Page 1

vacon® nx

ac drives

optcq

ethernet ip option board

user manual

Page 2

Page 3

1

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Table of contents

Document: DPD00893C

Version release date: 24.8.2017

1. Introduction ...................................................................................................................... 3

2. EtherNet/IP board technical data ..................................................................................... 4

2.1 Overview ..........................................................................................................................................................4

2.2 LED indications................................................................................................................................................5

2.3 EtherNet/IP ......................................................................................................................................................5

2.4 Connections and wiring ..................................................................................................................................7

3. Installation ....................................................................................................................... 8

3.1 Installing the EtherNet/IP option board in a VACON® NX unit ......................................................................8

3.2 NCDrive .......................................................................................................................................................... 10

3.3 IP tool NCIPConfig......................................................................................................................................... 10

3.3.1 Updating the OPTCQ option board program with the NCIPConfig tool ...................................................... 12

3.4 Configuring the option board parameters ................................................................................................... 13

4. Commissioning ............................................................................................................... 14

4.1 Speed and duplex .......................................................................................................................................... 15

4.2 IP address ...................................................................................................................................................... 16

4.3 Communication timeout ............................................................................................................................... 16

4.4 Input/Output assemblies .............................................................................................................................. 16

5. EtherNet/IP .................................................................................................................... 18

5.1 Overview ........................................................................................................................................................ 18

5.2 AC/DC drive profile ....................................................................................................................................... 18

5.3 EDS file .......................................................................................................................................................... 18

5.4 Explicit messaging ........................................................................................................................................ 19

5.4.1 List of object classes ..................................................................................................................................... 19

5.4.2 List of services .............................................................................................................................................. 19

5.4.3 List of data types ........................................................................................................................................... 20

5.4.4 Reset service ................................................................................................................................................. 20

6. Common industrial objects implemented by the option board ....................................... 21

6.1 Common required objects of the CIP ........................................................................................................... 21

6.1.1 Identity object, class 0x01 ............................................................................................................................. 21

6.1.2 Connection manager object, class 0x06 ...................................................................................................... 22

6.1.3 TCP/IP interface object, class 0xF5 ............................................................................................................. 23

6.1.4 Ethernet link object, class 0xF6 ................................................................................................................... 24

6.2 Objects present in an AC/DC drive ............................................................................................................... 25

6.2.1 Assembly object, class 0x04 ......................................................................................................................... 25

6.2.2 Motor data object, class 0x28 ....................................................................................................................... 25

6.2.3 Control supervisor object, class 0x29 .......................................................................................................... 26

6.2.4 AC/DC drive object, class 0x2A ..................................................................................................................... 27

6.3 Vendor-specific objects ................................................................................................................................ 28

6.3.1 Vendor parameter object, class 0xA0 .......................................................................................................... 28

6.3.2 Assembly instance selector object, class 0xBE .......................................................................................... 28

7. Assembly instances implemented by the option board .................................................. 29

7.1 Output instances ........................................................................................................................................... 29

7.1.1 Assembly instance 20 ................................................................................................................................... 29

7.1.2 Assembly instance 21 (default) .................................................................................................................... 29

7.1.3 Assembly instance 23 ................................................................................................................................... 29

7.1.4 Assembly instance 25 ................................................................................................................................... 30

7.1.5 Assembly instance 101 ................................................................................................................................. 30

7.1.6 Assembly instance 111 ................................................................................................................................. 31

7.1.7 Assembly instance 128 ................................................................................................................................. 31

7.2 Input instances .............................................................................................................................................. 33

7.2.1 Assembly instance 70 ................................................................................................................................... 33

7.2.2 Assembly instance 71 (default) .................................................................................................................... 33

Page 4

2

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

7.2.3 Assembly instance 73 ................................................................................................................................... 33

7.2.4 Assembly instance 75 ................................................................................................................................... 34

7.2.5 Assembly instance 107 ................................................................................................................................. 34

7.2.6 Drive state...................................................................................................................................................... 34

7.2.7 Assembly instance 117 ................................................................................................................................. 35

7.2.8 Assembly instance 127 ................................................................................................................................. 36

8. Data mapping ................................................................................................................. 37

8.1 Control word .................................................................................................................................................. 37

8.2 Status word .................................................................................................................................................... 37

8.3 Process Data OUT (Slave Master) ............................................................................................................ 37

8.4 Process Data IN (Master Slave) ............................................................................................................... 38

8.5 Additional information .................................................................................................................................. 39

8.5.1 Handling of the NetCtrl bit (Network Control) ............................................................................................ 39

8.5.2 Handling of the NetRef bit (Network Reference) ........................................................................................ 39

8.5.3 Handling of the NetProc bit in assembly instance 25 (Net Process) ......................................................... 39

8.5.4 Handling of RefFromNet and CtrlFromNet bits .......................................................................................... 39

Page 5

Introduction 3

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

1

1. INTRODUCTION

The VACON

®

NX AC drive can be connected to Ethernet by using an EtherNet/IP fieldbus board

OPTCQ. The OPTCQ is installed in the card slot D or E.

Every appliance connected to an Ethernet network has two identifiers; a MAC address and an IP

address. The MAC address (Address format: 00:21:99:xx:yy:zz) is unique to the appliance and cannot

be changed. The EtherNet/IP board's MAC address is found on the sticker attached to the board or

by using the VACON

®

IP tool software NCIPConfig. VACON® PC software can be downloaded from

http://drives.danfoss.com website.

In a local network, IP addresses can be defined by the user as long as all units connected to the

network are given the same network portion of the address. For more information about IP

addresses, contact your Network Administrator. Overlapping IP addresses cause conflicts between

appliances. For more information about setting IP addresses, see Chapter 3.

9000.emf

DANGER! When the AC drive is connected to the power source, the internal

components and circuit boards are at high potential. Coming into contact with

this voltage can cause death or severe injury.

If you need further information related to EtherNet/IP, contact your local support. See local

contacts: http://drives.danfoss.com/danfossdrives/local-contacts/.

NOTE! You can download the English and French product manuals with applicable safety, warning and caution

information from http://drives.danfoss.com/knowledge-center/technical-documentation/.

REMARQUE Vous pouvez télécharger les versions anglaise et française des manuels produit contenant

sements et mises en garde applicables sur le site

http://drives.danfoss.com/knowledge-center/technical-documentation/.

Page 6

4 EtherNet/IP board technical data

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

2

2. ETHERNET/IP BOARD TECHNICAL DATA

2.1 Overview

Table 1. EtherNet/IP board technical data

General

Card Name

OPTCQ

Ethernet connections

Interface

RJ-45 connector

Communications

Transfer cable

Shielded Twisted Pair

Speed

10 / 100 Mb

Duplex

half / full

IP address

Static IP or DHCP (firmware version

dependent)

V004 and newer: Default is DHCP

V003 and older: Default is static IP

192.168.0.10

Protocols

EtherNet/IP

Environment

Ambient operating

temperature

Storing

temperature

Humidity

<95%, no condensation allowed

Altitude

Max. 1000 m

Vibration

Safety

Fulfils EN50178 standard

Page 7

EtherNet/IP board technical data 5

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

2

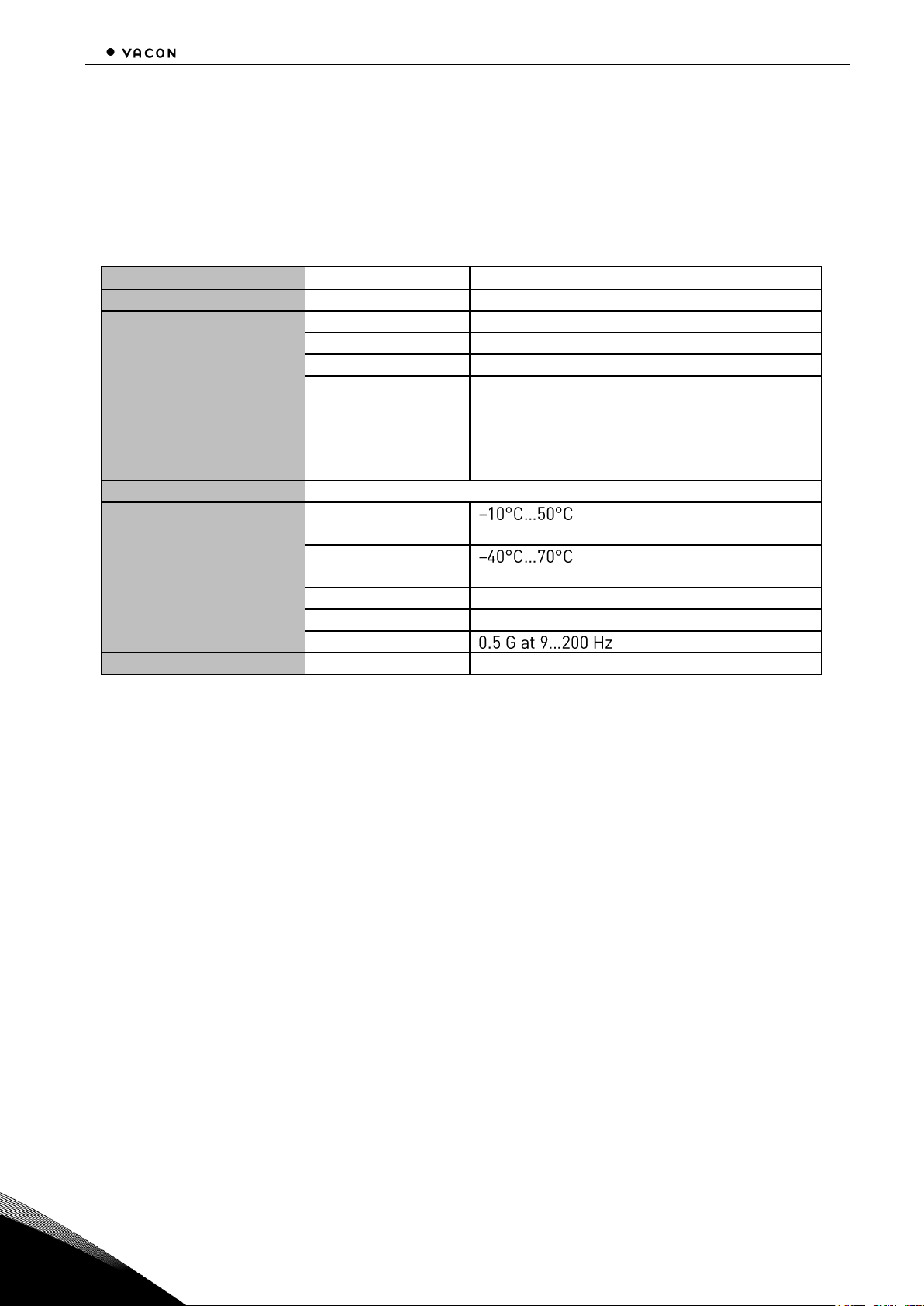

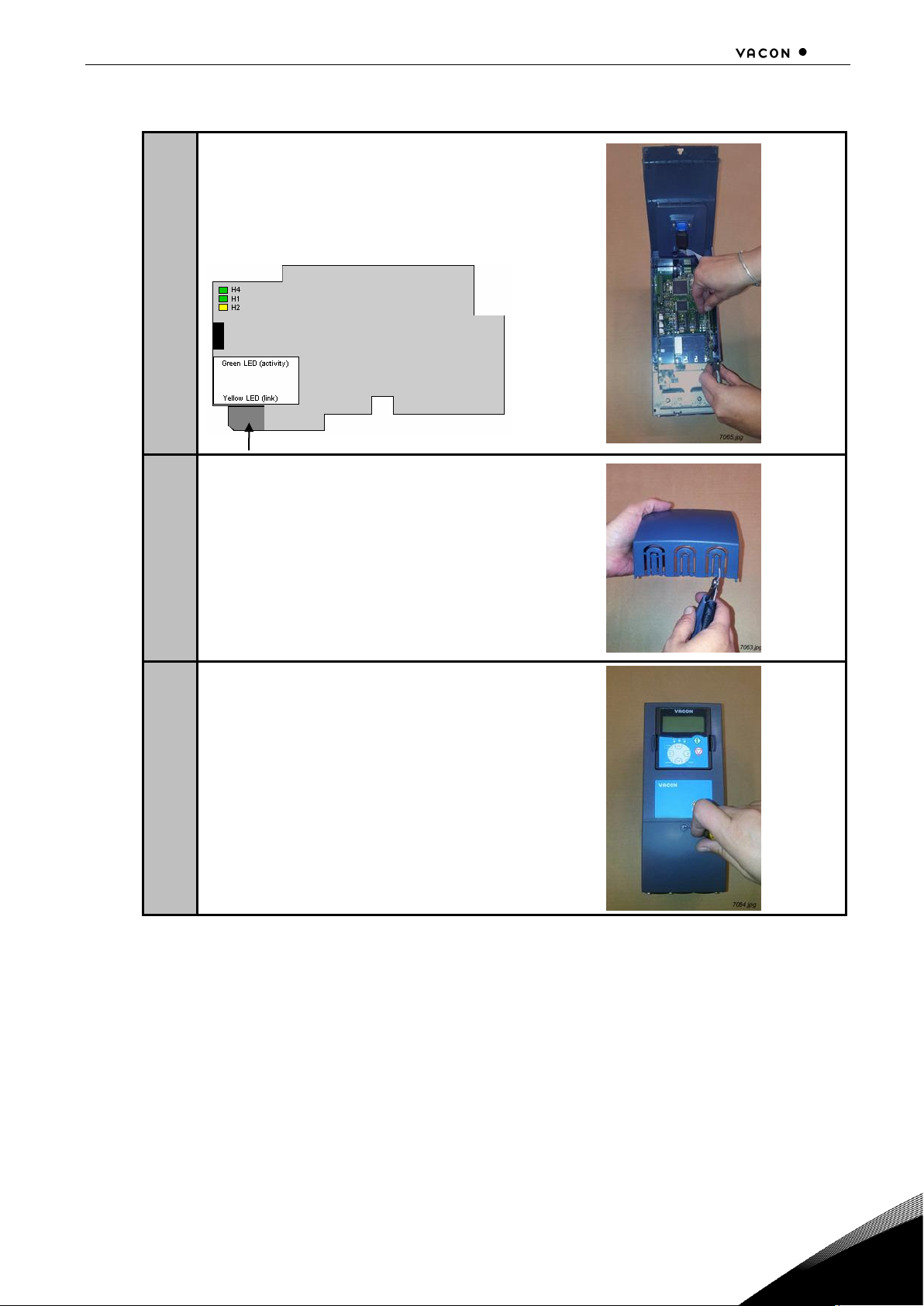

2.2 LED indications

Figure 1.

Table 2. Meaning of the LED indications

LED

Meaning

H4

LED is ON when board is powered.

H1

Blinking 0.25s ON / 0.25s OFF when board firmware is

corrupted (see Chapter 3.2).

OFF when board is operational.

H2

Blinking 2.5s ON / 2.5s OFF when board is ready for

external communication.

OFF when board is not operational.

2.3 EtherNet/IP

EtherNet/IP is a member of a family of networks that implements the Common Industrial Protocol

variety of manufacturing automation applications, including control, safety, synchronization, motion,

configuration and information. As a truly media-independent protocol that is supported by hundreds

of vendors around the world, CIP provides users with a unified communication architecture

throughout the manufacturing enterprise.

Common use-cases of Ethernet devices . Basic

features of these two use-cases are presented in Figures 2 and 3 below.

More information on EtherNet/IP can be found at www.odva.org.

Page 8

6 EtherNet/IP board technical data

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

2

Figure 2. Human to machine (graphical user interface, relatively slow communication)

NOTE! The VACON® NCDrive can be used in VACON® NXS and NXP drives via Ethernet. In VACON

®

NXL drives this is not possible.

Ethernet switch

Values

• Trends

• Fault history

NCDrive / NCIPConfig interface

• Parameter

• Slow rate actual

Page 9

EtherNet/IP board technical data 7

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

2

Figure 3. Machine to machine (industrial environment, fast communication)

2.4 Connections and wiring

The EtherNet/IP board supports 10 and 100Mb speeds in both Full and Half-duplex modes. The

boards must be connected to the Ethernet network with a shielded CAT-5e cable. Use a so-called

crossover cable (at least CAT-5e cable with STP, Shielded Twisted Pair) if you want to connect the

EtherNet/IP option board directly to the master appliance. Use only industrial standard components

in the network and avoid complex structures to minimize the length of response time and the

amount of incorrect dispatches.

PLC or Programmable Controller

PLC or Programmable Controller PLC or Programmable Controller

Master

Ethernet switch

Real-Time Control

• Start/Stop, Direction, etc.

• Reference

• Feedback

Page 10

8 Installation

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

3

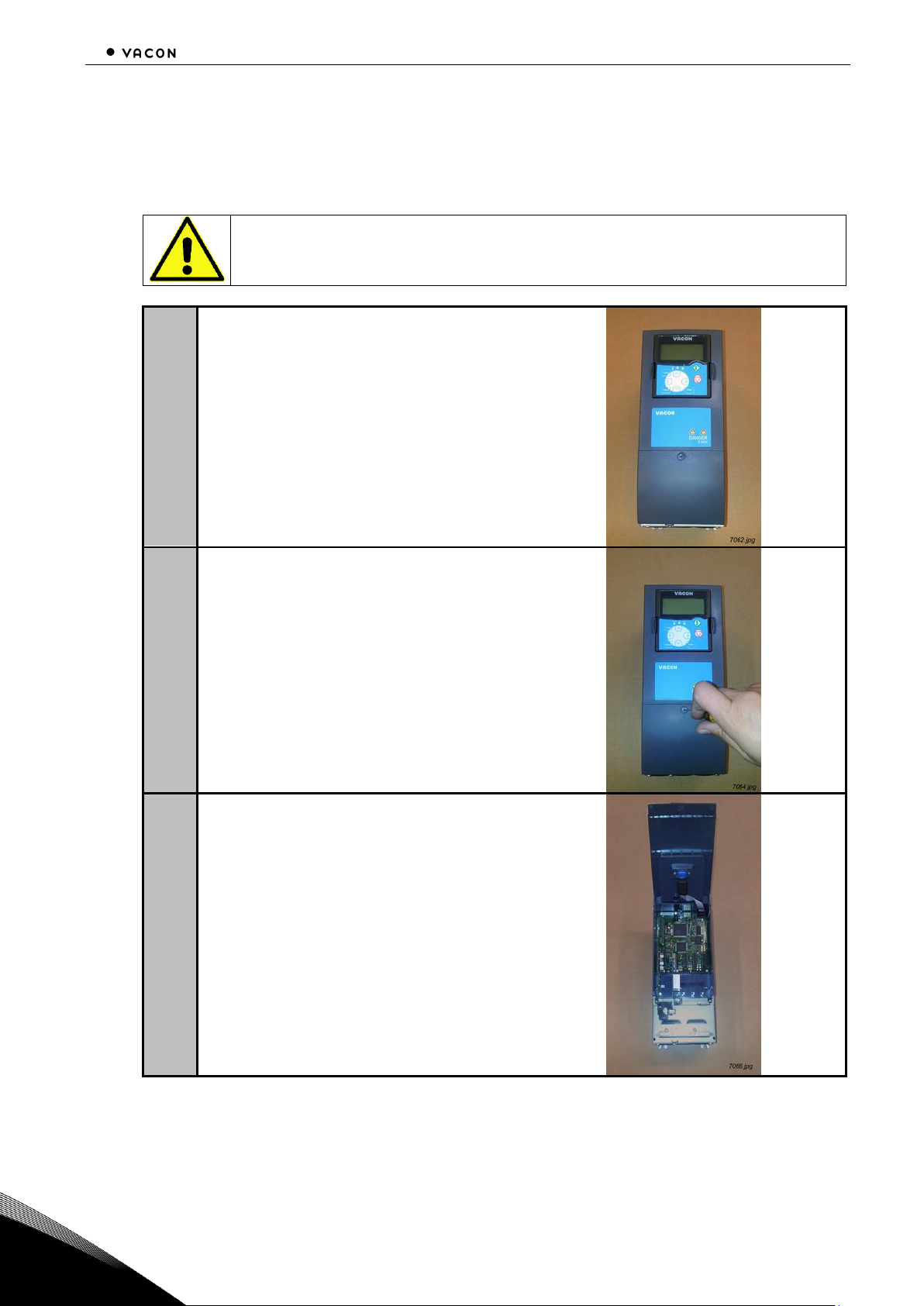

3. INSTALLATION

3.1 Installing the EtherNet/IP option board in a VACON

®

NX unit

13006.emf

CAUTION! Before an option or fieldbus board is changed or added, make sure

that the AC drive is switched off.

1

The VACON® NX AC drive.

2

Remove the cable cover.

3

Open the cover of the control unit.

Page 11

Installation 9

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

3

4

Install EtherNet/IP option board in slot

D or E on the control board of the AC

drive. Make sure that the grounding

plate (see below) fits tightly in the

clamp.

5

Make an opening for your cable by

cutting the grid as wide as necessary.

6

Close the cover of the control unit and

the cable cover.

Page 12

10 Installation

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

3

3.2 NCDrive

The VACON® NCDrive software can be used with the EtherNet/IP board in VACON® NXS and NXP

drives. However, it does not work with with NXL drives.

It is recommended that you use the VACON® NCDrive software only in LAN (Local Area Network).

NOTE! If an OPTCQ Ethernet option board is used for an NC Tools connection, like VACON® NCDrive,

the OPT-D3 board cannot be used.

NCLoad does not work via Ethernet. See VACON® NCDrive Help for further information.

3.3 IP tool NCIPConfig

To start using the VACON® EtherNet/IP board, the IP address must be correctly configured. The

OPTCQ board has static IP as default (firmware V003 and older) or DHCP as default (firmware V004

or newer).

If static IP is used, the correct IP address must be set before connecting the board to the network. If

DHCP is used, the board can be connected to the network, and when there is a DHCP server in the

network, the OPTCQ board will obtain its IP address from the DHCP server.

You need a PC with an Ethernet connection and the NCIPConfig tool installed to set the EtherNet/IP

board's IP addresses. To install the NCIPConfig tool, start the installation program from CD or

download it from the http://drives.danfoss.com website. After starting the installation program,

follow the on-screen instructions.

When the program is installed successfully, launch it by selecting it in the Windows Start menu.

Follow these instructions to set the IP addresses. Select

Help

-->

Manual

if you want more

information about the software features.

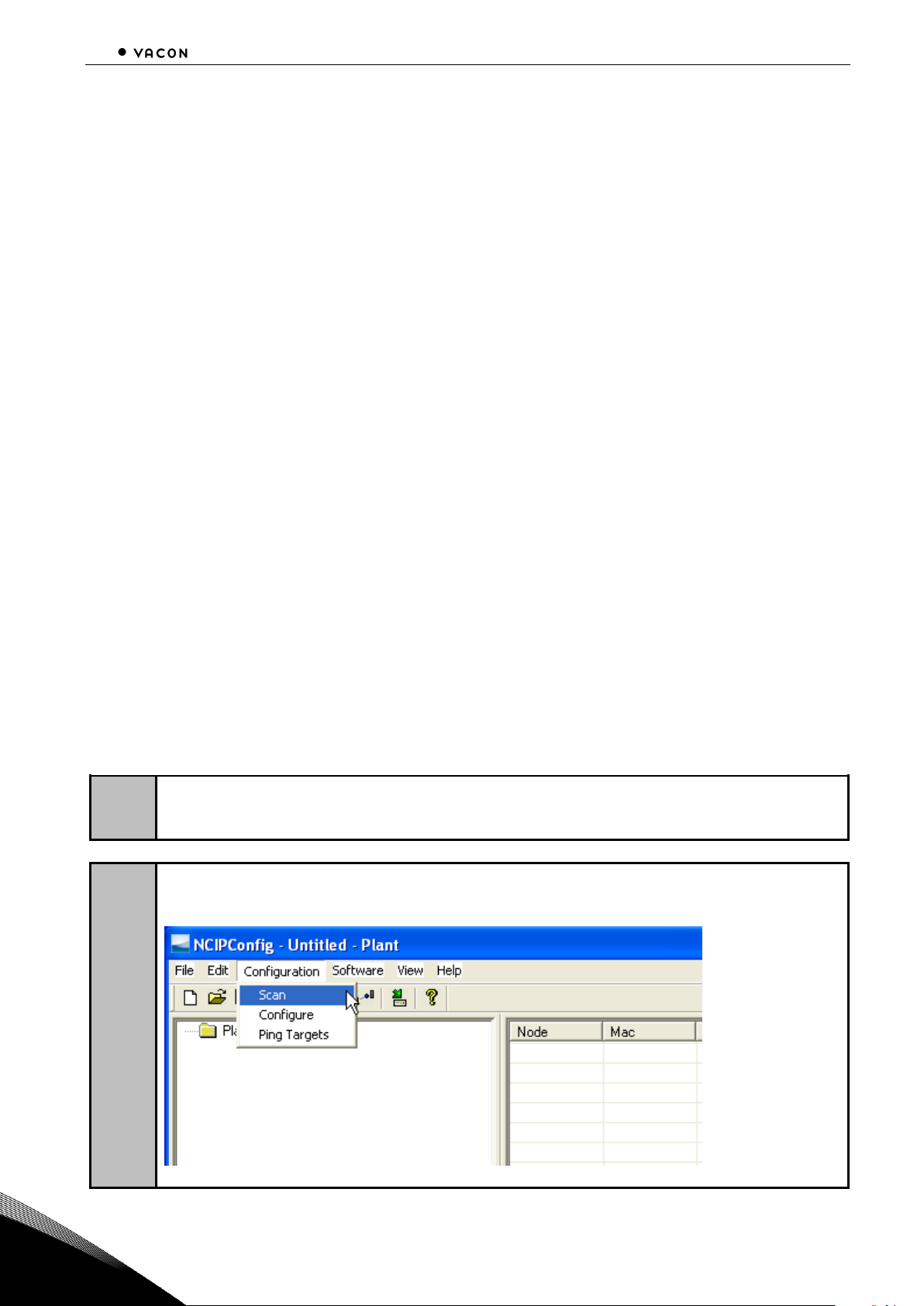

1

Connect your PC to the Ethernet network with an Ethernet cable.

You can also connect the PC directly to the device using a crossover cable. This option

may be needed if your PC does not support the Automatic crossover function.

2

Scan the network nodes. Select

Configuration

-->

Scan

and wait until the devices

connected to the bus in the tree structure are displayed to the left of the screen.

Page 13

Installation 11

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

3

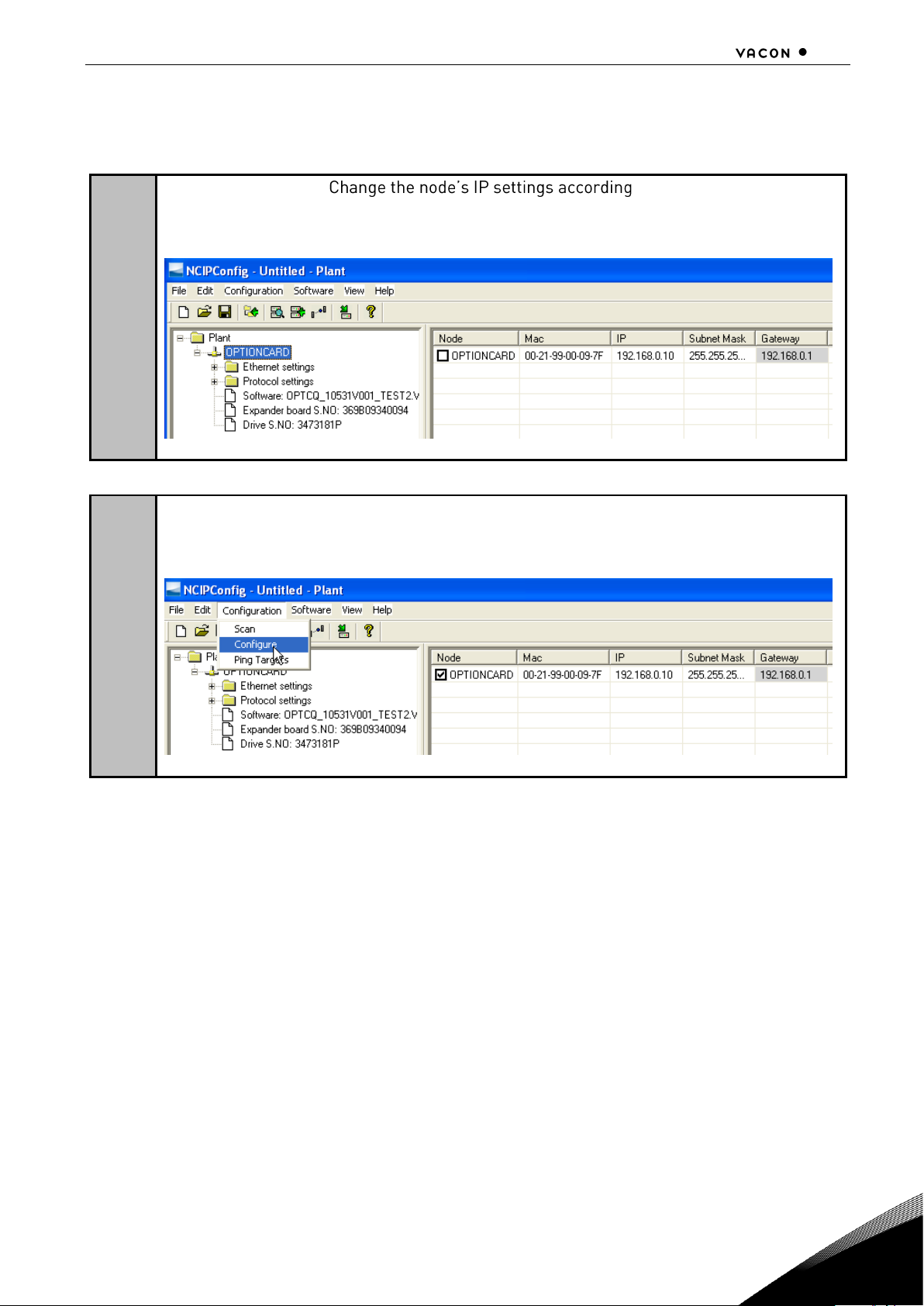

NOTE! Some switches block broadcast messages. In this case, each network node must be scanned

separately. Read the manual under Help menu.

3

Set the IP addresses. to the network IP settings.

The program reports conflicts with a red colour in a table cell. Read the manual under

Help

menu.

4

Send configuration to boards. In the table view, tick the boxes for boards whose

configuration you want to send. Select

Configuration

, then

Configure

. Your changes are

sent to the network and will be valid immediately.

NOTE! Only the symbols A-Z, a-z and 0-9 can be used in the drive name. Do not use special

characters or Scandinavian letters (ä, ö, etc.). The drive name can be freely formed using the

allowed characters.

Page 14

12 Installation

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

3

3.3.1 Updating the OPTCQ option board program with the NCIPConfig tool

In some cases it may be necessary to update the option board's firmware. Differing from other

VACON® option boards, the EtherNet/IP option board's firmware is updated with the VACON®

NCIPConfig tool. The IP addresses of the PC and the option board must be in the same area when

the software is loaded.

1

To start the firmware update, scan the nodes in the network according to the instructions

in Chapter 7. When you can see all nodes in the view, update the new firmware by clicking

the VCN packet field on the right in the table view of VACON® NCIPConfig.

2

Choose a new firmware packet in the window that opens.

3

Tick the new s box in the VCN Packet field at the right corner of the

table view. Select all nodes to be updated by ticking the boxes. Send the new firmware to

the board by selecting

Software

-->

Download

.

1.

2.

Page 15

Installation 13

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

3

NOTE! Do not do a power up cycle within 1 minute after downloading the option board software. This

can cause the option board to go to Safe Mode. This situation can only be solved by re-downloading

the software. The Safe Mode triggers a fault code (F54). The Board slot error F54 can also appear

due to a faulty board, a temporary malfunction of the board or a disturbance in the environment.

NOTE! If the OPTCQ board firmware is updated from V003 (or older) to V004 (or newer), the static IP

address assigned to the board will remain after the update. To activate the DHCP mode manually,

see Chapter 4.

3.4 Configuring the option board parameters

These features are available in the VACON® NCIPConfig tool version 1.6.

1

In the tree-view, expand the folders until you reach the board parameters.

2

Slowly double-click the parameter (

Comm. Time-out

in the figure below) and enter a new

value. When the modification is complete, the new parameter values are automatically

sent to the option board.

NOTE! If the fieldbus cable is broken or removed, a fieldbus error is generated. Reset the fault by

checking the installation. If the installation is correct, contact your local contacts. See VACON® NX

All in One Application Manual for resetting faults.

Page 16

14 Commissioning

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

4

4. COMMISSIONING

The VACON® EtherNet/IP board is commissioned with the control keypad by giving values to

appropriate parameters in menu M7 (or with the VACON® NCIPConfig tool, see Chapter 3.3). Keypad

commissioning is only possible with the VACON® NXP and NXS type AC drives. The VACON® NXL AC

drives require the VACON® NCIPConfig tool.

In the Expander board menu (M7) you can see which expander boards are connected to the control

board. You can also edit the parameters associated with the expander board.

1

Enter the following menu level (G#) with the arrow button right. Browse through slots A

to E with the arrow buttons up/down to see which expander boards are connected.

2

On the last line of the display, you see the number of parameter groups associated with

the board. Press the arrow button right once more to reach the parameter group level

where there is only one group in the EtherNet/IP board case: Parameters.

3

To go to Parameter group, press the arrow button right again.

Table 1. EtherNet/IP monitoring values

No

Name

Description

1

Speed/duplex

See chapter 4.1 for details.

Table 2. EtherNet/IP parameters

No

Name

Default

Range

Description

1

Comm. Timeout

0

255 s

0 = RPI (Requested Packet

Interval) x CTM (Connection

Timeout Multiplier)

2

IP Part 1

192

1 223

IP Address Part 1

3

IP Part 2

168

IP Address Part 2

4

IP Part 3 0

IP Address Part 3

5

IP Part 4

10

IP Address Part 4

6

SubNet Part 1

255

55

Subnet Mask Part 1

7

SubNet Part 2

255

Subnet Mask Part 2

8

SubNet Part 3

0

Subnet Mask Part 3

9

SubNet Part 4

0

Subnet Mask Part 4

10

DefGW Part 1

192

55

Default Gateway Part 1

11

DefGW Part 2

168

Default Gateway Part 2

12

DefGW Part 3

0

Default Gateway Part 3

13

DefGW Part 4

1

Default Gateway Part 4

14

OutputAssembly

21

See Chapter 7

15

InputAssembly

71

See Chapter 7

16

Speed/duplex

Autoneg.

-

Speed and duplex of the

Ethernet port. See chapter 4.1

for details.

Page 17

Commissioning 15

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

4

NOTE! The default value of parameter 1 is 0 in firmware versions V004 and newer. In earlier

versions the default value is 10 seconds.

NOTE! The default value of parameters 2-13 is 0 in firmware versions V004 and newer, because

DHCP is enabled by default.

4.1 Speed and duplex

Speed and duplex parameter can be used to set Ethernet port to use specific value, but it is

recommended that auto-negotiation is always used. Possible values are listed in table below.

No

Name

Description

1

autoneg.

Ethernet port speed and duplex

is detected automatically

2

10M HD

10 Mb half duplex

3

10M FD

10 Mb full duplex

4

100M HD

100 Mb half duplex

5

100M FD

100 Mb full duplex

Monitoring view shows current speed and duplex of the Ethernet port. If there is no connection then

value is "undefined". Possible values are listed in table below.

No

Name

Description

1

undefined

Ethernet port is not up. Speed

and duplex have not been

detected.

2

10M HD

10 Mb half duplex

3

10M FD

10 Mb full duplex

4

100M HD

100 Mb half duplex

5

100M FD

100 Mb full duplex

Page 18

16 Commissioning

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

4

4.2 IP address

The IP address is divided into four octets. The value is 0.0.0.0 when DHCP is used until the board has

been assigned an IP address. A static IP address is entered by editing the parameters from the

keypad or using NCIPConfig. This disables DHCP mode.

When the board has static IP, and the IP address is changed to *.0.0.0 through VACON® NCIPConfig

or the keypad, then DHCP mode will be re-enabled after the next power-up.

Changing the IP address to *.255.255.255 causes the board to change to static IP address

192.168.0.10 after the next power-up.

4.3 Communication timeout

With firmware version V004 or newer, when this parameter is assigned the value 0, the

communication timeout is the value of the Requested Packet Interval (RPI) multiplied with the

Connection Timeout Multiplier (CTM) as defined in the EtherNet/IP master. RPI for the OPTCQ board

is at minimum 16 milliseconds. If a value other than 0 is used as the communication timeout, this

means the total time (in seconds) including the RPI x CTM timeout. If communication with the

EtherNet/IP master device is inactive for a period longer than the defined communication timeout,

the drive generates a fieldbus fault.

With firmware version V003 or older, when this parameter is assigned the value 0, the

communication timeout is disabled. In this case a fieldbus fault is generated only if the Ethernet link

is lost (for example, if the cable is disconnected). You can change the Communication timeout value

from the keypad or with the VACON® NCIPConfig tool. See Chapter 3.3.

NOTE! If the fieldbus cable is broken or removed, a fieldbus error is generated. Reset the fault by

checking the installation. If the installation is correct, contact your local contacts. See VACON® NX

All in One Application Manual for resetting faults.

4.4 Input/Output assemblies

The I/O assemblies are changed in the keypad, through VACON® NCIPConfig, or in the EtherNet/IP

master. The same assembly must be selected in both the drive and the EtherNet/IP master. The

configuration assembly for the OPTCQ board must be set to 1 in the EtherNet/IP master.

All EtherNet/IP parameters are saved to the EtherNet/IP board (not to the control board). If the new

EtherNet/IP board is changed into the control board, you must configure the new EtherNet/IP board.

The option board parameters can be saved to the keypad, with the VACON® NCIPConfig tool or with

VACON® NCDrive.

Page 19

Commissioning 17

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

4

Figure 4. Configuration example from Rockwell PLC.

Figure 5. Configuration example from EIPScan tool.

Page 20

18 EtherNet/IP

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

5

5. ETHERNET/IP

5.1 Overview

EtherNet/IP (EtherNet/Industrial Protocol) is a communication system suitable for use in industrial

environments. EtherNet/IP allows industrial devices to exchange time-critical application

information. These devices include simple I/O devices such as sensors and actuators, as well as

complex control devices such as robots, programmable logic controllers, welders, and process

controllers.

EtherNet/IP uses CIP (Control and Information Protocol), the common network, transport and

application layers also shared by ControlNet and EtherNet/IP. EtherNet/IP then makes use of the

standard Ethernet and TCP/IP technology to transport CIP communications packets. The result is a

common, open application layer on top of the open and popular Ethernet and TCP/IP protocols.

EtherNet/IP Messaging Forms:

• Unconnected Messaging is used for connection establishment and for infrequent, low-

priority messages.

• Connected Messaging uses resources that are dedicated in advance to a particular purpose,

such as real-time I/O data transfer.

• EtherNet/IP Messaging Connections:

• Explicit Messaging Connections are general-purpose point-to-point connections. Messages

are sent through TCP protocol.

• Implicit (I/O Data) Connections are established to transfer application-specific I/O Data at

regular intervals. They are often set up as one-to-many relationships to take full advantage

of the producer-consumer multicast model. Implicit messages are sent through UDP

protocol.

5.2 AC/DC drive profile

To provide interoperability between devices from different manufacturers, a "standard" must be

defined so that:

• The devices behave in the same way.

• They produce and/or consume the same basic set of I/O data.

• They contain the same basic set of configurable attributes.

This information is called the device profile.

5.3 EDS file

The Electronic Data Sheet (EDS) is a specially formatted ASCII text file that contains configuration

data for specific device types. The EDS provides information about the context, content and format of

the device configuration data.

The information in the EDS allows configuration tools to provide informative screens that guide you

through the steps that are needed to configure a device.

The EDS provides all of the information necessary to access and alter the configurable parameters

of a device. This information matches the information provided by instances of the Parameter Object

Class. The CIP Object Library describes the Parameter Object Class in detail.

Page 21

EtherNet/IP 19

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

5

5.4 Explicit messaging

Explicit Messaging is used in commissioning and parametrising of the EtherNet/IP board. Explicit

messages provide multipurpose, point-to-point communication paths between two devices. They

provide the typical request/response-oriented network communication used to perform node

configuration and problem diagnosis. Explicit messages typically use low priority identifiers and

contain the specific meaning of the message right in the data field. This includes the service to be

performed and the specific object attribute address.

NOTE! If Class 1 connection (cyclic data) has been established, Explicit Messages cannot be used to

control Output Data. However, this restriction does not apply for I/O Data reading.

5.4.1 List of object classes

The Communication Interface supports the following object classes:

Table 3.

Class

Object

0x01

Identity Objects

0x04

Assembly Object

0x06

Connection Manager Object

0x28

Motor Data Object

0x29

Control Supervisor Object

0x2A

AC/DC Drive Object

0xA0

Vendor Parameters Object

0xBE

Assembly Instance Selector Object

0xF5

TCP/IP Interface Object

0xF6

Ethernet Link Object

5.4.2 List of services

The services supported by the object classes in Table 4 are shown below.

Table 4.

Service

Code

(in hex)

Service Name

Identity objec

t

Connection manager

TCP/IP interface

Ethernet link

Assembly

Motor Data

Control S

upervisor

AC/DC Drive

Vendor parameter

Assemly instance

selector

Class

Inst

Class

Inst

Class

Inst

Class

Inst

Class

Inst

Class

Inst

Class

Inst

Class

Inst

Class

Inst

Class Inst

01

Get_Attributes_All

Y Y Y Y Y Y 05

Reset (Type 0)

Y Y 0E

Get_Attribute_Single

Y Y Y Y Y Y Y Y Y Y Y Y Y Y 10

Set_Attribute_Single

Y Y Y Y Y Y

Y

4E

Forward Close

Y 52

Unconnected_Send

Y 54

Forward_Open

Y

See Chapter 6 for the Interface Object profiles.

Page 22

20 EtherNet/IP

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

5

5.4.3 List of data types

The attribute list that follows includes information on the Data Type of each attribute. The following

tables explain the Data, Structure, and Array Type codes used in the Data Type column.

Table 5. Elementary Data Types

Data Type Name

Data Type

Code (in hex)

Data Type Description

BOOL

C1

Logical Boolean with values

TRUE and FALSE

SINT

C2

Signed 8-bit integer value

INT

C3

Signed 16-bit integer value

USINT

C6

Unsigned 8-bit integer value

UINT

C7

Unsigned 16-bit integer value

UDINT

C8

Unsigned 32-bit integer value

BYTE

D1

Bit string - 8 bits

WORD

D2

Bit string - 16 bits

SHORT_STRING

DA

Character string (1 byte per

character, 1 byte length

indicator)

Table 6. Constructed Data Types

Type Code

Description

A1

Abbreviated array type encoding

A2

Formal structure type encoding

5.4.4 Reset service

The following table lists the different types of resets supported by the Identity Object. Resetting the

OPTCQ interface to its out-of-box configuration sets all the attributes to their default values. It also

changes the response of the drive to a loss of communications with the OPTCQ. The device has to be

re-configured for your application before resuming normal operation.

Table 7.

Value

Type of Reset

0

Emulate as closely as possible the cycling of power to

the OPTCQ EtherNet/IP Interface. This value is the

default if this parameter is omitted. The VACON® AC

drive stops if it is running.

Page 23

Common industrial objects implemented by the option board 21

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

6

6. COMMON INDUSTRIAL OBJECTS IMPLEMENTED BY THE OPTION BOARD

6.1 Common required objects of the CIP

6.1.1 Identity object, class 0x01

Table 8.

Class Attributes

Id

Description

Data Type

Access Rule

01h

Revision

Get 02h

Max Instances

UINT

Get Class Services

Id

Service

0Eh

Get_Attribute_Single

Instance Attributes

Id

Description

Data Type

Access Rule

01h

Vendor ID

UINT

Get 02h

Device Type

UINT

Get 03h

Product Code

UINT

Get

04h

Revision

STRUCT

of:

Get

Major Revision

USINT

Minor Revision

USINT

05h

Status

WORD

Get

Byte struct:

Bit0 = Owned

Bit2 = Configured

Bit8 = Minor Revocerable fault

Bit9 = Minor Unrecovable fault

Bit10 = Major Recoverable fault

Bit11 = Major Unrecoverable fault

Bit4 7:

0011 = No I/O connection

established

0110 = At least one I/O

connection in run mode

06h

Serial Number

UDINT

Get

07h

Product Name

SHORT_

STRING

Get

Instance Services

Id

Service

01h

Get_Attributes_All

05h

Reset*

0Eh

Get_Attribute_Single

*Only reset type 0 reset of the Option Board

Page 24

22 Common industrial objects implemented by the option board

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

6

6.1.2 Connection manager object, class 0x06

Table 9.

Class Attributes

Id

Description

Data

Type

Access Rule

01h

Revision

Get 02h

Max Instance

Get Class Services

Id

Service

01h

Get_Attributes_All

0Eh

Get_Attribute_Single

Instance Attributes

Id

Description

Data

Type

Access Rule

01h

Open Requests

UINT

Get 02h

Open Format Rejects

UINT

Get

03h

Open Resource

Rejects

UINT

Get

04h

Open Other Rejects

UINT

Get 05h

Close Requests

UINT

Get

06h

Close Format

Requests

UINT

Get

07h

Close Other Requests

UINT

Get 08h

Connection Timeouts

UINT

Get Instance Services

Id

Service

01h

Get_Attributes_All

0Eh

Get_Attribute_Single

4Eh

Forward Close

52h

Unconnected_Send

54h

Forward_Open

RPI = Requested Packet Intervall, minimum

time is 16ms

Page 25

Common industrial objects implemented by the option board 23

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

6

6.1.3 TCP/IP interface object, class 0xF5

Table 10.

Class Attributes

Id

Description

Data

Type

Access Rule

01h

Revision

Get 02h

Max Instance

UINT

Get Class Services

Id

Service

01h

Get_Attributes_All

0Eh

Get_Attribute_Single

Instance Attributes

Id

Description

Data

Type

Access Rule

01h

Status

DWORD

Get

02h

Configuration

Capability

DWORD

Get

03h

Configuration Control

DWORD

Get / Set

04h

Physical Link

STRUCT

of:

Get

Path Size

UINT

Path

Padded

EPATH

05h

Interface

Configuration

STRUCT

of:

Get / Set

IP Address

UDINT

Network Mask

UDINT

Gateway Address

UDINT

Name Server

UDINT

Name Server 2

UDINT

Domain Name

STRING

06h

Host Name

STRING

Get / Set

Instance Services

Id

Service

01h

Get_Attributes_All

0Eh

Get_Attribute_Single

10h

Set_Attribute_Single

Attribute Configuration Control supports only the value 0 (device is using configuration values that

are stored in non-volatile memory).

Attribute Host Name is used only for information purposes.

Page 26

24 Common industrial objects implemented by the option board

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

6

6.1.4 Ethernet link object, class 0xF6

Table 11.

Class Attributes

Id

Description

Data Type

Access Rule

01h

Revision

UINT

Get 02h

Max Instance

UINT

Get

03h

Number of

Instances

UINT

Get

Class Services

Id

Service

01h

Get_Attributes_All

0Eh

Get_Attribute_Single

Instance Attributes

Id

Description

Data Type

Access Rule

01h

Interface Speed

UDINT

Get 02h

Interface Flags

DWORD

Get

03h

Physical

Address

ARRAY of

6 USINTs

Get

Instance Services

Id

Service

0Eh

Get_Attribute_Single

Page 27

Common industrial objects implemented by the option board 25

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

6

6.2 Objects present in an AC/DC drive

6.2.1 Assembly object, class 0x04

Table 12.

Class Attributes

Id

Description

Access Rule

NOT SUPPORTED

Class Services

Id

Service

NOT SUPPORTED

Instance Attributes

Id

Description

Data Type

Access Rule

03h

Data

ARRAY of

BYTE

Get / Set

Instance Services

Id

Service

0Eh

Get_Attribute_Single

10h

Set_Attribute_Single

6.2.2 Motor data object, class 0x28

Table 13.

Class Attributes

Id

Description

Access Rule

NOT SUPPORTED

Class Services

Id

Service

Requirements

NOT SUPPORTED

Instance Attributes

Id

Description

Data

Type

Access

Rule

03h

Motor Type

USINT

Get 06h

Rated Current

UINT

Get / Set

07h

Rated Voltage

UINT

Get / Set

09h

Rated

Frequency

UINT

Get / Set

0Ch

Pole Count

UINT

Get

0Fh

Base Speed

UINT

Get / Set

Instance Services

Id

Service

0Eh

Get_Attribute_Single

10h

Set_Attribute_Single

Page 28

26 Common industrial objects implemented by the option board

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

6

6.2.3 Control supervisor object, class 0x29

Table 14.

Class Attributes

Id

Description

Access Rule

NOT SUPPORTED

Class Services

Id

Service

Requirements

NOT SUPPORTED

Instance Attributes

Id

Description

Data Type

Access Rule

03h

Run1

BOOL

Get / Set

04h

Run2

BOOL

Get / Set

05h

NetCtrl *

BOOL

Get / Set

06h

State

USINT

Get 07h

Running1

BOOL

Get 08h

Running2

BOOL

Get 09h

Ready

BOOL

Get 0Ah

Faulted

BOOL

Get 0Bh

Warning

BOOL

Get 0Ch

FaultRst

BOOL

Get / Set

0Fh

CtrlFromNet**

BOOL

Get Instance Services

Id

Service

0Eh

Get_Attribute_Single

10h

Set_Attribute_Single

05h

Reset

* Network Control (When Bit is set to 1 and control place is fieldbus, the drive gets control from the network).

NOTE! Does not force the drive to fieldbus control.

** Indicates the status of NetCtrl.

Figure 6. When both Run attributes (Run1 & Run2) are set, no action is taken.

Page 29

Common industrial objects implemented by the option board 27

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

6

6.2.4 AC/DC drive object, class 0x2A

Table 15.

Class Attributes

Id

Description

Access Rule

NOT SUPPORTED

Class Services

Id

Service

NOT SUPPORTED

Instance Attributes

Id

Description

Data Type

Access Rule

03h

AtReference

BOOL

Get 04h

NetRef*

BOOL

Get / Set

05h

NetProc**

BOOL

Get / Set

06h

DriveMode

USINT

Get / Set

07h

SpeedActual

INT

Get 08h

SpeedRef

INT

Get / Set

0Bh

TorqueActual

INT

Get 0Ch

TorqueRef

INT

Get / Set

0Dh

ProcessActual

INT

Get 0Eh

ProcessRef

INT

Get / Set

1Dh

RefFromNet***

BOOL

Get Instance Services

Id

Service

0Eh

Get_Attribute_Single

10h

Set_Attribute_Single

* Network Reference (When Bit is 1 and control place is fieldbus, the drive gets reference from the network).

** Network Process (used to write process reference)

• When Netproc = 1 & Drive mode = 0 (Vendor-specific), Process Reference is sent to the Drive

as Process Data 1

• When Netproc = 1 & Drive mode = 4 (Process Control), Process Reference is sent to the Drive

as Process Data 2

• When NetProc = 0, Process Reference must fail.

*** Indicates the status of NetRef.

Page 30

28 Common industrial objects implemented by the option board

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

6

6.3 Vendor-specific objects

6.3.1 Vendor parameter object, class 0xA0

Vendor Parameter Object is used to get access to the drive parameters. Because drive parameters

are identified by a 16-bit ID number, it is impossible to use only an Attribute ID, which is 8 bits in

length. To overcome this issue the following method is used to calculate the requested Drive

Parameter ID:

Drive Parameter ID = Instance ID (Higher Byte) + Attribute ID (Lower Byte).

Table 16.

Class Attributes

Id

Description

Access Rule

NOT SUPPORTED

Class Services

Id

Service

NOT SUPPORTED

Instance Attributes

Id

Description

Access Rule

LOWER BYTE OF THE PARAMETER ID

Instance Services

Id

Service

0Eh

Get_Attribute_Single

10h

Set_Attribute_Single

6.3.2 Assembly instance selector object, class 0xBE

Table 17.

Class Attributes

Id

Description

Access Rule

NOT SUPPORTED

Class Services

Id

Service

NOT SUPPORTED

Instance Attributes

Id

Description

Data Type

Access Rule

03h

InputInstance

USINT

Get / Set

04h

OutputInstance

USINT

Get / Set

Instance Services

Id

Service

0Eh

Get_Attribute_Single

10h

Set_Attribute_Single

Page 31

Assembly instances implemented by the option board 29

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

7

7. ASSEMBLY INSTANCES IMPLEMENTED BY THE OPTION BOARD

7.1 Output instances

The output instances of the drive are the following:

• Assemblys 20-25 ODVA AC/DC Profile

• Assemblys 71-75 ODVA AC/DC Profile

• Assemblys 100-> Vacon Profile.

7.1.1 Assembly instance 20

Table 18.

Instance 20 (Output)

Length = 4 Bytes

Byte

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0 0

FaultReset

RunFwd

1

2

Speed Reference (Low Byte), rpm

3

Speed Reference (High Byte), rpm

7.1.2 Assembly instance 21 (default)

Table 19.

Instance 21 (Output)

Length = 4 Bytes

Byte

Bit 7

Bit 6

Bit .5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0 0

NetRef

NetCtrl

FaultReset

RunRev

RunFwd

1

2

Speed Reference (Low Byte), rpm

3

Speed Reference (High Byte), rpm

7.1.3 Assembly instance 23

Table 20.

Instance 23 (Output)

Length = 6 Bytes

Byte

Bit 7

Bit 6

Bit .5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

0 NetRef

NetCtrl

FaultReset

RunRev

RunFwd

1

2

Speed Reference (Low Byte), rpm

3

Speed Reference (High Byte), rpm

4

Torque Reference (Low Byte), Nm

5

Torque Reference (High Byte), Nm

Page 32

30 Assembly instances implemented by the option board

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

7

Torque Reference is not sent to the drive if Motor Control Mode (Parameter ID 600) is set to values

other than:

• 2 Torque Control

• 4 Closed Loop Torque Control.

Torque Reference is sent to the drive as a Process Data 1.

NOTE! Torque reference is not functional in NXL.

7.1.4 Assembly instance 25

Table 21.

Instance 25 (Output)

Length = 6 Bytes

Byte

Bit 7

Bit 6

Bit .5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

0

NetProc

NetRef

NetCtrl

FaultReset

RunRev

RunFwd

1

Drive Mode

2

Speed Reference (Low Byte), rpm

3

Speed Reference (High Byte, rpm

4

Process Reference (Low Byte)

5

Process Reference (High Byte)

The following drive modes are supported:

• 0 (Vendor-specific) Process Reference is sent to the drive as Process Data 1.

• 4 (Process Control) Process Reference is sent to the drive as Process Data 2 (see Chapter

8.5.3).

Other drive modes are not supported. If they are used, the Process Reference is not handled.

7.1.5 Assembly instance 101

Table 22.

Process Data is sent to the drive independently of the NetRef bit and the NetCtrl bit settings.

Instance 101 (Output)

Length = 8 Bytes

Byte

Bit 7

Bit 6

Bit .5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0 0

NetRef

NetCtrl

FaultReset

RunRev

RunFwd

1

2

FBSpeed Reference (Low Byte), %

3

FBSpeed Reference (High Byte), %

4

FBProcessDataIn1(Low Byte)

5

FBProcessDataIn1(High Byte)

6

FBProcessDataIn2(Low Byte)

7

FBProcessDataIn2(High Byte)

Page 33

Assembly instances implemented by the option board 31

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

7

7.1.6 Assembly instance 111

Table 23.

* Reference 1 to the AC drive. Used normally as Speed reference. The allowed scaling is 0...10000. In the

application, the value is scaled in percentage of the frequency area between set minimum and maximum

frequency.

0 = 0.00 %, 10000 = 100.00 %

7.1.7 Assembly instance 128

Table 24.

Instance 128

Length = 20 Bytes

Byte

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

0

FBFixedControlWord (Low Octet)

1

FBGeneralControlWord (High Octet)

2

FBSpeedReference (Low Octet) in %

3

FBSpeedReference (High Octet) in %

4

FBProcessDataIn1 (Low Octet)

5

FBProcessDataIn1 (High Octet)

6

FBProcessDataIn2 (Low Octet)

7

FBProcessDataIn2 (High Octet)

8

FBProcessDataIn3 (Low Octet)

9

FBProcessDataIn3 (High Octet)

10

FBProcessDataIn4 (Low Octet)

11

FBProcessDataIn4 (High Octet)

Instance 111 (Output)

Length = 20 Bytes

Byte

Bit 7

Bit 6

Bit .5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

0

FBFixedControlWord (Low Byte)

1

FBFixedControlWord (High Byte)

2

FBSpeedReference (Low Byte) *

3

FBSpeedReference (High Byte) *

4

ProcessDataIn1 (LowByte)

5

ProcessDataIn1 (HighByte)

6

ProcessDataIn2 (LowByte)

7

ProcessDataIn2 (HighByte)

8

ProcessDataIn3 (LowByte)

9

ProcessDataIn3 (HighByte)

10

ProcessDataIn4 (LowByte)

11

ProcessDataIn4 (HighByte)

12

ProcessDataIn5 (LowByte)

13

ProcessDataIn5 (HighByte)

14

ProcessDataIn6 (LowByte)

15

ProcessDataIn6 (HighByte)

16

ProcessDataIn7 (LowByte)

17

ProcessDataIn7 (HighByte)

18

ProcessDataIn8 (LowByte)

19

ProcessDataIn8 (HighByte)

Page 34

32 Assembly instances implemented by the option board

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

7

12

FBProcessDataIn5 (Low Octet)

13

FBProcessDataIn5 (High Octet)

14

FBProcessDataIn6 (Low Octet)

15

FBProcessDataIn6 (High Octet)

16

FBProcessDataIn7 (Low Octet)

17

FBProcessDataIn7 (High Octet)

18

FBProcessDataIn8 (Low Octet)

19

FBProcessDataIn8 (High Octet)

7.1.7.1 Control word

Table 25.

Bit

Description

0

1

0

Start/Stop

Stop request from fieldbus

Run request from fieldbus

1

Direction

Requested direction is

"FORWARD"

Requested direction is

"REVERSE"

2

Fault Reset

No action

No action. Rising edge (0->1) =

Active faults, alarms and infos

are reset

3

Not in use

4

Not in use

5

Not in use

6

Not in use

7

Not in use

8

Request Fieldbus Control

Control Place is as

parameterised in the drive

(unchanged)

Control Place shall be

overridden to Fieldbus Control

9

Request Fieldbus

Reference

Source of setpoint value shall be

as parameterised in the drive

(unchanged)

Source of setpoint value shall

be overridden to Fieldbus

10

Not in use

11

Not in use

12

Not in use

13

Not in use

14

Not in use

15

Master connection state

Offline

Active

Page 35

Assembly instances implemented by the option board 33

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

7

7.2 Input instances

7.2.1 Assembly instance 70

Table 26.

Instance 70 (Input)

Length = 4 Bytes

Byte

Bit 7

Bit 6

Bit .5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0 0

Running1

Faulted 1

2

Speed Actual (Low Byte), rpm

3

Speed Actual (High Byte), rpm

7.2.2 Assembly instance 71 (default)

Table 27.

7.2.3 Assembly instance 73

Table 28.

NOTE! Torque reference is not functional in VACON® NXL.

Instance 71 (Input)

Length = 4 Bytes

Byte

Bit 7

Bit 6

Bit .5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

0

AtReference

RefFromNet

CtrlFromNet

Ready

Running2

Running1

Warning

Faulted

1

Drive State, see Chapter 7.2.6

2

Speed Actual (Low Byte), rpm

3

Speed Actual (High Byte), rpm

Instance 73 (Input)

Length = 6 Bytes

Byte

Bit 7

Bit 6

Bit .5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

0

AtReference

RefFromNet

CtrlFromNet

Ready

Running2

Running1

Warning

Faulted

1

Drive State, see Chapter 7.2.6

2

Speed Actual (Low Byte), rpm

3

Speed Actual (High Byte), rpm

4

Torque Actual (Low Byte), Nm

5

Torque Actual (High Byte), Nm

Page 36

34 Assembly instances implemented by the option board

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

7

7.2.4 Assembly instance 75

Table 29.

7.2.5 Assembly instance 107

Table 30.

7.2.6 Drive state

0x00 DN_NON_EXISTANT

0x01 DN_STARTUP

0x02 DN_NOT_READY

0x03 DN_READY

0x04 DN_ENABLED

0x05 DN_STOPPING

0x06 DN_FAULT_STOP

0x07 DN_FAULTED

Instance 75 (Input)

Length = 6 Bytes

Byte

Bit 7

Bit 6

Bit .5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

0

AtReference

RefFromNet

CtrlFromNet

Ready

Running2

Running1

Warning

Faulted

1

Drive State, see Chapter 7.2.6

2

Speed Actual (Low Byte), rpm

3

Speed Actual (High Byte), rpm

4

Process Actual (Low Byte)

5

Process Actual (High Byte)

Instance 107 (Input)

Length = 8 Bytes

Byte

Bit 7

Bit 6

Bit .5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

0

AtReference

RefFromNet

CtrlFromNet

Ready

Running2

Running1

Warning

Faulted

1

Drive State, see Chapter 7.2.6

2

% Speed Actual (Low Byte) *

3

% Speed Actual (High Byte) *

4

Process DataOut1 (Low Byte)

5

Process DataOut1 (High Byte)

6

Process DataOut2 (Low Byte)

7

Process DataOut2 (High Byte)

Page 37

Assembly instances implemented by the option board 35

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

7

7.2.7 Assembly instance 117

Table 31.

* The actual value from the AC drive. The value is between 0...10000. In the application, the value is scaled in

percentage of frequency area between set minimum and maximum frequency.

0 = 0.00 %, 10000 = 100.00 %

** The actual speed of the motor. The unit is RPM.

*** The actual speed of the motor with slip speed. The unit is RPM.

Instance 117 (Input): EIP Drive Status

Length = 34 bytes

Byte

Bit 7

Bit 6

Bit .5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

0

FBStatusWord (Low Byte)

1

FBStatusWord (High Byte)

2

% Speed Actual (Low Byte) *

3

% Speed Actual (High Byte) *

4

RPM Speed Actual (Low Byte) **

5

RPM Speed Actual (High Byte) **

6

RPM with Slip Speed Actual (Low Byte)***

7

RPM with Slip Speed Actual (High Byte) ***

8

Reserved

9

Reserved

10

Reserved

11

Reserved

12

Reserved

13

Reserved

14

Reserved

15

Reserved

16

Reserved

17

Reserved

18

ProcessDataOut1 (LowByte)

19

ProcessDataOut1 (HighByte)

20

ProcessDataOut2 (LowByte)

21

ProcessDataOut2 (HighByte)

22

ProcessDataOut3 (LowByte)

23

ProcessDataOut3 (HighByte)

24

ProcessDataOut4 (LowByte)

25

ProcessDataOut4 (HighByte)

26

ProcessDataOut5 (LowByte)

27

ProcessDataOut5 (HighByte)

28

ProcessDataOut6 (LowByte)

29

ProcessDataOut6 (HighByte)

30

ProcessDataOut7 (LowByte)

31

ProcessDataOut7 (HighByte)

32

ProcessDataOut8 (LowByte)

33

ProcessDataOut8 (HighByte)

Page 38

36 Assembly instances implemented by the option board

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

7

7.2.8 Assembly instance 127

Table 32.

Instance 127

Length = 20 Bytes

Byte

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

0

FBFixedStatusWord (Low Octet)

1

FBGeneralStatusWord (High Octet)

2

FBSpeedActual (Low Octet) in %

3

FBSpeedActual (High Octet) in %

4

FBProcessDataOut1 (Low Octet)

5

FBProcessDataOut1 (High Octet)

6

FBProcessDataOut2 (Low Octet)

7

FBProcessDataOut2 (High Octet)

8

FBProcessDataOut3 (Low Octet)

9

FBProcessDataOut3 (High Octet)

10

FBProcessDataOut4 (Low Octet)

11

FBProcessDataOut4 (High Octet)

12

FBProcessDataOut5 (Low Octet)

13

FBProcessDataOut5 (High Octet)

14

FBProcessDataOut6 (Low Octet)

15

FBProcessDataOut6 (High Octet)

16

FBProcessDataOut7 (Low Octet)

17

FBProcessDataOut7 (High Octet)

18

FBProcessDataOut8 (Low Octet)

19

FBProcessDataOut8 (High Octet)

Page 39

Data mapping 37

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

8

8. DATA MAPPING

8.1 Control word

Table 33.

Bit

0

1

0

STOP

RUN

1

Clockwise

Counterclockwise

2

Rising edge of this bit will reset active fault

3-15

Not in use

8.2 Status word

Table 34.

Bit

0

1

0

Ready status

Drive is not ready for

operation

Drive is ready for operation

1

Run/Stop status

Drive is stopped

Drive is running

2

Direction status

Drive is running clockwise

Drive is running

counterclockwise

3

Fault status

No fault is active

Drive is in fault state

4

Alarm status

No alarm is active

An alarm is active

5

Reference reached

Reference is not reached

Reference is reached

6

Zero speed

Motor is not running at zero

speed

Motor is running at zero speed

7

Motor magnetisation

Motor is not magnetised

Motor is magnetised

8-15

Not in use

8.3 Process Data OUT (Slave Master)

The fieldbus master can read the actual values of the AC drive by using process data variables. The

applications

Basic, Standard, Local/Remote, Multi-Step, PID control and Pump and fan control

use

process data as follows:

Table 35.

Data

Value

Unit

Scale

Process data OUT 1

Output Frequency

Hz

0.01 Hz

Process data OUT 2

Motor Speed

rpm

1 rpm

Process data OUT 3

Motor Current

A

0.1 A

Process data OUT 4

Motor Torque

%

0.1%

Process data OUT 5

Motor Power

%

0.1%

Process data OUT 6

Motor Voltage

V

0.1 V

Process data OUT 7

DC link voltage

V

1 V

Process data OUT 8

Active Fault Code

-

-

The

Multipurpose

application has a selector parameter for every Process Data. The monitoring

values and drive parameters are selected using the ID number (see VACON® NX All in One

Application Manual, Tables for monitoring values and parameters). Default selections are as in the

table above.

Page 40

38 Data mapping

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

8

8.4 Process Data IN (Master Slave)

ControlWord, Reference and Process Data are used with All-in One applications as explained in the

three following tables.

Table 36. Basic, Standard, Local/Remote, Multi-Step applications

Data

Value

Unit

Scale

Reference

Speed Reference

%

0.01%

ControlWord

Start/Stop

Command

Fault reset

Command

-

-

PD1 PD8

Not used

-

-

Table 37. Multipurpose control application

Data

Value

Unit

Scale

Reference

Speed Reference

%

0.01%

ControlWord

Start/Stop Command

Fault reset Command

-

Process Data IN1

Torque Reference

%

0.1%

Process Data IN2

Free Analogue INPUT

%

0.01%

Process Data IN3

Adjust Input

%

0.01%

PD3 PD8

Not Used

-

-

Table 38. PID control and Pump and fan control applications

Data

Value

Unit

Scale

Reference

Speed Reference

%

0.01%

ControlWord

Start/Stop Command

Fault reset Command

- - Process Data IN1

Reference for PID

controller

%

0.01%

Process Data IN2

Actual Value 1 to PID

controller

%

0.01%

Process Data IN3

Actual Value 2 to PID

controller

%

0.01%

PD4 PD8

Not Used

-

-

Page 41

Data mapping 39

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

8

8.5 Additional information

8.5.1 Handling of the NetCtrl bit (Network Control)

If NetCtrl bit is set, Output Instance to the drive. Additionally, BusCtrl bit of

the FBFixedControlWord is set.

8.5.2 Handling of the NetRef bit (Network Reference)

If NetRef bit is set, Torque Reference and Speed Reference are sent to the drive. Additionally,

BusRef bit of the FBFixedControlWord is set.

8.5.3 Handling of the NetProc bit in assembly instance 25 (Net Process)

If NetProc bit is set, Process Reference is sent to the drive.

8.5.4 Handling of RefFromNet and CtrlFromNet bits

RefFromNet and CtrlFromNet bits are set if value of REMOTEIndication is more than 0, and NetRef

and NetCtrl bits are set. See Chapters 6.2.3 and 6.2.4.

NOTE! When you contact a distributor or a factory because of a fault condition, always write down all

the texts and codes on the keypad display. Then send the problem description together with the

Drive Info File to the local distributor. See local contacts: http://drives.danfoss.com/danfoss-

drives/local-contacts/ . If possible, also send a "Wireshark" log from the situation if applicable.

Page 42

40 Data mapping

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

8

License for LWIP

Copyright (c) 2001, 2002 Swedish Institute of Computer Science.

All rights reserved.

Redistribution and use in source and binary forms, with or without modification, are permitted

provided that the following conditions are met:

1. Redistributions of source code must retain the above copyright notice, this list of conditions and

the following disclaimer.

2. Redistributions in binary form must reproduce the above copyright notice, this list of conditions

and the following disclaimer in the documentation and/or other materials provided with the

distribution.

3. The name of the author may not be used to endorse or promote products derived from this

software without specific prior written permission.

THIS SOFTWARE IS PROVIDED BY THE AUTHOR "AS IS" AND ANY EXPRESS OR IMPLIED

WARRANTIES, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE ARE DISCLAIMED. IN NO EVENT

SHALL THE AUTHOR BE LIABLE FOR ANY DIRECT, INDIRECT, INCIDENTAL, SPECIAL, EXEMPLARY,

OR CONSEQUENTIAL DAMAGES (INCLUDING, BUT NOT LIMITED TO, PROCUREMENT OF

SUBSTITUTE GOODS OR SERVICES; LOSS OF USE, DATA, OR PROFITS; OR BUSINESS

INTERRUPTION) HOWEVER CAUSED AND ON ANY THEORY OF LIABILITY, WHETHER IN CONTRACT,

STRICT LIABILITY, OR TORT (INCLUDING NEGLIGENCE OR OTHERWISE) ARISING IN ANY WAY OUT

OF THE USE OF THIS SOFTWARE, EVEN IF ADVISED OF THE POSSIBILITY OF SUCH DAMAGE.

Page 43

www.danfoss.com

Vacon Ltd

Member of the Danfoss Group

Runsorintie 7

65380 Vaasa

Finland

Document ID:

DPD00893C

Rev. C

Loading...

Loading...