Page 1

USER'S MANUAL

Interbus-S

Fieldbus

Option Board

VACON CX / CXL

Frequency

Subject to changes without notice

Converter

Page 2

VACON CX Interbus-S user’s manual

_________________________________________________________________________________________

INDEX

1. GENERAL....................................................................................................................................................... 3

1. SPECIFICATIONS.......................................................................................................................................... 4

1. INTERBUS-S .................................................................................................................................................. 5

4. INSTALLATION.............................................................................................................................................. 7

5. CONNECTIONS.................................................................................................................................................. 9

5.1 Board layout ............................................................................................................................................... 9

5.2 Interbus-S connections ............................................................................................................................ 10

5.3 /O-control connections ................................................................................................................................. 11

6. COMMISSIONING ............................................................................................................................................ 12

7. DRIVECOM................................................................................................................................................... 13

7.1 Device control State machine .................................................................................................................. 13

7.2 Profile Parameters ................................................................................................................................... 15

7.2.1 Process Input Data Description (6000HEX) .................................................................................... 16

7.2.2 Process Output Data Description (6001HEX) ................................................................................. 16

7.2.3 Process Output Data Enable (6002HEX) ........................................................................................ 17

7.2.4 Connection Abort Option Code (6007HEX).....................................................................................17

7.2.5 Malfunction code (603Fhex) ............................................................................................................ 18

7.2.6 Control Word (6040hex).................................................................................................................. 19

7.2.7 Nominal Speed (6042hex)............................................................................................................... 21

7.2.8 Speed Reference Variable (6043hex) ............................................................................................. 21

7.2.9 Actual Speed (6044hex) .................................................................................................................. 21

7.2.10 Speed Min Max Amount (6046hex) ................................................................................................. 22

7.2.11 Speed Acceleration (6048hex) ........................................................................................................ 22

7.2.12 Speed Deceleration (6049hex)........................................................................................................ 23

7.2.13 Face Value Factor (604Bhex) ......................................................................................................... 24

Page

2

8. VACON PARAMETERS ................................................................................................................................... 25

8.1 Monitoring variables ................................................................................................................................. 25

8.2 Parameter Write....................................................................................................................................... 26

8.3 Parameter read ........................................................................................................................................... 27

9. PCP-COMMUNICATION SERVICES .............................................................................................................. 28

9.1 Initiate....................................................................................................................................................... 28

9.2 Abort......................................................................................................................................................... 28

9.3 Status ....................................................................................................................................................... 28

9.4 Identify...................................................................................................................................................... 29

9.5 Get OV ..................................................................................................................................................... 29

9.6 Read......................................................................................................................................................... 29

9.7 Write......................................................................................................................................................... 29

10. EXTRA INFORMATION.................................................................................................................................. 30

_________________________________________________________________________________________

Vacon Plc Phone +358-201 2121 Fax: +358-201 212 205

Page 3

VACON CX Interbus-S user’s manual

_________________________________________________________________________________________

Page

3

1. GENERAL

Vacon frequency converters can be connected to Interbus-S fieldbus by using fieldbus board. The

converter can be then controlled, monitored and programmed from the Host system. Fieldbus board

follows connection profile 21 for frequency converters defined by DRIVECOM user’s group. This

guarantees that interfacing of the Vacon frequency converter to the Interbus-S fieldbus happens

according to the standardized parameters and functions. Then the commissioning of the frequency

converter speed up and control of the frequency converter facilitated. Vacon Fieldbus board is a remote

bus device.

The used I/O can be also extended by the Fieldbus board:

• 4 digital inputs (standard signals)

• 4 digital outputs (standard signals)

• Termistor input (can be directly connected into the motor termistors for over temperature trip)

• Encoder input

Fieldbus board can be installed into the existing option board place inside the frequency converter.

The control connections are isolated from the mains potential and I/O ground is connected to the frame

of the device via an 1 MΩ resistor and 4.7 nF capacitor*. The control I/O ground can be connected also

directly to the frame by changing the position of the jumper X9 (GND ON/OFF) to ON-position. Digital

inputs are also isolated from the I/O ground.

Internal components and circuit boards (except the isolated I/O terminals) are at mains

potential when the Vacon CX/CXL is connected to the mains. This voltage is extremely

dangerous and may cause death or severe injury if you come in contact with it.

The control I/O terminals are isolated from the mains potential, but the I/O:s (if jumper X9 is in

OFF position) may have dangerous voltage connected even if the power is off on the Vacon

CX/CXL.

* Default value (X9 is GND OFF- position)

_________________________________________________________________________________________

Vacon Plc Phone +358-201 2121 Fax: +358-201 212 205

Page 4

VACON CX Interbus-S user’s manual

Page

4

_________________________________________________________________________________________

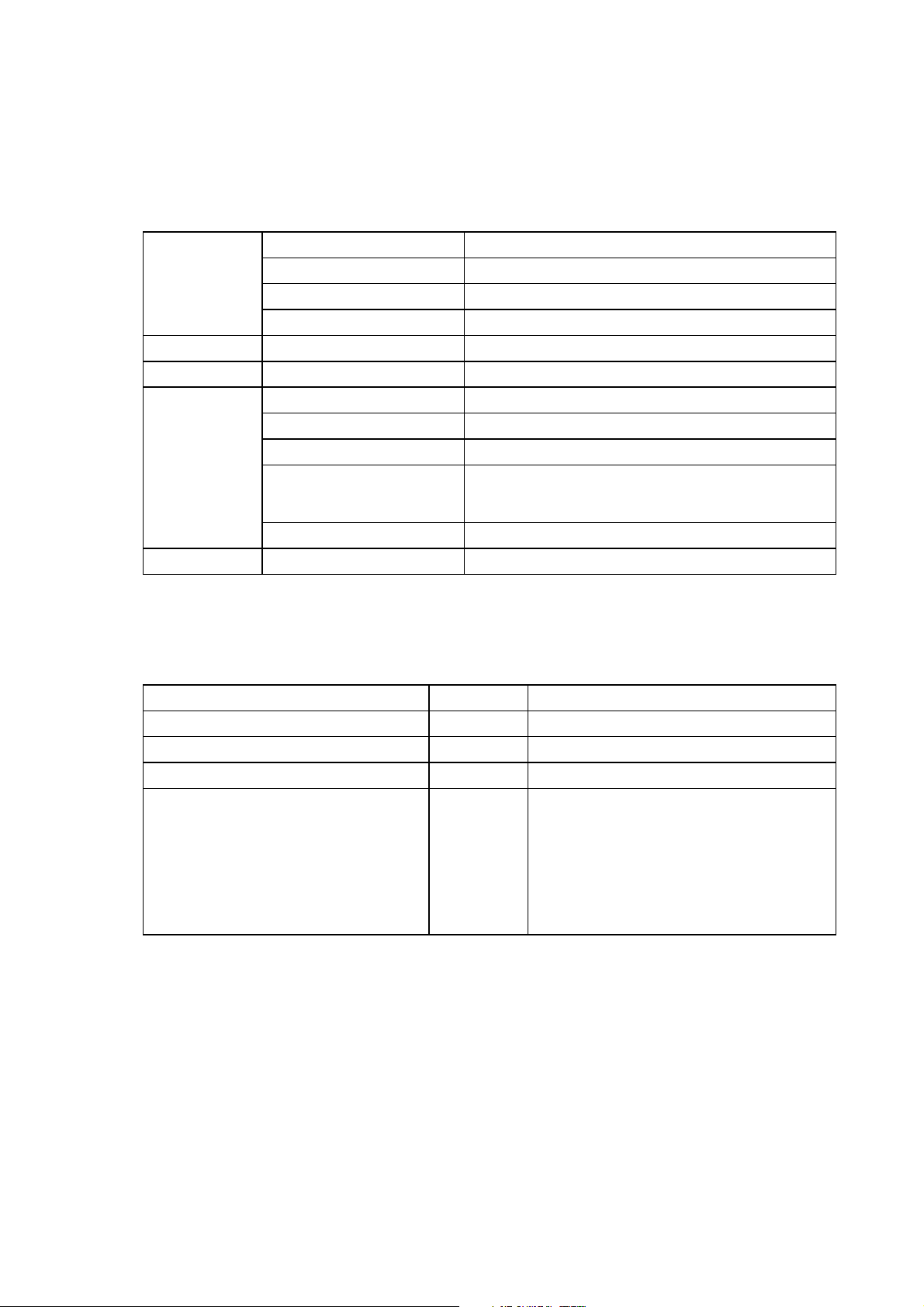

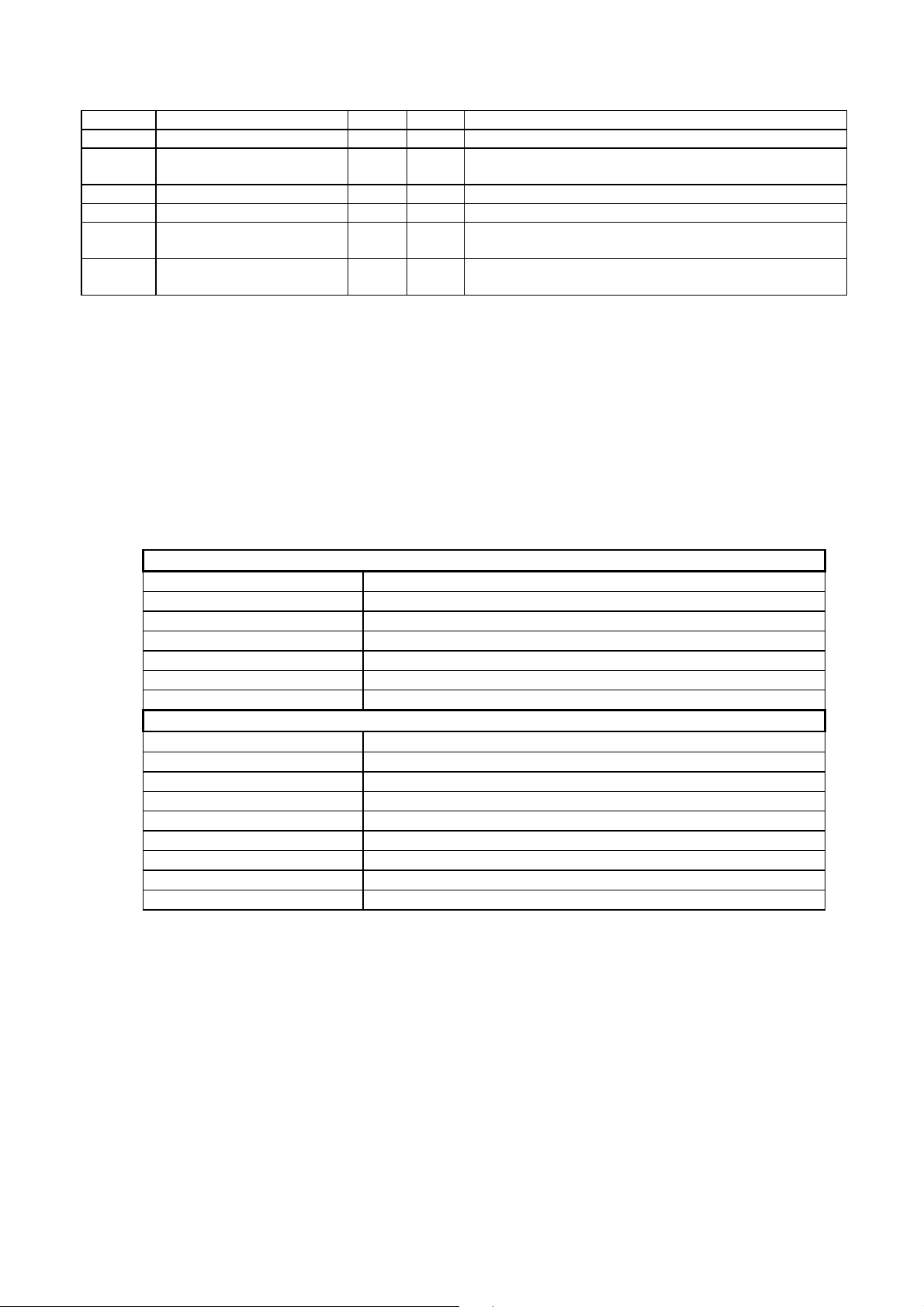

1. SPECIFICATIONS

IBS -

connections

I/O -control

connections

Safety

Table 1. Specifications

Interface Remote bus, 9-pin DSUB connector

Transfer method RS-485

Transfer cable Twisted pair (2 pair and ground)

Electrical isolation

- Remote bus in 500 V DC

Digital input (4 pcs)

24 V (± 15 %), R

= 5 kΩ

i

Digital output (4 pcs) Open collector output, 50 mA/48 V

Termistor input (1 pcs)

Encoder input (3 pcs)

Aux. voltage

= 4.7 kΩ

R

trip

24 V (± 30 V): “0” ≤10 V, “1” ≥18 V, R

5 V (± 10 V): “0” ≤2 V, “1” ≥3 V, R

i

24 V (±20%), max 50 mA

Fulfils EN50178 standard

= 3.3 kΩ

i

= 330 Ω

ID - Code

Profile

Process Data

PCP communication

Communication Reference List

- max. PDU length for Sending -high

- max. PDU length for Sending.-low

- max. PDU length for Receive -high

- max. PDU length for Receive -low

- supported services Client

- supported services Server

Table 2. Interbus-S communication data

227 Remote bus station with PCP

21 DRIVECOM

2 words

1 word

0 bytes

64 bytes

0 bytes

64 bytes

00 00 00

00 30 80

Read, Write, Information Report

_________________________________________________________________________________________

Vacon Plc Phone +358-201 2121 Fax: +358-201 212 205

Page 5

VACON CX Interbus-S user’s manual

_________________________________________________________________________________________

Page

5

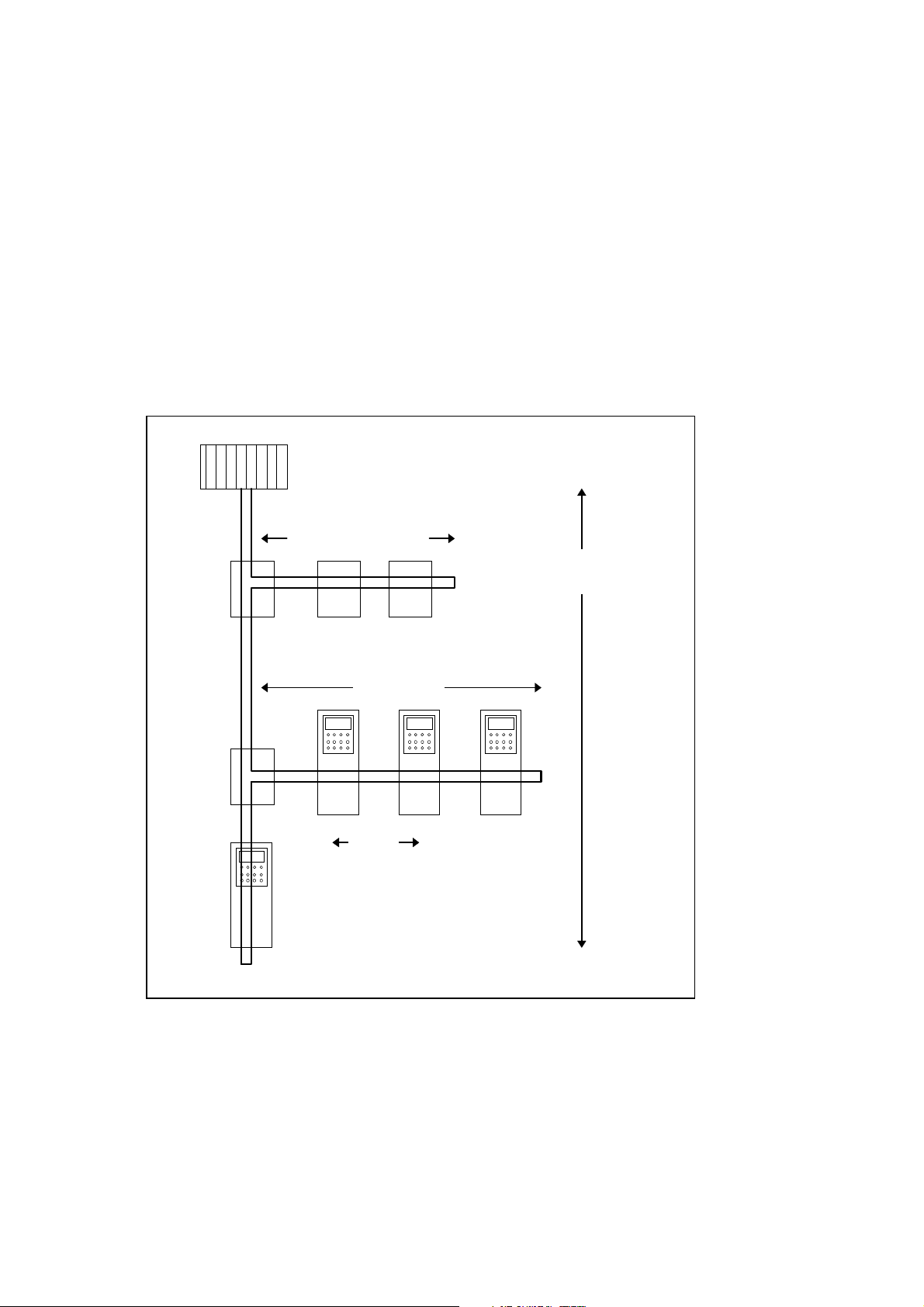

1. INTERBUS-S

Interbus-S is fast sensore/actuator fieldbus. Through Interbus-S fieldbus both individual I/O-device and

intelligent actuator can be controlled, such as frequency converter. Due to topology Interbus-S is able to

fast, under 10 ms, response times.

Interbus-S is from it’s topology a ring, where is one Host system. As a Host system can function for

example a programmable logic, industrial design PC or process station of the automation system.

Remote bus cable which begins from Host System combines the Bus terminals of the field. The long

displacements in the field are implemented by using Remote bus. If Bus terminal in the field does not

include repeat function, it will be connected to Interbus-S fieldbus by using Local bus. Local bus situated

in the field is local, switch cabinet’s internal bus, which is however a part of the Interbus-S circle. Vacon

equipped with Fieldbus board is Remote bus device.

Host System

Bus

terminal

Bus

terminal

Local bus

8 station 10 m

Remote bus

13 km

Remote bus

400 m

Figure 1. Interbus-S topology

_________________________________________________________________________________________

Vacon Plc Phone +358-201 2121 Fax: +358-201 212 205

Page 6

VACON CX Interbus-S user’s manual

Status Word

Sp

p

Page

6

_________________________________________________________________________________________

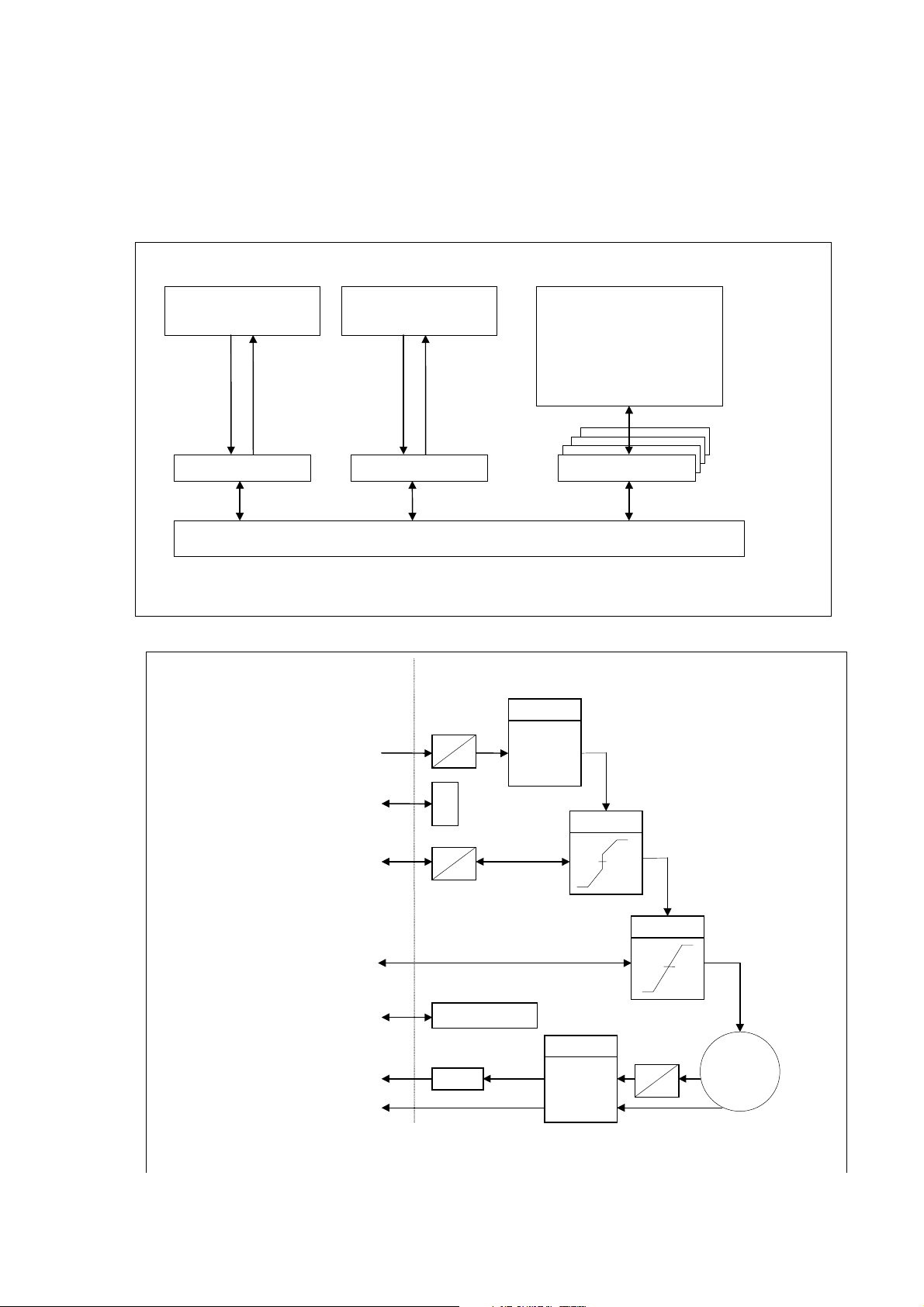

Information can be deliver two ways to the device, which is in the Interbus-S field. The Process channel

is used for the fast information delivery. With the support of this channel can be for example speed

reference of the frequency converter placed and get back the actual speed information. Slower, but

more information included parameter information delivery PCP channel is used (Peripheral

Communication Protocol), when message construction according to DRIVECOM Profile 21 is used.

Nominal Speed

Actual Value Speed

Control Word

Status Word

Speed Min Max Amount

Speed Acceleration

Speed Deceleration

Face Value Factor

.

.

Process channel 1 Process channel 2 PCP channel

DRIVE

Figure 2. Process channel/PCP channel

Connection of Vacon frequency converter to the Interbus-S field is described in the interface figure

below:

DRIVEMASTER

SCALE 1

a

X * -----

Nominal

rpm

b

Face Value

a

b

LIMIT

eed Min Max

Speed

Control Word

Actual Value Speed

Speed Reference

rpm

- Sli

State

SCALE 2

b

X * -----

a

RAMP

rpm

M

3 ~

Figure 3. Drivecom interface

_________________________________________________________________________________________

Vacon Plc Phone +358-201 2121 Fax: +358-201 212 205

Page 7

VACON CX Interbus-S user’s manual

_________________________________________________________________________________________

Page

7

4. INSTALLATION

Before doing any commissioning actions read carefully safety instructions from the "User's manual

CX/CXL/CXS frequency converter"- manual chapter 2. Check that you have got all the Fieldbus board

parts: Fieldbus board, plastic board, power cable (black terminal), data cable (blue terminal) and

earthing screw.

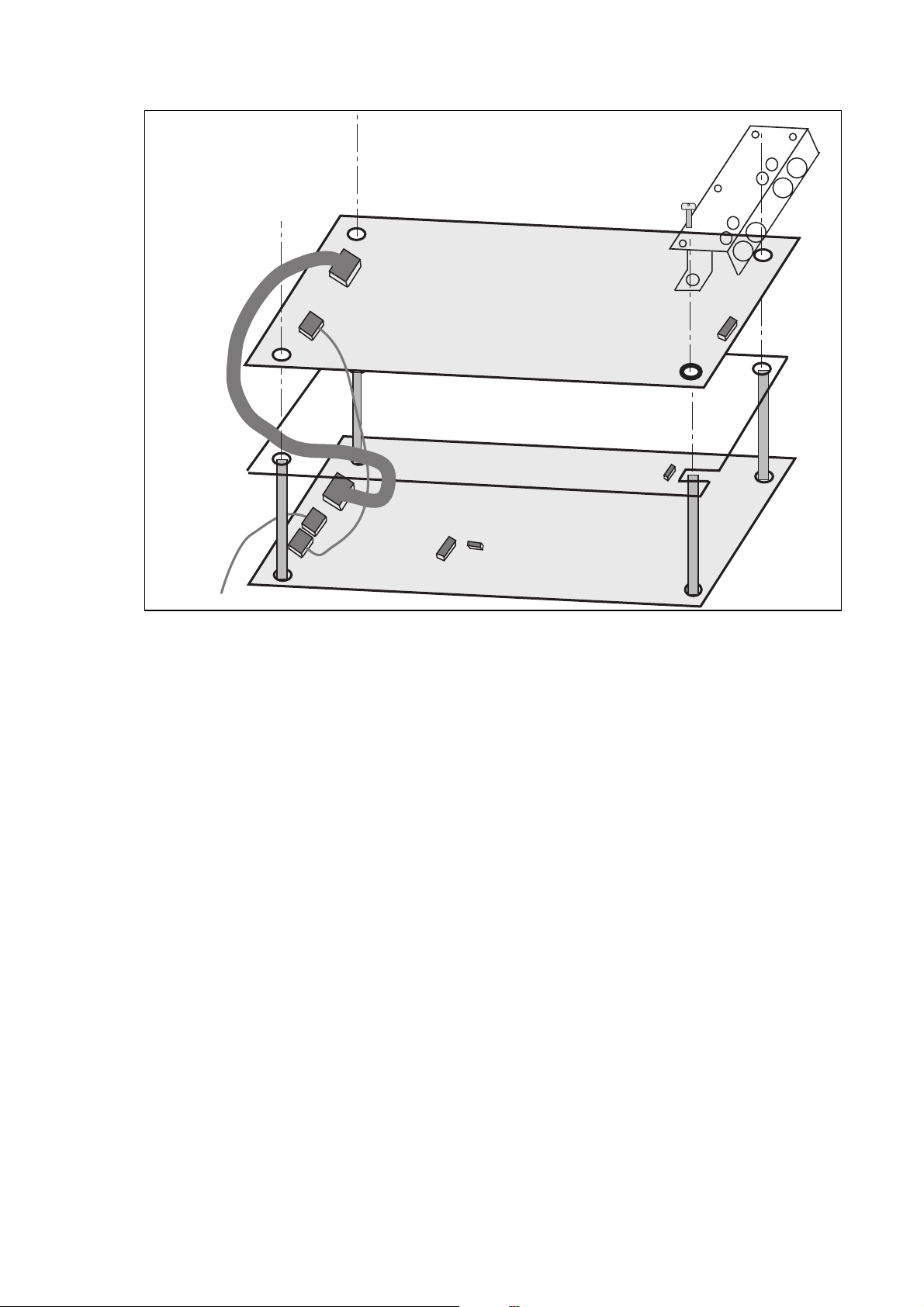

Fieldbus board can be installed into the existing option board place inside the frequency converter (see

figure 4-1).

Remove the control panel and the jumper X4 from the control board (1).

A

Install the power cable into the control board X5 -terminal (2) and data cable to the X14 -

B

terminal (3). Power cable can also be installed into the X6 -terminal, if the power cable from

the power board is connected into the X5 -terminal.

Bend the data cable to the "S-curve" as far as possible from the power board transformer

C

(4) before you install the plastic board into the control board.

Remove the protection foil of the plastic board and install the plastic board into the control

D

board, remember the right position of the plastic board (5).

Install the Fieldbus board into the plastic board from the larger holes and "push" it into the

E

right position in the narrow position of the screws . Check that the Fieldbus board is installed

stable. If you have difficulties to place the plastic board and Fieldbus board, bend slightly the

regulator A4 (6) and capasitor C59 (7) of the control board.

Install the power cable to the X6 -terminal of the Fieldbus board (8)and data cable to the

F

X14 -terminal (9).

Install the jumper which you remove from the X4 -terminal of the control board, into the X9 -

G

terminal of the Fieldbus board (10) ON or OFF position.

If the packet includes the cable cover (11), install that into position shown in figure 1.

H

Install the earthing screw (12).

I

After this install the control panel and connect the needed control signals.

J

If use 5 V encoder input, install the jumper to the X7-terminal (see Chapter 5, figure 1) of the

K

Fieldbus board.

_________________________________________________________________________________________

Vacon Plc Phone +358-201 2121 Fax: +358-201 212 205

Page 8

VACON CX Interbus-S user’s manual

_________________________________________________________________________________________

Page

8

11

12

9

Fieldbus board

8

10

4

Plastic board

5

6

3

2

Figure 1. Fieldbus board installed into the control board

Control board

7

1

_________________________________________________________________________________________

Vacon Plc Phone +358-201 2121 Fax: +358-201 212 205

Page 9

VACON CX Interbus-S user’s manual

Page

9

_________________________________________________________________________________________

5. CONNECTIONS

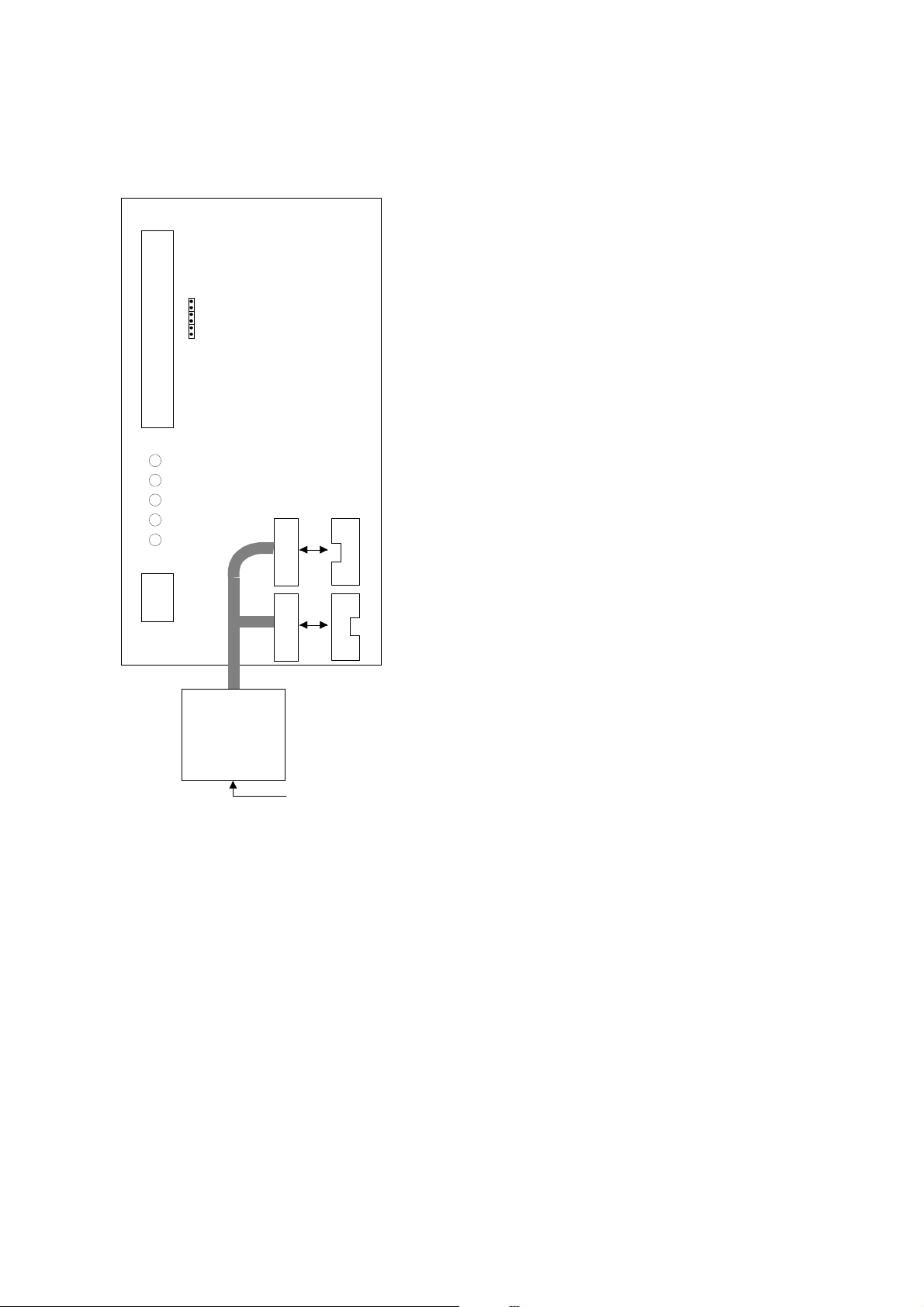

5.1 Board layout

Terminals:

X10

TR

RD

BA

RC

UL

X11

X7

Extra terminal

X10 I/O - terminals

X11 Termistor input

X7 Encoder terminal

X5 Interbus-S Input

X6 Interbus-S Output

X6

X5

D-sub connectors

Figure 1. Fieldbus board

UL Supply Voltage, Green.

UL led is active if the interface board has supply voltage.

RC Remote bus Check, Green.

RC led is active if the cable connection is good and the Interbus-S master is not

reset.

BA Bus Active, Green.

RD Remote bus Disabled, Red.

The red RD led is active if the outgoing remote bus is disabled.

TR Transmit/Receive, Green.

PCP communication is active.

_________________________________________________________________________________________

Vacon Plc Phone +358-201 2121 Fax: +358-201 212 205

Page 10

VACON CX Interbus-S user’s manual

Page

10

_________________________________________________________________________________________

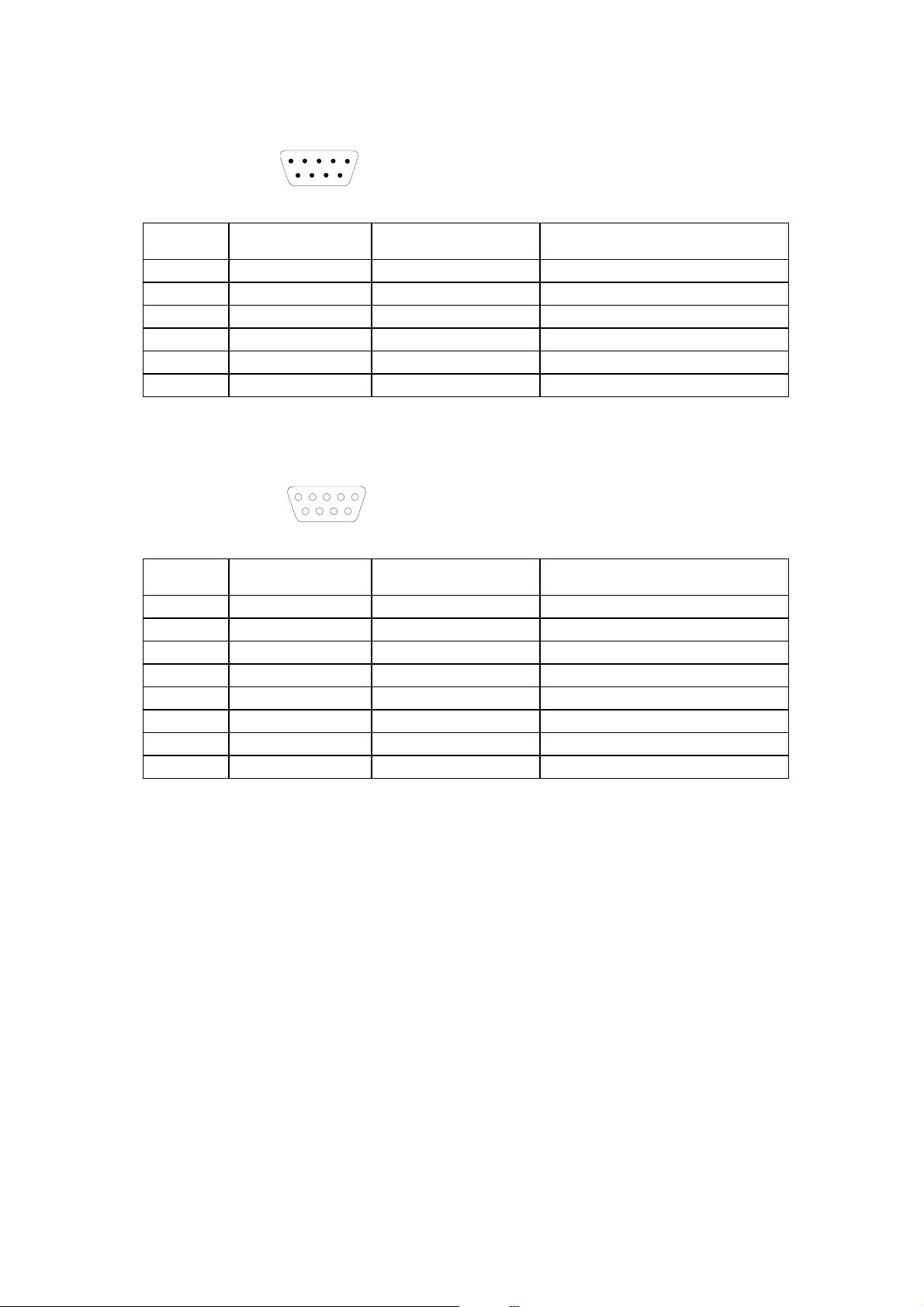

5.2 Interbus-S connections

Input (male):

Signal Connector

D SUB 9-pin

12345

9876

Board Connector

X5 - terminal

Description

DO 1 X5 - 1 Data Out

DI 2 X5 - 3 Data In

COM 3 X5 - 5 Common

/DO 6 X5 - 2 Data Out, Inverse

/DI 7 X5 - 4 Data In, Inverse

Shield X5 - 10 Cable shield

Table 1. Input D-sub connector

Output (female):

9876

Signal Connector

D SUB 9-pin

12345

Board Connector

X6 - terminal

Description

DO 1 X6 - 1 Data Out

DI 2 X6 - 3 Data In

COM 3 X6 - 5 Common

+ 5V 5 X6 - 9

/DO 6 X6 - 2 Data Out, Inverse

/DI 7 X6 - 4 Data In, Inverse

RBST 9 X6 - 8 Remote Bus Connector

Shield X6 - 10 Cable shield

Table 2. Output D-sub connector

_________________________________________________________________________________________

Vacon Plc Phone +358-201 2121 Fax: +358-201 212 205

Page 11

VACON CX Interbus-S user’s manual

Page

11

_________________________________________________________________________________________

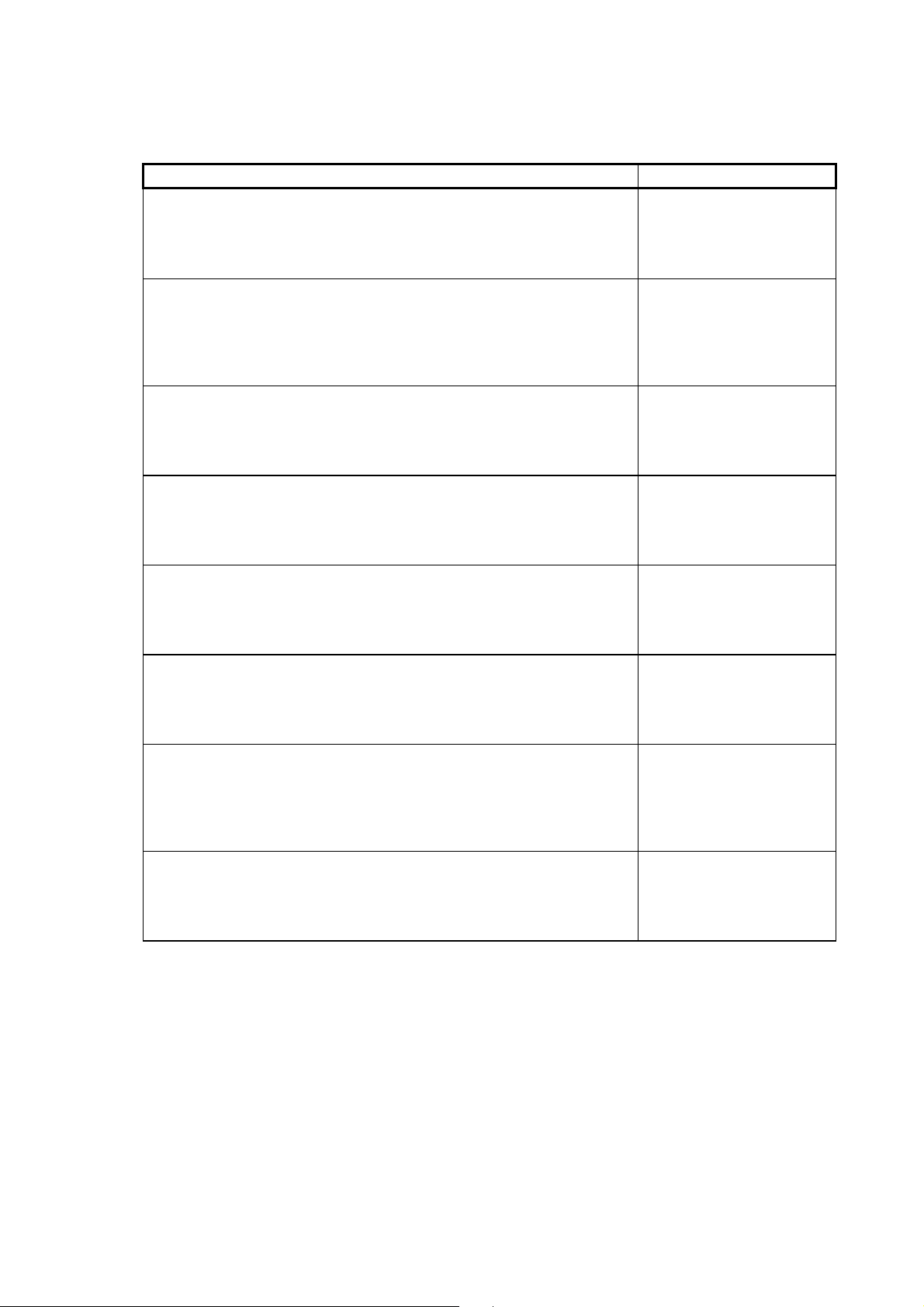

5.3 /O-control connections

Terminal Signal Description

301 DID1 External fault

(closing contact)

Contact open = no fault

Contact closed = fault

302 DID2 Run disable Contact open = start of motor enabled

Contact closed = start of motor disabled

303 DID3 Acceler. / Decel. time

selection

Contact open = time 1 selected

Contact closed = time 2 selected

304 DID4 Jogging speed selection Contact open = no action

Contact closed = jogging speed

305 COMD Common for DID1-DID2 Connect to GND or +24 V

306 +24 V Control voltage output Voltage for switches, etc. max. 0.1 A

307 COME Common for DIE3-DIE4 Connect to GND or +24 V

308 GND I/O ground Ground for reference and controls

309 DID5A+ Pulse input A

310 DID5A- (differential input)

Encoder

311 DID6B+ Pulse input B 90 degrees phase shift compared

312 DID6B- (differential input) to pulse input A

313 DID7Z+ Pulse input Z one pulse per one revolution

314 DID7Z- (differential input)

315 GND I/O ground Ground for reference and controls

316 DOD1 Open collector output 1 READY

317 DOD2 Open collector output 2 RUN

318 DOD3 Open collector output 3 FAULT

319 DOD4 Open collector output 4 FIELDBUS CONTROL

320 GND I/O ground Ground for reference and controls

Signal from

motor termistor

327 TI+ Termistor input

328 TI-

Figure 2. Control connections

_________________________________________________________________________________________

Vacon Plc Phone +358-201 2121 Fax: +358-201 212 205

Page 12

VACON CX Interbus-S user’s manual

_________________________________________________________________________________________

Page

12

6. COMMISSIONING

Check first commissioning of the frequency converter from User's manual CX/CXL frequency converter

(Chapter 8.)

Commissioning of the Fieldbus board:

1. Check that Multi-purpose Control Application II (or e.g. Fieldbus Application) is selected.

(Parameter P0.1 = 0)

2. Initial connection between Master - Drive using PCP-service, Initial.

3. Wait until Initial confirmation is received.

Start-up test:

DRIVE APPLICATION

1. Check that the active control place is I/O terminals (not control panel)

2. Set parameter “Fieldbus control select” to value 1(On).

MASTER SOFTWARE

1. ProcessDataInput 1 is now value xx60hex, SWITCH ON DISABLED

(if ProcessDataInput 1 = xx40hex)

- Parameters can be read and write

2. Write to ProcessDataOutput 1 value xxx6hex.

3. Wait until status ProcessDataInput 1 value is xx21hex, READY TO SWITCH ON

4. Write to ProcessDataOutput 1 value xxx7hex.

5. Wait until status ProcessDataInput 1 value is xx23hex, SWITCHED ON

6. Write to ProcessDataOutput 1 value xxxFhex.

7. Wait until status ProcessDataInput 1 value is xx27hex, OPERATION ENABLE

- Drive control is now enable (Run State = ON)

8. Set Nominal Speed Value using variable ProcessDataOutput 2 variable.

Read Actual Speed using variable ProcessDataInput 2.

If ProcessDataInput 1 = xx08hex or xx28hex Device status is MALFUNCTION

_________________________________________________________________________________________

Vacon Plc Phone +358-201 2121 Fax: +358-201 212 205

Page 13

VACON CX Interbus-S user’s manual

Page

13

_________________________________________________________________________________________

7. DRIVECOM

The DRIVECOM user group is standardizing the most important functions and parameters of the drive:

• Device control state machine

• Profile parameters

• PCP-communication services

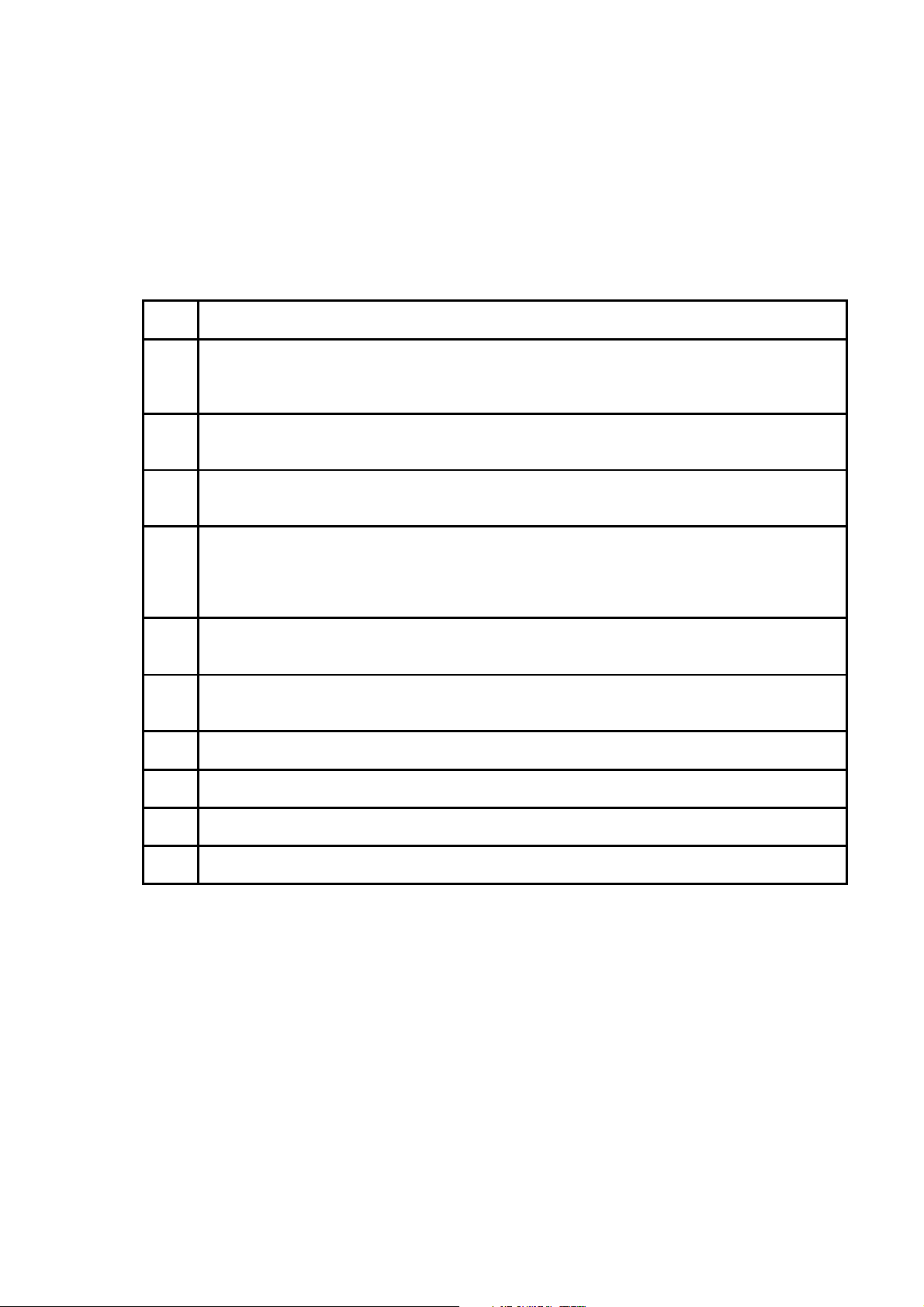

7.1 Device control State machine

The state machine describes the device status and the possible control sequence of the drive. The state

transitions can be generated by using “control word” parameter. The “status word” parameter indicates

the current status of state machine. The modes INIT, STOP, RUN and FAULT (see figure 7-1)

correspond to the actual mode of the Drive.

SWITCHED ON (=xx23 hex) is one value of the “status word”.

Shutdown (=xxxx x110 bin) is one value of the “control word”.

Fault

Power on

MALFUNCTION REACTION ACTIVE

FAULT

xxxFh or xx2Fh

Disable voltage

xxxx xx0x

Shutdown

xxxx x110

NOT READY TO SWITCH ON

INIT

xx00h

Automatic

SWITCH ON DISABLED

xx40h or xx60h

STOP

Shutdown

xxxx x110

READY TO SWITCH ON

xx21h

STOP

Switch on

xxxx x111

SWITCHED ON

STOP

xx23h

Disable voltage

xxxx xx0x

Quick stop

xxxx x01x

Shutdown

xxxx x110

MALFUNCTION

FAULT

Disable voltage

xxxx xx0x

Quick stop

xxxx x01x

xx08h or xx28h

AutomaticAutomatic

Reset malfunction

0xxx xxxx

1xxx xxxx

Disable voltage

xxxx xx0x

Enable operation

xxxx 1111

OPERATION ENABLED

RUN

Disable operation

xxxx 0111

xx27h

Quick stop

xxxx x01x

QUICK STOP ACTIVE

STOP

xx07h

Figure 1. States of the device control

_________________________________________________________________________________________

Vacon Plc Phone +358-201 2121 Fax: +358-201 212 205

Page 14

VACON CX Interbus-S user’s manual

_________________________________________________________________________________________

STATE STATUS OF THE DRIVE

Page

14

NOT READY TO SWITCH ON

-The interface board initialization is running.

-The drive function is disabled.

SWITCH ON DISABLED

-Initialization was completed.

-The parameters can read and write.

-The drive function is disabled.

READY TO SWITCH ON

-The parameters can read and write.

-The drive function is disabled.

SWITCHED ON

-The parameters can read and write.

-The drive function is disabled.

OPERATION ENABLED

-The parameters can read and write.

-The drive function is enabled.

INIT

STOP

STOP

STOP

RUN

MALFUNCTION REACTION ACTIVE

-The drive function is disabled.

-The fault trip occur

MALFUNCTION

-The drive function is disabled.

-The drive is fault state.

-The interface board waits for falling edge of reset malfunction bit.

QUICK STOP ACTIVE

-The parameters can read and write.

-The drive function is enabled.

Table 1. Descriptions of the states

FAULT

FAULT

STOP

_________________________________________________________________________________________

Vacon Plc Phone +358-201 2121 Fax: +358-201 212 205

Page 15

VACON CX Interbus-S user’s manual

Page

15

_________________________________________________________________________________________

7.2 Profile Parameters

Index Name Type Object Data Access

hex dec

length rights

6000 24576 Process Input Data Description PDD-structure Record 13 R

6001 24577 Process Output Data Description PDD-structure Record 13 R

6002 24578 Process Output Data Enable Boolean Var 1 R/W

6007 24583 Connection Abort Option Code Interger 16 Var 2 R/W

603F 24639 Malfunction Code Octet String Var 2 R

6040 24640 Control Word Octet String Var 2 R/W

6041 24641 Status Word Octet String Var 2 R

6042 24642 Nominal Speed Var 2 R/W

6043 24643 Speed Reference Variable Interger 16 Var 2 R

6044 24644 Actual Speed Interger 16 Var 2 R

6046 24646 Speed Min Max Amount Unsigned 32 Array 8 R/W

6048 24648 Speed Acceleration Ramp Record 6 R/W

6049 24649 Speed Deceleration Ramp Record 6 R/W

604B 24651 Face Value Factor Integer 16 Array 4 R/W

Table 2. List of the profile parameters

Type Value range

Boolean FALSE = 00hex

, TRUE = FFhex

Octet String 8 bit / byte binary coded

Integer 8 -128 ... 127

Unsigned 8 0 ... 255

Interger 16 -32768 ... 32767

Unsigned 16 0 ... 65535

Integer 32 -2147483648 ... 2147483647

Unsigned 32 0 ... 4294967295

PDD-structure Subindex 1: Process data length Unsigned 8

Subindex 2: 1-index process input/output data Unsigned 16

Subindex 3: 1-subindex process input/output data Unsigned 8

Subindex 4: 2-index process input/output data Unsigned 16

Subindex 5: 2-subindex process input/output data Unsigned 8

Ramp Subindex 1: Delta speed Unsigned 32

Subindex 2: Delta time Unsigned 16

R Read only

WWrite

_________________________________________________________________________________________

Vacon Plc Phone +358-201 2121 Fax: +358-201 212 205

Page 16

VACON CX Interbus-S user’s manual

_________________________________________________________________________________________

7.2.1 Process Input Data Description (6000HEX)

This parameter contains the data defining which process input data is mapped to which communication

objects. Input data is data from the drive to the master.

Object description

Index 6000 hex

Object code Record

Data type PDD structure

Access rights Read-all

Value description

Subindex 1 Process data length

Value range Unsigned 8

Default value 4

Subindex 2 1-index process input data

Value range Unsigned 16

Default value 6041 hex

Subindex 3 1-subindex process input data

Value range Unsigned 8

Default value 00 hex

Subindex 4 2-index process input data

Value range Unsigned 16

Default value 6044 hex

Subindex 5 2-subindex process input data

Value range Unsigned 8

Default value 00 hex

Page

16

7.2.2 Process Output Data Description (6001HEX)

This parameter contains the data defining which process output data is mapped to which

communication objects. Output data is data from the master to the drive.

Object description

Index 6001 hex

Object code Record

Data type PDD structure

Access rights Read-all

Value description

Subindex 1 Process data length

Value range Unsigned 8

Default value 4

Subindex 2 1-index process output data

Value range Unsigned 16

Default value 6040 hex

Subindex 3 1-subindex process output data

Value range Unsigned 8

Default value 00 hex

Subindex 4 2-index process output data

Value range Unsigned 16

Default value 6042 hex

Subindex 5 2-subindex process input data

Value range Unsigned 8

Default value 00 hex

_________________________________________________________________________________________

Vacon Plc Phone +358-201 2121 Fax: +358-201 212 205

Page 17

VACON CX Interbus-S user’s manual

_________________________________________________________________________________________

7.2.3 Process Output Data Enable (6002HEX)

This parameter enables/disables the process data channel.

Object description

Index 6002 hex

Object code Simple variable

Data type Boolean

Length 1 byte

Access rights Read-all, Write-all

Value description

Value range TRUE, FALSE

Default value TRUE

7.2.4 Connection Abort Option Code (6007HEX)

The parameter “Connection Abort Option Code” defines which function is executed when connection is

aborted.

Page

17

Object description

Index 6007 hex

Object code Simple variable

Data type Integer 16

Length 2 bytes

Access rights Read-all, Write-all

Value description

Value range Integer 16

Default value 0

Abort values:

Value Description

-32768 ... -1 No action

0 No action

1 Malfunction

2 “Voltage Disabled” device control command

3 “Quick Stop” device control command

4 ... 32767 No action

_________________________________________________________________________________________

Vacon Plc Phone +358-201 2121 Fax: +358-201 212 205

Page 18

VACON CX Interbus-S user’s manual

_________________________________________________________________________________________

7.2.5 Malfunction code (603Fhex)

When a fault trip occurs, device status is Malfunction and parameter “Malfunction code” indicates the

current fault code.

Object description

Index 603F hex

Object code Simple variable

Data type Octet string

Length 2 bytes

Access rights Read-all

Value description

Value range Unsigned 16

Default value 0

Malfunction codes:

Page

18

VACON Fault Code DRIVECOM

fault Code

1 Overcurrent 2300 General overcurrent

2 Overvoltage 3210 Overvoltage inside the device

3 Earth Fault 2330 Short to earth

4 Inverter Fault 5420 Gate drivers or IGBT bridge

5 Charging Switch 5120 DC link power supply

9 Under Voltage 3220 Undervoltage inside the device

10 Input Phase Supervision 3130 Phase failure

11 Output Phase Supervision 3130 Phase failure

12 Brake Chopper Supervision 7111 Brake chopper failure

13 Vacon Under Temperature 4210 Excess device temperature

14 Vacon Over Temperature 4220 Inadequete device temperature

15 Motor Stalled 7120 Motor

16 Motor Over Temperature 7120 Motor

17 Motor Underload 7120 Motor

18 Analog Input HW fault 5200 Control

19 OptionBoard Identification 7000 Additional modules

20 10 V Voltage Reference 5110 Low voltage power supply

21 24 V Supply 5112 +24 V power supply

22 EEPROM Checksum Fault 7600 Data memory

23 EEPROM Checksum Fault 7600 Data memory

24 EEPROM Checksum Fault 7600 Data memory

25 Microprocessor Watch Dog 6010 Software reset (Watchdog)

26 Panel Communication Error 7510 Communication

27 Fieldbus Communication Error 7510 Communication

28 Application Change 6200 Internal software

29 Termistor Fault 7200 Measurement circuits(Additional modules)

36 Analog Input Iin<4mA 5200 Control

37 Ap Fault Code 37 6200 Internal software

38 Ap Fault Code 38 6200 Internal software

39 Ap Fault Code 39 6200 Internal software

40 Ap Fault Code 40 6200 Internal software

41 External Fault 9000 External malfunction

Meaning

hex

_________________________________________________________________________________________

Vacon Plc Phone +358-201 2121 Fax: +358-201 212 205

Page 19

VACON CX Interbus-S user’s manual

Page

19

_________________________________________________________________________________________

7.2.6 Control Word (6040hex)

The Control command for the state machine (see figure 7.1). The state machine describes the device

status and the possible control sequence of the drive.

Object description

Index 6040 hex

Object code Simple variable

Data type Octet string

Length 2 bytes

Access rights Read-all, Write-all

Value description

Value range Unsigned 16

Default value -

The control word is composed of 16 bits that have the following meanings:

Bit Name

0 Switch on

1 Disable voltage

2 Quick stop

3 Enable operation

4 Not used

5 Not used

6 Not used

7 Reset malfunction

8 Reserved

9 Reserved

10 Reserved

11 Special

12 Special

13 Special

14 Special

15 Special

(*

(*

(*

(*

(*

(*

See Appendix A

The device control commands are triggered by following bit combinations in the control word:

Command Bit 7

Reset

malfunction

Bit 3

Enable

Operation

Bit 2

Quick Stop

Bit 1

Disable

voltage

Bit 0

Switch on

Shutdown X X 1 1 0

Switch on XX111

Disable voltage X X X 0 X

Quick stop X X 0 1 X

Disable operation X 0111

Enable operation X 1111

Reset malfunction0>1XXXX

0>1: Change from bit=0 to bit=1

X: Bit is irrelevant

Status Word (6041hex)

Information about the status of the device and messages is indicated in the status word.

_________________________________________________________________________________________

Vacon Plc Phone +358-201 2121 Fax: +358-201 212 205

Page 20

VACON CX Interbus-S user’s manual

_________________________________________________________________________________________

Object description

Index 6041 hex

Object code Simple variable

Data type Octet string

Length 2 bytes

Access rights Read-all

Value description

Value range Unsigned 16

Default value -

The status word is composed of 16 bits that have the following meanings:

Bit Name

0 Ready to switch on

1 Switched on

2 Operation enabled

3 Malfunction

4 Voltage disabled

5 Quick stop

6 Switch on disabled

7 Warning active

8 Drive RUN/STOP

9 Remote

10 Face value reached

11 Limit value

12 Not used

13 Not used

14 Not used

15 Not used

Page

20

The device status is indicated by the following bit combinations in the status word:

State Bit 6

Switch on

disabled

Not ready to switch on 0 X 0 0 0 0

Switch on disabled 1 X 0 0 0 0

Ready to switch on 0 1 0 0 0 1

Switched on 0 1 0 0 1 1

Operation enabled 0 1 1 1 1 1

Malfunction 0 X 0 0 0 0

Malfunc reaction active 0 X 1 1 1 1

Quick stop active 0 0 0 0 0 1

X: Bit is irrelevant

Bit 5

Quick Stop

Bit 3

Malfunction

Bit 2

Operation

enabled

Bit 1

Switched on

Bit 0

Ready to

switch on

_________________________________________________________________________________________

Vacon Plc Phone +358-201 2121 Fax: +358-201 212 205

Page 21

VACON CX Interbus-S user’s manual

_________________________________________________________________________________________

7.2.7 Nominal Speed (6042hex)

Speed reference of the drive. The unit of the “Nominal Speed” is rpm. It is multiplied by the “Face Value

Factor”.

Object description

Index 6042 hex

Object code Simple variable

Data type Integer 16

Length 2 bytes

Access rights Read-all, Write-all

Value description

Value range Integer 16

Default value 0

7.2.8 Speed Reference Variable (6043hex)

Page

21

Speed reference after ramp function, scaled to same unit as the “Nominal speed” (rpm). It is multiplied

by the inverse of the “Face Value Factor”.

Object description

Index 6043 hex

Object code Simple variable

Data type Integer 16

Length 2 bytes

Access rights Read-all

Value description

Value range Integer 16

Default value 0

7.2.9 Actual Speed (6044hex)

Actual speed of the motor, scaled to same unit as the “Nominal speed value” (rpm). It is multiplied by the

inverse of the “Face Value Factor”.

Object description

Index 6044 hex

Object code Simple variable

Data type Integer 16

Length 2 bytes

Access rights Read-all

Value description

Value range Integer 16

Default value 0

_________________________________________________________________________________________

Vacon Plc Phone +358-201 2121 Fax: +358-201 212 205

Page 22

VACON CX Interbus-S user’s manual

Page

22

_________________________________________________________________________________________

7.2.10 Speed Min Max Amount (6046hex)

Defines speed limits of the drive in rpm. The parameter consist of a minimum and a maximum speed.

Object description

Index 6046 hex

Object code Array

Data type Octet string

Length 2 bytes

Access rights Read-all, Write-all

Value description

Subindex 1 Speed min amount

Value range Unsigned 32

Default value 0

Subindex 2 Speed max amount

Value range Unsigned 32

Default value 1500 rpm

7.2.11 Speed Acceleration (6048hex)

This parameter specifies the slope of the acceleration ramp. The parameter consist of two parts: the

delta speed and the delta time.

v / rpm

delta speed

delta time

Object description

Index 6048 hex

Object code Record

Number of elements 2 elements

Data type Ramp

Access rights Read-all, Write-all

Value description

Subindex 1 Delta speed

Value range Unsigned 32

Default value 1500 rpm

Subindex 2 Delta time

Value range Unsigned 16

Default value 3 s

t / sec

_________________________________________________________________________________________

Vacon Plc Phone +358-201 2121 Fax: +358-201 212 205

Page 23

VACON CX Interbus-S user’s manual

Page

23

_________________________________________________________________________________________

7.2.12 Speed Deceleration (6049hex)

This parameter specifies the slope of the deceleration ramp. The parameter consist of two parts: the

delta speed and the delta time.

v / rpm

delta speed

delta time

t / sec

Object description

Index 6049 hex

Object code Record

Number of elements 2 elements

Data type Ramp

Access rights Read-all, Write-all

Value description

Subindex 1 Delta speed

Value range Unsigned 32

Default value 1500 rpm

Subindex 2 Delta time

Value range Unsigned 16

Default value 3 s

_________________________________________________________________________________________

Vacon Plc Phone +358-201 2121 Fax: +358-201 212 205

Page 24

VACON CX Interbus-S user’s manual

_________________________________________________________________________________________

7.2.13 Face Value Factor (604Bhex)

The “Face Value Factor” serves to modify the resolution or directing range of the specified face value. It

is included in calculation of the specified face value and the output variables of the speed function only.

Numerator

Speed Reference = Nominal Speed * ------------------------

Denominator

Denominator

Actual Speed = Actual Speed * ------------------------

Numerator

Object description

Index 604B hex

Object code Array

Number of elements 2 elements

Data type Integer 16

Length 2 bytes

Access rights Read-all, Write-all

Page

24

Value description

Subindex 1 Numerator

Value range 1 ... 100

Default value 1

Subindex 2 Denominator

Value range 1 ... 100

Default value 1

_________________________________________________________________________________________

Vacon Plc Phone +358-201 2121 Fax: +358-201 212 205

Page 25

VACON CX Interbus-S user’s manual

_________________________________________________________________________________________

Page

25

8. VACON PARAMETERS

The Vacon variables and parameters can be read and write using following indexes:

Index Name Type Object Data Access

hex dec

5FFF 24575 Monitoring variable 1 Interger 16 Array 4 R/W

5FFE 24574 Monitoring variable 2 Interger 16 Array 4 R/W

5FFD 24573 Monitoring variable 3 Interger 16 Array 4 R/W

5FFC 24572 Parameter Write Interger 16 Array 6 R/W

5FFB 24571 Parameter Read Interger 16 Array 6 R/W

8.1 Monitoring variables

Monitored item is chosen by writing the number (nX) of monitored item to the wanted index (see Table

below). After this the chosen monitored item can be read from the wanted index. Separate monitored

items can be chosen to every index “channel” (5FFD ... 5FFF).

Length rights

Object description

Index 5FFF ... 5FFD hex

Object code Array

Number of elements 2 elements

Data type Integer 16

Length 2 bytes

Access rights Read-all, Write-all

Value description

Subindex 1 Number of monitored data

Value range Integer 16

Default value -

Subindex 2 Number of monitored data

Value range Integer 16

Default value -

Number Data name Step Unit Description

n1 Output frequency 0,01 Hz Frequency to the motor

n2 Motor speed 1 rpm Calculated motor speed

n3 Motor current 0,1 A Measured motor current

n4 Motor torque 1 % Calculated actual torque/nominal torque of the unit

n5 Motor power 1 % Calculated actual power/nominal power of the unit

n6 Motor voltage 1 V Calculated motor voltage

n7 DC-link voltage 1 V Measured DC-link voltage

n8 Temperature 1 °C Temperature of the heat sink

n9 Operating day counter DD.dd

n10 Operating hours, "trip

counter”

n11 MW-hours 0,001 MWh Total MW-hours, not resetable

n12 MW-hours, "trip counter" 0,001 MWh MW-hours, can be reset with programmable button

n13 Voltage/analogue input 0,01 V Voltage of the terminal Uin+ (control board)

n14 Current/analogue input 0,01 mA Current of terminals Iin+ and Iin- (control board)

_________________________________________________________________________________________

Vacon Plc Phone +358-201 2121 Fax: +358-201 212 205

HH.hh

Operating days 1), not resetable

Operating hours 2), can be reset with program-button

#3

#4

Page 26

VACON CX Interbus-S user’s manual

Page

26

_________________________________________________________________________________________

n15 Digital input status, gr. A 0 = Open Input, 1 = Closed Input (Active)

n16 Digital input status, gr. B 0 = Open Input, 1 = Closed Input (Active)

n17 Digital and relay output

0 = Open Input, 1 = Closed Input (Active)

status

n18 Control program Version number of the control software

n19 Unit nominal power 0,1 kW Shows the power size of the unit

n20 Motor temperature rise 1 % 100%= temperature of motor has risen to nominal

value

1)

DD = full days, dd = decimal part of a day

2)

HH = full hours, hh = decimal part of an hour

Table. Monitored Items

8.2 Parameter Write

By using index 5FFC can be written in to Vacon parameter. The group number of parameter, parameter

number and parameter value will be written in to index. Numbering of the parameter as well as

parameter ranges and steps can be found in the application manual in question. The parameter value

should be given without decimals.

Object description

Index 5FFC hex

Object code Array

Number of elements 3 elements

Data type Integer 16

Length 2 bytes

Access rights Read-all, Write-all

Value description

Subindex 1 Parameter group number

Value range Integer 16

Default value -

Subindex 2 Parameter number

Value range Integer 16

Default value -

Subindex 3 Parameter value

Value range Integer 16

Default value -

Example: Write value 25 to Vacon parameter 1.2

command WRITE

subindex 1 0001 hex

subindex 2 0002 hex

subindex 3 0019 hex

_________________________________________________________________________________________

Vacon Plc Phone +358-201 2121 Fax: +358-201 212 205

Page 27

VACON CX Interbus-S user’s manual

_________________________________________________________________________________________

8.3 Parameter read

Reading of the Vacon parameter is accomplished in two stages. At the first stage the read group

number of the parameter and parameter value is written in to 5FFB, parameter value is not important. At

the second stage the parameter value will be read from the same index, when the parameter value

without desimals is received.

Object description

Index 5FFB hex

Object code Array

Number of elements 3 elements

Data type Integer 16

Length 2 bytes

Access rights Read-all, Write-all

Value description

Subindex 1 Parameter group number

Value range Integer 16

Default value -

Subindex 2 Parameter number

Value range Integer 16

Default value -

Subindex 3 Parameter value

Value range Integer 16

Default value -

Page

27

_________________________________________________________________________________________

Vacon Plc Phone +358-201 2121 Fax: +358-201 212 205

Page 28

VACON CX Interbus-S user’s manual

_________________________________________________________________________________________

Page

28

9. PCP-COMMUNICATION SERVICES

Following services are supported:

• Initiate Establish connection

• Abort Abort connection

• Status Read drive status

• Identify Read manufacturer’s name, type and version

• Get OV Read the object description

• Read Read communication objects

• Write Write communication objects

9.1 Initiate

Establish a communication connection between master and slave. The drive controller returns the

following service parameters when answering the initiate service:

Access Protection Supported: TRUE

Version OV: 0001hex

Profile Number: 0021hex

Password: 00hex

9.2 Abort

Abort communication connection between two communication partners. The parameter “Connection

Abort Option Code” defines which function is executed when connection is aborted.

9.3 Status

Request device and user status from the drive. The drive controller returns the following values:

Logical status

0 Ready to communicate Remote

1 Limited number of services Local

Logical status Device status

Physical status

Physical status Status of the device control

0 Ready for operation OPERATION ENABLE

1 Partly ready for operation All other states

2 Not ready for operation Device not ready

3

Local Detail

= Status word (index 6041hex)

_________________________________________________________________________________________

Vacon Plc Phone +358-201 2121 Fax: +358-201 212 205

Page 29

VACON CX Interbus-S user’s manual

_________________________________________________________________________________________

9.4 Identify

Request identification data from the communication partner. The drive controller returns the following

values:

Page

29

Device manufacturer name:

Model Name:

Device version:

9.5 Get OV

Read object dictionary of the communication partner.

9.6 Read

This service is read out of the parameters. The result is parameter value if service was processed

successfully. The result is fault indication if service was not processed successfully. The fault

indications:

Error

Class

6 3 00 No access rights

6 5 00 Subindex is invalid

6 5 10 A service parameter has assumed an invalid value

6 6 00 The object is not a parameter

6 7 00 The object does not exist

8 0 00 Service cannot be executed

8 0 20 Service can currently not be executed

Error

Code

VACON

VACON IBS-BOARD

Revision 1.0

Additional

Code

Meaning

9.7 Write

This service is read out of the parameters. The result is acknowledgment if service was processed

successfully. The result is fault indication if service was not processed successfully. The fault

indications:

Error

Class

6 3 00 No access rights

6 5 00 Subindex is invalid

6 5 10 A service parameter has assumed an invalid value

6 6 00 The object is not a parameter

6 7 00 No object exists under this index

6 8 00 The data does not correspond to the data type of the object

8 0 00 Service cannot be executed

8 0 20 Service can currently not be executed

8 0 21 Cannot be executed because of local control

_________________________________________________________________________________________

Vacon Plc Phone +358-201 2121 Fax: +358-201 212 205

Error

Code

Additional

Code

Meaning

Page 30

VACON CX Interbus-S user’s manual

_________________________________________________________________________________________

Page

30

10. Extra information

More information about Interbus-S system, Host Systems and DriveCom profile:

INTERBUS-S CLUB

Phone +49-631/79424

Fax +49-631/97658

Deutschland

_________________________________________________________________________________________

Vacon Plc Phone +358-201 2121 Fax: +358-201 212 205

Page 31

APPENDIX A

Special Actual Values

Default value of Index 6044hex (Process channel 1) is Actual Speed (RPM).

The user can also read the frequency converter’s actual values via a Process Channel 1. Meaning of

Process channel 1 can be selected by setting a Control Word (6040hex) bits 15...11. The user can

select to show one of the monitoring page variables or active fault code.

Control Word (bit 15...11) is binary code as follows:

Control Word Description

bit 15 bit 14 bit 13 bit 12 bit 11

0 0 0 0 0 Default, Actual Speed (RPM)

0 0 0 0 1 n1 (see table 8-1)

0 0 0 1 0 n2 (see table 8-1)

0 0 0 1 1 n3 (see table 8-1)

1 1 1 0 1 n29 (see table 8-1)

1 1 1 1 0 Active Fault Code

1 1 1 1 1 Actual Speed (RPM)

.

.

Process data channels

Nominal Speed

Actual Value Speed

Process channel 1 Process channel 2

Control Word

Status Word

DRIVE

Page 32

Vacon Plc

P.O. Box 25

Runsorintie 7

FIN-65381 VAASA

Finland

Phone: +358-201 2121

Fax: +358-201 212 205

UD00105G

Loading...

Loading...