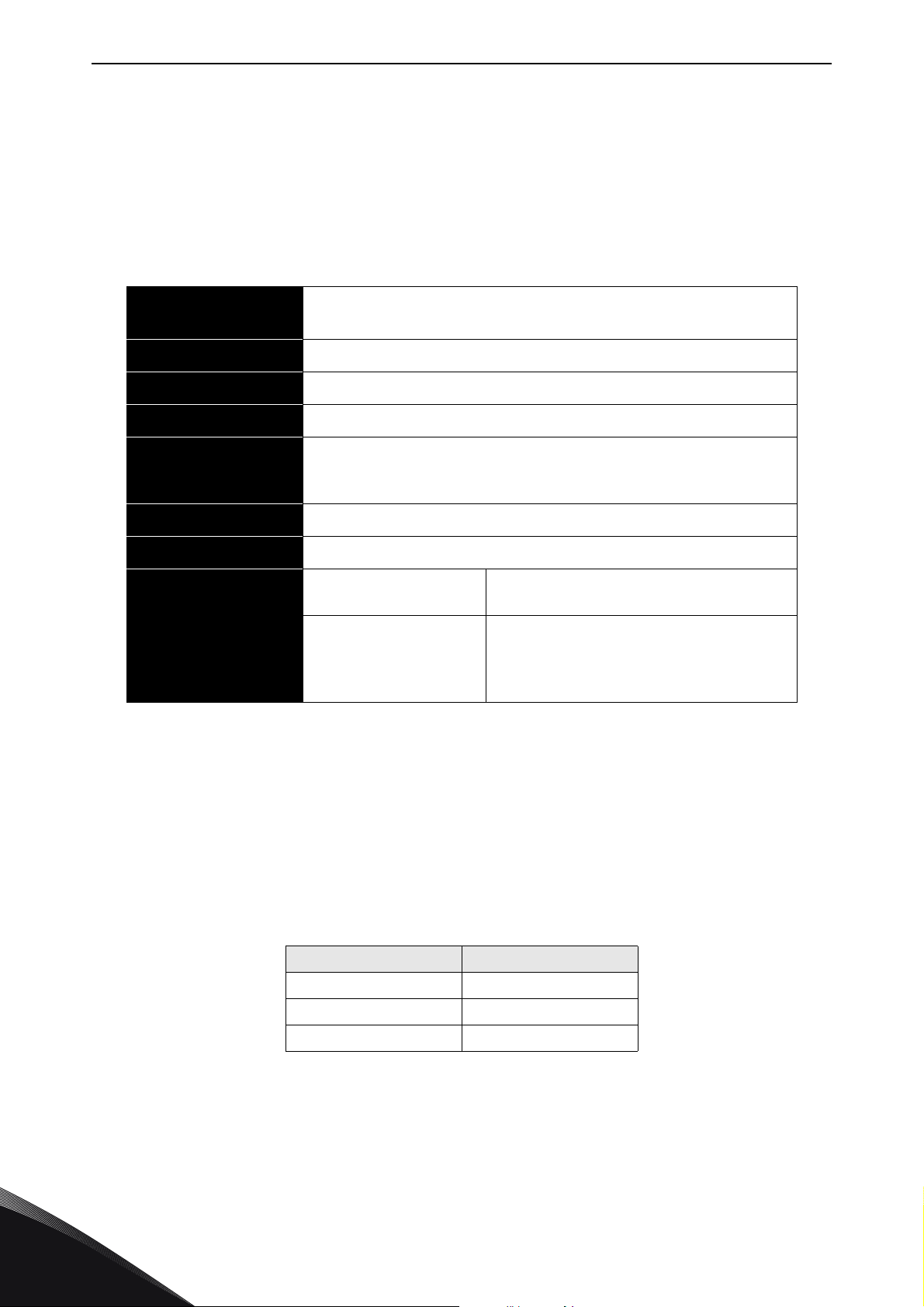

Table 4. Technical data of OPTE7 option board

CAN bus electrical

isolation

Ambient temperature As specified in drive specification (-10°C...40°C)

Storing temperature As specified in drive specification (-40°C...70°C)

Humidity 0-95%, non-condensing, corrosive

Vibration and

electrical safety

Emission C2 level, EN 61800-3 (2004)

Immunity C2 level, EN 61800-3 (2004)

CAN Interface

500 VDC

EN 61800-5-1 (2007)

5-15.8 Hz 1mm (peak)

15.8-150 Hz 1 G

Isolation

Protection

2500 V rms isolation with a less than

10-ns propagation delay

±8kV ESD IEC 61000-4-2 Contact

Discharge

±80V Fault Protection

greater than ±12V common Mode Range

3.2 CAN cable

The recommended cables for installation are 4-wire twisted and shielded cables with an impedance

of 120 Ohm. The network topology is a 2-wire bus line that is terminated at both ends by resistors

representing the characteristic impedance of the bus line. The typical CAN cable impedance is 120

Ohm, so you must use termination resistors of ~120 Ohm. For long networks, use a higher resistor

value (150-300 Ohm).

Table 5. Bus parameter relation to cable length

Cable length Max bit rate [kbit/s]

100 m 500

250 m 250

500 m 120

3

Tel. +358 (0) 201 2121 • Fax +358 (0)201 212 205

Page 13

DeviceNet option board OPTE7 - technical data vacon • 10

3.2.1 Recommended cable

For all DeviceNet installations the use of 4-wire cable is recommended.

Vacon recommends the following cable:

- UNITRONIC® BUS CAN FD P, colour-coded in accordance with DIN 47100.

Figure 3. Recommended cable

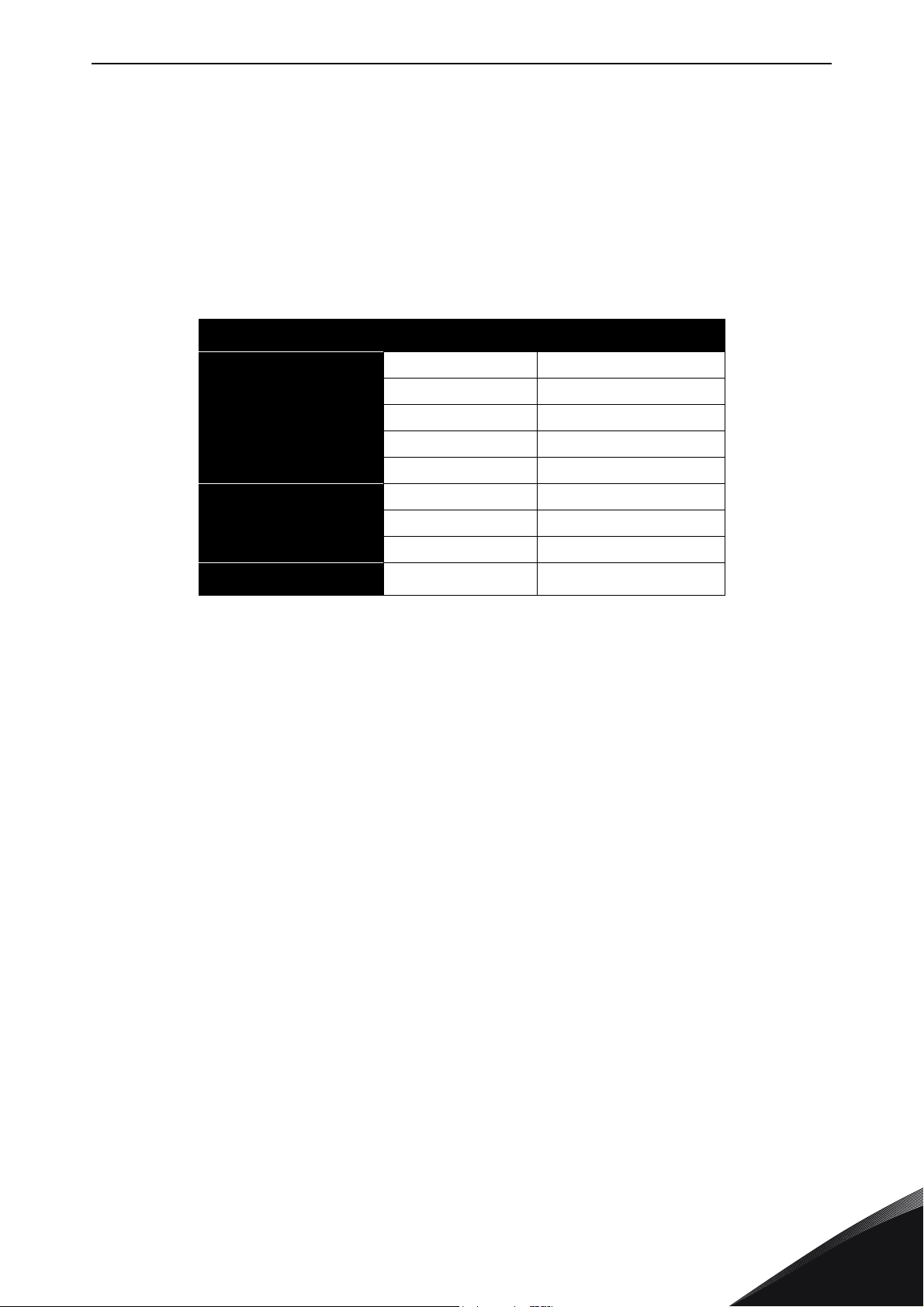

Table 6. Cable thickness, length and baud rate relation

Bit rate Min cable thickness [mm2]

500 kbit/s 0.34

250 kbit/s 0.34 0.6

125 kbit/s 0.34 0.6 0.6

Cable length [m] 100 250 500

24-hour support +358 (0)201 212 575 • Email: vacon@vacon.com

3

Page 14

vacon • 11 OPTE7 layout and connections

M/N A N/M

1

2

3

4

5

6

7

product code

serial no.

9338A_00

Pin 1

Pin 5

9340.emf

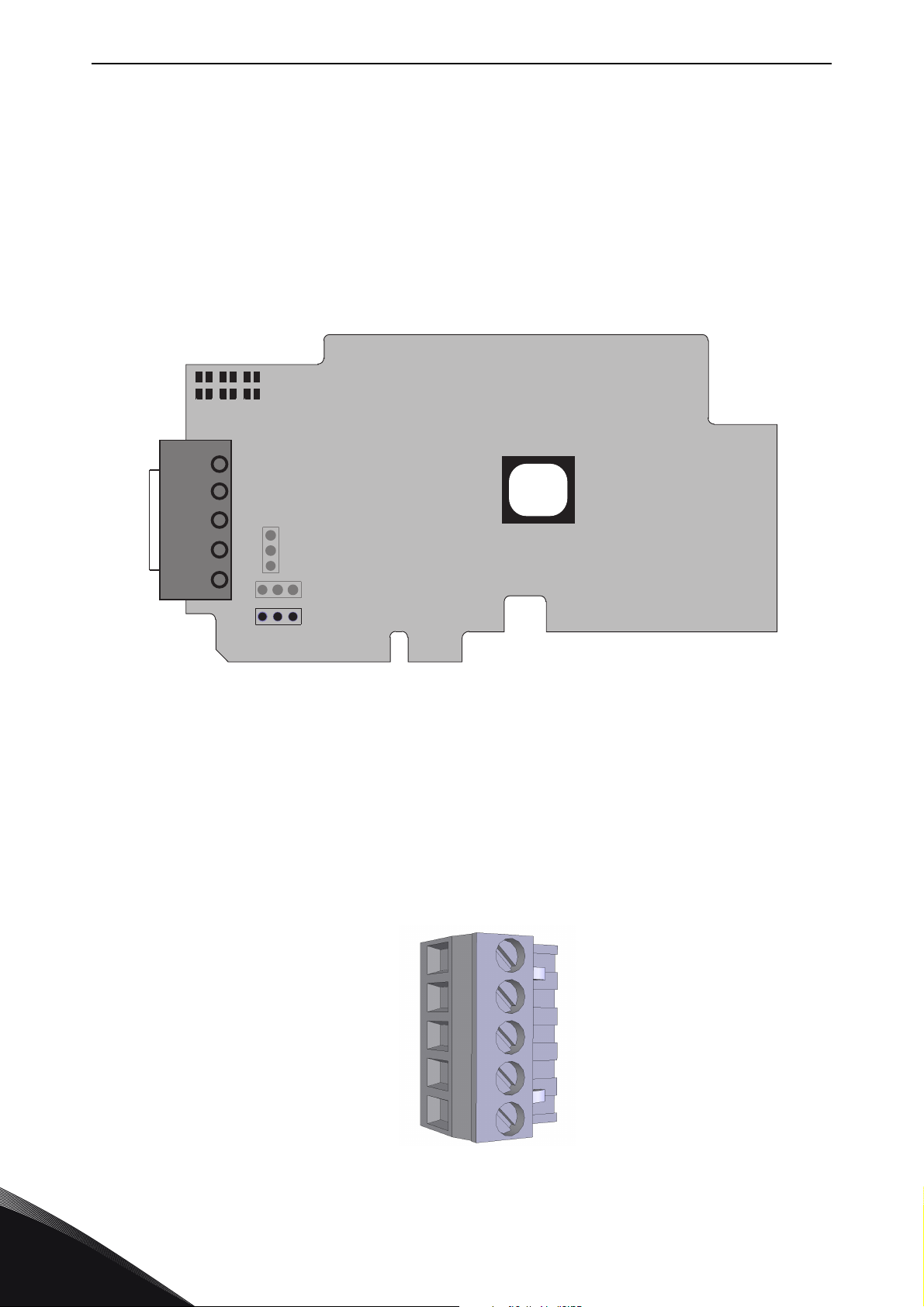

4. OPTE7 LAYOUT AND CONNECTIONS

4.1 Layout and connections

OPTE7 has two different hardware revisions with slightly different layouts. The layout is different in

the LED arrangement and the termination resistor orientation.

The two hardware revisions are marked with different product codes, and this product code can be

seen in the sticker on the top side of the option board (see the location in Figure 6).

The two hardware revisions are 70CVB01817 and 70CVB01555.

1 = V- (GND)

2 = CAN L

3 = SHIELD (shield connector)

4 = CAN H

5 = V+ (24V)

6 = Cable shield grounding option

7 = CAN bus termination jumper

Figure 4. OPTE7 board layout

4

Figure 5. CAN connector

Tel. +358 (0) 201 2121 • Fax +358 (0)201 212 205

Page 15

OPTE7 layout and connections vacon • 12

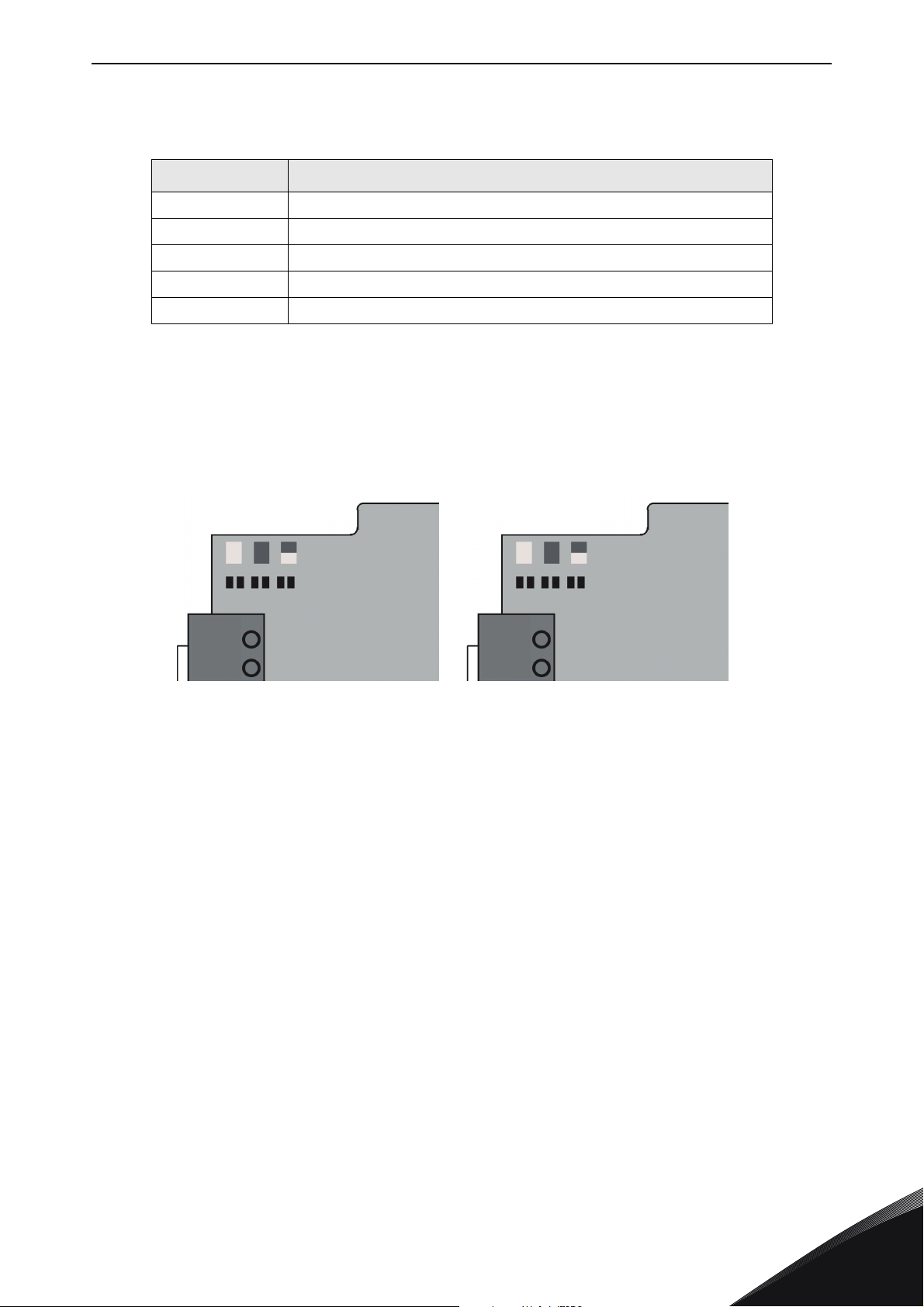

7086_00

N A MM A N

70CVB01817 70CVB01555

Table 7. CAN connector pinout

Pin Description

1 V-, isolated digital ground

2CAN LO

3 Shield connector

4CAN HI

5 V+ (24V), communication power supply

4.2 LED Indications

The DeviceNet option board includes two LED status indicators next to the connector: network

status (N), and module status (M).

Figure 6. OPTE7 LED indicators

The network status provides information on the network connection status, and the module status

provides information on the DeviceNet module.

24-hour support +358 (0)201 212 575 • Email: vacon@vacon.com

4

Page 16

vacon • 13 OPTE7 layout and connections

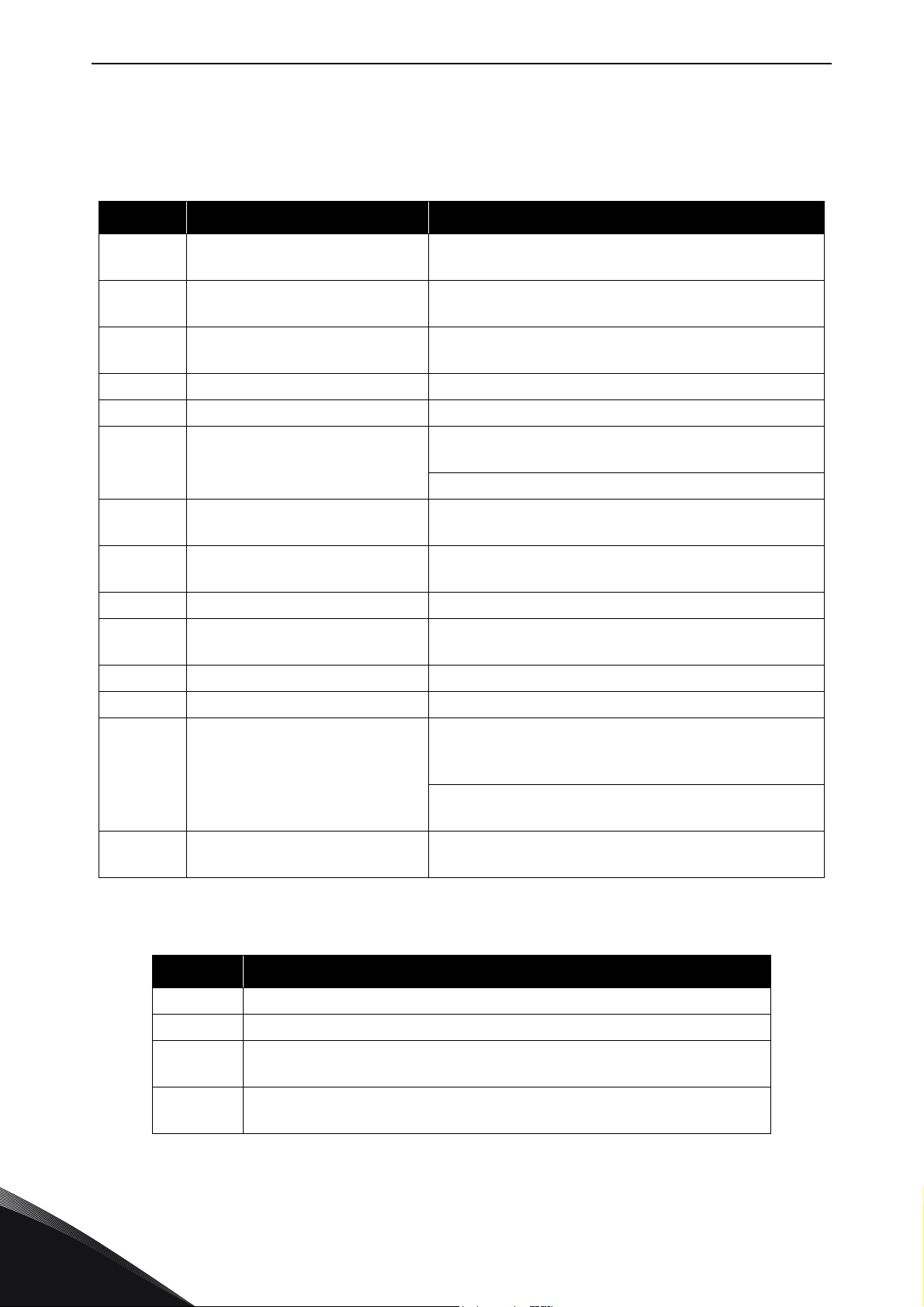

Table 8. Module status led

LED status Description

OFF No power is supplied to the drive.

Green OPTE7 is operating normally.

Flashing green

Flashing red The OPTE7 has detected a Recoverable Fault.

Red The OPTE7 has detected an Unrecoverable Fault.

LED status Description

OFF

Flashing green

Green The OPTE7 is online and allocated to a master.

Flashing red One or more I/O connections are in the Timed–Out state.

Red

OPTE7 is in the Standby state, or the device needs commissioning due to missing, incomplete or incorrect configuration.

Table 9. Network status led

OPTE7 is not online.

• The device has not completed the Dup_MAC_ID test yet.

• If the Module Status LED is off, the device is not powered.

The OPTE7 has passed the Dup_MAC_ID test, is online, but is

not allocated to a master.

The OPTE7 cannot communicate on the network (Duplicate MAC

ID, or Bus–off).

4

Tel. +358 (0) 201 2121 • Fax +358 (0)201 212 205

Page 17

OPTE7 layout and connections vacon • 14

3

4

5

6

7

3

4

5

6

7

7087_00

70CVB01817 70CVB01555

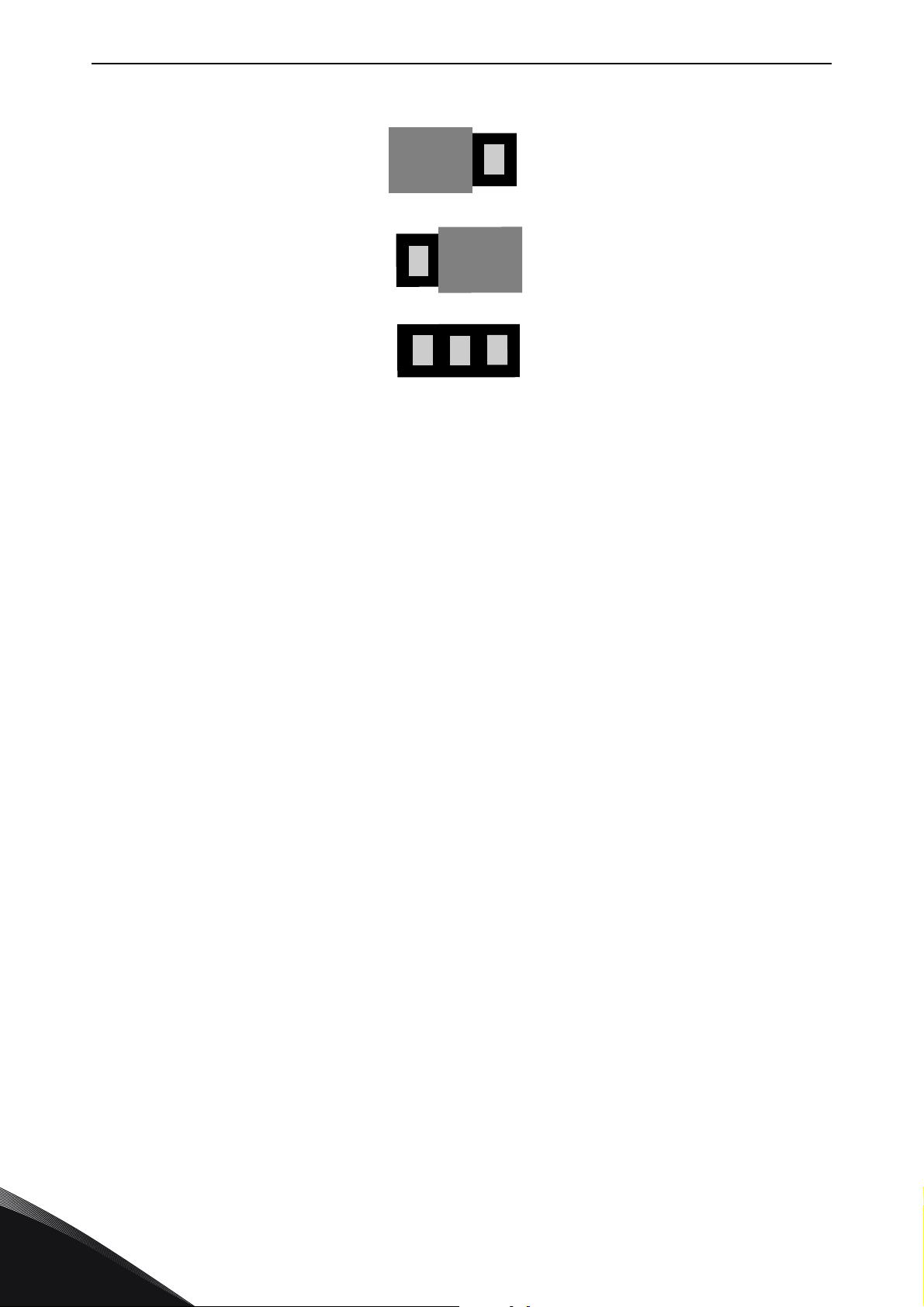

4.3 Jumpers

The termination resistor jumper location differs on used hardware version. The jumper locations

can be seen from figure below.

Figure 7. Jumper locations

The jumper settings for the CAN bus termination resistor are shown in the figure below.

1

2

A

1

B

1

C

3

A

2

3

3

2

2

3

1

3

2

1

B

70CVB0155570CVB01817

C

3

2

1

7088_00

Figure 8. Termination resistor settings

A = Termination resistor 120 Ohm connected

B = Termination resistor is not connected to the CAN bus. (Factory default setting)

C = Termination resistor is not connected to the CAN bus

The jumper settings for the CAN cable shield grounding are shown in the following figure.

24-hour support +358 (0)201 212 575 • Email: vacon@vacon.com

4

Page 18

vacon • 15 OPTE7 layout and connections

3

1

2

3

2

1

1

2

3

A

B

C

9342.emf

Figure 9. Cable shield grounding option

A = CAN connector pin 3 (shield) connected to the drive chassis with a high-impedance RC circuit.

Recommended option when equipotential bonding is poor.

B = CAN connector pin 3 (shield) connected directly into the drive chassis. Recommended option

when equipotential bonding is good. (Factory default setting).

C = CAN connector pin 3 is unconnected.

4

Tel. +358 (0) 201 2121 • Fax +358 (0)201 212 205

Page 19

Installation vacon • 16

M4x55

9174.emf

DANGER

5. INSTALLATION

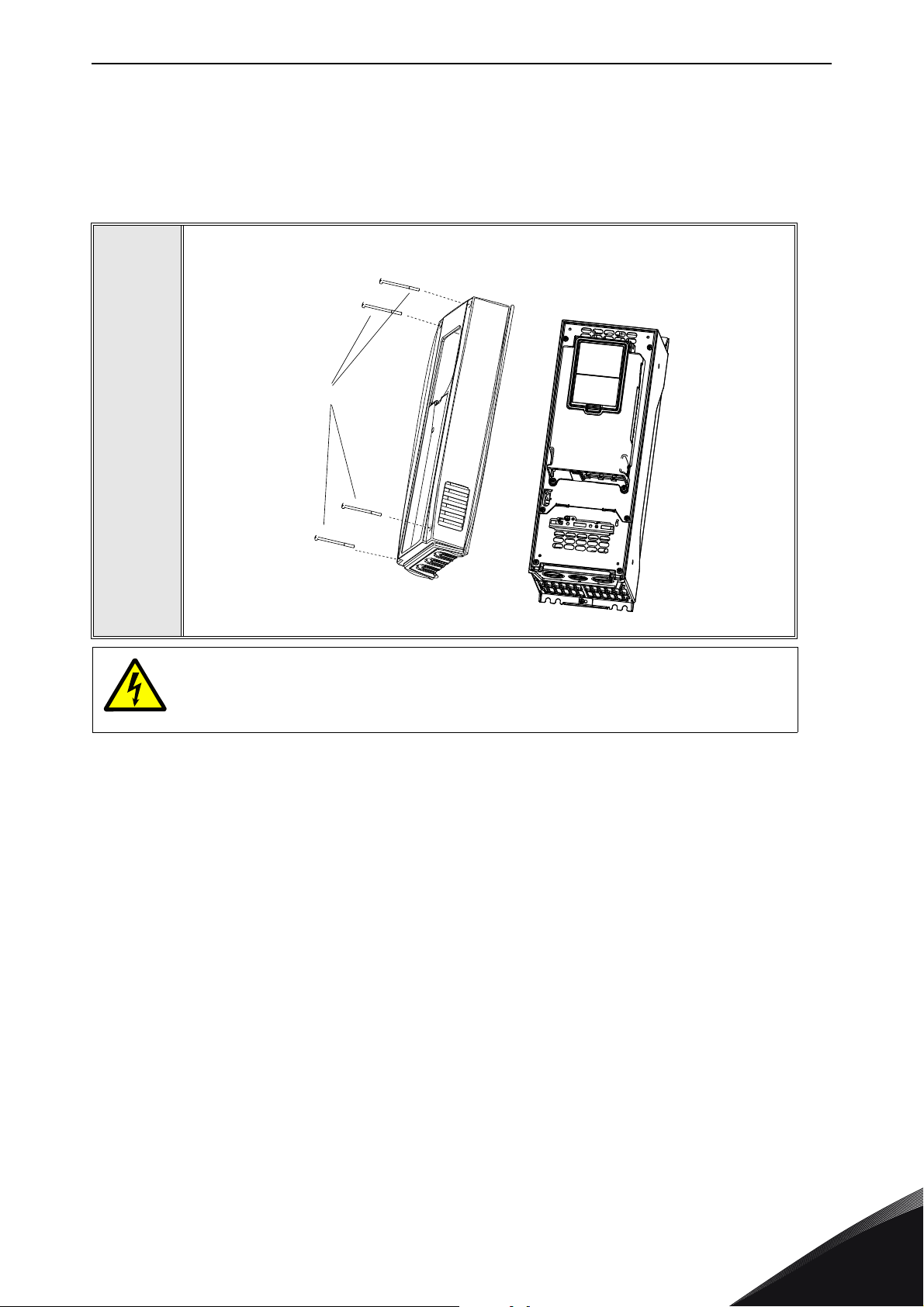

5.1 Installation in Vacon® 100

Open the cover of the AC drive.

1

The relay outputs and other I/O terminals may have a dangerous control voltage

present even when the AC drive is disconnected from mains.

24-hour support +358 (0)201 212 575 • Email: vacon@vacon.com

5

Page 20

vacon • 17 Installation

3023.emf

DE

3024.emf

Open the inner cover to reveal the option board slots (C,D,E).

2

3

Install the fieldbus board into slot D or E.

NOTE! Incompatible boards cannot be installed on the drive. Compatible boards

have a slot coding

that enable the placing of the board.

5

Tel. +358 (0) 201 2121 • Fax +358 (0)201 212 205

Page 21

Installation vacon • 18

10

5

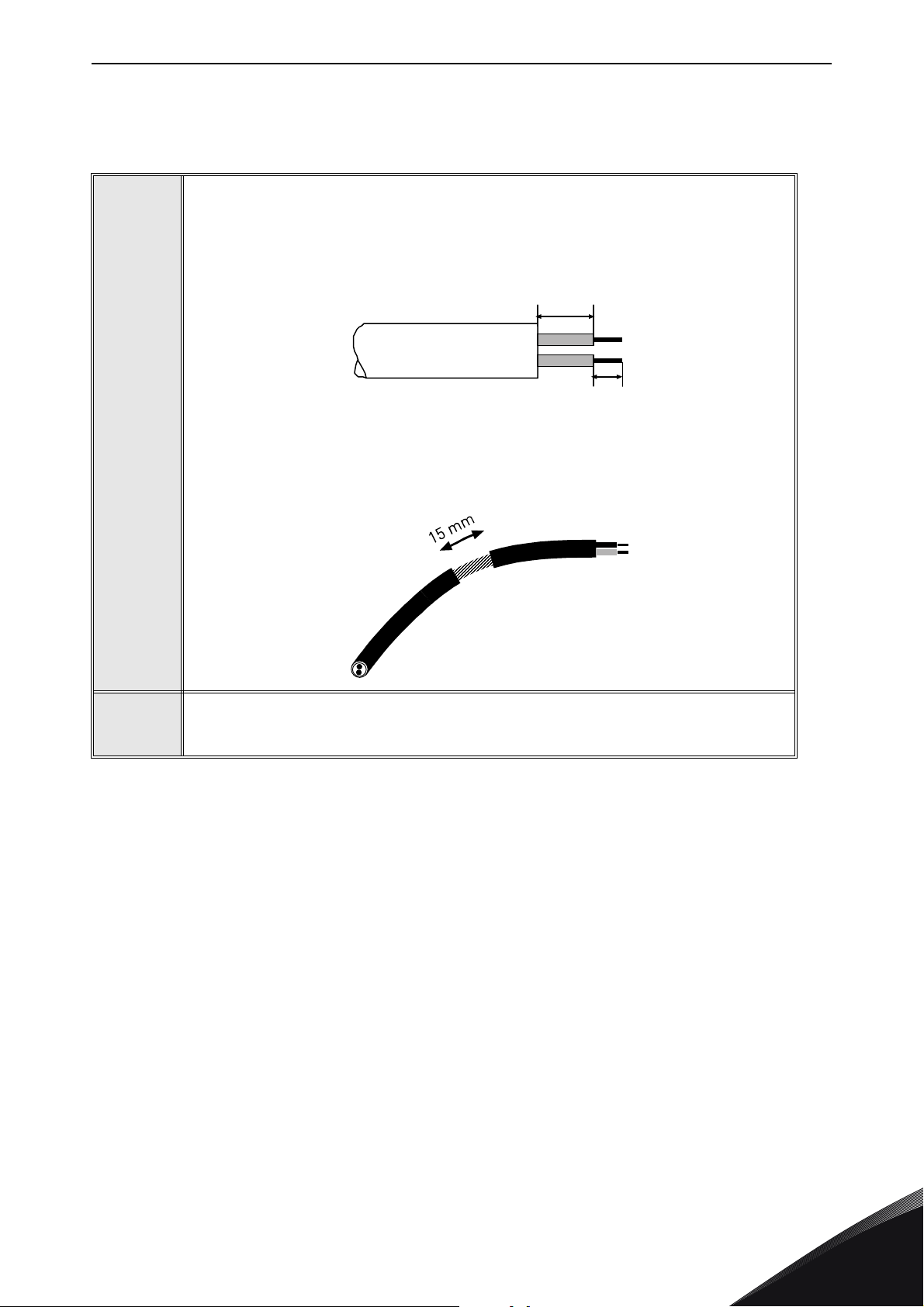

5.2 Prepare for use through fieldbus

Strip about 15 mm of the fieldbus cable and cut off the grey cable shield.

Remember to do this for both bus cables (except for the last device).

Leave no more than 10 mm of the cable outside the terminal block and strip the

cables at about 5 mm to fit in the terminals.

4

5

Also strip the cable now at such a distance from the terminal that you can fix it to

the frame with the grounding clamp. Strip the cable at a maximum length of 15

mm. Do not strip the aluminum cable shield!

Then connect the cable to its appropriate terminals on the OPTE7 DeviceNet

option board terminal block.

24-hour support +358 (0)201 212 575 • Email: vacon@vacon.com

5

Page 22

vacon • 19 Installation

Cable clamp

Using the cable clamp included in the delivery of the drive, ground the shield of

the CAN cable to the frame of the AC drive.

NOTE! This can be done in all drives if there is no difference in PE potential

between the drives. However, if there is PE potential difference then the shield

should be connected to PE only at one point in the system. The shields of the

cables shall be joint but not connected to several PE points with different potential.

6

7

8

If the AC drive is the last device on the bus, the bus termination must be set

with jumper X13.

Unless already done for the other control cables,

cut free the opening on the AC drive cover for the

fieldbus cable (protection class IP21).

NOTE! Cut the opening on the same side you

have installed the board in!

5

Tel. +358 (0) 201 2121 • Fax +358 (0)201 212 205

Page 23

Installation vacon • 20

9202.emf

Fieldbus

cables

Fieldbus cable

= Bus termination

Termination

activated

Ter min ation

activated with

jumper

Termination

deactivated

Vacon 100 Vacon 100 Vacon 100 Vacon 100 Vacon 100

3007.emf

Remount the AC drive cover and run the cable as

shown in picture.

NOTE! When planning the cable runs, remember

to keep the distance between the fieldbus cable

and the motor cable at a minimum of 30 cm. It is

recommended to route the option board cables

away from the power cables as shown in the picture.

9

The bus termination must be set for the first and the last device of the fieldbus

line. See also step 7 on page 19. We recommend that the first device on the bus

and, thus, terminated was the master device.

10

24-hour support +358 (0)201 212 575 • Email: vacon@vacon.com

5

Page 24

vacon • 21 Installation

11649_00

11556A_00

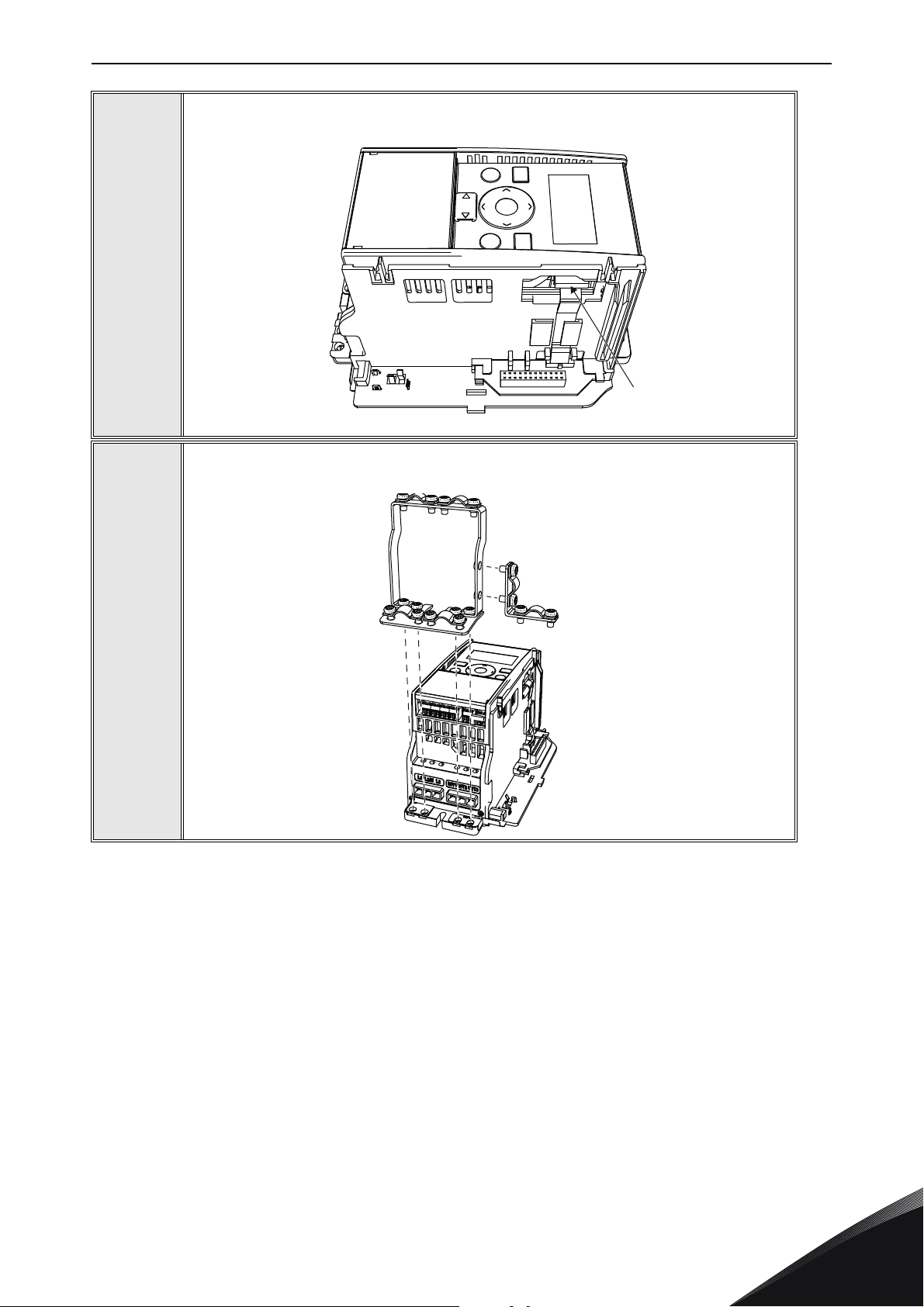

5.3 Installation in Vacon® 20

5.3.1 Frames MI1, MI2, MI3

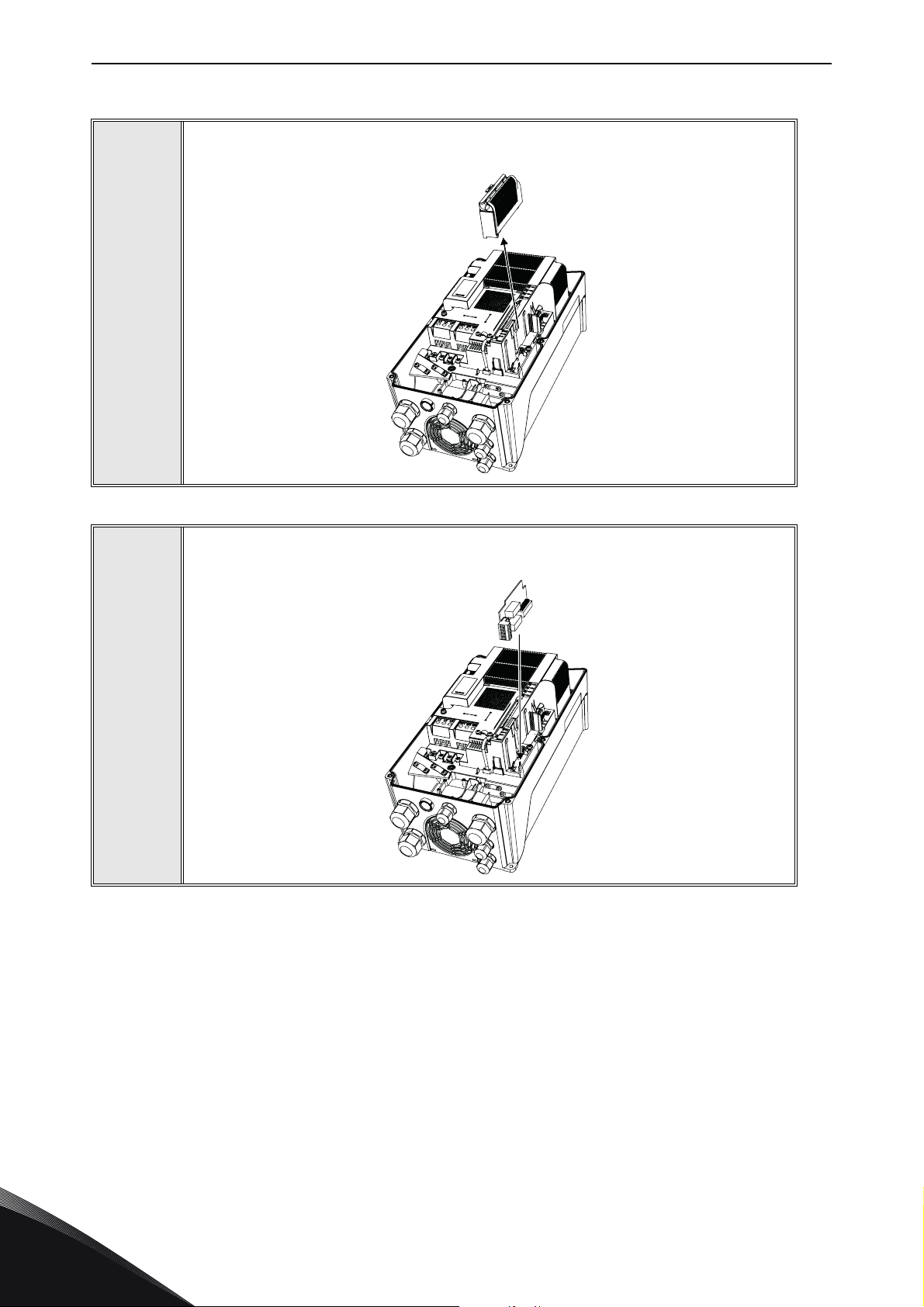

Remove the cable connector lid from the AC

drive.

1

11555A_00

2

3

Select a correct grounding plate and attach it to the

option board mounting frame. The grounding plate is

marked with the supported frame size.

Attach an option board mounting frame to the

drive.

5

Tel. +358 (0) 201 2121 • Fax +358 (0)201 212 205

Page 25

Installation vacon • 22

11558A_00

Connect the flat cable from the option board mounting frame to the drive.

4

11557A_00

If a cable strain relief is required, attach the parts as shown in the figure.

5

24-hour support +358 (0)201 212 575 • Email: vacon@vacon.com

5

Page 26

vacon • 23 Installation

11650_00

11560A_00

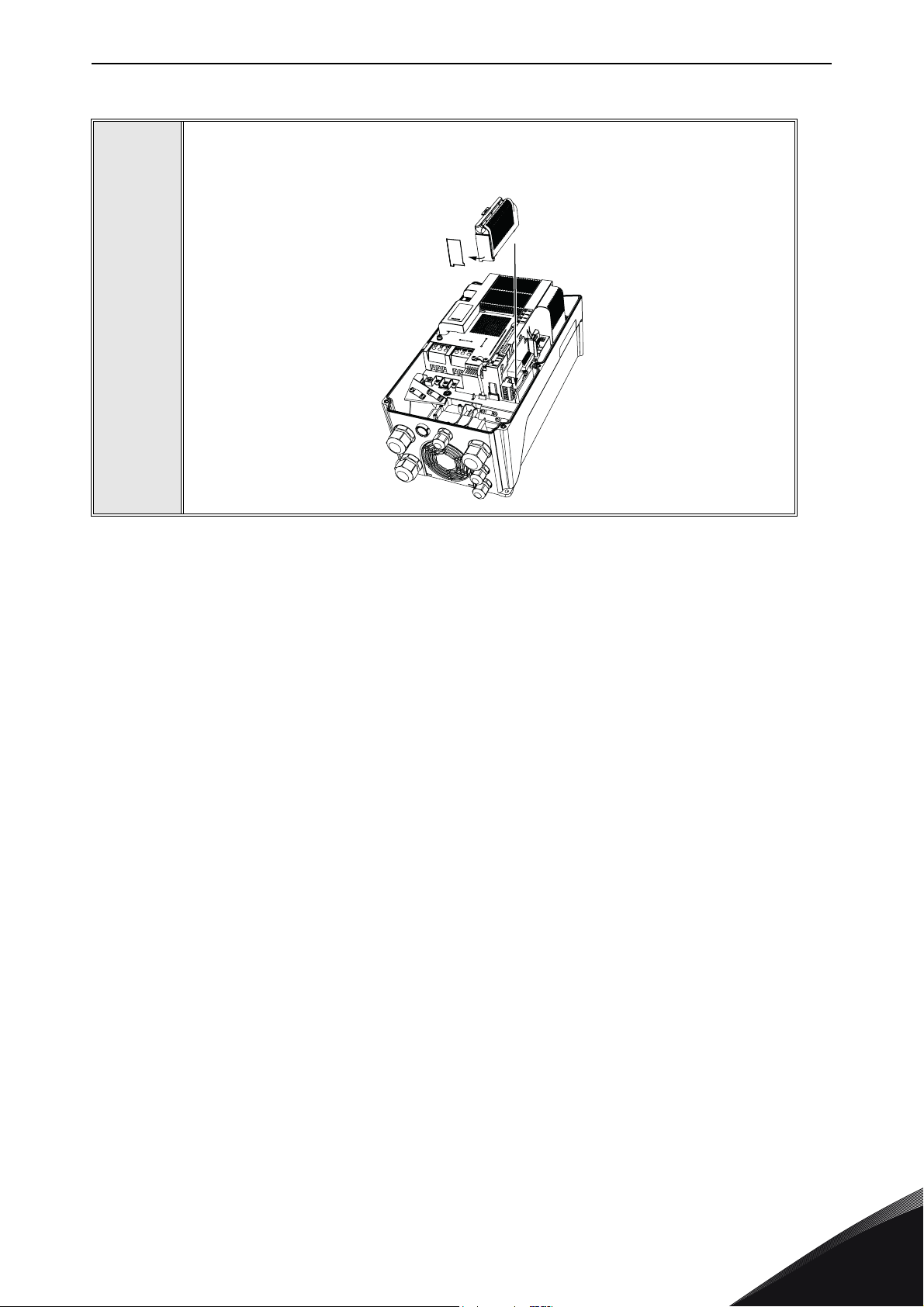

Install the option board to the option board

holder. Make sure that the option board is

securely fastened.

6

Cut free a sufficiently wide opening for the

option board connector.

7

8

Attach the option board cover to the drive. Attach the strain relief cable clamp

with screws if needed.

5

Tel. +358 (0) 201 2121 • Fax +358 (0)201 212 205

Page 27

Installation vacon • 24

13006.emf

11563_00

5.3.2 Frames MI4, MI5

Make sure power is disconnected before opening the cover of the drive.

1a: For MI4: Open the cover.

1

11561_00

1b: For MI5: Open the cover and release the fan connector.

11562_00

Attach the option board support.

2

24-hour support +358 (0)201 212 575 • Email: vacon@vacon.com

5

Page 28

vacon • 25 Installation

11564_00

11565_00

Connect the flex cable to option board connector PCB.

3

Connect the option board to connector PCB.

4

5

Attach the option board with connector PCB to the drive and connect the flex cable.

11566_00

5

Tel. +358 (0) 201 2121 • Fax +358 (0)201 212 205

Page 29

Installation vacon • 26

MI 04

MI 05

11567_00

11568_00

Attach a suitable grounding plate to the drive. The grounding plate is marked with

supported frame size.

6

Assemble a clamp on top of the grounding plate on both sides of the option board.

7

24-hour support +358 (0)201 212 575 • Email: vacon@vacon.com

5

Page 30

vacon • 27 Installation

11569_00

11570_00

8a: For MI4: Close the cover.

8

8b: For MI5: Remount the fan connector and close the cover.

5

Tel. +358 (0) 201 2121 • Fax +358 (0)201 212 205

Page 31

Installation vacon • 28

13006.emf

13006.emf

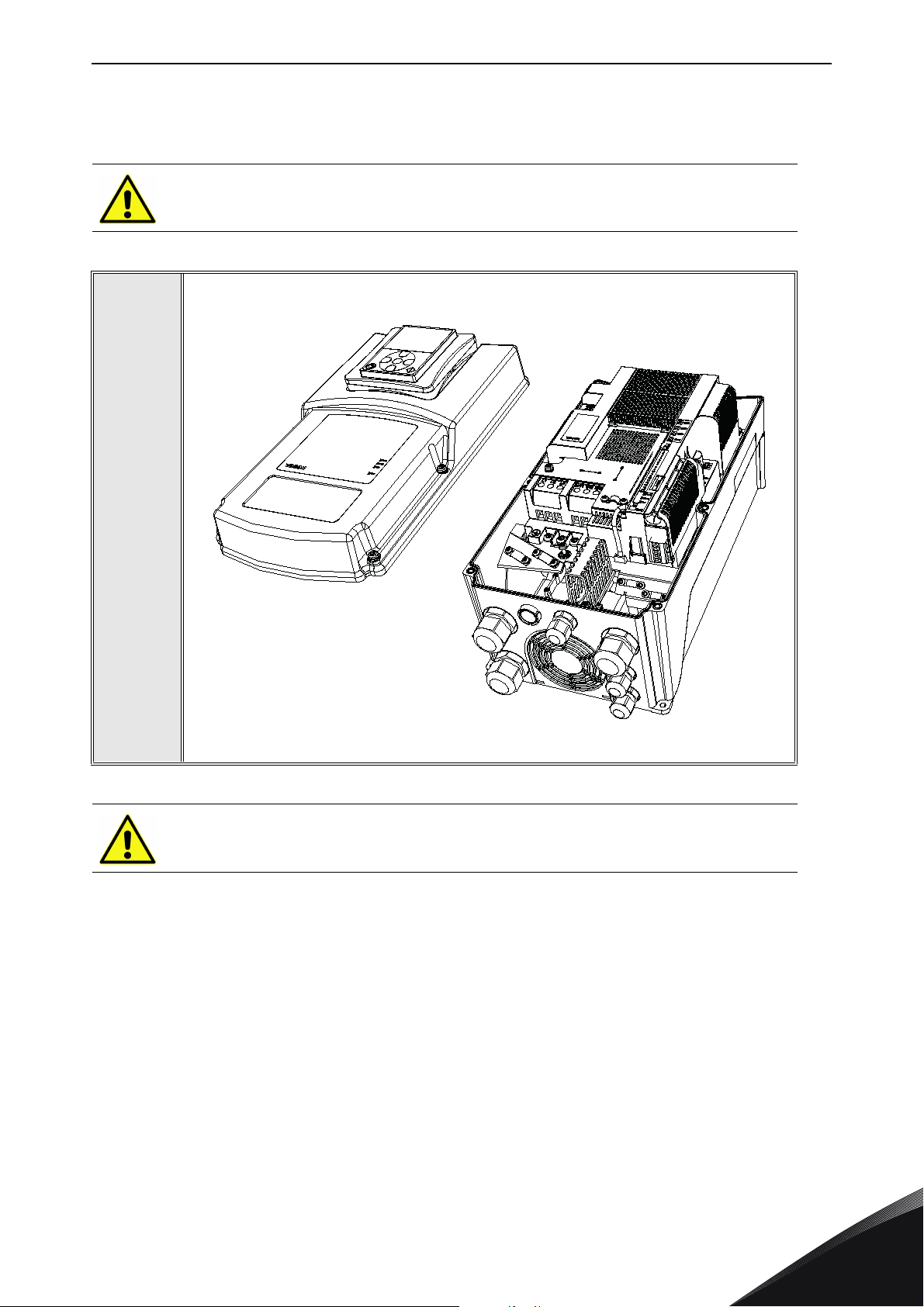

5.4 Installation in Vacon® 20 X and 20 CP

Do not add or replace option boards or fieldbus boards on an AC

drive with the power switched on. This may damage the boards.

Open the cover of the drive.

1

11643_00

MU3 example

The relay outputs and other I/O-terminals may have a dangerous control voltage

present even when the drive is disconnected from mains.

24-hour support +358 (0)201 212 575 • Email: vacon@vacon.com

5

Page 32

vacon • 29 Installation

7089_00

Remove the option slot cover.

2

3

Install the option board into the slot as shown in the figure.

7090_00

5

Tel. +358 (0) 201 2121 • Fax +358 (0)201 212 205

Page 33

Installation vacon • 30

7091_007091_00

Mount the option slot cover. Remove the plastic opening for the option board

terminals.

4

24-hour support +358 (0)201 212 575 • Email: vacon@vacon.com

5

Page 34

vacon • 31 Installation

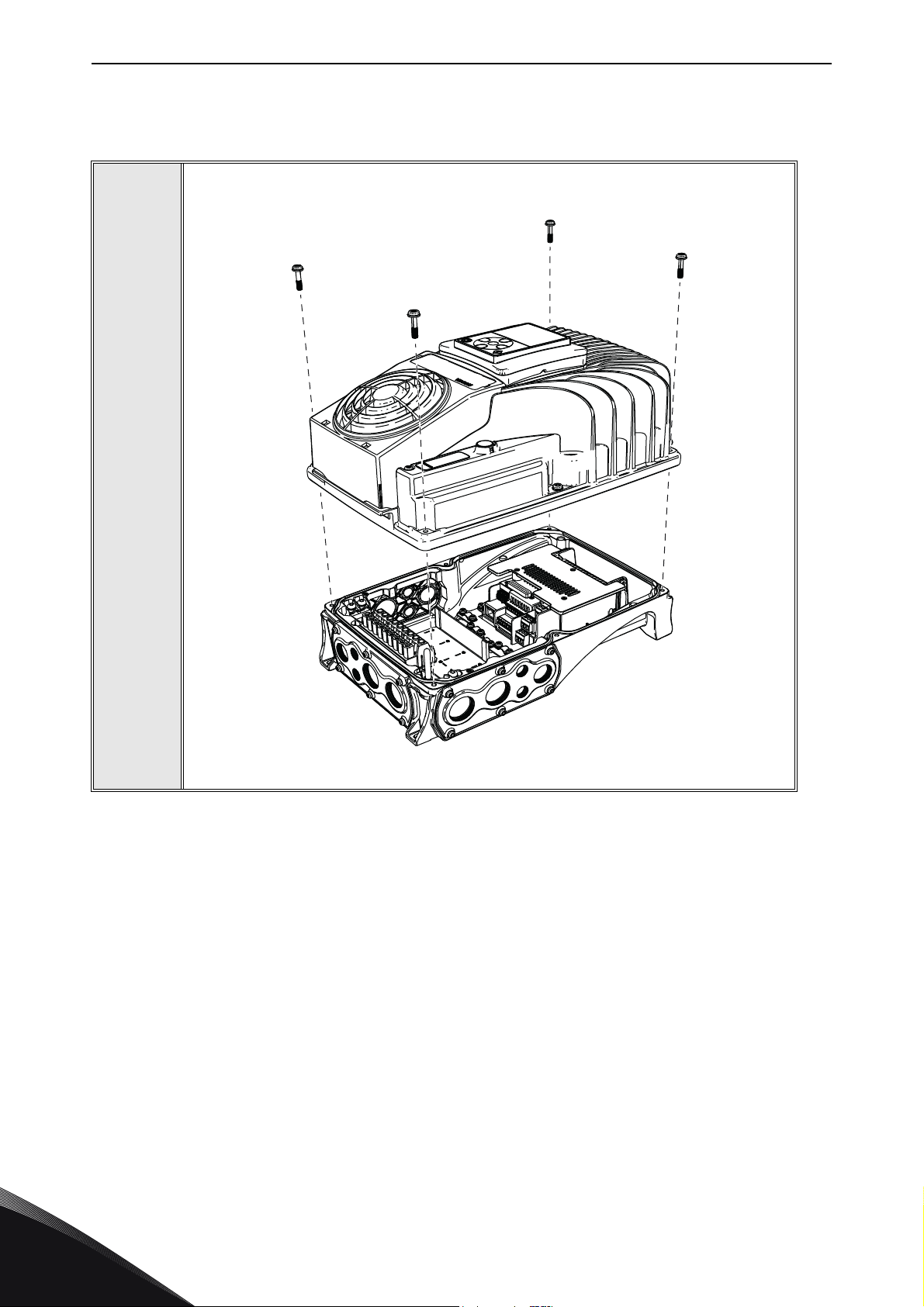

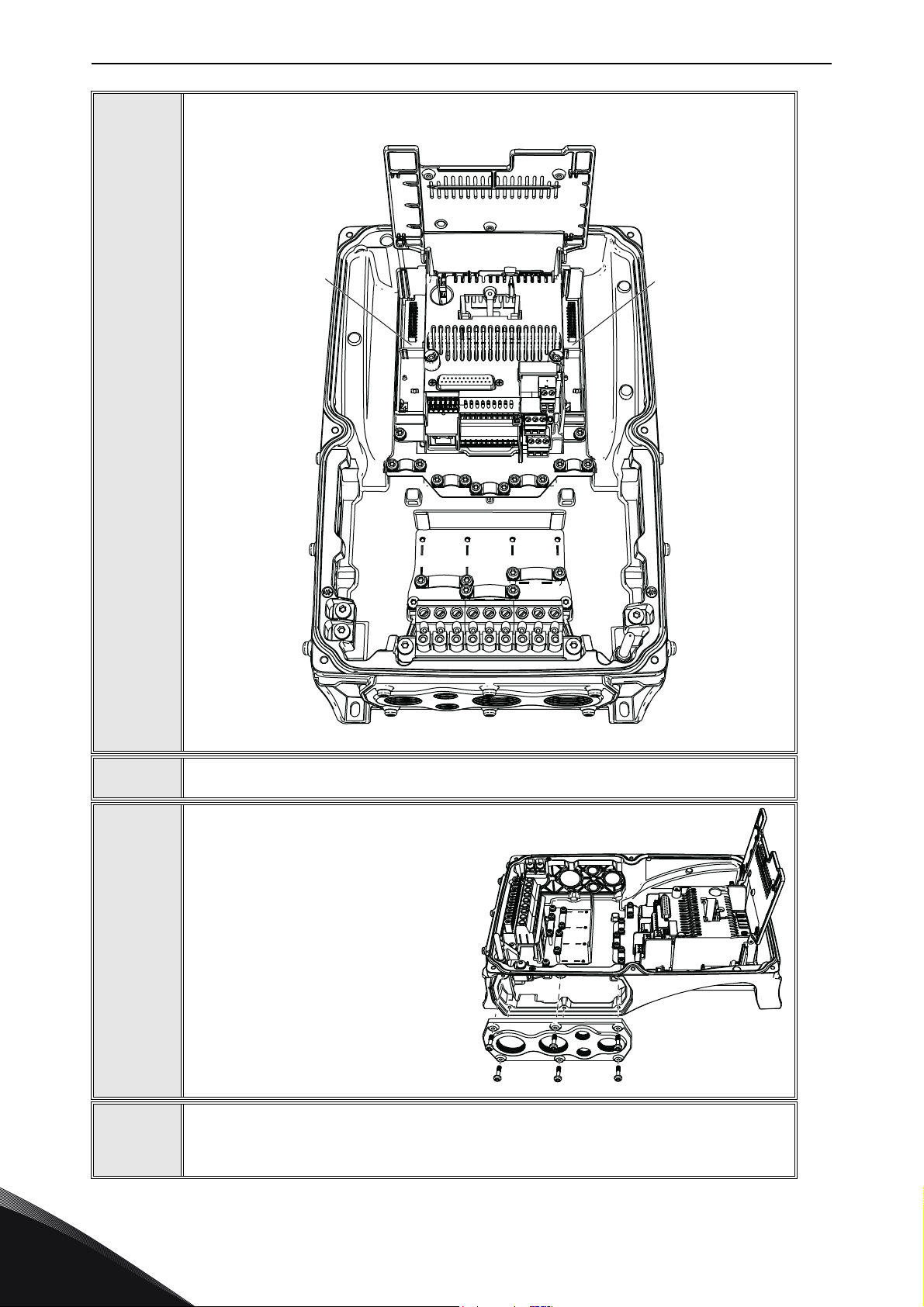

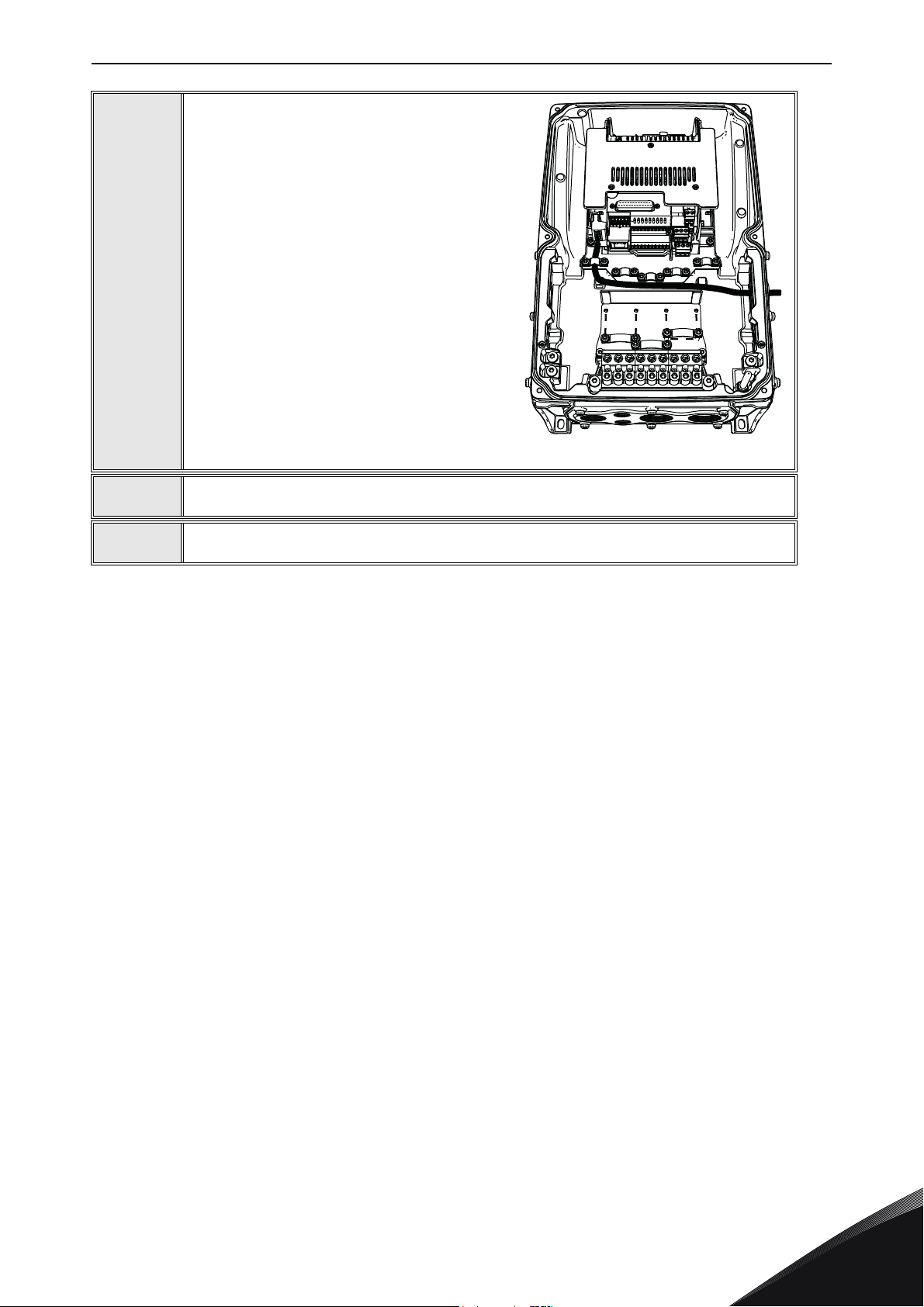

5.5 Installation in Vacon® 100 X (Frames MM4-MM6)

Open the cover of the AC drive.

1

11638_00

5

Tel. +358 (0) 201 2121 • Fax +358 (0)201 212 205

Page 35

Installation vacon • 32

11639_00

To get access to the option board slots, remove the screws and open the cover of

the control unit.

2

24-hour support +358 (0)201 212 575 • Email: vacon@vacon.com

5

Page 36

vacon • 33 Installation

DE

11640_00

11641_00

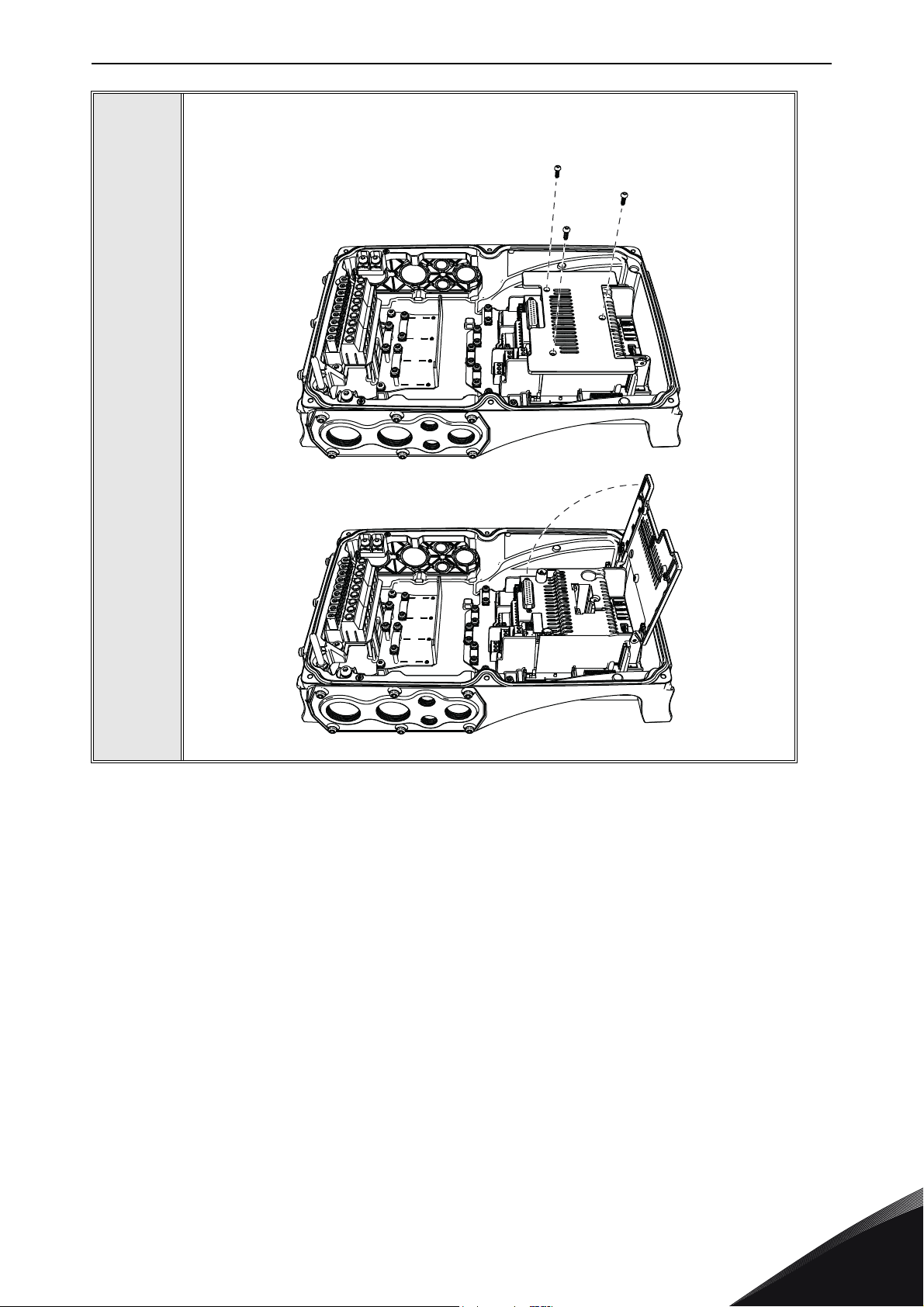

Install the option board into the correct slot, D or E.

3

4

5

6

Close the option board cover.

Remove the cable entry plate. If you

installed the option board in the slot

D, use the cable entry plate on the

right side. If you installed the option

board in the slot E, use the cable entry plate on the left side.

NOTE! The cable entry plate at the

bottom of the drive is used only for

mains and motor cables.

Open the necessary holes in the cable entry plate. Do not open the other holes.

See the Vacon

® 100X Installation Manual for the dimensions of the holes.

5

Tel. +358 (0) 201 2121 • Fax +358 (0)201 212 205

Page 37

Installation vacon • 34

11642_00

Attach a cable gland on the hole in the cable entry plate. Pull the fieldbus cable

through the hole.

NOTE! The fieldbus cable must go through

the correct cable entry plate to avoid going

near the motor cable.

7

8

9

Put the cable entry plate back.

Close the cover of the AC drive.

24-hour support +358 (0)201 212 575 • Email: vacon@vacon.com

5

Page 38

vacon • 35 Commissioning

6. COMMISSIONING

6.1 Parameter view

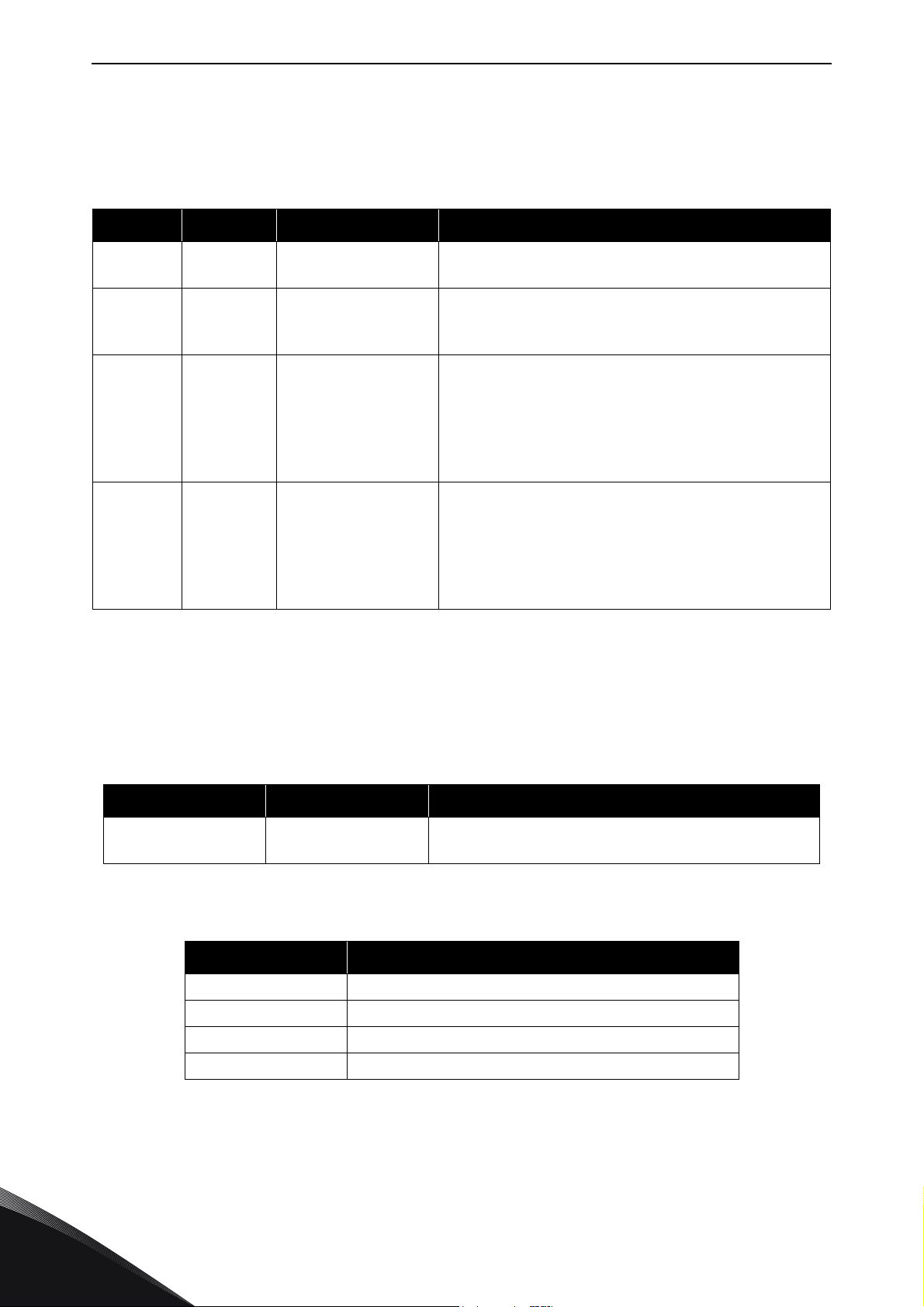

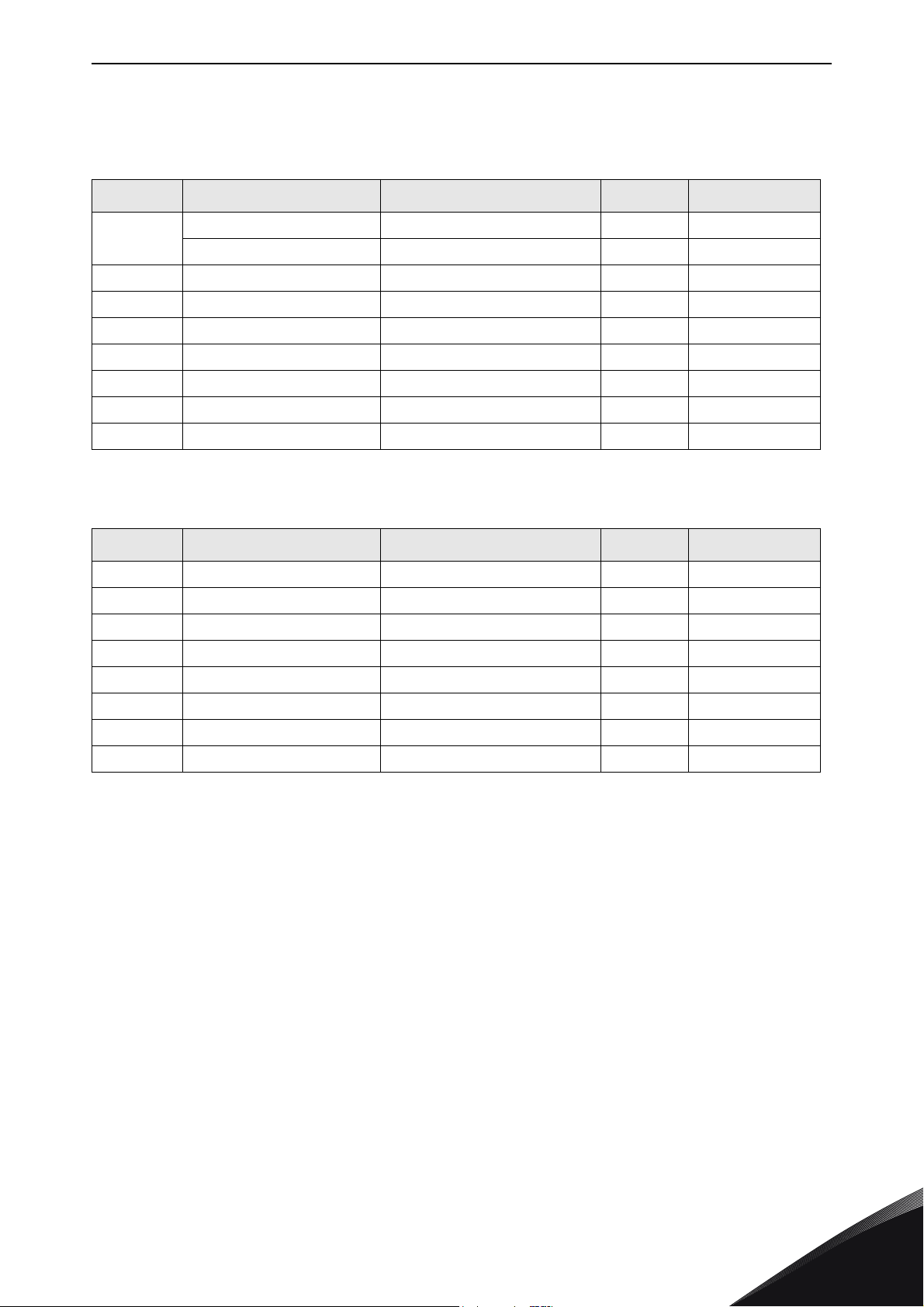

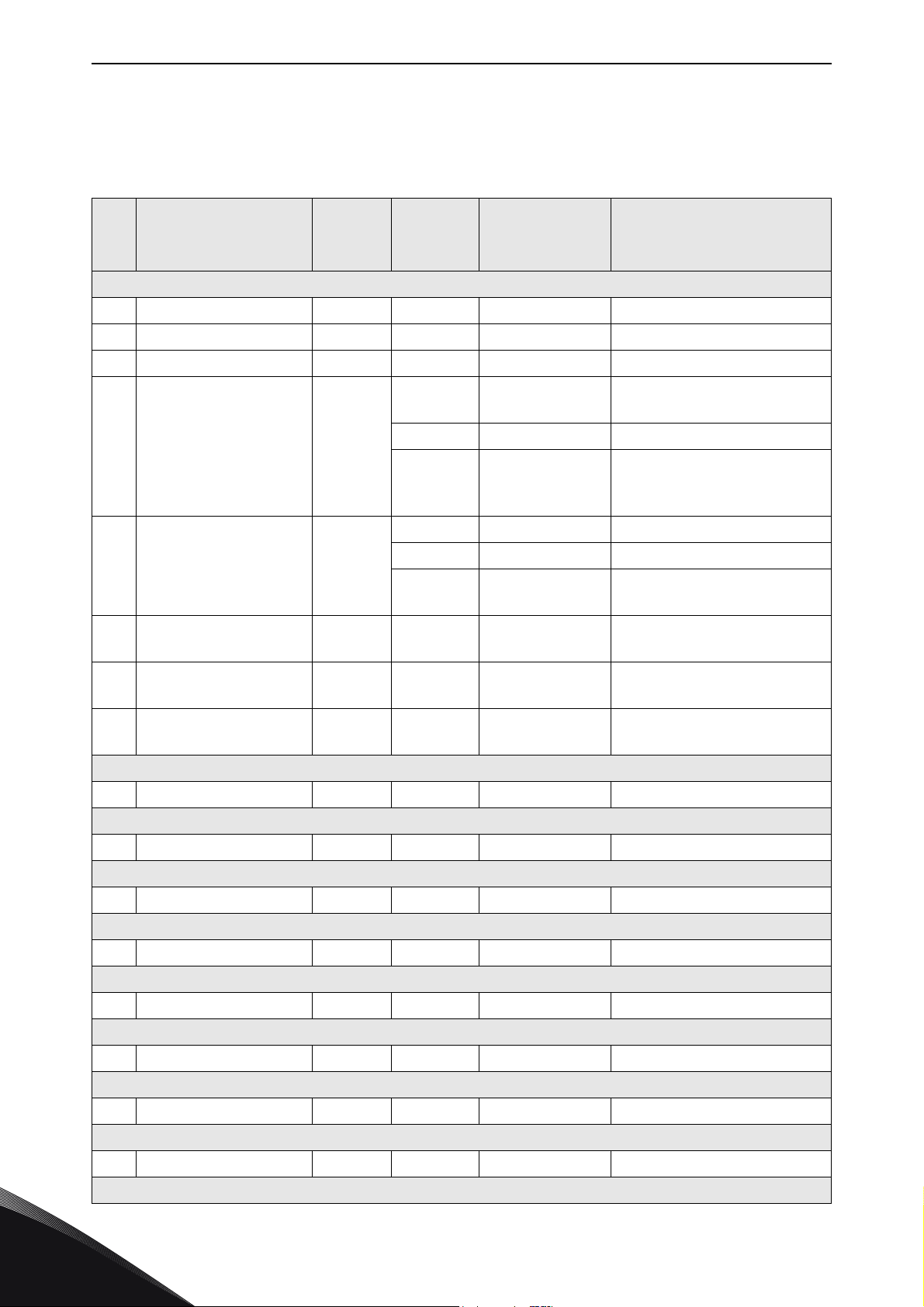

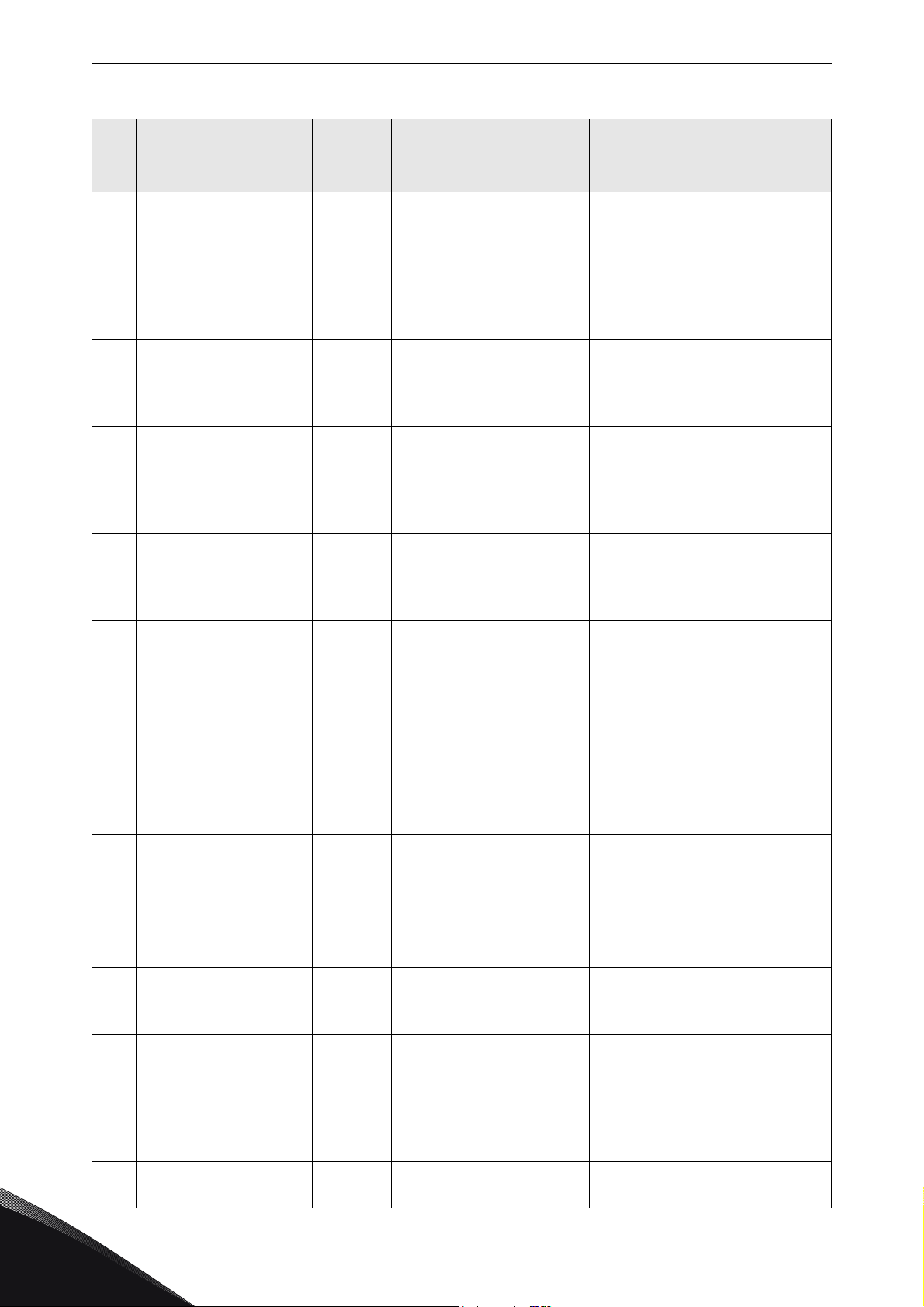

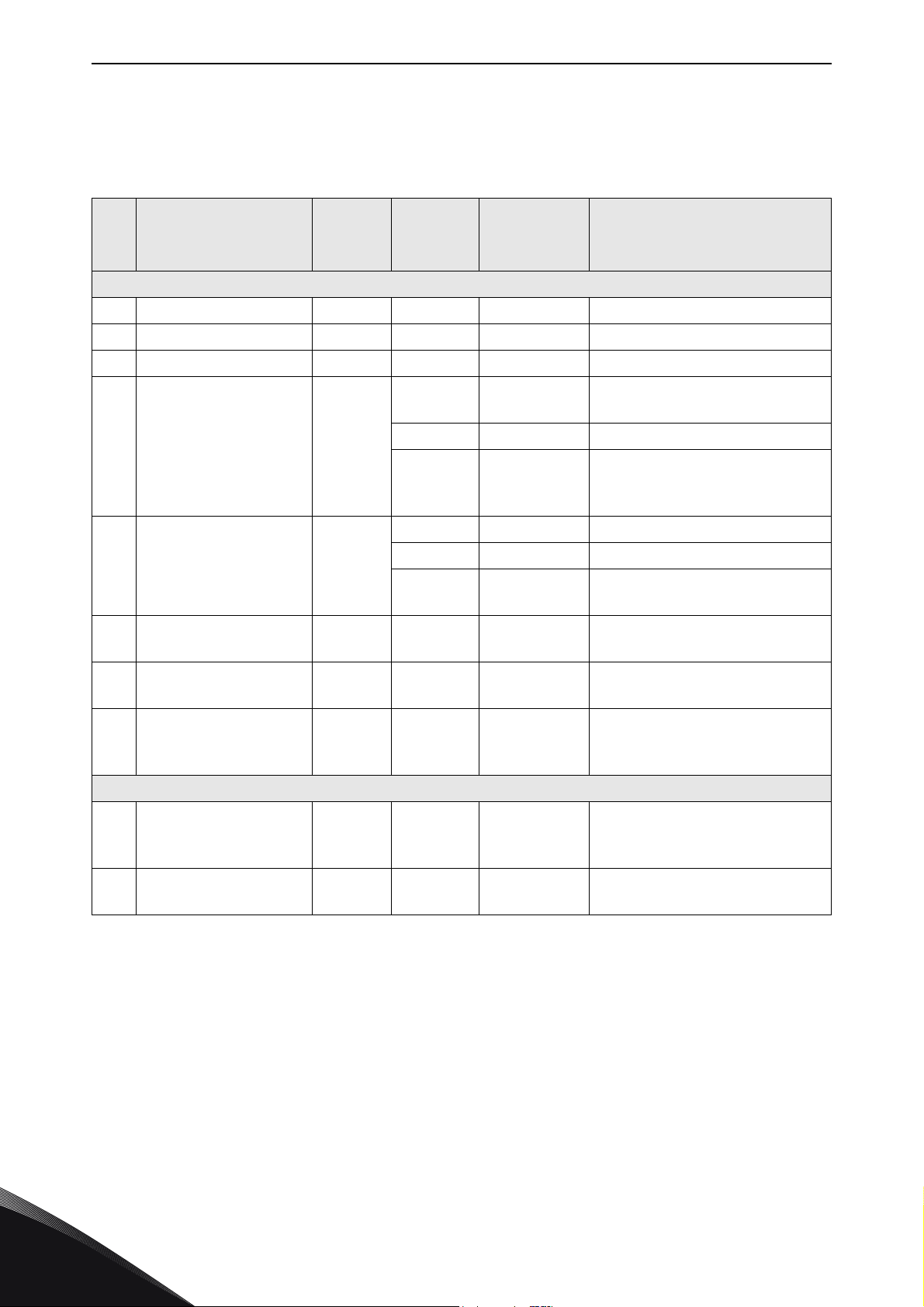

Table 10. Parameter view

Name Default Range Description

MAC ID 63 0...63

125 kbit/s

Baud rate 125 kbit/s

Output

assembly

Input

assembly

21

71

250 kbit/s

500 kbit/s

6.2 Monitor view

20

21

23

25

101

111

70

71

73

75

107

117

Slave address. Valid device addresses are in the

range of 0 to 63 decimal.

Communication speed

Output assembly used by the polled connection.

Setting of this value via panel is not allowed when

the I/O connection is established. If setting of this

value fails, the value is not updated.

Input assembly used by the polled connection. Setting of this value via panel is not allowed when the

I/O connection is established! If setting of this value

fails, the value is not updated.

Table 11. Monitor view

Name Range Description

DeviceNet Status Y.X

Table 12. DeviceNet status

DeviceNet Status Description

0 Non-existent

1 Configuring

3 Established

4 Timeout

Y = Message counter

X = DeviceNet status

6

Tel. +358 (0) 201 2121 • Fax +358 (0)201 212 205

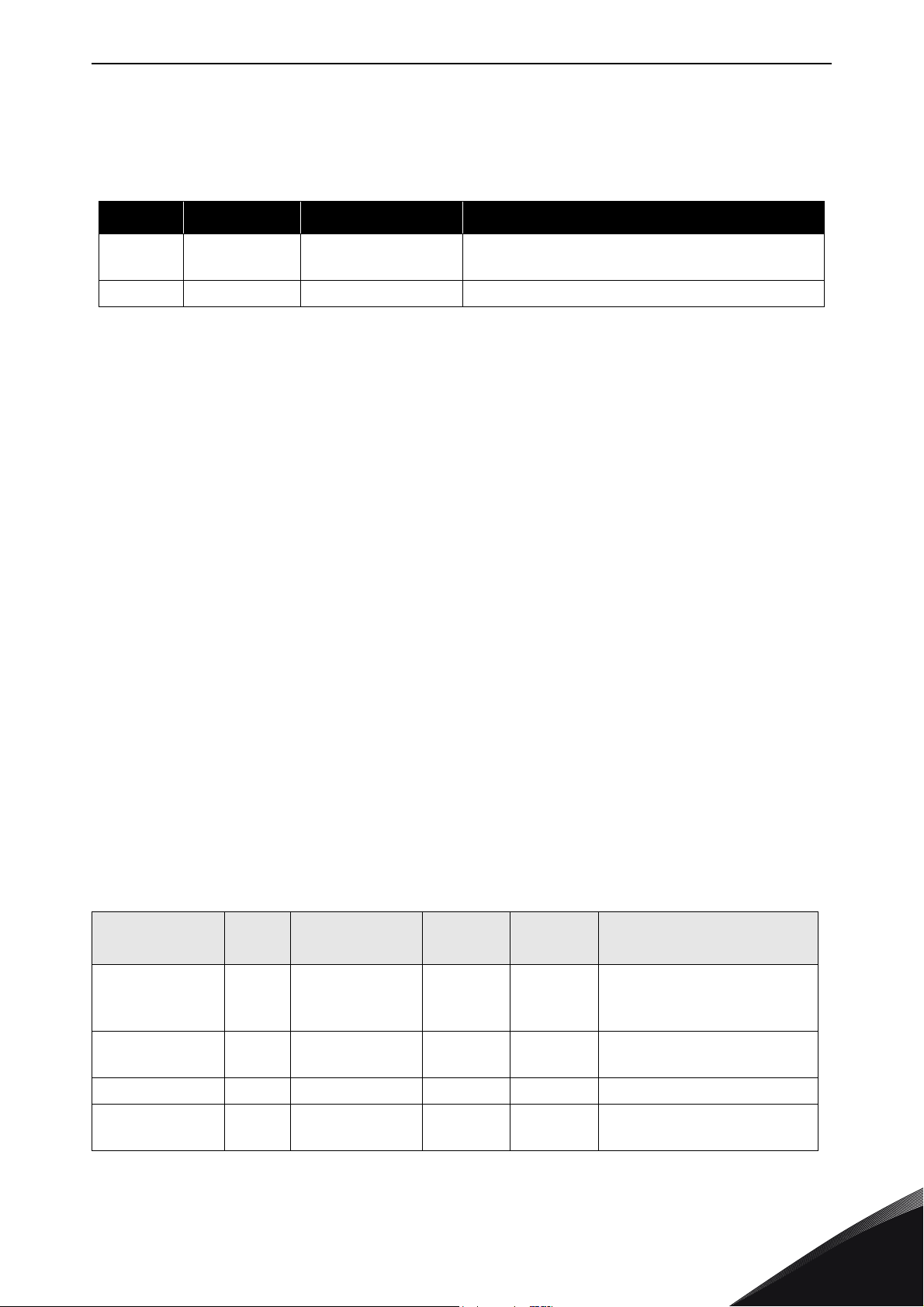

Page 39

Commissioning vacon • 36

6.3 Software info view

Table 13. Software info view

Number Name Range Description

1

2 Board status Shows the status of the option board

Version

number

Version number of the software in the option

board

6.4 Fieldbus parametrisation

The following chapter describes briefly, how to parametrise the AC drive in order for the motor to

be controllable via fieldbus. These instructions are written for some basic applications. For more

information, please consult the application-specific manual.

In order for the AC drive to accept commands from the fieldbus network, the control place of the AC

drive has to be set to fieldbus. The default value of the parameter “Control Place” is usually I/O. Note

that if the control unit firmware is updated, the default settings are restored. In addition, some

applications may have the remote speed reference selection set by default to other than fieldbus. In

these cases, the speed reference selection must be set to fieldbus, in order for the speed reference

to be controlled via fieldbus.

In DeviceNet, the bits NetCtrl, NetRef and NetProc must be set in order for the option board to send

commands / reference setpoint values to the AC drive. The bits Ctrl From Net and Ref From Net can

be read to determine the actual control / reference place. Note that these bits are valid only if

NetCtrl / NetRef bits are also set.

NOTE! The motor control mode should be selected to support the used process and profile.

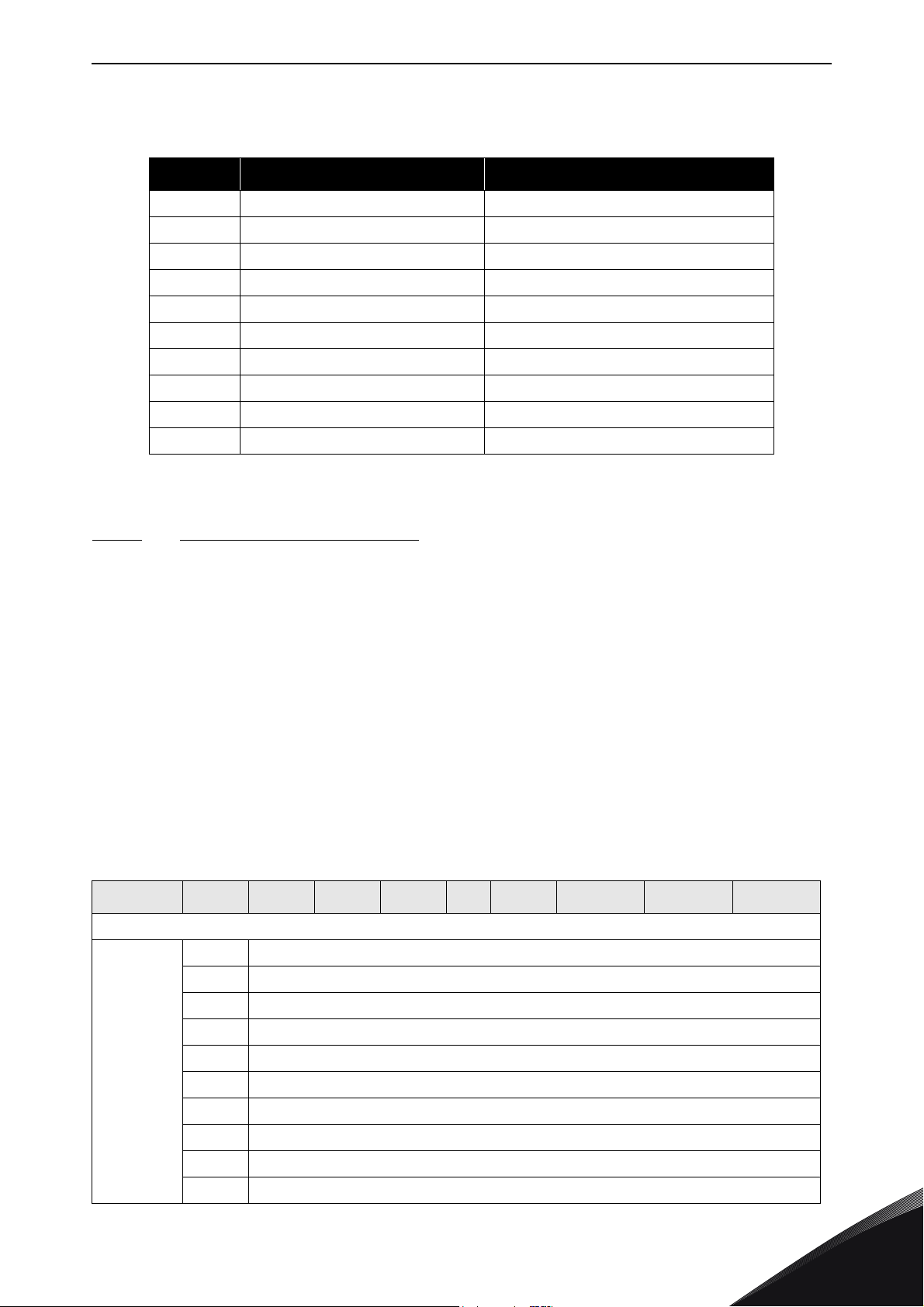

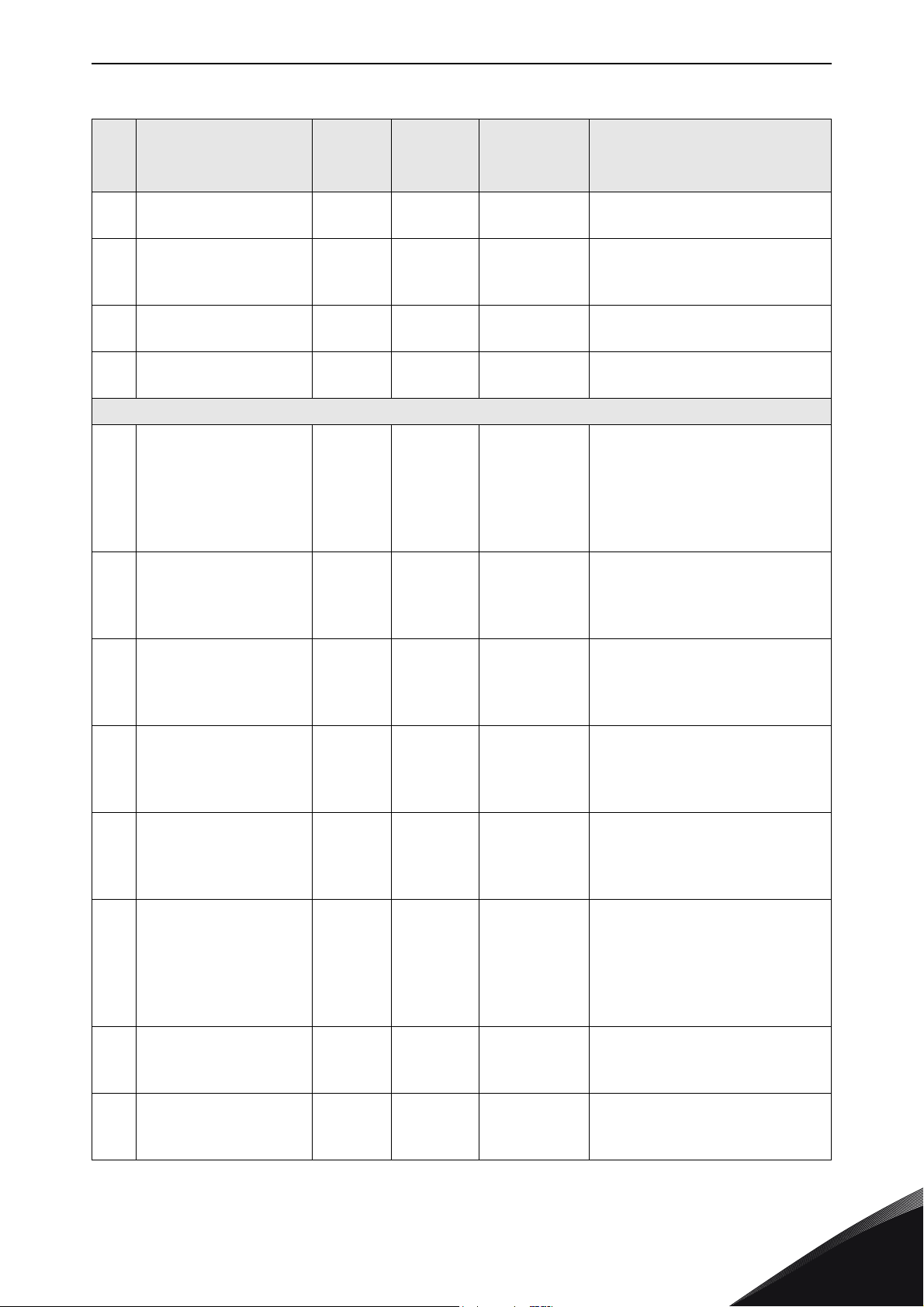

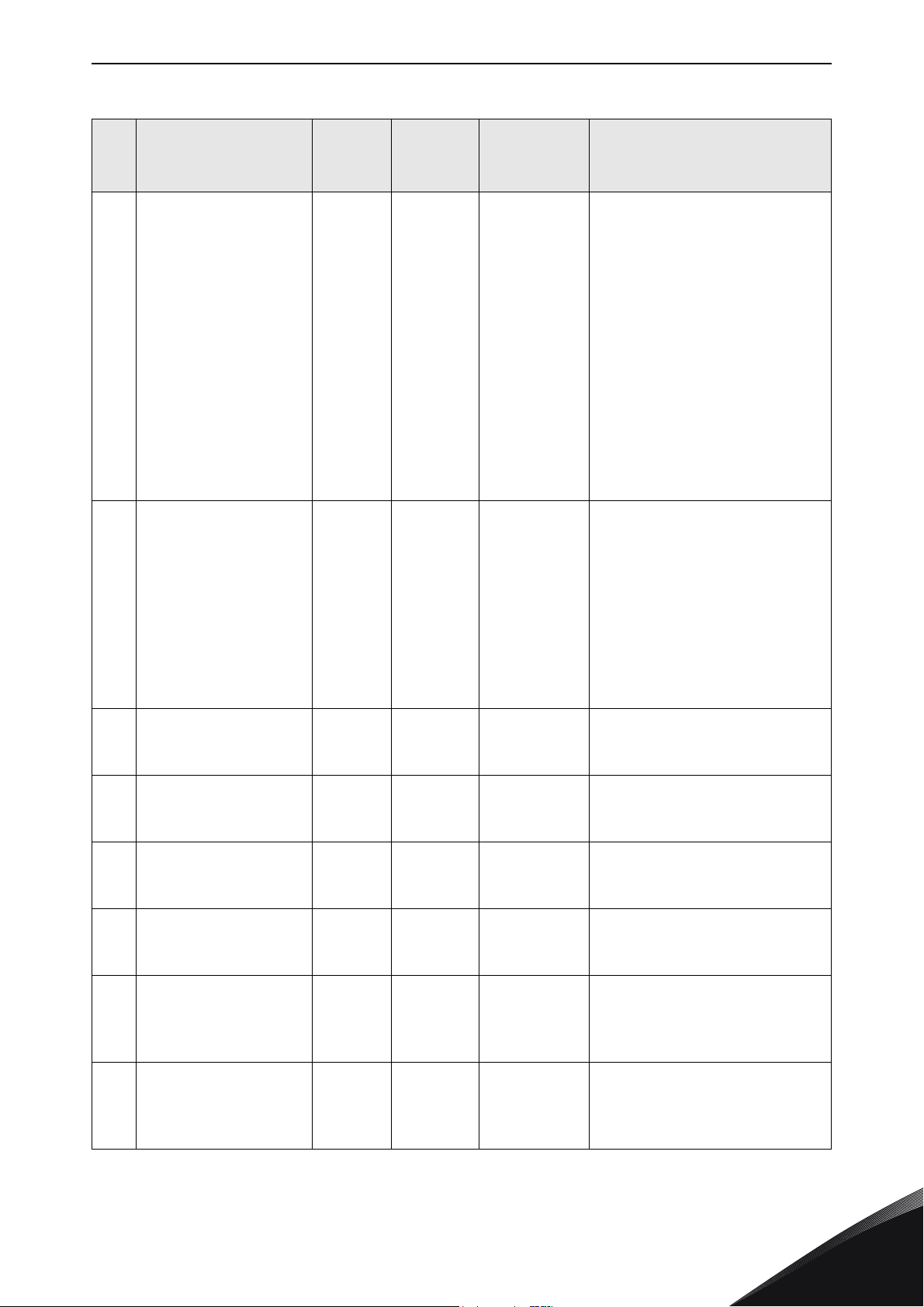

6.4.1 Fieldbus control and basic reference selection

The following tables list some of the parameters related to fieldbus control in case of three standard

applications, the Vacon

specific manuals for more detailed information.

Parameter

name

Control mode 600

Remote control

place

Local / remote 211 0 = Remote 0 P 3.2.2 0xA0, 0x01, 0xD3

Fieldbus ref.

sel.

® 100, Vacon® 20 and Vacon® 20X, for use via fieldbus. See the application-

Table 14. Parametrisation for Vacon

ID Value Default

0 = Frequency

1 = Speed

2 = Torque

172

122 3 = Fieldbus 3 P 3.3.1.10 0xA0, 0x01, 0x7A

1 = Fieldbus

CTRL

® 100 (standard application)

Panel

Tree

0 P 3.1.2.1 0xA0, 0x03, 0x58

0 P 3.2.1 0xA0, 0x01, 0xAC

Class, Instance, Attribute

24-hour support +358 (0)201 212 575 • Email: vacon@vacon.com

6

Page 40

vacon • 37 Commissioning

Table 15 . Para metris ation for Vacon

Parameter

name

Motor control

mode

Rem. control

place 1 sel.

Local / remote 211 0 = Remote 0 P 2.5 0xA0, 0x01, 0xD3

Rem. control

place 1 freq. ref.

sel.

Parameter

name

Motor control

mode

Control place

selection

Local / remote 211 0 = Remote 0 P 3.2.2 0xA0, 0x01, 0xD3

Frequency ref.

sel.

ID Value Default

600

172

117 3 = Fieldbus 7 P 3.3 0xA0, 0x01, 0x75

Table 16. Parametrisation for Vacon

600

125 2 = Fieldbus 0 P 1.11 0xA0, 0x01 0x7D

1819 5 = Fieldbus 5-7 P 1.12 0xA0, 0x08, 0x1B

0 = Frequency

1 = Speed

1 = Fieldbus

CTRL

ID Value Default

0 = Frequency

1 = Speed

® 20 (standard application)

Panel

Tree

0 P 1.8 0xA0, 0x03, 0x58

0 P 2.1 0xA0, 0x01, 0xAC

Class, Instance, Attribute

® 20X (standard application)

Panel

Tree

0 P 8.1 0xA0, 0x03, 0x58

Class, Instance, Attribute

6.4.2 Torque control parametrisation

Some extra parametrisation has to be made in order to control the frequency control with torque

control. The following instructions are for the Vacon 100 application, see the application-specific

manual for more detailed information.

• Motor control mode (ID 600) should be configured to “Torque control (Open Loop)” (2).

To configure the drive to use correct torque reference, parameter “Torque Reference Selection”

should be selected to ProcessDataIn1 (9). This can be done with:

• PC-tool or panel (P 3.3.2.1) / ID 641

• Vendor Parameter Object TorqueRefSel (Class 0xA0, Instance 0x03, Attribute 0x81)

6.4.3 Process data mapping and default settings

In DeviceNet, output instances 107 and 117 (Chapter 7.1.2.5 and 7.1.2.6), can be used to send

process data to network. This data is selectable in the application and the default settings vary

between drives. Refer to the application manual for details. The following tables show the default

values for Vacon 100, Vacon 20X and Vacon 20 applications.

6

Tel. +358 (0) 201 2121 • Fax +358 (0)201 212 205

Page 41

Commissioning vacon • 38

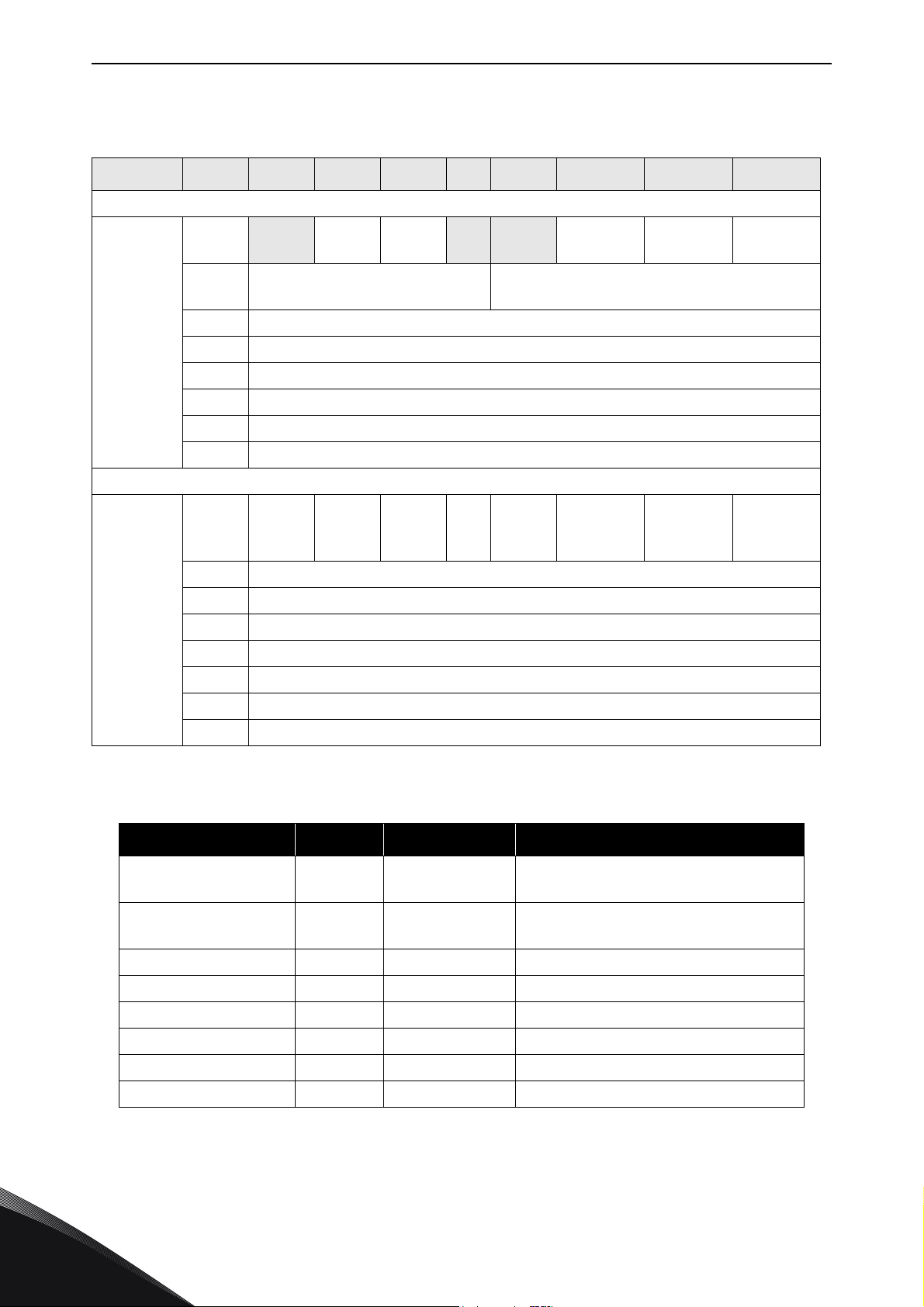

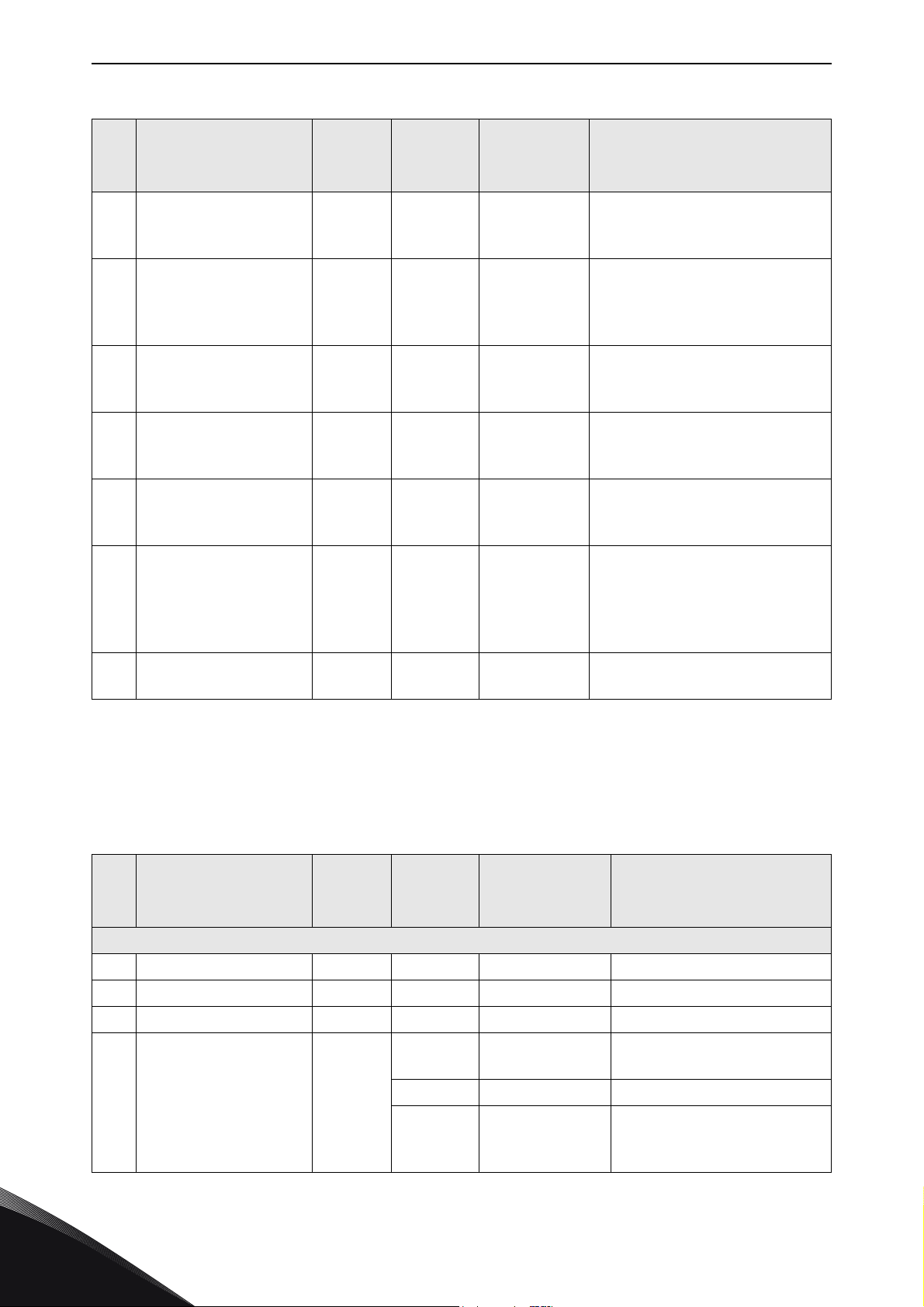

Table 17. Process data output mapping defaults for Vacon® 100 and Vacon® 20X (standard

applications)

PD Out AC Drive Mapped Application Data Unit Scale

1

2 Vacon 100 & Vacon 20X Motor Speed rpm 1 rpm

3 Vacon 100 & Vacon 20X Motor Current A Varies

4 Vacon 100 & Vacon 20X Motor Torque % 0.1%

5 Vacon 100 & Vacon 20X Motor Power % 0.1%

6 Vacon 100 & Vacon 20X Motor Voltage V 0.1 V

7 Vacon 100 & Vacon 20X DC Link Voltage V 1 V

8 Vacon 100 & Vacon 20X Last Active Fault Code - -

Table 18. Process data output mapping defaults for Vacon

PD Out AC Drive Mapped Application Data Unit Scale

1 Vacon 20 Frequency Reference Hz 0.01 Hz

2 Vacon 20 Output Reference Hz 0.01 Hz

3 Vacon 20 Motor Speed rpm 1 rpm

4 Vacon 20 Motor Voltage V 0.1 V

Vacon 100 Output Frequency Hz 0.01 Hz

Vacon 20X Output Current A Varies

® 20 (standard application)

5Vacon 20 Motor Torque%0.1%

6 Vacon 20 Motor Current A Varies

7 Vacon 20 Motor Power % 0.1%

8 Vacon 20 DC Link Voltage V 1 V

24-hour support +358 (0)201 212 575 • Email: vacon@vacon.com

6

Page 42

vacon • 39 DeciveNet interface

7. DECIVENET INTERFACE

Vacon supports two types of DeviceNet messaging. They are I/O Messaging and Explicit Messaging.

7.1 I/O messaging

I/O polling messages are for time-critical, control-oriented data. The messages are transferred

between the devices all the time and they are used for continuous control of the AC drive. They

provide a dedicated, special-purpose communication path between a producing application

(master) and one or more consuming applications (slaves). They are exchanged across single or

multi-cast connections, typically using high priority identifiers. I/O polling messages contain no

protocol in the 8-byte data field. The meaning of the message is implied by the connection ID (CAN

identifier). Before messages are sent using these IDs, both the device sending and receiving them

must be configured. The configuration contains the source and destination object attribute

addresses for the master and the slave.

Data (Output Assembly)

Master Slave

Data (Input Assembly)

Figure 10. DeviceNet I/O messaging

The contents of the data message are chosen by input and output assemblies. These assemblies

can be selected via panel or by setting Produced Connection Path (14) and Consumed Connection

Path (16) attributes in DeviceNet connection object. Note that setting of instances is not allowed via

panel, if I/O connection is open. See Chapter 10.2 for more details. Chapter 7.1.2 describes all

supported input and output assemblies.

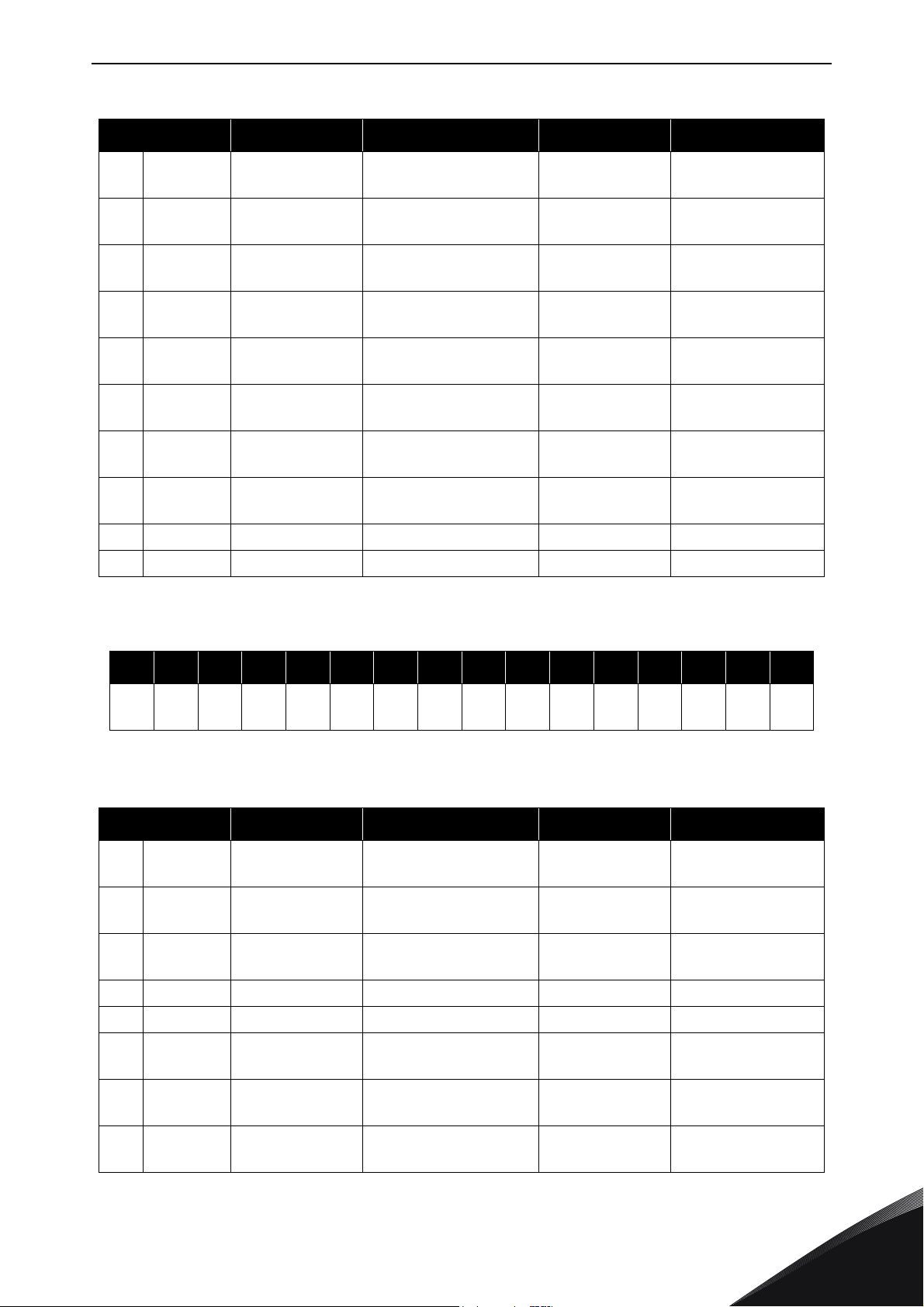

7.1.1 Connection behaviour

The following figure provides a general overview of the behaviour associated with an I/O connection

object (instance type attribute = I/O).

7080_UK

7

Tel. +358 (0) 201 2121 • Fax +358 (0)201 212 205

Page 43

DeciveNet interface vacon • 40

7081_UK

Non-existent

Delete from any state

Get_Attribute/

Set_Attribute/

Apply_Attributes

Get_Attribute/Set_Attribute/

Apply_Attributes/Reset/

Message Produced/Consumed

Inactivity/Watchdog

Timeout &

Watchdog_timeout_action=

Transition to Timed Out

Configuring

Create

Apply_Attributes

Delete

Reset

Established

Timed Out

Figure 11. I/O Connection Object State Transition Diagram

By default, Expected Packet Rate (EPR) of I/O connection is set to zero, meaning that no transition

to Timed Out state will occur. If EPR Timeout is set to other than zero, timeout will occur after four

times Expected Packet Rate (4 * EPR). For example value 1000 (ms) will result in timeout after four

seconds.

7.1.2 Input and Output Assemblies

The following chapters describe the used input/output assemblies.

Table 19. Supported Input / Output Assemblies

Name Profile Number Type

20 Output

Basic Speed Control CIP

70 Input

21 Output

Extended Speed Control (default) CIP

71 Input

23 Output

Extended Speed and Torque Control CIP

73 Input

25 Output

Process Control CIP

75 Input

101 Output

Dynamic Process Control Vacon

107 Input

Bypass Control Output Vacon

111 Output

117 Input

24-hour support +358 (0)201 212 575 • Email: vacon@vacon.com

7

Page 44

vacon • 41 DeciveNet interface

7.1.2.1 20/70 Basic Speed Control

Basic speed control is the most basic control type, where the run direction is limited to only forward,

and only Run and Fault reset commands are supported. Speed reference is given in revolutions per

minute. The run/stop commands work as described in Table 39, with Run Rev always interpreted as

zero. In this mode, the control supervisor attributes NetCtrl and NetRef bits are always set to one.

Table 20. Basic Speed Control Instance descriptions

Instance Byte Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0

Basic Speed Control Output

0

Fault Reset Run Fwd

20

70

7.1.2.2

1

2 Speed Reference (Low Byte)

3 Speed Reference (High Byte)

Basic Speed Control Input

0

1

2 Speed Actual (Low Byte)

3 Speed Actual (High Byte)

Table 21. Basic Speed Control Attribute descriptions

Attribute Unit Range Note

Speed Reference rpm 0-32767

Speed Actual rpm 0-32767

21/71 Extended Speed Control (default)

Running1 Faulted

7

Extended speed control provides more functionality over the basic speed control. NetRef and

NetCtrl bits must be set to one, in order for the commands and reference values to be sent to the

AC drive. When these bits are set, the actual control/reference place can be read from "Ctrl From

Net" and "Ref From Net" bits. Run Forward and Run Reverse bits are used to control the direction

of the motor. See Table 39 for complete description of the run commands.

Tel. +358 (0) 201 2121 • Fax +358 (0)201 212 205

Page 45

DeciveNet interface vacon • 42

Table 22. Basic Speed Control Instance descriptions

Instance Byte Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0

Extended Speed Control Output

21

0

1

2 Speed Reference (Low Byte)

3 Speed Reference (High Byte)

NetRef NetCtrl

Extended Speed Control Input

Fault

Reset

Run Rev Run Fwd

At Ref-

0

erence

71

Speed Reference rpm 0-32767

Speed Actual rpm 0-32767

7.1.2.3 23/73 Extended Speed and Torque Control

Extended speed and torque assemblies can be used when torque reference is needed.

Torque Reference is converted from

instance 2, attribute 24), to a %-value for the AC drive. This value is sent in ProcessDataIn1 for the

control unit when NetRef bit is set. Therefore, ProcessDataIn1 should be selected as torque

reference selection. See the application manual or Chapter 6.4.2 for more details.

1Drive State

2 Speed Actual (Low Byte)

3 Speed Actual (High Byte)

Table 23. Extended Speed Control Attribute descriptions

Attribute Unit Range Note

Drive State - 0-7 See Chapter 7.1.3

Ref

from

Net

Ctrl

from

Net

τ (Nm)/2n

, where n is the torque scale value (AC/DC Drive object,

Rea

dy

Runnin

g2

(Rev)

Running1 Warning Faulted

Table 24. Extended Speed and Torque Control Instance descriptions

Instance Byte Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0

Extended Speed and Torque Control Output

0

1

23

24-hour support +358 (0)201 212 575 • Email: vacon@vacon.com

2 Speed Reference (Low Byte)

3 Speed Reference (High Byte)

4 Torque Reference (Low Byte)

5 Torque Reference (High Byte)

NetRef NetCtrl

Fault

Reset

Run Rev Run Fwd

7

Page 46

vacon • 43 DeciveNet interface

Table 24. Extended Speed and Torque Control Instance descriptions

Instance Byte Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0

Extended Speed and Torque Control Input

At Ref-

0

erence

1Drive State

73

Speed Reference rpm 0-32767

Speed Actual rpm 0-32767

Torque Reference

Torq ue Act ual

2 Speed Actual (Low Byte)

3 Speed Actual (High Byte)

4 Torque Actual (Low Byte)

5 Torque Actual (High Byte)

Table 25. Extended Speed and Torque Control Attribute descriptions

Attribute Unit Range Note

Drive State - 0-7 See Chapter 7.1.3

from

Net

Nm/2

Nm/2

Ref

Torque Scale

Torque Scale

Ctrl

from

Net

-32768...32767

-32768...32767

Rea

dy

Runnin

g2

(Rev)

Running1 Warning Faulted

7.1.2.4 25/75 Extended Process Control

Extended process control assemblies can be used to send process reference value directly to the

application. The Process Reference value destination can be selected with Drive Mode byte

according to Table 28. This should be configured in application as the receiving input. Process Actual

value is always mapped to ProcessDataOut1. Note that process reference value is sent to drive only

when NetProc bit is set.

Table 26. Extended Process Control Instance descriptions

Instance Byte Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0

Extended Process Control Output

25

0

1Drive Mode

2 Speed Reference (Low Byte)

3 Speed Reference (High Byte)

NetProc

NetRef NetCtrl

Fault

Reset

Run Rev Run Fwd

7

4 Process Reference (Low Byte)

5 Process Reference (High Byte)

Tel. +358 (0) 201 2121 • Fax +358 (0)201 212 205

Page 47

DeciveNet interface vacon • 44

Table 26. Extended Process Control Instance descriptions

Instance Byte Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0

Extended Process Control Input

At Ref-

0

erence

1Drive State

75

Speed Reference rpm 0-32767

Speed Actual rpm 0-32767

Process Reference - - See Table 28

Process Actual - - ProcessDataOut1

2 Speed Actual (Low Byte)

3 Speed Actual (High Byte)

4Process Actual (Low Byte)

5Process Actual (High Byte)

Table 27. Extended Process Control Attribute descriptions

Attribute Unit Range Note

Drive Mode - - See Table 28

Drive State - 0-7 See Chapter 7.1.3

Ref

from

Net

Ctrl

from

Net

Rea

dy

Runnin

g2

(Rev)

Running1 Warning Faulted

Table 28. Drive Mode selection in Process Control

Drive

Mode

0ProcessDataIn1

4ProcessDataIn2

Other Not valid

7.1.2.5 101/107 Vendor Dynamic Process Control

These assemblies can be used to send/receive process data directly to and from the application. The

FB Speed Reference and the FB Speed Actual values are given as percentage of the minimum and

maximum frequency. The control and status words are still given as CIP standard specific values.

Process Reference Mapping

24-hour support +358 (0)201 212 575 • Email: vacon@vacon.com

7

Page 48

vacon • 45 DeciveNet interface

Table 29. Vendor Dynamic Process Control Instance descriptions

Instance Byte Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0

Dynamic Process Control Output

101

0

1

2 FB Speed Reference (Low Byte)

3 FB Speed Reference (High Byte)

4 ProcessDataIn1 (Low Byte)

5 ProcessDataIn1 (High Byte)

6 ProcessDataIn2 (Low Byte)

7 ProcessDataIn2 (High Byte)

Process Data 1 Selector (bits

NetRef NetCtrl

4-7)

Dynamic Process Control Input

Process Data 2 Selector (bits 0-3)

Fault

Reset

Run Rev Run Fwd

At Ref-

0

erence

1Drive State

2 FB Speed Actual (Low Byte)

107

FB Speed Reference %

FB Speed Actual %

ProcessDataIn1 - -

3 FB Speed Actual (High Byte)

4ProcessDataOut1 (Low Byte)

5 ProcessDataOut1 (High Byte)

6ProcessDataOut2 (Low Byte)

7 ProcessDataOut2 (High Byte)

Table 30. Vendor Dynamic Process Control Attribute descriptions

Attribute Unit Range Note

Ref

from

Net

Ctrl

from

Net

0-10000

(100.00%)

0-10000

(100.00%)

Rea

dy

Runnin

g2

(Rev)

Running1 Warning Faulted

7

ProcessDataIn2 - ProcessDataOut1 - - See Table 31

ProcessDataOut2 - - See Table 31

Process Data Selector - - See Table 31

Drive State - 0-7 See Chapter 7.1.3

Process data selector bits can be used to select what content is mapped to ProcessDataOut 1 & 2

(bytes 4-7). The following table describes what values in these fields correspond to which process

data items.

Tel. +358 (0) 201 2121 • Fax +358 (0)201 212 205

Page 49

DeciveNet interface vacon • 46

Table 31. Process Data Selector 1 & 2 description

Value Bytes 4-5 of instance 107 Bytes 6-7 of instance 107

0 * Speed Actual [%] Speed Actual [%]

1ProcessDataOut1 ProcessDataOut1

2ProcessDataOut2 ProcessDataOut2

3ProcessDataOut3 ProcessDataOut3

4ProcessDataOut4 ProcessDataOut4

5ProcessDataOut5 ProcessDataOut5

6ProcessDataOut6 ProcessDataOut6

7ProcessDataOut7 ProcessDataOut7

8ProcessDataOut8 ProcessDataOut8

Other ProcessDataOut1 ProcessDataOut2

* If both Process Data selectors are 0, bytes 4-5 are ProcessDataOut1 and bytes 6-7 are

ProcessDataOut2.

7.1.2.6

These assemblies can be used to bypass the CIP standard assemblies, and control the AC drive

application directly. The FB Speed Reference and the FB Speed Actual values are given as

percentage of the minimum and maximum frequency. The control and status words are applicationspecific values. Table 34 and Table 35 describe the control word, and Table 36 and Table 37 describe

the fieldbus status words that are commonly used. Note that not all applications support all bits,

and so application-specific manuals should be consulted.

Instance Byte Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0

111/117 Vendor Bypass Control

Table 32. Vendor Bypass Control Instance descriptions

Bypass Control Output

0-1 Control Word

2-3 FB Speed Reference

4-5 ProcessDataIn1

6-7 ProcessDataIn2

111

8-9 ProcessDataIn3

10-11 ProcessDataIn4

12-13 ProcessDataIn5

14-15 ProcessDataIn6

16-17 ProcessDataIn7

18-19 ProcessDataIn8

24-hour support +358 (0)201 212 575 • Email: vacon@vacon.com

7

Page 50

vacon • 47 DeciveNet interface

Table 32. Vendor Bypass Control Instance descriptions

Instance Byte Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0

Bypass Control Input

0-1 Status Word

2-3 FB Speed Actual [%]

4-5 FB Speed Actual [rpm]

6-7 Speed Actual With Slip

8-17 Reserved

18-19 ProcessDataOut1

117

FB Speed Reference %

FB Speed Actual %

FB Speed Actual rpm -32768…32767

Speed Actual With Slip rpm 0-32767 Slip compensated RPM value.

20-21 ProcessDataOut2

22-23 ProcessDataOut3

24-25 ProcessDataOut4

26-27 ProcessDataOut5

28-29 ProcessDataOut6

30-31 ProcessDataOut7

32-33 ProcessDataOut8

Table 33. Vendor Bypass Control Attribute descriptions

Attribute Unit Range Note

0-10000

(100.00%)

0-10000

(100.00%)

Ramp output frequency converted to

rpm.

7

Table 34. Fieldbus Control Word

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

---

Bit Name Description 0 1

12 ESTP Emergency Stop

11 JOG2 Jogging Request

10 JOG1 Jogging Request

ESTPJOG2JOG1BREFBCTRLZREFFRMPQRMPSTPM2STPM1FRS

T

Table 35. Fieldbus Control Word description

Request as fast stop

as possible

Select jogging with

reference 2

Select jogging with

reference 1

Tel. +358 (0) 201 2121 • Fax +358 (0)201 212 205

- Emergency Stop

- Select ref2 jogging

- Select ref1 jogging

DIR

STR

T

Page 51

DeciveNet interface vacon • 48

Table 35. Fieldbus Control Word description

Bit Name Description 0 1

9 BREF Bus Reference

8BCTRL Bus Control

7 ZREF Zero Ref

6 FRMP Ramp Freeze

5QRMP

4 STPM2 Stop Mode2 Stop mode ramping -

3 STPM1 Stop Mode1 Stop mode coasting -

2FRST Fault Reset

1 DIR Direction Rotation direction Clockwise Counterclockwise

0 STRT Start / Stop Start / Stop request Stop Run

Quick Ramp

Time

Force reference to

fieldbus

Force fieldbus control

active

Force reference to

zero

Freeze ramp

generator

Use quick ramp time

Request fault reset

from drive

Selected

reference place

Selected control

place

-

-

Normal ramp

time

-

Force fieldbus

reference

Force fieldbus

control

Force reference to

zero

Freeze ramp

generator

Quick Ramp Time

Stop By Ramp

Mode

Coasting Stop

Mode

Request reset from

drive

Table 36. Fieldbus Status Word

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

--------

Table 37. Fieldbus Status Word description

Bit Name Description 0 1

7 FRDY Flux Ready

6 ZSPD Zero Speed

5ATREFAt Reference

4 ALARM Alarm Alarm indication - Drive is in alarm

3 FLT Faulted Drive fault indication - Drive is faulted

2DIR Direction

1RUN Run

0RDY Ready

Motor magnetisation

Motor is running at

zero speed

Reference frequency

is reached

Motor running

direction

Motor running

information

Drive readiness

information

FRDYZSPDATREFALA

is ready

FLT DIR RUN RDY

RM

-Flux Ready

-

- Reference reached

Clockwise Counterclockwise

Stopped Running

-Ready

Zero speed

condition

24-hour support +358 (0)201 212 575 • Email: vacon@vacon.com

7

Page 52

vacon • 49 DeciveNet interface

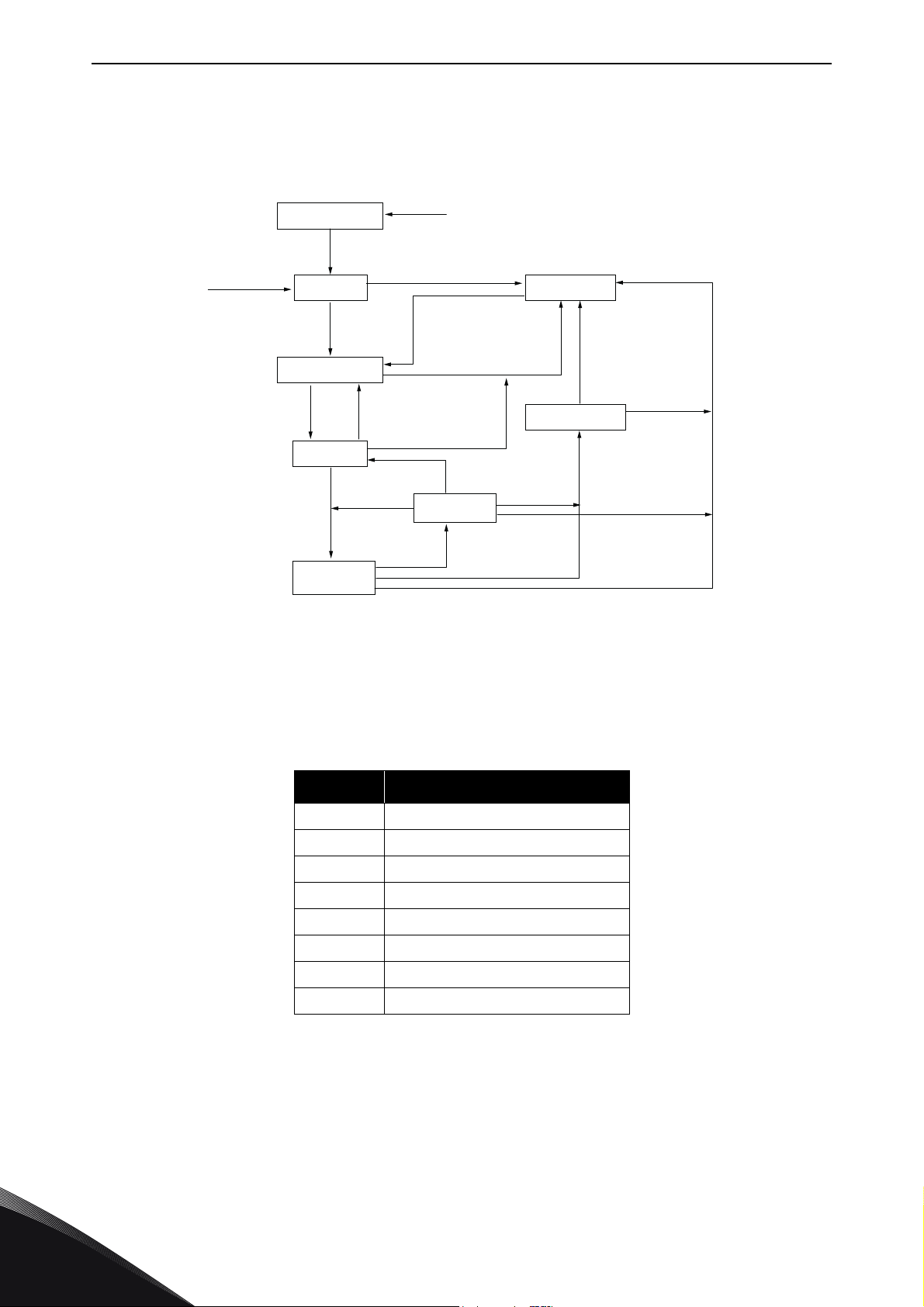

7.1.3 Control Supervisor Behaviour

The State Transition Diagram provides a graphical description of the states and the corresponding

state transitions for the control supervisor.

Non-existent

Switch On

Reset

Initialisation Complete

Main Power On

Startup

Not_Ready

Run

Enabled

Figure 12. Control Supervisor State Transition Diagram

Ready

Switch Off

Fault Detected

Fault Reset

Fault Detected

Main Power Off

Stopping

Stop

Complete

Stop

Faulted

Main Power Off

Fault_Stop

Complete

Fault_Stop

Fault

Detected

7082_UK

The current state of the Control Supervisor State can be read from Control Supervisor Object (Class

0x29), Instance 1, Attribute 6. The values correspond to the states according to the following table.

Table 38. Control Supervisor State

Value State

0 Non-existent

1Startup

2 Not_Ready

3Ready

4Enabled

5 Stopping

6Fault_Stop

7Faulted

The "Main Power On" and "Main Power Off" refer to the motor control status (READY / NOT READY).

Stop command will result in stop by "Stop Function". The stop mode is selectable in application.

7

Tel. +358 (0) 201 2121 • Fax +358 (0)201 212 205

Page 53

DeciveNet interface vacon • 50

Run1 and Run2 bits trigger Stop and Run commands according to Table 39. Fault Reset will occur

on a rising edge of the Reset command.

Table 39. Run/Stop Event Matrix

Run1 Run2 Trigger Event Run Type

0 0 Stop N/A

0 -> 1 0 Run Run1

00 -> 1RunRun2

0 -> 1 0 -> 1 No Action N/A

1 1 No Action N/A

1 -> 0 1 Run Run2

11 -> 0RunRun1

24-hour support +358 (0)201 212 575 • Email: vacon@vacon.com

7

Page 54

vacon • 51 DeciveNet interface

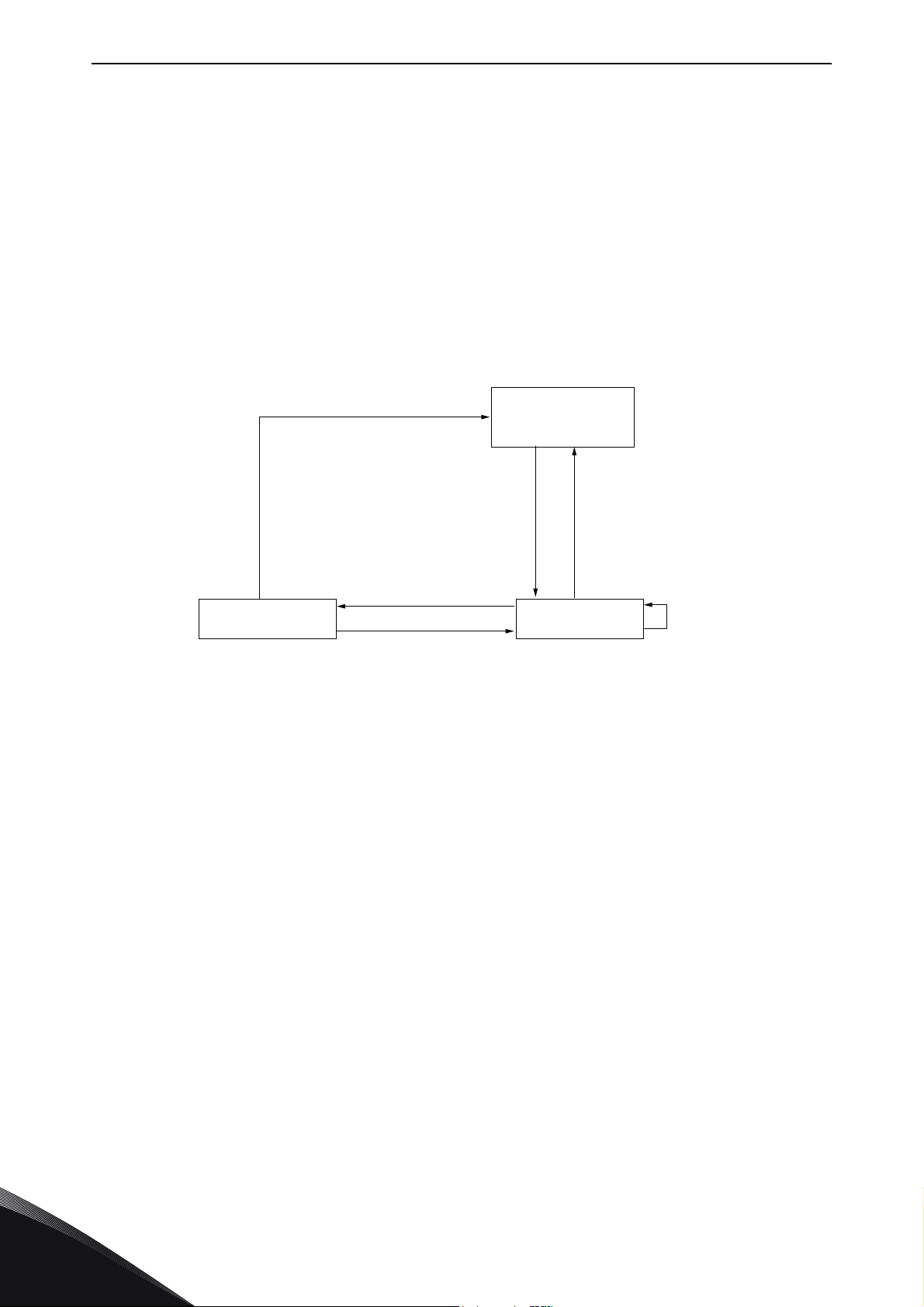

7.2 Explicit messaging

Explicit Messaging is used in commissioning and parametrising of the DeviceNet option board.

Explicit messages provide multipurpose, point-to-point communication paths between two devices.

They provide the typical request/response-oriented network communication used to perform node

configuration and problem diagnosis. Explicit messages typically use low priority identifiers and

contain the specific meaning of the message right in the data field. This includes the service to be

performed and the specific object attribute address.

7.2.1 Connection behaviour

Here you can see a general overview of the behaviour associated with an Explicit Messaging

Connection Object (Instance type attribute = Explicit Messaging).

Delete

Child instance

Deleted or

Transitions to Timed

Out and no other

child instances are in

the Established

state

Open Explicit Messaging

Connection Response

Transmitted by a server end-point

Open Explicit Messaging Connection Response

Received by a client end-point

Inactivity/Watchdog Timeout &

Watchdog_timeout_action=

Deferred Delete and at least one child

instance is in the Established state.

Non-existent

Delete

Inactivity/Watchdog Timeout &

Watchdog_timeout_action=

Auto Delete or this attribute is

set to Deferred Delete and no

child instances are in the

Established state.

Get_Attribute/

Deferred Delete Established

Receive Data/Reset

Set_Attribute/

Reset

7083_UK

Figure 13. Explicit Messaging Connection Object State Transition Diagram

Explicit Connection Expected Packet Rate (EPR) is set by default to 2500, meaning that watchdog

timeout action will occur after 10s.

7

Tel. +358 (0) 201 2121 • Fax +358 (0)201 212 205

Page 55

Fault handling vacon • 52

8. FAULT HANDLING

The following chapter describes different fault activation situations in OPTE7.

Table 40. Fault Activation Sources

Name Description N LED

BUS-OFF CAN driver in in bus-off state Red

DUP_MAC-ID Duplicate MAC ID is found during startup/ MAC ID change Red

PASSIVE CAN driver is in passive state -

EXT_PWR External +24V is not detected Off

PIO_TO

• Bus-off and passive states are cleared when CAN driver goes to active state.

• External power fault is cleared when +24V is connected to option board connector.

• Duplicate MAC check is made every time the MAC-ID is changed or the option board is

powered up. The fault is cleared, when the duplicate MAC-ID check passes.

• Polled I/O connection timeout is cleared when the I/O connection is released or allocated

Polled I/O connection Expected Packet Rate watchdog

timeout

Flashing red

How the AC drive will react to these fault situations can be defined in application:

Table 41. Fieldbus Fault Reaction in Vacon

Code Parameter Min Max Default ID Description

Vacon 100 Vacon 20

P3.9.1.6 P13.19

Table 42. Fieldbus Fault Reaction in Vacon

Code Parameter Min Max Default ID Description

P9.15

Response to fieldbus

Response to fieldbus

fault

fault

0 2 2 733

® 100 and Vacon® 20 (standard application)

0 4 3 733

® 20X (standard application)

0 = No action

1 = Warning

2 = Fault

0 = No response

1 = Alarm

2 = Fault, stop

by stop function

3 = Fault, stop

by coasting

24-hour support +358 (0)201 212 575 • Email: vacon@vacon.com

8

Page 56

vacon • 53 Fault handling

8.1 General and additional error codes

Table 43. General Error Codes

Code General Error Description

0x00 Success

0x02 Resource Unavailable

0x08 Service Not Supported

0x09 Invalid Attribute Value Invalid attribute data detected.

0x0B Already In Requested State Requested release connection does not exist.

0x0C Object State Conflict

0x0E Attribute Not Settable

0x10 Device State Conflict

0x13 Not Enough Data Explicit request was too short.

0x14 Attribute Not Supported

0x15 Too Much Data The service supplied more data than was expected.

0x16 Object Does Not Exist The object specified does not exist in the device.

Service was successfully performed by the object

specified.

Resources needed for the object to perform the

requested service were unavailable.

The requested service was not implemented or was

not defined.

The object cannot perform the requested service in

its current mode/state.

Already allocated to another master.

A request to modify a non-modifiable attribute was

received.

The current mode/state of the device prohibits the

execution of the requested service.

The attribute specified in the request is not supported.

0x20 Invalid Parameter

0x28 Invalid Member ID

Table 44. Additional Error Codes

Code Description

0x01 Predefined Master/Slave Connection Set allocation conflict

0x02 Invalid Allocation/Release Choice parameter

0x03

0x04

Message received on Group 2 Only Unconnected Explicit Request

message port that was not an Allocate or Release message

Resource required for use with the Predefined Master/Slave Connection Set is not available

Message received on Group 2 unconnected

requested port was not an allocate or release message.

A parameter associated with the request was

invalid.

The Member ID specified in the request does not

exist.

8

Tel. +358 (0) 201 2121 • Fax +358 (0)201 212 205

Page 57

Appendix A: Object dictionary vacon • 54

9. APPENDIX A: OBJECT DICTIONARY

9.1 Implemented CIP objects

9.1.1 List of Object Classes

The Communication Interface supports the following object classes.

Table 45. Implemented Object Classes

Class Object

0x01 Identity

0x02 Message Router

Required by DeviceNet

Required by Drive

Profile

0x03 DeviceNet

0x04 Assembly

0x05 DeviceNet Connection

0x28 Motor Data

0x29 Control Supervisor

0x2A AC/DC Drive

Vendor-Specific 0xA0 Vendor Parameter

24-hour support +358 (0)201 212 575 • Email: vacon@vacon.com

9

Page 58

vacon • 55 Appendix A: Object dictionary

Vendor

Parameter

Drive

AC/DC

Control

Supervisor

Data

Class Inst. Class Inst. Class Inst. Class Inst.

ed)

Inst.

(Poll

Connection Motor

Message

cit)

Inst.

(Expli

Y

Y

DeviceNet Assembly

Router

Class Inst Class Inst Class Inst Class Inst. Class

9

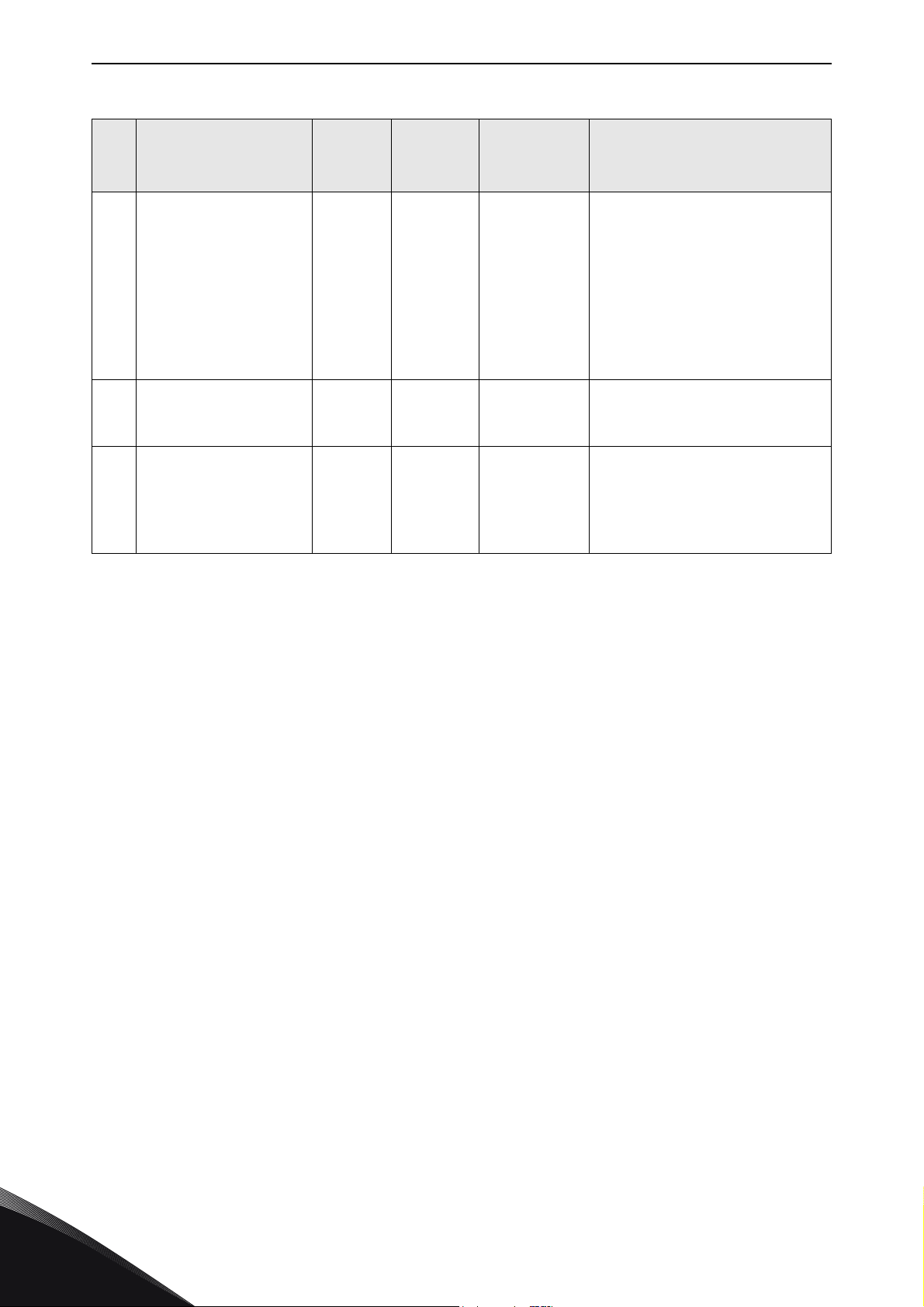

9.1.2 List of Services

The following table shows the services supported by these object classes.

Service Name Identity

Service

Code (in

hex)

0x4B

Slave_Connection_Set

Release_Master/

Slave_Connection_Set

* ) Supports reset type 0 and 1

0x4C

Tel. +358 (0) 201 2121 • Fax +358 (0)201 212 205

Allocate_Master/

0x05 Reset Y* Y Y

0x09 Delete Y Y

0x10 Set_Attribute_Single Y Y Y Y Y Y Y Y Y Y

0x0E Get_Attribute_Single Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y

Page 59

Appendix A: Object dictionary vacon • 56

9.1.3 Class Code 0x01 - Identity Object

Table 46.

Default

# Attribute Name Services

1 Revision Get 1 UINT Revision of this object

2 Max Instance Get 1 UINT Maximum instance number

3 Number of Instances Get 1 UINT Number of object instances

4 Optional Attribute List Get

5 Optional Service List Get

Minimum

Maximum

Instance 0

8 UINT Number of attributes

{1, 2, 3, 4,

5, 6, 7,

176}

2 UINT Number of services

{5, 14} ARRAY of UINT

Data Type Description

STRUCT of:

ARRAY of UINT

STRUCT of: List of optional services

List of optional instance

attributes

List of optional attribute

numbers

List of optional service

codes

Max Class Attribute

6

7

176 Object Name Get “Identity” SHORT_STRING

1 Vendor ID Get 443 UINT

2 Device Type Get 2 UINT

3 Product Code Get 2 UINT

4 Revision Get N/A

ID

Max Instance

Attribute ID

Get 176 UINT

Get 10 UINT

Instance 1

STRUCT of:

USINT Major revision

USINT Minor revision

The attribute ID number of

the last class attribute

The attribute ID number of

the last instance attribute

ASCII Name for the Object

Class

Identification of each vendor by number.

443 = Vacon Plc

Indication of the general

type of product.

2 = AC Drive

Identification of a particular product of an individual

vendor.

2 = OPTE7

Revision of the item the

Identity Object represents

24-hour support +358 (0)201 212 575 • Email: vacon@vacon.com

9

Page 60

vacon • 57 Appendix A: Object dictionary

Table 46.

Default

# Attribute Name Services

5Status Get

6 Serial Number Get N/A UDINT

7 Product Name Get “OPTE7” SHORT_STRING

8 State Get

Minimum

Maximum

N/A

0

65535

N/A

0

5

Data Type Description

Summary status of the

device. Defined in ODVA

DeviceNet specification.

Supported bits:

Bit 0 = Owned

Bit 7 = System fault

WORD

USINT

Bit 8 = Minor Recoverable

Fault

Bit 9 = Minor Unrecoverable

Fault

Bit 10 = Major Recoverable

Fault

Bit 11 = Major Unrecoverable Fault

Serial number of the device.

YYMMDDxxxx, where

YY = year of manufacture

MM = month of manufacture

DD = day of manufacture

xxxx = running number

Human readable identification

Present state of the device

as represented by the state

transition diagram.

0 = Nonexistent

1 = Device Self-Testing

2 = Standby

3 = Operational

4 = Major Recoverable Fault

5 = Major Unrecoverable

Fault

9

9

10 Heartbeat Interval

Configuration

Consistency Value

Get

Get

Set

N/A

0

65535

0

0

255

UINT

USINT

Tel. +358 (0) 201 2121 • Fax +358 (0)201 212 205

Contents identify configuration of the device

Heartbeat message send

interval in seconds. By

default disabled. Zero disables the transmission.

Page 61

Appendix A: Object dictionary vacon • 58

9.1.4 Class Code 0x02 - Message Router Object

Table 47.

Default

# Attribute Name Services

1 Revision Get 1 UINT Revision of this object

2 Max Instance Get 1 UINT Maximum instance number

3 Number of Instances Get 1 UINT Number of object instances

4 Optional Attribute List Get

5 Optional Service List Get

Minimum

Maximum

Instance 0

8 UINT Number of attributes

{1, 2, 3, 4,

5, 6, 7,

176}

1 UINT Number of services

{14} ARRAY of UINT

Data Type Description

STRUCT of:

ARRAY of UINT

STRUCT of: List of optional services

List of optional instance

attributes

List of optional attribute

numbers

List of optional service

codes

Max Class Attribute

6

7

176 Object Name Get

1 Object List Get N/A

9.1.5 Class Code 0x03 - DeviceNet Object

# Attribute Name Services

ID

Max Instance

Attribute ID

Get 176 UINT

Get 1 UINT

“Message

Router”

Instance 1

Table 48.

Default

Minimum

Maximum

SHORT_STRING

ARRAY of UINT Classes

The attribute ID number of

the last class attribute

The attribute ID number of

the last instance attribute

ASCII Name for the Object

Class

Structure with an array of

STRUCT of:

UINT Number of classes

Data Type Description

object class codes supported by the device

Instance 0

1 Revision Get 2 UINT Revision of this object

2 Max Instance Get 1 UINT Maximum instance number

24-hour support +358 (0)201 212 575 • Email: vacon@vacon.com

9

Page 62

vacon • 59 Appendix A: Object dictionary

Table 48.

Default

# Attribute Name Services

3 Number of Instances Get 1 UINT Number of object instances

4 Optional Attribute List Get

5 Optional Service List Get

Minimum

Maximum

8 UINT Number of attributes

{1, 2, 3, 4,

5, 6, 7,

176}

1 UINT Number of services

{14} ARRAY of UINT

Data Type Description

STRUCT of:

ARRAY of UINT

STRUCT of: List of optional services

List of optional instance

attributes

List of optional attribute

numbers

List of optional service

codes

Max Class Attribute

6

7

176 Object Name Get

1MAC ID

2Baud Rate

3

ID

Max Instance

Attribute ID

BOI (Bus-off

Interrupt)

Get 176 UINT

Get 10 UINT

Get

Set

Get

Set

Get

Set

“Device-

Net”

Instance 1

63

0

63

0

0

2

1

0

1

The attribute ID number of

the last class attribute

The attribute ID number of

the last instance attribute

SHORT_STRING

USINT Node address

USINT

BOOL

ASCII Name for the Object

Class

The baud rate of the device

0 = 125 kBaud

1 = 250 kBaud

2 = 500 kBaud

If value is changed via network, it will be taken into

use only after a reset /

power cycle. If changed via

panel, baud rate will be

taken into use immediately.

0 = Hold the CAN chip in

bus-off state upon detection

of a bus-off indication

1 = If possible, fully reset

the CAN chip and continue

communication upon detection of a bus-off indication

9

4Bus-off counter

Get

Set

0

0

255

Number of times CAN went

USINT

Tel. +358 (0) 201 2121 • Fax +358 (0)201 212 205

to bus-off state. Received

data is not used. Counter

always reset to 0.

Page 63

Appendix A: Object dictionary vacon • 60

Table 48.

Default

# Attribute Name Services

Minimum

Maximum

Data Type Description

STRUCT of:

5

100 Bus-off Separation Get 128 USINT

Allocation

Information

Get N/A

BYTE

USINT

Allocation Choice Master’s

Mac ID

Allocation Choice Byte

Bit 0 = Explicit messaging

Bit 1 = Polled I/O

Master’s MAC ID

0-63 = valid

255 = unallocated

Messages that have to be

received by the device to

leave bus-off state. This

value is set by the CAN controller.

24-hour support +358 (0)201 212 575 • Email: vacon@vacon.com

9

Page 64

vacon • 61 Appendix A: Object dictionary

9.1.6 Class Code 0x04 - Assembly Object

Table 49.

Default

# Attribute Name Services

1 Revision Get 2 UINT Revision of this object

2 Max Instance Get 117 UINT Maximum instance number

3 Number of Instances Get 12 UINT Number of object instances

4 Optional Attribute List Get

5 Optional Service List Get

Minimum

Maximum

Instance 0

8 UINT Number of attributes

{1, 2, 3, 4,

5, 6, 7,

176}

1 UINT Number of services

{14} ARRAY of UINT

Data Type Description

STRUCT of:

ARRAY of UINT

STRUCT of: List of optional services

List of optional instance

attributes

List of optional attribute

numbers