Operating Guide

VACON® NXS/NXP Air-cooled

Wall-mounted and Standalone

ContentsOperating Guide | VACON® NXS/NXP Air-cooled

Contents

1 Introduction 9

1.1 Purpose of this Operating Guide 9

1.2 Additional Resources 9

1.3 Disposal 9

1.4 Type Approvals and Certifications 9

1.5 Start-up Quick Guide 10

2 Safety 12

2.1 Danger and Warnings 12

2.2 Cautions and Notices 13

3 Product Overview 16

3.1 Intended Use 16

3.2 Manual Version 16

3.3 Package Label 16

3.4 Description of the Type Code 17

3.5 Enclosure Sizes 19

3.6 Available Protection Ratings 22

3.7 Available EMC Classes 23

3.8 Control Panel 24

3.8.1 Introduction to Control Panel 24

3.8.2 Keypad 24

3.8.3 Display 26

3.8.4 Basic Menu Structure 27

4 Receiving the Delivery 29

4.1 Checking the Delivery 29

4.1.1 Accessories for FR4/FI4–FR6/FI6 29

4.1.2 Accessories for FR7/FI7–FR8/FI8 30

4.1.3 Accessories for FR10–FR11 Standalone 30

4.2 Storing the Product 30

4.3 Lifting the Product 31

4.4 Using the Product Modified Label 33

5 Mounting the Unit 34

5.1 Environmental Requirements 34

5.1.1 General Environmental Requirements 34

5.1.2 High Altitude Installation 34

5.2 Cooling Requirements 35

5.2.1 General Cooling Requirements 35

AQ275638903263en-000301 / | 3Danfoss A/S © 2020.02

ContentsOperating Guide | VACON® NXS/NXP Air-cooled

5.2.2 Cooling of FR4 to FR9 35

5.2.3 Cooling of Standalone AC drives (FR10 to FR11) 38

5.3 Installation Sequence 39

5.3.1 Installation Sequence for Wall-mounted AC Drives 39

5.3.2 Installation Sequence for Standalone AC Drives 39

6 Electrical Installation 41

6.1 Cable Connections 41

6.1.1 General Cable Requirements 41

6.1.2 UL Standards on Cabling 42

6.1.3 Cable Selection and Dimensioning 42

6.1.4 Cable Selection and Dimensioning, North America 42

6.1.5 Fuse Selection 43

6.1.6 Principle of the Power Unit Topology 43

6.1.7 Brake Resistor Cables 43

6.2 EMC-compliant Installation 44

6.2.1 Installation in a Corner-grounded Network 45

6.3 Grounding 45

6.4 Get Access and Locate the Terminals 47

6.4.1 Get Access and Locate the Terminals for FR4/FI4 47

6.4.2 Get Access and Locate the Terminals for FR5 49

6.4.3 Get Access and Locate the Terminals for FR6/FI6 51

6.4.4 Get Access and Locate the Terminals for FR7/FI7 53

6.4.5 Get Access and Locate the Terminals for FR8/FI8 55

6.4.6 Get Access and Locate the Terminals for FR9 57

6.4.7 Get Access and Locate the Terminals for FR10 Standalone 59

6.4.8 Get Access and Locate the Terminals for FR11 Standalone 62

6.5 Installing the Cables 65

6.5.1 Additional Instructions for Cable Installation 66

6.5.2 Installing the Cables, FR4–FR6/FI4–FI6 66

6.5.3 Installing the Cables, FR7/FI7 70

6.5.4 Installing the Cables, FR8/FI8 75

6.5.5 Installing the Cables, FR9 79

6.5.6 Installing the Cables, FR10 Standalone 83

6.5.7 Installing the Cables, FR11 Standalone 88

6.6 Installation in an IT System 93

6.6.1 Installing the AC drive in an IT System, FR4–FR6 94

6.6.2 Installing the AC Drive in an IT System, FR7 97

6.6.3 Installing the AC Drive in an IT System, FR8–FR11 100

7 Control Unit 101

7.1 Control Unit Components 101

AQ275638903263en-000301 /4 | Danfoss A/S © 2020.02

ContentsOperating Guide | VACON® NXS/NXP Air-cooled

7.2 Control Voltage (+24 V/EXT +24 V) 102

7.3 Control Unit Cabling 103

7.3.1 Selection of the Control Cables 103

7.3.2 Control Terminals on OPTA1 103

7.3.2.1 Digital Input Signal Inversions 105

7.3.2.2 Jumper Selections on the OPTA1 Basic Board 106

7.3.3 Control Terminals on OPTA2 and OPTA3 107

7.4 Installation of Option Boards 109

7.5 Galvanic Isolation Barriers 109

8 Using the Control Panel 111

8.1 Navigating on the Control Panel 111

8.2 Using the Monitoring Menu (M1) 111

8.2.1 Monitored Values 112

8.3 Using the Parameter Menu (M2) 113

8.3.1 Finding the Parameter 113

8.3.2 Selecting Values 114

8.3.3 Editing the Values Digit by Digit 115

8.4 Using the Keypad Control Menu 116

8.4.1 Finding the Keypad Control Menu 116

8.4.2 Keypad Control Parameters M3 117

8.4.3 Changing the Control Mode 117

8.4.4 Keypad Reference 118

8.4.4.1 Editing the Frequency Reference 118

8.4.5 Changing the Rotation Direction 118

8.4.6 Disabling the Stop Motor Function 119

8.4.7 Special Functions in Keypad Control Menu 119

8.4.7.1 Selecting the Keypad as the Control Mode 119

8.4.7.2 Copying the Frequency Reference Set to the Control Panel 120

8.5 Using the Active Faults Menu (M4) 120

8.5.1 Finding the Active Faults Menu 120

8.5.2 Examining the Fault Time Data Record 121

8.5.3 Fault Time Data Record 121

8.6 Using the Fault History Menu (M5) 122

8.6.1 Fault History Menu (M5) 122

8.6.2 Resetting the Fault History 123

8.7 Using the System Menu (M6) 123

8.7.1 Finding the System Menu 123

8.7.2 System Menu Functions 123

8.7.3 Changing the Language 126

8.7.4 Changing the Application 126

8.7.5 Copy Parameters (S6.3) 127

AQ275638903263en-000301 / | 5Danfoss A/S © 2020.02

ContentsOperating Guide | VACON® NXS/NXP Air-cooled

8.7.5.1 Saving Parameter Sets (Parameter Sets S6.3.1) 127

8.7.5.2 Uploading Parameters to Control Panel (Up To Keypad, S6.3.2) 128

8.7.5.3 Downloading Parameters to Drive (Down From Keypad, S6.3.3) 128

8.7.5.4 Activating or Deactivating the Automatic Parameter Back-up (P6.3.4) 128

8.7.5.5 Comparing the Parameters 129

8.7.6 Security 130

8.7.6.1 Finding the Security Menu 130

8.7.6.2 Passwords 130

8.7.6.3 Setting a Password 130

8.7.6.4 Entering a Password 131

8.7.6.5 Deactivating the Password Function 131

8.7.6.6 Locking a Parameter 131

8.7.6.7 Start-up Wizard (P6.5.3) 132

8.7.6.8 Activating/Deactivating the Start-up Wizard 132

8.7.6.9 Enabling/Disabling the Change of Multimonitoring Items 132

8.7.7 Keypad Settings 133

8.7.7.1 Finding the Keypad Settings Menu 133

8.7.7.2 Changing the Default Page 133

8.7.7.3 Default Page in the Operating Menu (P6.6.2) 134

8.7.7.4 Setting the Timeout Time 134

8.7.7.5 Contrast Adjustment (P6.6.4) 134

8.7.7.6 Backlight Time (P6.6.5) 134

8.7.8 Hardware Settings 134

8.7.8.1 Finding the Hardware Setting Menu 134

8.7.8.2 Setting the Internal Brake Resistor Connection 135

8.7.8.3 Fan Control 135

8.7.8.4 Changing the Fan Control Settings 136

8.7.8.5 HMI Acknowledge Timeout (P6.7.3) 136

8.7.8.6 Changing the HMI Acknowledge Timeout 136

8.7.8.7 Changing the Number of Retries to Receive HMI Acknowledgement (P6.7.4) 137

8.7.8.8 Sine Filter (P6.7.5) 137

8.7.8.9 Pre-charge Mode (P6.7.6) 137

8.7.9 System Info 137

8.7.9.1 Finding the System Info Menu 137

8.7.9.2 Total Counters (S6.8.1) 137

8.7.9.3 Trip Counters (S6.8.2) 138

8.7.9.4 Resetting the Trip Counters 138

8.7.9.5 Software (S6.8.3) 138

8.7.9.6 Applications (S6.8.4) 139

8.7.9.7 Examining the Application Page 139

8.7.9.8 Hardware (S6.8.5) 139

8.7.9.9 Checking the Status of an Option Board 139

AQ275638903263en-000301 /6 | Danfoss A/S © 2020.02

ContentsOperating Guide | VACON® NXS/NXP Air-cooled

8.7.9.10 Debug Menu (S6.8.7) 140

8.8 Using the Expander Board Menu 140

8.8.1 Expander Board Menu 140

8.8.2 Examining the Connected Option Boards 140

8.8.3 Finding the Option Board Parameters 141

8.9 Further Control Panel Functions 141

9 Commissioning 142

9.1 Safety Checks before Starting the Commissioning 142

9.2 Commissioning the AC Drive 143

9.3 Measuring the Cable and Motor Insulation 144

9.3.1 Insulation Checks of the Motor Cable 144

9.3.2 Insulation Checks of the Mains Cable 145

9.3.3 Insulation Checks of the Motor 145

9.4 Checks after Commissioning 146

9.4.1 Testing the AC Drive after Commissioning 146

9.4.2 RUN Test without Load 146

9.4.2.1 Test A: Controls from the Control Terminals 146

9.4.2.2 Test B: Control from the Keypad 147

9.4.3 Start-up Test 147

9.4.4 Identification Run 147

10 Maintenance 148

10.1 Maintenance Schedule 148

10.2 Reforming the Capacitors 148

11 Fault Tracing 150

11.1 General Information on Fault Tracing 150

11.2 Resetting a Fault 150

11.3 Creating Service Info File 151

12 Specifications 152

12.1 Weights of the AC Drive 152

12.2 Dimensions 152

12.2.1 List of Dimension Information 152

12.2.2 Wall-mounted 153

12.2.2.1 Dimensions for FR4–FR6 153

12.2.2.2 Dimensions for FR7 155

12.2.2.3 Dimensions for FR8 157

12.2.2.4 Dimensions for FR9 159

12.2.3 Flange mounting 161

12.2.3.1 Dimensions for Flange Mounting, FR4–FR6 161

12.2.3.2 Dimensions for Flange Mounting, FR7–FR8 163

AQ275638903263en-000301 / | 7Danfoss A/S © 2020.02

ContentsOperating Guide | VACON® NXS/NXP Air-cooled

12.2.3.3 Dimensions for Flange Mounting, FR9 166

12.2.4 Standalone 167

12.2.4.1 Dimensions for FR10–FR11 Standalone 167

12.3 Cable and Fuse Sizes 170

12.3.1 List of Cable and Fuse Size Information 170

12.3.2 Cable and Fuse Sizes for 208–240 V and 380–500 V, FR4 to FR9 171

12.3.3 Cable and Fuse Sizes for 208–240 V and 380–500 V, FR4 to FR9, North America 172

12.3.4 Cable and Fuse Sizes for 525–690 V, FR6 to FR9 174

12.3.5 Cable and Fuse Sizes for 525–690 V (UL Rating 600 V), FR6 to FR9, North America 175

12.3.6 Cable and Fuse Sizes for 380–500 V, FR10 to FR11 Standalone 176

12.3.7 Cable and Fuse Sizes for 380–500 V, FR10 to FR11, North America 176

12.3.8 Cable and Fuse Sizes for 525–690 V, FR10 to FR11 177

12.3.9 Cable and Fuse Sizes for 525–690 V (UL Rating 600 V), FR10 to FR11, North America 178

12.4 Cable Stripping Lengths 178

12.5 Tightening Torques for Cover Screws 180

12.6 Tightening Torques of the Terminals 180

12.7 Power ratings 181

12.7.1 Overload Capability 181

12.7.2 Power Ratings for Mains Voltage 208–240 V 182

12.7.3 Power Ratings for Mains Voltage 208–240 V, North America 183

12.7.4 Power Ratings for Mains Voltage 380–500 V 184

12.7.5 Power Ratings for Mains Voltage 380–500 V, North America 185

12.7.6 Power Ratings for Mains Voltage 525–690 V (UL Rating 600 V) 187

12.7.7 Power Ratings for Mains Voltage 525–690 V (UL Rating 600 V), North America 188

12.8 VACON® NXP Technical Data 189

12.9 Brake Chopper Ratings 194

12.9.1 Brake Chopper Ratings 194

12.9.2 Brake Chopper Ratings for Mains Voltage 208–240 V 195

12.9.3 Brake Chopper Ratings for Mains Voltage 380–500 V 196

12.9.4 Brake Chopper Ratings for Mains Voltage 525–690 V 197

12.9.5 Internal Brake Resistors, FR4–FR6 (380–500 V) 197

12.10 Faults and Alarms 198

AQ275638903263en-000301 /8 | Danfoss A/S © 2020.02

Operating Guide | VACON® NXS/NXP Air-cooled

Introduction

1 Introduction

1.1 Purpose of this Operating Guide

This operating guide provides information for safe installation and commissioning of the AC drive. It is intended for use by qualified

personnel. Read and follow the instructions to use the drive safely and professionally. Pay particular attention to the safety instructions

and general warnings. Always keep this operating guide available with the drive.

1.2 Additional Resources

Other resources are available to understand advanced AC drive functions and programming.

• The VACON® NX manuals provide greater detail on working with parameters and show many application examples.

• The VACON® NX I/O Boards User Manual gives more information on the I/O boards and their installation.

• Instructions for operation with option boards and other optional equipment.

Supplementary publications and manuals are available from Danfoss.

NOTE! Download the English and French product manuals with applicable safety, warning and caution information from https://

www.danfoss.com/en/service-and-support/.

REMARQUE Vous pouvez télécharger les versions anglaise et française des manuels produit contenant l'ensemble des informations

de sécurité, avertissements et mises en garde applicables sur le site https://www.danfoss.com/en/service-and-support/.

1.3 Disposal

Context:

Do not dispose of equipment containing electrical components together with domestic waste. Collect it separately in accordance with

local and currently valid legislation.

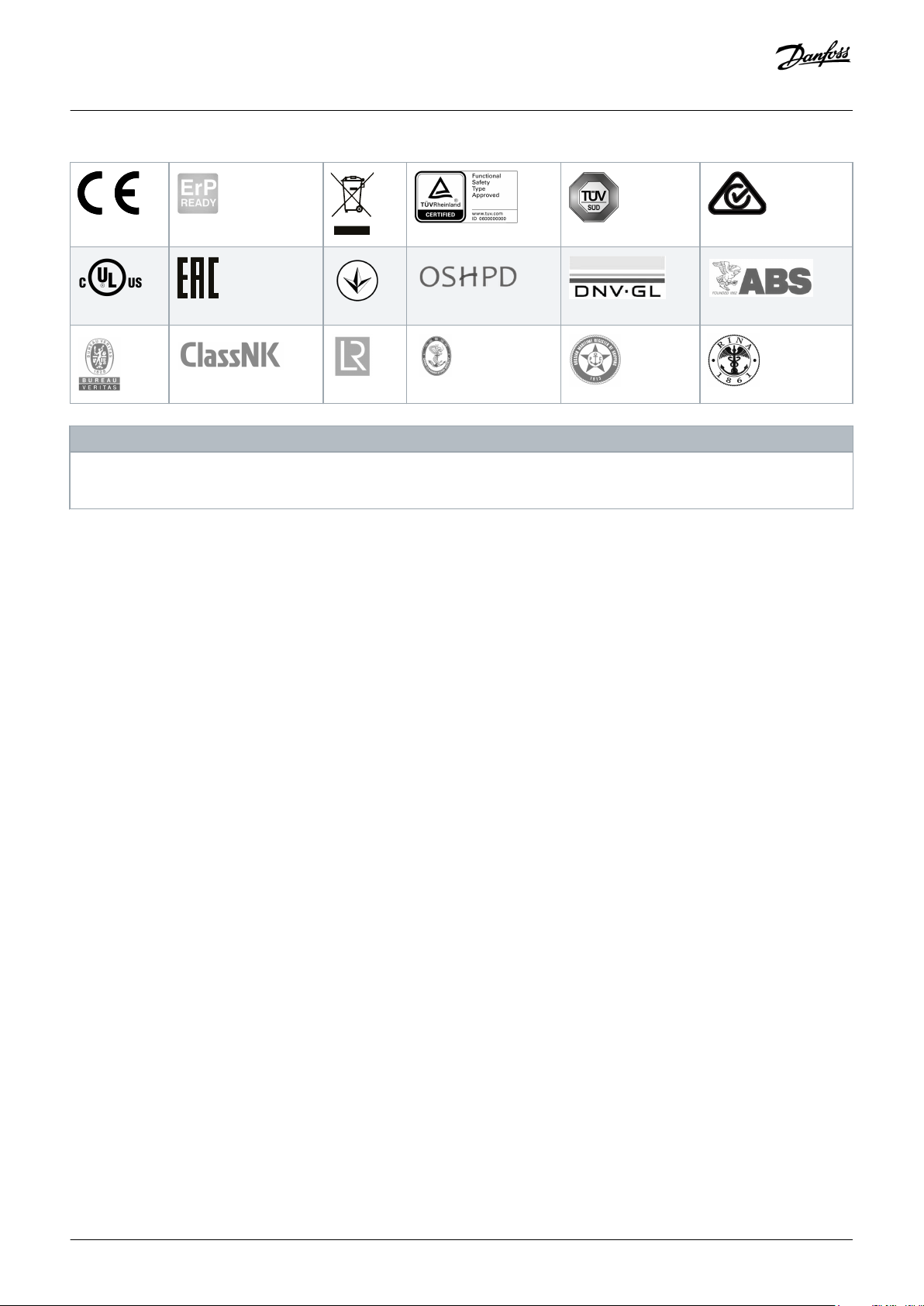

1.4 Type Approvals and Certifications

The following list is a selection of possible type approvals and certifications for Danfoss drives:

Danfoss A/S © 2020.02

AQ275638903263en-000301 / DPD00910| 9

089

Operating Guide | VACON® NXS/NXP Air-cooled

Introduction

NOTICE

The specific approvals and certification for the drive are on the nameplate of the drive. For more information, contact the local

Danfoss office or partner.

1.5 Start-up Quick Guide

Context:

Do at minimum these procedures during the installation and commissioning.

If there are problems, speak to the local distributor.

Vacon Ltd is not responsible for the use of the AC drives against the instructions.

10 | Danfoss A/S © 2020.02

AQ275638903263en-000301 / DPD00910

Operating Guide | VACON® NXS/NXP Air-cooled

Introduction

Procedure

1. Check that the delivery agrees to the order, see 4.1 Checking the Delivery.

2. Before starting the commissioning, read carefully the safety instructions in 2.1 Danger and Warnings and 2.2 Cautions and Notices.

3. Before the mechanical installation, check the minimum clearances around the AC drive ( 5.2.2 Cooling of FR4 to FR9 and 5.2.3

Cooling of Standalone AC drives (FR10 to FR11)) and check the ambient conditions in 12.8 VACON® NXP Technical Data.

4. Check the dimensions of the motor cable, mains cable, mains fuses and check the cable connections. Read

6.1 Cable Connections,

6.2 EMC-compliant Installation and 6.3 Grounding.

5. Obey the installation instructions, see 6.5 Installing the Cables.

6. Find information on the control connections in 7.3.2 Control Terminals on OPTA1.

7. If the start-up wizard is active, select the language of the control panel and the application. Accept the selections with the [enter]

button. If the start-up wizard is not active, obey the instructions a and b.

A Select the language of the control panel from the Menu M6, page 6.1. For instructions, see 8.7.3 Changing the Language.

B Select the application from the Menu M6, page 6.2. For instructions, see 8.7.4 Changing the Application.

8. All parameters have factory default values. To make sure that the AC drive operates correctly, make sure that these group G2.1

parameters have the same data as the nameplate. For more information on the parameters in the list, see the VACON® All in One

Application Manual.

• Nominal voltage of the motor

• Nominal frequency of the motor

• Nominal speed of the motor

• Nominal current of the motor

• Motor cos phi

9. Obey the commissioning instructions, see 9.2 Commissioning the AC Drive.

The VACON

®

NXS/NXP AC drive is ready for operation.

Danfoss A/S © 2020.02

AQ275638903263en-000301 / DPD00910| 11

Operating Guide | VACON® NXS/NXP Air-cooled

2 Safety

2.1 Danger and Warnings

DANGER

SHOCK HAZARD FROM POWER UNIT COMPONENTS

The power unit components are live when the drive is connected to mains. A contact with this voltage can lead to death or

serious injury.

Do not touch the components of the power unit when the drive is connected to mains. Before connecting the drive to

-

mains, make sure that the covers of the drive are closed.

DANGER

SHOCK HAZARD FROM TERMINALS

The motor terminals U, V, W, the brake resistor terminals, or the DC terminals are live when the drive is connected to mains, also

when the motor does not operate. A contact with this voltage can lead to death or serious injury.

Do not touch the motor terminals U, V, W, the brake resistor terminals, or the DC terminals when the drive is connected to

-

mains. Before connecting the drive to mains, make sure that the covers of the drive are closed.

Safety

DANGER

SHOCK HAZARD FROM DC LINK OR EXTERNAL SOURCE

The terminal connections and the components of the drive can be live 5 minutes after the drive is disconnected from the mains

and the motor has stopped. Also the load side of the drive can generate voltage. A contact with this voltage can lead to death

or serious injury.

Before doing electrical work on the drive:

-

• Disconnect the drive from the mains and make sure that the motor has stopped.

• Lock out and tag out the power source to the drive.

• Make sure that no external source generates unintended voltage during work.

• Wait 5 minutes before opening the cabinet door or the cover of the AC drive.

• Use a measuring device to make sure that there is no voltage.

WARNING

SHOCK HAZARD FROM CONTROL TERMINALS

The control terminals can have a dangerous voltage also when the drive is disconnected from mains. A contact with this

voltage can lead to injury.

Make sure that there is no voltage in the control terminals before touching the control terminals.

-

12 | Danfoss A/S © 2020.02

AQ275638903263en-000301 / DPD00910

Operating Guide | VACON® NXS/NXP Air-cooled

WARNING

ACCIDENTAL MOTOR START

When there is a power-up, a power break, or a fault reset, the motor starts immediately if the start signal is active, unless the

pulse control for Start/Stop logic is selected. If the parameters, the applications or the software change, the I/O functions

(including the start inputs) can change. If you activate the auto reset function, the motor starts automatically after an automatic

fault reset. See the Application Guide. Failure to ensure that the motor, system, and any attached equipment are ready for start

can result in personal injury or equipment damage.

Disconnect the motor from the drive if an accidental start can be dangerous. Make sure that the equipment is safe to

-

operate under any condition.

WARNING

LEAKAGE CURRENT HAZARD

Leakage currents exceed 3.5 mA. Failure to ground the drive properly can result in death or serious injury.

Ensure the correct grounding of the equipment by a certified electrical installer.

-

WARNING

Safety

SHOCK HAZARD FROM PE CONDUCTOR

The drive can cause a DC current in the PE conductor. Failure to use a residual current-operated protective (RCD) device Type B

or a residual current-operated monitoring (RCM) device can lead to the RCD not providing the intended protection and

therefore can result in death or serious injury.

Use a type B RCD or RCM device on the mains side of the drive.

-

2.2 Cautions and Notices

CAUTION

DAMAGE TO THE AC DRIVE FROM INCORRECT MEASUREMENTS

Doing measurements on the AC drive when it is connected to mains can damage the drive.

Do not do measurements when the AC drive is connected to mains.

-

CAUTION

DAMAGE TO THE AC DRIVE FROM INCORRECT SPARE PARTS

Using spare parts that are not from the manufacturer can damage the drive.

Do not use spare parts that are not from the manufacturer.

-

Danfoss A/S © 2020.02

AQ275638903263en-000301 / DPD00910| 13

Operating Guide | VACON® NXS/NXP Air-cooled

CAUTION

DAMAGE TO THE AC DRIVE FROM INSUFFICIENT GROUNDING

Not using a grounding conductor can damage the drive.

Make sure that the AC drive is always grounded with a grounding conductor that is connected to the grounding terminal

-

that is identified with the PE symbol.

CAUTION

CUT HAZARD FROM SHARP EDGES

There can be sharp edges in the AC drive that can cause cuts.

Wear protective gloves when mounting, cabling, or doing maintenance operations.

-

CAUTION

BURN HAZARD FROM HOT SURFACES

Touching surfaces, which are marked with the 'hot surface' sticker, can result in injury.

Do not touch surfaces which are marked with the 'hot surface' sticker.

-

Safety

NOTICE

DAMAGE TO THE AC DRIVE FROM STATIC VOLTAGE

Some of the electronic components inside the AC drive are sensitive to ESD. Static voltage can damage the components.

Remember to use ESD protection always when working with electronic components of the AC drive. Do not touch the

-

components on the circuit boards without proper ESD protection.

NOTICE

DAMAGE TO THE AC DRIVE FROM MOVEMENT

Movement after installation can damage the drive.

Do not move the AC drive during operation. Use a fixed installation to prevent damage to the drive.

-

NOTICE

DAMAGE TO THE AC DRIVE FROM INCORRECT EMC LEVEL

The EMC level requirements for the AC drive depend on the installation environment. An incorrect EMC level can damage the

drive.

Before connecting the AC drive to the mains, make sure that the EMC level of the AC drive is correct for the mains.

-

NOTICE

RADIO INTERFERENCE

In a residential environment, this product can cause radio interference.

Take supplementary mitigation measures.

-

14 | Danfoss A/S © 2020.02

AQ275638903263en-000301 / DPD00910

Operating Guide | VACON® NXS/NXP Air-cooled

NOTICE

MAINS DISCONNECTION DEVICE

If the AC drive is used as a part of a machine, the machine manufacturer must supply a mains disconnection device (refer to EN

60204-1).

NOTICE

MALFUNCTION OF FAULT CURRENT PROTECTIVE SWITCHES

Because there are high capacitive currents in the AC drive, it is possible that the fault current protective switches do not

operate correctly.

NOTICE

VOLTAGE WITHSTAND TESTS

Doing voltage withstand tests can damage the drive.

Do not do voltage withstand tests on the AC drive. The manufacturer has already done the tests.

-

Safety

Danfoss A/S © 2020.02

AQ275638903263en-000301 / DPD00910| 15

Operating Guide | VACON® NXS/NXP Air-cooled

Product Overview

3 Product Overview

3.1 Intended Use

The drive is an electronic motor controller intended for:

• Regulation of motor speed in response to system feedback or to remote commands from external controllers. A power drive

system consists of the AC drive, the motor, and equipment driven by the motor.

• System and motor status surveillance.

The drive can also be used for motor overload protection.

VACON® NXP drive can be used as programmable logic controller (PLC) in many applications due to extensive I/O and fieldbus options

and easy programmability. Custom application development can be done with VACON® Programming tool and standard PLC

programming languages defined in the IEC 61131/3.

Depending on the configuration, the drive can be used in standalone applications or form part of a larger appliance or installation.

The drive is allowed for use in residential, industrial, and commercial environments in accordance with local laws and standards.

NOTICE

In a residential environment, this product can cause radio interference, in which case supplementary mitigation measures can

be required.

Foreseeable misuse

Do not use the drive in applications which are non-compliant with specified operating conditions and environments. Ensure

compliance with the conditions specified in 12.8 VACON® NXP Technical Data.

3.2 Manual Version

This manual is regularly reviewed and updated. All suggestions for improvement are welcome.

The original language of this manual is English.

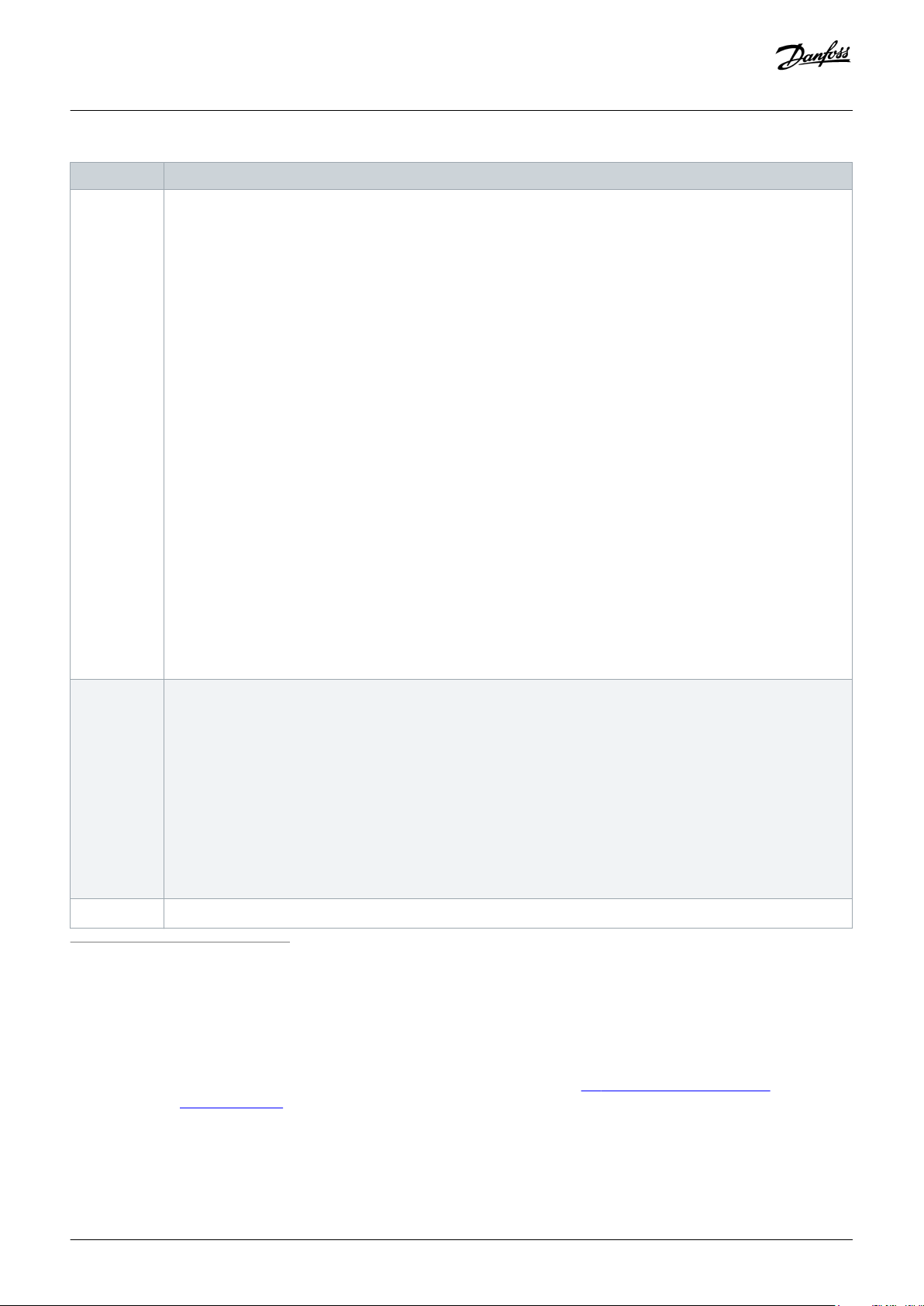

Table 1: Manual and Software Version

Edition Remarks

DPD00910I Added information about FR10 and FR11 Standalone drives throughout the manual.

Minor corrections throughout the manual.

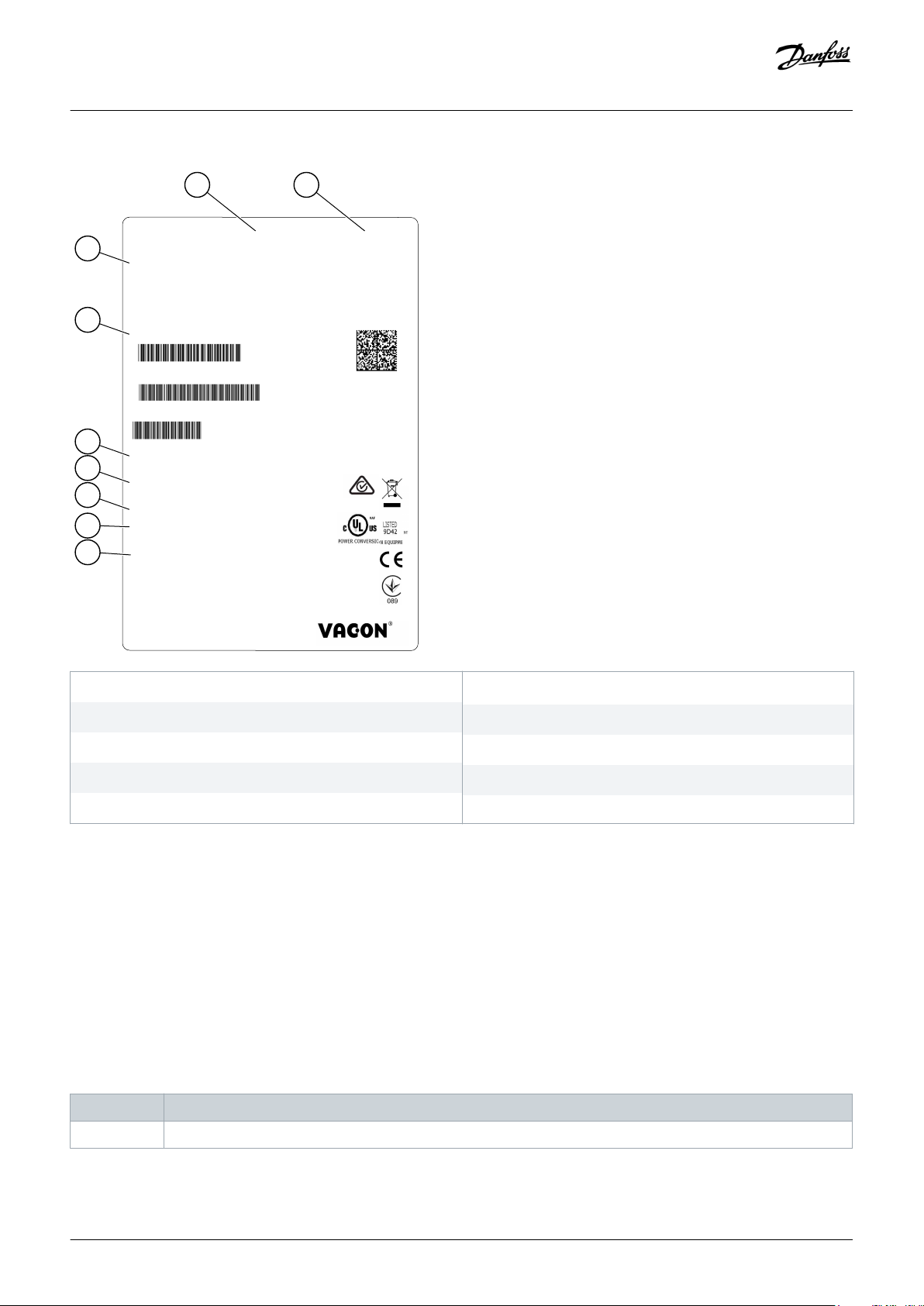

3.3 Package Label

The package label gives detailed information about the delivery.

16 | Danfoss A/S © 2020.02

AQ275638903263en-000301 / DPD00910

A B

H

G

F

E

D

C

I

e30bf961.10

1003322235

V00001687465

NXP00875-A2H1SSS-A1A2000000

171208

B.ID :

S/ N:

Type:

AC DR I VE

V00001687465

7DP-008752-116SC8

Made in Finland

Danfoss A/S, 6430 Nordborg, Denmark

135X9219

87A 40°C / 72A 50°C

87A 40°C / 72A 50°C

45kW:400V / 60HP:480V

IP21/Type1

3~AC,0-Uin, 0-320Hz,

Uin:3~AC,380-500V, 50/60Hz,

POWER :

OUTPUT:

INPUT:

Danfoss Limited

0018131571

NXP00002V195

Ma r ks:

Cust . Or d. No :

Appl icat ion :

Firm ware :

7DP-008752-116SC8

Code:

Operating Guide | VACON® NXS/NXP Air-cooled

Product Overview

A The batch ID

C The type code

E The mains voltage

G The protection rating

B

The order number of VACON

D The serial number

F The nominal output current

H The firmware code

®

I The order number of the customer

Illustration 1: Package Label of VACON® NXS/NXP AC Drives

3.4 Description of the Type Code

The type code of VACON® is made of standard codes and optional codes. Each part of the type code agrees to the data in the order.

Example:

The code can have this format, for example:

• NXP00035-A2H1SSS-A1A2C30000+DNOT

Table 2: Description of the Type Code

Code Description

VACON This part is same for all the products.

Danfoss A/S © 2020.02

AQ275638903263en-000301 / DPD00910| 17

Operating Guide | VACON® NXS/NXP Air-cooled

Code Description

NXP The product range:

• NXP = VACON® NXP

• NXS = VACON® NXS

0003 The drive rating in amperes. For example, 0003 = 3 A

5 The mains voltage:

• 2 = 208–240 V

• 5 = 380–500 V

• 6 = 525–600 V (IEC)

525–600 V (cULus)

A The control panel:

• A = standard (text display)

• B = no local control panel

• F = dummy keypad

• G = graphic display

Product Overview

2 The protection rating:

• 0 = IP00

• 2 = IP21 (UL Type 1)

• 5 = IP54 (UL Type 12)

• T = flange-mounted (through-hole mounted)

H The EMC emission level:

• C = complies with the category C1 of standard IEC/EN 61800-3 + A1, 1st environment, and nominal voltage less

than 1000 V

• H = complies with the category C2 of standard IEC/EN 61800-3 + A1, fixed installations, and nominal voltage

less than 1000 V

• L = complies with the category C3 of standard IEC/EN 61800-3 + A1, 2nd environment, and nominal voltage less

than 1000 V

• T = complies with the standard IEC/EN 61800-3 + A1 when used in IT networks (C4).

• N = No EMC emission protection. An external EMC filter is necessary.

1

The brake chopper:

(1)

• 0 = No brake chopper

• 1 = Internal brake chopper

• 2 = Internal brake chopper and resistor, available for:

- 208–240 V (FR4–FR6)

- 380–500 V (FR4–FR6)

18 | Danfoss A/S © 2020.02

AQ275638903263en-000301 / DPD00910

Operating Guide | VACON® NXS/NXP Air-cooled

Code Description

SSS The hardware changes:

• The supply, the first letter (Xxx):

- S = 6-pulse connection (FR4 to FR11)

- B = Additional DC-connection (FR8 to FR11)

- O = Standard and input switch (Standalone)

- J = FR10 to 11 stand-alone with main switch and DC-link terminals

- P = Standard and input swithc UL (Standalone)

- K = DC link connectors and input switch UL (Standalone)

• The mounting, the second letter: (xXx):

- S = Air-cooled drive

• The boards, the third letter (xxX):

- S = Standard boards (FR4 to FR8)

- V = Coated boards (FR4 to FR8)

- F = Standard boards (FR9 to FR11)

- G = Coated boards (FR9 to FR11)

- A = Fiber, Integrated control (FR10 to FR11 standalone drives)

- B = Fiber, Integrated control, Coated boards (FR10 to FR11 standalone drives)

- N = separate IP54 (UL Type 12) control box, standard boards, fiber connection (FR9 IP00, ≥ FR10)

- O = separate IP54 (UL Type 12) control box, coated boards, fiber connection (FR9 IP00, ≥ FR10)

- X = separate IP00 control box, standard boards (FR9 IP00)

- Y = separate IP00 control box, coated boards (FR9 IP00)

Product Overview

A1A2C30000 The option boards. 2 characters for each slot. 00 = the slot is not used

The option board abbreviations:

• A = basic I/O board

• B = expander I/O board

• C = fieldbus board

• D = special board

• E = fieldbus board

For example, C3 = PROFIBUS DP

+DNOT

1

A brake resistor is available as an option for external installation for 208–240 V (FR7–FR11), 380–500 V (FR7–FR11), and 525–690 V (all enclosure sizes).

The optional codes. See full list of option codes in the VACON® NXP Selection Guide.

3.5 Enclosure Sizes

Example:

The codes for nominal current and nominal mains voltage are part of the type code (see 3.4 Description of the Type Code) on the

package label (see 3.3 Package Label). Use these values to find out the enclosure size of the AC drive from the table.

Danfoss A/S © 2020.02

AQ275638903263en-000301 / DPD00910| 19

Operating Guide | VACON® NXS/NXP Air-cooled

Product Overview

In the example "NXP00035-A2H1SSS-A1A2C30000+DNOT", the code for nominal current is 0003 and the code for nominal mains

voltage is 5.

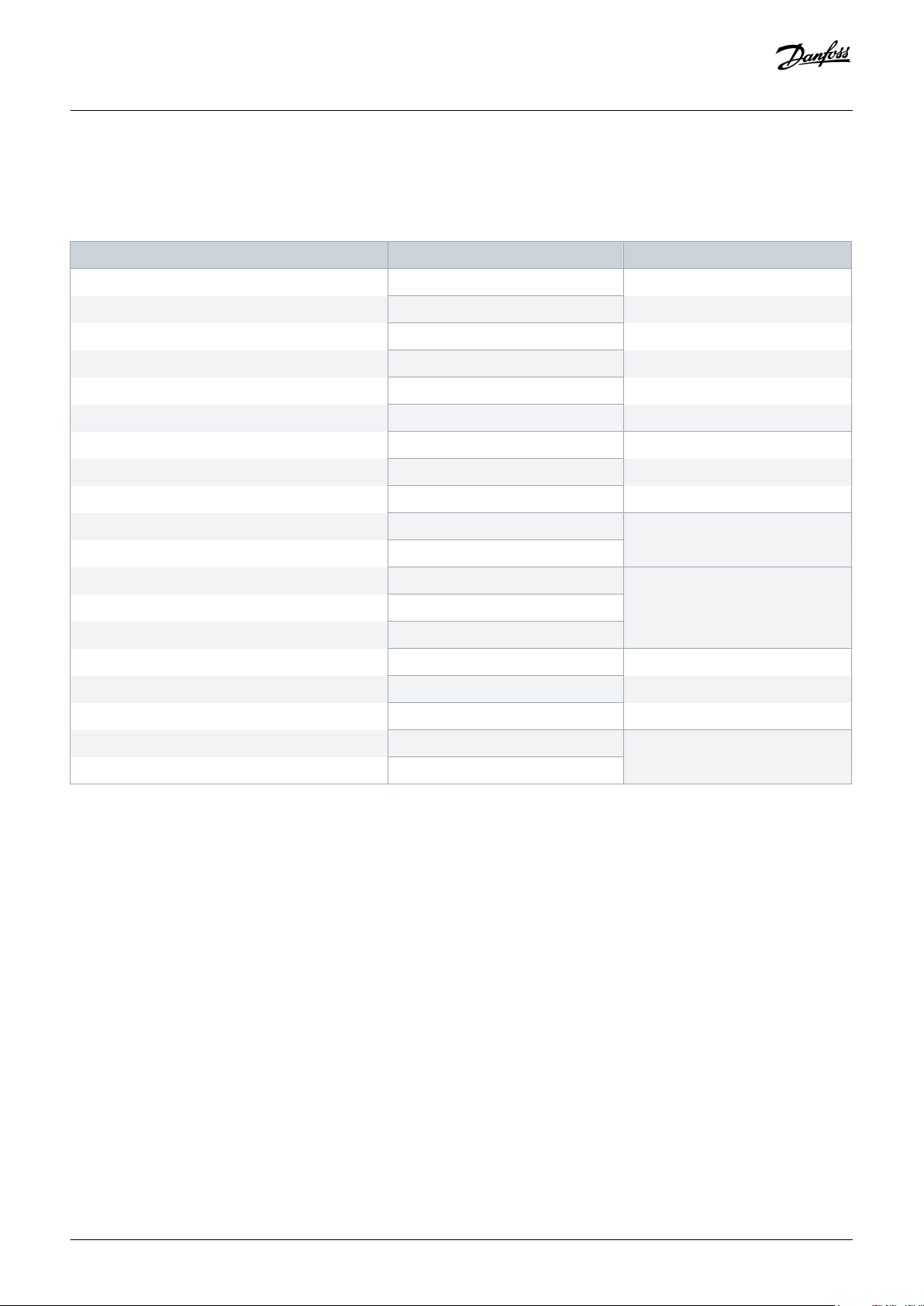

Table 3: Enclosure Sizes

Nominal mains voltage Nominal current Enclosure size

2 (208–240 V) 0003 FR4

0004

0007

0008

0011

0012

0017 FR5

0025

0031

0048 FR6

0061

0075 FR7

0088

0114

0140 FR8

0170

0205

0261 FR9

0300

20 | Danfoss A/S © 2020.02

AQ275638903263en-000301 / DPD00910

Operating Guide | VACON® NXS/NXP Air-cooled

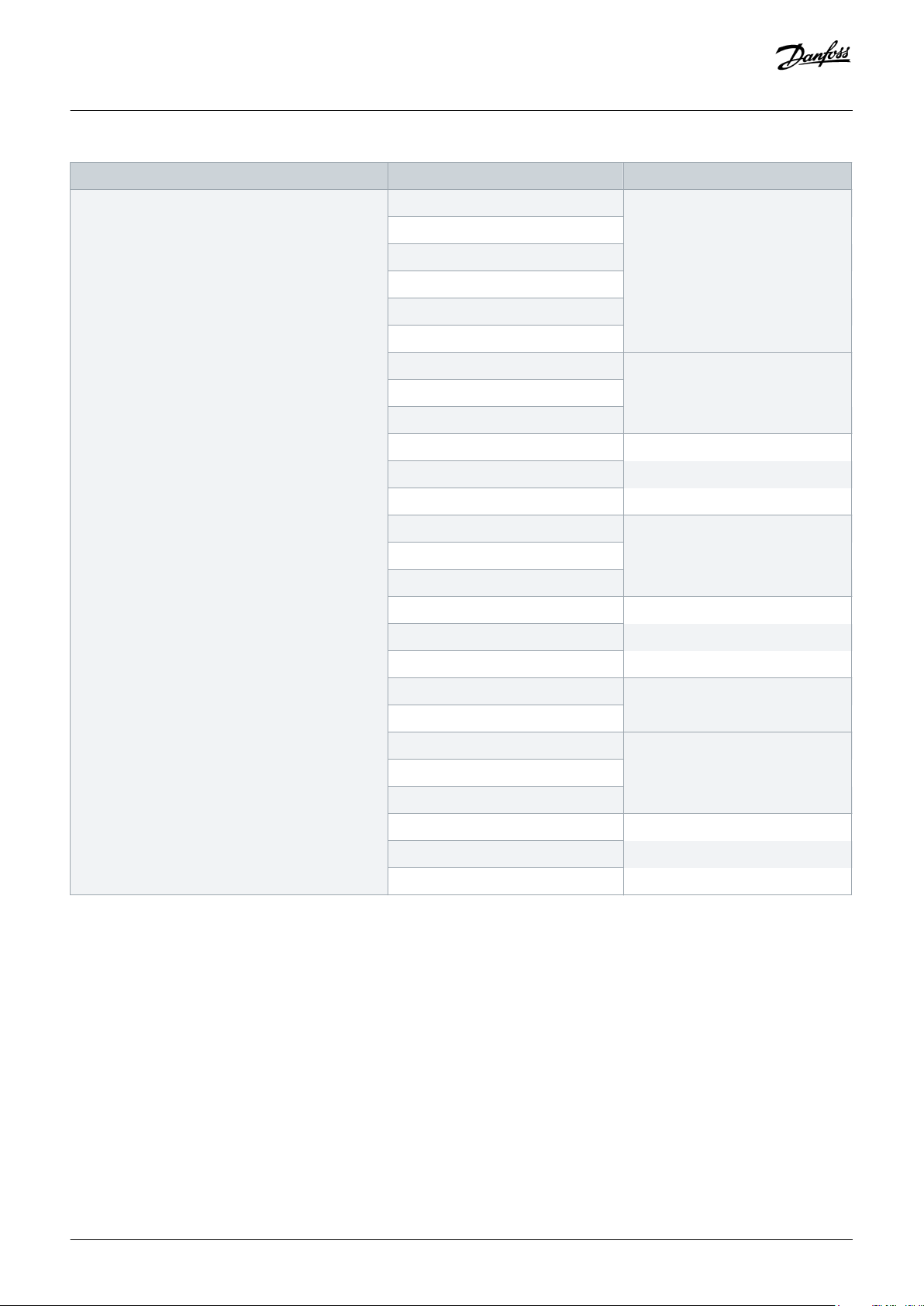

Nominal mains voltage Nominal current Enclosure size

5 (380–500 V) 0003 FR4

0004

0005

0007

0009

0012

0016 FR5

0022

0031

0038 FR6

0045

0061

0072 FR7

Product Overview

0087

0105

0140 FR8

0168

0205

0261 FR9

0300

0385 FR10 Standalone

0460

0520

0590 FR11 Standalone

0650

0730

Danfoss A/S © 2020.02

AQ275638903263en-000301 / DPD00910| 21

Operating Guide | VACON® NXS/NXP Air-cooled

Nominal mains voltage Nominal current Enclosure size

6 (500–690 V) 0004 FR6

0005

0007

0010

0013

0018

0022

0027

0034

0041 FR7

0052

0062 FR8

0080

Product Overview

0100

0125 FR9

0144

0177

0205

0261 FR10 Standalone

0325

0385

0416

0460 FR11 Standalone

0502

0590

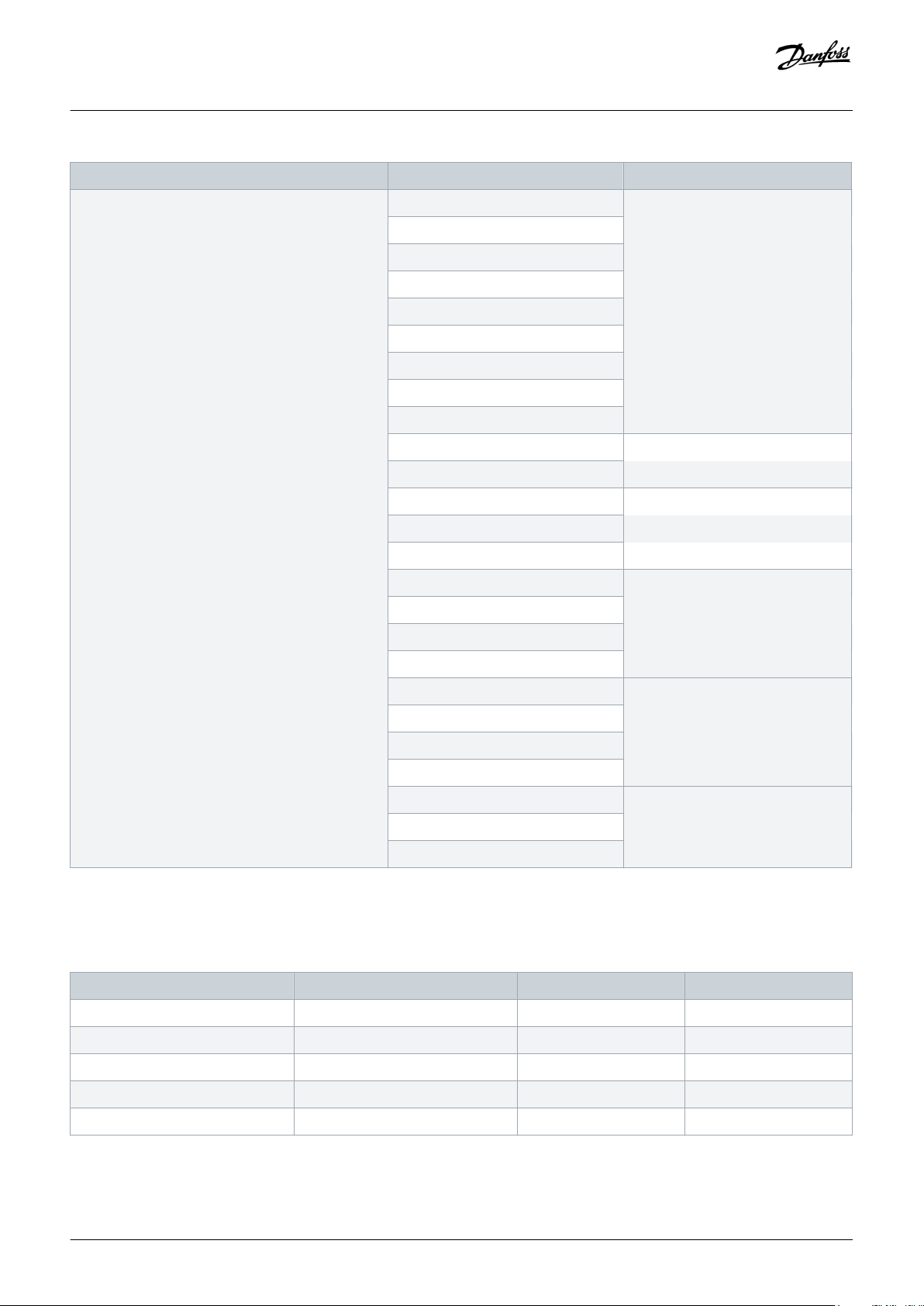

3.6 Available Protection Ratings

Table 4: Available Protection Ratings

Mains voltage Enclosure size IP21 (UL Type 1) IP54 (UL Type 12)

208–240 V FR4–FR9 x x

350–500 V FR4–FR9 x x

350–500 V FR10 Standalone x x

350–500 V FR11 Standalone x –

525–690 V FR4-FR9 x x

22 | Danfoss A/S © 2020.02

AQ275638903263en-000301 / DPD00910

Operating Guide | VACON® NXS/NXP Air-cooled

Mains voltage Enclosure size IP21 (UL Type 1) IP54 (UL Type 12)

525–690 V FR10 Standalone x x

525–690 V FR11 Standalone x –

Product Overview

3.7 Available EMC Classes

The product standard (EMC immunity requirements) IEC/EN 61800-3 + A1 has 5 categories. The VACON® AC drives are divided into 5

EMC classes that have equivalents in the standard. All VACON® NX AC drives comply with the standard IEC/EN 61800-3 + A1.

The type code tells which category requirement the AC drive complies with (see 3.4 Description of the Type Code).

The category changes when these properties in the AC drive change:

• the level of electromagnetic disturbances

• the requirements of a power system network

• the installation environment (see the standard IEC/EN 61800-3 + A1)

Table 5: Available EMC Classes

EMC class

in IEC/EN

61800-3 +

A1

C1 C The best EMC protection. These AC drives have the nominal voltage of less than

VACON

equiva‐

lent

EMC

class

®

Description Available for

1000 V. They are used in the 1st environment.

NOTIC E

If the protection rating of the AC drive is IP21 (UL Type 1), only the conducted

emissions are in the requirements of category C1.

C2 H Includes AC drives in fixed installations. These AC drives have the nominal voltage of

less than 1000 V. The category C2 AC drives can be used in the 1st and the 2nd environment.

C3 L Includes AC drives that have the nominal voltage of less than 1000 V. These AC

drives are used in the 2nd environment only.

380–500 V, FR4

to FR6, IP54 (UL

Type 12)

380–500 V, FR4

to FR9 and 208–

240 V, FR4 to

FR9

IP21 (UL Type 1)

and IP54 (UL

Type 12) in

380–500 V FR10

and larger, 525–

690 V FR6 and

larger

Danfoss A/S © 2020.02

AQ275638903263en-000301 / DPD00910| 23

Operating Guide | VACON® NXS/NXP Air-cooled

Product Overview

EMC class

in IEC/EN

61800-3 +

A1

C4 T These AC drives comply with the standard IEC/EN 61800-3 + A1 if they are used in IT

VACON

equiva‐

lent

EMC

class

®

Description Available for

systems. In IT systems, the networks are isolated from ground, or connected to

ground through high impedance to decrease the leakage current.

NOTIC E

If the AC drives are used with other supplies, they do not comply with the

EMC requirements.

To change the EMC class of the VACON® NX AC drive from C2 or C3 to C4, see the

instructions in 6.6 Installation in an IT System.

No EMC

emission

protection

N The AC drives of this category do not give EMC emission protection. These drives are

installed in enclosures.

NOTIC E

An external EMC filter is usually necessary to comply with the EMC emission

requirements.

All products

In IP00

NOTIC E

RADIO INTERFERENCE

In a residential environment, this product can cause radio interference.

Take supplementary mitigation measures.

-

3.8 Control Panel

3.8.1 Introduction to Control Panel

The control panel is the interface between the AC drive and the user. Use the control panel to control the speed of a motor and

monitor the status of the AC drive. Use it also to set the parameters of the AC drive.

The control panel can be removed from the AC drive. The control panel is isolated from the input line potential.

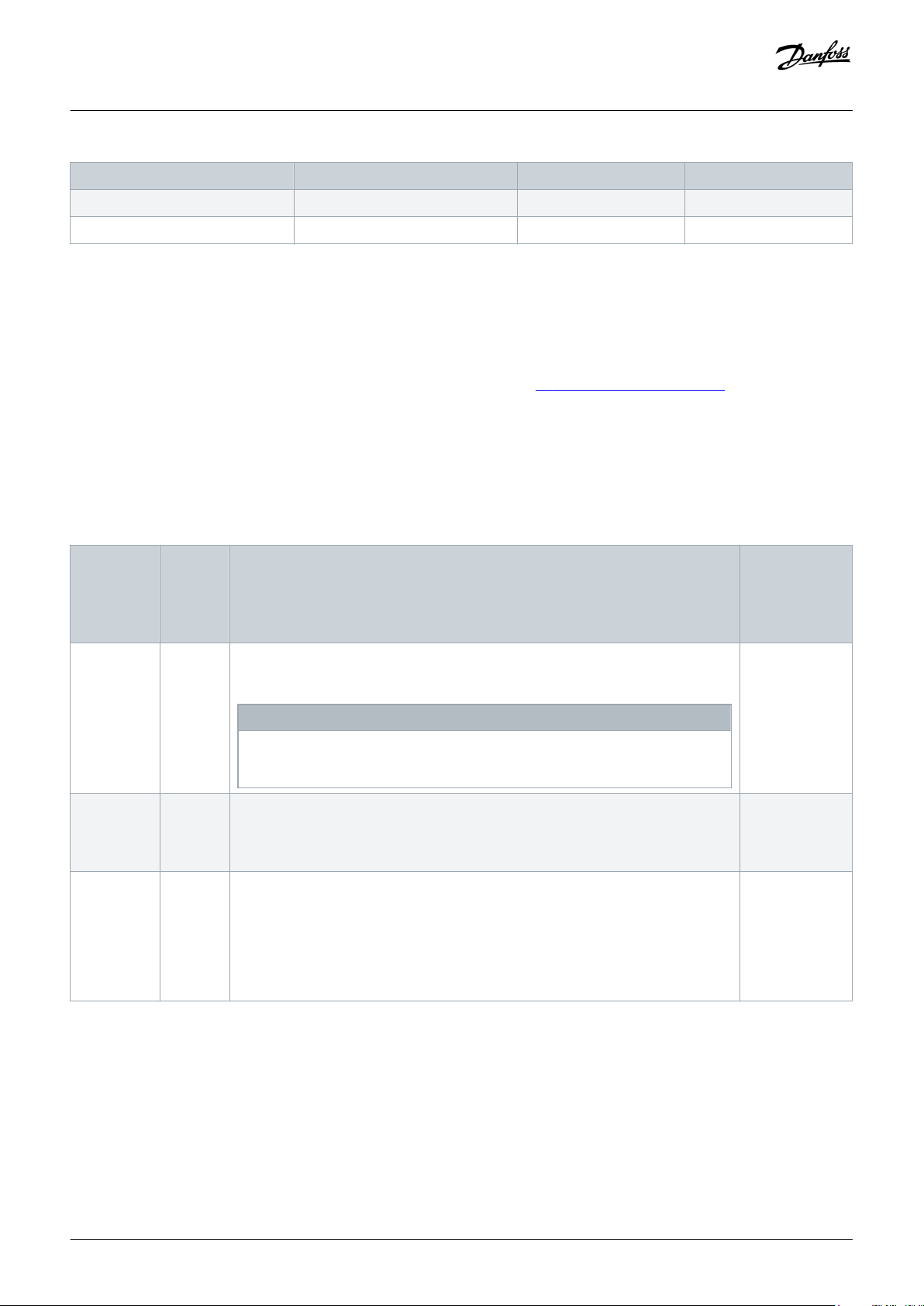

3.8.2 Keypad

The VACON® keypad has 9 buttons with which to control the AC drive (and motor), set parameters, and monitor values.

24 | Danfoss A/S © 2020.02

AQ275638903263en-000301 / DPD00910

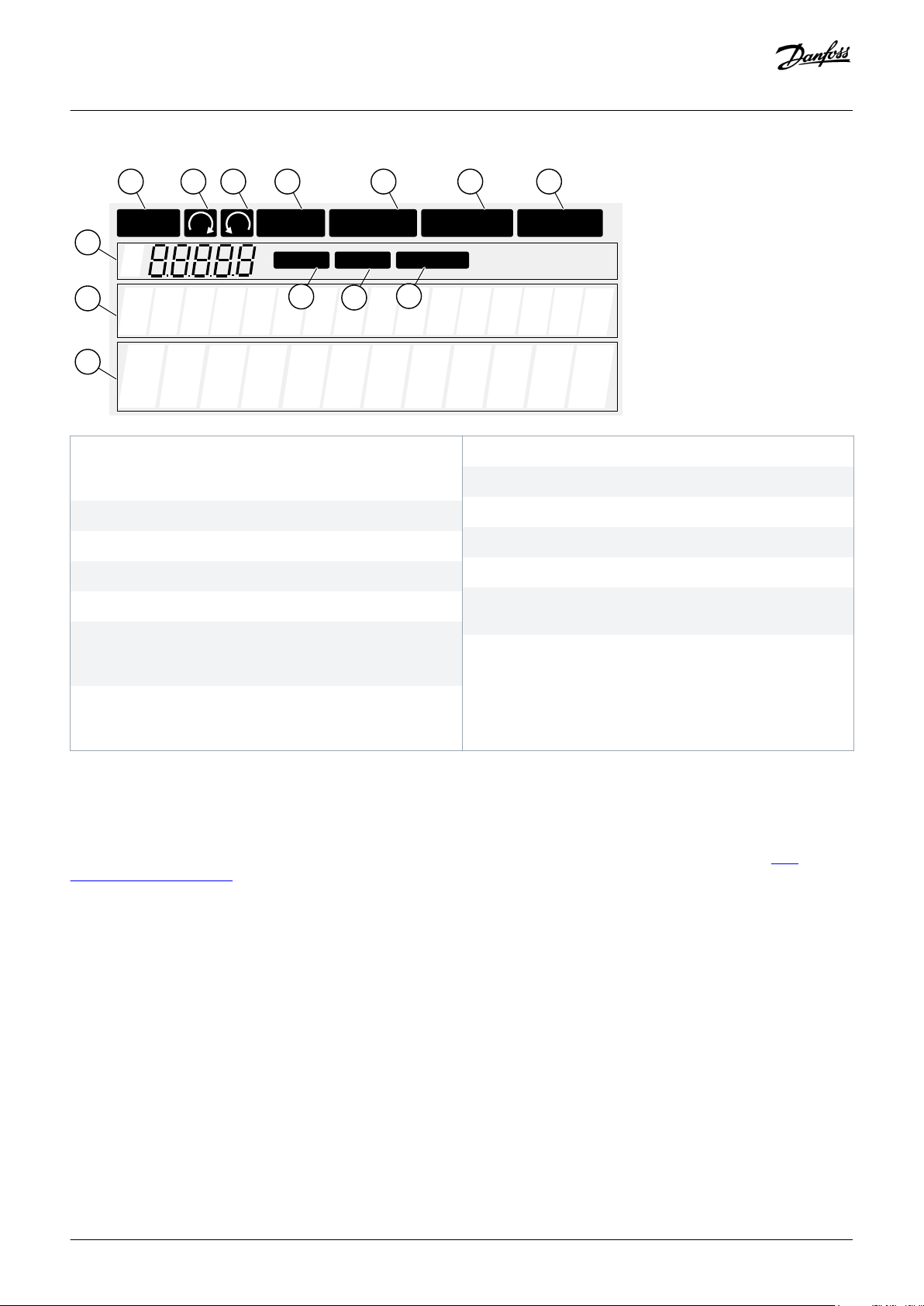

e30bf978.10

K

A B C

L

D

E

J

F

I H G

reset

ready

run

fault

select enter

Operating Guide | VACON® NXS/NXP Air-cooled

Product Overview

A The [ready] LED is on when the AC power is connected to the

drive and no faults are active. At the same time, the drive

status indication shows READY.

C The [fault] LED blinks when the AC drive is stopped because

of dangerous conditions (Fault Trip). See 8.5.1 Finding the

Active Faults Menu.

E The Stop button. The button stops the motor (unless the stop

is disabled by the parameter R3.4/R3.6). See 8.4.2 Keypad

Control Parameters M3.

G The [enter] button. Use it to accept a selection, reset the fault

history (push for 2–3 s).

I The [select] button. Use it to move between 2 last displays, for

example, to see how new value changes some other value.

K The [reset] button. Use it to reset a fault.

Illustration 2: Keypad Buttons for VACON® NXP

B The [run] LED is on when the drive operates. The LED blinks

when the Stop button is pushed and the drive ramps down.

D The Start button. When the keypad is the active control

mode, this button starts the motor. See 8.4.3 Changing the

Control Mode.

F The Menu button Right. Use it to move forward in the menu,

move the cursor right (in the parameter menu) and to go to

the edit mode.

H The Browser button Down. Use it to scroll the main menu

and the pages of different submenus and to decrease a

value.

J The Menu button Left. Use it to move back in the menu, move

the cursor left (in the Parameter menu).

L The Browser button Up. Use it to scroll the main menu and

the pages of different submenus and to increase a value.

Danfoss A/S © 2020.02

AQ275638903263en-000301 / DPD00910| 25

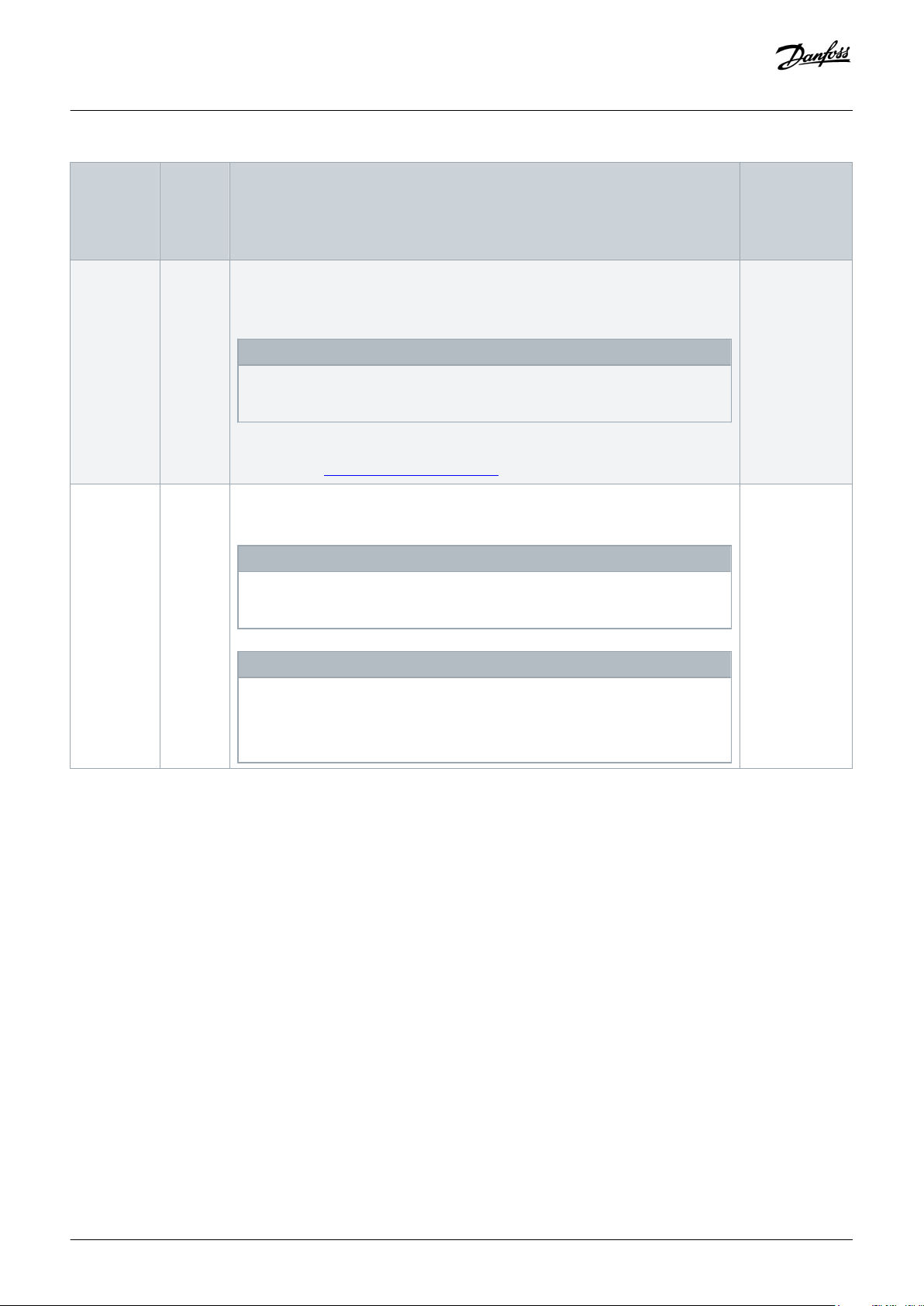

K

A

B

C

L

D

E

J

F

I H G

reset

START

STOP

ready

run

fault

select enter

e30bg072.10

Operating Guide | VACON® NXS/NXP Air-cooled

Product Overview

A The [ready] LED is on when the AC power is connected to the

drive and no faults are active. At the same time, the drive

status indication shows READY.

C The [fault] LED blinks when the AC drive is stopped because

of dangerous conditions (Fault Trip). See 8.5.1 Finding the

Active Faults Menu.

E The [STOP] button. The button stops the motor (unless the

stop is disabled by the parameter R3.4/R3.6). See 8.4.2

Keypad Control Parameters M3.

G The [enter] button. Use it to accept a selection, reset the fault

history (push for 2–3 s).

I The [select] button. Use it to move between 2 last displays, for

example, to see how new value changes some other value.

K The [reset] button. Use it to reset a fault.

Illustration 3: Keypad Buttons for VACON® NXS

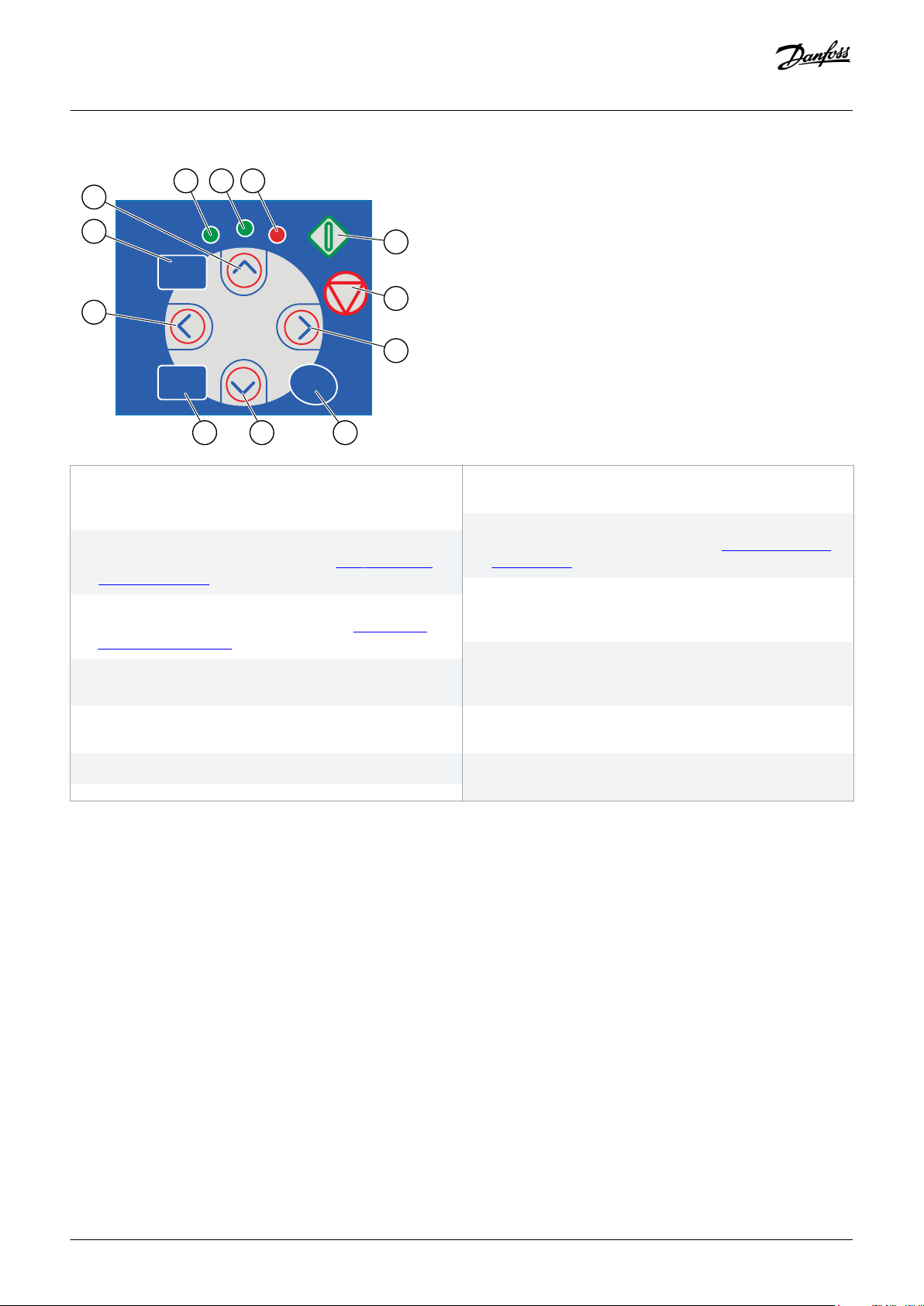

3.8.3 Display

The following figure describes the sections of the display.

B The [run] LED is on when the drive operates. The LED blinks

when the Stop button is pushed and the drive ramps down.

D The [START] button. When the keypad is the active control

mode, this button starts the motor. See 8.4.3 Changing the

Control Mode.

F The Menu button Right. Use it to move forward in the menu,

move the cursor right (in the parameter menu) and to go to

the edit mode.

H The Browser button Down. Use it to scroll the main menu

and the pages of different submenus and to decrease a

value.

J The Menu button Left. Use it to move back in the menu, move

the cursor left (in the Parameter menu).

L The Browser button Up. Use it to scroll the main menu and

the pages of different submenus and to increase a value.

26 | Danfoss A/S © 2020.02

AQ275638903263en-000301 / DPD00910

A

K

L

M

B C D E

H

I

J

F G

e30bf979.10

READY

FAULT

STOP

RUN

Bus/CommKeypadI/O term

ALARM

Operating Guide | VACON® NXS/NXP Air-cooled

Product Overview

A The motor is in RUN state. The indication starts to blink when

a stop command is given and blinks while the speed

continues to decrease.

C The motor rotation direction is reverse.

E The AC power is on.

G A fault is given and the AC drive is stopped.

I The control panel is the active control mode.

K The location indication. The line shows the symbol and

number of the menu, parameter, and so on. For example,

M2 = Menu 2 (Parameters) or P2.1.3 = Acceleration time.

M The value line. The line shows the numerical and text values

of references, parameters, and so on. It also shows the

number of submenus that are available in each menu.

Illustration 4: Display Indications

The drive status indicators (A–G) give information about the status of the motor and the AC drive.

The control mode indications (H, I, J) show the selection of the control mode. The control mode tells from where the START/STOP

commands are given and reference values are changed. To make this selection, go to the Keypad control menu (M3) (see

Changing the Control Mode).

B The motor rotation direction is forward.

D The drive does not operate.

F An alarm is given.

H The I/O terminals is the active control mode.

J The fieldbus is the active control mode.

L The description line. The line shows the description of the

menu, value, or fault.

8.4.3

The three text lines (K, L, M) give information about the current location in the menu structure and the operation of the drive.

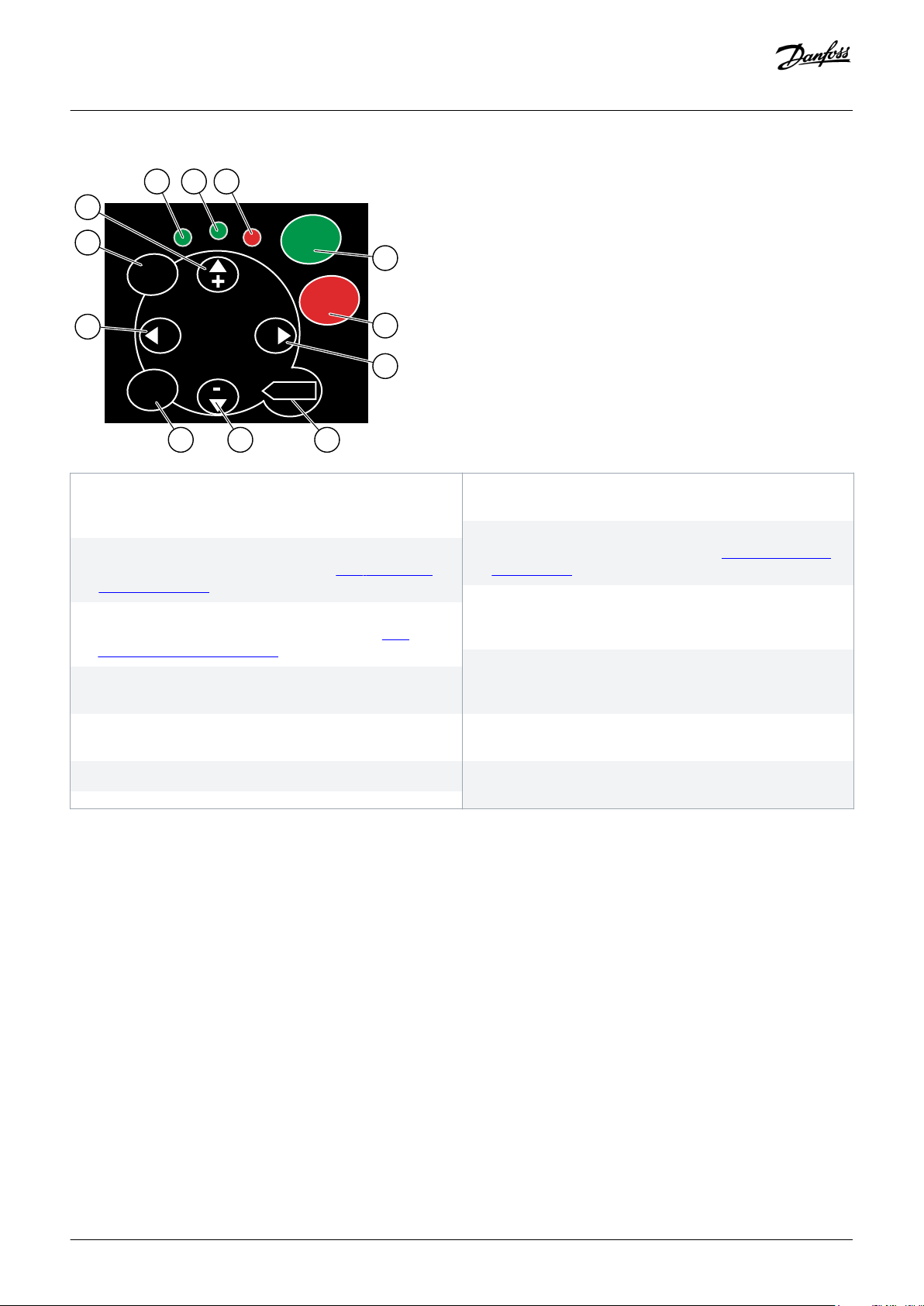

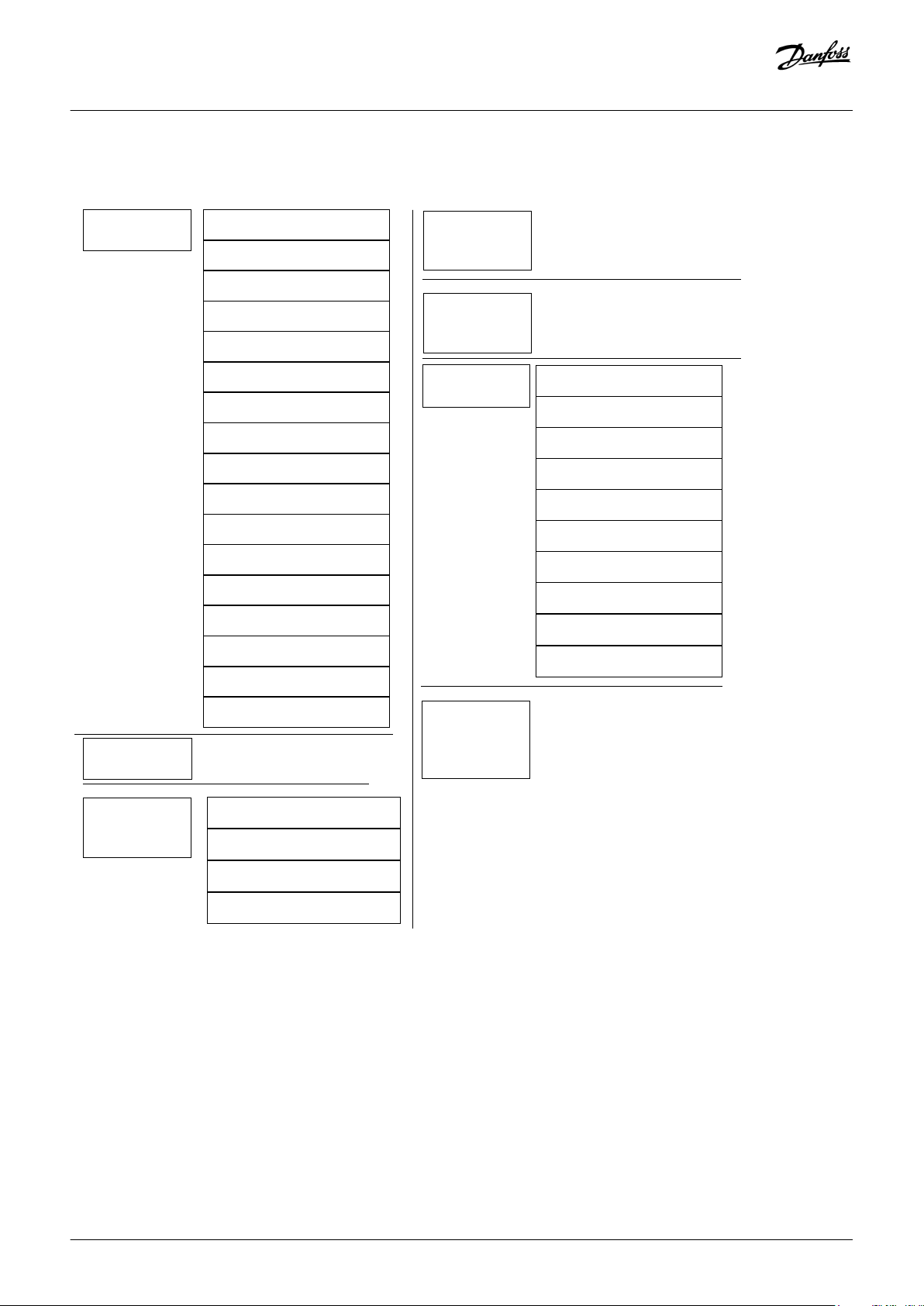

3.8.4 Basic Menu Structure

The data of the AC drive is in menus and submenus. The figure shows the basic menu structure of the AC drive.

This menu structure is only an example and the contents and items can vary depending on the application in use.

Danfoss A/S © 2020.02

AQ275638903263en-000301 / DPD00910| 27

e30bf981.10

Main menu

Submenus Submenus

See Application Manual

Main menu

M1 Monitor

V1.1 Output frequency

V1.2 Frequency ref.

V1.3 Motor speed

V1.4 Motor current

M3 Keypad

control

P3.1 Control place

R3.2 Keypad reference

P3.3

Direction (on keypad)

P3.4 Stop button

V1.5 Motor torque

V1.6 Motor power

V1.7 Motor voltage

V1.8 DC-link voltage

S6.1 Language selection

S6.2

Application selection

S6.3 Copy parameters

S6.4 Compare param.

S6.5 Security

S6.6 Keypad settings

S6.7 Hardware settings

S6.8 System information

S6.9 Power monitor

S6.11 Power

multi-monitor

V1.9 Unit temperature

V1.10 Motor temp.

V1.11 Analogue Input 1

V1.12 Analogue Input 2

V1.13 Current input

V1.14 DIN1, DIN2, DIN3

V1.15 DIN4, DIN5, DIN6

V1.16 Analogue output

V1.17 Multimonit. items

M2

Parameters

M6 System

menu

M4 Active

faults

M5 Fault

history

M7

Expander

boards

Operating Guide | VACON® NXS/NXP Air-cooled

Product Overview

Illustration 5: Basic Menu Structure of the AC Drive

28 | Danfoss A/S © 2020.02

AQ275638903263en-000301 / DPD00910

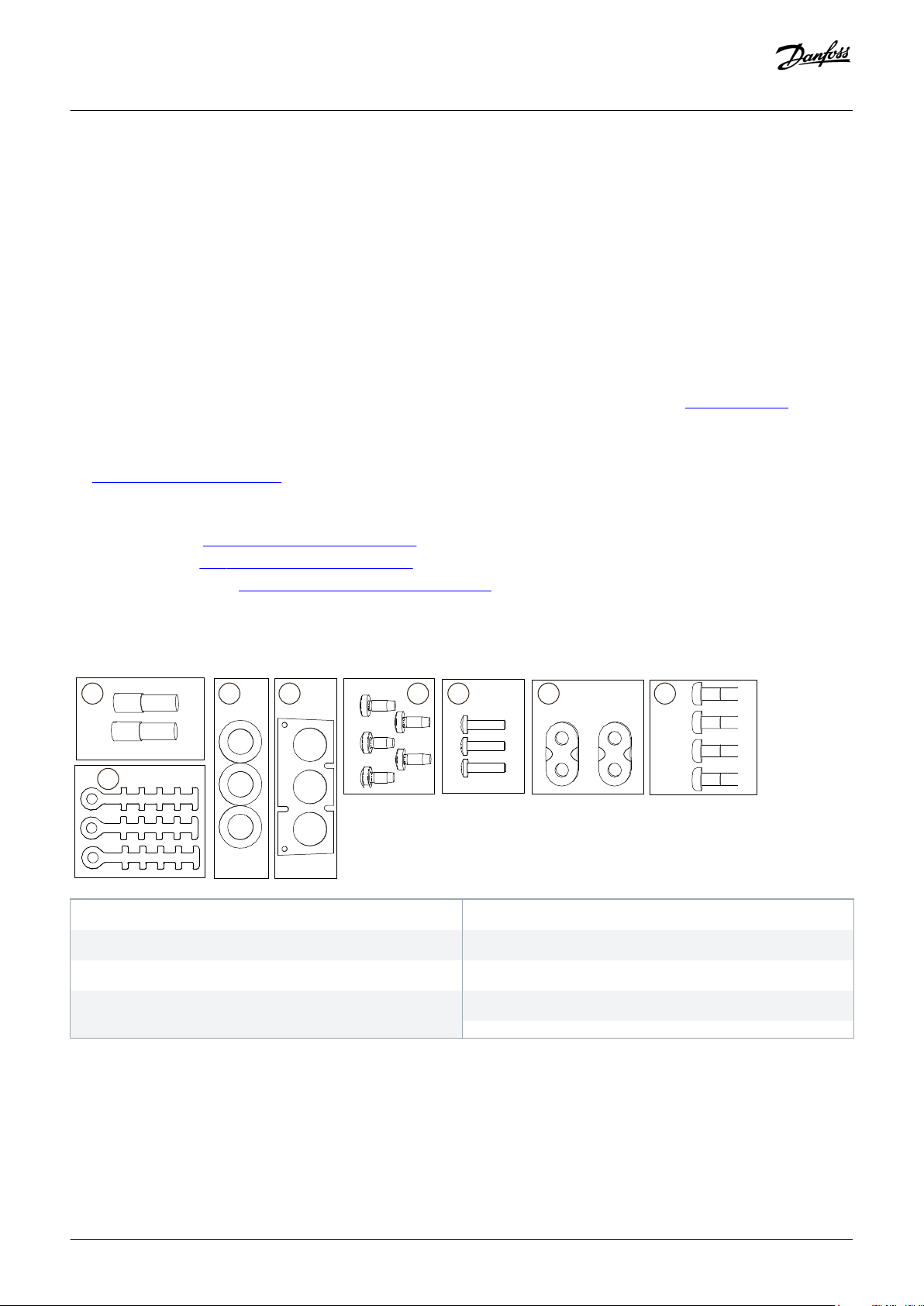

1

2

3 4 5 6 7 8

e30bf975.10

Operating Guide | VACON® NXS/NXP Air-cooled

Receiving the Delivery

4 Receiving the Delivery

4.1 Checking the Delivery

Context:

Before a VACON® AC drive is sent to the customer, the manufacturer makes many tests on the drive.

Procedure

1. After removing the packaging, examine the drive for transport damages.

If the drive was damaged during the shipping, speak to the cargo insurance company or the carrier.

2. To make sure that the delivery is correct, compare the order data to the data on the package label, see 3.3 Package Label.

If the delivery does not agree with the order, contact the vendor immediately.

3. To make sure that the contents of the delivery is correct and complete, compare the type code of the product to the type code, see

3.4 Description of the Type Code.

4. Check that the accessories bag contains the items shown in the figure. These accessories are part of the electrical installation. The

contents of the accessories bag is different for different enclosure sizes and protection ratings.

- FR4/FI4–FR4-FR6: 4.1.1 Accessories for FR4/FI4–FR6/FI6

- FR7/FI7–FR8/FI8:

- FR10–FR11 Standalone: 4.1.3 Accessories for FR10–FR11 Standalone

4.1.2 Accessories for FR7/FI7–FR8/FI8

4.1.1 Accessories for FR4/FI4–FR6/FI6

1 The grounding terminals (FR4/FI4, FR5), 2 pieces

3 The rubber grommets (sizes vary from class to class), 3 pieces

5 Screws, M4x10, 5 pieces

7 The grounding clamps for grounding conductor (FR6/FI6), 2

pieces

Illustration 6: Contents of the Accessories Bag for FR4–FR6/FI4–FI6

2 The grounding clamps for control cable, 3 pieces

4 The cable entry plate

6 Screws, M4x16, 3 pieces

8 The grounding screws M5x16 (FR6/FI6), 4 pieces

Danfoss A/S © 2020.02

AQ275638903263en-000301 / DPD00910| 29

2

3 41

e30bf976.10

e30bh766.10

Operating Guide | VACON® NXS/NXP Air-cooled

4.1.2 Accessories for FR7/FI7–FR8/FI8

Receiving the Delivery

1 Screws, M4x16, 3 pieces

3 The rubber grommets GD21 (FR7/FI7 IP54/UL Type 12),

2 The grounding clamps for control cable, 3 pieces

4 The rubber grommets GDM36 (FR7/FI7), 3 pieces

3 pieces / (FR8/FI8), 6 pieces

Illustration 7: Contents of the Accessories Bag for FR7–FR8/FI7–FI8

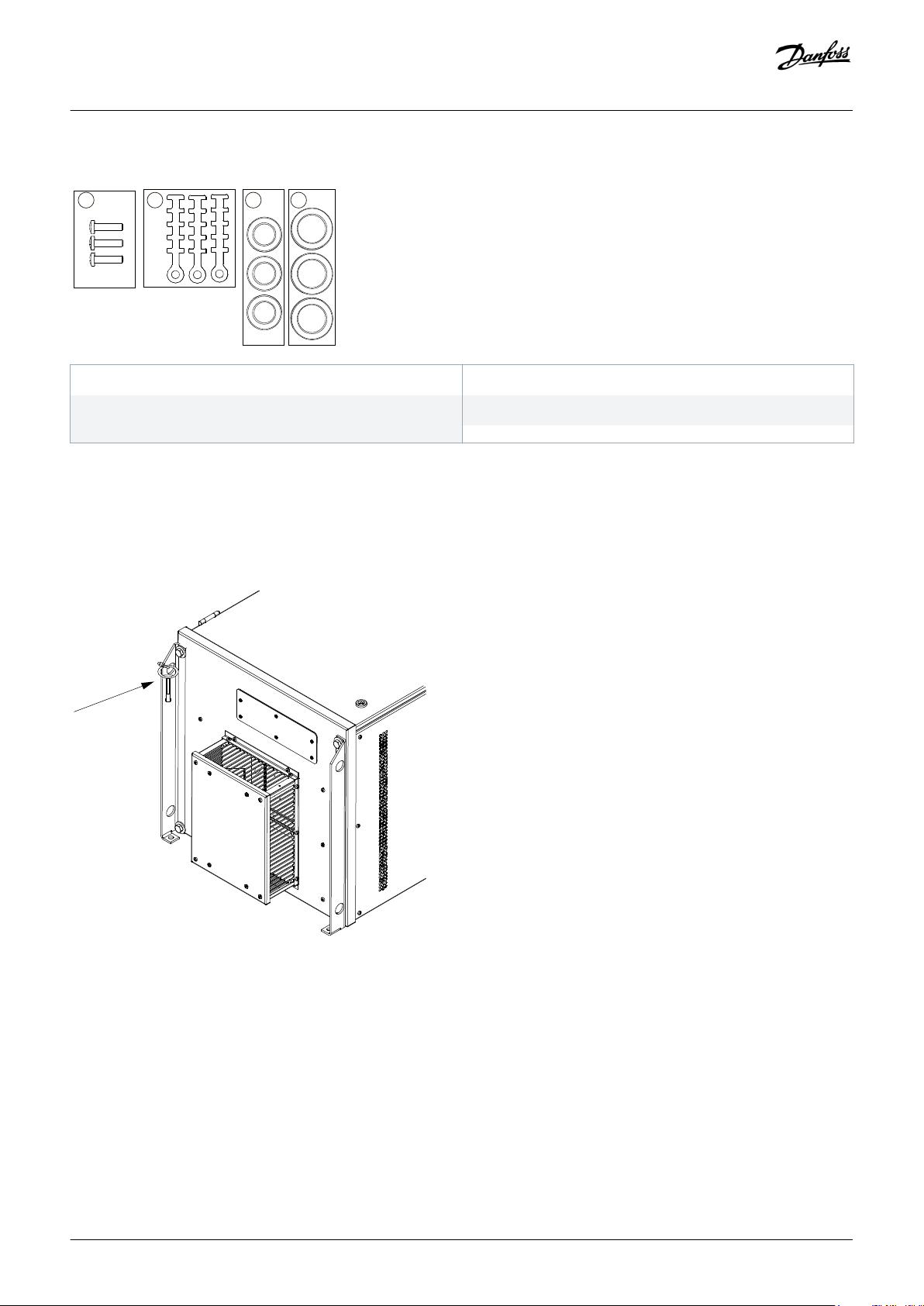

4.1.3 Accessories for FR10–FR11 Standalone

The cabinet door key is attached to the lifting rail at the top of the AC drive.

Illustration 8: The Cabinet Door Key Location at Delivery

4.2 Storing the Product

Context:

If the product has to be stored before installing it, follow these instructions.

30 | Danfoss A/S © 2020.02

AQ275638903263en-000301 / DPD00910

Loading...

Loading...