Page 1

VACON CX/CXL/CXS

FREQUENCY CONVERTERS

Profibus DP

Fieldbus

Option Board

USER'S MANUAL

Subject to changes without notice

F O R S M O O T H C O N T R O L

Page 2

VACON CX Profibus user’s manual Page 2

________________________________________________________________________________________

INDEX

1. GENERAL.......................................................................................................................................................3

2. SPECIFICATIONS ..........................................................................................................................................4

2.1 General.......................................................................................................................................................4

2.2 Profibus cable.............................................................................................................................................4

3. PROFIBUS DP................................................................................................................................................6

3.1 General.......................................................................................................................................................6

3.2 Profiles........................................................................................................................................................6

4. INSTALLATION..............................................................................................................................................7

5. CONNECTIONS..............................................................................................................................................9

5.1 Board layout................................................................................................................................................9

5.2 Profibus connections..................................................................................................................................9

5.3 I/O-control connections.............................................................................................................................10

6. COMMISSIONING.........................................................................................................................................11

7. PROFIBUS-VACON CX INTERFACE..........................................................................................................12

7.1 General.....................................................................................................................................................12

7.2 PPO-types ................................................................................................................................................12

7.3 Process Data............................................................................................................................................15

7.3.1 Control Word....................................................................................................................................15

7.3.2 Status Word.....................................................................................................................................16

7.3.3 State Machine..................................................................................................................................16

7.3.4 Speed Reference.............................................................................................................................17

7.3.5 Actual Value.....................................................................................................................................18

7.3.6 PD1-PD4..........................................................................................................................................18

7.4 Parameter Data ........................................................................................................................................19

7.4.1 Actual Values...................................................................................................................................19

7.4.2 Parameter Read and Write.................................................................................................

.............20

7.4.3 Fault Code .......................................................................................................................................20

8. FAULT TRACKING......................................................................................................................................21

9. TYPE FILES..................................................................................................................................................22

9.1 GSD-file....................................................................................................................................................22

APPENDIX A.........................................................................................................................................................23

Board layout........................................................................................................................................................23

Profibus connections..........................................................................................................................................23

APPENDIX B.........................................................................................................................................................24

APPENDIX C: INSTALLATION............................................................................................................................26

Installation of Profibus DP in Vacon CXS drives................................................................................................26

________________________________________________________________________________________

Vacon Oyj Phone +358-201-2121 Fax: +358-201-212 205

Page 3

VACON CX Profibus user’s manual Page 3

________________________________________________________________________________________

1. GENERAL

Vacon frequency converters can be connected to the Profibus DP by using a Fieldbus board. The

converter can then be controlled, monitored and programmed from the Host system.

The used I/O can also be extended with the Fieldbus board:

• 4 digital inputs (standard signals)

• 4 digital outputs (2 standard signal)

• 1 relay output (standard signal)

• Thermistor input (can be directly connected to the motor thermistors for overtemperature trip)

• Encoder input

The Profibus fieldbus board can be installed inside the frequency converter as instructed in this manual.

Note that the installation procedure is different for CX/CXL (board CX202OPT) and CXS frequency

converters (CX210OPT).

The control connections are isolated from the mains potential and the I/O ground is connected to the

frame of the device via a 1 MΩ resistor and 4.7 nF capacitor*. The control I/O ground can also be

connected directly to the frame by changing the position of the jumper X9 (GND ON/OFF) to ONposition. Digital inputs are also isolated from the I/O ground.

NOTE !

Internal components and circuit boards (except for the isolated I/O terminals) are at mains

potential when the frequency converter is connected to the mains. This voltage is extremely

dangerous and may cause death or severe injury if you come into contact with it.

The control I/O terminals are isolated from the mains potential, but the I/O:s (if jumper X9 is in

OFF-position) may have dangerous voltage connected even if the power is off on the

frequency converter.

* Default value = X9 is GND OFF- position)

________________________________________________________________________________________

Vacon Oyj Phone +358-201-2121 Fax: +358-201-212 205

Page 4

VACON CX Profibus user’s manual Page 4

________________________________________________________________________________________

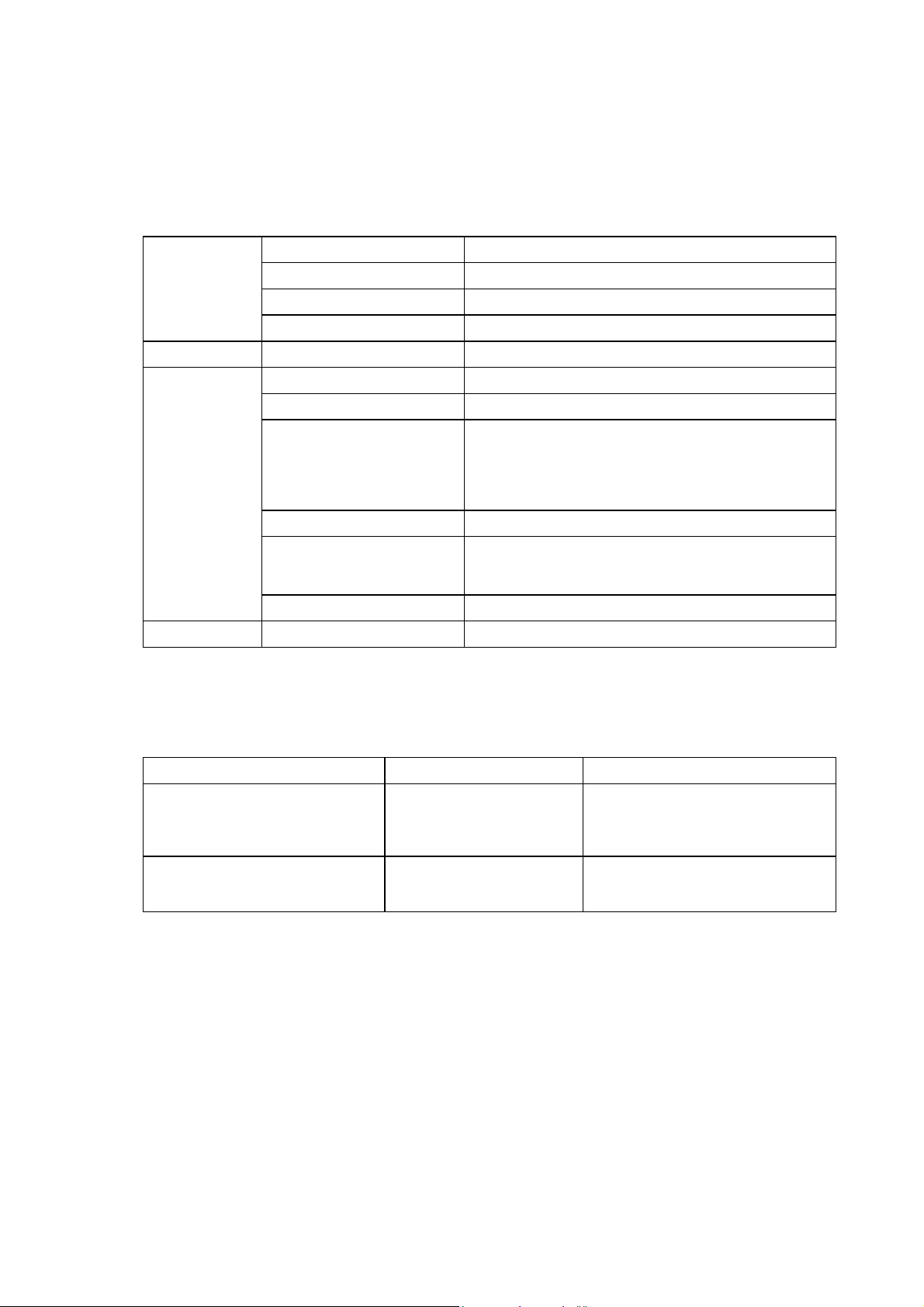

2. SPECIFICATIONS

2.1 General

Profibus DP connections

I/O -control

connections

Safety

Interface 9-pin DSUB connector (female)

Transfer method RS-485, Half duplex

Transfer cable Twisted pair (1 pair and shield)

Electrical isolation 500 V DC

Digital input (4 pcs)

24 V: “0” ≤10 V, “1” ≥18 V, R

= 5 kΩ

i

Digital output (4 pcs) Open collector output, 50 mA/48 V

Relay output (1 pcs) Max.switching voltage: 300 V DC, 250 V AC

Max.switching load: 8 A / 24 V DC

0,4 A / 300 V AV

2 kVA / 250 V DC

Max.continuous load: 2 A rms

Thermistor input (1 pcs)

Encoder input (3 pcs)

Aux. voltage

R

= 4.7 kΩ

trip

24 V: “0” ≤10 V, “1” ≥18 V, R

5 V : “0” ≤2 V, “1” ≥3 V, R

= 330 Ω

i

24 V (±20%), max 50 mA

= 3.3 kΩ

i

Fulfils EN50178 standard

Communication mode

PPO types

Communication parameters

- Address

- Baud Rate

Table 2-1. Profibus communication data

2.2 Profibus cable

Profibus devices are connected in a bus structure. Up to 32 stations (master or slaves) can be

connected in one segment. The bus is terminated by an active bus terminator at the beginning and end

of each segment (see figure 2-1). To ensure error-free operation, both bus terminations must always be

powered. When more than 32 stations are used, repeaters (line amplifiers) must be used to connect the

individual bus segments.

The maximum cable length depends on the transmission speed and cable type (see table 2-4). The

specified cable length can be increased by the use of repeaters. The use of more than 3 repeaters in

series is not recommended.

Profibus DP

1 to 127

9.6 kBaud to 12 MBaud

1

2

3

4

________________________________________________________________________________________

Vacon Oyj Phone +358-201-2121 Fax: +358-201-212 205

Page 5

VACON CX Profibus user’s manual Page 5

)

)

)

)

(3)

(5)

(8)

(6)

)

)

)

)

________________________________________________________________________________________

Parameter Line A Line B

Impedance

Capacity

Resistance

Wire gauge

Conductor area

135 ... 165 Ω

(3 to 20 Mhz)

< 30 pF/m

< 110 Ω / km

> 0,64 mm

> 0,34 mm

2

100 ... 130 Ω

( f > 100kHz)

< 60 pF/m

> 0,53 mm

> 0,22 mm

2

Table 2-2 Line Parameter

Baud rate (kbit/s) 9.6 19.2 93.75 187.5 500 1500 3000-12000

Length line A (m)

Length line B (m)

1200 1200 1200 1000 400 200 100

1200 1200 1200 600 200 - -

Table 2-3 Line length for different transmission speeds

Following cables can be used (e.g):

Belden Profibus Data Cable 3079A

Olflex Profibus Cable 21702xx

Siemens SINEC L2 LAN cable for profibus 6XV1 830-0AH10

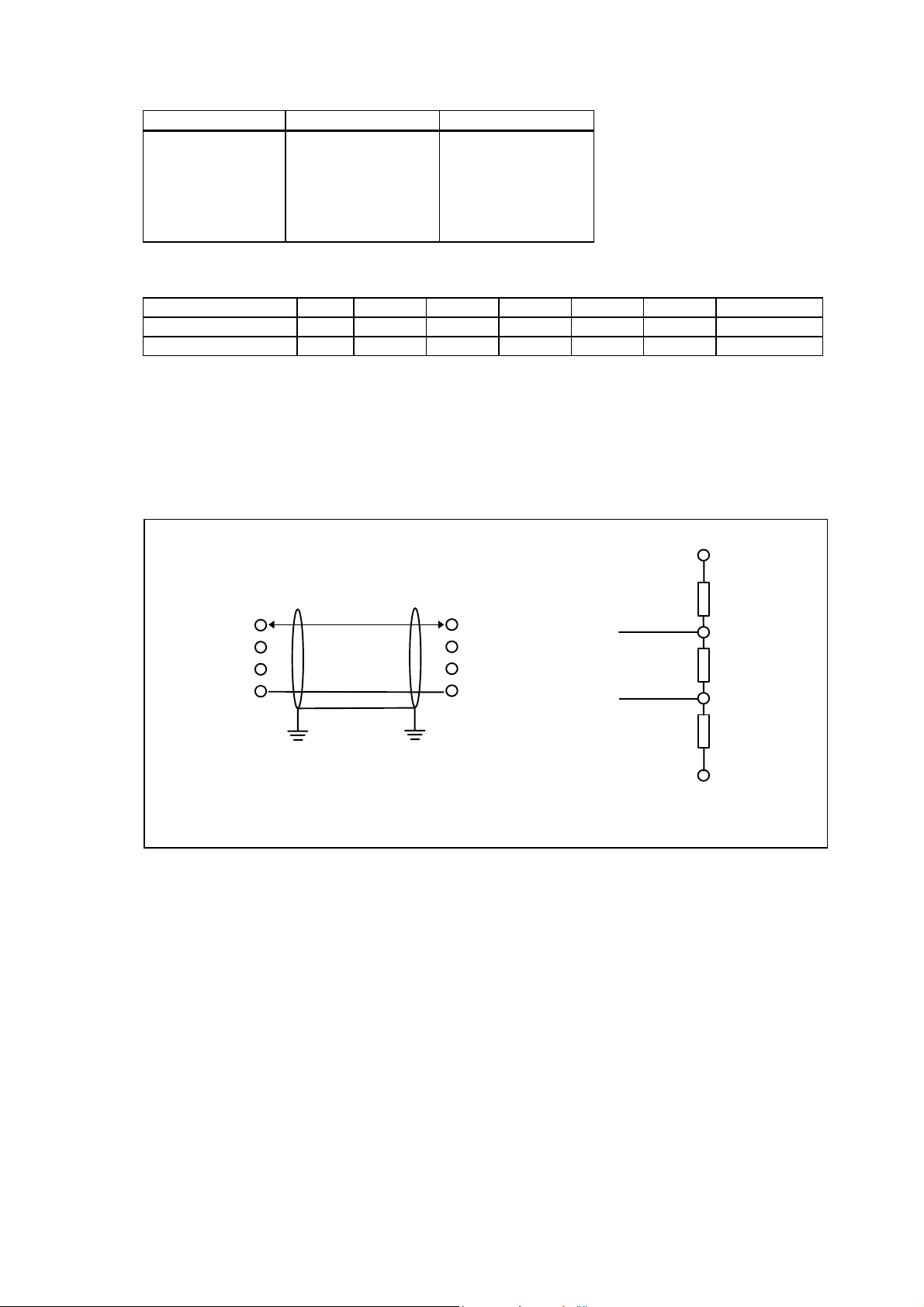

Station 1

RxD/TxD-P (3

DGND (5

VP (6

RxD/TxD-N (8

Shielding

Protective

ground

Protective

ground

Cabling

Figure 2-1 Cabling and bus termination

Station 2

RxD/TxD-P

DGND

VP

RxD/TxD-N

Data Line

Data Line

Bus Termination

VP (6

390

Ω

RxD/TxD-P (3

220

Ω

RxD/TxD-N (8

390

Ω

DGND (5

________________________________________________________________________________________

Vacon Oyj Phone +358-201-2121 Fax: +358-201-212 205

Page 6

VACON CX Profibus user’s manual Page 6

________________________________________________________________________________________

3. PROFIBUS DP

3.1 General

PROFIBUS is a vendor-independent, open fieldbus standard for a wide range of applications in

manufacturing, process and building automation. Vendor independence and openness are guaranteed

by the PROFIBUS standard EN 50 170. With PROFIBUS, devices of different manufacturers can

communicate without special interface adjustments. PROFIBUS can be used for both high-speed time

critical data transmission and extensive complex communication tasks. The PROFIBUS family consists

of three compatible versions.

PROFIBUS-DP

Optimized for high speed and inexpensive hookup, this PROFIBUS version is designed

especially for communication between automation control systems and distributed I/O at the

device level. PROFIBUS-DP can be used to replace parallel signal transmission with 24 V or 0

to 20 mA.

PROFIBUS-PA

PROFIBUS-PA is designed especially for process automation. It permits sensors and actuators

to be connected on one common bus line even in intrinsically-safe areas. PROFIBUS-PA

permits data communication and power over the bus using a 2-wire technology according to the

international standard IEC 1158-2.

PROFIBUS-FMS

PROFIBUS-FMS is the general-purpose solution for communication tasks at the cell level.

Powerful FMS services open up a wide range of applications and provide great flexibility.

PROFIBUS-FMS can also be used for extensive and complex communication tasks.

PROFIBUS specifies the technical and functional characteristics of a serial fieldbus system with which

decentralized digital controllers can be networked together from the field level to the cell level.

PROFIBUS distinguishes between master devices and slave devices.

Master devices determine the data communication on the bus. A master can send messages without an

external request when it holds the bus access rights (the token). Masters are also called active stations

in the PROFIBUS protocol.

Slave devices are peripheral devices. Typical slave devices include input/output devices, valves, drives

and measuring transmitters. They do not have bus access rights and they can only acknowledge

received messages or send messages to the master when requested to do so. Slaves are also called

passive stations.

3.2 Profiles

The PROFIBUS-DP protocol defines how user data are to be transmitted between the stations over the

bus. User data are not evaluated by the PROFIBUS-DP transmission protocol. The meaning is

specified in the profiles. In addition, the profiles specify how PROFIBUS-DP is to be used in the

application area. The following PROFIBUS-DP profile is used in VACON CX Profibus fieldbus board.

Variable-Speed Drive Profile (3.071)

Leading manufacturers of drive technology have jointly defined the PROFIDRIVE profile. The profile

specifies how the drives are to be parameterized and how the setpoints and actual values are to be

transmitted. This enables drives from different vendors to be exchanged. The profile contains necessary

specifications for speed control and positioning. It specifies the basic drive functions while leaving

sufficient freedom for application-specific expansions and further developments. The profile describes

the mapping of the application functions for DP or FMS.

________________________________________________________________________________________

Vacon Oyj Phone +358-201-2121 Fax: +358-201-212 205

Page 7

VACON CX Profibus user’s manual Page 7

________________________________________________________________________________________

4. INSTALLATION

NOTE! These instructions apply if you have received the Profibus board for Vacon CX or CXL

drives (CX202OPT) as an accessory. Otherwise the board has already been installed for you at

the factory.

Instructions for the installation of Profibus option board for Vacon CXS drives

will find in Appendix C.

Before doing any commissioning, carefully read the safety instructions in the "Vacon CX/CXL/CXS

frequency converter, User's manual" chapter “SAFETY”. Check that you have received all the Fieldbus

board parts: Fieldbus board, plastic board, power cable (black terminal), data cable (blue terminal) and

earthing screw.

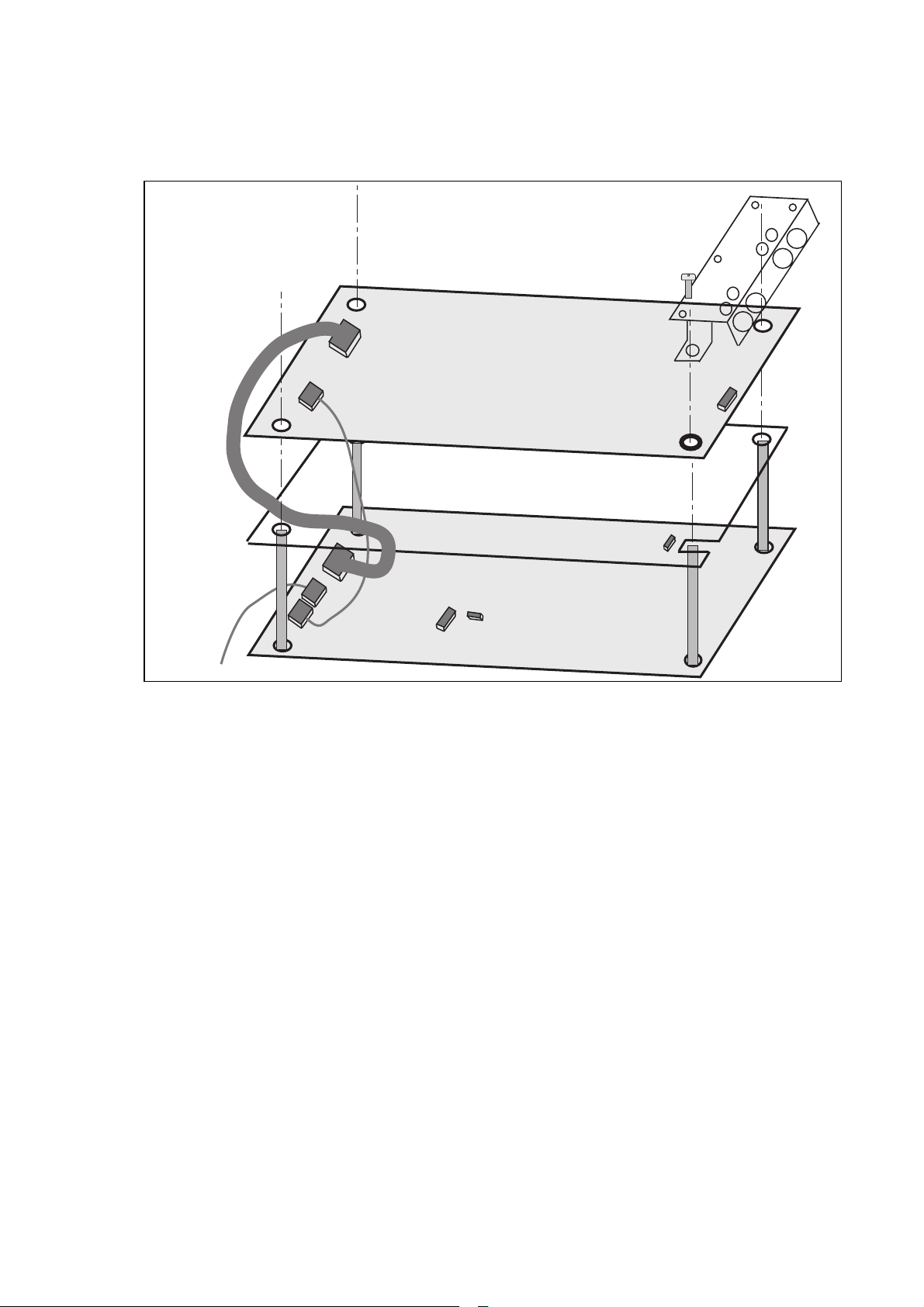

Fieldbus board can be installed in the place reserved for an option board inside the frequency converter

(see figure 4-1).

Remove the control panel and jumper X4 from the control board (1).

A

Connect the power cable to control board terminal X5 (2) and the data cable to terminal X14

B

(3). The power cable can also be connected to terminal X6, if the power cable from the

power board is connected to terminal X5.

Bend the data cable into an "S-curve" as far as possible from the power board transformer

C

(4) before you place the plastic board above the control board.

Remove the protection foil of the plastic board and place the plastic board on the control

D

board, remember the right position of the plastic board (5).

Install the Fieldbus board above the plastic board by the larger holes and push it downward

E

so that the narrow part of the hole in the board fits the cut on the sleeve. Check that the

installation is stable. If you have difficulties placing the plastic board and the Fieldbus board,

slightly bend the regulator A4 (6) and capacitor C59 (7) of the control board.

Connect the power cable to terminal X6 of the Fieldbus board (8) and the data cable to the

F

terminal X14 (9).

Install the jumper which you removed from the terminal X4 of the control board, on the

G

terminal X9 of the Fieldbus board (10) in ON or OFF position.

If the package includes the cable cover (11), fasten it into position as shown in figure 4-1.

H

Install the earthing screw (12).

I

After this install the control panel and connect the needed control signals.

J

If you use a 5 V encoder input, install the jumpers on terminal X15 (see figure 5-1) of the

K

Fieldbus board (one jumper on the two upper pins and the other on the two lower).

(CX210OPT) you

________________________________________________________________________________________

Vacon Oyj Phone +358-201-2121 Fax: +358-201-212 205

Page 8

VACON CX Profibus user’s manual Page 8

________________________________________________________________________________________

11

12

9

Fieldbus board

8

10

4

Plastic board

5

3

2

Figure 4-1. Fieldbus board installed onto the control board

Control board

7

1

6

________________________________________________________________________________________

Vacon Oyj Phone +358-201-2121 Fax: +358-201-212 205

Page 9

VACON CX Profibus user’s manual Page 9

________________________________________________________________________________________

5. CONNECTIONS (CX202OPT)

(For the board layout and connections of the small Profibus DP board, Vacon CX210OPT, see

Appendix A)

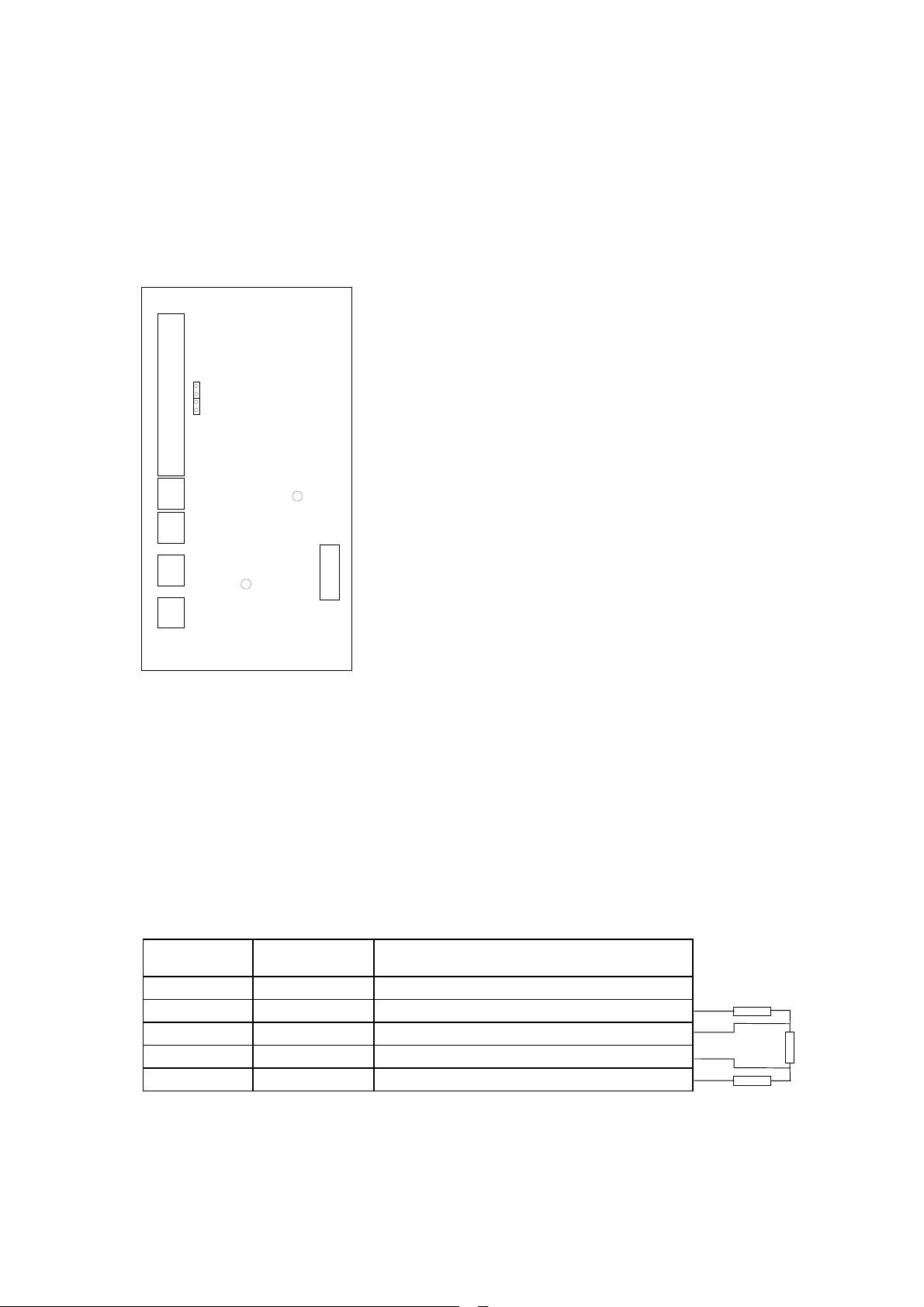

5.1 Board layout

Terminals:

X1 I/O - terminals

X10 Digital Output terminal

X1

X15

X10

X3

X7

H3

X4

H1

X5

Figure 5-1. Fieldbus board

Diagnostic LED:

H1 Data Exchange state for Profibus DP, Red. The red LED goes out when

communication is established

H1 led is active when Fieldbus board is not ready to exchange data

H3 Supply Voltage, Green.

H3 led is active if the Fieldbus board has supply voltage.

X3 Digital Output terminal

X7 Relay Output terminal

X4 Thermistor input

X15 Encoder input selection

X5 Screw terminal to Profibus DP

X9 Connection of control I/O ground:

ON - Directly to the frame of the

device

OFF- To the frame of the

device via RC filter

X17 Connection of control Fieldbus

cable shield:

ON - Directly to the frame of the

device

OFF- To the frame of the

device via RC filter

5.2 Profibus connections

Screw Connector connector X5: (Terminal resistors not included in the package)

Signal Connector X5

Shield X5-241 Cable shield

Description

Termination for

the last node

390 Ω

VP X5-242 Supply voltage of the terminating resistance

RxD/TxD-P X5-243 Receive/Transmission data positive (B)

RxD/TxD-N X5-244 Receive/Transmission data negative (A)

220 Ω

DGND X5-245 Data Ground

390 Ω

Table 5-1. X5 screw connector terminals

Note! If Vacon is the last device then the bus termination must be set. Install the resistors to the screw

terminal (see table 5-1)

________________________________________________________________________________________

Vacon Oyj Phone +358-201-2121 Fax: +358-201-212 205

Page 10

VACON CX Profibus user’s manual Page 10

________________________________________________________________________________________

5.3 I/O-control connections

Terminal Signal Description

201…205 Not used

206 +24 V Control voltage output Voltage for switches, etc. max. 0.05 A

207 GND I/O ground Ground for reference and controls

208 COME Common for DIE1-DIE4 Connect to GND or +24 V

209 DIE1 Programmable:

External fault

OR

Selection of active control

source

Contact open = no fault

Contact closed = fault

Contact open = VACON IO-terminal

Contact closed = Fieldbus

210 DIE2 Run disable Contact open = start of motor enabled

Contact closed = start of motor disabled

211 DIE3 Acceler. / Decel. time

selection

Contact open = time 1 selected

Contact closed = time 2 selected

212 DIE4 Jogging speed selection Contact open = no action

Contact closed = jogging speed

213 Not Used

214 DIE6A+

215 DIE6A-

Enco-

216 DIE7B+

der

217 DIE7B-

Pulse input A

(differential input)

Pulse input B

(differential input)

90 degrees phase shift compared

to pulse input A

218 DOE1 Encoder direction output

219 DOE2 Encoder divider 1/64 output

220 Not Used

Signal from

motor thermistor

222 TI 225 RO4/1

221 TI+

Thermistor input

Relay output 4, FAULT

226 RO4/2

231 DOE3 Open collector output 3 READY

232 GND I/O ground Ground for reference and controls

233 DOE4 Open collector output 4 RUN

234 GND I/O ground Ground for reference and controls

Figure 5-2. Control connections

NOTE! Thermistor input (Terminals 221 and 222) must be shorted if not used

READY = ON, when mains voltage has been applied and VACON CX is ready to operate

RUN = ON, when the motor is running

FAULT = ON, if a fault occurs

________________________________________________________________________________________

Vacon Oyj Phone +358-201-2121 Fax: +358-201-212 205

Page 11

VACON CX Profibus user’s manual Page 11

________________________________________________________________________________________

6. COMMISSIONING

READ FIRST THE COMMISSIONING OF THE FREQUENCY CONVERTER IN VACON CX/CXL/CXS

FREQUENCY CONVERTER USER'S MANUAL (CHAPTER 8.)

Commissioning of the Fieldbus board:

Check that Multi-purpose Control Application II (or e.g. Fieldbus Application) is selected.

- Parameter P0.1 = 0

For further information about use of parameters, see Vacon CX/CXL/CXS User's Manual, Chapter 7.

Start-up test:

FREQUENCY CONVERTER APPLICATION

1. Check that the control panel is not the active control source.

(See Vacon CX/CXL/CXS frequency converter User's manual, Chapter 7.)

2. Set parameter “Fieldbus control select” to value 1(On).

MASTER SOFTWARE

1. Set Control Word value to 0hex.

2. Set Control Word value to 47Fhex.

3. Frequency converter status is RUN

4. Set Reference value to 5000 (=50,00%).

5. The Actual value is 5000 and the frequency converter output frequency is 25,00 Hz

6. Set Control Word value to 7Dhex.

7. Frequency converter status is STOP

If Status Word bit 3 = 1 Status of frequency converter is FAULT.

________________________________________________________________________________________

Vacon Oyj Phone +358-201-2121 Fax: +358-201-212 205

Page 12

VACON CX Profibus user’s manual Page 12

________________________________________________________________________________________

7. PROFIBUS-VACON CX INTERFACE

Features of the Profibus-Vacon CX interface:

• Direct control of Vacon CX ( e.g. Run, Stop, Direction, Speed reference, Fault reset)

• Full access to all Vacon CX parameters

• Monitor Vacon CX status (e.g. Output frequency, Output current, Fault code ..)

7.1 General

Data transfer between Profibus DP master and slave takes place via the Input/Output data field. The

master writes to slave’s Output data and the slave answers by sending the contents of its Input data to

the master. The contents of Input /Output data is defined in a device profile, PROFIDRIVE is the device

profile for frequency converters.

The Vacon CX frequency converter can be controlled by Profibus DP master using PPO-types defined

in PROFIDRIVE (see next chapter). When fieldbus has been selected as the frequency converter’s

active control place, the frequency converter’s operation can be controlled from the Profibus DP master.

Whether or not the active control place is fieldbus, the frequency converter can be monitored and its

parameters can be set by the Profibus DP master.

7.2 PPO-types

PPOs (Parameter/Process Data Object)are communication objects in PROFIBUS DP. PPOs in VACON

CX:

PPO1

PPO2

PPO3

PPO4

Parameter Field Process Data Field

ID IND VALUE CW

Byte

ID Parameter type and number

IND Parameter subindex

SW

REF

ACT

PD1 PD2 PD3 PD4

VALUE Parameter value

CW Control Word

SW Status Word

REF Reference Value

ACT Actual Value

PD Process Data

________________________________________________________________________________________

Vacon Oyj Phone +358-201-2121 Fax: +358-201-212 205

Page 13

VACON CX Profibus user’s manual Page 13

________________________________________________________________________________________

ID

ID byte1 ID byte2

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Request/Response type SM Parameter Number

SM: Spontaneous bit (not used)

Request/Response types

Request Function Response Function

0 No request 0 No response

1 Read parameter value (word) 1 Parameter value ready (word)

2 Write parameter value (word) 7 Request rejected (+fault code)

Fault Number (if response = 7)

Fault Number Description

0 Illegal Parameter

1 Parameter is read only ( e.g. actual values)

2 Parameter value is out of limits

17 Request temporarily rejected (e.g. can be changed only for STOP state)

18 Other fault

101 Unknown request type

Example1, (PPO1 mode):

Read parameter number 102 (Par 1.2).

Start frequency converter and set speed reference 50,00%.

Command Master - Slave:

ID 1066 hex 1 - Read parameter value

066 - Parameter 102 (= Maximum frequency )

IND 0000 hex 0000 - No meaning

VALUE 0000 0000 hex 0000 0000 - No meaning

CW 047F hex 04 7F- Start command (see chapter control word and state machine)

REF 1388 hex Speed ref. 50,00% (= 25,00 Hz if parameter min. frequency 0 Hz and

max. frequency 50 Hz)

PPO1 frame:

10 66 00 00 00 00 00 00 04 7F 13 88

________________________________________________________________________________________

Vacon Oyj Phone +358-201-2121 Fax: +358-201-212 205

Page 14

VACON CX Profibus user’s manual Page 14

________________________________________________________________________________________

Answer Slave - Master:

ID 1066 hex 1 - Parameter value ready

066 - Parameter 102 (= Maximum frequency )

IND 0000 hex 0000 - No meaning

VALUE 0000 0032 hex 0000 0032 - Parameter value = 32hex ( 50 Hz)

SW 0000 hex 0000 - frequency converter status (see chapter status word and state

machine)

ACT 0000 hex Current speed 0,00% (= 0,00 Hz if parameter min. frequency 0 Hz

and max. frequency 50 Hz)

PPO1 frame:

10 66 00 00 00 00 00 32 00 00 00 00

Example 2, (PPO1 mode):

Write to parameter number 701 (Par 7.1) value 2.

Keep Run mode on and Send speed reference 75,00%.

Command Master - Slave:

ID 22BD hex 2 - Write parameter value

2BD - Parameter 701 (= Response to reference fault )

IND 0000 hex 0000 - No meaning

VALUE 0000 0002 hex 0000 0002 - Parameter value

CW 047F hex 04 7F- Start command (see chapter control word and state machine)

REF 1D4C hex Speed ref. 75,00% (= 37,50 Hz if parameter min. frequency 0 Hz and

max. frequency 50 Hz)

PPO1 frame:

22 BD 00 00 00 00 00 02 04 7F 1D 4C

Answer Slave - Master:

ID 12BD hex 1 - Parameter value ready

2BD - Parameter 701 (= Response to reference fault )

IND 0000 hex 0000 - No meaning

VALUE 0000 0032 hex 0000 0032 - Parameter value = 32HEX ( 50 Hz)

SW 0337 hex 0337- frequency converter status (see chapter status word and state

machine)

ACT 09C4 hex Current speed 25,00% (= 12,50 Hz if parameter min. frequency 0 Hz

and max. frequency 50 Hz)

PPO1 frame:

12 BD 00 00 00 00 00 00 03 37 09 C4

________________________________________________________________________________________

Vacon Oyj Phone +358-201-2121 Fax: +358-201-212 205

Page 15

VACON CX Profibus user’s manual Page 15

A

p

________________________________________________________________________________________

7.3 Process Data

Direct control of Vacon CX ( e.g. Run, Stop, Direction, Speed reference, Fault reset) and frequency

converter status (e.g. Output frequency, Output current, Fault code ..) can be handled by using PPO

types 1 to 4.

Fieldbus Board

P PROCESS DATA

R

O

F

I

B

U

S

D

P

M

A

S

T

E

R

Output

Control Word

Reference

PD1 Variables

RUN/STOP

DIRECTION

FAULT RESET

PD2 FAULT STATE

PD3

PD4 Output Frequency

In

PD2

PD3

PD4

Frequency Reference

(Frequency Reference 2)

ut CONTROL SOURCE

Status Word READY STATE

Actual Value RUN STATE

PD1 DIRECTION STATE

VACON CX

Parameters

ctive Fault Code

7.3.1 Control Word

The Control command for the state machine (see figure 7.1). The state machine describes the device

status and the possible control sequence of the frequency converter.

The control word is composed of 16 bits that have the following meanings:

Bit Description

Value = 0 Value = 1

0 STOP 1 (by ramp) ON 1

1 STOP 2 (by coast) ON 2

2 STOP 3 (by ramp) ON 3

3 RUN DISABLE ENABLE

4 No Action START

5 No Action START

6 No Action START

7 No Action FAULT RESET (0 -> 1)

8 No Action No Action

9 No Action No Action

________________________________________________________________________________________

Vacon Oyj Phone +358-201-2121 Fax: +358-201-212 205

Page 16

VACON CX Profibus user’s manual Page 16

________________________________________________________________________________________

10 Disable Profibus control Enable Profibus control

11 Not used Not used

12 Not used Not used

13 Not used Not used

14 Not used Not used

15 Not used Not used

7.3.2 Status Word

Information about the status of the device and messages is indicated in the status word.

The status word is composed of 16 bits that have the following meanings:

Bit Description

Value = 0 Value = 1

0 Not Ready (initial) READY

1 Not Ready READY

2 DISABLE ENABLE

3 NO FAULT FAULT ACTIVE

4 STOP 2 OFF STOP 2 ON

5 STOP 3 OFF STOP 3 ON

6 START ENABLE START DISABLE

7 No Warning Warning

8

Reference ≠ Actual value

Reference = Actual value

9 Fieldbus control OFF Fieldbus control ON

10 Not used Not used

11 Not used Not used

12 FC stopped Running

13 Not used Not used

14 Not used Not used

15 Not used Not used

7.3.3 State Machine

The state machine describes the device status and the possible control sequence of the frequency

converter. The state transitions can be generated by using “control word” parameter. The “status word”

parameter indicates the current status of the state machine. The modes INIT, STOP, RUN and FAULT

(see figure 7-1) correspond to the actual mode of the Frequency converter.

DISABLE (Bit6=1

) is one value of the “status word”.

Bit0=0 is one value of the “control word”.

________________________________________________________________________________________

Vacon Oyj Phone +358-201-2121 Fax: +358-201-212 205

Page 17

VACON CX Profibus user’s manual Page 17

________________________________________________________________________________________

Power ON

Fault

Bit0=0

STOP 1

STOP by ramp

Bit1=0

Bit3=0

RUN DISABLE

STOP Bit2=0

DISABLE

INIT Bit6=1

Bit0=0

NOT READY

STOP Bit6=0

Bit0=0

xxxx x1xx xxxx x110

READY 1

STOP Bit0=1

Bit0=1

READY 2

STOP Bit1=1

Bit3=1

FAULT ACTIVE

FAULT Bit3=1

Reset fault

Bit7=0

Bit7=1

Bit1=0

STOP 2

STOP by coast

Bit4=0

Bit2=0

STOP 3

STOP by ramp

Bit5=0

Figure 7-1. States of the device control

7.3.4 Speed Reference

Speed reference of the frequency converter. The range is -10000... 10000, percentage of frequency

area between set minimum and maximum frequency.

-10000 = 100,00 % (Direction reverse)

0 = 0,00 % (Direction forward)

10000 = 100,00 % (Direction forward)

ENABLE

STOP Bit2=1

Bit4=1, Bit5=1, Bit6=1

RUNNING

RUN

________________________________________________________________________________________

Vacon Oyj Phone +358-201-2121 Fax: +358-201-212 205

Page 18

VACON CX Profibus user’s manual Page 18

________________________________________________________________________________________

7.3.5 Actual Value

Actual value of the motor. The range is -10000... 10000, percentage of frequency area between set

minimum and maximum frequency.

-10000 = 100,00 % (Direction reverse)

0 = 0,00 % (Direction forward)

10000 = 100,00 % (Direction forward)

7.3.6 PD1-PD4

The master can read the frequency converter’s actual values using process data variables. There are

four process data variables and each of them can be selected to show one of the monitoring page

variables or active fault code. Selection can be done in two different ways:

By master: Parameter 916.1 PD1

916.2 PD2

916.3 PD3

916.4 PD4

By control panel: Parameter Process Data 1 PD1

Process Data 2 PD2

Process Data 3 PD3

Process Data 4 PD4

Set the number of the variable to be monitored (see table 7-1) or number 99 for the active fault code to

the value of the parameter.

Profibus DP master

PD1 PD2 PD3 PD4

Figure 7-2. Control of Process Data

Selector

Parameter

VACON CX

1 Output Frequency

2 Motor Speed

.

.

.

22 Fieldbus status

99 Active fault code

________________________________________________________________________________________

Vacon Oyj Phone +358-201-2121 Fax: +358-201-212 205

Page 19

VACON CX Profibus user’s manual Page 19

p

A

________________________________________________________________________________________

7.4 Parameter Data

Fieldbus Board

P PARAMETERS

R

O

F

I

B

U

S

D

P

M

A

S

T

E

R

The Vacon variables and fault codes can be read and parameters can be read and written using PPO

types 1 and 2.

Output

Parameter ID

Parameter Index

Parameter Value Variables

In

Parameter Value

ut

Parameter ID

Parameter Index

VACON CX

Parameters

ctive Fault Code

7.4.1 Actual Values

Actual Values can be read by using the parameter read function.

Profibus parameter numbers according to monitored item numbers are as follows.

Parameter number Vacon variable

1 n1

2 n2

. .

. .

98 n98

Number Data name Step Unit Description

V1 Output frequency 0,01 Hz Frequency to the motor

V2 Motor speed 1 rpm Calculated motor speed

V3 Motor current 0,1 A Measured motor current

V4 Motor torque 1 % Calculated actual torque/nominal torque of the unit

V5 Motor power 1 % Calculated actual power/nominal power of the unit

V6 Motor voltage 1 V Calculated motor voltage

V7 DC-link voltage 1 V Measured DC-link voltage

V8 Temperature 1 °C Temperature of the heat sink

________________________________________________________________________________________

Vacon Oyj Phone +358-201-2121 Fax: +358-201-212 205

Page 20

VACON CX Profibus user’s manual Page 20

________________________________________________________________________________________

V9 Operating day counter DD.dd

V10 Operating hours, "trip

HH.hh

counter”

Operating days 1), not resetable

Operating hours 2), can be reset with program-button

#3

V11 MW-hours 0,001 MWh Total amount of MW-hours, not resettable

V12 MW-hours, "trip counter" 0,001 MWh MW-hours, can be reset with programmable button

#4

V13 Voltage/analogue input 0,01 V Voltage of the terminal Uin+ (control board)

V14 Current/analogue input 0,01 mA Current of terminals Iin+ and Iin- (control board)

V15 Digital input status, gr. A 0 = Open Input, 1 = Closed Input (Active)

V16 Digital input status, gr. B 0 = Open Input, 1 = Closed Input (Active)

V17 Digital and relay output

0 = Open Input, 1 = Closed Input (Active)

status

V18 Control program Version number of the control software

V19 Unit nominal power 0,1 kW Shows the power size of the unit

V20 Motor temperature rise 1 % 100% = temperature of motor has risen to nominal

value

Table 7-1 Monitored Items

1)

DD = full days, dd = decimal part of a day

2)

HH = full hours, hh = decimal part of an hour

For Special Actual Values see Appendix B.

7.4.2 Parameter Read and Write

The Vacon variables and parameters can be read and written using the Parameter Read/Write function.

Profibus parameters according to parameter numbers are as follows.

Parameter

Vacon parameter group Vacon parameter number

Number

101 - 199 Group 1 1 - 99

201 - 299 Group 2 1 - 99

. .

. .

801 - 899 Group 8 1 - 99

901 - 999 Profibus DP parameter

1001 - 1099 Group 9 1 - 99

. .

. .

1901 - 1999 Group 18 1 - 99

Numbering of the parameter as well as parameter ranges and steps can be found in the application

manual in question. The parameter value should be given without decimals. The Profibus DP

parameter group can be set by the Profibus DP master only, not on the VACON CX control panel.

7.4.3 Fault Code

When a fault is active, fault codes can be read using the Parameter Read function. Profibus parameter

number according to the fault code is as follows.

Parameter number Vacon variable

99 Active fault code

List and description of the fault codes are in VACON CX/CXL/CXS USER’S MANUAL

________________________________________________________________________________________

Vacon Oyj Phone +358-201-2121 Fax: +358-201-212 205

Page 21

VACON CX Profibus user’s manual Page 21

________________________________________________________________________________________

8. FAULT TRACKING

Fault Type

Fault 19 is active in Vacon CX The data cable connection

Fault 27 is active in Vacon CX Profibus DP Master is not active

UL led is not active (Supply Voltage,

Green).

DE led is active (Data Exchange not

Ready) and actual value n22 = 0

DE led is active (Data Exchange not

Ready) and actual value n 22 = 1

Possible cause Checking

Check the installation

between control board and

fieldbus board is not working

and the control source is fieldbus

The power cable connection

between control board and

fieldbus board is not working

Fieldbus board has not received a

parameterization telegram or the

telegram is incorrect.

Bus wire break

Fieldbus board has not received a

configuration telegram or the

telegram is incorrect.

- if installation is correct contact the

nearest Vacon distributor

Check the system Master device

Check the installation

- if installation is correct contact the

nearest Vacon distributor

Check the configuration in the

Profibus DP master.

Check the bus cables

Check the type files (GSD)

________________________________________________________________________________________

Vacon Oyj Phone +358-201-2121 Fax: +358-201-212 205

Page 22

VACON CX Profibus user’s manual Page 22

________________________________________________________________________________________

9. Type Files

9.1 GSD-file

#Profibus_DP

GSD_Revision = 1

Vendor_Name = "Vaasa Control"

Model_Name = "Vacon CX202OPT"

Revision = "1.0"

Ident_Number = 0x9500

Protocol_Ident = 0

Station_Type = 0

FMS_supp = 1

Hardware_Release = "HW1.0"

Software_Release = "SW1.0"

9.6_supp = 1

19.2_supp = 1

93.75_supp = 1

187.5_supp = 1

500_supp = 1

1.5M_supp = 1

3M_supp = 1

6M_supp = 1

12M_supp = 1

MaxTsdr_9.6 = 60

MaxTsdr_19.2 = 60

MaxTsdr_93.75 = 60

MaxTsdr_187.5 = 60

MaxTsdr_500 = 100

MaxTsdr_1.5M = 150

MaxTsdr_3M = 250

MaxTsdr_6M = 450

MaxTsdr_12M = 800

Redundancy = 0

Repeater_Ctrl_Sig = 0

24V_Pins = 0

Implementation_Type = "Profibus for Vacon CX "

Freeze_Mode_supp = 1

Sync_Mode_supp = 1

Auto_Baud_supp = 1

Set_Slave_Add_supp = 0

Min_Slave_Intervall = 20

Modular_Station = 1

Max_Module = 4

Max_Input_Len = 20

Max_Output_Len = 20

Max_Data_Len = 40

Modul_Offset = 0

Fail_Safe = 1

Max_Diag_Data_Len = 6

Module = "VACON PPO 1" 0xF3, 0xF1

EndModule;

Module = "VACON PPO 2" 0xF3, 0xF5

EndModule;

Module = "VACON PPO 3" 0xF1

EndModule;

Module = "VACON PPO 4" 0xF5

EndModule;

________________________________________________________________________________________

Vacon Oyj Phone +358-201-2121 Fax: +358-201-212 205

Page 23

VACON CX Profibus user’s manual Page 23

________________________________________________________________________________________

APPENDIX A

CONNECTIONS (small Profibus DP Board, Vacon CX210OPT)

Board layout

H1

X5

H3

1 2 3 4 5

Figure 1. Profibus board

Terminals:

X5 Screw terminal to Profibus DP

Diagnostic LED:

H1 Data Exchange state for Profibus DP, Red.

H1 led is active when Fieldbus board is not ready to exchange data

H3 Supply Voltage, Red.

H3 led is active if the Fieldbus board has supply voltage.

Profibus connections

Screw Connector connector X5: (Terminal resistors not included in the package)

Signal Connector X5

Shield X5-1 Cable shield

VP X5-2 Supply voltage of the terminating resistance

RxD/TxD-P X5-3 Receive/Transmission data positive (B)

RxD/TxD-N X5-4 Receive/Transmission data negative (A)

DGND X5-5 Data Ground

Table 1. D-sub connector

Note! If Vacon is the last device then the bus termination must be set. Install the resistors to the screw

terminal (see table 5-1)

________________________________________________________________________________________

Vacon Oyj Phone +358-201-2121 Fax: +358-201-212 205

Description

Termination for

the last node

390 Ω

220 Ω

390 Ω

Page 24

VACON CX Profibus user’s manual Page 24

________________________________________________________________________________________

APPENDIX B

Special Actual Values

By default, the Actual Value corresponds to the motor rotation speed in percentage.

Actual Value can be attached some other monitored variable. Meaning of Actual Value can be selected

by resetting a Control Word bits 15...11. The user can choose to show one of the monitoring page

variables or the active fault code.

Control Word (bits 15...11) is binary coded as follows:

Control Word Description

bit 15 bit 14 bit 13 bit 12 bit 11

0 0 0 0 0 Default, Actual Speed (%)

0 0 0 0 1 V1 (see table 0-1)

0 0 0 1 0 V2 (see table 0-1)

0 0 0 1 1 V3 (see table 0-1)

.

.

1 1 1 0 1 V29 (see table 0-1)

1 1 1 1 0 Active Fault Code

1 1 1 1 1 Default, Actual Speed (%)

NOTE: The minimum interval allowed to change the bits above is 500ms!

# Data name Step Unit Description

V1 Output frequency 0,01 Hz Frequency to the motor

V2 Motor speed 1 rpm Calculated motor speed

V3 Motor current 0,1 A Measured motor current

V4 Motor torque 1 % Calculated actual torque/nominal torque of the

unit

V5 Motor power 1 % Calculated actual power/nominal power of the

unit

V6 Motor voltage 1 V Calculated motor voltage

V7 DC-link voltage 1 V Measured DC-link voltage

V8 Temperature 1 °C Temperature of the heat sink

V9 Operating day count DD.dd

V10 Operating hours, "trip

HH.hh

counter”

V11 MW-hours 0,001 MWh Total MW-hours, not resetable

V12 MW-hours, "trip

0,001 MWh MW-hours, can be reset with programmable

counter"

V13 Voltage/analogue

0,01 V Voltage of the terminal Uin+ (control board)

input

V14 Current/analogue

0,01 mA Current of terminals Iin+ and Iin- (control board)

input

V15 Digital input status,

0 = Open Input, 1 = Closed Input (Active)

gr. A

V16 Digital input status,

0 = Open Input, 1 = Closed Input (Active)

gr. B

V17 Digital and relay

0 = Open Input, 1 = Closed Input (Active)

output status

V18 Control program Version number of the control software

V19 Unit nominal power 0,1 kW Shows the power size of the unit

V20 Motor temperature

1 % 100%= temperature of motor has risen to nominal

rise

________________________________________________________________________________________

Vacon Oyj Phone +358-201-2121 Fax: +358-201-212 205

Operating days 1), not resetable

Operating hours 2), can be reset with program-

button #3

button #4

value

1)

DD = full days, dd = decimal part of a day

2)

HH = full hours, hh = decimal part of an hour

Page 25

APPENDIX C: INSTALLATION

Installation of Profibus DP in Vacon CXS drives

NOTE: The option boards on the pictures may not look exactly the same as the one you have

purchased. These instructions are, still, applicable.

Remove the control panel and the panel base.

A

Remove the fixing screw from the control

B

board and replace it with a stand sleeve (4).

Connect the power cable (5) to terminal X5

C

of the control board. The power cable can

also be connected to terminal X6 if terminal

X5 is already reserved by the power cable

from the power board.

4

5

Remove the protective foil of the plastic

D

board and place the plastic board above the

control board. Be sure to place the plastic

board correctly so that the stand sleeve (4)

comes out through the hole on the board.

E

Place the board on the protective plastic

board (6) and connect the data cable (2) to

terminal X14 of the control board. The stand

sleeve should come out through the metaledged hole.

F

Secure the board on the stand sleeve with

the screw (3) attached.

4

3

6

2

X14

Page 26

VACON CX Profibus user’s manual Page 26

________________________________________________________________________________________

Connect the power cable (5) to terminal X9

G

on the option board.

Attach the control panel base with four

H

screws.

Check the connections. Remove all foreign objects from inside the frequency drive. Put the

I

control panel and the frequency drive cover back to their places.

________________________________________________________________________________________

Vacon Oyj Phone +358-201-2121 Fax: +358-201-212 205

Page 27

V

ax:+358-20

ud188g.doc

13.5.2002

acon Oyj

P.O. Box 25

Runsorintie 7

FIN-65381 VAASA

FINLAND

Phone: +358-201-2121

F

1-212 205

Loading...

Loading...