vacon® nxc/p

ac drives

user manual

vacon • 3

TABLE OF CONTENTS

Document ID: DPD00890C

Revision release date: 21.3.2018

1. SAFETY .............................................................................................................6

1.1 Warnings .............................................................................................................................6

1.2 Safety instructions ..............................................................................................................7

1.3 grounding and earth fault protection .................................................................................7

1.4 Running the motor ..............................................................................................................8

2. INTRODUCTION .................................................................................................9

2.1 Manufacturer's declaration of conformity........................................................................10

3. RECEIPT OF DELIVERY.................................................................................... 11

3.1 Type designation code.......................................................................................................11

3.1.1 NX type designation..............................................................................................11

3.2 NXC additional option codes .............................................................................................12

3.2.1 Cabling (C-group) .................................................................................................12

3.2.2 External Terminals (T-group)...............................................................................12

3.2.3 Input Device (I-group)...........................................................................................12

3.2.4 Main Circuit (M-group) .........................................................................................12

3.2.5 Output Filters (O-group).......................................................................................12

3.2.6 Protection Devices (P-group) ...............................................................................12

3.2.7 General (G-group).................................................................................................13

3.2.8 Auxiliary Equipment (A-group).............................................................................13

3.2.9 Door Mounted (D-group) ......................................................................................13

3.3 Storage ..............................................................................................................................14

3.4 Maintenance......................................................................................................................15

4. TECHNICAL DATA ........................................................................................... 16

4.1 Power ratings....................................................................................................................16

4.1.1 VACON® NXC – Mains voltage 380-500 V ...........................................................16

4.1.2 VACON® NXC low harmonic drives – Mains voltage 380-500 V..........................17

4.1.3 VACON® NXP/C 6 – Mains voltage 500-690 V .....................................................18

4.1.4 VACON® NXC low harmonic drives – Mains voltage 525-690 V..........................19

4.2 Technical data ...................................................................................................................21

5. MOUNTING ......................................................................................................24

5.1 Dimensions .......................................................................................................................24

5.2 Lifting the unit out of the transport packaging ................................................................26

5.3 Fixing the unit to the floor or to the wall ..........................................................................27

5.3.1 Fixing to the floor and to the wall.........................................................................27

5.3.2 Fixing to the floor only..........................................................................................28

5.4 AC choke connections.......................................................................................................29

5.5 Auxiliary voltage transformer tappings............................................................................30

5.6 Cooling ..............................................................................................................................31

5.6.1 Free space around the cabinet.............................................................................31

5.7 Power losses .....................................................................................................................33

6. CABLING AND CONNECTIONS......................................................................... 34

6.1 Understanding the power unit topology ...........................................................................34

6.2 Power connections............................................................................................................36

6.2.1 LCL filter wiring diagram of NXC low-harmonic drive ........................................36

6.2.2 Mains and motor cables .......................................................................................38

6.2.3 Thermal supervision of option +ODC ...................................................................46

6.2.4 DC supply and brake resistor cables ...................................................................46

6.2.5 Control cable ........................................................................................................46

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

vacon • 4

6.2.6 Cable and fuse sizes, 380-500 V units..................................................................47

6.2.7 Cable and fuse sizes, 500/525-690 V units...........................................................50

7. LOW HARMONIC CABINET DRIVE....................................................................53

7.1 NXC Low-Harmonic Cabinet Pre-Charging and MCCB Operating Instructions..............53

7.1.1 Manual operation (MAN).......................................................................................54

7.1.2 Remote operation (REM) ......................................................................................55

7.1.3 Automatic operation (AUTO).................................................................................56

7.1.4 Circuit-Breaker TRIP due to overload or short-circuit........................................57

8. INSTALLATION INSTRUCTIONS.......................................................................58

8.1 Cable installation and the UL standards ..........................................................................60

8.1.1 Cable and motor insulation checks......................................................................61

8.2 Control unit .......................................................................................................................62

8.2.1 Control connections..............................................................................................63

8.2.2 Control terminal signals.......................................................................................65

8.3 Connecting power supply and internal control cables.....................................................69

8.4 Optic fibre cables, signal listing and connections............................................................70

9. CONTROL KEYPAD ..........................................................................................71

9.1 Indications on the Keypad display ....................................................................................71

9.1.1 Drive status indications ........................................................................................71

9.1.2 Control place indications......................................................................................72

9.1.3 Status LEDs (green – green – red).......................................................................72

9.1.4 Text lines...............................................................................................................72

9.2 Keypad push-buttons........................................................................................................73

9.2.1 Button descriptions ..............................................................................................73

9.3 Navigation on the control keypad .....................................................................................74

9.3.1 Monitoring menu (M1) ..........................................................................................76

9.3.2 Parameter menu (M2) ..........................................................................................77

9.3.3 Keypad control menu (M3) ...................................................................................78

9.3.4 Active faults menu (M4)........................................................................................80

9.3.5 Fault history menu (M5) .......................................................................................83

9.3.6 System menu (M6)................................................................................................84

9.3.7 Expander board menu (M7) ..................................................................................99

9.4 Further keypad functions................................................................................................100

10. COMMISSIONING........................................................................................... 101

10.1 Safety...............................................................................................................................101

10.2 Commissioning of the AC drive.......................................................................................102

11. FAULT TRACING............................................................................................104

11.1 Fault time data record ....................................................................................................104

11.2 Fault codes......................................................................................................................106

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

vacon • 5

AT LEAST THE FOLLOWING STEPS OF THE START-UP QUICK GUIDE MUST BE PERFORMED

DURING THE INSTALLATION AND COMMISSIONING.

IF ANY PROBLEMS OCCUR, PLEASE CONTACT YOUR LOCAL DISTRIBUTOR.

Start-up Quick Guide

1. Check that the delivery corresponds to your order, see Chapter 3.

2. Before taking any commissioning actions read carefully the safety instructions in

Chapter 1.

3. Before the mechanical installation, check the minimum clearances around the unit

(Chapter 5.6) and check the ambient conditions in Chapter 4.2.

4. Check the size of the motor cable, mains cable, mains fuses and check the cable

connections, read Chapters 6.2.2 to 6.2.7.

5. Follow the installation instructions, see Chapter 7.

6. Control connections are explained in Chapter 8.2.1.

7. If the Start-Up wizard is active, select the language of the keypad, the application you

want to use and set the basic parameters asked by the wizard. Always confirm by

pressing the

Enter button

. If the Start-Up wizard is not active, follow the instructions 7a

and 7b.

7a. Select the language of the keypad from the Menu M6, page 6.1. Instructions on using the

keypad are given in Chapter 9.

7b. Select the application you want to use from the Menu M6, page 6.2. Instructions on using

the keypad are given in Chapter 9.

8. All parameters have factory default values. In order to ensure proper operation, check

the rating plate data for the values below and the corresponding parameters of

parameter group G2.1.

• nominal voltage of the motor

• nominal frequency of the motor

• nominal speed of the motor

• nominal current of the motor

• motor cos

ϕ

Some options may require special parameter settings.

All parameters are explained in the VACON

®

All in One Application Manual.

9. Follow the commissioning instructions, see Chapter 10.

®

10. The VACON

NX_ AC drive is now ready for use.

Vacon Ltd is not responsible for the use of the frequency converters against the

instructions.

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

vacon • 6 SAFETY

9000.emf

9000.emf

13006.emf

13006.emf

13006.emf

13006.emf

13006.emf

13006.emf

13006.emf

13006.emf

13006.emf

13006.emf

1. SAFETY

ONLY A COMPETENT ELECTRICIAN MAY CARRY OUT THE

ELECTRICAL INSTALLATION

= DANGEROUS VOLTAGE!

= WARNING or CAUTION

1.1 Warnings

®

The VACON

NX AC drive is meant for fixed installations only.

Do not perform any measurements when the AC drive is connected to the mains.

Do not perform any voltage withstand tests on any part of VACON

®

NX. There is a

certain procedure according to which the tests shall be performed. Ignoring this

procedure may result in damaged product.

The AC drive has a large capacitive leakage current.

If the AC drive is used as a part of a machine, the machine manufacturer is

responsible for providing the machine with a main switch (EN 60204-1).

Only spare parts delivered by the manufacturer can be used.

The motor starts at power-up if the start command is 'ON'. Furthermore, the I/O

functionalities (including start inputs) may change if parameters, applications or

software are changed. Disconnect, therefore, the motor if an unexpected start can

cause danger.

1

Prior to measurements on the motor or the motor cable, disconnect the motor cables

from the AC drive.

Do not touch the components on the circuit boards. Static voltage discharge may

damage the components.

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

SAFETY vacon • 7

9000.emf

9000.emf

9000.emf

9000.emf

9000.emf

1.2 Safety instructions

The components of the power unit of the AC drive and all cabinet mounted devices

are potentially live when VACON

contact with this voltage is extremely dangerous and may cause death or severe

injury.

The motor terminals U, V, W and the DC-link/brake resistor terminals –/+ and all

other mains devices are potentially live when VACON

even if the motor is not running.

After disconnecting the AC drive from the mains, wait until the fan stops and the

indicators on the keypad go out (if no keypad is attached see the indicators on the

cover). Wait 5 more minutes before doing any work on VACON

not even open the cabinet door before this time has expired.

The control I/O-terminals are isolated from the mains potential. However, the relay

outputs and other I/O-terminals may have a dangerous control voltage present even

®

when VACON

NX is disconnected from mains.

Before connecting the AC drive to mains make sure that the VACON

cable covers as well as the cabinet doors are closed.

®

NX is connected to mains potential. Coming into

®

NX is connected to mains,

®

NX connections. Do

®

NX front and

NOTE! If a fault protection relay is used , it must be of at least type B, preferably B+ ( according to

EN 50178) , with a trip level of 300 mA. This is for fire protection, not for touch protection in grounded

systems.

1.3 grounding and earth fault protection

The VACON® NX AC drive must always be earthed with an grounding conductor connected to the PE

bar in the lower front side of the cabinet.

The earth fault protection inside the AC drive protects only the converter itself against earth faults

in the motor or the motor cable. It is not intended for personal safety.

NOTE! Due to the high capacitive currents present in the AC drive, fault current protective switches

may not function properly.

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

1

vacon • 8 SAFETY

9000.emf

13006.emf

9001.emf

13006.emf

13006.emf

13006.emf

13006.emf

13006.emf

1.4 Running the motor

Warning symbols

For your own safety, please pay special attention to the instructions marked with the following

symbols:

= Dangerous voltage

= General warning

= Hot surface – Risk of burn

MOTOR RUN CHECK LIST

Before starting the motor, check that the motor is mounted properly

and ensure that the machine connected to the motor allows the motor

to be started.

Set the maximum motor speed (frequency) according to the motor and

the machine connected to it.

Before reversing the motor make sure that this can be done safely.

Make sure that no power correction capacitors are connected to the

motor cable.

Make sure that the motor terminals are not connected to mains

potential.

1

NOTE! You can download the English and French product manuals with applicable safety,

warning and caution information from

http://drives.danfoss.com/knowledge-center/technical-documentation/.

REMARQUE Vous pouvez télécharger les versions anglaise et française des manuels produit

contenant l’ensemble des informations de sécurité, avertissements et mises en garde

applicables sur le site http://drives.danfoss.com/knowledge-center/technical-documentation/

.

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

INTRODUCTION vacon • 9

13006.emf

2. INTRODUCTION

The VACON® NXC is a product range of free standing enclosed AC drives for the high power range.

The NXC is a modular product intended for use in all applications where reliability and high

availability is appreciated.

This manual gives the basic information required to successfully perform installation and basic

commissioning. Due to the high amount of options available, not all possible variations are

described in this manual. For more information, refer to delivery-specific documentation. This

manual assumes good competence in installation and commissioning skills.

In the All in One Application Manual you will find information about the different applications

included in the All in One Application Package. Should these applications not meet the requirements

of your process please contact the manufacturer for information on special applications.

Information on the installation of the drive in a cabinet can be found in manuals 'NXP AC drives, IP00

Module Installation, Frames FR10 to FR14 as well as Frequency Inverter and Active Front End

manuals.

This manual is available in both paper and electronic editions. We recommend you to use the

electronic version if possible. If you have the electronic version at your disposal you will be able to

benefit from the following features:

The manual contains several links and cross-references to other locations in the manual which

makes it easier for the reader to move around in the manual, to check and find things faster.

The manual also contains hyperlinks to web pages. To visit these web pages through the links you

must have an internet browser installed on your computer.

In case you are in doubt about your ability to perform installation or commissioning,

do not proceed. Contact your local distributor for advice.

For the NXC low-harmonic drive also see the AFE application manual.

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

2

vacon • 10 INTRODUCTION

2.1 Manufacturer's declaration of conformity

Below you can find the Manufacturer's Declarations of Conformity assuring the compliance of

VACON

®

NXP/C AC drives with the EMC-directives.

2

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

RECEIPT OF DELIVERY vacon • 11

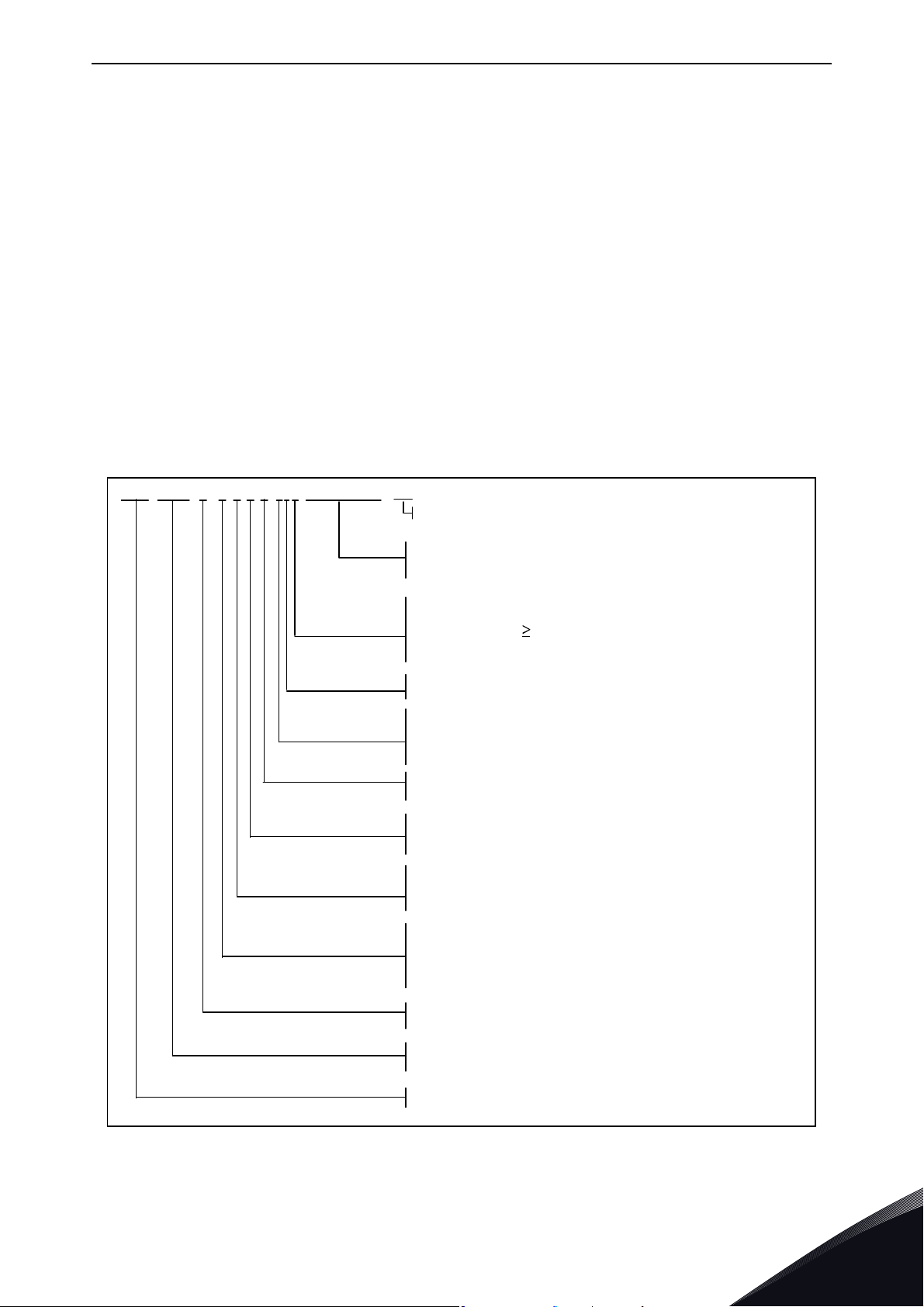

NX C 0 0 00

A 2 L 0 SSG A1A20000C3

+

IFD

5

Product range: NXC = cabinet

Nominal current (lowoverload)

e.g. 0460 =460A etc.

Nominal mains voltage(3-phase):

5 = 380–500Vac, 6 = 525–690Vac

Enclosureclass:

2=IP21/Nema1(cabinet-mounted),

5 = IP54/Nema 12(cabinet-mounted)

Control keypad:

A = standard (alpha-numeric)

B = no local control keypad

F = dummy keypad

G = graphic display

EMC emission level EN61800-3:

L = 2nd environment

T=ForITnetworks

Brake chop per

0 =No brake chopper, 1= Integrated brake chopper

Control

F=standardFR9andNXC

N = standard IP00 FR10 and NXC with IP54 control unit enclosure

G = as Fbut varnished boards

O = asN but varnished boards

Cooling

S = standard air-cooled

Supply

S=6-pulse

T=12-pulse

R = Regenerative low-harmonic (AFE)

Opti on bo ards; each slot is rep resen ted by two ch aracte rs w here :

Ax = basic I/ O board, Bx = expa nder I/O bo ard,

Cx = fieldb us bo ard, Dx = sp ecial bo

ard

NXC options

7001.emf

3. RECEIPT OF DELIVERY

VACON® NX AC drives have undergone scrupulous tests and quality checks at the factory before

they are delivered to the customer. However, after unpacking the product, check that no signs of

transport damages are to be found on the product and that the delivery is complete (compare the

type designation of the product to the code below).

Should the drive have been damaged during the shipping, please contact primarily the cargo

insurance company or the carrier.

If the delivery does not correspond to your order, contact the supplier immediately.

In the small plastic bag included in the delivery you will find a silver Drive modified sticker. The

purpose of the sticker is to notify the service personnel about the modifications made in the AC

drive. Attach the sticker to the equipment to avoid losing it. Should the AC drive be later modified

(option board added, IP or EMC protection level changed), mark the change in the sticker.

3.1 Type designation code

3.1.1 NX type designation

Figure 1. VACON® NXC type designation code

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

3

vacon • 12 RECEIPT OF DELIVERY

3.2 NXC additional option codes

The NXC enclosure solution contains additional pre-engineered hardware options. These options

are appended to the basic type code by using “+” codes. The most common NXC options are listed

below:

3.2.1 Cabling (C-group)

+CIT Input (mains) cabling from TOP

+COT Output motor cabling from TOP

3.2.2 External Terminals (T-group)

+TIO I/O+ aux terminals (35 pcs) X2

+TID I/O+ double aux terminals (70 pcs) Double-decker terminals X2

+TUP Separate terminals for 230 VAC CV X1

3.2.3 Input Device (I-group)

+ILS Load switch

+IFD Fused disconnecting switch With aR Fuses

+ICO Contactor

+IFU Fused With aR Fuses

+ICB Moulded-case or air circuit breaker

3.2.4 Main Circuit (M-group)

+MDC DC-bus bar connection Req. BSF converter hardware

3.2.5 Output Filters (O-group)

+OCM Common mode choke Ferrite

+OCH Common mode choke

+ODU dU/dt

+OSI Sine

3.2.6 Protection Devices (P-group)

Nanoperm

®

3

+PTR Thermistor relay PTB certified

+PES Em. stop (cat 0) DI3

+PED Em. stop (cat 1) DI6 (sys.appl.)

+PAP Arc protection

+PIF Insulation fault sensor For IT-networks

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

RECEIPT OF DELIVERY vacon • 13

3.2.7 General (G-group)

+G40 400 empty cabinet

+G60 600 empty cabinet

+G80 800 empty cabinet

+GPL 100 mm base/plinth For 400 mm, 600 mm or 800 mm

+GPH 200 mm base/plinth For 400 mm, 600 mm or 800 mm

3.2.8 Auxiliary Equipment (A-group)

+AMF Motor fan control

+AMH Motor heater feeder

+AMB Mechanical brake control

+ACH Cabinet heater

+ACL Cabinet light

+ACR Control relay

+AAI Analogue signal isolator AI1, AO1, AI2

+AAC Aux. contact (input device) Wired to DI3

+AAA Aux. contact (control voltage devices) Chained to DI3

+ATx Aux. Transformer 400-690/230 VAC x = 1 (200 VA)

+ADC Power supply 24 VDC 10 A

+ACS 230 VAC customer socket With 30 mA leak current prot.

3.2.9 Door Mounted (D-group)

+DLV Pilot light (Control voltage on) 230 VAC

+DLD Pilot light (DO1) 24 VDC, DO1

+DLF Pilot light (FLT) 230 VAC, RO2

+DLR Pilot light (RUN) 230 VAC, RO1

+DAR Potentiometer for reference AI1

+DCO MC operation switch 0-1-START

x = 2 (750 VA)

x = 3 (2500 VA)

x = 4 (4000 VA)

+DRO Local / Remote op. switch Loc/Rem wired to DI6

+DEP Emergency stop push-button

+DRP Reset push-button DI6

+DAM Analogue meter (AO1) 48 mm, std scale 0-100%

+DCM Analogue meter + current

transformer

+DVM Analogue vltg meter with sel.switch 0, L1-L2, L2-L3, L3-L1

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

48 mm, std scale 0-600 A

3

vacon • 14 RECEIPT OF DELIVERY

3.3 Storage

If the AC drive is to be kept in store before use make sure that the ambient conditions are acceptable:

Storing temperature –40…+70

Relative humidity <95%, no condensation

The environment should also be free from dust. If there is dust in the air the AC drive should be well

protected to make sure dust does not get into the AC drive.

If the AC drive is to be stored during longer periods the power should be connected to the AC drive

once in 24 months and kept on for at least 2 hours. If the storage time exceeds 24 months the

electrolytic DC capacitors need to be charged with caution. Therefore, such a long storage time is

not recommended.

If the storing time is much longer than 24 months, the recharging of the capacitors has to be carried

out so that the possible high leakage current through the capacitors is limited. The best alternative

is to use a DC-power supply with adjustable current limit. The current limit has to be set for example

to 300…500mA and the DC-power supply has to be connected to the B+/B- terminals (DC supply

terminals).

DC-voltage must be adjusted to nominal DC-voltage level of the unit (1.35*Un AC) and supplied at

least for 1 hour.

If DC-voltage is not available and the unit has been stored de-energized much longer than 1 year

consult factory before connecting power.

°C

3

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

RECEIPT OF DELIVERY vacon • 15

3.4 Maintenance

In normal conditions, VACON® NX AC drives are maintenance-free. However, we recommend to

keep the AC drive clean, e.g. by cleaning the heatsink with compressed air whenever necessary.

In IP54 units, the air filters in the door and in the roof should be cleaned or replaced regularly.

We also recommended to follow proactive maintenance schedule to ensure the highest possible

utilization rate of the cabinet drive.

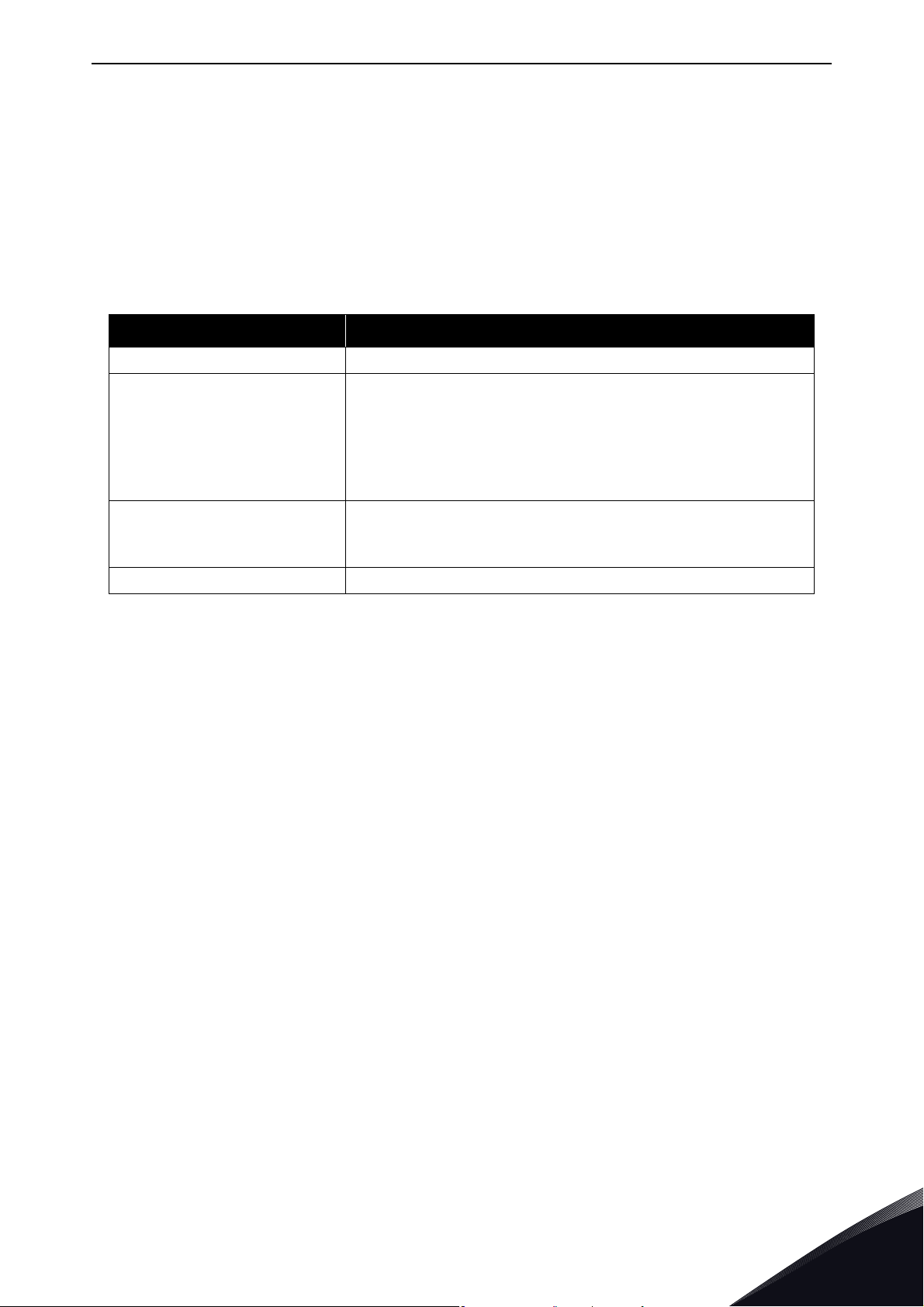

Table 1. Proactive maintenance schedule

Maintenance interval Maintenance action

12 months (if unit stored) • Reform capacitors (see separate instruction)

6-24 months

(depending on environment)

5-7 years • Change cooling fans:

•Check I/O terminals

• Check tightness of mains connection

• Clean cooling tunnel

• Check operation of cooling fan, check for corrosion on

terminals, busbars and other surfaces

• Check door and roof filters

-main fan

- fan of the LCL filter

5-10 years • Change DC bus capacitors if DC voltage ripple is high

.

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

3

vacon • 16 TECHNICAL DATA

4. TECHNICAL DATA

4.1 Power ratings

4.1.1 VACON® NXC – Mains voltage 380-500 V

High overload = Max current IS, 2 sec/20 sec, Rated overload current, 1 min/10 min

Following continuous operation at rated output current, rated overload

current for 1 min, followed by a period of load current less than rated

current, and of such duration that the r.m.s output current, over the duty

cycle, does not exceed rated output current (IH)

Low overload = Max current I

Following continuous operation at rated output current, rated overload

current for 1 min, followed by a period of load current less than rated

current, and of such duration that the r.m.s output current, over the duty

cycle, does not exceed rated output current (IL)

, 2 sec/20 sec, Rated overload current, 1 min/10 min

S

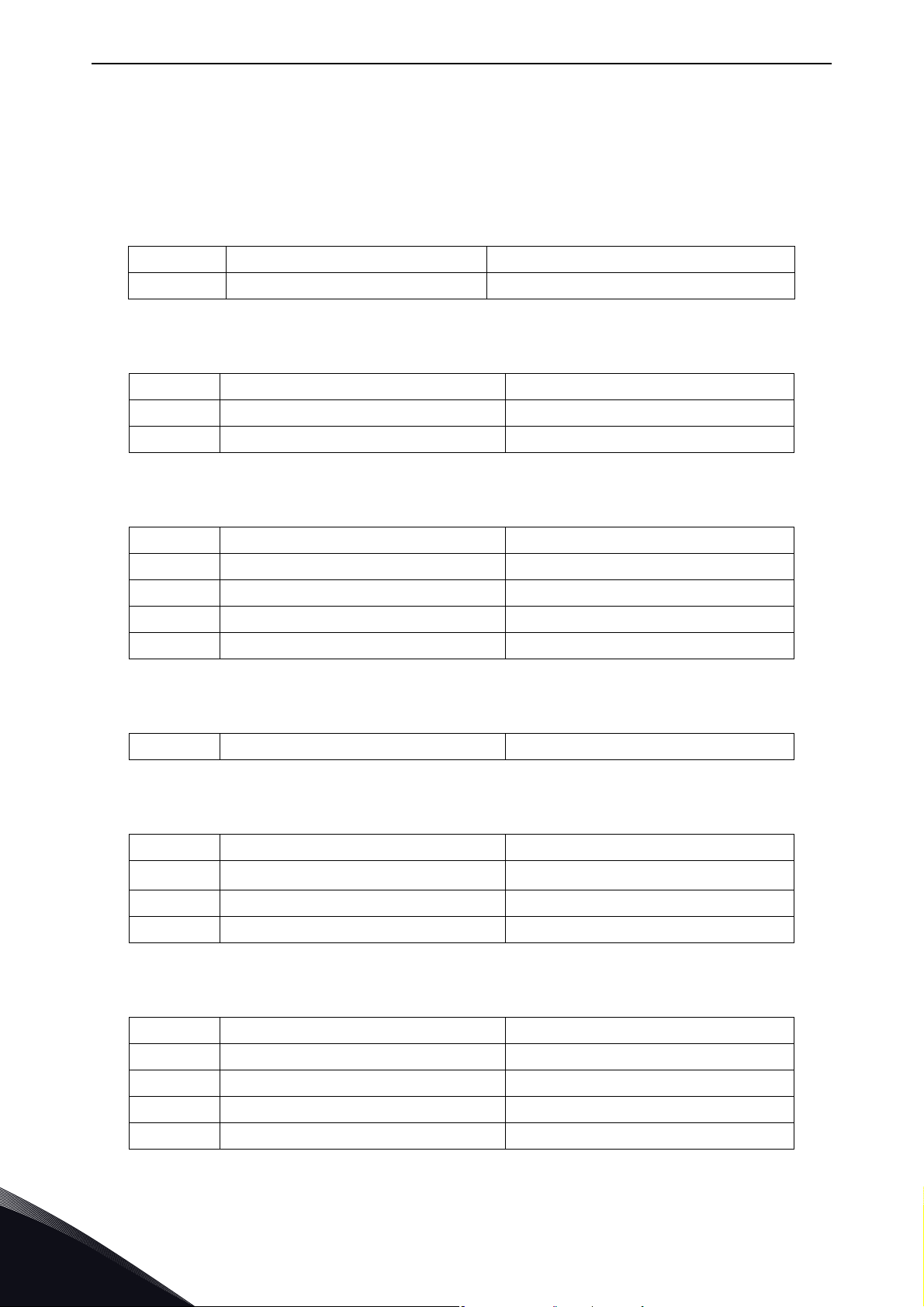

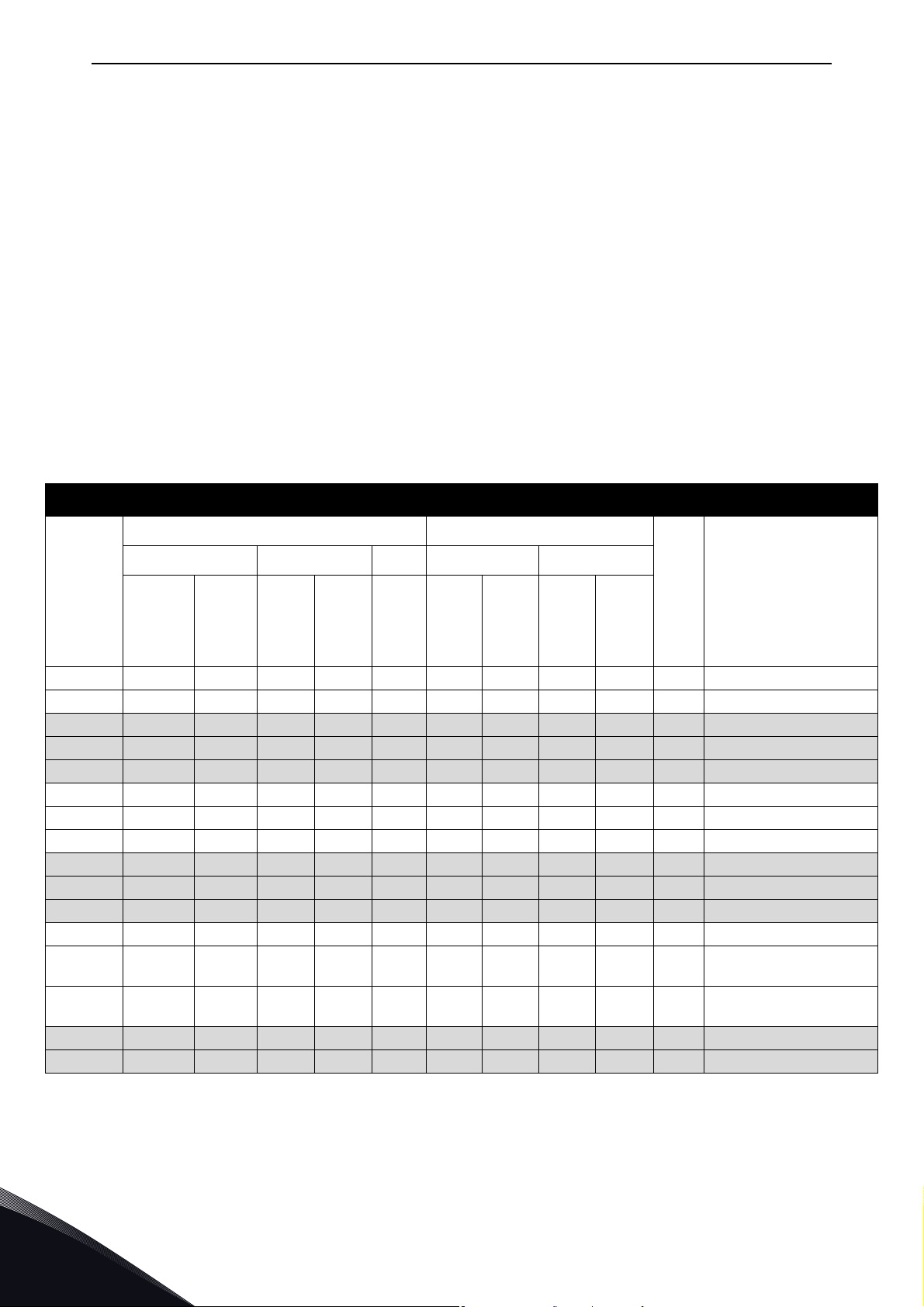

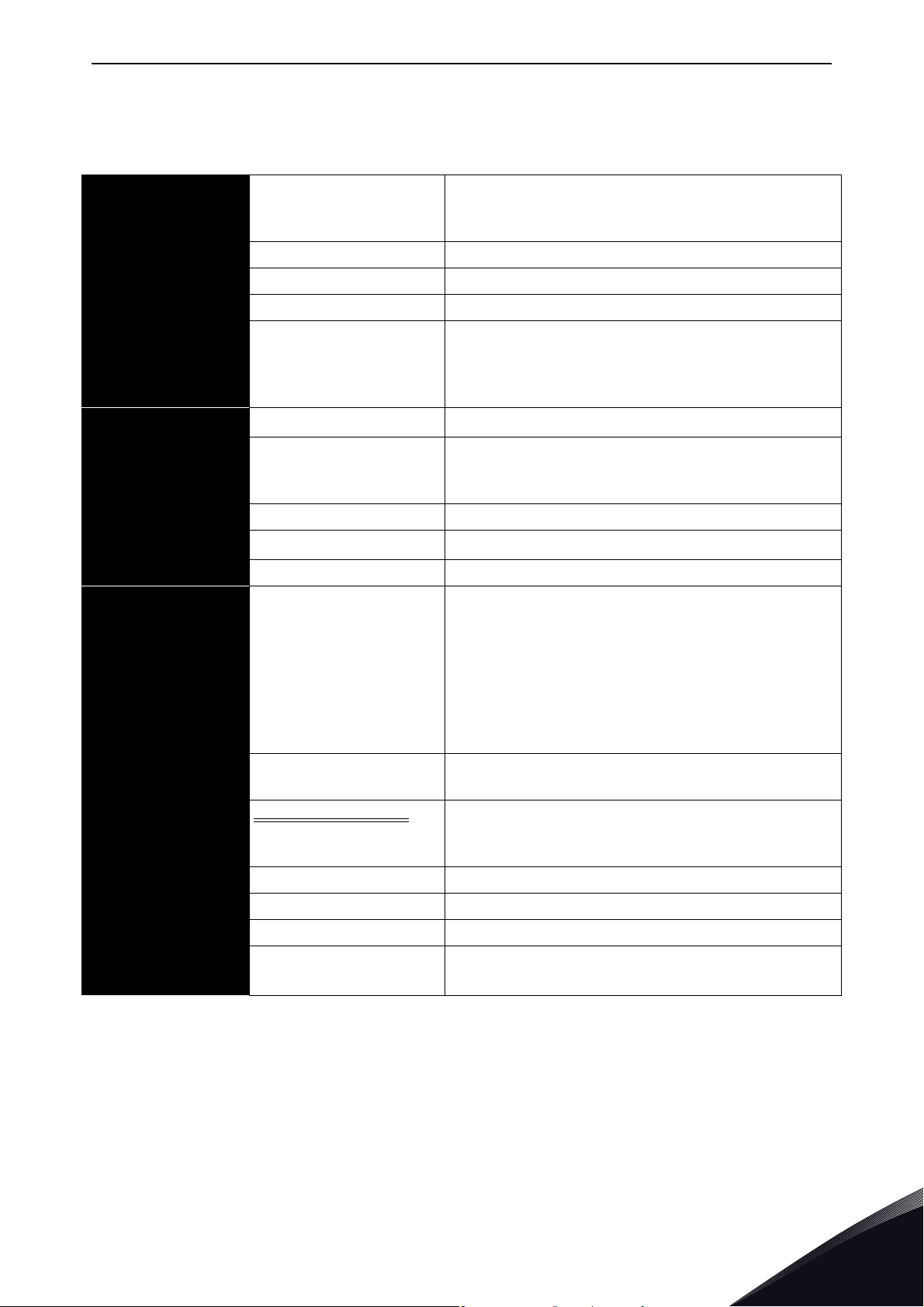

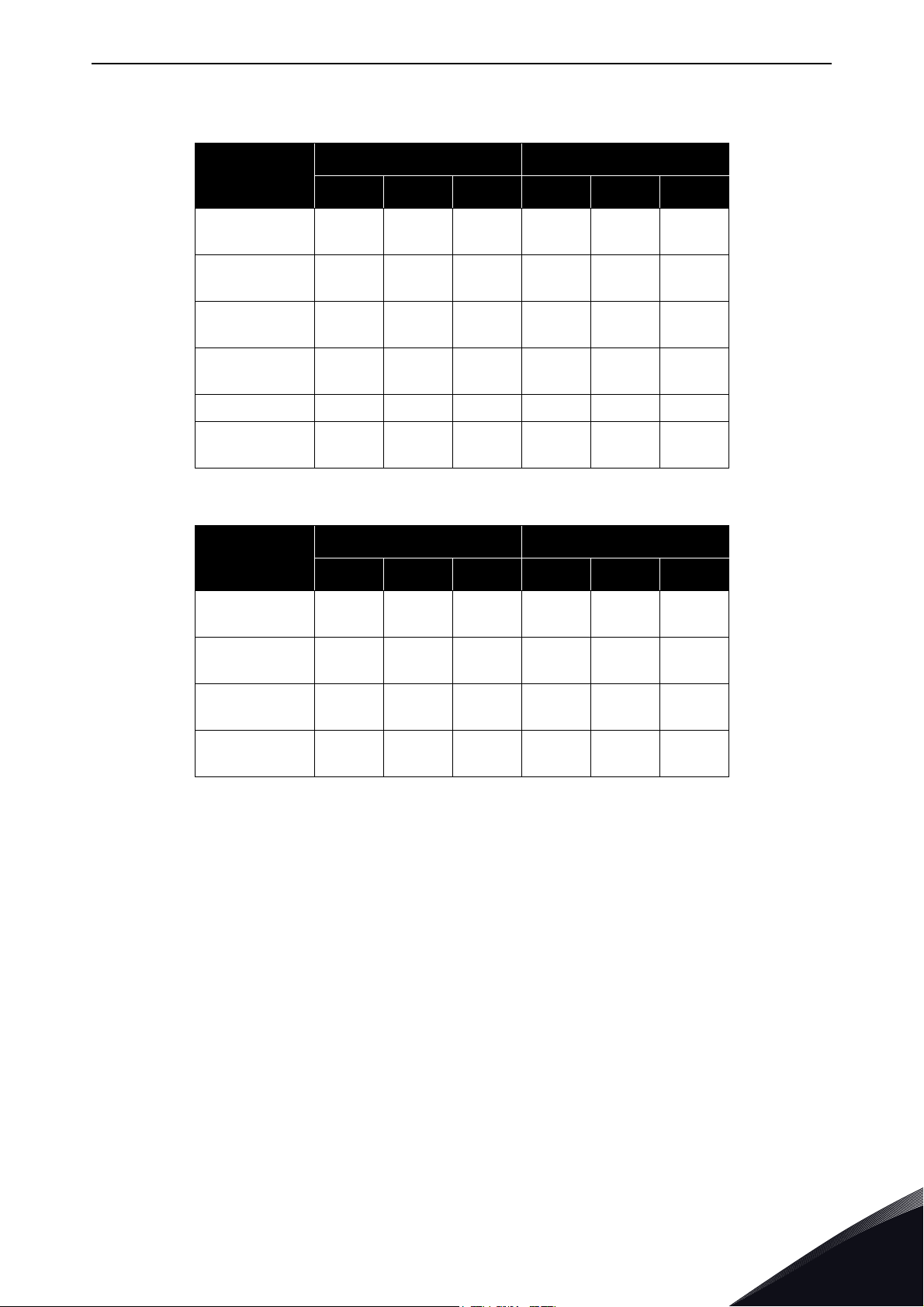

Table 2. Power ratings and dimensions of VACON

®

NX 6- and 12-pulse drives supply voltage 380-500V

Mains voltage 380-500 V, 50/60 Hz, 3~

Loadability Motor shaft power

Low High 400V supply 500V supply

AC drive

type

NXC0261 5 261 287 205 308 349 132 110 160 132 FR9 606x2275x605/371

NXC0300 5 300 330 245 368 444 160 132 200 160 FR9 606x2275x605/371

NXC0385 5 385 424 300 450 540 200 160 250 200 FR10 606x2275x605/371

NXC0460 5 460 506 385 578 693 250 200 315 250 FR10 606x2275x605/403

NXC0520 5 520 572 460 690 828 250 250 355 315 FR10 606x2275x605/403

NXC0590 5 590 649 520 780 936 315 250 400 355 FR11 806x2275x605/577

NXC0650 5 650 715 590 885 1062 355 315 450 400 FR11 806x2275x605/577

NXC0730 5 730 803 650 975 1170 400 355 500 450 FR11 806x2275x605/577

NXC0820 5 820 902 730 1095 1314 450 400 560 500 FR12 1206x2275x605/810

NXC0920 5 920 1012 820 1230 1476 500 450 630 560 FR12 1206x2275x605/810

NXC1030 5 1030 1133 920 1380 1656 560 500 710 630 FR12 1206x2275x605/810

NXC1150 5 1150 1265 1030 1545 1620 630 560 800 710 FR13 1406X2275X605/1000

NXC1300 5 1300 1430 1150 1725 2079 710 630 900 800 FR13

NXC1450 5 1450 1595 1300 1950 2484 800 710 1000 900 FR13

NXC1770 5 1770 1947 1600 2400 2880 1000 900 1200 1100 FR14 2806X2275X605/2440

NXC2150 5 2150 2365 1940 2910 3492 1200 1100 1500 1300 FR14 2806X2275X605/2500

Rated

contin.

current

(A)

I

L

Rated

overload

current

(A)

Rated

contin.

current

I

H

(A)

Rated

over-

load

current

(A)

Max

current

I

S

Low

over-

load

P(kW)

High

over-

load

P(kW)

Low

over-

load

P(kW)

High

over-

load

P(kW)

Enclo-

sure

Dimensions and weight*

WxHxD/kg

6-p: 1606X2275X605/1150

12-p: 2006X2275X605/1150

6-p: 1606X2275X605/1150

12-p: 2006X2275X605/1150

4

NOTE! The rated currents in given ambient temperatures are achieved only when the switching

frequency is equal to or less than the factory default (automatic thermal management).

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

TECHNICAL DATA vacon • 17

*The dimensions indicated are for the basic 6-pulse IP21 version of the AC drive cabinet. Some

options may increase the width, height or weight of the cabinet. See the delivery specific

documentation for more details.

4.1.2 VACON

®

NXC low harmonic drives – Mains voltage 380-500 V

High overload = Max current IS, 2 sec/20 sec, Rated overload current, 1 min/10 min

Following continuous operation at rated output current, rated overload

current for 1 min, followed by a period of load current less than rated

current, and of such duration that the r.m.s output current, over the duty

cycle, does not exceed rated output current (IH)

Low overload = Max current I

, 2 sec/20 sec, Rated overload current, 1 min/10 min

S

Following continuous operation at rated output current, rated overload

current for 1 min, followed by a period of load current less than rated

current, and of such duration that the r.m.s output current, over the duty

cycle, does not exceed rated output current (IL)

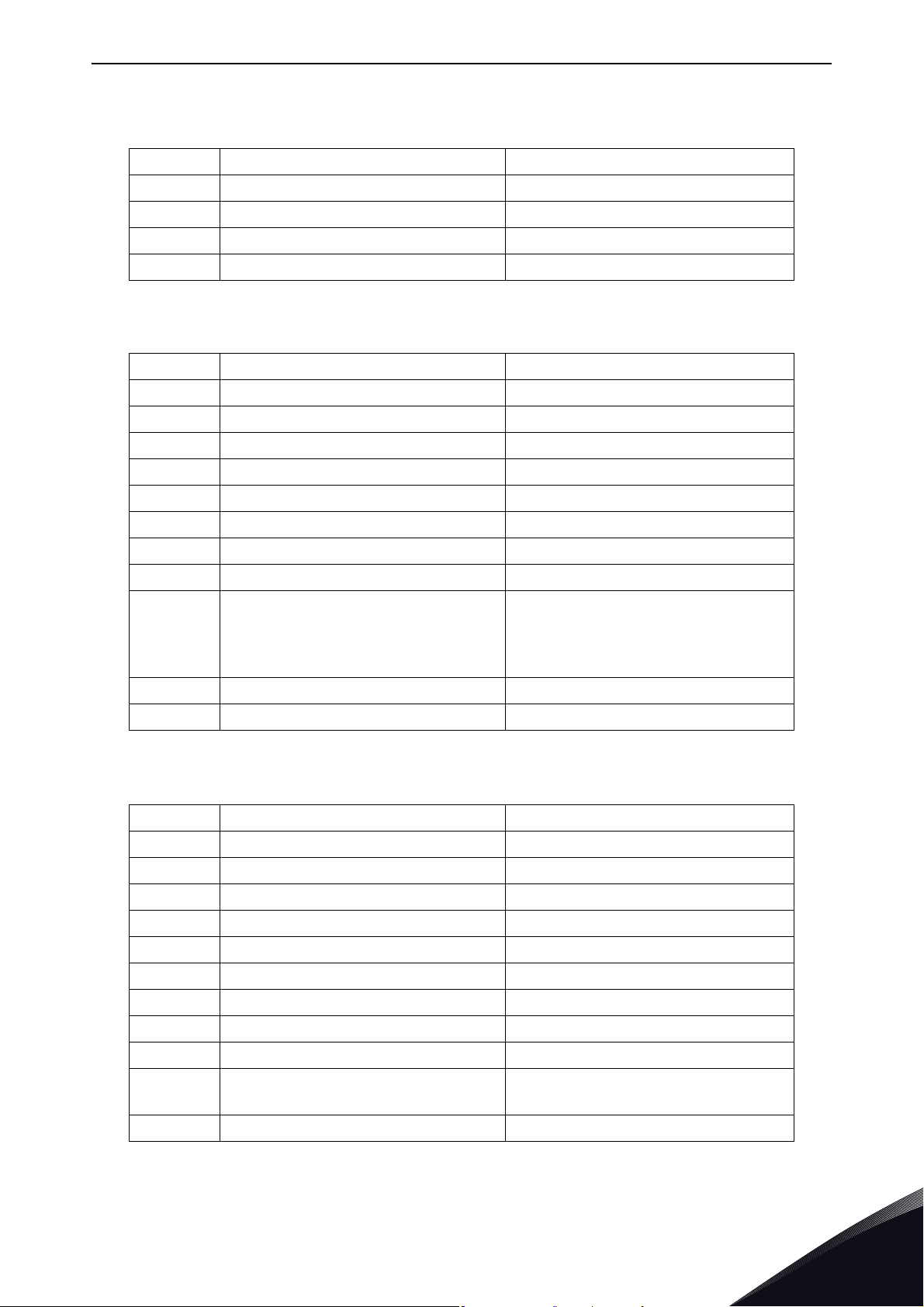

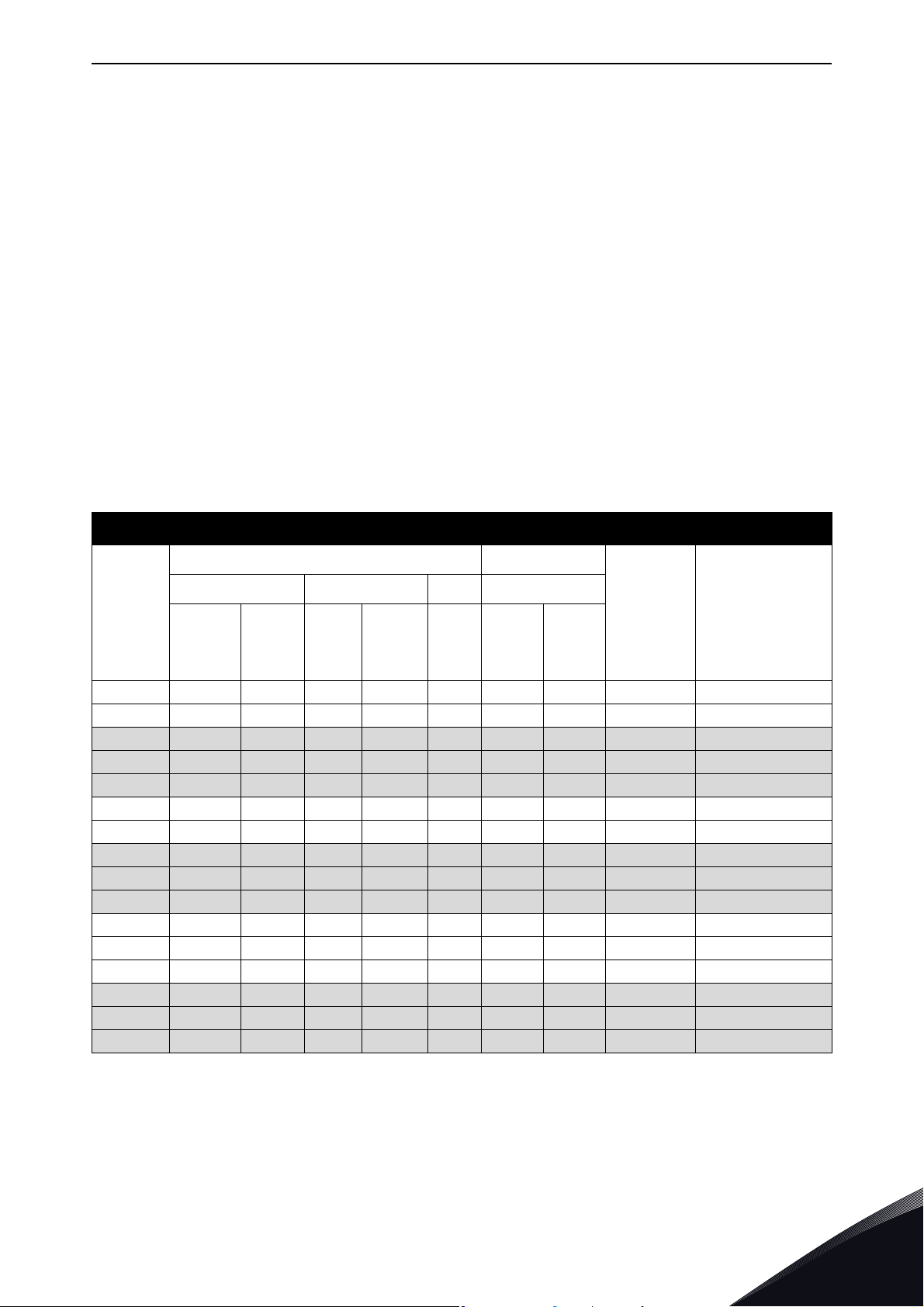

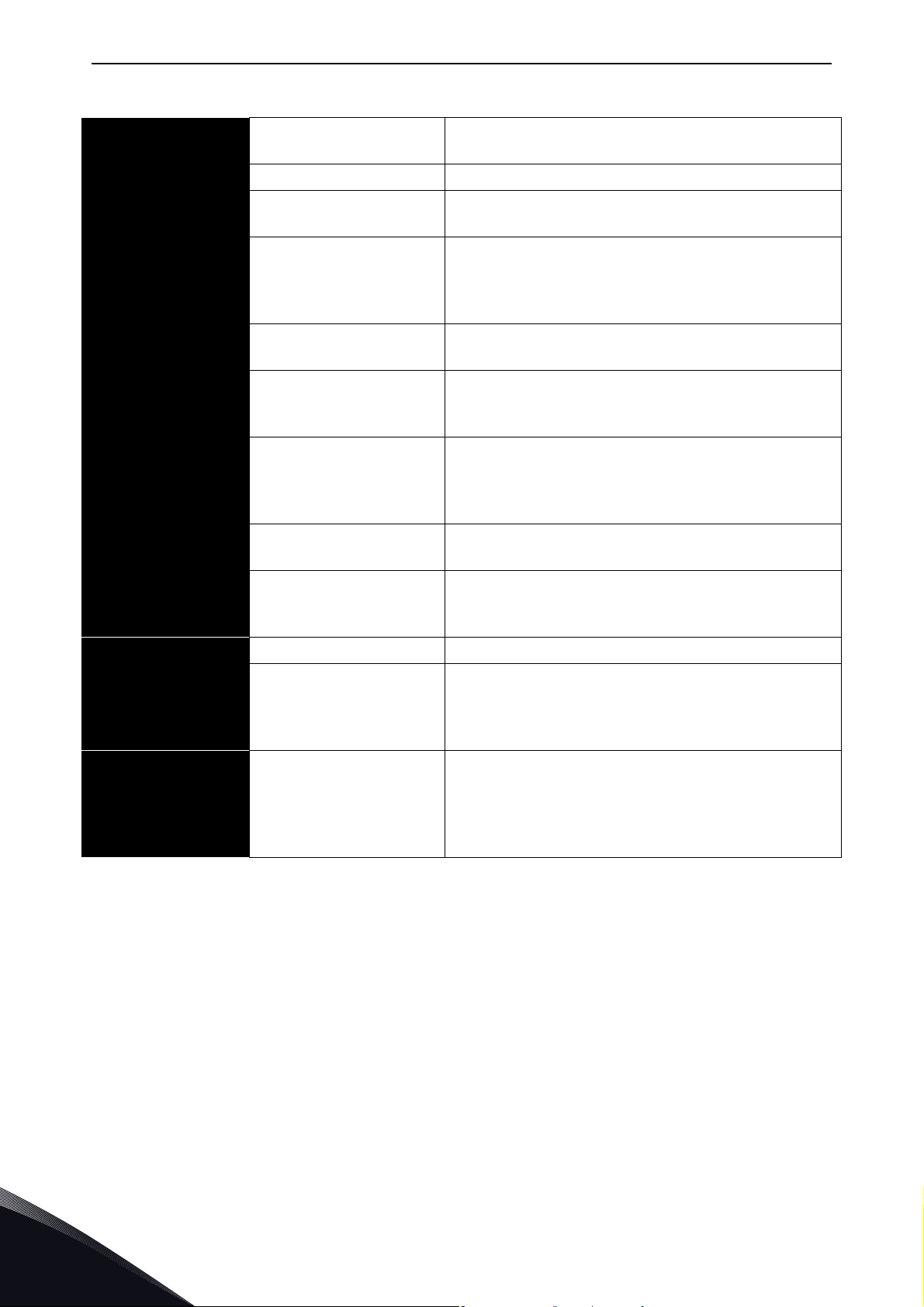

Table 3. Power ratings and dimensions of VACON

®

low-harmonic drives, supply voltage 380-

500V

Mains voltage 380-500 V, 50/60 Hz, 3~

Loadability Motor shaft power

AC drive

type

current IL

NXC0261 5 261 287 205 308 349 132 110 AF9+AF9 1006x2275x605/680

NXC0300 5 300 330 245 368 444 160 132 AF9+AF9 1006x2275x605/680

NXC0385 5 385 424 300 450 540 200 160 AF10+AF10 1006x2275x605/700

NXC0460 5 460 506 385 578 693 250 200 AF10+AF10 1006x2275x605/700

NXC0520 5 520 572 460 690 828 250 250 AF10+AF10 1006x2275x605/700

NXC0650 5 650 715 590 885 1062 355 315 2xAF10+AF12 2006x2275x605/1400

NXC0730 5 730 803 650 975 1170 400 355 2xAF10+AF12 2006x2275x605/1400

NXC0820 5 820 902 730 1095 1314 450 400 2xAF10+AF12 2006x2275x605/1400

NXC0920 5 920 1012 820 1230 1476 500 450 2xAF10+AF12 2006x2275x605/1400

NXC1030 5 1030 1133 920 1380 1656 560 500 2xAF10+AF12 2006x2275x605/1400

NXC1150 5 1150 1265 1030 1545 1620 630 560 AF13+AF13 2206X2275X605/1950

NXC1300 5 1300 1430 1150 1725 2079 710 630 AF13+AF13 2206X2275X605/1950

NXC1450 5 1450 1595 1300 1950 2484 800 710 AF13+AF13 2206X2275X605/1950

NXC1770 5 1770 1947 1600 2400 2880 1000 900 2xAF13+AF14 4406X2275X605/3900

NXC2150 5 2150 2365 1940 2910 3492 1200 1100 2xAF13+AF14 4406X2275X605/3900

NXC2700 5 2700 2970 2300 3278 3933 1500 1200 2xAF13+AF14 4406X2275X605/3900

Low High 400V supply

Rated

contin.

(A)

Rated

overload

current

(A)

Rated

contin.

current

(A)

I

H

Rated

overload

current

(A)

Max

current

I

S

Low

over-

load

P(kW)

High

over-

load

P(kW)

Enclosure

Dimensions and

weight*

WxHxD/kg

NOTE! The rated currents in given ambient temperatures are achieved only when the switching

frequency is equal to or less than the factory default (automatic thermal management).

*The dimensions indicated are for the basic low-harmonic IP21 version of the AC drive cabinet.

Some options increase the width, height or weight of the cabinet. Check the delivery specific

documentation for more details.

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

4

vacon • 18 TECHNICAL DATA

4.1.3 VACON® NXP/C 6 – Mains voltage 500-690 V

High overload = Max current IS, 2 sec/20 sec, Rated overload current, 1 min/10 min

Following continuous operation at rated output current, rated overload

current for 1 min, followed by a period of load current less than rated

current, and of such duration that the r.m.s output current, over the duty

cycle, does not exceed rated output current (IH)

Low overload = Max current IS, 2 sec/20 sec, Rated overload current, 1 min/10 min

Following continuous operation at rated output current, rated overload

current for 1 min, followed by a period of load current less than rated

current, and of such duration that the r.m.s output current, over the duty

cycle, does not exceed rated output current (IL)

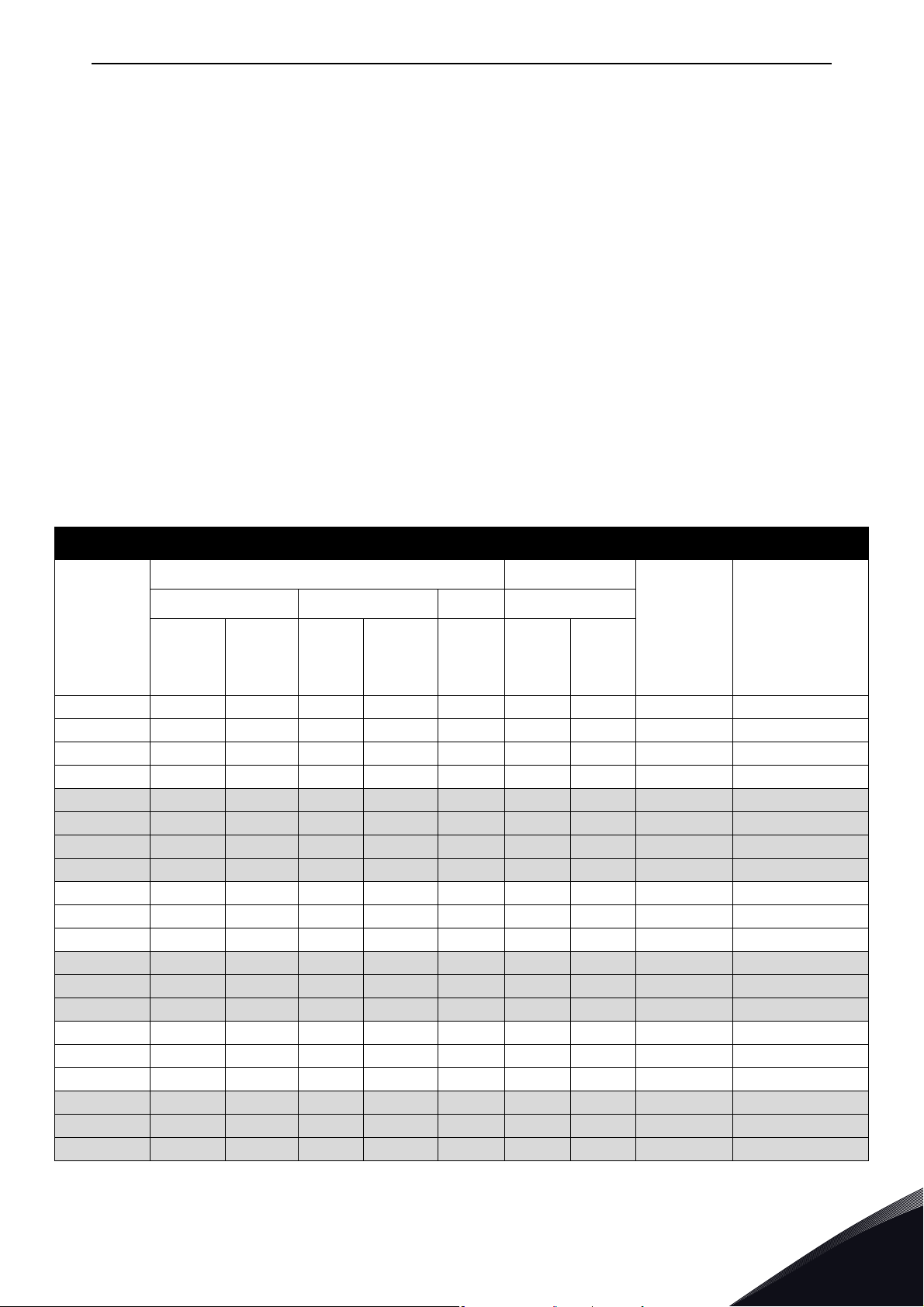

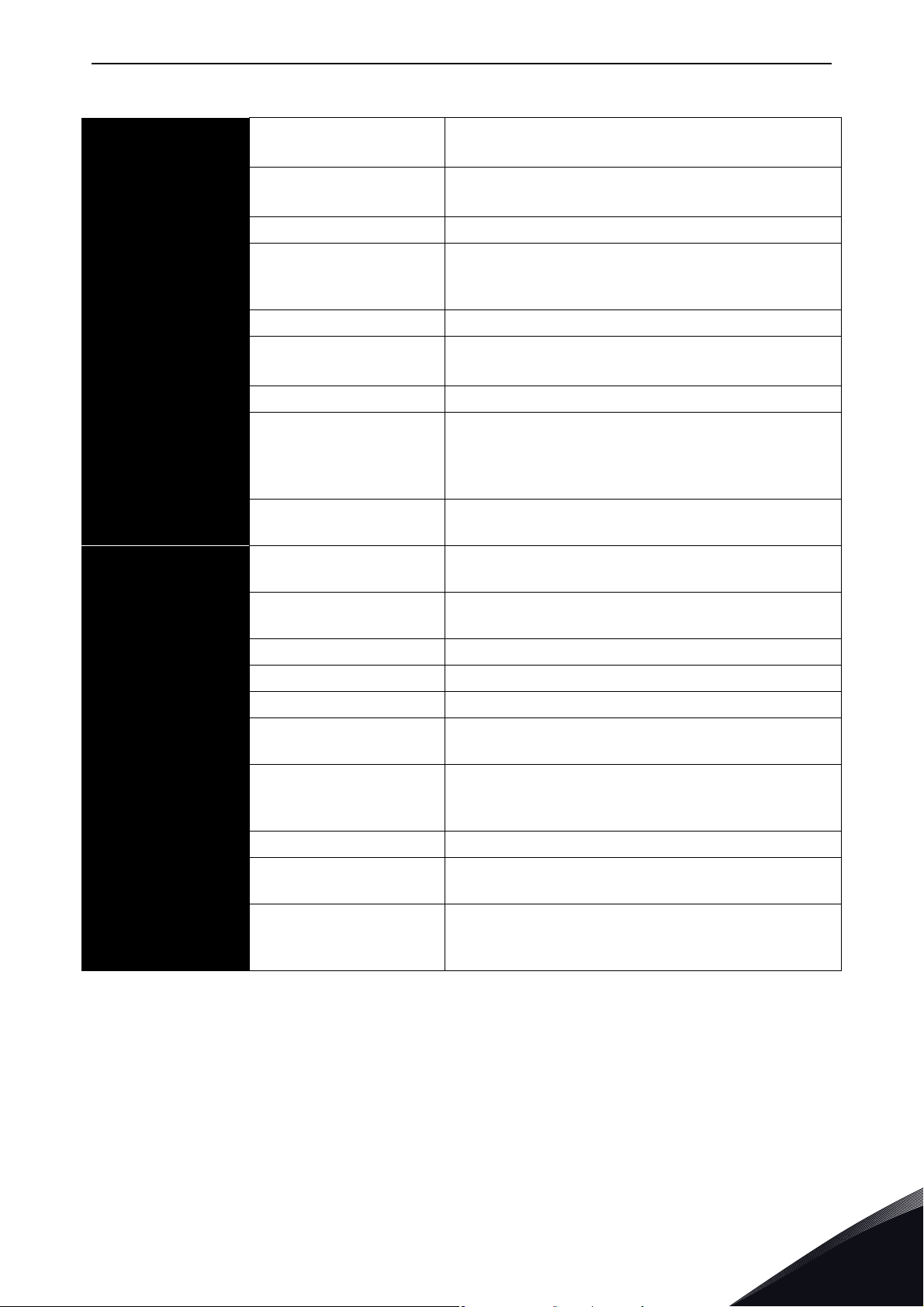

Table 4. Power ratings and dimensions of VACON

®

NX 6- and 12-pulse drives, supply voltage 500—

690V

Mains voltage 500-690 V, 50/60 Hz, 3~

Loadability Motor shaft power

Low High 690V supply 575V supply

50%

over-

load

current

(A)

Max

current

I

S

Low

over-

load

P(kW)

High

over-

load

P(kW)

Low

over-

load

P(hp)

AC drive type

NXC0125 6 125 138 100 150 200 110 90 125 100 FR9 606x2275x605/371

NXC0144 6 144 158 125 188 213 132 110 150 125 FR9 606x2275x605/371

NXC0170 6 170 187 144 216 245 160 132 150 150 FR9 606x2275x605/371

NXC0208 6 208 229 170 255 289 200 160 200 150 FR9 606x2275x605/371

NXC0261 6 261 287 208 312 375 250 200 250 200 FR10 606x2275x605/341

NXC0325 6 325 358 261 392 470 315 250 300 250 FR10 606x2275x605/371

NXC0385 6 385 424 325 488 585 355 315 400 300 FR10 606x2275x605/371

NXC0416 6** 416 416 325 488 585 400 315 450 300 FR10 606x2275x605/371

NXC0460 6 460 506 385 578 693 450 355 450 400 FR11 806x2275x605/524

NXC0502 6 502 552 460 690 828 500 450 500 450 FR11 806x2275x605/524

NXC0590 6** 590 649 502 753 904 560 500 600 500 FR11 806x2275x605/577

NXC0650 6 650 715 590 885 1062 630 560 650 600 FR12 1206x2275x605/745

NXC0750 6 750 825 650 975 1170 710 630 800 650 FR12 1206x2275x605/745

NXC0820 6** 820 902 650 975 1170 800 630 750 650 FR12 1206x2275x605/745

NXC0920 6 920 1012 820 1230 1410 900 800 900 800 FR13 1406x2275x605/1000

NXC1030 6 1030 1130 920 1380 1755 1000 900 1000 900 FR13 1406x2275x605/1000

NXC1180 6** 1180 1298 1030 1463 1755 1150 1000 1100 1000 FR13 1406x2275x605/1000

NXC1500 6 1500 1650 1300 1950 2340 1500 1300 1500 1350 FR14 2406X2275X605/2350

NXC1900 6 1900 2090 1500 2250 2700 1800 1500 2000 1500 FR14 2806X2275X605/2440

NXC2250 6** 2250 2475 1900 2782 3335 2000 1800 2300 2000 FR14 2806X2275X605/2500

Rated

contin.

current I

(A)

overloa

L

current

Rated

d

(A)

Rated

contin.

current

(A)

I

H

High

over-

load

P(hp)

Enclo-

sure

Dimensions and

weight*

WxHxD/kg

4

NOTE! The rated currents in given ambient temperatures are achieved only when the switching

frequency is equal to or less than the factory default (automatic thermal management).

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

TECHNICAL DATA vacon • 19

*The dimensions indicated are for the basic 6-pulse IP21 version of the AC drive cabinet. Some

options increase the width, height or weight of the cabinet. Check the delivery specific

documentation for more details.

** Maximum ambient temperature +35 °C.

4.1.4 VACON

®

NXC low harmonic drives – Mains voltage 525-690 V

High overload = Max current IS, 2 sec/20 sec, Rated overload current, 1 min/10 min

Following continuous operation at rated output current, rated overload

current for 1 min, followed by a period of load current less than rated

current, and of such duration that the r.m.s output current, over the duty

cycle, does not exceed rated output current (IH)

Low overload = Max current IS, 2 sec/20 sec, Rated overload current, 1 min/10 min

Following continuous operation at rated output current, rated overload

current for 1 min, followed by a period of load current less than rated

current, and of such duration that the r.m.s output current, over the duty

cycle, does not exceed rated output current (IL)

Table 5. Power ratings and dimensions of VACON

®

low-harmonic drives, supply voltage 525-690V

Mains voltage 525-690 V, 50/60 Hz, 3~

Loadability Motor shaft power

Low High 690V supply

AC drive type

NXC0125 6 125 138 100 150 200 110 90 AF9+AF9 1006x2275x605/680

NXC0144 6 144 158 125 188 213 132 110 AF9+AF9 1006x2275x605/680

NXC0170 6 170 187 144 216 245 160 132 AF9+AF9 1006x2275x605/680

NXC0208 6 208 229 170 255 289 200 160 AF9+AF9 1006x2275x605/680

NXC0261 6 261 287 208 312 375 250 200 AF10+AF10 1006x2275x605/700

NXC0325 6 325 358 261 392 470 315 250 AF10+AF10 1006x2275x605/700

NXC0385 6 385 424 325 488 585 355 315 AF10+AF10 1006x2275x605/700

NXC0416 6** 416 416 325 488 585 400 315 AF10+AF10 1006x2275x605/700

NXC0460 6 460 506 385 578 693 450 355 2xAF10+AF12 2006x2275x605/1400

NXC0502 6 502 552 460 690 828 500 450 2xAF10+AF12 2006x2275x605/1400

NXC0590 6** 590 649 502 753 904 560 500 2xAF10+AF12 2006x2275x605/1400

NXC0650 6 650 715 590 885 1062 630 560 2xAF10+AF12 2006x2275x605/1400

NXC0750 6 750 825 650 975 1170 710 630 2xAF10+AF12 2006x2275x605/1400

NXC0820 6** 820 902 650 975 1170 750 650 2xAF10+AF12 2006x2275x605/1400

NXC0920 6 920 1012 820 1230 1476 900 800 AF13+AF13 2206x2275x605/1950

NXC1030 6 1030 1133 920 1380 1656 1000 900 AF13+AF13 2206x2275x605/1950

NXC1180 6** 1180 1298 1030 1463 1755 1150 1000 AF13+AF13 2206x2275x605/1950

NXC1500 6 1500 1650 1300 1950 2340 1500 1300 2xAF13+AF14 4406X2275X605/3900

NXC1900 6 1900 2090 1500 2250 2700 1800 1500 2xAF13+AF14 4406X2275X605/3900

NXC2250 6** 2250 2475 1900 2782 3335 2000 1800 2xAF13+AF14 4406X2275X605/3900

Rated

contin.

current I

(A)

Rated

overload

L

current (A)

Rated

contin.

current

(A)

I

H

50%

overload

current (A)

Max

current

I

S

Low

overload

P(kW)

High

overload

P(kW)

Enclosure

Dimensions and

weight*

WxHxD/kg

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

4

vacon • 20 TECHNICAL DATA

NOTE! The rated currents in given ambient temperatures are achieved only when the switching

frequency is equal to or less than the factory default (automatic thermal management).

*The dimensions indicated are for the basic low-harmonic IP21 version of the AC drive cabinet.

Some options increase the width, height or weight of the cabinet. Check the delivery specific

documentation for more details.

** Maximum ambient temperature +35 °C.

4

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

TECHNICAL DATA vacon • 21

4.2 Technical data

Table 6. Technical data

Mains connection

Motor connection

Input voltage U

Input frequency 45…66 Hz

Connection to mains Once per minute or less (normal case);

Supply grounding system TN-S, TN-C, TN-CS, TT or IT

Short circuit ratings Defined by ratings of installed fuses or circuit

Output voltage 0—U

Continuous output cur-

rent

Overloadability High: 1.5 x IH (1 min/10 min), Low: 1.1 x IL (1 min/10 min)

Starting current IS for 2 s every 20 s

Output frequency 0…320 Hz; (higher with special SW)

Control performance • Open Loop Vector Control (5-150% of base

in

380…500 V; 500…690 V; –10%…+10%

380...500 V;525...690 V; –10%…+10% (low harmonic

drives)

breaker(s). Max permitted values 50 kA

at 380...500 VAC, 40 kA at 525...690 VAC. Refer to

cabinet specific documentation for more details

in

Ambient temperature max. +40 °C (up to +50 °C

with current derating 1,5% per 1°).

See Table 2 and Table 4.

speed):

speed control 0.5%, dynamic 0.3%sec, torque

lin. <2%, torque rise time ~5 ms

• Closed Loop Vector Control (entire speed

range):

speed control 0.01%, dynamic 0.2%sec,

torque lin. <2%, torque rise time ~2 ms

Control

characteristics

Switching frequency NX_5:

NX_6:

Frequency reference

Analogue input

Panel reference

Field weakening point 8…320 Hz

Acceleration time 0.1…3000 sec

Deceleration time 0.1…3000 sec

Braking DC brake: 30% * TN (without brake option); flux

Resolution 0.1% (10-bit), accuracy ±1%

Resolution 0.01 Hz

braking

1…6 kHz; Factory default 3.6 kHz *

1…6 kHz; Factory default 1.5 kHz *

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

4

vacon • 22 TECHNICAL DATA

Table 6. Technical data

Ambient conditions

EMC (at default

settings)

Ambient operating temperature

Storage temperature –40 °C…+70 °C

Relative humidity 0 to 95% RH, non-condensing, non-corrosive,

Air quality:

- chemical vapours

- mechanical

particles

Cabinet surface treatment

Altitude 100% load capacity (no derating) up to 1,000 m

Vibration

EN50178/EN60068-2-6

Shock

EN50178, EN60068-2-27

Enclosure class IP21/NEMA1 standard in entire kW/HP range

Immunity Fulfils all EMC immunity requirements

Emissions EMC level L: EN 61800-3 (2004), Category C3

–10 °C (no frost)…+40 ºC

no dripping water

IEC 721-3-3, unit in operation, class 3C2

IEC 721-3-3, unit in operation, class 3S2

Nanoceramic pretreatment. Anodic dipcoat-priming

and textured powder-coating.

1-% derating for each 100m above 1000;

max. 3000 m (690 V max 2000 m).

Displacement amplitude 0.25 mm (peak) at 5…31 Hz

Max acceleration 1 G at 31…150 Hz

Use anti-vibration mountings under the drive if

extra vibration resistance is required.

UPS Drop Test (for applicable UPS weights)

Storage and shipping: max 15 G, 11 ms (in package)

IP54/NEMA12 option in entire kW/HP range

Pollution degree PD2

EMC level T: Low earth-current solution for ITnetworks, EN 61800-3 (2004), Category C4 (can be

modified from level L units.

Safety

EN 50178 (1997), EN 60204-1 (1996), EN 60950

(2000, 3rd edition) (as relevant), CE, UL, CUL, EN

61800-5; (see unit nameplate for more detailed

approvals).

IEC 60664-1 and UL840 in overvoltage category III.

4

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

TECHNICAL DATA vacon • 23

Table 6. Technical data

Analogue input voltage 0…+10 V, Ri = 200 kW, (–10 V…+10 V joystick control)

Resolution 0.1%, accuracy ±1%

Analogue input current 0(4)…20 mA, Ri = 250 W differential; Resolution

0.1%, accuracy ±1%

Digital inputs (6) Positive or negative logic; 18…30 VDC

Auxiliary voltage +24 V, ±15%, max volt. ripple < 100 mVrms; max. 250

mA

Dimensioning: max. 1000 mA/control box

Control connections

(factory default I/O)

Output reference voltage +10 V, ±3%, max. load 10 mA

Analogue output 0(4)…20 mA; RL max. 500 W; Resolution 10 bit;

Accuracy ±2%

Digital outputs Open collector output, 50 mA/48 V

Relay outputs 2 programmable change-over relay outputs

Switching capacity: 24 VDC/8 A, 250 VAC/8 A,

125 VDC/0.4 A

Min. switching load: 5 V/10 mA

Protections

Thermistor input (OPTA3)

Overvoltage trip limit

Undervoltage trip limit

Earth fault protection In case of earth fault in motor or motor cable, only

Mains supervision Trips if any of the input phases is missing

Motor phase supervision Trips if any of the output phases is missing

Overcurrent protection Yes

Unit overtemperature

protection

Motor overload

protection

Motor stall protection Yes

Motor underload

protection

Short-circuit protection

of +24V and +10V

reference voltages

Galvanically isolated, Rtrip = 4.7 kΩ

NX_5: 911 VDC; NX_6: 1200 VDC

NX_5: 333 VDC; NX_6: 460 VDC

the AC drive is protected

Yes

Yes **

Motor overload protection provided at 110% of full

load current

Yes

Yes

* The rated currents in given ambient temperatures are achieved only when the switching frequency

is equal to or less than the factory default. Thermal management might reduce the switching

frequency.

** System software version NXP00002V186 (or newer) must be used for the motor thermal memory

and memory retention functionality to conform to UL 508C requirements. If an older system

software version is used, motor overtemperature protection is required at installation to comply

with UL requirements.

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

4

vacon • 24 MOUNTING

H1

W1

D1

11483_00

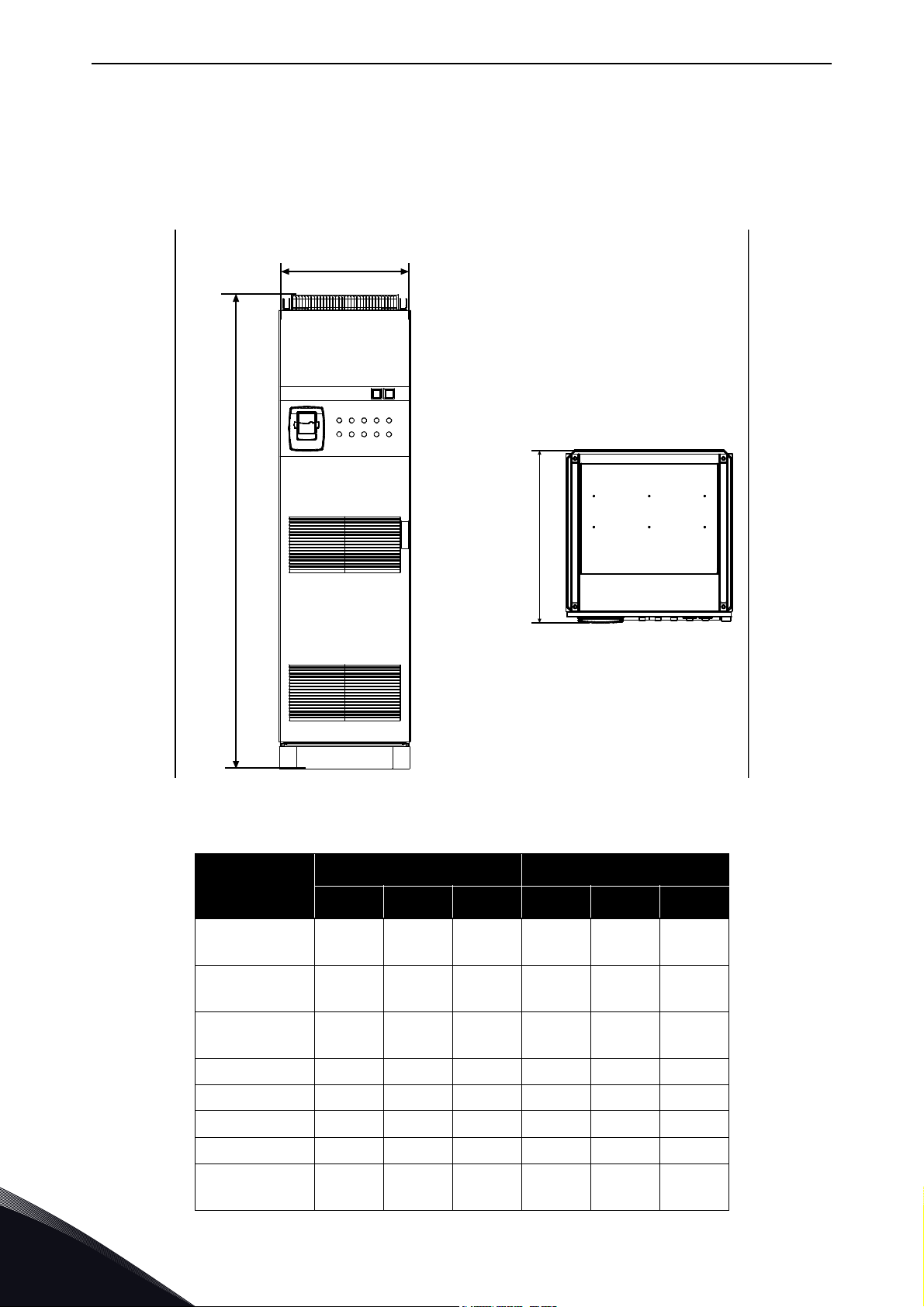

5. MOUNTING

5.1 Dimensions

The table below shows the dimensional drawing of the basic cabinet. It is allowed to install NXC

drives side by side. Please note that certain NXC options will further affect the total width or height

of the cabinet. Always refer to the delivery specific information for the exact dimensions.

Figure 2. Basic cabinet dimensions

Table 7. NXC 6-pulse drives cabinet dimensions

Dimensions [mm] IP21 Dimensions [mm] IP54

Type

W1 H1 D1 W1 H1 D1

0261—0520 5

0125—0416 6

0650—0730 5

0460—0590 6

0820—1030 5

0650—0820 6

1150 5 1406** 2275* 605 1206** 2400* 605

1300—1450 5 1606** 2275* 605 1606 2400 605

0920—1180 6 1406** 2275* 605 1406 2400 605

1500 6 2406 2275* 605 2406** 2400* 605

1770—2150 5

1900—2250 6

606** 2275* 605 606** 2400* 605

806** 2275* 605 806** 2400* 605

1206** 2275* 605 1206** 2400* 605

2806 2275* 605 2806** 2400* 605

5

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

MOUNTING vacon • 25

Table 8. NXC 12-pulse drives cabinet dimensions

Dimensions [mm] IP21 Dimensions [mm] IP54

Type

W1 H1 D1 W1 H1 D1

0385—0520 5

0261—0416 6

0590—0730 5

0460—0590 6

0820—1030 5

0650—0820 6

1150 5

0920—1180 6

1300—1450 5 2006** 2275* 605 2006** 2400* 605

1770—2150 5

1500—2250 6

Table 9. NXC drive low-harmonic cabinet dimensions

Type

0261—0520 5

0125—0416 6

0590—1030 5

0460—0820 6

1150—1450 5

0920—1180 6

1770—2700 5

1500—2250 6

606** 2275* 605 606** 2400* 605

806** 2275* 605 806** 2400* 605

1206** 2275* 605 1206** 2400* 605

1406** 2275* 605 1406** 2400* 605

2806** 2275* 605 2806** 2400* 605

Dimensions [mm] IP21 Dimensions [mm] IP54

W1 H1 D1 W1 H1 D1

1006** 2275* 605 1006** 2405* 605

2006** 2275* 605 2006** 2405* 605

2206** 2275* 605 2206** 2445* 605

4406** 2275* 605 4406** 2445* 605

* the options +GPL or +GPH (Plinth) increase the height by 100mm or 200mm respectively

** some options, e.g. +CIT (Top input cabling +400mm), +COT (Top output cabling +400mm) and +ODU

(output du/dt filter +400mm) affect the width of the cabinet

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

5

vacon • 26 MOUNTING

Min 60°

Min 60°

Min 60°

11484_00

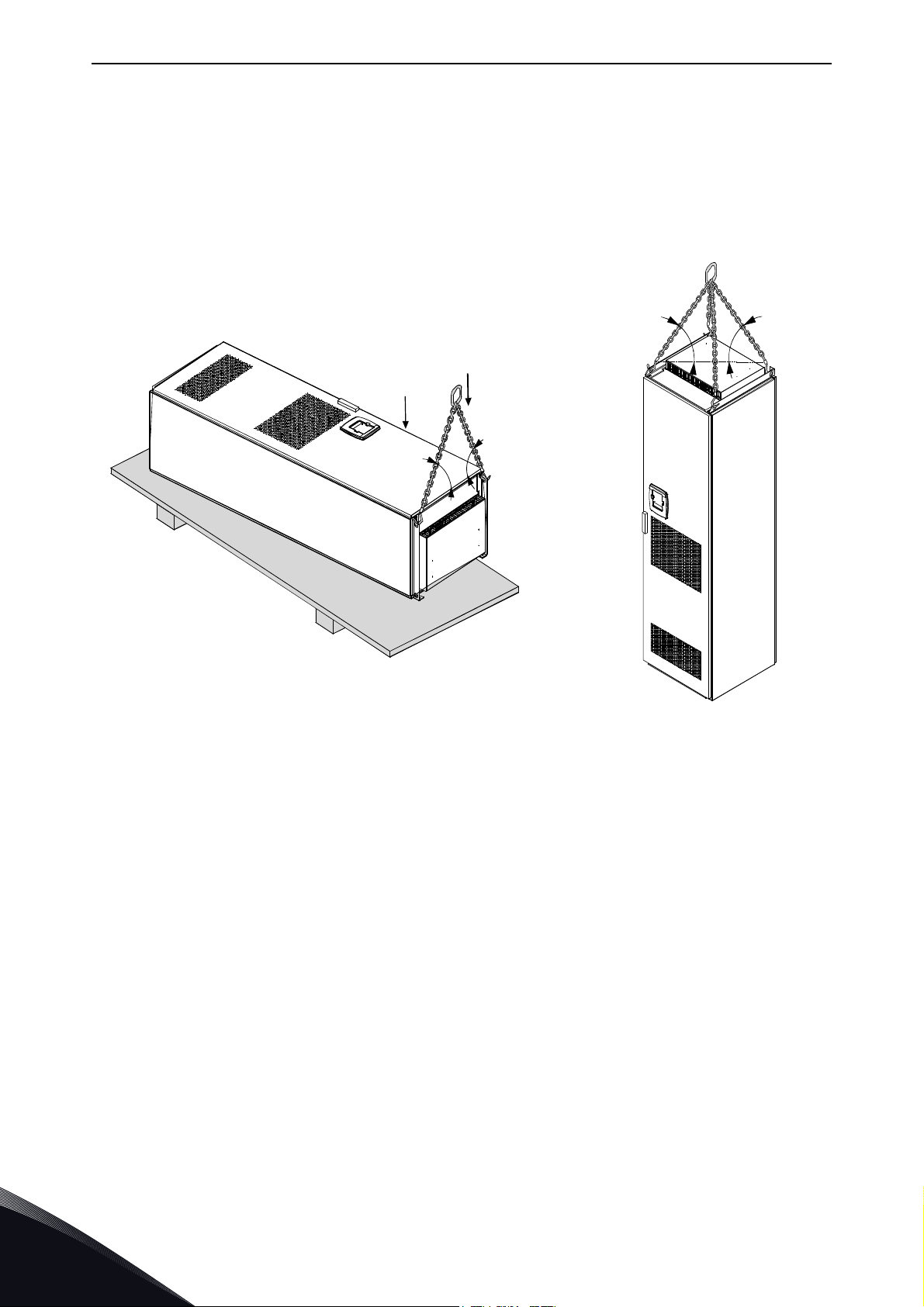

5.2 Lifting the unit out of the transport packaging

The unit is delivered either in a wooden box or a wooden cage. The box may be transported either

horizontally or vertically, while transportation of the cage in a horizontal position is not allowed.

Always refer to shipping marks for more detailed information. To lift the unit out of the box, use

lifting equipment capable of handling the weight of the cabinet.

There are lifting lugs on the top of the cabinet and these lugs can be used to lift the cabinet into an

upright position and to move it to the place needed.

Figure 3. Lifting the unit

NOTE! Location of lifting lugs varies between different enclosures.

Recycle the packaging material according to local regulations.

5

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

MOUNTING vacon • 27

13006.emf

11485_00

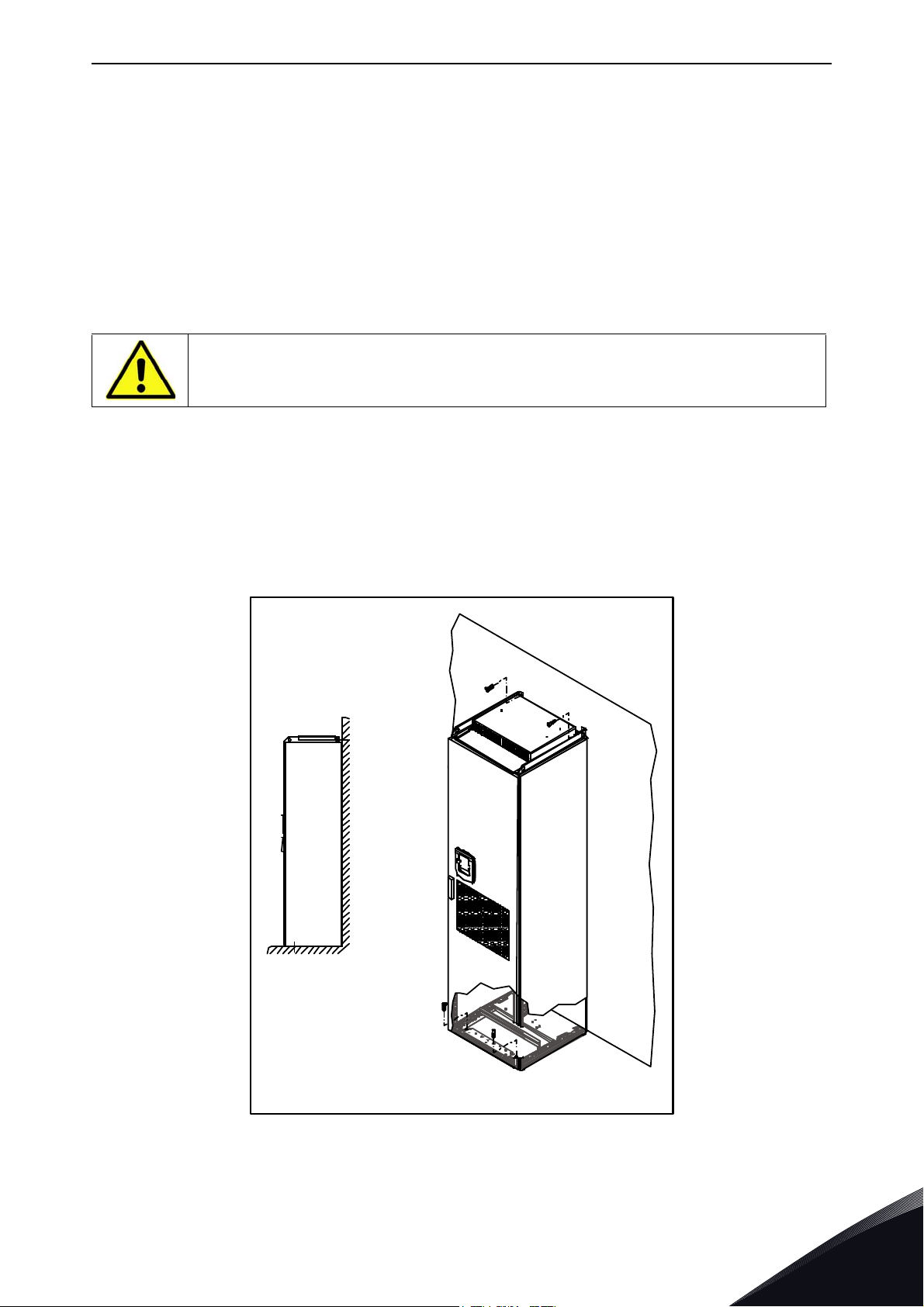

5.3 Fixing the unit to the floor or to the wall

Before starting the installation work make sure that the level of the floor is within acceptable limits.

The maximum deviation from the basic level can be no more than 5 mm over 3 m distance. The

maximum acceptable height difference between cabinet front and rear edges should be within +2/0mm limit.

The cabinet should always be fixed to the floor or to the wall. Depending on installation conditions,

the cabinet sections can be fixed in different ways. There are holes in the front corners which can

be used for fixing. Additionally, the rails on the top of the cabinet have fixing lugs for fixing the

cabinet to the wall.

Welding of the cabinet might risk sensitive components in the AC drive.

Ensure that no grounding currents can flow through any part of the AC drive.

5.3.1 Fixing to the floor and to the wall

In installations where the cabinet is mounted against the wall, it is more convenient to fix the top of

the cabinet to the wall. Fix the cabinet in the two front corners to the floor with bolts. Fix the top part

to the wall with bolts. Note that the rails and the fixing lugs can be moved horizontally to make sure

the cabinet stands in a horizontal position. In AC drives consisting of more than one cabinet section,

fix all sections in the same way.

Figure 4. Fixing the cabinet to the floor and to the wall

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

5

vacon • 28 MOUNTING

11486_00

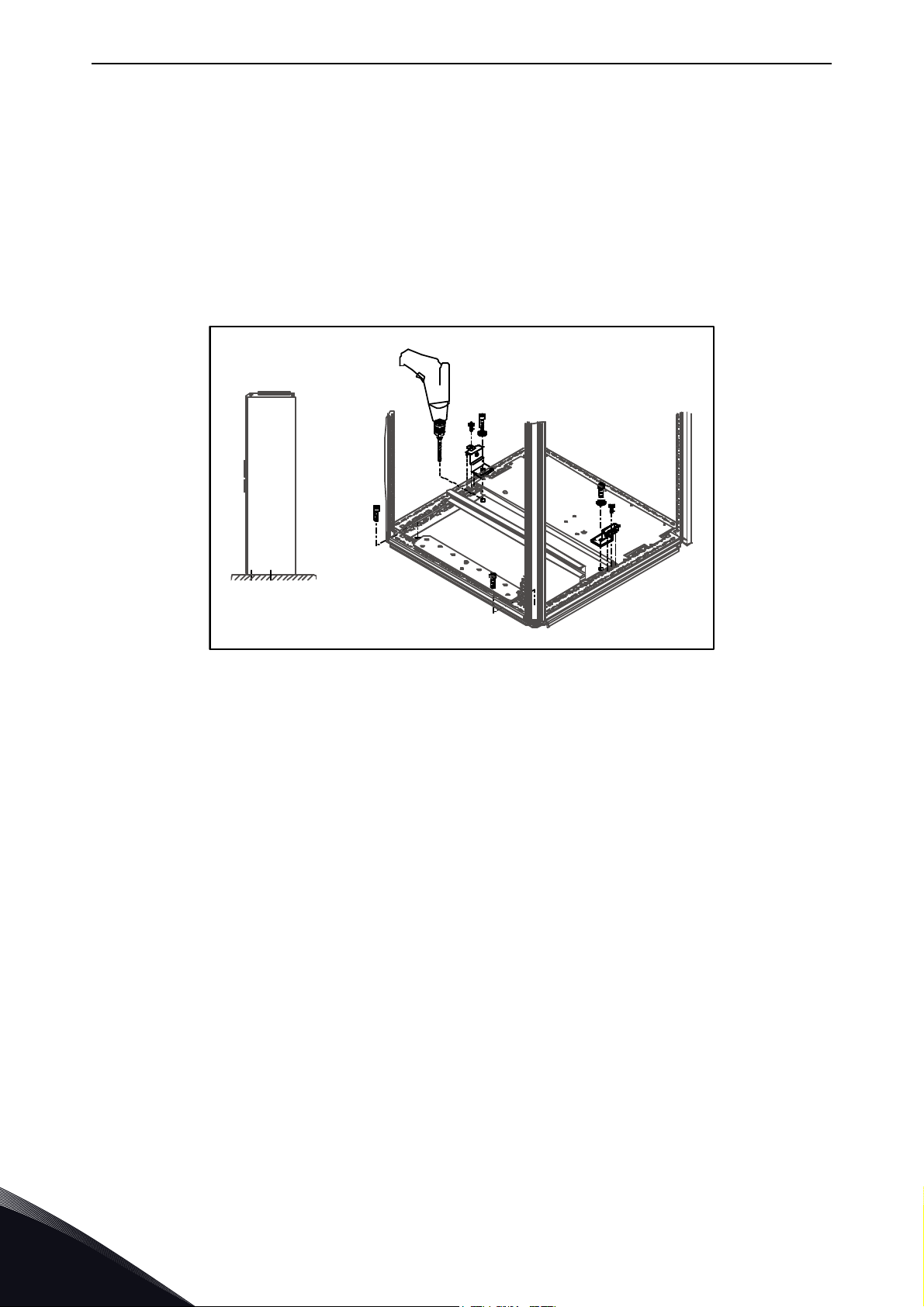

5.3.2 Fixing to the floor only

NOTE! This option is not available for FR13 and bigger units. For fixing FR13 and bigger units see

delivery specific documentation.

If bottom-only fixing is used, additional fixing brackets (Rittal part.nr. 8800.210) or equivalent are

necessary. Fix the cabinet to the floor in the front with bolts and use the fixing brackets in the

middle. Fix all cabinet sections in the same way.

Figure 5. Fixing all for corners to the floor

5

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

MOUNTING vacon • 29

13006.emf

111

333

222

Terminal numbers

11487_uk

Move the bridge plate to change

tapping

11488 uk

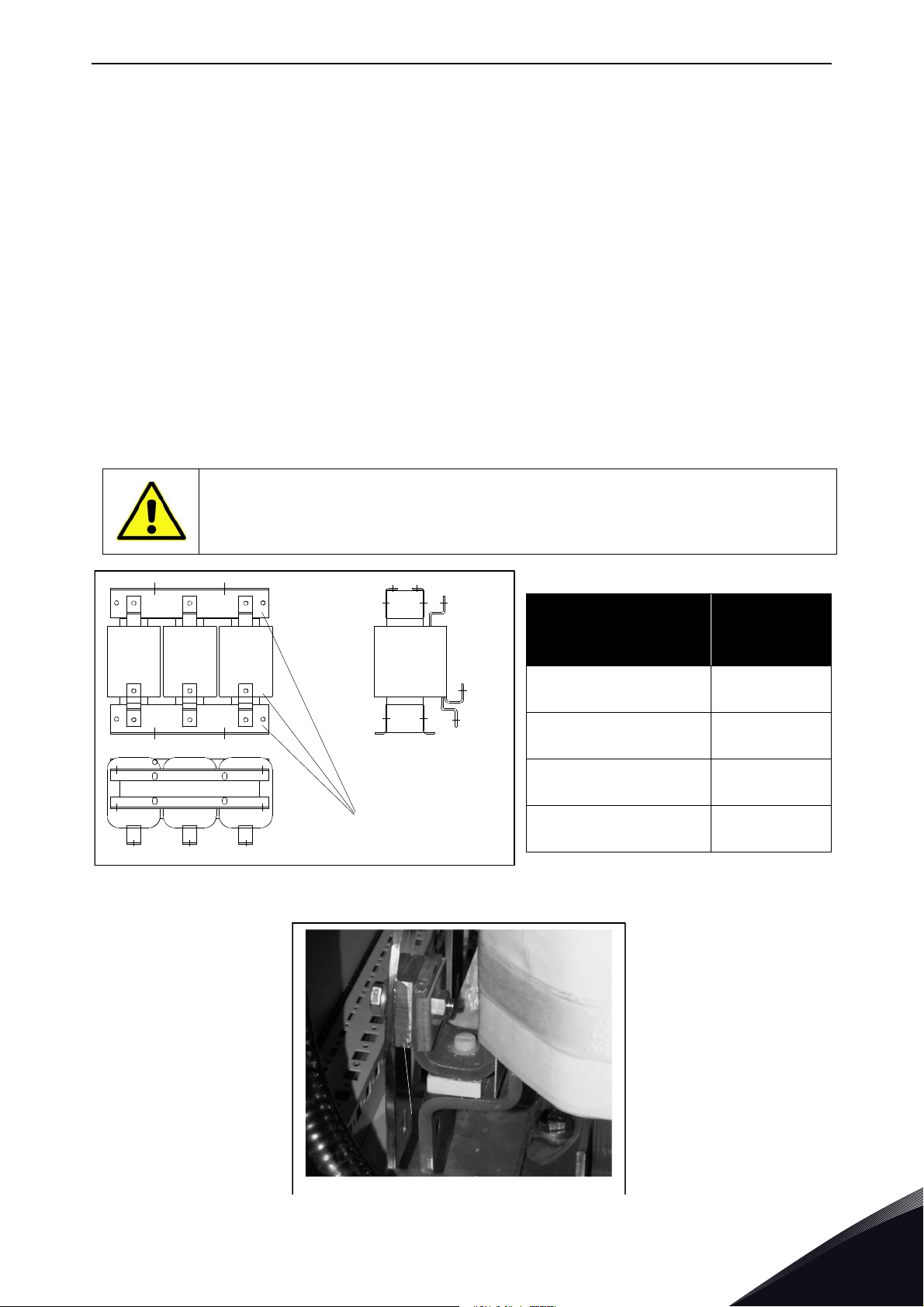

5.4 AC choke connections

NOTE! The NXC low-harmonic drive incorporates an LCL filter instead of AC chokes and this

instruction can be ignored.

The AC input choke carries out several functions in the VACON

input choke is needed as an essential component for motor control, to protect the input and DC-link

components against abrupt changes of current and voltage as well as to function as a protection

against harmonics.

The NXC 6- and 12-pulse AC drive is equipped with one or more input AC chokes. The chokes have

two inductance levels to optimise the functionality at different supply voltages. In the installation

phase, the wiring of the chokes should be checked and changed if needed (not for FR9).

The input is always connected to terminal #1 (see picture below) and should not be changed. The

output of the choke should be connected to terminal #2 or #3 (see picture below) according to the

table below. The terminals are marked with inductance values and applicable voltage.

In units FR10 to FR12, the connection is changed by moving the cable to the appropriate terminals.

In FR13/14, the bridges of the busbar connection should be moved according to the settings shown

in the table.

In units with two or more parallel chokes (some FR11 as well as all FR12 and FR13)

all chokes have to be wired in the same way. If chokes are wired differently the AC

drive may be damaged.

®

NX 6- and 12-pulse AC drive. The

Figure 6. Input chokes

Supply voltage

400-480 Vac/50-60 Hz

(500 V unit)

500 Vac/50 Hz

(500 V unit)

500 Vac/50 Hz

(690 V unit)

575-690 Vac/50-60 Hz

(690 V unit)

AC drive

connection

(terminals)

2

3

3

3

Figure 7. Input chokes tapping in FR13/14 units

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

5

vacon • 30 MOUNTING

5.5 Auxiliary voltage transformer tappings

NOTE! An auxiliary voltage transformer is always included as standard in NXC low-harmonic drives.

If the drive is ordered with an auxiliary voltage transformer for 230V auxiliary voltage supply (+ATx

option) the tappings of the transformer have to be set according to the mains voltage.

The tappings of the transformer in 500V drives is by default set to 400V or 500V and in 690V drives

to 690V unless otherwise ordered.

Locate the transformer in the lower part of the cabinet. The primary side of the transformer has

tappings that correspond to standard main voltages. Change to tapping to correspond to the mains

voltage in use.

5

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

MOUNTING vacon • 31

200 mm

800 mm

11489_00

5.6 Cooling

5.6.1 Free space around the cabinet

Enough space must be left above and in front of the cabinet to ensure sufficient cooling and space

for maintenance.

The amount of cooling air required is indicated in the table below. Also make sure that the

temperature of the cooling air does not exceed the maximum ambient temperature of the AC drive.

Figure 8.Space to be left free above (left) and in front of (right) the cabinet

Table 10. Required cooling air for NXC 6- and 12-pulse drives

Type Cooling air required [m3/h)

0261—0300 5

0125—0208 6

0385—0520 5

0261—0416 6

0590—0730 5

0460—0590 6

0820—1030 5

0650—0820 6

1300—1450 5 (6-p)

1300—1450 6 (12-p)

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

1000

2000

3000

4000

6000

7000

5

vacon • 32 MOUNTING

Table 10. Required cooling air for NXC 6- and 12-pulse drives

Type Cooling air required [m3/h)

1150 5

0920—1180 6

1500 6 (6-p) 9000

1770—2150 5

1900—2250 6

Table 11. Required cooling air for NXC low-harmonic drives

Type Cooling air required [m3/h)

0261—0520 5

0125—0416 6

0590—1030 5

0460—0820 6

1150—1450 5

0920—1180 6

1770—2700 5

1500—2250 6

5000

10000

3100

6200

7700

15400

5

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

MOUNTING vacon • 33

5.7 Power losses

The power loss of the AC drive varies greatly with load and output frequency as well as with the

switching frequency used. For dimensioning of cooling or ventilation equipment for electrical rooms

the following generic formula gives a good approximation of the heat losses for NXC 6- and 12-pulse

drives at nominal conditions.

P

[kw] = P

loss

Heat losses of NXC low-harmonic drives are roughly 1.5...2 times more compared to 6-p and 12pulse. Additional information on heat losses for specific enclosure size and current class is

available on request.

[kW] x 0,025

mot

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

5

vacon • 34 CABLING AND CONNECTIONS

M M M

M M M

NFE NFE NFE

INU

NFE NFE NFE

INU INU INU INU

NFE NFE NFE NFE

**

du/dt du/dtdu/dt

du/dt

FR9/10

Single input

Single output

FR11*

Double input*

Single output

FR12

Double input

Double output

No te!

Min cab le

length 5m**

*FR11types04606and05026 havesingleinput terminals

** 5 m is stated for matched power units only. For unmatched power units, a min of 40 m of cable

length is required from each power module if du/dt or sine filters are not used

FR1 3

Single input

Single output

FR14, NX 1500 6

Singleinput

Double output

FR14

Double input

Double output

** FR13 units NXP1300 and NXP1450 have three NFE units.

*** Du/dt filters are integrated by default in all NXC FR14 sizes

11490_uk

***

6. CABLING AND CONNECTIONS

6.1 Understanding the power unit topology

Figure 9 and Figure 10 show the principles for mains and motor connections of the basic 6-pulse

drive in enclosure sizes FR10 to FR14.

Some units built in enclosure size FR11 have double input devices and require an even number of

supply cables but an uneven number of motor cables can be used.

Units built in enclosure size FR12 consist of two power modules and require an even number of

supply and motor cables. See Figure 9 and the tables in Chapter 6.2.6.

The 12-pulse drives always have a double set of inputs. The motor connection is size dependent as

described above and in Figure 9.

6

Figure 9. Topology of mechanical sizes FR9 – FR14, 6/12-pulse supply

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

CABLING AND CONNECTIONS vacon • 35

M

INU

AFE

Single

input

Single

output

AF9-10

INU

AFE

Single

input

Single

output

AF12

INU

AFE

M

M

INU

AFE

Single

input

Single

output

AF13

INU

AFE

Double

input

Double

output

AF14

INU

AFE

M

du/dt du/dt

11491_uk

No te!

Min c able

length 5m**

** 5 m is stated for matched power units only. For unmatched power units, a min of 40 m of cable

length is required from each power module if du/dt or sine filters are not used

*** Du/dt filters are integrated by default in all NXC FR14 sizes

***

Figure 10. Topology of mechanical sizes NXC low-harmonic drives AF9 – AF14

NOTE! Some options affect the wiring direction and principle for power cables; always check

delivery specific documentation for exact information.

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

6

vacon • 36 CABLING AND CONNECTIONS

LCL FILTER

L1

L2

L3

U

V

W

U1

U2

V1

V2

W1

W2

-L2.1

-L2.2

-L2.3

-C1

-C2

-C3

-R1

-R4

-R2

-R3 -R6

-R5

-C2.1 -C2.2

-C5.2

-C1.1 -C1.2

-C5.1

-C4.1 -C4.2

-C3.1 -C3.2 -C6.1 -C6.2

-L1

11181_emf

6.2 Power connections

6.2.1 LCL filter wiring diagram of NXC low-harmonic drive

The LCL filter in the NXC low-harmonic drive contains a choke on the mains side, capacitors and a

choke on the AFE side. The LCL filter also includes capacitors connected against ground potential.

There are resistors connected across the capacitors for discharging these when the LCL filter is

disconnected from the input power.

Figure 11. VACON® LCL filter wiring diagram

6.2.1.1

Removing HF capacitors

If a PWM modulated rectifier of another manufacturer is connected to the same input transformer,

the capacitors must be removed. Otherwise the capacitors must not be removed.

Figure 12 ( AF9, AF10 and AF12) and Figure 13 (AF13 and AF14) have a red marking on the lead that

has to be removed from each capacitor if the interference suppression capacitors are not to be used.

Removing the lead disconnects the capacitors from ground potential.

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

6

CABLING AND CONNECTIONS vacon • 37

Remove

Remove

11492_uk

Remove

Remove

11493_uk

Figure 12. HF capacitors in NXC low-harmonic drive mechanical sizes AF9, AF10 and AF12 LCL

filter

Figure 13. HF capacitors in NXC low-harmonic drive mechanical sizes AF13-AF14 LCL filter

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

6

vacon • 38 CABLING AND CONNECTIONS

13006.emf

13006.emf

13006.emf

PE rail

EMC earthing

Cable f ixing clamps

11494_uk

6.2.2 Mains and motor cables

The mains cables are connected to terminals L1, L2 and L3 (12-pulse units 1L1, 1L2, 1L3, 2L1, 2L2,

2L3) and the motor cables to terminals marked with U, V and W, see Figure 15.

In AC drives consisting of double input sections, an even number of input cables is required. In AC

drives consisting of double power modules an even number of motor cables is needed. See Table 13

to Table 17 for cabling recommendations.

In 12-pulse drives with double inputs or outputs it is very important that the same

cable dimensions, type and routing is used for all cables. In case the cabling between

the AC drive modules is not symmetrical, unequal load might occur and reduce

loadability or even damage the AC drive.

In units with double motor outputs the motor cables must not be connected together

in the AC drive end. Always connect the parallel motor cables together in the motor

end only. The minimum motor cable length is 5 m.

If a safe switch between the AC drive and the motor is used, make sure that it is

switched on before setting the AC drive in run state.

The output cables to the motor must be 360

o

EMC earthed. Separate EMC grounding clamps are

supplied with NXC FR9 if an output filter is used and with all drives of sizes FR/AF10-12. In NXC FR/

AF13-14, EMC grounding is implemented directly through cable glands and grounding clamps are

unnecessary. See Chapter 6.2.2.1 for more information on EMC grounding for FR/AF13-14.The EMC

grounding clamps can, for instance, be installed on the mounting plate in front of the AC choke as

shown in Figure 14 below. The EMC grounding clamps must be suited to the output cable diameter

to give a 360

o

contact with the cables. See Chapters 6.2.6 and 6.2.7 for output cable diameters. See

Figure 14.

6

Figure 14. Figure Installing EMC grounding

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

CABLING AND CONNECTIONS vacon • 39

For more detailed cable installation instructions, see Chapter 8, step 6.

Use cables with a temperature rating of at least +70

°C. As a rule of thumb, cables and the fuses can

be dimensioned according to the AC drive nominal OUTPUT current which you can find on the rating

plate. Dimensioning according to the output current is recommended because the AC drive input

current never significantly exceeds the output current.

Table 13 and show the minimum dimensions of Cu- and Al-cables and the recommended aR fuse

sizes.

If the motor temperature protection of the drive (see VACON

®

All in One Application Manual) is used

as an overload protection, the cable should be chosen accordingly. If three or more cables are used

parallelly (per block) in bigger units each cable requires a separate overload protection.

Table 12. Cable types required to meet standards

Cable type

Level L

nd

(2

environment)

Level T

Mains cable 1 1

Motor cable 2 1/2*

Control cable 4 4

*Recommended

Level L

Level T

=

EN61800-3, 2nd environment

=

For IT networks

Power cable intended for fixed installation and the specific mains voltage.

=

1

2

4

Shielded cable not required (DRAKA NK CABLES - MCMK or similar

recommended).

Symmetrical power cable equipped with concentric protection wire and intended

=

for the specific mains voltage (DRAKA NK CABLES - MCMK or similar

recommended).

Screened cable equipped with compact low-impedance shield (DRAKA

=

NKCABLES - JAMAK, SAB/ÖZCuY-O or similar).

NOTE! The EMC requirements are fulfilled at factory defaults of switching frequencies (all enclosures).

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

6

vacon • 40 CABLING AND CONNECTIONS

Connect motor cables to

terminals U, V and W on

converter using cable

lugs

Connect mains cables to

terminals L1, L2 and L3

on the input device (if

used] or to power

terminals on the

converter using cable

lugs

EMC-earthing clamp for

motor cable screen

Connect the PE conductor

to the PE bar

11495_uk

Connect motor cables

to terminals U, V and

W on converter

Connect mains cabls to

terminals L1, L2 and L3

(behind the plexi glass)

on the converter

Connect the PE conductor

to the PE bar

Connect the PE conductor

to the PE bar

11496_uk

Figure 15. Routing of power cables, 6- and 12-pulse drives, bottom cabling, enclosures FR10-

6

FR12 (FR10 +ILS as example)

Figure 16. Routing of power cables, bottom cabling, enclosure FR13

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

CABLING AND CONNECTIONS vacon • 41

Conn c th PE

conductors to the PE bar

Connect the PE

conductors to the PE bar

11497_uk

Connect mains cables to terminals

L1, L2 and L3 (behind the plexi

glass) on the converter

Connect motor cables

to terminals U, V and W

on converter

Connect the PE conductor to

the PE bar

Connect the PE conductor to

the PE bar

Connect motor cables to

terminals U, V and W on

converter using cable

lugs

Connect mains

cables to terminals

L1, L2 and L3 power

terminals on the

converter using cable

EMC-earthing clamp for

motor cable screen

Connect the PE

conductor to the

PE bar

11498_uk

Figure 17. Routing of power cables, bottom cabling, enclosure FR14

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Figure 18. Routing of power cables, bottom cabling, enclosure AF10

6

vacon • 42 CABLING AND CONNECTIONS

Connect the PE conductor

to the PE bar

Connect

motor cables

to terminals

U, V and W on

converter

Connect mains cables to

terminals L1, L2 and L3

on AC drive

7019.emf

Connect motor cables to

terminals U, V and W on

converter

Connect mainscablesto

terminals L1, L2 and L3

(behind the plexi glass)

on the converter

11499_uk

Figure 19. Routing of power cables, bottom cabling, enclosure AF12 +ODU (optional)

6

Figure 20. Routing of power cables, bottom cabling, enclosure AF13

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

CABLING AND CONNECTIONS vacon • 43

11500_uk

11501_00

Figure 21. Routing of power cables, bottom cabling, enclosure AF14

6.2.2.1

Route the supply and motor cables in FR13-14/AF13-14 through the cabinet bottom as shown in

Figure 22. To conform to the EMC requirements, a particular cable gland shall be used. The cable

glands are designed to be used together with screened cables when electromagnetic compatibility

(EMC) is required.

Routing of power cables in FR13-14 or AF13-14 through bottom of cabinet

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

6

vacon • 44 CABLING AND CONNECTIONS

Rubber sealing

Bush ring

Cable

Assembly pl ate

PE(N) screen

Metal sock

Fastening spring

Cable tie

11502_uk

Figure 22. Routing of supply and power cables

Figure 23. Components of the cable gland set

Installing the cable gland

Unless the cable gland is already installed by the manufacturer, follow the procedure below to do

this:

1. Assemble the rubber sealing in the narrow groove of the bush ring. Make sure that the

gap between the assembly plate and the sealing is tight.

2. Since the fastening spring is rather stiff, we recommend to use a cone-shaped tool to fit

the metal sock in the bush ring and then to clamp it with the spring bent into a ring

shape. Draw the sock over the groove far enough to be easily fastened with the spring.

Make sure that the spring clamps the sock at 360°.

3. Roll up the sock as far as the fastening ring and remove the cone-shaped tool if used.

Now the cable installation is easier and the cable will not damage the sock.

4. Clamp the sock to the shielding of cable with a cable tie.

6

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

CABLING AND CONNECTIONS vacon • 45

Cone-shaped tool

Metal sock

Fastening spring

11503_uk

11504_00

6.2.2.2 Installation of ferrite rings (+OCM) on the motor cable

Slip only the phase conductors through the rings; leave the cable screen below and outside the

rings, see Figure 24. Separate the PE conductor. In case of parallel motor cables, reserve an equal

amount of ferrite ring sets for each cable and feed all the phase conductors of one cable through

one set of rings.

The delivery consists of fixed sets of ferrite rings (option). When ferrite rings are used to attenuate

the risk of bearing damages, use always two ferrite ring sets per motor cable.

NOTE! The ferrite rings are only additional protection. The basic protection against bearing currents

is an insulated bearing.

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

6

vacon • 46 CABLING AND CONNECTIONS

Ferrite rings

Metallic wall

of cabinet

Screen connected

to earth

Motor cable

PE

Mains cable

High frequency

earthing

Motor cable

Ferrite rings

Metallic wall

of cabinet

Screen conneted

to earth

11505_uk

13006.emf

13006.emf

Figure 24. Installation of ferrite rings on single (left) and parallel (right) motor cables

6.2.3 Thermal supervision of option +ODC

Option +ODC is equipped with a thermal supervision which will indicate if the filter temperature has

exceeded safe limits. Always refer to cabinet specific electrical drawings for details.This NC contact

is wired to the external fault input DIN3 by factory default.

NOTE! If the external fault input DIN3 is used for other purposes, make sure that the +ODU fan

supervision wiring is changed accordingly. It is also possible to connect the NC contact in series with

RUN or RUN ENABLE commands (see relevant application manual for more details).

6.2.4 DC supply and brake resistor cables

VACON

®

6- and 12-pulse AC drives can optionally be equipped with terminals for DC supply and with

an external brake resistor. These terminals are marked with B-, B+/R+ and R-. The DC bus

connection is made to terminals B– and B+ and the brake resistor connection to R+ and R– on the

AC drive module. The AC drive module terminals can also optionally be wired to customer terminals

in the cabinet. For additional information on integrated brake chopper and resistor values please

refer to NXS/NXP manual.

Make sure that the AC drive is equipped with a brake chopper before connecting a

brake resistor.

6

Do not connect the brake resistor between the terminals B- and B+ as this will

damage the drive.

6.2.5 Control cable

For information on control cables see Chapter 8.2. The control cables are routed down to the bottom

of the cabinet in the left inner side of the cabinet.

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

CABLING AND CONNECTIONS vacon • 47

6.2.6 Cable and fuse sizes, 380-500 V units

The table below shows typical cable sizes and types that can be used with the AC drive. The final

selection should be made according to local regulations, cable installation conditions and cable

specification.

6.2.6.1 6-pulse drives

Table 13. Cable and fuse sizes for VACON® NX_5, 6-pulse supply

Enclos

ure

FR9

FR10

FR11

FR12

FR13

FR14

Type

NXC0261 5 261

NXC0300 5 300

NXC0385 5 385

NXC0460 5 460

NXC0520 5 520

NXC0590 5 590

NXC0650 5 650

NXC0730 5 730

NXC0820 5 820

NXC0920 5 920

NXC1030 5 1030

NXC1150 5 1150 No additional drive fuses needed

NXC1300 5 1300 No additional drive fuses needed

NXC1450 5 1450 No additional drive fuses needed

NXC1770 5 1770 No additional drive fuses needed

NXC2150 5 2150 No additional drive fuses needed

I