Page 1

vacon®20 x

ac drives

BH application manual

Page 2

Page 3

vacon • 0

INDEX

Document ID: DPD01381A

Rev. A

Version release date: 11.10.13

Corresponds to application package ACIT1124V101.vcx

1. BH Application .................................................................................................2

1.1 Specific functions of Vacon BH application ...................................................................... 2

1.2 ASi Board Diagnostic........................................................................................................3

1.3 Description of the terminals (D-option with AS-interface) .............................................. 4

1.3.1 MU2 connections............................................................................................................... 4

1.3.2 MU3 connections............................................................................................................... 6

1.4 Description of the terminals (D-option with Profibus) ..................................................... 8

1.4.1 MU2 connections............................................................................................................... 8

1.4.2 MU3 connections............................................................................................................. 10

2. Description of Groups .................................................................................... 12

2.1 Monitor group: menu MON ............................................................................................. 12

2.1.1 ASi.................................................................................................................................... 12

2.1.2 Sensors............................................................................................................................ 12

2.1.3 Motor ............................................................................................................................... 12

2.1.4 Drive ................................................................................................................................ 13

2.2 Parameter Groups: Menu PAR ....................................................................................... 14

2.2.1 Group Motor settings: Menu PAR G1 .............................................................................. 15

2.2.2 Group Start/Stop Settings: Menu PAR G2....................................................................... 16

2.2.3 Group References: Menu PAR G3 ................................................................................... 17

2.2.4 Group Ramps: Menu PAR G4 .......................................................................................... 19

2.2.5 Group Input functions: Menu PAR G5 ............................................................................ 20

2.2.6 Group Output functions: Menu PAR G6........................................................................... 21

2.2.7 Group Mechanical brake: Menu PAR G7......................................................................... 22

2.2.8 Group Supervisions: Menu PAR G8................................................................................. 23

2.2.9 Group Motor Control: Menu PAR G9............................................................................... 24

2.2.10 Group Protections: Menu PAR G10................................................................................. 25

2.2.11 Group Automatic reset: Menu PAR G11.......................................................................... 27

2.2.12 Group Non-ASi fieldbus: Menu PAR G12........................................................................ 28

2.2.13 Group Analogue output: Menu Par G13.......................................................................... 29

2.2.14 Group User interface: Menu Par G14.............................................................................. 29

2.3 System parameters, Faults and History faults: Menu FLT ............................................ 30

2.4 Keypad Reference: Menu REF ........................................................................................ 32

3. Parameter description................................................................................... 34

3.1 Motor Settings ................................................................................................................. 34

3.2 Start/Stop settings ..........................................................................................................36

3.3 References ...................................................................................................................... 38

3.4 Ramps.............................................................................................................................. 40

3.5 Input functions................................................................................................................. 42

3.6 Output functions .............................................................................................................. 44

3.7 Mechanical brake ............................................................................................................ 46

3.8 Supervisions .................................................................................................................... 47

3.9 Motor control................................................................................................................... 48

3.10 Protections ...................................................................................................................... 52

3.11 Automatic reset............................................................................................................... 58

3.12 Non-ASi fieldbus ............................................................................................................. 59

3.12.1 Modbus fieldbus mapping............................................................................................... 60

3.13 Analogue Output.............................................................................................................. 62

3.14 User interface.................................................................................................................. 62

Service support: find your nearest Vacon service center at www.vacon.com

Page 4

vacon • 1

4. Fault tracing .................................................................................................. 64

Page 5

BH Application vacon • 2

1. BH APPLICATION

The VACON® 20 CP/X drive with +D option contains a preloaded application for instant use.

The parameters of this application are listed in chapter 2.2 of this manual and explained in

more detail in chapter 2.

1.1 Specific functions of Vacon BH application

The Vacon BH application allows flexible use of VACON® 20 CP/X frequency converters.

The visibility of parameters and monitors is arranged in three access levels, selected by parameter P14.1.

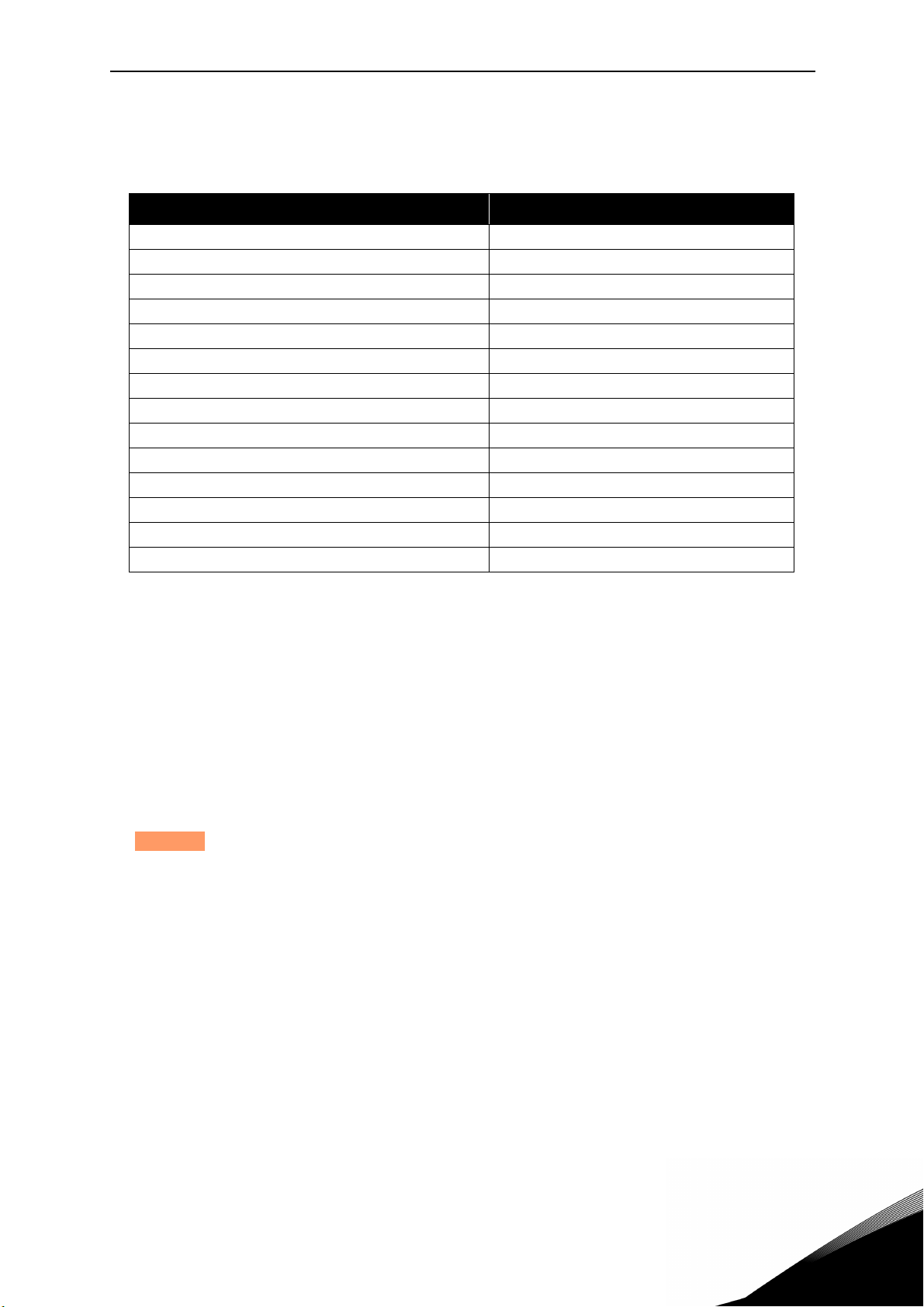

Code Parameter Min Max Default Description

0 = Basic

P14.1 Parameter access level 0 2 0

1 = Advanced

2 = Service

Basic:

• Monitor of ASi inputs and outputs (only with +D option and AS-interface connection)

• Monitor of sensors

• Monitor of main motor variables

• Setting of motor data

• Setting of Run control mode and commonly used speed reference

• Setting of basic ramp times

• Setting of quick stop function

• Setting of ASi inputs and outputs functions

Advanced:

• Basic + Monitor of more drive/motor variables

• More options for Start/stop and reference selection

• Setting of a second set of ramp times

• Setting of advanced motor control

• Setting of mechanical brake control

• Setting of protections and autoreset

Service:

• Advanced + Monitor of drive internal I/Os

• Setting of some extra motor control and protections features

• Setting of analogue and relay outputs

1)

1)

terminals of analogue output and relays are not accessible in standard Vacon 20 CP/X+D

drive.

Service support: find your nearest Vacon service center at www.vacon.com

1

Page 6

vacon • 3 BH Application

1.2 ASi Board Diagnostic

This information is valid only for Vacon® 20X with +D option and AS-interface connection.

Monitor V1.3 shows the state of ASi board, as numeric code.

Visual information is provided by red Fault led on the drive's cover.

Off: no anomaly

On: cumulative fault state. Reset is needed to restore operations.

Slow blinking: ASi board is not powered.

Fast blinking: ASi board is powered, but not communicating (to see V1.3).

A fault condition (code 64) is generated if communication fails while the drive is in Run state in

Automatic mode.

This fault is automatically reset when Manual mode is selected. The drive can operate in Manual mode, even though the ASi anomaly is still displayed (alarm code 64).

Run is prevented in Automatic mode, until communications is restored.

1

Page 7

BH Application vacon • 4

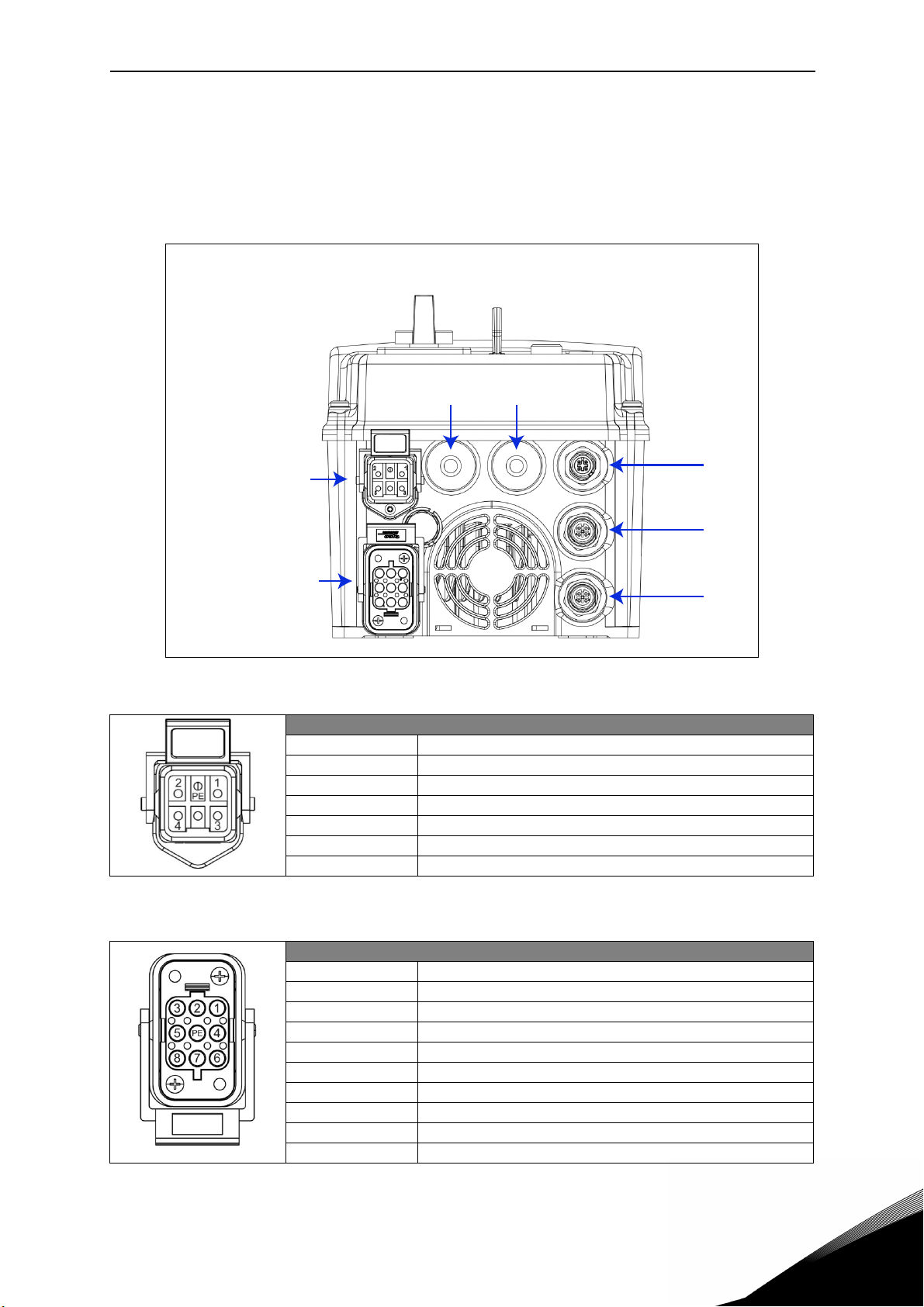

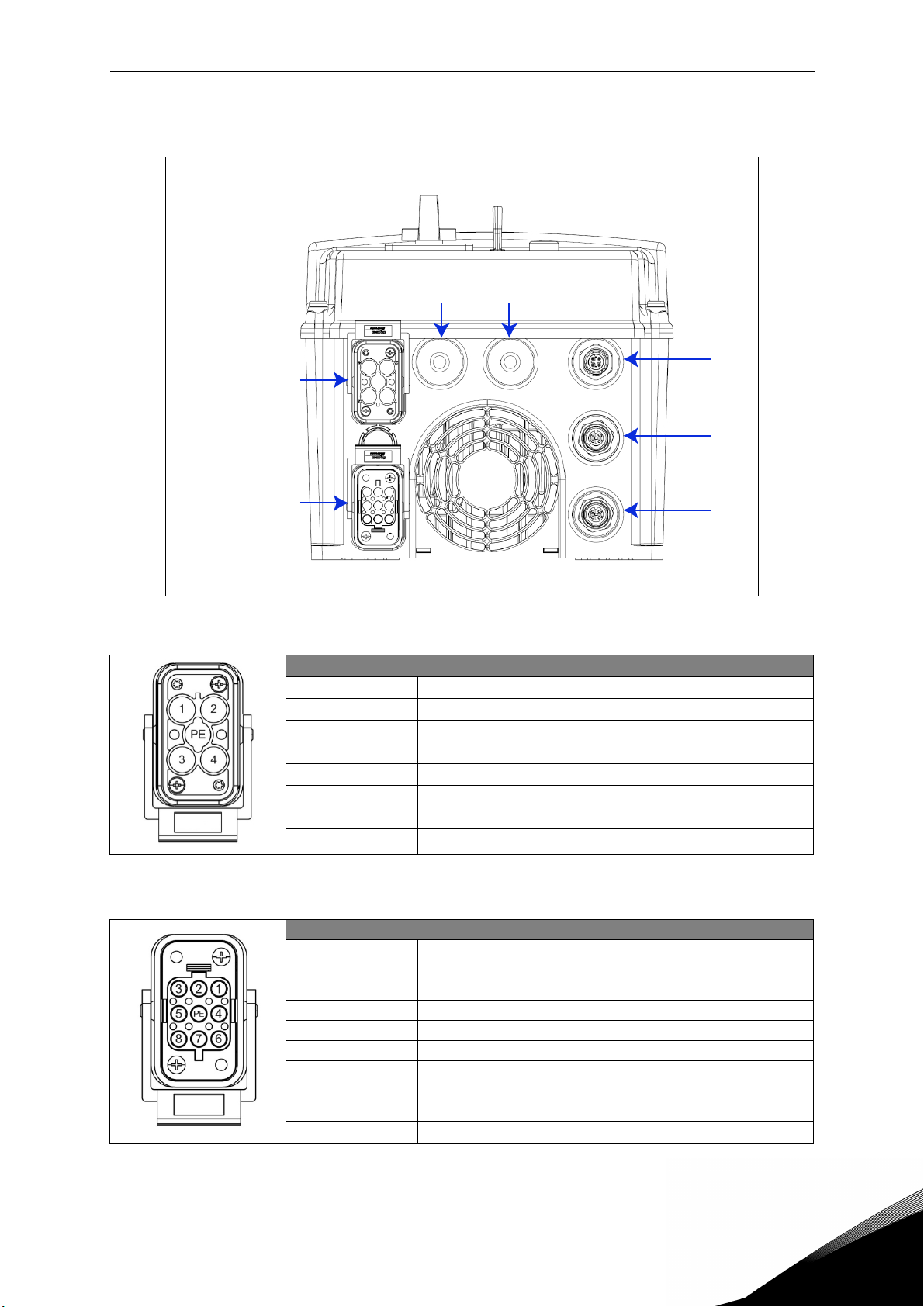

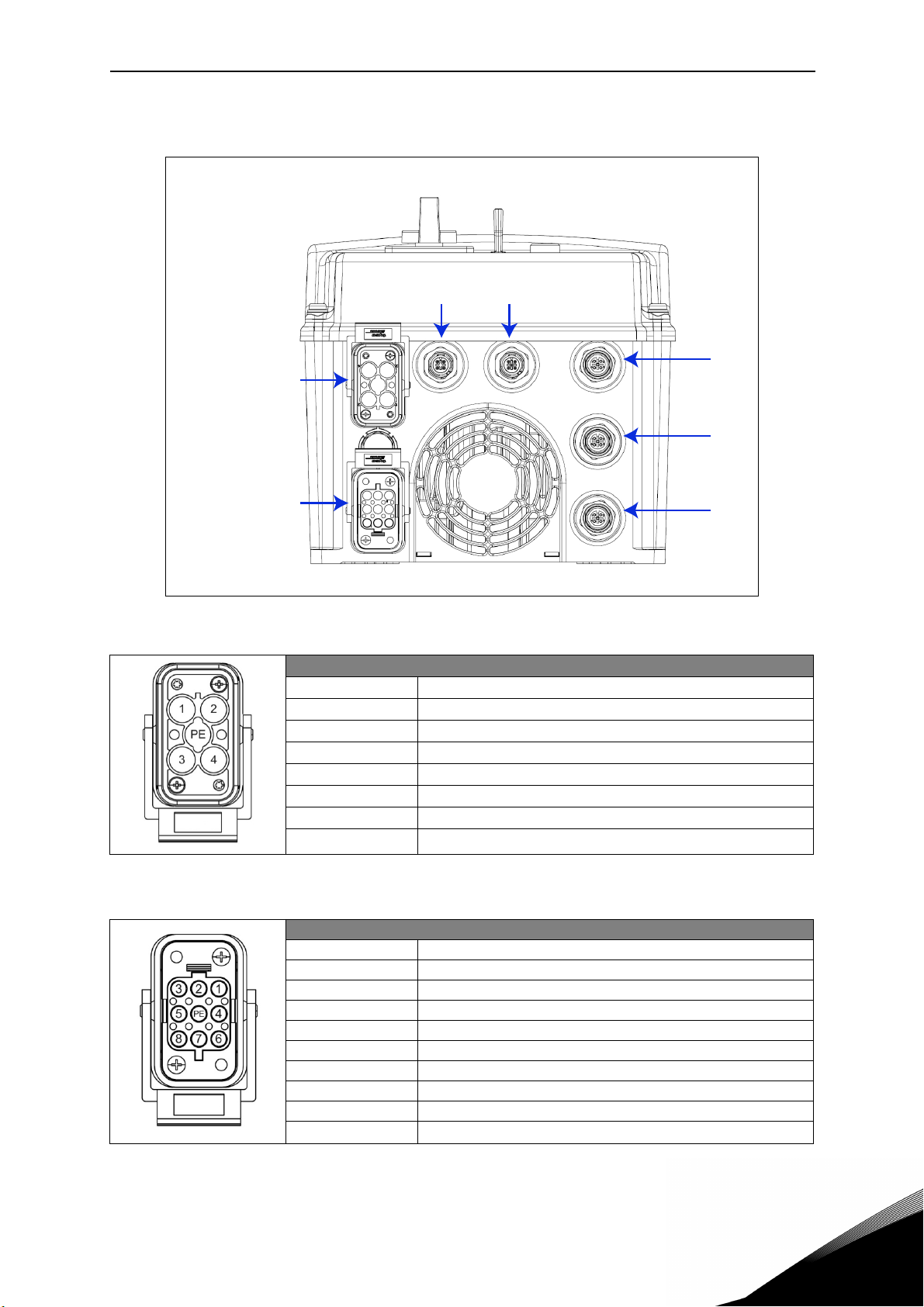

1.3 Description of the terminals (D-option with AS-interface)

The following pictures describe the power and M12 terminals in Vacon 20X drives with D-option

and AS-interface connection.

1.3.1 MU2 connections

X5 X4

Mains supply

Motor output

Figure 1. Power and control terminals in MU2.

Mains supply / Type HAN Q5/0 (Male)

Pin Function

1L1

2L2

3L3

45PE Protective Earth

X3

X2

X1

Table 1. Mains supply connector, MU2.

Motor output / Type HAN Q8 (Female)

Pin Function

1U

2 Not connected

3W

4Brake (-)

5Temperature sensor (+)

6Brake (+)

7V

8Temperature sensor (-)

PE Protective Earth

Table 2. Motor supply connector, MU2

Service support: find your nearest Vacon service center at www.vacon.com

1

Page 8

vacon • 5 BH Application

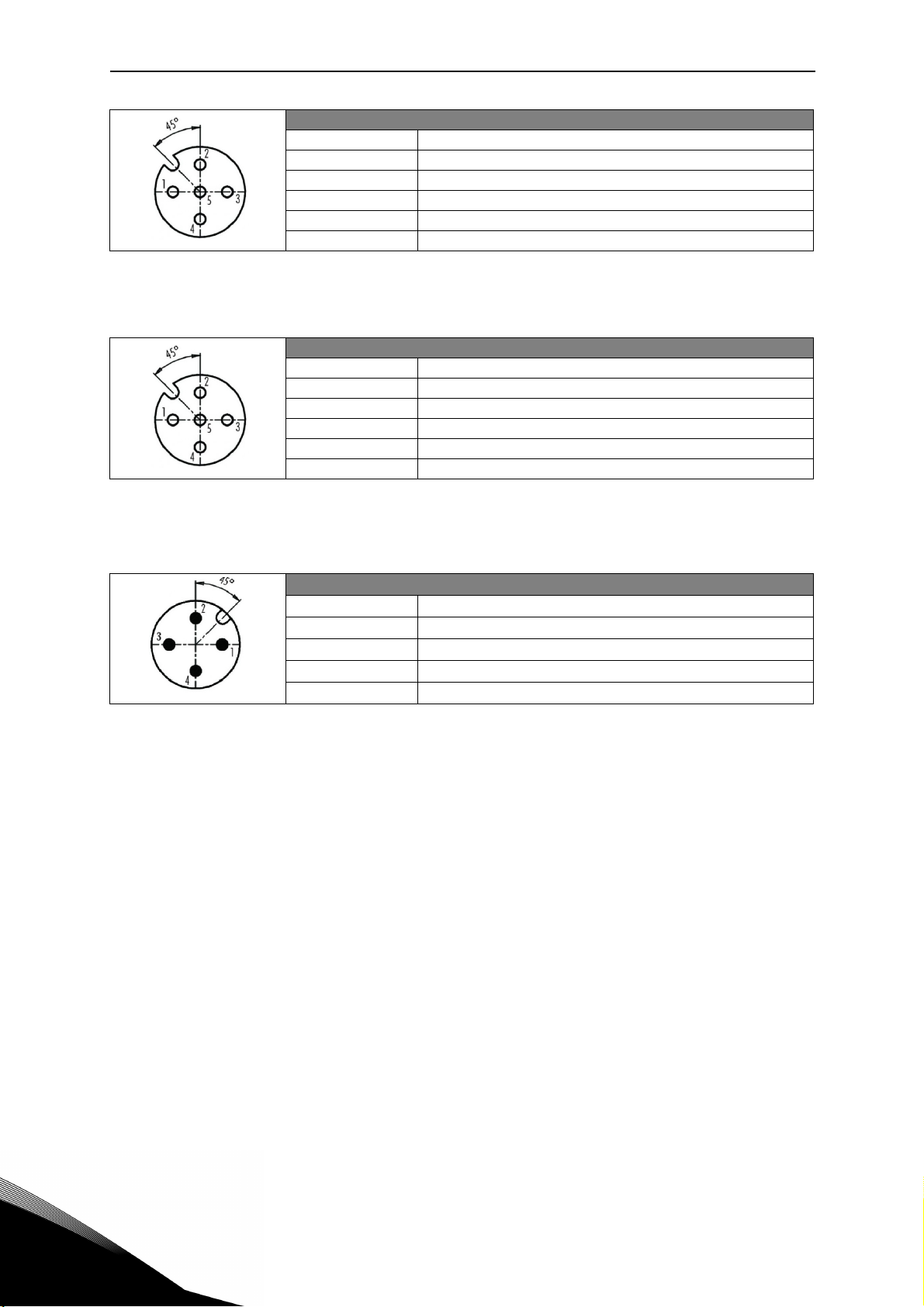

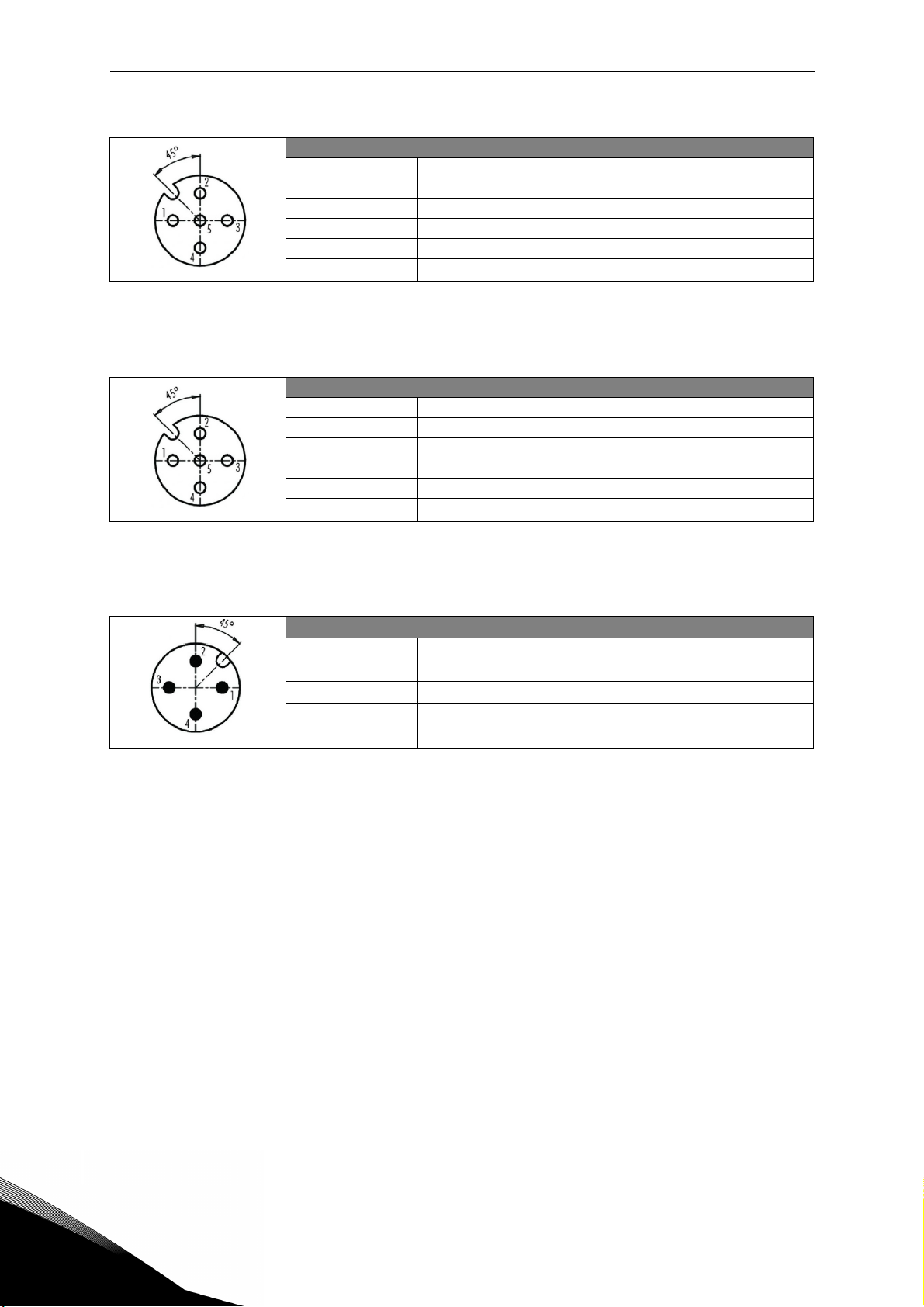

X1 Digital Input / Type M12 A-Coding – 5 pole (Female)

Pin Function

1 +24V (25mA max.)

2D input 1

3GND

4D input 2

5Functional Earth

Table 3. X1 connector, MU2.

X2 Digital Input / Type M12 A-Coding – 5 pole (Female)

Pin Function

1 +24V (25mA max.)

2D input 3

3GND

4D input 4

5Functional Earth

Table 4. X2 connector, MU2.

X3 ASi connections / Type M12 A-Coding – 4 pole (Male)

Pin Function

1ASi +

20V

3ASi 4 +24V

Table 5. AS-interface connector, MU2.

1

Page 9

BH Application vacon • 6

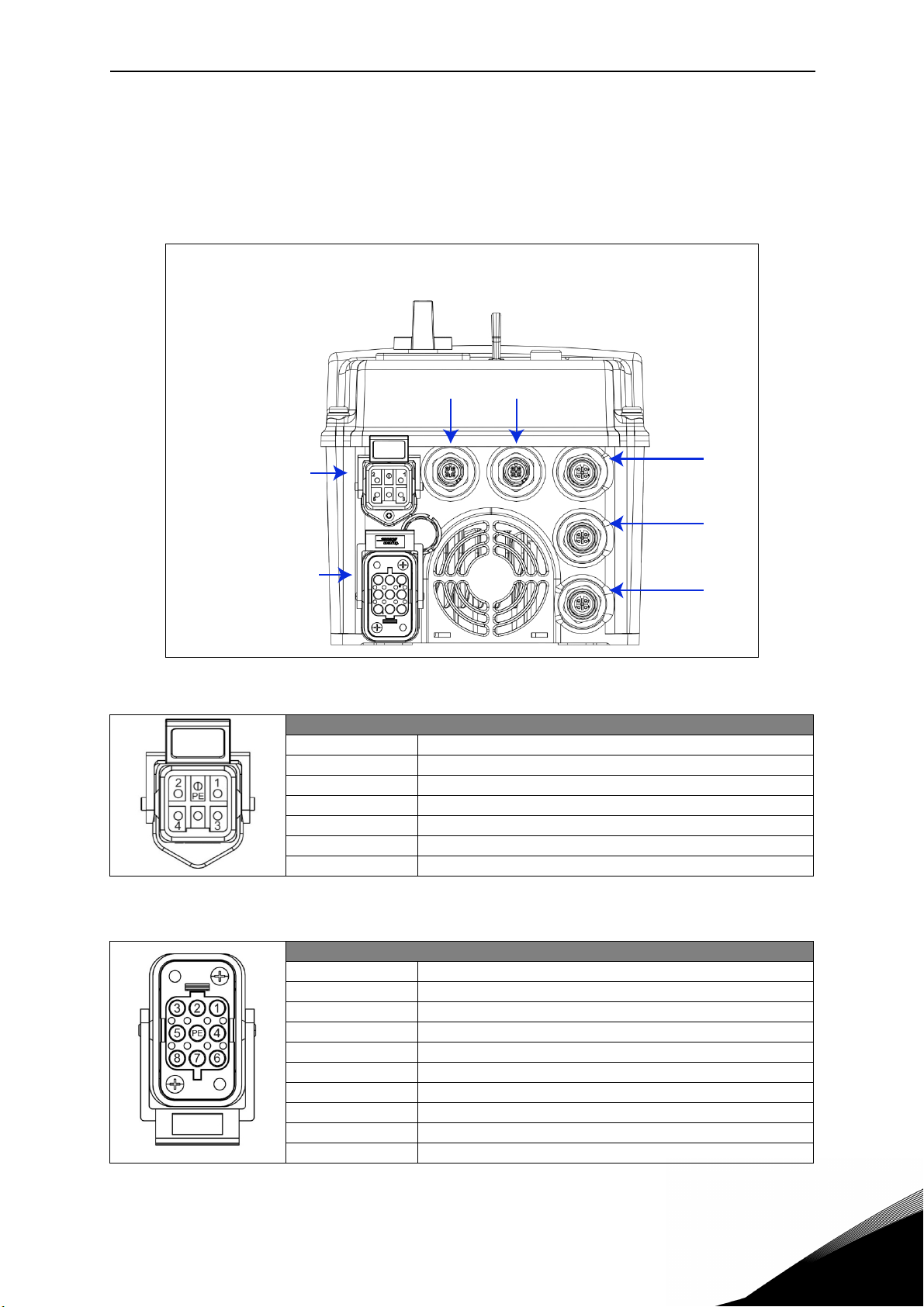

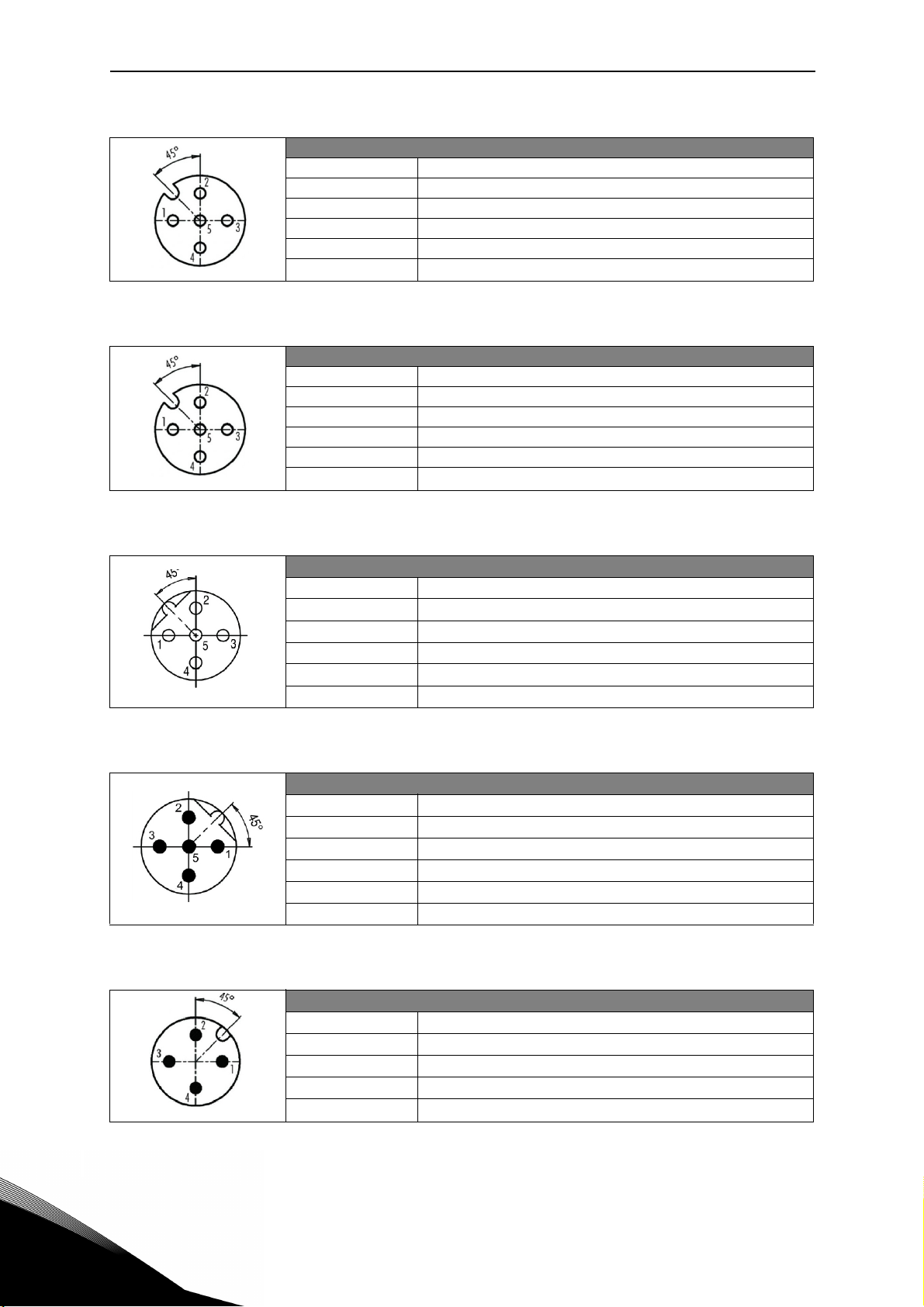

1.3.2 MU3 connections

X4X5

Mains supply

Motor output

Figure 2. Power and control terminals in MU3.

X3

X2

X1

Mains supply / Type HAN Q4/2 (Male)

Pin Function

1L1

2L2

3L3

411 12 -

PE Protective Earth

Table 6. Mains supply connector, MU3.

Motor output / Type HAN Q8 (Female)

Pin Function

1U

2 Not connected

3W

4Brake (-)

5Temperature sensor (+)

6Brake (+)

7V

8Temperature sensor (-)

PE Protective Earth

Table 7. Motor supply connector, MU3.

Service support: find your nearest Vacon service center at www.vacon.com

1

Page 10

vacon • 7 BH Application

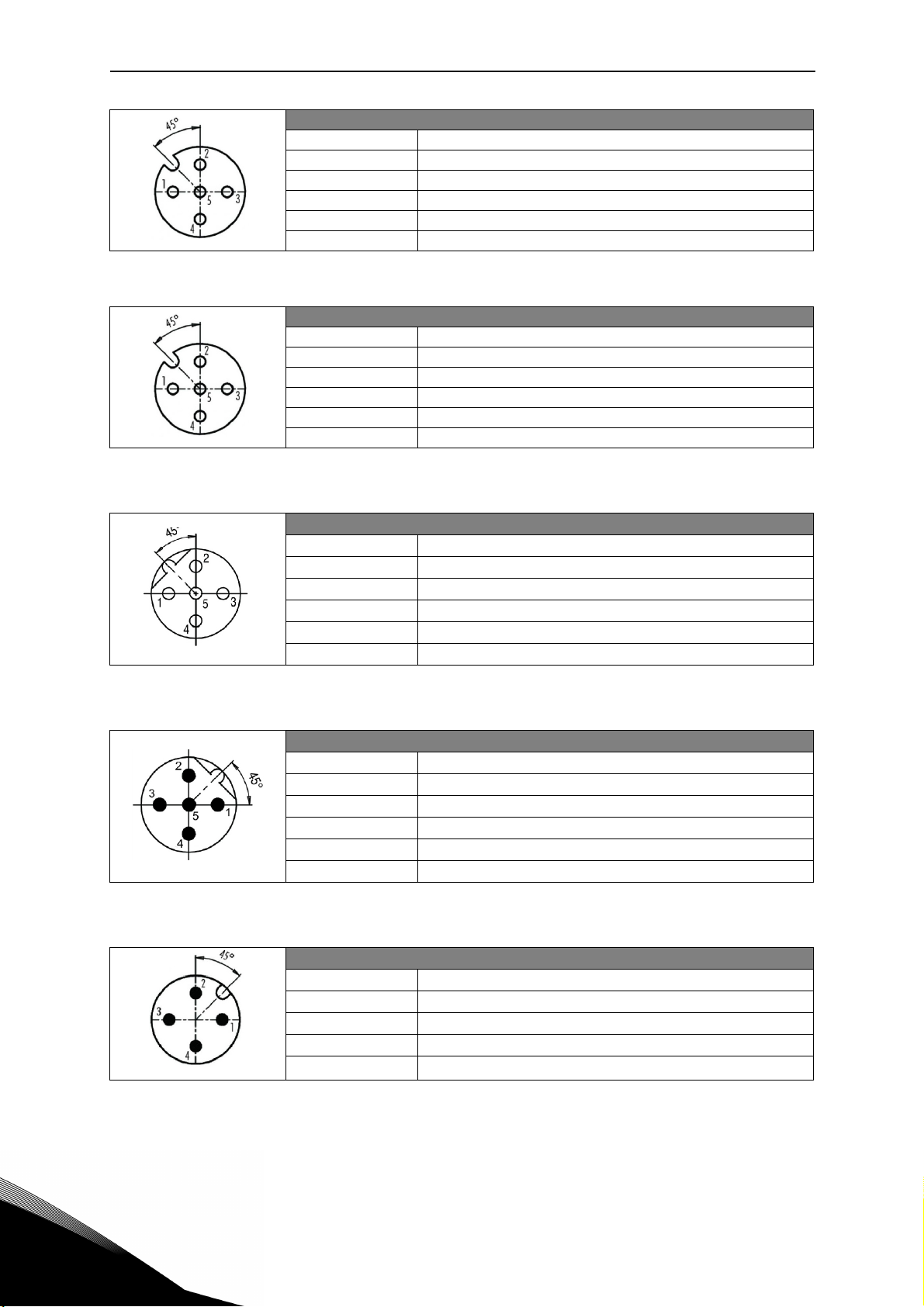

X1 Digital Input / Type M12 A-Coding – 5 pole (Female)

Pin Function

1 +24V (25mA max.)

2D input 1

3GND

4D input 2

5Functional Earth

Table 8. X1 connector, MU3.

X2 Digital Input / Type M12 A-Coding – 5 pole (Female)

Pin Function

1 +24V (25mA max.)

2D input 3

3GND

4D input 4

5Functional Earth

Table 9. X2 connector, MU3.

X3 ASi connections / Type M12 A-Coding – 4 pole (Male)

Pin Function

1ASi +

20V

3ASi 4 +24V

Table 10. AS-interface connector, MU3.

1

Page 11

BH Application vacon • 8

t

3X2

1.4 Description of the terminals (D-option with Profibus)

The following pictures describe the power and M12 terminals in Vacon 20X drives with D-option

and Profibus connection.

1.4.1 MU2 connections

X5 X4

Mains supply

Motoroutpu

Figure 3. Power and control terminals in MU2.

Mains supply / Type HAN Q5/0 (Male)

Pin Function

1L1

2L2

3L3

45PE Protective Earth

X

X1

Table 11. Mains supply connector, MU2.

Motor output / Type HAN Q8 (Female)

Pin Function

1U

2 Not connected

3W

4Brake (-)

5Temperature sensor (+)

6Brake (+)

7V

8Temperature sensor (-)

PE Protective Earth

Table 12. Motor supply connector, MU2

Service support: find your nearest Vacon service center at www.vacon.com

1

Page 12

vacon • 9 BH Application

X1 Digital Input / Type M12 A-Coding – 5 pole (Female)

Pin Function

1 +24V (25mA max.)

2D input 1

3GND

4D input 2

5Functional Earth

Table 13. X1 connector, MU2.

X2 Digital Input / Type M12 A-Coding – 5 pole (Female)

Pin Function

1 +24V (25mA max.)

2D input 3

3GND

4D input 4

5Functional Earth

Table 14. X2 connector, MU2.

X3 Profibus / Type M12 B-Coding – 5 pole (Female)

Pin Function

12 A (green)

34B (red)

5-

Table 15. Profibus Female connector, MU2.

X4 Profibus / Type M12 B-Coding – 5 pole (Male)

Pin Function

12 A (green)

34B (red)

5-

Table 16. Profibus Male connector, MU2.

X5 Auxiliary power supply / Type M12 A-Coding – 4 pole (Male)

Pin Function

1 Power supply +24V

23Power supply GND

4-

1

Table 17. Auxiliary power supply connector, MU2.

Page 13

BH Application vacon • 10

s

s

y

2X3

1.4.2 MU3 connections

X4X5

Main

uppl

Motor output

Figure 4. Power and control terminals in MU3.

X

X1

Mains supply / Type HAN Q4/2 (Male)

Pin Function

1L1

2L2

3L3

411 12 -

PE Protective Earth

Table 18. Mains supply connector, MU3.

Motor output / Type HAN Q8 (Female)

Pin Function

1U

2 Not connected

3W

4Brake (-)

5Temperature sensor (+)

6Brake (+)

7V

8Temperature sensor (-)

PE Protective Earth

Table 19. Motor supply connector, MU3.

Service support: find your nearest Vacon service center at www.vacon.com

1

Page 14

vacon • 11 BH Application

X1 Digital Input / Type M12 A-Coding – 5 pole (Female)

Pin Function

1 +24V (25mA max.)

2D input 1

3GND

4D input 2

5Functional Earth

Table 20. X1 connector, MU3.

X2 Digital Input / Type M12 A-Coding – 5 pole (Female)

Pin Function

1 +24V (25mA max.)

2D input 3

3GND

4D input 4

5Functional Earth

Table 21. X2 connector, MU3.

X3 Profibus / Type M12 B-Coding – 5 pole (Female)

Pin Function

12 A (green)

34B (red)

5-

Table 22. Profibus Female connector, MU3.

X4 Profibus / Type M12 B-Coding – 5 pole (Male)

Pin Function

12 A (green)

34B (red)

5-

Table 23. Profibus Male connector, MU3.

X5 Auxiliary power supply / Type M12 A-Coding – 4 pole (Male)

Pin Function

1 Power supply +24V

23Power supply GND

4-

1

Table 24. Auxiliary power supply connector, MU3.

Page 15

Description of Groups vacon • 12

2. DESCRIPTION OF GROUPS

2.1 Monitor group: menu MON

VACON® 20 CP/X AC drive provides you with a possibility to monitor the actual values of parameters and signals as well as statuses and measurements. Some of the values to be monitored are adjusted. See Table 25, Table 26, Table 27 and Table 28 in which the monitoring

values are presented.

2.1.1 ASi

Code Monitoring value Unit Level Description

V1.1 ASi Outputs 4, 3, 2,1 Basic State of received bits on ASi board

V1.2 ASi Inputs 4, 3, 2, 1 Basic State of transmitted bits on ASi board

0: power off

1: communication ok

V1.3 ASi board state Basic

2: no master

3: address=0

4: periphery fault

5: serious periphery fault

Table 25: ASi monitoring items.

NOTE: these values are valid only with Vacon 20 CP/X +D and AS-interface connection.

2.1.2 Sensors

Code Monitoring value Unit Level Description

V2.1 Sensors 4, 3, 2, 1 Basic State of sensors read on digital inputs

Table 26: Sensors monitoring item.

2.1.3 Motor

Code Monitoring value Unit Level Description

V3.1 Output frequency Hz Basic Output frequency to motor

V3.2 Frequency reference Hz Basic Frequency reference to motor control

V3.3 Motor speed rpm Basic Motor speed in rpm

V3.4 Motor current A Basic

V3.5 Motor torque % Advanced Calculated shaft torque

V3.6 Motor shaft power % Advanced Total power consumption of AC drive

V3.7 Motor voltage V Advanced

V3.8 Motor temperature % Advanced Calculated motor temperature

V3.9 Process variable Advanced Scaled process variable

Table 27: Motor monitoring items.

Service support: find your nearest Vacon service center at www.vacon.com

2

Page 16

vacon • 13 Description of Groups

2.1.4 Drive

Code Monitoring value Unit Level Description

V4.1 DC link voltage V Advanced

V4.2 Unit temperature °C Advanced Heatsink temperature

V4.3 Board temperature °C Service Power board temperature

V4.4

V4.5

V4.6 Analogue input 1 % Service Analogue input AI1

V4.7 Analogue input 2 % Service Analogue input AI2

V4.8 DI3, DI2, DI1 Service Digital inputs status

V4.9 DI6, DI5, DI4 Service Digital inputs status

V4.10 DO, RO2, RO1 Service Digital outputs status

V4.11 Analogue output % Service Analogue output

Actual output

frequency

Droop frequency

reference

Hz Service

Hz Service

Output frequency inclusive slip compensation

Frequency setpoint inclusive droop

correction

Table 28: Drive monitoring items.

2

Page 17

Description of Groups vacon • 14

2.2 Parameter Groups: Menu PAR

The Decentralized Application embodies the following parameter groups:

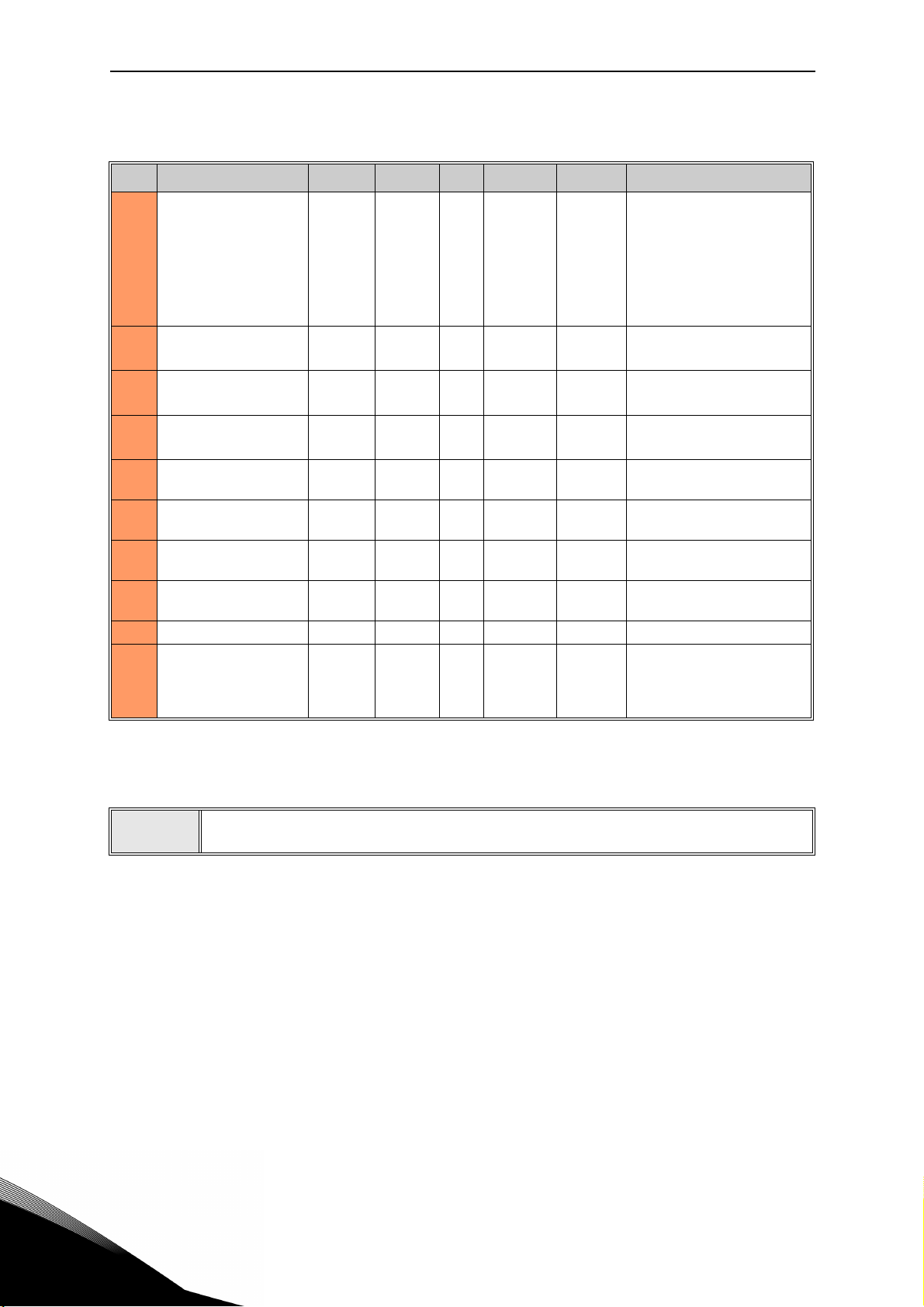

Menu and Parameter group Description

Group Motor settings: Menu PAR G1 Motor settings

Group Start/Stop Settings: Menu PAR G2 Start/Stop and mode settings

Group References: Menu PAR G3 Frequency reference selection

Group Ramps: Menu PAR G4 Ramp times

Group Input functions: Menu PAR G5 Digital input programming

Group Output functions: Menu PAR G6 ASi and digital output programming

Group Mechanical brake: Menu PAR G7 Mechanical brake programming

Group Supervisions: Menu PAR G8 Supervision programming

Group Motor Control: Menu PAR G9 Motor control and U/f parameters

Group Protections: Menu PAR G10 Protections configuration

Group Automatic reset: Menu PAR G11 Auto reset after fault configuration

Group Non-ASi fieldbus: Menu PAR G12 Non-ASi Fieldbus data out parameters

Group Analogue output: Menu Par G13 Analogue output programming

Group User interface: Menu Par G14 User interface parameters

Table 29: Parameter groups

Column explanations:

Code = Location indication on the keypad; Shows the operator the parameter num-

ber.

Parameter= Name of parameter

Min = Minimum value of parameter

Max = Maximum value of parameter

Unit = Unit of parameter value; Given if available

Default = Value preset by factory

ID = ID number of the parameter

Description= Short description of parameter values or its function

= The parameter may be changed only in Stop state

Service support: find your nearest Vacon service center at www.vacon.com

2

Page 18

vacon • 15 Description of Groups

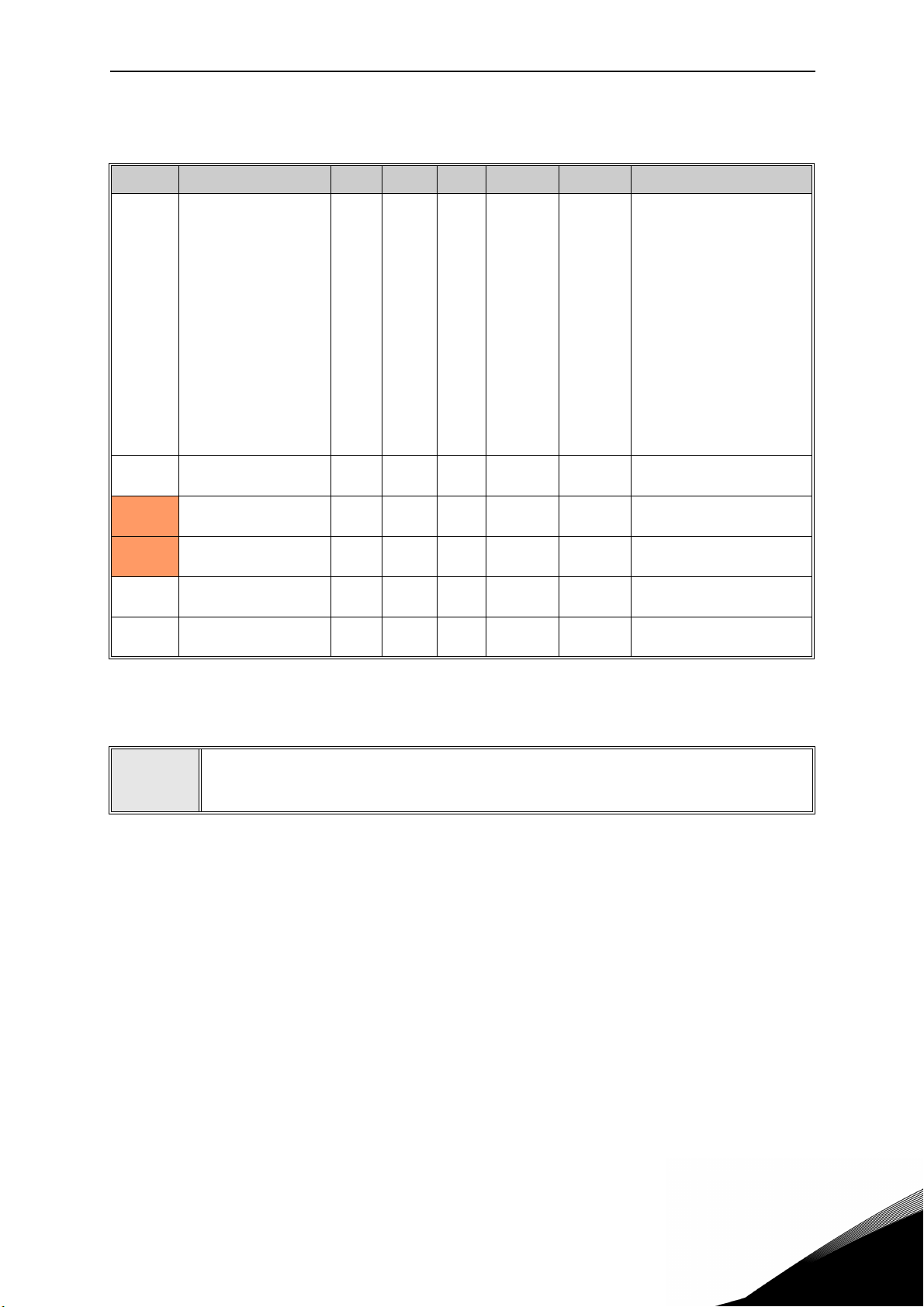

2.2.1 Group Motor settings: Menu PAR G1

Code Parameter Min Max Unit Default Level Description

Find this value U

rating plate of the motor.

This parameter sets the

P1.1 Motor nominal voltage 120 500 V 400 Basic

P1.2

P1.3 Motor nominal speed 80 20000 rpm 1440 Basic

P1.4 Motor nominal current

P1.5 Motor Cos Phi 0.30 1.00 0.85 Basic

P1.6

P1.7 U/f optimization 0 1 1 Basic

P1.8 Motor control mode 0 1 0 Advanced

P1.9 Load drooping 0.00 20.00 % 0.00 Advanced Speed loss at 100% load

P1.10 Motor Identification 0 1 0 Basic

Motor nominal

frequency

Motor current limit

8.00 320.00 Hz 50.00 Basic

0.2 x I

0.2 x I

2 x I

H

2 x I

H

A

H

A

H

I

H

1.5 x I

Basic

Basic

H

voltage at the field weakening point to 100% * U

Note also used connection

(Delta/Star).

Find this value f

ing plate of the motor.

Find this value nn on the rating plate of the motor.

Find this value In on the rating plate of the motor.

Find this value on the rating

plate of the motor

Maximum motor current

from AC drive

0 = Not active

1 = Auto torque boost

0 = Frequency control

1 = Speed control

0 = not active

1 = standstill identification

(to activate, RUN command

within 20s)

on the

n

nMotor

on the rat-

n

.

NOTE!

Table 30: Group Motor settings.

P1.6 is automatically set equal to 150% of motor nominal current when P1.4 is

modified

2

Page 19

Description of Groups vacon • 16

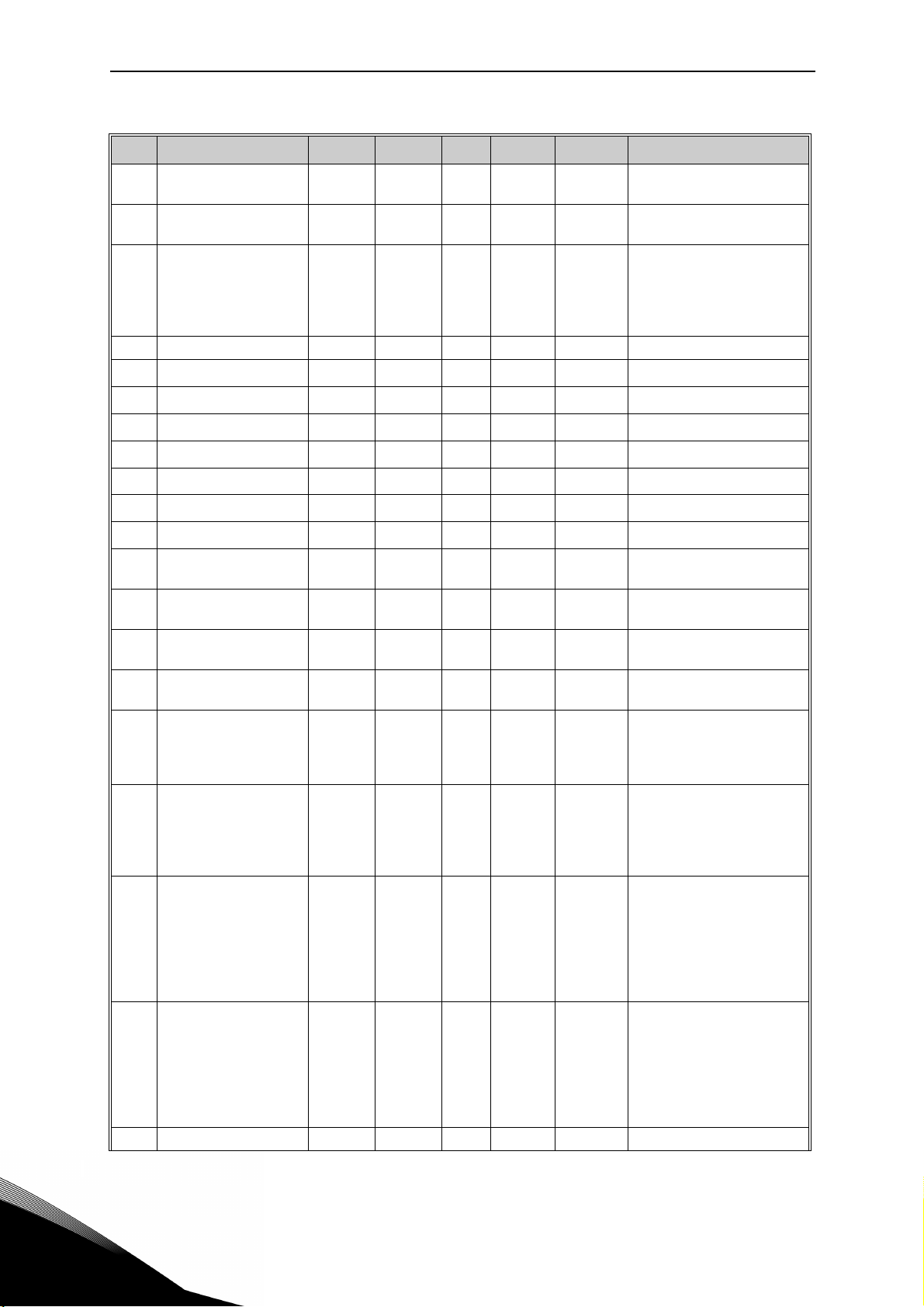

2.2.2 Group Start/Stop Settings: Menu PAR G2

Code Parameter Min Max Unit Default Level Description

Logic = 0:

Start sgn 1 = Start Forward

Start sgn 2 = Start Backward

Logic =1:

Start sgn 1 = Start Forward

P2.1

P2.2

P2.3 Start function 0 1 0 Advanced

P2.4 Stop function 0 1 0 Advanced

P2.5 Quick Stop Function 0 1 0 Basic

P2.6 Manual Start mode 0 1 1 Advanced

AUTO

Start/Stop logic

AUTO

Run control

03 0 Basic

01* 1Advanced

(edge)

Start sgn 2 = Start Backward (edge)

Logic = 2:

Start sgn 1 = Start

Start sgn 2 = Reverse

Logic = 3:

Start sgn 1 = Start (edge)

Start sgn 2 = Reverse

0= Start 1-Start 2 signals

1= non-ASi fieldbus

0=Ramping

1=Flying start

0=Coasting

1=Ramping

0=Signal level

1=Signal edge

0=Signal level

1=Signal edge

NOTE!

Table 31: Group Start/Stop settings.

(*)Selection 1 is available only if ASi board is not installed. In this case a different

fieldbus can be used to control the drive. When ASi board is installed this parameter is automatically set to 0.

Service support: find your nearest Vacon service center at www.vacon.com

2

Page 20

vacon • 17 Description of Groups

2.2.3 Group References: Menu PAR G3

Code Parameter Min Max Unit Default Level Description

P3.1 Minimum frequency 0.00 P3.2 Hz 0.00 Basic

P3.2 Maximum frequency P3.1 320.00 Hz 50.00 Basic

AUTO

P3.3

P3.4 Preset frequency 0 P3.1 P3.2 Hz 50.00 Basic Multistep speed 0

P3.5 Preset frequency 1 P3.1 P3.2 Hz 10.00 Basic

P3.6 Preset frequency 2 P3.1 P3.2 Hz 15.00 Basic

P3.7 Preset frequency 3 P3.1 P3.2 Hz 20.00 Basic

P3.8 Preset frequency 4 P3.1 P3.2 Hz 25.00 Advanced

P3.9 Preset frequency 5 P3.1 P3.2 Hz 30.00 Advanced

P3.10 Preset frequency 6 P3.1 P3.2 Hz 40.00 Advanced

P3.11 Preset frequency 7 P3.1 P3.2 Hz 50.00 Advanced

P3.12

P3.13

P3.14

P3.15

P3.16

P3.17

P3.18

P3.19

P3.20 Manual Preset speed 0.00 P3.2 Hz 50.00 Basic

Frequency reference

selection

Motor potentiometer

Mode

Motor potentiometer

Step Up

Motor potentiometer

Step Down

Motor pote ntiometer in

Reverse

Motor potentiometer

Ramp time

Motor potentiometer

Copy ref.

Motor potentiometer

Reset

MANUAL

Reference selection

0

01 0Advanced

0.01 50.00 Hz 5.00 Basic

0.01 50.00 Hz 5.00 Basic

01 0Basic

150Hz/s5Advanced

01 0Advanced

02 0Basic

02

1)

2

2Basic

3)

1

Advanced

Minimum allowed frequency reference

Maximum allowed frequency reference

Selection of AUTO reference

source:

0 = Preset frequency 0

1 = Motor potentiometer

2 = Non-ASi fieldbus

Multistep speed 1

Multistep speed 2

Multistep speed 3

Multistep speed 4

Multistep speed 5

Multistep speed 6

Multistep speed 7

0: Step up/down

1: Continuous

At any edge of increase signal

At any edge of decrease signal

0: Forward

1: Reverse

Rate of change in the motor

potentiometer reference

when increased or

decreased.

In case MotPot is alternated

with Preset.

0: Keep memory of previous

MotPot Ref

1: Start from actual Ref

Motor potentiometer frequency reference reset

logic.

0 = No reset

1 = Reset if stopped or powered down

2 = Reset if powered down

Selection of MANUAL reference source:

0 = Manual Preset speed

1 = Panel potentiometer

2 = Manual Preset speed +

Panel Potentiometer Correction

2)

2)

2)

2)

2)

2)

2)

2

Table 32: Group References.

Page 21

Description of Groups vacon • 18

P3.21

P3.22

P3.23

P3.24

NOTE!

Panel Potentiometer

Min. Frequency

Panel Potentiometer

Max. Frequency

Panel Potentiometer

Min. Correction

Panel Potentiometer

Max. Correction

0.00 P3.21 Hz 0.0 Advanced

P3.20 P3.2 Hz 50.00 Advanced

-100.00 0.00 % -10.00 Advanced

0.00 100.00 % 10.00 Advanced

Minimum freq. reference

from potentiometer

Maximum freq.reference

from potentiometer

Ref adjust at minimum

potentiometer signal

Ref adjust at maximum

potentiometer signal

Table 32: Group References.

1)

Selection 2 is available only if ASi board is not installed. In this case a different

fieldbus can be used to control the reference.When ASi board is installed this

parameter is automatically set to 0.

2)

In AUTO mode, preset speed 1-8 can be directly activated by ASi outputs or

Sensors signals, independently from P3.3 setting.

If P3.3 = 1 and the reference is restored to motor potentiometer, after a preset

speed, P3.17 defines the initial value for the reference.

3)

When ASi board is installed this parameter is automatically set to 0.

Service support: find your nearest Vacon service center at www.vacon.com

2

Page 22

vacon • 19 Description of Groups

2.2.4 Group Ramps: Menu PAR G4

Code Parameter Min Max Unit Default Level Description

Defines the time required

for the output frequency to

P4.1 Acceleration time 1 0.1 3000.0 s 3.0 Basic

P4.2 Deceleration time 1 0.1 3000.0 s 3.0 Basic

P4.3 Ramp 1 shape 0.0 10.0 s 0.0 Basic Rounded speed profile.

P4.4 Acceleration time 2 0.1 3000.0 s 10.0 Advanced

P4.5 Deceleration time 2 0.1 3000.0 s 10.0 Advanced

P4.6 Ramp 2 shape 0.0 10.0 s 0.0 Advanced Rounded speed profile.

P4.7

P4.8

P4.9

Acceleration time 2

freq. threshold

Deceleration time 2

freq. threshold

Quick Stop dec.

time

0.00 P3.2 Hz 0.00 Advanced

0.00 P3.2 Hz 0.00 Advanced

0.1 3000.0 s 1.0 Basic

increase from zero frequency to maximum frequency

Defines the time required

for the output frequency to

decrease from maximum

frequency to zero frequency

Time from 0 to max frequency

Time from 0 to max frequency

Threshold for auto change

from acc1 to acc2

Threshold for auto change

from dec2 to dec1

Time from max frequency

to 0

Table 33: Group Ramps.

2

Page 23

Description of Groups vacon • 20

2.2.5 Group Input functions: Menu PAR G5

Code Parameter Min Max Unit Default Level Description

Start signal 1 when control

place is I/O 1 (FWD)

See P2.1 for function.

0 = not used

1 = ASi Output 1

P5.1 Start signal 1 0 8 1 Basic

P5.2 Start signal 2 0 8 2 Basic

P5.3

P5.4

P5.5

P5.6 Fault reset 0 4 Basic Resets all active faults

P5.7 Force brake 0 8 0 Basic Forces brake open

P5.8 External fault open 0 8 0 Advanced

P5.9 External fault close 0 8 0 Advanced

P5.10 Run enable 0 8 0 Advanced

P5.11

P5.12

P5.13

P5.14 Quick Stop open 0 8 0 Basic

P5.15 Quick Stop open 0 8 0 Basic

Preset frequency

selection 0

Preset frequency

selection 1

Preset frequency

selection 2

Acc/dec ramp

selection

Motor potentiometer

UP

Motor potentiometer

DOWN

08 3Basic

08 0Basic

08 0Advanced

08 0Advanced

08 0Basic

08 0Basic

2 = ASi Output 1

3 = ASi Output 1

4 = ASi Output 1

5 = Sensor 1

6 = Sensor 2

7 = Sensor 3

8 = Sensor 4

Start signal 2 when control

place is I/O 1 (REV).

See P2.1 for function.

See P5.1 for selections.

Binary selector for Preset

speeds (0-7).

Binary selector for Preset

speeds (0-7).

Binary selector for Preset

speeds (0-7).

Fault is signal low

See P5.1 for selections

Fault if signal high

See P5.1 for selections

Must be on to set drive in

Ready state

Activates ramp 2

See P5.1 for selections

Reference increase

See P5.1 for selections

Reference decrease

See P5.1 for selections

If configured, low signal activates stop with specific ramp.

See P5.1 for selections.

If configured, high signal

activates stop with specific

ramp.

See P5.1 for selections.

Table 34: Group Input functions.

Service support: find your nearest Vacon service center at www.vacon.com

2

Page 24

vacon • 21 Description of Groups

2.2.6 Group Output functions: Menu PAR G6

Code Parameter Min Max Unit Default Level Description

Bit0 transmitted on ASi bus

0: not used

1: Sensor 1

2: Sensor 2

3: Sensor 3

4: Sensor 4

5: Ready + Auto

6: Run

7: Fault

P6.1 ASi Input 1 0 17 5 Basic

P6.2 ASi Input 2 0 17 13 Basic

P6.3 ASi Input 3 0 17 2 Basic

P6.4 ASi Input 4 0 17 4 Basic

P6.5

P6.6

P6.7 RO1 ON delay 0.00 320.00 s 0.00 Service ON delay for relay

P6.8 RO1 OFF delay 0.00 320.00 s 0.00 Service OFF delay for relay

P6.9 RO1 inversion 0 1 0 Service

P6.10 RO2 ON delay 0.00 320.00 s 0.00 Service See P6.7

P6.11 RO2 OFF delay 0.00 320.00 s 0.00 Service See P6.8

RO1 function

RO2 function

2)

2)

013 0Service

0 13 0 Service See P6.5

8: Fault or warning

9: Reverse

10: Running feedback

11: Automatic mode

12: At speed (internal)

13: Output freq superv

14: Output current superv

15: Brake command

16: Quick stop

17: Ready

Bit1 transmitted on ASi bus.

See P6.1 for selections

Bit2 transmitted on ASi bus.

See P6.1 for selections

Bit2 transmitted on ASi bus.

See P6.1 for selections

Function selection for RO1:

0 = Not used

1 = Ready

2 = Run

3 = General fault

4 = General fault inverted

5 = Warning

6 = Reversed

7 = At speed

8 = Output freq. supervision

9 = Output current superv.

10 = ASi Output 1

11 = ASi Output 2

12 = ASi Output 3

13 = ASi Output 4

0 = no inversion

1 = inverted

1)

2

Table 35: Group Output Functions.

Page 25

Description of Groups vacon • 22

Automatic Run Out Freq >= Setpoint Feedback

0 - - 0

1 0 - 1

1 1 0 0

1 1 1 1

1)

when Automatic mode is not assigned to any Input, Running Feedback includes

also information about Automatic.

NOTE!

2)

relay terminals are not accessible in standard V20X+D drive

2.2.7 Group Mechanical brake: Menu PAR G7

Code Parameter Min Max Unit Default Level Description

P7.1

P7.2 Brake open current 0.00 100.0 % 0.0 Advanced

P7.3 Brake close frequency 0.00 10.00 Hz 1.00 Advanced

P6.4 Brake close delay 0.00 10.00 s 0.00 Advanced

Brake open frequency

1)

0.00 10.00 Hz 0.00 Advanced

Frequency threshold for brake

open

Current threshold for brake

open

Frequency threshold for brake

close (Start = 0)

Respected in any condition

(fault, no enable), apart direct

control from Asi input.

NOTE!

Table 36: Group Mechanical brake.

1)

note: if P7.1 > 0Hz, frequency reference is internally limited to P7.1 + 0.1 Hz

until the brake is released. If the thresholds in P7.1 and P7.2 are not reached

within 3s from Start command Fault 56 “Brake Time Out” is triggered.

Service support: find your nearest Vacon service center at www.vacon.com

2

Page 26

vacon • 23 Description of Groups

2.2.8 Group Supervisions: Menu PAR G8

Code Parameter Min Max Unit Default Level Description

P8.1

P8.2

P8.3

P8.4

P8.5

P8.6

P8.7

Running Ok speed

tolerance

Output frequency

supervision

Frequency supervision

limit

Current supervision

limit

Process display source

selection

Process display

decimal digits

Process display max

value

0.0 100.0 % 90.0 Advanced

0 = not used

02 2Advanced

0.00 P3.2 Hz 35.00 Advanced

0.00

04 1Advanced

0 3 1 Advanced Decimals on display

0.0 3276.7 100.0 Advanced

2 x I

A0.00Advanced

H

1 = Low limit

2 = High limit

Output frequency supervision

threshold

Current supervision threshold

Selection of variable proportional to process:

0 = Output frequency

1 = Motor speed

2 = Motor torque

3 = Motor power

4 = Motor current

Process display max value (it

depends on P7.11: with zero

decimal digit the max value

is 32767; with 1 decimal digit

the max value is 3276.7)

Table 37: Group supervisions.

2

Page 27

Description of Groups vacon • 24

2.2.9 Group Motor Control: Menu PAR G9

Code Parameter Min Max Unit Default Level Description

P9.1

P9.2

P9.3 U/f ratio selection(*) 0 2 0 Advanced

P9.4

P9.5 U/f midpoint voltage(*) 0.00 P9.3 % 100.00 Advanced

P9.6

P9.7 RS voltage drop(*) 0.00 100.00 % 0.00 Advanced

P9.8 Switching frequency 1.5 16.0 kHz 4.0 Advanced

P9.9 Drooping Mode 0 1 1 Advanced

P9.10 Droop filter time 0.00 3.00 s 0.10 Advanced

P9.11 Brake chopper 0 2 0 Advanced

P9.12 Brake chopper level 600 900 V 650 Advanced

P9.13 DC brake current

P9.14

P9.15

P9.16

P9.17

P9.18

P9.19

Field Weakening Point

frequency

Field Weakening Point

voltage

U/f midpoint

frequency(*)

Zero frequency

voltage(*)

DC braking time at

stop

Frequency to stop DC

braking at ramp stop

DC braking time at

start

Overvoltage

controller

Undervoltage

controller

Switching frequency

controller

8.00 320.00 Hz 50.00 Advanced

10.00 200.00 % 100.00 Advanced

0.00 P9.2 Hz 50.00 Advanced

0.00 40.00 % 0.00 Advanced

0.3 x I

0.00 600.00 s 0.00 Basic

0.10 10.00 Hz 1.50 Basic

0.00 600.00 s 0.00 Basic

01 0Service

01 0Service

01 0Service

2 x I

H

A

H

I

H

Basic

Field weakening point frequency

Voltage at FWP as % of Motor

nominal voltage

0 = linear

1 = quadratic

2 = programmable

Midpoint frequency for programmable U/f curve

Midpoint voltage for programmable U/f curve

Voltage at 0,00 Hz as % of

Motor nominal voltage

Voltage drop on the motor

windings as % of Motor nominal voltage

Increasing the switching frequency reduces the capacity

of the drive.

0: constant

1: speed dependent

Constant time of filter on

droop calculation

0 = Disabled

1 = Enabled in RUN

2 = Enabled in READY

DC-link voltage to start chopper.

Defines the current injected

into the motor during DCbraking. 0 = Disabled

Determines if braking is ON

or OFF and the braking time

of the DC-brake when the

motor is stopping.

The output frequency at

which the DC-braking is

applied.

Determines the braking time

of the DC-brake when the

motor is starting.

0 = Enabled

1 = Disabled

0 = Enabled

1 = Disabled

0 = Enabled

1 = Disabled

Table 38: Group Motor control.

NOTE!

Service support: find your nearest Vacon service center at www.vacon.com

(*) Parameter is automatically set by motor identification.

2

Page 28

vacon • 25 Description of Groups

2.2.10 Group Protections: Menu PAR G10

Parameters of Motor thermal protection (P10.9 to P10.12 and P10.18-P10.19)

The motor thermal protection is to protect the motor from overheating. The drive is capable of

supplying higher than nominal current to the motor. If the load requires this high current there

is a risk that the motor will be thermally overloaded. This is the case especially at low frequencies. At low frequencies the cooling effect of the motor is reduced as well as its capacity. If the

motor is equipped with an external fan the load reduction at low speeds is small.

The motor thermal protection is based on a calculated model and it uses the output current of

the drive to determine the load on the motor.

The motor thermal protection can be adjusted with parameters. The thermal current I

fies the load current above which the motor is overloaded. This current limit is a function of the

output frequency.

The thermal stage of the motor can be monitored on the control keypad display. See chapter 1.

If you use long motor cables (max. 100m) together with small drives (1.5 kW) the

motor current measured by the drive can be much higher than the actual motor

current due to capacitive currents in the motor cable. Consider this when setting up

the motor thermal protection functions.

The calculated model does not protect the motor if the airflow to the motor is

reduced by blocked air intake grill. The model starts from zero if the control board is

powered off.

Parameters of Stall protection (P10.2 to P10.4)

The motor stall protection protects the motor from short time overload situations such as one

caused by a stalled shaft. The reaction time of the stall protection can be set shorter than that

of motor thermal protection. The stall state is defined with two parameters, P10.3 (

and P10.4 (

current limiter has reduced the output frequency below the P10.4 for the time P10.3 than the

set limit the stall state is true. There is actually no real indication of the shaft rotation. Stall

protection is a type of overcurrent protection.

Stall frequency limit). If the current is as high as the P1.6 (Current Limit) and the

speci-

T

Stall time)

2

If you use long motor cables (max. 100m) together with small drives (1.5 kW) the

motor current measured by the drive can be much higher than the actual motor

current due to capacitive currents in the motor cable. Consider this when setting up

the motor thermal protection functions.

Parameters of Underload protection (P10.5 to P10.8)

The purpose of the motor underload protection is to ensure that there is load on the motor

when the drive is running. If the motor loses its load there might be a problem in the process,

e.g. a broken belt or a dry pump.

Motor underload protection can be adjusted by setting the underload curve with parameters

P10.6 (Underload protection: Field weakening area load) and P10.7 (

Zero frequency load

frequency and the field weakening point. The protection is not active below 5Hz (the underload

time counter is stopped).

), see below. The underload curve is a squared curve set between the zero

Underload protection:

Page 29

Description of Groups vacon • 26

The torque values for setting the underload curve are set in percentage which refers to the

nominal torque of the motor. The motor's name plate data, parameter motor nominal current

and the drive's nominal current I

are used to find the scaling ratio for the internal torque val-

L

ue. If other than nominal motor is used with the drive, the accuracy of the torque calculation

decreases.

If you use long motor cables (max. 100m) together with small drives (1.5 kW) the

motor current measured by the drive can be much higher than the actual motor

current due to capacitive currents in the motor cable. Consider this when setting up

the motor thermal protection functions.

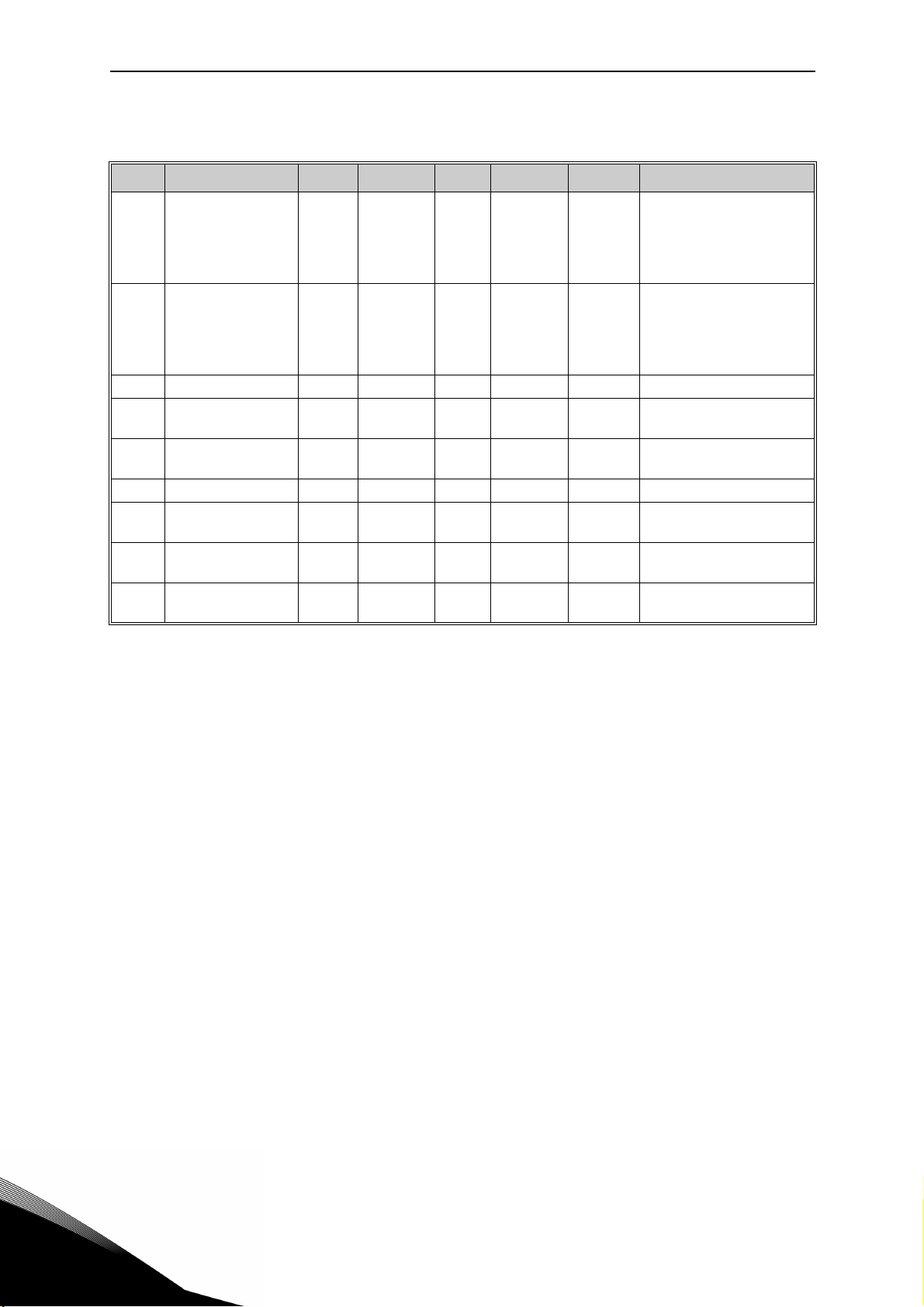

Code Parameter Min Max Unit Default Level Description

0 = No action

P10.1 Earth fault 0 2 2 Advanced

P10.2 Motor stall fault 0 2 1 Advanced See P10.1

P10.3 Stall time limit 0.0 300.0 s 5.0 Advanced

P10.4 Stall frequency limit 0.10 320.00 Hz 15.00 Advanced

P10.5 Underload fault 0 2 0 Advanced See P10.1

Underload protection:

P10.6

P10.7

P10.8

P10.9 Motor thermal fault 0 2 2 Advanced See P10.1

P10.10

P10.11

P10.12

P10.13

P10.14 Thermistor fault 0 2 0 Service See P10.1

Field weakening area

load

Underload fault:

Zero frequency load

Underload fault:

Time limit

Motor ambient

temperature factor

Motor thermal zero

speed cooling

Motor thermal time

constant

Fieldbus communica-

tion fault

10.0 150.0 % 50.0 Advanced

5.0 150.0 % 10.0 Advanced

1.0 300.0 s 20.0 Advanced

-20 100 °C 40 Advanced Ambient temperature in °C

0.0 150.0 % 40.0 Advanced

1 200 min 45 Advanced

0 2 1 Advanced See P10.1

1 = Warning

2 = Fault

This is the maximum time

allowed for a stall stage.

For a stall state to occur, the

output frequency must have

remained below this limit for

a certain time.

This parameter gives the

value for the minimum

torque allowed when the output frequency is above the

field weakening point.

This parameter gives value

for the minimum torque

allowed with zero frequency.

This is the maximum time

allowed for an underload

state to exist.

Defines the cooling factor at

zero speed in relation to the

point where the motor is running at nominal speed without external cooling.

The time constant is the time

within which the calculated

thermal stage has reached

63% of its final value.

Table 39: Group Protections.

Service support: find your nearest Vacon service center at www.vacon.com

2

Page 30

vacon • 27 Description of Groups

0 = No action

1 = Warning

P10.15

P10.16 Input phase fault 0 2 2 Service See P10.1

P10.17

P10.18

P10.19

Response to Safe

Torque Off

Input phase fault ripple

limit

Motor temperature

initialization

Motor temperature

initial value

03 1Advanced

075 0Service

02 2Service

0 100 % 33 Service

2 = Fault, not stored in history menu

3 = Fault, stored in history

menu

0 = internal value

1 = max sensitivity ->

75 = min sensitivity

0 = start from minimum

1 = start from constant value

2 = start from last value

Initial value(P10.18 = 1) or

factor for last previous

value(P10.18 = 2)

Table 39: Group Protections.

2.2.11 Group Automatic reset: Menu PAR G11

Code Parameter Min Max Unit Default Level Description

P11.1 Automatic reset 0 1 0 Basic

P11.2 Wait time 0.10 10.0 s 0.50 Advanced

P11.3 Trial time 0.00 60.0 s 30.00 Advanced

P11.4 Number of trials 1 10 3 Advanced

P11.5 Restart function 0 2 0 Advanced

0 = Disabled

1 = Enabled

Wait time before the first

reset is executed.

When the trial time has

elapsed, and the fault is still

active, the drive will trip to

fault.

NOTE: Total number of trials

(irrespective of fault type)

The start mode for Automatic

reset is selected with this

parameter:

0 = Ramp

1 = Flying start

2 = According to par. P2.3

Table 40: Group Automatic reset.

2

Page 31

Description of Groups vacon • 28

2.2.12 Group Non-ASi fieldbus: Menu PAR G12

Code Parameter Min Max Unit Default Level Description

Variable mapped on PD1:

0 = Output current

1 = Motor speed

2 = Motor current

3 = Motor voltage

4 = Motor torque

5 = Motor power

6 = DC-link voltage

7 = Active fault code

8 = Analogue AI1

9 = Analogue AI2

10 = Digital inputs state

11 = PID feedback value

12 = PID setpoint

13 = Analogue AI3

14 = Temperature 1

15 = Temperature 2

16 = Temperature 3

Variable mapped on PD2.

2)

See P12.1

Variable mapped on PD3.

2)

See P12.1

Variable mapped on PD4.

2)

See P12.1

Variable mapped on PD5.

2)

See P12.1

Variable mapped on PD6.

2)

See P12.1

Variable mapped on PD7.

2)

See P12.1

Variable mapped on PD8.

2)

See P12.1

PDI used as ASi outputs

emulator.

0 = Not used

1 = PDI1

2)

2 = PDI2

3 = PDI3

4 = PDI4

5 = PDI5

P12.1

P12.2

P12.3

P12.4

P12.5

P12.6

P12.7

P12.8

P12.9

Fieldbus Data OUT 1

selection

Fieldbus Data OUT 2

selection

Fieldbus Data OUT 3

selection

Fieldbus Data OUT 4

selection

Fieldbus Data OUT 5

selection

Fieldbus Data OUT 6

selection

Fieldbus Data OUT 7

selection

Fieldbus Data OUT 8

selection

ASi Outputs

emulation

2)

010 0

010 1

010 2

010 4

010 5

010 3

010 6

010 7

05 0

Basic /

Service2)

Basic /

Service

Basic /

Service

Basic /

Service

Basic /

Service

Basic /

Service

Basic /

Service

Basic /

Service

Basic /

Service

Table 41: Group Non-ASi fieldbus.

1)

Parameters of this group are visible at Basic level when ASi board is not

installed. They are anyway visible at Service level.

NOTE!

2

) A different fieldbus can also simulate ASi interface. Outputs and Inputs will be

mapped on Process Data.

Service support: find your nearest Vacon service center at www.vacon.com

2

Page 32

vacon • 29 Description of Groups

2.2.13 Group Analogue output: Menu Par G13

Code Parameter Min Max Unit Default Level Description

0 = Not used (fixed 100%)

1 = Freq. reference (0-fmax)

2 = Output freq. (0 -fmax)

P13.1 AO1 function 0 6 2 Service

P13.2 AO1 minimum 0 1 0 Service

P13.3 AO1 Output scale 0,0 1000,0 % 100.0 Service Scaling factor

P13.4 AO1 filter time 0.00 10.00 s 0.10 Service

3 = Motor speed (0 - Speed

max)

4 = Output current (0-I

5 = Motor torque (0-T

6 = Motor power (0-P

0 = 0V

1 = 2V

Filtering time of analogue output signal.

0 = No filtering

nMotor

nMotor

nMotor

)

)

)

Table 42: Group Analogue output.

2.2.14 Group User interface: Menu Par G14

Code Parameter Min Max Unit

P14.1 Parameters access level 0 2 0 Basic

P14.2 Parameters lock 0 1 0 Basic

Defau

lt

Table 43: Group User interface.

ID Description

0 = Basic

1 = Advanced

2 = Service

0 = Edit Enabled

1 = Edit Disabled

2

Page 33

Description of Groups vacon • 30

2.3 System parameters, Faults and History faults: Menu FLT

Code Parameter Min Max Unit

V1.1 API system SW ID 2314

V1.2 API system SW version 835

V1.3 Power SW ID 2315

V1.4 Power SW version 834

V1.5 Application ID 837

V1.6 Application revision 838

V1.7 System load 839

When no fieldbus board has been installed, the following values are visible:

V2.1 Communication status 808

P2.2 Fieldbus protocol 0 1 0 809

P2.3 Slave address 1 255 1 810

P2.4 Baud rate 0 8 5 811

P2.6 Parity type 0 2 0 813

P2.7 Communication time out 0 255 s 0 814

P2.8 Reset communication status 0 1 0 815

When OPTE6 (CANopen) option board has been installed, the following values are visible:

V2.1

P2.2 CANopen operation mode 1 2 1 14003

P2.3

CANopen communication

status

CANopen Node ID

1 127 1 14001

Defa

ult

ID Description

14004

Status of Modbus

communication.

Format: xx.yyy

where xx = 0 - 64

(Number of error

messages) yyy = 0 999 (Number of good

messages)

0 = Not used

1 = Modbus used

0 = 300

1 = 600

2 = 1200

3 = 2400

4 = 4800

5 = 9600

6 = 19200

7 = 38400

8 = 57800

0 = None

1 = Odd

2 = Even

P2.4 CANopen baud rate 1 8 6 14002

When OPTE7 (DeviceNet) option board has been installed, the following values are visible:

V2.1

P2.2 Output assembly type 20 111 21 14012

P2.3 MAC ID 0 63 63 14010

P2.4 Baud Rate 1 3 1 14011

DeviceNet communication

status

Table 44: System parameters, Faults and History faults.

Service support: find your nearest Vacon service center at www.vacon.com

14014

2

Page 34

vacon • 31 Description of Groups

P2.5 Input assembly type 70 117 71 14013

When OPTE3/E5(Profibus) option board has been installed, the following values are visible:

V2.1

P2.2 Fieldbus protocol 14023

P2.3 Active protocol 14024

P2.4 Active baud rate 14025

P2.5 Telegram type 14027

P2.6 Operate mode 1 3 1 14021

P2.7 Slave address 2 126 126 14020

V3.1 MWh counter 827

V3.2 Power on day counter 828

V3.3 Power on hour counter 829

V3.4 RUN day counter 840

V3.5 RUN hour counter 841

V3.6 Fault counter 842

V3.7

P4.2 Restore factory defaults 0 1 0 831

P4.3 Password 0 9999

P4.4 Time for keypad backlight 0 99 min 5 833

P4.5 Save parameters to Keypad 0 1 0

P4.6

F5.x Active fault menu 0 9

F6.x Fault history menu 0 9

Profibus communication sta-

tus

Panel parameter set status

monitor

Download parameters from

Keypad

14022

Other information:

000

0

01 0

Hidden when PC is connected

1 = Restore factory defaults

for all parameters

832

1= Upload all parameters to

Keypad

Hidden when PC is connected.

This function works properly

only with drive supplied.

1= Download all parameters

to Keypad

Hidden when PC is connected.

This function works properly

only with drive supplied.

2

Table 44: System parameters, Faults and History faults.

Page 35

Description of Groups vacon • 32

2.4 Keypad Reference: Menu REF

This menu is not used even if it is automatically entered when pressing the LOC/REM keypad

and shows the frequency reference in Local control mode.

The reference is also not active.

Service support: find your nearest Vacon service center at www.vacon.com

2

Page 36

vacon • 33 Description of Groups

2

Page 37

Parameter description vacon • 34

3. PARAMETER DESCRIPTION

Due to its user-friendliness and simplicity of use, the most parameters only require a basic description which is given in the parameter tables in chapter 2.2.

In this chapter, you will find additional information on certain most advanced parameters.

Should you not find the information you need contact your distributor.

3.1 Motor Settings

P1.1 MOTOR NOMINAL VOLTAGE

Value must be read on motor nameplate. Changing of the value will set the voltage at field

weakening point (P9.2) to value 100%.

P1.2 M

Value must be read on motor nameplate. Changing of the value will set the field weakening

point (P9.1) to same value.

P1.3 M

Value must be read on motor nameplate. Speed must be referred to nominal frequency and

nominal load condition (not synchronous speed).

P1.4 M

Value must be read on motor nameplate.

P1.5 M

Value must be read on motor nameplate.

P1.6 C

Maximum motor current supplied from the drive. This parameter is automatically set equal to

150% of motor nominal current, when P1.4 is modified. If a different limit is wanted, it must be

programmed after setting of P1.4.

OTOR NOMINAL FREQUENCY

OTOR NOMINAL SPEED

OTOR NOMINAL CURRENT

OTOR COS PHI

URRENT LIMIT

P1.7 U/

0: Not used

1: Automatic voltage boost (improves motor torque).

P1.8 M

0: Frequency control

1: Speed control (sensorless control)

In speed control, the motor slip is compensated.

P1.9 L

This function increases the natural slip of asynchronous motors, by decreasing the output

frequency proportionally to motor torque. Frequency is instead increased if the motor is braking. This can help the load sharing, when motors driven by different converters are mechanically coupled.

Service support: find your nearest Vacon service center at www.vacon.com

F CURVE OPTIMIZATION

OTOR CONTROL MODE

OAD DROOPING

3

Page 38

vacon • 35 Parameter description

The parameter sets the speed variation (as % of nominal speed) when the motor is at 100%

load. Normally droop action is decreased when the motor is running at low speed. Parameter

P9.9 allows to set a speed independent droop.

P1.10 M

This procedure measures motor stator resistance and automatically sets U/f characteristic, to

obtain good torque also at low speed.

0: not active

1: standstill identification

Run command must be given and hold high within 20s after programming the value 1. The motor does not rotate and the drive will automatically exit run state at the end of the measurements.

Procedure sets the following parameters: P9.3, P9.4, P9.5, P9.6, P9.7.

Also speed control (P1.8 =1) is activated.

Note: optimized U/f settings will cause motor current values comparable to nominal one, also

at very low speed. External cooling of the motor is needed if the motor works in this condition

for significant time.

OTOR IDENTIFICATION

3

Page 39

Parameter description vacon • 36

3.2 Start/Stop settings

P2.1 START/DIRECTION LOGIC

AUTO Start/Direction logic

These logics are based on Start1 and Start2 signals (defined with P5.1 and P5.2), which allow

the control of Run and direction in AUTOMATIC mode.

0 DIN1: run forward on signal level

DIN2: run backward on signal level

1 DIN1: run forward on signal rising edge

DIN2: run backward on signal rising edge

2 DIN1: run on signal level

DIN2: reverse on signal level

3 DIN1: run on signal rising edge

DIN2: reverse on signal level

For mode 0 and 1, only one signal can be high, otherwise alarm 55 is shown.

For mode 1 and 3, Run edge is acquired only if the drive is Ready, in Automatic mode and not

in Quick stop state. Run condition is then kept until the signal is high.

P2.2 AUTO R

This parameter is enabled when ASi board is not present. It defines the source for Run control.

0 Start1- Start2 signals

1 Non-ASi fieldbus

P2.3 S

0: Ramping

1: Flying start

P2.4 S

Selection

number

0Coasting

1Ramp

TOP FUNCTION

Selection name Description

UN CONTROL

TART FUNCTION

The motor is allowed to stop on its own inertia. The control

by the drive is discontinued and the drive current drops to

zero as soon as the stop command is given.

After the Stop command, the speed of the motor is decelerated according to the set deceleration parameters to zero

speed.

NOTE: this parameter is forced to 1, in case a Quick Stop signal has been configured.

NOTE: fall of Enable signal, when configured, always determines stop by coasting.

Service support: find your nearest Vacon service center at www.vacon.com

3

Page 40

vacon • 37 Parameter description

P2.5 QUICK STOP MODE

Quick stop is activated through the input signal defined in P5.14 (or P5.15).

Signal low (or high) forces the drive to stop, ramping down with the time defined in P4.9. The

ramp to zero is continued also in case the signal returns high (or low).

This parameter defines the mode Quick stop is managed.

0: Signal level

Quick stop is set when the signal is low (signal defined in P5.14) or high (signal defined in

P5.15).

It is reset when the drive has reached stop condition and the signal is restored to normal level.

How the drive in AUTO mode actually restarts the motor depend on logic set in P2.1.

If P2.1 = 1 or 3, a new rising edge on Start signal is needed.

If P2.1 = 0 or 2, the drive restarts immediately if Start signal is high.

In MANUAL mode it depends on logic set in P2.6.

If P2.6 = 0, the drive restarts immediately if Start command is still activated.

If P2.6 = 1, a new rising edge on Start command is needed.

1: Signal edge

Quick stop is set on falling edge (signal defined in P5.14) or rising edge (signal defined in P5.15)

of the signal.

It is reset when the drive has reached stop condition and the Start signal (Start command on

operator panel in MANUAL) is low, independently from the level of Quick stop signal.

Quick stop condition can be diagnosed through ASi input. It is also signalled by Alarm 63.

P2.6 M

0: Level

Once the drive is started in Manual mode, it will automatically resume Run condition after a

fault or a power loss (if ASi voltage is kept up).

It will restart also after a Quick Stop, if P2.5 = 0.

1: Edge

Once the drive is started in Manual mode, a new start is prevented after a fault, a power loss

or a Quick Stop. The previous Run command must be canceled by Stop button, to enable a new

start.

ANUAL START MODE

3

Page 41

Parameter description vacon • 38

3.3 References

P3.1 MIN FREQUENCY

Minimum frequency reference, for Automatic control. Manual control allows a different minimum.

Note: if motor current limit is reached, actual output frequency might be lower than parameter. If this is not acceptable, stall protection should be activated.

P3.2 M

AX FREQUENCY

Maximum frequency reference, for Automatic and Manual control.

P3.3 AUTO

REFERENCE SELECTION

Defines the source of main frequency reference in Automatic.

0: Preset speed 0

1: Motorpotentiometer

2: non ASi Fieldbus (only without ASi board)

Preset speed 1-8 can be directly activated by ASi outputs or sensors.

P3.4 P

RESET SPEED 0

Basic preset reference

P3.5 P

P3.6 P

P3.7 P

RESET SPEED 1

RESET SPEED 2

RESET SPEED 3

P3.8 PRESET SPEED 4

P3.9 P

P3.10 P

P3.11 P

RESET SPEED 5

RESET SPEED 6

RESET SPEED 7

Preset speeds are selected by digital signals defined in P5.3, P5.4 and P5.5 (binary code).

P3.12 M

OTOR POTENTIOMETER MODE

0: step up / down. Frequency reference is changed at any edge of Increase/Decrease signals,

of the quantity defined in P3.13 and P3.14.

1: continuous. Frequency reference is continuously changed when Increase/Decrease signals are high, with the rate defined in P3.15.

P3.13 M

OTPOT STEP UP

Service support: find your nearest Vacon service center at www.vacon.com

3

Page 42

vacon • 39 Parameter description

P3.14 MOTPOT STEP DOWN

Variation of reference at any Inc/Dec signals edge, when drive is in Run state.

Reference is anyway limited between P 3.1 and P 3.2 values.

P3.15 M

OTPOT IN REVERSE

0: same reference used in forward

1: different reference

P3.16 M

OTPOT RAMP

Rate of reference variation when Inc/Dec signals are high and drive is in Run state.

Reference is anyway limited between P 3.1 and P 3.2 values.

P3.17 M

OTPOT COPY REF

In case the reference is restored to motorpotentiometer, after a preset speed, P3.17 defines

the initial value for the reference.

0: keep memory of reference previously reached with motpot control

1: start from actual reference

P3.18 M

OTOR POTENTIOMETER MEMORY

0: No reset

1: Reset at stop or power down

2: Reset at power down

Note: memory of motopotentiometer is reset if both Inc and Dec signals are high for at least 3

seconds, when drive is in Stop state.

P3.19 MANUAL

REFERENCE SELECTION

Defines the source of frequency reference in Manual.

0: Preset speed

1: Panel potentiometer

2: Preset + Potent adjust (potentiometer adjusts preset speed)

P3.20 M

ANUAL PRESET SPEED

Basic preset reference for manual mode

P3.21 P

ANEL POTENTIOMETER MIN FREQ

P3.22 PANEL POTENTIOMETER MAX FREQ

Define the minimum and maximum reference controlled with potentiometer on panel.

3

Page 43

Parameter description vacon • 40

P4.1, P4.2

[Hz]

[t]

P4.3

P4.3

P3.23 PANEL POTENTIOMETER MIN CORRECTION

P3.24 PANEL POTENTIOMETER MAX CORRECTION

Define the minimum and maximum correction on preset reference, controlled with potentiometer on panel.

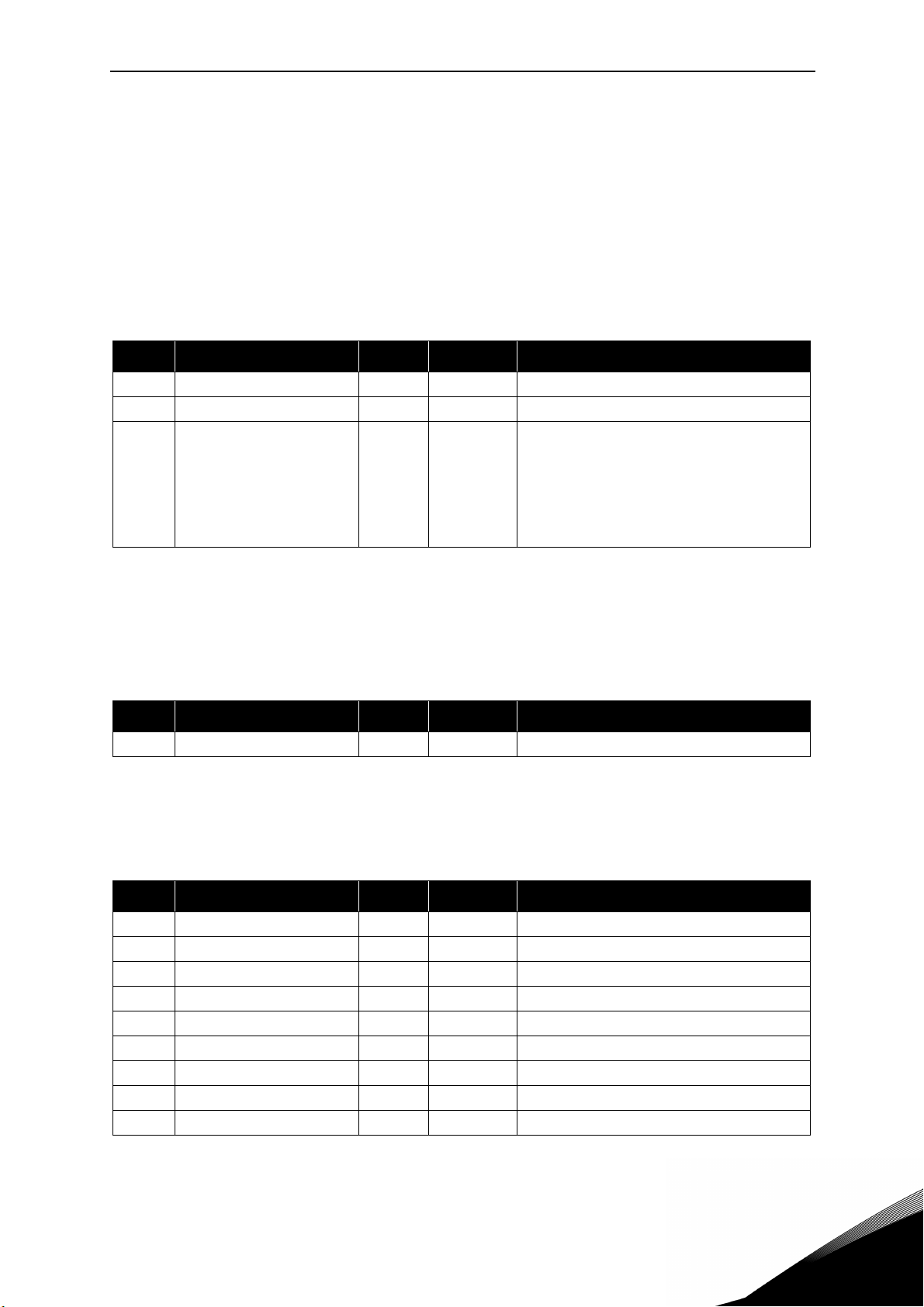

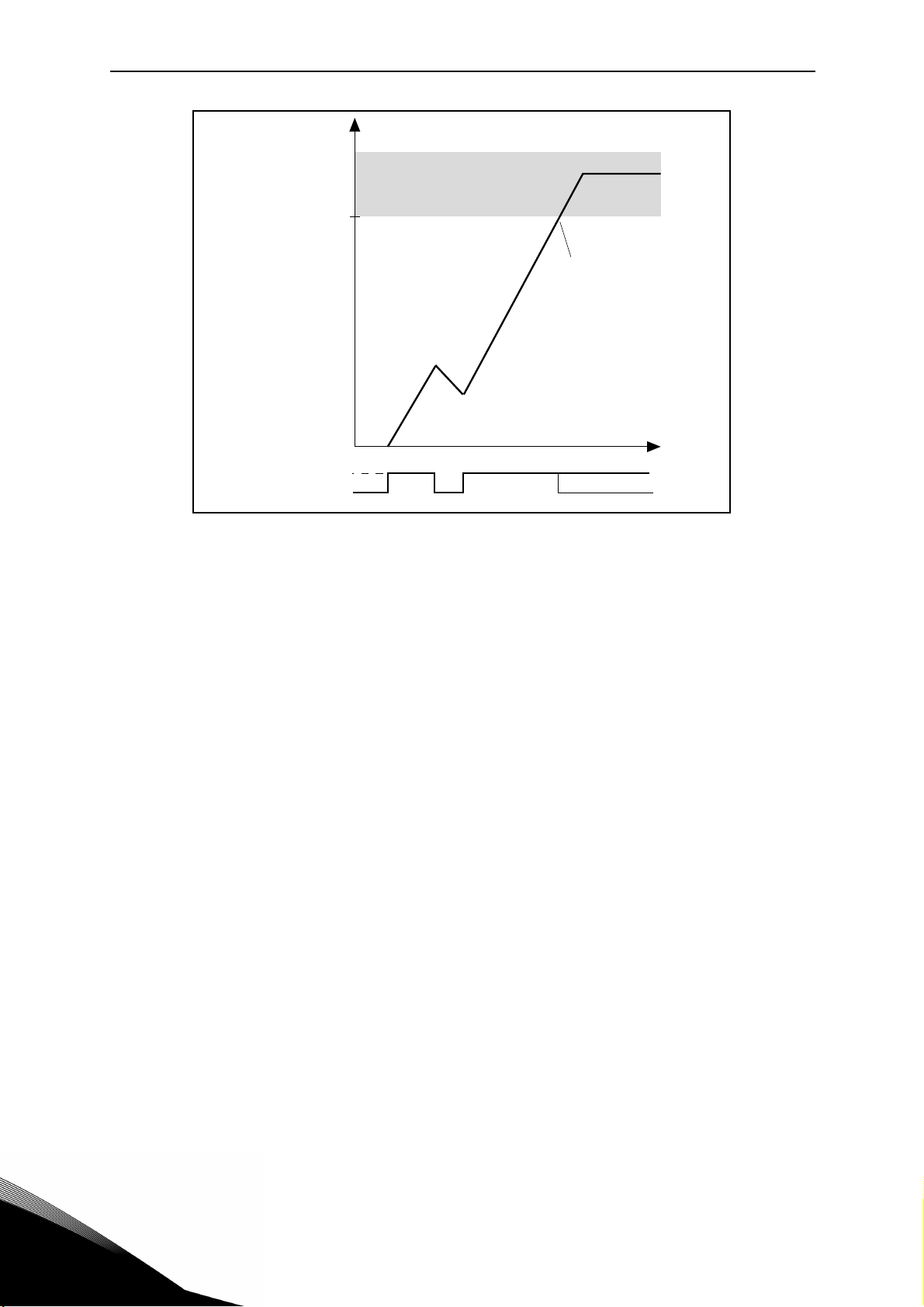

3.4 Ramps

P4.1 ACCELERATION TIME 1

Ramp time, referred to variation from zero frequency to max frequency.

P4.2 D

Ramp time, referred to variation from max frequency to zero.

P4.3 R

When value is greater than zero, acceleration and deceleration ramps have a S shape.

The parameter is the time needed to reach full acc/dec.

When value is greater than zero, acceleration and deceleration ramps have a S shape. The parameter is the time needed to reach full acc/dec.

The start and end of acceleration and deceleration ramps can be smoothed with this parameter. Setting value 0 gives a linear ramp shape which causes acceleration and deceleration to

act immediately to the changes in the reference signal.

Setting value 0.1…10 seconds for this parameter produces an S-shaped acceleration/deceleration. The acceleration time is determined with parameters P1.3 and P1.4.

ECELERATION TIME 1

AMP 1 S SHAPE

Figure 5. Acceleration/deceleration (S-shaped).

These parameters are used to reduce mechanical erosion and current spikes when the reference is changed.

Service support: find your nearest Vacon service center at www.vacon.com

3

Page 44

vacon • 41 Parameter description

P4.4 ACCELERATION TIME 2

P4.5 D

P4.6 R

Ramp 2 is available only in Automatic mode, and is activated through digital signal defined in

P5.11. Automatic activation based on output frequency is also available.

P4.7 T

P4.8 T

If P4.7 is not 0, acceleration time 2 is activated when output frequency is higher than the value.

If P4.8 is not 0, deceleration time 2 is activated when output frequency is higher than the value.

P4.9 Q

Specific ramp time for quick stop. To see description of P2.5 for details about the function.

ECELERATION TIME 2

AMP 2 S SHAPE

HRESHOLD ACCELERATION TIME 2

HRESHOLD DECELERATION TIME 2

UICK STOP DECELERATION TIME

3

Page 45

Parameter description vacon • 42

3.5 Input functions

P5.1 START SIGNAL 1

P5.2 S

TART SIGNAL 2

Signals for start and direction. Logic is selected with P2.1.

0: Function not used

1: ASi Output 1

2: ASi Output 2

3: ASi Output 3

4: ASi Output 4

5: Sensor 1

6: Sensor 2

7: Sensor 3

8: Sensor 4

P5.3 P

P5.4 P

P5.5 P

RESET SPEED BIT0

RESET SPEED BIT1

RESET SPEED BIT2

Signals for preset speed selection, with binary coding.

Required action Activated frequency

B2 B1 B0 Preset frequency 0

B2 B1 B0 Preset frequency 1

B2 B1 B0 Preset frequency 2

B2 B1 B0 Preset frequency 3

B2 B1 B0 Preset frequency 4

B2 B1 B0 Preset frequency 5

B2 B1 B0 Preset frequency 6

B2 B1 B0 Preset frequency 7

Table 45. Selection of preset frequencies; = input activated

P5.6 F

AULT RESET

Active on rising edge.

Note: an automatic fault reset is triggered when Manual mode is activated on operator panel.

P5.7 F

ORCE BRAKE

Signal high opens the mechanical brake.

Service support: find your nearest Vacon service center at www.vacon.com

3

Page 46

vacon • 43 Parameter description

P5.8 EXTERNAL FAULT, CLOSE

Fault is triggered by high signal.

P5.9 E

XTERNAL FAULT, OPEN

Fault is triggered by low signal.

P5.10 R

UN ENABLE

Motor stops by coasting if the signal is missing.

Note: The drive is not in Ready state when Enable is low.

P5.11 R

AMP TIME 2 SELECTION

Ramp 2 is selected by signal high.

P5.12 MOTOR POTENTIOMETER UP

Signal high causes speed increase.

P5.13 M

OTOR POTENTIOMETER DOWN

Signal high causes speed reduction.

P5.14 Q

UICK STOP OPEN

Signal low forces the drive to stop, ramping down with the time defined in P4.9.

To see description of P2.5 for details about the function.

P5.15 Q

UICK STOP CLOSE

Similar to P5.14, but in this case Quick Stop is activated by high signal.

3

Page 47

Parameter description vacon • 44

3.6 Output functions

P6.1 ASI INPUT 1

P6.2 AS

P6.3 AS

P6.4 AS

I INPUT 2

I INPUT 3

I INPUT 4

Meaning of ASi input bit.

0: not used

1: Sensor 1

2: Sensor 2

3: Sensor 3

4: Sensor 4

5: Ready + Automatic (both conditions are needed to have the bit high)

6: Run

7: Fault

8: Fault or warning

9: Reverse

10: Running feedback

1)

11: Automatic mode

12: At speed (reference reached, from internal motor control)

13: Output freq superv

14: Output current superv

15: Brake command

16: Quick stop active

1)

when Automatic mode is not assigned to a specific Input, Running Feedback input includes

also information about Automatic.

Automatic Run Output frequency <= Setpoint Feedback

0- - 0

10 - 1

11 0 0

11 1 1

Service support: find your nearest Vacon service center at www.vacon.com

3

Page 48

vacon • 45 Parameter description

P6.5 RO1 SIGNAL SELECTION

P6.6 RO2

Function for internal relays.

0: not used

1: Ready

2: Run

3: Fault

4: Fault inverted

5: Fault or warning

6: Reverse

7: At speed (motor control feedback)

8: Output freq superv

9: Output current superv

10: ASi Output 1

11: ASi Output 2

12: ASi Output 3

13: ASi Output 4

SIGNAL SELECTION

Note: relay terminals are not accessible in standard V20X+D drive.

P6.7 RO1 ON

P6.8 RO1 OFF DELAY

Possible delays for ON/OFF transitions.

P6.9 RO1 INVERSION

Inversion of relay state.

P6.10 RO2 ON DELAY

P6.11 RO2 OFF DELAY

Possible delays for ON/OFF transitions.

DELAY

3

Page 49

Parameter description vacon • 46

3.7 Mechanical brake

P7.1 BRAKE OPEN FREQUENCY

P7.2 BRAKE OPEN CURRENT

Thresholds that must be reached for external brake open at start.

If P7.1 > 0Hz, frequency reference is internally limited to P7.1 + 0.1 Hz until the brake is released.

Fault 56 Brake Time Out is triggered if the thresholds in P7.1 and P7.2 are not reached within

3s from Start command.

P7.3 B

The brake is closed when the start command is low and output frequency is below this threshold. Possible delay in P7.4.

P7.4 B

Respected in any stop condition (quick, fault, no enable), apart direct control from ASi input,

when the signal goes low.

RAKE CLOSE FREQUENCY

RAKE CLOSE DELAY

Service support: find your nearest Vacon service center at www.vacon.com

3

Page 50

vacon • 47 Parameter description

3.8 Supervisions

P8.1 RUNNING FEEDBACK TOLERANCE

When output frequency has reached this percentage of reference, running feedback is set high.

P8.2 F

REQUENCY SUPERVISION FUNCTION

0: No supervision

1: Low limit

2: High limit

P8.3 F

REQUENCY SUPERVISION LIMIT

Threshold value.

P8.4 C

URRENT SUPERVISION LIMIT

Threshold value.

P8.5 P

ROCESS DISPLAY SOURCE

Monitor V3.9 can show a process value, proportional to a variable measured by the drive.

Source variables are:

0: output frequency (max: Fmax)

1: motor speed (max: Speed at Fmax)

2: motor torque (max: Tnom)

3: motor power (max: Pnom)

4: motor current (max: Inom)

P8.6 P

ROCESS DISPLAY DECIMAL DIGITS

Number of decimals shown on monitor V3.9 and also on parameter P8.7.

P8.7 P

ROCESS DISPLAY MAX VALUE

Value shown on V3.9 when source variable is at its maximum. Proportionality is kept if the

source overtakes the maximum.

3

Page 51

Parameter description vacon • 48

U[V]

f[Hz]

Default: Nominal

voltage of the motor

Linear

Squared

Field

weakening

point

Default:

Nominal frequency

of the motor

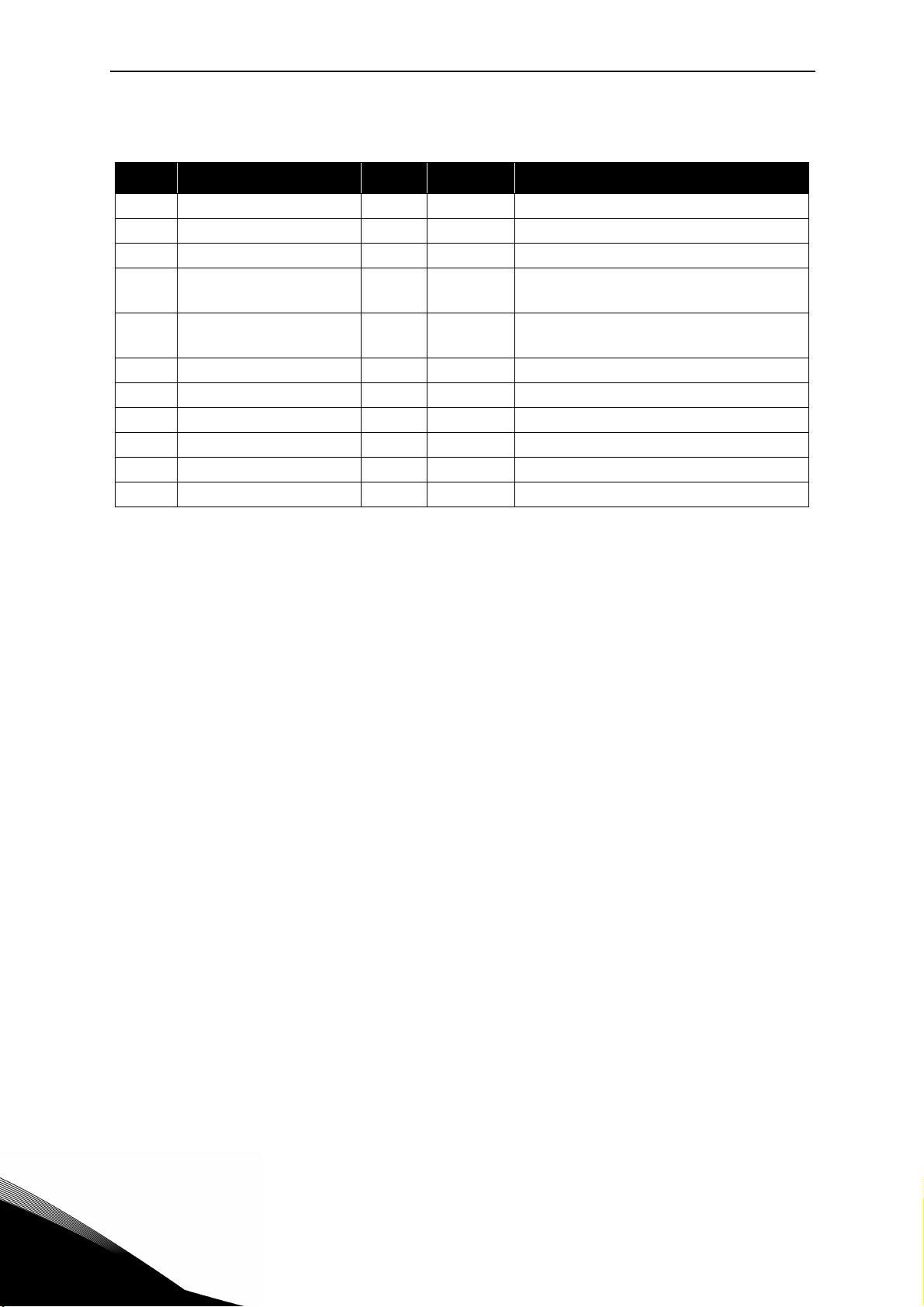

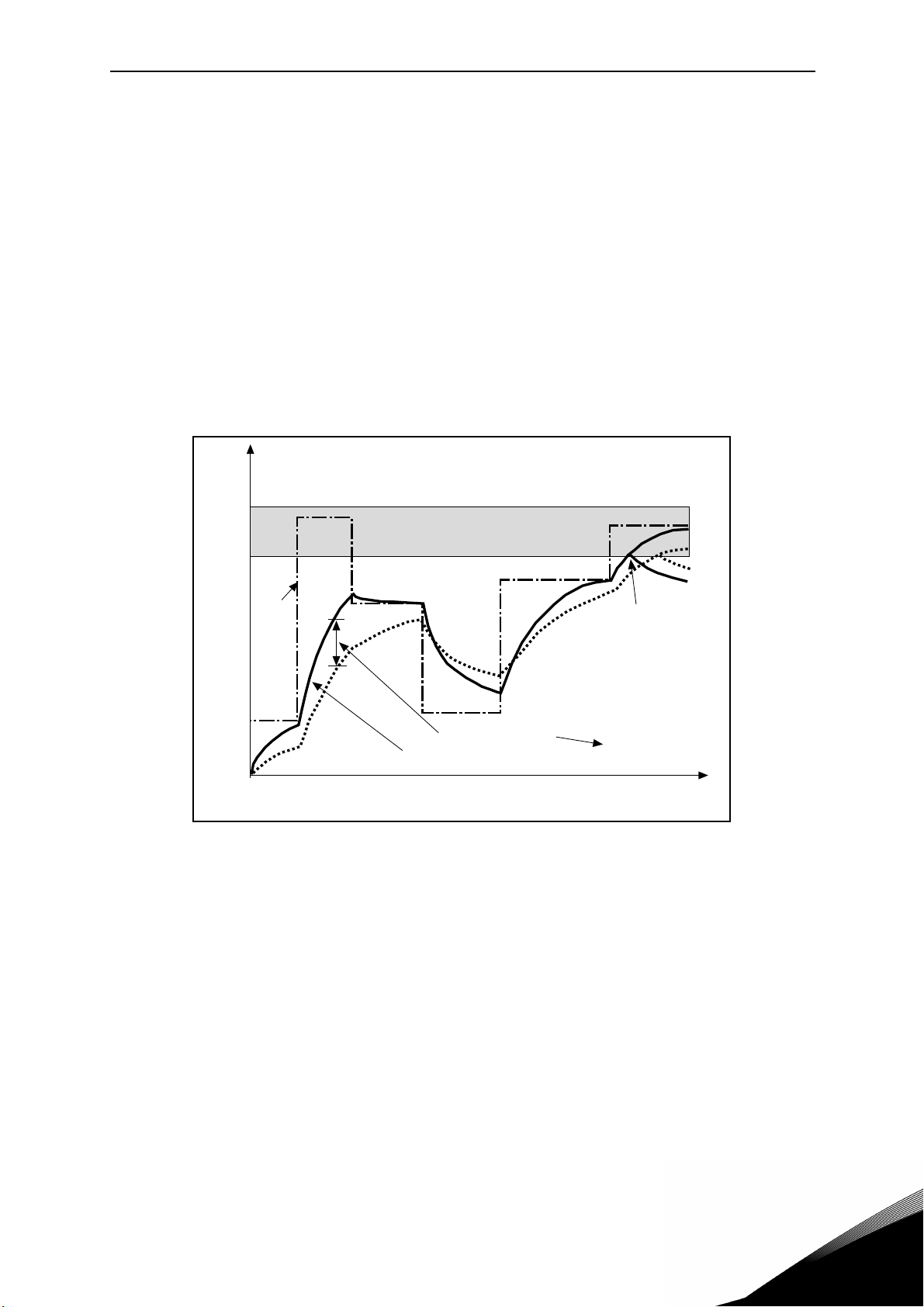

3.9 Motor control

P9.1 FIELD WEAKENING POINT

Output frequency corresponding to max voltage.

Note: if P1.2 Nominal Frequency is changed, P9.1 will be set at same value.

P9.2 F

Motor voltage when frequency is above FWP, defined as % of nominal voltage.

Note: if P1.1 Nominal Voltage is changed, P9.2 will be set at 100%.

P9.3 U/

0: linear

The voltage of the motor changes linearly as a function of output frequency

from zero frequency voltage P9.6 to the field weakening point (FWP)

voltage P9.2 at FWP frequency P9.1 This default setting should be

used if there is no special need for another setting.

IELD WEAKENING POINT VOLTAGE

F SELECTION

1: quadratic

(from voltage P9.6 at 0Hz, to voltage P9.2 at P9.1 frequency)

The voltage of the motor changes from zero point voltage P9.6 following a squared curve form

from zero to the field weakening point P9.2. The motor runs under-magnetized below the field

weakening point and produces less torque. Squared U/f ratio can be used in applications where

torque demand is proportional to the square of the speed, e.g. in centrifugal fans and pumps.

Service support: find your nearest Vacon service center at www.vacon.com

Figure 6. Linear and quadratic curve of the motor voltage.

3

Page 52

vacon • 49 Parameter description

U[V]

f[Hz]

P2

P3

P1

Default: Nominal

voltage of the motor

Linear

Field

weakening

point

Default:

Nominal frequency

of the motor

2: programmable

The U/f curve can be programmed with three different points: Zero frequency voltage (P1),

Midpoint voltage/frequency (P2) and Field weakening point (P3).

Programmable U/f curve can be used if more torque is needed at low frequencies. The optimal

settings can automatically be achieved with Motor identification run.

Note: motor identification automatically sets this parameter to 2.

P9.4 U/F MID POINT FREQUENCY

Enabled if P9.3= 2.

Note: motor identification automatically sets this parameter.

P9.5 U/

Enabled if P9.3= 2.

Note: motor identification automatically sets this parameter.

P9.6 V

Motor voltage at frequency zero.

Note: motor identification automatically sets this parameter.

P9.7 R

Voltage drop on stator windings, at motor nominal current, defined as % of nominal voltage.

Value affects motor torque estimation, slip compensation and voltage boost.

Figure 7. Programmable curve.

F MID POINT VOLTAGE

OLTAGE AT F0

S VOLTAGE DROP

3

Page 53

Parameter description vacon • 50

Note: it is suggested not to program manually the value, but to perform motor identification

procedure that automatically sets the value.

P9.8 S

WITCHING FREQUENCY

PWM frequency. Values above default can cause thermic overload of the drive.

P9.9 D

ROOPING MODE

0: constant.

Load drooping factor is constant through the whole frequency range.

1: speed dependent.

Load drooping is reduced linearly from nominal frequency to zero frequency.

P9.10 D

ROOP FILTER TIME

Time constant of the low pass filter applied to droop frequency variation.

P9.11 B

RAKE CHOPPER

0: Chopper disabled

1: Chopper enabled in Run state

2: Chopper enabled in Ready state

P9.12 B

RAKE CHOPPER LEVEL

DC link voltage above which chopper is activated.

P9.13 DC

BRAKING CURRENT

DC current injected at start or stop.

P9.14 S

TOP DC CURRENT TIME

Time for DC current injection at stop.

P9.15 S

TOP DC CURRENT FREQUENCY

DC current is injected below this frequency.

P9.16 S

TART DC BRAKE TIME

Time for DC current injection at start.

P9.17

OVERVOLTAGE REGULATOR

Overvoltage regulator automatically increases deceleration ramp time if the internal DC link

voltage is too high.

0: enabled

1: disabled

Service support: find your nearest Vacon service center at www.vacon.com

3

Page 54

vacon • 51 Parameter description

P9.18 UNDERVOLTAGE REGULATOR

Undervoltage regulator automatically decelerates the motor if the internal DC link voltage is

too low.

0: enabled

1: disabled

P9.19

Switching frequency regulator automatically decreases the PWM frequency if the unit temperature is too high.

0: enabled

1: disabled

SWITCHING FREQUENCY REGULATOR

3

Page 55

Parameter description vacon • 52

f

I

Par. P1.6

Par. P10.4

Stall area

3.10 Protections

P10.1 EARTH FAULT

0: No action

1: Warning

2: Fault

Output currents sum not zero.

P10.2 M

0: No action

1: Warning

2: Fault

This is an overload protection. Stall is recognized by maximum motor current (=P1.5) and low

output frequency.

OTOR STALL FAULT

Figure 8. Stall characteristic settings.

P10.3 STALL TIME LIMIT

This time can be set between 0.0 and 300.0 s.

This is the maximum time allowed for all stage. the stall time is counted by an internal up/down

counter. If the stall time counter value goes above this limit the protection will cause a trip.

Service support: find your nearest Vacon service center at www.vacon.com

3

Page 56

vacon • 53 Parameter description

Par. P10.3

Trip area

Time

Stall time counter

Stall•