Danfoss vacon 100 industrial, vacon 100 flow, vacon 100 hvac, optbj User guide

VACON® 100 INDUSTRIAL VACON® 100 FLOW VACON® 100 HVAC

AC DRIVES

OPTBJ

STO AND ATEX OPTION BOARD

SAFETY MANUAL

|

|

vacon • 3 |

|

TABLE OF CONTENTS |

|

|

Document: DPD00470G |

|

|

Release date : 28102020 |

|

1. |

Approvals............................................................................................................... |

4 |

2. |

General ................................................................................................................ |

10 |

2.1 |

References .............................................................................................................................. |

11 |

3. |

Installation of OPTBJ board ................................................................................. |

12 |

4. |

OPTBJ board layout.............................................................................................. |

15 |

4.1 |

Identifying board revision........................................................................................................ |

15 |

4.2 |

OPTBJ board jumpers............................................................................................................. |

16 |

4.3 |

STO jumper on the VACON® 100 family AC drive .................................................................. |

17 |

4.4 |

Cuttable jumper to separate control ground from PE ........................................................... |

18 |

5. |

STO and SS1 safety functions............................................................................... |

19 |

5.1 |

Safe Torque Off (STO) principle .............................................................................................. |

20 |

5.2 |

Safe Stop 1 (SS1) Principle ..................................................................................................... |

22 |

5.3 |

Technical details ..................................................................................................................... |

24 |

5.3.1 |

Response times....................................................................................................................... |

24 |

5.3.2 |

Input voltage levels ................................................................................................................. |

24 |

5.3.3 |

External dark test pulse filtering capability........................................................................... |

24 |

5.3.4 |

External light test pulse filtering capability ........................................................................... |

25 |

5.3.5 |

Connections............................................................................................................................. |

25 |

5.3.6 |

Relay output ............................................................................................................................ |

26 |

5.3.7 |

Safety-related data according to the standard ...................................................................... |

27 |

6. |

Commissioning .................................................................................................... |

29 |

6.1 |

General wiring instructions .................................................................................................... |

29 |

6.2 |

Wiring examples ..................................................................................................................... |

32 |

6.3 |

Parameterization of STO functionality.................................................................................... |

36 |

6.4 |

Checklist for commissioning the OPTBJ board...................................................................... |

37 |

6.5 |

Testing the Safe Torque Off (STO) or Safe Stop 1 (SS1) safety functions .............................. |

38 |

7. |

Maintenance......................................................................................................... |

39 |

7.1 |

Faults related to the Safe Torque Off (STO) or Safe Stop 1 (SS1) safety functions ............... |

39 |

8. |

Thermistor function (ATEX) ................................................................................. |

41 |

8.1 |

Technical data......................................................................................................................... |

45 |

8.1.1 |

Functional description ............................................................................................................ |

45 |

8.1.2 |

Hardware and connections..................................................................................................... |

45 |

8.1.3 |

Atex function ........................................................................................................................... |

45 |

8.1.4 |

Short circuit monitoring.......................................................................................................... |

46 |

8.2 |

Commissioning ....................................................................................................................... |

46 |

8.2.1 |

General wiring instructions .................................................................................................... |

46 |

8.2.2 |

Fault diagnosis of thermistor function ................................................................................... |

46 |

NOTE! You can download the English and French product manuals with applicable safety, warning and caution information from https://www.danfoss.com/en/service-and-support/.

REMARQUE Vous pouvez télécharger les versions anglaise et française des manuels produit contenant l’ensemble des informations de sécurité, avertissements et mises en garde applicables sur le site https://www.danfoss.com/en/service-and-support/.

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

vacon • 4 |

Approvals |

|

|

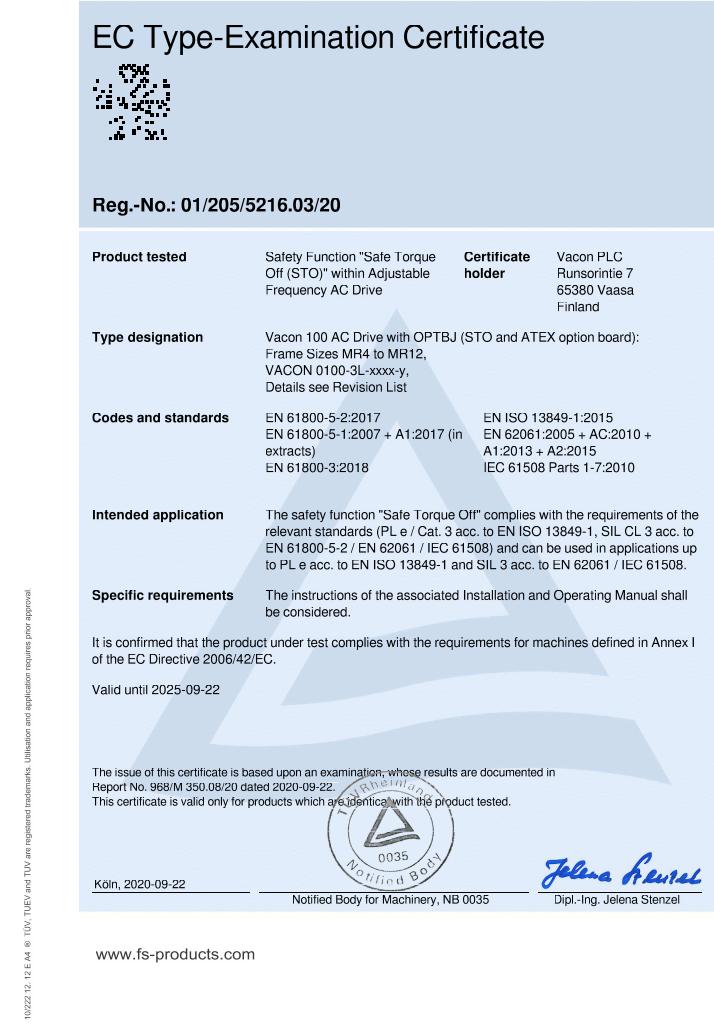

1.APPROVALS

DANFOSS A/S

DK-6430 Nordborg

Denmark

CVR nr.: 20 16 57 15

Telephone: +45 7488 2222

Fax: |

+45 7449 0949 |

EU DECLARATION OF CONFORMITY

Danfoss A/S

Vacon Ltd

declares under our sole responsibility that the

Product name |

Vacon OPTBJ option board to be used with Vacon 100 family products |

Product identification |

70CVB01380 |

Product Safety Functions |

Safe Torque Off (Specified in EN 61800-5-2) |

fulfils all of the relevant safety component requirements of EC Machinery Directive 2006/42/EC.

Notified body that carried out the EC type examination:

TÜV Rheinland Industrie Service GmbH (NB0035)

Am Grauen Stein, 51105 Köln, Germany

The following standards and/or technical specifications referenced below were used:

-EN 61800-5-2:2007

Adjustable speed electrical power drive systems, Part 5-2: Safety requirements – Functional

-EN 61800-5-1:2007 (only for LV Directive compliance)

Adjustable speed electrical power drive systems, Part 5-2: Safety requirements - Electrical, thermal and energy

-EN 61800-3:2004/A1:2012 (only for EMC Directive compliance)

Adjustable speed electrical power drive systems, Part 3: EMC requirements and specific test methods

-EN ISO 13849-1:2008 + AC:2009

Safety of machinery - Safety-related parts of control systems –, Part 1: General principles for design

-EN 62061:2005 + AC:2010

Safety of machinery - Functional safety of safety-related electrical, electronic and programmable electronic control systems

-IEC 61508 Parts 1-7:2010

Functional safety of electrical/electronic/programmable electronic safety-related systems

-EN 60204-1:2006 + A1:2009 + AC:2010 (in extracts)

Safety of machinery – Electrical equipment of machines – Part 1: General requirements

-EN 61326-3-1:2008

Electrical equipment for measurement, control and laboratory use – EMC, Part 3-1: Immunity requirements for safety-related systems and for equipment intended to perform safety-related functions (functional safety).

Date |

Issued by |

Date |

Approved by |

15-04-2016 |

Signature |

15-04-2016 |

Signature |

|

Name: Antti Vuola |

|

Name: Timo Kasi |

|

Title: Head of Standard Drives |

|

Title: VP, Design Center Finland and Italy |

|

|

|

|

Danfoss only vouches for the correctness of the English version of this declaration. In the event of the declaration being translated into any other language, the translator concerned shall be liable for the correctness of the translation.

ID No: DPD01856 |

Revision No: A |

Page 1 of 1 |

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

.

Approvals |

|

vacon • 5 |

||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

vacon • 6 |

Approvals |

|

|

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

.

Approvals |

vacon • 7 |

|

|

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

vacon • 8 |

Approvals |

|

|

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

.

Approvals |

vacon • 9 |

|

|

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

vacon • 10 |

General |

|

|

2.GENERAL

This document covers OPTBJ option board 70CVB01380 (141X4029) revision D (or newer).

Table 1. Version history of the manual

Date |

Revision |

Updates |

|

|

|

|

|

|

|

|

|

10/2020 |

G |

• Updated EC Type-Examination Certificate |

|

|

|

|

|

|

|

|

NOTE! Designing of safety-related systems requires special knowledge and skills. Only qualified persons are permitted to install and set up the OPTBJ board.

This document covers the OPTBJ option board 70CVB01380 (141X4029) functionality together with VACON® 100 family Control board 70CVB01582 (141X4153).

The OPTBJ option board together with VACON® 100 family control board provides the following safety functions with VACON® 100 family products.

The following safety-related abbreviations and expressions have been used in this manual:

SIL |

Safety Integrity Level |

|

|

|

|

|

|

|

PL |

Performance Level |

|

|

|

|

|

|

|

PFH |

Probability of a dangerous random hardware Failure per Hour |

|

|

|

|

|

|

|

Category |

Designated architecture for a safety function (from EN ISO 13849-1:2006) |

|

|

|

|

|

|

|

MTTFd |

Mean time to dangerous failure |

|

|

|

|

DCavg |

Average diagnostic coverage |

|

|

|

|

PFDavg |

Average probability of (random hardware) failure on demand |

|

|

|

|

TM |

Mission time |

|

|

|

|

Safety |

Device that controls the safety-related signal lines. Can be, for example, emergency button, |

|

actuator |

safety PLC, safety relay. |

|

|

|

|

|

|

|

OSSD |

Output Signal Switching Device, i.e. switch that controls the signal lines between actuator and |

|

the drive's signal input. |

||

|

Safe Torque Off (STO)

The hardware based 'Safe Torque Off' safety function prevents the drive from generating torque on the motor shaft. The STO safety function has been designed for use in accordance with the following standards:

•EN 61800-5-2 Safe Torque Off (STO) SIL3

•EN ISO 13849-1 PL"e" Category 3

•EN 62061: SILCL3

•IEC 61508: SIL3

•The function also corresponds to an uncontrolled stop in accordance with the stop category 0, EN 60204-1.

•The STO safety function has been certified by TÜV Rheinland

NOTE! The STO function is not the same as a prevention of unexpected start-up function. For fulfilling those requirements, additional external components are required according to appropriate standards and application requirements. Required external components may be for example:

•Appropriate lockable switch

•A safety relay providing a reset function

NOTE! The safety functions of OPTBJ do not comply with Emergency Switching Off according to EN 60204-1. NOTE! Do not use the STO function as a standard stop function of the drive.

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

.

General |

vacon • 11 |

|

|

NOTE! In an IGBT fault situation, the shaft of a permanent magnet motor can rotate up to 180 degrees around the pole of the motor.

NOTE! If the pollution degree 2 cannot be guaranteed, use the IP54 protection class.

CAUTION! The OPTBJ board and its safety functions do not electrically isolate the drive output from the mains supply. If electrical work is to be carried out on the drive, the motor or the motor cabling, the drive has to be completely isolated from the mains supply, for example, using an external supply disconnecting

13006.emf

switch. See, for example, EN60204-1 Chapter 6.5.

Safe Stop 1 (SS1)

The SS1 safety function is realized in compliance with type C of the drives safety standard EN 61800- 5-2 (Type C: "The PDS(SR) initiates the motor deceleration and initiates the STO function after an application specific time delay").

The SS1 safety function has been designed for use in accordance with the following standards:

•EN 61800-5-2 Safe Stop 1 (SS1) SIL2

•EN ISO 13849-1 PL"d" Category 3

•EN 62061: SILCL2

•IEC 61508: SIL2

•The function also corresponds to a controlled stop in accordance with the stop cat. 1, EN 60204-1.

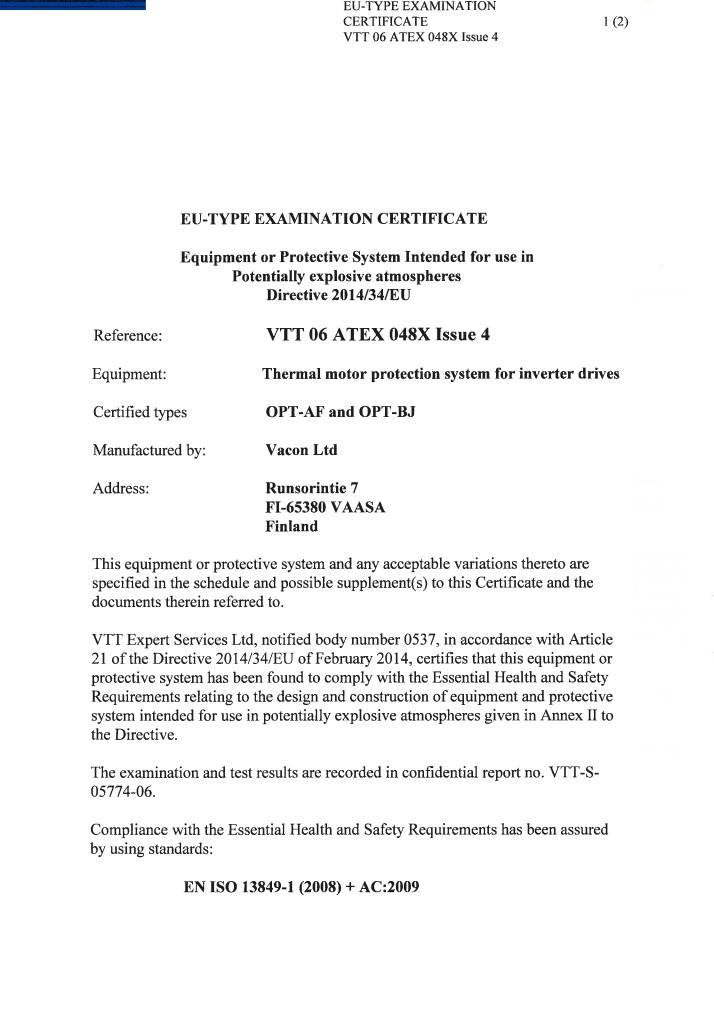

Motor Thermistor Over temperature protection (according to ATEX)

Overtemperature detection using thermistor. It can be used as a tripping device for ATEX certified motors.

The thermistor tripping function is certified by VTT* according to ATEX directive 94/9/EC. All safety functions of the OPTBJ board are described in this manual.

* VTT = Technical Research Centre of Finland

2.1References

VACON® 100 family Installation and Application manuals are downloadable at https://www.danfoss.com/en/service-and-support/.

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

vacon • 12 |

Installation of OPTBJ board |

|

|

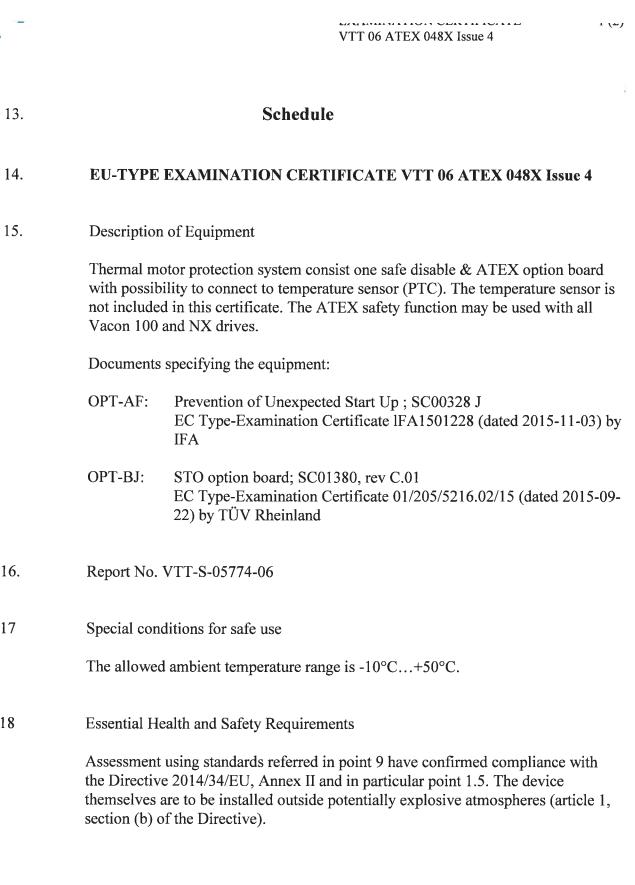

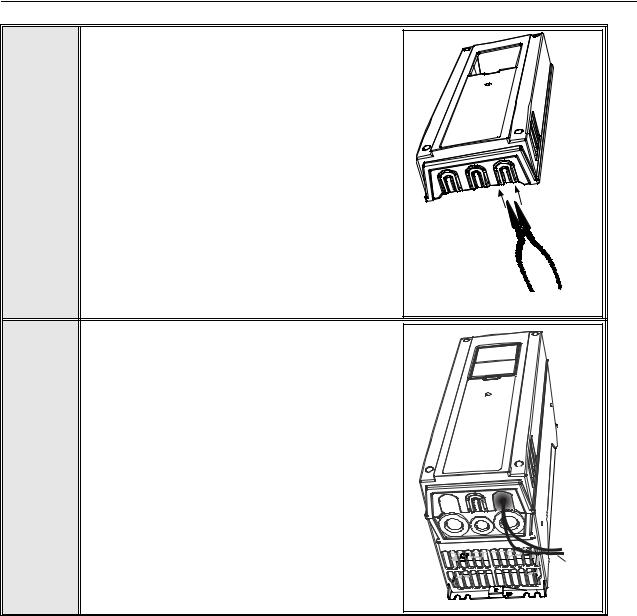

3.INSTALLATION OF OPTBJ BOARD

Open the cover of the AC drive.

M4x55

1

11573_00

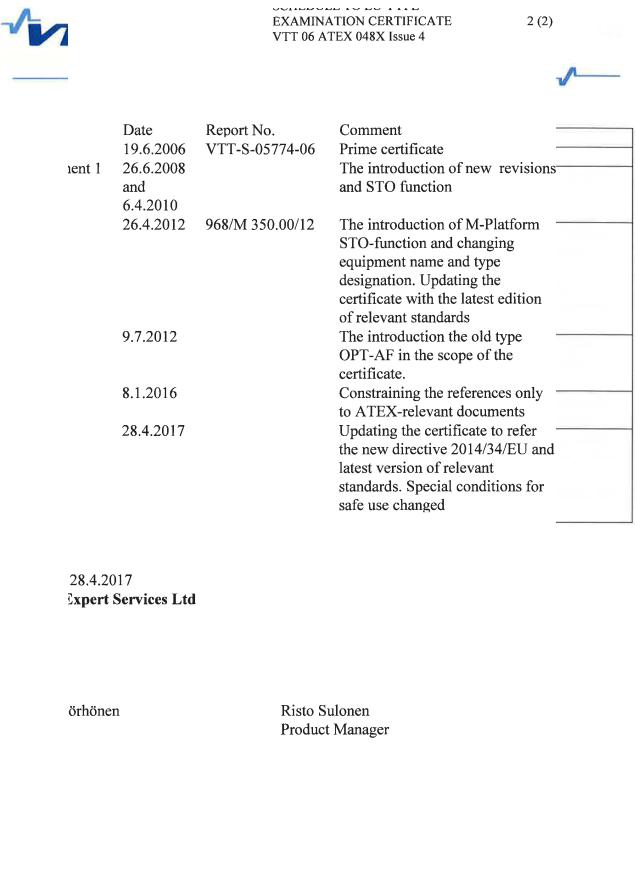

The relay outputs and other I/O-terminals may have a dangerous control voltage present even when VACON® 100 family AC drive is disconnected from mains.

9000.emf

2

A |

B |

3040A_00 |

NOTE: Incompatible boards cannot be installed on VACON® 100 family AC drives. Boards that are compatible for VACON® 100 family AC drives have two codings

that enable the placing of the board (see above): one for VACON® 100 family compatibility (A), and another for the slot-specific placing (B).

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

.

Installation of OPTBJ board |

vacon • 13 |

|

|

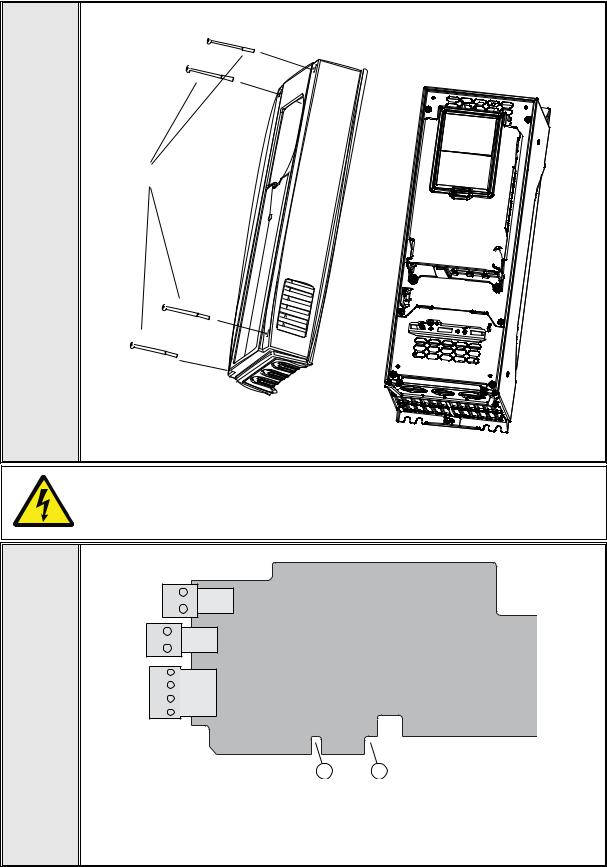

Open the inner cover to reveal the option board slots and install the OPTBJ board into slot E. Close the inner cover.

NOTE! See Chapter 4.2 for the jumper settings!

3

E

3041A_00

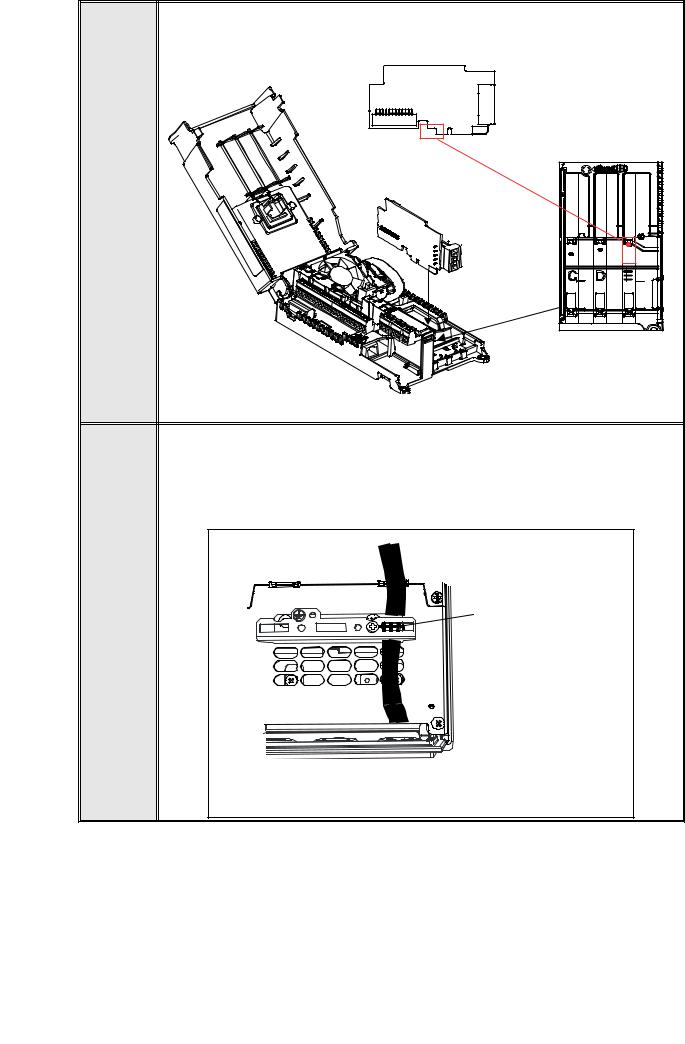

If shielded cable is used, ground the shield of the OPTBJ cable to the frame of the drive by using the grounding clamp for control cable included in the delivery of the drive.

NOTE! If shielded cable is used, grounding must be done according to best practice.

4 |

Grounding clamp for |

|

control cable |

||

|

11574A_uk

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

vacon • 14 |

Installation of OPTBJ board |

|

Unless already done for the other control cables, |

|

cut free the opening on the AC drive cover for the |

|

OPTBJ cable (protection class IP21). |

|

NOTE: Cut the opening on the side of the slot E! |

5

11576_00

Remount the AC drive cover and run the cable as shown in picture.

NOTE: When planning the cable runs, remember to keep the distance between OPTBJ cables and the motor cable at a minimum of 30 cm. It is recommended to route the OPTBJ cables away from the power cables as shown in the picture.

6

OPTBJ cables

11572_uk

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

.

OPTBJ board layout |

vacon • 15 |

|

|

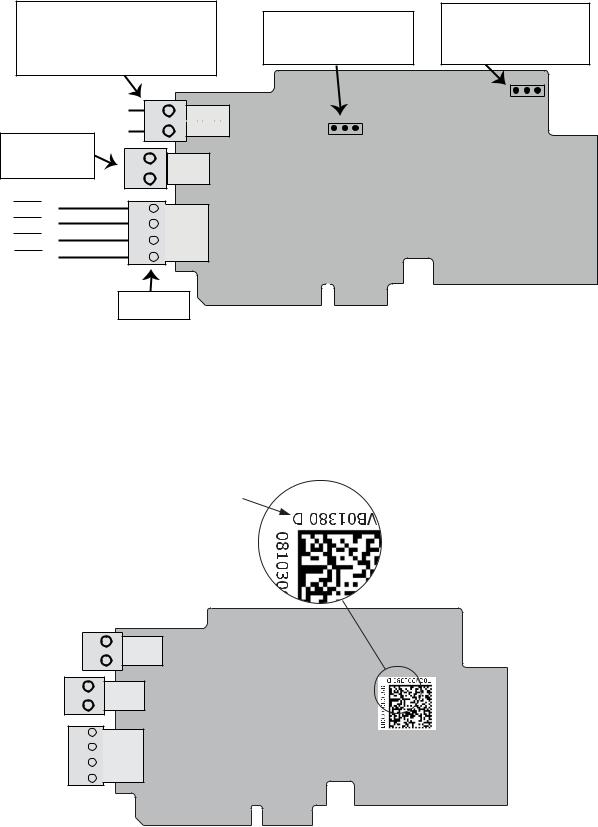

4.OPTBJ BOARD LAYOUT

Thermistor Input:

Thermistor active > 4000 ohm.

Jumperfor selecting

After being active, the faultcan

thermistor short circuit

be reset if resistance is < 2000 ohm

supervision

TI1+ |

28 |

|

TI1- |

29 |

X23 |

Relay output |

|

On Off |

25 |

Thermistor short |

|

for STO function |

circuit supervision |

|

|

26 |

|

STO1+ |

1 |

|

STO1- |

2 |

|

STO2+ |

3 |

|

STO2- |

4 |

|

STO inputs

Figure 1. OPTBJ board layout

Jumperfor STO board activation. Place here the 3-pin jumper from

the control board.

STO JMP

X10

3038A_uk

4.1Identifying board revision

The revision of OPTBJ board can be identified by checking the revision letter on the matrix bar code sticker. Revision letter is written after the board type code. For example, '70CVB01380 D' indicates that the board is of revision D. Some features may be introduced or changed during board updates.

11855_00

Figure 2. The board identification sticker on the OPTBJ board

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Loading...

Loading...