Page 1

vacon® nx

ac drives

optc6

canopen option board

user manual

Page 2

Page 3

1

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

INDEX Document code: DPD00896B

Date: 24.08.2017

1. GENERAL ........................................................................................................................... 2

2. CANOPEN OPTION BOARD TECHNICAL DATA .................................................................... 3

2.1 General ..................................................................................................................................... 3

2.2 CANopen cable ......................................................................................................................... 3

3. CANOPEN ........................................................................................................................... 4

4. CANOPEN OPTION BOARD LAYOUT AND CONNECTIONS .................................................. 5

4.1 CANopen option board ............................................................................................................. 5

4.2 Bus terminal resistors ............................................................................................................. 5

4.3 LED indications ......................................................................................................................... 6

4.4 Connection of CANopen bus cable ........................................................................................... 7

5. INSTALLATION OF VACON® NX CANOPEN BOARD ........................................................... 12

5.1 Board information sticker ...................................................................................................... 14

6. COMMISSIONING .............................................................................................................. 15

7. CANOPEN- VACON® NX INTERFACE................................................................................. 19

7.1 CANopen message frame ...................................................................................................... 19

7.2 Network Management (NMT) ................................................................................................. 21

7.3 Process data (PDO) ................................................................................................................. 22

7.4 Transmission types ................................................................................................................ 23

7.5 Controlling the drive via PDO messages with Drive Profile ................................................... 24

7.6 Using manufacturer specific PDOs with ByPass modes ................................ ........................ 27

7.7 Drive Monitoring ..................................................................................................................... 29

7.8 Anyparameter service ............................................................................................................ 30

8. Service Data (SDO) ........................................................................................................... 31

9. Node Guarding Protocol ................................................................................................... 44

10. Electronic Data Sheet, EDS-file ....................................................................................... 45

11. APPENDICES .................................................................................................................... 46

appendix a - device profile for drives ..................................................................................................... 46

appendix b sdo messages .................................................................................................................... 47

appendix c process data contents ....................................................................................................... 48

appendix d .............................................................................................................................................. 49

Page 4

2 GENERAL

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

1

1. GENERAL VACON

®

NX AC drives can be connected to the CANopen system using a fieldbus board. The AC drive

can then be controlled, monitored and programmed from the Host system.

The CANopen fieldbus board is installed in slot D or slot E on the control board of the AC drive.

DANGER

Internal components and circuit boards are at high potential when the AC drive is

connected to the power source. This voltage is extremely dangerous and may

cause death or severe injury if you come into contact with it.

NOTE! When experiencing problems with fieldbus functionalities, always write down all the texts and

codes on the keypad display. Then send the problem description together with the Drive Info File to

the local distributor. See local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/ .

NOTE! You can download the English and French product manuals with applicable safety, warning

and caution information from http://drives.danfoss.com/knowledge-center/technical-

documentation/.

REMARQUE Vous pouvez télécharger les versions anglaise et française des manuels produit

sur le site http://drives.danfoss.com/knowledge-center/technical-documentation/.

Page 5

CANOPEN OPTION BOARD TECHNICAL DATA 3

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

2

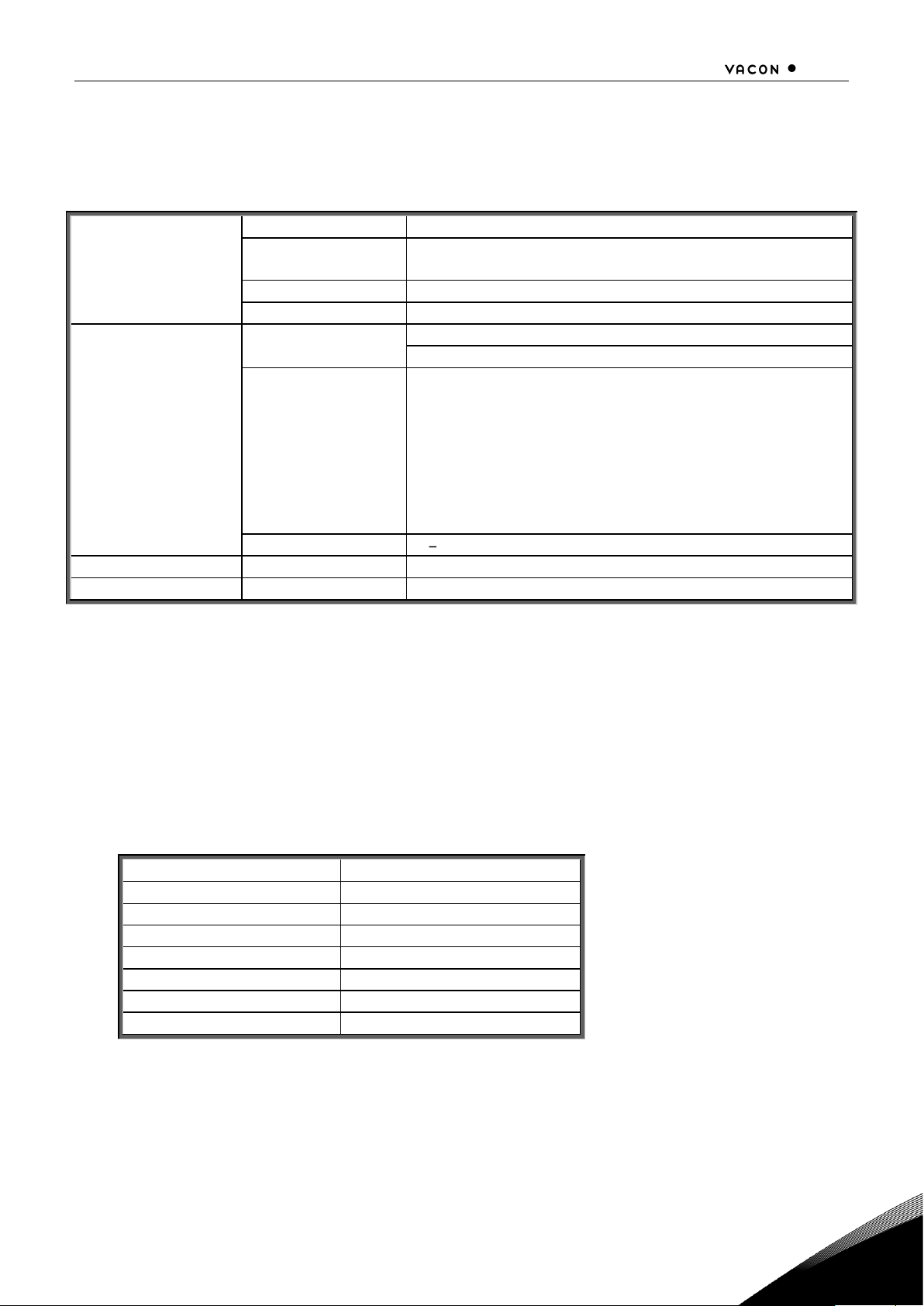

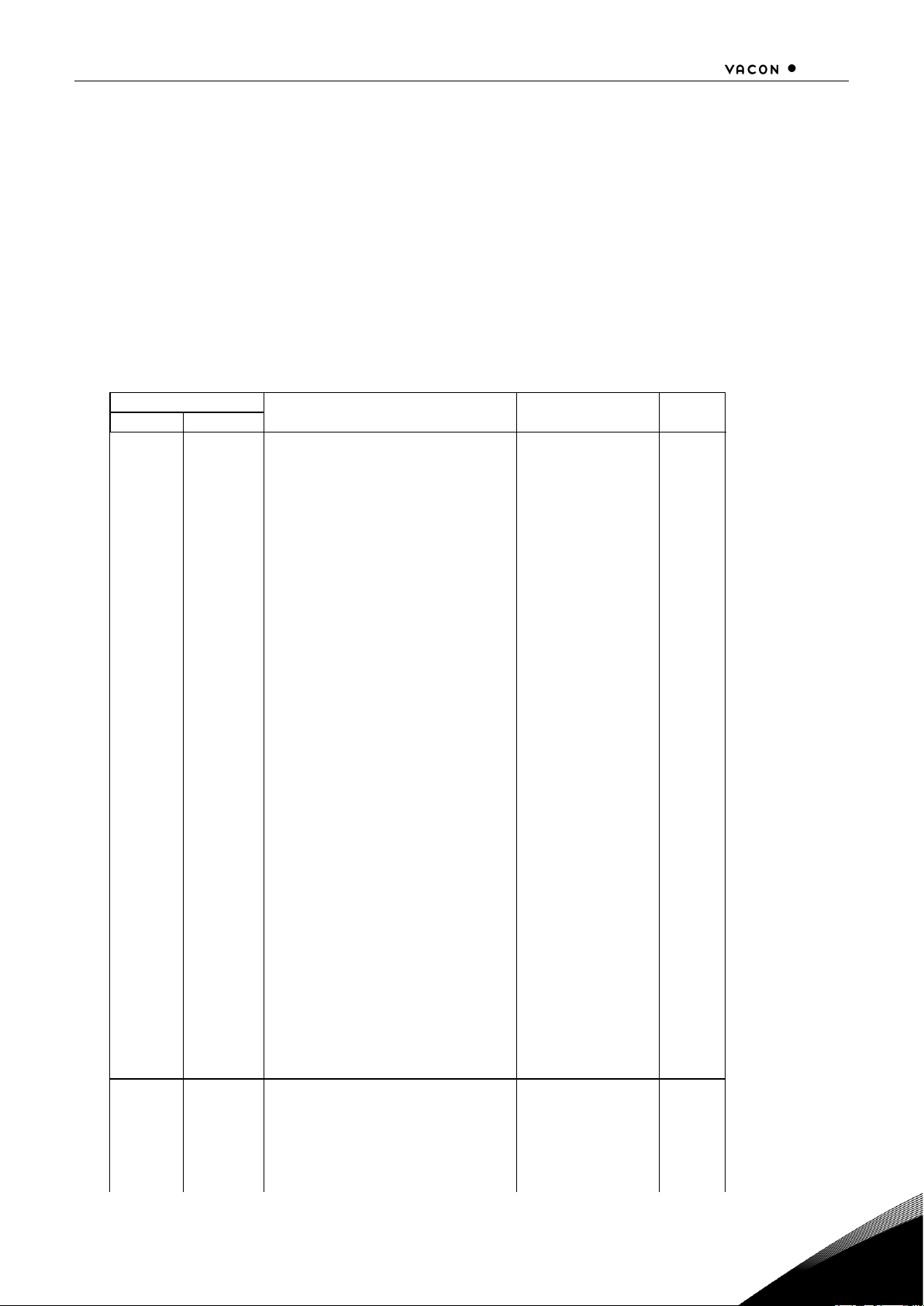

2. CANOPEN OPTION BOARD TECHNICAL DATA

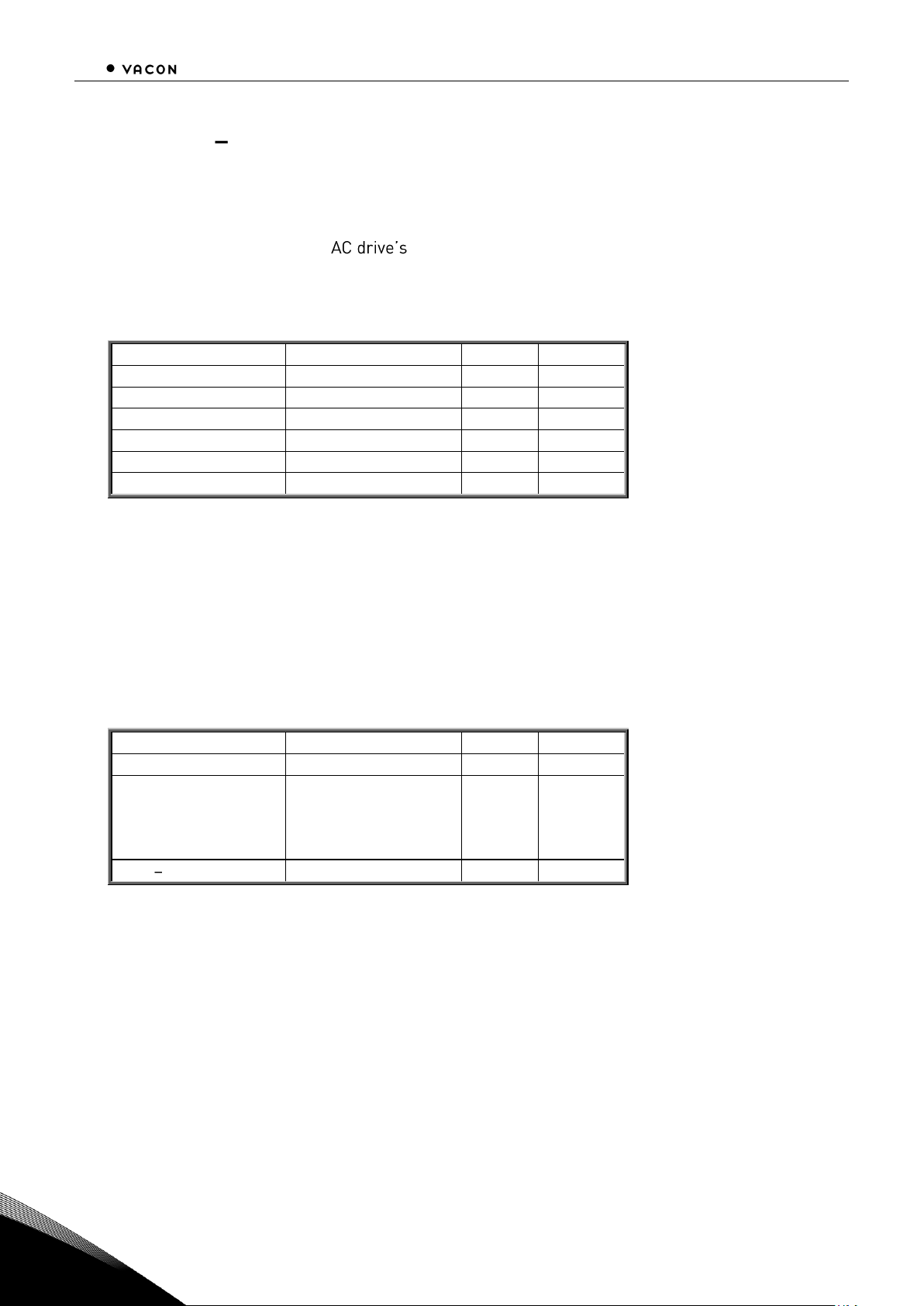

2.1 General

CANopen

connections

Interface

Open Style Connector (Pluggable connector, 5.08mm)

Data transfer

method

CAN (ISO 11898)

Transfer cable

2 wire twisted shielded cable

Electrical isolation

500 VDC

Communications

CANopen

CiA DS-301

CiA DSP-402

Baud rate

10 kBaud

20 kBaud

50 kBaud

100 kBaud

125 kBaud

250 kBaud

500 kBaud

1000 kBaud

Addresses

1 127

Environment

The specifications of the drive are applicable.

Safety

Fulfils EN50178 standard

Table 2-1. CANopen technical data

2.2 CANopen cable According to the ISO 11898 standard, cables to be chosen for CAN bus lines should have a nominal

impedance of 120, and a specific line delay of nominal 5 ns/m. Line termination has to be provided

through termination resistors of 120 located at both ends of the line. The length related resistance

should have 70 m/m. All these mentioned AC and DC parameters are suitable for a 1 Mbit/s

transmission rate.

The table below shows practical bus length for CANopen networks with less than 64 nodes:

Baudrate [Kbit/s]

Max. Bus length [m]

1000

30

800

50

500

100

250

250

125

500

50

1000

20

2500

Page 6

4 CANOPEN

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

3

3. CANOPEN CANopen is a networking system based on the serial bus Controller Area Network (CAN). The

CANopen Communication Profile (CiA DS-301) supports both direct access to device parameters and

time-critical process data communication. CANopen device profiles (CiA DS-40x) define standards for

basic device functionality while providing ample scope for additional vendor-specific device features.

CANopen leashes the full power of CAN by allowing direct peer to peer data exchange between nodes

in an organised and, if necessary, deterministic manner. The network management functions

specified in CANopen simplify project design, implementation and diagnosis by providing standard

mechanisms for network start-up and error management.

CANopen supports both-cyclic and event-driven communication. This makes it possible to reduce the

bus load to a minimum but still maintaining extremely short reaction times. High communication

performance can be achieved at relatively low baud rates, thus reducing EMC problems and

minimising cable costs.

CANopen is the ideal networking system for all types of automated machinery. One of the

distinguishing features of CANopen is its support for data exchange at the supervisory control level as

well as accommodating the integration of very small sensors and actuators on the same physical

network. This avoids the unnecessary expense of gateways linking sensor/actuator bus systems with

higher communication networks and makes CANopen particularly attractive to original equipment

manufacturers.

Device Profile Drives and Motion Control (CiA DSP-402)

document represents the standardised

CANopen Device Profile for digital controlled motion products like servo controllers, AC drives or

stepper motors. All the above-mentioned devices use communication techniques which conform to

those described in the CANopen Application Layer and Communication Profile. The starting and

stopping of the drive and several mode specific commands are executed by the statemachine. The

operation mode defines the behaviour of the drive. The following modes are defined in this profile:

Homing Mode

Profile Position Mode

Interpolated Position Mode

Profile Velocity Mode

Profile Torque Mode

Velocity Mode

VACON

®

CANopen Option Board supports the Velocity Mode

Page 7

CANOPEN OPTION BOARD LAYOUT AND CONNECTIONS 5

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

4

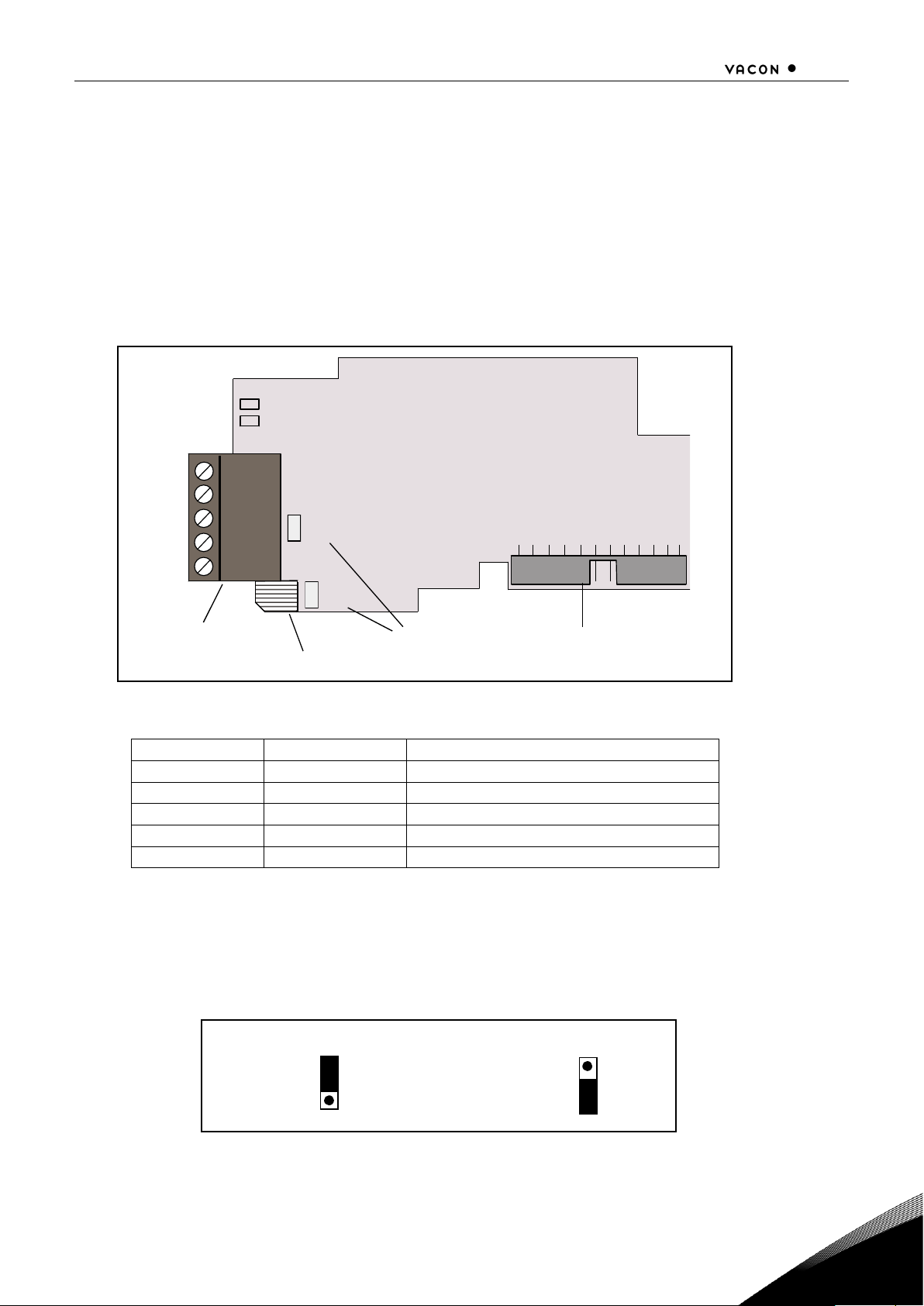

4. CANOPEN OPTION BOARD LAYOUT AND CONNECTIONS

VACON

®

CANopen Board is connected to the fieldbus through a 5-pin pluggable bus connector (board

NXOPTC6).

The communication with the control board of the AC drive takes place through the standard VACON

®

Interface Board Connector.

4.1 CANopen option board

Figure 4-1. VACON

®

CANopen option board OPT-C6

Signal

Connector

Description

CAN_GND

1

Ground / 0V / V-

CAN_L

2

CAN_L bus line (dominant low)

(CAN_SHLD)

3

Optional CAN shield

CAN_H

4

CAN_H bus line (dominant high)

(CAN_V+)

5

-

Table 4-1.OPT-C6 bus connector signals

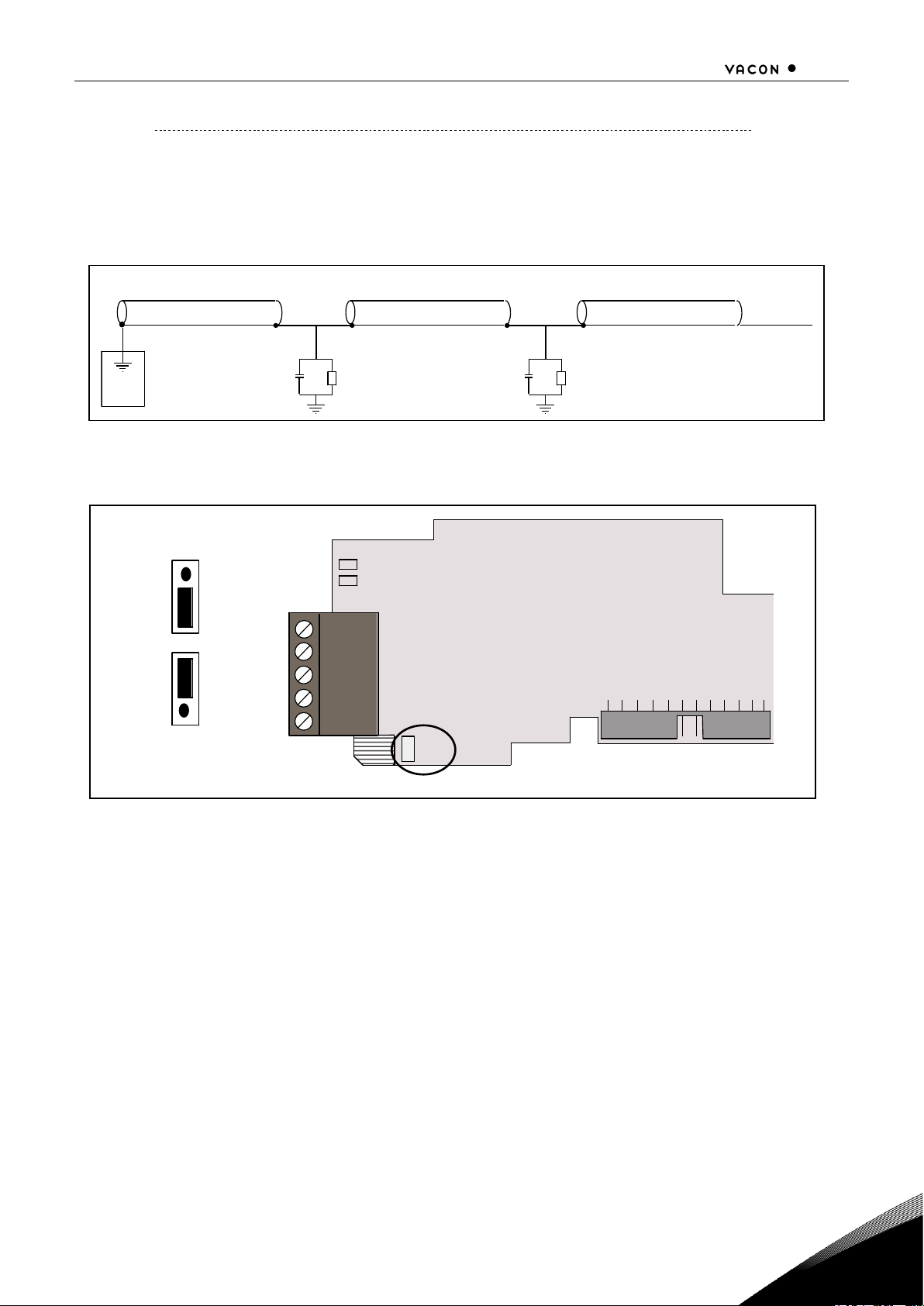

4.2 Bus terminal resistors If VACON

®

drive is the last device of the CANopen line the bus termination must be set. Use jumper

X6 (ON position see Figure 4-1), or an external resistor (120) connected to terminals 2 and 4.

ON OFF

X1

A

M

X6

Jumpers

Interface board

connector

Grounding plate

Bus connector

1

2

3

4

5

Page 8

6 CANOPEN OPTION BOARD LAYOUT AND CONNECTIONS

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

4

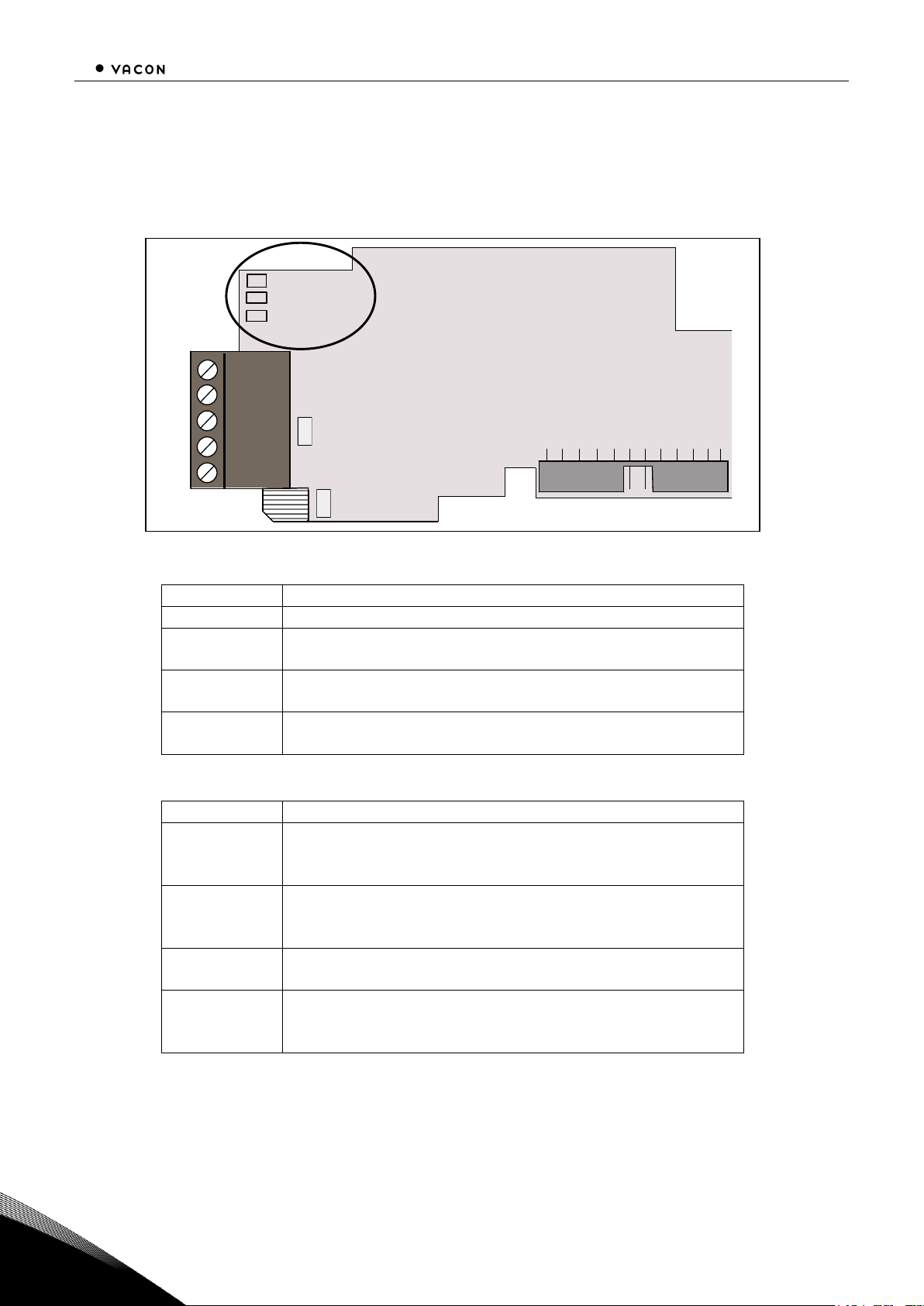

4.3 LED indications The CANopen Option Board includes two LED status indicators next to the connector: Fieldbus status

(M), CANopen(A). Led N is unused.

Figure 4-2. LED indications on the CANopen board

CANopen board status LED (A) GREEN

LED is:

Meaning:

OFF

Option board not activated

ON

Option board in initialisation state waiting for activation

command from the AC drive

Blinking fast

(1 blink / s)

Option board is activated and in RUN state

Option board is ready for external communication

Blinking slow

(1 blink/ 5s)

Option board is activated and in FAULT state

Internal fault of option board

Fieldbus status LED (M) GREEN

LED is:

Meaning:

OFF

Fieldbus module is waiting for parameters from the AC

drive

No external communication

ON

Fieldbus module is activated

Parameters received and module activated

Module is waiting for messages from the bus

Blinking fast

(1 blink / s)

Module is activated and receiving messages from the bus

Blinking slow

(1 blink / 5s)

Module is in FAULT state

No messages from Master within the watchdog time

Bus broken, cable loose or Master off line

X1

A

M

X6

N

Green

Green

Not used

1

2

3

4

5

Page 9

CANOPEN OPTION BOARD LAYOUT AND CONNECTIONS 7

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

4

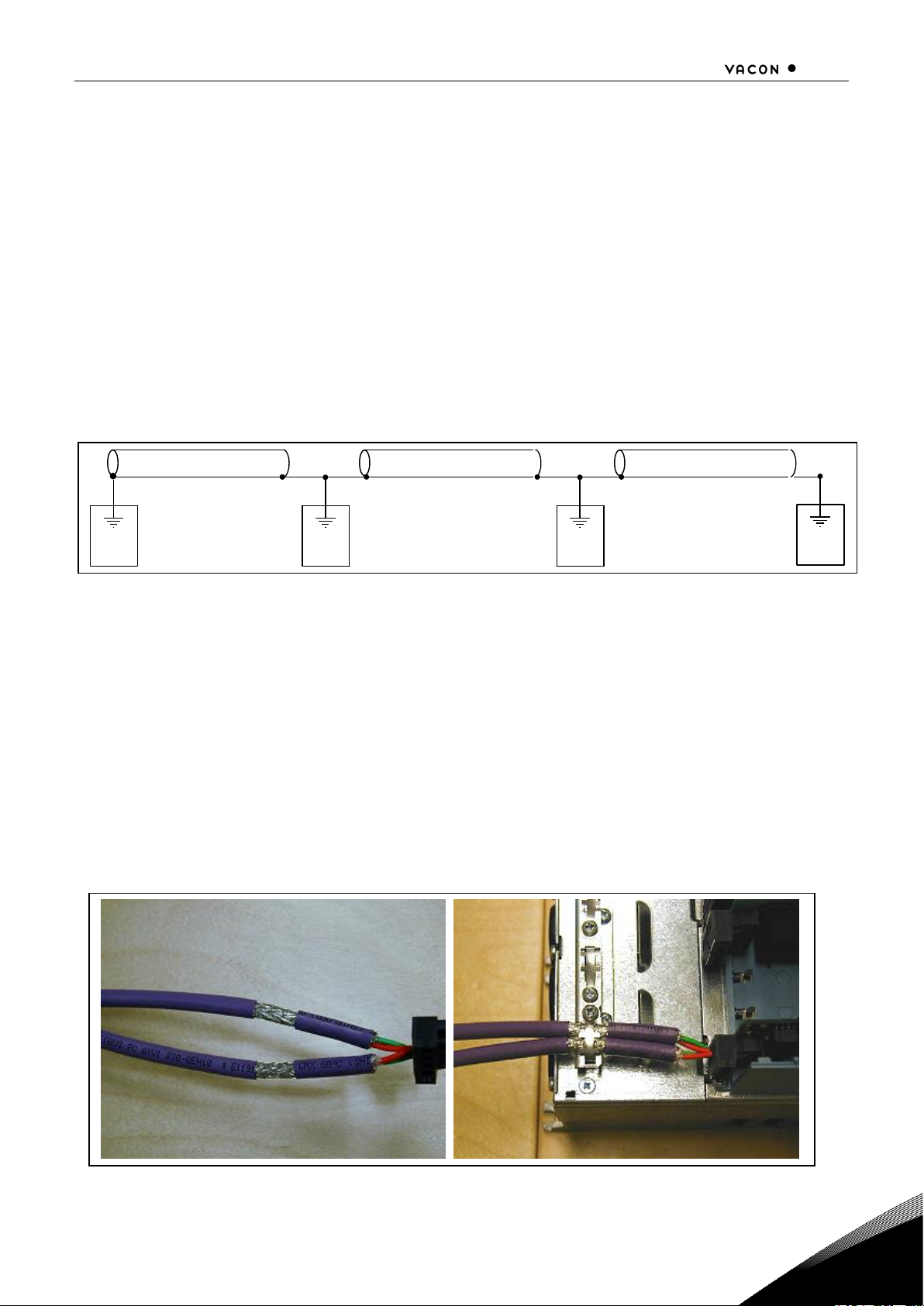

4.4 Connection of CANopen bus cable The bus cable shield can be grounded in three different ways:

a) clamping the cable to the AC drive frame

b) to the frame of the AC drive through an RC filter

c) directly to the AC drive frame

Note: Normally, the option board has already been installed in slot E of the control board. It is not

necessary to detach the whole board for the grounding of the bus cable shield. Just detach the

terminal block.

4.4.1

Grounding by clamping the cable to the AC drive frame

This manner of grounding is the most effective and especially recommended when the distances

between the devices are relatively short (see 4.4.2.1).

In this manner of grounding, the position of jumper X1 is of no importance

Figure 4-3. Grounding by clamping the cable to the AC drive frame

1 Strip about 5 cm of the CANopen cable in the same way as shown in Figure 4-4 but cut off the

grey cable shield.

Remember to do this for both bus cables (except for the last device).

2 Leave no more than 1 cm of the data cable outside the terminal block and strip the data cables at

about 0.5 cm to fit in the terminals. See Figures 4-5 and 4-6.

Note: Do this for both bus cabels

3 Insert the data cables of both CANopen cables into terminals #2 and #4. See Figure 4-7.

4 Strip the CANopen cable at such a distance from the terminal that you can fix it to the frame with

the grounding clamp.

Figure 4-4.

c a b l e

c a b l e c a b l e

C a n p e n O

C a n p e n O C a n p e n

O

Page 10

8 CANOPEN OPTION BOARD LAYOUT AND CONNECTIONS

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

4

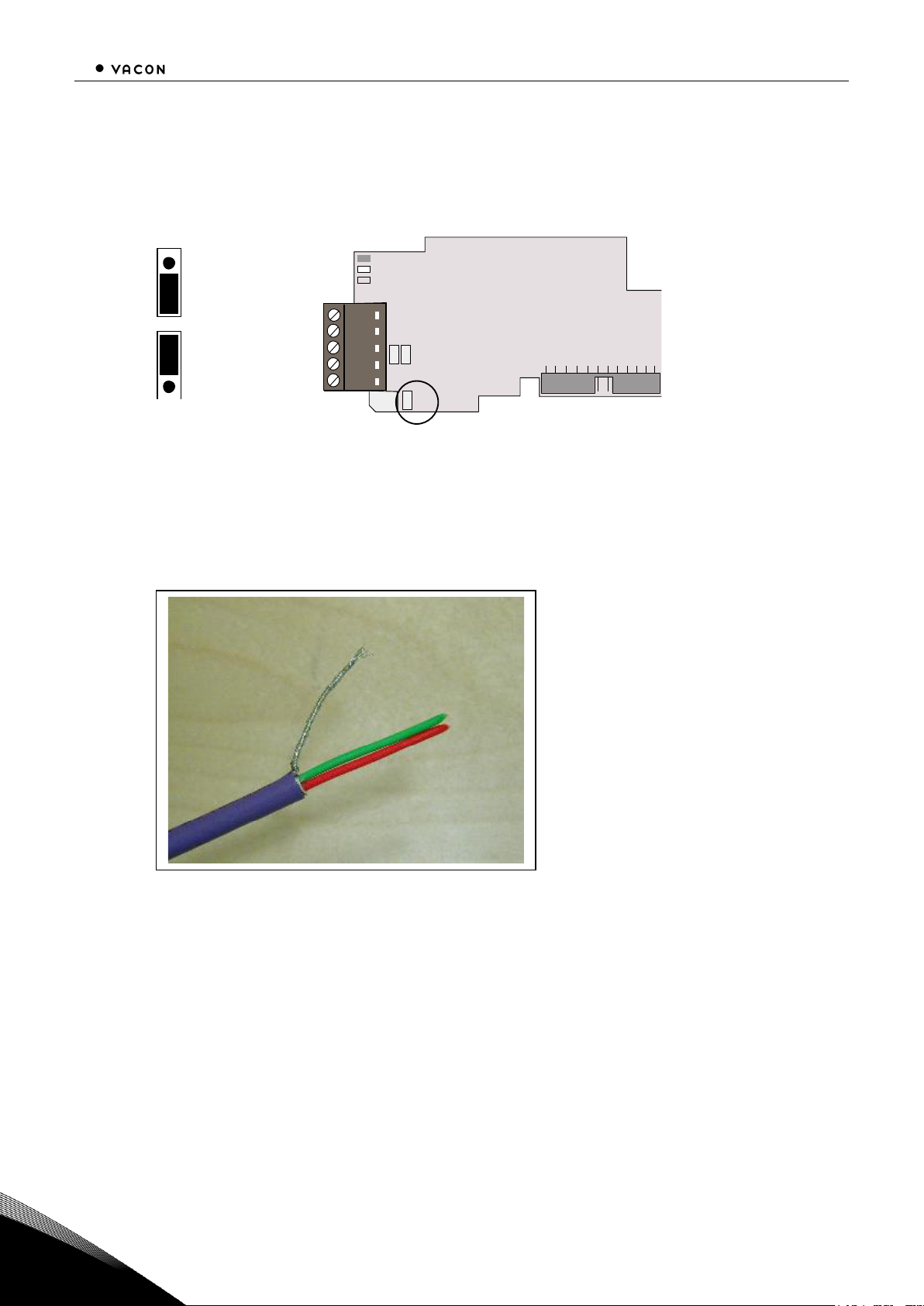

4.4.2

Grounding the bus cable shield directly to the AC drive frame using jumper X1

1 Set jumper X1 in ON position:

Figure 4-5. Jumper X1 positions

2 Strip about 5 cm of the CANopen cable as shown in the picture.

Note: Do the same for both bus cables (except for the last device). However, since the

grounding must be done on one cable only cut off the exposed part of the other grounding

cable.

Figure 4-6.

3 Leave no more than 1 cm of the red and green data cable outside the terminal block and

strip the data cables at about 0.5 cm to fit in the terminals. See pictures below.

Note: Do this for both bus cabels.

ON

OFF

X1

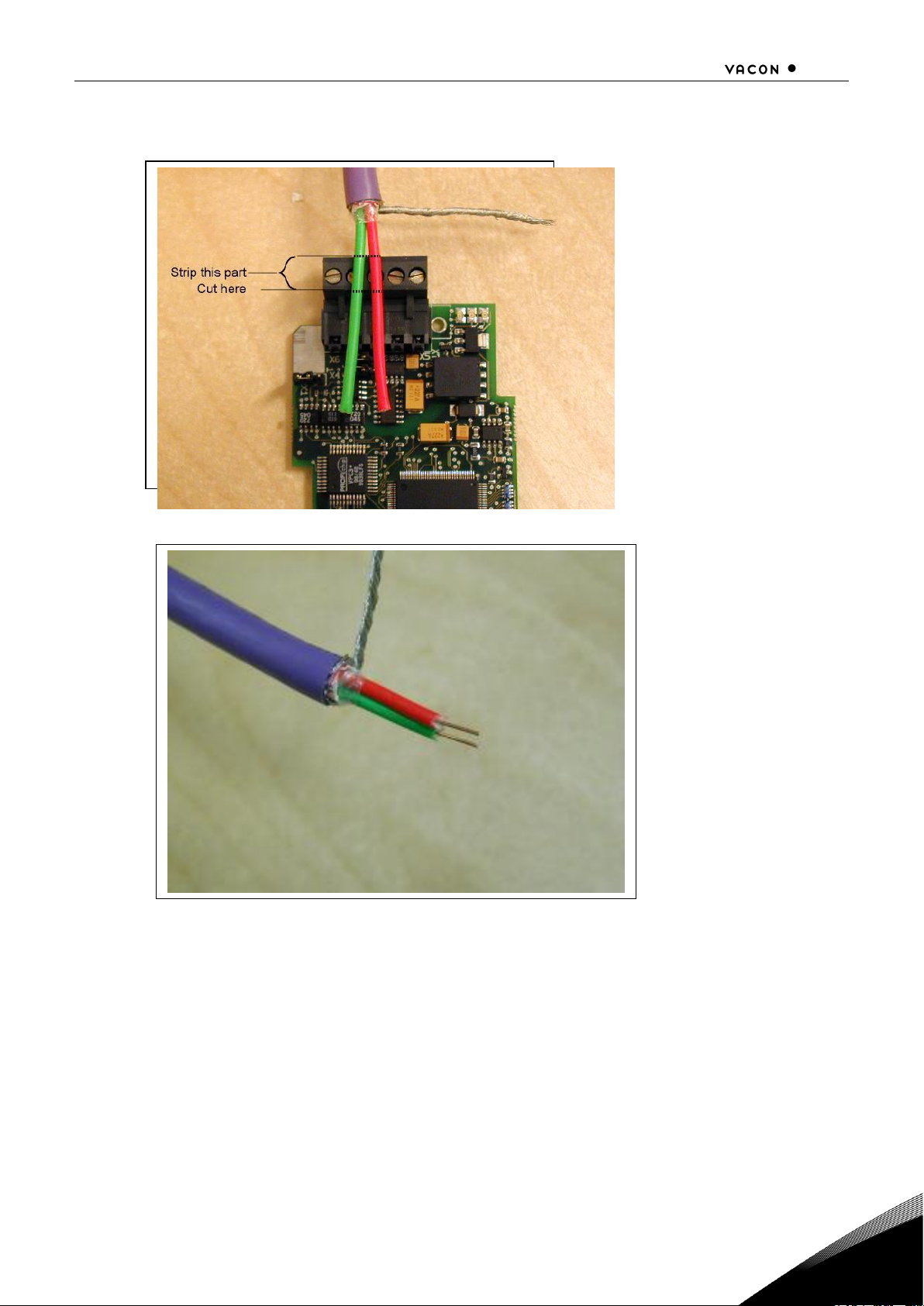

Page 11

CANOPEN OPTION BOARD LAYOUT AND CONNECTIONS 9

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

4

Figure 4-7.

Figure 4-8.

Page 12

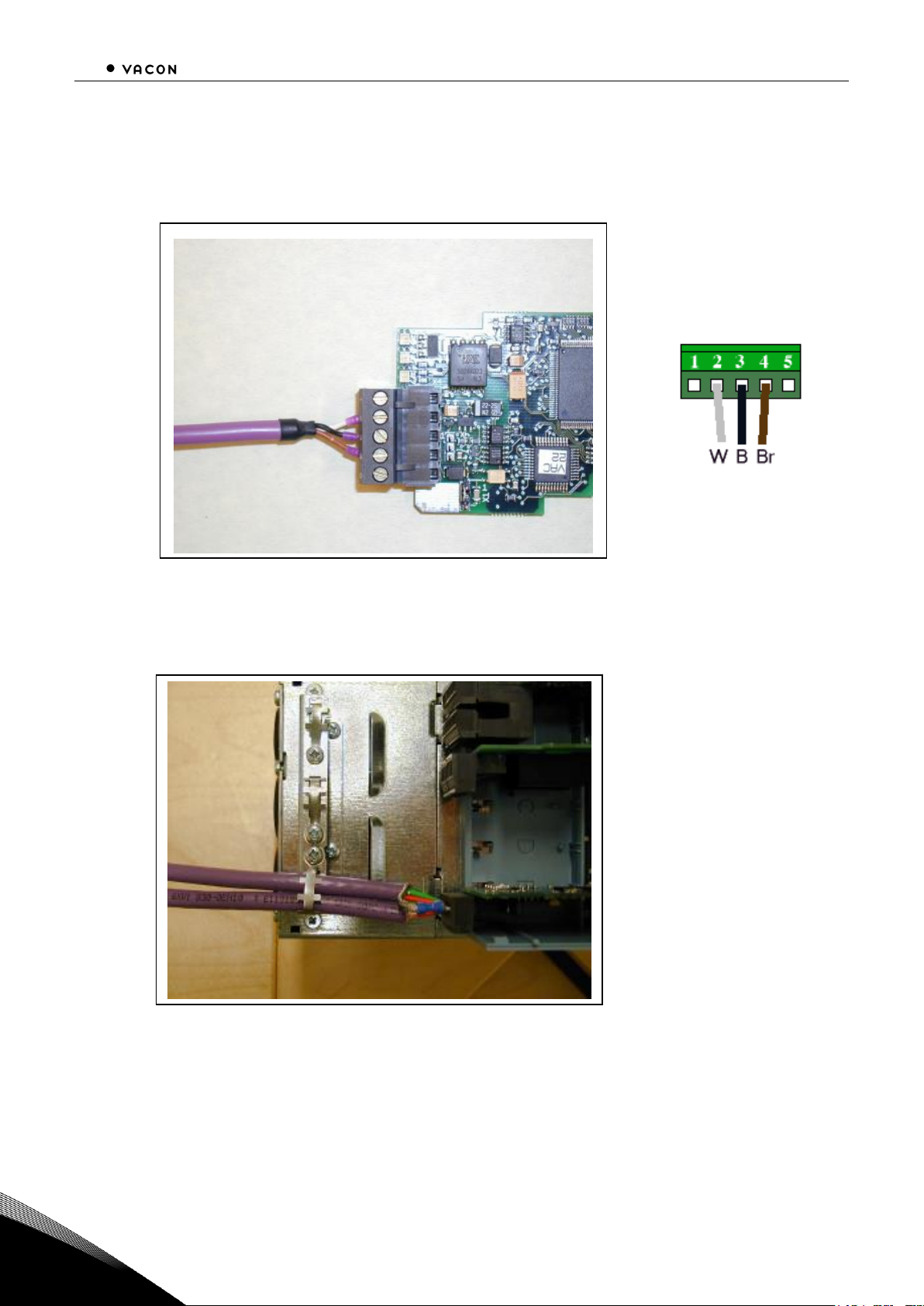

10 CANOPEN OPTION BOARD LAYOUT AND CONNECTIONS

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

4

4 We recommend you to use an Abico connector to fit the grounding cable into the grounding

terminal (#3).

Insert the white and brown data cables of both CANopen cables into terminals #2 (white)

and #4 (brown).

Figure 4-9.

5 Place the CANopen board into slot E of the control board (see board installation on page 12)

and fix both the CANopen cables on the frame with the clamp.

Figure 4-10.

Page 13

CANOPEN OPTION BOARD LAYOUT AND CONNECTIONS 11

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

4

4.4.2.1 Grounding the bus cable shield directly to the AC drive frame using an RC-filter

We recommend you to do the grounding in this manner when the distance between the devices

exceeds 50 meters (55 yds.). When the distance between the devices is long disturbances (e.g. voltage

spikes) are more likely to appear. In this grounding method, the disturbances are filtered out. Even if

the ground planes of A, B and C are different (which is very typical e.g. in construction) there is no

current between them because the points do not have a ground connection.

Figure 4-11. Grounding with RC filter

1 Set jumper X1 in OFF position

Figure 4-12. Jumper X1 positions

2 Carry out the grounding in the same way as advised in Chapter 4.4.1.

C a n O p e n c a b l e

c a b l e c a b l e

A B C

C a n p e n O C a n p e n

O

X1

A

M

ON

OFF

1

2

3

4

5

Page 14

12 INSTALLATION OF VACON® NX CANOPEN BOARD

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

5

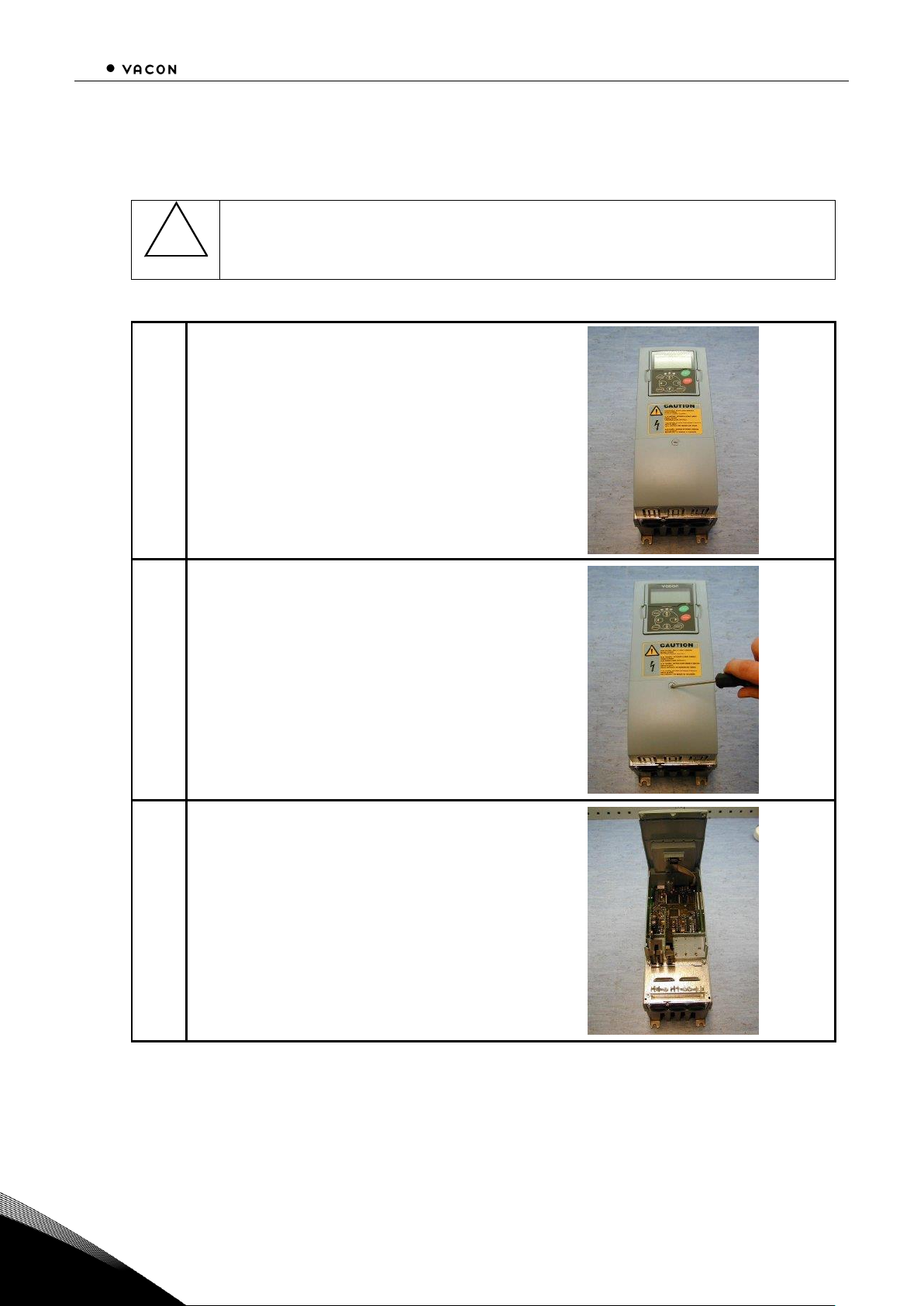

5. INSTALLATION OF VACON® NX CANOPEN BOARD

!

NOTE

MAKE SURE THAT THE AC DRIVE IS SWITCHED OFF BEFORE AN OPTION OR

FIELDBUS BOARD IS CHANGED OR ADDED!

A

VACON

®

NX AC drive

B

Remove the cable cover.

C

Open the cover of the control unit.

Page 15

INSTALLATION OF VACON® NX CANOPEN BOARD 13

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

5

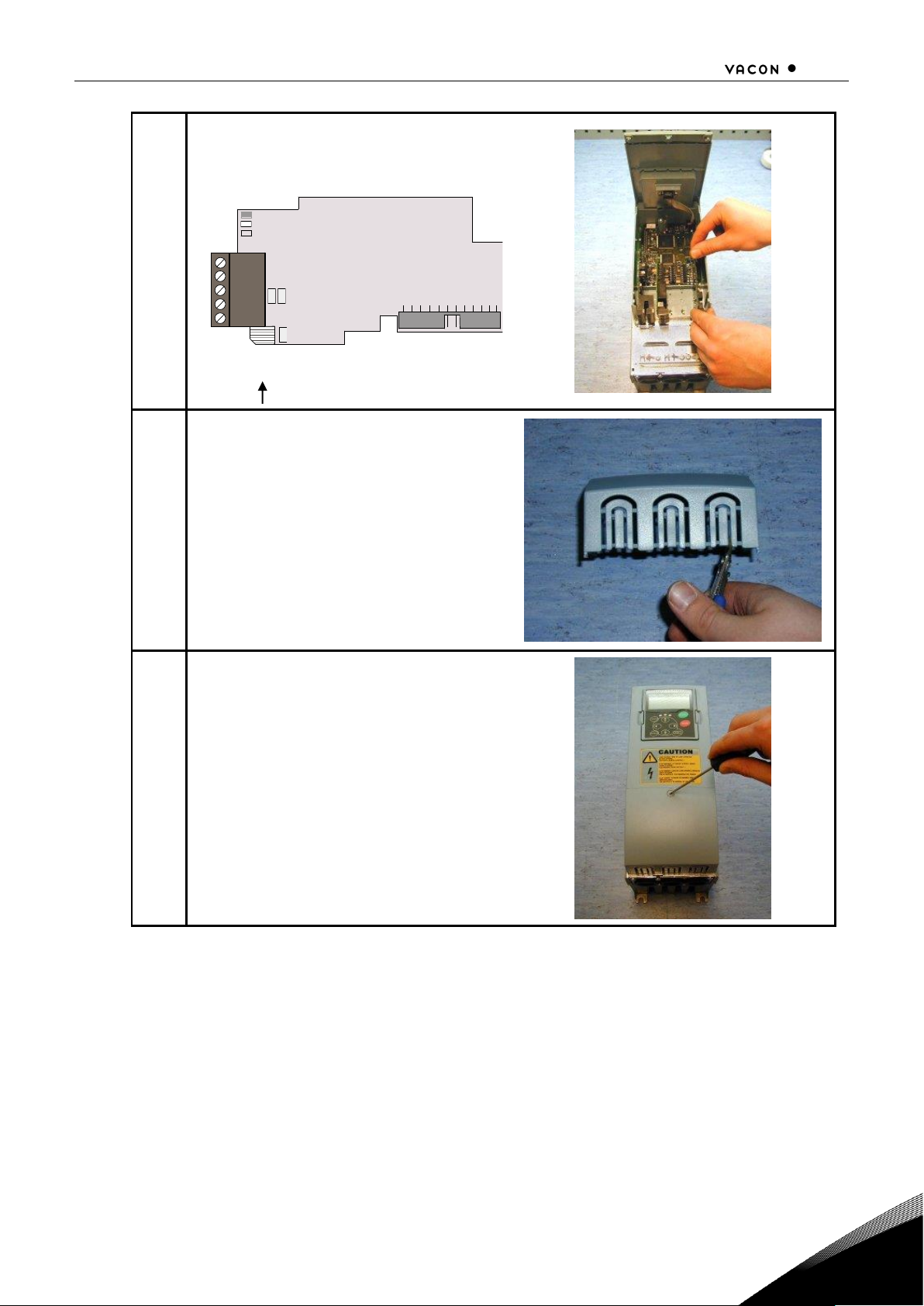

D

Install CANopen option board in slot E

on the control board of the AC drive.

Make sure that the grounding plate (see

below) fits tightly in the clamp.

X6

X1

1

2

3

4

5

E

Make a sufficiently wide opening for

your cable by cutting the grid as wide as

necessary.

F

Close the cover of the control unit and

the cable cover.

Page 16

14 INSTALLATION OF VACON® NX CANOPEN BOARD

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

5

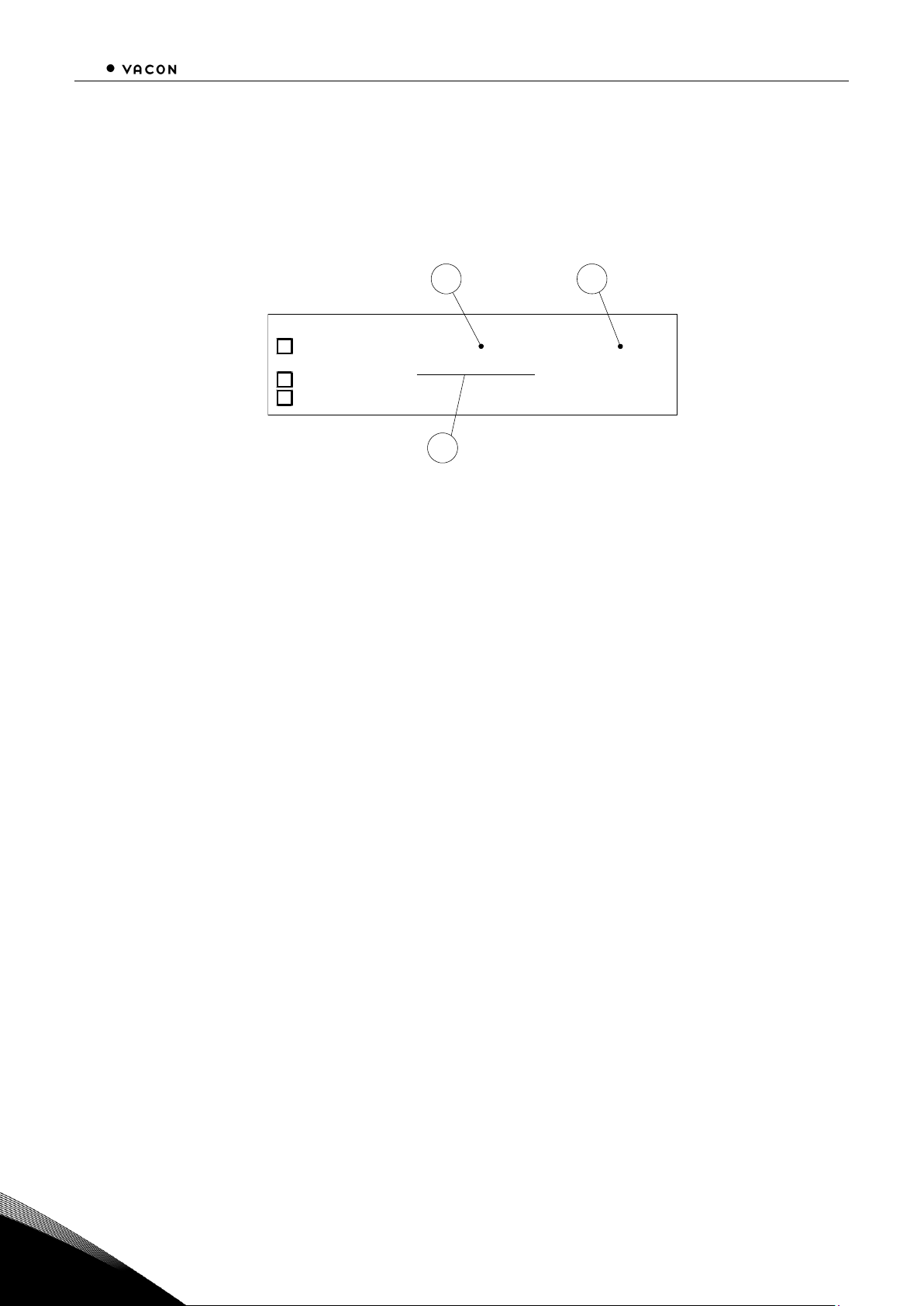

5.1 Board information sticker The CANopen option board package delivered by the factory includes a sticker (shown below). Please

mark the board type (1), the slot into which the board is mounted (2) and the mounting date (3) on the

sticker. Finally, attach the sticker on your drive.

Drive modified

:

Option board:

NXOPT................

IP54 upgrade/ Collar

in slot:

Date:...................

A B C D E

EMC level modified: H

T / T H

Date:...................

Date:...................

1

2

3

Page 17

COMMISSIONING 15

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

6

6. COMMISSIONING

READ FIRST CHAPTER 'COMMISSIONING' IN VACON

®

NX USER'S MANUAL VACON

®

NXS NXP Air-

cooled User Manual" or VACON® NXL User's Manual", go to http://drives.danfoss.com/knowledge-

center/technical-documentation/).

Note! You must select Fieldbus as the active control place, if you wish to control the AC drive through

fieldbus. See VACON

®

NX User Manual.

The VACON

®

CANopen board is commissioned with the control keypad by giving values to appropriate

parameters in menu M7 (for locating the expander board menu see VACON

®

NX User Manual.

Expander board menu (M7)

The

Expander board menu

makes it possible for the user 1) to see what expander boards are

connected to the control board and 2) to reach and edit the parameters associated with the expander

board.

Enter the following menu level (G#) with the

Menu button right

. At this level, you can browse through

slots A to E with the

Browser buttons

to see what expander boards are connected. On the lowermost

line of the display you also see the number of parameter groups associated with the board.

If you still press the

Menu button right

once you will reach the parameter group level where there are

two groups: Editable parameters and Monitored values. A further press on the

Menu button right

takes you to either of these groups.

CANopen parameters

To commission the CANopen board, enter the level P7.5.1.# from the

Parameters

group (G7.5.1). Give

desired values to all CANopen parameters.

Figure 6-1. Changing the CANopen option board parameters

G1G5

READY

E:NXOPTC6

READY

G1G2

READY

READY

enter

P1P3

READY

Expander boards

Parameters

Node ID

63

CHANGE VALUE

CONFIRM CHANGE

63

Node ID

Page 18

16 COMMISSIONING

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

6

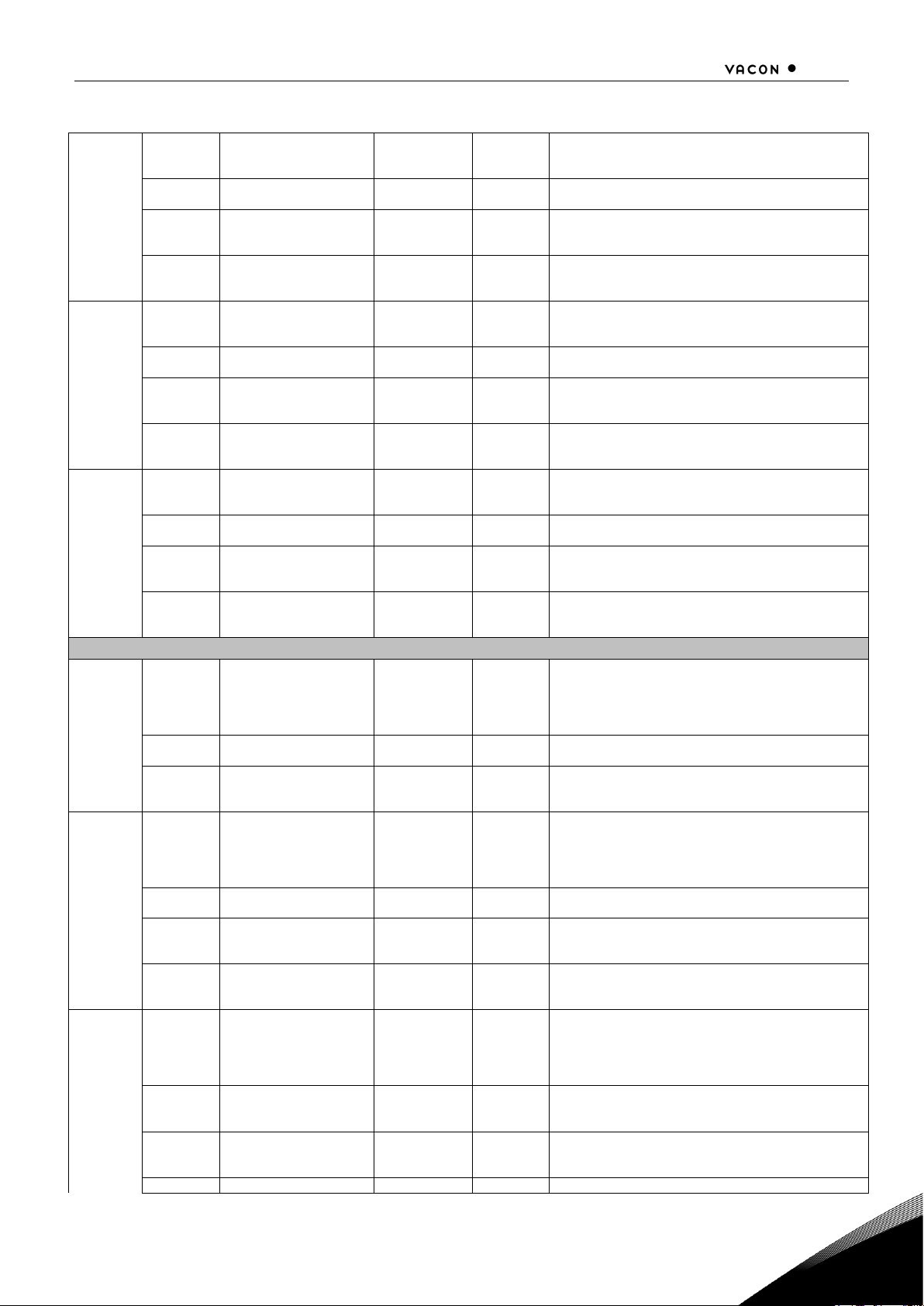

#

Name

Default

Range

Description

1

Node ID

1

1 127

2

BAUD RATE

6

1 10 kBaud

2 20 kBaud

3 50 kBaud

4 100 kBaud

5 125 kBaud

6 250 kBaud

7 500 kBaud

8 1000 kBaud

Communication speed

3

Operate mode

1

1 Drive Profile

2 ByPass

3 ByPass 2

4 Bypass 3

5 Bypass 4

Communication set selection

1 = xPDO1, xPDO6

2 = xPDO1, xPDO21, xPDO22

3 = xPDO1, xPDO21, xPDO22

4 = xPDO1, xPDO21, xPDO22,

xPDO23

5 = xPDO1, xPDO21, xPDO22,

xPDO23

Table 6-1. CANopen parameters

NOTE! Bypass modes 3 and 4 require OPTC6 V26 firmware or newer. See VACON

®

NX control

firmware requirements below.

Bypass and Bypass 3 modes can be used in customer-specific applications and in special

applications, such as System Interface application.

Bypass 2 and Bypass 4 modes are used with standard applications, e.g. VACON

®

NXL Multicontrol

application and VACON

®

All-in-One applications for VACON® NXS and NXP.

ByPass 2 mode is supported in the following System software versions:

• NXL NXL00005V253

• NXS NXS00001V174

• NXP NXP00002V174

ByPass 3 and 4 mode are supported in the following System software versions:

• NXP NXP00002V194

The parameters of every device must be set before connecting to the bus. Especially the parameters

ation.

CANopen status

To see the present status of the CANopen Fieldbus, enter the

CANopen Status

page from

Monitor

menu (G7.5.2)

. See picture and table below.

Page 19

COMMISSIONING 17

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

6

Figure 6-2. DeviceNet status

M o n i t o r

R E A D Y

I / O t e r m

V

1 V

1

C A N i o p e

n s t a t u s

R E A D Y

I / O t e r m

2 5 .

0

M e s s a g e c o u n t e r

CANopen

s t a t u

s

Page 20

18 COMMISSIONING

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

6

CANopen status

0

INITIALISING

4

STOPPED

5

OPERATIONAL

6

PRE_OPERATIONAL

7

RESET_APPLICATION

8

RESET_COMM

9

UNKNOWN

Table 6-2. CANopen status indications

Page 21

CANOPEN- VACON® NX INTERFACE 19

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

7

7. CANOPEN- VACON

®

NX INTERFACE

CANopen communication objects transmitted via the CAN network are described by services and

protocols. They are classified as follows:

- The real-time data transfer is performed by the Process Data Objects (PDOs) protocol

REAL-TIME CONTROL OF THE DRIVE

- Service Data Objects (SDO) protocols provide the read and write access to entries of a device

object dictionary

CONFIGURATION OF THE DRIVE, READ/WRITE DRIVE PARAMETERS

- The Network Management (NMT) protocols provide services for network initialization, error

control and device status control

START/STOP CANOPEN COMMUNICATION

7.1 CANopen message frame

SOF

COB-ID

RTR

CTRL

Data Segment

CRC

ACK

EOF

1bit

11bit

1bit

5bit

0-8bytes

16bits

2bits

7bits

SOF Start of Frame CRC Cyclic Redundancy Check

RTR Remote Transmission Request ACK Acknowledge

CTRL Control Field (i.e. Data Length) EOF End of Frame

COB-ID

The identification field of the CANopen-message is 11 bits.

ID-Bit

10 9 8 7 6 5 4 3 2 1 0

COB-ID

Function Code

Module-ID

The default identification field consists of a functional part and a module-ID part. The functional part

determines the object priority. This kind of identification field allows communication between a

master and 127 slaves. Broadcasting is indicated by a module-id of zero. Function codes are

determined with object dictionaries in device profiles.

Page 22

20 CANOPEN- VACON® NX INTERFACE

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

7

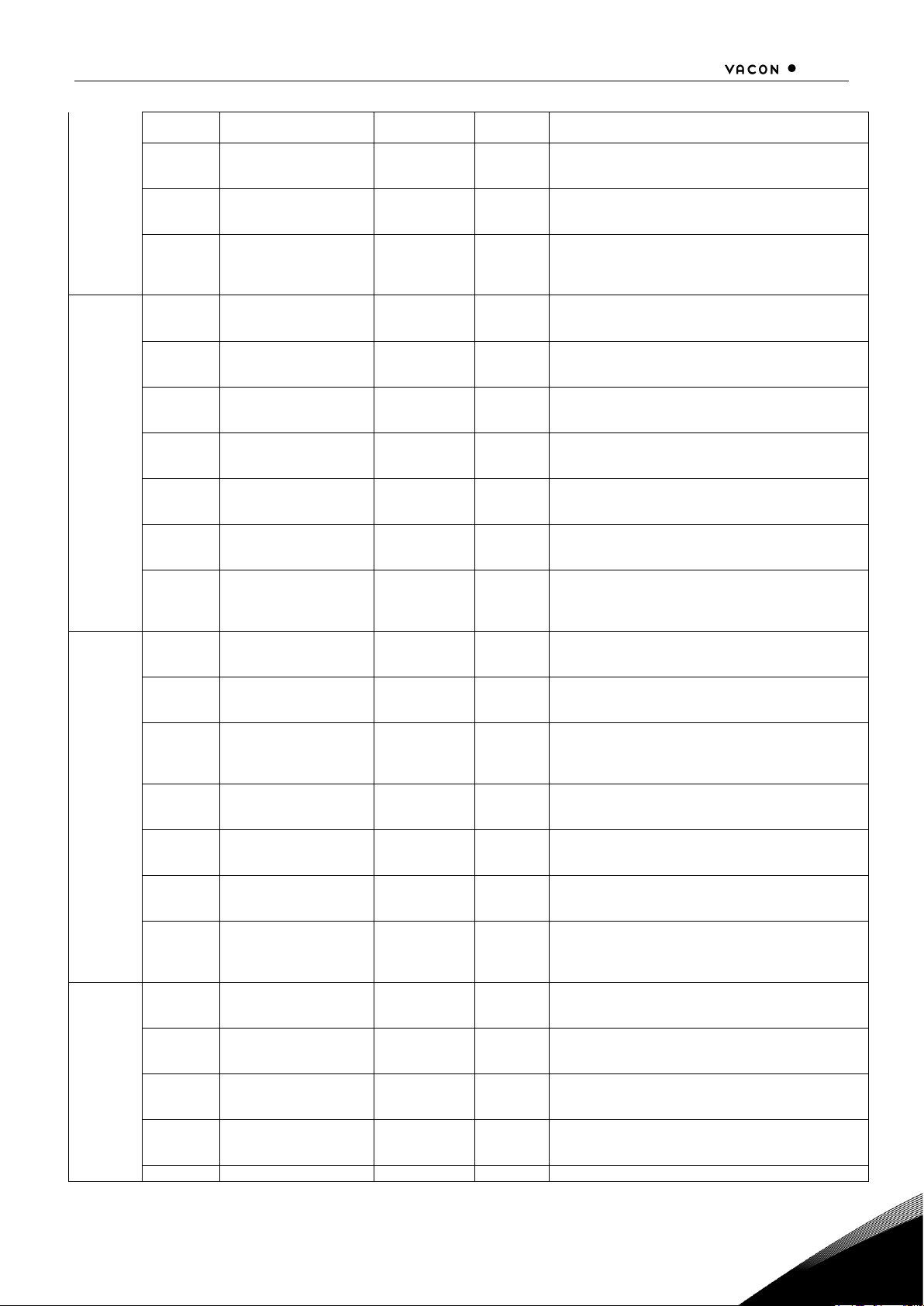

Predefined connection sets

CANopen option board has two different communication parameter sets. These sets can be selected

via Operate Mode

-profile described in CiA DSP-402.

Drive Profile - mode

Object

Function Code

(binary)

COB-ID

Comm. parameter at Index

NMT message

0000

0x0000

-

Sync Message

0001

0x0080

0x1005

Time-Stamp-Message

0001

0x0100

-

PDO1, Process Data Objects (tx)

0011

0x0180 +Node

0x1800

PDO1, Process Data Objects (rx)

0100

0x0200 +Node

0x1400

PDO6, Process Data Objects (tx)

0101

0x0280 +Node

0x1801

PDO6, Process Data Objects (rx)

0110

0x0300 +Node

0x1401

SDO, Service Data Objects (tx)

1011

0x0580 +Node

SDO, Service Data Objects (rx)

1100

0x0600 +Node

Node Guarding

1110

0x0700 +Node

(0x100E)

Table 7-1. Drive Profile -mode

ByPass - mode

Object

Function Code

(binary)

COB-ID

Comm. parameter at Index

NMT message

0000

0x0000

-

Sync Message

0001

0x0080

0x1005

Time-Stamp-Message

0010

0x0100

-

PDO1, Process Data Objects (tx)

0011

0x0180 +Node

0x1800

PDO1, Process Data Objects (rx)

0100

0x0200 +Node

0x1400

PDO21, Process Data Objects (tx)

0111

0x0380 +Node

0x1814

PDO21, Process Data Objects (rx)

1000

0x0400 +Node

0x1414

PDO22, Process Data Objects (tx)

1001

0x0480 +Node

0x1815

PDO22, Process Data Objects (rx)

1010

0x0500 +Node

0x1415

PDO23, Process Data Objects (tx)

0101

0x280 +Node

0x1816

PDO23, Process Data Objects (rx)

0110

0x300 +Node

0x1416

SDO, Service Data Objects (tx)

1011

0x0580 +Node

SDO, Service Data Objects (rx)

1100

0x0600 +Node

Node Guarding

1110

0x0700 +Node

(0x100E)

Table 7-2. Bypass -mode

Page 23

CANOPEN- VACON® NX INTERFACE 21

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

7

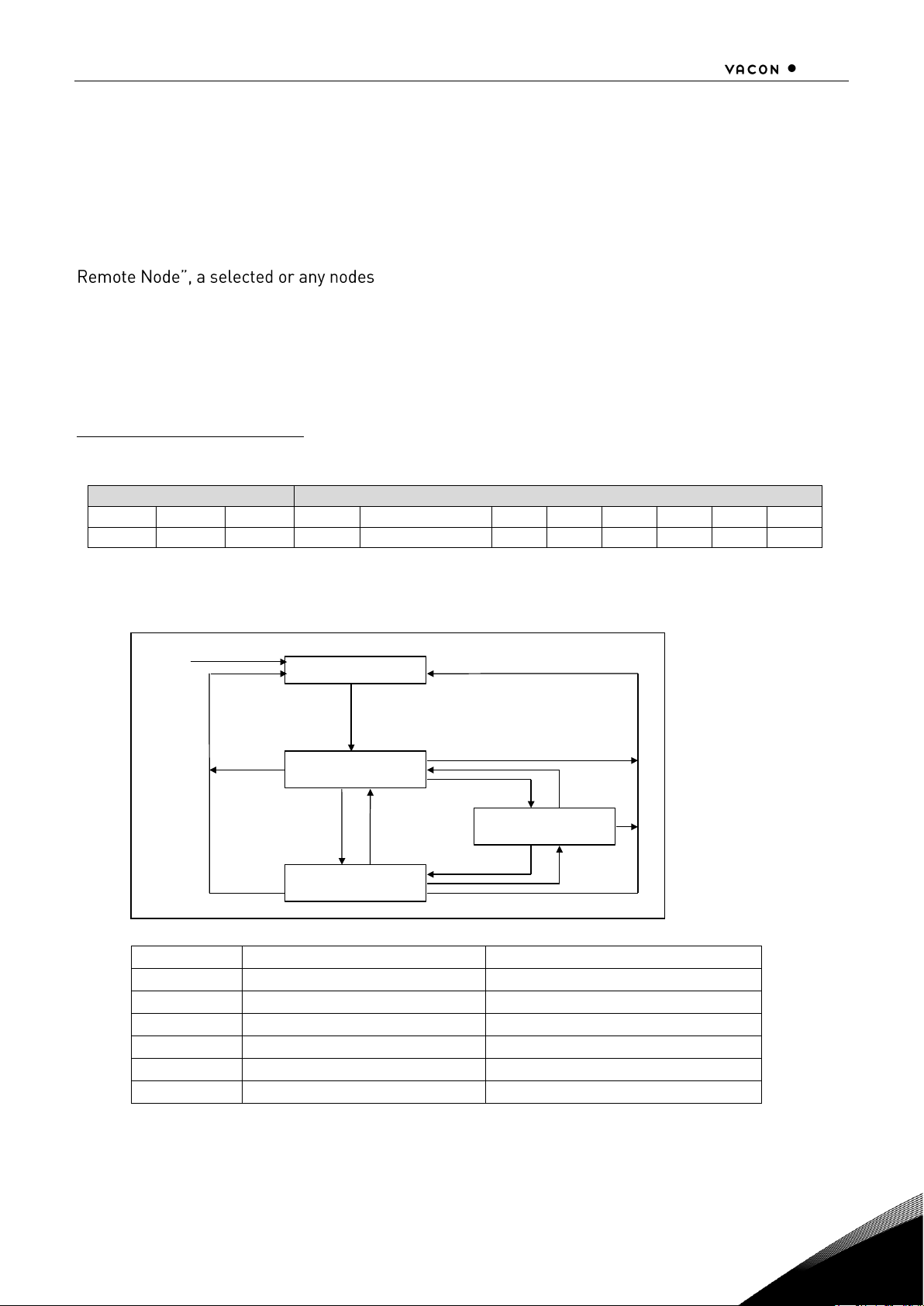

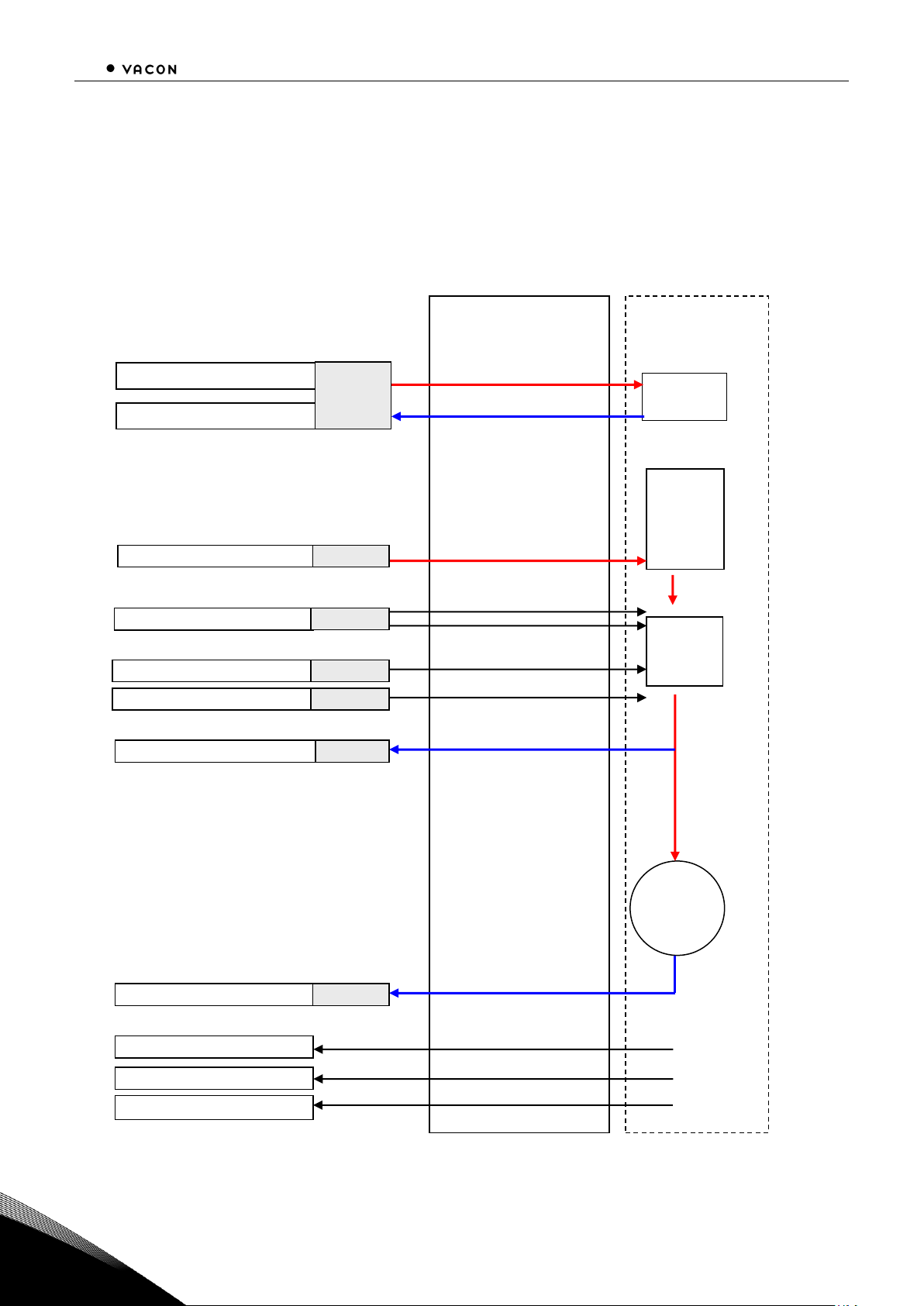

7.2 Network Management (NMT) The CANopen network management is node-oriented and follows a master/slave structure. It

requires one device in the network, which fulfills the function of the NMT master. The other nodes are

NMT slaves.

The CANopen NMT slave devices implement a state machine, see picture below. After power on a

node initialises and transits to the "Pre-operational State". In this state communication across SDO

channels is possible for node configuration, but not yet across PDOs. With the NMT message "Start

on the network can be set into the "Operational State". In this

state, also the exchange of data by means of PDOs is possible. With enabling the operation of all

nodes of a network at the same time, a co-ordinated operation of the communicating system is

secured (DS301).

To Set VACON

®

CANopen Option board to the "Operational State" the following message must be

sent:

Message: Start_Remote_Node

Master to Slave (1)

Header

Data

ID

RTR

Len

1 = CS

2 = Node ID

3 4 5 6 7 8 0000 0 2

01

01

Function of the internal state machine:

Change

Message / Event

Command Specifier (CS)

1

Start Remote Node

CS = 1

2

Stop Remote Node

CS = 2

3

Enter Pre-operational State

CS = 128

4

Reset Node

CS = 129

5

Reset Communication

CS = 130

6

Initialisation finished

Automatic

Initialization

Pre-Operational

Prepared

Operational

Power

On

6

4

5

1

3

2

3

1

2

Page 24

22 CANOPEN- VACON® NX INTERFACE

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

7

7.3 Process data (PDO)

The realPDOs is performed with no protocol overhead. Process Data is time-critical data used for control of

the drive and monitor status of the drive. Transmit PDOs support several transmission modes which

are cyclic, acyclic, synchronous, asynchronous and RTR only mode. Most PDOs support also Event

Timer for transmitting PDOs. TPDO1 is exception which is defined for asynchronous only operation.

Receive PDOs support only asynchronous transmission mode (event driven). VACON

®

CANopen

option board uses 8 types of PDOs as follows:

Cyclic Acyclic Synchronous

Asynchronous

(default

RTR Only mode Event Timer

PDO

Type

Mapped Data

Mapped Data

Mapped Data

Mapped Data

TPDO1

statusword

- - - x

TPDO6

statusword

vl_control_effort

- - X X X x X

X

TPDO21

nx_status_word

nx_actual_speed

process_data_out

1

process_data_out

2

X X X x X

X

TPDO22

process_data_out3

process_data_out4

process_data_out5

process_data_out6

X X X x X X RPDO1

controlword

- - - x

RPDO6

controlword

vl_target_velocity

- - x RPDO21

nx_control_word

nx_speed_reference

process_data_in1

process_data_in2

x RPDO22

process_data_in3

process_data_in4

process_data_in5

process_data_in6

x

Note: manufacturer specific PDOs (TPDO21/RPDO21/ TPDO22/RPDO22) consist of application specific

process data. See appendix for contents of these process datas in different applications. See Chapter

7.6 (Using manufacturer specific PDOs) or a specific application manual.

Note! All Tx objects are event-driven by default. (Message is sent out if one or several values within

the message change)

Page 25

CANOPEN- VACON® NX INTERFACE 23

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

7

7.4 Transmission types

transmission type

PDO transmission

cyclic

acyclic

synchronou

s

asynchronou

s

RTR only

0 X X

1-240 X X

241-251

- Reserved -

252 X

X

253 X

X

254 X

255 X

Table 7-3. Description of transmission type

Synchronous (transmission types 0-240 and 252) means that the transmission of the PDO shall be

related to the SYNC object. Preferably the devices use the SYNC as a trigger to output or actuate

based on the previous synchronous Receive PDO respectively to update the data transmitted at the

following synchronous Transmit PDO. Asynchronous means that the transmission of the PDO is not

related to the SYNC object. A transmission type of zero means that the message shall be transmitted

synchronously with the SYNC object but not periodically. A value between 1 and 240 means that the

PDO is transferred synchronously and cyclically. The transmission type indicating the number of

SYNC which are necessary to trigger PDO transmissions. Receive PDOs are always triggered by the

following SYNC upon reception of data independent of the transmission types 0 - 240.

The transmission types 252 and 253 mean that the PDO is only transmitted on remote transmission

request. At transmission type 252, the data is updated (but not sent) immediately after reception of

the SYNC object. At transmission type 253 the data is updated at the reception of the remote

transmission request (hardware and software restrictions may apply). These value are only possible

for TPDOs. For TPDOs transmission type 254 means, the application event is manufacturer specific

(manufacturer specific part of the Object Dictionary), transmission type 255 means, that the

application event is defined in the device profile. RPDOs with that type trigger the update of the

mapped data with the reception. PDOs Sub-index 3h contains the inhibit time. This time is a minimum

interval for PDO transmission. The value is defined as multiple of 100 s. It is not allowed to change

the value while the PDO exists (Bit 31 of sub-index 1 is 0).

In mode 254/255 additionally an event time can be used for TPDO. If an event timer exists for a TPDO

(value not equal to 0) the elapsed timer is considered to be an event. The event timer elapses as

multiple of 1 ms of the entry in sub-index 5h of the TPDO. This event will cause the transmission of

this TPDO in addition to otherwise defined events. The occurrence of the events set the timer.

Independent of the transmission type the RPDO event timer is used recognize the expiration of the

RPDO.

Page 26

24 CANOPEN- VACON® NX INTERFACE

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

7

7.5 Controlling the drive via PDO messages with Drive Profile

PDO1 Rx

Master to Slave (1)

Header

Data

ID

RTR

Len 1 2 3 4 5 6 7 8

0x201

0

2

controlword

- - - - -

-

PDO1 Tx

Slave (1) to Master

Header

Data

ID

RTR

Len 1 2 3 4 5 6 7 8

0x181

0

2

statusword

- - - - -

-

PDO6 Rx

Master to Slave (1)

Header

Data

ID

RTR

Len 1 2 3 4 5 6 7 8

0x301

0

4

controlword

vl_target_velocity

- - -

-

PDO6 Tx

Slave (1) to Master

Header

Data

ID

RTR

Len 1 2 3 4 5 6 7 8

0x281

0

4

statusword

vl_control_effort

- - -

-

The state of the drive can be controlled by the

controlword

The state of the drive is shown in the

statusword.

The

Statemachine

describes the device status and the possible control sequence of the drive.

controlword

statusword

bit

Name

bit

Name

0

Switch ON

0 Ready to Switch ON

1

Disable Voltage

1 Switched ON

2

Quick Stop

2 Operation Enable

3

Enable Operation

3 Fault

4

Operation Mode Specific

4 Voltage Disable

5

Operation Mode Specific

5 Quick Stop

6

Operation Mode Specific

6 Swich ON Disable

7

Reset Fault

7 Warning

8

Halt

8 Manufacturer Specific

9

Reserved

9 Remote

10

Reserved

10

Target Reached

11

Manufacturer Specific

11

Internal Limit Active

12

Manufacturer Specific

12

Operation Mode Specific

13

Manufacturer Specific

13

Operation Mode Specific

14

Manufacturer Specific

14

Manufacturer Specific

15

Manufacturer Specific

15

Manufacturer Specific

Page 27

CANOPEN- VACON® NX INTERFACE 25

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

7

By using a control word the drive can be controlled as follows:

Command

ControlWord

Description

Prepare READY

0006hex

Prepare RUN

0007hex

RUN

000Fhex

he active control

place

STOP

0007hex

Stop motor

FAULT RESET (step 1)

FAULT RESET (step 2)

bit 7 = 0

bit 7 = 1

Rising edge to bit 7

vl_target_velocity

The vl_target_velocity is the required speed reference to the AC drive.

The unit is RPM.

vl_control_effort

The vl_control_effort is the actual speed of the motor.

The unit is RPM.

Page 28

26 CANOPEN- VACON® NX INTERFACE

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

7

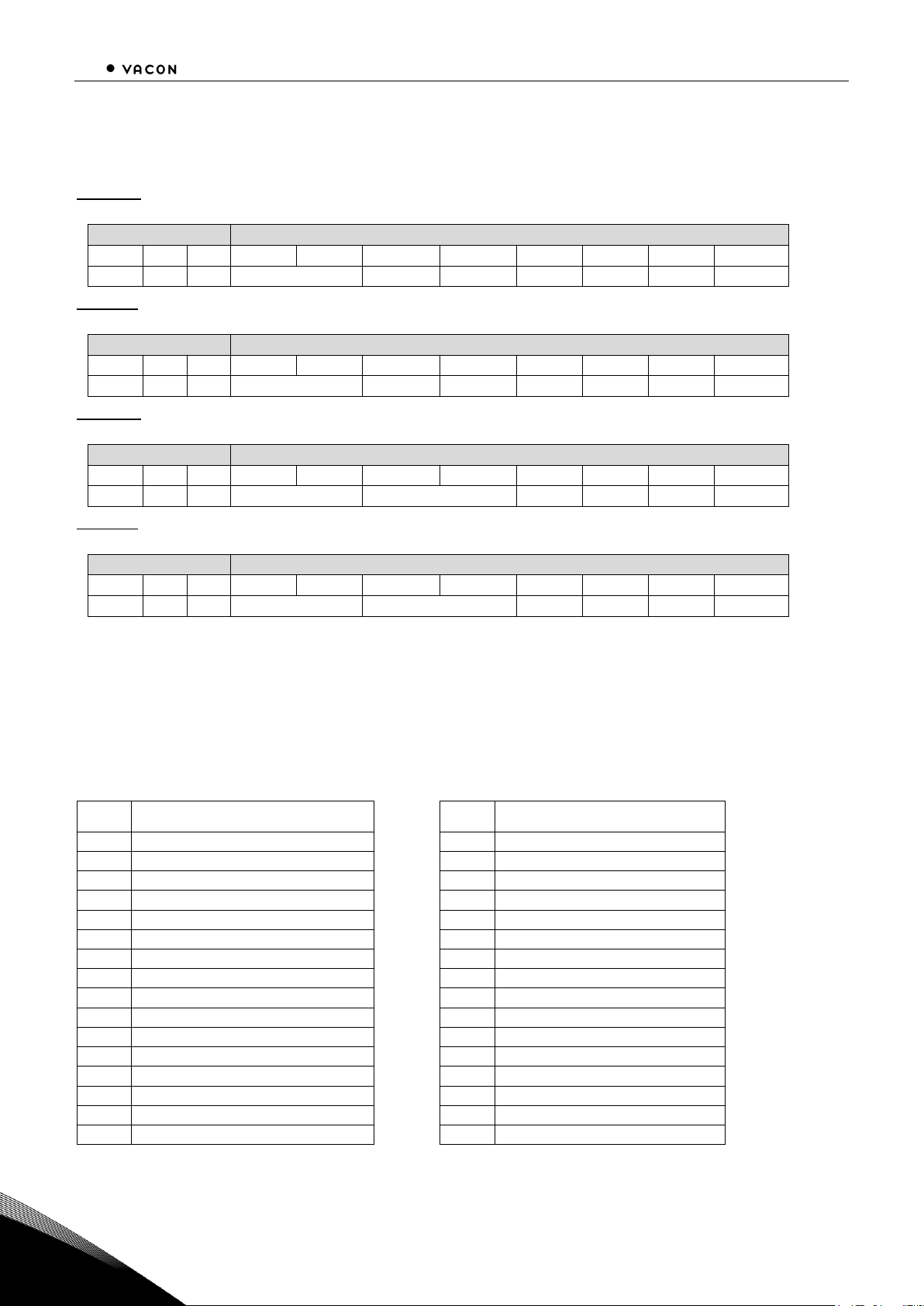

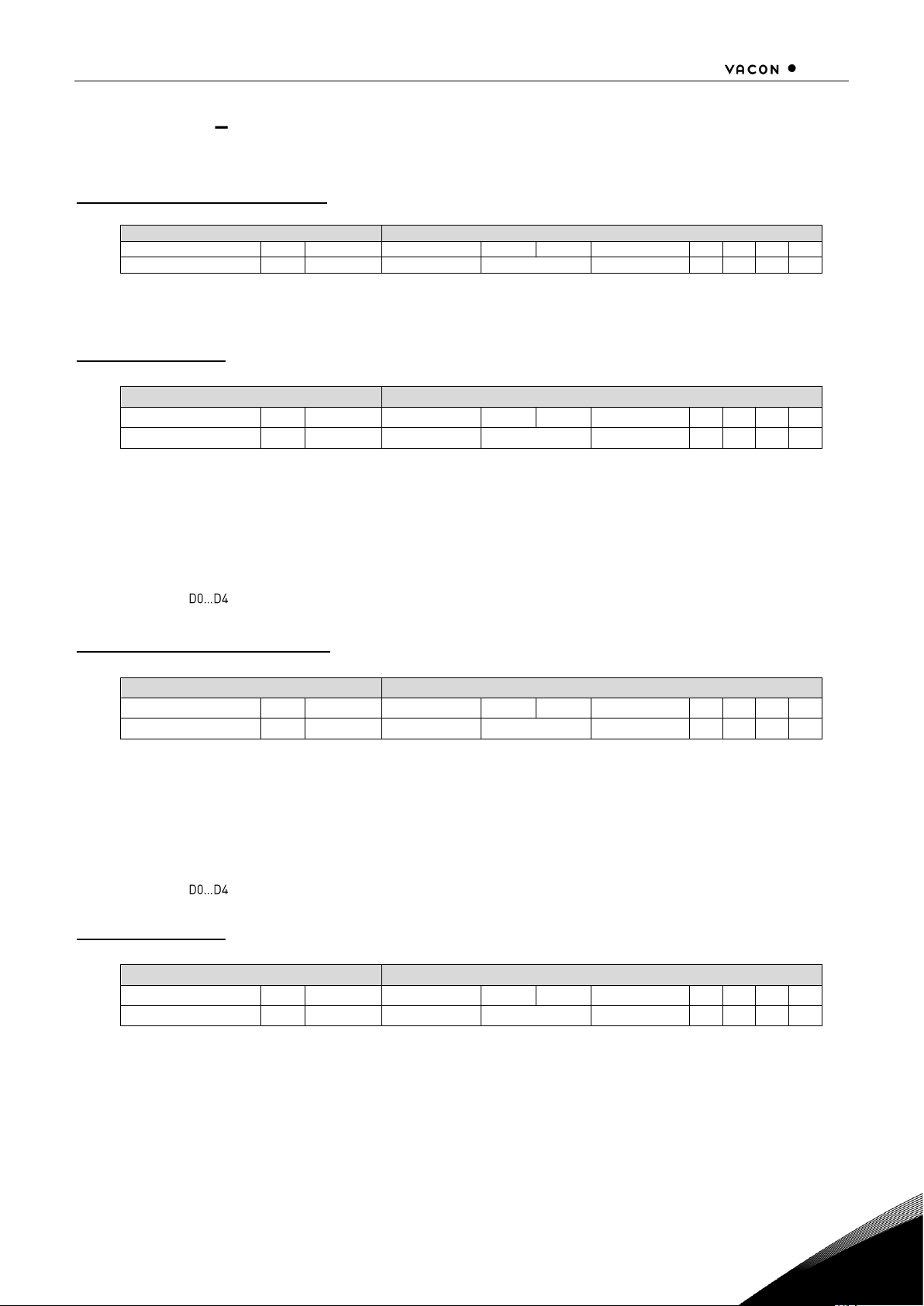

State Machine

The state machine describes the device status and the possible control sequence of the drive. The

current status of state machine. The modes

INIT, STOP, RUN

and

FAULT

correspond to the actual

mode of the Drive.

SW = StatusWord

CW = ControlWord word

MALFUNCTION

FAULT

SW:xx08h or xx28h

MALFUNCTION REACTION ACTIVE

FAULT

SW:xxxFh or xx2Fh

QUICK STOP ACTIVE

STOP

SW:xx07h

READY TO SWITCH ON

STOP

SWITCH ON DISABLED

STOP

SW:xx40h or xx60h

NOT READY TO SWITCH ON

IN IT

SW:xx00h

Power ON

OPERATION ENABLED

RUN

SW:xx27h

SWITCHED ON

STOP

SW: xx23h

Reset malfunction

CW: 0000h

CW: 0002h

CW: 0006h

CW: 0006h

CW: 0007h

CW: 0007h

CW: 000Fh

CW: 0006h

Automatic

Automatic

Automatic

Fault

CW: 0080h

CW: 0002h

CW: 000Dh

CW: 0003h

SW:xx21h

Page 29

CANOPEN- VACON® NX INTERFACE 27

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

7

7.6 Using manufacturer specific PDOs with ByPass modes

any Bypass

mode. For communication set used in ByPass modes, see Table 7-2. Manufacturer specific PDOs are

TPDO21, TPDO22, TPDO23, RPDO21, RPDO22 and RPDO23.

PDO21 Rx

Master to Slave (1)

Header

Data

ID

RTR

Len 1 2 3 4 5 6 7 8

0x401

0

8

nx_control_word

nx_speed_referense

process_data_in1

process_data_in2

PDO21 Tx

Slave (1) to Master

Header

Data

ID

RTR

Len 1 2 3 4 5 6 7 8

0x381

0

8

nx_status_word

nx_actual_speed

process_data_out1

process_data_out2

PDO22 Rx

Master to Slave (1)

Header

Data

ID

RTR

Len 1 2 3 4 5 6 7 8

0x501

0

8

process_data_in3

process_data_in4

process_data_in5

process_data_in6

PDO22 Tx

Slave (1) to Master

Header

Data

ID

RTR

Len 1 2 3 4 5 6 7 8

0x481

0

8

process_data_out3

process_data_out4

process_data_out5

process_data_out6

PDO23 Rx

Master to Slave (1)

Header

Data

ID

RTR

Len 1 2 3 4 5 6 7 8

0x301

0

4

process_data_in7

process_data_in8

-

-

TDO23 Tx

Slave (1) to Master

Header

Data

ID

RTR

Len 1 2 3 4 5 6 7 8

0x281

0

4

process_data_out7

process_data_out8

-

-

Page 30

28 CANOPEN- VACON® NX INTERFACE

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

7

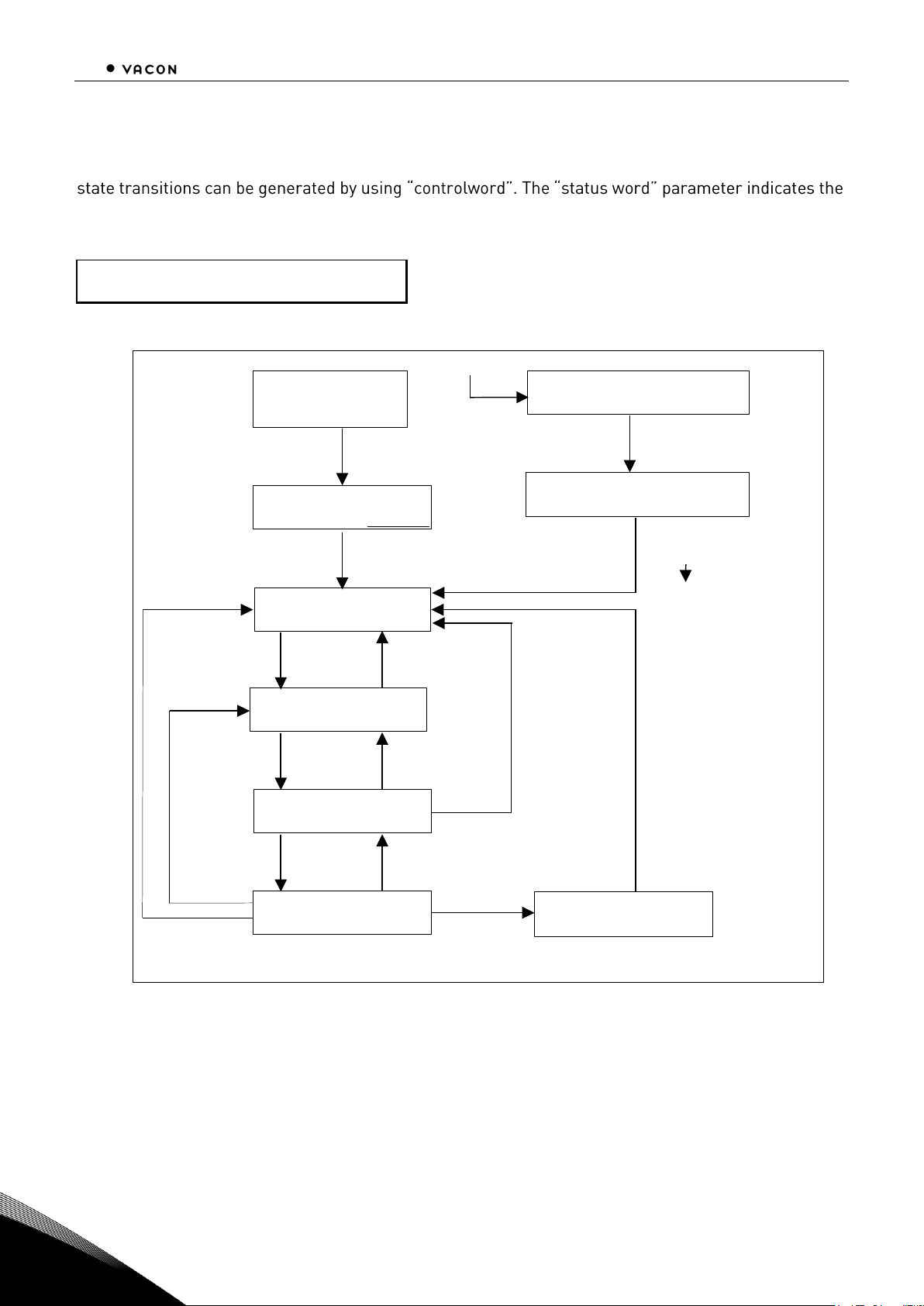

Controlling drive

NOTE: Some

VACON

®

terface. Refer to the specific application

manual for details

The Reference to the drive can be set also via manufacturer specific Process Data Object 21 (rx) when

option board is set to Bypass mode. In the application, the value is scaled in percentage of frequency

area between the set minimum and maximum frequencies.

nx_control_word, used only with Bypass 2 or Bypass 4 mode. When Bypass or Bypass 3 modes are used, check more detailed Control Word in the application manual

15

14

13

12

11

10 9 8 7 6 5 4 3 2 1 0

- - - - - - - - - - - - -

RST

DIR

RUN

In VACON

®

applications, the three first bits of the control word are used to control the AC drive.

However, you can customise the content of the control word for your own applications because the

control word is sent to the AC drive as such.

Bit

Description

Value = 0

Value = 1

0

Stop

Run

1

Clockwise

Counter clockwise

2

Rising edge of this bit will reset active fault

Not in use

Not in use

nx_speed_reference

15

14

13

12

11

10 9 8 7 6 5 4 3 2 1 0

MSB

LSB

This is the Reference 1 to the AC drive. Used normally as Speed reference. The allowed scaling is

10000...10000. In the application, the value is scaled in percentage of the frequency area between the

set minimum and maximum frequencies.

15

14

13

12

11

10 9 8 7 6 5 4 3 2 1 0

MSB

LSB

These are application specific process data. See APPENDIX C for content of these process data in

different applications.

Page 31

CANOPEN- VACON® NX INTERFACE 29

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

7

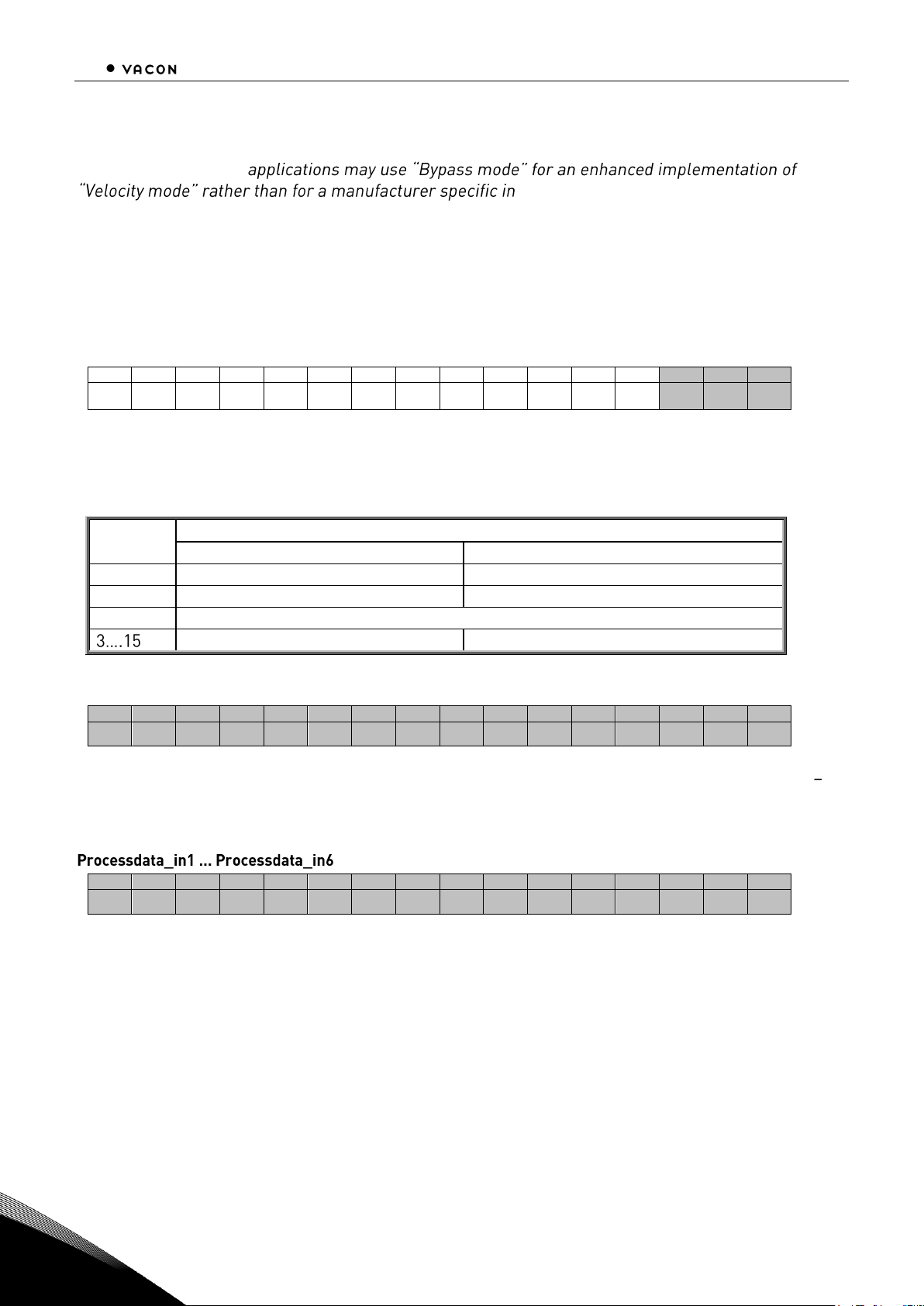

7.7 Drive Monitoring Several drive actual values/parameters can be monitored by using manufacturer specific PDOs.

nx_speed_reference

15

14

13

12

11

10 9 8 7 6 5 4 3 2 1 0

MSB

LSB

This is the reference 1 to the AC drive. Used normally as Speed reference.

The allowed scaling is 0..10000. In the application, the value is scaled in percentage of the frequency

area between set minimum and maximum frequency.

nx_status_word, used only Bypass 2 or Bypass 4 mode. When Bypass or Bypass 3 modes are used, check more detailed Status Word in the application manual

15

14

13

12

11

10 9 8 7 6 5 4 3 2 1 0

- - - - -

UVFS

DDIR

TCSPDL

FR Z AREF W FLT

DIR

RUN

RDY

Information about the status of the device and messages is indicated in the

Status word

. The

Status

word

is composed of 16 bits that have the following meanings:

Bit

Description

Value = 0

Value = 1

0

Not Ready

Ready

1

STOP

RUN

2

Clockwise

Counterclockwise

3

-

Faulted

4 - Warning

5

Ref. frequency not reached

Ref. Frequency reached

6 - Motor is running at zero speed

7

Flux Ready

Flux Not Ready

8

TC Speed Limit Active (depends on drive

model)

TC Speed Limit Not Active (depends on

drive model)

9

Detected Encoder Direction Clockwise

(depends on drive model)

Encoder Direction Counterclockwise

(depends on drive model)

10

UV Fast Stop Active (depends on drive

model)

UV Fast Stop Not Active (depends on drive

model)

11...15

Not In use

Not In use

Table 7-4. Status word bit descriptions

15

14

13

12

11

10 9 8 7 6 5 4 3 2 1 0

MSB

LSB

These are application specific process data. See APPENDIX C for content of these process data in

different applications.

Page 32

30 CANOPEN- VACON® NX INTERFACE

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

7

7.8 Anyparameter service SDO protocol can be used to read any parameter or actual value and write any parameter from drive.

These parameters are read from drive with its ID number specified in user manual. There are three

index in object dictionary as follow for anyparameter service.

Inde

x

Description

Size

Type

Hi 16b

Low 16b

2000

AnyparameterReadID

U16

RW - Read ID

2001

AnyparameterReadV

alue

U32

RO

Status

Value

2002

AnyparameterWrite

U32

RW

ID

Write Value

Reading anyparameter

Writing new value to index 2000 will trigger read event, while read is in process index 2001 is zero.

Read event will return value to index 2001. If read is success status will get value of ID and Value is

value of ID. If read fails Status will get value 0xFFFF (dec 65535).

Writing anyparameter

When new ID and value is written to index 2002 a write event will be triggered. Index 2002 value will

remain as long as writing is processed (normal sdo/pdo operation during this time). If write is success

index 2002 ID and value will be cleared and new write is possible. If write fails ID will clamp to 0xFFFF

and value zero.

Figure 7-1. Reading Any Parameter

Figure 7-2. Writing Any Parameter

Write ID with SDO protocol

0x0066

Index 2000

Index 2001

Read value with SDO protocol

0xFFFF 0x0000 = Fail

ID Value = OK

0x000 0x0000 = In process

16bit

16bi

16bit

.

. 100ms delay for read event

.

0x0066

0x0032

Status

Value

Write ID and value with SDO

protocol

Index 2002

Index 2002

Read write event status

0x0000 0x0000 = OK,

0xFFFF 0x0000 = Fail

0x0066 0x003c = In Process

16bi

16bit

.

. 100ms delay for write event

.

0x0000

0x0000

Status

16bi

16bit

0x0066

0x003C

ID

Value

Read ID

Page 33

Service Data (SDO) 31

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

8

8. SERVICE DATA (SDO)

With service Data Objects (SDOs) the access to entries of a device Object Dictionary is provided. Via

SDO all items from object dictionary can be read/written.

Service Data Objects (SDO)s are normally used for device configuration such as setting device

parameters. They are also used to define the type and format of information communicated using the

Process Data Objects. CANopen Configuration tools with EDS-files can be used for that purpose. The

construction and the method of operation of the SDOs can be found in the CANopen (DS301)

Communication Profile document. Appendix B consist of short description of the SDOs used with

VACON

®

CANopen option Board.

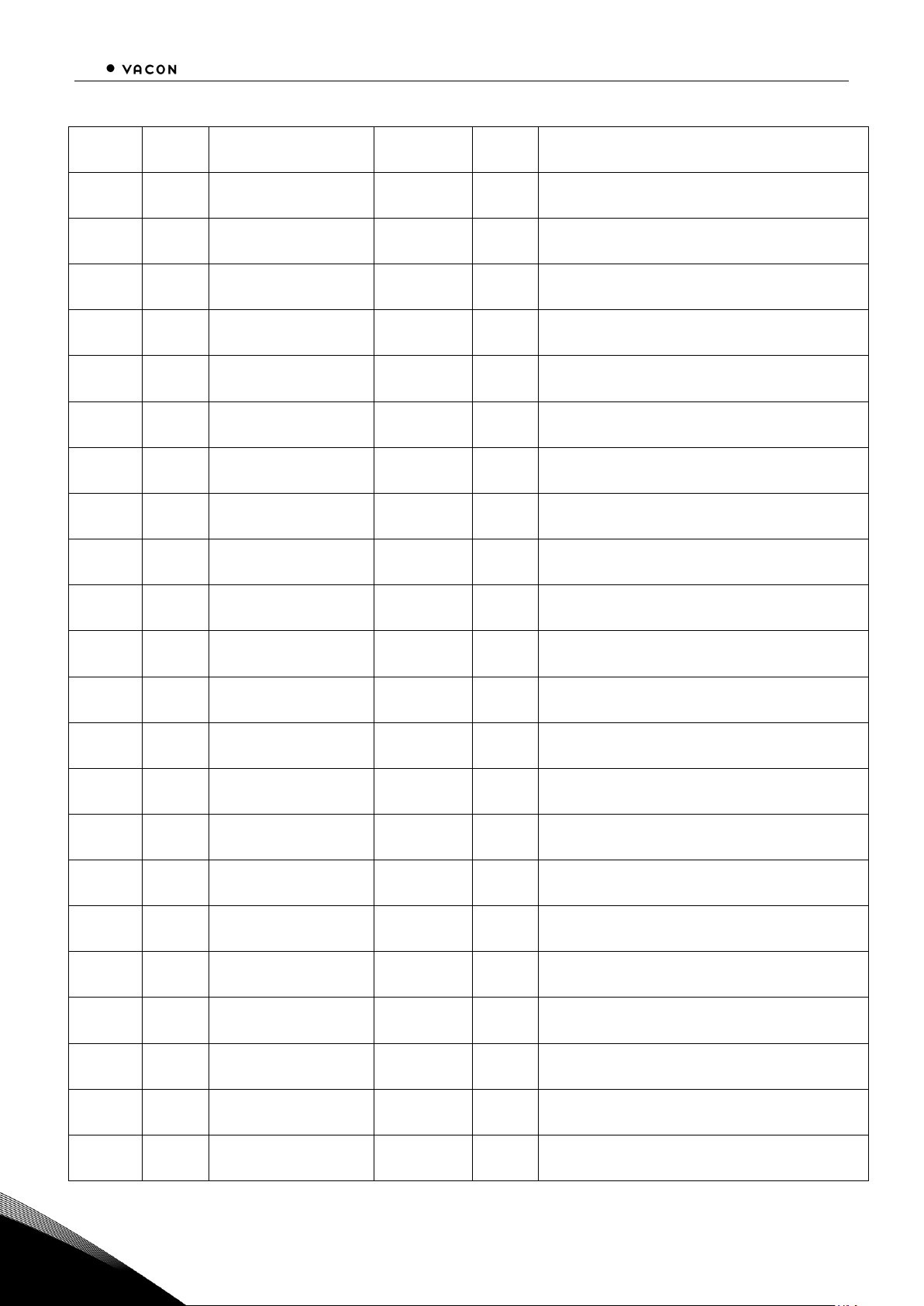

Object Dictionary

Index

Name

Type

Attr.

hex

dec

1000

4096

device_type

Unsigned32

CO

1001

4097

error_register

Unsigned8

RO

1003

4099

predefined error field

Unsigned32

RO

1005

4101

cob-id sync message

Unsigned32

RO

100C

4108

guard_time

Unsigned32

RW

100D

4109

life_time_factor

Unsigned32

RW

1018

4120

Identity Object

Identity

1200

4608

1st_server_SDO_parameter

SDOParameter

1400

5120

1st_receive_PDO_parameter

PDOCommPar

1405

5125

6st_receive_PDO_parameter

PDOCommPar

1414

5140

21st_receive_PDO_parameter

PDOCommPar

1415

5141

22st_receive_PDO_parameter

PDOCommPar

1600

5632

1st_receive_PDO_mapping

PDOMapping

1605

5637

6st_receive_PDO_mapping

PDOMapping

1614

5652

21st_receive_PDO_mapping

PDOMapping

1615

5653

22st_receive_PDO_mapping

PDOMapping

1800

6144

1st_transmit_PDO_parameter

PDOCommPar

1805

6149

6nd_transmit_PDO_parameter

PDOCommPar

1814

6164

21nd_transmit_PDO_parameter

PDOCommPar

1815

6165

22nd_transmit_PDO_parameter

PDOCommPar

1A00

6656

1st_transmit_PDO_mapping

PDOMapping

1A05

6661

6st_transmit_PDO_mapping

PDOMapping

1A14

6676

21st_transmit_PDO_mapping

PDOMapping

1A15

6677

22st_transmit_PDO_mapping

PDOMapping

2000

8192

AnyParameterReadID

Integer16

RW

2001

8193

AnyParameterReadValue

Integer32

RO

2002

8194

AnyParameterWrite

Integer32

RW

2003

8195

nx_current_percentage

Integer16

RO

2004

8196

nx_torque_percentage

Integer16

RO

2063

8291

nx_fault_code

Integer16

RO

27D1

10193

NX control word

Integer16

RW

27D3

10195

NX speed reference

Integer16

RW

27D4

10196

Process data in1

Integer16

RW

27D5

10197

Process data in2

Integer16

RW

27D6

10198

Process data in3

Integer16

RW

27D7

10199

Process data in4

Integer16

RW

27D8

10200

Process data in5

Integer16

RW

27D9

10201

Process data in6

Integer16

RW

27DA

10202

Process data in7

Integer16

RW

27DB

10203

Process data in8

Integer16

RW

Page 34

32 Service Data (SDO)

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

8

2836

10294

NX status word

Integer16

RO

2838

10296

NX actual speed

Integer16

RO

2839

10297

Process data out1

Integer16

RO

283A

10298

Process data out2

Integer16

RO

283B

10299

Process data out3

Integer16

RO

283C

10300

Process data out4

Integer16

RO

283D

10301

Process data out5

Integer16

RO

283E

10302

Process data out6

Integer16

RO

283F

10303

Process data out7

Integer16

RO

2840

10304

Process data out8

Integer16

RO

6040

24640

controlword

Unsigned16

RW

6041

24641

statusword

Unsigned16

RO

6042

24642

vl_target_velocity

Integer16

RW

6043

24643

vl_velocity_demand

Integer16

RO

6044

24644

vl_control_effort

Integer16

RO

6046

24646

vl_velocity_min_max_amount

Unsigned32

RW

6048

24648

vl_velocity_acceleration

Ramp

RW

6049

24649

vl_velocity_deceleration

Ramp

RW

604A

24650

vl_velocity_quick_stop

Ramp

RW

604E

24654

vl_velocity_reference

Unsigned32

RW

6060

24672

modes_of_operation

Integer8

RO

6061

24673

modes_of_operation_display

Integer8

RO

Page 35

Service Data (SDO) 33

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

8

Description of the Object Dictionary

Abbreviations

ro - read only i16 - Integer8

wo - write only i32 - Integer8

rw - read write u8 - Unsigned8

co - constant u16 - Unsigned16

bool - Boolean u32 - Unsigned32

i8 - Integer8 float - Floating Point

Index

(HEX)

SubIndex

Name

Default

Min

Max

Type

Attr.

Descriptions

General Parameters

1000

00

Device Type

0x00010192

0x00000000

0xFFFFFFFF

u32 co

The device type specifies the kind of device. The lower

16 bits contain the device profile number and the upper

16 bits an additional information.

1001

00

Error Register

0x00

0x00

0xFF

u8 ro

The error register is a field of 8 bits, each for a certain

error type. If an error occurs the bit has to be set.

Bit Meaning

0 generic error

1 current

2 voltage

3 temperature

4 communication error (overrun, error state)

5 device profile specific

6 reserved

7 manufacturer specific

1003 Pre-defined Error Field

This object holds errors that have occurred on the device

and have been signalled via Emergency Object. It is an

error history. Writing value 0 to sub index 0 deletes the

entire error history.

00

Number of Errors

0x0000

0x0000

0x00FE

u8 rw

01

Standard Error Field

0x00000000

0x00000000

0xFFFFFFFF

u32 ro

02

Standard Error Field

0x00000000

0x00000000

0xFFFFFFFF

u32 ro

03

Standard Error Field

0x00000000

0x00000000

0xFFFFFFFF

u32 ro

04

Standard Error Field

0x00000000

0x00000000

0xFFFFFFFF

u32 ro

05

Standard Error Field

0x00000000

0x00000000

0xFFFFFFFF

u32 ro

06

Standard Error Field

0x00000000

0x00000000

0xFFFFFFFF

u32 ro

07

Standard Error Field

0x00000000

0x00000000

0xFFFFFFFF

u32 ro

08

Standard Error Field

0x00000000

0x00000000

0xFFFFFFFF

u32 ro

09

Standard Error Field

0x00000000

0x00000000

0xFFFFFFFF

u32 ro

Page 36

34 Service Data (SDO)

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

8

0A

Standard Error Field

0x00000000

0x00000000

0xFFFFFFFF

u32 ro

1005

00

cob-id sync message

0x80000080

0x00000001

0xFFFFFFFF

u32 ro

cob-id used for synchronize PDO messages

100C

00

Guard Time

0x03E8

0x0000

0xFFFF

u16 rw

This entry contains the guard time in

milliseconds. It is 0, if not used.

Unit: ms

100D

00

Life Time Factor

0x02

0x00

0xFF

u8 rw

The life time factor multiplied with the guard time gives

the life time for the device. It is 0, if not used.

1018 Identity Object

This object contains general information about the

device.

00

Number of entries

0x4

0x1

0x4

u8 ro

01

Vendor Id

0x00000090

0x0

0xFFFFFFFF

u32 ro

Sub-Index 1 contains a unique value allocated each

manufacturer.

02

Product Code

0x00000119

0x0

0xFFFFFFFF

u32 ro

Sub-Index 2 identifies the manufacturer specific product

code (device version).

03

Revision number

0x00000001

0x0

0xFFFFFFFF

u32 ro

Sub-Index 3 contains the revision number. Bit 31-16 is

the major revision number and Bit 15-0 the minor

revision number.

04

Serial number

0x0

0x0

0xFFFFFFFF

u32 ro

Sub-Index 4 identified a manufacturer specific serial

number.

Server SDO Parameters

1200 Server SDO Parameter

The object contains the parameters for the SDOs for

which the device is the server.

00

Number of Entries

0x02 0x02

0x02

u8 ro

01

COB-ID Client -> Server

0x600+NodeID

0x00000601

0xFFFFFFFF

u32 ro

02

COB-ID Server -> Client

0x580+NodeID

0x00000581

0xFFFFFFFF

u32 ro

Receive PDO Communication Parameters

1400 Receive PDO 1

Communication

Parameter

It contains the communication parameters of the first

PDO the device is able to receive.

00

Number of Entries

0x02 0x02

0x05

U8 ro

Sub-index 0 contains the number of PDO-parameters

implemented.

01

COB-ID

0x200+NodeID

0x00000201

0xFFFFFFFF

U32 ro

Sub index 1 describes the COB-ID. If bit 31 is set the PDO

is disabled.

02

Transmission Type

0xFF

0x00

0xFF

u8 ro

The transmission mode is defined by sub-index 2.

Value 0xFF (255) = asynchronous transmission mode (

=event driven )

1405 Receive PDO 6

Communication

Parameter

It contains the communication parameters of the second

PDO the device is able to receive.

00

Number of Entries

0x02 0x02

0x05

u8 ro

Sub-index 0 contains the number of PDO-parameters

implemented.

01

COB-ID

0x300+NodeID

0x00000301

0xFFFFFFFF

u32 ro

Sub index 1 describes the COB-ID. If bit 31 is set the PDO

is disabled.

02

Transmission Type

0xFF

0x00

0xFF

u8 ro

The transmission mode is defined by sub-index 2.

Value 0xFF (255) = asynchronous transmission mode (

=event driven )

Page 37

Service Data (SDO) 35

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

8

1414 Receive PDO 21

Communication

Parameter

It contains the communication parameters of the

manufacturer specific PDO21 the device is able to

receive.

00

Number of Entries

0x02 0x02

0x05

u8 ro

Sub-index 0 contains the number of PDO-parameters

implemented.

01

COB-ID

0x400+NodeID

0x00000401

0xFFFFFFFF

u32 ro

Sub index 1 describes the COB-ID. If bit 31 is set the

PDO is disabled.

02

Transmission Type

0xFF 0x00

0xFF

u8 ro

The transmission mode is defined by sub-index 2.

Value 0xFF (255) = asynchronous transmission mode (

=event driven )

1415 Receive PDO 22

Communication

Parameter

It contains the communication parameters of the

manufacturer specific PDO22 the device is able to

receive.

00

Number of Entries

0x02 0x02

0x05

u8 ro

Sub-index 0 contains the number of PDO-parameters

implemented.

01

COB-ID

0x500+NodeID

0x00000501

0xFFFFFFFF

u32 ro

Sub index 1 describes the COB-ID. If bit 31 is set the

PDO is disabled.

02

Transmission Type

0xFF 0x00

0xFF

u8 ro

The transmission mode is defined by sub-index 2.

Value 0xFF (255) = asynchronous transmission mode (

=event driven )

1416

Receive PDO 23

Communication

Parameter

It contains the communication parameters of the

manufacturer specific PDO23 the device is able to

receive.

00

Number of Entries

0x02 0x02

0x05

u8 ro

Sub-index 0 contains the number of PDO-parameters

implemented.

01

COB-ID

0x300+NodeID

0x00000301

0xFFFFFFFF

u32 ro

Sub index 1 describes the Cob-ID. If bit 31 is set the

PDO is disabled.

02

Transmission Type

0xFF 0x00

0xFF

u8 ro

The transmission mode is defined by sub-index 2.

Value 0xFF (255) = asynchronous transmission mode (

=event driven )

Receive PDO Mapping Parameters

1600 Receive PDO 1 Mapping

Parameter

It contains the mapping parameters of the first PDO

the device is able to receive.

Sub-index 0 contains the number of the mapped data

objects. All further entries define the data by its index,

sub-index and length.

00

Number of Entries

0x01 0x00

0x40

u8 ro

01

PDO Mapping Entry

0x60400010

0x00000000

0xFFFFFFFF

u32 ro

1605 Receive PDO 6 Mapping

Parameter

It contains the mapping parameters of the PDO6 the

device is able to receive.

Sub-index 0 contains the number of the mapped data

objects. All further entries define the data by its index,

sub-index and length.

00

Number of Entries

0x02

0x0 0x40

u8 ro

01

PDO Mapping Entry

0x60400010

0x00000000

0xFFFFFFFF

u32 ro

02

PDO Mapping Entry

0x60420010

0x00000000

0xFFFFFFFF

u32 ro

1614 Receive PDO 21

Mapping Parameter

It contains the mapping parameters of the PDO21 the

device is able to receive.

Sub-index 0 contains the number of the mapped data

objects. All further entries define the data by its index,

sub-index and length.

00

Number of Entries

0x04

0x00

0x40

u8 ro

01

PDO Mapping Entry

0x27D10010

0x00000000

0xFFFFFFFF

u32 ro

02

PDO Mapping Entry

0x27D30010

u32 ro

Page 38

36 Service Data (SDO)

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

8

0x00000000

0xFFFFFFFF

03

PDO Mapping Entry

0x27D40010

0x00000000

0xFFFFFFFF

u32 ro

04

PDO Mapping Entry

0x27D50010

0x00000000

0xFFFFFFFF

u32 ro

1615 Receive PDO 22

Mapping Parameter

It contains the mapping parameters of the PDO22 the

device is able to receive.

Sub-index 0 contains the number of the mapped data

objects. All further entries define the data by its index,

sub-index and length.

00

Number of Entries

0x04

0x00

0x40

u8 ro

01

PDO Mapping Entry

0x27D60010

0x00000000

0xFFFFFFFF

u32 ro

02

PDO Mapping Entry

0x27D70010

0x00000000

0xFFFFFFFF

u32 ro

03

PDO Mapping Entry

0x27D80010

0x00000000

0xFFFFFFFF

u32 ro

04

PDO Mapping Entry

0x27D90010

0x00000000

0xFFFFFFFF

u32 ro

1616

Receive PDO 23

Mapping Parameter

It contains the mapping parameters of the PDO23 the

device is able to receive.

Sub-index 0 contains the number of the mapped data

00

Number of Entries

0x02

0x00

0x40

u8 ro

01

PDO Mapping Entry

0x27DA0010

0x00000000

0xFFFFFFFF

u32 ro

02

PDO Mapping Entry

0x27DB0010

0x00000000

0xFFFFFFFF

u32 ro

Transmit PDO Communication Parameters

1800 Transmit PDO 1

Communication

Parameter

It contains the communication parameters of the first

PDO the device is able to transmit.

00

Number of Entries

0x04

0x02

0x05

u8 ro

Sub-index 0 contains the number of PDO-parameters

implemented.

01

COB-ID

0x180+NodeID

0x00000181

0xFFFFFFFF

u32 ro

Sub index 1 describes the COB-ID. If bit 31 is set the

PDO is disabled.

02

Transmission Type

0xFF

0x00

0xFF

u8 ro

The transmission mode is defined by sub-index 2.

Value 0xFF (255) = asynchronous transmission mode (

=event driven )

03

Inhibit Time

0x03E8

0x0000

0xFFFF

u16 rw

An inhibit time can be defined on sub-index 3 in 100 µs.

This time is minimum interval for PD transmission.

Default 100 ms

04

Compatibility Entry

0x03

0x00

0xFF

u8 ro

1805 Transmit PDO 6

Communication

Parameter

It contains the communication parameters of the PDO

6 the device is able to transmit.

00

Number of Entries

0x05

0x02

0x05

u8 ro

Sub-index 0 contains the number of PDO-parameters

implemented.

01

COB-ID

0x280+NodeID

0x00000281

0xFFFFFFFF

u32 ro

Sub index 1 describes the COB-ID. If bit 31 is set the

PDO is disabled.

02

Transmission Type

0xFF

u8 rw

The transmission mode is defined by sub-index 2.

Page 39

Service Data (SDO) 37

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

8

0x00

0xFF

Value 0xFF (255) = asynchronous transmission mode (

=event driven )

03

Inhibit Time

0x03E8

0x0000

0xFFFF

u16 rw

An inhibit time can be defined on sub-index 3 in 100 µs.

This time is minimum interval for PD transmission.

Default 100 ms

04

Compatibility Entry

0x03

0x00

0xFF

u8 ro

05

Event Timer

0x0000

0x0000

0xFFFF

u16 rw

Event Time can be define on sub index 5 in 1ms

resolution. This is the time interval PDO will be

transmitted.

Value 0 = Disable Event Timer

1814 Transmit PDO 21

Communication

Parameter

It contains the communication parameters of the PDO

21 the device is able to transmit.

00

Number of Entries

0x05

0x02

0x05

u8 ro

Sub-index 0 contains the number of PDO-parameters

implemented.

01

COB-ID

0x380+NodeID

0x00000381

0xFFFFFFFF

u32 ro

Sub index 1 describes the COB-ID. If bit 31 is set the

PDO is disabled.

02

Transmission Type

0xFF

0x00

0xFF

u8 rw

The transmission mode is defined by sub-index 2.

Value 0xFF (255) = asynchronous transmission mode (

=event driven )

03

Inhibit Time

0x03E8

0x0000

0xFFFF

u16 rw

An inhibit time can be defined on sub-index 3 in 100 µs.

This time is minimum interval for PD transmission.

Default 100 ms

04

Compatibility Entry

0x03

0x00

0xFF

u8 ro

05

Event Timer

0x0000

0x0000

0xFFFF

u16 rw

Event Time can be define on sub index 5 in 1ms

resolution. This is the time interval PDO will be

transmitted.

Value 0 = Disable Event Timer

1815 Transmit PDO 22

Communication

Parameter

It contains the communication parameters of the PDO

22 the device is able to transmit.

00

Number of Entries

0x05

0x02

0x05

u8 ro

Sub-index 0 contains the number of PDO-parameters

implemented.

01

COB-ID

0x480 +

NodeID

0x00000481

0xFFFFFFFF

u32 ro

Sub index 1 describes the COB-ID. If bit 31 is set the

PDO is disabled.

02

Transmission Type

0xFF

0x00

0xFF

u8 rw

The transmission mode is defined by sub-index 2.

Value 0xFF (255) = asynchronous transmission mode (

=event driven )

03

Inhibit Time

0x03E8

0x0000

0xFFFF

u16 rw

An inhibit time can be defined on sub-index 3 in 100 µs.

This time is minimum interval for PD transmission.

Default 100 ms

04

Compatibility Entry

0x03

0x00

0xFF

u8 ro

05

Event Timer

0x0000

0x0000

0xFFFF

u16 rw

Event Time can be define on subindex 5 in 1ms

resolution. This is the time interval PDO will be

transmitted.

Value 0 = Disable Event Timer

1816

Transmit PDO 23

Communication

Parameter

It contains the communication parameters of the PDO

23 the device is able to transmit.

00

Number of Entries

0x05

0x02

0x05

u8 ro

Sub-index 0 contains the number of PDO-parameters

implemented.

01

COB-ID

0x280+NodeID

0x00000281

0xFFFFFFFF

u32 ro

Sub index 1 describes the COB-ID. If bit 31 is set the

PDO is disabled.

02

Transmission Type

0xFF

0x00

0xFF

u8 rw

The transmission mode is defined by sub-index 2.

Value 0xFF (255) = asynchronous transmission mode (

=event driven )

03

Inhibit Time

0x03E8

u16 rw

An inhibit time can be defined on sub-index 3 in 100 µs.

Page 40

38 Service Data (SDO)

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

8

0x0000

0xFFFF

This time is minimum interval for PD transmission.

Default 100 ms

04

Compatibility Entry

0x03

0x00

0xFF

u8 ro

05

Event Timer

0x0000

0x0000

0xFFFF

u16 rw

Event Time can be define on sub index 5 in 1ms

resolution. This is the time interval PDO will be

transmitted.

Value 0 = Disable Event Timer

Transmit PDO Mapping Parameters

1A00 Transmit PDO 1

Mapping Parameter

It contains the mapping parameter for the PDOs the

device is able to transmit.

Sub-index 0 contains the number of the mapped data

objects. All further entries define the data by its index,

sub-index and length. The structure of a mapping

entry is: index , sub index ,length

00

Number of Entries

0x01 0x00

0x40

u8 ro

01

PDO Mapping Entry

0x60410010

0x00000000

0xFFFFFFFF

u32 ro

1A05 Transmit PDO 6

Mapping Parameter

It contains the mapping parameter for the PDOs the

device is able to transmit.

Sub-index 0 contains the number of the mapped data

objects. All further entries define the data by its index,

sub-index and length. The structure of a mapping

entry is: index, sub index, length

00

Number of Entries

0x02 0x0

0x40

u8 ro

01

PDO Mapping Entry

0x60410010

0x00000000

0xFFFFFFFF

u32 ro

02

PDO Mapping Entry

0x60440010

0x00000000

0xFFFFFFFF

u32 ro

Page 41

Service Data (SDO) 39

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

8

1A14 Transmit PDO 21

Mapping Parameter

It contains the mapping parameter for the PDOs the

device is able to transmit.

Sub-index 0 contains the number of the mapped data

objects. All further entries define the data by its index,

sub-index and length. The structure of a mapping entry

is: index, sub index, length

00

Number of Entries

0x04

0x00 0x40

u8 ro

01

PDO Mapping Entry

0x28360010

0x00000000

0xFFFFFFFF

u32 ro

02

PDO Mapping Entry

0x28380010

0x00000000

0xFFFFFFFF

u32 ro

03

PDO Mapping Entry

0x28390010

0x00000000

0xFFFFFFFF

u32 ro

04

PDO Mapping Entry

0x283A0010

0x00000000

0xFFFFFFFF

u32 ro

1A15 Transmit PDO 22

Mapping Parameter

It contains the mapping parameter for the PDOs the

device is able to transmit.

Sub-index 0 contains the number of the mapped data

objects. All further entries define the data by its index,

sub-index and length. The structure of a mapping entry

is:

index,sub index,length

00

Number of Entries

0x04

0x00

0x40

u8 ro

01

PDO Mapping Entry

0x283B0010

0x00000000

0xFFFFFFFF

u32 ro

02

PDO Mapping Entry

0x283C0010

0x00000000

0xFFFFFFFF

u32 ro

03

PDO Mapping Entry

0x283D0010

0x00000000

0xFFFFFFFF

u32 ro

04

PDO Mapping Entry

0x283E0010

0x00000000

0xFFFFFFFF

u32 ro

1A16

Transmit PDO 23 Mapping

Parameter

It contains the mapping parameter for the PDOs the

device is able to transmit.

Sub-index 0 contains the number of the mapped data

objects. All further entries define the data by its index,

sub-index and length. The structure of a mapping entry

is: index, sub index, length

00

Number of Entries

0x02

0x00

0x40

u8 ro

01

PDO Mapping Entry

0x283F0010

0x00000000

0xFFFFFFFF

u32 ro

02

PDO Mapping Entry

0x28400010

0x00000000

0xFFFFFFFF

u32 ro

Manufacturer Specific Parameters

2000 AnyParameterReadID

0x0000

0x0000

0xFFFF

u16 rw

Page 42

40 Service Data (SDO)

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

8

2001 AnyParameterReadValue

0x00000000

0x00000000

0xFFFFFFFF

u32 ro

2002 AnyParameterWrite

0x00000000

0x00000000

0xFFFFFFFF

u32 rw

2003 NX current percentage

0x0000

0x0000

0xFFFF

u16 ro

Measured motor current. (1 = 0.01A)

2004 NX torque percentage

0x0000

0x0000

0xFFFF

u16 ro

Calculated torque. Scaled in 0.0%…100.0% (0…1000)

2063 NX fault code

0x0000

0x0000

0xFFFF

i16 ro

Shows the drive fault code (=0, if no fault active)

27D1 NX control word

0x0000

0x8000

0x7FFF

i16 rw

27D3 NX speed reference

0x0000

0x8000

0x7FFF

i16 rw

27D4 Process Data In1

0x0000

0x8000

0x7FFF

i16 rw

27D5 Process Data In2

0x0000

0x8000

0x7FFF

i16 rw

27D6 Process Data In3

0x0000

0x8000

0x7FFF

i16 rw

27D7 Process Data In4

0x0000

0x8000

0x7FFF

i16 rw

27D8 Process Data In5

0x0000

0x8000

0x7FFF

i16 rw

27D9 Process Data In6

0x0000

0x8000

0x7FFF

i16 rw

27DA

Process Data In7

0x0000

0x8000

0x7FFF

i16 rw

27DB

Process Data In8

0x0000

0x8000

0x7FFF

i16 rw

2836 NX status word

0x0000

0x8000

0x7FFF

i16 ro

2838 NX actual speed

0x0000

0x8000

0x7FFF

i16 ro

2839 Process data out1

0x0000

0x8000

0x7FFF

i16 ro

283A Process data out2

0x0000

0x8000

0x7FFF

i16 ro

283B Process data out3

0x0000

0x8000

0x7FFF

i16 ro

283C Process data out4

0x0000

0x8000

0x7FFF

i16 ro

283D Process data out5

0x0000

0x8000

0x7FFF

i16 ro

283E Process data out6

0x0000

0x8000

0x7FFF

i16 ro

Page 43

Service Data (SDO) 41

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

8

283F Process data out7

0x0000

0x8000

0x7FFF

i16 ro

2840 Process data out8

0x0000

0x8000

0x7FFF

i16 ro

Device Profile Parameters

6040 controlword

0x0000

0x0000

0xFFFF

u16 rw

The control command for the state machine. The state

machine describes the device status and possible

control sequence of the drive.

6041 statusword

0x0000

0x0000

0xFFFF

u16 ro

The status word indicates the current status of the drive.

6042 vl target velocity

0x0000

0x8000

0x7FFF

i16 rw

Speed reference of the drive.

Unit: RPM

6043 vl velocity demand

0x0000

0x8000

0x7FFF

i16 ro

Speed reference after ramp function.

Unit: RPM

6044 vl control effort

0x0000

0x8000

0x7FFF

i16 ro

Actual speed of the motor.

Unit: RPM

Page 44

42 Service Data (SDO)

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

8

6046 vl velocity min max

amount

Defines speed limits of the drive in rpm. The parameter

consist of a minimum and a maximum speed.

00

Number of Entries

0x02

0x00

0x02

u8 ro