Page 1

Fact Sheet | VACON® 1000

Configurable, versatile and

reliable medium-voltage

drive for industrial applications

drives.danfoss.com

2.4 kV up

to 11 kV

full range for

industrial MV

general purpose

drive applications

Page 2

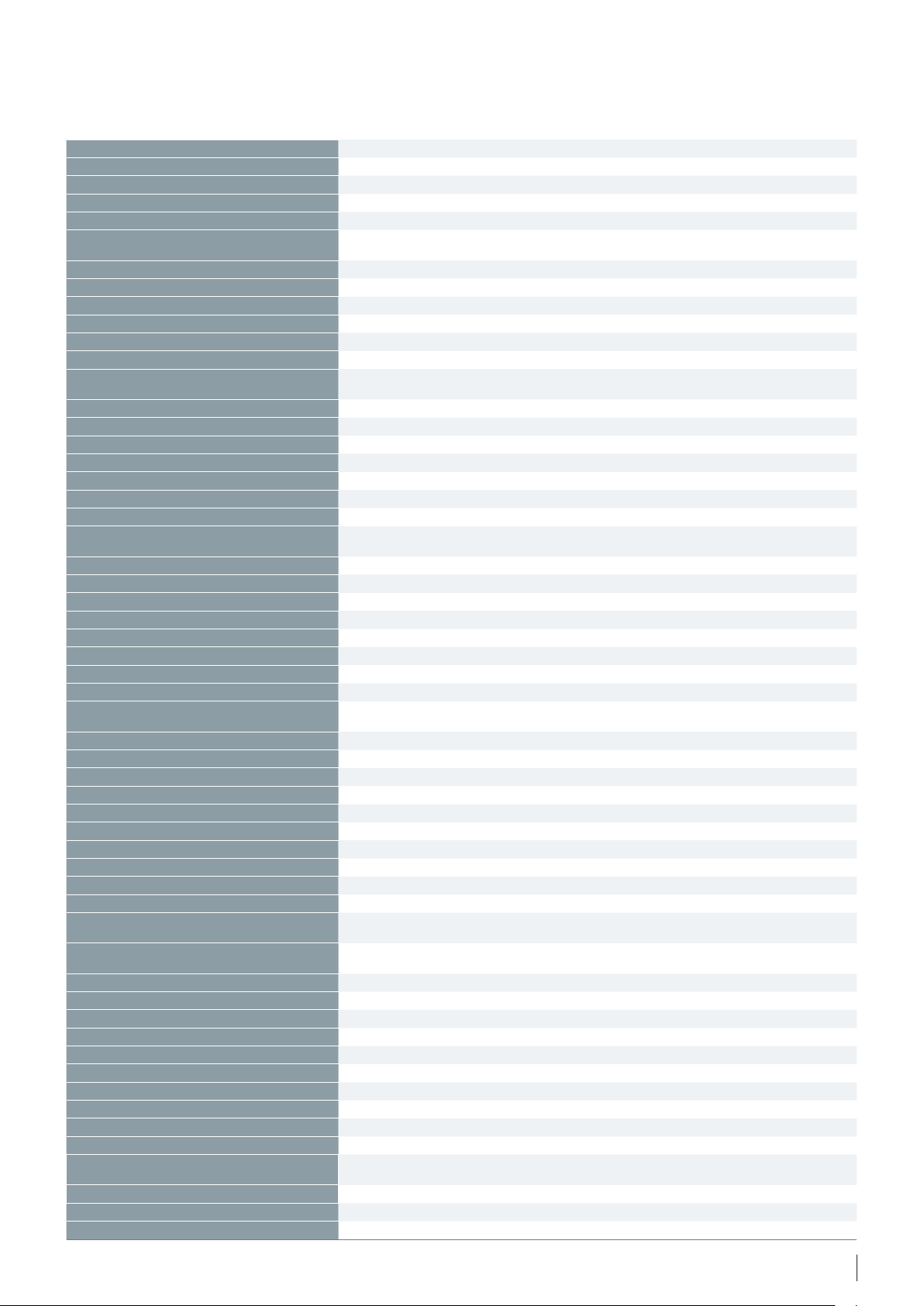

MV drive designed with you in mind

Danfoss’ unsurpassed experience in advanced AC drive technologies makes the VACON® 1000 air-cooled MV drive the preferred

choice for industrial medium-voltage general purpose applications, especially for variable torque loads such as pumps and fans

in the low and mid-power range. The standalone version, available at 215 A and below, is one of the most compact and versatile

multi-level MV drives in its class.

Feature Benefit

High reliability

High MTBF Up to 200,000 hours of non-stop operation (depending on voltage class and current rating)

Electronic bypass IGBT based power cell bypass function enables fast (1 ms) reaction time (optional, +PPCB)

Power cell redundancy Continued full power operation in case of fault in power cell (optional, +PPCR)

Low-voltage (LV) ride-through Allows for continued operation during <100 ms grid voltage sag down to -30% of nominal input

voltage

High temperature operation Up to +50° C derated operation to avoid overheating

Harsh environment IP31 as default, optional IP42, and chemical environment protection level IEC 660721: Class 3C2

Redundant cooling fan Enables non-stop operation in case of a fan failure and extended overall lifetime (optional, +QDFR)

UPS for control voltage (DC) Control stays on in case of supply interruptions

Air filter clogging sensor Additional protection to prevent overheating

Detailed fault monitoring Alarm and fault information for reduced downtime

External auxiliary power (LV) External source input for cooling fans (optional, +QDEX)

Safety

Door interlock (IEC versions: electromagnetic, Prevents opening of cabinet door unless mains power is off

UL versions: mechanical)

Residual voltage indicators LEDs and HMI as well as visual DC-link voltage indicators on power cells provide

complementary information for increased safety

PTC sensors for temperature monitoring Transformer thermal protection

MV drives standard compliance Complies with international MV drive safety requirements according to applicable IEC and UL

standards

Fiber optic cables between MV and LV control parts Galvanic isolation between LV controls and MV section

Low ownership cost

Less than 5% THDi Causes very low grid harmonics, minimal network disturbances, complies with IEEE-519

Designed for 20 years of operation Long lifetime

High total efficiency >96.5%, including transformer Short return on investment

Only front access required for installation and Easy service access, saves space in electric room (no back-access needed)

maintenance

No special requirements on motor insulation Motor-friendly

Up to 2000 m operation Install the drive in the optimal location, not necessarily next to motor

Process Performance

Vector control Closed-loop and sensorless vector control for applications requiring more percise control

U/f multipoint control Increases efficiency in pump and fan applications

Different autotuning modes Motor autotuning with three (3) different modes for easier start-up (coupled, uncoupled or

non-rotational motor)

Configurable overload Up to 300% maximum torque limit (with base load derating)

Overvoltage prevention during deceleration Automatic limit control during fast deceleration to avoid overvoltage tripping

Voltage boost Booster function for high starting torque requirements

Selectable for variable torque or constant torque Optimal drive selection according to application needs

rating

Multi-motor applications Drive can be configured for alternating change-over of up to 8 motors (VSD to DOL), optional bypass

switchgear needed

System bypass (Manual, Auto, Synchronous) Preconfigured bypass configurations (to and from DOL) including make-before-brake switch over

(optional, +PMBP Manual motor bypass, +PABP Automatic motor bypass, or +PSBP Synchronous

transfer for 1 motor only)

User-friendly

Easy and simple selections Wide variety of standard options supports flexible configuration

Touch screen as standard HMI 7’’ screen as default, optional 10’’ screen (+MHMI), for local control and monitoring

Commissioning tool PC tool for parameter setting with embedded oscilloscope-like function

Event log Log up to 500 events with event description

Fieldbus communication Most common communication protocols available for flexible system control (optional)

Space saving

High power density Standalone version with smallest footprint in the market available at 215 A and below (≤6.9 kV)

Standalone design (≤215 A, ≤6.9 kV) No on-site interconnection of separate sections needed

Simple cable installation Allows for top and bottom cabling for input and output power and control

2 Danfoss Drives · DKDD.PFP.909.A2.02

Page 3

Technical data

Seismic zone/Ground acceleration

System burn-in at factory prior to delivery

Danfoss Drives · DKDD.PFP.909.A2.02

Topology type

Multilevel IGBT topology (Cascade H-Bridge)

Technology Voltage source inverter (VSI)

Inverter configuration

Pulse Width Modulated (PWM) power modules

Input frequency

50/60 Hz (±5% transients)

Input voltage tolerance ±10% of nominal, unbalance up to 3%, per IEC 610002-4

Input voltage sag

-30% of nominal without tripping

Continuousoperation with reduced power, derated power between 70-90%

Short circuit current rating (SCCR)

31.5 kA, 100 ms

Input current THD <5% (at rated load)

Input voltage THD

<5% (at rated load)

Output current THDi (1st…49th)

<2% at rated speed

Output dU/dt <3000 V/µs

Power factor

>0.96 (at rated load)

System efficiency >98.5% (at rated load, excluding transformer)

>96.5% (at rated load, including transformer)

Output voltage range 2.4–11 kV

Output frequency range

0–75 Hz (higher frequencies, for example, 120 Hz can be evaluated)

Loading Squared torque; Constant torque; Constant torque and/or power

Motor control method U/F control; Sensorless vector control; Vector control with speed feedback; Speed and torque control

Motor type

Induction (asynchronous) motor or Synchronous motor (with separate excitation)

Frequency resolution 0.01 Hz

Speed control range 1–100% (with closed-loop vector control); 5–100% (with sensorless vector control)

Steady state speed control accuracy

±0.01% (with closed-loop vector control, depending on sensor accuracy)

(%of rated speed)

±0.5% (with sensorless vector control)

Acceleration/Deceleration time 0–3000 s (configurable)

Control voltage with circuit protection 1– 230 VAC, 50 Hz; 1– 220 VAC, 60 Hz

Control power Single phase AC 120–240V; Three Phase AC 240–480V; capacity 5 kVA (other voltages available)

Design operating time 24 hours/day

Minimum availability per 12 months

99.97%

MTBF Up to 200,000 hours of nonstop operation depending on the voltage class and current rating

Product lifetime 20 years

Input impedance device

Multiphase isolation transformer integrated into the drive

Transformer type of construction Dry type, phase shifting, Cu/Cu; Forced air cooling

AI/Cu orAI/AI available as an engineered option

Transformer insulation type

Class 180 (H)

Transformer inrush current limitation

In >215 A limited with start-up cabinet (optional, +PSTC)

Transformer secondary for auxiliaries Three phase, 460 VAC with neutral and with a 380 VAC tap, 50/60 Hz

Temperature sensors in transformer windings

3x PT100, one in each winding

Grounding system

As per IEC61936-1

Ground busbar Tin-plated grounding bus bar section

Cabinet sheet metal thickness

Doors and panels: 1.5 mm. Base plinth: 5 mm

Cabinet lights

In the control cabinet

Power cell bypass Automatic via IGBT, 1 ms bypass time (optional, +PPCB)

UPS for control voltage (DC) 30 minutes running time

External auxiliary AC voltage for cooling fan

380–460 VAC, 50 Hz

(optional, +QDEX)

380–460 VAC, 60 Hz

Enclosure IP and access

IP31 (IEC) (standard)

IP42 (IEC) (optional, +IP42)

Cables entry Input, motor and control cables: bottom and top

Cooling System Forced air cooling including fan monitoring. Fan redundancy (optional, +QDFR)

Ambient temperature (operation)

0°–40°C (normal operation); 40°–50°C (derated operation)

Ambient temperature (storage/transportation) -40–70° C

Relative humidity (operation) 5–95% non-condensing

Relative humidity (storage/transportation)

10–95% non-condensing

Chemical environment conditions IEC 60721-3-3: Class 3C2

Environment corrosion category According to ISO/EN 12944-2: C1 as default; C4 as an engineered option

Electromagnetic compatibility environment

IEC 61000-2-5: Industrial

Altitude <1000 m (standard); 1000–2000 m (derating); >2000 m (on request)

Zone 2 (standard)

Zone 4 (optional, +SZ04)

4 h minimum, according to IEEE 1566

ATEX area: Flammable product/Zone IEC 60079-10-1/2: as an engineered option, certified per EN 50495:2010

Noise level ≤85 dB(A) at 1 m from the enclosure

3

Page 4

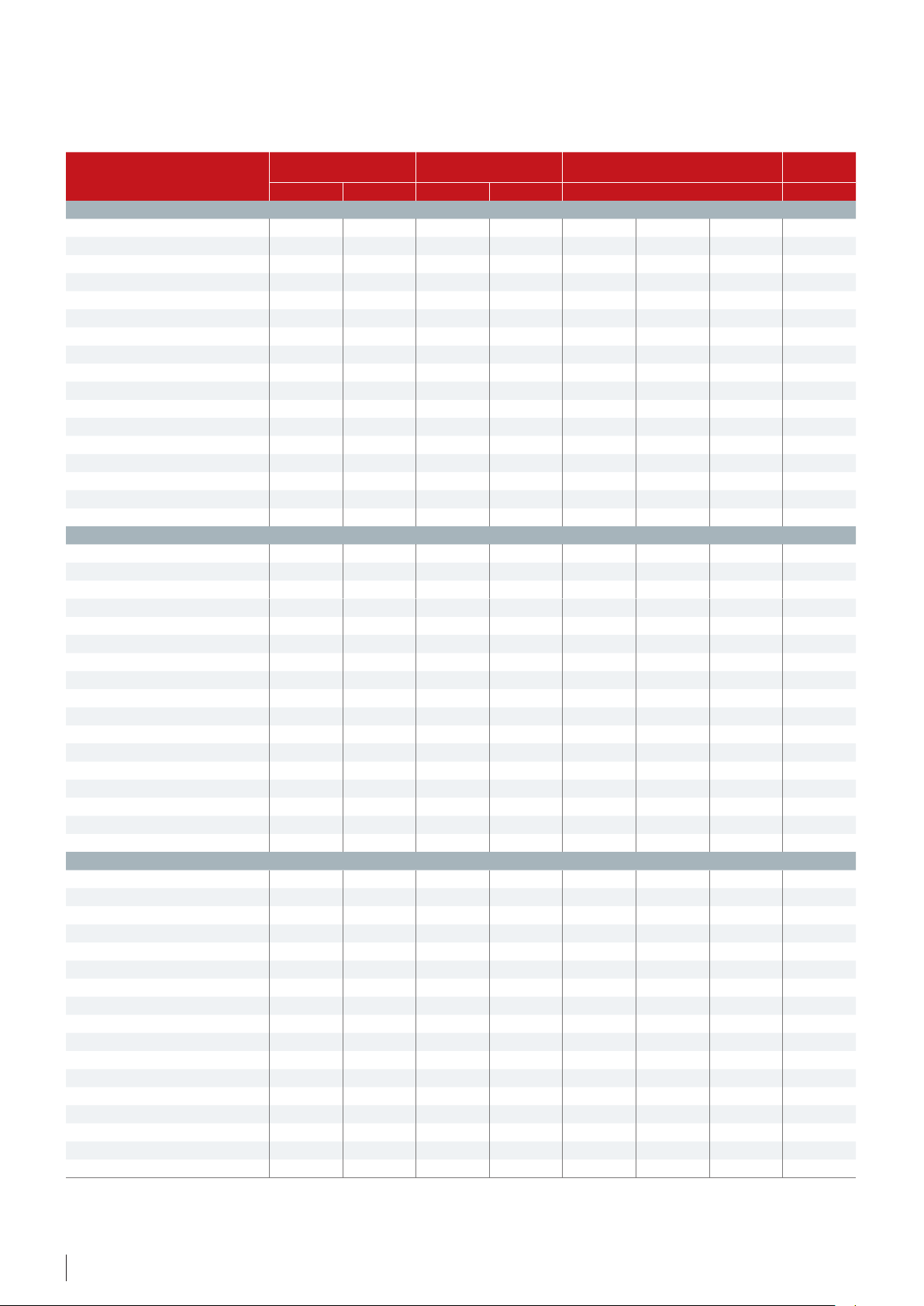

Power rating (IEC variant)

4 Danfoss Drives · DKDD.PFP.909.A2.02

Low overload rating

High overload rating

Cabinet dimensions Weight

110% (Variable torque)

150% (Constant torque)

AC drive type

IL [A] S [kVA] IHD [A] S [kVA] HxWxD [mm] [kg]

Nominal voltage 3000 V (18-pulse, 3 power cell per phase, 50 Hz)

VACON1000-ED-036-030+G2CE 36 180 26 130 2796 1210 1250 2000

VACON1000-ED-050-030+G2CE 50 250 36 180 2796 1210 1250 2050

VACON1000-ED-070-030+G2CE 70 360 51 260 2796 1210 1250 2100

VACON1000-ED-090-030+G2CE 90 460 66 340 2888 1610 1250 2850

VACON1000-ED-100-030+G2CE 100 510 73 370 2888 1610 1250 2900

VACON1000-ED-120-030+G2CE 120 620 88 450 2888 1610 1250 2950

VACON1000-ED-140-030+G2CE 140 720 102 530 2888 1610 1250 3000

VACON1000-ED-150-030+G2CE 150 770 110 570 2888 1910 1250 4350

VACON1000-ED-180-030+G2CE 180 930 132 680 2888 1910 1250 4400

VACON1000-ED-190-030+G2CE 190 980 139 720 2888 1910 1250 4450

VACON1000-ED-215-030+G2CE 215 1110 157 810 2888 1910 1250 4500

VACON1000-ED-250-030+G2CE 250 1290 183 950 2796 3810 1400 5100

VACON1000-ED-305-030+G2CE 305 1580 223 1150 2796 4110 1400 5500

VACON1000-ED-350-030+G2CE 350 1810 256 1330 2796 4110 1400 5800

VACON1000-ED-438-030+G2CE 438 2270 321 1660 2796 4710 1400 6950

VACON1000-ED-560-030+G2CE 560 2900 410 2130 2796 5010 1400 8300

VACON1000-ED-680-030+G2CE 680 3530 498 2580 2796 5010 1400 9350

Nominal voltage 3300 V (18-pulse, 3 power cell per phase, 50 Hz)

VACON1000-ED-036-033+G2CE 36 200 26 140 2796 1210 1250 2200

VACON1000-ED-050-033+G2CE 50 280 36 200 2796 1210 1250 2250

VACON1000-ED-070-033+G2CE 70 400 51 290 2796 1210 1250 2300

VACON1000-ED-090-033+G2CE 90 510 66 370 2888 1610 1250 3050

VACON1000-ED-100-033+G2CE 100 570 73 410 2888 1610 1250 3100

VACON1000-ED-120-033+G2CE 120 680 88 500 2888 1610 1250 3150

VACON1000-ED-140-033+G2CE 140 800 102 580 2888 1610 1250 3200

VACON1000-ED-150-033+G2CE 150 850 110 620 2888 1910 1250 4550

VACON1000-ED-180-033+G2CE 180 1020 132 750 2888 1910 1250 4600

VACON1000-ED-190-033+G2CE 190 1080 139 790 2888 1910 1250 4650

VACON1000-ED-215-033+G2CE 215 1220 157 890 2888 1910 1250 4700

VACON1000-ED-250-033+G2CE 250 1420 183 1040 2796 4110 1400 5300

VACON1000-ED-305-033+G2CE 305 1740 223 1270 2796 4110 1400 5800

VACON1000-ED-350-033+G2CE 350 2000 256 1460 2796 4110 1400 6100

VACON1000-ED-438-033+G2CE 438 2500 321 1830 2796 4710 1400 7450

VACON1000-ED-560-033+G2CE 560 3200 410 2340 2796 5010 1400 8700

VACON1000-ED-680-033+G2CE 680 3880 498 2840 2796 5010 1400 9950

Nominal voltage 4160 V (24-pulse, 4 power cell per phase, 50 Hz)

VACON1000-ED-036-041+G2CE 36 250 26 180 2796 1210 1250 2400

VACON1000-ED-050-041+G2CE 50 360 36 250 2796 1210 1250 2450

VACON1000-ED-070-041+G2CE 70 500 51 360 2796 1210 1250 2500

VACON1000-ED-090-041+G2CE 90 640 66 470 2888 1610 1250 3250

VACON1000-ED-100-041+G2CE 100 720 73 520 2888 1610 1250 3300

VACON1000-ED-120-041+G2CE 120 860 88 630 2888 1610 1250 3350

VACON1000-ED-140-041+G2CE 140 1000 102 730 2888 1610 1250 3400

VACON1000-ED-150-041+G2CE 150 1080 110 790 2888 1910 1250 4750

VACON1000-ED-180-041+G2CE 180 1290 132 950 2888 1910 1250 4800

VACON1000-ED-190-041+G2CE 190 1360 139 1000 2888 1910 1250 4850

VACON1000-ED-215-041+G2CE 215 1540 157 1130 2888 1910 1250 4900

VACON1000-ED-250-041+G2CE 250 1800 183 1310 2796 4610 1400 6150

VACON1000-ED-305-041+G2CE 305 2190 223 1600 2796 4610 1400 6850

VACON1000-ED-350-041+G2CE 350 2520 256 1840 2796 4610 1400 7450

VACON1000-ED-438-041+G2CE 438 3150 321 2310 2796 5410 1400 9000

VACON1000-ED-560-041+G2CE 560 4030 410 2950 2796 5410 1400 10700

VACON1000-ED-680-041+G2CE 680 4890 498 3580 2796 5810 1400 11950

Height excluding cooling fan is 2328 mm

Page 5

Power rating (IEC variant)

Danfoss Drives · DKDD.PFP.909.A2.02

Low overload rating

High overload rating

Cabinet dimensions Weight

110% (Variable torque)

150% (Constant torque)

AC drive type

IL [A] S [kVA] IHD [A] S [kVA] HxWxD [mm] [kg]

Nominal voltage 6000 V (30-pulse, 5 power cell per phase, 50 Hz)

VACON1000-ED-036-060+G2CE 36 370 26 270 2796 2310 1250 3500

VACON1000-ED-050-060+G2CE 50 510 36 370 2796 2310 1250 3550

VACON1000-ED-070-060+G2CE 70 720 51 530 2796 2310 1250 3600

VACON1000-ED-090-060+G2CE 90 930 66 680 2888 2710 1250 4850

VACON1000-ED-100-060+G2CE 100 1030 73 750 2888 2710 1250 4900

VACON1000-ED-120-060+G2CE 120 1240 88 910 2888 2710 1250 4950

VACON1000-ED-140-060+G2CE 140 1450 102 1060 2888 2710 1250 5000

VACON1000-ED-150-060+G2CE 150 1550 110 1140 2888 3010 1250 5850

VACON1000-ED-180-060+G2CE 180 1870 132 1370 2888 3010 1250 5900

VACON1000-ED-190-060+G2CE 190 1970 139 1440 2888 3010 1250 5950

VACON1000-ED-215-060+G2CE 215 2230 157 1630 2888 3010 1250 6000

VACON1000-ED-250-060+G2CE 250 2590 183 1900 2796 5160 1400 7700

VACON1000-ED-305-060+G2CE 305 3160 223 2310 2796 5160 1400 8600

VACON1000-ED-350-060+G2CE 350 3630 256 2660 2796 5160 1400 9200

VACON1000-ED-438-060+G2CE 438 4550 321 3330 2796 6410 1400 11500

VACON1000-ED-560-060+G2CE 560 5810 410 4260 2796 6610 1400 13750

VACON1000-ED-680-060+G2CE 680 7060 498 5170 2796 7210 1600 15500

Nominal voltage 6600 V (36-pulse, 6 power cell per phase, 50 Hz)

VACON1000-ED-036-066+G2CE 36 410 26 290 2796 2310 1250 3700

VACON1000-ED-050-066+G2CE 50 570 36 410 2796 2310 1250 3750

VACON1000-ED-070-066+G2CE 70 800 51 580 2796 2310 1250 3800

VACON1000-ED-090-066+G2CE 90 1020 66 750 2888 2710 1250 5050

VACON1000-ED-100-066+G2CE 100 1140 73 830 2888 2710 1250 5100

VACON1000-ED-120-066+G2CE 120 1370 88 1000 2888 2710 1250 5150

VACON1000-ED-140-066+G2CE 140 1600 102 1160 2888 2710 1250 5200

VACON1000-ED-150-066+G2CE 150 1710 110 1250 2888 3010 1250 6050

VACON1000-ED-180-066+G2CE 180 2050 132 1500 2888 3010 1250 6100

VACON1000-ED-190-066+G2CE 190 2170 139 1580 2888 3010 1250 6150

VACON1000-ED-215-066+G2CE 215 2450 157 1790 2888 3010 1250 6200

VACON1000-ED-250-066+G2CE 250 2850 183 2090 2796 5410 1400 8800

VACON1000-ED-305-066+G2CE 305 3480 223 2540 2796 5410 1400 9800

VACON1000-ED-350-066+G2CE 350 4000 256 2920 2796 5410 1400 10700

VACON1000-ED-438-066+G2CE 438 5000 321 3660 2796 6810 1400 13050

VACON1000-ED-560-066+G2CE 560 6400 410 4680 2796 7010 1400 15050

VACON1000-ED-680-066+G2CE 680 7770 498 5690 2796 7610 1600 18550

Nominal voltage 10000 V (48-pulse, 8 power cell per phase, 50 Hz)

VACON1000-ED-036-100+G2CE 36 620 26 450 2796 3410 1250 4100

VACON1000-ED-050-100+G2CE 50 860 36 620 2796 3410 1250 4400

VACON1000-ED-070-100+G2CE 70 1210 51 880 2796 3410 1250 4700

VACON1000-ED-090-100+G2CE 90 1550 66 1140 2888 3910 1250 6250

VACON1000-ED-100-100+G2CE 100 1730 73 1260 2888 3910 1250 6550

VACON1000-ED-120-100+G2CE 120 2070 88 1520 2888 3910 1250 6850

VACON1000-ED-140-100+G2CE 140 2420 102 1760 2888 3910 1250 7250

VACON1000-ED-150-100+G2CE 150 2590 110 1900 2888 4660 1250 10100

VACON1000-ED-180-100+G2CE 180 3110 132 2280 2888 4660 1250 10400

VACON1000-ED-190-100+G2CE 190 3290 139 2400 2888 4660 1250 10700

VACON1000-ED-215-100+G2CE 215 3720 157 2710 2888 4660 1250 11100

VACON1000-ED-250-100+G2CE 250 4330 183 3160 2796 6560 1400 11600

VACON1000-ED-305-100+G2CE 305 5280 223 3860 2796 6560 1400 13100

VACON1000-ED-350-100+G2CE 350 6060 256 4430 2796 6760 1400 14400

VACON1000-ED-438-100+G2CE 438 7580 321 5550 2796 9810 1400 18200

VACON1000-ED-560-100+G2CE 560 9690 410 7100 2796 10610 1400 21900

VACON1000-ED-680-100+G2CE 680 11770 498 8620 2796 11010 1400 25350

Height excluding cooling fan is 2328 mm

5

Page 6

Power rating (IEC variant)

VACON® 1000 Single line diagram

6 Danfoss Drives · DKDD.PFP.909.A2.02

Low overload rating

High overload rating

Cabinet dimensions Weight

110% (Variable torque)

150% (Constant torque)

AC drive type

IL [A] S [kVA] IHD [A] S [kVA] HxWxD [mm] [kg]

Nominal voltage 11000 V (54-pulse, 9 power cell per phase, 50 Hz)

VACON1000-ED-036-110+G2CE 36 680 26 490 2796 3410 1250 4400

VACON1000-ED-050-110+G2CE 50 950 36 680 2796 3410 1250 4800

VACON1000-ED-070-110+G2CE 70 1330 51 970 2796 3410 1250 5200

VACON1000-ED-090-110+G2CE 90 1710 66 1250 2888 3910 1250 6550

VACON1000-ED-100-110+G2CE 100 1900 73 1390 2888 3910 1250 6850

VACON1000-ED-120-110+G2CE 120 2280 88 1670 2888 3910 1250 7150

VACON1000-ED-140-110+G2CE 140 2660 102 1940 2888 3910 1250 7550

VACON1000-ED-150-110+G2CE 150 2850 110 2090 2888 4660 1250 10600

VACON1000-ED-180-110+G2CE 180 3420 132 2510 2888 4660 1250 10900

VACON1000-ED-190-110+G2CE 190 3610 139 2640 2888 4660 1250 11200

VACON1000-ED-215-110+G2CE 215 4090 157 2990 2888 4660 1250 11500

VACON1000-ED-250-110+G2CE 250 4760 183 3480 2796 6810 1400 12950

VACON1000-ED-305-110+G2CE 305 5810 223 4240 2796 7010 1400 14750

VACON1000-ED-350-110+G2CE 350 6660 256 4870 2796 7010 1400 16750

VACON1000-ED-438-110+G2CE 438 8340 321 6110 2796 10810 1400 20550

VACON1000-ED-560-110+G2CE 560 10660 410 7810 2796 11410 1400 24550

VACON1000-ED-680-110+G2CE 680 12950 498 9480 2796 12210 1600 28600

Height excluding cooling fan is 2328 mm

Page 7

Height excluding cooling fan is 2328 mm

Power rating (UL variant)

Danfoss Drives · DKDD.PFP.909.A2.02

Low overload rating

High overload rating

Cabinet dimensions Weight

110% (Variable torque)

150% (Constant torque)

AC drive type

IL [A] S [kVA] IHD [A] S [kVA] HxWxD [mm] [kg]

Nominal voltage 2400 V (18-pulse, 3 power cell per phase, 60 Hz)

VACON1000-ED-036-024+GAUL 36 180 26 130 2796 1210 1250 2000

VACON1000-ED-050-024+GAUL 50 250 36 180 2796 1210 1250 2050

VACON1000-ED-070-024+GAUL 70 360 51 260 2796 1210 1250 2100

VACON1000-ED-090-024+GAUL 90 460 66 340 2888 1610 1250 2850

VACON1000-ED-100-024+GAUL 100 510 73 370 2888 1610 1250 2900

VACON1000-ED-116-024+GAUL 116 600 85 440 2888 1610 1250 2925

VACON1000-ED-120-024+GAUL 120 620 88 450 2888 1610 1250 2950

VACON1000-ED-140-024+GAUL 140 720 102 530 2888 1910 1250 3000

VACON1000-ED-160-024+GAUL 160 830 117 600 2888 1910 1250 4350

VACON1000-ED-180-024+GAUL 180 930 132 680 2888 1910 1250 4400

VACON1000-ED-215-024+GAUL 215 1110 157 810 2888 1910 1250 4500

VACON1000-ED-230-024+GAUL 230 1190 168 870 2796 3810 1400 4600

VACON1000-ED-250-024+GAUL 250 1290 183 950 2796 3810 1400 4700

VACON1000-ED-265-024+GAUL 265 1370 194 1000 2796 3810 1400 4800

VACON1000-ED-285-024+GAUL 285 1480 209 1080 2796 3810 1400 4900

VACON1000-ED-305-024+GAUL 305 1580 223 1150 2796 3810 1400 5000

VACON1000-ED-325-024+GAUL 325 1680 238 1230 2796 4110 1400 5100

VACON1000-ED-350-024+GAUL 350 1810 256 1330 2796 4110 1400 5300

VACON1000-ED-378-024+GAUL 378 1960 277 1430 2796 4710 1400 5850

VACON1000-ED-408-024+GAUL 408 2120 299 1550 2796 4710 1400 6050

VACON1000-ED-438-024+GAUL 438 2270 321 1660 2796 4710 1400 6250

VACON1000-ED-475-024+GAUL 475 2460 348 1800 2796 4710 1400 6600

VACON1000-ED-515-024+GAUL 515 2670 377 1950 2796 4710 1400 6900

VACON1000-ED-560-024+GAUL 560 2900 410 2130 2796 5010 1400 7400

VACON1000-ED-600-024+GAUL 600 3110 440 2280 2796 5010 1400 7550

VACON1000-ED-640-024+GAUL 640 3320 469 2430 2796 5010 1400 7850

VACON1000-ED-680-024+GAUL 680 3530 498 2580 2796 5010 1400 8250

Nominal voltage 3000 V (18-pulse, 3 power cell per phase, 60 Hz)

VACON1000-ED-036-030+GAUL 36 180 26 130 2796 1210 1250 2100

VACON1000-ED-040-030+GAUL 40 200 29 150 2796 1210 1250 2125

VACON1000-ED-050-030+GAUL 50 250 36 180 2796 1210 1250 2150

VACON1000-ED-061-030+GAUL 61 310 44 220 2796 1210 1250 2175

VACON1000-ED-070-030+GAUL 70 360 51 260 2796 1210 1250 2200

VACON1000-ED-077-030+GAUL 77 400 56 290 2888 1610 1250 2900

VACON1000-ED-090-030+GAUL 90 460 66 340 2888 1610 1250 2950

VACON1000-ED-095-030+GAUL 95 490 69 350 2888 1610 1250 2975

VACON1000-ED-100-030+GAUL 100 510 73 370 2888 1610 1250 3000

VACON1000-ED-118-030+GAUL 118 610 86 440 2888 1610 1250 3025

VACON1000-ED-120-030+GAUL 120 620 88 450 2888 1610 1250 3050

VACON1000-ED-140-030+GAUL 140 720 102 530 2888 1610 1250 3100

VACON1000-ED-180-030+GAUL 180 930 132 680 2888 1910 1250 4500

VACON1000-ED-186-030+GAUL 186 960 136 700 2888 1910 1250 4525

VACON1000-ED-215-030+GAUL 215 1110 157 810 2888 1910 1250 4600

VACON1000-ED-230-030+GAUL 230 1190 168 870 2796 3810 1400 5000

VACON1000-ED-250-030+GAUL 250 1290 183 950 2796 4110 1400 5100

VACON1000-ED-265-030+GAUL 265 1370 194 1000 2796 4110 1400 5100

VACON1000-ED-285-030+GAUL 285 1480 209 1080 2796 4110 1400 5300

VACON1000-ED-305-030+GAUL 305 1580 223 1150 2796 4110 1400 5500

VACON1000-ED-325-030+GAUL 325 1680 238 1230 2796 4110 1400 5600

VACON1000-ED-350-030+GAUL 350 1810 256 1330 2796 4110 1400 5800

VACON1000-ED-378-030+GAUL 378 1960 277 1430 2796 4710 1400 6450

VACON1000-ED-408-030+GAUL 408 2120 299 1550 2796 4710 1400 6750

VACON1000-ED-438-030+GAUL 438 2270 321 1660 2796 4710 1400 6950

VACON1000-ED-475-030+GAUL 475 2460 348 1800 2796 5010 1400 7500

VACON1000-ED-515-030+GAUL 515 2670 377 1950 2796 5010 1400 7800

7

Page 8

Power rating (UL variant)

8 Danfoss Drives · DKDD.PFP.909.A2.02

Low overload rating

High overload rating

Cabinet dimensions Weight

110% (Variable torque)

150% (Constant torque)

AC drive type

IL [A] S [kVA] IHD [A] S [kVA] HxWxD [mm] [kg]

Nominal voltage 3000 V (18-pulse, 3 power cell per phase, 60 Hz)

VACON1000-ED-560-030+GAUL 560 2900 410 2130 2796 5010 1400 8300

VACON1000-ED-600-030+GAUL 600 3110 440 2280 2796 5010 1400 8550

VACON1000-ED-640-030+GAUL 640 3320 469 2430 2796 5010 1400 8850

VACON1000-ED-680-033+GAUL 680 3530 498 2580 2796 5010 1400 9350

Nominal voltage 3300 V (18-pulse, 3 power cell per phase, 60 Hz)

VACON1000-ED-036-033+GAUL 36 200 26 140 2796 1210 1250 2200

VACON1000-ED-040-033+GAUL 70 400 51 290 2796 1210 1250 2225

VACON1000-ED-050-033+GAUL 50 280 36 200 2796 1210 1250 2250

VACON1000-ED-061-033+GAUL 61 340 44 250 2796 1210 1250 2275

VACON1000-ED-070-033+GAUL 70 400 51 290 2796 1210 1250 2300

VACON1000-ED-077-033+GAUL 77 440 56 320 2888 1610 1250 3000

VACON1000-ED-090-033+GAUL 90 510 66 370 2888 1610 1250 3050

VACON1000-ED-095-033+GAUL 95 540 69 390 2888 1610 1250 3075

VACON1000-ED-100-033+GAUL 100 570 73 410 2888 1610 1250 3100

VACON1000-ED-118-033+GAUL 118 670 86 490 2888 1610 1250 3125

VACON1000-ED-120-033+GAUL 120 680 88 500 2888 1610 1250 3150

VACON1000-ED-140-033+GAUL 140 800 102 580 2888 1610 1250 3200

VACON1000-ED-180-033+GAUL 180 1020 132 750 2888 1910 1250 4600

VACON1000-ED-186-033+GAUL 186 1060 136 770 2888 1910 1250 4625

VACON1000-ED-215-033+GAUL 215 1220 157 890 2888 1910 1250 4700

VACON1000-ED-230-033+GAUL 230 1310 168 960 2796 4110 1400 5100

VACON1000-ED-250-033+GAUL 250 1420 183 1040 2796 4110 1400 5300

VACON1000-ED-265-033+GAUL 265 1510 194 1100 2796 4110 1400 5300

VACON1000-ED-285-033+GAUL 285 1620 209 1190 2796 4110 1400 5500

VACON1000-ED-305-033+GAUL 305 1740 223 1270 2796 4110 1400 5800

VACON1000-ED-325-033+GAUL 325 1850 238 1360 2796 4110 1400 5800

VACON1000-ED-350-033+GAUL 350 2000 256 1460 2796 4110 1400 6100

VACON1000-ED-378-033+GAUL 378 2160 277 1580 2796 4710 1400 6750

VACON1000-ED-408-033+GAUL 408 2330 299 1700 2796 4710 1400 7150

VACON1000-ED-438-033+GAUL 438 2500 321 1830 2796 5010 1400 7450

VACON1000-ED-475-033+GAUL 475 2710 348 1980 2796 5010 1400 7900

VACON1000-ED-515-033+GAUL 515 2940 377 2150 2796 5010 1400 8200

VACON1000-ED-560-033+GAUL 560 3200 410 2340 2796 5010 1400 8700

VACON1000-ED-600-033+GAUL 600 3420 440 2510 2796 5010 1400 9050

VACON1000-ED-640-033+GAUL 640 3650 469 2680 2796 5010 1400 9450

VACON1000-ED-680-033+GAUL 680 3880 498 2840 2796 5410 1400 9950

Nominal voltage 4160 V (24-pulse, 4 power cell per phase, 60 Hz)

VACON1000-ED-036-041+GAUL 36 250 26 180 2796 1210 1250 2400

VACON1000-ED-040-041+GAUL 40 280 29 200 2796 1210 1250 2425

VACON1000-ED-050-041+GAUL 50 360 36 250 2796 1210 1250 2450

VACON1000-ED-053-041+GAUL 53 380 38 270 2796 1210 1250 2475

VACON1000-ED-059-041+GAUL 59 420 43 300 2796 1210 1250 2500

VACON1000-ED-070-041+GAUL 70 500 51 360 2796 1210 1250 2500

VACON1000-ED-078-041+GAUL 78 560 57 410 2888 1610 1250 3200

VACON1000-ED-090-041+GAUL 90 640 66 470 2888 1610 1250 3250

VACON1000-ED-100-041+GAUL 100 720 73 520 2888 1610 1250 3300

VACON1000-ED-105-041+GAUL 105 750 77 550 2888 1610 1250 3325

VACON1000-ED-116-041+GAUL 116 830 85 610 2888 1610 1250 3325

VACON1000-ED-120-041+GAUL 120 860 88 630 2888 1610 1250 3350

VACON1000-ED-128-041+GAUL 128 920 93 670 2888 1610 1250 3375

VACON1000-ED-140-041+GAUL 140 1000 102 730 2888 1610 1250 3400

VACON1000-ED-160-041+GAUL 160 1150 117 840 2888 1910 1250 4750

VACON1000-ED-180-041+GAUL 180 1290 132 950 2888 1910 1250 4800

VACON1000-ED-193-041+GAUL 193 1390 141 1010 2888 1910 1250 4850

VACON1000-ED-215-041+GAUL 215 1540 157 1130 2888 1910 1250 4900

Height excluding cooling fan is 2328 mm

Page 9

Power rating (UL variant)

Danfoss Drives · DKDD.PFP.909.A2.02

Low overload rating

High overload rating

Cabinet dimensions Weight

110% (Variable torque)

150% (Constant torque)

AC drive type

IL [A] S [kVA] IHD [A] S [kVA] HxWxD [mm] [kg]

Nominal voltage 4160 V (24-pulse, 4 power cell per phase, 60 Hz)

VACON1000-ED-230-041+GAUL 230 1650 168 1210 2796 4610 1400 5850

VACON1000-ED-250-041+GAUL 250 1800 183 1310 2796 4610 1400 6150

VACON1000-ED-265-041+GAUL 265 1900 194 1390 2796 4610 1400 6350

VACON1000-ED-285-041+GAUL 285 2050 209 1500 2796 4610 1400 6550

VACON1000-ED-305-041+GAUL 305 2190 223 1600 2796 4610 1400 6850

VACON1000-ED-325-041+GAUL 325 2340 238 1710 2796 4610 1400 7050

VACON1000-ED-350-041+GAUL 350 2520 256 1840 2796 4910 1400 7450

VACON1000-ED-378-041+GAUL 378 2720 277 1990 2796 5410 1400 8200

VACON1000-ED-408-041+GAUL 408 2930 299 2150 2796 5410 1400 8500

VACON1000-ED-438-041+GAUL 438 3150 321 2310 2796 5410 1400 9000

VACON1000-ED-475-041+GAUL 475 3420 348 2500 2796 5410 1400 9400

VACON1000-ED-515-041+GAUL 515 3710 377 2710 2796 5810 1400 9900

VACON1000-ED-560-041+GAUL 560 4030 410 2950 2796 5810 1400 10700

VACON1000-ED-600-041+GAUL 600 4320 440 3170 2796 5810 1400 10950

VACON1000-ED-640-041+GAUL 640 4610 469 3370 2796 5810 1400 11450

VACON1000-ED-680-041+GAUL 680 4890 498 3580 2796 5810 1400 11950

Nominal voltage 6000 V (30-pulse, 5 power cell per phase, 60 Hz)

VACON1000-ED-025-060+GAUL 25 250 18 180 2796 2310 1250 3450

VACON1000-ED-036-060+GAUL 36 370 26 270 2796 2310 1250 3500

VACON1000-ED-040-060+GAUL 40 410 29 300 2796 2310 1250 3525

VACON1000-ED-050-060+GAUL 50 510 36 370 2796 2310 1250 3550

VACON1000-ED-060-060+GAUL 60 620 44 450 2796 2310 1250 3575

VACON1000-ED-070-060+GAUL 70 720 51 530 2796 2310 1250 3600

VACON1000-ED-080-060+GAUL 80 830 58 600 2888 2710 1250 4800

VACON1000-ED-090-060+GAUL 90 930 66 680 2888 2710 1250 4850

VACON1000-ED-100-060+GAUL 100 1030 73 750 2888 2710 1250 4900

VACON1000-ED-110-060+GAUL 110 1140 80 830 2888 2710 1250 4925

VACON1000-ED-120-060+GAUL 120 1240 88 910 2888 2710 1250 4950

VACON1000-ED-140-060+GAUL 140 1450 102 1060 2888 2710 1250 5000

VACON1000-ED-150-060+GAUL 150 1550 110 1140 2888 3010 1250 5850

VACON1000-ED-170-060+GAUL 170 1760 124 1280 2888 3010 1250 5875

VACON1000-ED-180-060+GAUL 180 1870 132 1370 2888 3010 1250 5900

VACON1000-ED-190-060+GAUL 190 1970 139 1440 2888 3010 1250 5950

VACON1000-ED-200-060+GAUL 200 2070 146 1510 2888 3010 1250 5975

VACON1000-ED-210-060+GAUL 210 2180 154 1600 2888 3010 1250 5975

VACON1000-ED-215-060+GAUL 215 2230 157 1630 2888 3010 1250 6000

VACON1000-ED-223-060+GAUL 223 2310 163 1690 2796 4860 1400 7100

VACON1000-ED-236-060+GAUL 236 2450 173 1790 2796 4860 1400 7400

VACON1000-ED-250-060+GAUL 250 2590 183 1900 2796 5160 1400 7700

VACON1000-ED-263-060+GAUL 263 2730 192 1990 2796 5160 1400 7800

VACON1000-ED-276-060+GAUL 276 2860 202 2090 2796 5160 1400 8000

VACON1000-ED-290-060+GAUL 290 3010 212 2200 2796 5160 1400 8300

VACON1000-ED-305-060+GAUL 305 3160 223 2310 2796 5160 1400 8600

VACON1000-ED-325-060+GAUL 325 3370 238 2470 2796 5160 1400 8800

VACON1000-ED-350-060+GAUL 350 3630 256 2660 2796 5160 1400 9200

VACON1000-ED-370-060+GAUL 370 3840 271 2810 2796 6010 1400 10200

VACON1000-ED-390-060+GAUL 390 4050 286 2970 2796 6410 1400 10500

VACON1000-ED-415-060+GAUL 415 4310 304 3150 2796 6410 1400 11000

VACON1000-ED-438-060+GAUL 438 4550 321 3330 2796 6410 1400 11500

VACON1000-ED-460-060+GAUL 460 4780 337 3500 2796 6410 1400 11950

VACON1000-ED-483-060+GAUL 483 5010 354 3670 2796 6410 1400 12250

VACON1000-ED-507-060+GAUL 507 5260 371 3850 2796 6410 1400 12650

VACON1000-ED-532-060+GAUL 532 5520 390 4050 2796 6610 1400 13150

VACON1000-ED-560-060+GAUL 560 5810 410 4260 2796 6610 1400 13750

Height excluding cooling fan is 2328 mm

9

Page 10

Power rating (UL variant)

10 Danfoss Drives · DKDD.PFP.909.A2.02

Low overload rating

High overload rating

Cabinet dimensions Weight

110% (Variable torque)

150% (Constant torque)

AC drive type

IL [A] S [kVA] IHD [A] S [kVA] HxWxD [mm] [kg]

Nominal voltage 6000 V (30-pulse, 5 power cell per phase, 60 Hz)

VACON1000-ED-588-060+GAUL 588 6110 431 4470 2796 6610 1400 14100

VACON1000-ED-617-060+GAUL 617 6410 452 4690 2796 6610 1400 14500

VACON1000-ED-648-060+GAUL 648 6730 475 4930 2796 7210 1600 15100

VACON1000-ED-680-060+GAUL 680 7060 498 5170 2796 7210 1600 15500

Nominal voltage 6300 V (36-pulse, 6 power cell per phase, 60 Hz)

VACON1000-ED-025-063+GAUL 25 270 18 190 2796 2310 1250 3600

VACON1000-ED-030-063+GAUL 30 310 22 220 2796 2310 1250 3625

VACON1000-ED-036-063+GAUL 36 370 26 270 2796 2310 1250 3625

VACON1000-ED-045-063+GAUL 45 460 33 340 2796 2310 1250 3650

VACON1000-ED-050-063+GAUL 50 510 36 370 2796 2310 1250 3650

VACON1000-ED-065-063+GAUL 65 670 47 480 2796 2310 1250 3675

VACON1000-ED-070-063+GAUL 70 720 51 530 2796 2310 1250 3700

VACON1000-ED-085-063+GAUL 85 880 62 640 2888 2710 1250 4950

VACON1000-ED-100-063+GAUL 100 1030 73 750 2888 2710 1250 5000

VACON1000-ED-115-063+GAUL 115 1190 84 870 2888 2710 1250 5050

VACON1000-ED-125-063+GAUL 125 1290 91 940 2888 2710 1250 5075

VACON1000-ED-140-063+GAUL 140 1450 102 1060 2888 2710 1250 5100

VACON1000-ED-160-063+GAUL 160 1660 117 1210 2888 3010 1250 5950

VACON1000-ED-170-063+GAUL 170 1760 124 1280 2888 3010 1250 5975

VACON1000-ED-180-063+GAUL 180 1870 132 1370 2888 3010 1250 6000

VACON1000-ED-190-063+GAUL 190 1970 139 1440 2888 3010 1250 6050

VACON1000-ED-205-063+GAUL 205 2130 150 1550 2888 3010 1250 6075

VACON1000-ED-210-063+GAUL 210 2180 154 1600 2888 3010 1250 6075

VACON1000-ED-215-063+GAUL 215 2230 157 1630 2888 3010 1250 6100

VACON1000-ED-230-063+GAUL 230 2390 168 1740 2796 5410 1400 8300

VACON1000-ED-250-063+GAUL 250 2590 183 1900 2796 5410 1400 8800

VACON1000-ED-265-063+GAUL 265 2750 194 2010 2796 5410 1400 9000

VACON1000-ED-285-063+GAUL 285 2960 209 2170 2796 5410 1400 9300

VACON1000-ED-305-063+GAUL 305 3160 223 2310 2796 5410 1400 9800

VACON1000-ED-325-063+GAUL 325 3370 238 2470 2796 5410 1400 10000

VACON1000-ED-350-063+GAUL 350 3630 256 2660 2796 5810 1400 10700

VACON1000-ED-378-063+GAUL 378 3920 277 2870 2796 6810 1400 11650

VACON1000-ED-408-063+GAUL 408 4240 299 3100 2796 6810 1400 12250

VACON1000-ED-438-063+GAUL 438 4550 321 3330 2796 6810 1400 13050

VACON1000-ED-475-063+GAUL 475 4930 348 3610 2796 7010 1400 13750

VACON1000-ED-515-063+GAUL 515 5350 377 3910 2796 7010 1400 14550

VACON1000-ED-560-063+GAUL 560 5810 410 4260 2796 7610 1600 15050

VACON1000-ED-600-063+GAUL 600 6230 440 4570 2796 7610 1600 16250

VACON1000-ED-640-063+GAUL 640 6650 469 4870 2796 7610 1600 16950

VACON1000-ED-680-063+GAUL 680 7060 498 5170 2796 9610 1400 18550

Nominal voltage 6600 V (36-pulse, 6 power cell per phase, 60 Hz)

VACON1000-ED-025-066+GAUL 25 280 18 200 2796 2310 1250 3650

VACON1000-ED-032-066+GAUL 32 360 23 260 2796 2310 1250 3675

VACON1000-ED-036-066+GAUL 36 410 26 290 2796 2310 1250 3700

VACON1000-ED-040-066+GAUL 40 450 29 330 2796 2310 1250 3725

VACON1000-ED-050-066+GAUL 50 570 36 410 2796 2310 1250 3750

VACON1000-ED-055-066+GAUL 55 620 40 450 2796 2310 1250 3775

VACON1000-ED-065-066+GAUL 65 740 47 530 2796 2310 1250 3775

VACON1000-ED-070-066+GAUL 70 800 51 580 2796 2310 1250 3800

VACON1000-ED-080-066+GAUL 80 910 58 660 2888 2710 1250 5050

VACON1000-ED-100-066+GAUL 100 1140 73 830 2888 2710 1250 5100

VACON1000-ED-120-066+GAUL 120 1370 88 1000 2888 2710 1250 5150

VACON1000-ED-140-066+GAUL 140 1600 102 1160 2888 2710 1250 5200

VACON1000-ED-155-066+GAUL 155 1770 113 1290 2888 3010 1250 6050

VACON1000-ED-160-066+GAUL 160 1820 117 1330 2888 3010 1250 6075

VACON1000-ED-180-066+GAUL 180 2050 132 1500 2888 3010 1250 6100

Height excluding cooling fan is 2328 mm

Page 11

Power rating (UL variant)

Danfoss Drives · DKDD.PFP.909.A2.02

Low overload rating

High overload rating

Cabinet dimensions Weight

110% (Variable torque)

150% (Constant torque)

AC drive type

IL [A] S [kVA] IHD [A] S [kVA] HxWxD [mm] [kg]

Nominal voltage 6600 V (36-pulse, 6 power cell per phase, 60 Hz)

VACON1000-ED-200-066+GAUL 200 2280 146 1660 2888 3010 1250 6150

VACON1000-ED-210-066+GAUL 210 2400 154 1760 2888 3010 1250 6175

VACON1000-ED-215-066+GAUL 215 2450 157 1790 2888 3010 1250 6200

VACON1000-ED-230-066+GAUL 230 2620 168 1920 2796 5410 1400 8300

VACON1000-ED-250-066+GAUL 250 2850 183 2090 2796 5410 1400 8800

VACON1000-ED-265-066+GAUL 265 3020 194 2210 2796 5410 1400 9000

VACON1000-ED-285-066+GAUL 285 3250 209 2380 2796 5410 1400 9300

VACON1000-ED-305-066+GAUL 305 3480 223 2540 2796 5410 1400 9800

VACON1000-ED-325-066+GAUL 325 3710 238 2720 2796 5410 1400 10000

VACON1000-ED-350-066+GAUL 350 4000 256 2920 2796 5810 1400 10700

VACON1000-ED-378-066+GAUL 378 4320 277 3160 2796 6810 1400 11650

VACON1000-ED-408-066+GAUL 408 4660 299 3410 2796 6810 1400 12250

VACON1000-ED-438-066+GAUL 438 5000 321 3660 2796 6810 1400 13050

VACON1000-ED-475-066+GAUL 475 5420 348 3970 2796 7010 1400 13750

VACON1000-ED-515-066+GAUL 515 5880 377 4300 2796 7010 1400 14550

VACON1000-ED-560-066+GAUL 560 6400 410 4680 2796 7610 1600 15050

VACON1000-ED-600-066+GAUL 600 6850 440 5020 2796 7610 1600 16250

VACON1000-ED-640-066+GAUL 640 7310 469 5360 2796 7610 1600 16950

VACON1000-ED-680-066+GAUL 680 7770 498 5690 2796 9610 1400 18550

Nominal voltage 6900V (36-pulse, 6 power cell per phase, 60 Hz)

VACON1000-ED-025-069+GAUL 25 290 18 210 2796 2310 1250 3750

VACON1000-ED-032-069+GAUL 32 380 23 270 2796 2310 1250 3800

VACON1000-ED-036-069+GAUL 36 430 26 310 2796 2310 1250 3825

VACON1000-ED-040-069+GAUL 40 470 29 340 2796 2310 1250 3850

VACON1000-ED-050-069+GAUL 050 590 36 430 2796 2310 1250 3875

VACON1000-ED-060-069+GAUL 060 710 44 520 2796 2310 1250 3900

VACON1000-ED-065-069+GAUL 065 770 47 560 2796 2310 1250 3900

VACON1000-ED-070-069+GAUL 070 830 51 600 2796 2310 1250 3900

VACON1000-ED-080-069+GAUL 080 950 58 690 2888 2710 1250 5300

VACON1000-ED-100-069+GAUL 100 1190 73 870 2888 2710 1250 5300

VACON1000-ED-120-069+GAUL 120 1430 88 1050 2888 2710 1250 5300

VACON1000-ED-140-069+GAUL 140 1670 102 1210 2888 2710 1250 5300

VACON1000-ED-150-069+GAUL 150 1790 110 1310 2888 3010 1250 6100

VACON1000-ED-160-069+GAUL 160 1910 117 1390 2888 3010 1250 6150

VACON1000-ED-180-069+GAUL 180 2150 132 1570 2888 3010 1250 6200

VACON1000-ED-190-069+GAUL 190 2270 139 1660 2888 3010 1250 6275

VACON1000-ED-200-069+GAUL 200 2390 146 1740 2888 3010 1250 6275

VACON1000-ED-210-069+GAUL 210 2500 154 1840 2888 3010 1250 6300

VACON1000-ED-215-069+GAUL 215 2560 157 1870 2888 3010 1250 6300

VACON1000-ED-230-069+GAUL 230 2740 168 2000 2796 5410 1400 8500

VACON1000-ED-250-069+GAUL 250 2980 183 2180 2796 5410 1400 9000

VACON1000-ED-265-069+GAUL 265 3160 194 2310 2796 5410 1400 9200

VACON1000-ED-285-069+GAUL 285 3400 209 2490 2796 5410 1400 9500

VACON1000-ED-305-069+GAUL 305 3640 223 2660 2796 5410 1400 10000

VACON1000-ED-325-069+GAUL 325 3880 238 2840 2796 5810 1400 10300

VACON1000-ED-350-069+GAUL 350 4180 256 3050 2796 5810 1400 11000

VACON1000-ED-378-069+GAUL 378 4510 277 3310 2796 6810 1400 11950

VACON1000-ED-408-069+GAUL 408 4870 299 3570 2796 7010 1400 12550

VACON1000-ED-438-069+GAUL 438 5230 321 3830 2796 7010 1400 13350

VACON1000-ED-475-069+GAUL 475 5670 348 4150 2796 7010 1400 14250

VACON1000-ED-515-069+GAUL 515 6150 377 4500 2796 7010 1400 15050

VACON1000-ED-560-069+GAUL 560 6690 410 4890 2796 7610 1600 16050

VACON1000-ED-600-069+GAUL 600 7170 440 5250 2796 7610 1600 16650

VACON1000-ED-640-069+GAUL 640 7640 469 5600 2796 9610 1400 18050

VACON1000-ED-680-069+GAUL 680 8120 498 5950 2796 9610 1400 19050

Height excluding cooling fan is 2328 mm

11

Page 12

Options

Options Description

Options Description

Degree of protection

Cabinet options

+IP42 Protection rating IP42

+QDFR Cooling fan redundancy

+QDEX External cooling fan supply

Input frequency

+QSPD Surge protection device

+LS50 50 Hz input frequency

(standard for UL, optional for IEC variants)

+LS60 60 Hz input frequency

+QT01 Control power without heater XFMR

I/O options

+QT02 Control power with heater XFMR

+IAF1 Synchronous transfer I/O (8DI/8DO)

Mechanical options

+IBF2 Advanced control module

+MHET Heater + Thermostat

+ICF3 Excitator control I/O

+MHEH Heater + Humidity sensor

+IDF4 PID control module

+MMKI Mechanical key interlock

+IEF5 Motor temperature module (8 channels)

(standard for UL, optional for IEC variants)

I/O PLC options

Input voltage options*

+IAP1 PLC DI module (16 DI)

+I023 Input voltage: 2300 V

+IBP2 PlC DIO module (8DI/8DO)

+I024 Input voltage: 2400 V

+ICP3 PLC AIO module (2AI/4AO)

+I030 Input voltage: 3000 V

+IDP4 Motor temperature module (8 channels)

+I033 Input voltage: 3300 V

Fieldbus options

+I040 Input voltage: 4000 V

+S_E2 Modbus RTU

+I041 Input voltage: 4160 V

+S_E5 PROFIBUS DP-V0

+I042 Input voltage: 4200 V

+S_E6 CANopen

+I048 Input voltage: 4800 V

+S_E7 DeviceNet™

+I050 Input voltage: 5000 V

+S_EC EtherCAT

+I060 Input voltage: 6000 V

+S_EI Modbus TCP

+I063 Input voltage: 6300 V

+S_EL POWERLINK

+S_EN ControNet™

+I066 Input voltage: 6600 V

+S_EP PROFINET I/O

+I069 Input voltage: 6900 V

+S_EQ EtherNet/IP™

+I072 Input voltage: 7200 V

User interface

+I084 Input voltage: 8400 V

+MHMI HMI 10”

+I100 Input voltage: 10000 V

System firmware

+I110 Input voltage: 11000 V

+F101 Asynchronous Motor

+I114 Input voltage: 11400 V

+F102 Synchronous Motor (external exciter)

+I120 Input voltage: 12000 V

Cell bypass

+I124 Input voltage: 12400 V

+PPCB Power cell bypass

+I132 Input voltage: 13200 V

Cell redundancy*

+I138 Input voltage: 13800 V

+PPCR Power cell redundancy

Environment

Cabinet bypass*

+THAL High altitude, >2000 m above sea level

+PMBP Manual motor bypass

+T50C 50° C ambient temperature operation

+PABP Automatic motor bypass

Seismic zone

+PSBP Synchronous transfer (1 motor only)

+SZ04 Zone 4

+PSB2 Engineered synchronous transfer

Factory acceptance test

Input devices*

+QFAT FAT

+PSTC Start-up cabinet available for drives >215 A

+QFNO No-load FAT

Output devices*

+POCK Reactor for synchronous transfer

+PODU dU/dt filter for cable <2000 m

*If this option is selected it could impact the overall dimensions and weight of the product.

DKDD.PFP.909.A2.02 © Copyright Danfoss Drives | 2021.08

EtherNet/IP™ and DeviceNet™ are trademarks of ODVA, Inc.

Loading...

Loading...