Page 1

vacon

vacon

®

20

®

20 x

vacon® 20 cp

ac drives

modbus rtu

user manual

Page 2

Page 3

vacon • 1

Table of Contents

Document: DPD01925A

Version release date: 30.5.17

1. Safety................................................................................................................2

1.1 Danger.................................................................................................................................2

1.2 Warnings .............................................................................................................................3

1.3 Earthing and earth fault protection ....................................................................................4

2. Modbus - general info.......................................................................................5

2.1 Restrictions .........................................................................................................................6

3. Modbus technical data ......................................................................................7

3.1 Modbus RTU protocol .........................................................................................................7

3.2 Connections and wiring ......................................................................................................7

4. Installation........................................................................................................8

4.1 Installation in VACON® 20 family AC drives ......................................................................8

4.1.1 Preparation for use through RS485....................................................................................8

5. Fieldbus parametrization ...............................................................................10

5.1 Fieldbus control and basic reference selection...............................................................10

5.2 Modbus RTU parameters and monitoring values ............................................................10

5.2.1 Fieldbus protocol ..............................................................................................................11

5.2.2 Slave address ....................................................................................................................11

5.2.3 Baud rate...........................................................................................................................11

5.2.4 Parity type .........................................................................................................................12

5.2.5 Communication timeout ...................................................................................................12

5.2.6 Reset communication status ............................................................................................12

5.2.7 Communication status......................................................................................................12

6. Communications .............................................................................................13

6.1 Modbus address area .......................................................................................................13

6.2 Supported Modbus Functions...........................................................................................13

6.3 Modbus data mapping.......................................................................................................14

6.3.1 Modbus process data in VACON® 20 Application ACCN1004..........................................14

6.3.2 Modbus process data in VACON® 20X and VACON® CP Application ACIT1075 .............17

6.4 Example messages ...........................................................................................................20

6.4.1 Example 1 - Write Process Data.......................................................................................20

6.4.2 Example 2 - Read process data ........................................................................................21

7. Fault tracing ...................................................................................................22

7.1 Typical fault conditions .....................................................................................................22

7.2 RS-485 bus biasing ...........................................................................................................22

7.3 Other fault conditions .......................................................................................................23

8. Quick setup .....................................................................................................24

9. APPENDIX 1 - PROCESS DATA ........................................................................25

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Page 4

vacon • 2 Safety

9000.emf

13006.emf

9001.emf

9000.emf

9000.emf

9000.emf

9000.emf

9000.emf

9000.emf

1. SAFETY

This manual contains clearly marked cautions and warnings which are intended for your personal

safety and to avoid any unintentional damage to the product or connected appliances.

Please read the information included in cautions and warnings carefully.

The cautions and warnings are marked as follows:

Table 1. Warning signs

= DANGER! Dangerous voltage

= WARNING or CAUTION

= Caution! Hot surface

1.1 Danger

The components of the power unit are live when the drive is connected to mains

potential. Coming into contact with this voltage is extremely dangerous and may

cause death or severe injury.

The motor terminals U, V, W and the brake resistor terminals are live when the

AC drive is connected to mains, even if the motor is not running.

After disconnecting the AC drive from the mains, wait until the indicators on the

keypad go out (if no keypad is attached see the indicators on the cover). Wait 5

more minutes before doing any work on the connections of the drive. Do not open

the cover before this time has expired. After expiration of this time, use a measuring equipment to absolutely ensure that no

absence of voltage before starting any electrical work!

The control I/O-terminals are isolated from the mains potential. However, the

relay outputs and other I/O-terminals may have a dangerous control voltage

present even when the AC drive is disconnected from mains.

voltage is present.

Always ensure

Before connecting the AC drive to mains make sure that the front and cable covers of the drive are closed.

During a ramp stop (see the Application Manual), the motor is still generating

voltage to the drive. Therefore, do not touch the components of the AC drive

before the motor has completely stopped. Wait until the indicators on the keypad

go out (if no keypad is attached see the indicators on the cover). Wait additional 5

minutes before starting any work on the drive.

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

1

Page 5

Safety vacon • 3

13006.emf

13006.emf

13006.emf

13006.emf

13006.emf

13006.emf

13006.emf

13006.emf

13006.emf

13006.emf

1.2 Warnings

The AC drive is meant for fixed installations only.

Do not perform any measurements when the AC drive is connected to the mains.

The earth leakage current of the AC drives exceeds 3.5mA AC. According to stan-

dard EN61800-5-1, a reinforced protective ground connection must be ensured.

See chapter 1.3.

If the AC drive is used as a part of a machine, the machine manufacturer is

responsible for providing the machine with a supply disconnecting device (EN

60204-1).

Only spare parts delivered by VACON

®

can be used.

At power-up, power break or fault reset the motor will start immediately if the

start signal is active, unless the pulse control for

Start/Stop logic has been selected

Futhermore, the I/O functionalities (including start inputs) may change if parameters, applications or software are changed. Disconnect, therefore, the motor if

an unexpected start can cause danger.

The motor starts automatically after automatic fault reset if the auto restart

function is activated. See the Application Manual for more detailed information.

Prior to measurements on the motor or the motor cable, disconnect the motor

cable from the AC drive.

Do not touch the components on the circuit boards. Static voltage discharge may

damage the components.

Check that the EMC level of the AC drive corresponds to the requirements of your

supply network.

.

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

1

Page 6

vacon • 4 Safety

13006.emf 13006.emf

1.3 Earthing and earth fault protection

CAUTION!

The AC drive must always be earthed with an earthing conductor connected to the earthing terminal

marked with .

The earth leakage current of the drive exceeds 3.5mA AC. According to EN61800-5-1, one or more

of the following conditions for the associated protective circuit shall be satisfied:

b) The protective conductor shall have a cross-sectional area of at least 10 mm2 Cu or 16

mm2 Al, through its total run.

c) Where the protective conductor has a cross-sectional area of less than 10 mm2 Cu or 16

mm2 Al, a second protective conductor of at least the same cross-sectional area shall be

provided up to a point where the protective conductor has a cross-sectional area not less

than 10 mm2 Cu or 16 mm2 Al.

d) Automatic disconnection of the supply in case of loss of continuity of the protective conduc-

tor.

The cross-sectional area of every protective earthing conductor which does not form part of the

supply cable or cable enclosure shall, in any case, be not less than:

-2.5mm

-4mm

2

if mechanical protection is provided or

2

if mechanical protection is not provided.

The earth fault protection inside the AC drive protects only the drive itself against earth faults in the

motor or the motor cable. It is not intended for personal safety.

Due to the high capacitive currents present in the AC drive, fault current protective switches may

not function properly.

Do not perform any voltage withstand tests on any part of the AC drive. There is

a certain procedure according to which the tests shall be performed. Ignoring this

procedure may result in damaged product.

NOTE! You can download the English and French product manuals with applicable safety,

warning and caution information from

http://drives.danfoss.com/knowledge-center/technical-documentation/.

REMARQUE Vous pouvez télécharger les versions anglaise et française des manuels produit

contenant l’ensemble des informations de sécurité, avertissements et mises en garde

applicables sur le site http://drives.danfoss.com/knowledge-center/technical-documentation/

.

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

1

Page 7

Modbus - general info vacon • 5

11608_uk

Master´s

message

Slave

response

Start

Address

Function

Data

CRC

End

Start

Address

Function

Data

CRC

End

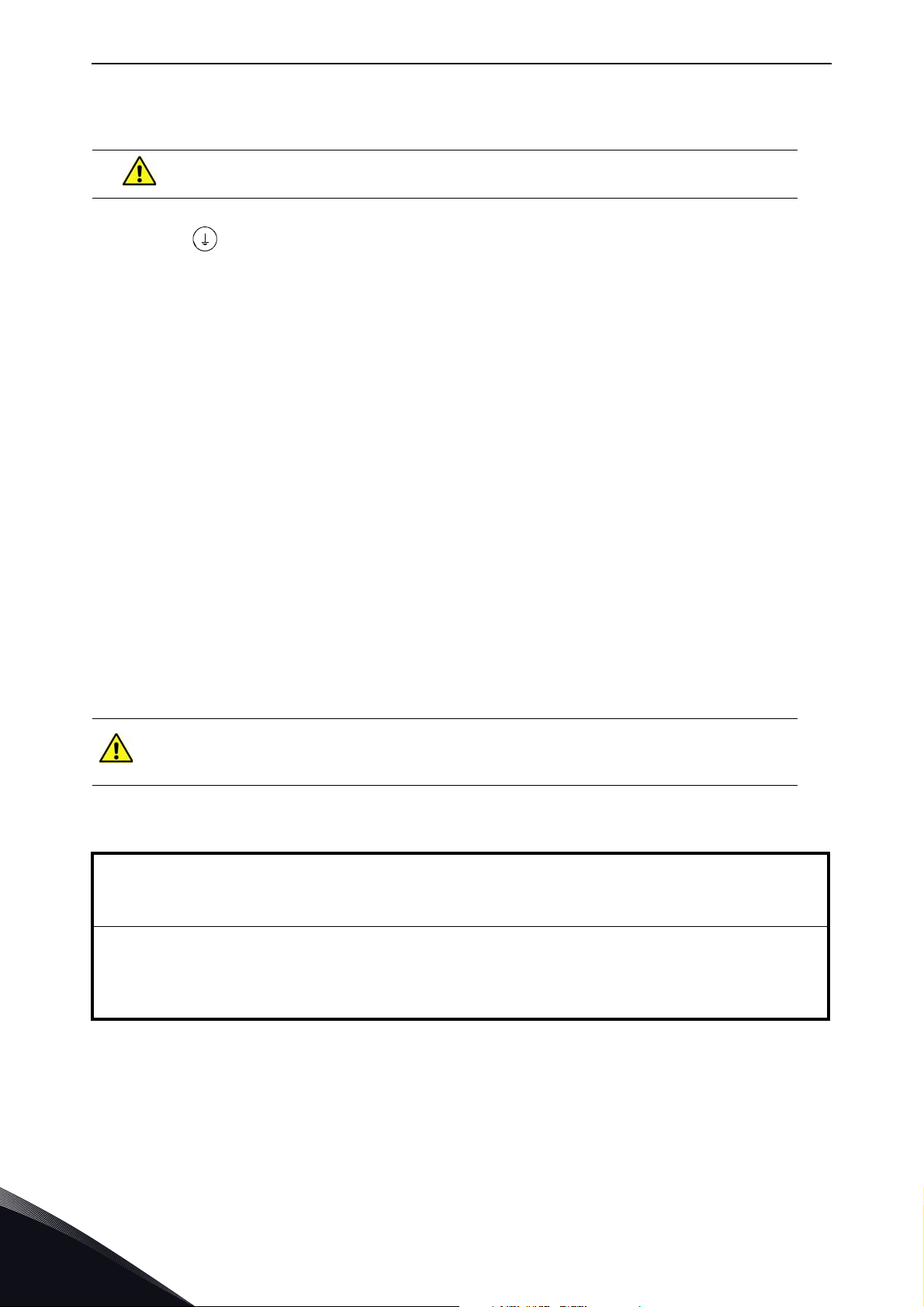

2. MODBUS - GENERAL INFO

Modbus is a communication protocol developed by Modicon systems. In simple terms, it is a way of

sending information between electronic devices. The device requesting the information is called the

Modbus Master and the devices supplying information are Modbus Slaves. The Master can also

write information to the Slaves. Modbus is typically used to transmit signals from instrumentation

and control devices back to a main controller or data gathering system.

Standard Modbus network contains one Master device and up to 247 Slave devices. In ModbusRTU

networks it is mandatory to define a unique Slave Address (or Unit identifier number) for the every

Slave Device. Slave Address is a number between 1 and 247. Modbus ASCII mode is not supported.

The Modbus communication interface is built around messages. The format of these Modbus messages is independent of the type of physical interface used. The same protocol can be used regardless of the connection type. Because of this, Modbus gives the possibility to easily upgrade the

hardware structure of an industrial network, without the need for large changes in the software. A

device can also communicate with several Modbus nodes at once, even if they are connected with

different interface types, without the need to use a different protocol for every connection.

Figure 1.Basic structure of Modbus frame

On simple interfaces like RS485, the Modbus messages are sent in plain form over the network. In

this case the network is dedicated to Modbus.

Each Modbus message has the same structure. Four basic elements are present in each message.

The sequence of these elements is the same for all messages, to make it easy to parse the content

of the Modbus message. A conversation is always started by a master in the Modbus network. A

Modbus master sends a message and—depending of the contents of the message—a slave takes

action and responds to it. Addressing in the message header is used to define which device should

respond to a message. All other nodes on the Modbus network ignore the message if the address

field does not match their own address.

Your VACON

tact VACON

with the Drive Info File taken with VACON

®

20 family AC drive is equipped with Modbus support as standard. If you need to con-

®

service in problems related to Modbus, send a description of the problem together

®

Live to customer support. If possible, also send a "Wire-

shark" log from the situation if applicable.

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

2

Page 8

vacon • 6 Modbus - general info

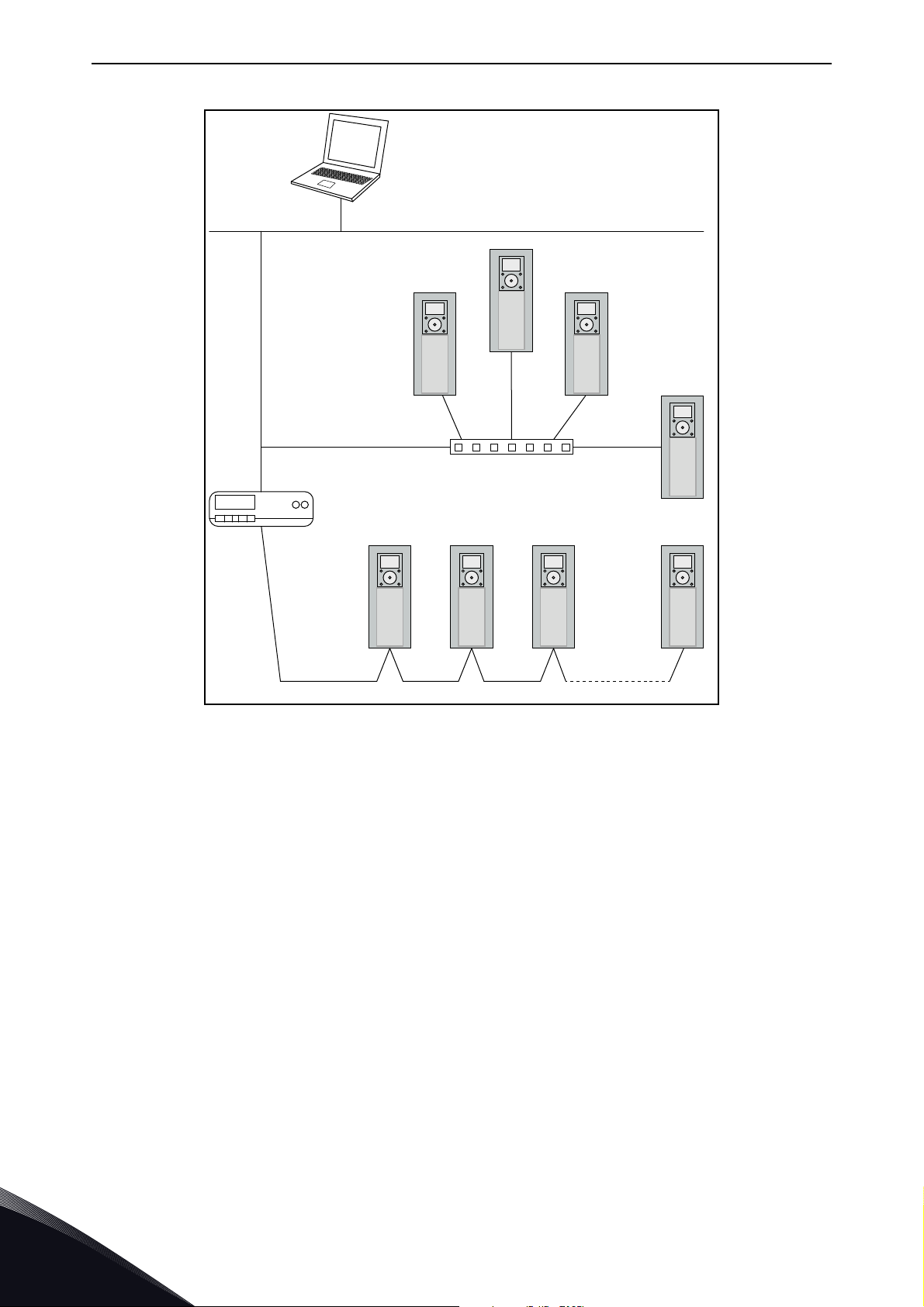

Ethernet

Modbus TCP

Switch

Modbus

RTU

master

Modbus RTU

11781_uk

Figure 2.Principal example diagram of Modbus

2.1 Restrictions

When a fieldbus option board or an OPTBH option board has been installed, Modbus is not working.

2

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Page 9

Modbus technical data vacon • 7

3. MODBUS TECHNICAL DATA

3.1 Modbus RTU protocol

Modbus RTU is the only supported transmission mode. Modbus ASCII mode is not supported.

Table 2.

Interface RS-485

Data transfer method RS-485 MS/TP, half-duplex

Transfer cable STP (Shielded Twisted Pair)

Connector

Connections and

communications

Electrical isolation Functional

Modbus RTU

Bitrate

Addresses 1 to 247

3.2 Connections and wiring

2.5 mm

As described in “Modicon Modbus Protocol Reference Guide”

300, 600, 1200, 2400, 4800, 9600, 19200,

38400, and 57600 bits/s

2

The maximum length of an RS-485 cable depends on the bitrate used, the cable (gauge, capacitance

or characteristic impedance) and the number of devices in the bus. The Modbus RTU specification

states that for a maximum 9600 bits/second bitrate and AWG26 or wider gauge, the maximum

length is 1000 meters. The actual cable length used in an installation can be lower than this number

depending on the aforementioned parameters.

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

3

Page 10

vacon • 8 Installation

10

5

4. INSTALLATION

4.1 Installation in VACON® 20 family AC drives

The connection for RS485 is on the standard I/O terminals (A and B). See VACON® 20 or VACON® 20

X /CP Installation Manual depending on the drive you are using.

4.1.1 Preparation for use through RS485

Strip about 15 mm of the RS485 cable and cut off the grey cable shield. Remember to do this for both bus cables (except for the last device).

Leave no more than 10 mm of the cable outside the terminal block and strip the

cables at about 5 mm to fit in the terminals. See picture below.

1

2

3

Also strip the cable now at such a distance from the terminal that you can fix it to

the frame with the grounding clamp. Strip the cable at a maximum length of 15

mm. Do not strip the aluminium cable shield!

Then connect the cable to its appropriate terminals on VACON® 20 CP AC drive

standard terminal block, terminals A and B (A = negative, B = positive).

Using the cable clamp included in the supply of the drive, ground the shield of

the RS485 cable to the frame of the AC drive.

4

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Page 11

Installation vacon • 9

4 5 13 14 15 16 2018

123678910

22 23 26

2425

AI2 GND DO- DI4 DI5 DI 6 AO DO+ R13 R14 * R24

+10VAI1 GND 24V DI-C DI1 DI2 DI 3 A B R21 R22

DI

Enco Nor

AO

V mA

AI2

V mA

RS485

- term

ON

OFF

J500

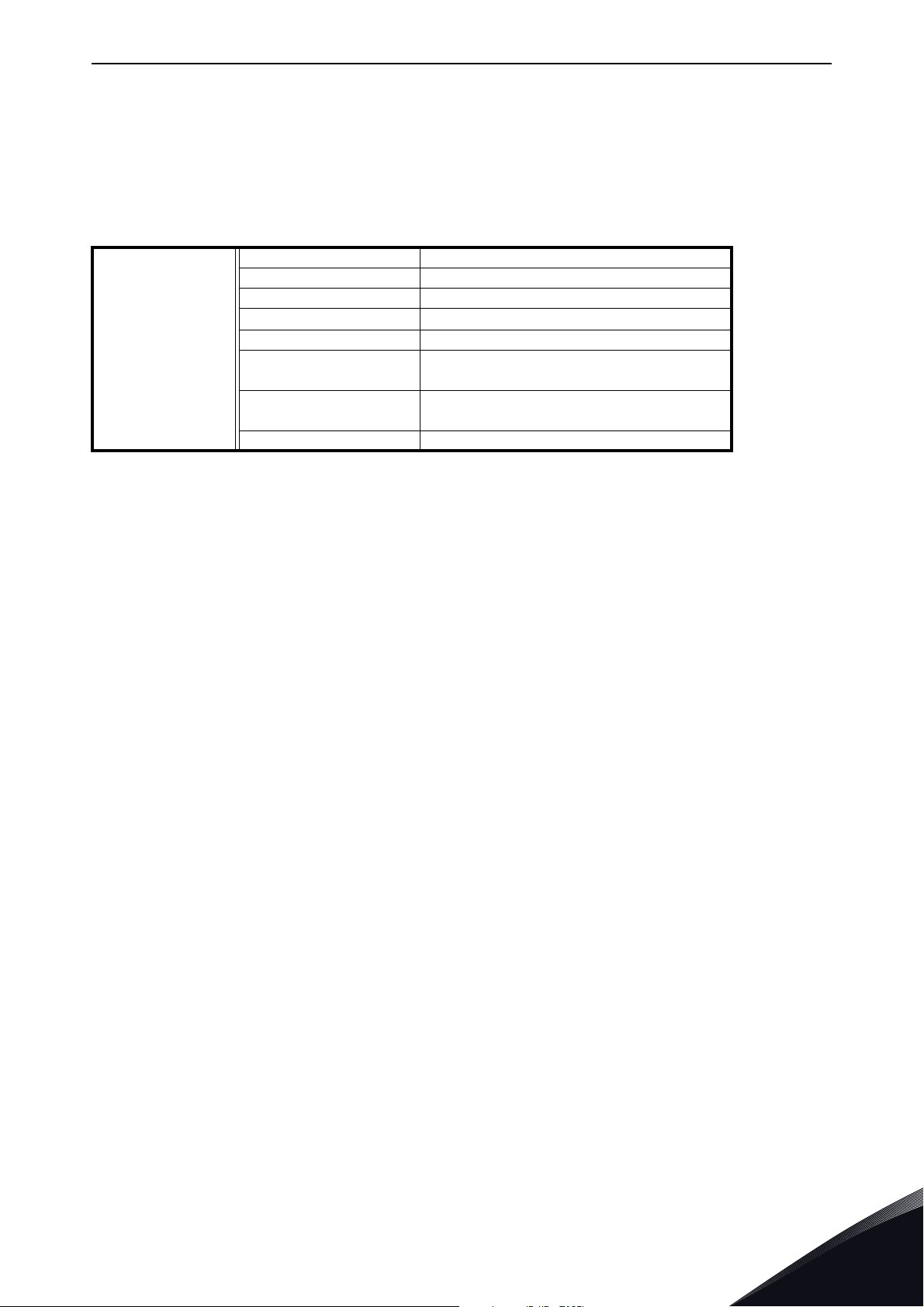

NOTE! This step is valid only for VACON® 20 CP and VACON® 20 X.

®

If VACON

the bus, the bus termination must be set. Locate the

switches to the right of the control terminals and turn

the SW4 switch to position “0”. Biasing is built in the

termination resistor.

20 Cold Plate drive is the last device on

4

NOTE! This step is valid only for VACON® 20.

The RS-485 bus is terminated with termination resistors of 120 ohms in both

ends. VACON

default (presented below). The termination resistor can be switched on and off

with the right hand dip switch located above IO-terminals in the front of the drive

(see below). Biasing is built in the termination resistor.

®

20 has a built-in termination resistor which is switched off as a

5

6

7

NOTE: When planning the cable runs, remember to keep the distance between

the fieldbus cable and the motor cable at a minimum of 30 cm.

The bus termination must be set for the first and the last device of the fieldbus

line. We recommend that the first device terminated is the Master device.

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

4

Page 12

vacon • 10 Fieldbus parametrization

5. FIELDBUS PARAMETRIZATION

The following chapter describes briefly how to parametrise the AC drive in order for the motor to be

controllable via fieldbus. These instructions are written for basic applications. For more

information, consult the application-specific manual.

In order for the AC drive to accept commands from the fieldbus network, the control place of the AC

drive has to be set to fieldbus. The default value of the parameter "Control Place" is usually I/O. Note

that if the control unit firmware is updated, the default settings are restored. In addition, some

applications may have the remote speed reference selection set by default to other than fieldbus. In

these cases, the speed reference selection must be set to fieldbus, in order for the speed reference

to be controlled via fieldbus.

NOTE! The motor control mode should be selected to support the used process and profile.

The navigation path to the fieldbus parameters may differ from application to application. The

®

exemplary paths below apply to the VACON

20 family AC drive.

5.1 Fieldbus control and basic reference selection

The following tables list some of the parameters related to fieldbus control. See the application

specific manuals for more detailed information.

Parameters can be read and written by using the drive panel, PC Tool or fieldbus protocol. Notice

that some of connection parameters for fieldbus may need to be set (depending on your

configuration) via panel or PC tool, before you can connect over fieldbus and write application

parameters.

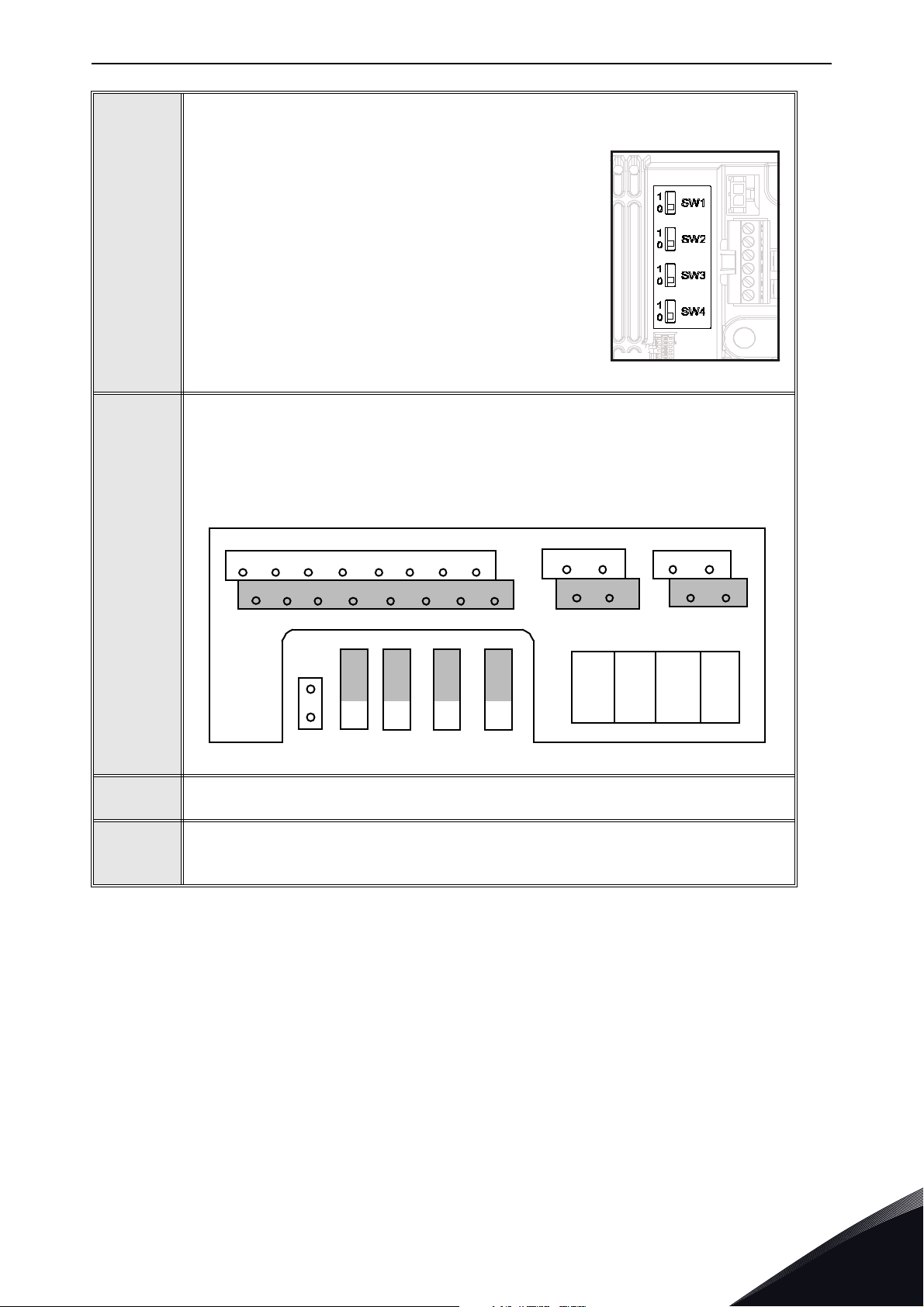

Table 3. Parametrization for VACON® 20 family AC drive (Standard application)

Parameter name Value

Control mode Frequency Speed

Remote control place Fieldbus CTRL

Local / remote Remote

Fieldbus ref. sel. Fieldbus

5.2 Modbus RTU parameters and monitoring values

5

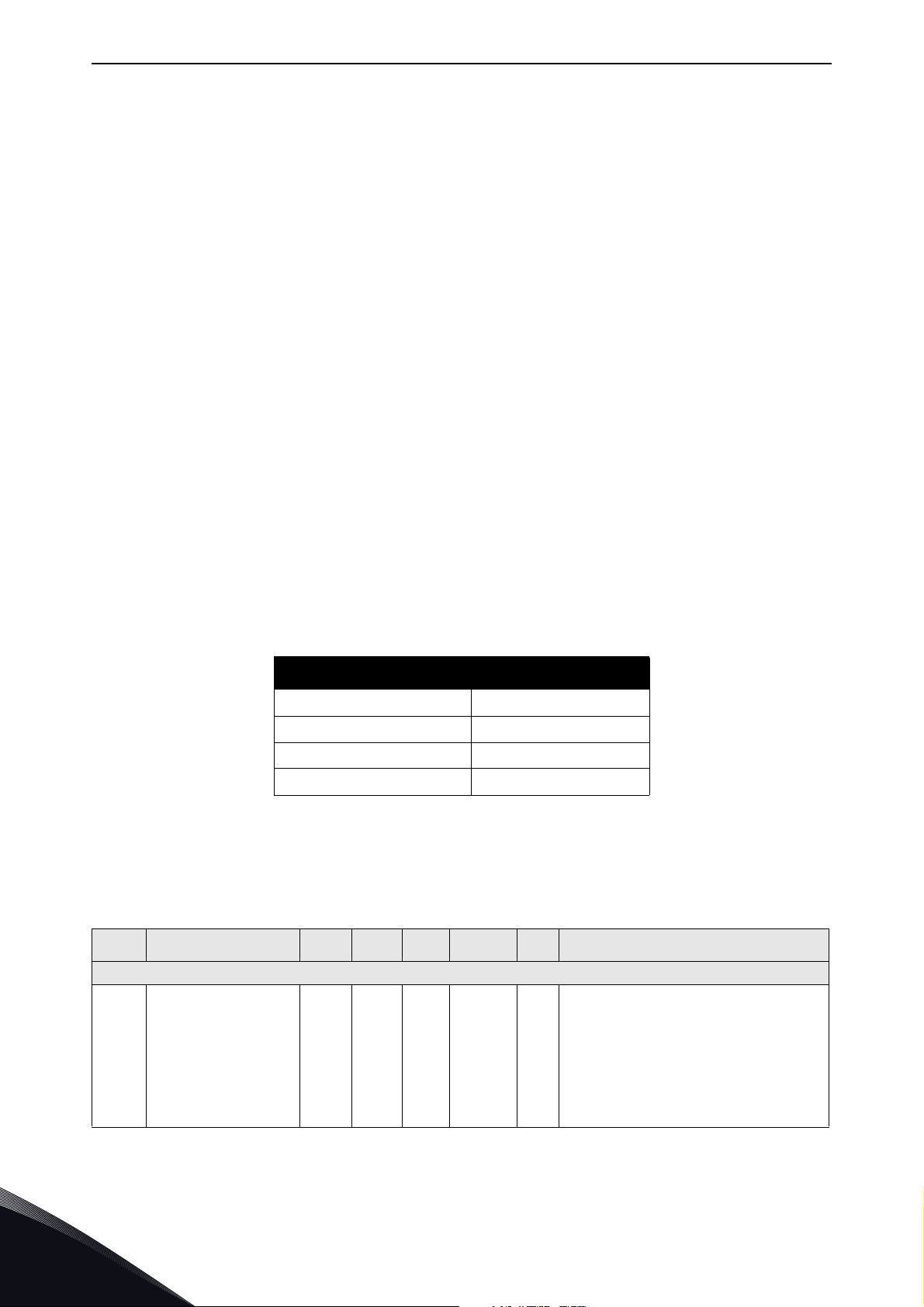

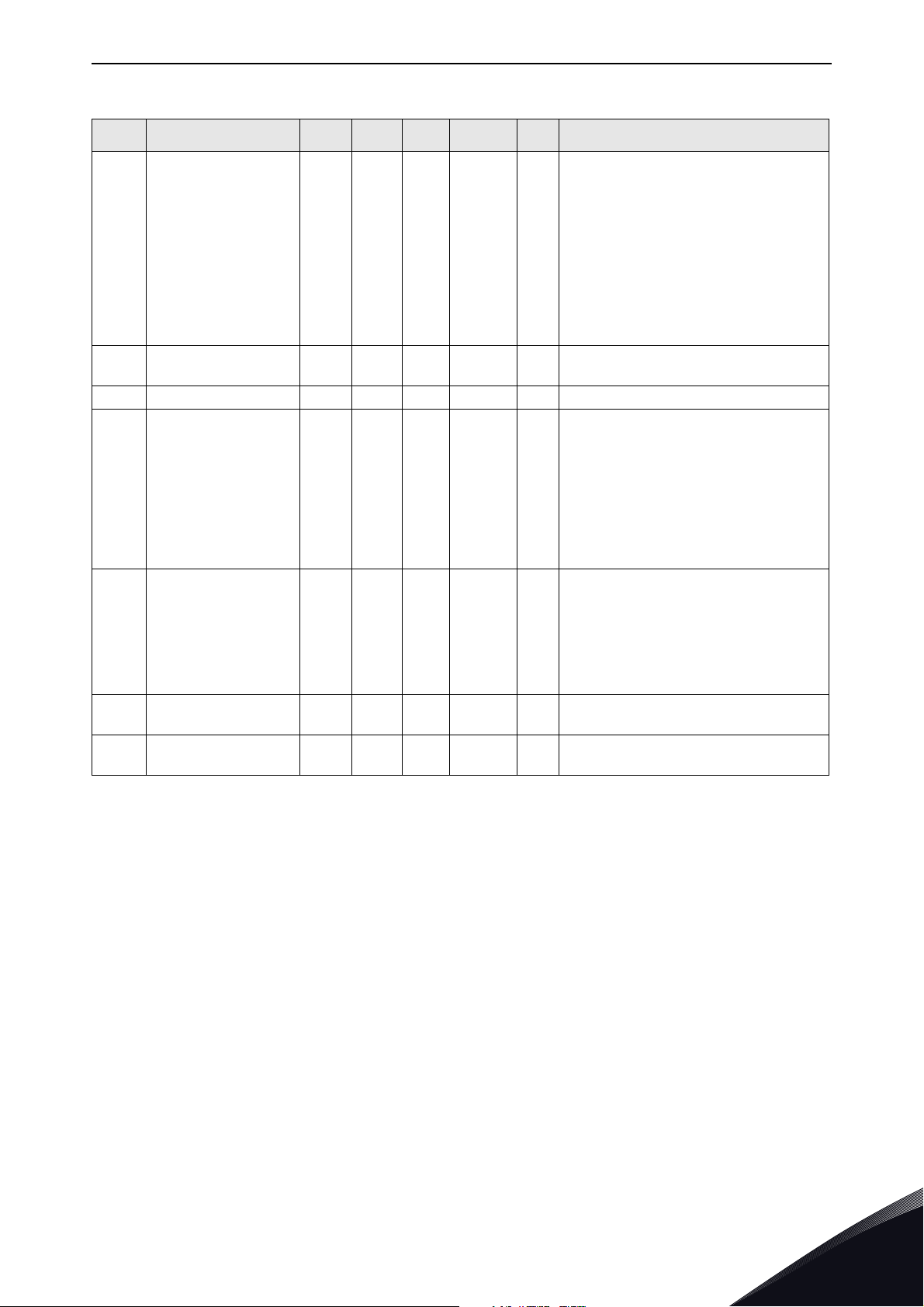

Table 4 .

Code Parameter Min Max Unit Default ID Description

When no fieldbus board or no OPTBH board has been installed, the following values are visible:

Status of Modbus communication.

Format: xx.yyy where

xx = 0 - 64 (Number of error messages)

V2.1 Communication status 808

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

This counter saturates when 64 error

messages are detected

yyy = 0 - 999 (Number of good messages)

This counter restarts counting from 0

when 999 good messages are detected

Page 13

Fieldbus parametrization vacon • 11

Table 4 .

Code Parameter Min Max Unit Default ID Description

The fault code related to the last counted

bad messages is shown:

1 = Illegal function

2 = Illegal address

V2.9 *

P2.2 Fieldbus protocol 0 1 0 809

P2.3 Slave address 1 247 1 810

P2.4 Baud rate 0 8 5 811

P2.6 Parity type 0 2 0 813

P2.7

P2.8

Last communication

fault

Communication time

out

Reset communication

status

0 255 s 10 814

01 0815

3 = Illegal data value

816

4 = Illegal slave device

53 = USART receive fault (parity error/

frame error/USART buffer overflow)

90 = Receive buffer overflow

100 = Frame CRC Error

101 = Ring buffer overflow

0 = Not used

1 = Modbus used

0 = 300

1 = 600

2 = 1200

3 = 2400

4 = 4800

5 = 9600

6 = 19200

7 = 38400

8 = 57800

Parity type:

0 = None

1 = Even

2 = Odd

Stop bit:

- 2-bits with parity type “None”;

- 1-bit with parity type “Even” and “Odd”.

(*) Only on VACON® 20CP/X.

5.2.1 Fieldbus protocol

Use this parameter to activate the Modbus protocol.

5.2.2 Slave address

Each slave must have a unique address (from 1 to 247) so that it can be addressed independently

from other nodes.

5.2.3 Baud rate

Select the communication speed for the network. The default value is 9600 baud.

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

5

Page 14

vacon • 12 Fieldbus parametrization

5.2.4 Parity type

You can select the parity type for the network. Modbus RTU specifies the stop bit configuration

shown in table below. You can modify this stop bit configuration manually using parameter.

Table 5. Parity type and stop bits

Parity Stopbits

Even 1

Odd 1

None 2

5.2.5 Communication timeout

Modbus initiates a communication error for a time defined with this parameter. '0' means that no

fault is generated.

5.2.6 Reset communication status

Used to reset the communication status shown in monitor value V2.1.

5.2.7 Communication status

The Communication status shows how many good and bad messages the drive has received. The

Communication status includes a common error counter that counts CRC and parity errors and a

counter for good messages.

Only messages to the current slave in use are counted in the good messages.

Table 6. Communication status description

Good messages

0…999 Number of messages received without errors

Bad messages

0…64 Number of messages received with errors

5

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Page 15

Communications vacon • 13

6. COMMUNICATIONS

Features of the Modbus-Vacon interface:

• Direct control of VACON® drive (e.g. Run, Stop, Direction, Speed reference, Fault reset)

®

• Full access to all VACON

®

• Monitor VACON

status (e.g. Output frequency, Output current, Fault code)

6.1 Modbus address area

The Modbus interface of VACON® 20/X uses the ID numbers of the application parameters as

addresses. The ID numbers can be found in the parameter tables described in specific Application

Manual.

When several parameters / monitoring values are read at a time, they must be consecutive.

11 addresses can be read and the addresses can be parameters or monitoring values.

NOTE: With some PLC manufacturers, the interface driver for Modbus RTU communicationmay

contain an offset of 1 (the ID number to be used would then subtract 1).

parameters

6.2 Supported Modbus Functions

The VACON® variables and fault codes as well as the parameters can be read and written from

Modbus. The parameter addresses are determined in the application. Every parameter and actual

value have been given an ID number in the application. The ID numbering of the parameter as well

as the parameter ranges and steps can be found in the application manual in question. The

parameter value must be given without decimals. If several parameters/actual values are read with

one message, the addresses of the parameters/actual values must be consecutive.

Table 7. Modbus RTU

Func t i o n

(dec)

3 Read Holding Registers All ID numbers No

4 Read Input Registers All ID numbers No

6 Write Single Register All ID numbers Yes

16 Write Multiple Registers All ID numbers Yes

Function Name Address

Broadcast

messages

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

6

Page 16

vacon • 14 Communications

6.3 Modbus data mapping

6.3.1 Modbus process data in VACON® 20 Application ACCN1004

Process data is an address area for fieldbus control. Fieldbus control is active when the value of

parameter 2.1 (Control place) is 1 (= fieldbus). The content of the process data can be programmed

in the application.The following tables present the process data contents in VACON

Please refer to VACON

ID Modbus register Name Scale Type

2101 32101, 42101 FB Status Word - Binary coded

2102 32102, 42102 FB General Status Word - Binary coded

2103 32103, 42103 Actual speed 0.01 %

2104 32104, 42104

2105 32105, 42105

2106 32106, 42106

®

20 Complete Manual for details.

Table 8. Output process data

Programmable by P10.1

(Default: Frequency reference)

Programmable by P10.2

(Default: Output frequency)

Programmable by P10.3

(Default: Motor speed)

--

0.01 +/- Hz

1 +/- Rpm

®

20 Application.

2107 32107, 42107

2108 32108, 42108

2109 32109, 42109

2110 32110, 42110

2111 32111, 42111

Programmable by P10.4

(Default: Motor voltage)

Programmable by P10.5

(Default: Motor torque)

Programmable by P10.6

(Default: Motor current)

Programmable by P10.7

(Default: Motor power)

Programmable by P10.8

(Default: DC link voltage)

0.1 V

0.1 +/- % (of nominal)

0.01 A

0.1 +/- % (of nominal)

1V

6

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Page 17

Communications vacon • 15

Table 9. Input process data

ID Modbus register Name Scale Type

2001 32001, 42001 FB Control Word Binary coded

2002 32002, 42002 FB General Control Word Binary coded

2003 32003, 42003 Actual speed 0.01 %

2004 32004, 42004 Programmable by P10.9

2005 32005, 42005 Programmable by P10.9

2006 32006, 42006 Programmable by P10.9

2007 32007, 42007 Programmable by P10.9

2008 32008, 42008 Programmable by P10.9

2009 32009, 42009 - - 2010 32010, 42010 - - 2011 32011, 42011 - - -

NOTE! 2004 - 2007 can set as PID Control Reference by setting P15.1(Setpoint selection) or PID

Actual value by setting P15.4 (Feedback value selection)!

2004 - 2007 can be set as the Analogue Output by P9.1, P9.5, P9.9.

2004 - 2008 can set as Aux Control Word with P10.9:

b0: Run enable

b1: acc / dec ramp 2 selection

b2: freq reference 2 selection

NOTE!

• AUX CW is active when configured, even if control place is not the fieldbus

• b0 Run enable is computed in AND with a possible Run enable signal from digital input. Fall

of enable will cause coasting stop.

Status word (output process data)

Information about the status of the device and messages is indicated in the Status word. The Status

word is composed of 16 bits the meanings of which are described in the table below:

Table 10. Status word (output process data)

Description

Bit

Value = 0 Value = 1

B0, RDY Drive not ready Drive ready

B1, RUN Stop Run

B2, DIR Clockwise Counter-clockwise

B3, FLT No fault Fault active

B4, W No alarm Alarm active

B5, AREF Ramping Speed reference reached

B6, Z - Drive is running at zero speed

B7 - B15 - -

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

6

Page 18

vacon • 16 Communications

General status word (output process data)

Information about the status of the device and messages is indicated in the General status word. The

General status word is composed of 16 bits the meanings of which are described in the table below:

Table 11. General status word (output process data)

Description

Bit

Value = 0 Value = 1

B0, RDY Drive not ready Drive ready

B1, RUN Stop Run

B2, DIR Clockwise Counter-clockwise

B3, FLT No fault Fault active

B4, W No alarm Alarm active

B5, AREF Ramping Speed reference reached

B6, Z - Drive is running at zero speed

B7, F - Fieldbus control active

B8 - B12 - -

Bit

I/O PC tool Keypad Fieldbus

B131000

B140110

Control Place

B150101

Actual speed (output process data)

This is actual speed of the AC drive. The scaling is -10000...10000. The value is scaled in percentage

of the frequency area between set minimum and maximum frequency.

Control word (input process data)

The three first bits of the control word are used to control the AC drive. By using control word it is

possible to control the operation of the drive. The meanings of the bits of control word are explained

in the table below:

Table 12. Control word (input process data)

Description

Bit

Value = 0 Value = 1

B0, RUN Stop Run

B1, DIR Clockwise Counter-clockwise

B2, RST Rising edge of this bit will reset active fault

B5 Not used

Speed reference (input process data)

6

This is the Reference 1 to the AC drive. Used normally as Speed reference. The allowed scaling is

0...10000. The value is scaled in percentage of the frequency area between the set minimum and

maximum frequencies.

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Page 19

Communications vacon • 17

6.3.2 Modbus process data in VACON® 20X and VACON® CP Application ACIT1075

Process data is an address area for fieldbus control. Fieldbus control is active when the value of

parameter 1.11 (Control place) is 2 (= fieldbus). The content of the process data can be programmed

in the application.The following tables present the process data contents in VACON

Application. Please refer to VACON

®

20 CP X Multipurpose Application Manual for details.

®

ACIT1075

6.3.2.1

Modbus

register

2001 Control word Drive control

2002 General control word Not used

2003 Speed reference Reference

2004 Fieldbus Data IN 1 Programmable 0...10000

2005 Fieldbus Data IN 2 Programmable 0...10000

2006 Fieldbus Data IN 3 Programmable 0...10000

Fieldbus Data IN: Master -> Slave

Table 13.

Name Description Range

Binary coded:

b0: Run

b1: Reverse

b2: Fault Reset(on edge)

b8: forces control place to fieldbus

b9: forces reference source to

fieldbus

0...10000 as 0,00...100,00% of

Min freq. - Max freq. range

2007 Fieldbus Data IN 4 Programmable 0...10000

2008 Fieldbus Data IN 5 Programmable 0...10000

2009 Fieldbus Data IN 6 Not used 2010 Fieldbus Data IN 7 Not used 2011 Fieldbus Data IN 8 Not used -

NOTE!

• CW b0 Run is acquired on edge, only if the drive is in Ready state (see Status Word b0) and

actual control place is Fieldbus.

• CW b2 Fault Reset is active even if control place is not the Fieldbus.

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

6

Page 20

vacon • 18 Communications

Fieldbus data input mapping

Fieldbus Data inputs from 1 to 5 can be configured, with parameters P11.9 - P11.12, as:

Table 14.

Process Data IN Description Note

• b0 Enable is considered only when

control place is the Fieldbus. It is

computed in AND with a possible

enable from digital input. Fall of

enable will cause coasting stop.

• b2 FreqRef2 Sel is considered only

when control place is the Fieldbus.

• functions related to bit1, b3 and b4

are available also when control

place is not the Fieldbus. Aux CW

must anyway be mapped onto a

PDI, by means of parameter P11.9.

Aux Control Word

b0: enable

b1: acc/dec ramp 2 selection

b2: freq reference 2 selection

b3: digital output 1 control

b4: digital output 2 control

active if P12.1 = 3, range 0 -

PID Setpoint

10000 as 0 - 100.00% of regulation.

active if P12.4 = 2, range 0 -

PID Actual value

10000 as 0 - 100.00% of regulation.

Analogue Out Cntrl

active if P5.1 = 8, range 0 10000 as 0 - 100.00% of output.

6

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Page 21

Communications vacon • 19

6.3.2.2 Fieldbus Data OUT: Slave -> Master

Table 15.

Modbus

Register

2101 Status word Drive state

2102 General Status word Drive state

2103 Actual speed Actual speed

2104 Fieldbus Data OUT 1 Programmable See P11.1

2105 Fieldbus Data OUT 2 Programmable See P11.2

2106 Fieldbus Data OUT 3 Programmable See P11.3

2107 Fieldbus Data OUT 4 Programmable See P11.4

2108 Fieldbus Data OUT 5 Programmable See P11.5

2109 Fieldbus Data OUT 6 Programmable See P11.6

2110 Fieldbus Data OUT 7 Programmable See P11.7

Name Description Range

Binary coded:

b0: Ready

b1: Run

b2: Reverse

b3: Fault

b4: Warning

b5: Freq. reference reached

b6: Zero speed

As Status word and:

b7: Control place is fieldbus

0...10000 as 0.00...100.00%

of Min freq. - Max freq.

range

2111 Fieldbus Data OUT 8 Programmable See P11.8

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

6

Page 22

vacon • 20 Communications

6.4 Example messages

6.4.1 Example 1 - Write Process Data

Write the process data 42001…42003 with command 16 (Preset Multiple Registers).

Command Master - Slave:

Table 16.

ADDRESS 01 hex Slave address 1 hex (= 1)

FUNCTION 10 hex Function 10 hex (= 16)

Starting address HI 07 hex

Starting address LO D0 hex

No. of registers HI 00 hex

No. of registers LO 03 hex

Byte count 06 hex Byte count 06 hex (= 6)

DATA

ERROR

CHECK

Message frame:

01 10 07 D0 00 03 06 00 01 00 00 13 88 C8 CB

Data HI 00 hex

Data LO 01 hex

Data HI 00 hex

Data LO 00 hex

Data HI 13 hex

Data LO 88 hex

CRC HI C8 hex

CRC LO CB hex

Table 17.

Starting address 07D0 hex (= 2000)

Number of registers 0003 hex (= 3)

Data 1 = 0001 hex (= 1). Setting control word run bit to 1.

Data 2 = 0000 hex (= 0).

Data 3 = 1388 hex (= 5000), Speed Reference to 50.00%

CRC field C8CB hex (= 51403)

6

The reply to Preset Multiple Registers message is the echo of 6 first bytes.

Answer Slave - Master:

Table 18.

ADDRESS 01 hex Slave address 1 hex (= 1)

FUNCTION 10 hex Function 10 hex (= 16)

DATA

ERROR

CHECK

Starting address HI 07 hex

Starting address LO D0 hex

No. of registers HI 00 hex

No. of registers LO 03 hex

CRC HI 80 hex

CRC LO 85 hex

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Starting address 07D0 hex (= 2000)

Number of registers 0003 hex (= 3)

CRC 8085 hex (= 32901)

Page 23

Communications vacon • 21

Reply frame:

Table 19.

01 10 07 D0 00 03 80 85

6.4.2 Example 2 - Read process data

Read the Process Data 42103…42104 with command 4 (Read Input Registers): for this example when

using ACCN1004 set P10.1=1, when using ACIT1075 set P11.1=0.

Command Master - Slave:

Table 20.

ADDRESS 01 hex Slave address 1 hex (= 1)

FUNCTION 04 hex Function 4 hex (= 4)

Starting address HI 08 hex

DATA

ERROR

CHECK

Message frame:

01 04 08 36 00 02 93 A5

The reply to the Read Input Registers message contains the values of the read registers.

Answer Slave - Master:

ADDRESS 01 hex Slave address 1 hex (= 1)

FUNCTION 04 hex Function 4 hex (= 4)

DATA

Starting address LO 36 hex

No. of registers HI 00 hex

No. of registers LO 02 hex

CRC HI 93 hex

CRC LO A5 hex

Table 21.

Byte count 04 hex Byte count 4 hex (= 4)

Data HI 13 hex

Data LO 88 hex

Starting address 0836 hex (= 2102)

Number of registers 0002 hex (= 2)

CRC field 93A5 hex (= 37797)

Table 22.

Actual Speed = 1388 hex (=5000 => 50.00%)

Data HI 09 hex

Data LO C4 hex

ERROR

CHECK

Reply frame:

01 04 04 13 88 09 C4 78 E9

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

CRC HI 78 hex

CRC LO E9 hex

Table 23.

Output Frequency = 09C4 hex (=2500 =>25.00Hz)

CRC field 78E9 hex (=30953)

6

Page 24

vacon • 22 Fault tracing

7. F AULT TRACING

When an unusual operating condition is detected by the AC drive control diagnostics, the drive initiates a notification visible, for example, on the keypad. The keypad will show the ordinal number of

the fault, the fault code.

The fault can be reset with the Reset button on the control keypad or via the I/O terminal. The faults

are stored in the Fault history menu which can be browsed. The different fault codes you will find

in the table below. This fault table presents only the faults related to the fieldbus in use.

NOTE! When contacting distributor or factory because of a fault condition, always write down all

texts and codes on the keypad display and send a description of the problem together with the

Info File

to your local support.

7.1 Typical fault conditions

Table 24. Typical fault conditions

Fault condition Possible cause Remedy

Drive

Termination

resistor

Cabling

Grounding Inadequate grounding.

Connections

Parameter

Missing or excessive termination resistor.

• Supply or motor cables are located

too close to the fieldbus cable

• Wrong type of fieldbus cable

• Too long cabling

Faulty connections.

• Excessive stripping of cables

• Conductors in wrong terminals

• Too loose connections of conductors

• Faulty address

• Overlapping slave addresses

• Wrong baud rate

• Wrong control place selected

Install termination resistors at both ends of the

fieldbus line.

Ensure grounding in all

points on the net

7.2 RS-485 bus biasing

When none of the devices on the RS-485 bus is sending data, all devices are in idle status. This being

the case, the bus voltage is in indefinite state, usually near 0 V due to the termination resistors. This

may cause problems in character reception because the single characters in serial communication

begin with start bit referring to bus status '0' with voltage of less than -200mV whereas the bus status '1' corresponds to bus voltage of more than +200mV. The RS-485 standard considers the voltage

interval -200mV...+200mV as undefined state. Bus biasing is therefore needed to maintain the voltage in status ‘1’ (above +200mV) also between the messages.

7

By activating the line termination using the dedicated dip switch described in Chapter 4.1.1, also a

560 Ohm resistor for line polarization is activated.

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Page 25

Fault tracing vacon • 23

.

Check cabling

Check grounding

9330A.emf

No communication

Counter OK

Poor

communication

Check communi-

cation status (par.

Counter does not

run

Counter for bad

frames

increases

Check fieldbus

parameters

bus parameters in

menu

Check other field-

Check selected

protocol

Check termination

resistors

Check that both

ends of the fieldbus

line hav termi-

nation resistors

(chapter 4)

Check parameters

e

Is the device in

READY state?

Check Master’s

parameters

Is fieldbus selected

as control place?

Does Master give

RUN command?

Check cabling

Check termination

resistors

Other bus devices

Check connections

Check the led on

keypad

Check external

interlockings (I/O)

Check configura-

tions (Sla e add-

ress, baudrate etc.)

v

Check distances

between cables,

see chapter 4.

Check cable types,

see chapter 3.

Check grounding,

see chapter 4. Re-

member to make

grounding for each

device!

Check terminals for

loose connections

Check stripping of

cables and

conductors, see

chapter 4.

Use keypad to

monitor variable

Check that both

ends of th fieldbus

line have t rmina-

tion resistors

(chapter 4)

e

e

Check cable for

cuts

Check correct place-

ment of conductors

in terminals

Check other

necessary devices

Drive does not

start from the bus

Check control place

parameter setting

V2.1)

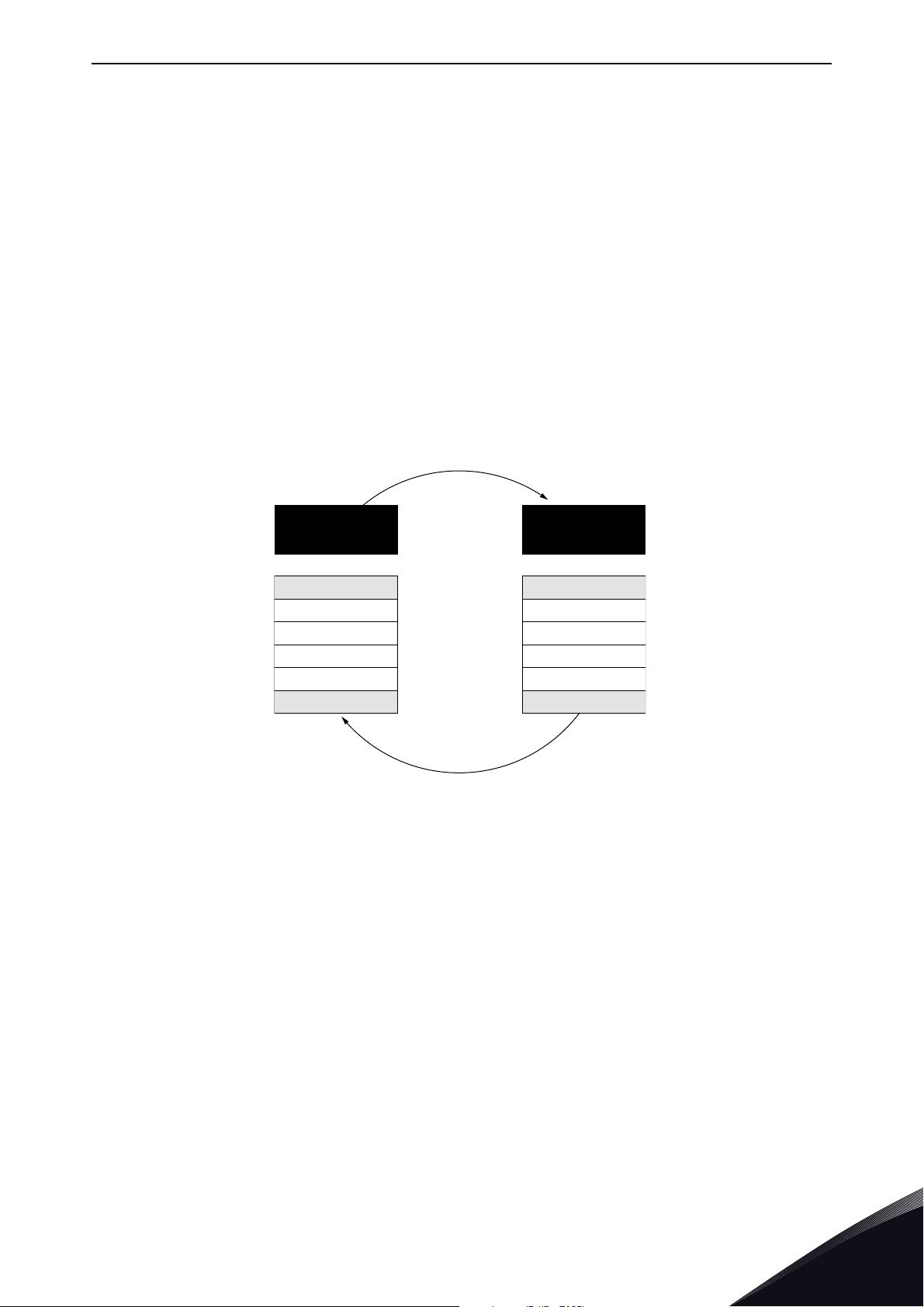

7.3 Other fault conditions

The following fault tracing diagram will help you to locate and fix some of the most usual problems.

If the problem persists contact your local distributor.

Figure 3. Fault tracing diagram for Modbus RTU

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

7

Page 26

vacon • 24 Quick setup

8. QUICK SETUP

Following these instructions, you can easily and fast set up your Modbus for use:

Choose control place.

1

2

A. Press LOC/REM button on keypad to select

Select Fieldbus as remote control place. The parameter depends on the appli-

B.

cation used:

• P2.1 in VACON

• P1.11 in VACON

Make these settings in the master software

A. Set Control Word to '0' by writing the data 0000h to the register 2001

B. Set Control Word to '1' by writing the data 0001h to the register 2001

C. AC drive status is RUN

D. Set Speed Reference value to '5000' (=50.00%) by writing the data 1388h to the

register 2003

Actual speed is 5000 (25.00 Hz if MinFreq is 0.00 Hz and MaxFreq is 50.00 Hz)

E.

F. Set Control Word to '0' by writing the data 0000h to the register 2001

G. AC drive status is STOP.

.

d

®

20

®

20 X and VACON® 20 CP

Remote Control Place

.

d

.

d

.

d

8

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Page 27

APPENDIX 1 - PROCESS DATA vacon • 25

9. APPENDIX 1 - PROCESS DATA

Process Data IN (Master to Slave)

Use of Process Data In variables depends on the used application. The configuration of the data is

free.

Process Data OUT (Slave to Master)

Use of Process Data Out variables depends on the used application.

The Fieldbus Master can read the AC drive’s actual values using process data variables.

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

9

Page 28

www.danfoss.com

Vacon Ltd

Member of the Danfoss Group

Runsorintie 7

65380 Vaasa

Finland

Document ID:

DPD01925A

Rev. A

Sales code: DOC-INSV20MODBUS+DLUK

Loading...

Loading...