Page 1

vacon® nx

ac drives

liquid-cooled drives

heat exchanger

application manual

Page 2

Page 3

vacon • 1

INDEX

Document code: DPD01890A

Date edited: 5.8.2016

1. General .............................................................................................................................. 2

2. Control I/O ......................................................................................................................... 3

3. Parameter lists .................................................................................................................. 4

3.1 Monitoring values (Control keypad: menu M1) .......................................................................... 4

3.2 Basic parameters (Control keypad: Menu M2 G2.1) ............................................................. 8

3.3 Input signals (Control keypad: Menu M2 G2.2) ..................................................................... 9

3.4 Output signals (Control keypad: Menu M2 G2.3) ................................................................. 10

3.5 Drive control parameters (Control keypad: Menu M2 G2.4) ............................................... 14

3.6 Prohibit frequency parameters (Control keypad: Menu M2 G2.5) ...................................... 14

3.7 Motor control parameters (Control keypad: Menu M2 G2.6) .............................................. 15

3.8 Protections (Control keypad: Menu M2 G2.7)...................................................................... 16

3.9 Autorestart parameters (Control keypad: Menu M2 G2.8) ................................................. 17

3.10 PID control parameters (Control keypad: Menu M2 G2.9).................................................. 17

3.11 Flow control parameters (Control keypad: Menu M2 G2.10).............................................. 18

3.12 Fieldbus parameters (Control Keypad: Menu M2 G2.11) ..................................................... 19

3.13

Keypad control (Control keypad: Menu M3) ............................................................................. 20

3.14 System menu (Control keypad: M6) ......................................................................................... 20

3.15 Expander boards (Control keypad: Menu M7) ......................................................................... 20

4. Description of parameters ............................................................................................... 21

4.1 Keypad control parameters ...................................................................................................... 52

24-hour support: +358 (0)201 212 575 • Email: vacon@vacon.com

Page 4

2 • vacon General

heat exchanger application

1. GENERAL

This application is aimed to be used in the Vacon liquid-cooled AC drive inside the Heat exchanger

unit.

The idea with the application is to maintain a constant flow of coolant through the heat exchanger

and through the Vacon liquid-cooled drive.

The user sets a certain speed for the pump of the heat exchanger unit that produces a sufficient flow

through the Vacon liquid-cooled drives to keep them cooled. This speed is NOT regulated but fixed

by a parameter set value.

The Vacon AC drive also handles the temperature of the water in the heat exchanger unit by

regulating the valve that handles the coolant intake to the heat exchanger element (from the

customer's system). This regulation is based on the temperature of the water in the pipes between

the outlet of the heat exchanger pump and the inlet of the cooling element of the Vacon liquid-cooled

drive.

The actual value of the temperature for the regulation comes from a sensor called FSA11. This is a

type of flow switch that measures both the temperature of the coolant and the flow in the pipes. If

there is not enough flow in the pipe the sensor gives a signal that tells the drive to stop due to

insufficient flow.

Vacon NX AC drives can be connected to the Profibus DP using a fieldbus board. The AC drive can

then be controlled, monitored and programmed from the Host system. Profibus fieldbus board

(OPT-C5) is normally included in the delivery of Vacon NX liquid-cooled drive Heat Exchanger

Solution. The Profibus fieldbus board must be installed in slot E on the control board of the AC drive.

For more information on the Profibus fieldbus board, see Vacon OPTC3/C5 Profibus Option Board

User Manual.

The standard delivery also includes I/O boards OPT-A1 (placed in slot A), OPT-A2 (placed in slot B)

and OPT-B5 (placed in slot C or D). The application, however, offers you more signals than the

standard set of I/O boards allows you to connect. If you wish to use one additional analogue input

signal and/or two additional analogue output signals, we recommend you to order Vacon I/O board

OPT-B4 and place it in the last free board slot (C or D).

1

Tel. +358 (0)201 2121 • Fax: +358 (0)201 2121 205

Page 5

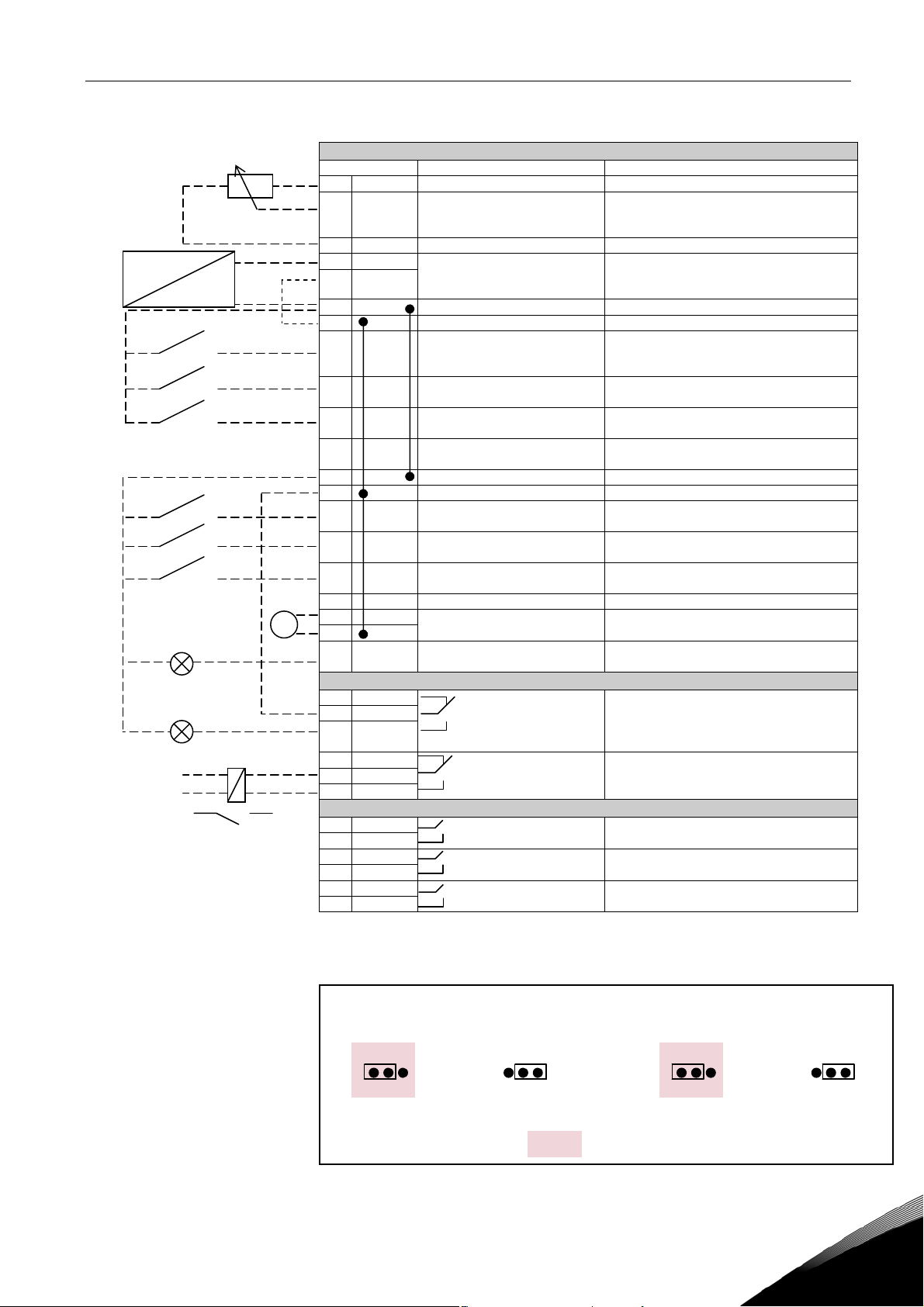

Control I/O vacon • 3

2. CONTROL I/O

Reference potentiometer,

1…10 kΩ

2-wire

transmitter

Actual

value I

(0)4…20 mA

READY

RUN

220

VAC

OPT-A1

Terminal Signal Description

1 +10V

2 AI1+ Analogue input, voltage range

3 AI1- I/O Ground Ground for reference and controls

–

4 AI2+ Analogue input, current range

5 AI2-

+

6 +24V Control voltage output Voltage for switches, etc. max 0.1 A

7 GND I/O ground Ground for reference and controls

8 DIN1 Start/Stop

9 DIN2 Flow fault NO/NC programmable

10 DIN3 External fault

11 CMA Common for DIN 1—DIN 3 Connect to GND or +24V

12 +24V Control voltage output Voltage for switches (see #6)

13 GND I/O ground Ground for reference and controls

14 DIN4 Pump 1

15 DIN5 Pump 2

16 DIN6 Sequence, 2-pump system Combined with DIN1

17 CMB Common for DIN4—DIN6 Connect to GND or +24V

mA

18 AO1+ Output frequency

19 AO120 DO1 Digital output

Reference output Voltage for potentiometer, etc.

ref

0—10V DC

0—20mA

Control place A (PID

controller)

(programmable)

Analogue output

READY

Pressure, outlet (pump)

Temperature

Contact closed = start

Contact open = External fault

Forced or single run

Combined with DIN1

Forced or single run

Combined with DIN1

Programmable

Range 0—20 mA/R

Programmable

Open collector, I≤50mA, U≤48 VDC

, max. 500Ω

L

OPT-A2

21 RO1 Relay output 1

22 RO1

23 RO1

24 RO2 Relay output 2

25 RO2

26 RO2

FAULT

Programmable

RUN

Programmable

OPT-B5

22 RO1 Relay output 1

23 RO1

25 RO2 Relay output 2

26 RO2

28 RO3 Relay output 3

29 RO3

COOLING OK

PUMP 1

PUMP 2

Table 1. Heat exchanger application I/O configuration example (with 2-wire

transmitter).

Ju m per block X 3:

CAN g rounding

Con nected to shiel d Not c o nnec ted to shi el d

24-hour support: +358 (0)201 212 575 • Email: vacon@vacon.com

Factory d efault

=

Ju m per block X 4:

CA N t erm i na ti on

Terminated Not terminated

2

Page 6

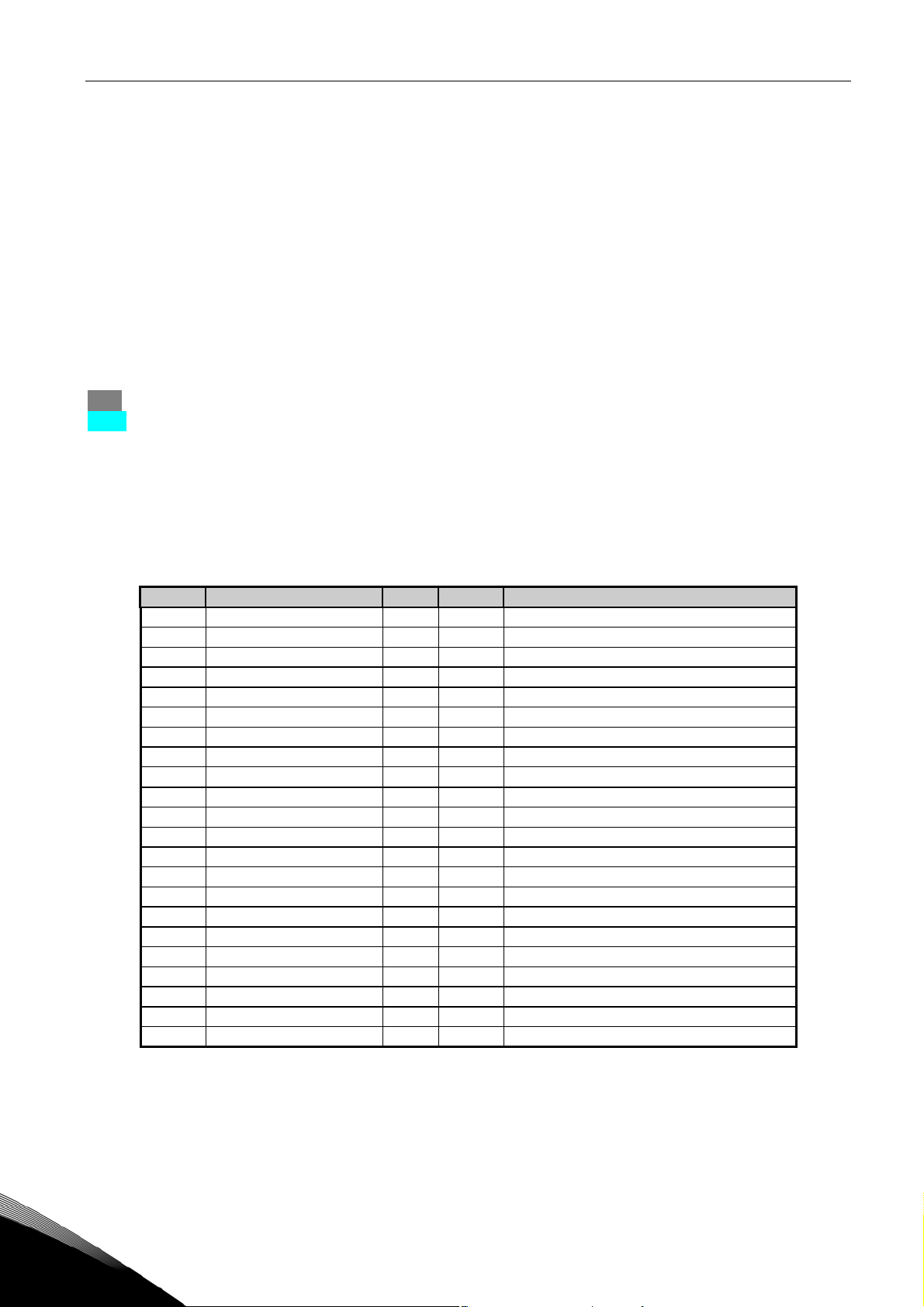

4 • vacon Parameter lists

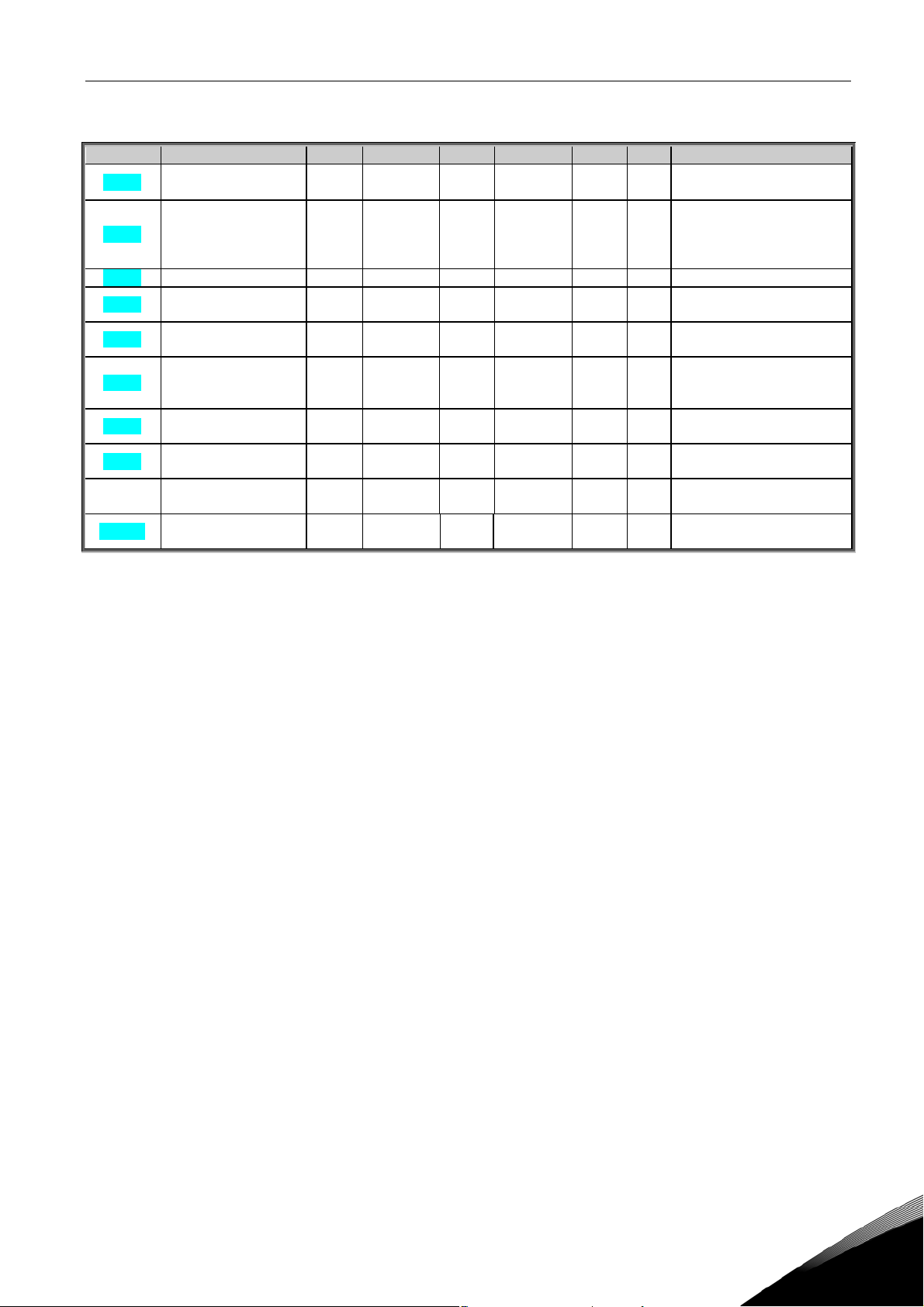

3. PARAMETER LISTS

On the next pages you will find the lists of parameters within the respective parameter groups. The

parameter descriptions are given on pages 21 to 52.

Column explanations:

Code = Location indication on the keypad; Shows the operator the present param. number

Parameter = Name of parameter

Min = Minimum value of parameter

Max = Maximum value of parameter

Unit = Unit of parameter value; Given if available

Default = Value preset by factory

Cust = Customer’s own setting

ID = ID number of the parameter

= In parameter row: Use TTF method to program these parameters.

= On parameter code: Parameter value can only be changed after the FC has been

stopped.

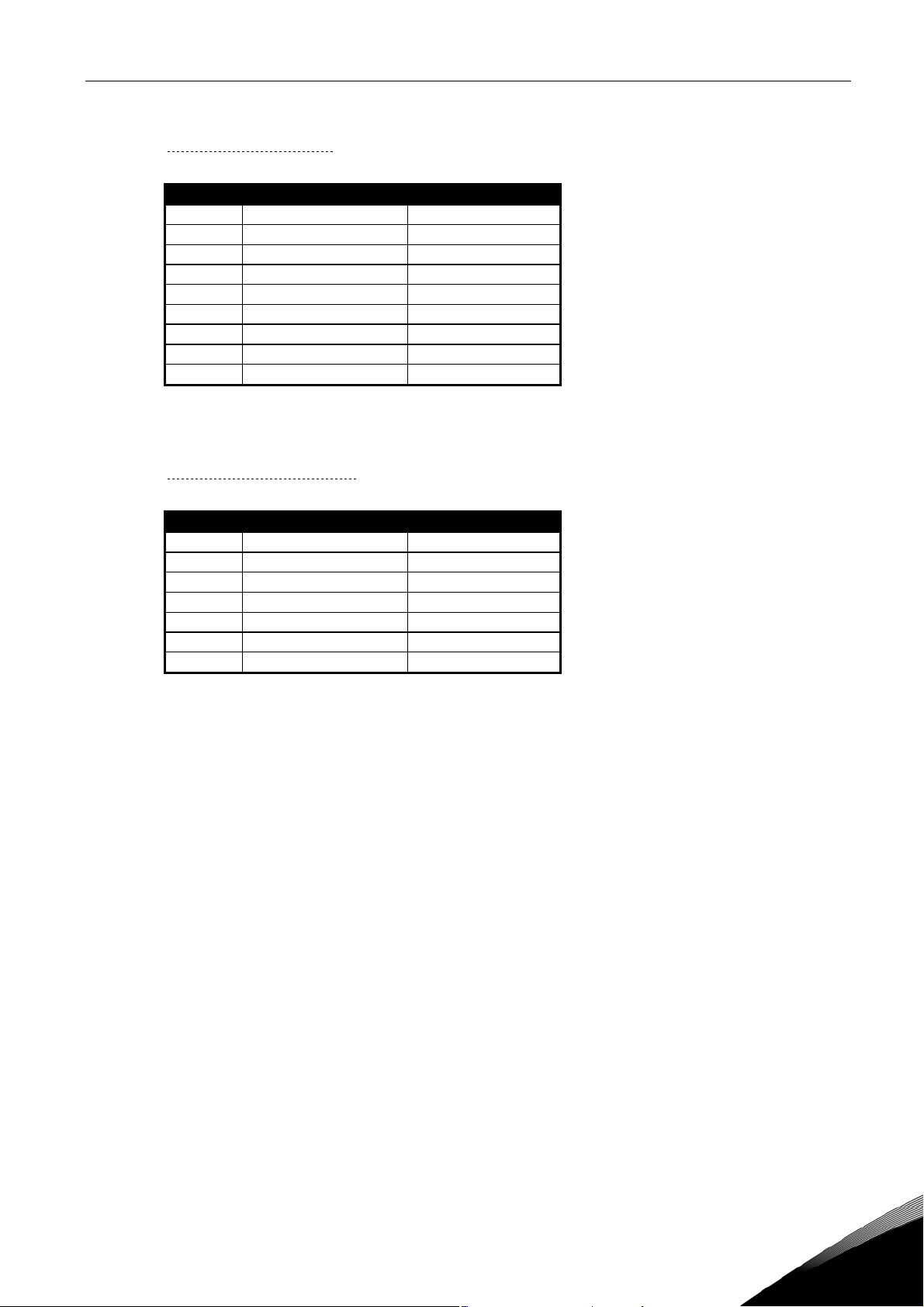

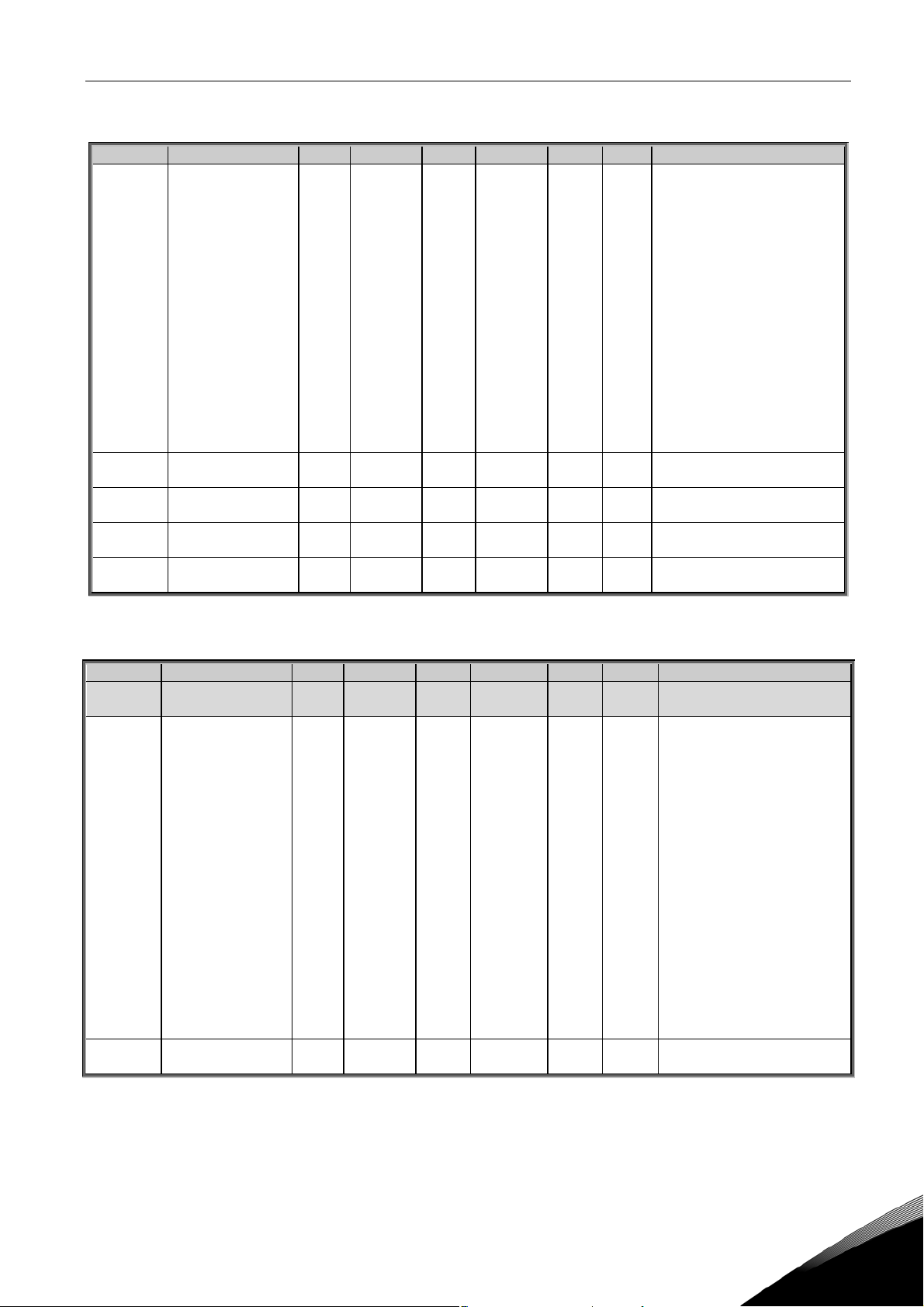

3.1 Monitoring values (Control keypad: menu M1)

The monitoring values are the actual values of parameters and signals as well as statuses and

measurements. Monitoring values cannot be edited.

See the product’s user manual for more information.

Code Parameter Unit ID Description

V1.1 Output frequency Hz 1 Output frequency to motor

V1.2 Frequency reference Hz 25 Frequency reference to motor control

V1.3 Motor speed rpm 2 Motor speed in rpm

V1.4 Motor current A 3

V1.5 Motor torque % 4 Calculated shaft torque

V1.6 Motor power % 5 Motor shaft power

V1.7 Motor voltage V 6

V1.8 DC link voltage V 7

V1.9

V1.10 Analogue input 1 V 13 AI1

V1.11 Analogue input 2 mA 14 AI2

V1.12 Analogue input 3 1543 AI3

V1.13 Analog Output1 26

V1.14 DIN1, DIN2, DIN3 15 Digital input statuses

V1.15 DIN4, DIN5, DIN6 16 Digital input statuses

V1.16 RO1, RO2, RO3 1516 Relay output statuses

V1.17 RO4, RO5, RO6 1574 Relay output statuses

V1.18 Temp reference °C 1500

V1.19 Actual temperature °C 1501

V1.20 Temp error value °C 1502

V1.21 PID output % 23 In % of the max. output value

V1.22 Inlet pressure bar 1511 PT11

Unit temperature

Table 2. Monitoring values

8 Heatsink temperature

°C

3

Tel. +358 (0)201 2121 • Fax: +358 (0)201 2121 205

Page 7

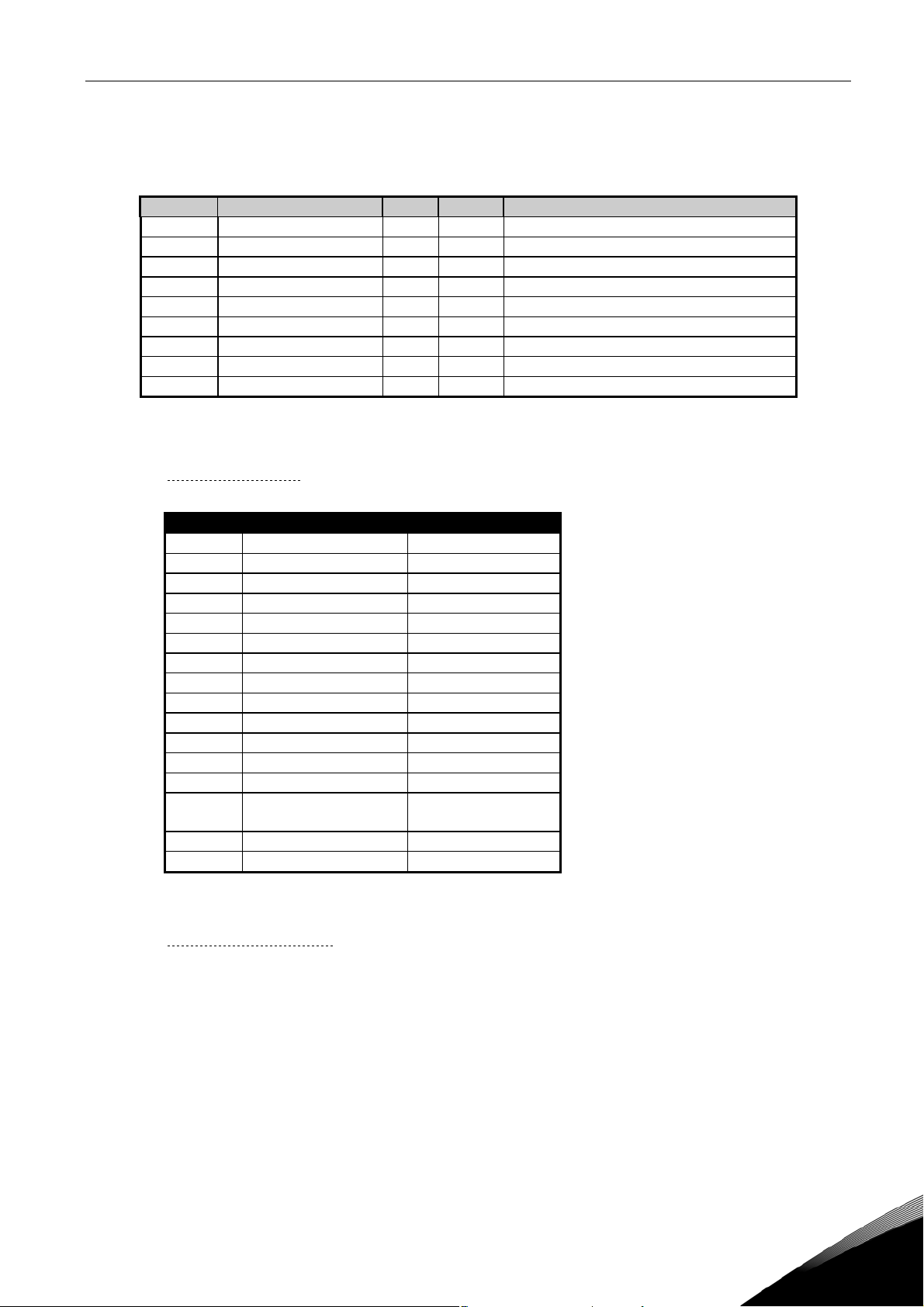

Parameter lists vacon • 5

3.1.1

FB Monitor

Code Parameter Unit ID Description

V1.23.1 Motor Current A 45 Motor current with one decimal

V1.23.2 Fault History 37 Last active fault code

V1.23.3 Status Word 43 Application status word

V1.23.4 Status Word 2 1800 Application status word 2

V1.23.5 Fault Word 1 1172 General fault word 1

V1.23.6 Fault Word 2 1173 General fault word

V1.23.7 Warning Word 1 1174 General warning word

V1.23.8 Fault Word 10 1202 Heat exchanger specific faults

V1.23.9 Warning Word 10 1269 Heat exchanger specific warnings

Table 3. Monitoring values (G1.24 FB Monitor)

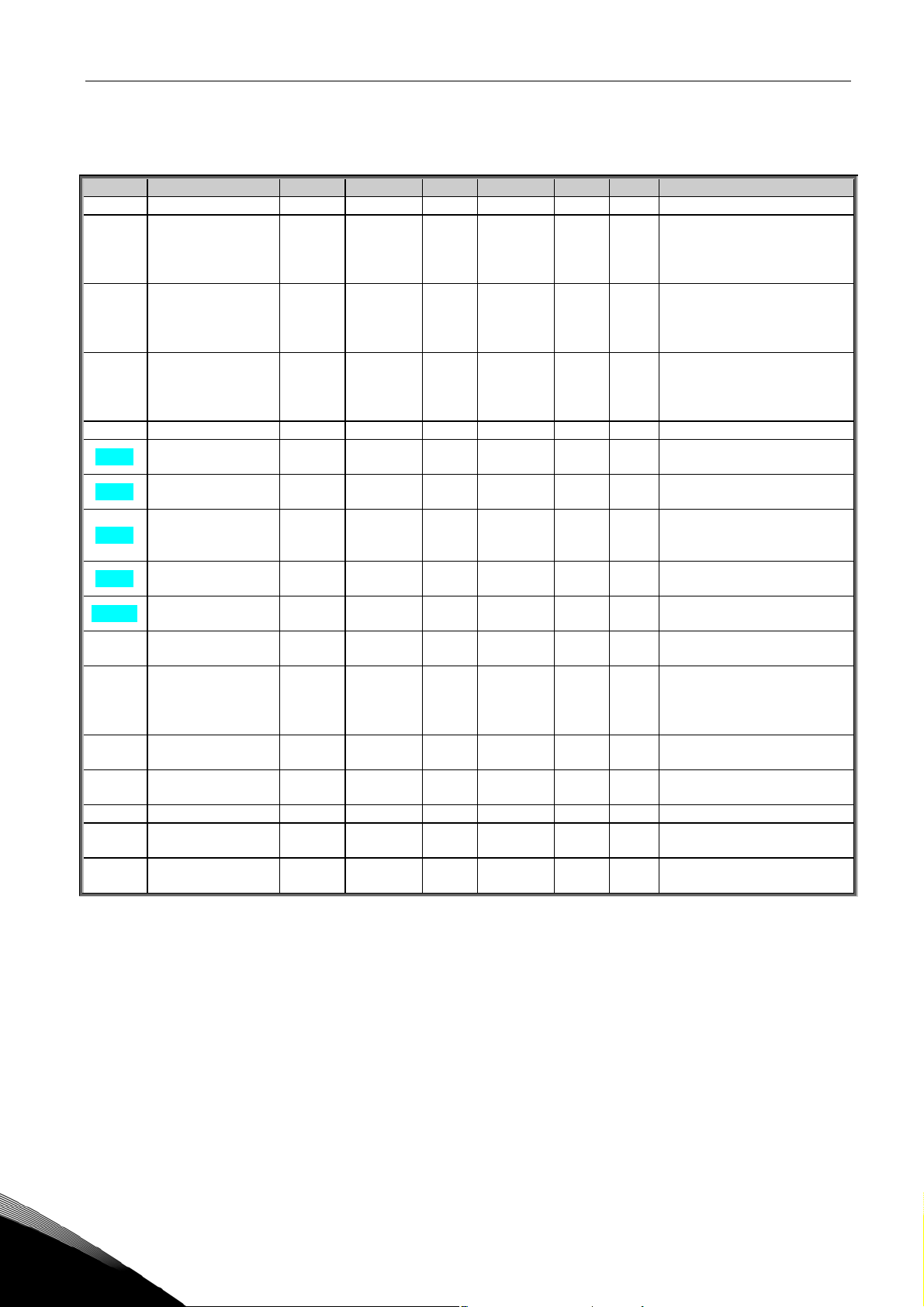

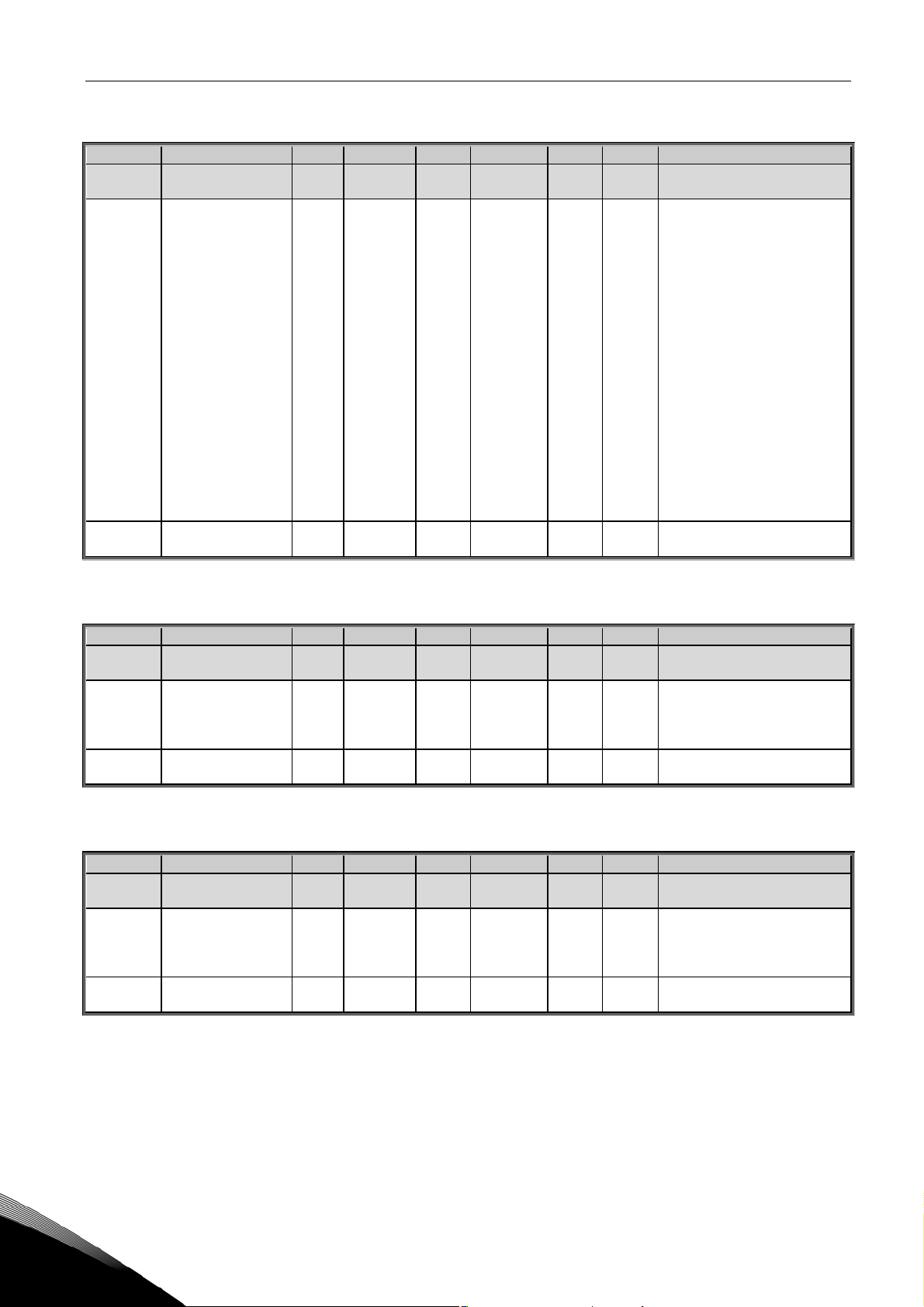

3.1.1.1 Status Word, ID43

Description Comment

b0

b1 Ready

b2 Run

b3 Fault

b4

b5

b6 Run enable

b7 Warning

b8

b9

b10 RO4 status

b11 RO5 status

b12 Run request

b13

b14

b15 Cooling OK

Motor regulator

active

Table 4. Status Word

3.1.1.2 Status Word 2, ID1800

Give this status word to Vacon personnel in case of problems with running the application.

24-hour support: +358 (0)201 212 575 • Email: vacon@vacon.com

3

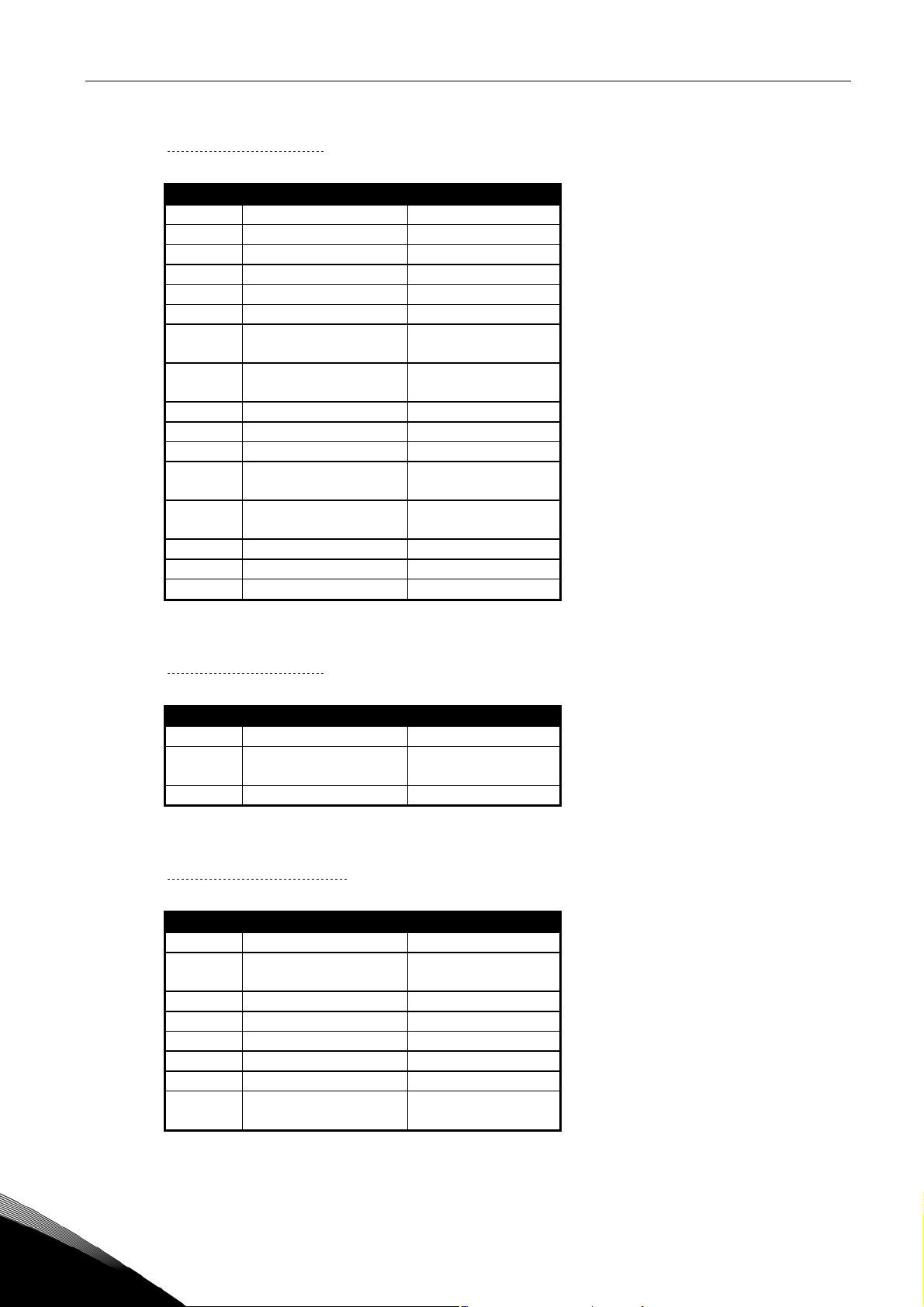

Page 8

6 • vacon Parameter lists

3.1.1.3 Fault Word 1, ID1172

Description Comment

b0 Over current F1

b1 Over voltage F2

b2 Under voltage F9

b3 Motor stalled F15

b4

b5 Motor underload F17

b6

b7

b8 Input phase F10

b9

b10

b11

b12

b13

b14 Slot communication F54

b15 4 mA F50

Unit over

temperature

Motor over

temperature

Keypad or PC

communication

Fieldbus

communication

F16

F52

F53

Table 5. Fault Word 1

3.1.1.4 Fault Word 2, ID1173

Description Comment

b0 Output phase F11

b6 External fault

b9 IGBT F41

Table 6. Fault Word 2

3.1.1.5 Warning Word 1, ID1174

Description Comment

b0 Motor stalled F15

b1

b2 Motor underload F17

b3 Input phase F10

b4 Output phase F11

b8 Unit temperature

b9 4 mA F50

b15

Motor over

temperature

Keypad

communication

Table 7. Warning Word 1

F51

(fault or warning)

F16,

F29 (fault or warn)

F52

3

Tel. +358 (0)201 2121 • Fax: +358 (0)201 2121 205

Page 9

Parameter lists vacon • 7

3.1.1.6 Fault Word 10, ID1202

Description Comment

b0

b1

b2

b3

b4

b5 Over temperature F85 (warning)

b6

b7 Inlet pressure low F88

b8 Flow F87

Table 8. Fault Word 10

3.1.1.7 Warning Word 10, ID1269

Description Comment

b0

b1

b2

b3 Inlet pressure low F82

b4 Over temperature F83

b5 Low temperature F86

b6

Table 9. Warning Word 10

24-hour support: +358 (0)201 212 575 • Email: vacon@vacon.com

3

Page 10

8 • vacon Parameter lists

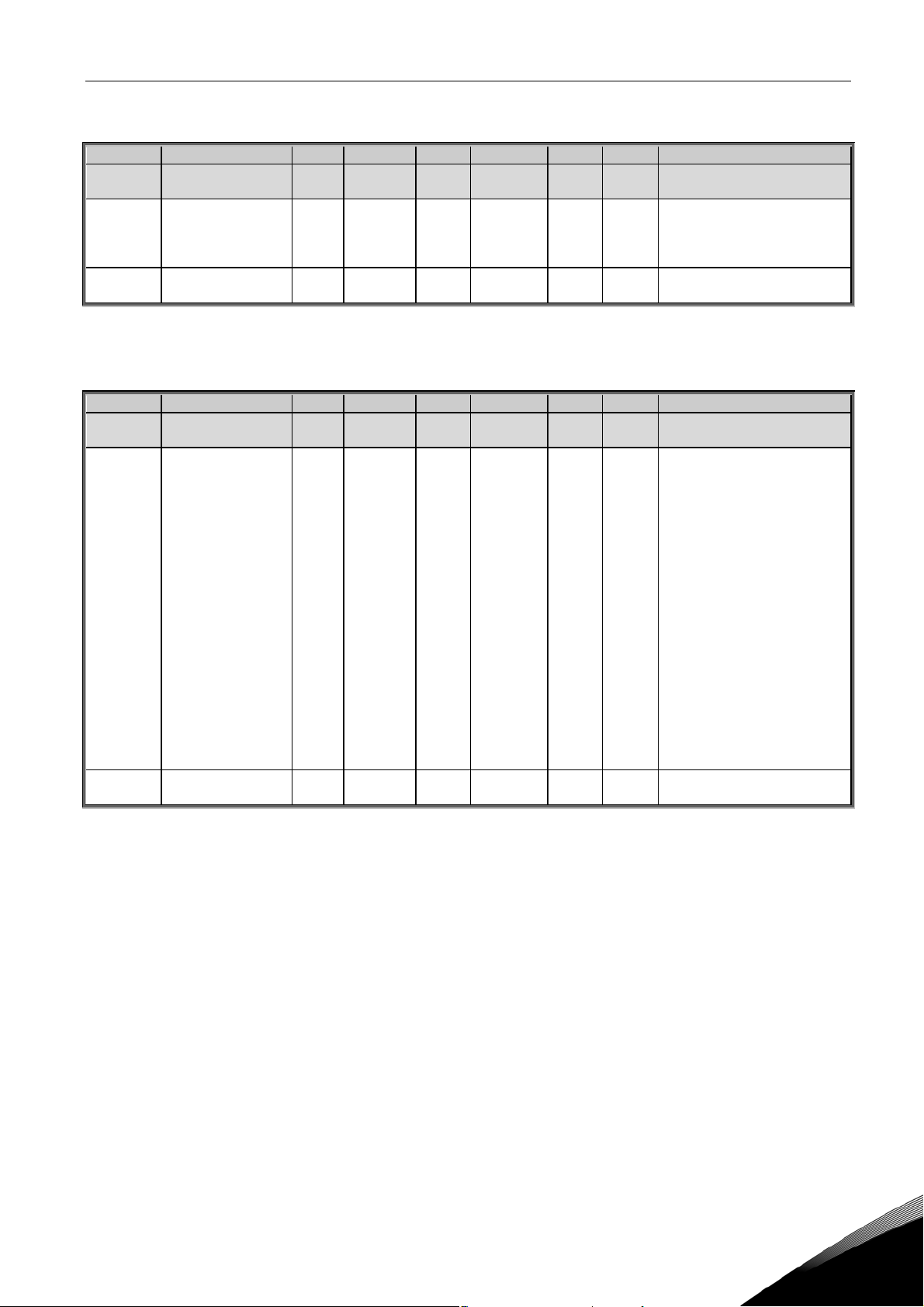

3.2 Basic parameters (Control keypad: Menu M2 G2.1)

Code Parameter Min Max Unit Default Cust ID Note

P2.1.1 Min Frequency 0.00 Par. 2.1.2 Hz 25.00 101

NOTE: If f

P2.1.2 Max Frequency Par. 2.1.1 320.00 Hz 50.00 102

P2.1.3 Acceleration time 1 0.1 3000.0 s 1.0 103

P2.1.4 Deceleration time 1 0.1 3000.0 s 1.0 104

P2.1.5 Current limit 0 2 x I

P2.1.6

P2.1.7

P2.1.8

P2.1.9

P2.1.10

P2.1.11 Start function 0 1 0 505

P2.1.12 Stop function 0 3 0 506

P2.1.13 U/f optimization 0 1 0 109

P2.1.14 I/O reference 0 1 0 117

P2.1.15 Preset speed1 0.00 Par. 2.1.2 Hz 10.00

P2.1.16 Automatic restart 0 1 0

P2.1.17 Parameter conceal 0 1 1

Nominal voltage of

the motor

Nominal frequency

of the motor

Nominal speed of

the motor

Nominal current of

the motor

Motor cosϕ

180 690 V 400V 110

30.00 320.00 Hz 50.00 111

300 20 000 rpm 1440 112

0.4 x I

2 x IH A IH 113

H

0.30 1.00 0.85 120

H

AI

L

motor synchronous speed,

check suitability for motor

and drive system

NOTE: If PID-controller is

used, Acceleration time 2

(par. 2.4.3) is automatically

applied

NOTE: If PID-controller is

used, Deceleration time 2

(par. 2.4.4) is automatically

applied

107

Check the rating plate of the

motor

The default applies for a 4pole motor and a nominal

size AC drive.

Check the rating plate of the

motor.

Check the rating plate of the

motor

0=Ramp

1=Flying start

0=Coasting

1=Ramp

2=Ramp+Run enable coast

3=Coast+Run enable ramp

0=Not used

1=Automatic torque boost

0=Keypad reference

1=Fieldbus reference

105

0=Not used

731

1=Automatic restart

0=All parameters visible

115

1=Basic group (G2.1) visible

> than the

max

Table 10. Basic parameters G2.1

3

Tel. +358 (0)201 2121 • Fax: +358 (0)201 2121 205

Page 11

Parameter lists vacon • 9

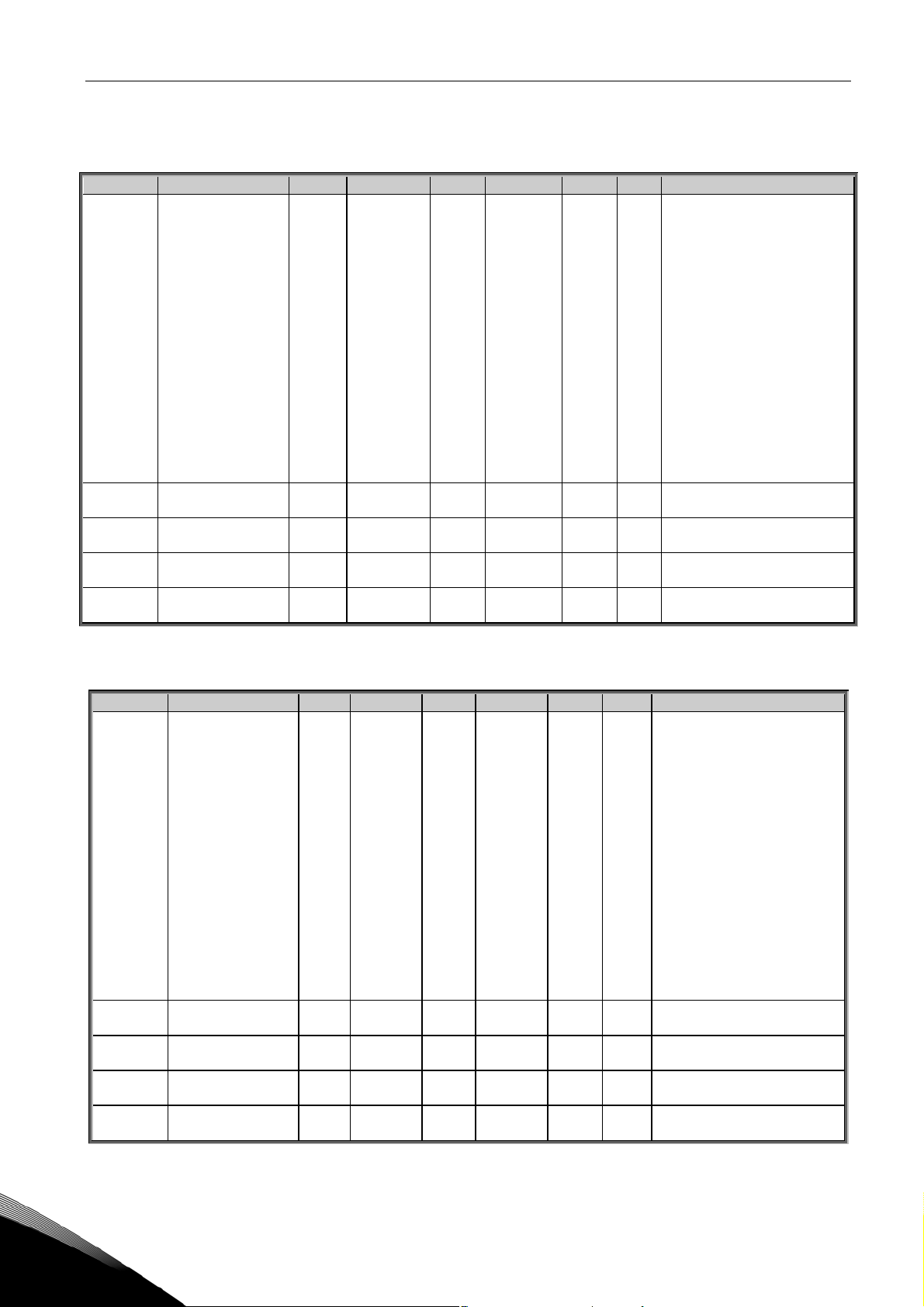

3.3 Input signals (Control keypad: Menu M2 G2.2)

Code Parameter Min Max Unit Default Cust ID Note

P2.2.1 DIN2 input 0 1 1 1590

P2.2.2 DIN3 function 0 10 3 301

P2.2.3 DIN6 Function 0 1 0 1572

P2.2.4 AI1 signal range 0 3 1 379

P2.2.5 AI1 supervision 0 1 0 1544

P2.2.6

P2.2.7

P2.2.8 AI1 inversion 0 1 0 387

P2.2.9 AI1 filter time 0.00 10.00 s 1.00 378 0=No filtering

P2.2.10 AI2 signal range 0 1 1 390

P2.2.11 AI2 supervision 0 1 1 1545

P2.2.12

P2.2.13

P2.2.14 AI2 inversion 0 1 0 398

P2.2.15 AI2 filter time 0.00 10.00 s 1.00 389 0=No filtering

P2.2.16 AI3 signal selection 0 59 1558 TTF programming method

P2.2.17 AI3 signal range 0 1 1 1520

P2.2.18 AI3 supervision 0 1 0 1546

P2.2.19

P2.2.20

P2.2.21 AI3 inversion 0 1 0 1529

P2.2.22 AI3 filter time 0.00 10.00 s 1.00 1526 0=No filtering

P2.2.23

P2.2.24

AI1 custom

minimum setting

AI1 custom

maximum setting

AI2 custom

minimum setting

AI2 custom

maximum setting

AI3 custom

minimum setting

AI3 custom

maximum setting

Keypad control

reference

Fieldbus control

reference

0.00 P2.2.6 % 0.00 380

0.00 100.00 % 100.00 381

0.00 P2.2.6 % 0.00 391

0.00 100.00 % 100.00 392

0.00 P2.2.18 % 0.00 1517

P2.2.17 100.00 % 100.00 1518

0 1 0 121

0 1 1 122

0=Normally open

1=Normally closed

0=Motor pot. UP(cc)

1=Reverse

2=External fault CC

3=External fault OC

4=Fault reset

5=Run enable

6=Preset speed 1

7=DC brake cmnd

8=PID disable

9=PID disable, go to preset

speed

10=PID keypad ref 2

0=Preset Speed 1

1=Fault Reset

0=Signal range 0-20mA

1=Signal range 4-20mA

2=0-10V

3=2-10V

0=Not inverted

1=Inverted

0=Signal range 0-20mA

1=Signal range 4-20mA

0=Not inverted

1=Inverted

0=Signal range 0-20mA

1=Signal range 4-20mA

0=Not inverted

1=Inverted

Keypad freq ref selection:

0=Reference from Keypad

1=FB reference

Fieldbus frequency

reference selection:

0=Reference from Keypad

1=FB reference

Table 11. Input signals, G2.2

*Remember to place jumpers of block X2 accordingly.

See the product's user manual.

24-hour support: +358 (0)201 212 575 • Email: vacon@vacon.com

3

Page 12

10 • vacon Parameter lists

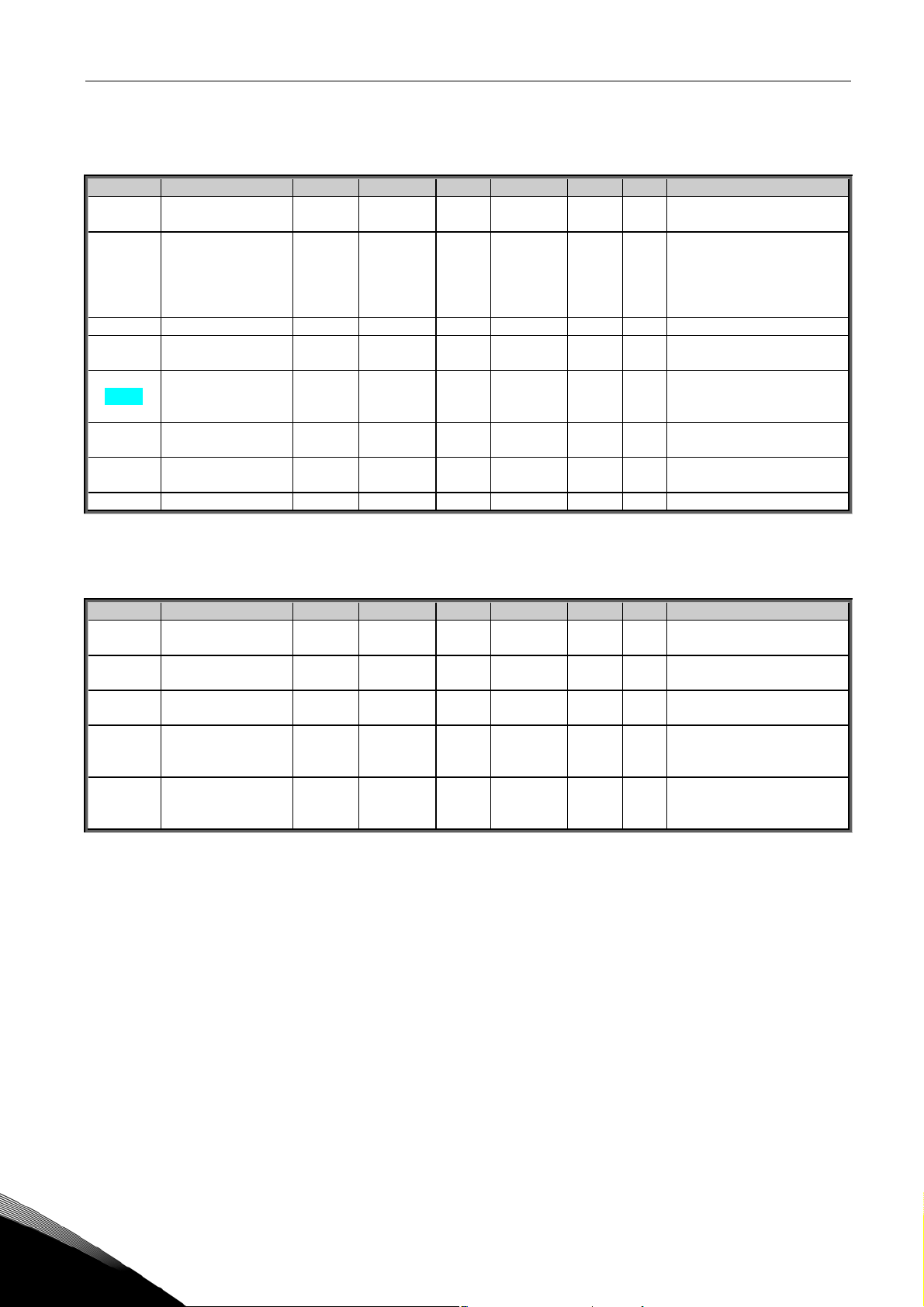

3.4 Output signals (Control keypad: Menu M2 G2.3)

3.4.1

Analogue output 1

Code Parameter Min Max Unit Default Cust ID Note

0=Not used

1=Output freq. (0—f

2=Freq. reference (0—f

max

)

)

max

3=Motor speed (0—Motor

nominal speed)

P2.3.1.1

Analogue output 1

function

4=Motor current (0—I

5=Motor torque (0—T

6=Motor power (0—P

0 13 13 307

7=Motor voltage (0-U

8=DC-link volt (0—1000V)

nMotor

nMotor

nMotor

nMotor

)

)

)

)

9=PI controller temp ref

10=PI contr. act. temp.

11=PI contr. temperature

error value

12=PI controller output

13=Pressure from PT11,

pump inlet

P2.3.1.2

P2.3.1.3

P2.3.1.4

P2.3.1.5

Analogue output 1

filter time

Analogue output 1

inversion

Analogue output 1

minimum

Analogue output 1

scale

0.00 10.00 s 1.00 308 0=No filtering

0 1 0 309

0 1 1 310

0=Not inverted

1=Inverted

0=0 mA

1=4 mA

10 1000 % 100 311

Table 12. Analogue output 1 signals

3.4.2

Analogue output 2

Code Parameter Min Max Unit Default Cust ID Note

0=Not used

1=Output freq. (0—f

2=Freq. reference (0—f

3=Motor speed (0—Motor

nominal speed)

4=Motor current (0—I

5=Motor torque (0—T

6=Motor power (0—P

7=Motor voltage (0-U

8=DC-link volt (0—1000V)

P2.3.2.1

Analogue output 2

function

0 13 10 1530

9=PID controller ref. value

10=PI contr. act. temp

11=PI contr. temperature

error value

12=PI controller output

13=Pressure from PT11,

pump inlet

P2.3.2.2

P2.3.2.3

P2.3.2.4

P2.3.2.5

Analogue output 2

filter time

Analogue output 2

inversion

Analogue output 2

minimum

Analogue output 2

scale

0.00 10.00 s 1.00 1531 0=No filtering

0 1 0 1532

0 1 0 1533

0=Not inverted

1=Inverted

0=0 mA

1=4 mA

10 1000 % 100 1534

Table 13. Analogue output 2 signals

max

)

max

nMotor

nMotor

nMotor

nMotor

)

)

)

)

)

3

Tel. +358 (0)201 2121 • Fax: +358 (0)201 2121 205

Page 13

Parameter lists vacon • 11

3.4.3

Analogue output 3

Code Parameter Min Max Unit Default Cust ID Note

0=Not used

P2.3.3.1

P2.3.3.2

P2.3.3.3

P2.3.3.4

P2.3.3.5

Analogue output 3

function

Analogue output 3

filter time

Analogue output 3

inversion

Analogue output 3

minimum

Analogue output 3

scale

1=Output freq. (0—f

2=Freq. reference (0—f

3=Motor speed (0—Motor

nominal speed)

4=Motor current (0—I

5=Motor torque (0—T

6=Motor power (0—P

0 13 4 1535

0.00 10.00 s 1.00 1536 0=No filtering

0 1 0 1537

0 1 0 1538

10 1000 % 100 1539

7=Motor voltage (0-U

8=DC-link volt (0—1000V)

9=PID controller ref. value

10=PI contr. act. temp

11=PI contr. temperature

error value

12=PID controller output

13=Pressure from PT11,

pump inlet

0=Not inverted

1=Inverted

0=0 mA

1=4 mA

max

)

max

nMotor

nMotor

nMotor

nMotor

)

)

)

)

)

Table 14. Analogue output 3 signals

3.4.4

Relay output 1

Code Parameter Min Max Unit Default Cust ID Note

P2.3.4.1

P2.3.4.2

P2.3.4.3

Relay output 1

signal selection

Relay output 1

function

Relay output 1

inversion

B.1 1549

0=Not used

1=Ready

2=Run

3=Fault

4=Fault inverted

5=FC overheat warning

6=Ext. fault or warning

7=Ref. fault or warning

8=Warning

0 18 2 313

0 1 0 1540

9=Reversed

10=Preset speed 1

11=At speed

12=Mot. regulator active

13=OP freq. limit superv.1

14=Control place: IO

15=Thermistor fault/warn.

16=Actual value supervision

17=Cooling OK

18=Alarm latched

0=Not inverted

1=Inverted

Table 15. Relay output 1 signals

24-hour support: +358 (0)201 212 575 • Email: vacon@vacon.com

3

Page 14

12 • vacon Parameter lists

3.4.5

Relay output 2

Code Parameter Min Max Unit Default Cust ID Note

P2.3.5.1

P2.3.5.2

P2.3.5.3

Relay output 2

signal selection

Relay output 2

function

Relay output 2

inversion

B.2 1550

0=Not used

1=Ready

2=Run

3=Fault

4=Fault inverted

5=FC overheat warning

6=Ext. fault or warning

7=Ref. fault or warning

8=Warning

0 18 3 1513

0 1 0 1541

9=Reversed

10=Preset speed 1

11=At speed

12=Mot. regulator active

13=OP freq. limit superv.1

14=Control place: IO

15=Thermistor fault/warn.

16=Actual value supervision

17=Cooling OK

18=Alarm latched

0=Not inverted

1=Inverted

Table 16. Relay output 2 signals

3.4.6

Relay output 3

Code Parameter Min Max Unit Default Cust ID Note

P2.3.6.1

P2.3.6.2

P2.3.6.3

Relay output 3

signal selection

Relay output 3

function

Relay output 3

inversion

D.1 1551

0=Not used

0 3 1 1515

0 1 0 1542

1=Cooling OK

2=Pump 1

3=Pump 2

0=Not inverted

1=Inverted

Table 17. Relay output 3 signals

3.4.7

Relay output 4

Code Parameter Min Max Unit Default Cust ID Note

P2.3.7.1

P2.3.7.2

P2.3.7.3

Relay output 4

signal selection

Relay output 4

function

Relay output 4

inversion

D.2 1552

0=Not used

0 3 2 1553

0 1 0 1554

1=Cooling OK

2=Pump 1

3=Pump 2

0=Not inverted

1=Inverted

Table 18. Relay output 4 signals

3

Tel. +358 (0)201 2121 • Fax: +358 (0)201 2121 205

Page 15

Parameter lists vacon • 13

3.4.8

Relay output 5

Code Parameter Min Max Unit Default Cust ID Note

P2.3.8.1

P2.3.8.2

P2.3.8.3

Relay output 5

signal selection

Relay output 5

function

Relay output 5

inversion

D.3 1555

0=Not used

0 3 3 1556

0 1 0 1557

1=Cooling OK

2=Pump 1

3=Pump 2

0=Not inverted

1=Inverted

Table 19. Relay output 5 signals

3.4.9

Relay output 6

Code Parameter Min Max Unit Default Cust ID Note

P2.3.9.1

P2.3.9.2

P2.3.9.3

Relay output 6

signal selection

Relay output 6

function

Relay output 6

inversion

A.1 1573

0=Not used

1=Ready

2=Run

3=Fault

4=Fault inverted

5=FC overheat warning

6=Ext. fault or warning

7=Ref. fault or warning

8=Warning

0 18 3 1567

0 1 0 1568

9=Reversed

10=Preset speed 1

11=At speed

12=Mot. regulator active

13=OP freq. limit superv.1

14=Control place: IO

15=Thermistor fault/warn.

16=Actual value supervision

17=Cooling OK

18=Alarm latched

0=Not inverted

1=Inverted

Table 20. Relay output 6 signals

24-hour support: +358 (0)201 212 575 • Email: vacon@vacon.com

3

Page 16

14 • vacon Parameter lists

3.5 Drive control parameters (Control keypad: Menu M2 G2.4)

Code Parameter Min Max Unit Default Cust ID Note

P2.4.1 Ramp 1 shape 0.0 10.0 s 0.0 500

P2.4.2 Brake chopper 0 3 0 504

P2.4.3 DC braking current 0.4 x IH 2 x I

P2.4.4

P2.4.5

P2.4.6

P2.4.7 Flux brake 0 1 0 520

P2.4.8 Flux braking current 0.4 x IH 2 x I

DC braking time

at stop

Frequency to start

DC braking during

ramp stop

DC braking time

at start

0.00 600.00 s 0.00 508 0=DC brake is off at stop

0.10 10.00 Hz 1.50 515

0.00 600.00 s 0.00 516 0=DC brake is off at start

H

H

AI

AI

H

H

0=Linear

>0=S-curve ramp time

0=Disabled

1=Used when running

2=External brake chopper

3=Used when stopped/

running

507

0=Off

1=On

519

Table 21. Drive control parameters, G2.4

3.6 Prohibit frequency parameters (Control keypad: Menu M2 G2.5)

Code Parameter Min Max Unit Default Cust ID Note

P2.5.1

P2.5.2

P2.5.3

P2.5.4

P2.5.5

Prohibit frequency

range 1 low limit

Prohibit frequency

range 1 high limit

Prohibit acc./dec.

ramp

Output frequency

limit 1 supervision

Output frequency

limit 1;

Supervised value

0.00 Par. 2.5.2 Hz 0.00 509 0=Not used

0.00 Par. 2.1.2 Hz 0.00 510 0=Not used

0.1 10.0 Times 1.0 518

0=No limit

0 2 0 315

0.00 Par. 2.1.2 Hz 0.00 316

1=Low limit supervision

2=High limit supervision

Table 22. Prohibit frequency parameters, G2.5

3

Tel. +358 (0)201 2121 • Fax: +358 (0)201 2121 205

Page 17

Parameter lists vacon • 15

3.7 Motor control parameters (Control keypad: Menu M2 G2.6)

Code Parameter Min Max Unit Default Cust ID Note

P2.6.1 Motor control mode 0 1 0 600

P2.6.2 U/f ratio selection 0 3 0 108

P2.6.3 Field weakening point 8.00 320.00 Hz 50.00 602

P2.6.4

P2.6.5

P2.6.6

P2.6.7

P2.6.8 Switching frequency 1.0 Varies kHz Varies 601

P2.6.9 Overvoltage controller 0 1 1 607

P2.6.10

Voltage at field

weakening point

U/f curve midpoint

frequency

U/f curve midpoint

voltage

Output voltage at zero

frequency

Undervoltage

controller

10.00 200.00 % 100.00 603 n% x U

0.00

0.00 100.00 % 100.00 605

0.00 40.00 % Varies 606 n% x U

0 1 1 608

par.

P2.6.4

Hz 50.00 604

0=Frequency control

1=Speed control

0=Linear

1=Squared

2=Programmable

3=Linear with flux optim.

nmot

n% x U

nmot

Parameter max. value =

par. 2.6.5

nmot

See Table 31 for exact

values

0=Not used

1=Used (no ramping)

0=Not used

1=Used

Table 23. Motor control parameters, G2.6

24-hour support: +358 (0)201 212 575 • Email: vacon@vacon.com

3

Page 18

16 • vacon Parameter lists

3.8 Protections (Control keypad: Menu M2 G2.7)

Code Parameter Min Max Unit Default Cust ID Note

0=No response

P2.7.1

P2.7.2

P2.7.3

P2.7.4

P2.7.5

P2.7.6

P2.7.7

P2.7.8

P2.7.9

P2.7.10

P2.7.11 Motor duty cycle 0 100 % 100 708

P2.7.12 Stall protection 0 3 1 709 See par. ID700

P2.7.13 Stall current 0.1 I

P2.7.14 Stall time limit 1.00 120.00 s 15.00 711

P2.7.15 Stall frequency limit 1.0 Par. 2.1.2 Hz 25.0 712

P2.7.16

P2.7.17

P2.7.18 Zero frequency load 5.0 150.0 % 10.0 715

P2.7.19

P2.7.20

P2.7.21

P2.7.22 Resp. to slot fault 0 3 2 734 See par. ID700

P2.7.23

P2.7.24

P2.7.25

Response to 4mA

reference fault

Response to

external fault

Input phase

supervision

Response to

undervoltage fault

Output phase

supervision

Earth fault

protection

Thermal protection

of the motor

Motor ambient

temperature factor

Motor cooling factor

at zero speed

Motor thermal time

constant

Underload

protection

Field weakening

area load

Underload protec-

tion time limit

Response to

thermistor fault

Response to

fieldbus fault

Actual value

supervision

function

Actual value

supervision limit

Actual value

supervision delay

0 3 1 700

0 3 1 701 See par. ID700

0 3 0 730 See par. ID700

1 3 2 727

0 3 2 702 See par. ID700

0 3 2 703 See par. ID700

0 3 2 704 See par. ID700

–100.0 100.0 % 0.0 705

0.0 150.0 % 40.0 706

1 200 min Varies 707

x 2 A I

nMotor

0 3 0 713 See par. ID700

10 150 % 50 714

2 600 s 20 716

0 3 0 732 See par. ID700

0 3 2 733 See par. ID700

0 4 0 735

0 100.0 % 10.0 736

0 3600 s 5 737

L

1=Warning

2=Fault,stop acc. to 2.1.12

3=Fault,stop by coasting

1=Warning

2=Fault,stop acc. to 2.1.12

3=Fault,stop by coasting

710

0=Not used

1=If below limit: Warning

2=If above limit: Warning

3=If below limit: Fault

4=If above limit: Fault

Table 24. Protections, G2.7

3

Tel. +358 (0)201 2121 • Fax: +358 (0)201 2121 205

Page 19

Parameter lists vacon • 17

3.9 Autorestart parameters (Control keypad: Menu M2 G2.8)

Code Parameter Min Max Unit Default Cust ID Note

P2.8.1 Wait time 0.10 10.00 s 0.50 717

P2.8.2 Trial time 0.00 60.00 s 30.00 718

0=Ramp

P2.8.3 Start function 0 2 0 719

1=Flying start

2=According to par. 2.1.11

Table 25. Autorestart parameters, G2.8

3.10 PID control parameters (Control keypad: Menu M2 G2.9)

Code Parameter Min Max Unit Default Cust ID Note

P2.9.1 PID activation 0 1 1 163

P2.9.2 PID reference 0 2 0 332

P2.9.3

P2.9.4 PID controller gain 0.0 1000.0 % 100.0 118 0=No part P used

P2.9.5

P2.9.6

P2.9.7

P2.9.8

P2.9.9 Error value inversion 0 1 0 340

P2.9.10 Dead band 0 10.00 °C 0.0 1575 0=Not Used

P2.9.11 Dead band delay 0 100.00 s 10.0 1576

Actual value 1

selection

PID controller I-

time

PID controller D-

time

Actual value 1

minimum scale

Actual value 1

maximum scale

0 2 1 334

0.00 320.00 s 5.00 119 320.00=No part I used

0.00 10.00 s 0.00 132 0=No part D used

–1000.0 1000.0 % 0.0 336 0=No minimum scaling

–1000.0 1000.0 % 100.0 337 100=No maximum scaling

0=Not used

1=PID control activated

0=PID ref from Keypad

control page, par. 3.4

1=PID ref from Keypad

control page, par 3.5

2=PID ref from fieldbus

(ProcessDataIN 1)

0=AI1 signal (c-board)

1=AI2 signal (c-board)

2=Fieldbus

0=No inversion

1=Inversion

ProcessDataIN2

Table 26. PID control parameters, G2.9

24-hour support: +358 (0)201 212 575 • Email: vacon@vacon.com

3

Page 20

18 • vacon Parameter lists

3.11 Flow control parameters (Control keypad: Menu M2 G2.10)

Code Parameter Min Max Unit Default Cust ID Note

P2.10.1 Constant speed Par. 2.1.1 Par. 2.1.1 Hz 50.00 1514

P2.10.2

P2.10.3

P2.10.4

P2.10.5

P2.10.6

P2.10.7

P2.10.8

P2.10.9

P2.10.10

P2.10.11

P2.10.12 Autochange interval 0 169 h 169 1599

P2.10.13 Delayed fault 1 30 s 2 1503

Coolant inlet pressure,

minimum

Coolant inlet pressure,

maximum

Coolant inlet pressure,

alarm limit

Coolant inlet pressure,

fault limit

Coolant inlet pressure,

supervision

Temperature sensor,

minimum value

Temperature sensor,

maximum value

Coolant outlet

temperature alarm,

lower limit

Coolant outlet

temperature alarm,

higher limit

Coolant outlet

temperature fault,

higher limit

0.00

Par.

2.10.2

0.00 100.00 bar 1.00 1570

0.00 100.00 bar 2.00 1571

0 1 0 1569

0.00 Par. 2.10.7 °C 0.00 1509

Par.

2.10.6

0.00 100.00 °C 22.00 1591

0.00 100.00 °C 30.00 1594

0.00 100.00 °C 40.00 1595

Par.

2.10.3

30.00 bar 10.00 1505

100.00 °C 100.00 1510

bar 0.00 1504

0=Off (No sensor)

1=On (Sensor installed)

0=Test mode

169=Single motor, no

change

Table 27. Flow control parameters, G2.10

3

Tel. +358 (0)201 2121 • Fax: +358 (0)201 2121 205

Page 21

Parameter lists vacon • 19

3.12 Fieldbus parameters (Control Keypad: Menu M2 G2.11)

Code Parameter Min Max Unit Default Cust ID Note

P2.11.1

P2.11.2

P2.11.3

P2.11.4

P2.11.5

P2.11.6

P2.11.7

P2.11.8

Fieldbus data out 1

selection

Fieldbus data out 2

selection

Fieldbus data out 3

selection

Fieldbus data out 4

selection

Fieldbus data out 5

selection

Fieldbus data out 6

selection

Fieldbus data out 7

selection

Fieldbus data out 8

selection

0 10000 1501 852

0 10000 2 853

0 10000 45 854

0 10000 1511 855

0 10000 1 856

0 10000 4 857

0 10000 5 858

0 10000 37 859

Choose monitoring data

with parameter ID

Choose monitoring data

with parameter ID

Choose monitoring data

with parameter ID

Choose monitoring data

with parameter ID

Choose monitoring data

with parameter ID

Choose monitoring data

with parameter ID

Choose monitoring data

with parameter ID

Choose controlled data

with parameter ID

Table 28. Fieldbus parameters, G2.11

24-hour support: +358 (0)201 212 575 • Email: vacon@vacon.com

3

Page 22

20 • vacon Parameter lists

3.13 Keypad control (Control keypad: Menu M3)

The parameters for the selection of control place and direction on the keypad are listed below. See

the Keypad control menu in the product's User Manual.

Code Parameter Min Max Unit Default Cust ID Note

1=I/O terminal

P3.1 Control place 1 3 1 125

R3.2 Keypad reference Par. 2.1.1 Par. 2.1.2 Hz

P3.3

R3.6 Stop button 0 1 1 114

R3.4 PID reference Par. 2.10.6 Par. 2.10.7 °C 25.00

R3.5 PID reference 2 Par. 2.10.6 Par. 2.10.7 °C 0.00

Direction (on

keypad)

0 1 0 123

2=Keypad

3=Fieldbus

0=Forward

1=Reverse

0=Limited function of

Stop button

1=Stop button always

enabled

Table 29. Keypad control parameters, M3

3.14 System menu (Control keypad: M6)

For parameters and functions related to the general use of the AC drive, such as application and

language selection, customised parameter sets or information about the hardware and software,

see the product's User manual.

3.15 Expander boards (Control keypad: Menu M7)

The M7 menu shows the expander and option boards attached to the control board and boardrelated information. For more information, see the product's User Manual.

3

Tel. +358 (0)201 2121 • Fax: +358 (0)201 2121 205

Page 23

Description of parameters vacon • 21

4. DESCRIPTION OF PARAMETERS

On the following pages you will find the parameter descriptions arranged according to the individual

ID number of the parameter. A shaded parameter ID number (e.g.

indicates that the

Manual).

Some parameter names are followed by a number code indicating the "All in One" applications in

which the parameter is included. If no code is shown the parameter is available in all applications.

See below. The parameter numbers under which the parameter appears in different applications are

also given.

101 Minimum frequency

102 Maximum frequency

Defines the frequency limits of the AC drive.

The maximum value for these parameters is 320 Hz.

The software will automatically check the values of parameters ID105, ID106 and ID728.

103 Acceleration time 1

104 Deceleration time 1

TTF programming method

(2.1.3)

(2.1.4)

is applied to this parameter (see All-in-One Application

(2.1.1)

(2.1.2)

418 Motor potentiometer UP

)

These limits correspond to the time required for the output frequency to accelerate from

the zero frequency to the set maximum frequency (par. ID102).

105 Preset speed 1

Parameter values are automatically limited between the minimum and maximum

frequencies (par. ID101, ID102).

(2.1.15)

107 Current limit

This parameter determines the maximum motor current from the AC drive. The

parameter value range differs from size to size. When this parameter is changed the

stall current limit (ID710) is internally calculated to 90% of current limit.

108 U/f ratio selection

Linear: 0 The voltage of the motor changes linearly with the frequency in the constant

flux area from 0 Hz to the field weakening point where the nominal voltage is

supplied to the motor. Linear U/f ration should be used in constant torque

applications. Use this default setting if there is no special need for

another setting.

Squared: 1 The voltage of the motor changes following a squared curve form with the

frequency in the area from 0 Hz to the field weakening point where the nominal voltage is also supplied to the motor. The motor runs undermagnetised

below the field weakening point and produces less torque and electromechanical noise. Squared U/f ratio can be used in applications where torque

demand of the load is proportional to the square of the speed, e.g. in

centrifugal fans and pumps.

(2.6.2)

(2.1.5

)

24-hour support: +358 (0)201 212 575 • Email: vacon@vacon.com

4

Page 24

22 • vacon Description of parameters

U[V]

Un

Default: Nominal

ID603

voltage of the motor

Linear

Field weakening

point

Squared

Default: Nominal

frequency of the

motor

NX12K07

f[Hz]

Figure 1. Linear and squared change of motor voltage

Programmable U/f curve:

2 The U/f curve can be programmed with three different points. Programmable

U/f curve can be used if the other settings do not satisfy the needs of the

application.

U[V]

Un

ID603

ID605

(Def. 10%)

ID606

(Def. 1.3%)

Default: Nominal

voltage of the motor

ID604

(Def. 5 Hz)

Field weakening point

Default: Nominal

frequency of the motor

ID602

f[Hz]

NX12K08

Figure 2. Programmable U/f curve

4

Linear with flux optimisation:

3 The AC drive starts to search for the minimum motor current in order to save

energy, lower the disturbance level and the noise. This function can be used

in applications with constant motor load, such as fans, pumps etc.

109 U/f optimisation

Automatic

torque boost

(2.1.13)

The voltage to the motor changes automatically which makes the motor

produce sufficient torque to start and run at low frequencies. The voltage

increase depends on the motor type and power. Automatic torque boost

can be used in applications where starting torque due to starting friction

is high, e.g. in conveyors.

Tel. +358 (0)201 2121 • Fax: +358 (0)201 2121 205

Page 25

Description of parameters vacon • 23

EXAMPLE:

What changes are required to start with load from 0 Hz?

♦ First set the motor nominal values (Parameter group 2.1).

Option 1: Activate the Automatic torque boost.

Option 2: Programmable U/f curve

To get torque you need to set the zero point voltage and midpoint voltage/frequency (in

parameter group 2.6) so that the motor takes enough current at low frequencies.

First set par. ID108 to

(ID606) to get enough current at zero speed. Set then the midpoint voltage (ID605) to

1.4142*ID606 and midpoint frequency (ID604) to value ID606/100%*ID111.

Programmable U/f curve

(value 2). Increase zero point voltage

NOTE! In high torque – low speed applications – it is likely that the motor will

overheat. If the motor has to run a prolonged time under these conditions, special attention must be paid to cooling the motor. Use external

cooling for the motor if the temperature tends to rise too high.

110 Nominal voltage of motor

(2.1.6)

Find this value Un on the rating plate of the motor. This parameter sets the voltage at the

field weakening point (ID603) to 100% * U

111 Nominal frequency of motor

Find this value fn on the rating plate of the motor. This parameter sets the field

weakening point (ID602) to the same value.

112 Nominal speed of motor

Find this value nn on the rating plate of the motor.

113 Nominal current of motor

Find this value In on the rating plate of the motor.

(2.1.8)

(2.1.9)

115 Parameter conceal

With this parameter you can hide all other parameter groups except the basic parameter

group (P2.1).

Note! The factory default of this parameter is 1, i.e. all parameter groups except P2.1

are hidden. The other parameter groups cannot be browsed or edited before the value of

this parameter is set to 0.

0 = Disabled (all parameter groups can be browsed with the keypad)

1 = Enabled (only the basic parameters, P2.1, can be browsed with the keypad)

(2.1.7)

. Note also used connection Delta/Star.

nMotor

24-hour support: +358 (0)201 212 575 • Email: vacon@vacon.com

4

Page 26

24 • vacon Description of parameters

117 I/O frequency reference selection

Defines which frequency reference source is selected when controlled from the I/O

control place.

0 = Keypad reference (Menu M3)

1 = Fieldbus reference

118 PID controller gain

This parameter defines the gain of the PID controller. If the value of the parameter is set

to 100% a change of 10% in the error value causes the controller output to change by

10%. If the parameter value is set to 0 the PID controller operates as ID-controller.

See examples at parameter ID132 below.

119 PID controller I-time

The parameter ID119 defines the integration time of the PID controller. If this parameter

is set to 1.00 second a change of 10% in the error value causes the controller output to

change by 10.00%/s. If the parameter value is set to 0.00 s the PID controller will operate

as PD controller.

See examples at parameter ID132 below.

120 Motor cos phi

(2.1.10)

(2.9.4)

(2.9.5)

(2.1.14)

Find this value “cos phi” on the rating plate of the motor.

121 Keypad frequency reference selection

Defines which frequency reference source is selected when controlled from the keypad.

0 Reference from keypad (Freq Ref)

1 Reference from fieldbus

122 Fieldbus frequency reference selection

Defines which frequency reference source is selected when controlled from the fieldbus.

0 Reference from keypad (Freq Ref)

1 Reference from fieldbus

132 PID controller D-time

The parameter ID132 defines the derivation time of the PID controller. If this parameter

is set to 1.00 second a change of 10% in the error value during 1.00 s causes the

controller output to change by 10.00%. If the parameter value is set to 0.00 s the PID

controller will operate as PI controller.

See examples below.

(2.9.6)

(2.2.22)

(2.2.23)

4

Tel. +358 (0)201 2121 • Fax: +358 (0)201 2121 205

Page 27

Description of parameters vacon • 25

Example 1:

In order to reduce the error value to zero, with the given values, the AC drive output

behaves as follows:

Given values:

Par. 2.1.12, P = 0%

Par. 2.1.13, I-time = 1.00 s

Par. 2.1.14, D-time = 0.00 s Min freq. = 0 Hz

Error value (setpoint – process value) = 10.00% Max freq. = 50 Hz

In this example, the PID controller operates practically as I-controller only.

According to the given value of parameter 2.1.13 (I-time), the PID output increases by 5

Hz (10% of the difference between the maximum and minimum frequency) every second

until the error value is 0.

Hz

PID output

Error value

10% I-Part=5 Hz/s

10%

10%

10%

Error=10%

1s

I-Part=5 Hz/s

I-Part=5 Hz/s

I-Part=5 Hz/s

I-Part=5 Hz/s

NX12k70

t

Figure 3. PID controller function as I-controller.

Example 2:

Given values:

Par. 2.1.12, P = 100%

Par. 2.1.13, I-time = 1.00 s

Par. 2.1.14, D-time = 1.00 s Min freq. = 0 Hz

Error value (setpoint – process value) = ±10% Max freq. = 50 Hz

As the power is switched on, the system detects the difference between the setpoint and

the actual process value and starts to either raise or decrease (in case the error value is

negative) the PID output according to the I-time. Once the difference between the setpoint and the process value has been reduced to 0 the output is reduced by the amount

corresponding to the value of parameter 2.1.13.

In case the error value is negative, the AC drive reacts reducing the output

correspondingly. See Figure 4.

24-hour support: +358 (0)201 212 575 • Email: vacon@vacon.com

4

Page 28

26 • vacon Description of parameters

Hz

PID output

D-part

D-part

D-part

Error value

P-part=5 Hz

Error=10%

Error= -10%

P-part= -5 Hz

NX12k69

t

Figure 4. PID output curve with the values of Example 2.

Example 3:

Given values:

Par. 2.1.12, P = 100%

Par. 2.1.13, I-time = 0.00 s

Par. 2.1.14, D-time = 1.00 s Min freq. = 0 Hz

Error value (setpoint – process value) = ±10%/s Max freq. = 50 Hz

As the error value increases, also the PID output increases according to the set values

(D-time = 1.00s)

Hz

PID output

Error value

D-part=10%=5,00 Hz

4

1,00 s

Figure 5. PID output with the values of Example 3.

163 PID activation

Activate the PID control by setting value 1 for this parameter.

Tel. +358 (0)201 2121 • Fax: +358 (0)201 2121 205

P-part=100% *PID error = 5,00Hz/s

10%

(2.9.1)

D-part= -10%= -5,00 Hz

NX12k72

t

Page 29

Description of parameters vacon • 27

301 DIN3 function

This parameter has 10 selections. The default value is 3.

0 Motor potentiometer UP

Contact closed: Reference increases until the contact is opened.

1 Enable PID reference 2

Contact open: PID controller reference selected with parameter R3.4.

Contact closed: PID controller keypad reference 2 selected with parameter R3.5.

2 External fault

Contact closed: Fault is displayed and motor stopped when the input is active

3 External fault

Contact open: Fault is displayed and motor stopped when the input is not active

4 Fault reset

Contact closed: All faults reset

5 Run enable

Contact open: Start of motor disabled

Contact closed: Start of motor enabled

6 Preset speed

7 DC-braking command

Contact closed: In Stop mode, the DC braking operates until the contact is opened

(2.2.2)

Output

frequency

DIN3

RUN

STOP

a) DIN3 as DC-brake command input and stop-mode =

Ramp

Figure 6. DIN3 as DC-brake command input: a) Stop mode = Ramp, b) Stop mode = coasting

8 PID disable

9 PID disabled; go to Preset speed

10 PID keypad reference 2

307 Analogue output 1 function

This parameter selects the desired function for the analogue output 1 signal.

0 Not used

1 Output frequency (0—f

max

)

2 Frequency reference (0—f

3 Motor speed (0—Motor nominal speed)

4 Motor current (0—Motor nominal current)

5 Motor torque (0—Motor nominal torque)

6 Motor power (0—Motor nominal power)

7 Motor voltage (0—Motor nominal voltage)

8 DC-link voltage (0—Motor nominal voltage)

ID515

t

NX12K83

(2.3.1.1)

)

max

DIN3

RUN

STOP

b) DIN3 as DC-brake command input and stop-mode =

Coasting

NX12K83

t

24-hour support: +358 (0)201 212 575 • Email: vacon@vacon.com

4

Page 30

28 • vacon Description of parameters

9 PI controller temperature reference

10 PI controller actual temperature (from FSA11)

11 PI controller error value of the temperature

12 PI controller output

13 Pressure from PT11, pump inlet

308 Analogue output 1 filter time

(2.3.1.2)

Defines the filtering time of the analogue output signal. Setting this parameter value 0

will deactivate filtering.

309 Analogue output 1 inversion

(2.3.1.3)

Inverts the analogue output signal:

Maximum output signal = Minimum set value

Minimum output signal = Maximum set value

See parameter ID311 below.

310 Analogue output 1 minimum

(2.3.1.4)

Defines the signal minimum to either 0 mA or 4 mA (living zero). Note the difference in

analogue output scaling in parameter ID311 (Figure 7).

0 Set minimum value to 0 mA

1 Set minimum value to 4 mA

311 Analogue output 1 scale

Scaling factor for analogue output.

(2.3.1.5)

Analogue

output

current

20 mA

12 mA

10 mA

ID310 = 1

4 mA

ID310 = 0

0 mA

0

ID311 =

200%

0.5

Figure 7. Analogue output scaling

ID311 =

100%

ID311 =

50%

Max. value of signal

selected by ID307

1.0

NX12K18

4

Tel. +358 (0)201 2121 • Fax: +358 (0)201 2121 205

Page 31

Description of parameters vacon • 29

313 Relay output 1 function

Setting value Signal content

0 = Not used Out of operation

1 = Ready The AC drive is ready to operate

2 = Run The AC drive operates (motor is running)

3 = Fault A fault trip has occurred

4 = Fault inverted A fault trip has not occurred

5 = FC overheat warning

6 = External fault or warning Fault or warning depending on par. ID701

7 = Reference fault or warning

8 = Warning Always if warning exists

9 = Reversed The reverse command has been selected

10 = Preset speed 1 The preset speed has been selected with digital input

11 = At speed The output frequency has reached the set reference

12 = Motor regulator activated Overvoltage or overcurrent regulator was activated

13 = Output frequency limit supervision

14 = Control from I/O terminals I/O control mode selected (in menu M3)

15 = Thermistor fault or warning (Appl.2) The thermistor input of option board indicates over-

16 = Actual value supervision Actual value supervision is active

17 = Cooling OK

(2.3.4.2)

The heat-sink temperature exceeds +70°C

Fault or warning depending on par. ID700

- if analogue reference is 4—20 mA and signal is <4mA

The output frequency goes outside the set supervision low limit/high limit (see parameter ID's 315

and 316 below)

temperature. Fault or warning depending on par.

ID732.

Table 30. Output signals via relay outputs RO1 and RO2.

315 Output frequency limit supervision function

0 No supervision

1 Low limit supervision

2 High limit supervision

If the output frequency goes under/over the set limit (ID316) this function generates a

warning message via the relay output RO1 or RO2 depending on the settings of

parameters ID313 and ID1513.

(2.5.4)

24-hour support: +358 (0)201 212 575 • Email: vacon@vacon.com

4

Page 32

30 • vacon Description of parameters

316 Output frequency limit supervision value

Selects the frequency value supervised by parameter ID315. See Figure 8.

ID316

Example:

f[Hz]

21 RO1

22 RO1

23 RO1

ID315 = 2

21 RO1

22 RO1

23 RO1

Figure 8. Output frequency supervision

332 PID controller reference signal

(2.9.2)

Defines which frequency reference place is selected for the PID controller.

0 Reference from keypad (PID reference 1, Menu M3, par. R3.4)

1 Reference from keypad (PID reference 2, Menu M3, par. R3.5)

2 Fieldbus reference (FBProcessDataIN1)

334 Actual value selection

(2.9.3)

(2.5.5)

t

21 RO1

22 RO1

23 RO1

NX12K19

0 AI1 (control board)

1 AI2 (control board)

2 Fieldbus (FBProcessDataIN2)

336 Actual value 1 minimum scale

Sets the minimum scaling point for Actual value.

See

Figure 9.

337 Actual value 1 maximum scale

Sets the maximum scaling point for Actual value.

See

Figure 9.

(2.9.7)

100

(2.9.8)

Scaled

input signal [%]

0

0

0

4

ID336 = 30%

ID337 = 80%

1008030

10,0 V8,03,0

16,0

6,0

8,8 20,0 mA

16,8

20, 0 m A

NX12k34.f h11

Analogue

input [%]

4

Figure 9. Example of actual value signal

scaling

Tel. +358 (0)201 2121 • Fax: +358 (0)201 2121 205

Page 33

Description of parameters vacon • 31

24-hour support: +358 (0)201 212 575 • Email: vacon@vacon.com

4

Page 34

32 • vacon Description of parameters

340 PID error value inversion

This parameter allows you to invert the error value of the PID controller (and thus the

operation of the PID controller).

0 No inversion

1 Inverted

378 AI1 signal filter time

When this parameter is given a value greater

than 0 the function that filters out disturbances

from the incoming analogue signal is activated.

Long filtering time makes the regulation

response slower. See Figure 10.

(2.9.9)

(2.2.8)

100%

63%

%

Unfiltered

signal

Filtered

signal

t [s]

ID378

NX12K74

379 AI1 signal range

(2.2.3)

0 Signal range 0...20 mA

1 Signal range 4...20 mA

2 Signal range 0...10 V

3 Signal range 2...10 V

380 AI1 custom setting minimum

381 AI1 custom setting maximum

These parameters set the analogue input signal for any input signal span between

0.00...100.00%. However, the max value of par. ID380 cannot be greater than the value

set for parameter ID381, and the min value of par. ID381 cannot be smaller than the max

value of par. ID380.

Note: Parameter ID379

AI1 signal range

See also Figure 11.

(2.2.5)

(2.2.6)

is inactivated if ID380 ≠ 0% or ID381 ≠ 100%.

Figure 10. AI1 signal filtering

4

Tel. +358 (0)201 2121 • Fax: +358 (0)201 2121 205

Page 35

Description of parameters vacon • 33

387 AI1 signal inversion

If this parameter = 0, no inversion of analogue signal takes place.

If this parameter = 1 inversion of analogue signal takes place.

(2.2.7)

AO signal

Max

ID379 = 0

AI1 = 0—20mA

Min

ID380

Figure 11. AI1 no signal inversion

ID381

AI1

100%0

NX12K71

389 AI2 signal filter time

See parameter ID378.

390 AI2 signal range

0 Signal range 0...20 mA

1 Signal range 4...20 mA

AO signal

Max

Min

ID380

Figure 12. AI1 signal inversion

(2.2.14)

(2.2.9)

ID320 = 0

AI1 = 0—20mA

ID381

AI1

100%0

NX12K73

24-hour support: +358 (0)201 212 575 • Email: vacon@vacon.com

4

Page 36

34 • vacon Description of parameters

391 AI2 custom setting minimum

392 AI2 custom setting maximum

(2.2.11)

(2.2.12)

See parameters ID380 and ID381.

398 AI2 signal inversion

(2.2.13)

See parameter ID387.

500 Acceleration/Deceleration ramp 1 shape

The start and end of acceleration and deceleration ramps can be smoothed with these

parameters. Setting value 0 gives a linear ramp shape which causes acceleration and

deceleration to act immediately to the changes in the reference signal.

Setting a value 0.1…10 seconds for this parameter produces an S-shaped acceleration/

deceleration. The acceleration time is determined with parameters ID103/ID104.

[Hz]

ID103, ID104

(2.4.1)

ID500

ID500

Figure 13. Acceleration/Deceleration (S-shaped)

504 Brake chopper

0 = No brake chopper used

1 = Brake chopper in use and tested when running. Can be tested also in READY state

2 = External brake chopper (no testing)

3 = Used and tested in READY state and when running

When the AC drive is decelerating the motor, the inertia of the motor and the load are fed

into an external brake resistor. This enables the AC drive to decelerate the load with a

torque equal to that of acceleration (provided that the correct brake resistor has been

selected). See separate Brake resistor installation manual.

[t]

NX12K20

(2.4.2)

4

Tel. +358 (0)201 2121 • Fax: +358 (0)201 2121 205

Page 37

Description of parameters vacon • 35

505 Start function

Ramp:

0 The AC drive starts from 0 Hz and accelerates to the set reference frequency

Flying start:

1 The AC drive is able to start into a running motor by applying a small torque to

506 Stop function

Coasting:

0 The motor coasts to a halt without any control from the AC drive, after the Stop

Ramp:

1 After the Stop command, the speed of the motor is decelerated according to

Normal stop: Ramp/ Run Enable stop: coasting

2 After the Stop command, the speed of the motor is decelerated according to

Normal stop: Coasting/ Run Enable stop: ramping

3 The motor coasts to a halt without any control from the AC drive. However,

(2.1.11)

within the set acceleration time. (Load inertia or starting friction may cause

prolonged acceleration times).

motor and searching for the frequency corresponding to the speed the motor

is running at. Searching starts from the maximum frequency towards the

actual frequency until the correct value is detected. Thereafter, the output

frequency will be increased/decreased to the set reference value according to

the set acceleration/deceleration parameters.

Use this mode if the motor is coasting when the start command is given. With

the flying start it is possible to ride through short mains voltage interruptions.

(2.1.12)

command.

the set deceleration parameters.

If the regenerated energy is high it may be necessary to use an external

braking resistor for faster deceleration.

the set deceleration parameters. However, when Run Enable is selected, the

motor coasts to a halt without any control from the AC drive.

when Run Enable signal is selected, the speed of the motor is decelerated

according to the set deceleration parameters. If the regenerated energy is

high it may be necessary to use an external braking resistor for faster

deceleration.

507 DC-braking current

(2.4.3)

Defines the current injected into the motor during DC-braking.

24-hour support: +358 (0)201 212 575 • Email: vacon@vacon.com

4

Page 38

36 • vacon Description of parameters

508 DC-braking time at stop

Determines if braking is ON or OFF and the braking time of the DC-brake when the

motor is stopping. The function of the DC-brake depends on the stop function, parameter

ID506.

0 DC-brake is not used

>0 DC-brake is in use and its function depends on the Stop function,

(param. ID506). The DC-braking time is determined with this parameter.

Par. ID506 = 0; Stop function = Coasting:

After the stop command, the motor coasts to a stop without control of the AC drive.

With DC-injection, the motor can be electrically stopped in the shortest possible time,

without using an optional external braking resistor.

The braking time is scaled according to the frequency when the DC-braking starts. If the

frequency is ≥ the nominal frequency of the motor, the set value of parameter ID508

determines the braking time. When the frequency is ≤10% of the nominal, the braking

time is 10% of the set value of parameter ID508.

f

out

(2.4.4)

f

out

f

n

Output frequency

Motor speed

DC-braking ON

t = 1 x Par. ID508

RUN

STOP

t

0,1 x f

f

n

n

RUN

STOP

Figure 14. DC-braking time when Stop mode = Coasting.

Par. ID506 = 1; Stop function = Ramp:

After the Stop command, the speed of the

motor is reduced according to the set

deceleration parameters, as fast as

possible, to the speed defined with

parameter ID515, where the DC-braking

starts.

The braking time is defined with parameter

ID508. If high inertia exists, it is recommended to use an external braking resistor

for faster deceleration. See Figure 15.

Output frequency

Motor speed

DC-braking ON

t = 0,1 x Par. ID508

f

par. ID515

RUN

STOP

out

t

NX12K21

Motor speed

Output frequency

DC-braking

t

t = Par. ID508

NX12K23

Figure 15. DC-braking time when Stop mode

= Ramp

4

Tel. +358 (0)201 2121 • Fax: +358 (0)201 2121 205

Page 39

Description of parameters vacon • 37

509 Prohibit frequency area 1; Low limit

510 Prohibit frequency area 1; High limit

In some systems it may be necessary to

avoid certain frequencies because of

mechanical resonance problems. With these

parameters it is possible to set limits for the

"skip frequency" region. See Figure 16.

515 DC-braking frequency at stop

(2.4.5)

(2.5.1)

(2.5.2)

Output

frequency [Hz]

ID509 ID510

Reference [Hz]

NX12K33

Figure 16. Example of prohibit frequency area

setting.

The output frequency at which the DC-braking is applied. See Figure 16.

516 DC-braking time at start

(2.4.6)

DC-brake is activated when the start command is given. This parameter defines the time

before the brake is released. After the brake is released, the output frequency increases

according to the set start function by parameter ID505.

518 Acceleration/deceleration ramp speed scaling ratio between prohibit frequency

limits 23457

(2.5.3, 2.5.7)

Defines the acceleration/deceleration time when the output frequency is between the

selected prohibit frequency range limits (parameters ID509 and ID510). The ramping

speed (selected acceleration/ deceleration time 1 or 2) is multiplied with this factor. E.g.

value 0.1 makes the acceleration time 10 times shorter than outside the prohibit

frequency range limits.

24-hour support: +358 (0)201 212 575 • Email: vacon@vacon.com

4

Page 40

38 • vacon Description of parameters

fout [Hz]

Par. ID518 = 0,2

Par. ID510

Par. ID509

Figure 17. Ramp speed scaling between prohibit frequencies

519 Flux braking current

Defines the flux braking current value. The value setting range depends on the used

application.

520 Flux brake

Instead of DC braking, flux braking is a useful way to raise the braking capacity in cases

where additional brake resistors are not needed.

When braking is needed, the frequency is reduced and the flux in the motor is increased,

which in turn increases the motor's capability to brake. Unlike DC braking, the motor

speed remains controlled during braking.

The flux braking can be set ON or OFF.

0 = Flux braking OFF

1 = Flux braking ON

Note: Flux braking converts the energy into heat at the motor, and should be used

intermittently to avoid motor damage.

600 Motor control mode

(2.6.1)

Par. ID518 = 1,2

Time [s]

NX12k81

(2.4.8)

(2.4.7)

4

0 Frequency control: The I/O terminal and keypad references are frequency ref-

erences and the AC drive controls the output frequency

(output frequency resolution = 0.01 Hz)

1 Speed control: The I/O terminal and keypad references are speed refer-

ences and the AC drive controls the motor speed

compensating the motor slip (accuracy ± 0.5%).

Tel. +358 (0)201 2121 • Fax: +358 (0)201 2121 205

Page 41

Description of parameters vacon • 39

601 Switching frequency

Motor noise can be minimised using a high switching frequency. Increasing the switching

frequency reduces the capacity of the AC drive unit.

The range of this parameter depends on the size of the AC drive:

Type Min. [kHz] Max. [kHz] Default [kHz]

0016—0061 NX_5 1.0 10,0 10.0

0072—2300 NX_5 1.0 10.0 3.6

0170—1500 NX_6 1.0 6.0 1.5

Table 31. Size-dependent switching frequencies

Note! The actual switching frequency might be reduced down to 1.5kHz by thermal

management functions. This has to be considered when using sine wave filters or

other output filters with a low resonance frequency.

(2.6.8)

602 Field weakening point

The field weakening point is the output frequency at which the output voltage reaches the

set (ID603) maximum value.

603 Voltage at field weakening point

Above the frequency at the field weakening point, the output voltage remains at the set

maximum value. Below the frequency at the field weakening point, the output voltage

depends on the setting of the U/f curve parameters. See parameters ID109, ID108, ID604

and ID605.

When the parameters ID110 and ID111 (nominal voltage and nominal frequency of the

motor) are set, the parameters ID602 and ID603 are automatically given the

corresponding values. If you need different values for the field weakening point and the

maximum output voltage, change these parameters after setting the parameters ID110

and ID111.

604 U/f curve, middle point frequency

(2.6.3)

(2.6.4)

(2.6.5)

If the programmable U/f curve has been selected with parameter ID108 this parameter

defines the middle point frequency of the curve. See Figure 2.

605 U/f curve, middle point voltage

If the programmable U/f curve has been selected with the parameter ID108 this

parameter defines the middle point voltage of the curve. See Figure 2.

606 Output voltage at zero frequency

If the programmable U/f curve has been selected with the parameter ID108 this

parameter defines the zero frequency voltage of the curve. NOTE: If the value of

parameter ID108 is changed this parameter is set to zero. See Figure 2.

(2.6.6)

(2.6.7)

24-hour support: +358 (0)201 212 575 • Email: vacon@vacon.com

4

Page 42

40 • vacon Description of parameters

607 Overvoltage controller

These parameters allow the under-/overvoltage controllers to be switched out of

operation. This may be useful, for example, if the mains supply voltage varies more than

–15% to +10% and the application will not tolerate this over-/undervoltage. In this case,

the regulator controls the output frequency taking the supply fluctuations into account.

0 Controller switched off

1 Controller switched on = Minor adjustments of OP frequency are made

608 Undervoltage controller

See par. ID607.

Note: Over-/undervoltage trips may occur when controllers are switched out of

operation.

0 Controller switched off

1 Controller switched on = Minor adjustments of OP frequency are made

700 Response to the 4mA reference fault

0 = No response

1 = Warning

2 = Fault, stop mode after fault according to ID506

3 = Fault, stop mode after fault always by coasting

A warning or a fault action and message is generated if the 4…20 mA reference signal is

used and the signal falls below 3.5 mA for 5 seconds or below 0.5 mA for 0.5 seconds.

The information can also be programmed into relay outputs RO1 or RO2.

701 Response to external fault

(2.6.9)

(2.6.10)

(2.7.1)

(2.7.2)

0 = No response

1 = Warning

2 = Fault, stop mode after fault according to ID506

3 = Fault, stop mode after fault always by coasting

A warning or a fault action and message is generated from the external fault signal in

the programmable digital input DIN3. The information can also be programmed into

relay outputs RO1 or RO2.

702 Output phase supervision

0 = No response

1 = Warning

2 = Fault, stop mode after fault according to ID506

3 = Fault, stop mode after fault always by coasting

Output phase supervision of the motor ensures that the motor phases have an

approximately equal current.

(2.7.5)

4

Tel. +358 (0)201 2121 • Fax: +358 (0)201 2121 205

Page 43

Description of parameters vacon • 41

703 Earth fault protection

(2.7.6)

0 = No response

1 = Warning

2 = Fault, stop mode after fault according to ID506

3 = Fault, stop mode after fault always by coasting

Earth fault protection ensures that the sum of the motor phase currents is zero. The

overcurrent protection is always working and protects the AC drive from earth faults with

high currents.

704 Motor thermal protection

(2.7.7)

0 = No response

1 = Warning

2 = Fault, stop mode after fault according to ID506

3 = Fault, stop mode after fault always by coasting

If tripping is selected the drive will stop and activate the fault stage. Deactivating the

protection, i.e. setting parameter to 0, will reset the thermal stage of the motor to 0%.

705 Motor thermal protection: Motor ambient temp. factor

The factor can be set between -100.0%...100.0%.

706 Motor thermal protection: Motor cooling factor at zero speed

(2.7.8)

(2.7.9)

The current can be set between 0—150.0% x I

. This parameter sets the value for

nMotor

thermal current at zero frequency. See Figure 18.

The default value is set assuming that there is no external fan cooling the motor. If an

external fan is used this parameter can be set to 90% (or even higher).

Note: The value is set as a percentage of

P

the motor name plate data, par. ID113

cooling

(Nominal current of motor), not the drive's

nominal output current. The motor's

nominal current is the current that the

100%

Overload area

motor can withstand in direct on-line use

without being overheated.

If you change the parameter Nominal

current of motor, this parameter is

automatically restored to the default value.

Par.

ID706=40%

Setting this parameter does not affect the

maximum output current of the drive which

is determined by parameter ID107 alone.

0

NX12k62

f

n

Figure 18. Motor thermal current IT curve

I

T

f

24-hour support: +358 (0)201 212 575 • Email: vacon@vacon.com

4

Page 44

42 • vacon Description of parameters

707 Motor thermal protection: Time constant

This time can be set between 1 and 200 minutes.

This is the thermal time constant of the motor. The bigger the motor, the bigger the time

constant. The time constant is the time within which the calculated thermal stage has

reached 63% of its final value.

The motor thermal time is specific to the motor design and it varies between different

motor manufacturers.

If the motor's t6–time (t6 is the time in seconds the motor can safely operate at six times

the rated current) is known (given by the motor manufacturer) the time constant

parameter can be set basing on it. As a rule of thumb, the motor thermal time constant

in minutes equals to 2xt6. If the drive is in stop stage the time constant is internally

increased to three times the set parameter value. The cooling in the stop stage is based

on convection and the time constant is increased. See also Figure 19.

708 Motor thermal protection: Motor duty cycle

Defines how much of the nominal motor load is applied. The value can be set to

0%…100%.

(2.7.10)

(2.7.11)

Motor temperature

105%

Motor

current

I/I

T

Figure 19. Motor temperature calculation

709 Stall protection

0 = No response

1 = Warning

2 = Fault, stop mode after fault according to ID506

3 = Fault, stop mode after fault always by coasting

Setting the parameter to 0 will deactivate the protection and reset the stall time counter.

Trip area

Time constant T

Motor temperature

*) Changes by motor size and

adjusted with parameter ID707

(2.7.12)

Θ

= (I/I

*)

)2 x (1-e

T

Fault/warning

par. ID704

-t/T

)

Time

NX12k82

4

Tel. +358 (0)201 2121 • Fax: +358 (0)201 2121 205

Page 45

Description of parameters vacon • 43

710 Stall current limit

The current can be set to 0.0…2*IH. For a

stall stage to occur, the current must have

exceeded this limit. See Figure 20. The

software does not allow entering a greater

value than 2*I

. If parameter ID107 Nominal

H

current limit of motor is changed, this

parameter is automatically calculated to

90% of the current limit.

711 Stall time

(2.7.14)

This time can be set between 1.0 and

120.0s.

This is the maximum time allowed for a

stall stage. The stall time is counted by an

internal up/down counter.

If the stall time counter value goes above

this limit the protection will cause a trip

(see ID709).

(2.7.13)

I

Stall area

Par. ID710

Par. ID712

Figure 20. Stall characteristics settings

Stall time counter

Par. ID711

Trip area

Trip/warning

par. ID709

Time

f

NX12k63

712 Stall frequency limit

The frequency can be set between 1-f

For a stall state to occur, the output frequency must have remained below this limit.

713 Underload protection

0 = No response

1 = Warning

2 = Fault, stop mode after fault according to ID506

3 = Fault, stop mode after fault always by coasting

If tripping is set active the drive will stop and activate the fault stage.

Deactivating the protection by setting the parameter to 0 will reset the underload time

counter to zero.

(2.7.15)

max

(2.7.16)

(ID102).

Stall

No stall

Figure 21. Stall time count

NX12k64

24-hour support: +358 (0)201 212 575 • Email: vacon@vacon.com

4

Page 46

44 • vacon Description of parameters

714 Underload protection, field weakening area load

The torque limit can be set between

10.0—150.0 % x T

nMotor

.

This parameter gives the value for the

minimum torque allowed when the output

frequency is above the field weakening

Par. ID714

point. See Figure 22.