Page 1

Feature fact sheet

VACON® NXP drive anti-sway functionality

Integrated sensorless control

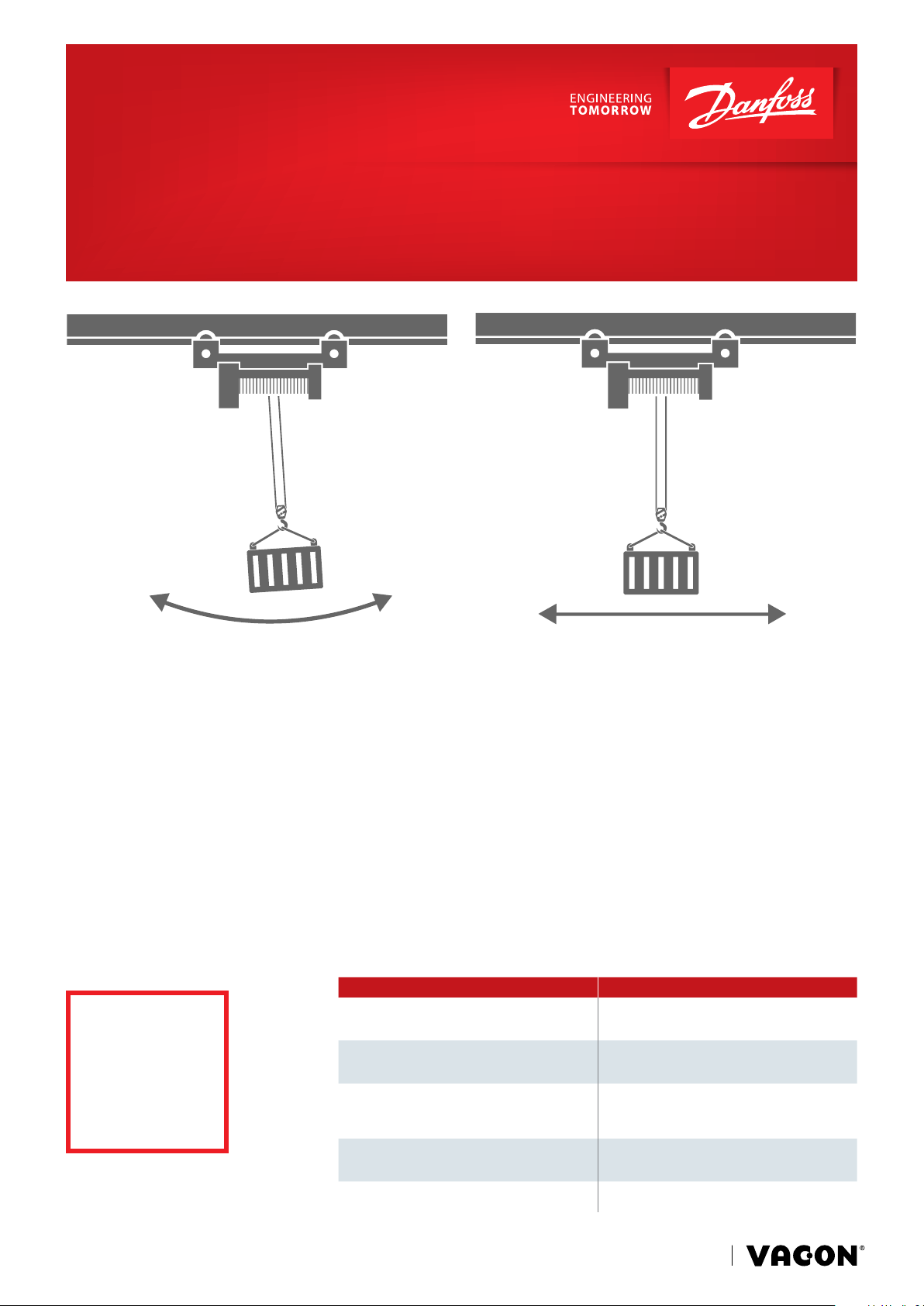

Anti-sway OFF Anti-sway On

The VACON® NXP drive saves time and

expense with the help of integrated

sensorless control in its anti-sway

functionality.

Cranes are typically used in

manufacturing or maintenance

processes, where productivity and

safety are considered the most

important requirements. Swinging

of loads during crane movement is a

severe problem affecting operation

efficiency. Delays in production can

be greatly reduced if load sway can be

prevented.

Up to

15%

improved

productivity

with anti-sway

functionality

Danfoss’ anti-sway solution provides:

stress on mechanical structures, for

example, trollies, hoists or gantries.

1. Better user experience

Simple commissioning without

complex tuning during commissioning

of the crane. The anti-sway feature

is easy to install with a license key,

and easy to configure and adapt to

3. Increased productivity

Using the anti-sway functionality

enables a 10–15% improvement in

productivity and a high return on

investment.

the crane type and movement with

only 2–3 additional parameters to be

configured in the field.

4. Improved system efficiency

Reduced stress on the complete crane

system reduces costs throughout its

2. Reduced structural stress

Anti-sway functionality increases the

lifetime and improves its operational

efficiency.

lifetime of the crane and reduce the

Feature Benefit

Integrated sensorless control

Independent axis control

Standard VACON® NXP hardware

Only 2–3 parameters to set

No skilled operator required to commission and

operate the crane

No extra hardware required

No encoder or external sensor required to access

anti-sway functionality

No drive-to-drive communication required

between hoist, trolley and travel axes to access

anti-sway functionality

Easy to order

Functionality can be activated by generating the

license during ordering process or upgrading in

the field later using the license key.

Easy to configure

Reduces commissioning time of the crane

Improves productivity

Enhanced user friendliness

drives.danfoss.com

Page 2

Danfoss anti-sway functionality is

built in to crane application software

for VACON® NXP products. It works

based on trolley and travel motion.

No communication with the hoist

drive is required to operate anti-sway

functionality.

There are two different methods to

eliminate load sway:

1. Maximum rope length

Maximum rope length (in cm), to be

entered in this parameter. Enter the

rope length from drum to hook touch

down to the ground or just above

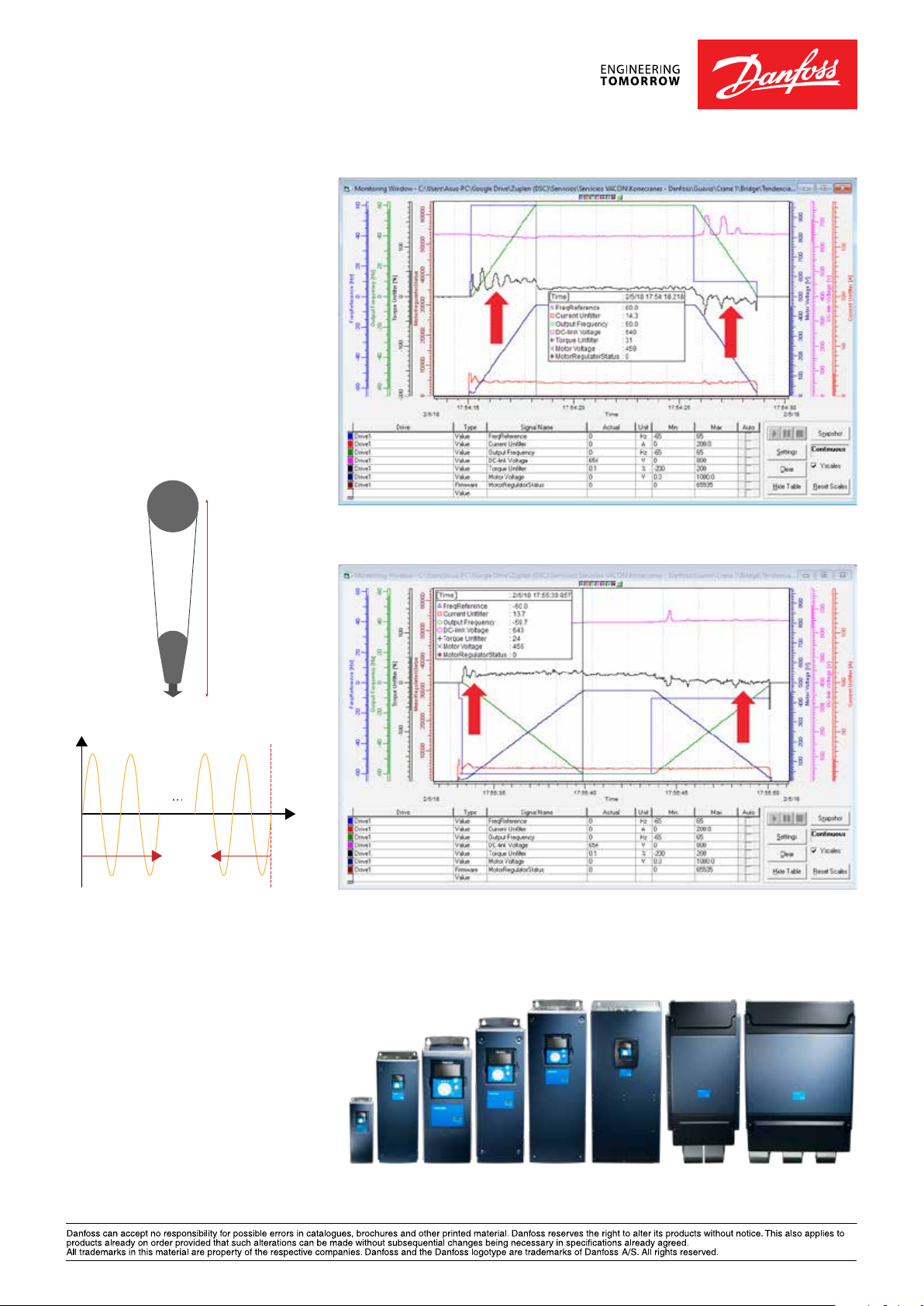

Actual motor torque behavior when anti-sway functionality is disabled (torque fluctuation

during acceleration/deceleration period) monitored through VACON® NCDrive software tool.

X

10 Swing

T = t/10

2. Average swinging time

Lower the hook/load to the lowest

practical position

Run the crane with speed and give

stop command

Measure the time from 5–10 swings

(back and forth) and calculate the

swinging period

Enter the swinging period in the

parameter

Actual motor torque behavior when anti-sway functionality is enabled (torque fluctuation

during acceleration/deceleration period) monitored through VACON® NCDrive software tool.

DKDD.PFF.905.A2.02 © Copyright Danfoss Drives | 2019.05

Loading...

Loading...