Operating Guide

VACON® 3000 Enclosed Drive

drives.danfoss.com

VACON® 3000 Enclosed Drive

Operating Guide

Contents

1

Introduction 9

1.1

Purpose of this Operating Guide 9

Additional Resources 9

1.2

Manual Version 9

1.3

Safety 10

2

Safety Symbols 10

2.1

Qualified Personnel 10

2.2

Danger and Warnings 10

2.3

Cautions and Notices 12

2.4

Main Circuit Breaker 14

2.5

Safety and Protection Requirements 14

2.5.1

Minimum Requirements for MCB and MCB Control 14

2.5.2

Contents

Product Overview 16

3

Intended Use 16

3.1

3.2

Product Description 16

3.2.1

AFE Drive 16

3.2.2

12-Pulse Drive 17

3.3

Type Code Description 17

3.4

Available Options 18

4

Receiving the Delivery 21

4.1

Checking the Delivery 21

4.2

Storage 21

4.3

Lifting and Moving the Enclosed Drive 21

5

Mechanical Installation 24

5.1

Operating Environment 24

5.2

Cabinet Installation 24

5.3

Dimensions of the Enclosed Drive 25

5.4

Liquid Cooling Requirements 26

5.4.1

Safety in Liquid-cooling 26

5.4.2

General Information on Liquid Cooling 26

5.4.3

Cooling Liquid 27

5.4.3.1

5.4.3.2

5.4.3.3

Quality Requirements for the Purified Water 27

Purified Water as Coolant 27

Antifreeze Mix as Coolant 27

AQ286660579921en-000101/DPD02033 | 3Danfoss A/S © 2021.09

VACON® 3000 Enclosed Drive

Operating Guide

5.4.3.4

5.4.3.5

5.4.4

Cooling System 30

5.4.4.1

5.4.4.2

5.4.4.3

5.5

Cooling and Free Space Around the Enclosed Drive 32

6

Electrical Installation 34

6.1

Galvanic Isolation Between the MV and LV Sections 34

6.2

Mains and Motor Cable Selection 35

6.3

Mains and Motor Cable Inlet and Termination 35

6.4

Grounding 38

6.4.1

Standard Grounding Configurations 38

6.5

Additional Instructions for Cable Installation 39

Temperature of the Cooling Liquid 28

Condensation 28

Materials 30

Cooling System Overview 31

Cooling Connections to the Enclosed Drive 31

Contents

6.6

Main Circuit Breaker Installation 40

6.7

Cabling of the Power Modules 40

6.7.1

Phase Module L20/L30 Terminals 40

6.7.2

DFE Power Module Terminals 40

6.7.2.1

6.7.3

Power Module Grounding 42

6.7.4

DC-Link Connections 43

6.7.5

Brake Chopper Installation 45

6.7.6

Terminal Screw Tightening Torque Specifications 45

6.7.7

LED Display on the Phase Module 45

6.7.8

LED Display on the DFE Power Module 47

6.8

Low-Voltage Power Supplies 48

6.8.1

Low-Voltage Power Supply Connections 48

6.8.2

Safety Notes for the Precharge Unit 49

6.8.3

Location of the Precharge Unit 49

6.9

Safety Functions 49

DFE Control Terminals 41

6.9.1

Safe Torque Off (STO) 50

6.9.2

Safe Stop 1 (SS1) 50

6.9.3

Safety Considerations 50

6.9.3.1

6.9.4

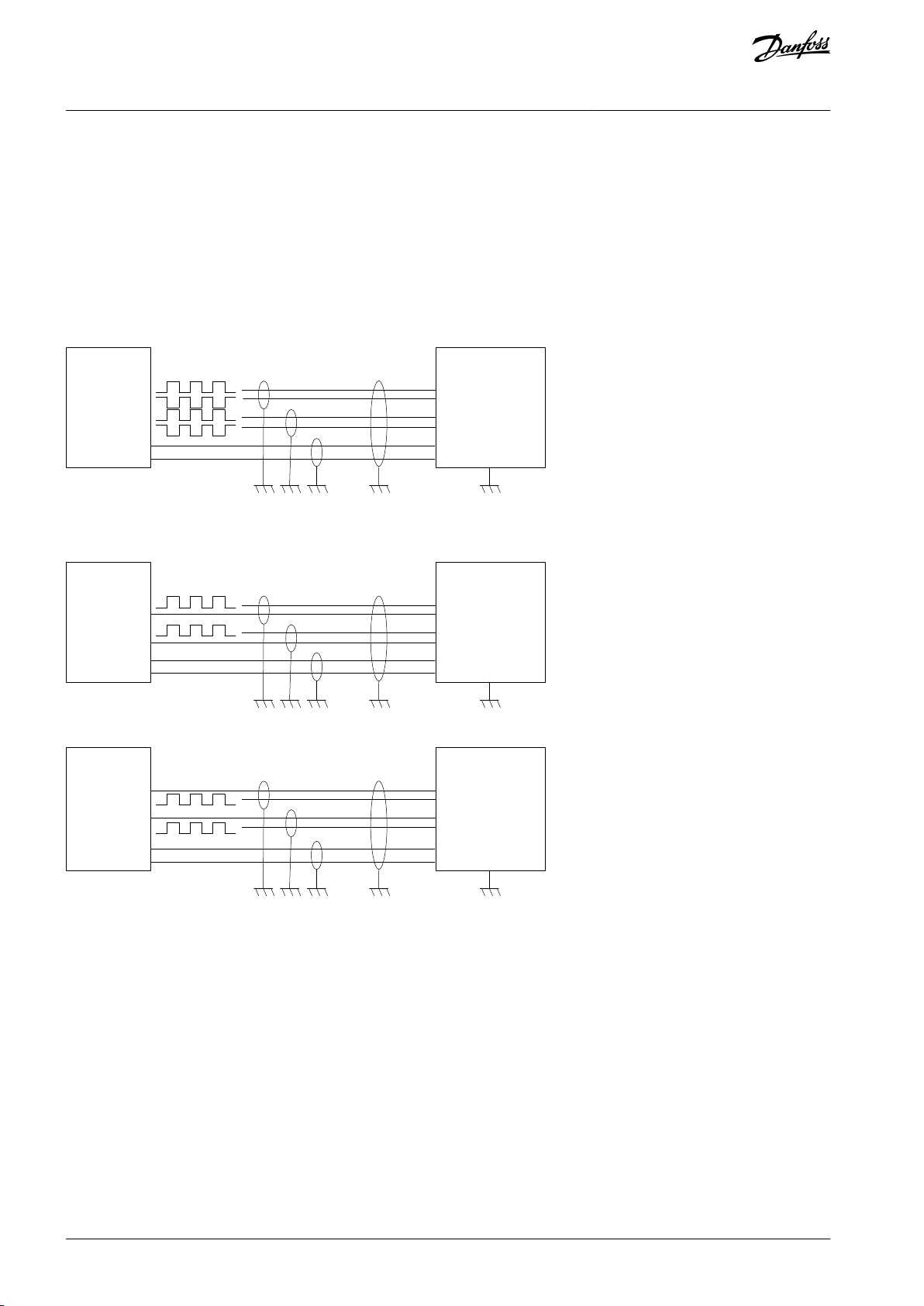

STO Operating Principle 51

6.9.5

SS1 Operating Principle 51

Diagnostic Test 50

AQ286660579921en-000101/DPD020334 | Danfoss A/S © 2021.09

VACON® 3000 Enclosed Drive

Operating Guide

7

Control Connections 52

Control Interface 52

7.1

7.2

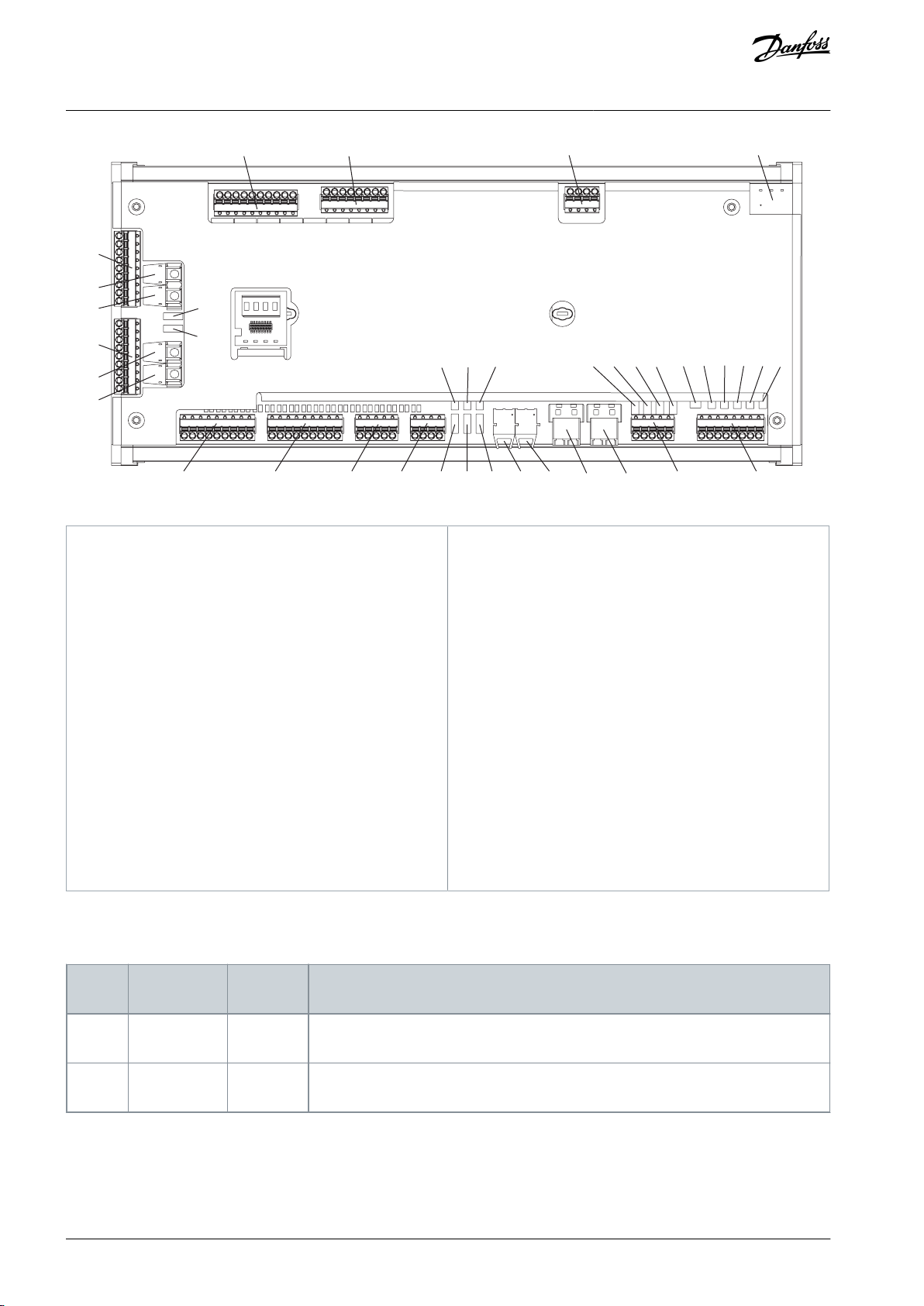

The Control Compartment of the Enclosed Drive 52

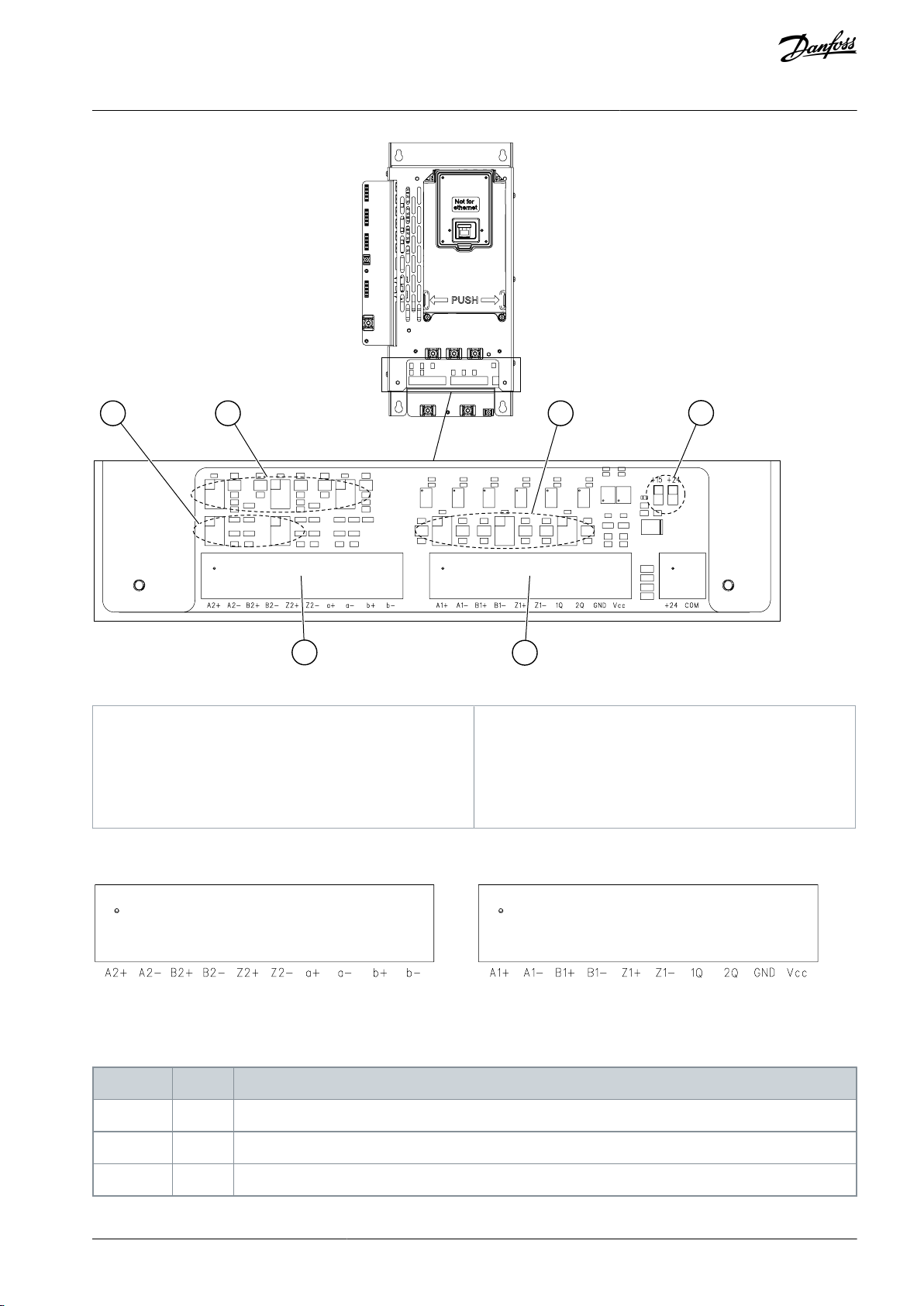

Control Unit Components 53

7.3

7.4

Control Unit Cabling 54

7.4.1

Selection of the Control Cables 55

7.4.2

Control Unit Terminals 55

7.5

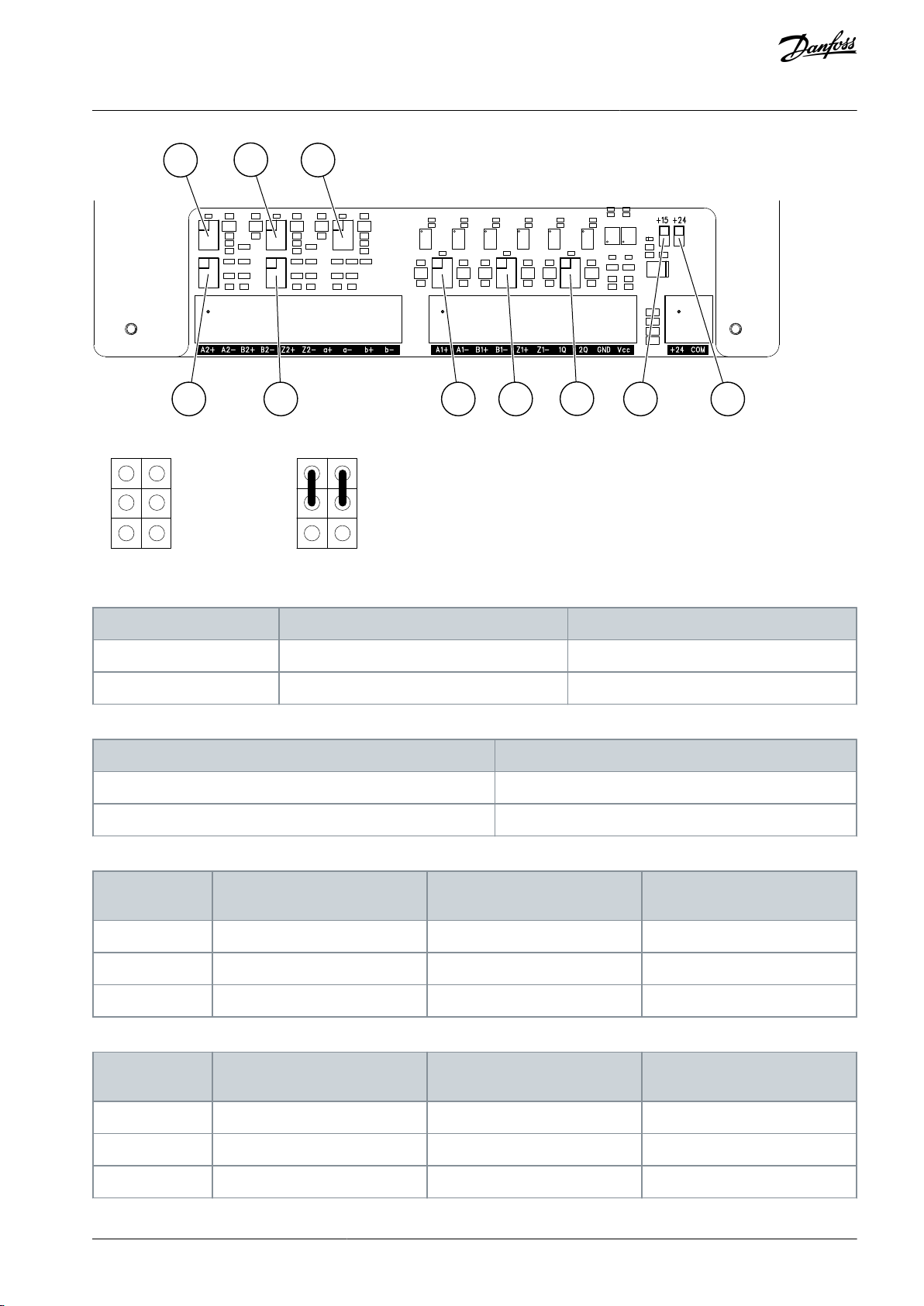

DIP Switches on the Control Unit 56

7.5.1

Selection of Terminal Functions with DIP Switches 56

7.5.2

Isolation of the Digital Inputs from Ground 57

7.6

Fieldbus Connection 58

7.6.1

Fieldbus Terminals 58

7.6.2

Using Fieldbus through an Ethernet Cable 59

7.6.3

Using Fieldbus through an RS485 Cable 60

Contents

Option Board Installation 62

7.7

7.8

Optical Fiber Connections 63

7.8.1

Selection of Optical Fiber Cables 66

7.8.2

Making Optical Fiber Cables 67

7.9

Encoder Interface 68

7.9.1

Encoder Terminals and Signals 69

7.9.2

Encoder Jumper Configurations 70

7.9.3

Encoder Connection 72

7.10

Battery for the Real-Time Clock (RTC) 73

7.11

Galvanic Isolation Barriers 73

7.12

System and Application Software 73

7.13

Technical Data on Control Connections 73

7.14

Auxiliary I/O Board 75

7.14.1

Connector Locations 75

7.14.2

Connector Specifications 76

7.14.3

LED Display on the Auxiliary I/O Board 80

8

Commissioning 82

8.1

Safety Checks before Starting the Commissioning 82

8.2

Operating the Grounding Switch 82

8.3

Commissioning the Drive 83

8.3.1

Basic Job Information 83

8.3.2

Before Power-up Checklist 84

8.3.3

Control and Auxiliary Power Commissioning Checklist 87

AQ286660579921en-000101/DPD02033 | 5Danfoss A/S © 2021.09

VACON® 3000 Enclosed Drive

Operating Guide

8.3.4

8.4

Commissioning Procedures 88

8.4.1

8.4.2

8.4.3

8.4.4

8.4.5

8.4.6

8.4.7

8.5

Insulation Resistance Measurements 106

8.5.1

8.5.2

Contents

Medium-Voltage Power Commissioning Checklist 88

Filling the Liquid Cooling System 88

Grid Voltage Feedback Configuration 92

Installing Software on the Control Unit 94

Verifying the Phase Module Connections 97

Commissioning Test 98

8.4.5.1

8.4.5.2

AFE Synchronization Test 101

Encoder Setup 105

Measuring the Switchgear Insulation Resistance 106

Measuring the Cable and Motor Insulation 107

Commissioning Test with HMI Touch Screen 99

Commissioning Test with VACON® Live 100

8.5.2.1

8.5.2.2

8.5.2.3

9

Maintenance 108

9.1

Preventive Maintenance Recommendations 108

9.2

Maintenance of the Heat Exchanger 110

10

Fault Tracing 111

10.1

Fault Types 111

10.2

Faults and Alarms 111

10.2.1

Fault Code 1 - Overcurrent 111

10.2.2

Fault Code 2 - Overvoltage 112

10.2.3

Fault Code 3 - Earth Fault 113

10.2.4

Fault Code 5 - Charging Switch 114

10.2.5

Fault Code 7 - Saturation 114

10.2.6

Fault Code 8 - System Fault 114

Insulation Checks of the Motor Cable 107

Insulation Checks of the Mains Cable 107

Insulation Checks of the Motor 107

10.2.7

Fault Code 9 - Undervoltage 122

10.2.8

Fault Code 10 - Input Phase 122

10.2.9

Fault Code 11 - Output Phase Supervision 124

10.2.10

Fault Code 12 - Brake Chopper Supervision 124

10.2.11

Fault Code 13 - AC Drive Undertemperature 125

10.2.12

Fault Code 14 - AC Drive Overtemperature 125

10.2.13

Fault Code 15 - Motor Stall 127

10.2.14

Fault Code 16 - Motor Overtemperature 127

AQ286660579921en-000101/DPD020336 | Danfoss A/S © 2021.09

VACON® 3000 Enclosed Drive

Operating Guide

10.2.15

10.2.16

10.2.17

10.2.18

10.2.19

10.2.20

10.2.21

10.2.22

10.2.23

10.2.24

10.2.25

10.2.26

10.2.27

10.2.28

Contents

Fault Code 17 - Motor Underload 127

Fault Code 19 - Power Overload 128

Fault Code 25 - Motor Control Fault 128

Fault Code 26 - Start-up Prevented 129

Fault Code 29 - ATEX Thermistor 129

Fault Code 30 - Safety 129

Fault Code 32 - Fan Cooling 132

Fault Code 33 - Fire Mode Enabled 132

Fault Code 37 - Device Changed (Same Type) 132

Fault Code 38 - Device Added (Same Type) 133

Fault Code 39 - Device Removed 134

Fault Code 40 - Device Unknown 134

Fault Code 41 - IGBT Temperature 135

Fault Code 43 - Encoder Fault 135

10.2.29

Fault Code 44 - Device Changed (Different Type) 137

10.2.30

Fault Code 45 - Device Added (Different Type) 138

10.2.31

Fault Code 46 - Real Time Clock 138

10.2.32

Fault Code 47 - Software Update 139

10.2.33

Fault Code 49 - Precharge 139

10.2.34

Fault Code 50 - AI Low Fault 143

10.2.35

Fault Code 51 - Device External Fault 143

10.2.36

Fault Code 52 - Keypad Communication Fault 144

10.2.37

Fault Code 53 - Fieldbus Communication Fault 144

10.2.38

Fault Code 54 - Slot Fault 144

10.2.39

Fault Code 57 - Identification 145

10.2.40

Fault Code 58 - Mechanical Brake 146

10.2.41

Fault Code 59 - Communication 146

10.2.42

Fault Code 61 - Speed Error Fault 146

10.2.43

Fault Code 63 - Quick Stop 146

10.2.44

Fault Code 65 - PC Communication Fault 147

10.2.45

Fault Code 66 - Thermistor Input Fault 147

10.2.46

Fault Code 67 - Module Test Stand 148

10.2.47

Fault Code 68 - Maintenance Counter 148

10.2.48

Fault Code 69 - Fieldbus Mapping Error 148

10.2.49

Fault Code 76 - Start Prevented 149

10.2.50

Fault Code 77 - >5 Connections 149

10.2.51

Fault Code 78 - Identification Ongoing 149

10.2.52

Fault Code 80 - Fieldbus Watchdog Fault 149

AQ286660579921en-000101/DPD02033 | 7Danfoss A/S © 2021.09

VACON® 3000 Enclosed Drive

Operating Guide

10.2.53

Fault Code 84 - Overspeed Error 149

10.2.54

Fault Code 111 - Temperature Input Fault 1 149

10.2.55

Fault Code 112 - Temperature Input Fault 2 150

10.2.56

Fault Code 114 - User Defined Fault 1 150

10.2.57

Fault Code 115 - User Defined Fault 2 151

10.2.58

Fault Code 200 - Precharge 151

10.2.59

Fault Code 201 - High Humidity/Temperature 152

10.2.60

Fault Code 202 - Encoder 152

10.2.61

Fault Code 203 - STO Fault 153

10.2.62

Fault Code 204 - Output Filter 153

10.2.63

Fault Code 205 - Coolant Temperature 153

10.2.64

Fault Code 300 - Unsupported 153

11

Specifications 154

11.1

Power Ratings 154

Contents

11.1.1

Power Ratings for Mains Voltage 3300 V 154

11.1.2

Power Ratings for Mains Voltage 4160 V 154

11.1.3

Overload Capability 155

11.2

Technical Data 155

11.2.1

Mains Supply 155

11.2.2

Motor Output 156

11.2.3

Control Properties 156

11.2.4

Drive Properties 157

11.2.5

Ambient Conditions 158

11.2.6

Cooling 159

11.2.7

Source Impedance Specifications 160

11.3

Main Circuit Diagrams 164

11.3.1

VACON® 3000 AFE Main Circuit Diagrams 164

11.3.2

VACON® 3000 12-Pulse Main Circuit Diagrams 166

11.4

Abbreviations 167

AQ286660579921en-000101/DPD020338 | Danfoss A/S © 2021.09

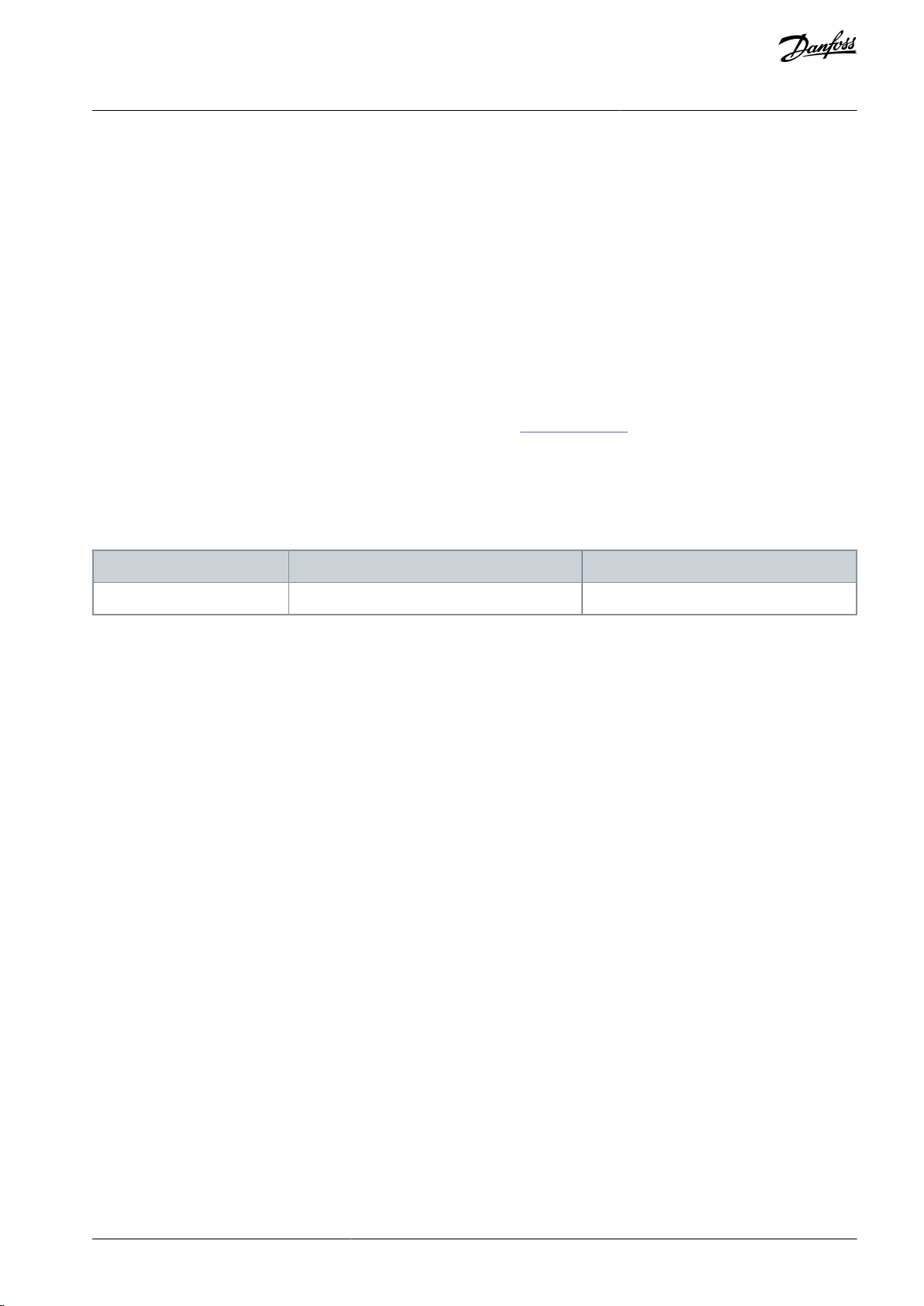

Version

Release date

Remarks

A

29.09.2021

First version

VACON® 3000 Enclosed Drive

Operating Guide

Introduction

1 Introduction

1.1 Purpose of this Operating Guide

This Operating Guide provides information for safe installation and commissioning of the AC drive. It is intended for use by qualified

personnel.

Read and follow the instructions to use the drive safely and professionally.

Pay particular attention to the safety instructions and general warnings. Always keep this Operating Guide with the drive.

1.2 Additional Resources

Other resources are available to understand advanced AC drive functions, programming, and options.

•

The VACON® 3000 application guides provide greater detail on how to work with the applications and how to set the parameters of the AC drive.

•

The operating and installation guides for VACON® options give detailed information about specific drive options.

Supplementary publications and manuals are available from Danfoss. See www.danfoss.com for listings.

1.3 Manual Version

This manual is regularly reviewed and updated. All suggestions for improvement are welcome.

The original language of this manual is English.

Table 1: VACON® 3000 Enclosed Drive Operating Guide Version

AQ286660579921en-000101 / DPD02033 | 9Danfoss A/S © 2021.09

VACON® 3000 Enclosed Drive

Operating Guide

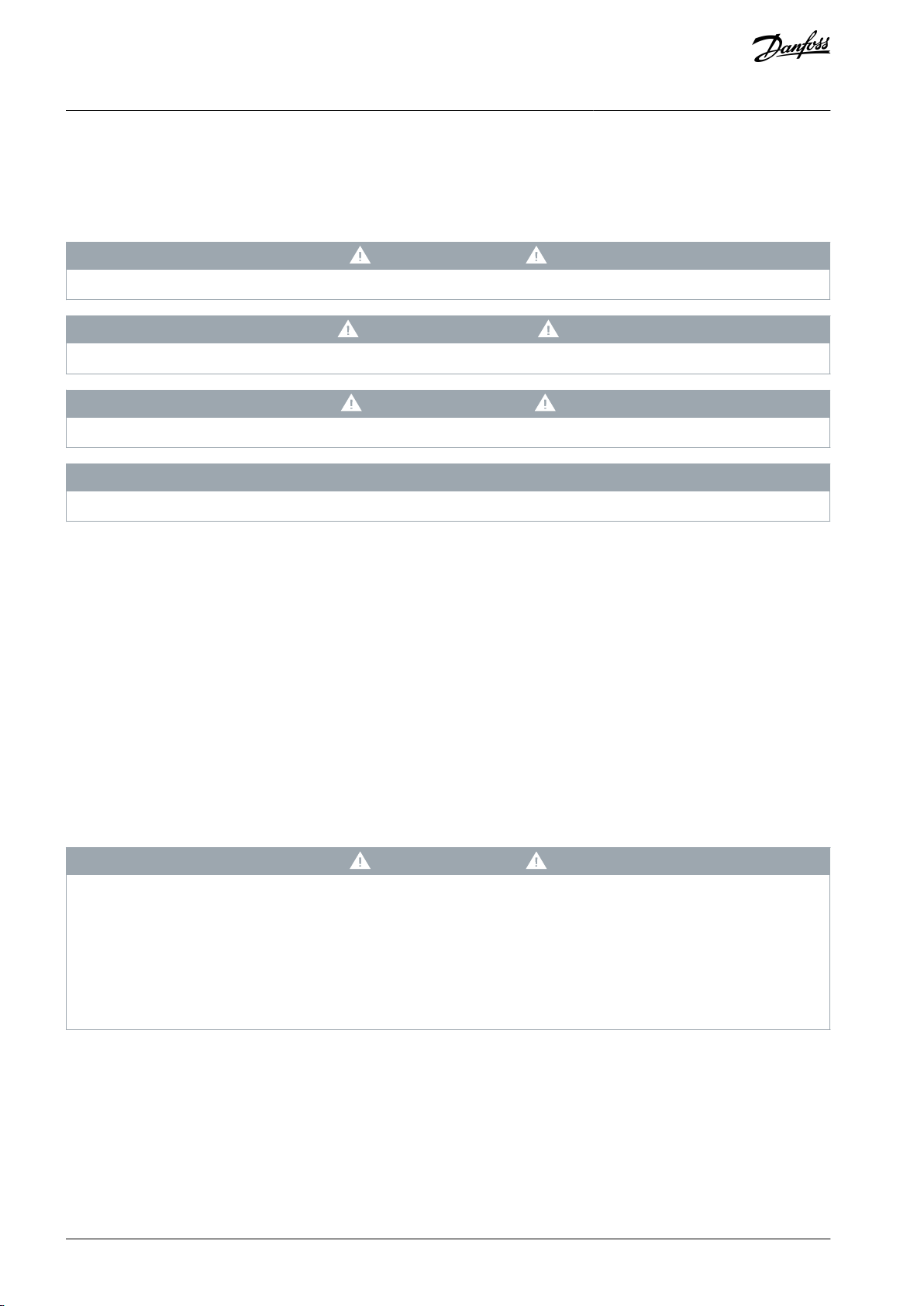

2 Safety

2.1 Safety Symbols

The following symbols are used in this manual:

D A N G E R

Indicates a hazardous situation which, if not avoided, will result in death or serious injury.

W A R N I N G

Indicates a hazardous situation which, if not avoided, could result in death or serious injury.

C A U T I O N

Indicates a hazardous situation which, if not avoided, could result in minor or moderate injury.

N O T I C E

Indicates information considered important, but not hazard-related (for example, messages relating to property damage).

Safety

2.2 Qualified Personnel

To allow trouble-free and safe operation of the unit, only qualified personnel with proven skills are allowed to transport, store, assemble, install, program, commission, maintain, and decommission this equipment.

Persons with proven skills:

•

Are qualified electrical engineers, or persons who have received training from qualified electrical engineers and are suitably

experienced to operate devices, systems, plant, and machinery in accordance with pertinent laws and regulations.

•

Are familiar with the basic regulations concerning health and safety/accident prevention.

•

Have read and understood the safety guidelines given in all manuals, especially the instructions given in the operating guide of

the unit.

•

Have good knowledge of the generic and specialist standards applicable to the specific application.

•

Are familiar with the structure and operation of medium-voltage drives and the related risks. Special training for medium-voltage installations may be necessary.

2.3 Danger and Warnings

D A N G E R

SHOCK HAZARD FROM POWER UNIT COMPONENTS

The power unit components are live when the drive is connected to mains. Contact with this voltage can result in death or seri-

ous injury.

Do not touch the components of the power unit when the drive is connected to mains.

-

Do not do any work on live equipment.

Before doing any work on internal drive components, follow proper lock out and tag out procedure.

Before connecting the drive to mains, make sure that all covers are installed on the drive and the enclosure doors are closed.

AQ286660579921en-000101 / DPD0203310 | Danfoss A/S © 2021.09

VACON® 3000 Enclosed Drive

Operating Guide

D A N G E R

SHOCK HAZARD FROM TERMINALS

The motor terminals U, V, W, the brake resistor terminals, and the DC-link terminals must be treated as live when the drive is

connected to mains. Contact with this voltage can lead to death or serious injury.

Do not touch the motor terminals U, V, W, the brake resistor terminals, or the DC terminals when the drive is connected to

-

mains.

Do not do any work on live equipment.

Before doing any work on the drive, follow proper lock out and tag out procedure.

Before connecting the drive to mains, make sure that all covers are installed on the drive and the enclosure doors are closed.

D A N G E R

SHOCK HAZARD FROM DC LINK OR EXTERNAL SOURCE

The terminal connections and the components of the drive can be live several minutes after the drive is disconnected from the

mains and the motor has stopped. The load side of the drive can also generate voltage. A contact with this voltage can lead to

death or serious injury.

Disconnect the drive from the mains and make sure that the motor has stopped.

-

Disconnect the motor.

Lock out and tag out the power source to the drive.

Make sure that no external source generates unintended voltage during work.

To ground the drive input and DC link, close the grounding switch. If there is no grounding switch, make sure that the drive

input and DC link are grounded for work. Also ground the motor terminals for work.

Wait for the DC-link capacitors to discharge fully before opening the cabinet door or the cover of the AC drive. The discharge

time is <7 minutes for AFE drives and <21 minutes for 12-pulse drives.

Use a measuring device to make sure that there is no voltage.

Safety

W A R N I N G

SHOCK HAZARD FROM CONTROL TERMINALS

The control terminals can have a dangerous voltage also when the drive is disconnected from mains. A contact with this voltage

can lead to injury.

Make sure that there is no voltage in the control terminals before touching the control terminals.

-

W A R N I N G

ACCIDENTAL MOTOR START

When there is a power-up, a power break, or a fault reset, the motor starts immediately if the start signal is active, unless the pulse

control for Start/Stop logic is selected. If the parameters, the applications or the software change, the I/O functions (including the

start inputs) can change. If you activate the auto reset function, the motor starts automatically after an automatic fault reset. See

the Application Guide. Failure to ensure that the motor, system, and any attached equipment are ready for start can result in

personal injury or equipment damage.

Disconnect the motor from the drive if an accidental start can be dangerous. Make sure that the equipment is safe to operate

-

under any condition.

AQ286660579921en-000101 / DPD02033 | 11Danfoss A/S © 2021.09

VACON® 3000 Enclosed Drive

Operating Guide

W A R N I N G

ELECTRICAL SHOCK HAZARD - LEAKAGE CURRENT HAZARD >3.5 MA

Leakage currents exceed 3.5 mA. Failure to connect the drive properly to protective earth (PE) can result in death or serious in-

jury.

Ensure reinforced protective earthing conductor according to IEC 60364-5-54 cl. 543.7 or according to local safety regula-

-

tions for high touch current equipment. The reinforced protective earthing of the drive can be done with:

a PE conductor with a cross-section of at least 10 mm2 (8 AWG) Cu or 16 mm2 (6 AWG) Al.

-

an extra PE conductor of the same cross-sectional area as the original PE conductor as specified by IEC 60364-5-54 with a

-

minimum cross-sectional area of 2.5 mm2 (14 AWG) (mechanical protected) or 4 mm2 (12 AWG) (not mechanical protected).

a PE conductor completely enclosed with an enclosure or otherwise protected throughout its length against mechanical

-

damage.

a PE conductor part of a multi-conductor power cable with a minimum PE conductor cross-section of 2.5 mm2 (14 AWG)

-

(permanently connected or pluggable by an industrial connector. The multi-conductor power cable shall be installed with an

appropriate strain relief).

NOTE: In IEC/EN 60364-5-54 cl. 543.7 and some application standards (for example IEC/EN 60204-1), the limit for requiring

-

reinforced protective earthing conductor is 10 mA leakage current.

2.4 Cautions and Notices

Safety

C A U T I O N

DAMAGE TO THE AC DRIVE FROM INCORRECT SPARE PARTS

Using spare parts that are not from the manufacturer can damage the drive.

Do not use spare parts that are not from the manufacturer.

-

C A U T I O N

DAMAGE TO THE AC DRIVE FROM CHANGES TO DRIVE COMPONENTS

Doing electrical or mechanical changes to the drive components can cause malfunctions and can damage the AC Drive.

Do not make electrical or mechanical changes to the drive components.

-

C A U T I O N

DAMAGE TO THE AC DRIVE FROM INSUFFICIENT GROUNDING

Not using a grounding conductor can damage the drive.

Always ground the AC drive with a grounding conductor that is connected to the grounding terminal that is identified with

-

the PE symbol. If no dedicated transformer is installed, the AC drive is intended for high resistance grounding systems with a

resistance grounded neutral point. For operation in an IT network without a dedicated transformer, consult Danfoss.

C A U T I O N

CUT HAZARD FROM SHARP EDGES

There can be sharp edges in the AC drive that can cause cuts.

Wear protective gloves when mounting, cabling, or doing maintenance operations.

-

C A U T I O N

BURN HAZARD FROM HOT SURFACES

Touching surfaces, which are marked with the 'hot surface' sticker, can result in injury.

Do not touch surfaces which are marked with the 'hot surface' sticker.

-

AQ286660579921en-000101 / DPD0203312 | Danfoss A/S © 2021.09

VACON® 3000 Enclosed Drive

Operating Guide

N O T I C E

DAMAGE TO THE AC DRIVE FROM STATIC VOLTAGE

Some of the electronic components inside the AC drive are sensitive to ESD. Static voltage can damage the components.

Use ESD protection when working with electronic components of the AC drive. Do not touch the components on the circuit

-

boards without proper ESD protection.

N O T I C E

DAMAGE TO THE AC DRIVE FROM MOVEMENT

Movement after installation can damage the drive.

Do not move the AC drive during operation. Use a fixed installation to prevent damage to the drive.

-

N O T I C E

DAMAGE TO THE AC DRIVE FROM INCORRECT EMC LEVEL

The EMC level requirements for the AC drive depend on the installation environment. An incorrect EMC level can damage the

drive.

Before connecting the AC drive to the mains, make sure that the EMC level of the AC drive is correct for the mains.

-

Safety

N O T I C E

RADIO INTERFERENCE

In a residential environment, this product can cause radio interference.

Take supplementary mitigation measures.

-

N O T I C E

MAINS DISCONNECTION DEVICE

If the AC drive is used as a part of a machine, the machine manufacturer must supply a mains disconnection device (refer to EN

60204-1).

N O T I C E

MALFUNCTION OF FAULT CURRENT PROTECTIVE SWITCHES

Because there are high capacitive currents in the AC drive, it is possible that the fault current protective switches do not operate

correctly.

N O T I C E

VOLTAGE WITHSTAND TESTS

If done improperly, doing voltage withstand tests can damage the drive.

Megohmmeter testing is the only recommended test type for field installations.

-

Only a qualified field service engineer is allowed to perform this test.

Refer to the proper high potential/megohmmeter testing instructions in the service guide.

N O T I C E

WARRANTY

If the power modules are opened, the warranty is not valid.

Do not open the power modules.

-

AQ286660579921en-000101 / DPD02033 | 13Danfoss A/S © 2021.09

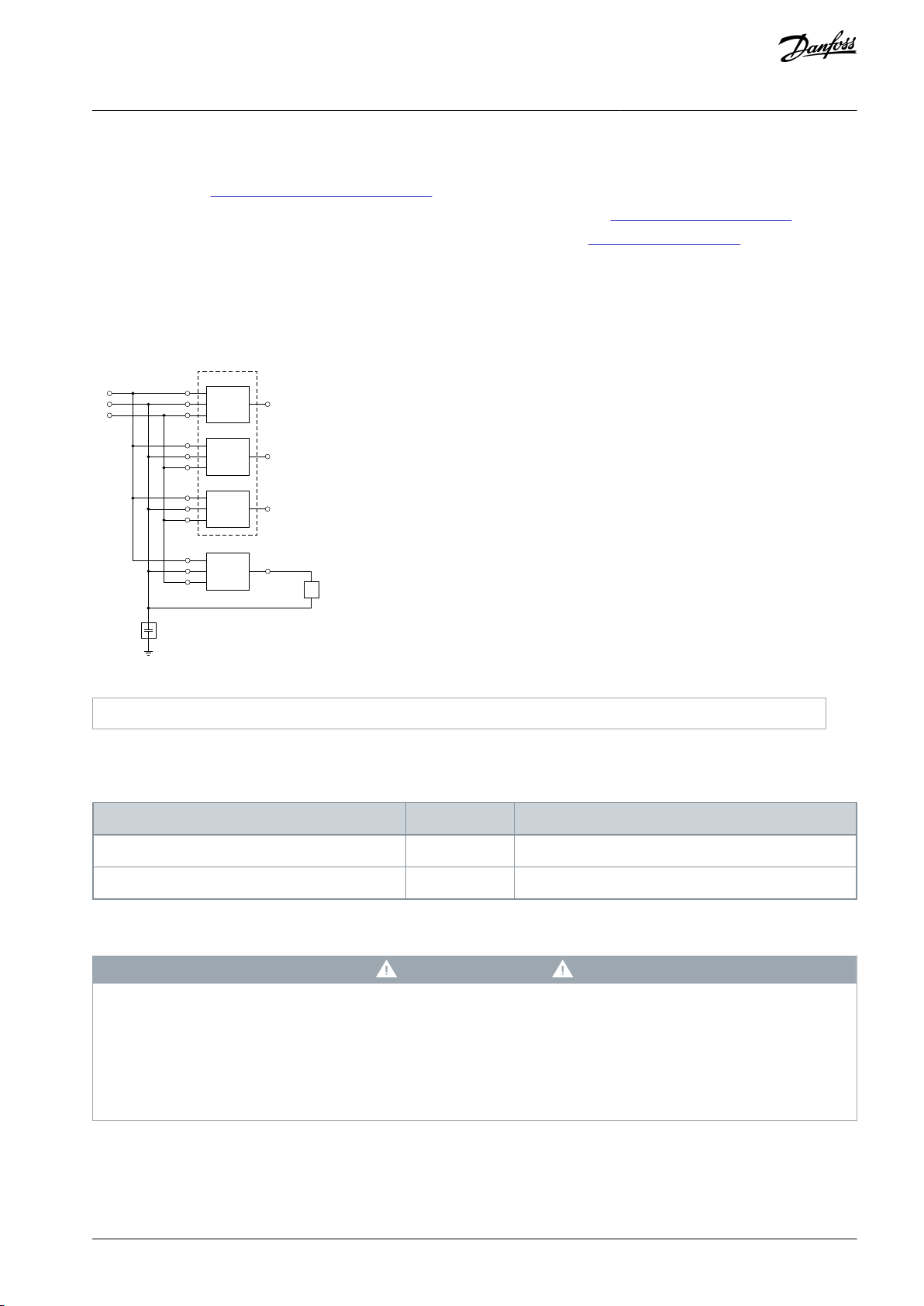

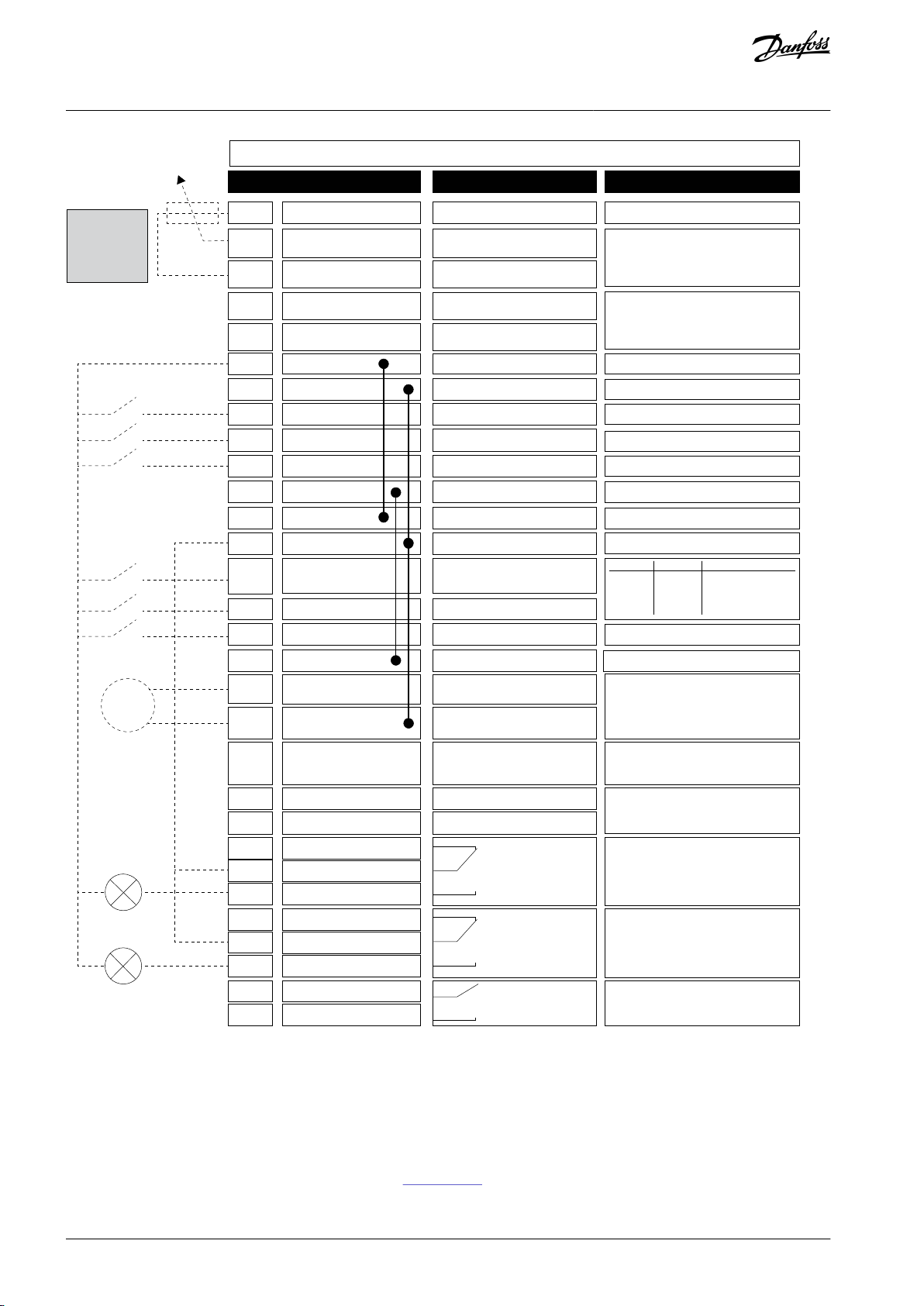

G

CB1

5

4

3

2

1

CB2

MVD

M

~

~

e30bi562.10

1

Trip coil: RO from VACON® 3000 (reaction time:

10 ms delay)

2

Undervoltage release (UVR): IGBT switch from arc

flash relay (reaction time: 2 ms delay)

3

Breaker open: RO from the breaker

4

Breaker closed: RO from the breaker

5

Breaker ready (optional): RO from the breaker

CB1

Circuit breaker 1

CB2

Circuit breaker 2

G

Grid or generator

M

Motor

MVD

VACON® 3000 medium-voltage drive

VACON® 3000 Enclosed Drive

Operating Guide

Safety

N O T I C E

PERSONAL PROTECTIVE EQUIPMENT AND APPROVED TOOLS

When doing electrical work on the AC drive, always use personal protective equipment (PPE) and tools which are approved for

work with medium-voltage devices.

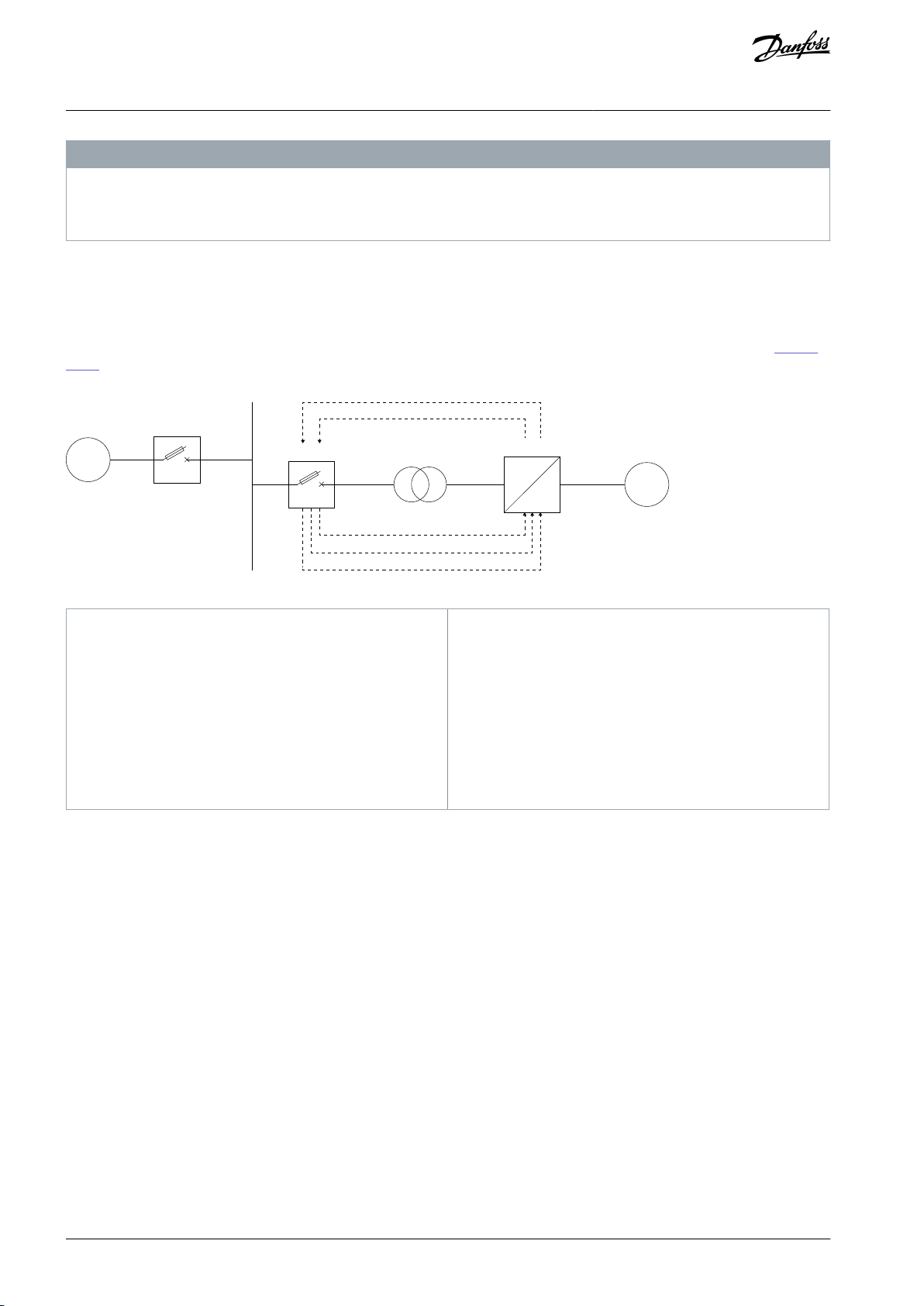

2.5 Main Circuit Breaker

The main circuit breaker (MCB) is an important protection device for the drive. If there is a serious fault in the drive, the MCB immediately disconnects the main supply to the drive. To protect personnel and to prevent further damage to the equipment, the main

supply must be disconnected immediately with an open or trip command from the drive.

If the drive is supplied through a dedicated transformer, install the MCB on the primary side of the supply transformer (see Illustra-

tion 1).

Illustration 1: Overview of the Drive System

2.5.1 Safety and Protection Requirements

For safety and protection, the MCB must meet the minimum requirements of the specifications of Danfoss medium-voltage drives.

The minimum requirements for the MCB are stated in this manual and in the respective MCB specifications, which are available for

each medium-voltage drive from Danfoss. The system integrator must make sure that the minimum requirements are met.

The safety requirements for the drive are based on the following standards:

•

EN ISO 13849-1: Safety of machinery, Safety-related parts of control systems, General principles for design, section 6.2.6 Category 3

•

UL347A, Edition 1: Standard for Medium Voltage Power Conversion Equipment

2.5.2 Minimum Requirements for MCB and MCB Control

Requirements

To meet the stipulated safety requirements, Danfoss requires the following:

•

MCB is equipped with 2 independent opening coils.

•

MCB is equipped with an opening coil and an undervoltage coil for monitoring of the control voltage.

•

Route the MCB open and trip commands directly from the drive to the MCB.

-

Do not route the trip command through any PLC or DCS (distributed control system) which is not certified to meet SIL 3level requirements and to fulfill the given timing requirements.

-

Opening of the MCB by the drive must be possible at any time. Do not interrupt the open and trip commands, for example,

by a local-remote switch in the MCB.

AQ286660579921en-000101 / DPD0203314 | Danfoss A/S © 2021.09

VACON® 3000 Enclosed Drive

Operating Guide

•

Closing the MCB locally is not permitted. When the MCB is in the service position, the drive must have exclusive control of closing the MCB.

•

The maximum opening time of the MCB must never exceed the product or project specific maximum time defined in the MCB

specifications.

•

Typical maximum protection and safety trip time for the drive: 60 ms

Recommendations

To meet the stipulated safety requirements, Danfoss recommends the following:

•

Provide an upstream protection coordination scheme which uses the "breaker failure" (ANSI 50BF) signal to trip the upstream

breaker automatically, in case the MCB does not open.

•

After a failure has occurred, the upstream breaker must open within the maximum protection and safety trip time.

Safety

AQ286660579921en-000101 / DPD02033 | 15Danfoss A/S © 2021.09

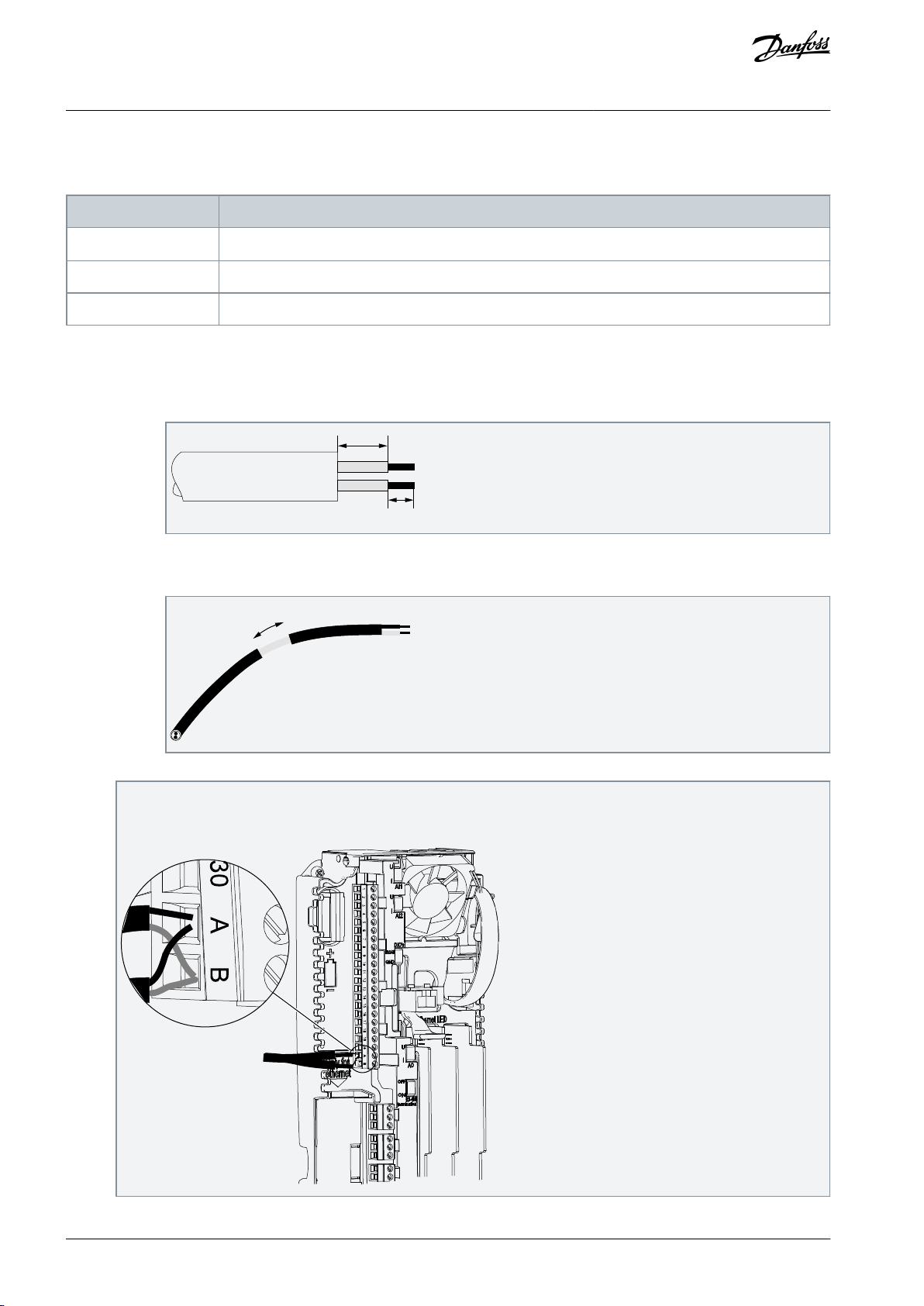

e30bg963.10

VACON® 3000 Enclosed Drive

Operating Guide

Product Overview

3 Product Overview

3.1 Intended Use

VACON® 3000 is a liquid-cooled AC drive for stepless speed or torque control of medium-voltage induction motors. VACON® 3000

Enclosed Drive is a complete medium-voltage drive installed in a cabinet.

VACON® 3000 Enclosed Drive is available for industrial applications with motor voltages of 3300 V and 4160 V, and in a power range

starting from 2 MW. Basic configurations have a power of 2 MW or 3 MW. These configurations can be paralleled for systems of 4

MW and above.

Two different drive configurations are available:

•

Regenerative, with an active front-end (AFE)

•

Non-regenerative, with a 12-pulse diode front-end (DFE)

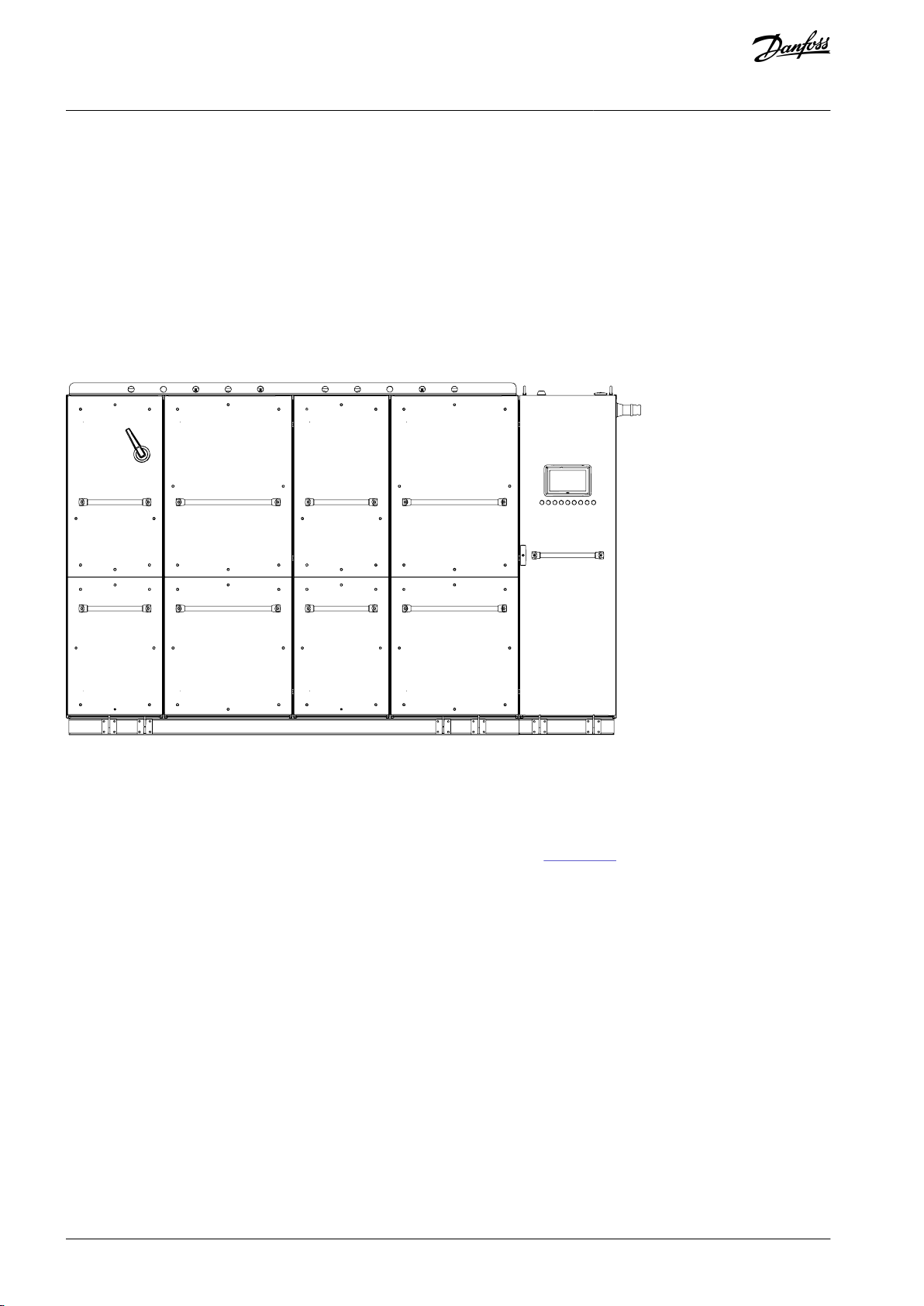

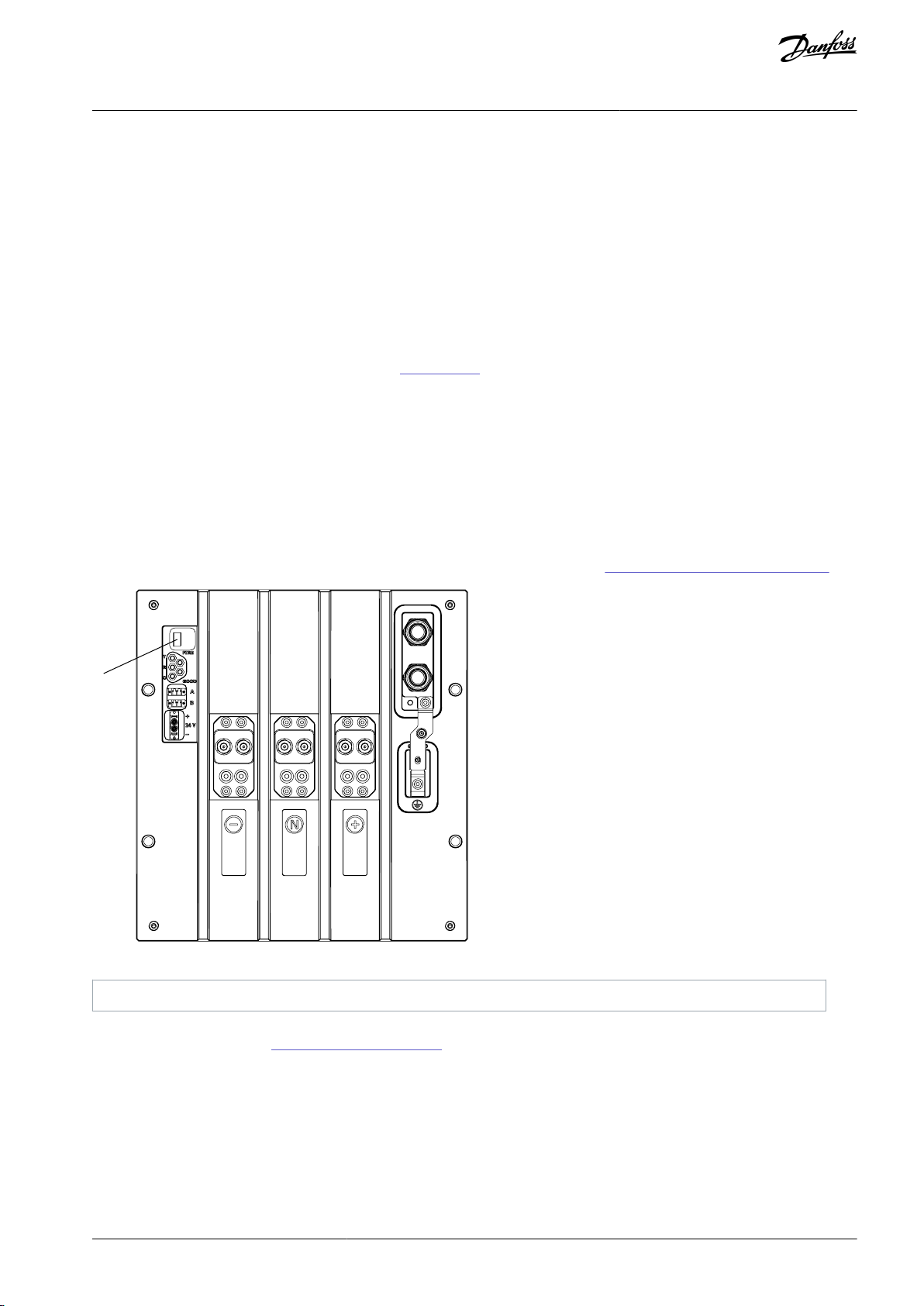

Illustration 2: Example of the VACON® 3000 Enclosed Drive

3.2 Product Description

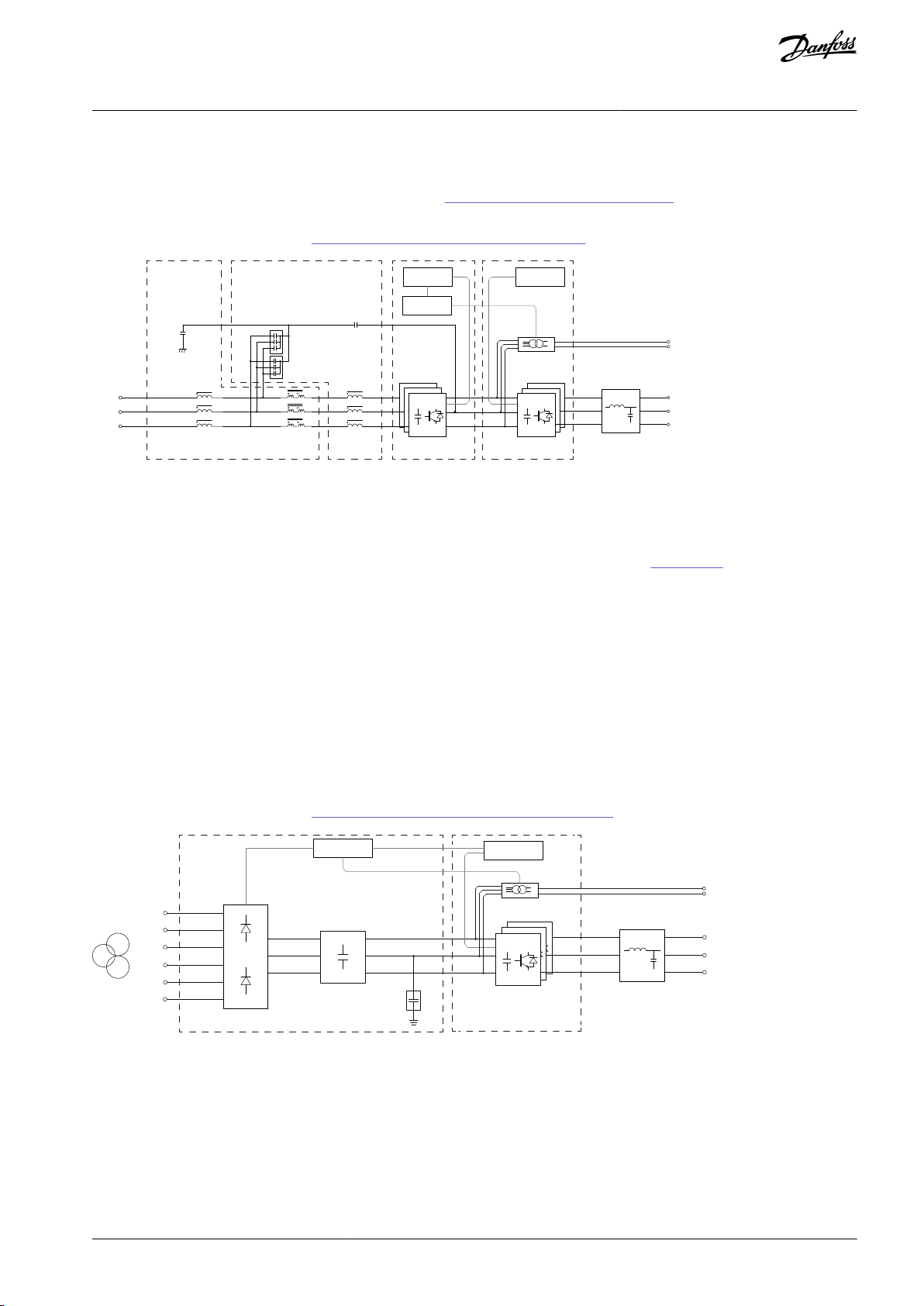

3.2.1 AFE Drive

An example diagram of the regenerative VACON® 3000 Enclosed Drive is shown in Illustration 3. The main components of the drive

are:

•

The active front-end (AFE) unit includes 3 or 6 liquid-cooled 1-phase power conversion units (PCU). 3 of the phase modules are

installed in parallel to make a 3-phase converter. The AFE converts the supplied AC voltage to DC voltage. It also enables the

supply of power to the supply network when the motor is braking.

•

The inverter unit (INU) includes 3 or 6 of the same liquid-cooled 1-phase modules, which are used in the AFE. The INU converts

the DC voltage to the AC voltage and frequency supplied to the motor.

•

The LC filter (FLC) limits harmonic current on the supply network.

•

The pre-charge unit (PRC) charges the DC-link capacitors.

•

The AFE and INU control units (CNU-AFE/CNU-INU) are connected to the power conversion units with optical fibers.

•

The auxiliary I/O board (AXU-IOB) provides galvanic separation between I/Os in the MV section and the control unit in the LV

section of the cabinet.

The basic VACON® 3000 AFE drive is intended for installations, where the system is supplied by a dedicated transformer and the

source impedance is small. These installations are usually on land. The drive includes an LC filter instead of an LCL filter, because the

supply side inductance is included in the dedicated transformer.

It is recommended to install a dedicated transformer for the drive. If the drive is not supplied by a dedicated transformer (that is,

there are other loads than the drive on the same supply):

AQ286660579921en-000101 / DPD0203316 | Danfoss A/S © 2021.09

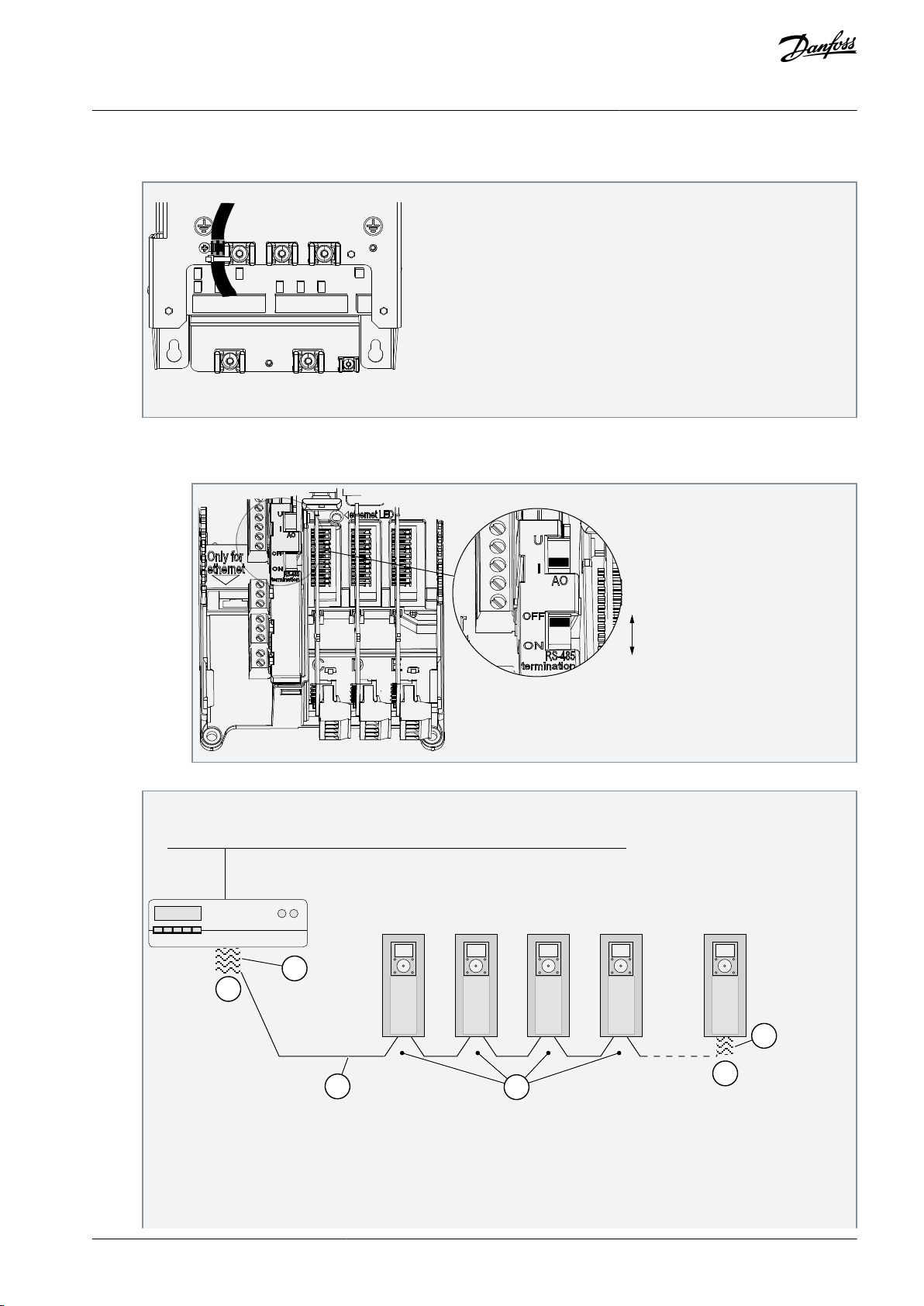

CCM

CCM

LGI LCM LCV

+

-

o

+

-

o

CNU-AFE CNU-INU

3 x PCU

3 x PCU

PRC

CSH

INUAFEFLC+PICM

MV~

+PODU

+POSI

Motor

LV~

e30bg606.10

AXU-IOB

+

-

CCM

+

-

00

+

-

0

Motor

CDC

PCU

3 x PCU

CNU-INU

AXU-IOB

PRC

MV~

LV~

MV~

12P-DFE

INU

+PODU

+POSI

Y

Δ

Δ

e30bg607.10

VACON® 3000 Enclosed Drive

Operating Guide

•

Install the drive in a high resistance grounding system with a resistance grounded neutral point.

•

Install an input common-mode filter (option +PICM).

Product Overview

If the source impedance is high, select the +PHSI option. See 11.2.7 Source Impedance Specifications.

For operation in an IT network without a dedicated transformer, contact Danfoss.

For the full main circuit diagrams, see 11.3.1 VACON® 3000 AFE Main Circuit Diagrams.

Illustration 3: Example Main Circuit Diagram of a VACON® 3000 AFE Drive

3.2.2 12-Pulse Drive

An example diagram of the 12-pulse non-regenerative VACON® 3000 Enclosed Drive is shown in Illustration 4. The main components of the drive are:

•

The diode front-end unit (DFE) is a liquid-cooled 12-pulse power conversion unit (PCU), which changes the supplied AC voltage

to DC voltage. The 12-pulse configuration is used to limit harmonics on the supply network.

•

The inverter unit (INU) includes 3 or 6 liquid-cooled 1-phase power conversion units (PCU). 3 of the phase modules are installed

in parallel to make a 3-phase converter. The INU converts the DC voltage to the AC voltage and frequency supplied to the motor.

•

The pre-charge unit (PRC) charges the DC-link capacitors.

•

The INU control unit (CNU-INU) is connected to the inverter units with optical fibers.

•

The auxiliary I/O board (AXU-IOB) provides galvanic separation between I/Os in the MV section and the control unit in the LV

section of the cabinet.

The 12-pulse DFE must be supplied by a dedicated transformer with two secondary windings.

For the full main circuit diagrams, see 11.3.2 VACON® 3000 12-Pulse Main Circuit Diagrams.

Illustration 4: Example Main Circuit Diagram of a VACON® 3000 12-Pulse Drive

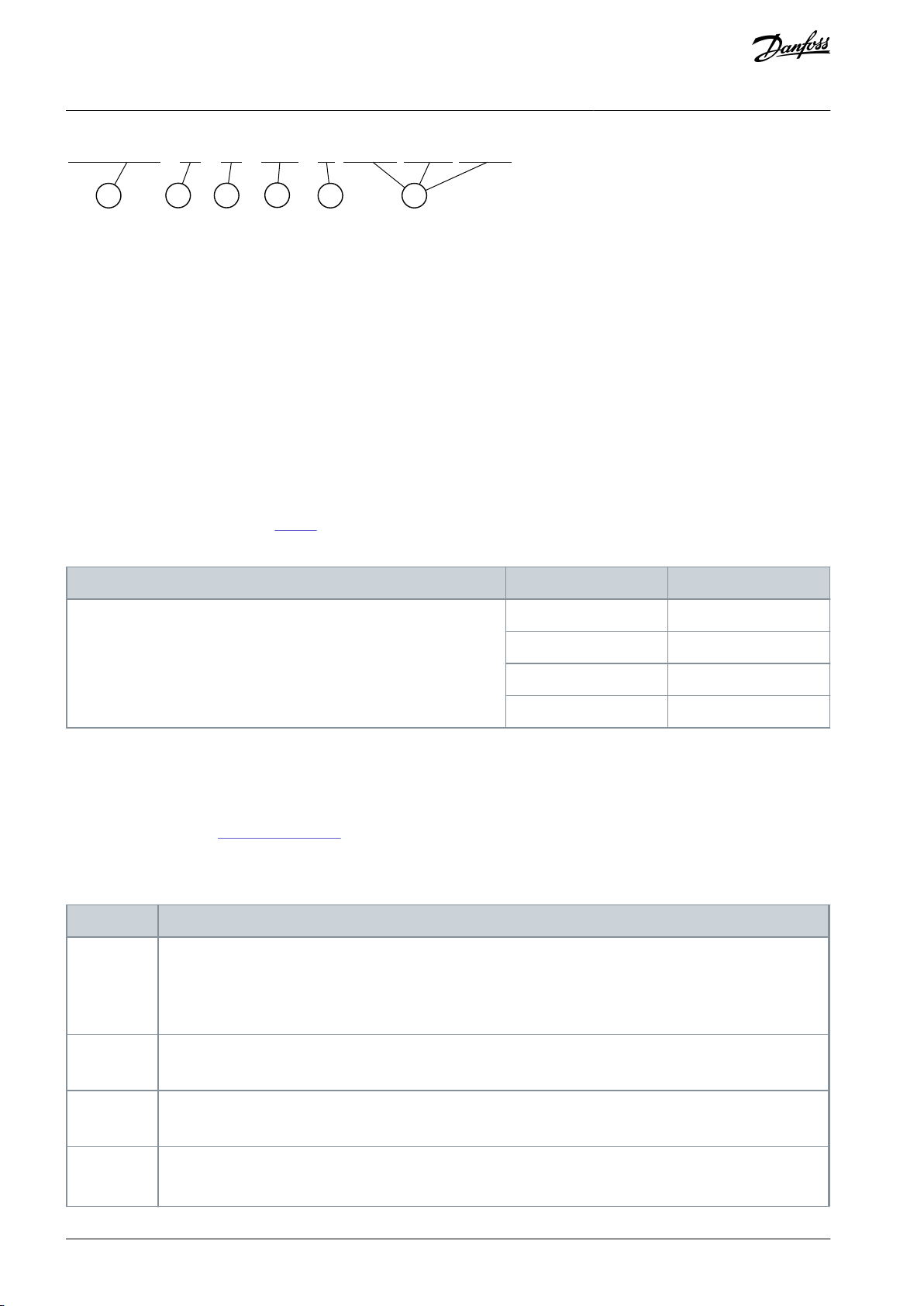

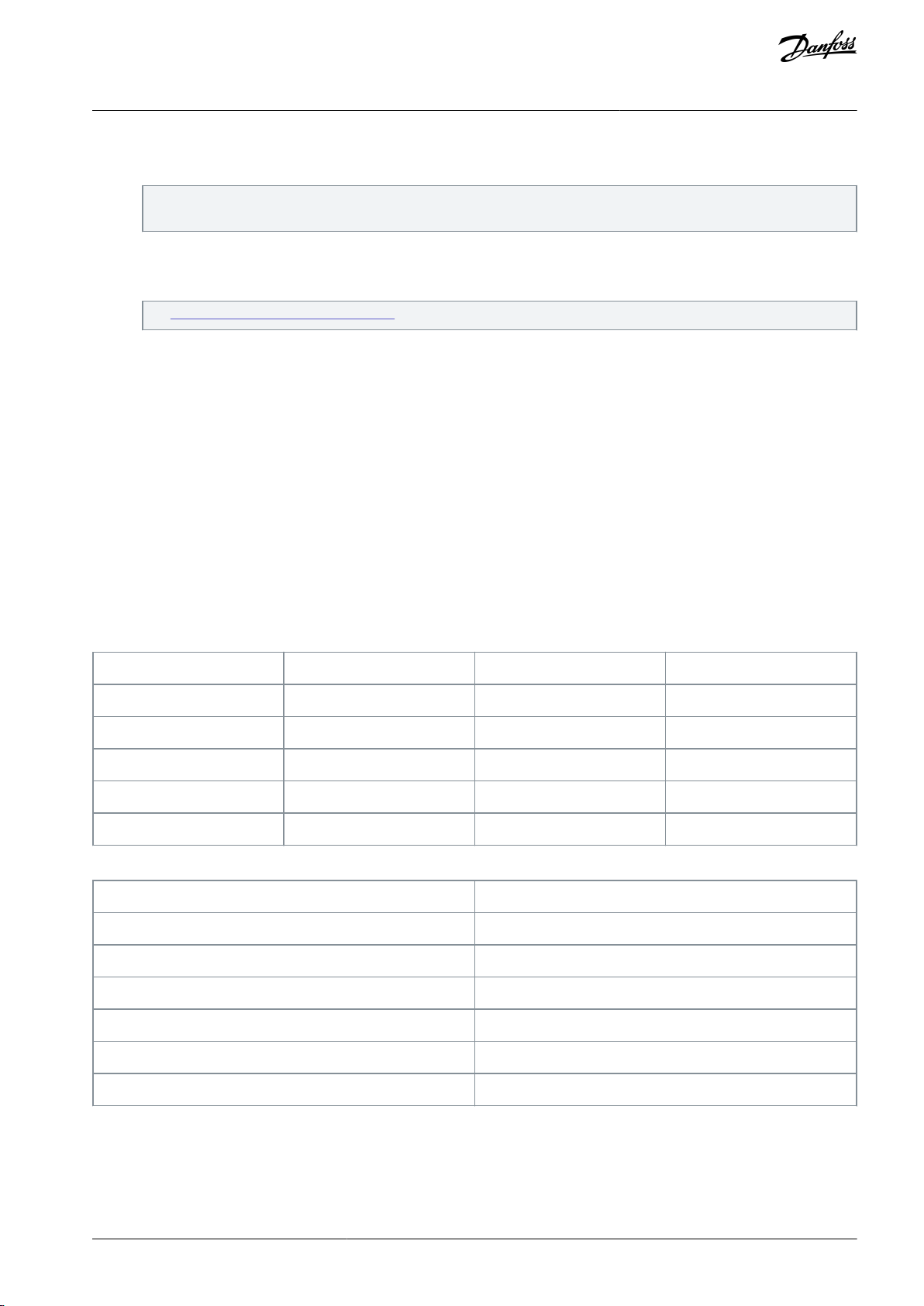

3.3 Type Code Description

The type code for VACON® 3000 has five basic parts (1–5) and option codes (6).

AQ286660579921en-000101 / DPD02033 | 17Danfoss A/S © 2021.09

1

3

4

5 6

2

V

ACON3000 - ED - 4Q - 0425 - 03 +XXXX +YYYY +ZZZZ

e30bg964.10

Input voltage [V]

3300

4160

Output current [A]

0425

0340

0640

0510

0820

0650

1230

0980

Option Code

Option Description

+PICM

(1)

Input common-mode filter

The option is only available for AFE drives.

Always include the input common-mode filter in VACON® 3000 AFE installations, which are not supplied by a

dedicated transformer.

+PODU

(1)

dU/dt output filter

+POSI

(1)

Sine-wave output filter

+POCM

(1)

Output common-mode filter

Contact Danfoss to check the common-mode capacitor option selection.

VACON® 3000 Enclosed Drive

Operating Guide

Illustration 5: VACON® 3000 Type Code Structure

Product Overview

1. Product series

VACON® 3000. This part of the code is always the same.

2. Product class

The VACON® 3000 product.

•

ED: Enclosed Drive

3. Drive type

There are two different drive types available. All kits include an inverter unit (INU) as default. The front-end type is specified in the

type code.

•

4Q: A regenerative drive with an active front end (AFE) and an LC input filter, supplied through a dedicated transformer. If the

drive is not supplied by a dedicated transformer, install a common-mode filter (available with option code +PICM).

•

12: A non-regenerative drive with a 12-pulse diode front end (DFE) rectifier and external DC capacitors. A dedicated transformer

with 2 secondary windings is necessary.

4. Nominal output current

See the available output currents in

Table 2.

Table 2: Available Output Current Ratings

5. Nominal input voltage

Nominal supply voltage: 03 = 3300 V or 04 = 4160 V.

6. Option codes

Optional components.

See the available codes in 3.4 Available Options.

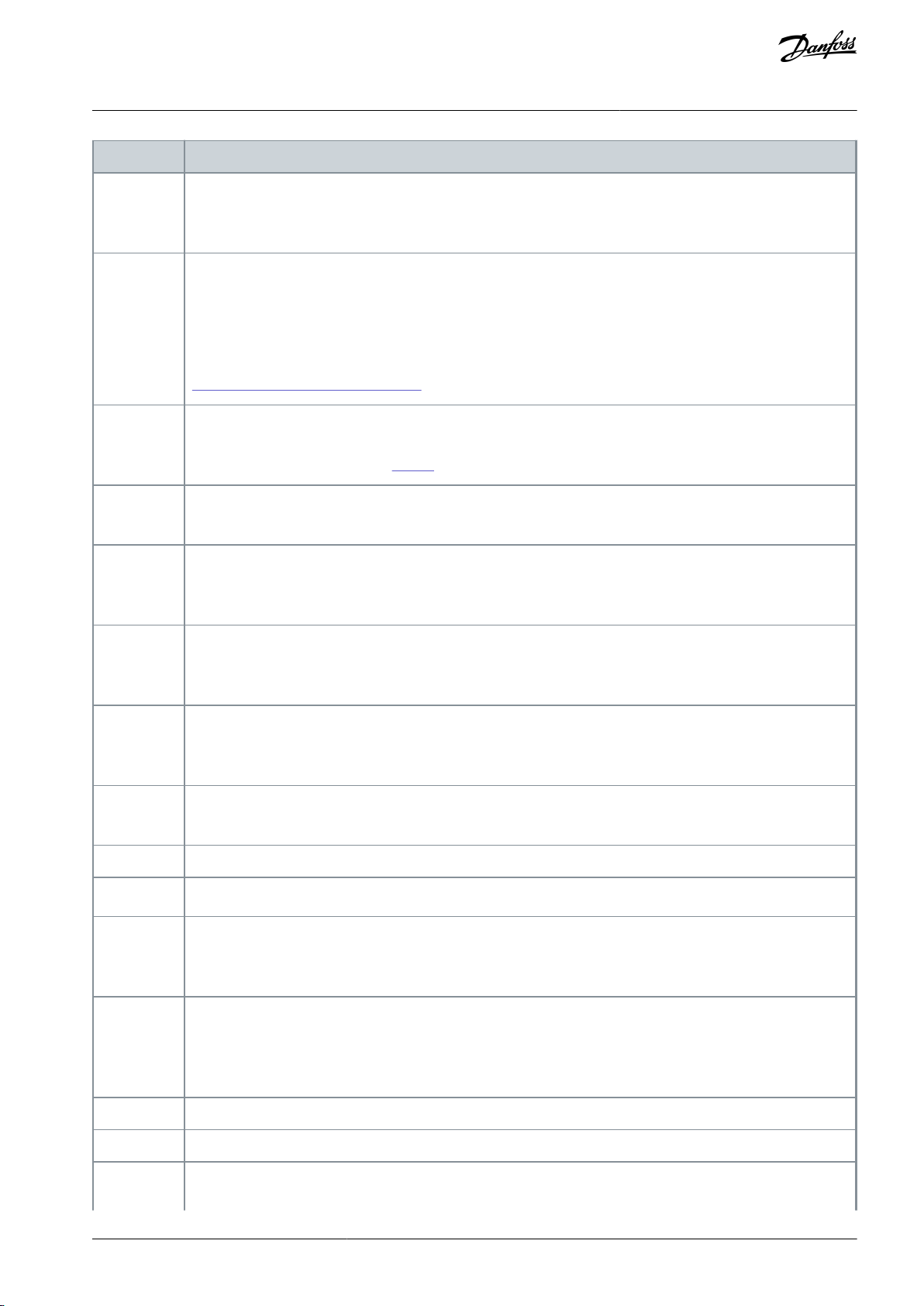

3.4 Available Options

Table 3: Available Options for VACON® 3000 Enclosed Drive

AQ286660579921en-000101 / DPD0203318 | Danfoss A/S © 2021.09

Option Code

Option Description

+DBCU

(1)

Brake chopper unit for dynamic braking

The option does not include a brake resistor.

The option is for 12-pulse drives. If a brake chopper is required for an AFE drive, contact Danfoss.

+PHSI

High source impedance

Option for installation locations with high source impedances (~10–15% SI). For example, marine applications

usually have a high source impedance. The option affects the size of the input filters. The default installation location has small source impedance (SSI).

This option is only available for AFE drives.

Examine each application one by one. To see if this option is necessary, find out the source impedance and see

11.2.7 Source Impedance Specifications. If necessary, consult Danfoss.

+SC__

+SD__

+SE__

C, D, and E slot option boards

Default: No option boards in slots C, D, and E.

See the available option boards in Table 4.

+QSTO

Safe torque off functionality.

Only available for AFE drives.

+QFV1

+QFV2

Control and fan supply voltage

115 V (default for 4160 V)

230 V (default for 3300 V)

+PGDR

+PGDN

Grounding of the heat sink and connection of the grounding resistor in power modules

R: DC neutral-to-ground resistor connected (default)

N: DC neutral-to-ground resistor not connected

+PLIN

+PLDI

Liquid cooling options

IN: Industrial water and grounded heat sink

DI: Deionized water and floating heat sink

+PUFE

Short-circuit current rating: 40 kA, for 100 ms.

Available only for AFE drives.

+PGC0

Common-mode capacitor to ground removed

+PLCT

Coolant input from the top

+PHET

+PH00

Heat exchanger option

ET: Titanium liquid-to-liquid heat exchanger included

00: Liquid-to-liquid heat exchanger not included

+QP24

+QP40

+QP48

Precharge input voltage

240 V

400 V (default for 3300 V)

480 V (default for 4160 V)

+GAUL

cUL certificate

+GACE

EU declaration, CE approval

+GADN

Marine approval

DN: Det Norske Veritas

VACON® 3000 Enclosed Drive

Operating Guide

Product Overview

AQ286660579921en-000101 / DPD02033 | 19Danfoss A/S © 2021.09

Option Code

Option Description

+GALR

LR: Lloyd's Register

Slot C

Slot D

Slot E

Option Board

(1)

+SCB1

+SDB1

+SEB1

I/O board OPTB1: 6 x Digital input/digital output, programmable

+SCB2

+SDB2

+SEB2

I/O board OPTB2: 1 x relay output (NO/NC), 1 x relay output (NO), Thermistor

+SCB4

+SDB4

+SEB4

I/O board OPTB4: 1 x analog input, 2 x analog output (isolated)

+SCB5

+SDB5

+SEB5

I/O board OPTB5: 3 x relay output

+SCB9

+SDB9

+SEB9

I/O board OPTB9: 1 x relay output, 5 x digital input (42–240 V AC)

+SCBF

+SDBF

+SEBF

I/O board OPTBF: 1 x analog output, 1 x digital output, 1 x relay output

+SCBH

+SDBH

+SEBH

I/O board OPTBH: 3 x Temperature measurement (support for PT100, PT1000, NI1000, KTY84-130,

KTY84-150, KTY84-131 sensors)

+SDD3

+SED3

Adapter board OPTD3: RS232 adapter

+SDE3

+SEE3

Fieldbus board OPTE3: PROFIBUS DP-V1 (Screw connector)

+SDE5

+SEE5

Fieldbus board OPTE5: PROFIBUS DP-V1 (D9 connector)

+SDE6

+SEE6

Fieldbus board OPTE6: CANopen

+SDE7

+SEE7

Fieldbus board OPTE7: DeviceNet

+SDE9

+SEE9

Fieldbus board OPTE9: 2-port Ethernet

+SDEA

+SEEA

Fieldbus board OPTEA: Advanced 2-port Ethernet

+SDEC

+SEEC

Fieldbus board OPTEC: EtherCAT

VACON® 3000 Enclosed Drive

Operating Guide

1

The nominal current and voltage selected in the type code of the VACON® 3000 affect this option. The correct size and number of parts is supplied

automatically. If a different size or number of parts is needed, an order for separate parts is possible.

Table 4: Available Option Boards for Slots C, D, and E

Product Overview

1

For a 12-pulse drive, the option includes one board. For an AFE drive, the option includes two boards, one for the AFE control unit and one for the

INU control unit. If the drive also has the brake chopper option (+DBCU), the option includes one more board for the brake chopper control unit.

AQ286660579921en-000101 / DPD0203320 | Danfoss A/S © 2021.09

VACON® 3000 Enclosed Drive

Operating Guide

Receiving the Delivery

4 Receiving the Delivery

4.1 Checking the Delivery

1.

After removing the packaging, examine the drive for transport damages.

-

If the drive was damaged during the shipping, speak to the cargo insurance company or the carrier.

2.

To make sure that the delivery is correct, compare the type code for the order to the type code on the package label. The

type code specifies the drive type, nominal output current, nominal input voltage, and option codes. See 3.3 Type Code

Description.

-

If the delivery does not agree with the order, speak to the vendor immediately.

4.2 Storage

N O T I C E

LIQUID IN THE HEAT SINK

If the cooling liquid is not removed from the heat sink before storage or shipping, the liquid can freeze and damage the drive.

Always remove the cooling liquid from the heat sink before storage or shipping.

-

If the AC drive is kept in storage, keep it in controlled conditions.

•

Storage temperature: -40…+70°C (-40... +158°F). If the storage temperature is below 0°C (+32°F), make sure that there is no

cooling liquid in the heat sink.

•

Relative humidity: < 96%, no condensation

Keep the equipment sealed in its packaging until installation.

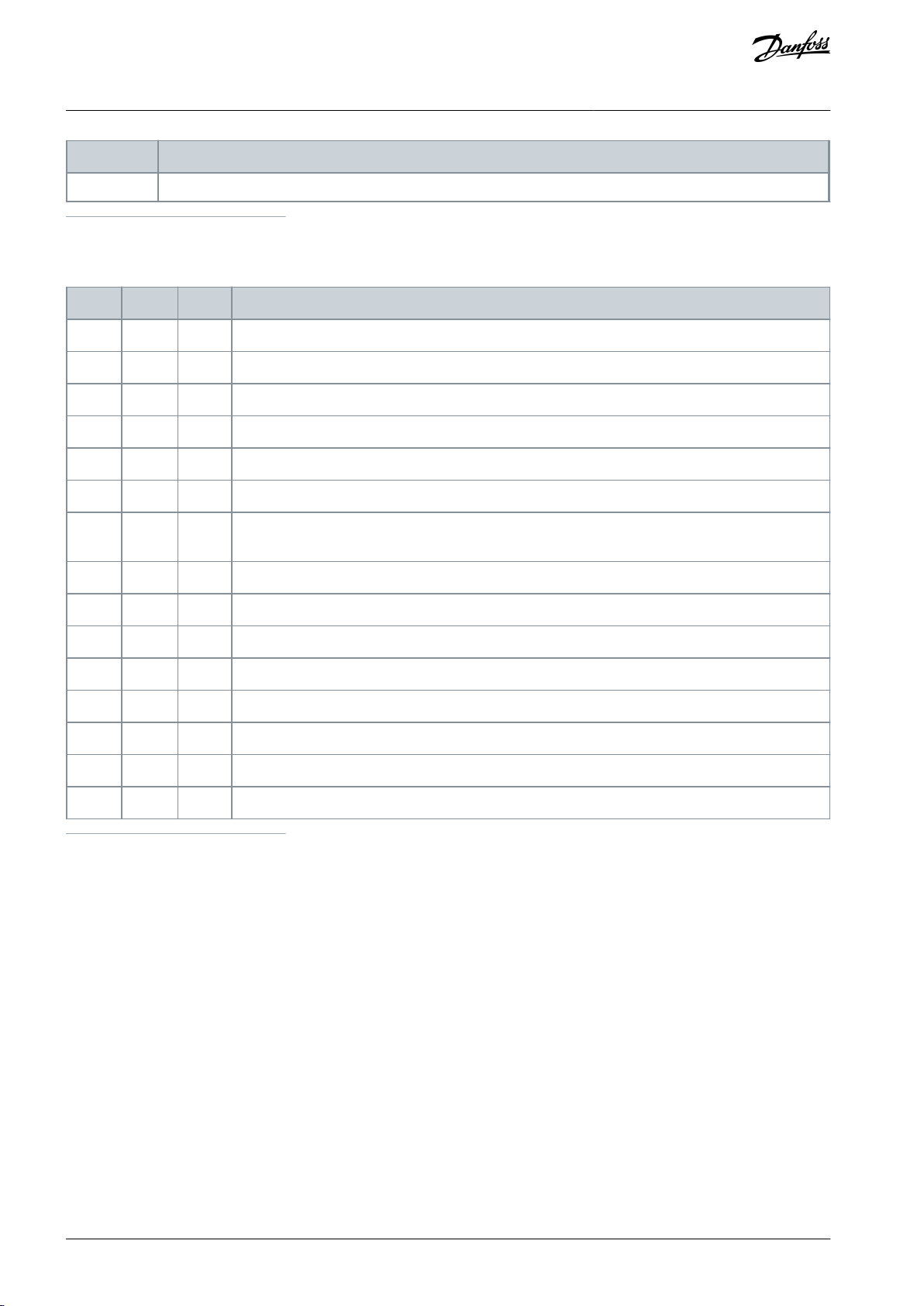

4.3 Lifting and Moving the Enclosed Drive

W A R N I N G

LIFTING HEAVY EQUIPMENT

Follow local safety regulations for lifting heavy weights. Failure to follow recommendations and local safety regulations can result

in death or serious injury.

Ensure that the lifting equipment is in proper working condition.

-

The cabinets must be moved vertically. Always refer to the shipping marks on the package for more information. Do not remove the

package material before installing the AC drive.

To lift the cabinets, use a lifting device that can lift the weight of the cabinets. There are lifting holes on the top of the cabinets. Use

these holes to lift the cabinets and to move them to the installation location. The minimum angle between the cabinets and the

chain is 60°.

To divide the weight of the cabinets equally, and to prevent damage to the equipment, always use 4 lifting holes. Align the lifting

locations with the horizontal center of gravity.

AQ286660579921en-000101 / DPD02033 | 21Danfoss A/S © 2021.09

e30bg965.10

>60°

>60°

e30bg966.10

VACON® 3000 Enclosed Drive

Operating Guide

Illustration 6: Lifting the Cabinets

Receiving the Delivery

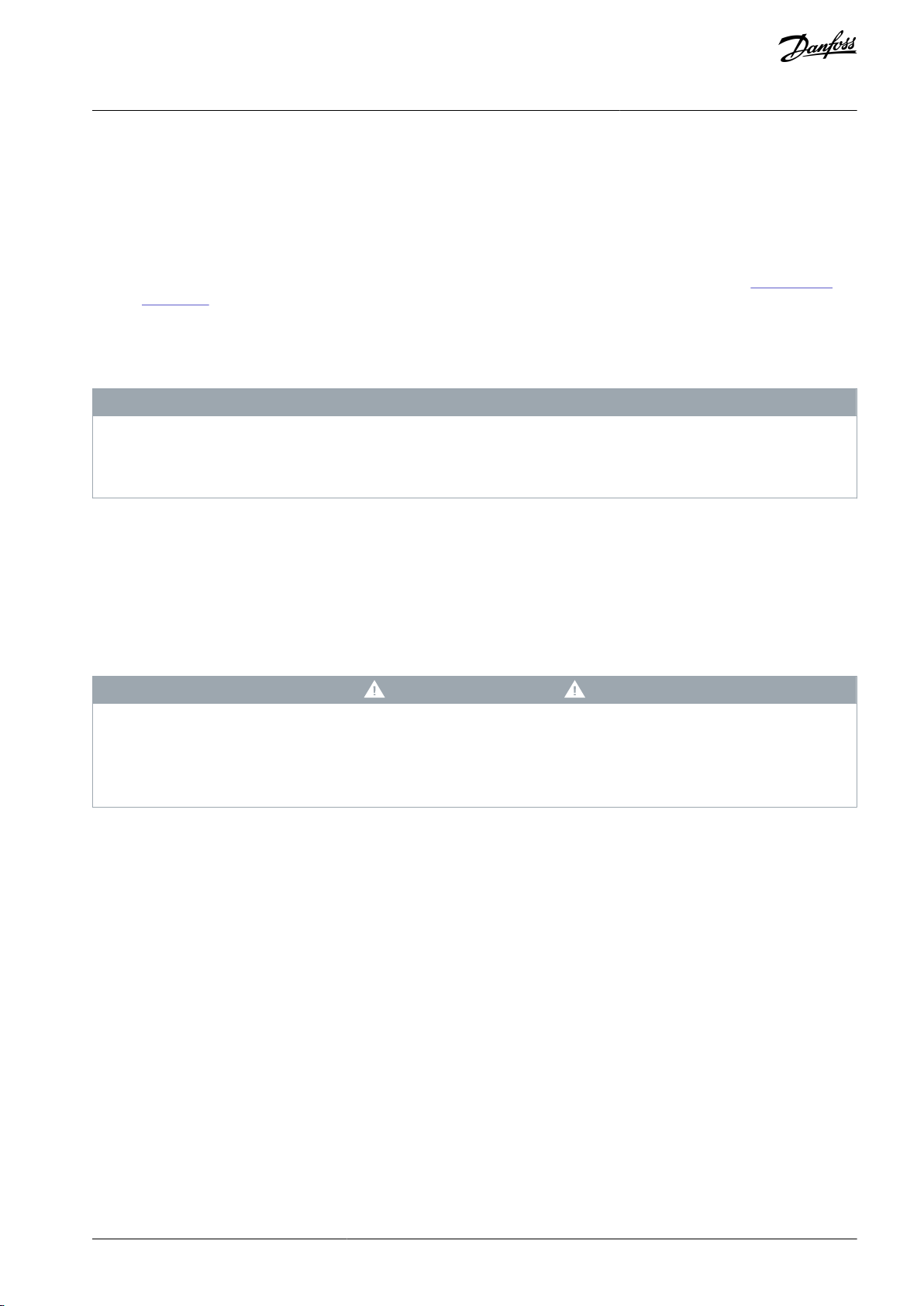

You can use rollers, for example, to move the cabinets.

Move the cabinets carefully. Switchgear parts can easily fall because their center of gravity is high up at the back of the cabinets.

Illustration 7: Moving the Cabinets

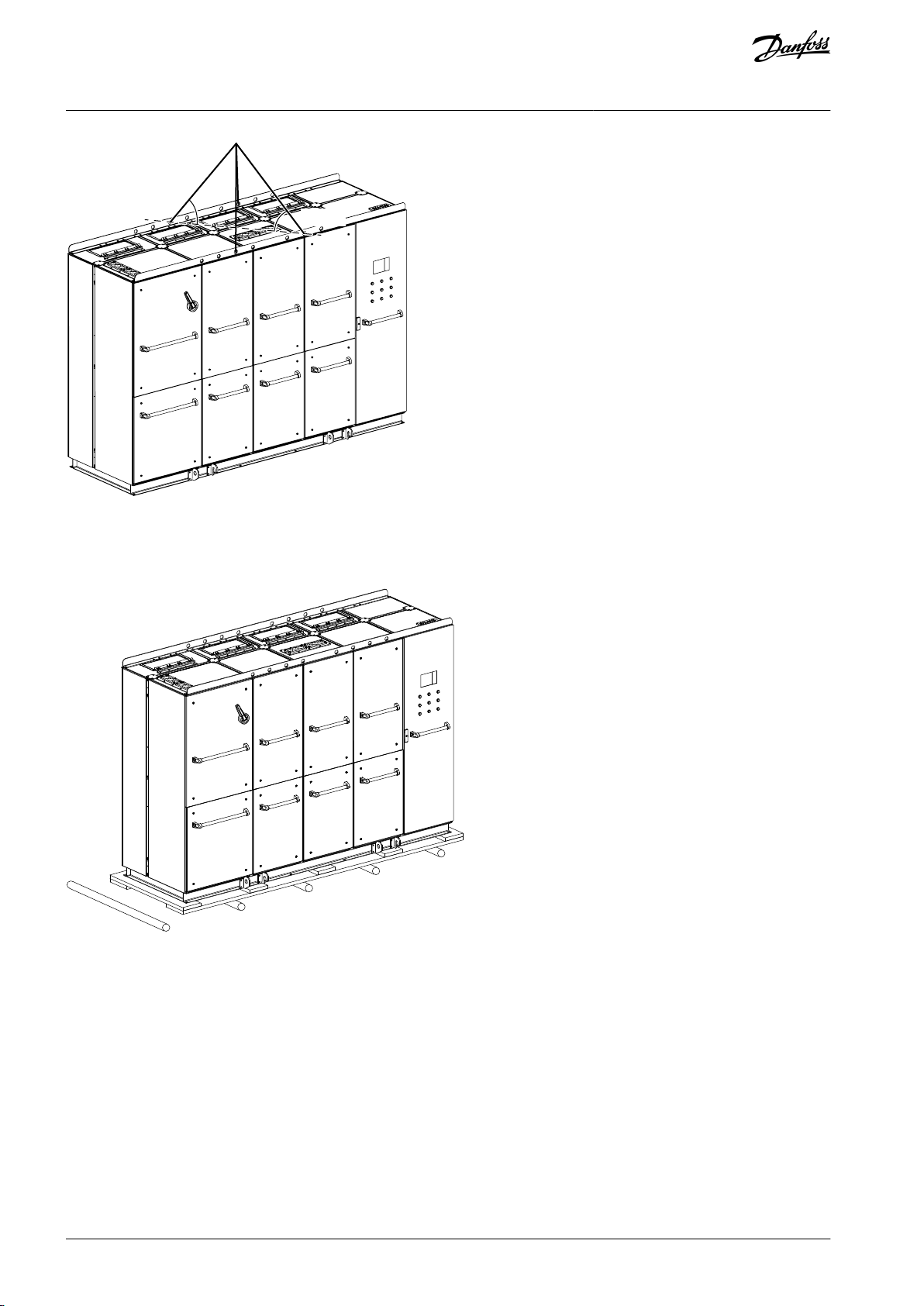

When the cabinet is in the installation location, it can be necessary to make small adjustments to the position of the cabinet. Use a

crowbar to move the cabinet from the special hooks on the cabinet base.

Remove the moving hooks from the base of the cabinet before installation.

AQ286660579921en-000101 / DPD0203322 | Danfoss A/S © 2021.09

e30bg967.10

VACON® 3000 Enclosed Drive

Operating Guide

Illustration 8: Hooks on the Cabinet Base for Adjusting the Position of the Cabinet

Receiving the Delivery

AQ286660579921en-000101 / DPD02033 | 23Danfoss A/S © 2021.09

VACON® 3000 Enclosed Drive

Operating Guide

Mechanical Installation

5 Mechanical Installation

5.1 Operating Environment

N O T I C E

CONDENSATION

Moisture can condense on the electronic components and cause short circuits.

Avoid installation in areas subject to frost.

-

Install space heaters to warm the air inside the cabinets.

Before powering the drive, run the cooling pumps to warm up the components, until the drive is warmer than the ambient

air.

N O T I C E

EXTREME AMBIENT CONDITIONS

Hot or cold temperatures compromise unit performance and longevity.

In environments with airborne liquids, particles, or corrosive gases, ensure that the IP/Type rating of the equipment matches the

installation environment. For specifications regarding ambient conditions, see 11.2.5 Ambient Conditions.

5.2 Cabinet Installation

Installation guidelines:

•

Locate the drive as near to the motor as possible.

•

Ensure unit stability by mounting the enclosure on a solid surface.

•

Make sure that the level of the floor is in permitted limits. The maximum deviation from the basic level can be no more than 5

mm (0.197 in) along a 3 m (9.84 ft) distance. The maximum permitted height difference between the cabinet front and rear

edges is 2 mm (0.079 in).

•

Ensure that the strength of the mounting location supports the unit weight.

•

It is not recommended to install the cabinet directly against a wall.

•

Attach the cabinet to the floor. There are holes in the base of the cabinet which can be used for the installation.

•

Ensure that there is enough space around the unit for proper cooling.

•

Ensure that there is enough room to open the cabinet doors and for working on the equipment.

•

Remove the moving hooks from the base of the cabinet before installation.

AQ286660579921en-000101 / DPD0203324 | Danfoss A/S © 2021.09

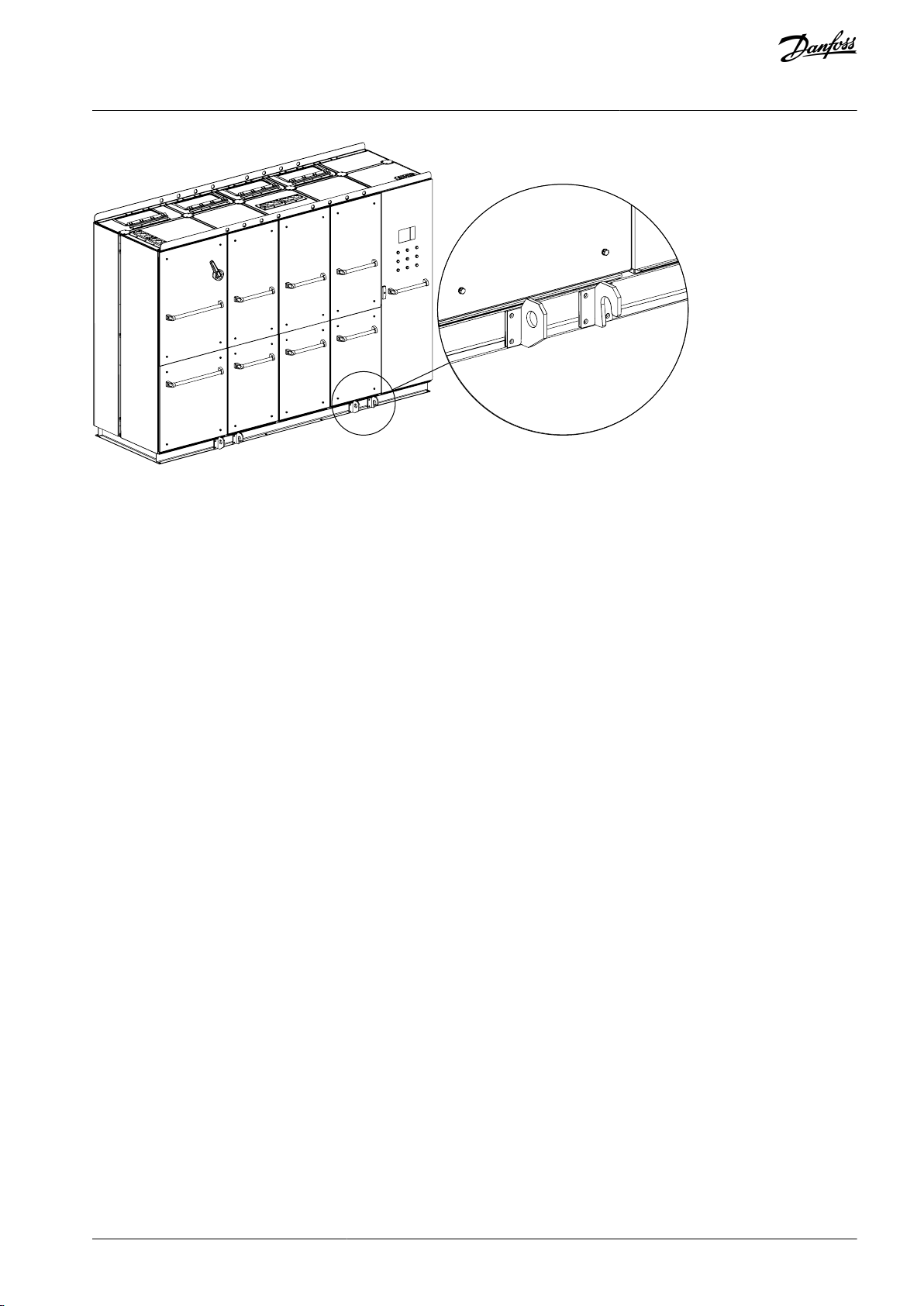

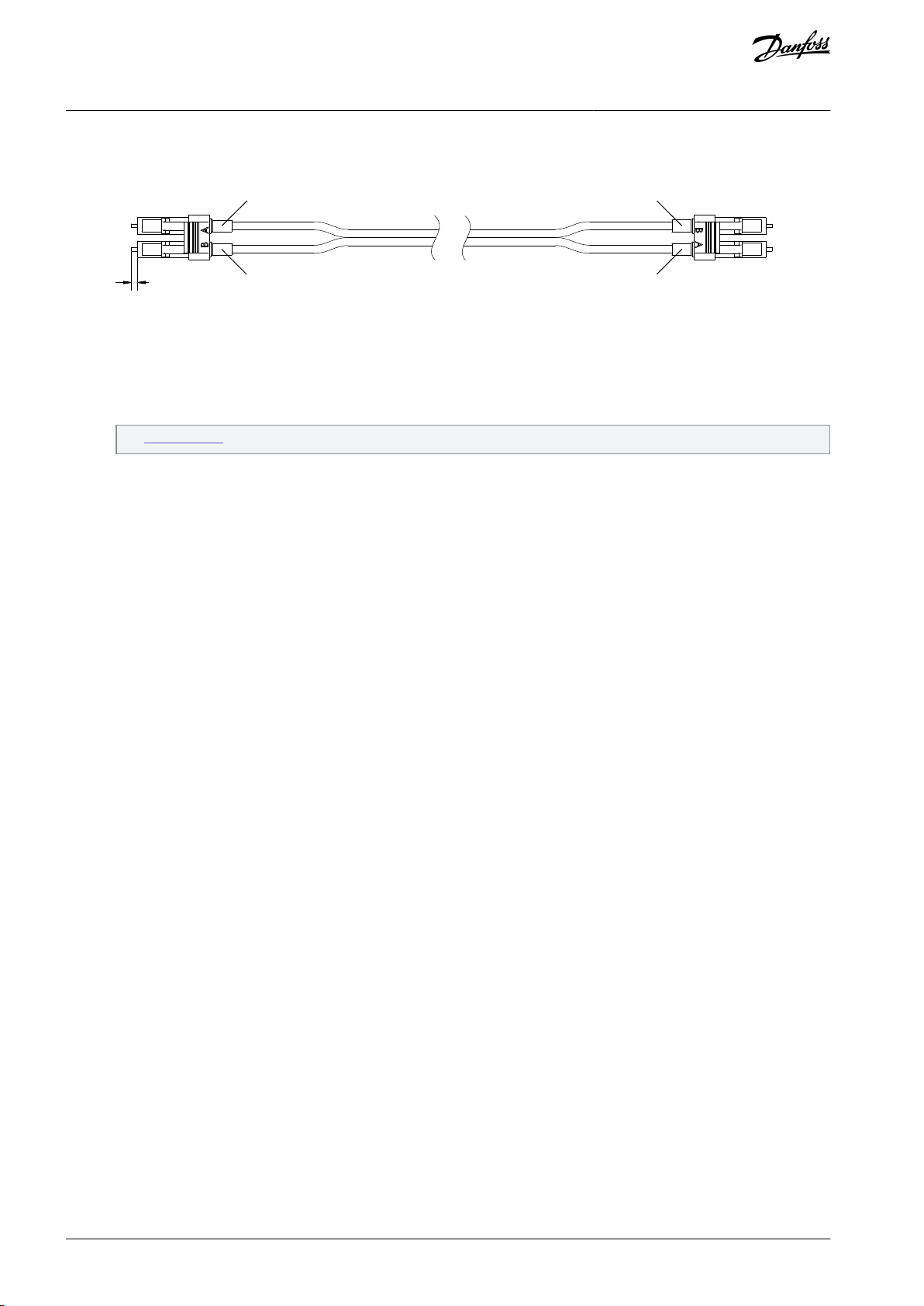

A C

B

e30bg968.10

A–C

See the dimensions in Table 5.

Type code

Dimension A

Dimension B

Dimension C

VACON3000ED-4Q-0425-03

2400 mm (7 ft 10.5 in)

2130 mm (6 ft 11.9 in)

1000 mm (3 ft 3.4 in)

VACON3000ED-4Q-0640-03

2600 mm (8 ft 6.4 in)

2130 mm (6 ft 11.9 in)

1000 mm (3 ft 3.4 in)

VACON3000ED-4Q-0820-03

3800 mm (12 ft 5.6 in)

2130 mm (6 ft 11.9 in)

1000 mm (3 ft 3.4 in)

VACON3000ED-4Q-1230-03

4400 mm (14 ft 5.2 in)

2130 mm (6 ft 11.9 in)

1000 mm (3 ft 3.4 in)

VACON3000ED-4Q-0340-04

2400 mm (7 ft 10.5 in)

2130 mm (6 ft 11.9 in)

1000 mm (3 ft 3.4 in)

VACON3000ED-4Q-0510-04

2600 mm (8 ft 6.4 in)

2130 mm (6 ft 11.9 in)

1000 mm (3 ft 3.4 in)

VACON3000ED-4Q-0650-04

3800 mm (12 ft 5.6 in)

2130 mm (6 ft 11.9 in)

1000 mm (3 ft 3.4 in)

VACON3000ED-4Q-0980-04

4400 mm (14 ft 5.2 in)

2130 mm (6 ft 11.9 in)

1000 mm (3 ft 3.4 in)

VACON3000ED-12-0425-03

2400 mm (7 ft 10.5 in)

2130 mm (6 ft 11.9 in)

1000 mm (3 ft 3.4 in)

VACON3000ED-12-0640-03

2600 mm (8 ft 6.4 in)

2130 mm (6 ft 11.9 in)

1000 mm (3 ft 3.4 in)

VACON3000ED-12-0820-03

3400 mm (11 ft 1.9 in)

2130 mm (6 ft 11.9 in)

1000 mm (3 ft 3.4 in)

VACON3000ED-12-1230-03

3800 mm (12 ft 5.6 in)

2130 mm (6 ft 11.9 in)

1000 mm (3 ft 3.4 in)

VACON® 3000 Enclosed Drive

Operating Guide

Mechanical Installation

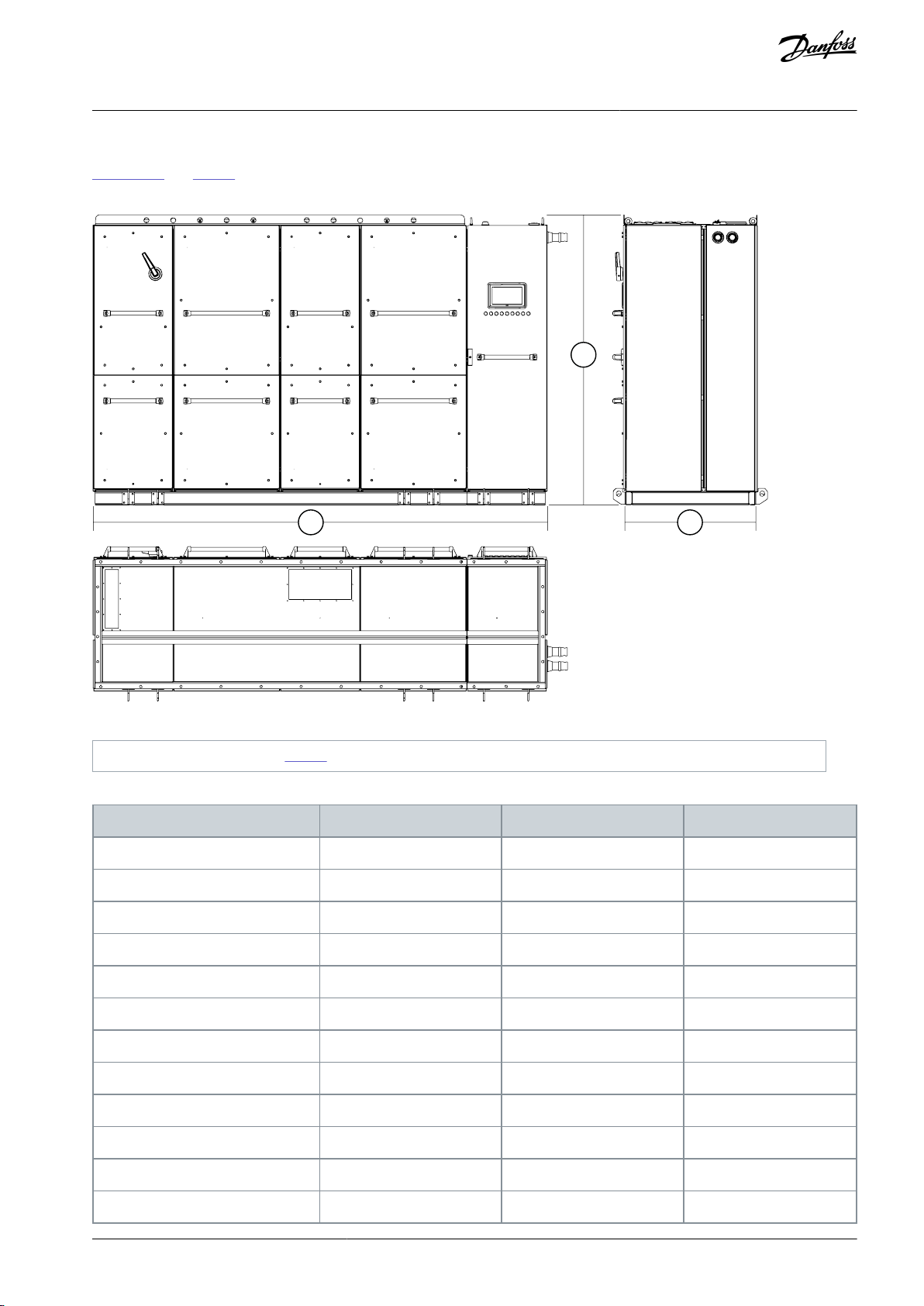

5.3 Dimensions of the Enclosed Drive

Illustration 9 and Table 5 show the dimensions of the basic VACON® 3000 Enclosed Drive. Some options can affect the total width or

height of the cabinet. Always refer to the delivery-specific information for the accurate dimensions.

Illustration 9: Dimensions of the VACON® 3000 Enclosed Drive

Table 5: Dimensions of the VACON® 3000 Enclosed Drive

AQ286660579921en-000101 / DPD02033 | 25Danfoss A/S © 2021.09

Type code

Dimension A

Dimension B

Dimension C

VACON3000ED-12-0340-04

2400 mm (7 ft 10.5 in)

2130 mm (6 ft 11.9 in)

1000 mm (3 ft 3.4 in)

VACON3000ED-12-0510-04

2600 mm (8 ft 6.4 in)

2130 mm (6 ft 11.9 in)

1000 mm (3 ft 3.4 in)

VACON3000ED-12-0650-04

3400 mm (11 ft 1.9 in)

2130 mm (6 ft 11.9 in)

1000 mm (3 ft 3.4 in)

VACON3000ED-12-0980-04

3800 mm (12 ft 5.6 in)

2130 mm (6 ft 11.9 in)

1000 mm (3 ft 3.4 in)

VACON® 3000 Enclosed Drive

Operating Guide

5.4 Liquid Cooling Requirements

5.4.1 Safety in Liquid-cooling

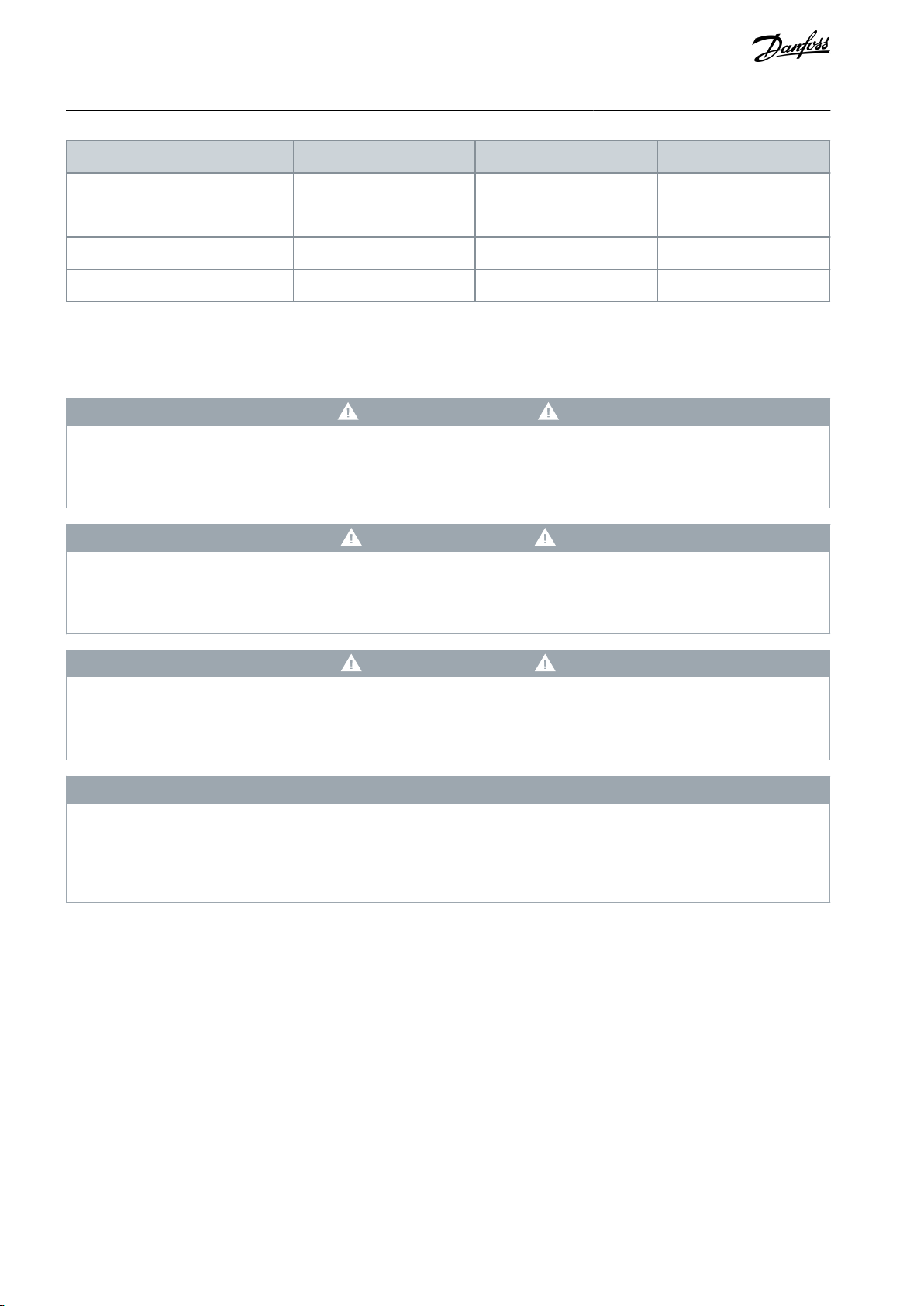

W A R N I N G

POISONOUS COOLANTS

Glycols and inhibitors are poisonous. If touched or consumed, they can cause injury.

Prevent the coolant from getting into the eyes. Do not drink the coolant.

-

C A U T I O N

HOT COOLANT

Hot coolant can cause burns.

Avoid contact with the hot coolant.

-

Mechanical Installation

C A U T I O N

PRESSURIZED COOLING SYSTEM

Sudden release of pressure from the cooling system can cause injury.

Be careful when operating the cooling system.

-

N O T I C E

INSUFFICIENT COOLING CAPACITY

Insufficient cooling can cause the product to become too hot and thus become damaged.

To make sure that the cooling capacity of the cooling system stays sufficient, make sure that the cooling system is vented

-

and that the coolant circulates properly.

5.4.2 General Information on Liquid Cooling

VACON® 3000 drives are liquid-cooled. The liquid circulation of the drive is connected to a heat-exchanger that cools down the

liquid circulating in the cooling elements of the drive. The power modules have aluminum heat sinks, which give good and safe

temperature control. Because the cooling elements are made of aluminum, the cooling liquids allowed to be used are inhibited

pure water, inhibited demineralized water, or an inhibited mixture of water and glycol.

The inductors of the input and output filters use air-to-liquid heat exchanger units for forced air cooling. The heat exchangers decrease the heat losses to the air and thus decreases the number of fans necessary for cooling the cabinet.

There are two types of cooling systems: open systems and closed systems.

An open system has no pressure but the hydrostatic and pumping pressure. It allows free contact between the cooling liquid and

air. Air is continuously dissolved into the cooling liquid.

In a closed system, the piping is air-tight and there is a preset pressure inside the pipes. The pipes must be made of metal, or a

specific plastic or rubber that includes an oxygen barrier that limits the diffusion of oxygen. Minimizing of oxygen content in the

cooling liquid decreases the risk of corrosion of the metal parts. Closed systems usually have an expansion vessel that allows for a

safe change of volume of the cooling liquid due to temperature changes.

Always use a closed system with Danfoss liquid-cooled drives.

AQ286660579921en-000101 / DPD0203326 | Danfoss A/S © 2021.09

Property

Required value

pH

6...8

Chlorides

≤ 25 ppm

Sulphate ions

≤ 25 ppm

Maximum particle size

≤ 50 µm

Total dissolved solids

≤ 200 ppm

Total hardness (CaCO3)

3…4.6 dH° (53…80 ppm)

Hydrogen carbonate

≤ 50 ppm

Electrical conductivity

≤ 500 µS/cm

VACON® 3000 Enclosed Drive

Operating Guide

5.4.3 Cooling Liquid

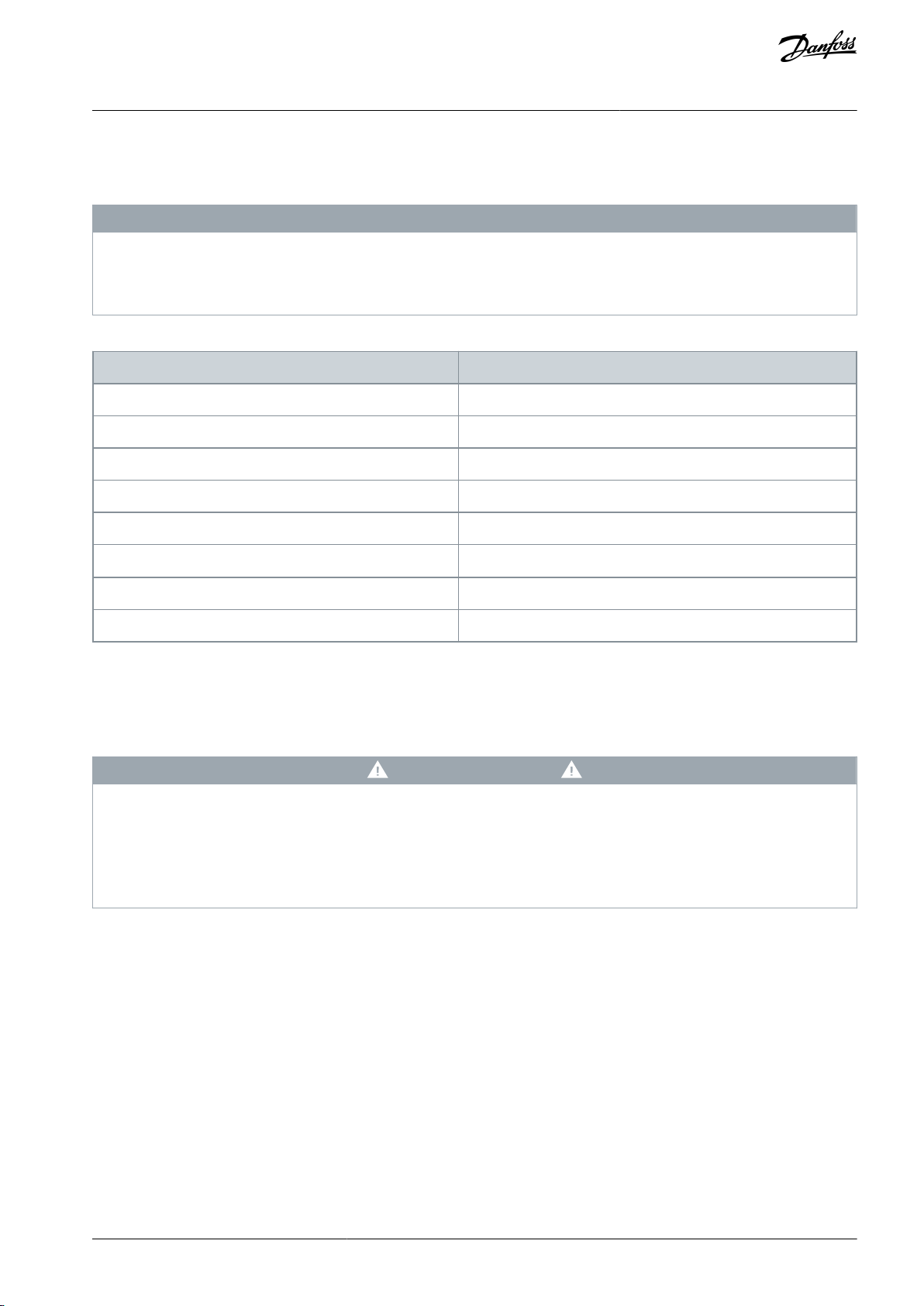

5.4.3.1 Quality Requirements for the Purified Water

N O T I C E

DAMAGE TO SYSTEM FROM THE USE OF HYDROCARBONS

Hydrocarbons damage the rubber seals of the cooling system.

Do not use hydrocarbons (for example mineral oil) as coolant. Do not mix hydrocarbons to coolant.

-

Table 6: Requirements for the Purified Water

Mechanical Installation

5.4.3.2 Purified Water as Coolant

Purified water can be used as coolant if there is no risk of freezing. Freezing water permanently damages the cooling system. Purified water is demineralized, deionized, or distilled water.

Always use an inhibitor Cortec VpCI-649 with 1.0% of volume with purified water.

C A U T I O N

CORROSION HAZARD WITH DRINKING WATER

Some components are made of aluminum, which has limited corrosion resistance against high chloride concentrations. Drinking

water can have a chloride concentration of 250 ppm, which increases the aluminum corrosion rate. High chloride concentration

exposes aluminum especially to pitting corrosion which can damage the system relatively quickly.

Use purified (demineralized, deionized, or distilled) water with corrosion inhibitors.

-

5.4.3.3 Antifreeze Mix as Coolant

The following antifreeze products are a good general solution for liquid cooling since they provide freeze protection and corrosion

protection.

The allowed antifreeze coolants are the following ethylene glycols and propylene glycols.

Ethylene glycols

•

DOWCAL 100

•

Clariant Antifrogen N

Propylene glycols

•

DOWCAL 200

•

Clariant Antifrogen L

These glycols already include corrosion inhibitors. Do not add any other inhibitor. Do not mix different glycol qualities because

there can be harmful chemical interactions.

AQ286660579921en-000101 / DPD02033 | 27Danfoss A/S © 2021.09

VACON® 3000 Enclosed Drive

Operating Guide

The glycol concentration of the coolant must be 25–55% by volume, according to the specified ambient temperature. Higher concentration reduces cooling capacity. Lower concentration results in biological growth and inadequate amount of corrosion inhibitors. Antifreeze must be mixed with purified water according to 5.4.3.1 Quality Requirements for the Purified Water.

Mechanical Installation

5.4.3.4 Temperature of the Cooling Liquid

To gain full performance of the product, the temperature of the cooling liquid entering the drive components must be a maximum

of 43°C (109°F) and above the dew point. While circulating inside the cooling element, the liquid transfers the heat produced by the

power semiconductors and other components. The temperature rise of the cooling liquid during the circulation is typically less than

4°C (7.2°F). Typically, more than 95% of the power losses are dissipated in the cooling liquid. It is recommended to equip the cooling

circulation with temperature supervision.

The secondary circuit maximum temperature must always be lower than the primary circuit temperature. The temperature difference must be at least 5°C (9°F) with equal flow. The temperature difference is necessary for the correct operation of the heat exchanger.

There are 3 external causes that affect the nominal temperature of the primary circuit:

•

The maximum ambient temperature at the drive installation location.

•

The maximum relative humidity at the drive installation location.

•

The maximum secondary circuit liquid temperature.

All these causes must be examined when calculating the primary circuit temperature. The primary circuit temperature can be different for each installation.

5.4.3.5 Condensation

Condensation must be avoided. Always keep the temperature of the cooling liquid a minimum 2°C (3.6°F) above the dew point. Use

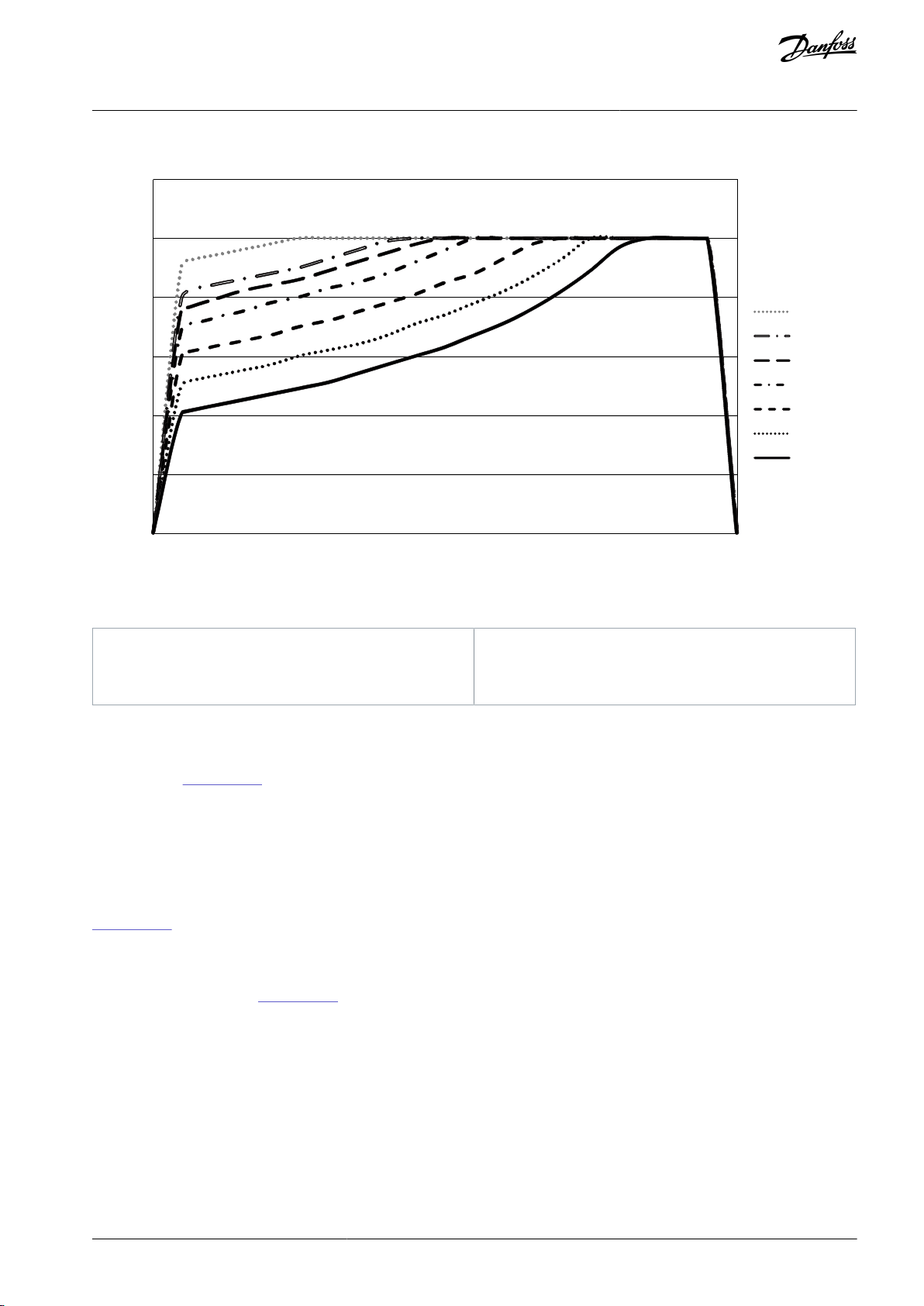

the graph in Illustration 10 to see if the conditions (combination of room temperature, humidity, and cooling liquid temperature)

are safe for the drive to operate.

The conditions are safe when the point is below the related (cooling liquid temperature) curve. If they are not, decrease the ambient

temperature or the relative humidity. Also the cooling liquid temperature can be increased. Note, that if the cooling liquid temperature is increased above the figures in loadability charts, it decreases the nominal output current of the drive. The curves in Illustra-

tion 10 are valid at sea level altitude (1013 mbar/14.69 psi).

If the temperature of the liquid in the secondary circuit is lower than the ambient temperature and the relative humidity is high,

condensation can occur on the secondary circuit pipes and the plate heat exchanger in the HX unit. The condensation is not dangerous, but it is not recommended. If there is condensation in the HX unit, it can cause the leak sensor in the cabinet to give a leak

alarm. If a leak alarm occurs again and again, install insulation in the secondary circuit pipes and the plate heat exchanger. The

insulation stops the condensation and thus prevents the incorrect leak alarms.

AQ286660579921en-000101 / DPD0203328 | Danfoss A/S © 2021.09

0 (32)

10 (50)

20 (68)

30 (86)

40 (104)

50 (122)

60 (140)

e30bg701.10

0

10

20

30

40

50

60

70

80

90

100

T

amb

, °C (°F)

Tc, °C (°F)

RH (%)

45 (113)

40 (104)

38 (100)

35 (95)

30 (86)

25 (77)

20 (68)

RH

Relative humidity

T

amb

Ambient temperature

TcCooling liquid temperature

VACON® 3000 Enclosed Drive

Operating Guide

Mechanical Installation

Illustration 10: Safe Operating Conditions in Relation to Condensation

Example

Safe Operating Conditions

If the ambient temperature is +30°C (+86°F), the relative humidity is 40% and the cooling liquid temperature is +20°C (+68°F, the

lowest curve in Illustration 10), then the drive operation conditions are safe.

If the ambient temperature increases to +35°C (+95°F) and the relative humidity to 60%, then the operation conditions of the drive

are not safe. To get safe operation conditions, the ambient temperature must be decreased to +28°C (+82°F) or below. If it is not

possible to lower the ambient temperature, then the cooling liquid temperature can be increased to +25°C (+77°F) or above.

Example

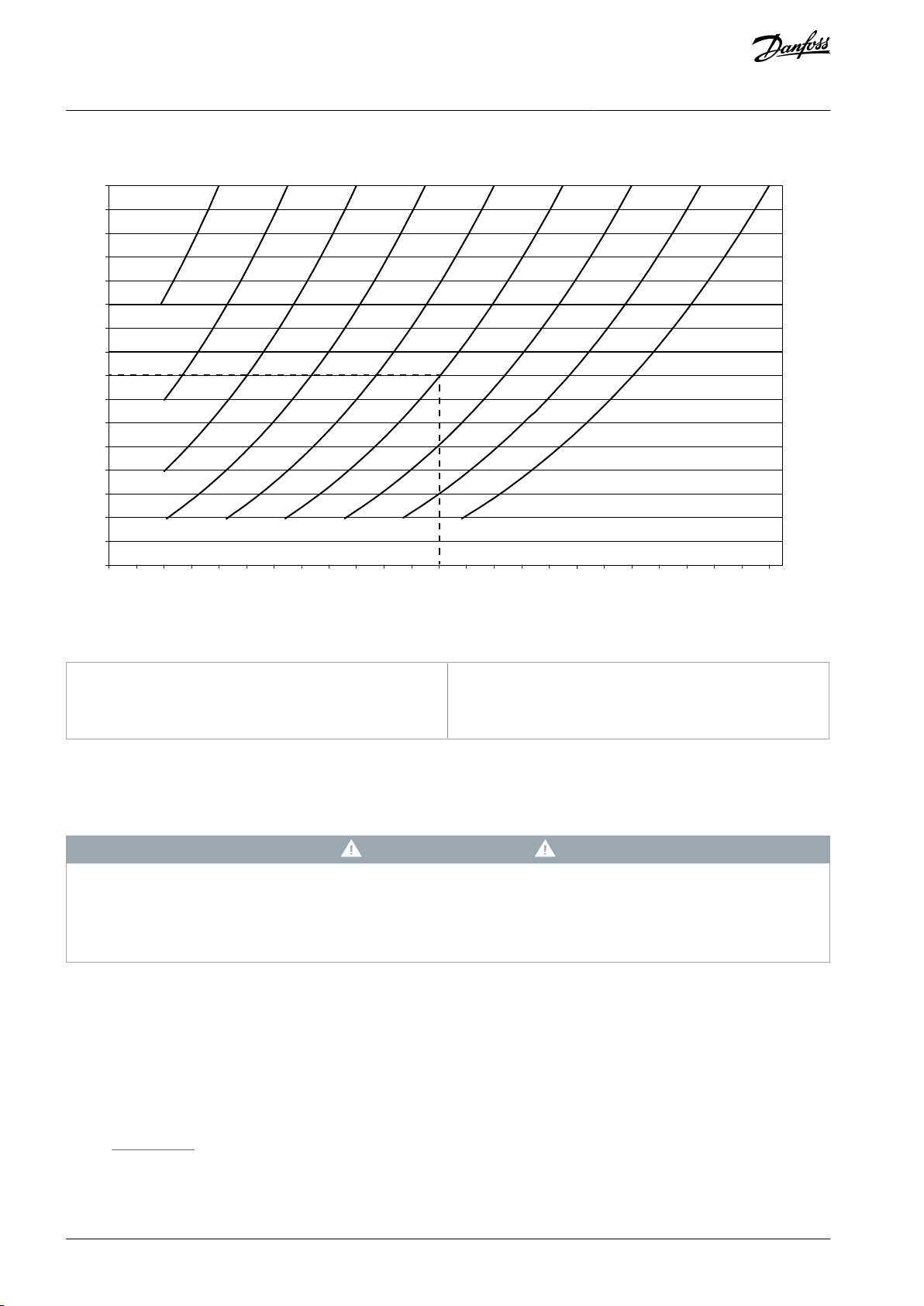

Dew Point and Primary Circuit Temperature

If the ambient temperature and the maximum relative humidity at the drive installation location is known, the dew point chart (see

Illustration 11) can be used to find the correct temperature for the primary circuit.

•

Ambient temperature = 35°C (95°F)

•

Maximum relative humidity = 60%

According to the diagram in Illustration 11, the dew point for the given values is 26°C (78.8°F). Always keep the temperature of the

cooling liquid a minimum 2°C (3.6°F) above the dew point. Thus the primary circuit minimum temperature is set to 28°C (82.4°F).

The secondary circuit maximum temperature must always be 5°C (9°F) lower than the primary circuit temperature. Thus, in this example, the secondary circuit temperature must be below 23°C (73.4°F) during operation.

Notice, that these conditions are valid for the starting of the drive. After the start, the temperature inside the cabinet starts to increase and the humidity decreases.

AQ286660579921en-000101 / DPD02033 | 29Danfoss A/S © 2021.09

Tamb (°C/°F)

20

2364396438461050125414571661186420682272247526792882308632903493369738

100401044210844111461154811850122°C°F

°C

°F

25

30

35

40

45

50

55

60

65

70

75

80

85

90

95

100

10

50

15

59

20

68

25

77

30

86

35

95

40

104

45

113

50

122

Tc (°C/°F)

RH (%)

e30bg702.10

RH

Relative humidity

T

amb

Ambient temperature

TcPrimary circuit temperature

VACON® 3000 Enclosed Drive

Operating Guide

Mechanical Installation

Illustration 11: Dew Point Diagram for Ambient Temperatures between +10°C...+50°C (+50°F...+122°F) at 1013 mbar (14.69 psi)

5.4.4 Cooling System

5.4.4.1 Materials

COPPER OR COPPER ALLOY PARTS DAMAGE THE SYSTEM

Using copper or copper alloy pipes or parts in contact with the cooling liquid damages the system.

Do not use pipes made of copper or alloys that include copper. If metallic pipes are used in the cooling system, use alumi-

-

num or stainless steel pipes.

Allowed materials in the cooling system

These materials are allowed in the cooling system if they are compatible with the cooling liquid:

•

Aluminum (EN-AW6060, EN-AW6063, or EN-AW6082)

•

Stainless steel (AISI 304/316)

•

Plastic*

•

Elastomers (EPDM, NBR, FDM)*

* If plastic or elastomers are used, check material compatibility within the temperature range of the cooling liquid. See the specifications in 11.2.6 Cooling.

Do not use PVC, copper, brass, or other materials not compatible with the heat sink material or cooling liquid.

Recommended material for pipes

C A U T I O N

AQ286660579921en-000101 / DPD0203330 | Danfoss A/S © 2021.09

= =

≈

=

≈≈

AFE

TT

TT

PT

PI

LI

LS

LS

T

E

PI

M

M

M

P

P

PT

Bleeding

Filling

Temperature control

Drain

Liquid to air

heat exchangers

INU

==

≈

=

≈ ≈

e30bg969.10

E

Heat exchanger

LI

Level indication

LS

Level switch

M

Motor

P

Pump

PI

Pressure indication

PT

Pressure transmitter

T

TankTTTemperature transmitter

VACON® 3000 Enclosed Drive

Operating Guide

•

PA11

•

PA12

•

PEX with oxygen barrier

•

PEX-AL-PEX

Mechanical Installation

The electrical resistance of the plastic and rubber pipes must be >109 Ω.

5.4.4.2 Cooling System Overview

The cooling system has a bypass valve in the primary line and valves at each power module inlet. They make it possible to open and

clean the cooling system. Open the bypass valve and close the valves to the AC drive when cleaning the system. While commissioning the system, close the bypass valve and open the valves to the AC drive.

The cooling system has temperature, pressure, and leak supervision. They can be connected to the External fault digital input function. If the cooling liquid flow or pressure is too low, the temperature too high or of there is a leak, the supervision stops the drive.

Illustration 12: The Cooling System of the VACON® 3000 Enclosed Drive

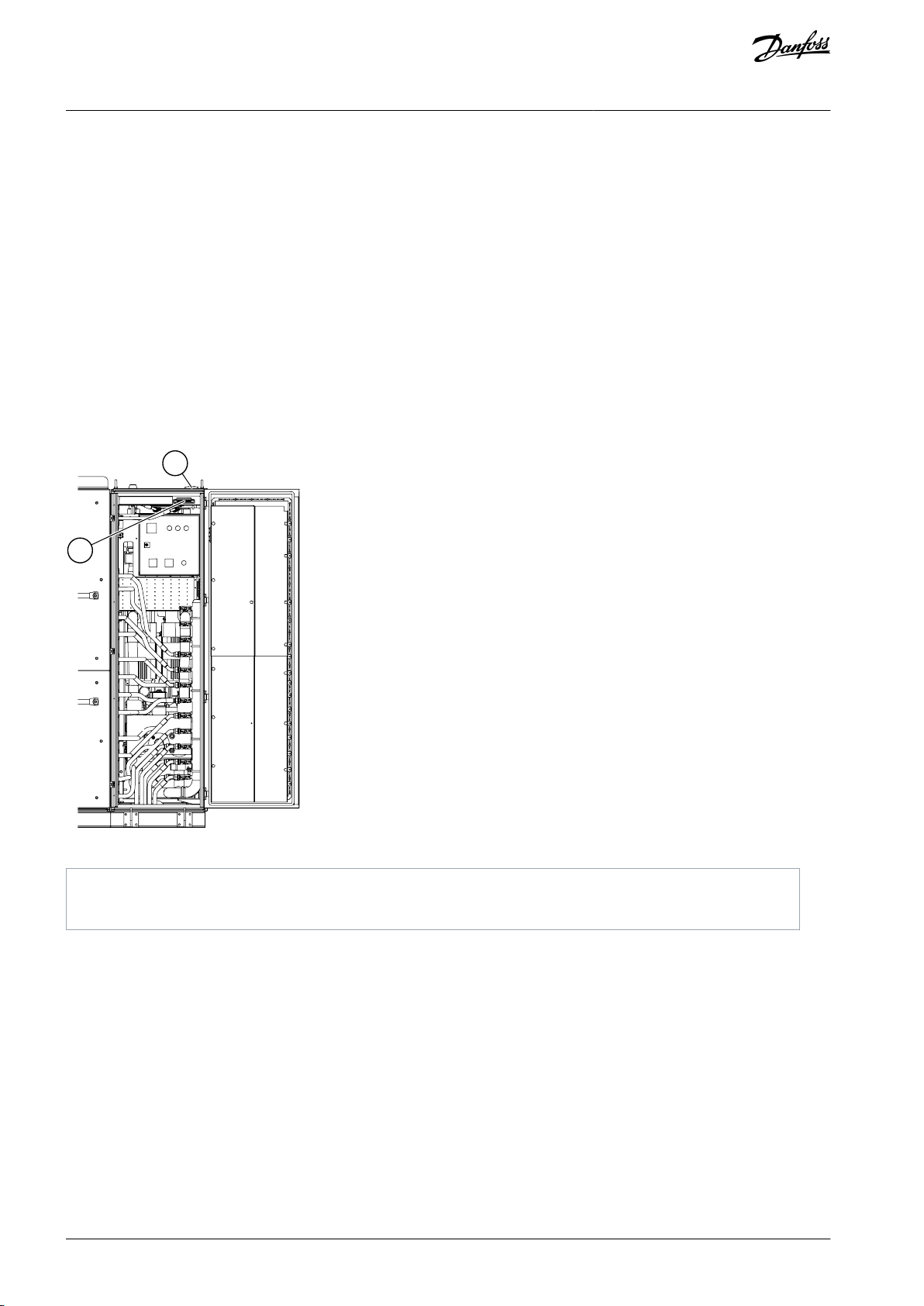

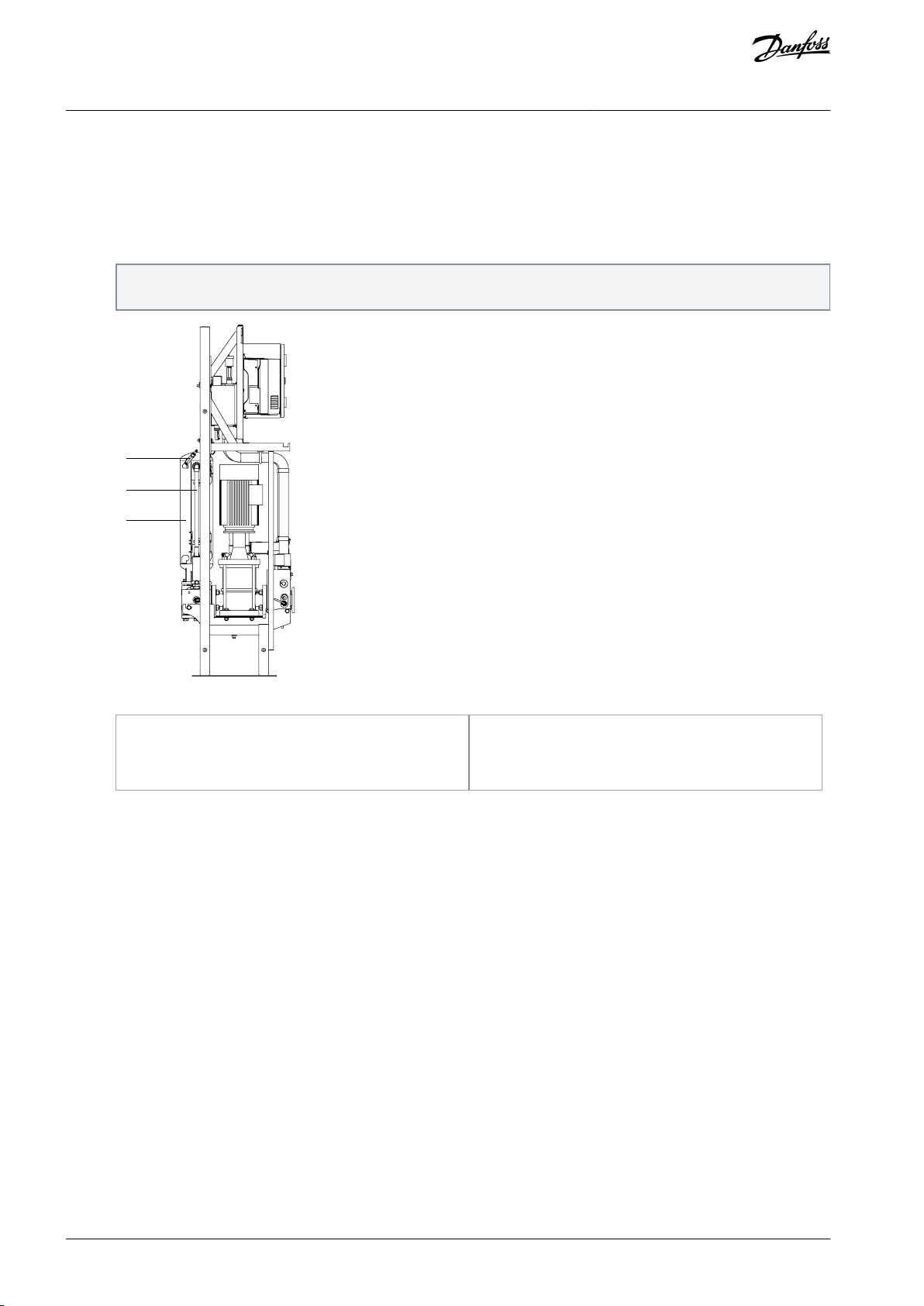

5.4.4.3 Cooling Connections to the Enclosed Drive

Connect the cooling pipes to the heat exchanger at the top on the right side of the cabinet. See the locations of the input and

output pipe connections in Illustration 13.

AQ286660579921en-000101 / DPD02033 | 31Danfoss A/S © 2021.09

I

O

e30bg970.10

I

Cooling liquid input

O

Cooling liquid output

VACON® 3000 Enclosed Drive

Operating Guide

Mechanical Installation

Illustration 13: Locations of the Cooling Connections

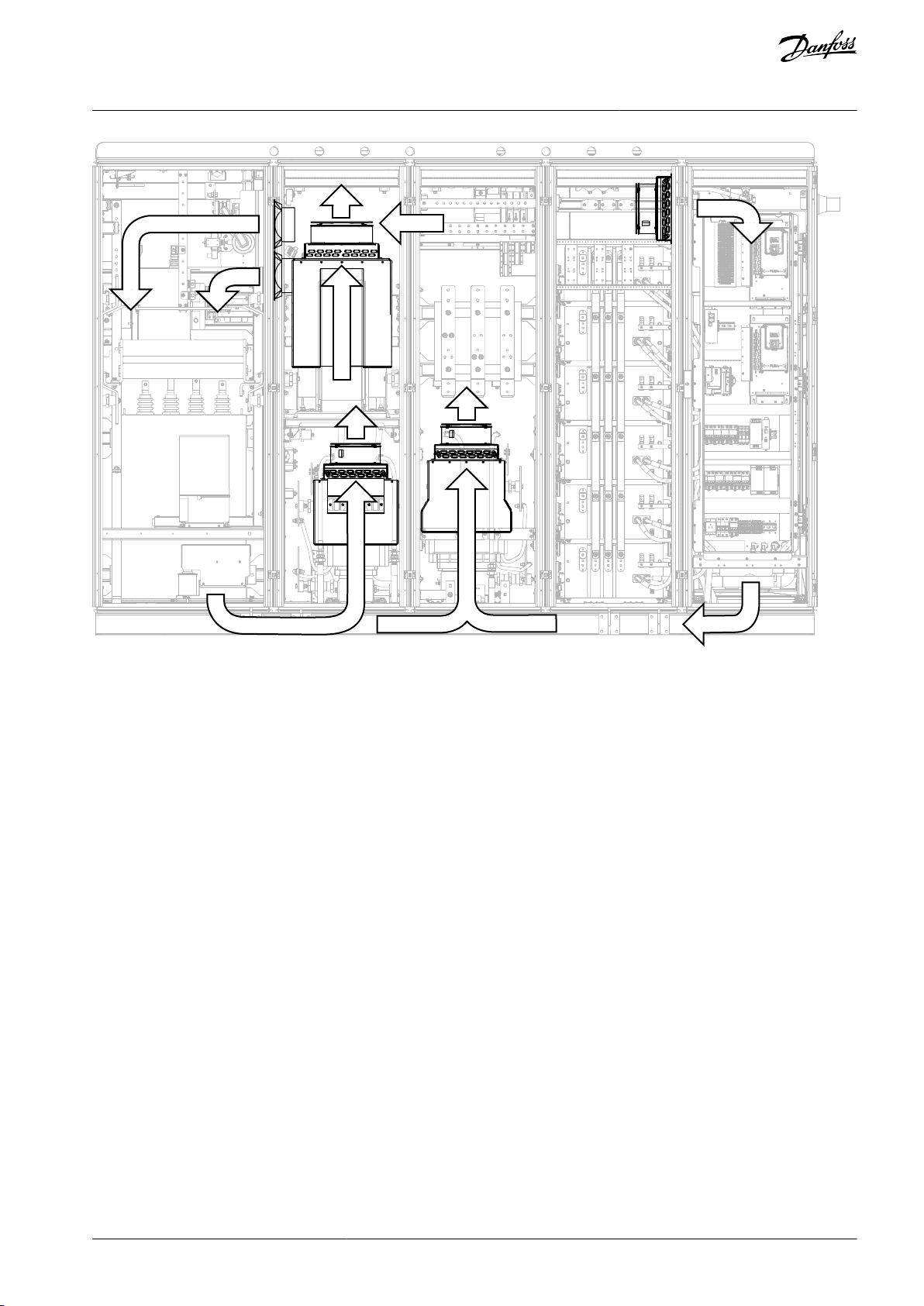

5.5 Cooling and Free Space Around the Enclosed Drive

The VACON® 3000 Enclosed Drive is a liquid-cooled AC drive, but in a liquid-cooled drive system, there are always some heat losses

to the air. The heat losses come from

•

busbars,

•

filters,

•

inductors,

•

other auxiliary components.

The AC drive uses liquid-to-air heat exchangers to cool the hot air from the inductors and other components. Fans in the cabinet

walls move the air between the cabinet sections. The structure of the cabinet is such, that the air can move freely through the cabinet.

There must be a minimum of 20 cm (7.87 in) of space above the cabinet without structures that can stop the airflow. Make sure that

the hot air goes out of the cabinet and does not come back into the cabinet. Some free space in front of the drive is also necessary

for maintenance.

The power loss of the AC drive can change significantly, when the load, the output frequency or the switching frequency changes. It

is useful to know the power loss, when planning the cooling equipment in an electrical room.

AQ286660579921en-000101 / DPD0203332 | Danfoss A/S © 2021.09

VACON® 3000 Enclosed Drive

Operating Guide

Mechanical Installation

e30bg713.11

Illustration 14: The Liquid-to-Air Heat Exchangers and Fans Used to Cool the Components in the Cabinets

AQ286660579921en-000101 / DPD02033 | 33Danfoss A/S © 2021.09

AFE

CSH

INU

CCM CCM

+PODU

+POSI

GSW

PTR

+

-

o

+

-

o

400/

480V

e30bg978.10

230/

120V

CNU-AFE

Aux I/O

CNU-INU

AIT

APS

PCU

PCU

LCVLGIMCB

LCM

Arc

flash

detector

L1

L2

L3

U

V

W

SPD

Cab

heater

Cab

heater

Cabinet

over temp

indicator

Cabinet

over temp

indicator

24 V - 20 A

24 V - 20 A

Panel

lighting

Panel

service

socket

L N PE

LSI

LCV

LCM

LGI

PRC

GSW

LD

MCB

COT

COT

DSI

Door safety

interlocks

HXLA

4160/

3300V

Motor

LOW-VOLTAGE SECTIONMEDIUM-VOLTAGE SECTION

Liq to air

HX

Power module

cabinet

Thermostat

Thermostat

Humidity

Magnetics

cabinet

Magnetics

cabinet

Magnetics

cabinet

PRC

Humidity

TB

HX Run O

I HX OK

Leak

detector

PS-BRK

L

N

HX

MTR

ESW

HMI

O - MX Start

I - KMX Status

I - VCB Status

O - VCB Close

O - MX Permissive

I - Power On

I - Power Off

I - GND SW Unlock

I - Arc Guard Online

I - Arc Guard Trip

I - HX OK

I - User Interlock

APS

24 V-10 A

24 V-10 A

Liq to airHXLiq to air

HX

A

B

C

C

E

D

Door safety

interlocks

Relay

Logic

L N

A

Galvanic isolation between the MV and LV sections

B

LV supply for the isolation transformer (AIT)

C

Optical fiber connections

D

Supply voltage feedback from the potential transformer (PTR) to the AFE control unit

E

LV supply for the pre-charge unit (PRC)

VACON® 3000 Enclosed Drive

Operating Guide

Electrical Installation

6 Electrical Installation

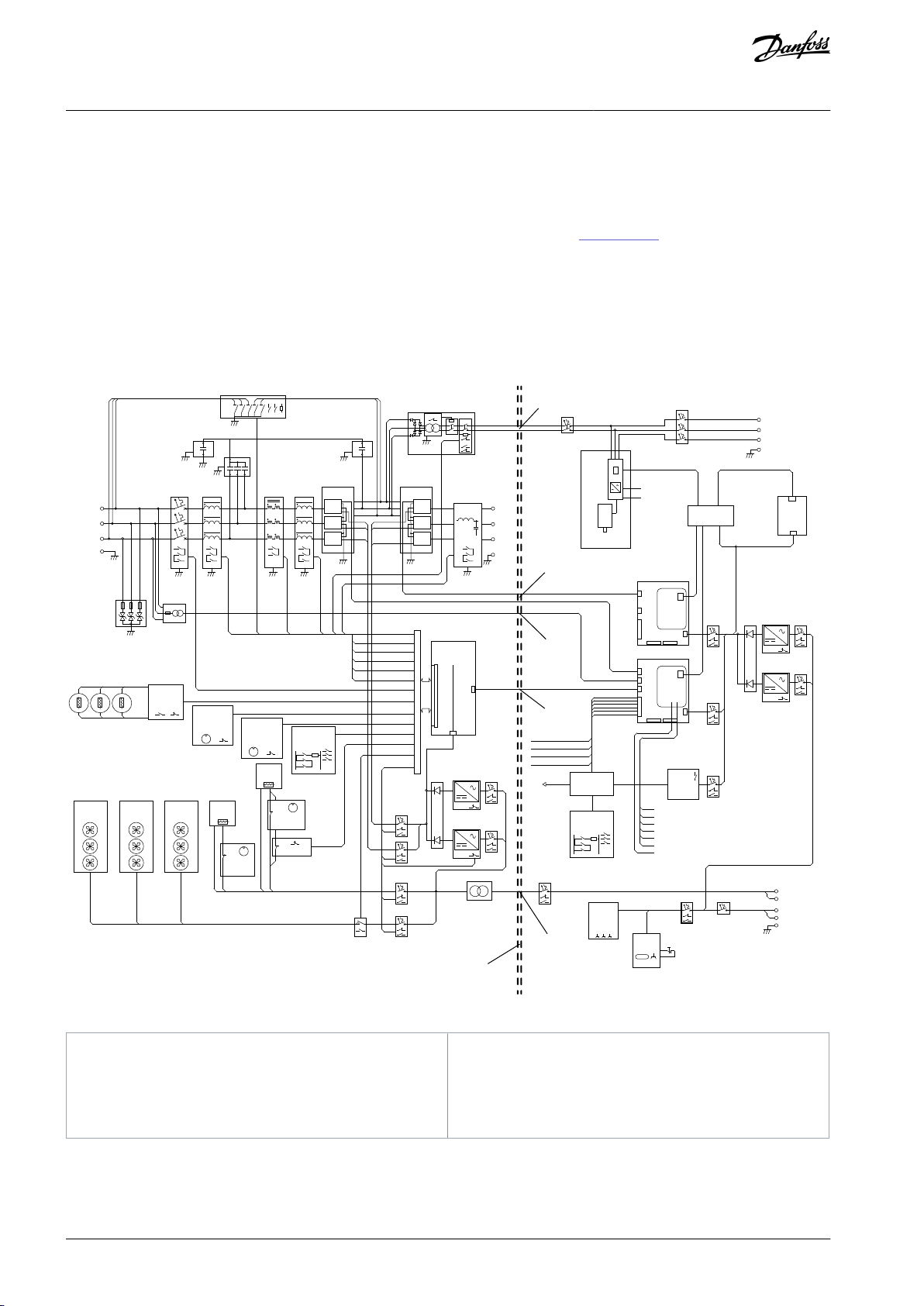

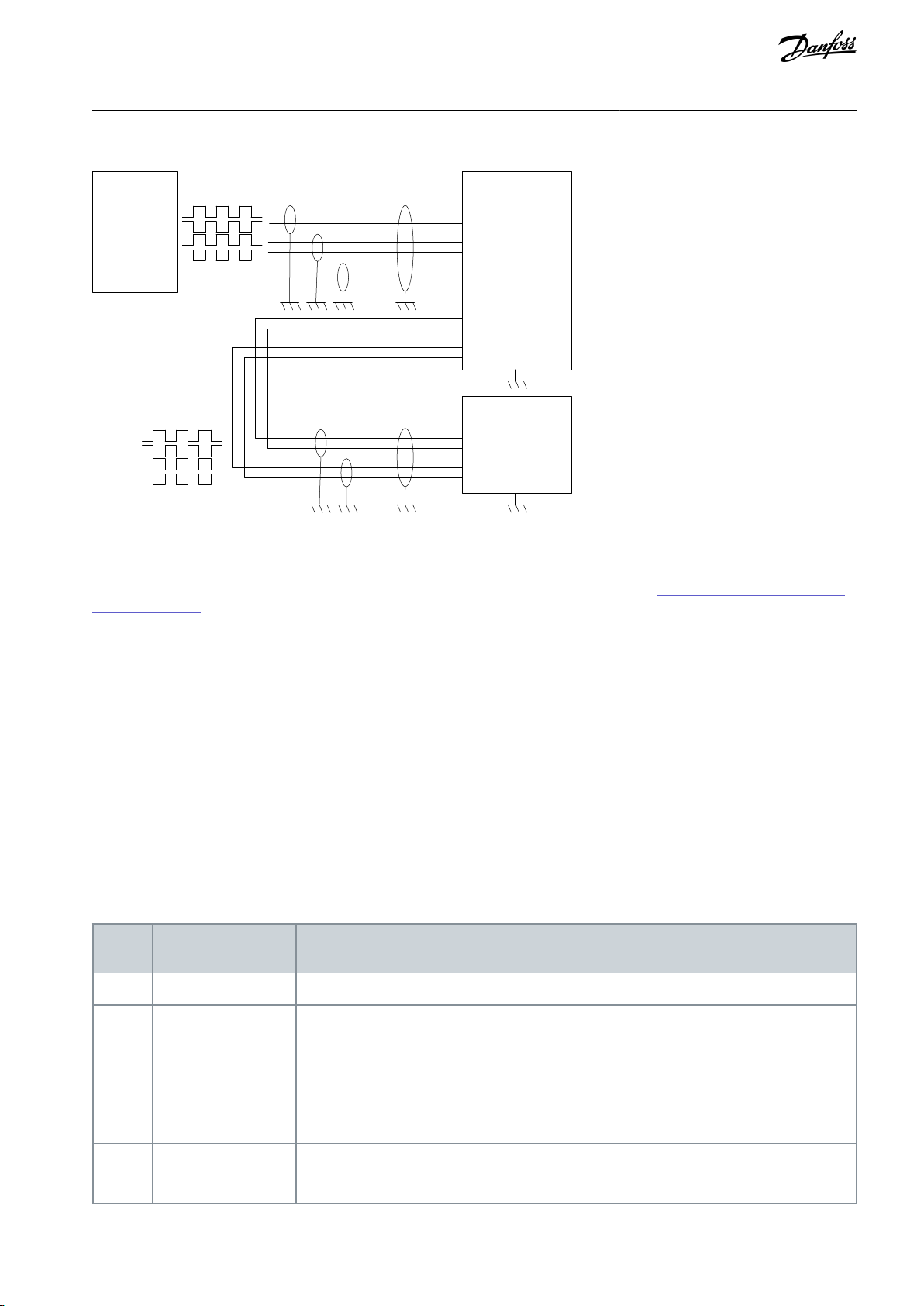

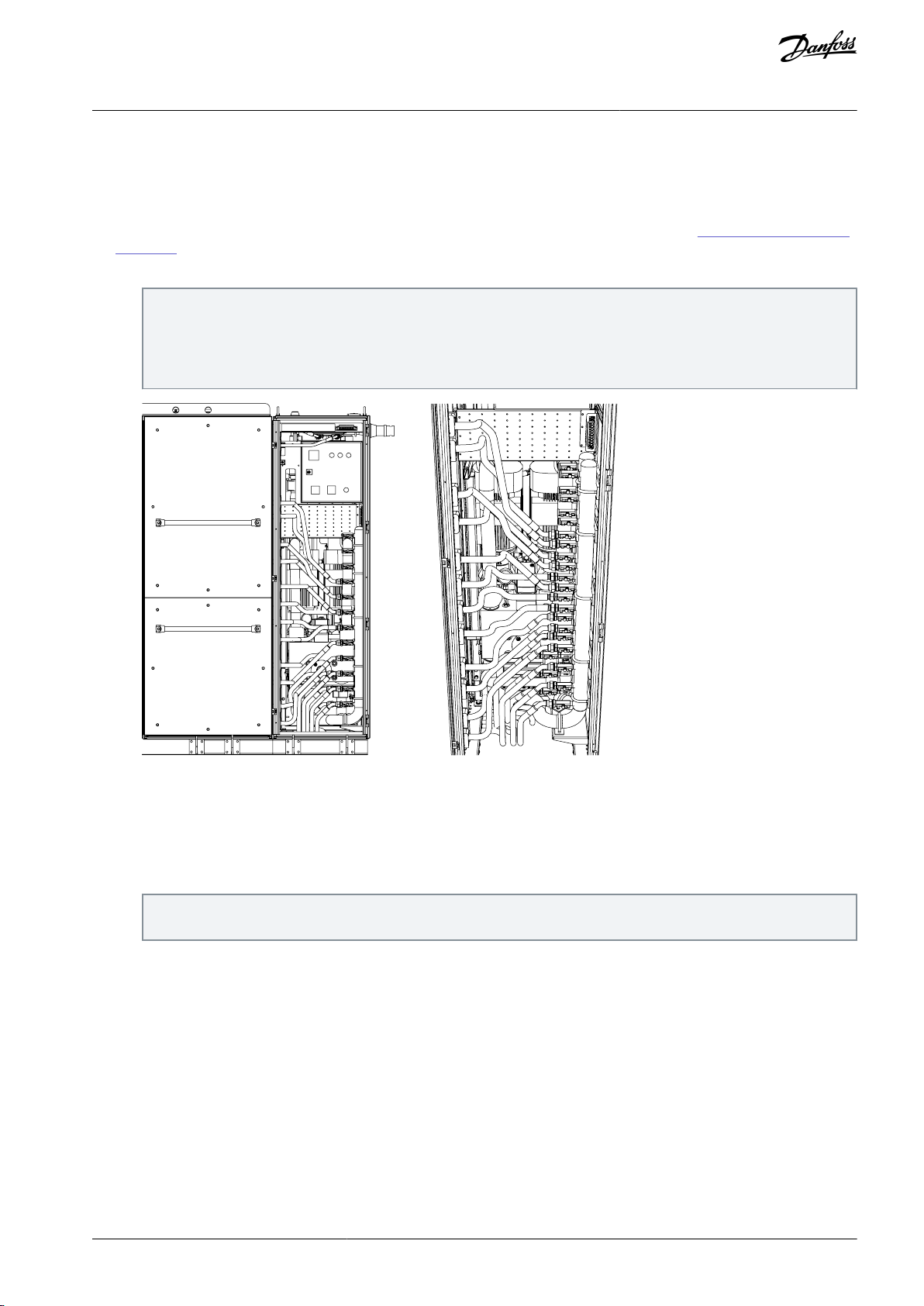

6.1 Galvanic Isolation Between the MV and LV Sections

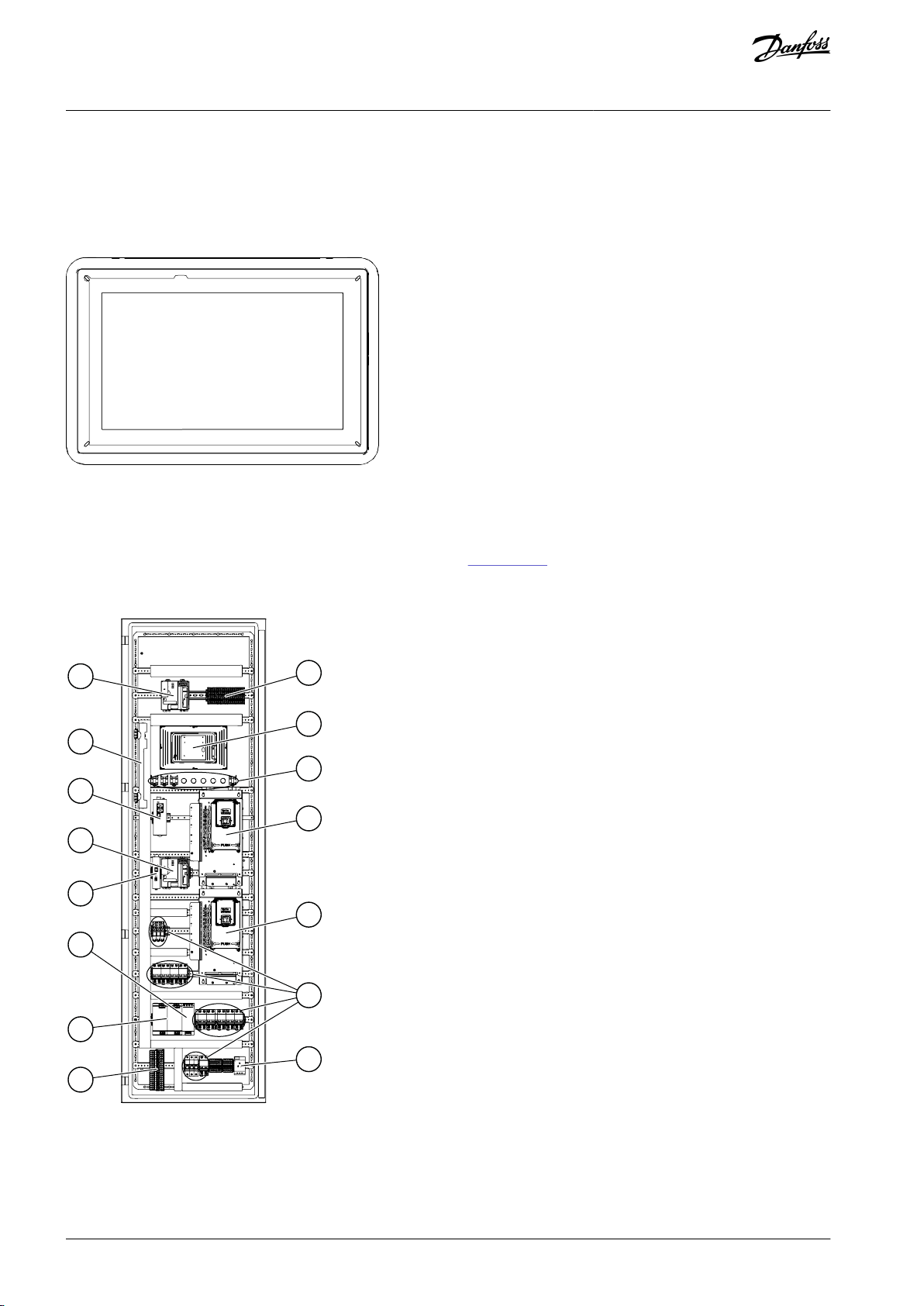

There is galvanic isolation between the low-voltage (LV) and medium-voltage (MV) sections of the cabinet. The insulation between

the sections gives the devices in the LV section protection from the MV section voltages. Illustration 15 shows which components

are installed in the MV and LV sections.

All connections between the LV and MV sections are done with optical fiber cables. The only LV connections between the MV and

LV sections are:

•

The LV supply for the pre-charge unit (PRC)

•

The LV supply for the isolation transformer (AIT)

•

The supply voltage feedback from the potential transformer (PTR) to the AFE control unit

Illustration 15: Connections between the MV and LV Sections of the Cabinet

AQ286660579921en-000101 / DPD0203334 | Danfoss A/S © 2021.09

e30bg973.10

VACON® 3000 Enclosed Drive

Operating Guide

Illustration 16: Locations of the Low-Voltage Sections in the VACON® 3000 Enclosed Drive

Electrical Installation

6.2 Mains and Motor Cable Selection

C A U T I O N

UNEQUAL LOAD

If the cable installation is not symmetrical, unequal load can occur in AC drives with parallel inputs or outputs. The unequal load

can decrease loadability or damage the drive.

In drives with parallel inputs or outputs, make sure that the cable size, cable length, cable type, and routing is the same for all

-

parallel cables.

Use cables with a nominal voltage U0/U of 3.6/6 kV and maximum voltage 7.2 kV. The size and type of the cable depends on the

application of the drive. The cable size is also affected by:

•

The current at continuous load,

•

the permitted short-circuit current,

•

the installation conditions.

To decrease EMI, use shielded 3-phase cables for the motor connection. If single-core cables are used in the input or output, they

must be shielded.

When selecting the cable, refer to the input voltage and the load current of the drive. Obey all applicable standards and local safety

regulations.

Example

Mains Cables for the VACON® 3000 4160 V 510 A AFE Drive

The recommendation for the VACON® 3000 4160 V 510 A AFE drive, is to use two 240 mm2 (500 kcmil) M2N type cables (available

from Liban Cables/Nexans) for each phase. The cables are 3.6/6 kV copper cables with one core, XLPE insulation, a PVC cover, shielded, and unarmored.

6.3 Mains and Motor Cable Inlet and Termination

There are cable entries at the top and bottom of the cabinet sections for the mains and motor cables. If an output filter option is

installed, cabling from the bottom is not possible.

AQ286660579921en-000101 / DPD02033 | 35Danfoss A/S © 2021.09

B

A

L1

L2

L3

W V U

e30bg971.10

A

The mains terminals (L1, L2, L3)

B

The motor terminals (U, V, W)

VACON® 3000 Enclosed Drive

Operating Guide

Illustration 17: The Mains and Motor Terminal Locations

Electrical Installation

Connect the mains cables to terminals L1, L2, and L3 in the mains input section. Connect the motor cables to the inverter section

terminals U, V, and W. Make openings for the cables in the grommets on the bottom or top of the cabinet and push through the

cables. Use cable clamps to attach the cables. Always connect the PE conductors of the mains and motor cables to the PE busbar.

In units with parallel motor outputs, do not connect the motor cables together in the AC drive end. Always connect the parallel

motor cables together in the motor end only. The minimum motor cable length is 5 m (16.4 ft).

Use medium-voltage cable lugs to connect the cables to the busbar terminals. Use heat shrink or cold shrink cable termination kits

on the cables, for example, the kits HIT1.1204L or CIT1.1204L available from Ensto.

The output cables to the motor must be 360° EMC grounded, for example, by installing EMC grounding clamps at the cable inlet. To

make a 360° connection with the grounding clamps and the cable shield, strip the cables. The EMC grounding clamps must be the

correct size to give a 360° contact with the cable shield.

AQ286660579921en-000101 / DPD0203336 | Danfoss A/S © 2021.09

E

D

C

B

A

F

e30bg732.10

A

Cable grommet

B

Cable clamp

C

360° EMC grounding

D

PE busbar

E

Cable termination

F

Cable lug

B

C

D

A

e30bh726.10

VACON® 3000 Enclosed Drive

Operating Guide

Electrical Installation

Illustration 18: Example of a 1-phase Motor Cable Inlet to the Cabinet

Illustration 19: Example of a 3-phase Motor Cable Inlet to the Cabinet

AQ286660579921en-000101 / DPD02033 | 37Danfoss A/S © 2021.09

A

Cable entry seal with 360° EMC grounding

B

PE busbar

C

Cable termination

D

Cable lug

e30bg972.10

VACON® 3000 Enclosed Drive

Operating Guide

Electrical Installation

6.4 Grounding

Ground the AC drive in accordance with applicable standards and directives.

In the specified ground fault conditions, the current density in the grounding conductor, if of copper, must not be more than:

•

200 A/mm2 for a short circuit of 1 s, and

•

125 A/mm2 for a short circuit of 3 s.

But, the cross-sectional area of the grounding conductor must not be less than 30 mm2 (AWG2). Refer to IEC62271-200.

There is a protective earthing (PE) busbar at the bottom front of the cabinets. Connect the PE rail to an external ground at the installation location as is approved in the applicable regulations. Obey the local regulations on the minimum size of the protective earthing conductor.

Illustration 20: The Grounding Busbar

The power module grounding terminals, the DC link neutral point, the grounding switch, and the transient voltage suppressors are

connected to the PE rail. Also the frames of the inductors and capacitors are grounded.

Always connect the PE conductors of the mains and motor cables to the PE busbar. The output cables to the motor must be 360°

EMC grounded. To make a 360° connection with the grounding clamps and the cable shield, strip the cables. Ground the motor

cable shield at the drive and motor ends of the cable.

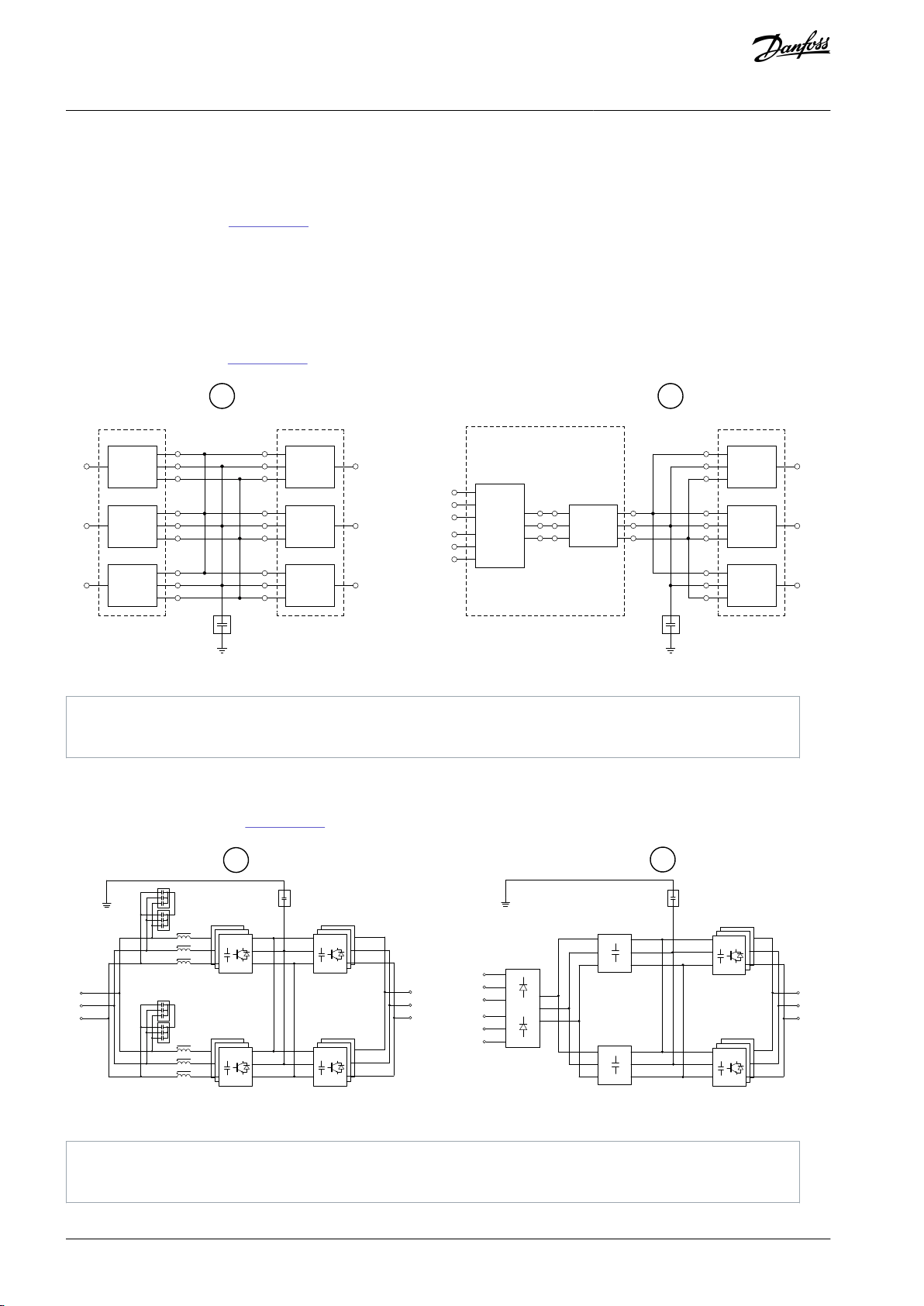

6.4.1 Standard Grounding Configurations

AQ286660579921en-000101 / DPD0203338 | Danfoss A/S © 2021.09

CLF

TR

CAB

3

3 3 3 3

DC+

DC0

DC-

MVC

CCM

GND

GND GND

CB

M

3~

3

3

e30bh722.10

CAB

Drive cabinet frame

CB

MV circuit breaker or fused contactor

CCM

Grounding capacitor

CLF

CL filter

GND

Grounding busbar

M

MV motor

MVC

MV cable

TR

MV transformer (secondary side ungrounded)

LCL

CCM

LCM

CAB

3

3

3

3

3

DC+

DC0

DC-

SP

MVC

MVC

MVS

GND

GND GND

CB

M

3~

3

3

3

e30bh723.10

CAB

Drive cabinet frame

CB

MV circuit breaker or fused contactor

CCM

Common-mode capacitor network (used in gridconnected systems only)

GND

Grounding busbar

LCL

LCL filter

LCM

Common-mode inductor

M

MV motor

MVC

MV cable

MVS

MV source (ungrounded or impedance grounded

only)SPStar point of shunt capacitor

VACON® 3000 Enclosed Drive

Operating Guide

Illustration 21: Grounding of Transformer-Isolated Drives

Electrical Installation

Illustration 22: Grounding of Grid-Connected Drives

6.5 Additional Instructions for Cable Installation

•

Before starting the installation, make sure that none of the components of the AC drive is live. Read carefully the warnings in the

Safety section.

•

Make sure that the motor cables are sufficiently far from other cables.

•

The motor cables must go across other cables at an angle of 90°.

•

If it is possible, do not put the motor cables in long parallel lines with other cables.

•

Only use symmetrically EMC shielded motor cables.

•

Make sure that there is sufficient clearance (approximately 25 mm/1 in) between the cables in the cabinet and between the

cables and conductor materials.

•

If cable insulation checks are necessary, see 8.5.2 Measuring the Cable and Motor Insulation.

AQ286660579921en-000101 / DPD02033 | 39Danfoss A/S © 2021.09

F

E

A

B C D

G

H

I

J

K

e30bg716.10

A

~, phase input (AFE) / motor output (INU), size M10

B

- , DC minus, size M10

C

0, DC link neutral point, size M10

D

+, DC plus, size M10

E

Heat sink terminal, size M6

F

Ground terminal, size M6

G

Cooling liquid terminal in (AFE) / out (INU)

H

Cooling liquid terminal in (INU) / out (AFE)

I

Optical fiber A

J

Optical fiber B

K

24 V supply for control

VACON® 3000 Enclosed Drive

Operating Guide

Electrical Installation

6.6 Main Circuit Breaker Installation

Install a main circuit breaker for the short-circuit protection of the AC drive. Use, for example, a fast vacuum circuit breaker. When

selecting the size of the mains circuit breaker, refer to the available short circuit power, continuous current, and supply voltage.

The VACON® 3000 AFE drive has a maximum short-circuit current of 31.5 kA. The operation time of the circuit breaker must not be

longer than 4 cycles (50 Hz: 80 ms, 60 Hz: 67 ms).

The function of the circuit breaker is to give short-circuit protection. For ground fault protection, install a protection relay and resistors.

See also 2.5 Main Circuit Breaker.

N O T I C E

CONNECTION TO ARC FLASH PROTECTION

Connect the circuit breaker to the arc flash detection system in the AC drive cabinet.

6.7 Cabling of the Power Modules

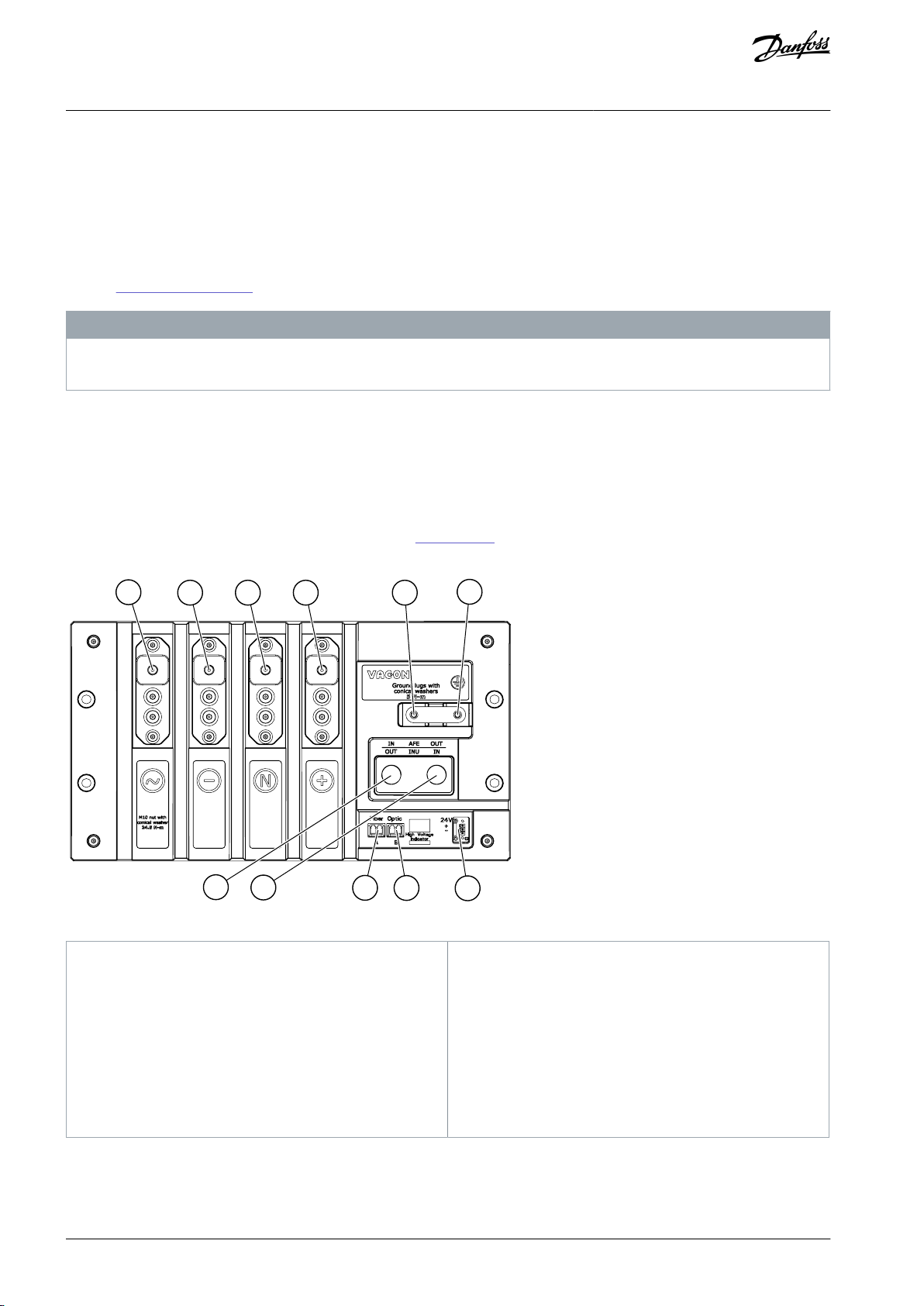

6.7.1 Phase Module L20/L30 Terminals

To make access and installation easy, all terminals are located in the front of the phase modules. Phase, DC, neutral, and ground

terminals have sufficient space between them and creepage walls on each side. To make the terminals compatible with different

cable lugs, the terminals can be changed by removing screws from the front.

See the functions of the AFE/INU phase module terminals in Illustration 23. If the phase module operates as an AFE or INU, some of

the terminals have different functions.

Illustration 23: AFE/INU Phase Module Terminals

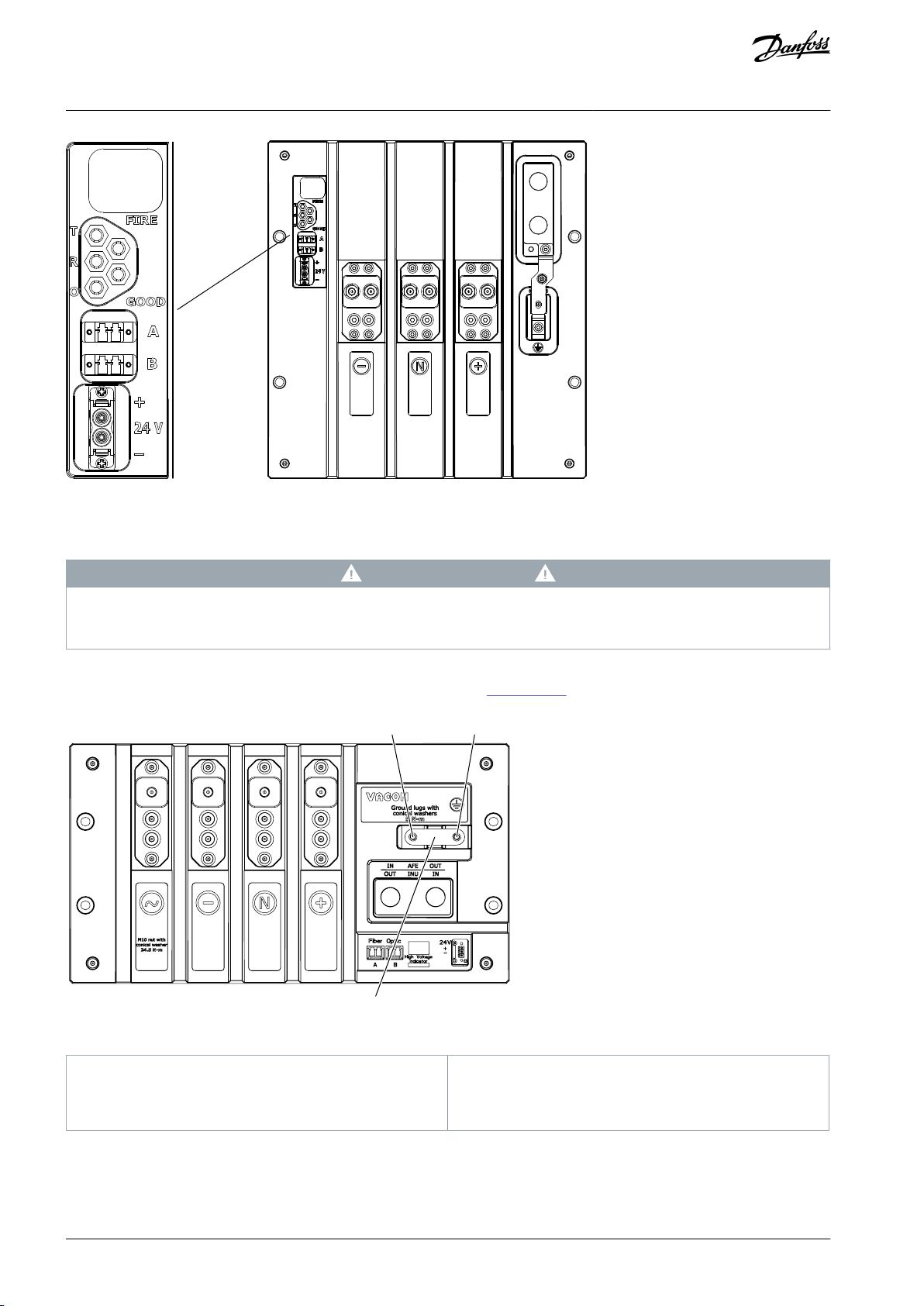

6.7.2 DFE Power Module Terminals

In the DFE power module, all terminals are at the front of the module, except the AC input terminals, which are at the back of the

module. DC, neutral, and ground terminals have sufficient space between them and creepage walls on each side. To make the DC

AQ286660579921en-000101 / DPD0203340 | Danfoss A/S © 2021.09

A

I

K

L

M

N

O

P

G

H

B C

F

E

D