Page 1

Application Guide

VACON® NX All-in-One

drives.danfoss.com

Page 2

Page 3

VACON® NX All-in-One

Application Guide

Contents

1

Introduction 8

1.1

Purpose of this Application Guide 8

Manual and Software Version 8

1.2

Additional Resources 8

1.3

1.4

Parameter Table Reading Guide 8

2

Basic Application 10

2.1

Introduction to Basic Application 10

2.1.1

Motor Protection Functions in the Basic Application 10

2.2

Control I/O in Basic Application 11

2.3

Control Signal Logic in Basic Application 12

2.4

Parameter Lists for Basic Application 12

2.4.1

Monitoring Values (Control Panel: Menu M1) 12

Contents

2.4.2

Basic Parameters (Control Panel: Menu M2 -> G2.1) 13

2.4.3

Keypad Control (Control Panel: Menu M3) 15

2.4.4

System Menu (Control Panel: Menu M6) 15

2.4.5

Expander Boards (Control Panel: Menu M7) 15

3

Standard Application 16

3.1

Introduction to Standard Application 16

3.2

Control I/O in Standard Application 17

3.3

Control Signal Logic in Standard Application 18

3.4

Parameter Lists for Standard Application 18

3.4.1

Monitoring Values (Control Panel: Menu M1) 12

3.4.2

Basic Parameters (Control Panel: Menu M2 -> G2.1) 19

3.4.3

Input Signals (Control Panel: Menu M2 -> G2.2) 20

3.4.4

Output Signals (Control Panel: Menu M2 ->G2.3) 21

3.4.5

Drive Control Parameters (Control Panel: Menu M2->G2.4) 23

3.4.6

Prohibit Frequency Parameters (Control Panel: Menu M2 -> G2.5) 23

3.4.7

Motor Control Parameters (Control Panel: Menu M2 -> G2.6) 24

3.4.8

Protections (Control Panel: Menu M2 -> G2.7) 25

3.4.9

Autorestart Parameters (Control Panel: Menu M2 -> G2.8) 27

3.4.10

Keypad Control (Control Panel: Menu M3) 27

3.4.11

System Menu (Control Panel: Menu M6) 15

3.4.12

Expander Boards (Control Panel: Menu M7) 15

4

Local/Remote Control Application 28

4.1

Introduction to Local/Remote Control Application 28

AB296635287482en-000201/DPD00903 | 3Danfoss A/S © 2020.12

Page 4

VACON® NX All-in-One

Application Guide

4.2

Control I/O in Local/Remote Control Application 29

4.3

Control Signal Logic in Local/Remote Control Application 31

4.4

Parameter Lists for Local/Remote Control Application 31

4.4.1

Monitoring Values (Control Panel: Menu M1) 12

4.4.2

Basic Parameters (Control Panel: Menu M2 -> G2.1 32

4.4.3

Input Signals (Control Panel: Menu M2 -> G2.2) 33

4.4.4

Output Signals (Control Panel: Menu M2 -> G2.3) 36

4.4.5

Drive Control Parameters (Control Panel: Menu M2->G2.4) 23

4.4.6

Prohibit Frequency Parameters (Control Panel: Menu M2 -> G2.5) 39

4.4.7

Motor Control Parameters (Control Panel: Menu M2 -> G2.6) 24

4.4.8

Protections (Control Panel: Menu M2 -> G2.7) 25

4.4.9

Autorestart Parameters (Control Panel: Menu M2 -> G2.8) 27

4.4.10

Keypad Control (Control Panel: Menu M3) 27

4.4.11

System Menu (Control Panel: Menu M6) 15

Contents

4.4.12

Expander Boards (Control Panel: Menu M7) 15

5

Multi-step Speed Control Application 44

5.1

Introduction to Multi-step Speed Control Application 44

5.2

Control I/O in Multi-step Speed Control 45

5.3

Control Signal Logic in Multi-step Speed Control Application 46

5.4

Parameter Lists for Multi-step Speed Control Application 47

5.4.1

Monitoring Values (Control Panel: Menu M1) 12

5.4.2

Basic Parameters (Control Panel: Menu M2 -> G2.1) 47

5.4.3

Input Signals (Control Panel: Menu M2 -> G2.2) 49

5.4.4

Output Signals (Control Panel: Menu M2 -> G2.3) 51

5.4.5

Drive Control Parameters (Control Panel: Menu M2->G2.4) 23

5.4.6

Prohibit Frequency Parameters (Control Panel: Menu M2 -> G2.5) 39

5.4.7

Motor Control Parameters (Control Panel: Menu M2 -> G2.6) 24

5.4.8

Protections (Control Panel: Menu M2 -> G2.7) 56

5.4.9

Autorestart Parameters (Control Panel: Menu M2 -> G2.8) 27

5.4.10

Keypad Control (Control Panel: Menu M3) 27

5.4.11

System Menu (Control Panel: Menu M6) 15

5.4.12

Expander Boards (Control Panel: Menu M7) 15

6

PID Control Application 59

6.1

Introduction to PID Control Application 59

6.2

Control I/O in PID Control Application 60

6.3

Control Signal Logic in PID Control Application 62

6.4

Parameter Lists for PID Control Application 62

AB296635287482en-000201/DPD009034 | Danfoss A/S © 2020.12

Page 5

VACON® NX All-in-One

Application Guide

6.4.1

Monitoring Values (Control Panel: Menu M1) 62

6.4.2

Basic Parameters (Keypad Panel: Menu M2 -> G2.1) 63

6.4.3

Input Signals (Control Panel: Menu M2 -> G2.2) 65

6.4.4

Output Signals (Control Panel: Menu M2 -> G2.3) 68

6.4.5

Drive Control Parameters (Control Panel: Menu M2 -> G2.4) 70

6.4.6

Prohibit Frequency Parameters (Control Panel: Menu M2 -> G2.5) 71

6.4.7

Motor Control Parameters (Control Panel: Menu M2 -> G2.6) 72

6.4.8

Protections (Control Panel: Menu M2 -> G2.7) 73

6.4.9

Autorestart Parameters (Control Panel: Menu M2 -> G2.8) 27

6.4.10

Keypad Control (Control Panel: Menu M3) 75

6.4.11

System Menu (Control Panel: Menu M6) 15

6.4.12

Expander Boards (Control Panel: Menu M7) 15

7

Multi-purpose Control Application 77

7.1

Introduction to Multi-purpose Control Application 77

Contents

7.2

Control I/O in Multi-purpose Control Application 78

7.3

Control Signal Logic in Multi-purpose Control Application 79

7.4

Parameter Lists for Multi-purpose Control Application 79

7.4.1

Monitoring Values (Control Panel: Menu M1) 79

7.4.2

Basic Parameters (Control Panel: Menu M2 -> G2.1) 90

7.4.3

Input Signals 92

7.4.4

Output Signals 97

7.4.5

Drive Control Parameters (Control Panel: Menu M2 -> G2.4) 102

7.4.6

Prohibit Frequency Parameters (Control Panel: Menu M2 -> G2.5) 71

7.4.7

Motor Control Parameters, VACON® NXS (Control Panel: Menu M2 -> G2.6) 104

7.4.8

Motor Control Parameters, VACON® NXP (Control Panel: Menu M2 -> G2.6) 107

7.4.9

Protections (Control Panel: Menu M2 -> G2.7) 111

7.4.10

Autorestart Parameters (Control Panel: Menu M2 -> G2.8) 27

7.4.11

Fieldbus Parameters (Control Panel: Menu M2 -> G2.9) 117

7.4.12

Torque Control Parameters (Control Panel: Menu M2 -> G2.10) 118

7.4.13

Master Follower Parameters, VACON® NXP (Control Panel: Menu M2 -> G2.11 119

7.4.14

Functional Safety (Control Panel: Menu M2 -> G.12) 120

7.4.15

Condition-based Monitoring (Control Panel: Menu M2 -> G.13) 121

7.4.16

Keypad Control (Control Panel: Menu M3) 125

7.4.17

System Menu (Control Panel: Menu M6) 15

7.4.18

Expander Boards (Control Panel: Menu M7) 15

8

Pump and Fan Control Application 127

8.1

Introduction to Pump and Fan Control Application 127

AB296635287482en-000201/DPD00903 | 5Danfoss A/S © 2020.12

Page 6

VACON® NX All-in-One

Application Guide

8.2

Control I/O in Pump and Fan Control Application 128

8.3

Control Signal Logic in Pump and Fan Control Application 131

8.4

Parameter Lists for Pump and Fan Control Application 131

8.4.1

Monitoring Values (Control Panel: Menu M1) 131

8.4.2

Basic Parameters (Control Panel: Menu M2 -> G2.1) 132

8.4.3

Input Signals 134

8.4.4

Output Signals 138

8.4.5

Drive Control Parameters (Control Panel: Menu M2 -> G2.4) 142

8.4.6

Prohibit Frequency Parameters (Control Panel: Menu M2 -> G2.5) 71

8.4.7

Motor Control Parameters (Control Panel: Menu M2 ->G2.6) 143

8.4.8

Protections (Control Panel: Menu M2 -> G2.7) 144

8.4.9

Auto Restart Parameters (Control Panel: Menu M2 -> G2.8) 146

8.4.10

Pump and Fan Control Parameters (Control Panel: Menu M2 -> G2.9) 146

8.4.11

Keypad Control (Control Panel: Menu M3) 148

Contents

8.4.12

System Menu (Control Panel: Menu M6) 15

8.4.13

Expander Boards (Control Panel: Menu M7) 15

9

Monitoring Value Descriptions 149

10

Parameter Descriptions 165

10.611

Keypad Control Parameters 298

10.612

Master/Follower Function 299

10.613

External Brake Control with Additional Limits (IDs 315, 316, 346–349, 352, 353) 300

10.614

Parameters of Motor Thermal Protection (IDs 704–708) 302

10.615

Parameters of Stall Protection (IDs 709–712) 303

10.616

Parameters of Underload Protection (IDs 713–716) 303

10.617

Fieldbus Control Parameters (IDs 850–859) 303

10.617.1

Process Data Out (Slave -> Master) 303

10.617.2

Current Scaling in Different Size of Units 303

10.617.3

Process Data in (Master -> Slave) 304

10.618

Closed Loop Parameters (IDs 612–621) 305

10.619

"Terminal to Function" (TTF) Programming Principle 305

10.619.1

Defining an Input/Output for a Certain Function on Keypad 305

10.619.2

Defining a Terminal for a Certain Function with VACON® NCDrive 306

10.619.3

Defining Unused Inputs/Outputs 307

10.620

Speed Control Parameters (Multi-Purpose Control Application Only) 307

10.621

Functional Safety Parameters (Multi-Purpose Control Application Only) 309

10.622

Automatic Changing Between Drives (Pump and Fan Control Application Only) 310

10.623

Interlock Selection (Pump and Fan Control Application Only) 310

AB296635287482en-000201/DPD009036 | Danfoss A/S © 2020.12

Page 7

VACON® NX All-in-One

Application Guide

10.624

Examples of Autochange and Interlock Selection 310

10.624.1

Pump and Fan Automatics with Interlocks and No Autochange 310

10.624.2

Pump and Fan Automatics with Interlocks and Autochange 311

10.625

Fieldbus Control in Detail 314

10.625.1

Combination 2: Bypass - ProfiDrive 314

10.625.2

Combination 3: Bypass - Standard 316

10.626

Condition-based Monitoring 317

10.626.1

Stages of Condition-based Monitoring 318

11

Fault Tracing 320

11.1

Faults and Alarms 320

Contents

AB296635287482en-000201/DPD00903 | 7Danfoss A/S © 2020.12

Page 8

•

•

•

•

•

•

•

•

•

-

-

•

Manual Edition

Remarks

Software code

DPD00903H

New and updated monitoring values

and parameters in Multi-purpose Control Application, for example, related to

Condition-based Monitoring.

New faults related to Condition-based

Monitoring

Other minor changes and corrections

throughout the manual.

Basic Application = ASFIFF01, Version 4.08

Standard Application = ASFIFF02, Version 4.08

Local/Remote Control Application = ASFIFF03, Version 4.08

Multi-step Speed Control Application = ASFIFF04, Version 4.08

PID Control Application = ASFIFF05, Version 4.11

Multi-purpose Control Application

VACON® NXS = ASFIFF06, Version 4.14

VACON® NXP = APFIFF06, Version 2.64

Pump and Fan Control Application = ASFIFF07, Version 4.09

NOTE! Download the English and French product manuals with applicable safety, warning and caution information from https://

www.danfoss.com/en/service-and-support/.

REMARQUE Vous pouvez télécharger les versions anglaise et française des manuels produit contenant l'ensemble des informations de sécurité, avertissements et mises en garde applicables sur le site https://www.danfoss.com/en/service-and-support/.

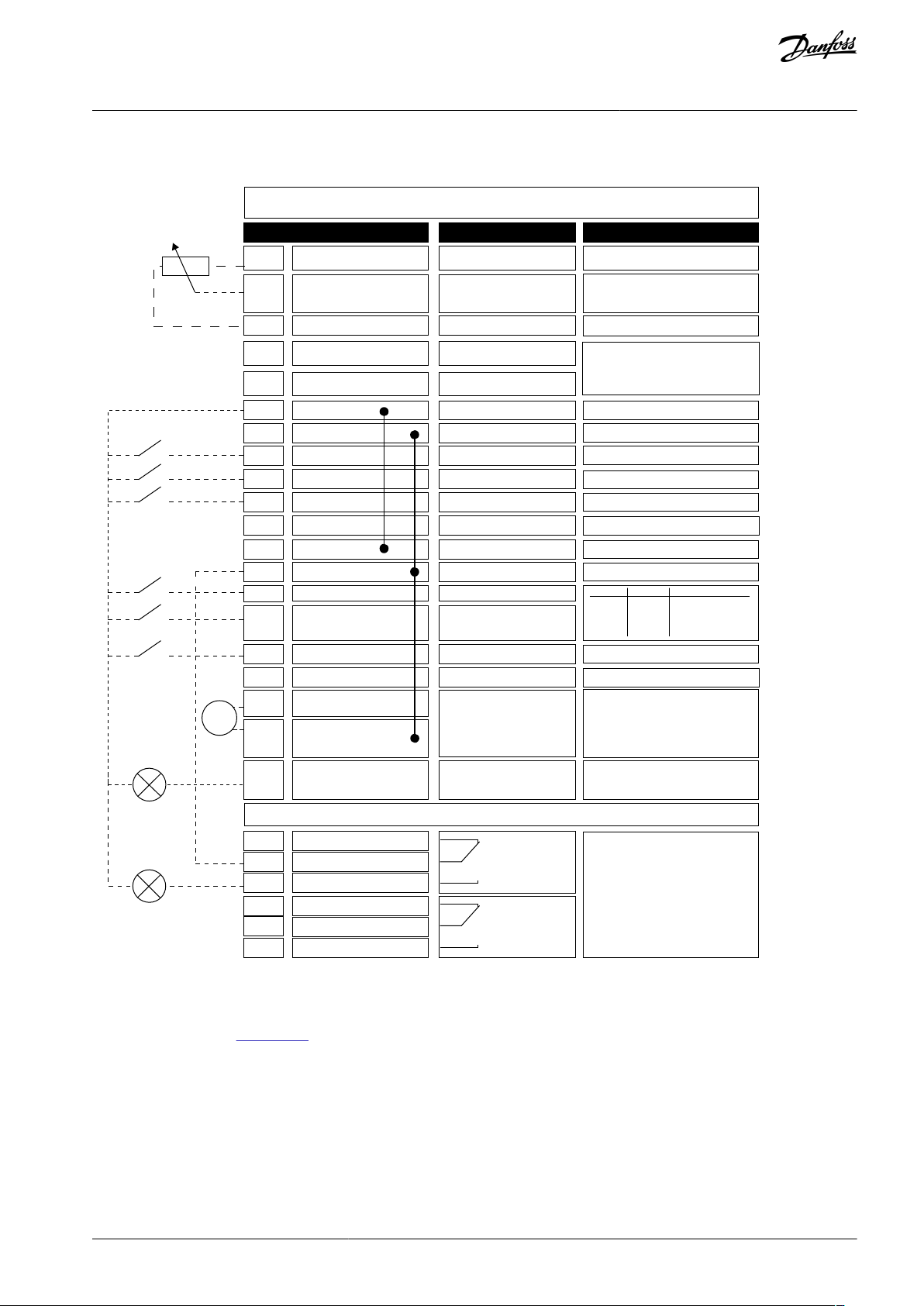

Index

Min Max Unit Default

ID Description

Parameter

e30bg858.10

A

B

C

D E F G H

VACON® NX All-in-One

Application Guide

Introduction

1 Introduction

1.1 Purpose of this Application Guide

This Application Guide provides information on functions of different applications, available parameters, and alarms to help in configuring the system, programming, and troubleshooting the AC drive. It is intended for use by qualified personnel. Read and follow

the instructions to use the drive safely and professionally. Pay particular attention to the safety instructions and general warnings

that are provided in this manual and other documentation delivered with the drive.

1.2 Manual and Software Version

This manual is regularly reviewed and updated. All suggestions for improvement are welcome.

The original language of this manual is English.

Table 1: Manual and Software Version

1.3 Additional Resources

Other resources are available to understand advanced AC drive functions and operation.

•

VACON® NXS/NXP Air-cooled Wall-mounted and Standalone Operating Guide

•

VACON® NXP NXC User Manual

VACON® NXP IP00 User Manual

•

VACON® NXP Liquid Cooled User Manual

•

Instructions for operation with option boards and other optional equipment.

•

Supplementary publications and manuals are available from Danfoss.

For US and Canada market:

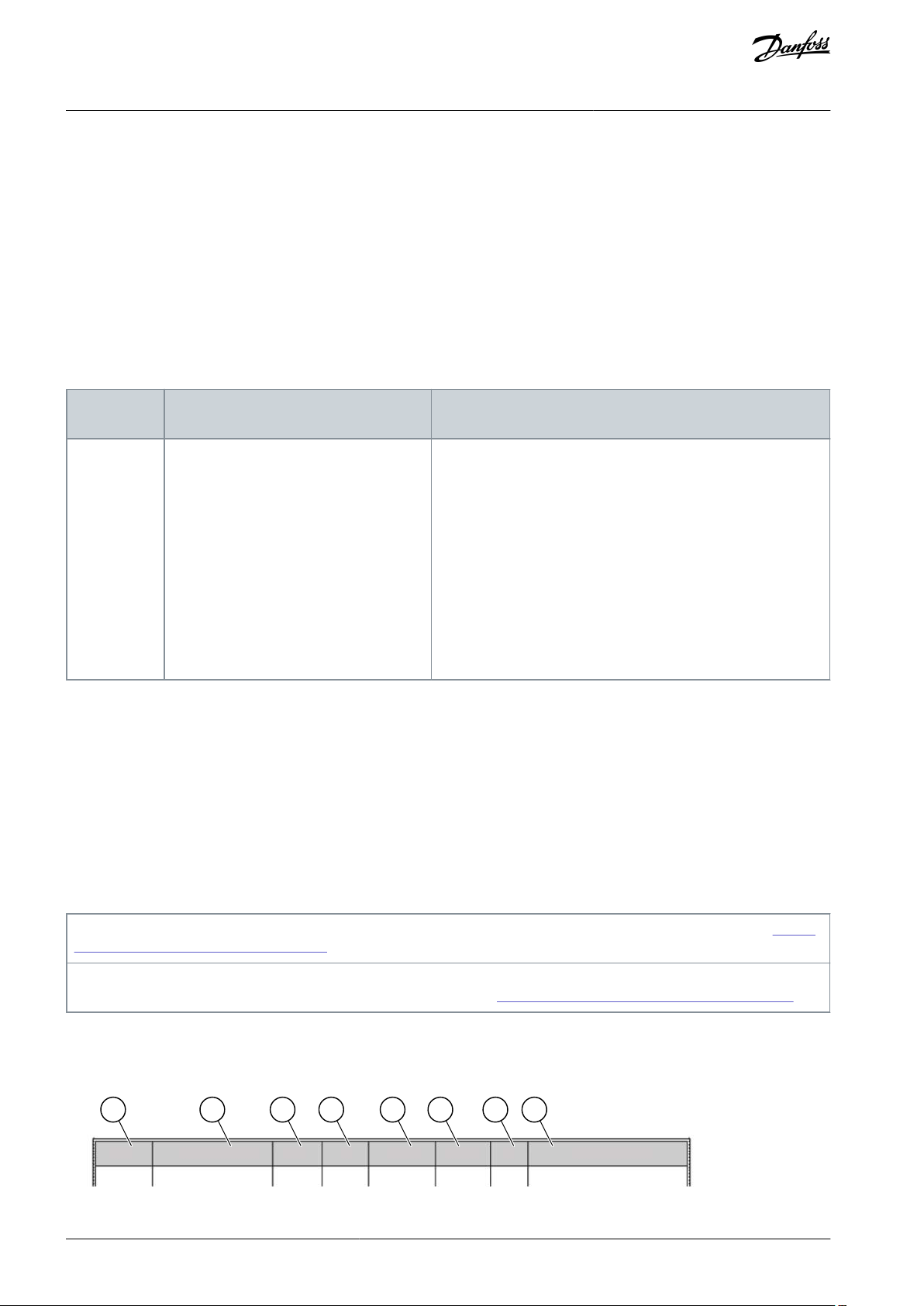

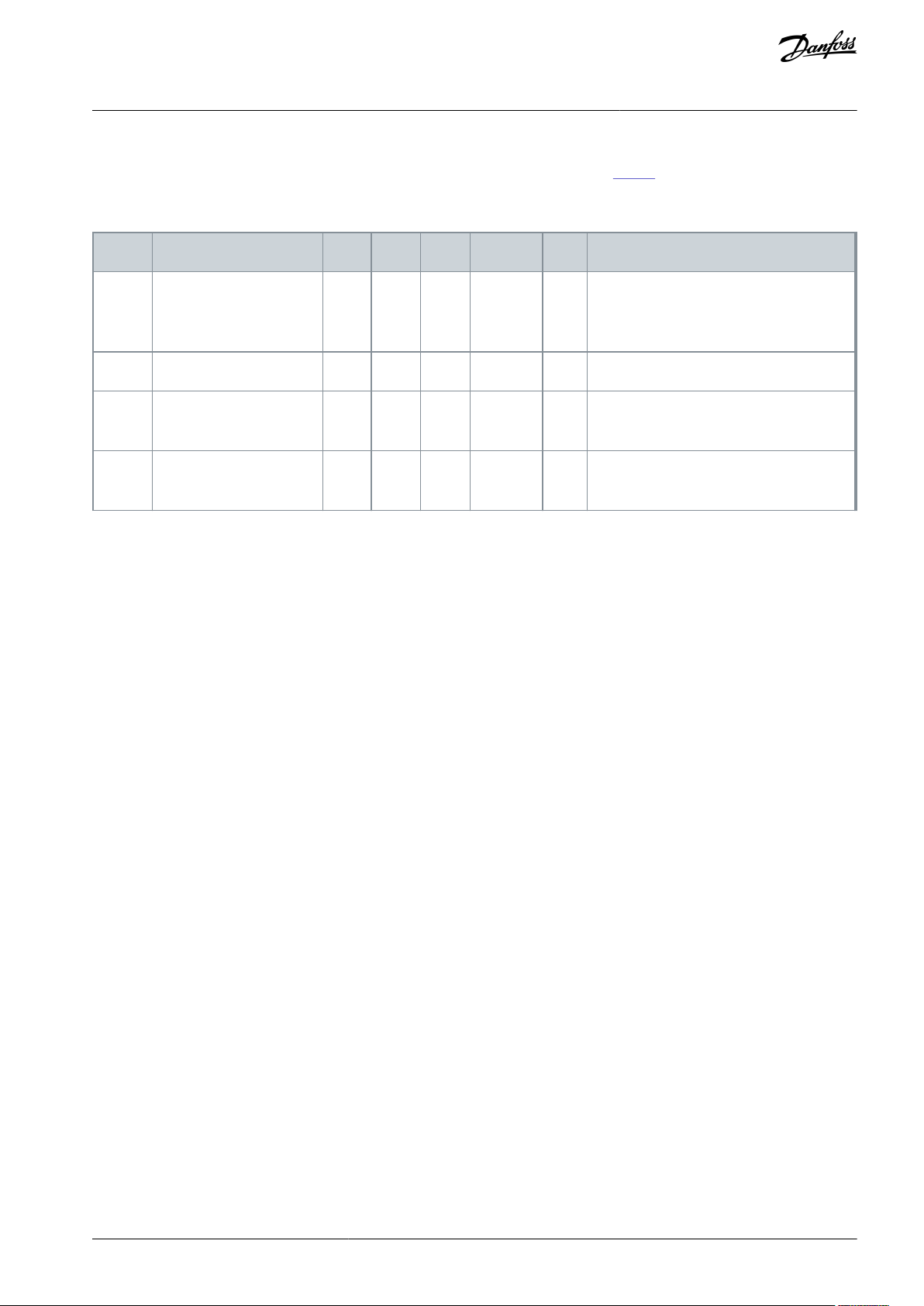

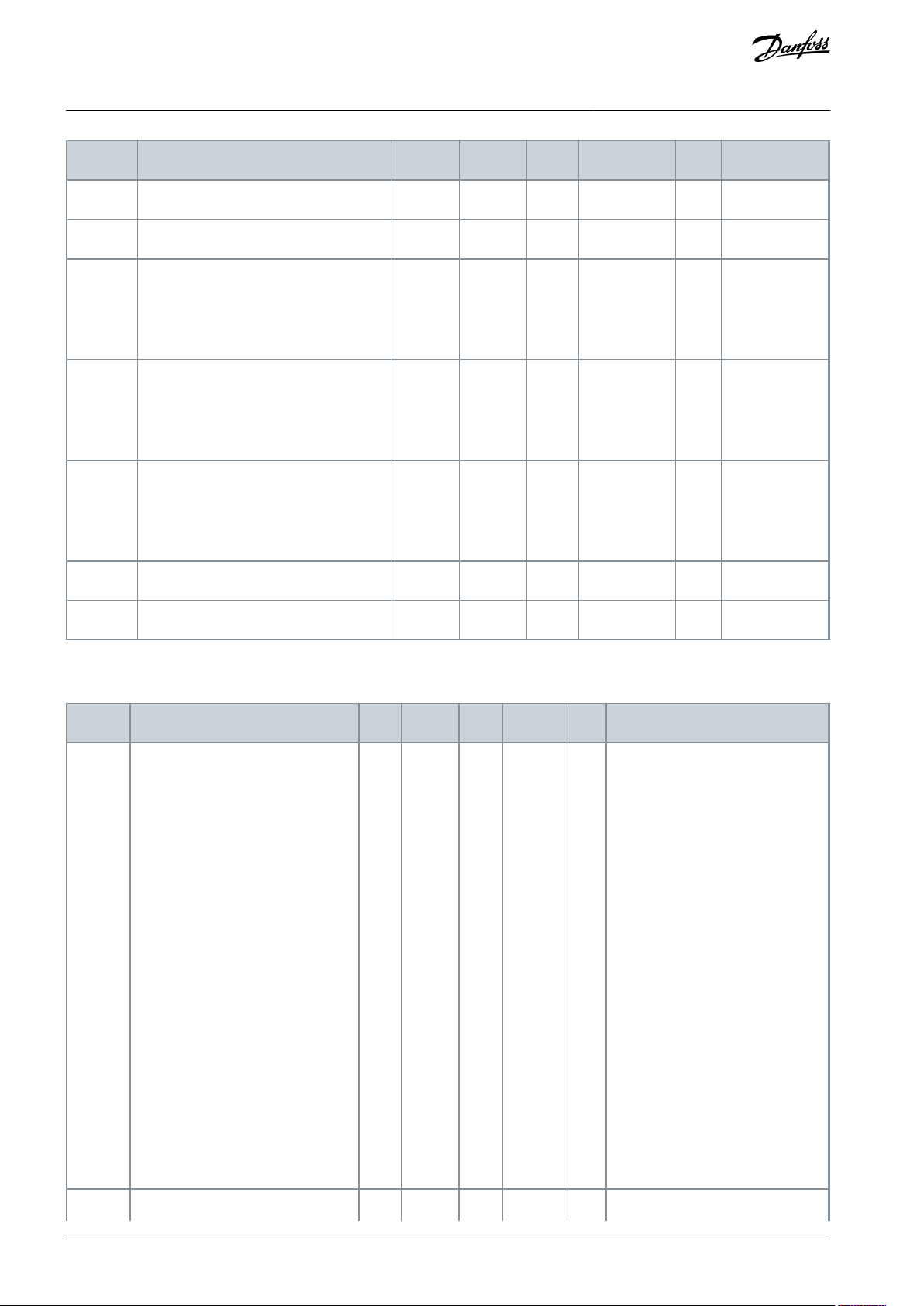

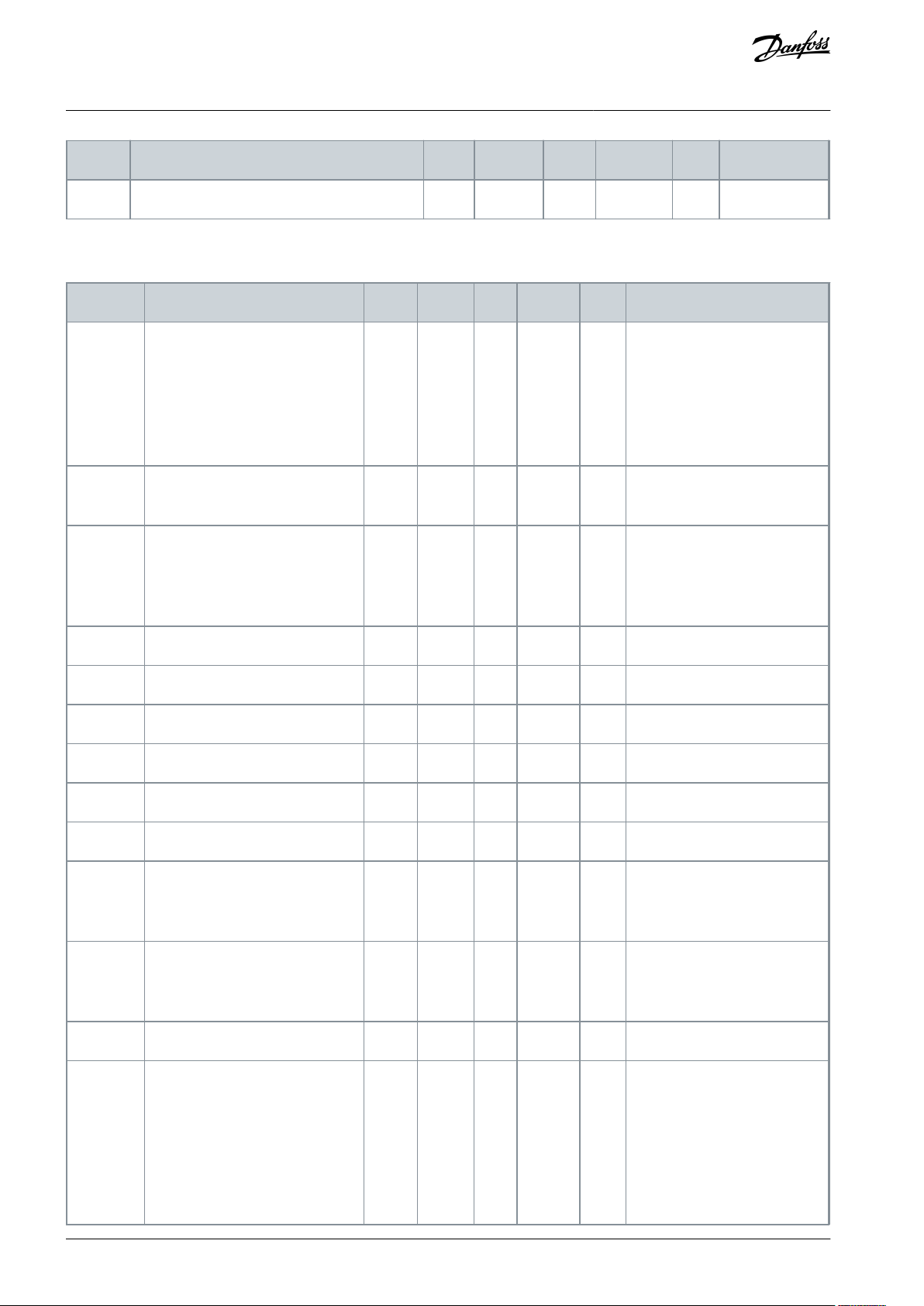

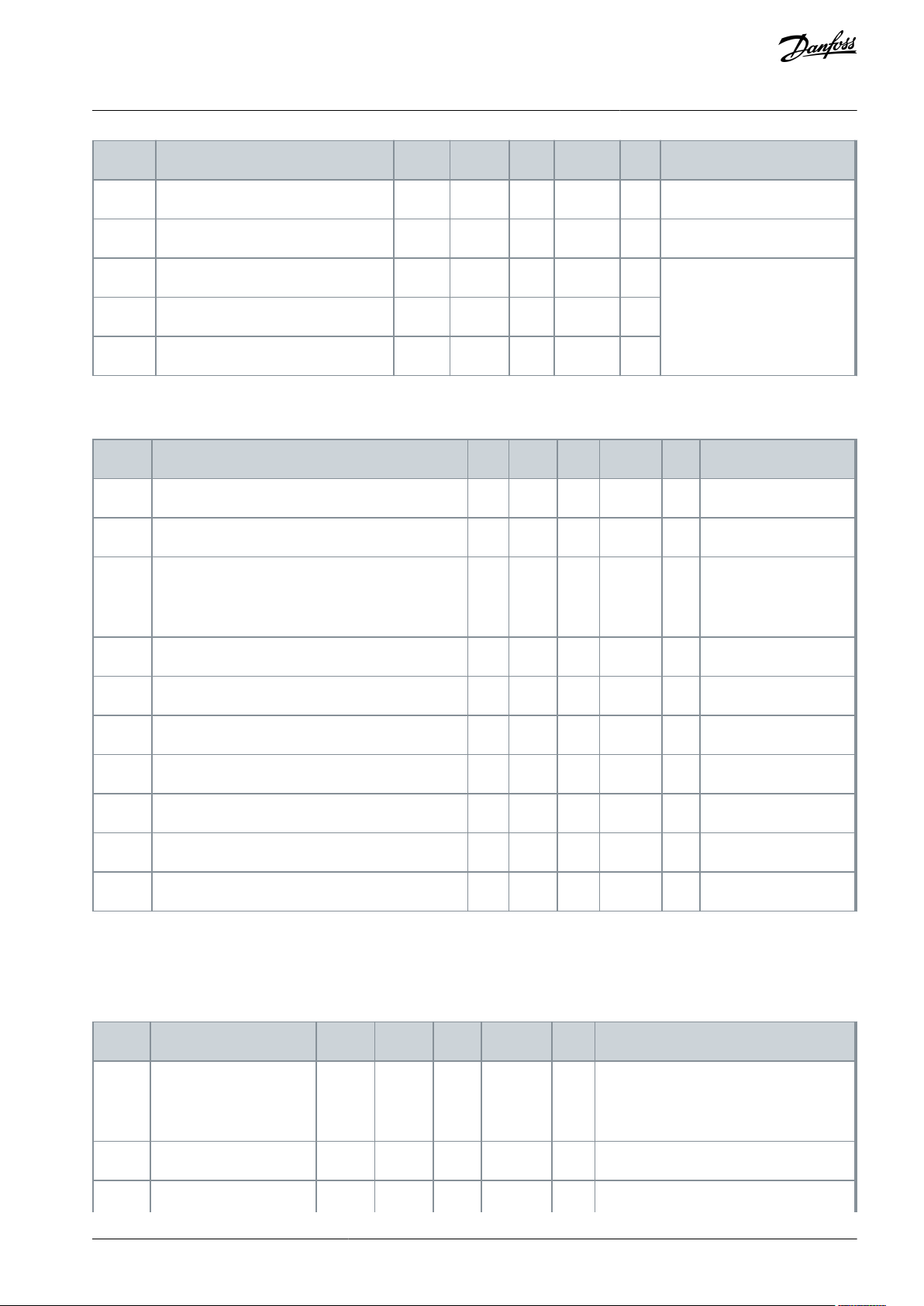

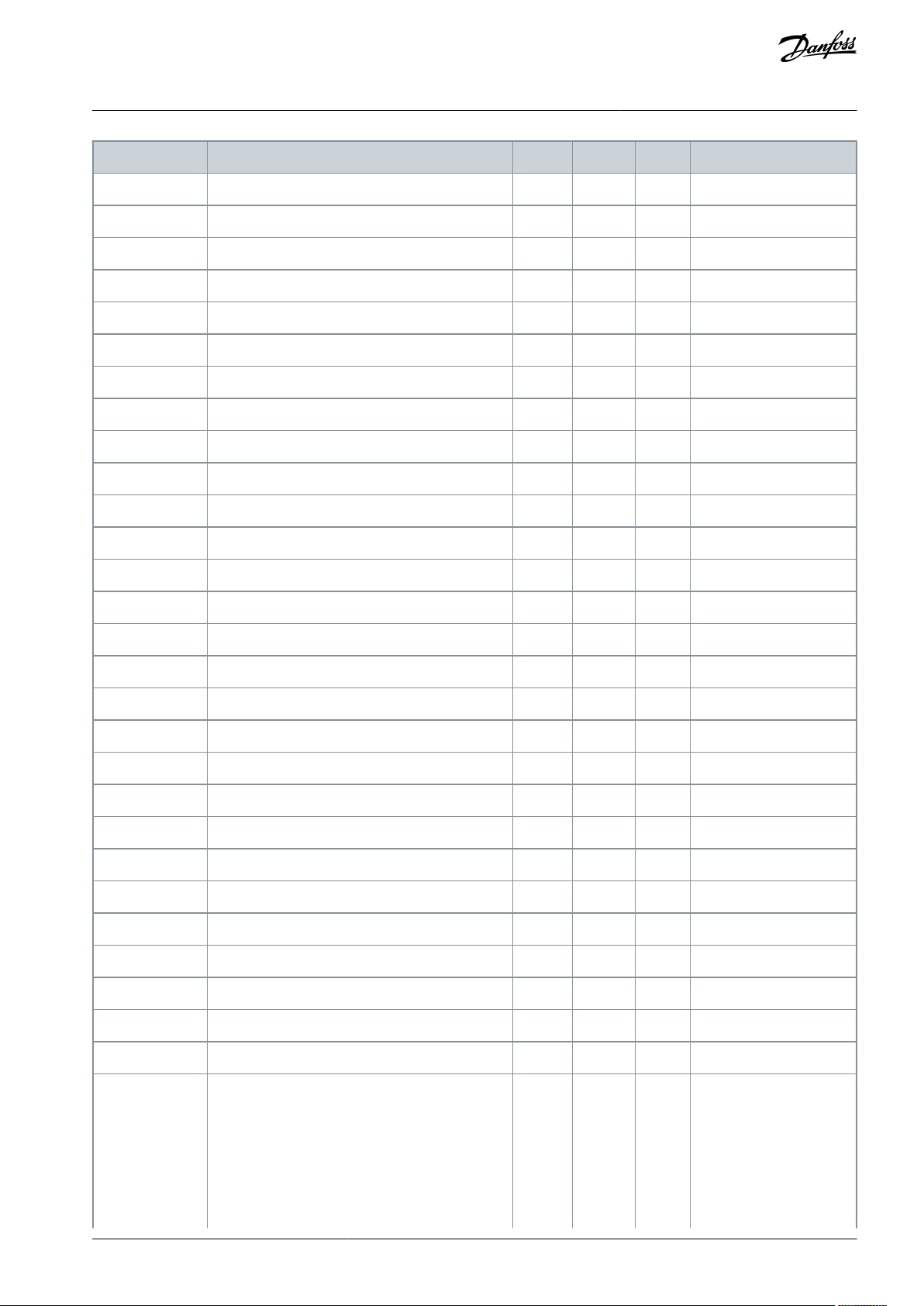

1.4 Parameter Table Reading Guide

This manual includes a large quantity of parameter tables. These instructions tell you how to read the tables.

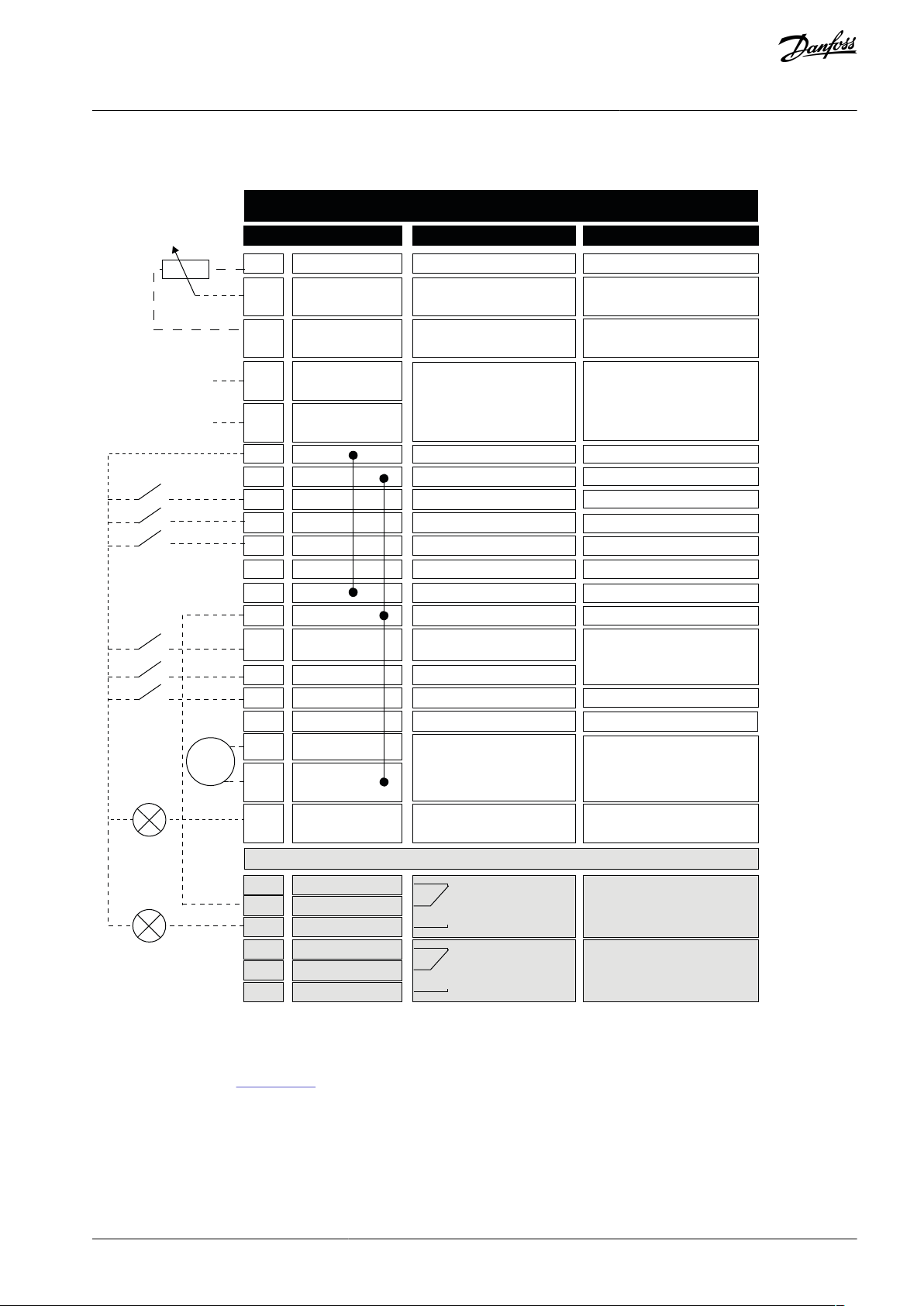

Illustration 1: Parameter Table Reading Guide

AB296635287482en-000201 / DPD009038 | Danfoss A/S © 2020.12

Page 9

A

The location of the parameter in the menu, that is,

the parameter number.

B

The name of the parameter.

C

The minimum value of the parameter.

D

The maximum value of the parameter.

E

The unit of the value of the parameter. The unit

shows if it is available.

F

The value that was set in the factory.

G

The ID number of the parameter.

H

A short description of the values of the parameter

and/or its function.

VACON® NX All-in-One

Application Guide

Introduction

AB296635287482en-000201 / DPD00903 | 9Danfoss A/S © 2020.12

Page 10

VACON® NX All-in-One

Application Guide

Basic Application

2 Basic Application

2.1 Introduction to Basic Application

The Basic Application is a simple and easy-to-use application. It is the default setting on delivery from the factory. Otherwise select

the Basic Application in menu M6 on page S6.2. See the User Manual of the product.

Digital input DIN 3 is programmable.

The parameters of the Basic Application are explained in Chapter Parameter descriptions of this manual. The explanations are ar-

ranged according to the individual ID number of the parameter.

2.1.1 Motor Protection Functions in the Basic Application

The Basic Application provides almost all the same protection functions as the other applications:

•

External fault protection

•

Input phase supervision

•

Undervoltage protection

•

Output phase supervision

•

Earth fault protection

•

Motor thermal protection

•

Thermistor fault protection

•

Fieldbus fault protection

•

Slot fault protection

Unlike the other applications, the Basic Application does not provide any parameters for choosing the response function or limit

values for the faults. For more information on the motor thermal protection, see 10.336 (ID 704) Motor Thermal Protection and

10.614 Parameters of Motor Thermal Protection (IDs 704–708).

AB296635287482en-000201 / DPD0090310 | Danfoss A/S © 2020.12

Page 11

1

6

2

3

4

5

18

19

20

12

7

13

8

9

10

14

15

16

21

OPTA 2 / OPTA 3

22

23

11

17

24

25

26

DIN4

DIN5

Voltage for

potentiometer, etc.

Ground for reference

and controls

Ground for reference

and controls

Ground for reference

and controls

Analogue input 2

frequency reference

Voltage for switches (see #6)

Connect to GND or +24 V

FAULT

External fault input

Programmable (P2.17)

Connect to

GND or +24 V

Contact open = no action

Contact closed = fault reset

Contact open = no fault

Contact closed = fault

Contact closed = start forward

Contact closed = start reverse

Analogue output 1

Output frequency

Programmable

(P2.16)

Range 0—20 mA/RL,

max. 500 Ω

Open collector,

I≤50 mA, U≤48 VDC

Digital output 1

READY

RUN

mA

READY

AO1-

DO1

+24V

GND

GND

DIN1

DIN2

DIN3

DIN4

DIN5

DIN6

R O1

R O1

R O1

CMA

CMB

R O2

R O2

R O2

Standard I/O board

Terminal Signal Description

+10V

ref

AI1+

AI1-

AI2+

AI2-

+24V

Reference output

Analogue input 1

Voltage range 0—10 V DC

Programmable (P2.14)

Analogue input 2

Current range 0-20mA

Control voltage output

I/O ground

I/O ground

Preset speed select 1

Preset speed select 2

Fault reset

Common for DIN 1—DIN 3

Common for DIN4-DIN6

Control voltge output

I/O ground

Relay output 1

Relay output 2

AO1+

Analogue input 1

frequency reference

Voltage for switches,

etc. max 0.1 A

Start forward

Start reverse

Freq. ref.

Open

Closed

Open

Closed

Open

Open

Closed

Closed

I/O ref (P2.14)

Preset Speed 1

Preset Speed 2

Max frequency

RUN

Reference potentiometer,

1-10kΩ

e30bh055.20

VACON® NX All-in-One

Application Guide

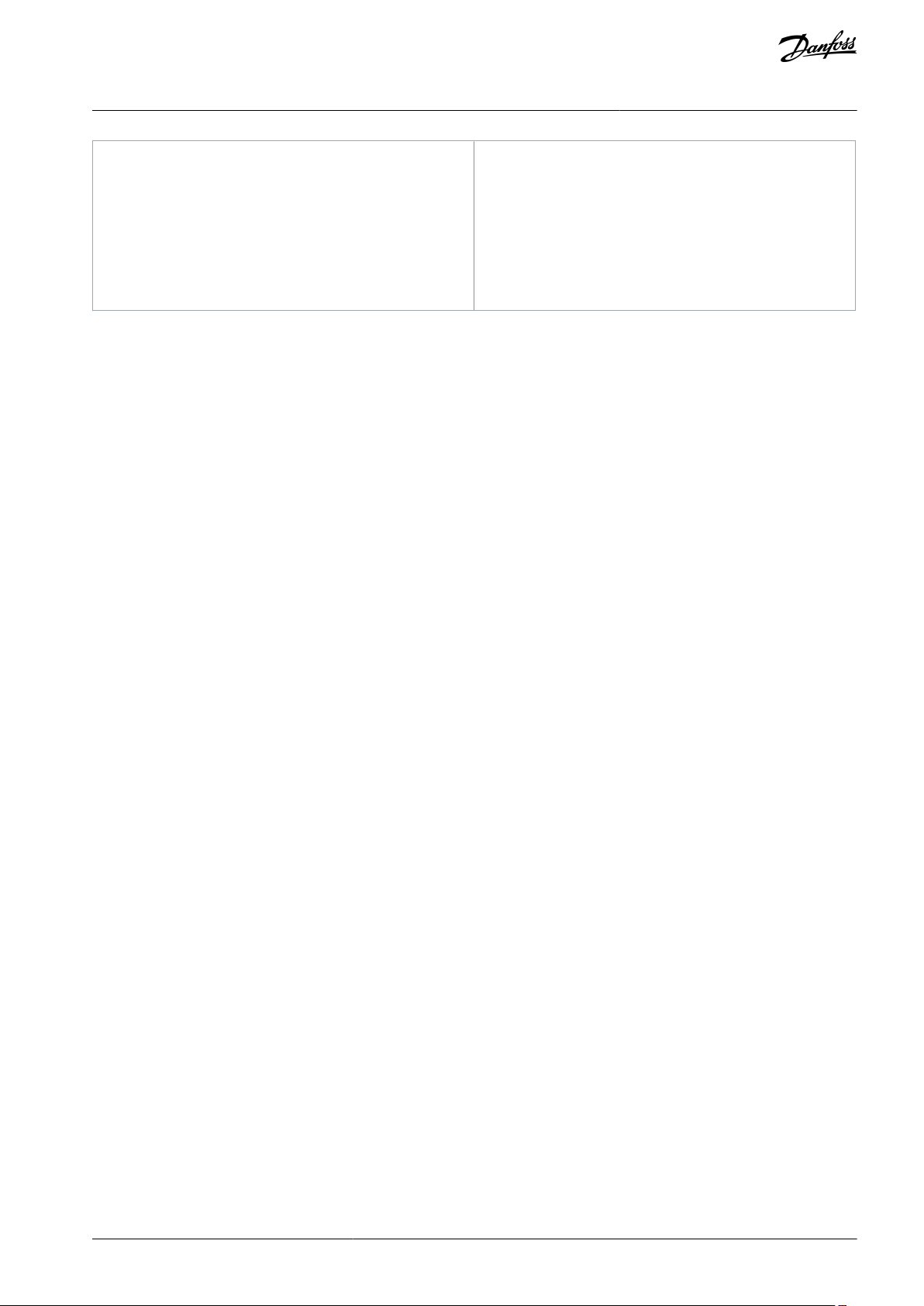

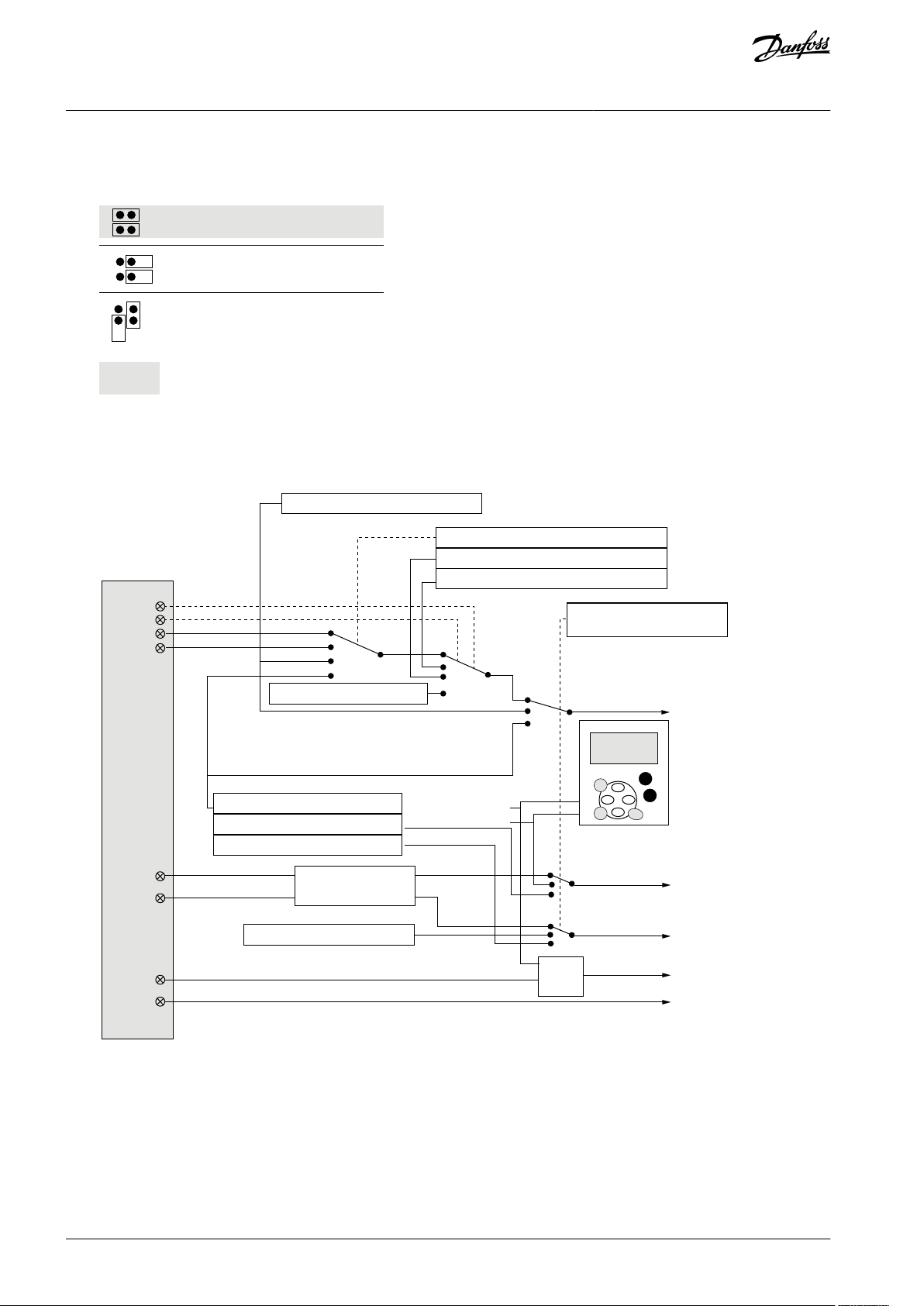

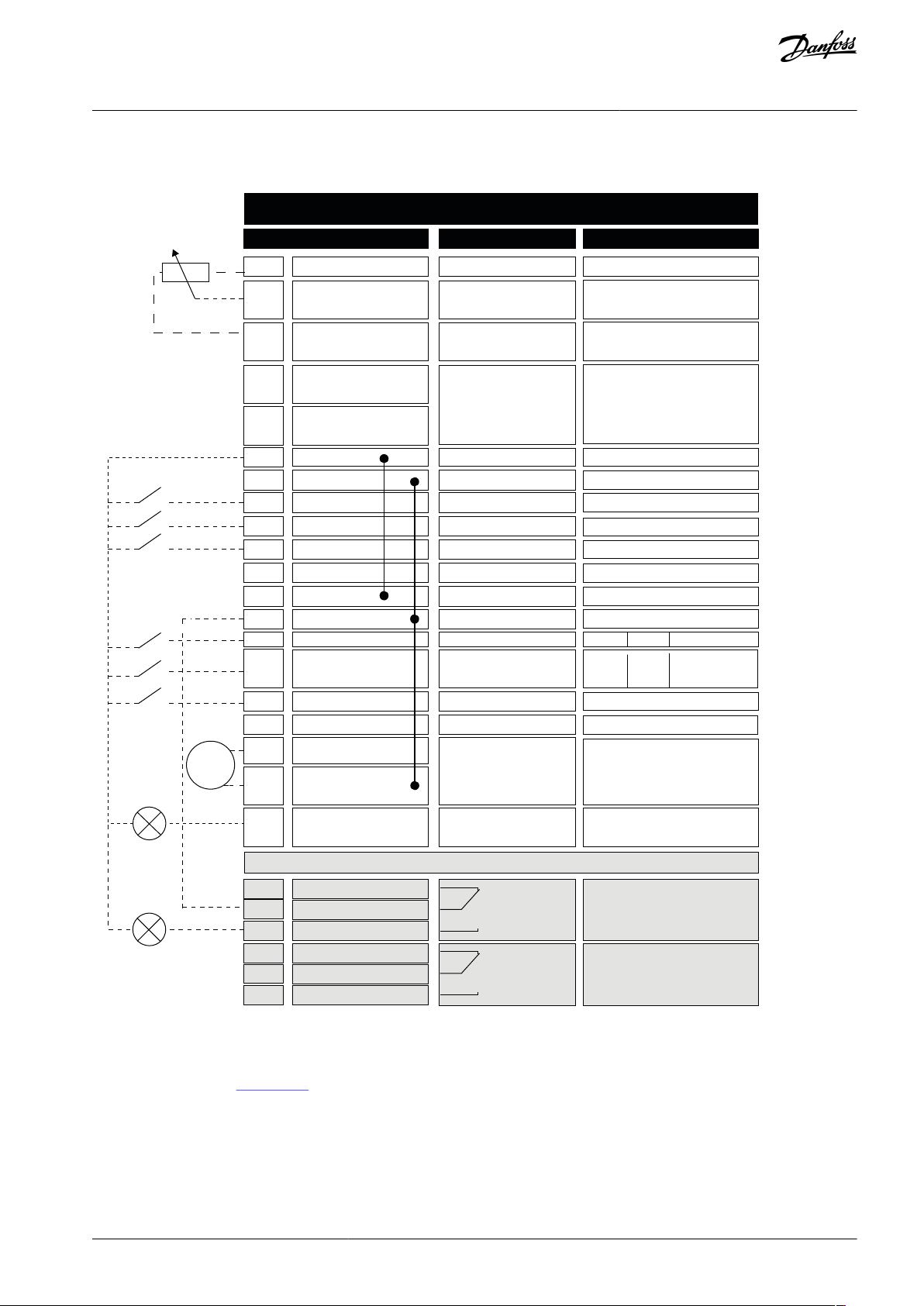

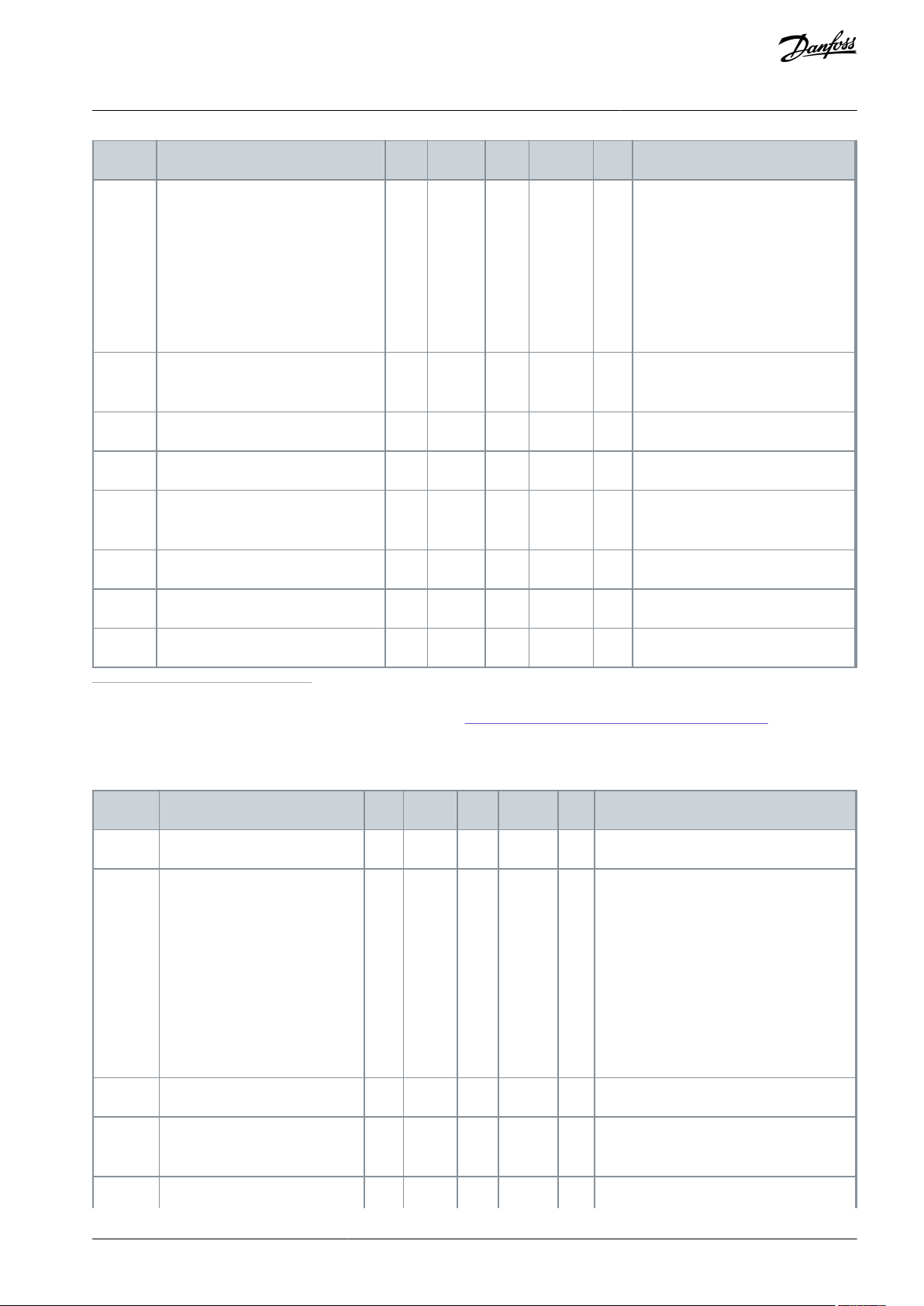

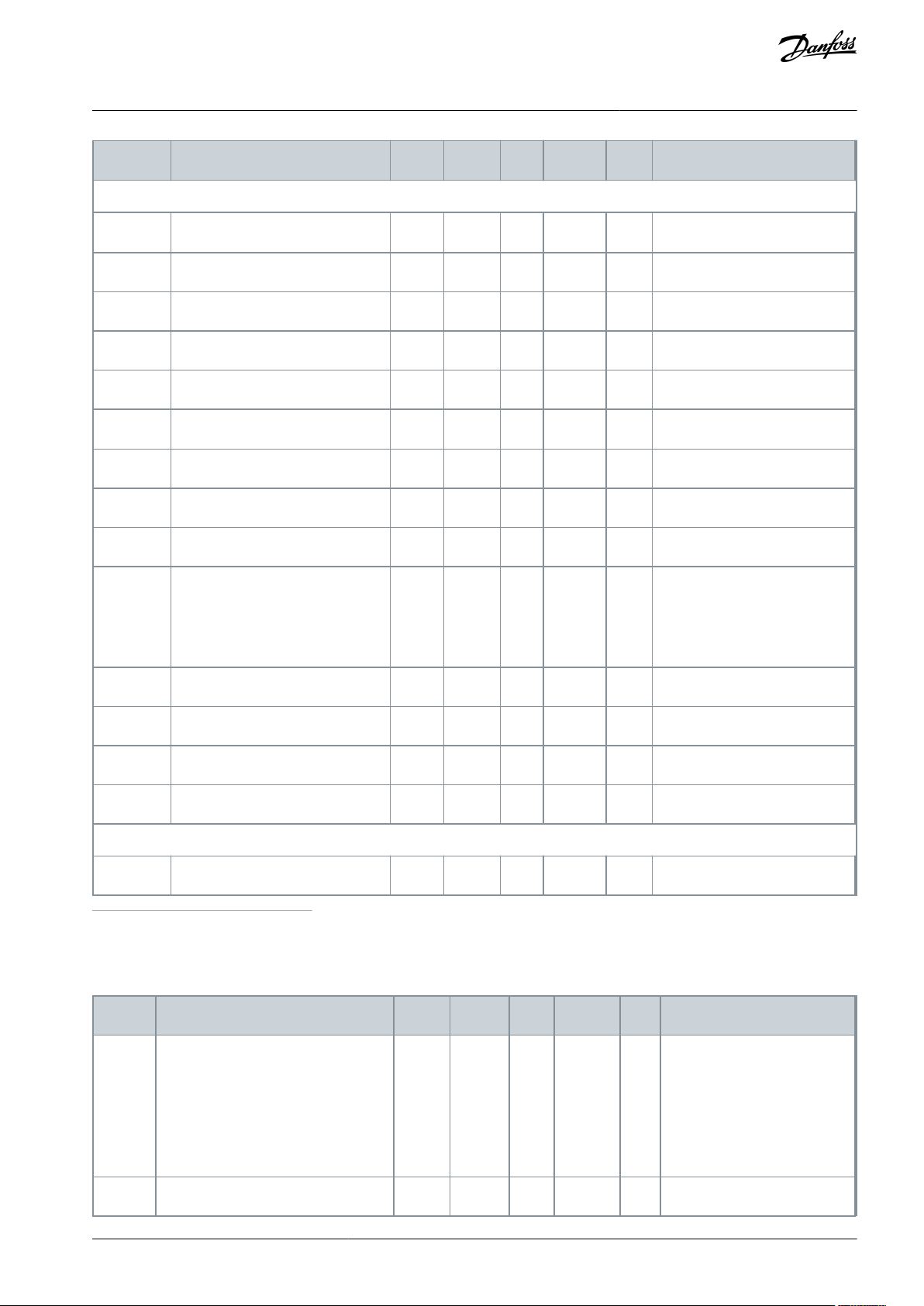

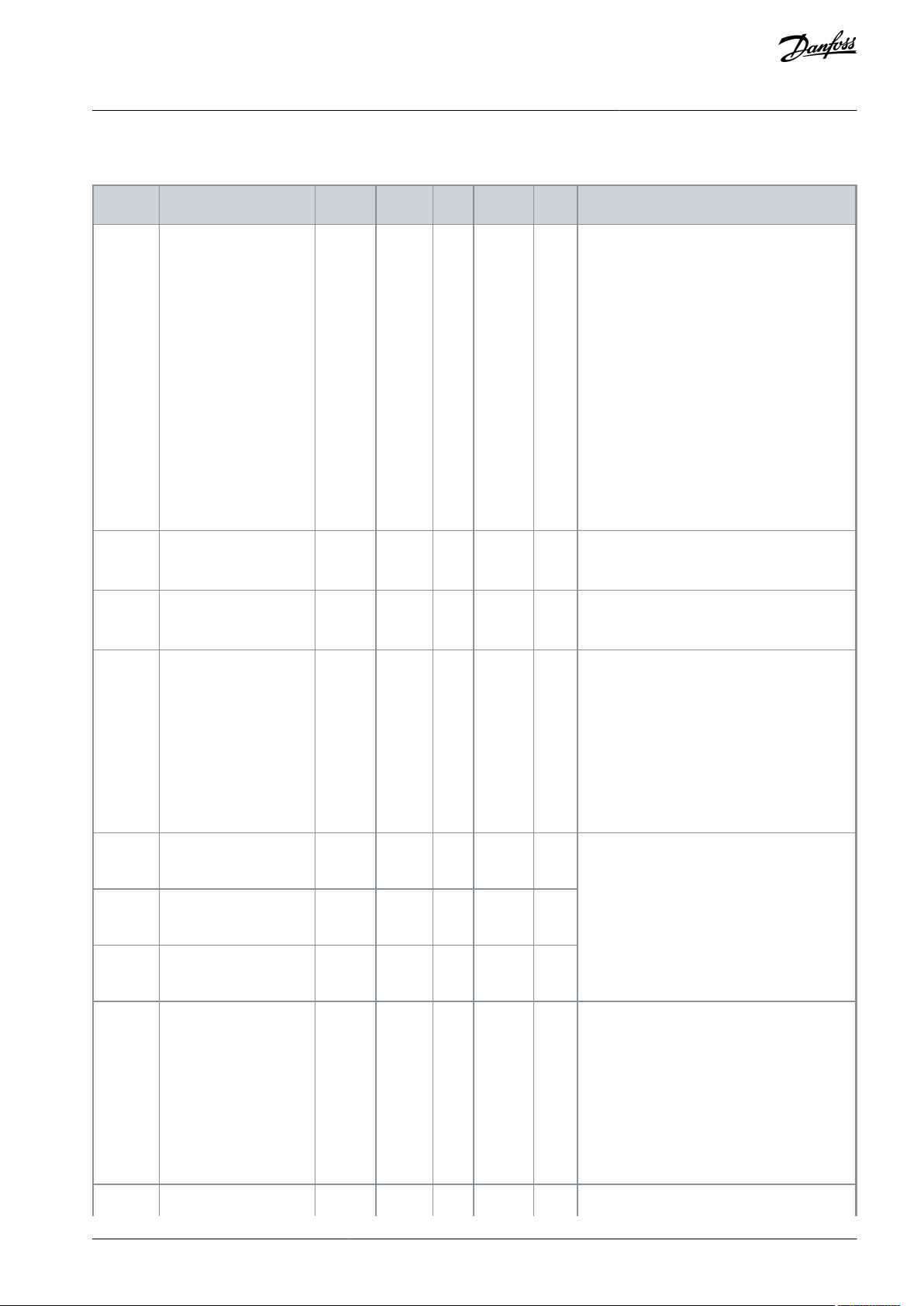

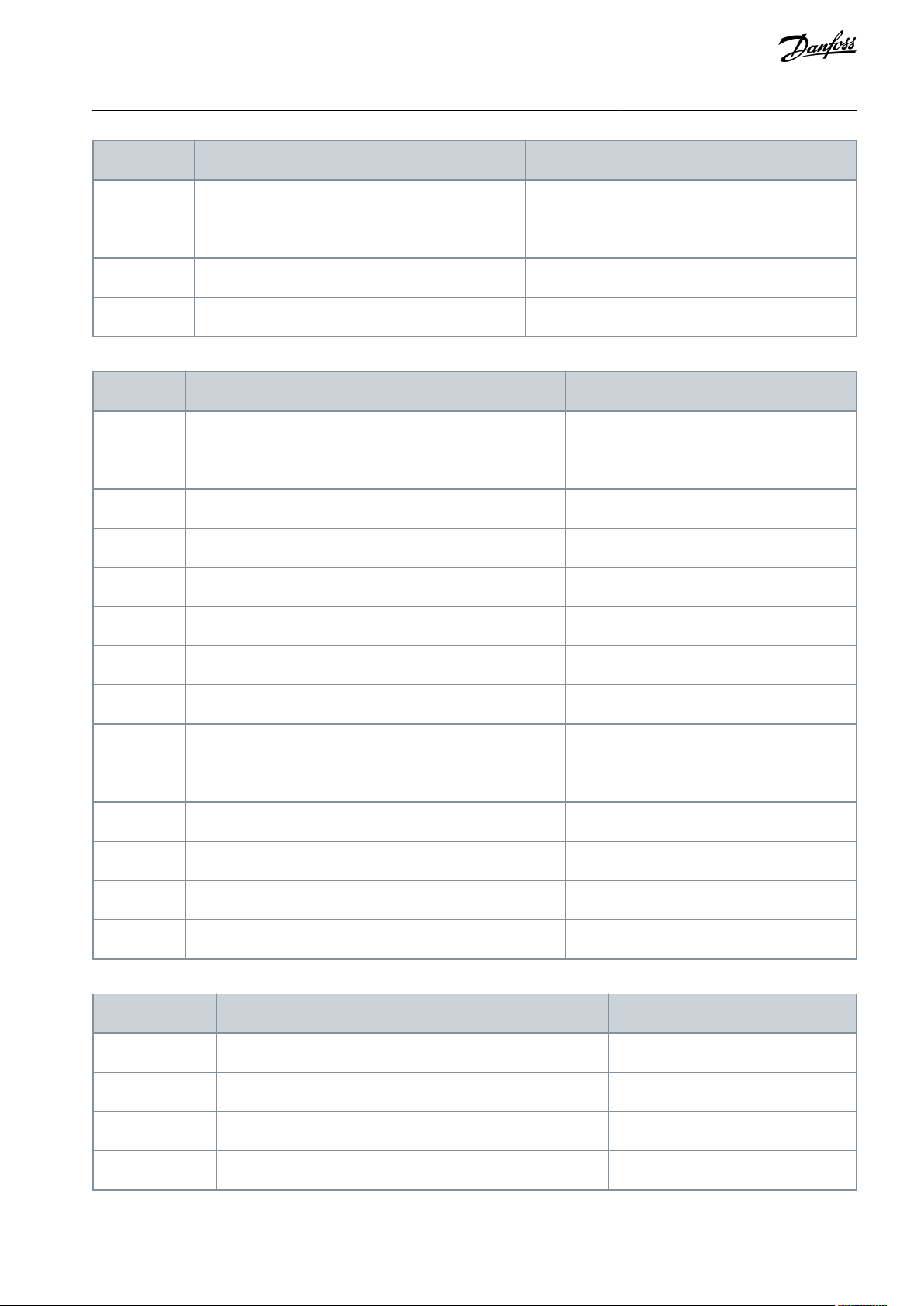

2.2 Control I/O in Basic Application

Illustration 2: Default I/O Configuration in Basic Application

The option board OPTA3 has no terminal for open contact on its second relay output (terminal 24 is missing).

See jumper selections in Illustration 3. More information in the User Manual of the product.

AB296635287482en-000201 / DPD00903 | 11Danfoss A/S © 2020.12

Basic Application

Page 12

Jumper block X3:

CMA and CMB grounding

CMB connected to GND

CMA connected to GND

CMB isolated from GND

CMA isolated from GND

CMB and CMA internally

connected together,isolated

from GND

= Factory default

e30bh013.10

e30bh049.10

DIN4

DIN5

AI1

AI2

DIN1

DIN2

DIN6

DIN3

≥ 1

3.2 Keypad reference

3.1 Control place

Start forward

Start reverse

Start/Stop

Reverse

Internal Start/Stop

Internal reverse

Internal fault reset

Fault reset input

External fault input (programmable)

Reset button

Start/Stop buttons

Reference from fieldbus

Start/Stop from fieldbus

Direction from fieldbus

3.3 Keypad direction

2.14 I/O Reference

2.19 Preset Speed 2

2.18 Preset Speed 1

2.2 Max Frequency

Start/Stop and

reverse logic

Internal frequency

reference

VACON® NX All-in-One

Application Guide

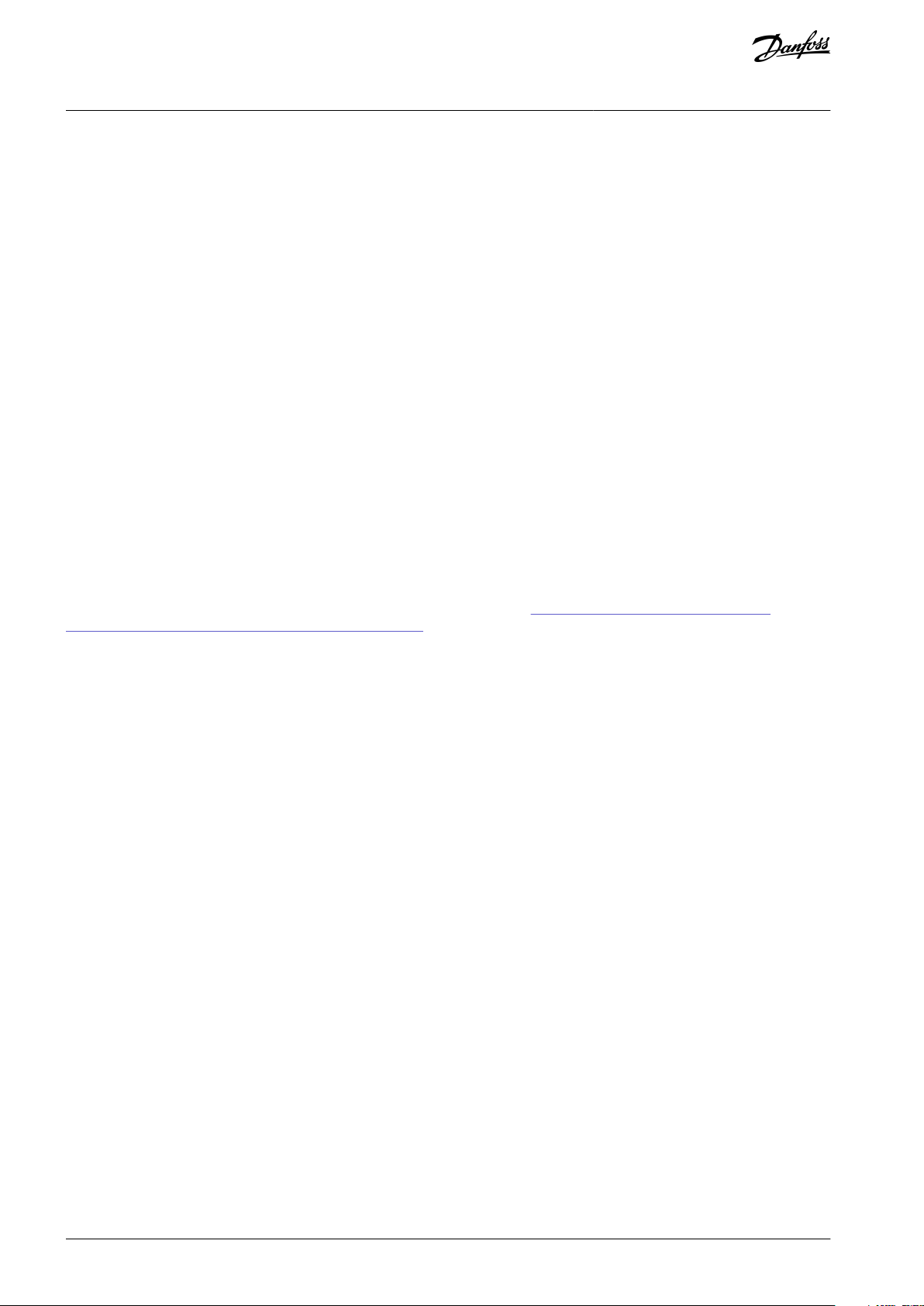

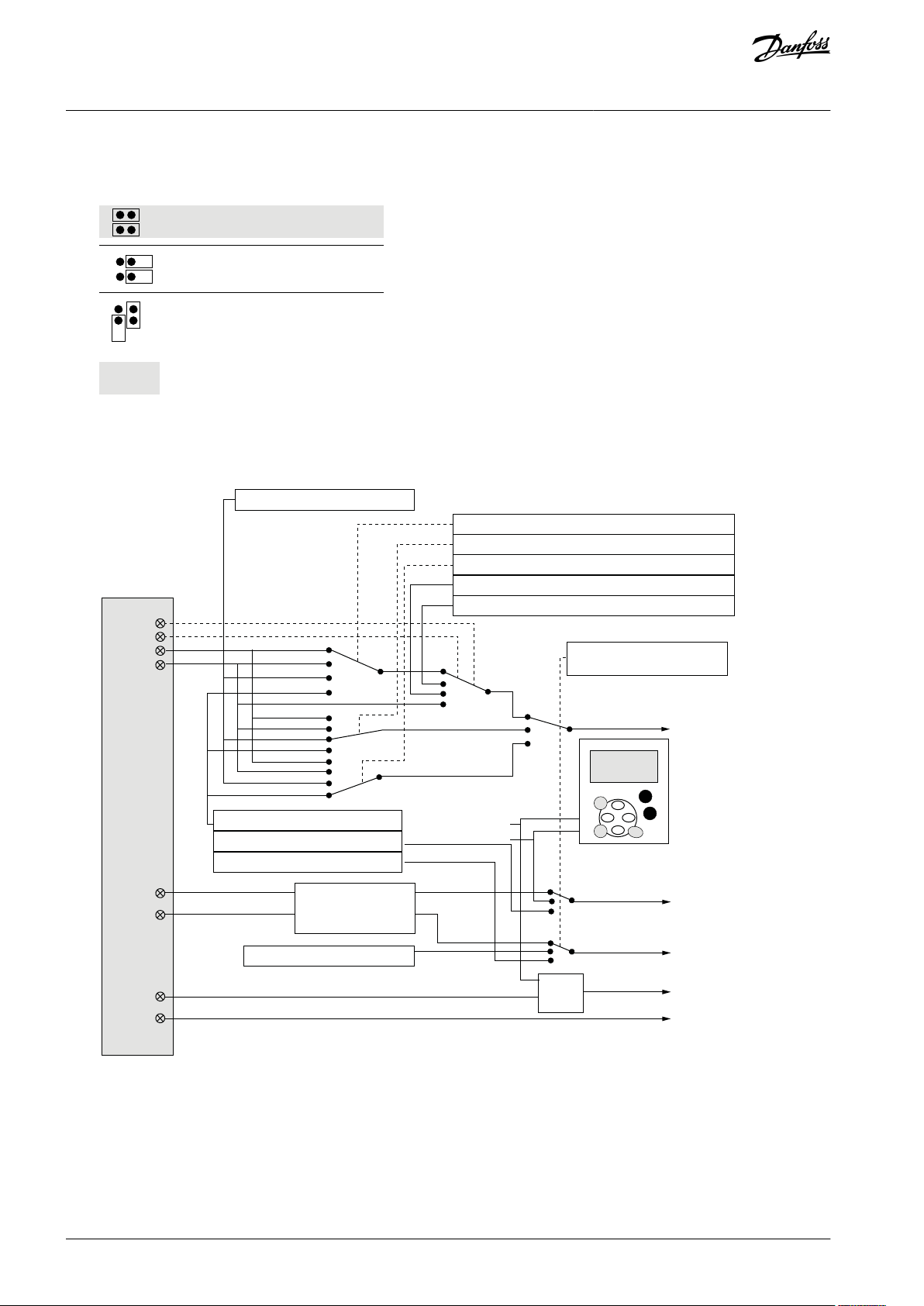

Illustration 3: Jumper Selections

2.3 Control Signal Logic in Basic Application

Basic Application

Illustration 4: Control Signal Logic of the Basic Application

2.4 Parameter Lists for Basic Application

2.4.1 Monitoring Values (Control Panel: Menu M1)

The monitoring values are the actual values of parameters and signals as well as statuses and measurements. Monitoring values

cannot be edited.

AB296635287482en-000201 / DPD0090312 | Danfoss A/S © 2020.12

Page 13

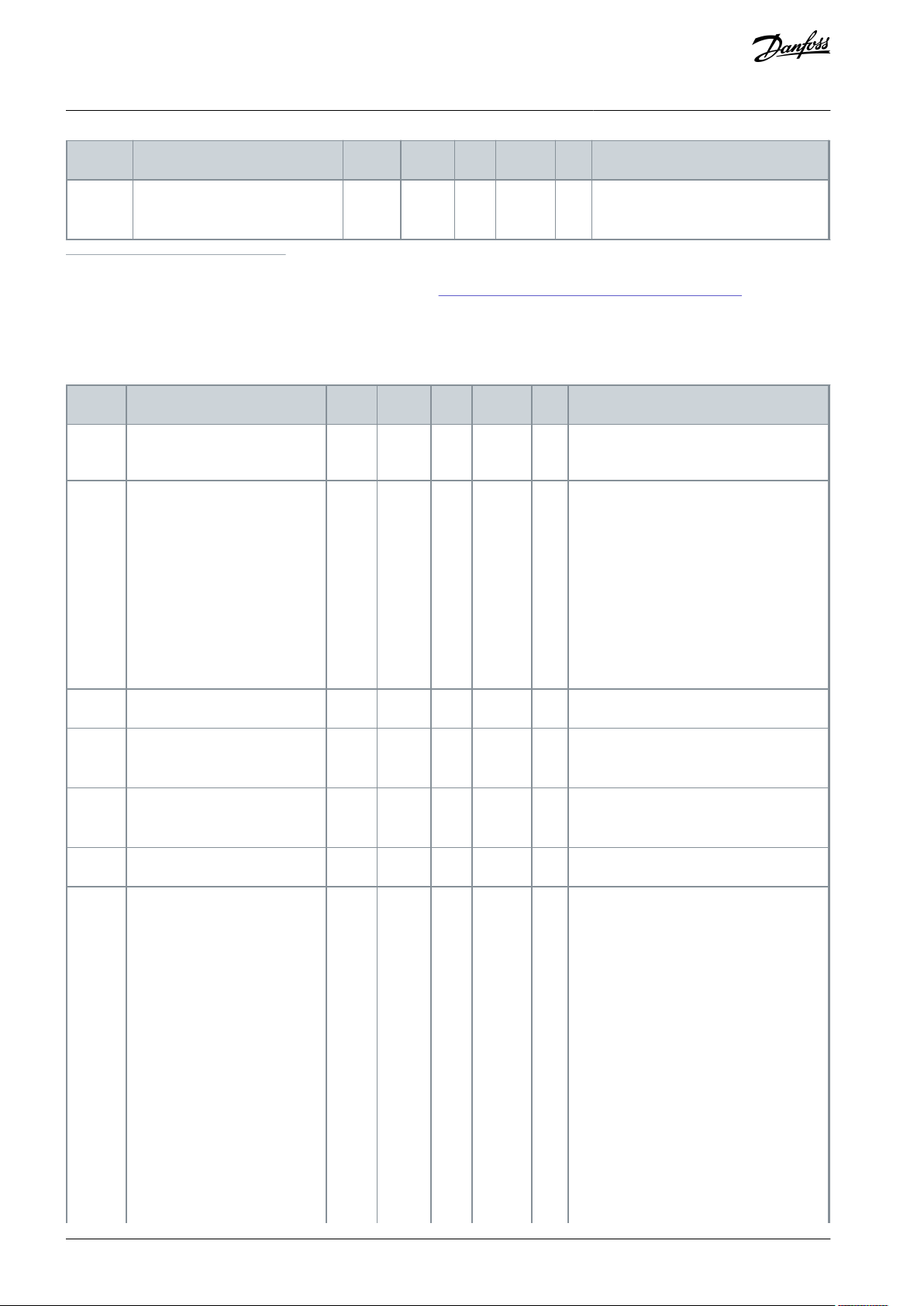

Index

Monitoring value

Unit

Form

ID

Description

V1.1

Output frequency

Hz

#.##1-

V1.2

Frequency reference

Hz

#.##25-

V1.3

Motor speed

RPM#2-V1.4

Motor current

A

Varies

3-V1.5

Motor torque

%

#.#4-

V1.6

Motor shaft power

%

#.#5-

V1.7

Motor voltage

V

#.#6-

V1.8

DC-link voltage

V#7-V1.9

Unit temperature

°C#8-V1.10

Motor temperature

%

#.#9-

V1.11

Analog input 1

V/mA

#.##13-

V1.12

Analog input 2

V/mA

#.##14-

V1.13

DIN 1, 2, 3

--15-V1.14

DIN 4, 5, 6

--16-V1.15

DO1, RO1, RO2

--17

-

V1.16

Analog I

out

mA

#.##26-

V1.17

Multimonitoring items

---

-

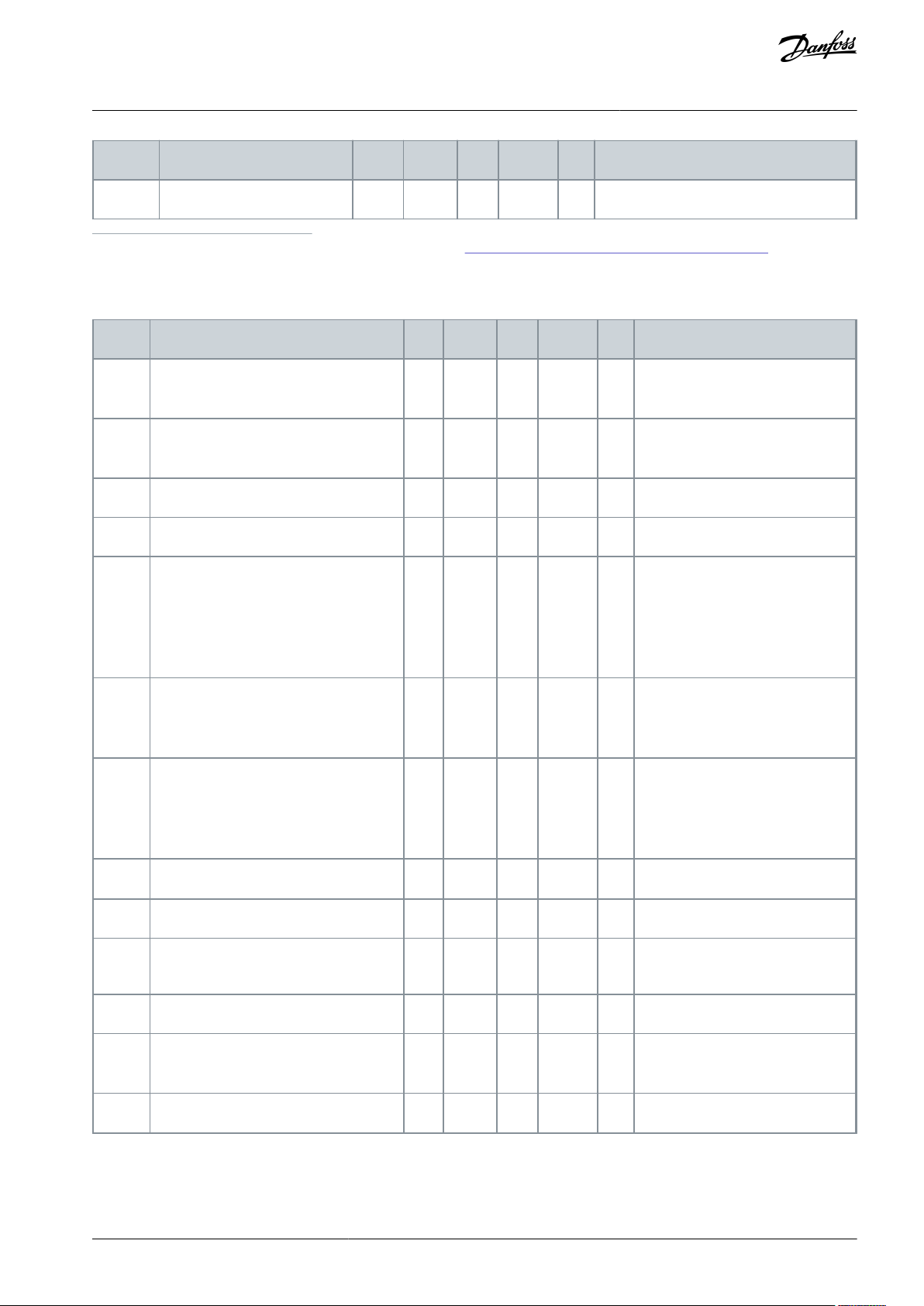

Index

Parameter

Min

Max

Unit

Default

ID

Description

P2.1

Min frequency

0.00

P2.2Hz0.00

101-P2.2

Max frequency

P2.1

320.00

Hz

50.00

102-P2.3

Acceleration time 1

0.1

3000.0

s

3.0

103-P2.4

Deceleration time 1

0.1

3000.0

s

3.0

104

-

P2.5

Current limit

0.1 x I

H

2 x IHA

IL107

-

P2.6

Nominal voltage of the motor

180

690VNX2: 230 V

NX5: 400 V

NX6: 690 V

110

-

P2.7

Nominal frequency of the motor

8.00

320.00

Hz

50.00

111

P2.8

Nominal speed of the motor

24

20 000

RPM

1440

112

-

VACON® NX All-in-One

Application Guide

Table 2: Monitoring Values

Basic Application

2.4.2 Basic Parameters (Control Panel: Menu M2 -> G2.1)

Table 3: Basic Parameters G2.1

AB296635287482en-000201 / DPD00903 | 13Danfoss A/S © 2020.12

Page 14

Index

Parameter

Min

Max

Unit

Default

ID

Description

P2.9

Nominal current of the motor

0.1 x I

H

2 X IHA

IH113

-

P2.10

Motor cos phi

0.30

1.00-0.85

120

-

P2.11

Start function

0

2-0

505

0 = Ramp

1 = Flying start

2 = Conditional flying start

P2.12

Stop function

0

3-0

506

0 = Coasting

1 = Ramp

2 = Ramp + Run enable coast Ramp

3 = Coast + Run enable ramp

P2.13

U/f optimization

0

1-0

109

0 = Not used

1 = Automatic torque boost

P2.14

I/O reference

0

3-0

117

0 = AI1

1 = AI2

2 = Keypad

3 = Fieldbus

P2.15

Analog input 2, reference offset

0

1-1

302

0 = 0–20 mA

1 = 4–20 mA

P2.16

Analog output function

0

8-1

307

0 = Not used

1 = Output freq. (0- f

max

)

2 = Freq. reference (0-f

max

)

3 = Motor speed (0-Motor nominal speed)

4 = Output current (0-InMotor)

5 = Motor torque (0-TnMotor)

6 = Motor power (0-PnMotor)

7 = Motor voltage (0-UnMotor)

8 = DC-link volt (0-1000V)

P2.17

DIN 3 function

0

7-1

301

0 = Not used

1 = Ext. fault, closing cont.

2 = Ext. fault, opening cont.

3 = Run enable, cc

4 = Run enable, oc

5 = Force cp. to I/O

6 = Force cp. to keypad

7 = Force cp. to fieldbus

P2.18

Preset speed 1

0.00

P2.2Hz0.00

105-P2.19

Preset speed 2

0.00

P2.2Hz50.00

106

-

P2.20

Automatic restart

0

1-0

731

0 = Disabled

2 = Enabled

VACON® NX All-in-One

Application Guide

Basic Application

AB296635287482en-000201 / DPD0090314 | Danfoss A/S © 2020.12

Page 15

Index

Parameter

Min

Max

Unit

Default

ID

Description

P3.1

Control place

1

3-1

125

1 = I/0 terminal

2 = Keypad

3 = Fieldbus

P3.2

Keypad reference

P2.1

P2.2Hz0.00

-

-

P3.3

Direction (on keypad)

0

1-0

123

0 = Forward

1 = Reverse

R3.4

Stop button

0

1-1

114

0 = Limited function of Stop button

1 = Stop button always enabled

VACON® NX All-in-One

Application Guide

Basic Application

2.4.3 Keypad Control (Control Panel: Menu M3)

The parameters for the selection of control place and direction on the keypad are listed in Table 4. See the Keypad control menu in

the User Manual of the product.

Table 4: Keypad Control Parameters, M3

2.4.4 System Menu (Control Panel: Menu M6)

For more information related to the general use of the AC drive, such as selecting application and language, customized parameter

sets, or hardware and software, see the User Manual of the product.

2.4.5 Expander Boards (Control Panel: Menu M7)

The M7 menu shows the expander and option boards attached to the control board and board-related information. For more information, see the User Manual of the product.

AB296635287482en-000201 / DPD00903 | 15Danfoss A/S © 2020.12

Page 16

VACON® NX All-in-One

Application Guide

Standard Application

3 Standard Application

3.1 Introduction to Standard Application

Select the Standard Application in menu M6 on page S6.2.

The Standard Application is typically used in pump and fan applications and conveyors for which the Basic Application is too limited

but where no special features are needed.

•

The Standard Application has the same I/O signals and the same control logic as the Basic Application.

•

Digital input DIN 3 and all the outputs are freely programmable.

Extra functions:

•

Programmable Start/Stop and Reverse signal logic

•

Reference scaling

•

One frequency limit supervision

•

Second ramps and S-shape ramp programming

•

Programmable start and stop functions

•

DC brake at stop

•

One prohibit frequency area

•

Programmable U/f curve and switching frequency

•

Auto restart

•

Motor thermal and stall protection: Programmable action; off, warning, fault

The parameters of the Standard Application are explained in Chapter Parameter descriptions of this manual. The explanations are

arranged according to the individual ID number of the parameter.

AB296635287482en-000201 / DPD0090316 | Danfoss A/S © 2020.12

Page 17

1

6

2

3

4

5

18

19

20

12

7

13

8

9

10

14

15

16

21

22

23

11

17

24

25

26

DIN4

DIN5

mA

READY

RUN

AO1-

DO1

+24 V

GND

GND

DIN1

DIN2

DIN3

DIN4

DIN5

DIN6

R O1

R O1

R O1

CMA

CMB

R O2

R O2

R O2

OPTA1

OPTA2 / OPTA3

Terminal Signal Description

+10 V

ref

AI1+

AI1-

AI2+

AI2-

+24V

Reference output

I/O Ground

Analogue input 2

Current range

0—20mA

Control voltage output

I/O ground

Start forward

Programmable logic (P2.2.1)

Start reverse

Ri min = 5

kΩ

External fault input

Programmable (P2.2.2)

Preset speed select 1

Preset speed select 2

Fault reset

Common for DIN 1—DIN 3

Common for DIN4—DIN6

Control voltage output

I/O ground

Analogue output 1

Output frequency

Programmable (P2.3.2)

Digital output 1

READY

Programmable (P2.3.7)

Open collector,

I≤50 mA, U≤48 VDC

Relay output 1

RUN

Programmable

(P2.3.8)

Relay output 2

FAULT

Programmable

(P2.3.9)

Range 0—20 mA/RL,

max. 500 Ω

Connect to GND or +24 V

Contact open = no action

Contact closed = fault reset

AO1+

Analogue input 1

frequency reference

Ground for reference

and controls

Analogue input 2

frequency reference

Contact closed = start forward

Contact closed = start reverse

Contact open = no fault

Contact closed = fault

Freq. ref.

Open

Closed

Open

Closed

Open

Open

Closed

Closed

I/O Reference

Preset Speed 1

Preset Speed 2

Analog input 2

Voltage for potentiometer, etc.

Analogue input 1

Voltage range 0—10V DC

Programmable (P2.1.11)

Voltage for switches,

etc. max 0.1 A

Voltage for switches (see #6)

Connect to GND or +24 V

Ground for reference and controls

Ground for reference and controls

Reference potentiometer,

1-10kΩ

e30bh091.20

VACON® NX All-in-One

Application Guide

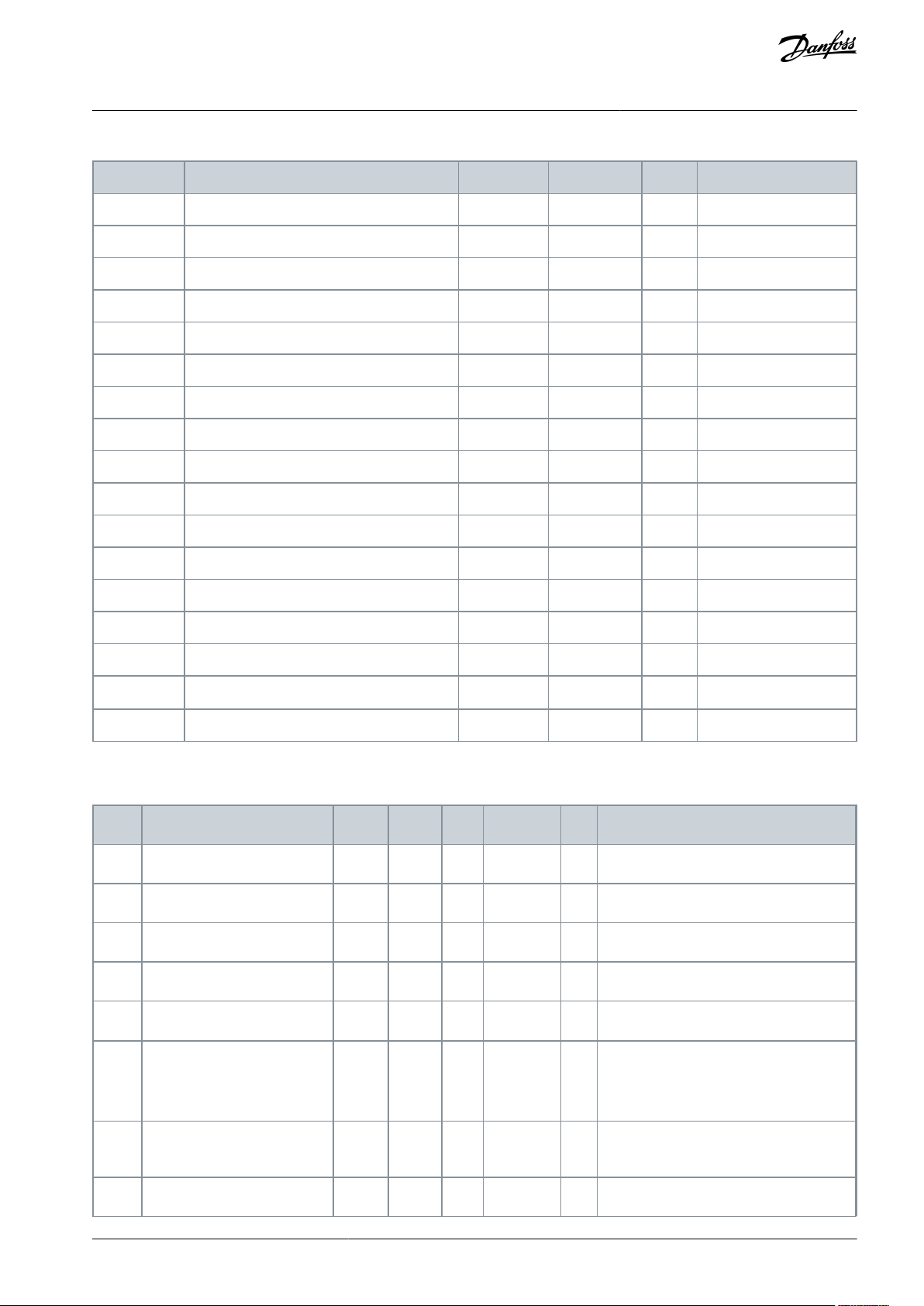

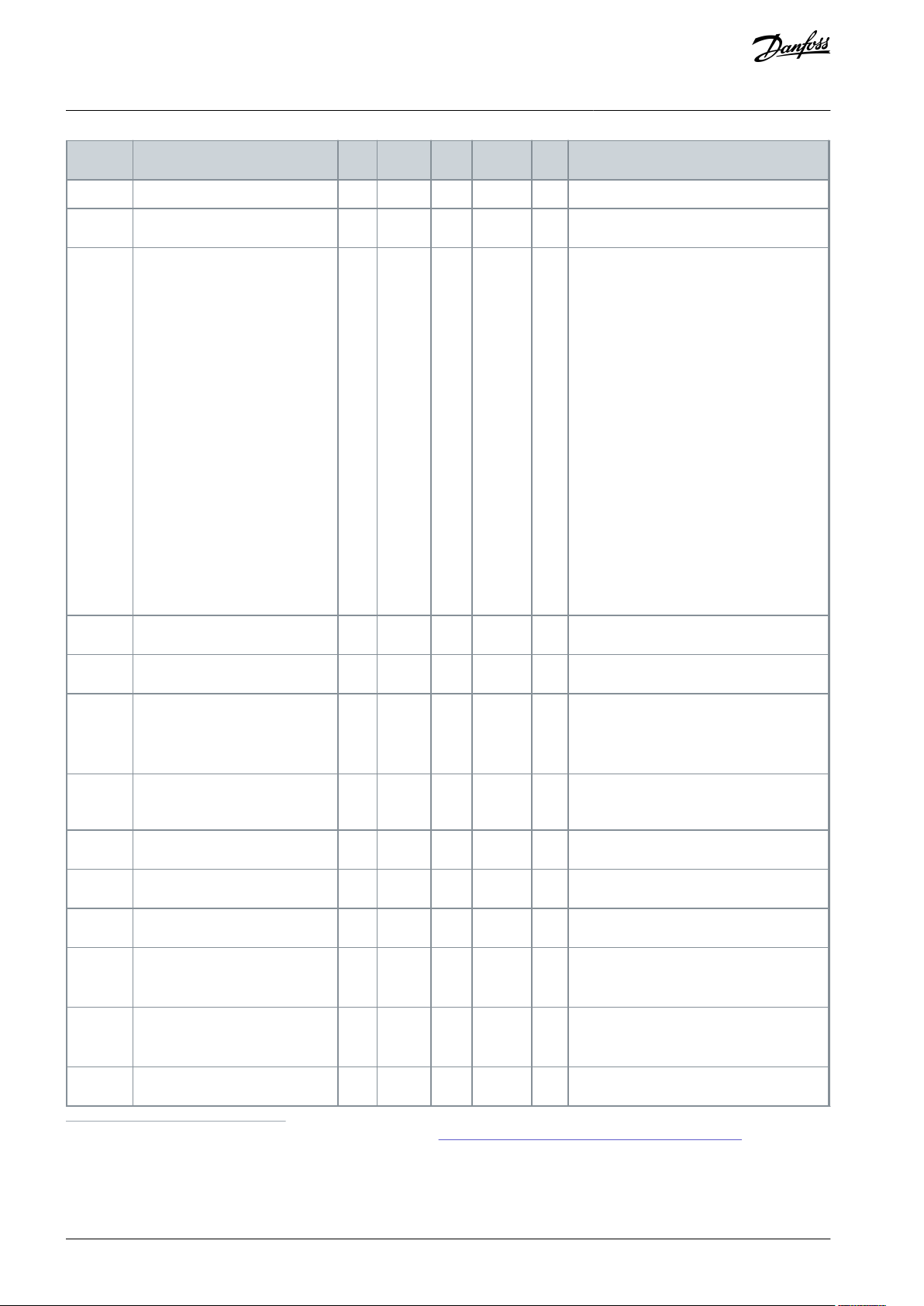

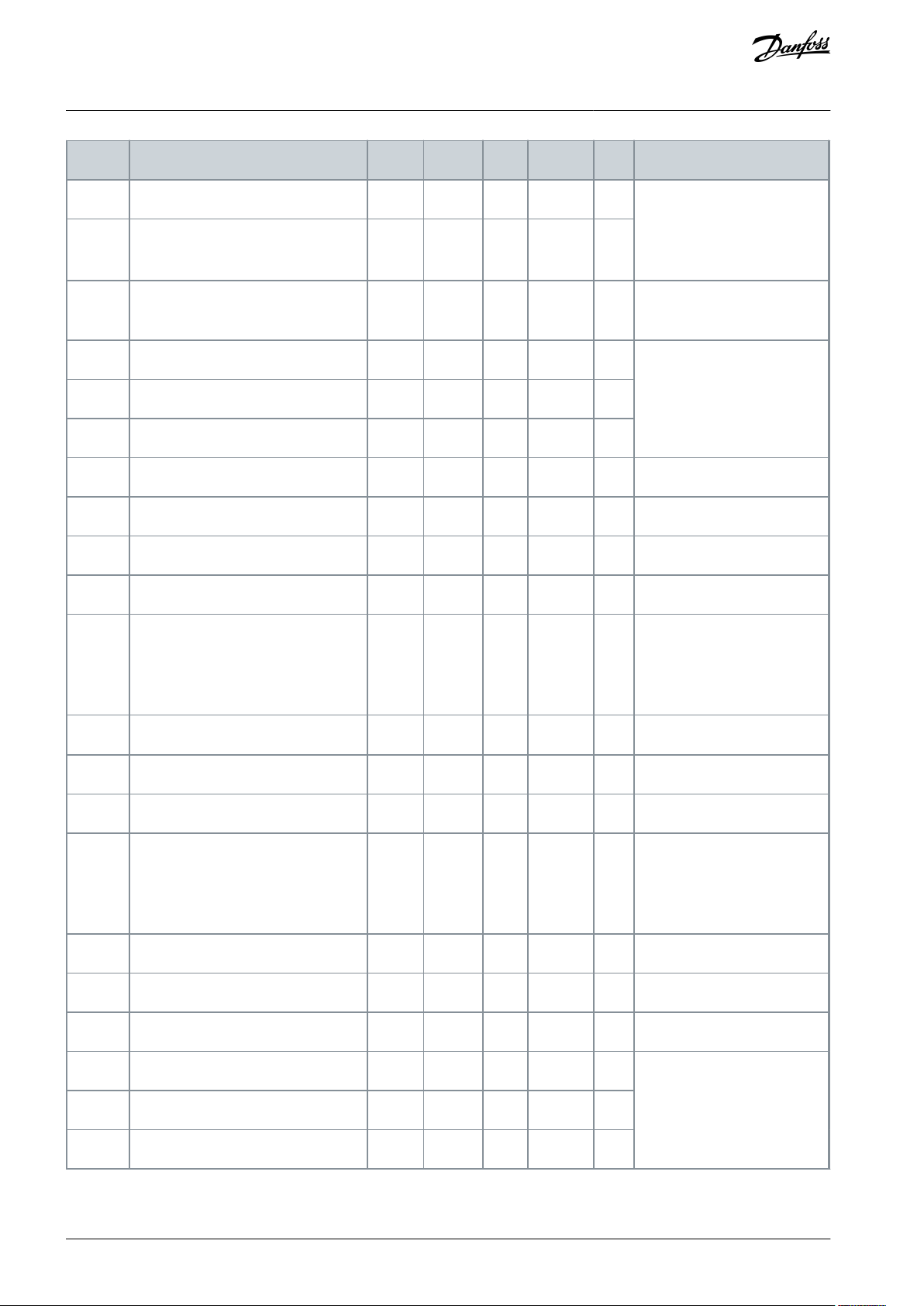

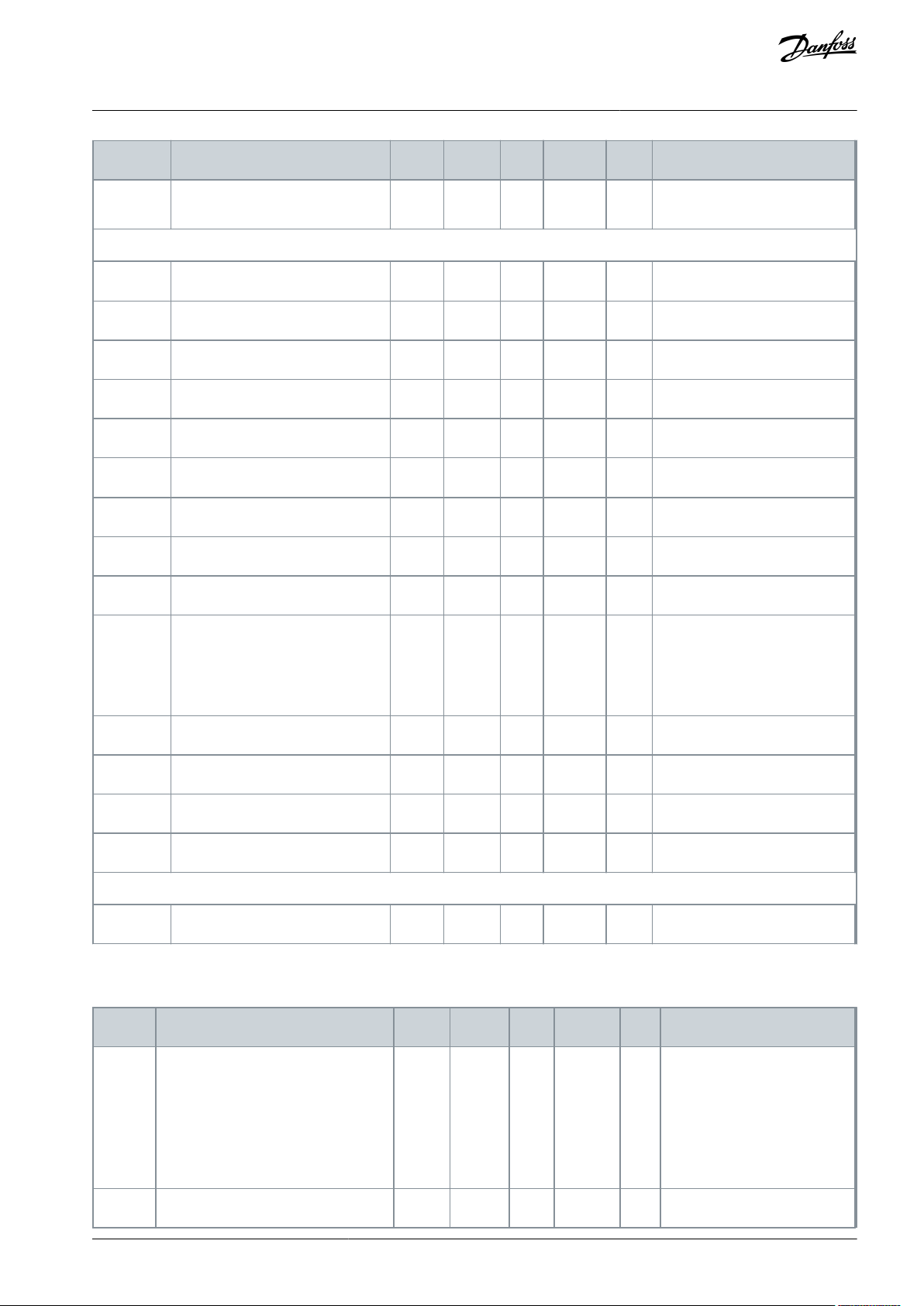

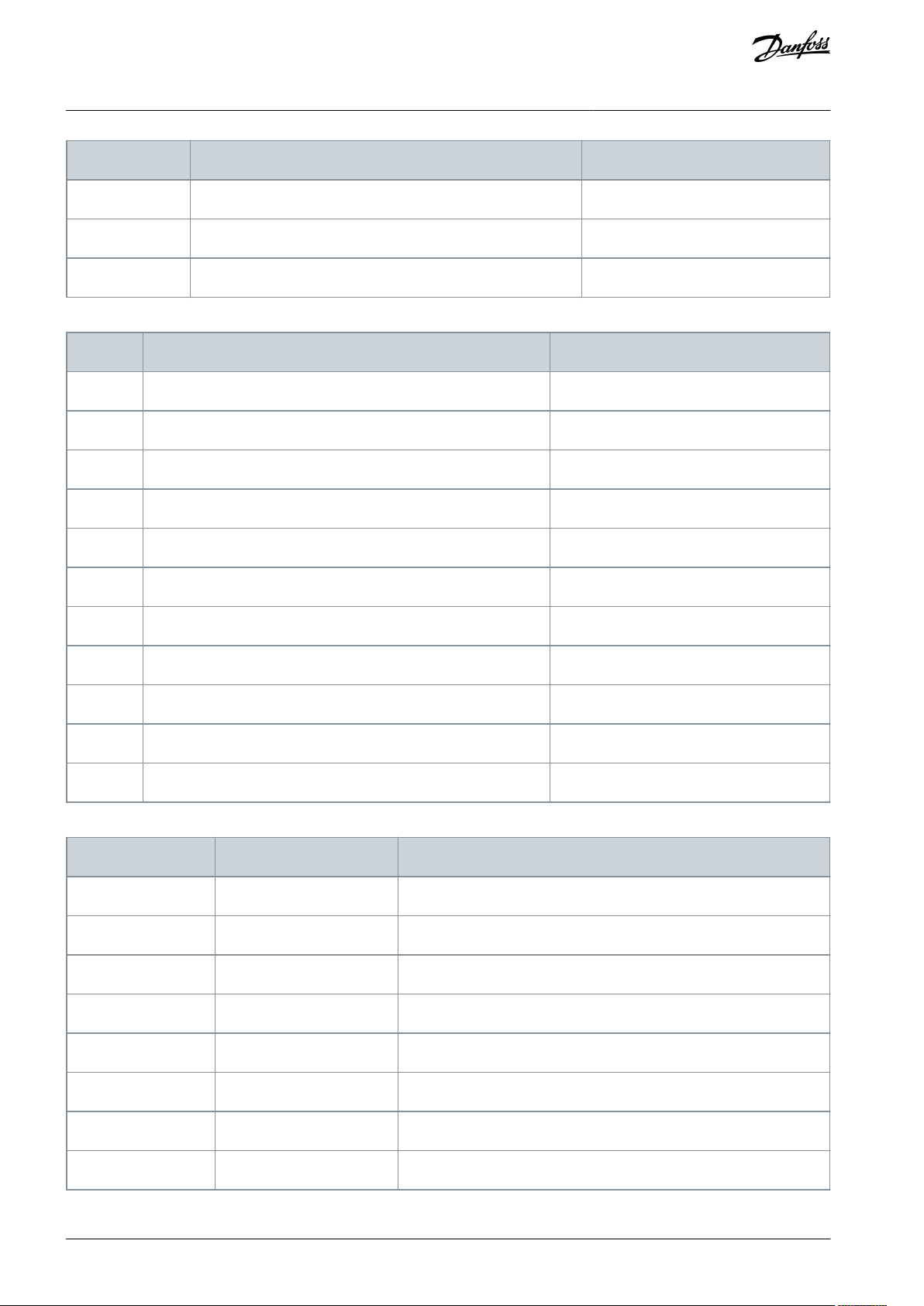

3.2 Control I/O in Standard Application

Standard Application

Illustration 5: Default I/O Configuration in Standard Application

The option board OPTA3 has no terminal for open contact on its second relay output (terminal 24 is missing).

See jumper selections in Illustration 6. More information in the User Manual of the product.

AB296635287482en-000201 / DPD00903 | 17Danfoss A/S © 2020.12

Page 18

Jumper block X3:

CMA and CMB grounding

CMB connected to GND

CMA connected to GND

CMB isolated from GND

CMA isolated from GND

CMB and CMA internally

connected together,isolated

from GND

= Factory default

e30bh013.10

e30bh050.10

DIN4

DIN5

AI1

AI2

DIN1

DIN2

DIN6

DIN3

≥ 1

3.2 Keypad reference

3.1 Control place

Start forward

Start reverse

Start/Stop

Reverse

Internal Start/Stop

Internal reverse

Internal fault reset

Fault reset input

External fault input (programmable)

Reset button

Start/Stop buttons

Reference from fieldbus

Start/Stop from fieldbus

Direction from fieldbus

3.3 Keypad direction

2.1.13 Fieldbus Ctrl Reference

2.1.15 Preset Speed 2

2.1.14 Preset Speed 1

2.1.11 I/O Reference

2..1.12 Keypad Ctrl Speed 1

Programmable

Start/Stop and

reverse logic

Internal frequency

reference

(programmable)

(programmable)

VACON® NX All-in-One

Application Guide

Illustration 6: Jumper Selections

3.3 Control Signal Logic in Standard Application

Standard Application

Illustration 7: Control Signal Logic of the Standard Application

3.4 Parameter Lists for Standard Application

3.4.1 Monitoring Values (Control Panel: Menu M1)

The monitoring values are the actual values of parameters and signals as well as statuses and measurements. Monitoring values

cannot be edited.

AB296635287482en-000201 / DPD0090318 | Danfoss A/S © 2020.12

Page 19

Index

Monitoring value

Unit

Form

ID

Description

V1.1

Output frequency

Hz

#.##1-

V1.2

Frequency reference

Hz

#.##25-

V1.3

Motor speed

RPM#2-V1.4

Motor current

A

Varies

3-V1.5

Motor torque

%

#.#4-

V1.6

Motor shaft power

%

#.#5-

V1.7

Motor voltage

V

#.#6-

V1.8

DC-link voltage

V#7-V1.9

Unit temperature

°C#8-V1.10

Motor temperature

%

#.#9-

V1.11

Analog input 1

V/mA

#.##13-

V1.12

Analog input 2

V/mA

#.##14-

V1.13

DIN 1, 2, 3

--15-V1.14

DIN 4, 5, 6

--16-V1.15

DO1, RO1, RO2

--17

-

V1.16

Analog I

out

mA

#.##26-

V1.17

Multimonitoring items

---

-

Index

Parameter

Min

Max

Unit

Default

ID

Description

P2.1.1

Min frequency

0.00

P2.1.2

Hz

0.00

101-P2.1.2

Max frequency

P2.1.1

320.00

Hz

50.00

102-P2.1.3

Acceleration time 1

0.1

3000.0

s

0.0

103-P2.1.4

Deceleration time 1

0.1

3000.0

s

0.0

104

-

P2.1.5

Current limit

0.1 x I

H

2 x IHA

IL107

-

P2.1.6

Nominal voltage of the motor

180

690VNX2: 230 V

NX5: 400 V

NX6: 690 V

110

-

P2.1.7

Nominal frequency of the motor

8.00

320.00

Hz

50.00

111-P2.1.8

Nominal speed of the motor

24

20 000

RPM

1440

112

-

VACON® NX All-in-One

Application Guide

Table 5: Monitoring Values

Standard Application

3.4.2 Basic Parameters (Control Panel: Menu M2 -> G2.1)

Table 6: Basic Parameters G2.1

AB296635287482en-000201 / DPD00903 | 19Danfoss A/S © 2020.12

Page 20

Index

Parameter

Min

Max

Unit

Default

ID

Description

P2.1.9

Nominal current of the motor

0.1 x I

H

2 X IHA

IH113

-

P2.1.10

Motor cos phi

0.30

1.00-0.85

120

-

P2.1.11

I/O reference

0

3-0

117

0 = AI1

1 = AI2

2 = Keypad

3 = Fieldbus

P2.1.12

Keypad control reference

0

3-2

121

0 = AI1

1 = AI2

2 = Keypad

3 = Fieldbus

P2.1.13

Fieldbus control reference

0

3-3

122

0 = AI1

1 = AI2

2 = Keypad

3 = Fieldbus

P2.1.14

Preset speed 1

0.00

P2.1.2

Hz

10.00

105-P2.1.15

Preset speed 2

0.00

P2.1.2

Hz

50.00

106

-

Index

Parameter

Min

Max

Unit

Default

ID

Description

P2.2.1

Start/Stop logic

0

6-0

300

Logic = 0

Ctrl sgn 1 = Start forward

Ctrl sgn 2 = Start reverse

Logic = 1

Ctrl sgn1 = Start/ Stop

Ctrl sgn 2 = Reverse

Logic = 2

Ctrl sgn 1 = Start/ Stop

Ctrl sgn 2 = Run enable

Logic = 3

Ctrl sgn 1 = Start pulse (edge)

Ctrl sgn 2 = Stop pulse

Logic = 4

Ctrl sgn 1 = Forward pulse (edge)

Ctrl sgn 2 = Reverse pulse (edge)

Logic = 5

Ctrl sgn 1 = Start pulse (edge)

Ctrl sgn 2 = Reverse pulse

Logic = 6

Ctrl sgn 1 = Start pulse (edge)

Ctrl sgn 2 = Enable pulse

P2.2.2

DIN 3 function

0

8-1

301

0 = Not used

VACON® NX All-in-One

Application Guide

Standard Application

3.4.3 Input Signals (Control Panel: Menu M2 -> G2.2)

Table 7: Input Signals, G2.2

AB296635287482en-000201 / DPD0090320 | Danfoss A/S © 2020.12

Page 21

Index

Parameter

Min

Max

Unit

Default

ID

Description

1 = Ext. fault, closing cont.

2 = Ext. fault, opening cont.

3 = Run enable

4 = Acc./Dec. time select.

5 = Force cp. to I/O

6 = Force cp. to keypad

7 = Force cp. to fieldbus

8 = Reverse

P2.2.3

(1)

Analog input 2 reference offset

0

1-1

302

0 = 0–20 mA (0–10 V)

1 = 4–20 mA (2–10 V)

P2.2.4

Reference scaling minimum value

0.00

320.00

Hz

0.00

303-P2.2.5

Reference scaling maximum value

0.00

320.00

Hz

0.00

304

-

P2.2.6

Reference inversion

0

1-0

305

0 = Not inverted

1 = Inverted

P2.2.7

Reference filter time

0.00

10.00

s

0.10

306

0 = No filtering

P2.2.8

(2)

AI1 signal selection

---

A1

377

-

P2.2.9

(2)

AI2 signal selection

---

A2

388

-

Index

Parameter

Min

Max

Unit

Default

ID

Description

P2.3.1

(1)

Analog output 1 signal selection

0

-

-

A.1

464

-

P2.3.2

Analog output function

0

8-1

307

0 = Not used (20 mA/10 V)

1 = Output freq. (0–f

max

)

2 = Freq. reference (0–f

max

)

3 = Motor speed (0–Motor nominal speed)

4 = Motor current (0-I

nMotor

)

5 = Motor torque (0-T

nMotor

)

6 = Motor power (0-P

nMotor

)

7 = Motor voltage (0-U

nMotor

)

8 = DC-link volt (0–1000 V)

P2.3.3

Analog output filter time

0.00

10.00

s

1.00

308

0 = No filtering

P2.3.4

Analog output inversion

0

1-0

309

0 = Not inverted

1 = Inverted

P2.3.5

Analog output minimum

0

1-0

310

0 = 0 mA (0 V)

VACON® NX All-in-One

Application Guide

Standard Application

1

Remember to place jumpers of block X2 according to the selection (0 or 1). See the User Manual of the product.

2

Use the Terminal to Function method (TTF) with these parameters, see

3.4.4 Output Signals (Control Panel: Menu M2 ->G2.3)

Table 8: Output Signals, G2.3

10.619 "Terminal to Function" (TTF) Programming Principle.

AB296635287482en-000201 / DPD00903 | 21Danfoss A/S © 2020.12

Page 22

Index

Parameter

Min

Max

Unit

Default

ID

Description

1 = 4 mA (2 V)

P2.3.6

Analog output scale

10

1000%100

311

-

P2.3.7

Digital output 1 function

0

16-1

312

0 = Not used

1 = Ready

2 = Run

3 = Fault

4 = Fault inverted

5 = AC drive overheat warning

6 = Ext. fault or warning

7 = Ref. fault or warning

8 = Warning

9 = Reversed

10 = Preset speed 1

11 = At speed

12 = Motor regulator active

13 = OP freq. limit 1 superv.

14 = Control place: I/O

15 = Thermistor fault/warning

16 = Fieldbus DIN 1

P2.3.8

RO1 function

0

16-2

313

As parameter 2.3.7

P2.3.9

RO2 function

0

16-3

314

As parameter 2.3.7

P2.3.10

Output frequency limit 1 supervision

0

2-0

315

0 = No limit

1 = Low limit supervision

2 = High limit supervision

P2.3.11

Output frequency limit 1; Supervised value

0.00

320.00

Hz

0.00

316

P2.3.12

(1)

Analog output 2 signal selection

0.1

E.10-0.1

471-P2.3.13

Analog output 2 function

0

8-4

472

As parameter 2.3.2

P2.3.14

Analog output 2 filter time

0.00

10.00

s

1.00

473

0 = No filtering

P2.3.15

Analog output 2 inversion

0

1-0

474

0 = Not inverted

1 = Inverted

P2.3.16

Analog output 2 minimum

0

1-0

475

0 = 0 mA (0 V)

1 = 4 mA (2 V)

P2.3.17

Analog output 2 scaling

10

1000%1.00

476

-

VACON® NX All-in-One

Application Guide

Standard Application

1

Use the Terminal to Function method (TTF) with these parameters, see

10.619 "Terminal to Function" (TTF) Programming Principle.

AB296635287482en-000201 / DPD0090322 | Danfoss A/S © 2020.12

Page 23

Index

Parameter

Min

Max

Unit

Default

ID

Description

P2.4.1

Ramp 1 shape

0.0

10.0s0.1

500

0 = Linear

100 = full acc/dec inc/dec tmes

P2.4.2

Ramp 2 shape

0.0

10.0s0.0

501

0 = Linear

100 = full acc/dec inc/dec tmes

P2.4.3

Acceleration time 2

0.1

3000.0

s

1.0

502-P2.4.4

Deceleration time 2

0.1

3000.0

s

1.0

503

-

P2.4.5

Brake chopper

0

4-0

504

0 = Disabled

1 = Used when running

2 = External brake chopper

3 = Used when stopped/running

4 = Used when running (no testing)

P2.4.6

Start function

0

2-0

505

0 = Ramp

1 = Flying start

2 = Conditional flying start

P2.4.7

Stop function

0

3-0

506

0 = Coasting

1 = Ramp

2 = Ramp+Run enable coast

3 = Coast+Run enable ramp

P2.4.8

DC braking current

0.00

ILA

0.7 x I

H

507

-

P2.4.9

DC braking time at stop

0.00

600.00

s

0.00

508

0 = DC brake is off at stop

P2.4.10

Frequency to start DC braking during

ramp stop

0.10

10.00

Hz

1.50

515

P2.4.11

DC braking time at start

0.00

600.00

s

0.00

516

0 = DC brake is off at start

P2.4.12

Flux brake

0

1-0

520

0 = Off

1 = On

P2.4.13

Flux braking current

0.00

ILA

IH519

-

Index

Parameter

Min

Max

Unit

Default

ID

Description

P2.5.1

Prohibit frequency range 1 low limit

0.00

320.00

Hz

0.00

509-P2.5.2

Prohibit frequency range 1 high limit

0.00

320.00

Hz

0.00

510

-

VACON® NX All-in-One

Application Guide

3.4.5 Drive Control Parameters (Control Panel: Menu M2->G2.4)

Table 9: Drive Control Parameters, G2.4

Standard Application

3.4.6 Prohibit Frequency Parameters (Control Panel: Menu M2 -> G2.5)

Table 10: Prohibit Frequency Parameters, G2.5

AB296635287482en-000201 / DPD00903 | 23Danfoss A/S © 2020.12

Page 24

Index

Parameter

Min

Max

Unit

Default

ID

Description

P2.5.3

Prohibit acc./dec. ramp

0.1

10.0x0.1

518

-

Index

Parameter

Min

Max

Unit

Default

ID

Description

P2.6.1

(1)

Motor control mode

0

1/4-0

600

0 = Frequency control

1 = Speed control

VACON® NXP:

2 = Open loop torque control

3 = Closed loop speed ctrl

4 = Closed loop torque control

P2.6.2

(1)

U/f optimisation

0

1-0

109

0 = Not used

1 = Automatic torque boost

P2.6.3

(1)

U/f ratio selection

0

3-0

108

0 = Linear

1 = Squared

2 = Programmable

3 = Linear with flux optim.

P2.6.4

(1)

Field weakening point

8.00

320.00

Hz

50.00

602

-

P2.6.5

(1)

Voltage at field weakening point

10.00

200.00

%

100.00

603

-

P2.6.6

(1)

U/f curve midpoint frequency

0.00

P2.6.4

Hz

50.00

604

-

P2.6.7

(1)

U/f curve midpoint voltage

0.00

100.00

%

100.00

605

-

P2.6.8

(1)

Output voltage at zero frequency

0.00

40.00

%

Varies

606-P2.6.9

Switching frequency

1.0

Varies

kHz

Varies

601

-

P2.6.10

Overvoltage controller

0

2-1

607

0 = Not used

1 = Used (no ramping)

2 = Used (ramping)

P2.6.11

Undervoltage controller

0

2-2

608

0 = Not used

1 = Used

2 = Used (ramping to zero)

P2.6.12

Load drooping

0.00

100.00

%

0.00

620

-

P2.6.13

Identification

0

2/5-0

631

0 = No action

1 = Identification w/o run

2 = Identification with run

Only VACON® NXP:

3 = Encoder ID run

4 = No action

5 = ID Run Failed

VACON® NX All-in-One

Application Guide

3.4.7 Motor Control Parameters (Control Panel: Menu M2 -> G2.6)

Table 11: Motor Control Parameters, G2.6

Standard Application

AB296635287482en-000201 / DPD0090324 | Danfoss A/S © 2020.12

Page 25

Index

Parameter

Min

Max

Unit

Default

ID

Description

Closed Loop parameter group 2.6.14

P2.6.14.1

Magnetizing current

0.00

2 x IHA

0.00

612

-

P2.6.14.2

Speed control P gain

1

1000-30

613-P2.6.14.3

Speed control I time

0.0

3200.0

ms

30.0

614-P2.6.14.5

Acceleration compensation

0.00

300.00

s

0.00

626-P2.6.14.6

Slip adjust

0

500%100

619

-

P2.6.14.7

Magnetizing current at start

0.00

ILA

0.00

627

-

P2.6.14.8

Magnetizing time at start

0

60000

ms0628-P2.6.14.9

0-speed time at start

0

32000

ms

100

615-P2.6.14.10

0-speed time at stop

0

32000

ms

100

616

-

P2.6.14.11

Start-up torque

0

3-0

621

0 = Not used

1 = Torque memory

2 = Torque reference

3 = Start-up torque fwd/rev

P2.6.14.12

Start-up torque FWD

-300.0

300.0

%

0.0

633-P2.6.14.13

Start-up torque REV

-300.0

300.0

%

0.0

634-P2.6.14.15

Encoder filter time

0.0

100ms0.0

618-P2.6.14.17

Current control P gain

0.00

100.00

%

40.00

617

-

Identification parameter group 2.6.15

P2.6.15.1

Speed step

-50.0

50.0-0.0

1252

-

Index

Parameter

Min

Max

Unit

Default

ID

Description

P2.7.1

Response to 4 mA reference fault

0

5-0

700

0 = No response

1 = Warning

2 = Warning+Previous Freq.

3 = Wrng+Preset- Freq 2.7.2

4 = Fault, stop acc. to 2.4.7

5 = Fault, stop by coasting

P2.7.2

4 mA reference fault frequency

0.00

P2.1.2

Hz

0.00

728

-

VACON® NX All-in-One

Application Guide

Standard Application

1

Parameter value can only be changed after the AC drive has been stopped.

3.4.8 Protections (Control Panel: Menu M2 -> G2.7)

Table 12: Protections, G2.7

AB296635287482en-000201 / DPD00903 | 25Danfoss A/S © 2020.12

Page 26

Index

Parameter

Min

Max

Unit

Default

ID

Description

P2.7.3

Response to external fault

0

3-2

701

0 = No response

1 = Warning

2 = Fault, stop acc. to 2.4.7

3 = Fault, stop by coasting

P2.7.4

Input phase supervision

0

3-0

730

P2.7.5

Response to undervoltage fault

0

1-0

727

0 = Fault stored in history

1 = Fault not stored

P2.7.6

Output phase supervision

0

3-2

702

0 = No response

1 = Warning

2 = Fault, stop acc. to 2.4.7

3 = Fault, stop by coasting

P2.7.7

Earth fault protection

0

3-2

703

P2.7.8

Thermal protection of the motor

0

3-2

704

P2.7.9

Motor ambient temperature factor

-100.0

100.0

%

0.0

705-P2.7.10

Motor cooling factor at zero speed

0.0

150.0

%

40.0

706-P2.7.11

Motor thermal time constant

1

200

min

Varies

707-P2.7.12

Motor duty cycle

0

150%100

708

-

P2.7.13

Stall protection

0

3-0

709

0 = No response

1 = Warning

2 = Fault, stop acc. to 2.4.7

3 = Fault, stop by coasting

P2.7.14

Stall current

0.00

2 x IHA

IH710

-

P2.7.15

Stall time limit

1.00

120.00

s

15.00

711-P2.7.16

Stall frequency limit

1.0

P2.1.2

Hz

25.00

712

-

P2.7.17

Underload protection

0

3-0

713

0 = No response

1 = Warning

2 = Fault, stop acc. to 2.4.7

3 = Fault, stop by coasting

P2.7.18

UP From Torque

10.0

150.0

%

50.0

714-P2.7.19

UP Zero frequency load

5.0

150.0

%

10.0

715-P2.7.20

Underload protection time limit

2.00

600.00

s

20.00

716-P2.7.21

Response to thermistor fault

0

3-2

732

0 = No response

1 = Warning

2 = Fault, stop acc. to 2.4.7

3 = Fault, stop by coasting

P2.7.22

Response to fieldbus fault

0

3-2

733

P2.7.23

Response to slot fault

0

3-2

734

VACON® NX All-in-One

Application Guide

Standard Application

AB296635287482en-000201 / DPD0090326 | Danfoss A/S © 2020.12

Page 27

Index

Parameter

Min

Max

Unit

Default

ID

Description

P2.8.1

Wait time

0.10

10.00

s

0.50

717-P2.8.2

Trial time

0.00

60.00

s

30.00

718

-

P2.8.3

Start function

0

2-0

719

0 = Ramp

1 = Flying start

2 = According to P2.4.6

P2.8.4

Number of tries after undervoltage trip

0

10-0

720-P2.8.5

Number of tries after overvoltage trip

0

10-0

721-P2.8.6

Number of tries after overcurrent trip

0

3-0

722-P2.8.7

Number of tries after 4 mA reference trip

0

10-0

723-P2.8.8

Number of tries after motor temperature fault trip

0

10-0

726-P2.8.9

Number of tries after external fault trip

0

10-0

725-P2.8.10

Number of tries after underload fault trip

0

10-0

738

-

Index

Parameter

Min

Max

Unit

Default

ID

Description

P3.1

Control place

1

3-1

125

1 = I/0 terminal

2 = Keypad

3 = Fieldbus

P3.2

Keypad reference

P2.1.1

P2.1.2

Hz

0.00

-

-

P3.3

Direction (on keypad)

0

1-0

123

0 = Forward

1 = Reverse

R3.4

Stop button

0

1-1

114

0 = Limited function of Stop button

1 = Stop button always enabled

VACON® NX All-in-One

Application Guide

3.4.9 Autorestart Parameters (Control Panel: Menu M2 -> G2.8)

Table 13: Autorestart Parameters, G2.8

Standard Application

3.4.10 Keypad Control (Control Panel: Menu M3)

The parameters for the selection of control place and direction on the keypad are listed in this table. See the Keypad control menu in

the User Manual of the product.

Table 14: Keypad Control Parameters, M3

3.4.11 System Menu (Control Panel: Menu M6)

For more information related to the general use of the AC drive, such as selecting application and language, customized parameter

sets, or hardware and software, see the User Manual of the product.

3.4.12 Expander Boards (Control Panel: Menu M7)

The M7 menu shows the expander and option boards attached to the control board and board-related information. For more information, see the User Manual of the product.

AB296635287482en-000201 / DPD00903 | 27Danfoss A/S © 2020.12

Page 28

VACON® NX All-in-One

Application Guide

Local/Remote Control Application

4 Local/Remote Control Application

4.1 Introduction to Local/Remote Control Application

Select the Local/Remote Control Application in menu M6 on page S6.2.

With the Local/Remote Control Application, it is possible to have two different control places. For each control place the frequency

reference can be selected from either the control panel, I/O terminal, or fieldbus. The active control place is selected with the digital

input DIN 6.

•

All outputs are freely programmable.

Extra functions:

•

Programmable Start/Stop and Reverse signal logic

•

Reference scaling

•

One frequency limit supervision

•

Second ramps and S-shape ramp programming

•

Programmable start and stop functions

•

DC brake at stop

•

One prohibit frequency area

•

Programmable U/f curve and switching frequency

•

Auto restart

•

Motor thermal and stall protection: Programmable action; off, warning, fault

The parameters of the Local/Remote Control Application are explained in Chapter Parameter descriptions of this manual. The explanations are arranged according to the individual ID number of the parameter.

AB296635287482en-000201 / DPD0090328 | Danfoss A/S © 2020.12

Page 29

Reference potentiometer,

1-10kΩ

1

6

2

3

4

5

18

19

20

12

7

13

8

9

10

14

15

16

21

22

23

11

17

24

25

26

mA

Remote Reference

0(4) - 20 mA

RUN

READY

AO1-

DO1

+24 V

GND

GND

DIN1

DIN2

DIN3

DIN4

DIN5

DIN6

R

O1

R

O1

R

O1

CMA

CMB

R

O2

R

O2

R

O2

OPTA1

OPTA2 / OPTA3

Terminal

Signal Description

+10 V

ref

AI1+

AI1-

AI2+

AI2-

+24V

Reference output

I/O Ground

Analogue input 2

Current range

0—20mA

Programmable

(P2.1.11)

Control voltage output

I/O ground

Place A: Start forward

Programmable logic (P2.2.1)

Place A: Start reverse

Ri min = 5 kohm

External fault input

Programmable (P2.2.2)

Place B: Start forward

Programmable logic (P2.2.15)

Place B: Start reverse

Ri min = 5 kΩ

Place A/B selection

Common for DIN 1—DIN 3

Common for DIN4—DIN6

Control voltage output

I/O ground

Analogue output 1

Output frequency

Programmable (P2.3.2)

Digital output

READY

Programmable (P2.3.7)

Open collector,

I≤50 mA, U≤48 VDC

Relay output 1

RUN

Programmable

(P2.3.8)

Relay output 2

FAULT

Programmable

(P2.3.9)

Range 0—20 mA/RL,

max. 500 Ω

Contact open = place A is active

Contact closed = Place B is active

Contact closed

= start forward

Contact closed

= start reverse

AO1+

Analogue input 1

reference for place B

Ground for reference

and controls

Analogue input 2

reference for place A

Contact closed = start forward

Contact closed = start reverse

Contact open = no fault

Contact closed = fault

Voltage for potentiometer, etc.

Analogue input 1

Voltage range 0—10V DC

Programmable (P2.1.12)

Voltage for switches,

etc. max 0.1 A

Voltage for switches (see #6)

Connect to GND or +24 V

Connect to GND or +24 V

Ground for reference and controls

Ground for reference and controls

e30bh092.20

VACON® NX All-in-One

Application Guide

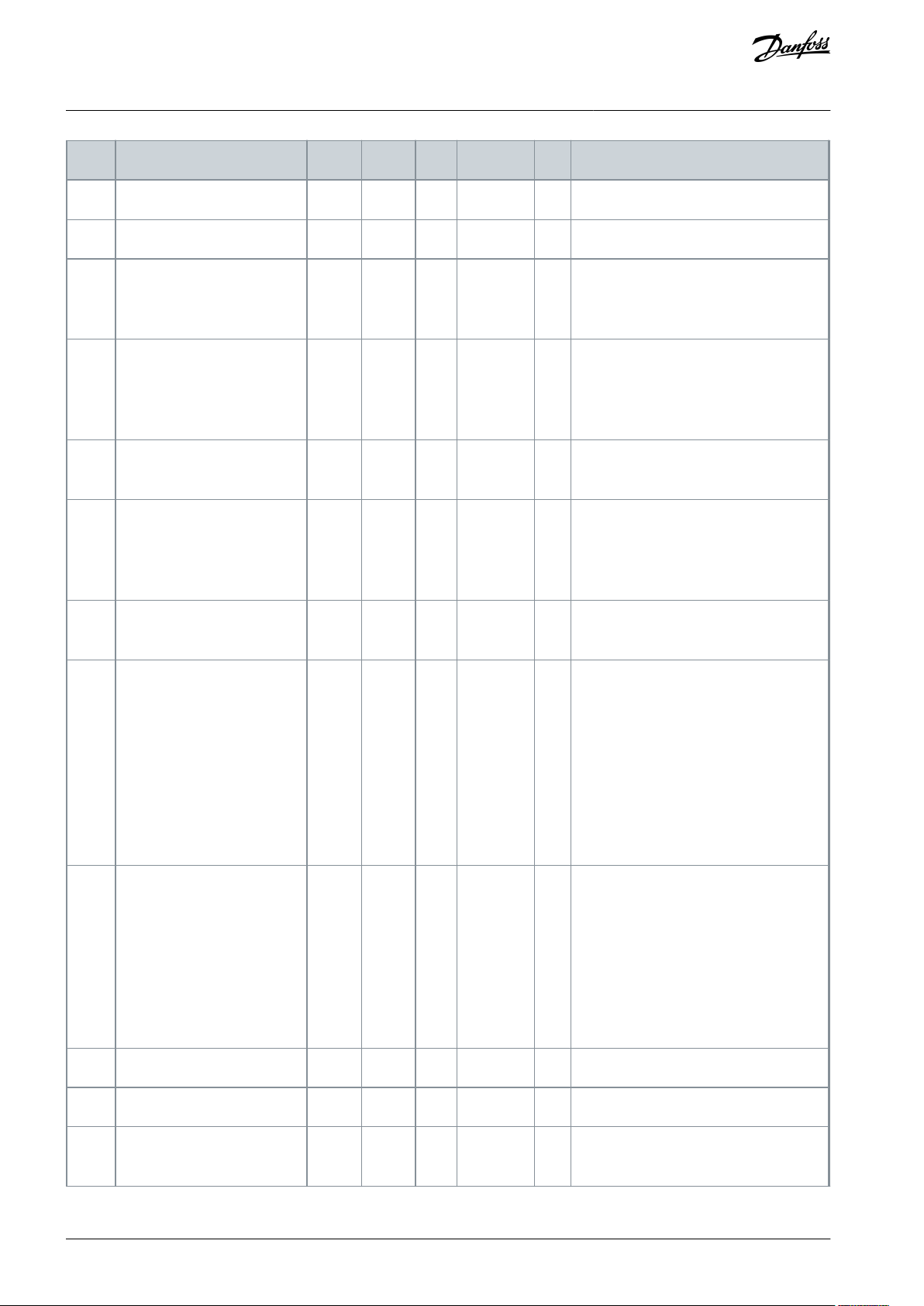

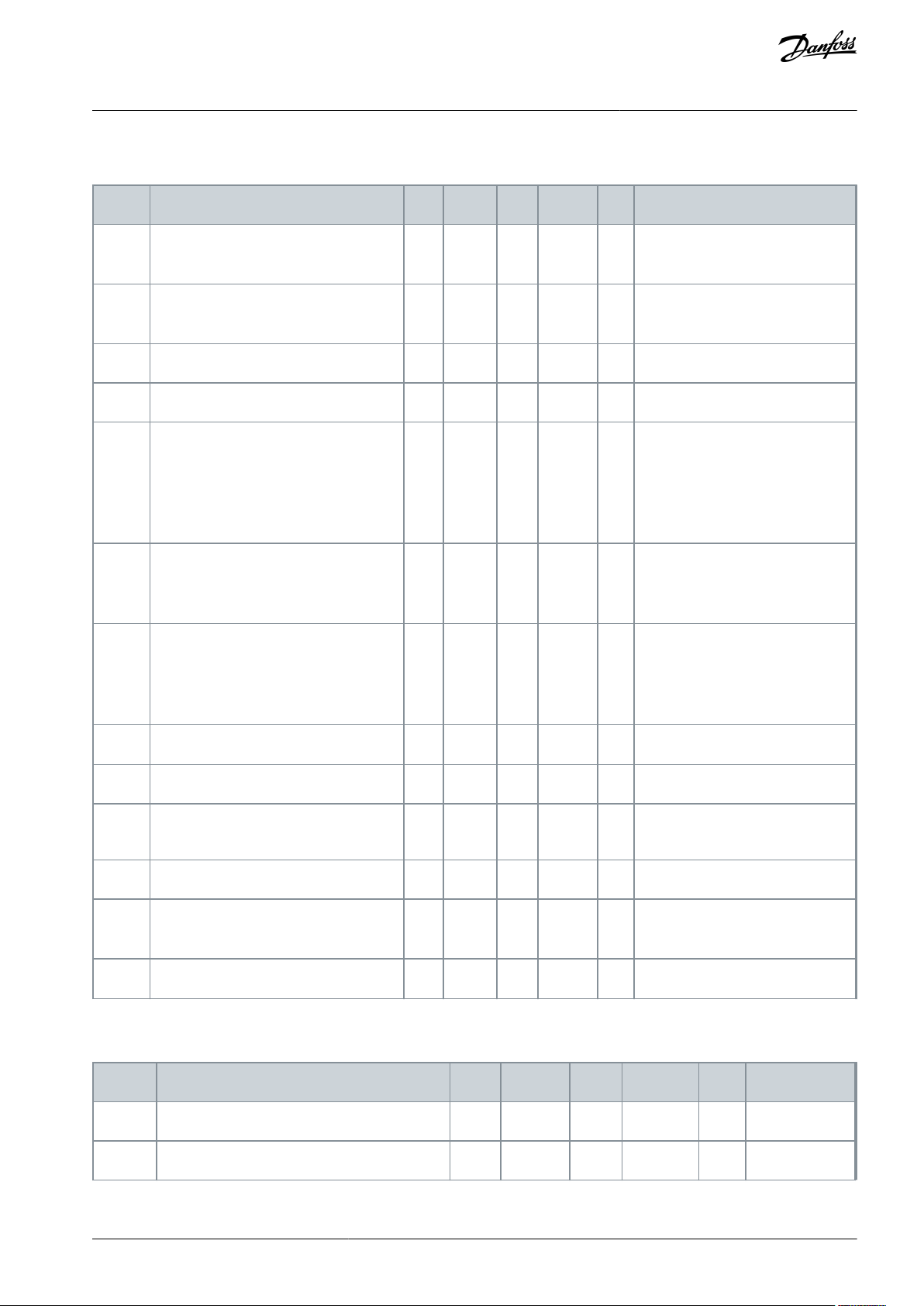

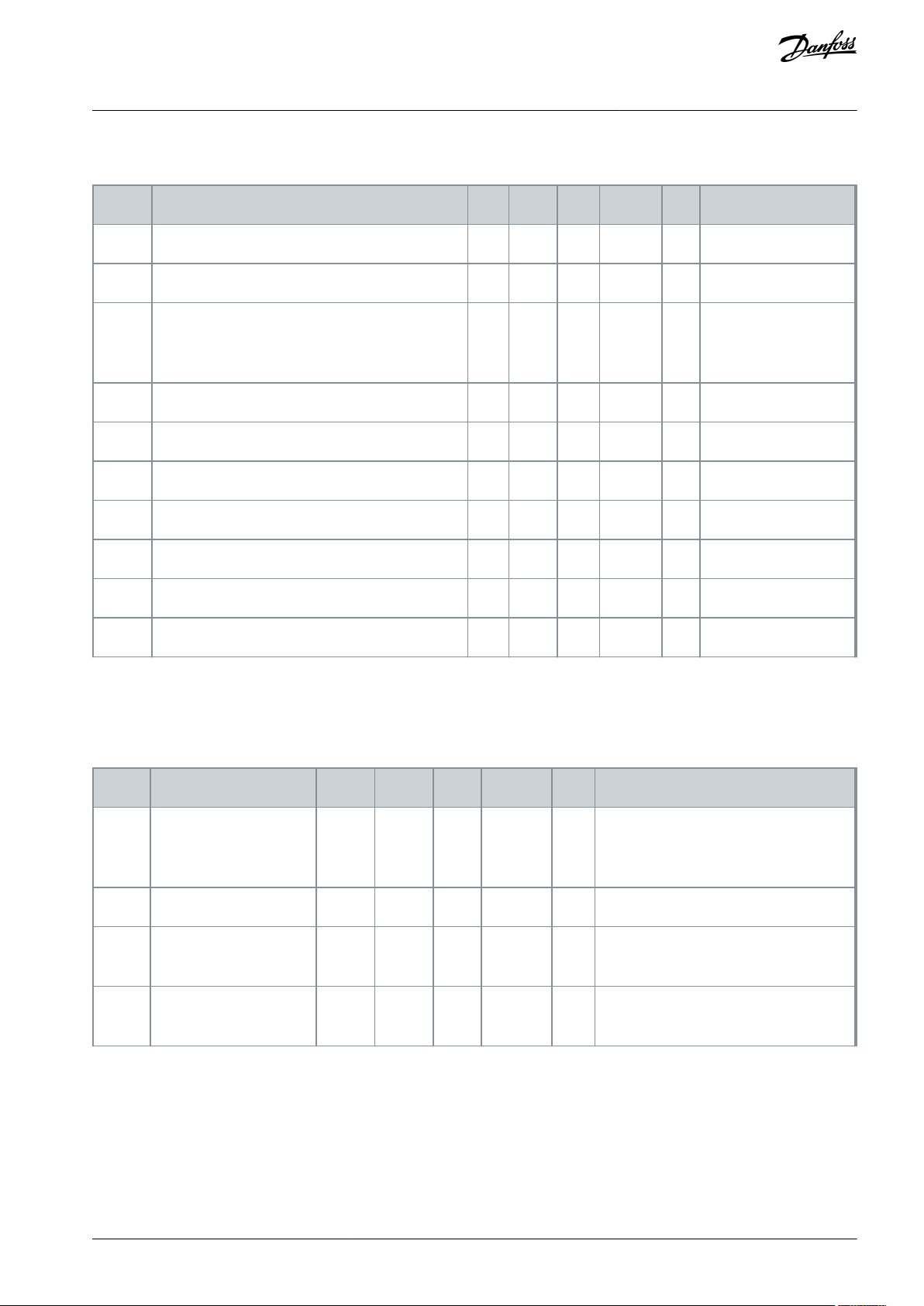

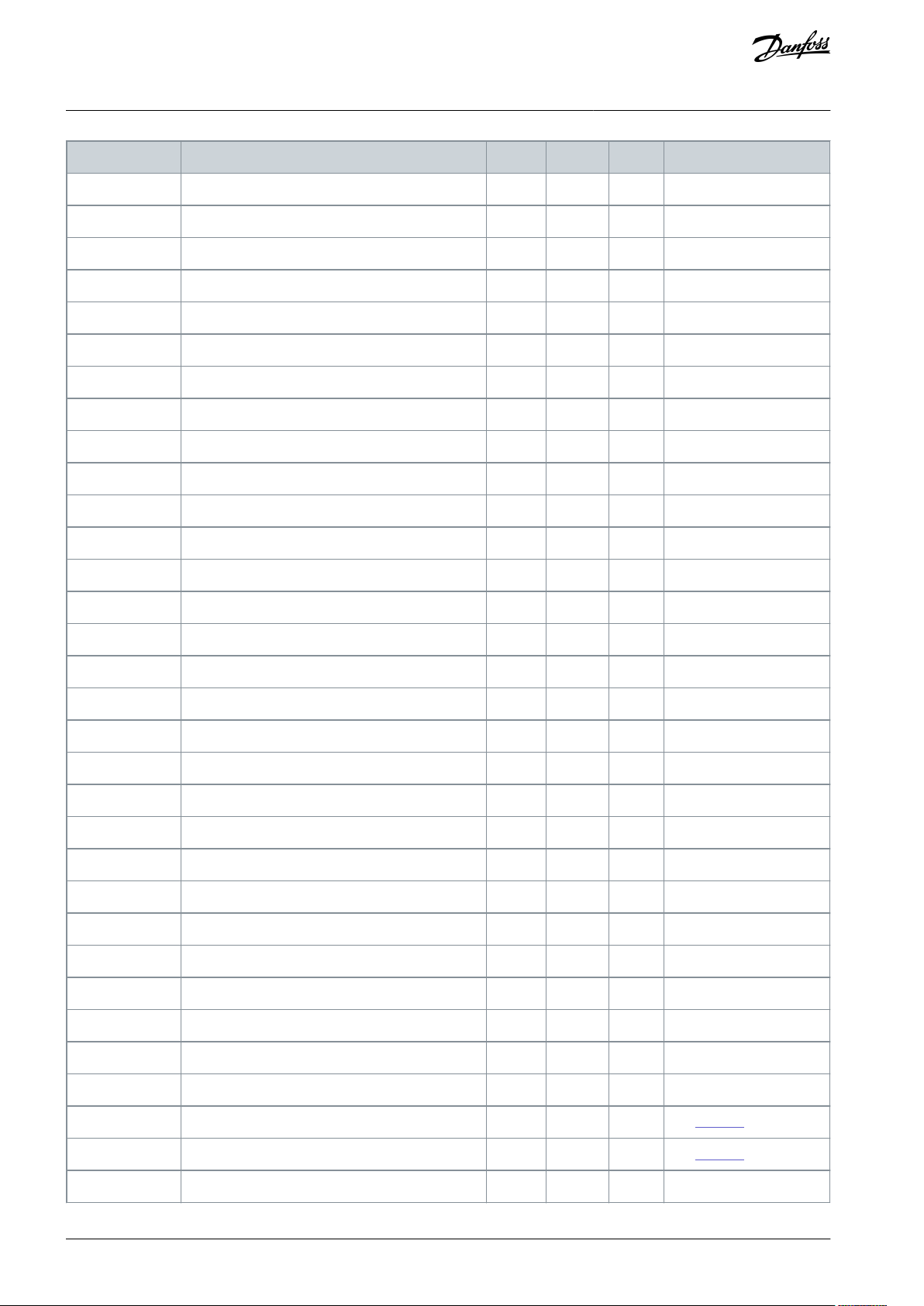

4.2 Control I/O in Local/Remote Control Application

Local/Remote Control Application

Illustration 8: Default I/O Configuration in Local/Remote Control Application

The option board OPTA3 has no terminal for open contact on its second relay output (terminal 24 is missing).

See jumper selections in Illustration 12. More information in the User Manual of the product.

AB296635287482en-000201 / DPD00903 | 29Danfoss A/S © 2020.12

Page 30

Jumper block X3:

CMA and CMB grounding

CMB connected to GND

CMA connected to GND

CMB isolated from GND

CMA isolated from GND

CMB and CMA internally

connected together,isolated

from GND

= Factory default

e30bh013.10

VACON® NX All-in-One

Application Guide

Illustration 9: Jumper Selections

Local/Remote Control Application

AB296635287482en-000201 / DPD0090330 | Danfoss A/S © 2020.12

Page 31

DIN3

≥

1

DIN6

AI1

AI2

DIN1

DIN2

DIN4

DIN5

A

B

A

B

A

B

Internal reverse

Internal fault reset

Fault reset input (programmable)

3.3 Keypad direction

Internal Start/Stop

Reference from fieldbus

Start/Stop from fieldbus

Direction from fieldbus

Start/Stop buttons

Reset button

Start forward

(programmable)

Start reverse

(programmable)

Start forward

Start reverse

(programmable)

(programmable)

Start/Stop

Reverse

Up

Down

3.1 Control

place

2.1.15 Jogging speed ref.

2.1.14 Fieldbus Ctrl reference

2.1.13 Keypad Ctrl reference

2.1.12 I/O B reference

2.1.11 I/O A reference

R3.2 Keypad reference

Motor

potentiometer

Programmable

Start/Stop and

reverse logic B

Programmable

Start/Stop and

reverse logic A

Internal

frequ ency ref.

e30bh051.10

Index

Monitoring value

Unit

Form

ID

Description

V1.1

Output frequency

Hz

#.##1-

VACON® NX All-in-One

Application Guide

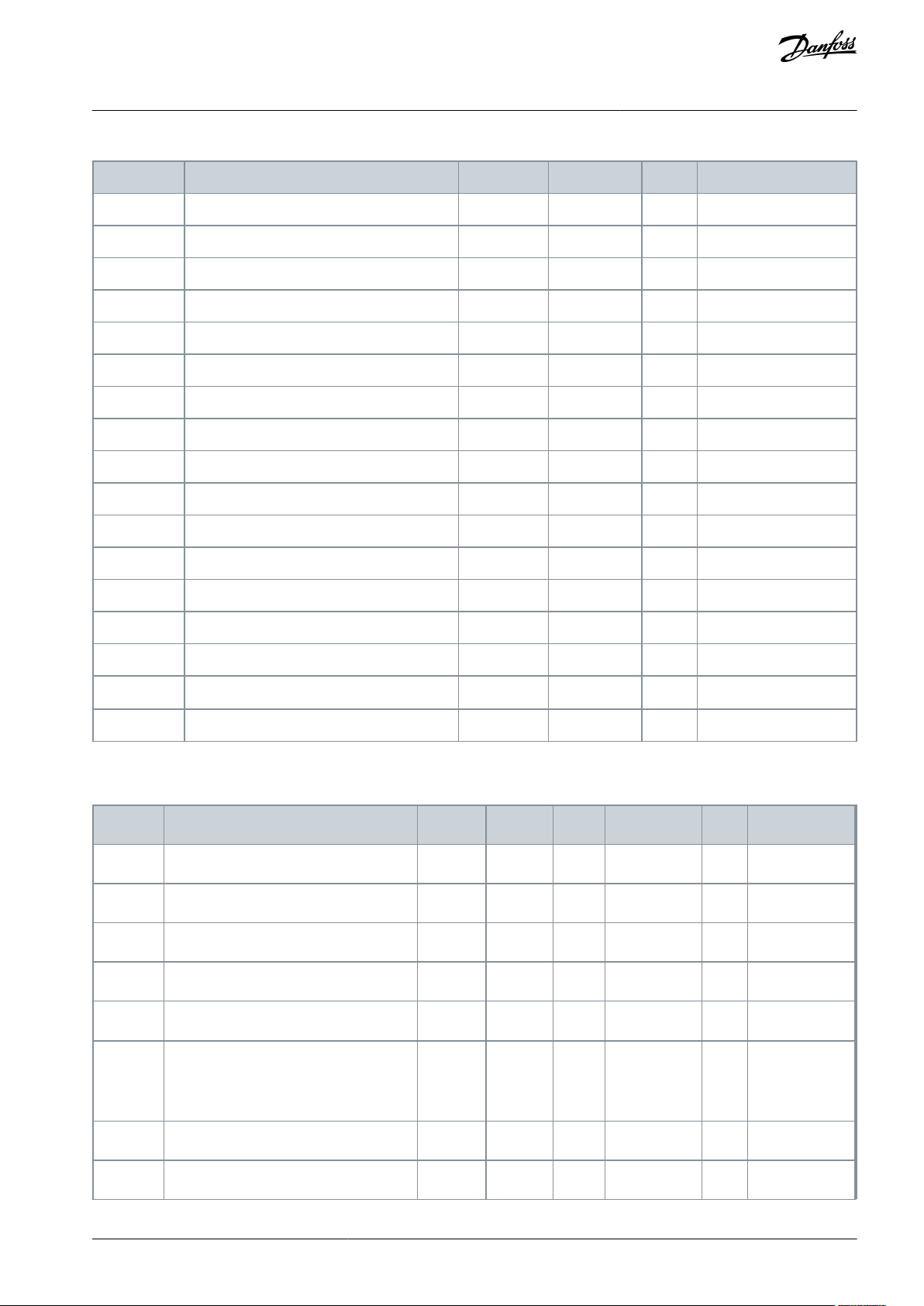

4.3 Control Signal Logic in Local/Remote Control Application

Local/Remote Control Application

Illustration 10: Control Signal Logic of the Local/Remote Control Application

4.4 Parameter Lists for Local/Remote Control Application

4.4.1 Monitoring Values (Control Panel: Menu M1)

The monitoring values are the actual values of parameters and signals as well as statuses and measurements. Monitoring values

cannot be edited.

Table 15: Monitoring Values

AB296635287482en-000201 / DPD00903 | 31Danfoss A/S © 2020.12

Page 32

Index

Monitoring value

Unit

Form

ID

Description

V1.2

Frequency reference

Hz

#.##25-

V1.3

Motor speed

RPM#2-V1.4

Motor current

A

Varies

3-V1.5

Motor torque

%

#.#4-

V1.6

Motor shaft power

%

#.#5-

V1.7

Motor voltage

V

#.#6-

V1.8

DC-link voltage

V#7-V1.9

Unit temperature

°C#8-V1.10

Motor temperature

%

#.#9-

V1.11

Analog input 1

V/mA

#.##13-

V1.12

Analog input 2

V/mA

#.##14-

V1.13

DIN 1, 2, 3

--15-V1.14

DIN 4, 5, 6

--16-V1.15

DO1, RO1, RO2

--17

-

V1.16

Analog I

out

mA

#.##26-

V1.17

Multimonitoring items

---

-

Index

Parameter

Min

Max

Unit

Default

ID

Description

P2.1.1

Min frequency

0.00

P2.1.2

Hz

0.00

101-P2.1.2

Max frequency

P2.1.1

320.00

Hz

50.00

102-P2.1.3

Acceleration time 1

0.1

3000.0

s

0.0

103-P2.1.4

Deceleration time 1

0.1

3000.0

s

0.0

104

-

P2.1.5

Current limit

0.1 x I

H

2 x IHA

IL107

-

P2.1.6

(1)

Nominal voltage of the motor

180

690VNX2: 230 V

NX5: 400 V

NX6: 690 V

110

-

P2.1.7

(1)

Nominal frequency of the motor

8.00

320.00

Hz

50.00

111

-

P2.1.8

(1)

Nominal speed of the motor

24

20 000

RPM

1440

112

-

P2.1.9

(1)

Nominal current of the motor

0.1 x I

H

2 X IHA

IH113

-

P2.1.10

(1)

Motor cos phi

0.30

1.00-0.85

120

-

VACON® NX All-in-One

Application Guide

Local/Remote Control Application

4.4.2 Basic Parameters (Control Panel: Menu M2 -> G2.1

Table 16: Basic Parameters G2.1

AB296635287482en-000201 / DPD0090332 | Danfoss A/S © 2020.12

Page 33

Index

Parameter

Min

Max

Unit

Default

ID

Description

P2.1.11

(1)

I/O A reference

0

4-1

117

0 = AI1

1 = AI2

2 = Keypad

3 = Fieldbus

4 = Motor potentiometer

P2.1.12

(1)

I/O B reference

0

4-0

131

0 = AI1

1 = AI2

2 = Keypad

3 = Fieldbus

4 = Motor potentiometer

P2.1.13

(1)

Keypad control reference

0

3-2

121

0 = AI1

1 = AI2

2 = Keypad

3 = Fieldbus

P2.1.14

(1)

Fieldbus control reference

0

3-3

122

0 = AI1

1 = AI2

2 = Keypad

3 = Fieldbus

P2.1.15

(1)

Jogging speed reference

0.00

P2.1.2

Hz

0.00

124

-

Index

Parameter

Min

Max

Unit

Default

ID

Description

P2.2.1

(1)

Place A Start/Stop logic selection

0

8-0

300

Logic = 0

Ctrl sgn 1 = Start forward

Ctrl sgn 2 = Start reverse

Logic = 1

Ctrl sgn1 = Start/ Stop

Ctrl sgn 2 = Reverse

Logic = 2

Ctrl sgn 1 = Start/ Stop

Ctrl sgn 2 = Run enable

Logic = 3

Ctrl sgn 1 = Start pulse (edge)

Ctrl sgn 2 = Stop pulse

Logic = 4

Ctrl sgn 1 = Start Forward

Ctrl sgn 2 = Motor potentiometer UP

Logic = 5

Ctrl sgn 1 = Start forward (edge)

Ctrl sgn 2 = Start reverse (edge)

Logic = 6

Ctrl sgn 1 = Start (edge) / Stop

VACON® NX All-in-One

Application Guide

Local/Remote Control Application

1

Parameter value can only be changed after the AC drive has been stopped.

4.4.3 Input Signals (Control Panel: Menu M2 -> G2.2)

Table 17: Input Signals, G2.2

AB296635287482en-000201 / DPD00903 | 33Danfoss A/S © 2020.12

Page 34

Index

Parameter

Min

Max

Unit

Default

ID

Description

Ctrl sgn 2 = Reverse

Logic = 7

Ctrl sgn 1 = Start (edge) / Stop

Ctrl sgn 2 = Run enable

Logic = 8

Ctrl sgn 1 = Start forward (edge)

Ctrl sgn 2 = Motor potentiometer UP

P2.2.2

DIN 3 function

0

13-1

301

0 = Not used

1 = Ext. fault, closing cont.

2 = Ext. fault, opening cont.

3 = Run enable

4 = Acc./Dec. time selection

5 = Force cp. to I/O

6 = Force cp. to keypad

7 = Force cp. to fieldbus

8 = Reverse

9 = Jogging speed

10 = Fault reset

11 = Acc./Dec. operation prohibit

12 = DC Braking command

13 = Motor potentiometer DOWN

P2.2.3

(2)

AI1 signal selection

0.1

E.10-A1

377

-

P2.2.4

(3)

AI1 signal range

0

2-0

320

0 = 0–10 V (0–20 mA)

1 = 2–10 V (4–20 mA)

2 = Custom setting range

P2.2.5

AI1 custom setting minimum

-160.00

160.00

%

0.00

321-P2.2.6

AI1 custom setting maximum

-160.00

160.00

%

0.00

322

-

P2.2.7

AI1 signal inversion

0

1-0

323

0 = Not inverted

1 = Inverted

P2.2.8

AI1 signal filter time

0.00

10.00

sA1324

-

P2.2.9

(2)

AI2 signal selection

0.1

E.10-A.2

388

-

P2.2.10

(3)

AI2 signal range

0

2-1

325

0 = 0–10 V (0–20 mA)

1 = 2–10 V (4–20 mA)

2 = Custom setting range

P2.2.11

AI2 custom setting minimum

-160.00

160.00

%

0.00

326-P2.2.12

AI2 custom setting maximum

-160.00

160.00

%

100.00

327

-

P2.2.13

AI2 signal inversion

0

1-0

328

0 = Not inverted

1 = Inverted

VACON® NX All-in-One

Application Guide

Local/Remote Control Application

AB296635287482en-000201 / DPD0090334 | Danfoss A/S © 2020.12

Page 35

Index

Parameter

Min

Max

Unit

Default

ID

Description

P2.2.14

AI2 signal filter time

0.00

10.00

s

0.10

329

-

P2.2.15

(1)

Place B Start/Stop logic selection

0

6-0

363

Logic = 0

Ctrl sgn 1 = Start forward

Ctrl sgn 2 = Start reverse

Logic = 1

Ctrl sgn 1 = Start/ Stop

Ctrl sgn 2 = Reverse

Logic = 2

Ctrl sgn 1 = Start/ Stop

Ctrl sgn 2 = Run enable

Logic = 3

Ctrl sgn 1 = Start pulse (edge)

Ctrl sgn 2 = Stop pulse

Logic = 4

Ctrl sgn 1 = Forward pulse (edge)

Ctrl sgn 2 = Reverse pulse (edge)

Logic = 5

Ctrl sgn 1 = Start pulse (edge)

Ctrl sgn 2 = Reverse pulse

Logic = 6

Ctrl sgn 1 = Start pulse (edge)

Ctrl sgn 2 = Enable pulse

P2.2.16

Place A Reference scaling minimum value

0.00

320.00

Hz

0.00

303-P2.2.17

Place A Reference scaling maximum value

0.00

---

304-P2.2.18

Place B Reference scaling minimum value

0.00

320.00

Hz

0.00

364

-

P2.2.19

Place B Reference scaling maximum value

0.00

320.00

Hz

0.00

365

0.00 = No scaling

>0 = scaled maximum value

P2.2.20

Free analog input, signal selection

0

2-0

361

0 = Not used

1 = Analog input 1

2= Analog input 2

P2.2.21

Free analog input, function

0

4-0

362

0 = No reset

1 = Reduces current limit (P2.1.5)

2 = Reduces DC braking current

3 = Reduces accel. and decel. times

4 = Reduces torque super vision limit

P2.2.22

Motor potentiometer ramp time

0.1

2000.0

Hz/s

10.0

331

-

P2.2.23

Motor potentiometer frequency

reference memory reset

0

2-1

367

0 = No reset

1 = Reset if stopped or powered down

2 = Reset if powered down

VACON® NX All-in-One

Application Guide

Local/Remote Control Application

AB296635287482en-000201 / DPD00903 | 35Danfoss A/S © 2020.12

Page 36

Index

Parameter

Min

Max

Unit

Default

ID

Description

P2.2.24

Start pulse memory

0

1-0

498

0 = Run state not copied

1 = Run state copied

Index

Parameter

Min

Max

Unit

Default

ID

Description

P2.3.1

(1)

Analog output 1 signal selection

0.1

E.10-A11

464

-

P2.3.2

Analog output function

0

8-1

307

0 = Not used (20 mA/10V)

1 = Output freq. (0–f

max

)

2 = Freq. reference (0–f

max

)

3 = Motor speed (0–Motor nominal speed)

4 = Motor current (0–I

nMotor

)

5 = Motor torque (0–T

nMotor

)

6 = Motor power (0–P

nMotor

)

7 = Motor voltage (0–U

nMotor

)

8 = DC-link volt (0–1000 V)

P2.3.3

Analog output filter time

0.00

10.00

s

1.00

308

0 = No filtering

P2.3.4

Analog output inversion

0

1-0

309

0 = Not inverted

1 = Inverted

P2.3.5

Analog output minimum

0

1-0

310

0 = 0 mA (0 V)

1 = 4 mA (2 V)

P2.3.6

Analog output scale

10

1000%100

311

-

P2.3.7

Digital output 1 function

0

22-1

312

0 = Not used

1 = Ready

2 = Run

3 = Fault

4 = Fault inverted

5 = AC drive overheat warning

6 = Ext. fault or warning

7 = Ref. fault or warning

8 = Warning

9 = Reversed

10 = Jogging speed selected

11 = At speed

12 = Mot. regulator active

13 = OP freq. limit 1 superv.

14 = OP freq. limit superv.2

15 = Torque limit superv.

VACON® NX All-in-One

Application Guide

1

Parameter value can only be changed after the AC drive has been stopped.

2

Use the Terminal to Function method (TTF) with these parameters, see 10.619 "Terminal to Function" (TTF) Programming Principle.

3

Remember to place jumpers of block X2 according to the selection (0, 1 or 2). See the User Manual of the product.

Local/Remote Control Application

4.4.4 Output Signals (Control Panel: Menu M2 -> G2.3)

Table 18: Output Signals, G2.3

AB296635287482en-000201 / DPD0090336 | Danfoss A/S © 2020.12

Page 37

Index

Parameter

Min

Max

Unit

Default

ID

Description

16 = Ref. limit superv.

17 = Ext. brake control

18 = Control place: I/O

19 = AC drive temp. limit superv.

20 = Unrequested rotation direction

21 = Ext. brake control inverted

22 = Thermistor fault/warn.

P2.3.8

RO1 function

0

22-2

313

See P2.3.7.

P2.3.9

RO2 function

0

22-3

314

See P2.3.7.

P2.3.10

Output frequency limit 1 supervision

0

2-0

315

0 = No limit

1 = Low limit supervision

2 = High limit supervision

P2.3.11

Output frequency limit 1; Supervised value

0.00

320.00

Hz

0.00

316

-

P2.3.12

Output frequency limit 2 supervision

0

2-0

346

0 = No limit

1 = Low limit supervision

2 = High limit supervision

P2.3.13

Output frequency limit 2; Supervision value

0.00

320.00

Hz

0.00

347

-

P2.3.14

Torque limit supervision function

0

2-0

348

0 = No

1 = Low limit

2 = High limit

P2.3.15

Torque limit supervision value

-300.0

300.0

%

0.0

349

-

P2.3.16

Reference limit supervision

function

0

2-0

350

0 = No

1 = Low limit

2 = High limit

P.2.3.17

Reference limit supervision value

0.0

100.0

%

0.0

351

P2.3.18

External brake Off-delay

0.0

100.0

s

0.5

352-P2.3.19

External brake On-delay

0.0

100.0

s

1.5

353

-

P2.3.20

Frequency converter temperature limit supervision

0

2-0

354

0 = No

1 = Low limit

2 = High limit

P2.3.21

Frequency converter temperature limit value

-10

100°C40

355

P2.3.22

Analog output 2 scaling

0.1

E.10-0.1

471

-

VACON® NX All-in-One

Application Guide

Local/Remote Control Application

AB296635287482en-000201 / DPD00903 | 37Danfoss A/S © 2020.12

Page 38

Index

Parameter

Min

Max

Unit

Default

ID

Description

P2.3.23

Analog output 2 function

0

8-4

472

As parameter 2.3.2

P2.3.24

Analog output 2 filter time

0.00

10.00

s

1.00

473

0 = No filtering

P2.3.25

Analog output 2 inversion

0

1-0

474

0 = Not inverted

1 = Inverted

P2.3.26

Analog output 2 minimum

0

1-0

475

0 = 0 mA (0 V)

1 = 4 mA (2 V)

P2.3.27

Analog output 2 scaling

10

1000%1.00

476

-

Index

Parameter

Min

Max

Unit

Default

ID

Description

P2.4.1

Ramp 1 shape

0.0

10.0s0.1

500

0 = Linear

100 = full acc/dec inc/dec tmes

P2.4.2

Ramp 2 shape

0.0

10.0s0.0

501

0 = Linear

100 = full acc/dec inc/dec tmes

P2.4.3

Acceleration time 2

0.1

3000.0

s

1.0

502-P2.4.4

Deceleration time 2

0.1

3000.0

s

1.0

503

-

P2.4.5

Brake chopper

0

4-0

504

0 = Disabled

1 = Used when running

2 = External brake chopper

3 = Used when stopped/running

4 = Used when running (no testing)

P2.4.6

Start function

0

2-0

505

0 = Ramp

1 = Flying start

2 = Conditional flying start

P2.4.7

Stop function

0

3-0

506

0 = Coasting

1 = Ramp

2 = Ramp+Run enable coast

3 = Coast+Run enable ramp

P2.4.8

DC braking current

0.00

ILA

0.7 x I

H

507

-

P2.4.9

DC braking time at stop

0.00

600.00

s

0.00

508

0 = DC brake is off at stop

P2.4.10

Frequency to start DC braking during

ramp stop

0.10

10.00

Hz

1.50

515

-

VACON® NX All-in-One

Application Guide

1

Use the Terminal to Function method (TTF) with these parameters, see 10.619 "Terminal to Function" (TTF) Programming Principle.

Local/Remote Control Application

4.4.5 Drive Control Parameters (Control Panel: Menu M2->G2.4)

Table 19: Drive Control Parameters, G2.4

AB296635287482en-000201 / DPD0090338 | Danfoss A/S © 2020.12

Page 39

Index

Parameter

Min

Max

Unit

Default

ID

Description

P2.4.11

DC braking time at start

0.00

600.00

s

0.00

516

0 = DC brake is off at start

P2.4.12

Flux brake

0

1-0

520

0 = Off

1 = On

P2.4.13

Flux braking current

0.00

ILA

IH519

-

Index

Parameter

Min

Max

Unit

Default

ID

Description

P2.5.1

Prohibit frequency range 1 low limit

0.00

320.00

Hz

0.00

509-P2.5.2

Prohibit frequency range 1 high limit

0.00

320.00

Hz

0.00

510

0 = Prohibit range 1 is off

P2.5.3

Prohibit frequency range 2 low limit

0.00

320.00

Hz

0.00

511-P2.5.4

Prohibit frequency range 2 high limit

0.00

320.00

Hz

0.00

512

0 = Prohibit range 2 is off

P2.5.5

Prohibit frequency range 3 low limit

0.00

320.00

Hz

0.00

513-P2.5.6