Application Guide

VACON® 3000

drives.danfoss.com

VACON® 3000

Application Guide

Contents

1

Introduction 10

1.1

Purpose of this Application Guide 10

Manual and Software Version 10

1.2

Additional Resources 10

1.3

1.4

Parameter Table Reading Guide 10

1.5

Start-up Quick Guide 10

1.5.1

Start-Up Wizard for INU 10

1.5.2

Start-Up Wizard for AFE 11

User Interfaces 12

2

Description of the Control Panel 12

2.1

Control Panel and the Keypad 12

2.1.1

Displays of the Control Panel 12

2.1.2

Contents

Graphical Display 13

2.2

2.2.1

Uses of the Monitor Menu 13

2.2.2

Multimonitor Monitoring 13

2.2.2.1

2.2.3

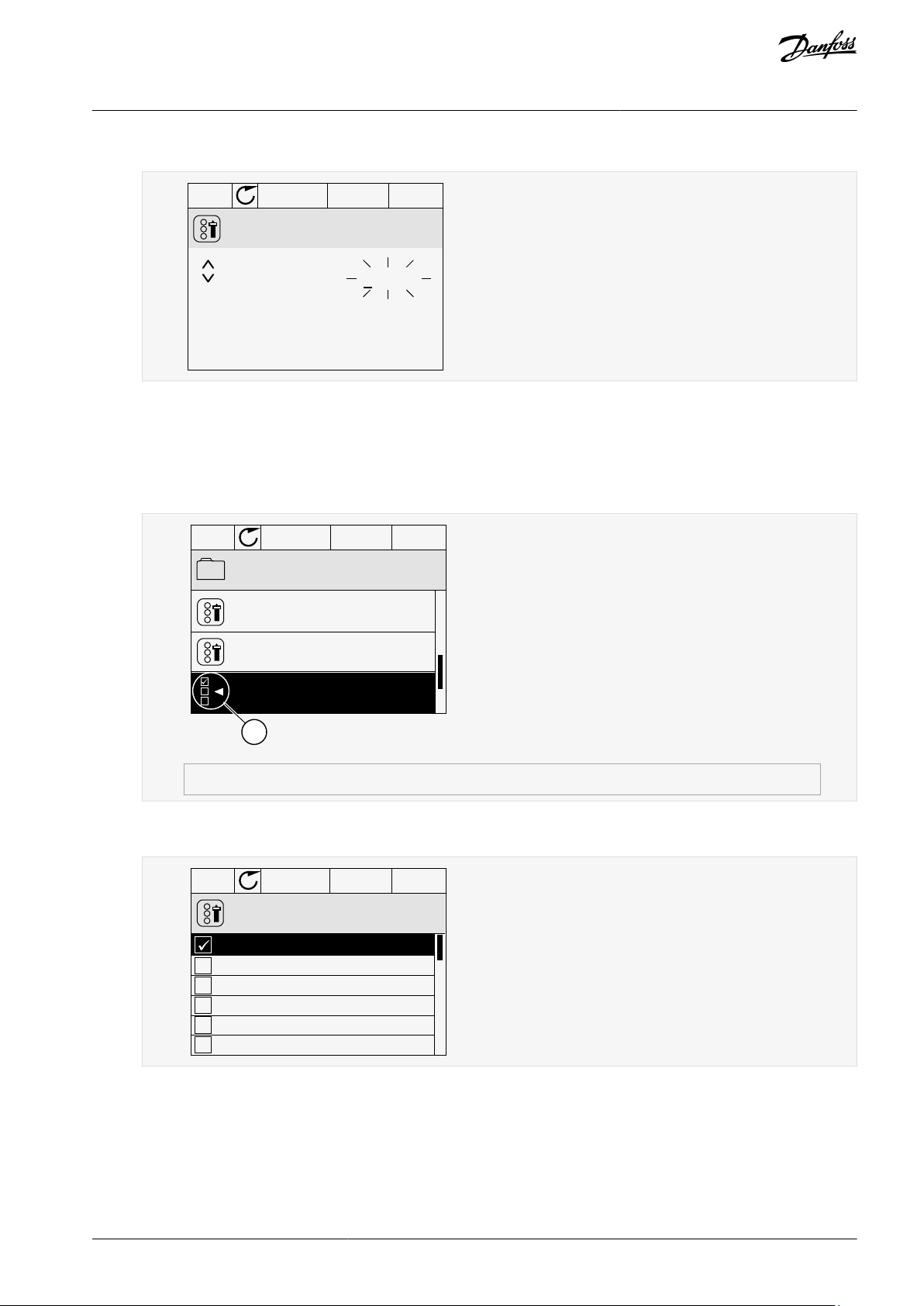

Editing the Text Values 14

2.2.4

Editing the Numerical Values 14

2.2.5

Selecting More than 1 Value 15

2.2.6

Faults 15

2.2.6.1

2.2.6.2

2.2.6.2.1

2.2.6.2.2

2.2.6.3

2.2.6.3.1

2.2.7

[FUNCT] Button 17

2.2.7.1

Changing the Items to Monitor 13

Uses of the Active Faults Submenu 15

Reset Faults 16

Resetting Faults with the [BACK/RESET] Button 16

Resetting Faults with a Parameter on the Graphical Display 16

Uses of the Fault History 16

Examining the Fault History on the Graphical Display 16

Different Control Places 17

2.2.7.2

2.2.7.3

2.2.7.4

2.2.7.5

2.2.8

Copying the Parameters of an AC Drive 19

2.2.9

Comparing the Parameters 20

2.2.10

Reading Help Texts 21

2.2.11

Using the Favourites Menu 22

Changing the Control Place 17

Going into the Control Page 18

Changing the Rotation Direction 18

Using the Quick Edit Function 19

AB319735759636en-000101/DPD01822 | 3Danfoss A/S © 2021.09

VACON® 3000

Application Guide

2.2.11.1

2.2.11.2

2.3

VACON® Live PC Tool 23

3

Programming of Digital and Analog Inputs 24

3.1

General Information on the Programming 24

3.2

DIP Switches on the Control Unit 24

3.2.1

Selection of Terminal Functions with DIP Switches 24

3.2.2

Isolation of the Digital Inputs from Ground 25

3.3

Programming of Digital Inputs 26

3.3.1

Programming of Digital Inputs in the Graphical Display 27

3.4

Programming of Analog Inputs 27

3.4.1

Programming of Analog Inputs in the Graphical Display 28

3.5

Descriptions of Signal Sources 29

3.6

Default Functions of Programmable Inputs 29

Adding an Item to the Favourites 22

Removing an Item from the Favourites 22

Contents

4

INU Application 30

4.1

Overview 30

4.2

Menu Structure 31

4.3

Quick Setup 33

4.4

Monitor Menu 35

4.4.1

Basic Monitoring 35

4.4.1.1

4.4.1.2

4.4.2

I/O Monitoring 36

4.4.3

Extras and Advanced 36

4.4.4

PID Controller Monitoring 38

4.4.5

Fieldbus Process Data Monitoring 38

4.4.6

Encoder Monitoring 40

4.4.7

Precharge Monitoring 42

4.5

Parameters Menu 46

4.5.1

Group 3.1: Motor Settings 46

Uses of the Basic Monitoring 35

Basic Monitoring Parameters 35

4.5.2

Group 3.2: Start/Stop Setup 51

4.5.3

Group 3.3: References 52

4.5.4

Group 3.4: Ramps and Brakes Setup 56

4.5.5

Group 3.5: I/O Configuration 57

4.5.6

Group 3.6: Fieldbus Data Mapping 64

4.5.7

Group 3.7: Prohibit Frequencies 65

4.5.8

Group 3.8 Supervisions 66

AB319735759636en-000101/DPD018224 | Danfoss A/S © 2021.09

VACON® 3000

Application Guide

4.5.9

Group 3.9: Protections 66

4.5.10

Group 3.10: Automatic Reset 71

4.5.11

Group 3.11: Application Settings 72

4.5.12

Group 3.12: PID Controller 73

4.5.13

Group 3.13: Motor Preheat Parameters 75

4.5.14

Group 3.14: Mechanical Brake 75

4.5.15

Group 3.15: Encoders 76

4.5.16

Group 3.17: Precharge 79

4.6

Diagnostics Menu 83

4.6.1

Counters 83

4.6.1.1

4.6.1.2

4.6.2

Software Info 84

4.6.3

Drive Info 84

Contents

Total Counters 83

Trip Counters 84

4.6.4

Unit Status 84

4.7

I/O and Hardware Menu 85

4.7.1

Basic I/O 85

4.7.2

Option Board Slots 85

4.7.3

Real-time Clock 86

4.7.4

Simple Network Time Protocol (SNTP) 86

4.7.5

Power Unit Settings 87

4.7.6

Keypad 87

4.7.7

Fieldbus 88

4.7.8

Fieldbus General 89

4.7.9

Fieldbus Redundancy 90

4.7.10

Aux Chain 91

4.7.11

MV-star 92

4.8

User Settings 93

4.8.1

User Settings Parameters 93

4.8.2

Parameter Backup Parameters 93

4.8.3

Parameter Compare Parameters 93

4.8.4

License Parameters 93

5

AFE Application 94

5.1

Overview 94

5.2

Menu Structure 94

5.3

Quick Setup 95

5.4

Monitor Menu 96

AB319735759636en-000101/DPD01822 | 5Danfoss A/S © 2021.09

VACON® 3000

Application Guide

5.4.1

AFE Monitor 96

5.4.2

I/O Monitoring 97

5.4.3

Extras and Advanced 98

5.4.4

Maintenance Counters 99

5.4.5

Fieldbus Process Data Monitoring 99

5.4.6

Precharge Monitoring 100

5.5

Parameters Menu 104

5.5.1

Group 3.1: Basic Parameters 104

5.5.2

Group 3.2: Control Parameters 105

5.5.3

Group 3.3: Precharge Parameters 107

5.5.4

Group 3.4: Start/Stop Setup 112

5.5.5

Group 3.5: I/O Configuration 113

5.5.6

Group 3.6: Fieldbus Data Mapping 119

5.5.7

Group 3.7 Supervisions 121

Contents

5.5.8

Group 3.8: Protections 122

5.5.9

Group 3.9: Automatic Reset 124

5.5.10

Group 3.10: Application Settings 125

5.5.11

Group 3.11: Maintenance Counters 125

5.6

Diagnostics Menu 126

5.6.1

Counters 126

5.6.1.1

5.6.1.2

5.6.2

Software Info 126

5.6.3

Drive Info 127

5.6.4

Unit Status 84

5.7

I/O and Hardware Menu 127

5.7.1

Basic I/O 127

5.7.2

Option Board Slots 85

5.7.3

Real Time Clock 128

5.7.4

Simple Network Time Protocol (SNTP) 129

Total Counters 126

Trip Counters 126

5.7.5

Power Unit Settings 87

5.7.6

Keypad 87

5.7.7

Fieldbus 88

5.7.8

Fieldbus General 131

5.7.9

Fieldbus Redundancy 132

5.7.10

Aux Chain 133

5.7.11

MV-star 92

5.8

User Settings 135

AB319735759636en-000101/DPD018226 | Danfoss A/S © 2021.09

VACON® 3000

Application Guide

5.8.1

User Settings Parameters 135

5.8.2

Parameter Backup Parameters 135

5.8.3

Parameter Compare Parameters 135

5.8.4

License Parameters 135

6

Monitoring value descriptions 136

7

Parameter descriptions 156

Fault tracing 269

8

Fault Types 269

8.1

Fault Code Definitions and Troubleshooting 269

8.2

Fault Code 1 - Overcurrent 269

8.2.1

Fault Code 2 - Overvoltage 270

8.2.2

Fault Code 3 - Earth Fault 271

8.2.3

8.2.4

Fault Code 5 - Charging Switch 272

Contents

8.2.5

Fault Code 7 - Saturation 272

8.2.6

Fault Code 8 - System Fault 272

8.2.7

Fault Code 9 - Undervoltage 278

8.2.8

Fault Code 10 - Input Phase 278

8.2.9

Fault Code 11 - Output Phase Supervision 280

8.2.10

Fault Code 12 - Brake Chopper Supervision 281

8.2.11

Fault Code 13 - AC Drive Undertemperature 281

8.2.12

Fault Code 14 - AC Drive Overtemperature 281

8.2.13

Fault Code 15 - Motor Stall 283

8.2.14

Fault Code 16 - Motor Overtemperature 283

8.2.15

Fault Code 17 - Motor Underload 283

8.2.16

Fault Code 19 - Power Overload 284

8.2.17

Fault Code 25 - Motor Control Fault 284

8.2.18

Fault Code 26 - Start-up Prevented 284

8.2.19

Fault Code 29 - ATEX Thermistor 285

8.2.20

Fault Code 30 - Safety 285

8.2.21

Fault Code 32 - Fan Cooling 288

8.2.22

Fault Code 33 - Fire Mode Enabled 288

8.2.23

Fault Code 37 - Device Changed (Same Type) 288

8.2.24

Fault Code 38 - Device Added (Same Type) 289

8.2.25

Fault Code 39 - Device Removed 289

8.2.26

Fault Code 40 - Device Unknown 290

8.2.27

Fault Code 41 - IGBT Temperature 290

AB319735759636en-000101/DPD01822 | 7Danfoss A/S © 2021.09

VACON® 3000

Application Guide

8.2.28

Fault Code 43 - Encoder Fault 291

8.2.29

Fault Code 44 - Device Changed (Different Type) 292

8.2.30

Fault Code 45 - Device Added (Different Type) 293

8.2.31

Fault Code 46 - Real Time Clock 294

8.2.32

Fault Code 47 - Software Update 294

8.2.33

Fault Code 49 - Precharge 294

8.2.34

Fault Code 50 - AI Low Fault 299

8.2.35

Fault Code 51 - Device External Fault 299

8.2.36

Fault Code 52 - Keypad Communication Fault 299

8.2.37

Fault Code 53 - Fieldbus Communication Fault 299

8.2.38

Fault Code 54 - Slot Fault 300

8.2.39

Fault Code 57 - Identification 301

8.2.40

Fault Code 58 - Mechanical Brake 301

8.2.41

Fault Code 59 - Communication 302

Contents

8.2.42

Fault Code 61 - Speed Error Fault 302

8.2.43

Fault Code 63 - Quick Stop 302

8.2.44

Fault Code 65 - PC Communication Fault 302

8.2.45

Fault Code 66 - Thermistor Input Fault 303

8.2.46

Fault Code 67 - Module Test Stand 303

8.2.47

Fault Code 68 - Maintenance Counter 303

8.2.48

Fault Code 69 - Fieldbus Mapping Error 304

8.2.49

Fault Code 76 - Start Prevented 304

8.2.50

Fault Code 77 - >5 Connections 304

8.2.51

Fault Code 78 - Identification Ongoing 305

8.2.52

Fault Code 80 - Fieldbus Watchdog Fault 305

8.2.53

Fault Code 84 - Overspeed Error 305

8.2.54

Fault Code 111 - Temperature Input Fault 1 305

8.2.55

Fault Code 112 - Temperature Input Fault 2 306

8.2.56

Fault Code 114 - User Defined Fault 1 306

8.2.57

Fault Code 115 - User Defined Fault 2 306

8.2.58

Fault Code 200 - Precharge 306

8.2.59

Fault Code 201 - High Humidity/Temperature 308

8.2.60

Fault Code 202 - Encoder 308

8.2.61

Fault Code 203 - STO Fault 308

8.2.62

Fault Code 204 - Output Filter 308

8.2.63

Fault Code 205 - Coolant Temperature 309

8.2.64

Fault Code 300 - Unsupported 309

8.3

Total and Trip Counters 309

AB319735759636en-000101/DPD018228 | Danfoss A/S © 2021.09

VACON® 3000

Application Guide

8.3.1

Operating Time Counter 309

8.3.2

Operating Time Trip Counter 310

8.3.3

Run Time Counter 310

8.3.4

Power on Time Counter 311

8.3.5

Energy Counter 311

8.3.6

Energy Trip Counter 312

9

Precharge 314

Contents

AB319735759636en-000101/DPD01822 | 9Danfoss A/S © 2021.09

Edition

Software version

DPD01822A

FW3000V004

Index

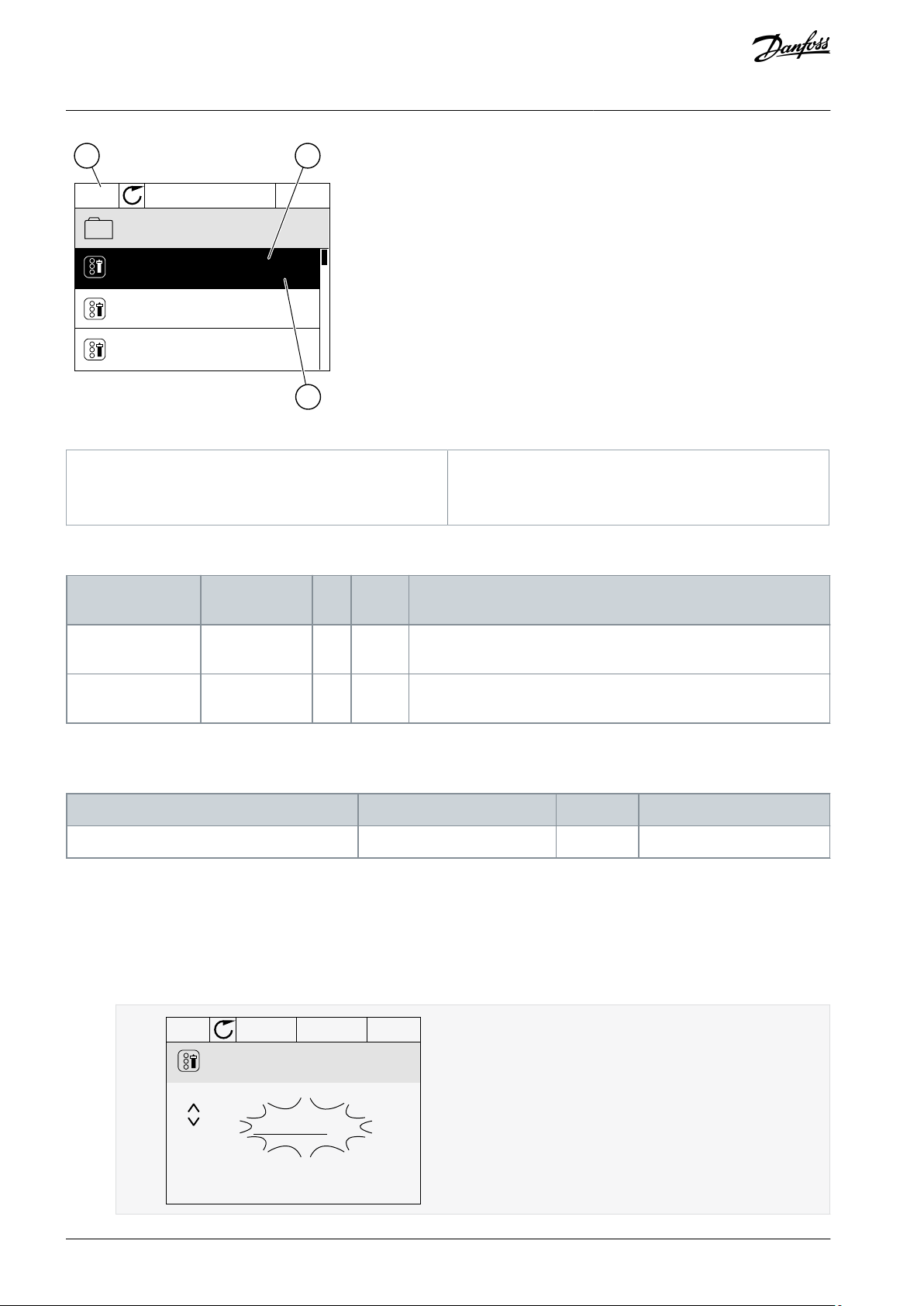

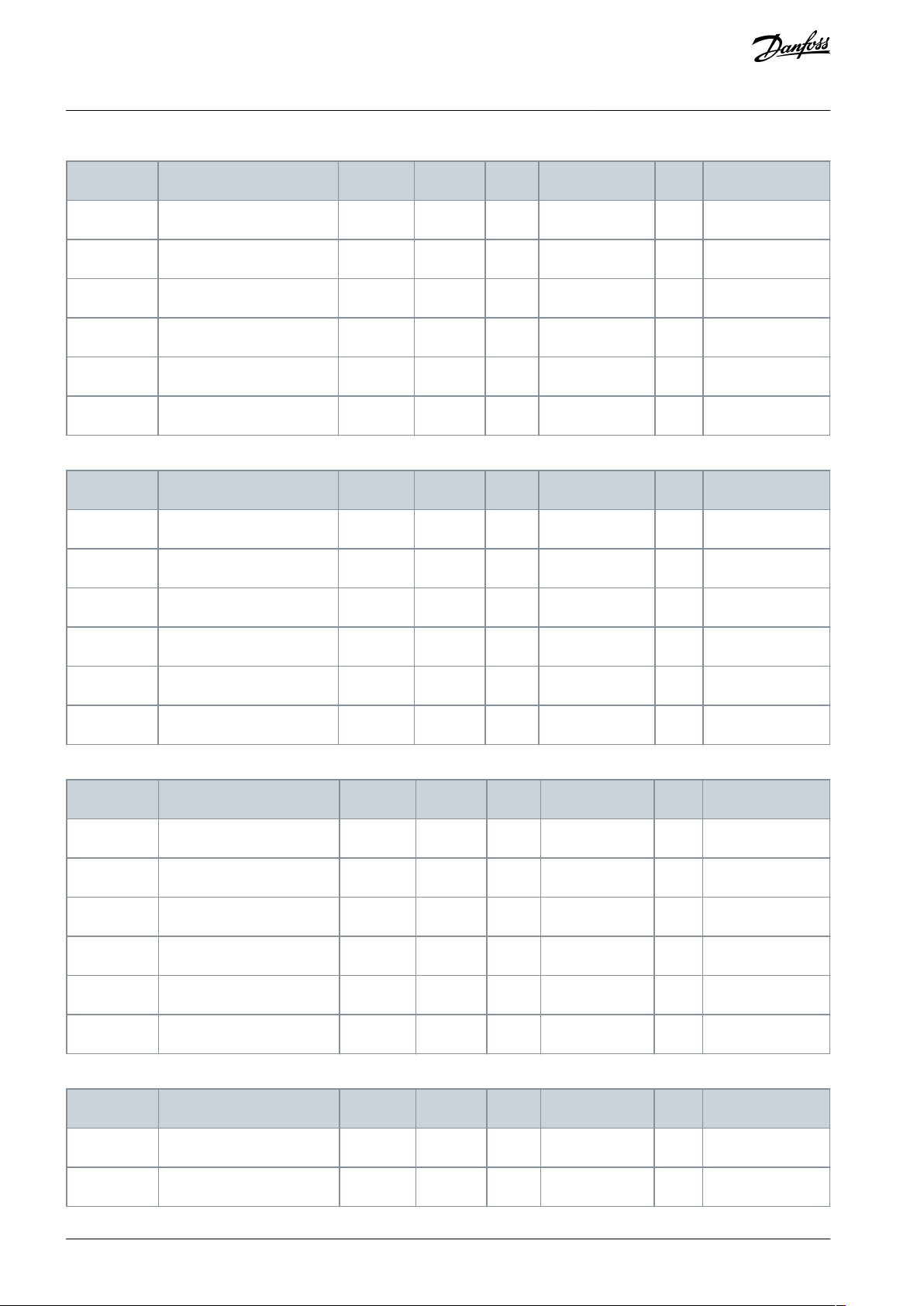

Min Max Unit Default

ID Description

Parameter

e30bg858.10

A

B

C

D E F G H

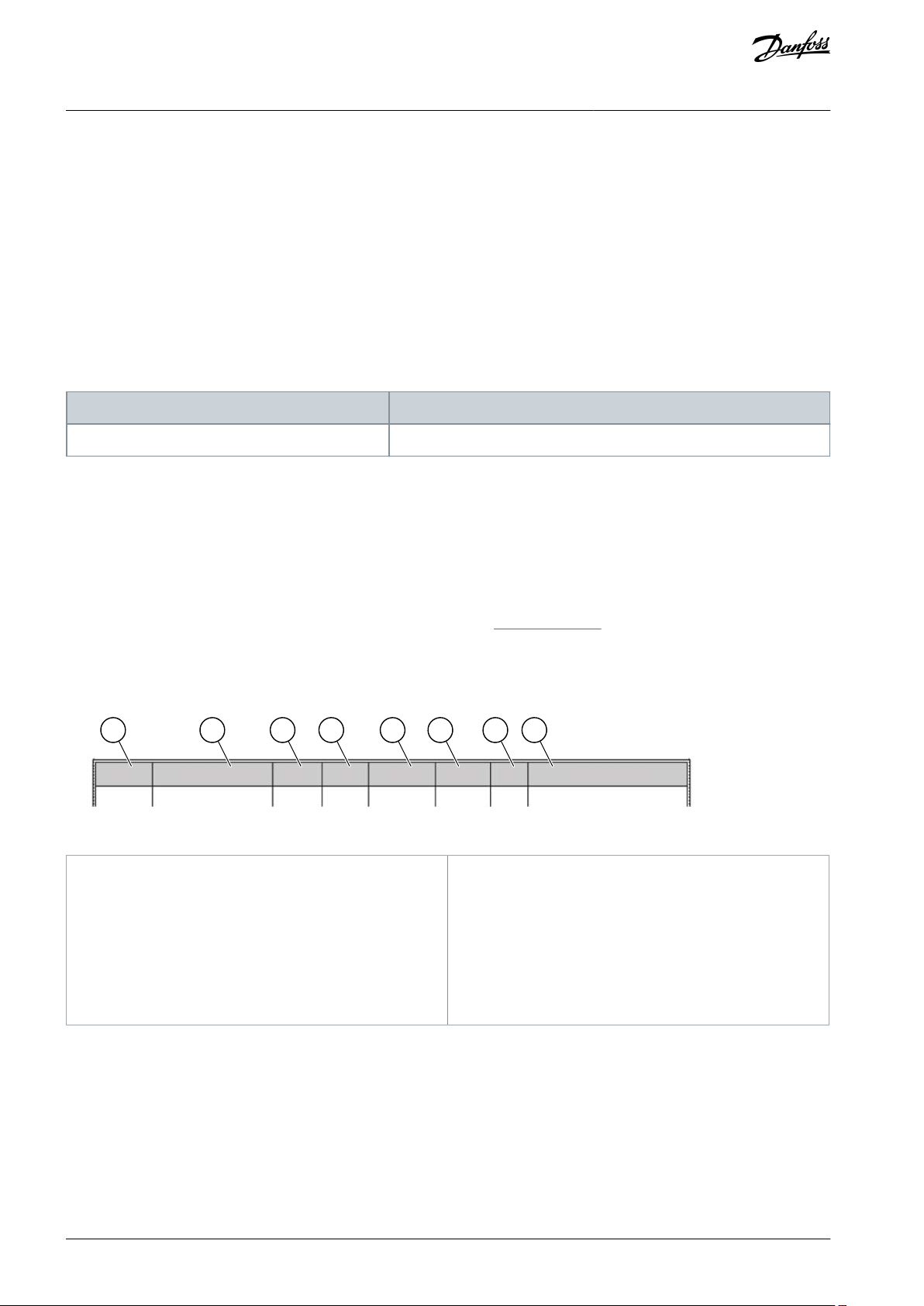

A

The location of the parameter in the menu, that is,

the parameter number.

B

The name of the parameter.

C

The minimum value of the parameter.

D

The maximum value of the parameter.

E

The unit of the value of the parameter. The unit

shows if it is available.

F

The value that was set in the factory.

G

The ID number of the parameter.

H

A short description of the values of the parameter

and/or its function.

VACON® 3000

Application Guide

Introduction

1 Introduction

1.1 Purpose of this Application Guide

This Application Guide provides information for configuring the system, controlling the AC drive, accessing parameters, programming, and troubleshooting of the AC drive. It is intended for use by qualified personnel. Read and follow the instructions to use the

drive safely and professionally. Pay particular attention to the safety instructions and general warnings that are provided in this

manual and other documentation delivered with the drive.

1.2 Manual and Software Version

This manual is regularly reviewed and updated. All suggestions for improvement are welcome.

The original language of this manual is English.

Table 1: Manual and Software Version

1.3 Additional Resources

Other resources are available to understand advanced AC drive functions and operation.

•

The VACON® 3000 Design Guide provides technical information to understand the capabilities of the VACON® 3000 Drive Kit for

integration into motor control and monitoring systems.

•

The VACON® 3000 Operating Guides provide detailed information for the installation, commissioning, and start-up of the drive.

•

The operating and installation guides for VACON® options give detailed information about specific drive options.

Supplementary publications and manuals are available from Danfoss. See www.danfoss.com for listings.

1.4 Parameter Table Reading Guide

This manual includes a large quantity of parameter tables. These instructions tell you how to read the tables.

Illustration 1: Parameter Table Reading Guide

1.5 Start-up Quick Guide

The start-up wizard makes the commissioning of the drive easy and reduces the manual work with the parameters. It is also possible

to edit these parameters later.

1.5.1 Start-Up Wizard for INU

The start-up wizard tells you to give necessary data for the drive to control your procedure.

Procedure

AB319735759636en-000101 / DPD0182210 | Danfoss A/S © 2021.09

VACON® 3000

Application Guide

1.

Select language (P6.1).

If a battery is installed, the steps 2–5 are shown.

2.

Set daylight saving time (P5.5.5). (Russia, US, EU, or OFF)

3.

Set time (P5.5.2).

4.

Set year (P5.5.4).

5.

Set date (P5.5.3).

6.

Run start-up wizard?

If the selection is No, the start-up wizard ends.

7.

Set a value for P3.1.2.2 Motor Type (so that it agrees with the nameplate).

8.

Set a value for P3.1.1.1 Motor Nominal Voltage (so that it agrees with the nameplate).

9.

Set a value for P3.1.1.2 Motor Nominal Frequency (so that it agrees with the nameplate).

10.

Set a value for P3.1.1.3 Motor Nominal Speed (so that it agrees with the nameplate).

11.

Set a value for P3.1.1.4 Motor Nominal Current.

12.

Set a value for P3.1.1.5 Motor Cos Phi.

13.

Set a value for P3.3.1.1 Minimum Frequency Reference.

14.

Set a value for P3.3.1.2 Maximum Frequency Reference.

15.

Set a value for P3.4.1.2 Acceleration Time 1.

16.

Set a value for P3.4.1.3 Deceleration Time 1.

After these selections, the start-up wizard is completed. To start the start-up wizard again, go to the parameter B6.5.1 Restore Factory Defaults.

Introduction

1.5.2 Start-Up Wizard for AFE

The start-up wizard tells you to give necessary data for the drive to control your procedure.

Procedure

1.

Select language (P6.1).

If a battery is installed, the steps 2–5 are shown.

2.

Set daylight saving time (P5.5.5). (Russia, US, EU, or OFF)

3.

Set time (P5.5.2).

4.

Set year (P5.5.4).

5.

Set date (P5.5.3).

After these selections, the start-up wizard is completed. To start the start-up wizard again, go to the parameter B6.5.1 Restore Factory Defaults.

AB319735759636en-000101 / DPD01822 | 11Danfoss A/S © 2021.09

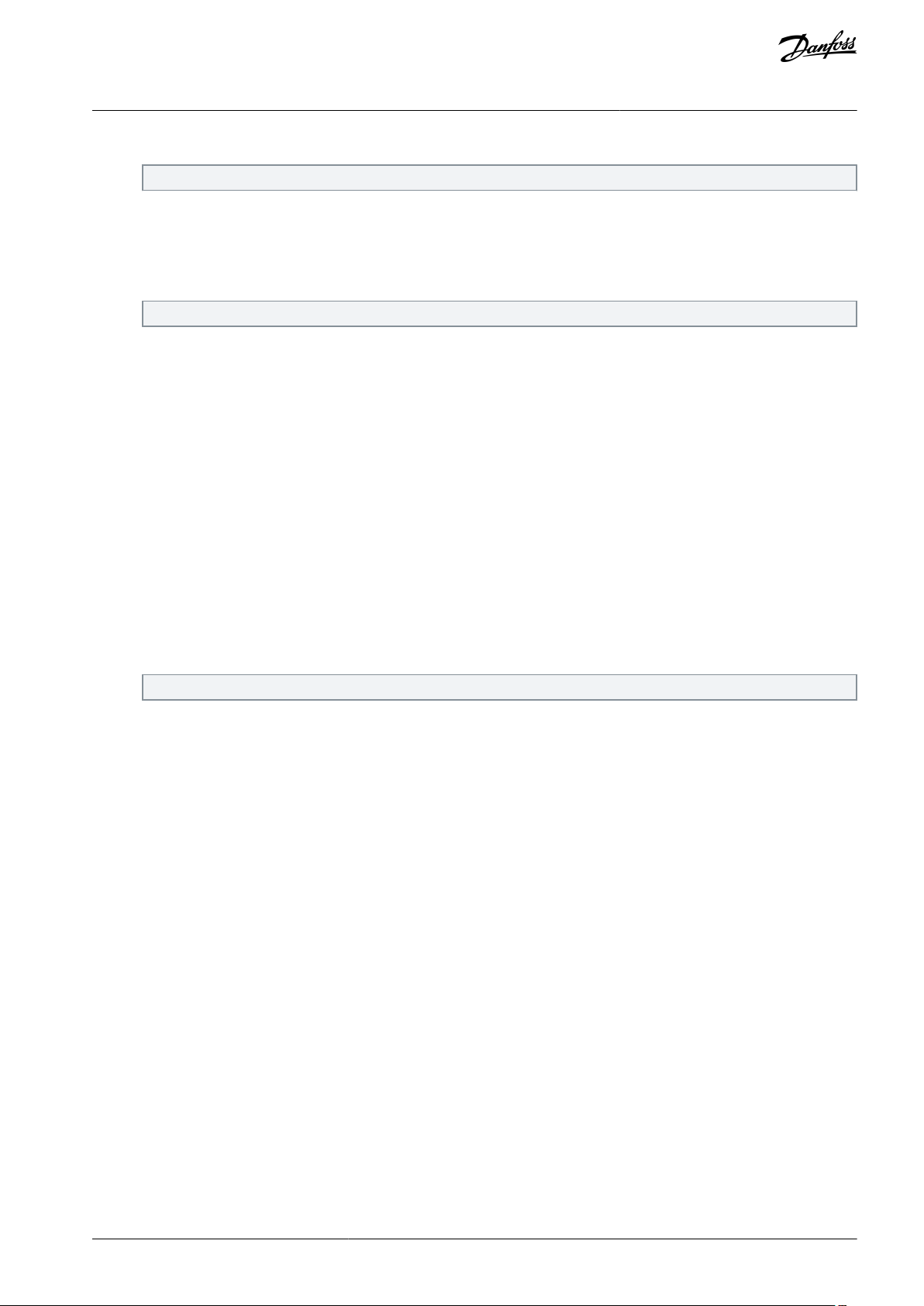

e30bu012

A

B C

I

H D

G

F E

A

The [BACK/RESET] button. Use it to move back in the

menu, exit the Edit mode, reset a fault.

B

The arrow button UP. Use it to scroll up the menu

and to increase a value.

C

The [FUNCT] button. Use it to change the rotation

direction of the motor, access the control page, and

change the control place.

D

The arrow button RIGHT.

E

The START button.

F

The arrow button DOWN. Use it to scroll the menu

down and to decrease a value.

G

The STOP button.

H

The arrow button LEFT. Use it to move the cursor

left.

I

The [OK] button. Use it to go into an active level or

item, or to accept a selection.

VACON® 3000

Application Guide

User Interfaces

2 User Interfaces

2.1 Description of the Control Panel

2.1.1 Control Panel and the Keypad

The control panel is the interface between the AC drive and the user. With the control panel, you can control the speed of a motor

and monitor the status of the AC drive. You can also set the parameters of the AC drive.

Illustration 2: Buttons of the Keypad

2.1.2 Displays of the Control Panel

The display shows this data.

•

The status of the motor and the drive.

•

Faults in the motor and in the drive.

•

Your location in the menu structure.

If the text in the text display is too long for the display, the text scrolls to show the full text string. Some functions are only available

in the graphical display.

AB319735759636en-000101 / DPD0182212 | Danfoss A/S © 2021.09

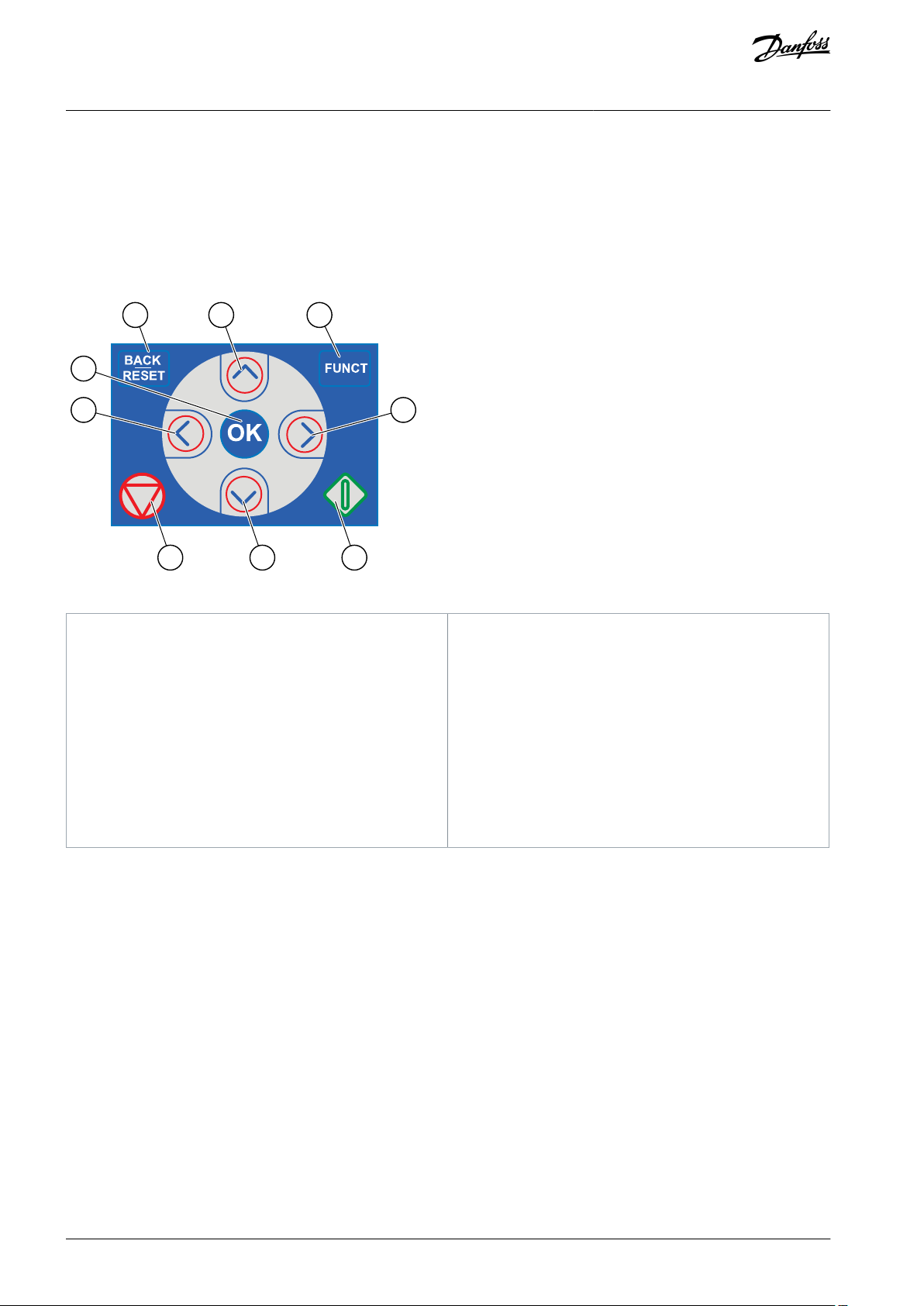

STOP

READY

I/O

Main Menu

A

B C D E

F

H

G

Quick Setup

( 17 )

Monitor

( 5 )

Parameters

( 12 )

M1ID:

e30bu013.10

A

The first status field: STOP/RUN

B

The rotation direction of the motor

C

The second status field: READY/NOT READY/FAULT

D

The alarm field: ALARM/-

E

The control place field: PC/I/O/KEYPAD/ FIELDBUS

F

The location field: the ID number of the parameter

and the current location in the menu

G

An activated group or item

H

The number of items in the group in question

STOP

READY I/O

ID:25

FreqReference

Multimonitor

20.0 Hz

Motor Curre

0.00A

DC-link volt

0.0V

Output Freq

0.00 Hz

Motor Speed

0.0 rpm

Motor Voltage

0.0V

Motor Tempera

0.0%

Motor Torque

0.00 %

Unit Tempera

81.9°C

FreqReference

e30bg686.10

VACON® 3000

Application Guide

Illustration 3: Graphical Display of the Control Panel

User Interfaces

2.2 Graphical Display

2.2.1 Uses of the Monitor Menu

Monitor Menu allows monitoring the actual values of the parameters and signals. It also allows monitoring the statuses and measurements. Some of the values to be monitored can be customized.

2.2.2 Multimonitor Monitoring

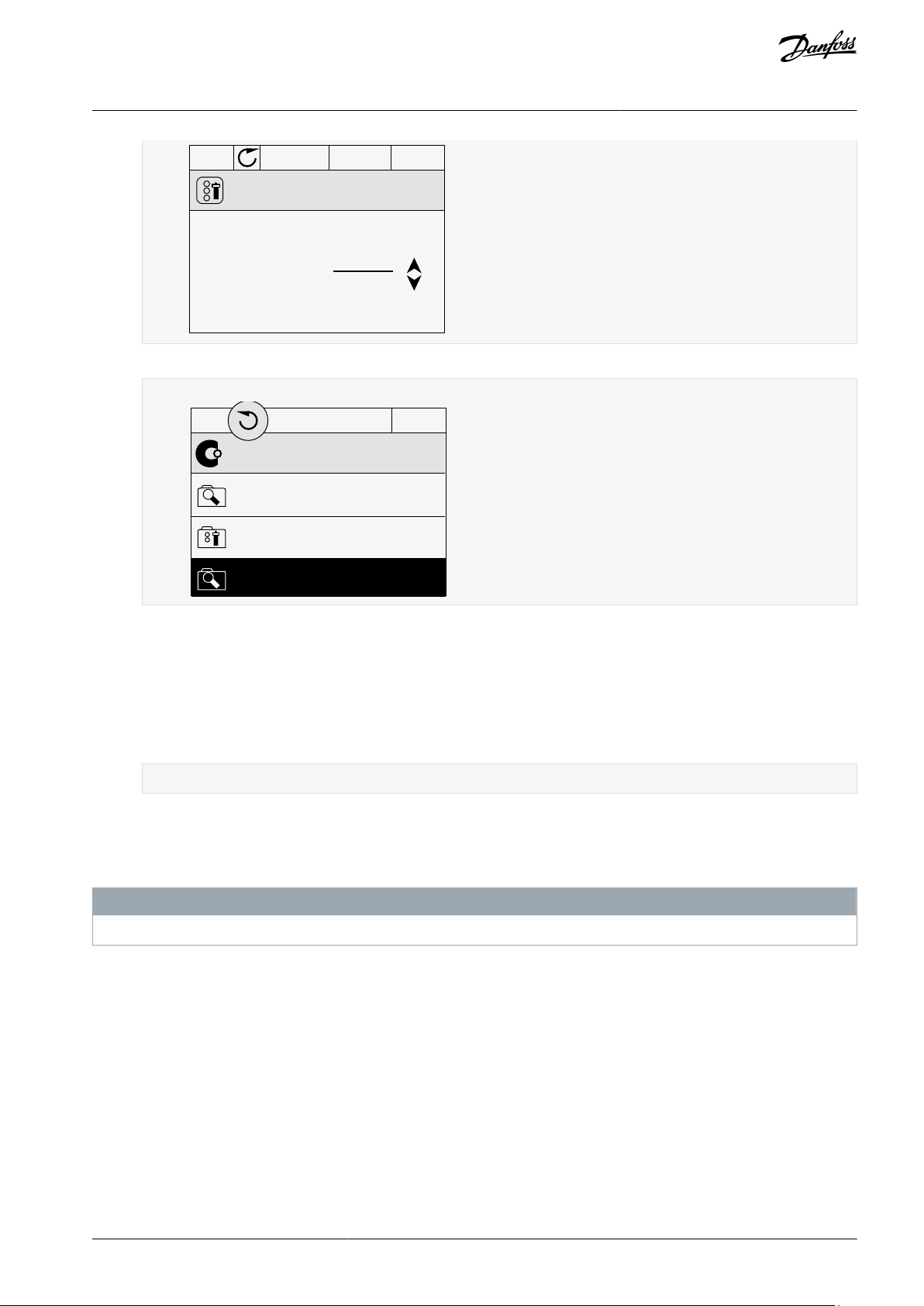

2.2.2.1 Changing the Items to Monitor

On the Multimonitor page, 4–9 items can be monitored. Select the number of items with the parameter Multimonitor View (ID 1196)

in the Application Settings menu.

Procedure

1.

Go into the Monitor menu with the [OK] button.

2.

Go into Multimonitor.

To replace an old item, activate it. Use the arrow buttons.

3.

AB319735759636en-000101 / DPD01822 | 13Danfoss A/S © 2021.09

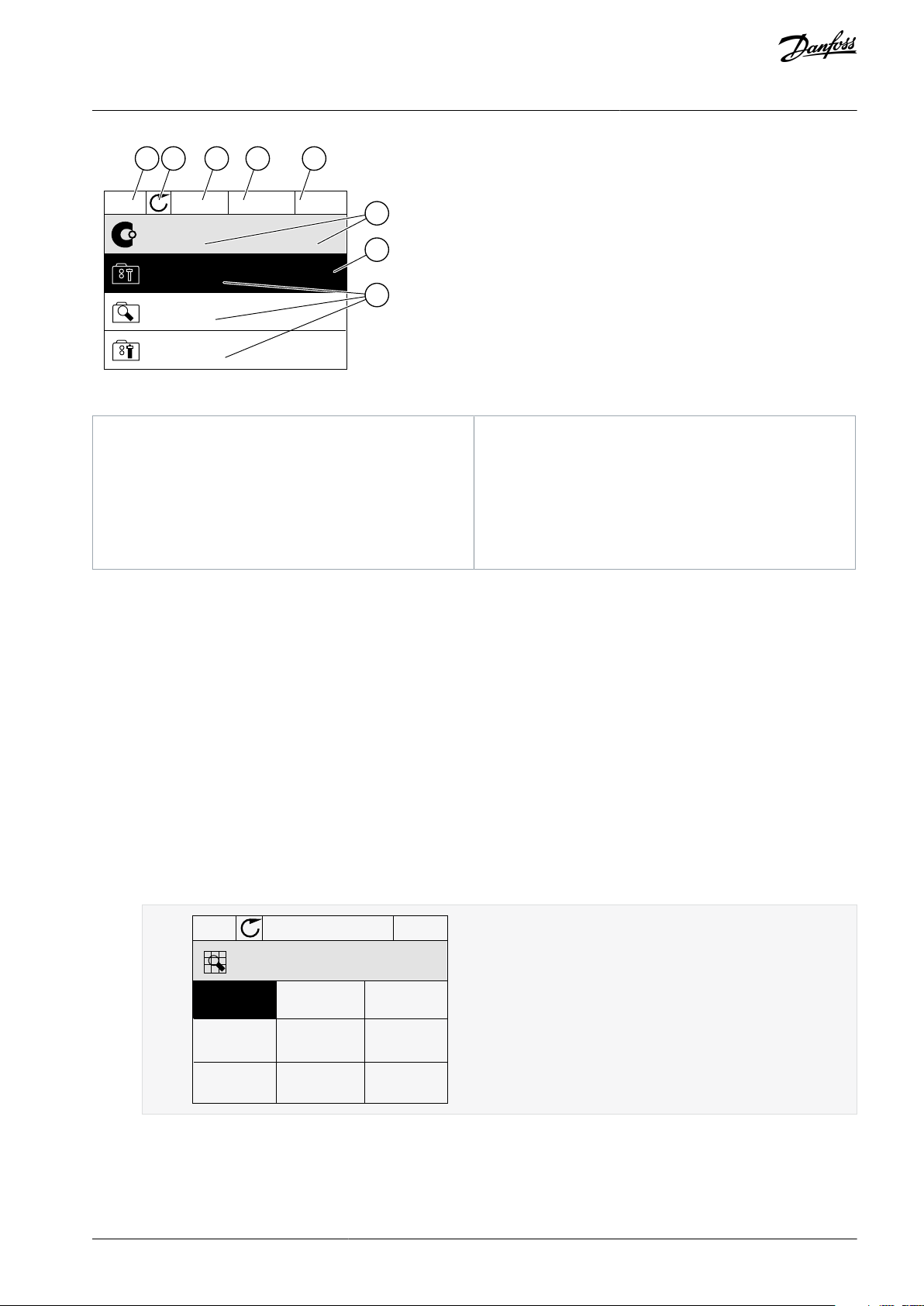

STOP

READY I/O

ID:1 M2.1.1.1

FreqReference

0.00 %

Motor Power

Output frequency

FreqReference

Motor Speed

Motor Current

Motor Torque

0.00 Hz

10.00 Hz

0.00 rpm

0.00 A

0.00 %

e30bg687.10

STOP

READY

I/O

Rem Control Place

M3.2.1

ID:

Edit

Help

Add to favourites

e30bu017.10

STOP

READY

I/O

Rem Control Place

M3.2.1ID:

FieldbusCTRL

I/O Control

e30bu018.10

VACON® 3000

Application Guide

4.

To select a new item in the list, push [OK].

2.2.3 Editing the Text Values

This topic gives instructions on how to edit the text values on the graphical display.

Procedure

1.

Find the parameter with the arrow buttons.

2.

To go to the Edit mode, push the [OK] button 2 times or push the arrow button Right.

User Interfaces

3.

To set a new value, push the arrow buttons Up and Down.

4.

To accept the change, push the [OK] button. To ignore the change, use the [BACK/RESET] button.

2.2.4 Editing the Numerical Values

This topic gives instructions on how to edit the numerical values on the graphical display.

Procedure

1.

Find the parameter with the arrow buttons.

2.

To go to the Edit mode, push the [OK] button 2 times or push the arrow button Right.

AB319735759636en-000101 / DPD0182214 | Danfoss A/S © 2021.09

STOP

READY

I/O

MinFreqReference

P3.3.1.1

ID:101

0.00 Hz

Min: 0.00Hz

Max: 50.00Hz

e30bu020.10

STOP

READY

I/O

P3.12.1.3ID:1466

Interval 1

00:00:00

00:00:00

ON Time

OFF Time

Days

0

A

e30bu023.10

A

The symbol of the checkbox selection

STOP

READY

I/O

M 3.12.1.3.1

ID:

Days

Monday

Tuesday

Wednesday

Thursday

Friday

Sunday

e30bu025.10

VACON® 3000

Application Guide

3.

Move from digit to digit with the arrow buttons Left and Right. Change the digits with the arrow buttons Up and Down.

4.

To accept the change, push the [OK] button. To ignore the change, use the [BACK/RESET] button.

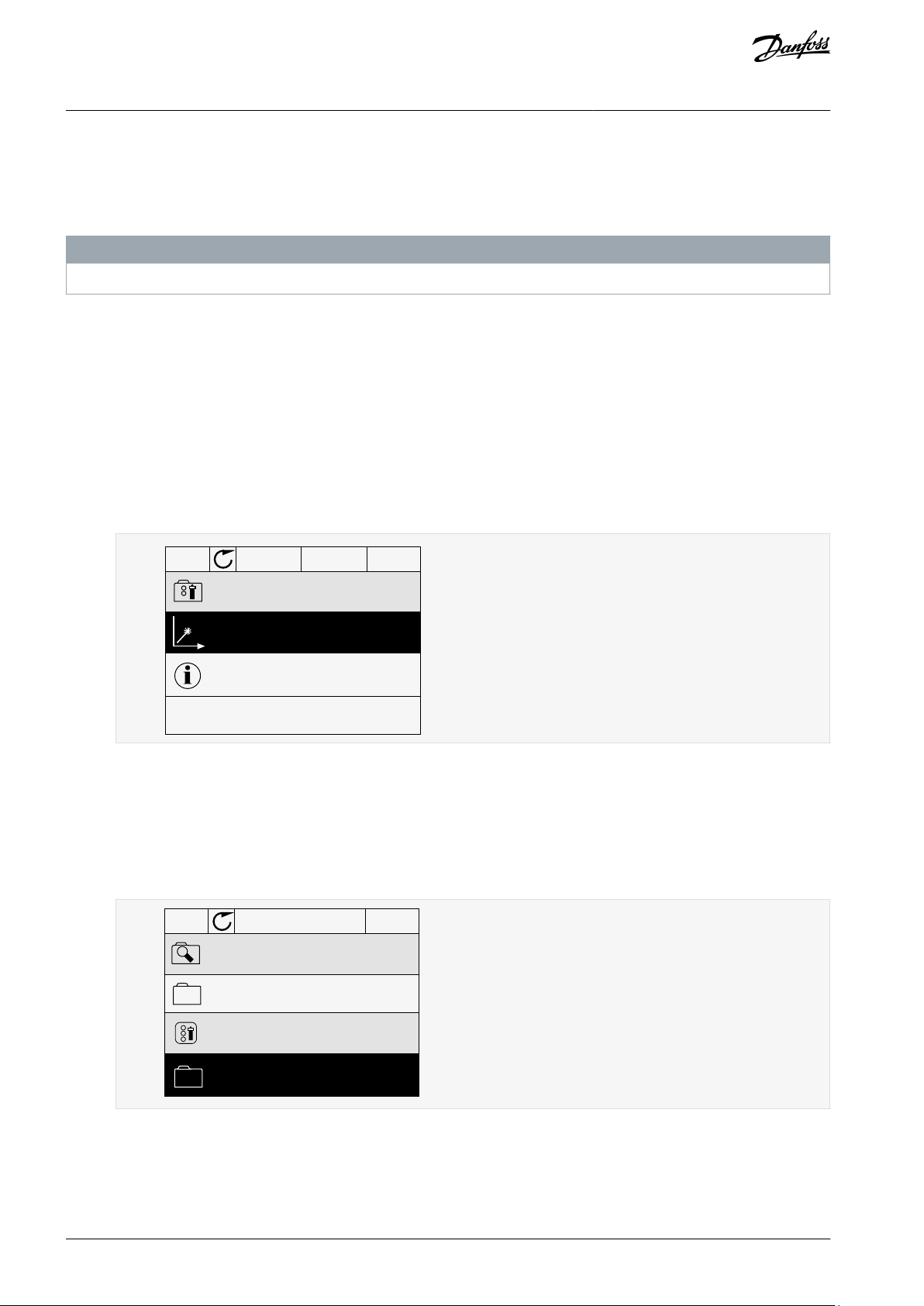

2.2.5 Selecting More than 1 Value

With some parameters, more than 1 value can be selected. Select a checkbox at each necessary value.

Procedure

1.

Find the parameter. There is a symbol on the display when a checkbox selection is possible.

User Interfaces

2.

To move in the list of values, use the arrow buttons Up and Down.

3.

To add a value into your selection, select the box that is next to it with the arrow button Right.

2.2.6 Faults

2.2.6.1 Uses of the Active Faults Submenu

When there is a fault or many faults, the display shows the name of the fault and blinks. Push [OK] to go back to the Diagnostics

menu. The submenu Active faults shows the number of faults. To see the fault-time data, select a fault and push [OK].

The Active faults submenu can keep storage of maximum 10 faults. The submenu shows the faults in the sequence in which they

occurred.

AB319735759636en-000101 / DPD01822 | 15Danfoss A/S © 2021.09

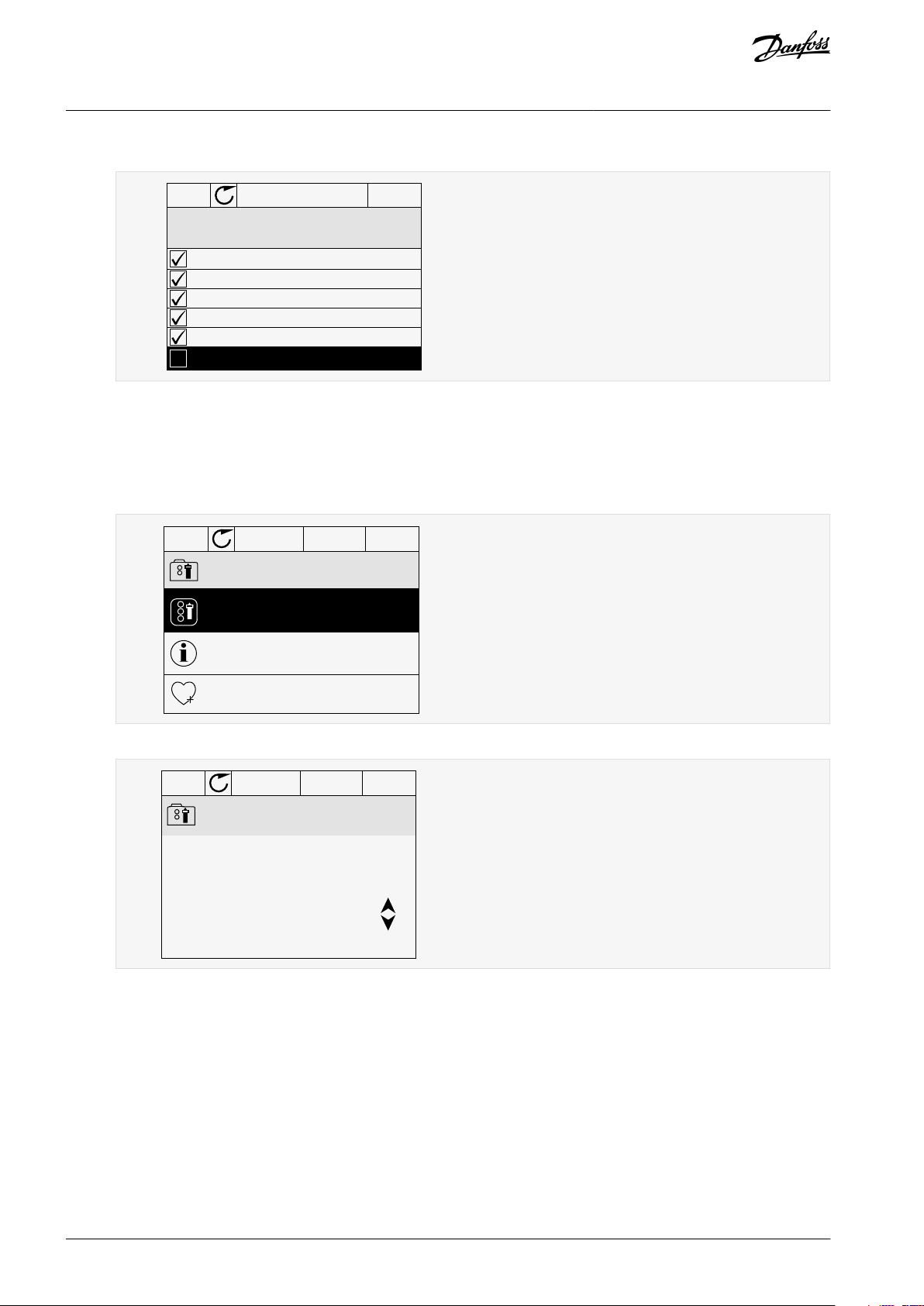

STOP

READY I/O

ID: M4.2

Reset faults

Help

Reset faults

e30bg663.10

Active faults

( 0 )

( 39 )

STOP

READY I/O

Diagnostics

M4.1ID:

Reset faults

Fault history

e30bg665.10

VACON® 3000

Application Guide

User Interfaces

2.2.6.2 Reset Faults

When the drive shows a fault and stops, examine the cause of fault, and reset the fault. The fault stays active until it is reset.

There are 2 procedures to reset a fault in the local control place: with the [BACK/RESET] button and with a parameter. It is also possi-

ble to reset faults by using I/O, a fieldbus, or a PC tool.

N O T I C E

Before resetting the fault, remove the external control signal to prevent restarting the drive accidentally.

2.2.6.2.1 Resetting Faults with the [BACK/RESET] Button

Procedure

1.

Push the [BACK/RESET] button on the keypad of the control panel for 2 seconds.

2.2.6.2.2 Resetting Faults with a Parameter on the Graphical Display

Faults can be reset with the parameter Reset Faults.

Procedure

1.

Go to the Diagnostics Menu.

2.

Go to the submenu Reset faults.

Select the parameter Reset Faults.

3.

2.2.6.3 Uses of the Fault History

The Fault history shows more data on the faults. There is a maximum number of 40 faults in the Fault history.

2.2.6.3.1 Examining the Fault History on the Graphical Display

Procedure

1.

To see more data on a fault, go to Fault history.

2.

To examine the data of a fault, push the Arrow button Right.

AB319735759636en-000101 / DPD0182216 | Danfoss A/S © 2021.09

STOP

READY

I/O

Code 39

Source 3

Source 1

ID

380

State

Info old

Date

7.12.2009

Time

04:46:33

Operating time

862537s

Source 2

Fault history

M4.3.3.2ID:

e30bg666.10

STOP

READY Keypad

ID:1805

Choose action

Control page

Change direction

Local/Remote

e30bu027.10

VACON® 3000

Application Guide

3.

Examine the data in a list.

2.2.7 [FUNCT] Button

The [FUNCT] button can be used for 4 functions.

•

To have access to the Control page.

•

To change easily between the Local and Remote control places.

•

To change the rotation direction.

•

To edit quickly a parameter value.

User Interfaces

2.2.7.1 Different Control Places

The selection of the control place determines from where the AC drive takes the start and stop commands. All the control places

have a parameter for the selection of the frequency reference source. The Local control place is always Keypad. The Remote control

place is I/O or Fieldbus. The status bar of the display shows the current control place.

It is possible to use I/O A, I/O B, and Fieldbus as Remote control places. I/O A and Fieldbus have the lowest priority. Select them with

P3.2.1 (Remote Control Place). I/O B can bypass the Remote control places I/O A and Fieldbus with a digital input. Select the digital

input with parameter P3.5.1.7 (I/O B Control Force).

Keypad is always used as a control place when the control place is Local. Local control has higher priority than Remote control. For

example, if parameter P3.5.1.7 bypasses the control place with a digital input, and Local is selected in Remote control, Keypad becomes the control place. Use the [FUNCT] button or P3.2.2 Local/Remote to change between the Local and Remote control.

2.2.7.2 Changing the Control Place

This topic gives instructions on how to change the control place on the control panel.

Procedure

Anywhere in the menu structure, push the [FUNCT] button.

1.

To select Local/Remote, use the arrow buttons Up and Down. Push the [OK] button.

2.

AB319735759636en-000101 / DPD01822 | 17Danfoss A/S © 2021.09

STOP

READY Keypad

ID:211

Local/Remote

Remote

Local

e30bu028.10

STOP

READY Keypad

ID: 168

Keypad Reference

0.00Hz

Output Frequency

Motor Current

Motor Torque

Motor Power

0.00Hz

0.00A

0.00%

0.00%

e30bg671.10

VACON® 3000

Application Guide

3.

To select Local or Remote, use the arrow buttons Up and Down again. To accept the selection, push the [OK] button.

User Interfaces

4.

If Remote control place is changed to Local, that is, Keypad, give a keypad reference.

After the selection, the display goes back into the same location where it was when the [FUNCT] button was push-

ed.

2.2.7.3 Going into the Control Page

It is easy to monitor the most important values in the Control page.

If other control places or reference values are used, the display shows the frequency reference, which cannot be edited. The other

values on the page are Multimonitor values. These monitoring values can be selected.

Procedure

Anywhere in the menu structure, push the [FUNCT] button.

1.

2.

To select the Control page, push the arrow buttons Up and Down. Go in with the [OK] button.

The Control page opens.

With the Local control place and the keypad reference selected, P3.3.1.8 Keypad Reference can be set with the [OK] button.

3.

To change the digits in the value, push the arrow buttons Up and Down. Accept the change with the [OK] button.

4.

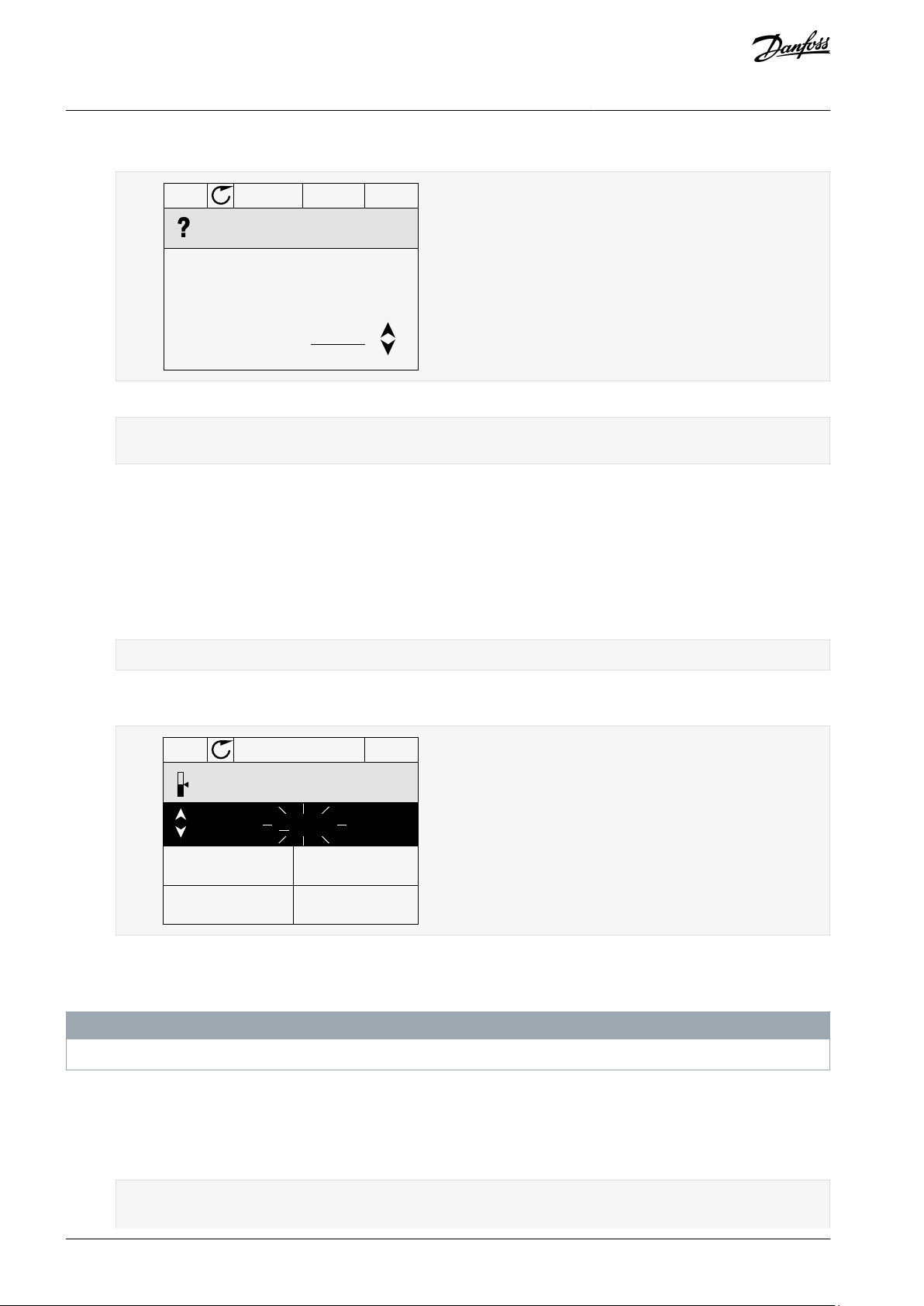

2.2.7.4 Changing the Rotation Direction

The rotation direction of the motor can be changed quickly with the [FUNCT] button.

N O T I C E

The command Change direction is available in the menu only if the current control place is Local.

Procedure

1.

Anywhere in the menu structure, push the [FUNCT] button.

2.

To select Change direction, push the arrow buttons Up and Down. Push the [OK] button.

3.

Select a new rotation direction.

The current rotation direction blinks.

AB319735759636en-000101 / DPD0182218 | Danfoss A/S © 2021.09

RUN

READY Keypad

ID:1805

Choose action

Forward

Reverse

e30bg672.10

STOP

READY I/O

ID:

M1

Main Menu

Monitor

( 7 )

Parameters

( 15 )

Diagnostics

( 6 )

e30bg673.10

VACON® 3000

Application Guide

4.

Push the [OK] button.

The rotation direction changes immediately. The arrow indication in the status field of the display changes.

User Interfaces

2.2.7.5 Using the Quick Edit Function

With the Quick Edit function, a parameter can be accessed quickly by typing the ID number of the parameter.

Procedure

1.

Anywhere in the menu structure, push the [FUNCT] button.

2.

Push the arrow buttons Up and Down to select Quick Edit and accept with the [OK] button.

Write the ID number of a parameter or monitoring value. Push [OK].

3.

The display shows the parameter value in the edit mode and the monitoring value in the monitoring mode.

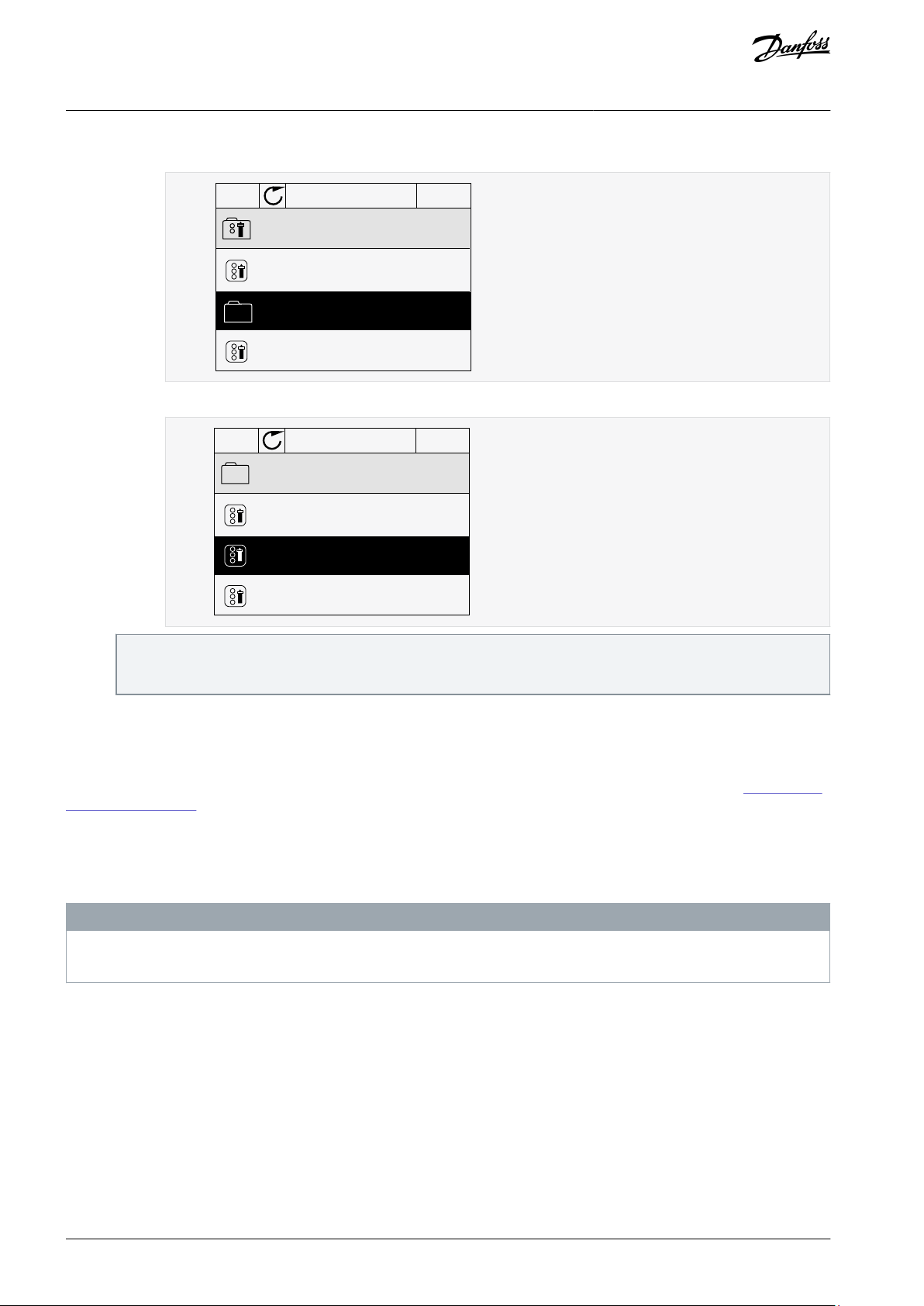

2.2.8 Copying the Parameters of an AC Drive

Use this function to copy parameters from a drive to another. Before downloading parameters from the control panel to the drive,

stop the drive.

N O T I C E

This function is available only in the graphical display.

Procedure

1.

Save the parameters to the control panel.

a.

Go into the User settings menu.

AB319735759636en-000101 / DPD01822 | 19Danfoss A/S © 2021.09

STOP

READY Keypad

ID: M6.5

User settings

Language selection

English

Parameter backup

( 7 )

Drive name

Drive

e30bg674.10

STOP

READY Keypad

ID: M6.5.1

Parameter backup

Restore factory defaults

Save to keypad

Restore from keypad

e30bg675.10

VACON® 3000

Application Guide

b.

Go into the Parameter backup submenu.

c.

Use the arrow buttons Up and Down to select a function. Accept the selection with the [OK] button.

User Interfaces

The command Restore factory defaults brings back the parameter settings that were made at the factory. Use the command Save to keypad to copy all the parameters to the control panel. The command Restore from keypad copies all the

parameters from the control panel to the drive.

2.

Detach the control panel and connect it to another drive.

3.

Download the parameters to the new drive with the command Restore from keypad.

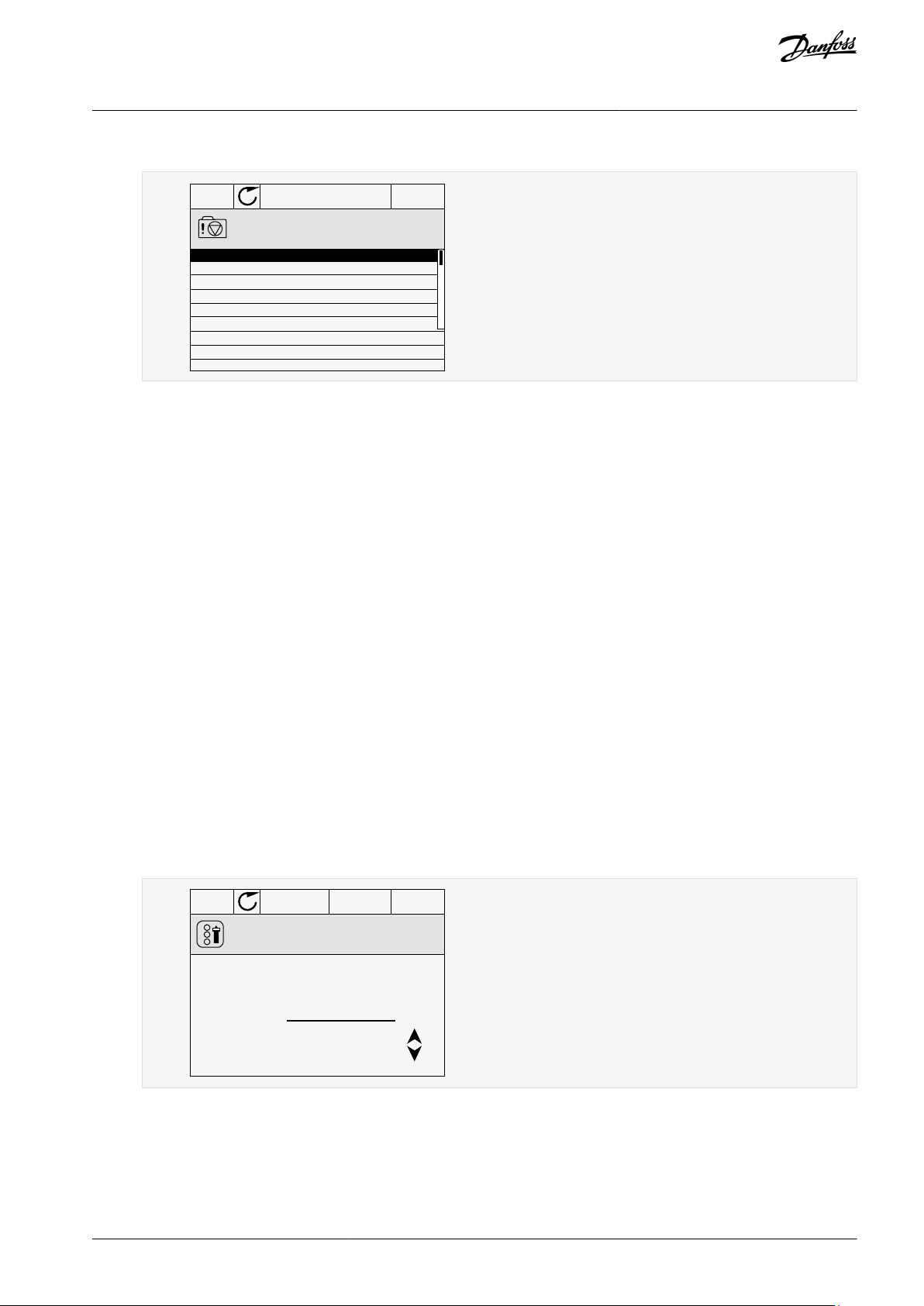

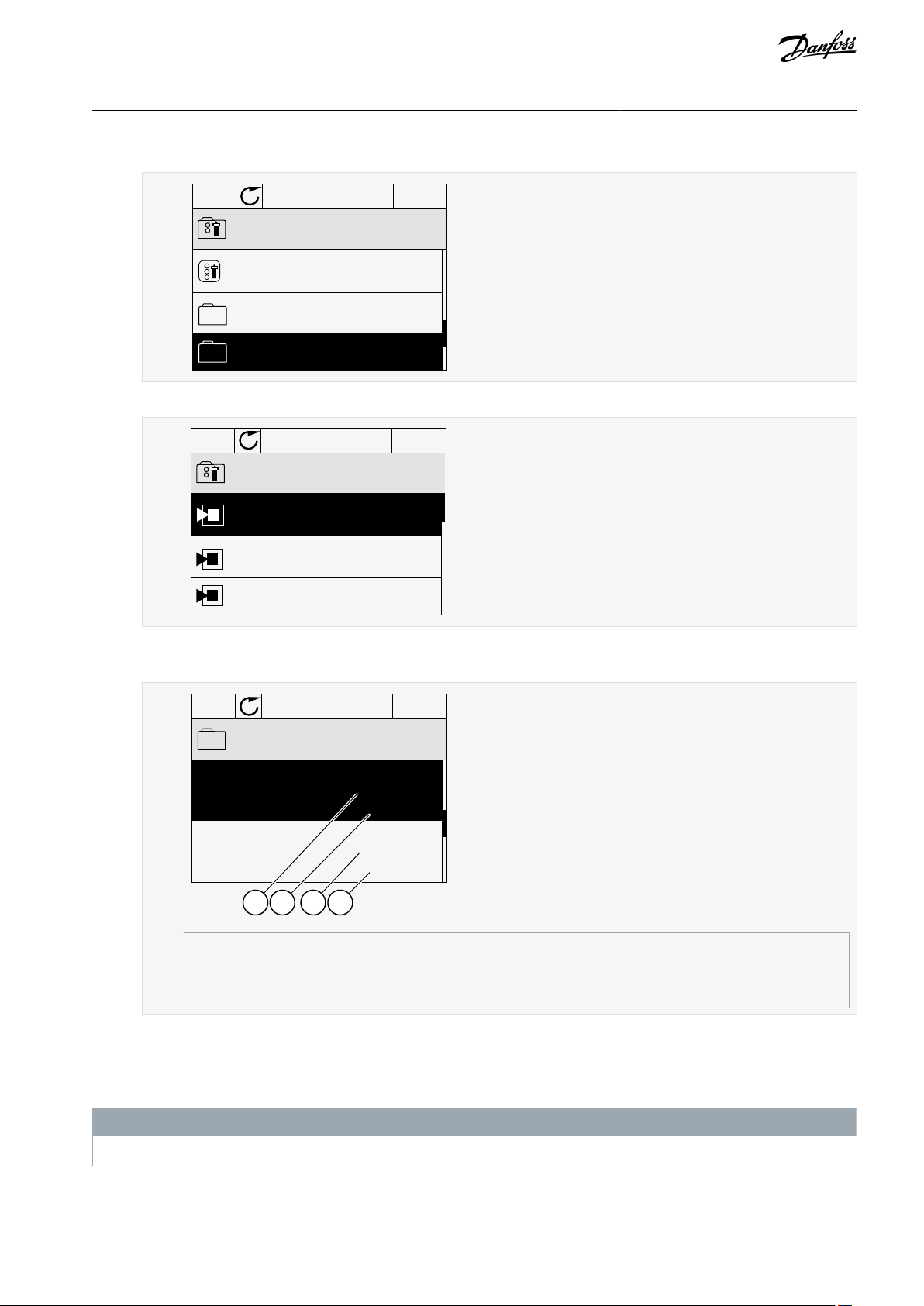

2.2.9 Comparing the Parameters

Use this function to compare the current parameter set with one of these 4 sets. See more about these parameters in 4.8.2 Parame-

ter Backup Parameters.

•

Set 1 (B6.5.4 Save to Set 1)

•

Set 2 (B6.5.6 Save to Set 2)

•

Defaults (B6.5.1 Restore Factory Defaults)

N O T I C E

If you have not saved the parameter set with which you want to compare the current set, the display shows the text Comparing

failed.

Procedure

1.

Go into the User settings menu.

AB319735759636en-000101 / DPD0182220 | Danfoss A/S © 2021.09

STOP

READY I/O

ID: M6.6

User Settings

Language Selection

Parameter Backup

Parameter Compare

English

(4)

(7)

e30bg676.10

STOP

READY I/O

ID:

B6.6.1

Parameter Compare

Active set-Set 1

Active set-Set 2

Active set-Defaults

e30bg677.10

STOP

READY I/O

ID:113

Active set-Set 1

Motor Nom Currnt

Motor Cos Phi

0.56A

1.90A

0.68

1.74

A B C D

e30bg678.10

A

The current value

B

The value of the other set

C

The current value

D

The value of the other set

VACON® 3000

Application Guide

2.

Go into the Parameter Compare function.

3.

Select the pair of sets. Push [OK] to accept the selection.

User Interfaces

4.

5.

2.2.10 Reading Help Texts

The graphical display can show help texts on many topics. All the parameters have a help text. The help texts are also available for

the faults, alarms, and the start-up wizard.

The help texts are always in English.

Procedure

1.

Select Active and push [OK].

Examine the comparing between the current values and the values of the other set.

N O T I C E

Find the item to read.

AB319735759636en-000101 / DPD01822 | 21Danfoss A/S © 2021.09

STOP

READY I/O

ID:403 M3.5.1.1

Ctrl signal 1 A

Edit

Help

Add to favourites

e30bg679.10

STOP

READY

I/O

Motor Nom Freq

Edit

Help

Add to favourites

e30bg659.10

VACON® 3000

Application Guide

2.

Use the arrow buttons Up and Down to select Help.

User Interfaces

3.

To open the help text, push the [OK] button.

2.2.11 Using the Favourites Menu

This menu is not available in the VACON® Live tool.

If the same items are used frequently, they can be added into Favourites. You can collect a set of parameters or monitoring signals

from all the control panel menus. It is not necessary to find them in the menu structure one by one. As an alternative, add them into

the Favourites folder where it is easy to find them.

2.2.11.1 Adding an Item to the Favourites

It is possible to add frequently used items into Favourites where they are easily accessible.

Procedure

1.

Find the item to be added to Favourites. Push the [OK] button.

2.

Select Add to favourites and push the [OK] button.

The steps are now completed.

3.

To continue, read the instructions on the display.

2.2.11.2 Removing an Item from the Favourites

Procedure

1.

Go to the Favourites.

2.

Find the item to be removed. Push the [OK] button.

AB319735759636en-000101 / DPD0182222 | Danfoss A/S © 2021.09

STOP

READY

I/O

Motor Nom Freq

Rem from favourites

Help

Monitor

e30bg660.10

e30bg685.10

VACON® 3000

Application Guide

3.

Select Rem from favourites.

User Interfaces

4.

To remove the item, push the [OK] button again.

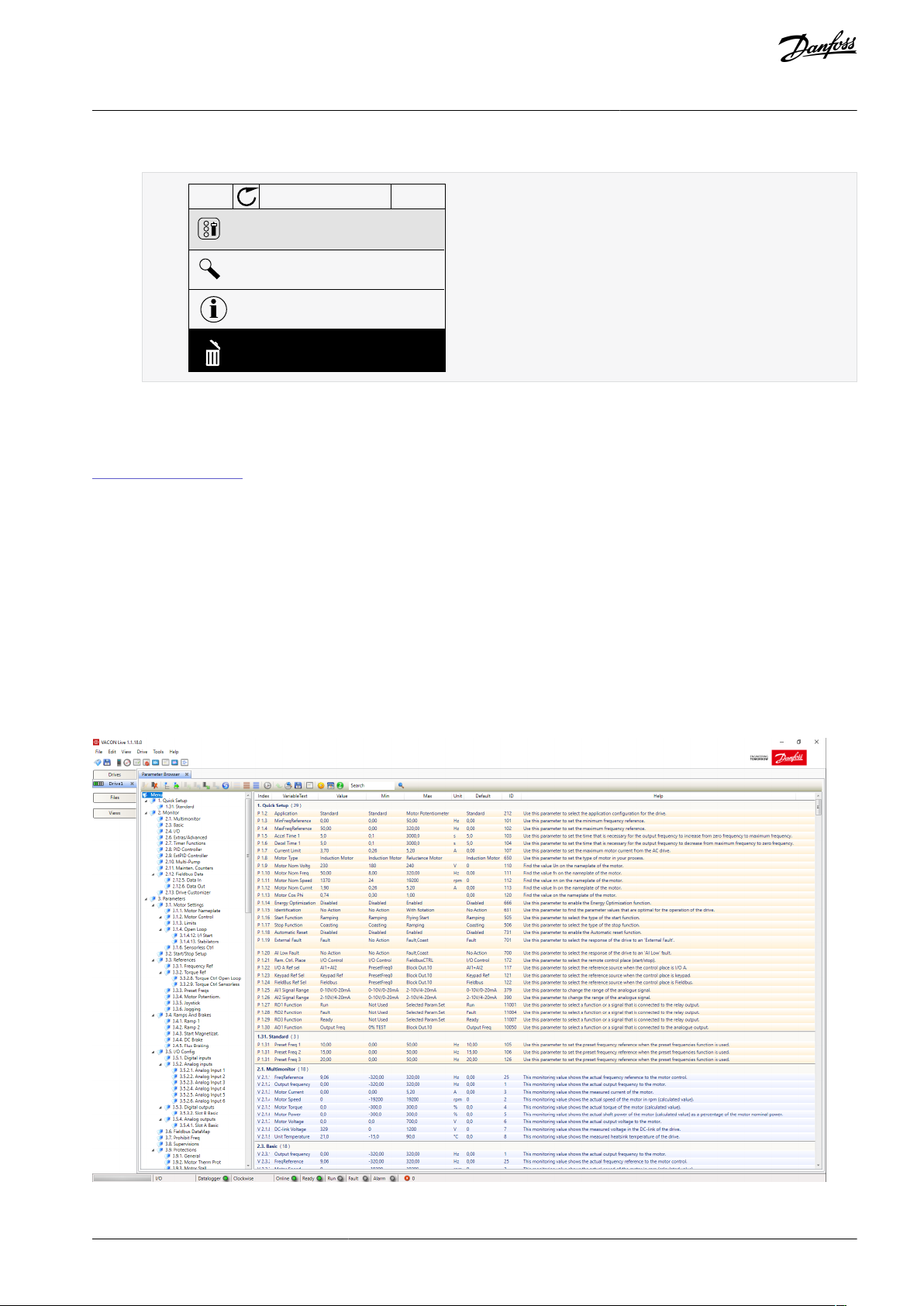

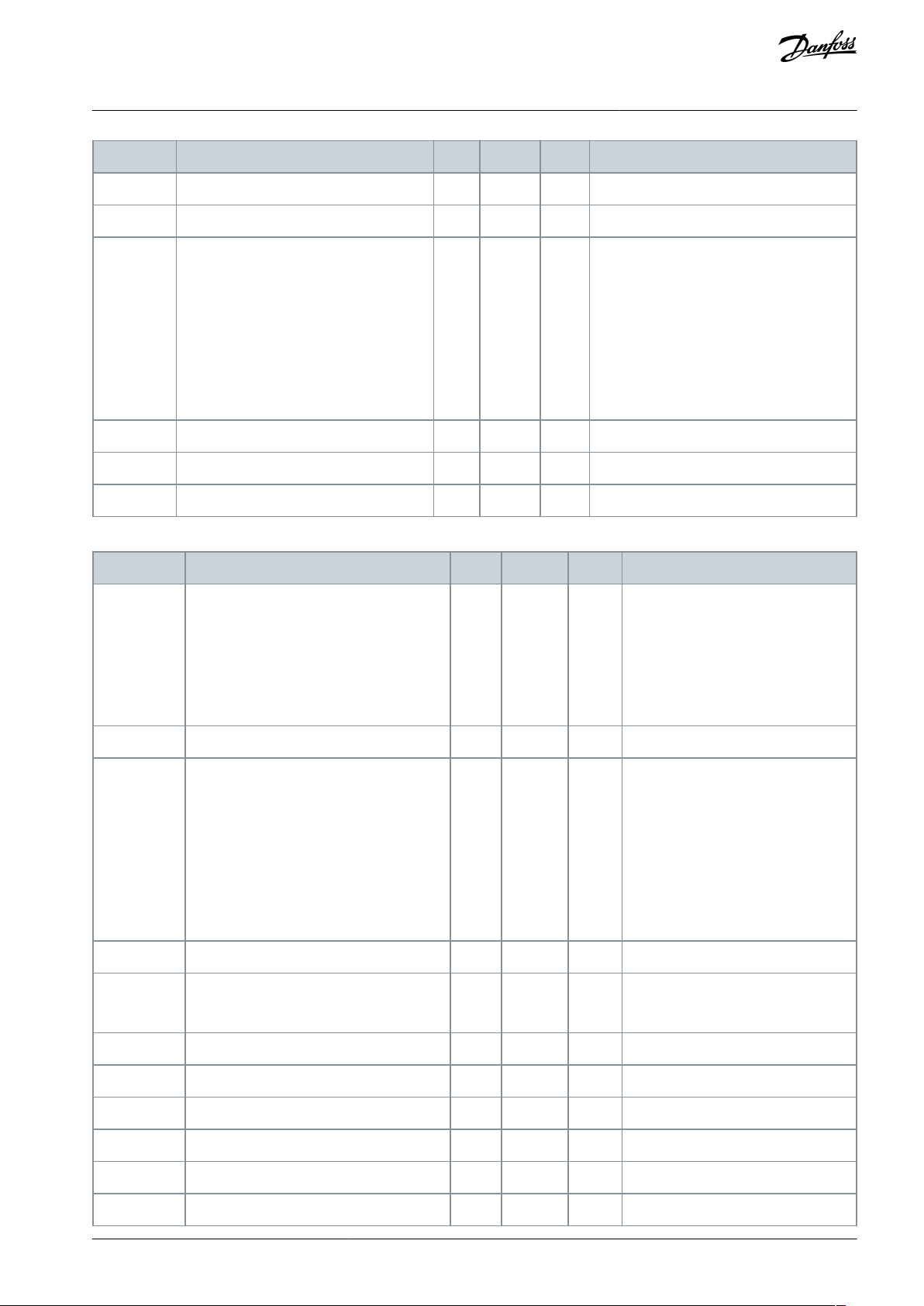

2.3 VACON® Live PC Tool

VACON® Live is a PC tool for commissioning and maintenance of the VACON® AC drives. VACON® Live can be downloaded from

https://www.danfoss.com.

The VACON® Live PC tool includes these functions.

•

Parameterization, monitoring, drive info, data logger, and so on.

•

The software download tool VACON® Loader

Serial communication and Ethernet support

•

Windows XP, Vista, 7, 8, and 10 support

•

17 languages: English, German, Spanish, Finnish, French, Italian, Russian, Swedish, Chinese, Czech, Danish, Dutch, Polish, Portu-

•

guese, Romanian, Slovak and Turkish

Make the connection between the AC drive and the PC tool with the VACON® serial communication cable. The serial communication drivers are installed automatically during the installation of VACON® Live. After the cable is installed, VACON® Live finds the

connected drive automatically.

See more on how to use VACON® Live in the help menu of the program.

Illustration 4: The VACON® Live PC Tool

AB319735759636en-000101 / DPD01822 | 23Danfoss A/S © 2021.09

21

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

30

A

B

21

22

23

24

25

26

33

34

Slot A

Slot B

C

A

B

D

E

A.1

G

F

A.2 A.1

A.2 A.3 A.4 A.5 A.6

e30bg493.10

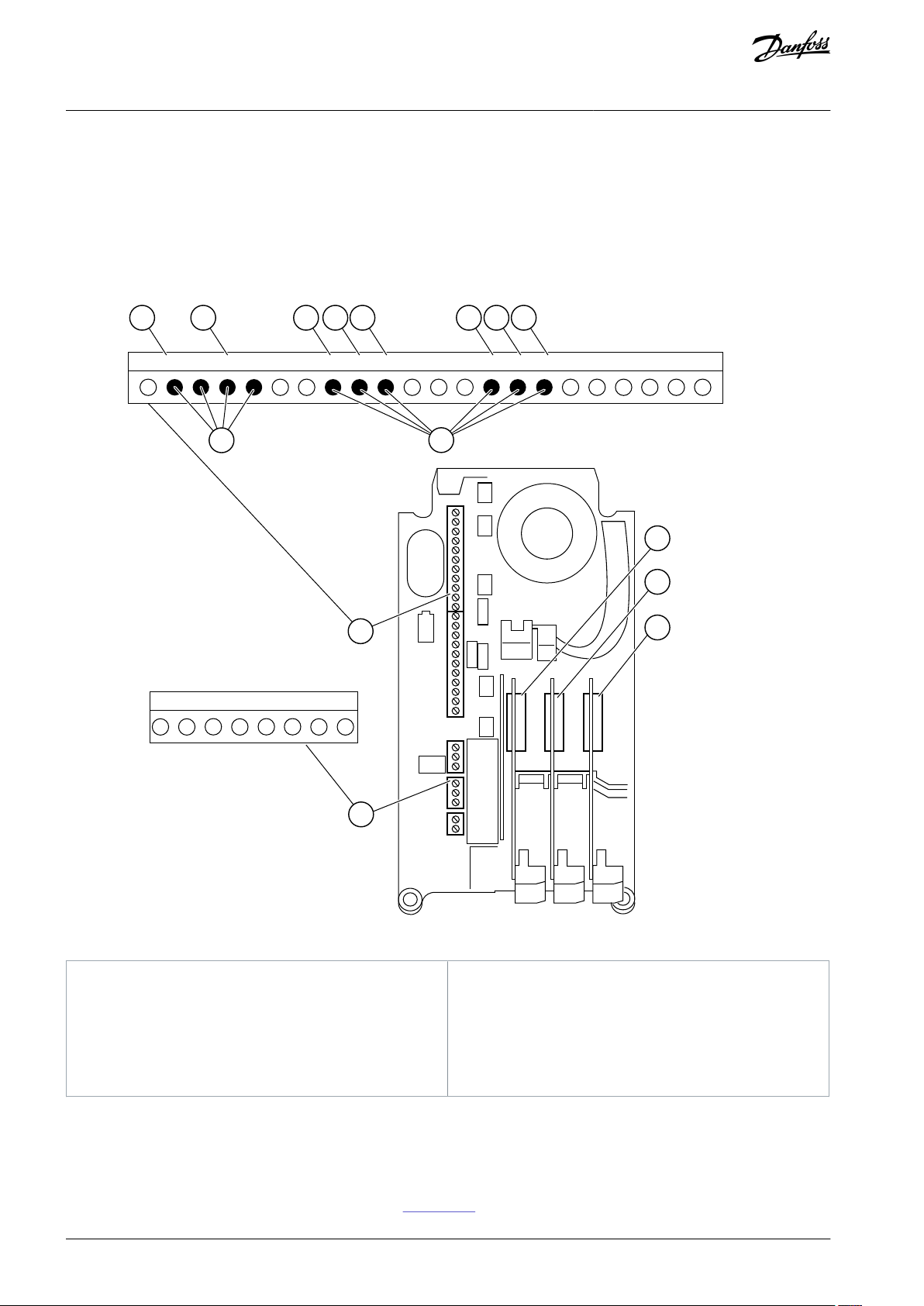

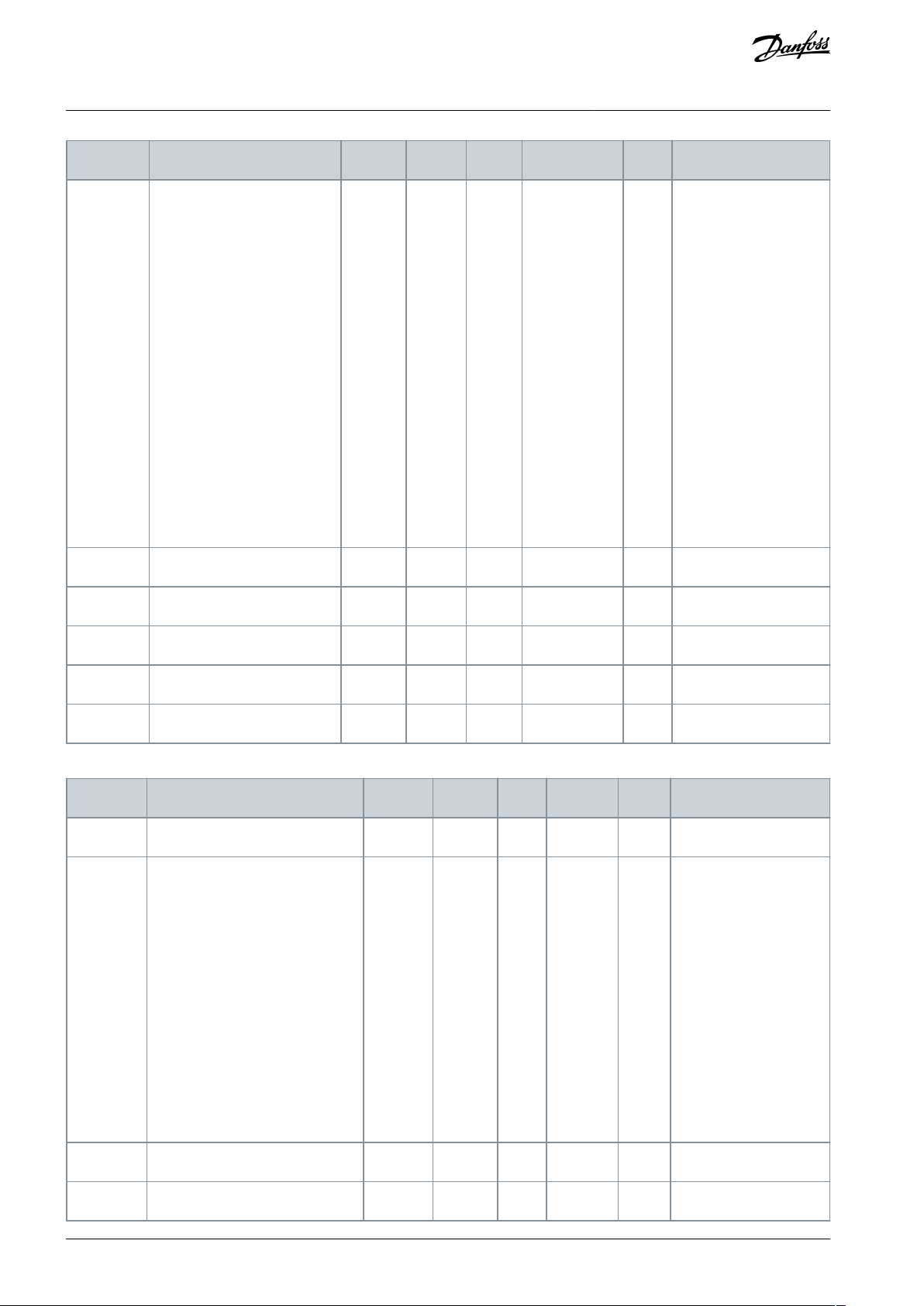

A

Standard board slot A and its terminals

B

Standard board slot B and its terminals

C

Option board slot C

D

Option board slot D

E

Option board slot E

F

Programmable digital inputs (DI)

G

Programmable analog inputs (AI)

VACON® 3000

Programming of Digital and

Application Guide

Analog Inputs

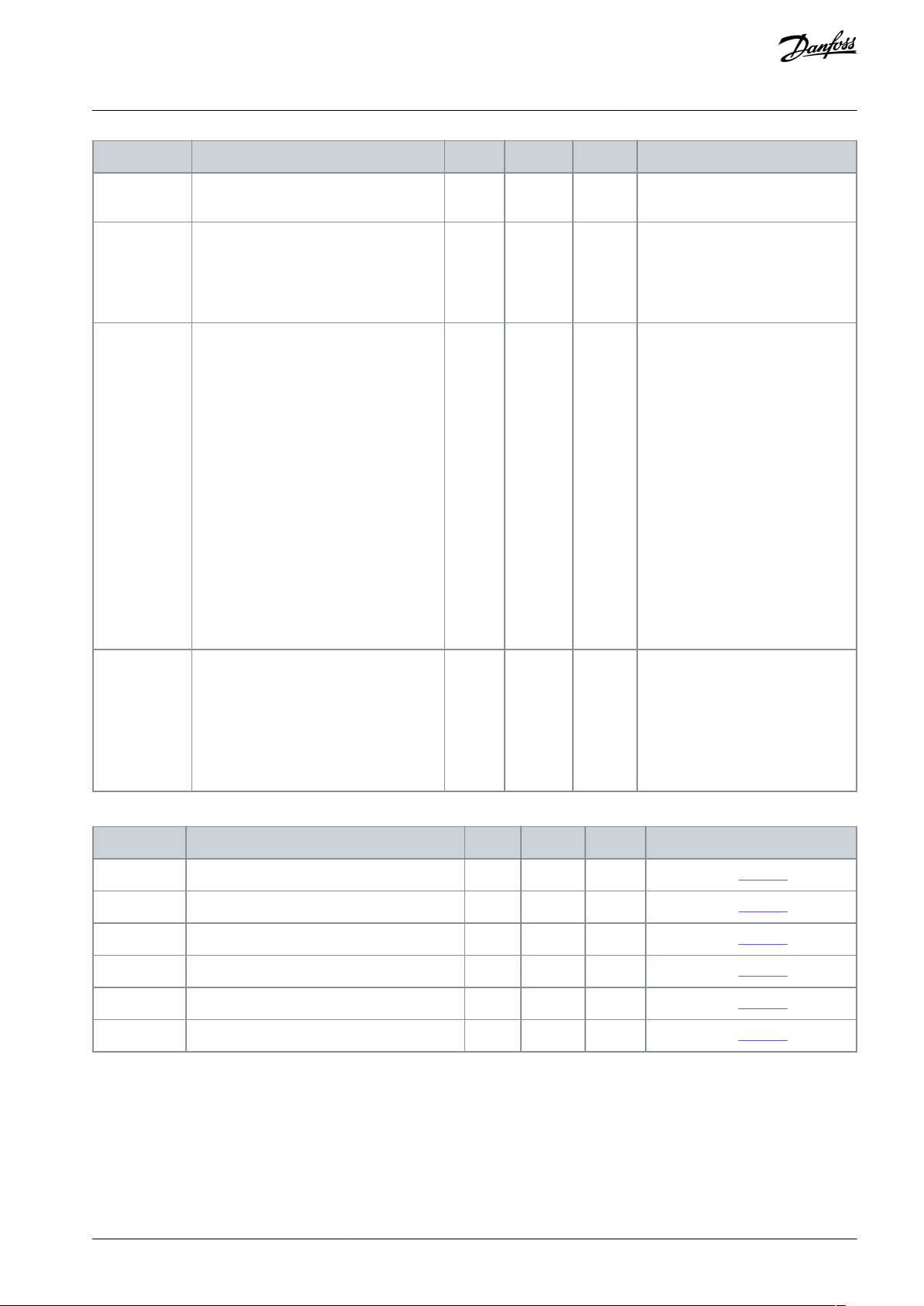

3 Programming of Digital and Analog Inputs

3.1 General Information on the Programming

The programming of inputs of the AC drive is flexible. It is possible to use freely the available inputs of the standard and optional I/O

for different functions.

It is possible to expand the available capacity of I/O with option boards. It is possible to install the option boards in the slots C, D,

and E. For more data on the installation of option boards, see the Installation Guide.

Illustration 5: The Option Board Slots and Programmable Inputs

3.2 DIP Switches on the Control Unit

3.2.1 Selection of Terminal Functions with DIP Switches

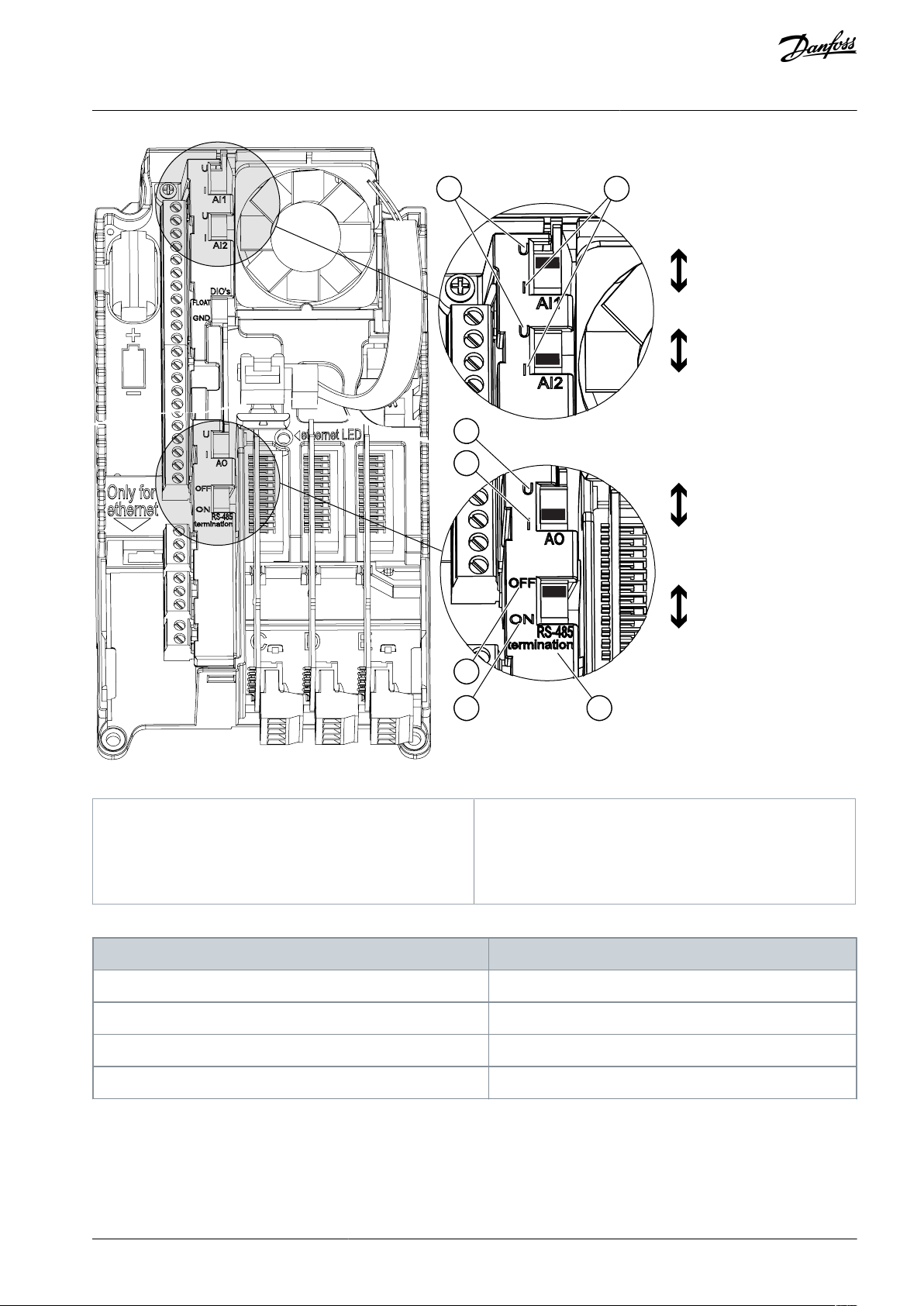

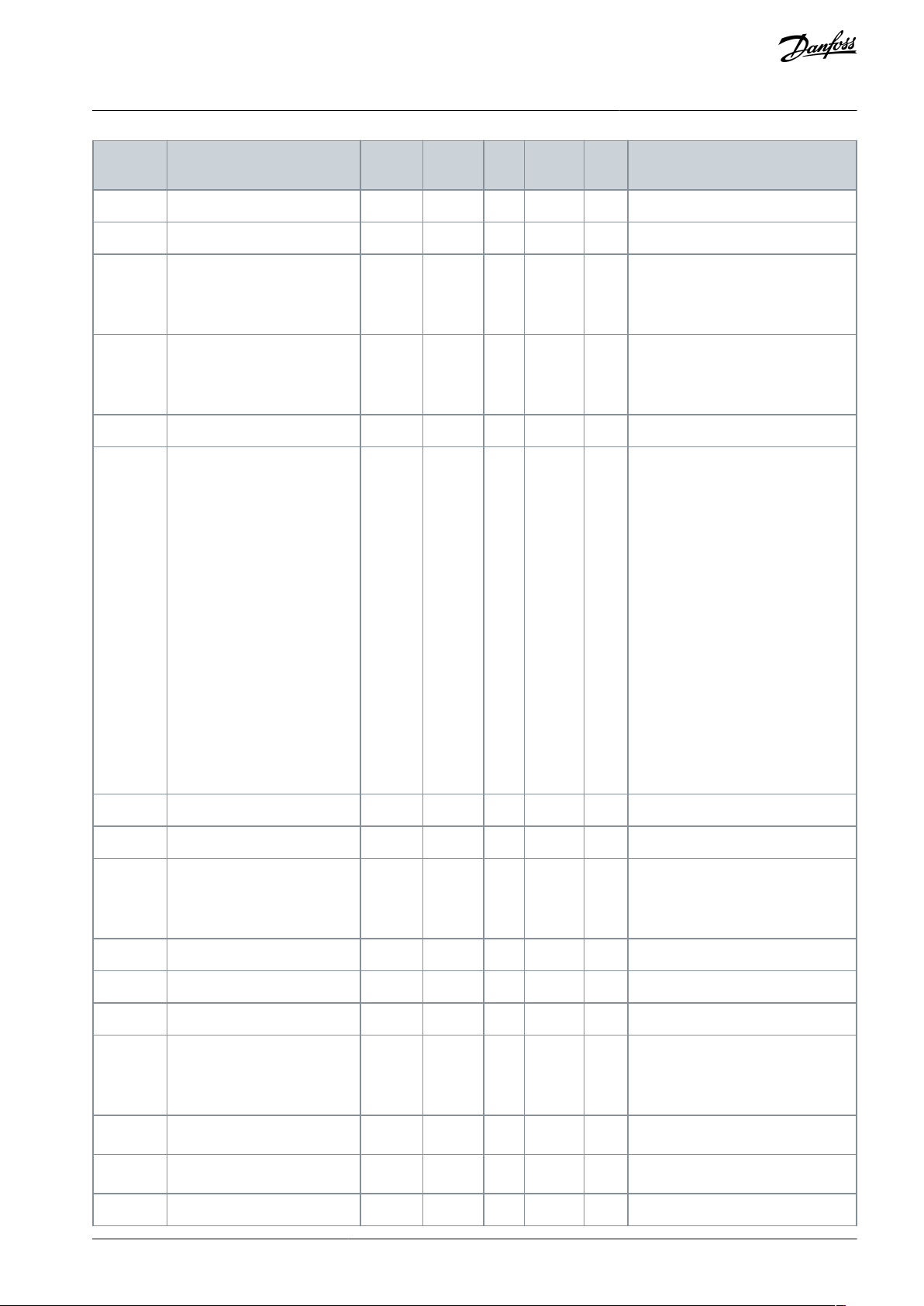

Two selections for specified terminals can be done with the DIP switches. The switches have two positions: up and down. See the

location of the DIP switches and the possible selections in Illustration 6.

AB319735759636en-000101 / DPD0182224 | Danfoss A/S © 2021.09

A B

A

B

C

D

E

AI1

U

I

AO1

U

I

RS485

OFF

ON

AI2

U

I

e30bg737.10

A

The voltage signal (U), 0–10 V input

B

The current signal (I), 0–20 mA input

C

OFFDONEThe RS485 bus termination

The DIP switch

The default position

AI1UAI2IAO1IRS485 bus termination

OFF

VACON® 3000

Application Guide

Programming of Digital and

Analog Inputs

Illustration 6: The Selections of the DIP Switches

Table 2: The Default Positions of the DIP Switches

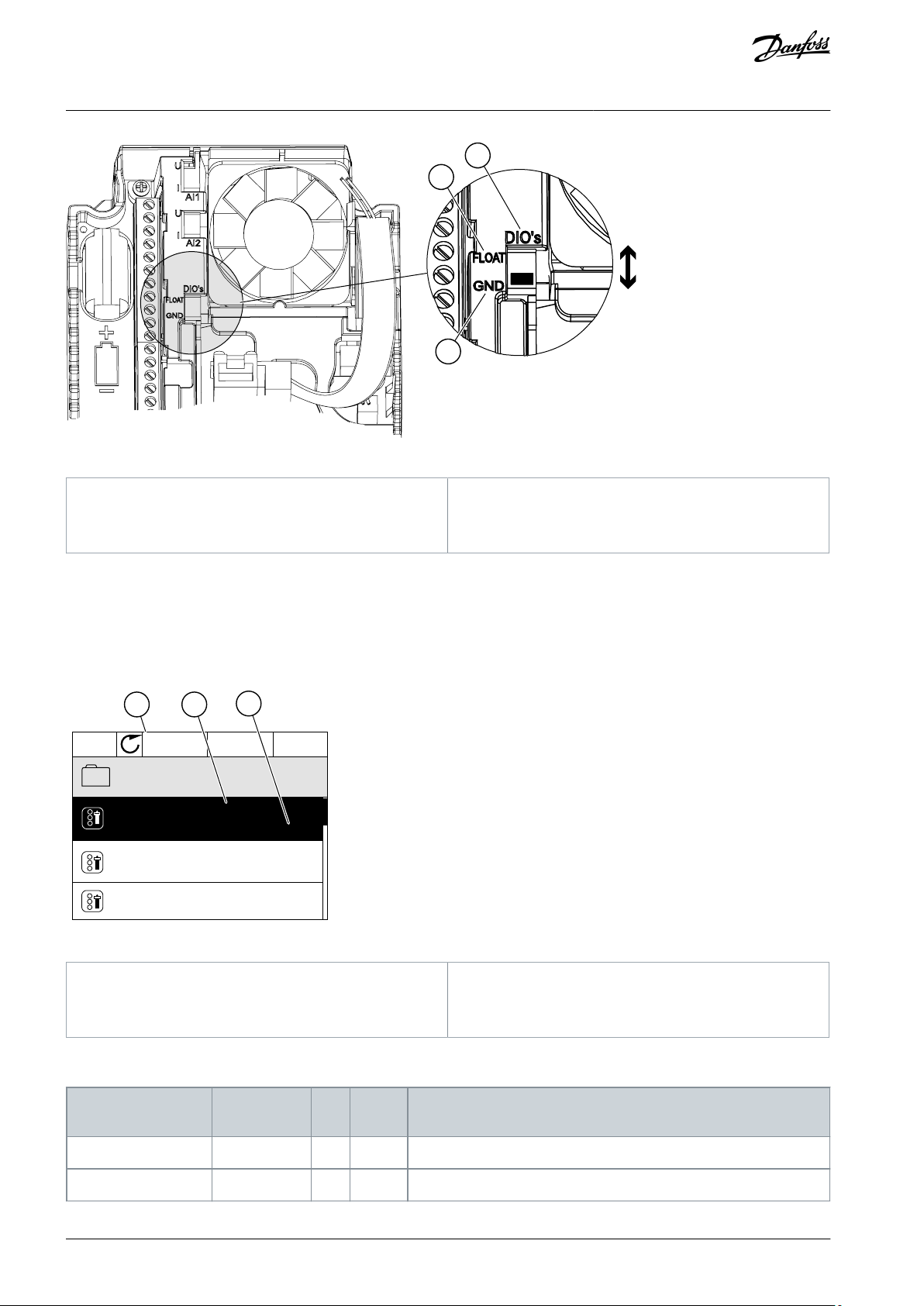

3.2.2 Isolation of the Digital Inputs from Ground

It is possible to isolate from ground the digital inputs (terminals 8–10 and 14–16) on the standard I/O board. To do this, change the

position of a DIP switch on the control board.

AB319735759636en-000101 / DPD01822 | 25Danfoss A/S © 2021.09

A

B

C

e30bg738.10

A

The digital inputs

B

Floating

C

Connected to ground (default)

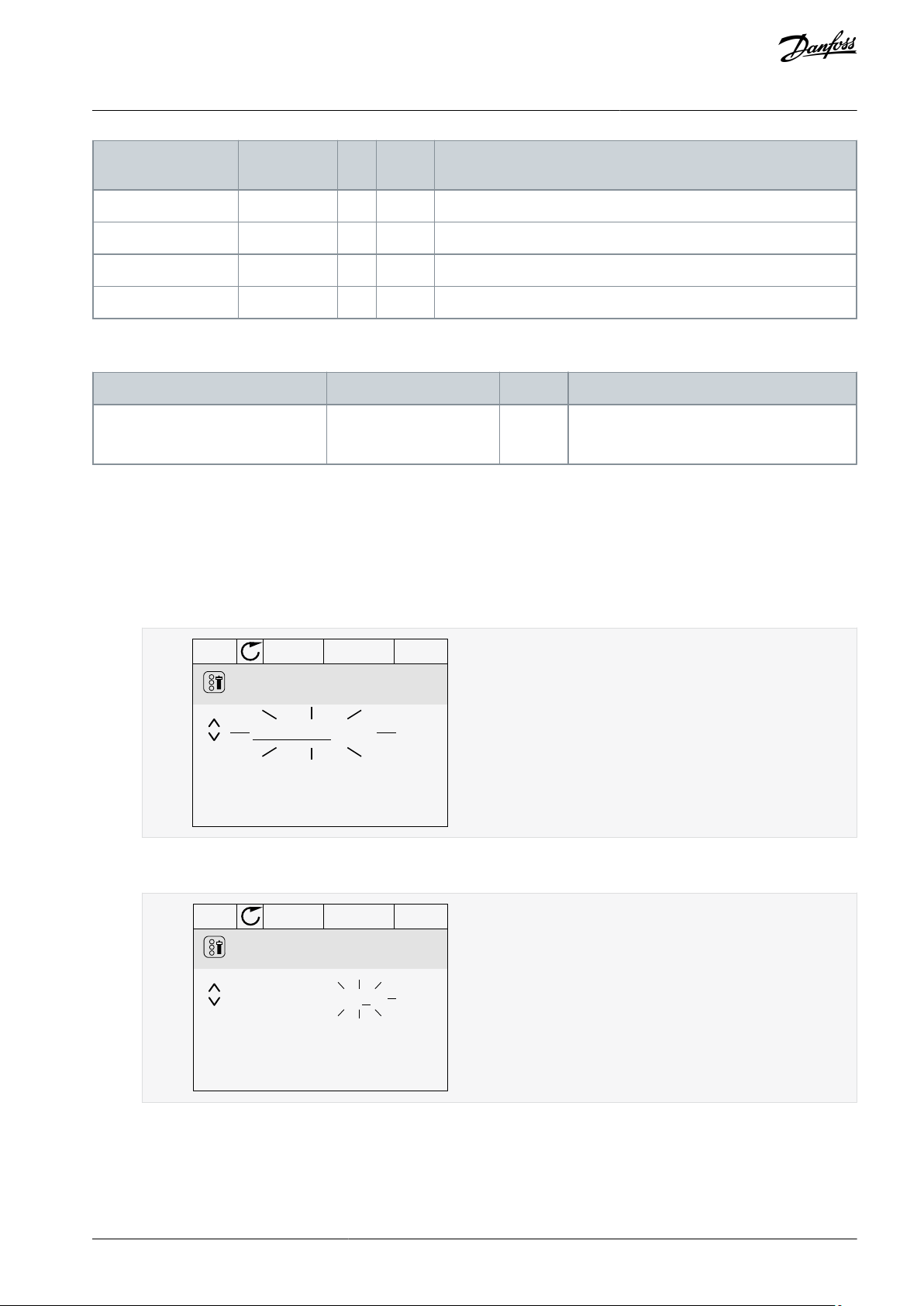

STOP

READY

I/O

ID:405

P3.5.1.11

Digital Inputs

BA

C

DigINSlotA.3

DigINSlot0.2

DigINSlotA.6

Fault Reset Close

Ext Fault Open

Ext Fault Close

e30bg692.10

A

The graphical display

B

The name of the parameter, that is, the function

C

The value of the parameter, that is, the set digital input

Input type (graphical

display)

Input type

(text display)

Slot

Input #

Explanation

DigIN

dIA1

Digital input #1 (terminal 8) on a board in Slot A (standard I/O board).

DigIN

dIA2

Digital input #2 (terminal 9) on a board in Slot A (standard I/O board).

VACON® 3000

Application Guide

Illustration 7: Change the Position of This Switch to Isolate the Digital Inputs from Ground

Programming of Digital and

Analog Inputs

3.3 Programming of Digital Inputs

The digital input parameters are functions that you can connect to a digital input terminal. The text DigIn Slot A.2 means the second

input on the slot A. It is also possible to connect the functions to time channels. The time channels work as terminals.

You can monitor the statuses of the digital inputs and the digital outputs in the Multimonitoring view.

To give a digital input to a function, set a value to the correct parameter.

Illustration 8: The Digital inputs menu in the graphical display

Example

In the standard I/O board compilation, there are 6 digital inputs available: the slot A terminals 8, 9, 10, 14, 15 and 16.

AB319735759636en-000101 / DPD0182226 | Danfoss A/S © 2021.09

Input type (graphical

display)

Input type

(text display)

Slot

Input #

Explanation

DigIN

dIA3

Digital input #3 (terminal 10) on a board in Slot A (standard I/O board).

DigIN

dIA4

Digital input #4 (terminal 14) on a board in Slot A (standard I/O board).

DigIN

dIA5

Digital input #5 (terminal 15) on a board in Slot A (standard I/O board).

DigIN

dIA6

Digital input #6 (terminal 16) on a board in Slot A (standard I/O board).

Parameter

Default

ID

Description

External fault close

DigIN SlotA.3

405

OPEN = OK

CLOSED = External fault

STOP

READY I/O

Ext Fault Close

P3.5.1.11

ID:405

Min:

Max:

DigIN SlotA .3

e30bg705.10

STOP

READY I/O

Ext Fault Close

P3.5.1.11

ID:405

Min:

Max:

DigIN SlotA. 6

e30bg706.10

VACON® 3000

Programming of Digital and

Application Guide

The function External Fault Close (ID 405) gets the default value DigIN SlotA.3 in the graphical display, and dI A.3 in the text display.

After this selection, a digital signal to the digital input DI3 (terminal 10) controls External Fault Close.

To change the input from DI3 to, for example, DI6 (terminal 16) on the standard I/O, obey these instructions.

Analog Inputs

3.3.1 Programming of Digital Inputs in the Graphical Display

Procedure

1.

Select a parameter. To go into the Edit mode, push the arrow button Right.

2.

In the Edit mode, the slot value DigIN SlotA is underlined and blinks. If there are more digital inputs available in the I/O, for

example, because of option boards in slots C, D, or E, select them.

3.

To activate the terminal 3, push the arrow button Right again.

4.

To change the terminal to 6, push the arrow button Up 3 times. Accept the change with the [OK] button.

5.

3.4 Programming of Analog Inputs

You can select the target input for the signal of the analog frequency reference from the available analog inputs.

If the digital input DI6 was already used for some other function, a message shows on the display. Change one of these

selections.

AB319735759636en-000101 / DPD01822 | 27Danfoss A/S © 2021.09

STOP

READY I/O

ID:377 P3.5.2.1.1

Analog Input 1

AI1 Signal Sel

AI1 Filter Time

AnINSlotA.1

0.10s

0-10V/0-20mA

AIl Signal Range

A B

C

e30bg709.10

A

The graphical display

B

The name of the parameter

C

The value of the parameter, that is, the set analog input

Input type (graphical display)

Input type (text

display)

Slot

Input #

Explanation

AnINAIA1Analog input #1 (terminals 2/3) on a board in Slot A (standard I/O

board).

AnINAIA2Analog input #2 (terminals 4/5) on a board in Slot A (standard I/O

board).

Parameter

Default

ID

Description

AI1 Signal Selection

AnIN SlotA.1

377

STOP

READY I/O

AI1 Signal Sel

AnIN SlotA .1

P3.5.2.1.1

ID:377

Min:

Max:

e30bg711.10

VACON® 3000

Application Guide

Illustration 9: The Analog inputs menu in the graphical display

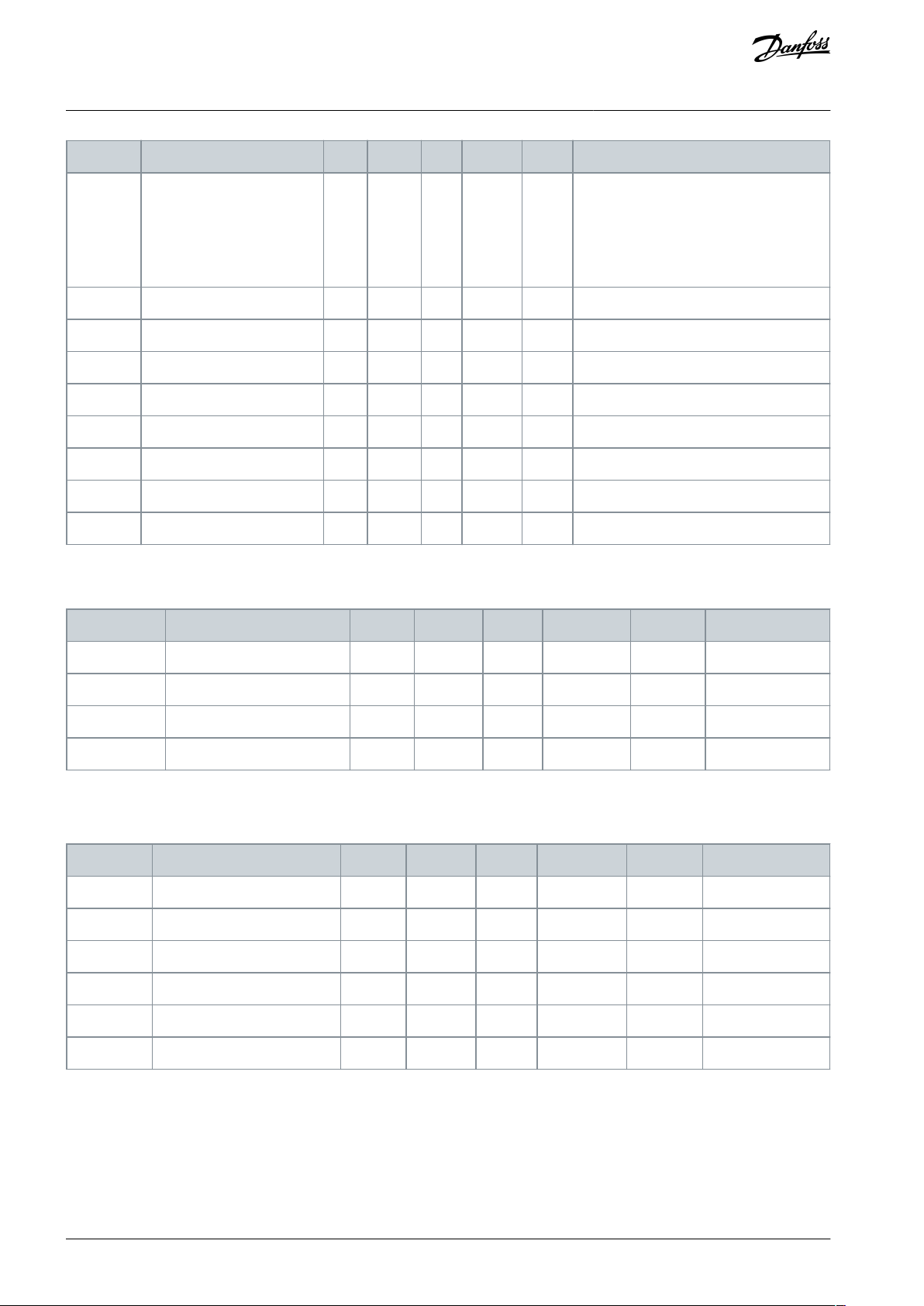

Programming of Digital and

Analog Inputs

Example

In the standard I/O board compilation, there are 2 analog inputs available: the slot A terminals 2/3 and 4/5.

AI1 Signal Selection (ID 377) gets the default value AnIN SlotA.1 in the graphical display or AI A.1 in the text display. The target input

for the signal of the analog frequency reference AI1 is then the analog input in the terminals 2/3. Use the dip switches to set the

signal to be voltage or current. See the Installation manual for more data.

To change the input from AI1 to, for example, the analog input on your option board in slot C, obey these instructions.

3.4.1 Programming of Analog Inputs in the Graphical Display

Procedure

1.

To select the parameter, push the arrow button Right.

2.

In the Edit mode, the value AnIN SlotA is underlined and blinks.

AB319735759636en-000101 / DPD0182228 | Danfoss A/S © 2021.09

Source

Function

Slot0.#

Digital inputs:

You can use this function to set a digital signal to be in a constant OPEN or CLOSED state. The manufacturer set

some signals so that they are always in the CLOSED state, for example parameter ID 407 (Run Enable). The Run

Enable signal is always on if you do not change it.

# = 1: Always OPEN

# = 2-10: Always CLOSED

Analog inputs (used for testing purposes):

# = 1: Analog input = 0% of the signal strength

# = 2: Analog input = 20% of the signal strength

# = 3: Analog input = 30% of the signal strength etc.

# = 10: Analog input = 100% of the signal strength

SlotA.#

Number (#) agrees to a digital input in slot A.

SlotB.#

Number (#) agrees to a digital input in slot B.

SlotC.#

Number (#) agrees to a digital input in slot C.

SlotD.#

Number (#) agrees to a digital input in slot D.

SlotE.#

Number (#) agrees to a digital input in slot E.

FieldbusCW.#

Number (#) refers to a control word bit number.

FieldbusPD.#

Number (#) refers to the process data 1 bit number.

Aux 14–Aux 17

Auxiliary I/O signals

MV-star

MV-star signals

Input

Terminal(s)

Reference

Function

Parameter ID

DI18A.1

Control Signal 1 A

403

DI29A.2

Control Signal 2 A

404

DI310A.3

External Fault Close

405

DI414A.4

Preset Frequency Selection 1

419

DI515A.5

Preset Frequency Selection 2

420

DI616A.6

Fault Reset Close

414

AI1

2/3

A.1

AI1 Signal Selection

377

AI2

4/5

A.2

AI2 Signal Selection

388

VACON® 3000

Programming of Digital and

Application Guide

3. To change the value to AnIN SlotC, push the arrow button Up. Accept the change with the [OK] button.

3.5 Descriptions of Signal Sources

Table 3: Descriptions of Signal Sources

Analog Inputs

3.6 Default Functions of Programmable Inputs

Table 4: Default functions of the programmable digital and analog inputs

AB319735759636en-000101 / DPD01822 | 29Danfoss A/S © 2021.09

VACON® 3000

Application Guide

INU Application

4 INU Application

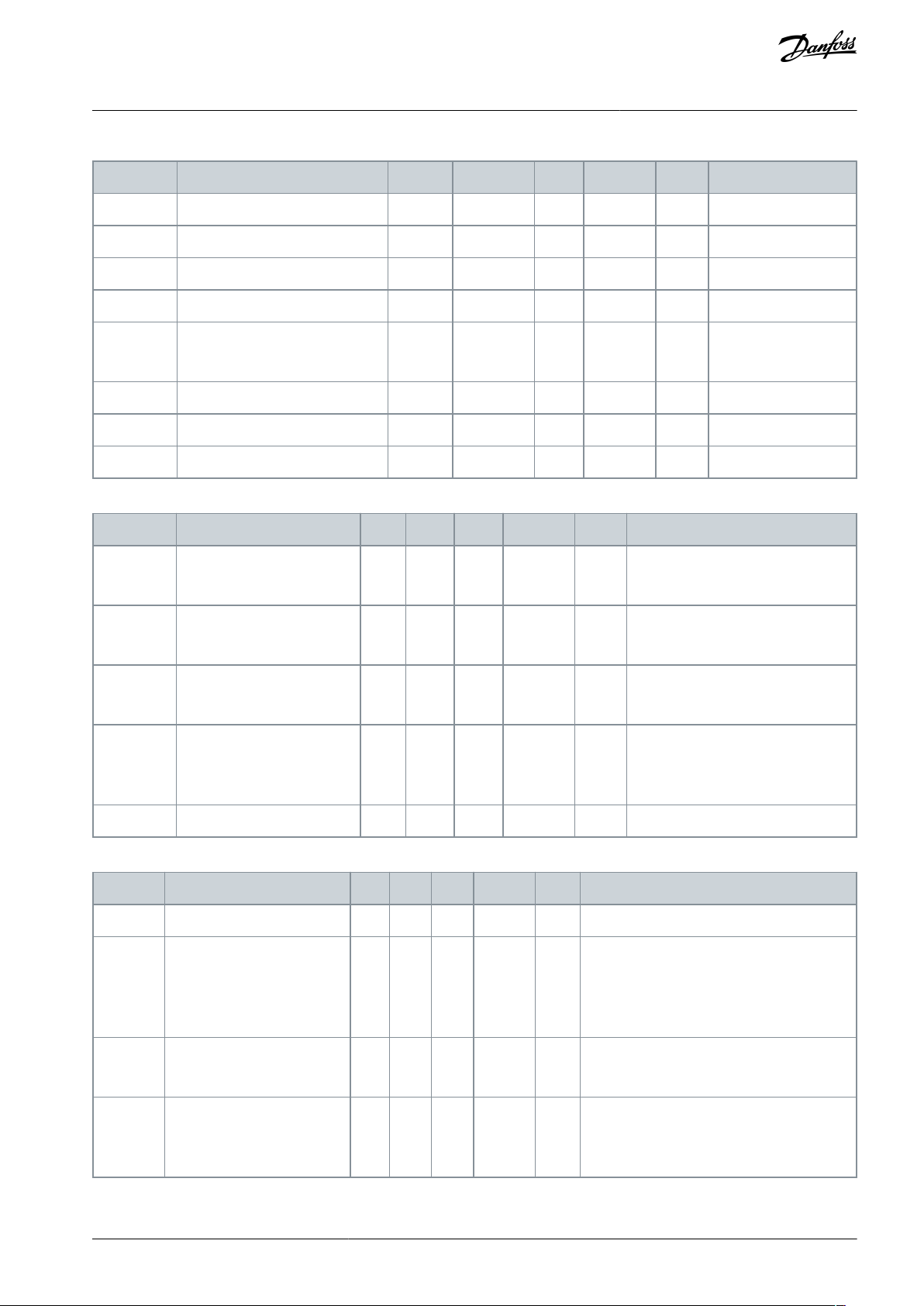

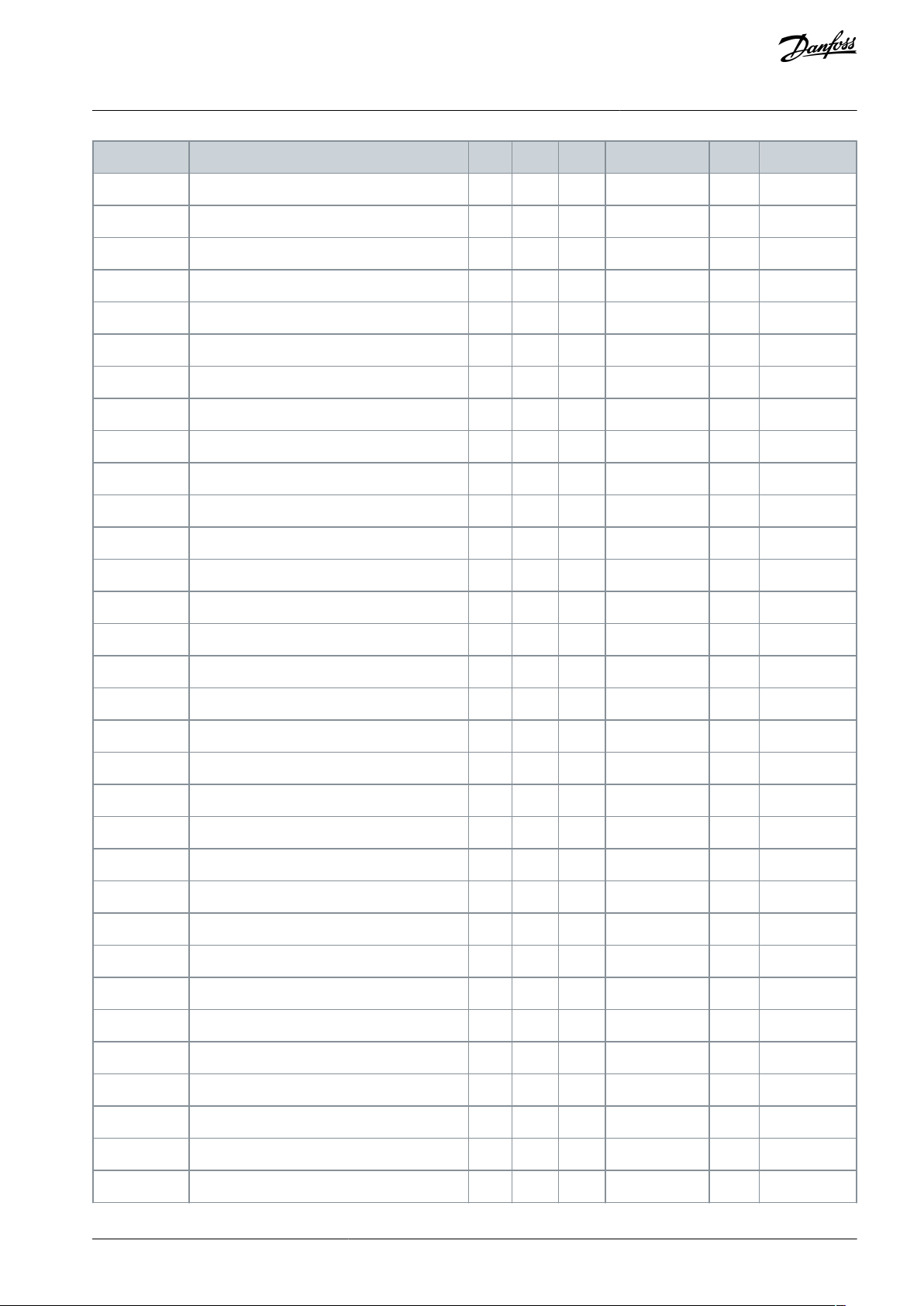

4.1 Overview

The INU application is used to control the INU phase modules of the VACON® 3000.

It is possible to control the drive from the control panel (keypad), Fieldbus, or I/O terminal.

When controlling the drive with the I/O terminal, the frequency reference signal is connected to AI1 (0…10 V) or AI2 (4…20 mA).

The connection depends the type of the signal. There are also 3 preset frequency references available. The preset frequency references can be activated with DI4 and DI5. The start/stop signals of the drive are connected to DI1 (start forward) and DI2 (start reverse).

It is possible to configure all the drive outputs freely. There is 1 analog output (Output Frequency) and 3 relay outputs (Run, Fault,

Ready) available on the Basic I/O board.

AB319735759636en-000101 / DPD0182230 | Danfoss A/S © 2021.09

DI4

DI5

Modbus RTU,

N2, BACnet

1

6

2

3

4

5

18

19

30

12

7

13

8

9

10

14

15

16

21

22

23

11

17

A

B

24

25

26

32

33

mA

FAULT

RUN

RUN

AO1-

+24Vin

24Vout

GND

GND

DI1

DI2

DI3

DI4

DI5

DI6

RO1/1 NC

RO1/2 CM

RO1/3 NO

CM

CM

RS485

RS485

RO2/1 NC

RO2/2 CM

RO2/3 NO

RO3/2 CM

RO3/3 NO

Standard I/O board

Terminal Signal Description

+10Vref

AI1+

AI1-

AI2+

AI2-

24Vout

Reference output

Analog input 1+

Analog input 1-

Analog input 2+

Analog input 2-

24 V auxiliary voltage

I/O ground

Digital input 1

Digital input 2

Digital input 3

Digital input 4

Digital input 5

Digital input 6

Common for DI1-DI6

Common for DI1–DI6

24 V auxiliary voltage

I/O ground

Analog output 1+

Analog output 1-

24 V auxiliary

input voltage

Output

frequency

(0...20 mA)

READY

Serial bus, negative

Serial bus, positive

Relay output 1

Relay output 2

Relay output 3

FAULT

Fault reset

AO1+

Frequency reference

(default 0...10 V)

Frequency reference

(Default 4...20 mA)

Start forward

Start reverse

External fault

Freq. ref.

Open

Closed

Open

Closed

Open

Open

Closed

Closed

Analog input 1

Preset Freq. 1

Preset Freq. 2

Preset Freq. 3

Referencepotentiometer

1...10 kΩ

e30bg736.11

VACON® 3000

Application Guide

INU Application

Illustration 10: The Default Control Connections of the INU Application

4.2 Menu Structure

The data of the AC drive is in menus and submenus. To move between the menus, use the arrow buttons Up and Down in the

keypad. To go into a group or an item, push the [OK] button. To go back to the previous level, push the [BACK/RESET] button.

The display shows the current location in the menu, for example M3.2.1, and the name of the group or item.

AB319735759636en-000101 / DPD01822 | 31Danfoss A/S © 2021.09

Menu

Function

M1 Quick setup

Quick setup

M2 Monitor

Multimonitor

Basic

I/O

Extras/Advanced

PID controller

Fieldbus data

Encoders

Precharge

M3 Parameters

Motor settings

Start/Stop setup

References

Ramps and brakes

I/O Configuration

Fieldbus data mapping

Prohibit frequencies

Supervisions

Protections

Automatic reset

Application settings

PID controller

Motor preheat

Mechanical brake

Encoders

Precharge

M4 Diagnostics

Active faults

Reset faults

Fault history

Total counters

Trip counters

Software info

Drive info

VACON® 3000

Application Guide

Table 5: Menu Structure

INU Application

AB319735759636en-000101 / DPD0182232 | Danfoss A/S © 2021.09

Menu

Function

Unit status

M5 I/O and Hardware

Basic I/O

Slot C

Slot D

Slot E

Real-time clock

Power unit settings

RS485

Ethernet

Fieldbus general

Aux chain

MV-star

M6 User settings

Language selections

Parameter back-up

Parameter compare

Drive name

Licenses

M7 Favorites

Favorites

Index

Parameter

Min

Max

Unit

Default

ID

Description

1.2

Minimum Frequency Reference

0.00

60.00

Hz

0.00

101

1.3

Maximum Frequency Reference

0.00

320.00

Hz

0.00

102

1.4

Acceleration Time 1

0.1

3000.0

s

5.0

103

1.5

Deceleration Time 1

0.1

3000.0

s

5.0

104

1.6

Current Limit

34

420A0

107

1.7

Motor Nominal Voltage

180

4160V0

110

Find this value Un on the nameplate of the motor.

N O T I C E

Find out if the motor connection is Delta or

Star.

VACON® 3000

Application Guide

INU Application

4.3 Quick Setup

Table 6: M1 Quick Setup

AB319735759636en-000101 / DPD01822 | 33Danfoss A/S © 2021.09

Index

Parameter

Min

Max

Unit

Default

ID

Description

1.8

Motor Nominal Frequency

8.00

320.00

Hz

0.00

111

Find this value fn on the nameplate of the motor.

1.9

Motor Nominal Speed

24

19200

RPM0112

Find this value nn on the nameplate of the motor.

1.10

Motor Nominal Current

34

680A0

113

Find this value In on the nameplate of the motor.

1.11

Motor Cos Phi (Power Factor)

0.30

1.00

0.00

120

Find this value on the nameplate of the motor.

1.12

Identification

020

631

0 = No action

1 = At standstill

2 = With rotation

1.13

Start Function

010

505

0 = Ramping

1 = Flying Start

1.14

Stop Function

010

506

0 = Coasting

1 = Ramping

1.15

Automatic Reset

010

731

0 = Disabled

1 = Enabled

1.16

Response to External Fault

032

701

0 = No action

1 = Alarm

2 = Fault (Stop according to stop mode)

3 = Fault (Stop by coasting)

1.17

Response to AI Low Fault

050

700

0 = No action

1 = Alarm

2 = Alarm+preset fault frequency (P3.9.1.1)

3 = Alarm + previous frequency

4 = Fault (Stop according to stop mode)

5 = Fault (Stop by coasting)

1.18

Remote Control Place

010

172

0 = I/O control

1 = Fieldbus control

1.19

I/O Control Reference A

Selection

0106

117

1 = Preset Frequency 0

2 = Keypad Reference

3 = Fieldbus

4 = AI1

5 = AI2

6 = AI1+AI2

7 = PID Reference

8 = Motor Potentiometer

9 = Joystick Reference

10 = Jogging Reference

1.20

Keypad Control Reference

Selection

0102

121

See P1.19.

1.21

Fieldbus Control Reference Selection

0103

122

See P1.19.

VACON® 3000

Application Guide

INU Application

AB319735759636en-000101 / DPD0182234 | Danfoss A/S © 2021.09

Index

Parameter

Min

Max

Unit

Default

ID

Description

1.22

AI1 Signal Range

010

379

0 = 0...10 V/0...20 mA

1 = 2...10 V/4...20 mA

1.23

AI2 Signal Range

011

390

0 = 0...10 V/0...20 mA

1 = 2...10 V/4...20 mA

1.24

RO1 Function

0582

11001

See P3.5.3.2.1

1.25

RO2 Function

0583

11004

See P3.5.3.2.4

1.26

RO3 Function

0581

11007

See P3.5.3.2.7

1.27

AO1 Function

0312

10050

See P3.5.4.1.1

1.28

Preset Frequency 1

0.00

60.00

Hz

10.0

105

1.29

Preset Frequency 2

0.00

60.00

Hz

15.0

106

1.30

Preset Frequency 3

0.00

60.00

Hz

20.0

126

Index

Monitoring value

Unit

Scale

ID

Description

V2.3.1

Output frequency

Hz

0.011V2.3.2

Frequency reference

Hz

0.0125V2.3.3

Motor speed

RPM12

V2.3.4

Motor current

A

Varies

3

V2.3.5

Motor torque

%

0.14V2.3.7

Motor shaft power

%

0.15V2.3.8

Motor shaft power

kW/hp

Varies

73

V2.3.9

Motor voltage

V

0.16V2.3.10

DC-link voltage

V17

V2.3.11

Unit temperature

°C

0.1

8

VACON® 3000

Application Guide

INU Application

4.4 Monitor Menu

4.4.1 Basic Monitoring

4.4.1.1 Uses of the Basic Monitoring

Only the standard I/O board statuses are available in the Monitor menu. For the statuses of all the I/O board signals as raw data, see

the I/O and Hardware menu.

Check the statuses of the expander I/O board in the I/O and Hardware menu when the system asks.

4.4.1.2 Basic Monitoring Parameters

Table 7: Items in the Basic Monitoring Menu

AB319735759636en-000101 / DPD01822 | 35Danfoss A/S © 2021.09

Index

Monitoring value

Unit

Scale

ID

Description

V2.3.12

Motor temperature

%

0.19V2.3.13

Torque reference

%

0.118V2.3.14

Output power

kW179

Index

Monitoring value

Unit

Scale

ID

Description

V2.4.1

Slot A DIN 1, 2, 3

115V2.4.2

Slot A DIN 4, 5, 6

116V2.4.3

Slot B RO 1, 2, 3

117V2.4.4

Analog input 1

%

0.0159Slot A.1 as default.

V2.4.5

Analog input 2

%

0.0160Slot A.2 as default.

V2.4.6

Analog input 3

%

0.0161Slot D.1 as default.

V2.4.7

Analog input 4

%

0.0162Slot D.2 as default.

V2.4.8

Analog input 5

%

0.0175Slot E.1 as default.

V2.4.9

Analog input 6

%

0.0176Slot E.2 as default.

V2.4.10

Slot A AO1

%

0.01

81

Index

Monitoring value

Unit

Scale

ID

Description

V2.6.1

Drive Status Word

1

43

B1 = Ready

B2 = Run

B3 = Fault

B6 = Run Enable

B7 = Alarm Active

B10 = DC current in stop

B11 = DC brake active

B12 = Run Request

B13 = Motor Regulator Active

V2.6.2

Ready status

1

78

B0 = Run Enable high

B1 = No fault active

B2 = Charge switch closed

B3 = DC voltage within limits

B4 = Power manager initialized

B5 = Power unit is not blocking start

B6 = System software is not blocking start

V2.6.3

Application Status Word1

1

89

B0 = Interlock 1

B1 = Interlock 2

VACON® 3000

Application Guide

4.4.2 I/O Monitoring

Table 8: I/O Signal Monitoring

INU Application

4.4.3 Extras and Advanced

Table 9: Monitoring of the advanced values

AB319735759636en-000101 / DPD0182236 | Danfoss A/S © 2021.09

Index

Monitoring value

Unit

Scale

ID

Description

B2 = Reserved

B3 = Ramp 2 active

B4 = Mechanical brake control

B5 = I/O A control active

B6 = I/O B control active

B7 = Fieldbus Control Active

B8 = Local control active

B9 = PC control active

B10 = Preset frequencies active

B11 = Jogging active

B13 = Motor Preheat active

B14 = Quick stop active

B15 = Drive stopped from keypad

V2.6.4

Application Status Word2

1

90

B0 = Acc/Dec prohibited

B1 = Motor switch open

B5 = Precharge ready

B6 = Precharge inhibit

B7 = Precharge started

B8 = Supervision 1

B9 = Supervision 2

V2.6.5

DIN Status Word 1

156V2.6.6

DIN Status Word 2

157V2.6.7

Motor current 1 decimal

0.1

45

V2.6.8

Frequency reference source

1

1495

0 = PC

1 = Preset Freqs

2 = Keypad Reference

3 = Fieldbus

4 = AI1

5 = AI2

6 = AI1+AI2

7 = PID Controller

8 = Motor Potentiometer

9 = Joystick

10 = Jogging

100 = Not defined

101 = Alarm,PresetFreq

V2.6.9

Last active fault code

137V2.6.10

Last active fault ID

195V2.6.11

Last active alarm code

174V2.6.12

Last active alarm ID

1

94

V2.6.13

Motor regulator status

1

77

B0 = Current Limit (Motor)

B1 = Current Limit (Generator)

B2 = Torque Limit (Motor)

B3 = Torque Limit (Generator)

VACON® 3000

Application Guide

INU Application

AB319735759636en-000101 / DPD01822 | 37Danfoss A/S © 2021.09

Index

Monitoring value

Unit

Scale

ID

Description

B4 = Overvoltage Control

B5 = Undervoltage Control

B6 = Power Limit (Motor)

B7 = Power Limit (Generator)

V2.6.14

Motor speed filtered

RPM14500

V2.6.15

Fault word 1

1

1172

V2.6.16

Fault word 2

1

1173

V2.6.17

Cos Phi actual

0.0168V2.6.18

Enclosure humidity and temperature

1

3586

V2.6.19

Output filter status word

1

4502

V2.6.20

Motor torque lp 16

%

0.1

4503

V2.6.21

Motor torque unfilt

%

0.1

4504

Index

Monitoring value

Unit

Scale

ID

Description

V2.7.1

PID setpoint

Varies

As is set in P3.13.1.7 (See 4.5.12 Group

3.12: PID Controller.)

20

V2.7.2

PID feedback

Varies

As is set in P3.13.1.7

21

V2.7.3

PID error value

Varies

As is set in P3.13.1.7

22

V2.7.4

PID output

%

0.01

23

V2.7.5

PID status

1

24

0 = Stopped

1 = Running

3 = Sleep mode

4 = In dead band (see 4.5.12 Group 3.12:

PID Controller)

Index

Monitoring value

Unit

Scale

ID

Description

V2.8.1

Fieldbus Control Word

1

874

V2.8.2

Fieldbus Status Word

1

864

V2.8.3

Fieldbus Speed Reference

Hz

0.01

875

V2.8.4

Fieldbus Speed Actual

%

0.01

865

V2.8.5

Fieldbus General Control Word

1

861

V2.8.6

Fieldbus General Status Word

1

862

V2.8.7

Fieldbus Speed Actual Signed

%

0.01

4501

VACON® 3000

Application Guide

INU Application

4.4.4 PID Controller Monitoring

Table 10: Monitoring of the values of the PID controller

4.4.5 Fieldbus Process Data Monitoring

Table 11: Fieldbus process data monitoring

AB319735759636en-000101 / DPD0182238 | Danfoss A/S © 2021.09

Index

Monitoring value

Unit

Scale

ID

Description

V2.8.8.1

FB Data In 1

1

876

V2.8.8.2

FB Data In 2

1

877

V2.8.8.3

FB Data In 3

1

878

V2.8.8.4

FB Data In 4

1

879

V2.8.8.5

FB Data In 5

1

880

V2.8.8.6

FB Data In 6

1

881

V2.8.8.7

FB Data In 7

1

882

V2.8.8.8

FB Data In 8

1

883

V2.8.8.9

FB Data In 9

1

229

V2.8.8.10

FB Data In 10

1

230

V2.8.8.11

FB Data In 11

1

231

V2.8.8.12

FB Data In 12

1

232

V2.8.8.13

FB Data In 13

1

233

V2.8.8.14

FB Data In 14

1

234

V2.8.8.15

FB Data In 15

1

235

V2.8.8.16

FB Data In 16

1

236

Index

Monitoring value

Unit

Scale

ID

Description

V2.8.9.1

FB Data Out 1

1

866

V2.8.9.2

FB Data Out 2

1

867

V2.8.9.3

FB Data Out 3

1

868

V2.8.9.4

FB Data Out 4

1

869

V2.8.9.5

FB Data Out 5

1

870

V2.8.9.6

FB Data Out 6

1

871

V2.8.9.7

FB Data Out 7

1

872

V2.8.9.8

FB Data Out 8

1

873

V2.8.9.9

FB Data Out 9

1

245

V2.8.9.10

FB Data Out 10

1

246

V2.8.9.11

FB Data Out 11

1

247

V2.8.9.12

FB Data Out 12

1

248

V2.8.9.13

FB Data Out 13

1

249

VACON® 3000

Application Guide

Table 12: Fieldbus Data In

INU Application

Table 13: Fieldbus Data Out

AB319735759636en-000101 / DPD01822 | 39Danfoss A/S © 2021.09

Index

Monitoring value

Unit

Scale

ID

Description

V2.8.9.14

FB Data Out 14

1

250

V2.8.9.15

FB Data Out 15

1

251

V2.8.9.16

FB Data Out 16

1

252

Index

Monitoring value

Unit

Scale

ID

Description

V2.10.1

Encoder HW Fallback Count

1

3007

V2.10.2

Encoder SW Fallback Count

1

3008

Index

Monitoring value

Unit

Scale

ID

Description

V2.10.3.1

Encoder Status Word

1

3050

1 = Direction State

2 = Pulse State

4 = Input A State

8 = Input B State

16 = Input Z State

32 = Input M State

V2.10.3.2

Encoder Glitch Count

1

3051

V2.10.3.3

Encoder Error Flags

1

3052

1 = Resolution Range

2 = Resolution Prescale Range

4 = Invalid Encoder Mode

8 = Timebase Prescale Range

16 = Debounce Time Range

32 = Strobe Timeout

64 = Hysteresis Filter Config

128 = Glitch Detected

256 = Hardware

V2.10.3.4

Frequency Error

Hz

0.0001

3053

V2.10.3.5

Encoder Direction

1

3054

0 = CCW (Forward)

1 = CW (Reverse)

V2.10.3.6

Encoder Electrical Frequency

Hz

0.0001

3055

V2.10.3.7

Encoder Mechanical Frequency

RPM

0.0001

3056

V2.10.3.8

Encoder Electrical Angle

deg

0.0001

3057

V2.10.3.9

Encoder Mechanical Angle

deg

0.0001

3058

V2.10.3.10

Revolutions

1

3059

V2.10.3.11

Encoder Update Position

1

3060

V2.10.3.12

Encoder Index Position

1

3061

VACON® 3000

Application Guide

4.4.6 Encoder Monitoring

Table 14: Encoder Monitoring Values

Table 15: Monitoring of the Encoder Channel A Values

INU Application

AB319735759636en-000101 / DPD0182240 | Danfoss A/S © 2021.09

Index

Monitoring value

Unit

Scale

ID

Description

V2.10.3.13

Encoder Marker Position

1

3062

V2.10.3.14

Encoder Alternate Marker Position

1

3063

V2.10.3.15

Encoder Fault Detection Status Word

1

3066

b0 = Fallback active

b1 = HW detection unfiltered

b2 = HW detection active

b3 = SW detection active

b4 = SW detection speed limits not OK

b5 = SW difference detection active

b6 = Fault timeout active

b7 = Fault repeat timeout active

V2.10.3.16

Encoder HW Error Count

1

3067

V2.10.3.17

Encoder SW Error Count

1

3068

V2.10.3.18

Encoder SW Error Peak

Hz

0.001

3069

Index

Monitoring value

Unit

Scale

ID

Description

V2.10.4.1

Encoder Status Word

1

3070

1 = Direction State

2 = Pulse State

4 = Input A State

8 = Input B State

16 = Input Z State

32 = Input M State

V2.10.4.2

Encoder Glitch Count

1

3071

V2.10.4.3

Encoder Error Flags

1

3072

1 = Resolution Range

2 = Resolution Prescale Range

4 = Invalid Encoder Mode

8 = Timebase Prescale Range

16 = Debounce Time Range

32 = Strobe Timeout

64 = Hysteresis Filter Config

128 = Glitch Detected

V2.10.4.4

Frequency Error

Hz

0.0001

3073

V2.10.4.5

Encoder Direction

1

3074

0 = CCW (Forward)

1 = CW (Reverse)

V2.10.4.6

Encoder Electrical Frequency

Hz

0.0001

3075

V2.10.4.7

Encoder Mechanical Frequency

RPM

0.0001

3076

V2.10.4.8

Encoder Electrical Angle

deg

0.0001

3077

V2.10.4.9

Encoder Mechanical Angle

deg

0.0001

3078

V2.10.4.10

Revolutions

1

3079

V2.10.4.11

Encoder Update Position

1

3080

VACON® 3000

Application Guide

Table 16: Monitoring of the Encoder Channel B Values

INU Application

AB319735759636en-000101 / DPD01822 | 41Danfoss A/S © 2021.09

Index

Monitoring value

Unit

Scale

ID

Description

V2.10.4.12

Encoder Index Position

1

3081

V2.10.4.13

Encoder Marker Position

1

3082

V2.10.4.14

Encoder Alternate Marker Position

1

3083

Index

Monitoring value

Unit

Scale

ID

Description

V2.12.1

Precharge state

1

3510

0 = Reset

1 = Failed

2 = Not Ready

3 = Ready

4 = Charging

5 = Synchronizing

6 = Contactor Close

7 = Stabilizing

8 = Operational

9 = Loaded

V2.12.2

Precharge inhibit

1

3511

V2.12.3

Precharge error flags

1

3568

b0 = Software

b1 = Main Pilot Open TO

b2 = Mx Open TO

b3 = PC Contactor Open TO

b4 = DC-link Discharge TO

b5 = Front End Fault Clear TO

b6 = DC-link Overvoltage

b7 = Front End Lost Phase Lock

b8 = Front End Faulted

b9 = Mx Premature Close

b10 = Main Pilot Premature Close

b11 = Precharge Premature Termination

b12 = Max Charge Rate Exceeded

b13 = Min Charge Rate Deficient

b14 = Precharge TO

b15 = DC-link Voltage Deficient

b16 = Synchronization TO

b17 = Main Pilot Close TO

b18 = Front End Lost Synchronization

b19 = Mx Close TO

b20 = Mx Premature Open

b21 = Stabilization TO

b22 = Front End Deactivated

b23 = Front End Lost Stabilization

b24 = Unexpected Parameterization

b25 = Invalid Parameterization

b26 = Test Mode Activated While Hot

b27 = INU Became Faulted

VACON® 3000

Application Guide

4.4.7 Precharge Monitoring

Table 17: Precharge Monitoring Values

INU Application

AB319735759636en-000101 / DPD0182242 | Danfoss A/S © 2021.09

Index

Monitoring value

Unit

Scale

ID

Description

b28 = Precharge Contactor Unexpected Close

V2.12.4

Precharge status word

1

3513

b0 = Precharge Permissive

b1 = Mx Permissive

b2 = Mx Start

b3 = PCC Interlock

b4 = Precharge Inhibit

b5 = Precharge Ready

b6 = Precharge Started

b7 = PCC Gating Enabled

b8 = Kpc State

b9 = Kmx State

b10 = Mx State

b11 = GSW Permissive

b12 = Kpc Sub State

b13 = Kmx Sub State

b14 = Mx Sub State

b15 = Reserved

M2.12.5

Internal control

See Table 18.

M2.12.6

Interlocks

See Table 19.

M2.12.7

Interlocks @ Last Fault

See Table 20.

Index

Monitoring value

Unit

Scale

ID

Description

V2.12.5.1

Power on state

1

3520

0 = Reset

1 = Failed

2 = Initializing

3 = Ready

4 = Cooling

5 = Charging

6 = Contactor Close

7 = Stabilizing

8 = Operational

V2.12.5.2

Power on status word

1

3574

b0 = PowerOn Req

b1 = Power Off

b2 = Reset

b3 = Run Cooling

b4 = Precharge

b5 = Power On

b6 = Fault

b7 = Precharge Ready

b8 = PreStart OK

(1)

b9 = MCBs and Interlocks OK

b10 = Leak Detection OK

b11 = LCL OK (AFE)

b12 = GSW AFR DSI OK

VACON® 3000

Application Guide

INU Application

Table 18: Internal Control Monitoring Values

AB319735759636en-000101 / DPD01822 | 43Danfoss A/S © 2021.09

Index

Monitoring value

Unit

Scale

ID

Description

b13 = Cooling OK

(2)

b14 = DC Capacitors OK (INU)

V2.12.5.3

Power on state fault

1

3521

See ID 3520.

V2.12.5.4

Power on status word fault

1

3583

See ID 3574.

V2.12.5.5

Precharge status word fault

1

3514

See ID 3513.

V2.12.5.6

Precharge error flags @ fault

1

3580

See ID 3568 in Table 17.

Index

Monitoring value

Unit

Scale

ID

Description

V2.12.6.1

GSW UFES status word

1

3575

b0 = GSW Open 1

b1 = GSW Open 2

b2 = GSW Open 3

b3 = GSW Open 4

b4 = GSW Not Closed 1

b5 = GSW Not Closed 2

b6 = GSW Not Closed 3

b7 = GSW Not Closed 4

b12 = AFR Online

b13 = AFR Not Faulted

b14 = DSI Ok

V2.12.6.2

MCB status word

1

3570

b0 = ENC HX MCB 1

b1 = ENC HX MCB 2

b2 = ENC HX MCB 3

b3 = ENC HX MCB 4

b4 = TEMPCL MCB 1

b5 = TEMPCL MCB 2

b6 = TEMPCL MCB 3

b7 = TEMPCL MCB 4

b8 = Interlock Open 1

b9 = Interlock Open 2

b10 = Interlock Open 3

b11 = Interlock Open 4

b12 = Interlock Close 1

b13 = Interlock Close 2

b14 = Interlock Close 3

V2.12.6.3

Leak detection status word

1

3571

b0 = LD Sys Ok 1

b1 = LD Sys Ok 2

b2 = LD Sys Ok 3

b3 = LD Sys Ok 4

b4 = LD No Leak 1

b5 = LD No Leak 2

VACON® 3000

Application Guide

1

PreStart OK requires that all of the following status words are OK: MCB Status (ID 3570), Leak Det. Status (ID 3571), GSW UFES Status (ID 3575), and

DC Cap Status (ID 3584).

2

Cooling OK requires that all of the following status words are OK: Enc HX Status (ID 3572), and HEX Status (ID 3573).

Table 19: Interlocks Monitoring Values

INU Application

AB319735759636en-000101 / DPD0182244 | Danfoss A/S © 2021.09

Index

Monitoring value

Unit

Scale

ID

Description

b6 = LD No Leak 3

b7 = LD No Leak 4

V2.12.6.4

HEX status word

1

3573

b0 = HX Cooling Ok 1

b1 = HX Cooling Ok 2

b2 = HX Cooling Ok 3

b3 = HX Cooling Ok 4

V2.12.6.5

ENC HX status word

1

3572

b0 = ENC HX 1

b1 = ENC HX 2

b2 = ENC HX 3

b3 = ENC HX 4

b4 = ENC FAN 1.1

b5 = ENC FAN 1.2

b6 = ENC FAN 1.3

b7 = ENC FAN 2.1

b8 = ENC FAN 2.2

b9 = ENC FAN 2.3

b10 = ENC FAN 3.1

b11 = ENC FAN 3.2

b12 = ENC FAN 3.3

b13 = ENC FAN 4.1

b14 = ENC FAN 4.2

V2.12.6.6

DC capacitor status word

1

3584

b0 = DC Choke Ok 1

b1 = DC Choke Ok 2

b2 = DC Cap Ok 1

b3 = DC Cap Ok 2

b4 = DC Cap Ok 3

b5 = DC Cap Ok 4

Index

Monitoring value

Unit

Scale

ID

Description

V2.12.7.1

GSW UFES status word fault

3582