Page 1

vacon

ac drives

®

optec

ethercat option board

installation manual

Page 2

Page 3

vacon • 3

TABLE OF CONTENTS

Document: DPD01207D

Release date: 27/5/20

1. Safety...............................................................................................................6

1.1 Danger................................................................................................................................6

1.2 Warnings ............................................................................................................................7

1.3 grounding and earth fault protection ................................................................................8

2. OPTEC EtherCAT - General ..............................................................................9

2.1 New features ....................................................................................................................11

3. EtherCAT option board technical data............................................................12

3.1 General.............................................................................................................................12

3.2 Cables...............................................................................................................................12

4. Layout and connections..................................................................................13

4.1 Layout and connections ...................................................................................................13

4.2 LED Indications ................................................................................................................14

4.3 Topologies ........................................................................................................................16

4.4 Connecting the board in line topology .............................................................................16

5. Installation.....................................................................................................17

5.1 Installation in VACON® NXP............................................................................................17

5.2 Installation in VACON® 20...............................................................................................19

5.2.1 Frames MI1, MI2, MI3 ......................................................................................................19

5.2.2 Frames MI4, MI5 ..............................................................................................................22

5.3 Installation in VACON® 20 X and 20 CP ..........................................................................25

5.4 Installation in VACON® 100 family..................................................................................27

6. Commissioning ..............................................................................................30

6.1 AC drive and OPTEC EtherCAT option board parametrization........................................30

6.1.1 Option board parameters.................................................................................................30

6.1.2 Option board monitor values ...........................................................................................32

6.2 EtherCAT master configuration.......................................................................................38

6.2.1 Importing OPTEC EtherCAT ESI files...............................................................................38

6.2.2 Establishing connection to OPTEC EtherCAT..................................................................38

6.2.3 Addressing and identification ..........................................................................................56

6.2.4 Setting the watchdog .......................................................................................................60

6.2.5 Sync unit assignment.......................................................................................................60

6.3 Operation mode selection................................................................................................62

6.3.1 Operation mode selection using parameter....................................................................62

6.3.2 Operation mode selection using CoE object....................................................................62

6.3.3 Operation mode selection using PDO assignment..........................................................62

6.4 ESI file selection...............................................................................................................67

6.4.1 ESI file selection mode ....................................................................................................67

6.5 Controlling the motor ......................................................................................................70

6.5.1 Controlling in CiA-402 Drive Profile mode ......................................................................71

6.5.2 Controlling in Bypass mode.............................................................................................73

6.5.3 Controlling the motor with CODESYS V3.x ......................................................................74

6.6 VACON® PC-tools............................................................................................................77

6.6.1 PC tool support ................................................................................................................77

6.6.2 OPTEC option board firmware update with VACON® Loader.........................................78

6.6.3 PC Tools for VACON® NXP: NCDrive ..............................................................................80

6.6.4 PC Tools for VACON® 100 and VACON® 20: VACON® Live ...........................................82

7. EtherCAT........................................................................................................ 86

7.1 Data object list .................................................................................................................86

7.2 Data Object Descriptions .................................................................................................95

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 4

vacon • 4

7.2.1 RxPDO assign ...................................................................................................................96

7.2.2 TxPDO assign ...................................................................................................................98

7.2.3 Sync Manager...................................................................................................................99

7.2.4 Drive System Time .........................................................................................................100

7.2.5 Drive Information ...........................................................................................................100

7.2.6 ESI File Selection Mode .................................................................................................101

7.2.7 Operating Energy Counters ...........................................................................................102

7.2.8 Operating Trip Time Counters .......................................................................................102

7.2.9 Operating Time Counters...............................................................................................103

7.2.10 Parameter Channel Read ..............................................................................................103

7.2.11 Parameter Channel Write..............................................................................................104

7.2.12 Bypass Control...............................................................................................................105

7.2.13 Bypass status.................................................................................................................105

7.2.14 Bypass Speed SetPoint Value ........................................................................................106

7.2.15 Bypass Speed Actual Value............................................................................................106

7.2.16 Process Data In..............................................................................................................107

7.2.17 Process Data Out ...........................................................................................................109

7.2.18 CiA-402 Control Word ....................................................................................................110

7.2.19 CiA-402 Status Word......................................................................................................111

7.2.20 CiA-402 vl Target Velocity..............................................................................................111

7.2.21 CiA-402 vl Velocity Demand...........................................................................................112

7.2.22 CiA-402 vl Velocity Actual Value ....................................................................................112

7.2.23 CiA-402 vl Velocity Min Max Amount .............................................................................112

7.2.24 CiA-402 vl Velocity Acceleration ....................................................................................113

7.2.25 CiA-402 vl Velocity Deceleration....................................................................................113

7.2.26 CiA 402 Modes of Operation...........................................................................................114

7.2.27 CiA-402 Modes of Operation Display .............................................................................115

7.2.28 CiA-402 supported Drive Modes ....................................................................................115

7.3 Operating modes............................................................................................................116

7.3.1 CiA-402 Drive profile mode............................................................................................116

7.3.2 Bypass mode ..................................................................................................................119

7.4 Accessing drive parameters via CoE MailBox ...............................................................120

7.4.1 CoE objects in ESI files ..................................................................................................121

7.4.2 Adding CoE objects into ESI files ...................................................................................121

7.4.3 Error codes.....................................................................................................................122

7.4.4 Example 1: Reading ID 103 'acceleration time' using the parameter channel ............123

7.4.5 Example 2: Writing ID 103 'acceleration time' using the parameter channel..............124

7.4.6 Example 3: Attempting to write an invalid value using the parameter channel ..........125

7.4.7 Example 4: Writing to parameter using CoE object list ................................................126

7.5 Ethernet over EtherCAT.................................................................................................127

7.5.1 Master configuration......................................................................................................127

8. Fault tracing.................................................................................................129

8.1 Diagnostic information...................................................................................................129

8.2 Typical fault conditions ..................................................................................................129

8.2.1 No connection between EtherCAT master and OPTEC EtherCAT ................................129

8.2.2 EtherCAT master cannot find OPTEC EtherCAT option board......................................129

8.2.3 OPTEC EtherCAT option board does not go to Operational state .................................130

8.2.4 OPTEC EtherCAT is Operational but process data is not transferred ..........................130

8.2.5 Drive does not start to run.............................................................................................130

8.2.6 Drive runs with wrong speed .........................................................................................131

8.2.7 AC drive reports F53 Fieldbus timeout fault .................................................................131

8.2.8 F53 Fieldbus timeout fault cannot be reset ..................................................................131

8.3 Fieldbus timeout fault (F53)...........................................................................................131

8.3.1 OPTEC EtherCAT Fault conditions.................................................................................131

8.3.2 Fieldbus timeout fault (F53) diagnostic info..................................................................132

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 5

vacon • 5

8.3.3 Fieldbus fault activation timers .....................................................................................133

9. APPENDIX A: CANOPEN DS301 SPECIFIC DATA OBJECT DESCRIPTIONS.....134

9.1 Object 1001h: Error Register .........................................................................................135

10. APPENDIX B: DEVICE PROFILE FOR DRIVES ................................................136

11. APPENDIX C - CONTROL AND STATUS WORD ..............................................137

11.1 Control Word bit description ...................................................................................137

11.2 Status Word Descriptions ........................................................................................139

11.3 Control word bit support in drives...........................................................................140

11.4 Status word bit support in drives.............................................................................141

12. APPENDIX D - FIELDBUS PARAMETRISATION .............................................142

12.1 Fieldbus control and basic reference selection ............................................................142

12.2 Controlling Fieldbus Parameter ....................................................................................143

12.3 Torque control parametrization ....................................................................................144

13. APPENDIX E - FIELDBUS PROCESS DATA mAPPING AND SCALING............. 145

14. APPENDIX F - FIELDBUS OPTION BOARD COMMUNICATION ....................... 148

14.1 Requirements for communication modes.....................................................................148

14.2 Fiedlbus communication mode features and limitations .............................................149

14.3 Normal fieldbus communication ...................................................................................149

14.4 Fast fieldbus communication ........................................................................................150

14.5 Fast PROFIBUS fieldbus communication ......................................................................151

14.6 Normal Extended Mode .................................................................................................151

15. APPENDIX G - PARAMETERS FOR APPLICATION DEVELOPERS ...................152

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 6

vacon • 6 Safety

9000.emf

13006.emf

9001.emf

9000.emf

9000.emf

9000.emf

9000.emf

9000.emf

9000.emf

1. SAFETY

This manual contains clearly marked cautions and warnings that are intended for your personal

safety and to avoid any unintentional damage to the product or connected appliances.

Please read the information included in cautions and warnings carefully.

The cautions and warnings are marked as follows:

Table 1. Warning signs

= DANGER! Dangerous voltage

= WARNING or CAUTION

= Caution! Hot surface

1.1 Danger

The components of the power unit are live when the drive is connected to mains

potential. Coming into contact with this voltage is extremely dangerous and may

cause death or severe injury.

The motor terminals U, V, W and the brake resistor terminals are live when the

AC drive is connected to mains, even if the motor is not running.

After disconnecting the AC drive from the mains, wait until the indicators on the

keypad go out (if no keypad is attached, see the indicators on the cover). Wait 5

more minutes before doing any work on the connections of the drive. Do not open

the cover before this time has expired. After expiration of this time, use a

measuring equipment to absolutely ensure that no

ensure absence of voltage before starting any electrical work!

The control I/O-terminals are isolated from the mains potential. However, the

relay outputs and other I/O-terminals may have a dangerous control voltage

present even when the AC drive is disconnected from mains.

voltage is present.

Always

Before connecting the AC drive to mains make sure that the front and cable

covers of the drive are closed.

During a ramp stop (see the Application Manual), the motor is still generating

voltage to the drive. Therefore, do not touch the components of the AC drive

before the motor has completely stopped. Wait until the indicators on the keypad

go out (if no keypad is attached, see the indicators on the cover). Wait additional 5

minutes before starting any work on the drive.

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

1

Page 7

Safety vacon • 7

13006.emf

13006.emf

13006.emf

13006.emf

13006.emf

13006.emf

13006.emf

13006.emf

13006.emf

13006.emf

1.2 Warnings

The AC drive is meant for fixed installations only.

Do not perform any measurements when the AC drive is connected to the mains.

The earth leakage current of the AC drives exceeds 3.5mA AC. According to

standard EN61800-5-1, a reinforced protective ground connection must be

ensured. See Chapter 1.3.

If the AC drive is used as a part of a machine, the machine manufacturer is

responsible for providing the machine with a supply disconnecting device (EN

60204-1).

Only spare parts delivered by the manufacturer can be used.

At power-up, power brake or fault reset the motor will start immediately if the

start signal is active, unless the pulse control for

Start/Stop logic has been selected

Furthermore, the I/O functionalities (including start inputs) may change if

parameters, applications or software are changed. Disconnect, therefore, the

motor if an unexpected start can cause danger.

.

The motor starts automatically after automatic fault reset if the auto restart

function is activated. See the Application Manual for more detailed information.

Prior to measurements on the motor or the motor cable, disconnect the motor

cable from the AC drive.

Do not touch the components on the circuit boards. Static voltage discharge may

damage the components.

Check that the EMC level of the AC drive corresponds to the requirements of your

supply network.

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

1

Page 8

vacon • 8 Safety

13006.emf 13006.emf

1.3 grounding and earth fault protection

CAUTION!

The AC drive must always be earthed with an grounding conductor connected to the grounding

terminal marked with .

The earth leakage current of the drive exceeds 3.5mA AC. According to EN61800-5-1, one or more

of the following conditions for the associated protective circuit must be satisfied:

a) The protective conductor must have a cross-sectional area of at least 10 mm2 Cu or 16

mm2 Al, through its total run.

b) Where the protective conductor has a cross-sectional area of less than 10 mm2 Cu or 16

mm2 Al, a second protective conductor of at least the same cross-sectional area must be

provided up to a point where the protective conductor has a cross-sectional area not less

than 10 mm2 Cu or 16 mm2 Al.

c) Automatic disconnection of the supply in case of loss of continuity of the protective

conductor.

The cross-sectional area of every protective grounding conductor which does not form part of the

supply cable or cable enclosure must, in any case, be not less than:

-2.5mm

-4mm

2

if mechanical protection is provided or

2

if mechanical protection is not provided.

The earth fault protection inside the AC drive protects only the drive itself against earth faults in the

motor or the motor cable. It is not intended for personal safety.

Due to the high capacitive currents present in the AC drive, fault current protective switches may

not function properly.

Do not perform any voltage withstand tests on any part of the AC drive. There is

a certain procedure according to which the tests must be performed. Ignoring

this procedure can cause damage to the product.

NOTE! You can download the English and French product manuals with applicable safety,

warning and caution information from https://www.danfoss.com/en/service-and-support/.

REMARQUE Vous pouvez télécharger les versions anglaise et française des manuels produit

contenant l’ensemble des informations de sécurité, avertissements et mises en garde

applicables sur le site

https://www.danfoss.com/en/service-and-support/.

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

1

Page 9

OPTEC EtherCAT - General vacon • 9

Init

Operational

Boot

Pre-operational

10 111

9

7

34

8

56

2

Safe-operational

11870_uk

2. OPTEC ETHERCAT - GENERAL

OPTEC EtherCAT option board is field bus option for VACON® drives. With OPTEC option board it is

possible to connect a VACON

via EtherCAT field bus.

EtherCAT is a fieldbus protocol which uses standard Ethernet network as its media to transfer data

structures between other EtherCAT devices in the bus. EtherCAT uses Master-Slave type communication. EtherCAT master device controls the states of the EtherCAT bus. States of the EtherCAT

bus can be seen from the table below.

®

AC drive to an EtherCAT network and command/monitor the drive

State

transition

1 Start mailbox communication

2 Stop mailbox communication

3 Start process data transfer from EtherCAT slave to EtherCAT master

4 Stop process transfer from EtherCAT slave to EtherCAT master

5 Start process data transfer from EtherCAT master to EtherCAT slave

6 Stop process data transfer from EtherCAT master to EtherCAT slave

7 Stop process data transfers

8

9 Stop mailbox communication, stop process data transfers

10 Start bootup mode (not supported in OPTEC EtherCAT)

11 Restart device (not supported in OPTEC EtherCAT)

Stop mailbox communication, stop process data transfer from Ether-

Figure 1. EtherCAT device states

Table 2. EtherCAT device states

Service activation/deactivation

CAT slave to EtherCAT master

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

2

Page 10

vacon • 10 OPTEC EtherCAT - General

OPTEC option board is EtherCAT-slave device and requires EtherCAT-Master device presence in

the bus to operate.

The VACON

Device Profile Drives and Motion Control (CiA DSP-402) document represents the standardized

CANopen Device Profile for digitally controlled motion products like servo controllers, AC drives or

stepper motors. All the above-mentioned devices use communication techniques which conform to

those described in the CANopen Application Layer and Communication Profile. The starting and

stopping of the drive and several mode specific commands are executed by the statemachine. The

operation mode defines the behaviour of the drive. The following modes are defined in this profile:

•Homing Mode

•Profile Position Mode

• Interpolated Position Mode

• Profile Velocity Mode

• Profile Torque Mode

• Velocity Mode

®

EtherCAT Option Board uses CAN application protocol over EtherCAT (CoE).

The VACON

®

EtherCAT Option Board supports the Velocity Mode

Table 3. List of abbreviations used in this document

Abbreviation Explanation

EoE Ethernet over EtherCAT

FB Fieldbus

PPO Parameter Process Data Object

PLC Programmable Logic Controller

PHY(X)

PDO

RPM Revolutions per minute

SDO

EtherCAT physical interface X, where X represents the number

of interface

Process Data Object (Inputs and outputs. Values of type rota-

tional speed, voltage, frequency, electric current, etc.)

Service Data Object (Configuration settings, possibly node ID,

baud rate, offset, gain, etc.)

Table 4. List of data types used in this document

2

Type name Bit size Explanation

INT8 8 Signed short integer

UINT8 8 Unsigned short integer

INT16 16 Signed integer

UINT16 16 Unsigned integer

INT32 32 Signed long integer

UINT32 32 Unsigned long integer

FLOAT32 32 32-bit floating point

STRING3 24 Three byte string

STRING5 40 Five byte string

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 11

OPTEC EtherCAT - General vacon • 11

2.1 New features

The following table shows the new features that are added in the OPTEC EtherCAT option board's

firmware versions.

Table 5. OPTEC EtherCAT firmware versions

New features Firmware version

• Support for VACON® NXP and VACON® 20 drives.

• Support for VACON® 100 INDUSTRIAL, VACON® 100 FLOW,

®

VACON

• Support for panel parameters and monitor values. See details

in Chapter 6.1 "AC drive and OPTEC EtherCAT option board

parametrization"

• Support for Fast Communication and 16 process data when

installed to VACON

FIELDBUS OPTION BOARD COMMUNICATION”

• Ethernet over EtherCAT support, see Chapter 6 "Commissioning" and Chapter 7.5 "Ethernet over EtherCAT".

• Added support for SM sync and DC sync modes, see

Chapter 7.2.3 "Sync Manager".

• Support for EtherCAT Device ID, see Chapter 6 "Commissioning".

• New CANOpen objects: 0xFFF1 Fault history object and 0x604B

velocity setpoint factor.

• Added new parameters and monitor values.

• Support for 16 process data items for VACON

or 32bit.

100 X and VACON® 20 X/CP drives.

®

NXP drive. See details in “APPENDIX F -

®

100, either 16bit

V001

V002

V003

V004

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

2

Page 12

vacon • 12 EtherCAT option board technical data

3. ETHERCAT OPTION BOARD TECHNICAL DATA

3.1 General

Table 6. Technical data

General Board name OPTEC

Interface Two RJ-45 connectors

Shielded and Foiled Twisted

Pair (S/FTP) CAT5e *

Shielded Twisted Pair (STP)

EtherCAT connections

Communications

Transfer cable

Speed 10 / 100 Mb

Supported features

Synchronization Freerun/SM sync, DC sync

CAT5e

Foiled Twisted Pair (FTP)

CAT5e

Unshielded Twisted Pair (UTP)

CAT5e**

Mailbox - CoE

• SDO Upload/Download

•SDO Info Service

Mailbox - EoE

Protocol EtherCAT

Ambient operating temperature

Storing temperature -40°C…70°C

Environment

Safety Fulfils EN50178 standard.

* Shielded and foiled twisted pair cable is recommended cable for EtherCAT connections

** Unshielded cable is not recommended for industrial purpose

Humidity

Altitude Max. 1000 m

Vibration 0.5 G at 9...200 Hz

-10°C…50°C

<95%, no condensation

allowed

3.2 Cables

For connecting the EtherCAT devices use only Ethernet cables that meet at least the requirements

of category 5 (CAT5) according to EN 50173 or ISO/IEC 11801. EtherCAT uses 4 wires for signal

transfer. We recommend that shielded CAT5 cables are used.

3

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 13

Layout and connections vacon • 13

Interface Board

Connector

EtherCAT bus

connectors IN/OUT

RUN ERR BS

J2

J1

9399A_uk

OUT

IN

4. LAYOUT AND CONNECTIONS

The VACON® EtherCAT Option Board is connected to EtherCAT bus using the RJ-45 connectors

compatible with Ethernet standard (ISO/IEC 8802-3). The communication between the control

board and the AC drive takes place through a standard VACON

Table 7. EtherCAT connector pin assignment

Pin Core colouring Signal Description

1 yellow TD + Transmission Data +

2 orange TD - Transmission Data 3 white RD + Receiver Data +

6 blue RD - Receiver Data -

4.1 Layout and connections

®

Interface Board Connector.

Figure 2.VACON® EtherCAT option board OPTEC

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Table 8. EtherCAT connectors

EtherCAT connector Description

J1 EtherCAT bus IN (PHY1)

J2 EtherCAT bus OUT (PHY2)

4

Page 14

vacon • 14 Layout and connections

OUT

IN

Interface Board

Connector

LED indications

RUN ERR BS

J2

J1

9400A_uk

4.2 LED Indications

The RUN LED indicator describes the state of the bus and the ERR LED indicator describes the status of the board. OPTEC EtherCAT stays in INITIALISATION state until EtherCAT master device commands it into another state.

Figure 3. VACON® EtherCAT option board OPTEC LED indicators

Table 9. EtherCAT RUN, GREEN

LED RUN Meaning

OFF OPTEC EtherCAT is in INITIALISATION state.

Blinking

(once/0,2 s)

Single Flash

(once/2 s)

OPTEC EtherCAT is in PRE-OPERATIONAL state.

OPTEC EtherCAT is in SAFE-OPERATIONAL state.

Flickering OPTEC EtherCAT is in INITIALISATION state.

ON OPTEC EtherCAT is in OPERATIONAL state.

Table 10. EtherCAT ERR, RED

LED ERR Meaning

OFF No Error

(once/0,4 s)

Single Flash

(once/2 s)

Blinking

Invalid configuration

ASIC synchronization error

Double Flash Process Data Watchdog Timeout/EtherCAT Watchdog Timeout

Flickering ASIC hardware failure

4

ON Application Controller Failure

LED ERR Green is used by EtherCAT option board only at startup to indicate boot status.

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 15

Layout and connections vacon • 15

Table 11. EtherCAT ERR, GREEN

LED ERR Meaning

OFF No Error

Blink once Option board is powered on

Blinking Option board boot failure

LED BS provides information about the EtherCAT option board internal state.

Table 12. BS = OPTEC board status, GREEN

LED BS Meaning

OFF Option board is not activated.

ON

Blinking fast

(once /1 s)

Option board is in initialization state, waiting activation com-

mand from the AC drive.

Option board is activated and in RUN state

• Option board is ready for external communication

In the case of unrecoverable error the OPTEC board will notify you of this by using the red error LED.

The cause of the error will be coded into a series of long and short flashes. The sequence coded

error message will repeat indefinitely. If more than one error has occurred the board will cycle

through each error code repeatedly.

Table 13. Error codes

Error

number

1 Initialization Error 1 2 Board Initialization Failed

2 Setup Error 1 3 Board Setup Failed

3 System Error 1 1 4 Internal System Error 1

4 System Error 2 2 1 Internal System Error 2

5 System Error 3 2 2 Internal System Error 3

6 EEPROM Error 2 3 Option Board EEPROM Read/Write Error

7 ASIC Error 2 4 EtherCAT ASIC Communication Error

8 Fieldbus Error 3 1 Fieldbus Interface Error

9 OB Service Error 3 2 Option Board Service Error

Error name

Long

flashes

Short

flashes

Description

10 OB Manager Error 3 3 Option Board Manager Error

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

4

Page 16

vacon • 16 Layout and connections

OPTEC

Board

Tx-Led

9419_uk.emf

Rx-Led

4.3 Topologies

EtherCAT supports the following Ethernet topologies:

•Line

•Daisy chain

• Daisy chain branches

•Tree

•Star

• Cable redundancy

Each of these topologies has its own advantages. Note that the start address may vary depending

on which Master implementation is used. The OPTEC boards are connected using line topology.

4.4 Connecting the board in line topology

Connect the EtherCAT master to IN connector of the OPTEC Option Board using an Ethernet cable.

For more information, see the figure below.

Switch-PT-Empty

EtherCAT Master

ETH

IN

PHY1

Switch-PT-Empty

OPTEC-Slave1

OUT

PHY2

IN

PHY1

Switch-PT-Empty

OPTEC-Slave2

9420_uk

Figure 4. VACON® OPTEC option board EtherCAT IN/OUT

After the EtherCAT master is connected to the OPTEC Option Board and the power is switched on

in both devices, the Rx-Led of the IN connector in the OPTEC Option Board should be on or blinking

depending on if there is communication in the bus or not. The Tx-Led is not used.

4

Figure 5.OPTEC option board EtherCAT in connector

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 17

Installation vacon • 17

13006.emf

5. INSTALLATION

The VACON® OPTEC EtherCAT option board can be used with the following VACON® AC drives.

Table 14. Supported AC drives and slots

AC drive Slots

VACON

VACON

5.1 Installation in VACON

®

VACON® 100 FLOW

VACON

VACON

Make sure that the AC drive is switched off before an option or fieldbus board is

changed or added!

VACON® NXP AC drive.

®

NXP

100 INDUSTRIAL

and 100 X

®

20 X and CP

®

20

From AC drive SW

version on

D, E NXP00002V187 V001

D, E FW0072V016 V002

D, E FW0159V010 V002

- FW0117V006 V002

- FW0107V009 V001

®

NXP

From OPTEC SW

version on

1

2

Remove the cable cover.

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

5

Page 18

vacon • 18 Installation

Open the cover of the control unit.

3

Install the OPTEC EtherCAT Option Board in slot D or E on the control board of the

AC drive. Make sure that the grounding plate fits tightly in the clamp.

4

5

6

Make a sufficiently wide opening for your cable by cutting the grid as wide as

necessary.

Close the cover of the control unit and the cable cover.

5

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 19

Installation vacon • 19

11556A_00

5.2 Installation in VACON® 20

5.2.1 Frames MI1, MI2, MI3

Remove the cable connector lid from the

AC drive.

1

2

11555A_00

Select a correct grounding plate and attach it to the

option board mounting frame. The grounding plate is

marked with the supported enclosure size.

11649_00

Attach an option board mounting frame to

the AC drive.

3

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

5

Page 20

vacon • 20 Installation

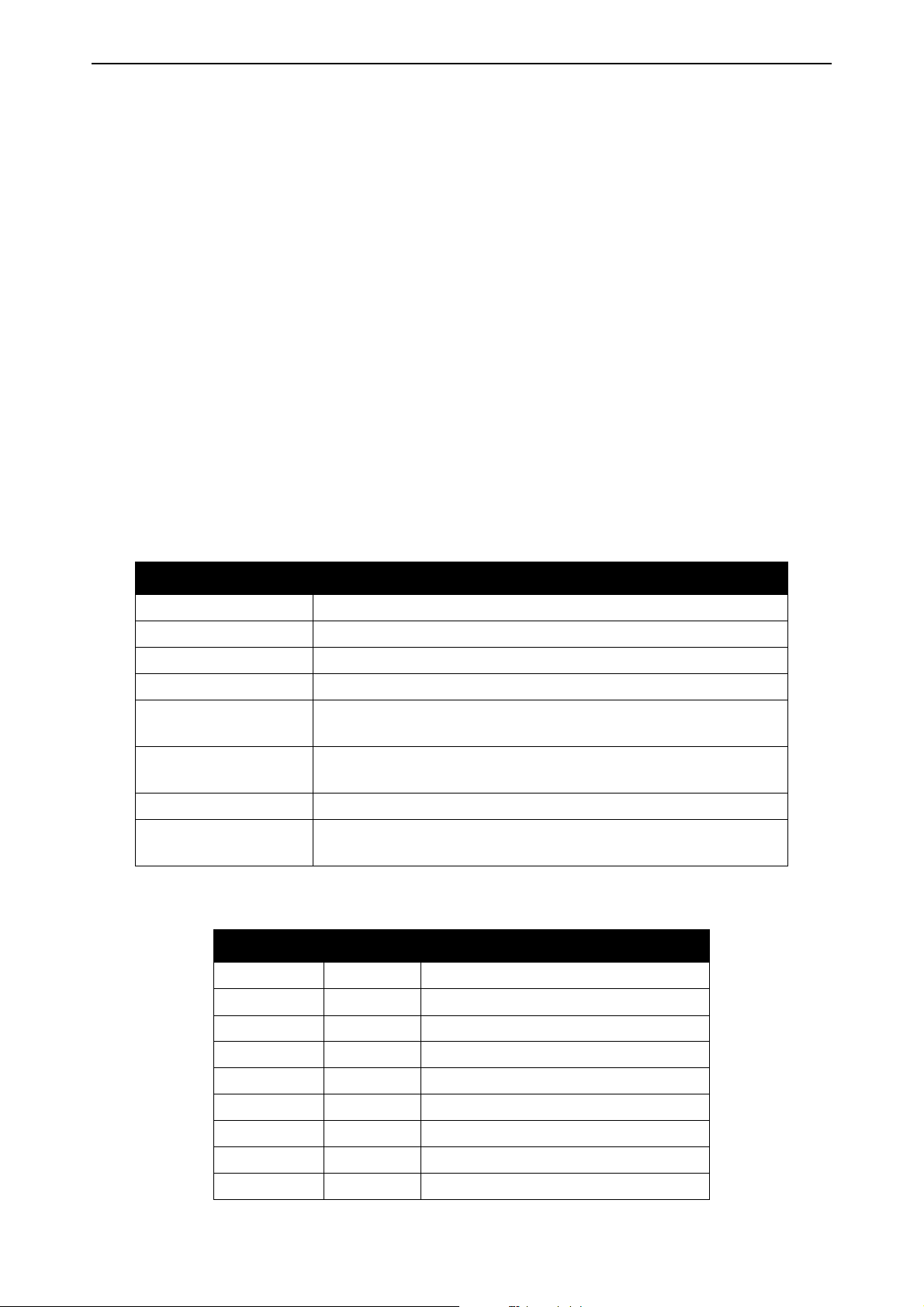

Connect the flat cable from the option board mounting frame to VACON® 20.

4

11557A_00

If a cable strain relief is required, attach the parts as shown in the figure.

5

11558A_00

5

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 21

Installation vacon • 21

11559A_00

11560A_00

Install the option board to the option board

holder. Make sure that the option board is

securely fastened.

6

7

Cut free a sufficiently wide opening for the

option board connector.

Attach the option board cover to VACON

20. Attach the strain relief cable clamp with

screws if needed.

®

11650_00

8

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

5

Page 22

vacon • 22 Installation

13006.emf

11562_00

11564_00

5.2.2 Frames MI4, MI5

®

Make sure power is disconnected before opening the VACON

1a: For MI4: Open the cover.

20 cover.

1

2

11561_00

1b: For MI5: Open the cover and release the fan connector.

Connect the flex cable to option board connector PCB.

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

5

Page 23

Installation vacon • 23

11565_00

MI 04

MI 05

11567_00

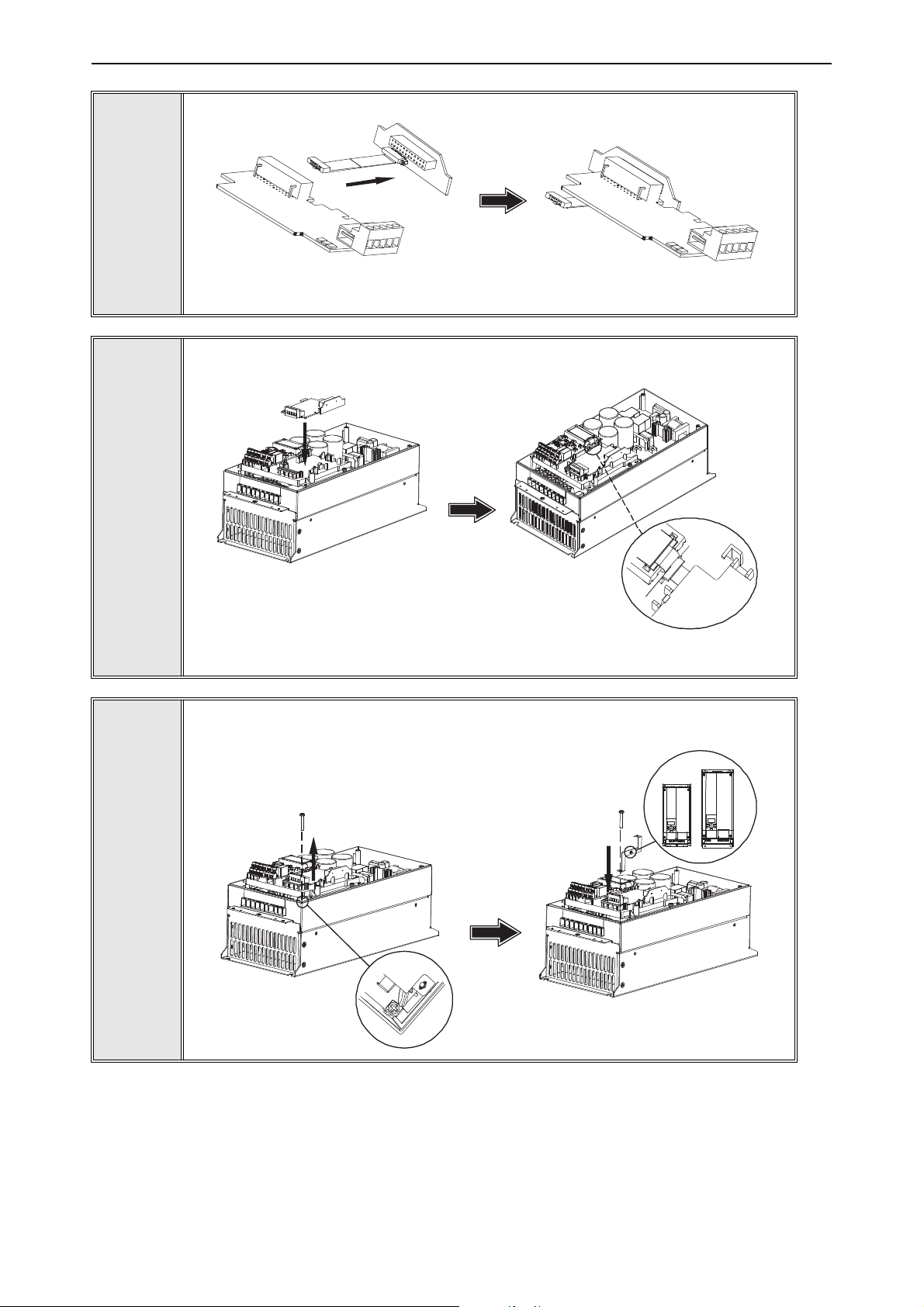

Connect the option board to connector PCB.

3

Attach the option board with connector PCB to VACON® 20 and connect the flex

cable.

4

5

11566_00

Attach a suitable grounding plate to VACON® 20. The grounding plate is marked

with supported enclosure size.

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

5

Page 24

vacon • 24 Installation

11568_00

11569_00

11570_00

Assemble a clamp on top of the grounding plate on both sides of the option board.

6

8a: For MI4: Close the cover.

7

8b: For MI5: Remount the fan connector and close the cover.

5

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 25

Installation vacon • 25

13006.emf

11643_00

13006.emf

5.3 Installation in VACON® 20 X and 20 CP

Do not add or replace option boards or fieldbus boards on an AC drive with the power

switched on. This may damage the boards.

Open the cover of the drive.

1

MU3 example

The relay outputs and other I/O-terminals may have a dangerous control voltage

present even when the drive is disconnected from mains.

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

5

Page 26

vacon • 26 Installation

7089_00

7090_00

7091_007091_00

Remove the option slot cover.

2

Install the option board into the slot as shown in the figure.

3

4

Mount the option slot cover. Remove the plastic opening for the option board

terminals.

5

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 27

Installation vacon • 27

M4x55

9174.emf

DANGER

5.4 Installation in VACON® 100 family

Open the cover of the AC drive.

1

The relay outputs and other I/O-terminals may have a dangerous control voltage

present even when VACON

®

100 family AC drive is disconnected from mains.

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

5

Page 28

vacon • 28 Installation

3023.emf

DE

3024.emf

Open the inner cover to reveal the option board slots (C,D,E).

2

3

Install the fieldbus board into slot D or E.

NOTE: Incompatible boards cannot be installed on VACON

Compatible boards have a slot coding

that enable the placing of the board.

®

100 family AC drive.

5

4

Then connect the cable to its appropriate OPTEC EtherCAT option board RJ-45

connector.

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 29

Installation vacon • 29

9202.emf

Fieldbus

cables

Unless already done for the other control cables,

cut free the opening on the AC drive cover for the

fieldbus cable (protection class IP21).

NOTE: Cut the opening on the same side you

have installed the board in!

5

Remount the AC drive cover and run the cable as

shown in picture.

NOTE: When planning the cable runs, remember

to keep the distance between the fieldbus cable

and the motor cable at a minimum of 30 cm. It is

recommended to route the option board cables

away from the power cables as shown in the picture.

6

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

5

Page 30

vacon • 30 Commissioning

6. COMMISSIONING

This chapter explains the configuration of AC drive and EtherCAT master to enable communication

between EtherCAT master and OPTEC EtherCAT option board.

6.1 AC drive and OPTEC EtherCAT option board parametrization

VACON® AC drive and OPTEC EtherCAT option board parameters can be read and modified with AC

®

drive control keypad or with PC tools. See description of VACON

PC tools in Chapter 6.6 "VACON®

PC-tools".

Step 1. Enable field bus control in AC drive to make AC drive to be controllable via field bus. Enabling of field bus control in a different VACON

®

AC drives is described in Chapter 12 "APPENDIX D

- FIELDBUS PARAMETRISATION".

If OPTEC EtherCAT is used only for monitoring and data collection purposes, then Step 1 is no required.

Step 2. Parametrize OPTEC EtherCAT option board and monitor option board status.

•In case of VACON

•In case of VACON

®

NXP parameters are located under the menu M7 Expander boards menu.

®

100 family parameters are located under the menu M5 I/O and Hardware

menu.

Minimum AC drive firmware version required by OPTEC EtherCAT parameter and monitor value

functionality is described in the following table. With older control firmware versions, the parameters and monitor values are not available. In this case parametrization must be done via EtherCAT

bus.

Table 15. EtherCAT parameters and monitor value support

AC drive AC drive SW version

From OPTEC EtherCAT

SW version

®

100 INDUSTRIAL

VACON

VACON

®

and 100 X

VACON® 100 FLOW

®

VACON

20 X and CP

VACON

NXP

®

20

NXP00002V196 OPTEC_FW0128V003

FW0072V029 OPTEC_FW0128V003

FW0159V019 OPTEC_FW0128V003

To be defined OPTEC_FW0128V003

To be defined OPTEC_FW0128V003

6.1.1 Option board parameters

OPTEC EtherCAT can be parametrized with a following option board parameters. Option board parameters are stored into AC drive permanent memory. It is possible to backup and restore AC drive

parameters. See details of backup and restore operation in AC drive user manual.

Using of parameters is optional, OPTEC EtherCAT can be fully parametrized by EtherCAT master.

In this case parameters are set into default values.

Table 16. OPTEC EtherCAT Parameters

Name Default Range Description

6

Operation mode Drive Profile

Drive Profile (1),

Bypass (2)

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Operation mode defines how EtherCAT

master can control the motor.

Page 31

Commissioning vacon • 31

Table 16. OPTEC EtherCAT Parameters

Name Default Range Description

Comm. Timeout 0 s 0…65535 s Communication timeout in seconds

Station Alias 0 0…65535

Device ID 1 1...65535 Device ID of OPTEC EtherCAT

Vl setpoint factor 1 1, 10, 100

6.1.1.1 Operation mode

Operation mode parameter defines how EtherCAT master can control the motor and monitor the

motor control status.

• Drive Profile means CiA-402 Drive and Motion Control Profile's Velocity mode.

• Bypass means VACON

See details of operation mode in Chapter 7.3 "Operating modes".

®

specific control mode

Configured Station Alias for OPTEC

EtherCAT.

Scaling factor for vl speed reference

(only in NXP).

Operation mode can be selected with a following methods that are described in Chapter 6.3 "Operation mode selection". Latest modification is taken into use and currently used setting is stored into

Operation mode parameter. Currently used Operation mode can be seen in Operation mode monitor

value.

• Operation mode selection with parameter

• Operation mode selection by writing into 0x6060 CiA-402 Modes of Operation object. See

details in Chapter 7.2.26 "CiA 402 Modes of Operation".

• Operation mode selection with PDO assignment. See details in Chapter 6.3.3 "Operation

mode selection using PDO assignment".

NOTE! If EtherCAT master assigns only Bypass specific process data objects and CiA-402 specific

process data objects (RxPDO 0x1600, TxPDO 0x1A00) are not assigned then selecting of Drive Profile is not possible.

NOTE! In CiA-402 Drive Profile mode it is recommended to set AC drive's "Fieldbus min scale" and

"Fieldbus max scale" parameters value to zero. In otherwise RPM scaling does not work properly.

Part of NXP applications contains "Fieldbus min scale" and "Fieldbus max scale" settings. In

APFIFF06 Multipurpose application these parameters can be found from menu P2.9.1 and P2.9.2.

6.1.1.2 Communication timeout

Communication timeout parameter defines wait time in seconds for fault activation.

In EtherCAT communication EtherCAT master typically defines SM watchdog time to the EtherCAT

slave device. If OPTEC EtherCAT cannot receive process data from EtherCAT master within SM

watchdog time, then it activates F53 Field bus fault.

With Communication timeout parameter it is possible to extend the time when F53 field bus fault is

activated.

• If Communication timeout is 0 then F53 field bus fault is activated after SM watchdog time

• If Communication timeout is other than 0 then F53 field bus fault is activated after SM

watchdog time + Communication timeout time (seconds)

See details of communication time out behavior in Chapter 8.3 "Fieldbus timeout fault (F53)".

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

6

Page 32

vacon • 32 Commissioning

6.1.1.3 Station alias

Station Alias parameter defines Configured Station Alias for OPTEC EtherCAT. EtherCAT master

devices can use the alias for node addressing. Usage of the alias is optional for the master device.

• If Station alias parameter is 0 then OPTEC uses Configured Station Alias defined by EtherCAT master. EtherCAT master (PLC or EtherCAT configuration tool) can write Configured

Station Alias to OPTEC EtherCAT EEPROM. New alias is taken into use after power cycle of

variable-frequency drive.

• If Station alias parameter is other than 0 then OPTEC EtherCAT uses Configured Station

Alias defined by AC drive panel parameter. New alias is taken into use immediately after

change.

See more about Configured Station Alias in Chapter 6.2.3 "Addressing and identification".

6.1.1.4 Device ID

This parameter can be used to set the unique device identification value for OPTEC EtherCAT within

the EtherCAT network. EtherCAT master needs to be configured to use this identification method.

If EtherCAT master does not use Device ID as identification method, this parameter has no effect.

More detailed description is found in Chapter 6.2.3 "Addressing and identification".

6.1.1.5 Vl setpoint factor

If the default RPM range of vl target velocity and vl velocity actual in not enough for high speed applications, this parameter can be used to increase the range by 10 or 100. The default speed range

with vl setpoint factor 1 is -32768...+32767 RPM. With vl scaling factor 10 this is -327680...327670.

In practice, this means that vl target velocity value of 100 RPM translates to 1000 RPM internally

and vl velocity actual value of 100 RPM needs to be multiplied by 10 to get actual RPM of the drive.

NOTE! This panel parameter is only visible in VACON

6.1.2 Option board monitor values

OPTEC EtherCAT option board monitor values tells useful information about the option board status.

Table 17. OPTEC EtherCAT monitor values

Name Range Description

Initializing (1),

Stopped (2),

FB Protocol Status

EtherCAT Run

Communication status 0.0…6553.9

Operate Mode

Operational (3),

Faulted (4),

Failing (5),

Pre-Operational (6)

Init (1),

Pre-Operational (3),

Safe-Operational

(4),

Operational (5)

None (1),

Drive Profile (2),

Bypass (3)

®

NXP drives.

Generic communication status

EtherCAT RUN indicator

Number of successfully received process data

frames and error frames during a second.

Currently used Operate mode

6

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 33

Commissioning vacon • 33

Table 17. OPTEC EtherCAT monitor values

Name Range Description

AL Status Code 0x0…0xFFFF EtherCAT AL Status Code

SM Watchdog 0…65535 SM Watchdog time in milliseconds

Station Alias 0…65535 Currently used Configured Station Alias

Drive control word - Control word in drive format

Drive status word - Status word in drive format

Protocol control word - Control word in protocol format

Protocol status word - Status word in protocol format

Sub menu: ESI Selection

Mode

Off (1),

ESI Selection Mode

Product Code 0…0xFFFFFFFF Currently used EtherCAT Product Code

Revision Number 0…0xFFFF Currently used EtherCAT Revision Number

Sub menu EoE

Automatic (2),

Static (3)

ESI file selection mode

IP part 1 0-255 IP address part 1

IP part 2 0-255 IP address part 2

IP part 3 0-255 IP address part 3

IP part 4 0-255 IP address part 4

Subnet P1 0-255 Subnet mask part 1

Subnet P2 0-255 Subnet mask part 2

Subnet P3 0-255 Subnet mask part 3

Subnet P4 0-255 Subnet mask part 4

Default GW P1 0-255 Gateway IP address part 1

Default GW P2 0-255 Gateway IP address part 2

Default GW P3 0-255 Gateway IP address part 3

Default GW P4 0-255 Gateway IP address part 4

EoE Enabled / Disabled Shows if EoE is enabled or disabled by master

6.1.2.1 FB Protocol status

FB Protocol status monitor value shows generic status of field bus. When device has started, it

stays in "Initializing" status until the connection is opened to the device.

When EtherCAT master commands OPTEC EtherCAT to Pre-Operational or Safe-Operational state

then the status changes to "Pre-Operational".

When EtherCAT master commands OPTEC EtherCAT to Operational state then the status changes

to "Operational".

See EtherCAT state machine states in Chapter 2 "OPTEC EtherCAT - General".

If the connection is closed or lost, the status changes to "Failing" until communication time out time

has elapsed. Then the status changes to "Faulted". See details of communication time out behavior

in Chapter 8.3 "Fieldbus timeout fault (F53)".

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

6

Page 34

vacon • 34 Commissioning

6.1.2.2 EtherCAT Run

EtherCAT Run monitor value shows EtherCAT state. See EtherCAT state machine states in

Chapter 2 "OPTEC EtherCAT - General". When device has started, it stays in "Initialisation" state

until the connection is opened to the device.

State is changed to "Initialisation", "Pre-operational", "Safe-operational", or "Operational" when

EtherCAT master commands OPTEC EtherCAT to move into these states.

OPTEC EtherCAT moves from "Operational" to "Safe-operational" when it cannot get process data

from EtherCAT master within time defined by SM Watchdog time.

Bootstrap state is not supported at a moment in OPTEC EtherCAT.

6.1.2.3 Communication status

Communication status monitor value is shown in format "nnnn.y":

• nnnn shows number of successfully received process data frames during a second

• y shows number of error frames during a second. Processing of these frames failed.

NOTE! When using virtual EtherCAT master in PC workstation non-EtherCAT data frames might be

passed to the Ethernet interface in which OPTEC EtherCAT is connected to. In this case the diagnostic shows that OPTEC EtherCAT receives error frames.

6.1.2.4 Operate Mode

Operate Mode monitor value shows currently used operate mode.

• None means that operate mode is not defined.

• Drive Profile means CiA-402 Drive and Motion Control Profile's Velocity mode.

• Bypass means VACON specific control mode.

6.1.2.5 AL Status Code

AL Status Code value shows OPTEC EtherCAT option board's EtherCAT Application Layer status

which might tell information about possible EtherCAT communication or configuration problem.

Acronyms I, P, S, O, E on the table below describes EtherCAT states: Initialization, Pre-operational,

Safe-operational, Operational, Error. See EtherCAT state machine states in Chapter 2 "OPTEC EtherCAT - General".

Table 18. EtherCAT AL Status Codes

Code Description

0x0000 No error Any Current state

0x0001 Unspecified error Any I + E, P + E, S + E

0x0002 No memory Any I + E, P + E, S + E

Current state or

state changes

Resulting state

6

0x0003 Invalid device setup P -> S P + E

0x0011 Invalid requested state change

0x0012 Unknown requested state Any I +E, P + E, S + E

0x0013 Bootstrap not supported I -> B I + E

0x0014 No valid firmware I -> P I + E

0x0015 Invalid mailbox configuration I -> B I + E

0x0016 Invalid mailbox configuration I -> P I + E

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

I -> S, I -> O, P -> O,

O -> B, S -> B, P -> B

I +E, P + E, S + E

Page 35

Commissioning vacon • 35

Table 18. EtherCAT AL Status Codes

Code Description

0x0017 Invalid sync manger configuration P -> S, S -> O Current state + E

0x0018 No valid inputs available S, O, S -> O S + E

0x0019 No valid outputs O, S -> O S + E

0x001A Synchronization error O, S -> O S + E

0x001B Sync manager watchdog O, S S + E

0x001C Invalid Sync Manager Types O, S, P -> S S + E

0x001D Invalid Output Configuration O, S, P -> S P + E

0x001E Invalid Input Configuration O, S, P -> S P + E

0x001F Invalid Watchdog Configuration O, S, P -> S P + E

0x0020 Slave needs cold start Any I + E, P + E, S + E

0x0021 Slave needs INIT B, P, S, O I + E, P + E, S + E

0x0022 Slave needs PREOP S, O S + E

0x0023 Slave needs SAFEOP O S + E

0x0024 Invalid Input Mapping P -> S P + E

0x0025 Invalid Output Mapping P -> S P + E

0x0026 Inconsistent Settings P -> S P + E

Current state or

state changes

Resulting state

0x0027 Freerun not supported P -> S P + E

0x0028 SyncMode not supported P -> S P + E

0x0029 Freerun needs 3 buffer mode P -> S P + E

0x002A Background Watchdog S, O P + E

0x002B No Valid Inputs and Outputs O, S -> O S + E

0x002C Fatal Sync Error O S + E

0x002D No Sync Error S -> O S + E

0x0030 Invalid DC SYNC Configuration O, S -> O, P -> S P + E, S + E

0x0031 Invalid DC Latch Configuration O, S -> O, P -> S P + E, S + E

0x0032 PLL Error O, S -> O S + E

0x0033 DC Sync IO Error O, S -> O S + E

0x0034 DC Sync Timeout Error O, S -> O S + E

0x0035 DC Invalid Sync Cycle Time P -> S P + E

0x0036 DC Sync0 Cycle Time P -> S P + E

0x0037 DC Sync1 Cycle Time P -> S P + E

0x0041 MBX_AOE B, P, S, O I + E, P + E, S + E

0x0042 MBX_EOE B, P, S, O I + E, P + E, S + E

0x0043 MBX_COE B, P, S, O I + E, P + E, S + E

0x0044 MBX_FOE B, P, S, O I + E, P + E, S + E

0x0045 MBX_SOE B, P, S, O I + E, P + E, S + E

0x004F MBX_VOE B, P, S, O I + E, P + E, S + E

0x0050 EEPROM no access Any I + E, P + E, S + E

0x0051 EEPROM Error Any I + E, P + E, S + E

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

6

Page 36

vacon • 36 Commissioning

Table 18. EtherCAT AL Status Codes

Code Description

Current state or

state changes

Resulting state

0x0060 Slave restarted locally Any I

0x0061 Device Identification value updated P P + E

6.1.2.6 SM Watchdog

SM Watchdog monitor value tells SM watchdog time in milliseconds. If usage of SM watchdog is

configured into EtherCAT master device then the master configures this time the to EtherCAT slave

devices before process data communication is started.

See setting of SM watchdog in Chapter 6.2.4 "Setting the watchdog".

6.1.2.7 Station Alias

Station Alias monitor value shows currently used Configured Station Alias. EtherCAT master devices can use the alias for node addressing.

See setting of the alias in Chapter 6.2.3.2 "Configured station alias".

6.1.2.8 Drive control word

Drive control word monitor value shows the control word in AC drive specific format. In most cases

®

the control word is transferred to AC drive in VACON

format which is described in Chapter 11 "AP-

PENDIX C - CONTROL AND STATUS WORD".

If PROFIdrive operate mode is used, then OPTEC EtherCAT converts the control word into VACON

®

format before transmitting it to the application. In Bypass mode PLC can send the control word in

a special application specific format to the application.

6.1.2.9 Drive status word

Drive status monitor value shows the status word in AC drive specific format. In most cases the sta-

®

tus word is transferred from AC drive application to OPTEC EtherCAT in VACON

format which is

described in Chapter 11 "APPENDIX C - CONTROL AND STATUS WORD".

If CiA-402 Drive Profile operate mode is used, then OPTEC EtherCAT converts the status word into

CiA-402 Drive Profile format before transmitting it to the PLC. In Bypass mode AC drive application

can send the status word in a special application specific format to OPTEC EtherCAT which then

passed the status word to the PLC.

6.1.2.10 Protocol control word

Protocol control word monitor value shows the control word that was received from EtherCAT master.

If Operate mode is "Drive Profile" then control word is in CiA-402 format. See CiA-402 Drive profile

mode.

If Operate mode is "Bypass" then control word is usually in VACON

®

specific format. See Chapter 11

"APPENDIX C - CONTROL AND STATUS WORD". Special applications might use other formats.

6.1.2.11 Protocol status word

Protocol status word monitor value shows the status word that OPTEC EtherCAT option board

sends to EtherCAT master.

If Operate mode is "Drive Profile" then status word is in CiA-402 format. See CiA-402 Drive profile

mode.

If Operate mode is "Bypass" then status word is usually in VACON

®

specific format. See Chapter 11

"APPENDIX C - CONTROL AND STATUS WORD". Special applications might use other formats.

6

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 37

Commissioning vacon • 37

6.1.2.12 ESI Selection Mode

ESI Selection Mode shows currently used ESI Selection Mode. See details of this functionality in

Chapter 6.4 "ESI file selection".

6.1.2.13 Product Code

Product Code monitor value shows currently used EtherCAT Product Code. It affects into automatic

selection of Slave Information (ESI) file in EtherCAT master configuration tools. See details of this

functionality in Chapter 6.4 "ESI file selection".

6.1.2.14 Revision Number

Revision Number monitor value shows currently used EtherCAT Revision Number. It affects into

automatic selection of Slave Information (ESI) file in EtherCAT master configuration tools. See details of this functionality in Chapter 6.4 "ESI file selection".

6.1.2.15 IP part 1

The most significant byte of OPTEC IP address.

6.1.2.16 IP part 2

Second byte of OPTEC IP address.

6.1.2.17 IP part 3

Third byte of OPTEC IP address.

6.1.2.18 IP part 4

The least significant byte of OPTEC IP address.

6.1.2.19 Subnet mask P1

The most significant byte of OPTEC subnet mask.

6.1.2.20 Subnet mask P2

Second byte of OPTEC subnet mask.

6.1.2.21 Subnet mask P3

Third byte of OPTEC subnet mask.

6.1.2.22 Subnet mask P4

The least significant byte of OPTEC subnet mask.

6.1.2.23 Default GW IP P1

The most significant byte of default gateway IP address.

6.1.2.24 Default GW IP P2

Second byte of default gateway IP address.

6.1.2.25 Default GW IP P3

Third byte of default gateway IP address.

6.1.2.26 Default GW IP P4

The least significant byte of gateway IP address.

6.1.2.27 EoE

Status of Ethernet over EtherCAT. Shows “Enabled” if OPTEC EoE is activated by master and other

monitor values (IP part 1 etc) are valid. If status is “Disabled” OPTEC has no valid IP address and it

cannot be connected via VACON

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

®

live for example.

6

Page 38

vacon • 38 Commissioning

6.2 EtherCAT master configuration

EtherCAT master (PLC) is typically connected to OPTEC EtherCAT option board with a following procedure.

Step 1. Import EtherCAT Slave Information files (ESI files) into EtherCAT master configuration tool.

Step 2. Connect EtherCAT master to OPTEC EtherCAT option board.

Step 3. Configure connection to OPTEC EtherCAT.

6.2.1 Importing OPTEC EtherCAT ESI files

ESI file defines slave device's functionality and object list to EtherCAT master device. Using of ESI

files is optional, but eases data mapping between EtherCAT master and EtherCAT slave.

OPTEC EtherCAT option board ESI files can be downloaded from https://www.danfoss.com/en/service-and-support/ -> Software -> Select “Drives” as Business unit -> Fieldbus configuration files.

• OPTEC_VACON_OPTEC_Vxx_yyyymmdd.xml is generic ESI file for OPTEC option. It can be

used with all VACON

objects for accessing of application specific IDs.

• AC drive and AC drive application specific ESI files (for example

OPTEC_VACON_NX_ALLINONE_yyyymmdd.xml) defines CoE objects for accessing of application specific parameters.

NOTE! Application specific parameters can be accessed even when ESI file does not does not define

CoE objects for them. See details in Chapter 7.4 "Accessing drive parameters via CoE MailBox".

®

AC drives and AC drive applications. This ESI file does not define CoE

ESI files must be imported to the PC hard disk from where EtherCAT master configuration tool can

find them. In some case restart of EtherCAT master configuration tool is required before new ESI

files are taken into use.

• In case of TwinCAT 2.x ESI file default location is: C:\TwinCAT\Io\EtherCAT

• In case of TwinCAT 3.x ESI file default location is: C:\TwinCAT\3.x\Config\Io\EtherCAT

• In case of CODESYS V3.x ESI file is selected as part of EtherCAT slave device importing process. See Chapter 6.2.2.3 "Slave scan in CODESYS V3.x"

See more about ESI file selection logic in Chapter 6.4 "ESI file selection".

6.2.2 Establishing connection to OPTEC EtherCAT

The following chapters shows scanning of OPTEC EtherCAT option board in TwinCAT 2.x and TwinCAT 3.x.

6.2.2.1 Slave scan in TwinCAT 2.x

Connect the Ethernet cable from the Ethernet card of the computer to the IN

1

Connector of the OPTEC Option Board EtherCAT (for more information see

Chapter 4.1 "Layout and connections").

6

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 39

Commissioning vacon • 39

Start the TwinCAT System Manager by right-clicking on the toolbar icon and by

selecting ‘System Manager’.

2

3

In the TwinCAT System Manager, go to ‘Options’ -> ‘Show Real Time Ethernet

Compatible Devices…’

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

6

Page 40

vacon • 40 Commissioning

In the first phase your Ethernet card is shown under "Incompatible devices". Select the card and click "Install". After this operation the card is visible under "Installed and ready to use devices.

4

5

6

Make sure that TwinCAT is in the Config mode (check that the text Config mode is

visible in the bottom right corner).

If this is not the case, switch the TwinCAT System Manager to the Config Mode by

clicking 'Set/Reset TwinCAT to Config Mode'.

6

7

8

In the 'Load I/O devices?' dialog, click 'Yes'.

In the 'Active Free Run?' dialog, click 'No'

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 41

Commissioning vacon • 41

9

10

Start a new project by clicking 'New' from the toolbar or by clicking 'File' -> 'New'.

Scan the devices by right-clicking on top of the 'I/O devices' tree item and by selecting 'Scan Devices…'.

11

12

13

Select the Ethernet card used for communication with the OPTEC Option Board

(the Ethernet card which is connected to the IN connector of the OPTEC Option

Board), and click 'OK'.

In the 'Scan for boxes?' dialog, click 'Yes'.

To switch the EtherCAT bus to OPERATIONAL state, click 'Yes' in the 'Activate

free run?' dialog.

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

6

Page 42

vacon • 42 Commissioning

When the connection has been established, TwinCAT looks like in the picture below.

14

6

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 43

Commissioning vacon • 43

6.2.2.2 Slave scan in TwinCAT 3.x

Connect the Ethernet cable from the Ethernet card of the computer to the IN Con-

1

nector of the OPTEC EtherCAT option board. For more information see Chapter 4

"Layout and connections".

Open TwinCAT XAE program from Windows Programs folder.

2

3

4

Define Ethernet interface for TwinCAT by opening “TWINCAT” -> “Show Realtime

Ethernet Compatible Devices…”

From the list, select the Ethernet interface in which EtherCAT master is connected. After that, select “Install”.

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

6

Page 44

vacon • 44 Commissioning

In Solution Explorer, add EtherCAT master to the project. EtherCAT master can

be searched by scanning (see A below). Alternatively, EtherCAT master can be

added with "Add New Item…" option (see B below).

5

5A. In case of scanning TwinCAT shows Ethernet interface which is connected to

EtherCAT devices. Select the interface and press “OK”.

5B. In case of "Add New Item…" select "EtherCAT master" device from the list and

press “OK”.

6

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 45

Commissioning vacon • 45

After this TwinCAT shows list of Ethernet interfaces. Select the interface in which

EtherCAT master device is connected and press “OK”.

6

Set TwinCAT into configuration mode. Press “OK” to the following "Restart TwinCAT System in Config Mode" and "Load I/O Devices" queries.

7

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

6

Page 46

vacon • 46 Commissioning

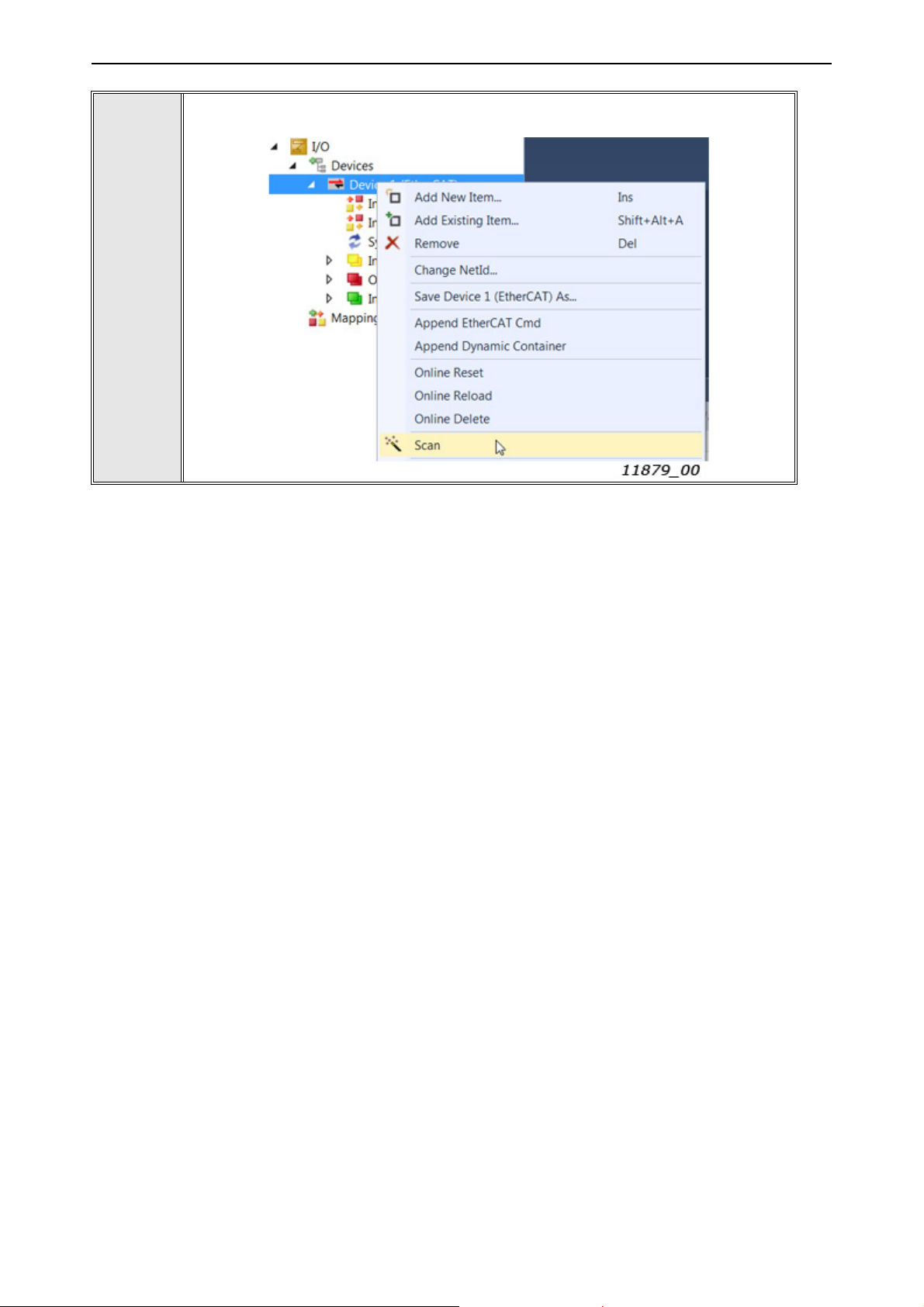

Scan Ethernet boxes (slave devices) by pressing right mouse key over EtherCAT

master device. After that select "Scan".

8

6

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 47

Commissioning vacon • 47

New EtherCAT slave box should appear into menu tree if TwinCAT finds a correct

ESI file for the device.

If TwinCAT cannot find ESI file for the device then it is possible to use object online

description. Press “Yes” for online description query. After that "OPTEC" box

should appear into menu tree.

9

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

6

Page 48

vacon • 48 Commissioning

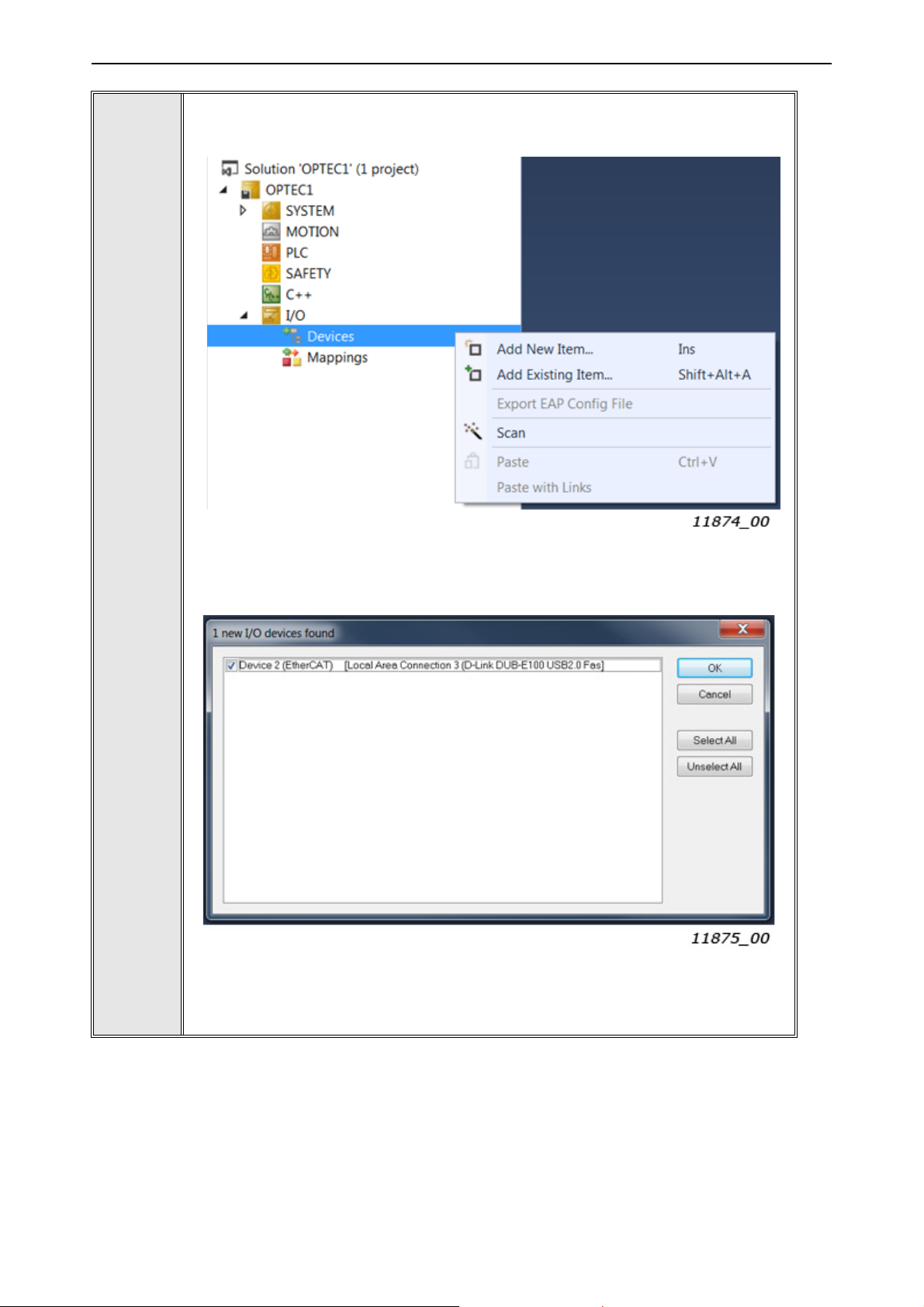

6.2.2.3 Slave scan in CODESYS V3.x

Make sure WinPCAP Ethernet drivers are installed into your PC. Scanning of

1

2

EtherCAT slave devices with CODESYS virtual EtherCAT master is going to fail

without WinPCAP driver.

Open Gateway configuration file which is located in C:\Program Files (x86)\3S

CODESYS\GatewayPLC\ CODESYSControl.cfg. Then add "SysEthernet" component into Component manager.

[ComponentManager]

Component.1=CmpTargetVisuStub

Component.2=CmpWebServer

Component.3=CmpWebServerHandlerV3

Component.4=SysEthernet

;Component.4=CmpHilscherCIFX

;Component.5=CmpPCANBasicDrv

Start "CODESYS V.3x" program and select "New Project..."

3

6

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 49

Commissioning vacon • 49

Select for example "Standard Project" as a base project and write name for the

project. Then press "OK".

4

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

6

Page 50

vacon • 50 Commissioning

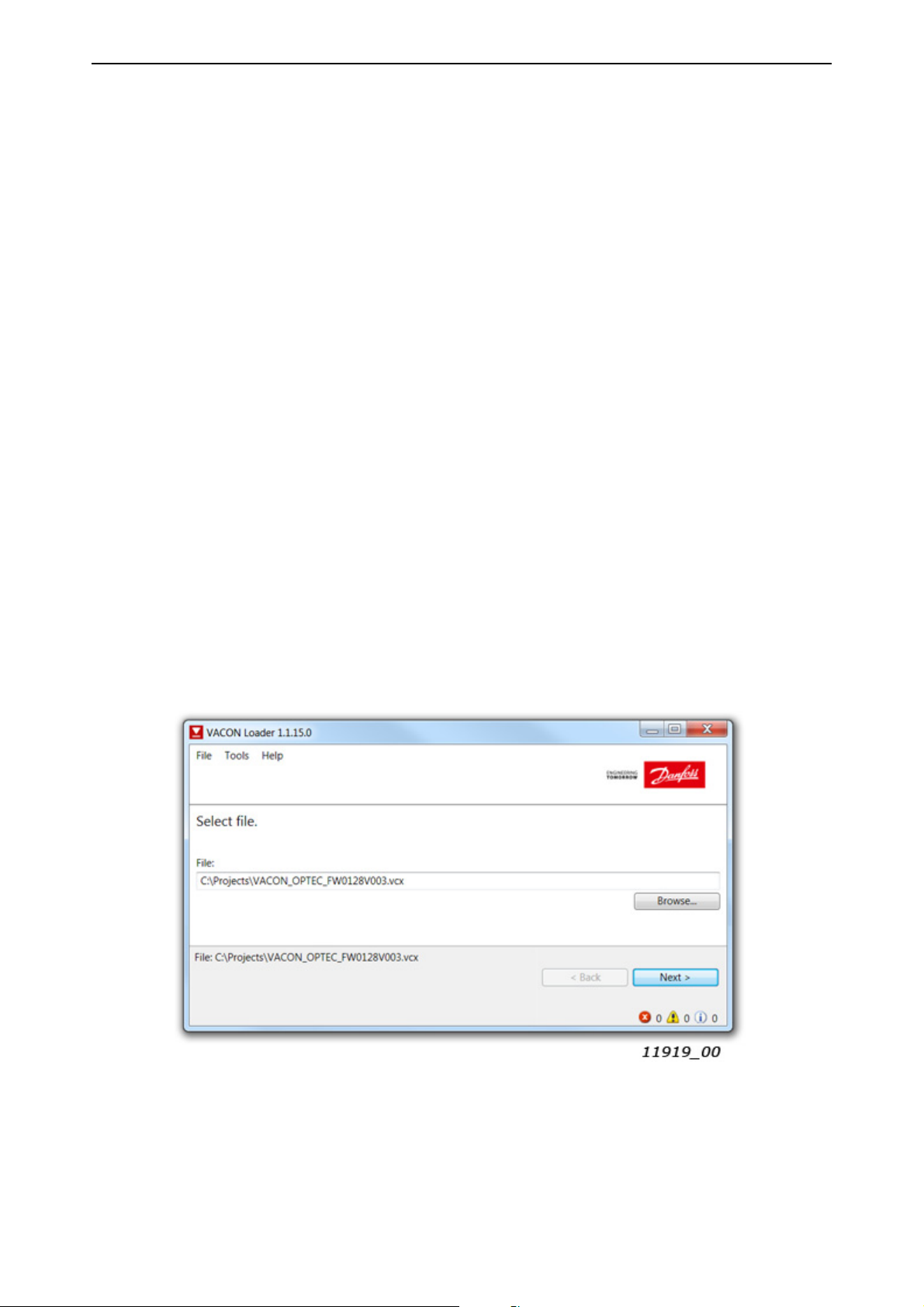

Select "Tools" -> "Device Repository..." menu. Then click "Install..." and select

ESI file for OPTEC EtherCAT.

NOTE! In this example generic OPTEC_VACON_OPTEC_Vxx_yyyymmdd.xml ESI

file is used. As a result, OPTEC EtherCAT is shown in CODESYS with name "OPTEC". The device name is different when using drive and application specific ESI

file.

After selecting the ESI file the device is added into "Installed devices" list. Device

Repository can be now closed.

5

6

Double click "Device (CODESYS Control Win V3)" in Devices list.

6

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 51

Commissioning vacon • 51

Check that Gateway module's IP-Address is "localhost". If not, then create a new

Gateway from "Gateway" -> "Add new gateway..." and define localhost address

for it.

7

Check from Windows system tray that CODESYS PLC is running. Click "Start PLC"

if it is in stopped state.

8

9

Select "Scan Network..." and then select the device which is your PC computer.

Then click "OK".

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

6

Page 52

vacon • 52 Commissioning

If operation is successful, then Device view shows green color for both Gateway

module and PC computer.

10

Select with right mouse "Device (CODESYS Control Win V3)" -> "Add Device.."

11

12

Select from "Add Device" menu "EtherCAT Master". Then click "Add device" and

close "Add Device menu".

6

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 53

Commissioning vacon • 53

EtherCAT_Master should appear into left side Devices menu. Open EtherCAT

master configuration page by double clicking "EtherCAT_Master (EtherCAT Master)".

13

Select Ethernet interface for EtherCAT master by clicking "Browse...". Then select Ethernet interface in which OPTEC EtherCAT is connected to. After that click

"OK" in Select Network Adapter view.

14

After this EtherCAT_Master tab should show your network interface name and

MAC address.

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

6

Page 54

vacon • 54 Commissioning

Select with left mouse key "EtherCAT_Master (EtherCAT Master)" -> "Scan for

Devices...". Scan Devices window is opened. Then click "Scan Devices" button

from the left corner of the window.

15

6

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 55

Commissioning vacon • 55

EtherCAT device should appear into Scanned Devices list.

CODESYS shows Alias Address of the device. This alias is same as shown in OPTEC EtherCAT's monitor value view (Chapter 6.1.2.7 "Station Alias"). The alias

can be changed by changing the value and then clicking "Assign Address". After

power cycle of VACON

Click "Copy to project".

®

AC drive the new alias is taken into use.

16

17

OPTEC EtherCAT is added under EtherCAT_Master.

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

6

Page 56

vacon • 56 Commissioning

6.2.3 Addressing and identification

EtherCAT protocol supports various of different mechanisms for EtherCAT slave device addressing

and identification. Following mechanisms are possible with OPTEC EtherCAT option board:

• Positional addressing where EtherCAT master defines address for each slave device via its

physical position in the communication ring.

• Configured Station Alias which is stored permanently into EtherCAT slave device.

• Device ID value that is loaded to AL status code register upon request from master.

Additionally, EtherCAT master and EtherCAT configuration tool might use following information for

EtherCAT slave device identification:

•Vendor ID

•Product Code

• Revision Number

6.2.3.1 Positional addressing

Part of EtherCAT master devices supports positional addressing where EtherCAT master defines

address for each slave device via its physical position in the communication ring.

For example, Beckhoff TwinCAT supports "Auto-increment" addressing where EtherCAT master

assigns automatically addresses for the slave devices during the start-up phase. The first slave in

the ring has an address of 0 and following the addresses are decremented 0xFFFF(-1), 0xFFFE(-2)

etc.

6.2.3.2 Configured station alias

Configured station alias is stored into permanent memory of EtherCAT slave device. In start-up the

slave device writes the station alias value into EtherCAT register 0x0012, from where it can be read

by the EtherCAT master. The master can then use this unique address for slave device identification

and addressing.

Configured station alias can be set to OPTEC EtherCAT with two methods.

1. EtherCAT master or EtherCAT configuration tool writes configured station alias permanently

into EtherCAT slave device's EEPROM. In startup the EtherCAT slave device loads this address

into its EtherCAT register 0x0012.

2. Configured station alias can be set with Station alias panel parameter. In startup OPTEC EtherCAT writes Station alias panel parameter value into EtherCAT register 0x0012.

Using of Station alias panel parameter might be useful in following cases:

• Special tools for writing EtherCAT slave device EEPROM are not available.

• Configured station alias must be stored into AC drive parameter backup.

OPTEC EtherCAT currently used Configured station alias can be seen in Station alias monitor value.

See monitor and parameter value usage in Chapter 6.1 "AC drive and OPTEC EtherCAT option board

parametrization".

6.2.3.3 Device ID value

Device ID value of OPTEC is set via panel parameter “Device ID”. It is permanently saved to nonvolatile memory and loaded during startup.

6

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 57

Commissioning vacon • 57

6.2.3.4 Configured station alias in TwinCAT

Step 1. Beckhoff TwinCAT can write Configured station alias into EtherCAT slave device's EEPROM.

Go to EtherCAT tab -> Advanced Settings… -> ESC Access -> E2PROM -> Configured Station Alias.

In this view TwinCAT also shows EtherCAT slave device's currently used Configured Station Alias.

Figure 6.Configured station alias settings in TwinCAT

Step 2. Select Configured Station Alias as an identification method in General -> Idenfication settings.