Page 1

User Guide

VACON® OPTE3/E5 PROFIBUS DP

Page 2

Page 3

VACON® OPTE3/E5 PROFIBUS DP

User Guide

Contents

1

Introduction 8

1.1

Purpose of the Manual 8

Additional Resources 8

1.2

Manual and Software Version 8

1.3

1.4

Type Approvals and Certications 9

1.5

Product Overview 10

1.5.1

PROFIBUS 10

1.5.2

PROFIBUS DP 10

1.5.3

Features of PROFIBUS DP–VACON® Interface 10

Technical Data 10

1.5.4

VACON® PC Tools 11

1.5.5

Symbols and Abbreviations 11

1.6

Contents

Safety 13

2

2.1

Safety Symbols 13

2.2

Danger and Warnings 13

2.3

Cautions and Notices 14

2.4

Grounding 16

3

Commissioning 18

3.1

Before Commissioning 18

3.1.1

Installing VACON® PC Tools 18

3.1.2

Downloading Fieldbus Option Firmware 18

3.2

Commissioning with VACON® PC Tools 19

3.2.1

Updating Fieldbus Firmware with VACON® Loader 19

3.2.2

Adjusting Communication Settings 20

3.2.2.1

3.2.2.2

3.2.3

Setting Drive and PROFIBUS DP Parameters 21

3.2.3.1

Adjusting Serial Communication Settings in VACON® NCDrive 20

Adjusting Serial Communication Settings in VACON® Live 20

Setting Drive and PROFIBUS DP Parameters with VACON® NCDrive 21

3.2.3.2

3.3

Replacing VACON® NXS or NXL AC Drive with VACON® 100 Family AC Drive 23

4

Control Interface and Communication 25

4.1

PROFIBUS DP Communication Overview 25

4.1.1

Determining the PROFIBUS DP Cycle Time 25

4.2

Fieldbus Option Board Communication Modes 26

4.2.1

Requirements for Communication Modes 26

Setting Drive and PROFIBUS DP Parameters with VACON® Live 22

BC346130363093EN-US-000101/DPD00997 | 3Danfoss A/S © 2020.06

Page 4

VACON® OPTE3/E5 PROFIBUS DP

User Guide

4.3

Contents

4.2.2

Fieldbus Communication Mode Features and Limitations 27

4.2.3

Normal Fieldbus Communication 28

4.2.4

Fast Fieldbus Communication 28

4.2.5

Fast Safety Fieldbus Communication 29

4.2.6

Normal Extended Mode 29

Drive Control 29

4.3.1

PROFIBUS DP Modules 29

4.3.2

Fieldbus Process Data 30

4.3.3

Bypass Operating Mode 33

4.3.3.1

4.3.3.2

4.3.3.3

4.3.4

Echo Operating Mode 41

4.3.5

PROFIdrive 4.1 Control Prole 41

Control Word Overview 33

Status Word Overview 37

Control and Status Word Monitoring Values 40

4.3.5.1

4.3.5.2

4.3.5.3

4.3.5.4

4.3.5.5

4.3.5.6

4.3.5.7

4.3.5.8

4.3.5.9

4.3.5.10

4.3.5.11

4.3.5.12

4.3.6

PROFIdrive 2.0 Control Prole 55

4.3.6.1

4.3.6.2

4.3.6.3

PROFIdrive 4.1 Prole Overview 41

PROFIdrive 4.1 State Machine 41

Standard Telegrams 43

Vendor-Specic Telegrams 45

PPO Types 48

PROFIdrive 4.1 Control Word (STW1) 50

PROFIdrive 4.1 Status Word (ZSW1) 51

Setpoint Value 52

Actual Speed Value 53

Normalization Reference Parameter 53

Shortlist of Commands to Start the Drive 53

Coding of Data Signals 54

PROFIdrive 2.0 Control Word 55

PROFIdrive 2.0 Status Word 56

State Machine for PROFIdrive 2.0 57

4.3.6.4

4.4

PROFIsafe 59

4.4.1

Introduction to PROFIsafe 59

4.4.2

PROFIdrive on PROFIsafe 60

5

Parameter Access 61

5.1

Parameter Access in PROFIdrive 4.1 61

5.1.1

Parameter Access Sequence 61

PPO Types 58

BC346130363093EN-US-000101/DPD009974 | Danfoss A/S © 2020.06

Page 5

VACON® OPTE3/E5 PROFIBUS DP

User Guide

5.1.2

Parameter Requests 61

5.1.2.1

5.1.2.2

5.1.2.3

5.1.2.4

5.1.3

Parameter Responses 64

5.1.3.1

5.1.3.2

5.1.3.3

5.1.3.4

5.1.3.5

5.1.3.6

5.1.3.7

5.1.3.8

DP-V1 Header 62

Request Header 62

Parameter Address 63

Parameter Value 63

DP-V1 Header 64

Error Response 64

PROFIdrive 4.1 Error Classes and Codes 65

PROFIdrive Parameter Access Errors 66

Response Header 67

Parameter Values 68

Parameter Description Elements 68

Identier Field 68

Contents

5.1.3.9

5.1.3.10

5.1.3.11

5.1.3.12

5.1.3.13

5.1.3.14

5.1.3.15

5.1.3.16

5.1.4

Example Requests and Responses 71

5.1.4.1

5.1.4.2

5.1.4.3

5.1.4.4

5.1.4.5

5.1.4.6

5.1.4.7

Number of Array Elements Field 69

Standardization Factor Field 69

Variable Attribute Field 69

Name Field 70

Low/High Limit Fields 70

ID Extension Field 70

Normalization Reference Parameter Field 70

Normalization Field 71

Request Parameter PNU918 Value 71

Read Response to Request Parameter PNU918 Value 72

Request All Elements of Parameter PNU964 72

Read Response to Request Parameter PNU964 73

Request the Value of Unsupported Parameter PNU900 73

Read Response to Request of Unsupported Parameter PNU900 74

Request the Value of Drive Parameter ID 103 74

5.1.4.8

5.1.4.9

5.1.4.10

5.1.4.11

5.1.4.12

5.1.5

Supported Parameters 82

5.1.6

PROFIdrive Fault Buer 86

5.1.7

Drive System Time 87

Change the Value of Drive Parameter ID 103 (Successful) 75

Change the Value of Drive Parameter ID 103 (Unsuccessful) 75

Request Multiple Values from Drive 76

Change Values of Multiple Drive Parameters (Successful) 78

Change Values of Multiple Drive Parameters (Unsuccessful) 80

BC346130363093EN-US-000101/DPD00997 | 5Danfoss A/S © 2020.06

Page 6

VACON® OPTE3/E5 PROFIBUS DP

User Guide

5.1.7.1

5.1.7.2

5.2

Parameter Access in PROFIdrive 2.0 88

5.2.1

DP-V1 with PROFIdrive 2.0 88

5.2.2

Parameter Field (PKW) in PPO Types 88

5.2.3

Example Requests and Responses 89

5.2.3.1

5.2.3.2

6

Parameters 91

6.1

PROFIBUS DP Board Parameters 91

6.1.1

Slave Address 91

6.1.2

Operate Mode 91

6.1.3

Compatib. Mode 93

6.2

Parameters Congured in PLC 94

Read Drive System Time 87

Write Drive System Time 87

Read Maximum Frequency (ID = 102) 89

Write Control Place (ID = 125) 90

Contents

6.2.1

Operate Mode 94

6.2.2

DP Mode 94

6.3

Safety Parameters 94

6.4

AC Drive Parameters 94

6.4.1

AC Drive Parameters for Fieldbus Control and Reference Selection 94

6.4.2

Fieldbus Parameters for VACON® 100 Family Standard Application 95

6.4.3

Fieldbus Parameters for VACON® 20 Standard Application 95

6.4.4

Fieldbus Parameters for VACON® 20 X Multipurpose Application 96

6.4.5

Fieldbus Parameters for VACON® NXP Multipurpose Application 96

6.5

Response to Fieldbus Fault Parameter 96

6.6

VACON® NXP System Software Parameters for Application Developers 97

6.6.1

System Software Variables for Selecting Communication Modes 97

6.6.2

System Software Variables for Monitoring Supported Communication Modes 97

6.6.3

System Software Variables for Selecting the Input Process Data Slot 98

7

Monitoring Values 99

7.1

PROFIBUS DP Board Monitoring Values 99

7.1.1

PROFIBUS DP Status 104

7.1.2

FB Protocol Status 104

7.1.3

Protocol 104

7.1.4

Baud Rate 104

7.1.5

PPO Type 104

7.1.6

Telegram Type 104

7.1.7

Safety Telegram 104

BC346130363093EN-US-000101/DPD009976 | Danfoss A/S © 2020.06

Page 7

VACON® OPTE3/E5 PROFIBUS DP

User Guide

7.1.8

Protocol CW/Fieldbus CW 105

7.1.9

Protocol SW/Fieldbus SW 105

7.1.10

Drive CW 105

7.1.11

Drive SW 105

8

Fault Tracing 106

8.1

LED Indications on PROFIBUS Option Boards 106

8.2

PROFIBUS DP Diagnosis 107

8.2.1

Standard Diagnosis 107

8.2.2

Channel-Related Diagnosis 108

8.3

Fault Handling 109

8.4

Gathering Diagnostic Data 109

8.5

Typical Fault Conditions 109

8.5.1

Source3 Fault Codes 110

Contents

BC346130363093EN-US-000101/DPD00997 | 7Danfoss A/S © 2020.06

Page 8

•

•

•

•

•

•

•

NOTE! Download the English and French product manuals with applicable safety, warning and caution information from https://

www.danfoss.com/en/service-and-support/.

REMARQUE Vous pouvez télécharger les versions anglaise et française des manuels produit contenant l'ensemble des informations de sécurité, avertissements et mises en garde applicables sur le site https://www.danfoss.com/en/service-and-support/.

Manual version

New features

Firmware

version

DPD00997B

Support for VACON® 100 INDUSTRIAL, VACON® 100 FLOW, VACON® 100 X, VACON® 20 X/CP, and VACON® 20 drives.

V004

DPD00997C

Support for new B version hardware. Firmware can also be used with older A version hardware.

Improved functionality of Control-By-PLC bit. This bit does not any more force control and reference place to eldbus. This bit is still required so that control from the eldbus is possible.

V005

Support for VACON® NXP drive.

Support for PROFIsafe when OPTE3/E5 board is used together with Advanced safety option board.

See details in 4.4 PROFIsafe.

Support for Fast Communication and 16 process data when installed to VACON® NXP drive. See

details in 4.2 Fieldbus Option Board Communication Modes.

Support for "C3 C5 Mode" compatibility mode when OPTE3/E5 is installed to VACON® NXP drive.

See details in 6.1 PROFIBUS DP Board Parameters.

Support for "NX Mode" compatibility mode when OPTE3/E5 is installed to VACON® 100 family and

VACON® 20 drives. See details in 6.1 PROFIBUS DP Board Parameters.

V006

VACON® OPTE3/E5 PROFIBUS DP

User Guide

Introduction

1 Introduction

1.1 Purpose of the Manual

The PROFIBUS DP programming guide provides information about conguring the system, controlling the drive, accessing parameters, programming, troubleshooting, and some typical application examples.

The programming guide is intended for use by qualied personnel, who are familiar with the VACON® drives, PROFIBUS technology,

and with the PC or PLC that is used as a master in the system.

Read the instructions before programming and follow the procedures in this manual.

1.2 Additional Resources

Resources available for the drive and optional equipment are:

•

VACON® RS485 CAN bus Installation Guide provides the necessary information to install the option board to the AC drive.

•

The Operating Guide of the AC drive provides the necessary information to get the drive up and running.

•

The Application Guide of the AC drive provides more details on working with parameters and many application examples.

•

VACON® OPTEA/OPTE9 Ethernet Board Programming Guide provides information on Ethernet settings.

Supplementary publications and manuals are available from drives.danfoss.com/knowledge-center/technical-documentation/.

For US and Canadian markets:

1.3 Manual and Software Version

This manual is regularly reviewed and updated. All suggestions for improvement are welcome.

The original language of this manual is English.

Table 1: Manual and Software Version

BC346130363093EN-US-000101 / DPD009978 | Danfoss A/S © | 2020.06

Page 9

•

•

•

•

•

•

•

•

•

Manual version

New features

Firmware

version

DPD00997D

Support for PPO_PROFIdrive mode which enables usage of PROFIdrive 4.1 together with PPO

types. See details in 6.1 PROFIBUS DP Board Parameters.

Support for drive fault history with time stamps. See details in 5.1.5 Supported Parameters.

Support for Drive CW and Drive SW monitor values. See details in 7.1 PROFIBUS DP Board Monitor-

ing Values.

V007

DPD00997E

PROFIsafe over PROFIBUS for VACON® NXP extended for advanced safety option boards OPTBL,

OPTBM and OPTBN in slots C and E in addition to slot D.

Maintance improvements and xes.

Conguration le updated.

The structure of the manual updated. Installation information removed (see VACON® RS485 CAN

bus Installation Guide).

V008

Telegram 140

PNU 10129

V009

089

VACON® OPTE3/E5 PROFIBUS DP

User Guide

Introduction

1.4 Type Approvals and Certications

The following list is a selection of possible type approvals and certications for Danfoss drives:

N O T I C E

The specic approvals and certication for the drive are on the nameplate of the drive. For more information, contact the local

Danfoss oce or partner.

BC346130363093EN-US-000101 / DPD00997 | 9Danfoss A/S © 2020.06

Page 10

Technical item or function

Technical data

Connections

Interface

OPTE3: Pluggable connector (5.08 mm)

OPTE5: 9-pin D-SUB connector (female)

Data transfer method

RS485, half duplex

Transfer cable

Shielded Twisted Pair

Electrical isolation

500 V DC

Communications

Drive prole

PROFIdrive

Standard Telegrams

1, 20

Vendor Telegrams

100, 101, 138, 139

Standard (Safety) Telegrams

30, 31

(1)

Vendor (Safety) Telegrams

58000

(1)

PPO types

1, 2, 3, 4, 5, 6

Baud rate

9.6 kBd to 12 MBd. Autobaud detect is always on.

Addresses

2–126

Environment

Ambient operating temperature

-10°C…50°C (For further information, see the installation manual of the AC

drive)

Storing temperature

-40°C…60°C

Humidity

<95%, no condensation, or frost allowed, non-corrosive

VACON® OPTE3/E5 PROFIBUS DP

User Guide

Introduction

1.5 Product Overview

1.5.1 PROFIBUS

PROFIBUS is an international standard for eldbus communication in automation technology (IEC 61158 and IEC 61784). The member companies of the PROFIBUS International User Community support the standard.

For information about PROFIBUS and downloads for PROFIBUS DP and the PROFIdrive prole, refer to www.probus.com.

1.5.2 PROFIBUS DP

The PROFIBUS DP protocol enables communication between PROFIBUS masters and slaves.

The master devices control the communication. The master can send data without a separate command when a token is given to

the Master. The slave devices are peripheral devices. Typical slave devices include input/output devices, valves, drives, and measuring transmitters. They do not have bus access rights and they can only acknowledge received messages or send messages to the

master when requested to do so.

VACON® AC drives can be connected to the PROFIBUS DP network using a eldbus board. The drive can then be controlled, monitored, and programmed from the Host system.

OPTE5/E3 option board also supports connection from DP Master (class 2) when DP-V1 is enabled. In this case, the master class 2

can initiate a connection, read and write parameters using the PROFIdrive Parameter Access service, and close the connection.

1.5.3 Features of PROFIBUS DP–VACON® Interface

Features of the PROFIBUS DP–VACON® interface:

•

Direct control of VACON® AC drives (for example, Run, Stop, Direction, Speed reference, Fault reset)

•

Full access to all VACON® AC drive parameters

•

Monitor VACON® AC drive status (for example, output frequency, output current, fault code)

1.5.4 Technical Data

Table 2: PROFIBUS DP Option Board Technical Data

BC346130363093EN-US-000101 / DPD0099710 | Danfoss A/S © | 2020.06

Page 11

Technical item or function

Technical data

Altitude

Maximum 1000 m

Vibration

0.5 G at 9…200 Hz

Safety

Fullls EN 50178 standard

Tool

VACON® 100 family

VACON® NXS/NXP

VACON® 20 family

VACON® Loader

Serial

(1)

Serial

(1)

Serial

(1)

VACON® Live

Serial

(1)

, Ethernet

(2)

Serial

(1)

VACON® NCIPCong

Not used with OPTE3/E5 PROFIBUS DP

VACON® NCDrive

Serial

(1)

, Ethernet

(2)

VACON® NCLoad

Not used with OPTE3/E5 PROFIBUS DP

Abbreviation

Denition

CW

Control word

DP

Distributed periphery

DU

Data unit

EEPROM

Electrical erasable programmable read-only memory

EMC

Electromagnetic compatibility

FB

Fieldbus

FDT

Field device tool

GSD

Generic Station Description

HMI

Human machine interface

VACON® OPTE3/E5 PROFIBUS DP

User Guide

1

Select only when Advanced safety option board with PROFIsafe is connected.

Introduction

1.5.5 VACON® PC Tools

With VACON® PC tools, it is possible to do following operations for OPTE3/E5 PROFIBUS DP:

•

Update rmware into OPTE3/E5 PROFIBUS DP option board (with VACON® Loader), see 3.2.1 Updating Fieldbus Firmware with

VACON® Loader

•

Set parameters for OPTE3/E5 PROFIBUS DP (with VACON® NCDrive or VACON® Live), see 3.2.3.1 Setting Drive and PROFIBUS DP

Parameters with VACON® NCDrive and 3.2.3.2 Setting Drive and PROFIBUS DP Parameters with VACON® Live

•

Read monitor values of OPTE3/E5 PROFIBUS DP (with VACON® NCDrive or VACON® Live)

For instructions on downloading and installing the tools, see 3.1.1 Installing VACON® PC Tools.

The following table describes what PC tools are supported in each AC drive type.

Table 3: The Supported PC Tools with Dierent AC Drives

1

The connection type "serial" is a direct serial connection to the AC drive.

2

The connection type "Ethernet" is an Ethernet connection, for example, VACON® 100 family built-in Ethernet interface, or a connection via OPTEA/

OPTE9 Dual Port Ethernet option board.

1.6 Symbols and Abbreviations

Table 4: Symbols and Abbreviations

BC346130363093EN-US-000101 / DPD00997 | 11Danfoss A/S © 2020.06

Page 12

Abbreviation

Denition

IND

Sub index

LED

Light emitting diode

PC

Personal computer

PDI

Process Data In

PDO

Process Data Out

PLC

Programmable logic controller

PNU

Parameter number

PPO

Process parameter object

SW

Status word

VACON® OPTE3/E5 PROFIBUS DP

User Guide

Introduction

BC346130363093EN-US-000101 / DPD0099712 | Danfoss A/S © | 2020.06

Page 13

VACON® OPTE3/E5 PROFIBUS DP

User Guide

2 Safety

2.1 Safety Symbols

The following symbols are used in this manual:

D A N G E R

Indicates a hazardous situation which, if not avoided, will result in death or serious injury.

W A R N I N G

Indicates a hazardous situation which, if not avoided, could result in death or serious injury.

C A U T I O N

Indicates a hazardous situation which, if not avoided, could result in minor or moderate injury.

N O T I C E

Indicates information considered important, but not hazard-related (for example, messages relating to property damage).

Safety

2.2 Danger and Warnings

D A N G E R

SHOCK HAZARD FROM POWER UNIT COMPONENTS

The power unit components are live when the drive is connected to mains. A contact with this voltage can lead to death or seri-

ous injury.

Do not touch the components of the power unit when the drive is connected to mains. Before connecting the drive to mains,

-

make sure that the covers of the drive are closed.

D A N G E R

SHOCK HAZARD FROM TERMINALS

The motor terminals U, V, W, the brake resistor terminals, or the DC terminals are live when the drive is connected to mains, also

when the motor does not operate. A contact with this voltage can lead to death or serious injury.

Do not touch the motor terminals U, V, W, the brake resistor terminals, or the DC terminals when the drive is connected to

-

mains. Before connecting the drive to mains, make sure that the covers of the drive are closed.

D A N G E R

SHOCK HAZARD FROM DC LINK OR EXTERNAL SOURCE

The terminal connections and the components of the drive can be live 5 minutes after the drive is disconnected from the mains

and the motor has stopped. Also the load side of the drive can generate voltage. A contact with this voltage can lead to death or

serious injury.

Before doing electrical work on the drive:

-

Disconnect the drive from the mains and make sure that the motor has stopped.

Lock out and tag out the power source to the drive.

Make sure that no external source generates unintended voltage during work.

Wait 5 minutes before opening the cabinet door or the cover of the AC drive.

Use a measuring device to make sure that there is no voltage.

BC346130363093EN-US-000101 / DPD00997 | 13Danfoss A/S © 2020.06

Page 14

VACON® OPTE3/E5 PROFIBUS DP

User Guide

Safety

W A R N I N G

SHOCK HAZARD FROM CONTROL TERMINALS

The control terminals can have a dangerous voltage also when the drive is disconnected from mains. A contact with this voltage

can lead to injury.

Make sure that there is no voltage in the control terminals before touching the control terminals.

-

W A R N I N G

ACCIDENTAL MOTOR START

When there is a power-up, a power break, or a fault reset, the motor starts immediately if the start signal is active, unless the pulse

control for Start/Stop logic is selected. If the parameters, the applications or the software change, the I/O functions (including the

start inputs) can change. If you activate the auto reset function, the motor starts automatically after an automatic fault reset. See

the Application Guide. Failure to ensure that the motor, system, and any attached equipment are ready for start can result in

personal injury or equipment damage.

Disconnect the motor from the drive if an accidental start can be dangerous. Make sure that the equipment is safe to operate

-

under any condition.

W A R N I N G

LEAKAGE CURRENT HAZARD

Leakage currents exceed 3.5 mA. Failure to ground the drive properly can result in death or serious injury.

Ensure the correct grounding of the equipment by a certied electrical installer.

-

W A R N I N G

SHOCK HAZARD FROM PE CONDUCTOR

The drive can cause a DC current in the PE conductor. Failure to use a residual current-operated protective (RCD) device Type B or

a residual current-operated monitoring (RCM) device can lead to the RCD not providing the intended protection and therefore

can result in death or serious injury.

Use a type B RCD or RCM device on the mains side of the drive.

-

2.3 Cautions and Notices

C A U T I O N

DAMAGE TO THE AC DRIVE FROM INCORRECT MEASUREMENTS

Doing measurements on the AC drive when it is connected to mains can damage the drive.

Do not do measurements when the AC drive is connected to mains.

-

C A U T I O N

DAMAGE TO THE AC DRIVE FROM INCORRECT SPARE PARTS

Using spare parts that are not from the manufacturer can damage the drive.

Do not use spare parts that are not from the manufacturer.

-

C A U T I O N

DAMAGE TO THE AC DRIVE FROM INSUFFICIENT GROUNDING

Not using a grounding conductor can damage the drive.

Make sure that the AC drive is always grounded with a grounding conductor that is connected to the grounding terminal

-

that is identied with the PE symbol.

BC346130363093EN-US-000101 / DPD0099714 | Danfoss A/S © | 2020.06

Page 15

VACON® OPTE3/E5 PROFIBUS DP

User Guide

C A U T I O N

CUT HAZARD FROM SHARP EDGES

There can be sharp edges in the AC drive that can cause cuts.

Wear protective gloves when mounting, cabling, or doing maintenance operations.

-

C A U T I O N

BURN HAZARD FROM HOT SURFACES

Touching surfaces, which are marked with the 'hot surface' sticker, can result in injury.

Do not touch surfaces which are marked with the 'hot surface' sticker.

-

N O T I C E

DAMAGE TO THE AC DRIVE FROM STATIC VOLTAGE

Some of the electronic components inside the AC drive are sensitive to ESD. Static voltage can damage the components.

Remember to use ESD protection always when working with electronic components of the AC drive. Do not touch the com-

-

ponents on the circuit boards without proper ESD protection.

Safety

N O T I C E

DAMAGE TO THE AC DRIVE FROM MOVEMENT

Movement after installation can damage the drive.

Do not move the AC drive during operation. Use a xed installation to prevent damage to the drive.

-

N O T I C E

DAMAGE TO THE AC DRIVE FROM INCORRECT EMC LEVEL

The EMC level requirements for the AC drive depend on the installation environment. An incorrect EMC level can damage the

drive.

Before connecting the AC drive to the mains, make sure that the EMC level of the AC drive is correct for the mains.

-

N O T I C E

RADIO INTERFERENCE

In a residential environment, this product can cause radio interference.

Take supplementary mitigation measures.

-

N O T I C E

MAINS DISCONNECTION DEVICE

If the AC drive is used as a part of a machine, the machine manufacturer must supply a mains disconnection device (refer to EN

60204-1).

N O T I C E

MALFUNCTION OF FAULT CURRENT PROTECTIVE SWITCHES

Because there are high capacitive currents in the AC drive, it is possible that the fault current protective switches do not operate

correctly.

BC346130363093EN-US-000101 / DPD00997 | 15Danfoss A/S © 2020.06

Page 16

Cross-sectional area of the phase conductors (S) [mm2]

The minimum cross-sectional area of the protective earthing conductor in question [mm2]

S ≤ 16

S

16 < S ≤ 35

16

35 < S

S/2

VACON® OPTE3/E5 PROFIBUS DP

User Guide

N O T I C E

VOLTAGE WITHSTAND TESTS

Doing voltage withstand tests can damage the drive.

Do not do voltage withstand tests on the AC drive. The manufacturer has already done the tests.

-

2.4 Grounding

Ground the AC drive in accordance with applicable standards and directives.

C A U T I O N

DAMAGE TO THE AC DRIVE FROM INSUFFICIENT GROUNDING

Not using a grounding conductor can damage the drive.

Make sure that the AC drive is always grounded with a grounding conductor that is connected to the grounding terminal

-

that is identied with the PE symbol.

W A R N I N G

LEAKAGE CURRENT HAZARD

Leakage currents exceed 3.5 mA. Failure to ground the drive properly can result in death or serious injury.

Ensure the correct grounding of the equipment by a certied electrical installer.

-

Safety

The standard EN 61800-5-1 tells that 1 or more of these conditions for the protective circuit must be true.

The connection must be xed.

•

The protective earthing conductor must have a cross-sectional area of minimum 10 mm2 Cu or 16 mm2 Al. OR

•

There must be an automatic disconnection of the mains, if the protective earthing conductor breaks. OR

•

There must be a terminal for a second protective earthing conductor in the same cross-sectional area as the rst protective

earthing conductor.

The values of the table are valid only if the protective earthing conductor is made of the same metal as the phase conductors. If this

is not so, the cross-sectional area of the protective earthing conductor must be determined in a manner that produces a conductance equivalent to that which results from the application of this table.

The cross-sectional area of each protective earthing conductor that is not a part of the mains cable or the cable enclosure, must be a

minimum of:

•

2.5 mm2 if there is mechanical protection, and

•

4 mm2 if there is not mechanical protection. With cord-connected equipment, make sure that the protective earthing conductor

in the cord is the last conductor to be interrupted, if the strain-relief mechanism breaks.

Obey the local regulations on the minimum size of the protective earthing conductor.

N O T I C E

MALFUNCTION OF FAULT CURRENT PROTECTIVE SWITCHES

Because there are high capacitive currents in the AC drive, it is possible that the fault current protective switches do not operate

correctly.

BC346130363093EN-US-000101 / DPD0099716 | Danfoss A/S © | 2020.06

Page 17

VACON® OPTE3/E5 PROFIBUS DP

User Guide

Safety

N O T I C E

VOLTAGE WITHSTAND TESTS

Doing voltage withstand tests can damage the drive.

Do not do voltage withstand tests on the AC drive. The manufacturer has already done the tests.

-

W A R N I N G

SHOCK HAZARD FROM PE CONDUCTOR

The drive can cause a DC current in the PE conductor. Failure to use a residual current-operated protective (RCD) device Type B or

a residual current-operated monitoring (RCM) device can lead to the RCD not providing the intended protection and therefore

can result in death or serious injury.

Use a type B RCD or RCM device on the mains side of the drive.

-

BC346130363093EN-US-000101 / DPD00997 | 17Danfoss A/S © 2020.06

Page 18

VACON® OPTE3/E5 PROFIBUS DP

User Guide

Commissioning

3 Commissioning

3.1 Before Commissioning

VACON® OPTE3/E5 PROFIBUS DP can be commissioned through the control panel of the AC drive or by using the VACON® PC tools.

Before starting the commissioning, check the following:

•

When using the control panel of the AC drive for commissioning: for instructions on how to use the control panel, see the Operating Guide for VACON® NXP products or the Application Guide for the VACON® 100 family.

•

When using VACON® PC tool for commissioning: the correct tool installed.

-

For a list of supported PC tools, see 1.5.5 VACON® PC Tools.

-

For instructions on installing the tools, see 3.1.1 Installing VACON® PC Tools.

•

VACON® AC drive in which OPTE3/E5 PROFIBUS DP option board installed. See VACON® RS485 CAN bus Installation Guide for

instructions.

•

When using serial connection:

-

VACON® NXP is connected to PC with RS232 serial cable. The cable is connected from PC to the 9-pin D-SUB connector

(female) of the VACON® NXP control unit. If PC does not contain RS232 serial port, then USB - RS232 converter device is

needed between PC and VACON® NXP control unit.

-

VACON® 100 family and VACON® 20 are connected to PC with VACON® Serial Cable.

•

When using Ethernet connection:

-

Ethernet cable which is connected to the Ethernet interface of the option board, or, in VACON® 100 family drives, of the

control board.

-

VACON® NXP requires option board supporting Ethernet communication. For example, OPTEA/OPTE9 Dual Port Ethernet

option board.

3.1.1 Installing VACON® PC Tools

Prepare for commissioning by installing the needed VACON® PC Tools.

Procedure

1.

Go to www.danfoss.com/.

2.

Select Downloads from Service and Support drop-down menu.

3.

Select Drives as business unit.

4.

Download the VACON® PC tool depending on the used AC drive.

•

VACON® 100 family AC drive: VACON® Loader and VACON® Live

•

VACON® 20 AC drive: VACON® Loader and VACON® Live

•

VACON® NXP AC drive: VACON® NCDrive and VACON® Loader

5.

Start the installation program and follow the on-screen instructions.

6.

After installation, launch VACON® PC tool from Windows Start menu.

7.

For more information about software features, go to Help drop-down menu and select Contents.

3.1.2 Downloading Fieldbus Option Firmware

Prepare for commissioning by downloading the Fieldbus Option Firmware.

Procedure

Go to

1.

2.

3.

4.

www.danfoss.com/.

Select Downloads from Service and Support drop-down menu.

Select Drives as business unit.

Download le Fieldbus rmware.

BC346130363093EN-US-000101 / DPD0099718 | Danfoss A/S © | 2020.06

Page 19

e30bh634.10

e30bh635.10

VACON® OPTE3/E5 PROFIBUS DP

User Guide

Commissioning

3.2 Commissioning with VACON® PC Tools

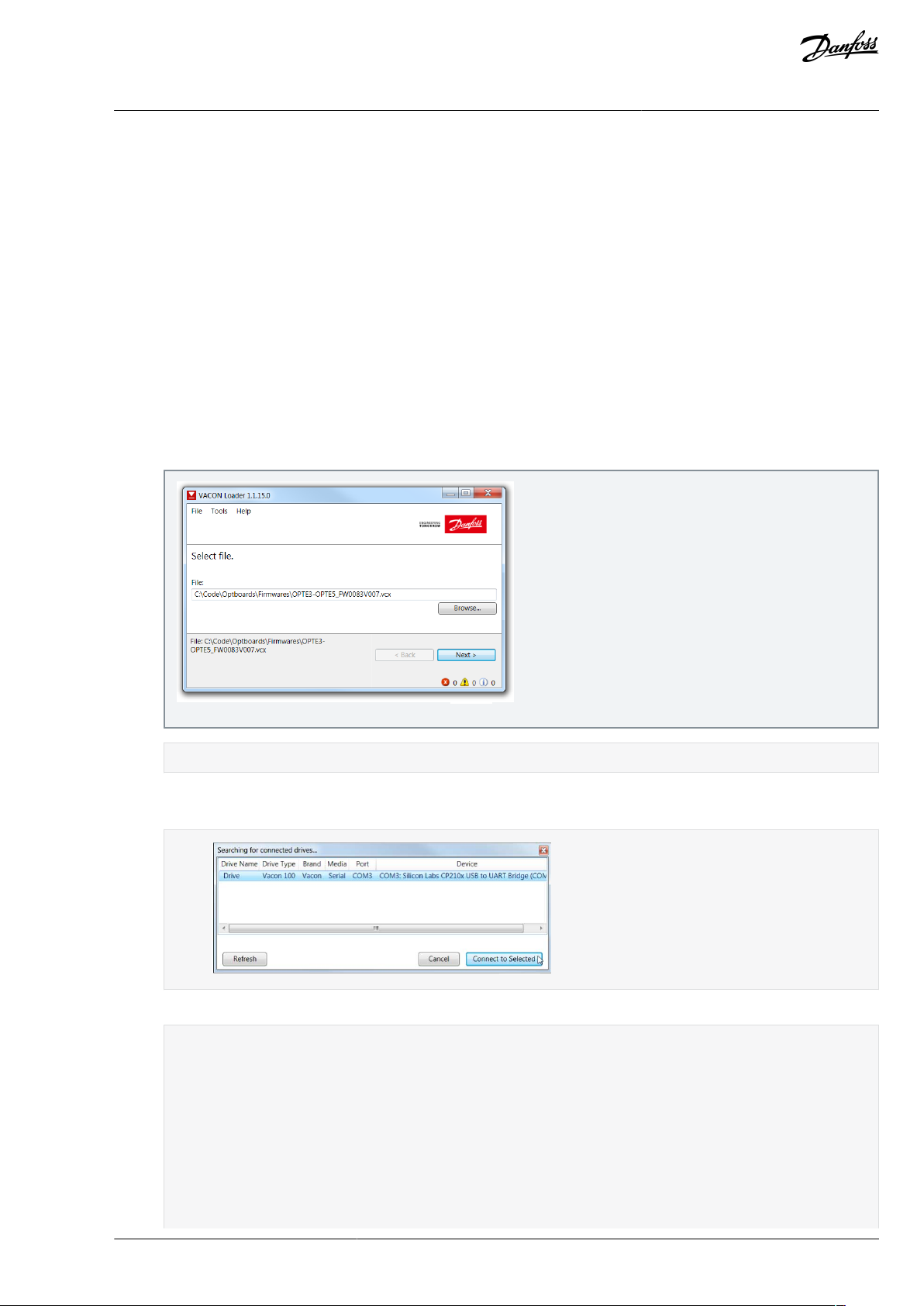

3.2.1 Updating Fieldbus Firmware with VACON® Loader

Use these instructions to upload the eldbus rmware with VACON® Loader.

NOTE! Screenshots in these instructions are examples only. The product information shown in them is dierent depending on

which option board is used.

Check the list in Before commissioning.

Adjust the baud rate if needed:

•

With VACON® 20, use the baud rate 9600.

•

With VACON® 20 X and VACON® 20 CP, the following baud rates are supported: 9600, 19200, 38400 or 57600.

•

With VACON® 100 family and VACON® NXP drives, VACON® Loader selects a correct baud rate automatically.

Procedure

1.

Connect your PC to the controller by using the serial cable.

2.

Open the File Explorer and select the rmware le to be updated to the option board and double-click it.

VACON® Loader software opens.

3.

Press Next and wait for the loader to nd the network drives.

4.

Select a drive from the list and press Connect to Selected.

5.

Select the modules to be updated, and press Next.

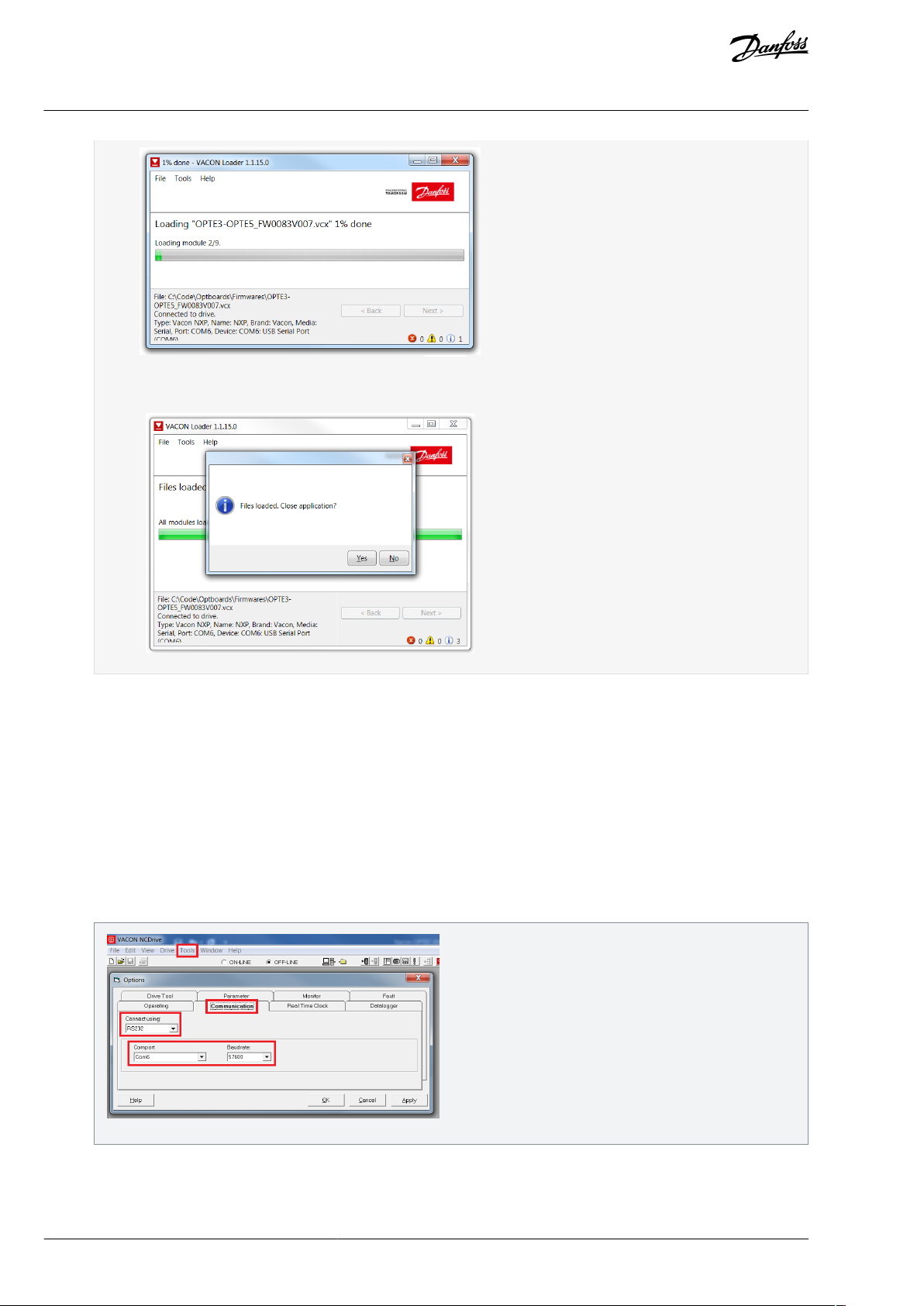

Firmware starts to load:

BC346130363093EN-US-000101 / DPD00997 | 19Danfoss A/S © 2020.06

Page 20

e30bh636.10

e30bh637.10

e30bh638.10

VACON® OPTE3/E5 PROFIBUS DP

User Guide

Commissioning

Loading is nished:

3.2.2 Adjusting Communication Settings

3.2.2.1 Adjusting Serial Communication Settings in VACON® NCDrive

Use these instructions to adjust the serial communication settings in VACON® NCDrive.

Procedure

1.

Connect your PC to the control unit by using the USB/RS232 cable.

2.

Select Tools.

3.

Select Options….

4.

Select Communication tab.

5.

Dene settings for the USB - RS232 adapter and press OK.

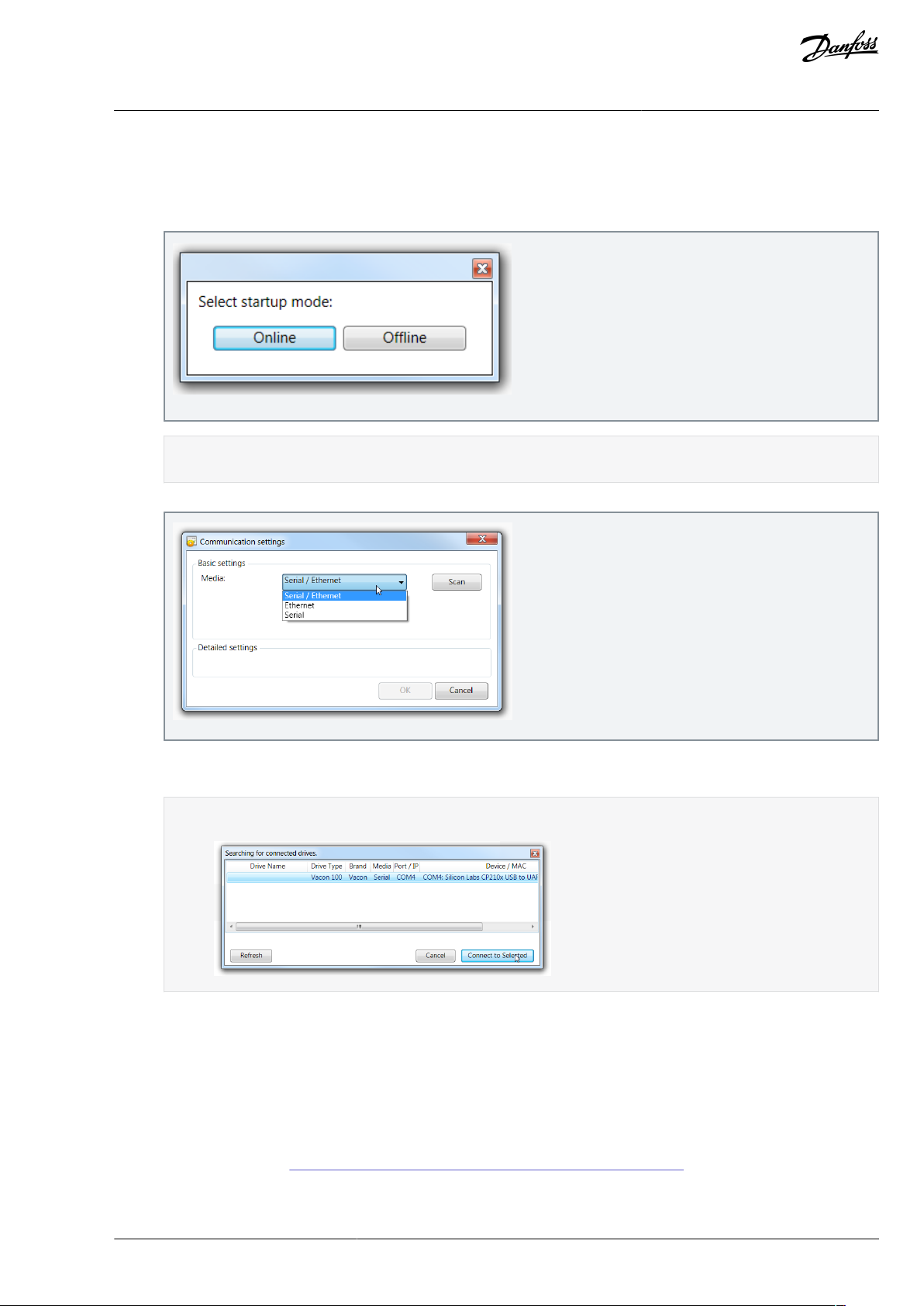

3.2.2.2 Adjusting Serial Communication Settings in VACON® Live

Use these instructions to adjust the serial communication settings in VACON® Live.

BC346130363093EN-US-000101 / DPD0099720 | Danfoss A/S © | 2020.06

Page 21

e30bh642.10

e30bh643.10

e30bh644.10

VACON® OPTE3/E5 PROFIBUS DP

User Guide

Procedure

1.

Connect the PC to VACON® AC drive with VACON® Serial Cable.

2.

Start VACON® Live.

3.

When the program starts, select Online for start-up mode.

4.

If VACON® Live cannot nd your AC drive, ensure that Serial / Ethernet or Serial is selected.

Commissioning

The program scans compatible drives. After successful scanning, VACON® Live shows the drive in connected drives

window.

5.

Press Scan.

6.

Select the drive and press Connected to Selected.

VACON® Live reads parameter and monitor value tree from the drive.

3.2.3 Setting Drive and PROFIBUS DP Parameters

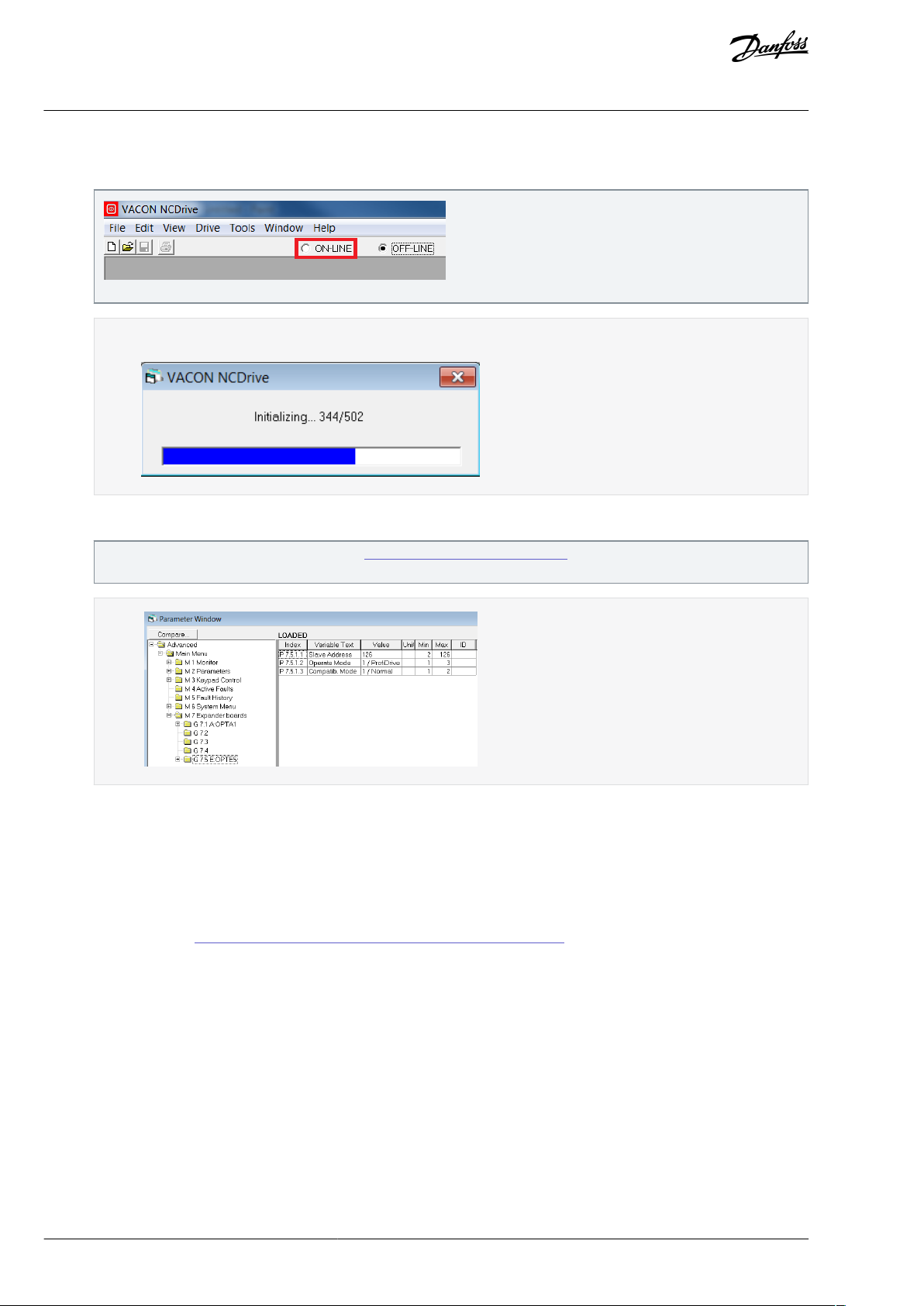

3.2.3.1 Setting Drive and PROFIBUS DP Parameters with VACON® NCDrive

Use these instructions to set the Drive and PROFIBUS DP Parameters with VACON® NCDrive.

Make sure that the communications have been adjusted. More information:

•

Serial communication:

-

VACON® NCDrive, see 3.2.2.1 Adjusting Serial Communication Settings in VACON® NCDrive

•

When using Ethernet communication, see VACON OPTEA/OPTE9 Programming Guide for instructions.

BC346130363093EN-US-000101 / DPD00997 | 21Danfoss A/S © 2020.06

Page 22

e30bh639.10

e30bh640.10

e30bh641.10

VACON® OPTE3/E5 PROFIBUS DP

User Guide

Procedure

1.

Press the ON-LINE button.

2.

To change the option board settings, navigate to the M7 Expander boards menu, and select the slot to which OPTE3/E5

PROFIBUS DP is connected.

Commissioning

The NCDrive connects to the drive and starts loading parameter information.

It is possible to change parameters dened in 6.1 PROFIBUS DP Board Parameters. Add at least the PROFIBUS slave address.

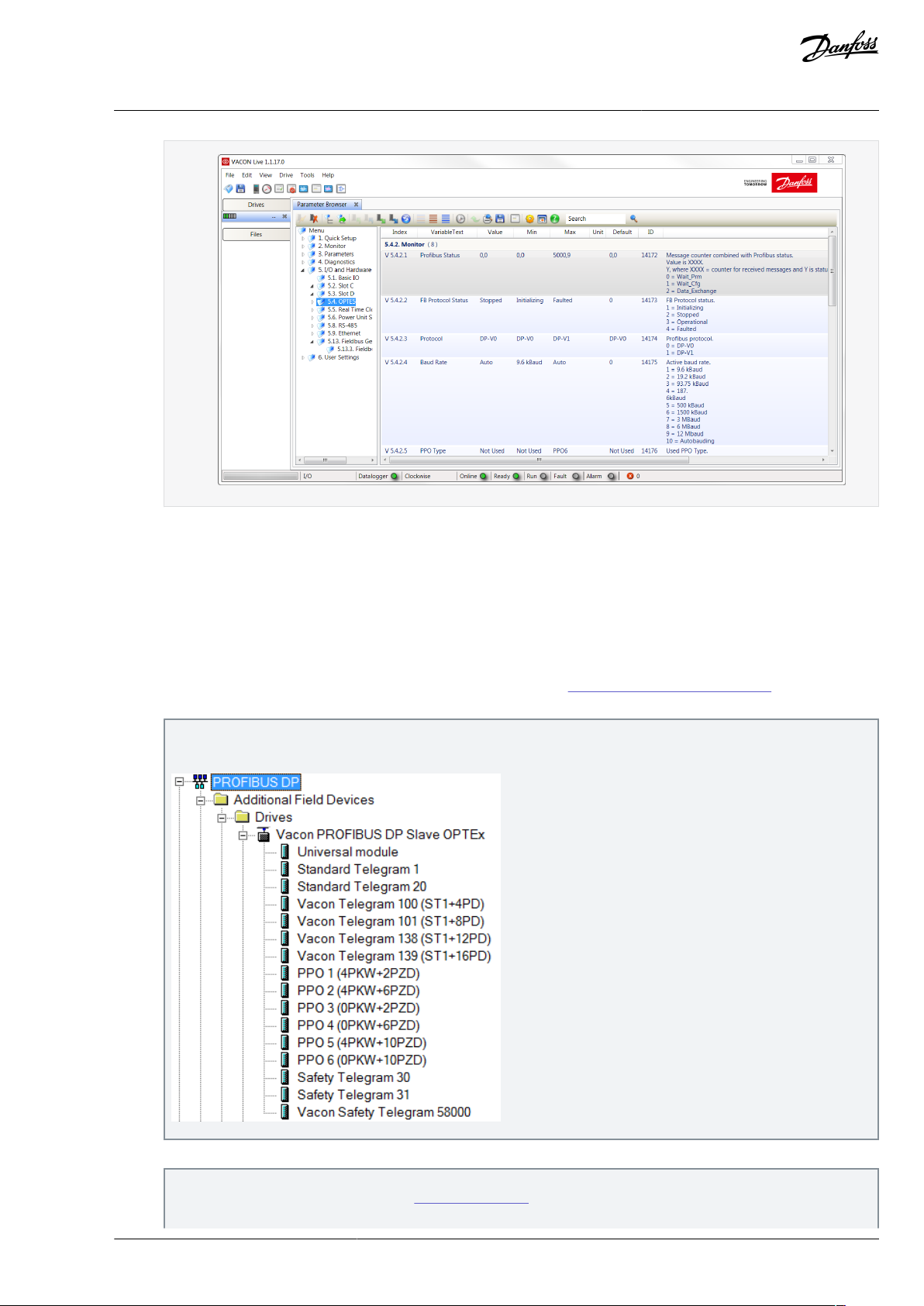

3.2.3.2 Setting Drive and PROFIBUS DP Parameters with VACON® Live

Use these instructions to nd the Drive and PROFIBUS DP Parameters with VACON® Live.

With VACON® Live, it is possible to modify OPTE3/E5 PROFIBUS DP parameters and view monitor values.

Make sure that the communications have been adjusted. More information:

•

Serial communication:

-

VACON® Live, see 3.2.2.2 Adjusting Serial Communication Settings in VACON® Live

•

When using Ethernet communication, see VACON OPTEA/OPTE9 Programming Guide for instructions.

Procedure

1.

Open VACON® Live.

2.

Navigate to 5. I/O and Hardware menu. Add at least the PROFIBUS slave address.

BC346130363093EN-US-000101 / DPD0099722 | Danfoss A/S © | 2020.06

Page 23

e30bh645.10

e30bh646.10

VACON® OPTE3/E5 PROFIBUS DP

User Guide

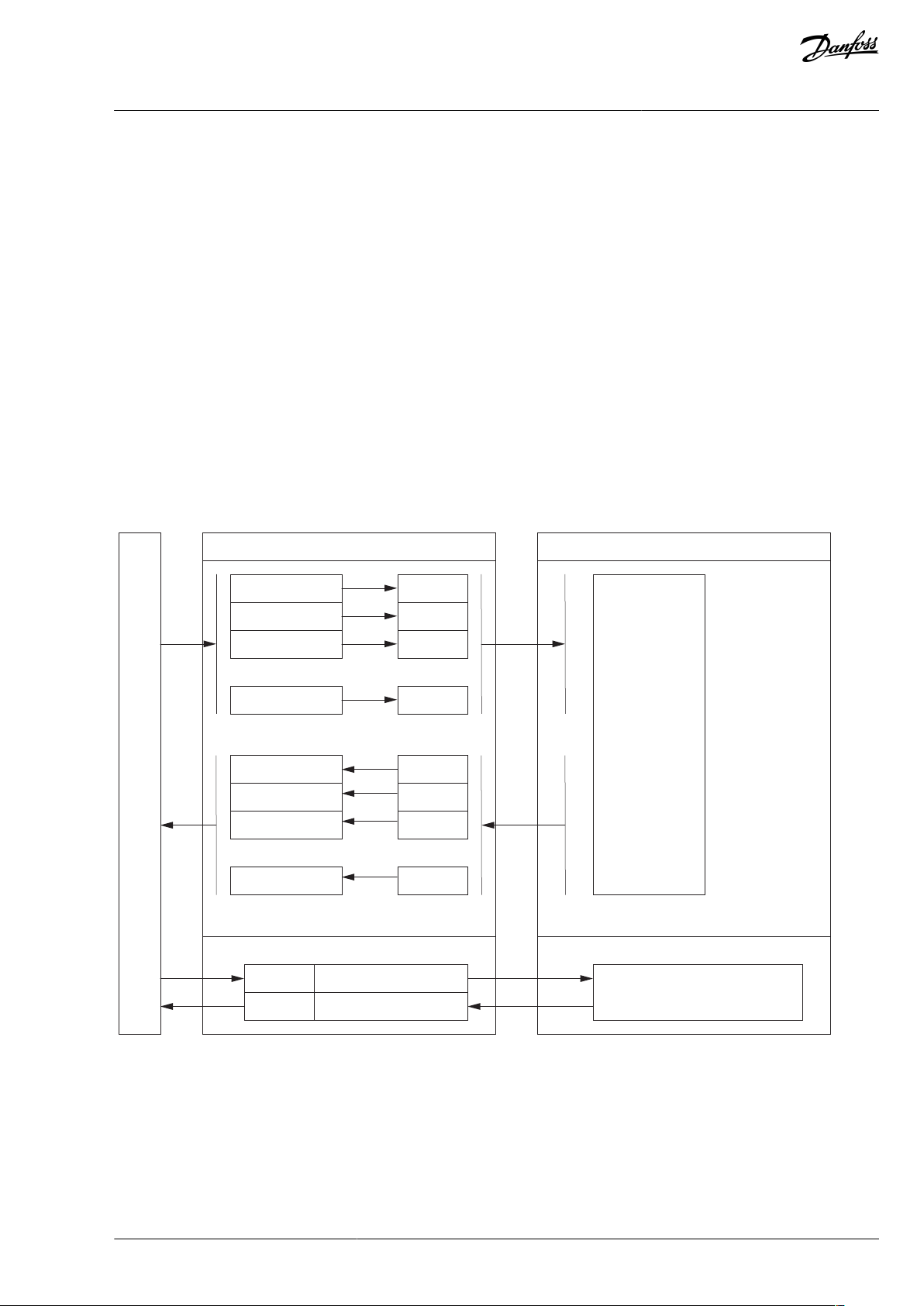

3.3 Replacing VACON® NXS or NXL AC Drive with VACON® 100 Family AC Drive

Make these adjustments when replacing VACON® NXS or VACON® NXL AC Drive with VACON® 100 Family AC Drive.

Commissioning

With VACON® 100 Family AC drive and OPTE3/E5, the baud rate is always automatically selected.

Procedure

1.

Take the newer GSD le into use in the PLC.

a.

Download the GSD les from http://drives.danfoss.com.

b.

If the Mode parameter is set to NX mode or C3/C5 mode (see 6.1 PROFIBUS DP Board Parameters), use the GSD le

for OPTC3/C5. This option can be used to support old installations.

By default, the OPTE3/E5 uses a dierent GSD le containing more modules than OPTC3/C5. The PPO types supported in

OPTC3/C5 (1–5) are still supported and are compatible with OPTE3/E5.

2.

To select operate mode with panel parameter, use Local.

In OPTC3/C5, the PPO type and operate mode are selected using panel parameters. In OPTE3/E5, when Local is not selected, it is possible to do it with the PLC. See 6.1.2 Operate Mode for more information.

BC346130363093EN-US-000101 / DPD00997 | 23Danfoss A/S © 2020.06

Page 24

e30bh625.10

VACON® OPTE3/E5 PROFIBUS DP

User Guide

Commissioning

3.

If needed, remove FBDIN bits used in PROFIdrive 2.0. VACON® 100 family AC drives do not support them.

BC346130363093EN-US-000101 / DPD0099724 | Danfoss A/S © | 2020.06

Page 25

PROFIBUS DP MASTER

Application

Control Word

Option Board Control Board

PDI[0]

PDI[2]

PDI[4]

PDI[10]

PDO[0]

PDO[2]

PDO[4]

PDO[10]

Speed Reference

ProcessData 1

ProcessData 2

ProcessData 1

ProcessData 2

ProcessData

Service Data

Parameter Field (4 word) Parameter Definit ons and values

Parameter Field (4 word) Variable Definit ons and values

Request

Response

Status Word

Actual Speed

..

.

...

.

...

...

e30bh618.10

VACON® OPTE3/E5 PROFIBUS DP

Control Interface and

User Guide

Communication

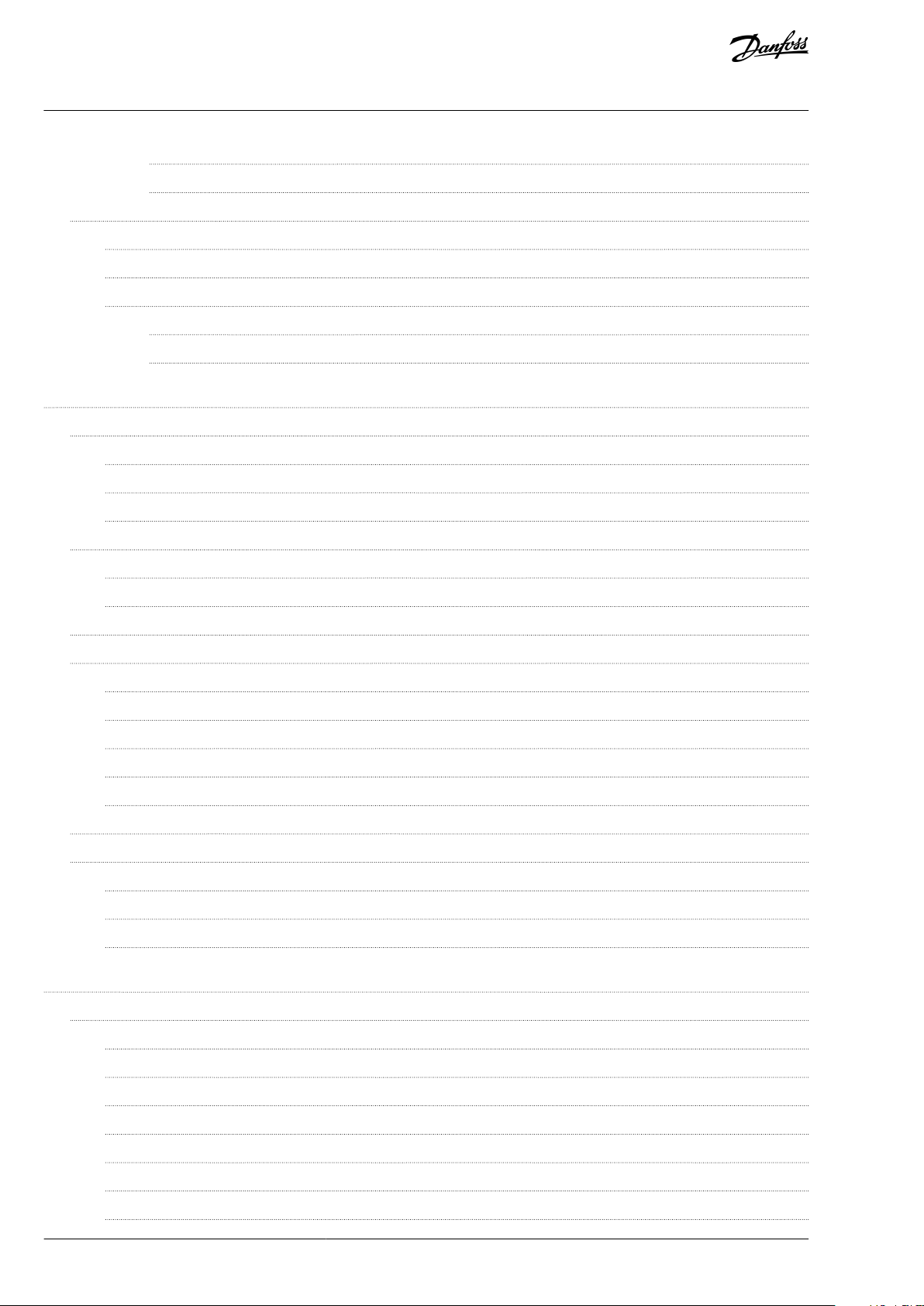

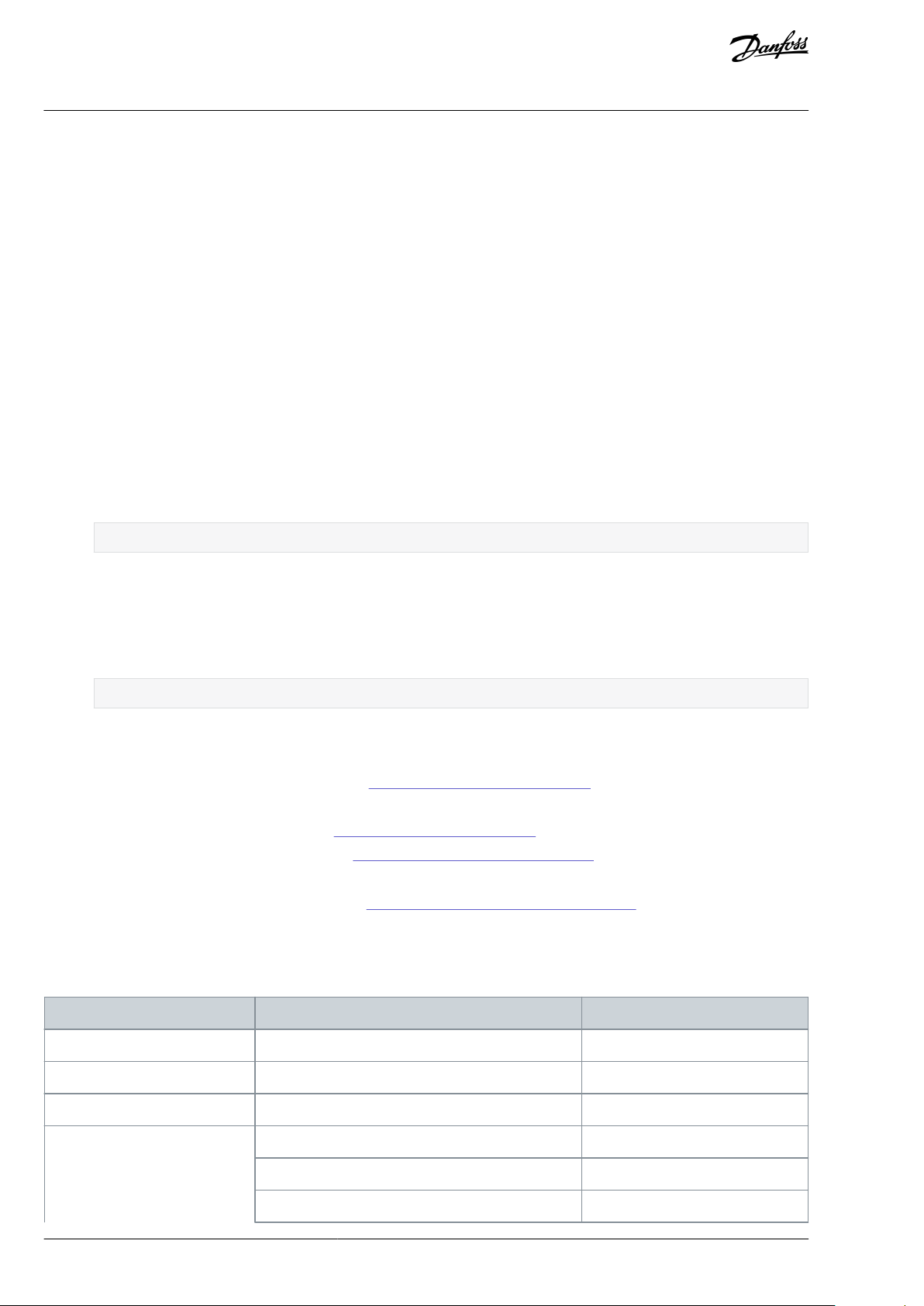

4 Control Interface and Communication

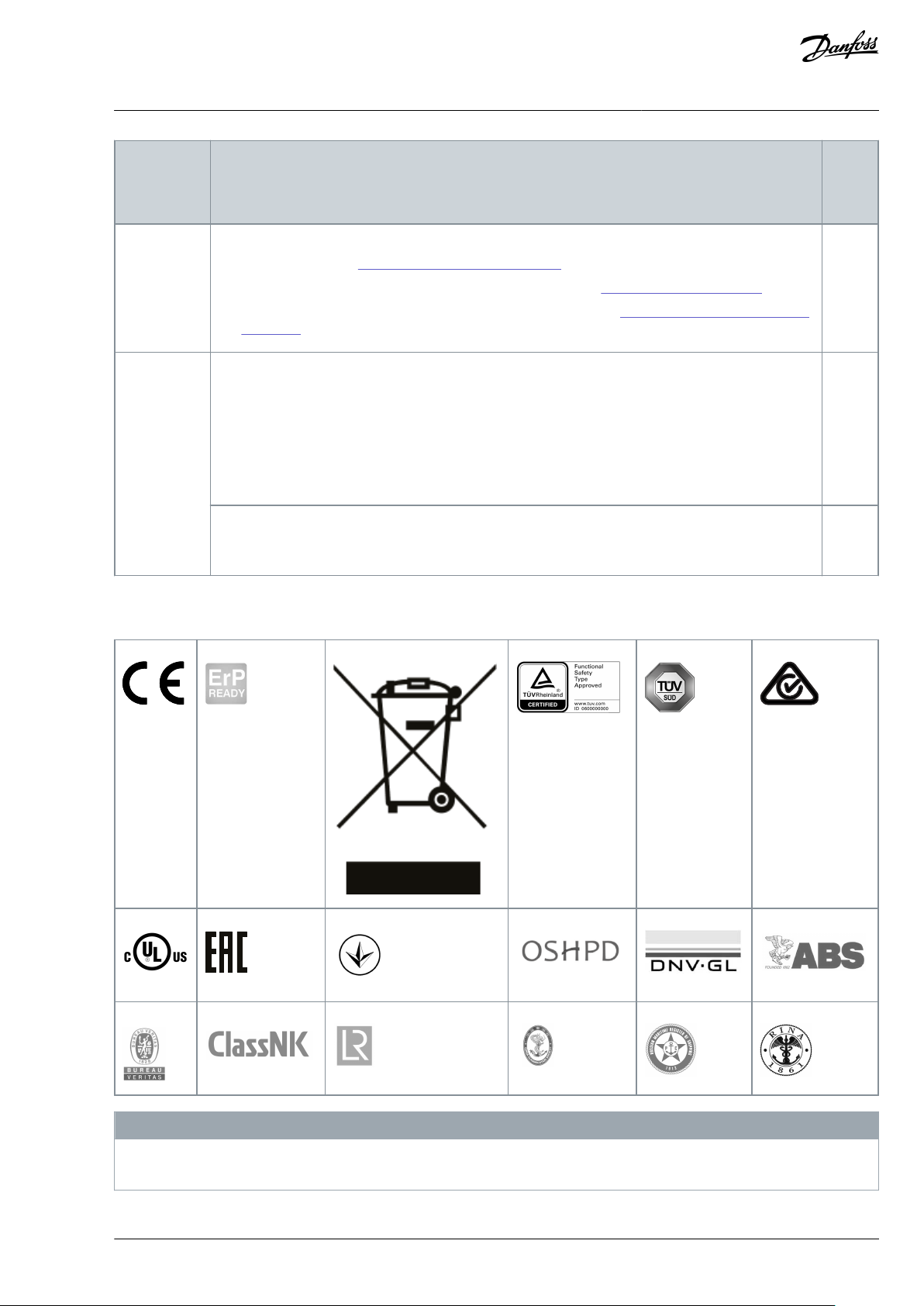

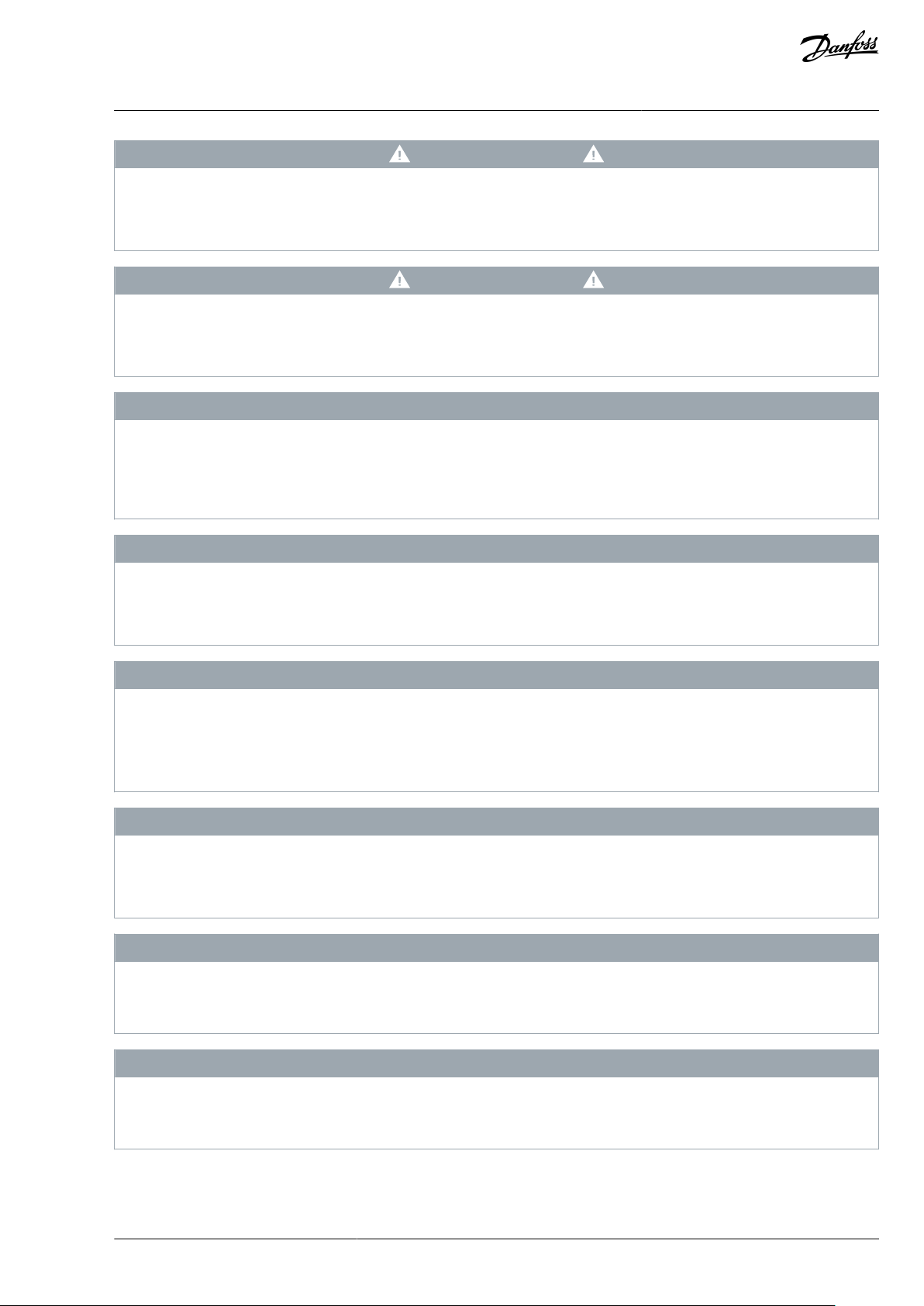

4.1 PROFIBUS DP Communication Overview

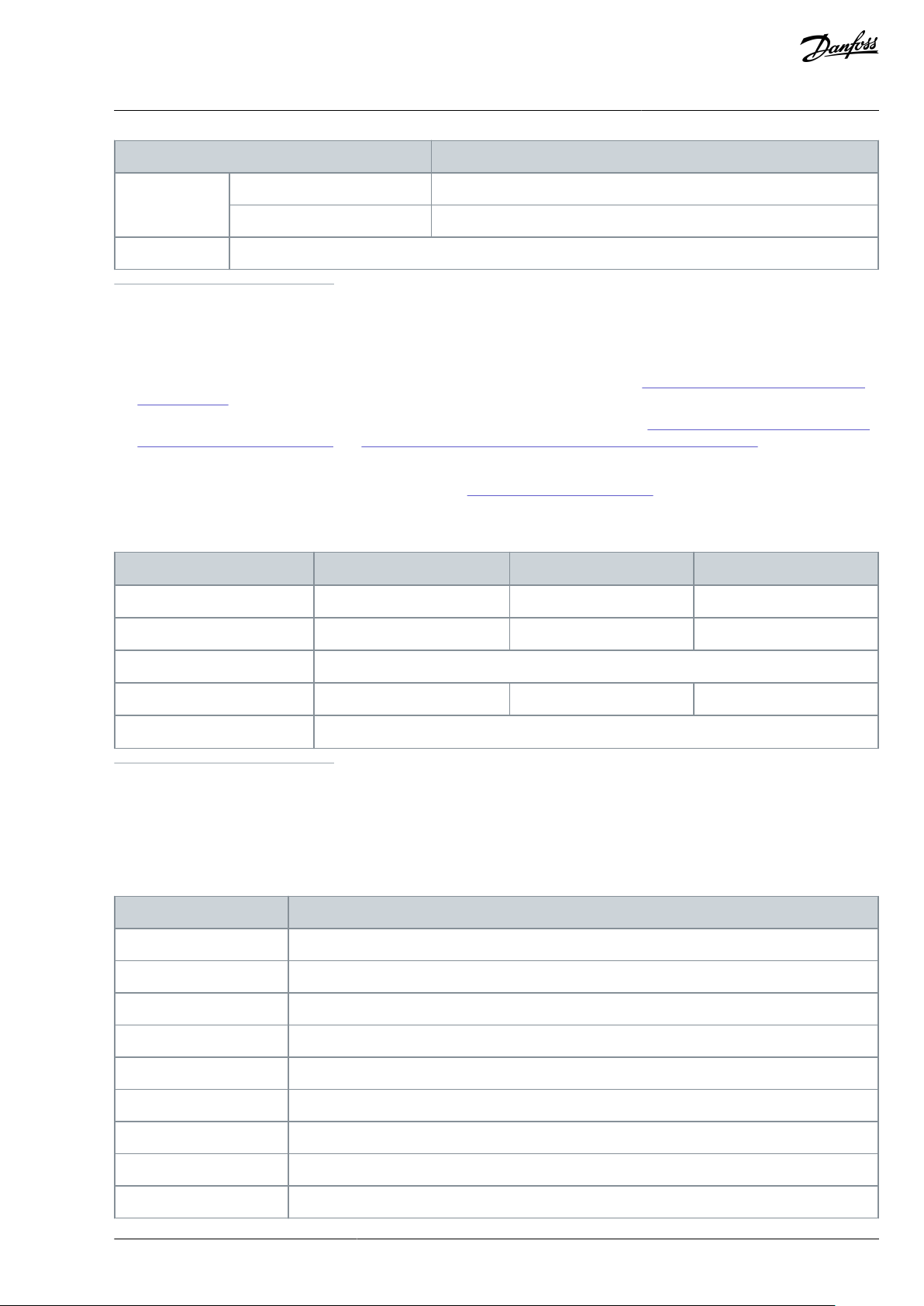

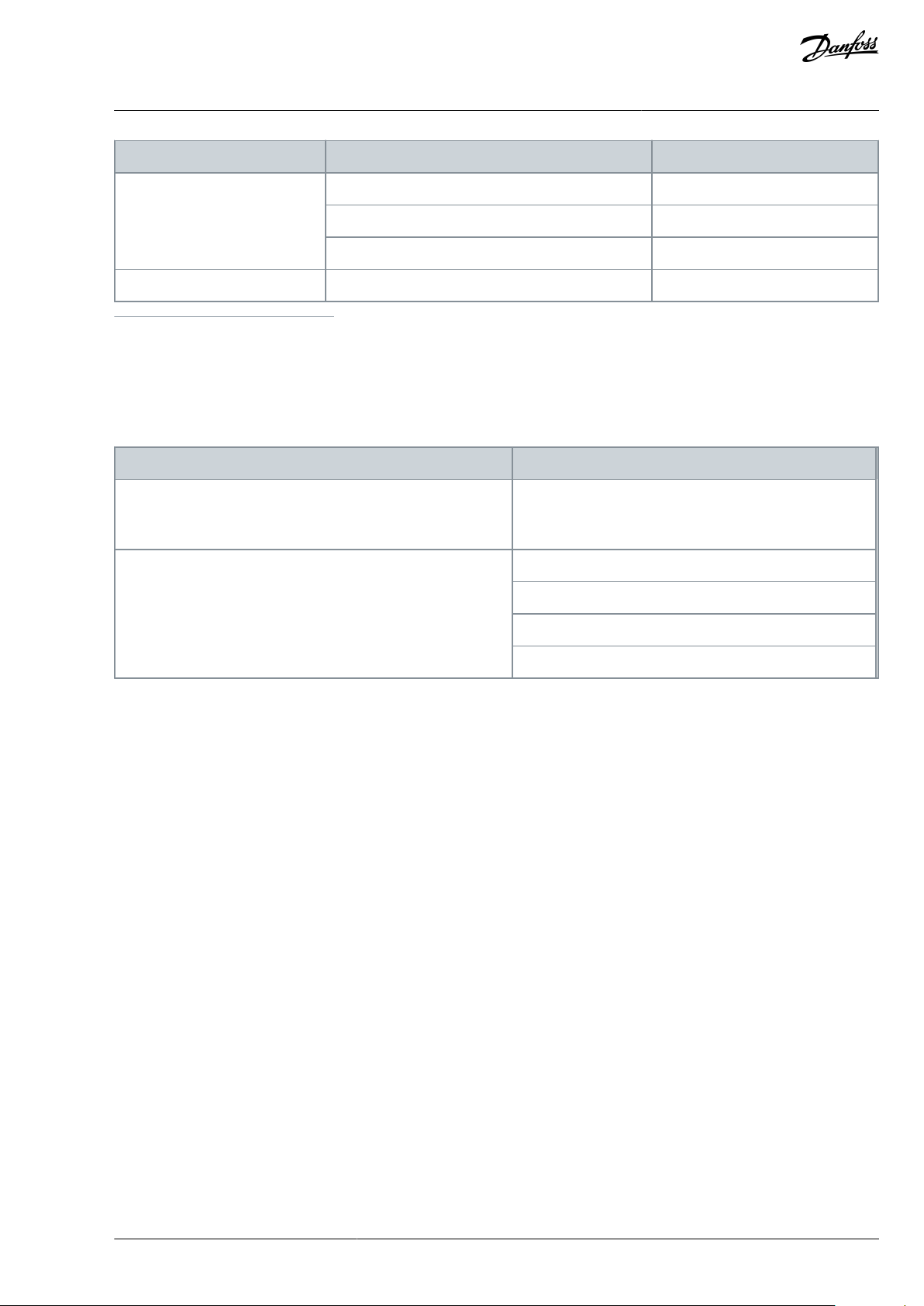

The data transfer between the PROFIBUS DP master and the slave takes place via the input/output data eld. The Master writes to

the output data of the Slave and the Slave answers by sending the contents of its input data to the Master. The contents of the

input/output data is dened in the device prole. The device prole for AC drives is PROFIdrive.

When eldbus has been selected as the active control place on the AC drive, the operation of the AC drive can be controlled from

the PROFIBUS DP Master. Regardless if the active control place is eldbus, the AC drive can be monitored and its parameters set by

the PROFIBUS DP Master.

The communication between the PROFIBUS DP board and the AC drive can be split into two types:

•

Process Data

-

Process Data In (PDI): For controlling AC drive, maximum of 18 words

-

Process Data Out (PDO): Is used for fast monitoring of the AC drive, maximum of 18 words

•

Service Data: Used for Write/Read parameters and variables. Available only when the device is congured to use PPO1, PPO2, or

PPO5. In this case, PROFIdrive 2.0 is used by the default. PROFIdrive 4.1 can be used together with PPO types by enabling

"PPO_PROFIdrive Mode" setting. See details in chapter 5.1 PROFIBUS DP board parameters.

NOTE! If Standard Telegrams are used in data exchange, Service Data is communicated using the acyclic data exchange as specied

in DP-V1 and the PROFIdrive 4.1 specication.

Illustration 1: Data Transfer between PROFIBUS DP Master and VACON® AC drive

4.1.1 Determining the PROFIBUS DP Cycle Time

The PROFIBUS DP cycle time must be determined, for example, when using PROFIsafe over PROFIBUS DP, as it must be considered

for the safety watchdog time.

The PROFIBUS DP master calculates the cycle time based on these variables:

BC346130363093EN-US-000101 / DPD00997 | 25Danfoss A/S © 2020.06

Page 26

Software or hardware

Fast/Normal Extended

Fast safe

Control Board

NXP (serial number 761 or later)

NXP (serial number 761 or later)

System Software

NXP00002V196.vcn

NXP00002V196.vcn

Applications

(1)

Multipurpose V236 or later (Normal Extended Mode)

Any

(2)

Fieldbus option rmware version

OPTE3/E5 V006 or later

OPTE3-E5_FW0083V006.vcx or later

OPTE9 V007 or later

-

OPTEA V001 or later

OPTEA V001 or later

(3)

VACON® OPTE3/E5 PROFIBUS DP

User Guide

•

Number of slaves

•

Transmission rate

•

Data volume (input and output data)

Use the PLC program to check the value.

Instructions use this setup:

•

PLC with 4 VACON® AC drives

•

congured with 16 bytes of Process Data

•

on a transmission rate of 1.5 Mbps.

NOTE! These examples do not include the eect of acyclic data exchange, alarms, or retransmissions.

Using Siemens TIA Portal V13

1.

Open Network view.

2.

Select the PROFIBUS network.

3.

Select General.

4.

Select PROFIBUS.

5.

Select Bus parameters.

6.

Select Ttr typical.

Control Interface and

Communication

The following value is shown: 3.3 ms.

Using Beckho TwinCAT System Manager V2

1.

Open I/O - Conguration.

2.

Select PROFIBUS master.

3.

Select EL6731 (in this example).

4.

Select Estimated DPCycle.

The following value is shown: 3.1 ms.

4.2 Fieldbus Option Board Communication Modes

The VACON® eldbus option boards support the following eldbus board communication modes:

Normal mode, for most commonly used setups (see

•

•

Normal extended mode, for setups that requires 16 process data items

•

Fast mode, with low latency process data (see 4.2.4 Fast Fieldbus Communication)

•

Fast safety mode with safety "black channel" (see 4.2.5 Fast Safety Fieldbus Communication)

•

Fast PROFIBUS mode. Use other modes with new installations.

NOTE! Not all boards support all modes. For details, see 4.2.1 Requirements for Communication Modes.

The fast communication modes can be enabled to get minimum communication delay between the eldbus and application.

4.2.3 Normal Fieldbus Communication)

4.2.1 Requirements for Communication Modes

Table 5: Requirements for Dierent Fieldbus Communication Modes for VACON® NXP

BC346130363093EN-US-000101 / DPD0099726 | Danfoss A/S © | 2020.06

Page 27

•

•

Software or hardware

Fast/Normal Extended

Fast safe

OPTEC V003 or later

-

OPTE6 V010 or later

-

OPTE7 V006 or later

-

Advanced safety option

-

OPTBL_FW0227V001 or later

Software

Normal Extended

System Software

INDUSTRIAL FW0072V030

FLOW FW0159V022

Fieldbus option rmware version

OPTE9: V010

OPTEA: V003

OPTE7: V006

OPTE3/OPTE5: V008

VACON® OPTE3/E5 PROFIBUS DP

Control Interface and

User Guide

1

For latest information about application support for eldbus communication modes, refer to application-specic manuals.

2

If safety option is congured to use a safety eldbus, the fast safe mode is automatically enabled regardless of used application. However, the

availability of 16 process items is limited by the application in use. Also the process data application cycle is normally set to 10 ms, instead of 1 ms for

fast application.

3

Only with Advanced Safety Option

Table 6: Requirements for Normal Extended Communication Mode for VACON® 100 Family

Communication

4.2.2 Fieldbus Communication Mode Features and Limitations

Fast mode

•

1 ms process data interval

•

Available in VACON® NXP slots D and E

-

Possible to run both slots simultaneously

-

Have similar process data latency in both slots

•

Service data latency is also reduced

-

Running multiple service data queries at high interval can cause high CPU load in VACON® NXP AC drive.

Fast safe mode

•

1 ms process data interval

•

Includes safety "black channel"

•

Activated/deactivated automatically, not available for setting

•

Safety eldbus must be activated in safety conguration

-

Advanced safety option board must be installed into slot D

-

Safety eldbus must be activated in safety conguration

16 process data items

•

16 process data items always require support from application

•

Available in Fast, Fast safe, and Normal extended mode

•

If no support is available in the application, the process data out is always '0', while incoming process data items 9–16 are discarded

BC346130363093EN-US-000101 / DPD00997 | 27Danfoss A/S © 2020.06

Page 28

Communication cycle

Update interval

IO Data

Cyclic

x ms

Acyclic

Parameters, etc.

Low

Priority

High

Priority

Software

10ms

10ms

Update

interval

5ms

Application

task

10-50ms

Process

Data

Application

task

50-500ms

Service

Data

Option Board Drive Control Board

e30bh626.10

VACON® OPTE3/E5 PROFIBUS DP

Control Interface and

User Guide

Communication

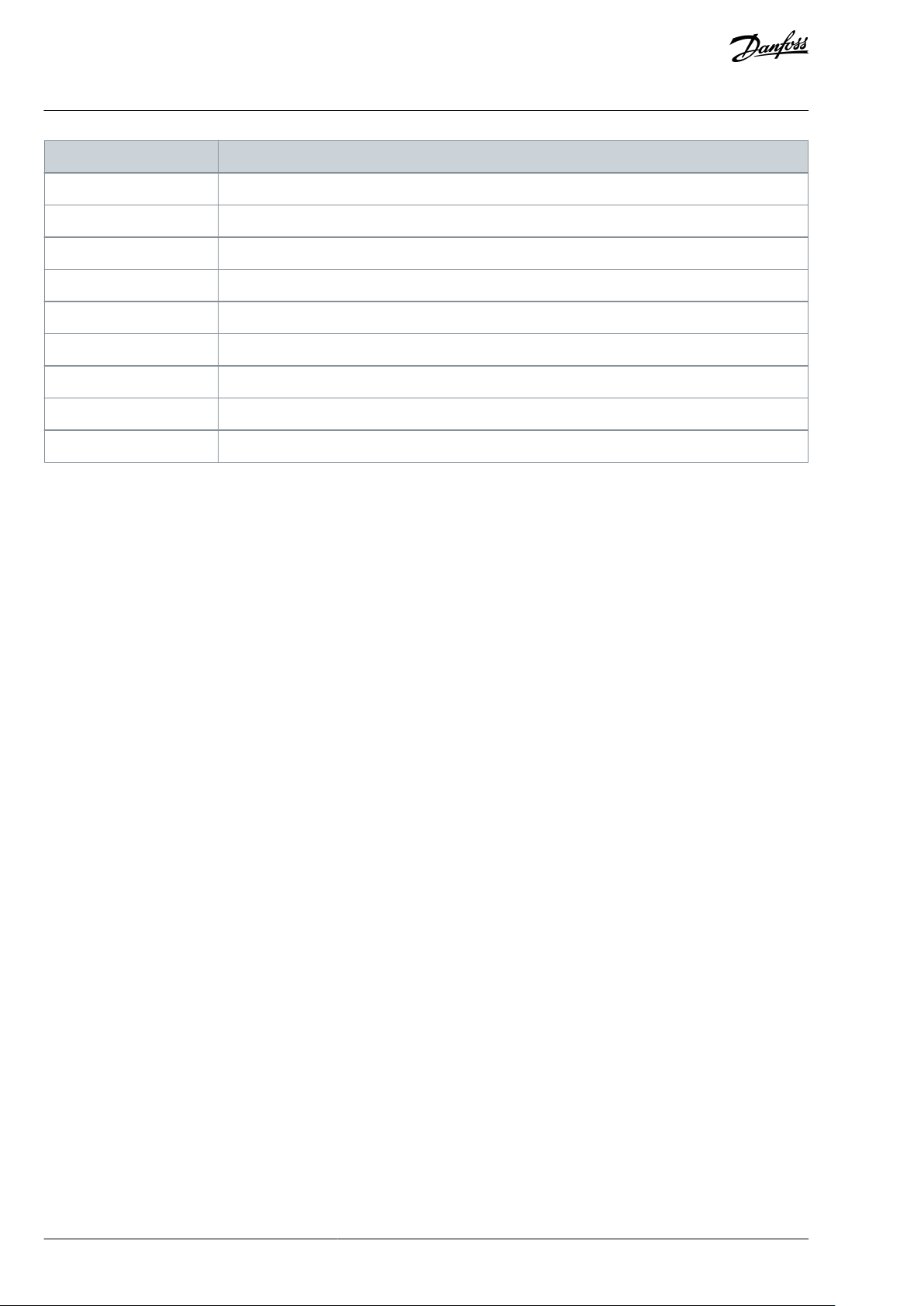

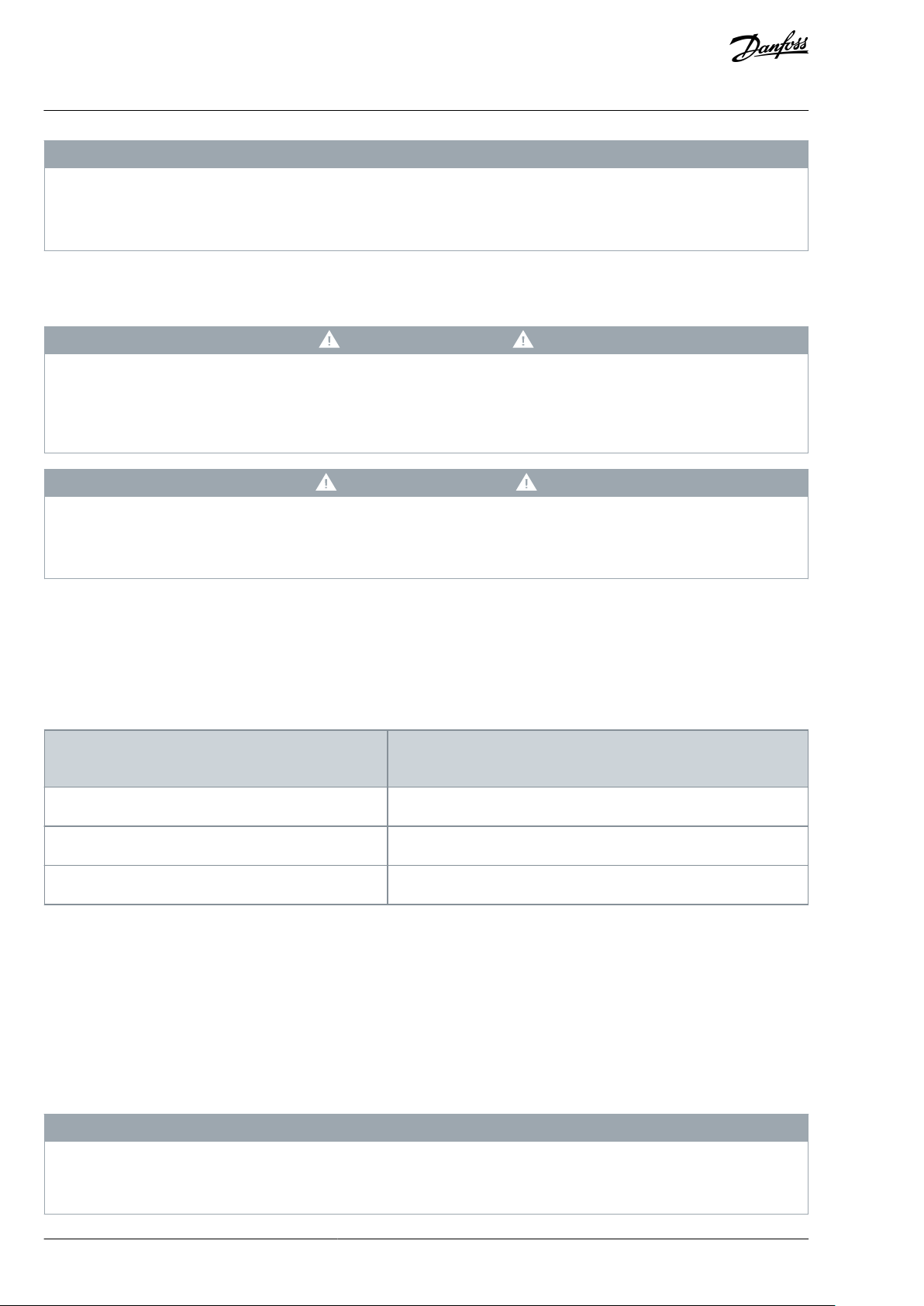

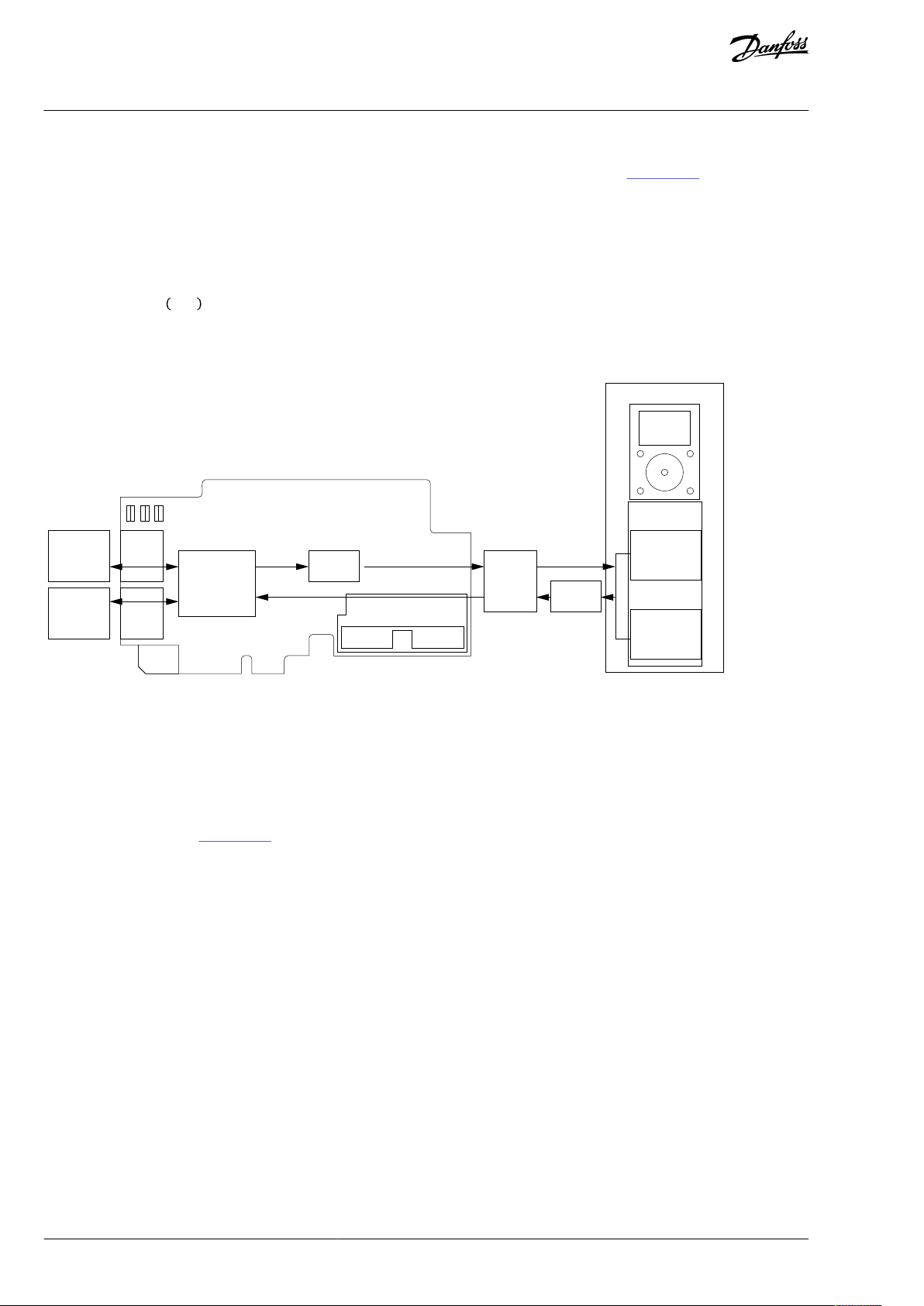

4.2.3 Normal Fieldbus Communication

The normal eldbus communication between option board and the AC drive application is shown in Illustration 2. In normal communication, both process data, and service data are transferred in succession at 5 ms interval.

Communication delay for process data can be calculated by summing all delays together:

t = t

IOdatacycle

+ t

updateinterval

+ 2 ⋅ t

communicationdelay

+ t

applicationcycle

Example: With eldbus cycle time of 4 ms and application cycle of 10 ms, the delay is:

t = 4ms + 10ms + 2 ⋅ 5 ms + 10ms = 34ms

NOTE!: This value does not include delays of the eldbus master, jitter in the process data cycle of the communication protocol or

resending due to electronic interference.

Illustration 2: Normal Fieldbus Communication

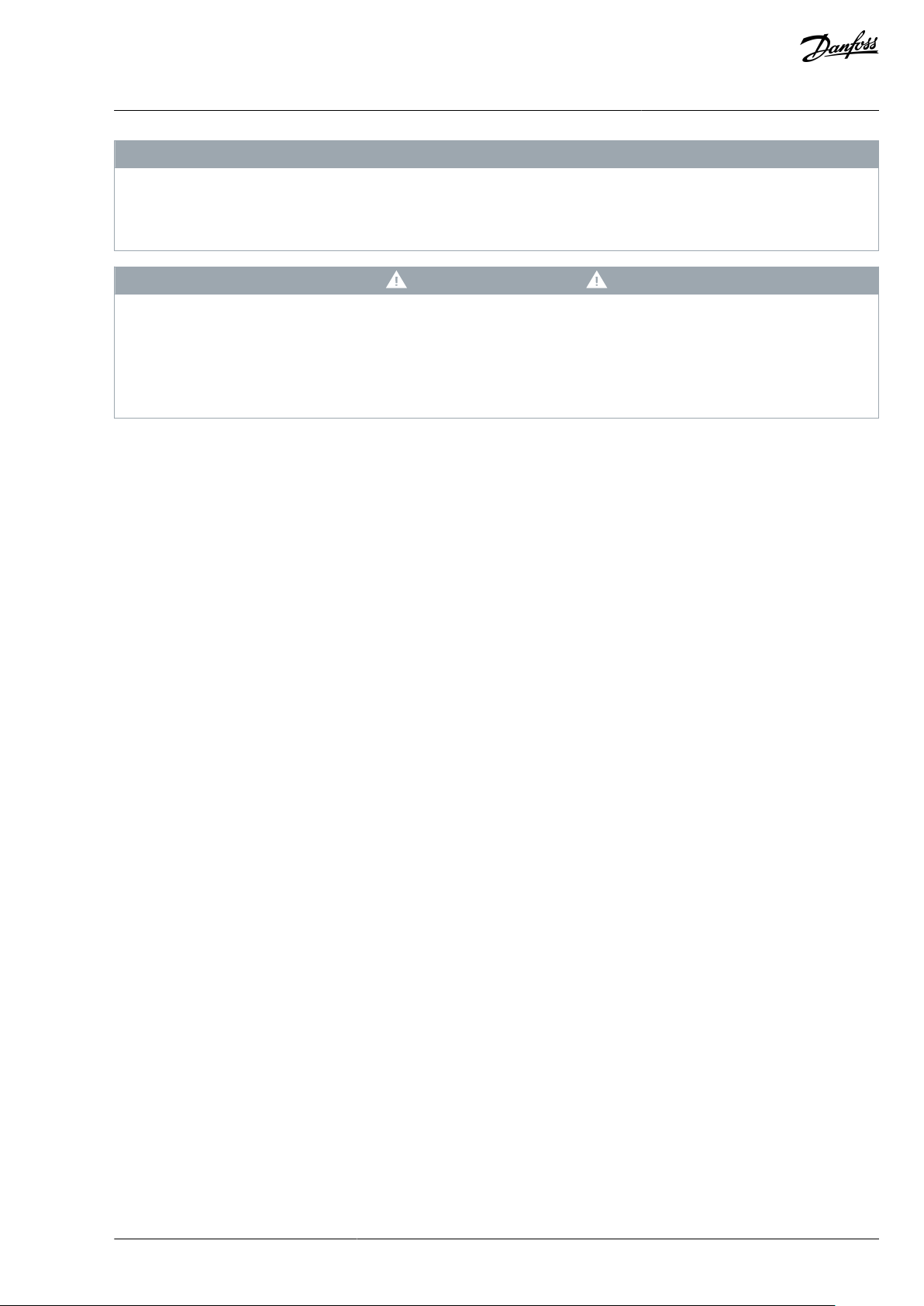

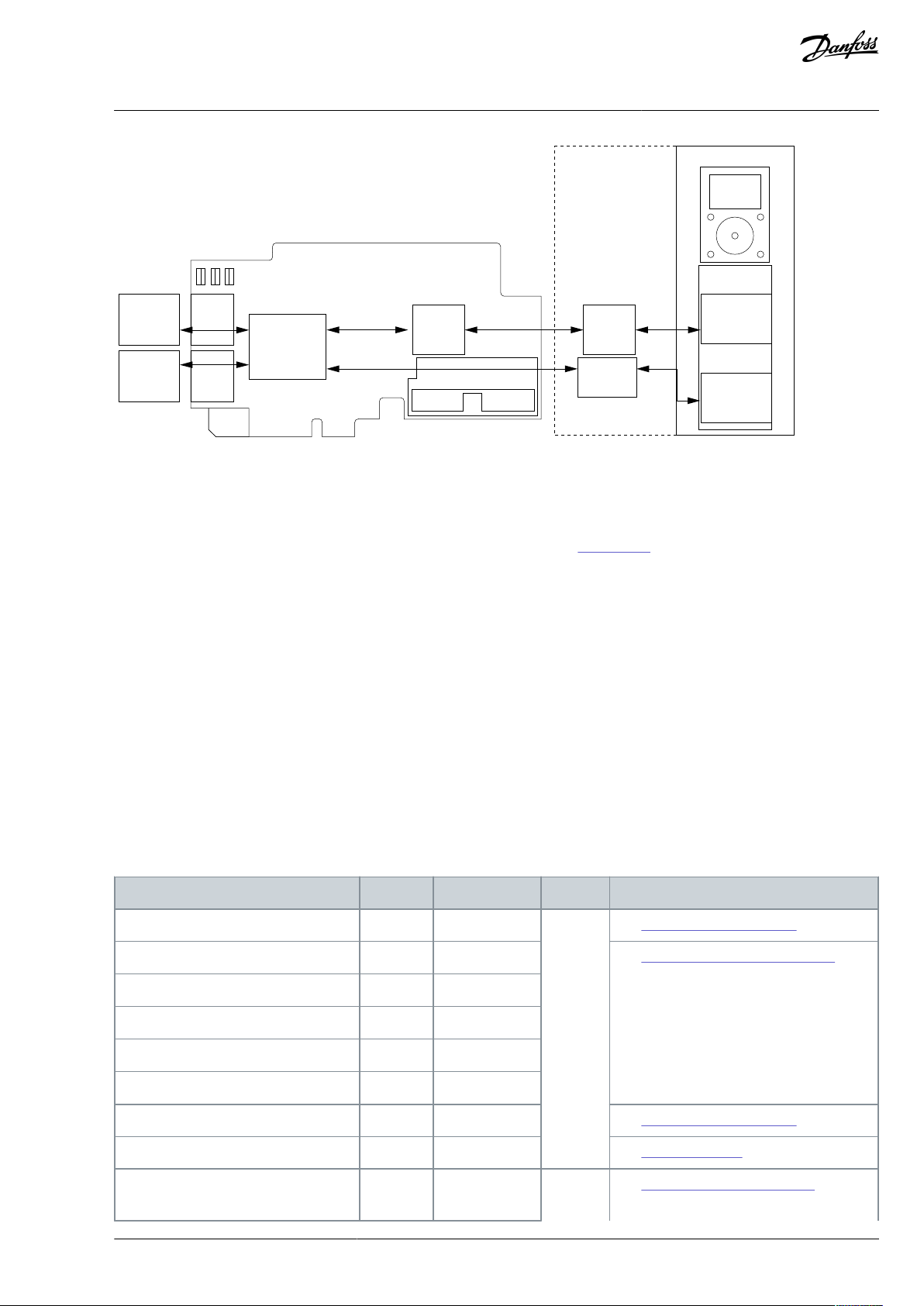

4.2.4 Fast Fieldbus Communication

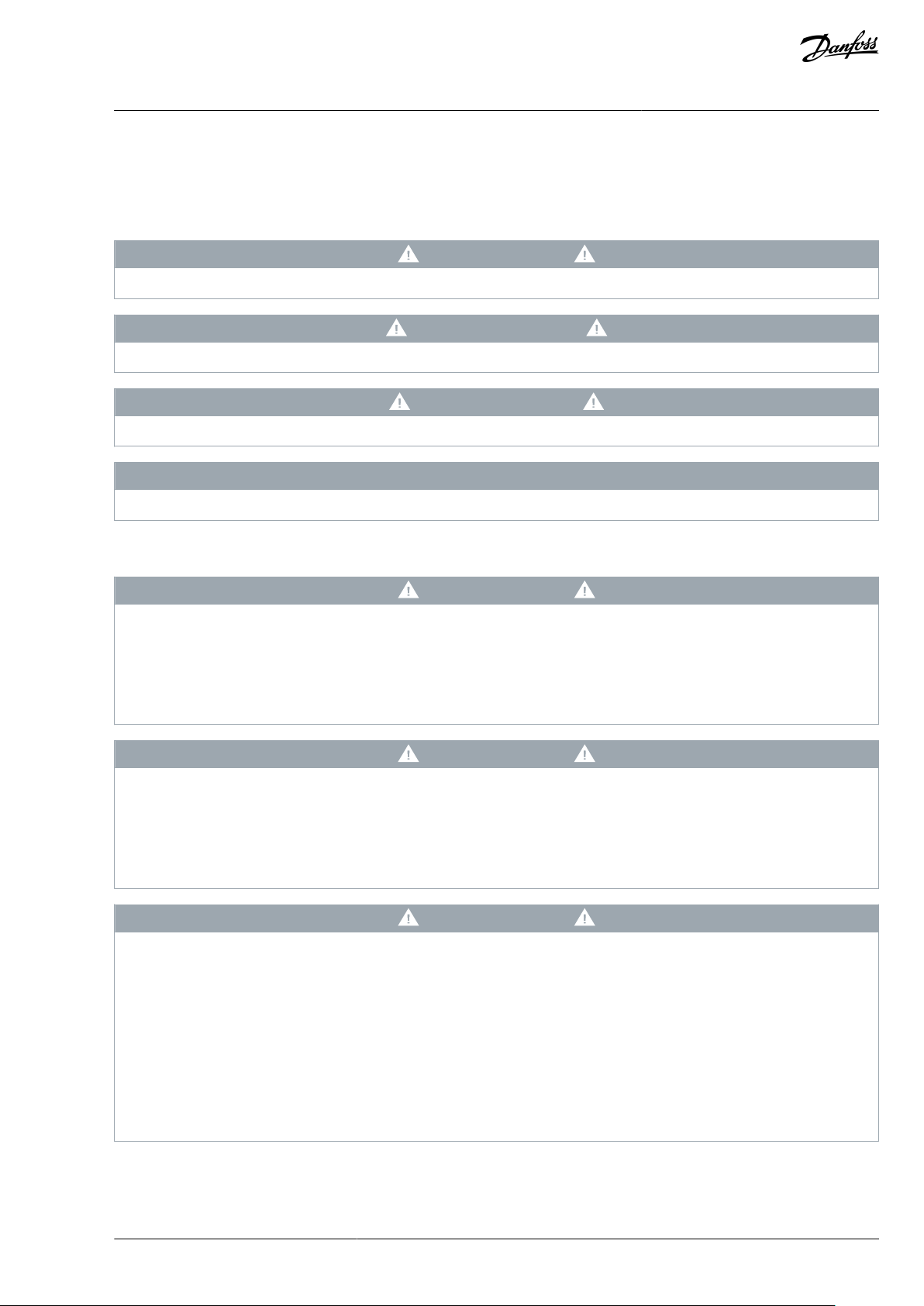

The fast mode decreases the communication delay between the PLC and the AC drive application signicantly by using two communication channels separately for process and service data. The process data interval is set to 1 ms, while other data is sent acyclically. When the fast mode is activated, the application can be synchronized to run with the communication cycle. The Fast communication mode is shown in Illustration 3. This mode also includes the ability to transfer 16 process data items.

The communication delay for process data in fast communication mode is (when application task is synchronized with communication):

t = t

IOdatacycle

Example: With eldbus cycle time of 1 ms, an application cycle of 1 ms the delay is:

t = 1ms + 1+1ms = 3ms

NOTE: This value does not include delays of the eldbus master, jitter in the process data cycle of the communication protocol or

resending due to electronic interference.

+ t

updateinterval

+ t

applicationcycle

BC346130363093EN-US-000101 / DPD0099728 | Danfoss A/S © | 2020.06

Page 29

Low priority

IO Data

Cyclic

x ms

Acyclic

Parameters, etc.

Low

Priority

High

Priority

Software

Option Board Drive Control Board

1ms

1ms

Application

task

1-50ms

Process

Data

Application

task

50-500ms

Service

Data

Acyclic

Update

interval

Communication cycle

e30bh627.10

Module name

Number

Abbreviation

Type

Description

Standard Telegram 1

7

ST1

Drive

(1)

See 4.3.5.3 Standard Telegrams.

VACON® Telegram 100

8

ST1+4PD

See 4.3.5.4 Vendor-Specic Telegrams.

VACON® Telegram 101

9

ST1+8PD

VACON® Telegram 138

11

ST1+12PD

VACON® Telegram 139

12

ST1+16PD

VACON® Telegram 140

16

GCW+16PD

Standard Telegram 20

10

ST20

See 4.3.5.3 Standard Telegrams.

Parameter-Process Data Type 1…6

1...6

PPO1…PPO6

See 4.3.6.4 PPO Types.

Standard Telegram 30

13

ST30

Safety

(2)

See 4.4.2 PROFIdrive on PROFIsafe.

VACON® OPTE3/E5 PROFIBUS DP

User Guide

Illustration 3: Fast Fieldbus Communication

Control Interface and

Communication

4.2.5 Fast Safety Fieldbus Communication

The fast safety mode uses the same communication methods as in "Fast mode" (Illustration 3), but also transfers safety "black channel" data used to the advanced safety option board.

NOTE: This mode is automatically enabled, if an advanced safety option board is connected to slot D and the safety eldbus is acti-

vated and is not available for setting. This mode is also automatically turned o when the advanced safety option board is removed.

4.2.6 Normal Extended Mode

The normal extended mode uses the same communication method as in "Fast mode", but reduces the communication cycle to 10

ms. This mode can be used in applications where 16 process data items are required but the lowest possible communication delay is

not needed. It can also be used in these applications when the increased CPU load of Fast mode to VACON® NXP drives is undesirable.

NOTE! This mode can be automatically enabled in VACON® applications supporting 16 process data items.

4.3 Drive Control

4.3.1 PROFIBUS DP Modules

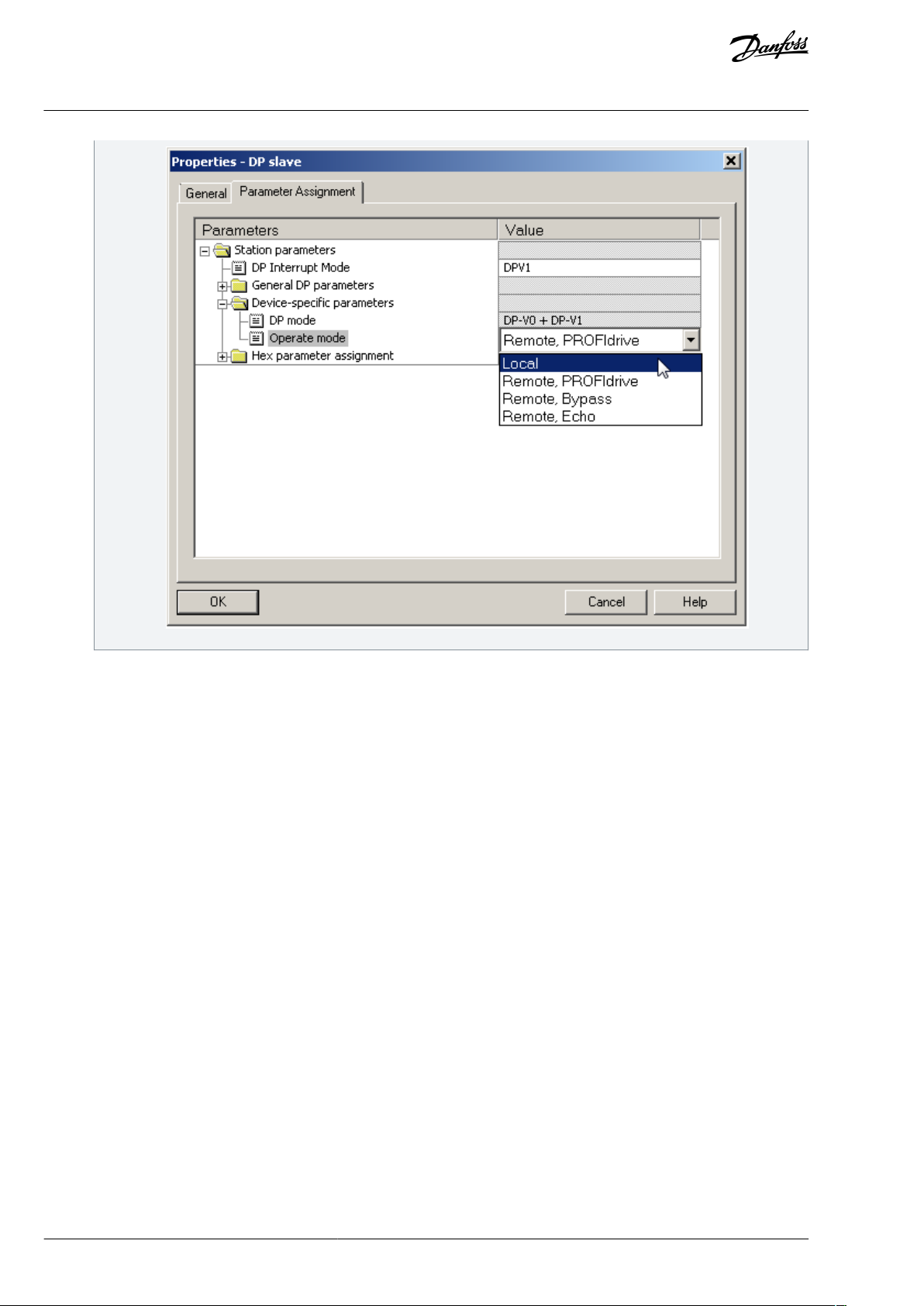

The OPTE3/E5 option board implements the following PROFIBUS DP modules:

Table 7: OPTE3/E5 Modules

BC346130363093EN-US-000101 / DPD00997 | 29Danfoss A/S © 2020.06

Page 30

Module name

Number

Abbreviation

Type

Description

Standard Telegram 31

14

ST31

VACON® Telegram 58000

15

ST58000

Slot 1

Slot 2: Empty

Slot 2: ST1(+PD)

Slot 2: ST20

Slot 2:PPO1...6

Empty

-

allowed

allowed

allowed

ST1(+PD)

allowed

---

ST20

allowed

---

ST30, 31

-

allowed

--ST58000

-

allowed

--PPO1...6

allowed

---

VACON® OPTE3/E5 PROFIBUS DP

User Guide

1

Drive module rules:

•

Only 1 drive module is allowed.

•

Always congure 1 drive module.

2

Safety module rules:

•

If a safety module is congured, it must always be in slot 1.

•

Only 1 safety module is allowed.

•

ST20 and PPO1...6 is not allowed with safety modules.

•

In the Advanced Safety option board, select the same safety module as congured.

The supported module combinations are described in

Table 8: Supported Module Combinations

Table 8.

Control Interface and

Communication

An invalid module conguration causes a diagnostic conguration fault. As a result, the device returns to parameterization state and

does not start the data exchange with PROFIBUS DP master.

If there is a safety module fault, a channel-related diagnosis (see 8.2.2 Channel-Related Diagnosis) is activated to notify the master of

a problem with the safety module. The data exchange is started with PROFIBUS DP master.

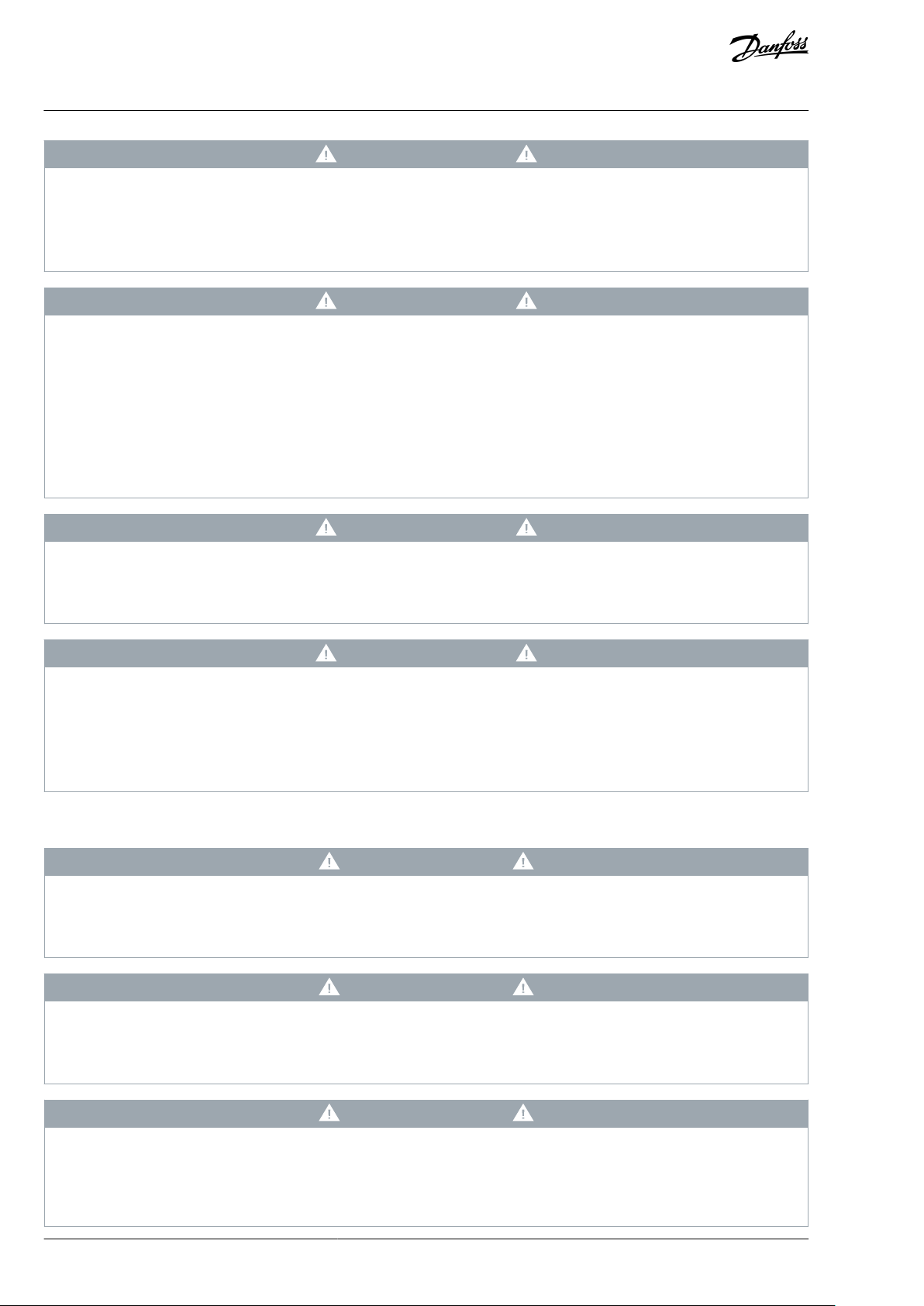

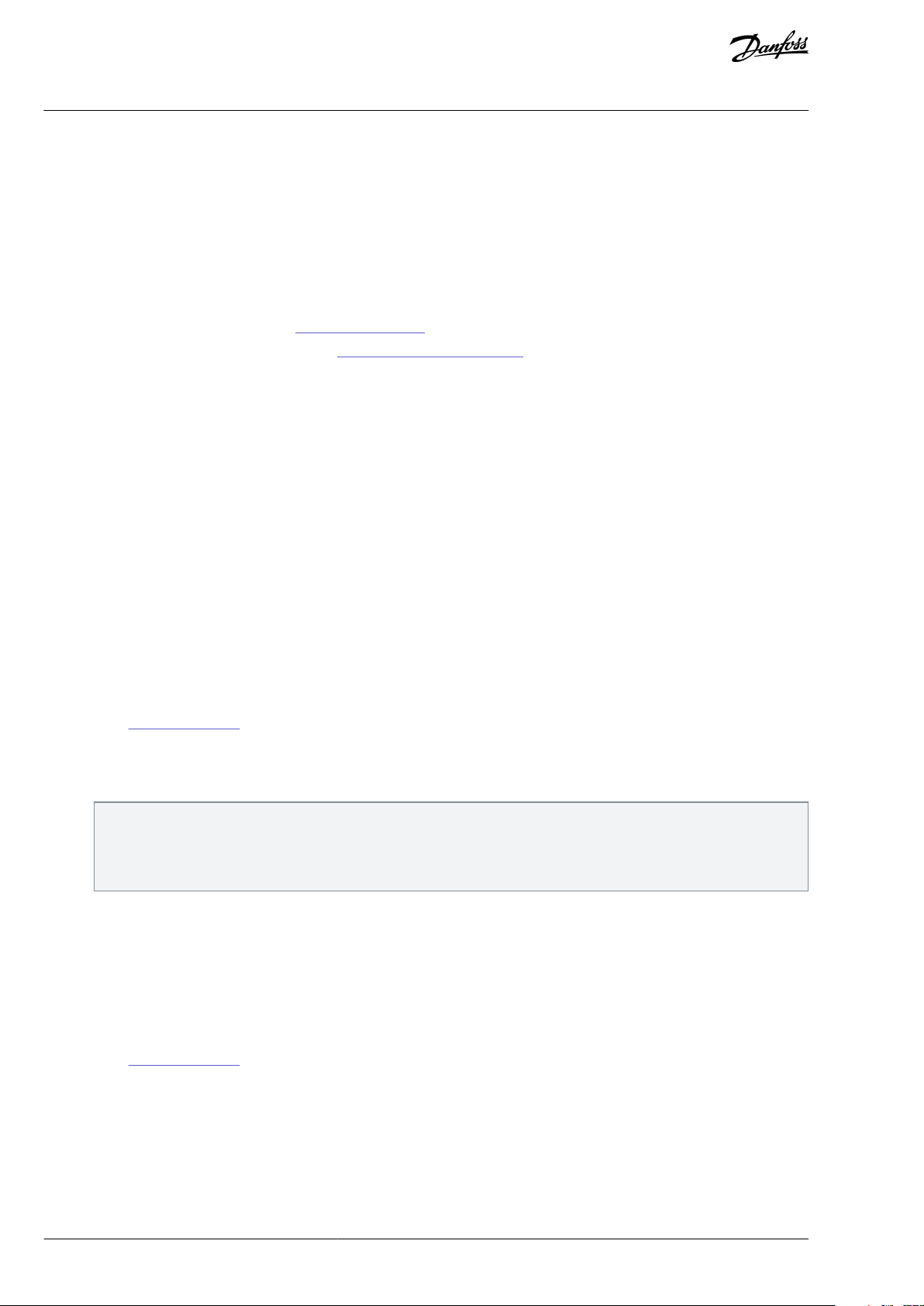

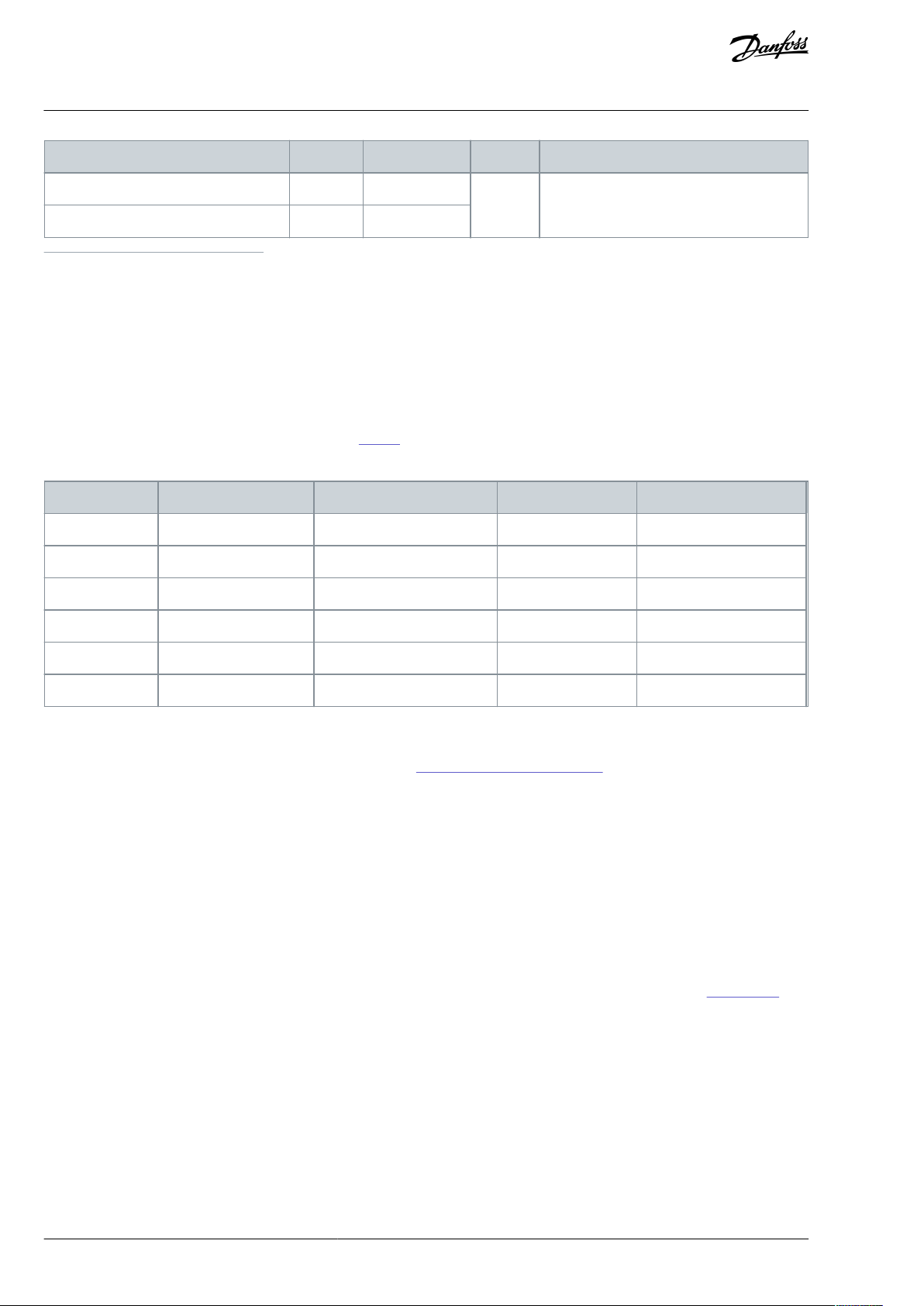

4.3.2 Fieldbus Process Data

The process data items are directly sent unmodied from eldbus to the application. Therefore the process data mapping and usage

must be congured in application. For the latest information, see the application-specic manual.

Fieldbus process data items can be used to write and read variables quickly and periodically to/from VACON® AC drives. Incoming

process data can be used for multiple dierent purposes (for example, torque reference), and outgoing process data can be used for

information about the state of the AC drive.

For fast access to any VACON® AC drive application ID over any eldbus, generic Process Data Out parameters are dened. The content of the process data items is selected with the FB DataOut Selection parameters. Writing any application ID number to these

parameters then maps the data value of that application ID to be sent in the corresponding Process Data Out variable.

The eldbus data-mapping (FB DataOut x Sel) aects the data of the corresponding Process Data Out variable (see Illustration 4). By

writing ID value 1 to FB DataOut1 Selection (ID 852), the value of ID 1 (Output Frequency) is sent in Process Data Out 1. The value is

always raw value in process data out, so for example, 16.43 Hz has value 1643. The scaling of the parameters can be checked from

application manuals.

The status word and actual speed values cannot be changed. However, if a prole is used, the values sent by the eldbus protocol

can dier. In Bypass mode, these values are given as is.

BC346130363093EN-US-000101 / DPD0099730 | Danfoss A/S © | 2020.06

Page 31

# Value

1 1

2 2

3 3

4 4

5 5

6 6

7 7

8 37

Fieldbus DataMap

ID Value

1 Output Frequency

2 Motor Speed

3 Motor Current

4 Motor Torque

5 Motor Power

6 Motor Voltage

7 DC-link Voltage

... ...

Vacon® ID’s

Value

16.43 Hz

486 RPM

0.12 A

4.9%

1.6%

80.2 V

332 V

37 LastActiveFaultCode

172 Rem Control Place

600 Control Mode

852 FB DataOut 1 Sel

... ...

859 FB DataOut 8 Sel

... ...

864 FB Speed Word

0

0=I/O Control

0=I/O Frequency Ctrl

Item

Process Data Out 1

Process Data Out 2

Process Data Out 3

Process Data Out 4

Process Data Out 5

Process Data Out 6

Process Data Out 7

Process Data Out 8

Fieldbus ProcessData

Value

1643

486

12

49

16

802

332

Fixed Status Word

General Status Word

Actual Speed

0x0023

0

0x2000

3284

1

...

37

0x20000023

865 FB Speed Actual

...

...

32.84%

e30bh647.10

Parameter name

ID

Index in panel tree

for VACON® 100

family

Index in panel tree for

VACON® NXP Multipurpose application

(1)

Index in panel

tree for VACON

®

20

Index in panel tree

for VACON® 20

X/CP

FB DataOut 1 Selection

852

P3.6.1

P2.13.3

P10.1

P11.1

FB DataOut 2 Selection

853

P3.6.2

P2.13.4

P10.2

P11.2

...

...

...

...

...

...

FB DataOut 8 Selection

859

P3.6.8

P2.13.10

P10.8

P11.8

FB DataOut 9 Selection

(2)

(2)-(2)

--FB DataOut 10 Selection

(2)

(2)-(2)

--...

...-...--

FB DataOut 16 Selection

(2)

(2)-(2)

-

-

PD

Mapped Application Data

ID

Unit

Scale

1

Output Frequency

1Hz0.01 Hz

2

Motor Speed

2

RPM

1 RPM

3

Motor Current

3AVaries

(1)

4

Motor Torque

4%0.1%

VACON® OPTE3/E5 PROFIBUS DP

User Guide

Control Interface and

Communication

Illustration 4: Fieldbus Data Mapping

Table 9: Fieldbus Process Data Selection Indexes in Panel Tree for VACON® AC drives

1

For other applications, see the application manuals.

2

Supported in VACON® NXP when Fast mode or Normal extended mode is enabled. See details in

and 6.6 VACON® NXP System Software Parameters for Application Developers.

Table 10: Default Process Data Mapping for VACON® 100 Family

4.2 Fieldbus Option Board Communication Modes

BC346130363093EN-US-000101 / DPD00997 | 31Danfoss A/S © 2020.06

Page 32

PD

Mapped Application Data

ID

Unit

Scale

5

Motor Power

5%0.1%6Motor Voltage

6V0.1 V7DC-link voltage

7V1 V8Last Active Fault Code

37--

PD

Mapped Application Data

ID

Unit

Scale

1

Output Frequency

1Hz0.01 Hz

2

Motor Speed

2

RPM

1 RPM

3

Motor Current

45A0.1 A4Motor Torque

4%0.1%5Motor Power

5%0.1%6Motor Voltage

6V0.1 V7DC-link voltage

7V1 V8Last Active Fault Code

37--

PD

Mapped Application Data

ID

Unit

Scale

1

Output Frequency

1Hz0.01 Hz

2

Motor Speed

2

RPM

1 RPM

3

Motor Current

3AVaries

(1)

4

Motor Torque

4%0.1%5Motor Power

5%0.1%6Motor Voltage

6V0.1 V7DC-link voltage

7V1 V8Last Active Fault Code

37--

PD

Mapped Application Data

ID

Unit

Scale

1

Frequency Reference

25Hz0.01 Hz

2

Output Reference

1Hz0.01 Hz

3

Motor Speed

2

RPM

1 RPM

4

Motor Voltage

6V0.1 V

VACON® OPTE3/E5 PROFIBUS DP

User Guide

1

Scaling is based on drive nominal power, see Table 14.

Table 11: Default Process Data Mapping for VACON® NXP Multipurpose Application

Control Interface and

Communication

Table 12: Default Process Data Mapping for VACON® 20 X/CP

1

Scaling is based on drive nominal power, see Table 14.

Table 13: Default Process Data Mapping for VACON® 20

BC346130363093EN-US-000101 / DPD0099732 | Danfoss A/S © | 2020.06

Page 33

PD

Mapped Application Data

ID

Unit

Scale

5

Motor Torque

4%0.1%6Motor Current

3AVaries

(1)

7

Motor Power

5%0.1%8DC-link voltage

7V1 V

Nominal power

Current scale

< 5 kW

0.01 A

5–100 kW

0.1 A

> 100 kW

1 A

Setpoint value

Speed

Direction of rotation

Description of command

0x0000 (0d)

0.00%

N/A

Minimum Frequency

0x2710 (+10000d)

+100.00%

Control word dep.

Full speed

Actual value

Speed

Direction of rotation

Description of value

0x0000 (0d)

0.00%

N/A

At Minimum Frequency

0x2710 (+10000d)

+100.00%

FORWARD

Full speed

VACON® OPTE3/E5 PROFIBUS DP

User Guide

1

Scaling is based on drive nominal power, see Table 14.

Table 14: Current Scaling Based on Nominal Power

Control Interface and

Communication

4.3.3 Bypass Operating Mode

In the Bypass operating mode, the control word, and status word elds in Process Data do not use the PROFIdrive bit denitions.

Instead, the internal control and status word bit denitions are used. These denitions can dier depending on the used application.

Operate mode can be set either on the control panel (see

For the control and status word denitions in the standard applications, see the following topics:

•

4.3.3.1 Control Word Overview

•

4.3.3.2 Status Word Overview

For latest information and special applications, see the application-specic manual.

Bypass Setpoint and Actual Value

In the Bypass operating mode, the valid ranges for setpoint and actual values is 0…10000d, which corresponds to 0.00% to

100.00%. The scale of the setpoint value is 0.01%. In this case, the value 0% corresponds to the parameterized Minimum Frequency

in the drive, while 100% corresponds to Maximum Frequency.

The desired direction of rotation is announced using bit 1 in the control word, whereas bit 2 in the status word indicates the actual

direction.

Table 15: Setpoint Value with Operate Mode "Bypass"

Table 16: Actual Speed Value with Operate Mode "Bypass" or "Echo"

6.1.2 Operate Mode) or in the PLC (see 6.2.1 Operate Mode).

4.3.3.1 Control Word Overview

The VACON® Control Word is composed of 32 bits. This control data is split into two words: FBFixedControlWord consist of the rst

16 bits and FBGeneralControlWord consist of the remaining 16 bits.

While functionality of the FBFixedControlWord is xed in VACON® standard applications, functionality of the FBGeneralControlWord

is application-specic and can vary even in VACON® standard applications.

FBFixedControlWord bit denitions are described in the tables:

BC346130363093EN-US-000101 / DPD00997 | 33Danfoss A/S © 2020.06

Page 34

Bit

Function

Value

Description

0

Start/Stop

0

Stop request from eldbus

1

Run request from eldbus

1

Direction

0

Requested direction is "FORWARD"

1

Requested direction is "REVERSE"

2

Fault reset

0

No action

1

Rising edge (0-->1) resets active faults, alarms, and info

3

Stop mode 1

0

Stop mode is unmodied

1

Stop mode is overridden to "Ramping"

4

Stop mode 2

0

Normal deceleration ramp time

1

Deceleration ramp is switched to shorter than normal

5

Quick ramp time

0

Normal deceleration ramp time

1

Deceleration ramp is switched to shorter than normal

6

Freeze setpoint

0

Changes in the setpoint value from eldbus (FB Speed Reference) are taken into

use by the application

1

Changes in the setpoint value from eldbus (FB Speed Reference) are not taken

into use by the application

7

Setpoint to Zero

0

The setpoint value from eldbus is taken from FB Speed Reference

1

The setpoint value from eldbus is changed to 0

8

Request Fieldbus Control

0

Control Place is as parameterized in the drive (unchanged)

1

Control Place is overridden to Fieldbus Control

9

Request Fieldbus Reference

0

Source of the setpoint value is as parameterized in the drive (unchanged)

1

Source of the setpoint value is overridden to Fieldbus

10

Jogging 1

0

No action

1

Jogging request with jogging reference 1

11

Jogging 2

0

No action

1

Jogging request with jogging reference 2

12

Quick stop

0

No action

1

Drive executes quick stop/emergency stop

VACON® OPTE3/E5 PROFIBUS DP

User Guide

•

VACON® 100 Family: Table 17

•

VACON® NXP: Table 18

•

VACON® 20: Table 19

•

VACON® 20 X/CP: Table 20

.

Set all unused bits to zero.

Table 17: Denition of FBFixedControlWord in VACON® 100 Family

Control Interface and

Communication

BC346130363093EN-US-000101 / DPD0099734 | Danfoss A/S © | 2020.06

Page 35

Bit

Function

Value

Description

13–15

Reserved

-

-

Bit

Function

Value

Description

0

Start/Stop

0

Stop request from eldbus

1

Run request from eldbus

1

Direction

0

Requested direction is "FORWARD"

1

Requested direction is "REVERSE"

2

Fault reset

0

No action

1

Rising edge (0-->1) resets active faults, alarms, and info

3

Fieldbus DIN 1

0

Fieldbus DIN 1 o

1

Fieldbus DIN 1 on

4

Fieldbus DIN 2

0

Fieldbus DIN 2 o

1

Fieldbus DIN 2 on

5

Fieldbus DIN 3

0

Fieldbus DIN 3 o

1

Fieldbus DIN 3 on

6

Fieldbus DIN 4

0

Fieldbus DIN 4 o

1

Fieldbus DIN 4 on

7

Fieldbus DIN 5

0

Fieldbus DIN 5 o

1

Fieldbus DIN 5 on

8

Request Fieldbus Control

0

Control Place is as parameterized in the drive (unchanged)

1

Control Place is overridden to Fieldbus Control

9

Request Fieldbus Reference

0

Source of the setpoint value is as parameterized in the drive (unchanged)

1

Source of the setpoint value is overridden to Fieldbus

10

Not supported

--11

Not supported

--12

Not supported

--13–15

Reserved

-

-

Bit

Function

Value

Description

0

Start/Stop

0

Stop request from eldbus

1

Run request from eldbus

1

Direction

0

Requested direction is "FORWARD"

VACON® OPTE3/E5 PROFIBUS DP

User Guide

Table 18: Denition of FBFixedControlWord in VACON® NXP

Control Interface and

Communication

Table 19: Denition of FBFixedControlWord in VACON® 20

BC346130363093EN-US-000101 / DPD00997 | 35Danfoss A/S © 2020.06

Page 36

Bit

Function

Value

Description

1

Requested direction is "REVERSE"

2

Fault reset

0

No action

1

Rising edge (0-->1) resets active faults, alarms, and info

3

Not supported

--4

Not supported

-

-

5

Quick ramp time

0

Normal deceleration ramp time

1

Deceleration ramp is switched to shorter than normal

6

Not supported

--7

Not supported

--8

Not supported

--9

Not supported

--10

Not supported

--11

Not supported

--12

Not supported

--13–15

Reserved

-

-

Bit

Function

Value

Description

0

Start/Stop

0

Stop request from eldbus

1

Run request from eldbus

1

Direction

0

Requested direction is "FORWARD"

1

Requested direction is "REVERSE"

2

Fault reset

0

No action

1

Rising edge (0-->1) resets active faults, alarms, and info

3

Stop mode 1

0

Stop mode is unmodied

1

Stop mode is overridden to "Ramping"

4

Stop mode 2

0

Normal deceleration ramp time

1

Deceleration ramp is switched to shorter than normal

5

Quick ramp time

0

Normal deceleration ramp time

1

Deceleration ramp is switched to shorter than normal

6

Freeze setpoint

0

Changes in the setpoint value from eldbus (FB Speed Reference) are taken into

use by the application

1

Changes in the setpoint value from eldbus (FB Speed Reference) are not taken

into use by the application

VACON® OPTE3/E5 PROFIBUS DP

User Guide

Control Interface and

Communication

Table 20: Denition of FBFixedControlWord in VACON® 20 X/CP

BC346130363093EN-US-000101 / DPD0099736 | Danfoss A/S © | 2020.06

Page 37

Bit

Function

Value

Description

7

Setpoint to Zero

0

The setpoint value from eldbus is taken from FB Speed Reference

1

The setpoint value from eldbus is changed to 0

8

Request Fieldbus Control

0

Control Place is as parameterized in the drive (unchanged)

1

Control Place is overridden to Fieldbus Control

9

Request Fieldbus Reference

0

Source of the setpoint value is as parameterized in the drive (unchanged)

1

Source of the setpoint value is overridden to Fieldbus

10

Not supported

--11

Not supported

-

-

12

Quick stop

0

No action

1

Drive executes quick stop/emergency stop

13–15

Reserved

-

-

Bit

Function

Value

Description

0

Ready

0

Drive is not ready

1

Drive is ready to run

1

Run

0

Motor is not running

1

Motor is running

2

Direction

0

Motor is running clockwise

1

Motor is running counterclockwise

3

Fault

(1)

0

No fault active

1

Drive has an active fault

4

Alarm

(1)

0

No alarm active

1

Drive has an active alarm

5

At reference

0

Motor is not running at reference speed

1

Motor is running at reference speed

VACON® OPTE3/E5 PROFIBUS DP

User Guide

Control Interface and

Communication

4.3.3.2 Status Word Overview

The VACON® Status Word is composed of 32 bits. This status data is split into two words: FBFixedStatusWord consist of the rst 16

bits and FBGeneralStatusWord consist of the remaining 16 bits.

While functionality of the FBFixedStatusWord is xed in VACON® standard applications, functionality of the FBGeneralStatusWord is

application-specic and can vary even in VACON® standard applications.

FBFixedStatusWord bit denitions are described in the tables. Unused bits are set to zero.

•

VACON® 100 Family: Table 21

•

VACON® NXP: Table 22

•

VACON® 20: Table 23

•

VACON® 20 X/CP: Table 24

Table 21: Denition of FBFixedStatusWord for VACON® 100 Family

BC346130363093EN-US-000101 / DPD00997 | 37Danfoss A/S © 2020.06

Page 38

Bit

Function

Value

Description

6

Zero speed

0

Motor is not at zero speed

1

Motor is running at zero speed

7

Flux ready

0

Motor is not magnetized

1

Motor is magnetized

8

Info

(1)

0

No info active

1

Drive has an active info

9–15

Reserved

-

-

Bit

Function

Value

Description

0

Ready

0

Drive is not ready

1

Drive is ready to run

1

Run

0

Motor is not running

1

Motor is running

2

Direction

0

Motor is running clockwise

1

Motor is running counterclockwise

3

Fault

(1)

0

No fault active

1

Drive has an active fault

4

Alarm

(1)

0

No alarm active

1

Drive has an active alarm

5

At reference

0

Motor is not running at reference speed

1

Motor is running at reference speed

6

Zero speed

0

Motor is not at zero speed

1

Motor is running at zero speed

7

Flux ready

0

Motor is not magnetized

1

Motor is magnetized

8

Not supported

--9–15

Reserved

-

-

VACON® OPTE3/E5 PROFIBUS DP

User Guide

1

Drive faults have three levels: fault, alarm, and info. Bits 3, 4, and 8 are set to 1 when given fault type is activated.

NOTE! In VACON® NXP series AC drives, the FBFixedStatusWord comes from rmware variable "MCStatus".

Table 22: Denition of FBFixedStatusWord for VACON® NXP

Control Interface and

Communication

1

Drive faults have three levels: fault, alarm, and info. Bits 3 and 4 are set to 1 when given fault type is activated.

BC346130363093EN-US-000101 / DPD0099738 | Danfoss A/S © | 2020.06

Page 39

Bit

Function

Value

Description

0

Ready

0

Drive is not ready

1

Drive is ready to run

1

Run

0

Motor is not running

1

Motor is running

2

Direction

0

Motor is running clockwise

1

Motor is running counterclockwise

3

Fault

(1)

0

No fault active

1

Drive has an active fault

4

Alarm

(1)

0

No alarm active

1

Drive has an active alarm

5

At reference

0

Motor is not running at reference speed

1

Motor is running at reference speed

6

Not supported

--7

Not supported

--8

Not supported

--9–15

Reserved

-

-

Bit

Function

Value

Description

0

Ready

0

Drive is not ready

1

Drive is ready to run

1

Run

0

Motor is not running

1

Motor is running

2

Direction

0

Motor is running clockwise

1

Motor is running counterclockwise

3

Fault

(1)

0

No fault active

1

Drive has an active fault

4

Alarm

(1)

0

No alarm active

1

Drive has an active alarm

5

At reference

0

Motor is not running at reference speed

1

Motor is running at reference speed

VACON® OPTE3/E5 PROFIBUS DP

User Guide

Table 23: Denition of FBFixedStatusWord for VACON® 20

Control Interface and

Communication

1

Drive faults have three levels: fault, alarm, and info. Bits 3 and 4 are set to 1 when given fault type is activated.

Table 24: Denition of FBFixedStatusWord for VACON® 20 X/CP

BC346130363093EN-US-000101 / DPD00997 | 39Danfoss A/S © 2020.06

Page 40

Bit

Function

Value

Description

6

Zero speed

0

Motor is not at zero speed

1

Motor is running at zero speed

7

Not supported

--8

Not supported

--9–15

Reserved

-

-

Signal

Index in panel tree

VACON® Live Monitoring Values

FBFixedControlWord

V2.12.1 (Low Word)

FB Control Word (Low Word)

FBGeneralControlWord

V2.12.1 (High Word)

FB Control Word (High Word)

FBFixedStatusWord

V2.12.11 (Low Word)

FB Status Word (Low Word)

FBGeneralStatusWord

V2.12.11 (Low Word)

FB Status Word (High Word)

Signal

Index in panel tree

VACON® NCDrive Monitoring Values

FBFixedControlWord

V1.24.1

(1)

FBFixedControlWord

FBGeneralControlWord

-

FBGeneralControlWord

FBFixedStatusWord

V1.24.16

(1)

MCStatus

FBGeneralStatusWord

V1.24.3

(1)

FBGeneralStatusWord

Signal

Index in panel tree for VACON®20

VACON® Live Monitoring Values

FBFixedControlWord

--FBGeneralControlWord

--FBFixedStatusWord

V3.1

Drive status word