vacon nx

®

ac drives

dc/dc converter

operating guide

vacon • 1

TABLE OF CONTENTS

Document ID:DPD01901A

Revision release date: 01.11.2016

1. Introduction ................................................................................................................ 2

1.1 Application functionality........................................................................................................ 2

1.2 Connection............................................................................................................................. 2

2. Parameters................................................................................................................. 7

2.1 Source side parameters........................................................................................................ 7

2.1.1 Basic parameters.................................................................................................... 7

2.1.2 Voltage reference.................................................................................................... 8

2.1.3 Current reference ................................................................................................... 9

2.1.4 Source voltage ...................................................................................................... 10

2.1.5 Current limit.......................................................................................................... 10

2.2 DC-link side parameters..................................................................................................... 11

2.2.1 Over voltage control for DC-link voltage.............................................................. 11

2.2.2 Under voltage control for DC-link voltage ........................................................... 11

3. Control IO.................................................................................................................. 12

NOTE! You can download the English and French product manuals with applicable safety,

warning and caution information from

http://drives.danfoss.com/knowledge-center/technical-documentation/.

REMARQUE Vous pouvez télécharger les versions anglaise et française des manuels produit

contenant l’ensemble des informations de sécurité, avertissements et mises en garde

applicables sur le site http://drives.danfoss.com/knowledge-center/technical-documentation/

.

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

vacon • 2 Introduction

1. INTRODUCTION

The DC/DC application creates output according to the needs of the system, and it is possible to

integrate into the system with different topologies. Choosing applicable topology, see the Design

Guide, Hybridization (DPD01887A).

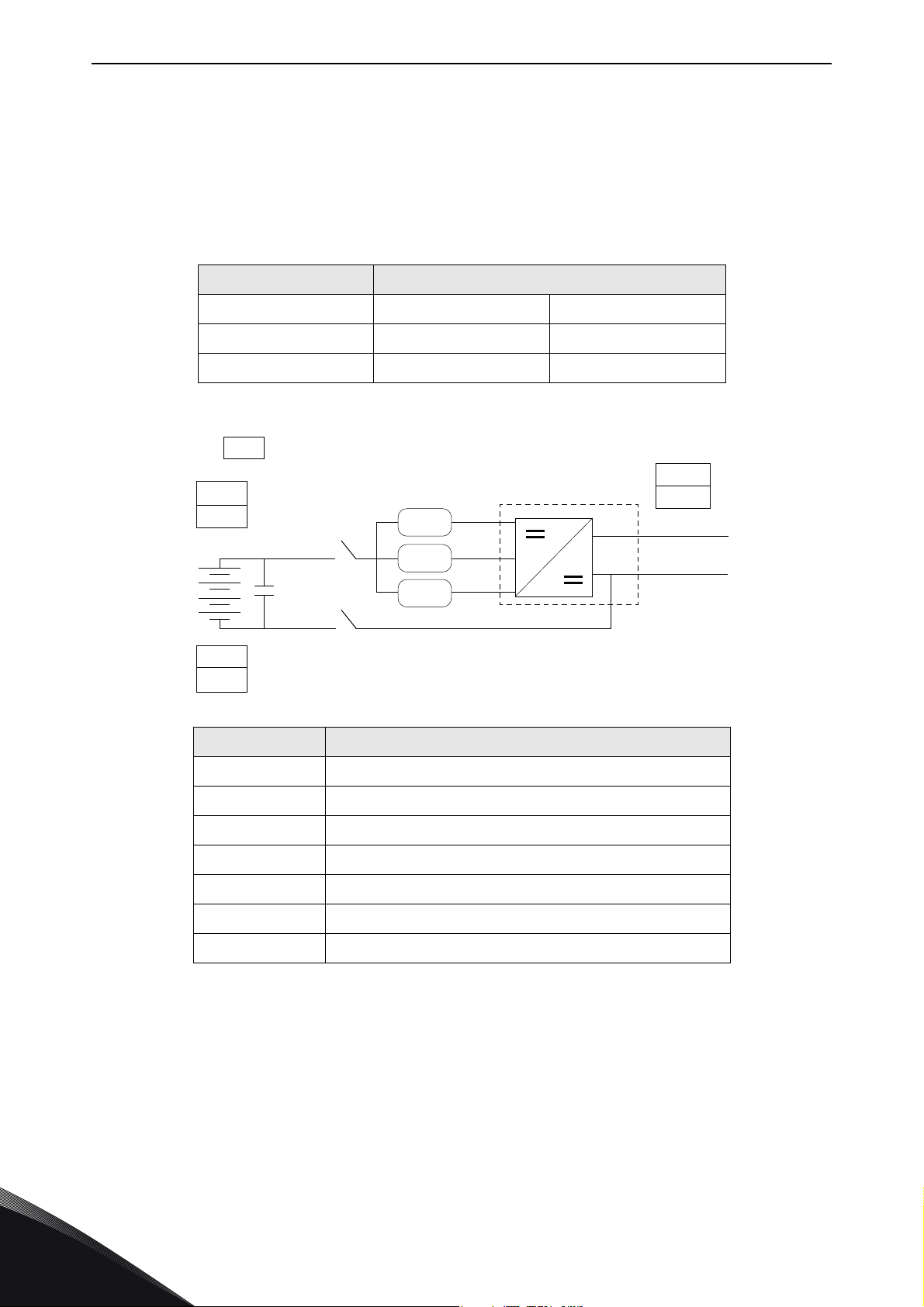

1.1 Application functionality

DC-link side Controlled source side

Control Control Limit

Under voltage Voltage Voltage

Over voltage Current Current

P2.1

P2.5.3

P2.2.1

P2.2.2

Source DC

L

L

C

L

U

V

W

DC/DC Converter

NX

P2.5.2

DC+

DC-Link

DC-

B-

P2.5.4

P2.5.1

Reference Parameter

P2.1 Basic parameters

P2.2.1 Voltage reference

P2.2.2 Current reference

P2.5.1 Current limit

P2.5.2 Under voltage control for DC-link voltage

P2.5.3 Over voltage control for DC-link voltage

P2.5.4 Source voltage

Figure 1. DC/DC connection

For more detailed parameter information, see Chapter 2 "Parameters".

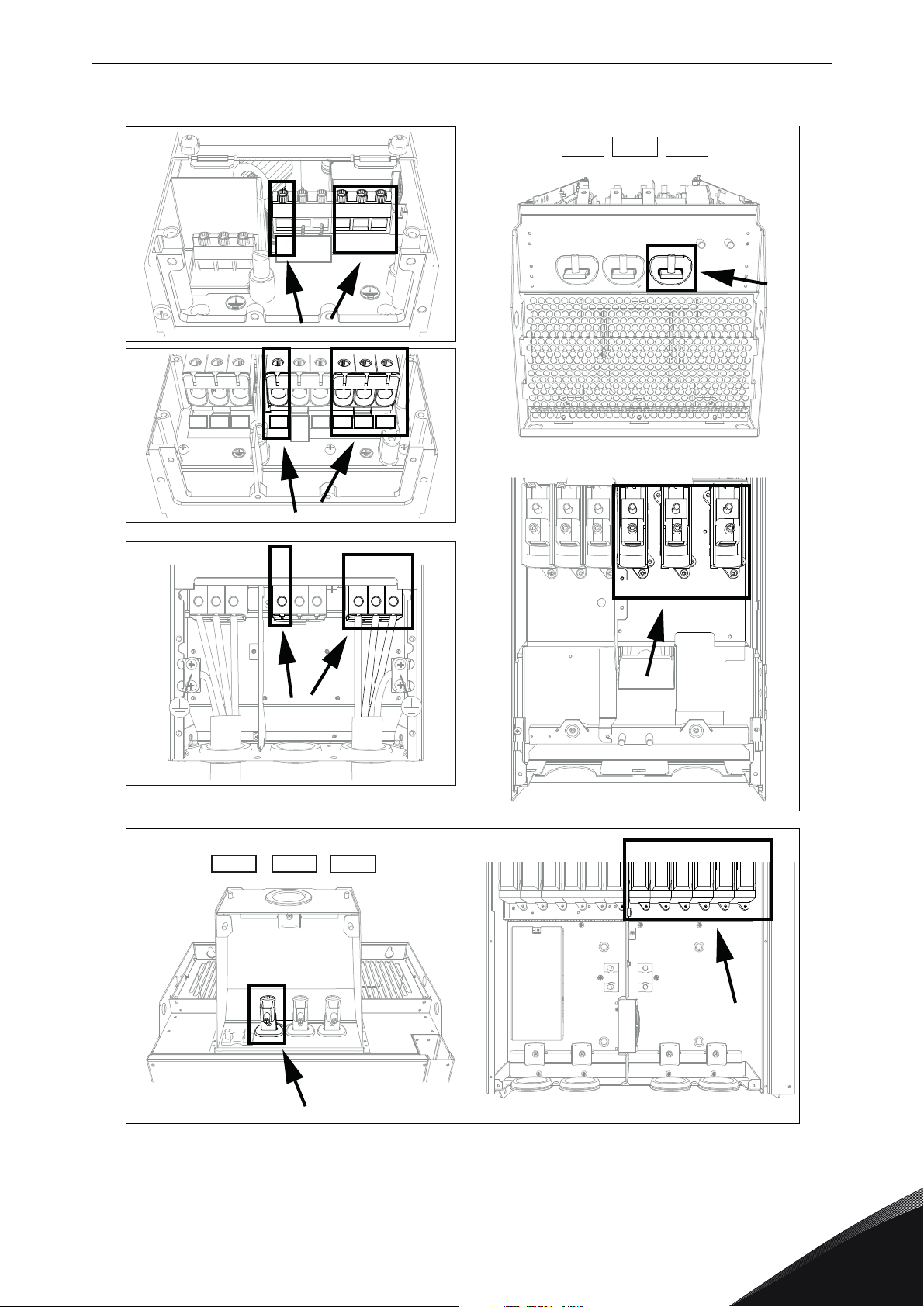

1.2 Connection

Connect the phase cables (U, V and W) and cable B-/DC- to correct terminals. See Figure 2, “FR4FR9 main terminals,” on page 3, Figure 3, “CH62 main terminals,” on page 4, Figure 4, “FI4-FI10

basic wiring diagrams,” on page 5 and Figure 5, “2 x FI10 basic wiring diagram,” on page 6.

1

NOTE: The connection varies according to drive. Always check the connection terminals from the

instruction manual of the drive in question. E.g. in FR4-FR6 INU devices (FI4-FI6) B- = DC-.

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Introduction vacon • 3

FR4

FR5

FR6

FR7

L1 L2 L3

L1 L2 L3

L1 L2 L3

B- R-

B+

R+

R+

B+

B- R-

R+

UVW

VWB- R-B+

U

VW

U

R-

L2L1 L3

B+/R+ B-

FR8

U/T1 V/T2

W/T3

FR9

B- B+/R+ R-

L1 L2 L3 L1L2L3

Figure 2. FR4-FR9 main terminals

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

VWUVW

U

1

vacon • 4 Introduction

DC+

DC-

WV U

Figure 3. CH62 main terminals

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

1

Introduction vacon • 5

+

-

+

-

NXP

CONTROL

X10

FI 9/10

B+

DC+ DC-

B-

X15X9

H1..H7

PE

FI4-FI8

FI9-FI10

B+

B+ DC+ DC-

B-

UVW

PEU

COOLING

FAN

VW

NOTE: The location and selection of fuses varies according to system design.

Figure 4. FI4-FI10 basic wiring diagrams

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

1

vacon • 6 Introduction

X15X9X10

H1-H7

X15X9X10

H1-H7

+

-

NXP

CONTROL

B+

DC+ DC-

B-

FI10

Module 1

FI10

Module2

PEU

COOLING

FAN

VW

B+

DC+ DC-

B-

PE

U

COOLING

FAN

V

W

FI10 FI10

NXP

CONTROL

Figure 5. 2 x FI10 basic wiring diagram

NOTE: The location and selection of fuses varies according to system design.

1

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Parameters vacon • 7

2. PARAMETERS

2.1 Source side parameters

2.1.1 Basic parameters

Table 1. Basic parameters

Code Parameter Min Max Unit Default ID Note

P2.1.1 Source Nom Current 0.0 Varies A Varies 113 Capacity of supply

P2.1.2 Source Nom Voltage 200 1099 V Varies 110

P2.1.3 Source Nom Power 0 32000 kW 0 116

P2.1.4 Control Mode 0 1 0 1858

P2.1.5 Identification 0 1 0 631

P2.1.1 SOURCE NOM CURRENT ID113

0 = Current

1 = Voltage

0 = No Action

1 = Current, Meas, Offset

This parameter defines the current value that is used as the 100 % current for e.g. charging current

limit.

P2.1.2 SOURCE NOM VOLTAGE ID110

This parameter defines the absolute voltage value that is used as the 100 % voltage for e.g. the

voltage reference.

P2.1.3 SOURCE NOM POWER ID116

This parameter is used for scaling the percentage power monitoring value.

P2.1.4 CONTROL MODE ID1858

This parameter is used to select the control mode of the drive.

0 = Current control mode

1 = Voltage control mode

P2.1.5 IDENTIFICATION ID631

This parameter is used to calibrate the current measurement.

0 = No Action

1 = Current measurement offset

When the identification is finished, the drive must be connected to the battery system or the used

DC power source. There should also not be any load on the DC-link.

Select the identification run and give the DC/DC converter a start command within 20 seconds after

the identification mode is selected.

24-hour support +358 (0)201 212 575 • Email: service@vacon.com

2

vacon • 8 Parameters

2.1.2 Voltage reference

Table 2. Voltage reference handling

Code Parameter Min Max Unit Default ID Note

P2.2.1.1 Voltage Reference 0 320 % 100 1462

P 2.2.1.2 Drooping 0 100 % 0 620

P 2.2.1.3

P2.2.1.4

P2.2.1.5

P2.2.1.1 DC VOLTAGE REFERENCE ID1462

Voltage Reference

Ramp Rate

Volt age Reference A t

Start

Start Voltage

Reference

-1 320 %/s 5 1867

0 2 3 1864

0 320 % 90 1865

0 = Reference

1 = Start Voltage Reference

2 = Measurement

3 = 80%

Voltage reference in percentage of Source Nom Voltage.

P2.2.1.2 DROOPING ID620

Voltage reference drooping. Used when parallel DC-DC converters are used.

P2.2.1.3 REACTIVE CURRENT REFERENCE SOURCE SELECTION ID1867

Voltage reference ramp rate in in percentage or in seconds.

P2.2.1.4 VOLTAGE REFERENCE AT START ID1864

This parameter is used to define how the voltage reference starting value is handled in a start. The

start will be smoother when the value is close to the actual source voltage.

0 = Reference

Starting voltage is a directly given reference P2.2.1.1 Voltage Reference.

1 = V Ref Start

Starting voltage is defined by parameter P2.2.1.5 Start Voltage Reference and ramped to actual

reference with set ramp rate.

2 = Measurement

Starting voltage is taken from measured voltage V1.12.11 Voltage Meas. ID1866. This monitoring

value can be written by analogue ID function or from fieldbus.

3 = 80 %

Drive will start as an initial guess of 80% of source voltage.

P2.2.1.5 START VOLTAGE REFERENCE ID1865

The voltage value that is used for the initial start voltage when P2.2.1.4 Voltage Reference At Start

is 1 / V Ref Start.

2

Tel. +358 (0) 201 2121 • Fax +358 (0)201 212 285

Parameters vacon • 9

2.1.3 Current reference

Table 3. Current reference handling

Code Parameter Min Max Unit Default ID Note

P2.2.2.1 Current Reference -150 150 % 0 1860

P 2.2.2.2.1 Phase Reference Mode 0 1 0 1859

P 2.2.2.2.2 IU Current Reference -300 300 % 0 128

P2.2.2.2.3 IV Current Reference -300 300 % 0 129

P2.2.2.2.4 IW Current Reference -300 300 % 0 130

P2.2.2.1 CURRENT REFERENCE ID1860

Common reference for all

phases.

0 = Common

1 = Individual

The active current reference of the drive in percentage of Source Nominal Current.

Active Curr. Ref > 0: Current flow from drive DC-Link to source.

Active Curr. Ref < 0: Current flow from source to drive DC-Link.

P2.2.2.2.1 PHASE REFERENCE MODE ID1859

This parameter is used to select if the same current reference is used for all phases or if the current

is controlled individually.

0 = Common

P: Current reference is used for all phases.

1 = Individual phase control

Each phase is controlled separately with G2.2.2.2 parameters.

Used when each phase have a separate DC source.

P2.2.2.2.2 IU CURRENT REFERENCE ID128

The U phase current reference on an individual mode.

P2.2.2.2.3 IV CURRENT REFERENCE ID129

The V phase current reference on an individual mode.

P2.2.2.2.4 IW CURRENT REFERENCE ID130

The W phase current reference on an individual mode.

24-hour support +358 (0)201 212 575 • Email: service@vacon.com

2

vacon • 10 Parameters

2.1.4 Source voltage

Table 4. Source voltage

Code Parameter Min Max Unit Default ID Note

P2.5.4.1 Source min voltage 50.0 1100.0 Vdc 200/345 1893 Discharge limit

P2.5.4.2 Source max voltage 50.0 1100.0 Vdc 749/1099 1895 Charge limit

P2.5.4.3

P2.5.4.1 SOURCE MIN VOLTAGE ID1893

Source voltage

hysteresis

0.0 100.0 Vdc 5.0 1896

If Source DC voltage reaches this minimum value, discharging is disabled.

P2.5.4.2 SOURCE MAX VOLTAGE ID1895

If Source DC voltage reaches this maximum value, charging is disabled.

P2.5.4.3 SOURCE VOLTAGE HYSTERESIS ID1896

The hysteresis for the limiting functions.

2.1.5 Current limit

Table 5. Current limit

Code Parameter Min Max Unit Default ID Note

P2.5.1.1 Current Limit 0 Varies A Varies 107 Total current limit

P2.5.1.2 Charging Limit 0 300 % 105 1290 A percentage of nom current

P2.5.1.2 Discharging Limit 0 300 % 105 1289 A percentage of nom current

P2.5.1.1 CURRENT LIMIT ID107

Current limit in amperes.

P2.5.1.2 CHARGING LIMIT ID1290

The charging current limit in percentage of Source Nom Current.

P2.5.1.3 DISCHARGE LIMIT ID107

The discharging current limit in percentage of Source Nom Current.

2

Tel. +358 (0) 201 2121 • Fax +358 (0)201 212 285

Parameters vacon • 11

2.2 DC-link side parameters

2.2.1 Over voltage control for DC-link voltage

Table 6. Over voltage control for DC-link voltage

Code Parameter Min Max Unit Default ID Note

A percentage of unit nominal DC-

P 2.5.3.1 Over voltage reference 0 320 % 118 1528

P 2.5.3.2 Over voltage droop 0 100 % 0 1862

P2.5.3.1 OVER VOLTAGE REFERENCE ID1528

The over voltage reference in percentage of Nominal DC Voltage of the drive.

P2.5.3.2 OVER VOLTAGE DROOP ID1862

The over voltage reference drooping. The set drooping is reached when the active current is 100%.

2.2.2 Under voltage control for DC-link voltage

Link voltage.

500 Vac unit: 675 Vdc

690 Vac unit: 931 Vdc

Table 7. Under voltage control for DC-link voltage

Code Parameter Min Max Unit Default ID Note

A percentage of nominal DC-Link

P 2.5.2.1

P 2.5.2.2 Under Voltage Droop 0 100 % 0 1863

P2.5.2.1 UNDER VOLTAGE REFERENCE D1567

Under Voltage

Reference

0 320 % 65 1567

voltage.

500 Vac unit: 675 Vdc

690 Vac unit: 931 Vdc

The under voltage reference in percentage of Nominal DC Voltage of the drive.

P2.5.2.2 UNDER VOLTAGE DROOP ID1863

The under voltage reference drooping. The set drooping is reached when the active current is 100%.

NOTE: For more detailed parameter information, see the Vacon NX Programming Guide

(DPD01886A).

24-hour support +358 (0)201 212 575 • Email: service@vacon.com

2

vacon • 12 Control IO

K1

NXOPTA1

NXOPTA2

Terminal Signal Description

1

+10 Vref Reference voltege output

2

AI1+

Analogue input 1.

Range 0-10V, R

i

= 200

Ω

Range 0-20 mA, Ri= 250

Ω

Analogue input 2.

Range 0-10V, Ri= 200Ω

Range 0-20 mA, Ri= 250Ω

3

AI1-

I/O ground

4

AI2+

5

AI2-

6

+24V

7

GND I/O ground

8

DIN1

Contact closed = Start Request

9

DIN2

10

DIN3

11

CMA

Common for DIN 1—DIN 3

12

+24V

13

GND I/O ground

14

DIN4

Contact closed = MCC Closed

15

DIN5

16

DIN6

No function defined at default

17

CMB

18

AOA1+

Output range selected by jumpers.

Range 0—20 mA. R

L

, max. 500Ω

Range 0—10 V. R

L

> 1kΩ

19

AOA1-

20

21

22

23

DOA1

Digital output

Ready / Warning (Blinking)

mA

9429

Voltege for

potentiometer, etc.

Analogue input 1Input range

selected by jumpers.

Default range: Voltage 0–10 V

Ground for reference

and controls

Ground for reference

and controls

Analogue input 2

Input range selected by

jumpers.

Default range:

Current 0 – 20 mA

Voltage for switches, etc.

max 0.1 A

Start Request

Programmable G2.3.1

Programmable G2.3.1

Fault reset

Programmable G2.3.1

No function defined at default

Rising edge will reset active

faults.

No function defined at default

Connect to GND or +24V

Voltage for switches (see #6)

Ground for reference and

controls

Programmable G2.3.1

Programmable G2.3.1

Connect to GND or +24V

Analogue output 1

Programmable P2.3.1

Programmable

Open collector, I≤50mA,

U≤48 VDC

RO 1

RO 1

RO 1

24

25

26

RO 2

RO 2

RO 2

Relay output 1

Programmable G2.4.1

Relay output 2

Switchin capacity

24 VCD / 8 A

250 VAC / 8 A

125 VDC / 0.4 A

220

VAC

K1

Control voltage output

Programmable G2.3.1

Common for DIN4—DIN6

Control voltage output

3. CONTROL IO

Table 8. Default I/O configuration

3

Tel. +358 (0) 201 2121 • Fax +358 (0)201 212 285

www.danfoss.com

Vacon Ltd

Member of the Danfoss Group

Runsorintie 7

65380 Vaasa

Finland

Document ID:

DPD01901A

Rev. A

Sales code: DOC-INSDCDC+DLUK

Loading...

Loading...